Patents

Literature

52 results about "Patch model" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

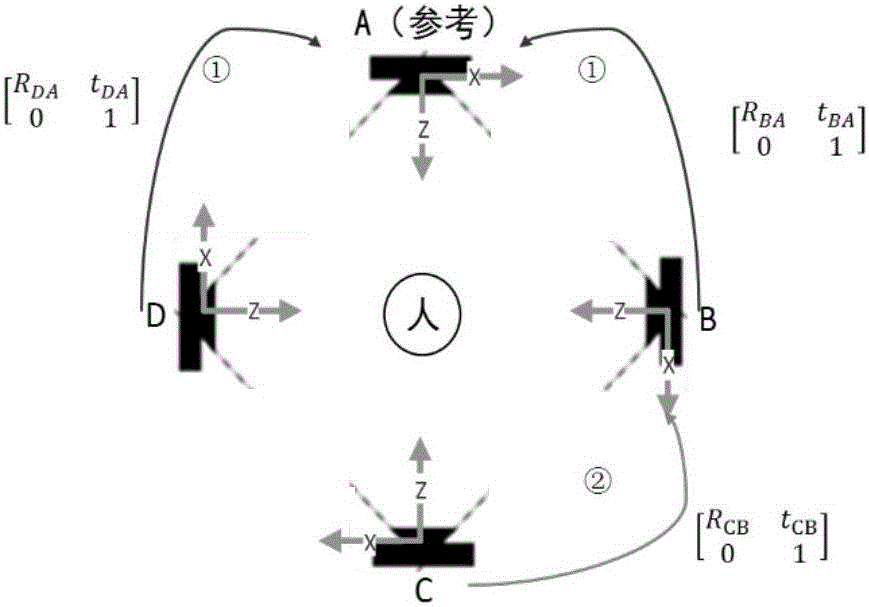

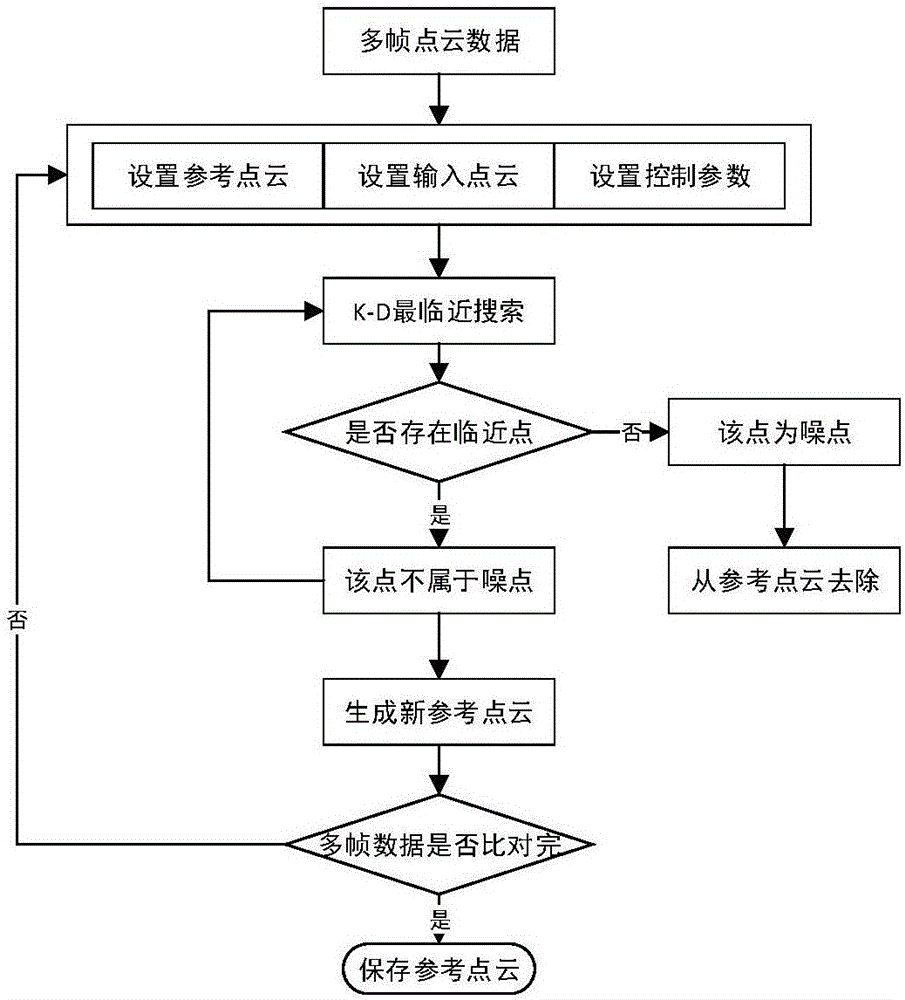

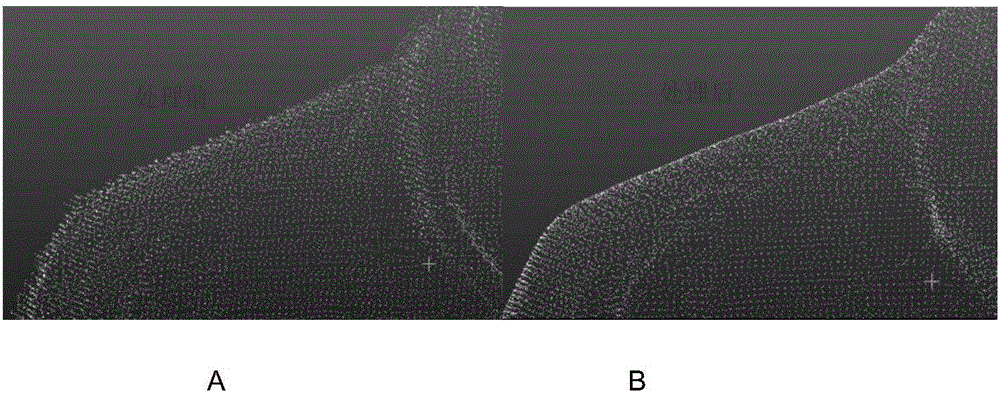

RGBD camera-based three-dimensional human body rapid modeling system

ActiveCN106709947AFast automatic calibrationImprove robustnessImage enhancementImage analysisColor mappingPoint cloud

The invention discloses an RGBD camera-based three-dimensional human body rapid modeling system. The system is executed through the following steps of: establishing a scanning array by utilizing a plurality of RGB-D cameras; calibrating the scanning array by using an automatic calibration technology, so as to obtain a calibrated matrix and automatically guide the calibrated matrix into a scanning system; enabling the RGB-D cameras in the array to independently scan a target object after the scanning is started, so as to obtain point cloud data of corresponding poses; processing the acquired point cloud data by utilizing a point cloud optimization technology, so as to obtain high-quality point clouds which can be used for triangular meshing; realizing reconstruction from the point clouds to a triangular patch model by utilizing a rapid triangular meshing algorithm; and obtaining a colored three-dimensional human body model by utilizing a color mapping technology. According to the system disclosed by the invention, a technology which is used for constructing the scanning matrix on the basis of the plurality of RGB-D cameras, rapidly acquiring human body feature data and realizing the construction of the human body three-dimensional model with high precision and refined color texture is provided.

Owner:XI AN JIAOTONG UNIV

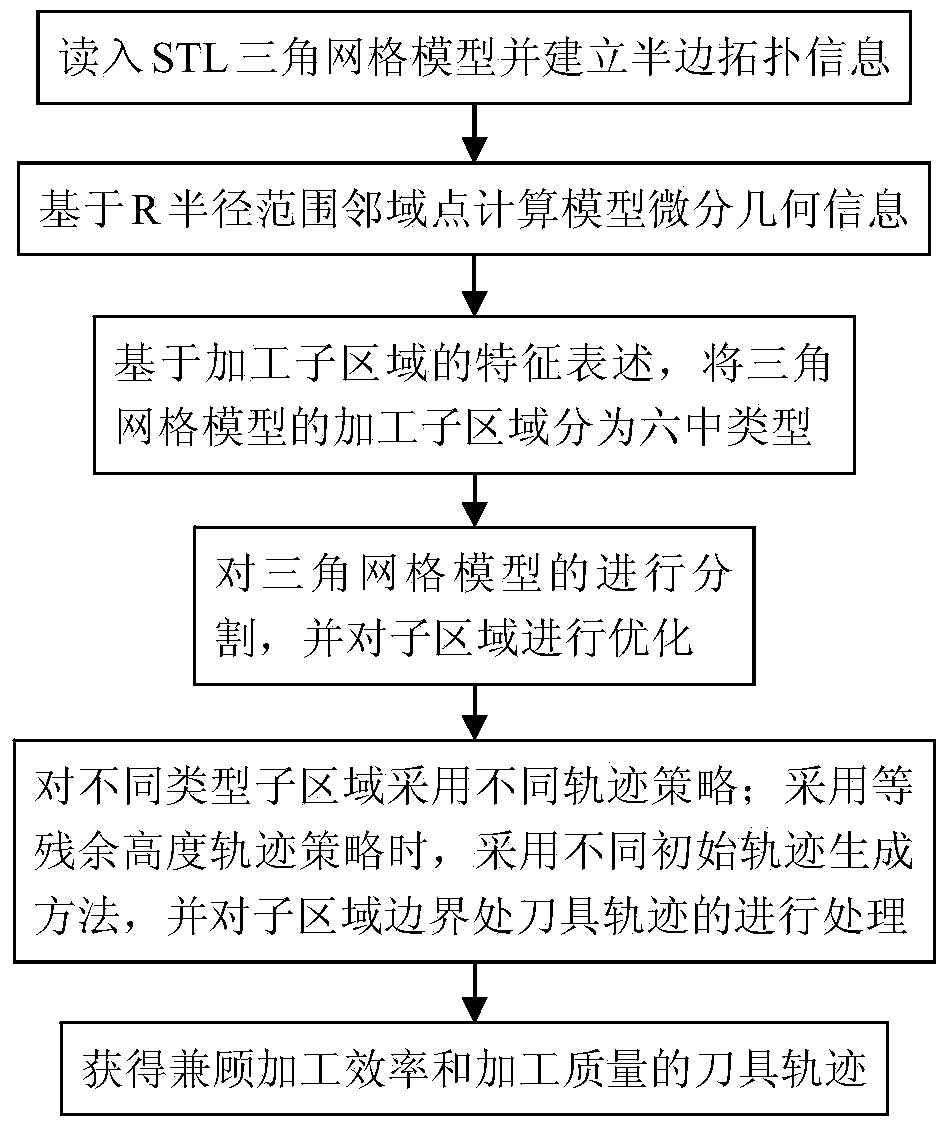

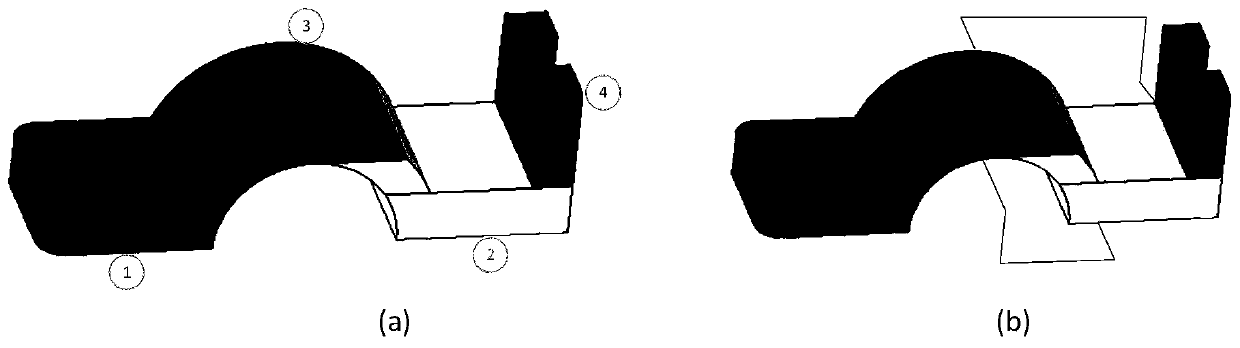

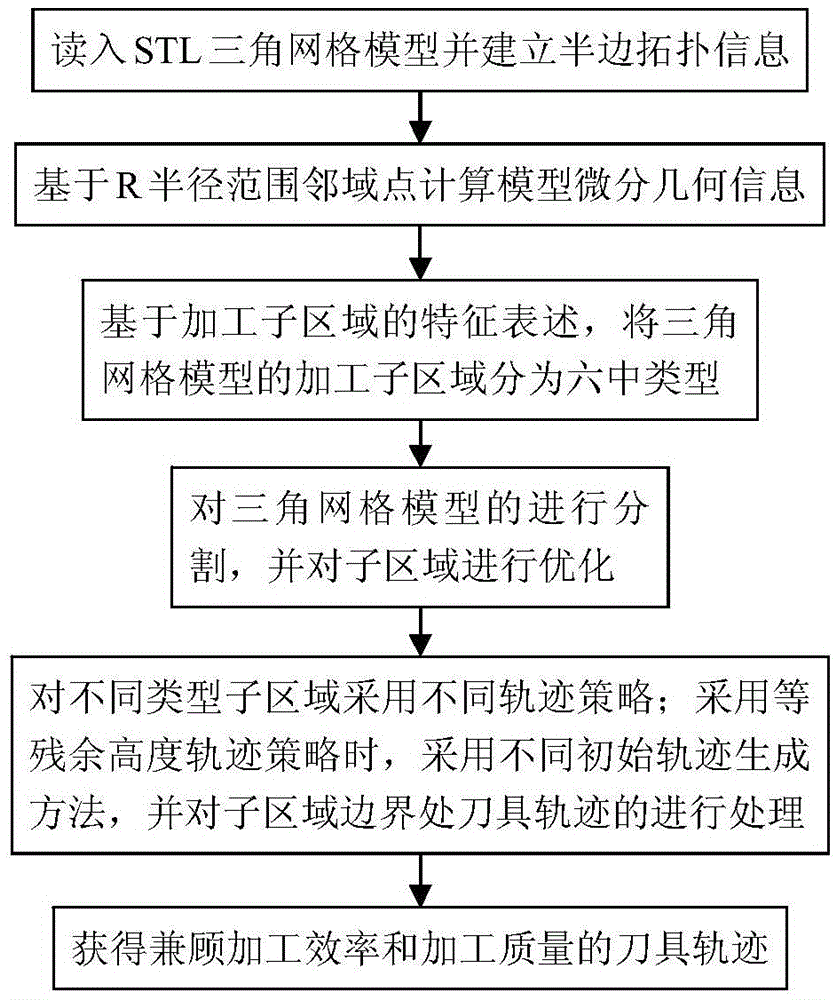

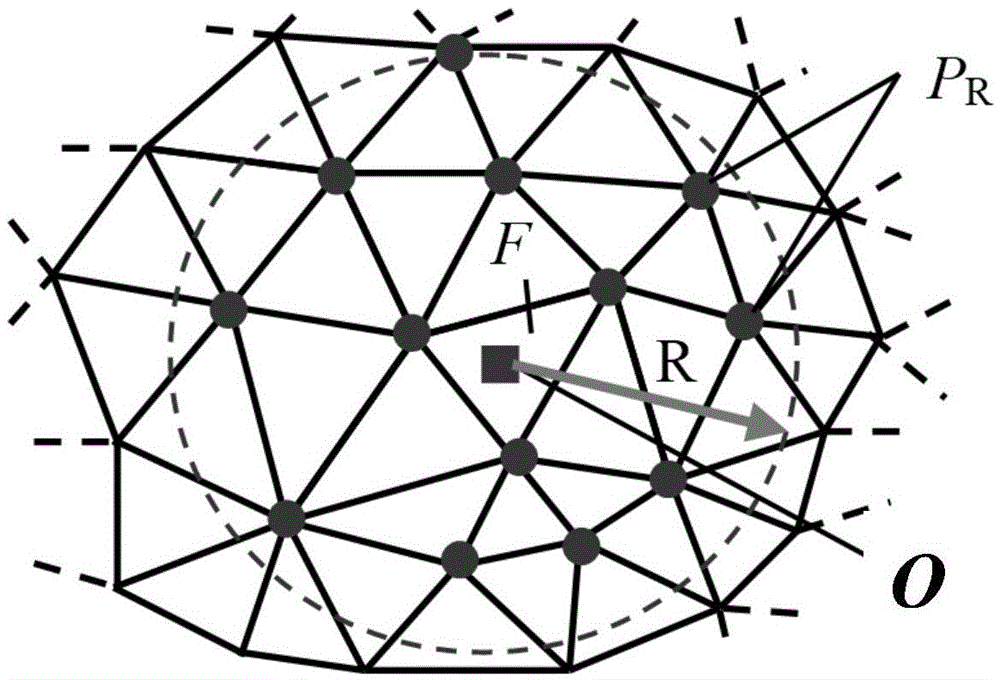

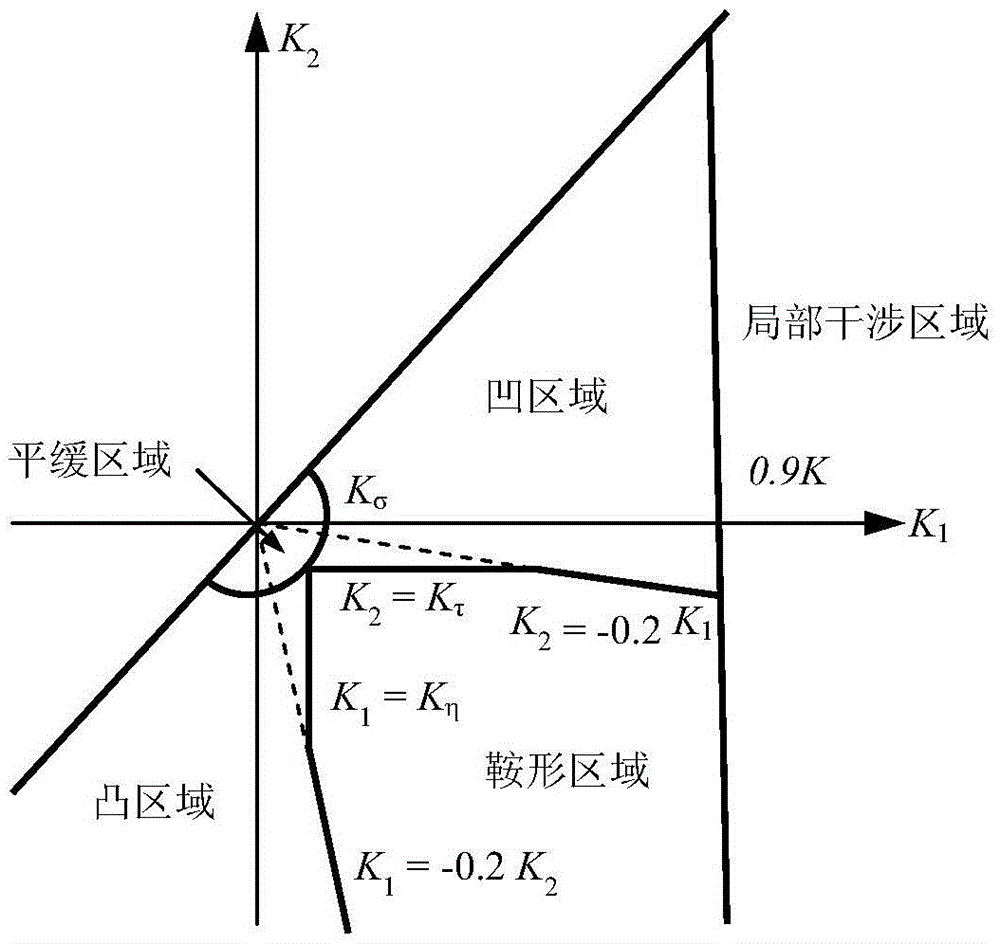

Partition machining method of triangular mesh model

InactiveCN103885385ADivide and conquer processingAvoid problems with large differences in region sizesNumerical controlNumerical controlCam

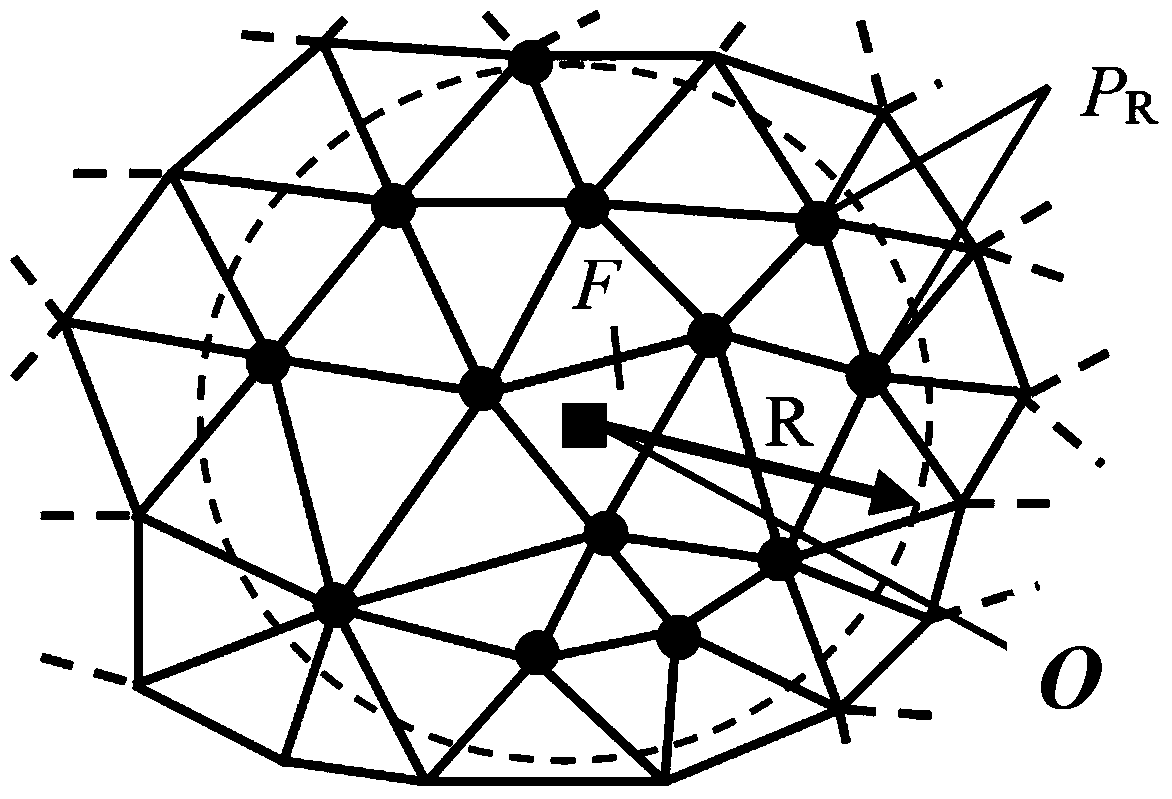

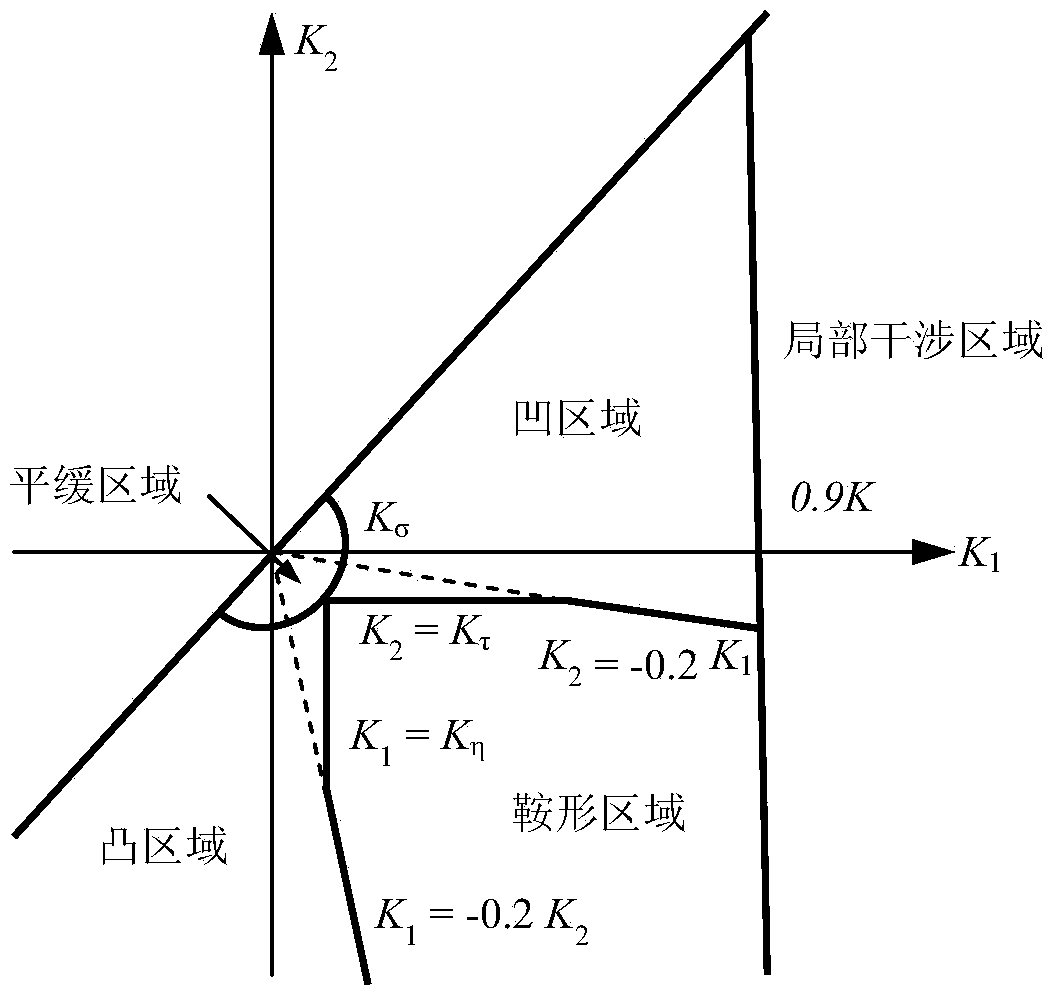

The invention provides a partition machining method of a triangular mesh model, and belongs to the technical field of CAM. The partition machining method of the triangular mesh model is characterized in that the partition machining method includes the steps that neighborhood points within an R radius range are selected so as to calculate differential geometry information of a triangular patch model accurately; the triangular patch model is segmented into sub-regions with different characteristics with characteristic statements of sub-regions to be machined as growth principles, optimization merging is conducted on small-area regions and wrongly judged regions so as to eliminate over-segmentation phenomena, and boundary smoothing is conducted on the sub-regions so as to reduce saw-toothed boundaries; different track strategies are adopted in different types of the sub-regions to be machined, when a constant scallop height track is generated, the circular cutting initial track generation method is adopted in the convex sub-regions and the concave sub-regions, the linear cutting initial track generation method is adopted in the saddle-shaped sub-regions, machining is conducted on tracks at the positions of sub-region boundaries when bias extension is conducted on cutter track projection, and reasonable and complete sub-region machining tracks are obtained. According to the partition machining method, numerical control machining cutter tracks giving consideration to the machining efficiency and the machining quality are effectively generated from the complicated triangular patch model.

Owner:HUAQIAO UNIVERSITY

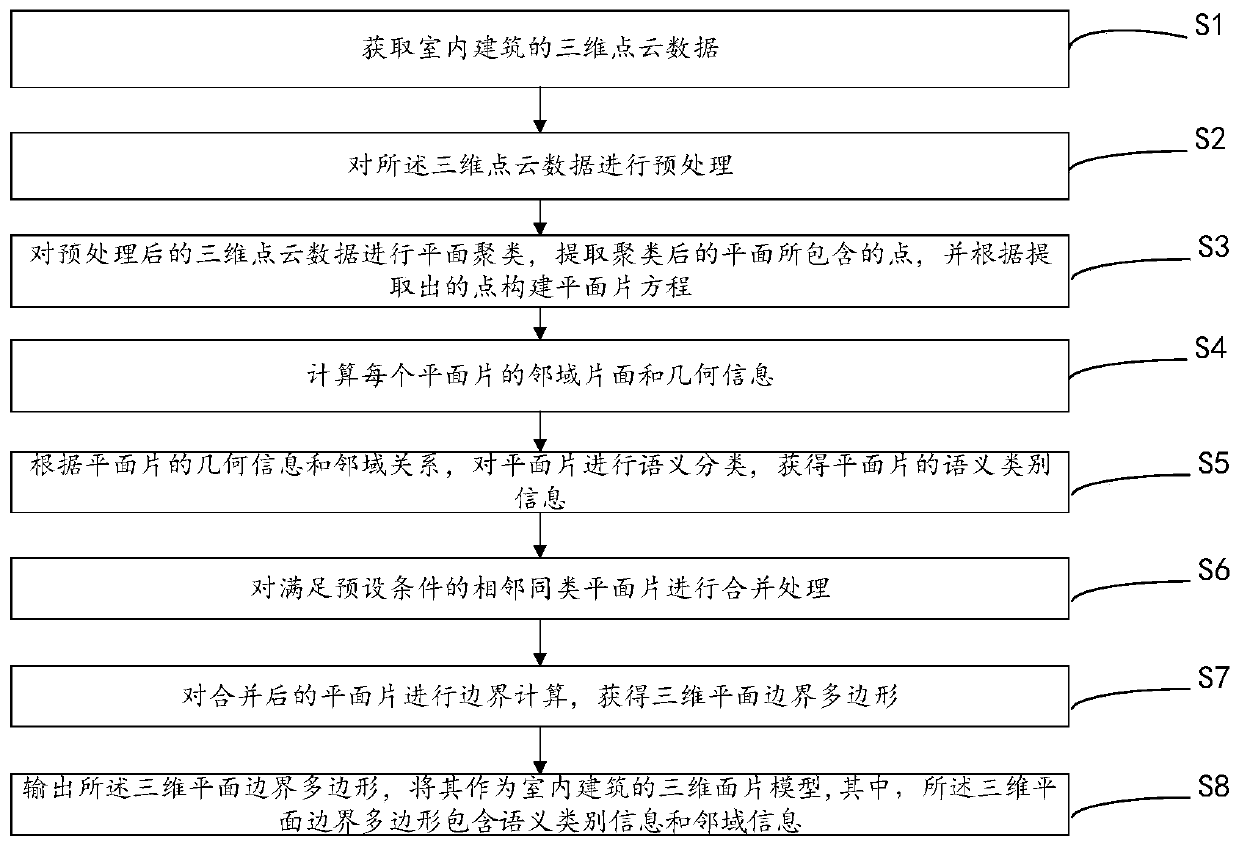

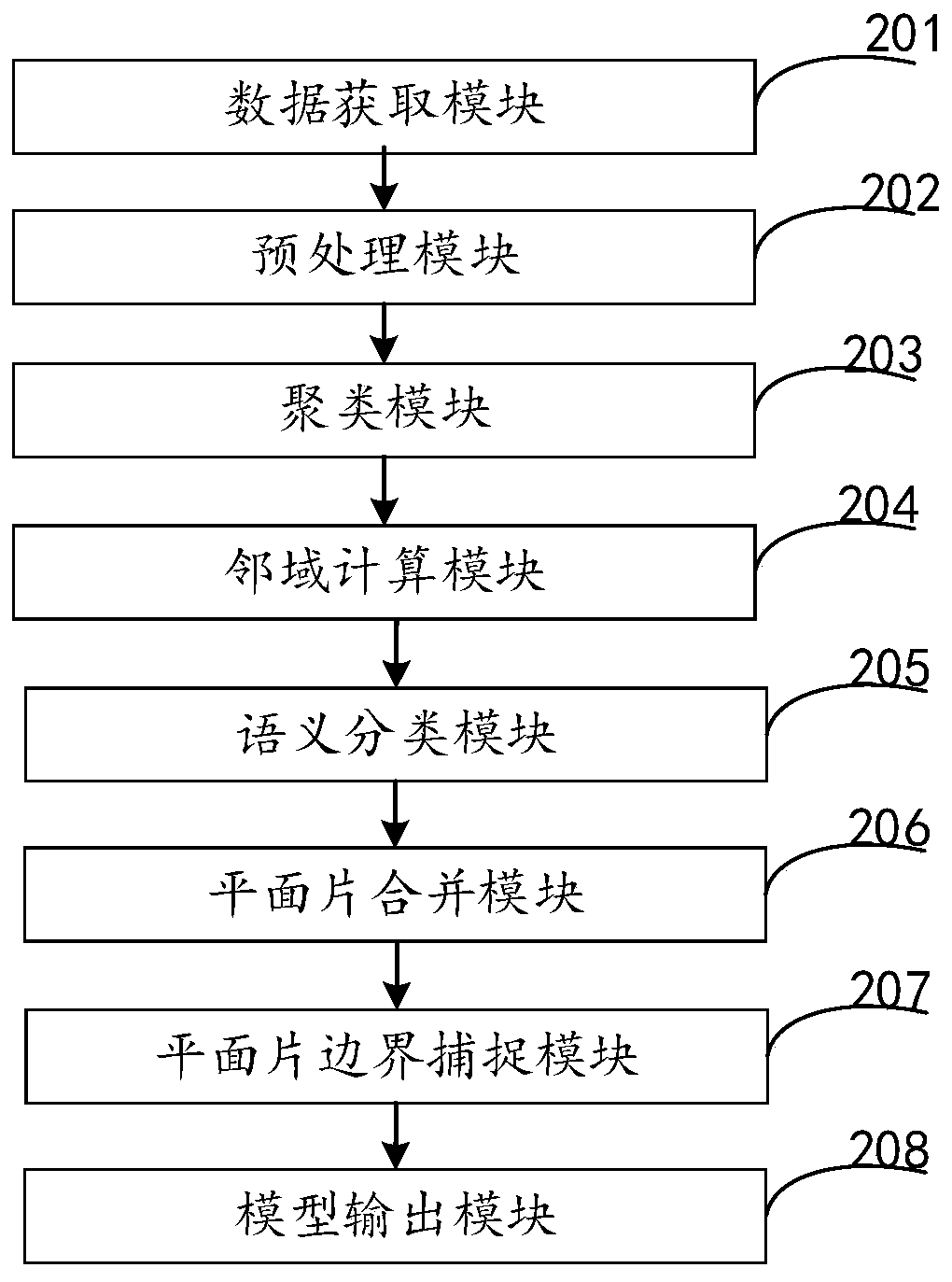

An indoor building three-dimensional modeling method and device based on point cloud data

InactiveCN109887082AImprove modeling efficiencyRich data baseCharacter and pattern recognition3D modellingObservational errorWork flow

The invention provides an indoor building three-dimensional modeling method based on point cloud data. The method comprises the steps of firstly, obtaining and preprocessing the three-dimensional point cloud data; then carrying out the point cloud plane clustering to extract plane patches, calculating the neighborhoods of the plane patches according to a point set contained in the plane patches and used for plane semantic classification, merging processing, plane boundary capturing and topological information generation, and finally outputting a closed three-dimensional patch model which is composed of three-dimensional plane polygons and contains semantic and topological information of the indoor building. According to the invention, the problems such as the measurement errors existing inpoint cloud data, the density distribution unevenness, the data is incomplete due to indoor object shielding and the lack of semantic information, are overcome, a working process for automatically and quickly establishing the three-dimensional surface patch model of the indoor building by utilizing the three-dimensional point cloud is provided, the three-dimensional point cloud data of differentsources can be processed, a new method is provided for automatic and quick modeling of the indoor building, and a rich data basis is established for the indoor three-dimensional model in the fields ofmeasurement, building decoration, property management and the like.

Owner:WUHAN UNIV

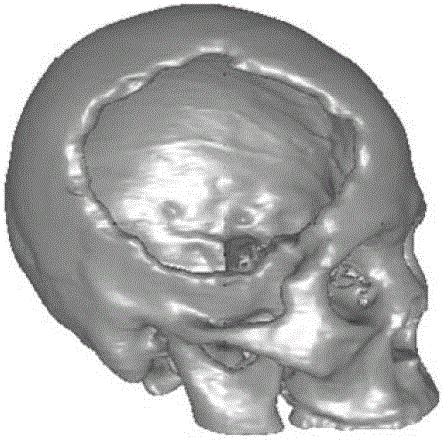

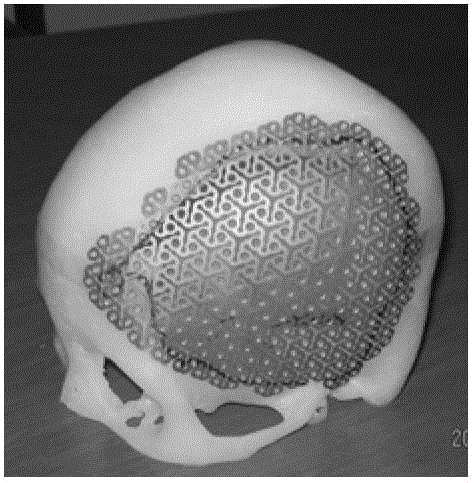

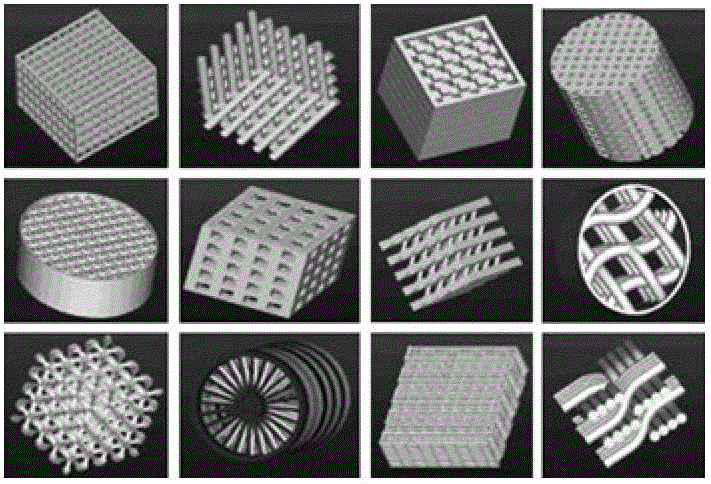

Bionic design method of skull tissue engineering scaffold

InactiveCN102973334ASuitable for growthSuitable for requirementsBone implantPatch modelThree dimensional model

The invention discloses a bionic design method of a skull tissue engineering scaffold, which comprises the following steps of: implementing three-dimensional reconstruction according to naturally aired skull micro CT (computed tomography) data to obtain a skull sample three-dimensional model; implementing statistics and analysis for the skull sample three-dimensional model to build a skull microporous structure parametric model; implementing skull scaffold bionic design through the skull microporous structure parametric model; and generating a bionic scaffold. Based on measurement of a natural skull micro CT image, the method raises three elements of a space network architecture, a cavity and a connection tube to implement the bionic design for the scaffold; an obtained internal microporous architecture is similar to a bone trabecula of a natural skull, and the average hole scale is about 500-700 microns, so that bone cell growth and climbing demands are satisfied; and moreover, the skull scaffold, obtained by intersection operation with a patch model of a coloboma part, can be matched with an adjacent part, so that the communication among holes is realized, and a bone structure of a true skull is suited better.

Owner:TIANJIN UNIV

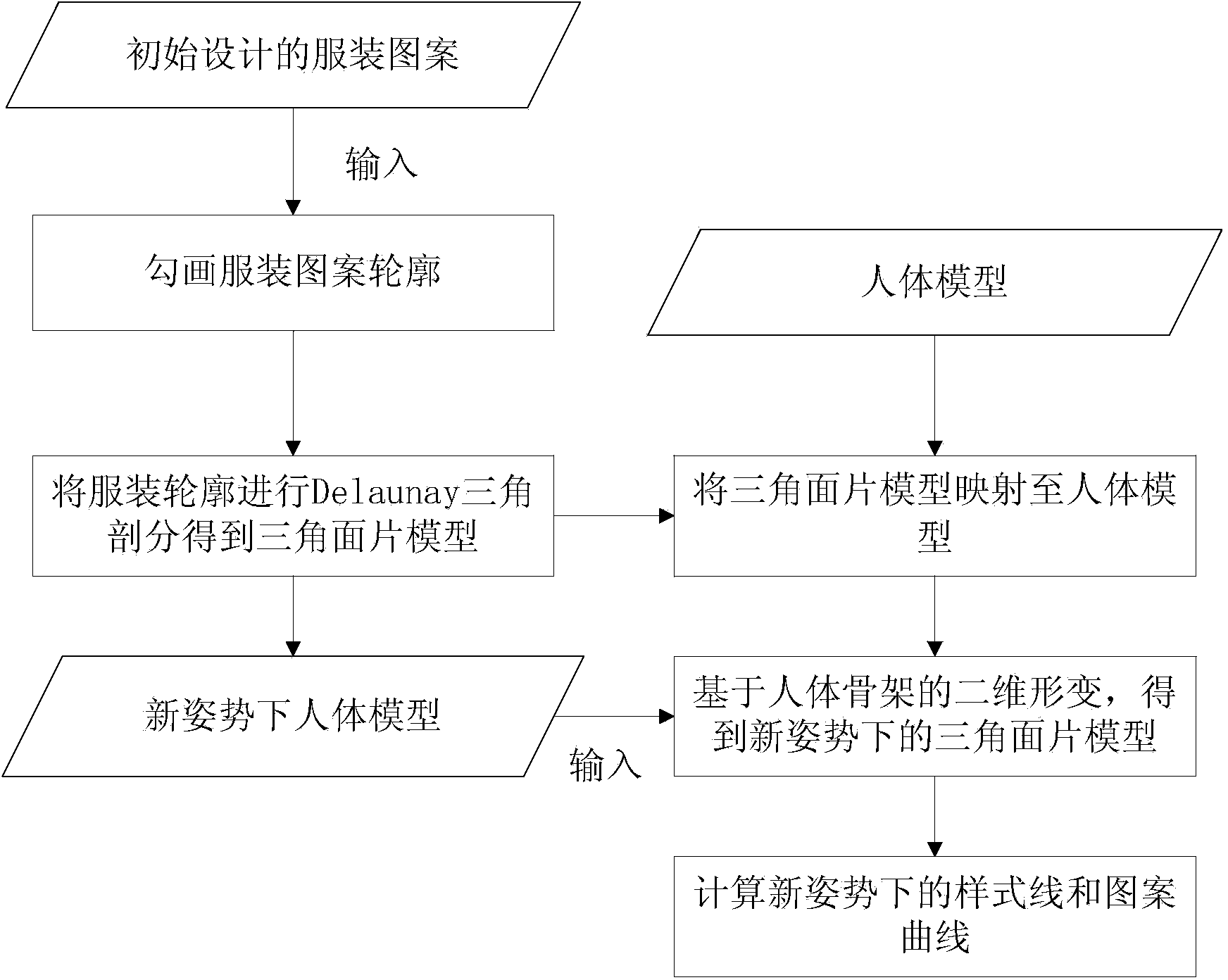

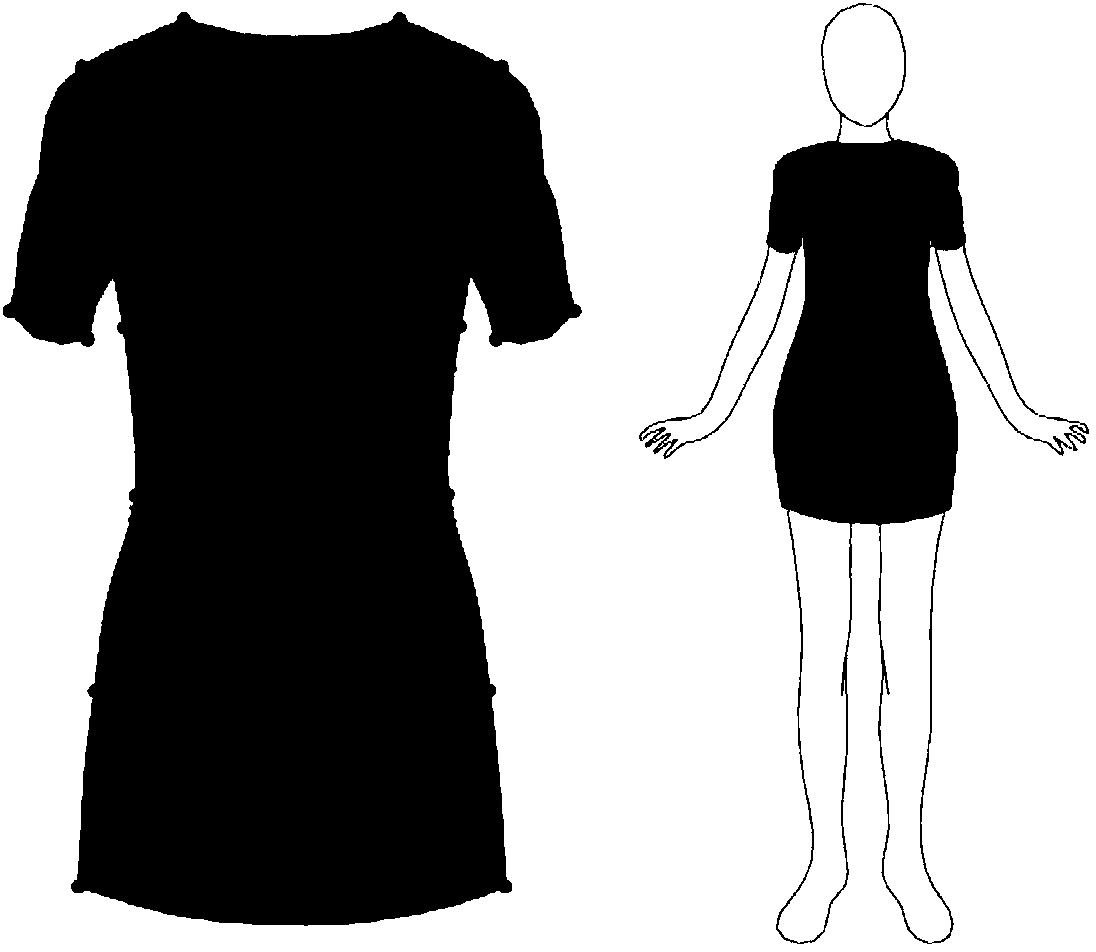

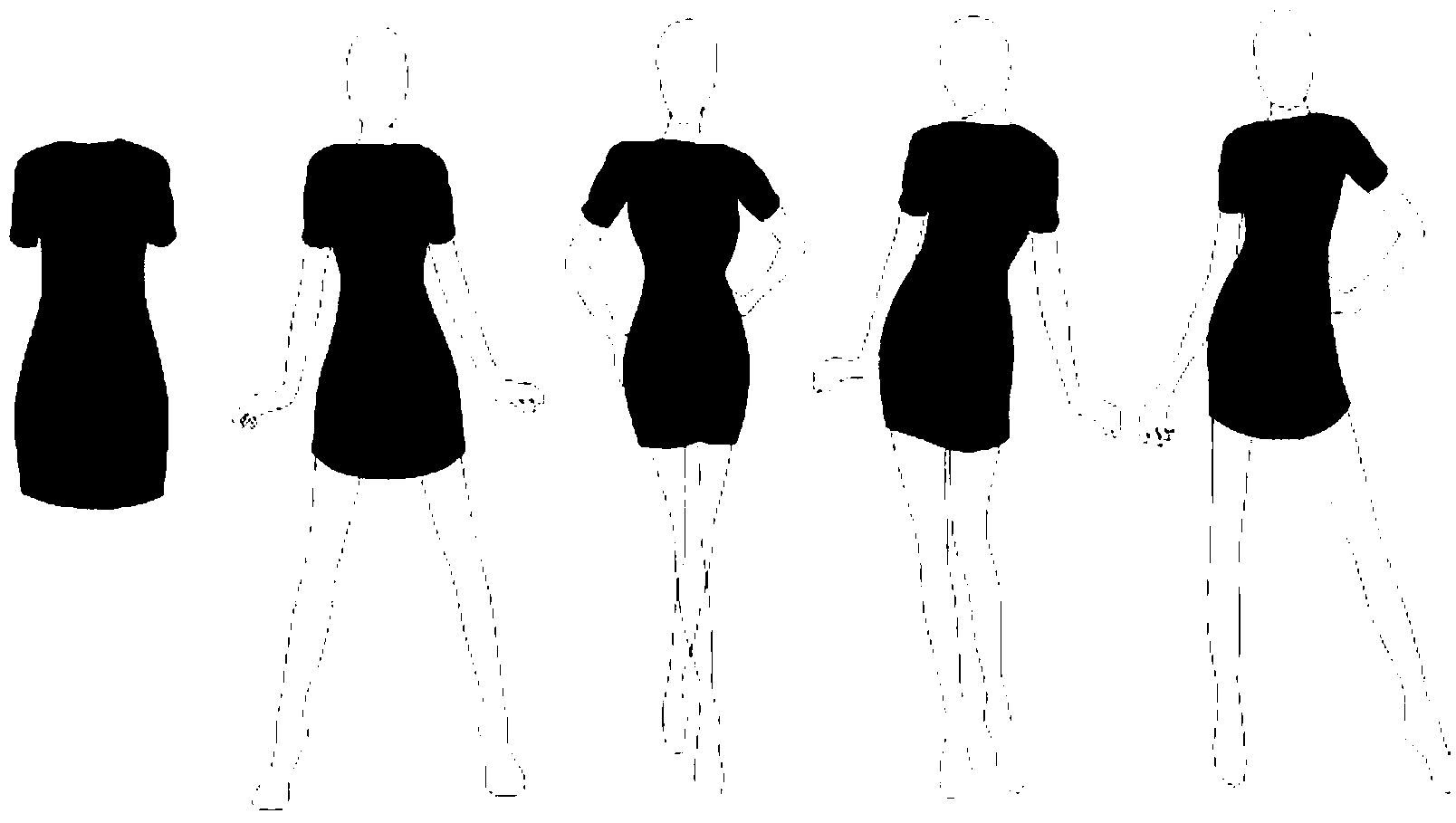

Realistic clothes creating method based on human skeleton and two-dimensional deformation

The invention provides a realistic clothes creating method based on a human skeleton and two-dimensional deformation. The realistic clothes creating method comprises the steps that (1) a clothes design is converted into a triangular patch model, the triangular patch model is mapped to a human model built in advance, the relative position relation between the triangular patch model and the human skeleton in the human model is built, and two-dimensional deformation control points of the triangular patch model are obtained; (2) the posture of the human skeleton is changed, the new positions of all the two-dimensional deformation control points are obtained according to the relative position relation obtained in the step (1), and a triangular patch model under the new posture is calculated according to the new positions of all the two-dimensional deformation control points; (3) based on the triangular patch model of the new posture, style lines and design curves in the clothes design are calculated again and rendered, and a clothes design formed after two-dimensional deformation is obtained. By means of the realistic clothes creating method, a designer can simulate fitting effects of two-dimensional clothes under different postures through a computer so that the better close-fitting clothes can be designed.

Owner:SHANGHAI LINCTEX DIGITAL TECH CO LTD

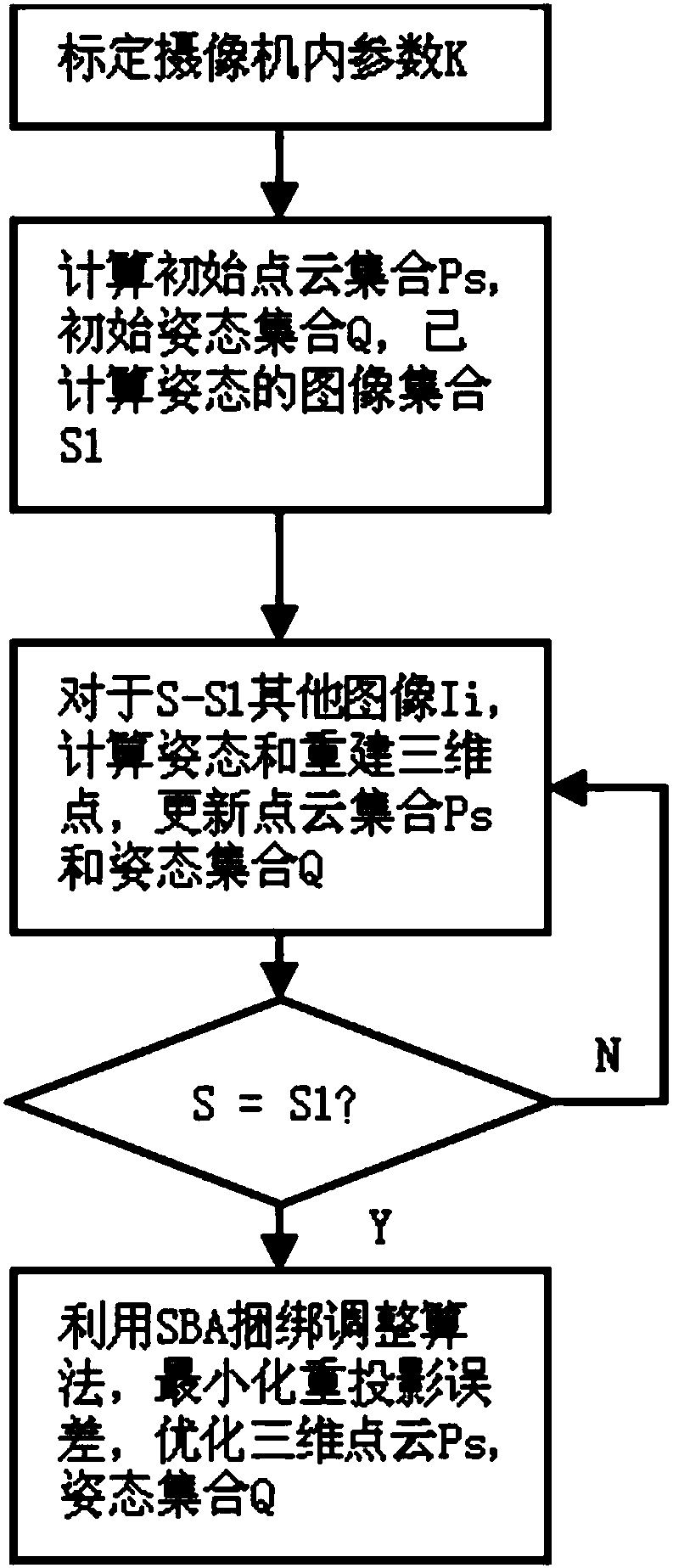

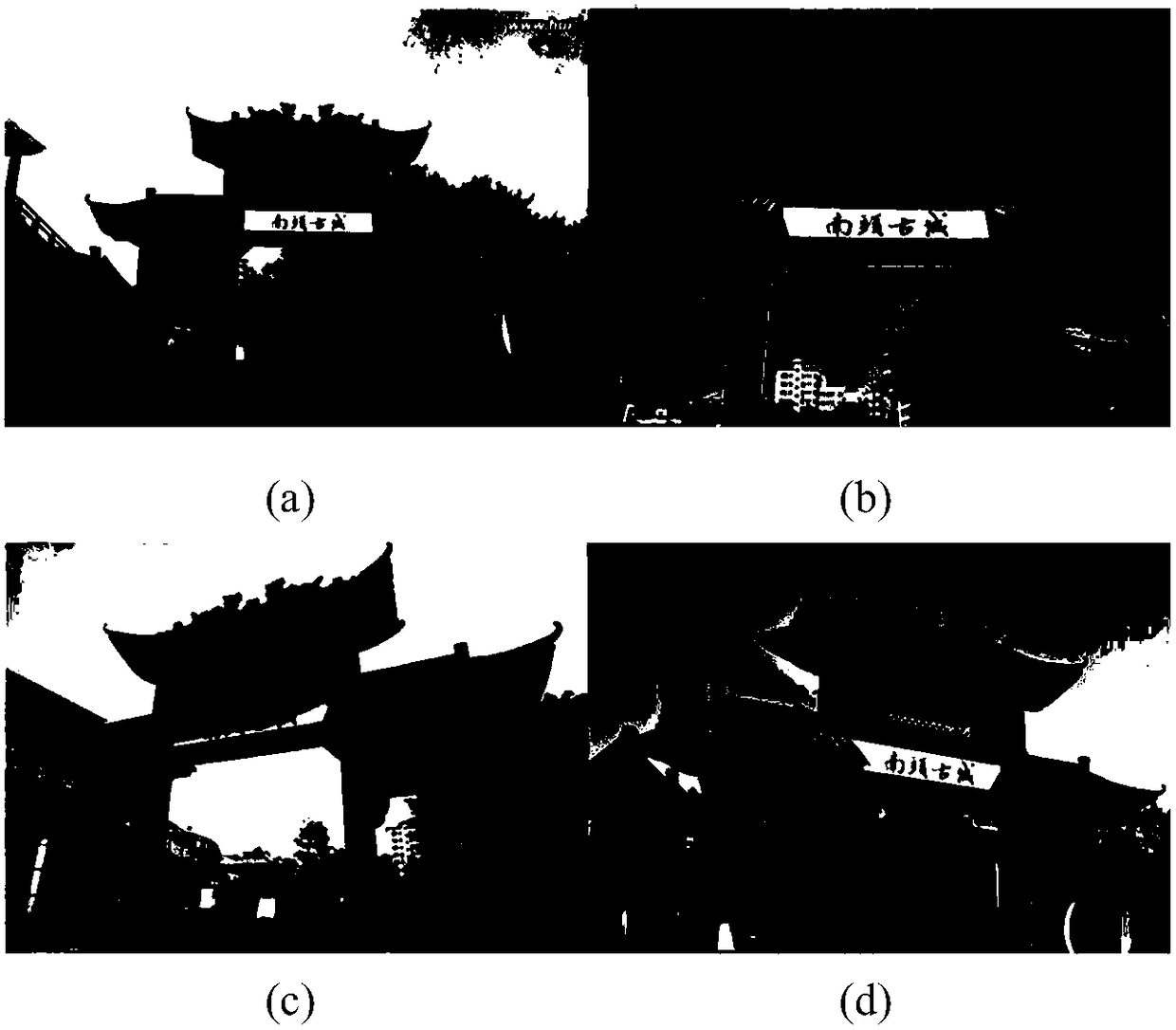

Method and device for generating ancient building model based on visual three-dimensional reconstruction

InactiveCN108537865AMeet the demands of digitalizationFast and efficient automatic generationImage enhancementImage analysisPoint cloudDimensional modeling

The invention relates to a method and device for generating an ancient building model based on visual three-dimensional reconstruction. The method comprises the following steps: 1) images of an ancient building from different visual angles are obtained; 2) features of ancient building images are extracted, and feature matching operation is performed; 3) according to a feature matching result, a relative position and posture of a camera and sparse three dimensional point clouds of ancient building are calculated at a picture taking moment; 4) according to the relative position and posture of the camera and the sparse three dimensional point clouds of the ancient building at the picture taking moment, image patch matching is used to obtain dense three dimensional point clouds of the ancientbuilding; 5) according to the dense three dimensional point clouds of the ancient building, a triangular patch model of the ancient building is generated; 6) the triangular patch model of the ancientbuilding is used to calculate texture mapping and generate a three dimensional model of the ancient building according to matching relationship between three dimensional points and images. Via the method and device, images can be rapidly and effectively generated into the three dimensional model in an automatic manner; the method and device are advantaged by high safety, low cost, strong feasibility, and the like; current demand for digitalization of the ancient building can be met.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

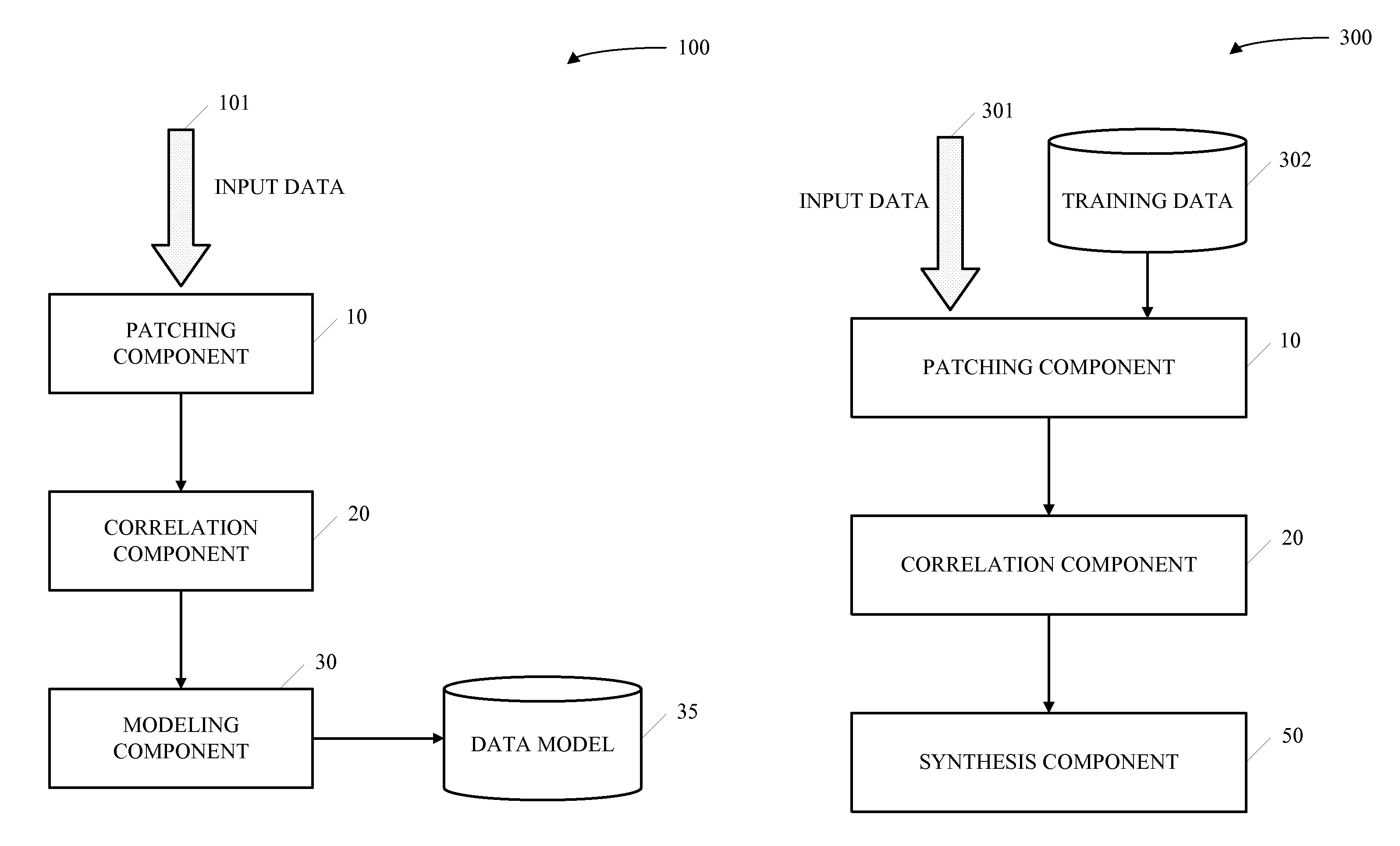

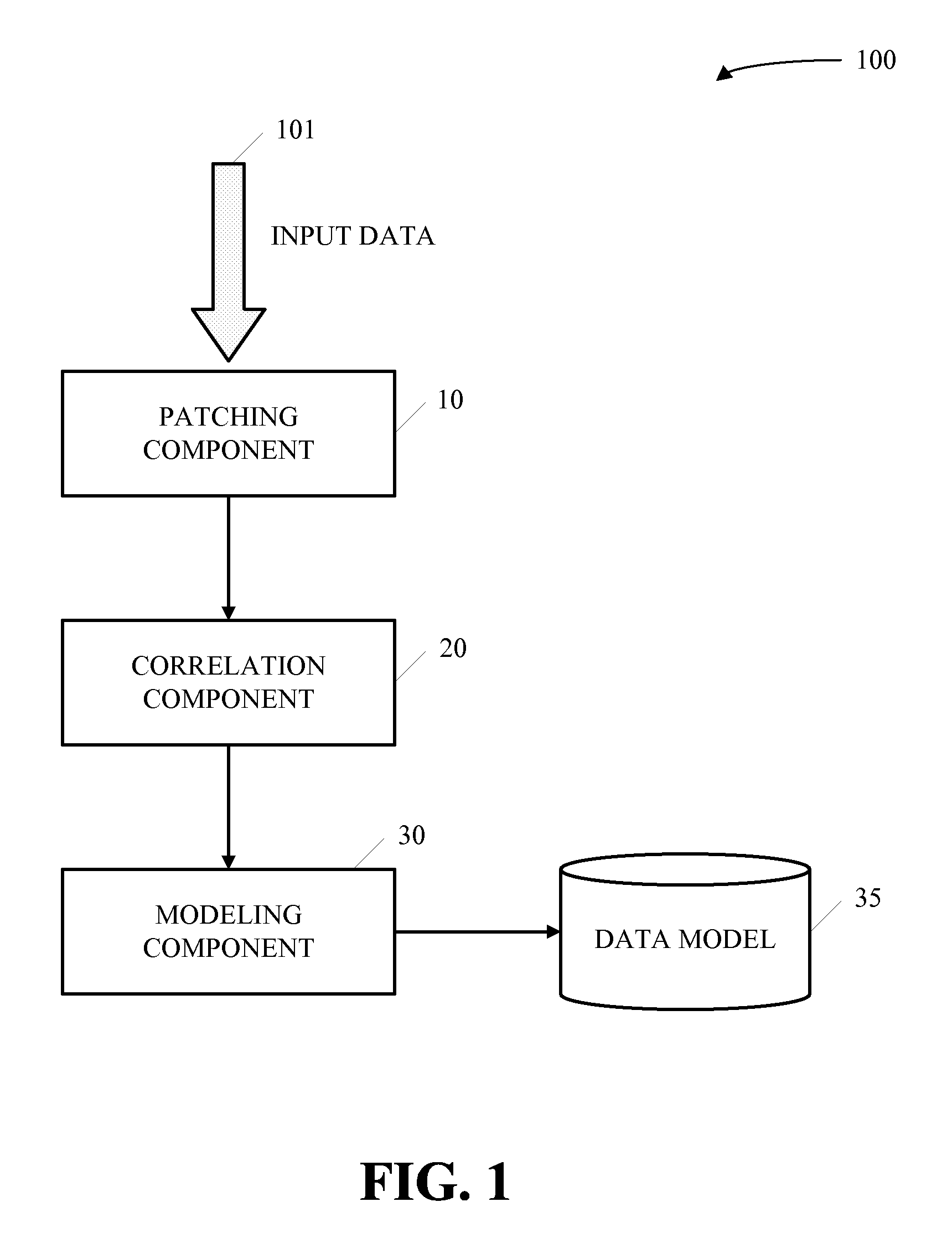

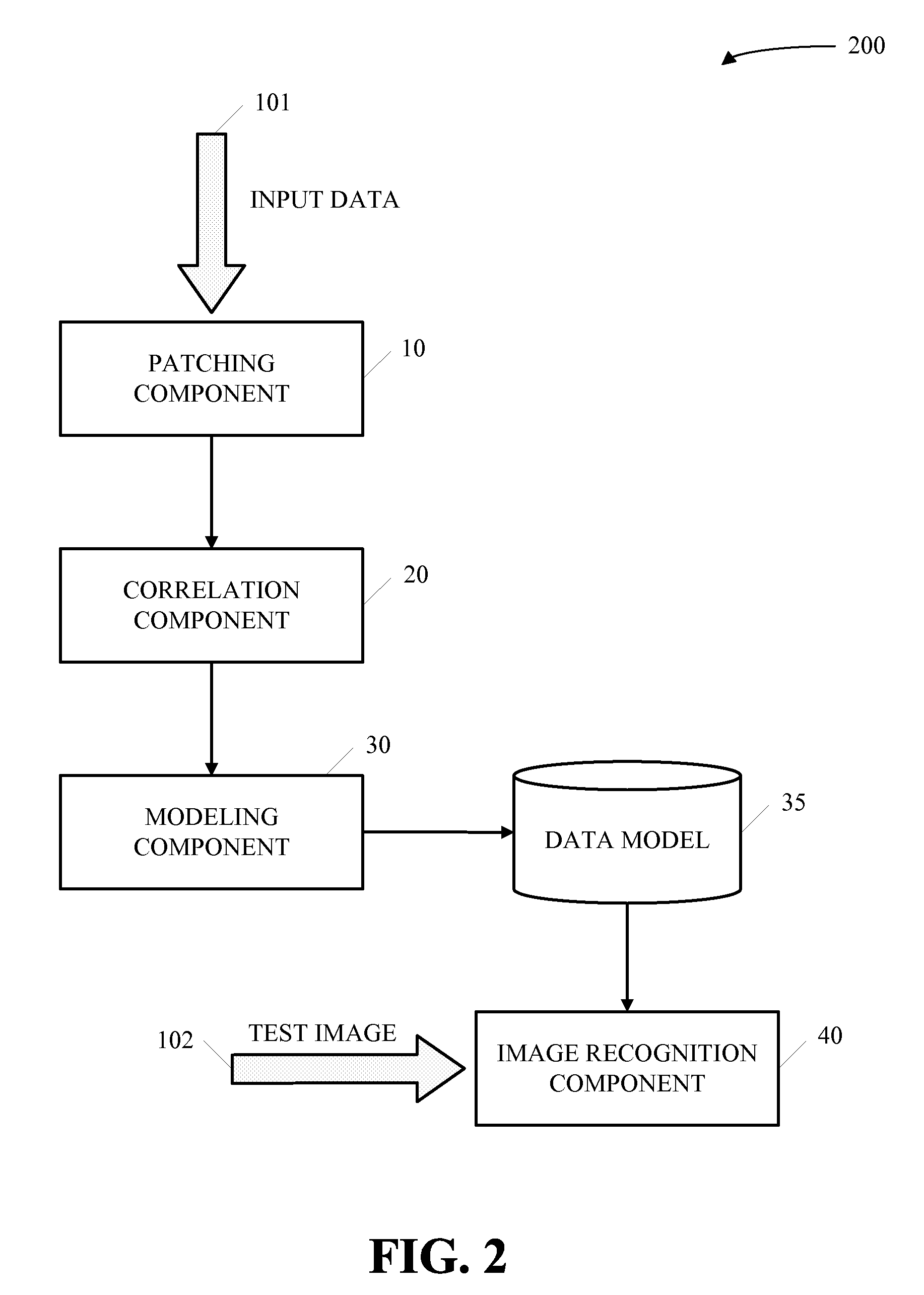

Capturing long-range correlations in patch models

Systems and methodologies for modeling data in accordance with one or more embodiments disclosed herein are operable to receive input data, create data patches from the input data, obtain long-range correlations between the data patches, and model the input data as a patch model based at least in part on the data patches and the long-range correlations. Various learning algorithms are additionally provided for refining the patch model created in accordance with one or more embodiments disclosed herein. Further, systems and methodologies for synthesizing a patch model created in accordance with various aspects of the present invention with a set of test data to perform a transformation represented by the patch model on the test data are provided.

Owner:MICROSOFT TECH LICENSING LLC

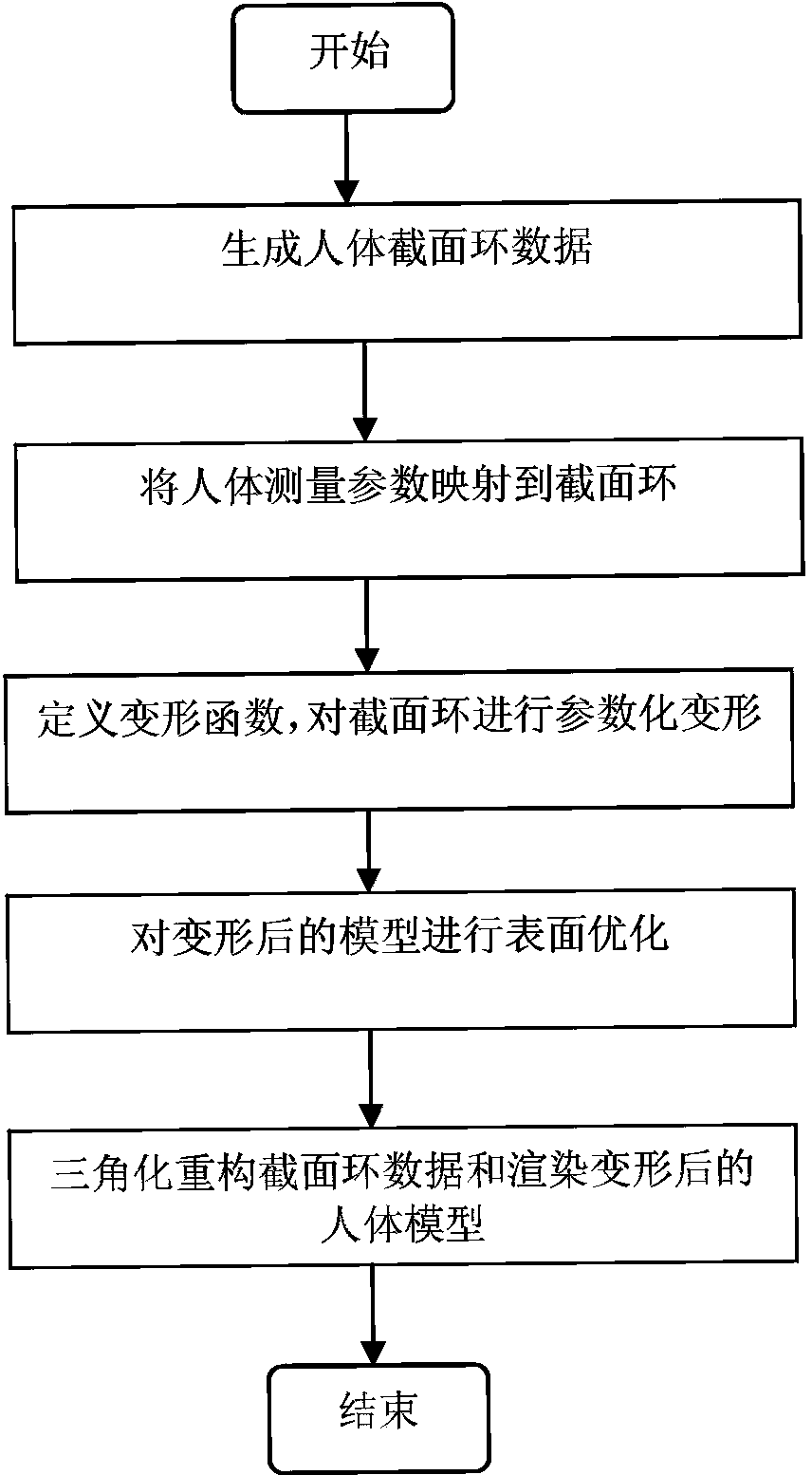

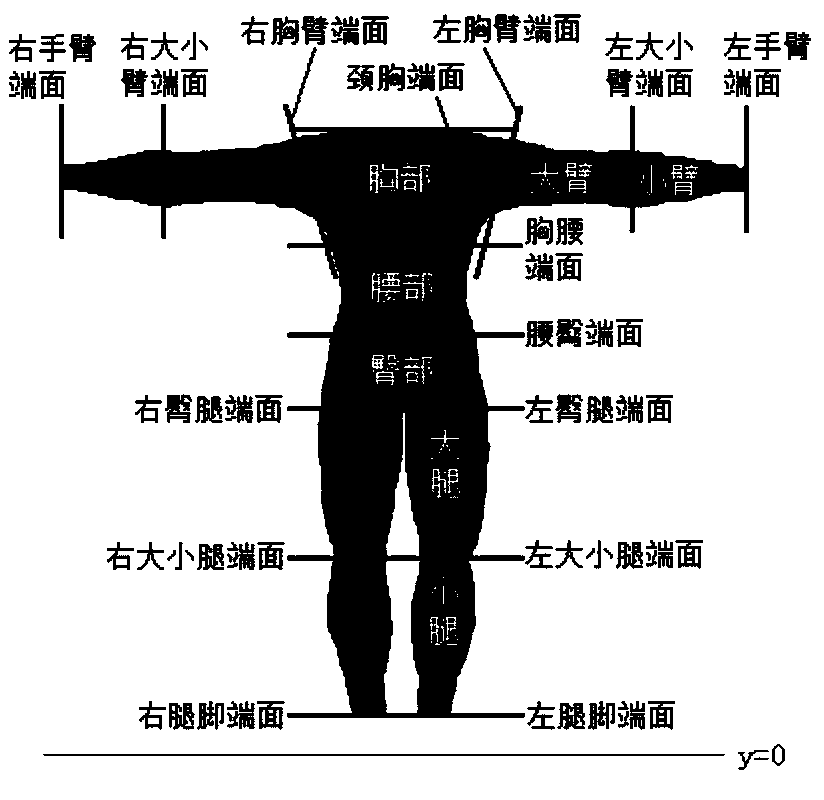

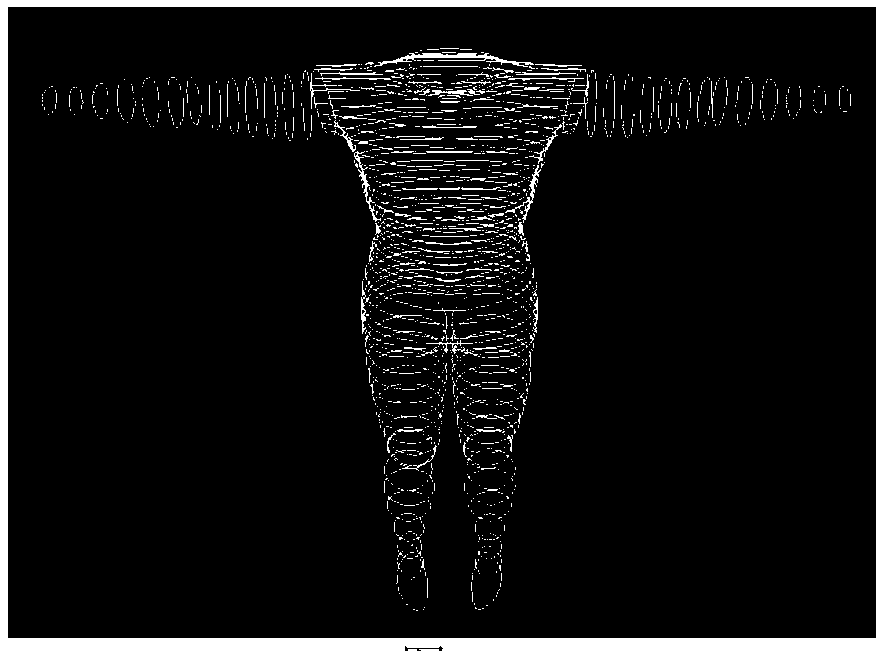

Human body section ring based parametric deformation method

InactiveCN103810750AStrong sense of realityEasy to operate3D modellingModel parametersComputer science

A human body section ring based parametric deformation method is characterized in that a human body model is organized into a section ring data structure, the whole modeling process only needs 13 commonly used human body measurement parameters, the measurement parameters are mapped with human body section rings to define a deformation function, parametric deformation is performed on the section rings, and surface optimization is performed on the deformed model, so that human body deformation with a good sense of reality can be achieved. The human body section ring based parametric deformation method includes the steps of (1) parameterizing a human body triangular patch model into a section ring data structure which is used as a standard human body model of follow-up parametric deformation; (2) mapping the selected human body measurement parameters to the human body section ring data structure; (3) defining the deformation function, and performing parametric deformation on the section rings in each part; (4) performing surface optimization on the deformed model, reconstructing section ring data into a triangular mesh structure, and rendering the deformed human body model.

Owner:BEIHANG UNIV

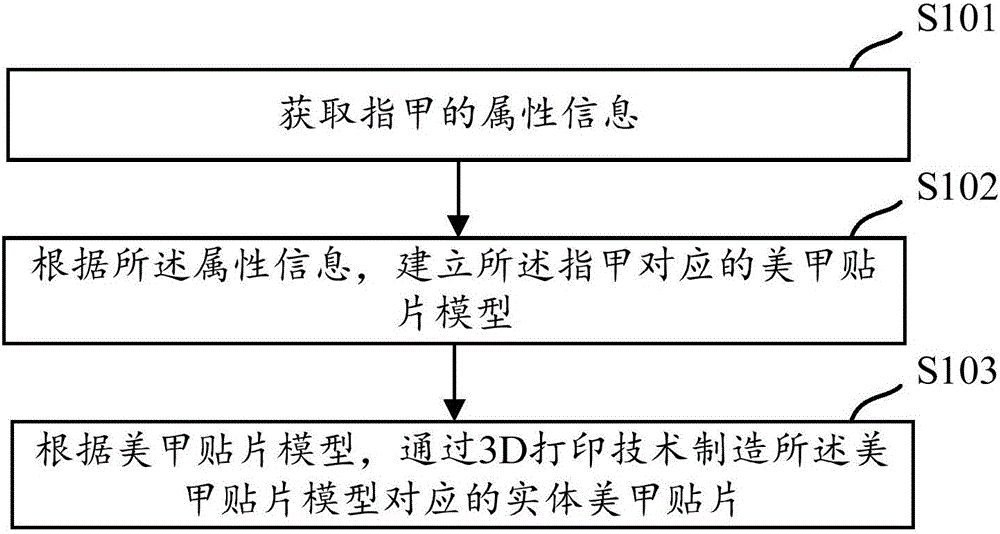

Nail patch manufacturing method and device

InactiveCN106003725AGuaranteed quality effectLong durationAdditive manufacturing apparatusPatch modelBiomedical engineering

The present application discloses a method and device for manufacturing a nail patch. The method manufactures a solid nail patch corresponding to the nail patch model through 3D printing technology according to the nail patch model. Through the above method, no matter what the pattern in the nail patch required by the customer is, the nail patch required by the customer can be printed out, which effectively reduces the requirement for the manicurist's hand-painted skills and ensures the quality of the nail art. , and can effectively deal with delicate and complex customized patterns, and the nail stickers are all integrally formed by 3D printing technology, which can effectively prevent the surface accessories from falling off, and the nail effect lasts for a long time.

Owner:北京易速普瑞科技股份有限公司

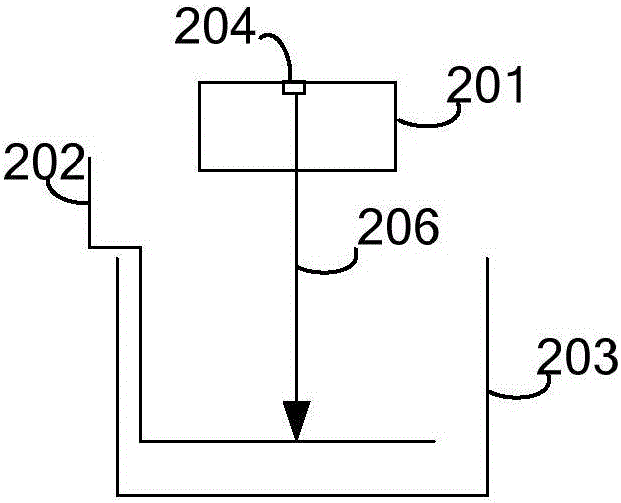

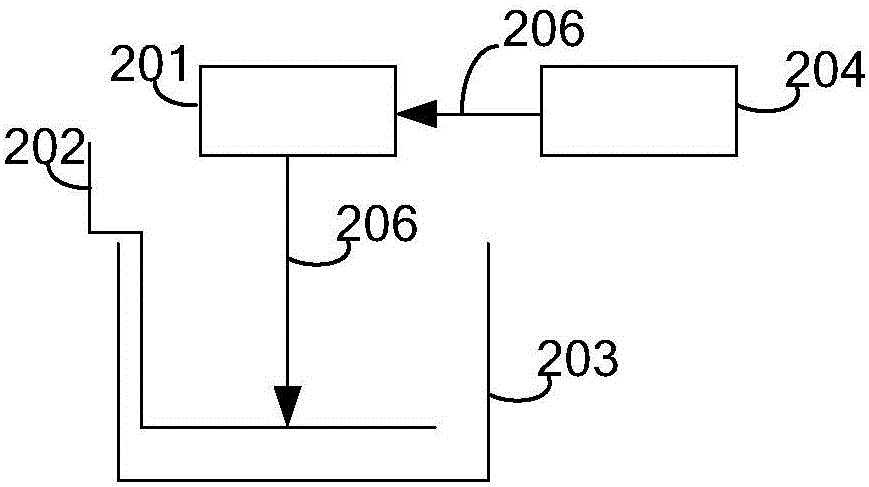

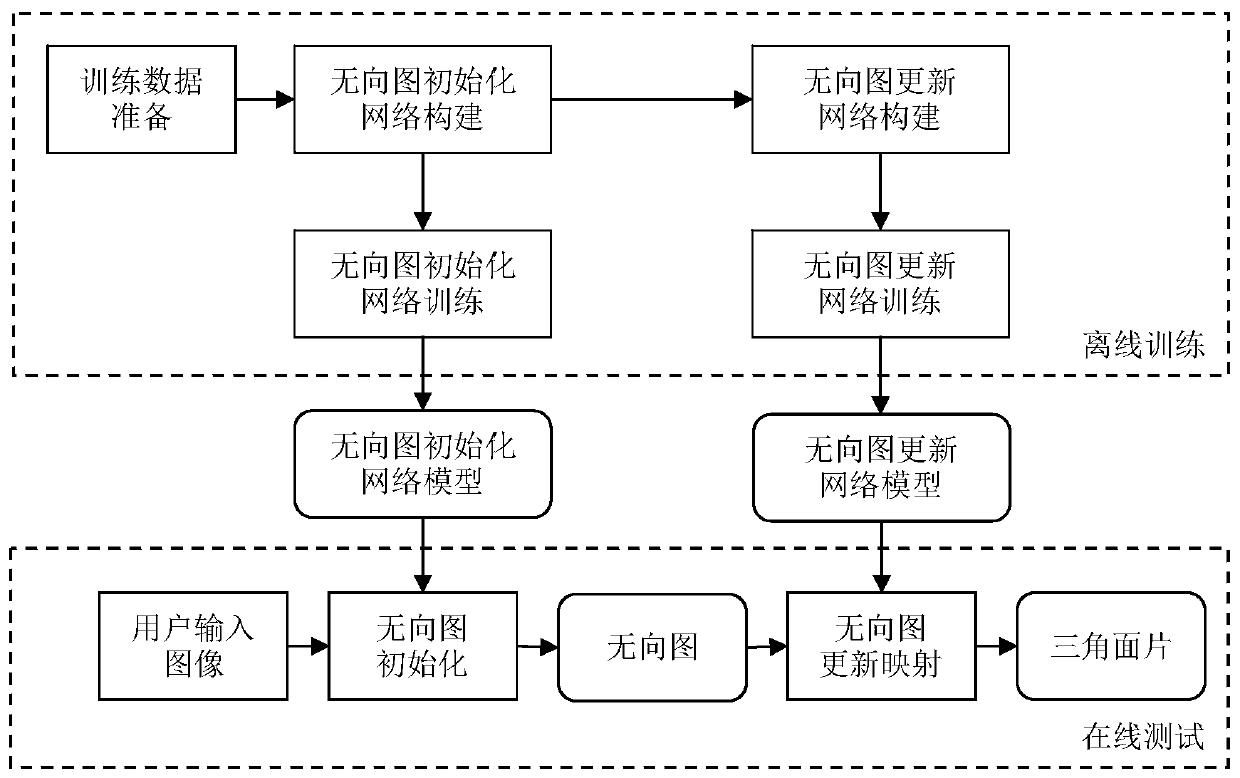

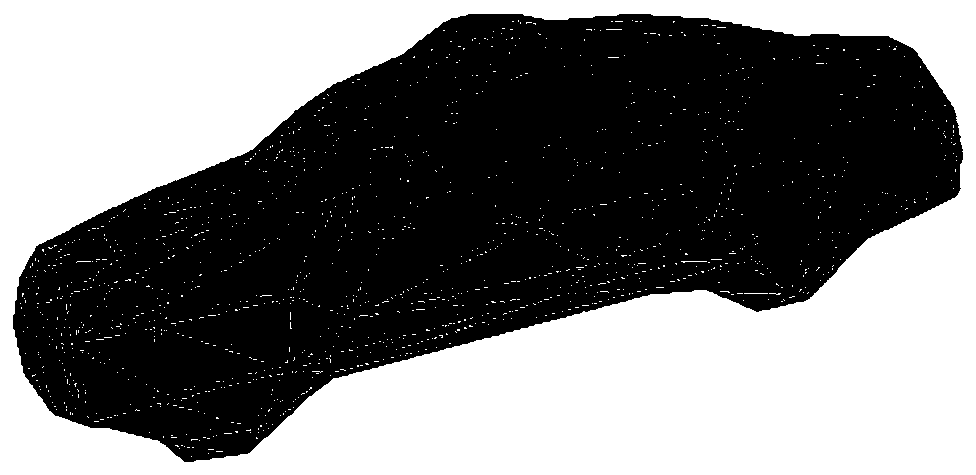

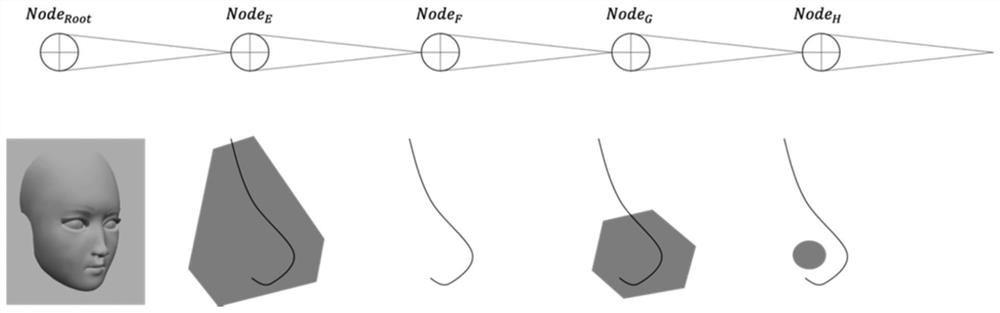

Single image patch reconstruction method based on undirected graph learning model

ActiveCN110163974AReduced shooting burdenEasy to useImage enhancementImage analysisNODALUndirected graph

The invention discloses a single image patch reconstruction method based on an undirected graph learning model. The method comprises the steps of performing multi-view rendering on three-dimensional models in an existing three-dimensional model set to obtain a training image set; representing the patch by using an undirected graph learning model, establishing an undirected graph initialization network consisting of image coding and camera view angle estimation, obtaining camera view angle parameters corresponding to the image, and projecting the initial patch according to the camera view angleparameters obtained by estimation to obtain undirected graph initial characteristics; establishing an undirected graph LSTM network structure and an undirected graph CNN network structure, performingfeature updating on the undirected graph model, and mapping each node of the undirected graph to coordinates in a three-dimensional space to obtain each vertex position of the triangular patch; establishing an undirected graph initialization network and an undirected graph updating network loss, and performing multi-stage training on the neural network; and performing three-dimensional reconstruction on the input image by using the trained network to obtain a final patch model.

Owner:NANJING UNIV

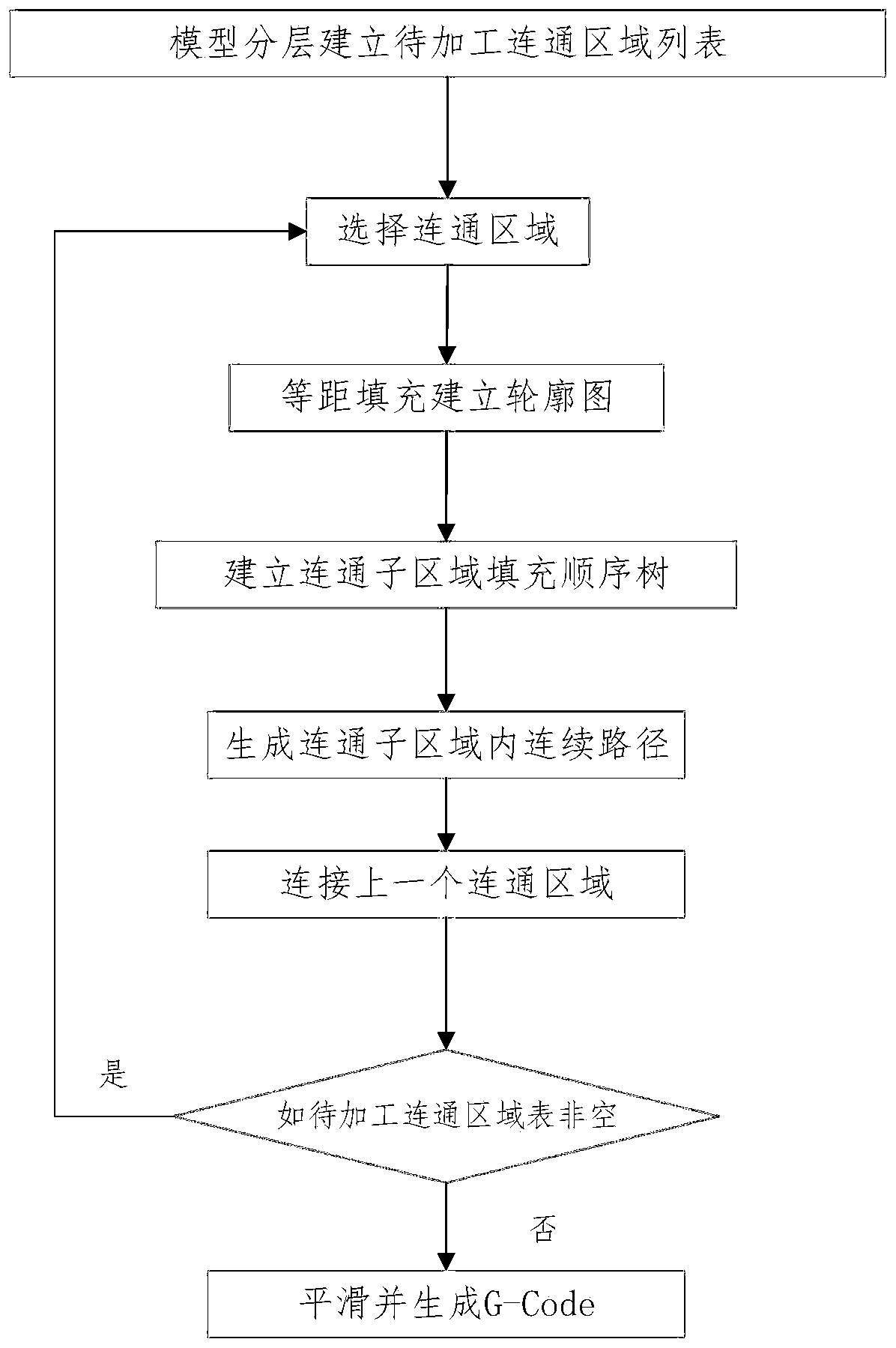

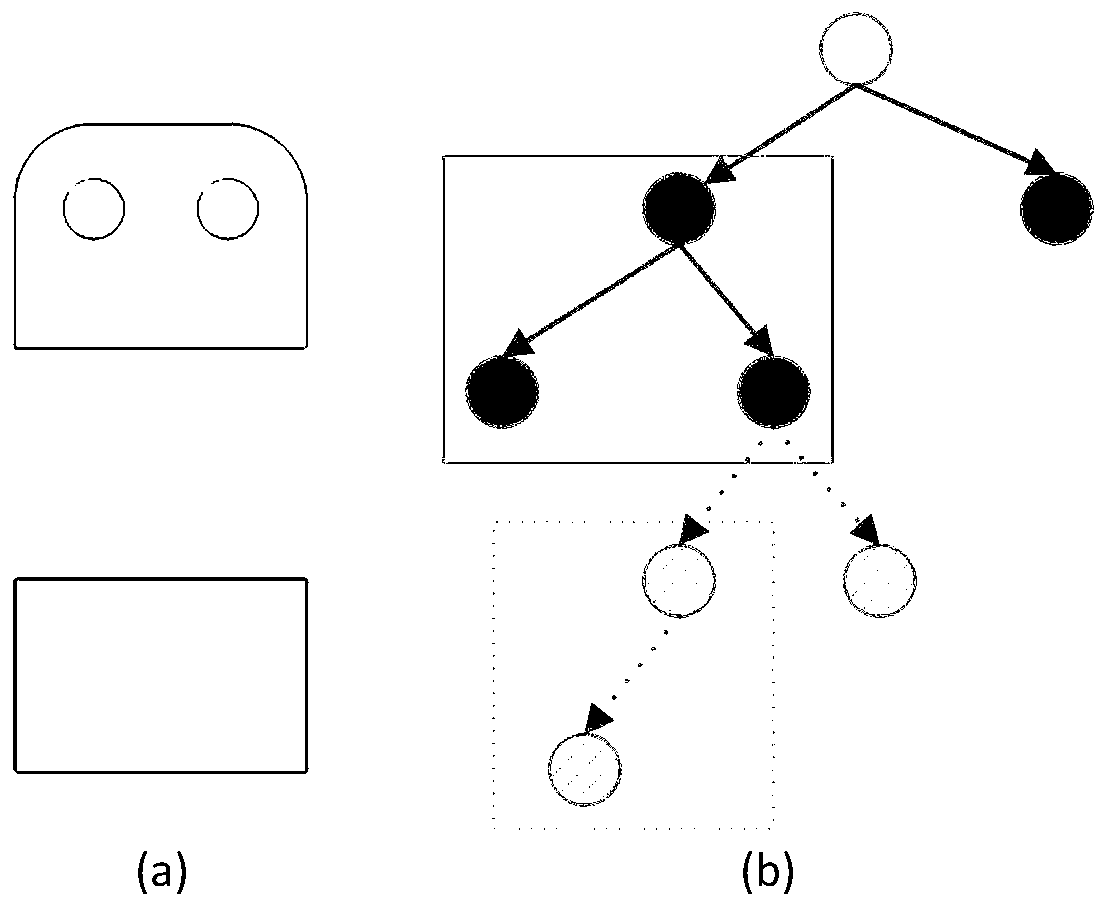

3D continuous route generation method for fused deposition manufacturing

ActiveCN109808171AAvoid designLow costAdditive manufacturing apparatus3D object support structuresGlass fiberFiber

The invention relates to a 3D continuous route generation method for fused deposition manufacturing. The method comprises the following steps: obtaining a group of slices for processing a triangular surface patch model based on the printing direction and layer thickness, and obtaining a closing boundary of each given communication zone; sequentially accessing each layer from the communication zonewith the maximum area of the slices at the first layer; sequentially selecting the next communication area based on the area of zone, distance and collision detection relation, and building a communication sub-zone array to be treated; sequentially generating continuous 2D filling routes of which entrances are close to exits for each communication sub-zone in the communication sub-zone array to be treated; and connecting the entrances and the exits of filling routes in adjacent communication sub-zones in the communication sub-zone array to be treated so as to generate the 3D continuous filling route. The experiment verifies that the method is applicable to fused deposition printing technologies on the basis of continuous reinforced carbon fiber materials, continuous biological fiber materials and continuous glass fiber materials; an additional front end fiber cutting device is not designed, so that the cost is decreased; and the difficulty in post-treatment is reduced.

Owner:HANGZHOU DIANZI UNIV

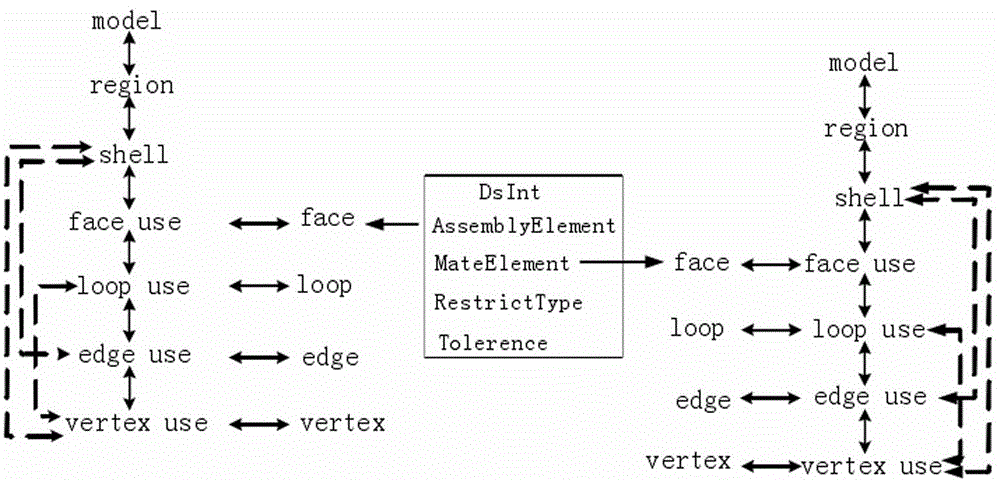

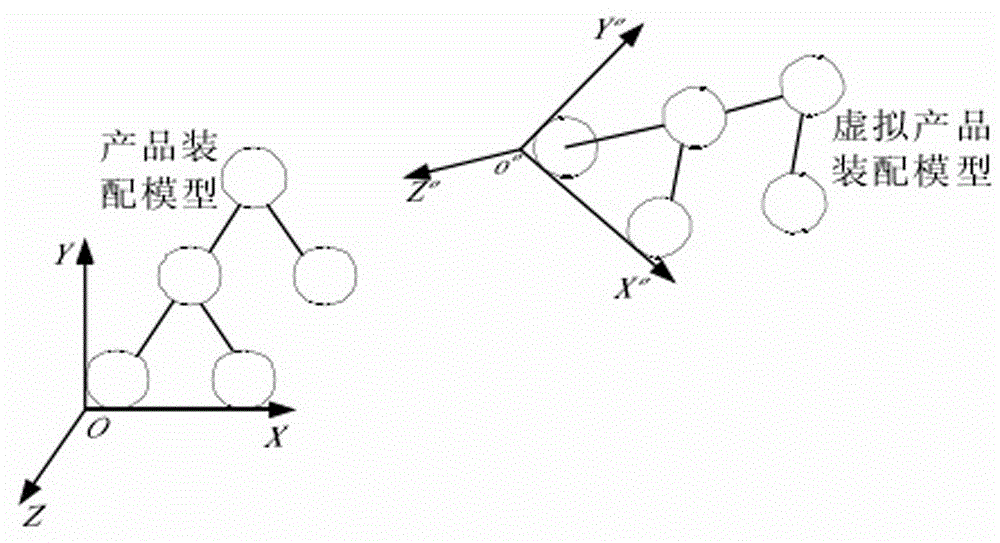

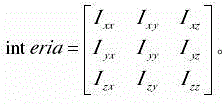

Construction method of product simulation three-dimensional model

InactiveCN104598697AAvoid lostAccurate analysisSpecial data processing applicationsComputer Aided DesignReal-time simulation

The invention provides a construction method of a product simulation three-dimensional model. The method is characterized by comprising the following steps: S1, acquiring prototype data of components, and obtaining physical attribute of the components; establishing a geometric model formed by a triangular patch model outputted by a CAD (computer aided design) system; S2, setting a constraint condition for assembling the components; S3, establishing assembly relation information of the components; generating an assembly relation information set of virtual components; S4, automatically searching the assembly relation information set of the component, finding characteristics of the component corresponding to the assembly relation information set, and realizing the assembly by virtue of the characteristics and the constraint relation between the component and the corresponding component characteristics; S5, simulating the physical attribute of the component. The design information is inputted into a real-time simulation virtual environment in the process for inputting the CAD data into the virtual environment, and the assembly relation information of the components is mapped to the real-time simulation virtual component model, so that the completeness of the design information of the components can be guaranteed.

Owner:GUANGDONG HANGYU SATELLITE TECH

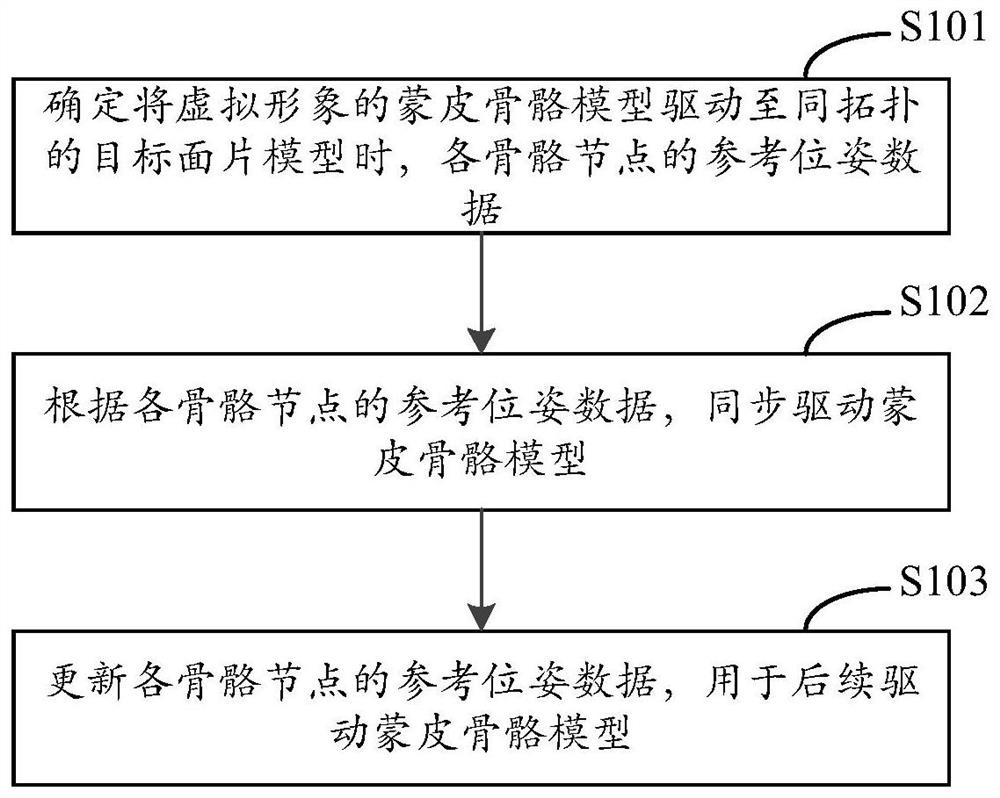

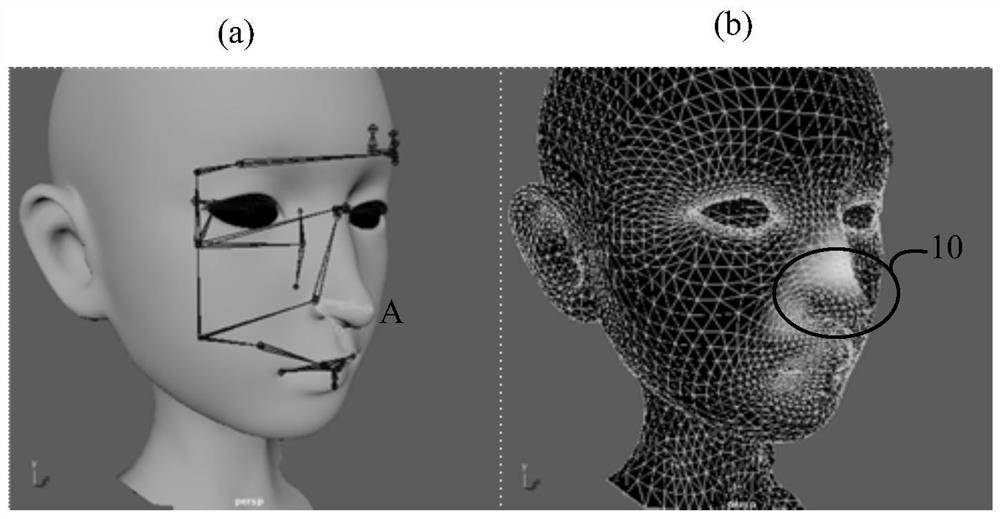

Virtual image driving method and device, equipment and storage medium

The invention discloses a virtual image driving method, device and equipment and a storage medium, and relates to the field of computer vision, augmented reality and deep learning. According to the specific implementation scheme, the method comprises the steps of determining reference pose data of each skeleton node when a skin skeleton model of a virtual image is driven to a target patch model ofthe same topology; synchronously driving the skin skeleton model according to the reference pose data of each skeleton node; and updating the reference pose data of each skeleton node for subsequently driving the skinned skeleton model. The driving efficiency of the skinned skeleton model is improved.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

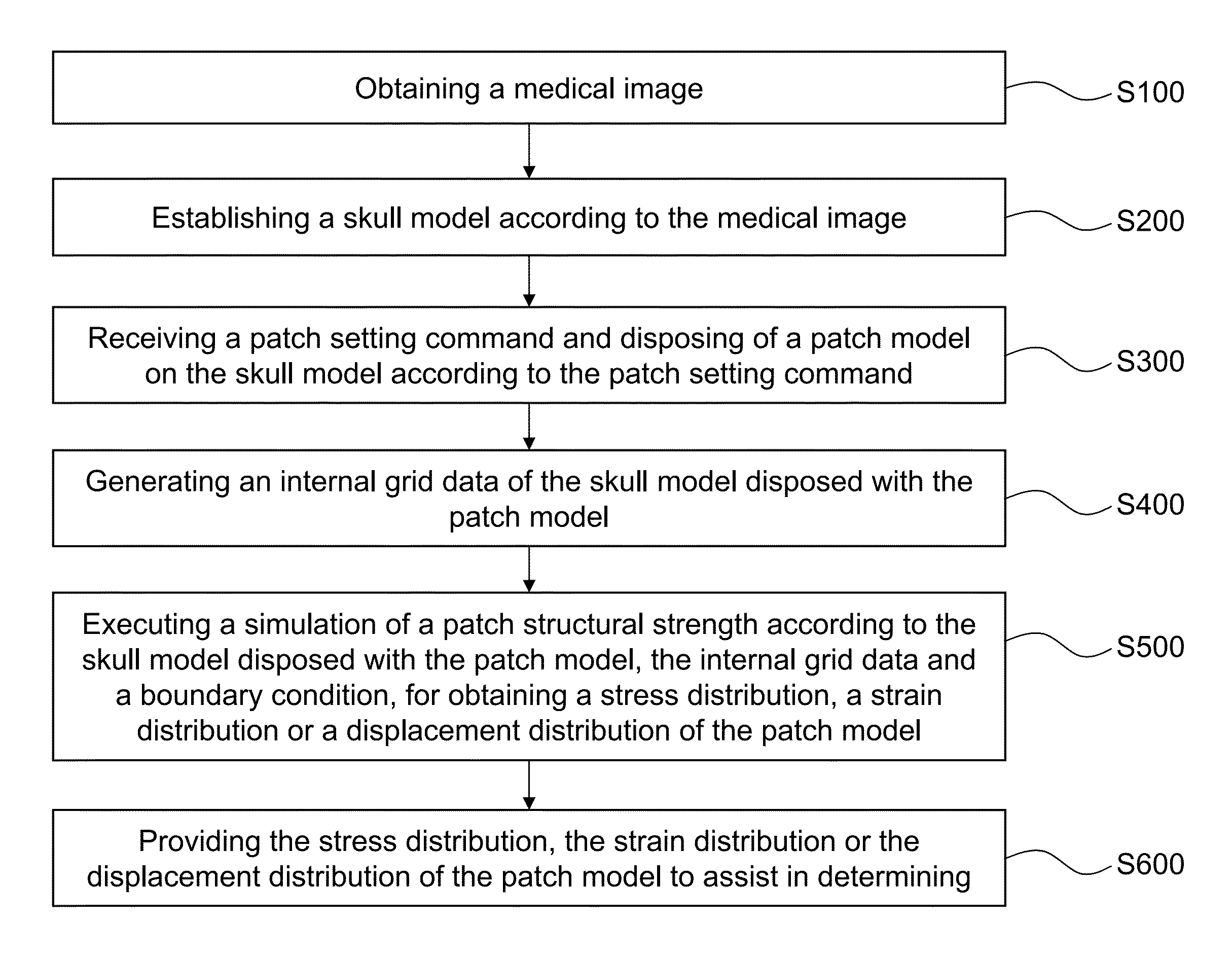

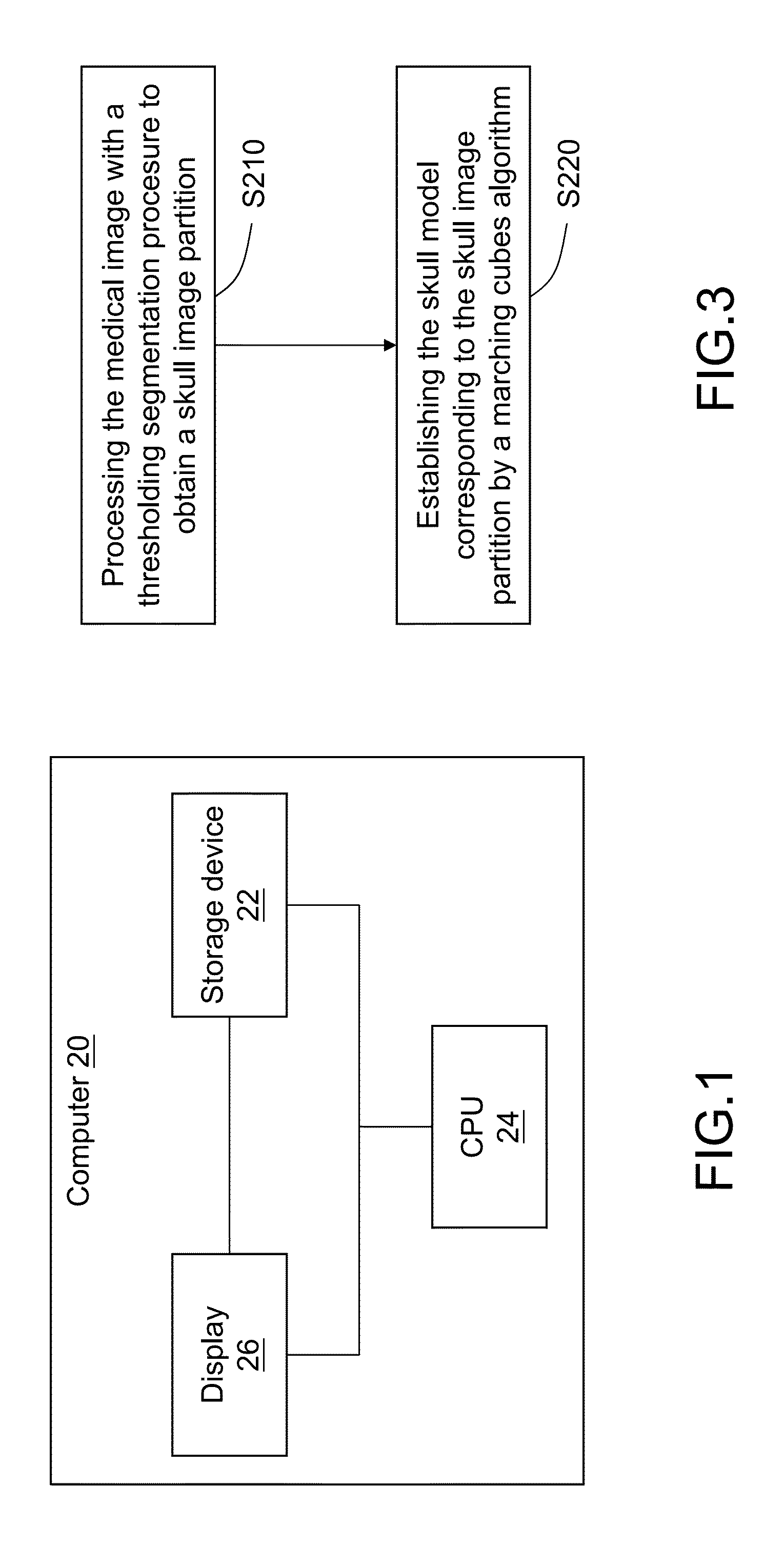

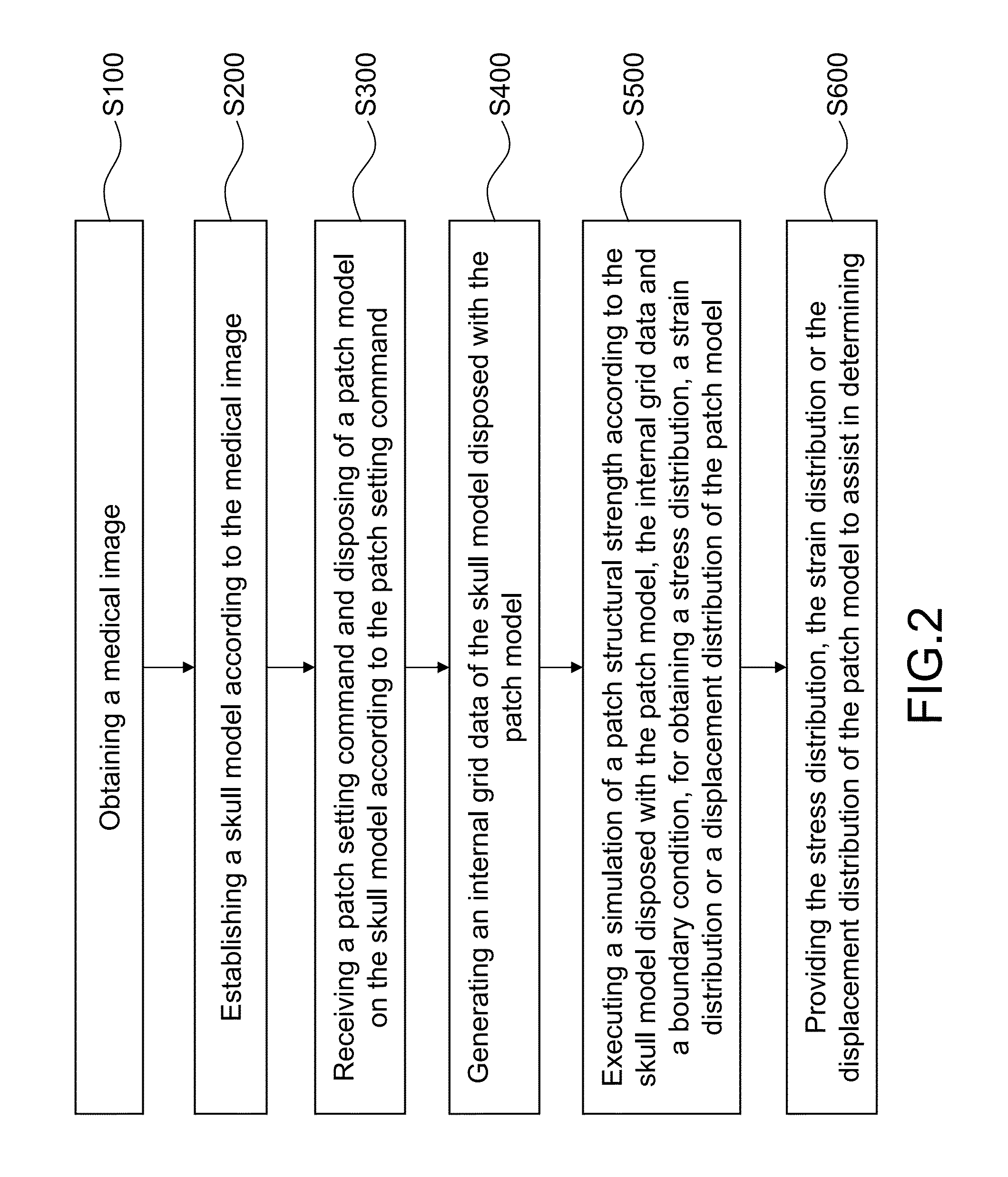

Method for assisting in determining strength of fixing craniofacial surgery patch and computer using the same

InactiveUS20130103375A1Analogue computers for chemical processesImage data processingStress distributionCraniofacial surgery

A computer for assisting in determining the strength of fixing a craniofacial surgery patch comprises a storage device for storing a medical image and a central processing unit, the central processing unit carry out a method for assisting in determining the strength of fixing a craniofacial surgery patch. The method includes obtaining a medical image; establishing a skull model according to the medical image; receiving a patch setting command, and disposing a patch model on the skull model according to the patch setting command; generating an internal grid mesh data of the skull model disposed with the patch model; executing a biomechanical simulation of a patch structural strength according to the skull model disposed with the patch model, the internal grid mesh data and a boundary condition; and providing a stress distribution, a strain distribution or a displacement distribution of the patch model to assist in determining.

Owner:NAT APPLIED RES LAB

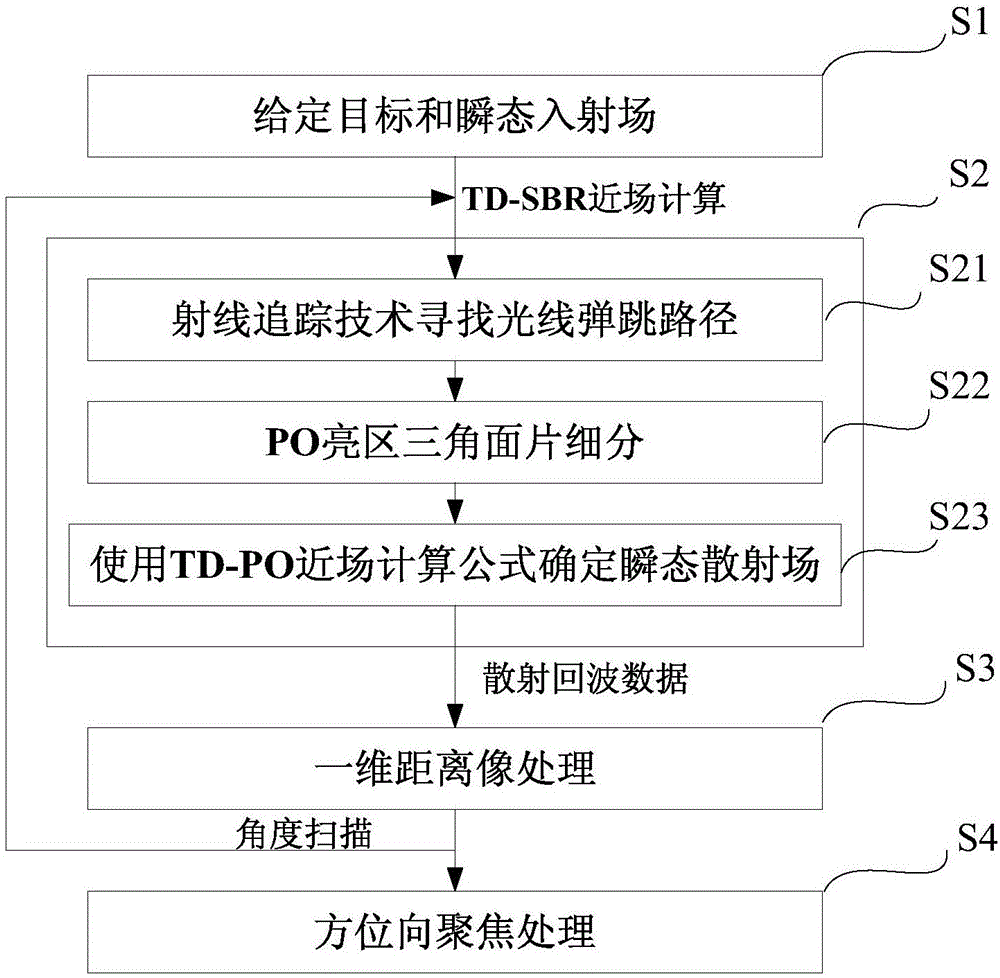

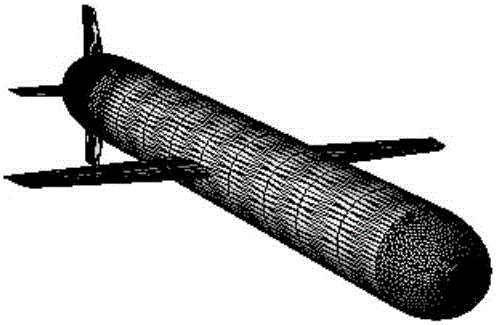

ISAR imaging simulation method based on time domain shooting bouncing ray quick near-field calculation

ActiveCN106556833ACalculation speedImprove calculation accuracyRadio wave reradiation/reflectionPatch modelDelay calculation

The invention relates to an ISAR imaging simulation method based on time domain shooting bouncing ray-method quick near-field calculation. The method comprises steps of (S1) setting a target triangular patch model and transient incident field capable of being any time domain waveform, (S2) employing a time domain shooting bouncing ray quick near-field calculation method to calculate a transient near-field scattering echo illuminated on the target triangular patch model by time domain plane waves, (S3) unifying the target transient near-field scattering echo in a frequency domain according to an incident signal, and (S4) repeatedly executing step 2 and 3 according to angle width and sampling density required by ISAR imaging definition to achieve echo data of a selected angle sample, and then conducting azimuth focusing to achieve a target ISAR image. Real narrow pulse broadband radar close range imaging detection can be simulated; quick calculation speed, high calculation precision and wide application range can be achieved; and pre-estimating data can be provided for target near-field scattering image diagnosis, so cost can be reduced.

Owner:SHANGHAI RADIO EQUIP RES INST

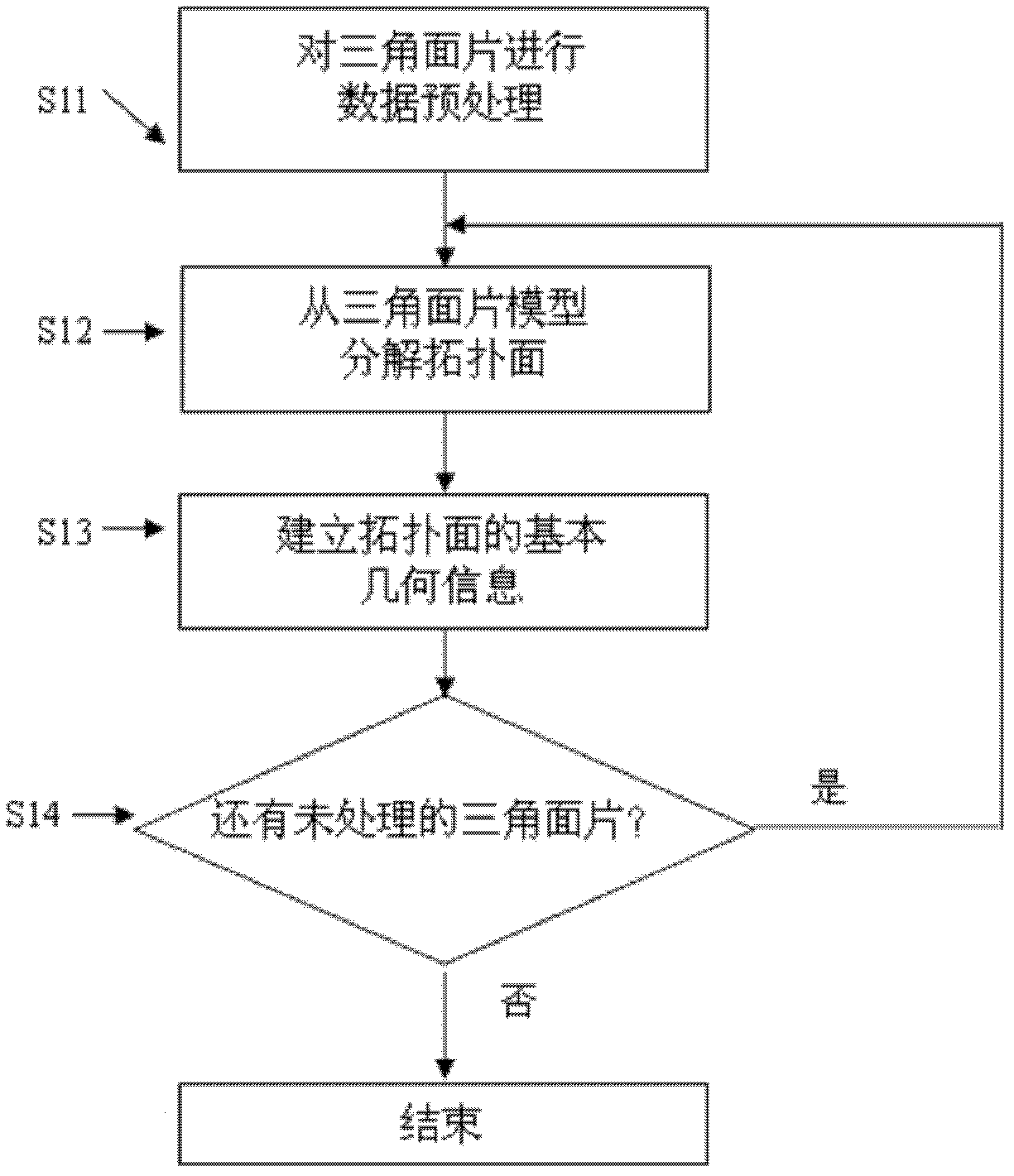

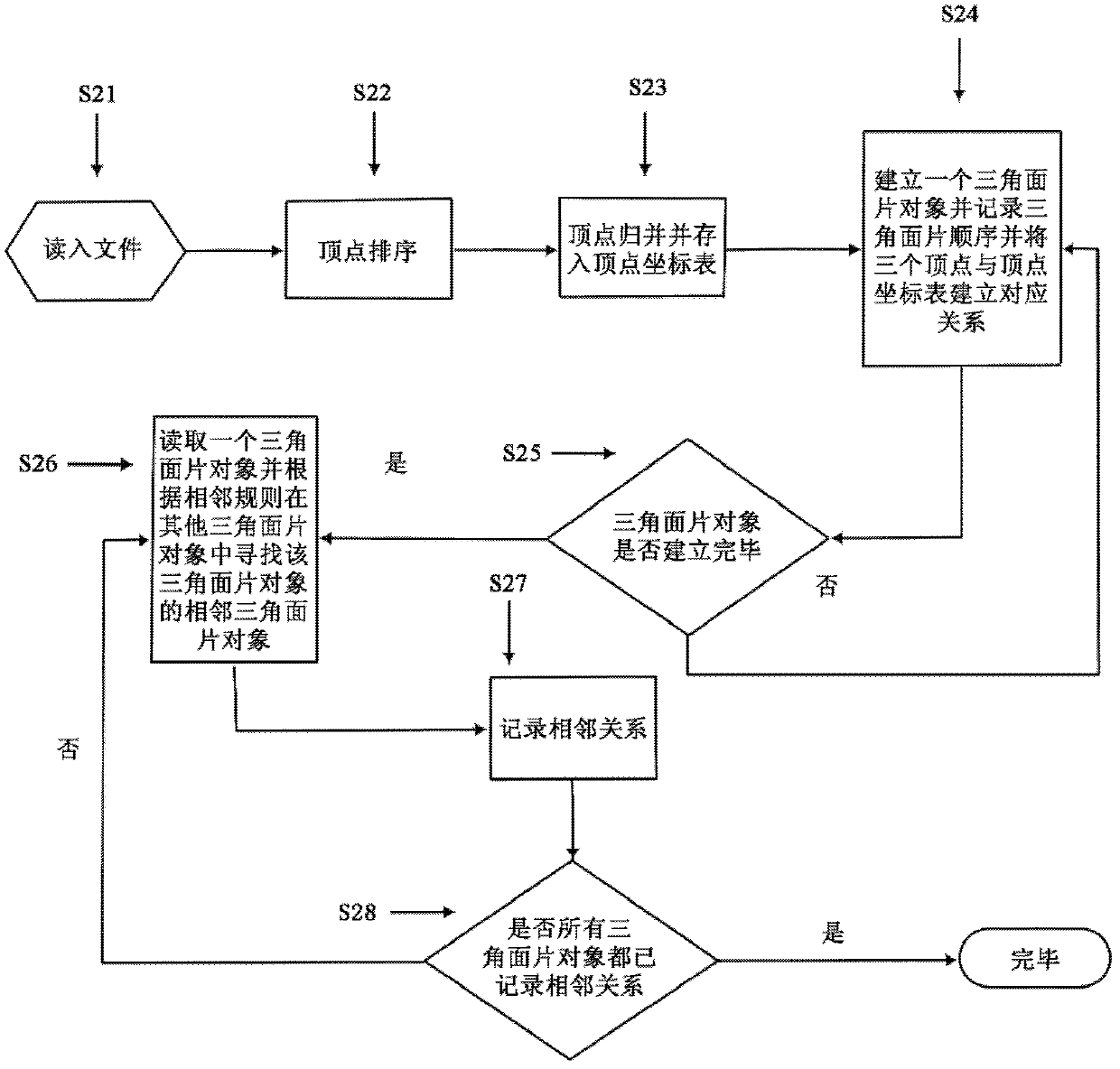

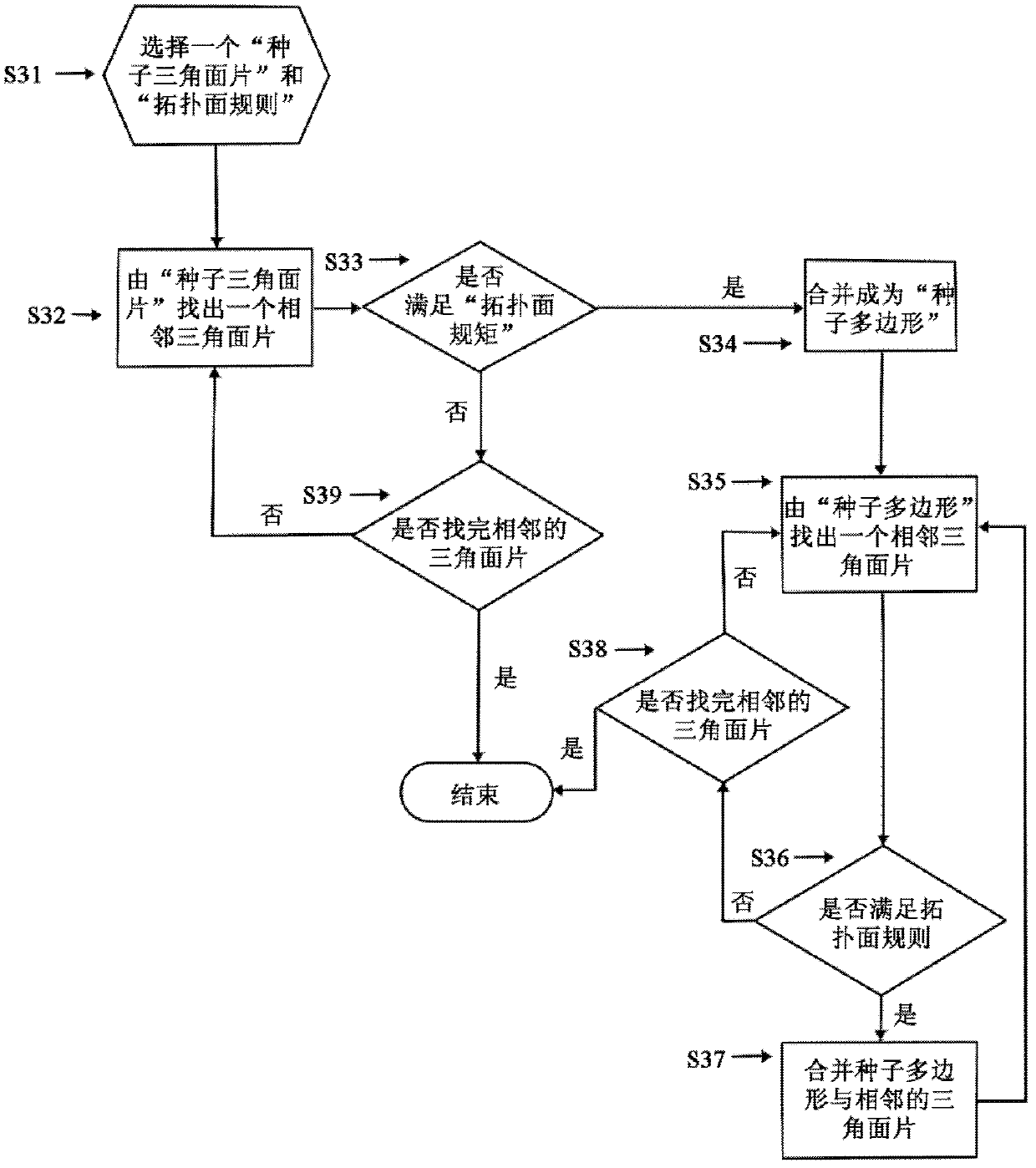

Method for separating topological face based on triangular patch model

The invention relates to a method for separating a topological face based on a triangular patch model. The method comprises the steps of: 1) carrying out data pre-processing on the triangular patches in the triangular patch model; 2) decomposing a topological face from the triangular patch model by the combination of the triangular patches; 3) building basic geometric information of the topological face; and 4) judging whether all topological faces are decomposed from all triangular patches in the triangular patch model; if not, decomposing the topological faces from all triangular patches in the triangular patch model and returning to the step 2); or else, finishing the separating method.

Owner:BEIJING UNIV OF POSTS & TELECOMM +1

Local repairing method of machine learning model

InactiveCN107067033AImprove performanceCharacter and pattern recognitionMachine learningOriginal dataSpatial transformation

The present invention provides a local repairing method of a machine learning model. The method comprises: collecting of analysis feedback data: collecting user feedback data, and extracting mispredicted data samples; performing spatial alternation: converting an original data space to a new data space through scale learning, reducing a distance between the mispredicted data samples as much as possible in the new data space, and increasing a distance between the mispredicted data samples and correctly predicted data samples as much as possible; learning incorrect data samples to establish a patch model in the new data space, and defining the application range of the patch model; and in the new data space, learning incorrect data samples to establish the patch model, and defining the application range of the patch model. The local repairing method of the machine learning model improves the performance of the machine learning model.

Owner:邹霞

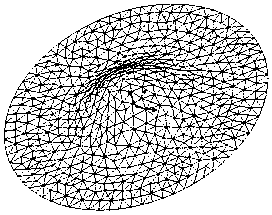

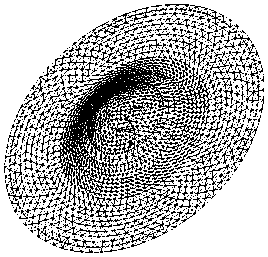

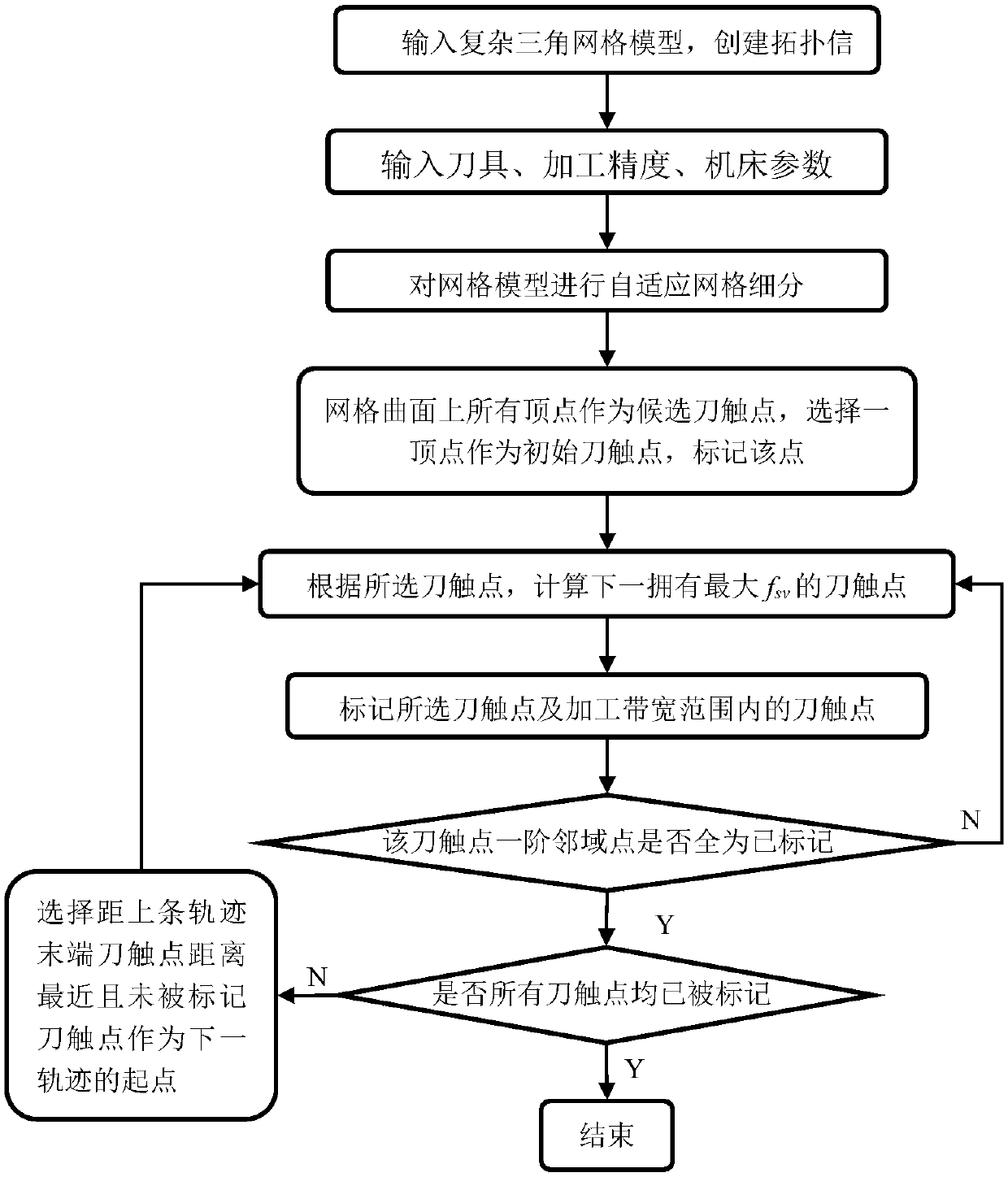

Multi-constrained numerical control machining trajectory generation method for triangular mesh model

The invention provides a multi-constrained numerical control machining trajectory generation method for a triangular mesh model. The method comprises the following steps: after reading a three-grid model and establishing topology information, performing adaptive mesh subdivision with processing bandwidth as a constraint; using a certain unmarked vertex on the surface of the subdivided mesh as an initial point of trajectory, calculating selective measure indexes of respective unmarked vertices in the current cutter contact first-order field, and using the vertex with the largest value as the next cutter contact, wherein the selective measure index is the weighted sum of the maximum feed speed, machining bandwidth, and optimal tooling direction weight of the current cutter contact to respective candidate point directions; marking all the selected cutter contacts and the cutter contacts within the tooling bandwidth range, ending the trajectory when the first-order neighborhood of a certain cutter contact has no unmarked points; and repeatedly generating the next trajectory until all vertices of the grid are marked. The method can effectively generate and satisfy the constraints such as machine tool kinematics and geometric machining precision by complex triangular patch models.

Owner:HUAQIAO UNIVERSITY

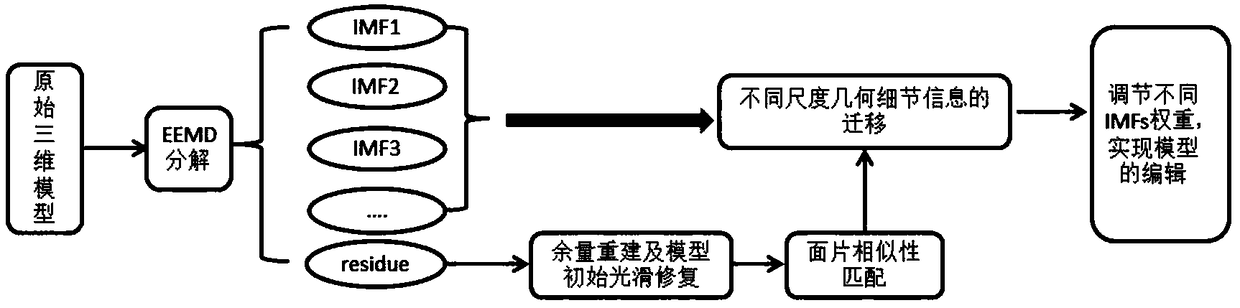

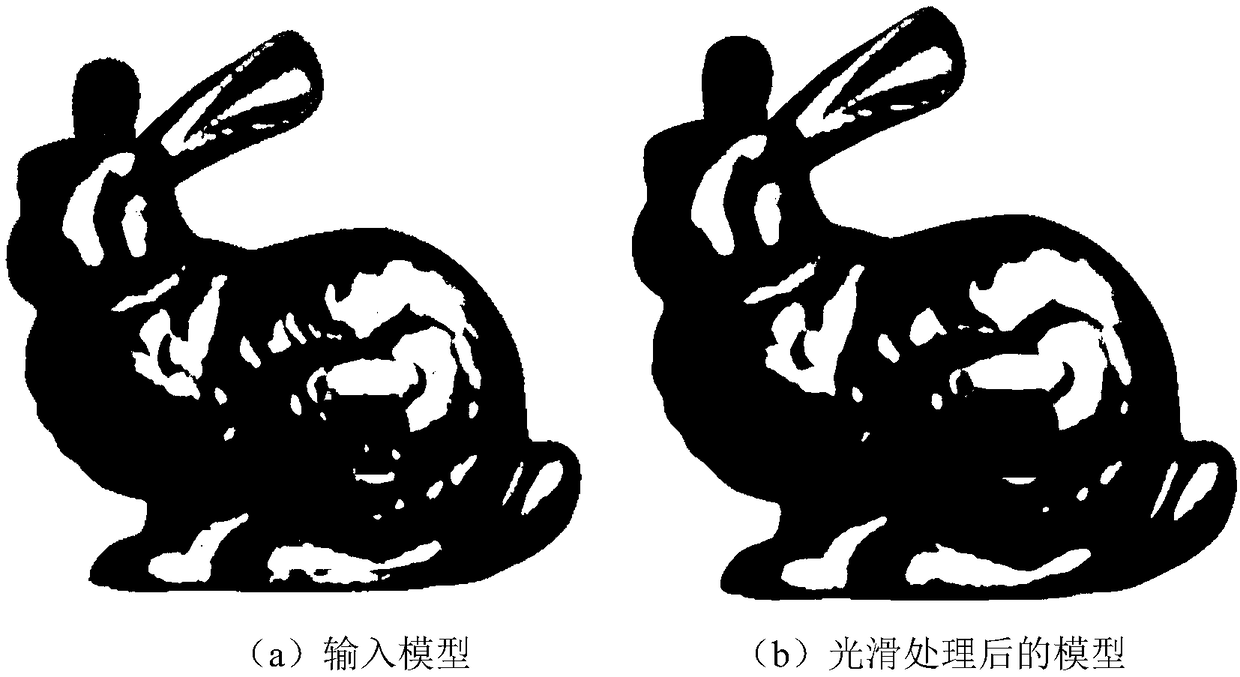

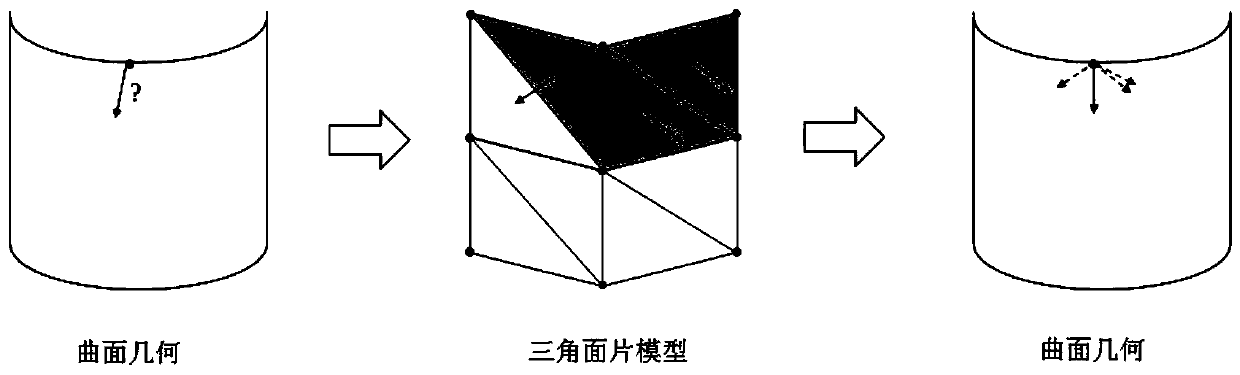

Full-frequency detail repair method for geometric model

PendingCN109118589AFacilitates full frequency geometric detail restorationSimple method3D modellingInformation transmissionDecomposition

The geometric model full-frequency detail repair method of the invention is based on an adaptive decomposition to keep the original details of the geometric model, so as to effectively migrate and repair the missing geometric detail information of the model surface, thereby solving the problems of complex boundary alignment process and distortion of the model. Comprises the following steps: (1) inthe geometric model full-frequency detail decomposition stage, the average curvature is used as the input signal of the adaptive decomposition of the triangular mesh model, and the signal is decomposed to obtain the full-frequency geometric detail information including a group of intrinsic mode functions and the signal margin; (2), an optimal match stage of that patch model; (3), in that phase ofgeometric structure information transmission and model full-frequency repair, accord to the matching result obtain in the step 2, the full-frequency geometric detail information obtained in the step1 is transferred from a similarity patch to a target patch; for each signal, the mesh model is reconstructed, and different geometric details are restored, so that the model can be edited.

Owner:QINGDAO RES INST OF BEIHANG UNIV

Polarization process of the electret capacitance microphone

InactiveCN101035395AImprove stabilityReduce manufacturing costElectrets selectrostatic transducerCapacitanceEngineering

The invention relates to a polarizing techniques of electrets capacitance model microphone, it adopting high-handed happening-equipment bring more then ten thousand volt DC voltage to let air engender happened ionization, then high voltage throw the electric ion coming from ionization air into electrets material, let electrets have electrification, the temperature of the polarizing techniques is 200-250 Deg.C. The invention is in charge relatively stable, if the microphone is adopted 260 Deg.C. temperature-resistant material to make of, then can seal from 260 Deg.C reflux-machine, its change of sensitivity can kept within 3dB, compared with the traditional microphone, the invention of the microphone is enhanced the stability, can exhibit patch model to product, therefore economize manpower and improve efficiency of produce.

Owner:SHENZHEN KTC INDAL DEV

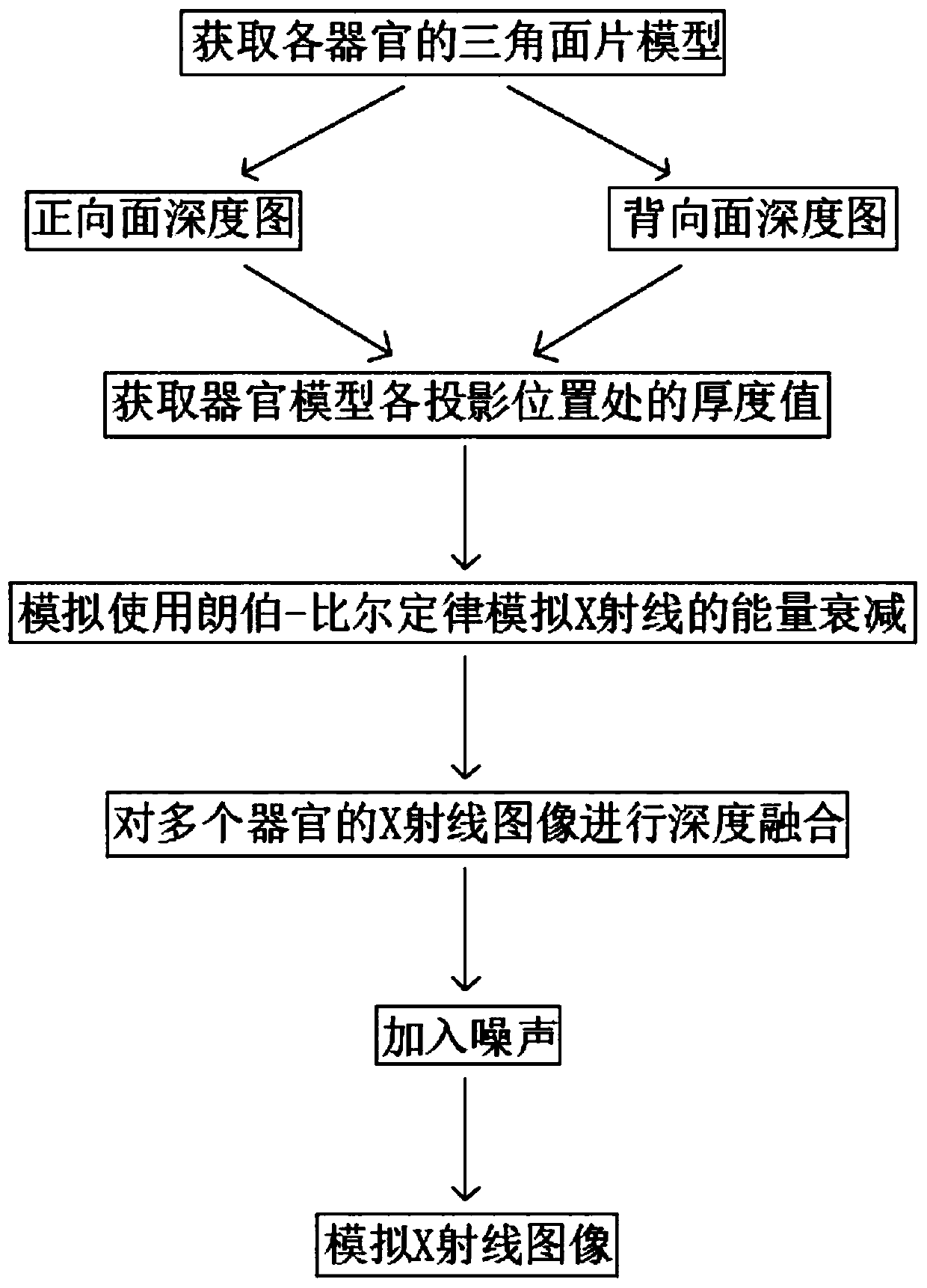

The invention discloses an model

ActiveCN109872395ASimulation is accurateIncrease authenticity3D-image rendering3D modellingUltrasound attenuationHuman body

The invention discloses an X-ray image simulation method based on a patch model, which relates to the technical field of medical virtual reality and comprises the following steps of: segmenting from aCT image to obtain a triangular patch model of each organ; carrying out sequential unrelated fusion mixing operation on the forward face depth map and the backward face depth map of the model of eachorgan to obtain a thickness value of each projection position of the organ model; simulating the energy attenuation of X-rays by using a Lambert-Beer law for each organ model;carrying out deep fusionon the X-ray images of the plurality of organs; and adding noise to the fused X-ray image. According to the technical scheme, the interventional operation is simulated more accurately, and the authenticity of virtual training and rehearsal is improved; The melting and mixing operation is completed by using a transparent technology irrelevant to the sequence, so that the problem that the geometricbody possibly has self-intersection to cause that the sorting cannot be completed is solved; Attenuation generated when X-rays penetrate through a human body is effectively reduced; And a light projection algorithm is used to solve the problem of deep sorting of a plurality of organ models.

Owner:PEKING UNION MEDICAL COLLEGE HOSPITAL CHINESE ACAD OF MEDICAL SCI +1

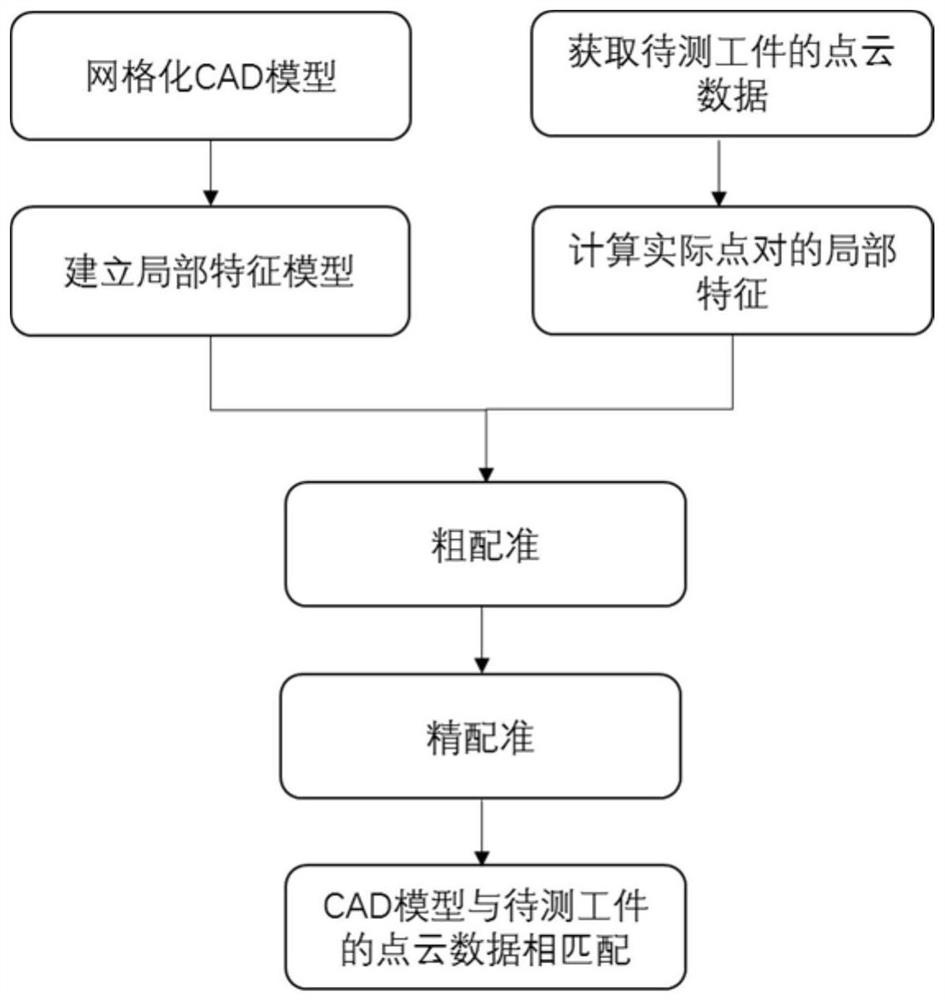

Image registration method and device based on point cloud data

PendingCN113643270AHigh precisionA large amountImage enhancementImage analysisPoint cloudComputer graphics (images)

The invention discloses an image registration method based on point cloud data. The method comprises the steps: griding a CAD model into a triangular patch model; calculating local features and spatial positions of all model point pairs in the triangular patch model, and establishing a local feature model; acquiring point cloud data of a to-be-measured workpiece; calculating local features of actual point pairs; matching the local features of the actual point pairs with the local features in a local feature model to obtain a coarse registration rigid transformation matrix; calculating a fine registration rigid transformation matrix of the CAD model and the point cloud data based on the coarse registration rigid transformation matrix; and performing rotation and translation transformation on the point cloud data according to the precise registration rigid transformation matrix, so that the CAD model is matched with the point cloud data of the to-be-detected workpiece. Through the method, the local features of the to-be-measured workpiece can be accurately calculated, when the accuracy of the local features is high, the precision of coarse registration can be improved, and meanwhile, an accurate initial transformation matrix can be provided for fine registration. The invention further provides an image registration device based on the point cloud data.

Owner:BEIJING LUSTER LIGHTTECH +1

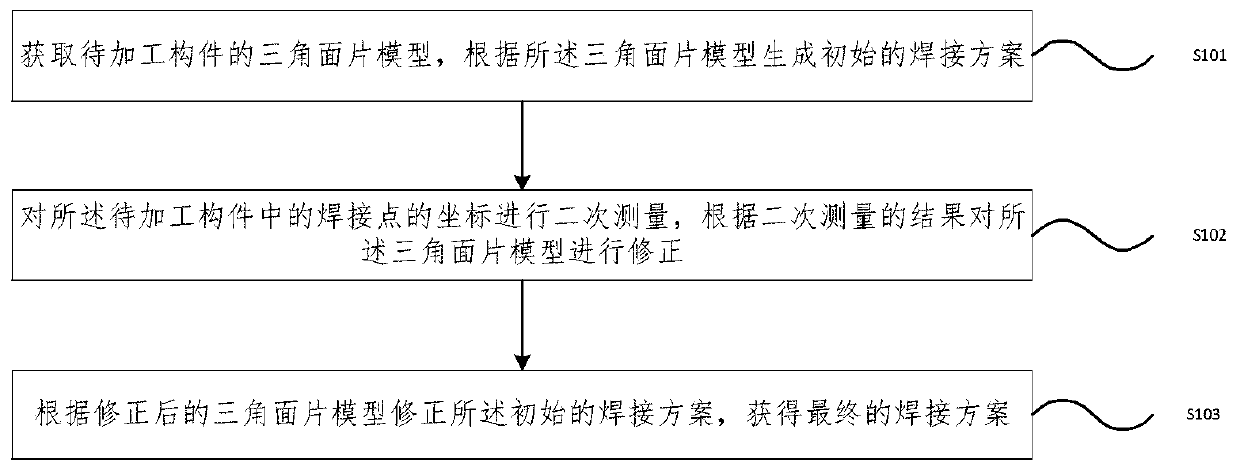

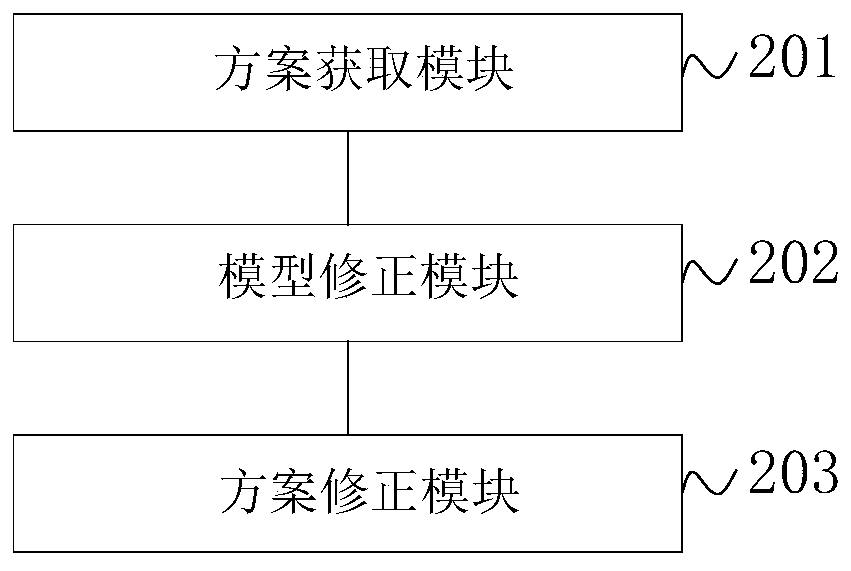

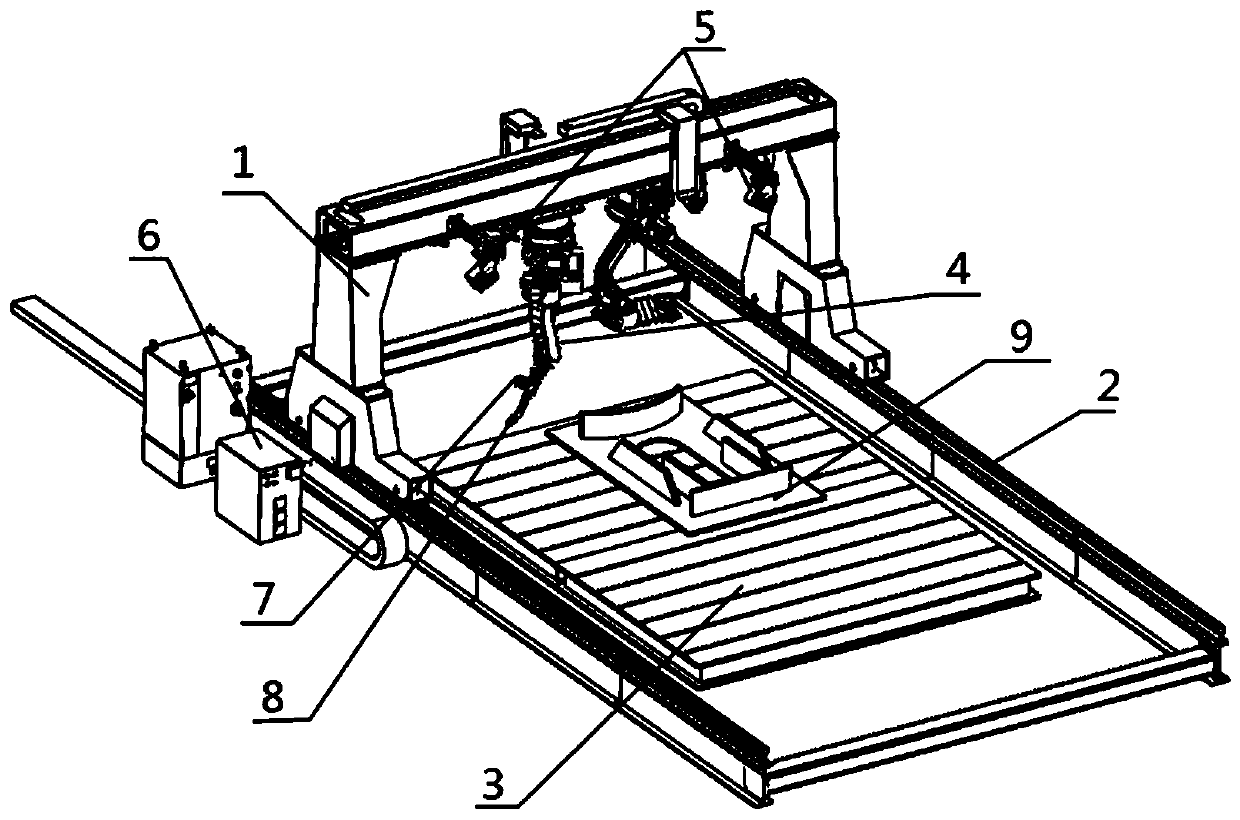

Welding scheme generation method, welding scheme generation device and welding system

ActiveCN110153582ASimple structureWith online correction functionUsing optical meansWelding apparatusEngineeringMachining time

The embodiment of the invention provides a welding scheme generation method, a welding scheme generation device and a welding system. The welding scheme generation method comprises the following steps: obtaining a triangular patch model of a to-be-processed member and generating an initial welding scheme according to the triangular patch model; measuring the coordinate of a welding point in the to-be-processed member secondarily and correcting the triangular patch model according to a secondary measuring result; and correcting the initial welding scheme according to the corrected triangular patch model to obtain a final welding scheme. The welding scheme generation method, the welding scheme generation device and the welding system are particularly suitable for processing members of steelplate structures, similar to small assemblies, in shipbuilding industry. The members are relatively simple in structure, so that the demand on artificial participation by equipment can be further reduced, the processing time is saved, and the processing efficiency is improved.

Owner:TSINGHUA UNIV

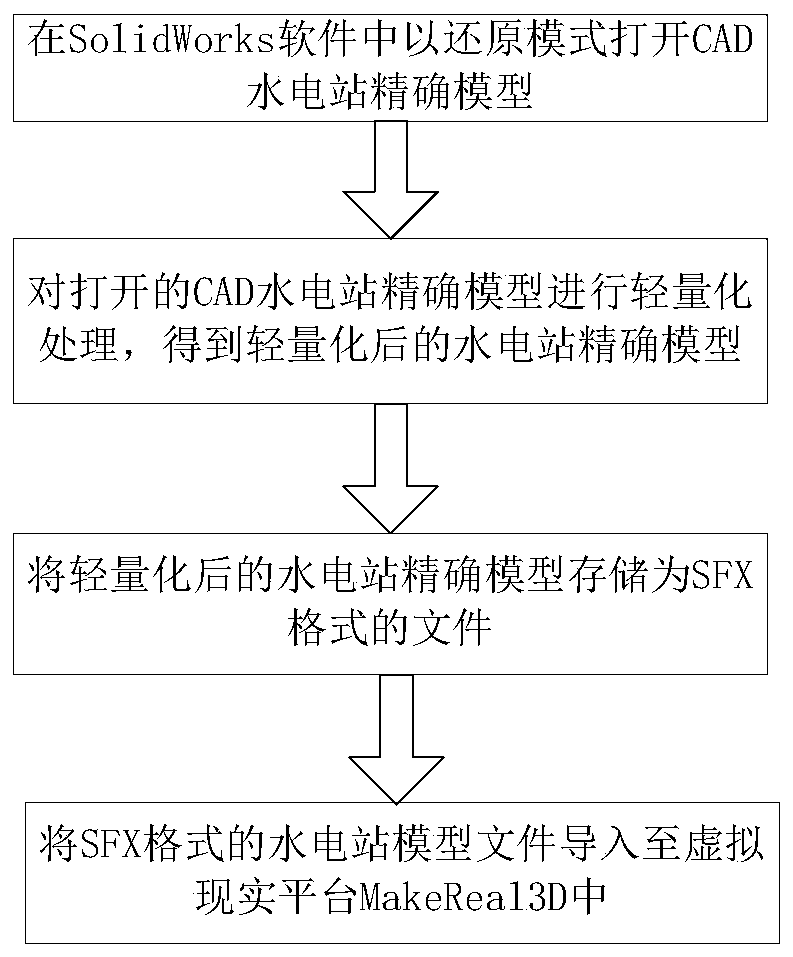

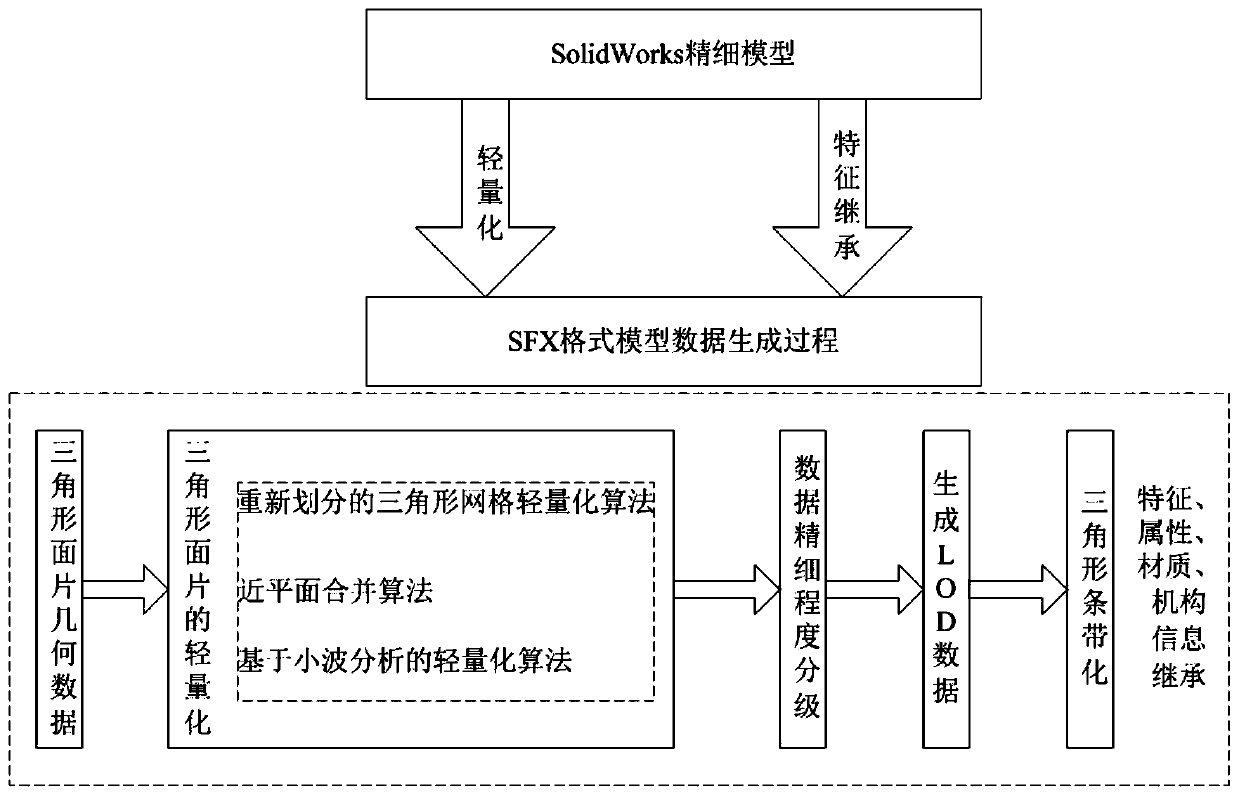

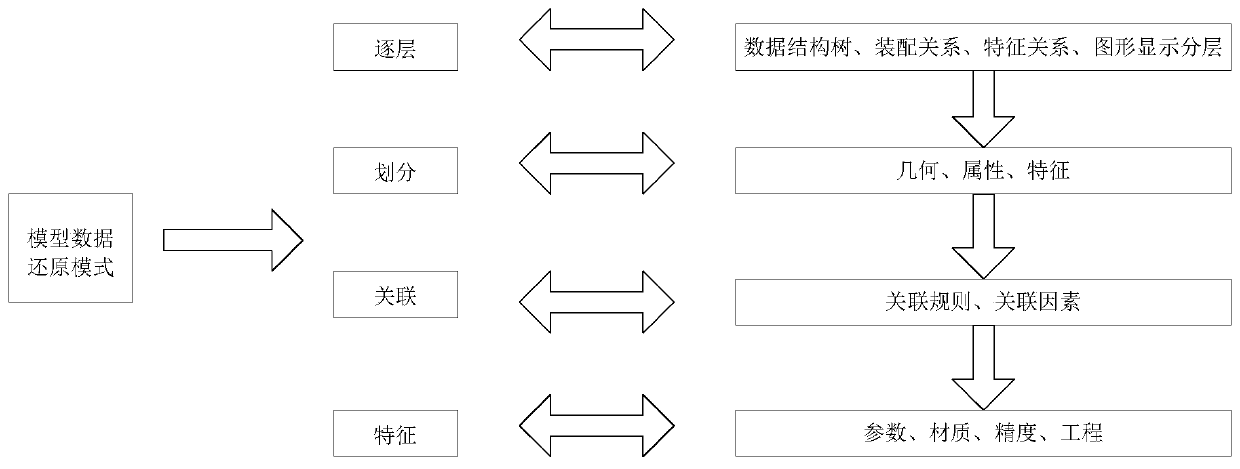

Application of virtual reality technology based on CAD oversized model in hydropower station simulation system

ActiveCN109858059ASolve application problemsWork fastSpecial data processing applicationsComputer scienceHydropower

The invention discloses an application of a virtual reality technology based on a CAD oversized model in a hydropower station simulation system. The application comprises the following steps: openinga CAD hydropower station accurate model in SolidWorks software in a reduction mode; performing lightweight processing on the opened CAD hydropower station accurate model to obtain a lightweight hydropower station model; storing the lightweight hydropower station model as a file in an SFX format; and importing the hydropower station model file in the SFX format into a virtual reality platform MakeReal3D, wherein the obtained model inherits the characteristics, attributes, materials and mechanism linkage information of the CAD hydropower station precise model. According to the method, the application problem of the super-large CAD model of the hydropower station in a virtual reality simulation system is fundamentally solved. Repeated establishment of a triangular patch model is avoided, a mode of model format conversion and automatic light weight is adopted, model processing work becomes faster and more efficient, and research and development personnel can put main energy on content production of later simulation application.

Owner:SOUTHERN POWER GRID PEAK LOAD & FREQUENCY REGULATION GENERATING CO LTD

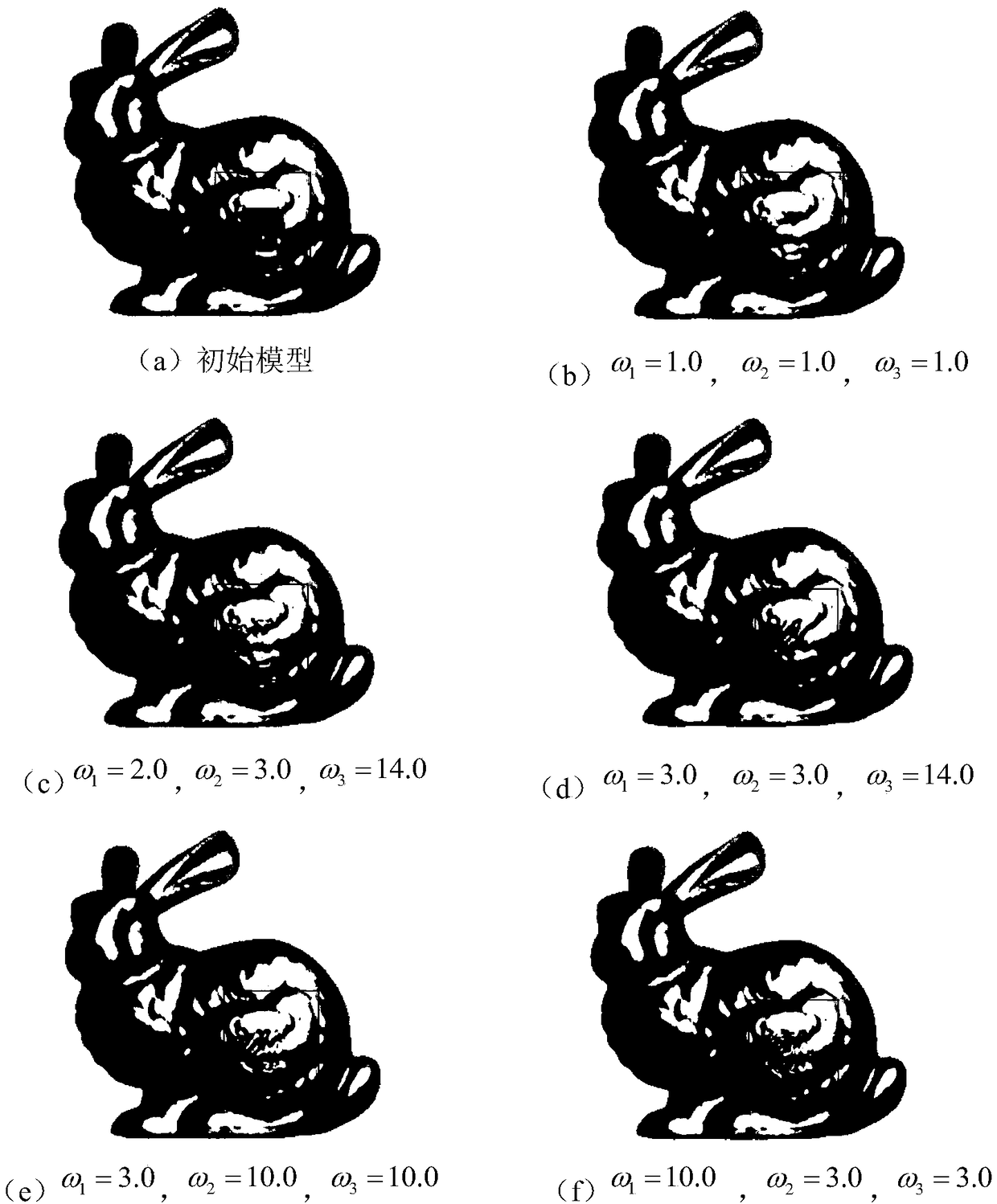

A Divide and Conquer Processing Method for Triangular Mesh Model

InactiveCN103885385BDivide and conquer processingAvoid problems with large differences in region sizesNumerical controlNumerical controlTrigonal crystal system

The invention provides a partition machining method of a triangular mesh model, and belongs to the technical field of CAM. The partition machining method of the triangular mesh model is characterized in that the partition machining method includes the steps that neighborhood points within an R radius range are selected so as to calculate differential geometry information of a triangular patch model accurately; the triangular patch model is segmented into sub-regions with different characteristics with characteristic statements of sub-regions to be machined as growth principles, optimization merging is conducted on small-area regions and wrongly judged regions so as to eliminate over-segmentation phenomena, and boundary smoothing is conducted on the sub-regions so as to reduce saw-toothed boundaries; different track strategies are adopted in different types of the sub-regions to be machined, when a constant scallop height track is generated, the circular cutting initial track generation method is adopted in the convex sub-regions and the concave sub-regions, the linear cutting initial track generation method is adopted in the saddle-shaped sub-regions, machining is conducted on tracks at the positions of sub-region boundaries when bias extension is conducted on cutter track projection, and reasonable and complete sub-region machining tracks are obtained. According to the partition machining method, numerical control machining cutter tracks giving consideration to the machining efficiency and the machining quality are effectively generated from the complicated triangular patch model.

Owner:HUAQIAO UNIVERSITY

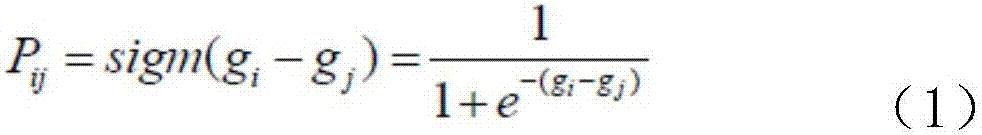

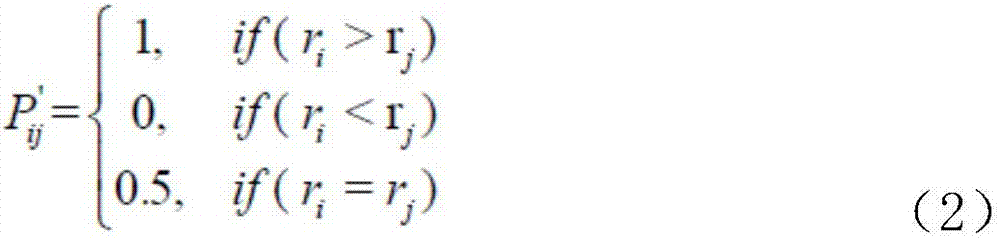

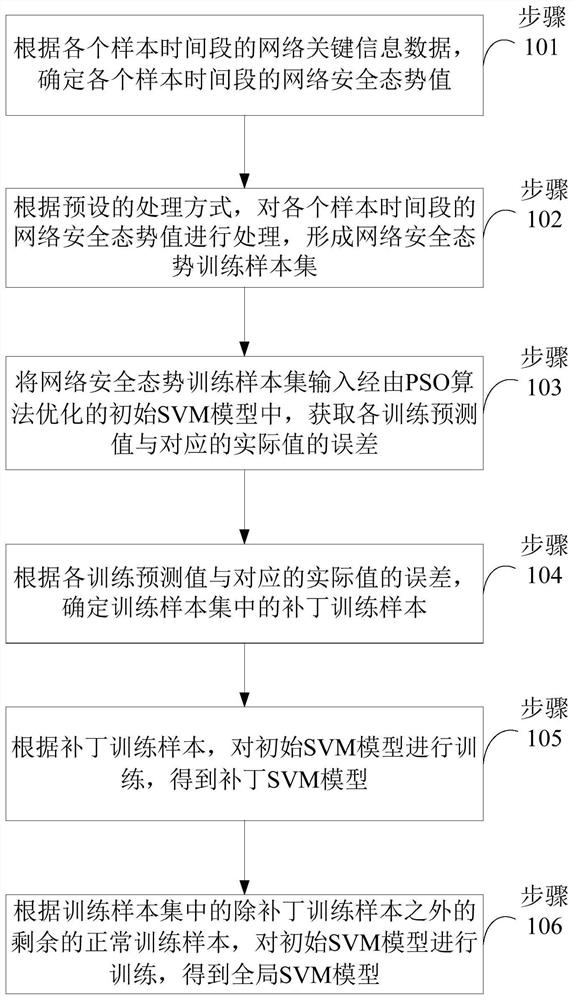

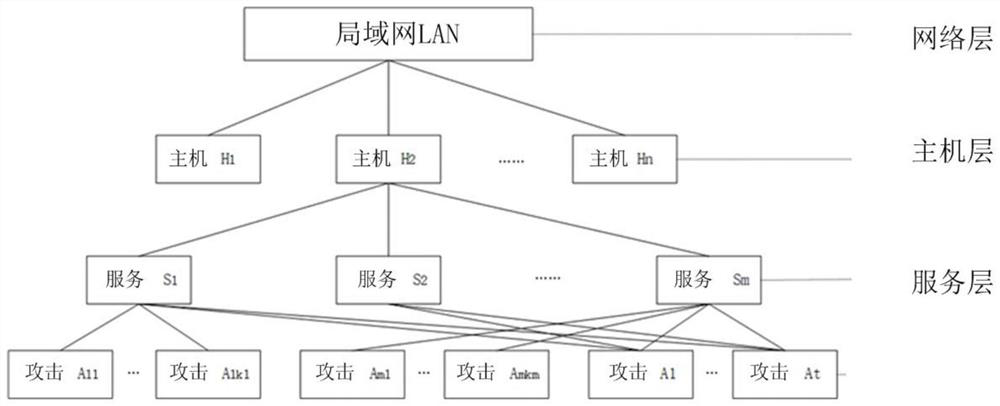

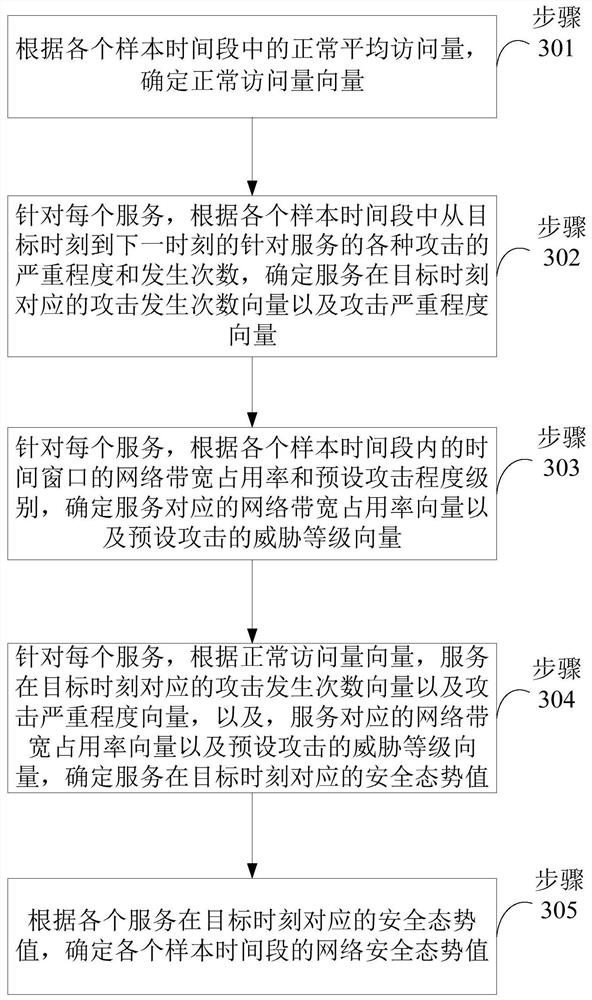

Model training method, network situation prediction method and device, equipment and medium

ActiveCN112653680AImprove performanceReduce mistakesKernel methodsTransmissionEngineeringMachine learning

The invention discloses a model training method, a network situation prediction method and device, equipment and a medium. The method comprises the steps of determining a network security situation value of each sample time period; according to the processing mode, processing the network security situation value of each sample time period to form a network security situation training sample set; inputting the network security situation training sample set into an initial SVM model optimized by a PSO algorithm to obtain errors between each training prediction value and the corresponding actual value; determining a patch training sample in the training sample set according to the error between each training prediction value and the corresponding actual value; training the initial SVM model according to the patch training sample to obtain a patch SVM model; and training the initial SVM model according to the remaining normal training samples except the patch training samples in the training sample set to obtain a global SVM model. The model training method is high in training efficiency, and the accuracy of the trained SVM model is high.

Owner:GUANGDONG POWER GRID CO LTD +1

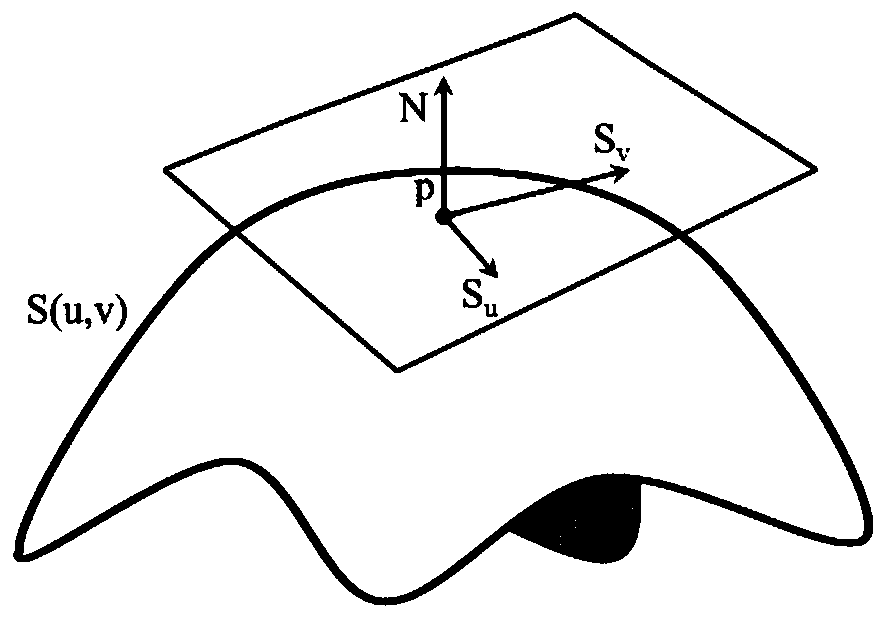

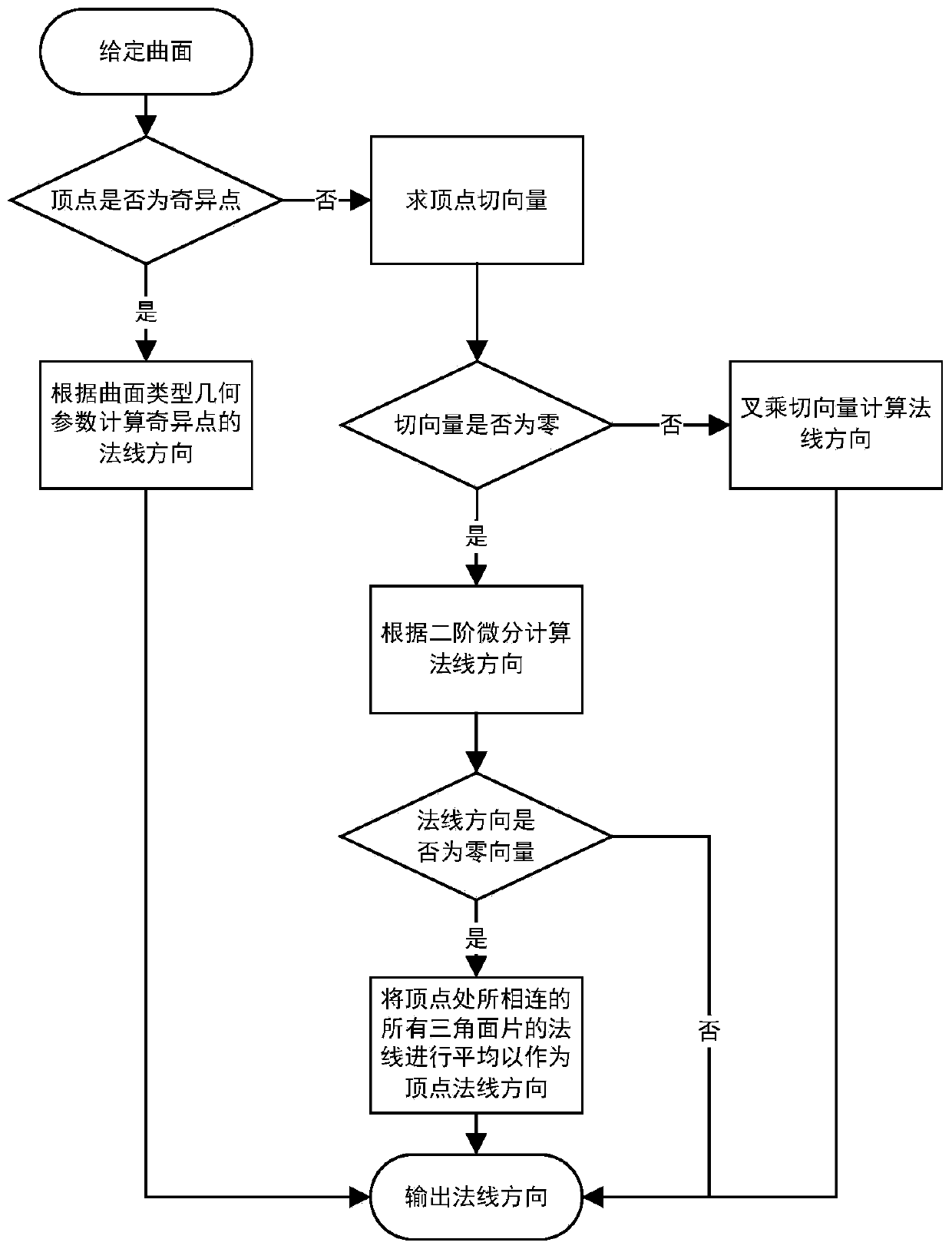

Improved method for calculating vertex normal of curved surface grid in grid division

An improved method for curved surface grid vertex normal calculation in grid division comprises the steps: S1, judging whether the vertex of a given curved surface is a singular point or not: if yes,executing the step S2, and otherwise, executing the step S3; S2, based on the geometric parameters of the given curved surface, calculating the normal direction of the singular point, and entering S7;S3, solving a tangent vector in the UV direction at the vertex, judging whether the tangent vector is zero or not: if so, entering S4, and otherwise, entering S5; S4, calculating the normal directionof the vertex, judging whether the normal direction is a non-zero vector or not: if yes, entering S7, and otherwise, entering S6; S5, obtaining the normal direction through cross multiplication of the two tangent vectors, executing the step S7; S6, averaging the normal lines of all the triangular patches connected to the vertex to serve as a vertex normal line direction, and entering S7; S7, outputting a normal direction; S8, when a point set is generated based on the boundary of the triangular patch model, interpolating to generate the point set on the boundary according to the normal direction, and performing triangular mesh generation on a given curved surface.

Owner:上海索辰信息科技股份有限公司

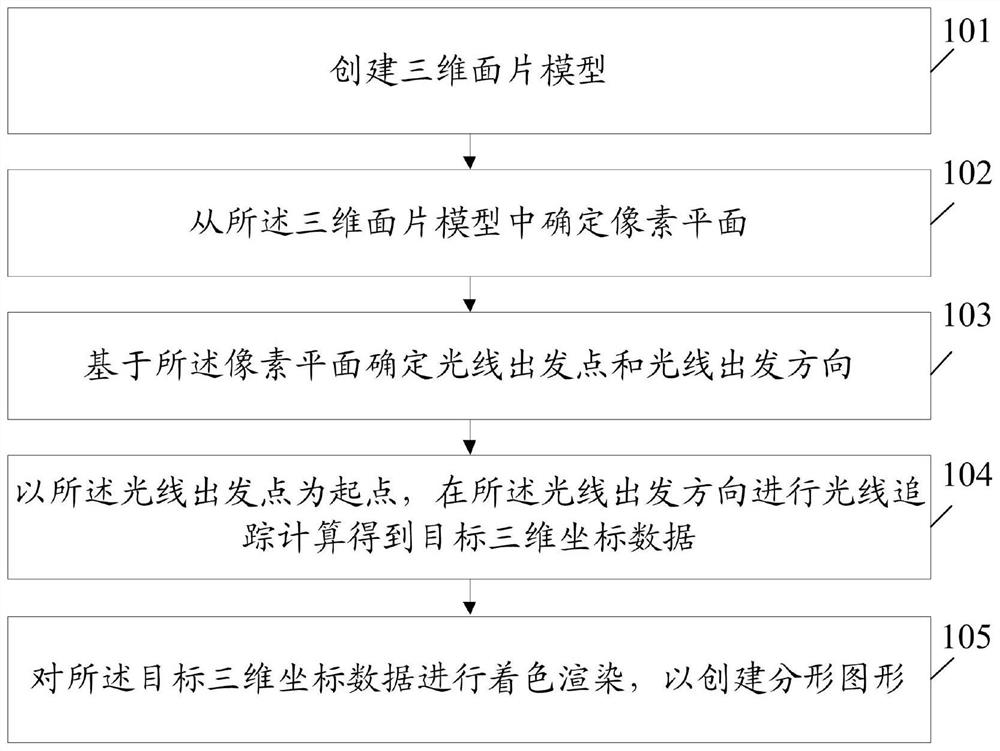

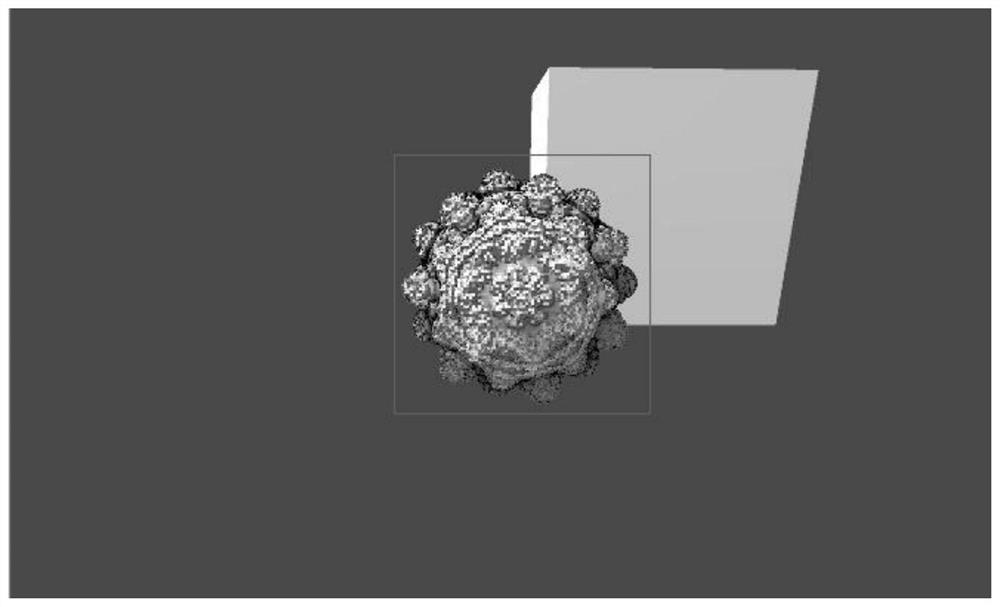

Fractal graph creation method and device, electronic equipment and storage medium

Embodiments of the invention provide a fractal graph creation method and a device, an electronic equipment and a storage medium. The method comprises the steps of creating a three-dimensional patch model; determining a pixel plane from the three-dimensional patch model; determining a light ray starting point and a light ray starting direction based on the pixel plane; taking the light ray startingpoint as a starting point, and performing light ray tracking calculation in the light ray starting direction to obtain target three-dimensional coordinate data; and performing coloring rendering on the target three-dimensional coordinate data to create a fractal graph. According to the embodiment of the invention, light tracking and coloring rendering only need to be carried out on the pixel screen in the screen in the three-dimensional patch model, and light tracking and coloring rendering do not need to be carried out on the whole screen, so that a large amount of computing resources can besaved.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

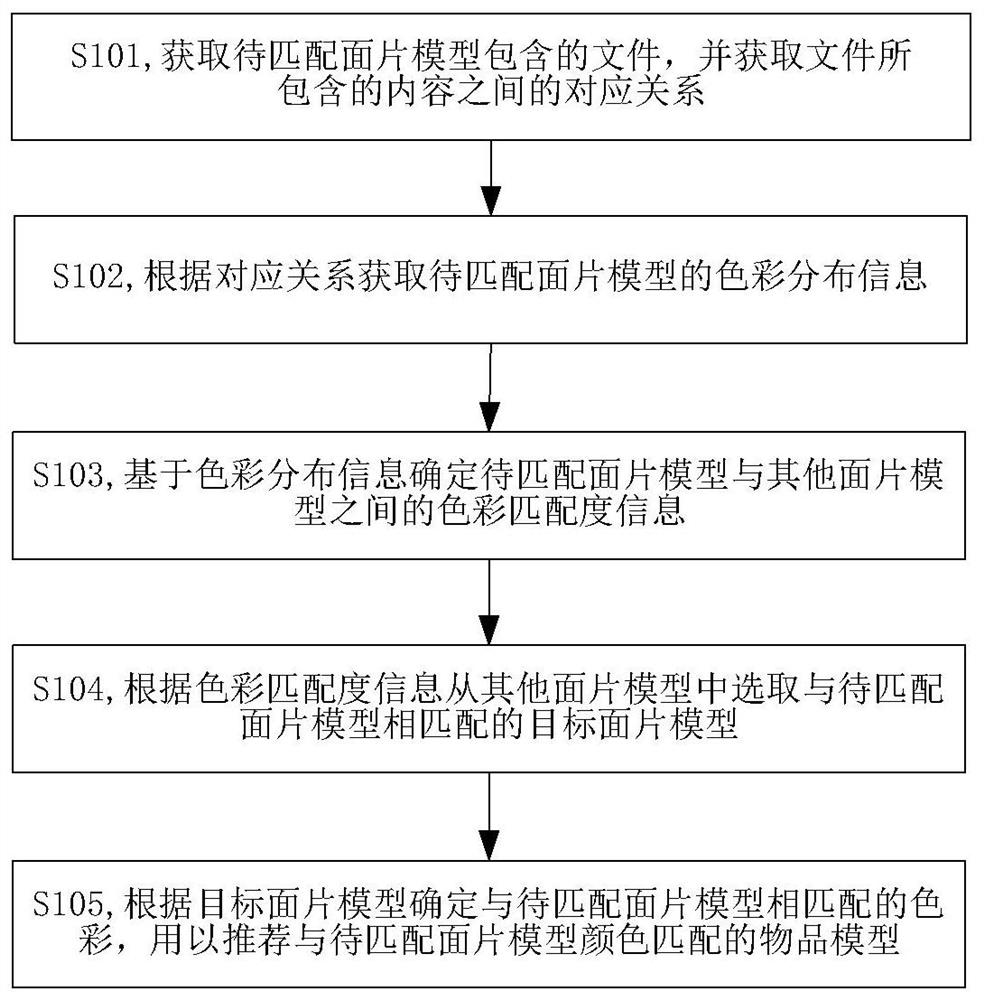

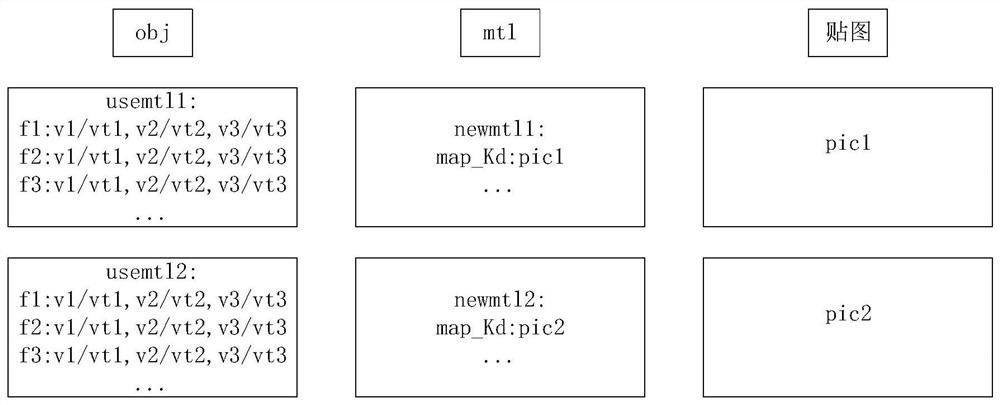

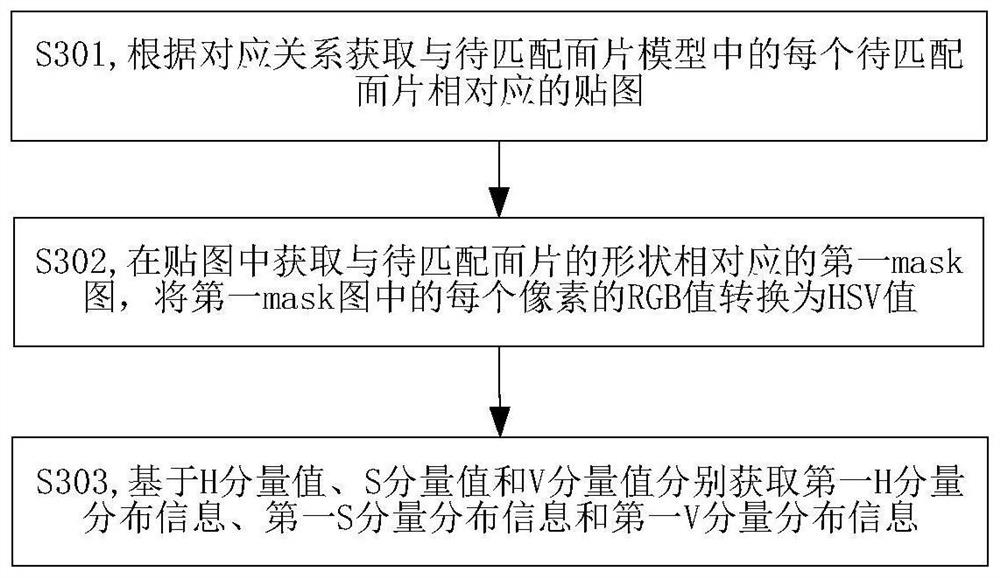

Color matching method and device for patch model and storage medium

ActiveCN112489230ASolve the problem of color matchingMeet the requirements of color matchingImage generationColor analysisAlgorithm

The invention provides a color matching method and device for a patch model, electronic equipment and a storage medium, and relates to the technical field of computers, and the method comprises the steps: obtaining the color distribution information of the to-be-matched patch model according to the corresponding relation of file contents contained in the to-be-matched patch model, determining color matching degree information between the to-be-matched patch model and other patch models to select a target patch model matched with the to-be-matched patch model from the other patch models, and determining a color matched with the to-be-matched patch model according to the target patch model to recommend an article model. According to the method and device, the electronic equipment and the storage medium, the problem of color matching degree between color extraction and determination of the surface piece model is solved, so that the color matching requirement of the object model and the color analysis requirement of the surface piece model are met, color matching of different objects is accurate and rapid, and the quality of AI home decoration design can be ensured.

Owner:BEIKE TECH CO LTD

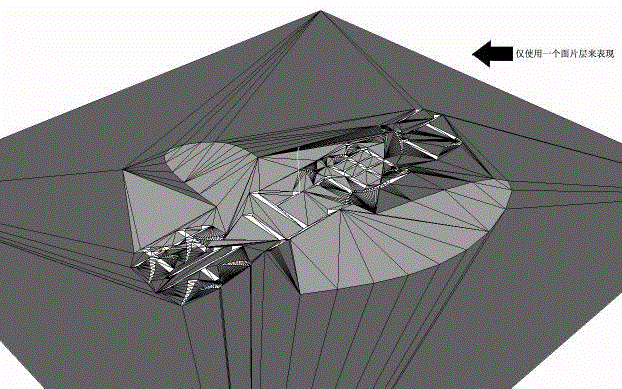

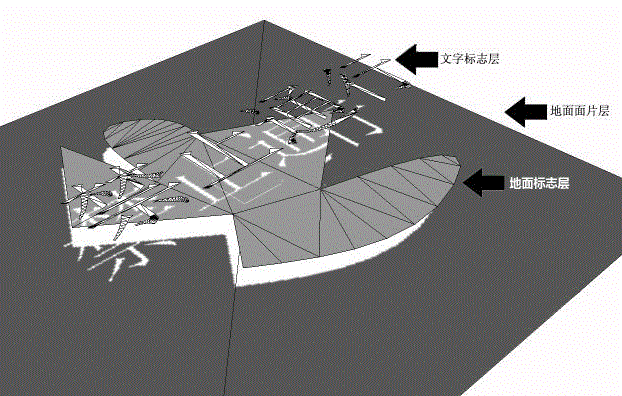

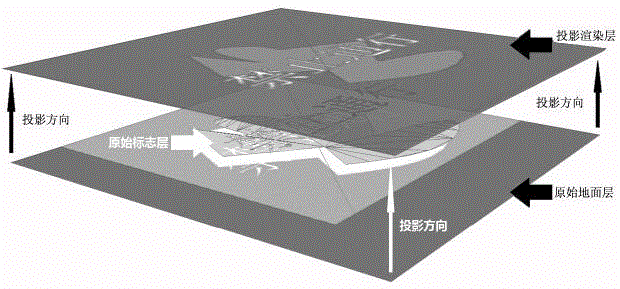

Virtual airport model ground surface texture projection rendering method

ActiveCN105654542AFree up computing resourcesIncrease profitProcessor architectures/configuration3D-image renderingVideo memoryComputer graphics (images)

The invention discloses a virtual airport model ground surface texture projection rendering method comprising the following steps that S1: a texture map is established; S2: the map is outputted to a newly built undivided surface patch model having the same area with projection area through a texture map channel; S3: the newly built undivided surface patch model and the texture map are stored in video memory; and S4: a visual engine loads the newly built surface patch model and the captured texture map and schedules video card resources for rendering. According to the method, model vertex information conventionally computed by a CPU is transferred to the texture map channel and computed by directly scheduling the GPU resources of the video card, and the information is also directly stored in the video memory to be directly scheduled by the GPU without reallocation in a system memory through a system bus so that utilization rate and processing speed of system resources can be greatly enhanced, computational resources of the CPU can also be released and the whole system is enabled to be more efficient.

Owner:HANGKE TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com