Patents

Literature

189 results about "Saddle-shaped" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Prosthetic mitral valve

InactiveUS20070173932A1Improve performanceLow thrombogenicityHeart valvesSurgeryAnterior leafletPosterior leaflet

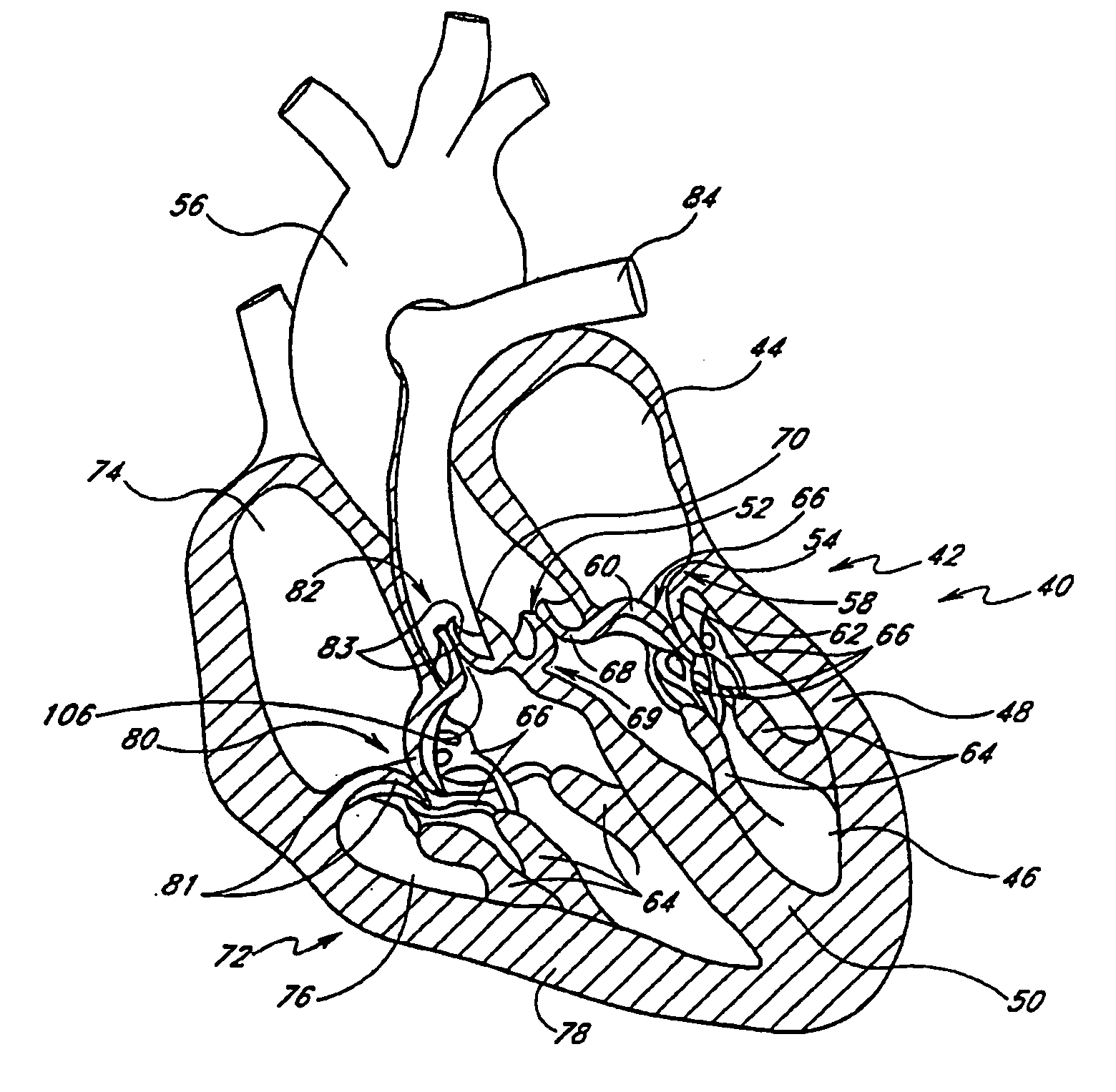

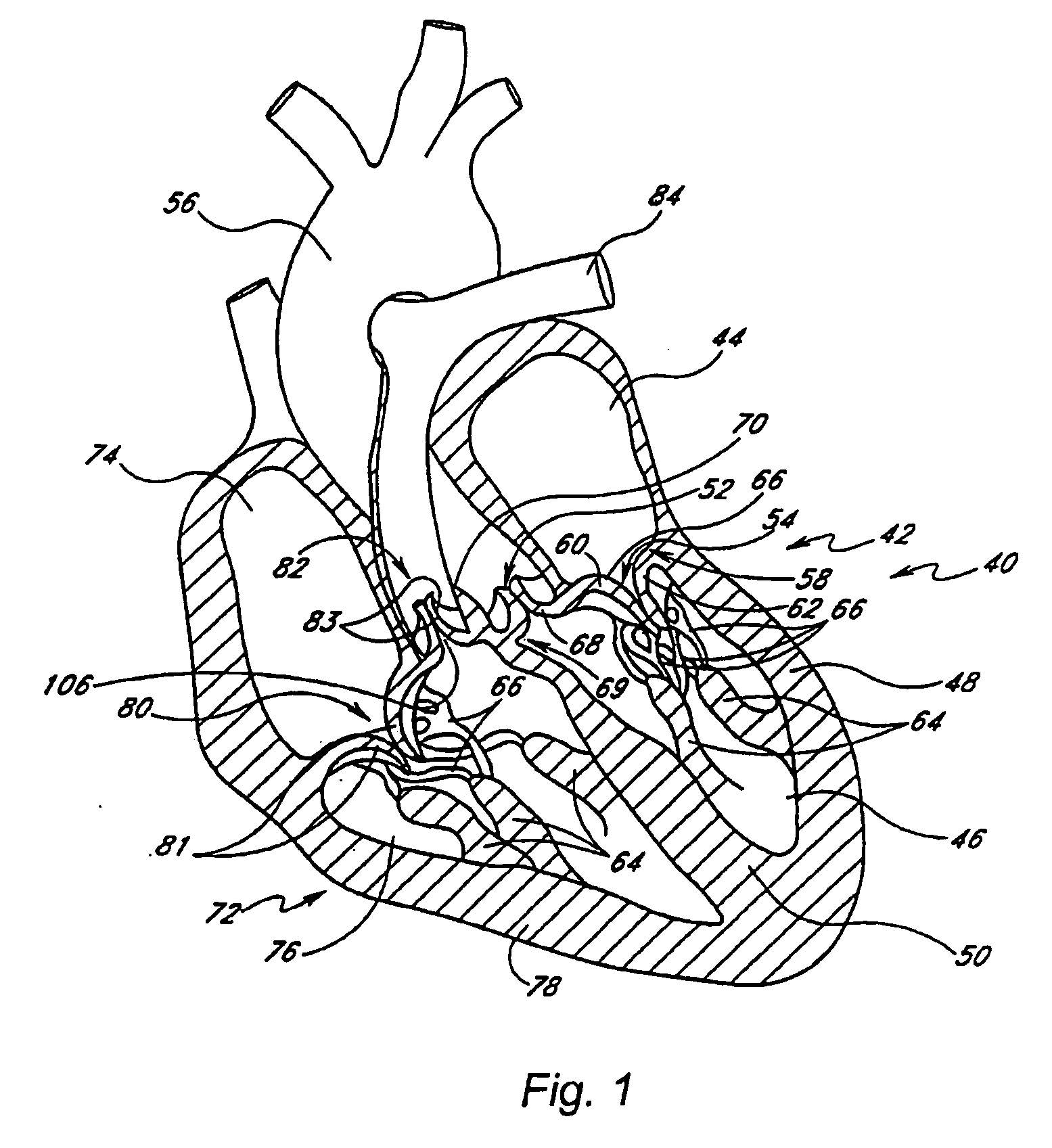

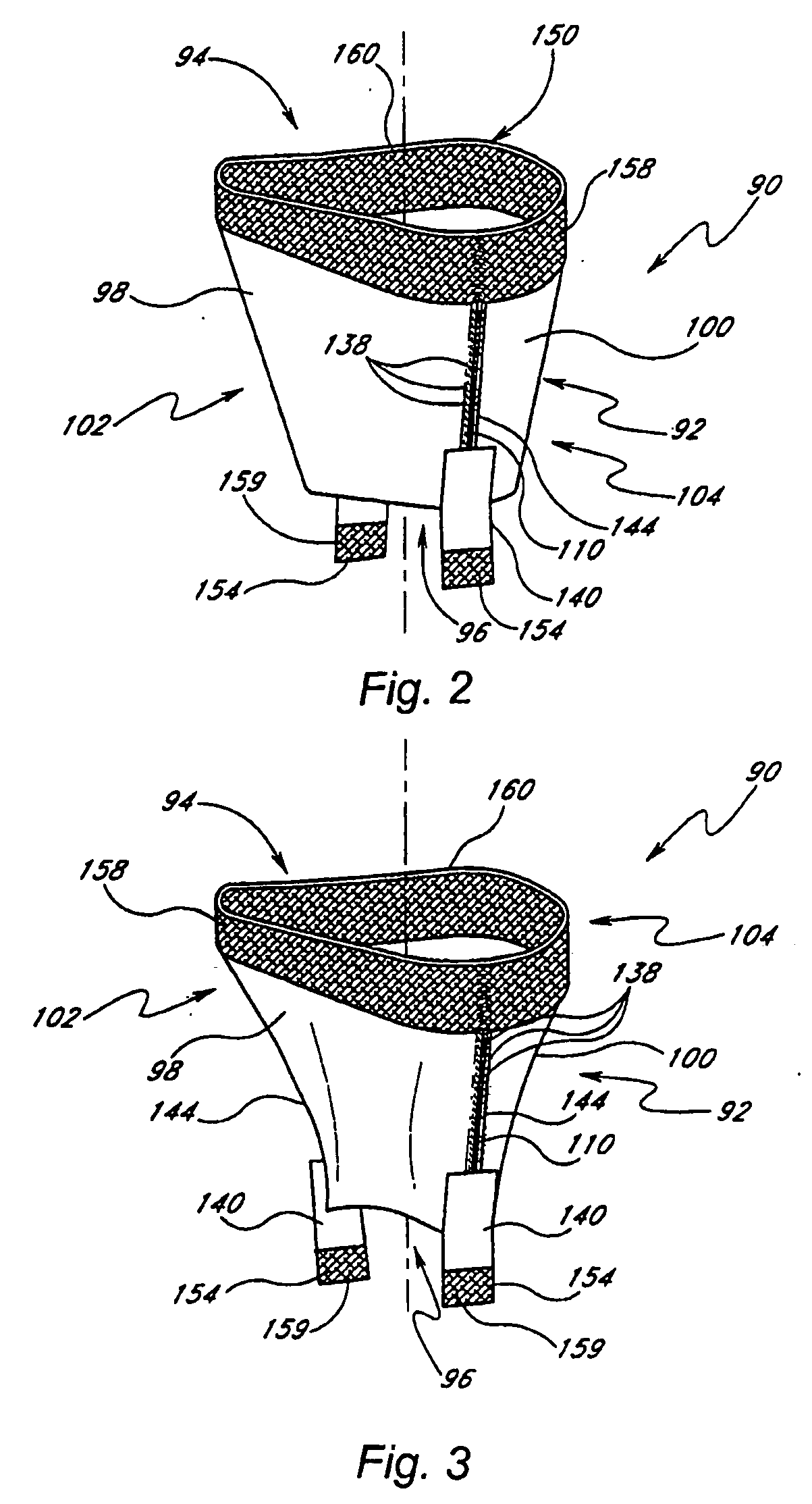

An improved prosthetic mitral valve is provided having advantageous hemodynamic performance, nonthrombogenicity, and durability. The valve includes a valve body having an inflow annulus and an outflow annulus. Commissural attachment locations are disposed adjacent the outflow annulus. An anterior leaflet and a posterior leaflet of the valve are shaped differently from one another. The inflow annulus preferably is scalloped so as to have a saddle-shaped periphery having a pair of relatively high portions separated by a pair of relatively low portions. The anterior high portion preferably is vertically higher than the posterior high portion.

Owner:MEDTRONIC 3F THERAPEUTICS

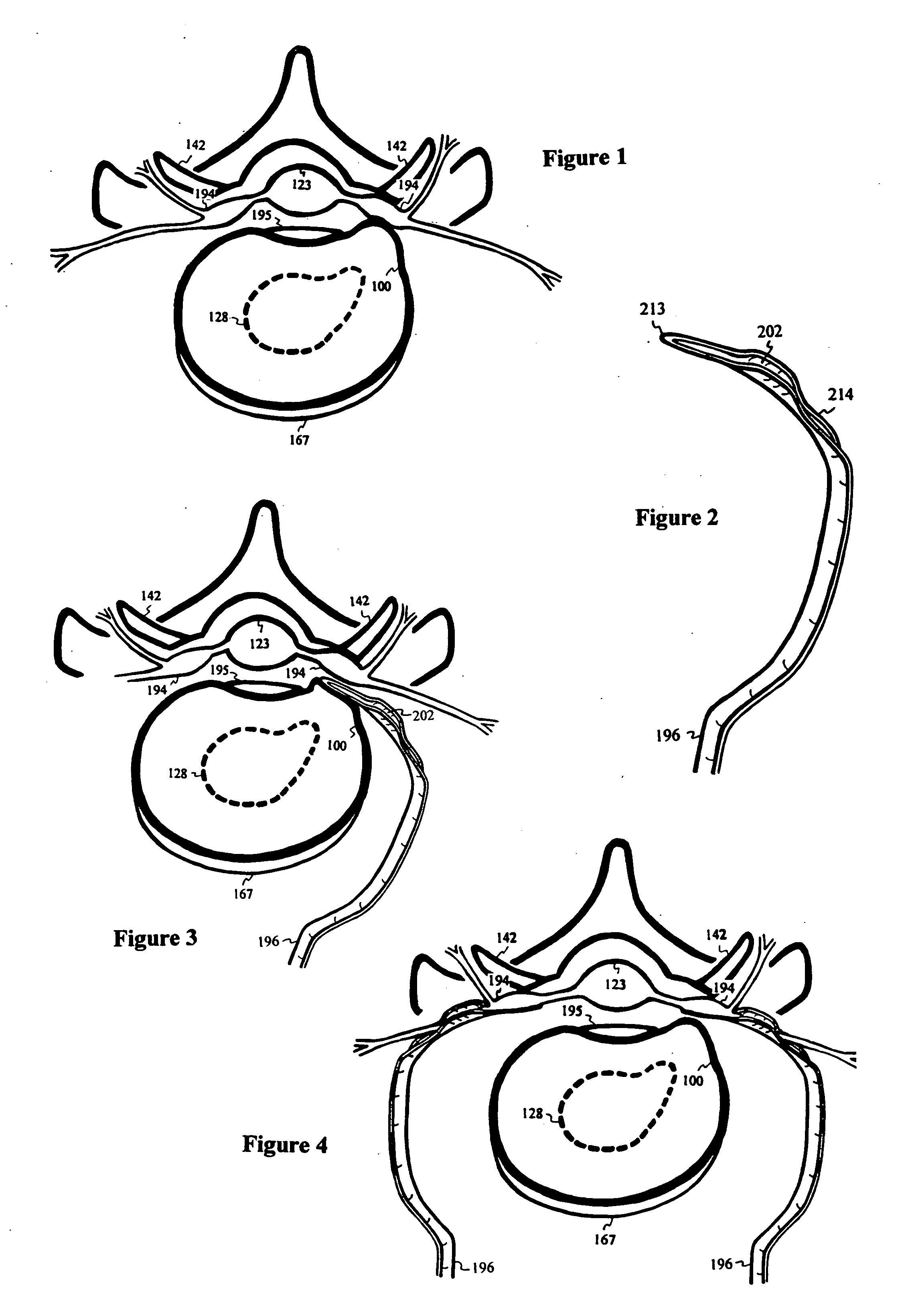

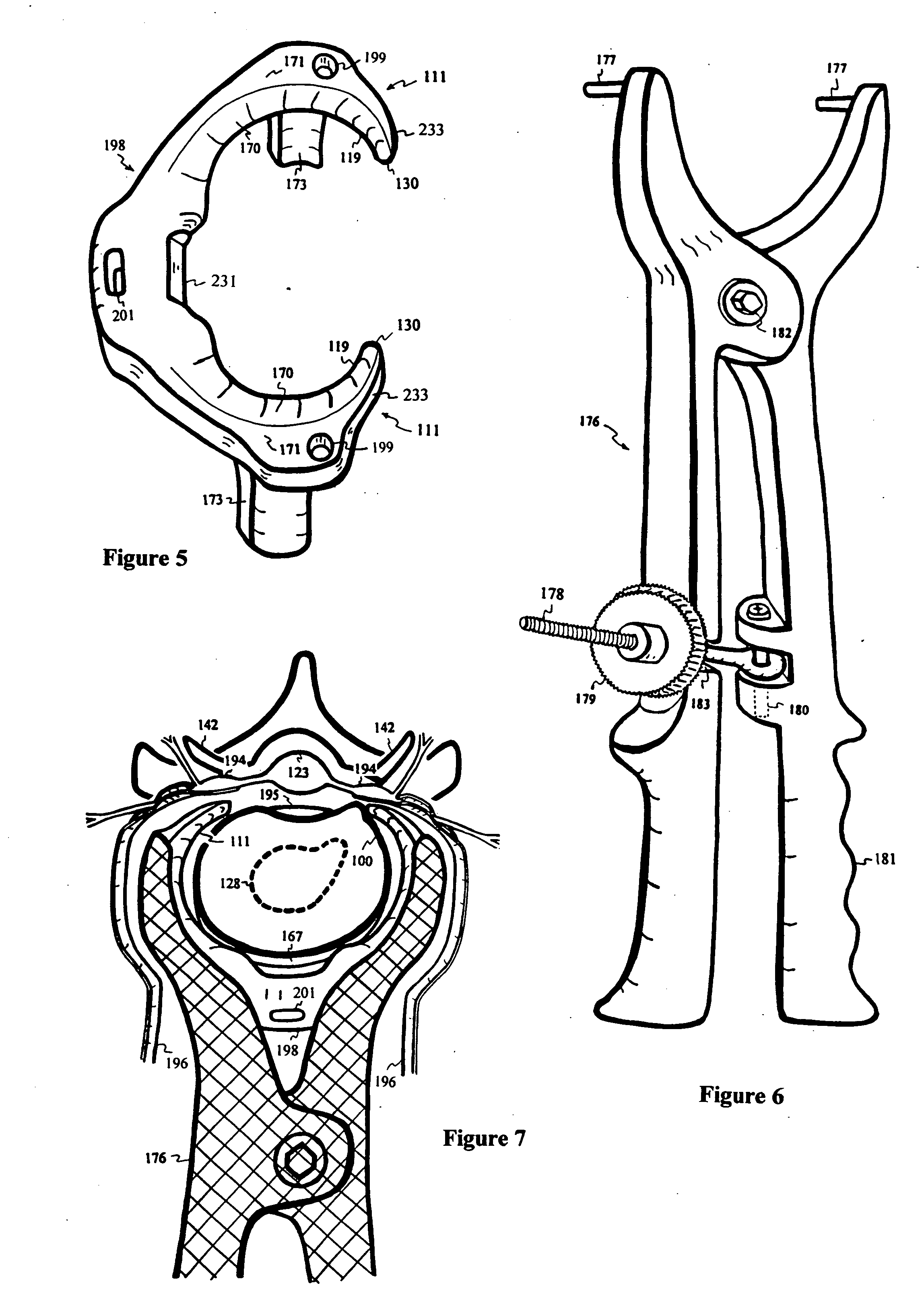

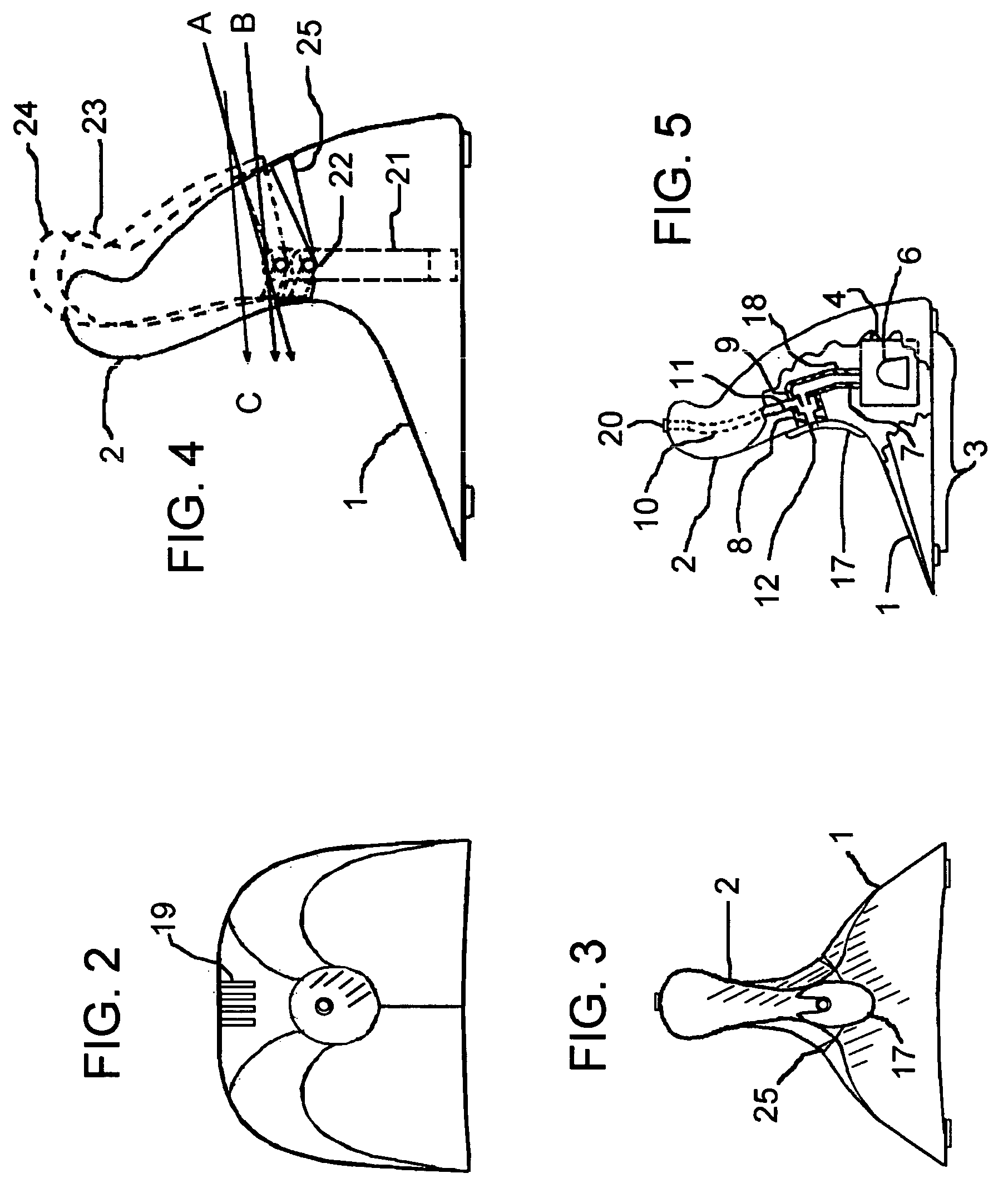

Intervertebral disc repair

InactiveUS20040097927A1Alleviate nerve impingementMinimize segmental instabilitySuture equipmentsInternal osteosythesisAtrophySpinal stenosis

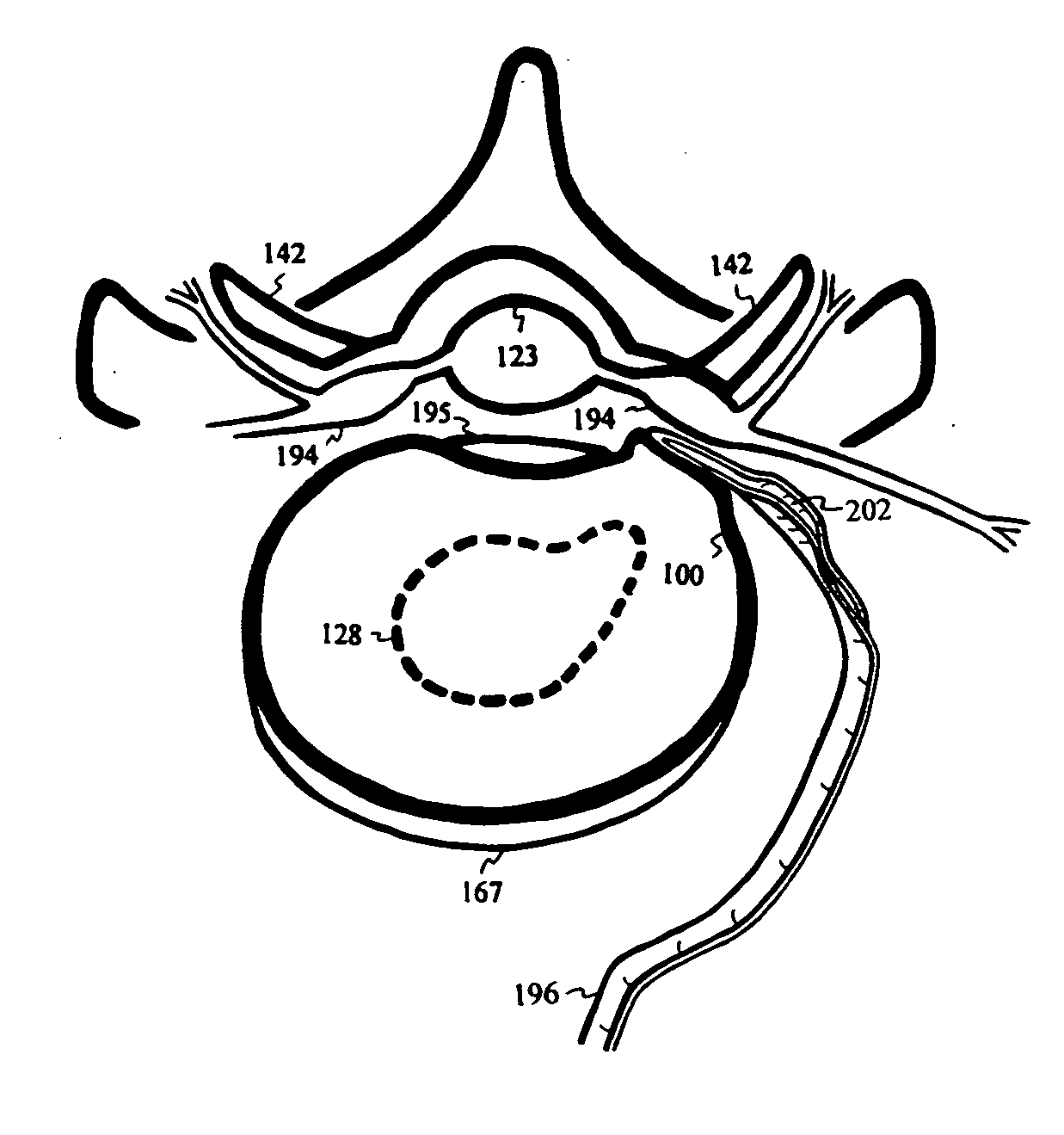

A saddle-shaped compression device and methods of fastening a dysfunctional intervertebral disc are used to (1) compress a protrusion to alleviate nerve impingement, (2) fortify the annulus to stabilize a motion segment, (3) minimize the inward / outward bulging and delamination of the annulus, (4) atrophy the nerve to treat discogenic pain, (5) correct the curvature of spinal deformities, (6) elevate the disc space to treat spinal stenosis, and (7) seal the seepage of nucleus pulposus from a herniated disc.

Owner:YEUNG JEFFREY E +1

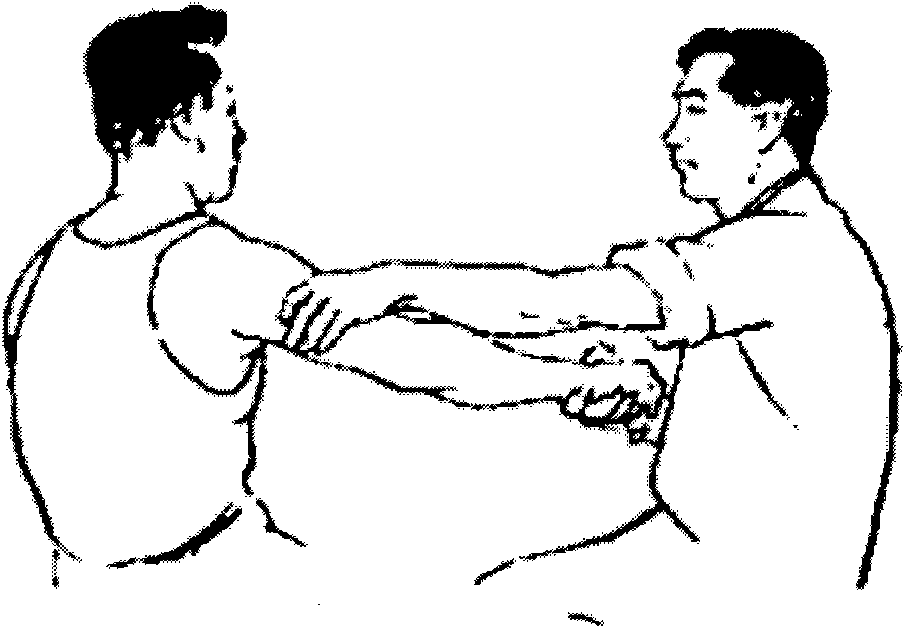

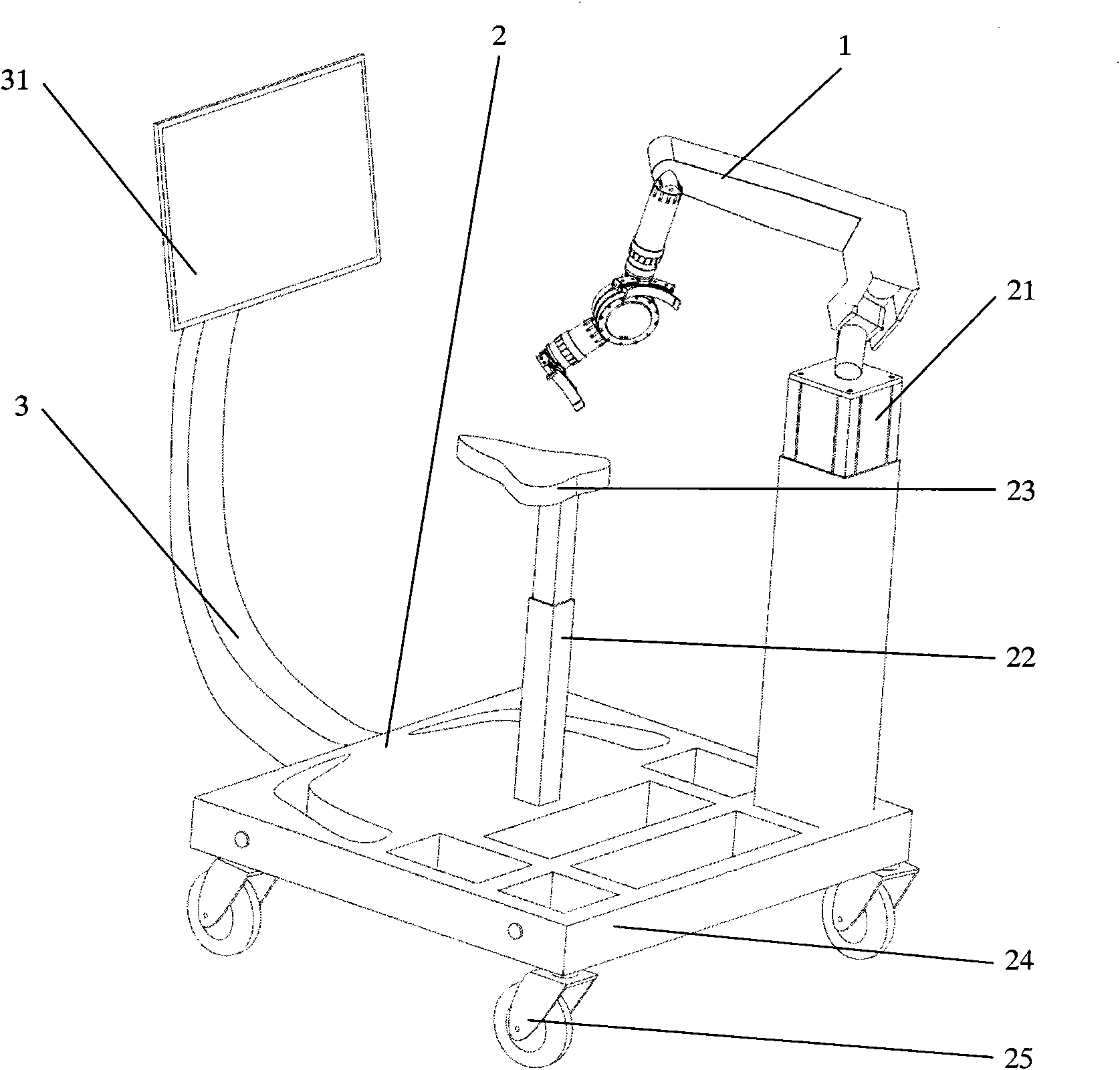

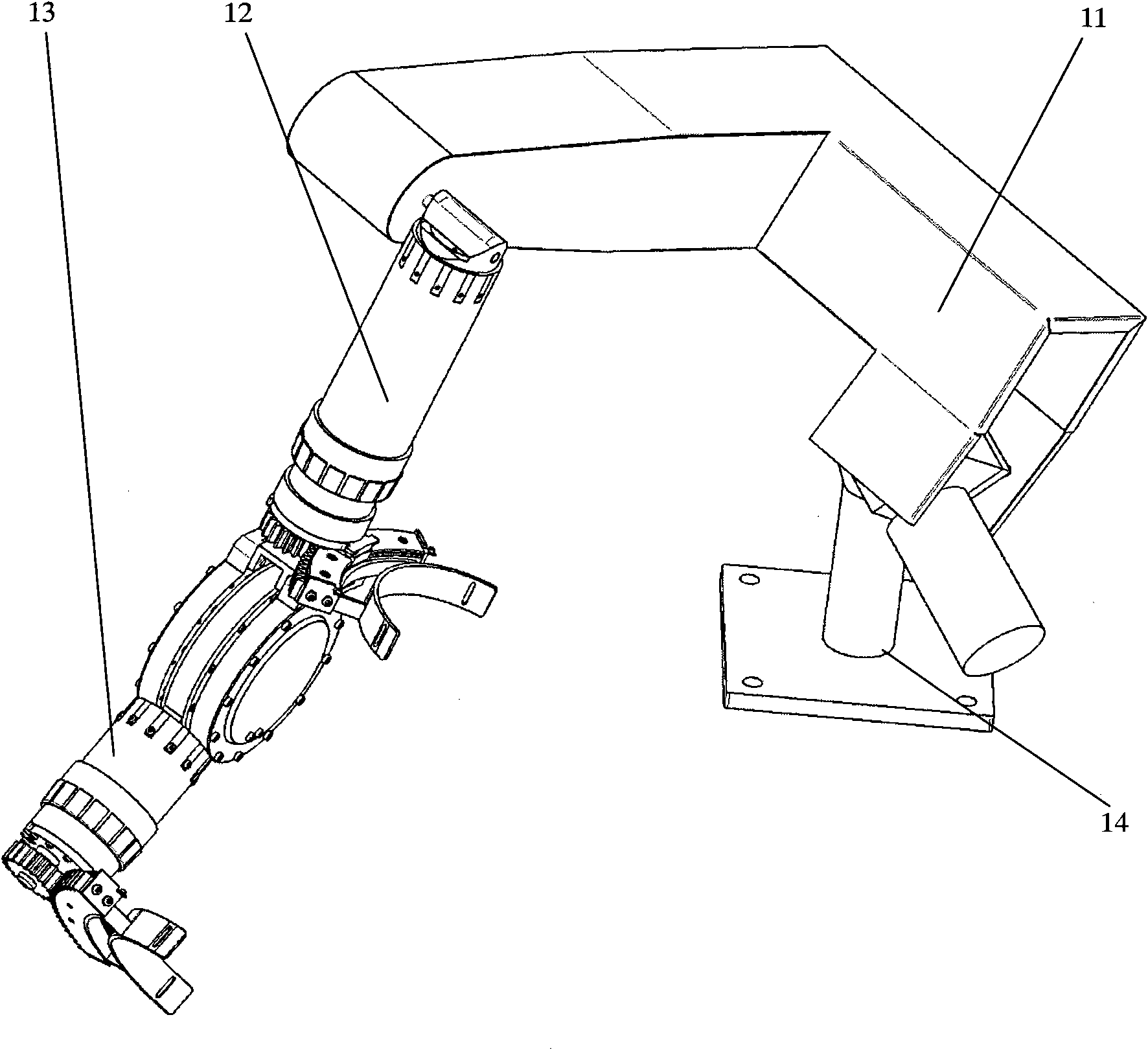

Exoskeleton type upper limb rehabilitation robot

InactiveCN102309393AEnsure safetyPromote plastic developmentChiropractic devicesDisplay deviceEngineering

The invention provides an exoskeleton type upper limb rehabilitation robot, comprising a five-degree-of-freedom or three-degree-of-freedom mechanical arm, an auxiliary mechanism and a control system. In the five-degree-of-freedom mechanical arm, a cross arm, a big arm and a small arm are sequentially connected in series to constitute an outreaching / adduction degree of freedom of a shoulder joint, a bending / stretching degree of freedom of the shoulder joint, and a bending / stretching degree of freedom of an elbow joint; the big arm and the small arm are respectively blocked by an arc-shaped sliding rail to respectively constitute an inwards rotation / outwards rotation degree of freedom of the shoulder joint and the inwards rotation / outwards rotation degree of freedom of a wrist joint; and the three-degree-of-freedom mechanical arm comprises three degrees of freedom of the shoulder joint. The auxiliary mechanism comprises a mobile base, servo stand columns and a saddle-shaped seat. The heights of the mechanical arm and the seat relative to the mobile base are respectively regulated by the two stand columns. By matched usage of mechanical limiting and electronic limiting, the rehabilitation safety of a patient is guaranteed. A display device placed before a patient seat can simulate training states under different scenes, and the training states can serve as input signals to control a virtual training game so as to improve the rehabilitation effect of the patient.

Owner:赵奇

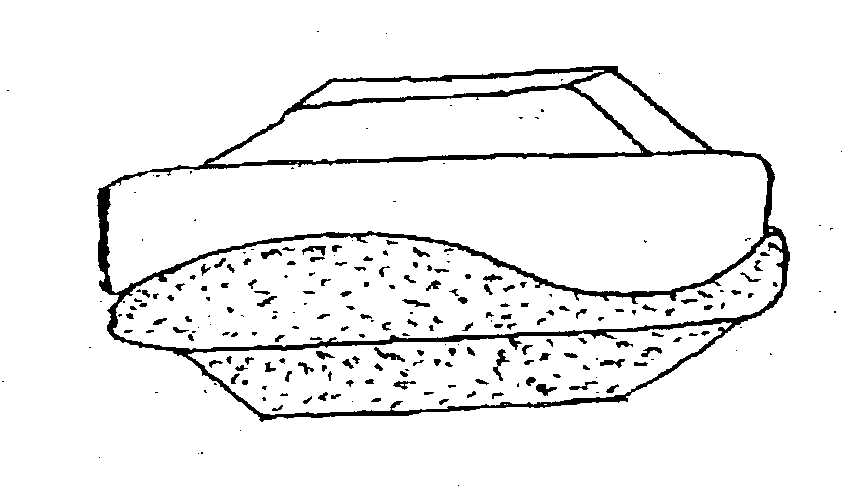

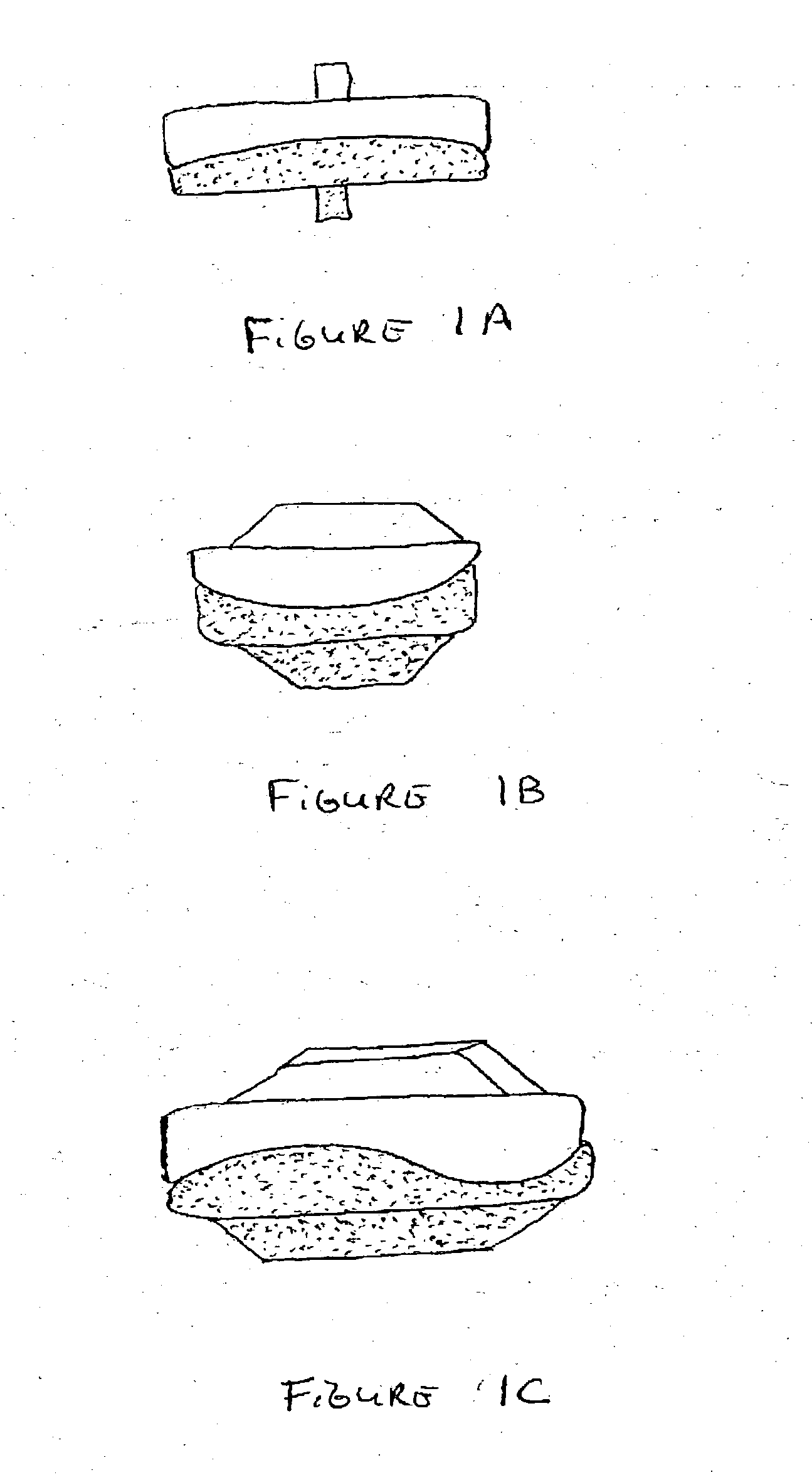

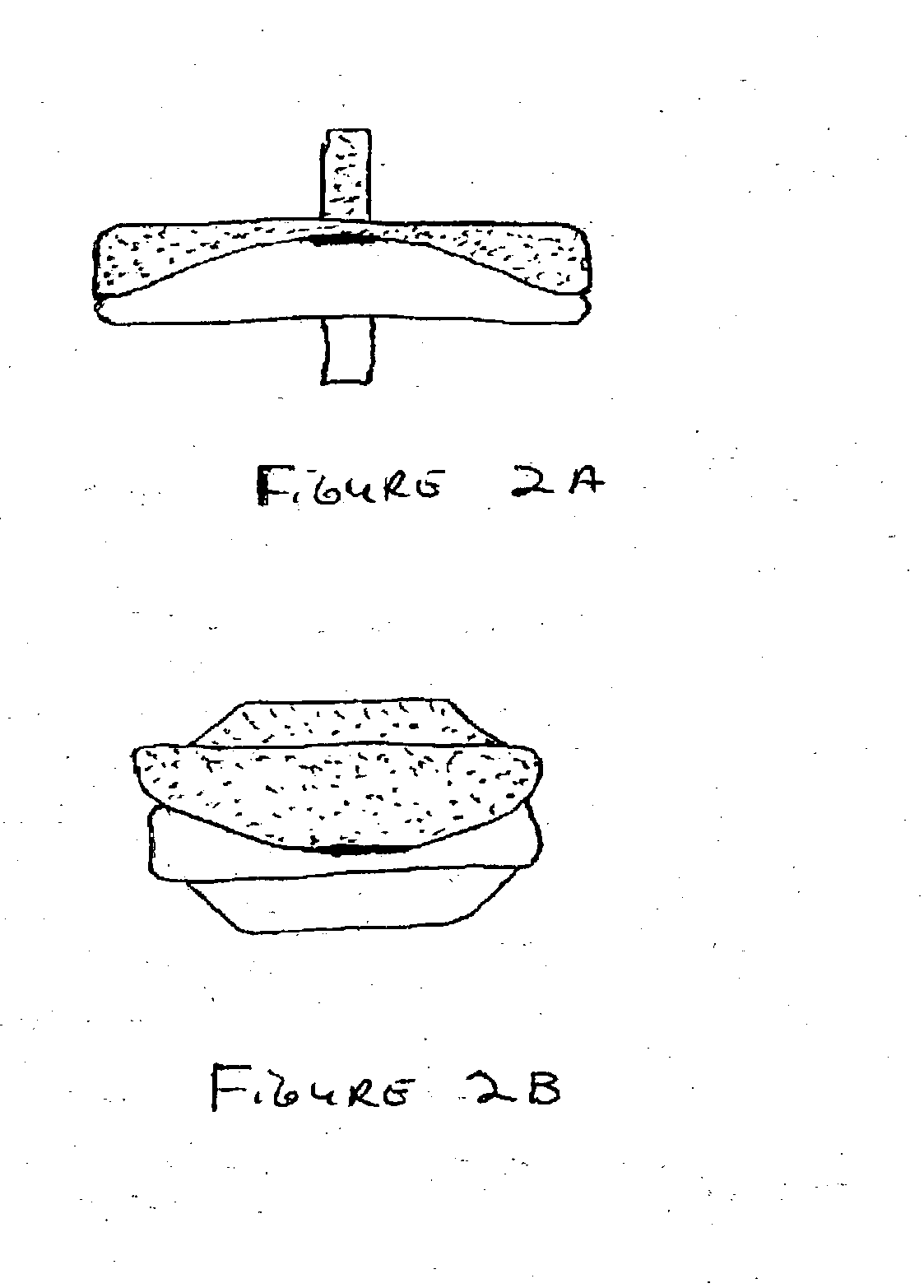

Spacerless artificial disc replacements

InactiveUS20080027548A9More wear-resistantMore flexiblyJoint implantsSpinal implantsAlloyAxial rotation

Spacerless artificial disc replacements (ADRs) are disclosed. One preferred embodiment includes two saddle-shaped components to facilitate more normal spinal flexion, extension, and lateral bending while limit axial rotation, thereby protecting the facet joints and the annulus fibrosus (AF). Either or both the superior and inferior components are made of a hard material such as chrome cobalt, titanium, or a ceramic including alumina, zirconia, or calcium phosphate. The articulating surfaces of the ADR are also preferably highly polished to reduce friction between the components. Metals, alloys or other materials with shape-memory characteristics may also prove beneficial.

Owner:HOWMEDICA OSTEONICS CORP

Breath training device

The inventive breath training device comprises a respiratory tube, a low-frequency mechanical air oscillation generator provided with an oscillation chamber embodied therein and provided with an input channel which is embodied in the form of an upwardly extending saddle-shaped body of revolution, contains a spherical ball and is connected to the respiratory tube and to an output channel communicating with ambient air, wherein the respiratory tube is provided with a jacket in which the body of the low-frequency mechanical air oscillation generator rotatable about a horizontal axis is fixed and a bypass chamber provided with an inspiratory tube is formed, said inspiratory tube comprises an inspiratory valve provided with a tubular attachment and the output channel of the oscillation chamber of the low-frequency mechanical air oscillation generator is also provided with an expiratory valve.

Owner:OOO SPORT TECH

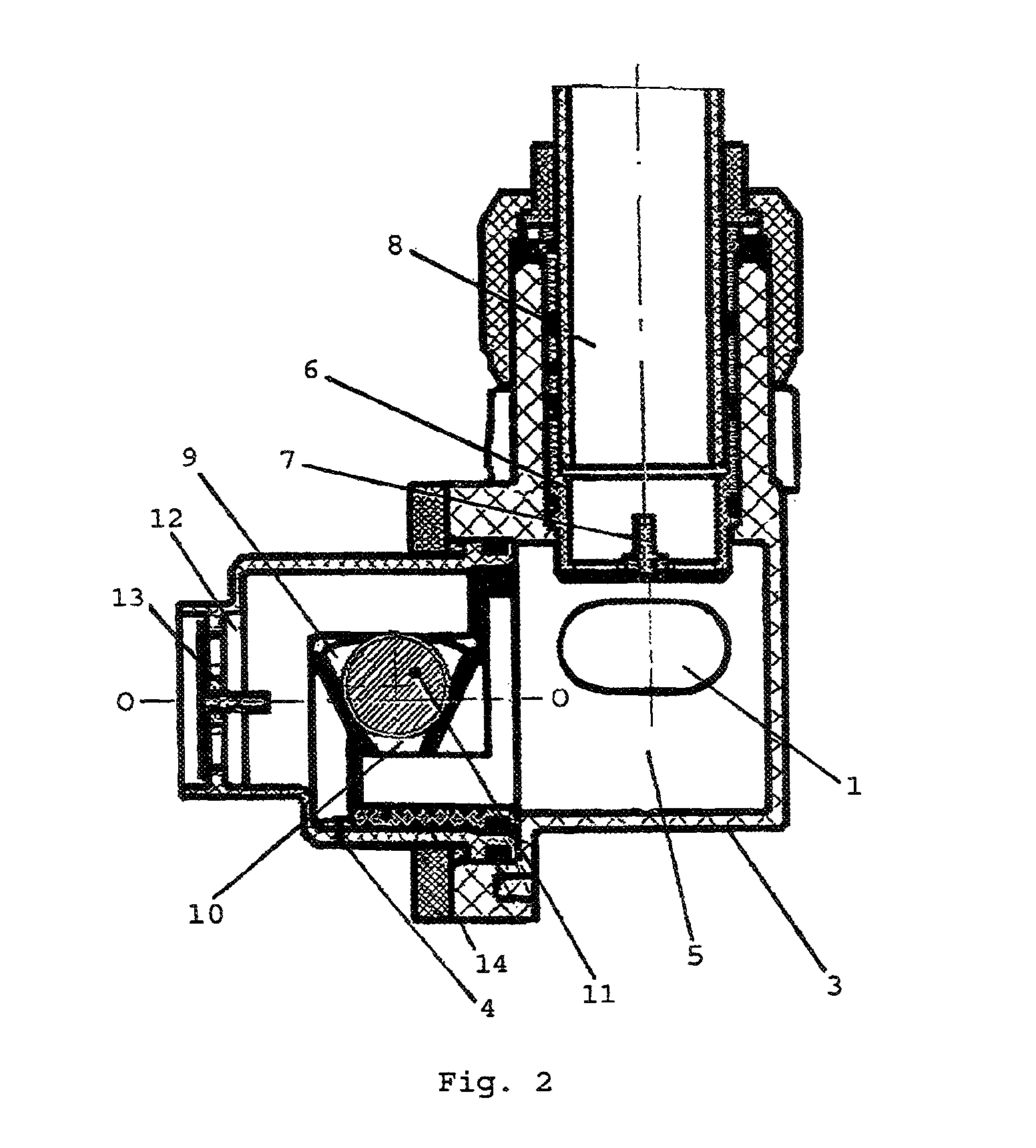

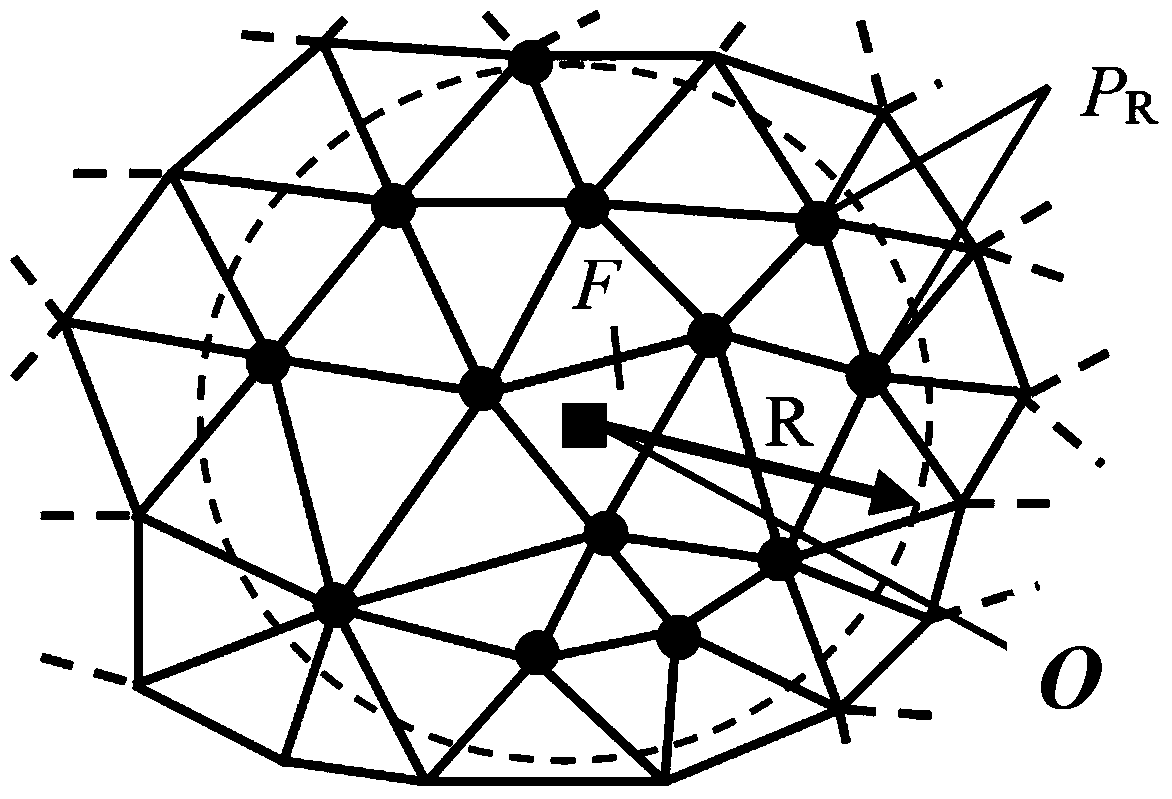

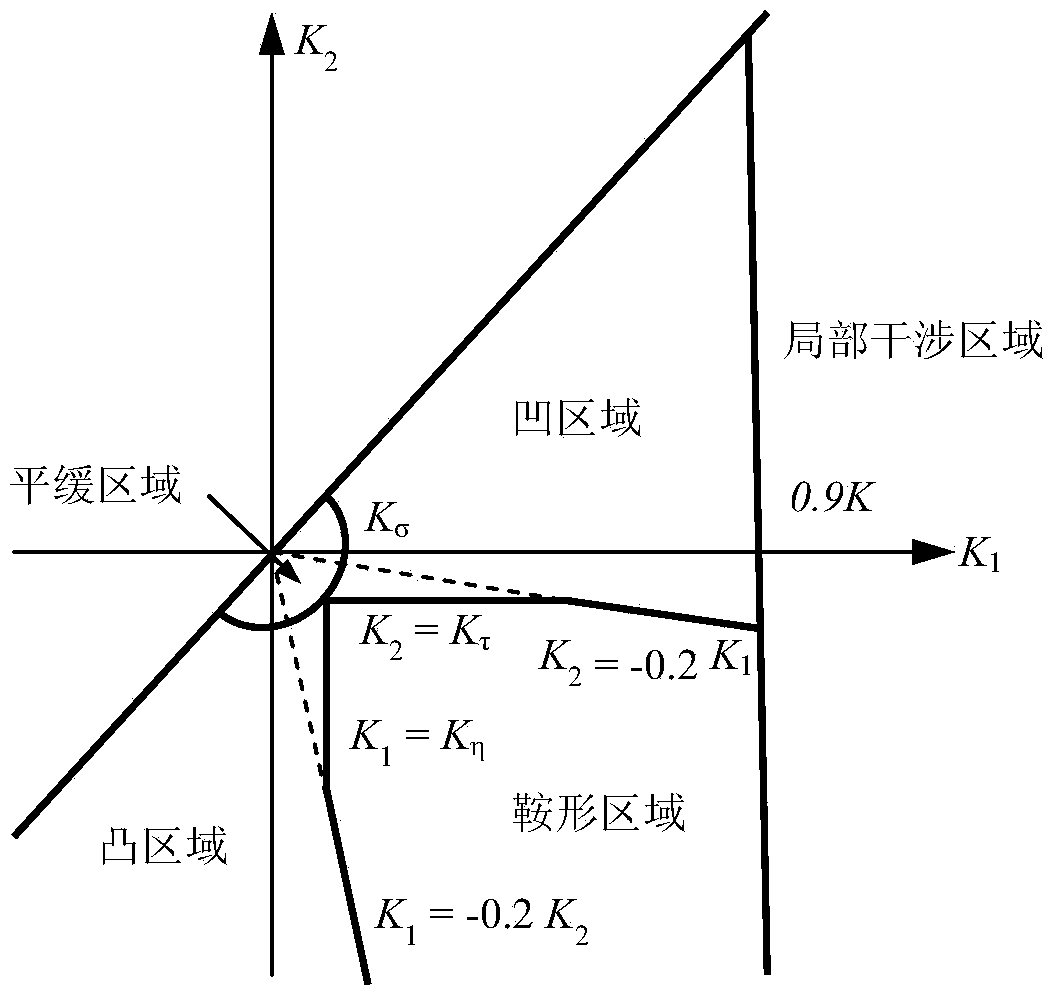

Partition machining method of triangular mesh model

InactiveCN103885385ADivide and conquer processingAvoid problems with large differences in region sizesNumerical controlNumerical controlCam

The invention provides a partition machining method of a triangular mesh model, and belongs to the technical field of CAM. The partition machining method of the triangular mesh model is characterized in that the partition machining method includes the steps that neighborhood points within an R radius range are selected so as to calculate differential geometry information of a triangular patch model accurately; the triangular patch model is segmented into sub-regions with different characteristics with characteristic statements of sub-regions to be machined as growth principles, optimization merging is conducted on small-area regions and wrongly judged regions so as to eliminate over-segmentation phenomena, and boundary smoothing is conducted on the sub-regions so as to reduce saw-toothed boundaries; different track strategies are adopted in different types of the sub-regions to be machined, when a constant scallop height track is generated, the circular cutting initial track generation method is adopted in the convex sub-regions and the concave sub-regions, the linear cutting initial track generation method is adopted in the saddle-shaped sub-regions, machining is conducted on tracks at the positions of sub-region boundaries when bias extension is conducted on cutter track projection, and reasonable and complete sub-region machining tracks are obtained. According to the partition machining method, numerical control machining cutter tracks giving consideration to the machining efficiency and the machining quality are effectively generated from the complicated triangular patch model.

Owner:HUAQIAO UNIVERSITY

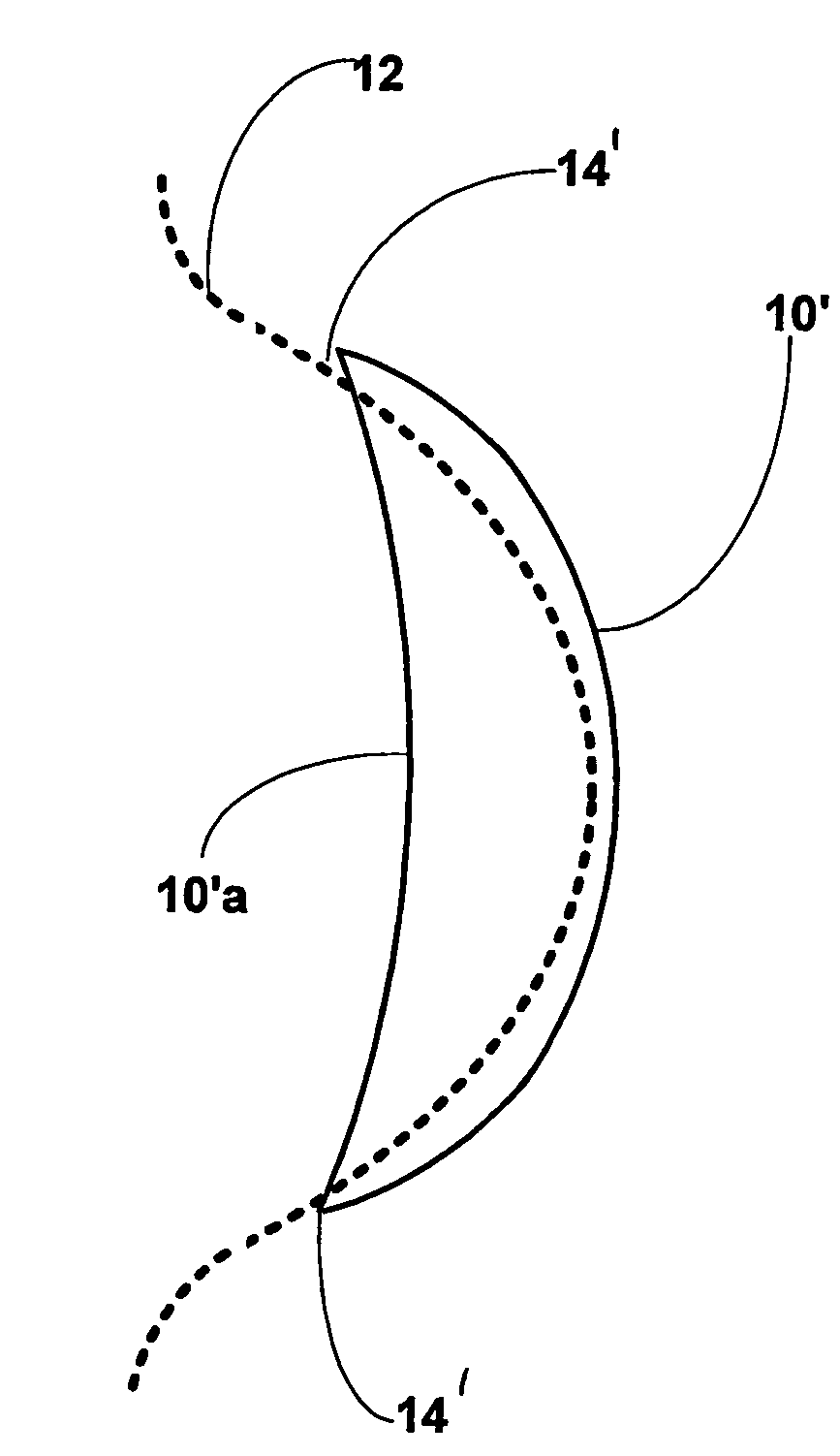

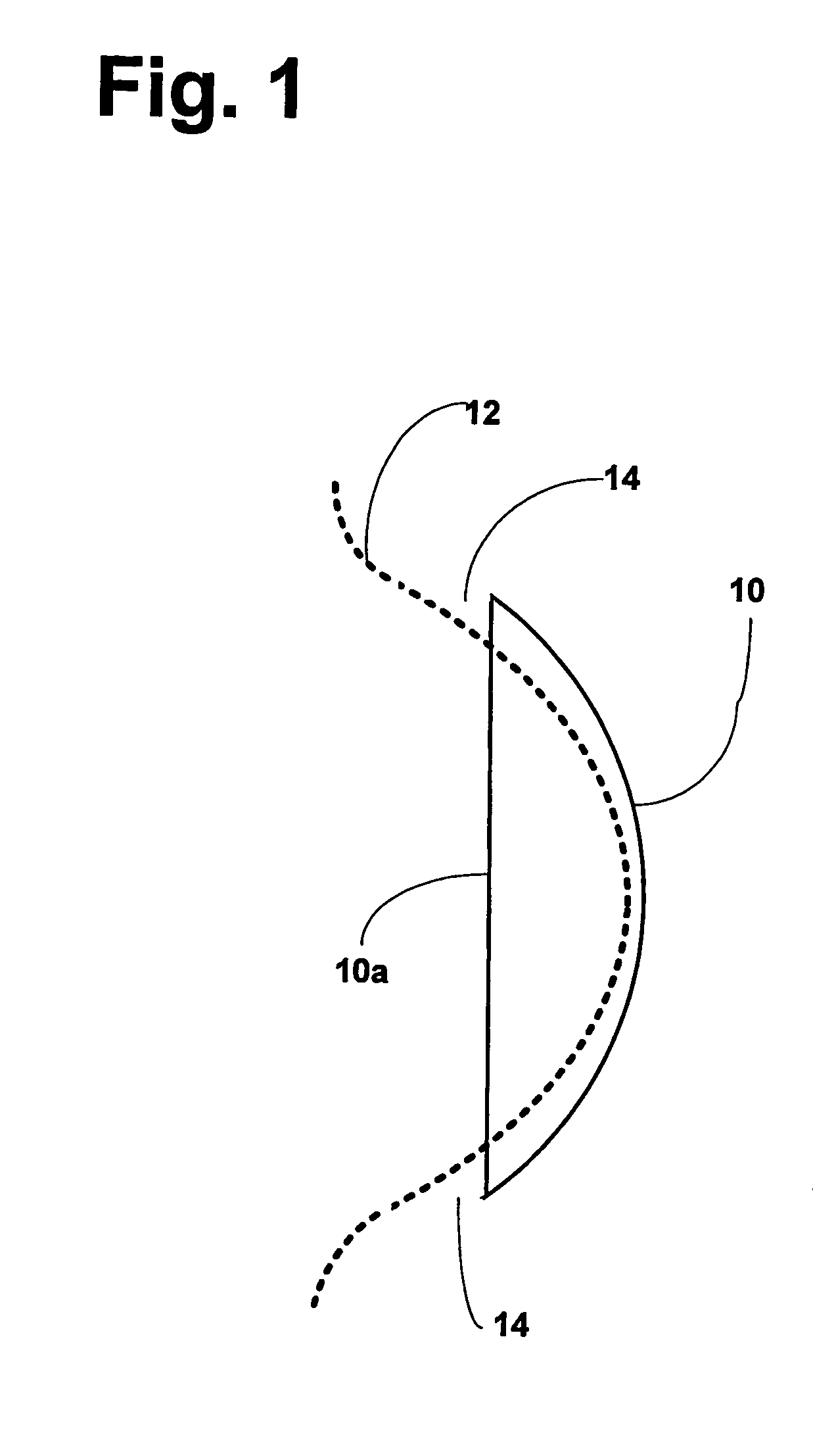

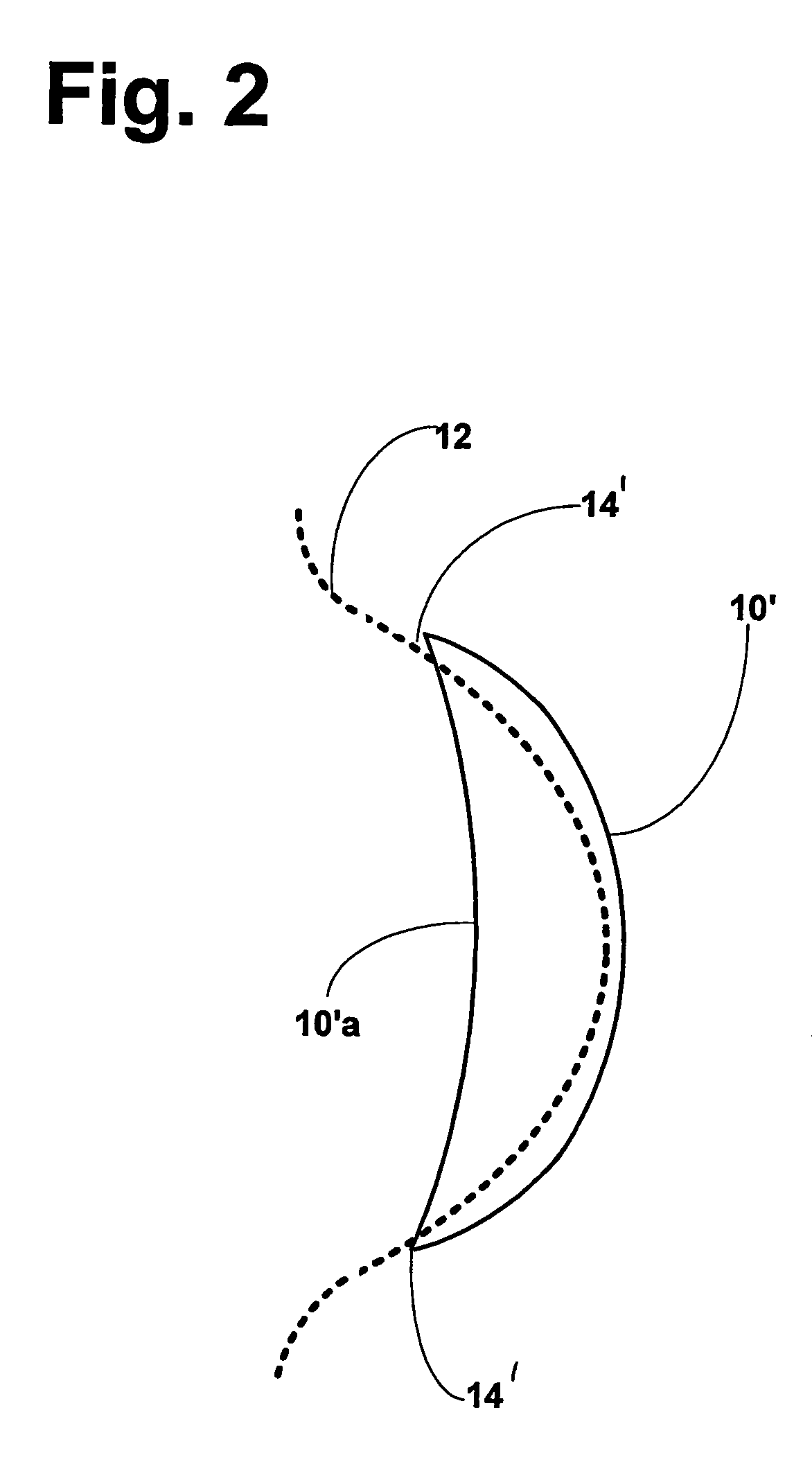

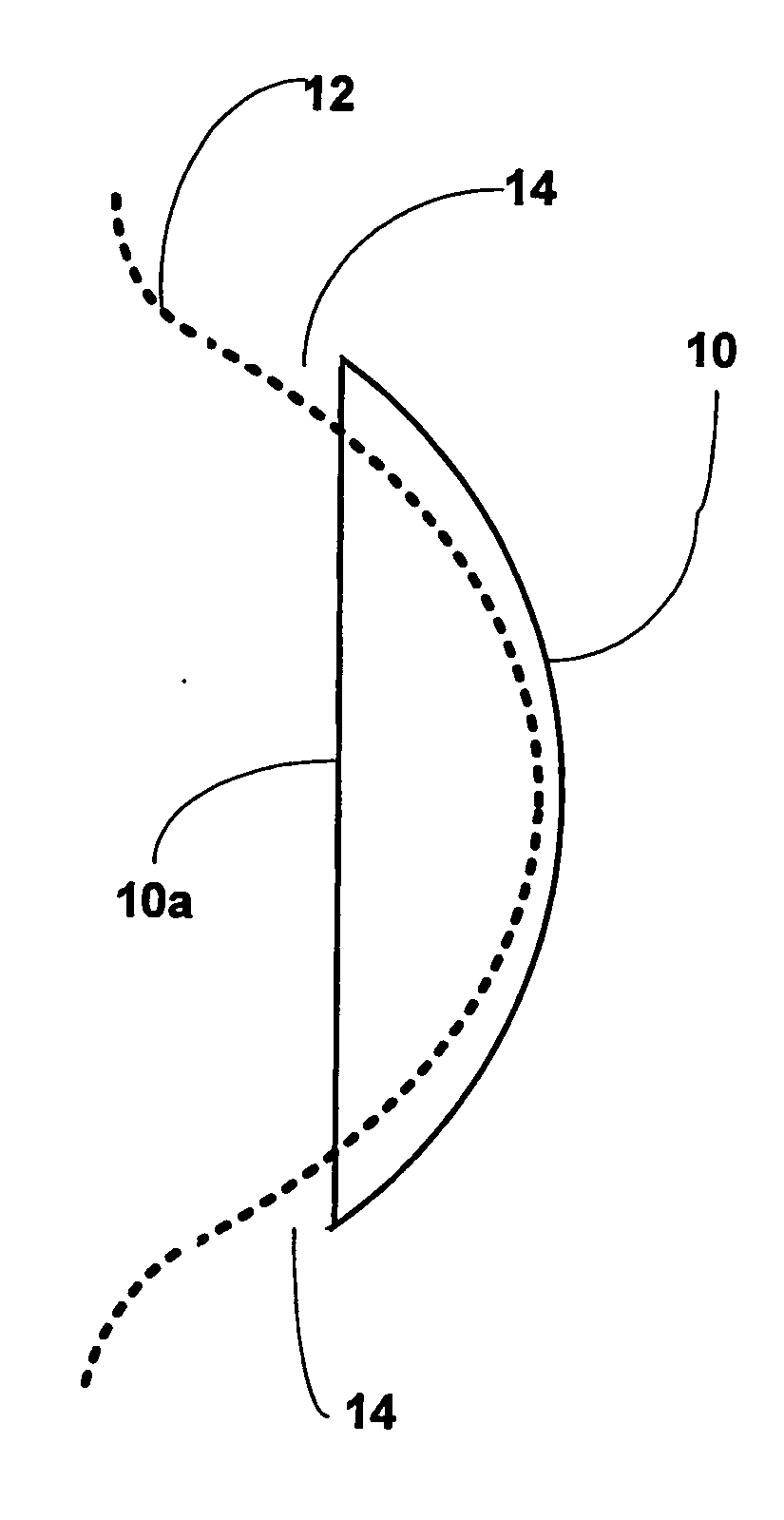

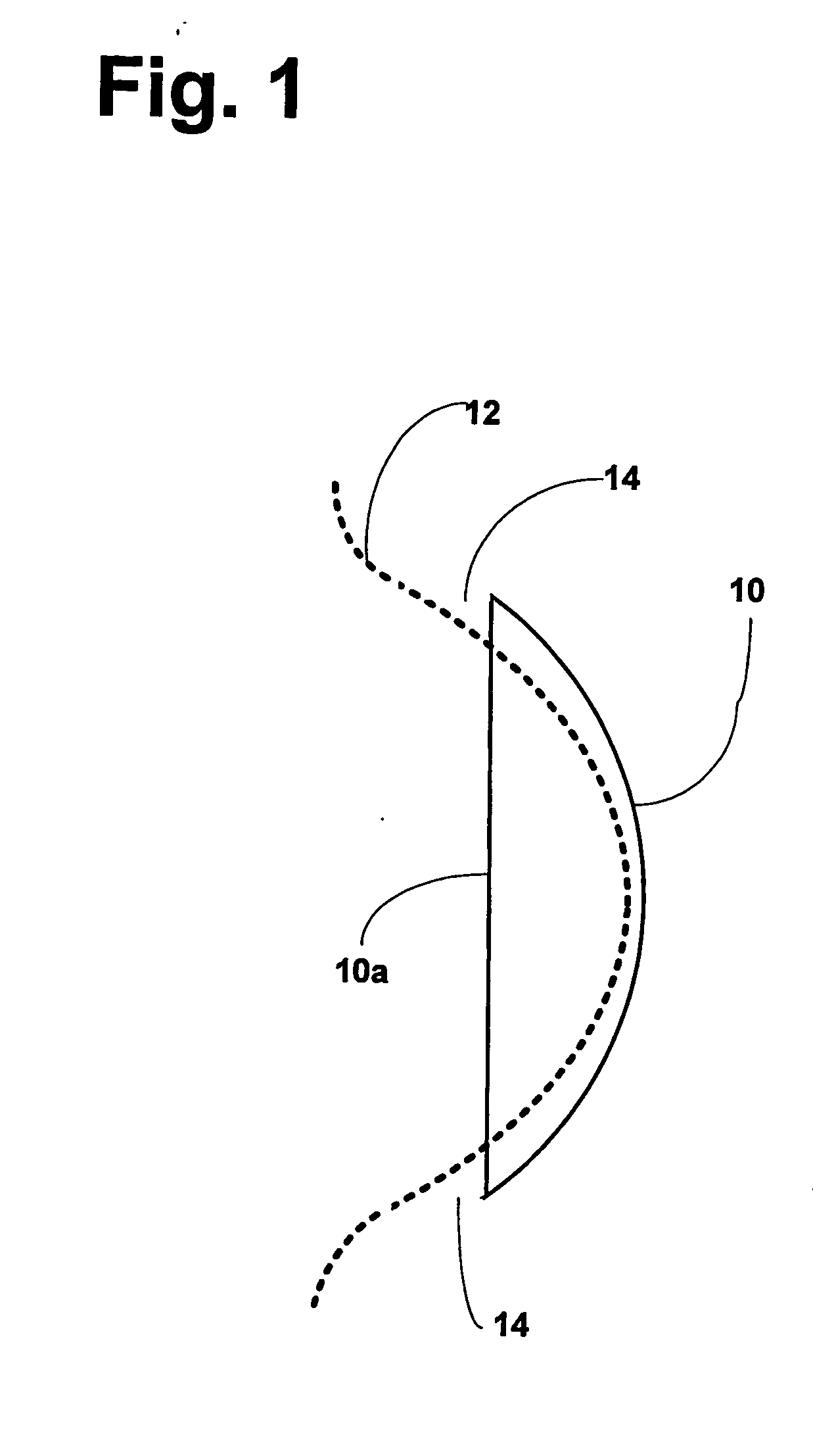

Contact lens with shaped periphery

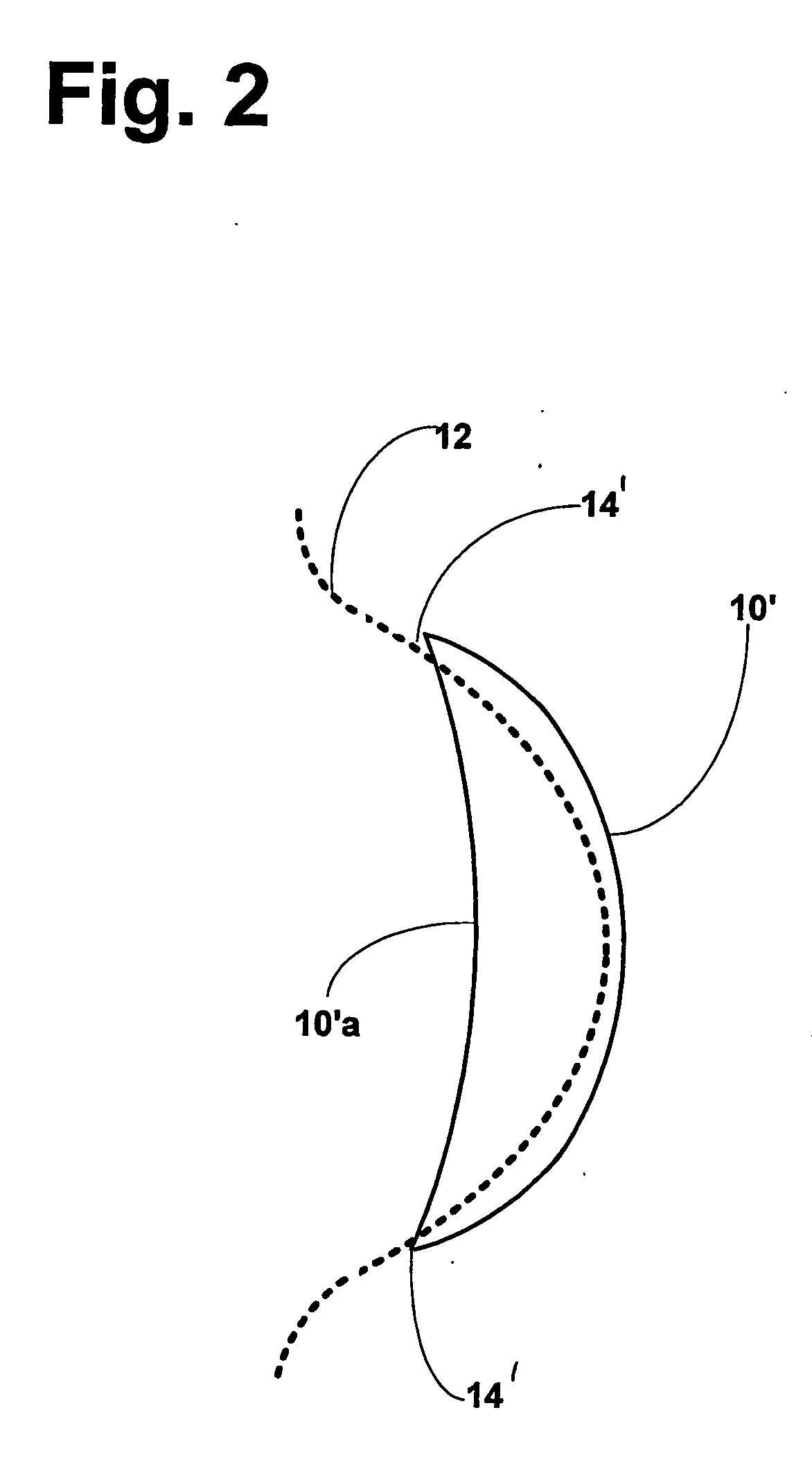

InactiveUS7338160B2Quality improvementImprove comfortEye diagnosticsOptical partsContact lens tintSaddle-shaped

Eye measurements taken on a patient being fitted for contact lens will include a refraction test and an additional measurement representing corneal depth variation on the surface of an imaginary cylinder having the same diameter as the lens. This information then used during lens manufacture to produce lens in which the perimeter is not circular and does not lie in a plane, but which drops backwards towards the eye at appropriate points to produce a saddle-shaped perimeter.

Owner:SCI OPTICS INC

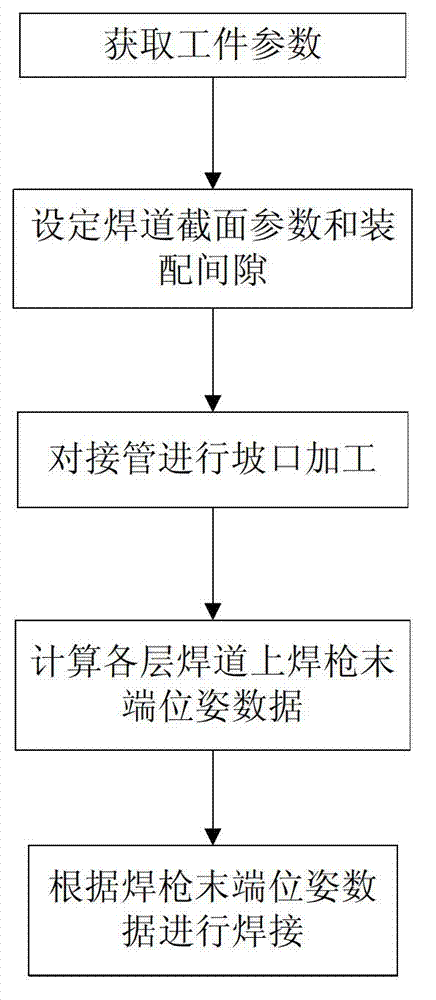

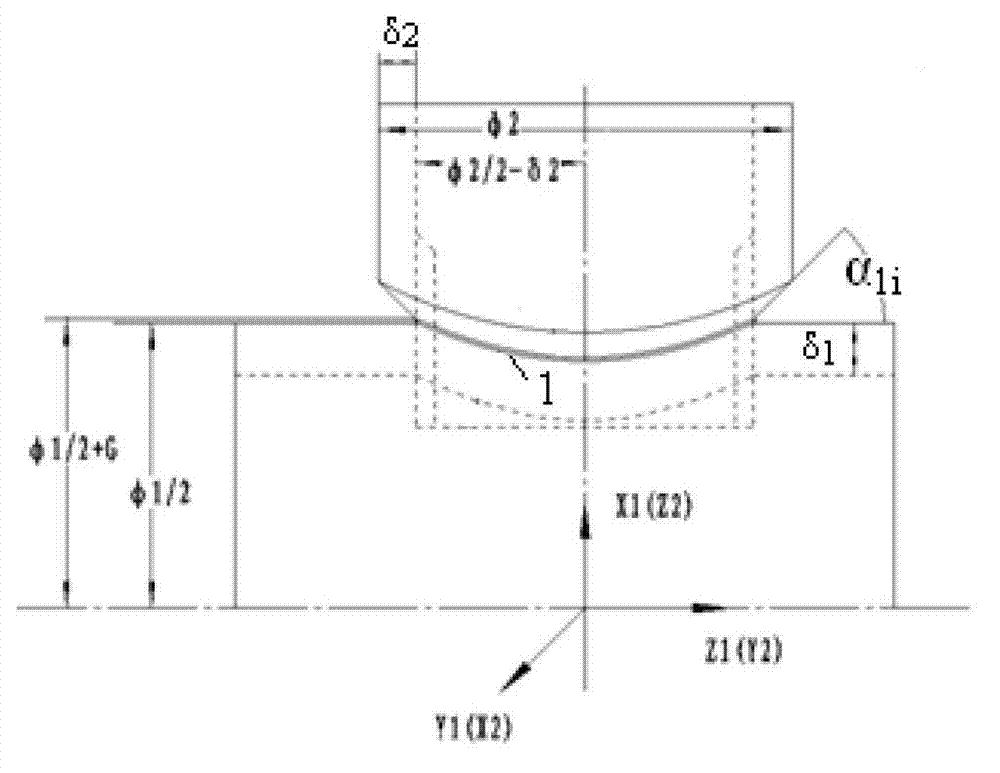

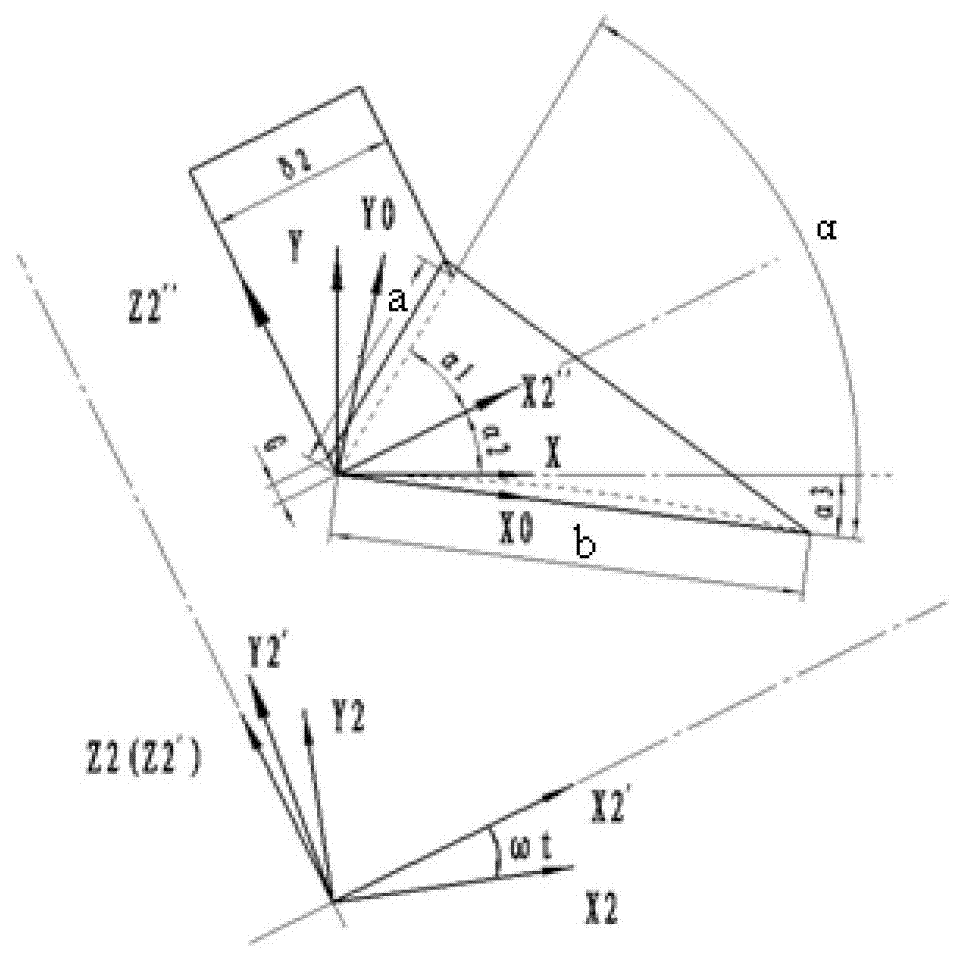

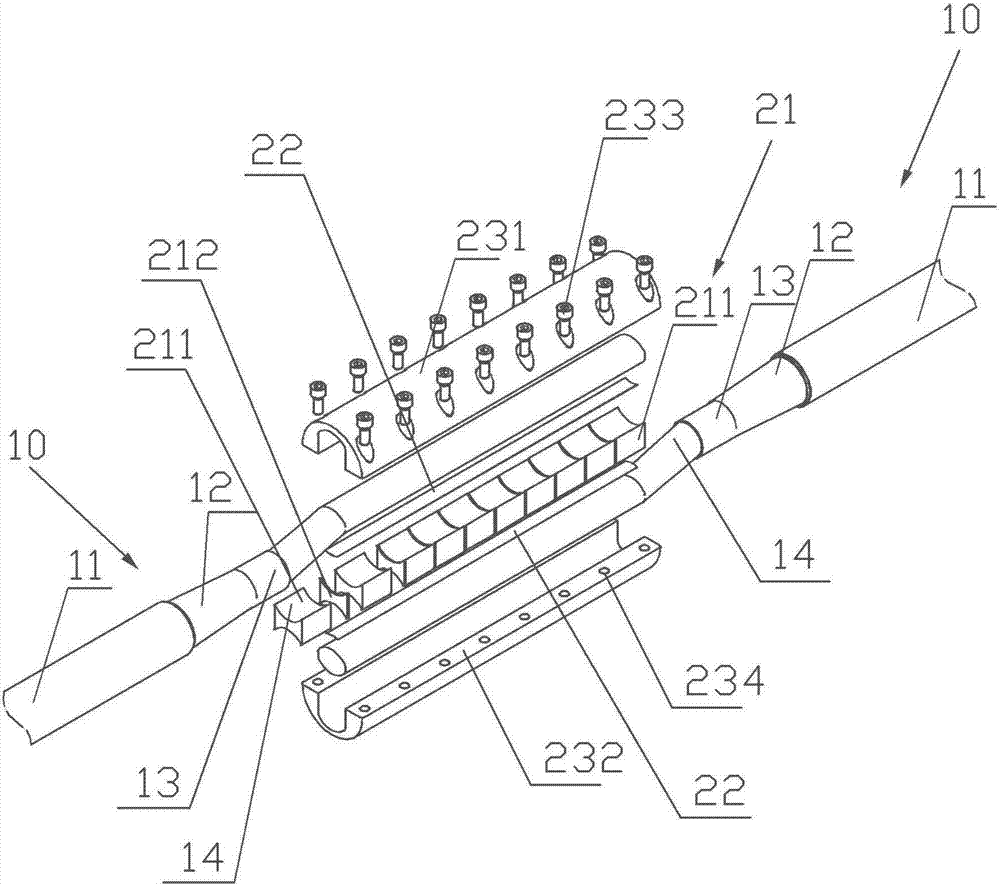

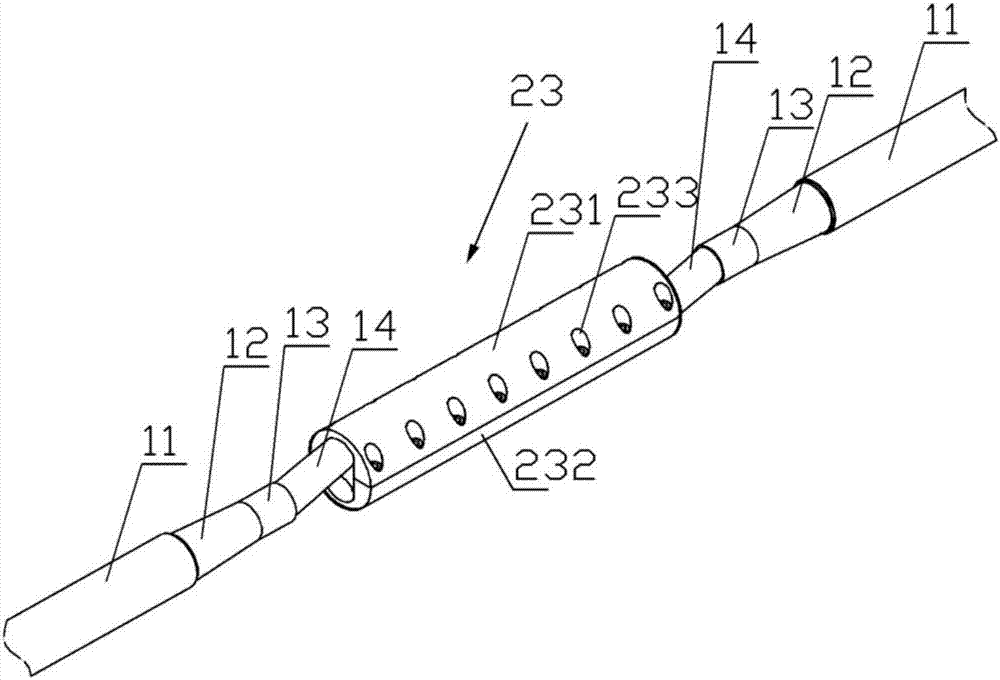

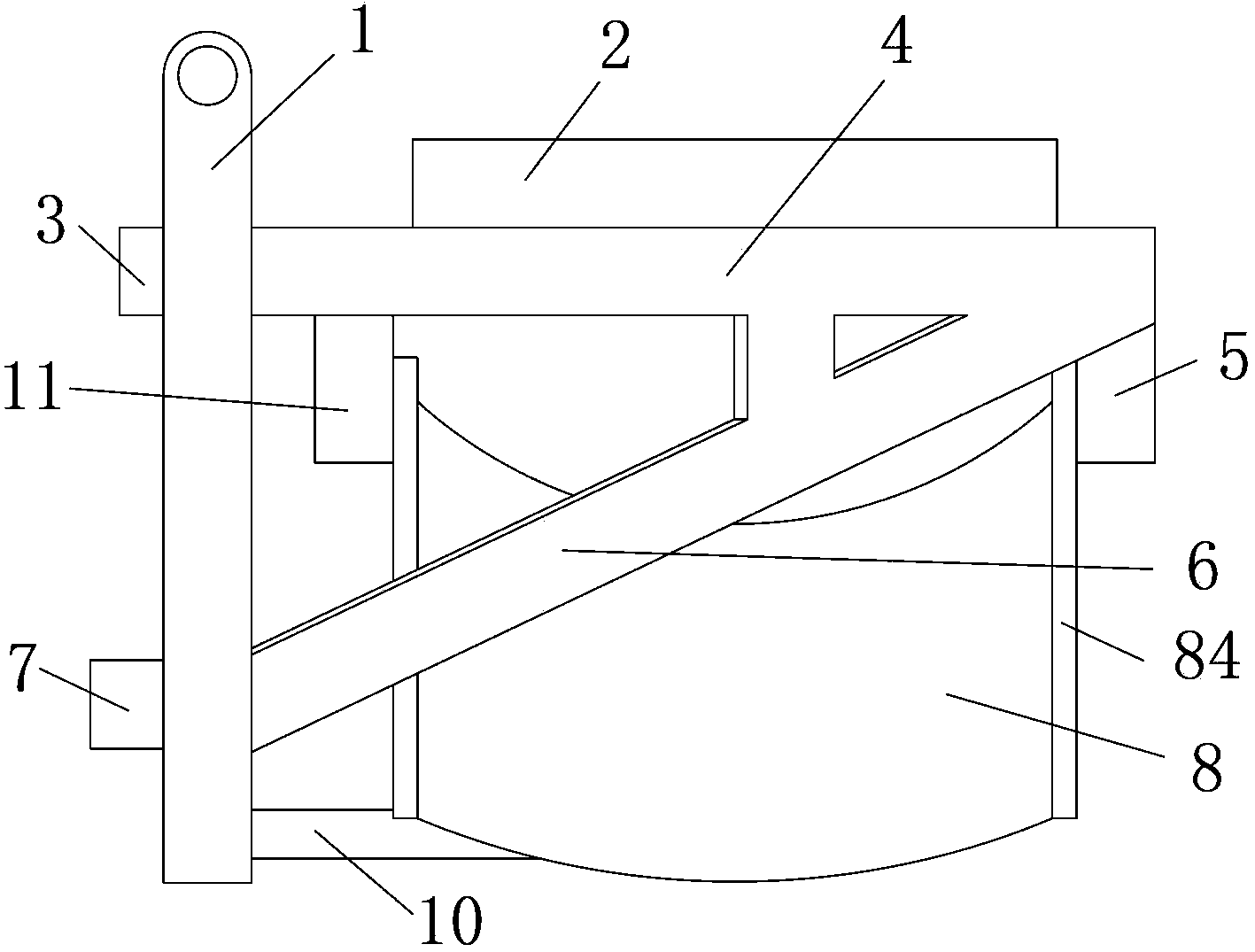

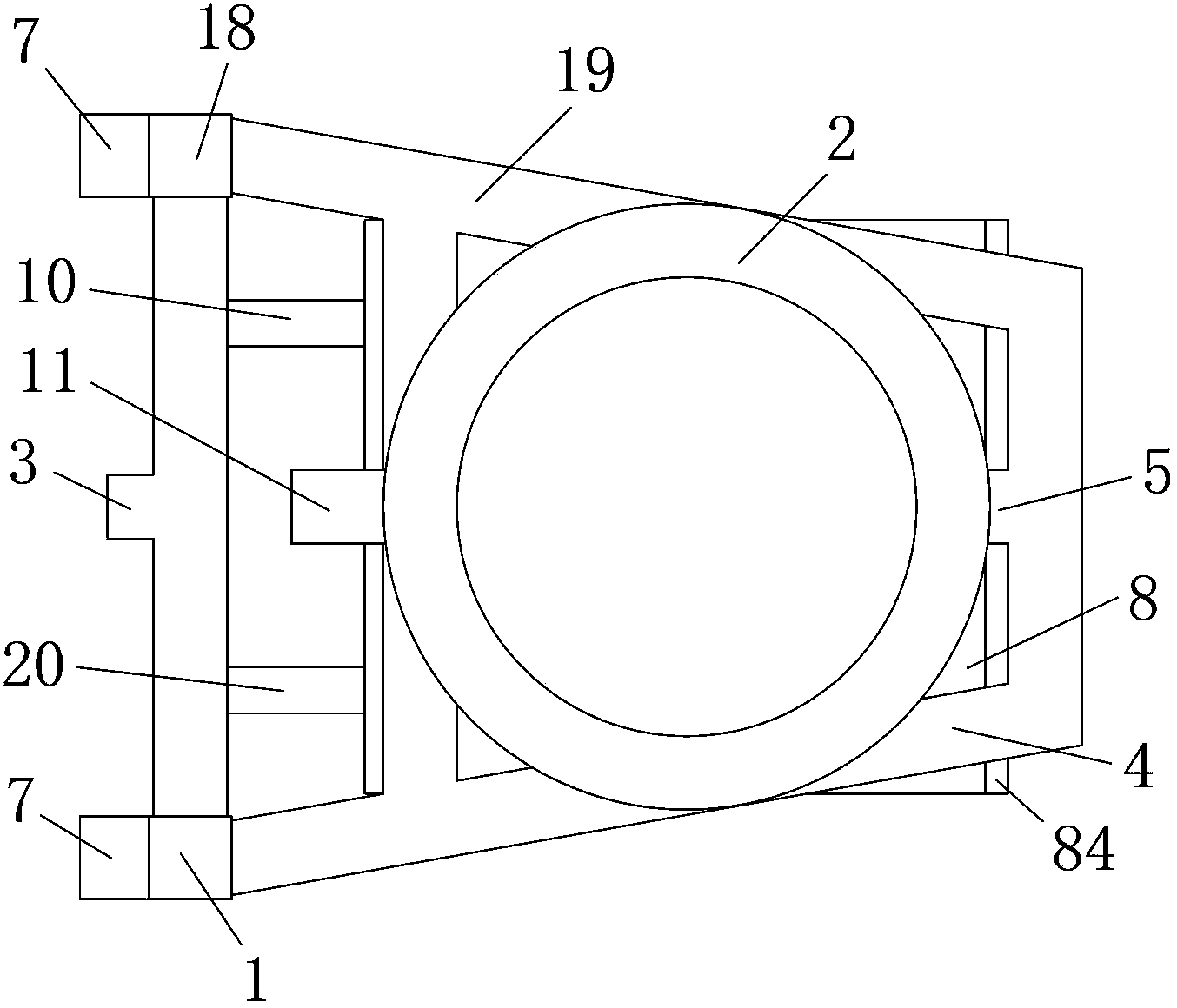

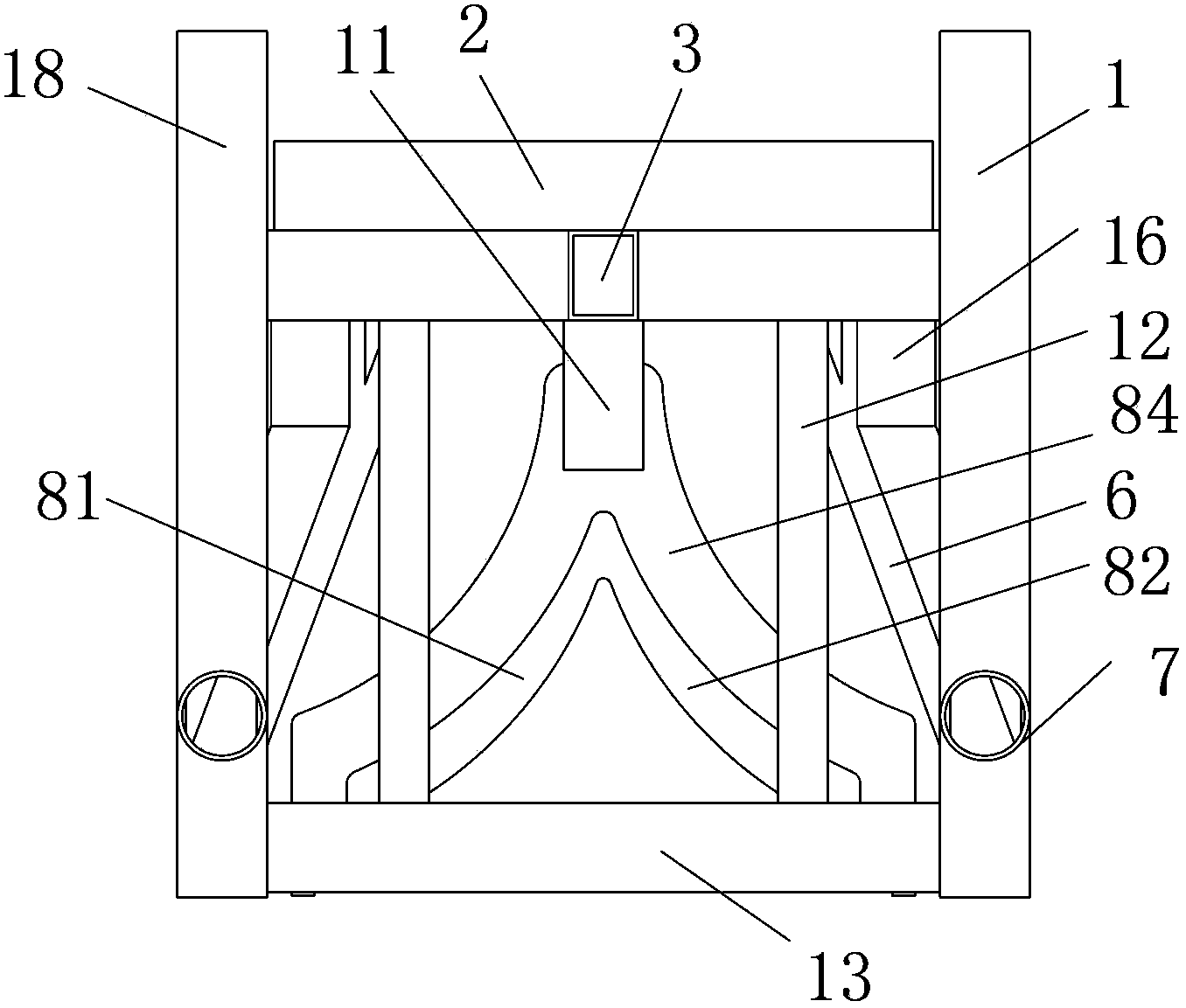

Saddle-shaped track automation welding method of collection box large tube socket

ActiveCN103111730ASolve automatic continuous weldingSuitable temperatureArc welding apparatusNumerical controlTube socket

The invention relates to a saddle-shaped track automation welding method of a collection box large tube socket. The saddle-shaped track automation welding method comprises a first step of acquiring tool parameters, a second step of setting weld pass section parameters and a fit-up gap G, a third step of edge preparation, wherein bevel angles of connecting tubes and female tube intersecting lines at different positions are determined according to a design principle of a uniform section bevel angle, connector portions of the connecting tubes are machined in a cutting mode, a fourth step of inputting the weld pass section parameters, the fit-up gap G, the tool parameters, the bevel angles and related technological parameters of planned adoptive welding technology into a numerical control welding system to calculate pose data of the tail end of a welding gun, and a fifth step of controlling the welding gun to continuously weld in a layer mode by the numerical control welding system according to the pose data. According to the saddle-shaped track automation welding method of the collection box large tube socket, the purpose of automatic, fast and continuous welding of the intersection line track under different pipe diameters is achieved, weld pass is arranged reasonably, connector quality is good, appearance is attractive, arrangement is ordered, and a technique is wide in application range.

Owner:WISE WELDING TECH & ENG

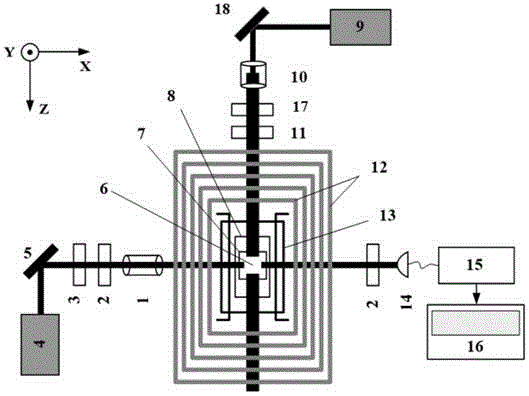

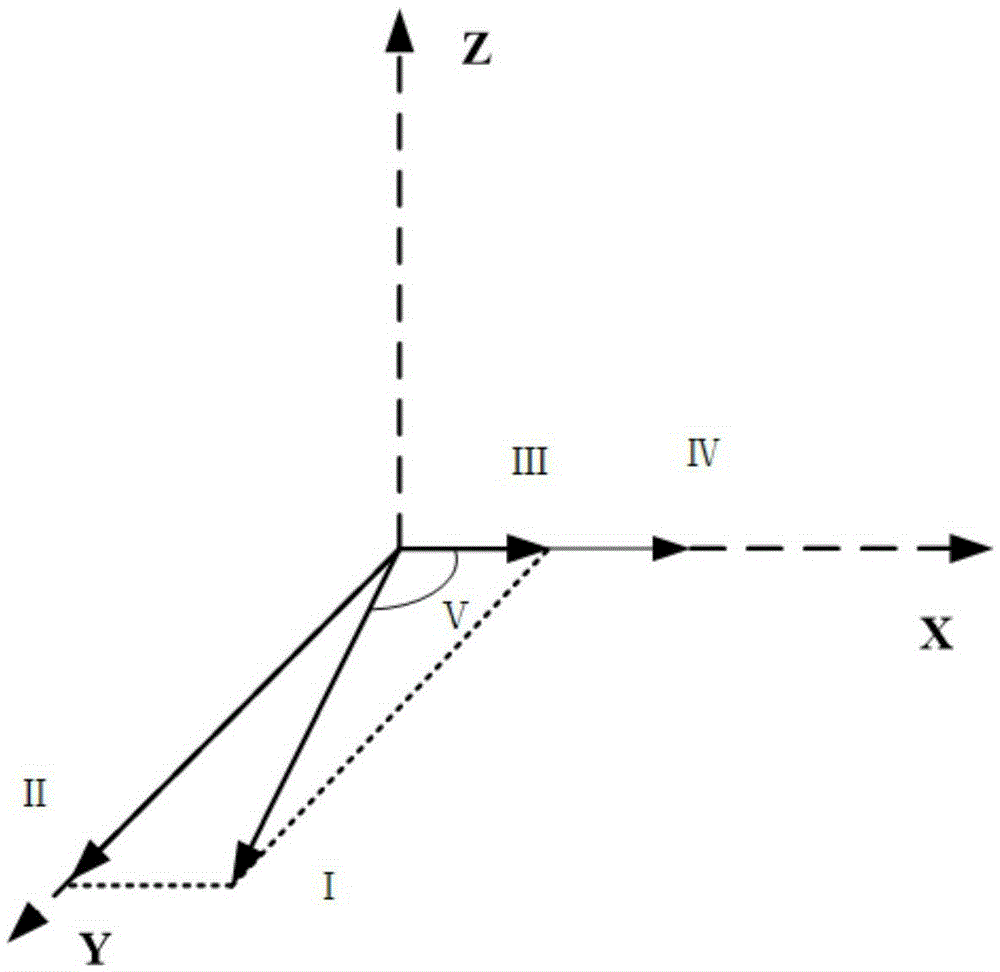

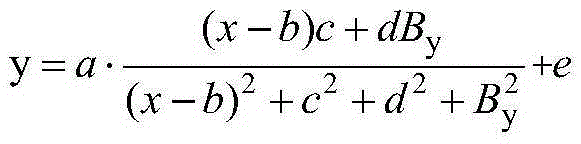

Measuring device and method of non-orthogonal angle between magnetic coil X and Y axes of atom magnetometer

The invention aims to provides a measuring device and method suitable for a non-orthogonal angle between saddle-shaped coil X and Y axes of an SERF atom magnetometer, and belongs to the technical fields of optical detection, weak magnetic detection and uniform magnetic field coils. Aimed at the problem that non-orthogonality of three-dimensional magnetic coils influences the sensitivity of the SERF atom spin magnetometer, the measuring method and device of the non-orthogonal angle between the saddle-shaped coil X and Y axes, which are based on Bloch kinetic equations, are provided. The invention fills in the blanks of the measuring method and device of the non-orthogonal angle between the saddle-shaped coil X and Y axes of the atom magnetometer, effective references are provided for the atom magnetometer to estimate and compensate a magnetic field deviation value, and the improvement of the sensitivity of the SERF atom magnetometer is ensured.

Owner:SOUTHEAST UNIV

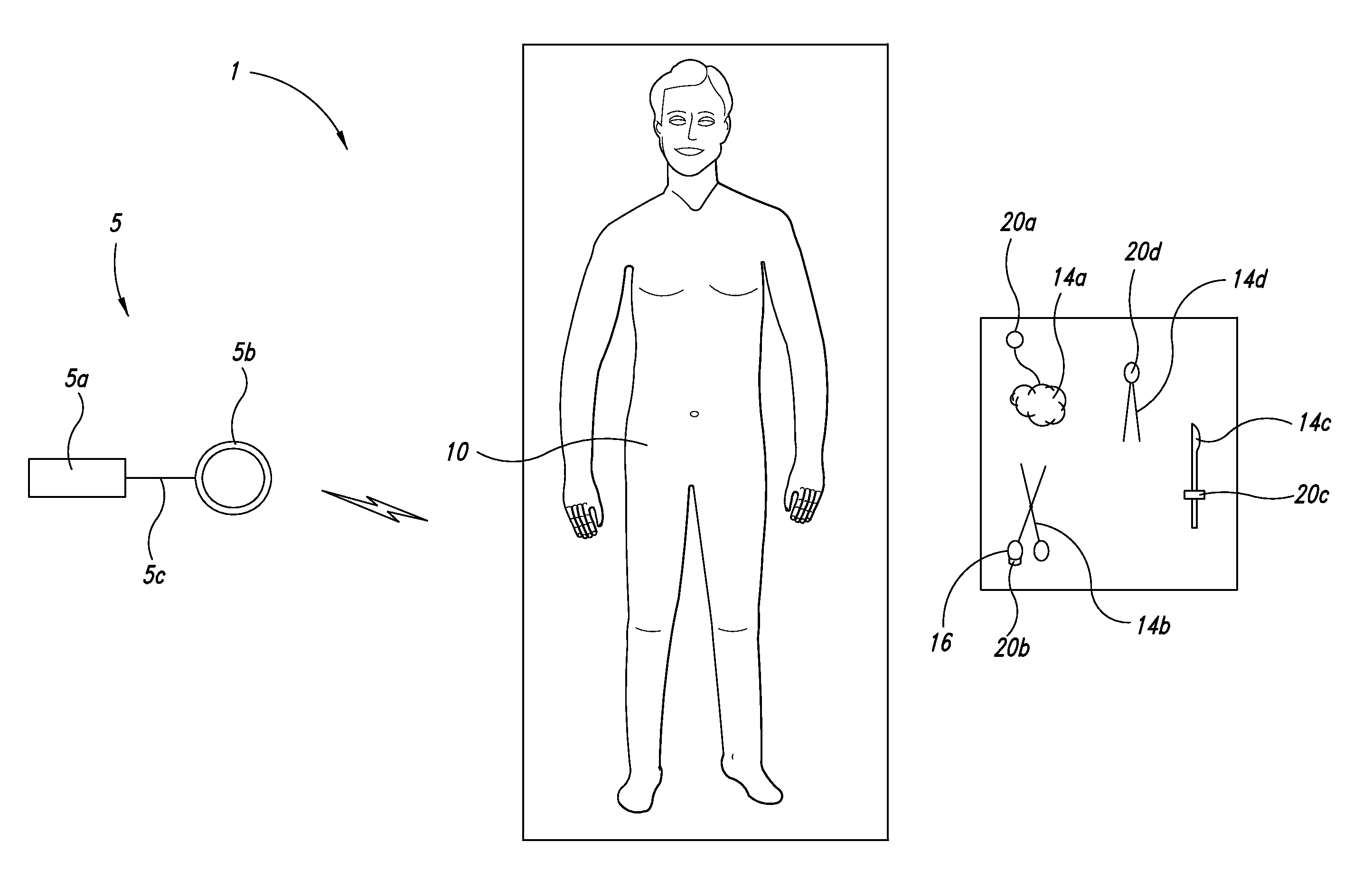

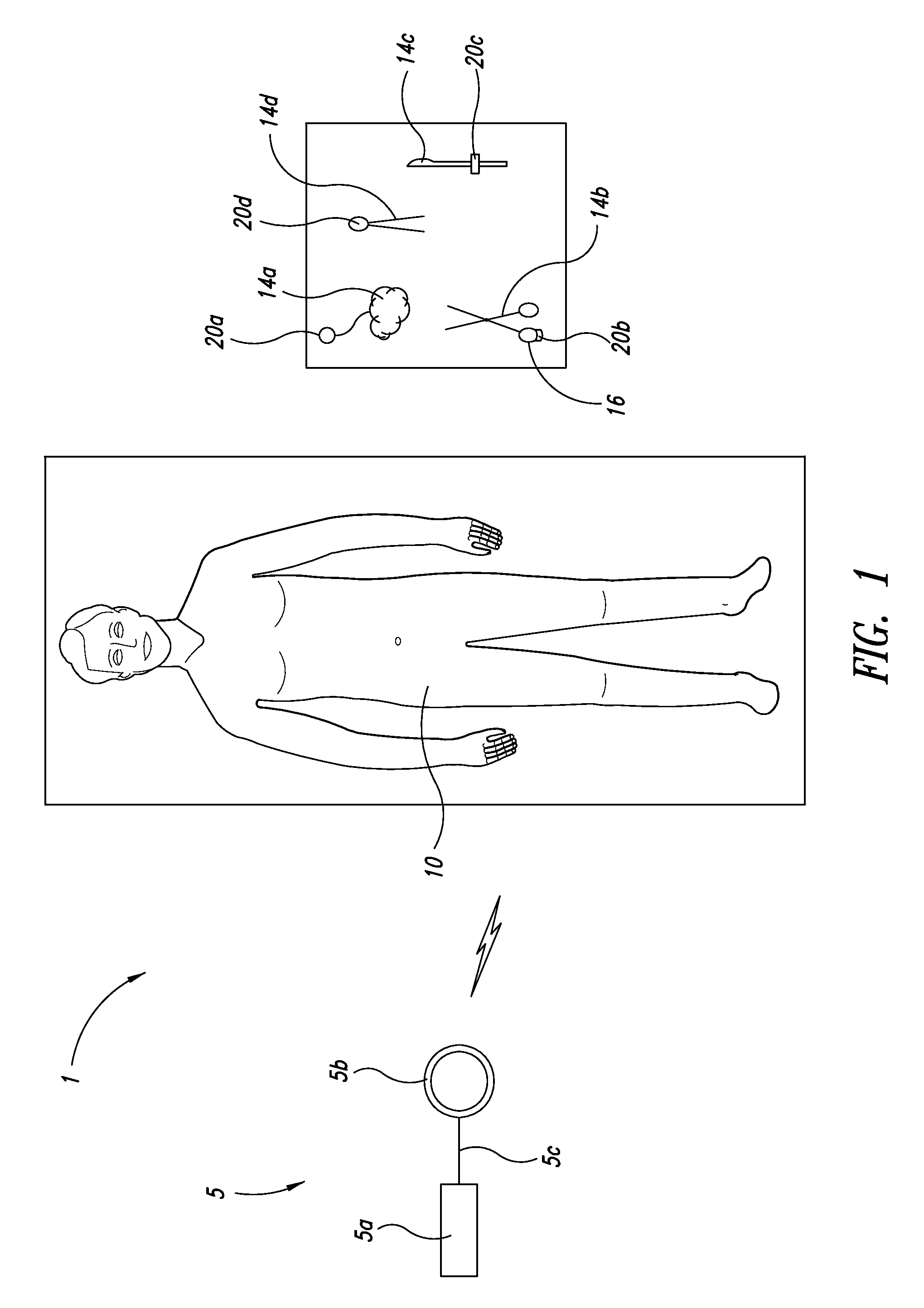

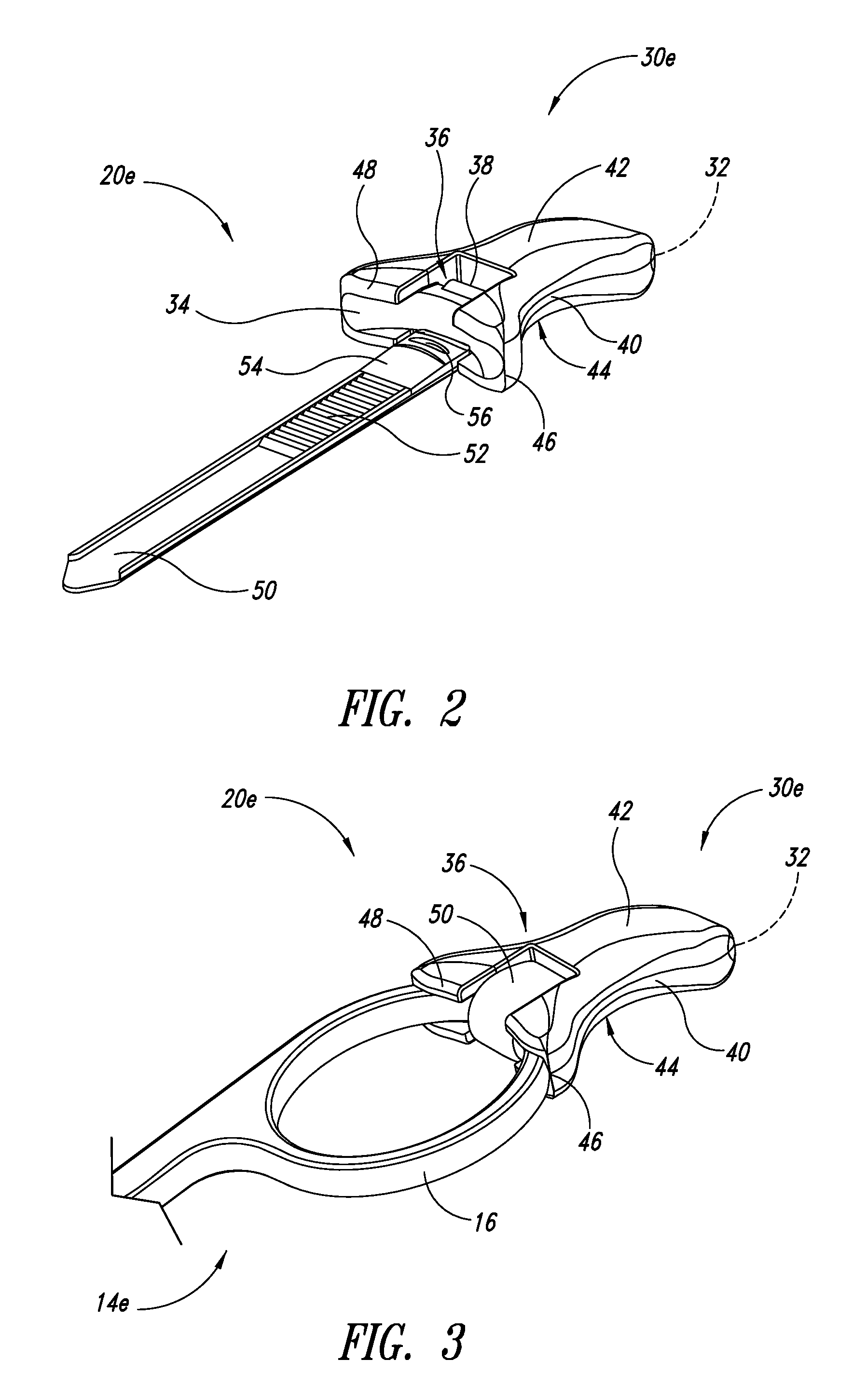

Transponder device to mark implements, such as surgical implements, and method of manufacturing and using same

ActiveUS8354931B2Increased leverageMultiplex system selection arrangementsDiagnosticsEngineeringSupport surface

A transponder device to mark a surgical implement, such as a metallic surgical instrument, is provided that comprises a transponder housing attachable to a portion of the surgical implement. The housing may include a transponder receiving cavity spaced at least 1 millimeter, and preferably at least 2 millimeters, from any portion of the surgical implement when the housing is attached to the surgical implement, and preferably includes a saddle-shaped finger support surface or a stabilizing surface sized and configured to receive a finger of a user for providing additional leverage and / or stabilizing structure when operating the implement. The housing may be removably attached to the surgical implement or permanently attached. In use, a transponder is retained in the device. Methods of manufacturing transponder devices and methods of detecting a transponder indicating the possible presence of a surgical implement are also provided.

Owner:TYCO HEALTHCARE GRP LP

Contact lens with shaped periphery

InactiveUS20060268225A1Quality improvementImprove comfortEye diagnosticsOptical partsOptometryContact lens

Eye measurements taken on a patient being fitted for contact lens will include a refraction test and an additional measurement representing corneal depth variation on the surface of an imaginary cylinder having the same diameter as the lens. This information then used during lens manufacture to produce lens in which the perimeter is not circular and does not lie in a plane, but which drops backwards towards the eye at appropriate points to produce a saddle-shaped perimeter.

Owner:SCI OPTICS INC

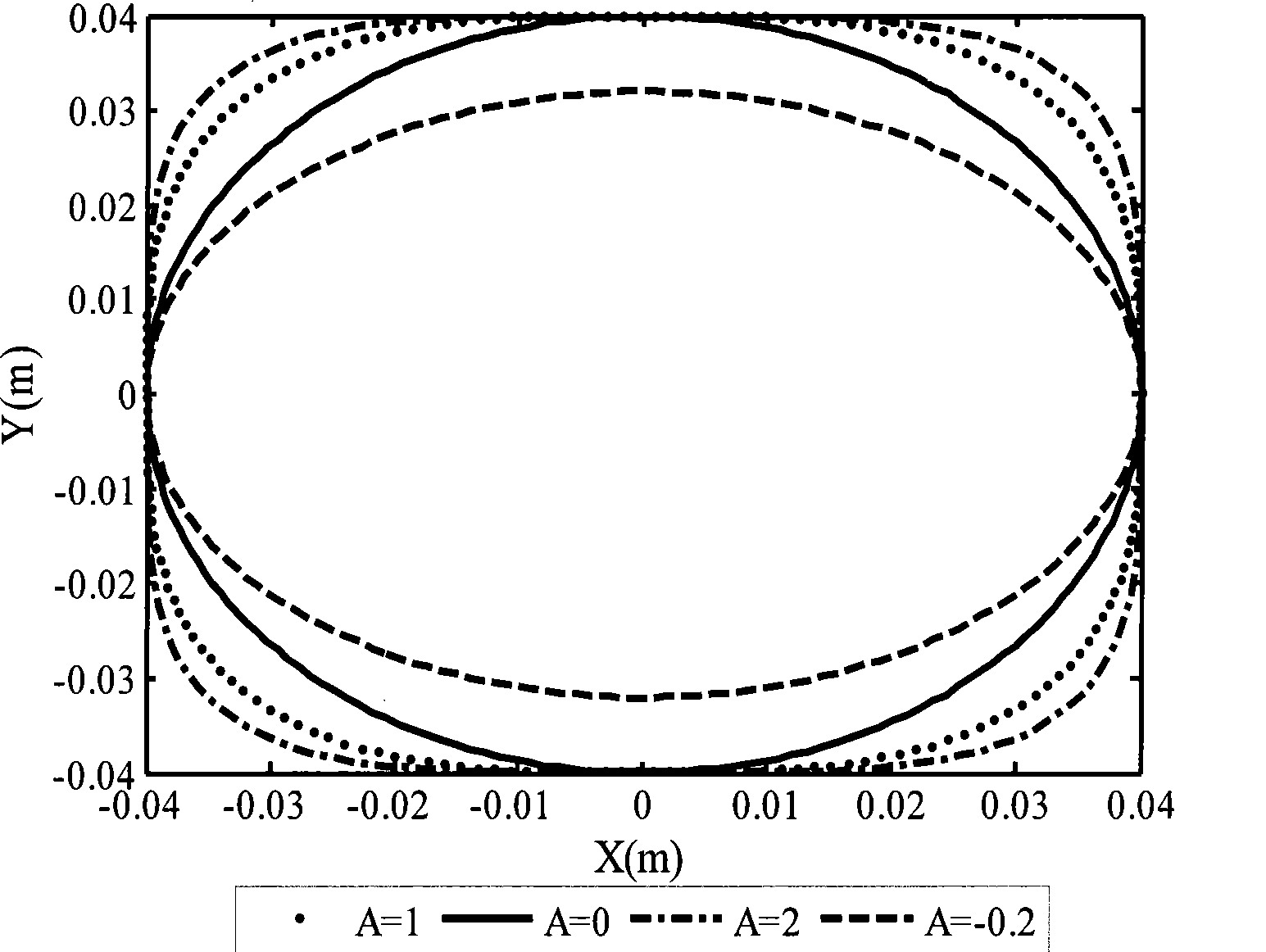

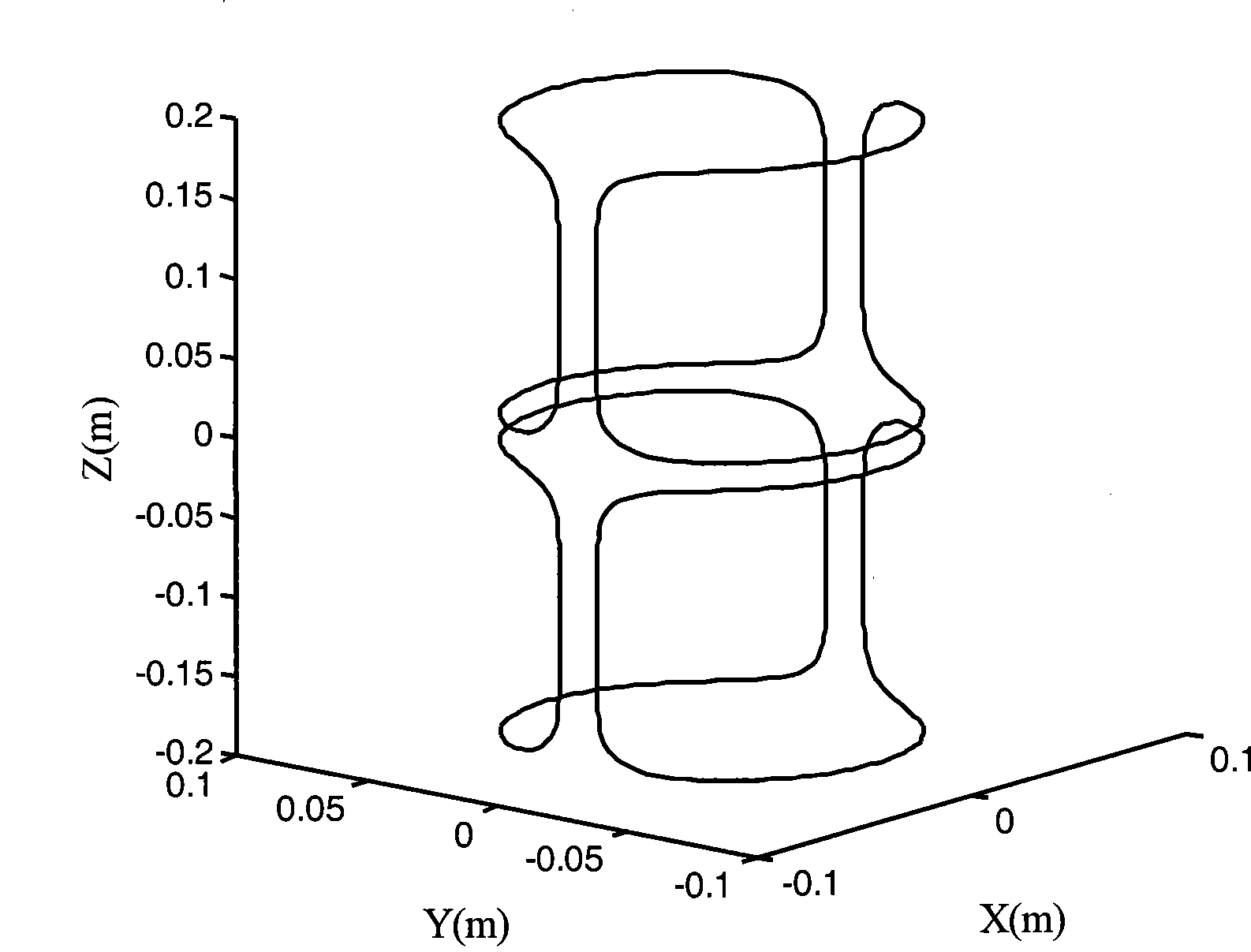

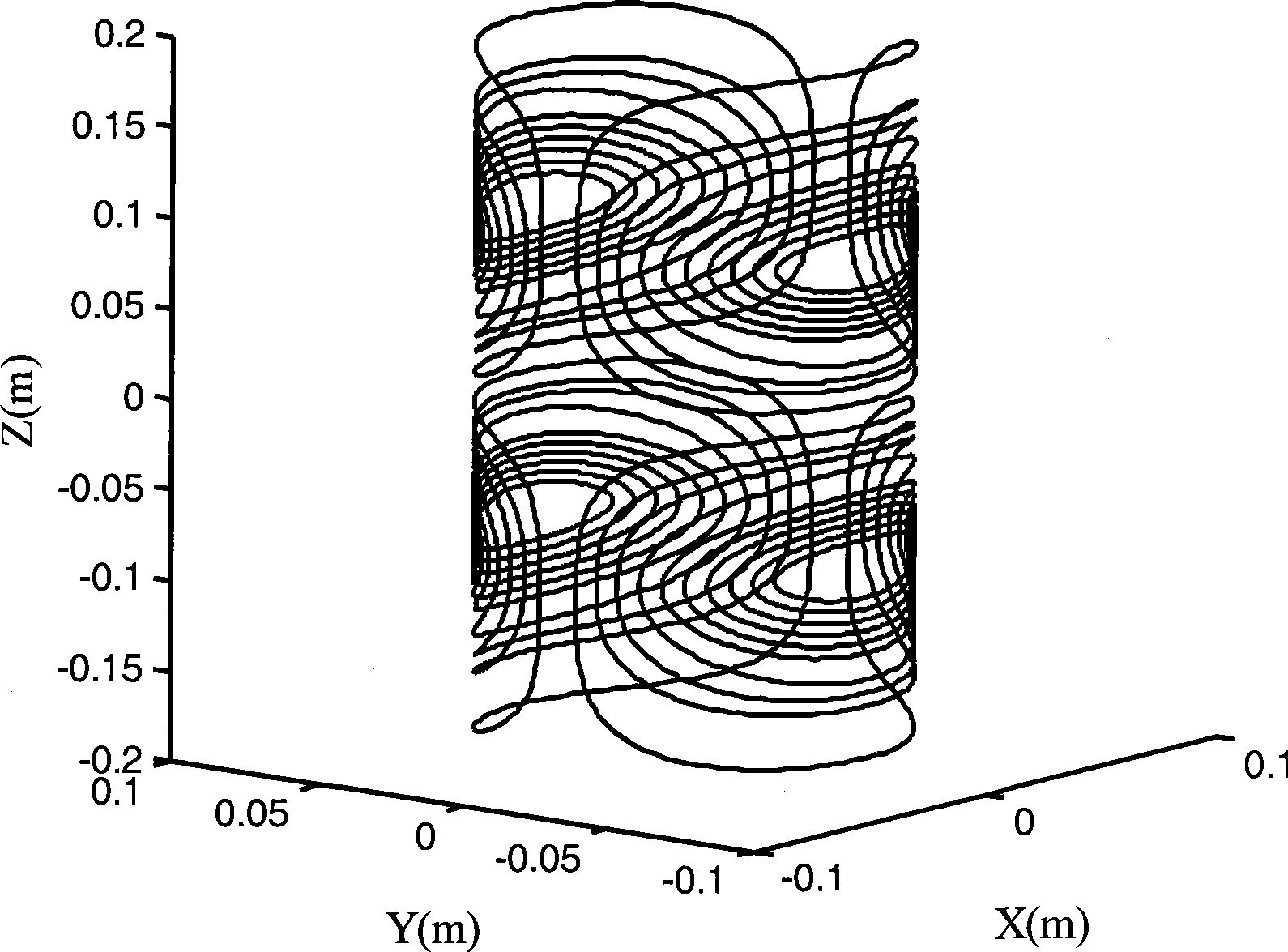

Computer aided design method for magnetic resonance imaging transverse gradient coil

InactiveCN101464924ALinearity dropImprove linearitySpecial data processing applicationsComputer Aided DesignGradient strength

A computer aided design method for magnetic resonance imaging transverse gradient coil, which belongs to the application of superconducting technology. The method is characterized in that parametric description for space trace of the transverse gradient coil is realized through introducing the basic shape of an ellipse-like double-saddle shaped coil, then space tracking parameter of the coil serves as optimization variable, and the mean square deviation of the gradient strength value and the gradient set value of each target point on an imaging space surface serves as an objective function for realizing the optimum design of the gradient linearity of the transverse gradient coil. The method is used for designing the transverse gradient coil, and has the advantages that the counting is simple and direct, the linearity of the design result is high, and the processing and the manufacturing are convenient.

Owner:TSINGHUA UNIV

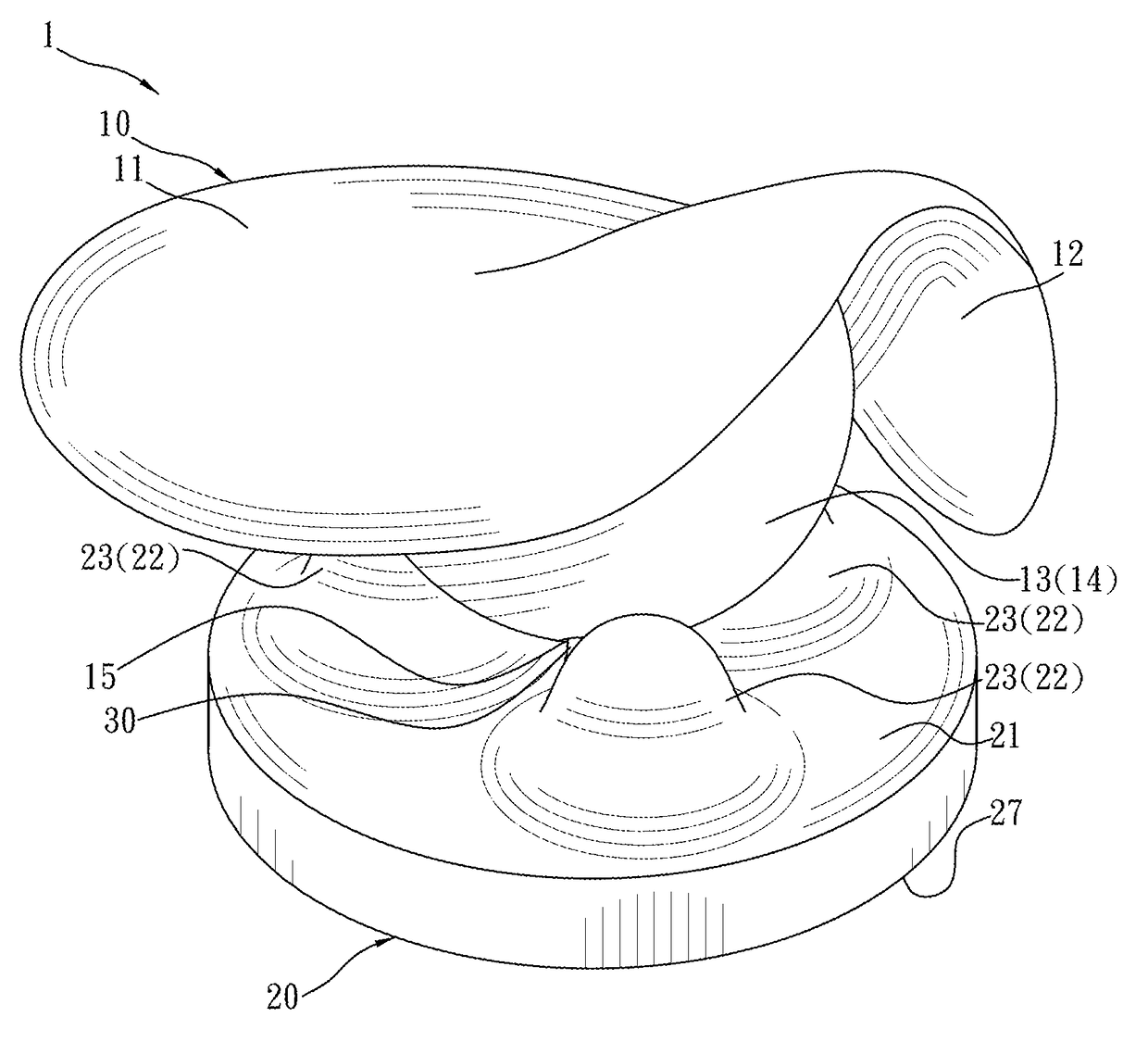

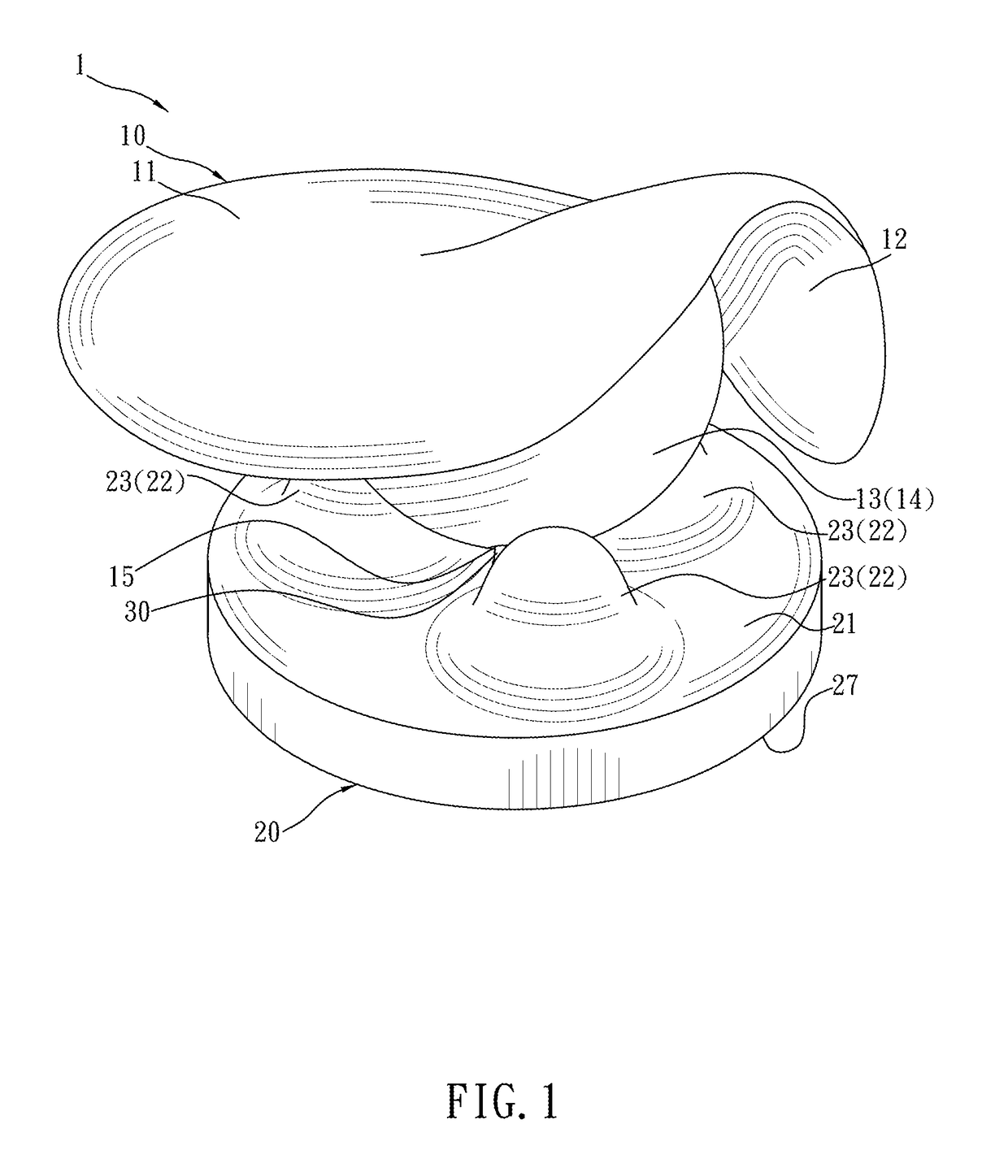

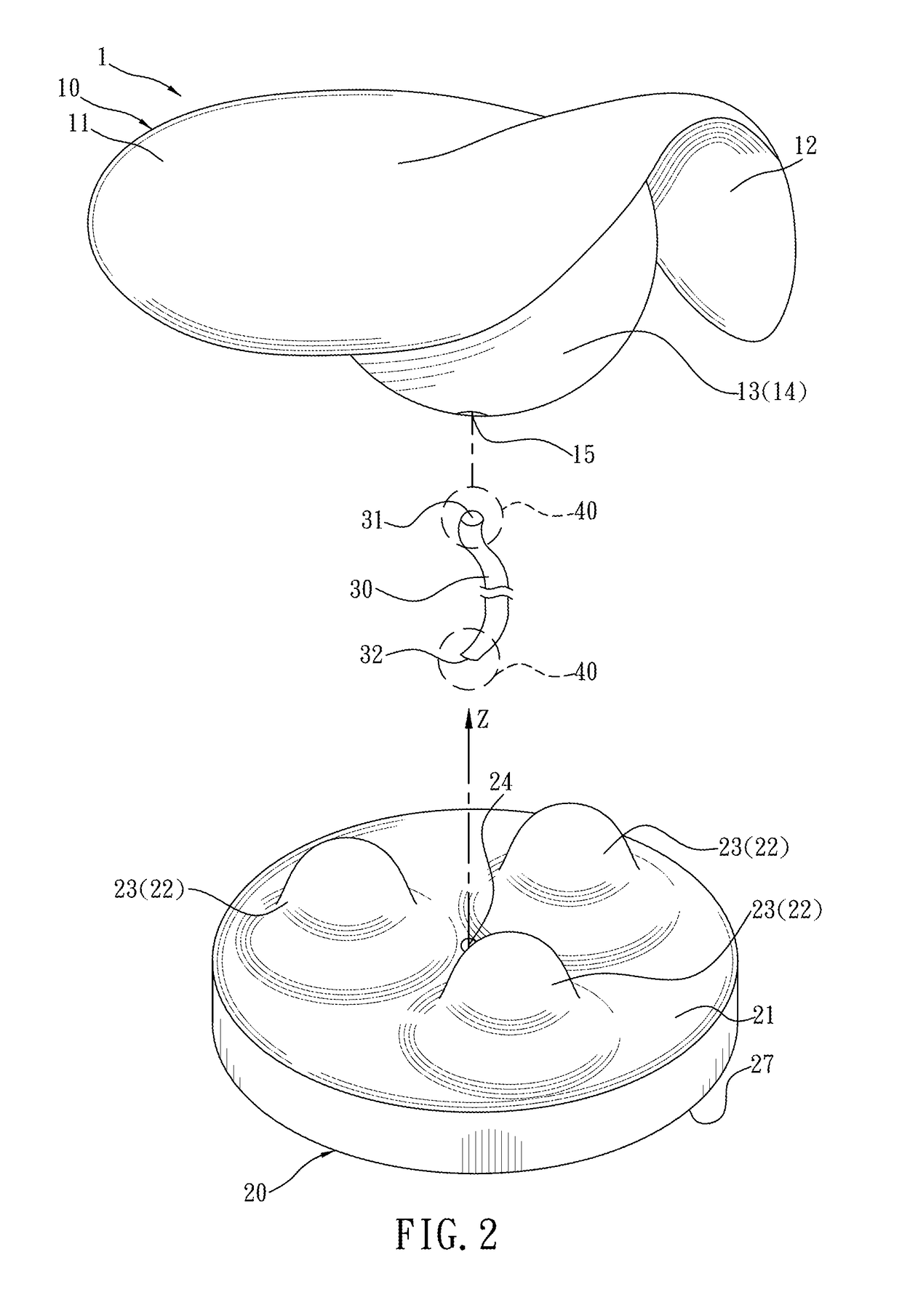

Seat for hip shaking

A seat for hip shaking is set on a surface of a chair while in use. The seat for hip shaking includes a seat member and a base member arranged under the seat member. A top surface of the seat member is disposed with a saddle-shaped seat surface for users to sit thereon while a spherical surface is projecting downward from a bottom surface of the seat member. The base member has at least one support part on a top surface thereof. The spherical surface of the seat member is moveably supported by the support part of the base member and is rotated at an arbitrary angle. When a user sits on the saddle-shaped seat surface, he / she shakes the hip or maintains the balance to get the benefits of exercise like horse riding.

Owner:TECVIEW GRP CO LTD

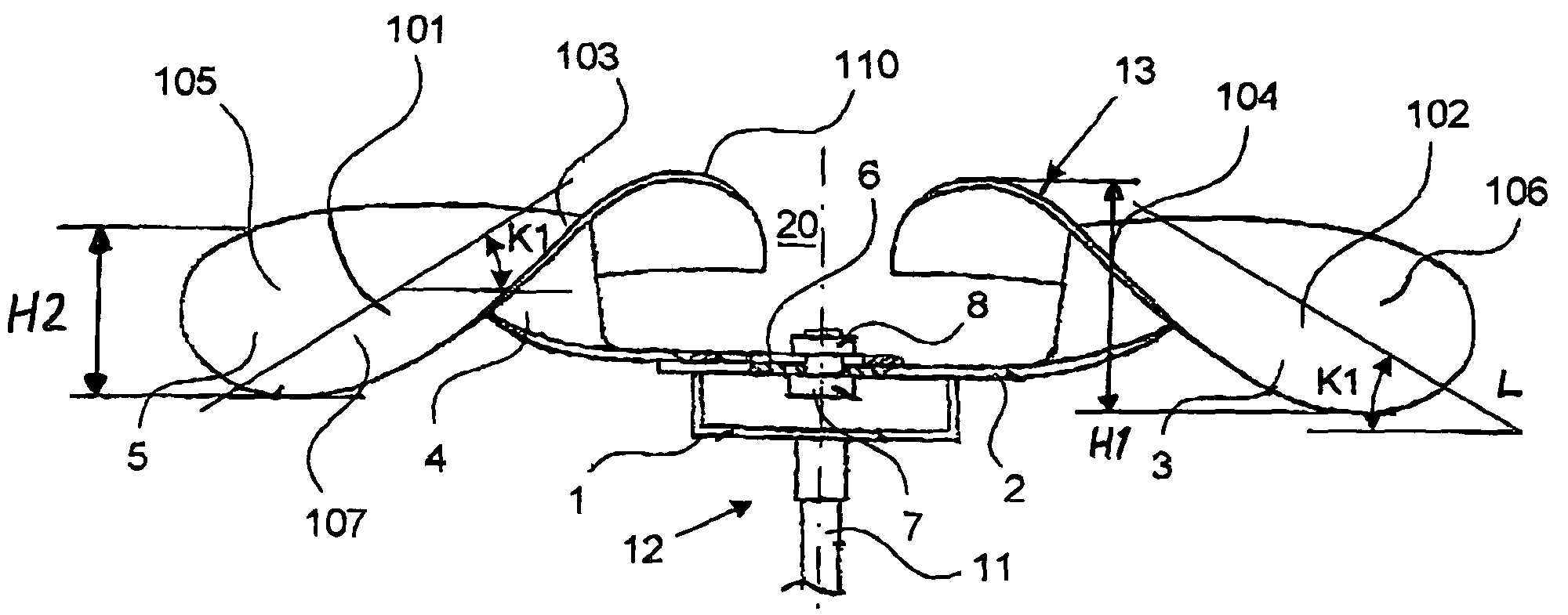

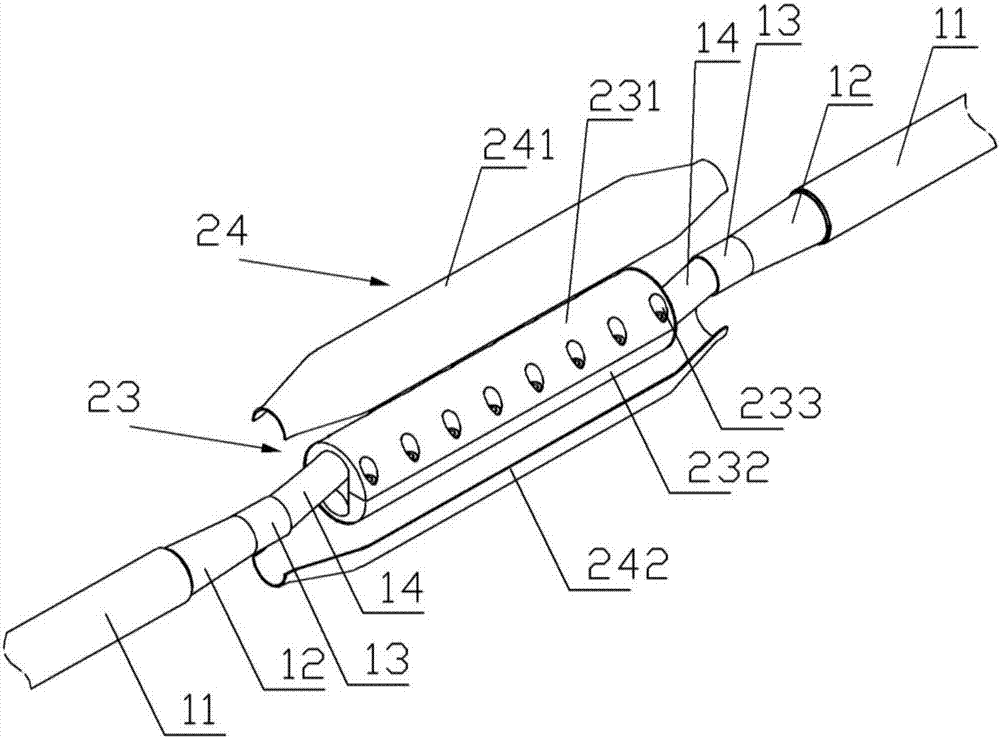

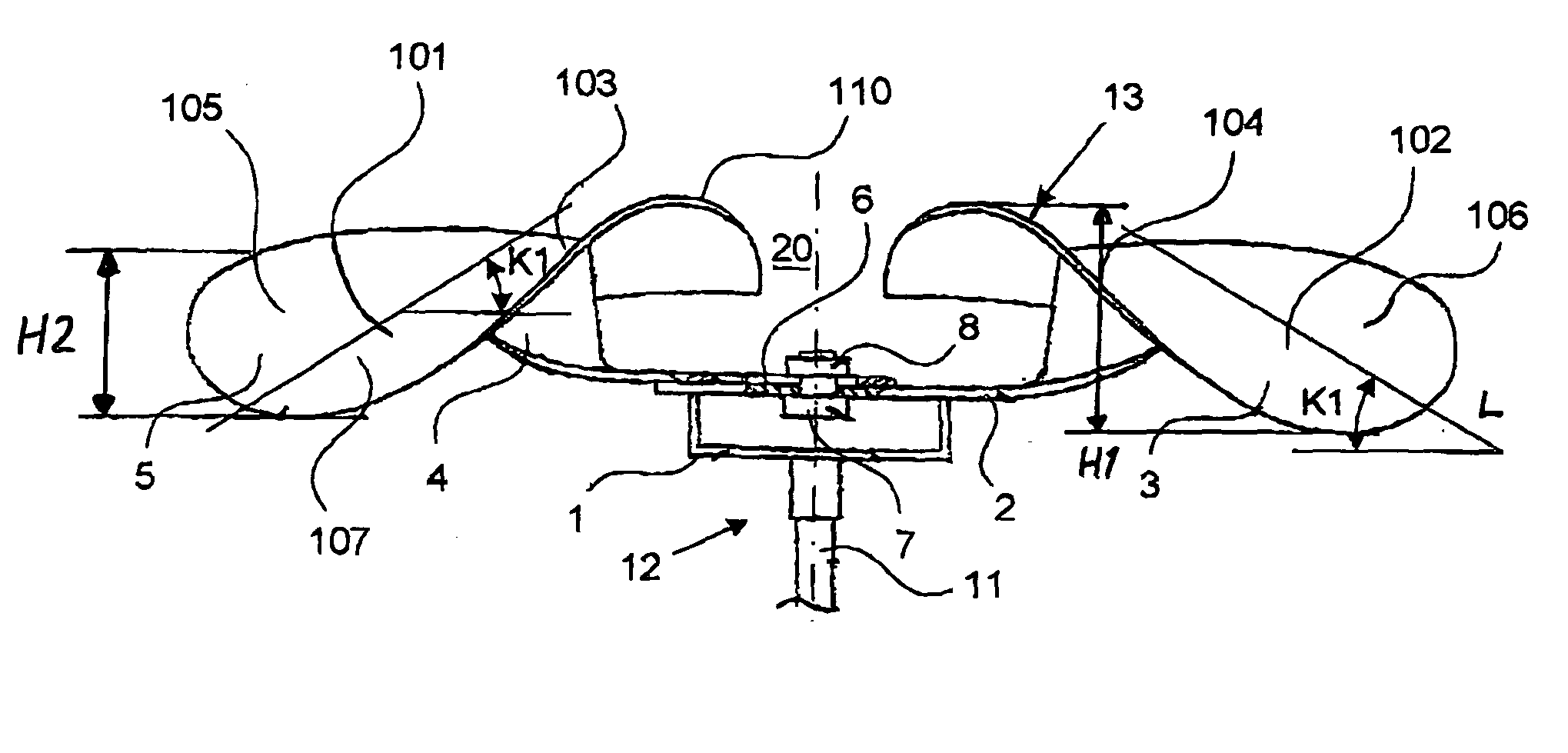

Chair for elimination of problems of sedentary origin

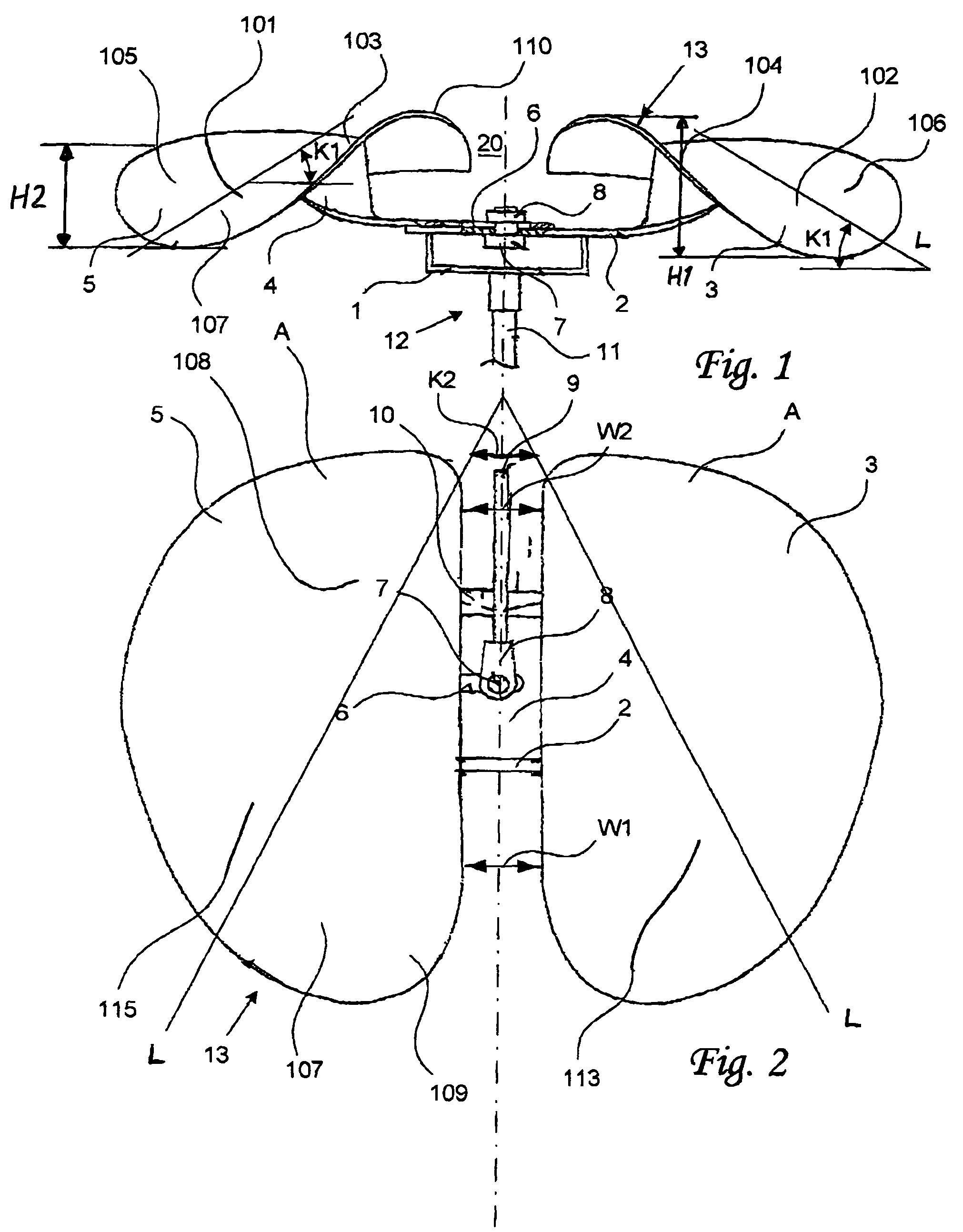

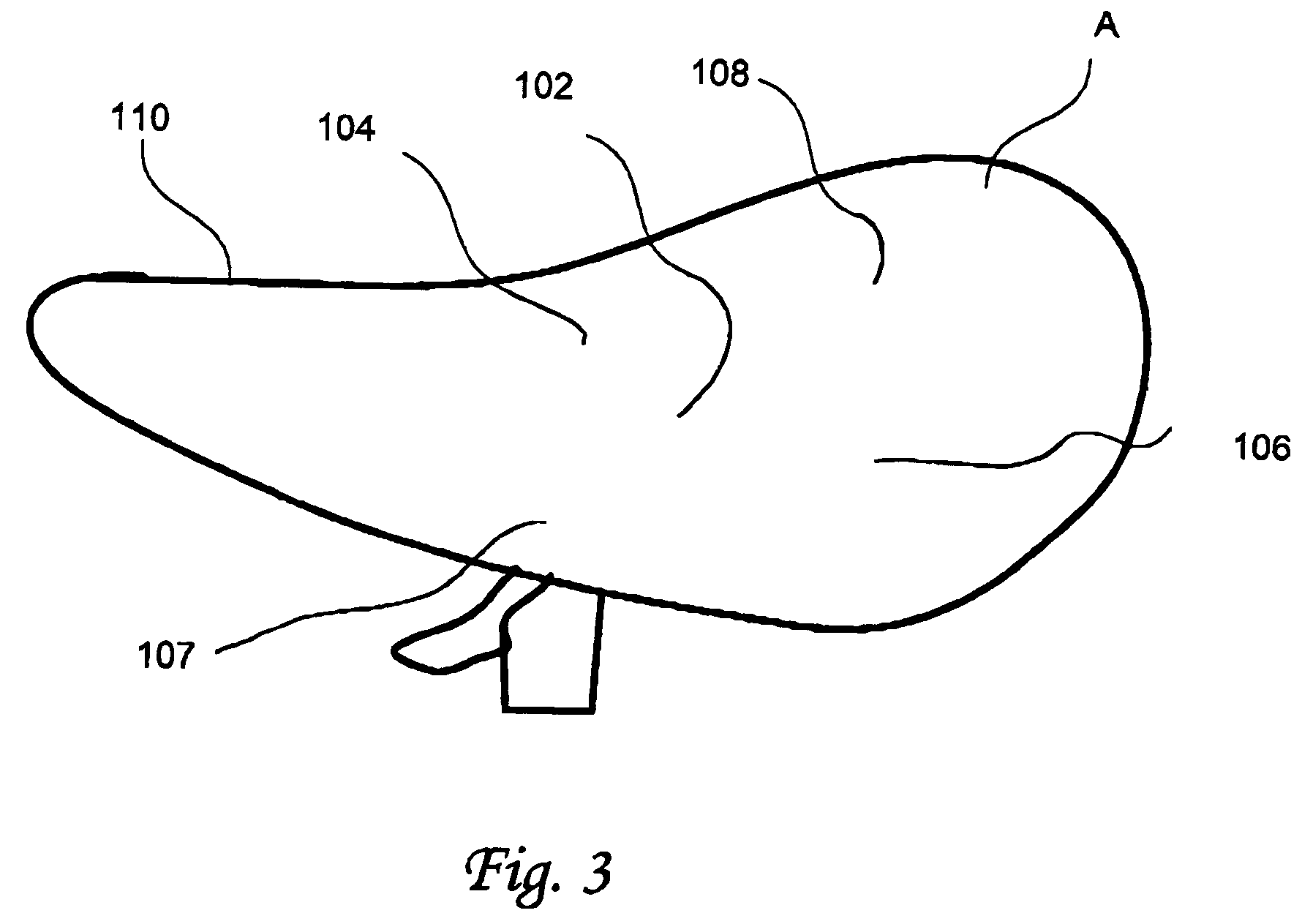

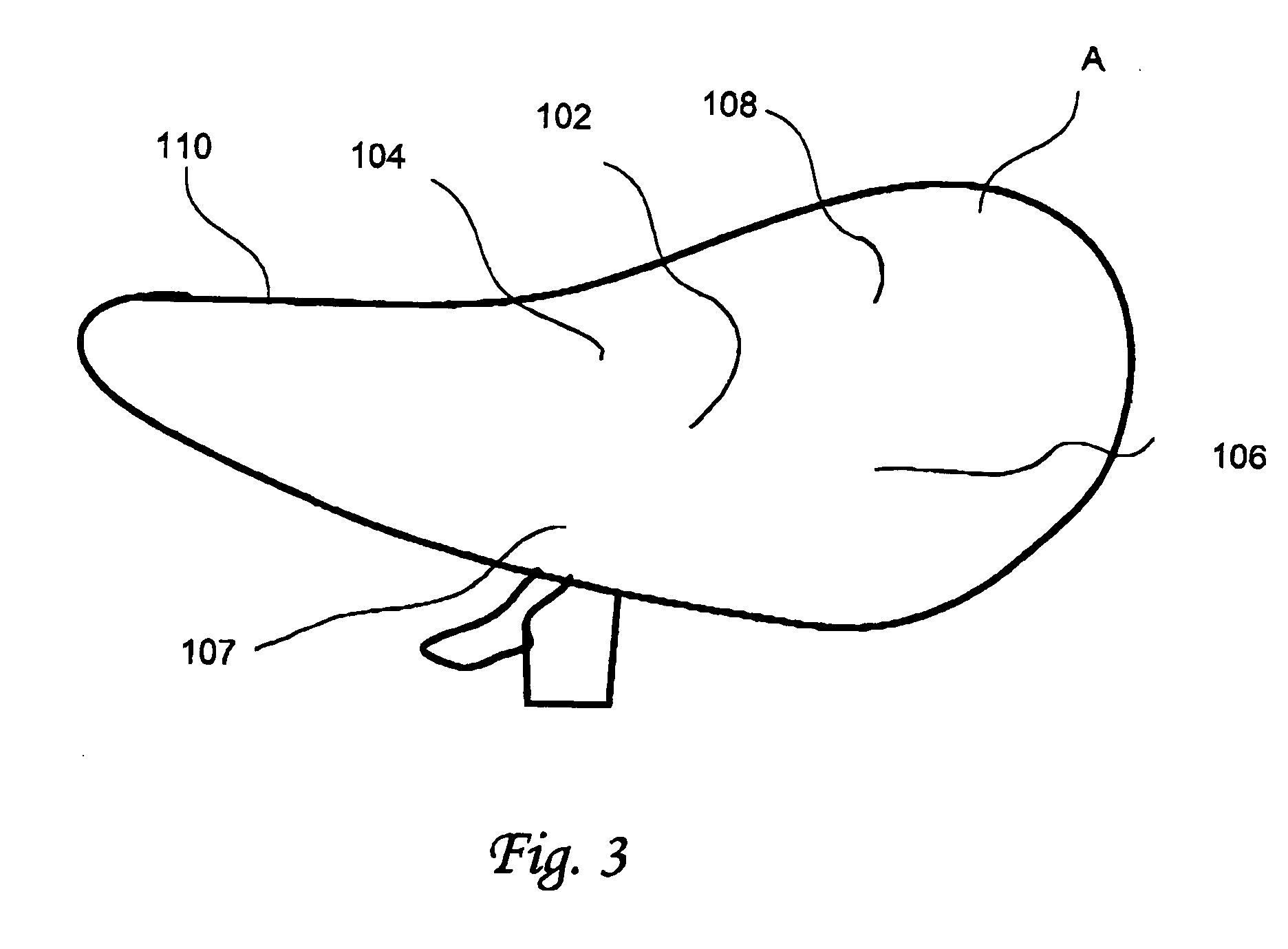

The present invention relates to a chair for eliminating problems of sedentary origin, which chair consists a saddle-shaped seat part (13) supporting the pelvis and the thigh muscles of the seated person which seat part has two curved thigh troughs (113, 115), which both have a bottom section (101, 102) and its opposite sides there is an inner side section (103 and 104) and outer side section (105 and 106) in relation to the other thigh trough, and which mentioned sections form lengths (L) to the mentioned thigh troughs and within this length there are front sections (107) and back sections (108) for the thigh troughs; when the inner side sections rise from their front sections towards each other, thus forming a central ridge (110) longitudinal to the seat part and mentioned back sections form a back section (A), where from the mentioned lengths reach down-wards and at the same time away from each other. In the chair according to the invention the thigh troughs (113, 115) are at least two separate parts (3, 5) between of which there is a central opening (20) parallel with the mentioned central ridge (110).

Owner:EASYDOING

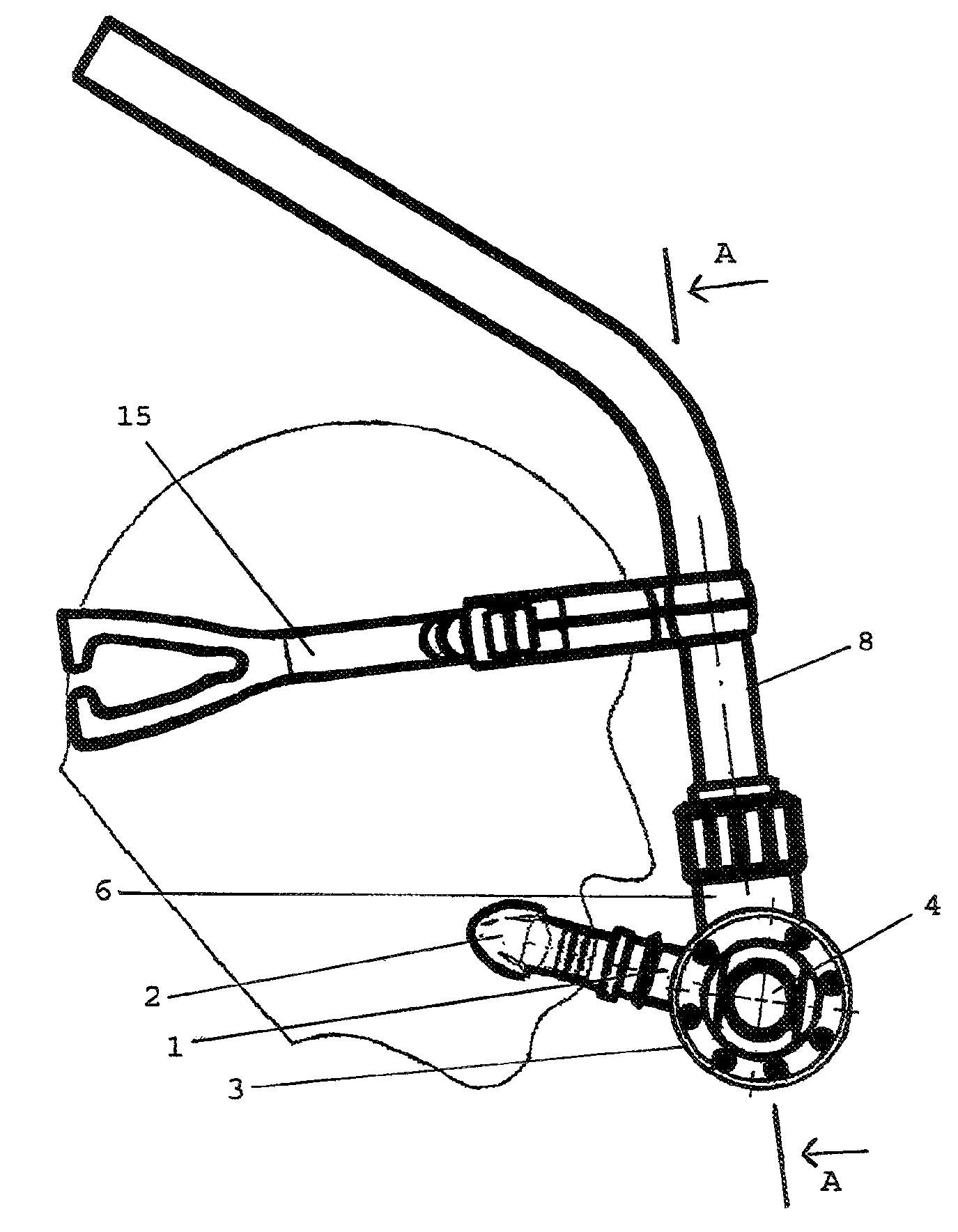

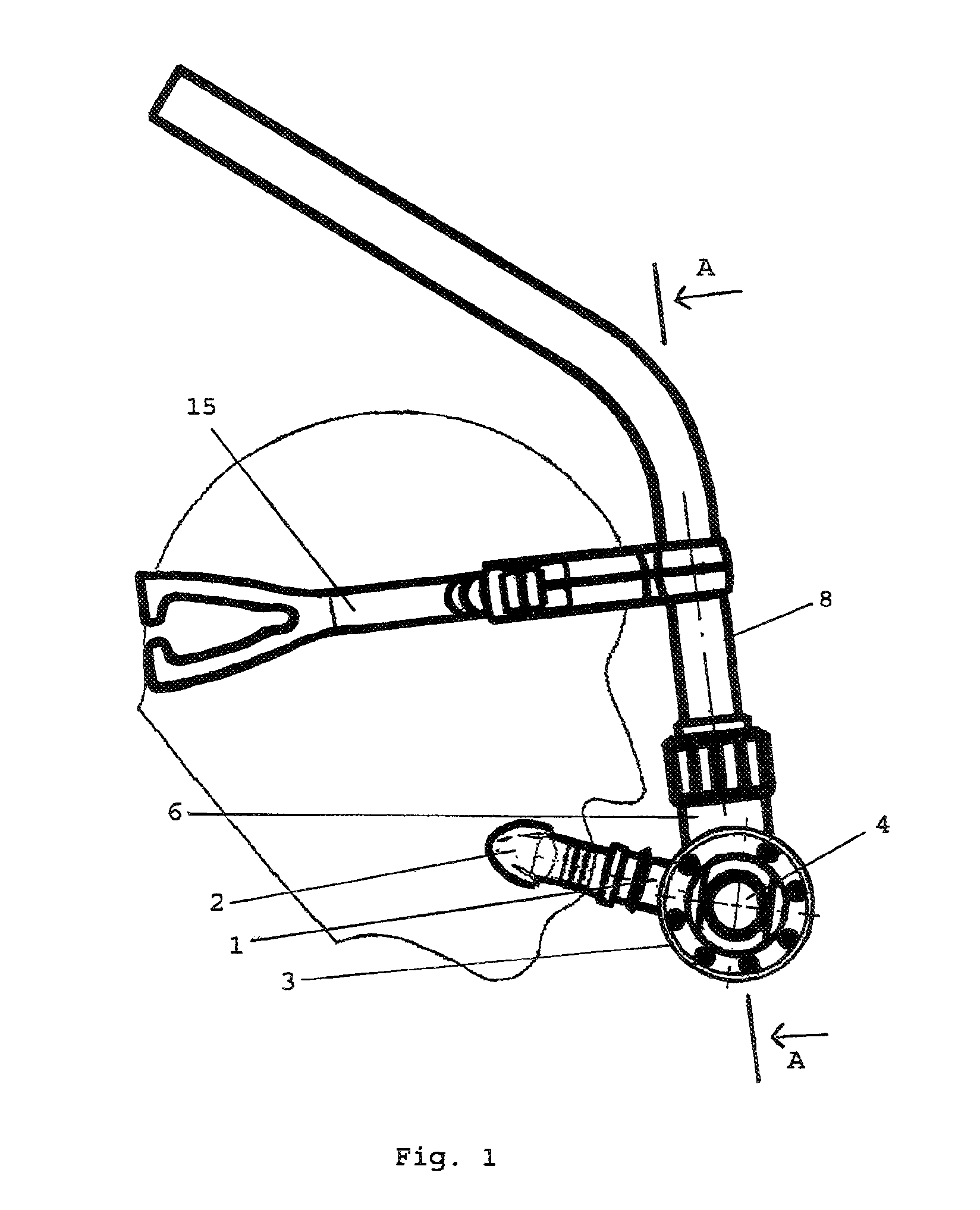

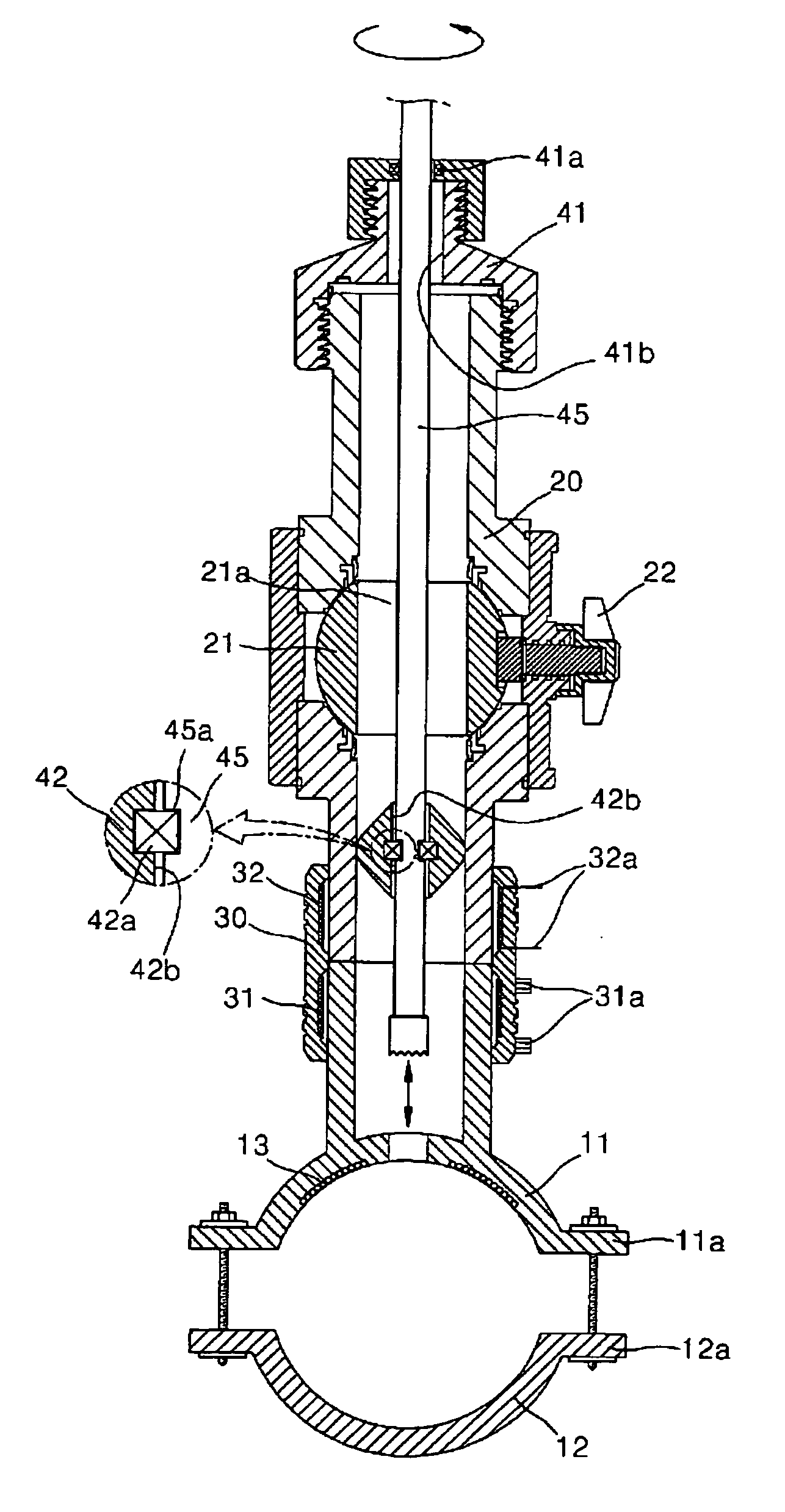

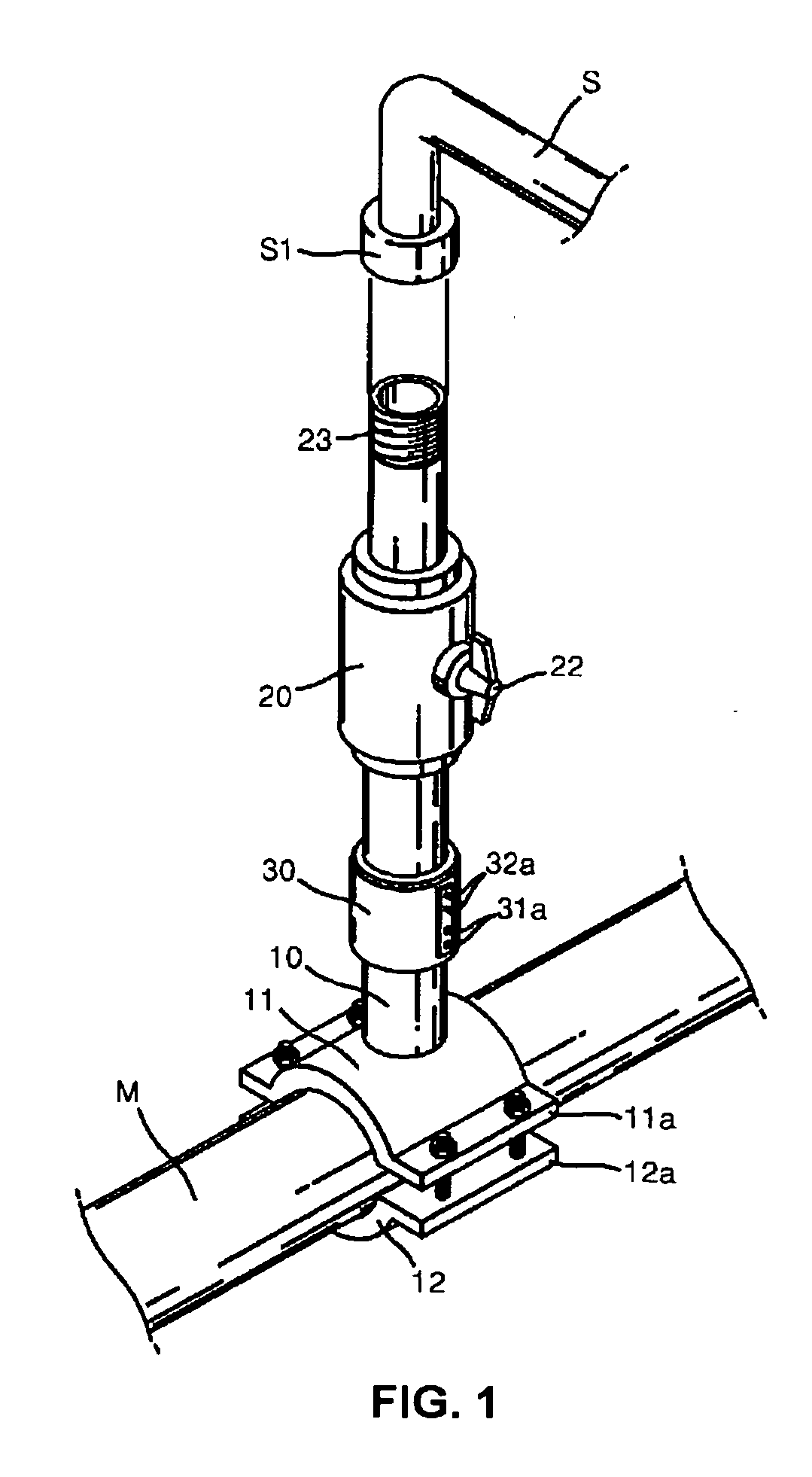

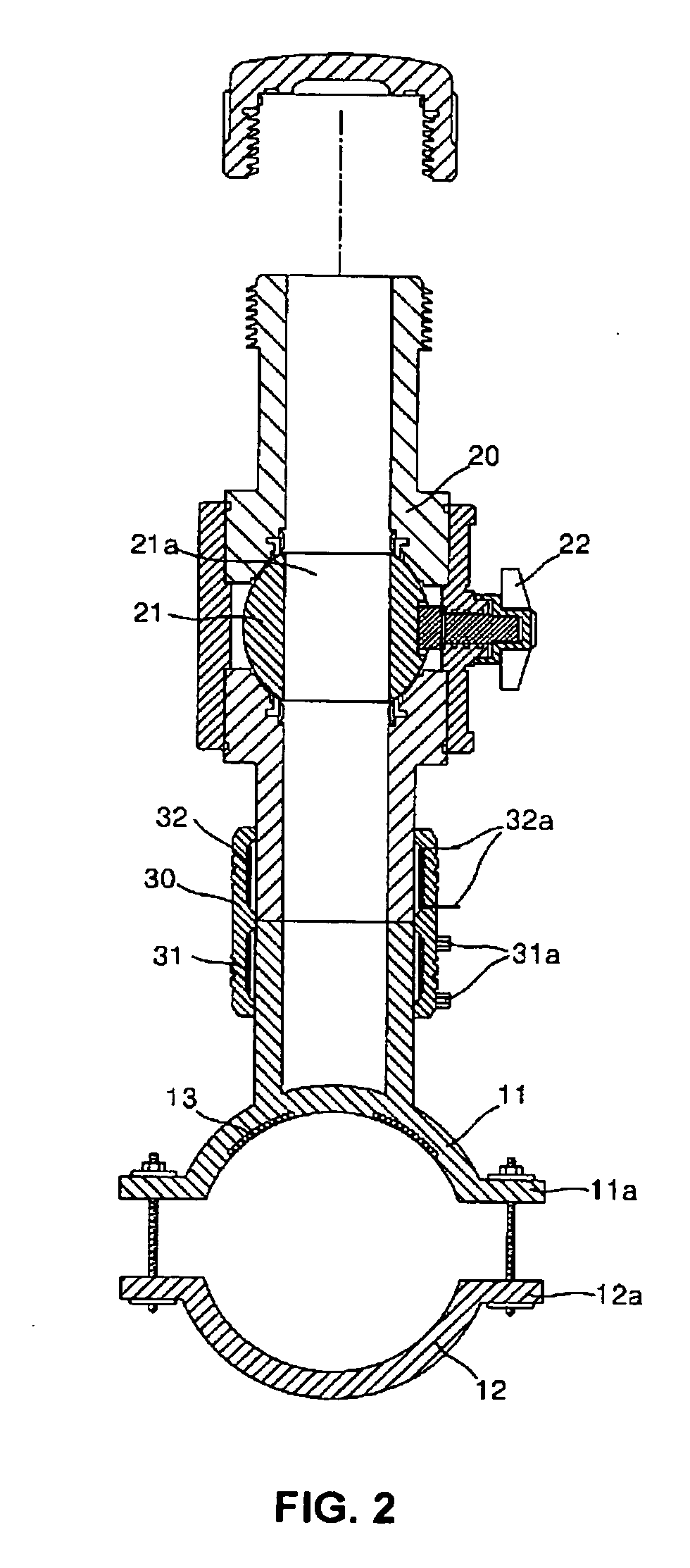

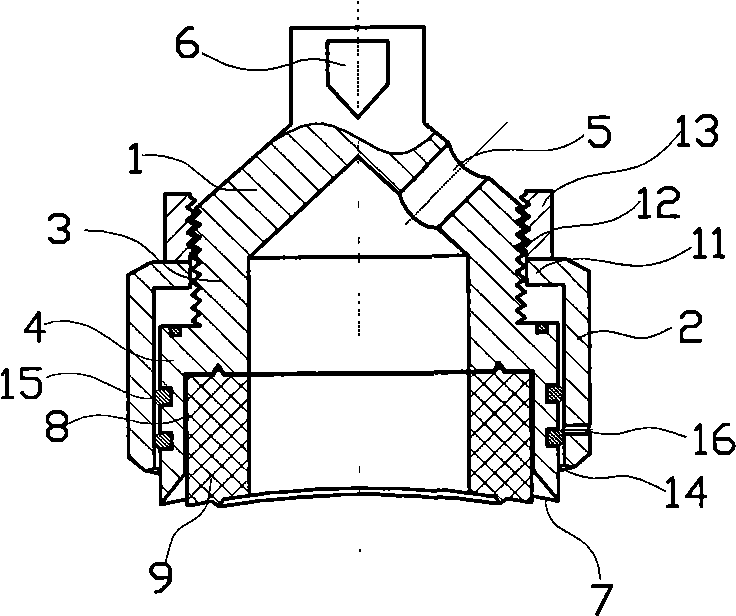

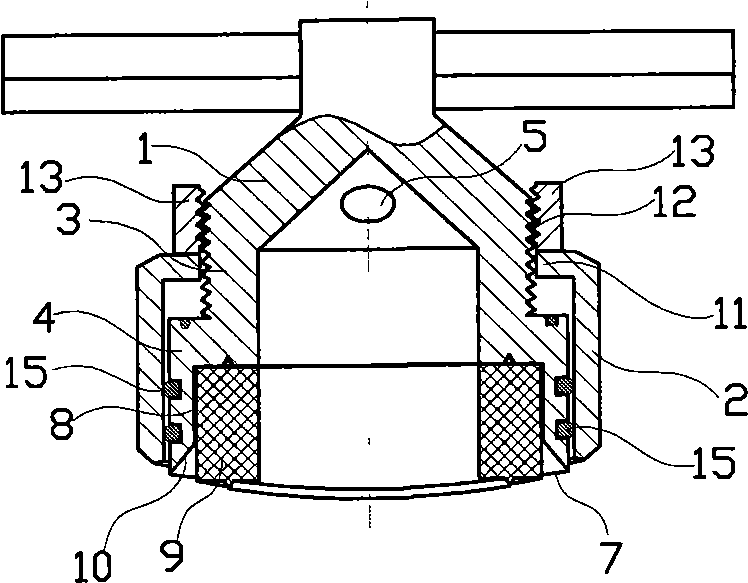

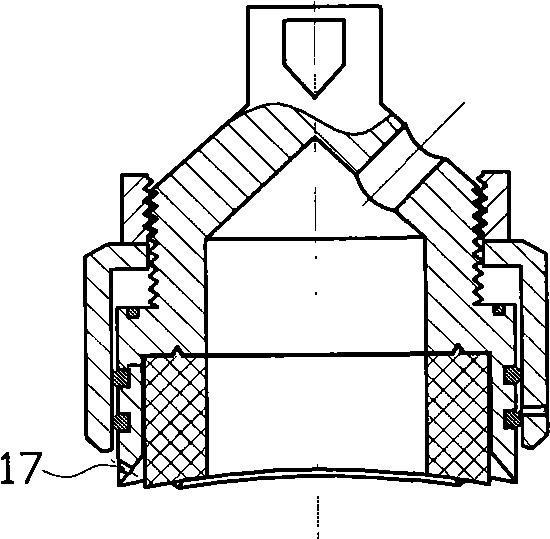

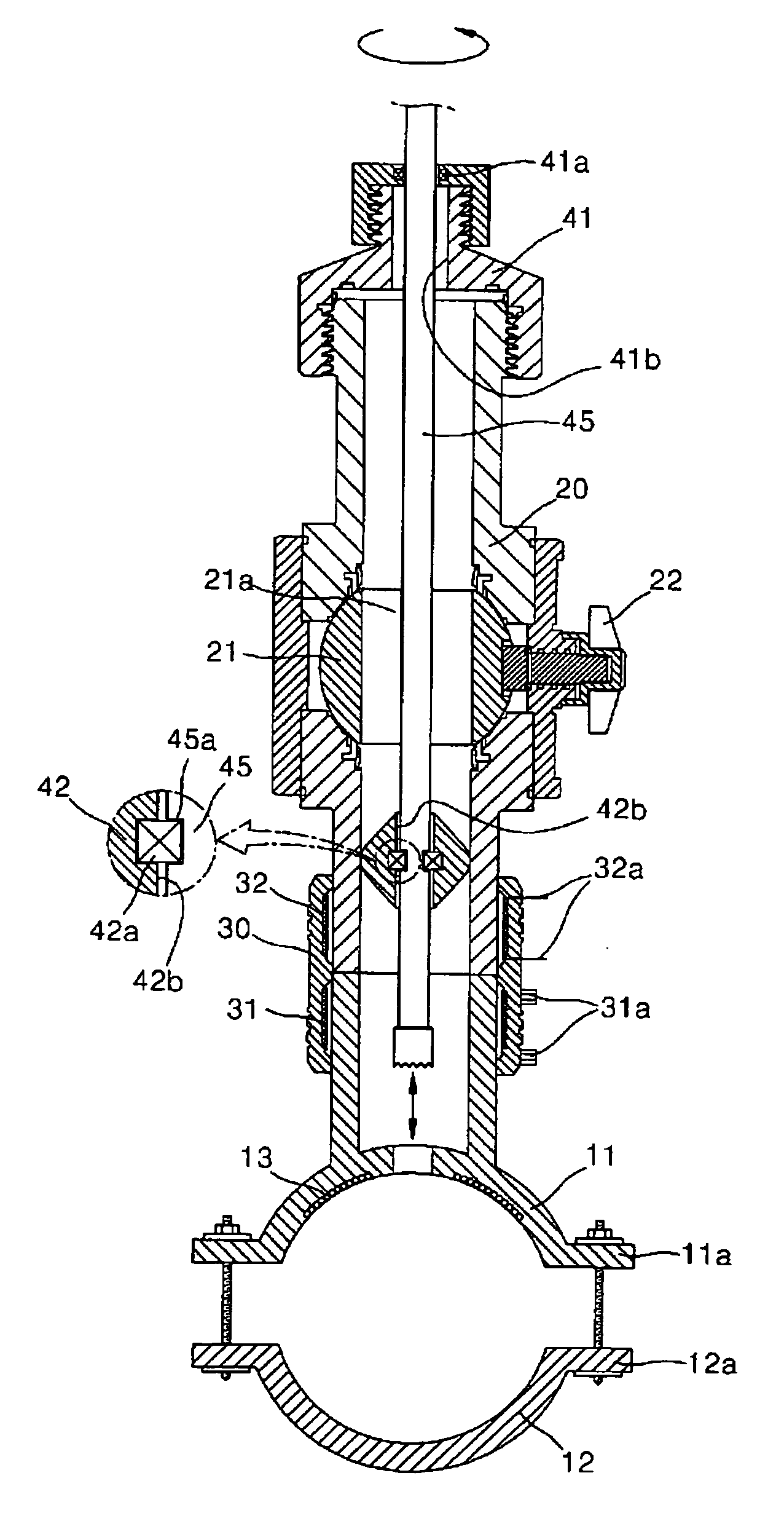

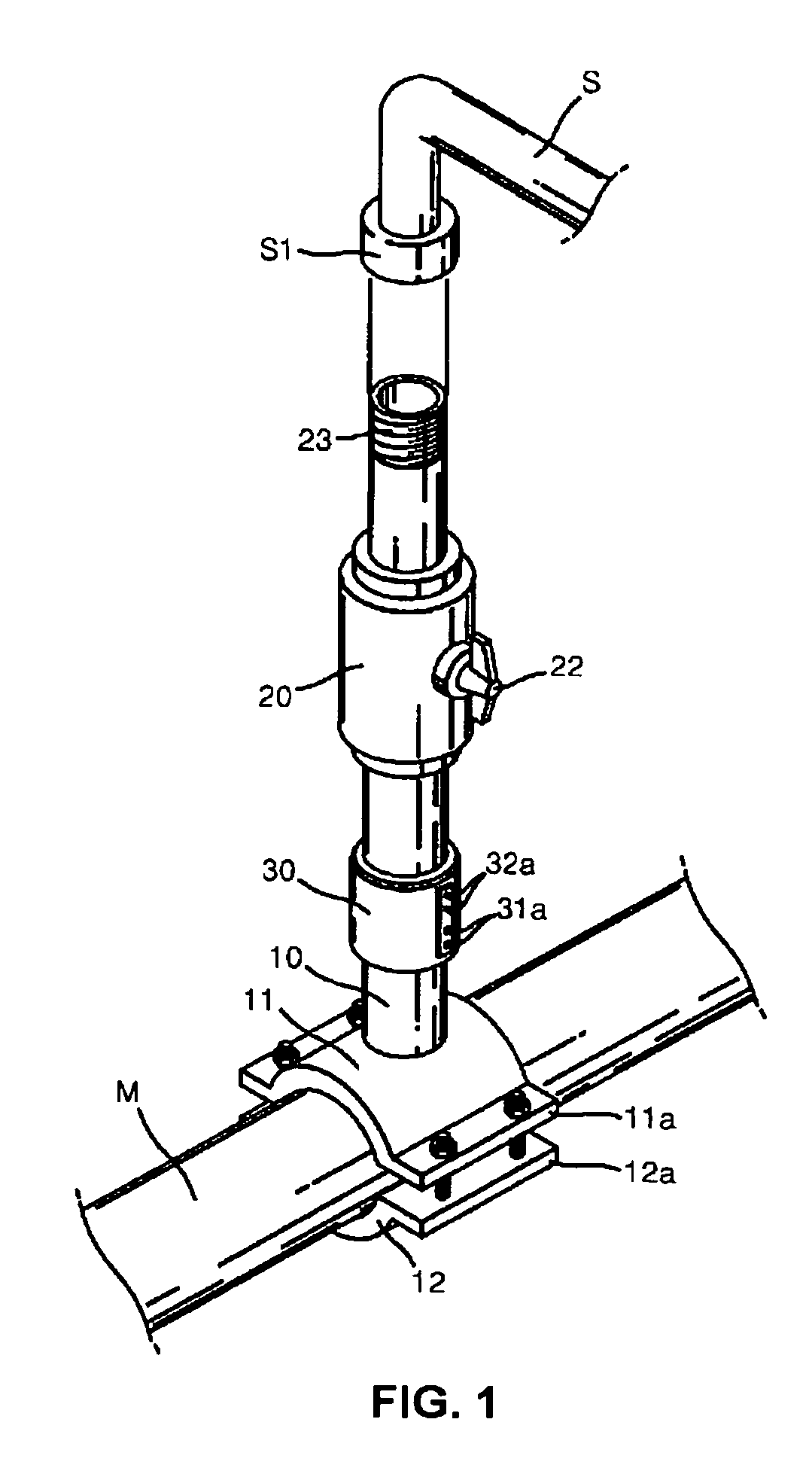

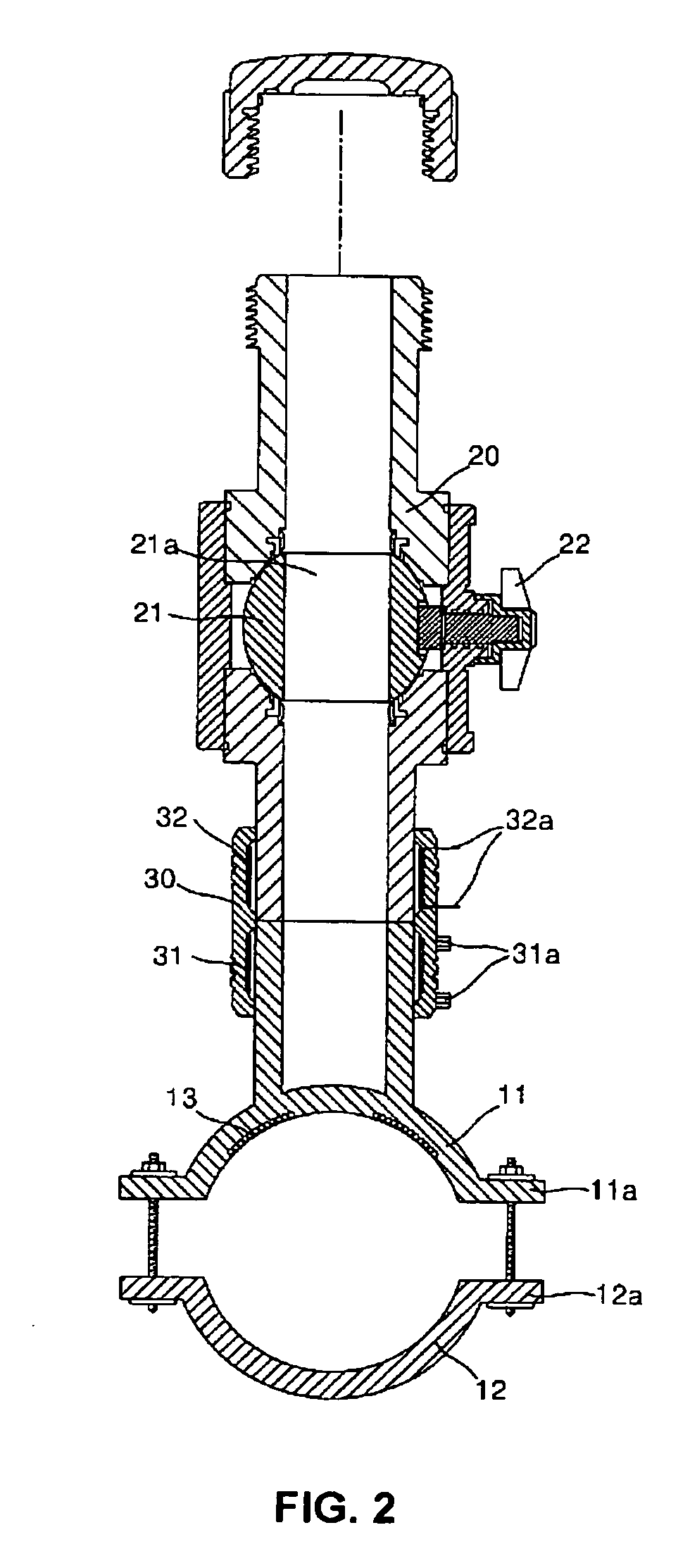

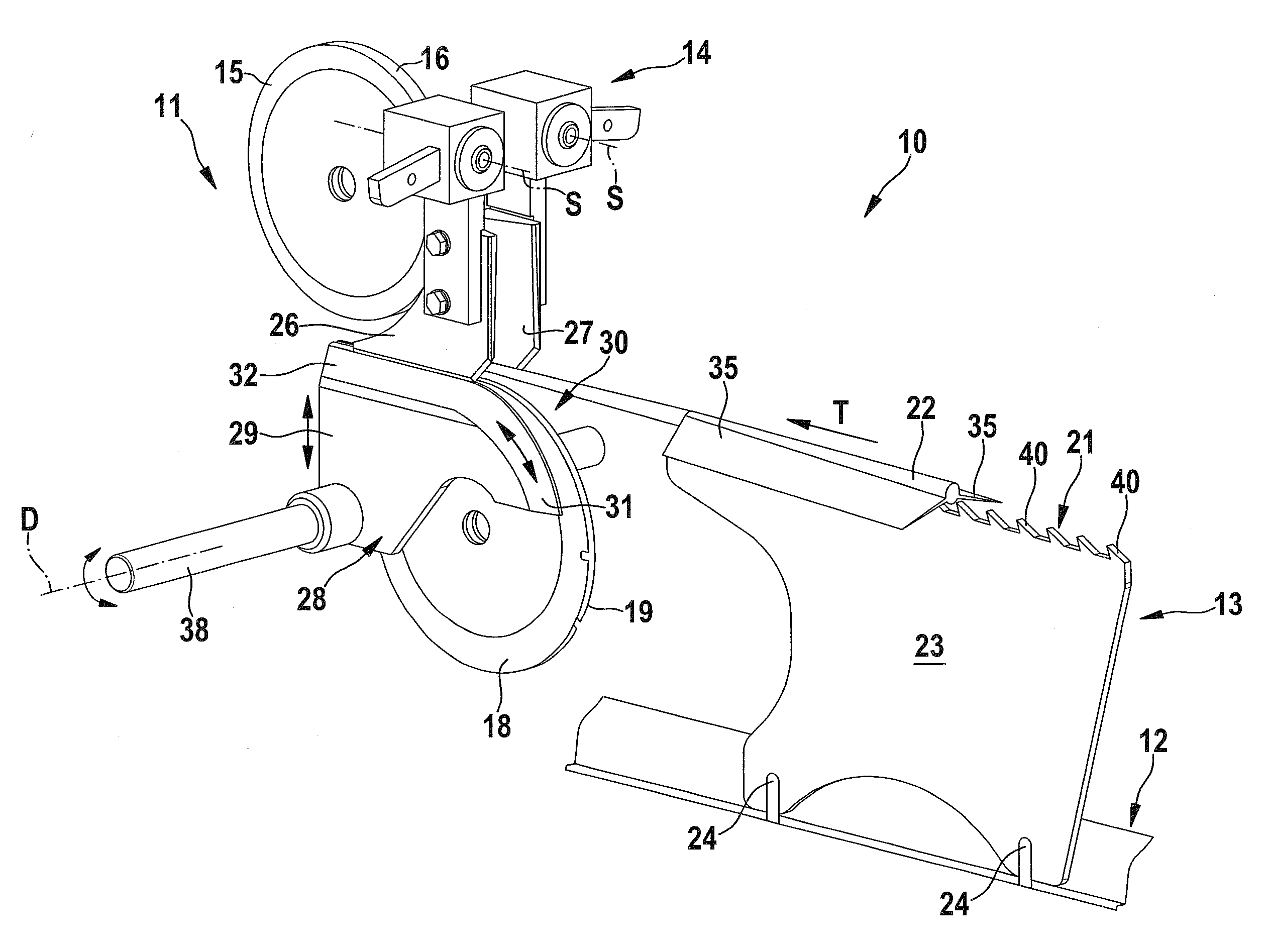

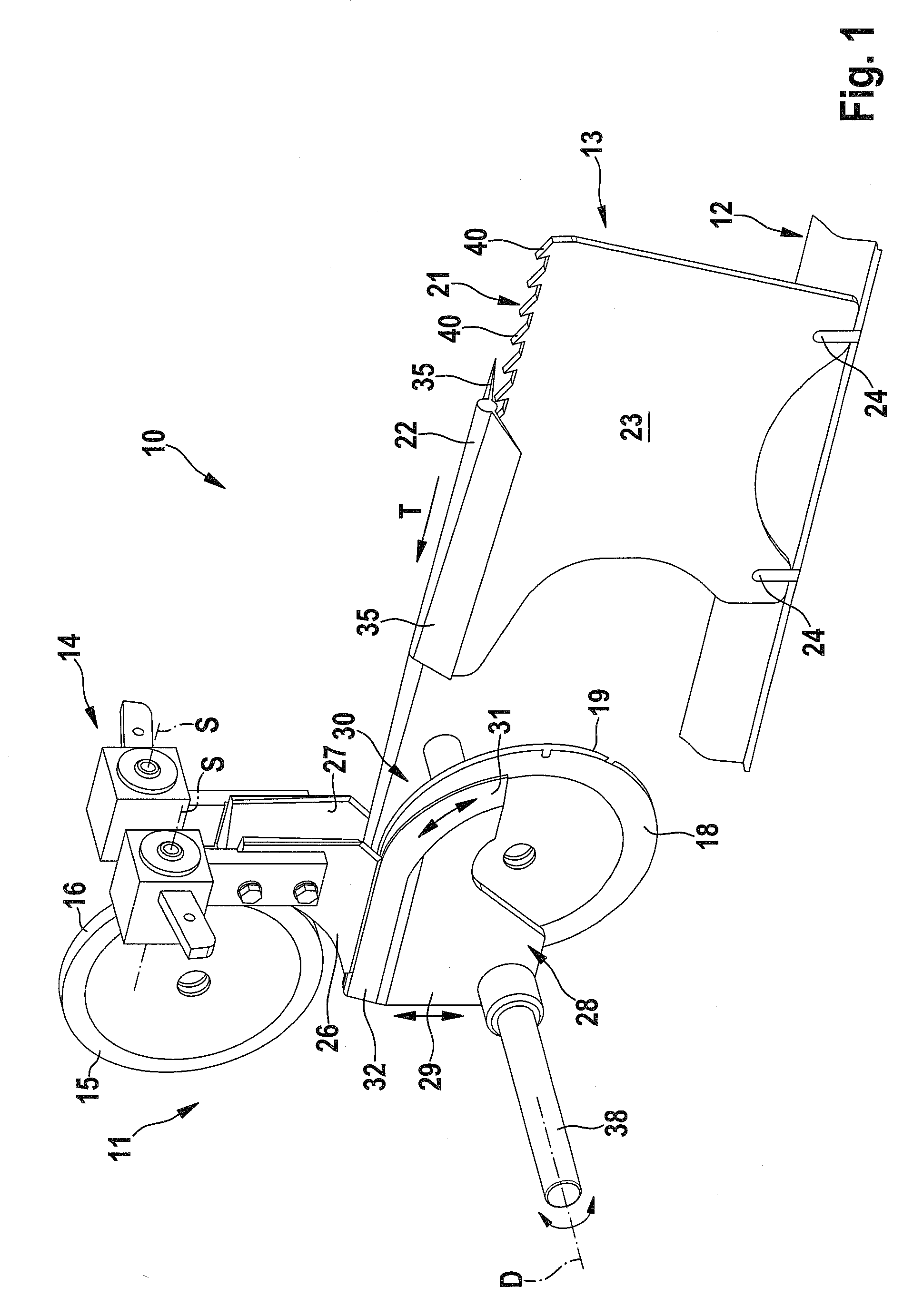

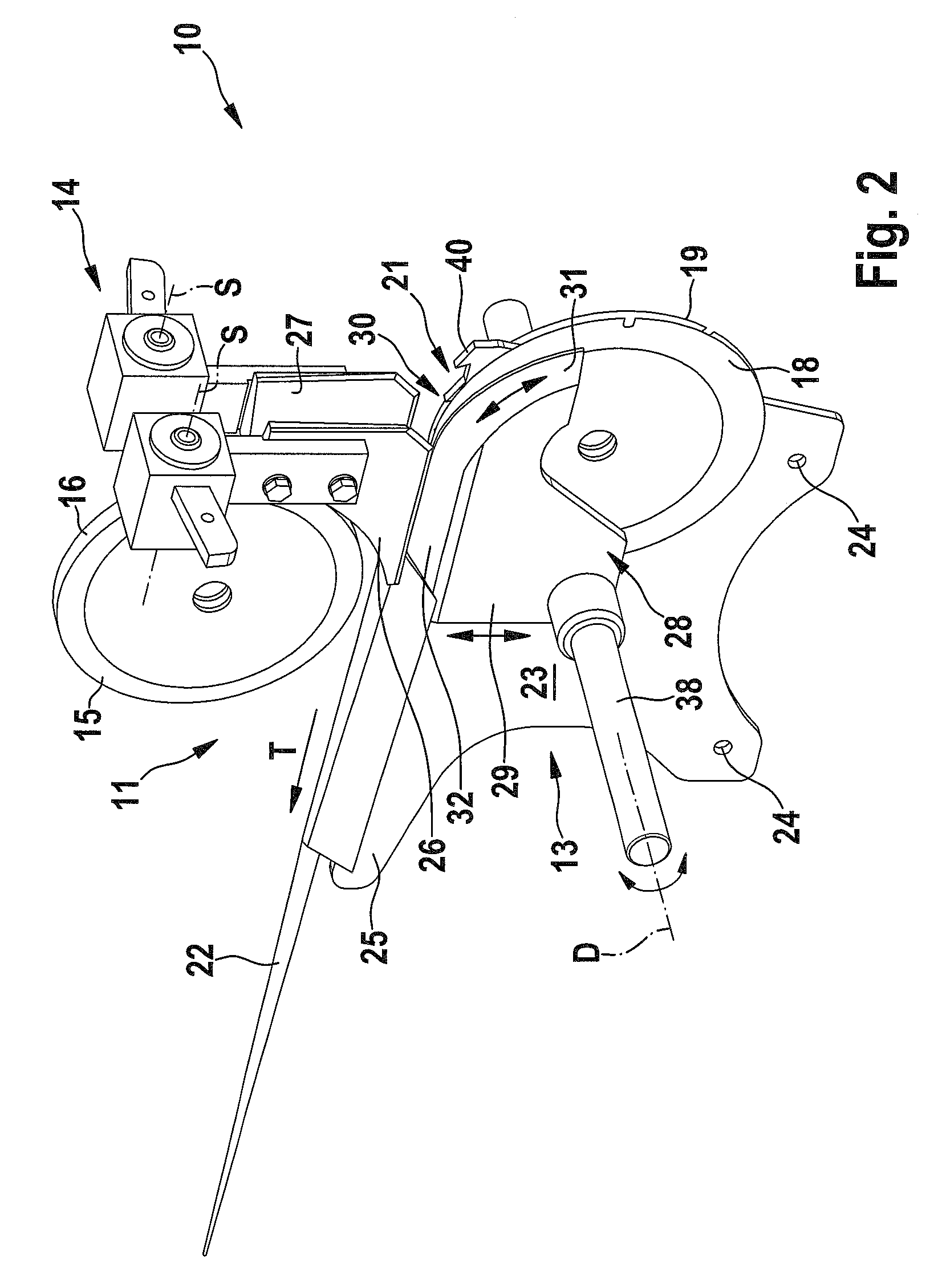

Pipe tapping apparatus

ActiveUS20060027266A1Enhanced couplingEconomical efficiency can be improvedValve arrangementsPipe elementsCouplingEngineering

The present invention provides a pipe tapping apparatus to couple new pipes to an existing pipe. The pipe tapping apparatus includes a base pipe, having a saddle-shaped socket part to be in close contact with the main pipe to pass a fluid therein; and a bending part coupled to the saddle-shaped socket part. The pipe tapping apparatus further includes a coupling pipe to be coupled to the sub-pipe extending to a predetermined place in which the supplied fluid is used, with a ball valve provided in the coupling pipe to control the flow of fluid passing through the coupling pipe. The pipe tapping apparatus further includes an electric heat-welding pipe to couple the coupling pipe to the base pipe. The electric heat-welding pipe has a first heating wire which is provided in the electric heat-welding pipe to weld the electric heat-welding pipe to the base pipe, and a second heating wire which is provided in the electric heat-welding pipe to integrate the coupling pipe with the electric heat-welding pipe. The pipe tapping apparatus further includes a first positioning unit which is removably coupled to an end of the coupling pipe, with a first through hole provided in the center of the first positioning unit, thus guiding a process of tapping the main pipe using the cutting drill passing through the first through hole of the first positioning unit.

Owner:ISCO INDS +1

Building technology for pile leg of self-elevating wind power vessel

The invention relates to a building technology for a pile leg of a self-elevating wind power vessel. The building technology mainly comprises the following steps that cylinders are rolled, wherein rolling is carried out on the two ends, the middle part is rolled after the two ends are rolled in place, rolling is carried out in place again, longitudinal seam welding is carried out after positioned welding, and final roundness restoration is carried out; the cylinders are welded, wherein the cylinders are matched, an assembling machine is used for assembling, positioning welding is carried out, and finally welding is carried out; pre-assembling is carried out in a workshop, wherein the overall linearity of a reference section, the gap and the alignment tolerance are adjusted, technological flanges are assembled and welded in place, and the cross central line, the height reference line and the central line of a bolt hole are marked out on the reference section; bolt holes are cut, wherein an upper section and a lower section are rotated to the position of a saddle-shaped cutting machine, the central line of the pile leg is adjusted to be parallel to a track of the saddle-shaped cutting machine, and cutting is carried out according to the marked lines. The building technology has the advantages that various building requirements of the pile leg can be ensured, meanwhile, the building efficiency can be improved, and the building cost can be reduced.

Owner:NANTONG ZHENHUA HEAVY EQUIP MFG

Oil gas pipeline rapid pressured plugging apparatus and plugging method

InactiveCN101498394ANormal delivery does not affectReduce laborPipe elementsPetroleum engineeringSaddle-shaped

The invention relates to an oil-gas pipeline rapid no-stop plugging device and an oil-gas pipeline rapid no-stop plugging method. The non-stop plugging device is provided with an internal steel cover and an external closed pipe which are sleeved together; the internal steel cover is a round pipe cover; the external wall of the internal steel cover is provided with an upper part and a lower part with different diameters; the outer diameter of the upper round pipe is smaller than that of the lower round pipe; the upper round pipe wall is provided with threads and screw nuts; the cover top is provided with an oblique draining opening; the upper end of the outer side of the cover top is provided with a horizontal pressing rod hole; a sealing ring is arranged on a saddle-shaped cover opening; the upper end of an external closed pipe is provided with an inward edge; an internal hole of the edge is sleeved on the upper round pipe; a sealing ring is arranged between the internal wall of the external closed pipe and the outer wall of the lower round pipe of the internal steel cover; and a binder filling hole is arranged at the side wall between the lower pipe opening of the external closed pipe and the sealing ring. The oil-gas pipeline rapid no-stop plugging device is provided with the steel cover, and the outer side of the steel cover is sleeved with the external closed pipe; when leaked points of an oil-gas pipeline are plugged, sequentially the steel cover is used to combine with the sealing ring and the external closed pipe is used to combine with the binders to carry out the rapid non-stop plugging of the leaked points on the oil-gas transportation pipeline in the process of the normal transportation of the oil-gas pipeline, so that the work amount is little, the consumed time is short, the cost is low and the normal transportation of oil and gas is not influenced in the process of plugging.

Owner:杨立东 +1

Connector assembly of two low-temperature superconduction cable terminals and fabrication method of connector assembly

ActiveCN107104293ACompact structureReduce AC lossLine/current collector detailsNuclear energy generationSolderingCopper

The invention discloses a connector assembly of two low-temperature superconduction cable terminals and a fabrication method of the connector assembly. A connector for welding two low-temperature superconduction cable terminals is provided with a copper cushion layer, two soldering layers and a fixture mechanism, wherein two sides of the copper cushion layer are arranged at the two low-temperature superconduction cable terminals in parallel, the two soldering layers are sandwiched between the two low-temperature superconduction cable terminals and the copper cushion layer, the fixture mechanism wraps outer surfaces of the low-temperature superconduction cable terminals, and the copper cushion layer, the soldering layers and the low-temperature superconduction cable terminals are tightly clamped in the fixture mechanism from inside to outside. The invention provides the connector assembly of the two low-temperature superconduction cable terminals, the connector assembly is compact in structure, the welding of the low-temperature superconduction cable terminals is achieved by employing the fixture mechanism to extrude a saddle-shaped copper cushion block, the conduction of a helium flow cooling loop is achieved by hermetical welding of an inner-layer shell, and the high-voltage insulation fabrication of the low-temperature superconduction cable terminals is achieved by hermetical welding of an outer-layer shell.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Chair for the elimination of problems of sedentary origin

The present invention relates to a chair for eliminating problems of sedentary origin, which chair consists a saddle-shaped seat part (13) supporting the pelvis and the thigh muscles of the seated person which seat part has two curved thigh troughs (113, 115), which both have a bottom section (101, 102) and its opposite sides there is an inner side section (103 and 104) and outer side section (105 and 106) in relation to the other thigh trough, and which mentioned sections form lengths (L) to the mentioned thigh troughs and within this length there are front sections (107) and back sections (108) for the thigh troughs; when the inner side sections rise from their front sections towards each other, thus forming a central ridge (110) longitudinal to the seat part and mentioned back sections form a back section (A), where from the mentioned lengths reach down-wards and at the same time away from each other. In the chair according to the invention the thigh troughs (113, 115) are at least two separate parts (3, 5) between of which there is a central opening (20) parallel with the mentioned central ridge (110).

Owner:EASYDOING

Protection type cantilever launching platform with built-in water channel and manufacturing method thereof

ActiveCN103542771AEasy to assembleSimplify the maintenance processRocket launchersWater channelRocket

A protection type cantilever launching platform with a built-in water channel and a manufacturing method thereof are used for launching rockets. The protection type cantilever launching platform comprises a launching platform supporting frame and a fluid director mounted on the launching platform supporting frame, the launching platform supporting frame is provided with a frame internal circulating cooling channel, the fluid director is provided with a fluid director cooling channel which is used for absorbing fuel gas heat which is transmitted through a fluid guide plate of the fluid director to lower the temperature inside and outside the fluid guide plate, the frame internal circulating cooling channel is communicated with the fluid director cooling channel, the frame internal circulating cooling channel is provided with a cooling liquid inlet and a cooling liquid outlet respectively, and cooling liquid enters from the cooling liquid inlet, circulates along the frame internal circulating cooling channel and the fluid director cooling channel and then is discharged from the cooling liquid outlet. The manufacturing method comprises the steps of arranging the saddle-shaped guide director, arranging the cantilever launching platform supporting frame and assembling the cantilever platform.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

Preparation method for small grainsize polybutadiene latex

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Pipe tapping apparatus

The present invention provides a pipe tapping apparatus to couple new pipes to an existing pipe. The pipe tapping apparatus includes a base pipe, having a saddle-shaped socket part to be in close contact with the main pipe to pass a fluid therein; and a bending part coupled to the saddle-shaped socket part. The pipe tapping apparatus further includes a coupling pipe to be coupled to the sub-pipe extending to a predetermined place in which the supplied fluid is used, with a ball valve provided in the coupling pipe to control the flow of fluid passing through the coupling pipe. The pipe tapping apparatus further includes an electric heat-welding pipe to couple the coupling pipe to the base pipe. The electric heat-welding pipe has a first heating wire which is provided in the electric heat-welding pipe to weld the electric heat-welding pipe to the base pipe, and a second heating wire which is provided in the electric heat-welding pipe to integrate the coupling pipe with the electric heat-welding pipe. The pipe tapping apparatus further includes a first positioning unit which is removably coupled to an end of the coupling pipe, with a first through hole provided in the center of the first positioning unit, thus guiding a process of tapping the main pipe using the cutting drill passing through the first through hole of the first positioning unit.

Owner:ISCO INDS +1

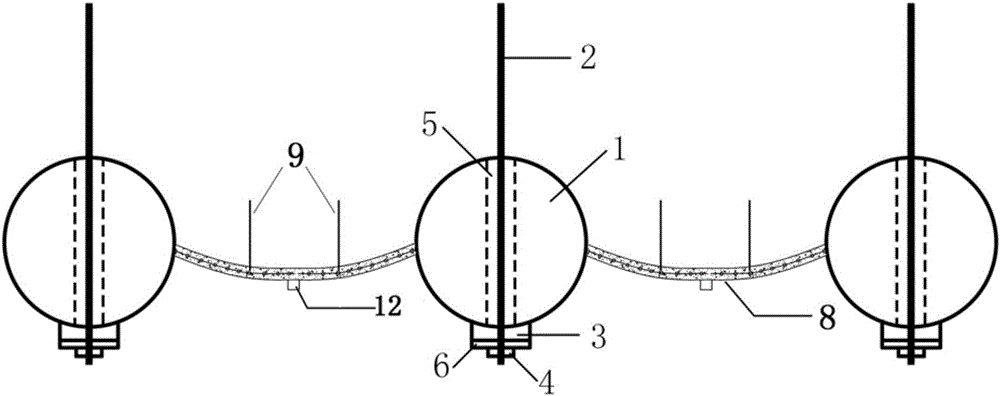

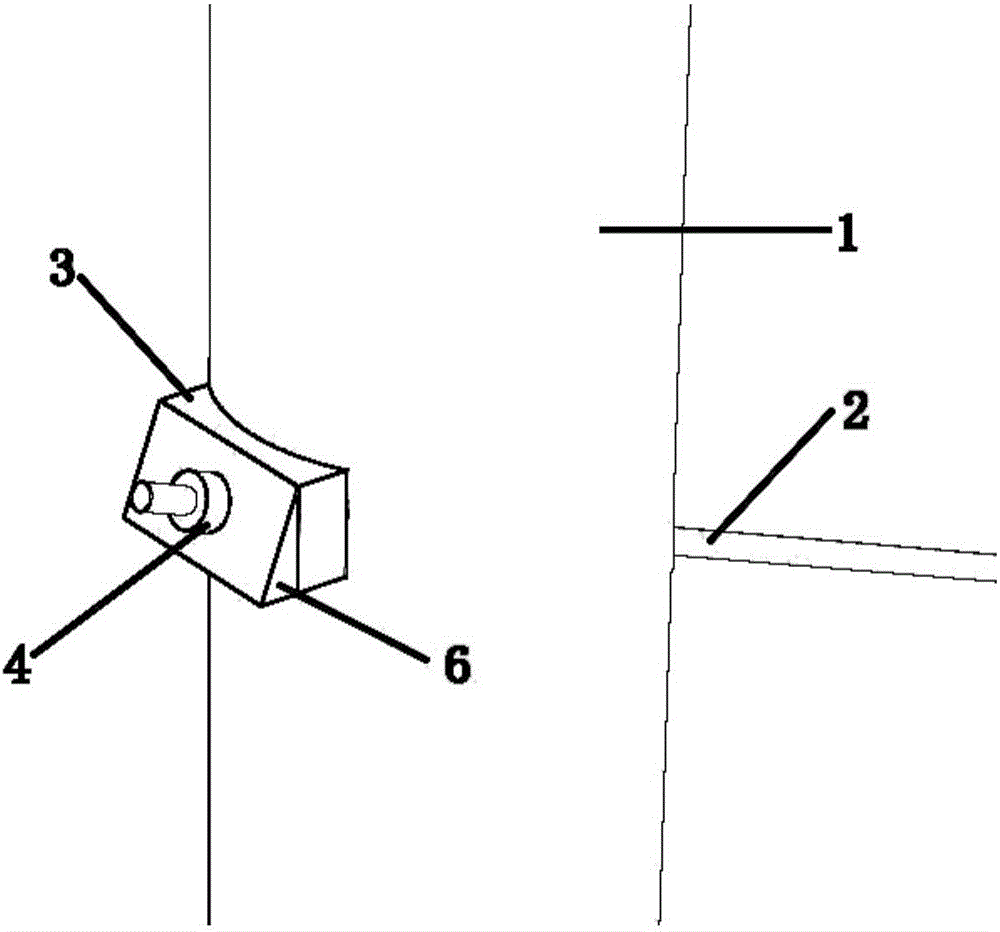

Deep-foundation-pit pile-anchor supporting system with anchor heads arranged on pile bodies and implementing method of system

The invention discloses a deep-foundation-pit pile-anchor supporting system with anchor heads arranged on pile bodies and an implementing method of the system. The supporting system comprises retaining piles, anchor rods, saddle-shaped cushion blocks, anchor devices, PVC pipes, wedges and locking beams; the PVC pipes are arranged inside the retaining piles in advance; inner ends of the anchor rods penetrate through the PVC pipes and are inserted in the foundation pit wall, and outer ends of the anchor rods are fixedly connected with the anchor devices; and included angles being 15-25 degrees are formed between axes of the anchor devices and the horizontal plane and are kept consistent with inclination angles of the anchor rods. Waist beams in a traditional pile-anchor system are canceled, so that the prestress loss caused by deformation of the waist beams is avoided. The force of the anchor rods is directly transferred to the retaining piles, the anchor rods and the retaining piles can be better integrally and synergistically stressed, and a supporting structure is better in integrity, safe and reliable. A lot of connecting batten plates and welding rods are canceled, so that profile steel materials and the electricity consumption are greatly saved. Heavy and dangerous waist beam mounting work is avoided, procedures are simplified, and the construction period is shortened.

Owner:DALIAN JIAOTONG UNIVERSITY

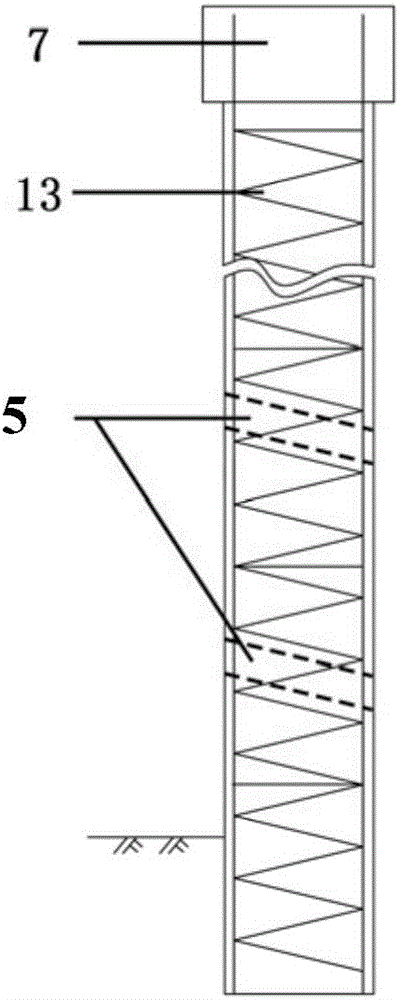

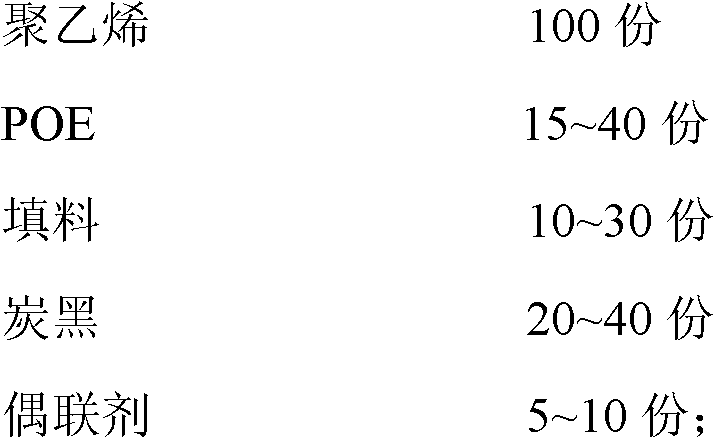

High elasticity PE modified material, and its application in rectification and circle-restoration of PE pipe fittings

InactiveCN102660064AHigh hardnessIncrease elasticityPipe connection arrangementsPipe fittingHardness

The invention provides a high elasticity PE modified material, which comprises the following components, by weight, 100 parts of the PE, 15-40 parts of POE, 10-30 parts of a filler, 20-40 parts of carbon black, and 5-10 parts of a coupling agent. The high elasticity PE modified material allows the Shore hardness and the elastic modulus of a PE resin to be greatly improved, prepared products subjected to bearing deformation to be rapidly restored and the restoration cost to be low, and is especially suitable for PE fused saddle-shaped pipe fittings to be subjected to rapid rectification and circle-restoration.

Owner:上海乔治费歇尔亚大塑料管件制品有限公司

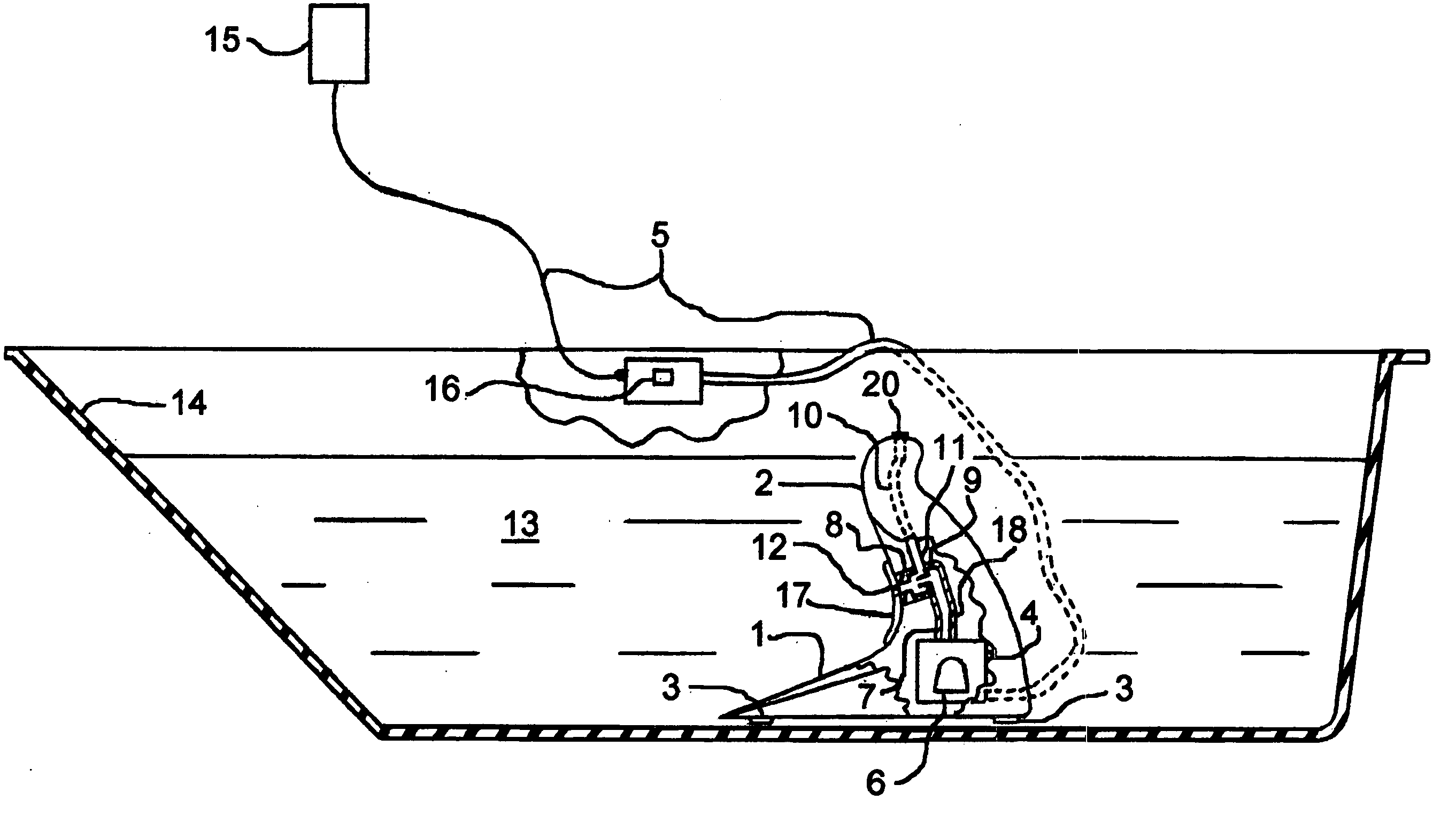

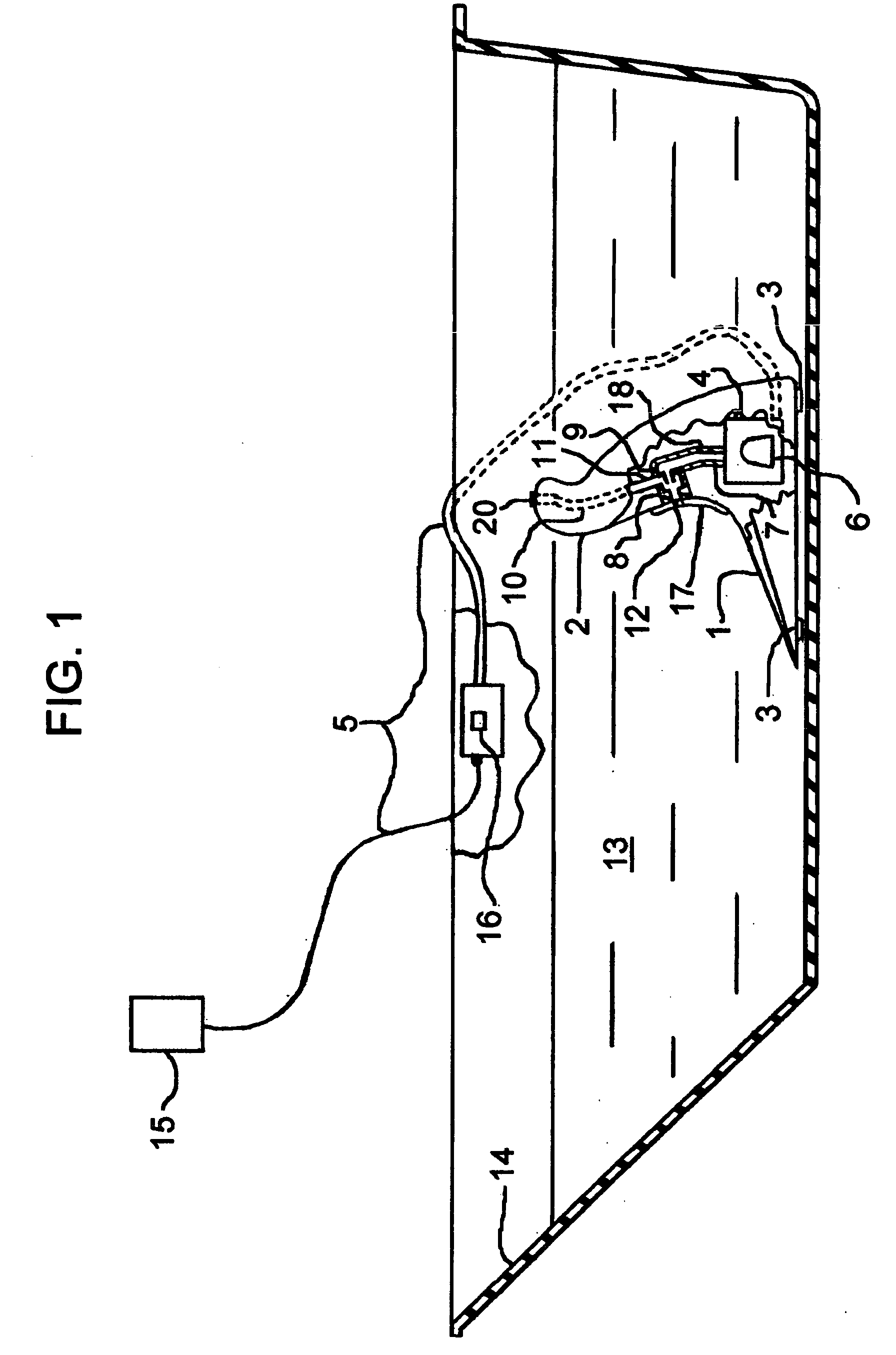

Feminine hydro-therapeutic massage device

InactiveUS20050197604A1Change is minimalImproves hydrotherapy stimulation deviceBathing devicesGenitals massagePelvic regionButtocks

A portable hydro massage device for submersion in a body of water containing a female user, i.e. a bathtub, provides a local massage to the labium region and a focused stimulant to the female user's clitoris thereby resulting in a superior sensation to the entire body promoting an overall euphoric state and calming effect. The apparatus employs a saddle shaped housing, where the buttocks are placed, and a saddle horn for controlling the stimulus. Disposed within the midsection of the saddle horn is a hydro jet with a driven flow from a circulating water pump that draws suction from the main body of water. The hydro jet is adjustable in pressure and a method is provided for aeration of the water discharged to allow for a rhythmic pulsation effect. The saddle horn may be held and the lower body positioned as needed to focus the discharged stream from the hydro jet to the desired point of the pelvic region.

Owner:BUBBLE LOVE

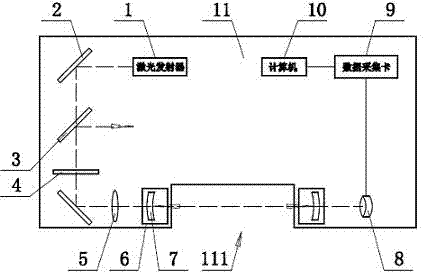

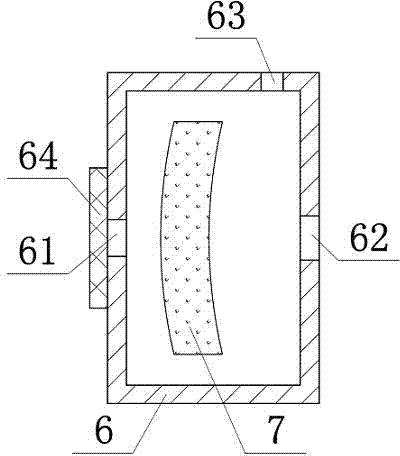

Atmosphere visibility measurement device based on optical cavity ring down spectroscopy technology

InactiveCN104729998AAccurate measurementMaterial analysis by optical meansObservational errorLaser transmitter

The invention provides an atmosphere visibility measurement device based on an optical cavity ring down spectroscopy technology and relates to a meteorological observation device. The atmosphere visibility measurement device comprises a saddle-shaped shell; a pair of high-reflectivity cavity mirrors are located at the two sides of a concave opening of the shell to form a ring down cavity; after laser transmitted by a laser transmitter penetrates through a polaroid, a 1 / 4 wave plate and a coupling lens in sequence and then is mitted into a first high-reflectivity cavity mirror, one path is reflected by the first high-reflectivity cavity mirror and is emitted into the polaroid through the 1 / 4 wave plate to be reflected and output; and the other path is vibrated in the ring down cavity, penetrates through the second high-reflectivity cavity mirror to be transmitted to a photomultiplier, and then is transmitted to a computer by a data acquisition card. By virtue of the atmosphere visibility measurement device, the technical problems that a measurement error is caused by the fact that the deviation is caused between the sampling of a sample to be detected for measuring the atmosphere visibility and the actual measurement in the prior art are solved. The atmosphere visibility measurement device has the beneficial effects that the open type ring down cavity can be in direct contact with atmosphere, and atmosphere extinction coefficient changes caused by gas molecules, aerosol and rainwater can be comprehensively measured, so that the accurate measurement of the atmosphere visibility is realized.

Owner:ZHEJIANG MEASUREMENT SCI RES INST

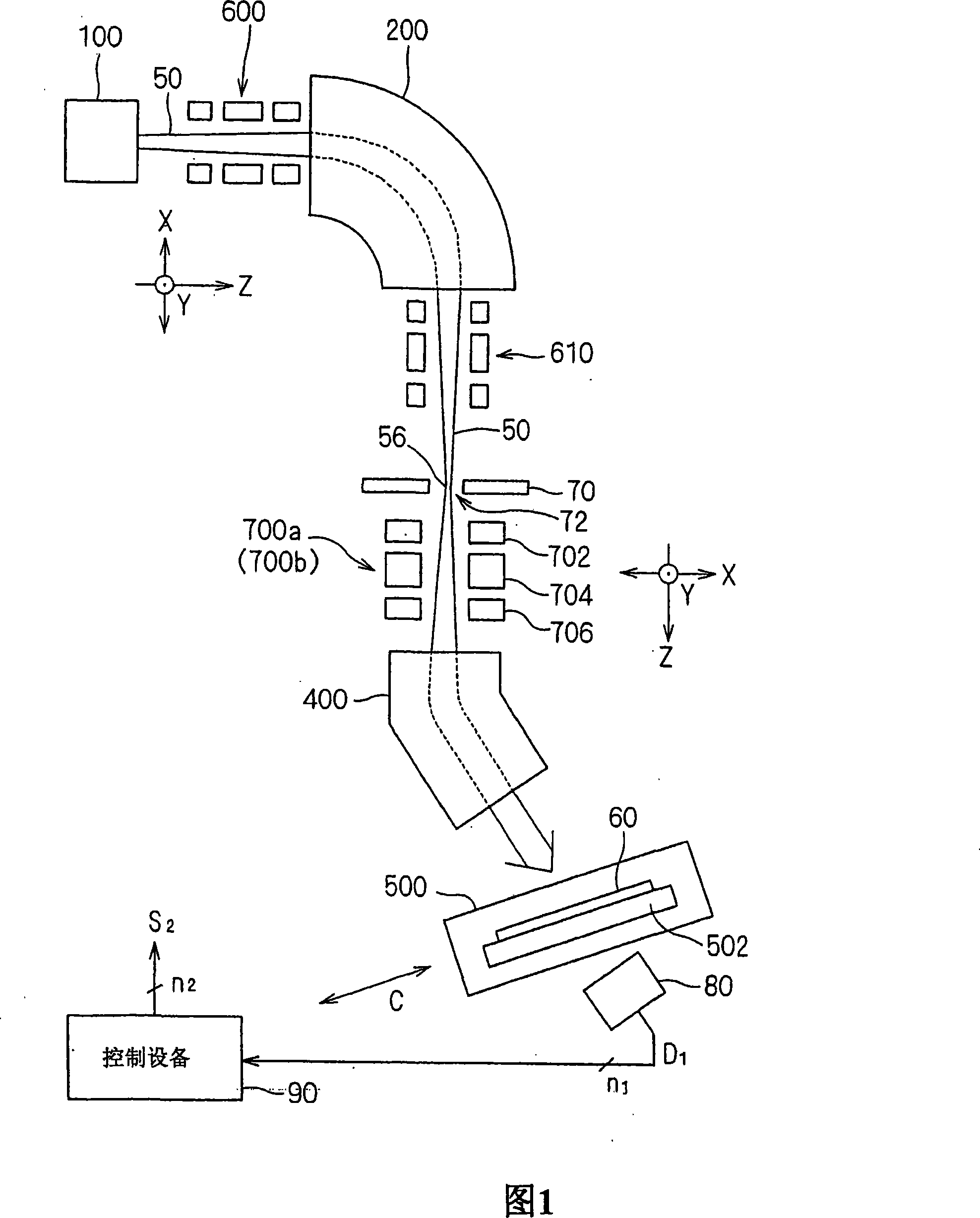

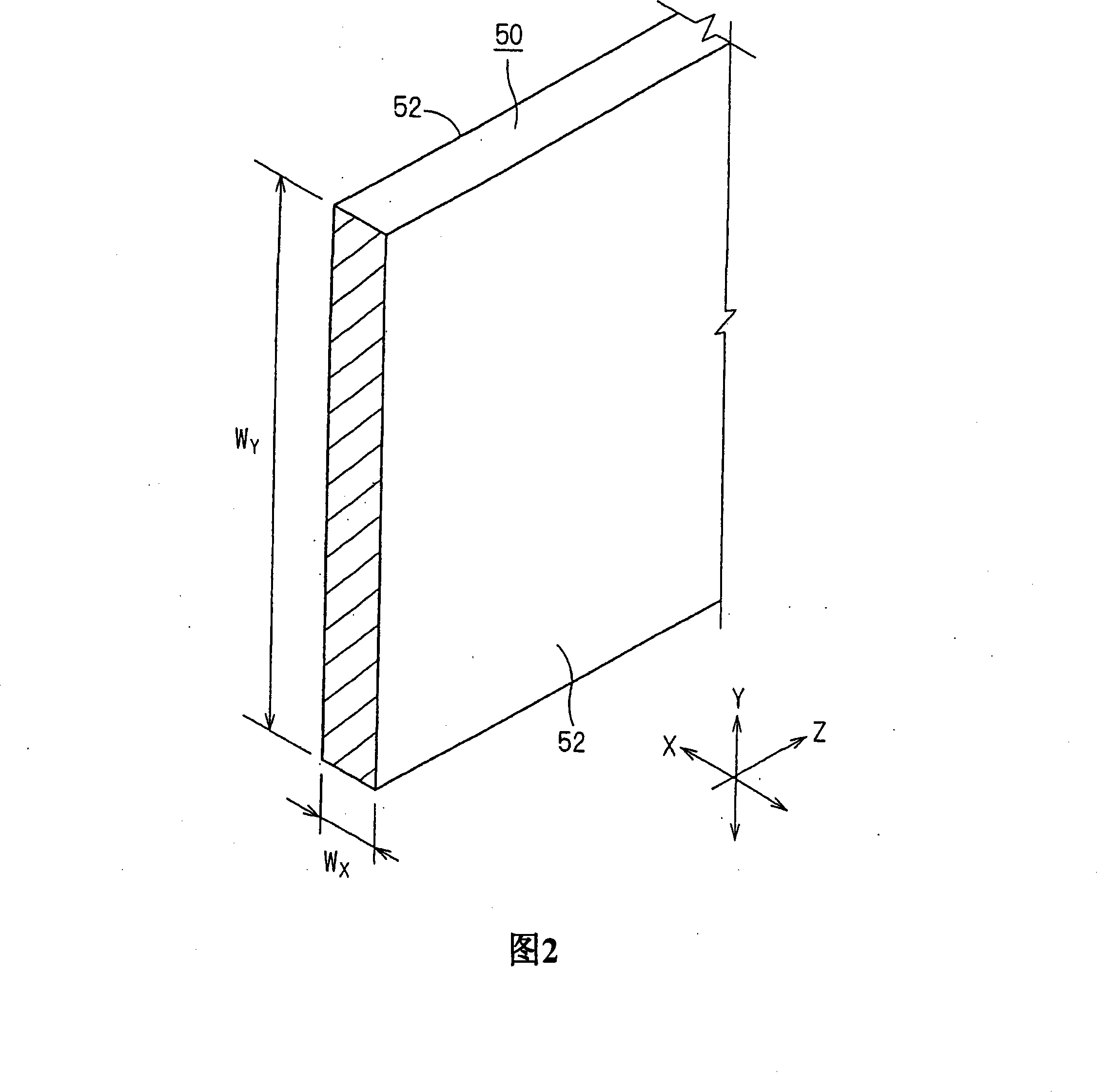

Ion injector

InactiveCN101162679AReduce protrusion distanceSmall sizeElectric discharge tubesSemiconductor/solid-state device manufacturingIon beamIon implantation

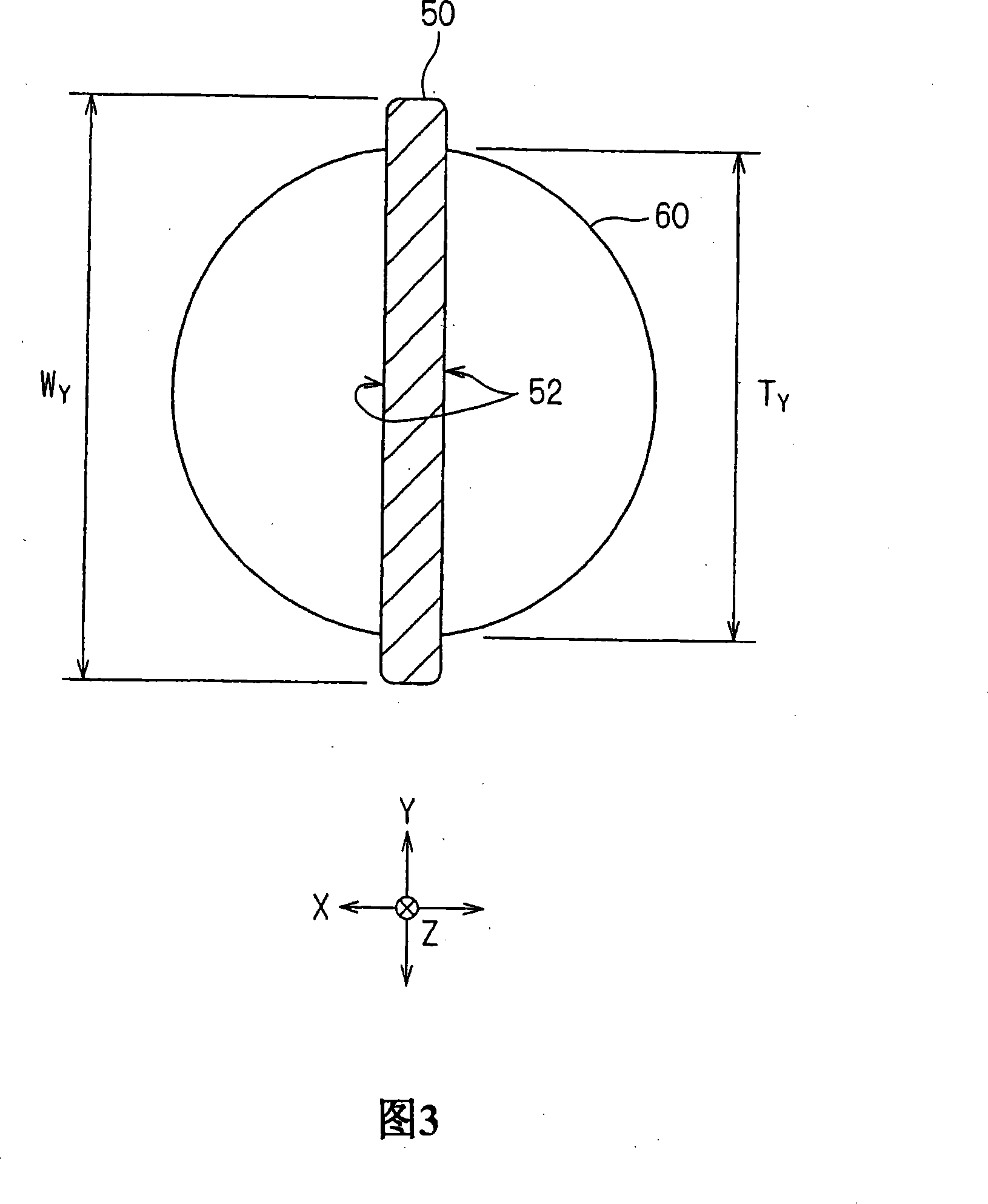

An analyzing electromagnet which forms the ion implantation device comprises a first interior loop, a second interior loop, three first exterior loops, three second exterior loops and a yoke. The interior loop is saddle-shaped loop and collaborates with each other to generate the main magnetic field which bends the ion beam in the X-direction. Each exterior loop is saddle-shaped loop which generates a secondary magnetic field that revises the main magnetic field. Each loop has the structure that the groove part lies in the flabellate cylindrical band wound coil and the band wound coil is configured as follows: the periphery surface of the laminated-sheet insulator is winded with the laminated-sheet multi-turn of the insulation sheet and the conductor sheet; and the periphery surface is formed with a laminated-sheet insulator.

Owner:NISSIN ION EQUIP CO LTD

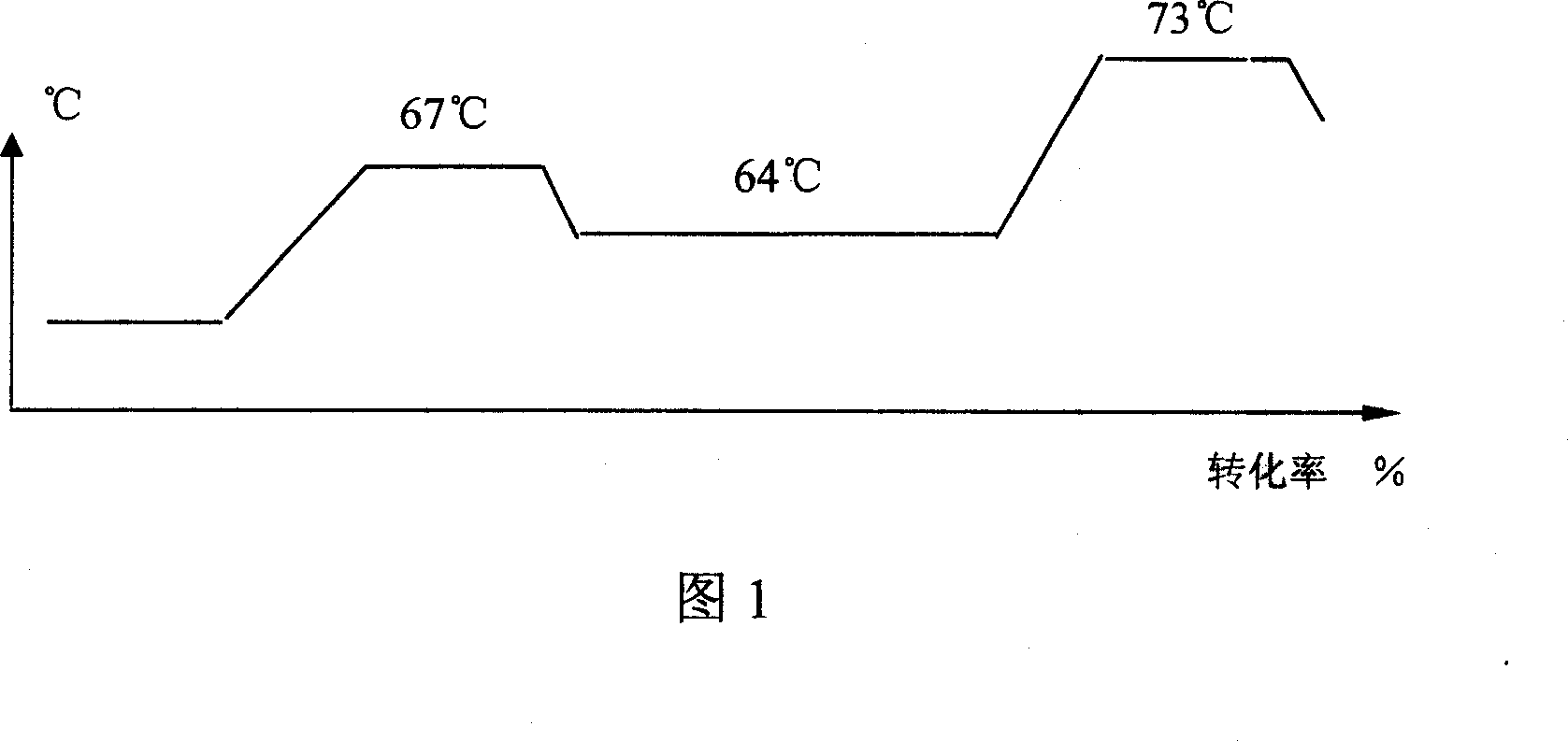

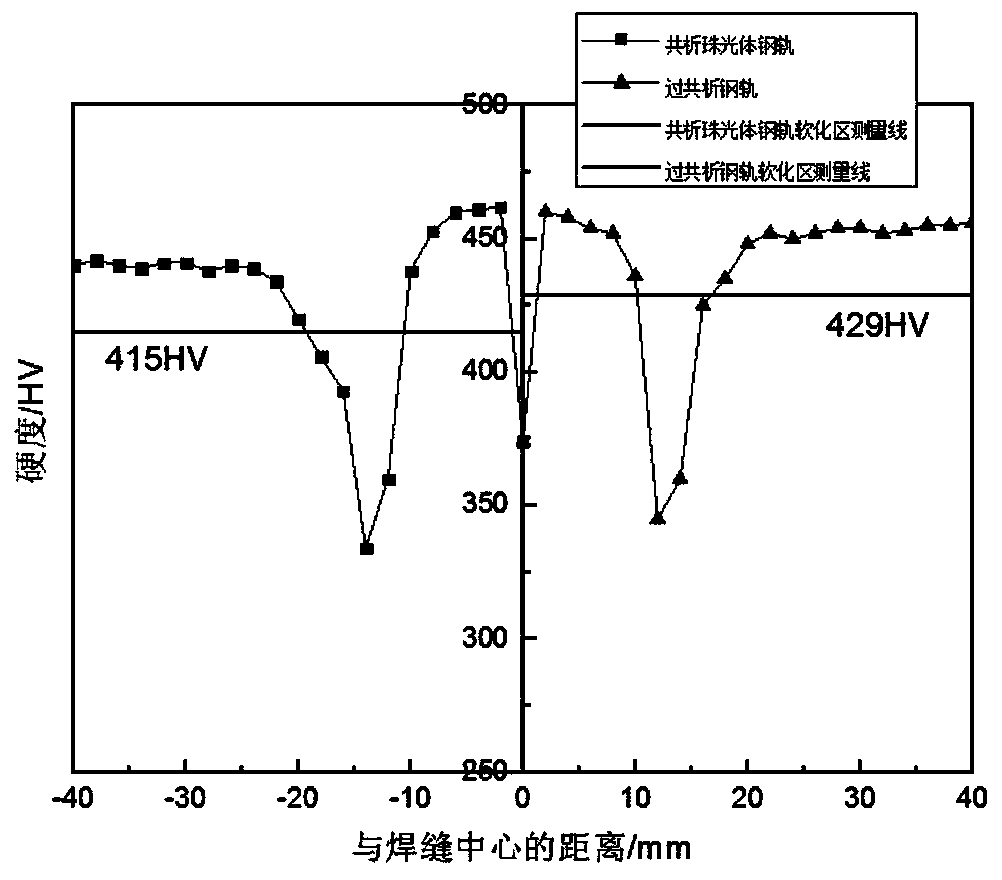

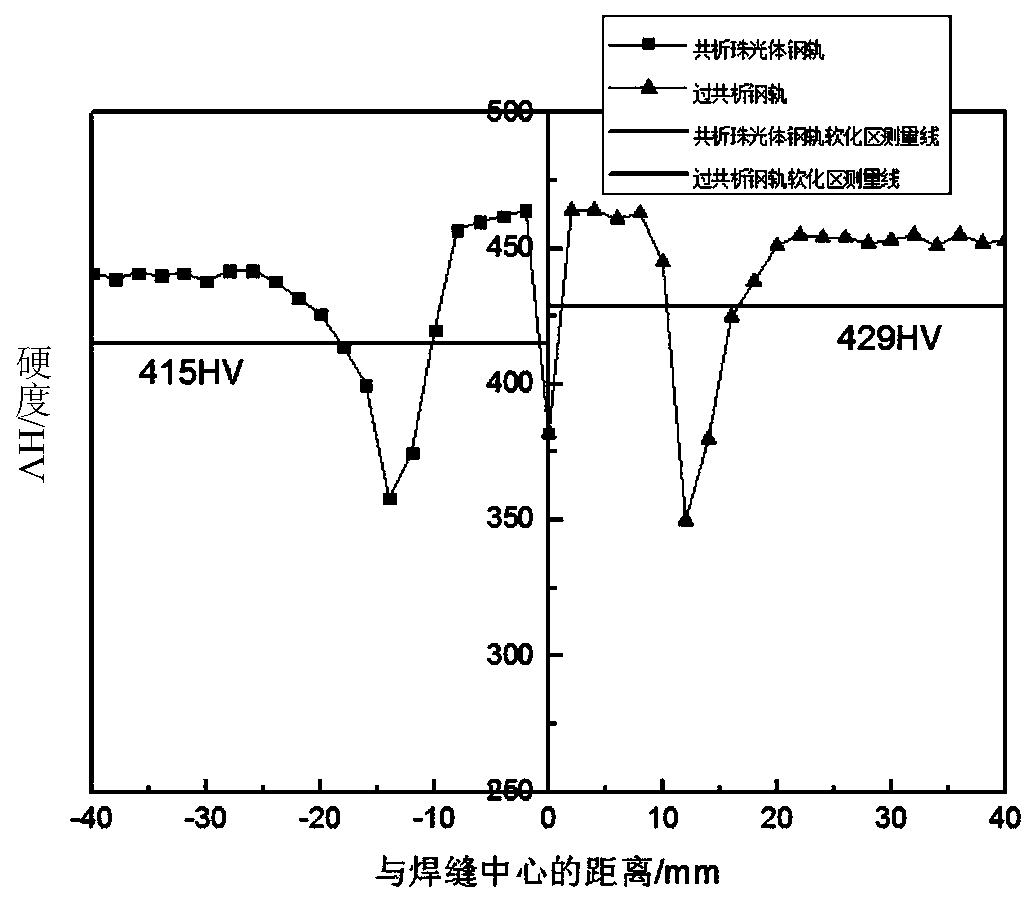

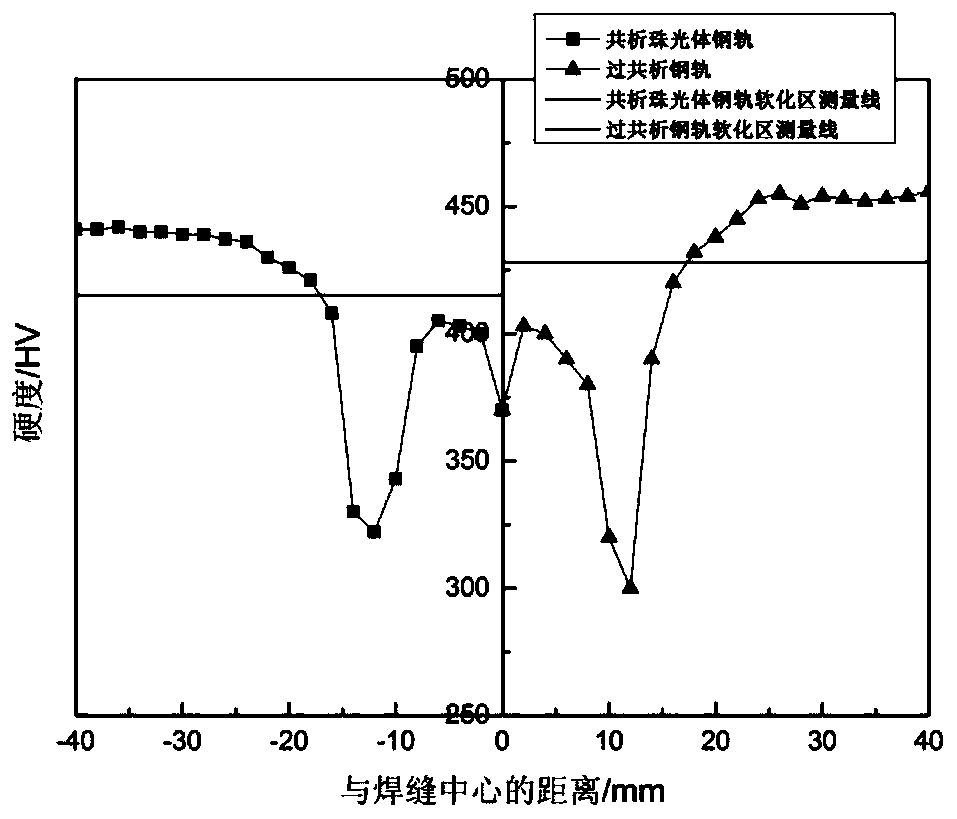

Heat treatment method of steel rail welding joint

InactiveCN110358906AImprove toughnessGuaranteed fatigue lifeFurnace typesHeat treatment furnacesHardnessFlash welding

The invention discloses a heat treatment method of a steel rail welding joint, and belongs to the technical field of steel rail welding. The heat treatment method of the steel rail flash welding jointaims at solving the technical problems of saddle-shaped abrasion and early fatigue fracture of the steel rail welding joint of a steel rail caused by low hardness of a welding area or abnormal microstructure of the joint in the line service process. According to the method, the steel rail welding joint is sequentially subjected to a first cooling stage, a second cooling stage and a third coolingstage, the cooling speed and temperature of each stage are controlled, so that no martensite structure exists in the metallographic structure of the steel rail welding joint, saddle-shaped abrasion and early fatigue fracture of the steel rail welding joint of the steel rail caused by low hardness of the welding area or abnormal microstructure of the joint in the line service process are avoided, and it is ensured that the fatigue life of the steel rail welding joint reaches 3 million times or more.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

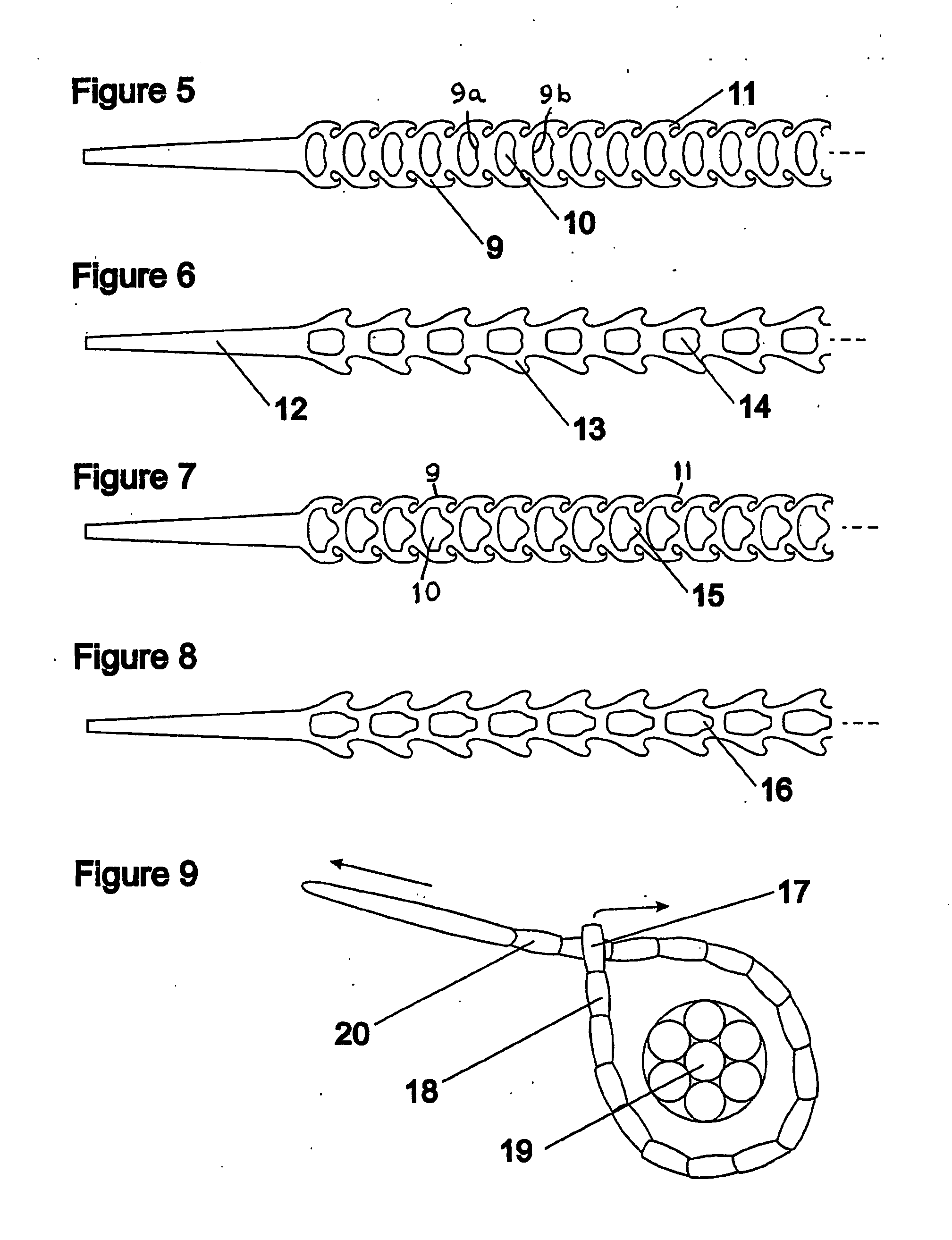

Apparatus and method for filleting beheaded and gutted fish

ActiveUS8298050B2Improved centringSimpler and cheapSplitting instrumentsFish filletingEngineeringSaddle-shaped

Owner:NORDISCHER MASCHINENBAU RUD BAADER GMBH CO KG

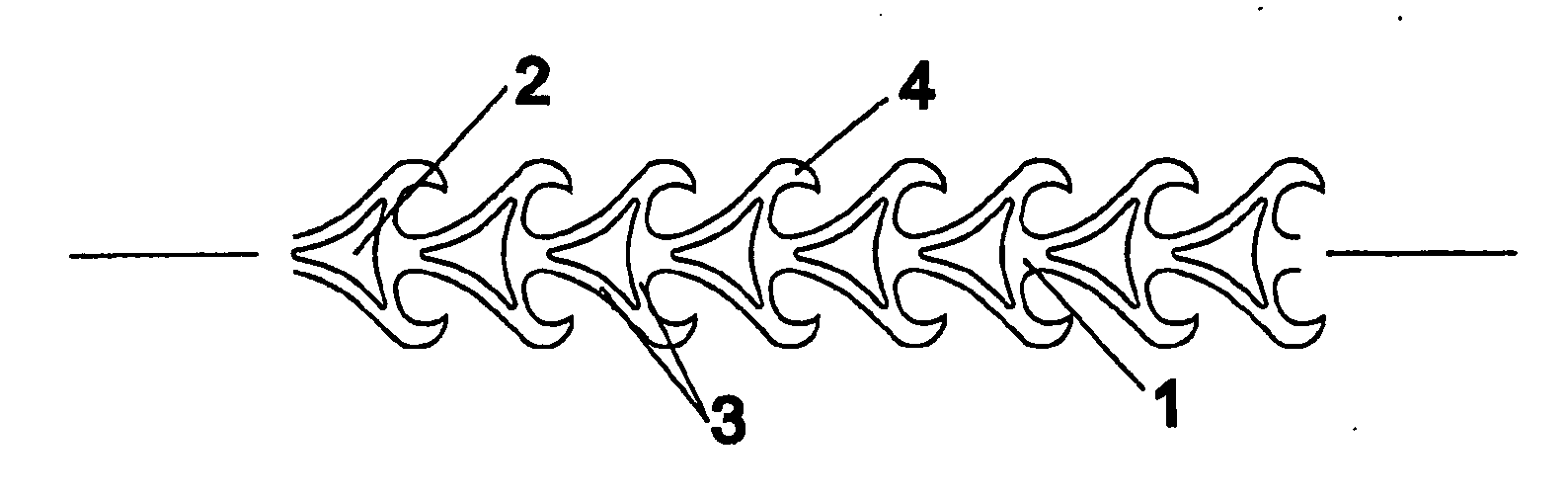

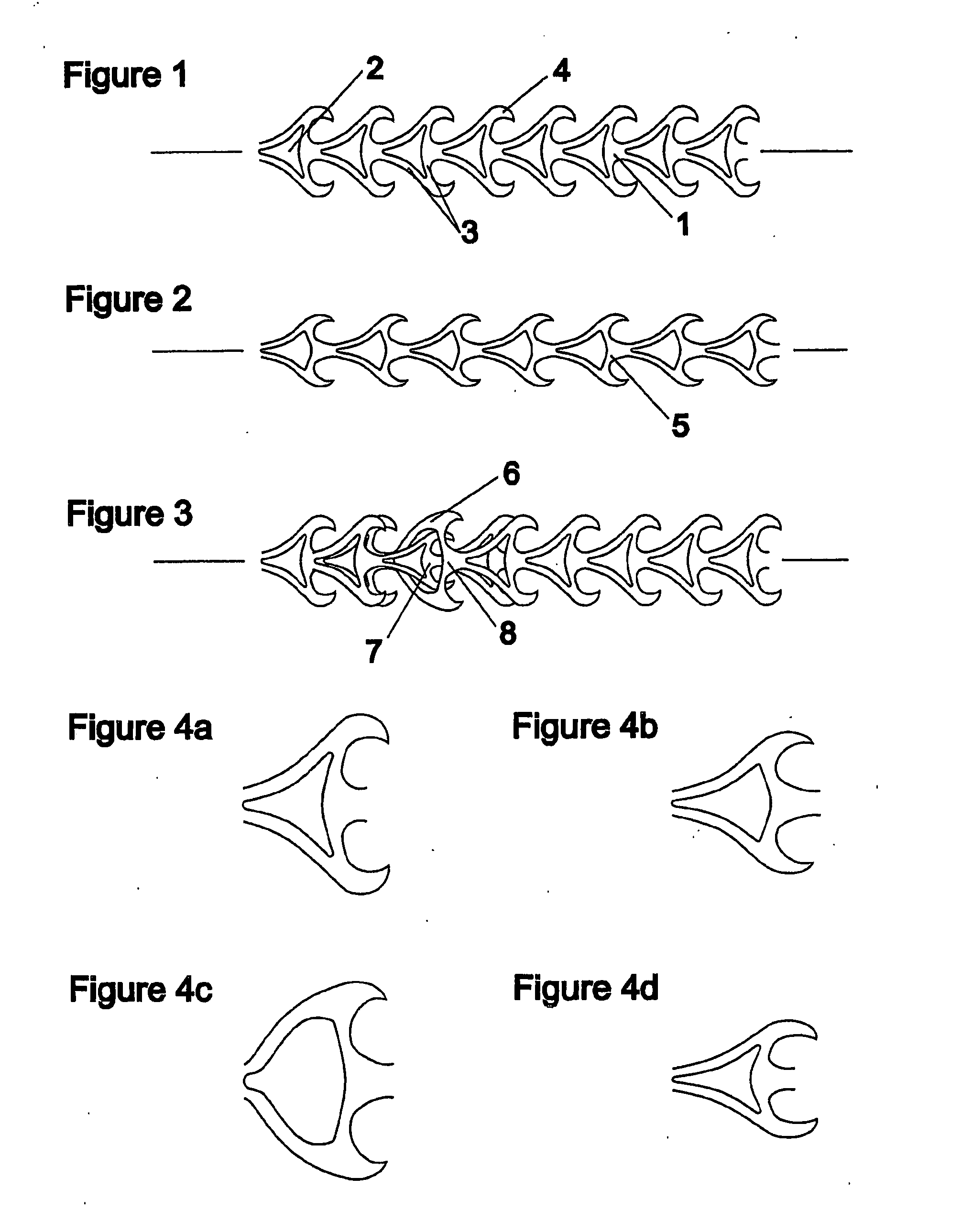

Tie strips

InactiveUS20060127638A1Increase widthFacilitate their threading and subsequent latchingPipe supportsLayered productsEngineeringMechanical engineering

A flexible, integrally formed tie strip for forming a loop when passed through itself comprises a plurality of identical cells formed in a strip, the cells forming generally loop-shaped enclosed apertures (10) bounded by wall portions of the cells, each aperture allowing the passage of further cells through it. The cells are further provided with one or more latching members (11) allowing passage of one cell through another in one direction but preventing passage of the cell in the reverse direction. The walls (9) bounding the apertures can be folded to a saddle shape about radial and longitudinal axes, so as to increase the width of the aperture without stretching the material of the walls, thereby facilitating the passage of a penetrating cell through the aperture of another cell. Moreover the penetrating cell is designed to fold so as to pass through still more easily. This three-dimensional deformation is promoted by a notch (15) in the rear of each aperture wall.

Owner:HARSLEY ANDREW JOHN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com