Patents

Literature

59 results about "Eye measurements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Eye Measurements. Look for an ophthalmologist who takes more than the two standard measurements required for Medicare reimbursement: one axial length reading (from the front of the cornea to the retina) and one keratometry reading, known as K reading (measures average curvature of the cornea).

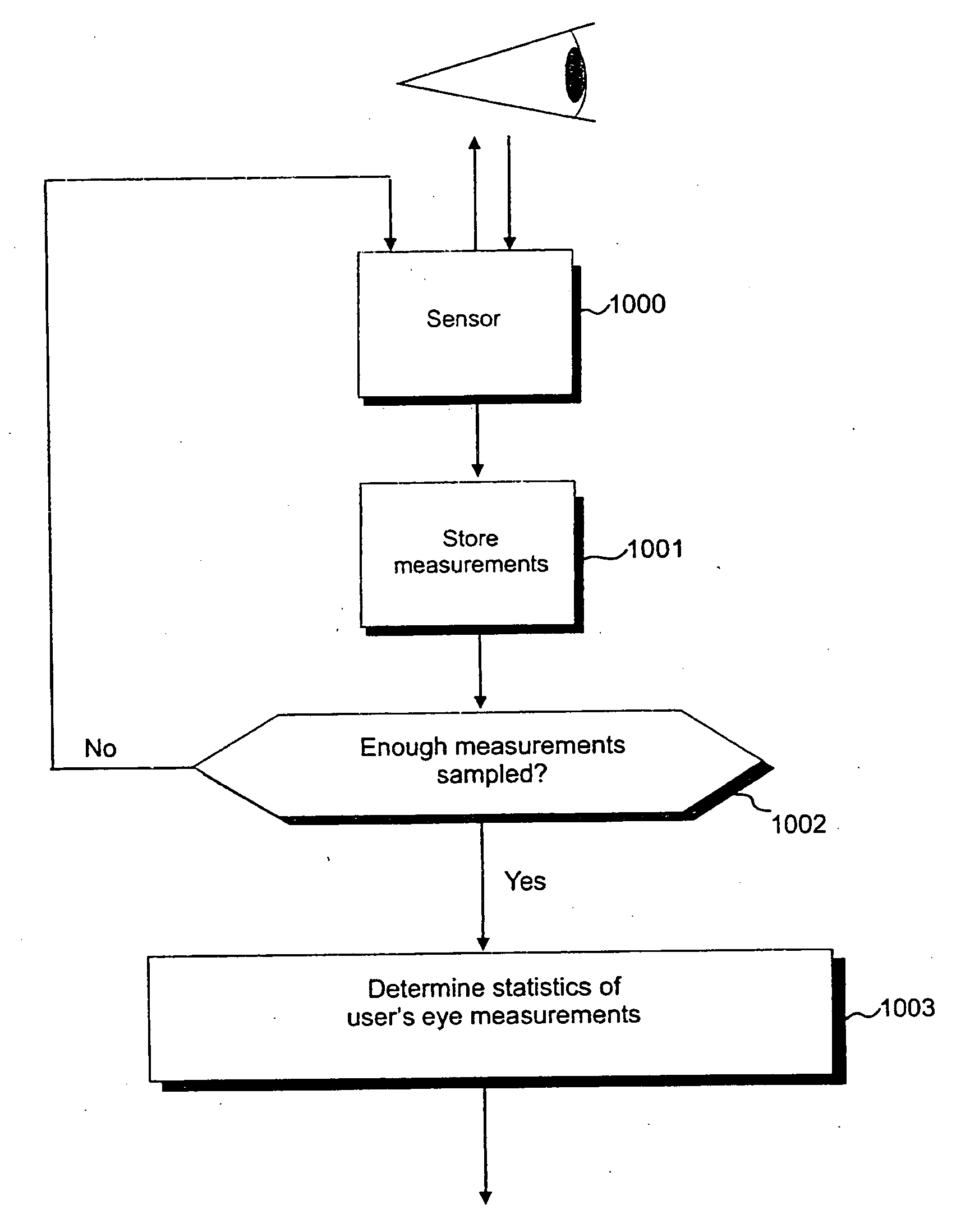

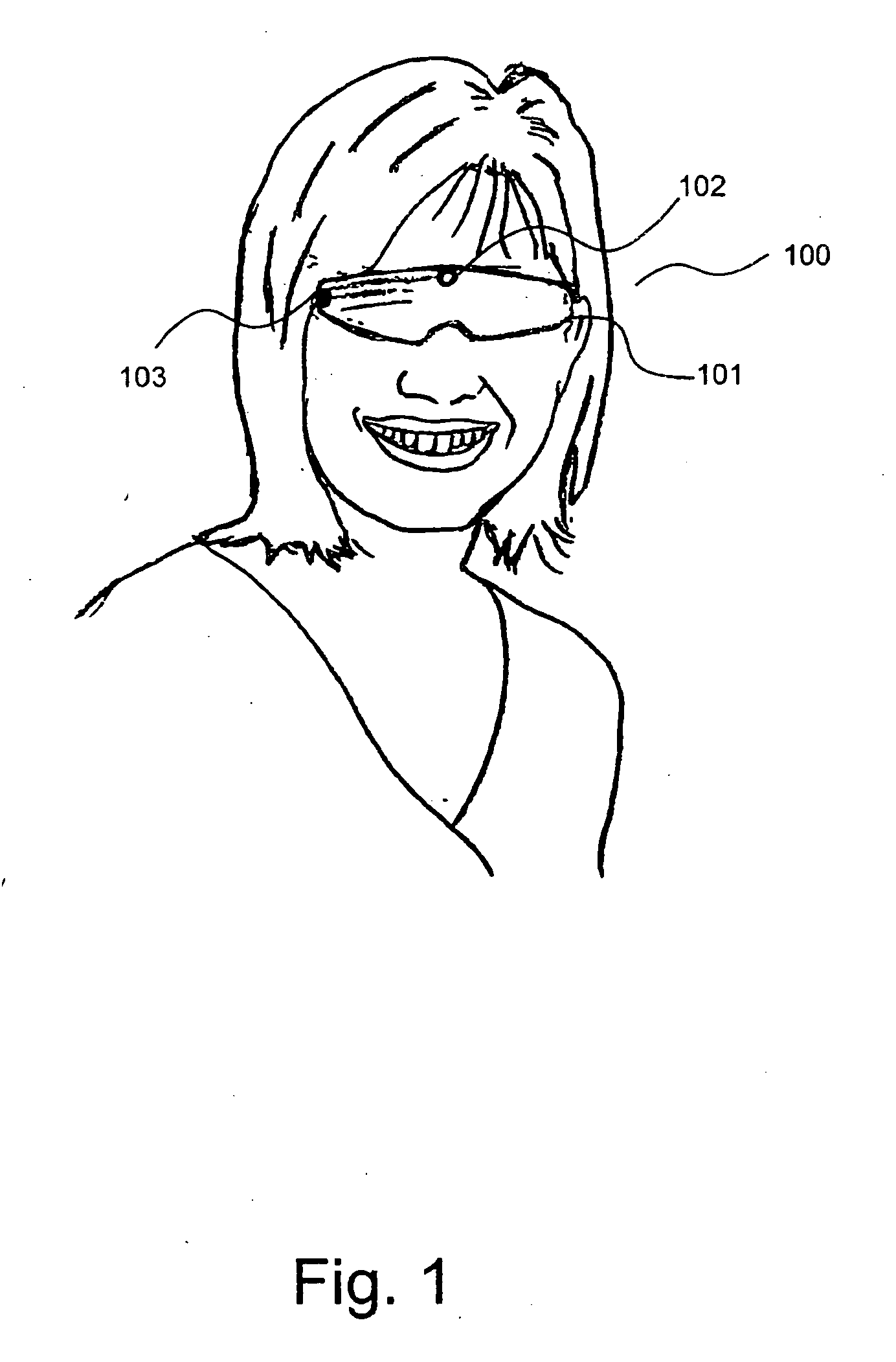

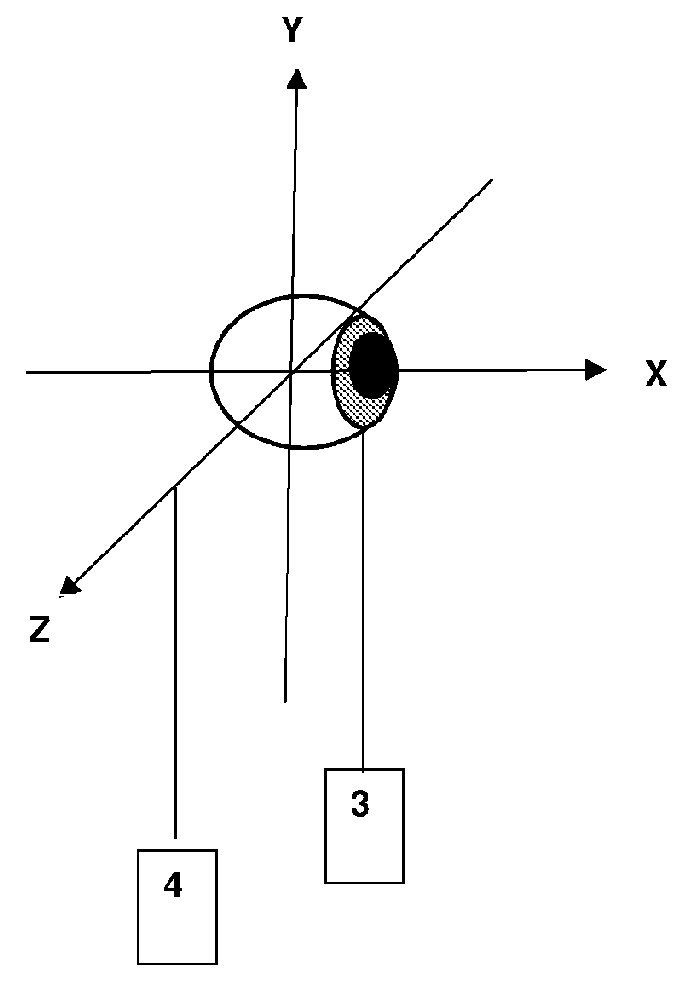

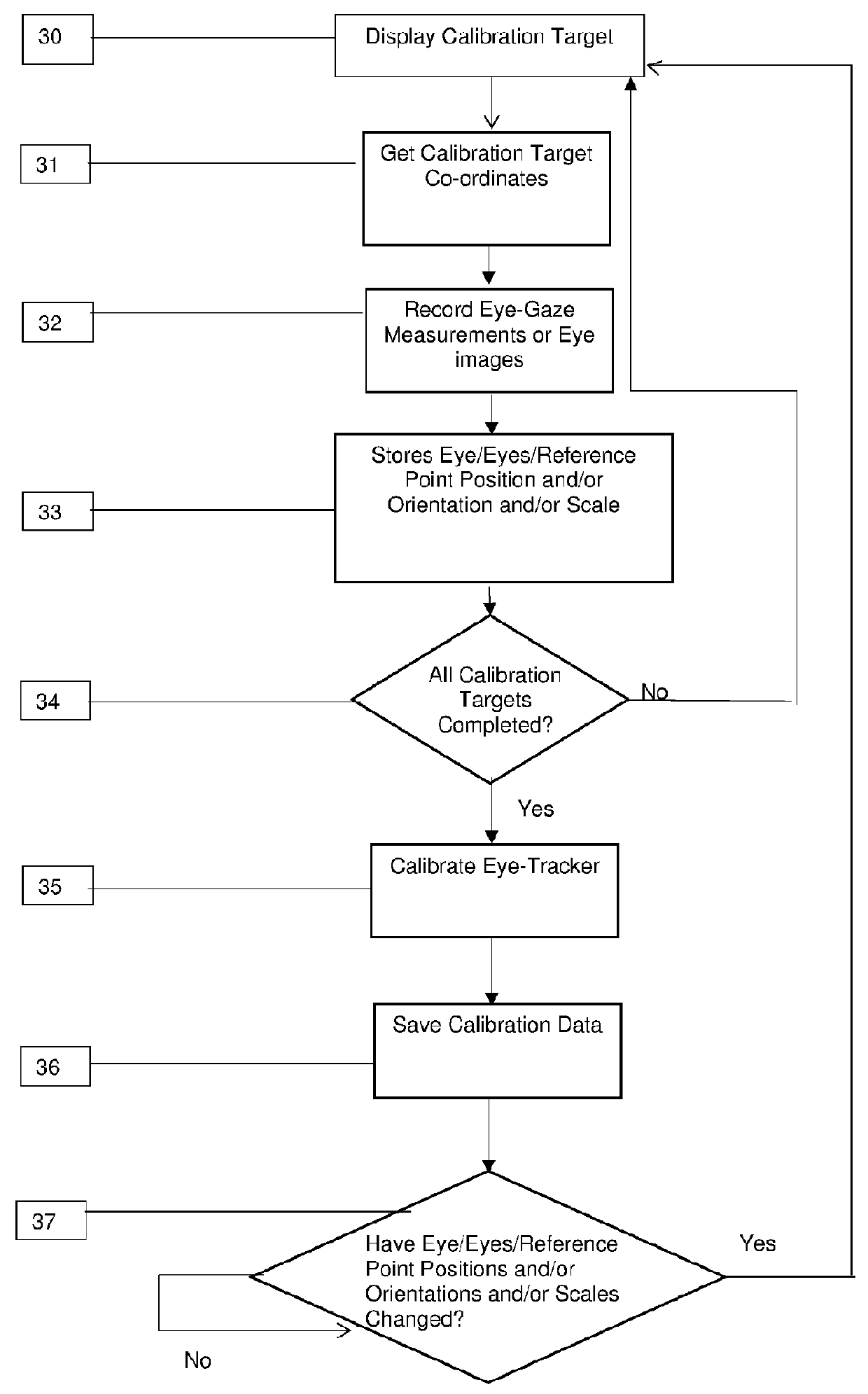

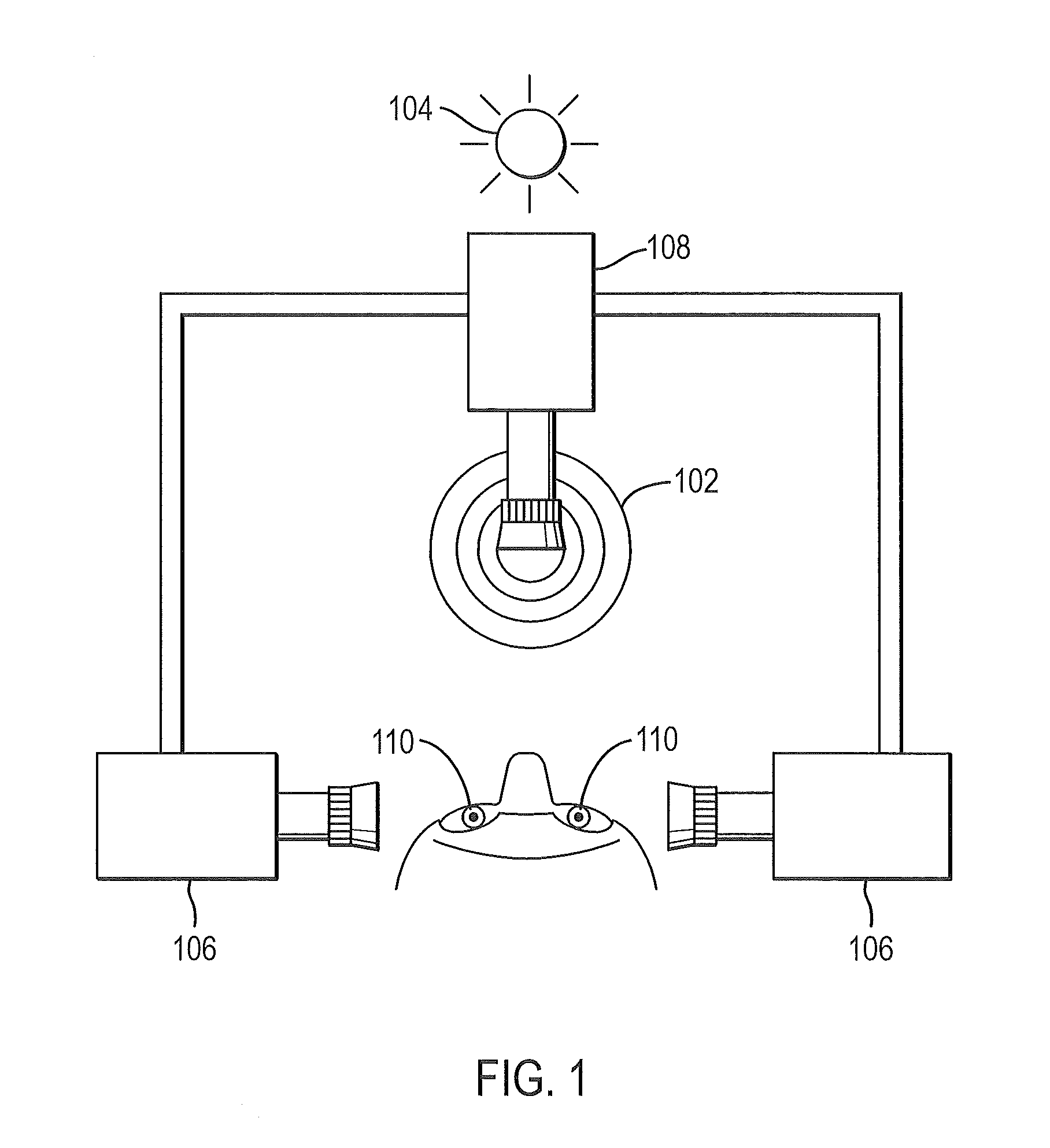

Self-calibration for an eye tracker

ActiveUS20050225723A1Input/output for user-computer interactionAcquiring/recognising eyesPosition dependentEye tracking system

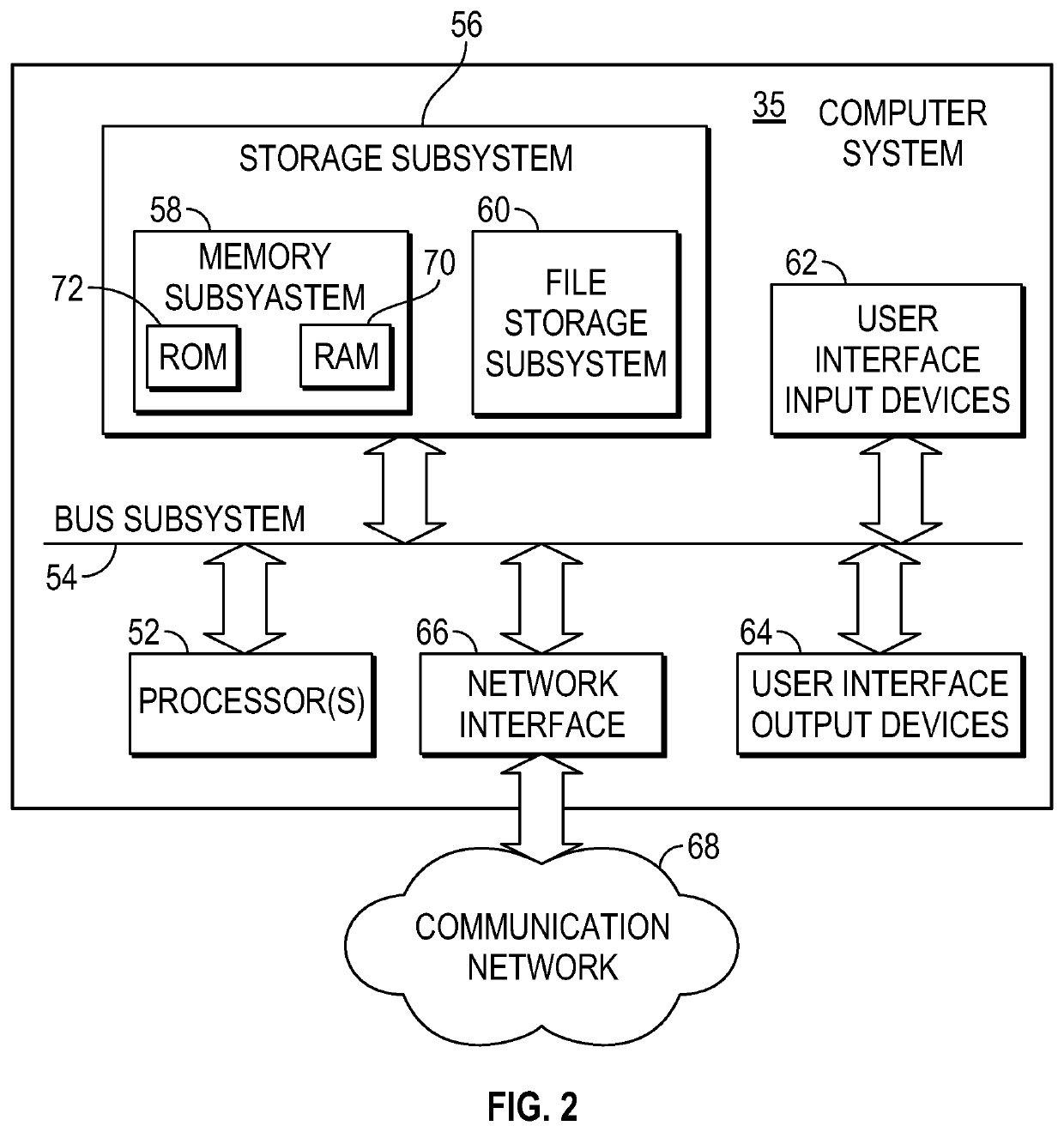

Automatic calibration of an eye tracking system involves capturing a plurality of eye measurements, wherein each said eye measurement relates to a corresponding eye gaze position of a human eye; determining a set of statistics data from said plurality of eye gaze measurements; comparing said set of statistics of said eye gaze measurements with a set of statistics relating to a plurality of pre-measured eye gaze positions of at least one person; and as a result of said comparison, determining a calibration correction factor which, when applied to said statistics of said eye gaze measurement, give an optimum match between said statistics of eye gaze measurement and said statistics of predetermined eye gaze positions.

Owner:HEWLETT PACKARD DEV CO LP

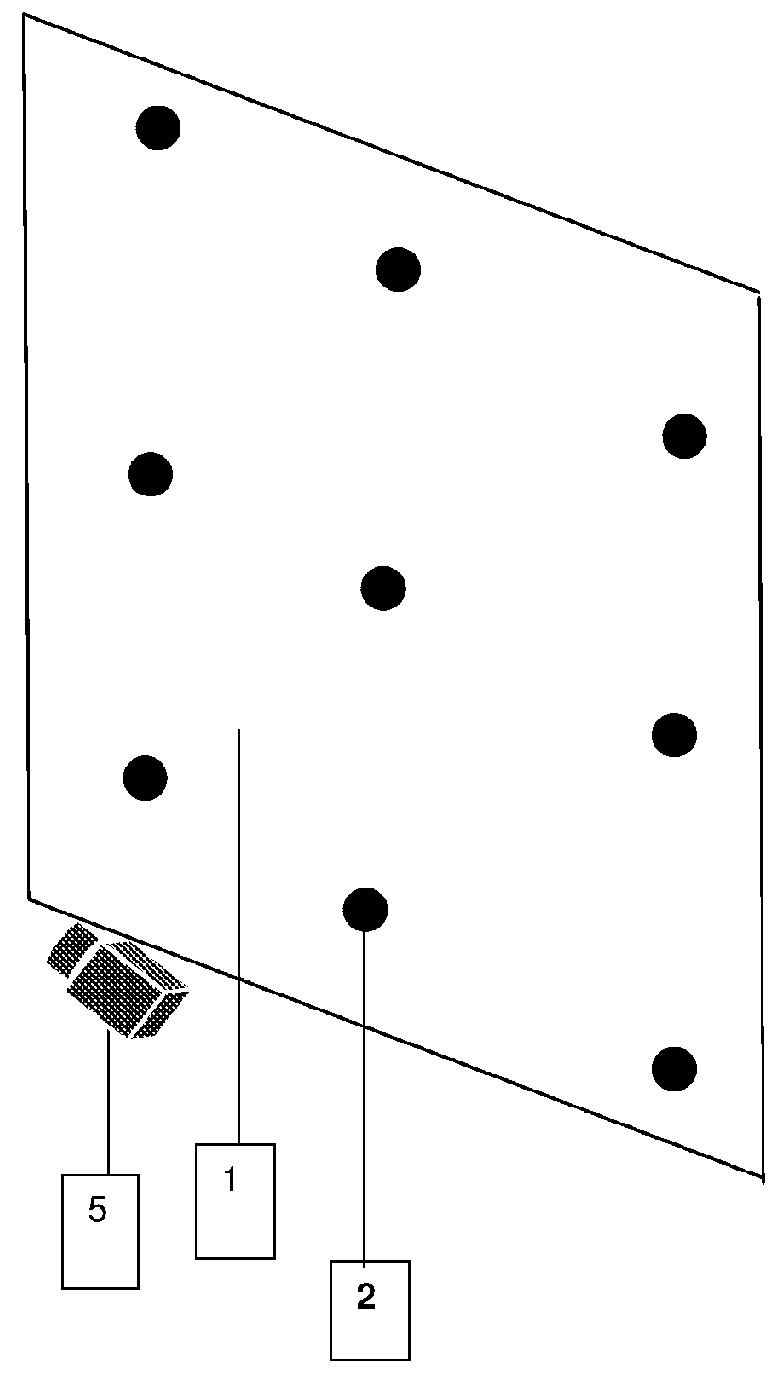

Eye tracking calibration

InactiveUS20160029883A1Improve tracking accuracyReduce needInput/output for user-computer interactionAcquiring/recognising eyesComputer scienceVisual perception

Method, system and apparatus for calibrating an eye tracker comprising presenting a subject with a visual target. Detemiining a physical arrangement in space of the subject. Obtaining an eye measurement of the subject. Storing a record of the subject's physical arrangement in space and data derived from the eye measurement of the subject, associated with the visual target presented to the subject. Repeating for one or more further different visual targets.

Owner:EYE TRACKING ANALYSTS

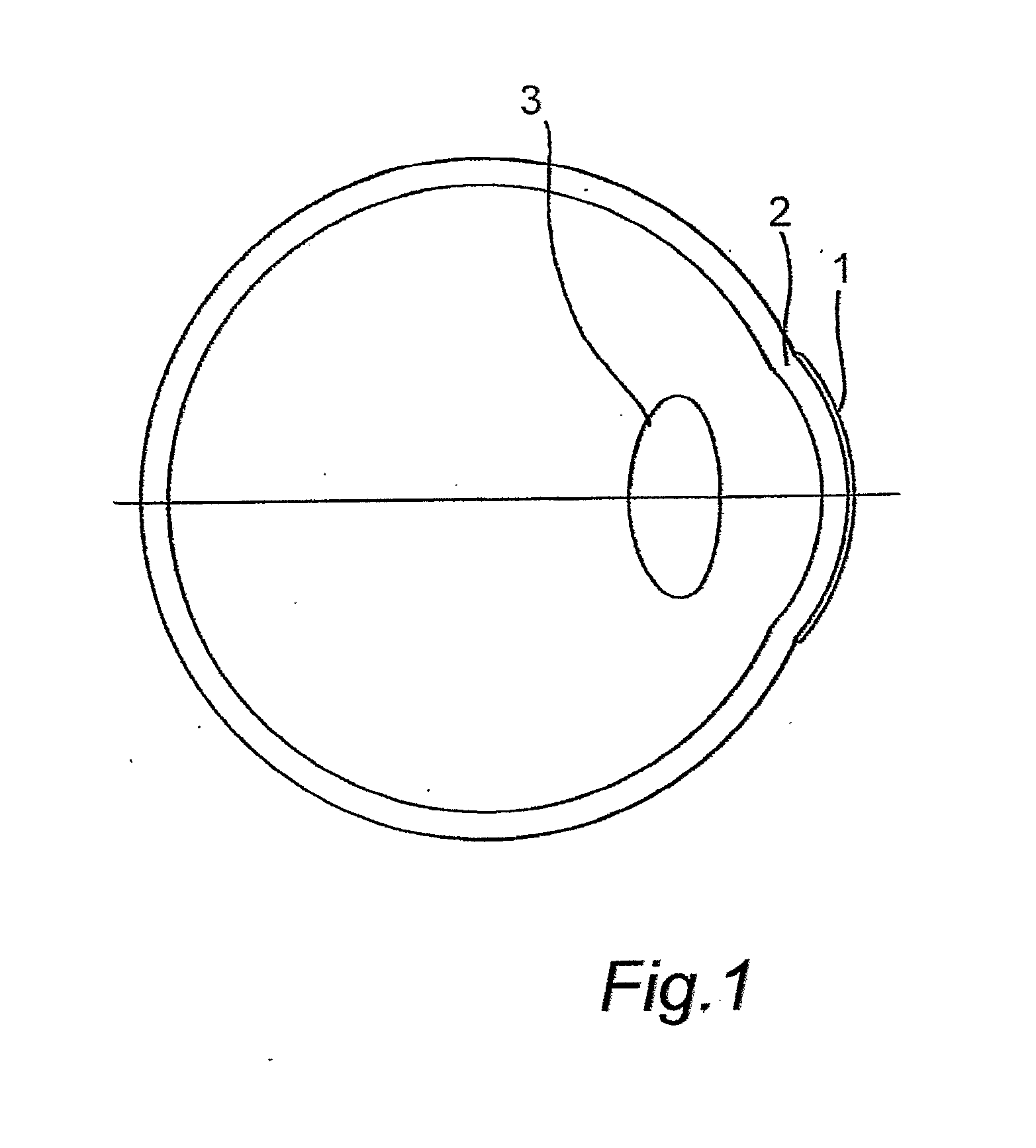

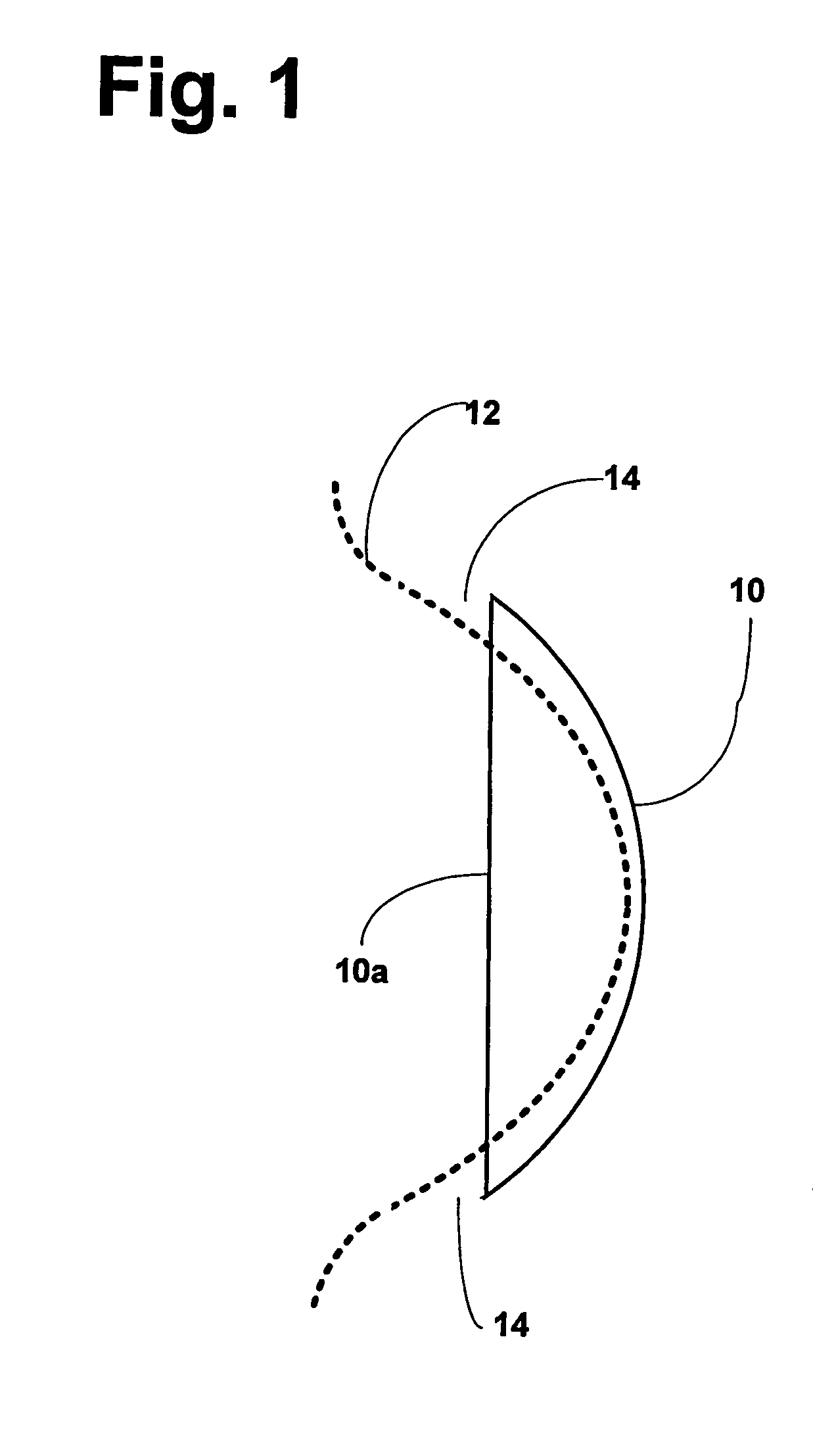

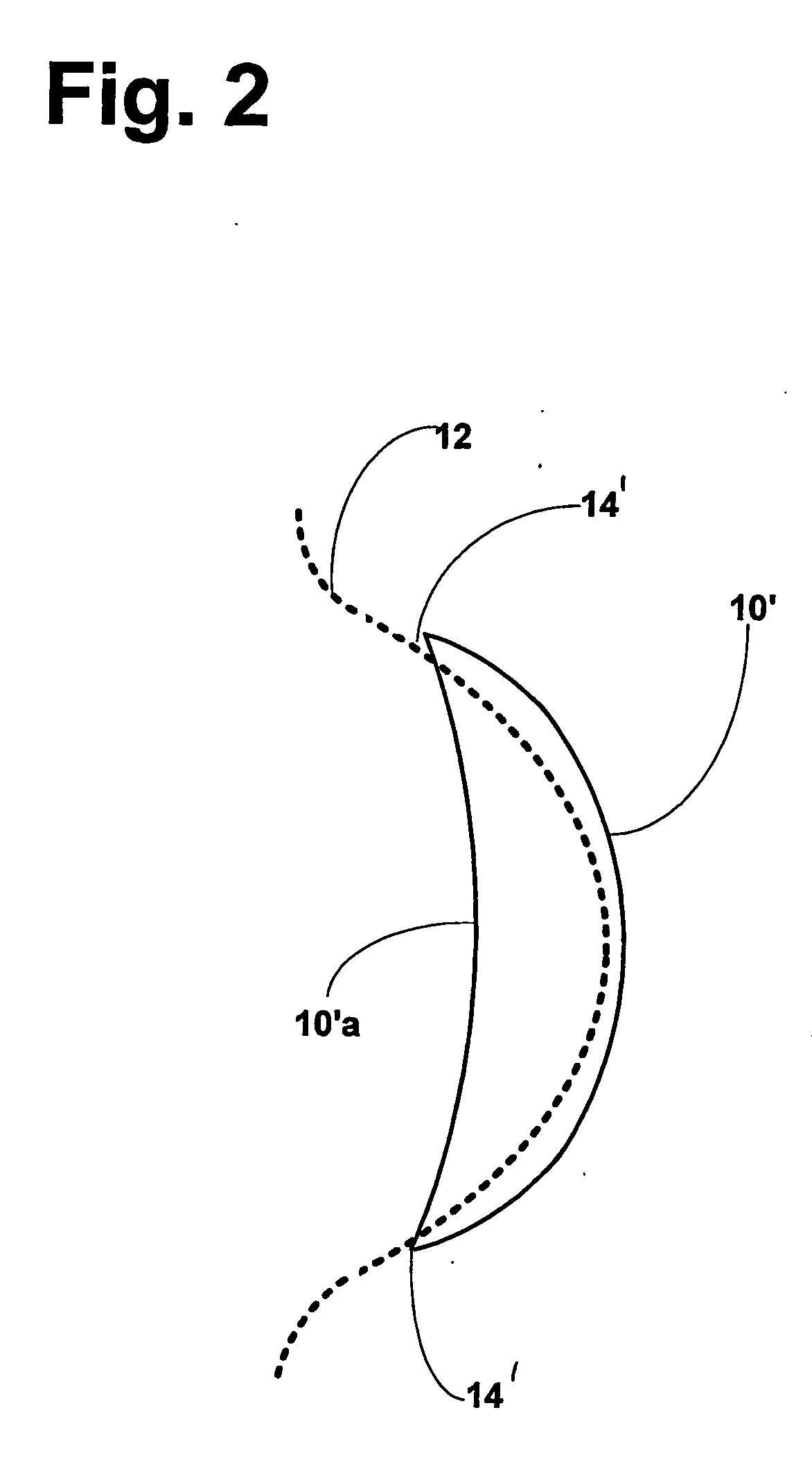

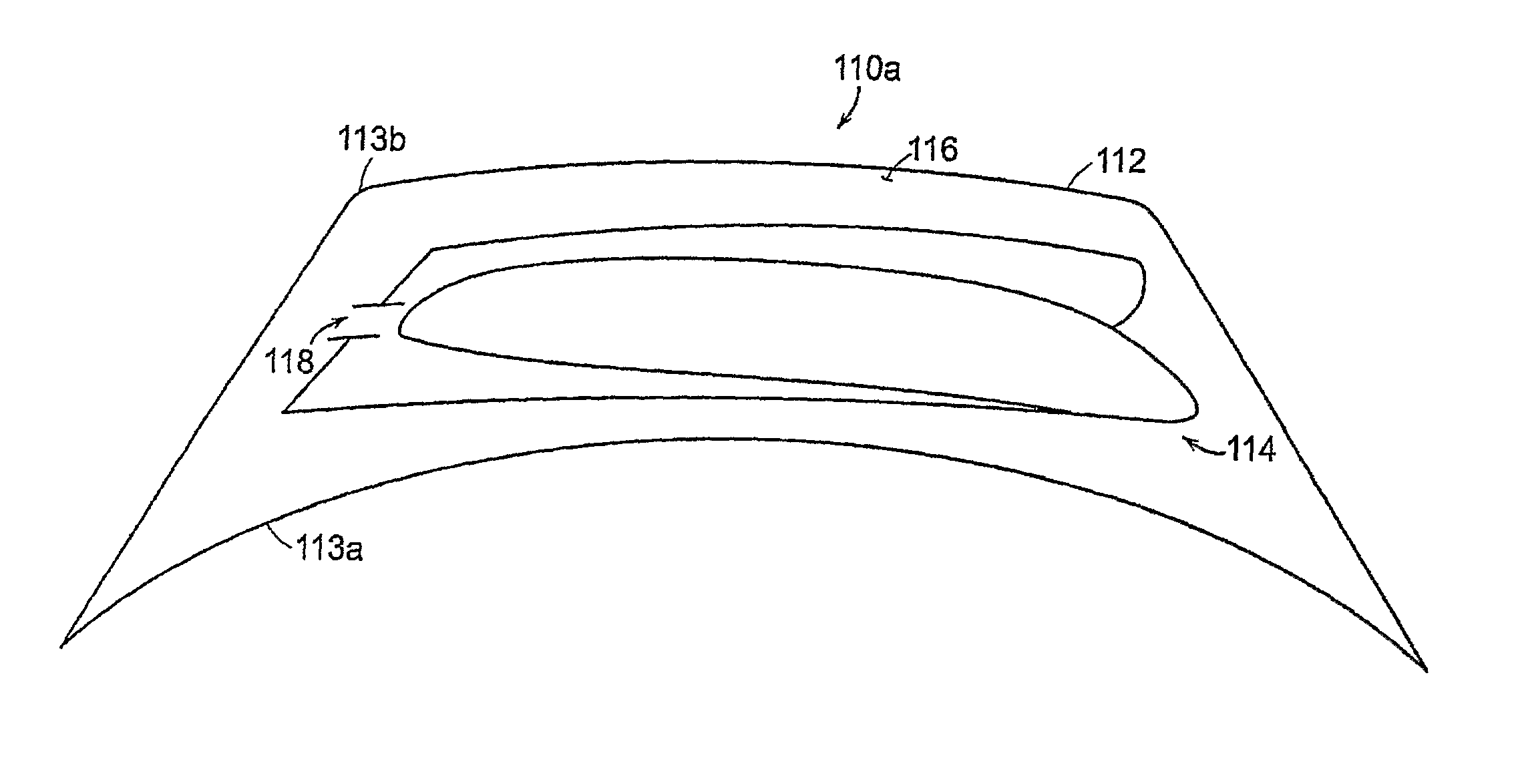

Contact Lenses

ActiveUS20080055545A1Confer rotational and translational stabilitySimplify fitting and makingSpectales/gogglesEye diagnosticsLayer thicknessLandform

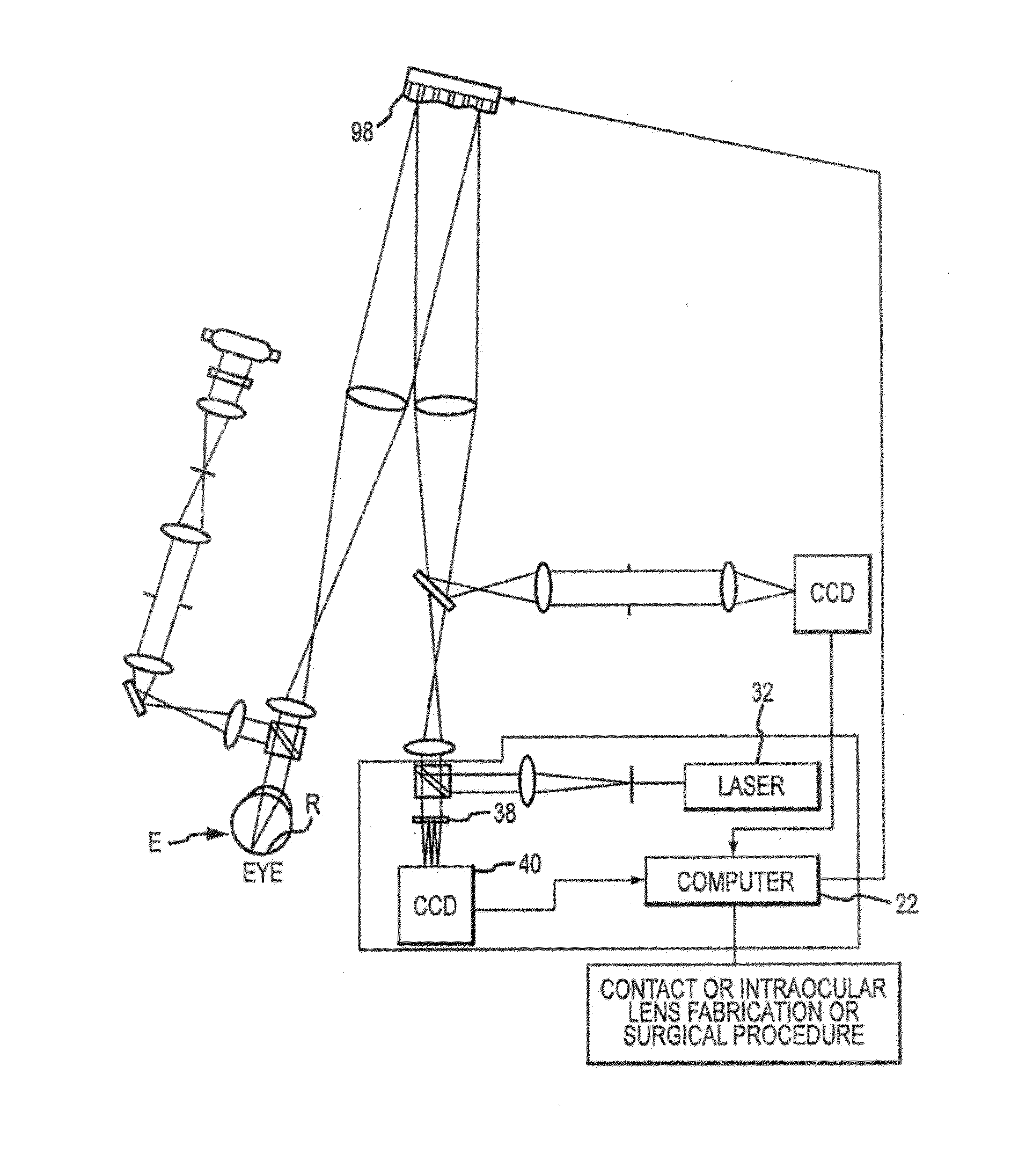

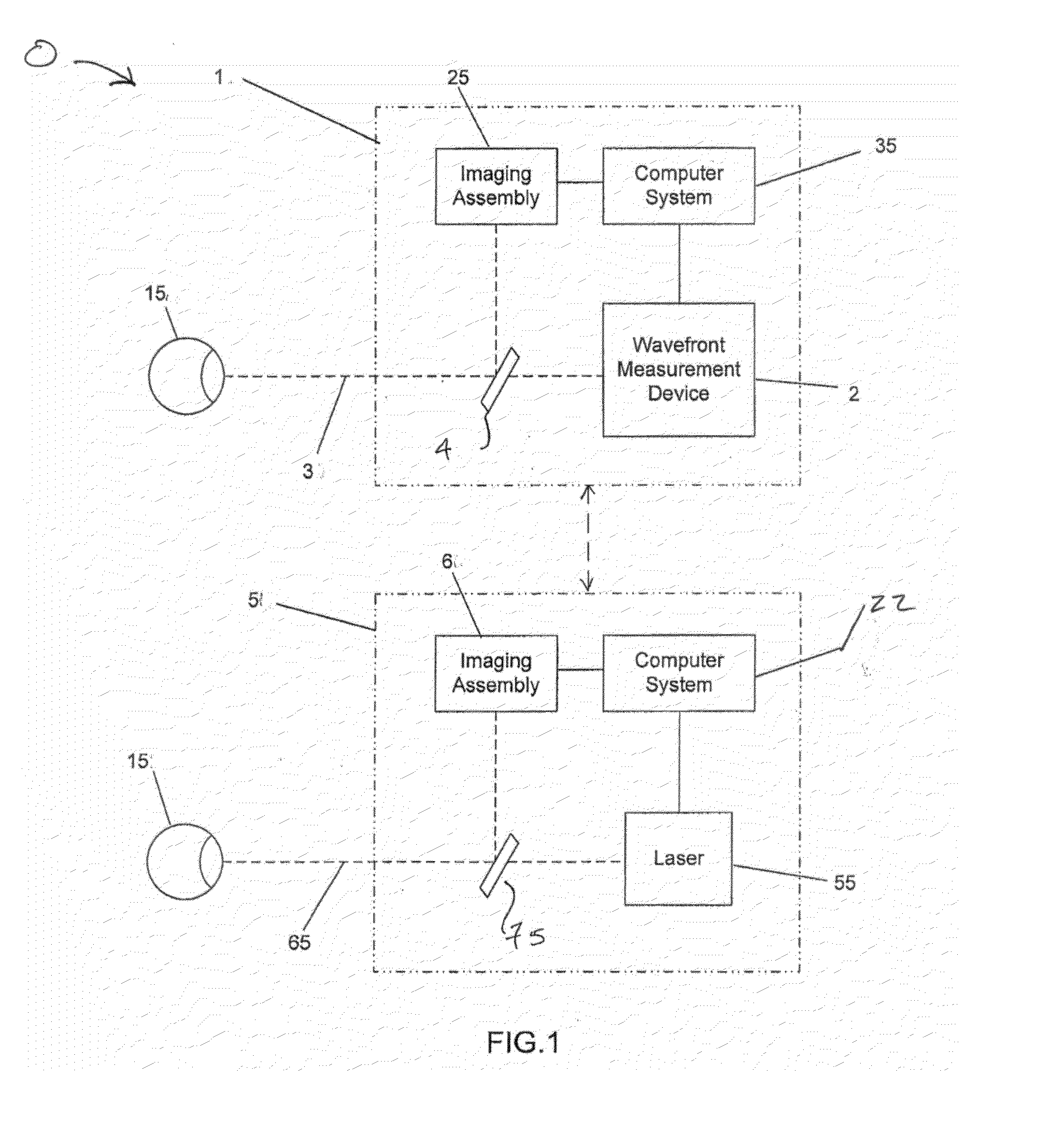

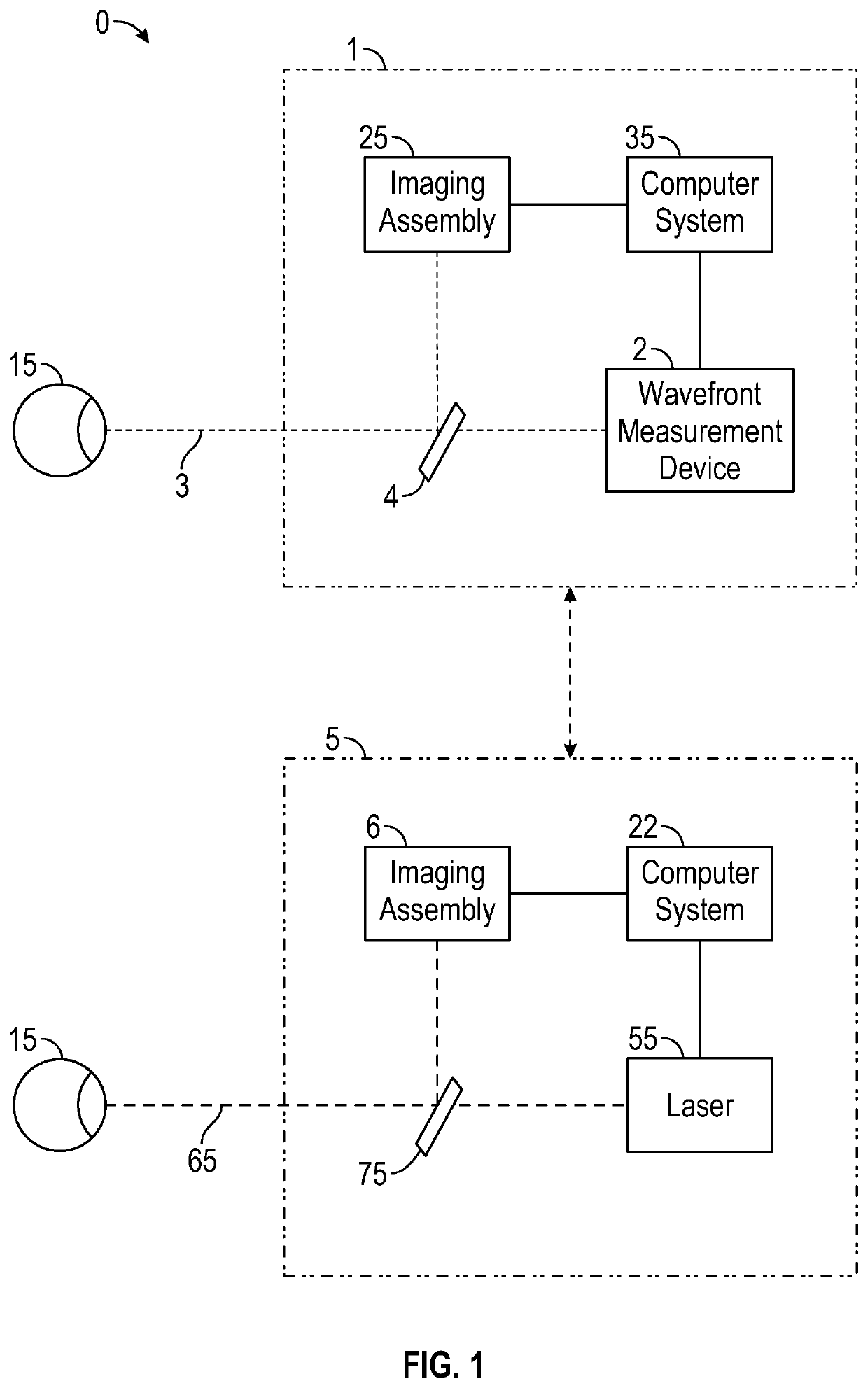

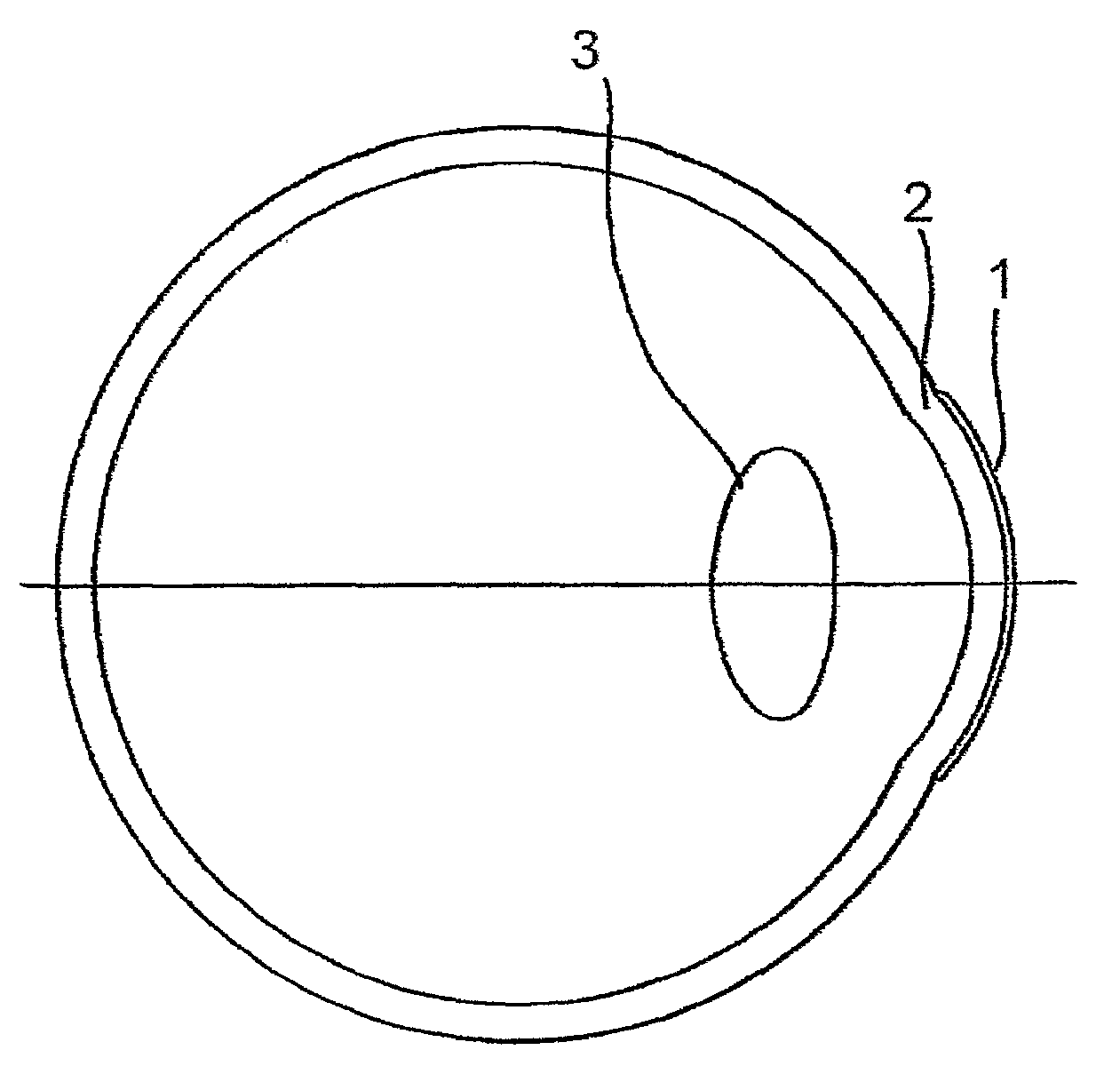

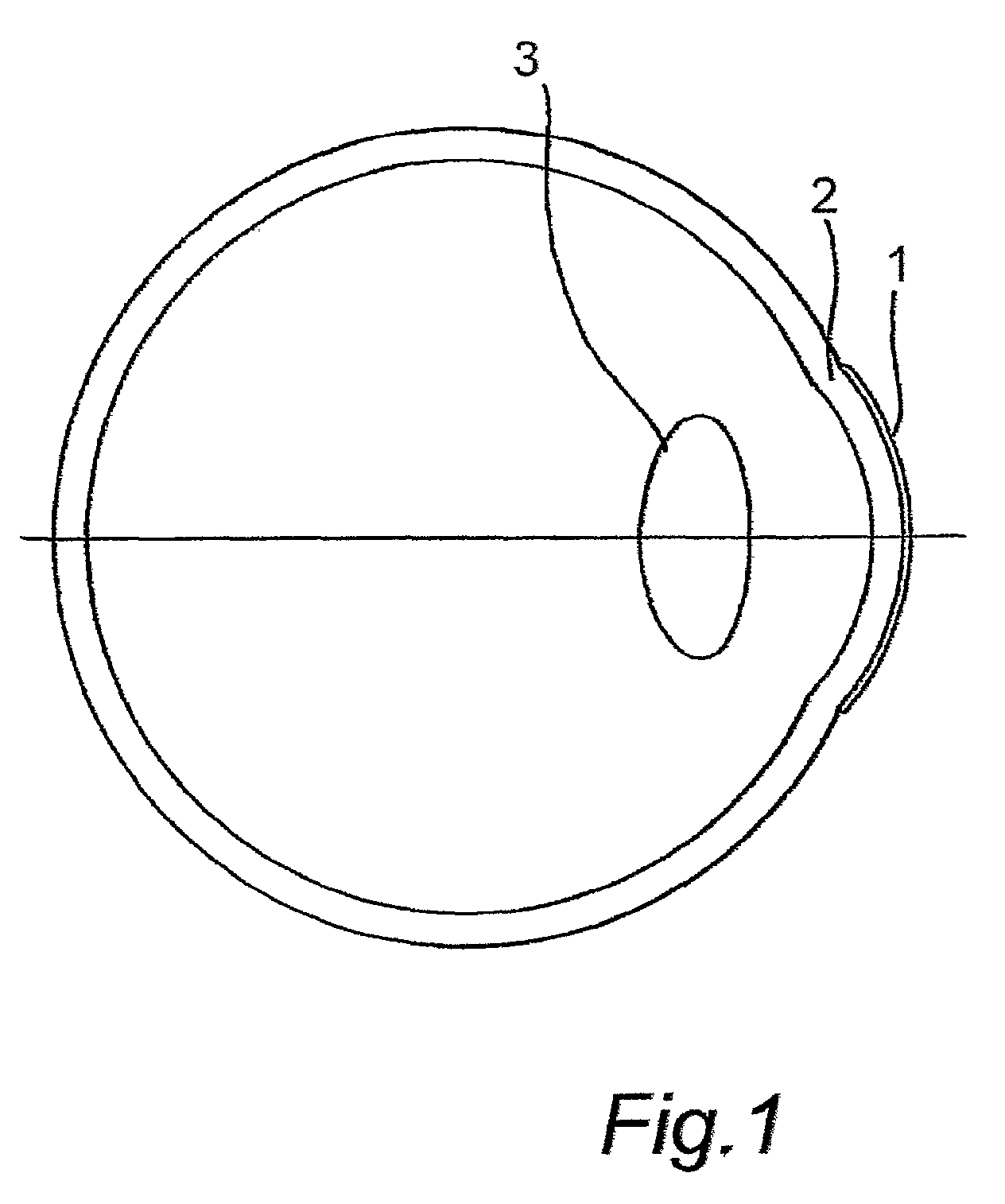

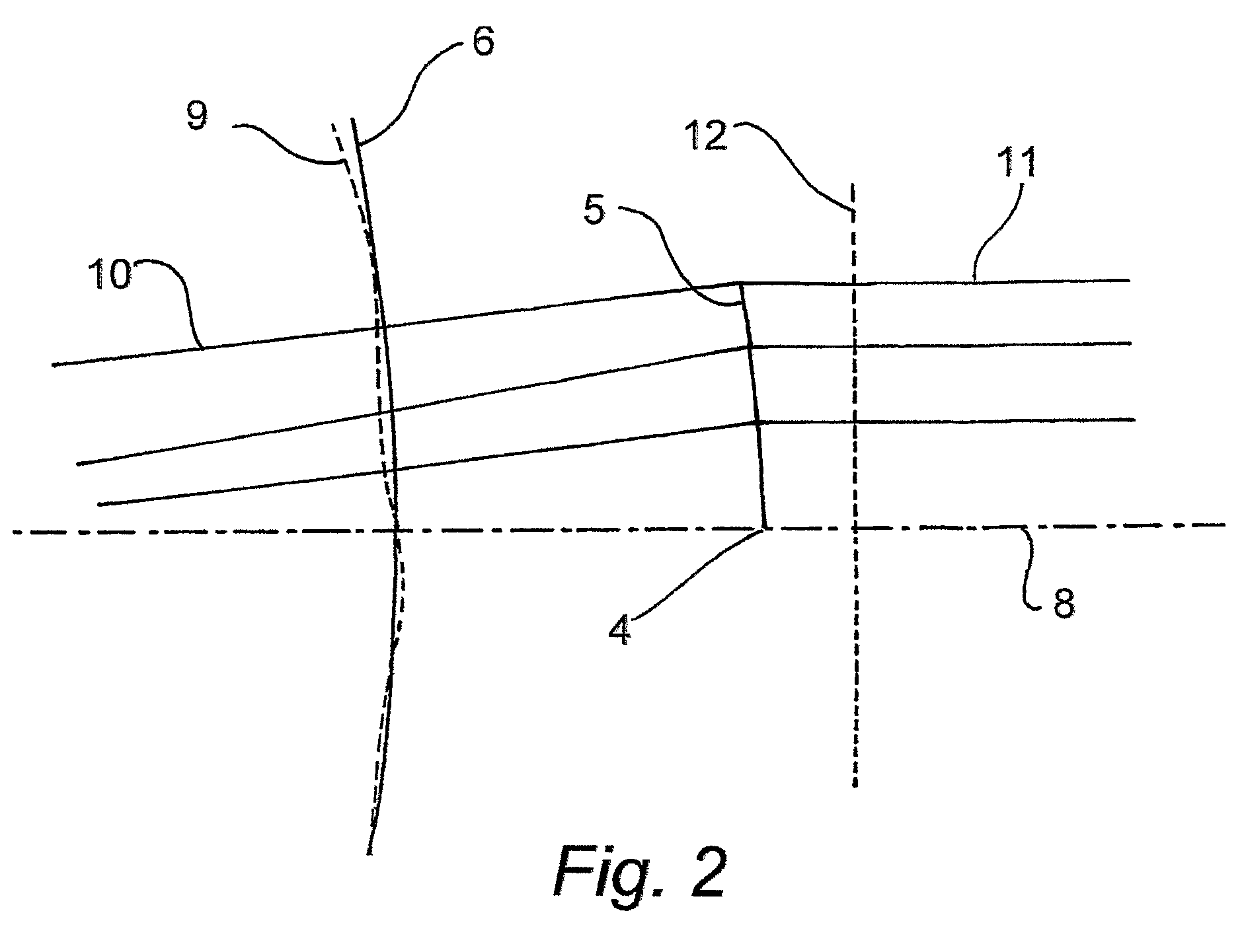

Disclosed is a method of designing a soft contact lens, the method comprising the steps of: (a) measuring or defining a wavefront generated by passage of light through a selected eye and using the wavefront to generate a computer model of the optical characteristics of the selected eye; (b) measuring or defining the topography of the cornea of the selected eye; (c) incorporating into the computer model a soft contact lens, the posterior surface topography of which is defined by the topography of the cornea, offset by an arbitrary amount intended to represent the tear layer thickness of the selected eye, said lens having a defined thickness at a selected locus on the anterior surface; (d) calculating a desired topography for the anterior surface of the lens such that the wavefront will be corrected to assume a desired pattern (for example, preferably planar, the plane of which is perpendicular to the optical axis of the lens) when passing through the computer model eye / lens combination; (e) remodelling the lens off-eye by adapting the posterior topography of the lens to a desired posterior topography to be manufactured; and (f) recalculating a modified anterior topography required as a result of adapting the posterior topography, the modified anterior topography being intended to preserve the desired wavefront pattern defined in (d) when the lens is in situ on the selected eye.

Owner:CONTACT LENS PRECISION LAB

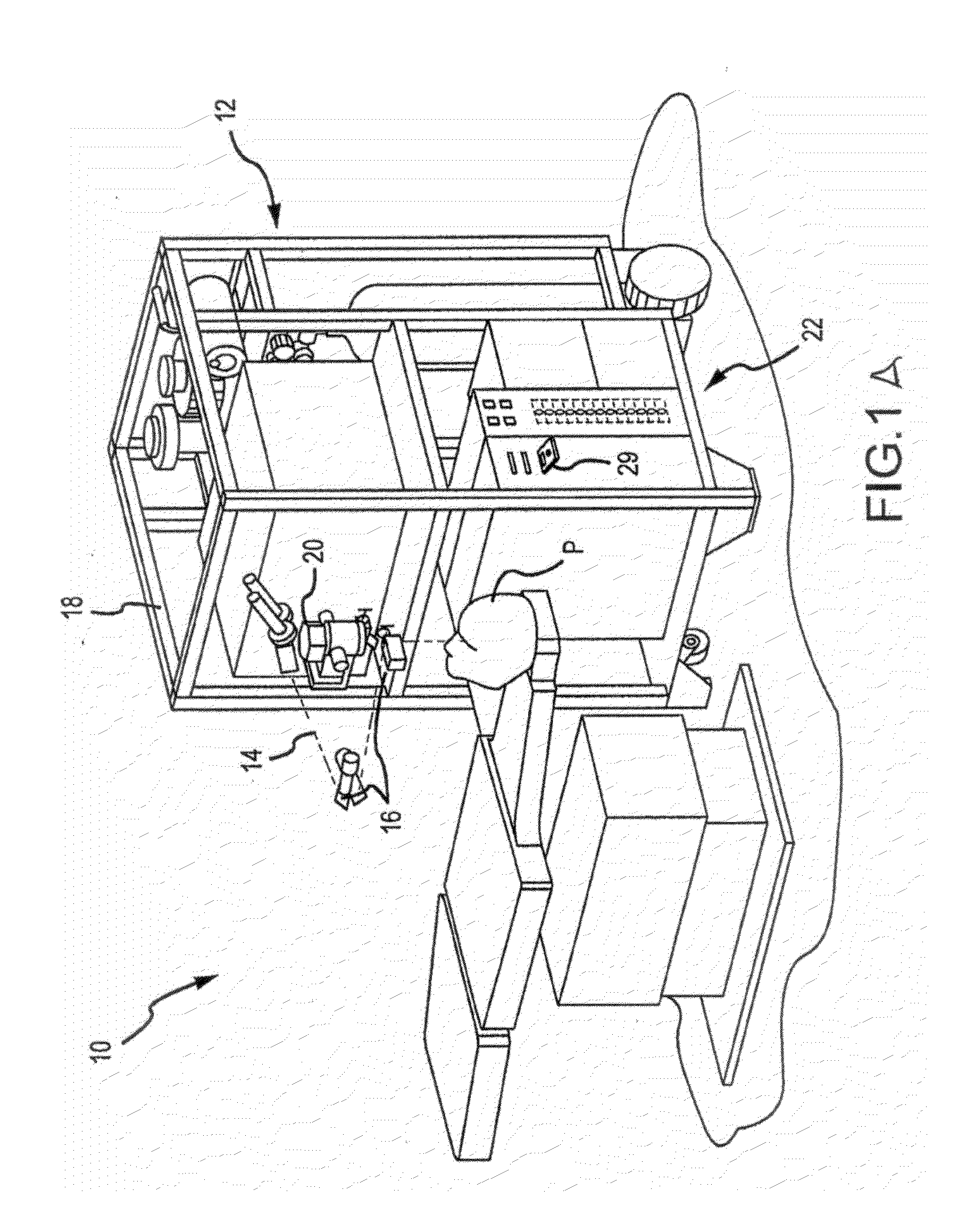

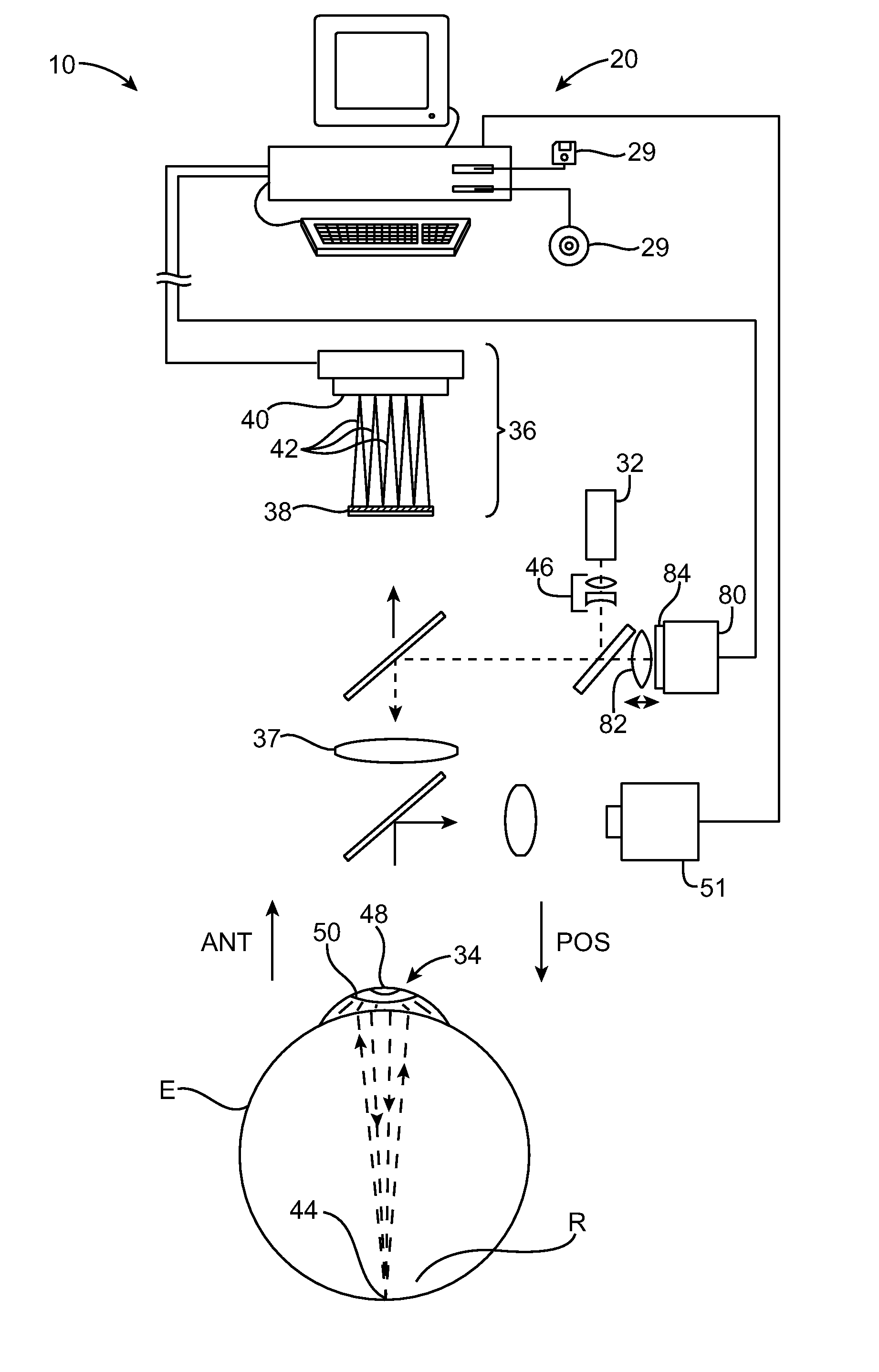

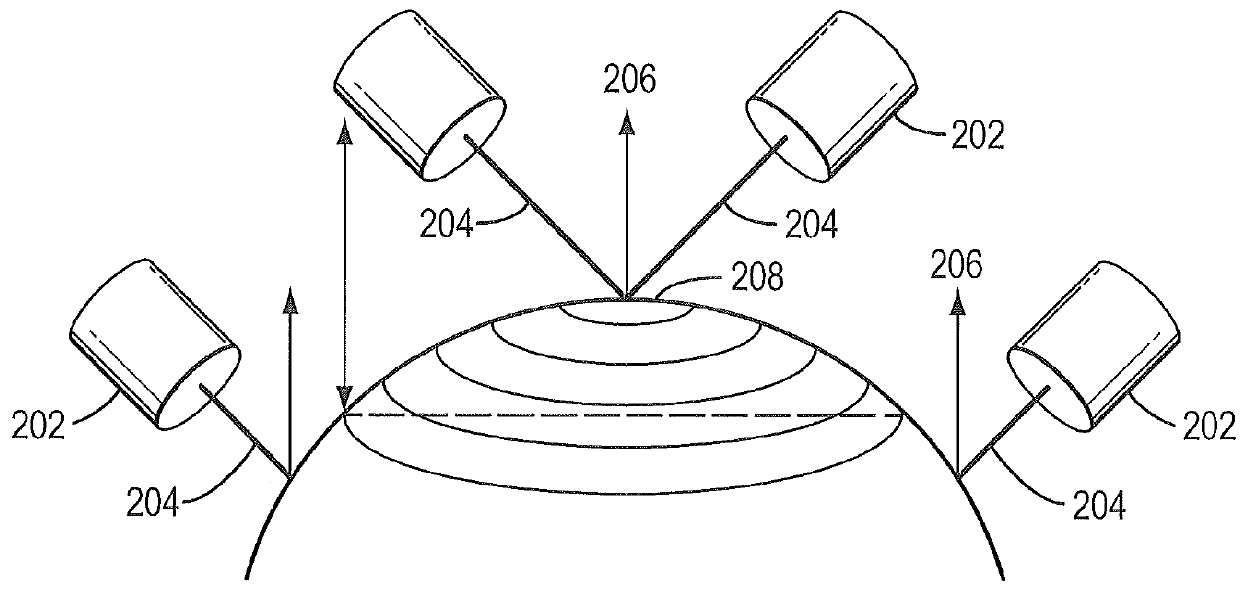

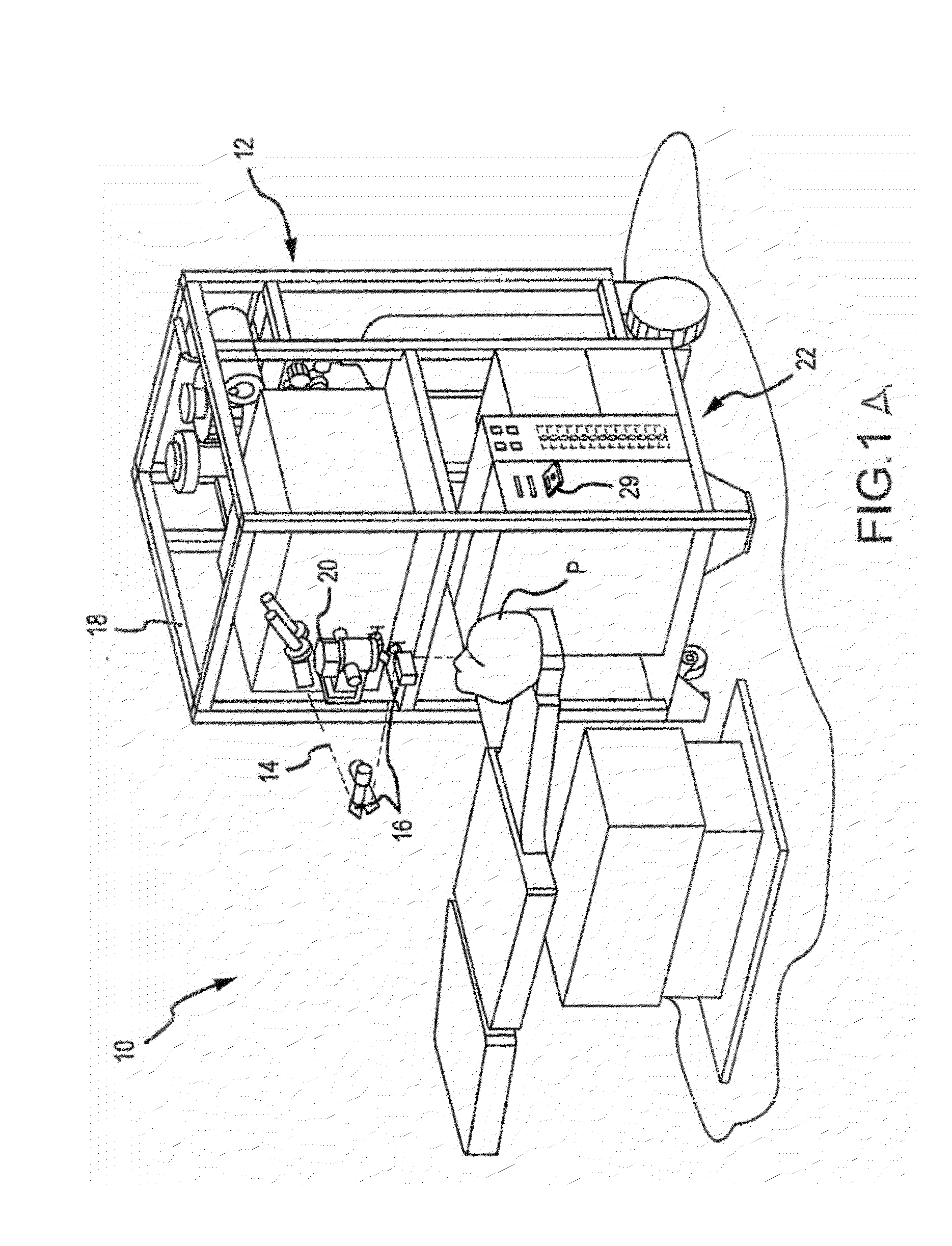

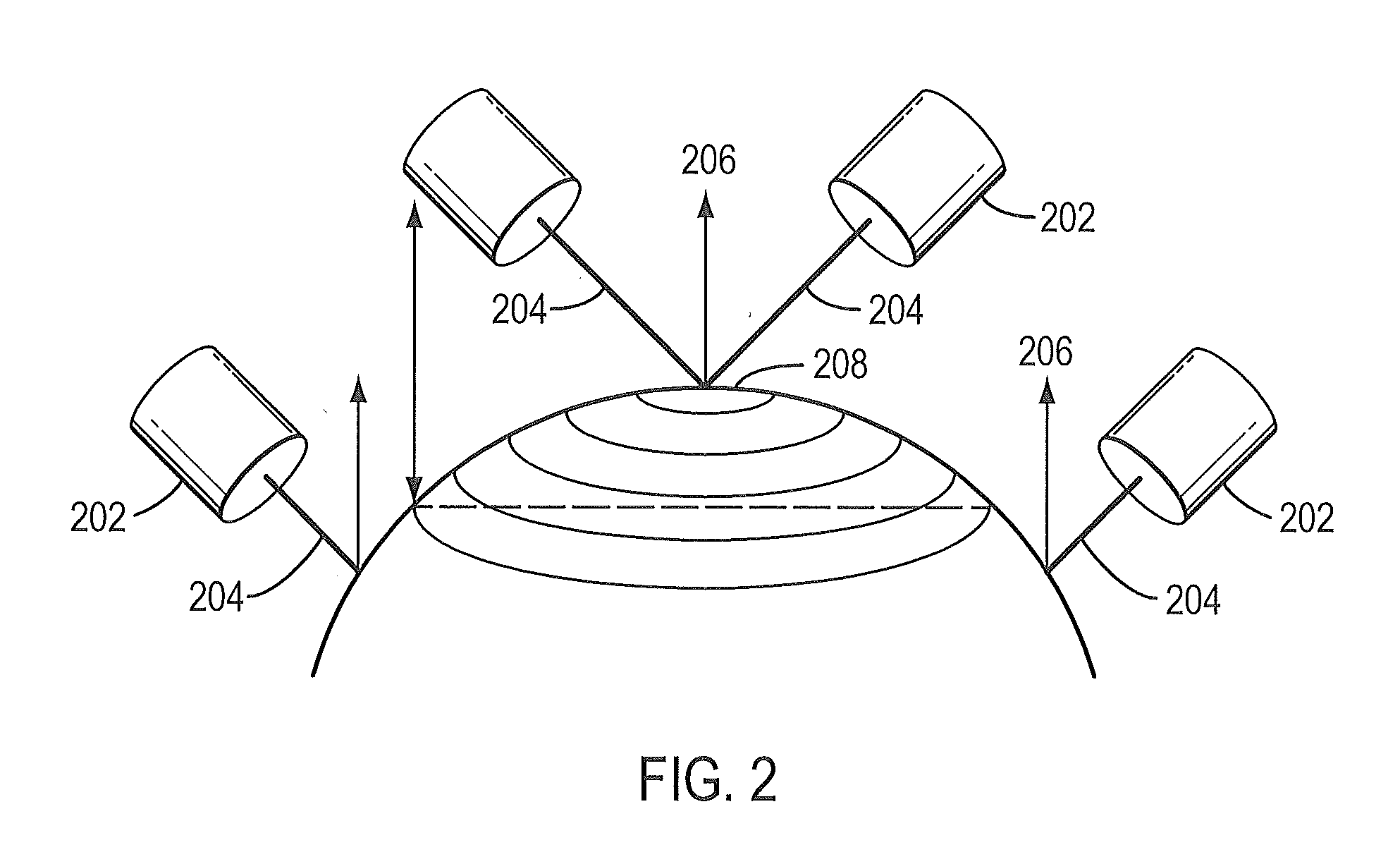

Eye Measurement Apparatus and a Method of Using Same

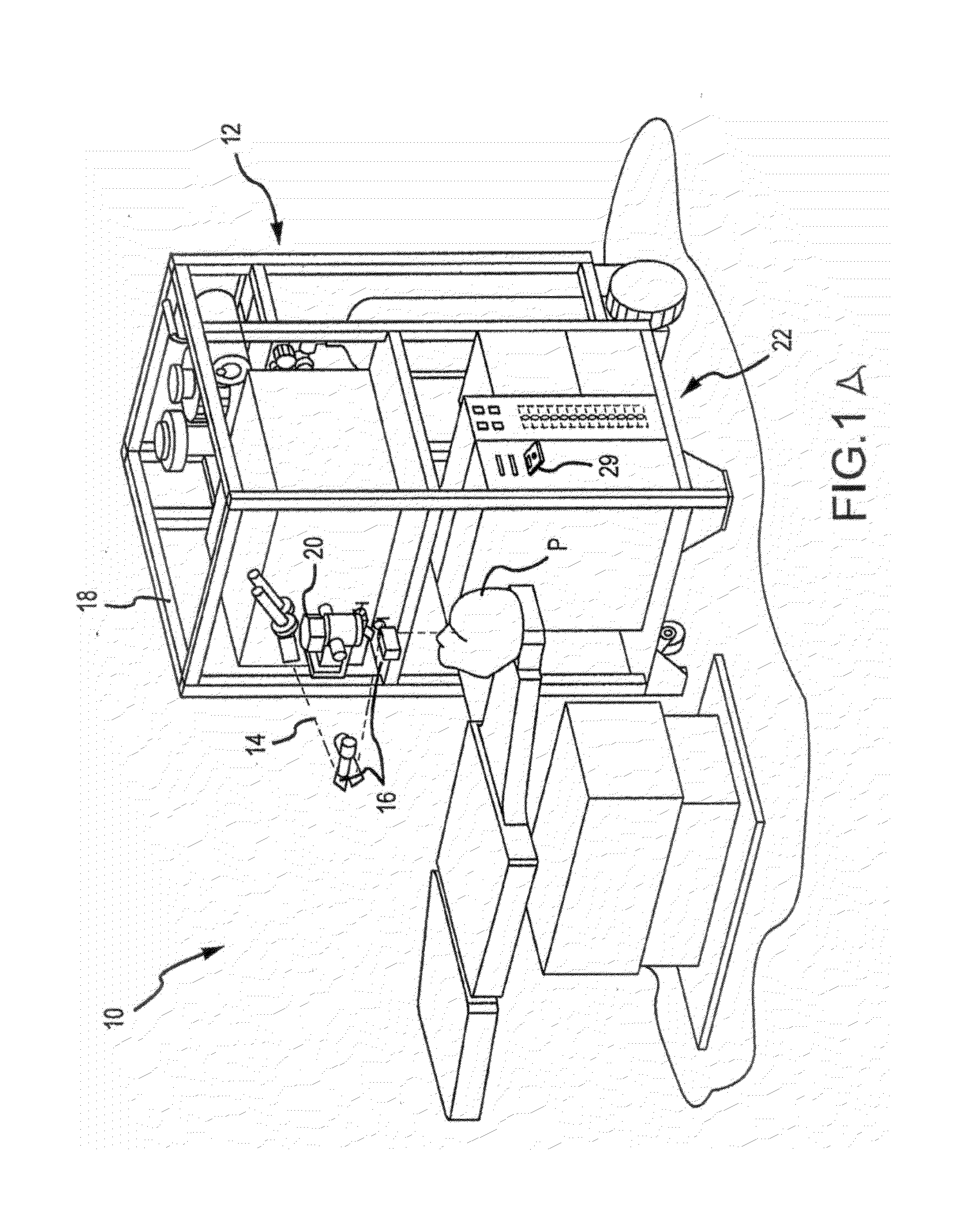

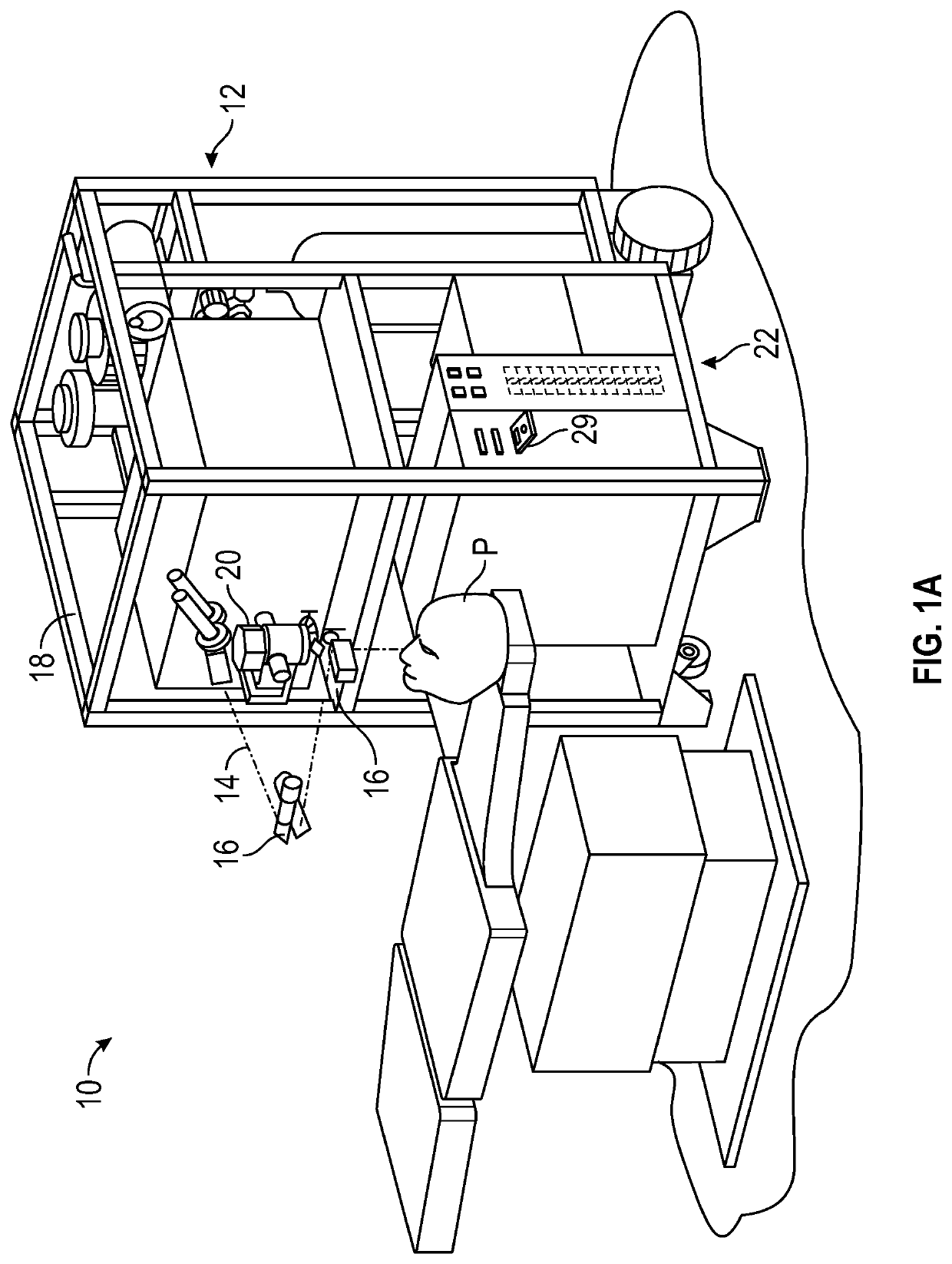

An apparatus for measuring a subject's eye having an instrument axis, comprising an eye tracker apparatus comprising a first projector and a first camera, a slit projector rotatable about the instrument axis independent of the eye tracker apparatus, and a second camera rotatable about the instrument axis independent of the eye tracker.

Owner:BAUSCH & LOMB INC

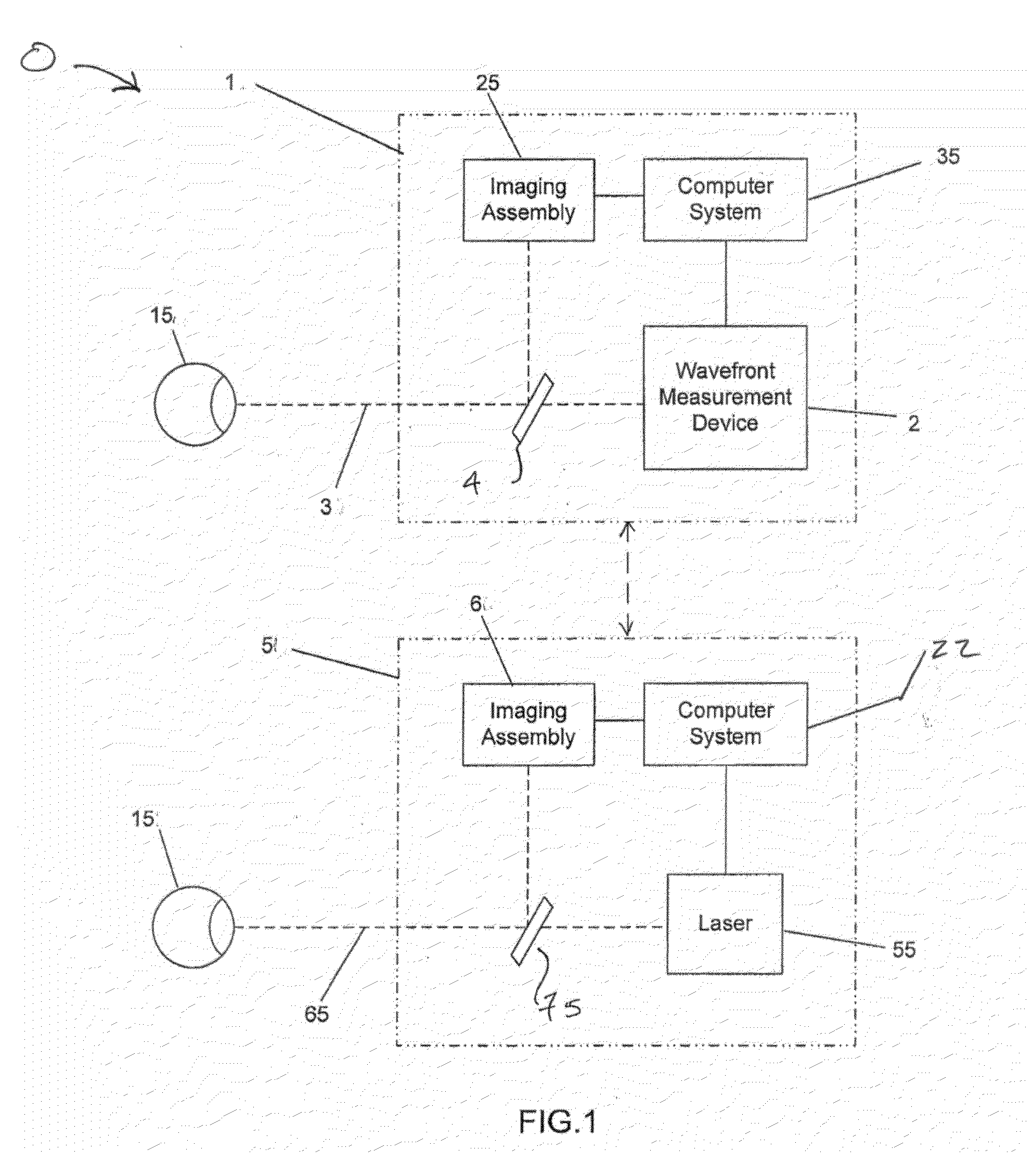

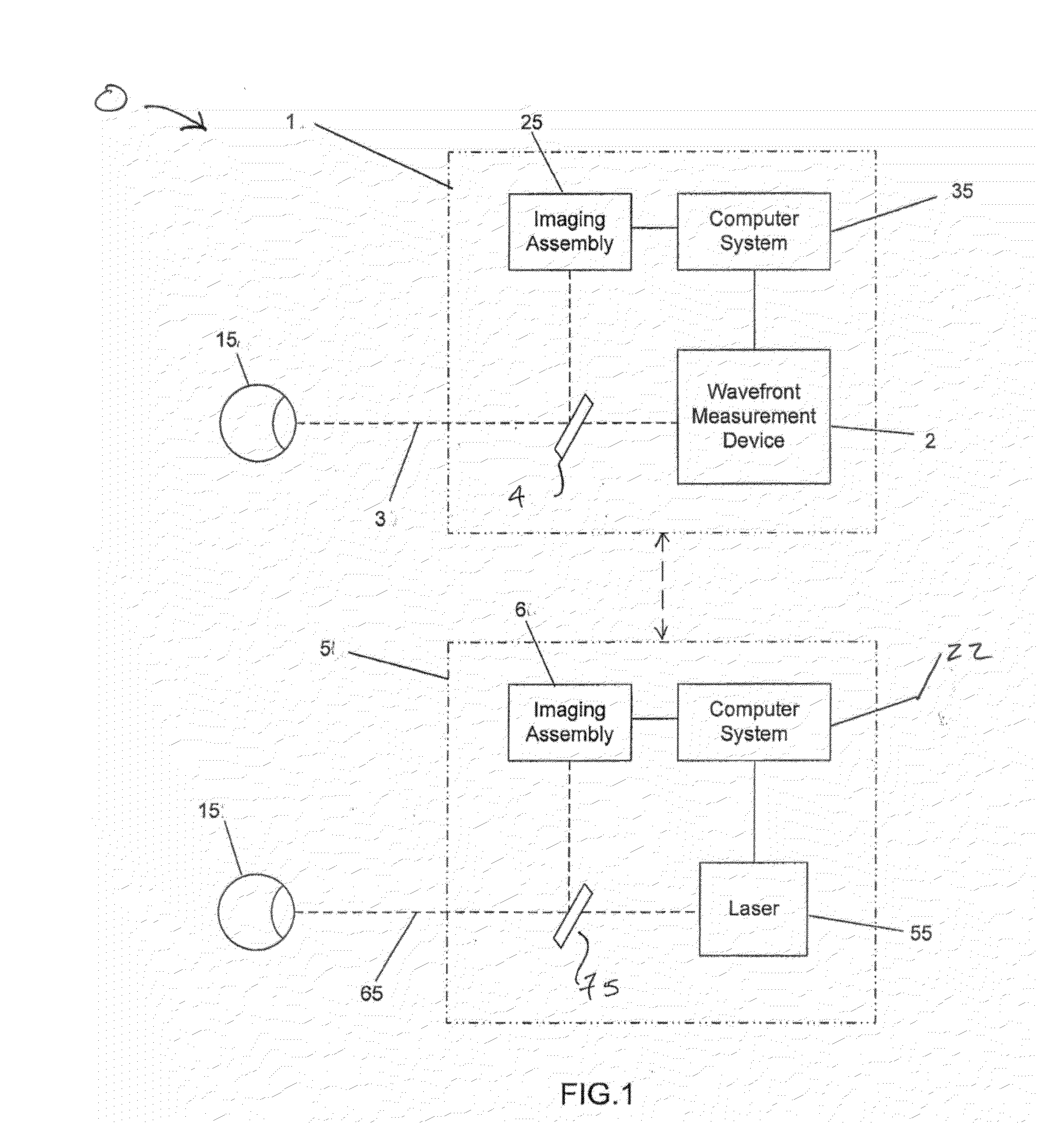

Method and system for eye measurements and cataract surgery planning using vector function derived from prior surgeries

ActiveUS20160150952A1Good curative effectImproved refractive correctionsLaser surgeryComputer-aided planning/modellingCorrective surgeryIntraocular lens

Improved devices, systems, and methods for planning cataract surgery on an eye of a patient incorporate results of prior corrective surgeries into a planned cataract surgery of a particular patient by driving an effective surgery vector function based on data from the prior corrective surgeries. The exemplary effective surgery vector employs an influence matrix which may allow improved refractive corrections to be generated so as to increase the overall efficacy of a cataract surgery by specifying one or more parameters of an intraocular lens (IOL) to be implanted during the cataract surgery.

Owner:AMO DEVMENT

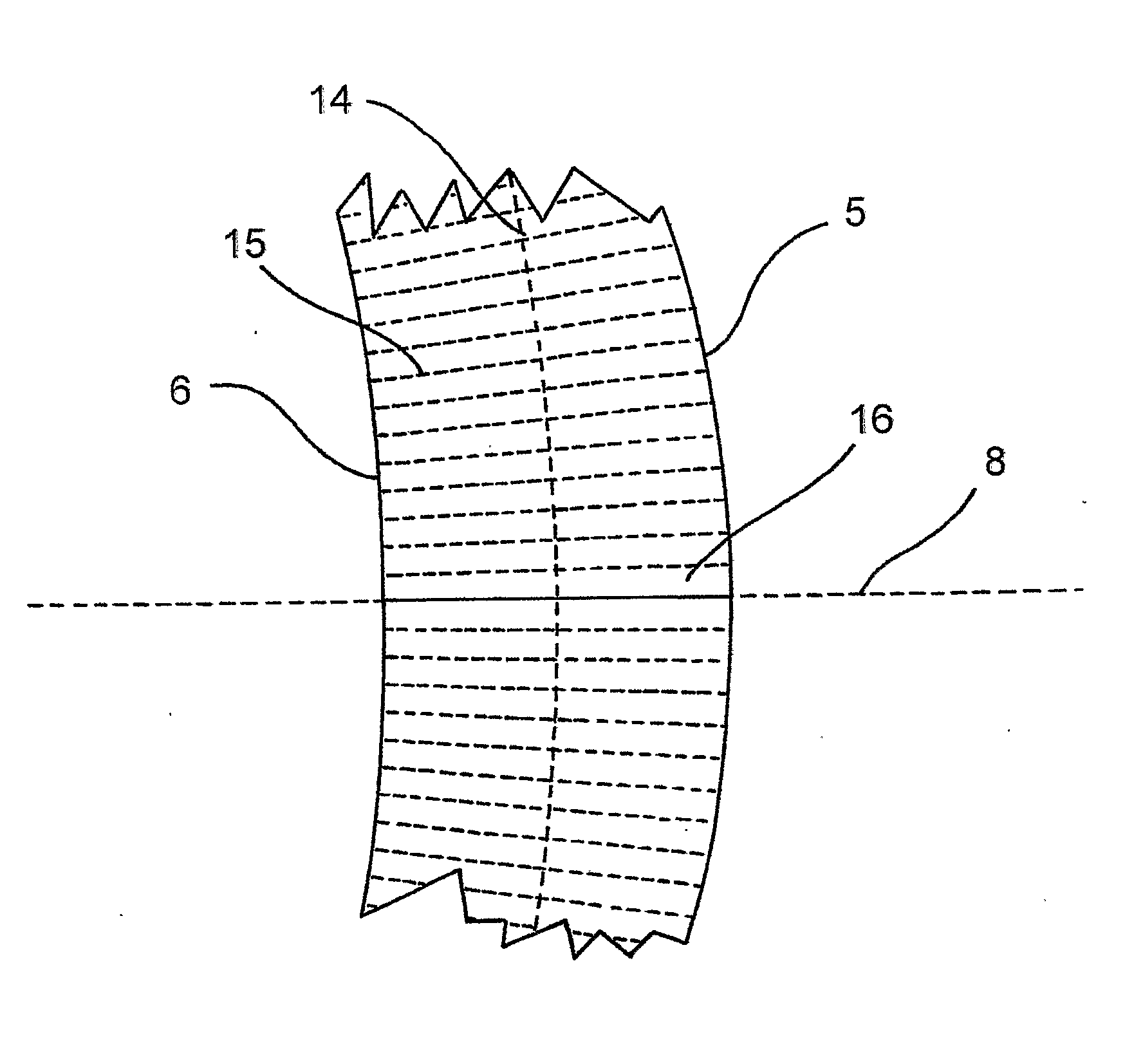

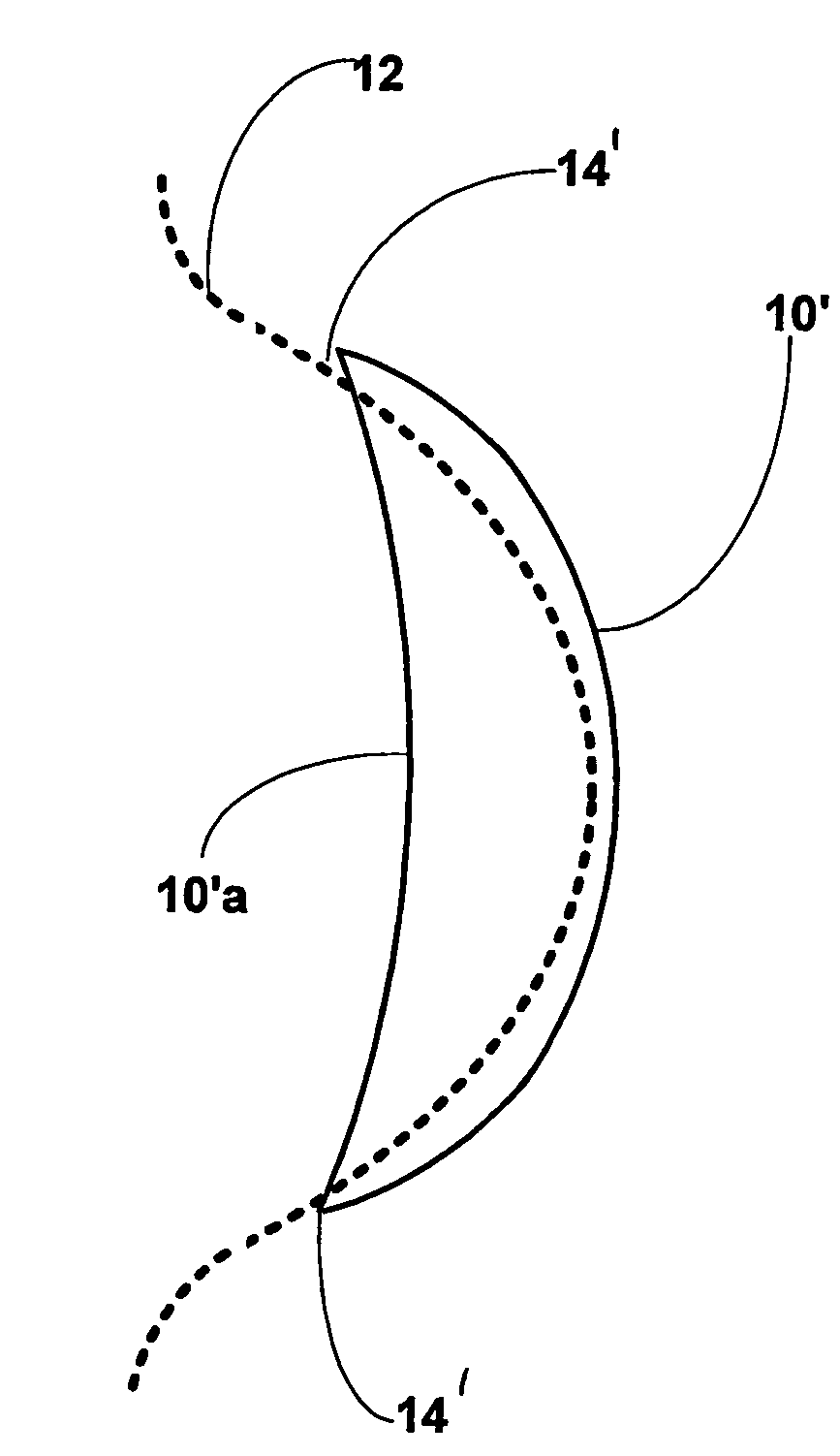

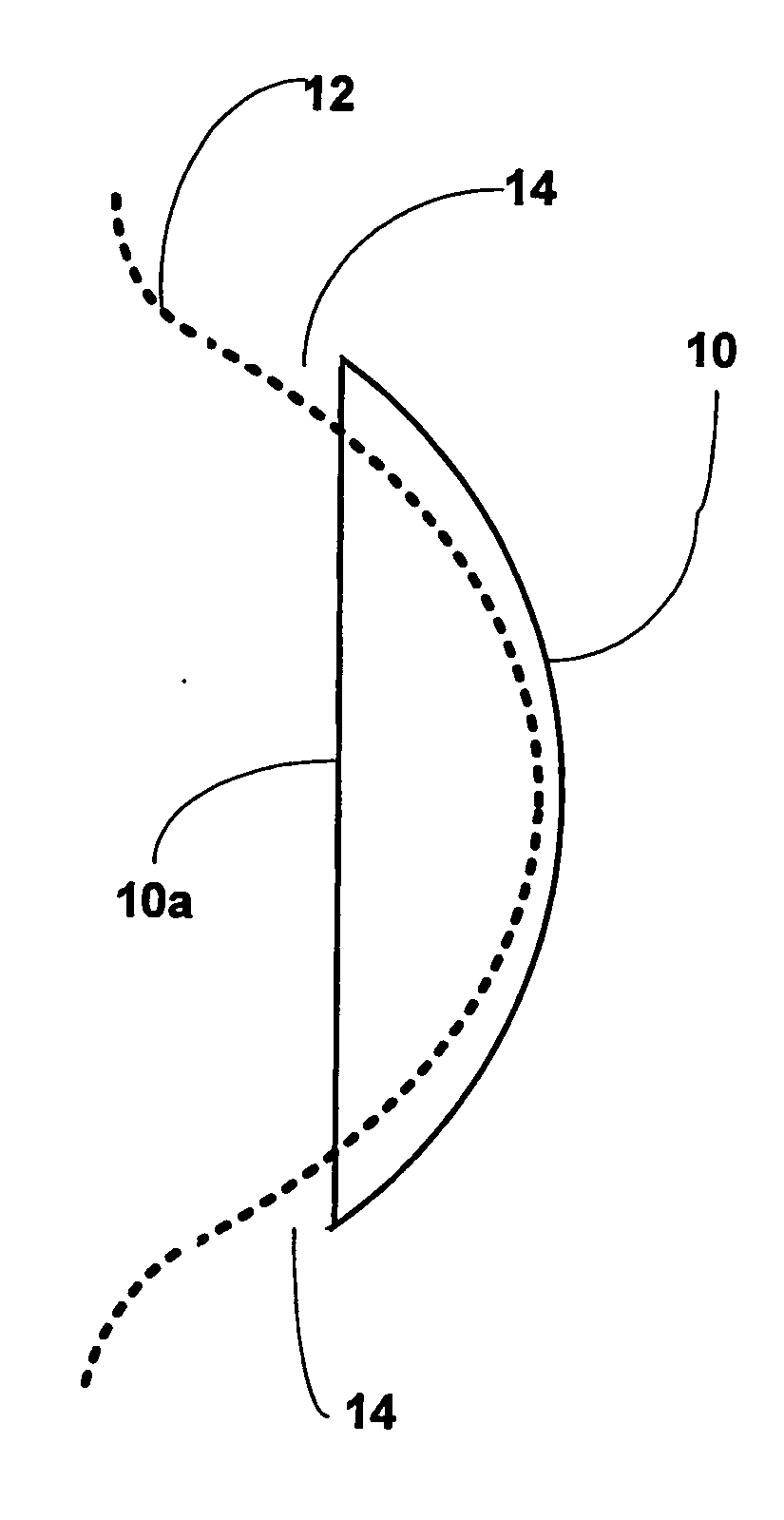

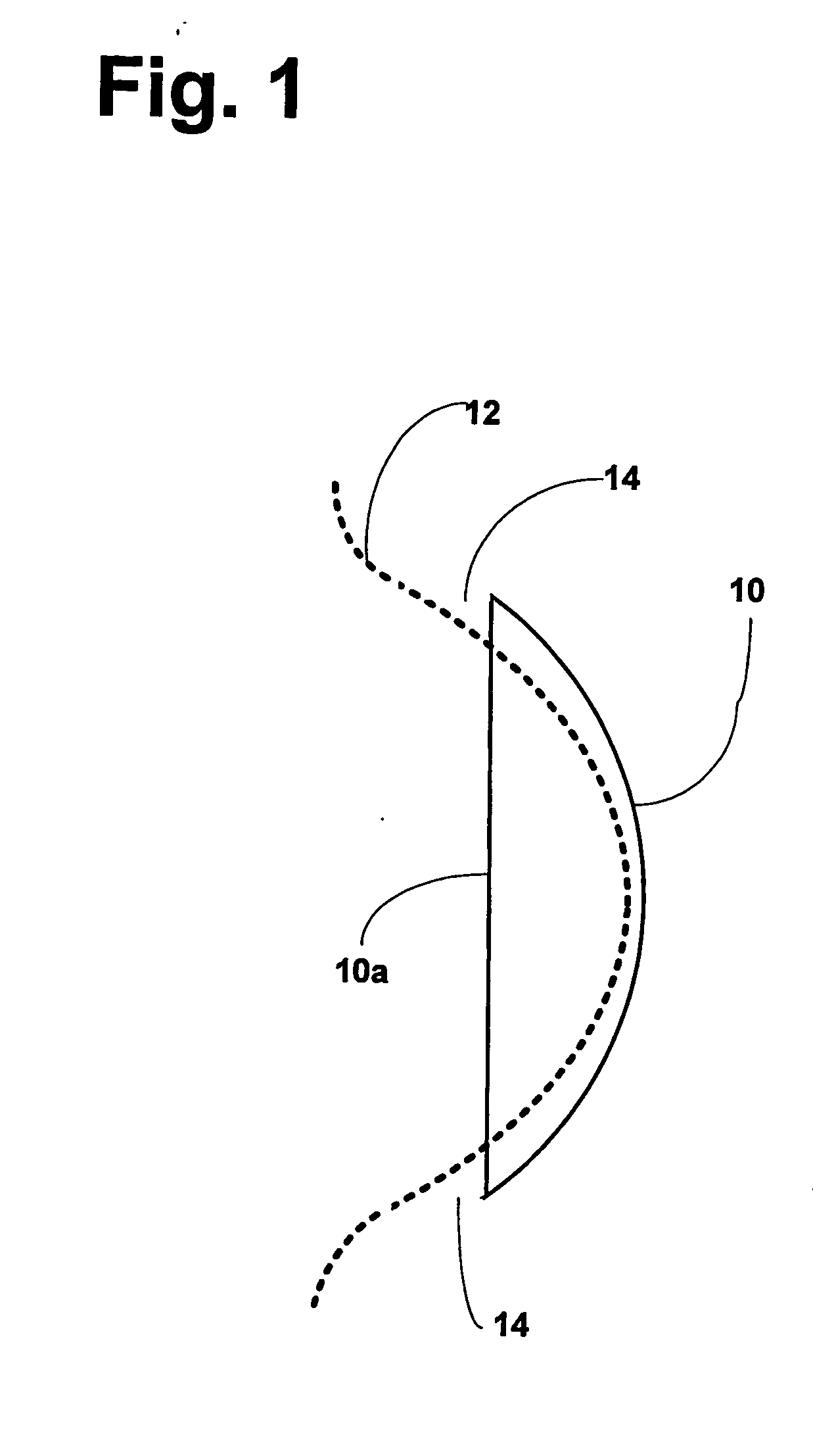

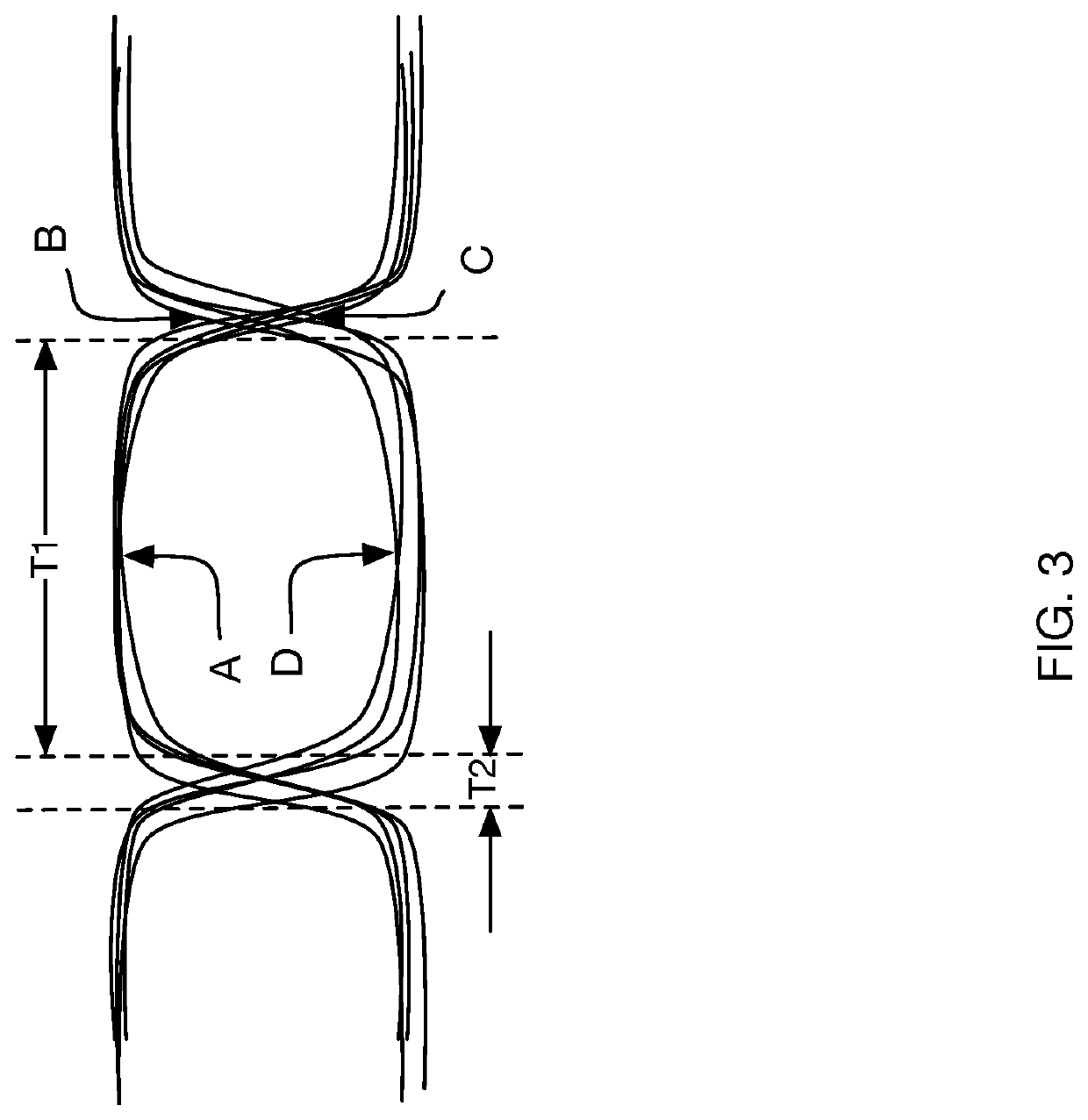

Contact lens with shaped periphery

InactiveUS7338160B2Quality improvementImprove comfortEye diagnosticsOptical partsContact lens tintSaddle-shaped

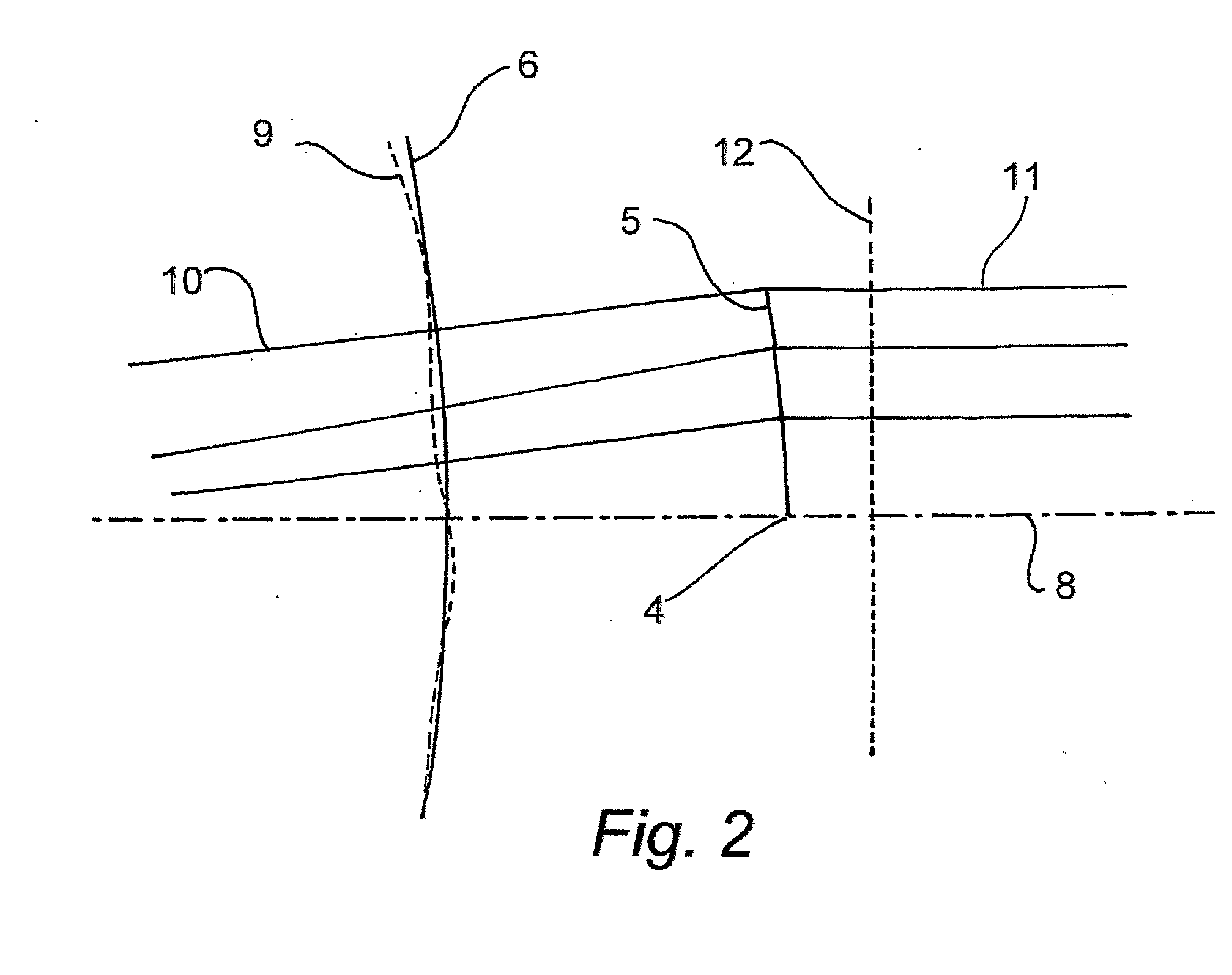

Eye measurements taken on a patient being fitted for contact lens will include a refraction test and an additional measurement representing corneal depth variation on the surface of an imaginary cylinder having the same diameter as the lens. This information then used during lens manufacture to produce lens in which the perimeter is not circular and does not lie in a plane, but which drops backwards towards the eye at appropriate points to produce a saddle-shaped perimeter.

Owner:SCI OPTICS INC

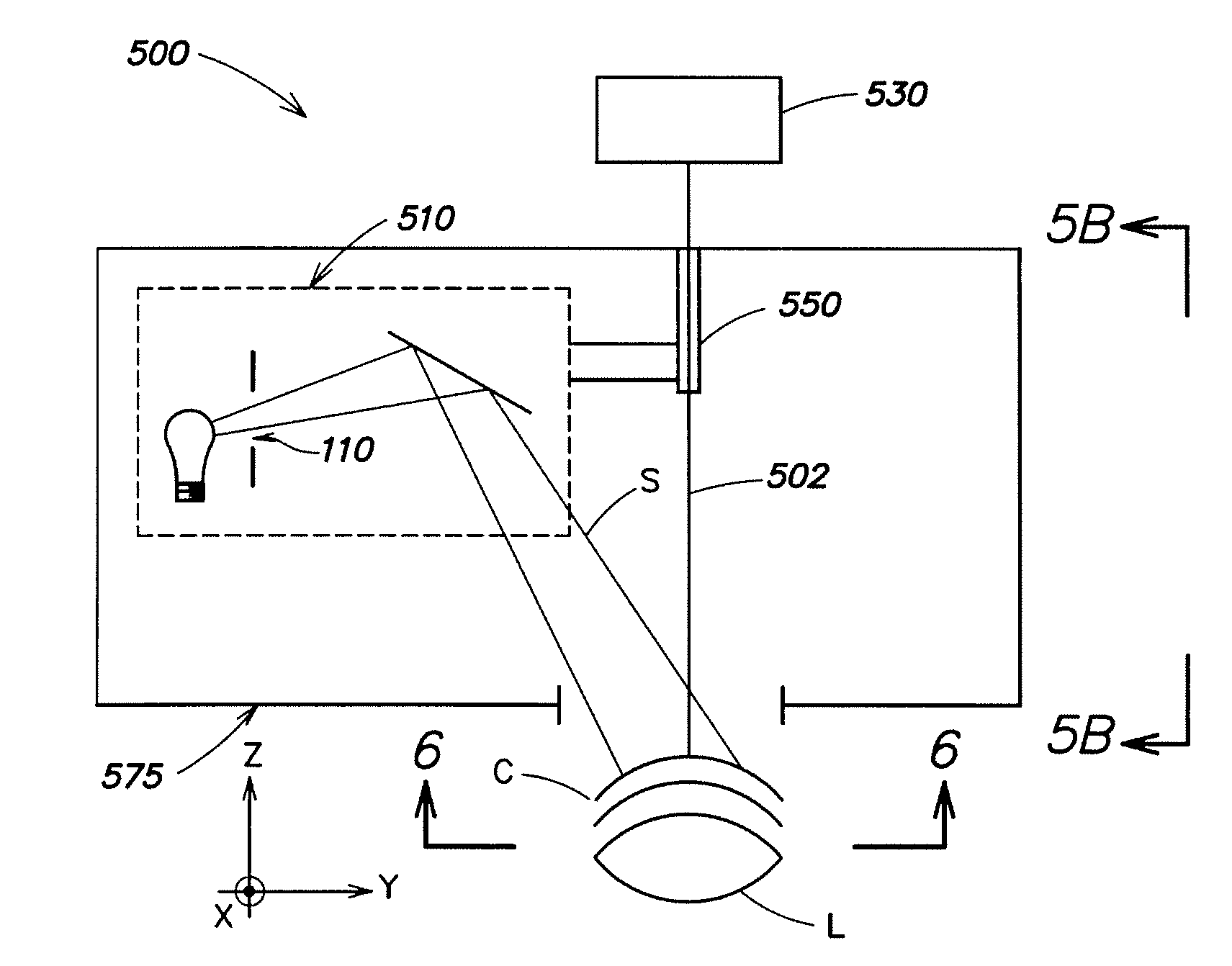

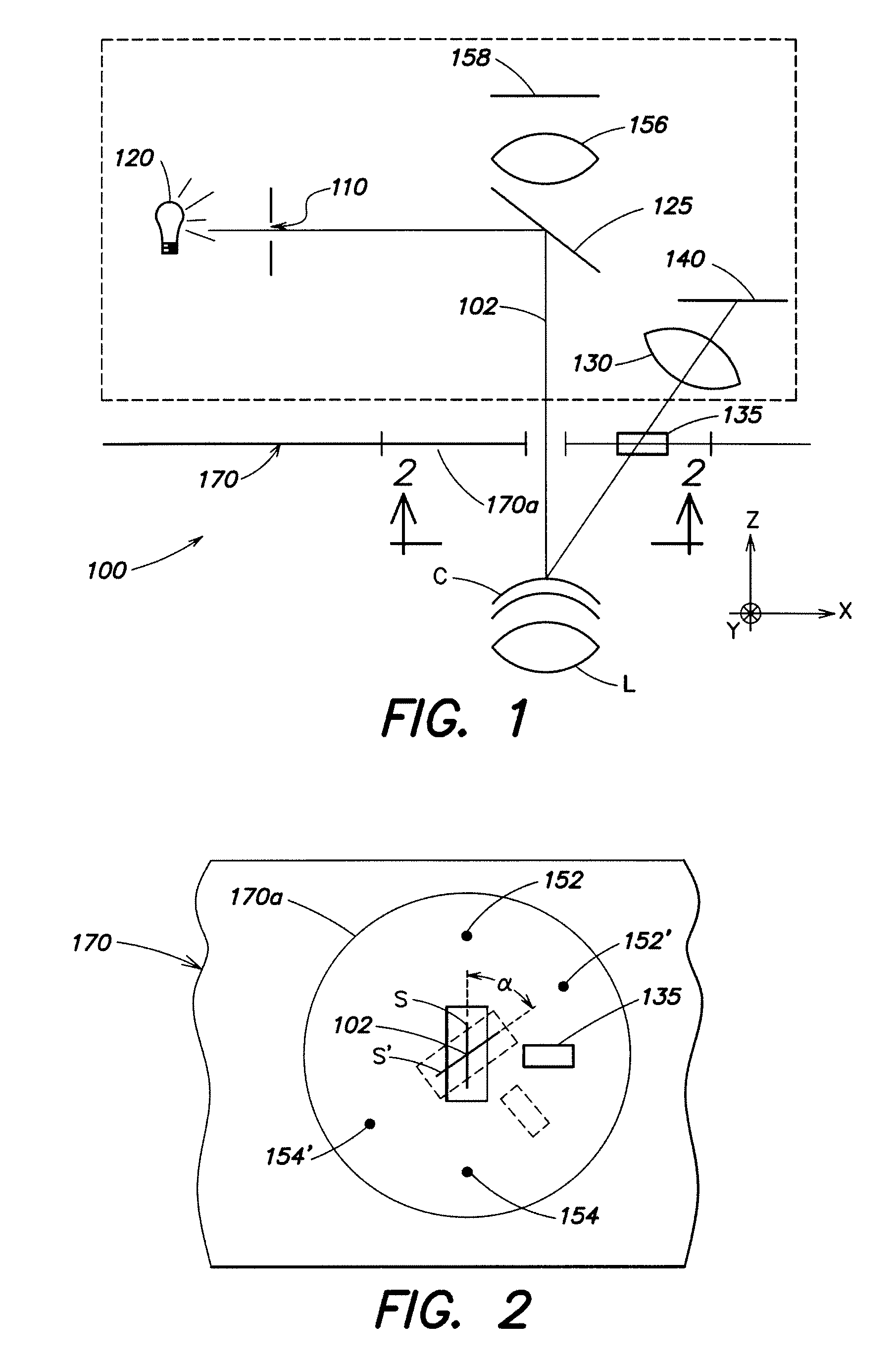

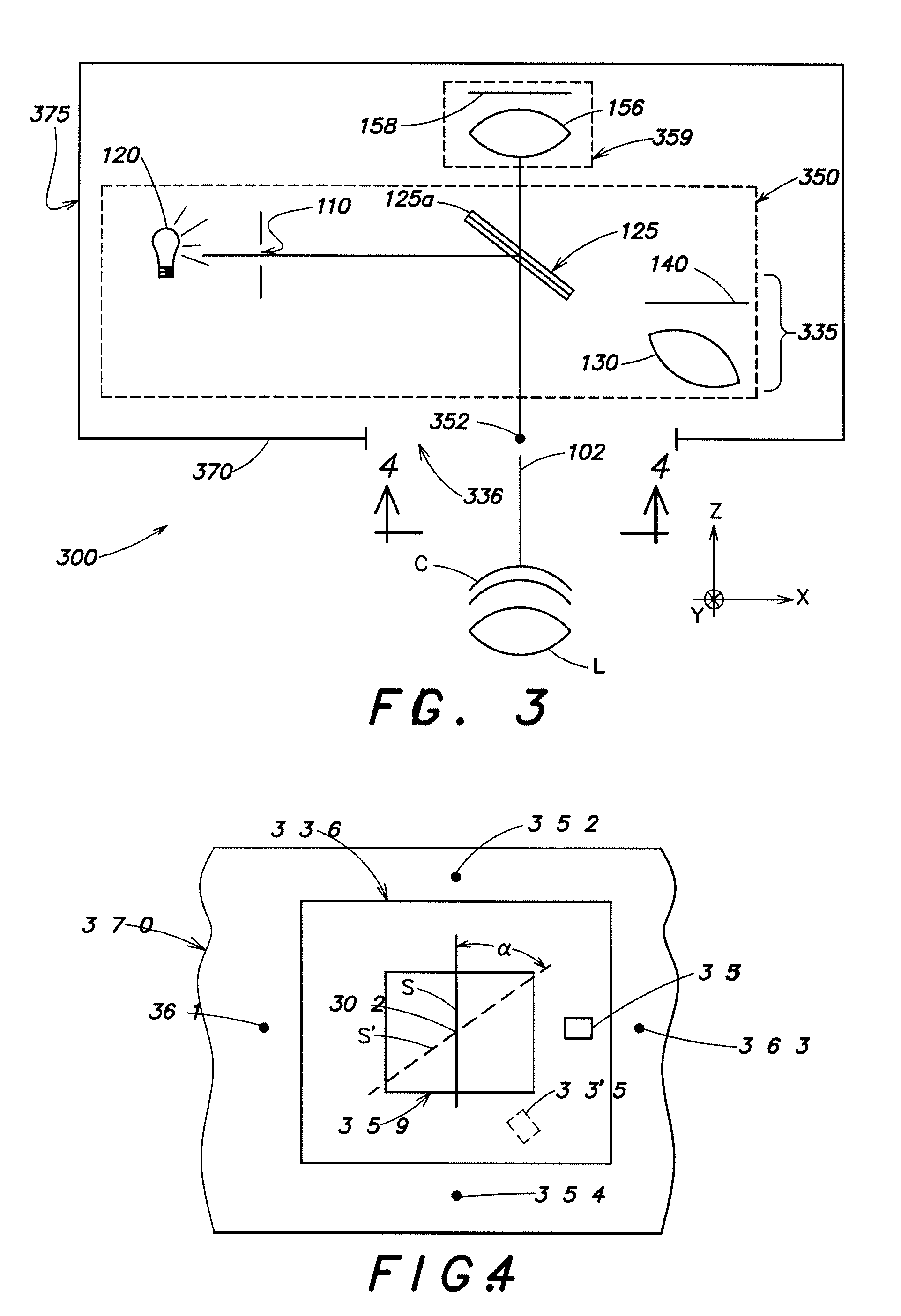

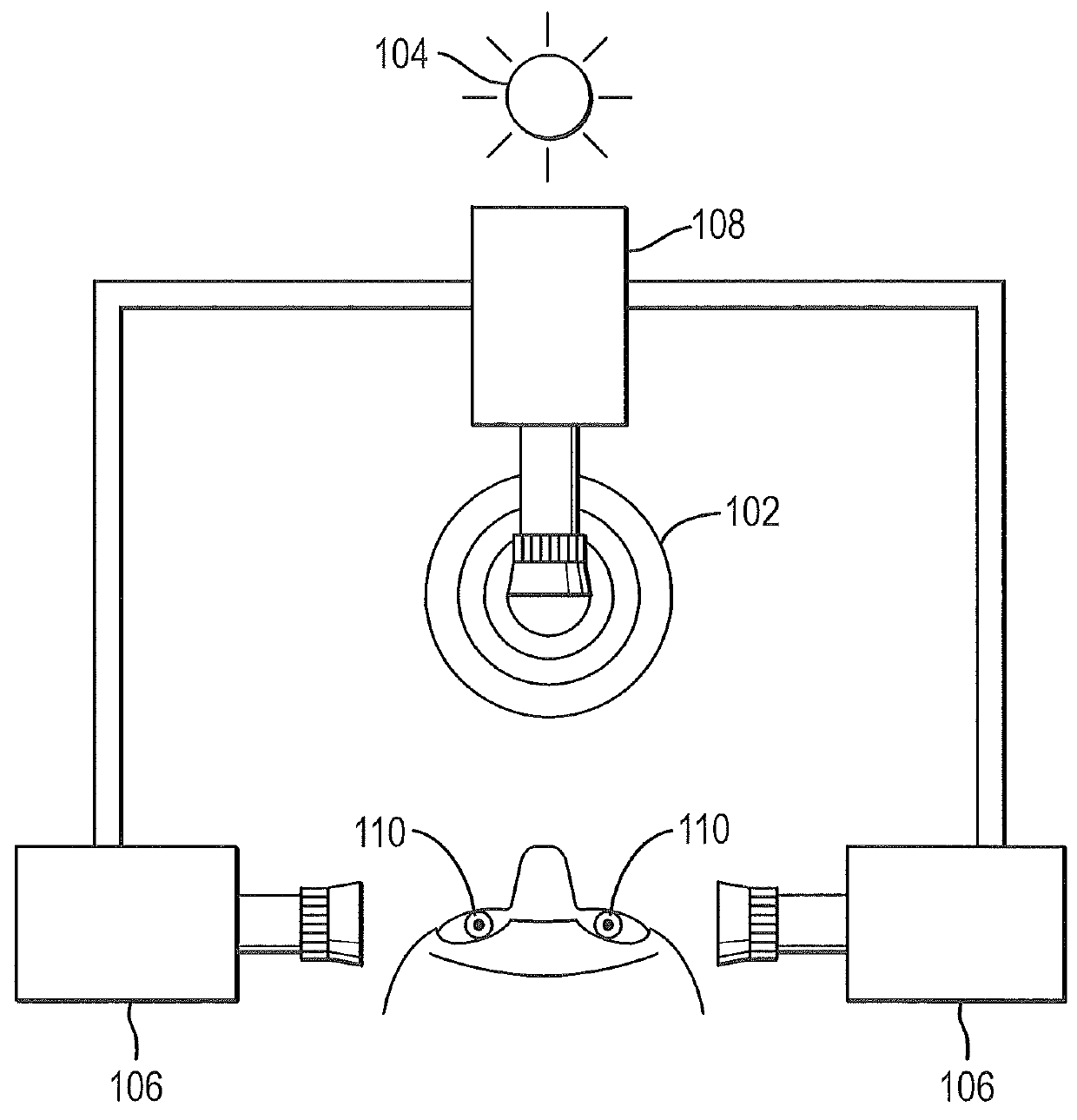

System and method for illumination and fixation with ophthalmic diagnostic instruments

An eye measurement system may include a target that moves transverse to an optical path from the target to eye, so as to relax accommodation of the lens of the eye. The target may move transverse to the optical path on a display. The patient may be fogged while the target moves transverse to the optical path, and the target may become smaller such that the patient perceives the target to be moving away from the patient. A pupil camera may measure eye position that can be correlated with the position of the target on the display to determine that the patient has maintained fixation on the moving target. A visible measurement light beam may be pulsed subsequent to and / or during motion of the target that relaxes accommodation of the eye so as to avoid visual interference of the measurement light beam with the target on the display.

Owner:AMO DEVMENT

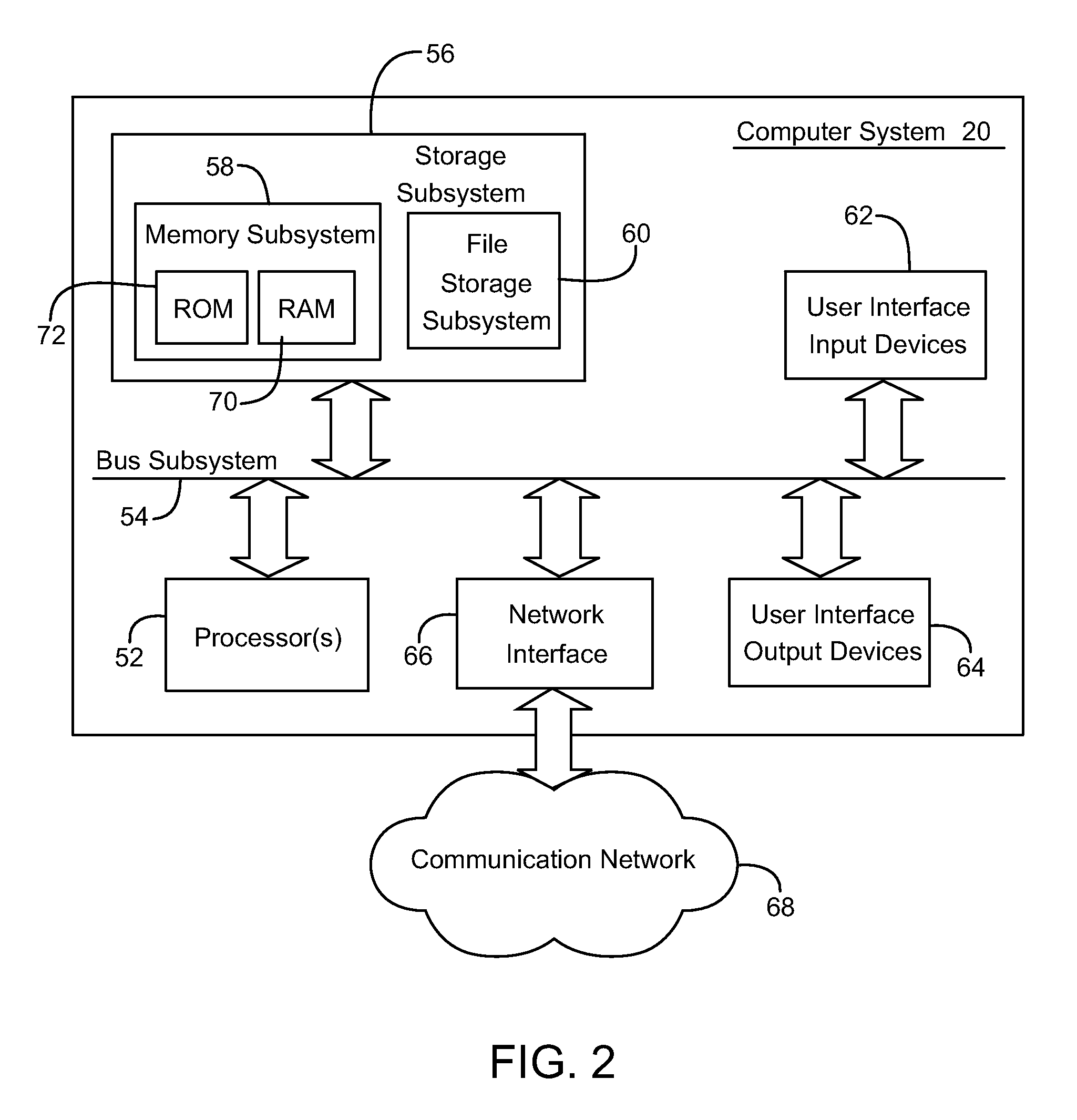

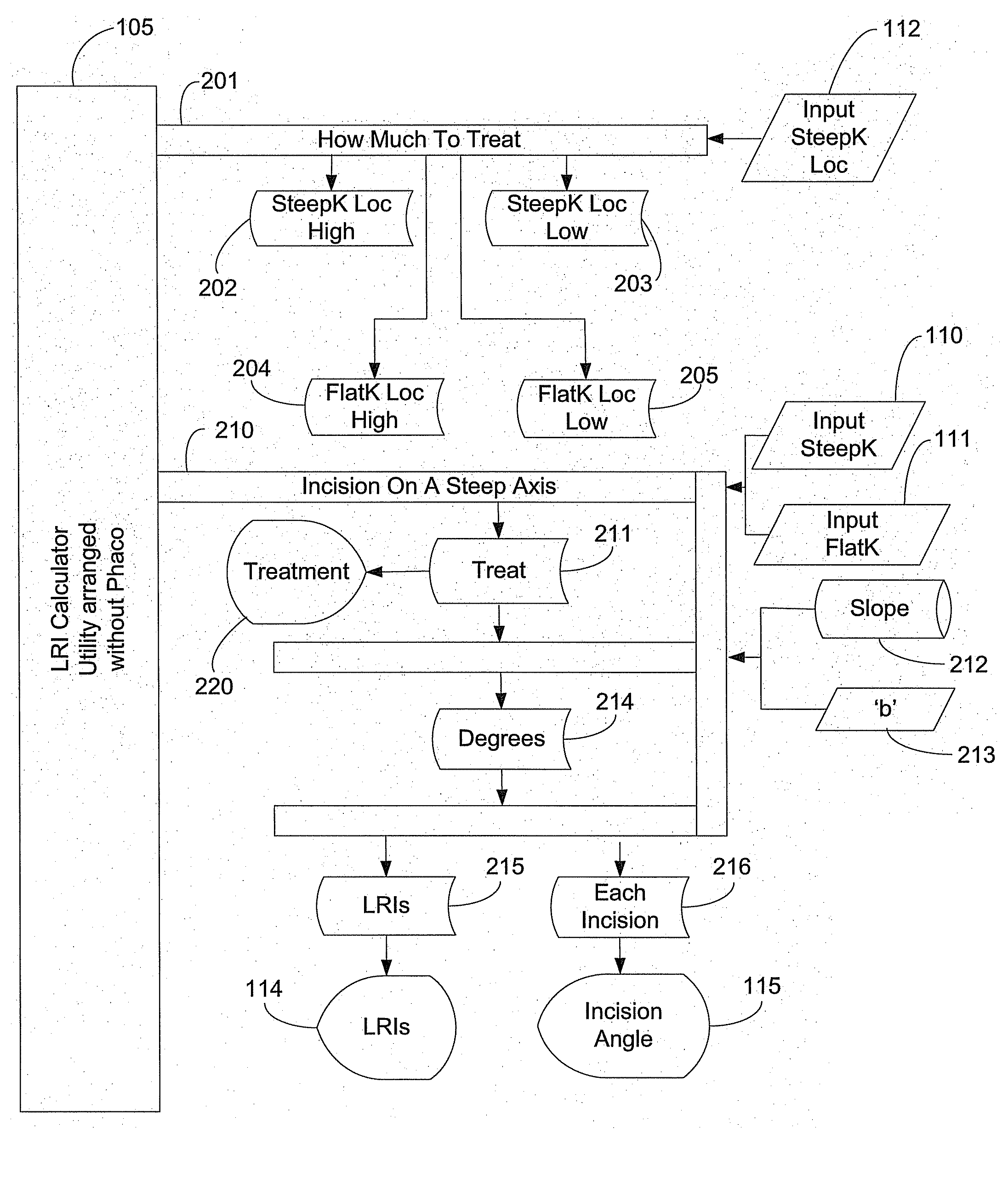

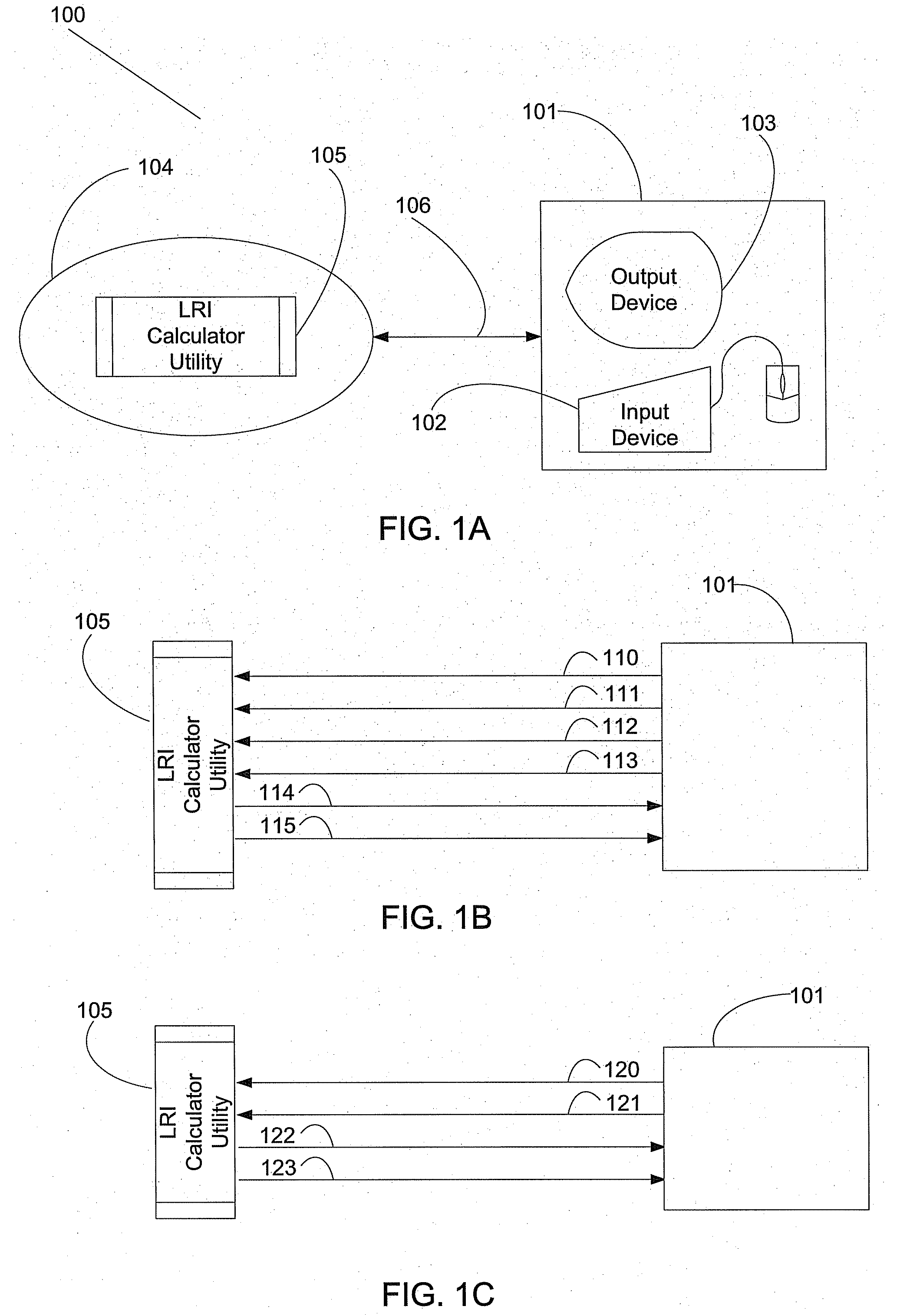

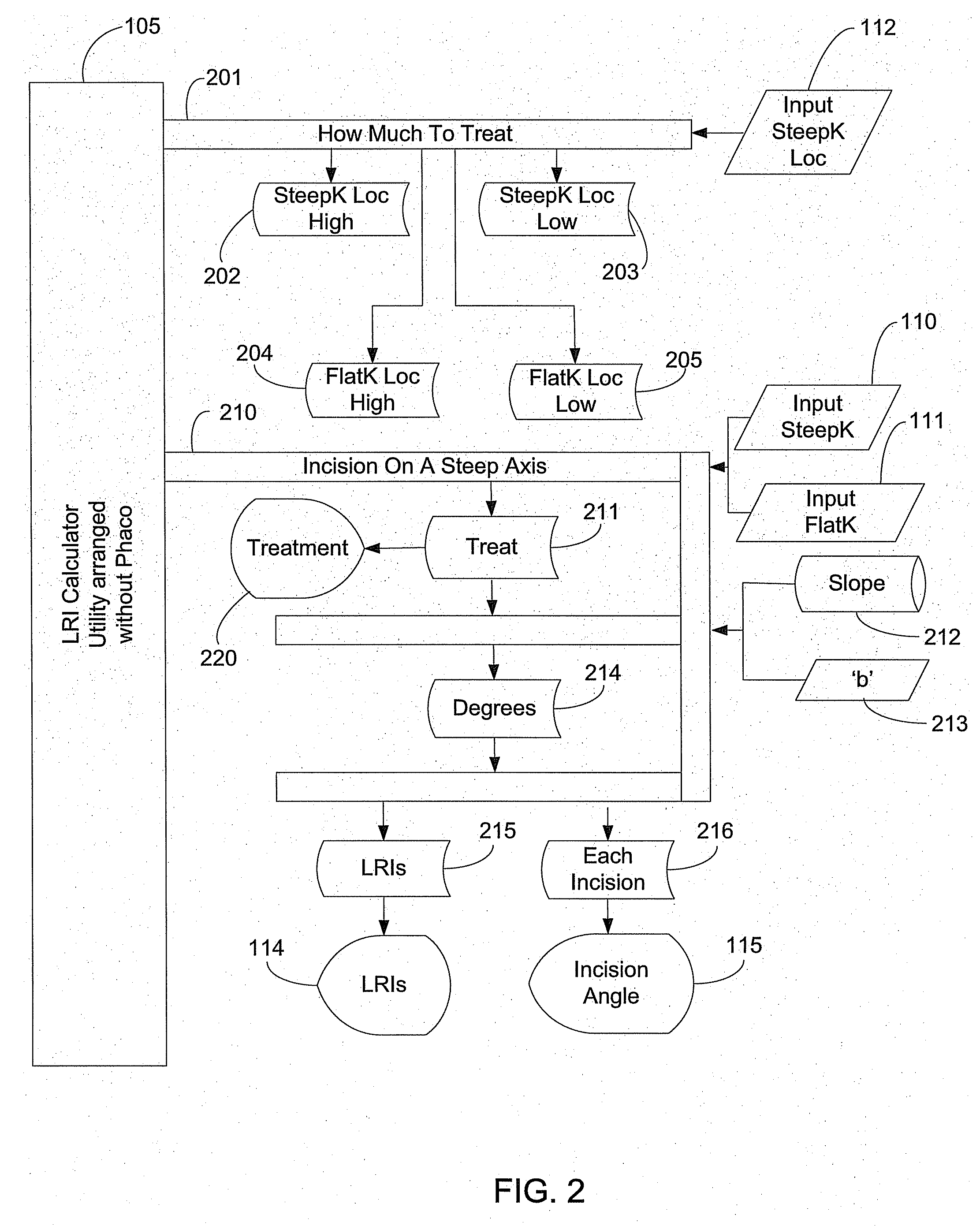

System and method for calculating limbal relaxing incisions

A method and system for calculating ocular incision positions to address astigmatism in an eye. The present design includes providing biometric information, determining an incision location:and angle based on the biometric information and a nomogram such as a Donnenfeld nomogram, relating astigmatism conditions and incision conditions, and presenting the incision location and angle to a user, such as via a graphical user interface. The design is intended to be employed on a general purpose computer and the utility employed, an LRI (Limbal Relaxation Incision) calculator utility may be executed to compute the desired results based on a set of eye measurement inputs.

Owner:ABBOTT MEDICAL OPTICS INC

Contact lens with shaped periphery

InactiveUS20060268225A1Quality improvementImprove comfortEye diagnosticsOptical partsOptometryContact lens

Eye measurements taken on a patient being fitted for contact lens will include a refraction test and an additional measurement representing corneal depth variation on the surface of an imaginary cylinder having the same diameter as the lens. This information then used during lens manufacture to produce lens in which the perimeter is not circular and does not lie in a plane, but which drops backwards towards the eye at appropriate points to produce a saddle-shaped perimeter.

Owner:SCI OPTICS INC

Wireless scleral search coil including systems for measuring eye movement and methods related thereto

InactiveUS7967439B2Great freedomSimplify surgical proceduresEye diagnosticsTransmitter coilEngineering

Featured is a wireless scleral search coil that includes one or more passive, resonant coils and in a particular embodiment two orthogonal, passive, resonant coils, where each coil resonates at a different frequency. Each resonant coil includes a coil-capacitor circuit, each circuit being configured to resonant at a different frequency. Such a wireless scleral search coil is disposed within a biocompatible material that is shaped to conform and rest upon the eye of a subject. Also featured are system including such a wireless scleral search coil, one or more transmitter coils, an assembly of one or more receiver coils and a calculating sub-system for processing signal data to obtain eye measurement information.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

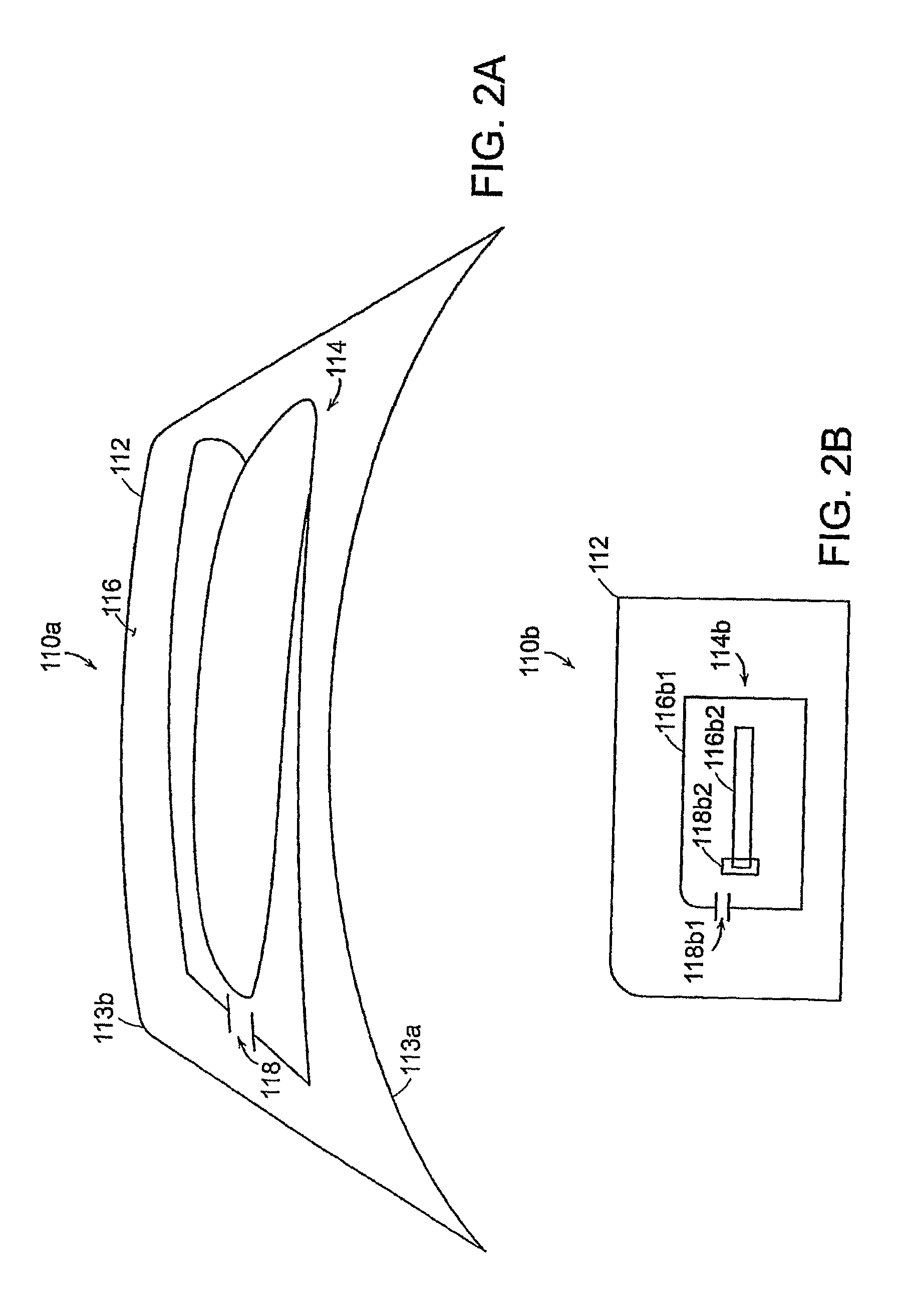

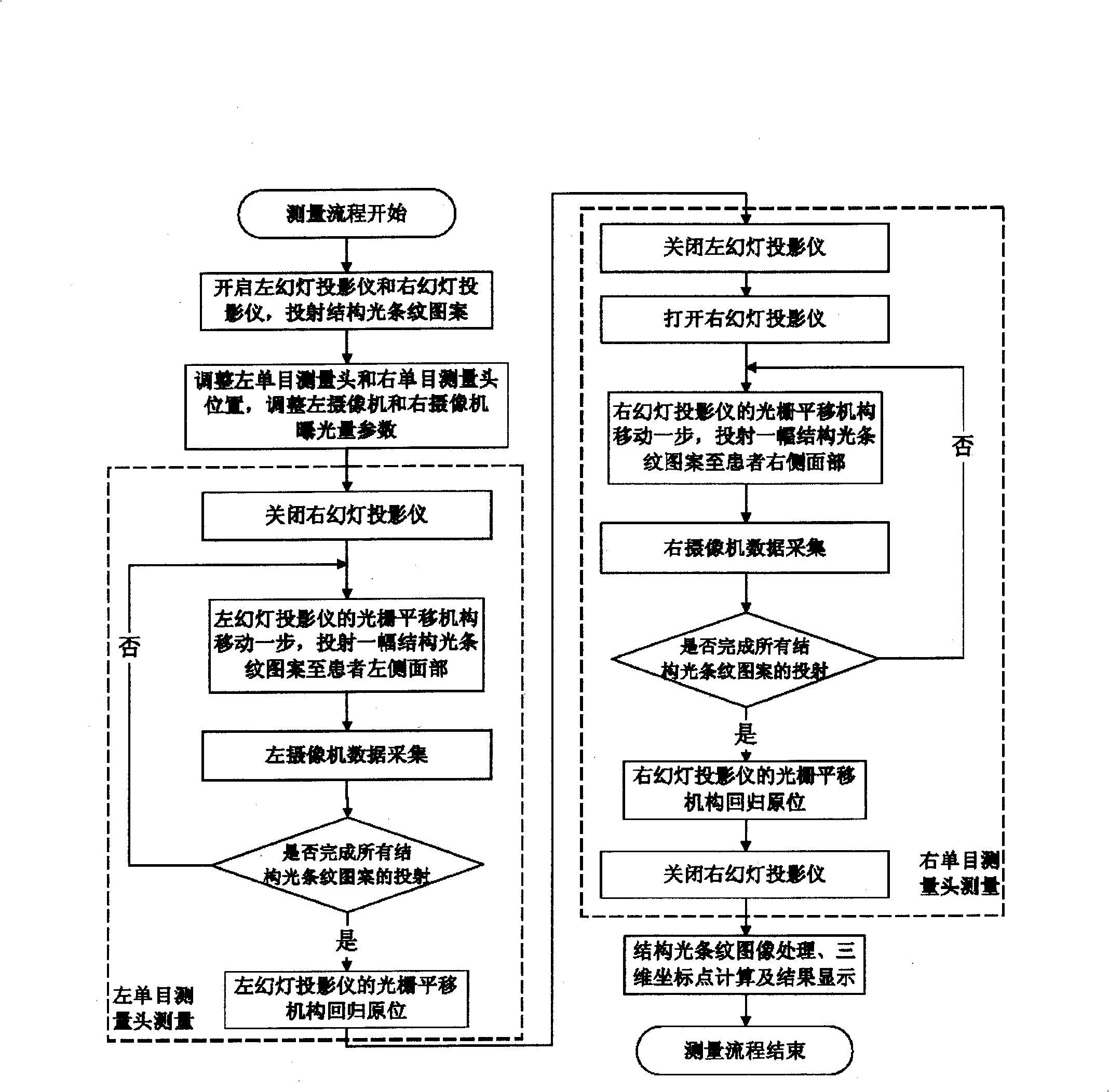

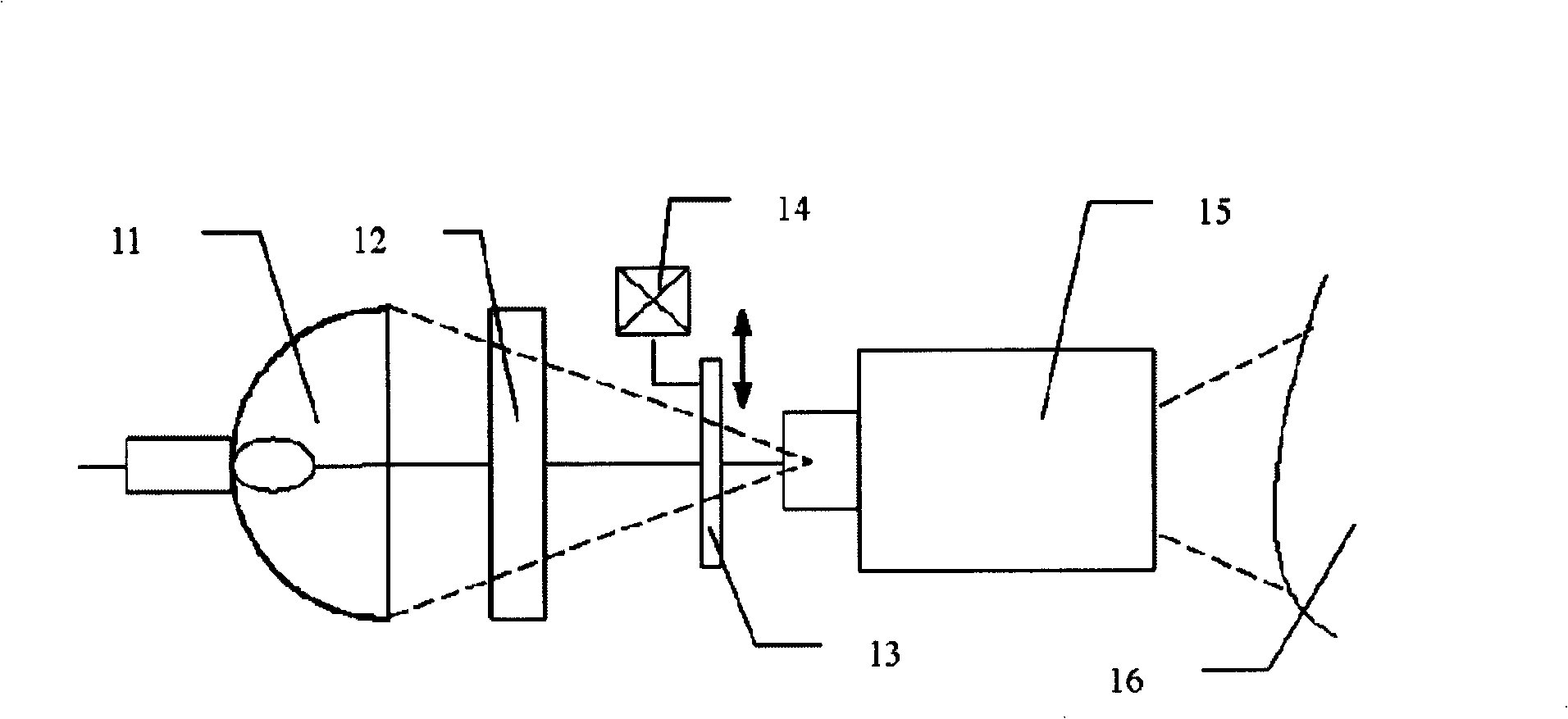

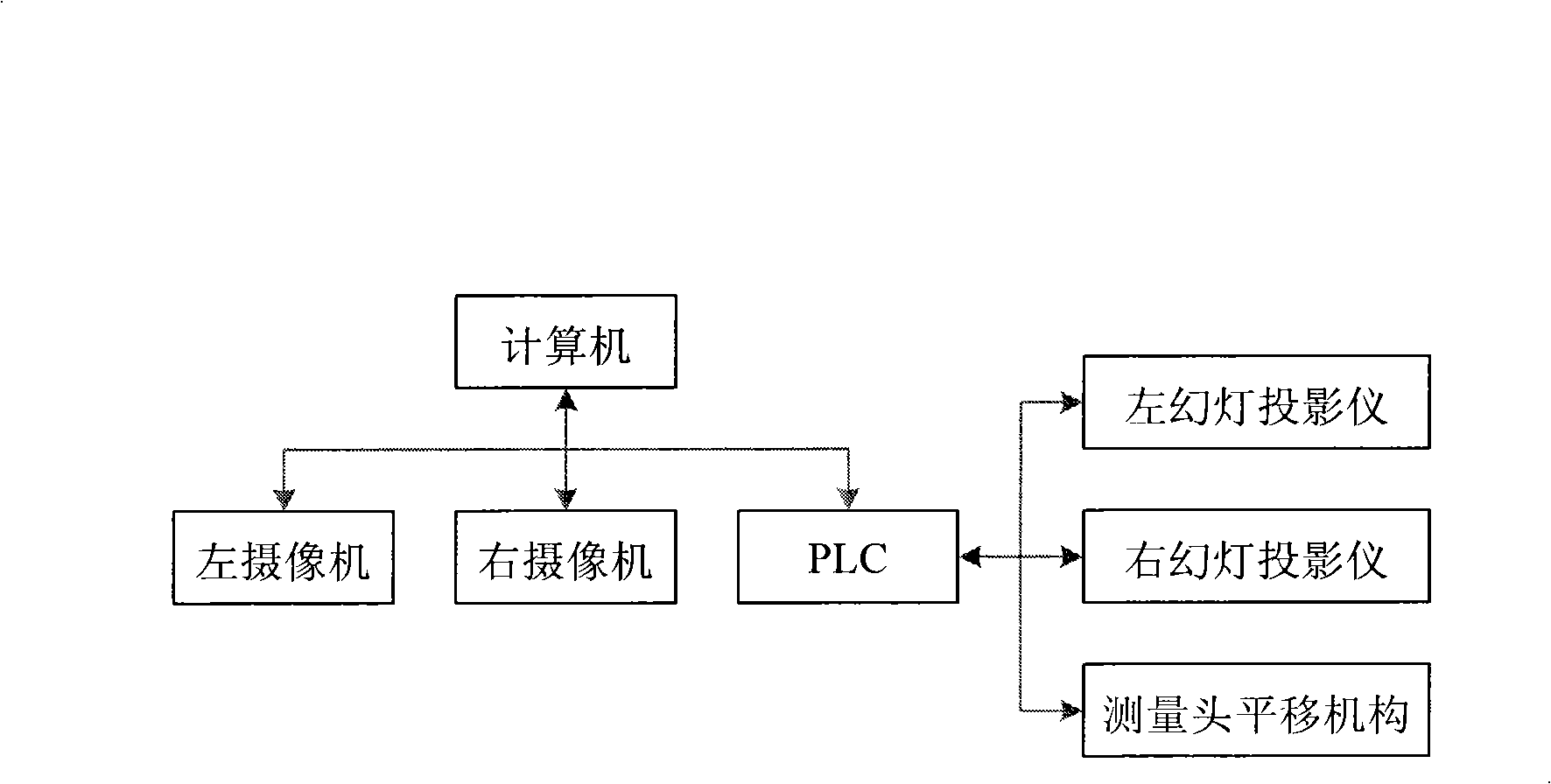

Method for measuring three-dimensional feature of face on patient with defected face

InactiveCN101301200AConvenient human-computer interaction operationQuick collectionDiagnostic recording/measuringSensorsParenchymaOriginal data

A method for measuring face three-dimensional appearance of face defect patients belongs to fields of optical measurement, mechanical engineering and medical engineering. Based on structure optical projection three-dimensional vision measurement technique, a double-monocular white light three-dimensional measurement system used for face defect restoration of patients is employed, Gray codes and phase shift coding structure optical stripe patterns are respectively projected on left and right face of patients by controlling a left magic lantern projector and a right magic lantern projector, after a left camera and a right camera respectively take a view of deformed structure optical stripe patterns, measurement of complete three-dimensional face appearance of patients is realized by image decoding, triangle principle and double-eye measurement data combination. The measurement system can realize accurate data collection of natural state parenchyma of patient faces under non-contact condition and provide credible three-dimensional appearance original data of patient faces for clinic appearance defect restoring therapy.

Owner:SHANGHAI JIAO TONG UNIV

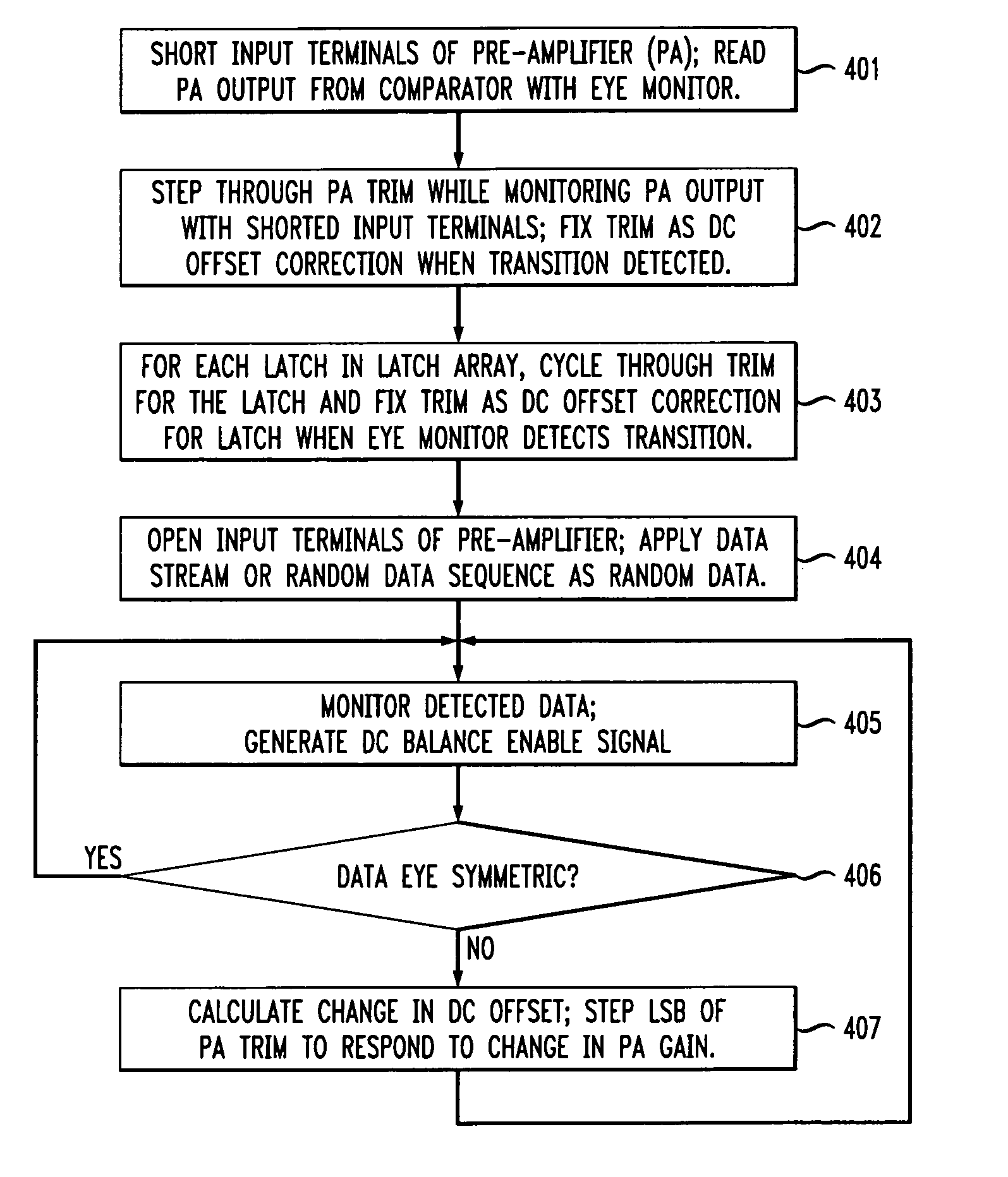

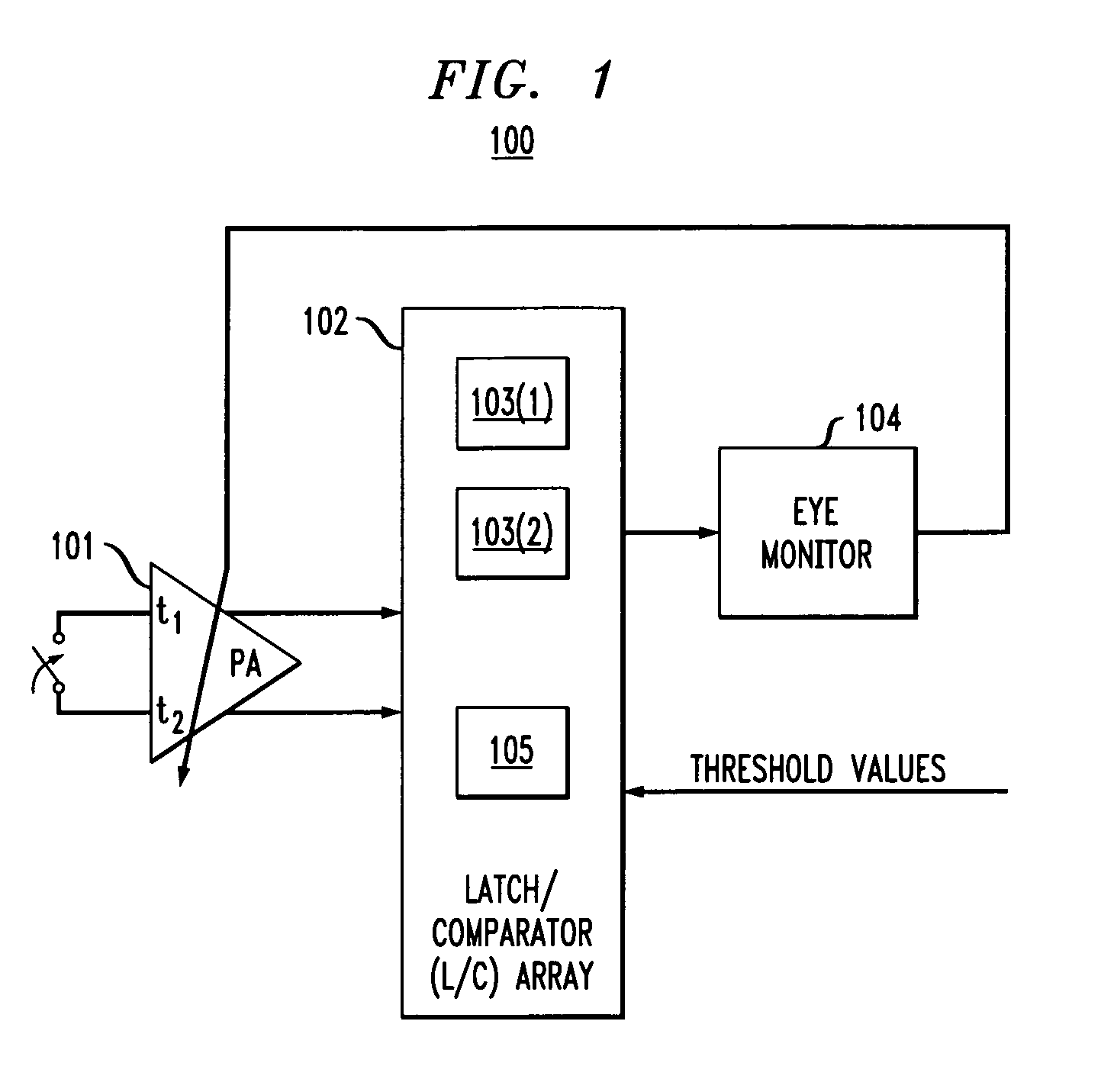

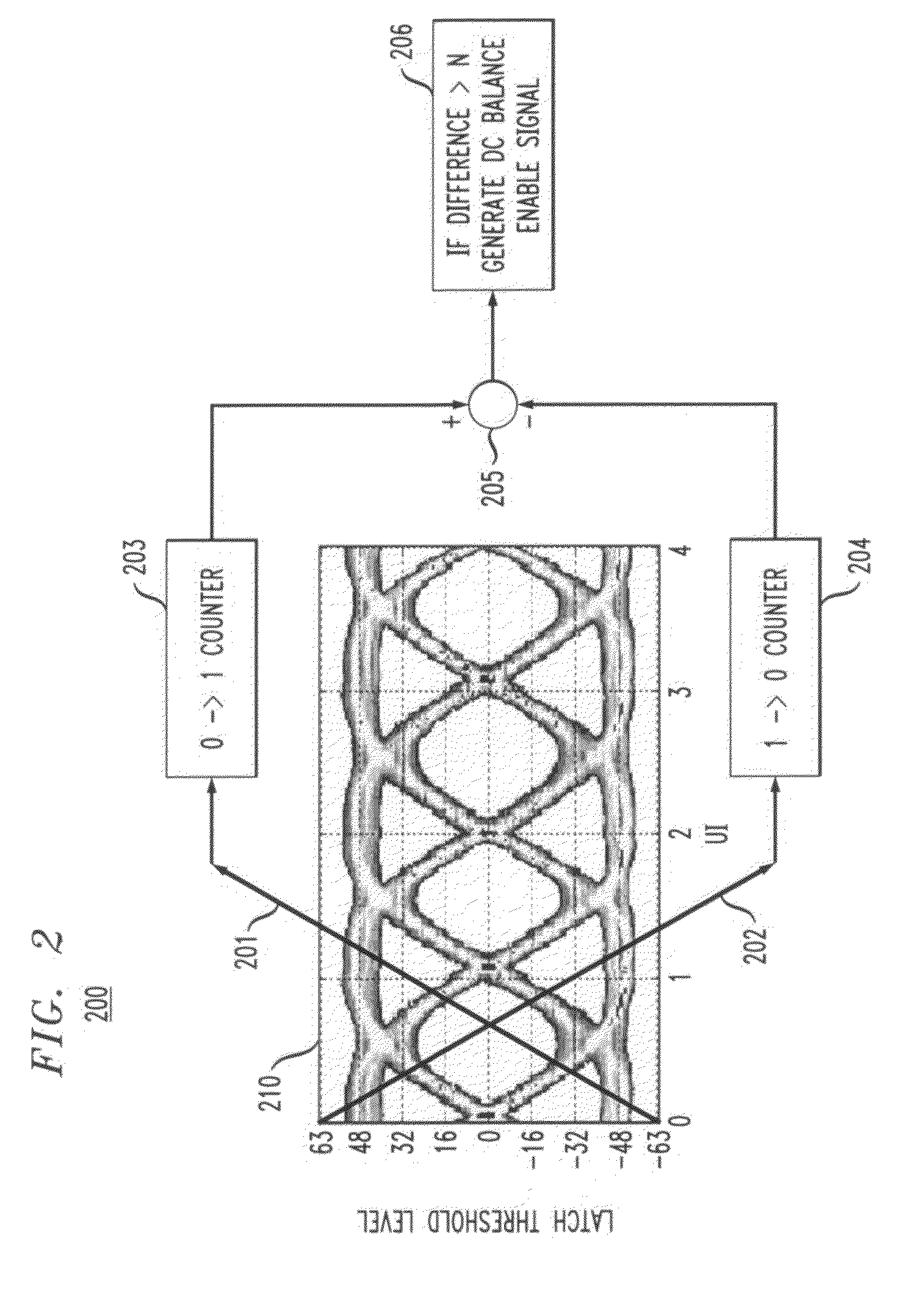

DC offset detection and correction for user traffic

ActiveUS7812749B2Electric signal transmission systemsAnalogue-digital convertersAudio power amplifierCommunications system

Owner:LSI CORP

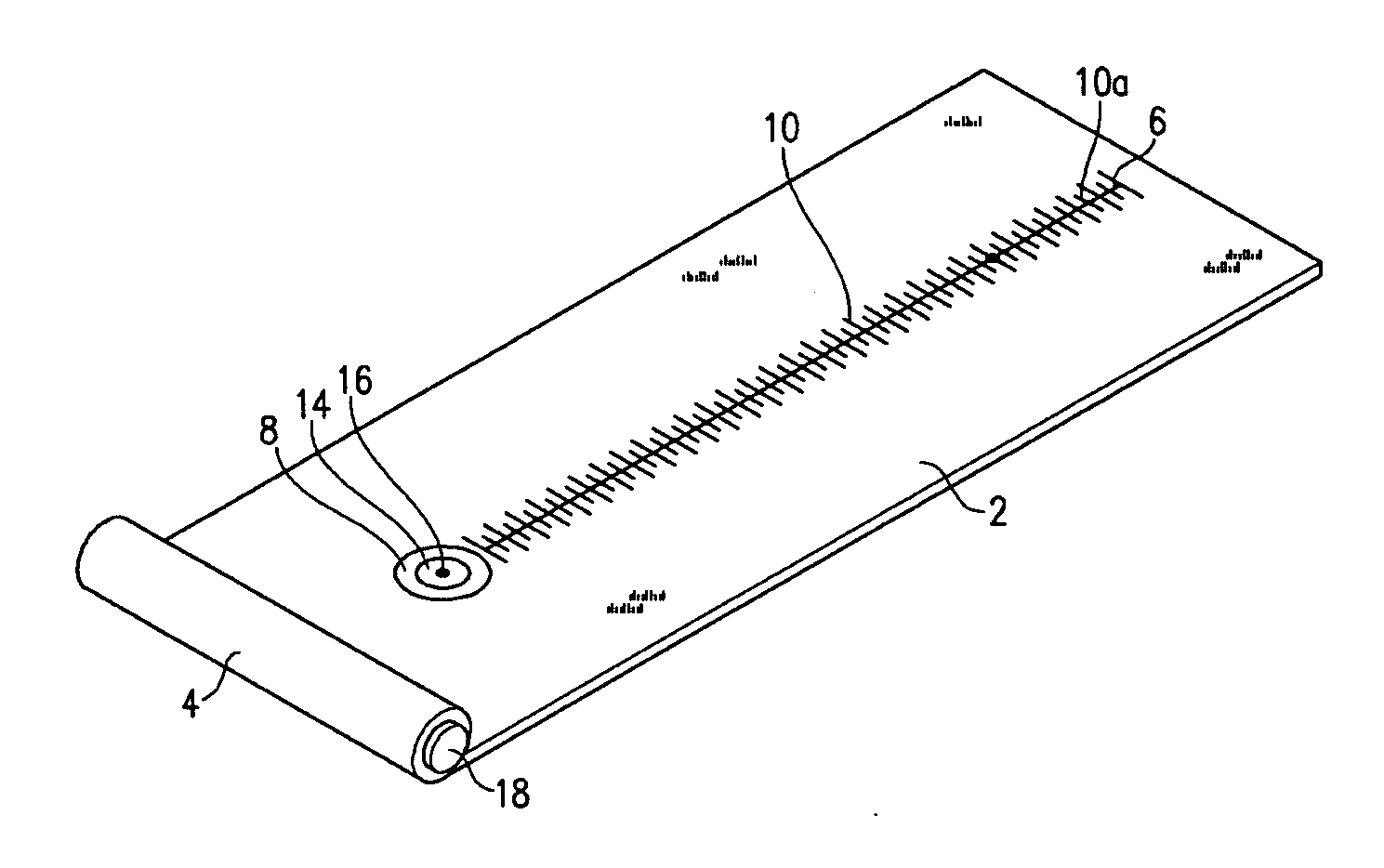

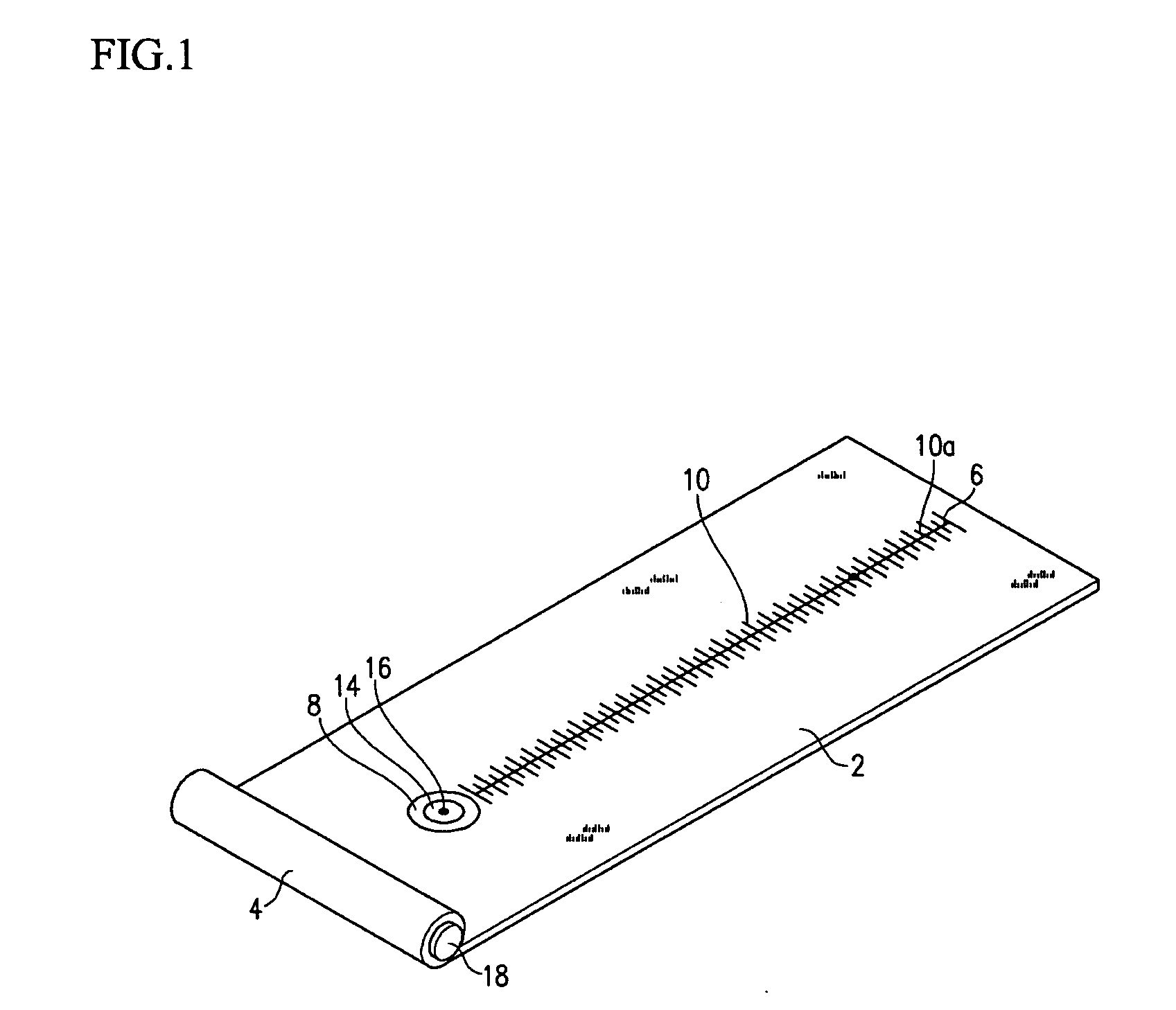

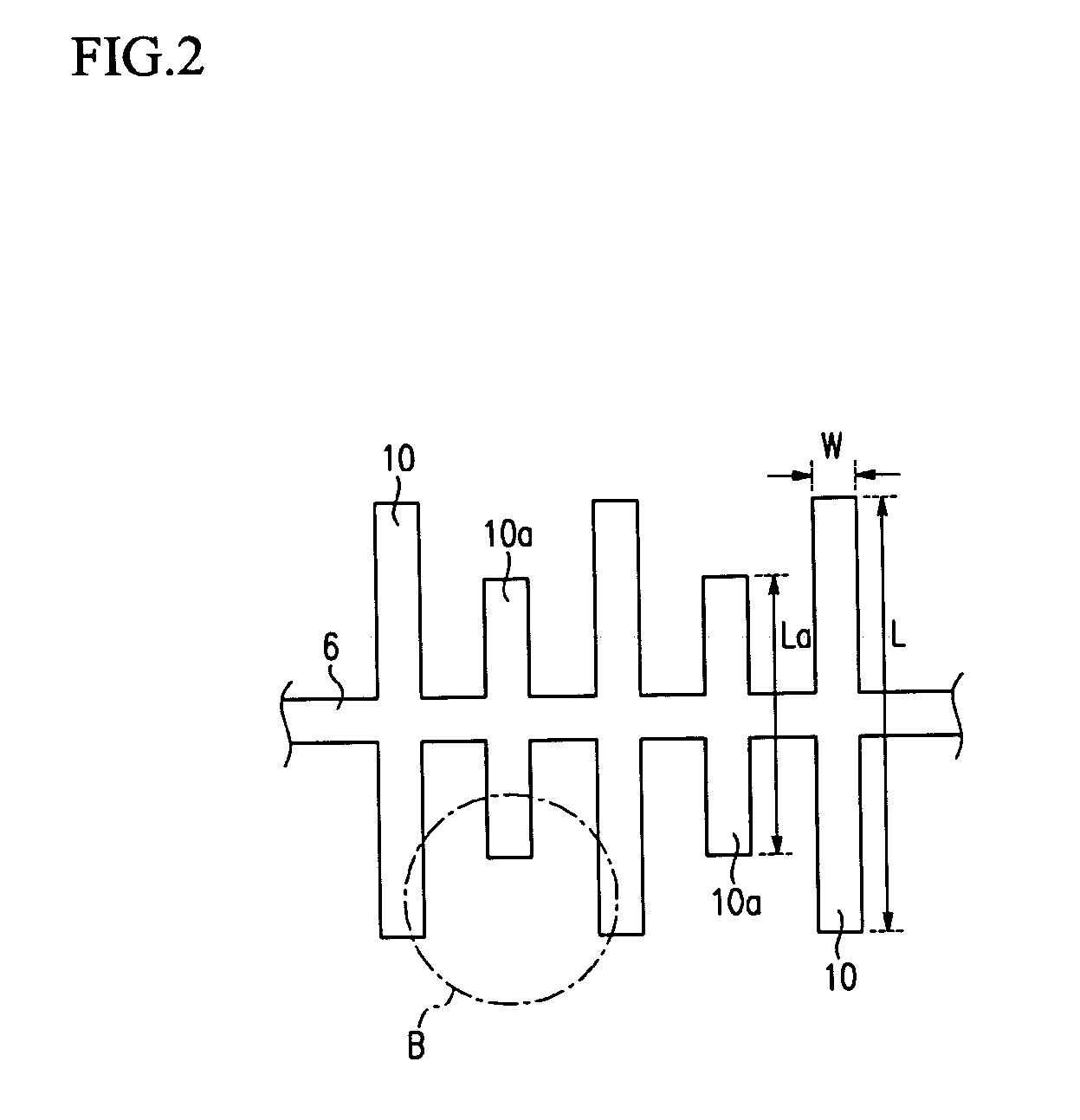

Scale mark mat for putting practice

The present invention relates to a rectangle mat for putting practice. The mat includes a cylindrical stopper, an imitative hole cup mark thereon, and a putting line straightly drawn along the center on the mat and divided by the square scales for eye measurement. According to the present invention, three requisites of putt for hitting the golf ball to the intended direction and distance; a) the putter is swung straight along the putting line; b) the golf ball is stroked with the putter face square to the putting line; and c) the backswing length is accurately determined according to the condition of the putt; are practiced by; first, numerating and calculating the backswing length for the putt by the number of the scales, second, by objectifying and determining the backswing spot and throughswing spot on the putting line, then, by putting straight from the backswing spot to the throughswing spot for one second by the seesaw movement of the shoulders, keeping and stopping the putter face square to the putting line at each of the two spots. And the putting techniques are checked and improved by observing the speed and trajectory of the ball passing the imitative hole cup mark.

Owner:SHIN SAM KYU

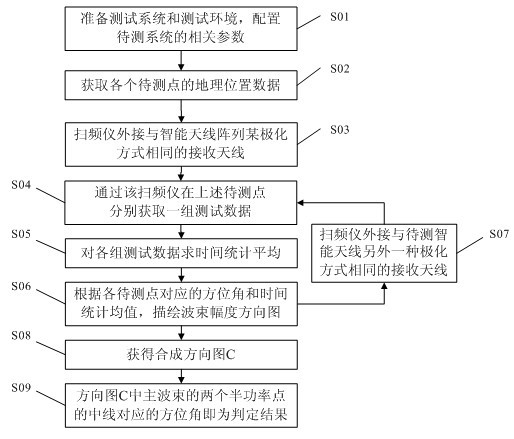

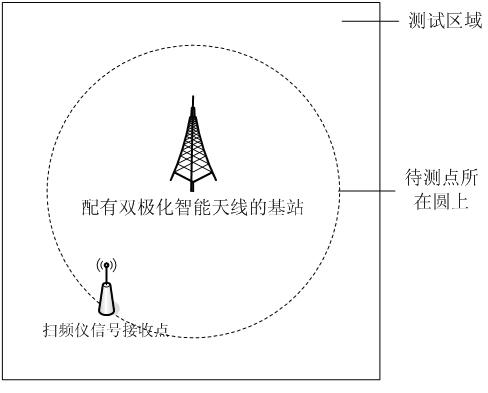

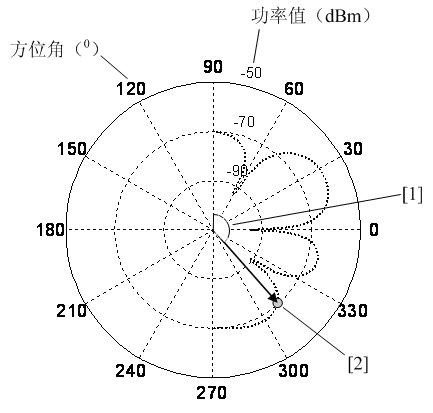

Method for measuring reference direction of dual-polarization intelligent antenna business beam

InactiveCN101848045AOvercome visual inspectionOvercome the defect of determining the reference direction based on experienceTransmission monitoringGeolocationSmart antenna

The invention provides a method for measuring a reference direction of a dual-polarization intelligent antenna business beam, which comprises the following steps that: N test points with the geographic position of a dual-polarization intelligent antenna array to be measured as the circle center and a certain distance as the radius and uniformly distributed on a circle are selected to test the geographic position information of the circle center and the N test points; a sweeper is respectively and externally connected with a receiving antenna which is the same with one polarization direction of the dual-polarization intelligent antenna, measures at a point to be tested, and the beam amplitude directional patterns of an intelligent antenna system to be measured in different polarization forms are respectively obtained; the obtained two directional patterns are synthesized to obtain a new directional pattern; and a midline between two half-power points of a main beam on the new directional pattern corresponds to the reference direction of the business beam. The method overcomes the defects of the prior art that the reference direction is determined according to the eye measurement and the experience of an engineer, and provides favorable conditions for accurately measuring the position of a mobile terminal and the direction of arrival of the business beam of the mobile terminal in the external field testing of the dual-polarization intelligent antenna.

Owner:HUAZHONG UNIV OF SCI & TECH

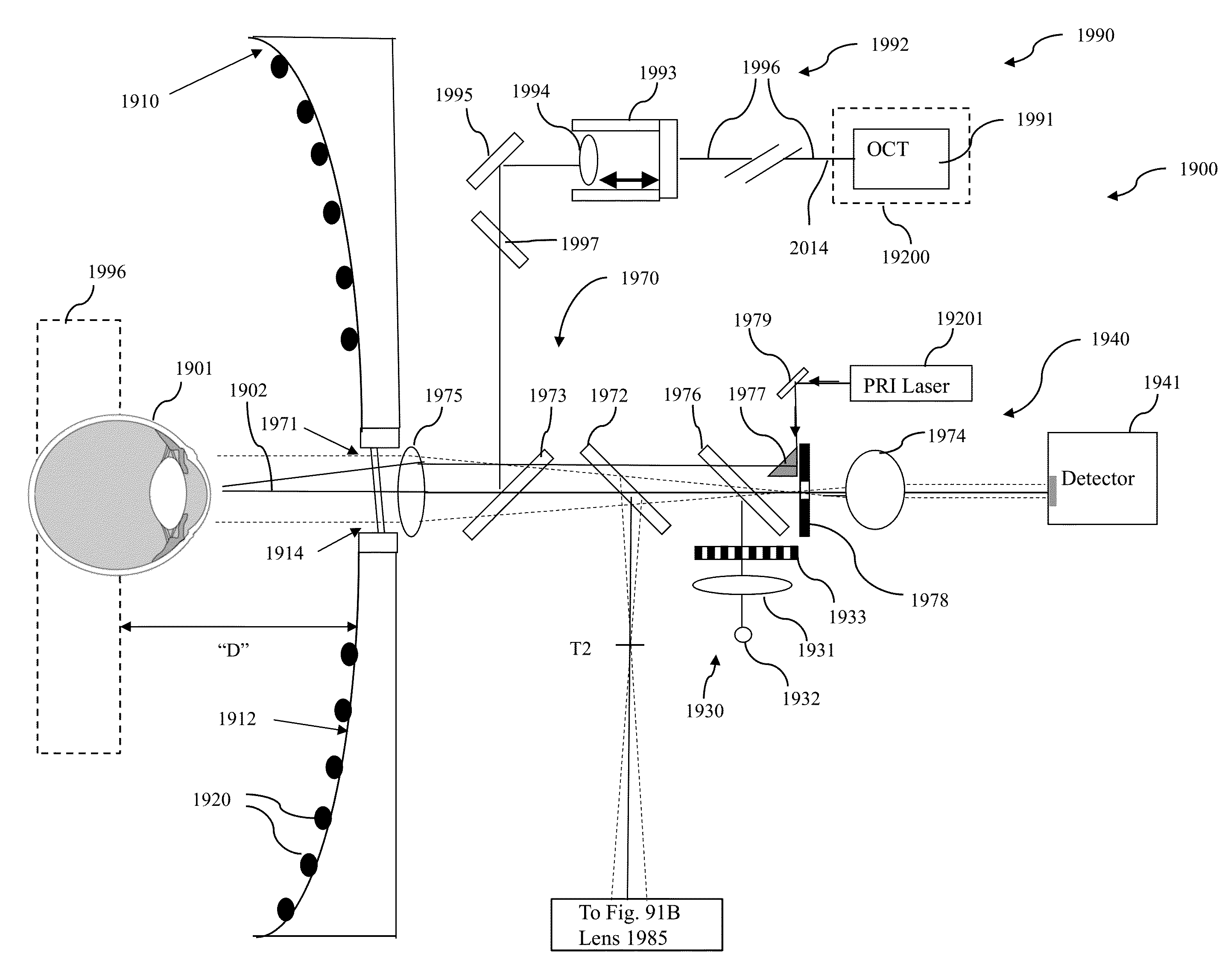

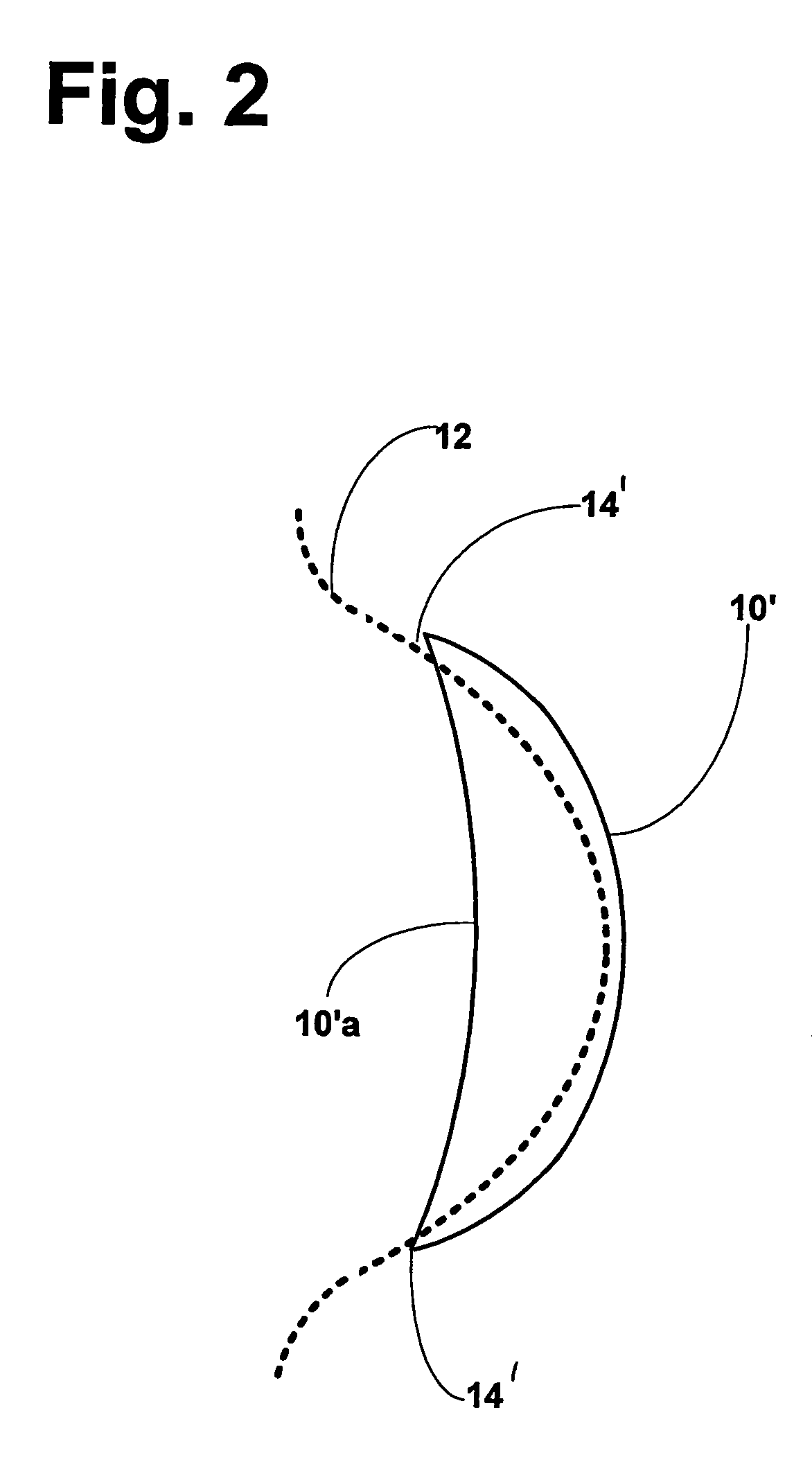

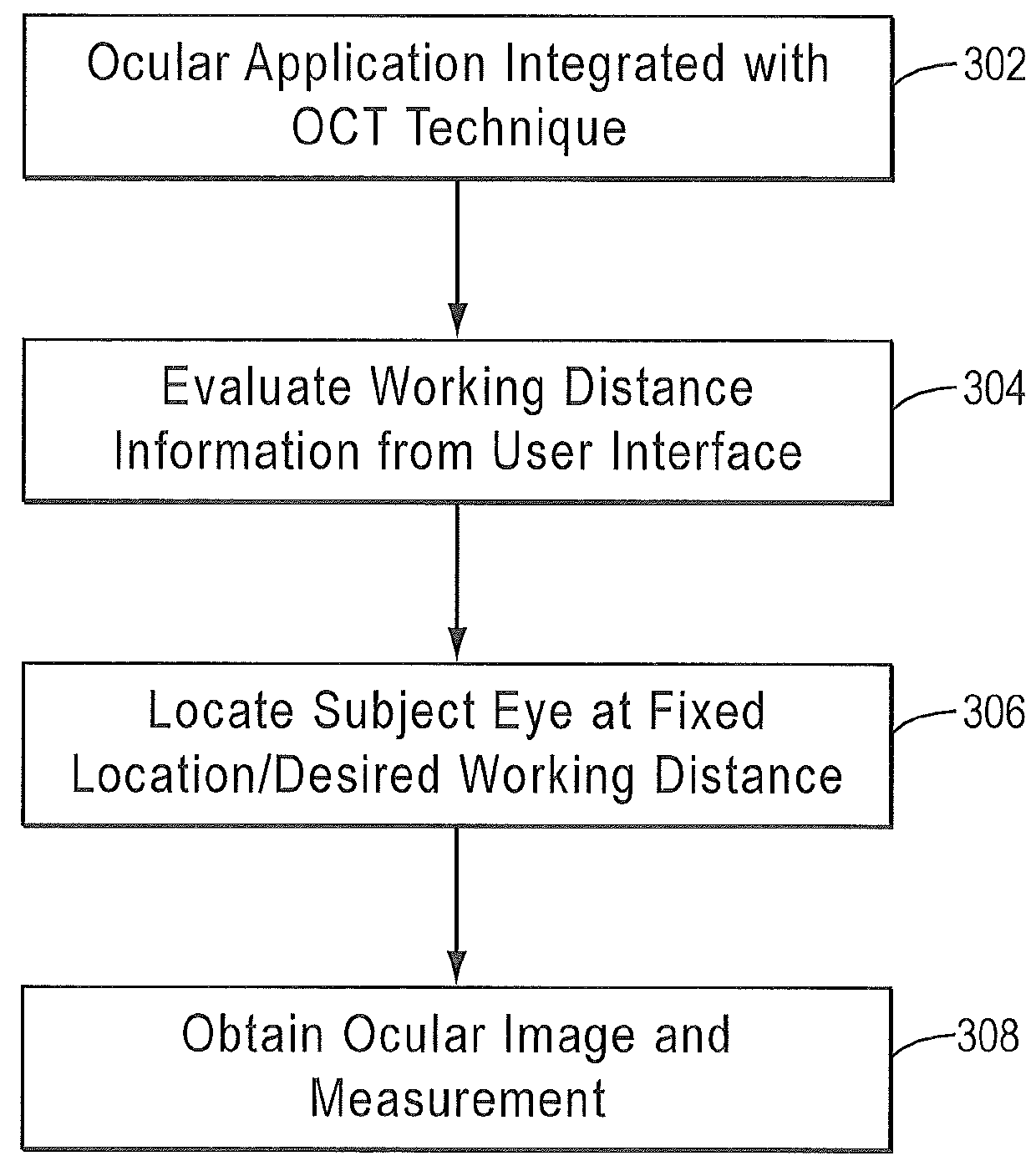

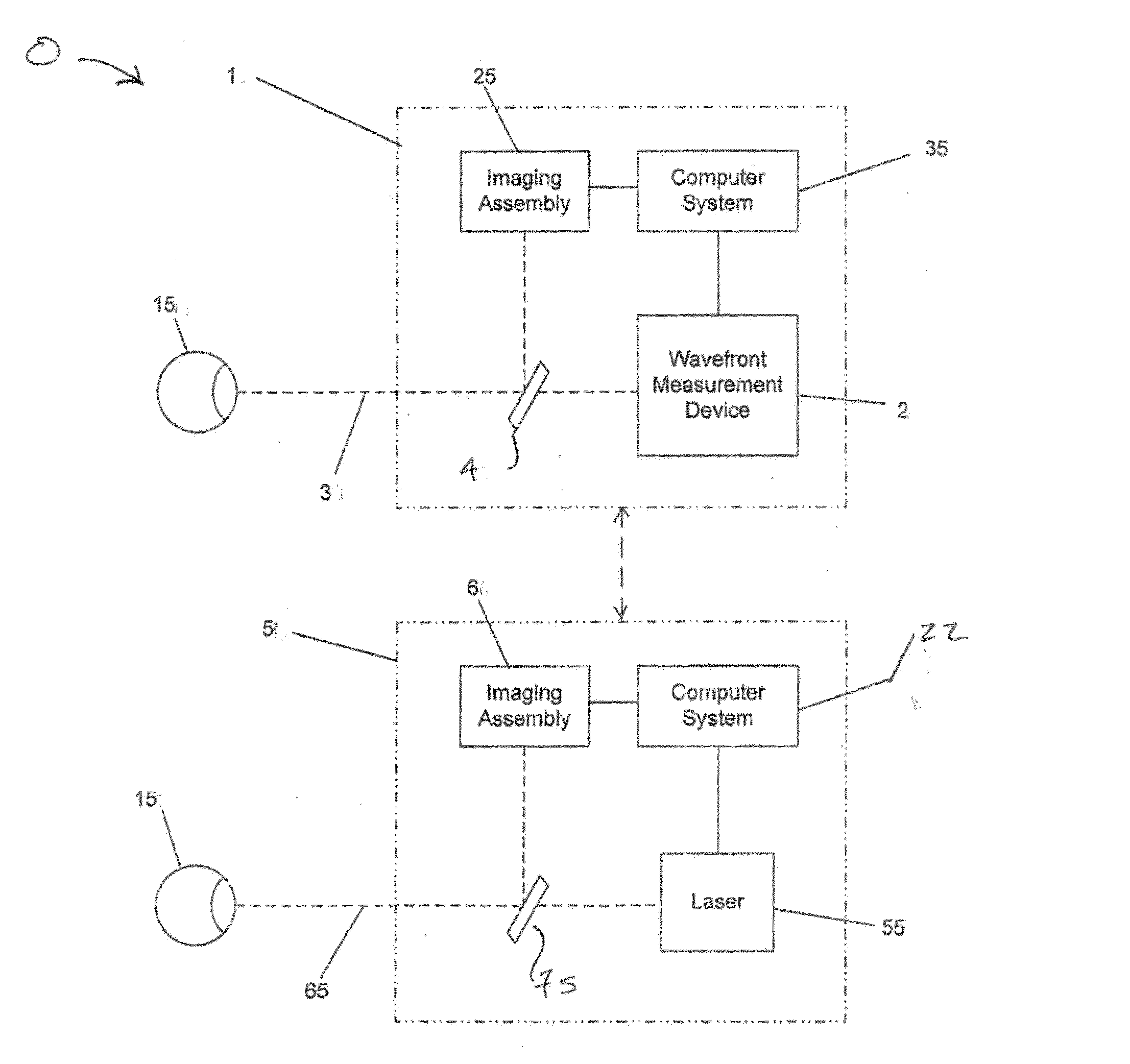

Method and apparatus for enhanced eye measurements

An imaging method according to some embodiments of the present invention includes obtaining working distance information from an optical coherence tomography system, the working distance being the working distance to the sample; obtaining information from one or more ocular systems; combining the information from said optical coherence tomography information and said ocular system; and displaying said combined information.

Owner:OPTOVUE

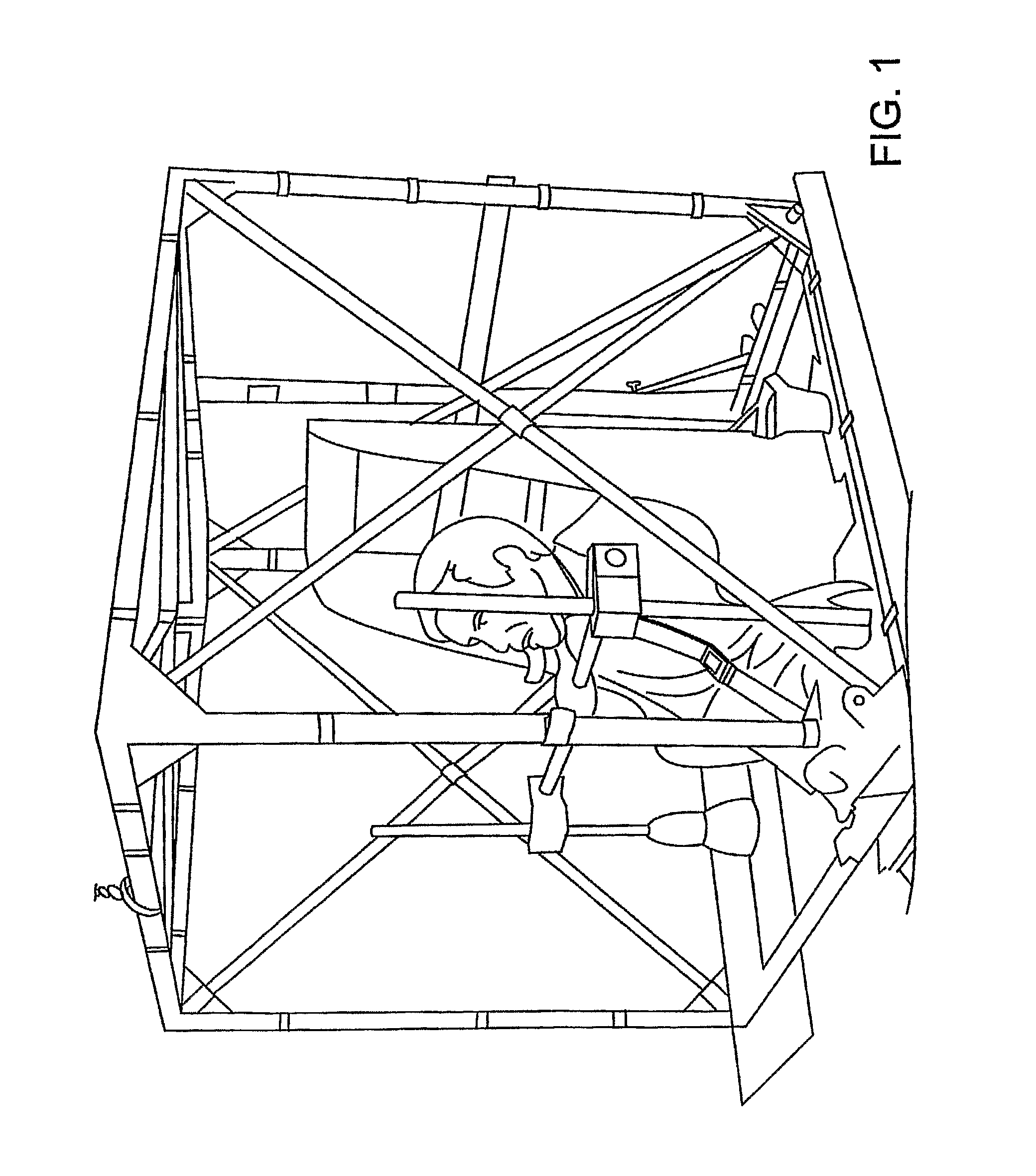

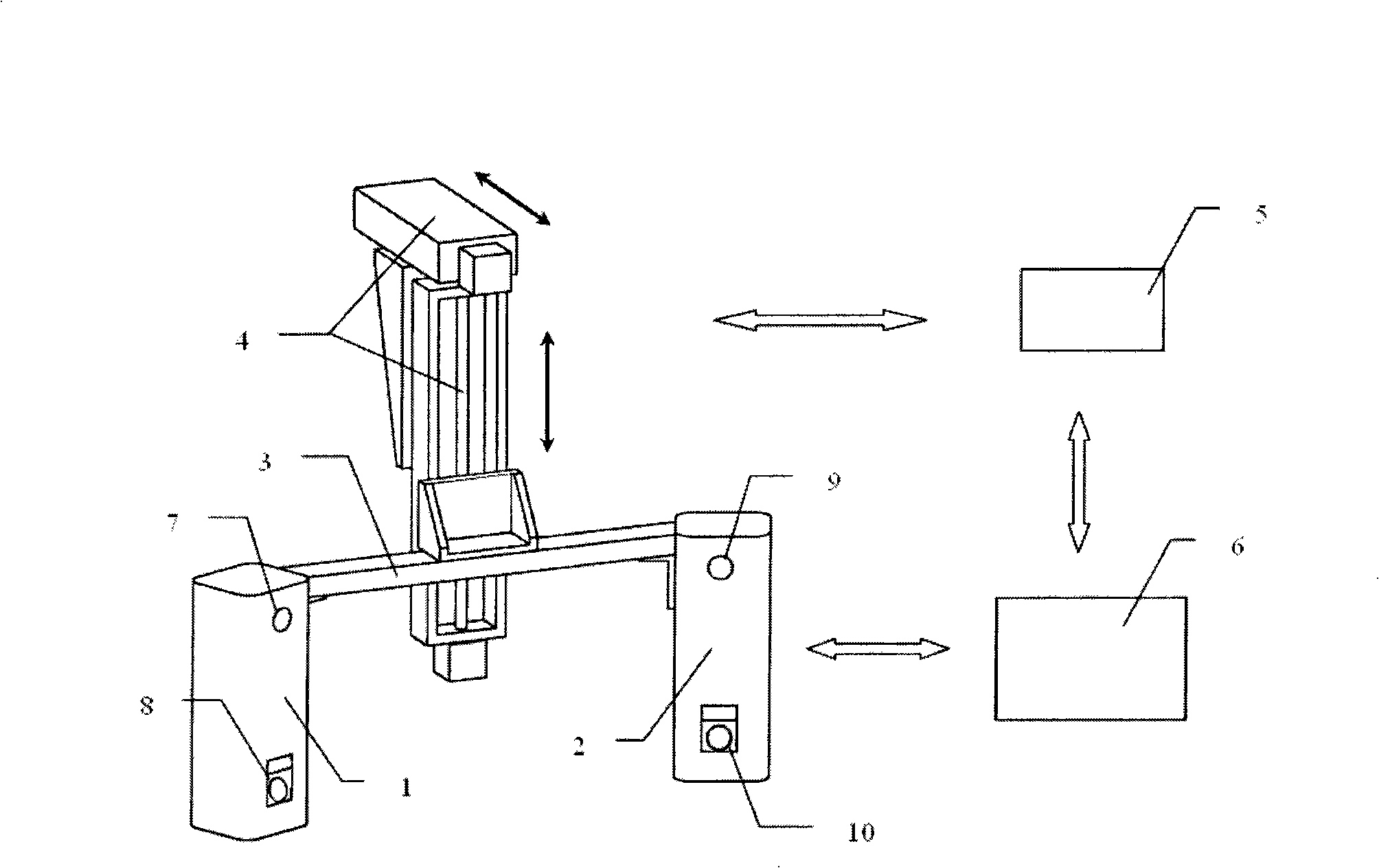

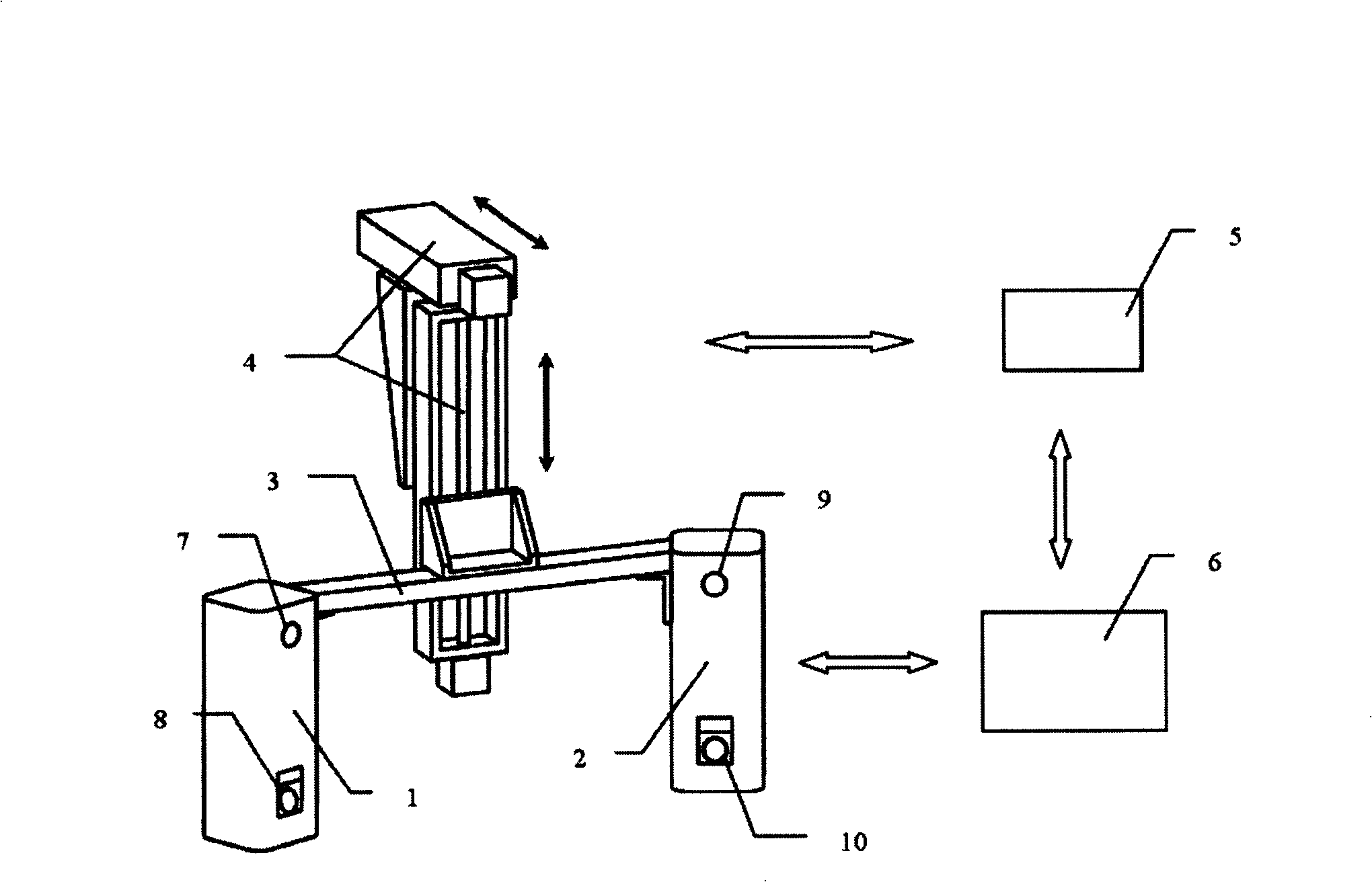

Double/single ocular white light three-dimensional measuring system for repairing defects of patient face

InactiveCN101301199AAvoid stitching errorsIncrease contrastDiagnostic recording/measuringSensorsHuman bodyParenchyma

A double-monocular white light three-dimensional measurement system used for restoring face defect of patients belongs to fields of optical measurement, mechanical engineering and medical engineering. The measurement system includes a left monocular measurement head, a right monocular measurement head, a measurement head support, a measurement head translation mechanism, a control cabinet and a computer. Based on structure optical projection three-dimensional vision measurement technique, the measurement system employs double-monocular measurement structure, white light sources which are safe for human body are employed in a left magic lantern projector and a right magic lantern projector for rear projection of physical coding grating, Gray codes and phase shift coding stripes are projected on left and right faces of patients, after a left camera and a right camera take a view of deformed gating images, measurement of complete three-dimensional face appearance of patients is realized by image decoding, triangle principle and double-eye measurement data combination. The measurement system can realize accurate data collection of natural state parenchyma of patient faces under non-contact condition and provide credible three-dimensional appearance original data of patient faces for clinic appearance defect restoring therapy.

Owner:SHANGHAI JIAO TONG UNIV

Method and system for eye measurements and cataract surgery planning using vector function derived from prior surgeries

ActiveUS20160074125A1Good curative effectImproved refractive correctionsLaser surgeryDiagnosticsCorrective surgeryIntraocular lens

Improved devices, systems, and methods for planning cataract surgery on an eye of a patient incorporate results of prior corrective surgeries into a planned cataract surgery of a particular patient by driving an effective surgery vector function based on data from the prior corrective surgeries. The exemplary effective surgery vector employs an influence matrix which may allow improved refractive corrections to be generated so as to increase the overall efficacy of a cataract surgery by specifying one or more parameters of an intraocular lens (IOL) to be implanted during the cataract surgery.

Owner:AMO DEVMENT

Method and apparatus for enhanced eye measurement

An imaging method according to some embodiments of the present invention includes obtaining working distance information from an optical coherence tomography system, the working distance being the working distance to the sample; obtaining information from one or more ocular systems; combining the information from said optical coherence tomography information and said ocular system; and displaying said combined information.

Owner:OPTOVUE

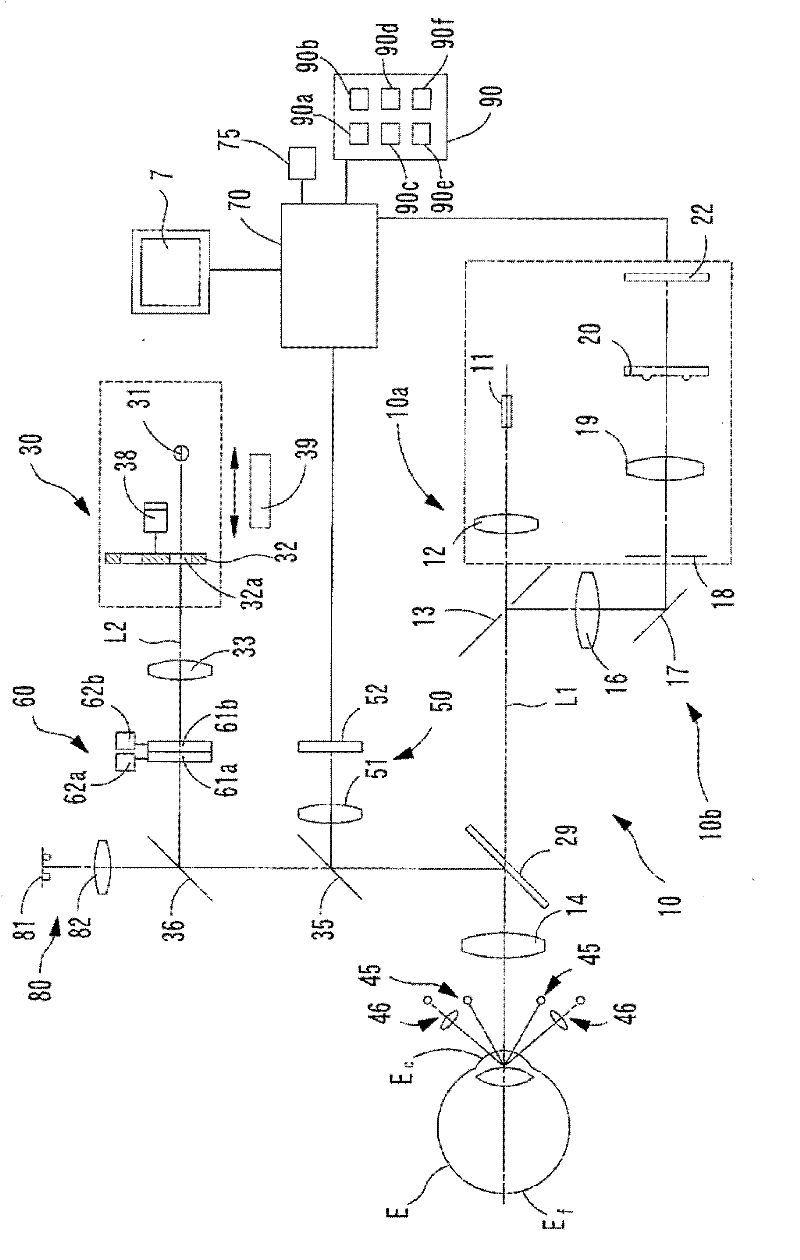

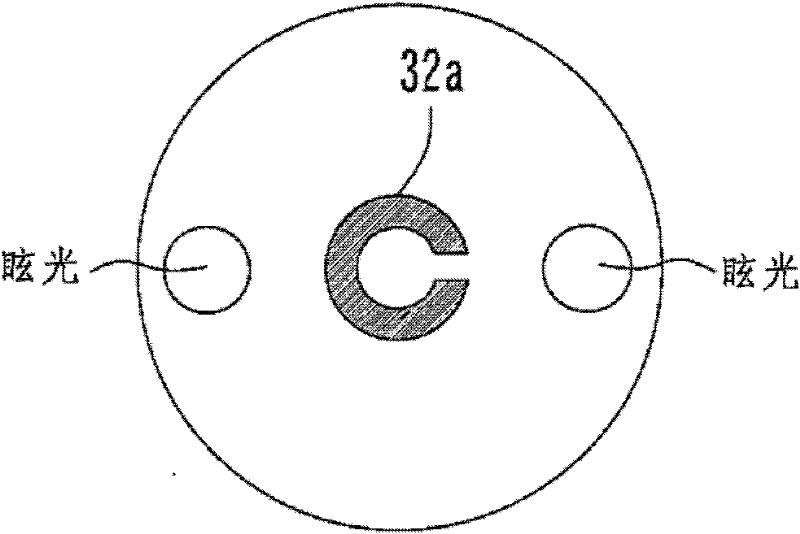

Eye measurement apparatus

An eye measurement apparatus includes: a subjective measurement optical system configured to subjectively measure an examinee's eye, the subjective measurement optical system including: a chart to be presented to the examinee's eye; and a glare light source for irradiating the examinee's eye with a glare light; and a control part configured to determine presence or absence of opacity in a light transmitting part of the examinee's eye and, when the presence of opacity is determined, to allow display of necessity for a glare test which is a subjective measurement to be performed in a state that the examinee's eye is irradiated with the glare light.

Owner:NIDEK CO LTD

Quarter-sawn timber visual measurement and mechanical classification method of fir sapwood of wind electric blade composite

InactiveCN101226137AThe method is simple and fastIncrease productivityMaterial analysis by optical meansElectricityTurbine blade

The invention discloses an eye-measurement and mechanical classifying method of fir wood sapwood quartersawn lumber of wind turbine blade composite material, which comprises (1) selecting the straight raw fir wood whose diameter is larger than 30cm, without surface defects, (2) blanking the fir wood radially, (3) cutting the blanked fir wood into suitable blank sheets, drying until water content is lower than 12%, (4), using eye-measurement to select the blank with straight texture, uniform material quality, less than 2mm uniform growth ring width and non surface growth defects and processing defects as object work pieces. The invention is quick and simple, via which the fir wood pass percent can reach 99%. Compared with prior method that only detects bend elastic modulus of material, the invention can improve production efficiency more than 10 powers to support the fir wood batch application in wind-generated electricity blade production.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Method and system for eye measurements and cataract surgery planning using vector function derived from prior surgeries

ActiveUS20160073868A1Good curative effectImproved refractive correctionsLaser surgeryRefractometersIntraocular lensCorrective surgery

Improved devices, systems, and methods for planning cataract surgery on an eye of a patient incorporate results of prior corrective surgeries into a planned cataract surgery of a particular patient by driving an effective surgery vector function based on data from the prior corrective surgeries. The exemplary effective surgery vector employs an influence matrix which may allow improved refractive corrections to be generated so as to increase the overall efficacy of a cataract surgery by specifying one or more parameters of an intraocular lens (IOL) to be implanted during the cataract surgery.

Owner:AMO DEVMENT

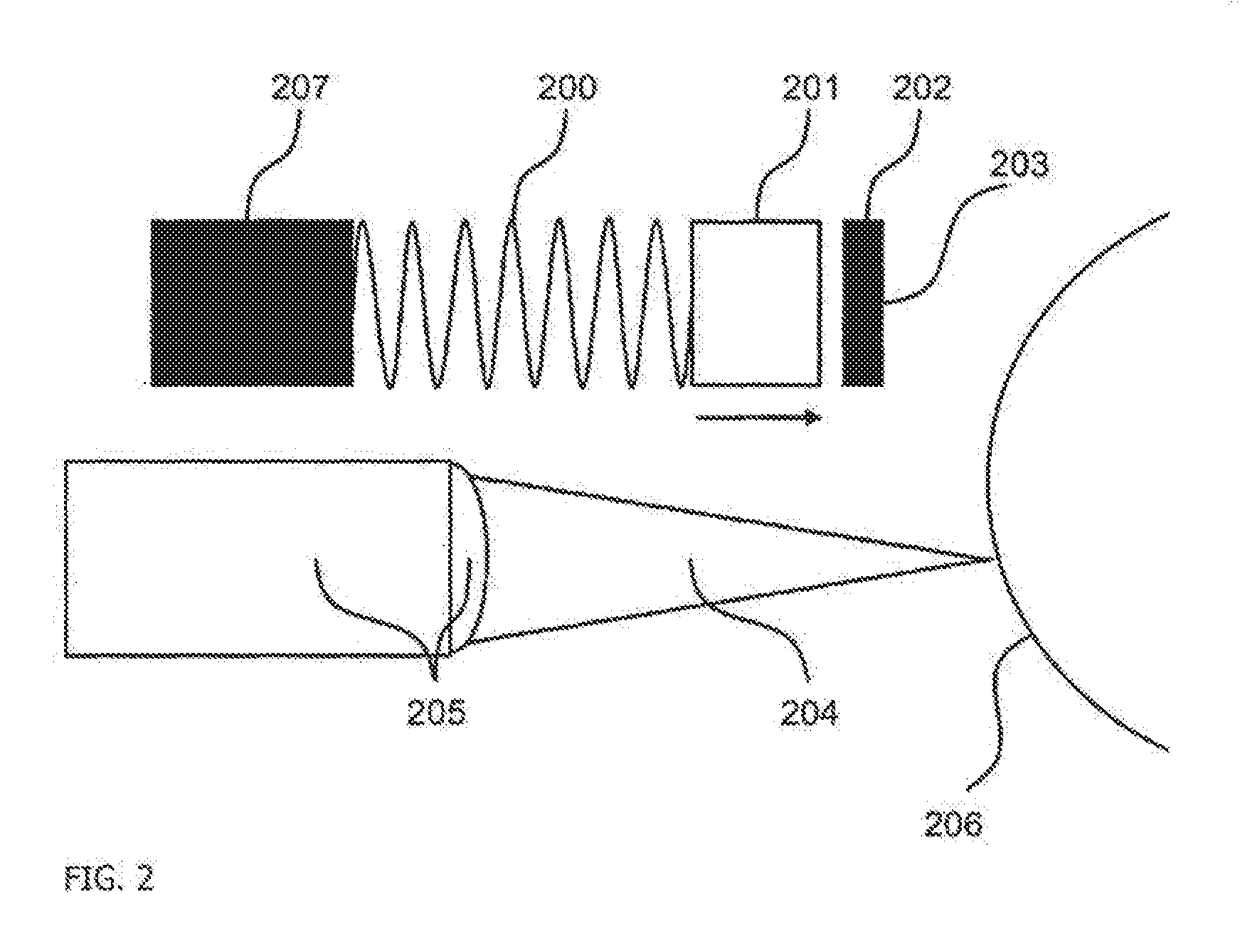

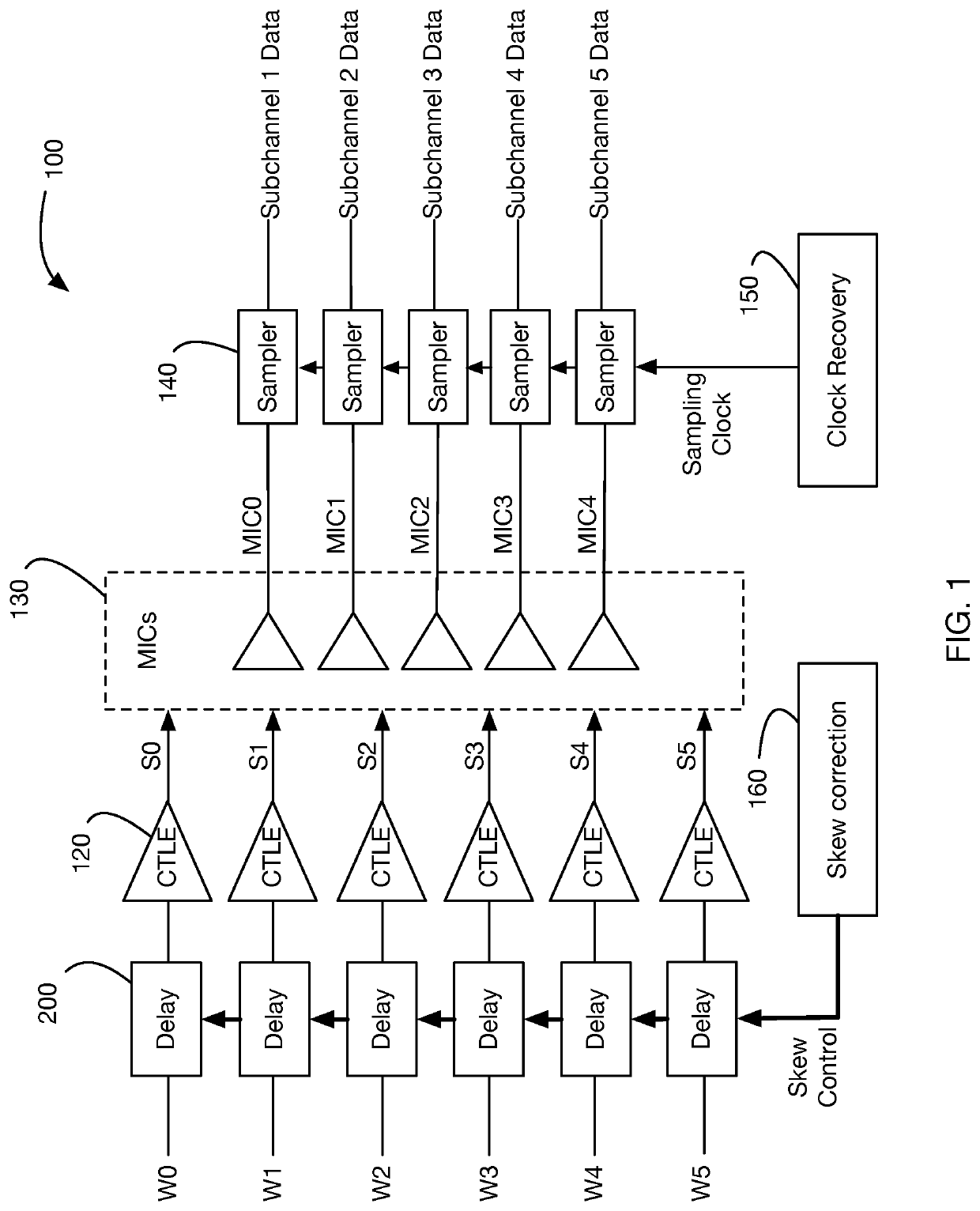

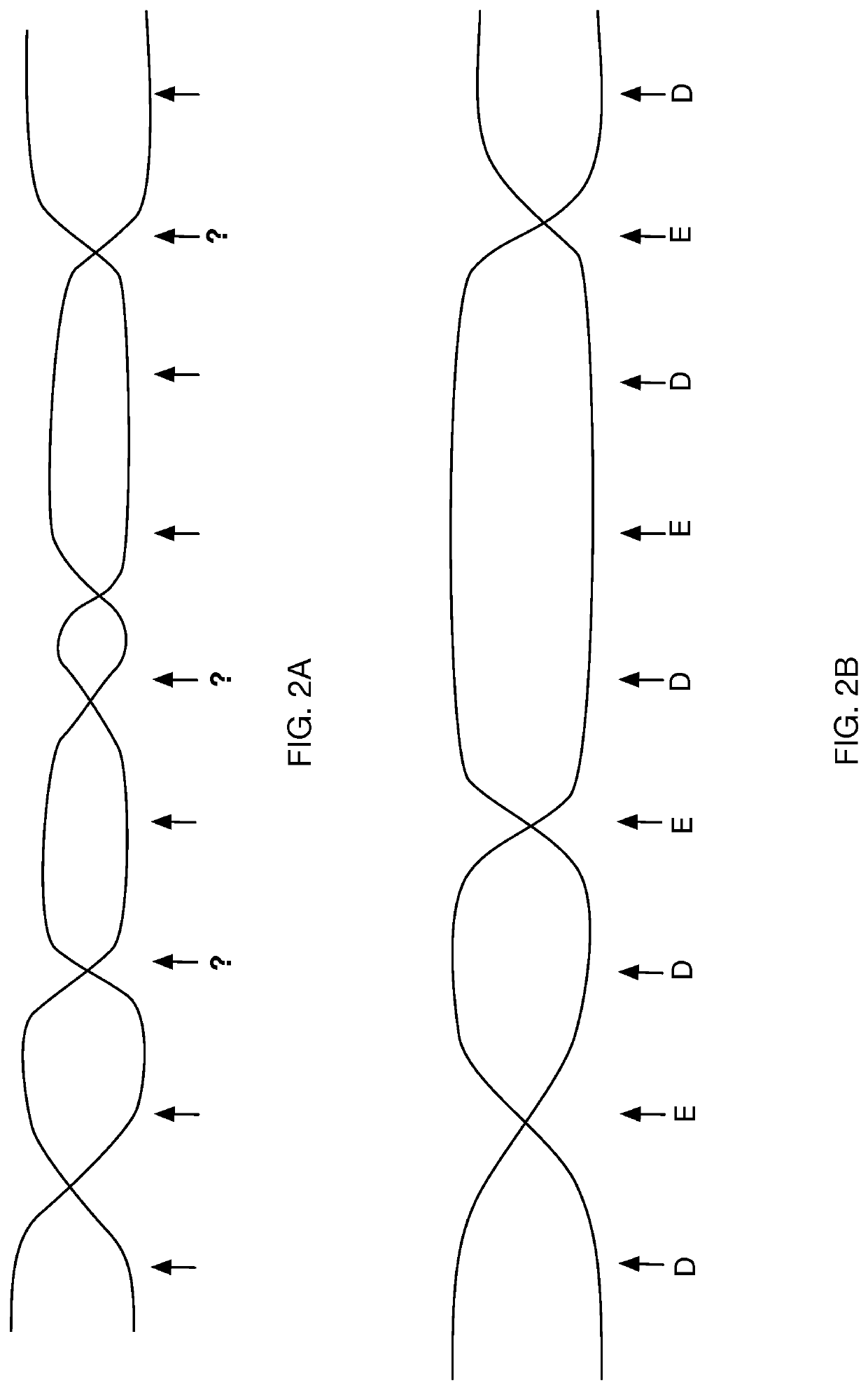

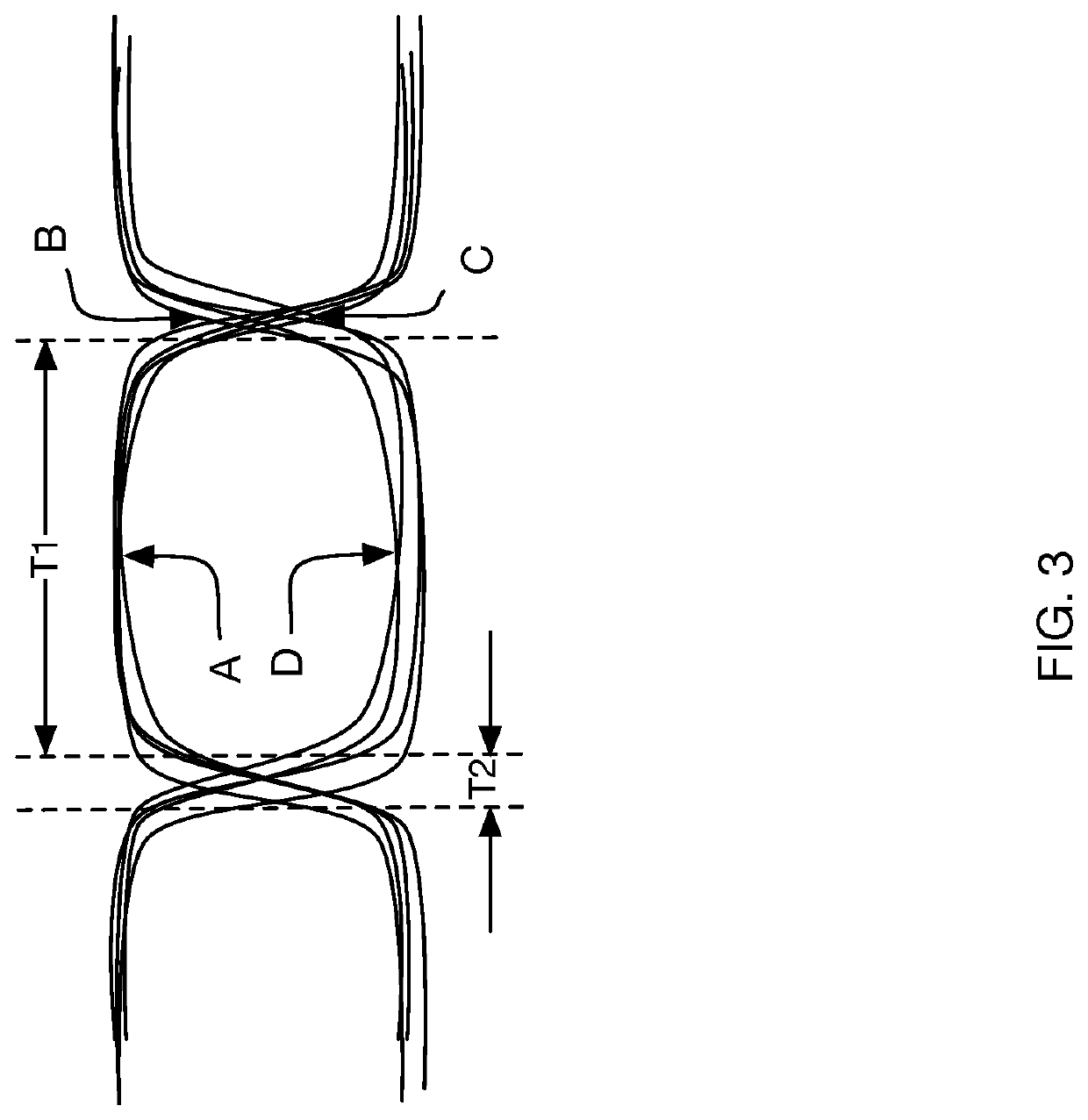

Method for measuring and correcting multiwire skew

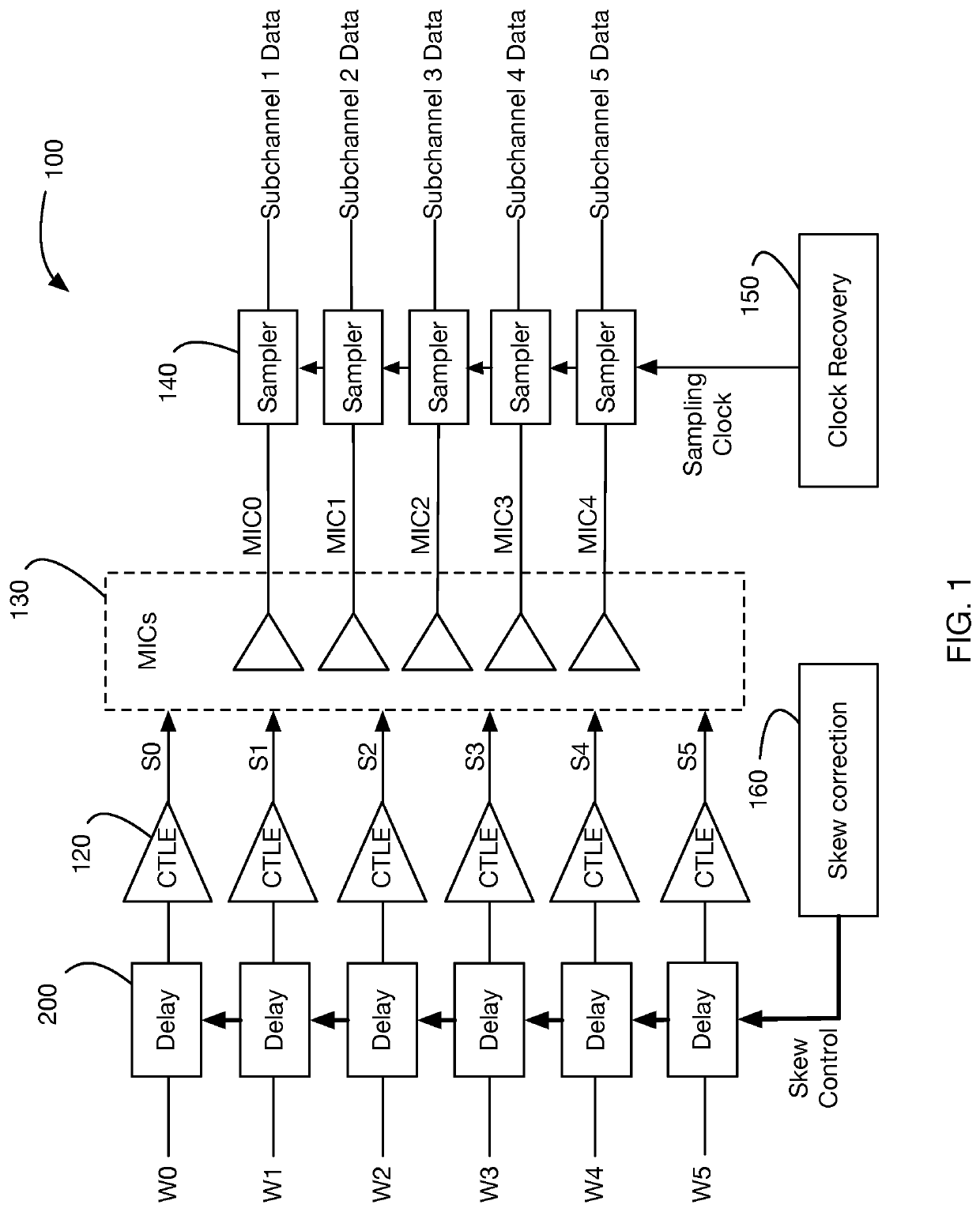

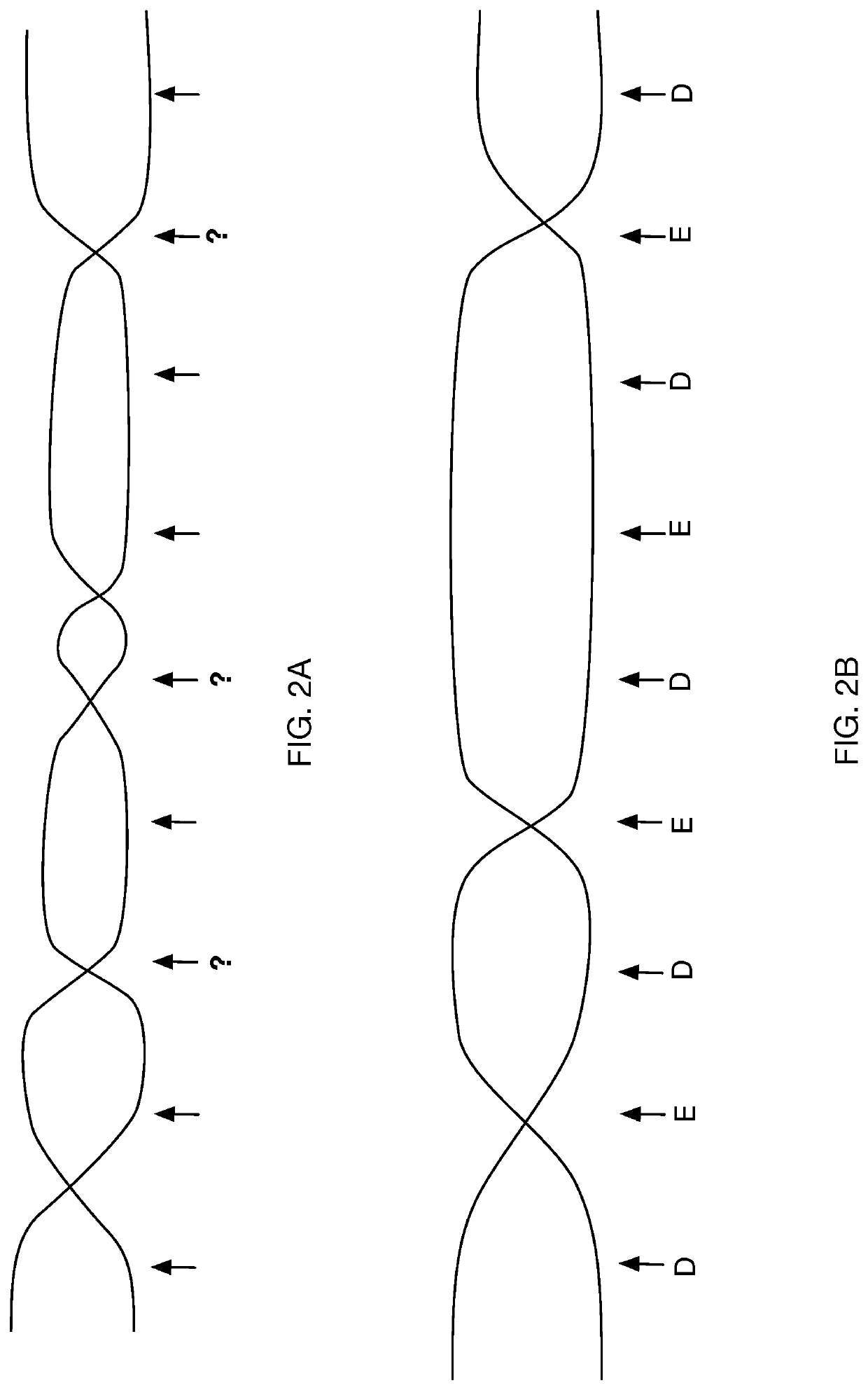

ActiveUS20200119901A1Reliable detectionAccurate interpretationSynchronisation information channelsError detection/correctionData streamAlgorithm

Methods and systems are described for sequentially obtaining a plurality of data streams, the plurality of data streams comprising a data stream in a current condition, a data stream in a skewed-forward condition, and a data stream in a skewed-backward condition, calculating, for each data stream in the plurality of data streams, a corresponding set of cost-function values by obtaining a corresponding set of eye measurements, the eye measurements obtained by adjusting a sampling threshold of a sampler generating a plurality of samples of the data stream, the plurality of samples comprising edge samples and data samples, wherein the data stream is sampled at a rate equal to twice a rate of the data stream and calculating the corresponding set of cost-function values based on the corresponding set of eye measurements, and generating a skew control signal based on a comparison of the sets of calculated cost-function values.

Owner:KANDOU LABS

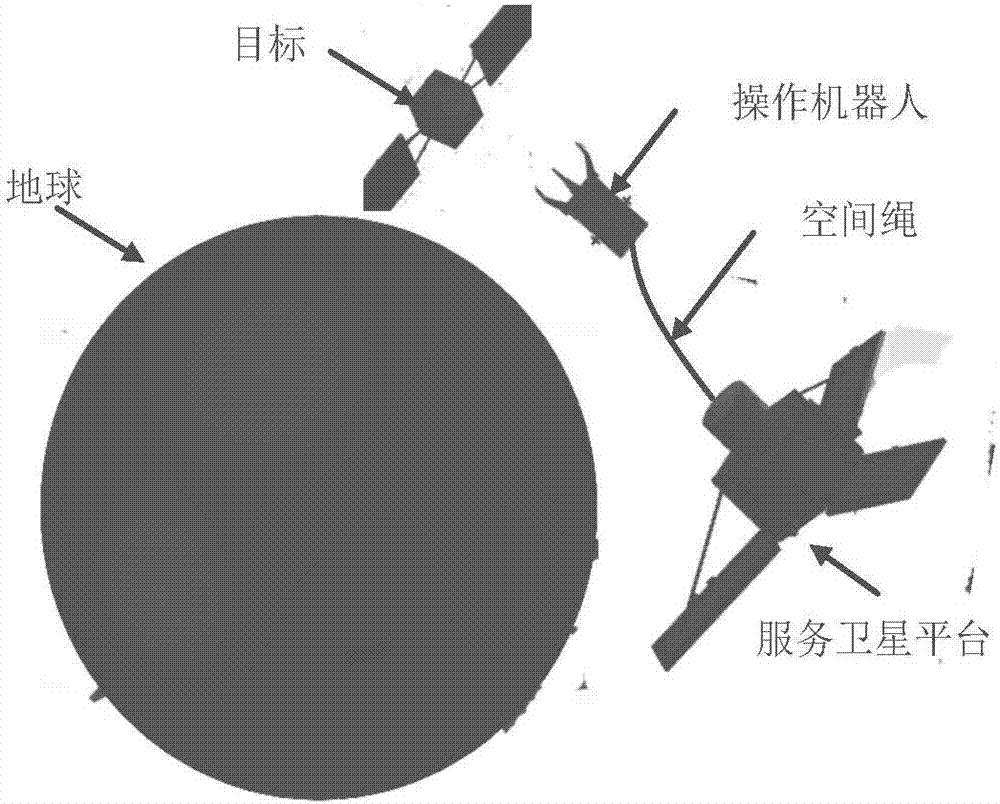

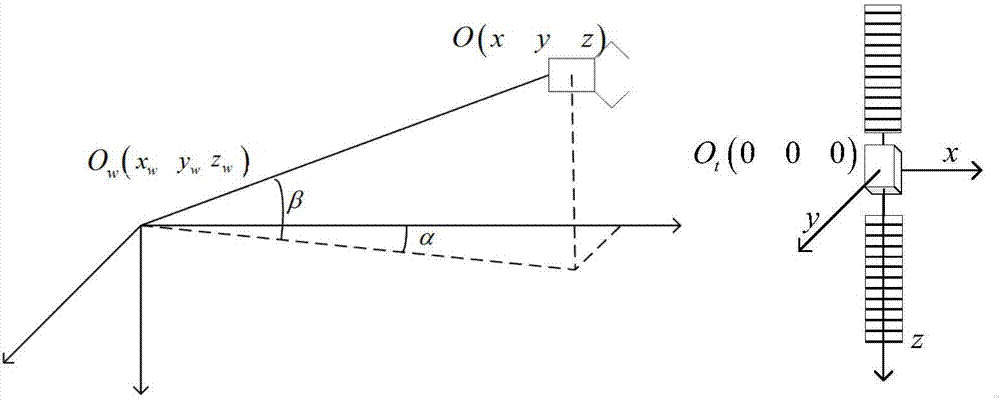

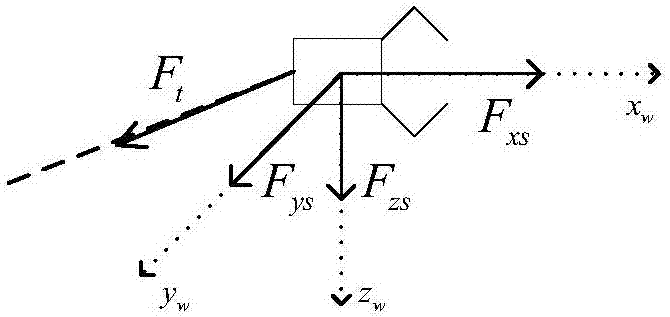

Space rope system robot vision accurate approach method

The invention relates to a space rope system robot vision accurate approach method. A camera is used for building state estimation based on a kalman filter for angle information obtained by a target, a model prediction control algorithm is used for controlling the direction and the speed of an operation robot, the state estimation of the filter and path tracking union are optimized, and therefore the space operation robot approaches the target on one hand, and relative location estimation with guaranteed accuracy is obtained through single-eye measurement on the other hand. The space rope system robot vision accurate approach method has the beneficial effects that a space rope system robot single-eye accurate approach method based on model prediction control is used, under the condition that the single-eye camera is used, real-time accurate positioning of the space rope system robot on the target can be achieved, and accurate target approaching is achieved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

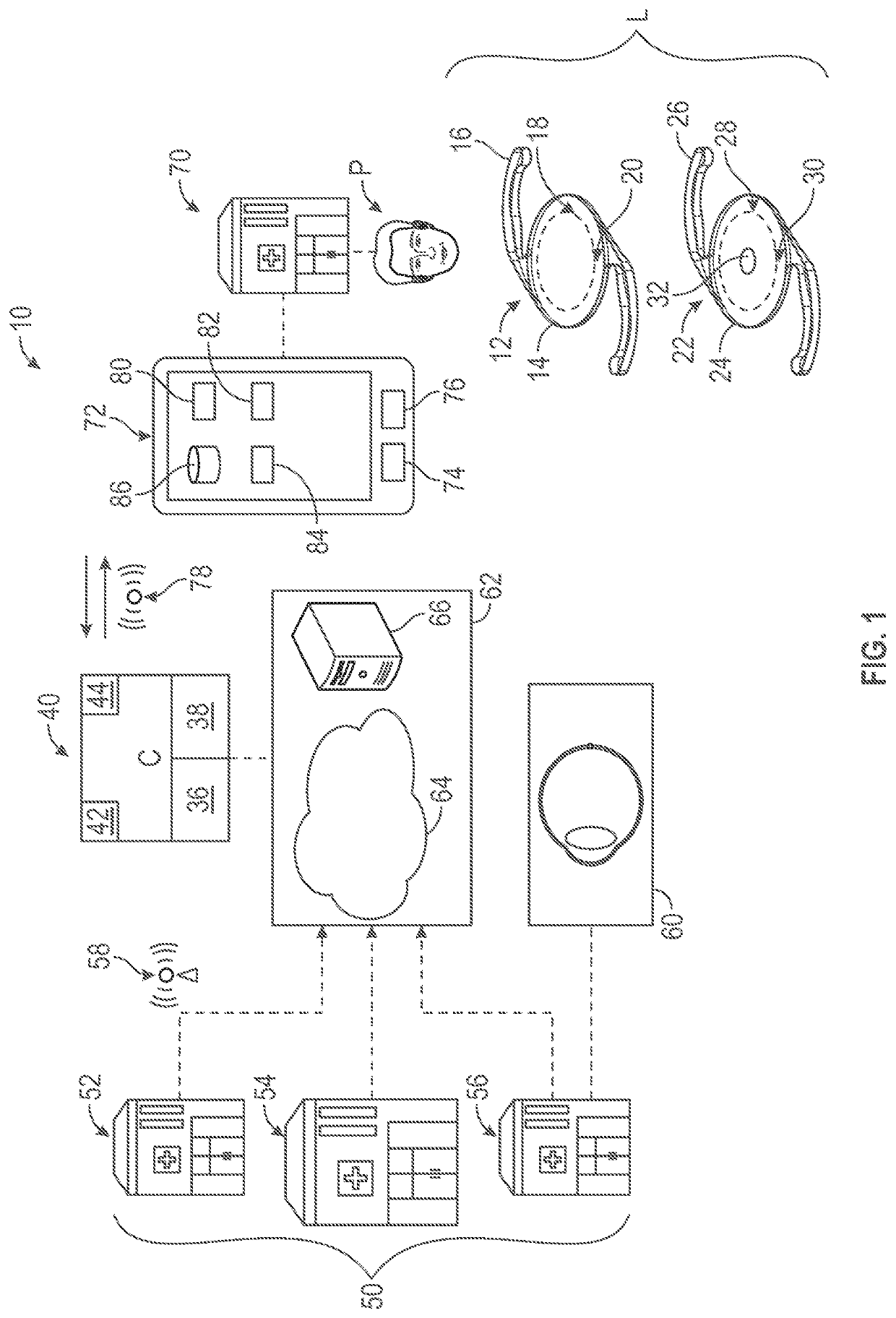

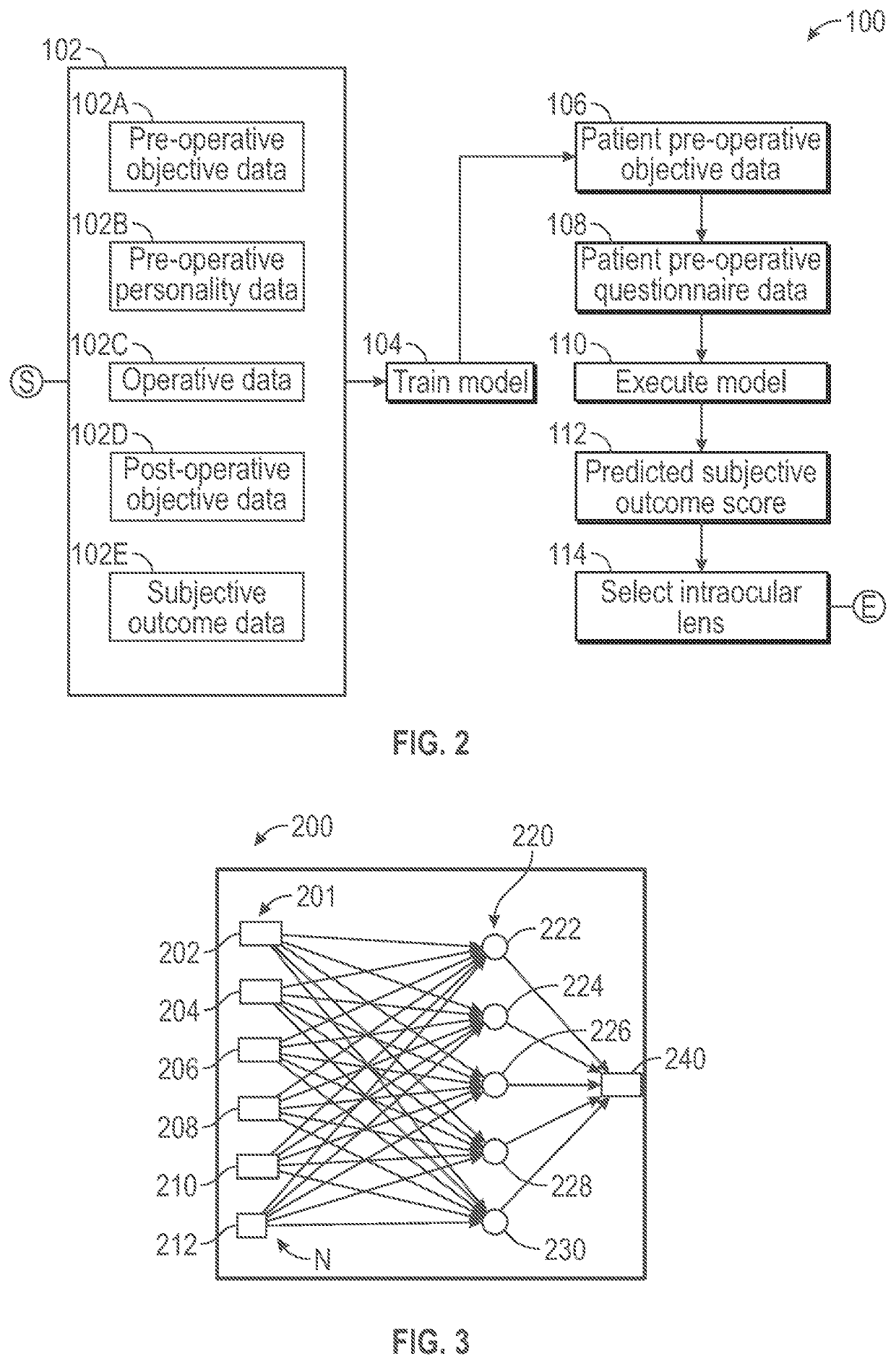

Selection of intraocular lens based on a predicted subjective outcome score

PendingUS20210369106A1Mechanical/radiation/invasive therapiesHealth-index calculationPhysical medicine and rehabilitationIntraocular lens

A system and method for selecting an intraocular lens, for implantation into an eye, includes a controller having a processor and a tangible, non-transitory memory on which instructions are recorded. The controller is configured to selectively execute a machine learning model trained with a training dataset. Execution of the instructions by the processor causes the controller to obtain pre-operative objective data for the patient, including one or more anatomic eye measurements. The controller is configured to obtain pre-operative questionnaire data for the patient, including at least one personality trait. The pre-operative objective data and the pre-operative questionnaire data are entered as respective inputs to the machine learning model. A predicted subjective outcome score for the patient is generated as an output of the machine learning model. The intraocular lens is selected based in part on the predicted subjective outcome score.

Owner:ALCON INC

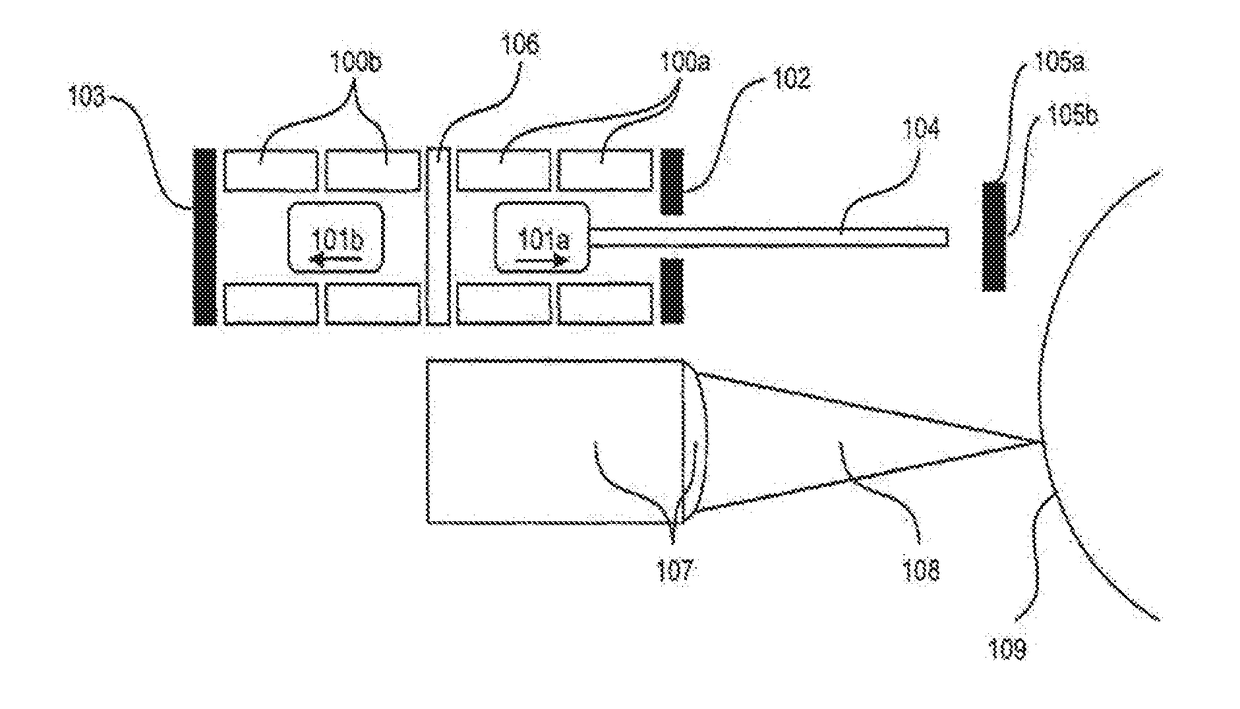

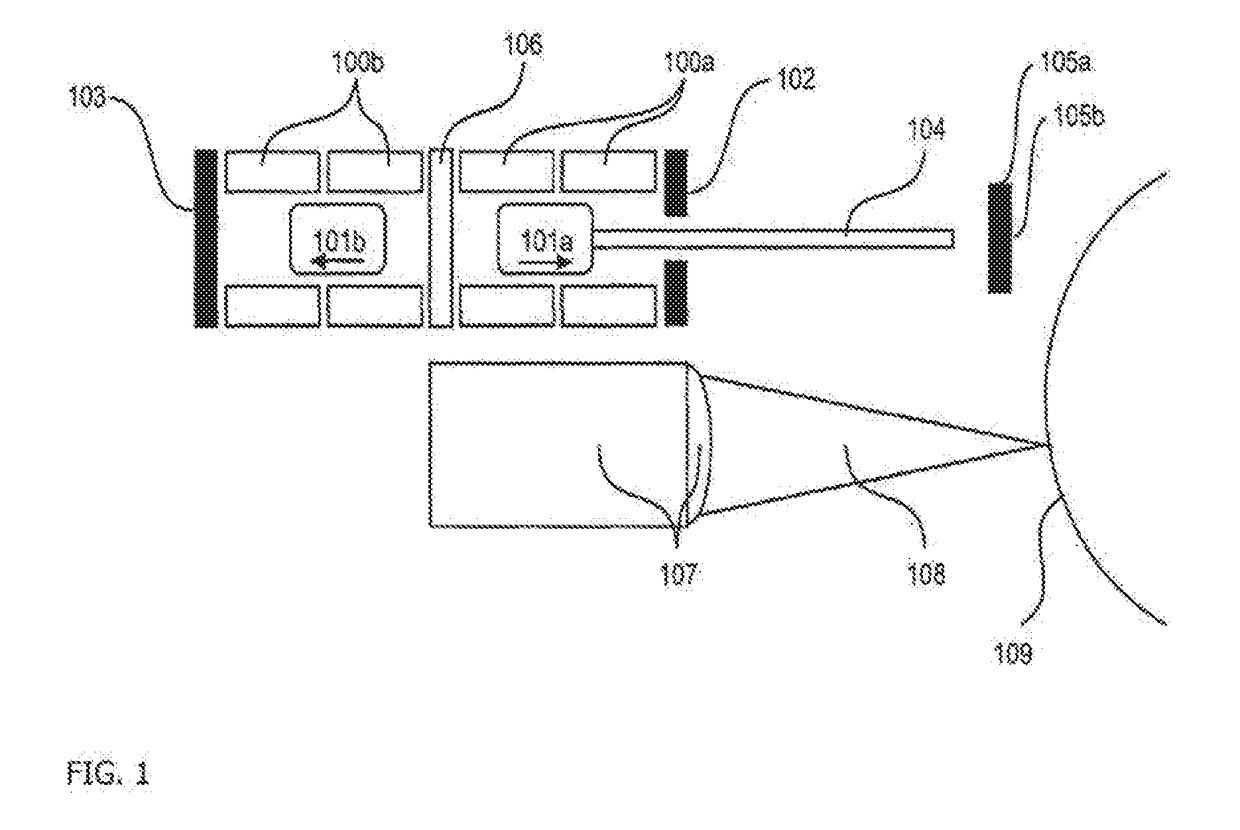

Method and arrangement for eye measurements

An intraocular pressure measurement arrangement is disclosed for measuring pressure of an eye of a patient. The arrangement can detect at least one of acoustic reflectivity, optical reflectivity, optical path difference, positioning of intraocular pressure measurement arrangement with respect to the eye, orientation of intraocular pressure measurement arrangement with respect to the eye, shape of cornea and corneal thickness. At least one source can produce acoustic, nonlinear acoustic, mechanical or a nonlinear mechanical wave from a distance, coupling to the eye to generate at least one surface wave. Upon triggering data acquisition, at least one surface wave from a distance from the eye can be detected to extract surface wave information with pressure information of the eye being based on the surface wave information.

Owner:PHOTONO OY

Method for measuring and correcting multiwire skew

ActiveUS10819499B2Reliable detectionAccurate interpretationSynchronisation information channelsSynchronisation error detectionData streamAlgorithm

Methods and systems are described for sequentially obtaining a plurality of data streams, the plurality of data streams comprising a data stream in a current condition, a data stream in a skewed-forward condition, and a data stream in a skewed-backward condition, calculating, for each data stream in the plurality of data streams, a corresponding set of cost-function values by obtaining a corresponding set of eye measurements, the eye measurements obtained by adjusting a sampling threshold of a sampler generating a plurality of samples of the data stream, the plurality of samples comprising edge samples and data samples, wherein the data stream is sampled at a rate equal to twice a rate of the data stream and calculating the corresponding set of cost-function values based on the corresponding set of eye measurements, and generating a skew control signal based on a comparison of the sets of calculated cost-function values.

Owner:KANDOU LABS

Method and system for eye measurements and cataract surgery planning using vector function derived from prior surgeries

ActiveUS10583039B2Good curative effectImproved refractive correctionsLaser surgeryIntraocular lensCorrective surgeryCataract surgery

Improved devices, systems, and methods for planning cataract surgery on an eye of a patient incorporate results of prior corrective surgeries into a planned cataract surgery of a particular patient by driving an effective surgery vector function based on data from the prior corrective surgeries. The exemplary effective surgery vector employs an influence matrix which may allow improved refractive corrections to be generated so as to increase the overall efficacy of a cataract surgery by specifying one or more parameters of an intraocular lens (IOL) to be implanted during the cataract surgery.

Owner:AMO DEVMENT

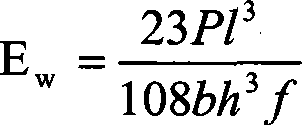

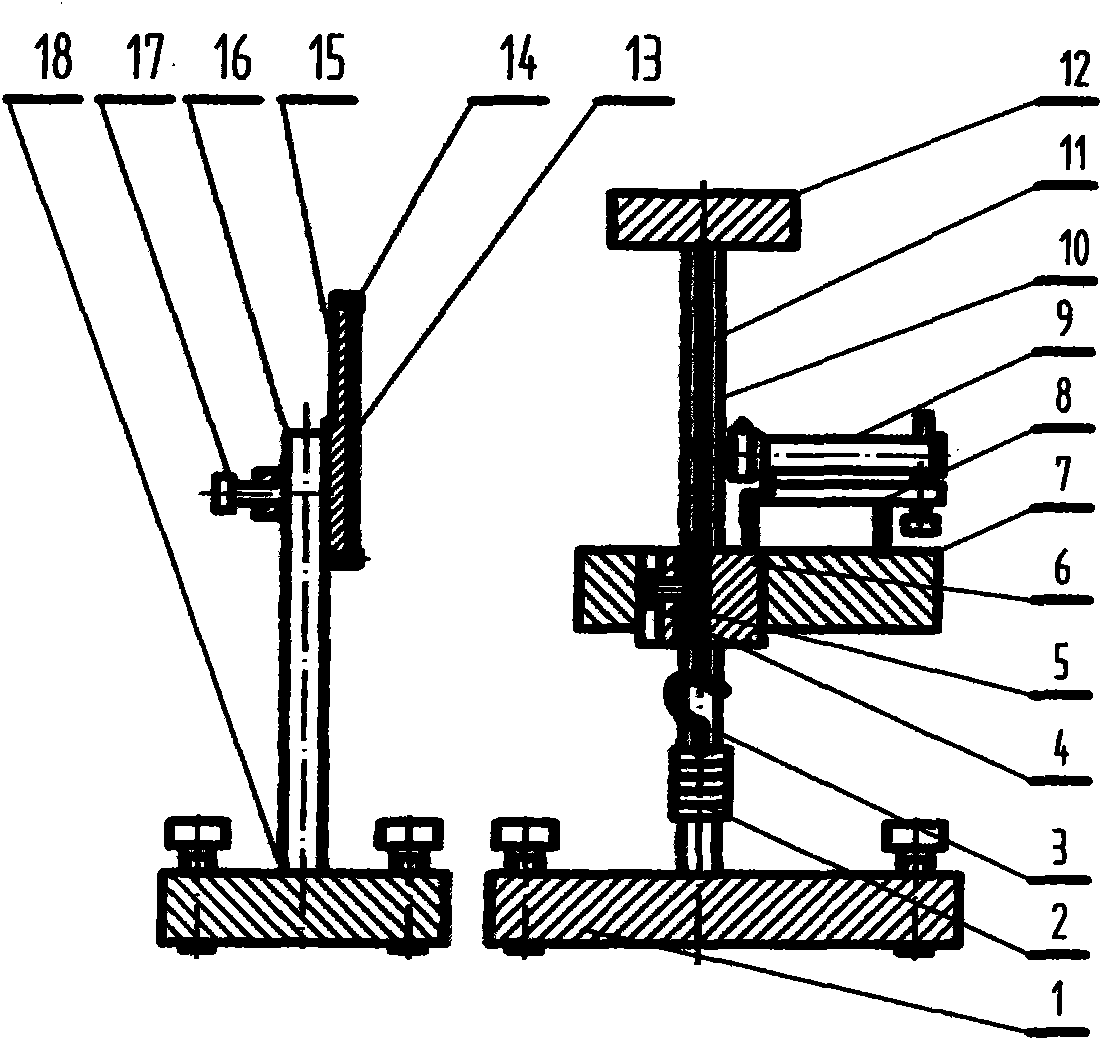

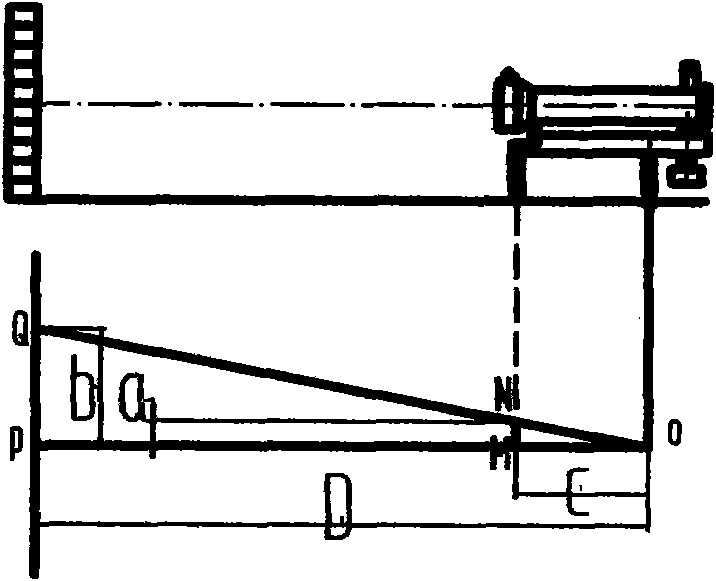

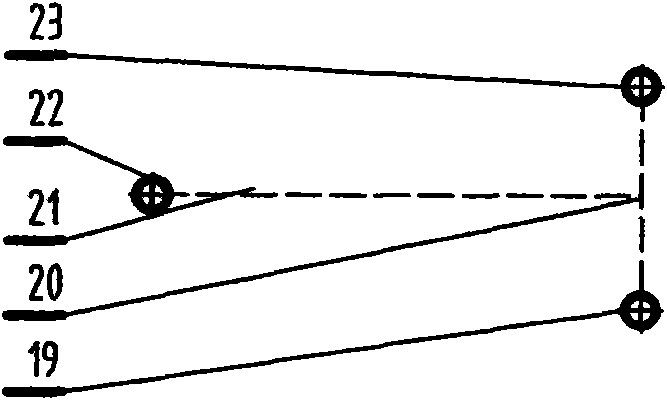

Young's elastic modulus tester with optical lever without reflector

InactiveCN101620044AOvercoming breakageEasy to adjustMaterial strength using tensile/compressive forcesUsing optical meansEyepieceOptical axis

The invention relates to a Young's elastic modulus tester with an optical lever without a reflector. A steel wire is fixed in a mode of the existing instrument structure, and a plane mirror is not needed. A telescope is arranged on a tripod, wherein a front foot of the tripod is arranged on the upper end face of a movable clamping head of the steel wire, and the other two rear feet are arranged in a small end face groove of a workbench with a groove of the Young's elastic modulus tester. The optical axis of the telescope is parallel to a vertical line of the connection line of the front foot and the two rear feet of the tripod. A scaleplate component is put on the right front of the optical axis of the telescope, and during debugging, the optical axis of the telescope is horizontally aligned to the middle of the scaleplate by eye measurement. The focal lengths of an eyepiece and an objective lens of the telescope are fine debugged so as to ensure that a scale image is clear. Then high and low positions are also debugged, and other operations are carried out as a routine method. Because the target of the scaleplate is large, and the optical axis of the telescope is directly aligned to the scaleplate, an operator is easy to align to the target and debug the focal length. Because the plane mirror is not used, the loss of breaking the plane mirror is radically avoided.

Owner:SICHUAN UNIV

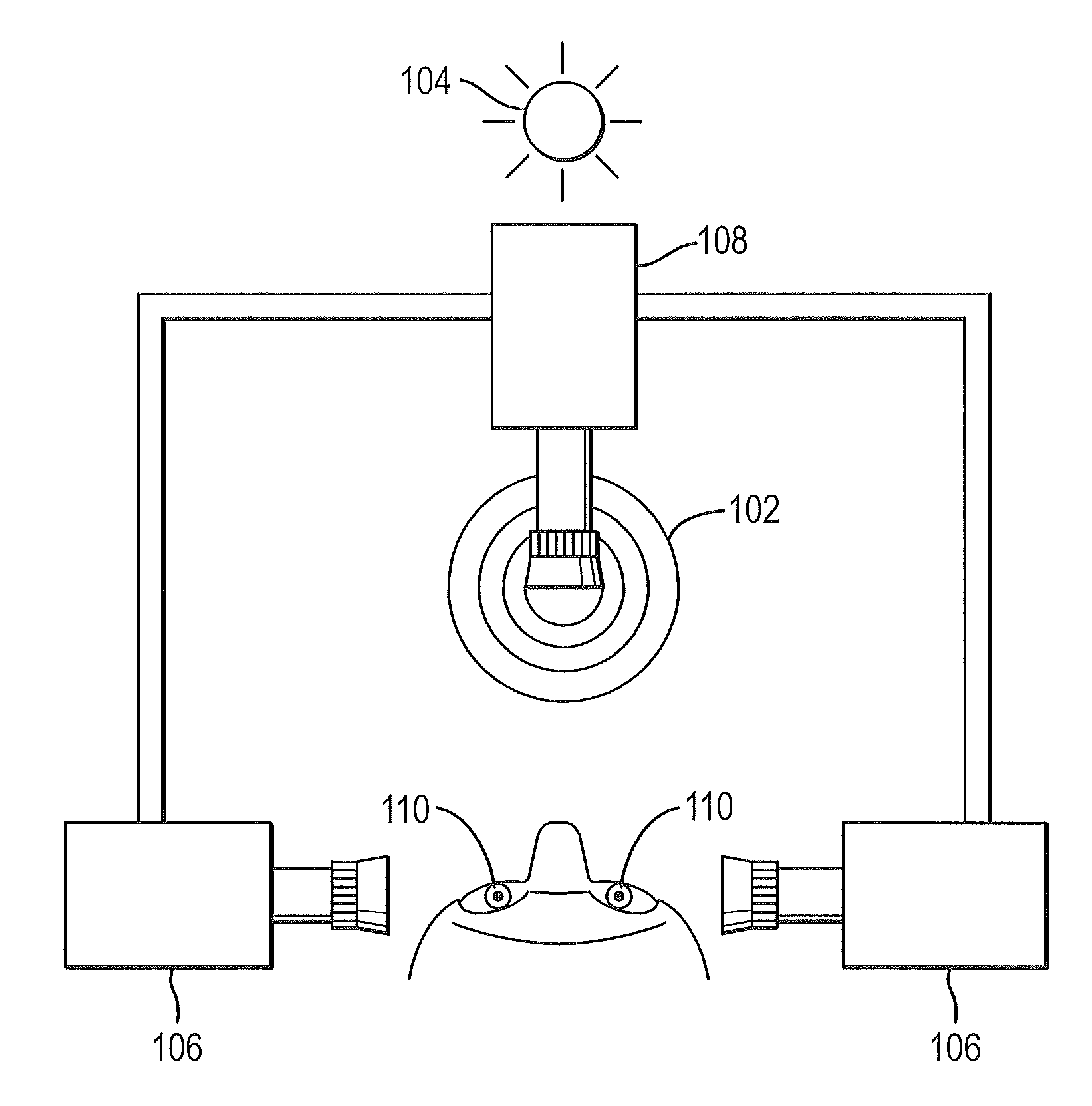

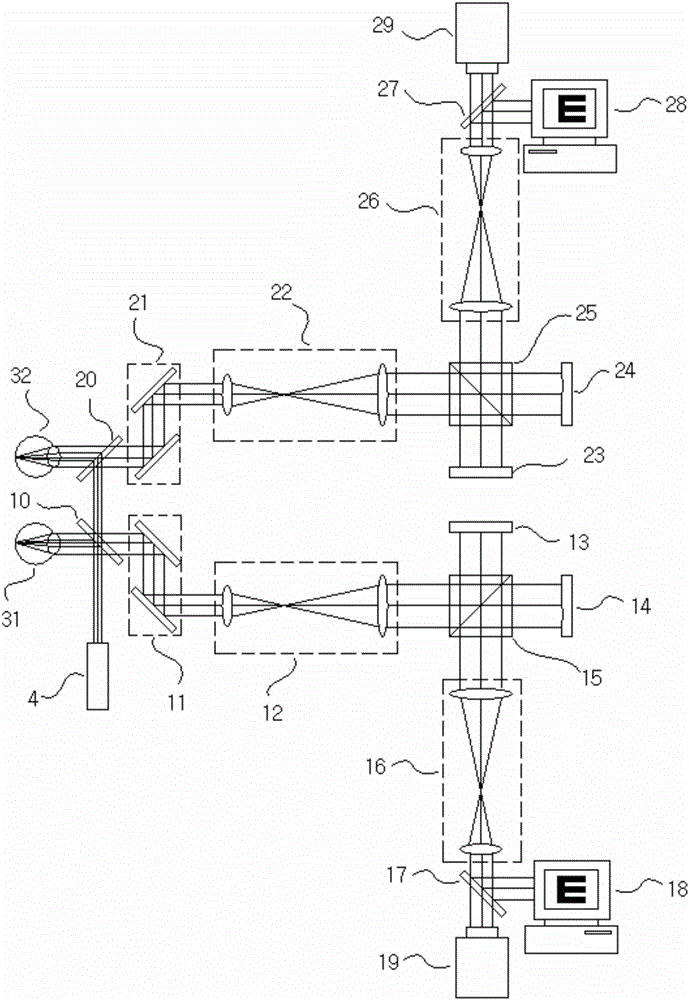

Binocular wave front aberration vision optical analysis system

The invention relates to a binocular wave front aberration vision optical analysis system, relates to the technical field of medical optics, and is used for achieving the technical effect of correcting binocular aberration. The system comprises a laser light source, a right eye subsystem and a left eye subsystem, wherein the right eye subsystem forms one right eye reference light path and one right eye measurement and correction light path through a right first spectroscope, a right dispersion prism, a right flat mirror, a right anamorphoscope, a right second spectroscope, a right Hartmann-Shack sensor, a right eye vision object, a right reflection unit, a right beam expanding unit, and a right beam shrinking unit; the left eye subsystem forms one left eye reference light path and one left eye measurement and correction light path through a left first spectroscope, a left dispersion prism, a left flat mirror, a left anamorphoscope, a left second spectroscope, a left Hartmann-Shack sensor, a left eye vision object, a left reflection unit, a left beam expanding unit, and a left beam shrinking unit. By adopting the system, the measurement and correction of binocular aberration can be realized.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Contact lenses

ActiveUS7717563B2Confer rotational and translational stabilitySimplify fitting and makingSpectales/gogglesEye diagnosticsWavefrontOptical property

Disclosed is a method of designing a soft contact lens, the method comprising the steps of: (a) measuring or defining a wavefront generated by passage of light through a selected eye and using the wavefront to generate a computer model of the optical characteristics of the selected eye; (b) measuring or defining the topography of the cornea of the selected eye; (c) incorporating into the computer model a soft contact lens, the posterior surface topography of which is defined by the topography of the cornea, offset by an arbitrary amount intended to represent the tear layer thickness of the selected eye, said lens having a defined thickness at a selected locus on the anterior surface; (d) calculating a desired topography for the anterior surface of the lens such that the wavefront will be corrected to assume a desired pattern (for example, preferably planar, the plane of which is perpendicular to the optical axis of the lens) when passing through the computer model eye / lens combination; (e) remodeling the lens off-eye by adapting the posterior topography of the lens to a desired posterior topography to be manufactured; and (f) recalculating a modified anterior topography required as a result of adapting the posterior topography, the modified anterior topography being intended to preserve the desired wavefront pattern defined in (d) when the lens is in situ on the selected eye.

Owner:CONTACT LENS PRECISION LAB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com