Quarter-sawn timber visual measurement and mechanical classification method of fir sapwood of wind electric blade composite

A composite material and wind power blade technology, which is applied in the direction of material analysis, analysis material, measuring device and other directions by optical means, can solve the problems of difficulty in meeting the industrialized mass production of fir, time-consuming and labor-intensive, etc., and achieves the improvement of production efficiency, and the method is quick and easy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention specifically carries out material selection and processing according to the following steps:

[0017] Step 1: Select a number of new Chinese fir logs with a diameter of more than 30 cm, a straight trunk, and no defects in appearance (including decay, bending, etc.);

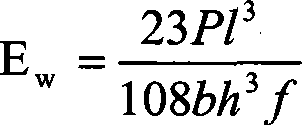

[0018] Step 2: Carry out "meter"-shaped blanking on the selected material, as shown in Figure 2, the arrow in the figure indicates the sawing direction;

[0019] Step 3: Saw the standard fir sapwood quarter-cut board rough, dry it in a drying kiln until the moisture content is lower than 12%, remove various wood defects, and finish it into 500mm×20mm×20mm (length×width×thickness) The standard slats are spare;

[0020] Step 4: Through visual inspection, the selected rough plate meets the following requirements: straight texture, uniform material, annual ring width less than 2mm and uniform distribution, no growth defects and processing defects in appearance, and the number of "mountai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Flexural modulus of elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com