Magnetic mesoporous silica microsphere material with yolk structure and preparing method thereof

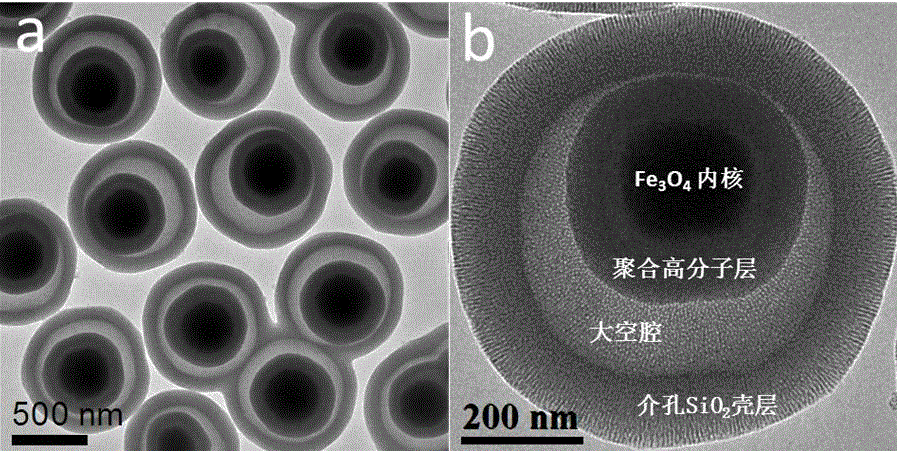

A technology of mesoporous silica and egg yolk structure, applied in magnetic materials, microsphere preparation, silica, etc., can solve problems such as uneven morphology of composite materials, difficulty in controlling cavity size, and destruction of mesoporous channel structure, achieving The effects of rapid magnetic response, uniform morphology, and high pore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Evenly disperse 0.1g of magnetic iron ferric oxide particles with a size of about 300nm in 40mL of ethanol and 20mL of deionized water, add 1mL of concentrated ammonia water (28wt%) to neutralize 0.2g of resorcinol, stir at room temperature for 5 minutes, and then Add 0.2 g of formaldehyde solution, stir at room temperature for 6 hours, and obtain magnetic composite microspheres coated with a layer of phenolic resin on the surface. The product is separated by a magnet and washed with a mixed solution of ethanol and water. After washing, the product is dried at room temperature before use.

[0024](2) Ultrasonically disperse 0.1g of magnetic Fe3O4 composite microspheres coated with a layer of phenolic resin in 80mL of dissolved 0.5g of cetyltrimethylammonium bromide (CTAB) and 0.8g of concentrated ammonia water. 20ml of n-hexane dissolved in 2ml of tetraethyl orthosilicate (TEOS) was added dropwise to the deionized water. Stir in a water bath at 30°C for 12 hours, se...

Embodiment 2

[0026] (1) 0.1g magnetic NiFe with a size of about 250nm 2 o 4 The particles are uniformly dispersed in 60mL ethanol and 40mL deionized water, add 0.8mL concentrated ammonia water (28wt%) and 0.2g 3-aminophenol, stir at room temperature for 5min, add 0.2g formaldehyde solution to it, and obtain a layer of polymer resin polymer coated on the surface. The magnetic composite microspheres are separated by a magnet and washed with a mixed solution of ethanol and water. After washing, the product is dried at room temperature and then used.

[0027] (2) 0.1g of magnetic NiFe coated with a layer of polymer resin polymer on the surface 2 o 4 The composite microspheres were ultrasonically dispersed in 60mL of deionized water dissolved in 0.4g of cetyltrimethylammonium chloride (CTAC) and 0.6ml of concentrated ammonia water, and 2ml of tetramethylorthosilicate (TMOS) was added dropwise 20ml of cyclohexane, mechanically stirred at 40 degrees for 12h, the product was separated with a ma...

Embodiment 3

[0029] (1) Evenly disperse 0.1g of magnetic γ-iron sesquioxide particles with a size of about 400nm in 10mL of ethanol and 80mL of deionized water, add 0.05gKOH, 0.3ml of formaldehyde, stir for 5min, add 0.3g of resorcinol, stir for 6h , to obtain magnetic composite microspheres coated with a layer of phenolic resin polymer on the surface, the product is separated by a magnet and washed with a mixed solution of ethanol and water, and the product is dried at room temperature after washing.

[0030] (2) Ultrasonic disperse the magnetic γ-ferric oxide composite microspheres coated with a layer of phenolic resin polymer in 60mL deionized water dissolved in 0.4gCTAB and 0.05gNaOH, and add dropwise 2ml of orthosilicon 30ml of n-hexane with ethyl acetate (TEOS), mechanically stirred at 45°C for 10h, the product was separated by a magnet and washed with a mixed solution of ethanol and water, after drying, in order to further remove the surfactant in the mesoporous channels Clean, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com