Nanometer immune-magnetic bead, and preparation method thereof and kit thereof

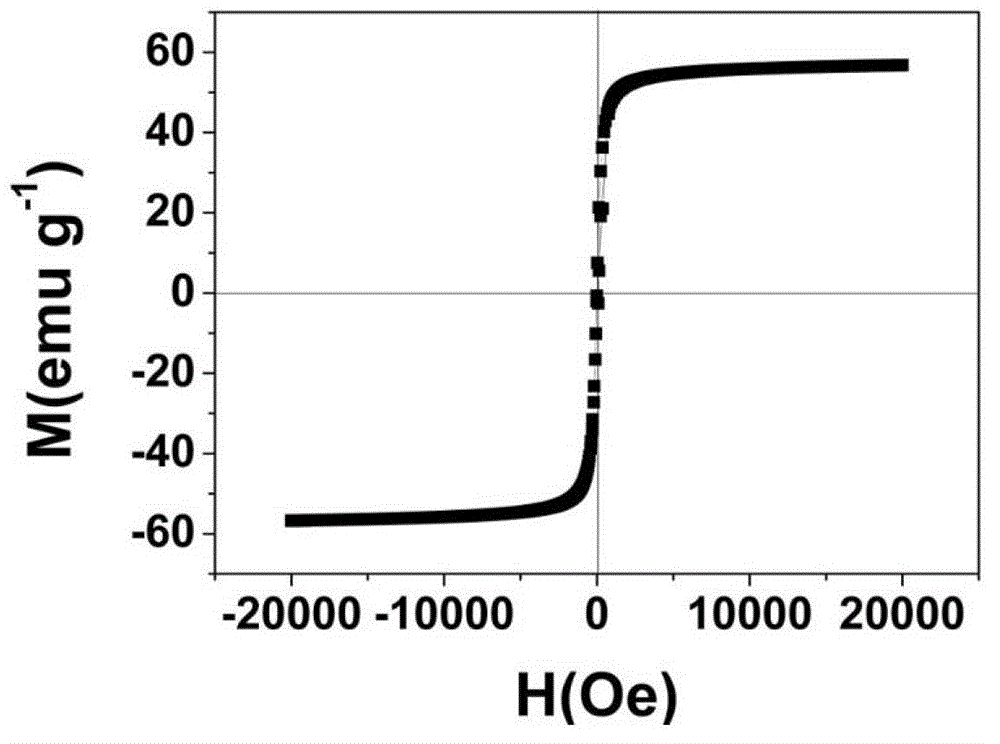

A technology of immunomagnetic beads and kits, which is applied in the field of preparation of nano-immunomagnetic beads, can solve the problems of easy aggregation and precipitation, many operation steps, and low saturation magnetization, and achieve good dispersion stability, simple preparation process, and magnetic response. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The method for preparing nano-immunomagnetic beads provided by the invention comprises the following steps:

[0023] (1) In an inert atmosphere, inject an alkaline solution into a mixed solution containing an iron source and a stabilizer to obtain magnetic nanoparticles; the volume ratio of the alkaline solution to the mixed solution is 1:(8-10) , the mol ratio of the iron source, the stabilizer and the alkaline substance in the alkaline solution is 1:(5-10):(10-14);

[0024] (2) Modification of antibodies with specific immune activity on the surface of magnetic nanoparticles.

[0025] According to the present invention, the alkaline substance can be any alkali metal hydroxide commonly used in the field, preferably sodium hydroxide and / or potassium hydroxide. In the alkaline solution, there is no particular limitation on the concentration of the alkaline substance, preferably 2-3 mmol / mL.

[0026] According to the present invention, the solvents in the alkaline soluti...

Embodiment 1

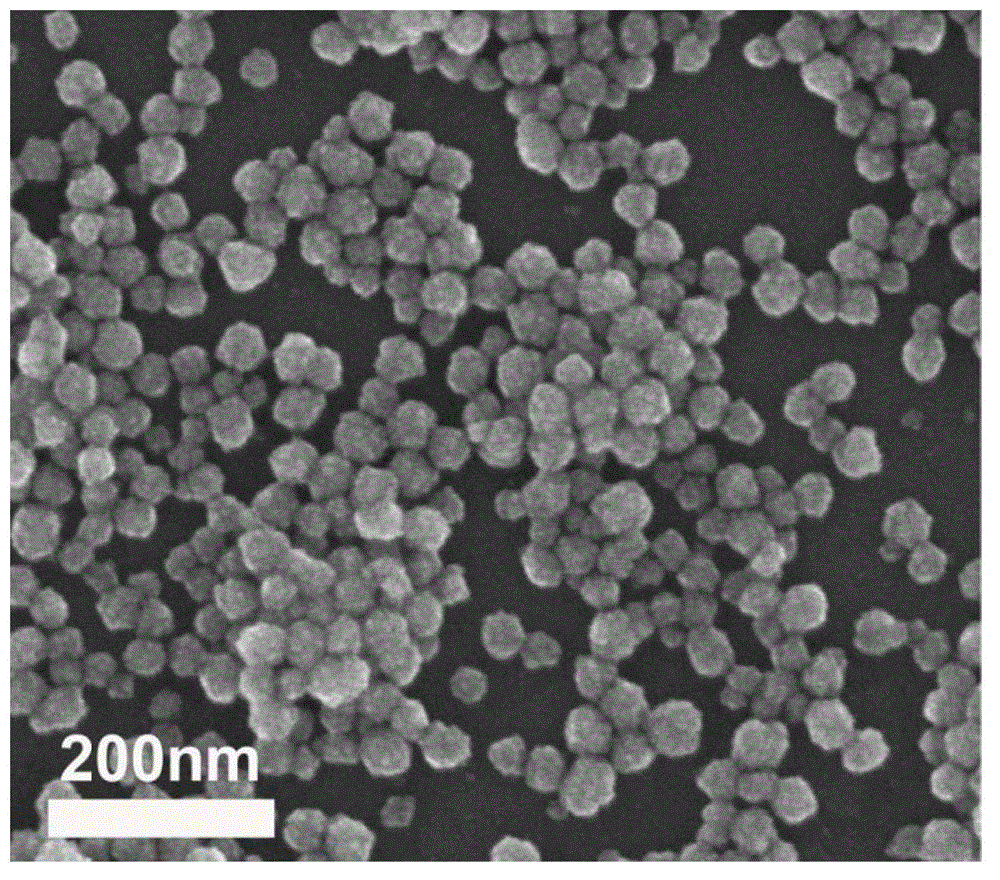

[0044] (1) Preparation of magnetic nanoparticles

[0045] Add sodium hydroxide to the diethylene glycol solvent, heat to 110°C under the protection of argon, keep it for 1h, and then cool down to 70°C to obtain a sodium hydroxide solution with a mass concentration of 0.1g / mL;

[0046] Add anhydrous ferric chloride and polyacrylic acid to diethylene glycol solvent (the amount of solvent is 42mL per millimole of anhydrous ferric chloride), and mix under the conditions of mechanical stirring and argon protection. The solution was heated to 220°C and kept for 30 minutes, wherein the molar ratio of anhydrous ferric chloride and polyacrylic acid was 1:10;

[0047] At 220°C, inject 3.5mL of sodium hydroxide solution into 34mL of the mixture of anhydrous ferric chloride and polyacrylic acid within 1s, adjust the temperature to 210°C after injection, and allow the reaction to continue for 1h at this temperature, Naturally cooling the reaction solution to 25°C to obtain a solution cont...

Embodiment 2

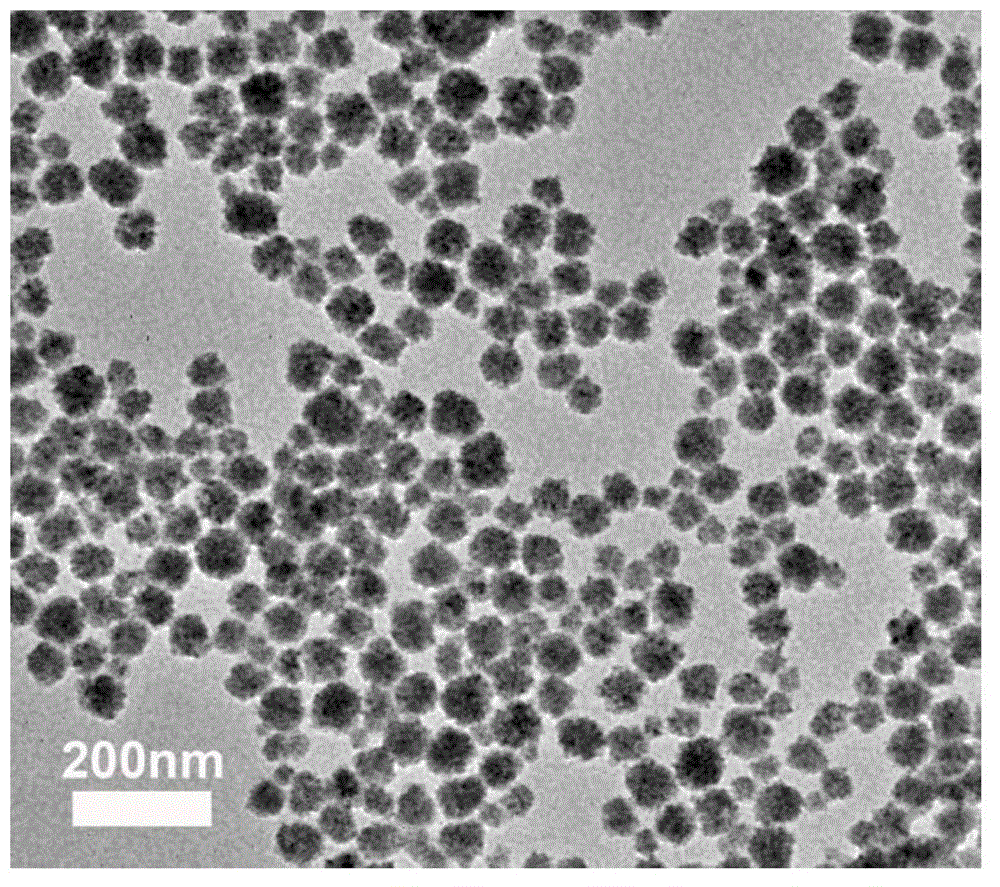

[0057] (1) Preparation of magnetic nanoparticles

[0058] Add sodium hydroxide to the diethylene glycol solvent, heat to 110°C under the protection of argon, keep it for 1h, and then cool down to 70°C to obtain a sodium hydroxide solution with a mass concentration of 0.1g / mL;

[0059] Add anhydrous ferric chloride and polyacrylic acid to diethylene glycol solvent (the amount of solvent is 42mL per millimole of anhydrous ferric chloride), and mix under the conditions of mechanical stirring and argon protection. The solution was heated to 220°C and kept for 30 minutes, wherein the molar ratio of anhydrous ferric chloride and polyacrylic acid was 1:5;

[0060] At 220°C, inject 3.5mL of sodium hydroxide solution into 34mL of the mixture of anhydrous ferric chloride and polyacrylic acid within 5s, adjust the temperature to 210°C after injection, and keep the reaction at this temperature for 1h, Naturally cooling the reaction solution to 25°C to obtain a solution containing magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com