Method for preparing carbon-copper-coated ferroferric oxide composite magnetic oil removal particles

A technology of ferroferric oxide and composite magnetism, applied in chemical instruments and methods, separation methods, alkali metal compounds, etc., can solve the problems of high cost of polymer compounds, inability to produce in large quantities, cumbersome preparation process, etc., and achieve stable carbon layer , efficient recovery, and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

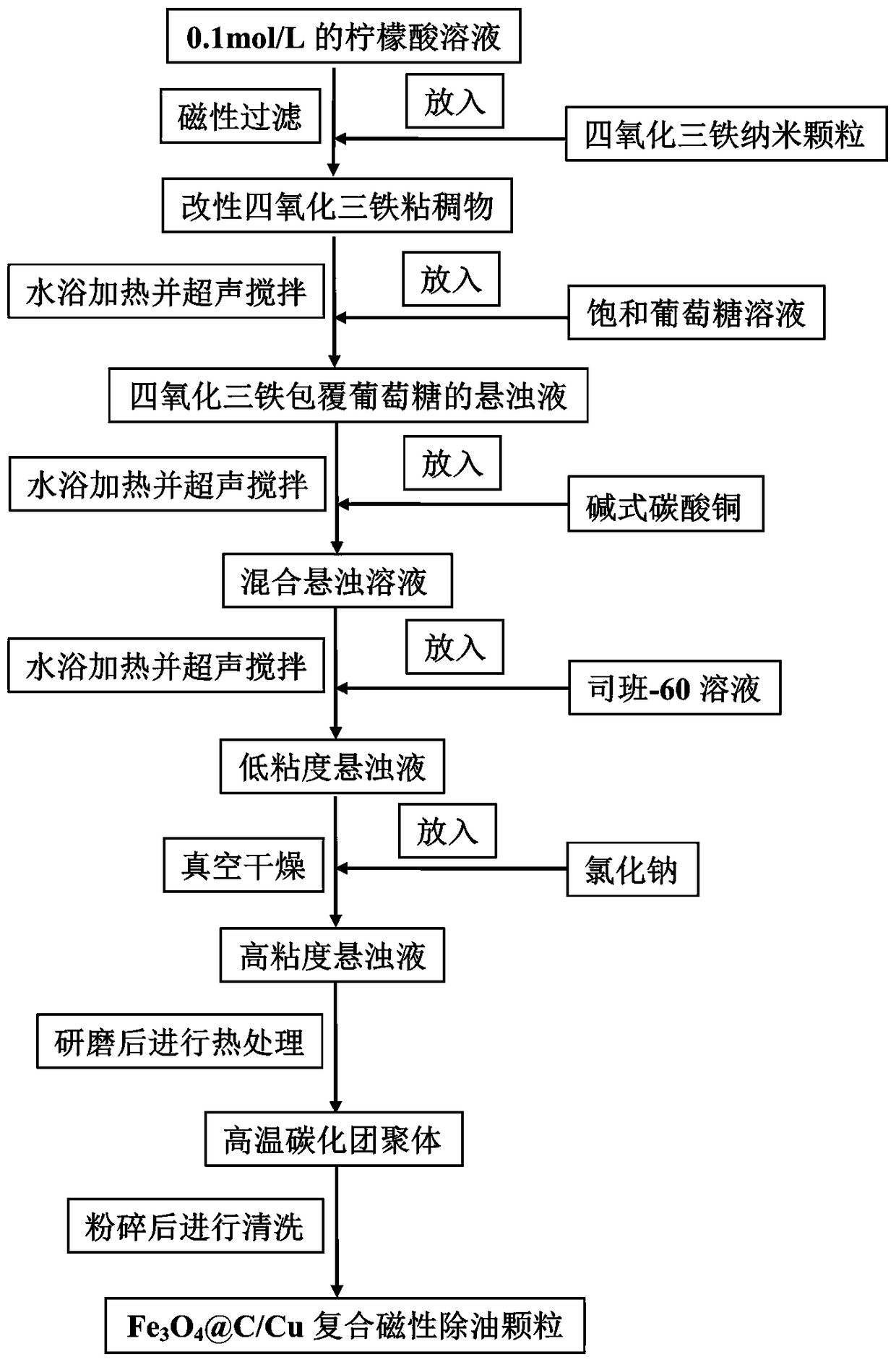

[0037] Such as figure 1 as shown, figure 1 is Fe 3 o 4 Flow chart of the preparation of @C / Cu composite magnetic degreasing particles.

[0038]In the preparation of 0.1mol / L citric acid modified solution, first weigh 0.600g of citric acid with an electronic balance and put it into a beaker, then add 20ml of distilled water and 4ml of absolute ethanol, put the beaker into a water bath heating pot at 60°C Heat the water for 5-10 minutes and stir until it is completely dissolved until the solution is clear to obtain a 0.1mol / L citric acid modified solution.

[0039] When preparing a saturated glucose solution, first weigh 15.0-20.0g of glucose with an electronic balance and put it into another beaker, then add 15-20ml of distilled water, put the beaker into a water-bath heating pot, heat it at 60°C and stir it. It dissolved completely until the solution was clear, giving a saturated glucose solution.

[0040] When preparing the Span-60 solution, first weigh 0.8-1.0g Span-60 ...

Embodiment 2

[0057] A method for preparing carbon copper-coated ferric oxide composite magnetic degreasing particles, characterized in that: the specific steps of the method are as follows:

[0058] Step 1: Prepare 0.1mol / L citric acid modification solution: distilled water and absolute ethanol are prepared as a solvent in a volume ratio of 4:1, heated in a water bath at 50°C for 5 minutes, and stirred until completely dissolved to obtain 0.1mol / L citric acid modified solution;

[0059] Step 2: Prepare a saturated glucose solution: at room temperature, weigh 15.0 g of glucose and put it into a beaker, add 15 ml of distilled water, heat and stir in a water bath at 50°C to completely dissolve until the solution is clear, and obtain a saturated glucose solution;

[0060] Step 3: Prepare Sipan-60 solution: prepare Sipan-60 solution with a concentration of 0.4g / mL, heat in a water bath at 50°C for 5min, stir until completely dissolved, and obtain a Sipan-60 solution with a concentration of 0.4g...

Embodiment 3

[0075] A method for preparing carbon copper-coated ferric oxide composite magnetic degreasing particles, characterized in that: the specific steps of the method are as follows:

[0076] Step 1: Prepare 0.1mol / L citric acid modification solution: distilled water and absolute ethanol are prepared as a solvent in a volume ratio of 4:1, heat in a water bath at 70°C for 10 minutes, stir until completely dissolved, and obtain 0.1mol / L citric acid modified solution;

[0077] Step 2: Prepare a saturated glucose solution: at room temperature, weigh 20.0 g of glucose and put it into a beaker, add 20 ml of distilled water, heat and stir in a water bath at 70°C to completely dissolve until the solution is clear, and obtain a saturated glucose solution;

[0078] Step 3: Prepare Sipan-60 solution: prepare Sipan-60 solution with a concentration of 0.5g / mL, heat in a water bath at 70°C for 10min, stir until completely dissolved, and obtain a Sipan-60 solution with a concentration of 0.5g / mL; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com