Inorganic magnetic three-dimensional ordered macro-porous material and preparation method thereof

A three-dimensional ordered, macroporous material technology, applied in the direction of magnetic properties of inorganic materials, inorganic ineffective components, etc., can solve the problems of poor magnetic response, expensive synthetic raw materials, and high toxicity of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

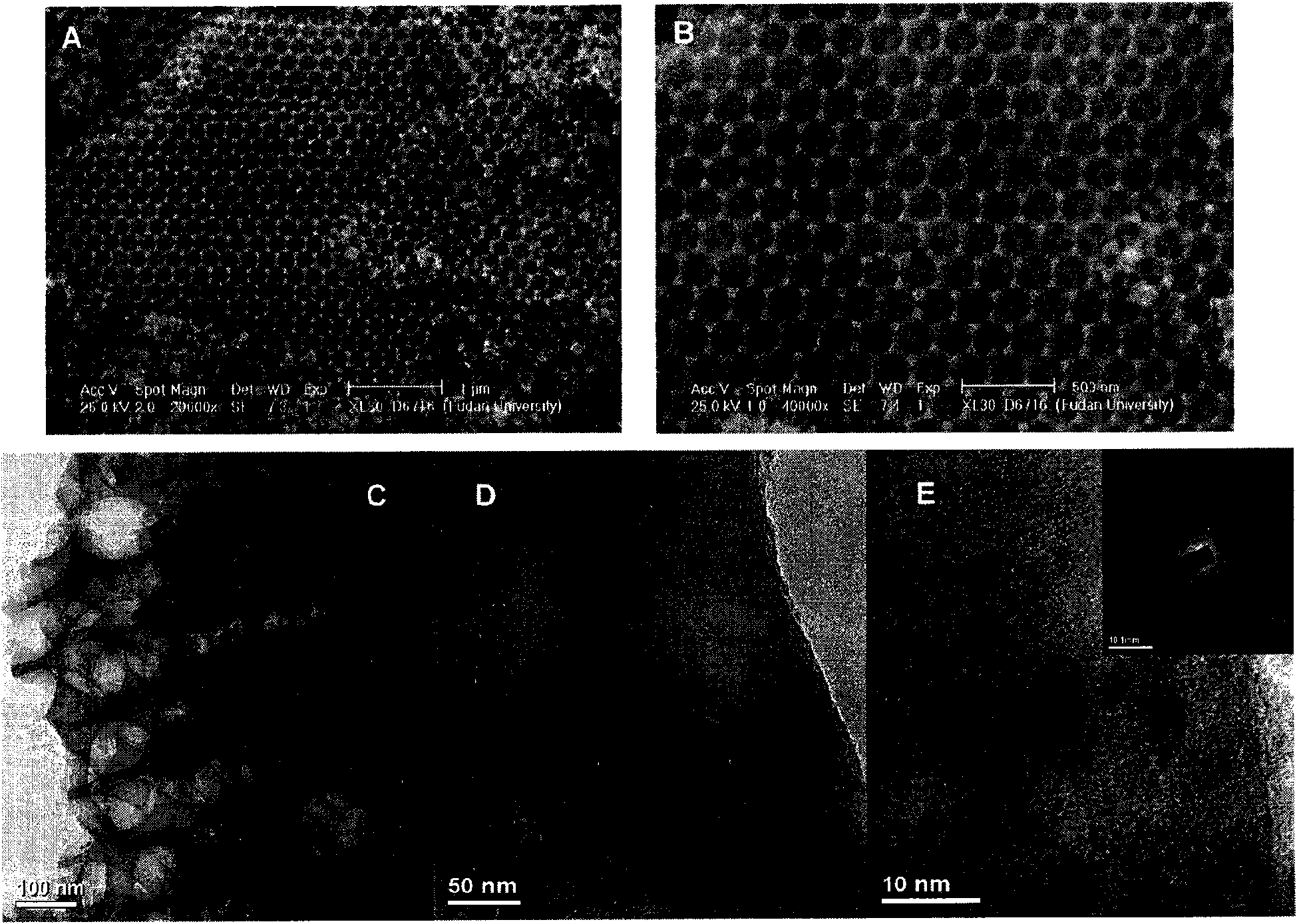

Image

Examples

Embodiment 1

[0015] (1) 0.2g of superparamagnetic 10nm Fe 3 o 4 Ultrasonic dispersion of nanoparticles into 20ml 2M HNO 3 Perform pretreatment in the solution for 1-2 minutes, fully wash the magnetic nanoparticles with deionized water, and then ultrasonically disperse them again in a mixed solution of 4.4 g of sodium citrate and 20 ml of deionized water. Finally, the product was separated with a magnet, and dispersed in 5 ml of deionized water to obtain a stable dispersion for later use.

[0016] (2) disperse the polymethyl methacrylate microspheres of 10g 300nm in 300g deionized water, then get 5g of this solution and the above-mentioned Fe 3 o 4 The nanoparticle solutions were mixed, and then the mixture was dried in an oven at 35°C. After drying, put it in an oven at 80°C for 24 hours. The obtained solid was immersed in a mixed solution of 0.9g TEOS, 0.1g 2M HCl, 8g ethanol and 2g deionized water, and stood until the solution evaporated to dryness. The resulting solid was placed i...

Embodiment 2

[0018] (1) 0.2g superparamagnetic 15nm γ-Fe 2 o 3 Ultrasonic dispersion of nanoparticles into 20ml 2M HNO 3 Perform pretreatment in the solution for 1-2 minutes, fully wash the magnetic nanoparticles with deionized water, and then ultrasonically disperse them again in a mixed solution of 4.4 g of sodium citrate and 20 ml of deionized water. Finally, the product was separated with a magnet, and dispersed in 5 ml of deionized water to obtain a stable dispersion for later use.

[0019] (2) Disperse 10g of 380nm polystyrene beads into 300g of deionized water, then take 5g of this solution and the above-mentioned γ-Fe 2 o 3 The nanoparticle solutions were mixed, and then the mixture was dried in an oven at 32°C. After drying, put it in an oven at 80°C for 24 hours. The obtained solid was immersed in a mixed solution of 0.9g TEOS, 0.1g 2M HCl, 8g ethanol and 2g deionized water, and stood until the solution evaporated to dryness. The resulting solid was placed in a 5 ml crucibl...

Embodiment 3

[0021] (1) 0.2g of superparamagnetic 10nm Fe 3 o 4 Ultrasonic dispersion of nanoparticles into 20ml 2M HNO 3 Perform pretreatment in the solution for 1-2 minutes, fully wash the magnetic nanoparticles with deionized water, and then ultrasonically disperse them again in a mixed solution of 4.4 g of sodium citrate and 20 ml of deionized water. Finally, the product was separated with a magnet, and dispersed in 5 ml of deionized water to obtain a stable dispersion for later use.

[0022] (2) Disperse 10g of 1μm polystyrene pellets into 300g of deionized water, and then take 5g of this solution with the above-mentioned Fe 3 o 4 The nanoparticle solutions were mixed, and then the mixture was dried in an oven at 40°C. After drying, put it in an oven at 80°C for 24 hours. The obtained solid was immersed in a mixed solution of 0.9 g TEOS, 0.1 g 2M HCl, 8 g methanol and 2 g deionized water, and stood until the solution evaporated to dryness. The resulting solid was placed in a 5 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com