Patents

Literature

37results about How to "High degree of carbonation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

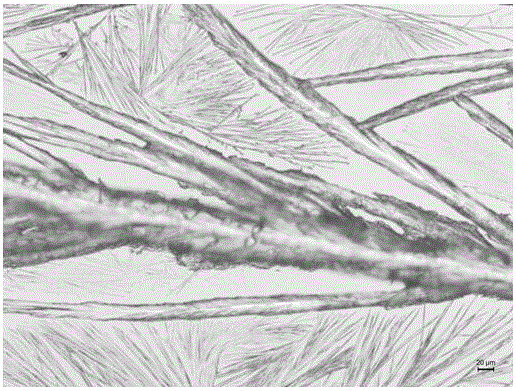

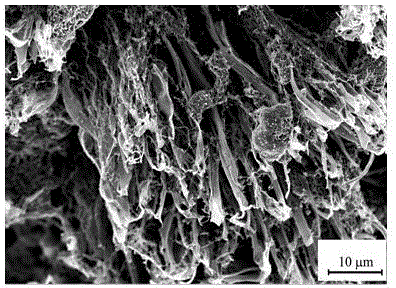

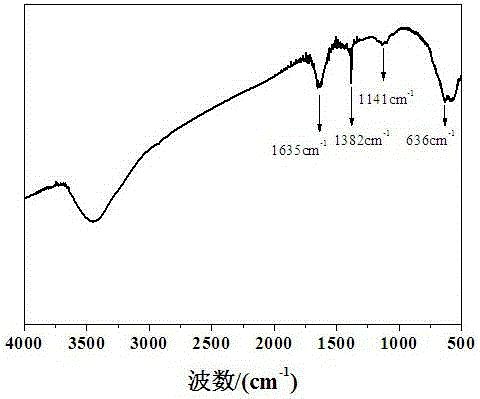

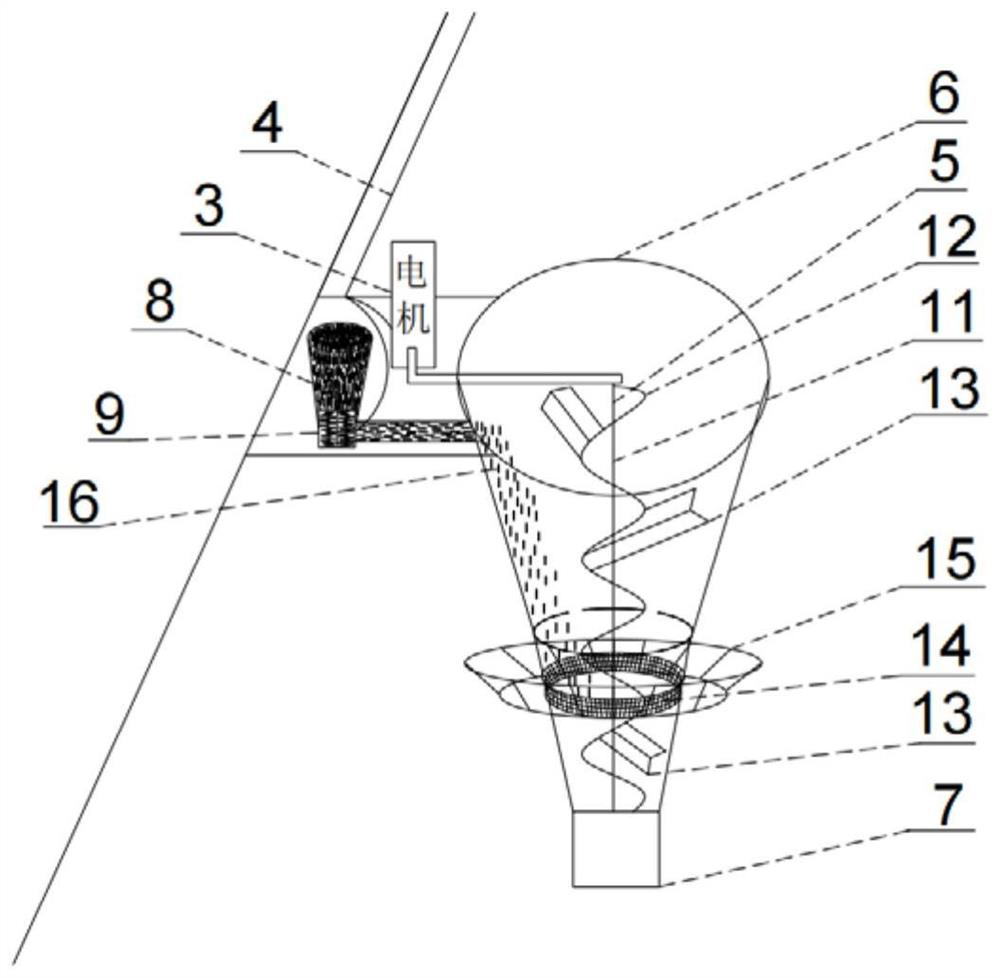

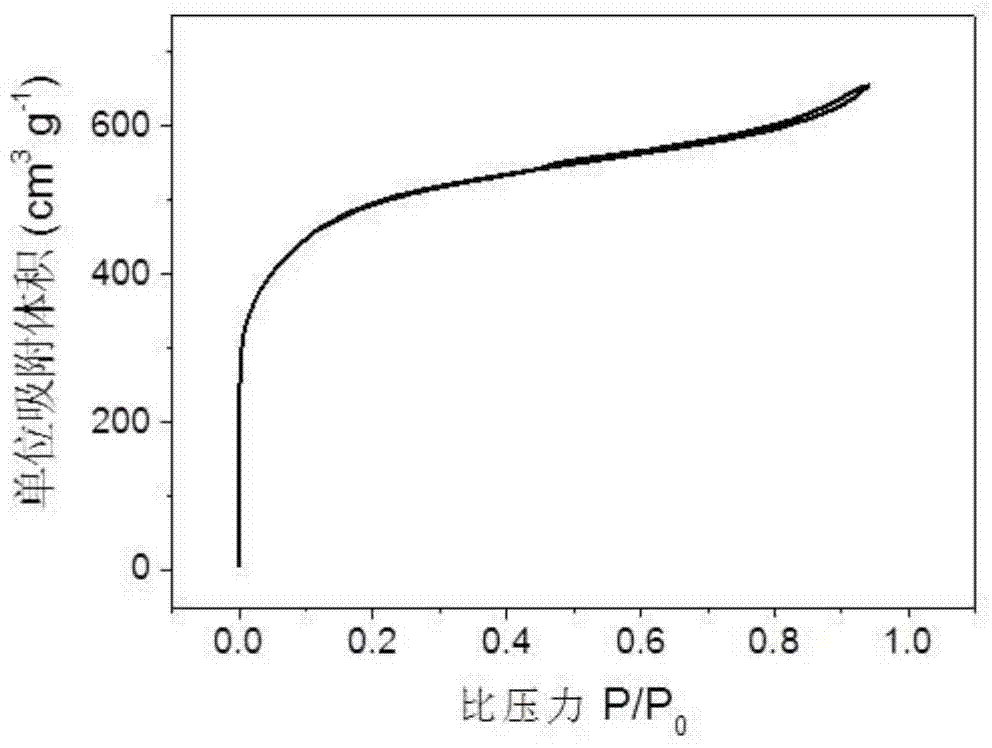

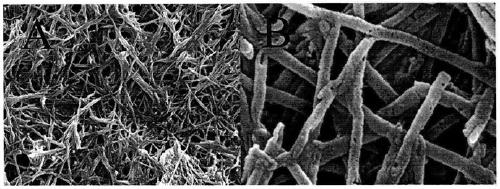

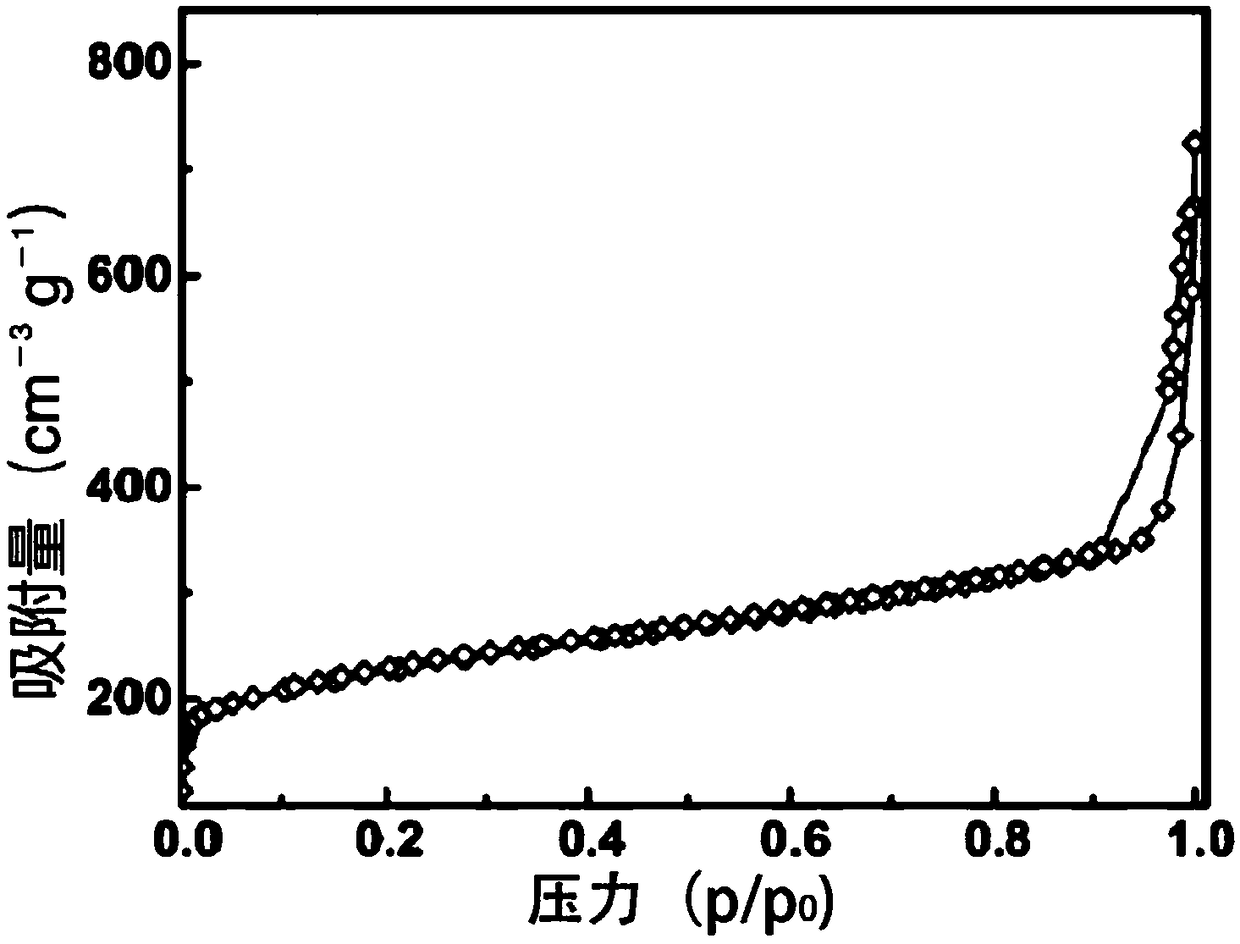

Preparation method for nitrogen-doped mesoporous carbon nanofiber

InactiveCN106087119AHigh degree of carbonationReduce lossesHybrid capacitor electrodesHybrid/EDL manufactureCarbonizationEvaporation

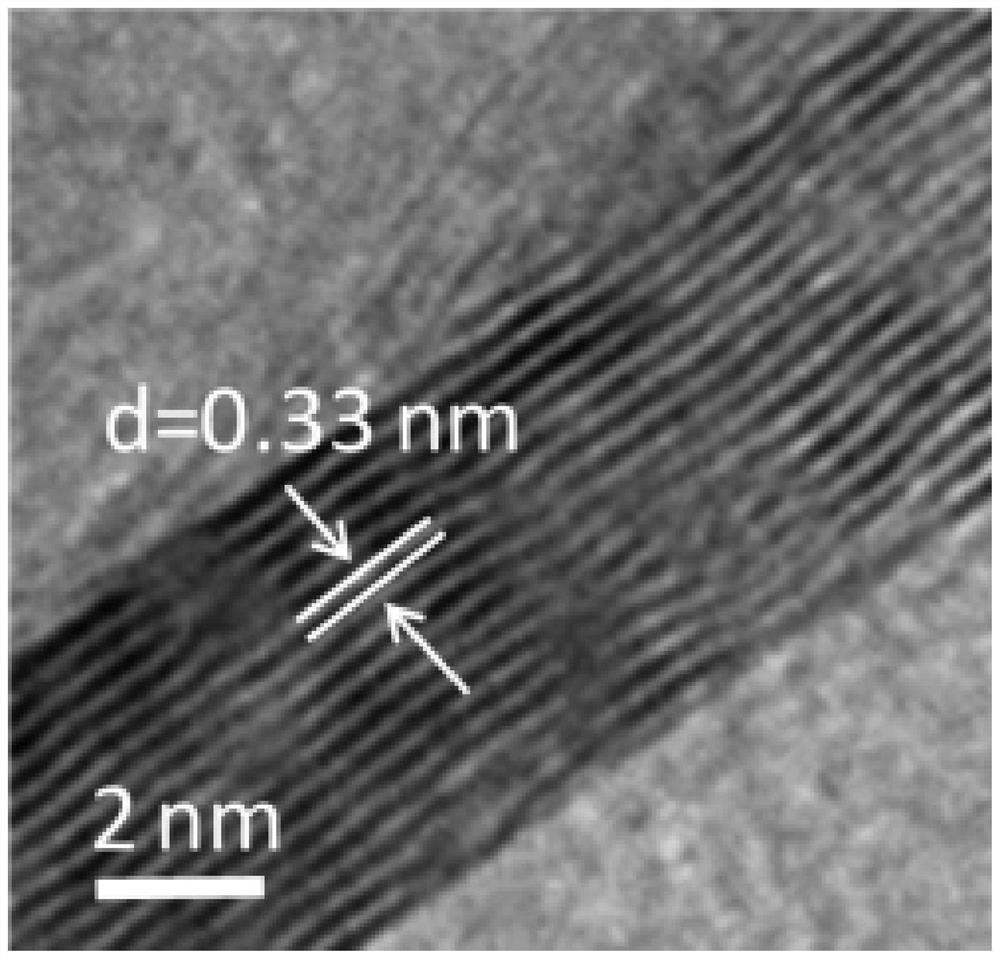

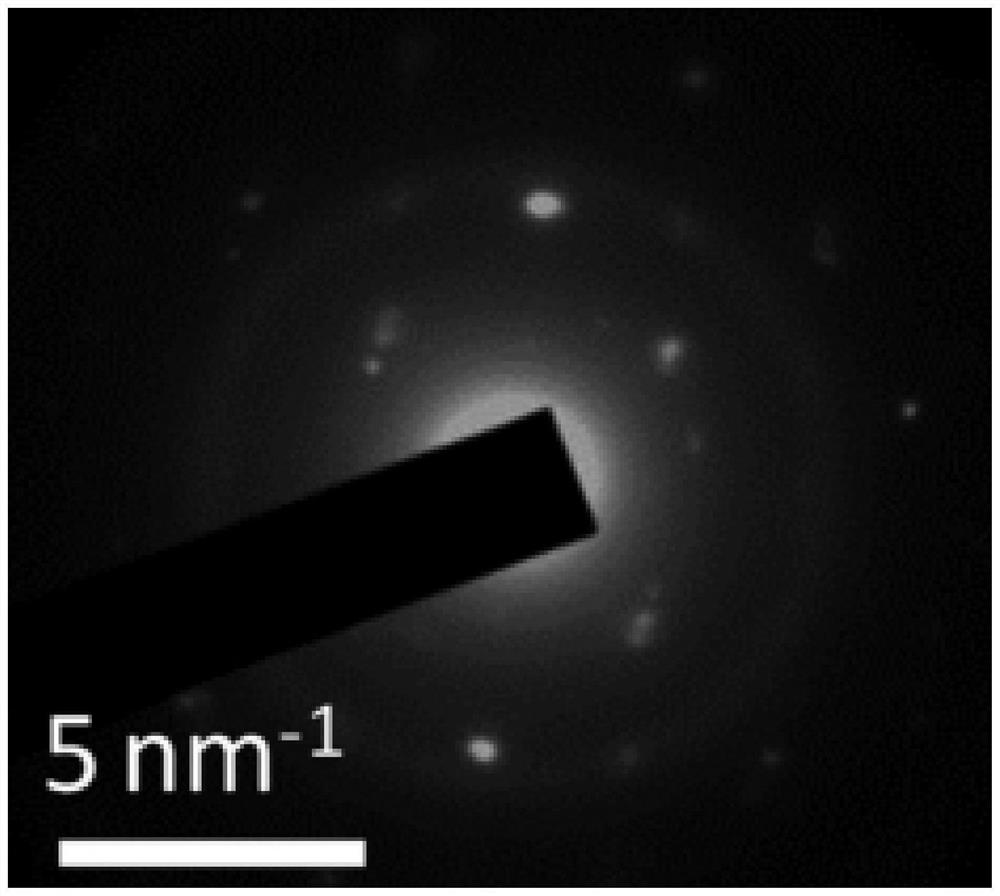

A preparation method for nitrogen-doped mesoporous carbon nanofiber relates to the technical field of electrode materials of supercapacitors. According to the preparation method, gelatin is taken as a carbon source, urea is taken as a nitrogen source and a template, under evaporation driving of a solvent water, urea is crystalized, gelatin molecules are self-assembled on the surface of urea crystal, gelatin is subjected to condensation and carbonization at a high temperature, urea molecules are decomposed and nitrogen atoms are doped into the carbon material, and finally nitrogen-doped mesoporous carbon nanofiber is prepared. The advantages comprise that the prepared electrode material possesses relatively high nitrogen content, large specific surface area and high graphitization degree, also possesses relatively good electrochemical performances, and also possesses important application value in fields of capacitor electrode materials and the like.

Owner:YANGZHOU UNIV

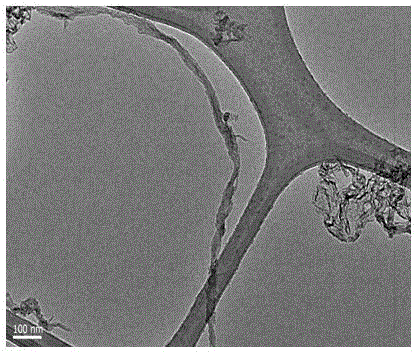

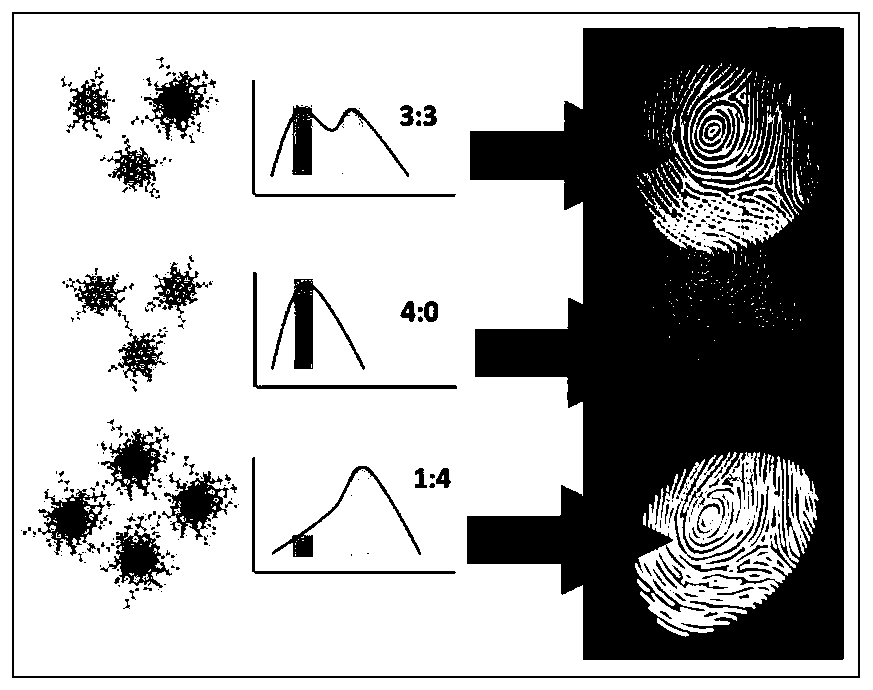

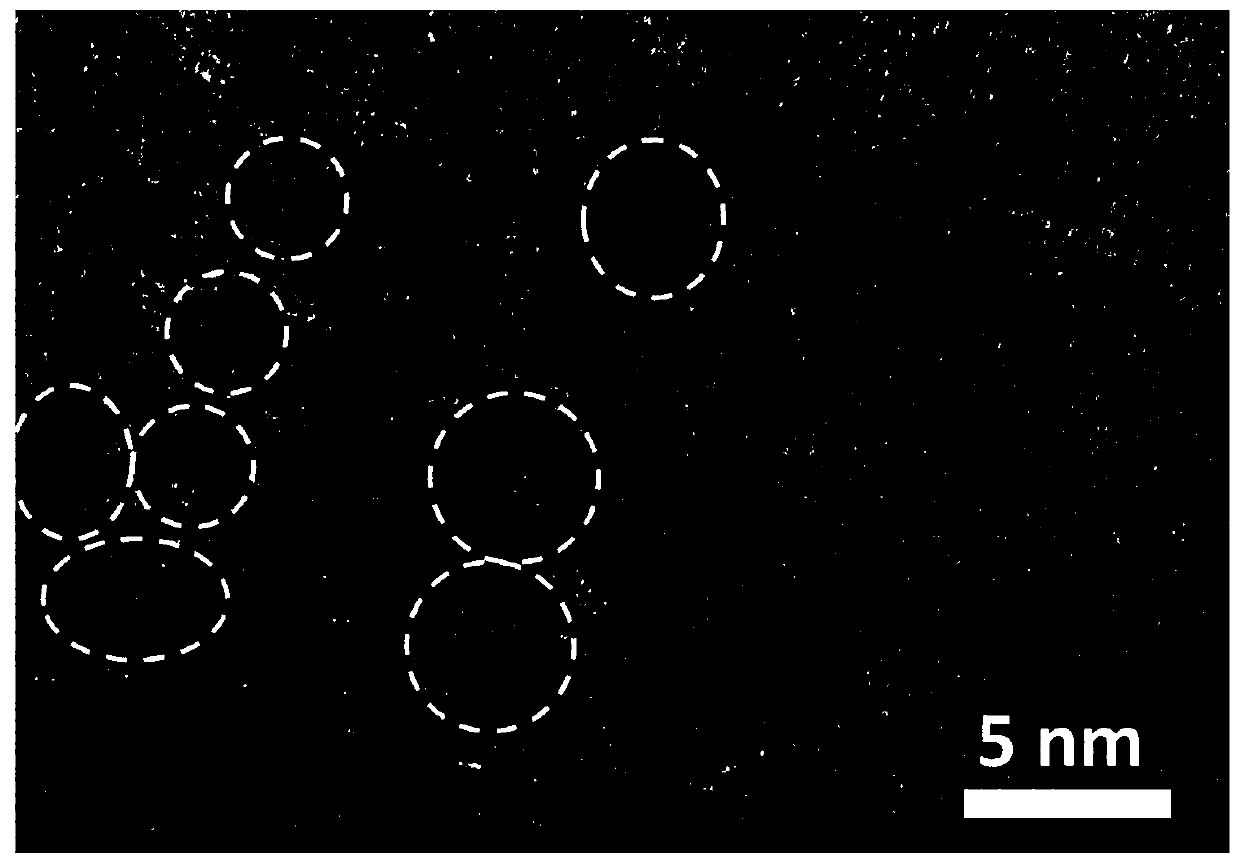

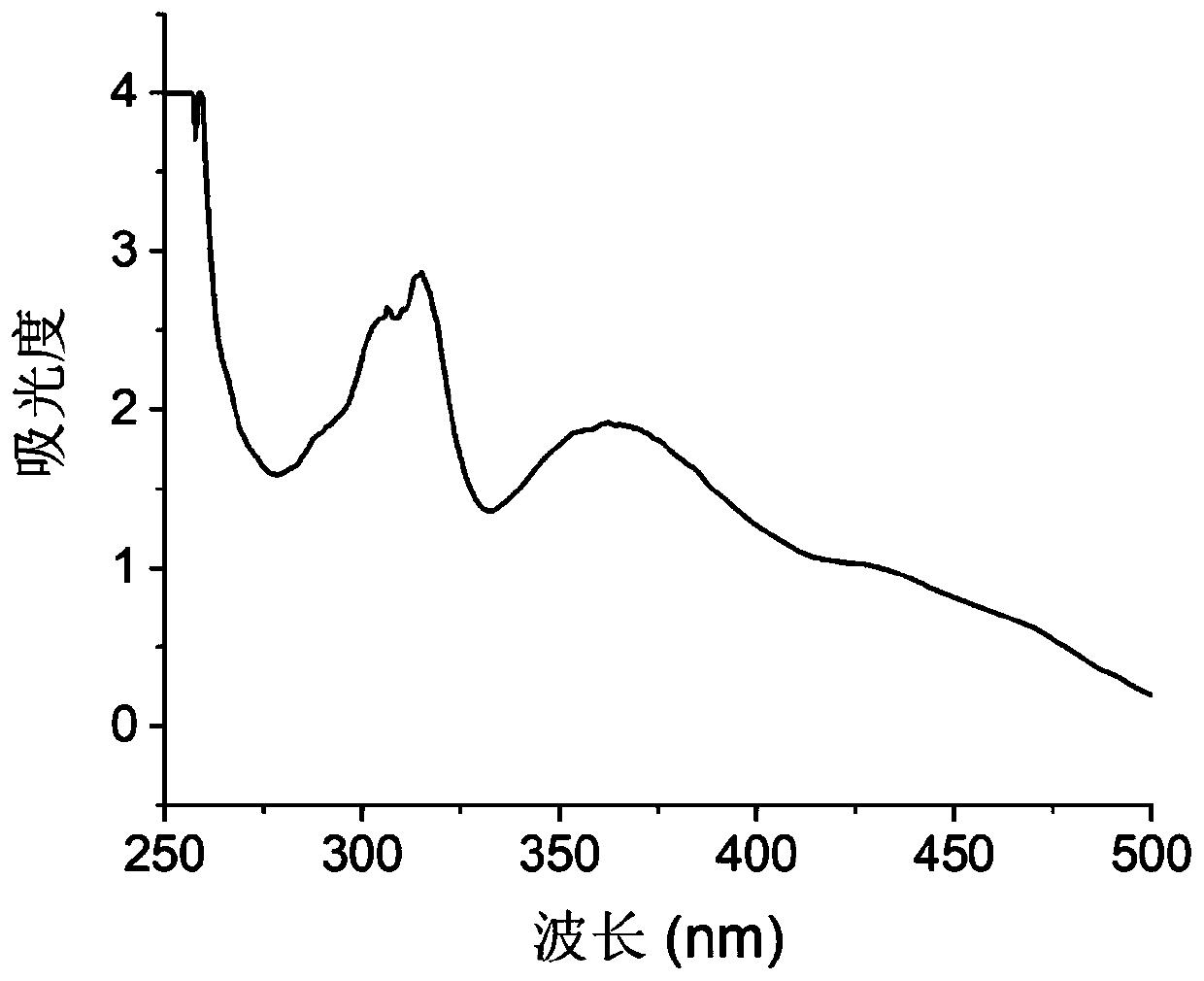

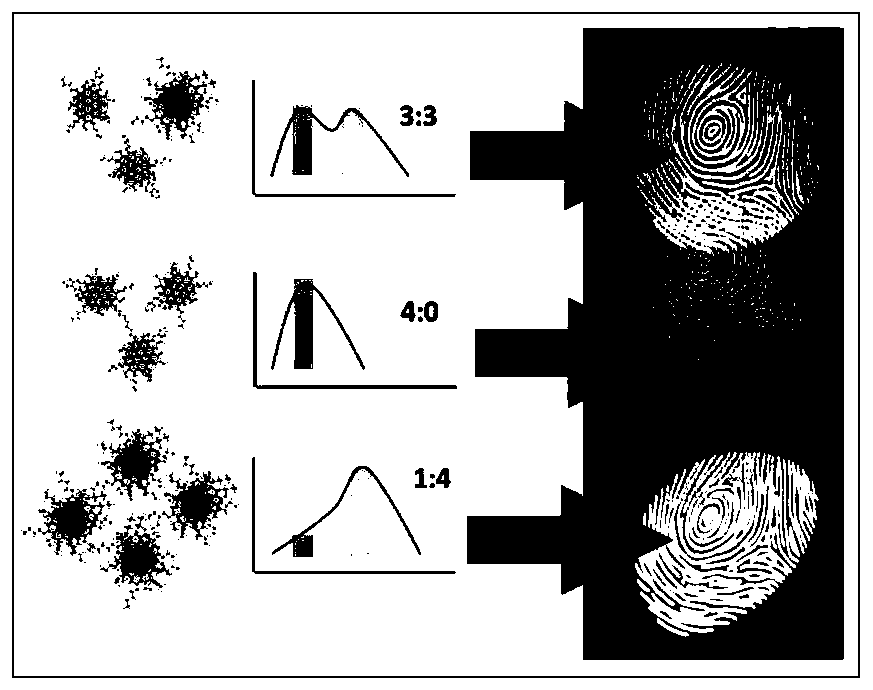

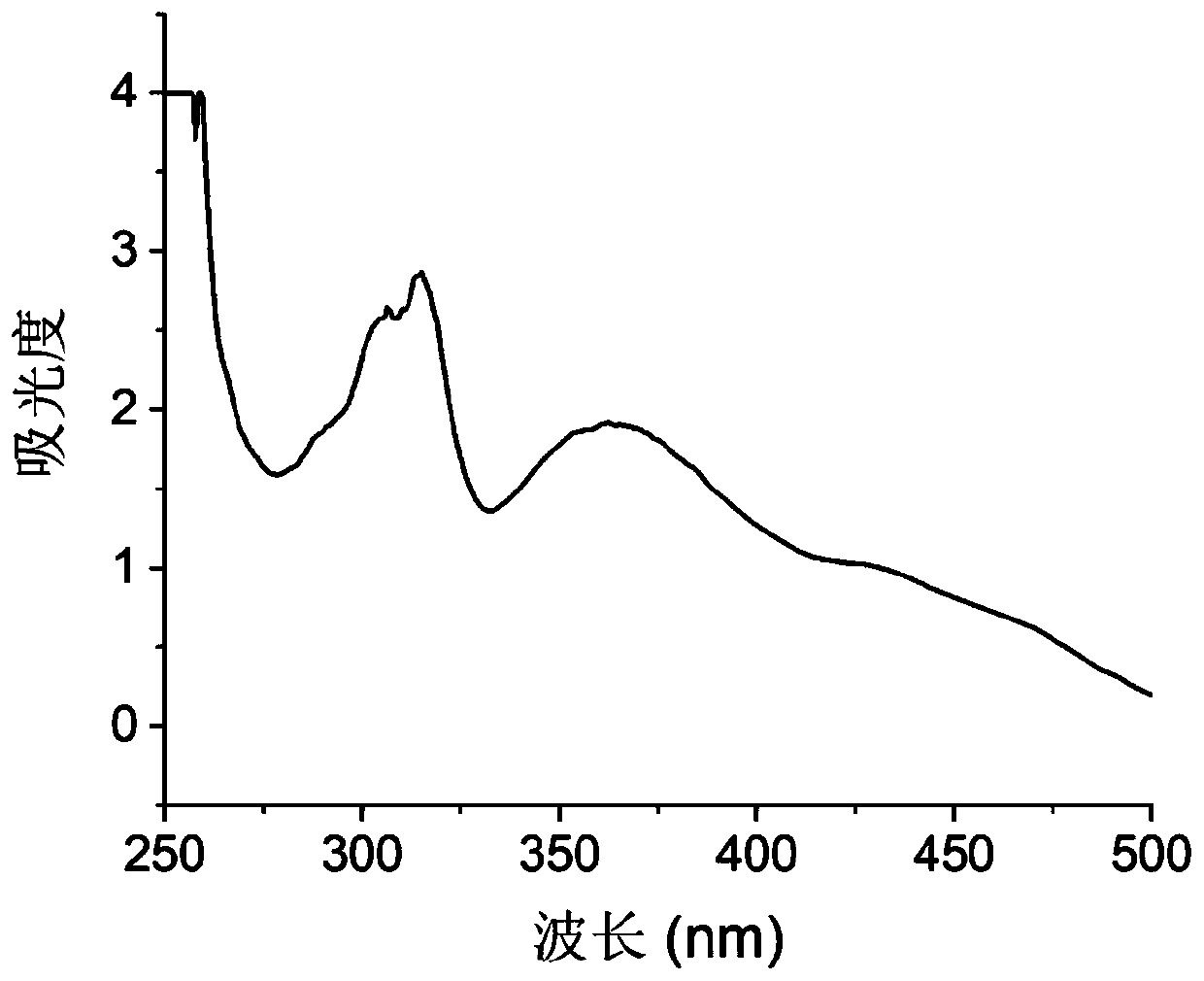

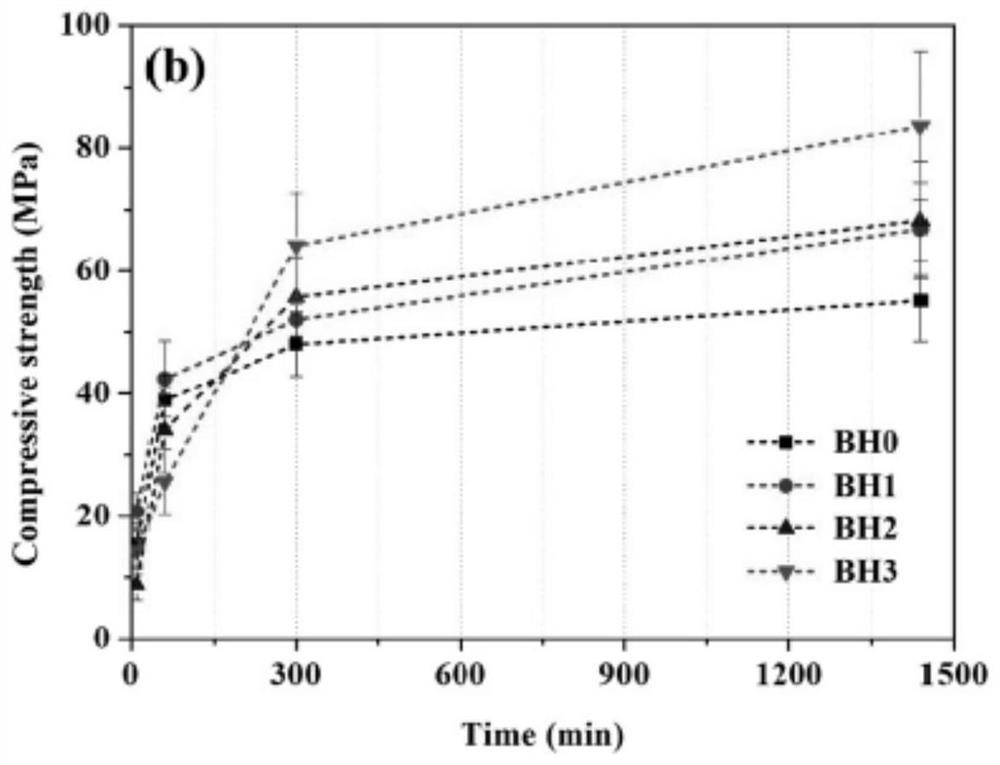

Amphiphilic graphene quantum dot material, preparation method thereof, fluorescent coding anti-counterfeiting ink based on the material and preparation method of the ink

ActiveCN110615428AInhibit side effectsSimple separation and purification processMaterial nanotechnologyGrapheneQuantum yieldCarbonization

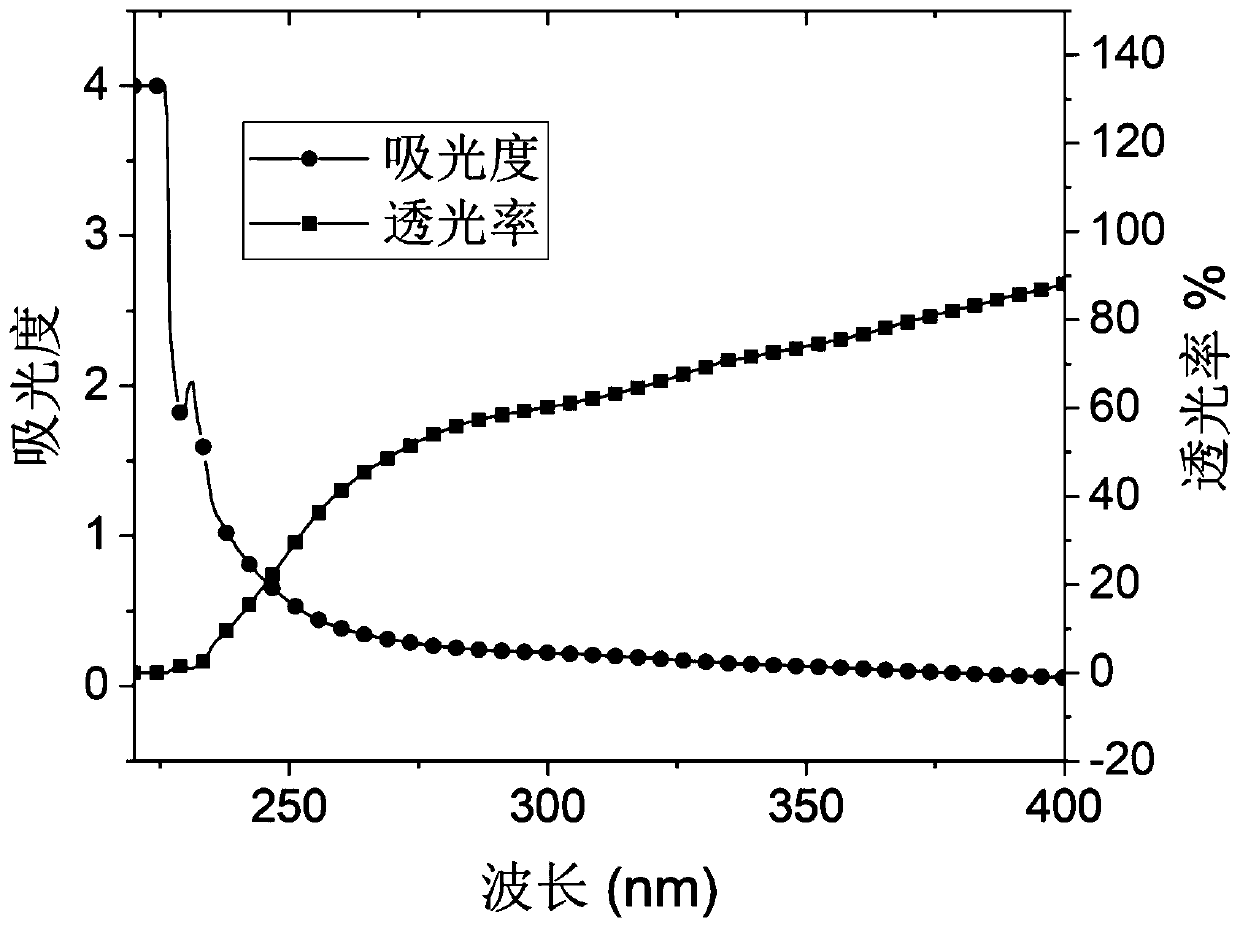

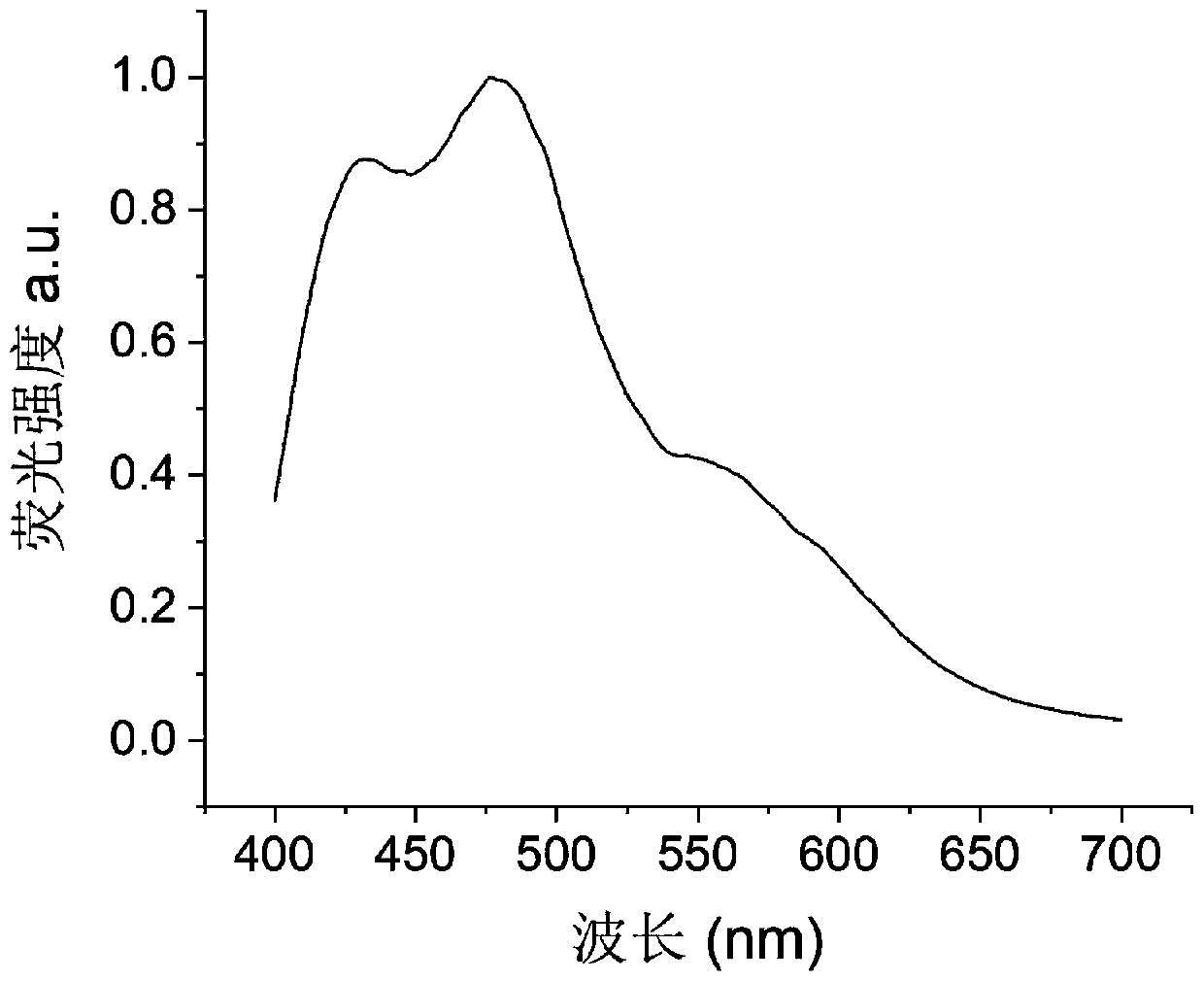

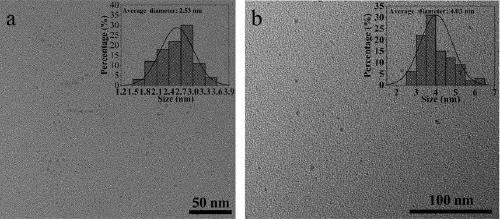

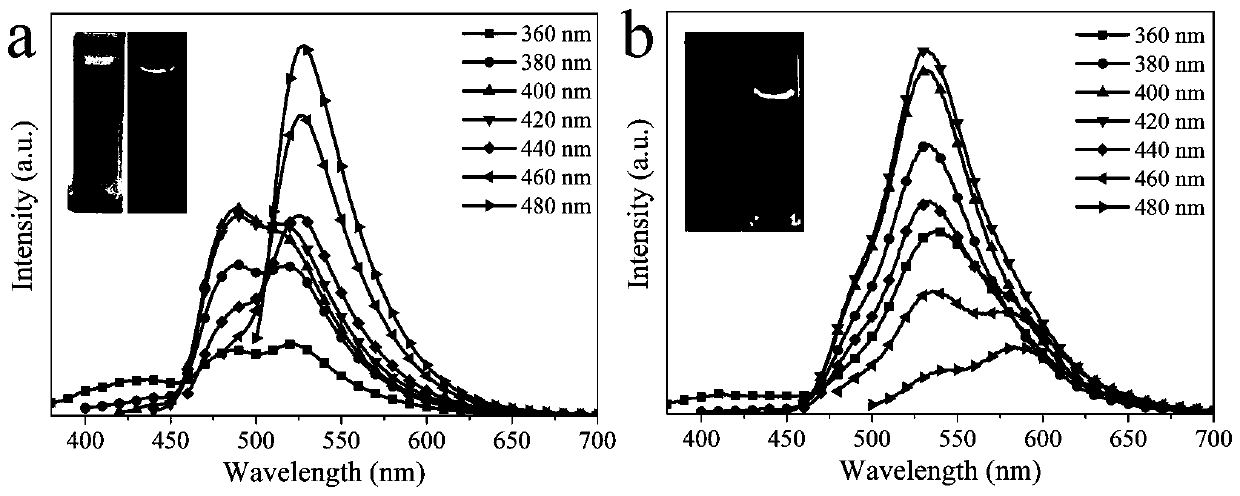

The invention discloses an amphiphilic graphene quantum dot material, a preparation method thereof, fluorescent coding anti-counterfeiting ink based on the amphiphilic graphene quantum dot material and a preparation method of the fluorescent coding anti-counterfeiting ink. Hydrophobic citrate is used as a carbon source, hydrophilic amino alcohol is used as a nitrogen doping agent, and the amphiphilic graphene quantum dot material with hydrophobic ester groups and hydrophilic alcoholic hydroxyl edge groups is prepared through carbonization treatment. The prepared amphiphilic graphene quantum dot material has a high fluorescence quantum yield and good light, heat and chemical stability, and can be dispersed in various polar and non-polar solvents. Under certain conditions, the amphiphilic graphene quantum dot material can form an aggregate on the surfaces of a solution and a solid, and fluorescence emission of the amphiphilic graphene quantum dot material is changed from a single peak tomultiple peaks. The aggregation degree and aggregation state of the amphiphilic graphene quantum dot material are regulated and controlled, so that the fluorescence emission intensities of the amphiphilic graphene quantum dot material at different wavelengths are correspondingly changed, and the fluorescence coding marking based on the fluorescence intensity ratio is realized.

Owner:XI AN JIAOTONG UNIV

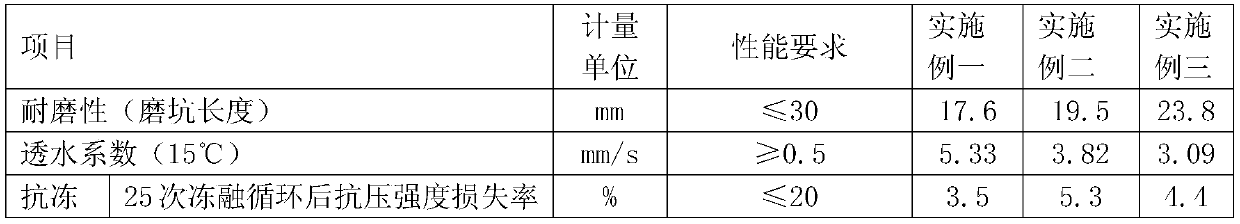

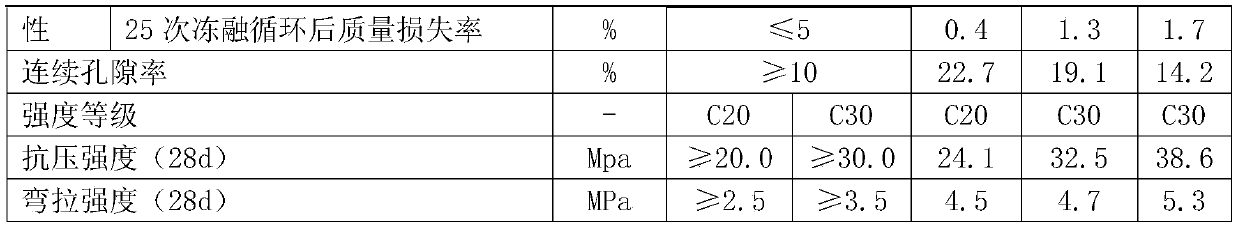

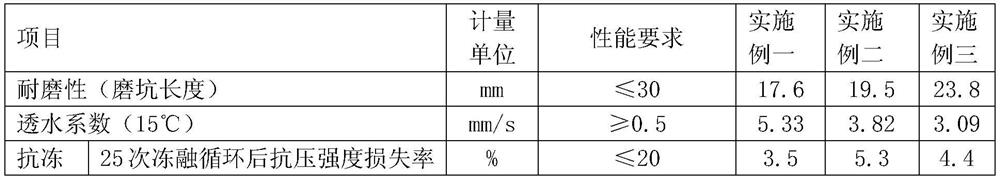

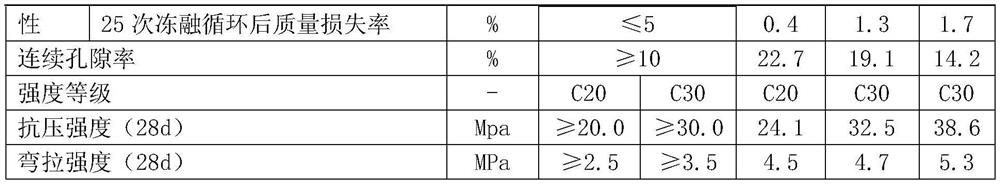

Carbon dioxide cured prefabricated water-permeable concrete and preparation method thereof

ActiveCN109824321ALow alkalinity requirementLow Pre-Care RequirementsEnvironmental resistanceCellulose

The invention discloses a carbon dioxide cured prefabricated water-permeable concrete and a preparation method thereof. The water-permeable concrete is composed of following components in parts by weight: 55 to 80 parts of regenerated aggregate, 7 to 30 parts of nickel slag sand, 18 to 40 parts of cementing material, 5 to 25 parts of water, 0.01 to 2 parts of naphthalene water reducer, 0 to 0.02 part of cellulose ether, and 0 to 0.01 part of welan gum. The cementing material is composed of following components in parts by weight: 70 to 90 parts of common silicate cement, 5 to 15 parts of fly ash, 10 to 30 parts of steel slag, 5 to 15 parts of lime or lime slag, and 0.02 to 1 part of nano calcium carbonate. The technology is simple, the structure advantage of water-permeable concrete and the properties of industrial byproducts such as nickel slag, steel slag, fly ash, and the like are fully utilized; carbon dioxide curing is utilized to realize rapid, efficient and environmentally friendly production; high strength, durable and water permeable concrete is obtained, the energy consumption is reduced, the industrial tail gas, metallurgy slag, and building waste are effectively utilized, and good economic benefits, social benefits, and environmental benefits are generated.

Owner:SOUTHEAST UNIV

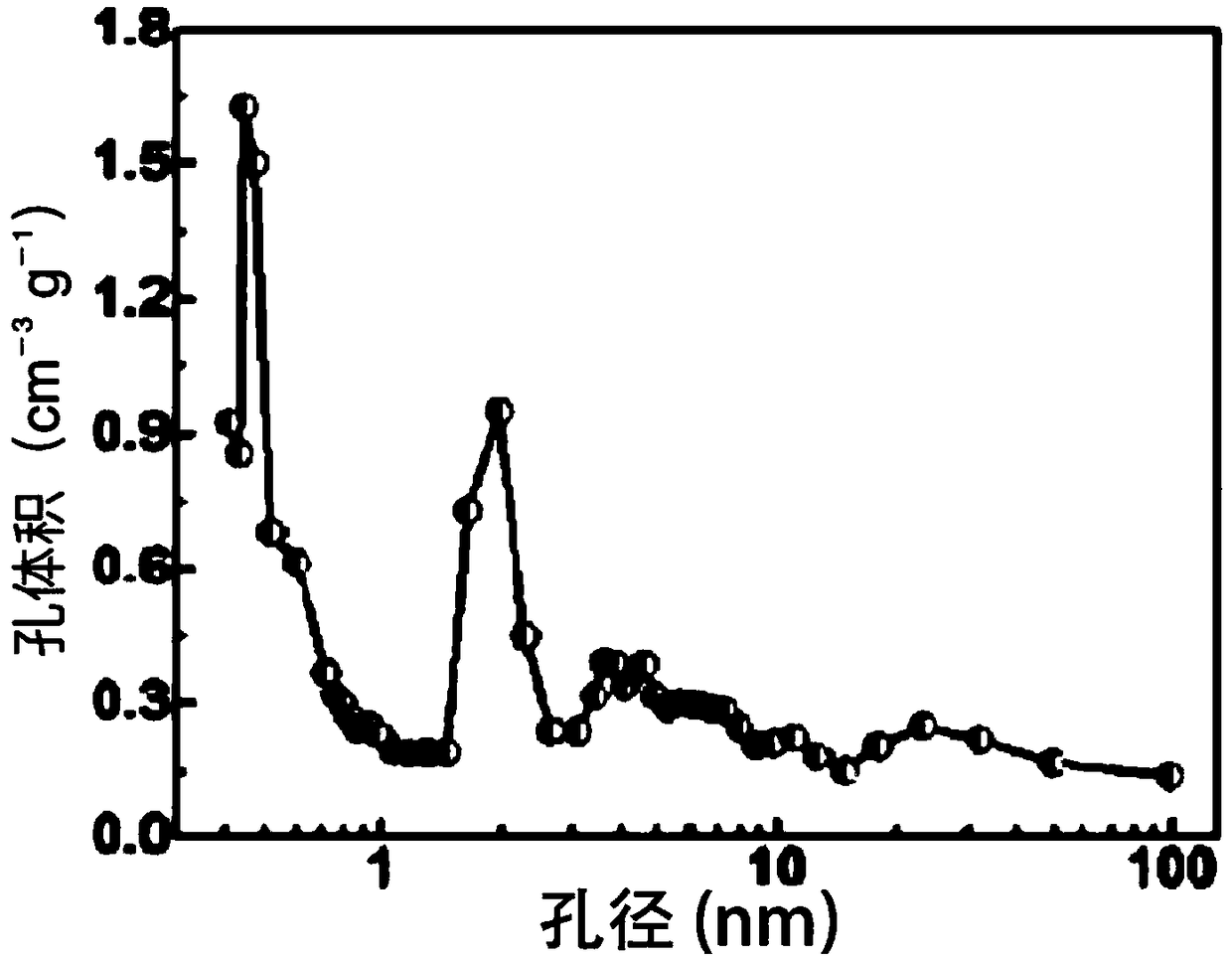

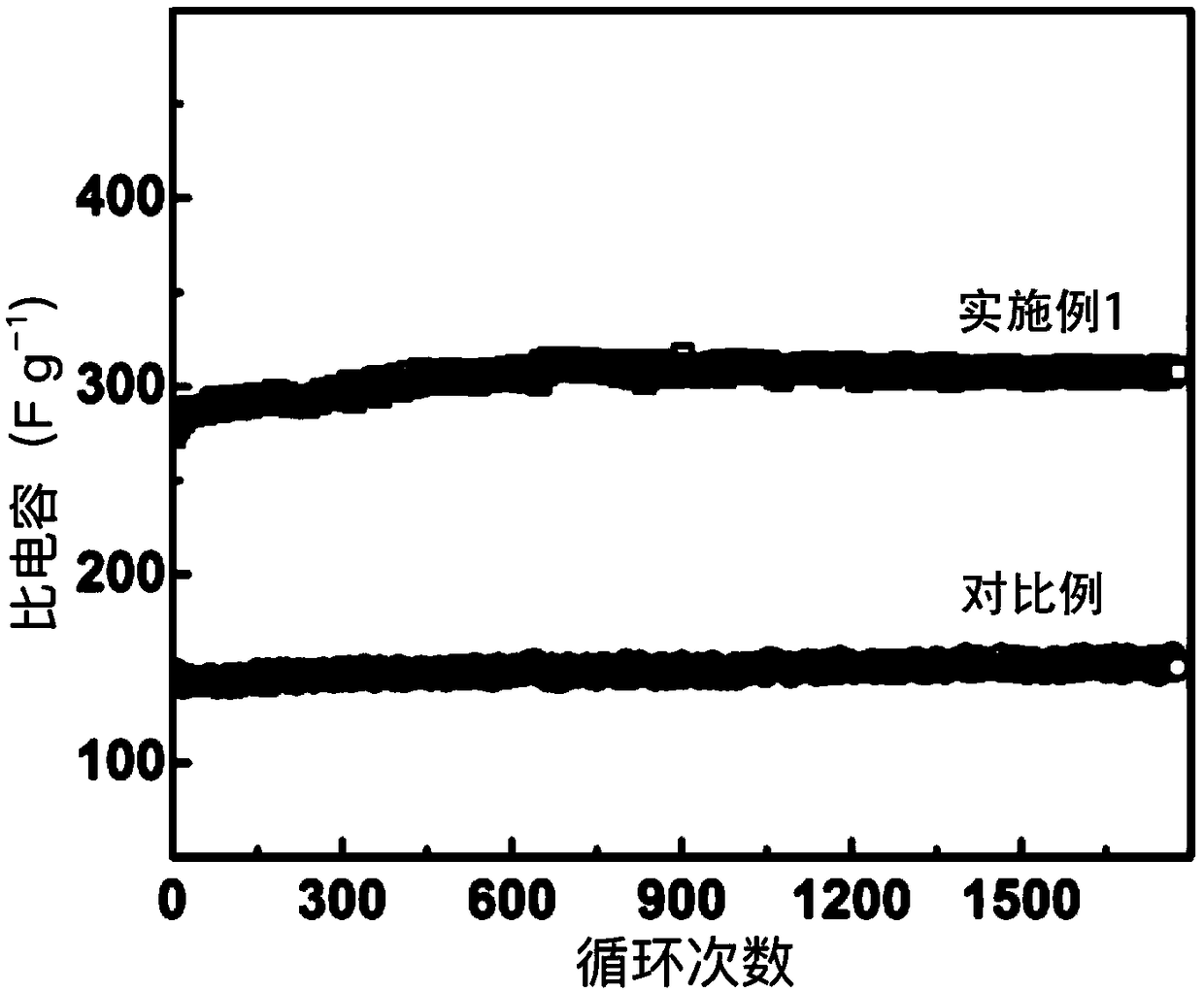

Method for preparing multistage porous carbon materials

ActiveCN106229152AHigh specific capacitancePromote circulationHybrid capacitor electrodesHybrid/EDL manufacturePower performanceCapacitance

The invention belongs to the technical field of materials, and discloses a method for preparing a multistage porous carbon material. The method includes the steps of dissolving tin salt, carbohydrate compound and organic sulfur compound to obtain a clear mixed solution, conducting hydrothermally reaction to obtain SnS / C composite material precipitate, calcinating at a high temperature after washing and drying to obtain a sulfur-doped multistage porous carbon material. The porous carbon structure improves the sufficient wettability between the material and an electrolyte and ensures excellent charge conduction. Trace sulfur elements play a role in improving the charge-adsorption capacity in the porous carbon structure, and the synergetic effect of the two effectively improves the specific capacitance of the material, multiplying power performance and cycling performance.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

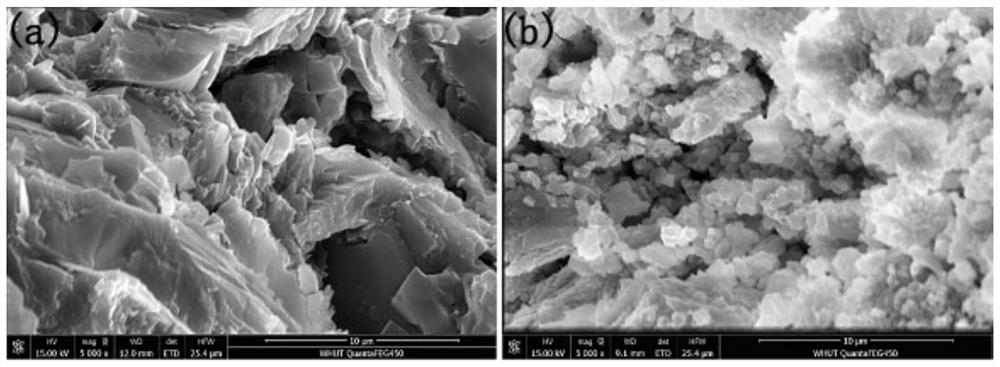

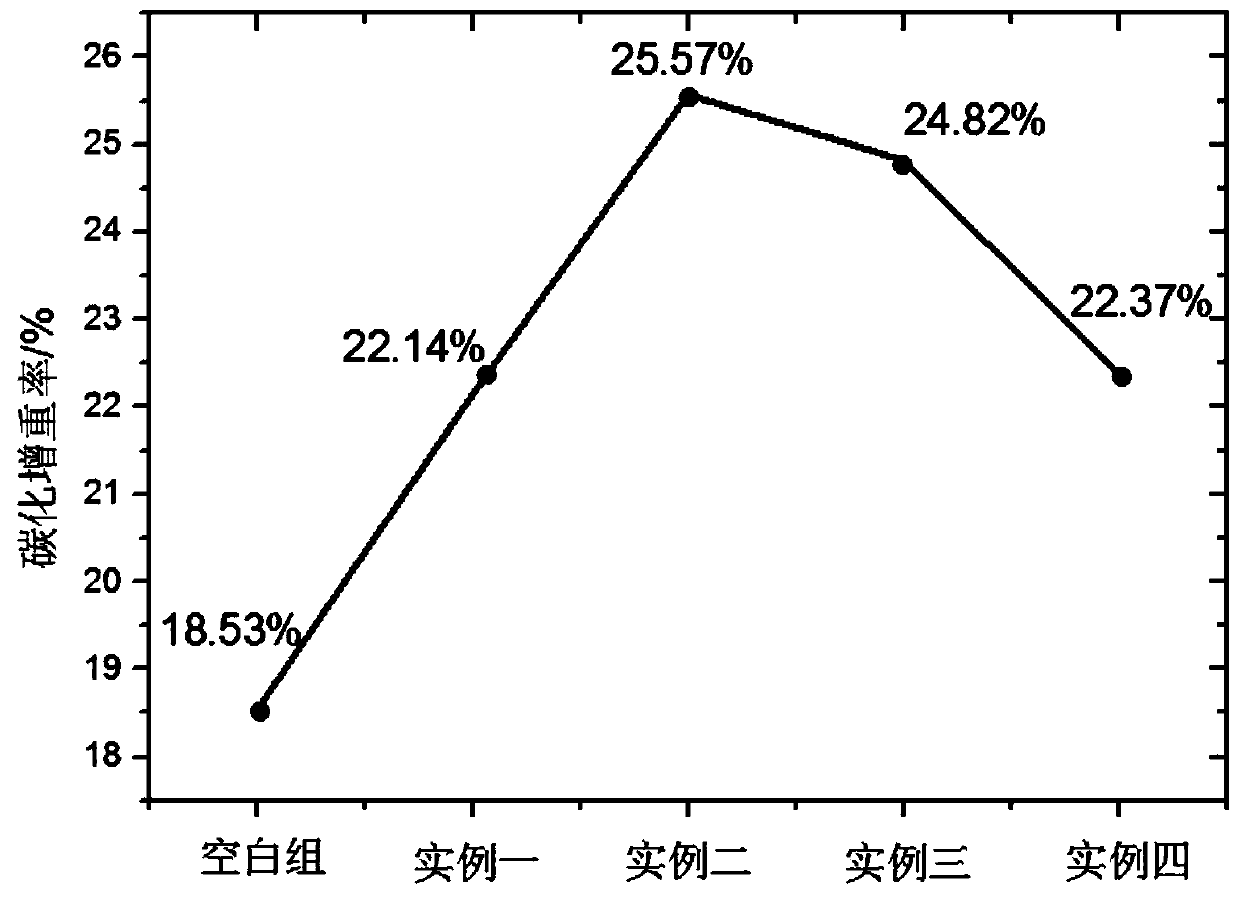

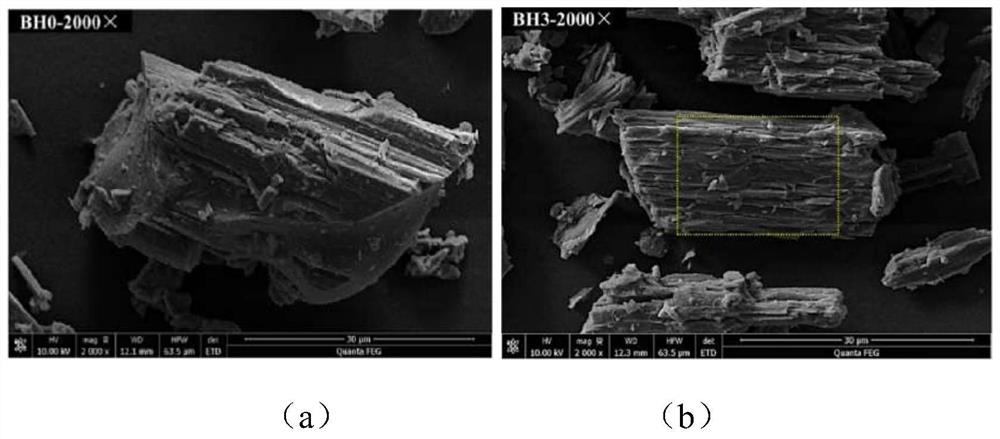

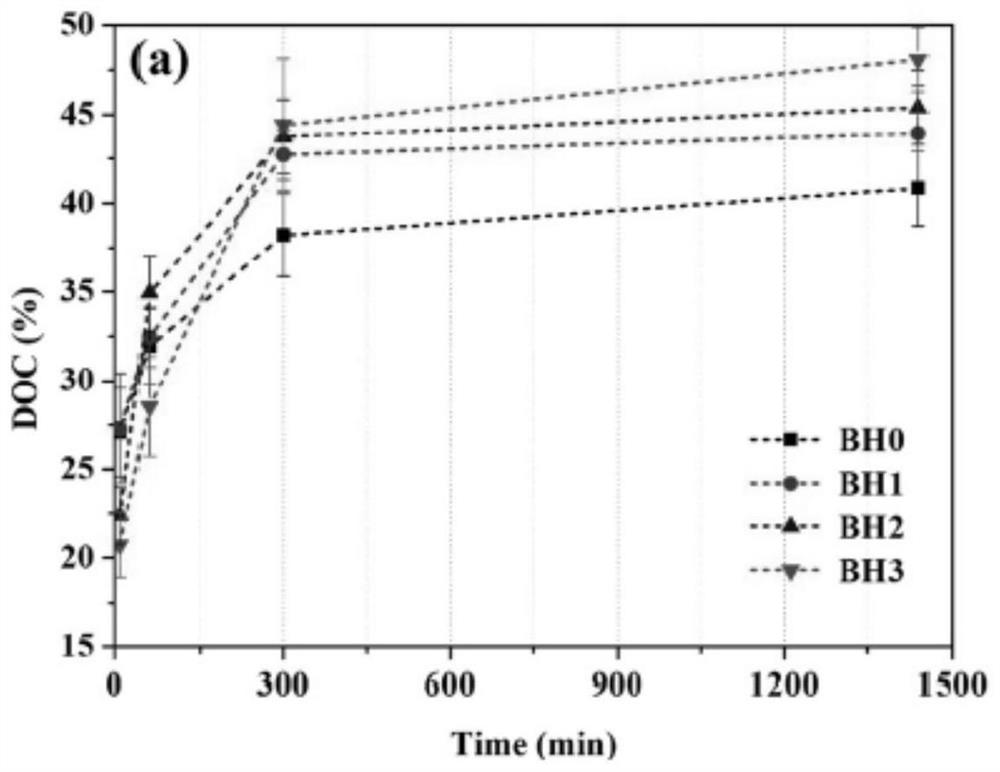

In-situ carbonization method for improving structural properties of carbonized product

The invention discloses an in-situ carbonization method for improving the structural properties of a carbonized product. Before the carbonized product is formed, when raw materials are mixed, alkali-resistant bacteria capable of performing the urea hydrolysis reaction are added and uniformly distributed in the raw materials; when the product is formed, a urea nutrient solution replaces a water-mixed water to form the product; after forming, demolding and carbonization maintenance, the product is immersed in the urea nutrient solution for continuous maintenance. According to the method, the bacterial powder is added in the carbonized product, the bacteria are in contact with the urea nutrient solution in the later maintenance process, and therefore the urea hydrolysis reaction is conducted;urea is decomposed into carbon dioxide and water through the metabolism of the bacteria, carbonate ions are generated from the inside, and therefore the carbonization process from inside to outside is achieved. By means of the method, the carbonization degree of the carbonized product can be increased, and the compactness and the strength are improved accordingly; compared with methods for greatly increasing the pressure of carbon dioxide and the like, the cost is low, and the process is simple.

Owner:WUHAN UNIV OF TECH

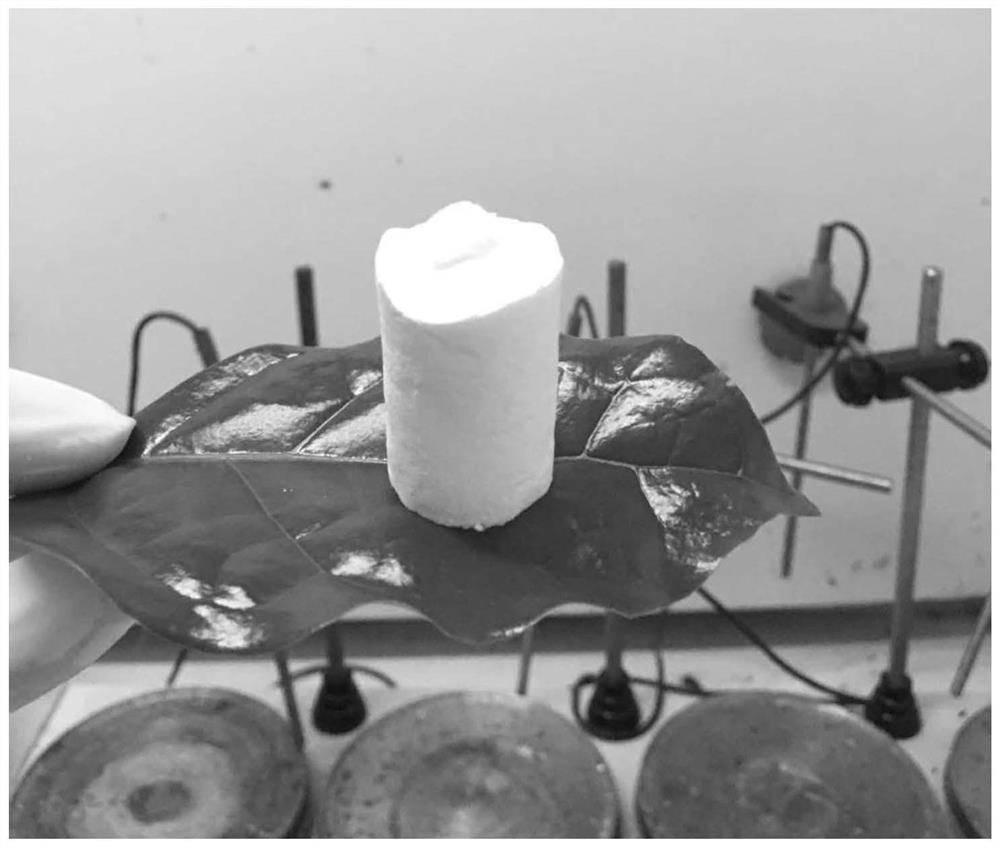

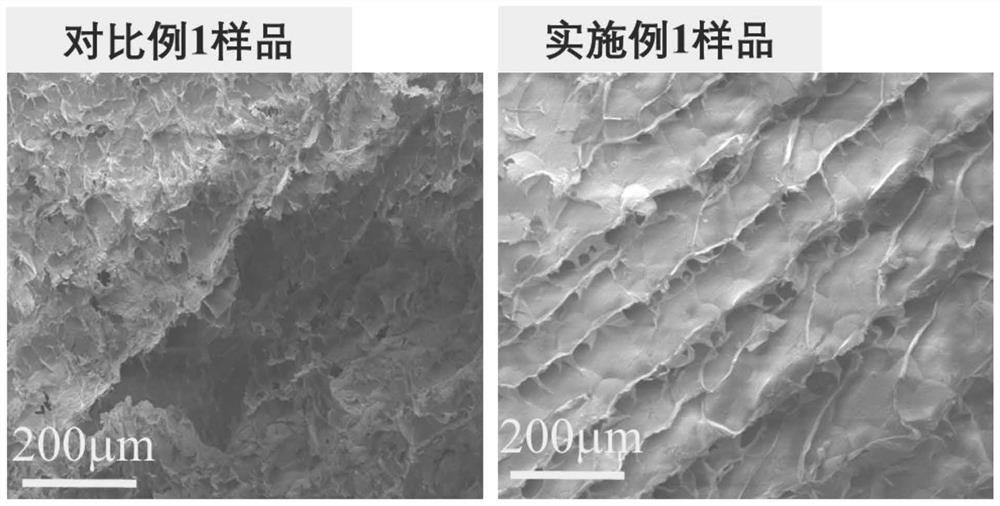

Flame-retardant nano-cellulose composite aerogel with oriented structure and preparation method thereof

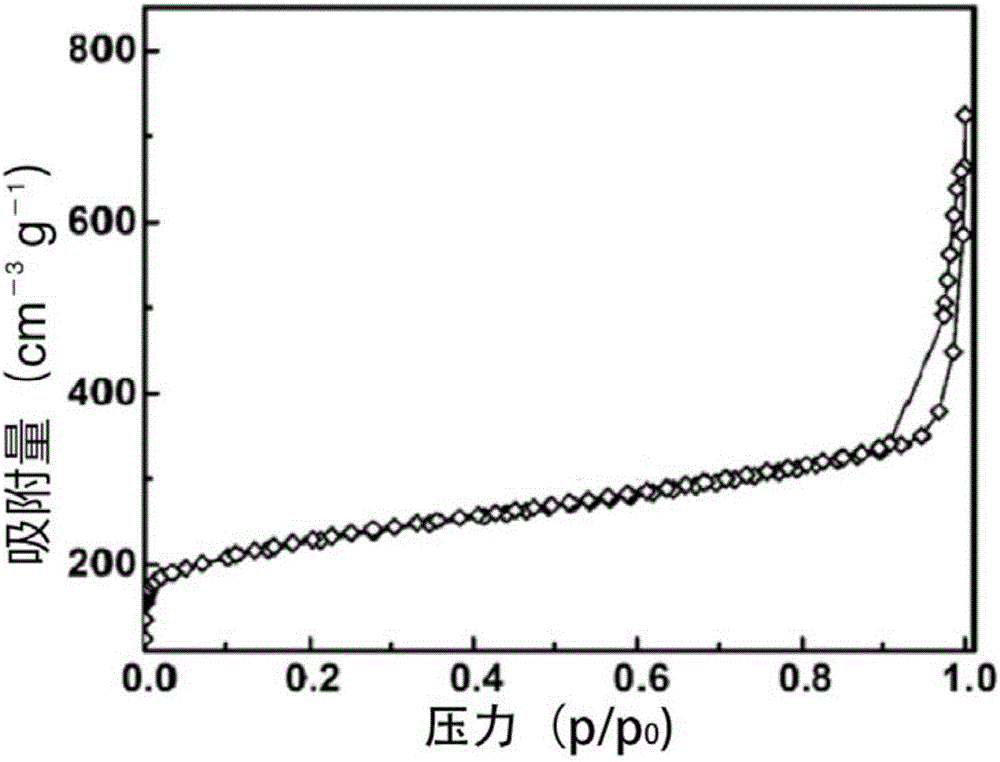

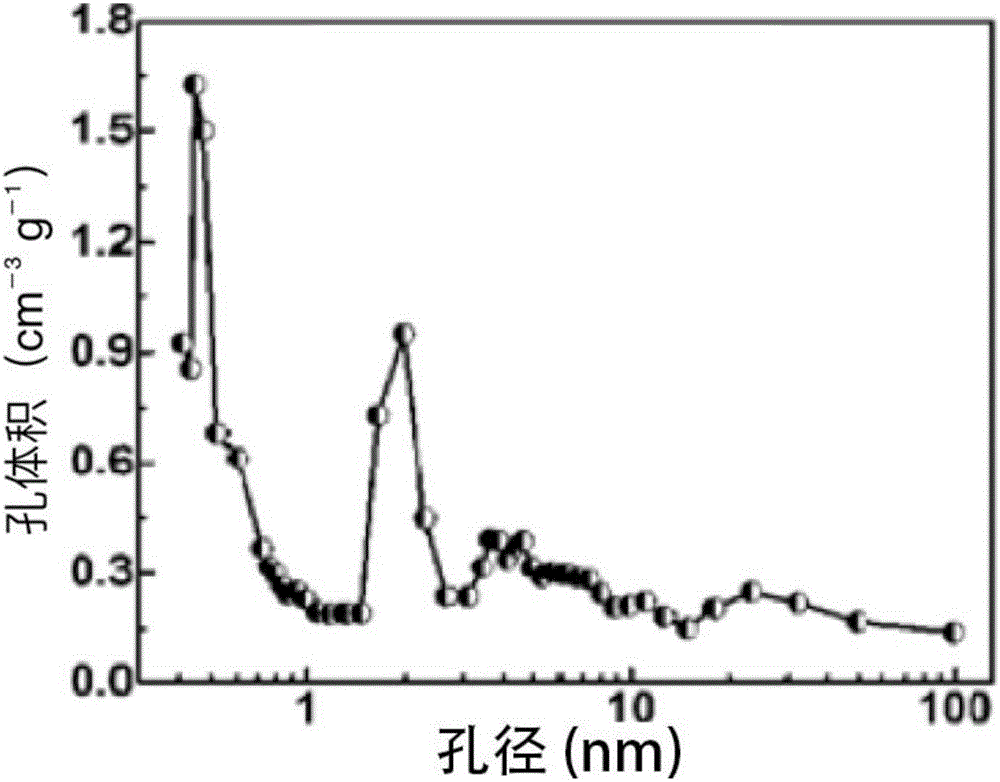

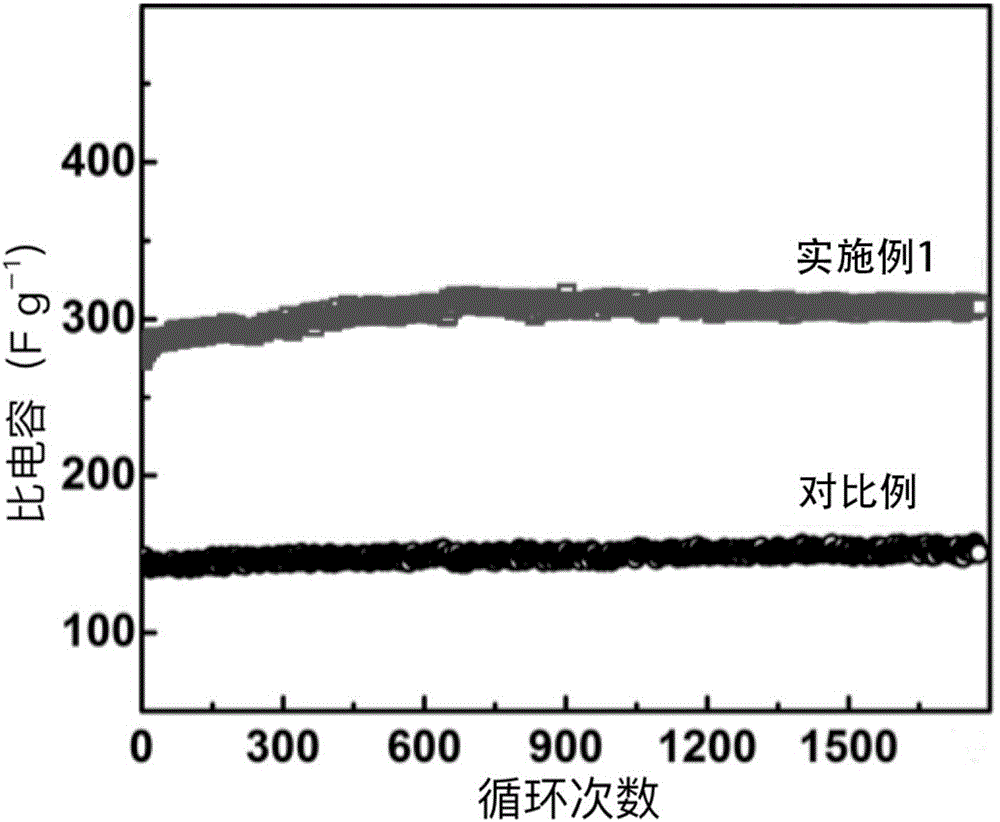

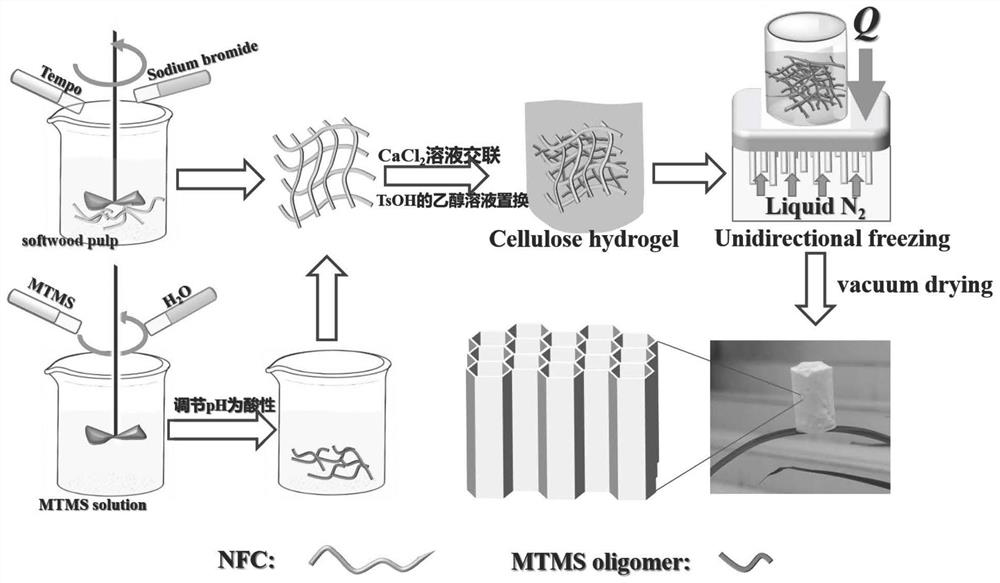

ActiveCN112662015AHuge security riskHigh degree of carbonationBulk chemical productionComposite nanofibersAlcohol

The invention provides a flame-retardant nano-cellulose composite aerogel with an oriented structure and a preparation method of the flame-retardant nano-cellulose composite aerogel. The preparation method comprises the following steps: S1, mixing a nano-cellulose suspension with a siloxane hydrolysate, and carrying out a crosslinking reaction with a water-soluble metal salt to obtain a composite nano-cellulose hydrogel; S2, performing solution replacement on the composite nano-cellulose hydrogel in an alcoholic solution containing a carbonizing agent to obtain an alcoholic gel containing the carbonizing agent, preferably, the carbonizing agent being p-toluenesulfonic acid; and S3, carrying out directional freezing on the alcohol gel containing the carbonizing agent to obtain the flame-retardant nano-cellulose composite aerogel with a directional structure. In the preparation process, carbonizing agents such as methylbenzenesulfonic acid are added, so that the carbonizing degree of cellulose is improved, and heat and combustible volatile components are prevented from being transferred; meanwhile, siloxane is introduced in situ during preparation, so that the flame-retardant effect is further achieved. The nanocellulose composite aerogel disclosed by the invention is low in heat conductivity coefficient and excellent in heat preservation and insulation performance.

Owner:UNIV OF SCI & TECH OF CHINA

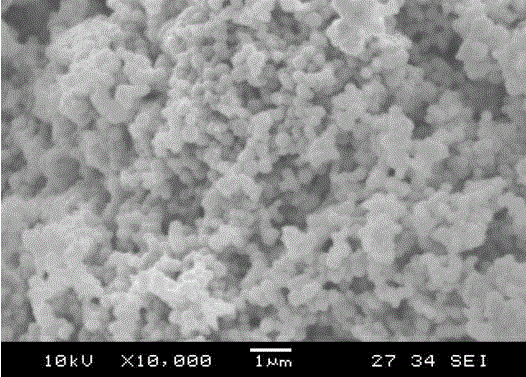

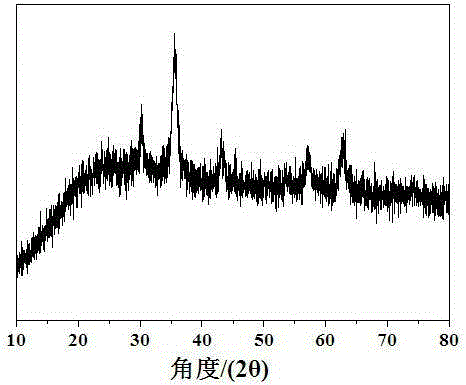

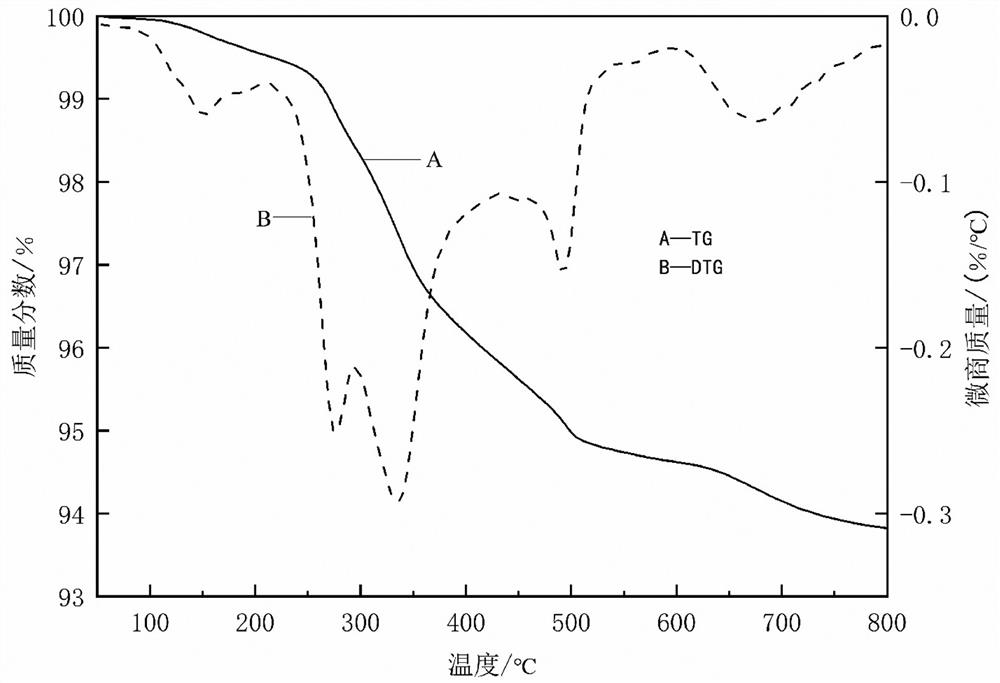

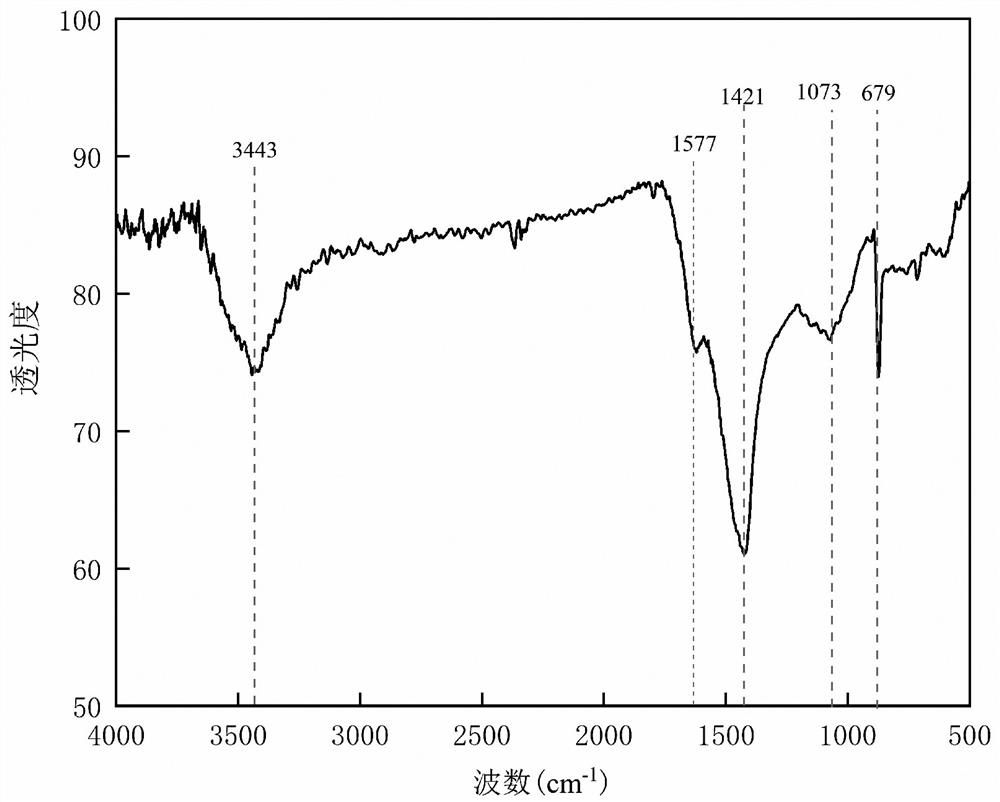

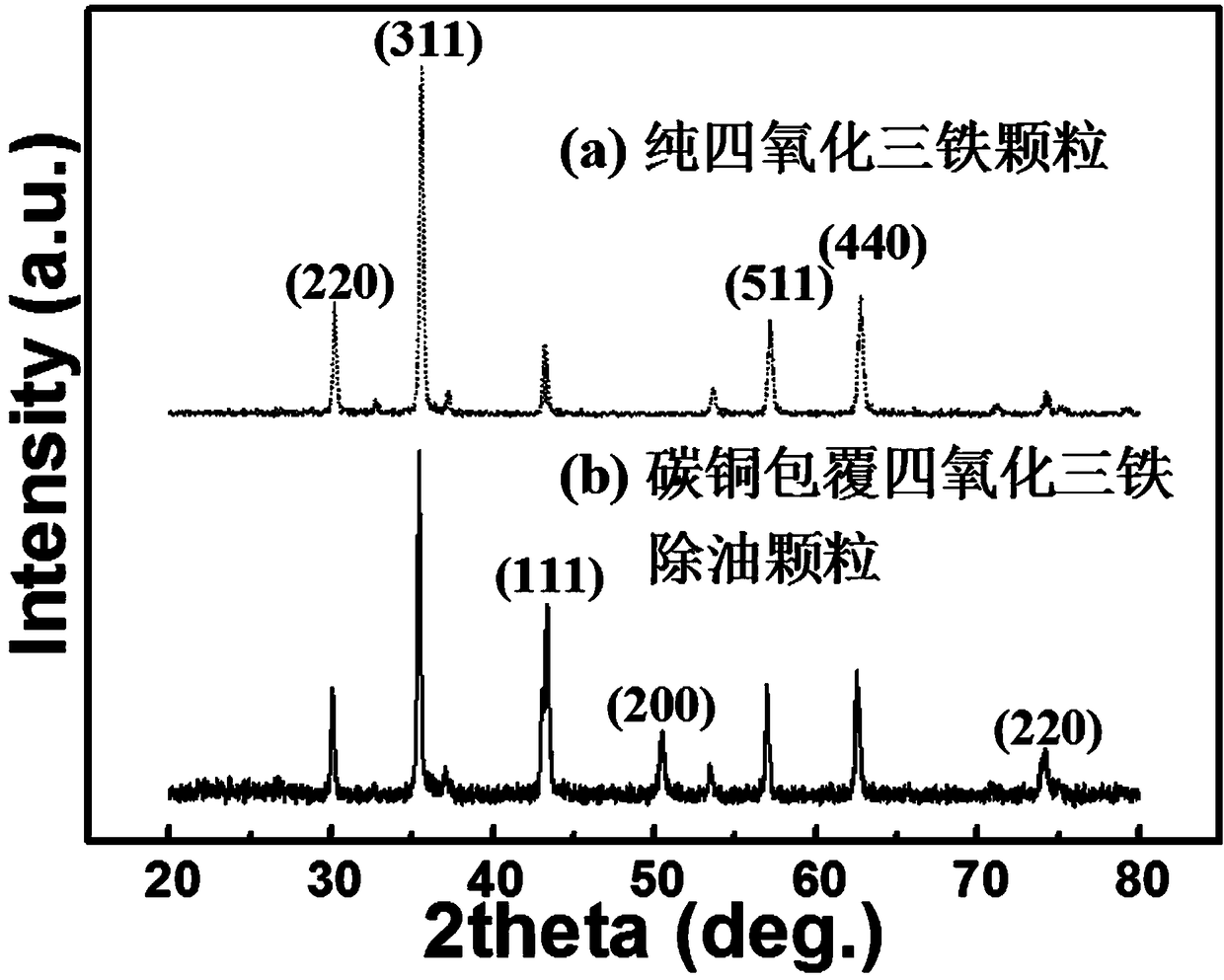

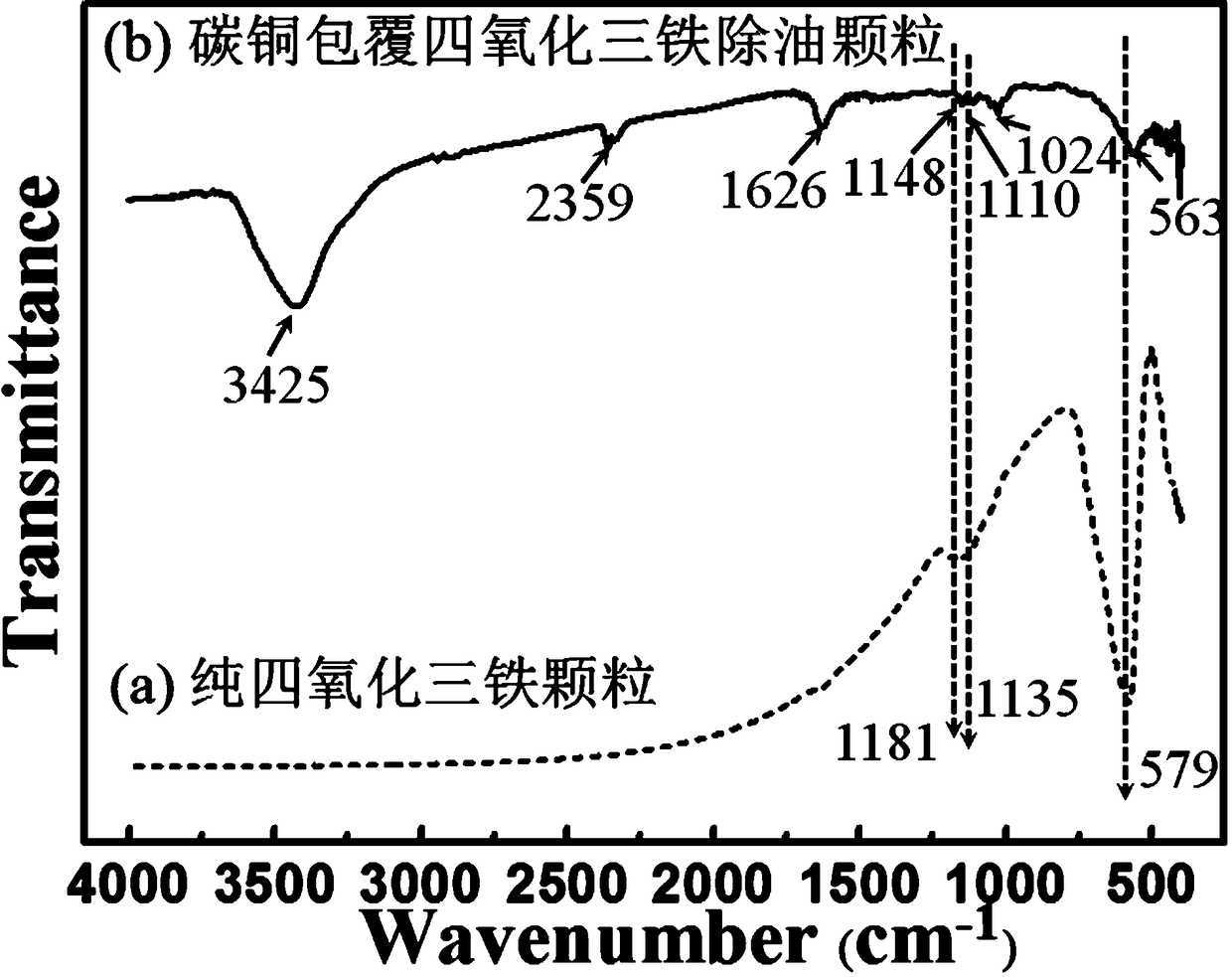

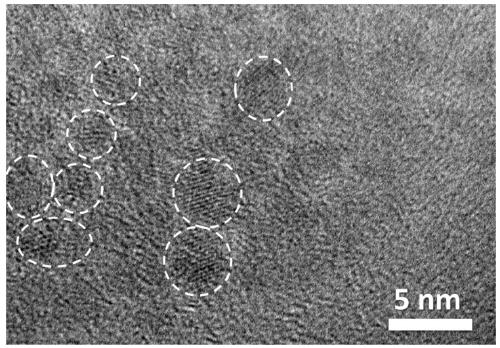

Preparation method of ferriferrous oxide@nitrogen doped carbon compound

InactiveCN105253920AImprove bindingThickness is easy to controlFerroso-ferric oxidesCarbonizationPhysical chemistry

The invention discloses a preparation method of a ferriferrous oxide@nitrogen doped carbon compound. The preparation method comprises the following steps: 1, mixing analytically pure aniline with 0.01mol / L of an inorganic acid to prepare an aniline-inorganic solution; 2, using ferriferrous oxide and distilled water to prepare a ferriferrous oxide solution with the mass concentration of 5-20mg / mL; 3, adding the aniline-inorganic solution into the ferriferrous oxide solution; 4, adding hydrogen peroxide with the mass percentage of 30% into the solution obtained in step 3 in a dropwise manner, reacting for 5-24h, carrying out magnetic separation, washing the obtained precipitate with water, and drying to prepare ferriferrous oxide@polyaniline nanoparticles; and 5, carrying out high temperature carbonization on the ferriferrous oxide@polyaniline nanoparticles obtained in step 4, and annealing in N2 atmosphere for 3-5h to prepare the ferriferrous oxide@nitrogen doped carbon compound. The ferriferrous oxide@nitrogen doped carbon compound prepared in the invention has the advantages of strong binding force, high carbonization degree, controllable thickness, and improvement of the conductivity of nitrogen doped carbon.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Streptomycin fungus residue resource utilization method

InactiveCN112940766ASufficient raw materialsEasy to sampleBiofuelsSpecial form destructive distillationBiotechnologyO-Phosphoric Acid

The invention relates to a streptomycin fungus residue resource utilization method. The method comprises the following steps: (1) taking fermented streptomycin fungus residues, and adjusting the water content of the streptomycin fungus residues to 50-60%; (2) crushing the streptomycin mushroom dregs treated in the step (1), sieving, and drying to constant weight; (3) putting the dried streptomycin fungus residues into a tubular muffle furnace, and performing high-temperature pyrolysis under the protection of nitrogen to obtain original biochar; (4) sieving the original biochar to obtain formed biochar; (5) soaking the formed biochar in a phosphoric acid solution with the mass concentration of 40-60%, and oscillating at 40-60 DEG C for 2-4h; then adjusting the supernate to be neutral, washing the precipitate with purified water, and drying to obtain phosphoric acid modified charcoal; the ratio of the mass of the formed biochar to the volume of the phosphoric acid solution is 11-13g: 50-70mL. The treatment cost is low, resource utilization of the antibiotic mushroom dregs can be achieved, and the method is applied to the related fields of soil improvement, greenhouse gas and heavy metal ion absorption, anaerobic digestion enhancement and the like.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for preparing modified biochar from plant waste and application

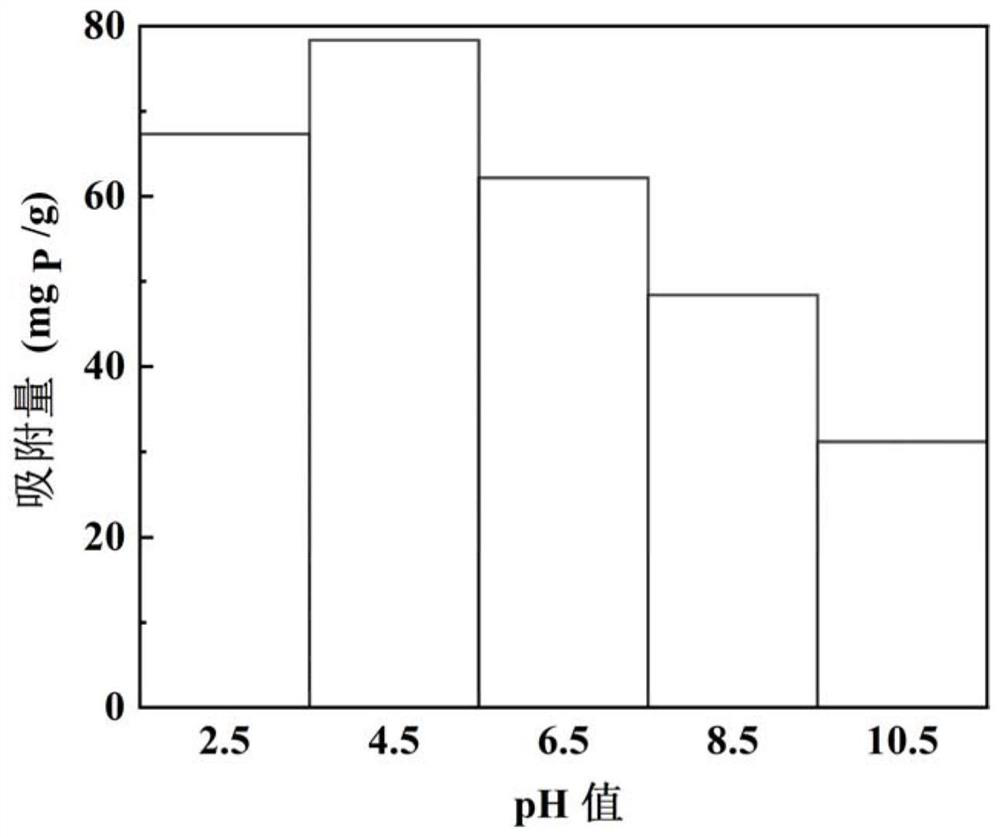

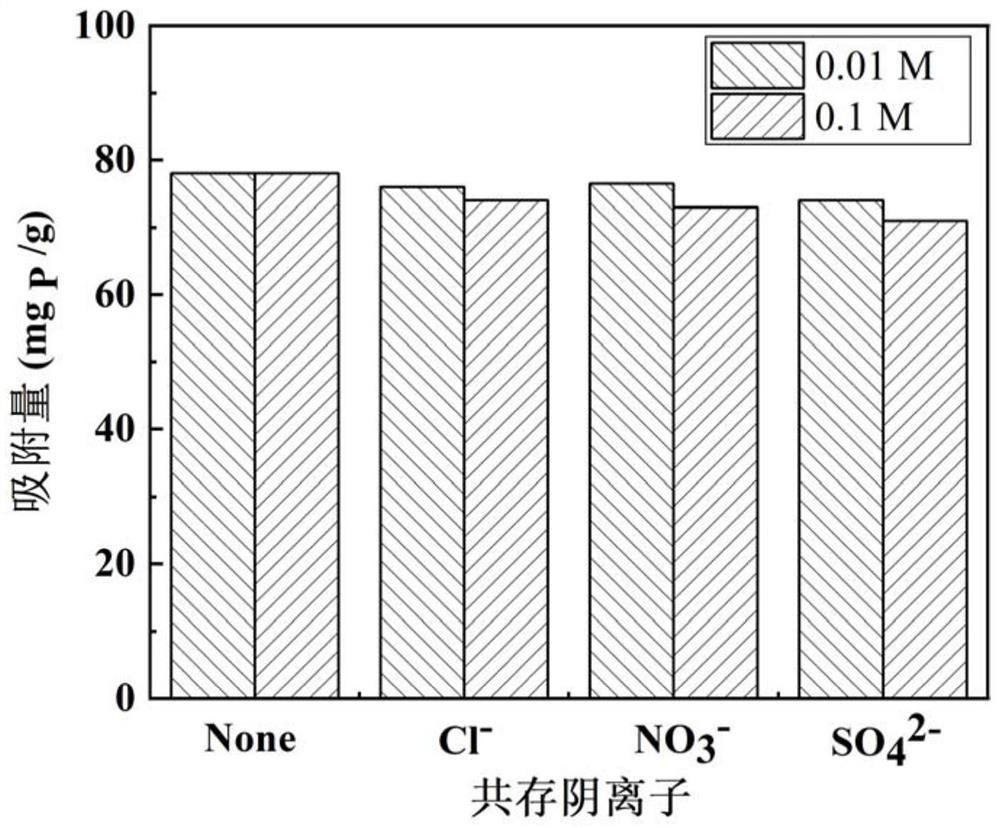

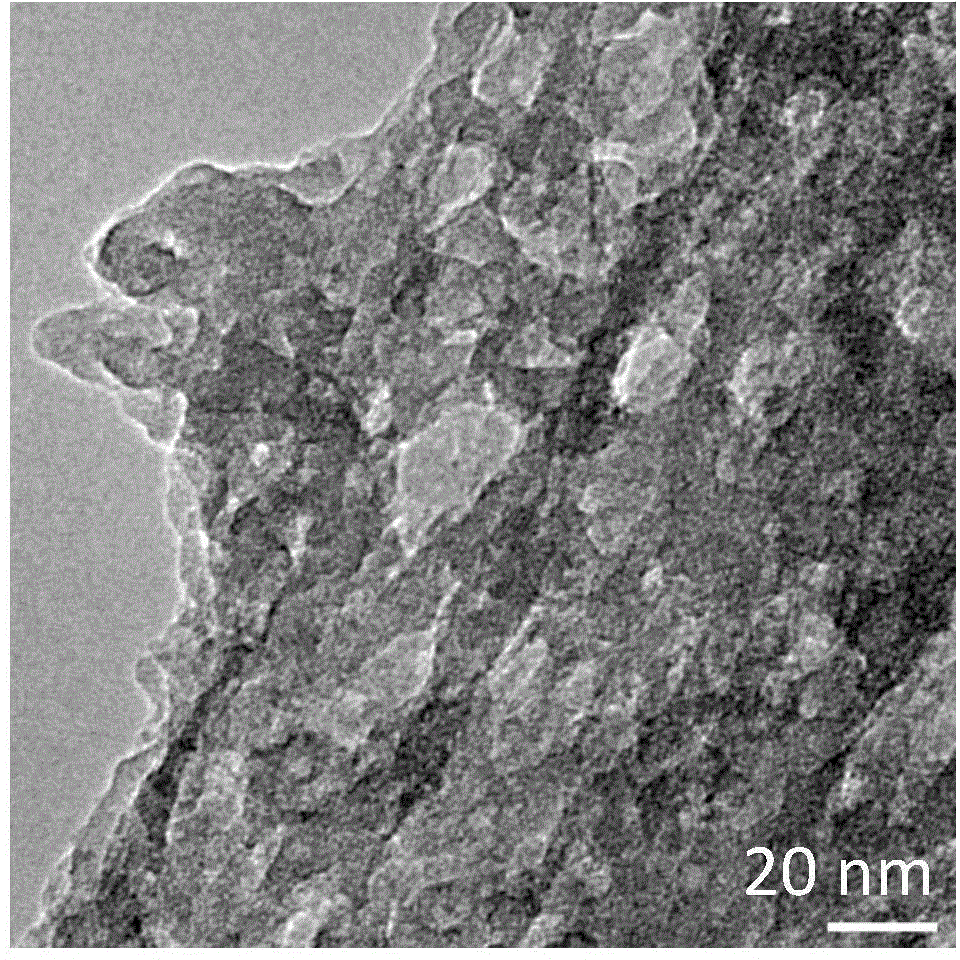

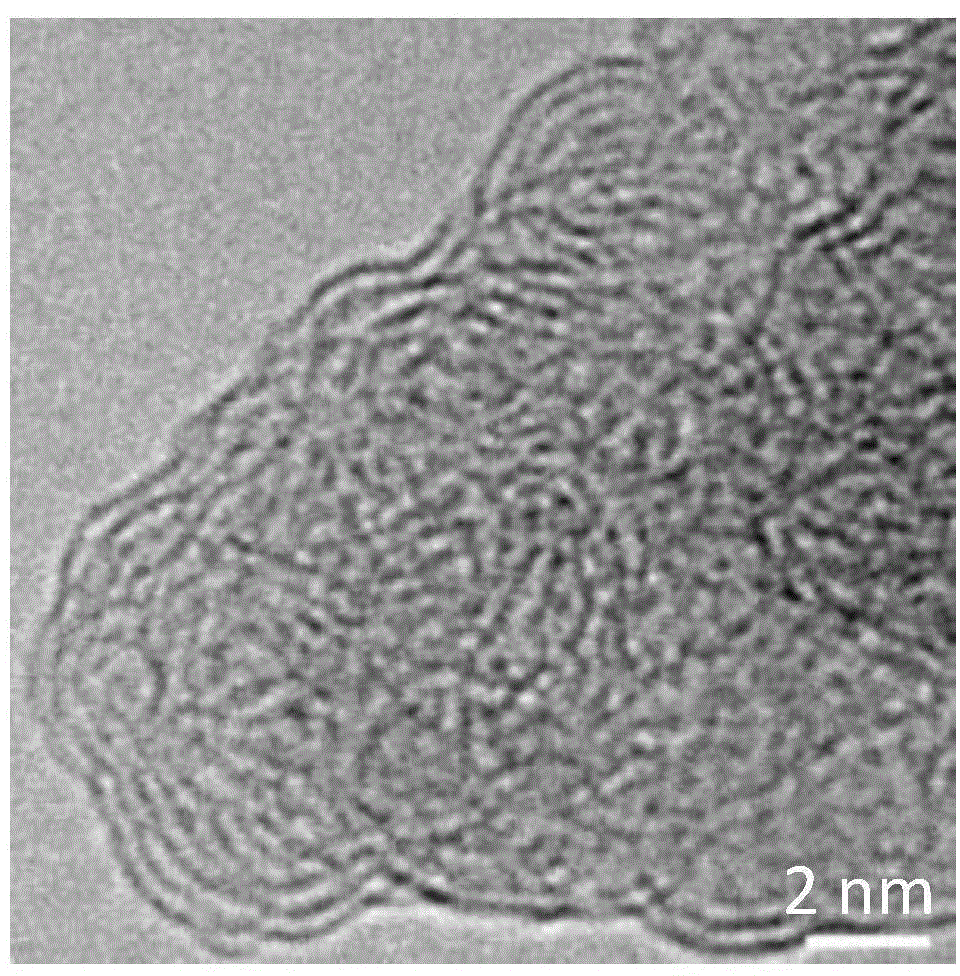

InactiveCN112619600AHydrophilicity and enhanced polarityLarge pore volume and pore sizeOther chemical processesWater contaminantsBiomassWaste treatment

The invention discloses a method for preparing modified biochar from plant waste and application of the modified biochar. The method comprises the following steps: fully mixing and infiltrating plant dry powder, a magnesium salt and water, performing drying, fully grinding the mixture, and carrying out pyrolytic reaction in a nitrogen atmosphere to obtain the modified biochar. Compared with other carbon-based adsorbents of the same type, the modified biochar prepared through the method has good adsorption performance on phosphate; the technology provided by the invention has the characteristics of low energy consumption, simple operation and short treatment period in plant waste treatment and resource utilization, and can fully realize the goals of reduction, harmlessness and resource utilization of biomass solid wastes.

Owner:SUN YAT SEN UNIV

Method for preparing heteroatom-doped carbon material at room temperature

The invention relates to a method for preparing a heteroatom-doped carbon material at a room temperature. The method comprises the following steps: mixing a halogenated macromolecule and strong base with a strong polar solvent so as to obtain a mixture, grinding the mixture at the room temperature, and directly cleaning and drying after completion of grinding, so as to obtain the heteroatom-doped carbon material, wherein the halogenated macromolecule is polyvinylidene difluoride, polyvinylidene chloride or polyvinyl chloride, the strong base is alkali (earth) metal hydroxide, alkali (earth) metal alkoxide, alkali (earth) metal sulfide, alkali (earth) metal amides or alkali (earth) metal nitride, the strong polar solvent is N,N-dimethylformamide, N,N-dimethylacetamide, dimethyl sulfoxide or nitrogen methyl pyrrolidone and the room temperature refers to 10-40 DEG C. According to the method, the raw materials are cheap and easy to obtain, the operation is simple, safety is high and the method is very suitable for industrial expanded production.

Owner:BEIJING UNIV OF CHEM TECH

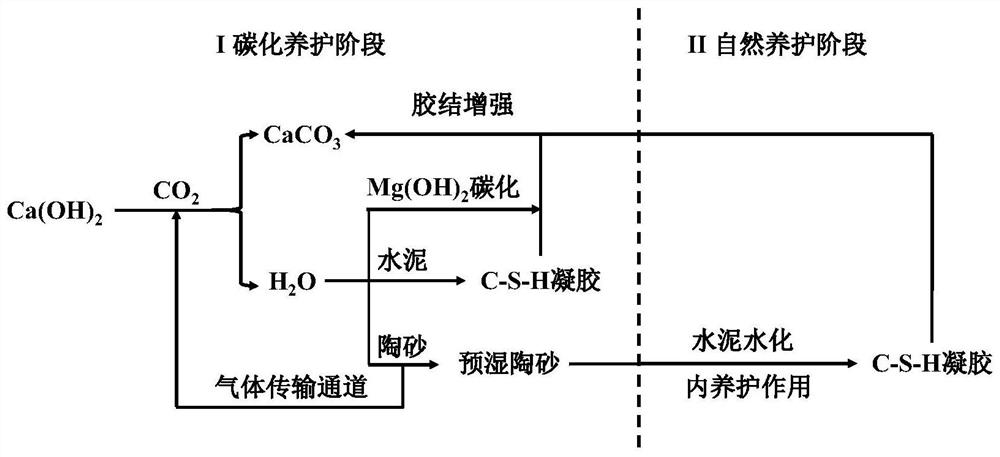

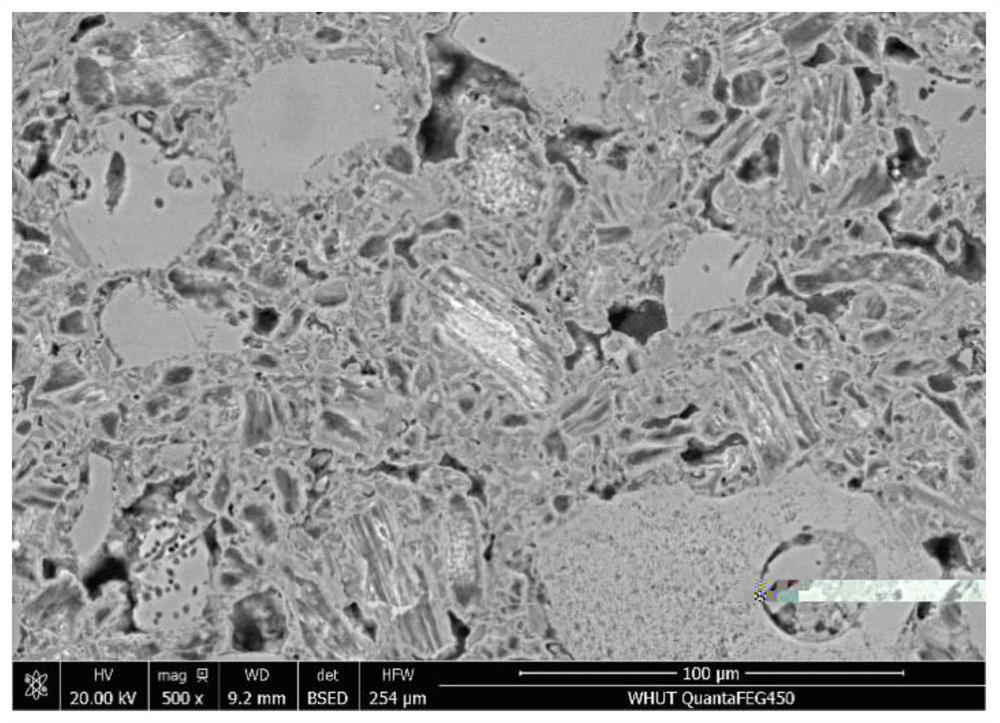

Method for improving strength of calcium hydroxide carbonized hardened body and product

The invention relates to a method for improving the strength of a calcium hydroxide carbonized hardened body and a product. The method for improving the strength of the calcium hydroxide carbonized hardened body comprises the following steps: uniformly mixing a calcium hydroxide raw material, ordinary Portland cement, magnesium hydroxide, pottery sand and water according to a mass ratio of 100: (15-20): (15-20): (40-80): (10-20), and carrying out compression molding, carbonization curing and natural curing to obtain the product. Through the synergistic effect of physical adsorption and chemical reaction, moisture generated by carbonization of calcium hydroxide is consumed, and meanwhile, the carbonization degree and the gelling property of a reaction product are further improved through the C-S-H gelling effect generated by hydration of cement, the cementing effect of a carbonized product of magnesium hydroxide and the gas transmission channel and internal curing effect of pottery sand; therefore, the strength of calcium hydroxide carbonized and hardened body is greatly improved.

Owner:WUHAN UNIV OF TECH

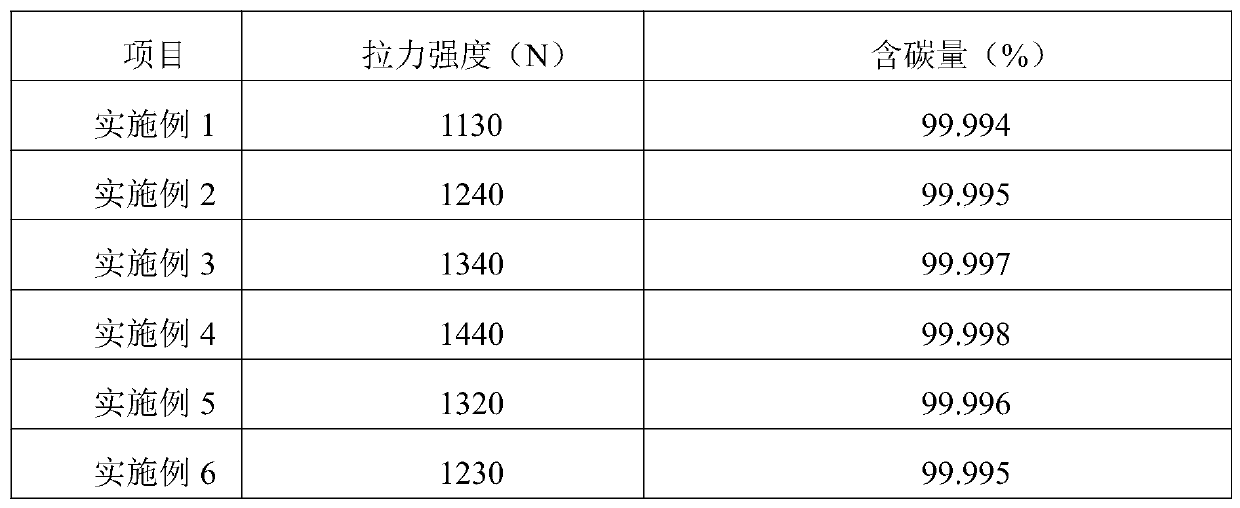

Preparation method of viscose high-temperature graphite carbon fibers

ActiveCN109957860AAdd carbonization application objectsHigh carbon contentFibre chemical featuresPolymer scienceCarbon fibers

The invention relates to a preparation method of viscose high-temperature graphite carbon fibers. The method comprises the following steps: (1) dipping into chemicals: dipping the viscose fibers intoa dilute solution of diammonium hydrogen phosphate or ammonium bromide for not less than 24h at room temperature, wherein the viscose fibers are cloth made of tows; (2) drying: introducing the viscosefibers, dipped into the chemicals, into a drying oven at 180 DEG C or enabling the viscose fibers to be naturally dried, and controlling the humidity not to exceed 10%; (3) carrying out step-by-stepcarbonization: enabling the dried viscose fibers to be sequentially subjected to the low-temperature precuring, medium-temperature carbonization and high-temperature carbonization to obtain the viscose high-temperature graphite carbon fibers. The preparation method provided by the invention can not only carbonize the viscose fiber tows, but also carbonize the cloth made of viscose fiber tows, thusincreasing the application targets of carbonization, and further promoting a carbonization process of the viscose fibers; furthermore, the carbon content of the obtained viscose high-temperature graphite carbon fibers is as high as 99.99%, and the degree of carbonization is high, so that the acting force between carbon atoms in the carbon fibers is further improved, and the performance of the carbon fibers is better maximized.

Owner:梁继选

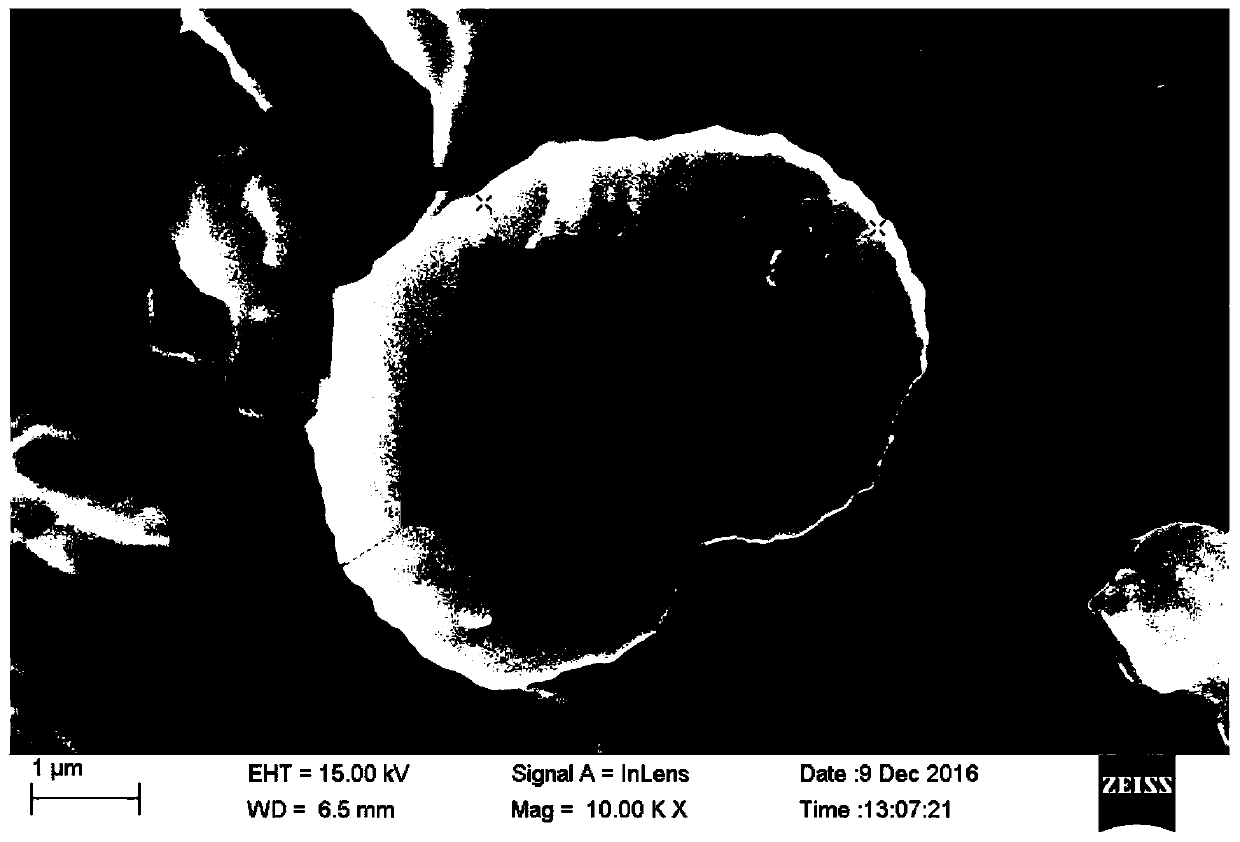

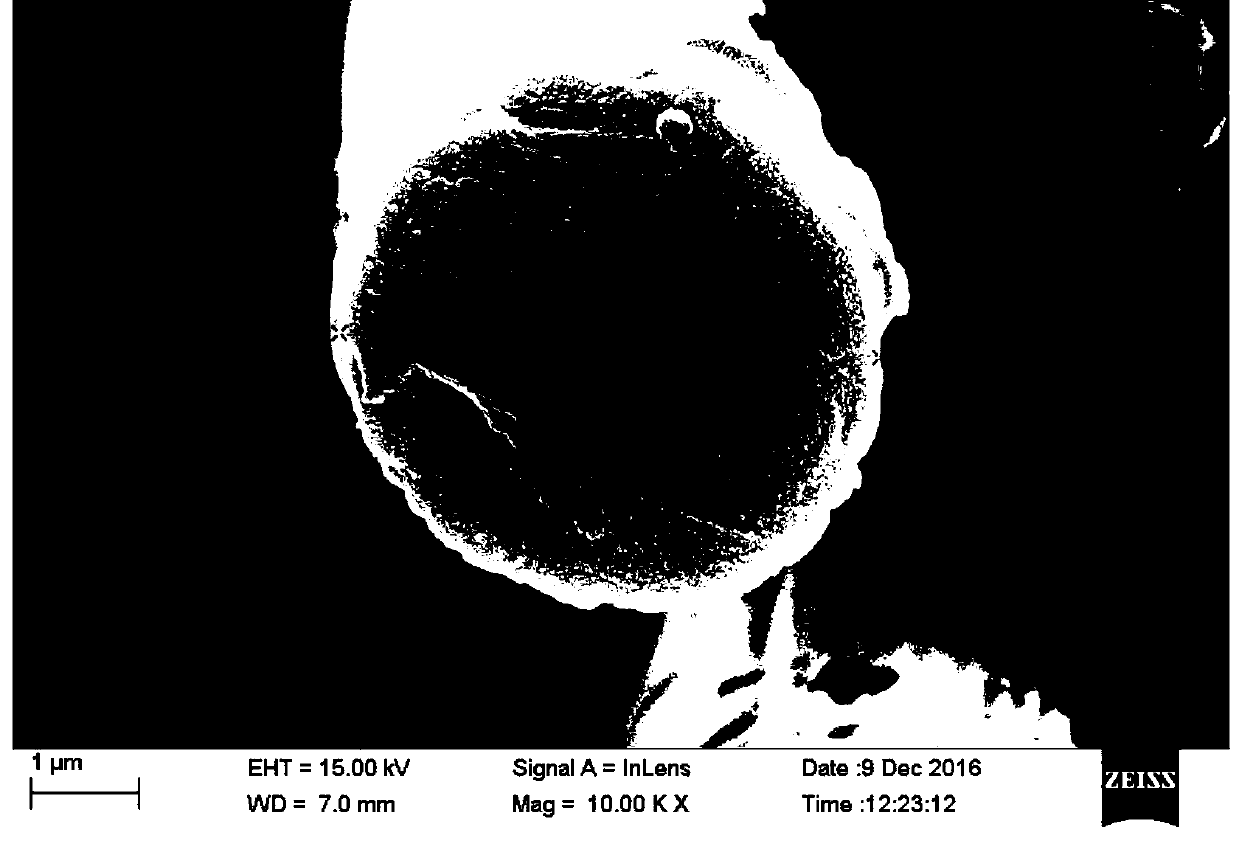

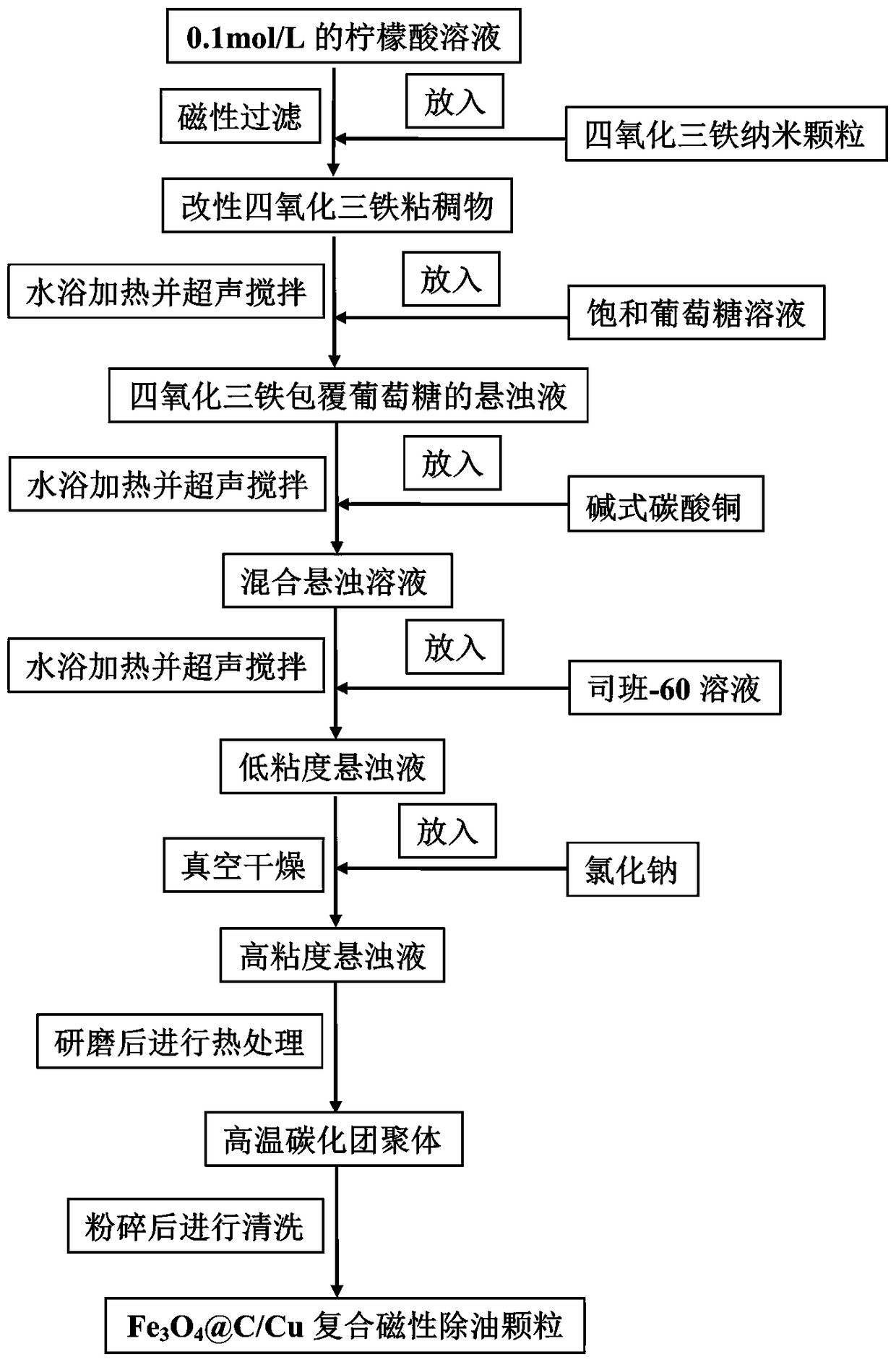

Method for preparing carbon-copper-coated ferroferric oxide composite magnetic oil removal particles

ActiveCN108568289AStrong magnetic responseHigh degree of carbonationFatty/oily/floating substances removal devicesOther chemical processesCarbon layerHigh volume manufacturing

The invention discloses a method for preparing carbon-copper-coated ferroferric oxide composite magnetic oil removal particles. The method comprises the following steps of modifying ferroferric oxide,introducing a carbon source, adding a lubricant, an emulsifying and thickening agent and a stabilizer, and then carrying out heat treatment so as to prepare the Fe3O4@C / Cu composite magnetic oil removal particles. The method has the advantages that the technical problems that a floating oil cleaning technology is tedious in preparation process, incapable of realizing mass production and the likecan be solved; and the particles prepared through the method is high in surface carbonization degree and stable in carbon layer, mass production can be realized, and the good particle preparation method solves the problem of floating oil on the water surface.

Owner:SHENYANG POLYTECHNIC UNIV

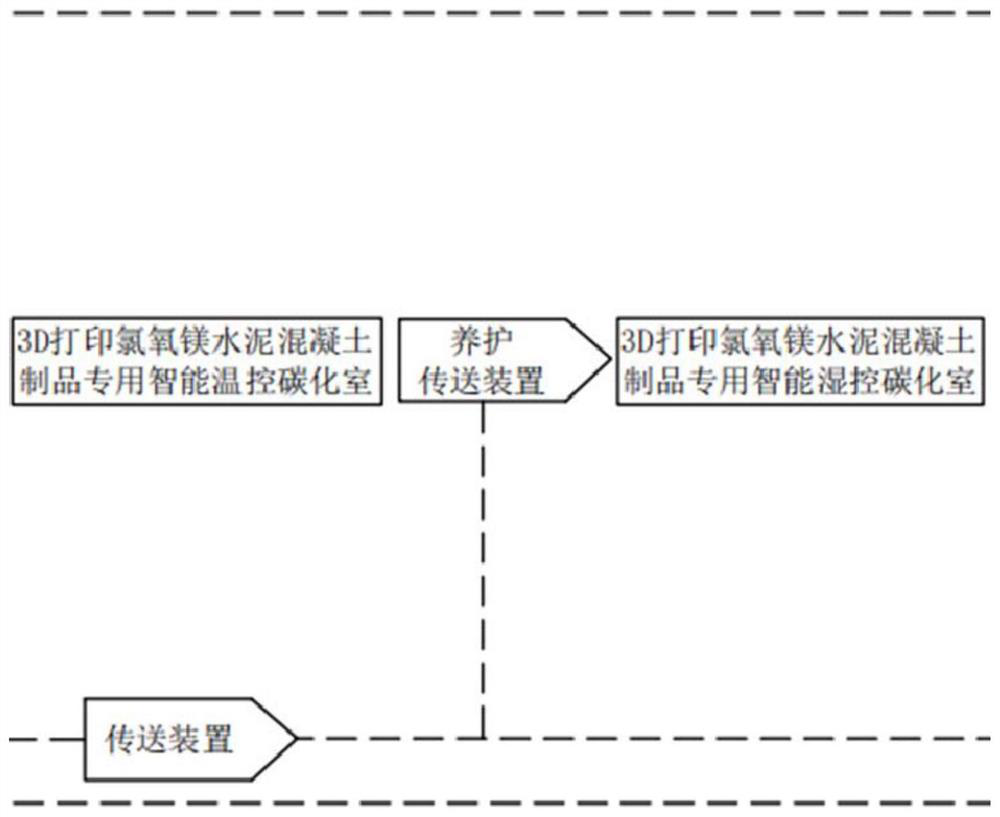

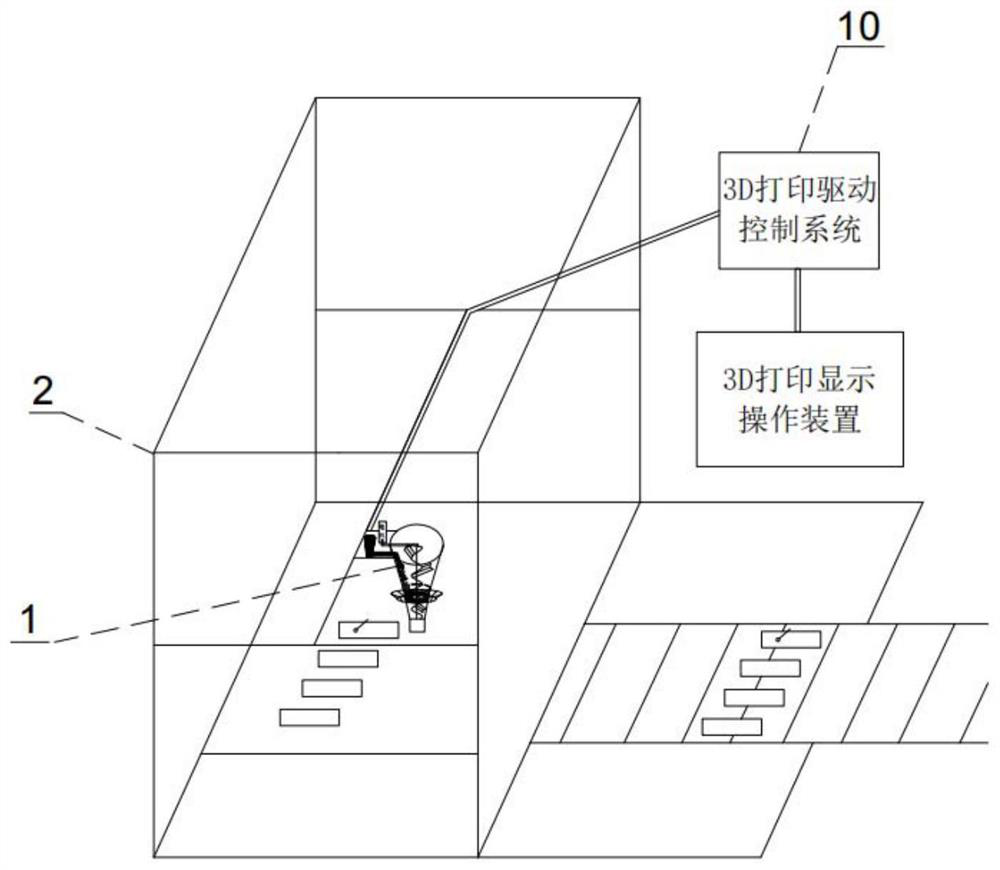

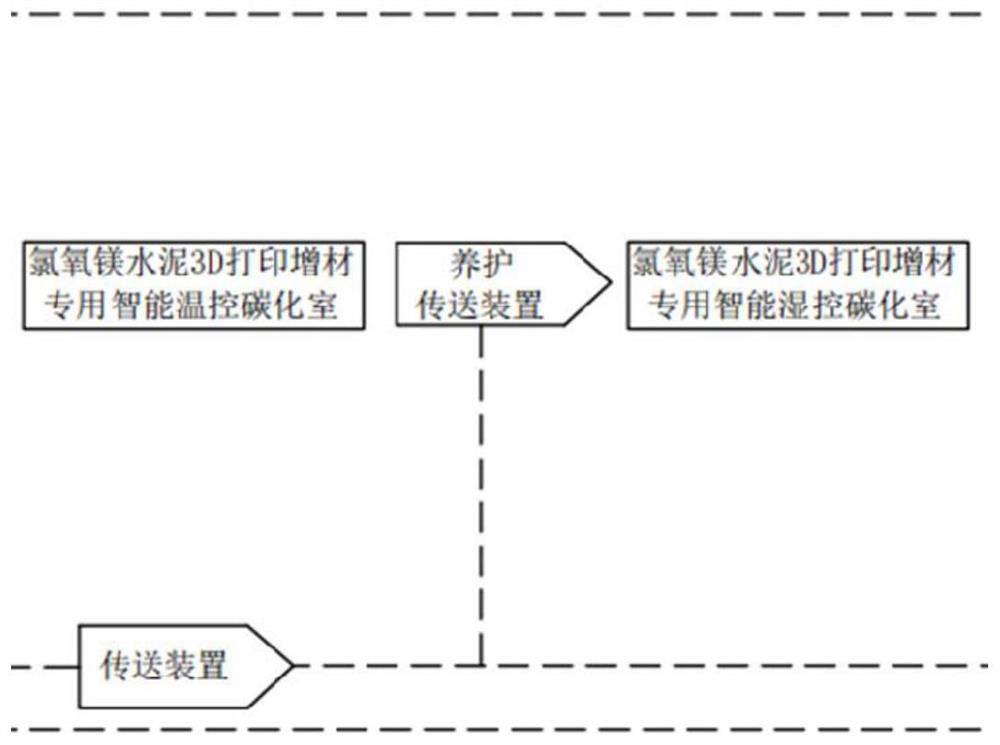

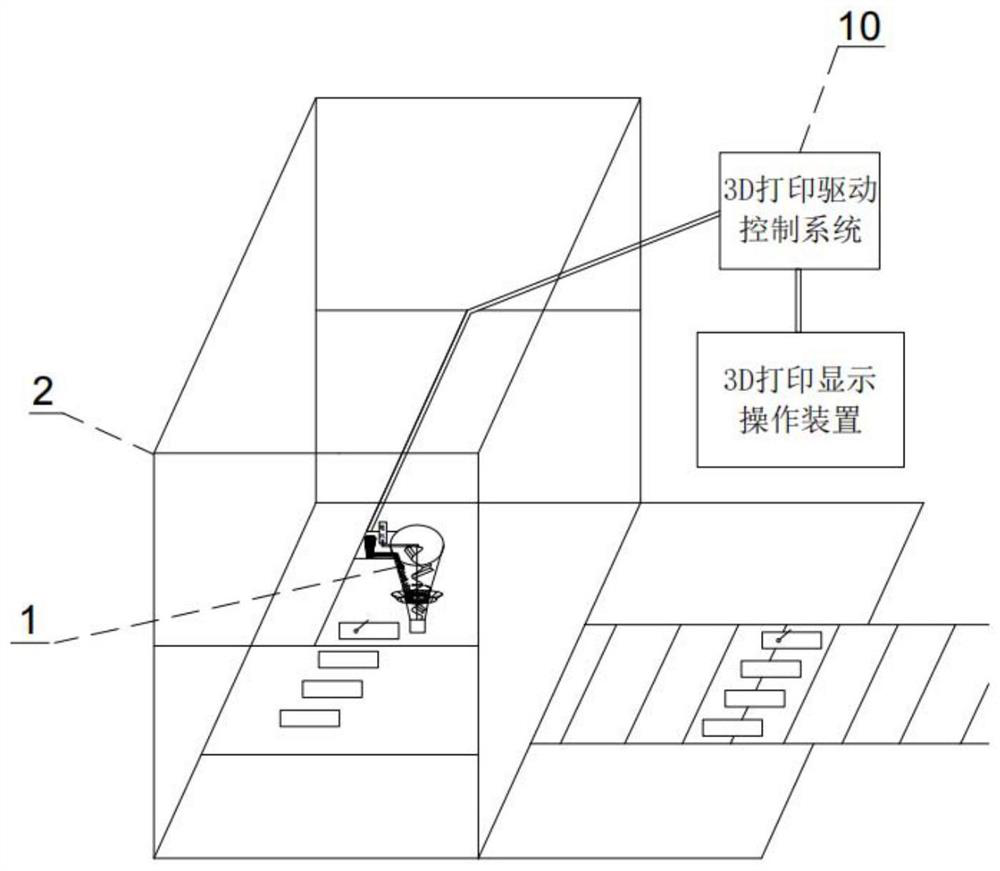

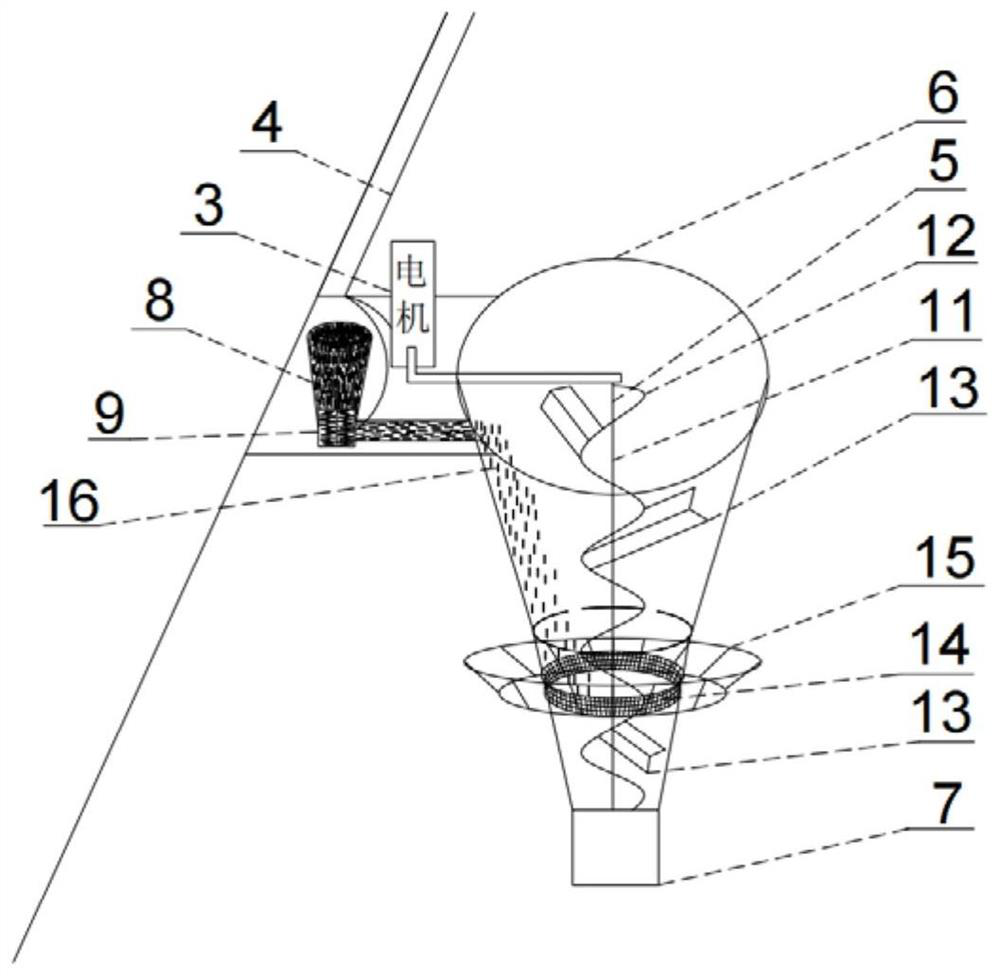

3D printing magnesium oxychloride cement concrete product and maintenance method thereof

ActiveCN113213882AImprove the level of industrializationPromote engineering applicationAdditive manufacturing apparatusSolid waste managementSteelmakingSlurry

The invention discloses a 3D printing magnesium oxychloride cement concrete product and a maintenance method thereof. The magnesium oxychloride cement concrete product comprises the following raw materials in parts by weight: 100 parts of light calcined magnesia, 100-150 parts of magnesium-based standard sand, 0-70 parts of water granulated slag sand, 130-200 parts of magnesium chloride hexahydrate, 0-40 parts of engineering residue soil, 0.5-10 parts of an additive, 10-30 parts of dry ice and 30-60 parts of water. According to the method, the dry ice is added into the magnesium oxychloride cement mortar additive newly-mixed slurry, the temperature of the newly-mixed slurry before final setting of magnesium oxychloride cement is reduced at low cost, carbon dioxide gas is conveniently introduced into the magnesium oxychloride cement newly-mixed slurry, magnesium hydroxide generated by reaction is fully carbonized, and the carbonization degree of the magnesium oxychloride cement newly-mixed slurry is remarkably improved; and the water granulated slag sand and the engineering residue soil generated by steelmaking are directly added into a magnesium oxychloride cement concrete product, resource utilization is achieved, the magnesium oxychloride cement mortar additive is used for 3D printing, and engineering application of magnesium oxychloride cement is promoted.

Owner:SHENZHEN UNIV

A kind of preparation method of doped carbon material for supercapacitor

ActiveCN104900423BLow costWide variety of sourcesHybrid capacitor electrodesHybrid/EDL manufactureAlkaline earth metalN dimethylformamide

The invention relates to a preparing method for a doped carbon material of a super-capacitor, which comprises the following steps: mixing polyvinylidene chloride, strong base and strong polar solvent for obtaining a mixture; then grinding the mixture; after grinding, calcining the ground mixture in an inert gas; and then performing cleaning and drying for obtaining the doped carbon material. The strong base is alkaline-earth metal hydroxide, alkaline-earth metal oxide, zinc oxide, alkaline-earth metal amide, alkaline-earth metal sulfide, alkaline-earth metal nitride or alkaline-earth metal alkoxide. The strong polar solvent is N,N-Dimethylformamide, N,N-Dimethylacetamide, dimethyl sulfoxide or N-methyl pyrrolidone. The preparing method has advantages of low price and easy availability of raw material, low cost, simple preparing process, high safety and environment-friendly performance. The prepared carbon material has excellent double-layer capacitance and important popularization value.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method and application of composite material

InactiveCN113963955AHigh crystallinityImprove conductivityHybrid capacitor electrodesGraphite carbonPtru catalyst

The invention discloses a preparation method and application of a composite material, the preparation raw materials comprise nickel mercaptide, cube sugar and polystyrene, and the nickel mercaptide is used as a catalyst to improve the crystallinity of the sugar / polystyrene composite material in the hydrogenation process so as to improve the conductivity and electrochemical performance of the material; the porous cube sugar is used as a carbon source while being used as a soft template for bearing polystyrene and a catalyst, so that the carbonization degree of the material is improved, and the need of additional high-pressure carbon source supplementation in a high-temperature graphitization process is avoided; the preparation method of the composite material provided by the invention is green and environment-friendly, waste polystyrene can be effectively utilized and converted into a graphite carbon electrode with high capacity and long cycle stability under high magnification to be used as energy storage equipment, and the problem of large-scale white pollution at present is solved.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

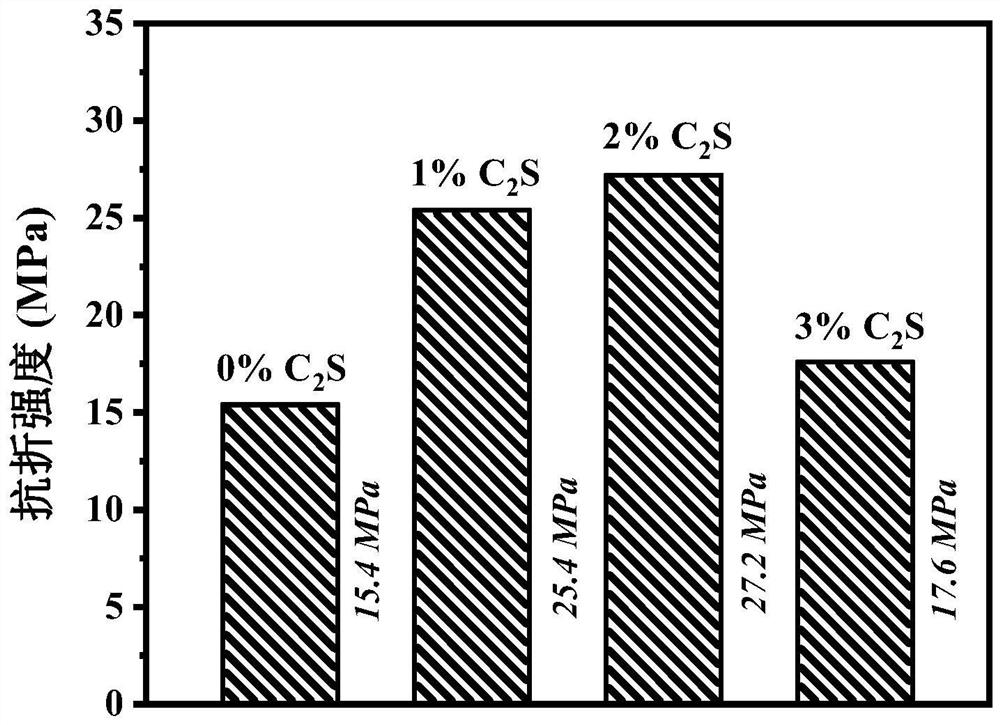

Calcium silicate board and preparation method thereof

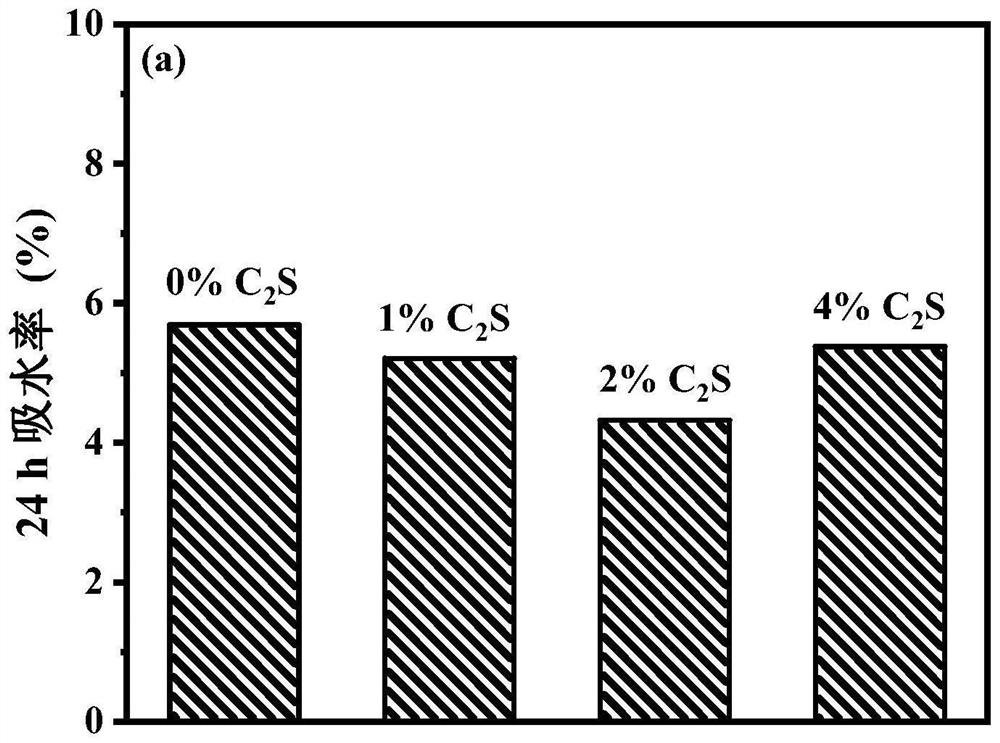

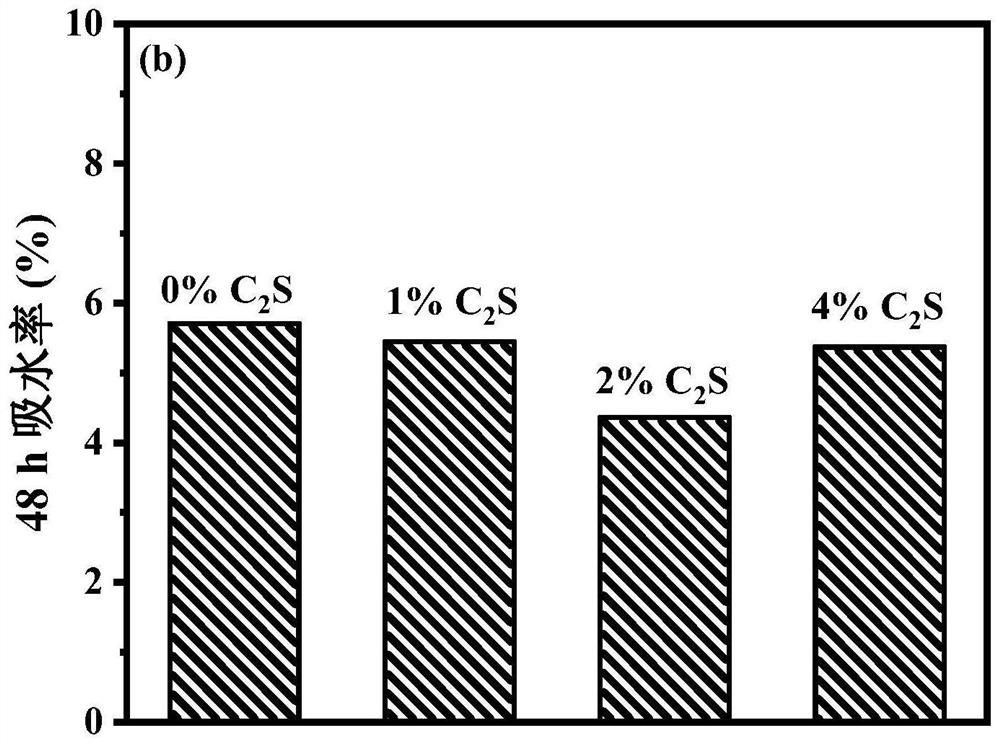

PendingCN113998933AHigh degree of carbonationStrong flexural strengthCeramic shaping apparatusIron oxideMineralogy

The invention discloses a calcium silicate board and a preparation method thereof, belonging to the technical field of inorganic boards. The preparation method of the calcium silicate board comprises the following steps: mixing iron oxide green, a dispersing agent and water to obtain a mixed solution; mixing a white material, tailings and stone powder to obtain a mixture; mixing the mixed solution and the mixture to obtain a wet material; pressing the wet material into a green body, drying the green body at 30-60 DEG C until a water loss rate reaches 50-70%, and then taking out the green body to obtain a calcium silicate substrate; and carbonizing the calcium silicate substrate in a vacuum CO2 environment to obtain the calcium silicate board. The calcium silicate board is high in breaking strength, low in water absorption rate and high in carbonization degree.

Owner:山东汉博昱洲新材料有限公司

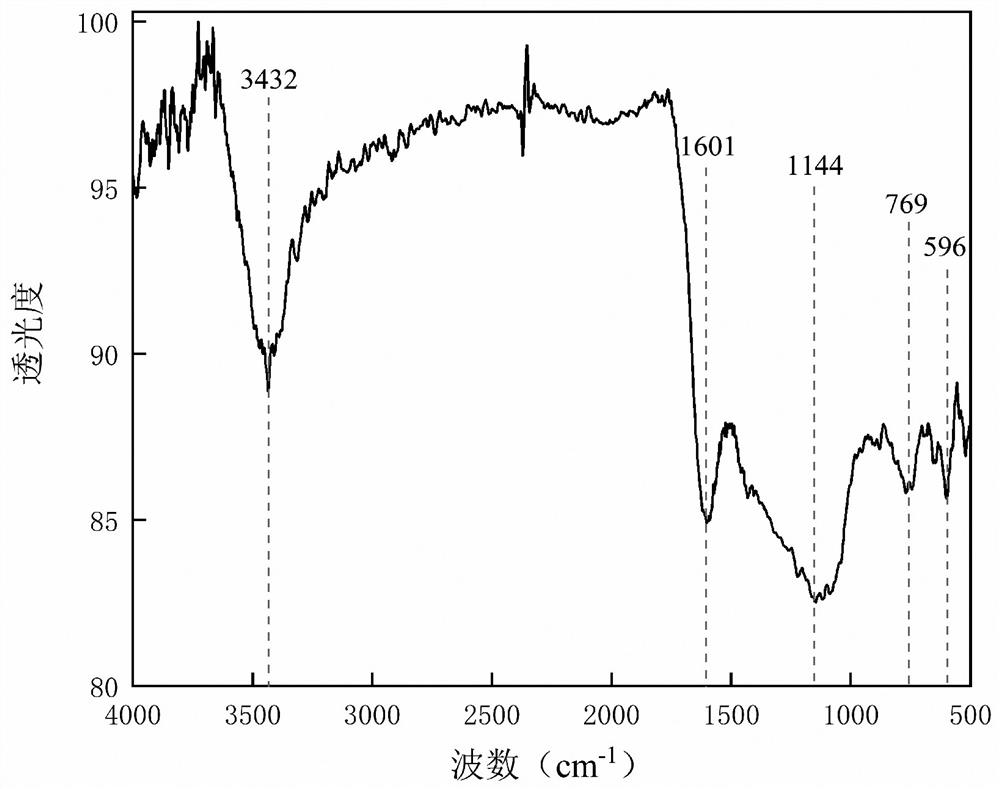

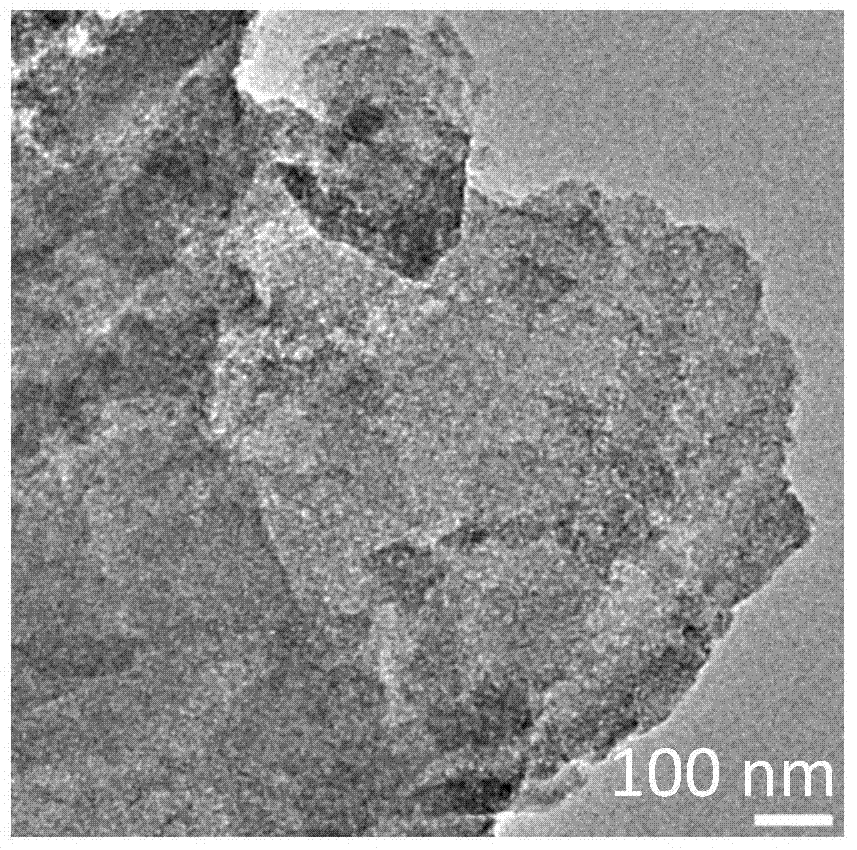

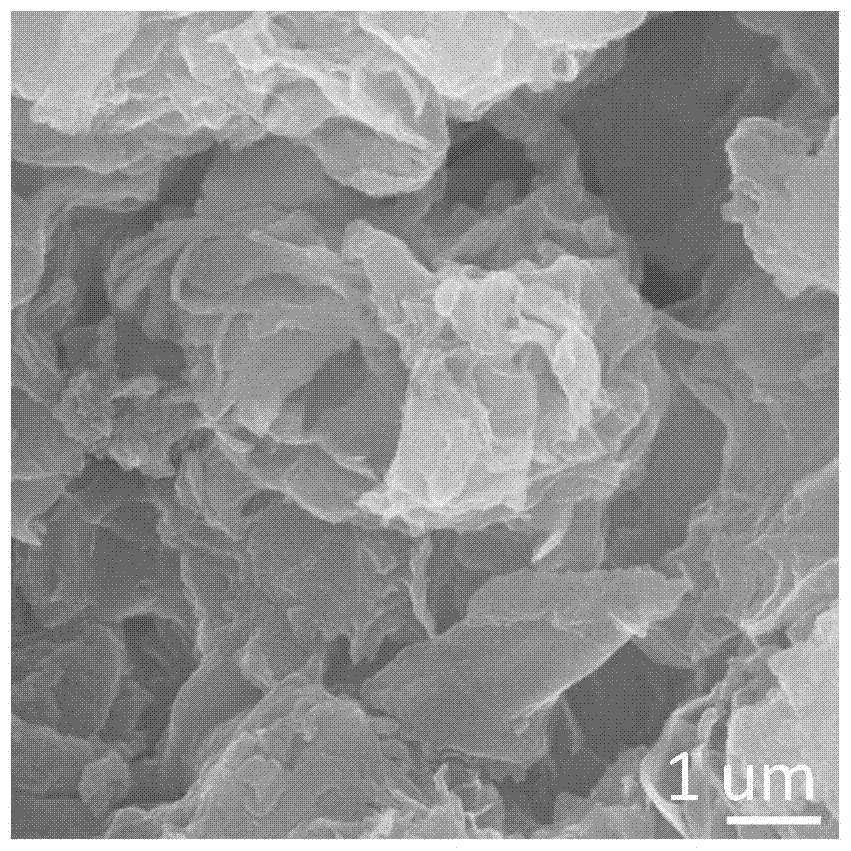

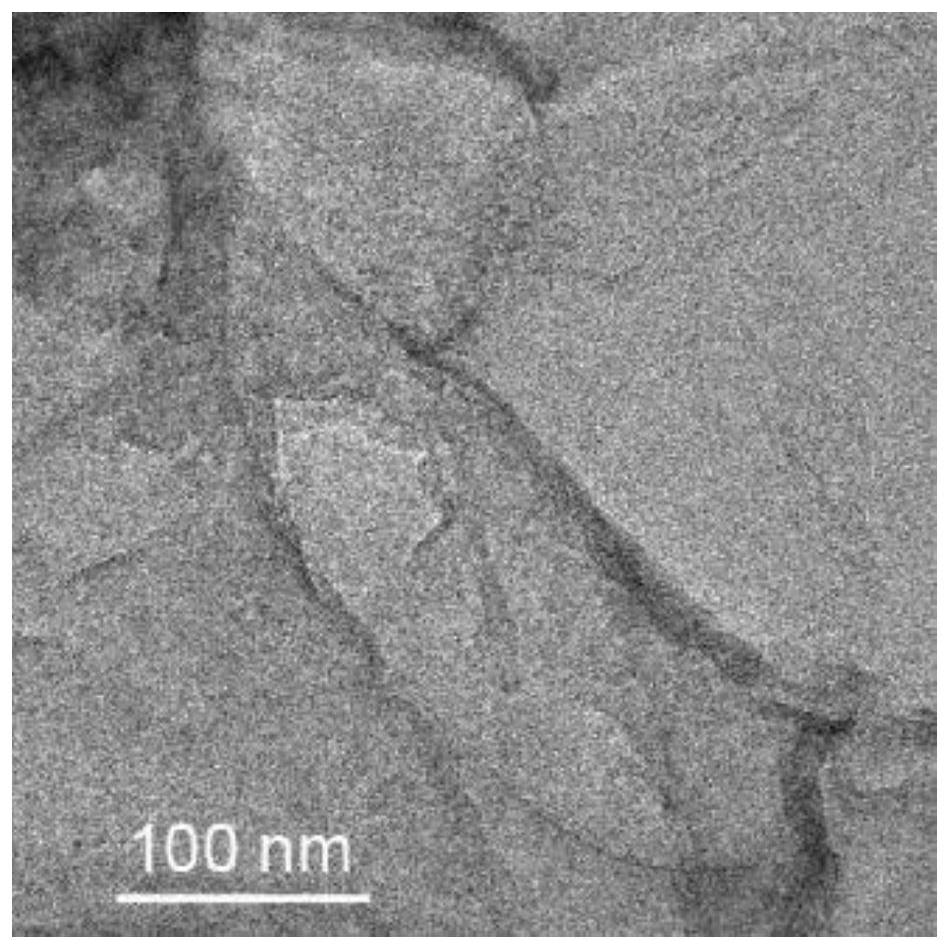

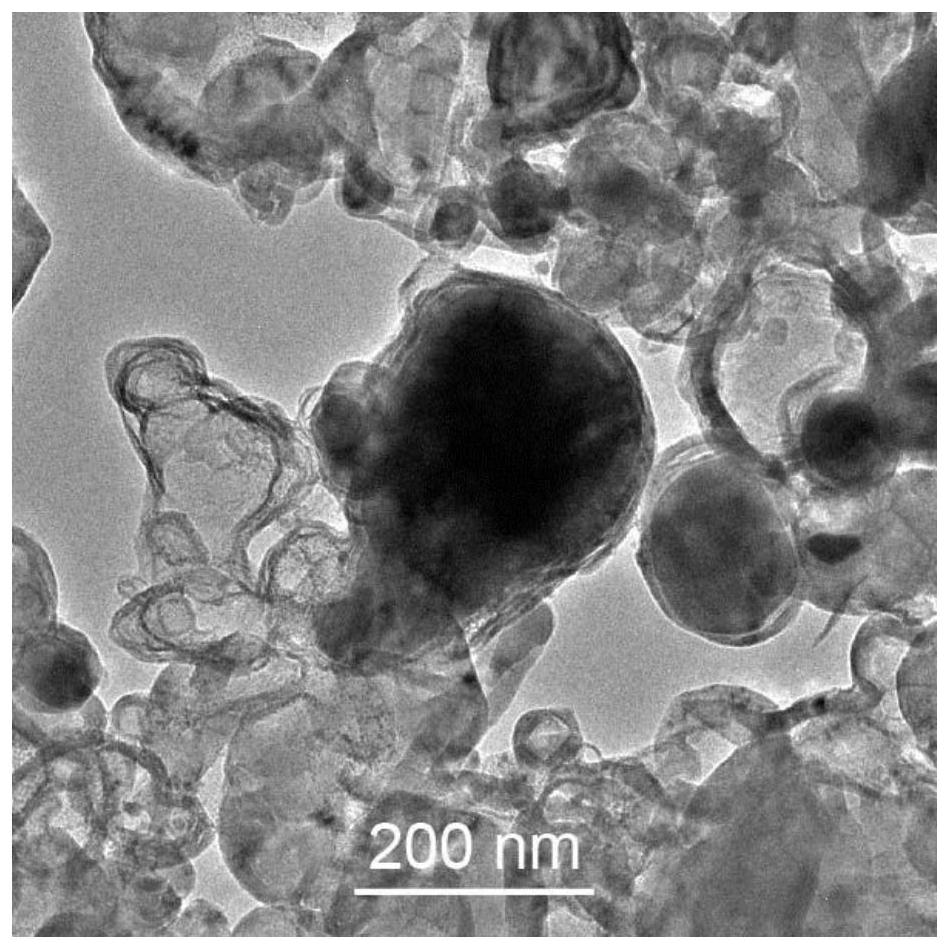

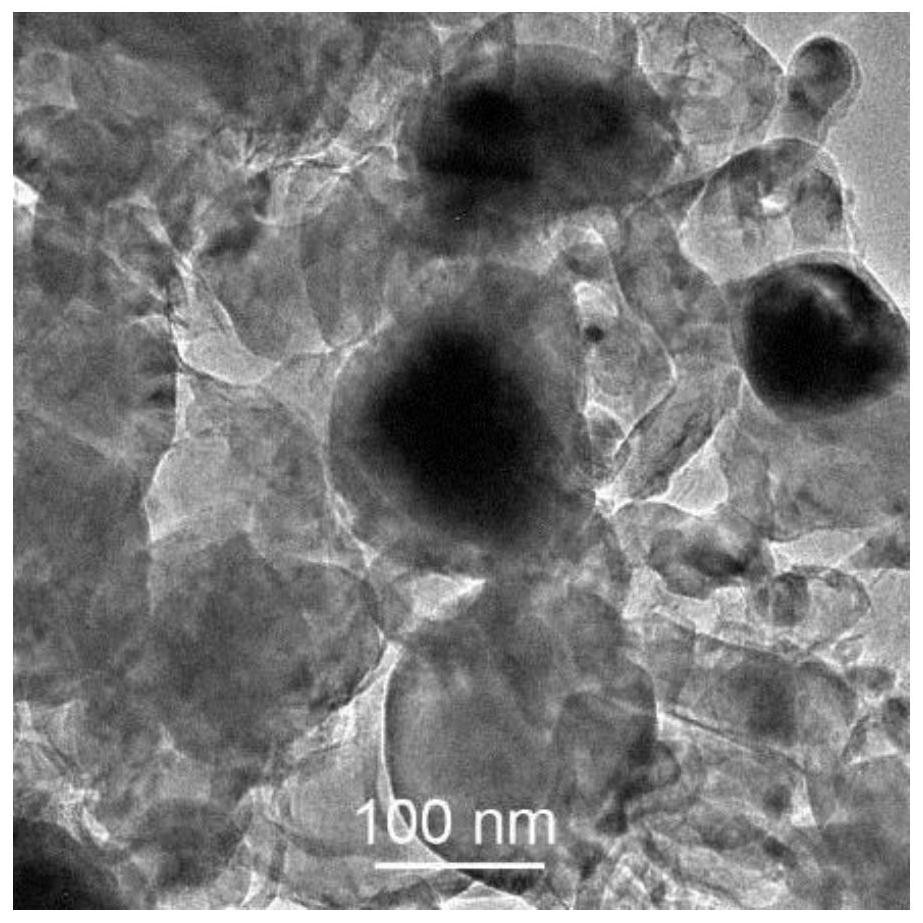

A kind of transition metal-nitrogen doped carbon-based composite material and preparation method thereof

ActiveCN109078649BHigh degree of carbonationLarge specific surface areaPhysical/chemical process catalystsCarbon compositesNanoparticle

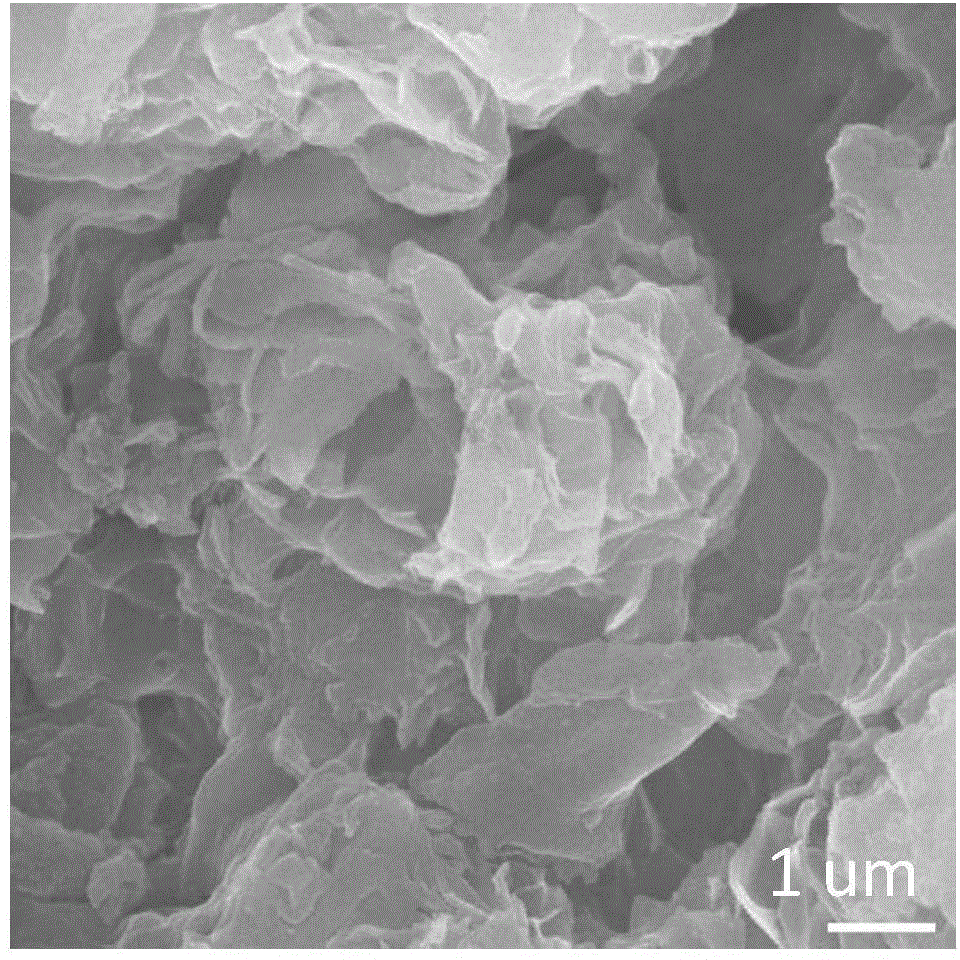

The invention discloses a transition metal-nitrogen co-doped carbon-based composite material and a preparation method thereof. Transition metal chloride salts and nitrogen-containing organic small molecules are used as transition metal sources and carbon and nitrogen sources, and transition metals are directly obtained by a one-step method. Coordinated macrocyclic mixtures, and then carbonized to obtain transition metal-nitrogen-doped carbon-based composites, the preparation method is simple and quick, suitable for large-scale production preparation; the structure of the synthesized transition metal-nitrogen-doped carbon composites Nanosheets are produced, and the transition metals on the nanosheets exist in two forms, one is transition metal nanoparticles and the other is transition metal nitride nanoparticles; the synthesized transition metal and nitrogen-doped carbon composites have nitrogen-doped Carbon, transition metals and nitrogen atoms are coordinated and active sites with more defects and have a larger specific surface area; it is conducive to the application of transition metals and nitrogen-doped carbon-based composites in the fields of catalysis and energy storage.

Owner:SHAANXI NORMAL UNIV

Method for promoting carbonization of quicklime

The invention relates to a method for promoting carbonization of quicklime. The method comprises the steps: (1) preparing magnesium hydroxide powder; (2) weighing calcium carbonate and magnesium carbonate at a certain molar ratio, performing mixing, then performing ball grinding on the mixed powder at a certain ball-to-material ratio, and performing sieving for later use; (3) weighing quicklime and magnesium hydroxide at a certain molar ratio, weighing the mixed powder obtained in the step (2) at an amount of 0.1-5% of the total mass of the quicklime and magnesium hydroxide powder, mixing thequicklime, the magnesium hydroxide and the mixed powder obtained in the step 2 uniformly in a beaker; (4) adding water at an amount of 20-45% of the total mass of the powder obtained in the step (3),and performing uniform stirring; and (5) putting the mixed powder together the beaker in a pressure reactor for carbonization and solidification, and performing curing in a reactor with CO2 curing gasso as to obtain the product with a carbonization degree higher than the unmodified quicklime after completion of curing. Through the method, the degree of carbonization of quicklime can be improved.

Owner:HUBEI UNIV OF TECH

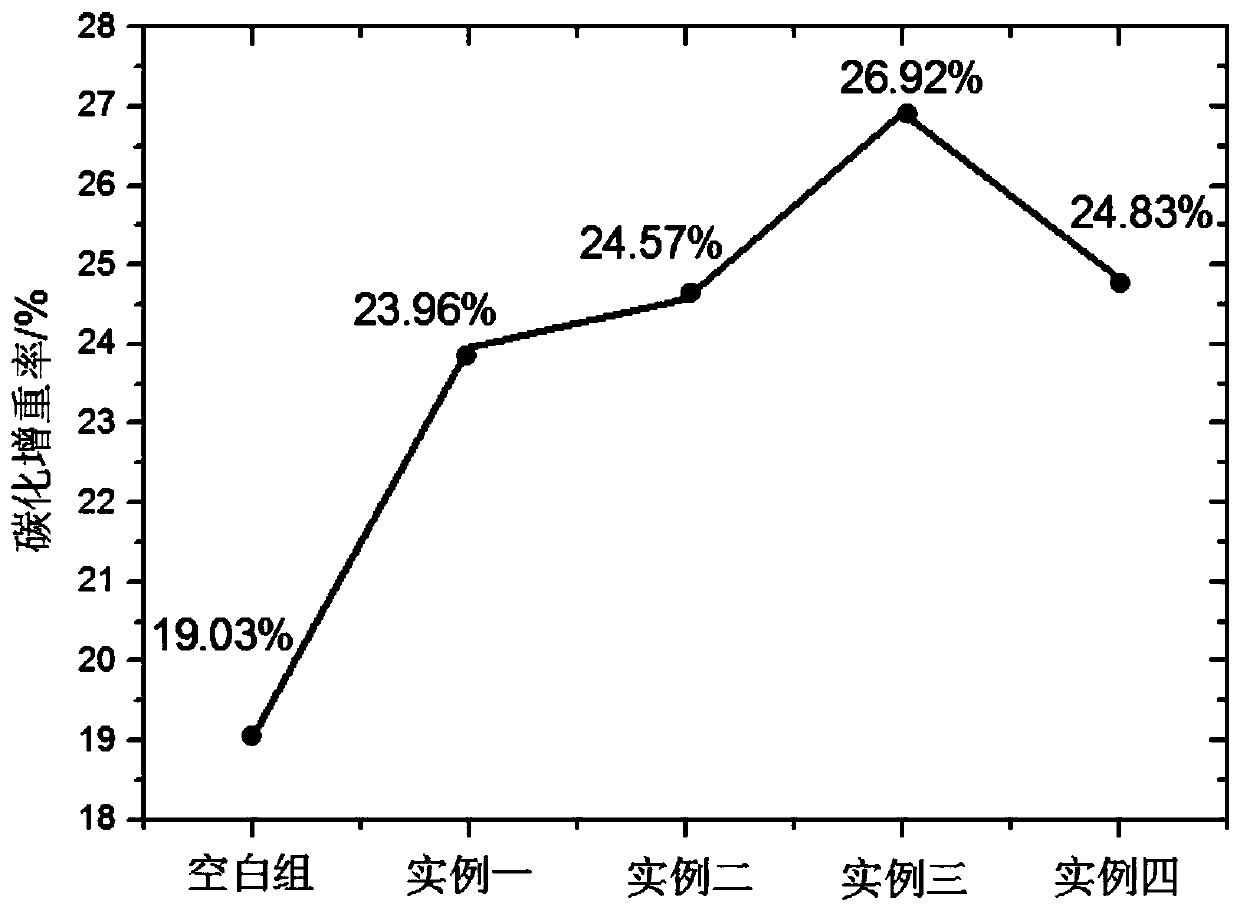

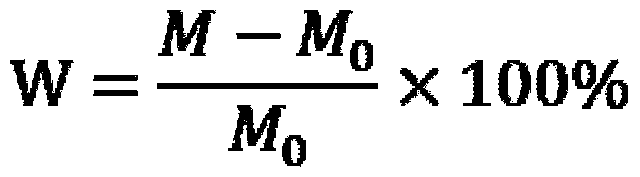

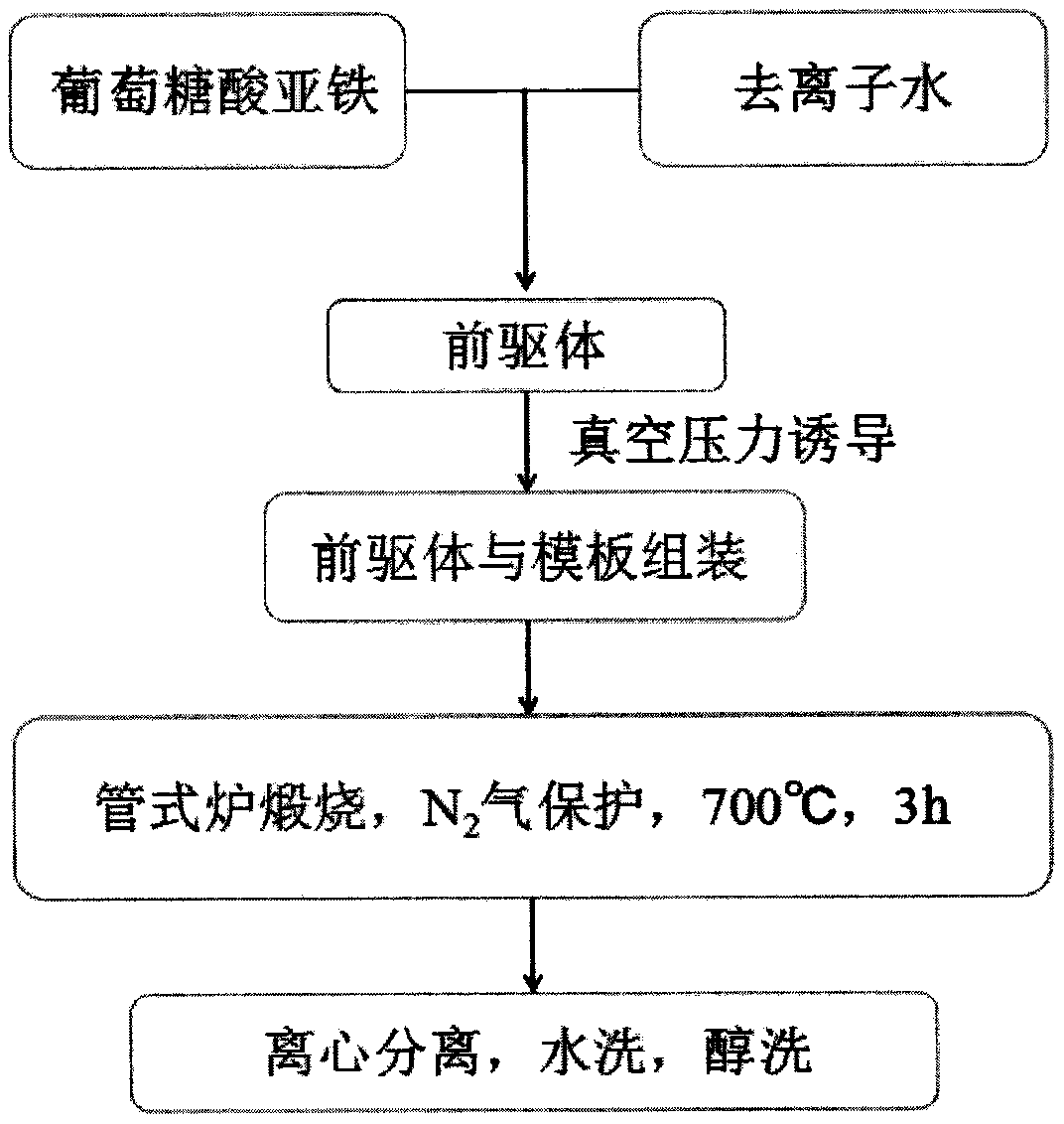

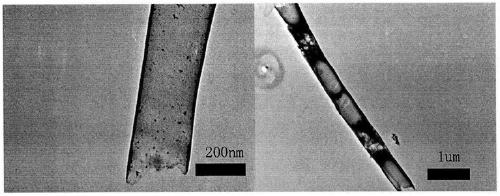

Preparation method of gamma-Fe2O3-doped hollow carbon nanofiber membrane material

The invention relates to a preparation method of a gamma-Fe2O3-doped hollow carbon nanofiber membrane material. The method comprises the specific steps of (1) preparing a precursor; (2) preparing an anodised aluminium AAO template with the precursor; (3) calcining the anodised aluminium AAO template assembled with the precursor to obtain gamma-Fe2O3-doped hollow carbon nanofibers in a template nanochannel, and placing the calcined AAO template in a NaOH solution to remove the anodised aluminium template; (4) preparing gamma-Fe2O3-doped hollow carbon nanofibers; (5) dispersing the prepared gamma-Fe2O3-doped hollow carbon nanofibers in an ethyl alcohol solution, using a syringe for extraction, adding liquid on a bare glassy carbon electrode surface dropwise, and obtaining the gamma-Fe2O3-doped hollow carbon nanofiber membrane material after airing and film-forming are conducted at a room temperature. Metal nanometer particles are evenly dispersed in the hollow fibers, the shape is straight, and is in accordance with that of the template channel, moreover, the hollow fibers are independent from one another, and have a high degree of graphitization, and the crystal forms of the metal particles dispersed in the hollow fibers are complete.

Owner:QIQIHAR UNIVERSITY

Method for promoting carbonization of quicklime by taking calcium carbonate as template agent

The invention relates to a method for promoting carbonization of quicklime by taking calcium carbonate as a template agent. The method comprises the following steps: (1) putting calcium carbonate intoa ball mill according to a certain ball-material ratio to carry out ball milling, then carrying out grinding by using a mortar, and carrying out sieving for later use; (2) weighing calcium carbonateaccording to 0.3%-3% of the mass of quicklime, and uniformly mixing the quicklime and the calcium carbonate in a beaker; (3) adding water accounting for 25%-50% of the total mass of the quicklime andthe calcium carbonate, and uniformly carrying out stirring; (4) putting the uniformly stirred powder and the beaker into a pressure reaction kettle together for carbonization and solidification, and carrying out curing in the reaction kettle, wherein the curing gas is CO2, the pressure range is 0.05-0.9 MPa, and the curing time is 2 hours, so that a product with a carbonization degree higher thanthe carbonization degree of unmodified quicklime is obtained after curing is finished. The ground calcium carbonate exerts a template induction function in the carbonization process and promotes carbonization. According to the method, the carbonization degree of quicklime can be improved.

Owner:HUBEI UNIV OF TECH

A kind of preparation method of hierarchical porous structure carbon material

ActiveCN106229152BHigh specific capacitancePromote circulationHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceOrganic sulfide compound

The invention belongs to the technical field of materials, and discloses a method for preparing a multistage porous carbon material. The method includes the steps of dissolving tin salt, carbohydrate compound and organic sulfur compound to obtain a clear mixed solution, conducting hydrothermally reaction to obtain SnS / C composite material precipitate, calcinating at a high temperature after washing and drying to obtain a sulfur-doped multistage porous carbon material. The porous carbon structure improves the sufficient wettability between the material and an electrolyte and ensures excellent charge conduction. Trace sulfur elements play a role in improving the charge-adsorption capacity in the porous carbon structure, and the synergetic effect of the two effectively improves the specific capacitance of the material, multiplying power performance and cycling performance.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

A kind of preparation method of amphiphilic graphene quantum dot material

ActiveCN110615428BInhibit side effectsSimple separation and purification processMaterial nanotechnologyGrapheneQuantum yieldCITRATE ESTER

Owner:XI AN JIAOTONG UNIV

Magnesium oxychloride cement additive for 3D printing and application thereof

ActiveCN113563045AFacilitate exothermic reactionsImprove the level of industrializationAdditive manufacturing apparatusSolid waste managementPhysical chemistryDry ice

The invention discloses a magnesium oxychloride cement additive for 3D printing and an application thereof. The magnesium oxychloride cement is prepared from the following raw materials in parts by weight: 100 parts of light calcined magnesia, 122.4-150.0 parts of magnesium chloride hexahydrate, 0-6.5 parts of an additive, 0-20 parts of dry ice and 40-73 parts of water, according to the method, dry ice is added into the magnesium oxychloride cement fresh mixed paste, so that the technical problem of cooling of the magnesium oxychloride cement fresh mixed paste is solved, carbon dioxide generated by the dry ice promotes an exothermic reaction of the magnesium oxychloride cement, the carbonization degree of a hydration product is improved, and the early microstructure and macroscopic performance of the magnesium oxychloride cement additive are effectively improved; the temperature of the curing environment is kept consistent with that of the magnesium oxychloride cement additive through a temperature control carbonization chamber, so that microdefects and microcracks caused by temperature stress in the hydration process of the magnesium oxychloride cement additive are effectively reduced; the magnesium oxychloride cement additive is used for 3D printing, the industrialization level of the magnesium oxychloride cement is improved, and engineering application of the magnesium oxychloride cement is promoted.

Owner:SHENZHEN UNIV

a gamma-c 2 s activation modification method

ActiveCN111393049BEnhance carbonization activityHigh degree of carbonationCement productionSilenesCarbonization

The present invention provides a γ-C 2 The activation modification method of S, the activation modification method, comprises the following steps: 1) according to the calcium-silicon molar ratio of 2:1, mixes the calcium raw material and the silicon raw material, then, adds the metal ion compound, mixes by ball milling, and obtains sintering raw materials; 2) mixing the sintering raw materials with 10% alcohol, pressing them into green bodies, drying, sintering, and natural cooling to obtain metal ion-doped γ-C 2 S. The present invention adopts metal ion doping firing pair γ-C 2 S was modified to prepare γ‑C with high specific surface area and high carbonization activity 2 S, and after being doped with metal ions and fired, the metal ions are enriched at the grain boundaries and replace part of the calcium ions to form a continuous solid solution. The carbonized products prepared by the activated γ-C2S have a higher degree of carbonization and resistance to carbonization. compressive strength.

Owner:山东汉博昱洲新材料有限公司

A graphene quantum dot material with high ultraviolet absorption characteristics and lipophilicity and preparation method thereof

Owner:XI AN JIAOTONG UNIV

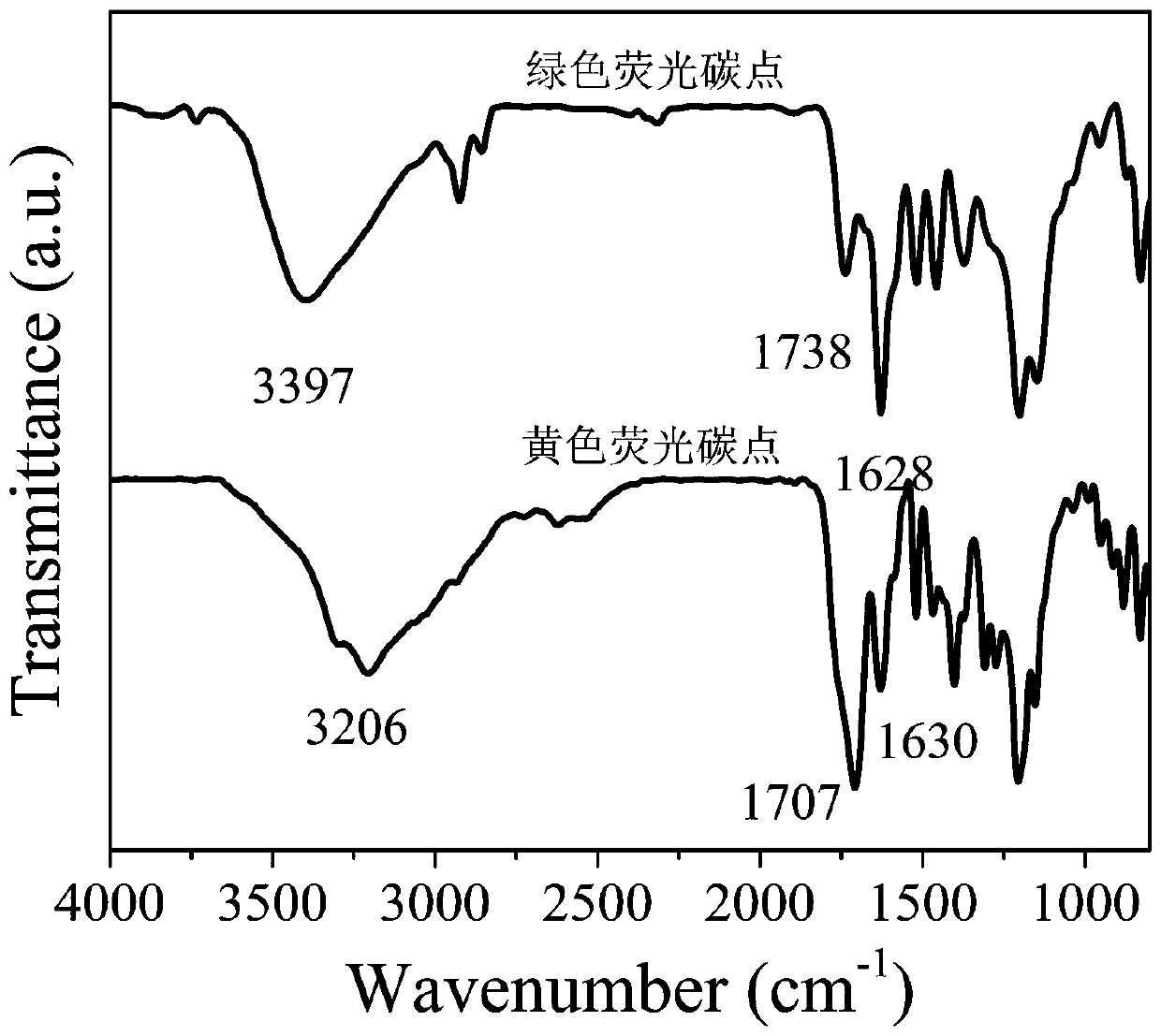

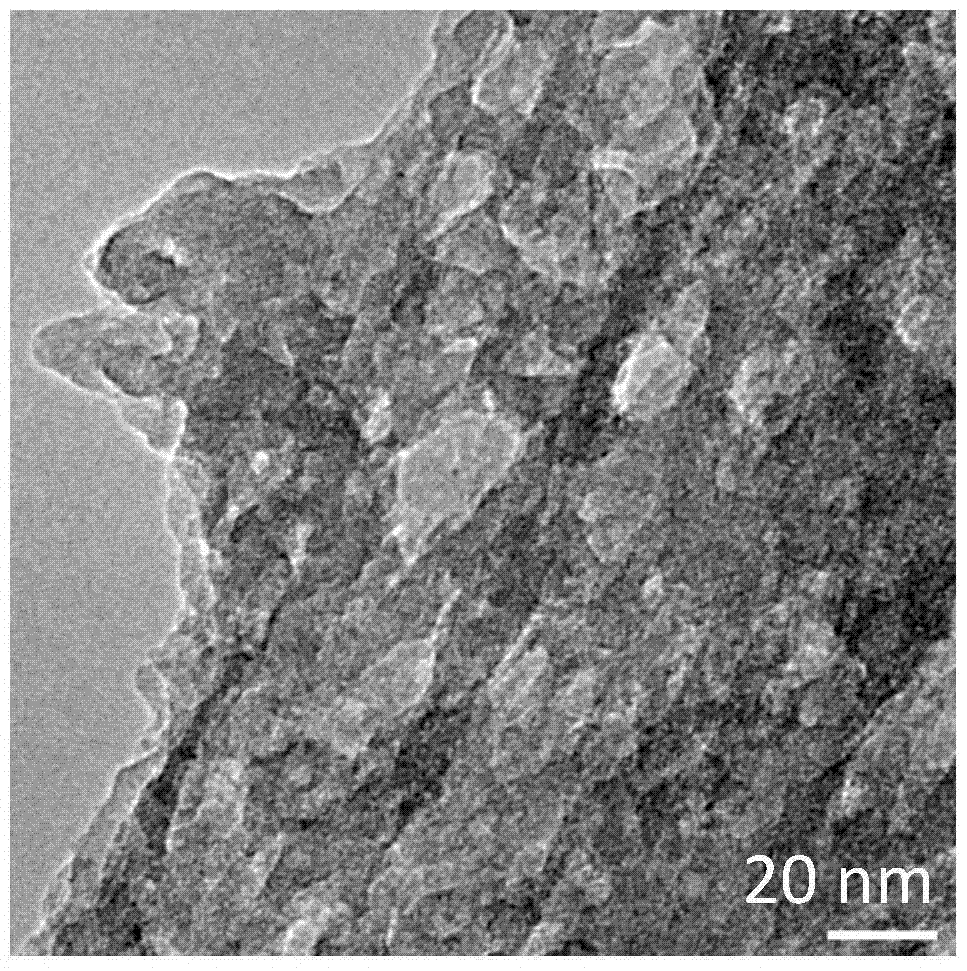

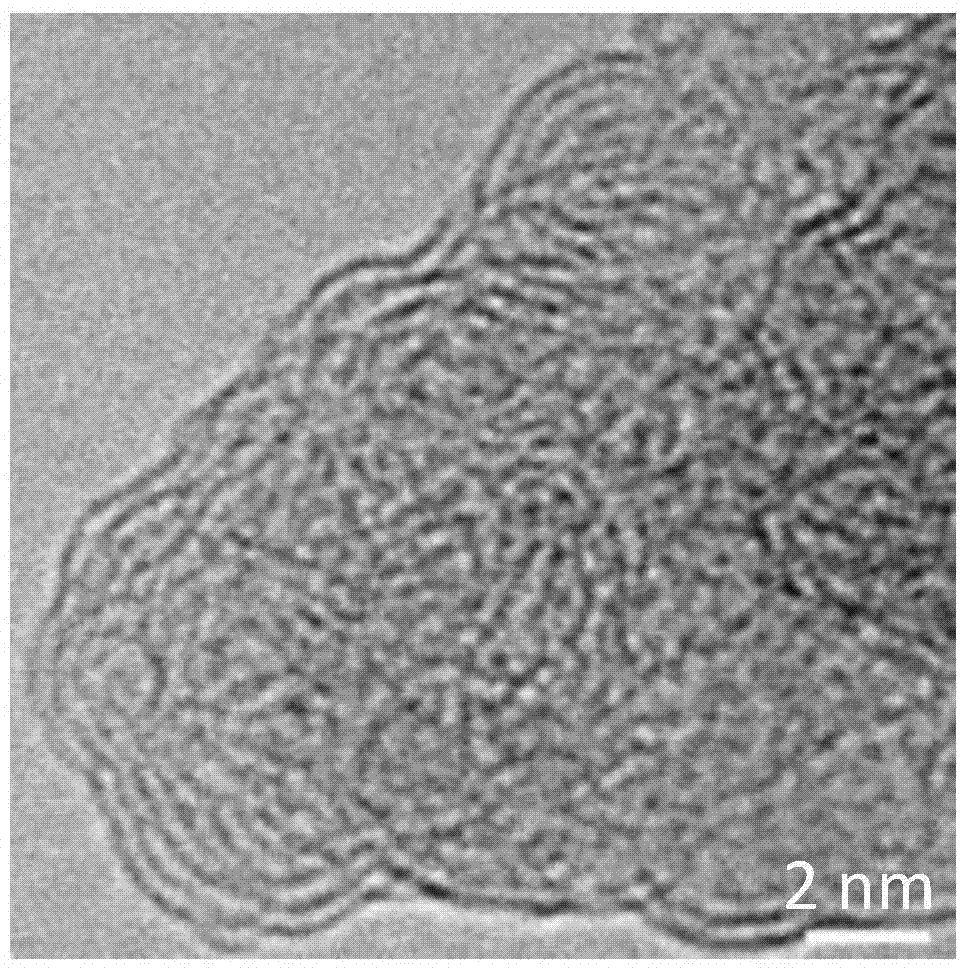

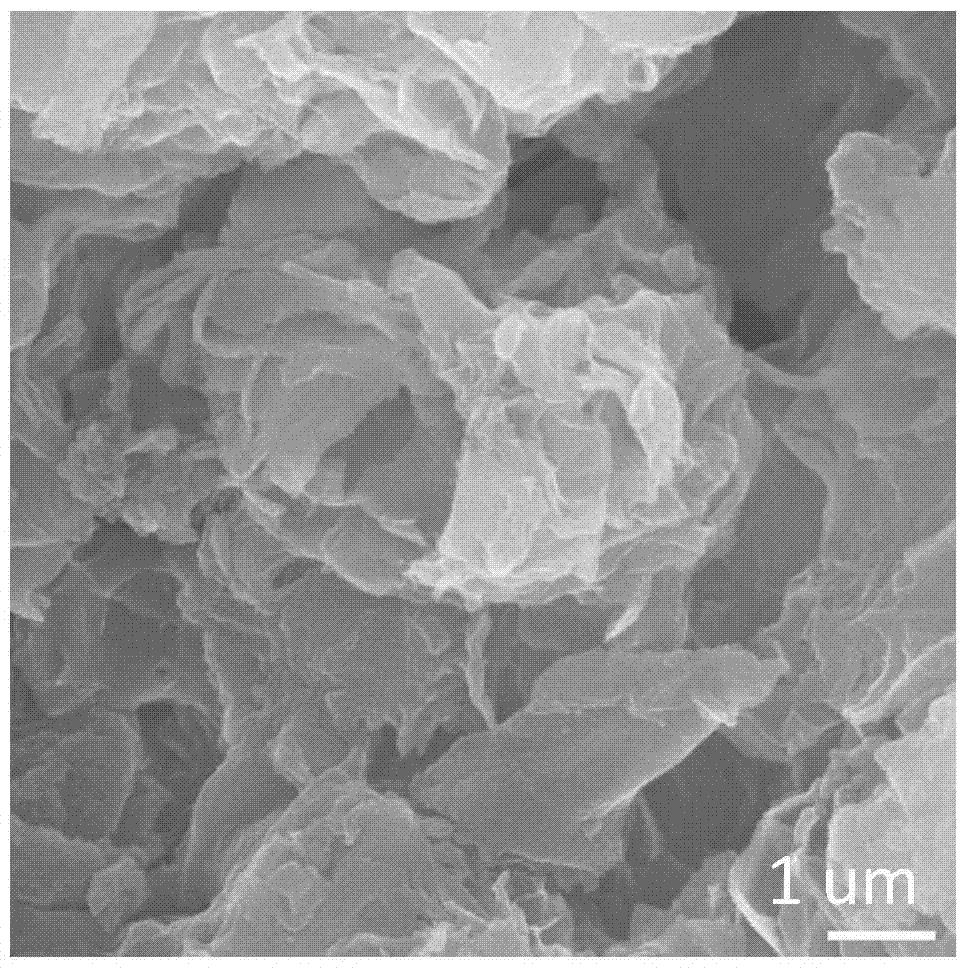

Carbon dot with high thermal stability and preparation method thereof

ActiveCN111234817AImprove thermal stabilityIncrease the degree of conjugationNanoopticsNano-carbonHeat stabilityCitric acid

The invention relates to a carbon dot with high thermal stability and a preparation method thereof, which comprises the following steps: by taking 2,7-dihydroxynaphthalene and citric acid as carbon sources and water as a solvent, preparing yellow fluorescent carbon dots by adopting a hydrothermal method, heating to 200-400 DEG C in the inert environment, and performing annealing treatment, therebyobtaining the green fluorescent carbon dots. The carbon dot prepared by the invention emits green fluorescence under the excitation of ultraviolet exciting light, has high thermal stability, can bearthe high temperature of 250 DEG C, and can be used as light conversion fluorescent powder to be applied to the preparation of a laser diode light-emitting device.

Owner:TAIYUAN UNIV OF TECH

A kind of room temperature preparation method of heteroatom-doped carbon material

ActiveCN104891475BLow priceLow costCarbon preparation/purificationN dimethylformamidePolyvinyl chloride

The invention relates to a method for preparing a heteroatom-doped carbon material at a room temperature. The method comprises the following steps: mixing a halogenated macromolecule and strong base with a strong polar solvent so as to obtain a mixture, grinding the mixture at the room temperature, and directly cleaning and drying after completion of grinding, so as to obtain the heteroatom-doped carbon material, wherein the halogenated macromolecule is polyvinylidene difluoride, polyvinylidene chloride or polyvinyl chloride, the strong base is alkali (earth) metal hydroxide, alkali (earth) metal alkoxide, alkali (earth) metal sulfide, alkali (earth) metal amides or alkali (earth) metal nitride, the strong polar solvent is N,N-dimethylformamide, N,N-dimethylacetamide, dimethyl sulfoxide or nitrogen methyl pyrrolidone and the room temperature refers to 10-40 DEG C. According to the method, the raw materials are cheap and easy to obtain, the operation is simple, safety is high and the method is very suitable for industrial expanded production.

Owner:BEIJING UNIV OF CHEM TECH

Carbon dioxide curing prefabricated permeable concrete and preparation method thereof

The present invention is a carbon dioxide curing prefabricated permeable concrete and a preparation method thereof. The permeable concrete consists of the following parts by mass: 55-80 parts of recycled aggregate, 7-30 parts of nickel slag sand, 18-40 parts of cementing material, 5 parts by mass ~25 parts of water, 0.01~2 parts of naphthalene-based water reducer, 0~0.02 parts of cellulose ether, and 0~0.01 parts of Wenlun rubber. The cementing material is composed of the following parts by mass: 70-90 parts of ordinary Portland cement, 5-15 parts of fly ash, 10-30 parts of steel slag, 5-15 parts of lime or lime slag, 0.02-1 part of nano-carbonate calcium composition. The invention has a simple process, fully utilizes the structural advantages of permeable concrete and the material properties of industrial by-products such as nickel slag, steel slag, and fly ash, and uses carbon dioxide curing to realize efficient, fast, and environmentally friendly production, while obtaining high-strength and high-durability permeable concrete products , which not only reduces energy consumption, but also effectively utilizes industrial tail gas, smelting waste residue and construction waste, and has good economic, environmental and social benefits.

Owner:SOUTHEAST UNIV

Method for preparing lightweight aggregate from silicothermic magnesium smelting slag

The invention discloses a method for preparing lightweight aggregate from silicothermic magnesium smelting slag. The method comprises the following steps of: 1, putting slowly cooled silicothermic magnesium smelting slag into a ball mill, and grinding and sieving to obtain magnesium slag powder; 2, putting the magnesium slag powder into a granulator, spraying water to the magnesium slag powder, and carrying out rotary granulation to obtain magnesium slag ceramsite; 3, pre-curing the magnesium slag ceramsite to obtain pre-cured magnesium slag ceramsite; and 4, carbonizing the pre-cured magnesium slag ceramsite in a closed container into which hot flue gas is introduced, and naturally cooling to obtain carbonized magnesium slag lightweight aggregate. According to the method, the magnesium slag ceramsite is prepared from the slowly-cooled silicothermic magnesium smelting slag as a raw material and is pre-cured and carbonized in sequence, so that a large number of small holes are formed in the magnesium slag ceramsite, the density of the carbonized magnesium slag lightweight aggregate is reduced, the diffusion efficiency of carbon dioxide gas is improved, the carbonization time is shortened, uniform carbonization is achieved, the carbonization degree is improved, the strength of the magnesium carbide slag lightweight aggregate is improved, and the high-strength and lightweight magnesium carbide slag lightweight aggregate is obtained.

Owner:SHAANXI ACAD OF ARCHITECTONICS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com