Carbon dioxide curing prefabricated permeable concrete and preparation method thereof

A technology of permeable concrete and carbon dioxide, applied in the field of building materials preparation, can solve the problems of low production efficiency, slow growth of permeable concrete strength, uneven distribution of voids, etc., to promote the improvement of strength, meet product service requirements, and efficient carbonization process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

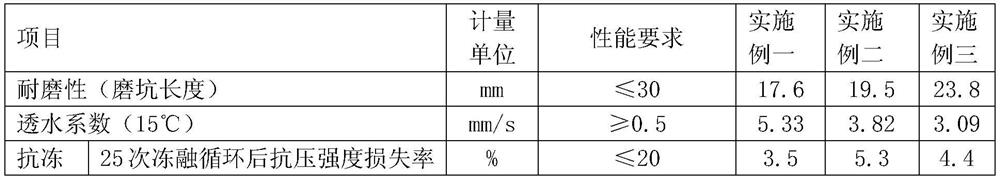

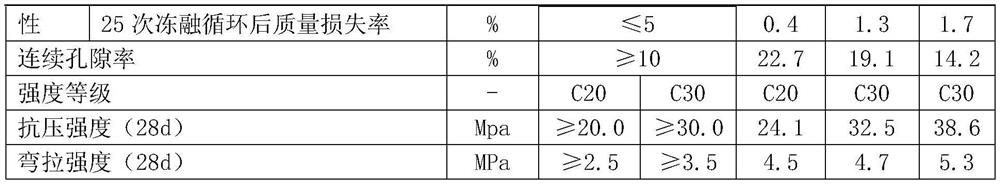

Examples

preparation example Construction

[0038] The preparation method of the carbon dioxide curing prefabricated permeable concrete comprises the following steps:

[0039] 1) The recycled aggregate absorbs water until saturated surface dry;

[0040] 2) Add the recycled aggregate, nickel slag sand and 40-60% water into the mixer according to the proportion, and stir for 0.5-1 minute;

[0041] 3) Add cement and stir for 1 to 2 minutes;

[0042] 4) Add the remaining water, water reducer, cellulose ether and Wenlun glue, and stir for 1 to 5 minutes;

[0043] 5) Pour the concrete in step 3) into the mold, use a low-frequency plate vibrator to vibrate in layers, and transfer the mold to a closed curing box or curing room;

[0044] 6) Inflate carbon dioxide gas into the airtight curing box or curing room, control the relative humidity of the curing box or curing room to 40-70%, the mass fraction of carbon dioxide to 20-100%, and perform carbon dioxide curing on concrete products for 6-24 hours;

[0045] 7) Demoulding afte...

Embodiment 1

[0047] Prefabricated permeable concrete using carbon dioxide curing is composed of the following components by mass: 60 parts of recycled concrete aggregate, 30 parts of nickel slag sand, 14 parts of ordinary Portland cement, 2 parts of fly ash, 4 parts of steel slag, 1.2 parts of lime, 0.1 It consists of 1 part of nano-calcium carbonate, 6 parts of water, 0.4 part of naphthalene-based water reducer, 0.003 part of cellulose ether, and 0.001 part of Wenlun glue.

[0048] The preparation of carbon dioxide cured prefabricated pervious concrete prepared from nickel slag, steel slag and recycled aggregate includes the following steps:

[0049] Contains the following steps:

[0050] 1) The recycled aggregate absorbs water until saturated surface dry;

[0051] 2) Add the recycled aggregate, nickel slag sand and 40% water into the mixer according to the proportion, and stir for 0.5 minutes;

[0052] 3) Add cement and stir for 1 minute;

[0053] 4) Add the remaining water, water red...

Embodiment 2

[0058] Carbon dioxide cured prefabricated permeable concrete prepared by using nickel slag, steel slag and recycled aggregate consists of the following components by mass: 70 parts of recycled concrete aggregate, 20 parts of nickel slag sand, 24 parts of ordinary Portland cement, and 1.5 parts of fly ash , 4.5 parts of steel slag, 1 part of lime, 0.14 parts of nano-calcium carbonate, 10 parts of water, 0.55 parts of naphthalene-based water reducer, 0.005 parts of cellulose ether, and 0.002 parts of Wenlun glue.

[0059] The preparation of carbon dioxide cured prefabricated pervious concrete prepared from nickel slag, steel slag and recycled aggregate includes the following steps:

[0060] Contains the following steps:

[0061] 1) The recycled aggregate absorbs water until saturated surface dry;

[0062] 2) Add the recycled aggregate, nickel slag sand and 50% water into the mixer according to the proportion, and stir for 1 minute;

[0063] 3) Add cement and stir for 2 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com