Patents

Literature

103results about How to "Meet service requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steel plate for hot-rolled double-side enamel and method for producing same

InactiveCN1966753AIncrease productivityUniform compositionTemperature control deviceSheet steelChemical composition

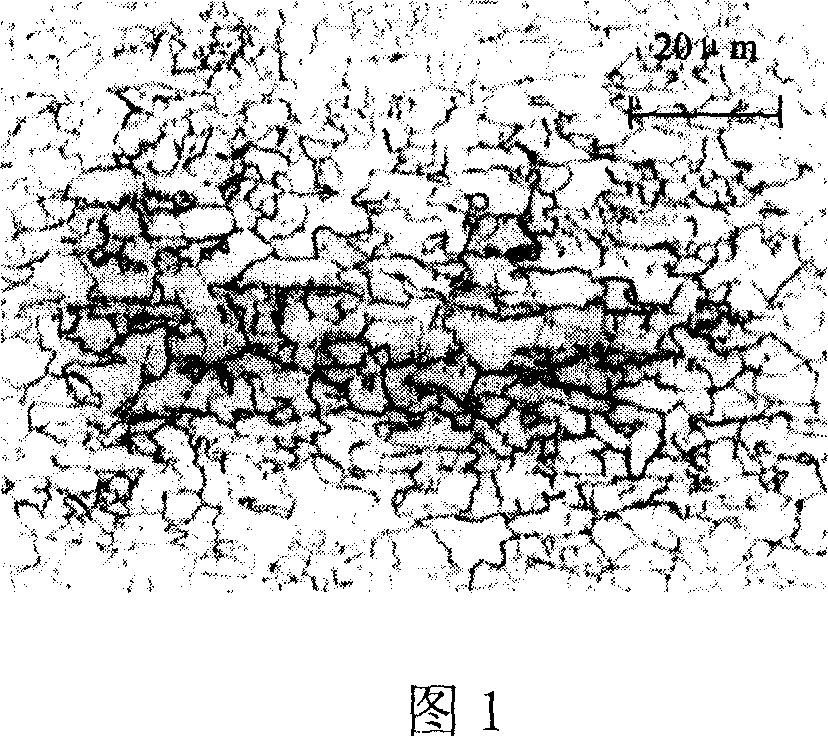

The invention provides a kind of hot-rolled double-sided enamel-used nickelclad, the chemical components of which is: C 0.02%-0.06%, Si <=0.50%, Mn 0.15%-0.40, P <=0.15%, S <=0.006%, N<=0.003%, Ti 0.08%-0.20%, Als 0.005%-0.055%, Ti / C 2.2-5,unavoidable impurities and Fe as balance. The architecture of the nickelclad is ferrite with grain diameter = 2 mum-20 mum under hot rolling conditions, and TiC particles (diameter < 20nm is uniformly distinguished in the architecture. V 0.015%-0.060% and / or Cr 0.05%-0.20% can also be added. The production method of the clad is: producing unburnt earthenware with continuous cast method, heating to 1180-1260DEG C, descaling with high-handed water, rough rolling, finish rolling for 5-7 passes at 1100-960 DEG C and finally at 920DEG C-840DEG C, continuously cooling to 450- 630DEG C at a speed of >=30DEG C / S in 0-7S, and coiling. The nickelclad has the advantages of good performance and high strength, and can meet the requirement of large scaled engineering fembers.

Owner:ANGANG STEEL CO LTD

High-plasticity cast aluminum alloy and extrusion casting preparation method thereof

The invention discloses a high-plasticity cast aluminum alloy and an extrusion casting preparation method thereof, belonging to the technical fields of metal materials and metallurgy. The alloy comprises the following components in percentage by weight: 7.5-13.5% of Si, 0.5-0.8% of Mg, 0.2-0.5% of Mn, 0.1-0.4% of Ti, 0.01-1.5% of RE, 0.6-1.3% of Fe, at most 100 ppm of P, 100-600 ppm of Sr and the balance of Al. The RE is one or more of Gd, Y, Nd, Sm, Er, Yb and La. After the high-plasticity cast aluminum alloy is subjected to extrusion casting and solid solution+artificial aging treatment, the elongation percentage delta of the alloy is greater than or equal to 22%. The alloy has the advantages of excellent casting performance and low cost. The method has the advantages of simple technique, high production efficiency and obvious progress, and widens the application range of the Al-Si cast aluminum alloy.

Owner:SHANGHAI JIAO TONG UNIV

High-plasticity cast aluminum alloy and gravity casting preparation method thereof

The invention discloses a high-plasticity cast aluminum alloy and a gravity casting preparation method thereof, and belongs to the fields of metal materials and metallurgy. The high-plasticity cast aluminum alloy is prepared from the following components in percentage by weight: 7.5 to 13.5% of Si, 0.5 to 0.8% of Mg, 0.2 to 0.5% of Mn, 0.1 to 0.4% of Ti, 0.01 to 1% of RE, not greater than 0.4% of Fe, not greater than 100ppm of P, 100 to 600ppm of Sr, and the balance of Al, wherein RE is one or some of Gd, Y, Nd, Sm, Er, Yb and La. After gravity casting, solid solution treatment and artificial aging treatment, the high-plasticity cast aluminum alloy has the elongation delta of being not less than 18%. The prepared alloy is outstanding in casting performance, low in cost, simple in process, high in production efficiency, and obvious in progress, and the applicable scope of Al-Si cast aluminum alloy is expanded.

Owner:SHANGHAI JIAO TONG UNIV

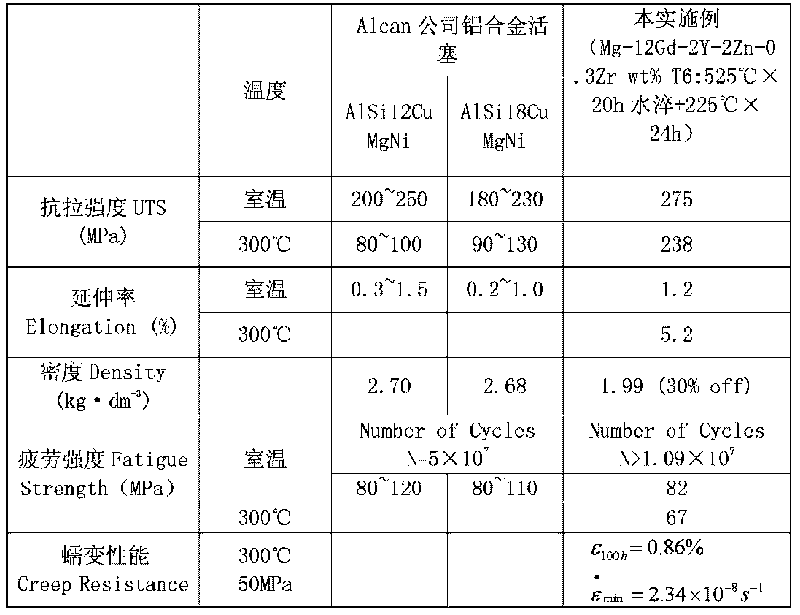

Low-pressure casting preparation method of heat resistant rare earth-magnesium alloy engine pistons

ActiveCN101693971AFine grainImprove creep resistanceMachines/enginesPistonsManufacturing technologyPressure casting

A low-pressure casting preparation method of heat resistant rare earth-magnesium alloy engine pistons in the field of the automobile manufacturing technology comprises preparing master alloy Mg-Y, Mg-Gd, Mg-Zr, industrial pure magnesium and industrial pure zinc, smelting alloy, obtaining magnesium alloy fused mass, squeezing and casting the magnesium alloy fused mass, obtaining the primary blank of a magnesium alloy piston, and obtaining a heat resistant tare earth-magnesium alloy engine piston through orderly carrying out the solid solution treatment, the cold treatment and the aging treatment. The method can prepare pistons with excellent high-temperature strength, fatigue strength and creep resistance performance through applying 0.2-0.8 atm pressure and selecting proper heat resistant rare earth-magnesium alloy, selecting proper low-pressure casting technical parameter and adjusting corresponding heat processing technology.

Owner:SHANGHAI JIAO TONG UNIV

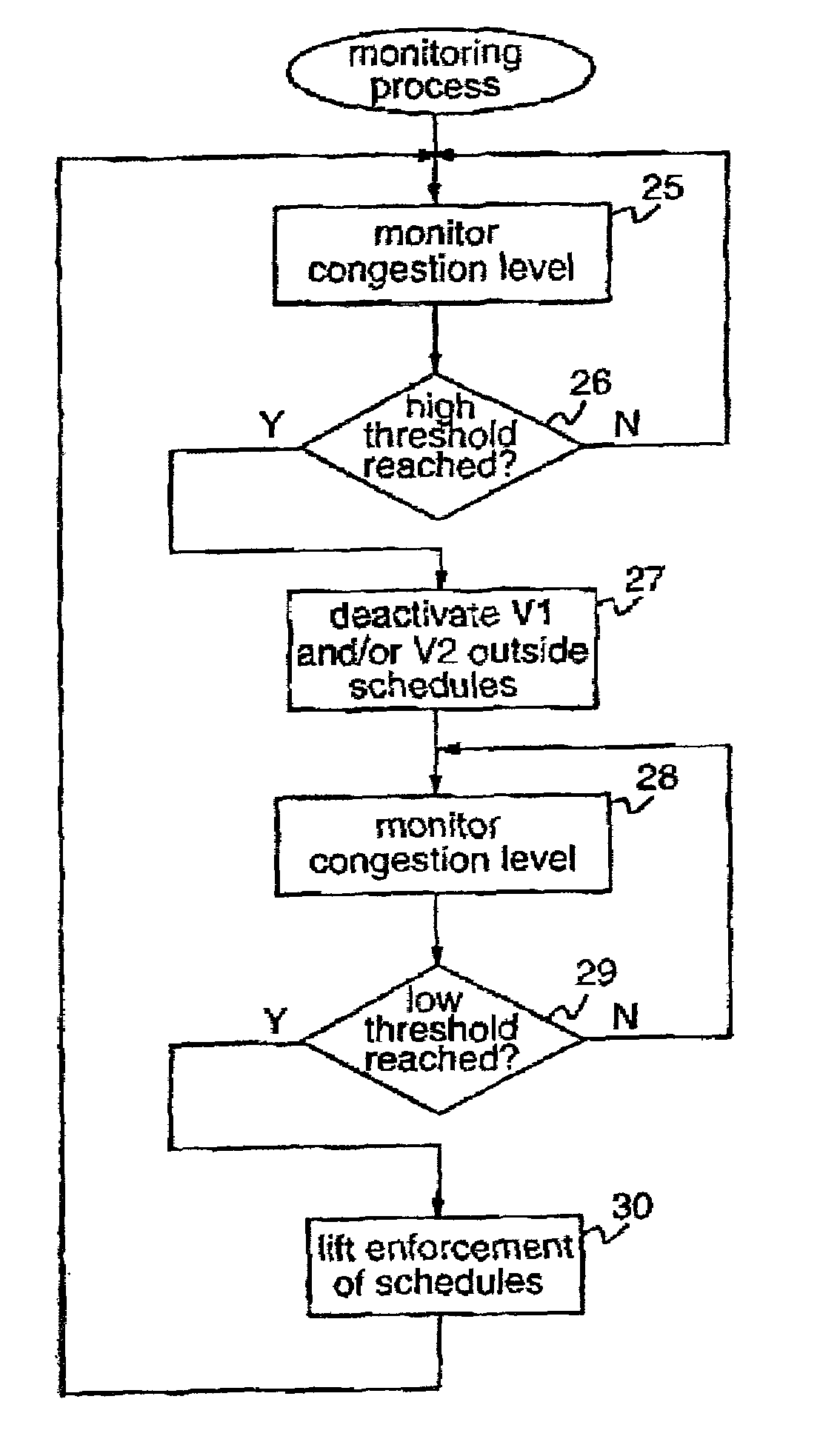

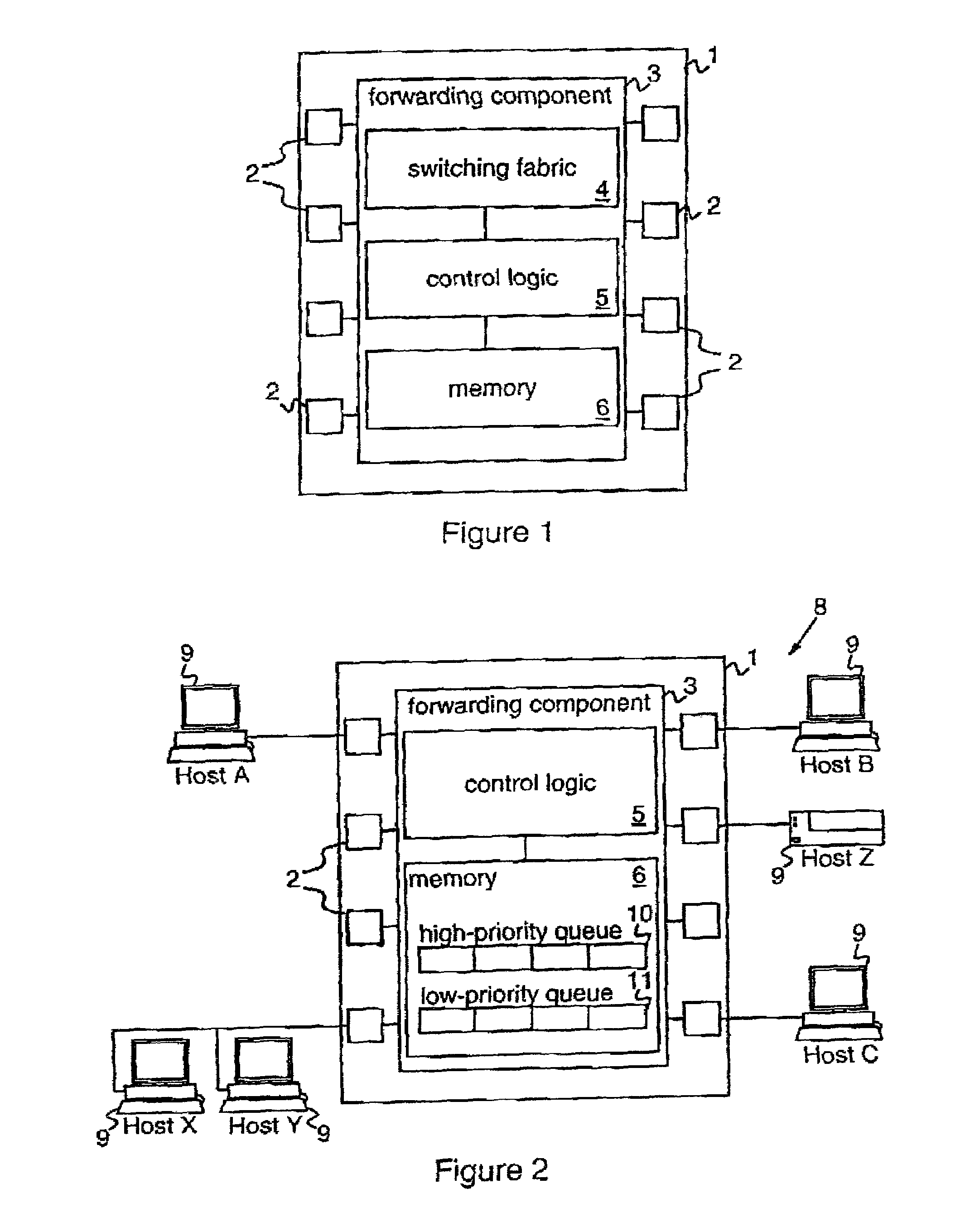

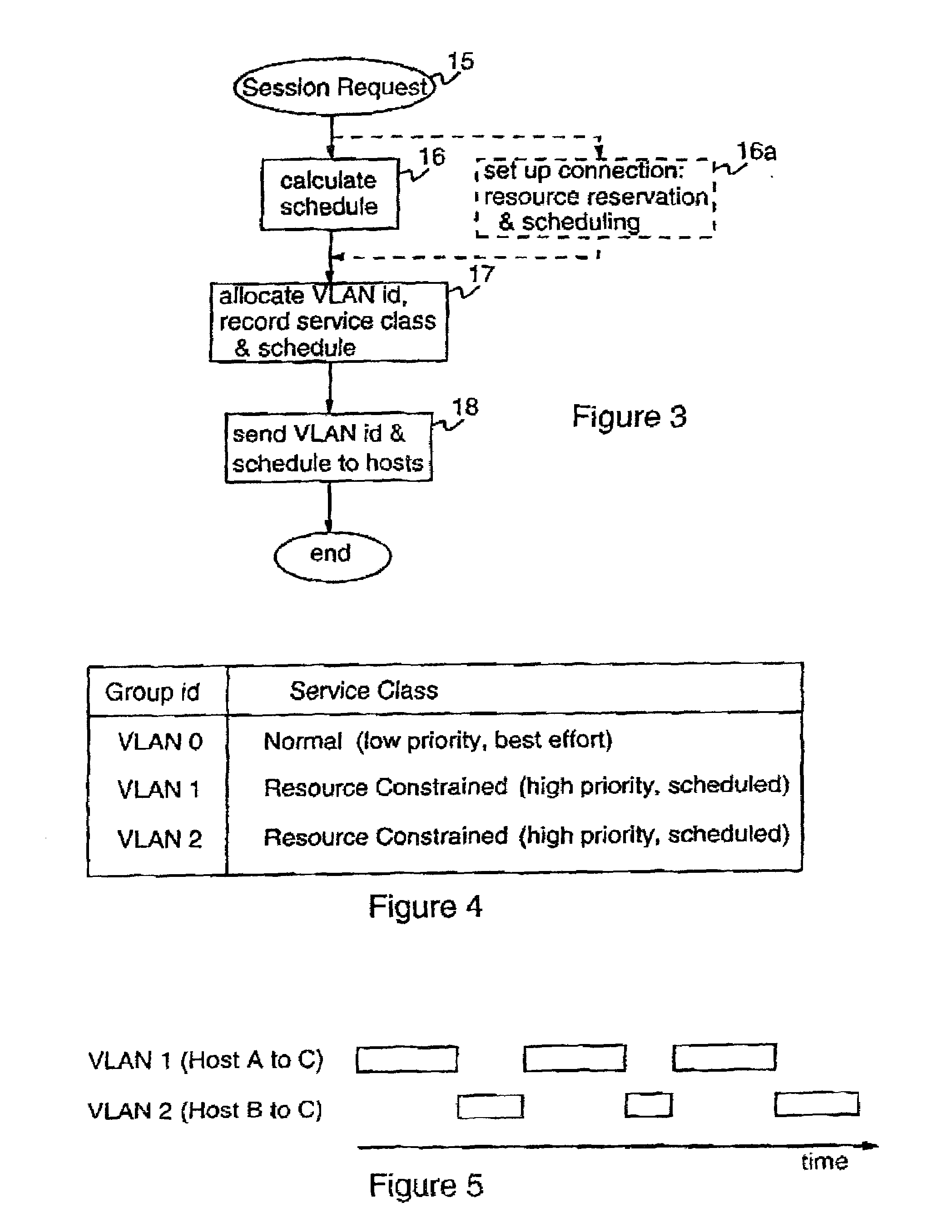

Switched ethernet networks

InactiveUS7136351B2Meet the requirementsCompromise abilityMultiplex system selection arrangementsError preventionSwitched ethernetDistributed computing

Methods and apparatus are provided for managing data communications between hosts (9) of a switched Ethernet network (8). Hosts (9) are assigned to logical groups of hosts such that the hosts participating in a data communication are assigned to the same group. In a switch (1) of the network, each group is associated with a service class indicative of requirements for forwarding data across the switch (1) for data communications between hosts (9) in that group. Data received by the switch (1) is forwarded across the switch in a manner dependent on the service class of the group to which hosts (9) participating in the data communication are assigned. In the switch (1), data communications between hosts (9) in one or more of said groups are disabled when required to satisfy the forwarding requirements for at least one said service class.

Owner:IBM CORP

Multi-component microalloyed bainite gray cast iron, cylinder liner and preparation method thereof

The invention discloses a multi-component microalloyed bainite gray cast iron, a cylinder liner and a preparation method thereof. The bainite gray cast iron is composed of the following components by weight: 2.70%-2.95% of carbon, 1.80%-2.15% of silicon, 0.30%-0.55% Mn, larger than 0 but smaller than or equal to 0.1% of P, larger than 0 but smaller than or equal to 0.1% of S, 0.3%-0.5% of copper, 0.10%-0.18% of molybdenum, 0.01%-0.05% of boron, 0.35%-0.60% of chromium, 0.04%-0.10% of nitrogen, 0.2%-0.4% of niobium, 0.25%-0.35% of vanadium, 0.065%-0.025% of titanium, and the balance being Fe. The multi-component microalloyed bainite gray cast iron increases high-temperature structure stability of a bainite matrix, guarantees that high-temperature strength of the gray cast iron is at a relatively high level, has excellent high-temperature structure properties and low production cost, and is suitable for manufacturing high-temperature, high-speed and heavy-load engine cylinder liners.

Owner:HENAN UNIV OF SCI & TECH

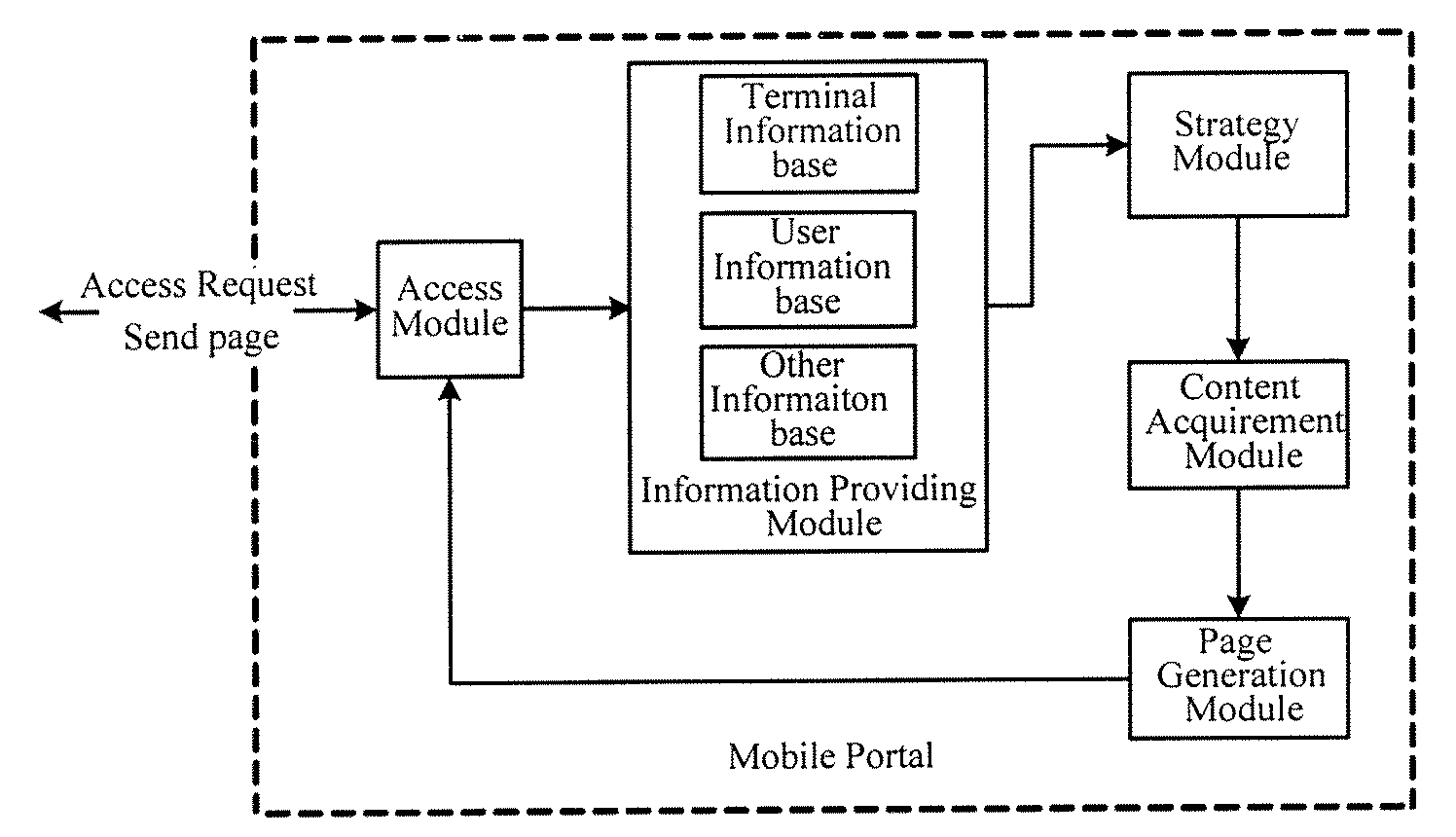

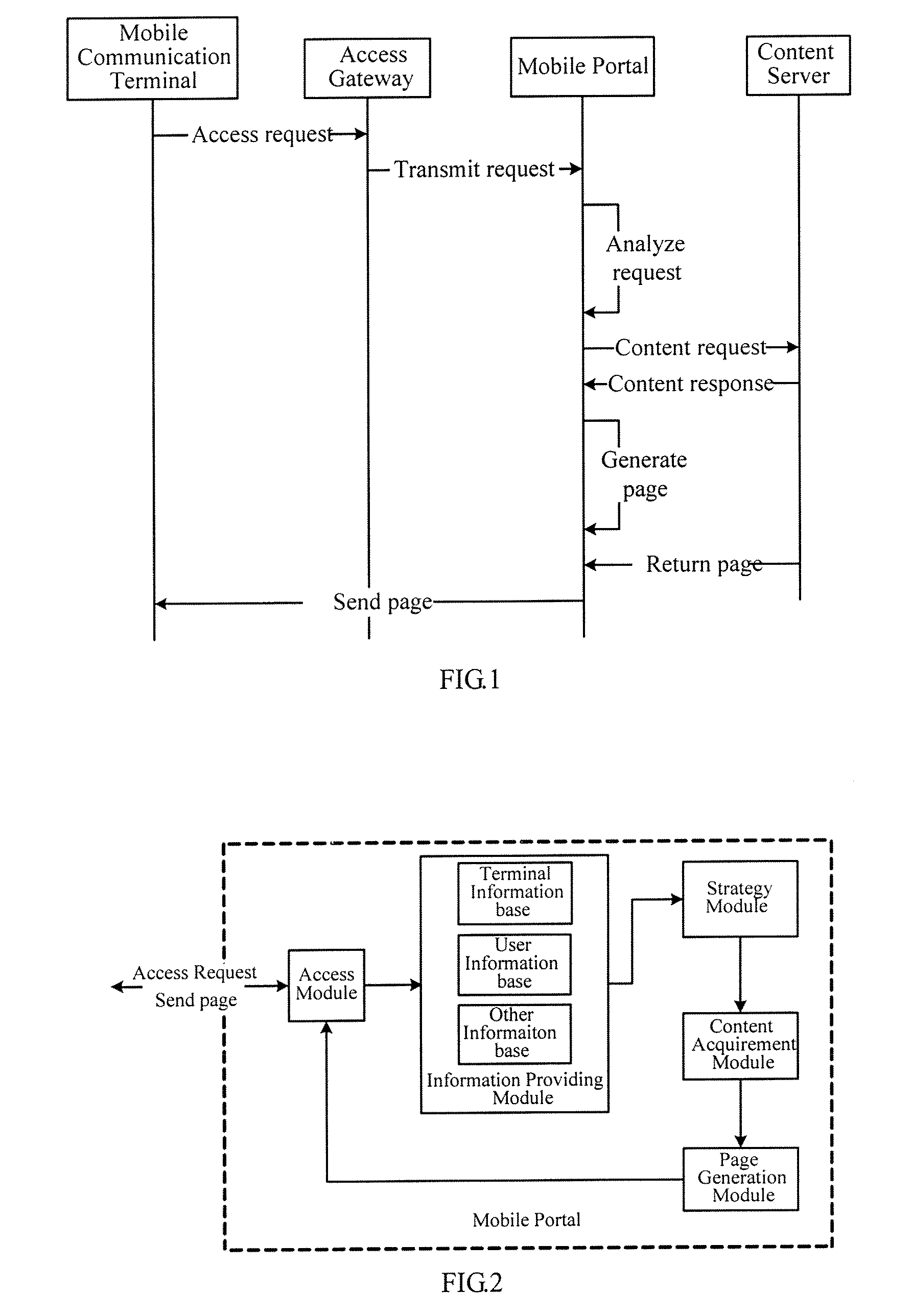

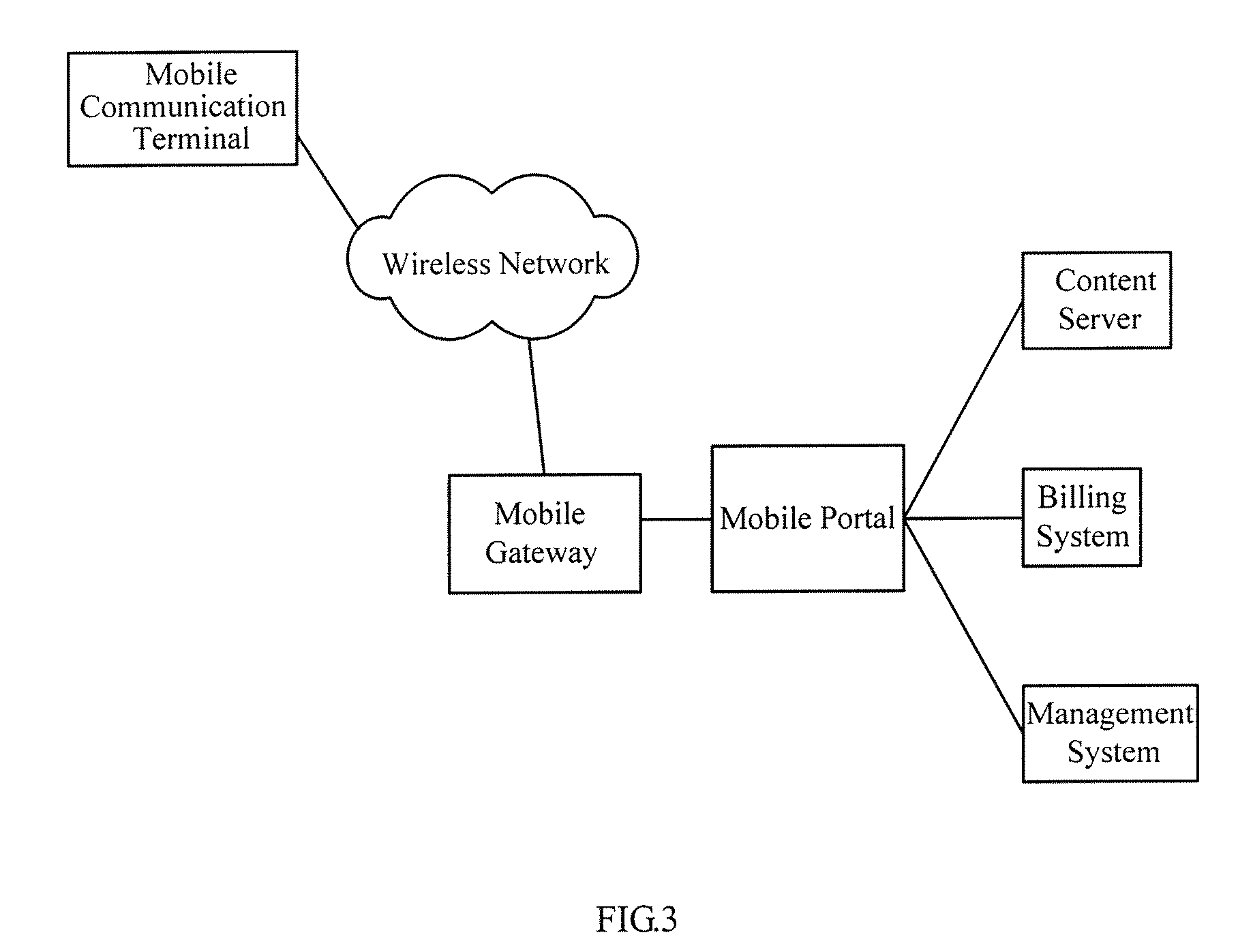

Method and system for matching the web page of mobile communication terminal

InactiveUS20090138798A1Easy to optimizeMeet service requirementsAccounting/billing servicesInformation formatWeb sitePersonalization

The present invention disclosed a method and a system for processing the page information for a mobile communication terminal. The system comprises an access module, an information providing module, a strategy module, a content acquirement module and a page generation module. The information providing module generates the detailed information of a display page according to the access request information, and sends to the strategy module. The strategy module matches the detailed information of the display page with the strategy rule, and obtains a customized rule parameter of the display page, and sends to the content acquirement module. The content acquirement module communicates with the content server of a content service web site, and obtains the page information of the mobile communication terminal. The page generation module generates a browse page according to the customized rule parameter and the page information. The access module sends the browse page to the mobile communication terminal. The present invention processes the access request information and matches with the corresponding service strategy, so that the browse page can be conveniently optimized to match with the mobile communication terminal, and the personalized requirements of the users can be met.

Owner:CHINA MOBILE COMM GRP CO LTD

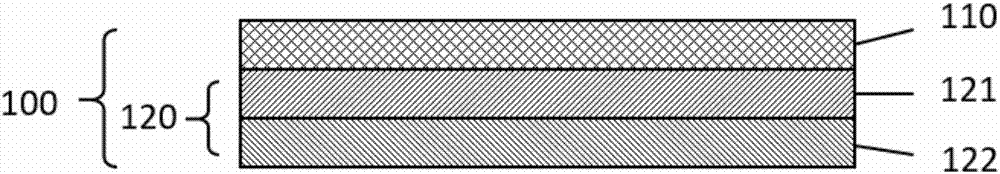

Photovoltaic transparent composite film, and preparation method and application thereof

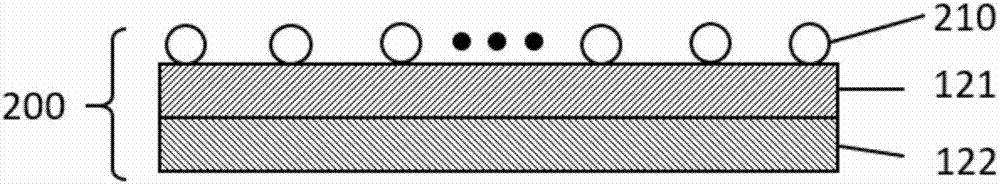

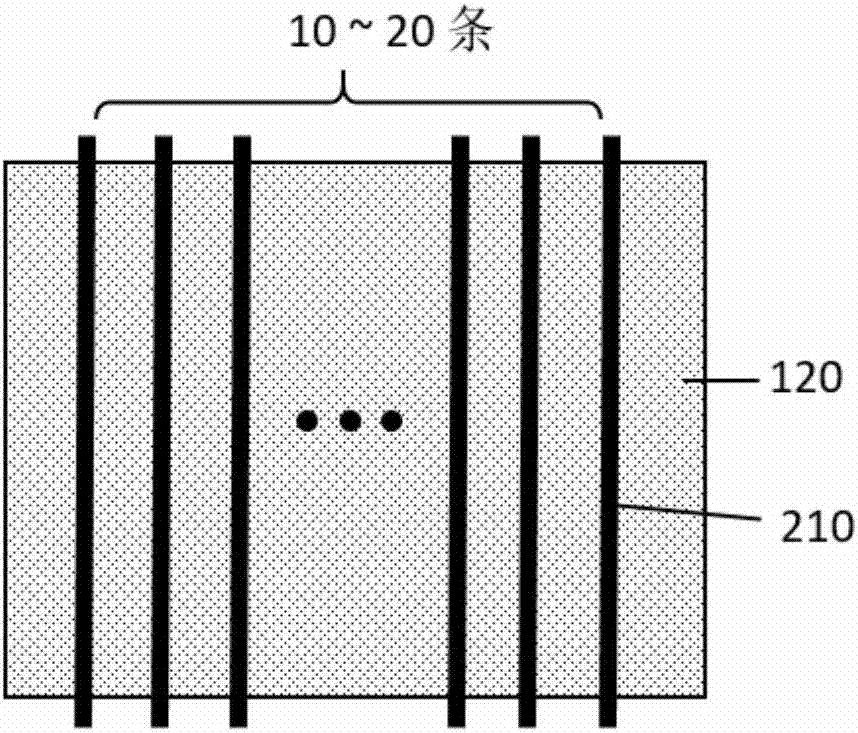

InactiveCN106960891AImprove adhesionAchieve bondingPhotovoltaic energy generationSemiconductor devicesComposite filmMetallic materials

The invention discloses a photovoltaic transparent composite film, and a preparation method and application thereof. The transparent composite film comprises a release paper layer and a function layer, the function layer comprises a supporting layer and a bonding layer, and at least one of the supporting layer and the bonding layer is mixed with a light conversion agent which can converting part of ultraviolet light into visible light. The lower surface of the supporting layer is connected with the bonding layer, and the upper surface and the lower surface of the supporting layer are both flat surfaces or at least one surface is provided with certain light tripping microstructures. The bonding layer is formed by an acrylic ester pressure-sensitive adhesive and can bond metal materials well. The transparent composite film can be applied to multi-main grid and non-main grid photovoltaic modules, and plays a role in applying brass wires to a battery piece, and has high transmissivity and an excellent anti-ultraviolet ageing performance, and can satisfy the usage demand of photovoltaic modules.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

Method for manufacturing compound piston blank used for internal combustion engine

The invention relates to a method for manufacturing a compound piston blank used for an internal combustion engine and belongs to the technical field of vehicle manufacturing. In the method, a melt of a cast steel, a AC9B transcocrystallized Al-Si alloy, a AC8A cocrystallized Al-Si alloy, a heat-resistant magnesium alloy with high rare earth content, a heat-resistant rare-earth magnesium alloy or a metallic matrix composite thereof is utilized as a top melt of a piston, and a melt of the AC8A cocrystallized Al-Si alloy, the heat-resistant rare-earth magnesium alloy, a common heat-resistant magnesium alloy or the metallic matrix composite thereof is utilized as a skirt part melt of the piston, wherein the skirt part melt of the piston and the top melt of the piston are made of different materials; and manufacturing the compound piston blank by using a gravity casting method or an extrusion casting method to process the two melts. An end product manufactured by using the method can meet the demands of enhancing the strength, reducing the weight and lowering the cost.

Owner:SHANGHAI JIAO TONG UNIV

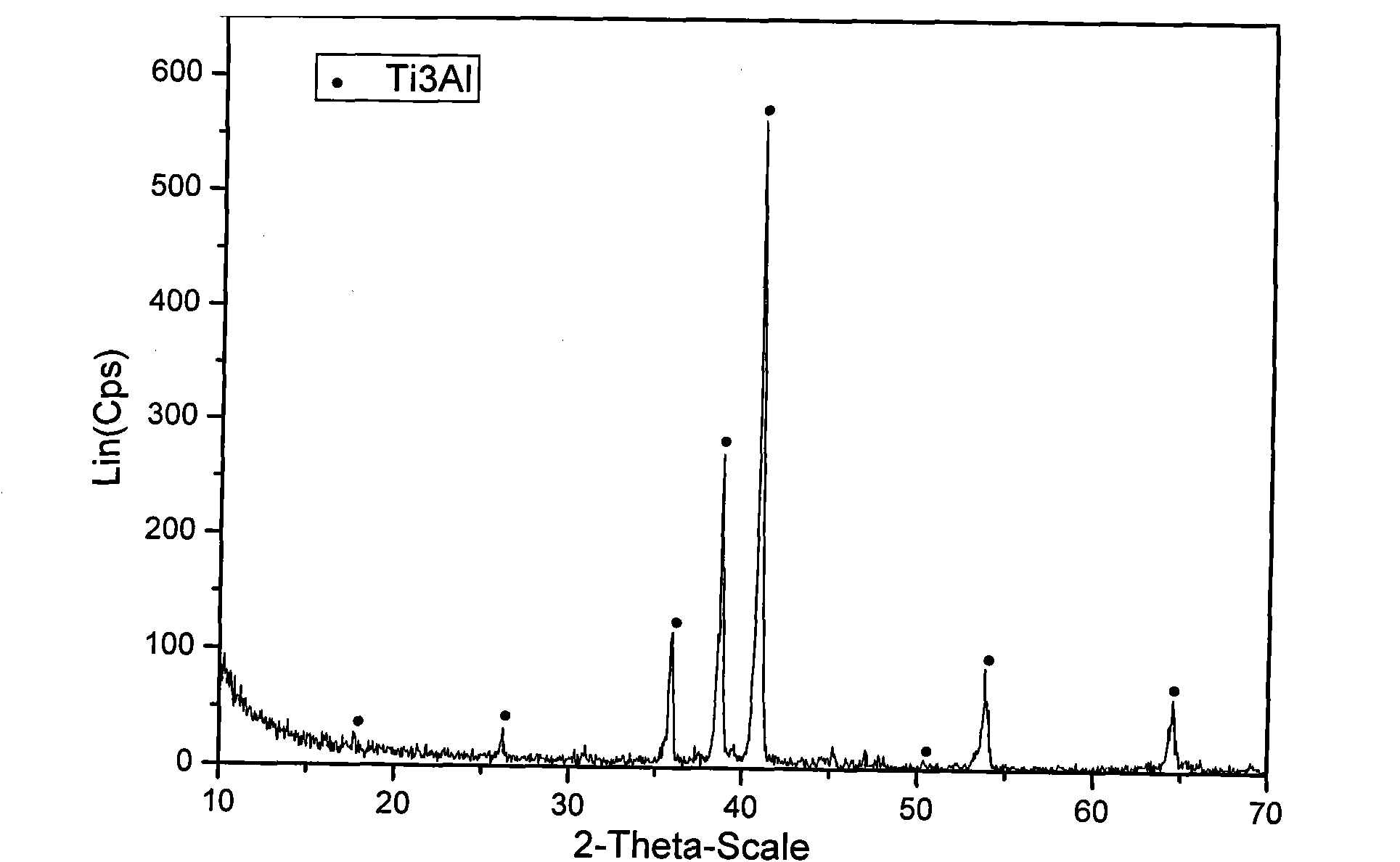

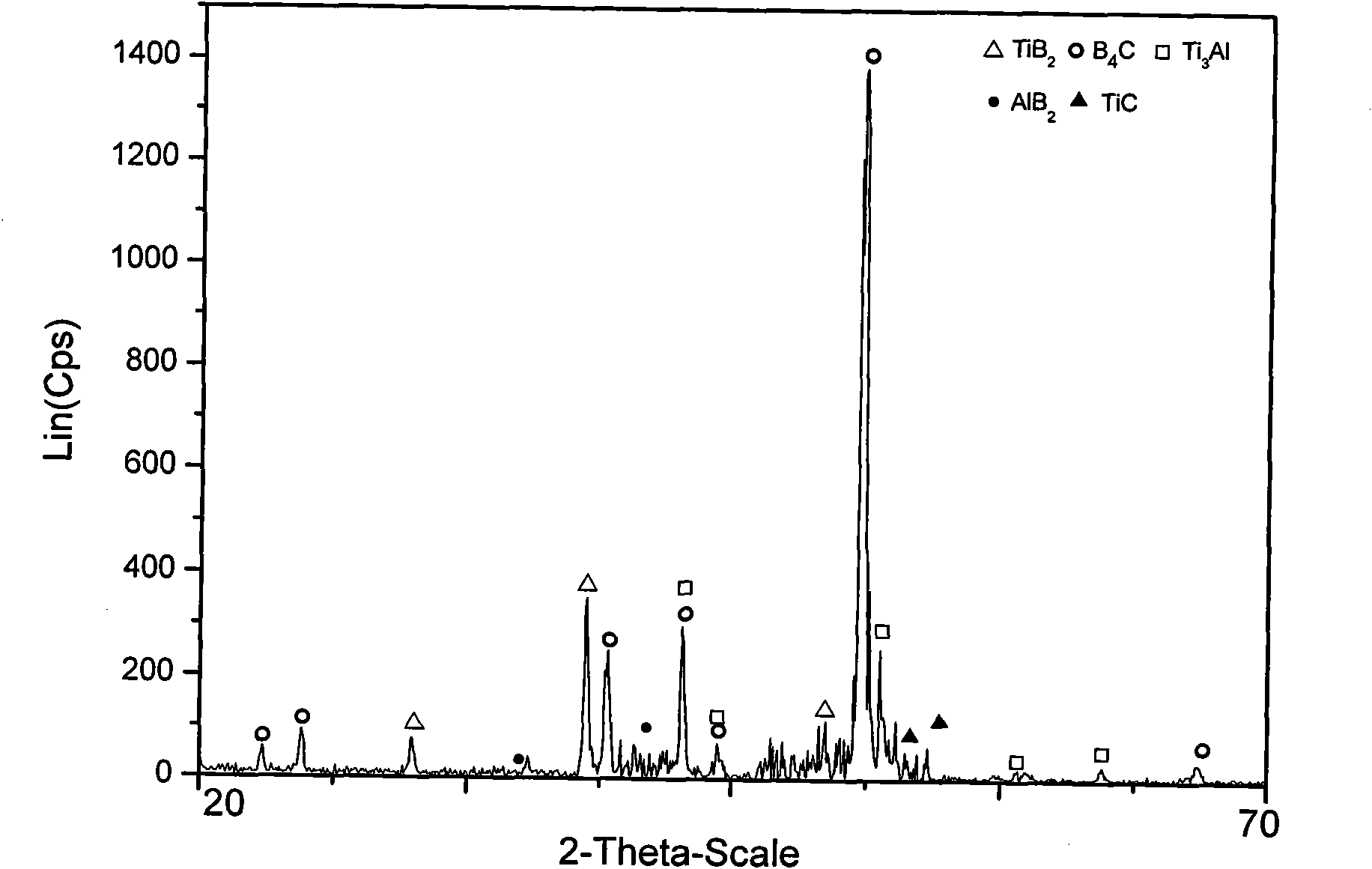

Carbon nano tube (CNT) toughened TiAl/B4C ceramic matrix composite and preparation method thereof

The invention relates to a high-strength light ceramic matrix composite applied to abyssal environment and a preparation method thereof. The composite consists of three parts: CNT, Ti-Al intermetallic compound and B4C. The preparation method comprises the steps of preparing Ti-Al intermetallic compound powder from titanium powder, aluminum powder and microelement additive through a mechanical alloying technology, then mixing the Ti-Al intermetallic compound powder with the CNT and the B4C powder to prepare powder, and performing hot pressing to the powder for shaping under protective atmosphere. The invention utilizes the advantages of the intermetallic compound and a ceramic material to make up the disadvantages, and performs toughening via the CNT, so as to develop and prepare the high-strength light ceramic matrix composite applied to the abyssal environment.

Owner:SHANGHAI MARITIME UNIVERSITY

Ultra-fine-grain ultra-high-obdurability high-speed axle steel and heat treatment method thereof

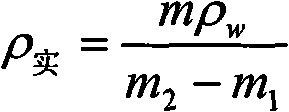

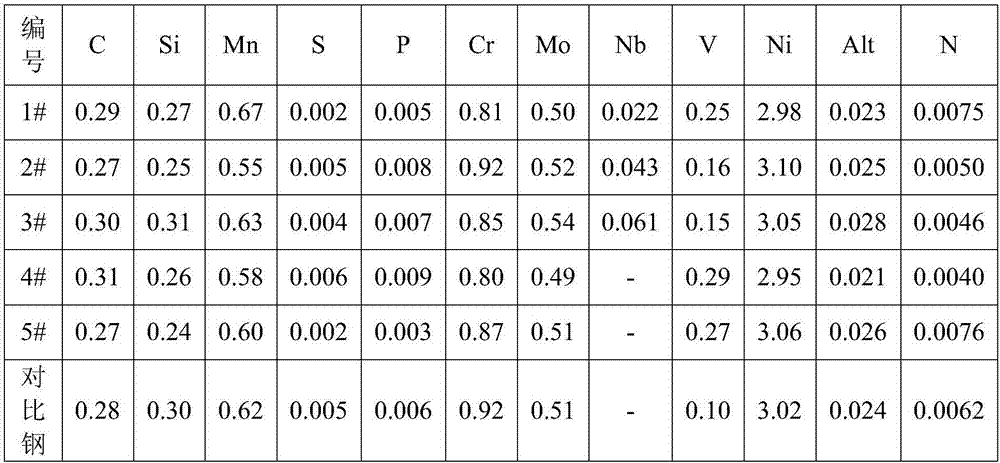

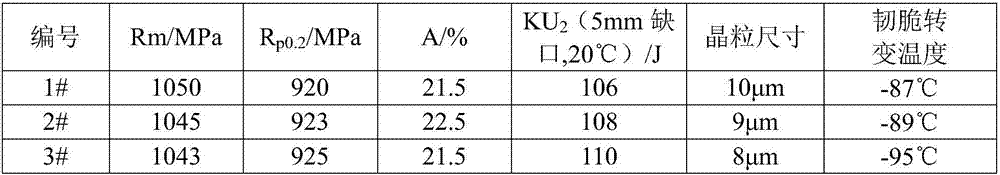

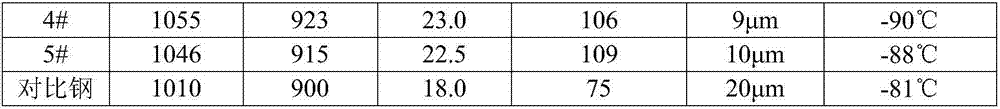

Provided is ultra-fine-grain ultra-high-obdurability high-speed axle steel. The axle steel comprises uniform fine-grained austenite grains and an Nb micro-alloyed nanometer second-phase-enhanced martensite structure. The average grain size of the austenite grains is below 10 micrometers. The axle steel comprises, by mass percentage, 0.00-0.06% of Nb and 0.16-0.30% of V. The invention further provides a heat treatment method for the steel. The method comprises the steps that the functions of each element in the axle steel are fully played, two-time quenching and high-temperature tempering heattreatment is adopted, and finally a high-speed axle has good serviceability such as impact resistance and fatigue resistance, excellent obdurability matching and good hardenability. The average grainsize of the austenite grains in the structure of the axle steel is below 10 micrometers, the yield strength Rp0.2 is larger than or equal to 900 MPa, the tensile strength Rm is larger than or equal to1,000 MPa, the elongation rate A is larger than or equal to 15%, the 5-mm gap longitudinal impact absorbing energy KU2 at the room temperature is larger than or equal to 100 J, and the ductile-brittle transformation temperature is lower than negative 80 DEG C.

Owner:CENT IRON & STEEL RES INST +1

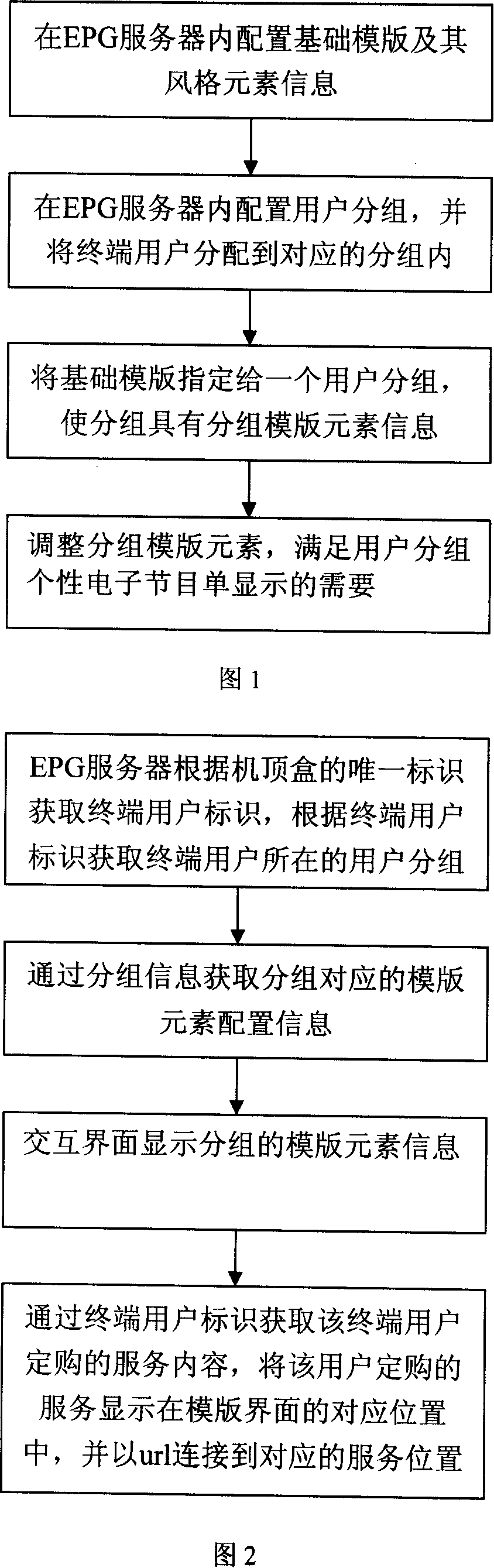

Personal electric playbill indication method based on user grouping

ActiveCN101132513ARealize personality displaySolve the problem of diversity in interface requirementsSimultaneous/sequential multiple television signal transmissionTransmissionHuman–computer interactionEnd user

This invention discloses a display method for individual electronic program lists based on user packets, in which, a basic interface is collocated based on a user packet as a unit, and users in a user packet apply a same interface display style, based on the packet collocated interface, the interface of a single user interface gets different order services of users and displays interfaces individually according to different service contents, which realizes dynamic user packets and dynamic display of operation interface of a single user and solves the problem of variety needs to user intrfaces.

Owner:郑州威科姆科技股份有限公司

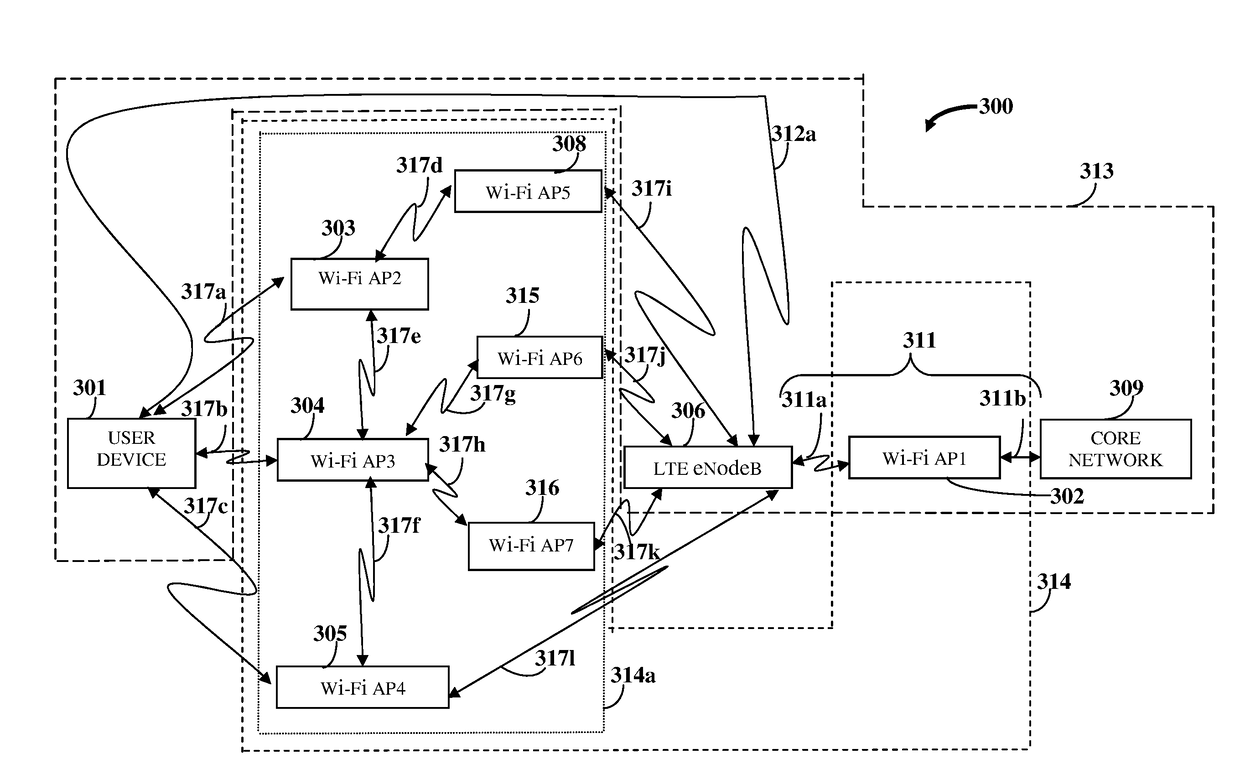

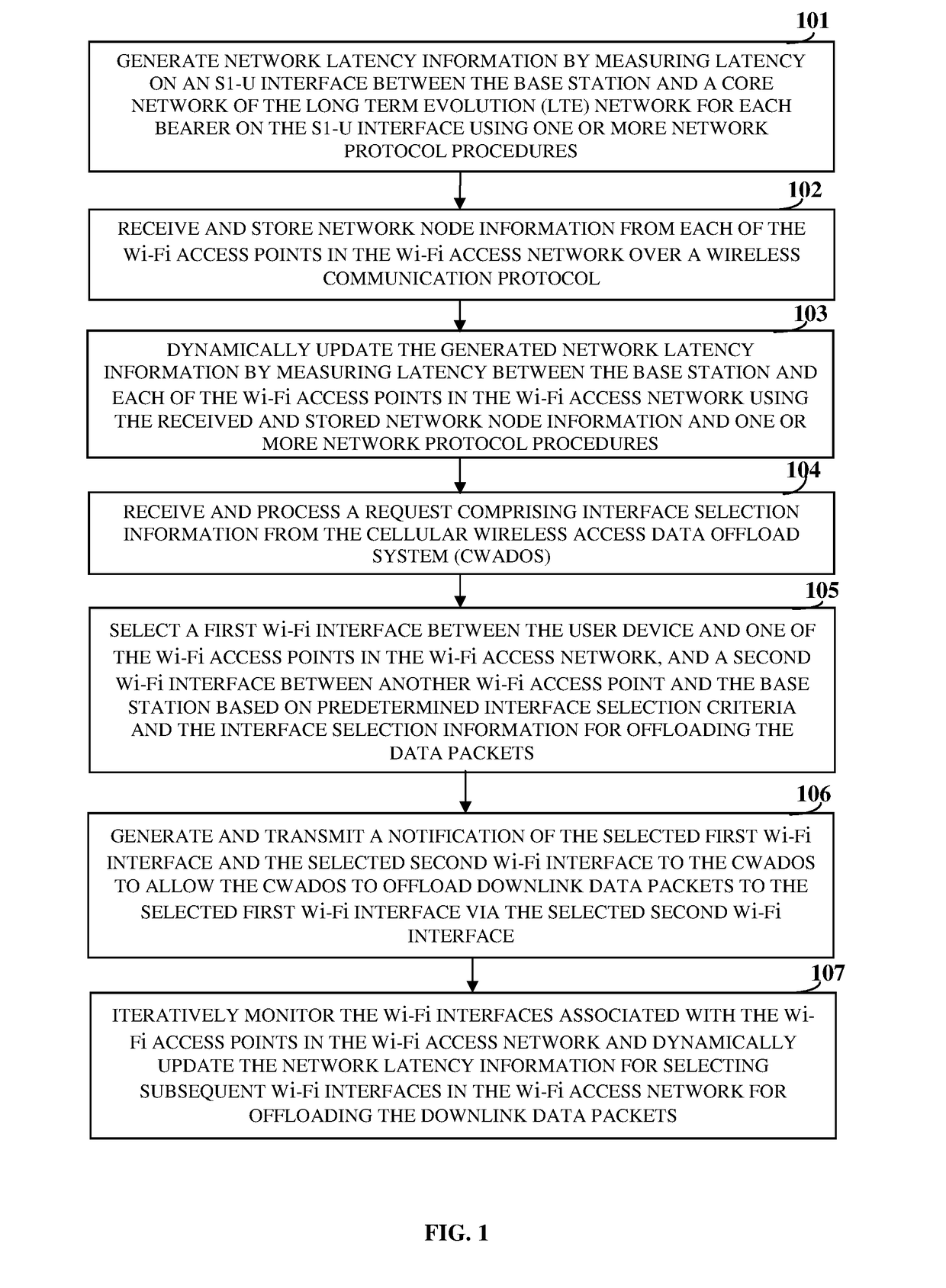

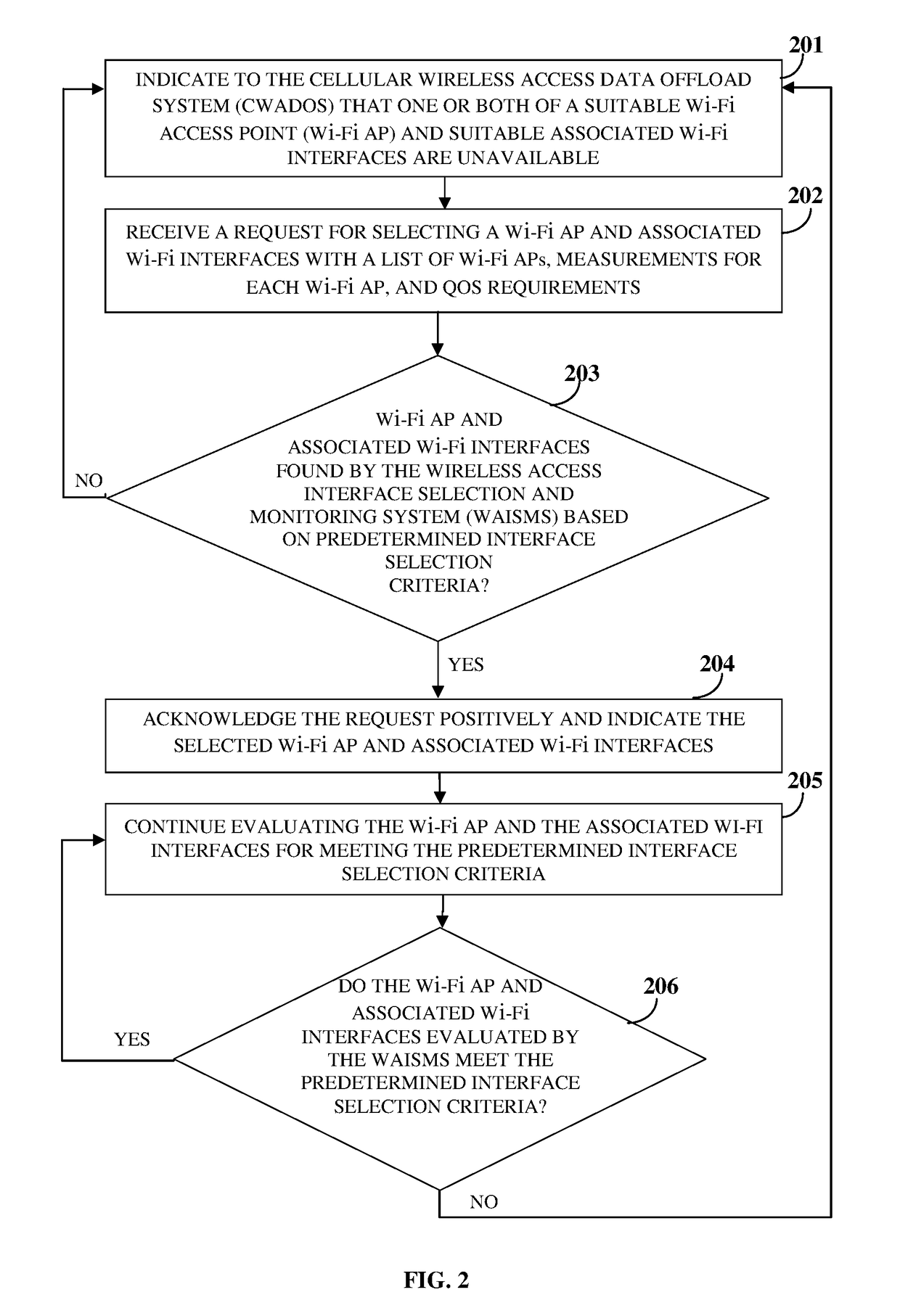

Dynamic Selection And Monitoring Of Wireless Communication Interfaces For Cellular Wireless Access Data Offload In A Wireless Access Network

ActiveUS20170295512A1Reduce power consumptionMeet service requirementsPower managementNetwork traffic/resource managementAccess networkCommunication interface

A method and a wireless access interface selection and monitoring system (WAISMS) for dynamically selecting and monitoring wireless communication interfaces (WCIs) associated with wireless access points (WAPs) in a wireless access network for offloading data from a cellular wireless communication (CWC) interface in a CWC network to the selected WCIs are provided. The WAISMS generates and dynamically updates network latency information (NLI) by measuring latency on a cellular wireless network interface and the WCIs based on network node information received from the WAPs. The WAISMS receives and processes a request from a cellular wireless access data offload system (CWADOS), selects a first WCI (FWCI) and a second WCI (SWCI) based on predetermined interface selection criteria and interface selection information, generates and transmits a notification of the selected FWCI and SWCI to the CWADOS for offloading data packets, iteratively monitors the WCIs, and dynamically updates the NLI for selecting subsequent WCIs.

Owner:SOOKTHA CONSULTING PTE LTD

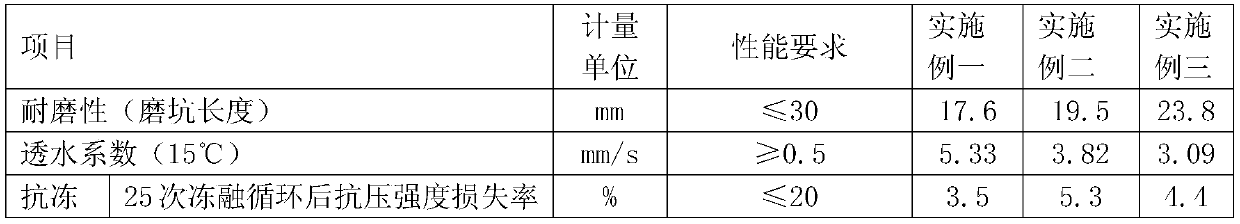

Carbon dioxide cured prefabricated water-permeable concrete and preparation method thereof

ActiveCN109824321ALow alkalinity requirementLow Pre-Care RequirementsEnvironmental resistanceCellulose

The invention discloses a carbon dioxide cured prefabricated water-permeable concrete and a preparation method thereof. The water-permeable concrete is composed of following components in parts by weight: 55 to 80 parts of regenerated aggregate, 7 to 30 parts of nickel slag sand, 18 to 40 parts of cementing material, 5 to 25 parts of water, 0.01 to 2 parts of naphthalene water reducer, 0 to 0.02 part of cellulose ether, and 0 to 0.01 part of welan gum. The cementing material is composed of following components in parts by weight: 70 to 90 parts of common silicate cement, 5 to 15 parts of fly ash, 10 to 30 parts of steel slag, 5 to 15 parts of lime or lime slag, and 0.02 to 1 part of nano calcium carbonate. The technology is simple, the structure advantage of water-permeable concrete and the properties of industrial byproducts such as nickel slag, steel slag, fly ash, and the like are fully utilized; carbon dioxide curing is utilized to realize rapid, efficient and environmentally friendly production; high strength, durable and water permeable concrete is obtained, the energy consumption is reduced, the industrial tail gas, metallurgy slag, and building waste are effectively utilized, and good economic benefits, social benefits, and environmental benefits are generated.

Owner:SOUTHEAST UNIV

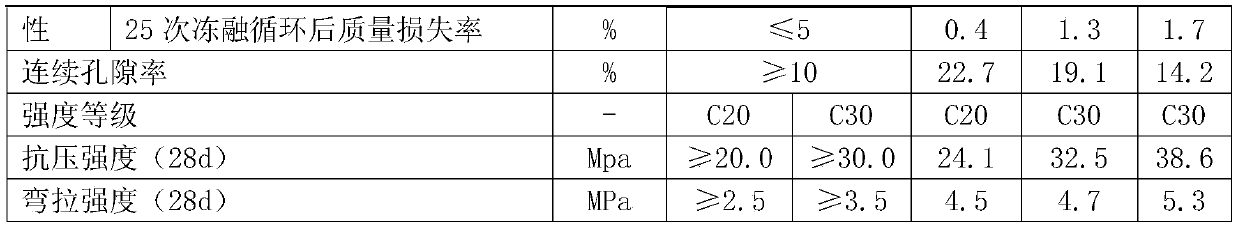

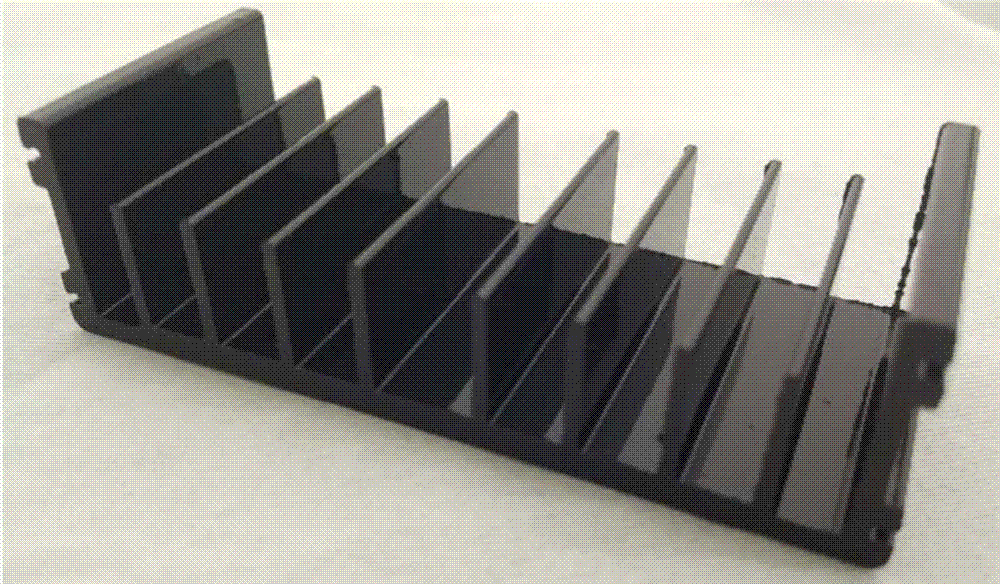

Anti-corrosion and heat-conducting composite coating on light-alloy radiator surface, preparation method of anti-corrosion and heat-conducting composite coating and light alloy radiator

InactiveCN107513746AImprove heat transfer performanceImprove cooling effectAnodisationElectrophoretic coatingsMicro arc oxidationPlasma electrolytic oxidation

The invention discloses an anti-corrosion and heat-conducting composite coating on the light-alloy radiator surface, a preparation method of the anti-corrosion and heat-conducting composite coating and a light alloy radiator with the anti-corrosion and heat-conducting composite coating. The composite coating comprises a metal oxide layer formed by oxidizing light alloy radiator base metal in situ and an electrophoretic paint film layer provided with carbon nano-particles dispersedly distributed and located on the metal oxide layer in a covering manner. The preparation method comprises the steps that (1), micro-arc oxidation is conducted, and the metal oxide layer formed by oxidizing the light alloy radiator base metal in situ is formed on the surface of the light alloy radiator base material; and (2), electrophoretic deposition is conducted, and the layer of electrophoretic paint film is deposed on the surface of the metal oxide layer. The composite coating has the beneficial effects of being uniform, dense, excellent in anticorrosion performance, good in thermal conductivity, ultralong in service life and the like. The preparation method is environmentally-friendly, safe, reliable, good in repeatability, capable of achieving automatic large-batch industrial production with low cost and short processes.

Owner:NANJING UNIV OF TECH

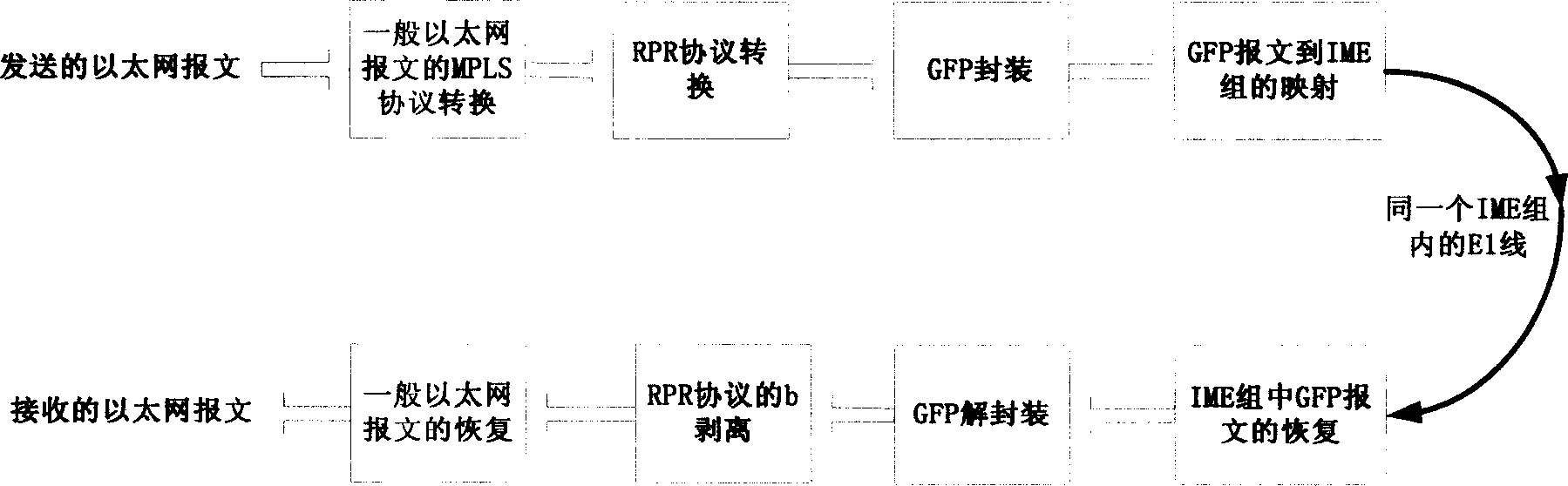

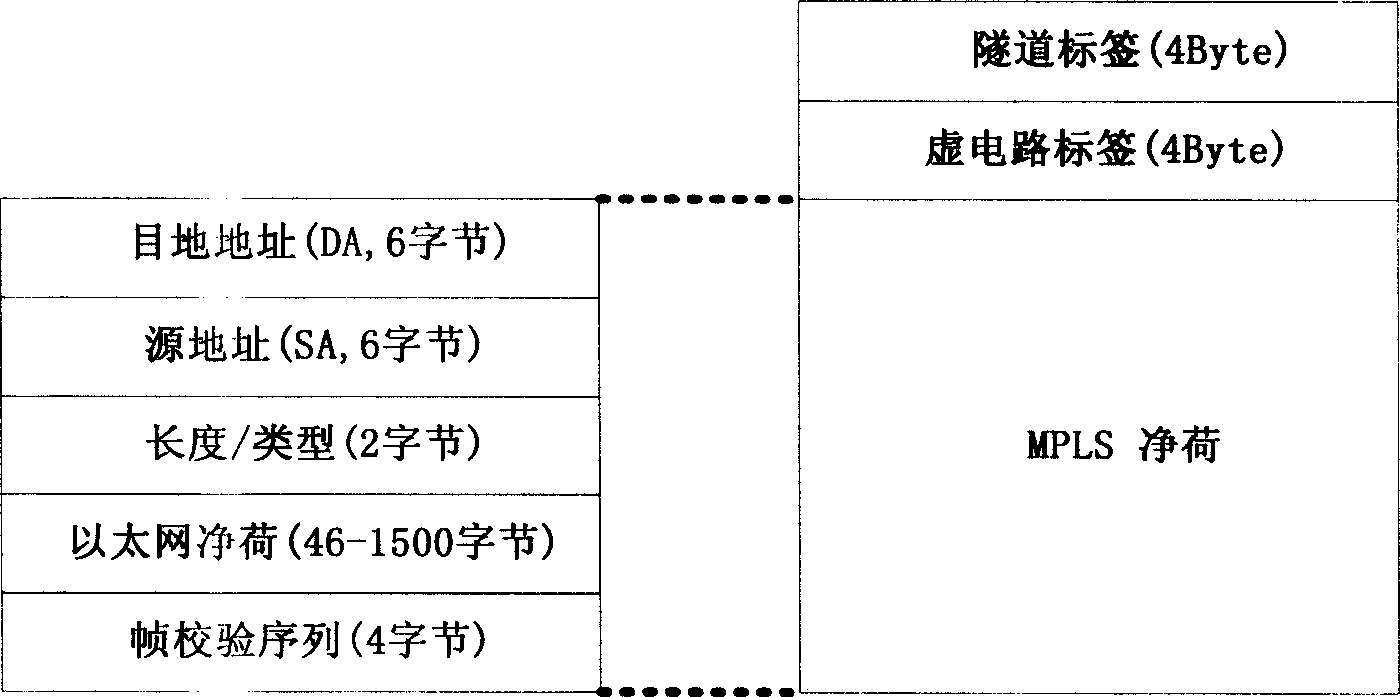

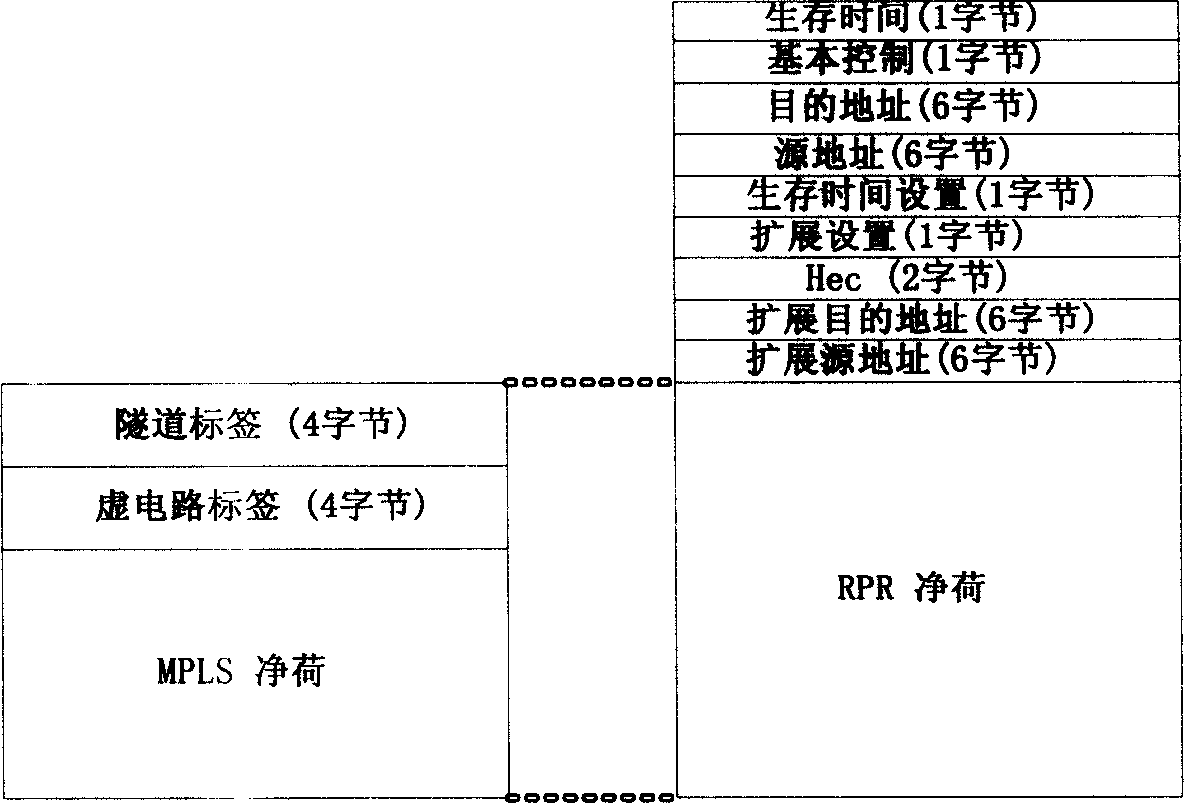

A method of Ethernet transmission in a plurality of E1 channels

InactiveCN1722699AMeet service requirementsReduce in quantityLoop networksNetworks interconnectionEthernetComputer science

This invention relates to a method of the Ethernet transferring in several E1 channels, characterized in that it uses carrying platform to transfer Ethernet, wherein the carrying platform uses several E1 as the physics layer of the RPR; it applies MPLS agreement and RPR agreement to enclose the Ethernet message; for the group with RPR format, using backward multiply usage method to transfer in several E1, adjusting the belt width through increasing or decreasing the number of E1 channel; it also can build loop based on E1, making several technical index of MPLS and RPS transferring in E1 channel.

Owner:BEIJING HUAWEI DIGITAL TECH

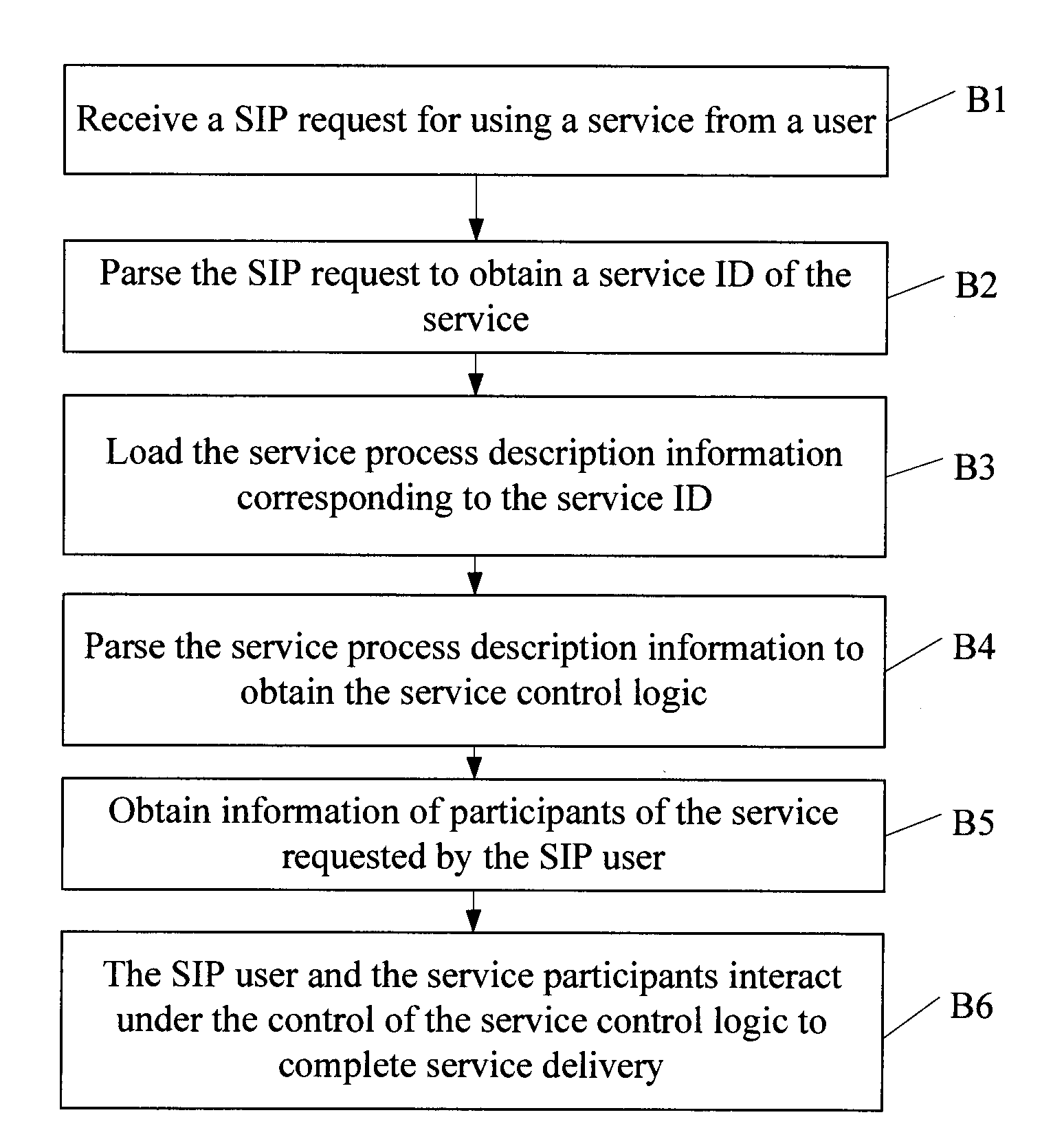

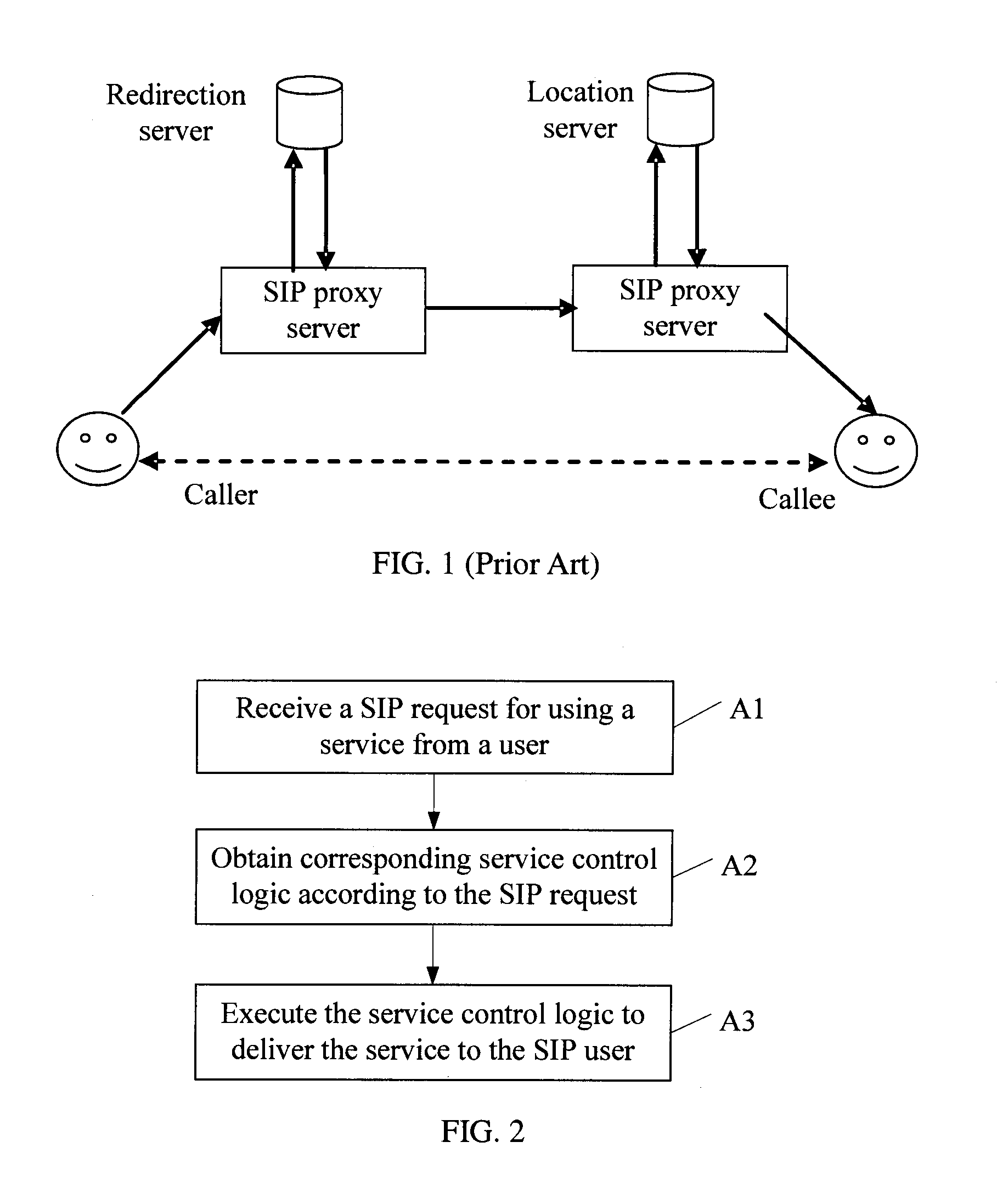

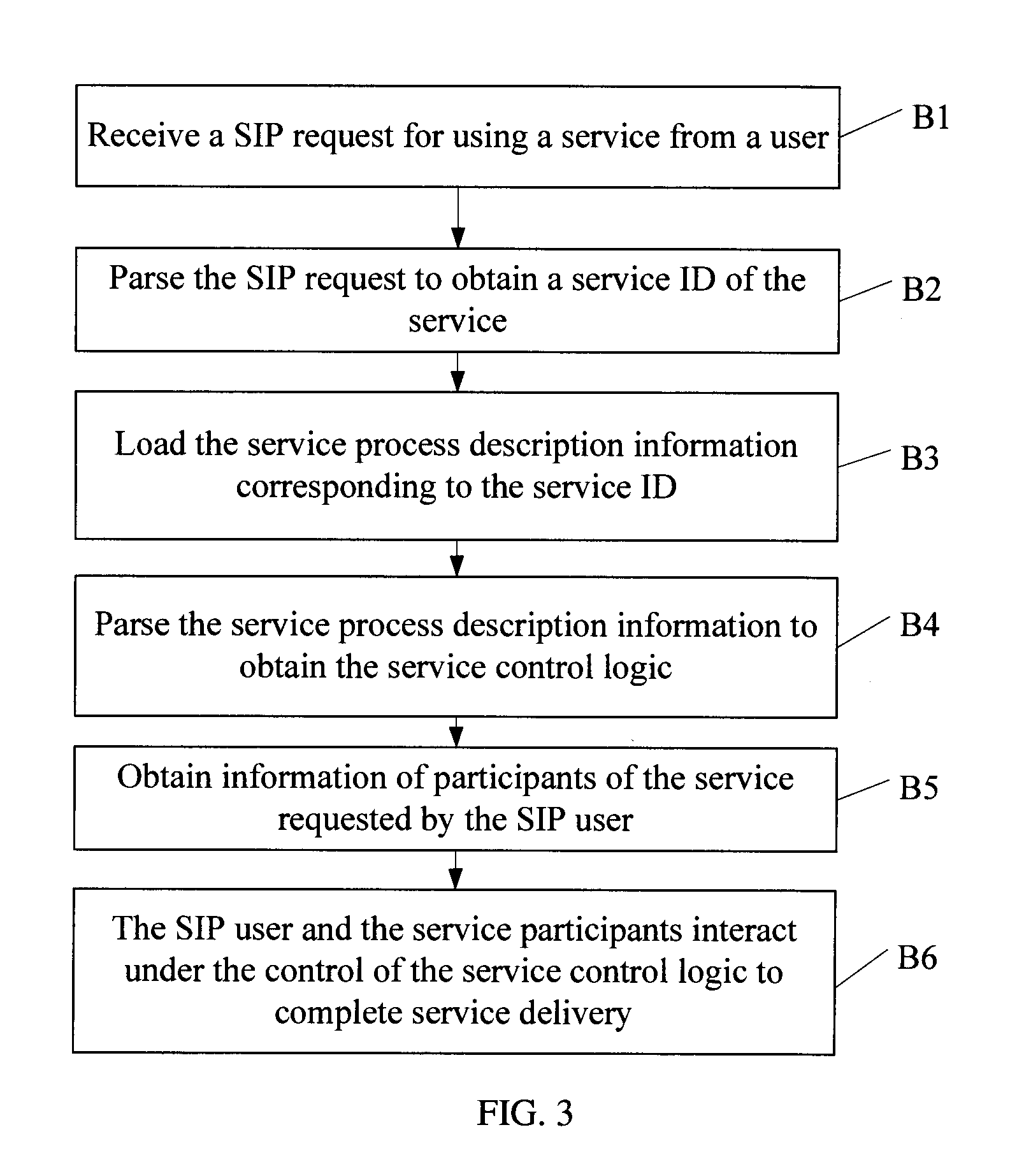

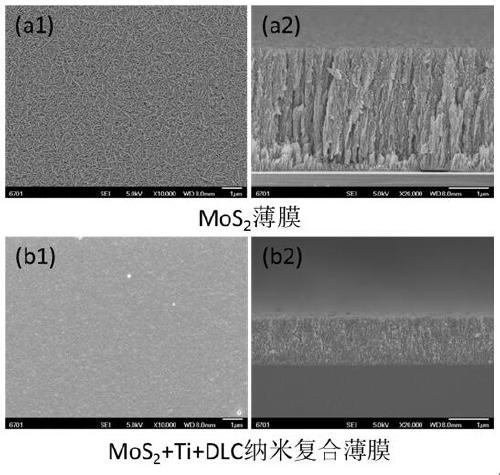

Service enhancement method, proxy server and communication system

InactiveUS20100262702A1Meet service requirementsEnhance the SIP proxy serverMultiple digital computer combinationsTransmissionSession Initiation ProtocolCommunications system

A service enhancement method includes: receiving a Session Initiation Protocol (SIP) request for using a service from a SIP user, obtaining service control logic according to the SIP request; and executing the service control logic to deliver the service to the SIP user.

Owner:HUAWEI TECH CO LTD

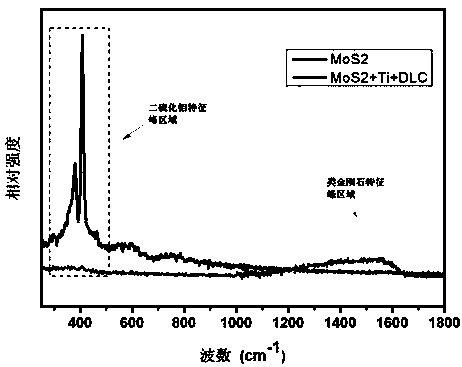

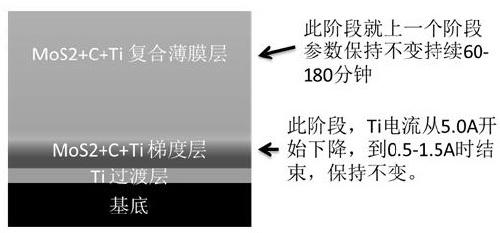

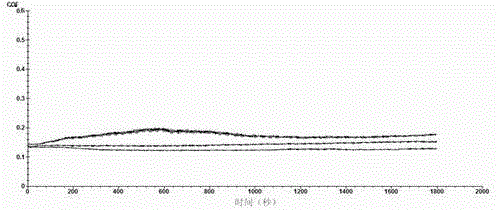

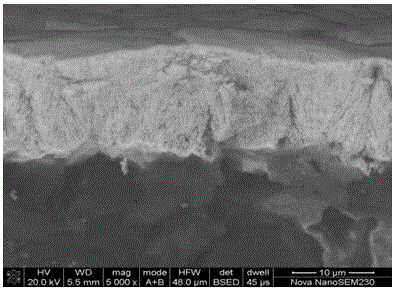

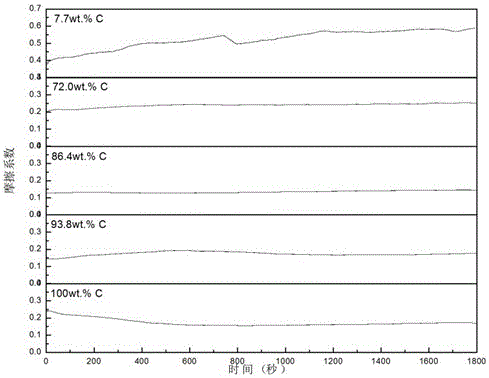

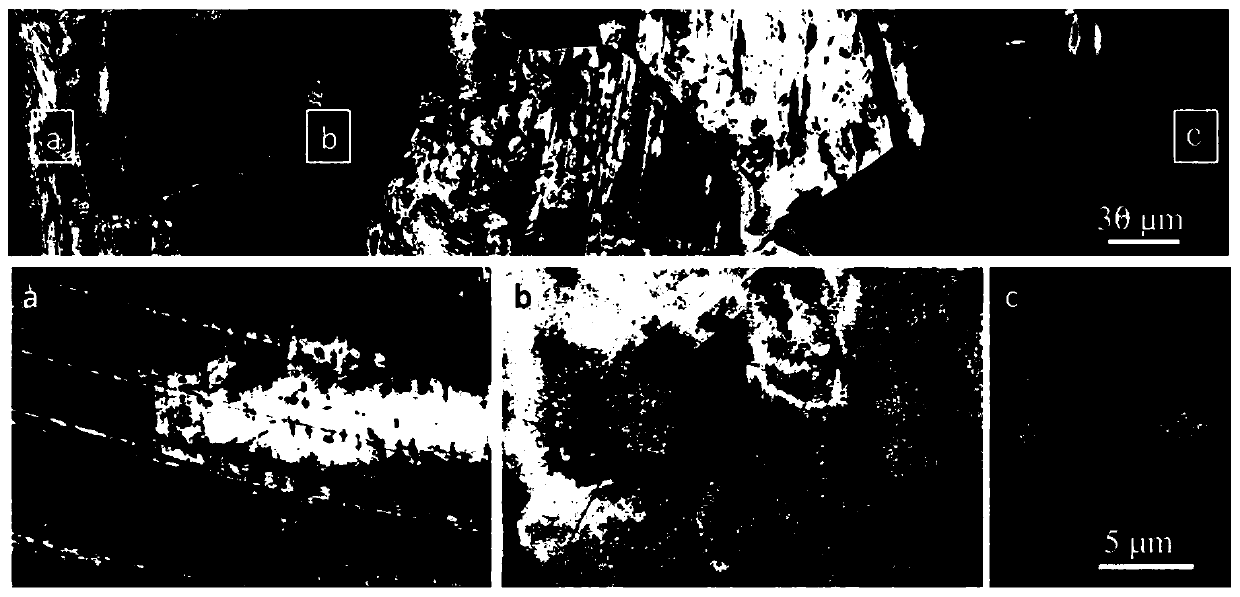

Preparation method of molybdenum disulfide (MoS2) based nanocomposite film doped with Ti and C

InactiveCN111304616AImprove lubricating propertiesImprove adaptabilityVacuum evaporation coatingSputtering coatingComposite filmNanoscopic scale

The invention discloses a preparation method of a molybdenum disulfide (MoS2) based nanocomposite film doped with Ti and C. The preparation method comprises the steps that a multi-target reactive magnetron sputtering system is utilized, MoS2 is used as a matrix material, nanoscale porous channels of the MoS2 film are filled with active Ti and DLC hard cluster particles through a reactive sputtering means, and thus a nanocomposite solid lubricating film with high environmental adaptability is constructed; and meanwhile through the deposition of Ti element gradient layers, the strength and film-base adhesion of the film are improved by using the principle of element mutual diffusion, so as to prolong the wear resistance life of the composite film. The mechanical properties test results showthat the hardness, elastic modulus and elastic recovery of the nanocomposite film are all significantly higher than those of pure MoS2 film; and the friction performance test results show that the nanocomposite film has a low friction coefficient and long wear resistance life under vacuum and atmospheric environment, and thus the service requirements of a remote control system of a nuclear fusiondevice are met.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

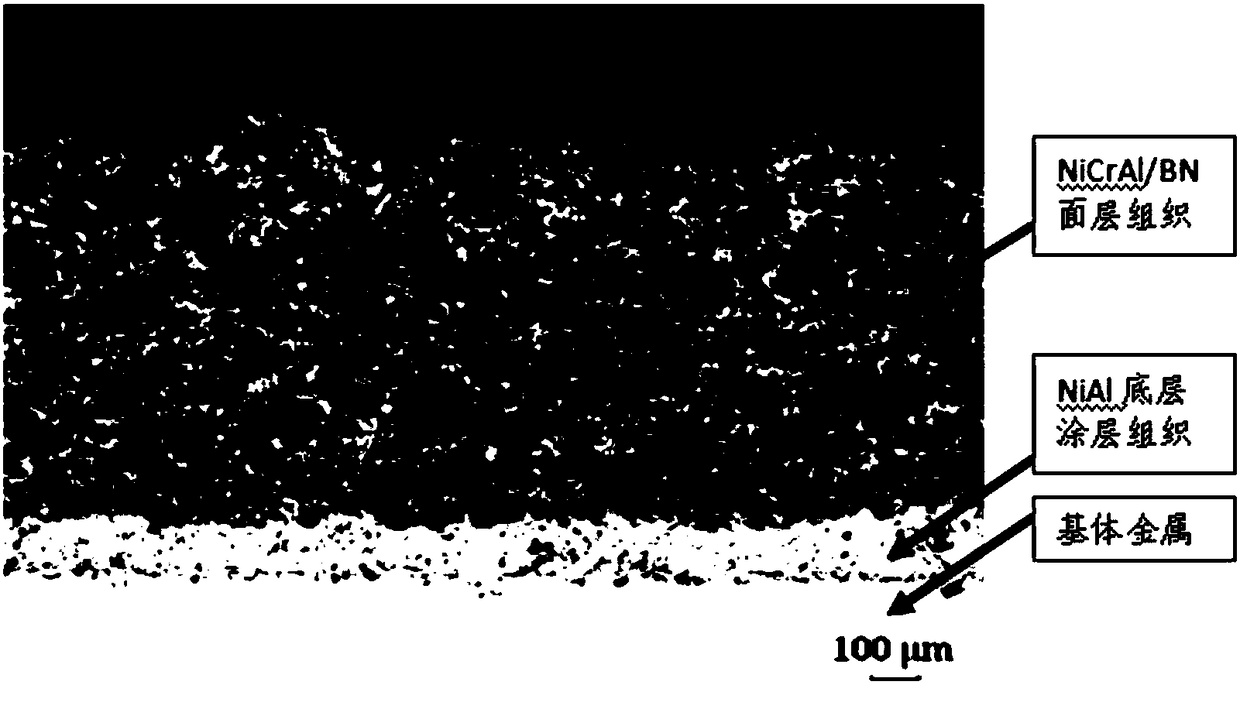

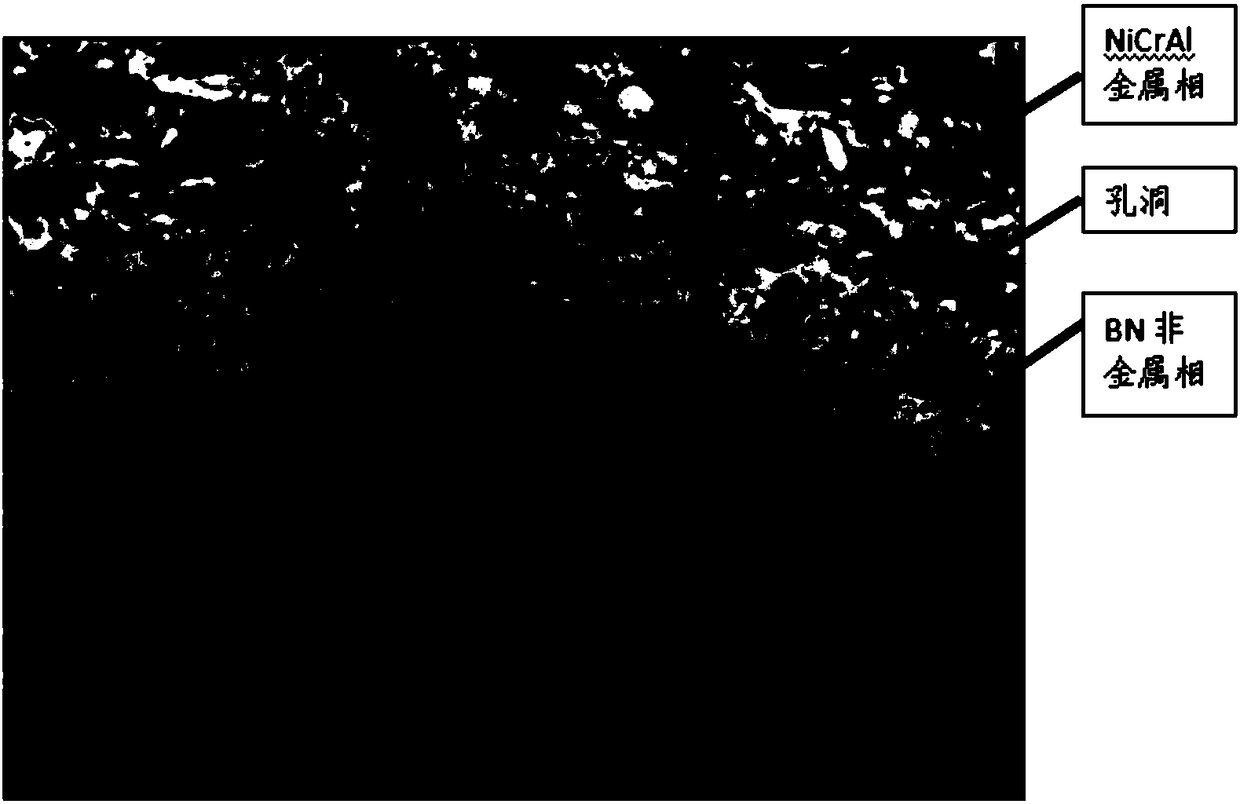

Marine corrosion-resistant thermal spraying abradable seal coating and preparation method thereof

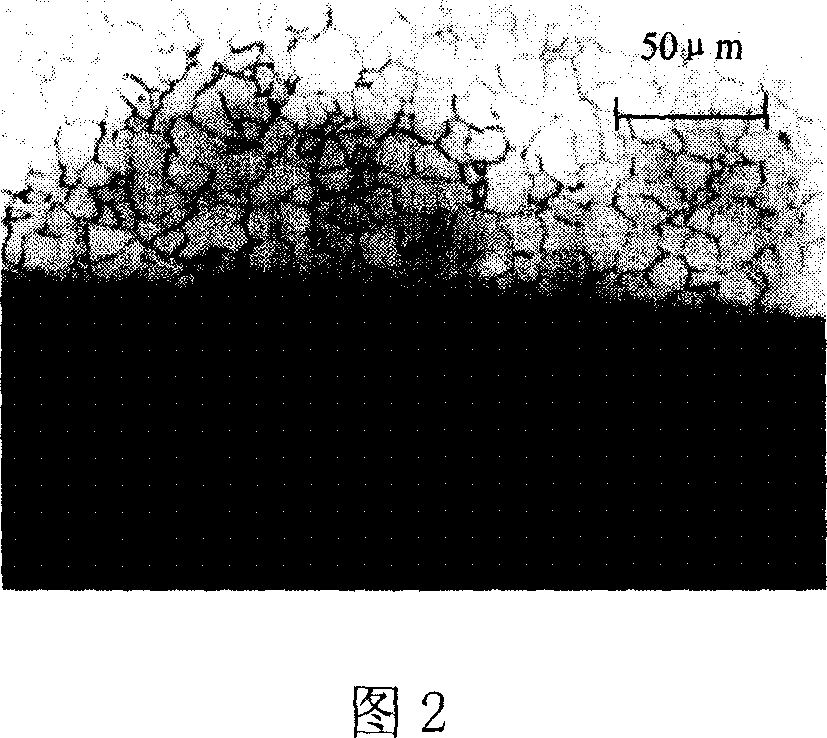

ActiveCN108203799AImprove resistance to salt sprayImprove overall service performanceHot-dipping/immersion processesMolten spray coatingCorrosion resistantBonding strength

The invention belongs to the gas path seal coating technology of components such as the inner wall of an aero-engine compressor case, and particularly relates to a marine corrosion-resistant thermal spraying abradable seal coating and a preparation method thereof. The method comprises the following steps that (1), a bottom layer is prepared, and a NiAl bottom layer on the surface of a high-temperature alloy substrate is prepared by adopting an atmospheric plasma spraying method; and (2), an abradable surface layer is prepared, and a NiCrAl / BN surface layer is prepared on the NiAl bottom layerby adopting the atmospheric plasma spraying method, wherein NiCrAl / BN surface layer phases are composed of a NiCrAl alloy phase and a non-metal phase h-BN, and the prepared NiCrAl / BN surface layer isof a typical porous multi-phase structure. The corrosion-resistant seal coating has good marine environmental corrosion resistance, and decrement of the coating hardness, the bonding strength and thelike of the coating is low after the coating is subjected to marine environment corrosion, so that the use requirements of aero-engine gas path sealing are met.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Low-friction nanometer TaC-reinforced carbon-based composite film preparation method

InactiveCN105839070AEasy to prepareImprove stabilityChemical vapor deposition coatingComposite filmThermal insulation

The invention discloses a low-friction nanometer TaC-reinforced carbon-based composite film preparation method. The preparation method comprises putting a graphite base into a chemical vapor deposition furnace, carrying out vacuum-pumping to pressure of 100pa or less, carrying out heating to a temperature of 900-1200 DEG C, carrying out thermal insulation, feeding a TaC15-Ar-C3H6 reaction gas system for preparing C and TaC into a reactor through Ar as carrying gas according to a TaCl5 carrying gas Ar flowing amount of 0.04-0.40L / min<-1> and a propylene flowing amount of 0.2-1.2L / min<-1>, and depositing C and TaC on the surface of the graphite base to obtain a C-TaC composite multilayer film which comprises nanometer TaC crystal grains coated with pyrolytic carbon and has layer number of 3-20, a mass fraction of 5.0-25.0% and thickness of 6-30 microns. The nanometer composite multilayer structure has the advantages of high hardness, low friction coefficient, high wear resistance, high thermal conductivity, low thermal expansion coefficient, good chemical stability and good oxidation resistance.

Owner:CENT SOUTH UNIV

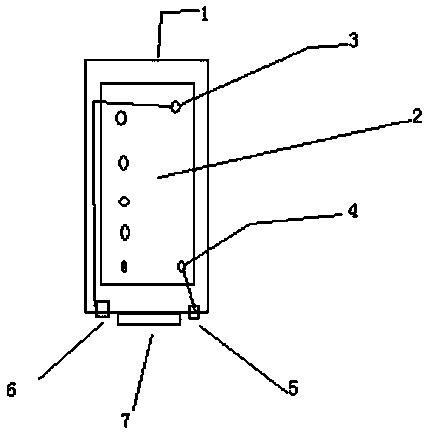

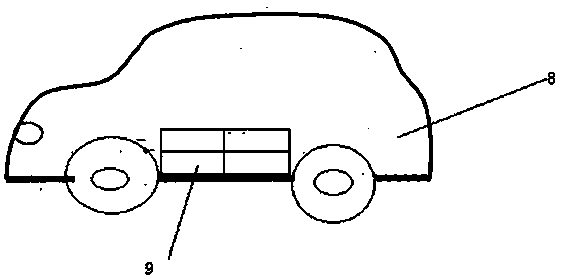

Commercially operating mode of battery station of new energy vehicle (electrical vehicle)

InactiveCN104201301AReduce use costLow construction conditionsCharging stationsCell component detailsElectricityNew energy

The invention relates to a commercially operating mode of a battery station of a new energy vehicle (an electrical vehicle). The mode includes: a battery module, an electrical vehicle body and the battery station. The battery module is uniform in size and is in the shape of a drawer. A storage battery is accommodated in the drawer. A pulling handle and an externally-connecting interface are disposed on an external body of the battery module. A large-size battery space is formed inside the electrical vehicle body and is designed into a plurality of battery module holes. Power supply modules, which are fully charged, are stored in the battery station for satisfying a replacement requirement of a user at any time. Meanwhile, uniform charging facilities are arranged so that exhausted batteries can be charged uniformly in a low-peak electricity consumption time. In the commercially operating mode of the battery station of the new energy vehicle (the electrical vehicle), the electrical vehicle is separated from the battery so that price of the electrical vehicle body is reduced. The electrical vehicle, when being exhausted, is not subjected to a charging process but subjected to a replacement process with a charged battery module so that a problem of long charging time of the battery is effectively solved. The battery module is used in a renting manner so that the problem of high cost of the electrical vehicle is effectively solved. The electrical vehicle is provided with the large-size battery space and allows a plurality of battery modules to be accommodated so that the problem that traveling distances of the electrical vehicle are limited by the battery.

Owner:李晓静

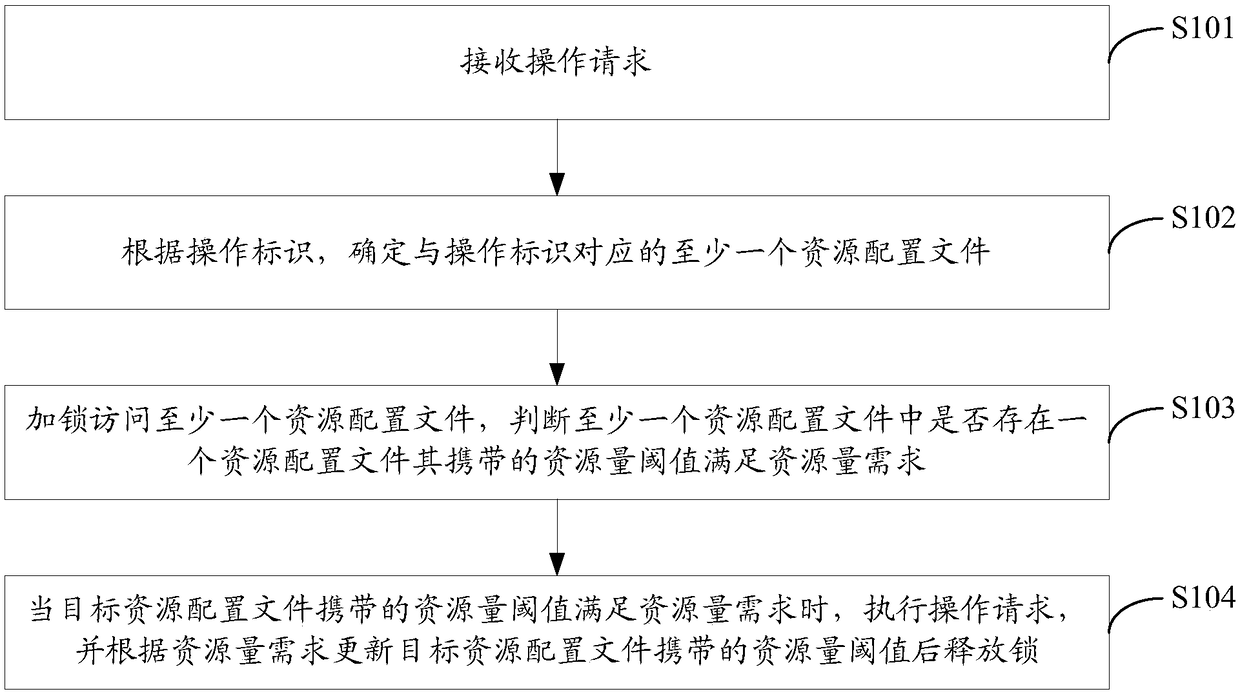

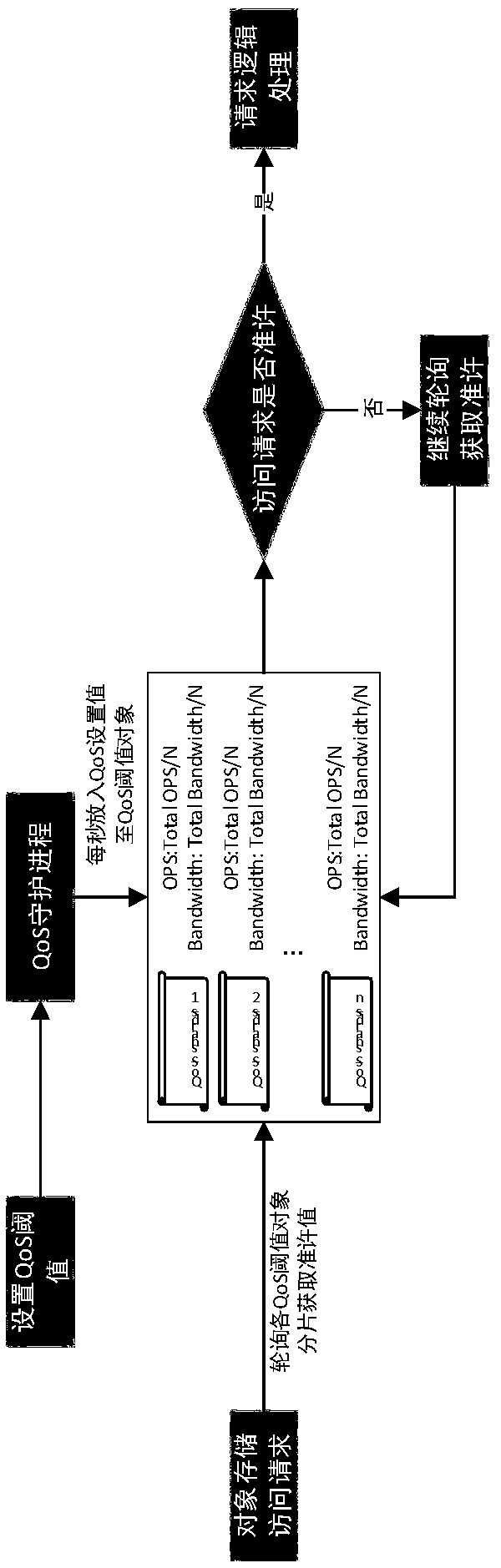

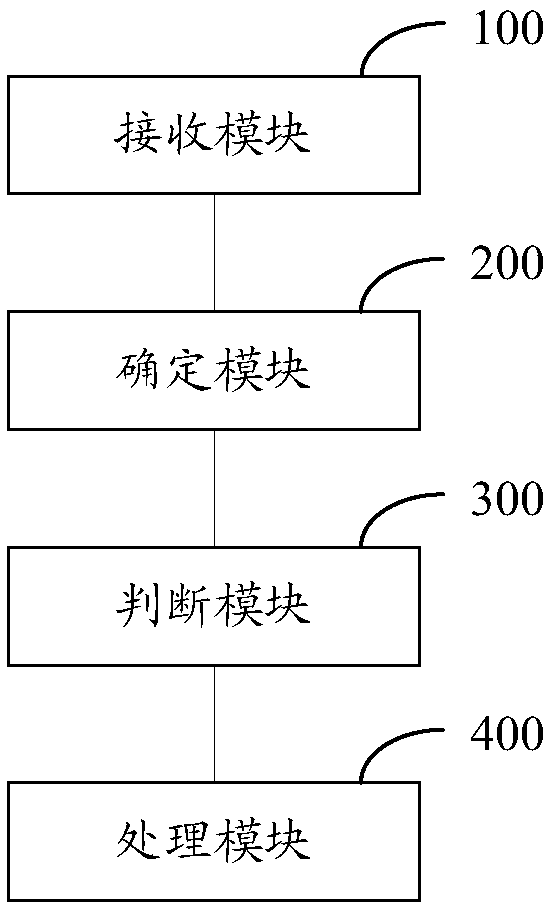

A method and apparatus for quality of service control of distribute storage

ActiveCN108989439AMeet service requirementsGuaranteed resourcesTransmissionObject storageService control

The embodiment of the invention discloses a distributed storage service quality control method and a device. The method comprises: receiving an operation request; determining at least one resource configuration file corresponding to the operation identifier according to the operation identifier; accessing at least one resource configuration file by locking, and judging whether there is a resourceconfiguration file in the at least one resource configuration file, and the resource amount threshold value carried by the resource configuration file satisfies the resource amount requirement; when the resource amount threshold carried by the target resource configuration file meets the resource amount requirement, executing the operation request, and updating the resource amount threshold carried by the target resource configuration file according to the resource amount requirement, and releasing the lock. The embodiment of the present application realizes the restriction on the access of auser or a storage bucket, improves the cluster service quality, satisfies the user service requirements, ensures the resource scheduling and balance of the entire object storage system, and provides abetter object storage service quality.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

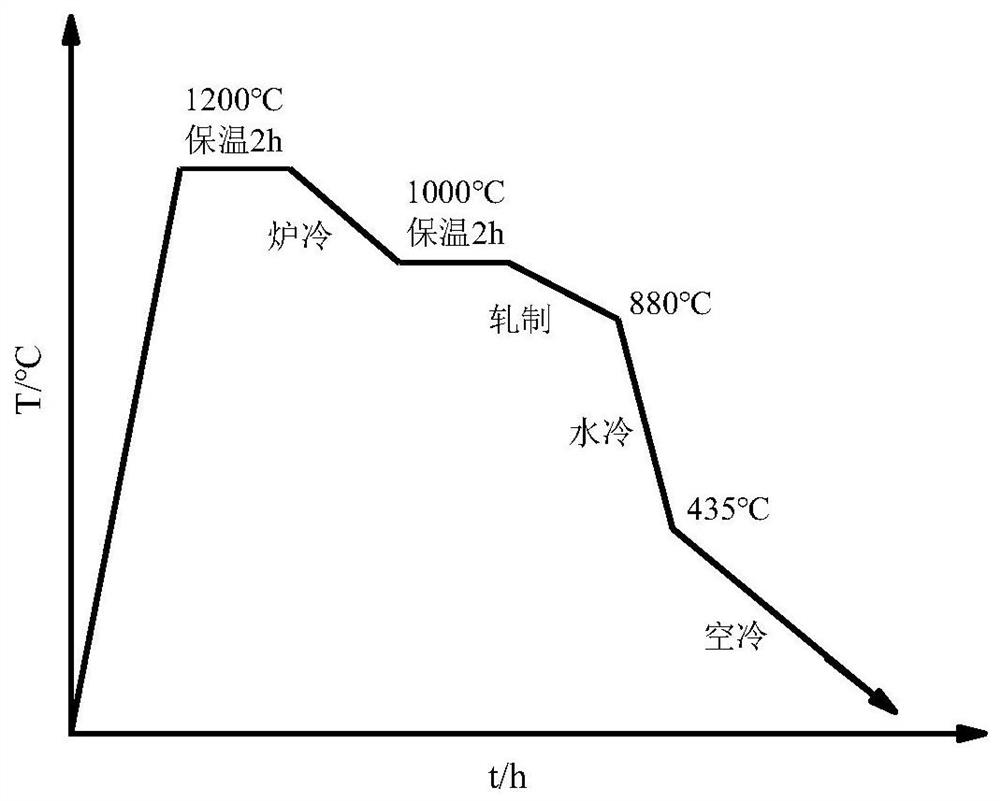

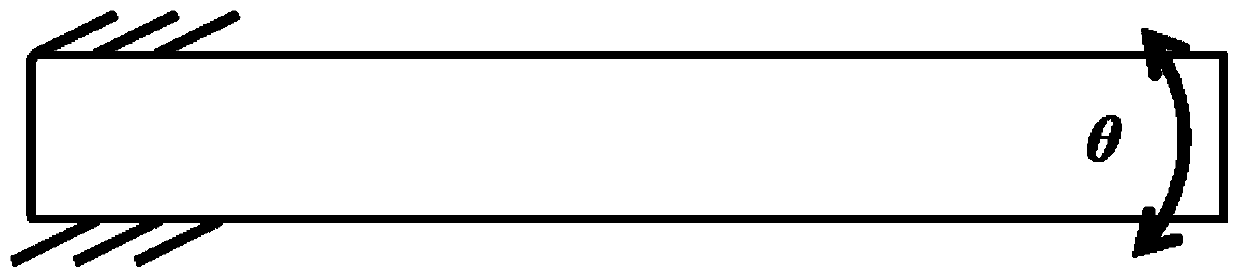

Corrosion fatigue resistant steel for engineering and preparation method thereof

The invention discloses corrosion fatigue resistant steel and a preparation method thereof, and belongs to the field of low alloy steel manufacturing. According to the steel, on the basis that E690 steel comprises the main elements of 0.04%-0.07% of C, 0.20%-0.26% of Si, 1.45%-1.60% of Mn, less than or equal to 0.01% of P, less than or equal to 0.015% of S and 0.44%-0.50% of Cr, element regulation and control are carried out, and the steel comprises the characteristic elements of 0.28%-0.66% of Cu, 0.76%-1.55% of Ni, 0.03%-0.12% of Sb and the balance Fe and inevitable impurities. According to the corrosion fatigue resistant steel for engineering and the preparation method thereof, the alloy elements Cu, Ni and Sb are adjusted and added to inhibit corrosion fatigue crack initiation and expansion while the comprehensive mechanical property requirement is ensured through alloy element regulation and control, so that the corrosion fatigue life is prolonged to meet the requirement of engineering steel on corrosion fatigue resistance design. A steel ingot meeting the component design range is smelted through a vacuum induction furnace, through laboratory corrosion fatigue performance evaluation and corresponding follow-up component design and preparation process optimization, the corrosion fatigue resistant steel with the structure being bainite is finally obtained, and the corrosion fatigue life of the corrosion fatigue resistant steel can be prolonged by 52% at most.

Owner:UNIV OF SCI & TECH BEIJING +1

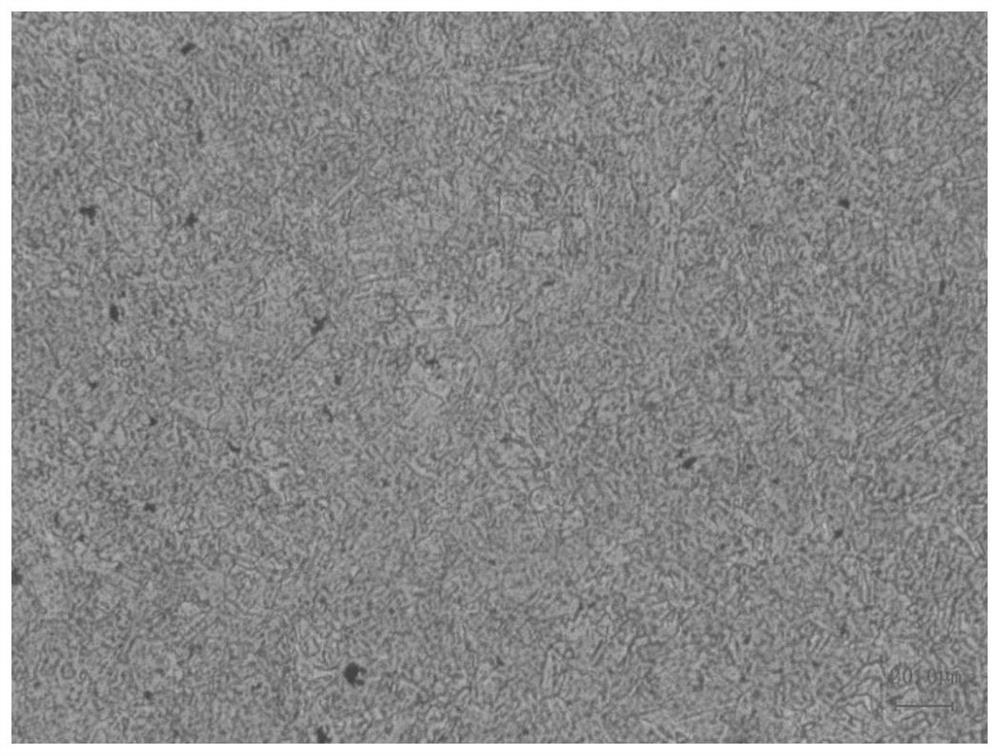

Preparation method of high-strength and high-plasticity 304 austenitic stainless steel with low martensite content

The invention discloses a preparation method of high-strength and high-plasticity 304 austenitic stainless steel with low martensite content, and belongs to the technical field of metal material strengthening. According to the method, small-angle circulating and reciprocating torsional deformation treatment is conducted on a coarse-grain 304 stainless steel bar or pipe, so that dislocation and nano twin crystal deformation microstructures distributed in a gradient mode are introduced into an original coarse-grain structure of 304 stainless steel, and meanwhile, the martensite structure contentof the surface layer of the material is less than 7%; the small-angle cyclic torsional deformation treatment means that one end of the bar or the pipe is fixed, and a force is applied to enable the other end of the bar or the pipe to rotate around the center axis of the bar or the pipe in a reciprocating mode, so one-time reciprocating rotation is one cyclic torsional cycle. Compared with a uniform coarse grain structure with the same components, the material treated by the circulating torsion process is improved by more than 1.5 times in the yield strength, and the metal material has uniformplasticity equivalent to that of coarse grains.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

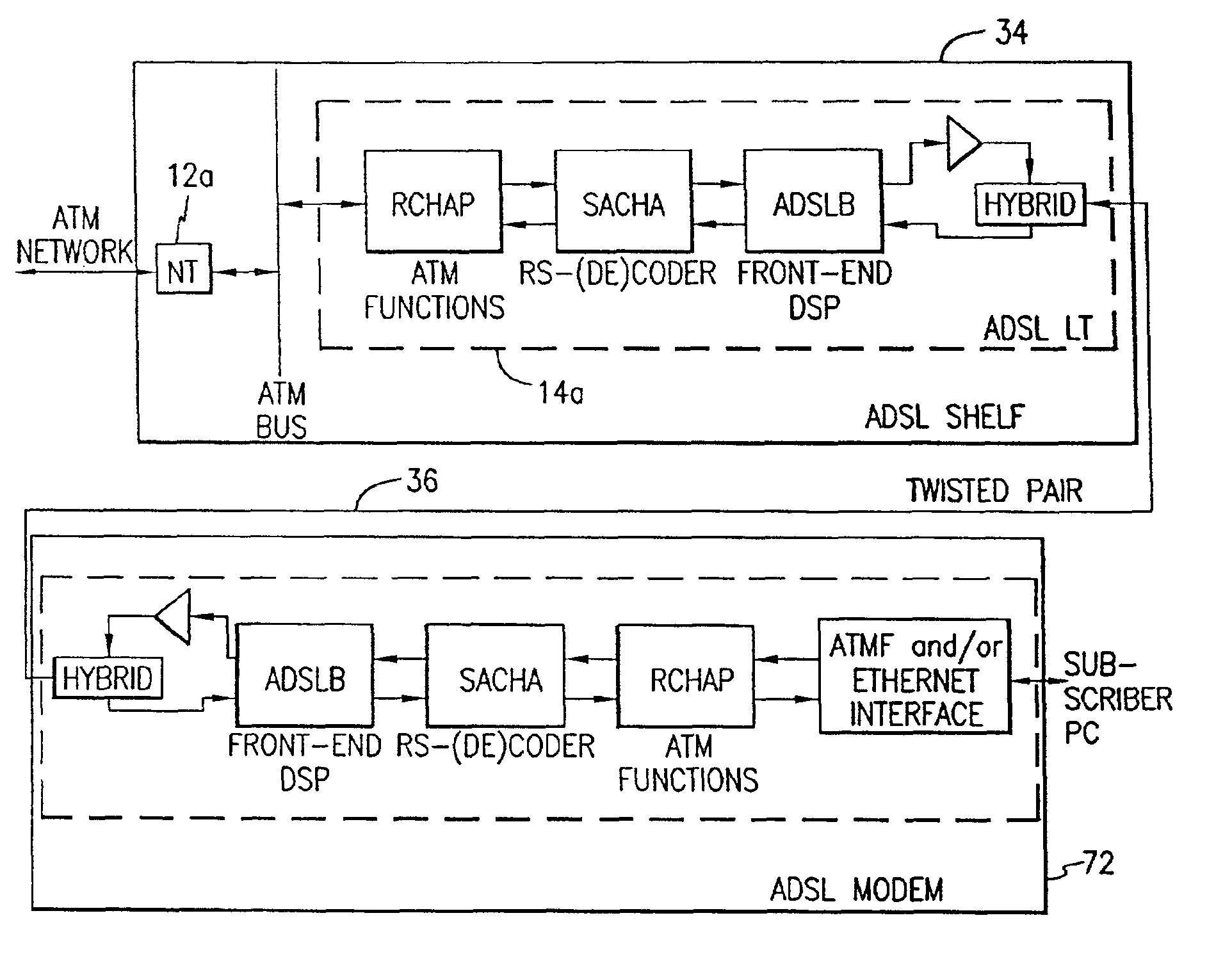

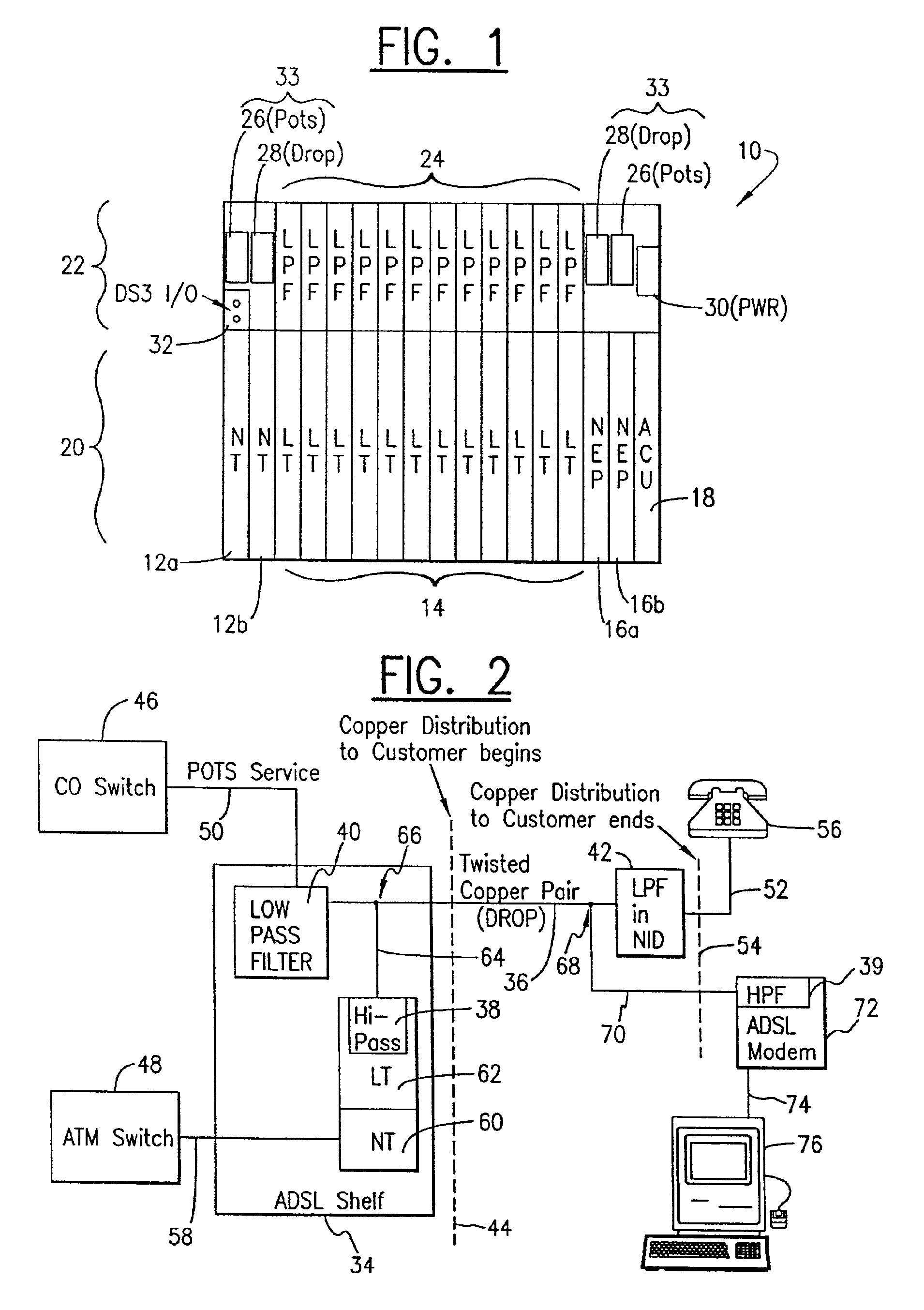

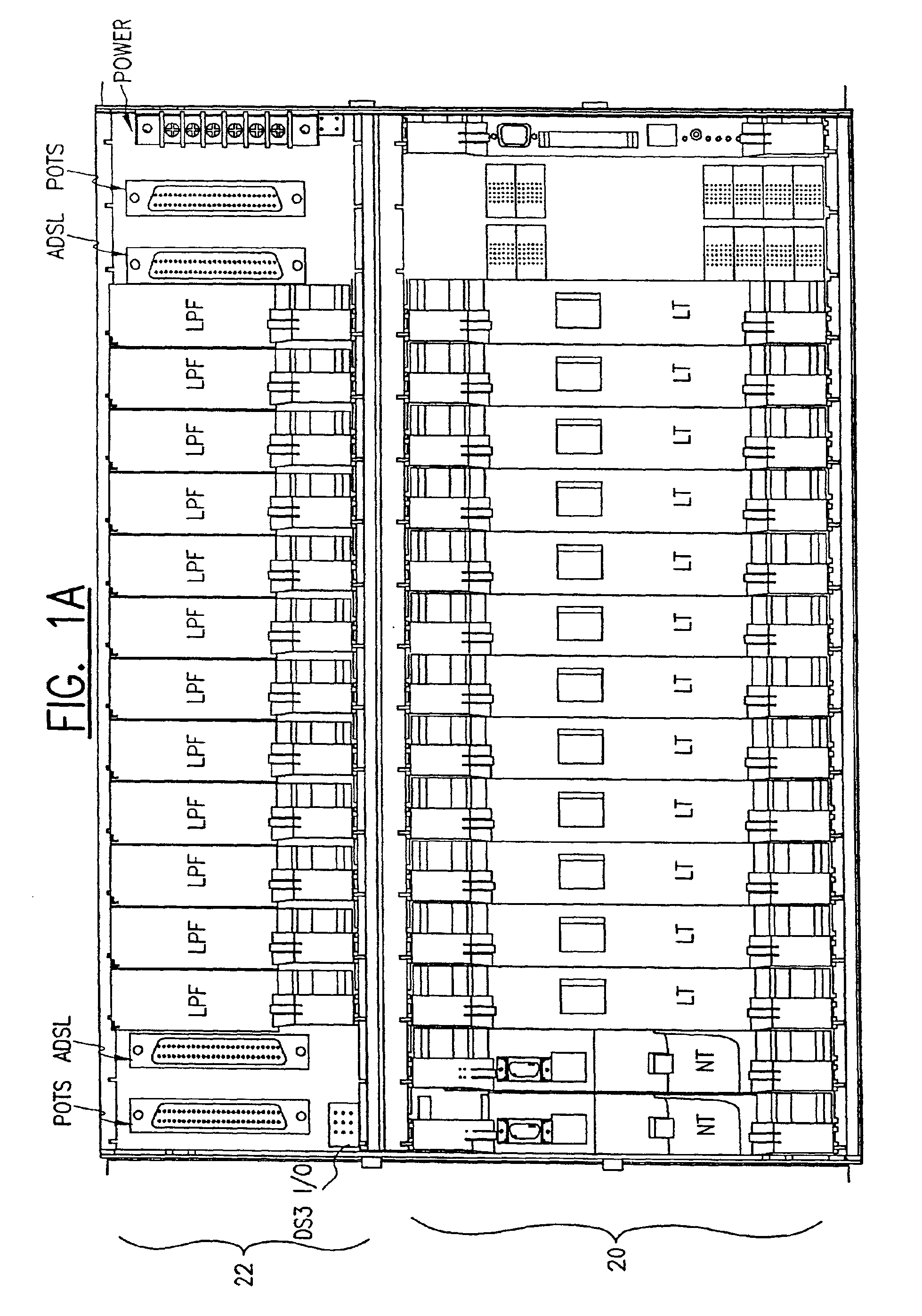

Line termination equipment

InactiveUS6940859B2Provide maintainabilityEliminate congestion problemsTransmission path divisionData switching by path configurationTerminal equipmentPrinted circuit board

Line termination equipment may include a replaceable printed circuit board or card for use in a shelf of a telecommunications system with plural twisted pairs connected to corresponding plural subscribers via said card, each subscriber channel on each card including a hybrid circuit connected to one of the plural twisted pairs, a highpass filter, a modulator / encoder and a demodulator / decoder.

Owner:ALCATEL LUCENT SAS

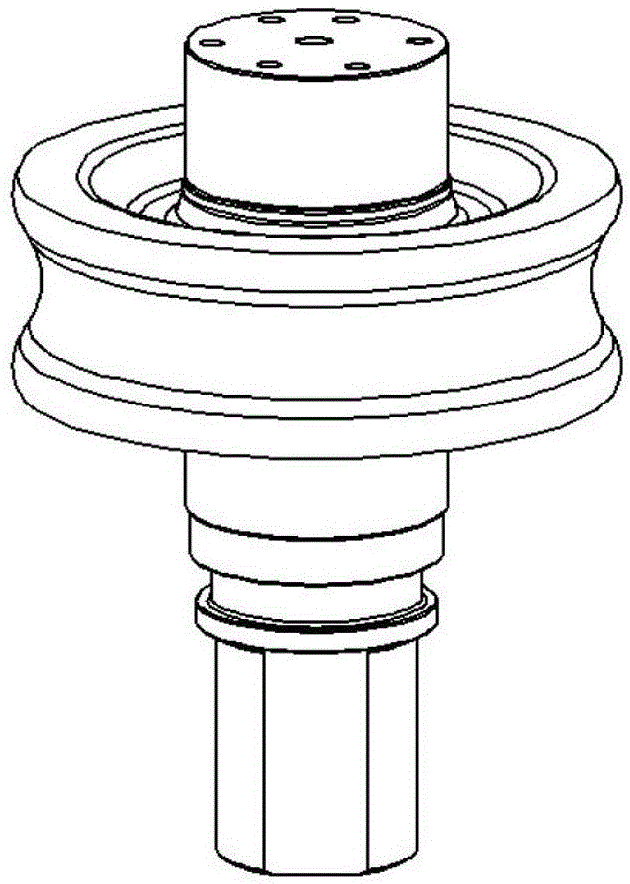

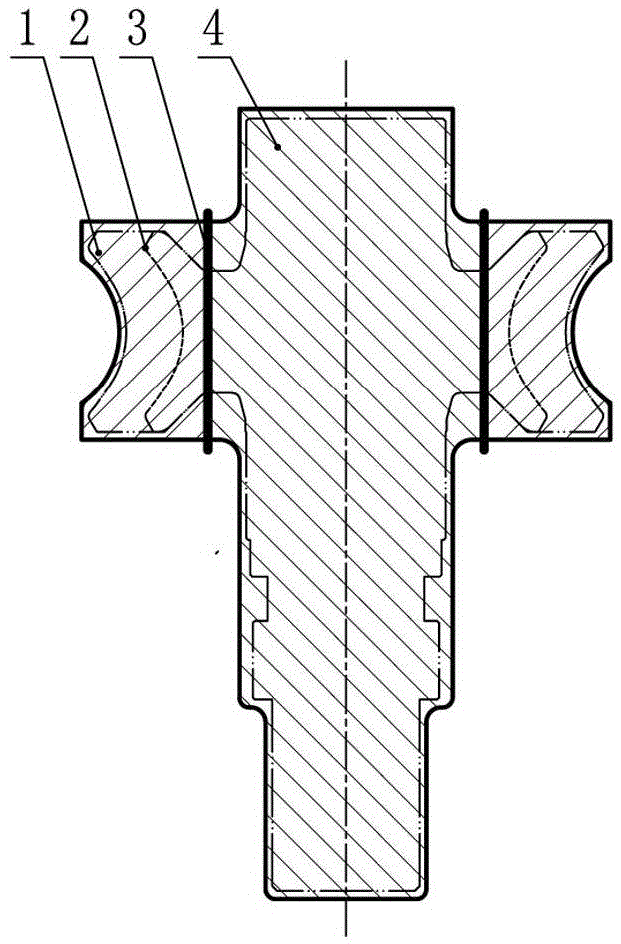

Composite roller of particle-reinforced hot-rolled seamless steel pipe tandem mill and preparing method thereof

ActiveCN105543641AGuarantee casting qualityMeet service requirementsQuenching agentsSteel tubeQuenching

The invention discloses a composite roller of a particle-reinforced hot-rolled seamless steel pipe tandem mill and a preparing method thereof. Composite particles adopted by the composite roller consist of reinforcing particles, an active wetting agent and a matrix reinforcer. Through reinforcing nodular cast iron matrix metal melt and adopting a technical method separately casting two parts, the composite roller of the particle-reinforced hot-rolled seamless steel pipe tandem mill is cast. Through carrying out isothermal quenching and processing on the composite roller, the composite roller of the seamless steel pipe tandem mill, which is high in strength and high in tenacity, is obtained. The composite roller is resistant to wear and resistant to impact, the service life of the roller is prolonged by more than 1.5 times, the production cost is reduced, and the production efficiency and the economic benefit of steel pipe production enterprises are improved.

Owner:SHANDONG PROVINCE SIFANG TECHN DEV

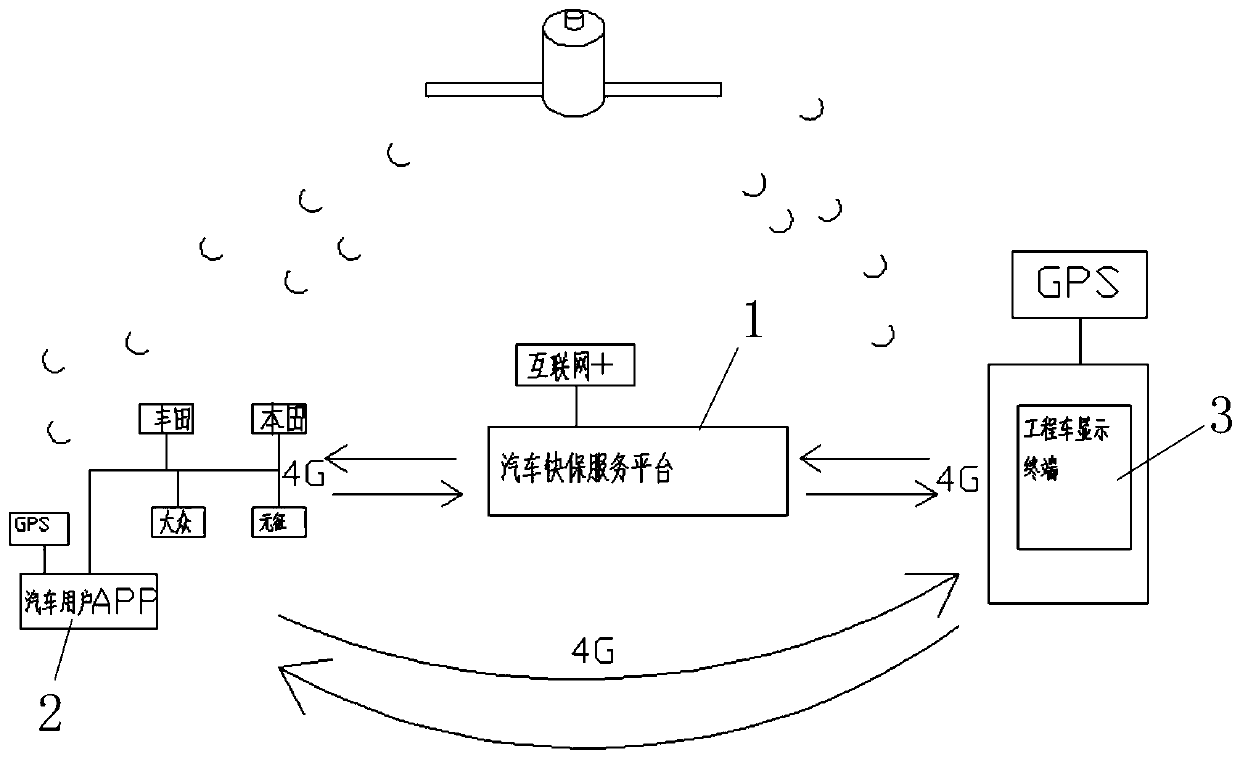

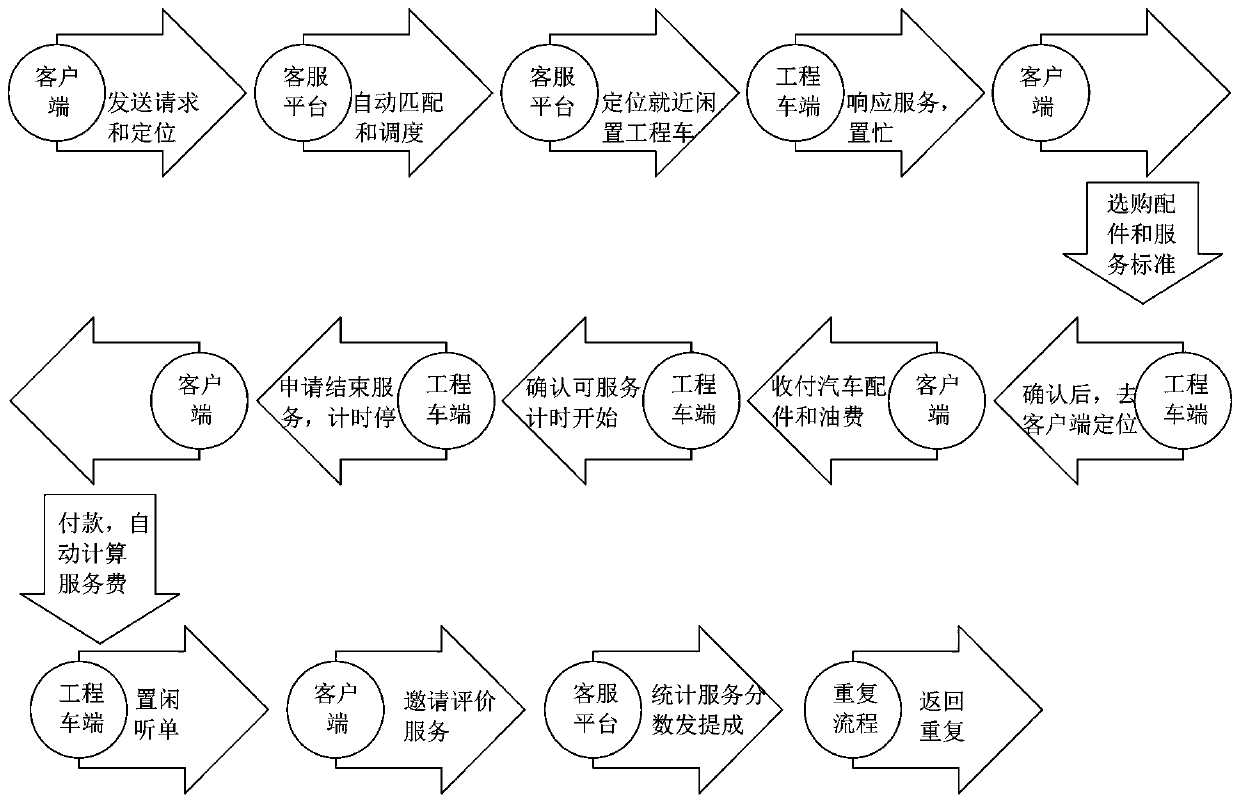

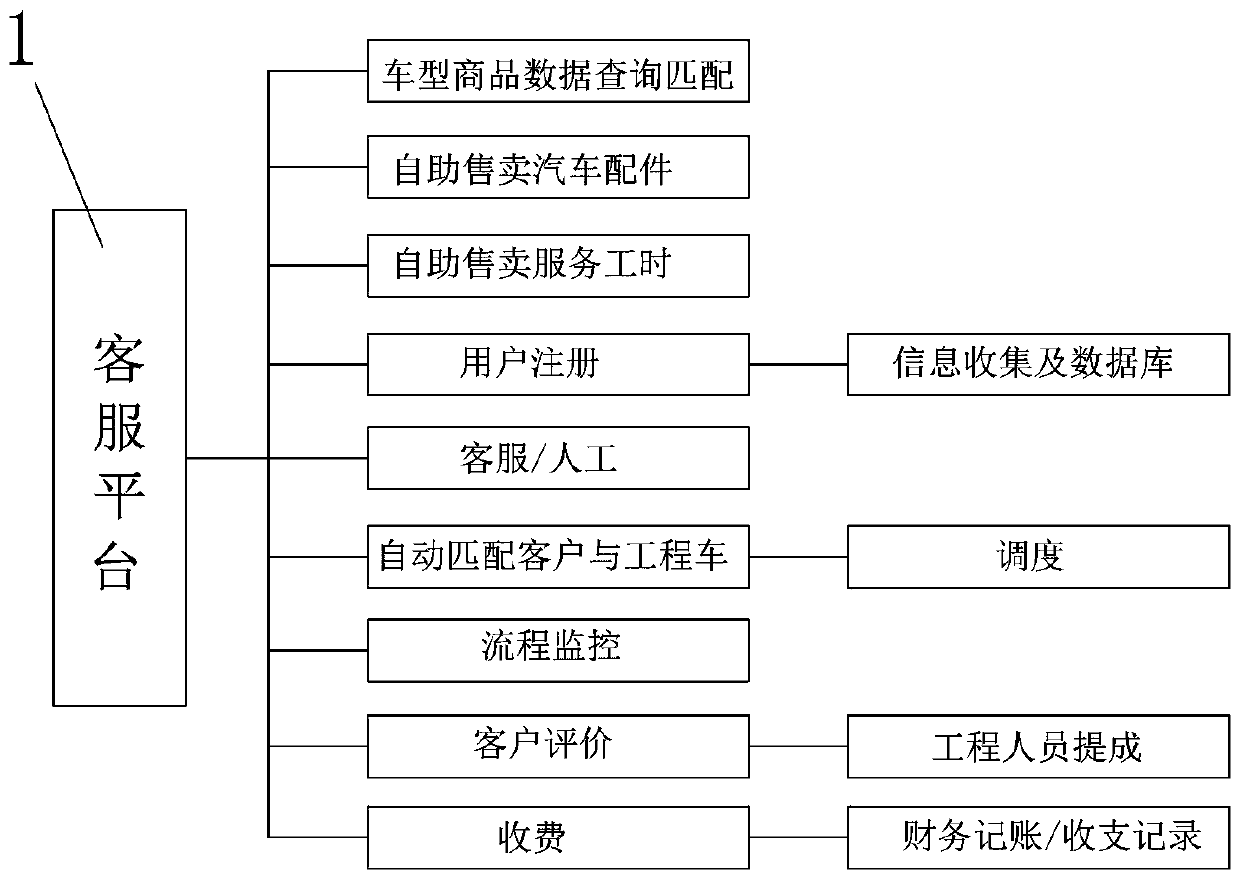

Intelligent automotive fast repairing and maintenance system based on mobile internet application

PendingCN107738608AImprove service experienceShorten the timeItem transportation vehiclesVehicle servicing/repairingComputer networkService experience

The invention relates to an automotive service platform, in particular to an intelligent automotive fast repairing and maintenance system based on a mobile internet application. The system includes acustomer service platform, client side APPs and an engineering vehicle side; the customer service platform matches the client side APPs and calls the engineering vehicle side, and each client side APPhas the functions of sending a request and a location to the customer service platform and achieving on-line interaction with the customer service platform and on-line payment; the engineering vehicle side responds to the customer service platform, allocates a movable engineering vehicle to a locating point provided by one client side APP, and is capable of achieving a GPS locating function and aself-service automotive part selling function and supplying a fast repairing and maintenance platform. A user only needs to use an APP to apply for a fast repairing or maintenance service, then the customer service platform can fast match a nearby automotive repairing engineering vehicle on call at anytime and anywhere, the service experience of customers is optimized to the maximum degree, the customers' time is saved to the maximum degree, and the fast, cheap and professional automotive repairing and maintenance service can be achieved.

Owner:DONGGUAN POLYTECHNIC

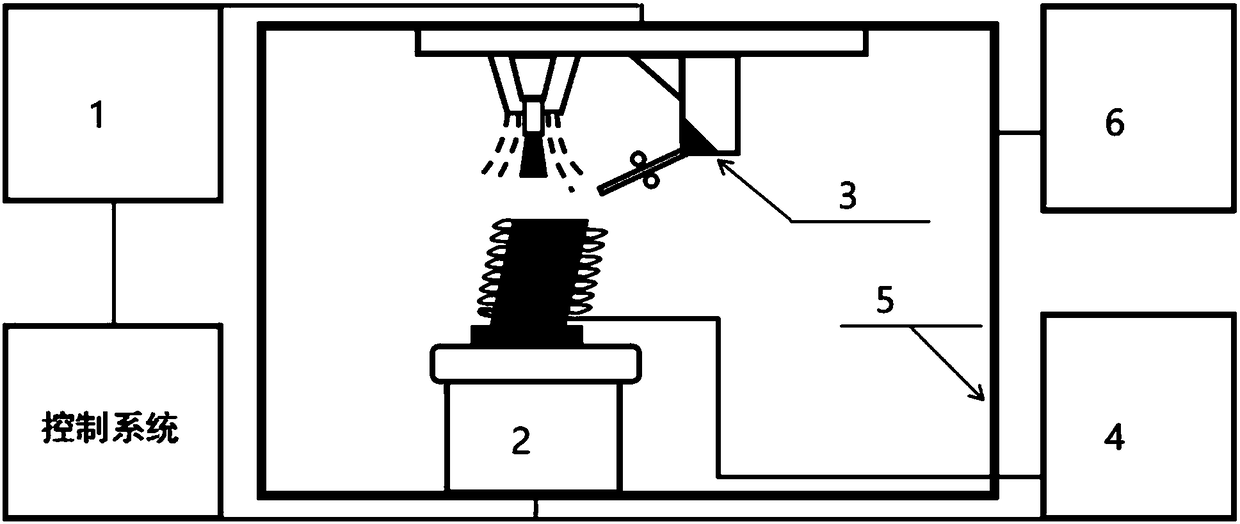

System used for restoring single crystal or oriented crystal alloy blade

ActiveCN108115249AMeet service requirementsExtended service lifeWelding protection meansSingle crystalAlloy

The invention discloses a system used for restoring a single crystal or oriented crystal alloy blade. The system comprises a welding torch and an assorted device thereof, a blade motion device, a restoration material feeding device, a thermal control device, a protection cabin device and a system used for restoring path planning; the blade motion device is arranged at the bottom inside the protection cabin device, the welding torch and a welding torch of the assorted device are arranged at the portion, corresponding to the blade motion device, of the upper portion, and the restoration materialfeeding device is arranged at the side of the welding torch; the blade motion device is provided with a sensing heating coil controlled by a heating control device. All the devices are synergeticallycooperated to automatically and efficiently restore a blade to be restored, the restored and subsequently machined blade meets blade service requirements, and the service life is prolonged.

Owner:XI AN JIAOTONG UNIV

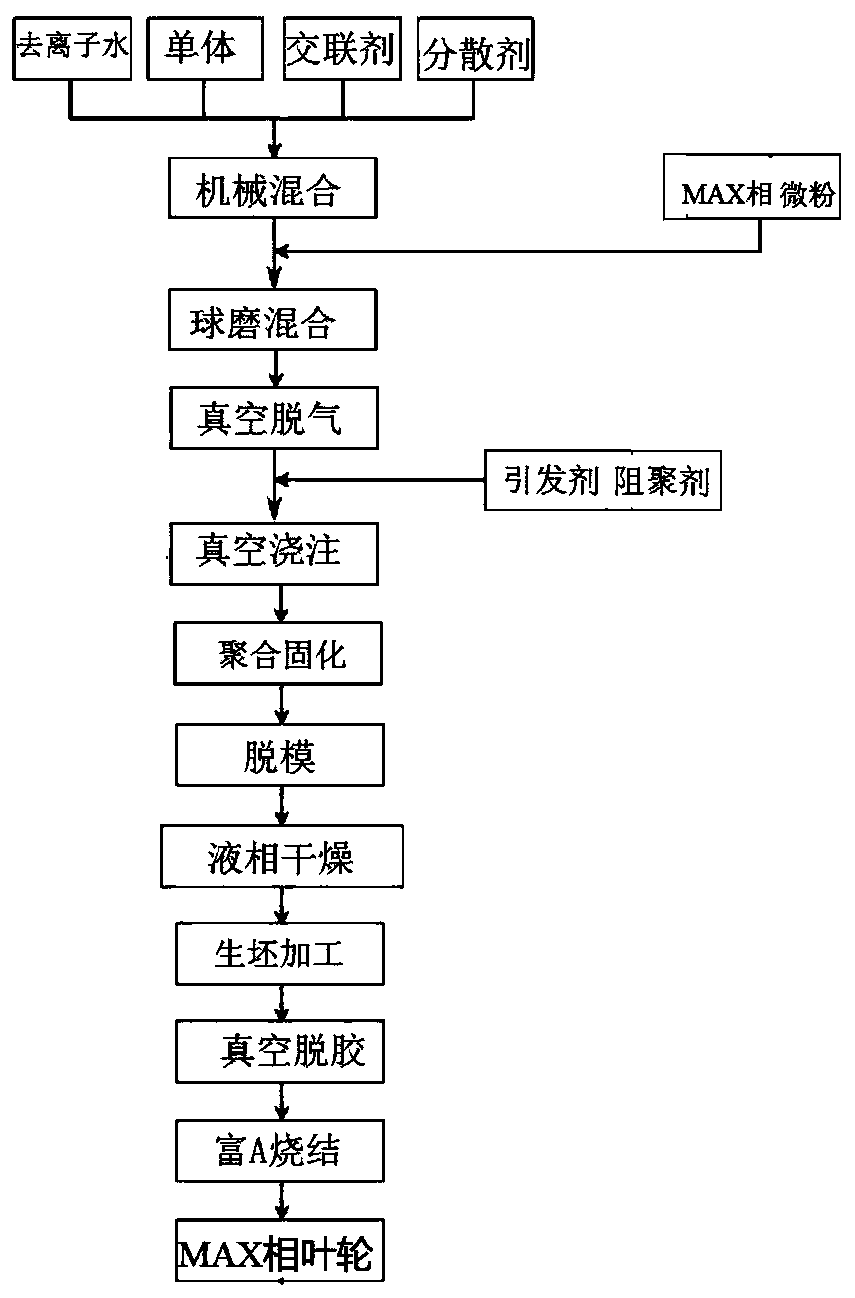

Preparation method of large size MAX phase ceramic impeller

ActiveCN110330339ASolve many technical problems in the preparation processSolve technical problemsNuclear powerSlurry

The invention provides a preparation method of a large size MAX phase ceramic impeller. The preparation method is capable of preparing the large size MAX phase ceramic impeller with complex shape characteristics. According to the preparation method, gel injection moulding technology is adopted, argon gas and A-enriched atmosphere are introduced as sintering protection atmosphere, and pressurelesssolid-phase sintering of MAX phase ceramic impeller is carried out. The preparation method comprises following steps: ceramic slurry preparation, mould injection, demoulding, drying, green compact processing, degumming, pressureless sintering, and polishing and refining. The preparation method is capable of solving difficult technological problems in the prior art that settlement is easily causedbecause of large MAX ceramic slurry density, and cracking and deformation are easily caused in drying and sintering process; and successive preparation of the large size MAX phase ceramic impeller isrealized at last. The large size MAX phase ceramic impeller possesses excellent corrosion resistance, irradiation resistance, wear resistance, oxidation resistance, and high temperature resistance, and can be widely used in the fields of nuclear power, chemistry, metallurgy, oil field, and thermal power.

Owner:UNIV OF SCI & TECH BEIJING

Fire-resistant steel and preparation method thereof

InactiveCN109680215AMeet service requirementsOptimizing industrial preparation processesRare-earth elementSulfur

The invention discloses fire-resistant steel and a preparation method thereof, and relates to the technical field of fire-resistant steel. According to the technical scheme mainly adopted, the fire-resistant steel comprises the following components including, by weight, 0.05-0.2% of carbon, 0-1.0% of silicon, 0-2.0% of manganese, 0.01-0.04% of aluminum, 0-0.005% of sulphur, 0-0.015% of phosphorus,50 ppm-500 ppm of rare earth and the balance Fe and inevitable impurities. The invention mainly provides the fire-resistant steel modified and optimized based on the rare earth element microalloyingprinciple and a preparation method thereof. While the fire-resistant steel is made to have a high-temperature service property, no Nb, Mo and V is added or the contents of the Nb, Mo and V are decreased, and the production cost of the fire-resistant steel is lowered.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com