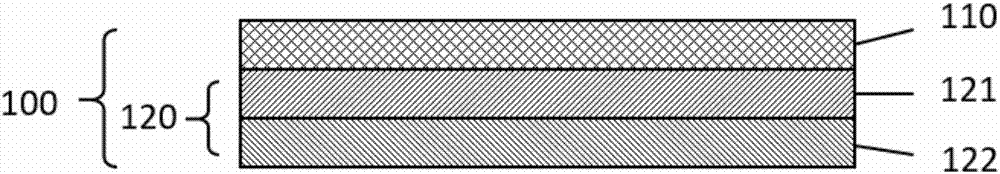

Photovoltaic transparent composite film, and preparation method and application thereof

A composite film, optically transparent technology, used in photovoltaic power generation, electrical components, circuits, etc., to achieve the effect of being beneficial to photoelectric conversion efficiency and power, excellent UV aging resistance, and high optical transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

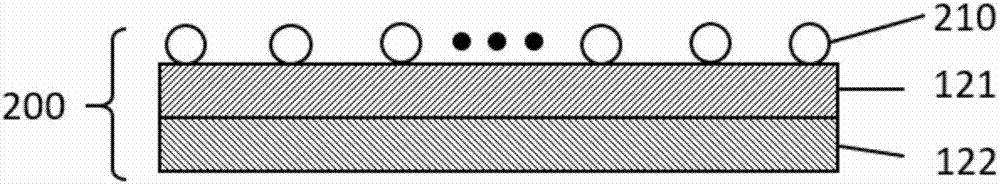

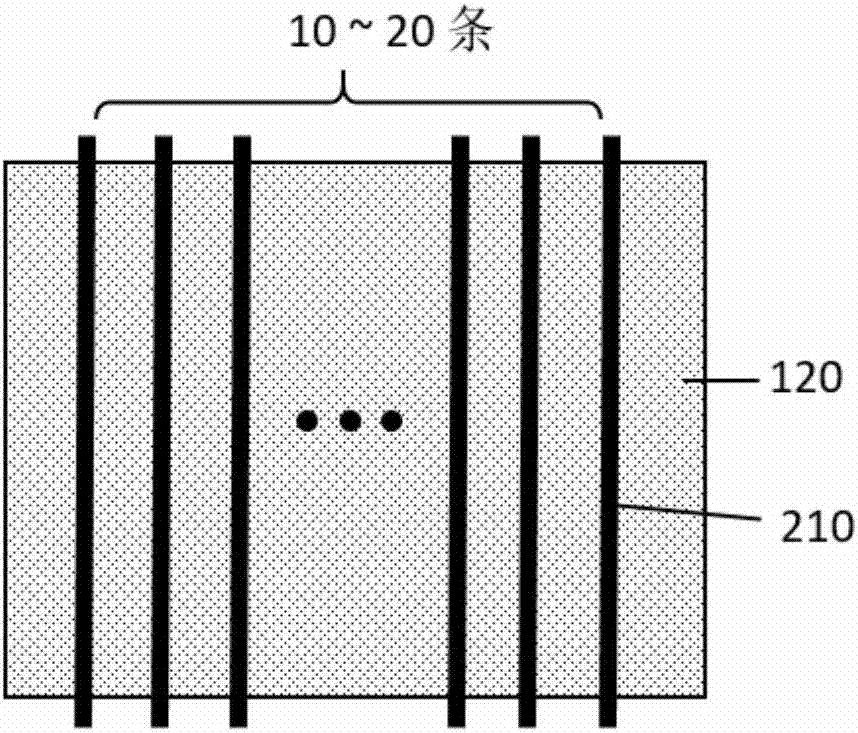

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: A transparent composite film bonding layer for photovoltaics, the raw material formula of the bonding layer includes the following raw materials by weight.

[0041]

[0042] In the above formula, the (meth)acrylate monomers are n-butyl acrylate, 2-hydroxyethyl acrylate and ethyl methacrylate in a weight ratio of 1:1:3. The diluent is toluene, the initiator is azobisisobutyronitrile, the coupling agent is γ-methacryloxypropyltrimethoxysilane, the antioxidant is selected antioxidant 1035, and the ultraviolet stabilizer is 2-( 2'-Hydroxy-5'-methylphenyl)benzotriazole, the crosslinking agent is isocyanate.

[0043] The preparation process includes the following steps:

[0044] 1. Mix (meth)acrylate hard monomer, soft monomer, and diluent in a certain proportion, add them into the stirring tank, stir and heat to 95°C, and react for 8 hours, during which a certain proportion of initiator is continuously dropped, Finally, an acrylic adhesive with a viscosity...

Embodiment 2

[0047] Embodiment 2: A transparent composite film bonding layer for photovoltaics, the raw material formula of the bonding layer includes the following raw materials by weight.

[0048]

[0049]

[0050] In the above formula, the (meth)acrylate monomers are ethyl acrylate and 2-hydroxypropyl methacrylate, and the weight ratio is 2:3. The diluent is butyl acetate, the initiator is azobisisoheptanonitrile, the coupling agent is 3-aminopropyltrimethoxysilane, the antioxidant is selected as antioxidant 1076, and the ultraviolet stabilizer is 2-hydroxy-4- Methoxybenzophenone, crosslinking agent is isocyanate.

[0051] The preparation process includes the following steps:

[0052] 1. Mix acrylate hard monomer, soft monomer and diluent in a certain proportion, add them into the stirring tank, stir and heat to 90°C, and react for 10 hours. 3000cps acrylic adhesive;

[0053] 2. Mix and stir the acrylate adhesive prepared in step 1 with a certain proportion (the proportion in t...

Embodiment 3

[0055] Embodiment 3: A transparent composite film bonding layer for photovoltaics, the raw material formula of the bonding layer includes the following raw materials by weight.

[0056]

[0057] In the above formula, the (meth)acrylate monomers are cyclohexyl acrylate, 2-hydroxyethyl acrylate and butyl methacrylate in a weight ratio of 2:1:1. The diluent is butanone, the initiator is dimethyl azobisisobutyrate, the coupling agent is γ-methacryloxypropyltrimethoxysilane, the antioxidant is antioxidant 1010, and UV stabilizer It is 2-hydroxy-4-methoxybenzophenone, the crosslinking agent is isocyanate, and the light conversion agent is SrAl 2 o 4 : Eu 2+ , Dy 3+ , in the form of nanoparticles with a particle size of 50nm.

[0058] The preparation process includes the following steps:

[0059] 1. Mix acrylate hard monomer, soft monomer and diluent in a certain proportion, add them into the stirring tank, stir and heat to 90°C, and react for 8 hours. 5000cps acrylic adhesi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com