Patents

Literature

143results about How to "Good UV aging resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

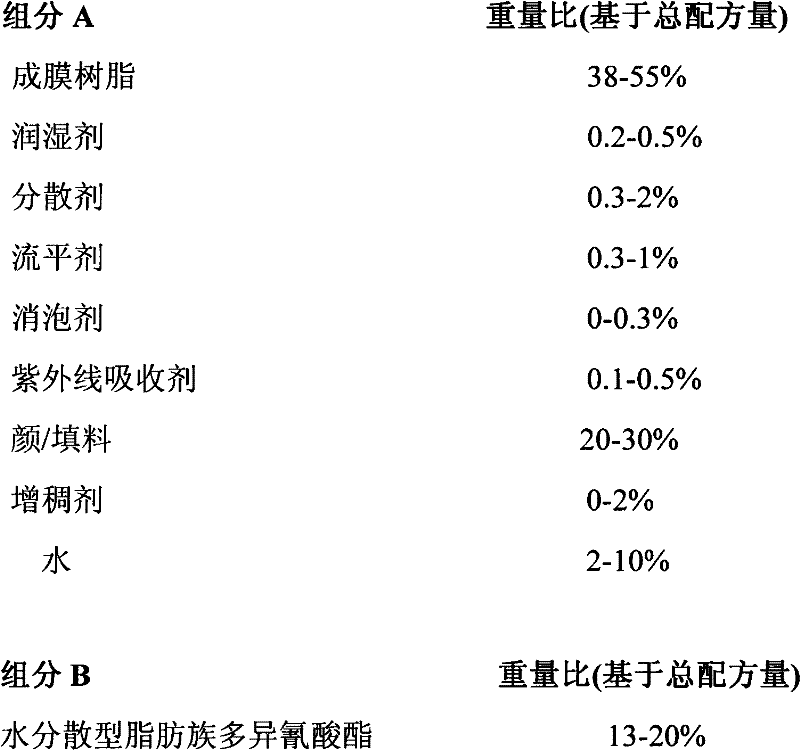

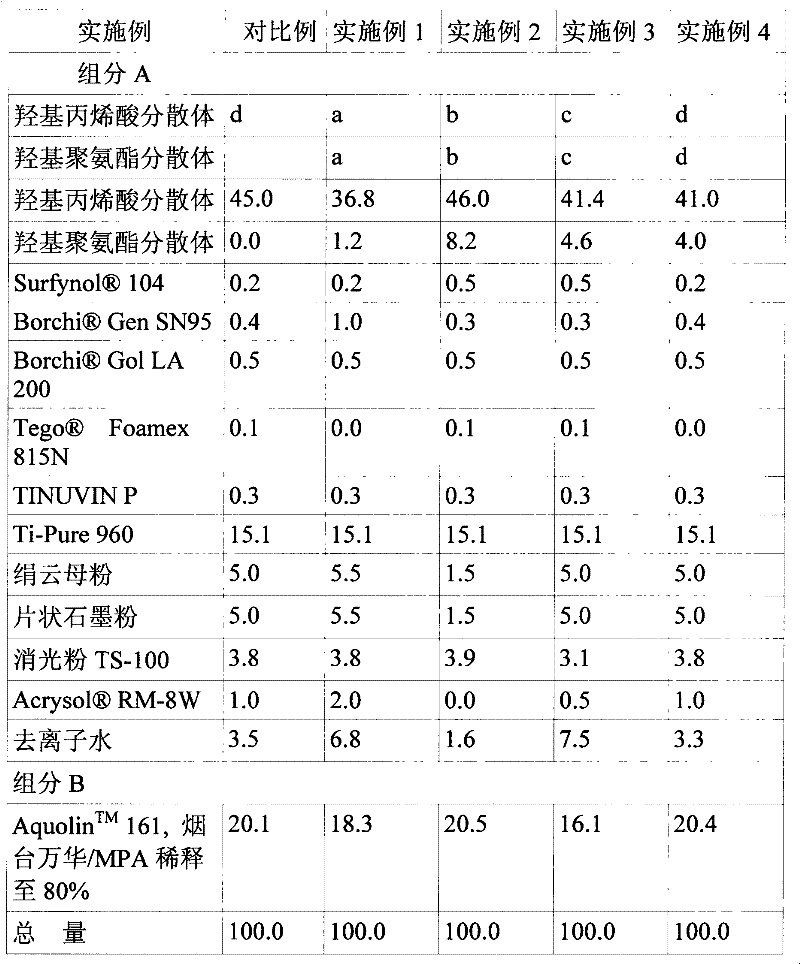

Water-based coating and preparation method and application thereof

ActiveCN102533078AGood UV aging resistanceImprove wear resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedPolyurethane dispersion

The invention discloses a water-based coating and a preparation method and an application thereof. The water-based coating belongs to a water-based two-component polyurethane coating for a wind turbine blade, and can be taken as priming paint and finishing paint. Film forming resin consists of a hydroxyl acrylic acid dispersion and a hydroxyl polyurethane dispersion; due to the adoption of a acrylic acid structure and a polyurethane structure, excellent ultraviolet ray resistance and high wear resistance can be provided respectively; and water-dispersible aliphatic diisocyanate is taken as a curing agent. The coating has excellent adhesive ability on the wind turbine blade, has excellent tolerance, and can be used for effectively prolonging the service life of wind power equipment.

Owner:WANHUA CHEM GUANGDONG +2

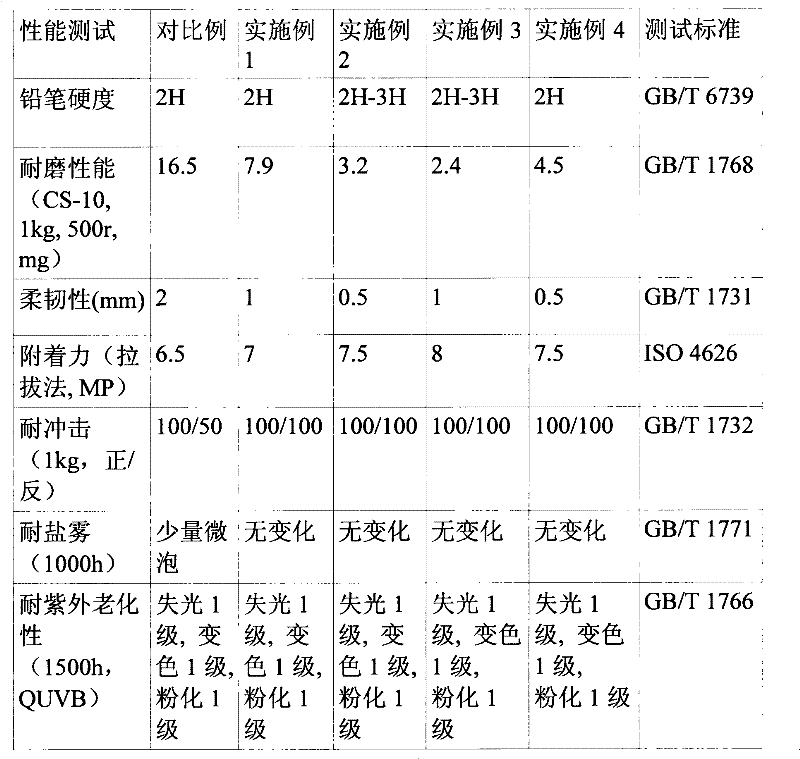

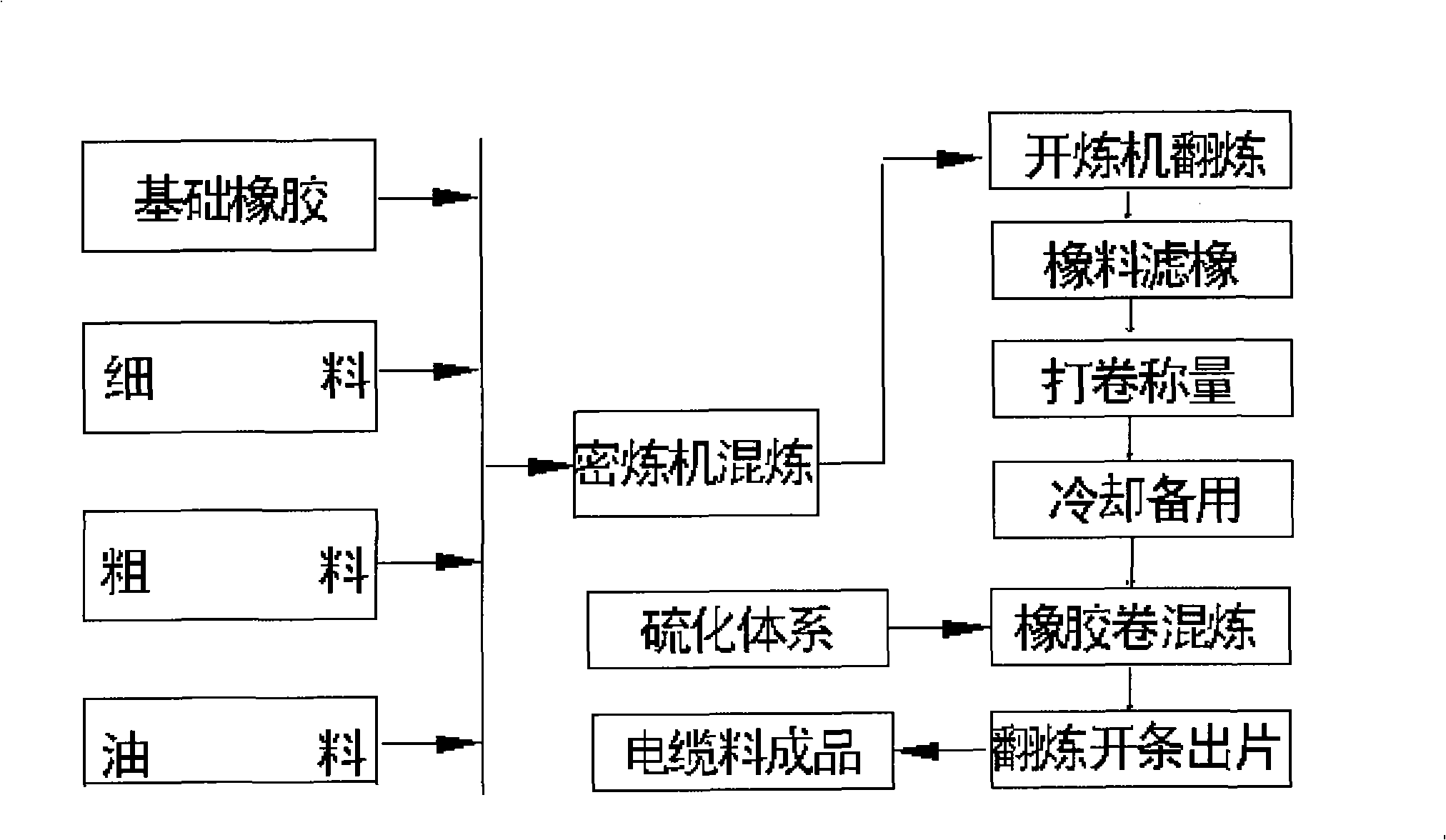

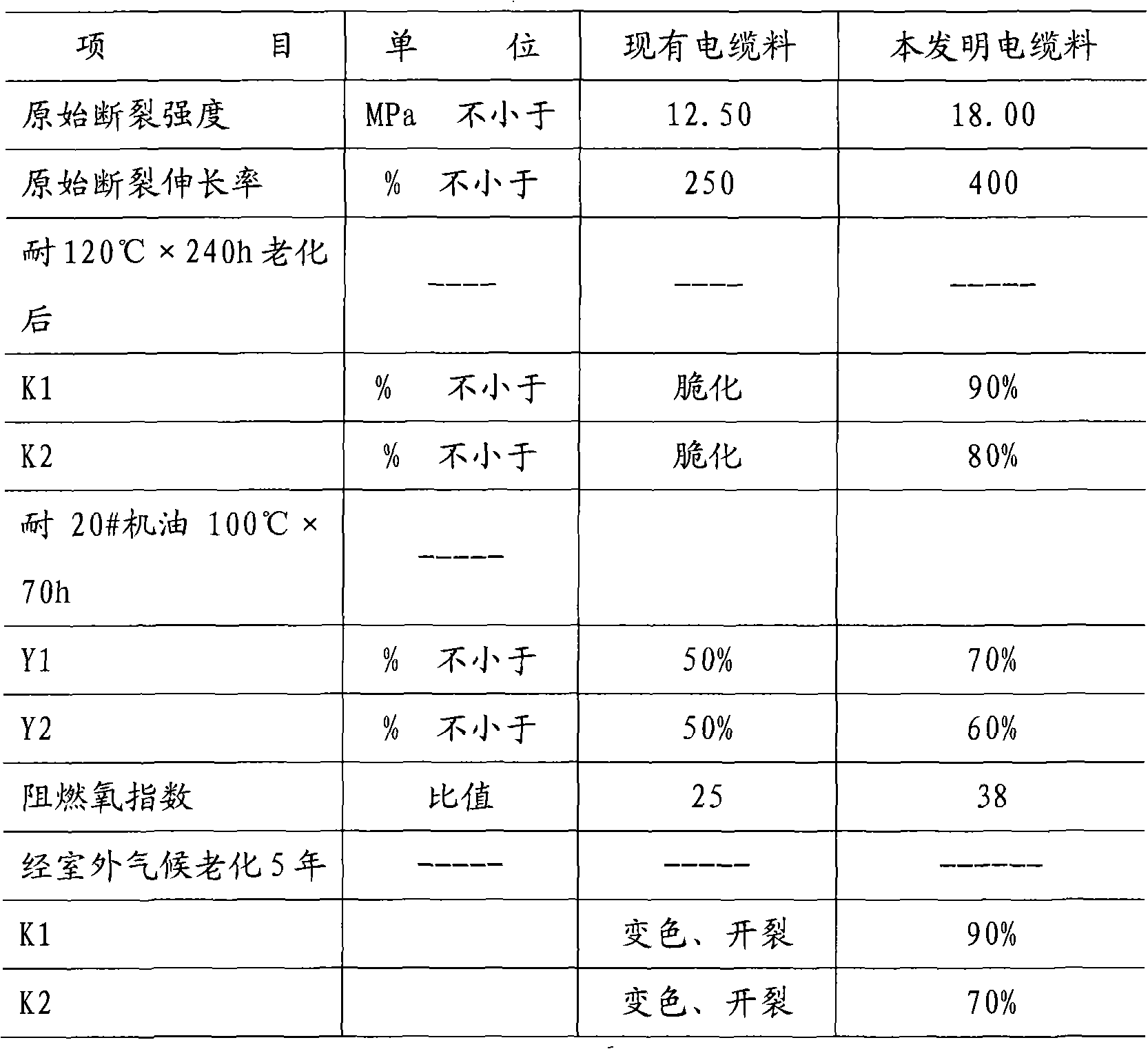

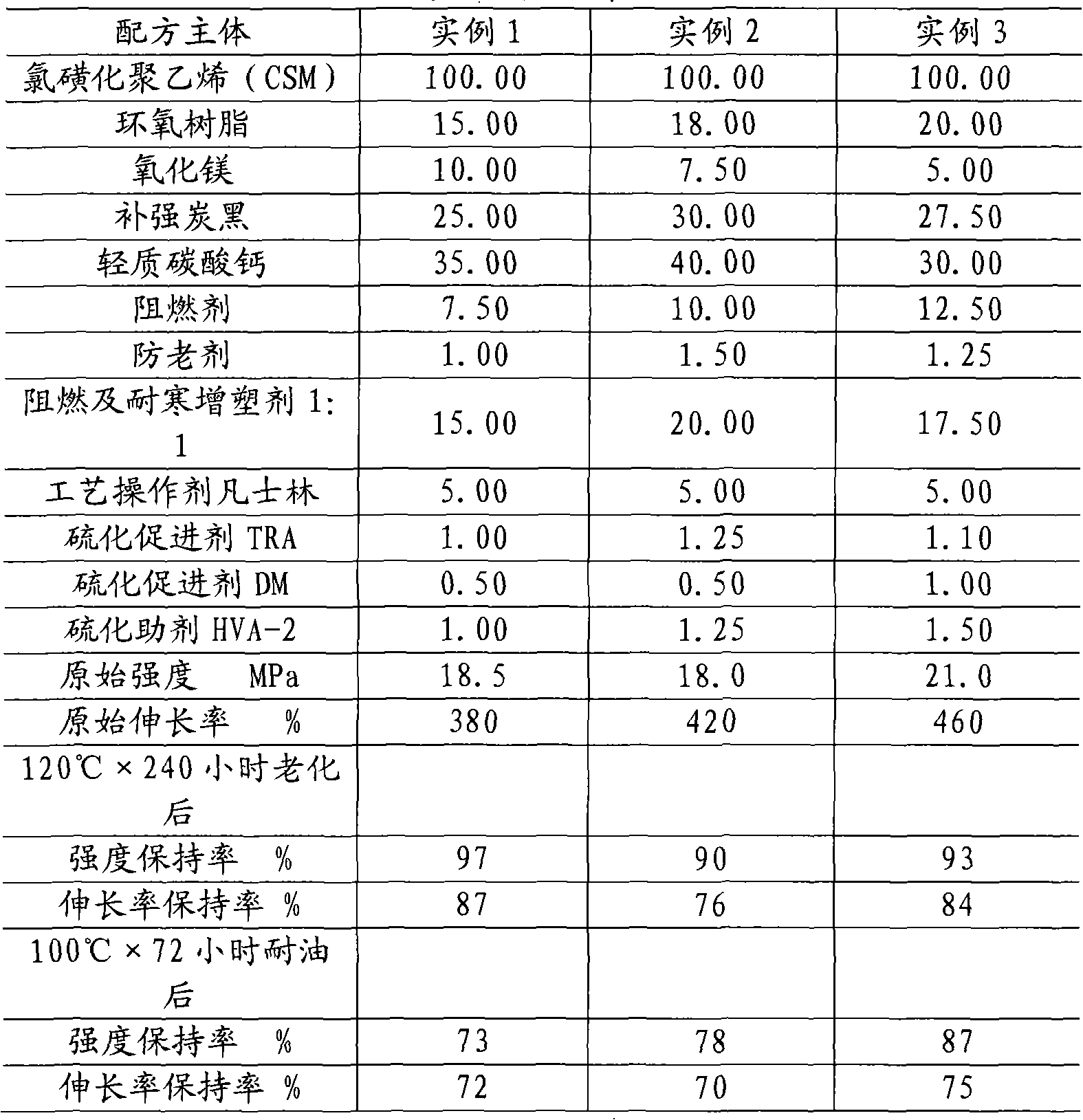

External rubber sleeve material of cable for wind power generation

InactiveCN101538391AEasy to operateImprove water resistanceInsulated cablesInsulated conductorsEpoxyVulcanization

The invention discloses an external rubber sleeve material of a cable used for wind power generation, comprising the following components by weight parts: 100.00 parts of chlorosulfonated polyethylene rubber, 15.00-20.00 parts of vulcanizing agent epoxy resin, 5.00-10.00 parts of magnesium oxide acid acceptor, 1.00-1.50 parts of vulcanization aid, 0.20-1.50 parts of vulcanization accelerator, 10.00-15.00 parts of fire-retardant plasticizer, 5.00-10.00 parts of cold resistant plasticizer, 30.00-40.00 parts of reinforcing agent, 40.00-50.00 parts of filling agent, 0.50-2.00 parts of anti-ageing agent, 0.50-2.00 parts of process operation agent, and 10.00-15.00 parts of flame retardant. The external rubber sleeve material of the cable used for wind power generation has the greatest advantages of extremely high physical and mechanical performance, excellent oil resistance and climate resistance, extremely softness and flame retarding, and the like.

Owner:ANHUI ZONGHENG HI TECH CABLE +1

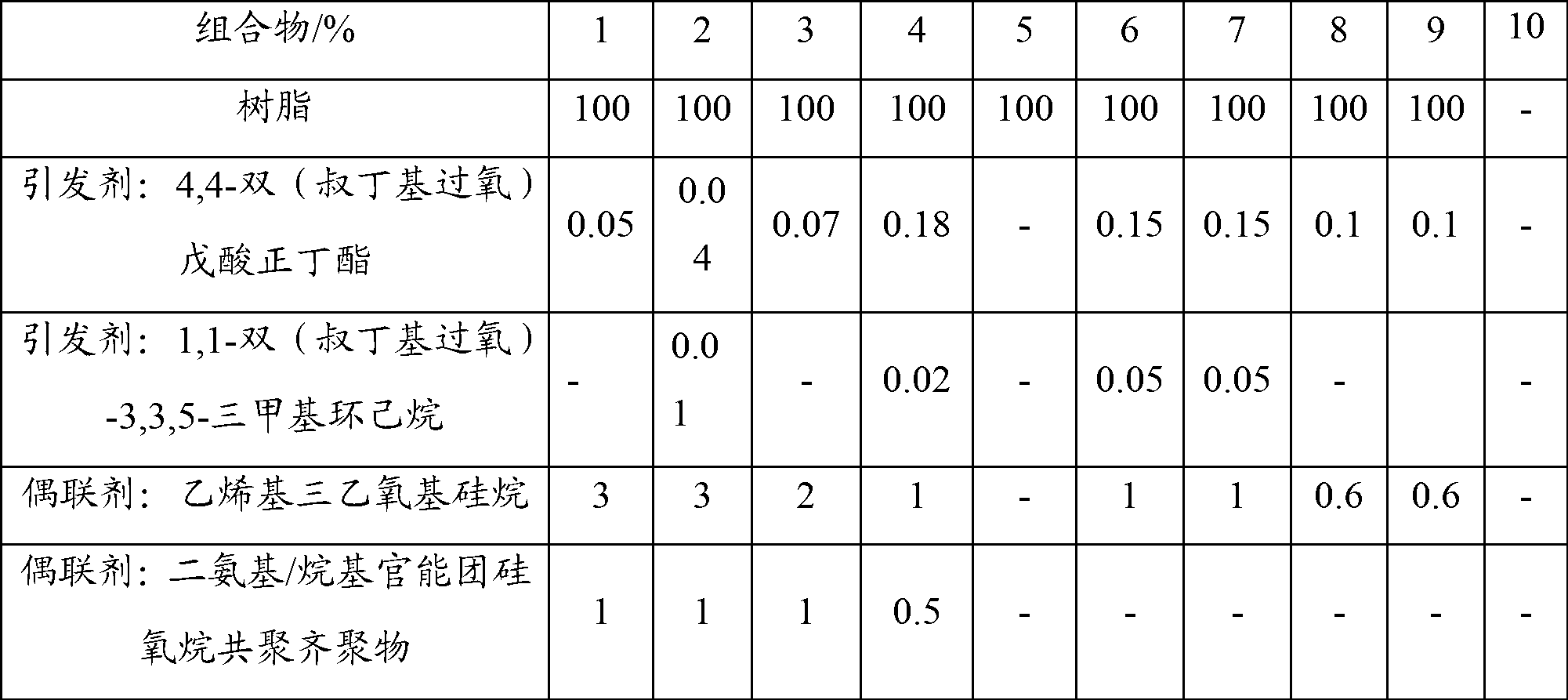

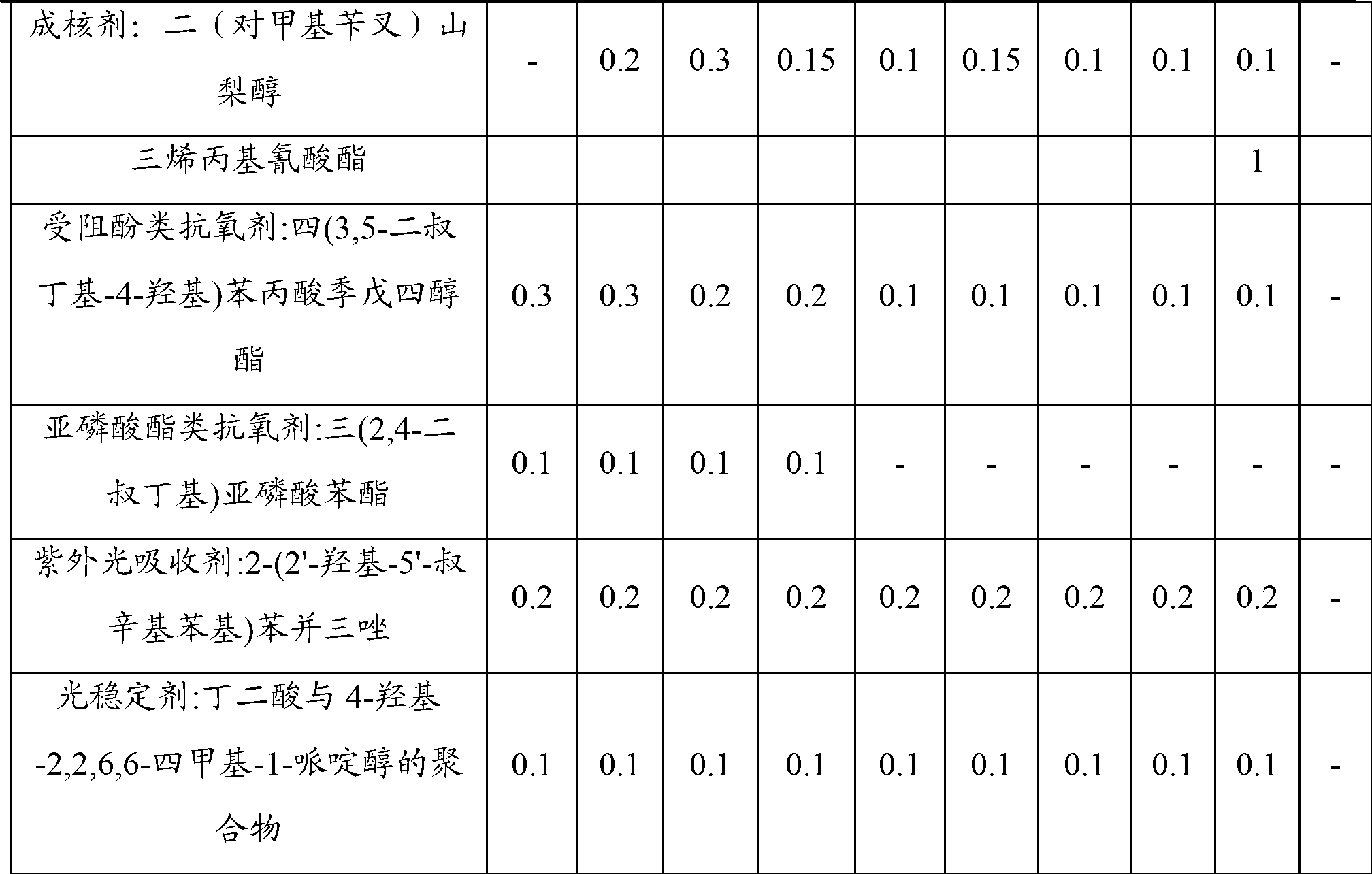

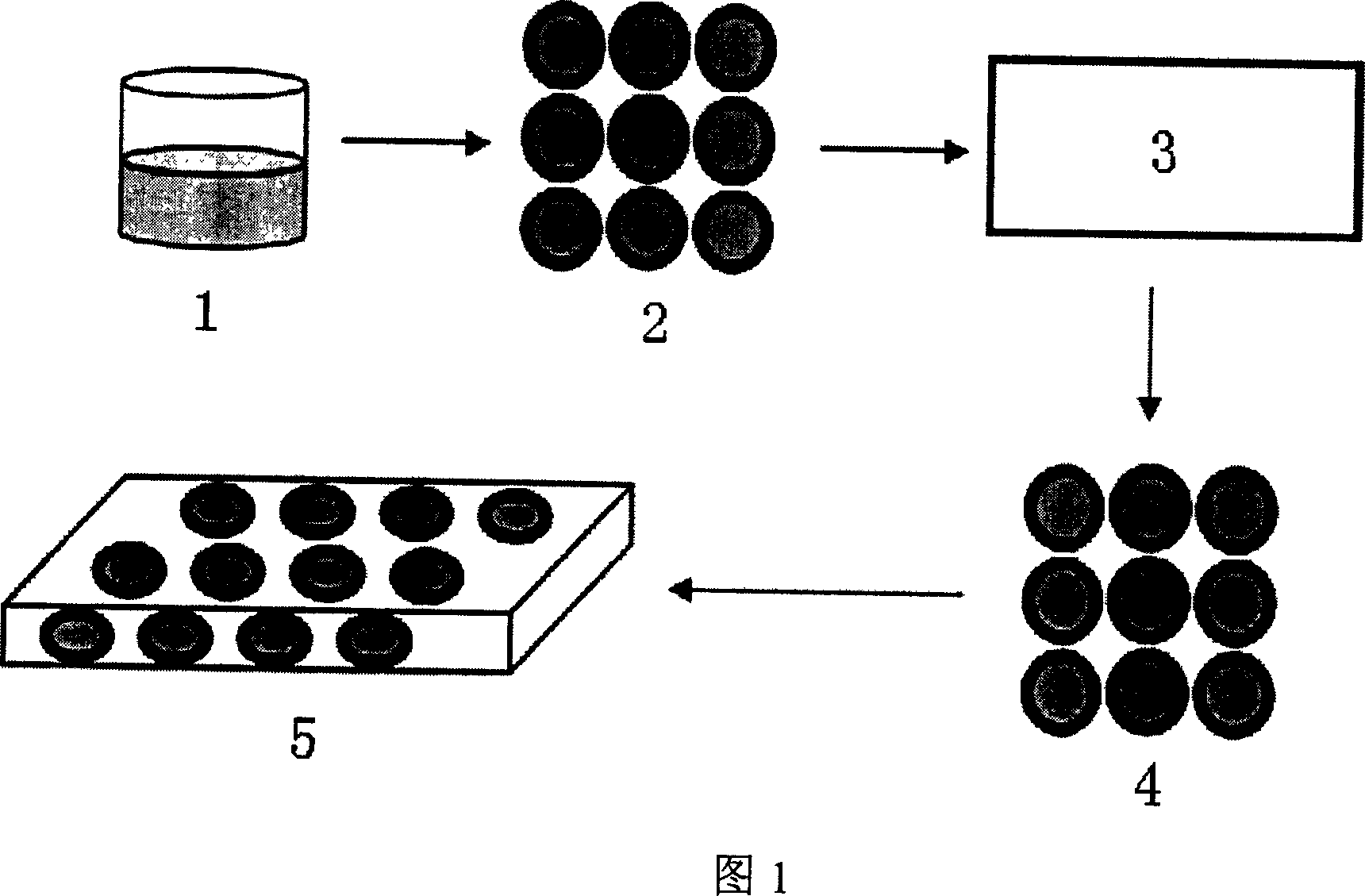

Polyolefin packaging adhesive film, preparation method thereof and application thereof

ActiveCN103059753AGood optical performanceGood adhesionFilm/foil adhesivesPhotovoltaic energy generationVapor barrierPolymer science

The invention discloses polyolefin packaging adhesive film, a preparation method of the polyolefin packaging adhesive film and application of the polyolefin packaging adhesive film. The packaging adhesive film is prepared, by weight, from the components of polymer resin including 1-60% of polyolefin X and 40-99% of polyolefin Y, and processing agent with the use level 0.1-5% of the weight of the polymer resin. A composition of the polyolefin packaging adhesive film has excellent optical performance and adhesive property of conventional ethylene-vinyl acetate copolymer (EVA) packaging adhesive film, cross bonding is not required, and the composition has thermoplasticity which can not be achieved by the conventional EVA packaging adhesive film, and the recycle of an assembly is favorable. Further, the composition has better ultraviolet aging resistance performance, water and vapor barrier performance and electrical performance than the conventional EVA packaging adhesive film.

Owner:JIANGSU LUSHAN PHOTOVOLTAIC TECH +1

Transparent epoxy nano composite material and its preparation method and use

InactiveCN101077923AOvercoming Light Scattering PhenomenonHigh light transmittanceOther chemical processesSilica particleUltraviolet

The present invention relates to one kind of transparent composite epoxy material and its preparation process and use. The transparent composite epoxy material has nanometer composite inorganic stuffing comprising nanometer silica particle serving as core, titania serving as shell coating the silica particle core and outer silica layer coating the titania shell. The transparent composite epoxy material possesses high transparency, excellent ultraviolet ray shielding effect, high ultraviolet ray tolerance, low heat expansion coefficient, high heat conductivity and other advantages, and is suitable for use in pacing LED and other light emitting semiconductor devices.

Owner:广东中科顺威新材料科技发展有限公司

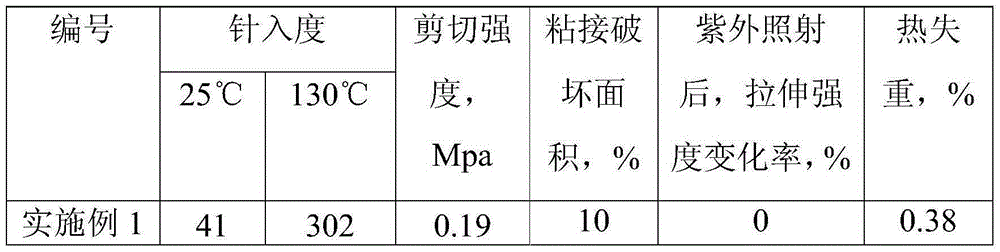

Butyl hot melt adhesive and preparation method thereof

ActiveCN105385388ALow water vapor transmission rateGood UV aging resistanceMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesAlloyButyl rubber

The invention discloses a butyl hot melt adhesive and a preparation method thereof. The preparation method comprises the following steps that in a high temperature kneader, the temperature is set at 130 DEG C-150 DEG C, 180-600 parts by weight of polyisobutene, 100 parts by weight of butyl rubber and 30-120 parts by weight of tackifying resin are firstly added into the kneader, the temperature is increased to 110 DEG C-130 DEG C, and stirring is performed until the materials are uniform; 450-1000 parts by weight of packing, 0-7 parts by weight of an anti-aging agent and 1-25 parts by weight of a softening agent are sequentially added, vacuumizing and stirring are performed for 0.5-2.5 hours, 20-100 parts by weight of the retained polyisobutene is added, vacuumizing and continuous stirring are performed for 0.5-2 hours, and the butyl hot melt adhesive is prepared. The butyl hot melt adhesive prepared through the method is excellent in anti-ultraviolet property and easy to construct, has the excellent adhesive property on hollow glass materials and aluminum alloy strips and can not only meet usage of hollow glass, but also be applied to the fields such as photovoltaic backboard adhesion.

Owner:CHENGDU GUIBAO SCI & TECH

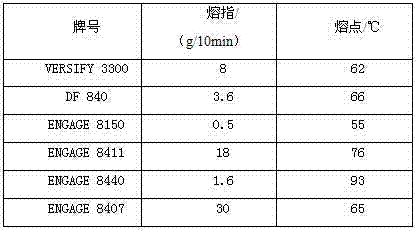

Polyolefin packaging adhesive film for photovoltaic module

InactiveCN104263285AOptimal optical properties and adhesive propertiesGood UV aging resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesPolyolefinDamp heat

The invention discloses a polyolefin packaging adhesive film for a photovoltaic module. The polyolefin packaging adhesive film comprises the components in parts by mass: 100 parts of polyolefin, 0.1-1 part of cross-linking agent, 0.1-3 parts of coupling agents and 0.01-1 part of antiaging agent, wherein polyolefin is polyolefin of which melting index is 0.5-18g / 10min and a melting point is between 55 and 93 DEG C. The polyolefin packaging adhesive film is a micro-crosslinking type polyolefin adhesive film, and the problems of apparent problems such as bubbles and poor thermal creeping resistance of the polyolefin adhesive film during packaging can be effectively solved; the polyolefin packaging adhesive film is high in optical performance, adhesion performance, ultraviolet-aging resistance and damp-heat aging resistance, is easy for control on production, and can completely meet the requirement of the lamination process of the existing photovoltaic modules.

Owner:乐凯胶片股份有限公司

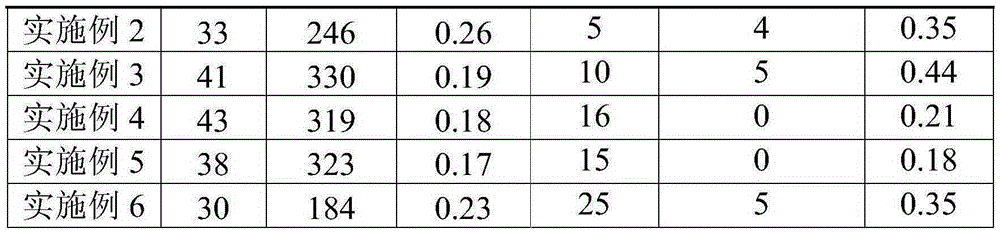

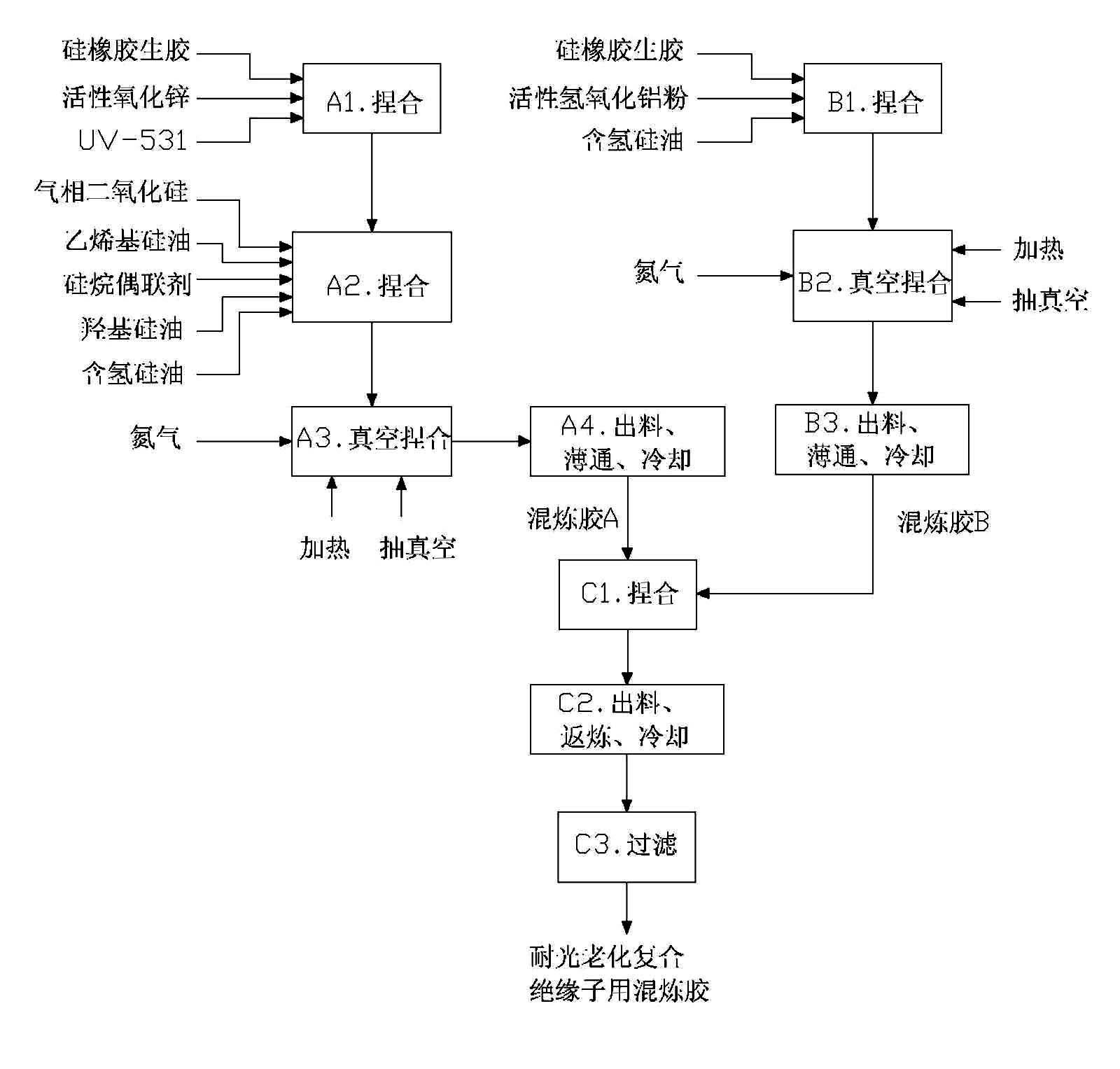

Light ageing resistant blend for composite insulator and preparation method thereof

The invention relates to a technology for preparing a blend for a composite insulator, and provides a light ageing resistant blend for a composite insulator and a preparation method thereof. The light ageing resistant blend is prepared from the following raw materials in part by weight: 100 parts of raw silicon rubber, 3 to 10 parts of activated zinc oxide, 18 to 40 parts of modified fumed silica, 0 to 5 parts of vinyl silicone oil, 1 to 10 parts of silane coupling agent, 1 to 6 parts of hydroxy silicone oil, 90 to 180 parts of active aluminum hydroxide powder, 0.2 to 2 parts of hydro silicon oil and 0.1 to 1 part of ultraviolet absorber (UV-531), and can be prepared by the conventional blend preparation process. The invention also provides a new preparation process, which comprises the following steps of: preparing a blend A and a blend B; and kneading, recycling, cooling and filtering the blend A and the blend B to obtain the light ageing resistant blend for the composite insulator. The blend has good ultraviolet ageing resistance, and is suitable for composite insulators in high altitude areas.

Owner:广州麦科凌电力装备有限公司 +1

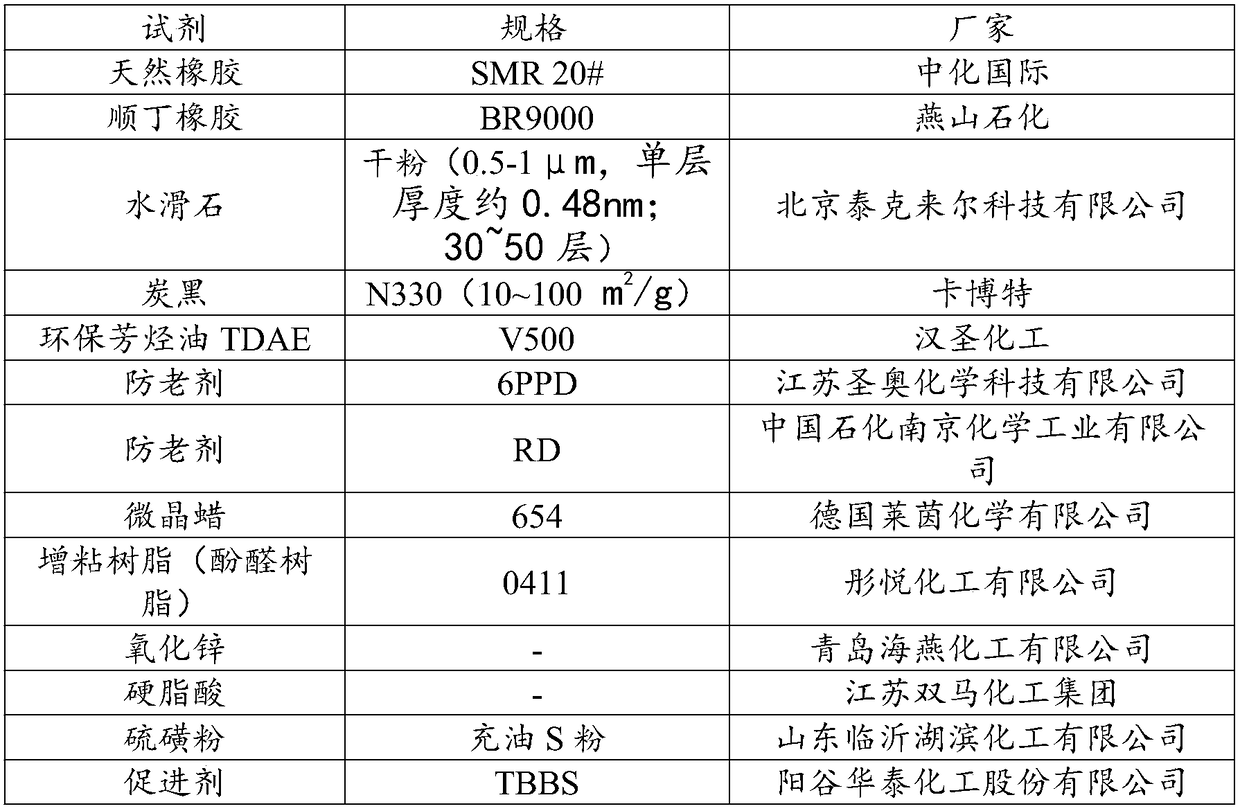

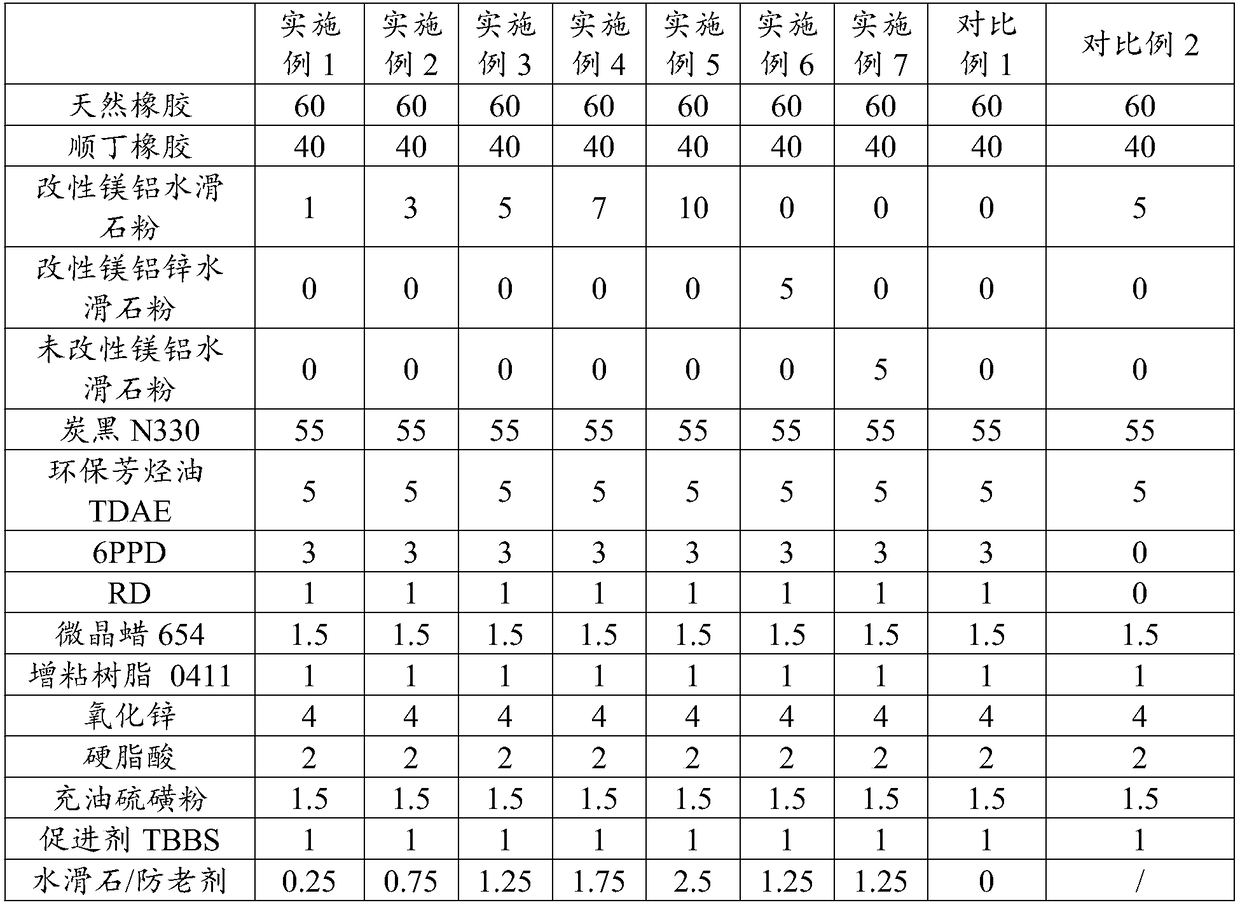

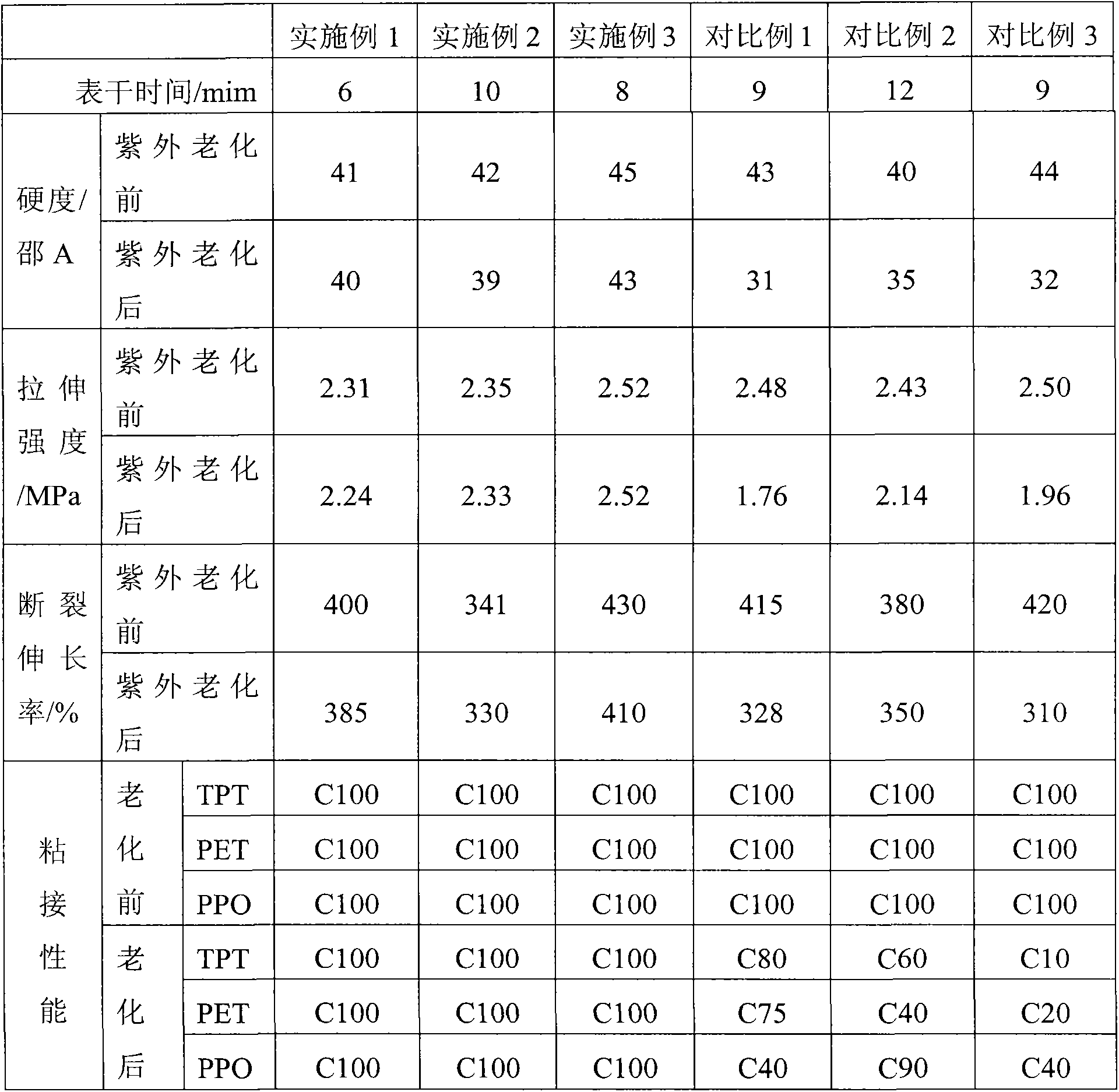

Tire sidewall rubber composite material and preparation method thereof

ActiveCN108239306AWarranty requirementsExcellent heat and oxygen aging resistanceSpecial tyresStearic acidOxygen

The invention relates to a composite material for tires, and in particular relates to a tire sidewall rubber composite material. The material comprises 100 parts by weight of rubber, by weight of rubber, 1-10 parts by weight of hydrotalcite, 40-70 parts by weight of carbon black, 4.0-8.0 parts by weight of environment-friendly aromatic hydrocarbon oil, 3.0-9.0 parts by weight of an anti-aging agent, 1.0-4.0 parts by weight of wax, 0.5-3.0 parts by weight of tackifying resin, 1.5-5.0 parts by weight of zinc oxide, 1.0-3.5 parts by weight of stearic acid, 1.0-3.0 parts by weight of sulfur powderand 0.5-2.0 parts by weight of an accelerant. A preparation method of the composite material comprises the following steps: plasticating rubber in an internal mixer, adding other components except the sulfur powder and the accelerator for mixing, lifting a top bolt at the temperature of 120-125 DEG C, performing dumping at 150-160 DEG C to obtain the mixed rubber, mixing the mixed rubber, the sulfur powder and the accelerator in an open mill, rolling for 4-5 times, and conducting thin-pass for 5-8 times to obtain a product. The composite material disclosed by the invention not only meets thebasic mechanical property requirements of the sidewall rubber, but also obviously improves the heat oxygen aging resistance and the ultraviolet aging resistance of the sidewall rubber and the servicelife of the tire can be effectively prolonged.

Owner:SHANDONG LINGLONG TIRE

Ageing resistant type solar photovoltaic component sealing material and preparation method thereof

ActiveCN104277759AImprove anti-agingSmall mechanical propertiesNon-macromolecular adhesive additivesOther chemical processesUltraviolet lightsSolar cell

The invention discloses an ageing resistant type solar photovoltaic component sealing material and a preparation method thereof. The ageing resistant type solar photovoltaic component sealing material comprises the following components in parts by weight: 100 parts of poly organic siloxane, 5-20 parts of a plasticizer, 50-150 parts of a filler, 0.2-5 parts of a water absorbent, 1-10 parts of paste containing an ultraviolet light absorber, 1-15 parts of a crosslinking agent, 0.1-5 parts of a viscosity thickening agent and 0.1-1 part of a catalyst. The ageing resistant type solar photovoltaic component sealing material has the advantages that the paste containing the ultraviolet light absorber is added in the components, so that the obtained product is reduced by less than 5% in mechanical property after an ultraviolet aging test is carried out, has good bonding force with an aluminium frame of a photovoltaic cell and is non-corrosive to an EVA (ethylene vinyl acetate copolymer) adhesive film and a battery circuit; and the provided preparation method is simple in technology, equipment requirement is not harsh, and the technical effects of good ultraviolet ageing resistance and high curing speed of a one-component solar cell module sealant are realized.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

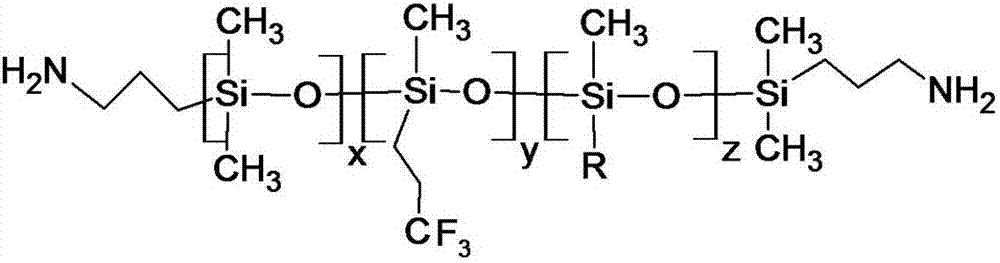

Fluorosilicate self-cleaning glass nanophase material and producing method thereof

The invention discloses a silicon fluoride self-cleaning glass nano-material, which is composed of solvent and active ingredients; the active ingredients are fluorinated modified silicone nano-particles, and the reaction raw materials comprise ortho-silicon ester and fluorine modified alkyl silane, with the ratio volume and dosage reaching 1.5-3:0.15-1.8. The invention also discloses a manufacturing method for the silicon fluoride self-cleaning glass nano-material, comprising two steps: synthesizing the surface modification of silica nano-particles, silica nano-particles; the ratio between volume and dosage for each added reactant is as follows: solvent: water: ortho-silicon ester: fluorine modified alkyl silane equals to 100: 1.5-3: 1.5-3: 0.15-1.8. The invention has simple production process, stable product performance, higher storage stability, excellent chemical properties, low surface energy and good tolerance against pollution, which is used for glass surface treatment; the contact angle between water and coating is greater than 110 degrees.

Owner:GUANGZHOU BAIYUN CHEM IND

Fluoro resin/acrylic ester mixed emulsion and method for preparation thereof

The present invention discloses one kind of mixed fluororesin / acrylate emulsion and its preparation process, and solves the technological problems in mixing said two kinds of resin. The emulsion of the present invention is prepared with fluororesin 1-20 wt%, C1-C10 alkyl acrlyate 30-60 wt%, C1-C10 methyl alkyl acrlyate 20-40 wt% and cross-linking monomer 1-10 wt%, and through in-situ polymerization or interpenetrating polymerization. The emulsion of the present invention has greatly raised water resistance, ageing resistance and antifouling property, and may be used widely in paint, adhesive, textile assistant and other fields. The present invention has simple preparation process and low cost, and fluororesin adding amount as low as 1-12 wt% may results in obvious effect.

Owner:NANJING UNIV OF TECH

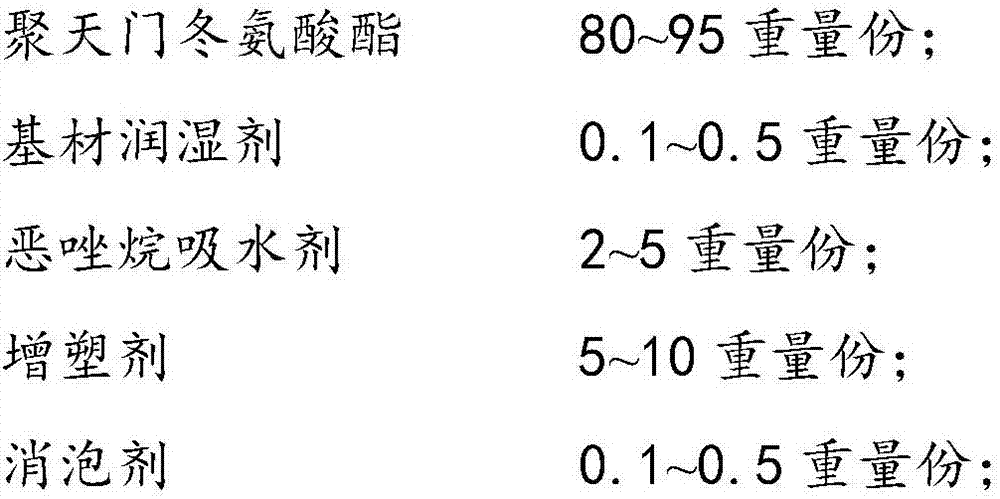

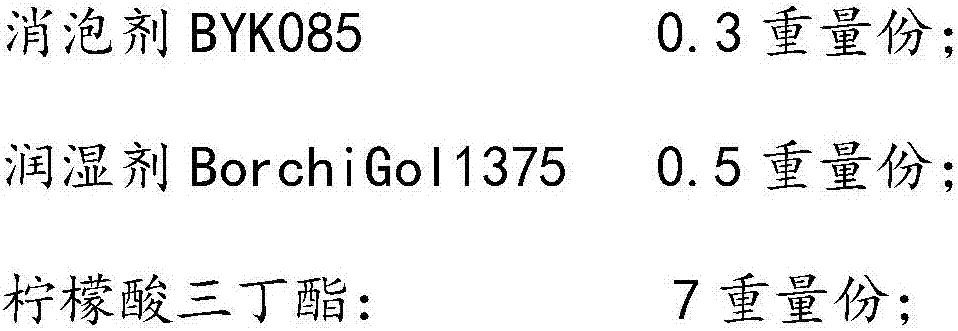

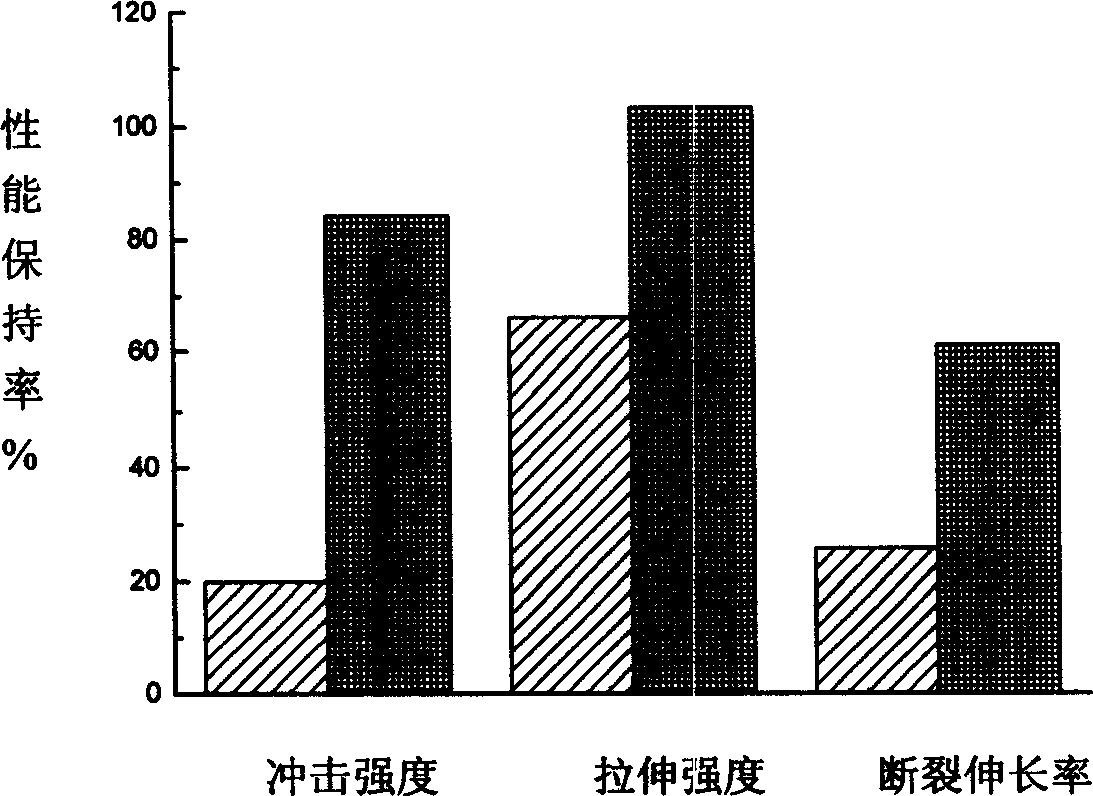

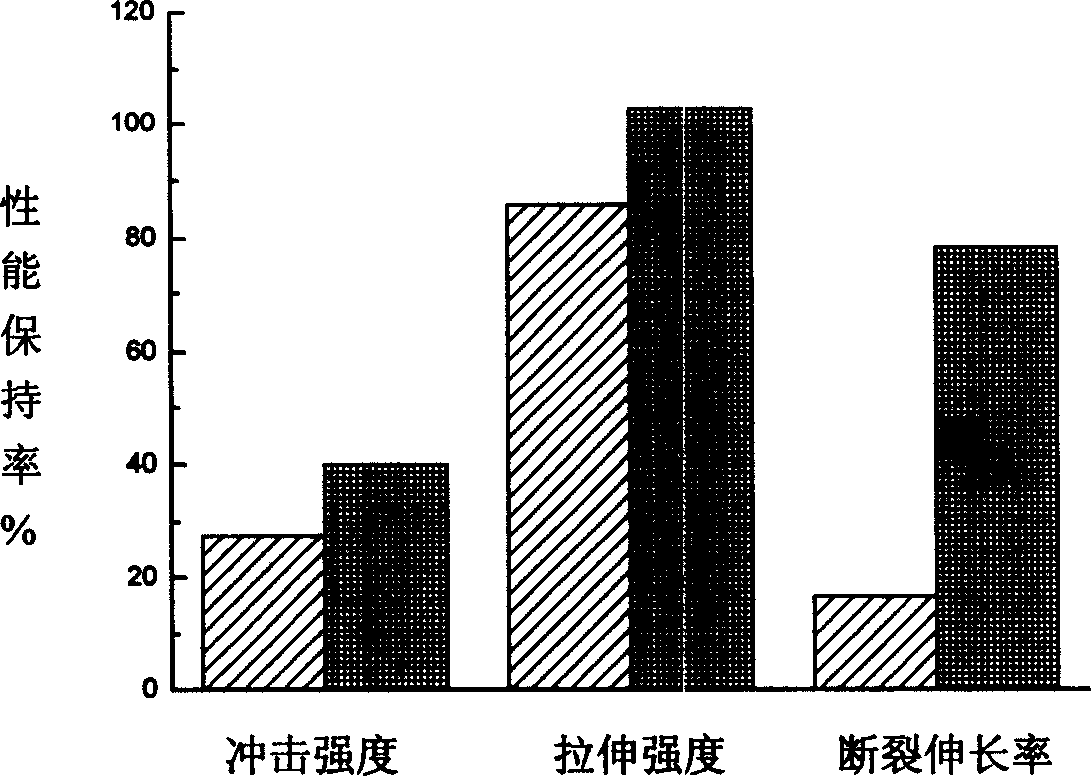

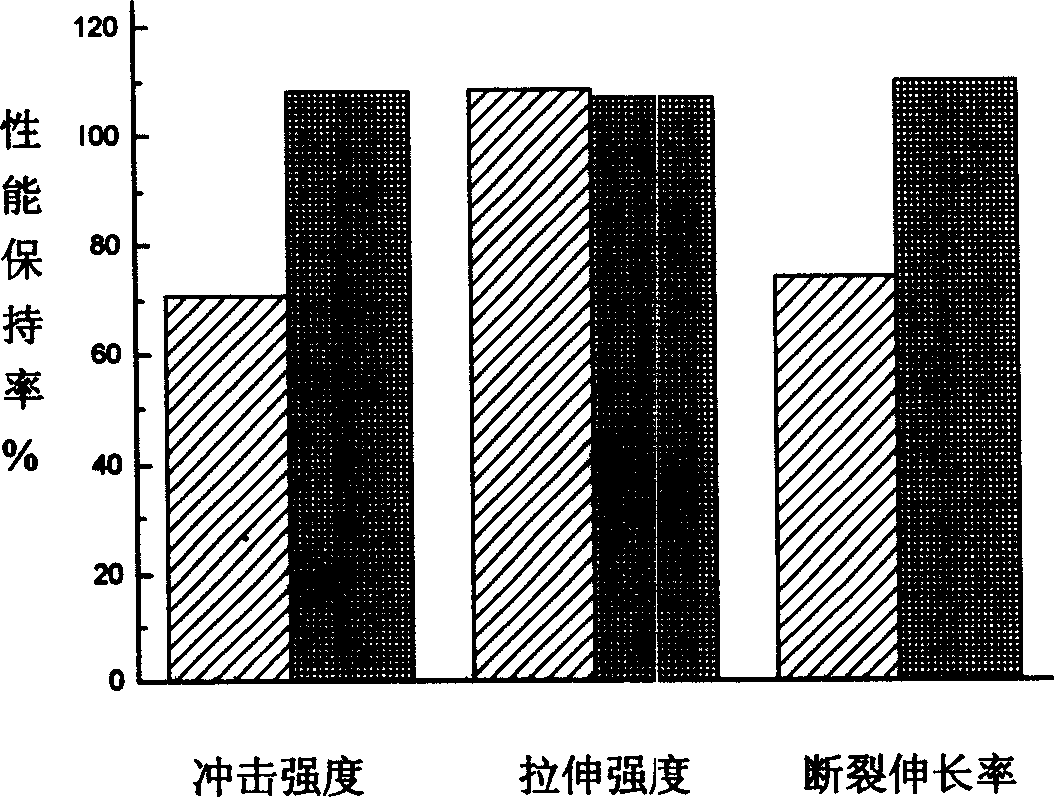

Bicomponent carbamide polyaspartate hard adhesive and use method and application thereof

ActiveCN107216842ANo toxicityStrong construction operabilityPolyureas/polyurethane adhesivesAdhesivePlasticizer

The invention belongs to the field of preparation of adhesives and relates to a bicomponent carbamide polyaspartate hard adhesive and a use method and application thereof. The adhesive is prepared from a main agent, i.e., a component A and a curing agent, i.e., a component B, wherein the component A is prepared from the ingredients in parts by weight: 80-95 parts of polyaspartate, 0.1-0.5 part of substrate humectant, 2-5 parts of oxazolidine water absorbent, 5-10 parts of plasticizer and 0.1-0.5 part of antifoamer; the component B and the component A are equal in equivalent proportioning ratio; the curing agent is prepared from an HDI trimer and a hydroxyl resin modified curing agent which are in the weight ratio of (10 to 30): (70 to 90). According to the bicomponent carbamide polyaspartate hard adhesive and the use method and application thereof, asphalt substrates and inorganic antiskidding aggregates can be excellently bound, and meanwhile, the problem that the existing polyurethane and epoxy materials are poor in ultraviolet aging resistance is solved; the bicomponent carbamide polyaspartate hard adhesive has good ultraviolet aging resistance; meanwhile, aspartate resin and this kind of curing agents are relatively high in curing rate, so that sufficient operating time and fast curing are ensured, and problems, temporary closure and opening of roads are solved.

Owner:深圳市飞扬特化新材料有限公司

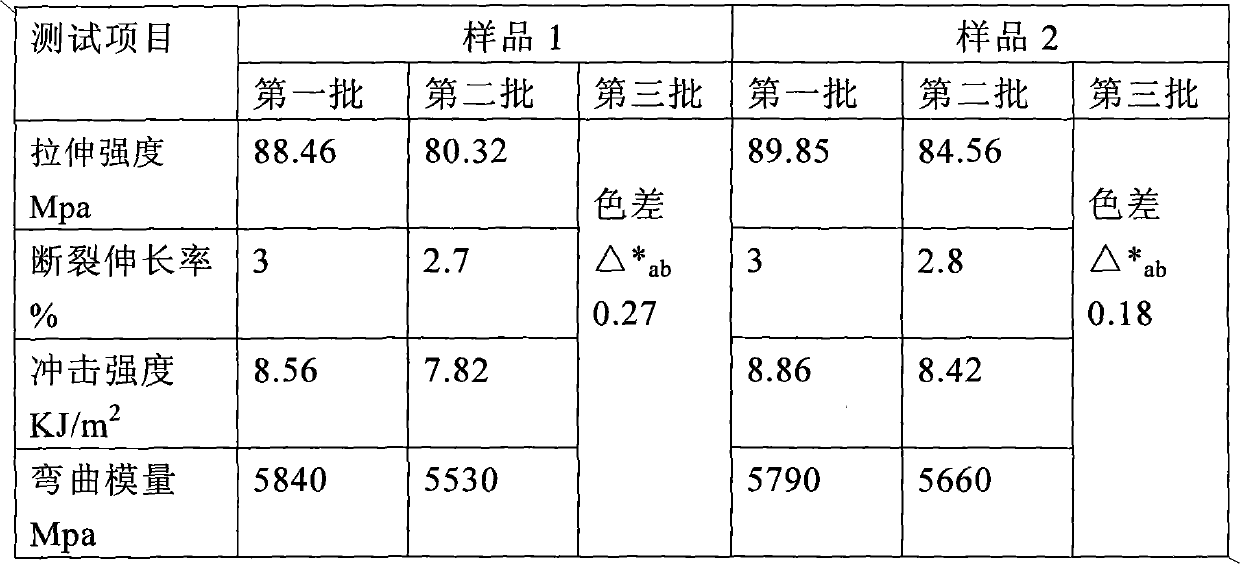

Ultraviolet aging resisting fiber-reinforced polymer base composite

The invention relates to an ultraviolet aging resisting fiber-reinforced polymer base composite which comprises the following raw materials in parts by weight: 0.1-10 parts of a compound ultraviolet aging resisting agent, 40-90 parts of matrix resin, 5-60 parts of reinforced fiber and 3-30 parts of a curing agent and an accelerating agent together. Through the addition of the compound ultraviolet aging resisting agent and the reinforced fiber, the ultraviolet aging resisting fiber-reinforced polymer base composite has good ultraviolet aging resisting performance and excellent mechanical performance, can be used for manufacturing outdoor large-sized composite products, and can effectively improve the weather resistance of the products and prolong the service life of the products; when the composite is irradiated under ultraviolet rays for 1000 h, the falling range of the mechanical strength is less than 3%.

Owner:孙仁华

Weatherability type polyformaldehyde material and its preparation method

An anti-weathering polyoxymethylene material is prepared from atoleine and polyoxymethylene through proportioning, surface wetting, adding inorganic particles, optical stabilizer and thermooxidative stabilizer, fusing, pugging, extruding out for granulating, and injection moulding. Its advantage is high resistance to weathering, UV, thermooxidizing and hot water.

Owner:SICHUAN UNIV +1

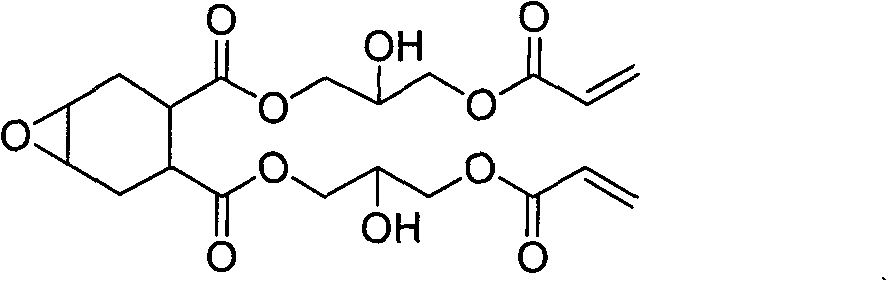

UV-curing water-based alicyclic epoxy acrylate emulsion

The invention relates to a UV-curing water-based alicyclic epoxy acrylate emulsion. The preparation method of the UV-curing water-based alicyclic epoxy acrylate emulsion comprises the following steps: preheating an emulsifier and a regulator to 50 DEG C, adding epoxy resin, a cross-linking monomer, a polymerization degree regulator and an acrylic acid monomer, and keeping the temperature for 0.5 hours while refluxing; heating part of the solution and an initiator to 80 DEG C; when emitting blue light, adding the rest of the solution and supplementing the initiator within 2.5 hours, keeping the temperature for 1 hour while refluxing, heating to 88 DEG C, and aging for 1 hour; regulating the temperature of the emulsion to 85 DEG C, adding glycidyl methacrylate, and heating to 90 DEG C to react for 2.5 hours; and after the reaction finishes, cooling to room temperature, and adding a free-radical initiator. The UV-curing water-based alicyclic epoxy acrylate emulsion has the advantages of high film hardness and high water resistance, overcomes the defects of poor weather resistance, poor damp heat resistance and the like in the existing bisphenol A epoxy resin, avoids the environmental pollution of the traditional solvent type paint, can be used for preparing outdoor paints, photocuring inks, technical paints and the like, and is a material having wide market prospects.

Owner:SHANGHAI ZHONGXIN YUXIANG CHEM

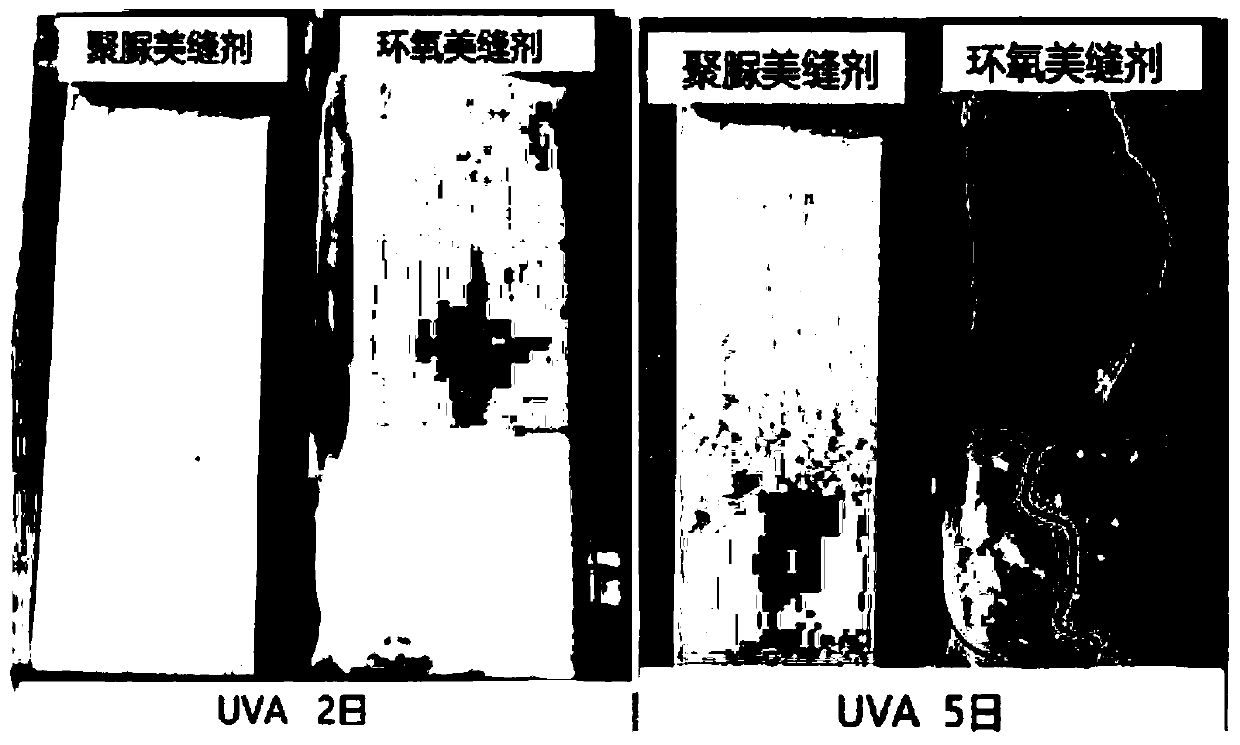

Seam beautifying agent

ActiveCN110317528AGood weather resistanceImprove aging resistancePolyurea/polyurethane coatingsPolymer scienceWeather resistance

The invention discloses a seam beautifying agent and relates to the technical field of caulking agents. According to the seam beautifying agent provided by the embodiment of the invention, an aliphatic isocyanate curing agent reacts with aspartate resin to obtain a double-component polyurea seam beautifying agent material. The aspartate resin has good yellowing resistance and can form a polyurea polymer by reacting with aliphatic isocyanate, and urea bonds have high strength and toughness and good UV aging resistance and yellowing resistance. Therefore, the obtained seam beautifying agent hasgood weather resistance, aging resistance and yellowing resistance.

Owner:SHENZHEN FEIYANG JUNYAN TECH DEV

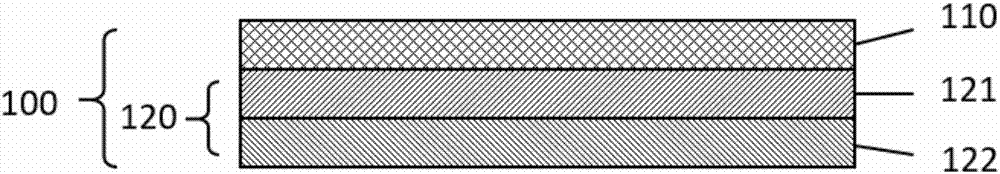

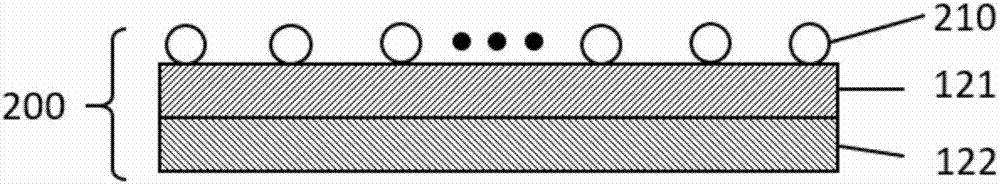

Photovoltaic transparent composite film, and preparation method and application thereof

InactiveCN106960891AImprove adhesionAchieve bondingPhotovoltaic energy generationSemiconductor devicesComposite filmMetallic materials

The invention discloses a photovoltaic transparent composite film, and a preparation method and application thereof. The transparent composite film comprises a release paper layer and a function layer, the function layer comprises a supporting layer and a bonding layer, and at least one of the supporting layer and the bonding layer is mixed with a light conversion agent which can converting part of ultraviolet light into visible light. The lower surface of the supporting layer is connected with the bonding layer, and the upper surface and the lower surface of the supporting layer are both flat surfaces or at least one surface is provided with certain light tripping microstructures. The bonding layer is formed by an acrylic ester pressure-sensitive adhesive and can bond metal materials well. The transparent composite film can be applied to multi-main grid and non-main grid photovoltaic modules, and plays a role in applying brass wires to a battery piece, and has high transmissivity and an excellent anti-ultraviolet ageing performance, and can satisfy the usage demand of photovoltaic modules.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

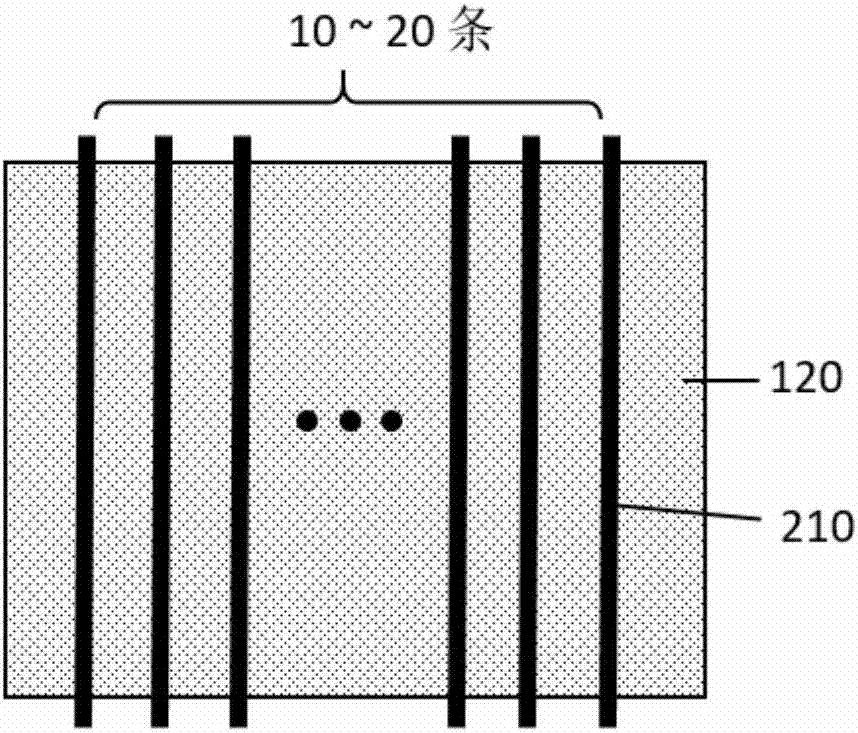

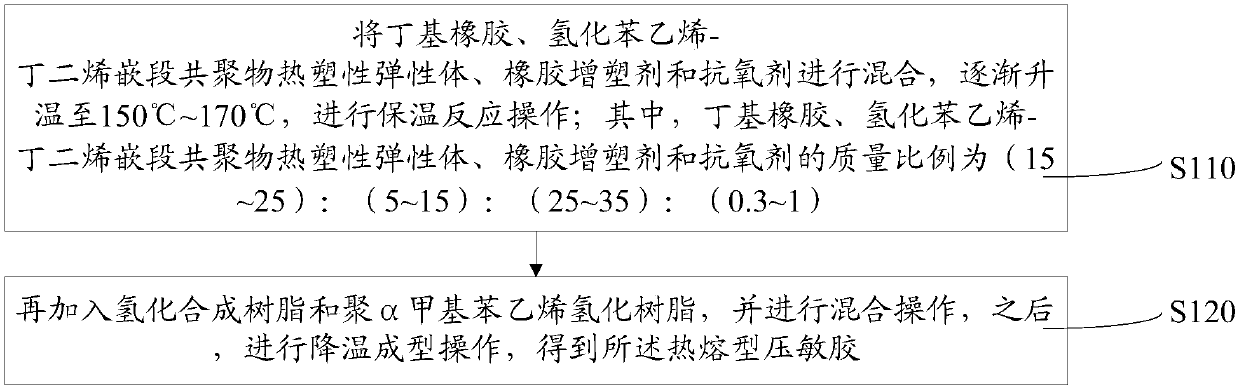

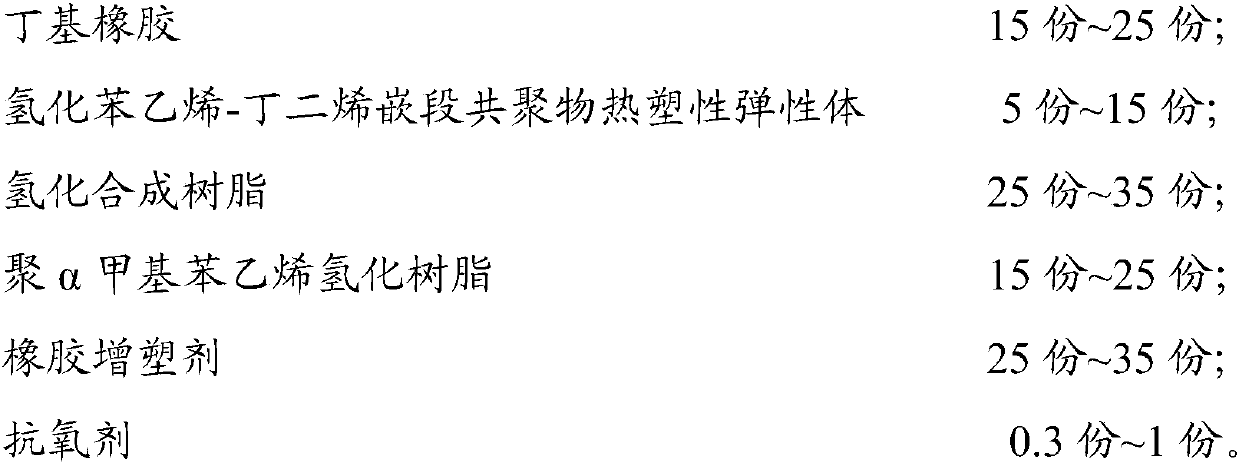

Hot-melt pressure-sensitive adhesive and preparation method thereof

ActiveCN107603537AGood adhesionGood UV aging resistanceMineral oil hydrocarbon copolymer adhesivesMacromolecular adhesive additivesAntioxidantUltraviolet

The invention relates to a hot-melt pressure-sensitive adhesive and a preparation method of the pressure-sensitive adhesive. The pressure-sensitive adhesive comprises the following ingredients in parts by mass: 15-25 parts of butyl rubber, 5-15 parts of hydrogenated styrene-butadiene segmented copolymer thermoplastic elastomers, 25-35 parts of hydrogenated synthetic resin, 15-25 parts of poly- alpha methyl styrene hydrogenated resin, 25-35 parts of a rubber plasticizer and 0.3-1 part of an antioxidant. The hot-melt pressure-sensitive adhesive solves the disadvantages of small cohesion and poorthermal creep resistance of butyl rubber and can also achieve good mutual dissolution; since the butyl rubber hot-melt pressure-sensitive adhesive has a good bonding property with various high polymer coiled materials and good ultraviolet aging resistance, when the pressure-sensitive adhesive is applied to the self-adhesive film water-proof coiled materials, the pressure-sensitive adhesive has the characteristics of excellent high and low temperature resistance, excellent ultraviolet aging resistance, high stripping strength with cement mortar after bonding, a wide application scope of the water-proof coiled materials, low cost and the like, and is better in water-proof performance.

Owner:HUIZHOU NENGHUI CHEM CO LTD

Strengthened and toughened polypropylene composite and its preparing process

A three-element composition is prepared from polypropene (PP) (72-91 wt%), POE or MPOE (1-13) and BaSO4 (7-20) through mixing, stirring, kneading and extruding out. Its advantages are high impact strength, high toughness, high P / C ratio, high resistance to thermal or ultraviolet ageing, and low cost.

Owner:SUN YAT SEN UNIV

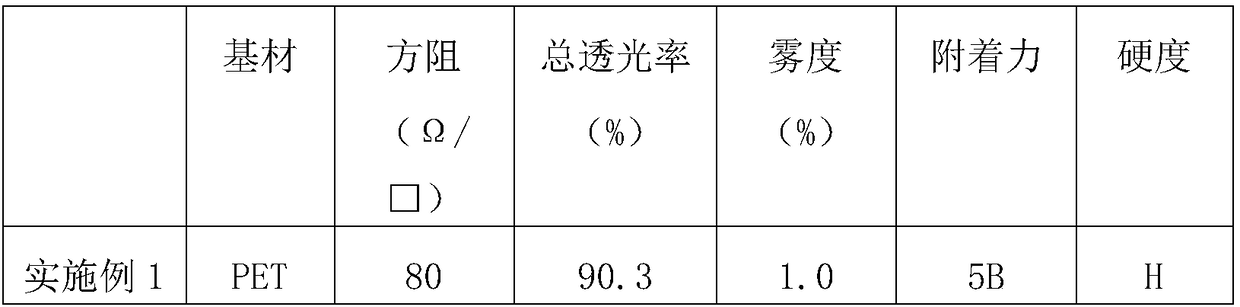

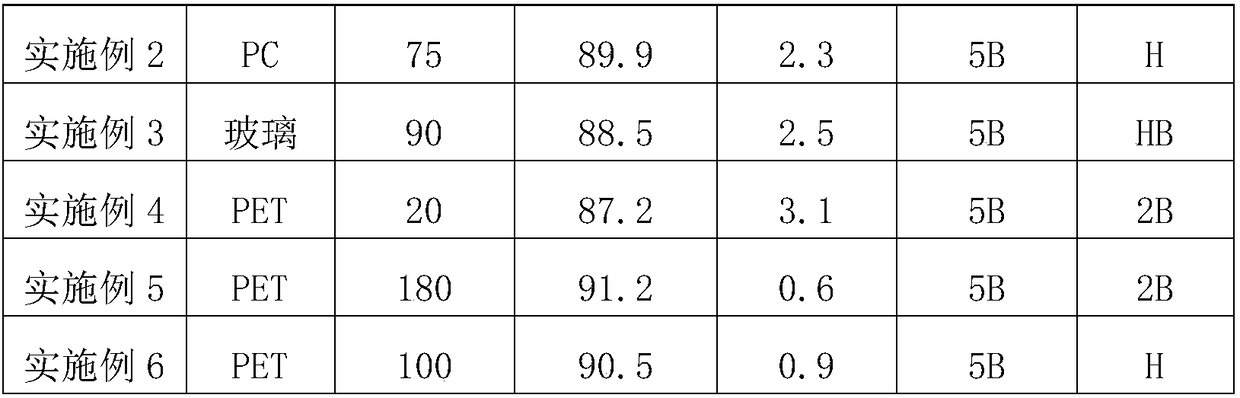

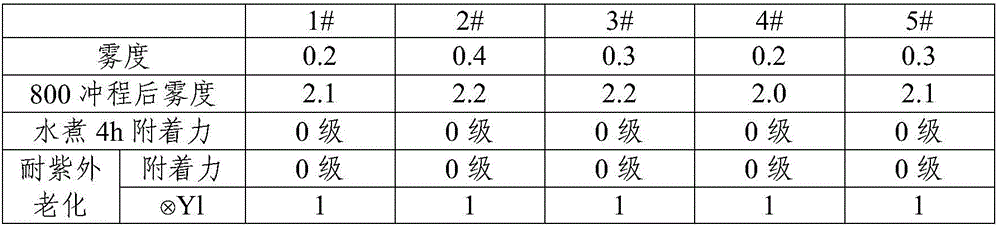

Silk-screen transparent conductive slurry, preparation method of silk-screen transparent conductive slurry and application of silk-screen transparent conductive slurry

InactiveCN108269645ASolving Printability IssuesGood printabilityMaterial nanotechnologyNon-conductive material with dispersed conductive materialOrganic solventAdhesive

The present invention discloses a silk-screen transparent conductive slurry. The silk-screen transparent conductive slurry is prepared by the following raw materials comprising, percentage by weight:0.05-0.5% of silver nanowire, 0-0.25% of PEDOT / PSS, 0.01-0.05% of surfactant, 0.01-0.05% of flatting agent, 0.01-0.5% of dispersing agent, 0.01-0.5% of coupling reagent, 0.01-0.5% of antifoaming agent, 0.01-1% of adhesive, 0.01-1% of thickening agent, 0-0.5% of emulgator, 0-30% of organic solvent, and balance water. The present invention further discloses a preparation method of silk-screen transparent conductive slurry and an application of silk-screen transparent conductive slurry. The silk-screen transparent conductive slurry can improve the condition of bluish hue of the conducting layer,can greatly improve the appearance effect, has good printability, and is stable in square resistance, high in light transmittance and low in haze.

Owner:珠海纳金科技有限公司

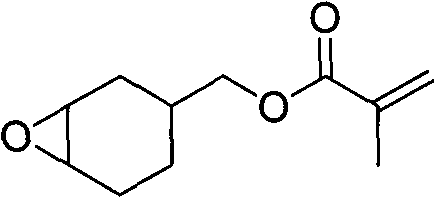

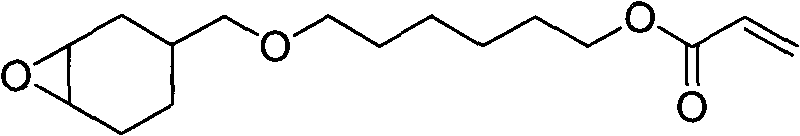

Novel aqueous light-cured alicyclic epoxy acrylic acid emulsion and preparation method thereof

InactiveCN102659976AGood chemical arc resistanceGood UV aging resistanceCoatingsCross-linkSolubility

The invention relates to a novel aqueous light-cured alicyclic epoxy acrylic acid emulsion and a preparation method thereof. The method comprises the following steps: adding an emulsifier and a regulator in a reactor, preheating to 50 DEG C, then adding epoxy resin, cross-linking monomers, polymerization degree regulator and acrylic acid monomers, preserving the heat of reflux for 0.5h; heating partial solution and an initiator to 80 DEG C, when glowing blue, adding dropwisely the rest solution in 2.5 h, and refilling the initiator, preserving the heat of reflux for 1h, cooling to room temperature after the reaction, and then adding a photoinitiator. The invention provides a light-cured alicyclic epoxy acrylic acid emulsion with stability and good water-solubility, overcomes the defects of bad weatherability and bad resistance to heat and humidity of existing bisphenol-A epoxy resin, and simultaneously prevents the environment from being polluted by traditional solvent-based coating. The emulsion can be used for preparing outdoor coatings, light-cured printing ink, craft paints and the like, has the advantages of excellent performance, simple technology, and low cost, and is an environment friendly material with a wide market prospect.

Owner:SHANGHAI ZHONGXIN YUXIANG CHEM

Coupling agent modified silicon dioxide doped cycloaliphatic epoxy resin LED packaging adhesive

InactiveCN102838957AExtended service lifeReduce absorptionNon-macromolecular adhesive additivesOther chemical processesAntioxidantAdhesive

The invention relates to a coupling agent modified silicon dioxide doped cycloaliphatic epoxy resin LED packaging adhesive. The adhesive is characterized in that: it is composed of component A and component B that are mixed in a ratio of 1: (0.9-1) for construction. Specifically, the component A consists of cycloaliphatic epoxy resin, an active diluent, a transparent blue-violet purple dye color paste, a defoaming agent and a softening agent. The component B consists of a curing agent, an accelerator, a silane coupling agent modified nano-ultraviolet absorbent, polyol and an antioxidant. The nano-silicon dioxide doped cycloaliphatic epoxy resin LED packaging adhesive provided in the invention has the advantages of good ageing resistance, strong binding power, fast curing, low viscosity and moisture absorption, so that employment of organosilicone with a high cost can be avoided. Meanwhile, the defects of high moisture absorption, poor ultraviolet resistance and low shortwave transmittance and the like of existing bisphenol A type epoxy resin can be overcome. The LED packaging adhesive provided in the invention is more suitable to be used as a high-end LED packaging adhesive, a high power LED packaging adhesive or an ultraviolet light-based white light and blue light LED packaging adhesive.

Owner:JIANGSU TETRA NEW MATERIAL TECH

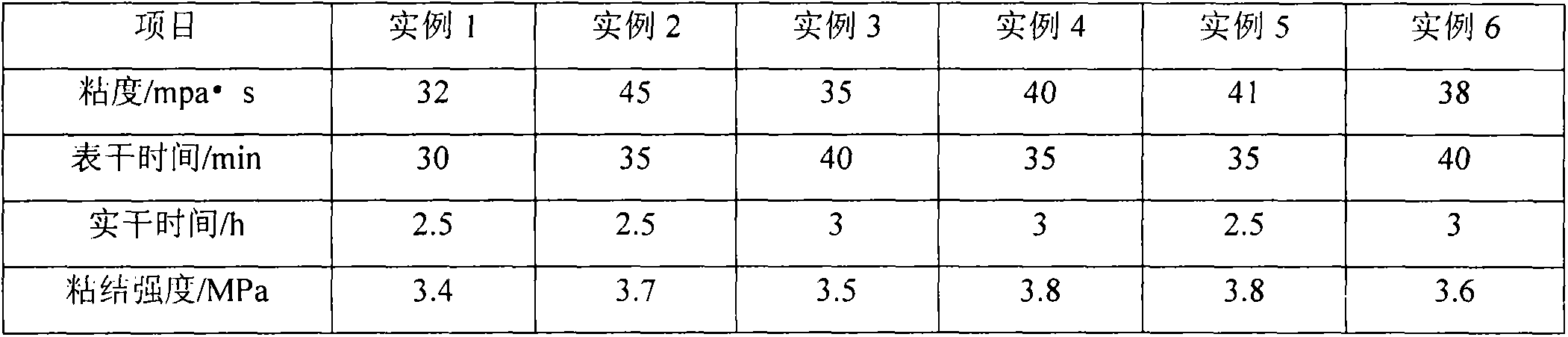

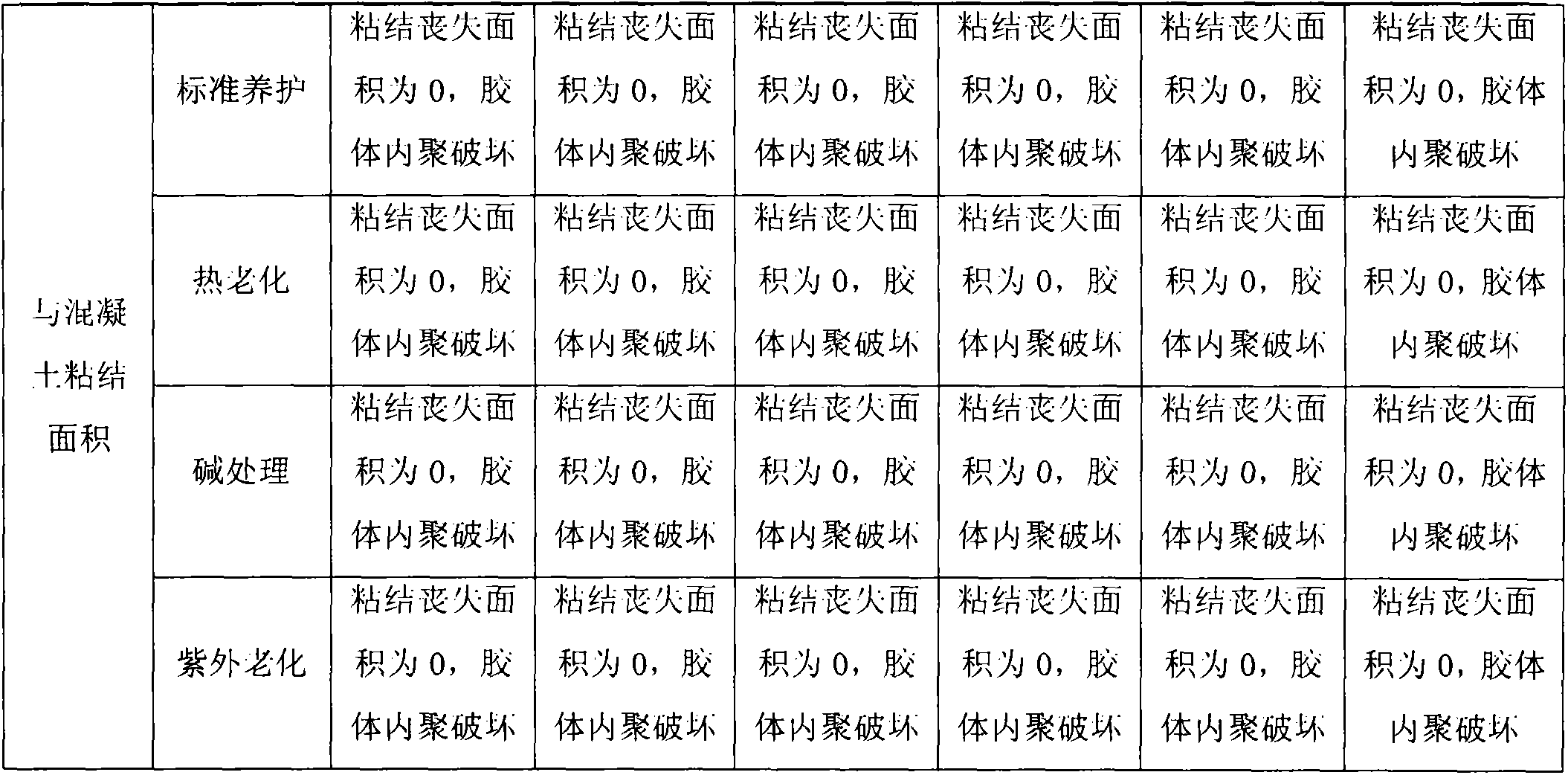

Interface agent for high-speed railway ballastless track polyurethane caulking material and preparation method thereof

The invention relates to an interface agent for a high-speed railway ballastless track polyurethane caulking material and a preparation method thereof. The interface agent comprises the following raw materials in parts by weight: 100 parts of isocyanate prepolymers, 80-120 parts of solvents, 0.1-0.5 part of catalysts, 0.5-2.5 parts of water removal agents and 0.5-2.5 parts of anti-aging agents. The preparation method comprises the following two steps of: (1) slowly dripping polyhydric alcohol to isocyanate at the temperature of (85+ / -5) DEG C, then increasing the temperature to (90+ / -5) DEG C for continuous reaction, when the content of NCO groups is 14%-16%, adding organic silicon coupling agents, and reacting till the content of the NCO groups is 10%-12% so as to obtain a prepolymer; (2) adding the solvents, the catalysts, the water removal agents and the anti-aging agents to the prepolymer, uniformly stirring, and debubbling in vacuum (at vacuum degree less than or equal to -0.09MPa) to obtain the interface agent for the polyurethane caulking material. The interface agent disclosed by the invention has the characteristics of low viscosity, good impregnation property, high toughness, excellent hydrolysis-resistant property and alkali-resistant property, excellent adhesive property with concrete and the polyurethane caulking material, and the like.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

Composite material capable of resisting ageing for long time and preparation method of composite material

InactiveCN102558685AImprove mechanical propertiesExcellent heat and oxygen aging resistanceGlass fiberAging resistance

The invention relates to a composite material capable of resisting ageing for a long time and a preparation method of the composite material. The composite material comprises the following components in percent by weight: 45-75 percent of polypropylene, 10-40 percent of glass fiber, 3-10 percent of compatilizer, 10-20 percent of antioxygen and 0.1-0.5 percent of lubricating agent. The preparation method comprises the steps of: placing raw material in a high speed mixer and then placing the raw materials in a double-screw extruder for granulating, controlling the rotating speed of the double-screw extruder to be 300-700 turns / min and the temperature to be 190-220 DEG C, melting and then extruding and granulating to obtain the composite material. Compared with the prior art, the PP / GF (polypropylene / glass fiber) composite material capable of resisting the ageing for a long time, prepared in the invention has excellent mechanical property, heat and oxygen ageing resistance and ultraviolet ageing resistance. The composite material can be used for manufacturing a member with higher ageing performance, and can be widely applied to the fields such as electric products and automobile parts.

Owner:SHANGHAI SUNNY

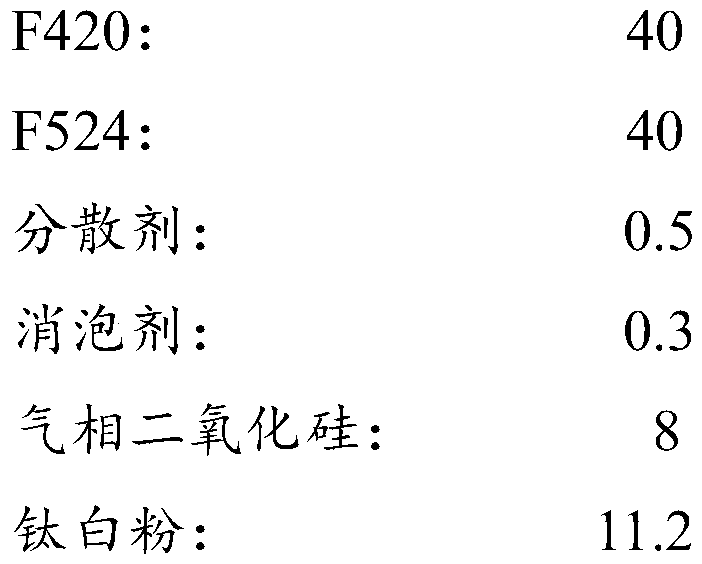

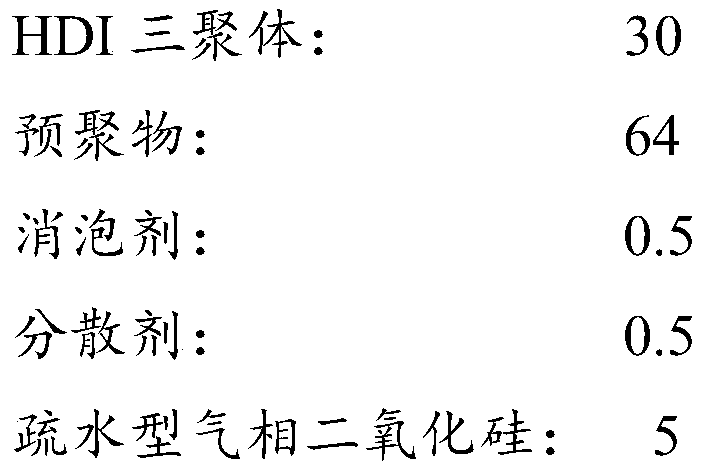

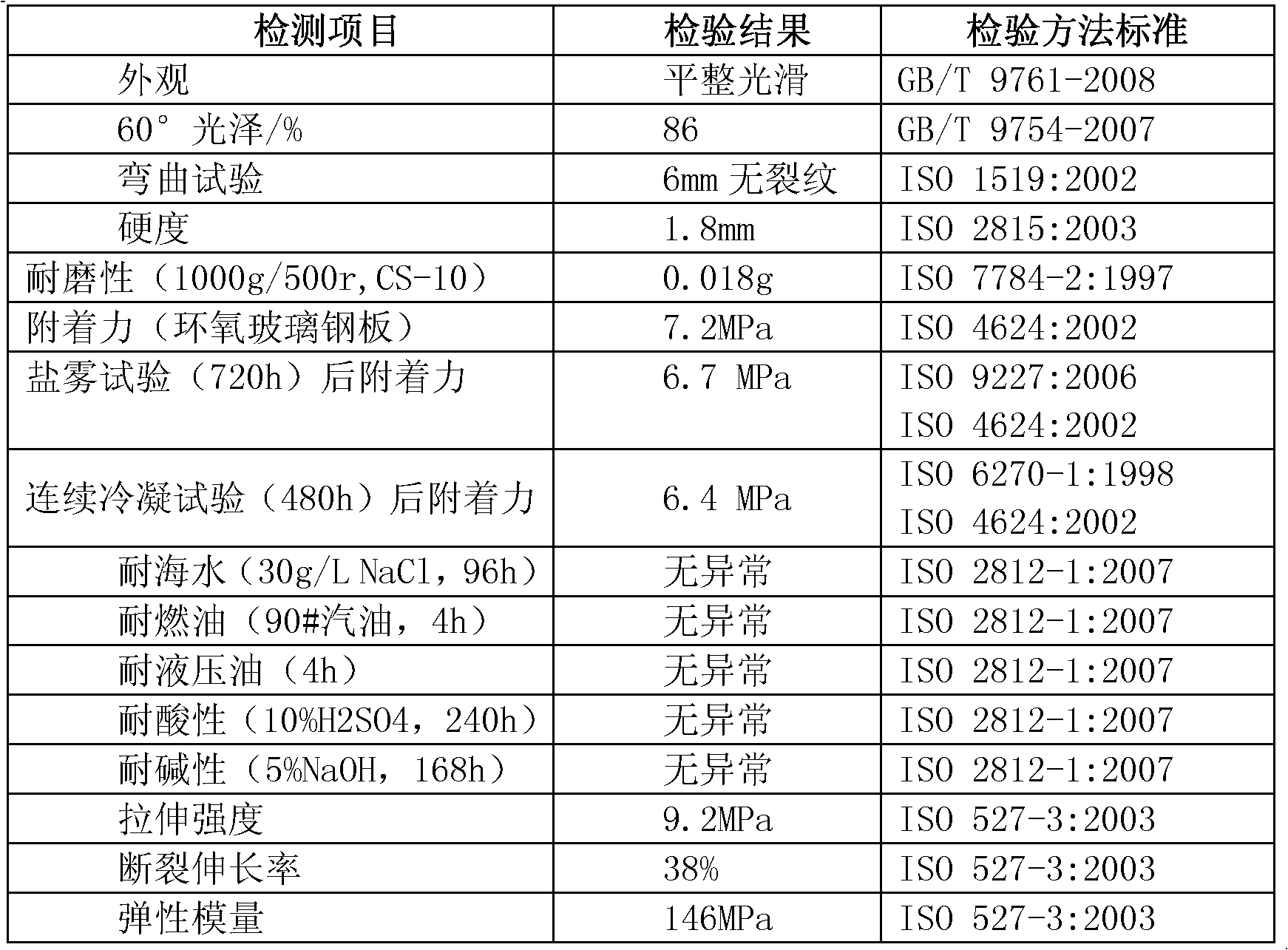

Wear-resistant nonskid polyurethane deck paint, and manufacture method thereof

InactiveCN102190954AGood chemical stabilityImprove acid and alkali corrosion resistancePolyurea/polyurethane coatingsGas phaseWear resistant

The invention relates to a wear-resistant nonskid polyurethane deck paint, and a manufacture method thereof. The manufacture method comprises the following steps of: adding a hydroxyl acrylic resin, polyether polyol, hydroxyl-containing fluorocarbon acrylic resin, a polyacrylate copolymer solution, poly(methyl alkyl siloxane) solution and [b-[3-(2-H-benzotriazol-2-yl)-5-(1,1-dimethylethyl)-4-hydroxyphenyl]-1-oxopropyl]-hydroxypoly(oxo-1,2-ethanediyl) to a mixed solvent of xylene, n-butyl acetate, methyl isobutyl ketone and butanone for high-speed stirring; adding rutile titanium white powder, talcum powder, aluminum oxide ceramic powder, sericite powder, silicon micropowder, carbon black and gas-phased silicon dioxide; milling with a sand mill while controlling fineness of a mixture not higher than 60 mu m to obtain a liquid A; and forming a liquid B by a mixed solution of 1,6-hexamethylene diisocyanate tripolymer, anhydrous xylene and n-butyl acetate, and mixing 1 weight part of the liquid A with 0.2-1.0 weight part of the liquid B for use. The obtained wear-resistant nonskid polyurethane deck paint can be used for the corrosion protection of the steel surfaces of deck and ocean facilities.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +2

Self-permeability-increasing high-permeability acid-resistant epoxy resin waterproof coating material and preparation method therefor

InactiveCN107298921AReduce surface tensionSelf-increasingAnti-corrosive paintsEpoxy resin coatingsChemical compoundSilanes

The invention discloses a self-permeability-increasing high-permeability acid-resistant epoxy resin waterproof coating material and a preparation method therefor. The self-permeability-increasing high-permeability acid-resistant epoxy resin waterproof coating material consists of a component A and a component B, wherein the component A is prepared from epoxy resin, a fluorinated organosilicone modified epoxy reactive diluent and a carbonyl compound, and the component B is prepared from polyamine, a silane coupler and an accelerant. The self-permeability-increasing high-permeability acid-resistant epoxy resin waterproof coating material is good in permeability, plays dual roles in preventing seepage and reinforcing and has good acid resistance and low-temperature flexibility.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Uvioresistant antibacterial release paper and preparation method thereof

ActiveCN103966897AGood flexibilityGood acid and alkali resistanceCoatings with pigmentsPaper/cardboardEmulsionUltraviolet

The invention discloses a preparation method of an uvioresistant antibacterial release paper. The method comprises the following steps of coating one side or two sides of base paper of the release paper with a film coating layer; coating the surface of the film coating layer with a release layer; performing super press polishing on the coated release layer; coating the surface of the release layer with an antibacterial agent to obtain an antibacterial layer; coating the surface of the antibacterial layer with a polyethylene glycol terephthalate (PET) film layer; airing the antibacterial layer at the temperature of 20-25 DEG C to obtain the uvioresistant antibacterial release paper. The release paper having an uvioresistant and antibacterial function can resist tearing; by adding vinyl acetate-ethylene (VAE) emulsion, the release paper has functions of high flexibility, acid-base resistance property, ultraviolet ageing resistance and the like; meanwhile, due to the addition of organic antibacterial agents, the release paper has extremely high antibacterial effect and can be widely used in the field of chemical engineering packaging.

Owner:JIXIANGBAO TAICANG RELEASE MATERIAL TECH CO LTD

Aqueous weather-resisting polysiloxane coating

InactiveCN105385342AStrong adhesionImprove anti-corrosion performanceEpoxy resin coatingsHydroxypropylmethyl celluloseCycloaliphatic epoxy

Owner:ANHUI JINDUN PAINT

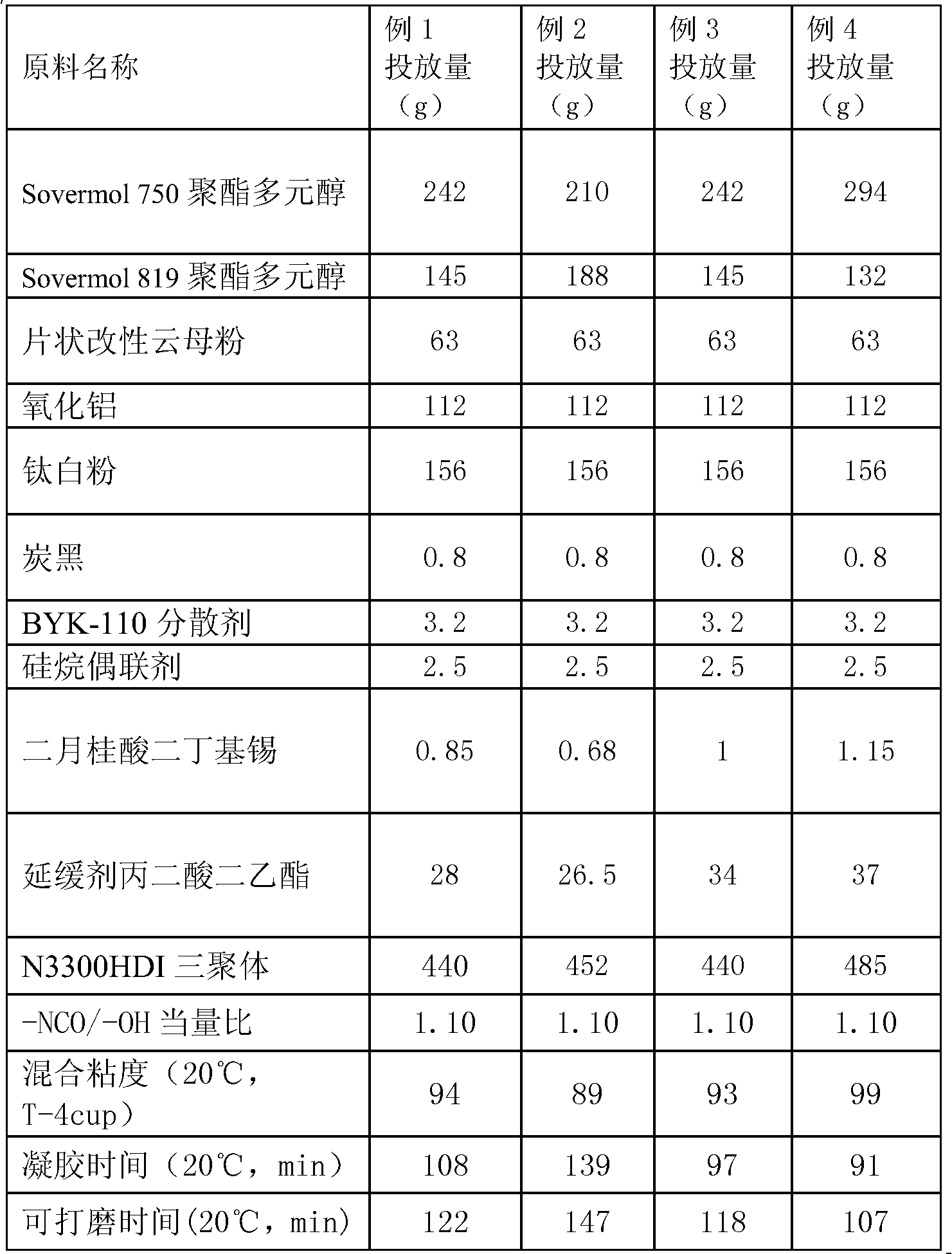

Polyurethane gel coat combination capable of spraying blades of fan conventionally and preparation method of polyurethane gel coat combination

ActiveCN102585684ASolve the contradiction between gel time and sandability and drynessGood protectionPolyurea/polyurethane coatingsSolventPolyester

The invention provides a polyurethane gel coat combination capable of spraying blades of a fan conventionally and a preparation method of the polyurethane gel coat combination. The combination is prepared by the following steps: mixing polyester polyol and an isocyanate curing agent according to a certain proportion to serve as a main film former, and adding a filler, a pigment, auxiliaries and areaction regulator. The reaction regulator includes a drier and a retardant, and the retardant includes one or more Louis acidic compounds having double-teeth ligand structures. Therefore, the gelation time of the polyurethane gel coat is effectively prolonged, the spraying operation can be realized with conventional coating equipment, the current reality that solvent-free gel coats for the blades of a fan can only be coated in a roller coating way or by adopting special equipment is changed, not only is the excellent protecting performance of the solvent-free polyurethane gel coats realized,but also the fine processability of the solvent-free polyurethane gel coats is realized. The invention also provided a preparation method of the polyurethane gel coat combination. The polyurethane gel coat combination prepared according to the invention also has the excellent properties of being tough and tensile, wear-resisting, sand-wind-resisting, ultraviolet-resisting and ageing-resisting andthe like.

Owner:天津德威涂料化工有限公司

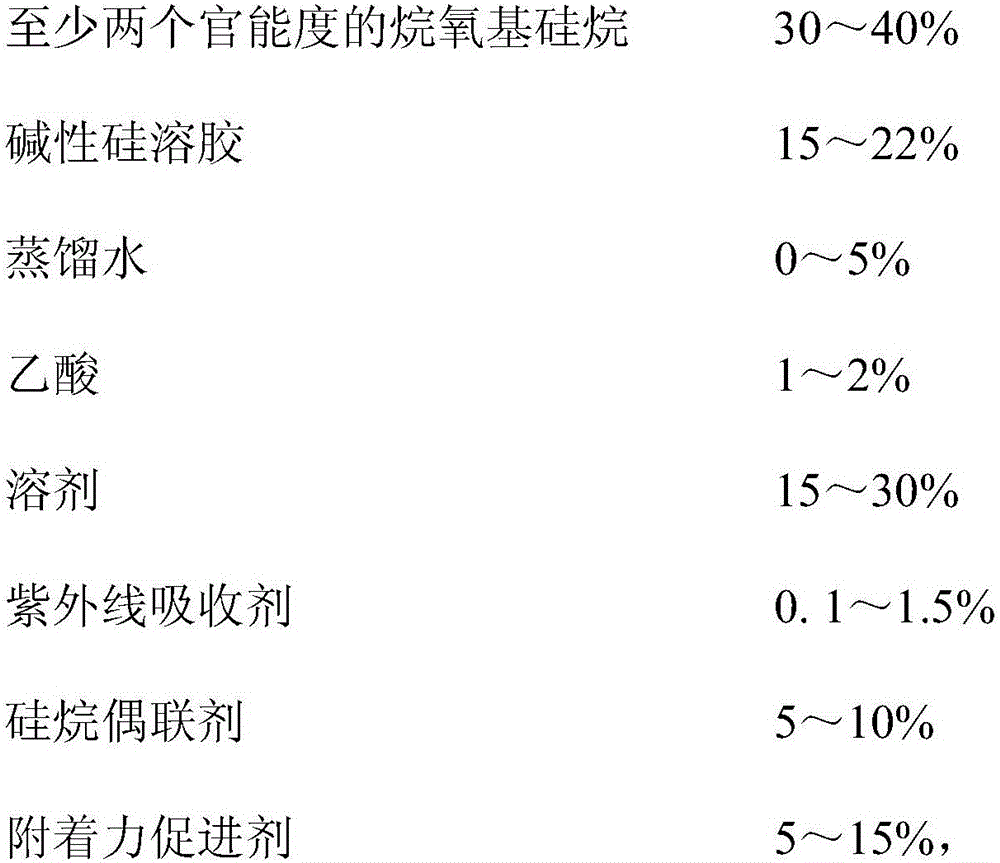

Wear resistance and anti-ultraviolet coating for polycarbonate and preparation thereof

The invention discloses a wear resistance and anti-ultraviolet coating for polycarbonate, and the coating is prepared through the following method: adding alkaline silica sol, distilled water, ultraviolet light absorber and acetic acid into a reactor; heating, and starting to dropwise add alkoxy silane with at least two degrees of functionality when a system temperature reaches 60 DEG C, wherein the dropwise adding takes 1 to 3 hours and the reaction system temperature in a dropwise adding process is controlled to be 60 to 72 DEG C; adding an adhesion promoter for heating and refluxing for 0.5 to 2 hours after dropwise adding, and adding a silane coupling agent and a solvent after cooling to below 40 DEG C. The coating layer obtained from the coating has performances of good transparency, wear resistance, water resistance, anti-ultraviolet ageing and the like.

Owner:中昊北方涂料工业研究设计院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com