Wear resistance and anti-ultraviolet coating for polycarbonate and preparation thereof

A polycarbonate, UV-resistant technology, applied in the coating and other directions, can solve the problems of poor storage stability, poor storage stability, easy yellowing, etc., and achieve the effect of good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

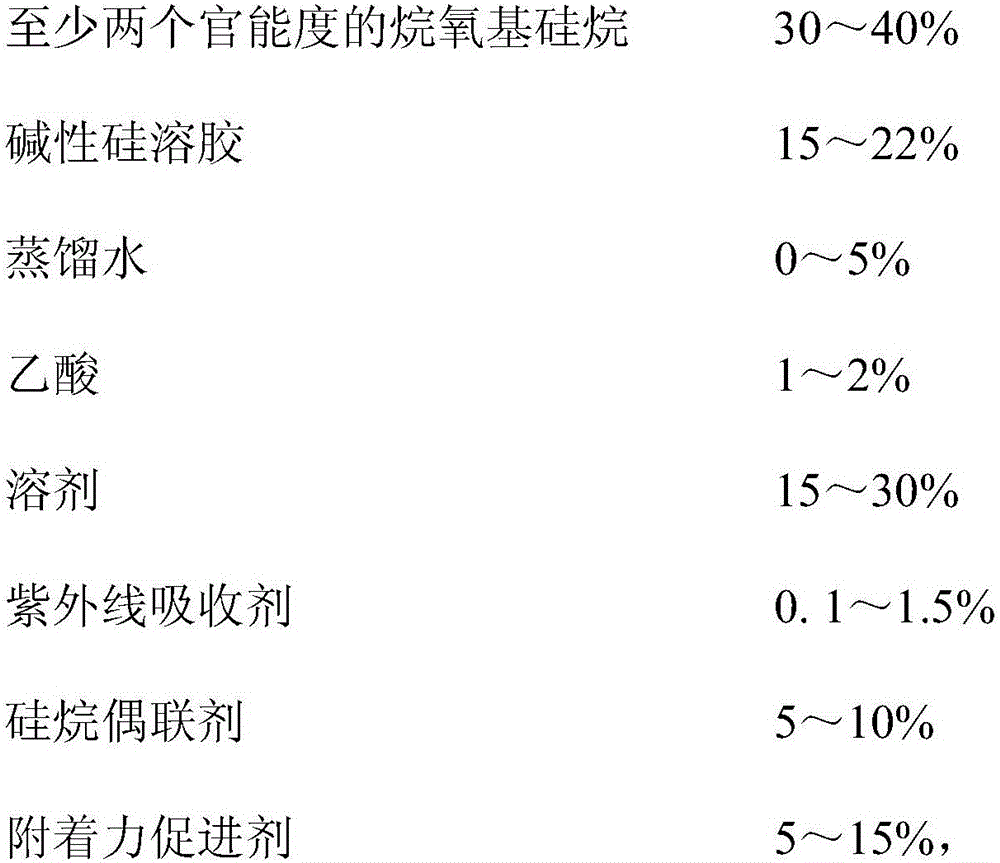

Method used

Image

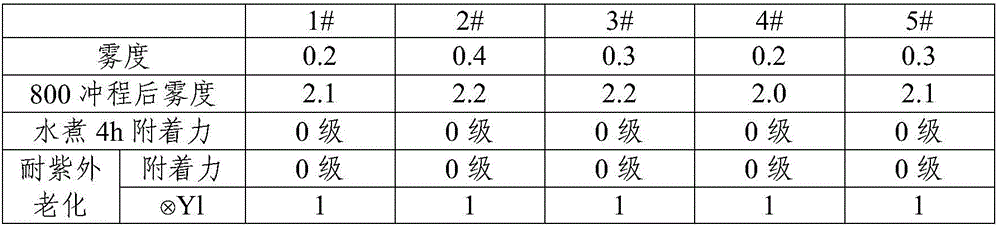

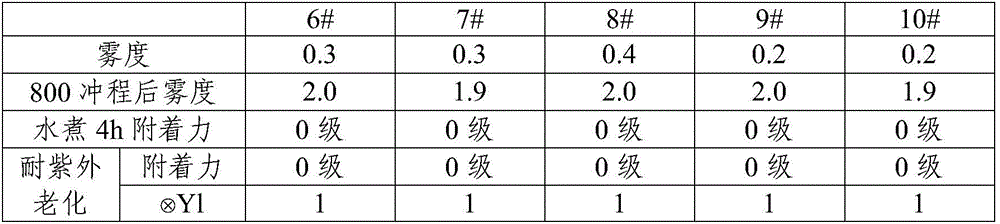

Examples

preparation example 1

[0023] Preparation of adhesion promoter: Add 50g of polyether diol with a molecular weight of 200 and 148g of 3-isocyanatopropyltrimethoxysilane into the reactor, add 2 drops of 10% organotin catalyst, and let the system continue to stir at room temperature for 12 When the measured NCO content in the system reached or approached the theoretical value, the reaction was stopped, and the adhesion promoter number A-1 was obtained.

preparation example 2

[0025] Preparation of adhesion promoter: Add 45g of polyether diol with a molecular weight of 400 and 56g of 3-isocyanatopropyltriethoxysilane into the reactor, add 2 drops of 10% organotin catalyst, and let the system continue to stir at room temperature After 12 hours, when the NCO content in the system was measured to reach or approach the theoretical value, the reaction was stopped, and the adhesion promoter number A-2 was obtained.

preparation example 3

[0027] Preparation of adhesion promoter: add 45g polyether triol and 65g 3-isocyanatopropyltrimethoxysilane in the reactor, add 2 drops of 10% organotin catalyst, let the system continuously stir at room temperature for 12 When the measured NCO content in the system reached or approached the theoretical value, the reaction was stopped, and the adhesion promoter number A-3 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com