Patents

Literature

231results about How to "Improve boiling resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for forming ultrahigh-voltage anode foil for aluminum electrolytic capacitors

ActiveCN102610390AImprove compactnessIncrease costSurface reaction electrolytic coatingCapacitor electrodesConvertersPhosphorous acid

The invention relates to the production of electronic components, and discloses a method for forming anode foil for electrolytic capacitors. The ultrahigh-voltage anode foil is formed through six stages, wherein from the stage 1 to stage 5, each stage has a formation tank, and in the stage 6, three formation tanks are connected in parallel; and an acid fluid mixture containing a boric acid, a citric acid or an azelaic acid (the electric conductance and pH value thereof are adjusted by using carbon-containing inorganic salts) and ammonium hypophosphite or sodium monophosphate for improving the boiled performance of an oxidation film is filled in each formation tank. Correspondingly, the processing step is also adjusted, and the produced anode foil not only can be applied to the fields and industries of aerospace and automotive frequency converters and industrial frequency converters and the like meeting the ultrahigh voltage requirements on a withstand voltage of 700-1200V, but also is dense in oxidation film surface, high in specific volume and short in boosting time.

Owner:新疆金泰新材料技术股份有限公司

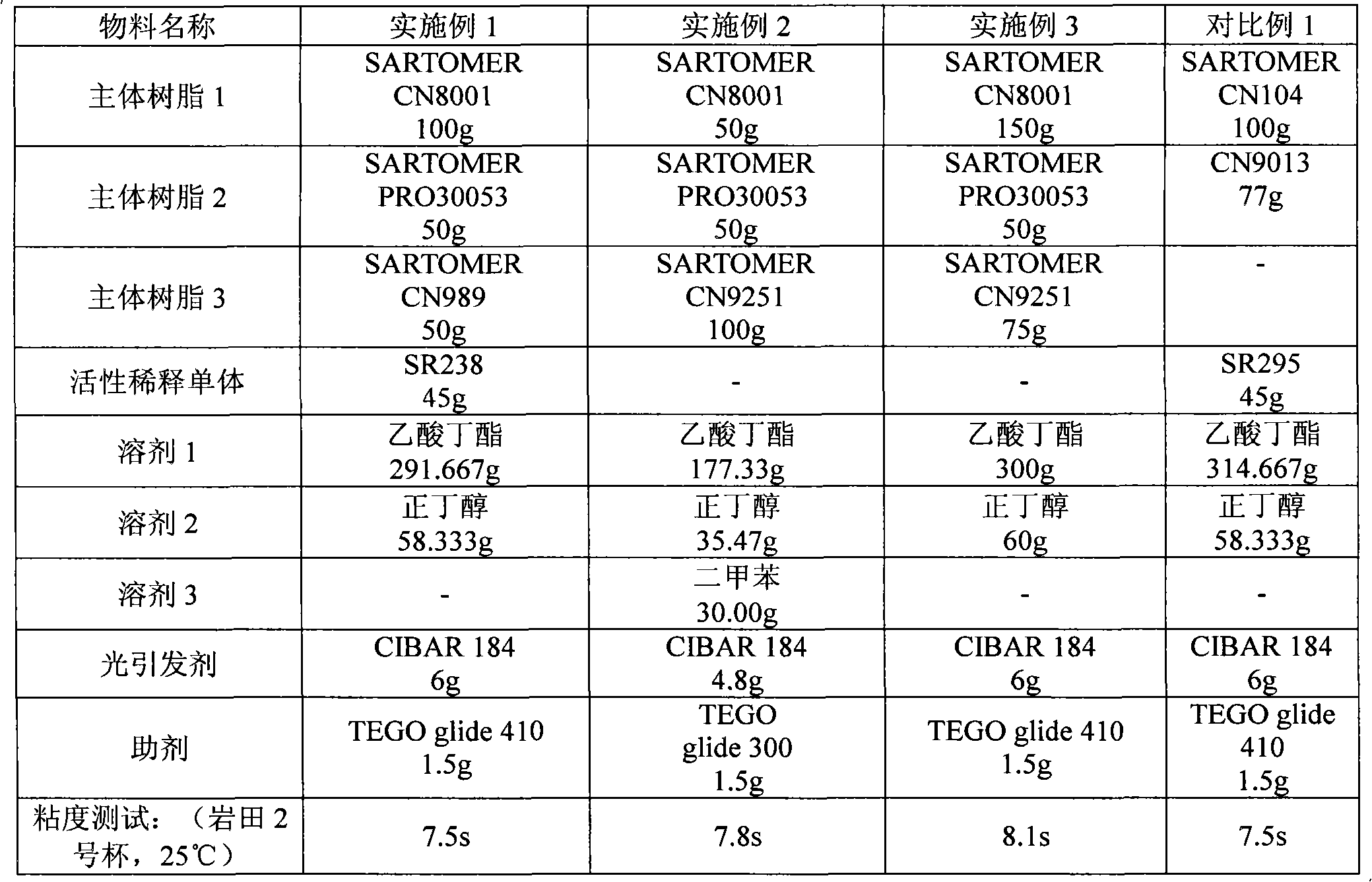

Photo-setting adhesive

InactiveCN101392152AImprove adhesivenessExcellent adhesive abilityPolyureas/polyurethane adhesivesOrganic non-macromolecular adhesiveAdhesiveEpoxy acrylate

The invention discloses a photo-curing adhesive, in particular relates to an adhesive of ultraviolet rays or visible light. The adhesive comprises components of the following weight ratios: 10 percent to 75 percent of matrix resin, 5 percent to 50 percent of assisted resin and 10 percent to 70 percent of acrylate monomer, wherein, the matrix resin is a mixture of one or the mixture of polyether-based polyurethane and polybutadiene acrylate and the assisted resin is one or the mixture of polyurethane acrylate or epoxy acrylate. The photo-curing adhesive provided by the invention has better adhesive performance than a common adhesive, especially has very high adhesive strength to glass, crystal and metal, meanwhile, the photo-curing adhesive has excellent resistance performance to high temperature, high humidity and water boiling, thereby having wide application prospect.

Owner:GUANGDONG HENGDA NEW MATERIALS TECH

Weather resistant polyester resin with excellent water-boiling resisting performance and method for preparing same

ActiveCN101735431AImprove boiling resistanceImprove the level ofPowdery paintsPolyester coatingsMelt viscosityChemistry

The invention discloses weather resistant polyester resin with excellent water-boiling resisting performance, which is prepared through the melt polycondensation of the following components: 20-45 percent by weight of polyol, 40-55 percent by weight of aromatic polybasic acid, 0-8 percent by weight of fat polybasic acid, 0-5 percent by weight of branching agent, 5-15 percent by weight of acidolysis agent and 0.01-0.15 percent by weight of esterification catalyst. The invention also discloses a method for preparing the weather resistant polyester resin with excellent water-boiling resisting performance. The polyester resin prepared with the method has high glass transition temperature, high softening point, appropriate melt viscosity and appropriate storage stability. The powder coating produced from the polyester resin has excellent water-boiling resisting performance, good leveling performance and good impact performance, etc.

Owner:GUANGZHOU KINTE IND

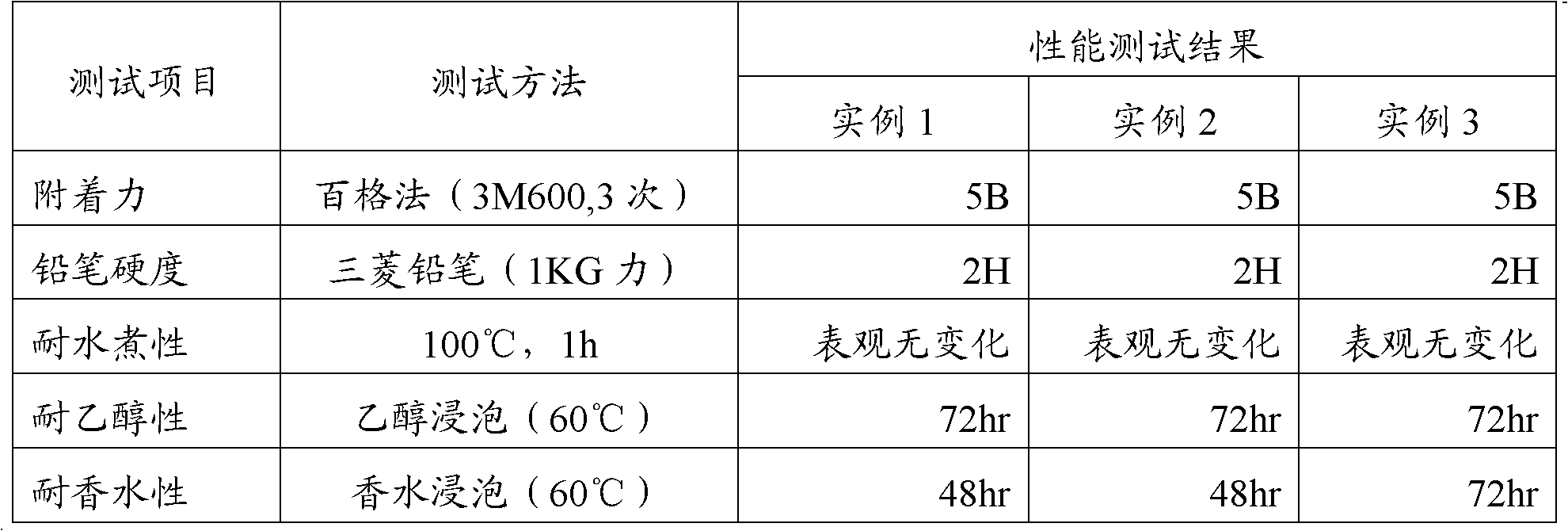

UV (ultraviolet)-curing glass coating paint

ActiveCN102134437AFast curingImprove boiling resistancePolyurea/polyurethane coatingsEpoxy resin coatingsOrganic solventAcrylic resin

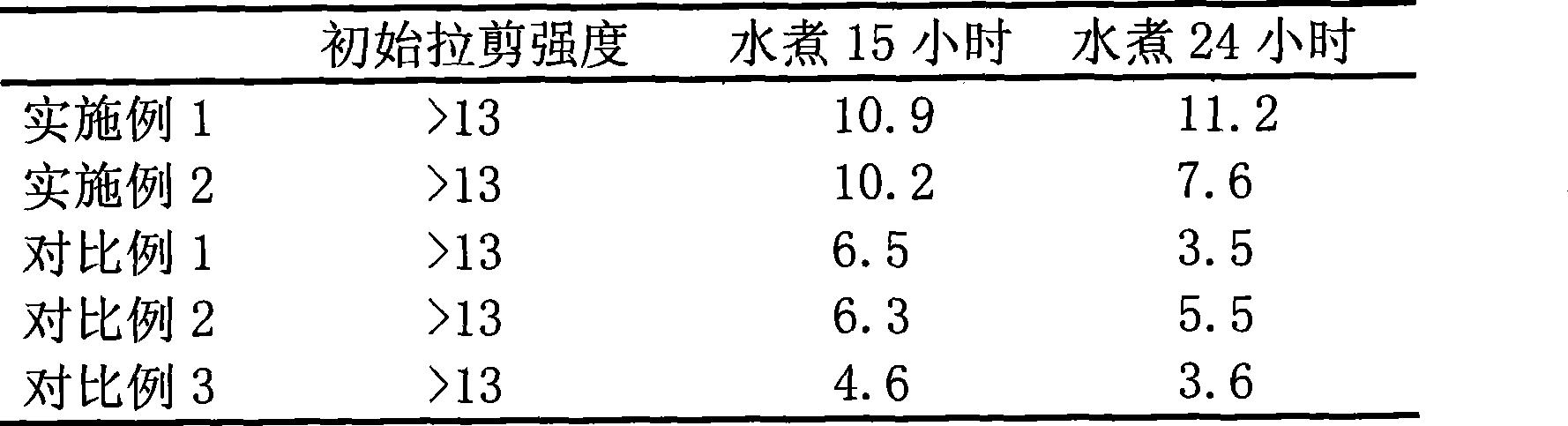

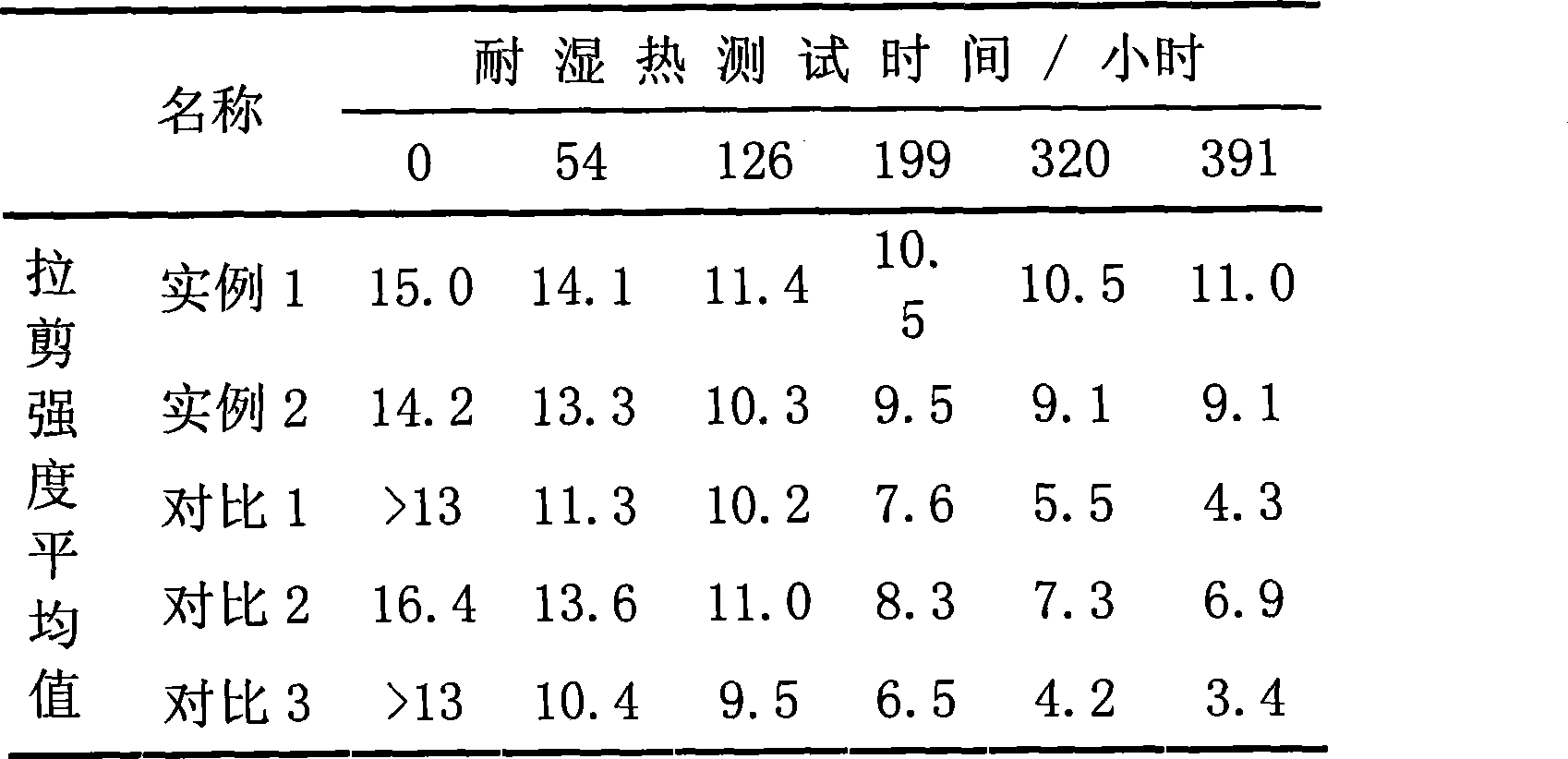

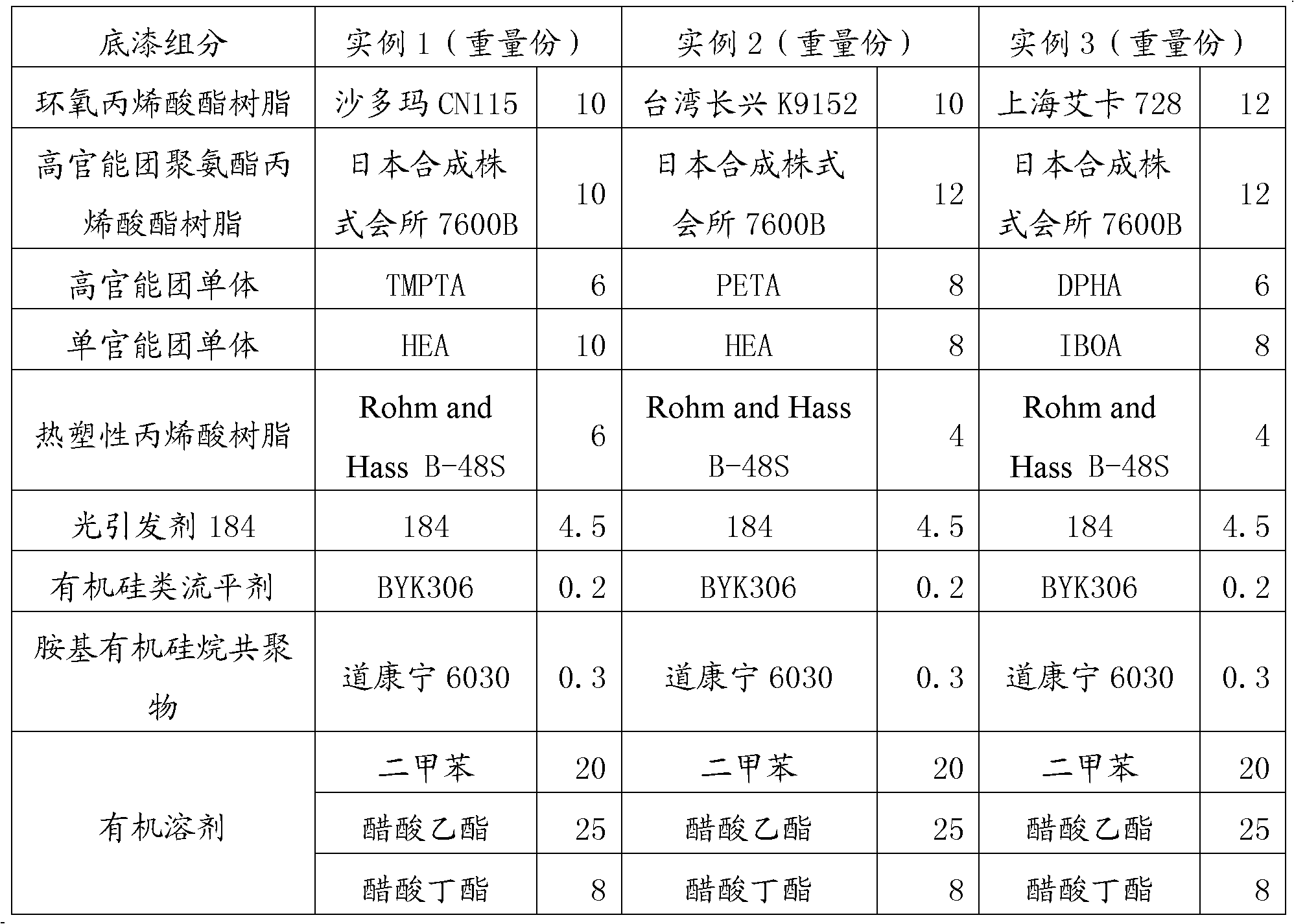

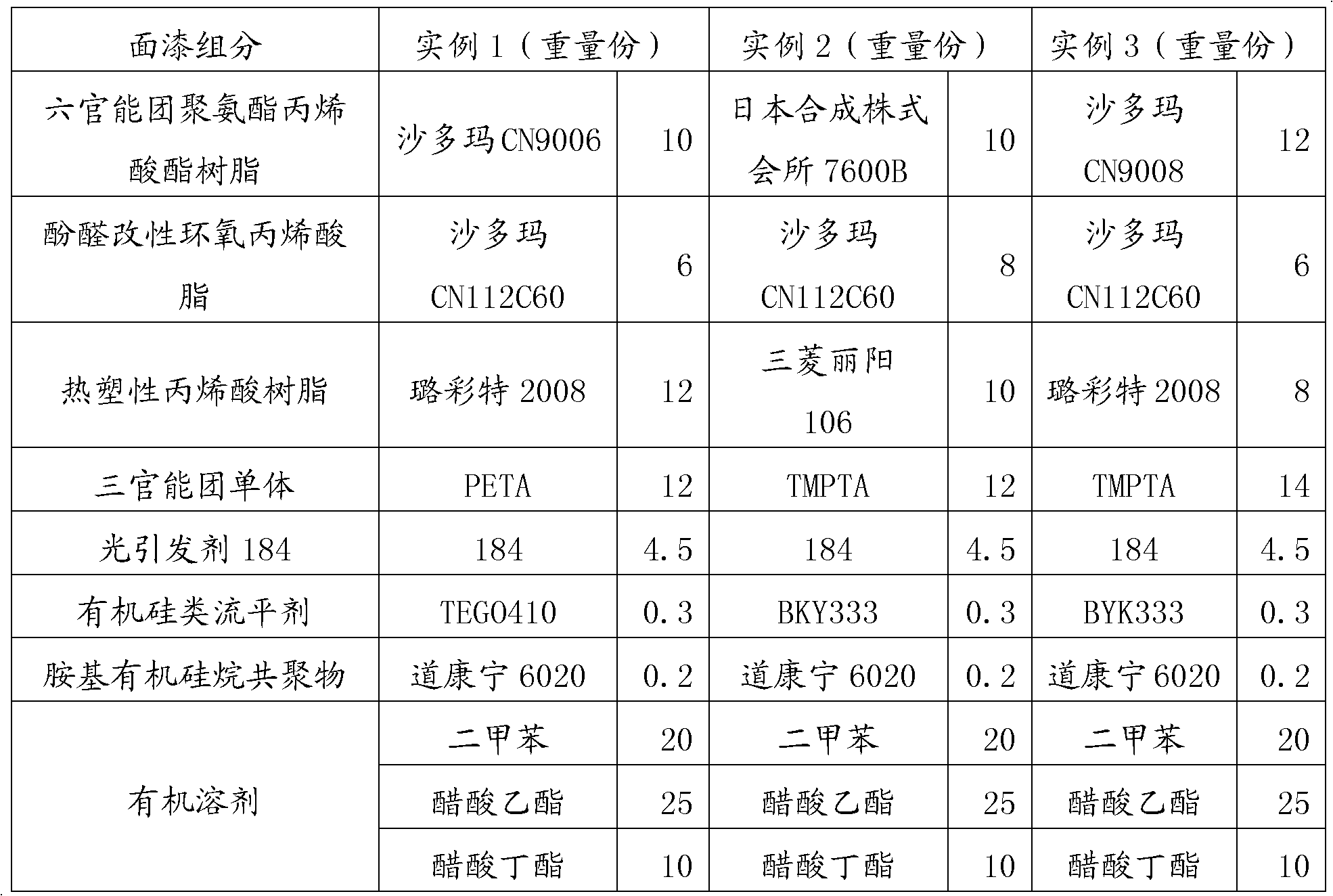

The invention discloses a UV (ultraviolet)-curing glass coating paint which comprises a primer and a finish, wherein the primer comprises epoxy acrylate resin, high-functional-group polyurethane-acrylate resin, high-functional-group monomer, single-functional-group monomer, thermoplastic acrylic resin, photoinitiator 184, organosilicon leveling agent, amido-organosilane copolymer and organic solvent; and the finish comprises six-functional-group polyurethane-acrylate resin, phenolic modified epoxy acrylate, thermoplastic acrylic resin, three-functional-group monomer, photoinitiator 184, organosilicon leveling agent, amido-organosilane copolymer and organic solvent. The plating bottom surface coat of the paint has the advantages of high curing speed, higher crosslinking density during construction, high boiling resistance, high ethanol resistance and high perfume resistance.

Owner:ZHEJIANG UVCHEM SPECIAL COATINGS CO LTD

Preparation method of polyester resin for mixing type powdery coating

InactiveCN1962717AReduce melt viscosityUniform molecular weightPowdery paintsPolyester coatingsPolymer sciencePolymer resin

Owner:GUANGZHOU QINGTIAN INDAL

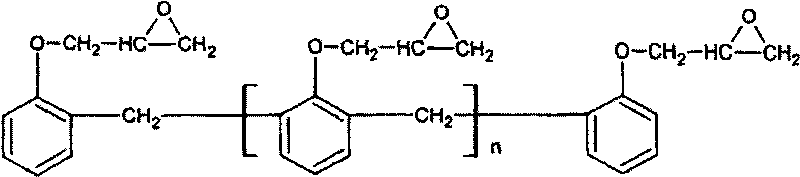

Fused-bonded epoxy powder paint with high resistance to cathodic disbonding

InactiveCN101698775AImprove corrosion resistanceReduce internal stressAnti-corrosive paintsPowdery paintsHigh resistanceMetallurgy

The invention provides fused-bonded epoxy powder paint with high resistance to cathodic disbanding. The paint comprises the following components in percentage by weight: 50 to 60 percent of novolac epoxy resin, 10 to 13 percent of curing agent, 25 to 32 percent of filler, 0.5 to 1 percent of pigment, 0.5 to 1 percent of benzoin, 0.4 to 1 percent of leveling agent, and 0.5 to 3 percent of toughening agent. The paint provided by the invention has the advantage of improving the heat resistance, boiling resistance, bending resistance, impact resistance and other performance of powder coatings while improving the resistance to cathodic disbanding.

Owner:SHANGHAI HILONG ANTI CORROSION TECH ENG

Special cassava modified starch for instant noodles and production method thereof

InactiveCN101735485AImprove viscosity and elasticityIncrease contentFood preparationInstant noodleOil consumption

The invention discloses a special cassava modified starch for instant noodles and a production method thereof, cassava starch is taken as raw material, and etherified-esterified-cross-linked starch is matched with a natural colloid-konjac gum according to a certain adding proportion, thereby obtaining the composite modified starch with excellent properties of high viscosity, good film-forming property, low gelatinization temperature, good viscoelasticity and the like; and the application of the special cassava modified starch in the food production of the instant noodles can lead the instant noodles to have the advantages of reducing the oil consumption, prolonging the rehydration time, increasing the elasticity, increasing the boiling resistance, not muddying the soup and the like and further increase the whiteness of a dough. The invention is applicable to enterprises with production conditions of the modified starch, and the adoption of an all-wet process route and a kneading machine or a dry powder stirring machine for production has no special requirements on production equipment.

Owner:广西农垦明阳生化有限公司

High-performance coating for composite material

ActiveCN103805041AImprove heat resistanceImprove hydrophobicityPolyurea/polyurethane coatingsCyanate compoundPrepolymer

The invention brings forward a high-performance coating for a composite material. The coating uses organosilicon modified polyurethane as a main resin component and comprises the following components by weight: 10 to 50 parts of polyurethane prepolymer and 5 to 30 parts of organosilicon modified polyurethane, wherein the organosilicon modified polyurethane is one selected from or a mixture of a block copolymer and a grafted copolymer, the content of organosilicon in the organosilicon modified polyurethane is 5% to 35%, the molecular weight of the organosilicon modified polyurethane is 2000 to 50000, the polyurethane prepolymer is one selected from or a mixture of cyanate prepolymer, hydroxyl terminated prepolymer, silicyl terminated prepolymer and acrylate terminated prepolymer, and the molecular weight of the polyurethane prepolymer ranges from 1000 to 100000. The coating provided by the invention has good heat resistance, hydrophobicity and weatherability; in use of the elastic coating, spraying pretreatment of a material surface is not needed, and the elastic coating has good adhesion.

Owner:GUANGDONG JANUS SMART GRP CO LTD

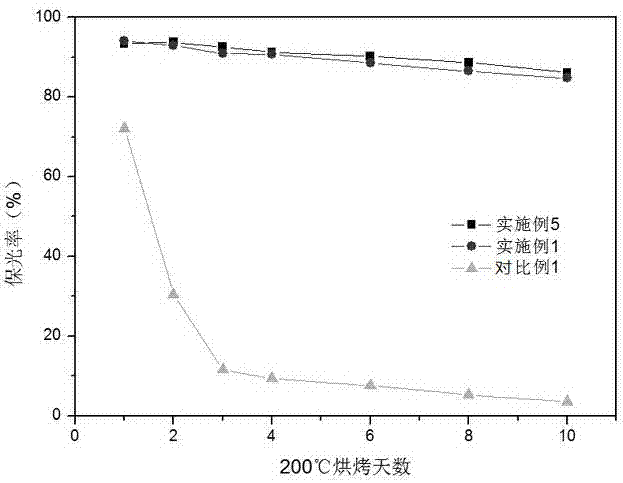

Pure polyester resin for TGIC cured high temperature resistant powder coatings, and preparation method thereof

ActiveCN104292441ASuitable glass transition temperatureAppropriate viscosityPowdery paintsPolyester coatingsGlass transitionMonomer

The invention discloses a pure polyester resin for TGIC cured high temperature resistant powder coatings. The acid value, the glass transition temperature, the softening point and the 200DEG C melt viscosity of the pure polyester resin are 30-35mgKOH / g, 70-78DEG C, 112-118DEG C and 15000-20000mPa.s respectively. The pure polyester resin is obtained through a melt condensation polymerization reaction of monomers comprising 33-38mass% of diol, 58-65mass% of aromatic dibasic acid, and 1.5-5mass% of polyol. The invention also discloses a preparation method of the pure polyester resin. The pure polyester resin has a high glass transition temperature and is suitable for a TGIC curing system, and powder coatings prepared by using the pure polyester resin have the advantages of excellent heat resistance, and no gloss loss and high gloss retention of coating layers baked at 270DEG C for 2h or baked at 300DEG C for 0.5h.

Owner:GUANGZHOU KINTE IND

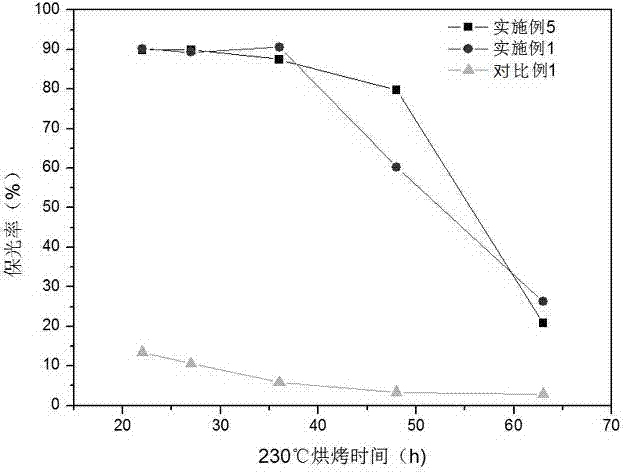

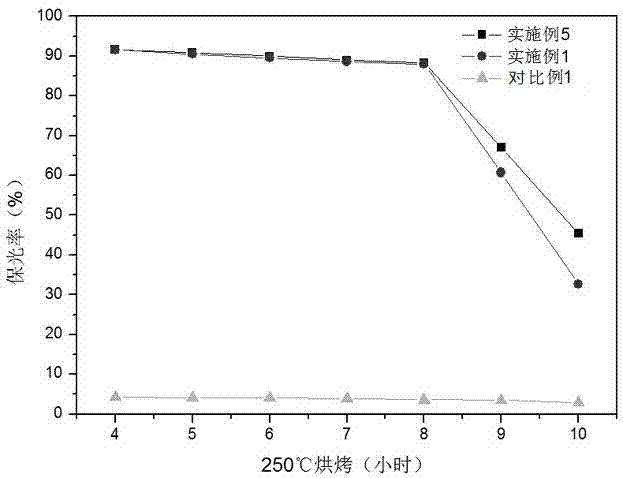

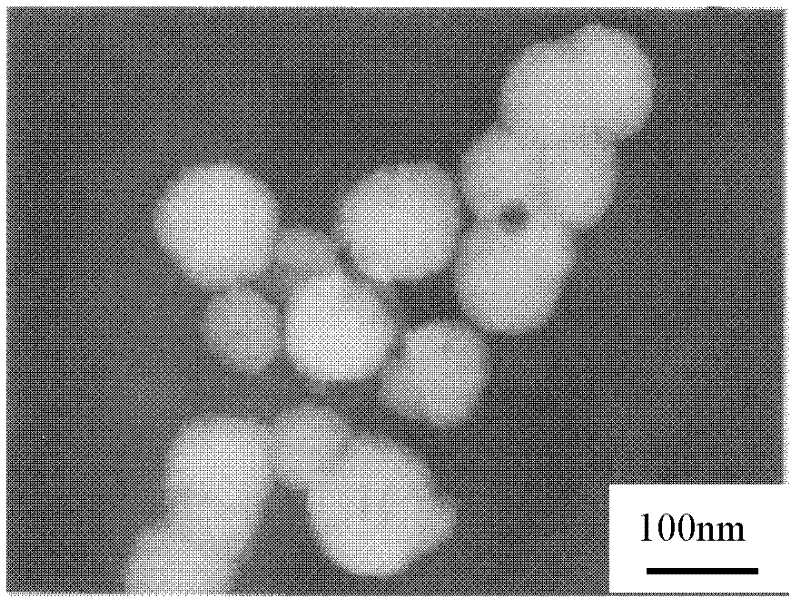

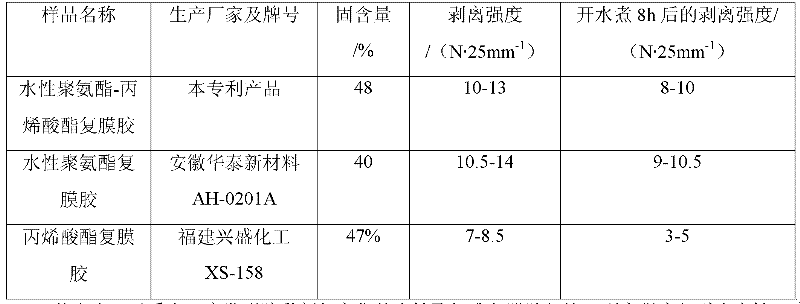

Preparation method of nuclear shell water-based polyurethane-acrylate composite emulsion adhesive for polyolefin film composition

ActiveCN102492383AImprove cohesive strengthStrong adhesionEster polymer adhesivesHydrocarbon polymer adhesivesWater basedPolyolefin

The invention discloses a preparation method of a core-shell water-based polyurethane-acrylate composite emulsion adhesive for polyolefin film lamination. The preparation method comprises: preparation of a vinyl-terminated net-shaped polyurethane emulsion, preparation of a core layer polyurethane-acrylate interpenetrating network polymer and preparation of the core-shell polyurethane-acrylate composite emulsion adhesive. By using the method, the defects that the existing water-based laminating glue product is low in adhering strength, poor in water tolerance and low in drying speed are solved. The adhesive prepared by using the method has the advantages of high peeling strength, good water tolerance, high drying speed and low VOC (volatile organic compound) content and the like.

Owner:HEFEI UNIV OF TECH

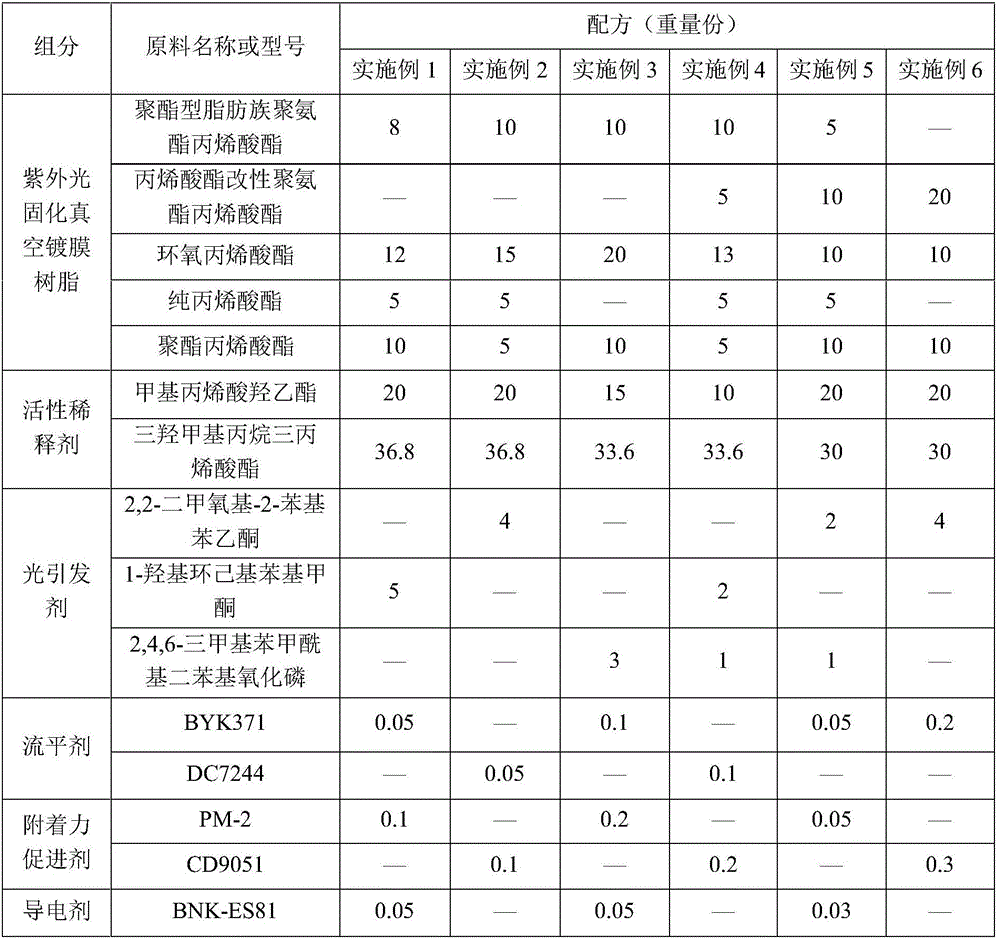

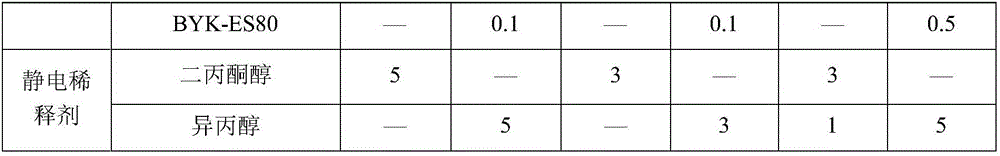

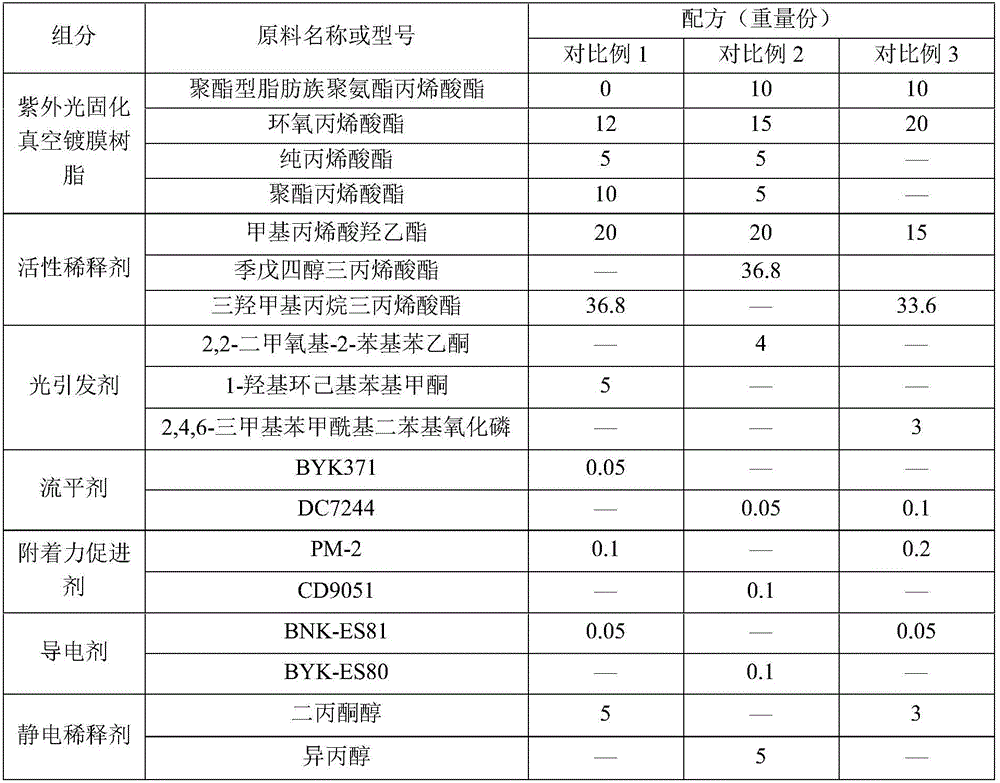

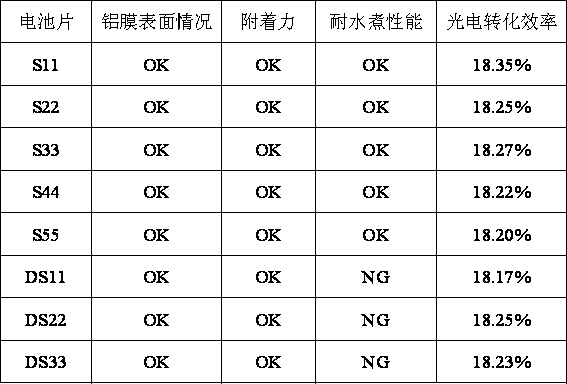

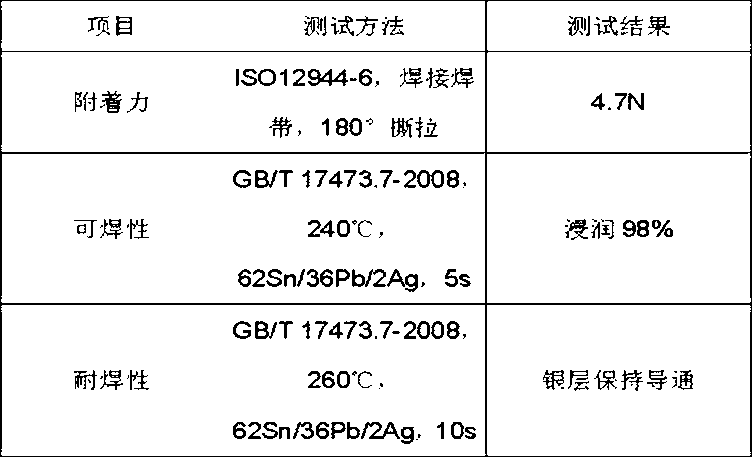

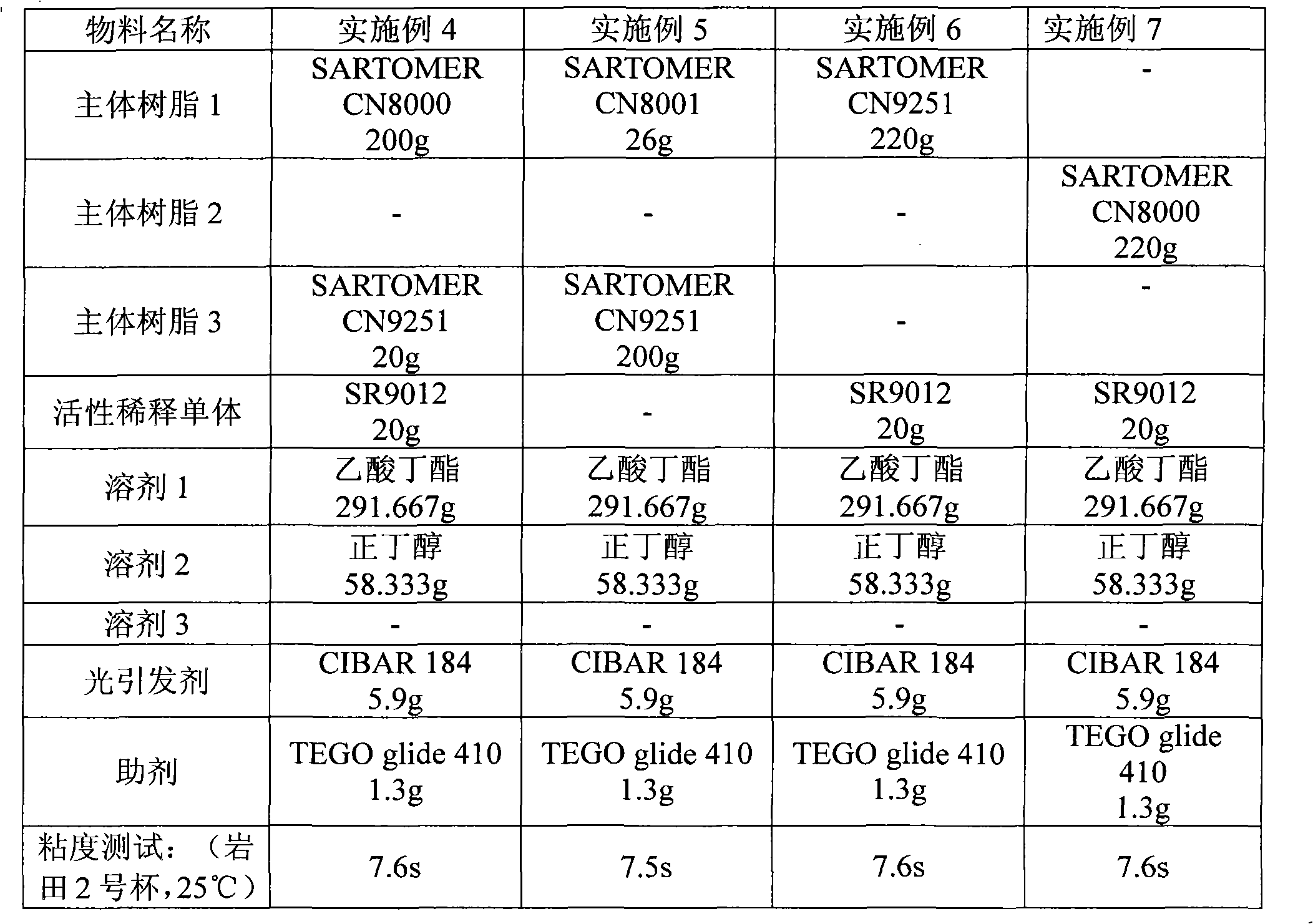

Ultraviolet curing vacuum coating metal primer capable of achieving electrostatic spraying

ActiveCN105670463ALow priceHigh viscosityPolyurea/polyurethane coatingsPowdery paintsUltravioletUrethane acrylate

The invention discloses ultraviolet curing vacuum coating metal primer capable of achieving electrostatic spraying and a preparation method thereof.The ultraviolet curing vacuum coating metal primer capable of achieving electrostatic spraying is prepared from, by weight, 5-20 parts of urethane acrylate, 10-20 parts of epoxy acrylate, 0-5 parts of pure acrylate, 5-10 parts of polyesteracrylate, 30-40 parts of trimethylolpropane triacrylate, 10-20 parts of low-functionality active diluted monomers, 2-5 parts of photoinitiator, 0.05-0.1 part of a flatting agent, 0.05-0.5 part of adhesion promoter, 0.01-0.5 part of a conductive agent and 3-5 parts of electrostatic thinner.The ultraviolet curing vacuum coating metal primer prepared through the method can be used for electrostatic spraying, has the advantages of being good in coating performance, good in adhesion, high in salt fog resistance, high in production efficiency, high in paint utilization rate and the like, and has wide market prospects.

Owner:GUANGDONG SHEN ZHAN IND CO LTD

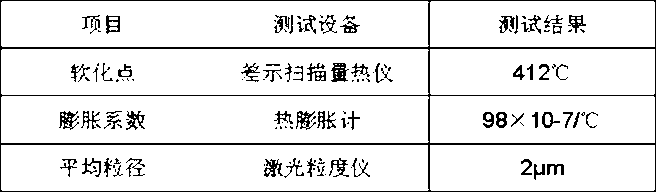

Glass raw material composition, inorganic glass powder, crystalline silicon solar battery aluminum conductive paste and preparation method of the crystalline silicon solar battery aluminum conductive paste

ActiveCN103130413AIncrease the oxidizing atmospherePrevent high temperature reductionNon-conductive material with dispersed conductive materialCable/conductor manufactureConductive pasteNitrate

The invention provides a glass raw material composition. The glass raw material composition comprises, by weight, 35 to 60 parts of Bi2O3, 10 to 30 parts of B2O3, 10 to 20 parts of SiO2, 1 to 5 parts of CaO, 0.5 to 5 parts of MgO, 0 to 5 parts of Al2O3, 3 to 8 parts of Sb2O3 and Sb2O5, and a nitrate of which the content is 0.5 to 1.5 times the content of Sb2O3, wherein the nitrate is magnesium nitrate or calcium nitrate. The invention also provides inorganic glass powder prepared from the glass raw material composition, crystalline silicon solar battery aluminum conductive paste prepared from the inorganic glass powder, and a preparation method of the crystalline silicon solar battery aluminum conductive paste. The clear inorganic glass powder can be prepared from the glass raw material composition and thus a battery piece prepared from the crystalline silicon solar battery aluminum conductive paste containing the inorganic glass powder has high photoelectric conversion efficiency and high water boiling resistance.

Owner:BYD CO LTD

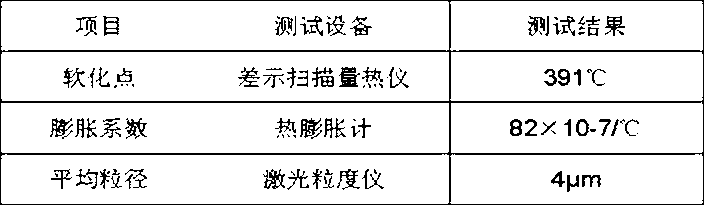

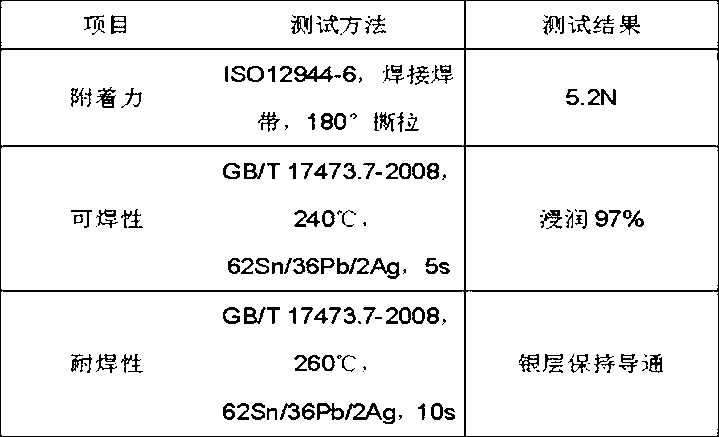

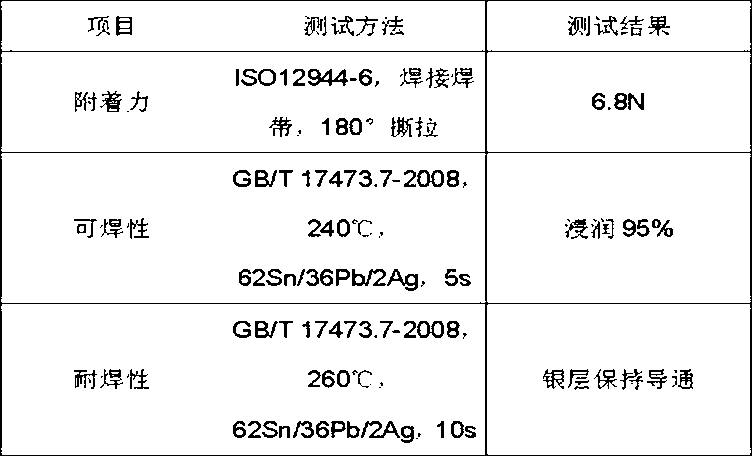

Lead-free glass powder for silver paste on back of crystalline silicon solar cell and preparation method thereof

The invention relates to a lead-free glass powder for silver paste on the back of a crystalline silicon solar cell and a preparation method thereof. The lead-free glass powder comprises the following raw materials in parts by weight: 40-70 parts of Bi2O3, 5-15 parts of B2O3, 0.5-5 parts of ZrO2, 10-20 parts of SiO2, 5-20 parts of ZnO, 1-5 parts of TiO2, 5-20 parts of Al2O3 and 1 part of P2O5. The preparation method comprises the following steps of: placing the raw materials in a mixer, and uniformly mixing to form a mixture; preheating a quartz crucible to 600-800 DEG C, placing the mixture in the quartz crucible and carrying out heat preservation for 20 minutes; then smelting for 20 minutes to 40 minutes at 900-1200 DEG C; pouring molten glass into deionized water for quenching, carrying out wet-process ball milling on the quenched glass to 2-5mu m, and drying to obtain the lead-free glass powder. The lead-free glass powder has the advantages that the technological process is simple, time consumption for smelting is short and cost is low; when in use, the lead-free glass powder has good wettability with silver powder and a silicon substrate; and after the lead-free glass powder is sintered, the adhesive force between the lead-free glass powder and the silicon substrate is above 5N.

Owner:JIANGSU ZHENGNENG ELECTRONICS TECH CO LTD

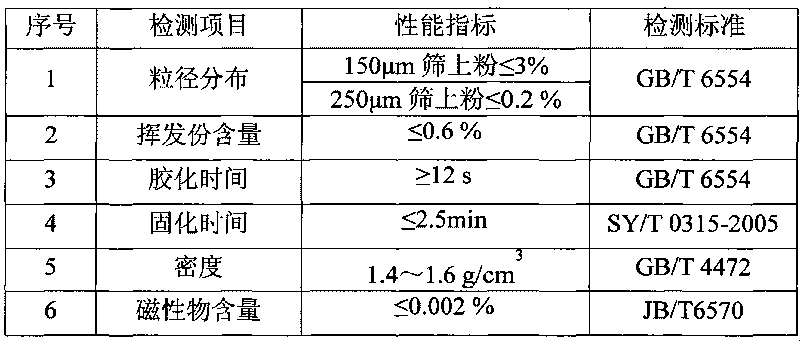

Boiling-endurable sand-ripple powder paint for coating corners of aluminum section and preparation method thereof

ActiveCN103483988AEfficient coatingImprove the powder ratePowdery paintsPolyester coatingsPolyester resinPowder coating

The invention discloses boiling-endurable sand-ripple powder paint for coating corners of an aluminum section. The paint comprises polyester resin, a curing agent, filler, conventional auxiliary, a sand ripple agent, pigment and gas-phase oxide. The invention also discloses a preparation method of the powder paint. The powder paint has an excellent coating performance on corners of an aluminum section, and has a high coating rate on corners of the aluminum section.

Owner:GUANGZHOU KINTE IND +1

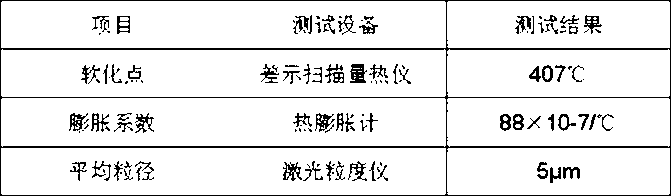

Unleaded back silver paste used for crystalline silicon solar cell and preparation method thereof

ActiveCN103219064ALow shrinkageGood printabilityNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteButyl carbitol

The invention relates to an unleaded back silver paste used for a crystalline silicon solar cell and a preparation method of the unleaded back silver paste used for the crystalline silicon solar cell. Raw materials comprise 60 parts of aluminum powder, 29-42 parts of organic binding agents and 1-10 parts of inorganic binding agents, the organic binding agents comprise 40-70 parts of terpilenol, 5-10 parts of butyl carbitol, 5-10 parts of butyl carbitol acetic ester, 3-10 parts of ethyl cellulose, 5-15 parts of diethyl phthalate and 2 parts of sorbitol anhydride stearate, and the inorganic binding agents comprise 30-60 parts of Bi2O3, 5-15 parts of B2O3, 1-2 parts of NaF, 10-20 parts of SiO2, 5-10 parts of ZnO, 1-5 parts of TiO2, 10-20 parts of Al2O3 and 2 parts of P2O5. After being mixed evenly, the components are rolled until the fineness degree is smaller than or equal to 10 microns, and viscosity is 30-100 Pa.s. The unleaded back silver paste used for the crystalline silicon solar cell is high in adhesive force and good in weldability and welding resistance.

Owner:JIANGSU ZHENGNENG ELECTRONICS TECH CO LTD

UV-light curing coating

The invention provides a UV-light curing coating, containing matrix resin, active diluent monomer, organic solvent, and light initiator, wherein the matrix resin is an oligomer body of three functional groups of aliphatic polyurethane acrylic ester and / or an oligomer body of six functional groups of aliphatic polyurethane acrylic ester. The UV-light curing coating has good boiling resistance, and after the coating is boiled for 24 h in boiling water (98-99 DEG C), the paint film still has highlight, no blistering and no shedding and is plump. The coating cannot break up matters under the condition of heating at a temperature of no higher than 200 DEG C, is safe and green, is the first choice of batch production, and can be widely applied in PC, PC / ABS and other plastic shells. At present, the coating is successfully used in the scan shell of a coffee machine.

Owner:浙江曼得丽涂料有限公司

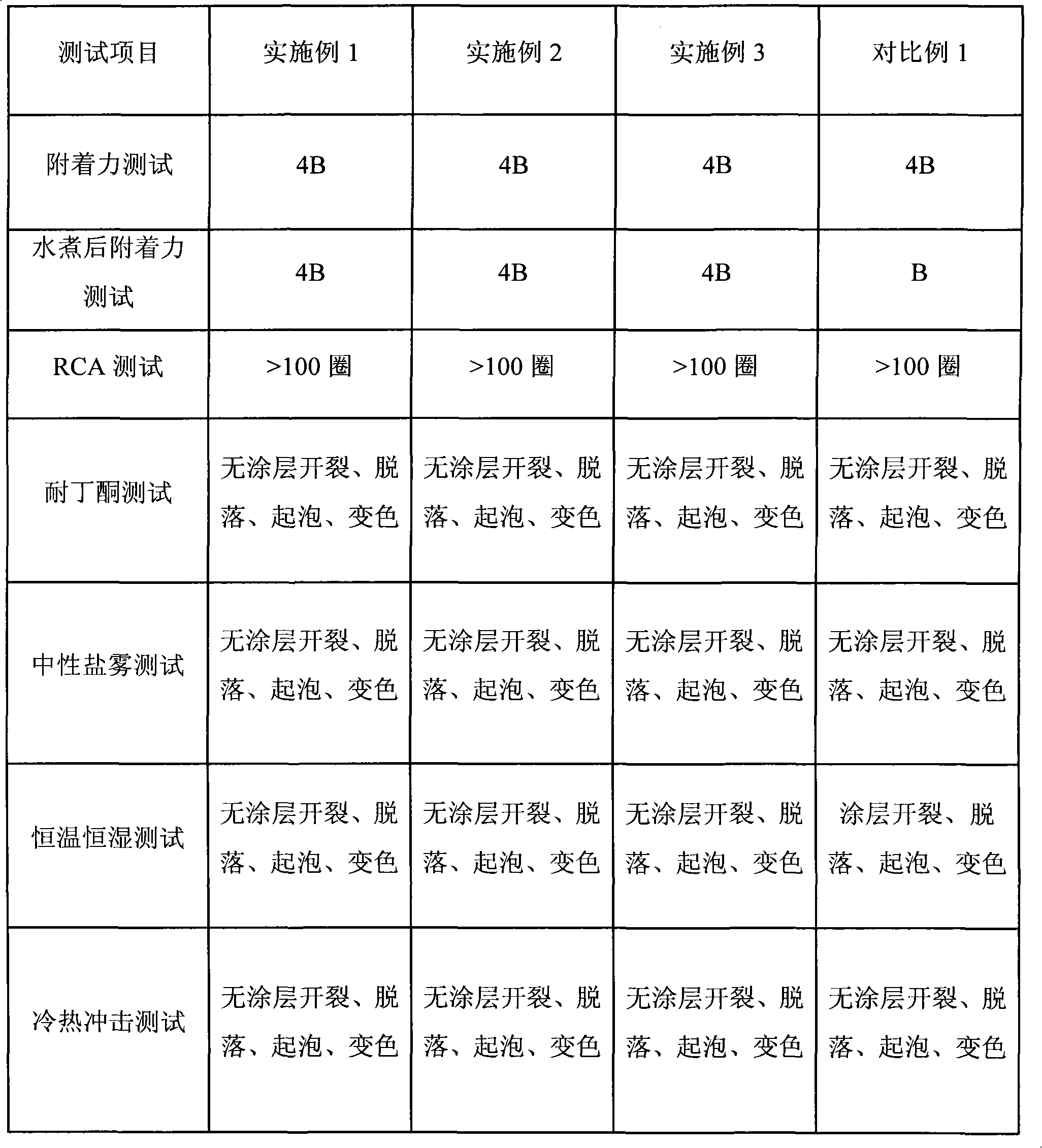

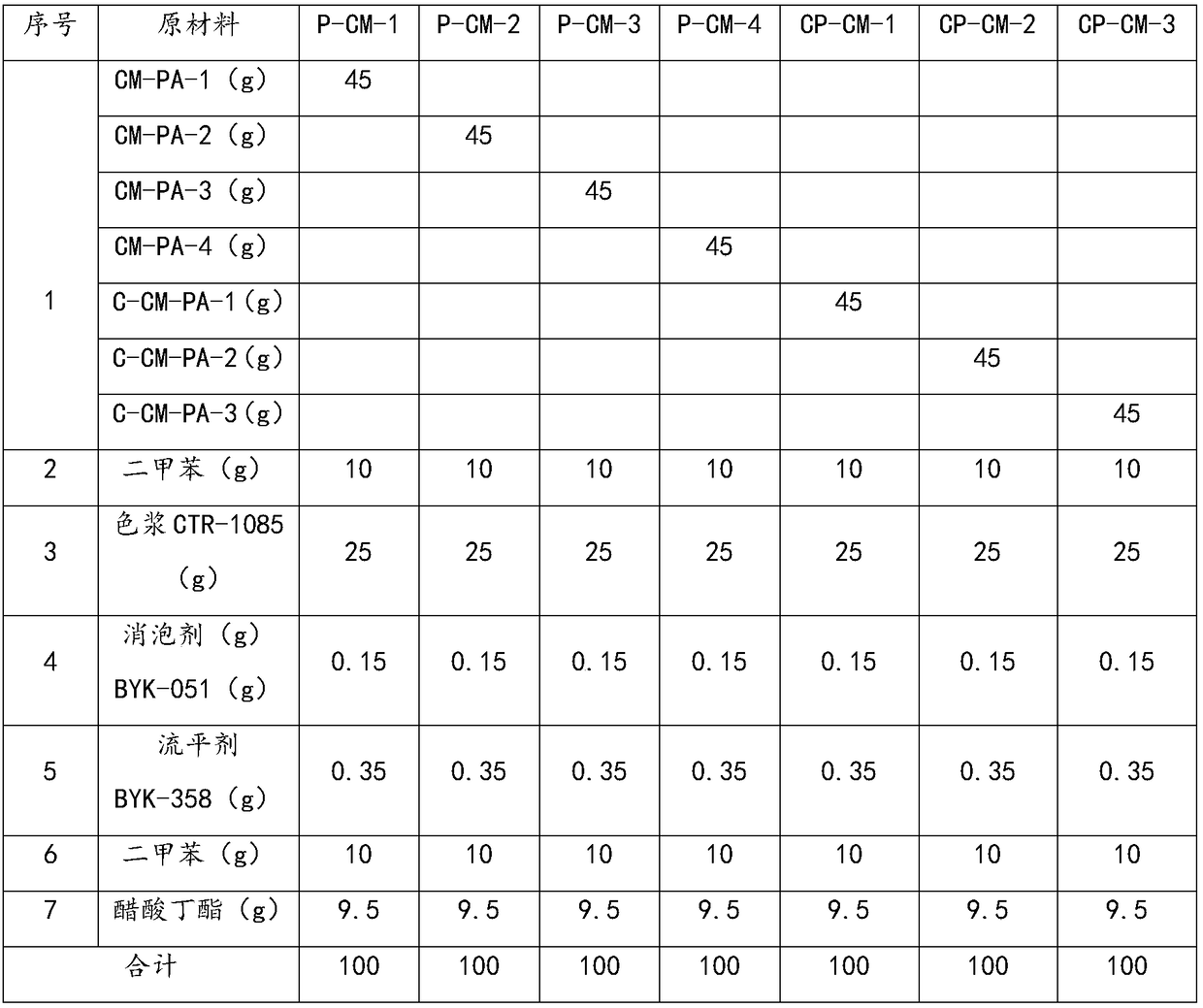

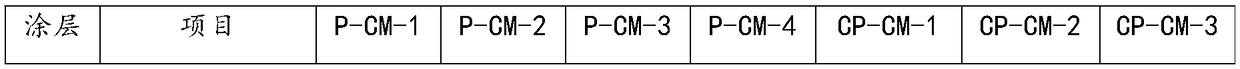

Chlorinated polypropylene-modified acrylic resin having excellent interlayer adhesion force and preparation method thereof

ActiveCN109400815AImprove water resistancePlay a protective effectCoatingsAdhesion forceFunctional monomer

The invention relates to the technical field of polymers, and particularly relates to chlorinated polypropylene-modified acrylic resin having excellent interlayer adhesion force and a preparation method thereof. The chlorinated polypropylene-modified acrylic resin is prepared from, by mass, 20-50% of a cosolvent, 5-20% of the chlorinated polypropylene, 3-15% of a polar monomer, 5-20% of a functional monomer, 0.05-3% of an initiator A, 15-50% of a vinyl monomer, and 0.05-3% of an initiator B. By grafting copolymerization of the chlorinated polypropylene and acrylic resin and introducing the polar monomer and functional monomer into resin, the resin is enhanced in polarity, so that the interlayer adhesion force of an undercoat, prepared by the synthetic resin, and a finishing coat layer; through a two-step dropwise adding method, the polar group and a naphthenic functional group, having strong hydrophobicity and large steric hindrance, are polymerized, so that the resin, on the basis ofthe excellent adhesion force, has excellent anti-water-boiling performance.

Owner:CHINA NAT OFFSHORE OIL CORP +3

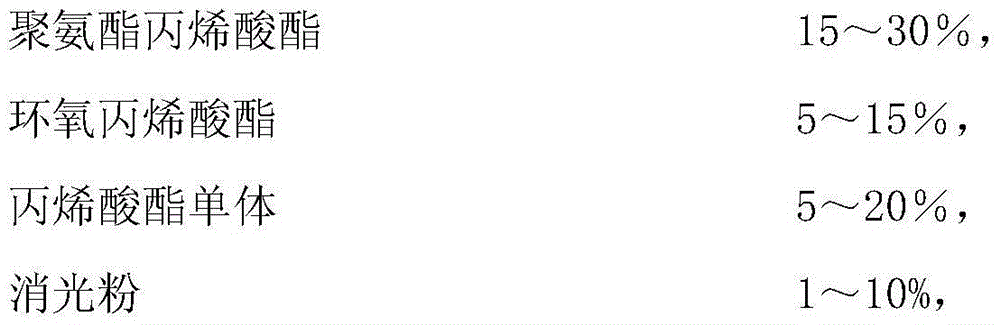

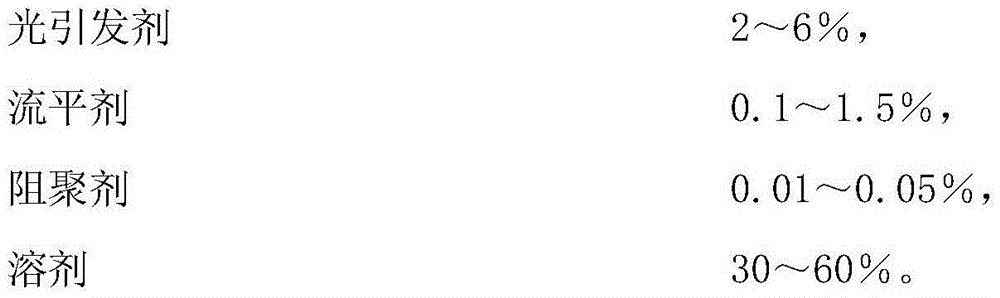

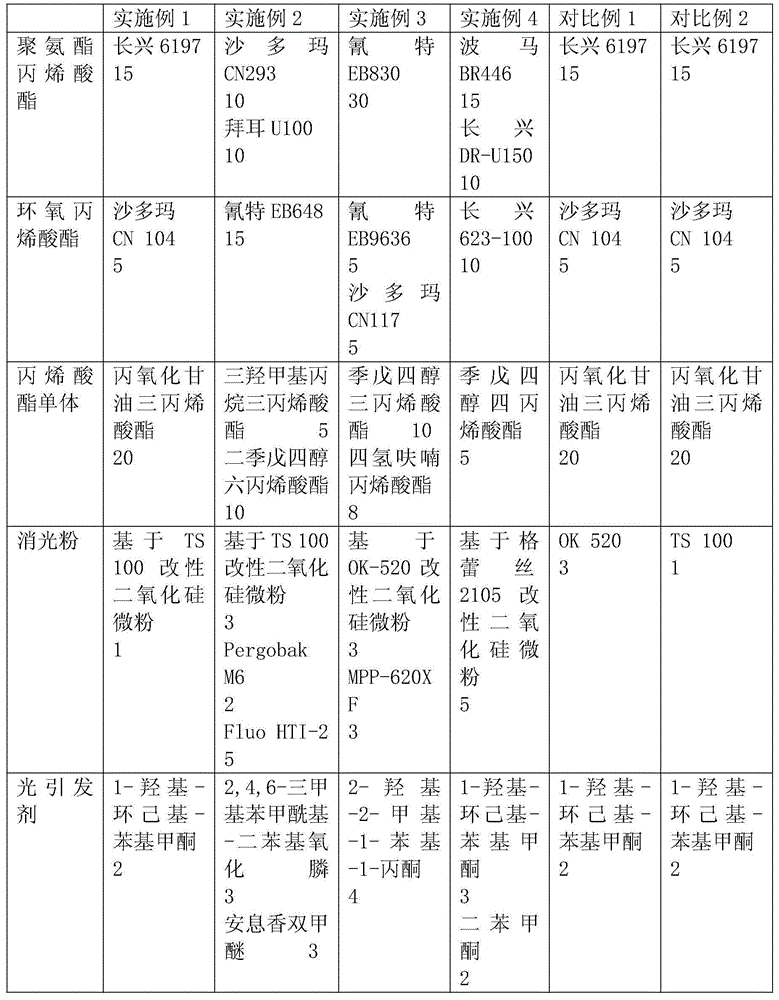

Matte ultraviolet-curing coating composition used for PET (polyethylene terephthalate) metal-imitating wire drawing film

InactiveCN103555186AUniform coatingHigh dumbnessPolyurea/polyurethane coatingsEpoxy resin coatingsPolyethylene terephthalate glycolUltraviolet

The invention relates to a matte ultraviolet-curing coating composition used for a PET (polyethylene terephthalate) metal-imitating wire-drawing film, and the matte ultraviolet-curing coating composition comprises the following components: by weight, 15 ~ 30% of polyurethane acrylate, 5 ~ 15% of epoxy acrylate, 5 ~ 20% of acrylate monomer, 1 ~ 10% of extinction powder, 2 ~ 6% of a light initiator, 0.1 ~ 1.5% of a levelling agent, 0.01 ~ 0.05% of a polymerization inhibitor and 30 ~ 60% of a solvent. Compared with the prior art, the matte ultraviolet-curing coating composition has high quality, good stability, good coating-film visual effects, and good PET film adhesion fastness and has good high scratch resistance, high impact resistance, high-temperature resistance, water cooking and chemical resistance and other excellent comprehensive performances.

Owner:SHANGHAI WEIKAI CHEM +1

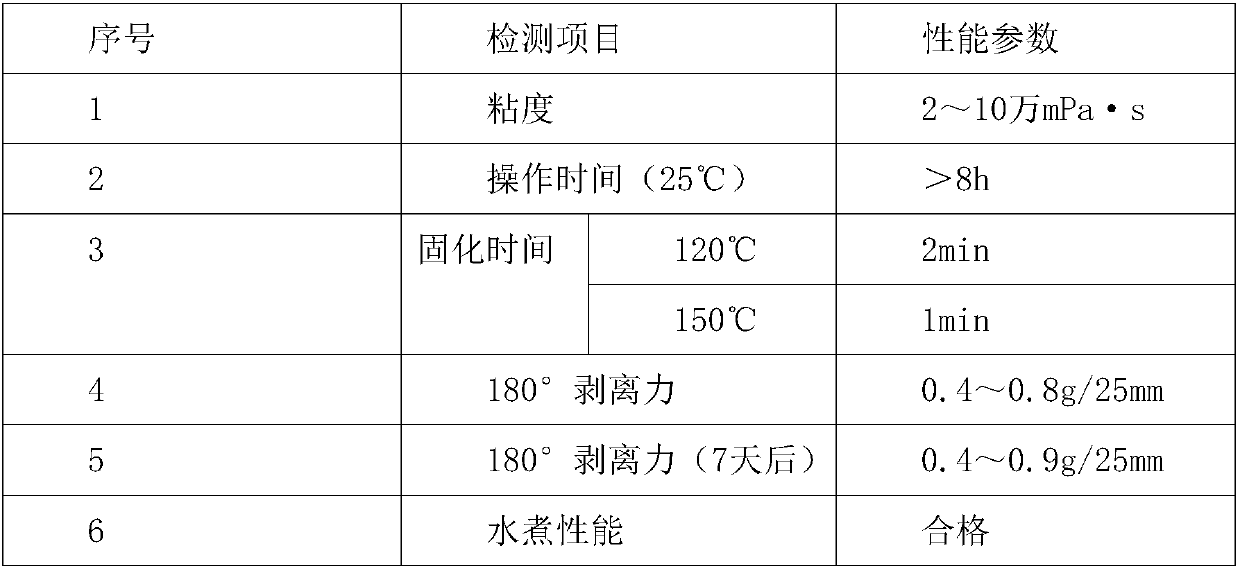

Organosilicon pressure-sensitive adhesive and preparation method thereof

InactiveCN110157374AReduce adhesionLow peel strengthMacromolecular adhesive additivesPressure sensitive film/foil adhesivesAdhesive materialsBond Force

The invention discloses an organosilicon pressure-sensitive adhesive, and a preparation method thereof, and belongs to the technical field of organosilicon pressure-sensitive adhesive material, and especially relates to an organosilicon pressure-sensitive adhesive extremely low in peel strength and a preparation thereof. The organosilicon pressure-sensitive adhesive is prepared from two vinyl polysiloxanes of different molecular weights, so that the organosilicon pressure-sensitive adhesive is provided with excellent levelability, and operationality; vinyl content and hydroxyl content are controlled, so that the organosilicon pressure-sensitive adhesive is provided with extremely low peel strength; an anchoring agent capable of taking part in crosslinking is selected, so that the bonding force of the organosilicon pressure-sensitive adhesive with PET base material is increased, and no degumming or picking is caused after 4h of water boiling. The organosilicon pressure-sensitive adhesive can be widely used in fields such as pressure-sensitive adhesive tape, electronic product protective film, or isolated film with requirements on low peel strength.

Owner:昆山普瑞凯纳米技术有限公司

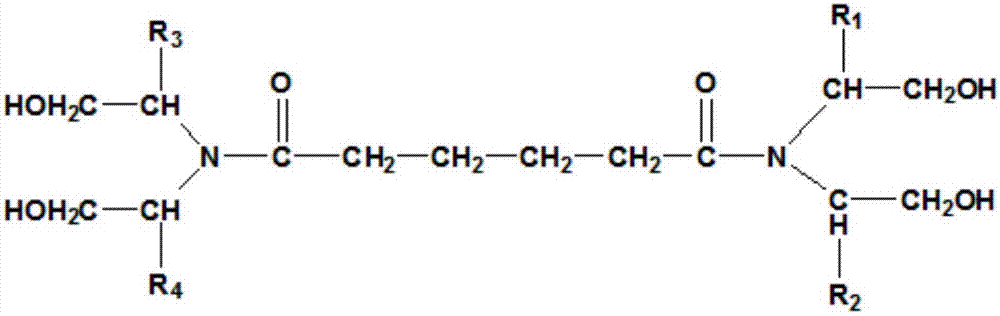

Waterborne polyester with excellent water boiling resistance, and preparation method thereof

InactiveCN107099024AExcellent molecular chain flexibilityImprove water resistancePolyester coatingsEpoxyPolyester

The invention discloses waterborne polyester with excellent water boiling resistance. The waterborne polyester with excellent water boiling resistance comprises, by mass, 40 to 80 parts of a polyol monomer at least containing dimerdiol, 40 to 80 parts of a polyacid monomer at least containing dimer acid, 10 to 30 parts of a branching agent, 10 to 50 parts of a hydrophilic monomer, 10 to 30 parts of an epoxy modifier, and 10 to 20 parts of a neutralizer. The waterborne polyester possesses excellent water boiling resistance and mechanical properties.

Owner:KITO CHEM CO LTD

Back passivation solar cell aluminum paste

InactiveCN106328249AImprove photoelectric conversion efficiencyImprove adhesionFinal product manufactureNon-conductive material with dispersed conductive materialFinenessCrystalline silicon

The invention relates to a back passivation solar cell aluminum paste, which is characterized in that the aluminum paste is composed of, by weight, 75 to 85% of aluminum powder, 2 to 8% of lead-free glass powder, 15 to 23% of an organic bond, 1.5 to 3.6% of an inorganic bond, the remaining being an organic carrier, wherein the sum of weight percents of all components is 100%; and the aluminum powder, the organic bond, the inorganic bond, the organic carrier and the lead-free glass powder are uniformly mixed and then rolled by using a three-roll grinder to be the back passivation solar cell aluminum paste with the fineness no more than 15 mum and the viscosity 25 to 37 Pa.s. The crystalline silicon solar cell back field aluminum paste has the advantages that the photoelectric conversion efficiency is high; the adhesion is high; the adhesion conversion efficiency attenuation after high-temperature aging is reduced; and the water boiling-resistance performance is good.

Owner:JIANGSU ZHENGNENG ELECTRONICS TECH CO LTD

Crystalline silicon solar cell back surface field aluminum paste and preparation method thereof

ActiveCN103208321AUniform fluidityBalanced thixotropyNon-conductive material with dispersed conductive materialCable/conductor manufactureBack surface fieldWater boil

The invention relates to crystalline silicon solar cell back surface field aluminum paste and a preparation method thereof. The crystalline silicon solar cell back surface field aluminum paste comprises, by weight, 74 parts of aluminum powder, 20-25 parts of organic bonds, 1-4 parts of lead-free glass powder and 0.1-2 parts of additives, wherein the organic bond comprises, by weight, 40-70 parts of terpineol, 5-10 parts of butyl carbitol, 5-10 parts of butyl carbitol acetic ester, 3-10 parts of ethyl cellulose, 5-15 parts of dibutyl phthalate and one part of sorbitol anhydride stearate; the lead-free powder comprises, by weight, 30-60 parts of Bi2O3, 5-15 parts of B2O3, 3 parts of BiF3, 10-20 parts of SiO2, 5-10 parts of ZnO, 1-5 parts of TiO2, 10-20 parts of Al2O3 and 1-3 parts of P2O5; and the additive is spherical copper powder with the purity larger than 99% and the fineness being 20000 meshes. The aluminum powder, the organic bonds, the lead-free glass powder and the additives are evenly mixed and then rolled by a three-roll grinder until the fineness is smaller than or equal to 10 mum and the viscosity is 30-60Pa*s. The crystalline silicon solar cell back surface field aluminum paste is high in photoelectric conversion efficiency and adhesive force, the adhesive force conversion efficiency after high temperature aging declines, and the water-boiling resistance is good.

Owner:JIANGSU ZHENGNENG ELECTRONICS TECH CO LTD

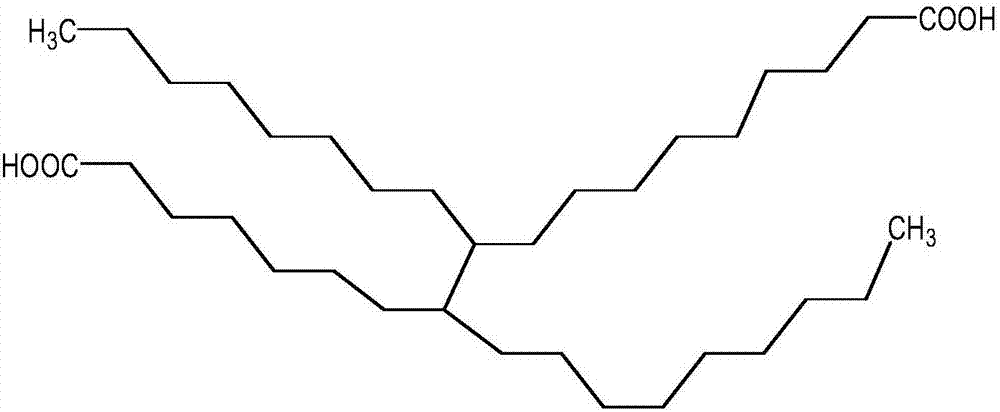

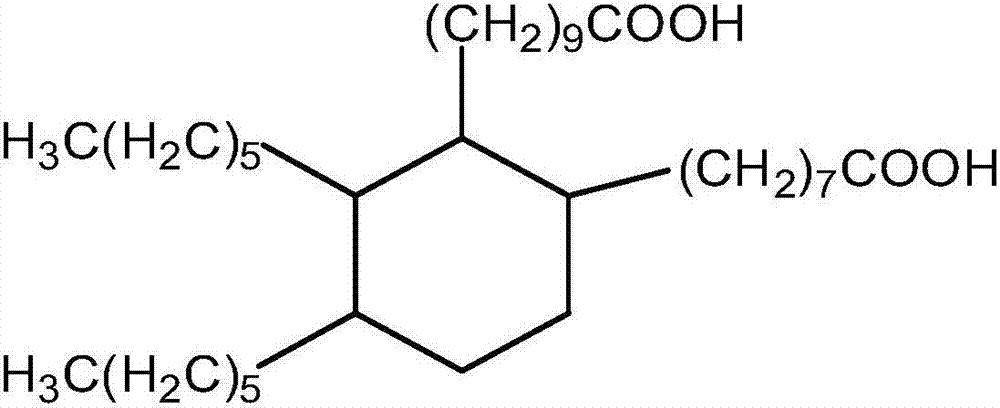

Polyester resin used for beta-hydroxyl alkyl amide solidified powdery paint having good water resistance and preparation method thereof

InactiveCN107254035AImprove hydrophobicityGood water resistancePowdery paintsPolyester coatingsChemistryWater resistance

The invention relates to polyester resin used for a powdery paint and a preparation method thereof, and provides the polyester resin used for the beta-hydroxyl alkyl amide solidified powdery paint having good water resistance and the preparation method thereof. The polyester resin comprises the following components by mass percentage through melt polymerization: a polyol component A, a polyatomic acid component B, a hydrogenated dimeric acid component C, an esterification catalyst component D, an alcoholysis agent component E and an anti-oxidant component F; the method comprises the following steps: adding the component A, then adding the component B, the component C and the component D, stirring the materials while heating gradually; performing fusion and esterification condensation; adding the component E and performing an acidolysis reaction; adding the component F, stirring the materials for a reaction; cooling the material and discharging the material, and cooling the product and crushing the product. A beta-hydroxyl alkyl amide solidified powdery paint film prepared by the polyester resin has excellent water resistance and boiling resistance, excellent levelability and fullness, and has machinery performances such as good impact resistance and bending.

Owner:ZHEJIANG CHUANHUA TIANSONG NEW MATERIAL CO LTD

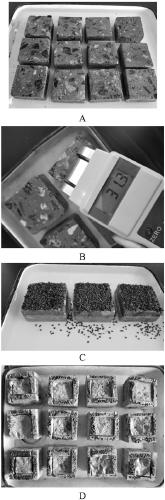

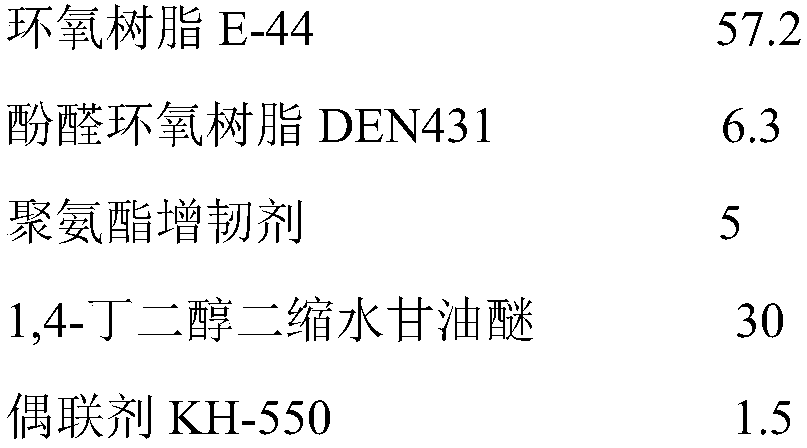

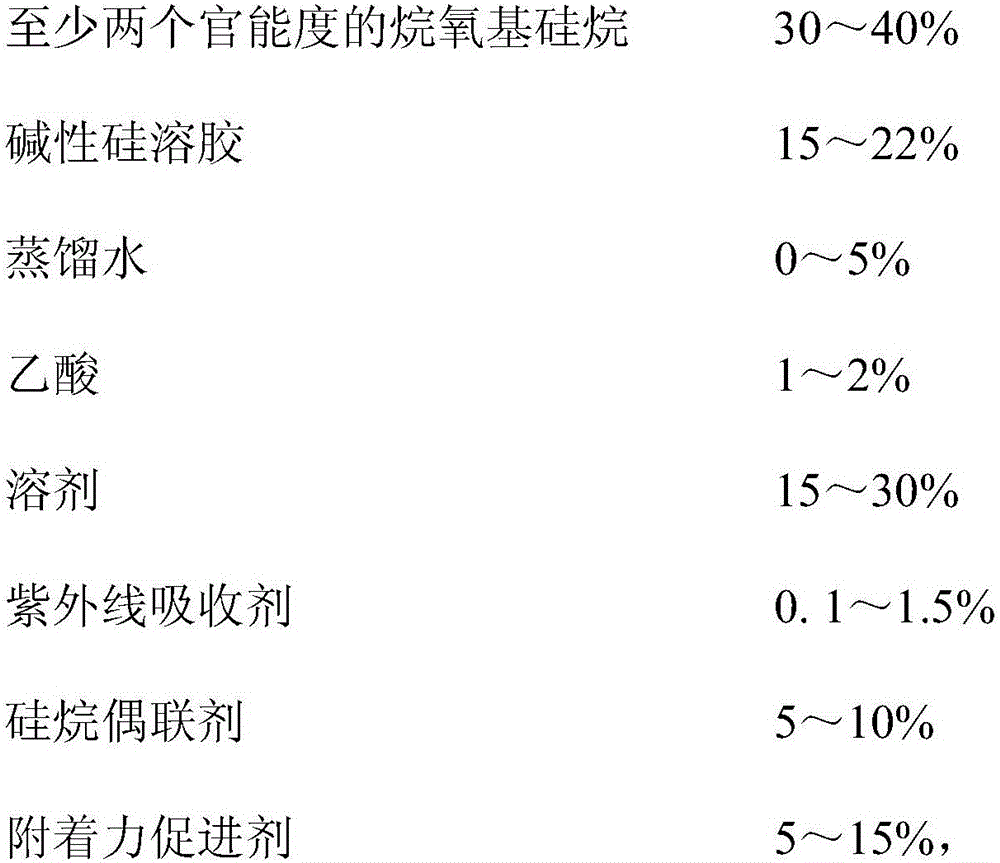

Thin layer paving material for wet road and bridge surface, and preparation method thereof

The invention discloses a thin layer paving material for a wet road and bridge surface. The thin layer paving material comprises an epoxy resin binder and a wear-resistant aggregate, wherein the epoxyresin binder comprises a component A and a component B according to a mass ratio of 1:(0.5-0.85), the component A mainly comprises the following raw materials: 60-80 parts of an epoxy resin, 5-15 parts of a toughening agent, 10-30 parts of an active dilution agent, and 0.5-1.5 parts of a coupling agent, and the component B mainly comprises the following raw materials: 5-8 parts of a curing accelerator, and 92-95 parts of a curing agent. The invention further discloses a preparation method of the thin layer paving material for the wet road and bridge surface. According to the present invention, the thin layer paving material can be used for wet road and bridge surfaces, and has advantages of good sliding resistance, excellent wear resistance, excellent interface bonding performance, good water resistance, low water absorption, good boiling aging resistance and good durability.

Owner:广东建科交通工程质量检测中心有限公司

Wear resistance and anti-ultraviolet coating for polycarbonate and preparation thereof

The invention discloses a wear resistance and anti-ultraviolet coating for polycarbonate, and the coating is prepared through the following method: adding alkaline silica sol, distilled water, ultraviolet light absorber and acetic acid into a reactor; heating, and starting to dropwise add alkoxy silane with at least two degrees of functionality when a system temperature reaches 60 DEG C, wherein the dropwise adding takes 1 to 3 hours and the reaction system temperature in a dropwise adding process is controlled to be 60 to 72 DEG C; adding an adhesion promoter for heating and refluxing for 0.5 to 2 hours after dropwise adding, and adding a silane coupling agent and a solvent after cooling to below 40 DEG C. The coating layer obtained from the coating has performances of good transparency, wear resistance, water resistance, anti-ultraviolet ageing and the like.

Owner:中昊北方涂料工业研究设计院有限公司

Transparent acrylic acid intermediate-coating paint base stock and preparation method thereof

ActiveCN103254715AImprove boiling resistanceNo difference in high temperature and high humidity resistanceCoatingsCyclohexanonePolycarbonate plastic

The invention discloses a transparent acrylic acid intermediate-coating paint base stock and a preparation method thereof. The base stock comprises the following ingredients in percentage by weight: 40.0%-45.0% of polymethyl methacrylate, 35.0%-40.0% of iso-octyl methacrylate, 1.0%-5.0% of butyl acetate, 1.0%-5.0% of isobutyl acetate, 1.0%-5.0% of cyclohexanone, 1.0%-5.0% of methyl ethyl ketone, 1.0%-5.0% of methyl isobutyl ketone, and 0-3.5% of cellulose acetate. The transparent acrylic acid intermediate-coating paint base stock can meet the requirement of mobile phone industry on no halogen in paint. Transparent acrylic acid intermediate-coating paint produced by the base stock is additionally provided with a mating curing agent, spraying diluents, halogen-free acrylic acid primer and ultraviolet radiation curing finishing paint for use and then is sprayed onto polycarbonate ester plastics, and a dried and cured coating has excellent boiling resistance.

Owner:深圳市美丽华科技股份有限公司

Self-catalysis fast curing type pure polyester resin as well as preparation method and application thereof

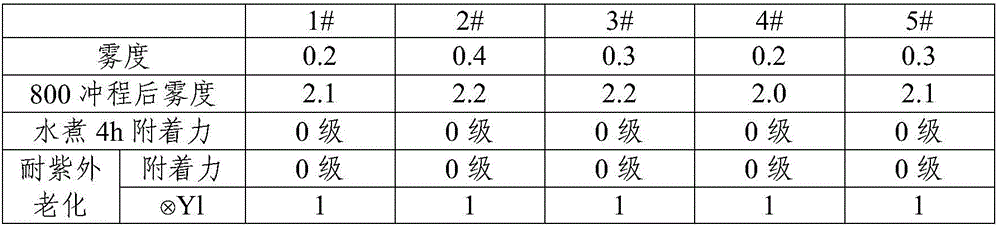

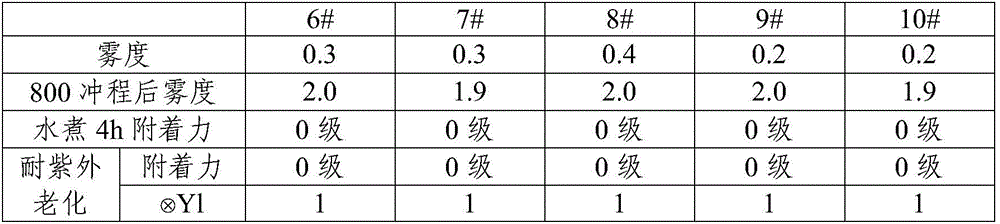

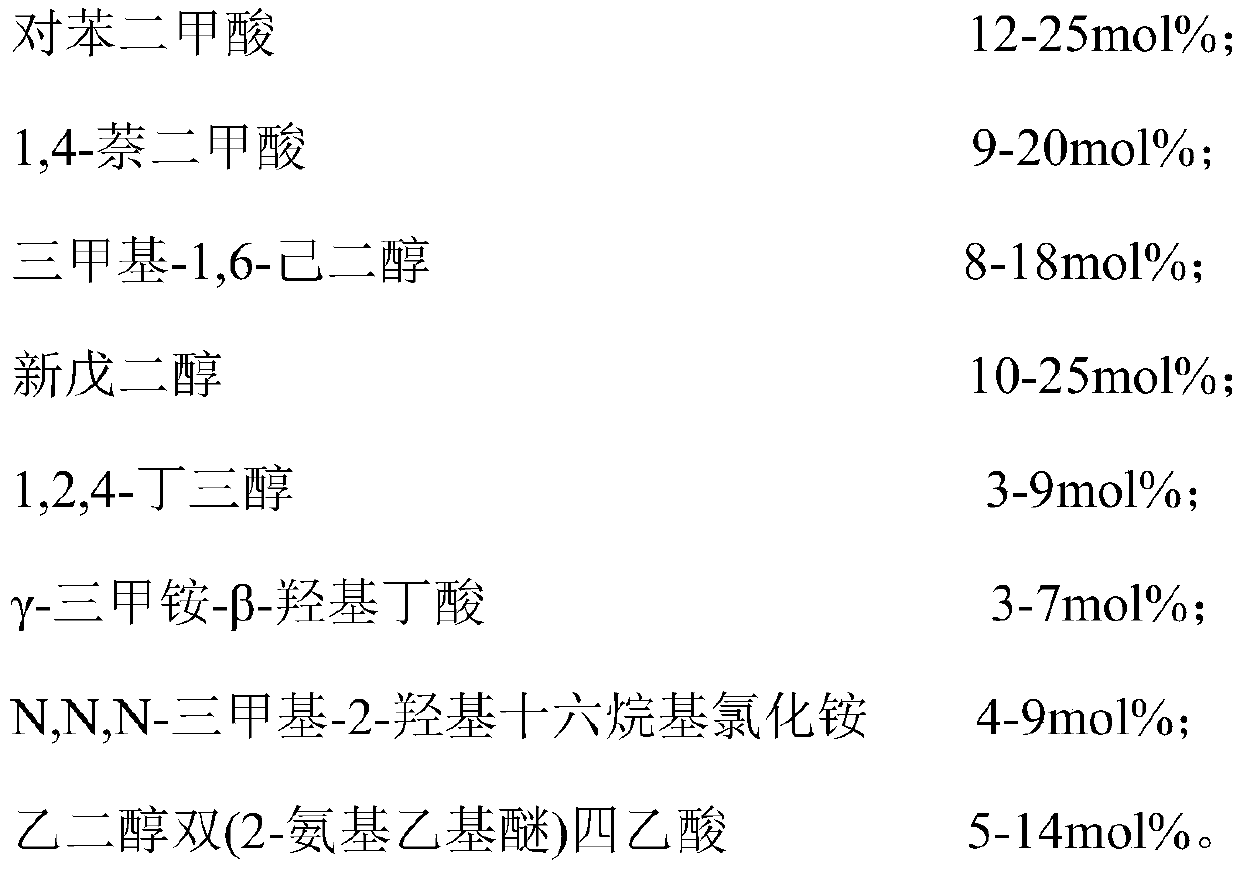

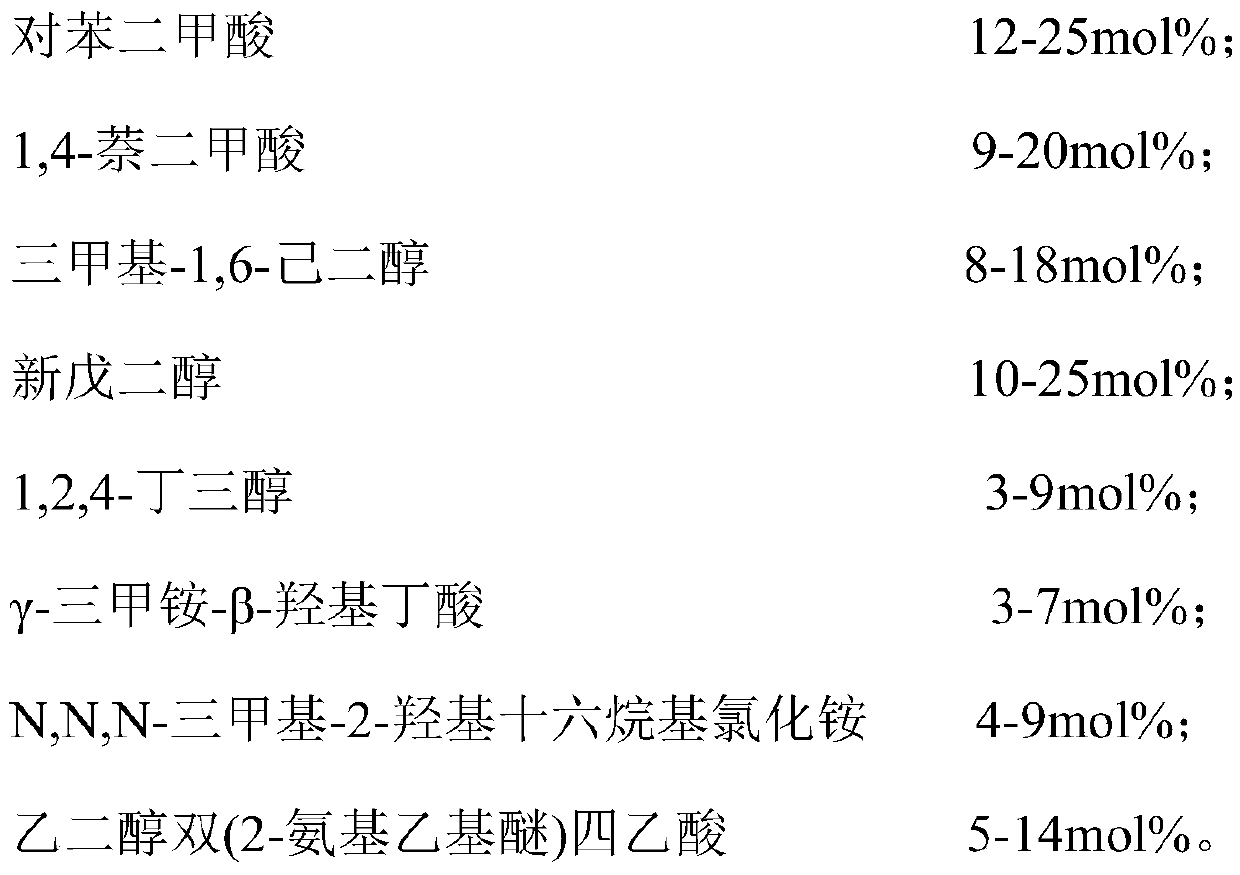

ActiveCN109880072AOutstanding self-catalysis performanceImprove boiling resistancePowdery paintsPolyester coatingsBeta-Hydroxybutyric acidButanediol

The invention belongs to the technical field of powdery paint, and particularly relates to self-catalysis fast curing type pure polyester resin, and further discloses a preparation method of the elf-catalysis fast curing type pure polyester resin and a purpose of the elf-catalysis fast curing type pure polyester resin for preparing outdoor TGIC powder paint. The self-catalysis fast curing type pure polyester resin is prepared by using terephthalic acid, 1,4-naphthalic acid, trimethyl-1,6-hexanediol, neopentyl glycol, 1,2,4-butanediol, gamma-trimethylamine-beta-hydroxybutyric acid, N,N,N-trimethyl-2-hydroxyhexadecyl ammonium chloride and glycol bis(2-aminoethyl ether) tetraacethyl as raw materials through polymerization. The self-catalysis performance of the polyester resin is prominent; the curing activity is high; under the condition without additionally adding a curing accelerant, the fast curing with a curing agent TGIC can be realized. A curing membrane prepared by the self-catalysis fast curing type pure polyester resin has excellent performance; the performance in all aspects better reaches the use requirements of outdoor pure polyester resin.

Owner:黄山市向荣新材料有限公司

Photosensitive developed special line transfer glue for sapphire glass base material and preparation method thereof

InactiveCN108517196AImprove performanceGood synergyNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPhosphate

The invention discloses photosensitive developed special line transfer glue for a sapphire glass base material and a preparation method thereof. The photosensitive developed special line transfer glueis prepared from an acrylic ester active monomer, a photoinitiator, an acrylic acid phosphate assistant, a silane coupling agent, polyester acrylate, and urethane acrylate. The transfer glue does notcontain an organic solvent, and is environmentally friendly. A transfer technology is used as the foundation, and the advantages of a photosensitive developing technology are organically fused, the advantages are adopted and the defects are avoided. Especially, a product of the transfer glue not only can use the organic solvent for developing, but also can use pure water for developing, and is environmentally friendly, non-inflammable and non-explosible, and is a future tendency. The transfer glue has the excellent properties of solvent corrosion resistance, cold and thermal shock resistanceand the like after curing, and an adhesive force of a glue layer and the sapphire glass base material is excellent, especially, the adhesive force of the glue layer and the sapphire glass base material is greater than or equal to 4B after a water boiling test. The transfer glue is capable of solving problems of current UV glue that the adhesive force on the sapphire glass base material is poor, the water boiling is not resistant, and the solvent is not resistant.

Owner:SUZHOU BETELY POLYMER MATERIALS CO LTD +1

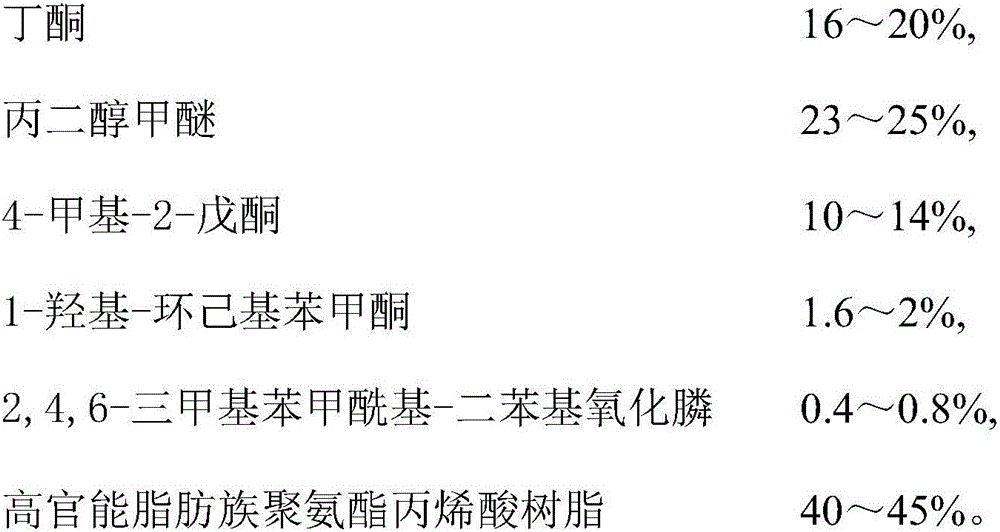

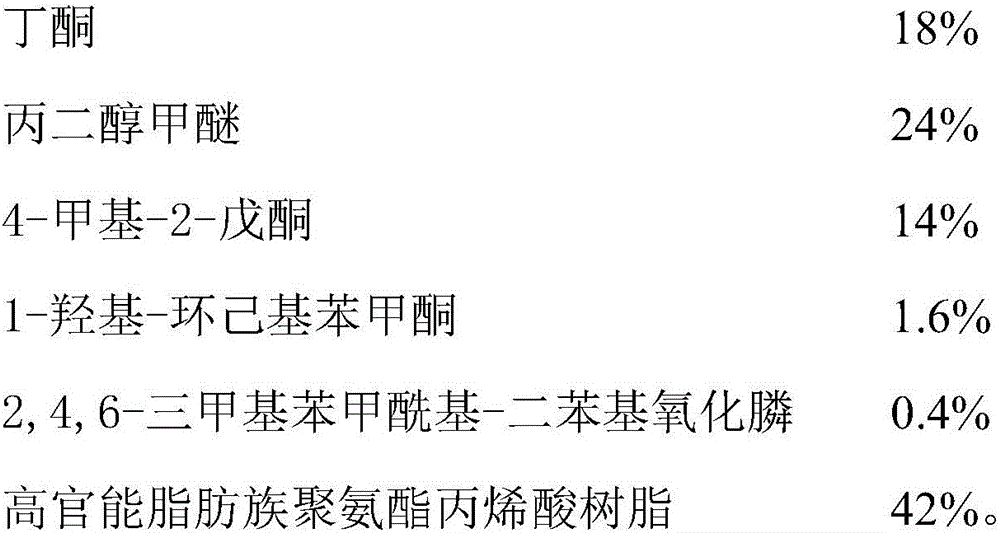

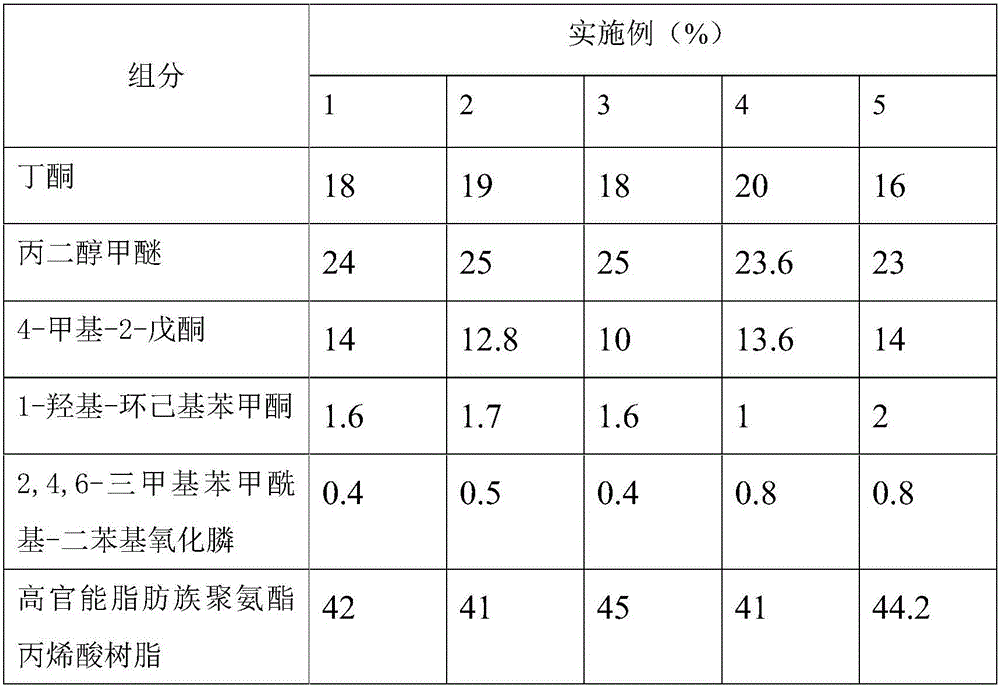

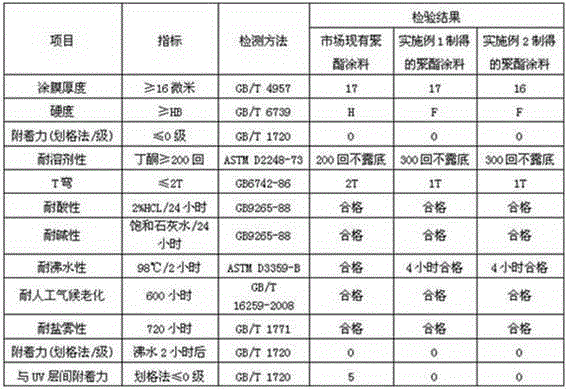

UV hardening liquid for PET electronic membrane as well as preparation method and application thereof

InactiveCN106833356ALow viscosityImprove adaptabilityPolyurea/polyurethane coatingsAcrylic resinDiphenylphosphine oxide

The invention discloses UV hardening liquid for a PET electronic membrane. According to the key points of the technical scheme, the UV hardening liquid for the PET electronic membrane comprises the following components by weight percent: 16-20% of butanone, 23-25% of propylene glycol monomethyl ether, 10-14% of 4-methyl-2-pentanone, 1.6-2% of 1-hydroxyl- phenylcyclohexyl ketone, 0.4-0.8% of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide and 40-45% of highly functionalized aliphatic polyurethane acrylic resin. The invention aims at overcoming the defects of existing solvent type UV hardening paint and providing economic applicable UV hardening liquid which is used for the PET electronic membrane, simple in preparation technology and convenient and efficient to use and has excellent optical and physical properties after film formation. The invention provides a preparation method of the UV hardening liquid. The invention also provides application of the UV hardening liquid.

Owner:ZHONGSHAN BOHAI SPECIAL CHEM CO LTD

Environment-friendly polyester coating for aluminum-plastic composite panel and preparation method of coating

InactiveCN104479515AGood weather resistanceImprove water resistanceAnti-corrosive paintsPolyester coatingsPhosphateAntioxidant

The invention discloses an environment-friendly polyester coating for an aluminum-plastic composite panel and a preparation method of the coating. The coating is prepared from the following components in percentage by mass: 40-50% of saturated polyester resin, 5-8% of enclosed curing agent, 0.1-0.3% of organic tin catalyst, 28-32% of titanium dioxide, 0.5-1% of epoxy phosphate resin, 0.5-1% of antioxidant, 0.5-1% of ultraviolet light absorber, 1-3% of other auxiliaries and 12-20% of mixed solvent; the components are selected according to the formula, and the saturated polyester resin, the mixed solvent and the auxiliaries are put into a mixer for primary mixing; the titanium dioxide and the mixed solvent are added to the mixer for secondary mixing; the mixture is ground by use of a basket mill to obtain a semi-finished product; the semi-finished product and the other components of the formula are added for third mixing and dispersed evenly to obtain the finished product; the environment-friendly polyester coating can be used independently as an aluminum-plastic composite panel finishing coat or as a UV jet-ink primer, so that the application range of the UV jet-ink is expanded.

Owner:SUZHOU COLOR WAY ENTERPRISE DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com