Self-catalysis fast curing type pure polyester resin as well as preparation method and application thereof

A polyester resin, fast curing technology, used in polyester coatings, coatings, powder coatings, etc., can solve problems such as loss of catalytic activity, poor film performance stability, and inability to guarantee curing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

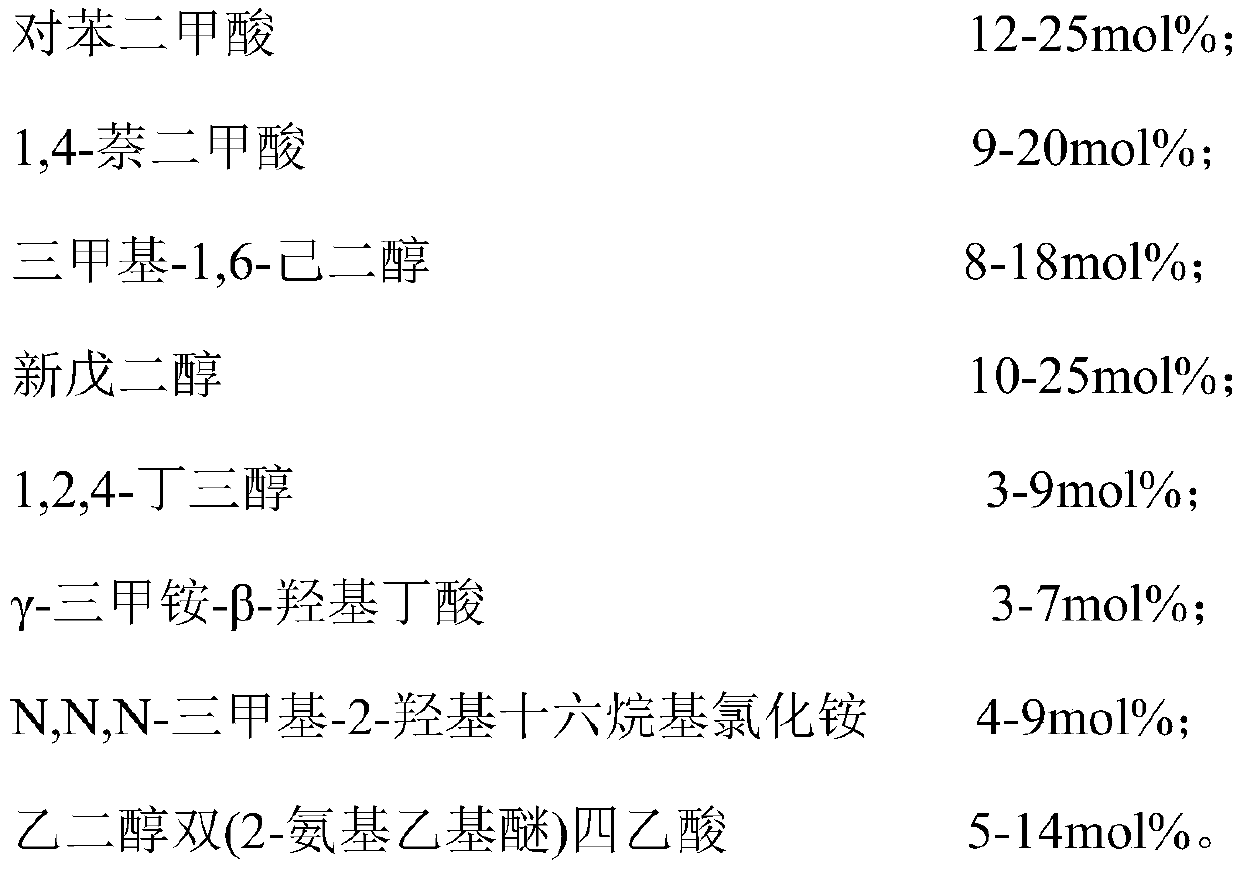

[0027] The self-catalyzed fast-curing pure polyester resin described in this embodiment, based on the total amount of raw materials for preparing the polyester resin, includes the following raw material components in molar percentages:

[0028]

[0029] The preparation method of self-catalyzed fast curing type pure polyester resin of the present invention comprises the steps:

[0030] (1) Mix the catalyst, terephthalic acid, 1,4-naphthalene dicarboxylic acid, trimethyl-1,6-hexanediol and neopentyl glycol in the formula amount, and first control the temperature below 165°C Esterification reaction 3-6h;

[0031] (2) When the acid value of the mixed material is reduced to 180mgKOH / g or below, nitrogen is introduced into the reaction system for protection, and the temperature of the above mixed material is gradually raised to 205°C at a heating rate of 5°C / h for heat preservation reaction 4-8h;

[0032] (3) When the acid value of the reaction mixture is reduced to 75mgKOH / g o...

Embodiment 2

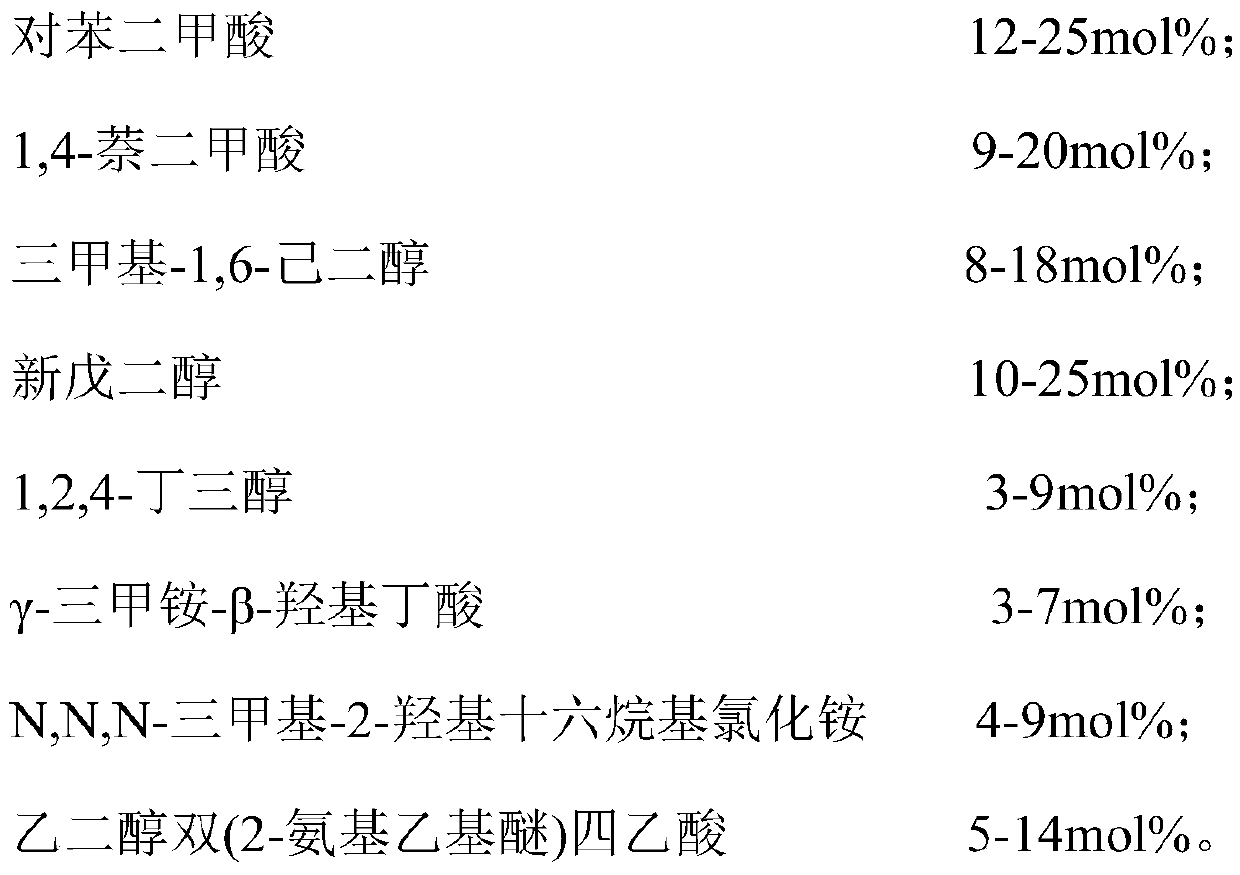

[0038] The self-catalyzed fast-curing pure polyester resin described in this embodiment, based on the total amount of raw materials for preparing the polyester resin, includes the following raw material components in molar percentages:

[0039]

[0040]

[0041] The preparation method of self-catalyzed fast curing type pure polyester resin of the present invention comprises the steps:

[0042](1) Mix the catalyst, terephthalic acid, 1,4-naphthalene dicarboxylic acid, trimethyl-1,6-hexanediol and neopentyl glycol in the formula amount, and first control the temperature below 165°C Esterification reaction 3-6h;

[0043] (2) When the acid value of the mixed material is reduced to 180mgKOH / g or below, nitrogen is introduced into the reaction system for protection, and the temperature of the above mixed material is gradually raised to 215°C at a heating rate of 5°C / h for heat preservation reaction 4-8h;

[0044] (3) When the acid value of the reaction mixture is reduced to ...

Embodiment 3

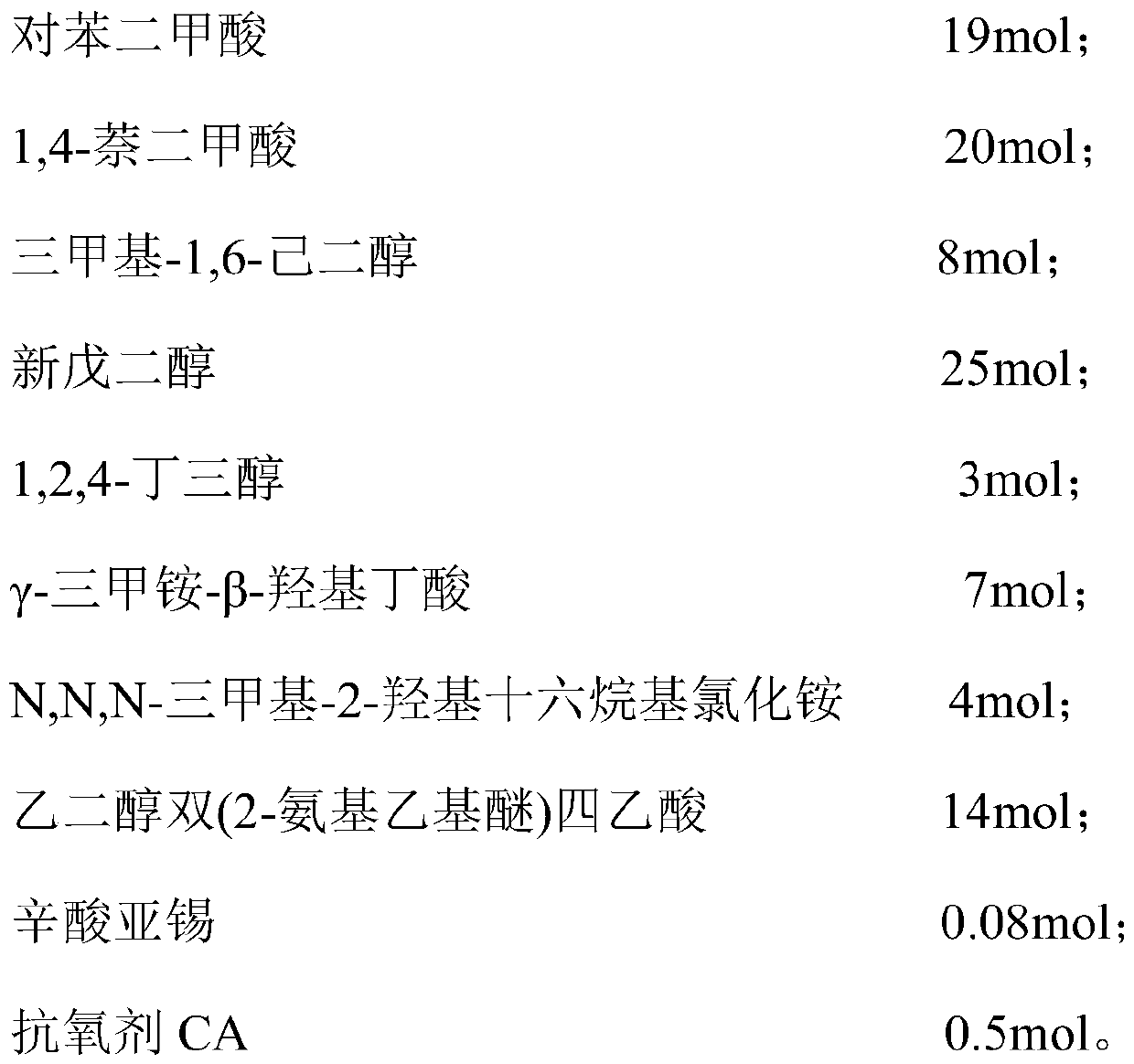

[0050] The self-catalyzed fast-curing pure polyester resin described in this embodiment, based on the total amount of raw materials for preparing the polyester resin, includes the following raw material components in molar percentages:

[0051]

[0052] The preparation method of self-catalyzed fast curing type pure polyester resin of the present invention comprises the steps:

[0053] (1) Mix the catalyst, terephthalic acid, 1,4-naphthalene dicarboxylic acid, trimethyl-1,6-hexanediol and neopentyl glycol in the formula amount, and first control the temperature below 165°C Esterification reaction 3-6h;

[0054] (2) When the acid value of the mixed material is reduced to 180mgKOH / g or below, nitrogen is introduced into the reaction system for protection, and the temperature of the above mixed material is gradually raised to 210°C at a heating rate of 5°C / h for heat preservation reaction 4-8h;

[0055] (3) When the acid value of the reaction mixture is reduced to 75mgKOH / g o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com