Environment-friendly polyester coating for aluminum-plastic composite panel and preparation method of coating

A technology of aluminum-plastic composite board and environmentally friendly polyester, which is applied in polyester coatings, anti-corrosion coatings, coatings, etc., can solve the problems of poor adhesion between UV ink layers, poor color hiding power, and poor water boiling resistance, and achieve improved Boil resistance, improved weather resistance, effects of improved water resistance and chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

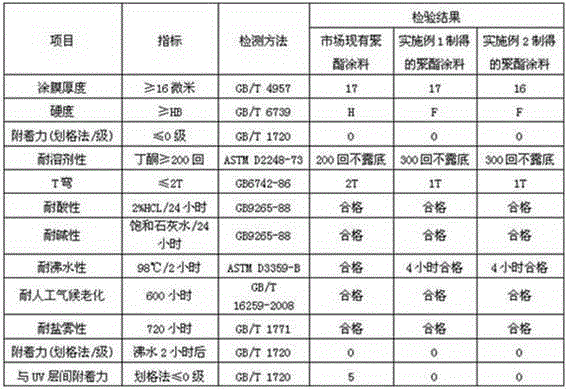

Examples

Embodiment 1

[0012] Example 1: An environmentally friendly polyester coating for aluminum-plastic composite panels, the components and their mass percentages in the formula are: saturated polyester resin 45%, organic solvent 15.5%, rutile titanium dioxide powder 30%, closed curing 6% agent, 0.5% dispersant, 0.5% defoamer, 0.8% epoxy phosphate resin, 0.5% antioxidant, 0.5% UV absorber, 0.5% leveling agent, and 0.2% organic tin catalyst.

[0013] The preparation method of the environment-friendly polyester coating comprises the following steps:

[0014] (1) Select each component according to the formula, put in saturated polyester resin, mixed solvent, dispersant, defoamer in sequence, put it into a mixer for one stirring, and disperse evenly. The speed of the mixer is 400 rpm during one stirring. , the stirring time is 2 minutes;

[0015] (2) After the completion of step (1), the rutile titanium dioxide powder and the mixed solvent are added to the mixer for secondary stirring to obtain a ...

Embodiment 2

[0026] Example 2: An environmentally friendly polyester coating for aluminum-plastic composite panels, the components in the formula and their mass percentages are: saturated polyester resin 40%, organic solvent 16.3%, rutile titanium dioxide powder 32%, closed curing 7% of dispersant, 0.8% of dispersant, 0.3% of defoamer, 1% of epoxy phosphate resin, 1% of antioxidant, 1% of UV absorber, 0.3% of leveling agent, and 0.3% of organic tin catalyst.

[0027] The preparation method of the environment-friendly polyester coating comprises the following steps:

[0028] (1) Select each component according to the formula, put in saturated polyester resin, mixed solvent, dispersant, defoamer in sequence, put it into a mixer for one stirring, and disperse evenly. The speed of the mixer is 400 rpm during one stirring. , the stirring time is 2 minutes;

[0029] (2) After the completion of step (1), the rutile titanium dioxide powder and the mixed solvent are added to the mixer for secondar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com