Patents

Literature

150 results about "Polycarbonate plastic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

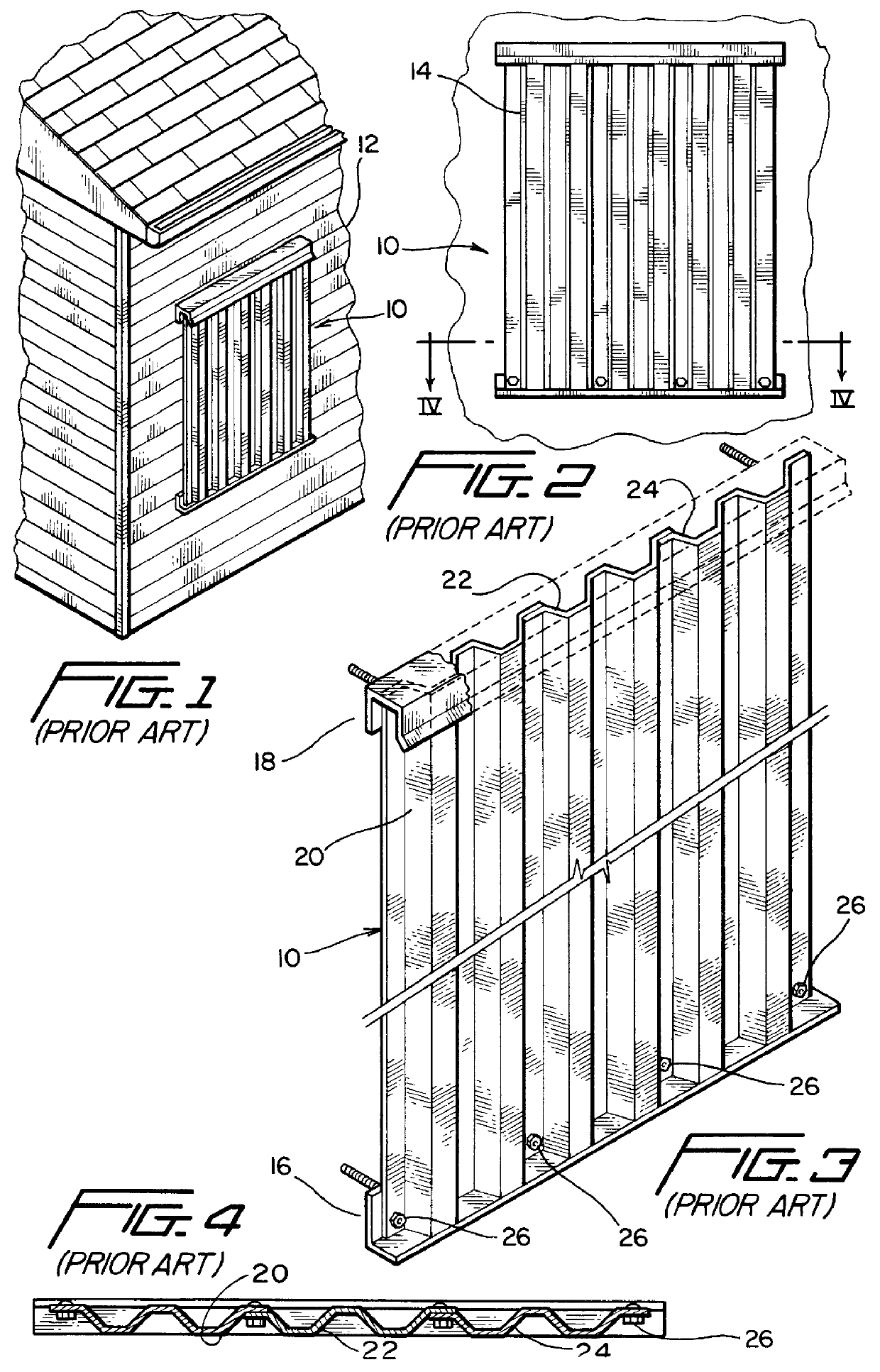

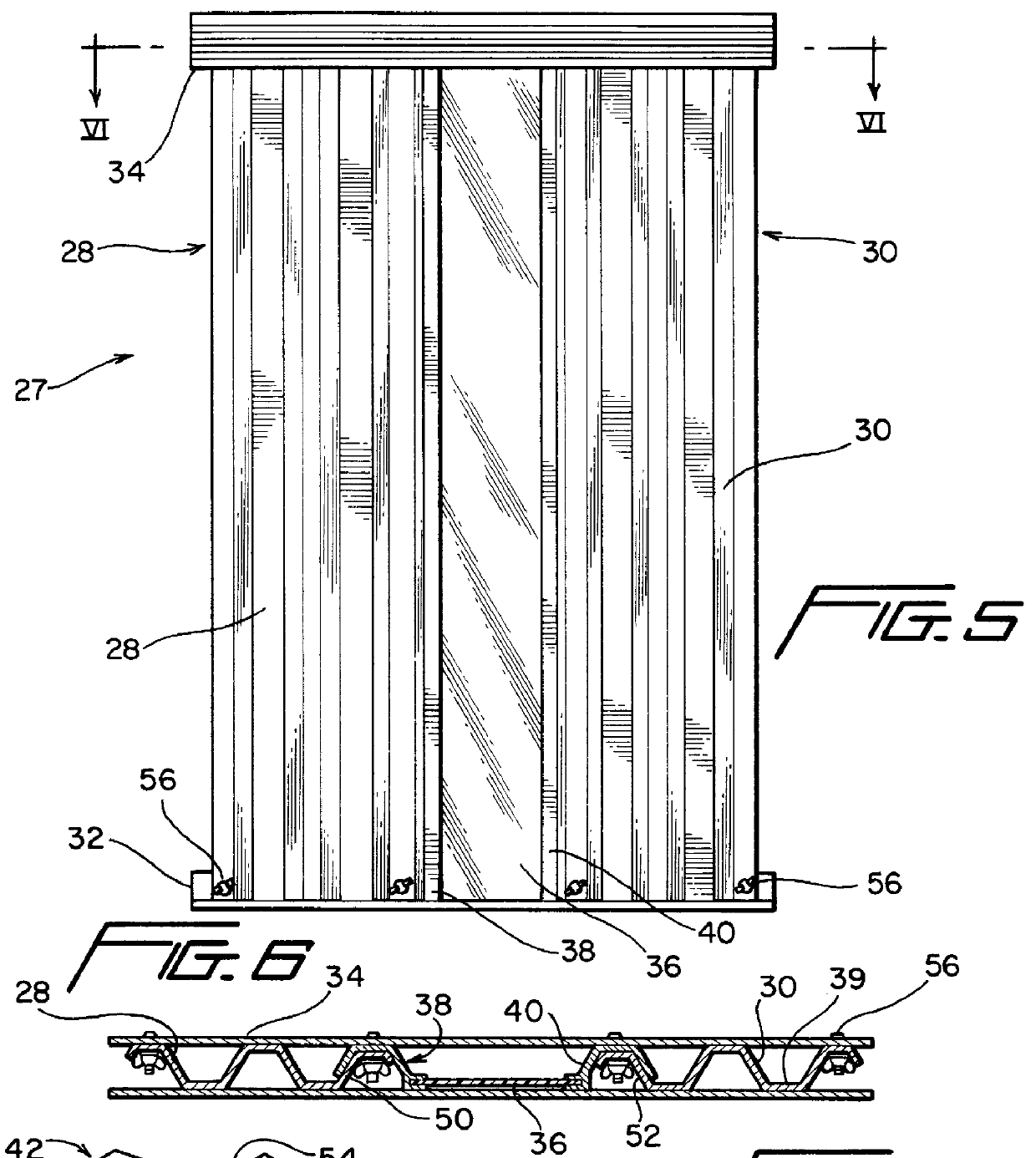

Partially transparent storm shutter

A partially transparent storm shutter for protecting glass windows, doors, and similar building openings from damage due to wind forces and wind driven flying objects is formed of a plurality of adjacent corrugated sheet metal and transparent protective, impact resistant sheet panels rigidly connected together along their respective adjacent edges. Special connector members are utilized to connect the transparent panel or panels to the corrugated sheet metal panel(s) and special connector members may be utilized to connect together adjacent transparent panels used in the storm shutter. The transparent panels may be formed of tough, impact resistant, polycarbonate plastic sheet material.

Owner:SHAVER D SCOTT

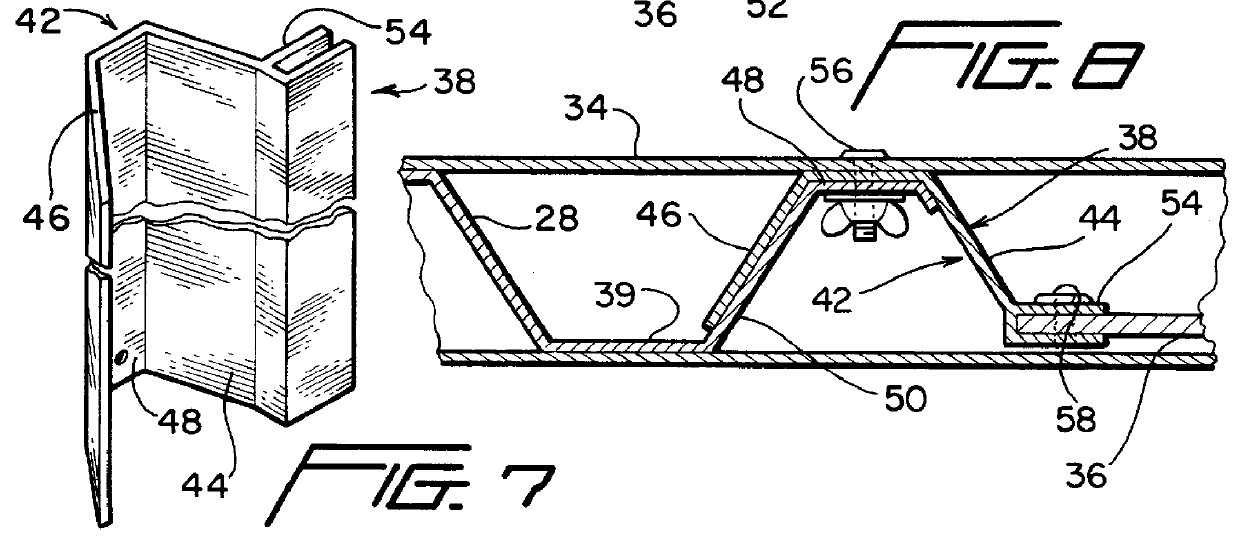

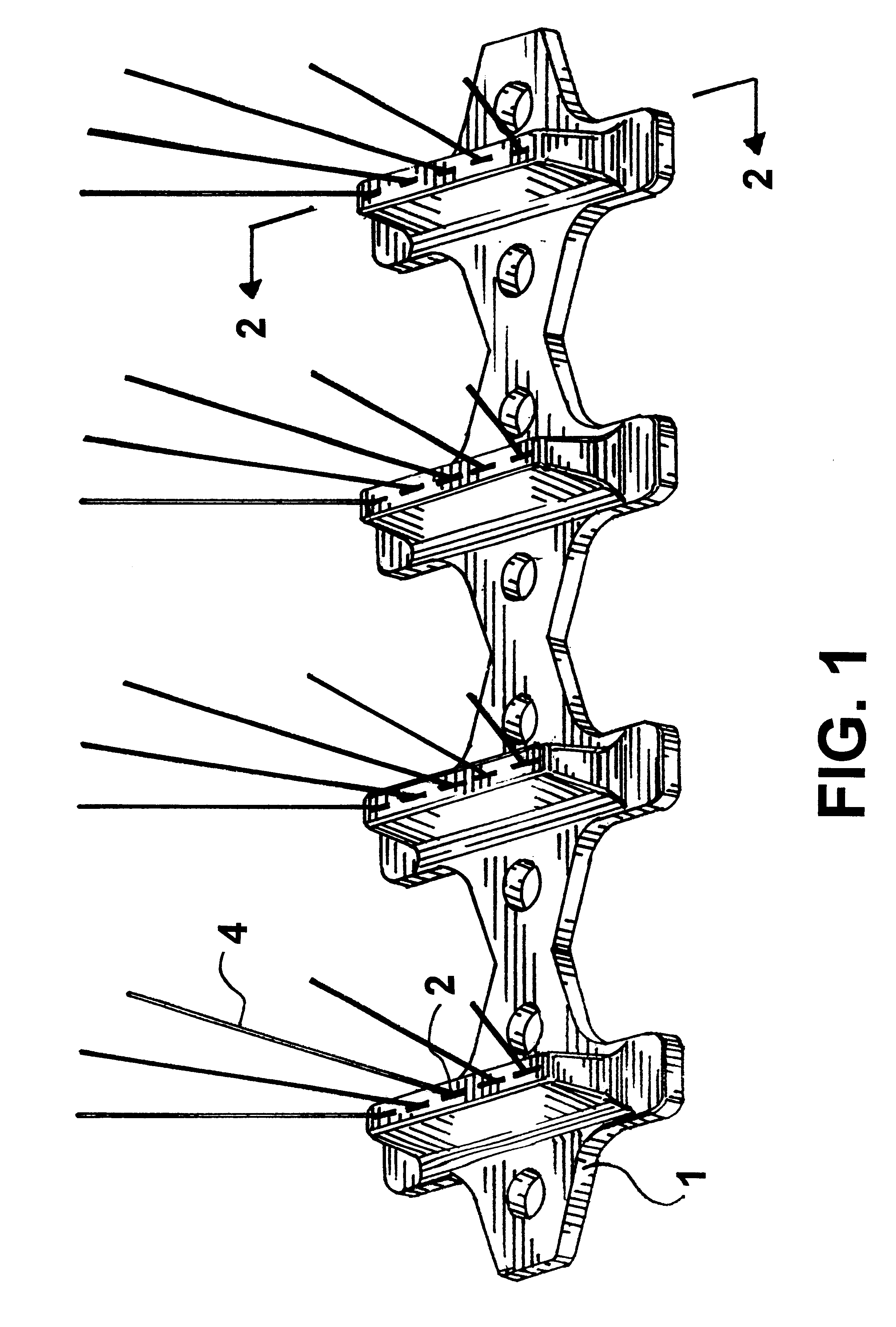

Preventive device against nuisance from birds

InactiveUS6250023B1Pasturing equipmentProtective buildings/sheltersPolycarbonate plasticUltraviolet lights

A preventative device against nuisance from birds comprised of a base to which spikes are fitted to extend opposite surfaces of a structure to be protected in order to discourage birds from landing on those surfaces. The base is provided with canals and each spike has a knurled end. The maximum cross section of the knurls is slightly larger than the cross section of the canals. The spikes are force fit into the canals so as to be held firmly therein. In an illustrated embodiment, the base of the device is made from ultraviolet light-protected polycarbonate plastic in a variety of colors to match the area covered.

Owner:BIRD B GONE

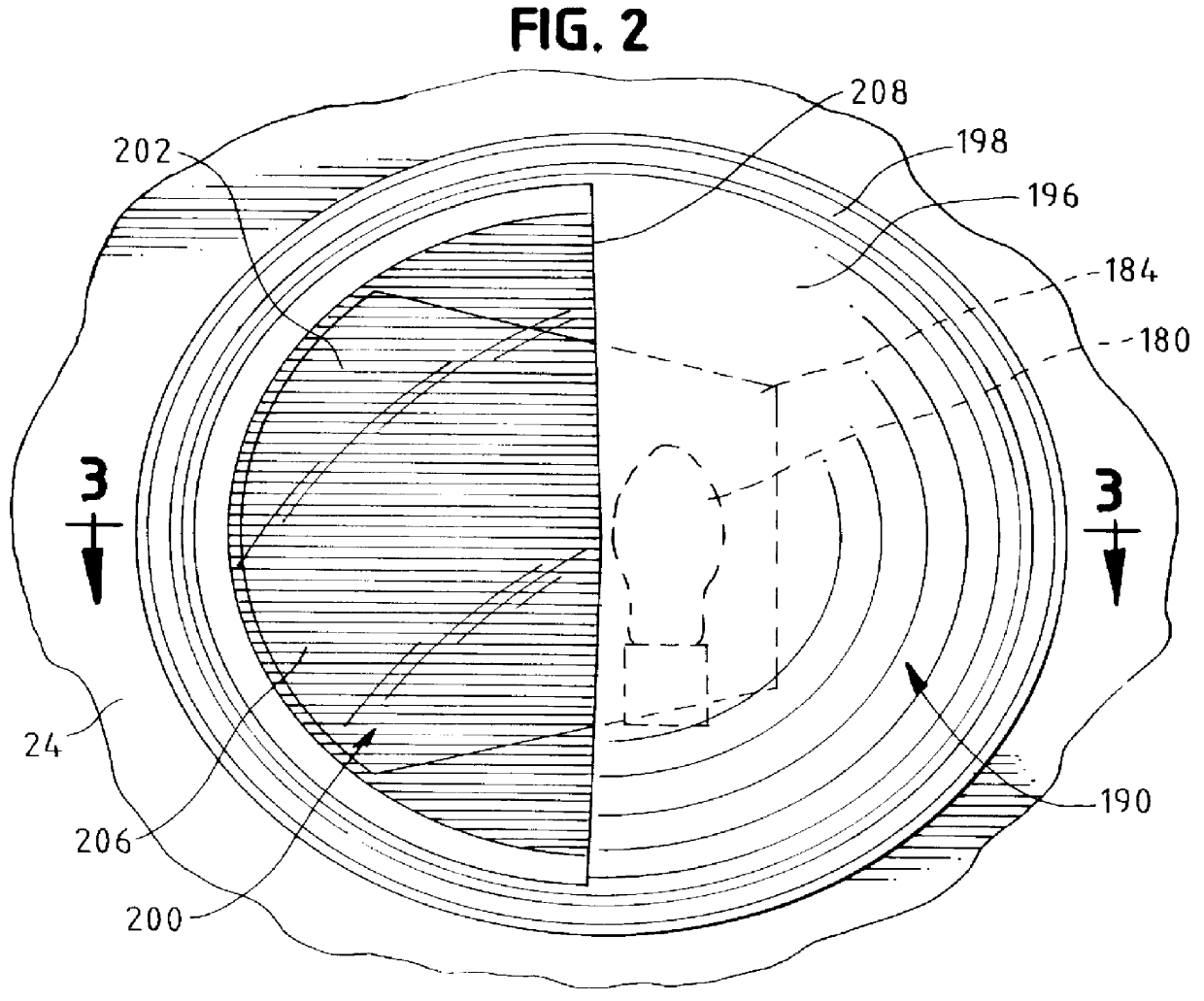

Multi-configured lighting fixture for surface mounting

InactiveUS6042251AEasy to adaptReadily and simply achievableLighting support devicesPoint-like light sourcePolycarbonate plasticSurface mounting

There is described a multi-configurational, multi-functional electrical lighting fixture for high-abuse application and structured for surface mounting. The fixture includes a lens of U.V. stabilized, high impact-resistant, injection molded polycarbonate plastics, integrally formed with two selective, separate and distinct, high-performance reflector / refractor surface systems carried by the single lens, as separate zonal areas. The first system generates a long and narrow "throw", and the second system a short and wide "throw". A molded, opaque "eyelid" provides optimum lamp shielding and controls light distribution. The lens surmounts a lens base to which it is secured by means of unique internal, integrally-molded lugs received in cooperating hook-shaped slots. An 0-ring gasket establishes a water-tight seal. Unlocking of the assembly is deterred by means of a single, tamper-resistant screw. The lens base is mounted on a deep casting, with or without an interposed cast aluminum baseplate. Alternatively, the lens base may be mounted directly on the cast aluminum baseplate, without the deep casting, to provide a low-profile fixture structure.

Owner:KENALL MFG

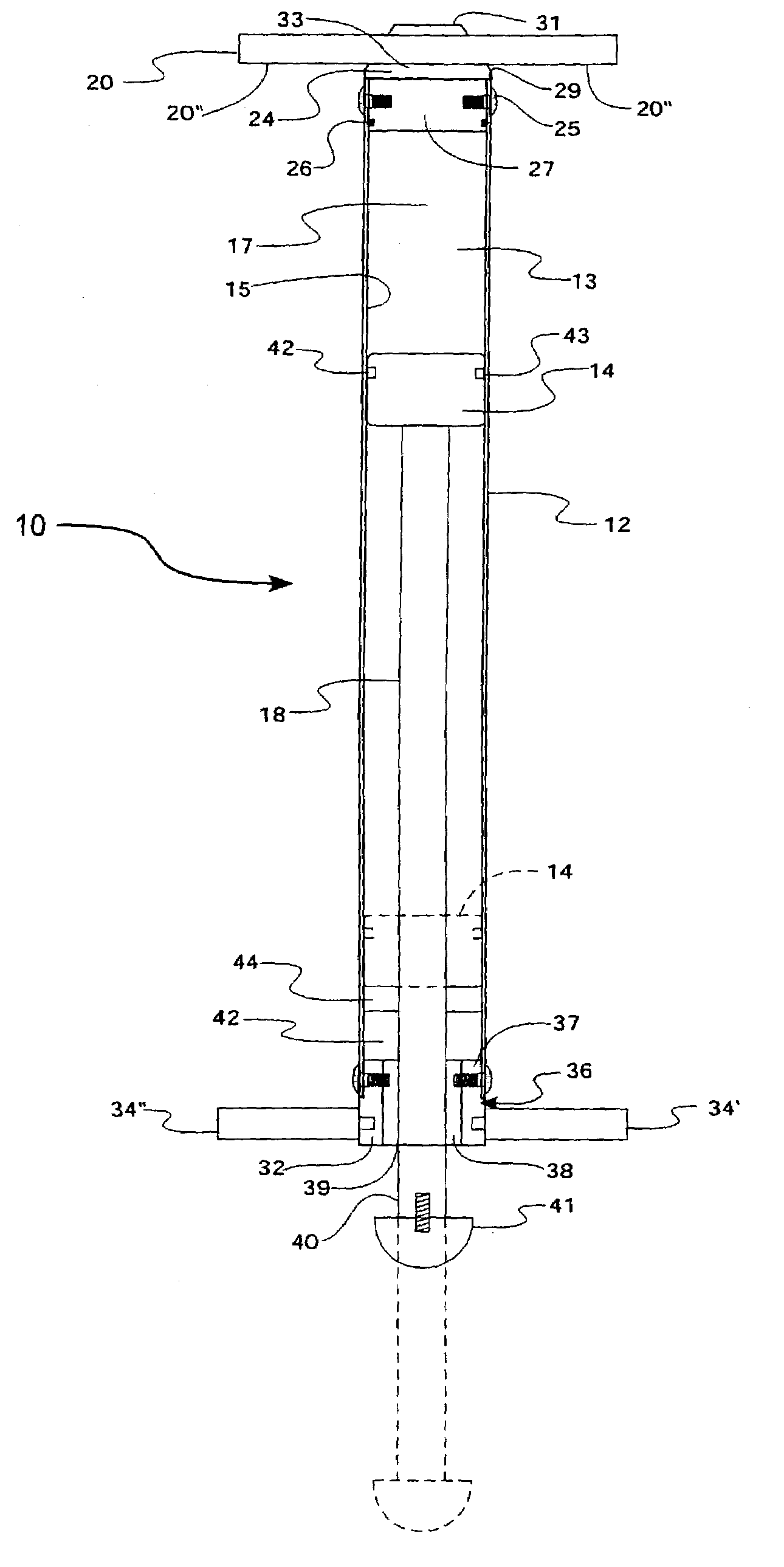

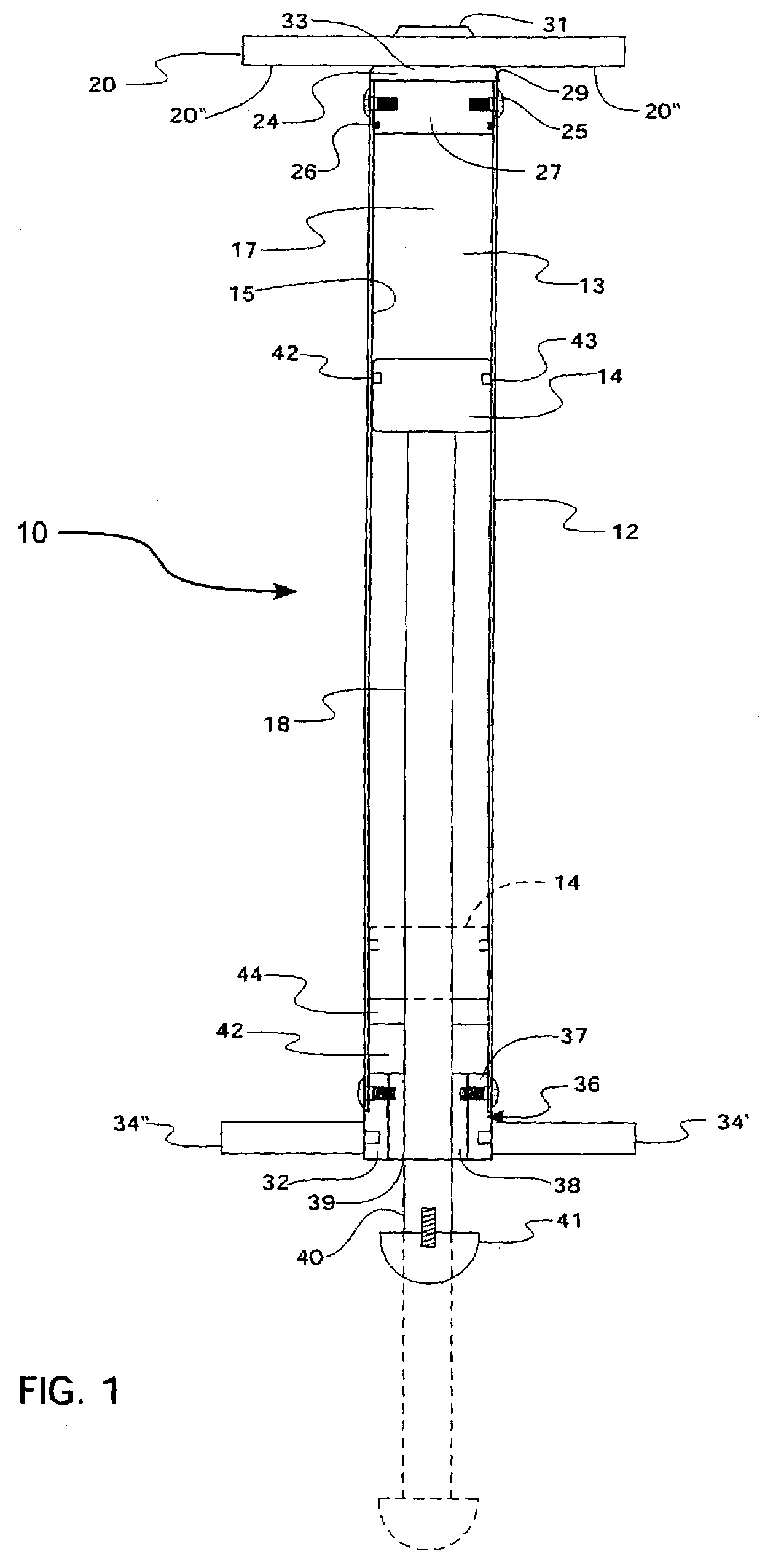

Pneumatic pogo stick

InactiveUS7011608B2Smooth rideAvoid vibrationStiltsMuscle exercising devicesPolycarbonate plasticFoot supports

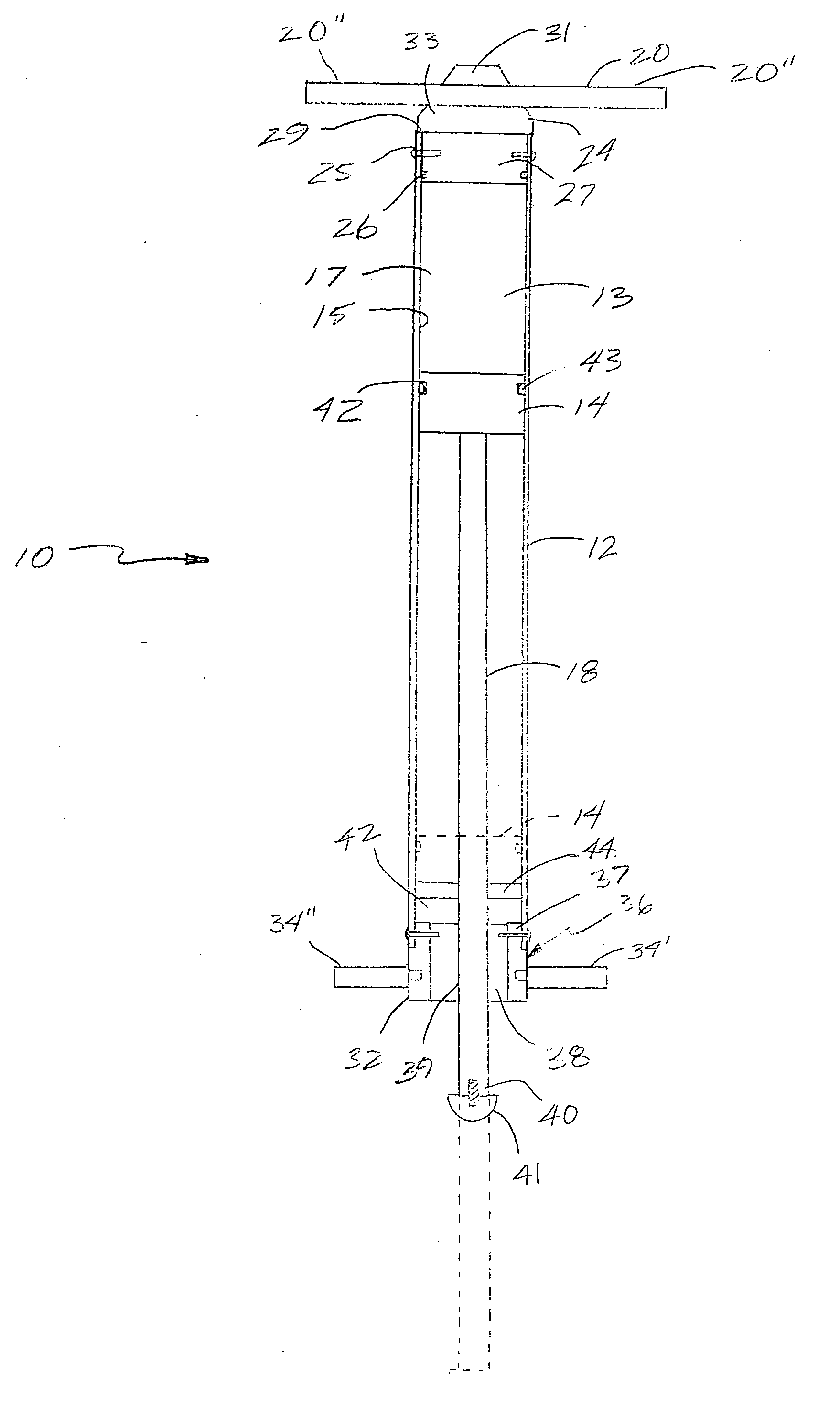

A pneumatic pogo stick is comprised of an elongate cylindrical housing which forms a cylinder. The housing is formed from a clear polycarbonate plastic. A top cap is attached to one end of the housing to form the top of an air chamber. A plastic piston, slidable within the cylinder, forms the bottom of the air chamber. An elongate shaft is coupled to the bottom of the piston and is moveable therewith, extending from the distal end of said housing as the piston moves within the cylinder. A bottom bracket assembly is attached to the bottom of the housing and a bushing for maintaining the lateral position of the shaft relative to the housing is attached to the bottom bracket assembly. The bushing prevents the shaft from rotating relative to the housing. User foot supports are also attached to the bottom bracket for supporting the feet of the user and handle bars are attached to the top cap for grasping with the hands of a user.

Owner:VURTEGO

Pneumatic pogo stick

A pneumatic pogo stick is comprised of an elongate cylindrical housing which forms a cylinder. The housing is formed from a clear polycarbonate plastic. A top cap is attached to one end of the housing to form the top of an air chamber. A plastic piston, slidable within the cylinder, forms the bottom of the air chamber. An elongate shaft is coupled to the bottom of the piston and is moveable therewith, extending from the distal end of said housing as the piston moves within the cylinder. A bottom bracket assembly is attached to the bottom of the housing and a bushing for maintaining the lateral position of the shaft relative to the housing is attached to the bottom bracket assembly. The bushing prevents the shaft from rotating relative to the housing. User foot supports are also attached to the bottom bracket for supporting the feet of the user and handle bars are attached to the top cap for grasping with the hands of a user.

Owner:SPENCER BRUCE L

Screen Protector

InactiveUS20150227226A1Good lookingDigital data processing detailsCathode-ray tube indicatorsPolycarbonate plasticPolyethylene terephthalate

A protective cover for a device having a touchscreen and a fingerprint sensor includes a Polyethylene terephthalate touchscreen cover that covers the touchscreen while allowing the touchscreen to be used. A die cut opening in the touchscreen cover corresponds to a location of the fingerprint sensor and a flexible membrane covers the opening. The flexible membrane is preferably constructed from Thermoplastic polyurethane that is bonded to the touchscreen cover. The touchscreen cover is then glued to an injected polycarbonate plastic rigid frame to for the front of a protective device case assembly.

Owner:VINCI BRANDS LLC

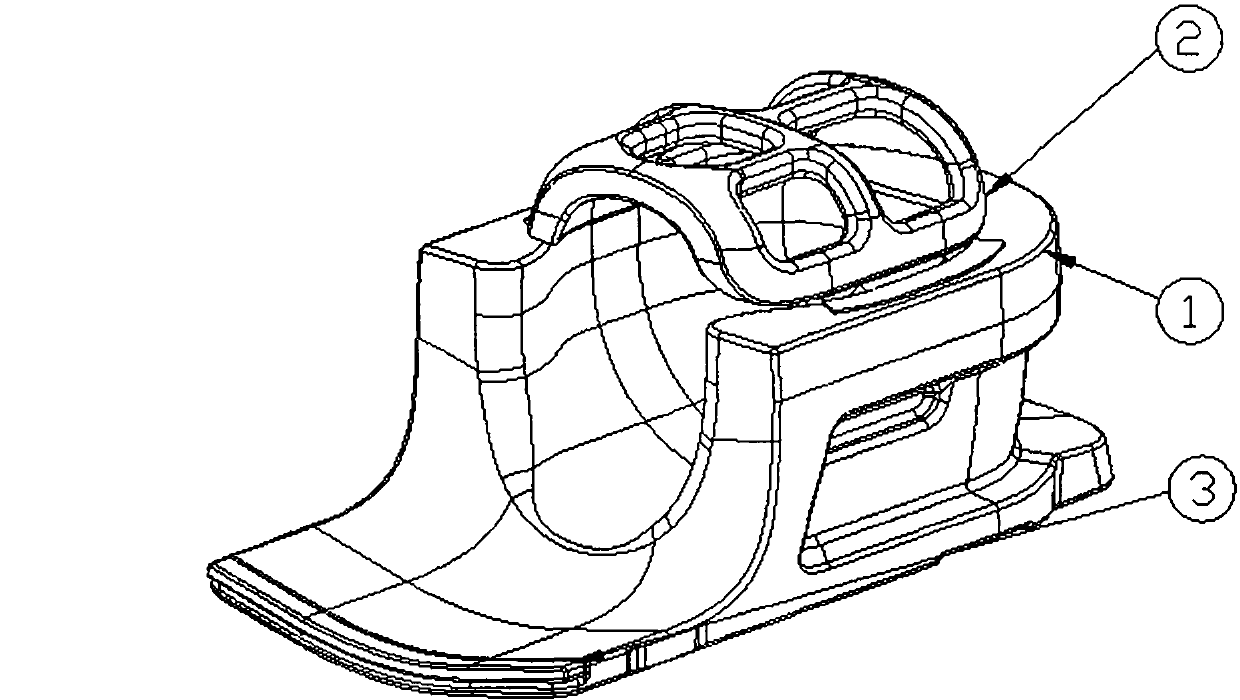

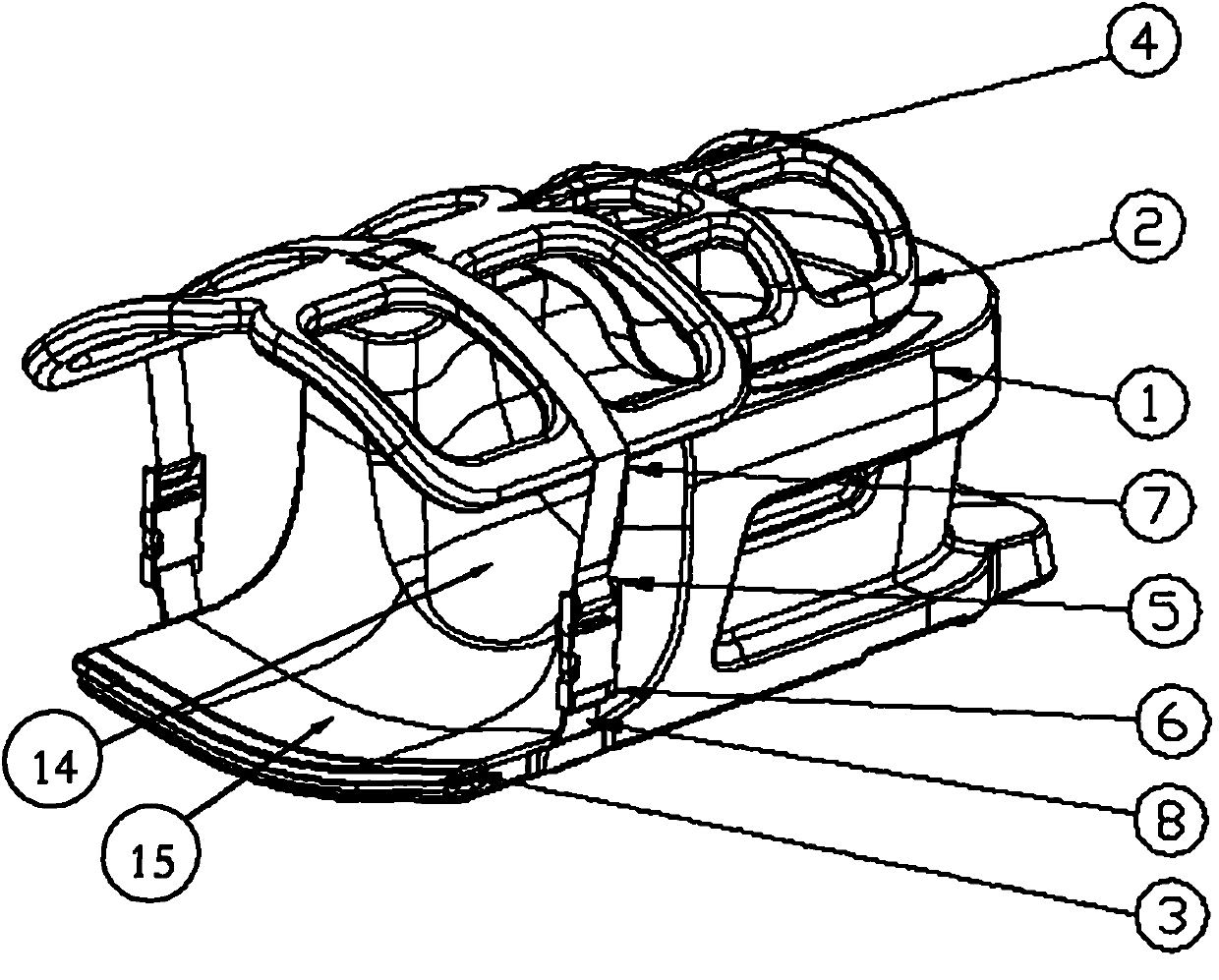

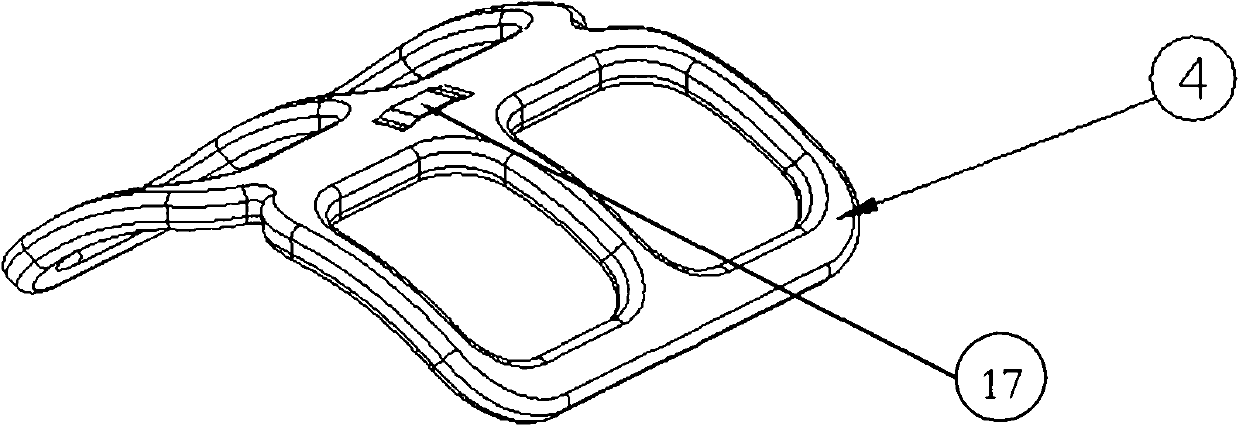

Intracranial and cervical joint radio frequency coil device for magnetic resonance imaging system

InactiveCN101950006AEasy to disassembleShorten inspection timeDiagnostic recording/measuringSensorsPolycarbonate plasticImaging quality

The invention discloses an intracranial and cervical joint radio frequency coil device for a magnetic resonance imaging system. The device comprises a base, an intracranial upper coil and a cervical upper coil in detachable combination, wherein the intracranial upper coil and the cervical upper coil are formed by packaging a coil circuit by deformable flexible polyethylene foams; a cavity of which the upper end and the cervical side are provided with openings is formed on the base; and the coil circuit is arranged around the cavity. The device has the advantages of weight far lighter than that of a conventional united coil made of hard polycarbonate plastic, convenient movement, smaller distance to a human body through the deformable coil, better imaging quality, respectively independent use or combined use of three parts of coils, and capacities of replacing a common coil, meeting detection requirements on common parts of all MRI and saving economic input.

Owner:SHANGHAI CHENGUANG MEDICAL TECH

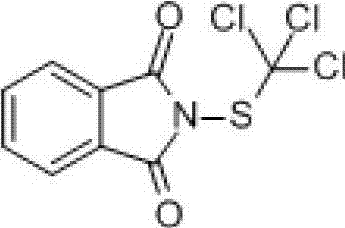

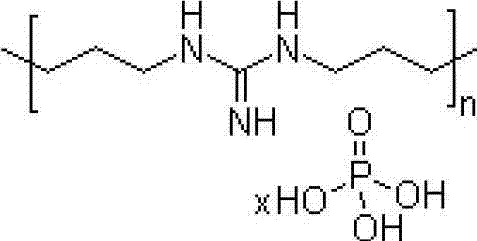

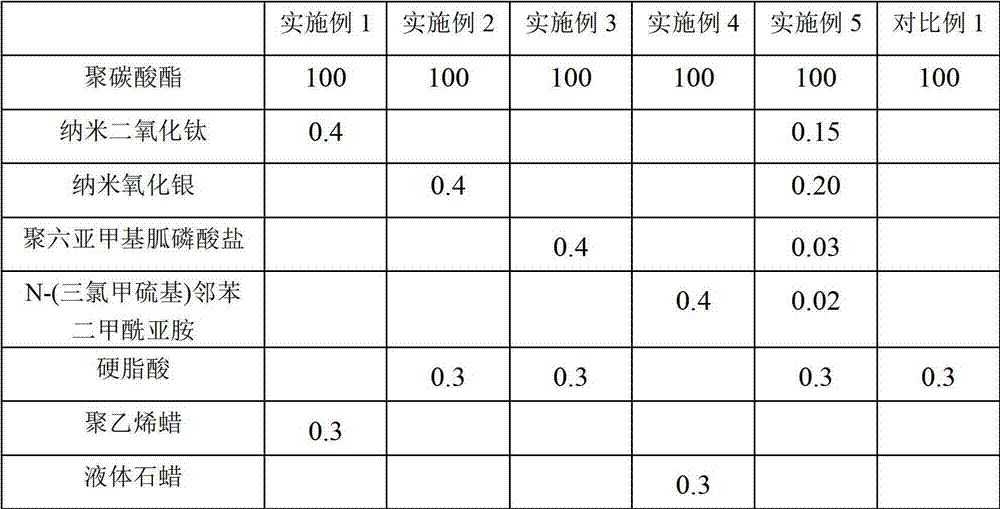

Antimicrobial polycarbonate plastic and preparation method thereof

InactiveCN102827469ABroad-spectrum antibacterialImmediate effectPolycarbonate plasticPolyhexamethylene guanidine

The invention discloses an antimicrobial polycarbonate plastic and a preparation method thereof. The antimicrobial polycarbonate plastic comprises the following components in parts by weight: 100 parts of polycarbonate, 0.3-0.5 part of antimicrobial agent and 0.2-0.4 part of dispersant. The antimicrobial agent is one or mixture of nano titanium dioxide, nano silver oxide, polyhexamethyleneguanidine phosphate and N-(trichloromethylthio)phthalimide. The antimicrobial polycarbonate plastic disclosed by the invention can be easily processed into various shapes of interior ornaments of automobiles by an injection molding technique. The antimicrobial polycarbonate plastic disclosed by the invention has strong effects of bacterium control and killing and mold resistance.

Owner:SHANGHAI HAN MOLDING SHAPE CO LTD

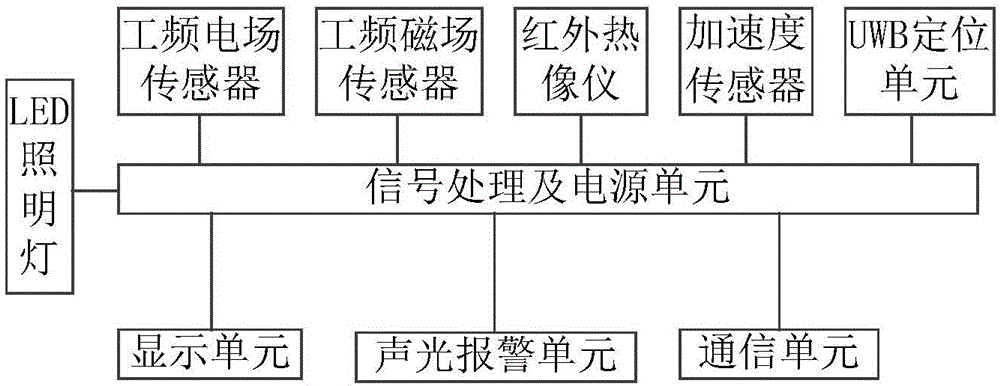

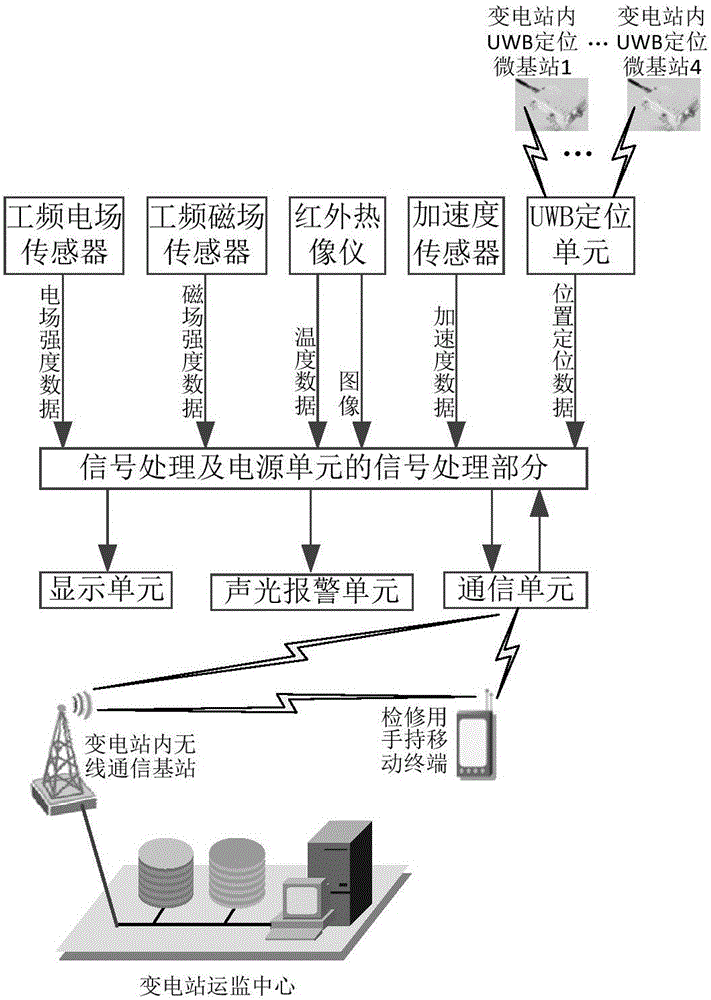

Intelligent patrol safety helmet for transformer substation

InactiveCN106418865AGood effectEnsure personal safetyHelmetsHelmet coversPolycarbonate plasticElectric field sensor

The invention provides an intelligent patrol safety helmet for a transformer substation. The safety helmet comprises a shell and a functional unit, wherein the shell is prepared from modified polypropylene plastic, ultra-high molecular weight polyethylene plastic or polycarbonate plastic; the functional unit comprises a power frequency electric field sensor, a power frequency magnetic field sensor, a thermal infrared imager, an acceleration sensor, a UWB positioning unit, a signal processing and power supply unit, an LED lighting lamp, a display unit, a sound-light alarm unit and a communication unit. The invention provides an intelligent wearing article for transformer substation intelligentization, automation and safety patrol, guarantee is provided for life safety, the safety patrol means of transformer substation equipment is improved, the maintenance quality and the maintenance efficiency of the transformer substation are improved, and convenience is provided for transformer substation maintenance.

Owner:STATE GRID CORP OF CHINA +1

Wear-resistant coating material without primer on polycarbonate surface and preparation method thereof

The invention relates to a wear-resistant coating material without a primer on a polycarbonate surface and a preparation method thereof, in particular to a coating material. The invention provides a wear-resistant coating material without a primer on a polycarbonate surface, which can adhere to the polycarbonate surface without the primer, can increase the surface hardness of the polycarbonate plastic and has a wear-resistant function, and a preparation method thereof. The wear-resistant coating material is prepared from at least two functionalities of alkoxy silane and a composition thereof, acidic silica sol, water, an acid catalyst, a diluting agent, polymer polyol, a silane coupling agent, a flatting agent and a curing agent. The preparation method comprises the following steps: mixing the at least two functionalities of alkoxy silane and the composition thereof, the water and the acidic silica sol for reacting; adding the acid catalyst; heating for refluxing; adding the polymer polyol for continuously refluxing; and after cooling, adding the silane coupling agent, the curing agent, the flatting agent and the diluting agent to obtain the wear-resistant coating material without the primer on the polycarbonate surface.

Owner:厦门威亮光学涂层技术有限公司

Ultraviolet solidified coating and preparing method thereof

InactiveCN1456621AImprove adhesionDoes not affect bonding fastnessPolyurea/polyurethane coatingsHigh resistancePolyester

An ultraviolet solidified paint suitable for DVD is prepared from active oligomer (aminoformate-acrylate ester), active diluent, optical trigger, diluent and other assistants. Its advantages are high adhesion to aluminium and polycarbonate plastics, and high resistance to salty fog, high temp and humidity.

Owner:FUXIN COATING WUXI CITY

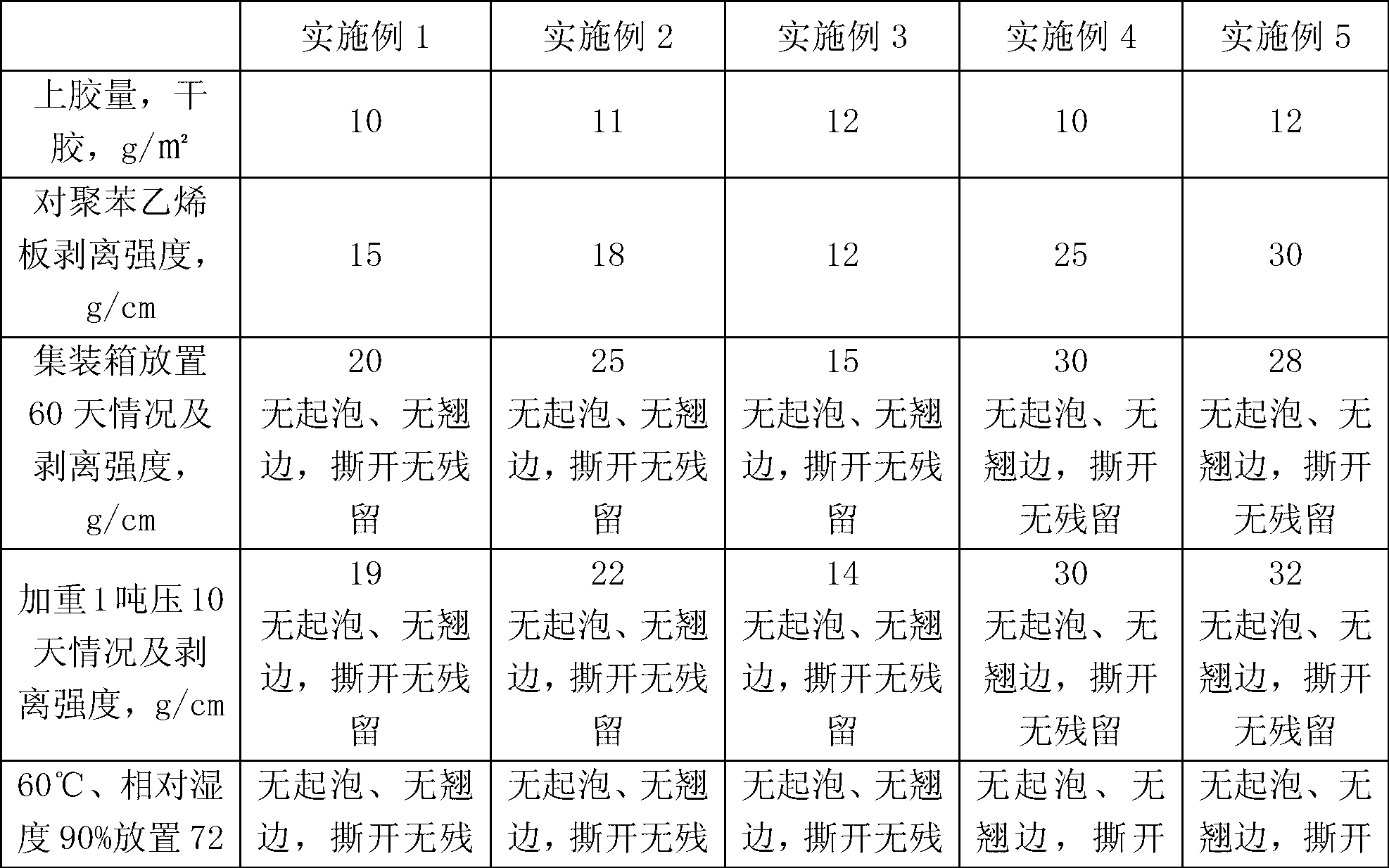

Aqueous pressure-sensitive adhesive and preparation method thereof

InactiveCN103013383AAchieve protectionMineral oil hydrocarbon copolymer adhesivesNatural rubber adhesivesPolycarbonate plasticPolymer science

The invention provides an aqueous pressure-sensitive adhesive, which comprises the following components in percentage by weight: 54-81% of rubber latex, 5-10% of acrylic resin emulsion, 10-30% of tackifying resin emulsion and 4-6% of anti-aging agent emulsion, wherein the weight percentages of the various components are dry basis weights of the components. The invention further provides a preparation method of the aqueous pressure-sensitive adhesive. When being applied to surface protective paper, the aqueous pressure-sensitive adhesive provided by the invention is capable of protecting surfaces of products, such as acrylic plates, polycarbonate plastic plates, polystyrene plates, polyvinyl chloride plates, glass, marble and wood furniture decorative plates, under the ultra-low peeling strength, and avoiding the conditions, such as foaming, edge warping, and residual after tearing.

Owner:麦广明

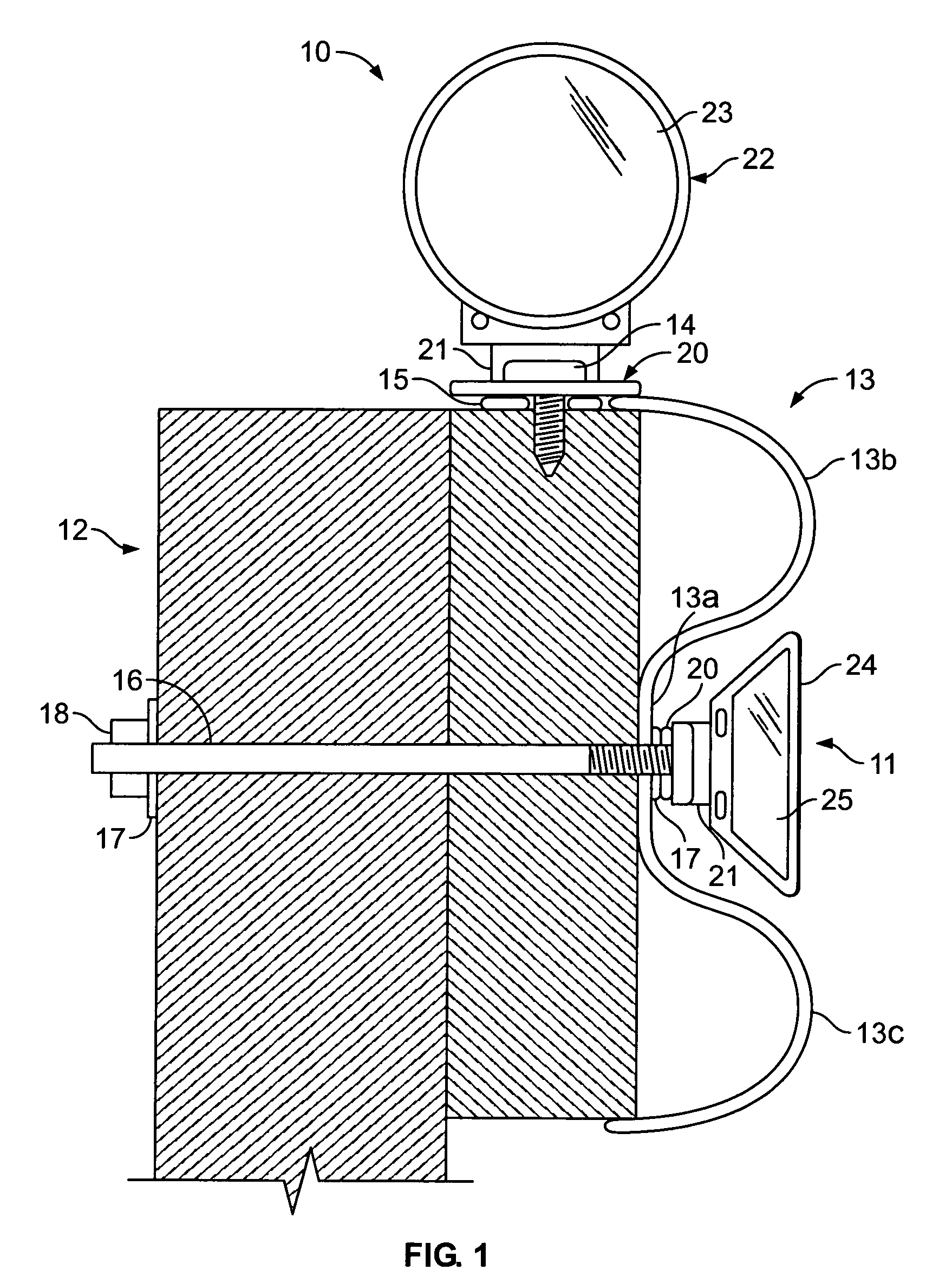

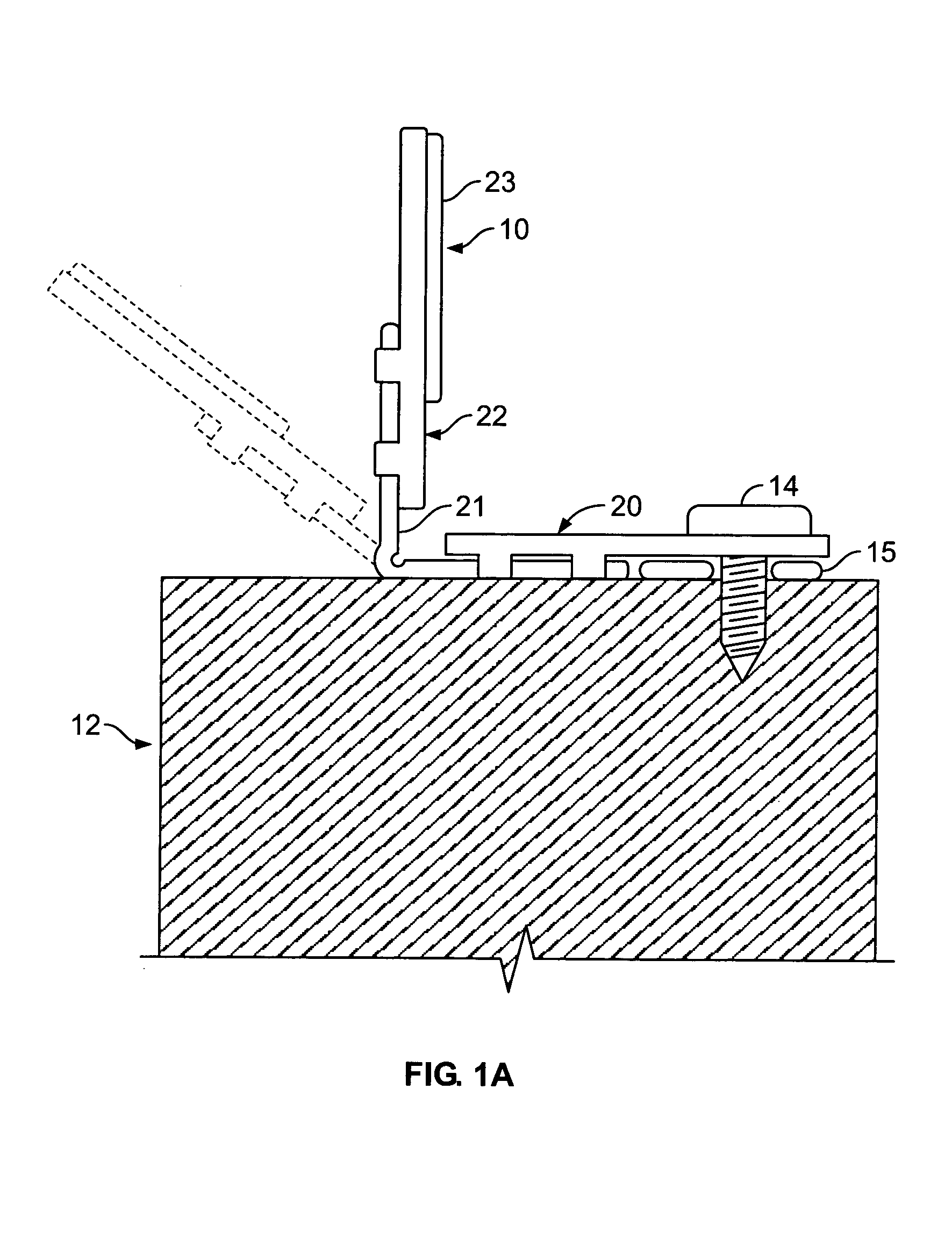

Articulated guardrail reflector assembly

An articulated guard rail reflector assembly includes a standardized base adapted for mounting the corrugations of a metal guardrail or on top of a guard rail and a pair of interchangeable top reflector holding members, one being circular in outline and one being trapezoidal in outline to fit in the corrugation of a metal highway barrier. The base member and the reflective member are joined by a spring steel L-shape clip that snaps into place. The base and reflector holding members may be made of sheet or galvanized metal, aluminum, polycarbonate plastic, ABS plastic or the like. The L-shape member is made of spring steel and allows the reflector to be moved backwardly of its direction facing traffic by either brushing forces rubbing against the guardrail, or by the pressure of packed snow being pushed against the guardrail by a motor vehicle carrying a snowplow or the like. Preferred reflector material includes plastic lenses and / or reflective tape.

Owner:HALLEN PRODS

Antibacterial polycarbonate plastic

ActiveCN103059541ABroad-spectrum antibacterialEnhanced inhibitory effectChemistryPolycarbonate plastic

The invention discloses antibacterial polycarbonate plastic comprising the components of, by weight, 100 parts of polycarbonate and 0.3-0.5 parts of a composite antibacterial agent. The composite antibacterial agent is composed of the components of, by weight: 2-6 parts of cedar oil, 4-8 parts of chitosan, 10-20 parts of nano-grade titanium dioxide, 15-25 parts of nano-grade silver oxide, 30-50 parts of polyhexamethylene guanidine phosphate, and 2-4 parts of N-(trichloromethylthio)phthalimide. The antibacterial polycarbonate plastic provided by the invention has a broad-spectrum antimicrobial effect, and high bacterium inhibition, bacterium killing, and anti-mildew effects. The plastic is mainly used as engineering plastic and is widely applied in transparent materials, electrical parts, medical equipment, machinery casings, and the like.

Owner:HUIZHOU HUANMEISHENG NEW MATERIAL CO LTD

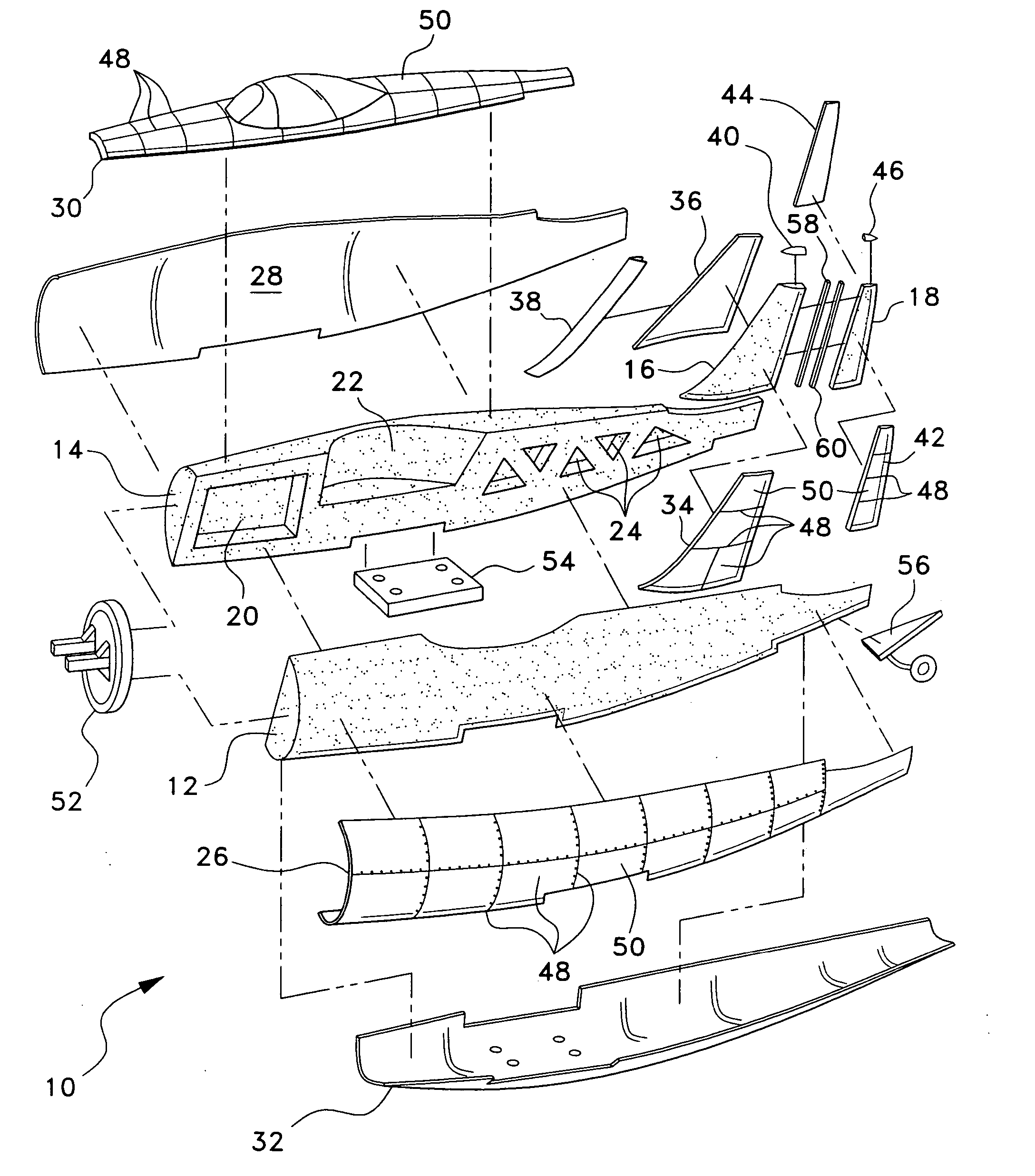

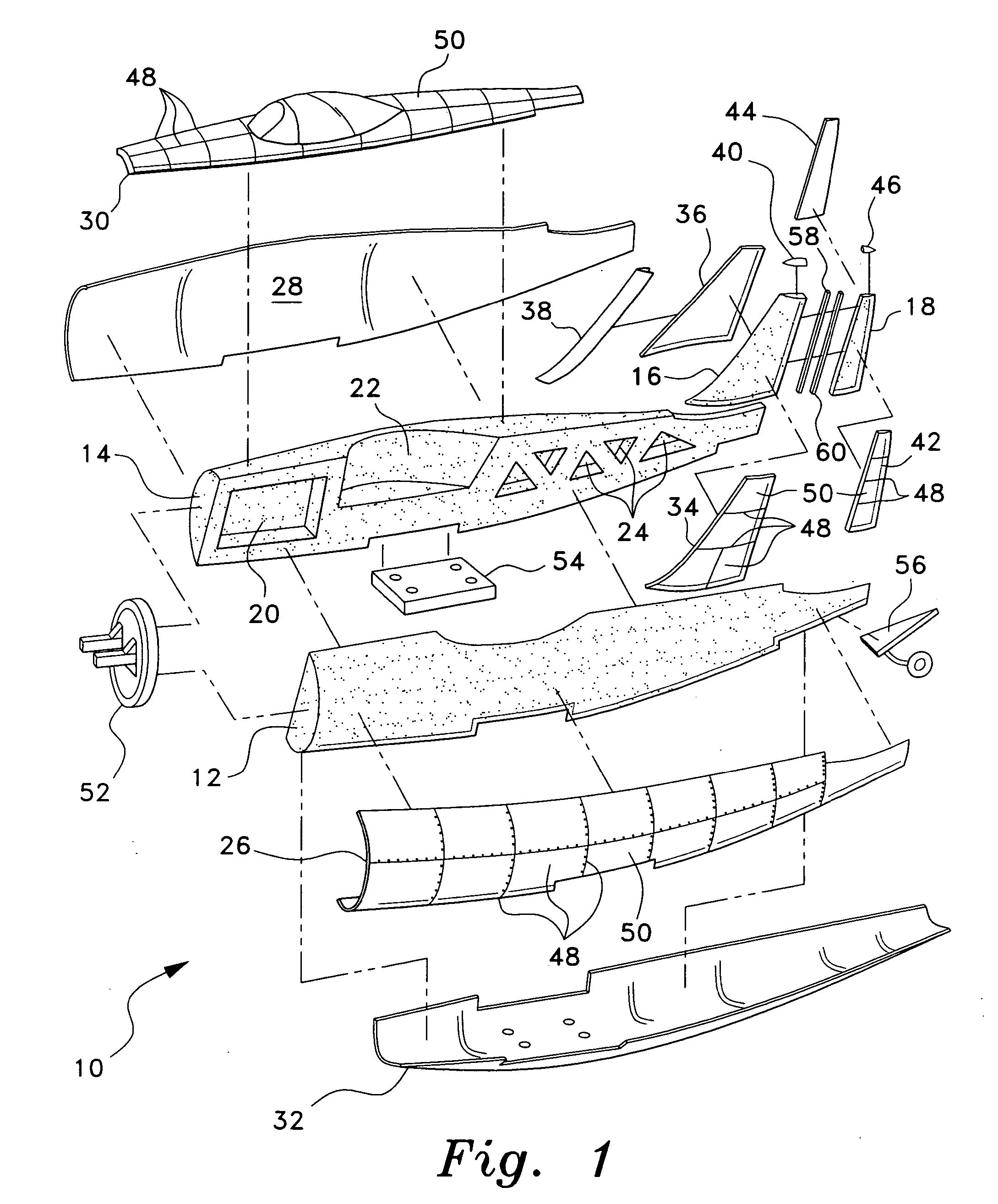

Composite model construction and method

InactiveUS20050227582A1High degreeImproved solution in model constructionToy aircraftsRemote-control toysPolycarbonate plasticEngineering

The composite model construction uses a semi-flexible expanded polypropylene foam plastic core with a thin, semi-rigid polycarbonate plastic shell adhesively attached to the core. The core includes various rigid structural members installed therein, as required, for sufficient structural stiffness for the model. The core and plastic shell components may be formed by injection molding, vacuum forming, or other processes. The model construction method provides a highly accurate outer surface for a model, with the outer shell being formed with scale details, such as panel seams, rivet lines, etc. during the molding or forming process. A motor or other prime mover may be added to the composite model body. The materials used in the composite model are resilient with a flexible yet tough outer shell to resist impact damage, and allow repairs to be made quickly and easily when required.

Owner:KLOOS WADE M

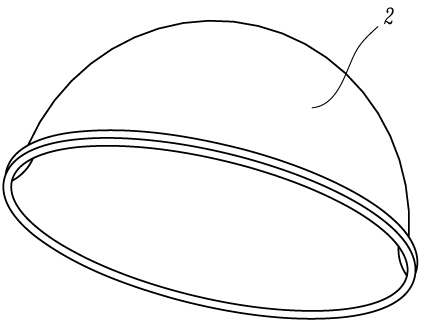

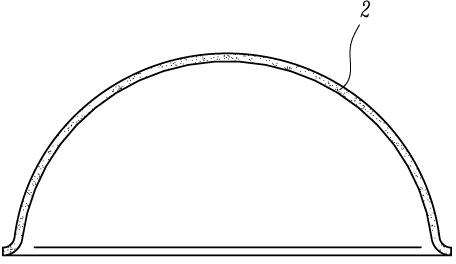

Glass fiber reinforced plastic helmet shell and fabrication technique thereof

InactiveCN102068071AImprove quality and efficiencyIncrease productivityHelmetsHelmet coversGlass fiberPolycarbonate plastic

The invention relates to a glass fiber reinforced plastic helmet shell and a fabrication technique thereof, and the helmet shell is a composite-structured helmet shell with a plastic shell attached on the outer surface of a base shell. In the fabrication method, the base shell of the helmet shell is made of fiber-reinforced plastic, the plastic shell is made of polyvinyl chloride plastic, polycarbonate plastic, polydiphenyl ether plastics, polyethylene plastic or other material, and the fabrication method is carried out according to a certain sequence, such as placing the plastic shell in a mold cavity, laying a fiber layer, coating resin, closing a mold, increasing the temperature and the pressure, and taking out the helmet shell after the pressure is kept for a period of time. The glass fiber reinforced plastic helmet fabricated according to the method has a composite structure, that is, the plastic shell is attached on the outer surface of the base shell, so the outer surface of the helmet shell becomes bright, clean, smooth and compact, consequently, the invention solves the defects of the shell directly made of glass fiber reinforced plastic, such as poor air tightness and poor anti-seepage property, processes, such as deburring, air bubble carving, gray filling and polishing, can be dispensed with, so that a great deal of manpower and a large quantity of material resources are saved, and the product quality and production efficiency of the helmet are increased.

Owner:JIANGMEN PENGCHENG HELMETS

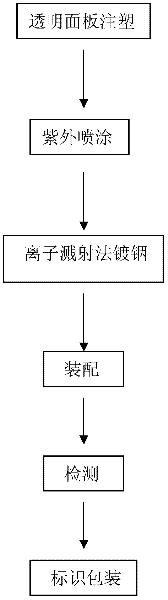

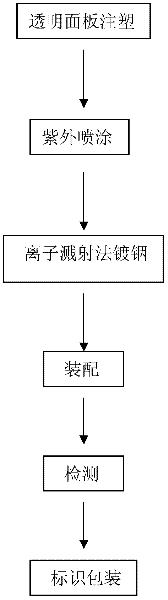

Manufacturing method for automobile sign capable of realizing radar active cruise function

ActiveCN102514533AHigh hardnessImprove wear resistanceVacuum evaporation coatingSputtering coatingPolycarbonate plasticUltrasound attenuation

The invention discloses a manufacturing method for an automobile sign capable of realizing a radar active cruise function. The manufacturing method includes obtaining a transparent plastic sign by means of manufacturing transparent polycarbonate plastics into a cambered panel with the thickness ranging from 5mm to 6mm by the aid of an injection molding machine; obtaining a transparent plastic sign with a metallic impression and a protecting layer by the aid of UV (ultraviolet) spraying materials; obtaining an indium-plated plastic sign by means of forming an indium metal film on the transparent plastic sign by an ion sputtering method; forming a seamless automobile sign finished product with uniform wall thickness ranging from 7cm to 8cm by means of assembling the indium-plated plastic sign with a plastic base; and finally detecting attenuation and obtaining the qualified automobile sign with the attenuation lower than 2.0DB (decibel) and the capability of realizing the radar active cruise function. The automobile sign has the advantages that the automobile sign has metallic luster, is penetrable by radar microwaves, can realize a function of radar measurement for front and rear automobile distances and the active cruise function, has an appearance decoration function and can meet safety requirements.

Owner:NINGBO SWELL IND CO LTD

High gloss, high hardness and uvioresistant polycarbonate plastic alloy

The invention relates to a polycarbonate plastic alloy composition with high gloss, high hardness and ultraviolet resistance, which comprises polycarbonate, phenethylene based resin, methacrylic ester resin, acrylate grafting rubber and other fillers. The components have the following weight portion: 40 to 80 portions of the polycarbonate, 10 to 25 portions of the methacrylic ester resin, 5 to 20 portions of the phenethylene based resin, and 5 to 15 portions of acrylate elastomer. The PC plastic alloy has the advantages of high gloss, high impact resistance, high surface hardness and good fluidity, can save processes of surface spray painting and coating, and can be used for shells of automotive instrument displays and household appliances such as mobile phones, mobile DVD electronic products, televisions, liquid crystal displays and the like.

Owner:CHONGQNG PRET NEW MATERIAL +2

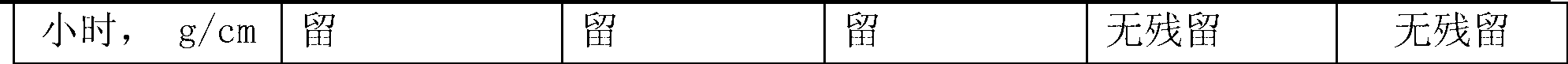

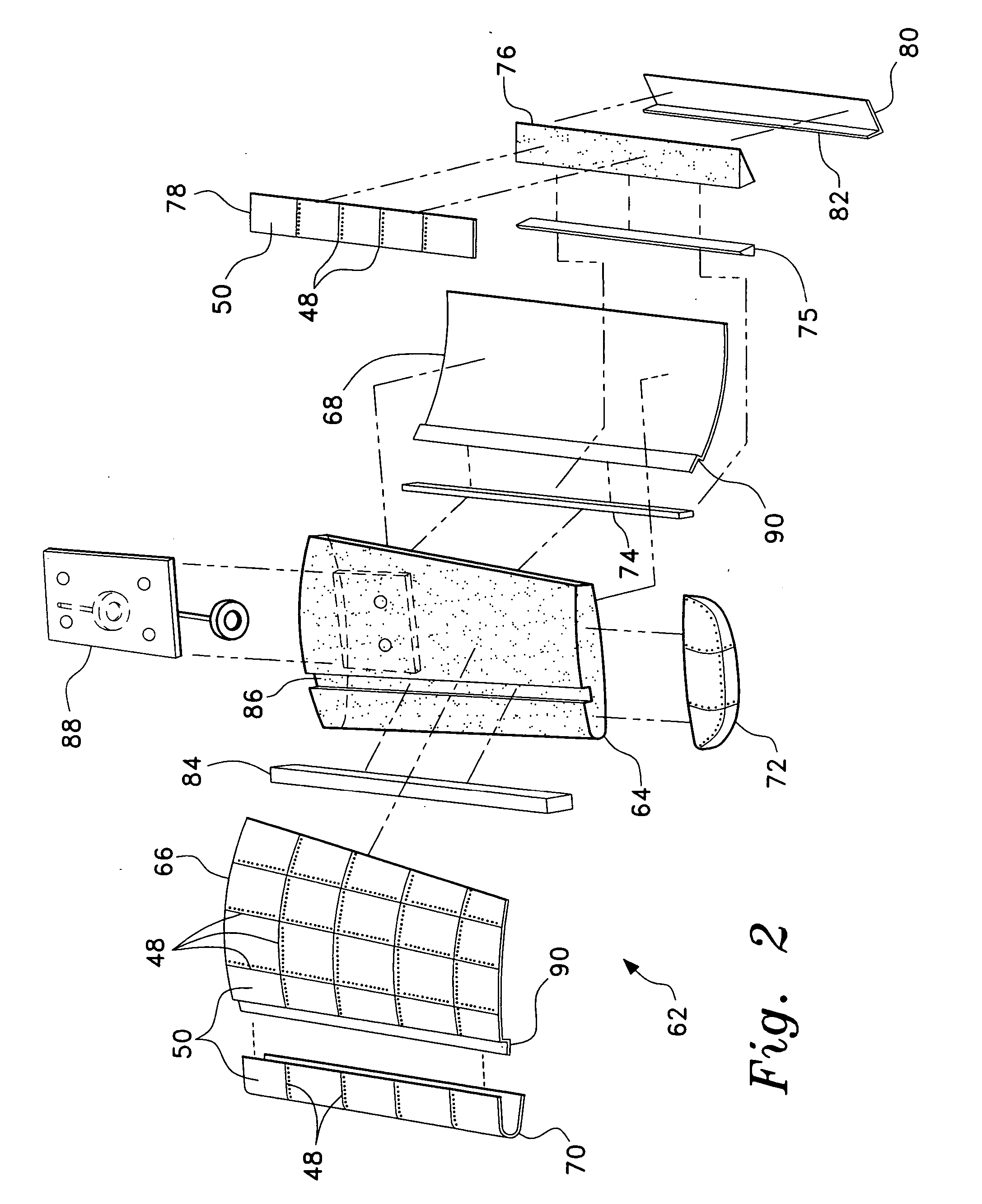

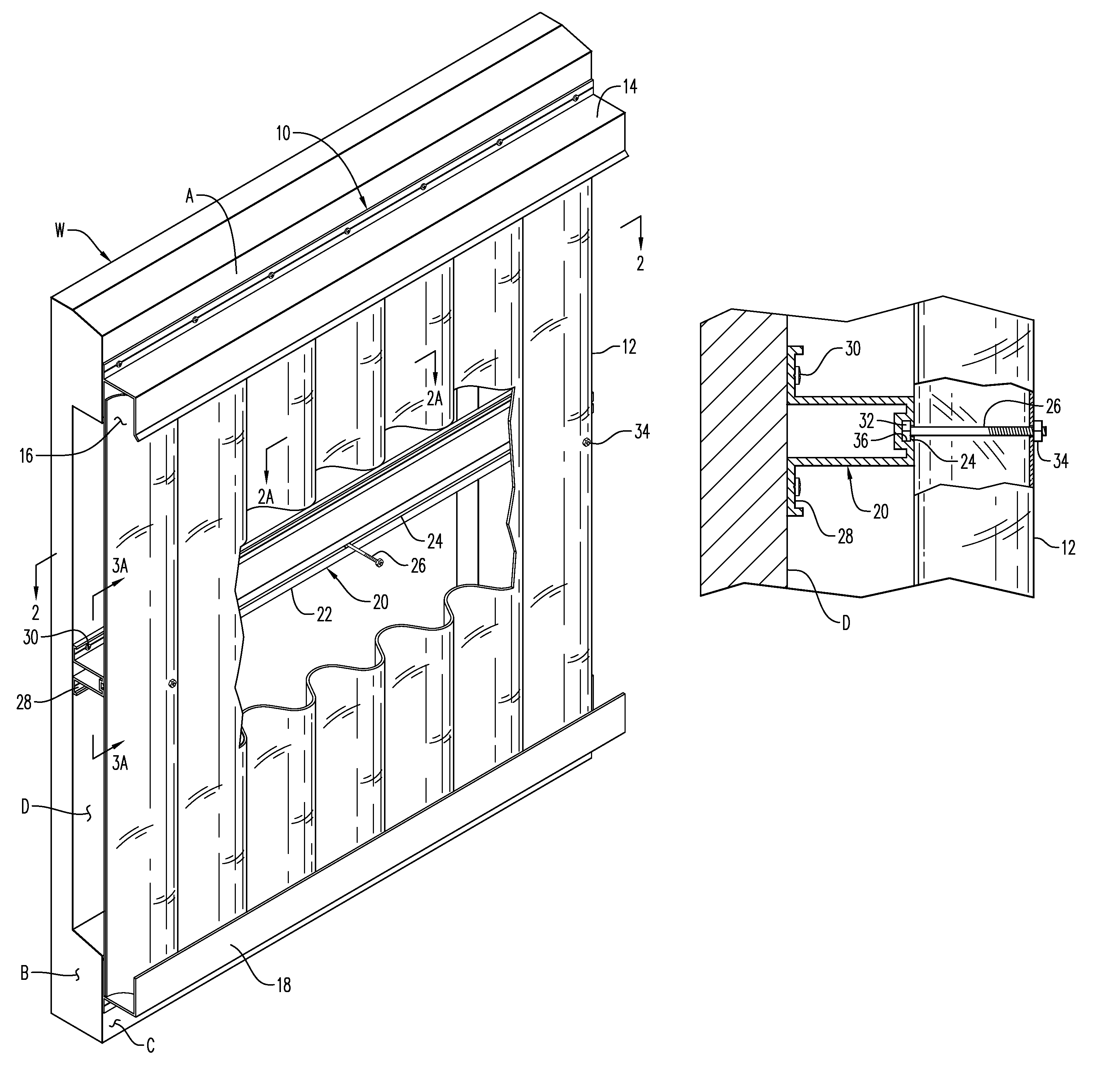

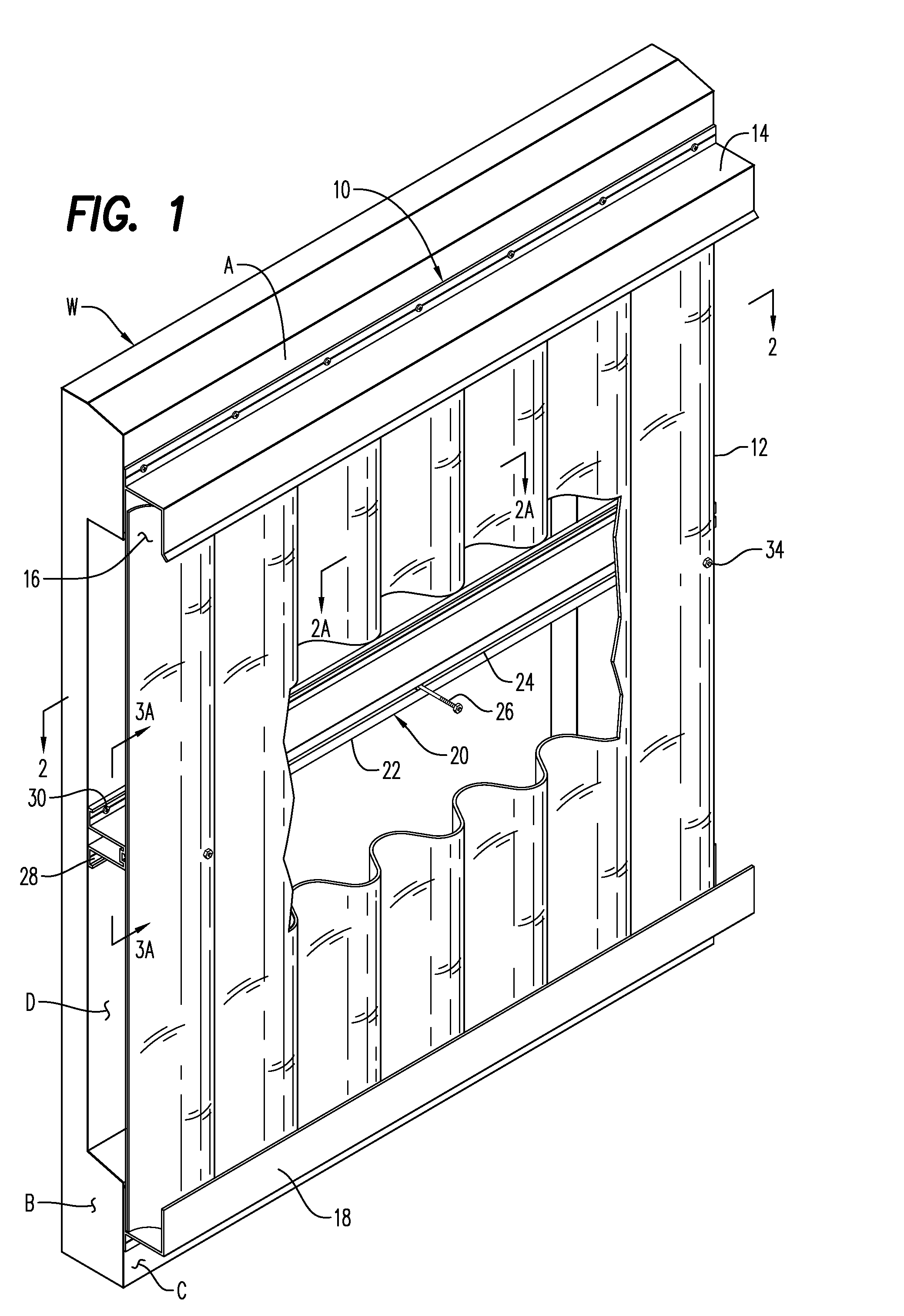

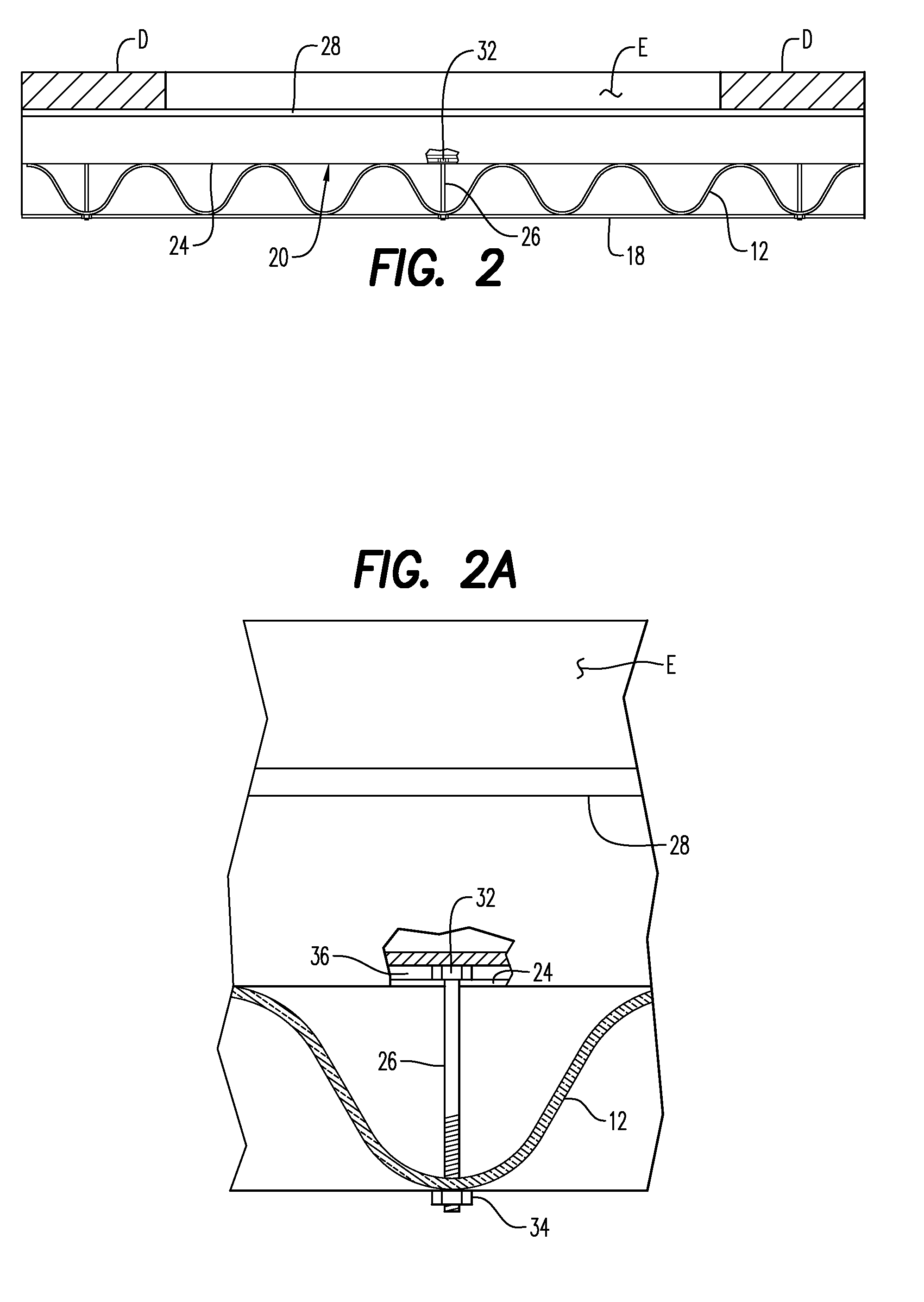

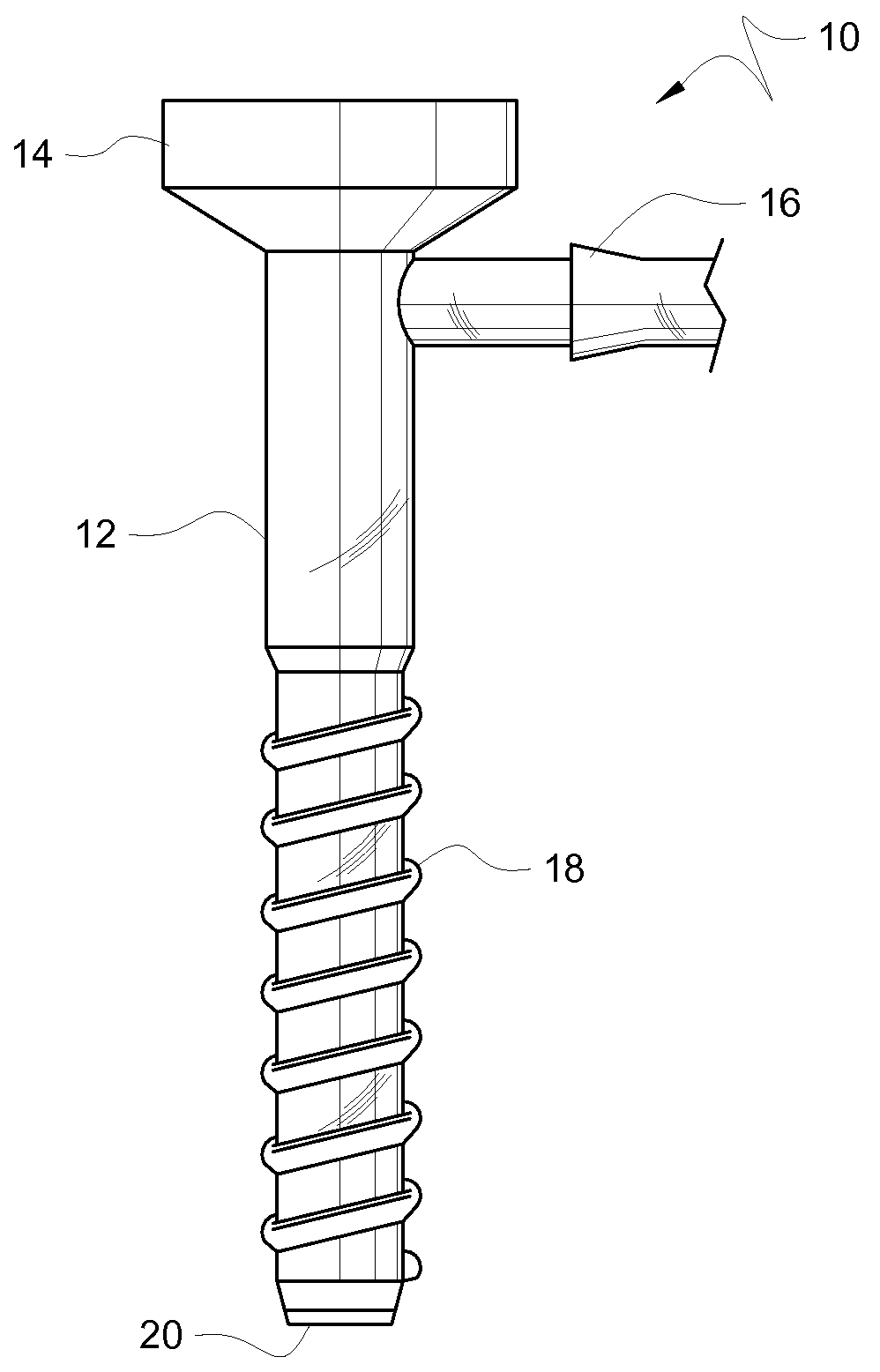

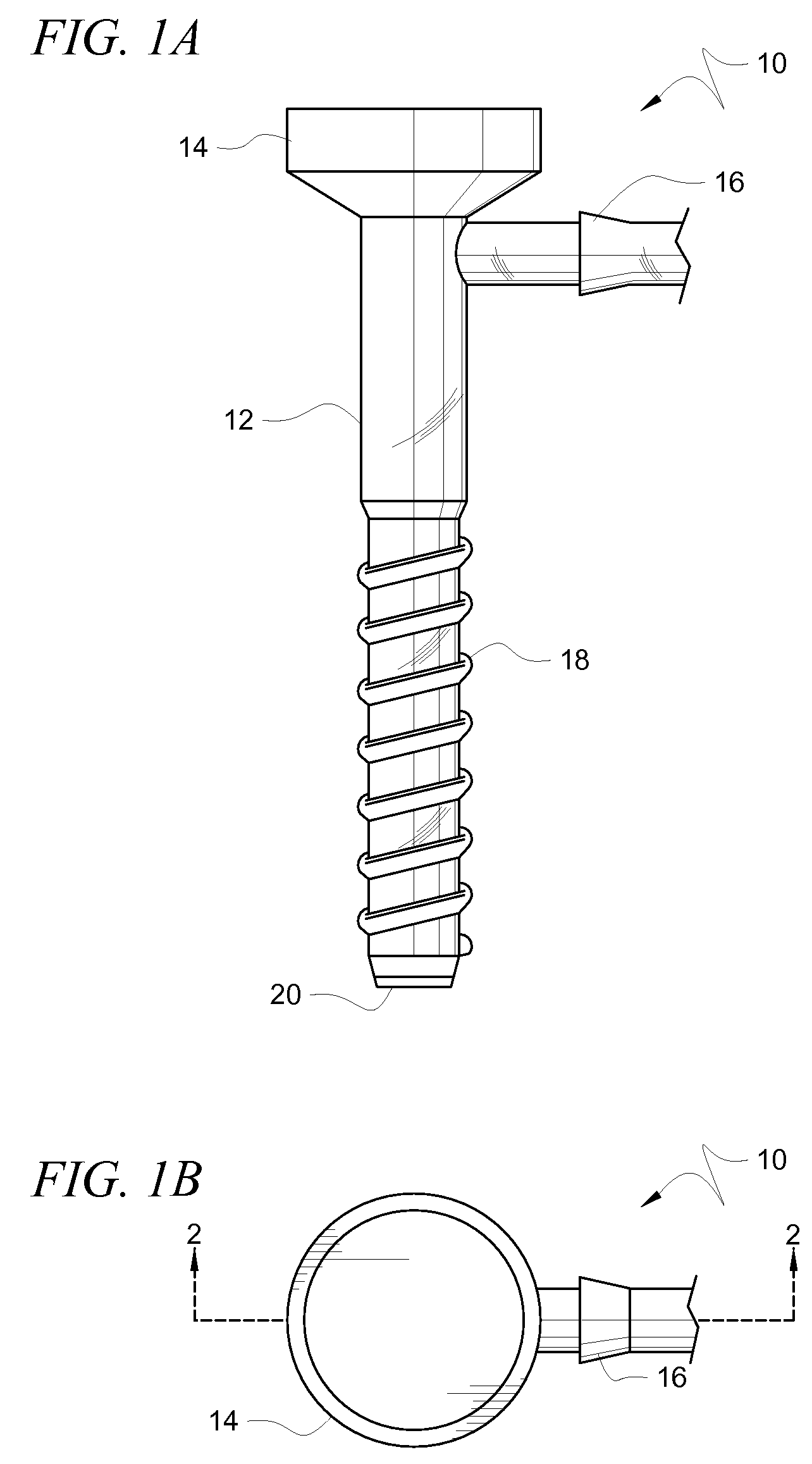

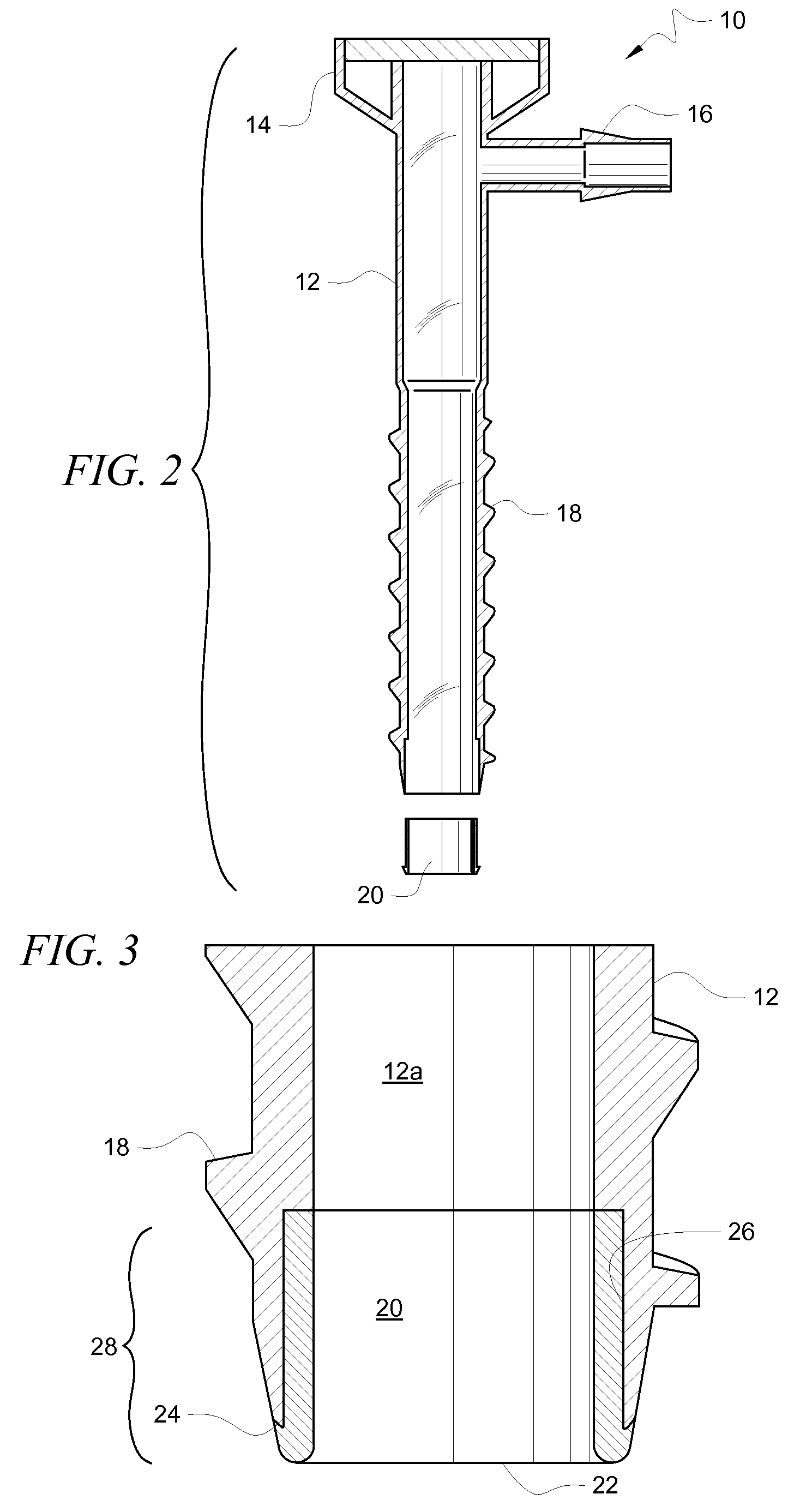

Storm reinforcing brace for a corrugated hurricane shutter and system

ActiveUS8074408B1Easy to installHigh impact strengthHurricane shuttersShutters/ movable grillesThreaded fastenerPolycarbonate plastic

A storm reinforcing brace for a corrugated polycarbonate plastic hurricane shutter panel, and the combination thereof. The brace includes an elongated bar member extrusion-formed as a single one-piece unit and having a continuous, uniform generally hat-shaped section defining a central portion, leg or side portions, and mounting flange portions thereof. The central portion is preferably flat with an inwardly extending C-shaped channel sized to entrappingly slidably receive a head of a separate threaded fastener from either end of the channel, the threaded fastener being held in the channel in an outwardly extending adjustably slidable orientation along the length of the brace. Each of the mounting flange portions lie in a plane inwardly offset from the central portion and laterally extending from each corresponding leg portion, each of the mounting flange portions for receiving fasteners therethrough anchoring the brace against the upright side members of a window frame. The central portion is offset from the plane of the mounting flanges a distance sufficient for the central portion to support an inner planar surface of the shutter panel, the threaded fastener passing through the shutter panel to boltably secure the shutter panel against the central surface.

Owner:MOTOSKO STEPHEN J +1

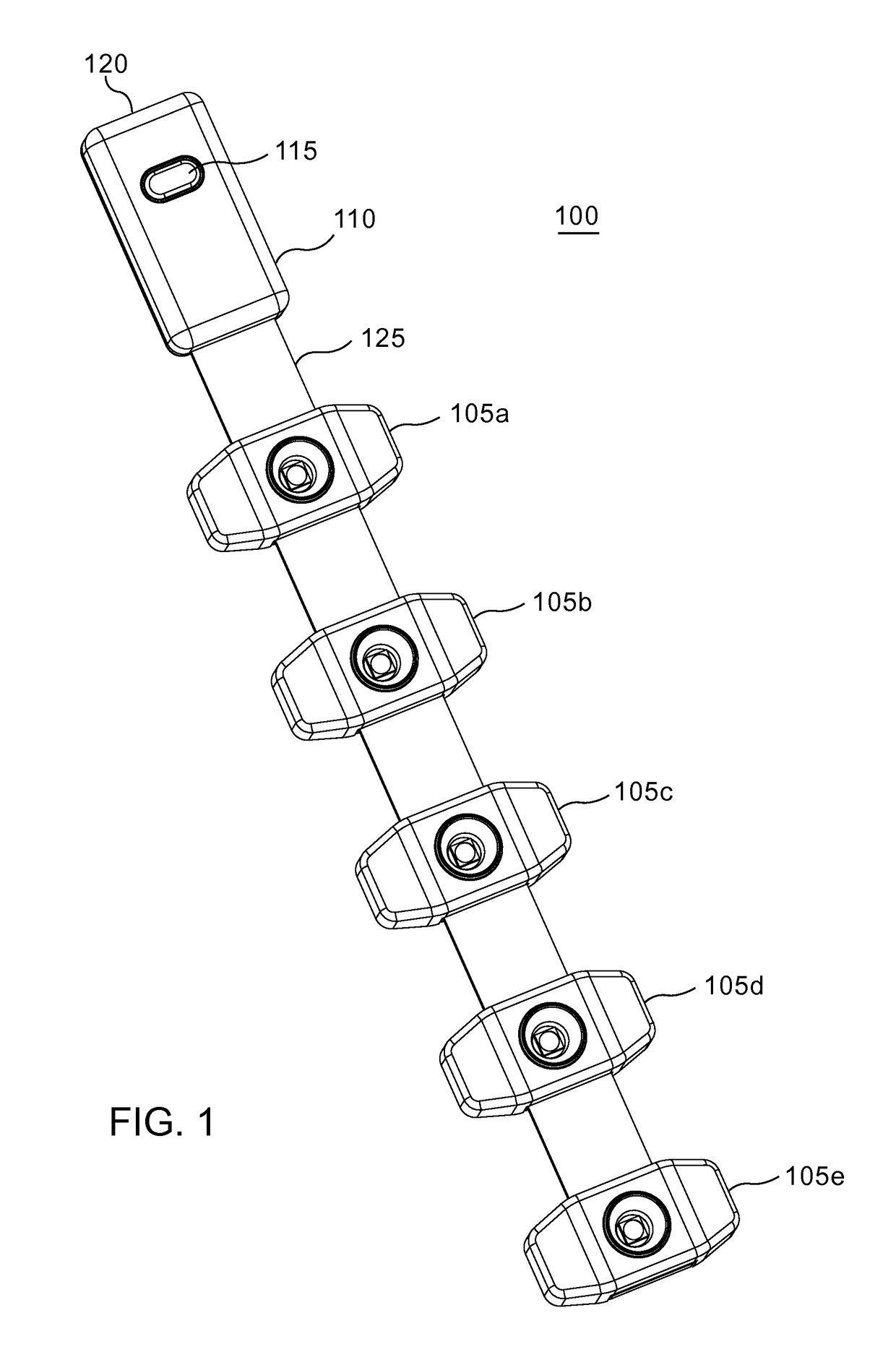

Cannula Having Unbreakable Tip

A cannula includes an elongate cannula body formed of a translucent polycarbonate plastic having a distal end and the distal end has a sharp edge that frays and weakens sutures that rub against it. A distal tip has a rounded leading end and is disposed in overlying, protective relation to the distal end of the cannula body and the sharp edge. The distal tip is formed of a material that is substantially unbreakable upon contact with bone or other hard material encountered during surgery. The material may be a metal, a thermoplastic urethane or a thermoplastic urethane rubber. An annular recess formed in a lumen of the cannula body at the distal end of the cannula body accommodates the distal tip so that the lumen of the cannular body and the lumen of the distal tip are flush with one another.

Owner:POWERS DAVID M +1

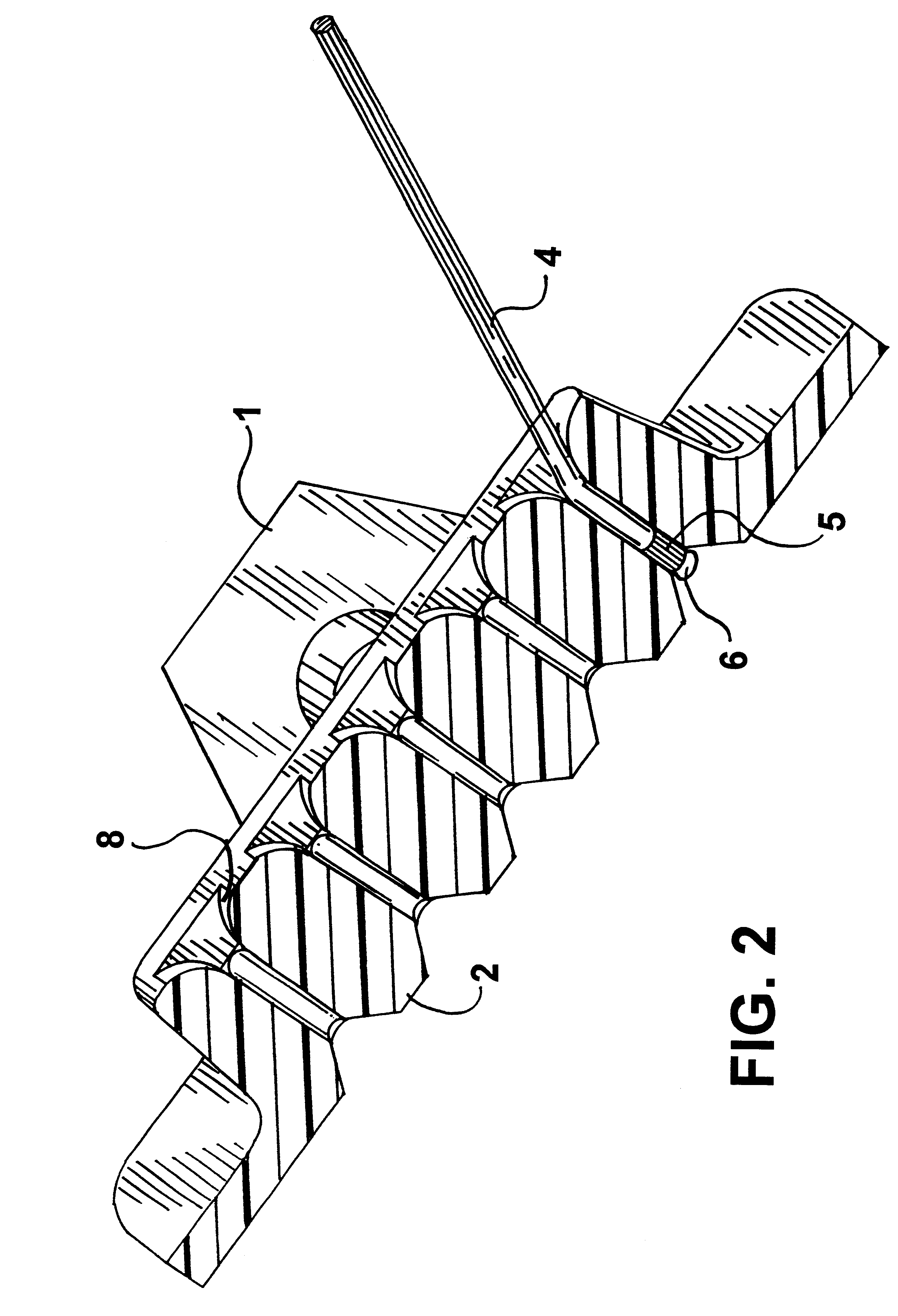

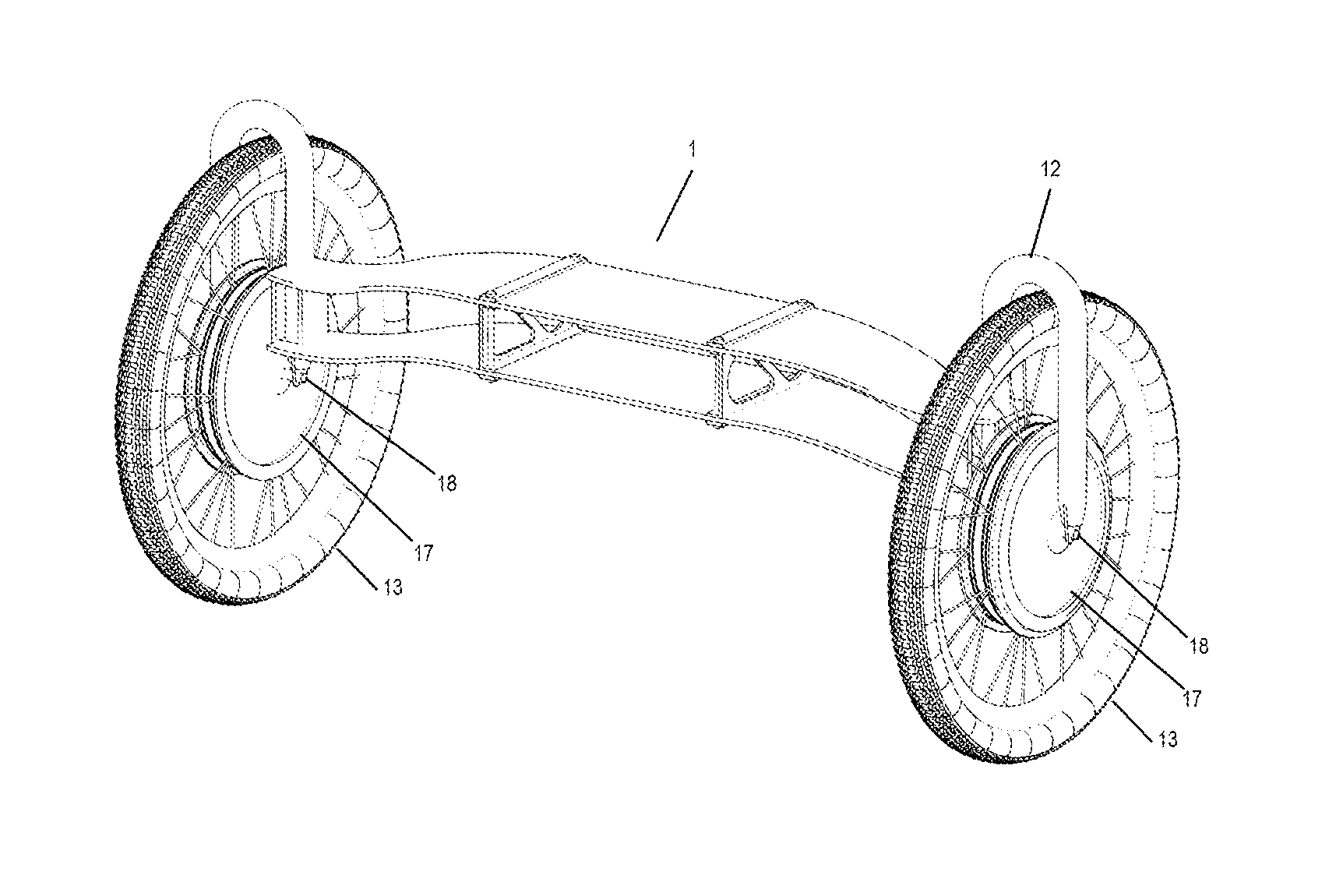

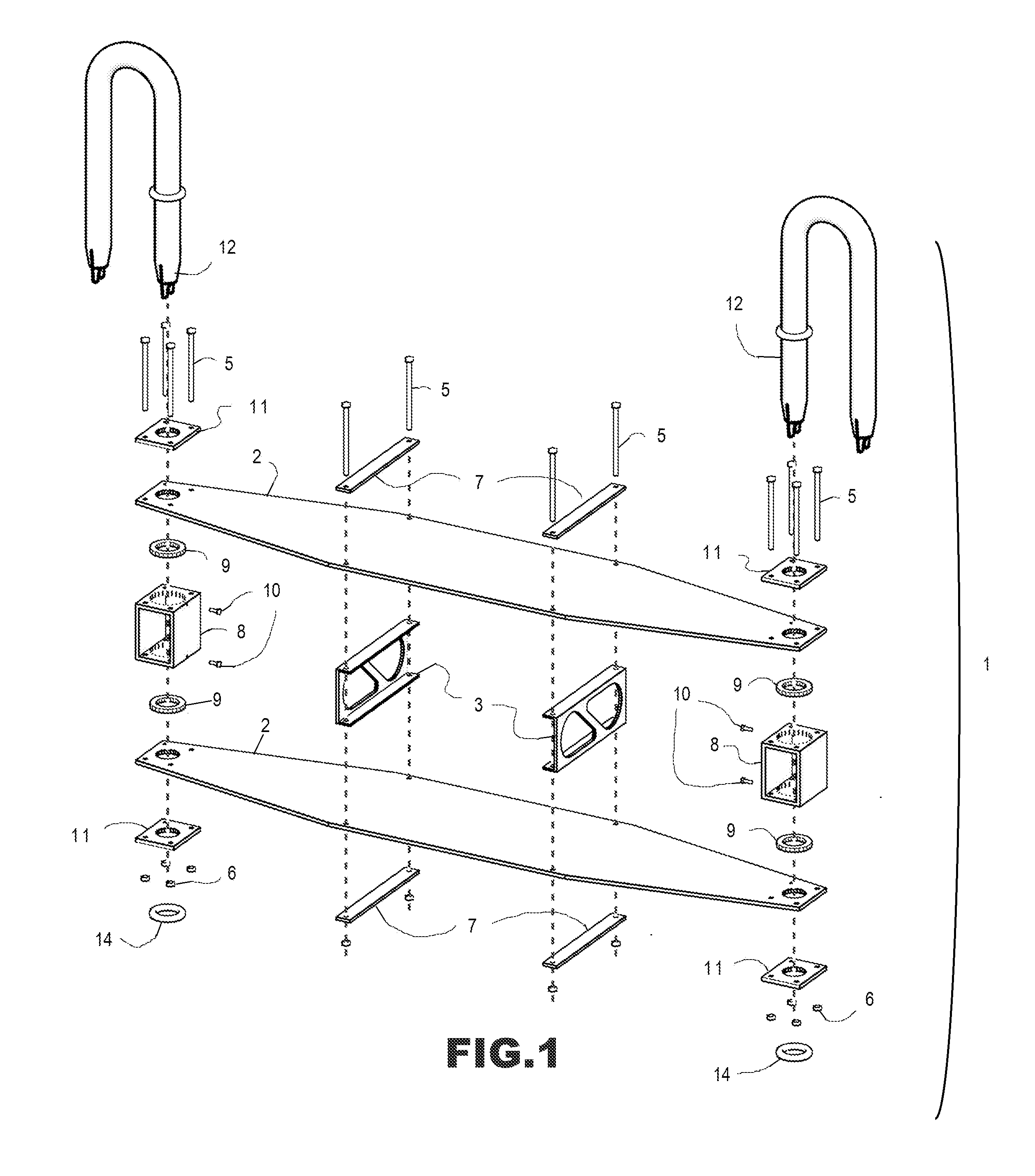

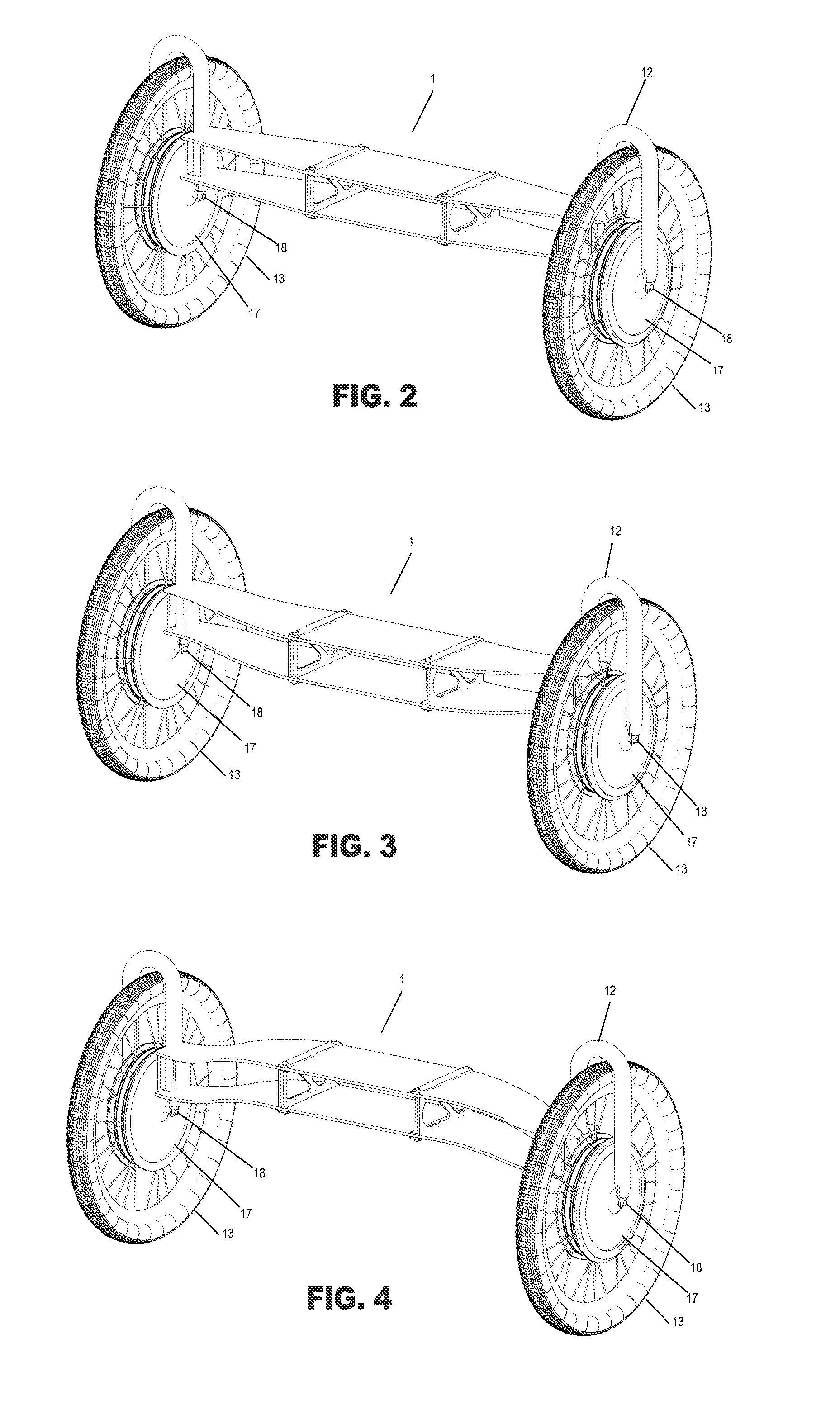

Lightweight polycarbonate suspension for vehicle

InactiveUS20140345958A1Improves at least some of the deficienciesConsiderable weightPassengers carsMotor depositionPolycarbonate plasticElectric vehicle

A lightweight suspension system for vehicles comprised of resilient polycarbonate plastic is disclosed. The system includes front and rear suspension components for four wheeled electric vehicles.

Owner:LAVARACK GARY KENNETH

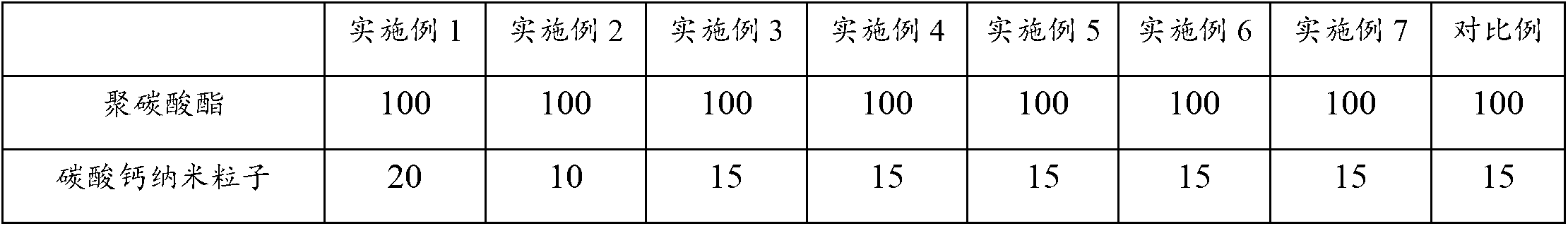

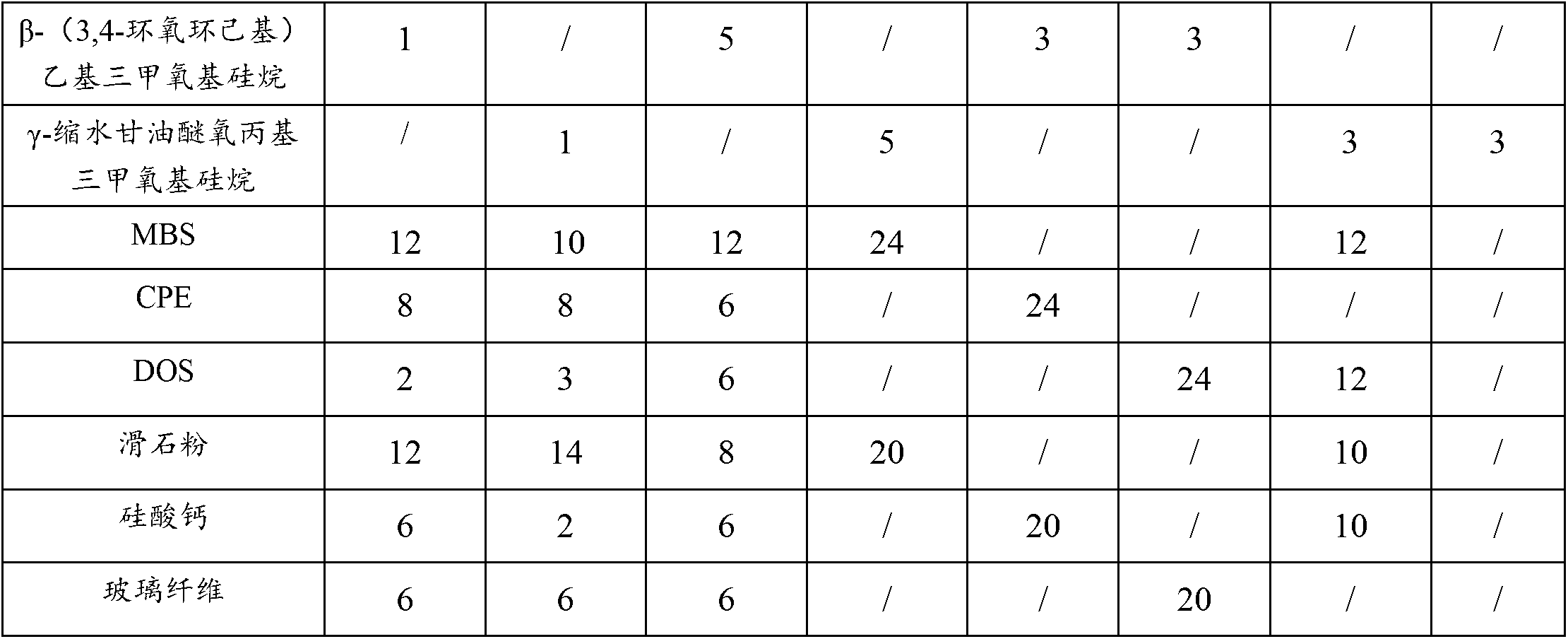

Anti-impact modified polycarbonate plastics for automotive interior parts and preparation method thereof

The invention discloses anti-impact modified polycarbonate plastics for automotive interior parts and a preparation method thereof. The polycarbonate plastics comprise the following ingredients in parts by weight: 100 parts of polycarbonate, 10-20 parts of calcium carbonate nanoparticles, 1-5 parts of coupling agent, 15-40 parts of anti-impact modifier and 10-35 parts of filler modifier. The preparation method comprises the following steps of: weighing raw materials according to a proportioning ratio, mixing the raw materials to be uniform, then, carrying out melting compounding, and carrying out extrusion pelleting, thereby obtaining the polycarbonate plastics. The anti-impact modified polycarbonate plastics for the automotive interior parts, disclosed by the invention, have the appearance and performance of a rubber body, have higher pulling strength, bending strength, bending modulus and gap impact strength and can be easily processed into automotive interior parts of various shapes through an injection molding process, such as a glove box inner cover plate, a glove box bucket, a vice instrument panel body, a storage box liner and a panel storage box.

Owner:SHANGHAI HAN MOLDING SHAPE CO LTD

Method for producing acrylic acid priming paint base-material and acrylic acid priming paint

The invention discloses a method for producing an acrylic acid priming paint base-material and an acrylic acid priming paint. The polystyrene modified methyl methacrylate and 80-200 seconds nitro cellulose liquid are taken as the main components in an acrylic acid priming paint base-material formula, and a solvent and a leveling agent are also concluded. The acrylic acid priming paint base-material formula accords with the halogen-free requirement of the cell phone industry on paint (bromine content in the formula is less than 900ppm, chlorine content in the formula is less than 900ppm, the total content of bromine and chlorine is less than 1500ppm). The acrylic acid priming paint produced by the base-material formula is matched with a spraying diluent and an ultraviolet radiation solidification topcoat to spray on the polycarbonate plastics, the dried and solidified coating has excellent water-boiling resistance, the coating has no foaming, no cracking and no discoloration after being boiled for 30 minutes in boiling water at the temperature of 100 DEG C.

Owner:深圳市美丽华科技股份有限公司

White acrylic resin plastic cement primer and its preparation method

InactiveCN102363682AHalogen Free CompliantImprove boiling resistanceCoatingsCellulosePolycarbonate plastic

The invention discloses a white acrylic resin plastic cement primer and its preparation method. The white acrylic resin plastic cement primer provided by the invention contains main components of polystyrene modified methyl methacrylate, polymethyl methacrylate, a cellulose nitrate liquid of 80-200 second and titanium dioxide, and simultaneously contains a solvent and an auxiliary agent. The white primer prepared by the formula accords with the requirement on halogen-free paints in the mobile-phone industry. A diluent and an ultraviolet curing top finish are sprayed on polycarbonate plastic housing and buttons of a handset. The dried and cured coating has excellent boiling resistance. After boiled in water of 100 DEG C for 30 minutes, the coating will not foam, crack and change color.

Owner:深圳市美丽华科技股份有限公司

Transparent acrylic acid intermediate-coating paint base stock and preparation method thereof

ActiveCN103254715AImprove boiling resistanceNo difference in high temperature and high humidity resistanceCoatingsCyclohexanonePolycarbonate plastic

The invention discloses a transparent acrylic acid intermediate-coating paint base stock and a preparation method thereof. The base stock comprises the following ingredients in percentage by weight: 40.0%-45.0% of polymethyl methacrylate, 35.0%-40.0% of iso-octyl methacrylate, 1.0%-5.0% of butyl acetate, 1.0%-5.0% of isobutyl acetate, 1.0%-5.0% of cyclohexanone, 1.0%-5.0% of methyl ethyl ketone, 1.0%-5.0% of methyl isobutyl ketone, and 0-3.5% of cellulose acetate. The transparent acrylic acid intermediate-coating paint base stock can meet the requirement of mobile phone industry on no halogen in paint. Transparent acrylic acid intermediate-coating paint produced by the base stock is additionally provided with a mating curing agent, spraying diluents, halogen-free acrylic acid primer and ultraviolet radiation curing finishing paint for use and then is sprayed onto polycarbonate ester plastics, and a dried and cured coating has excellent boiling resistance.

Owner:深圳市美丽华科技股份有限公司

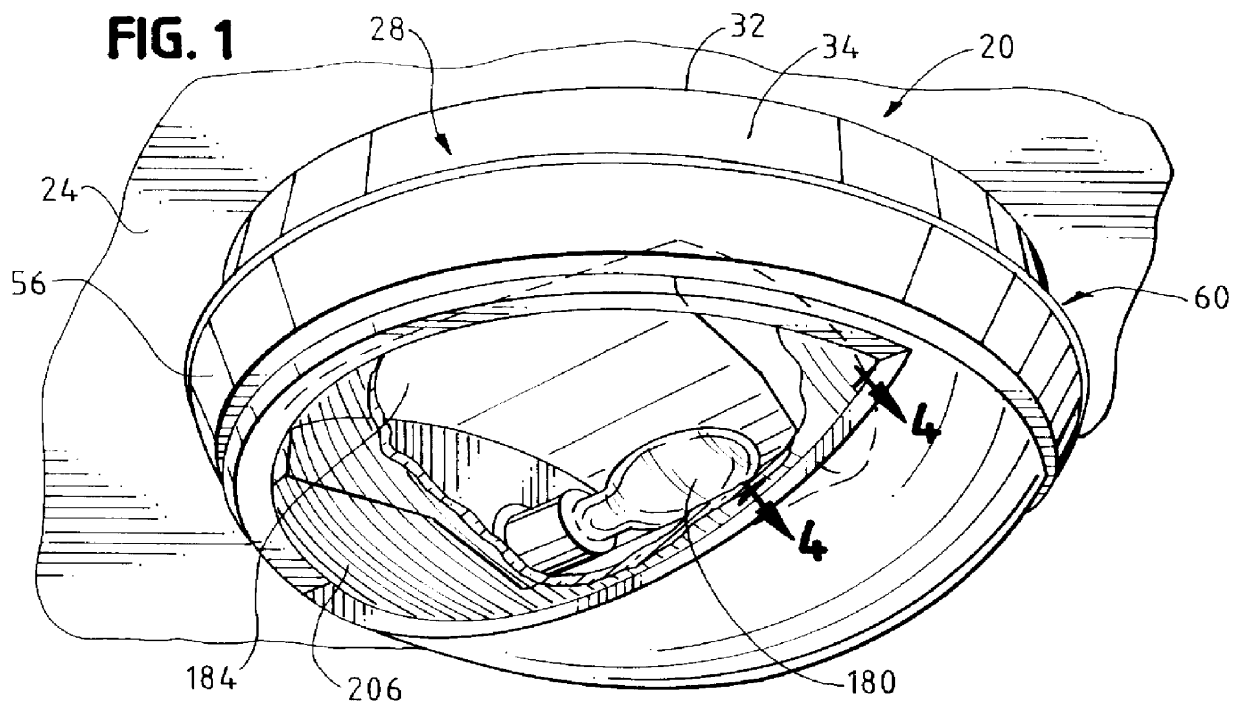

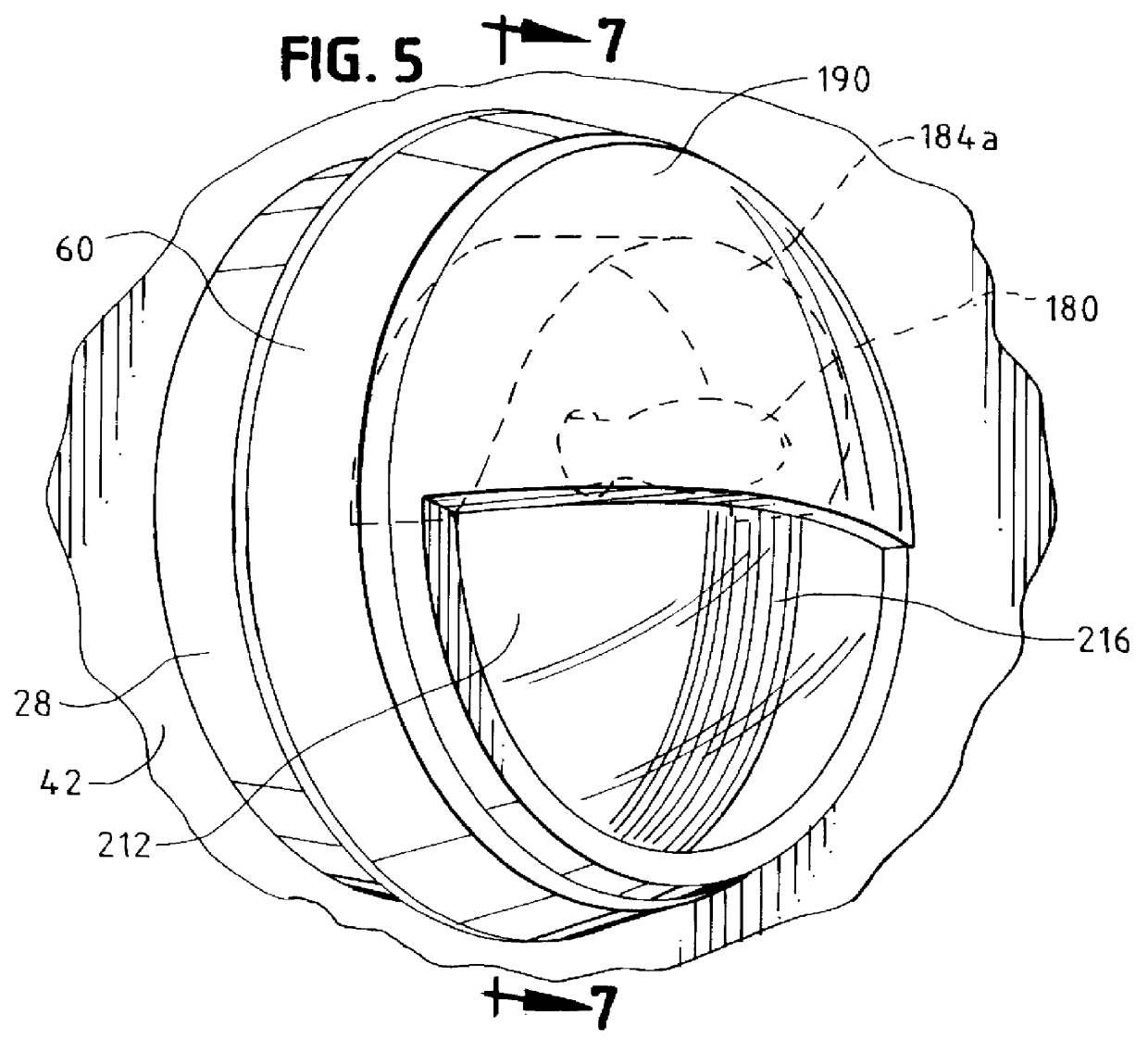

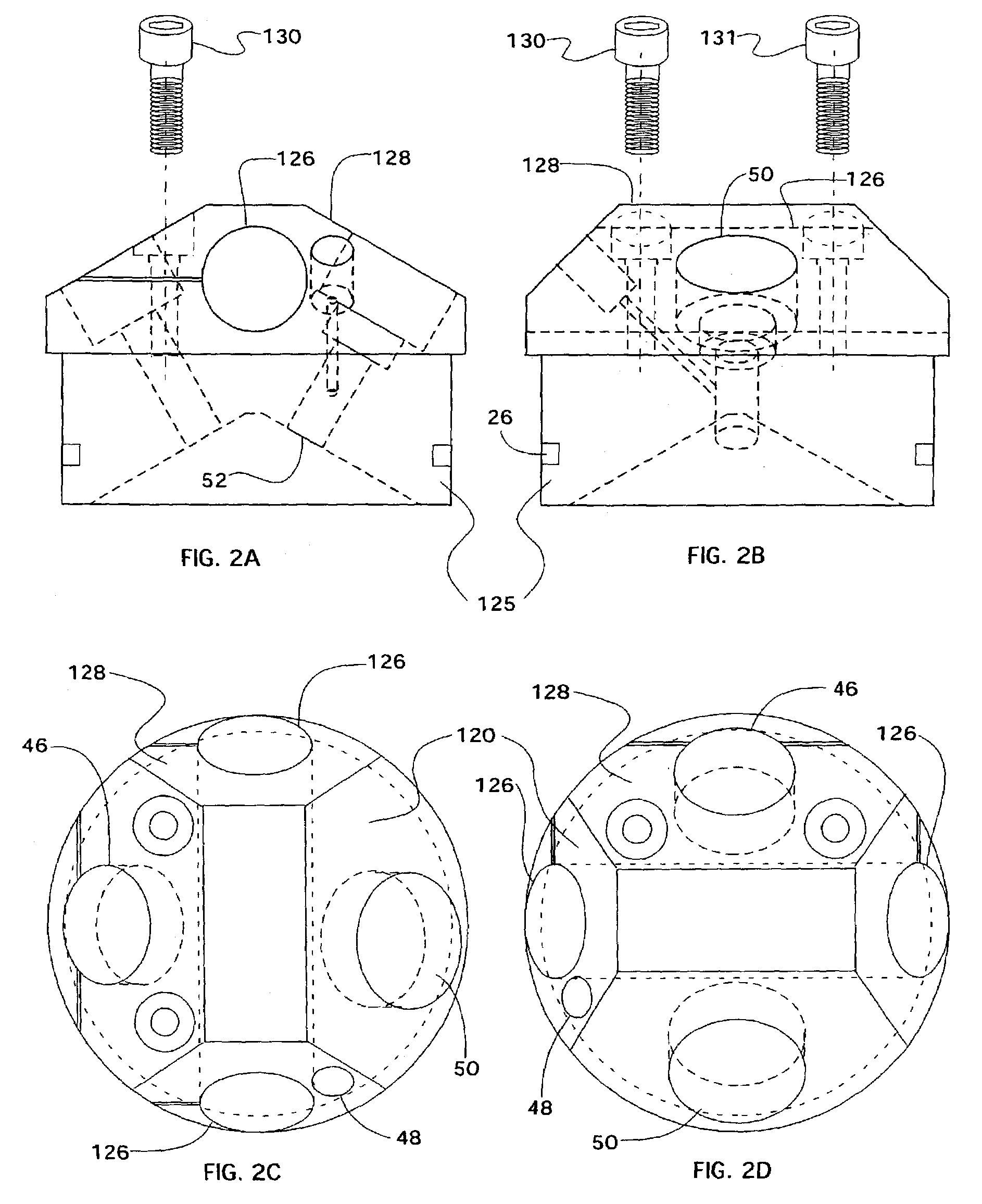

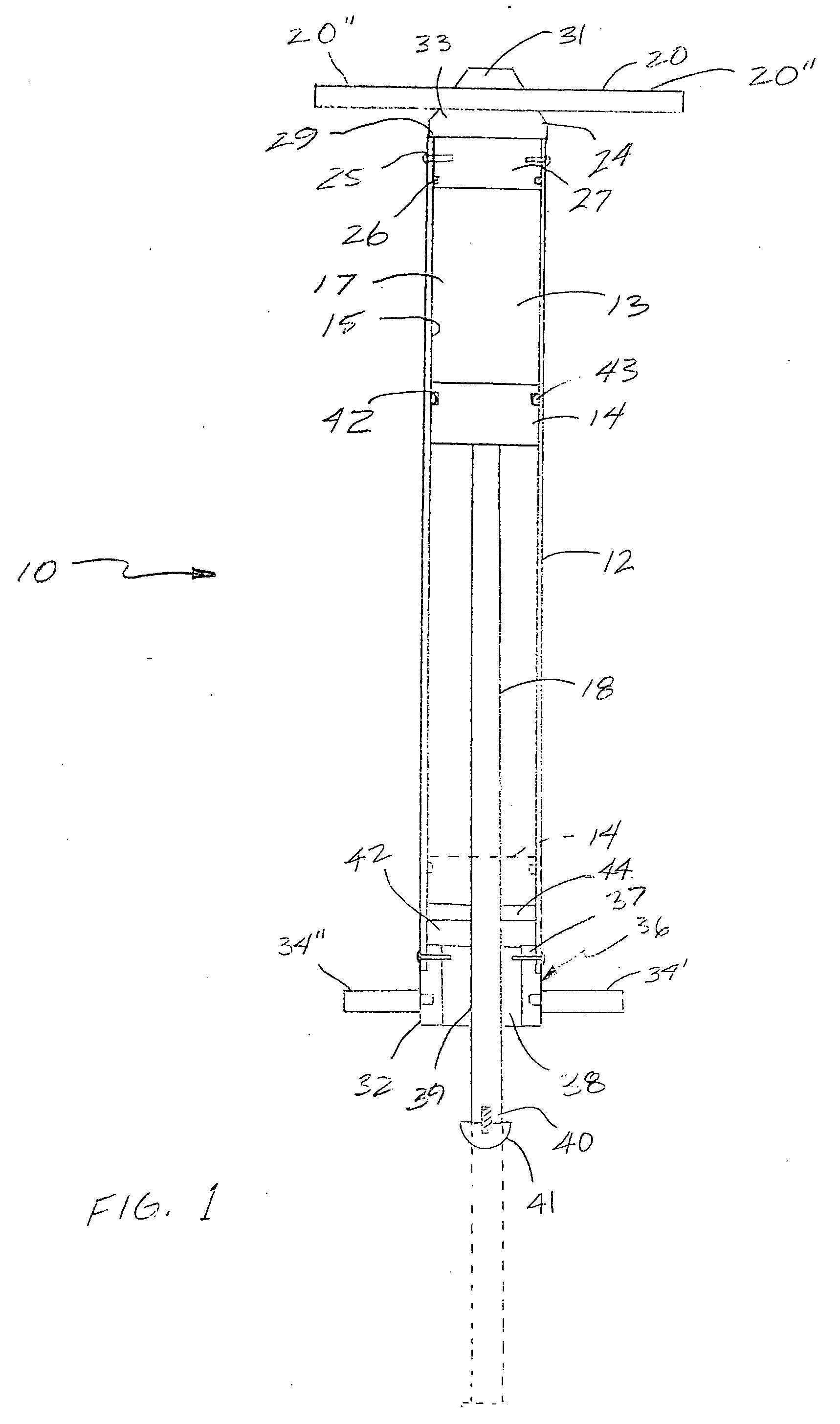

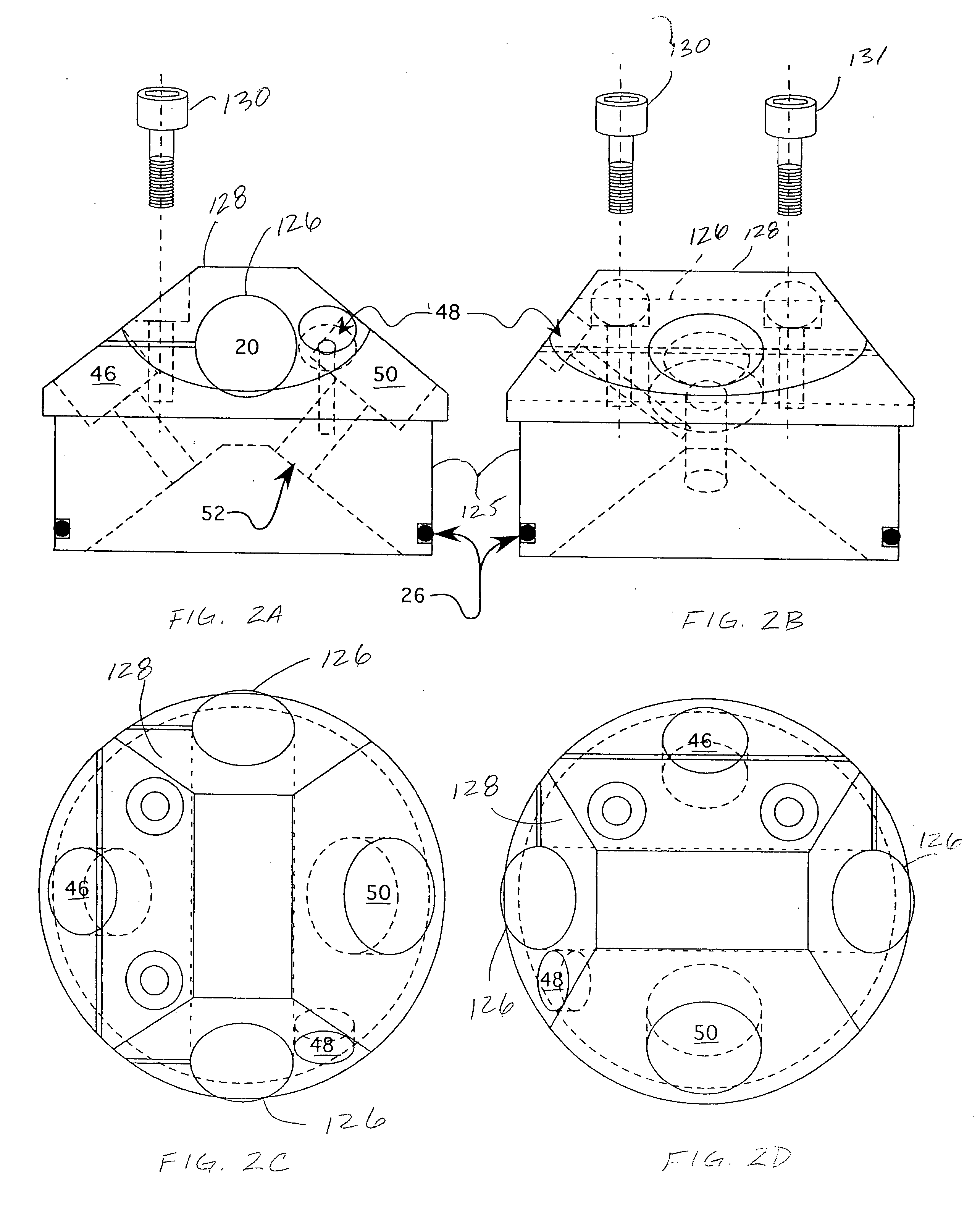

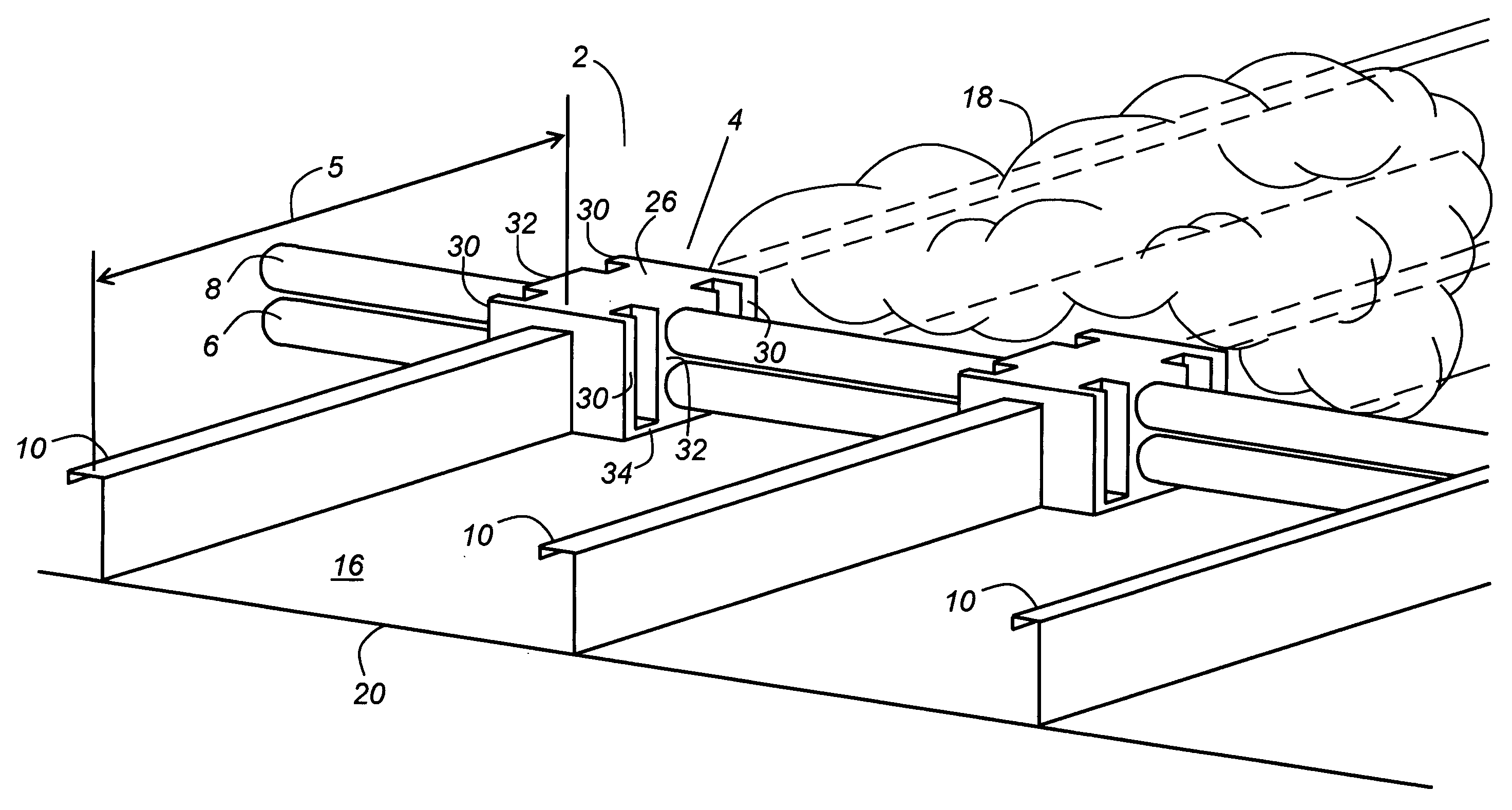

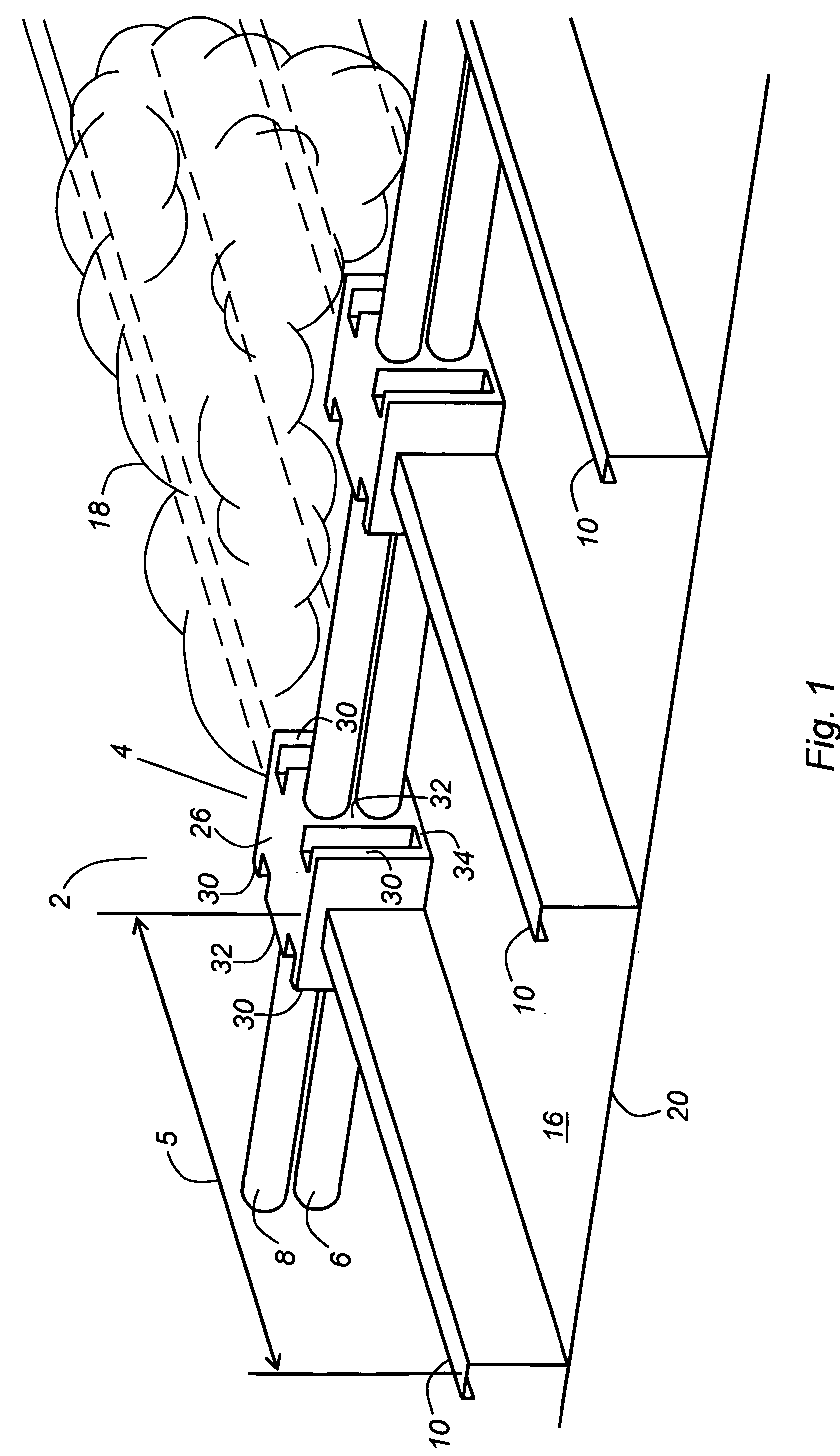

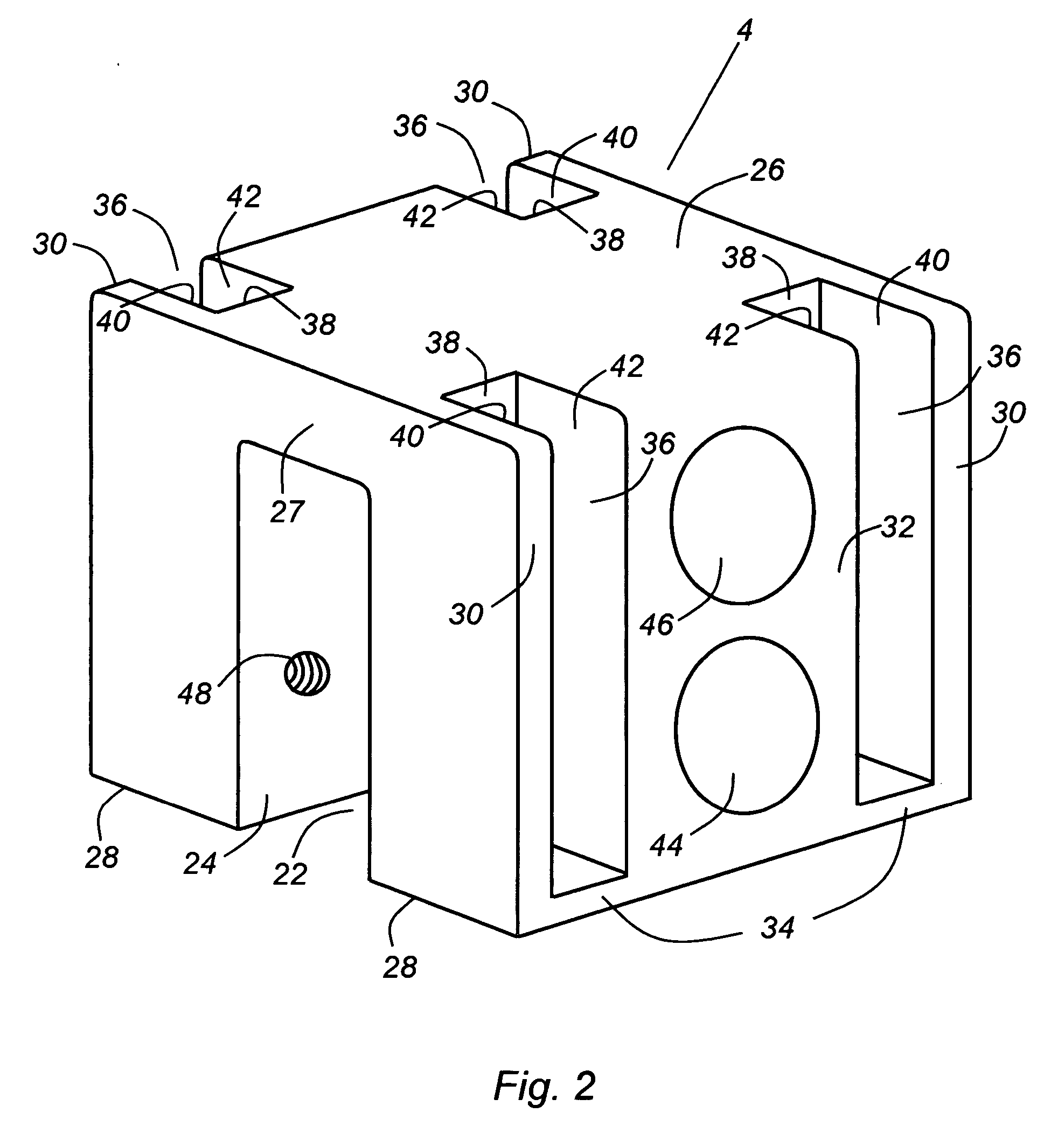

Snow guard apparatus and method

A snow guard for a raised portion on a building metal roof surface, having a unitary transparent mounting body is formed from a polycarbonate material. A transparent acrylic snow-holding bar fits into the transparent mounting body. An ice-holding bar also is provided and is formed from clear acrylic. In one aspect, the mounting body includes vertical structural stiffeners 30 by walls 42 of bar supporting central columns 32 and by outside surface 38 of wall 24 and horizontal stiffeners 27 extending downwardly under top 26 and which are integral part of the mounting body and of walls 24 providing a rigid, strong connection of the two structural support sides 28, top portion 26 and horizontal stiffeners 27 and structural support sides 28 all molded in one piece, made of ultraviolet proof, high impact, high izod polycarbonate plastic. In one aspect, the mounting body include bar insertion cavities 46 and stops 52 to prevent snow-holding bar 8 from sliding through its insertion cavities.

Owner:TREVORROW THOMAS P +1

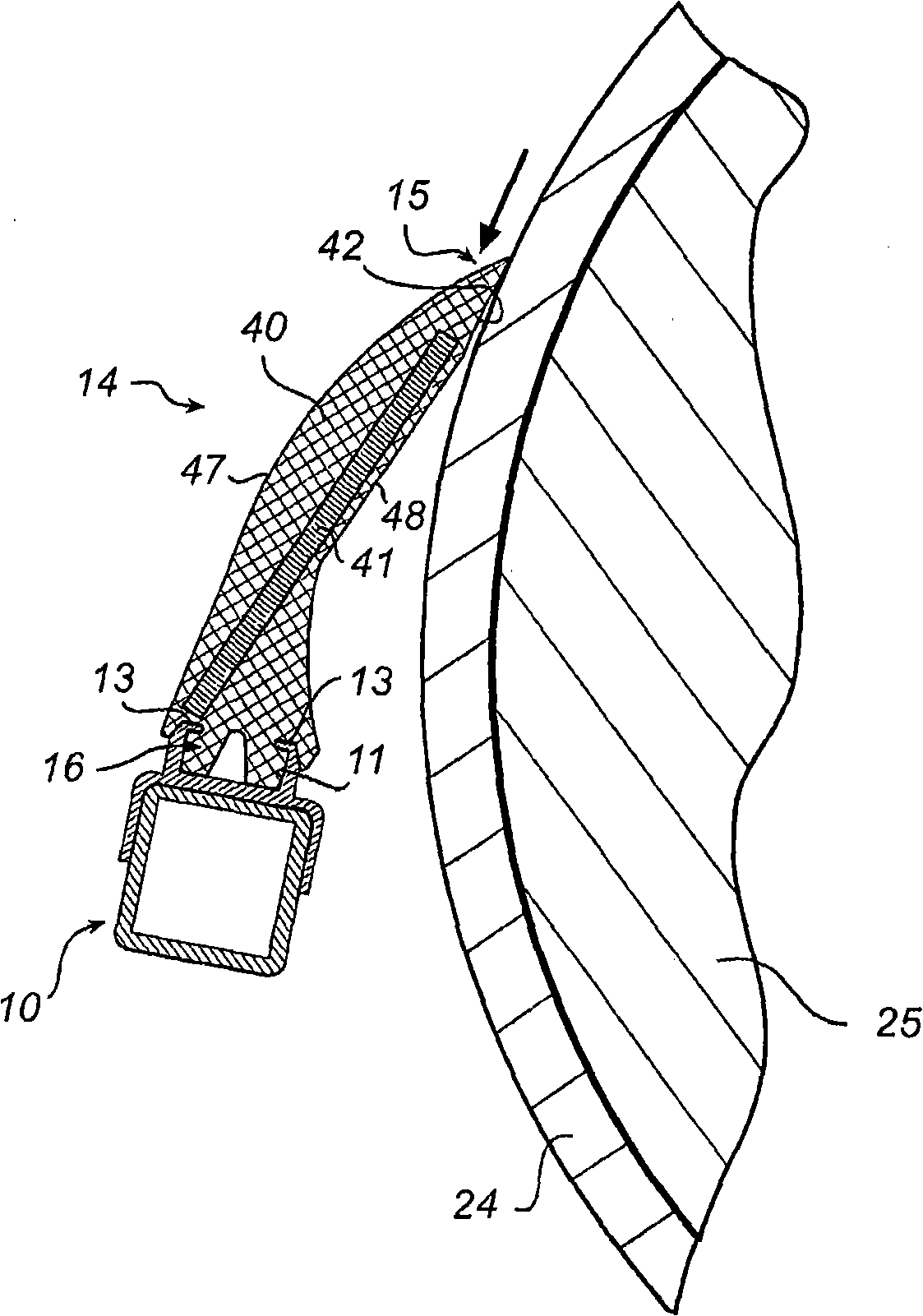

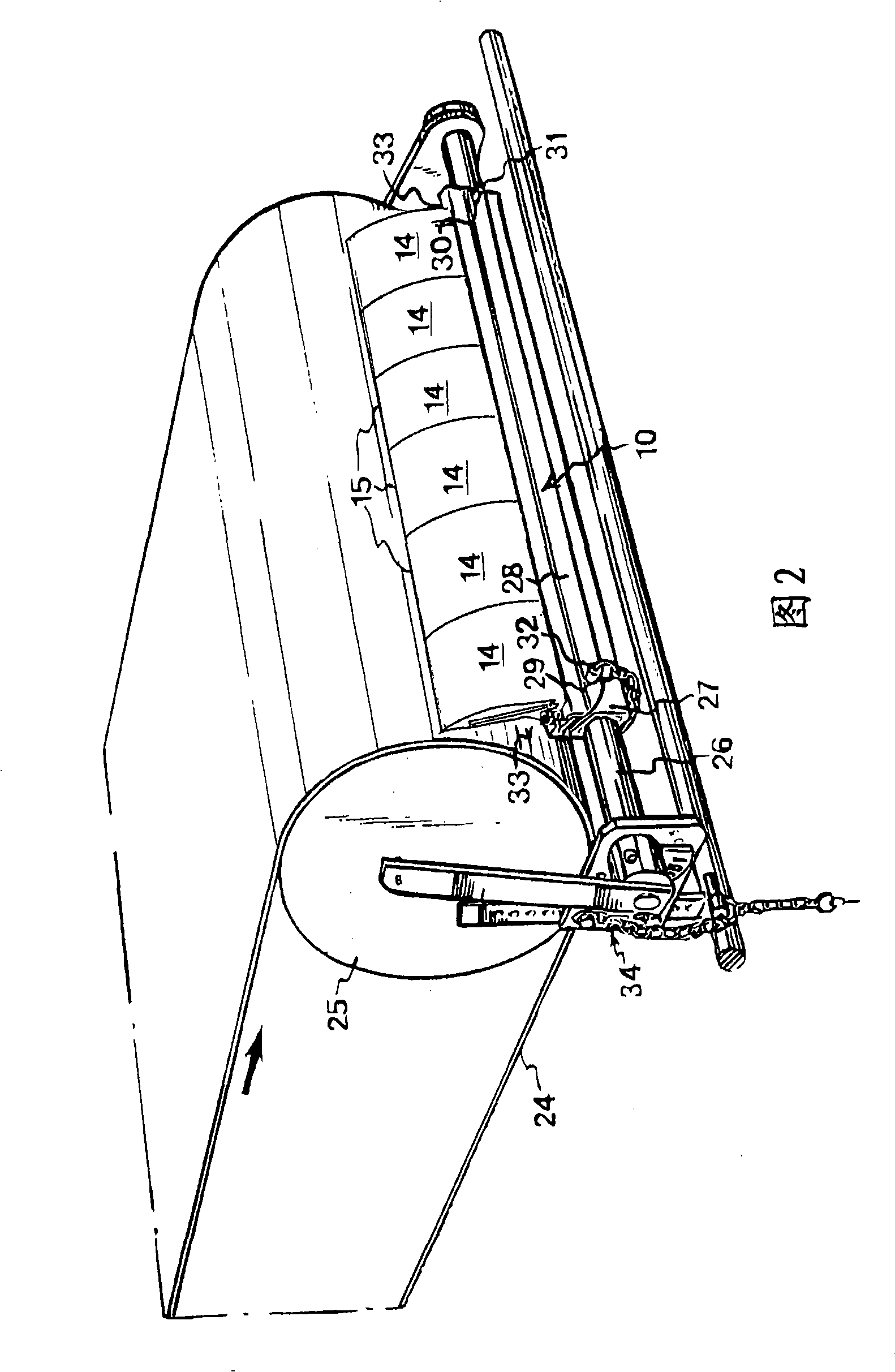

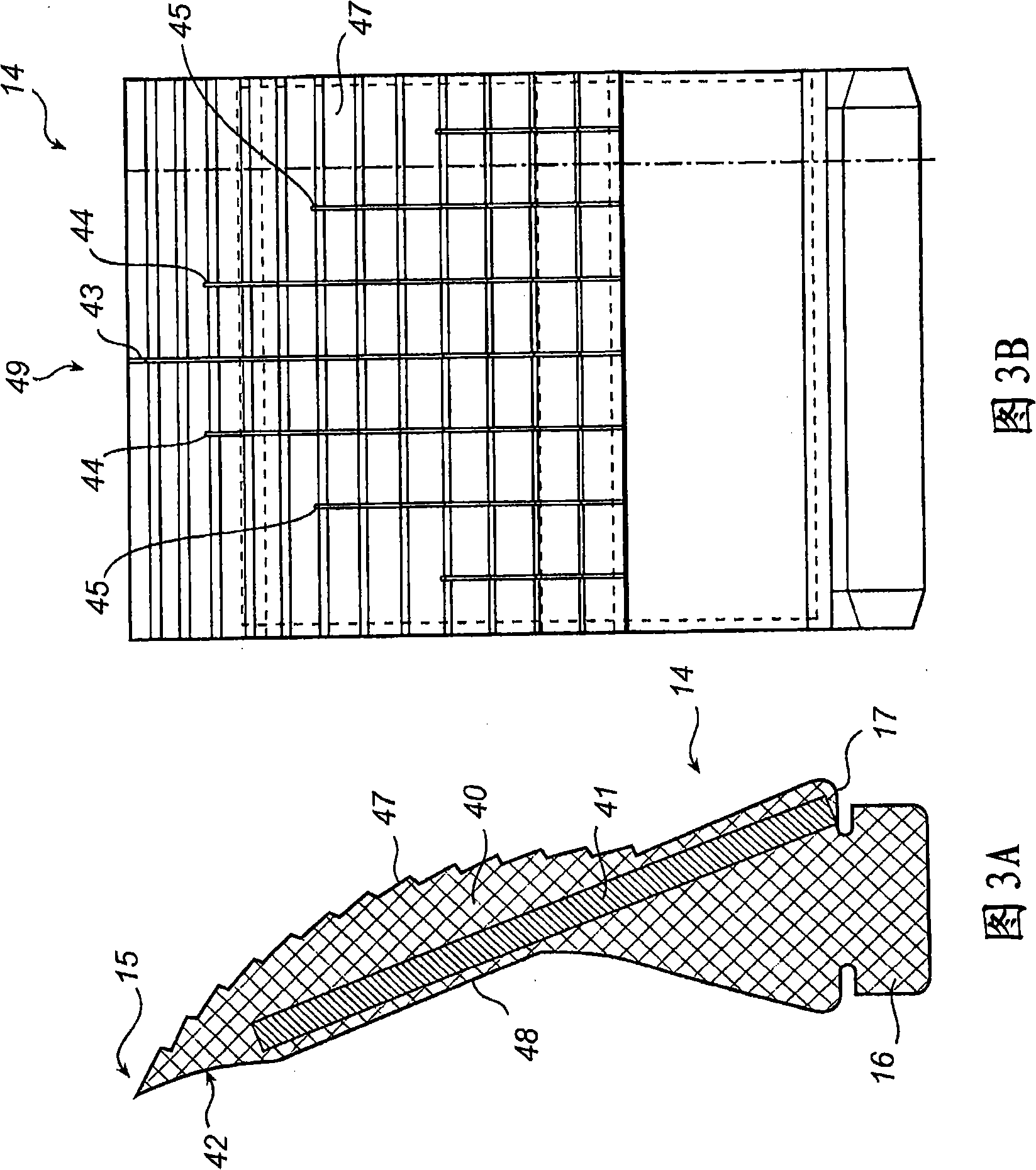

Scraper blade and method of manufacturing the same

A scraper blade adapted to scrape off material from a conveyor bel surface (24) has a scraper tip (15) at one end and a mounting bas (16) at its other end and is tapered towards the tip at least in th outer end of the scraper blade, its scraper blade portion whic extends from the tip (15) and to a point adjacent to or in th mounting base (16) being made with at least two layers (40, 41) , which extend longitudinally along said scraper blade portion, and is characterised in that at least one first layer (40) is made o polyurethane with a lower hardness and a higher abrasion resistanc than at least one second layer (41) which is mainly made o polycarbonate plastic, said at least one second polycarbonat plastic layer (41) being adapted to reinforce and stiffen said a least one first layer, which constitutes a main contact surface (42) against said surface (24) . A method of manufacturing scraper blade for scraping webs of material is also included.

Owner:METSO OUTOTEC (FINLAND) OY

Polycarbonate plastic sheet

InactiveCN103554890AHigh impact strengthUV protectionOptical elementsCross-linkPolycarbonate plastic

The invention discloses a polycarbonate plastic sheet. The polycarbonate plastic sheet comprises polycarbonate plastics and additives, wherein the additives comprise a shock resistant modifier, an ultraviolet absorber, a slip agent, an antifogging agent, a nucleating agent and a cross-linking agent, wherein the shock resistant modifier is ethylene-vinyl acetate copolymer, the ultraviolet absorber is benzophenone, the slip agent is organic siloxane emulsion, the antifogging agent is sorbitan monopalmitate, the nucleating agent is butadiene rubber, and the cross-linking agent is poly alkyl acrylate. The polycarbonate plastic sheet has high shock resistance, is not easy to scratch, can well absorb ultraviolet rays of sunlight, and has a long service life. And the lens has a smooth surface and fog is not easy to form on the surface of the lens.

Owner:苏州市双赢包装材料有限公司

Wear-resistant coating material without primer on polycarbonate surface and preparation method thereof

The invention relates to a wear-resistant coating material without a primer on a polycarbonate surface and a preparation method thereof, in particular to a coating material. The invention provides a wear-resistant coating material without a primer on a polycarbonate surface, which can adhere to the polycarbonate surface without the primer, can increase the surface hardness of the polycarbonate plastic and has a wear-resistant function, and a preparation method thereof. The wear-resistant coating material is prepared from at least two functionalities of alkoxy silane and a composition thereof, acidic silica sol, water, an acid catalyst, a diluting agent, polymer polyol, a silane coupling agent, a flatting agent and a curing agent. The preparation method comprises the following steps: mixing the at least two functionalities of alkoxy silane and the composition thereof, the water and the acidic silica sol for reacting; adding the acid catalyst; heating for refluxing; adding the polymer polyol for continuously refluxing; and after cooling, adding the silane coupling agent, the curing agent, the flatting agent and the diluting agent to obtain the wear-resistant coating material without the primer on the polycarbonate surface.

Owner:厦门威亮光学涂层技术有限公司

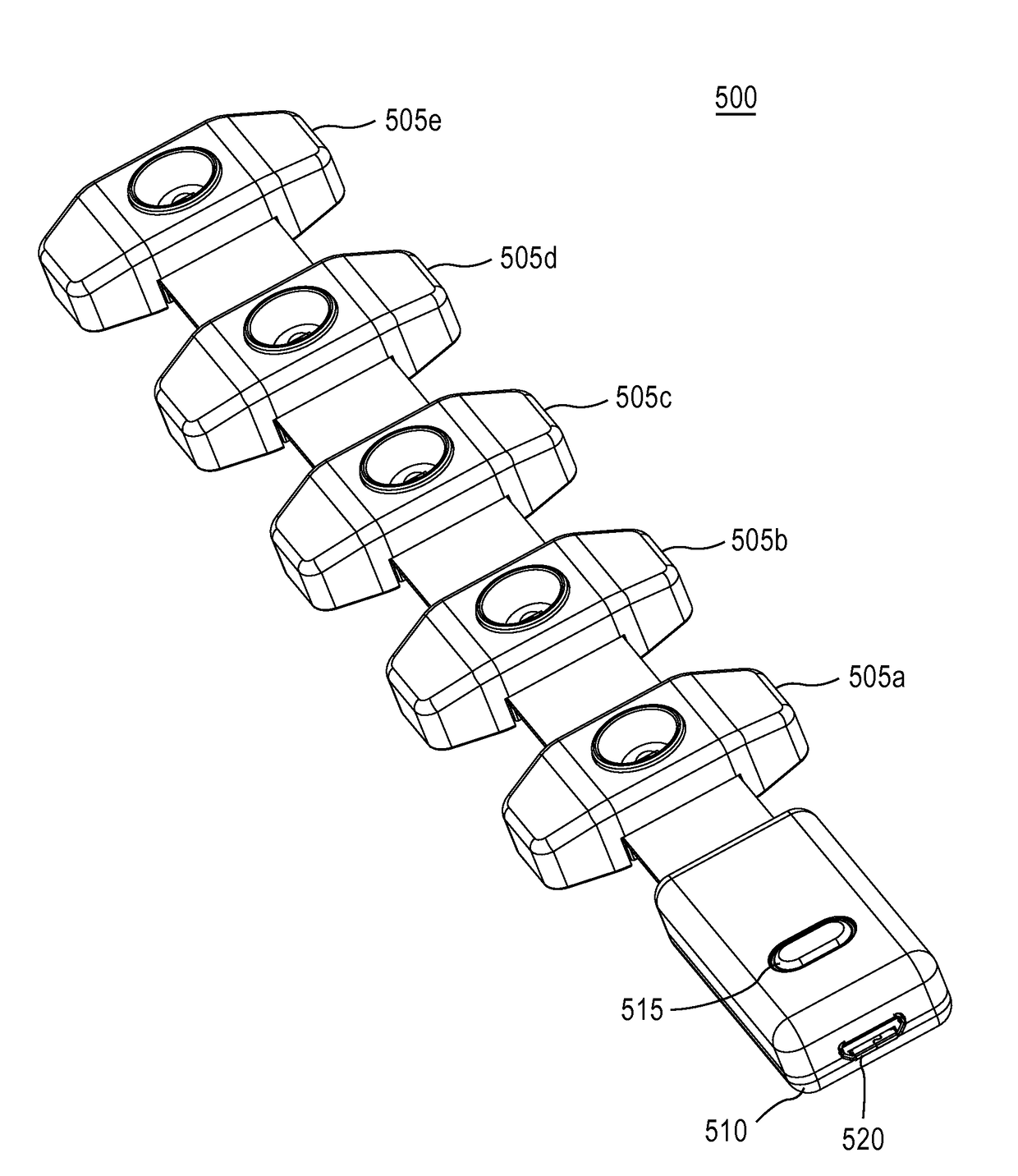

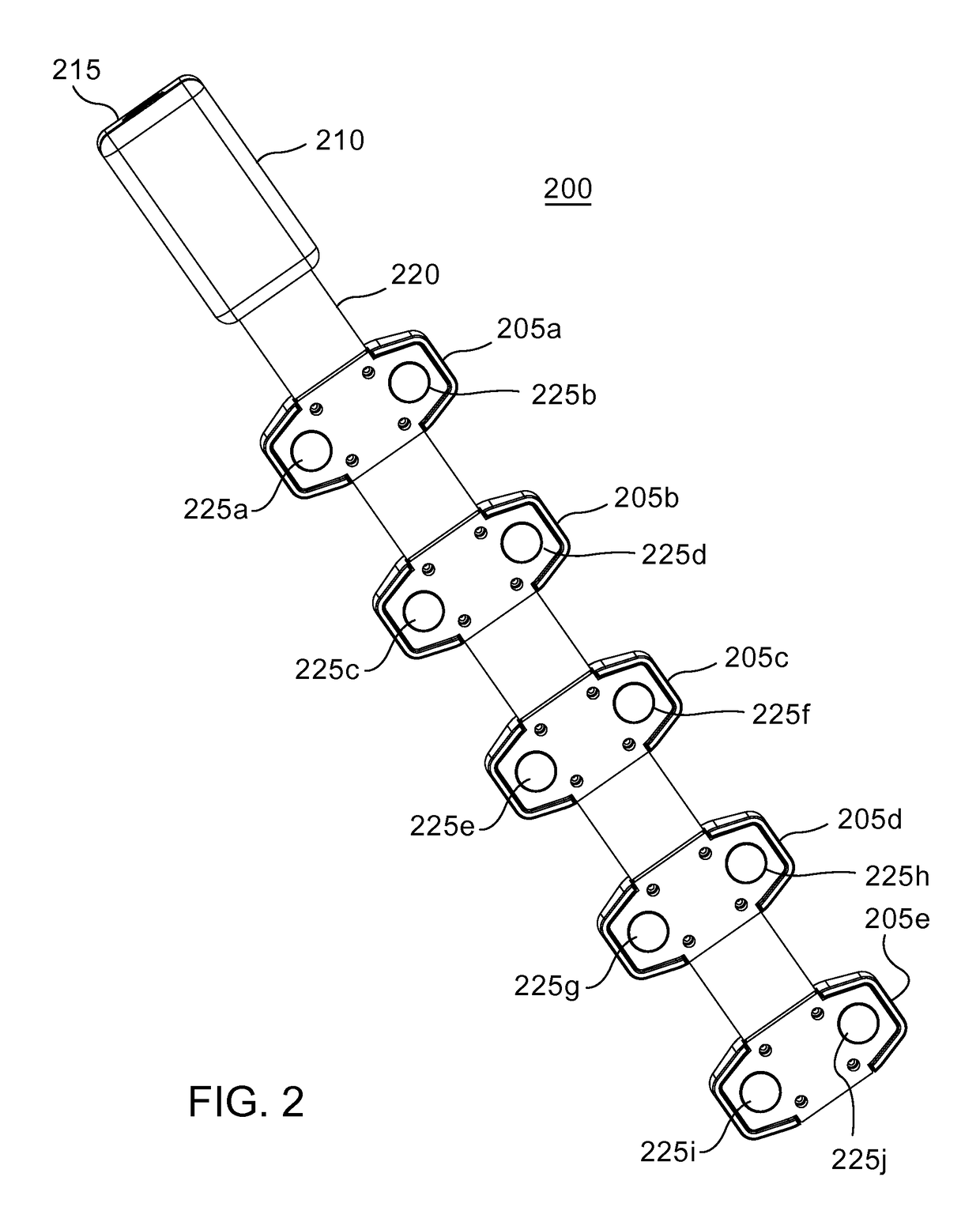

Multi-element flexible strap light

Disclosed herein is a multi-element flexible strap light which includes a plurality of light elements disposed on a flexible chassis. The flexible chassis may include a first flexible layer, a printed circuit board, and a second flexible layer. The flexible chassis may be further contained within a third flexible layer, such as a layer of polycarbonate plastic. Further disclosed is a multi-element flexible strap light system which includes a plurality of light elements disposed on a flexible chassis and a remote battery.

Owner:ZYNTONY INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com