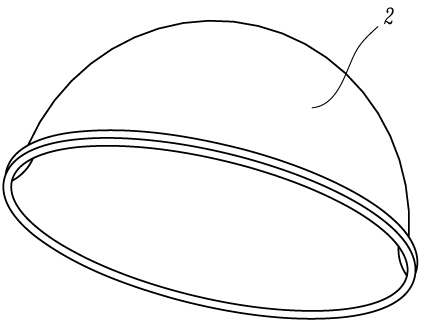

Glass fiber reinforced plastic helmet shell and fabrication technique thereof

A manufacturing process, glass fiber reinforced plastic technology, applied to the field of fiberglass helmet shell and its manufacturing process, can solve the adverse effects of helmet air tightness and impermeability, the outer surface of the shell is not smooth and smooth, and the helmet processing such as painting and decals is troublesome. and other problems, to overcome the weak anti-penetration performance, improve product quality and production efficiency, and ensure the effect of production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

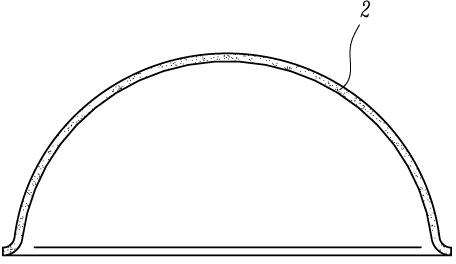

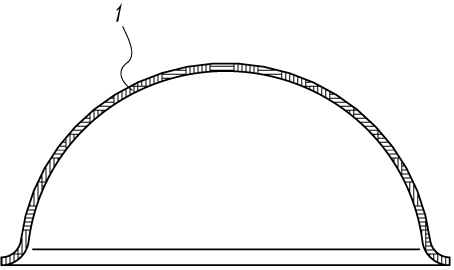

[0032] Making the plastic shell 2 → placing the plastic shell 2 in the mold cavity → laying a fiber layer in the plastic shell 2 → pouring resin on the fiber layer → closing the mold, heating and pressurizing → keeping the pressure → opening the mold and taking out the glass steel helmet shell.

Embodiment 2

[0034] Making the plastic shell 2 → laying the fiber layer in the plastic shell 2 → placing the plastic shell 2 in the mold cavity → pouring resin on the fiber layer → closing the mold, heating and pressurizing → keeping the pressure → opening the mold and taking out the glass steel helmet shell.

Embodiment 3

[0036] Making the plastic shell 2 → laying the fiber layer in the plastic shell 2 → pouring resin on the fiber layer → placing the plastic shell 2 in the mold cavity → closing the mold, heating and pressurizing → maintaining the pressure → opening the mold and taking out the glass steel helmet shell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com