Production method for spray-drying Chinese yam powder without using sulfur to protecting color

A production method and technology of yam powder, which are applied in the directions of pharmaceutical formulas, skin care preparations, botanical equipment and methods, etc., can solve problems such as easy browning, browning of products, excessive sulfur content, etc., and achieve less damage to nutrients, The effect of good product quality and large production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

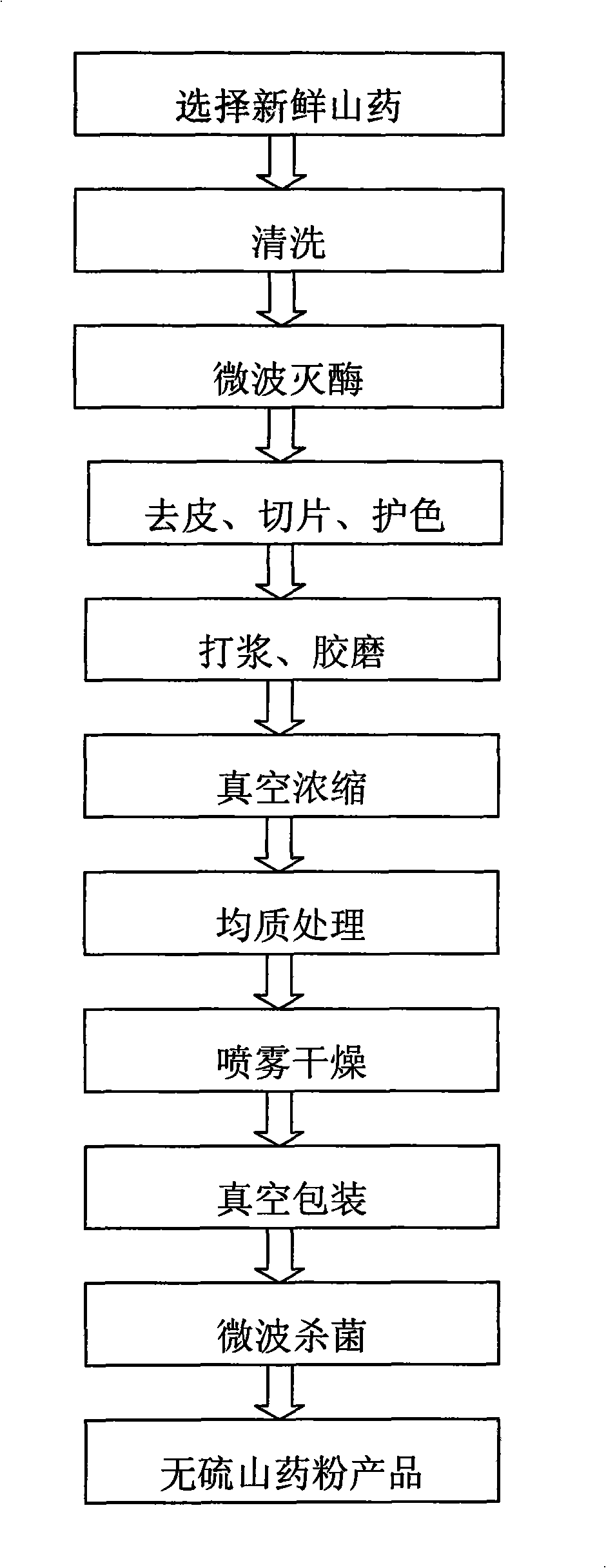

[0023] The production method comprises the following steps:

[0024] (1) Raw material selection: the operation method is the same as the specific operation step (1) in the "Content of the Invention";

[0025] (2) Cleaning: the operation method is the same as the specific operation step (2) in the "Content of the Invention";

[0026] (3) Microwave inactivating enzyme treatment: the operation method is the same as the specific operation step (3) in the "Summary of the Invention";

[0027] (4) Peeling, slicing, and color protection: the operation method is the same as the specific operation step (4) in "Content of the Invention", the color protection time is 5 hours, and the ratio of color protection solution is phytic acid 0.10mL / L, ethylenediamine Disodium acetate 0.10g / L, vitamin C 0.20g / L, citric acid 10.0g / L;

[0028] (5) beating, rubber mill: the operation method is the same as the specific operation step (5) in the "summary of the invention";

[0029] (6) Vacuum concent...

example 2

[0034] The production method comprises the following steps:

[0035] (1) Raw material selection: the operation method is the same as the specific operation step (1) in the "Content of the Invention";

[0036] (2) Cleaning: the operation method is the same as the specific operation step (2) in the "Content of the Invention";

[0037] (3) Microwave inactivating enzyme treatment: the operation method is the same as the specific operation step (3) in the "Summary of the Invention";

[0038] (4) Peeling, slicing, and color protection: the operation method is the same as the specific operation step (4) in "Content of the Invention", the color protection time is 4 hours, and the ratio of color protection solution is phytic acid 0.10mL / L, ethylenediamine tetramine Disodium acetate 0.20g / L, vitamin C 0.20g / L, citric acid 10.0g / L;

[0039] (5) beating, rubber mill: the operation method is the same as the specific operation step (5) in the "summary of the invention";

[0040] (6) Vacu...

example 3

[0045] The production method comprises the following steps:

[0046] (1) Raw material selection: the operation method is the same as the specific operation step (1) in the "Content of the Invention";

[0047] (2) Cleaning: the operation method is the same as the specific operation step (2) in the "Content of the Invention";

[0048] (3) Microwave inactivating enzyme treatment: the operation method is the same as the specific operation step (3) in the "Summary of the Invention";

[0049] (4) Peeling, slicing, and color protection: the operation method is the same as the specific operation step (4) in "Content of the Invention", the color protection time is 4 hours, and the ratio of color protection solution is phytic acid 0.15mL / L, ethylenediamine tetramine Disodium acetate 0.10g / L, vitamin C 0.20g / L, citric acid 10.0g / L;

[0050] (5) beating, rubber mill: the operation method is the same as the specific operation step (5) in the "summary of the invention";

[0051] (6) Vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com