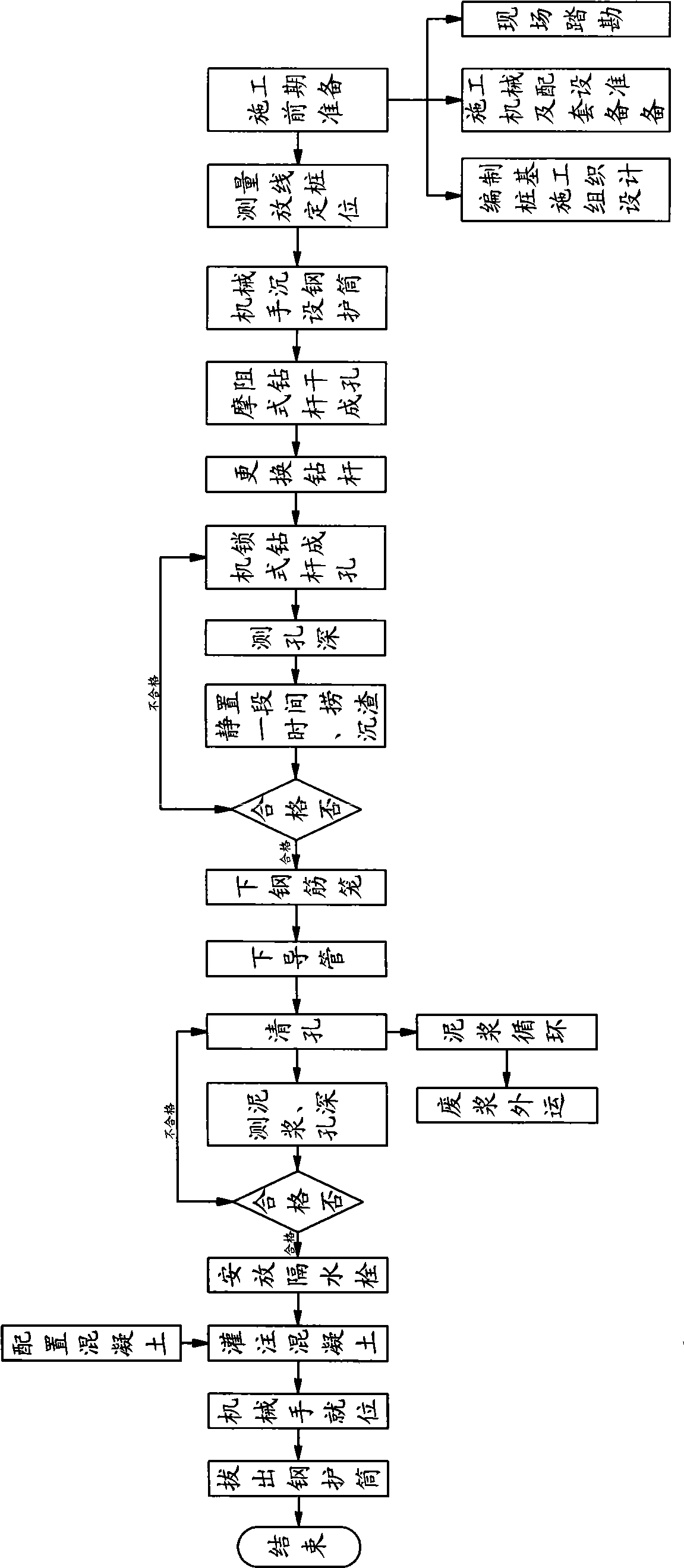

Construction process of cast-in-situ bored pile

A technology of bored piles and construction technology, which is applied to sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of difficult removal of slag at the bottom of the pile, lowering the quality of the pile body, and prone to collapse holes, etc., so as to improve the pile body. Quality and operational efficiency, highlighting substantive features, avoiding the effect of pile diameter expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to clearly illustrate the technical characteristics of this solution, the following will describe this solution through specific implementation modes and in conjunction with the accompanying drawings.

[0015] The construction technology of bored piles in this scheme includes the following steps:

[0016] (1) Set the steel casing: use the manipulator to place the steel casing, adjust the position and verticality, then vibrate and sink to the upper surface of the compact soil layer. The steel casing has an inner diameter 100mm larger than the pile diameter and a wall thickness Steel plate spiral welded pipe ≥8mm, length ≥7m, and the upper part of the steel casing has an overflow port.

[0017] (2) Hole forming: In the soft soil layer, a rotary drilling rig with a friction drill rod is used to dry the hole. The drill bit used when forming the hole is a rotary drilling bucket, and the diameter of the rotary drilling bucket is equal to the pile diameter. The soft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com