Patents

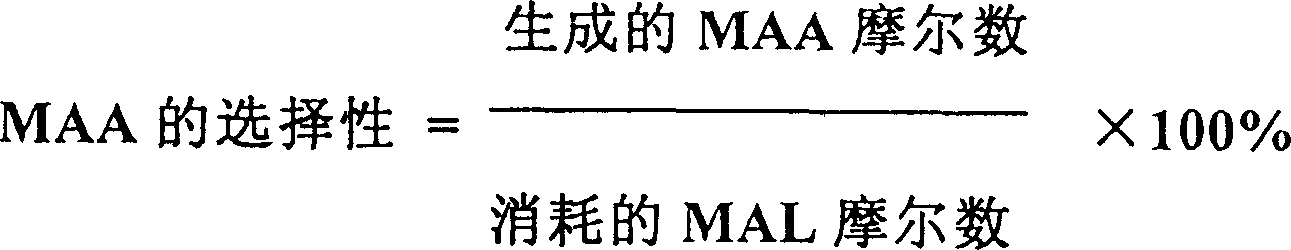

Literature

1659 results about "Heteropoly acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A heteropoly acid is a class of acid made up of a combination of hydrogen and oxygen with particular metals and non-metals.

Aqueous dispersion for chemical mechanical polishing

InactiveUS6527818B2Pigmenting treatmentOther chemical processesColloidal silicaOXALIC ACID DIHYDRATE

There is provided an aqueous dispersion for CMP with an excellent balance between chemical etching and mechanical polishing performance. The aqueous dispersion for CMP of the invention is characterized by comprising an abrasive, water and a heteropolyacid. Another aqueous dispersion for CMP according to the invention is characterized by comprising an abrasive, water, a heteropolyacid and an organic acid. Yet another aqueous dispersion for CMP according to the invention is characterized by comprising colloidal silica with a primary particle size of 5-100 nm, water and a heteropolyacid. Preferred for the heteropolyacid is at least one type selected from among silicomolybdic acid, phosphorotungstic acid, silicotungstic acid, phosphoromolybdic acid and silicotungstomolybdic acid. Preferred for the organic acid is at least one selected from among oxalic acid, malonic acid, succinic acid, glutaric acid, adipic acid, maleic acid, fumaric acid, phthalic acid, malic acid, tartaric acid and citric acid.

Owner:JSR CORPORATIOON

Catalyst for selectively oxidizing methyl acrylic aldehyde to synthesize methyl propenoic acid and its use

ActiveCN1647854AHigh reactivityHigh selectivityPhysical/chemical process catalystsOrganic compound preparationHeteropoly acidGas phase

The present invention provides catalyst for selectively oxidizing methyl acrolein to synthesize methylpropenoic acid and its usage in catalyzing gas phase oxidation of methyl acrolein to synthesize methylpropenoic acid. The catalyst is one heteropoly acid salt containing Mo, P, K, Sb, Cu, As, etc., and has high catalytic activity and stability, long service life, methyl acrolein converting rate higher than 85 % and methylpropenoic acid selectivity over 87 % in the presence of molecular oxygen and diluting gas.

Owner:SHANGHAI HUAYI NEW MATERIAL

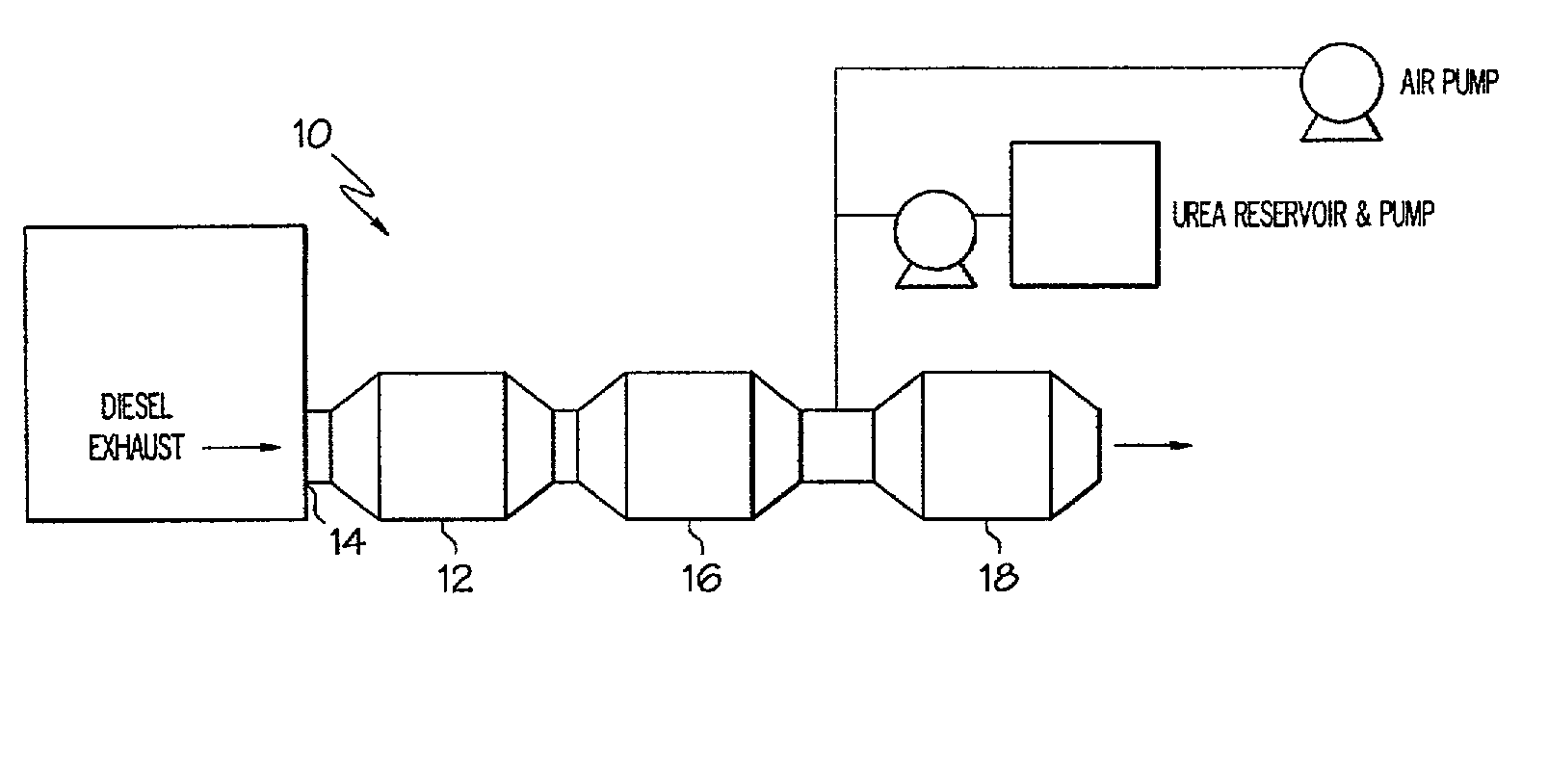

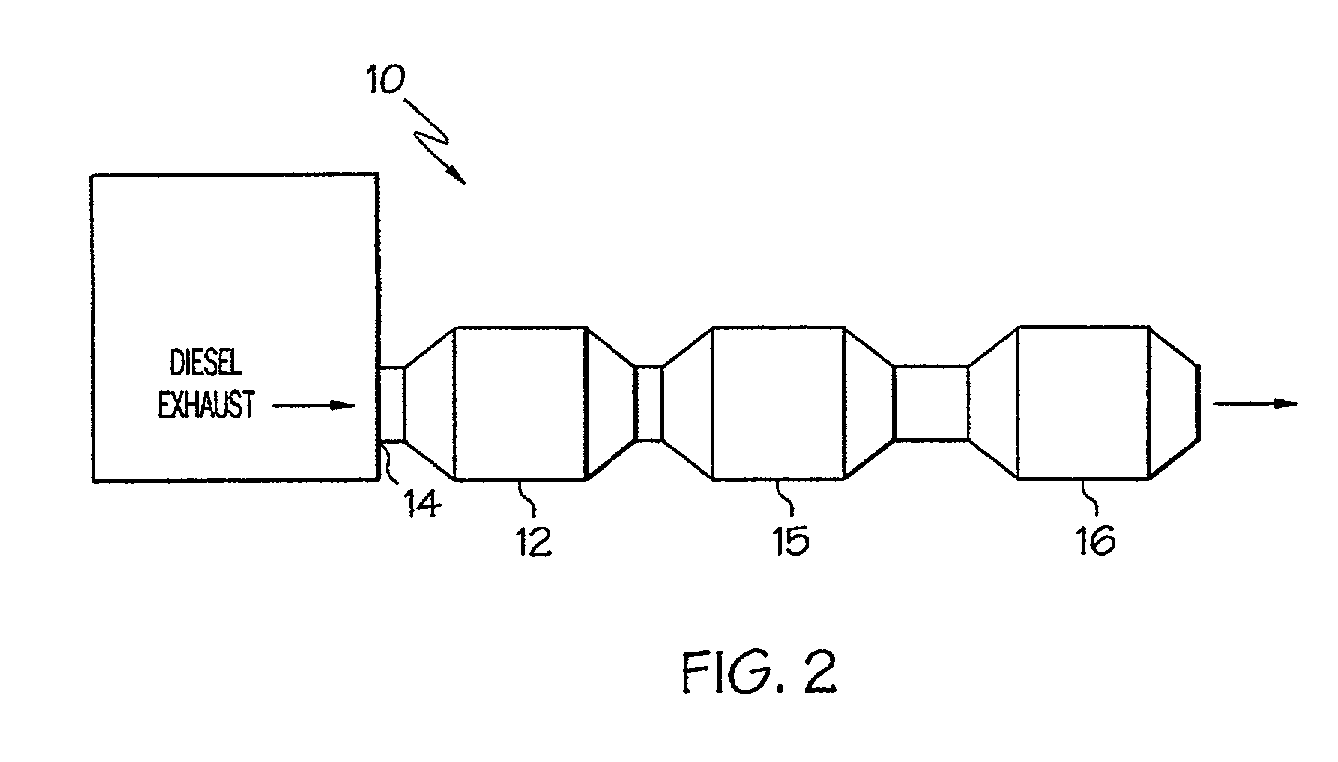

Method of treating diesel exhaust gases

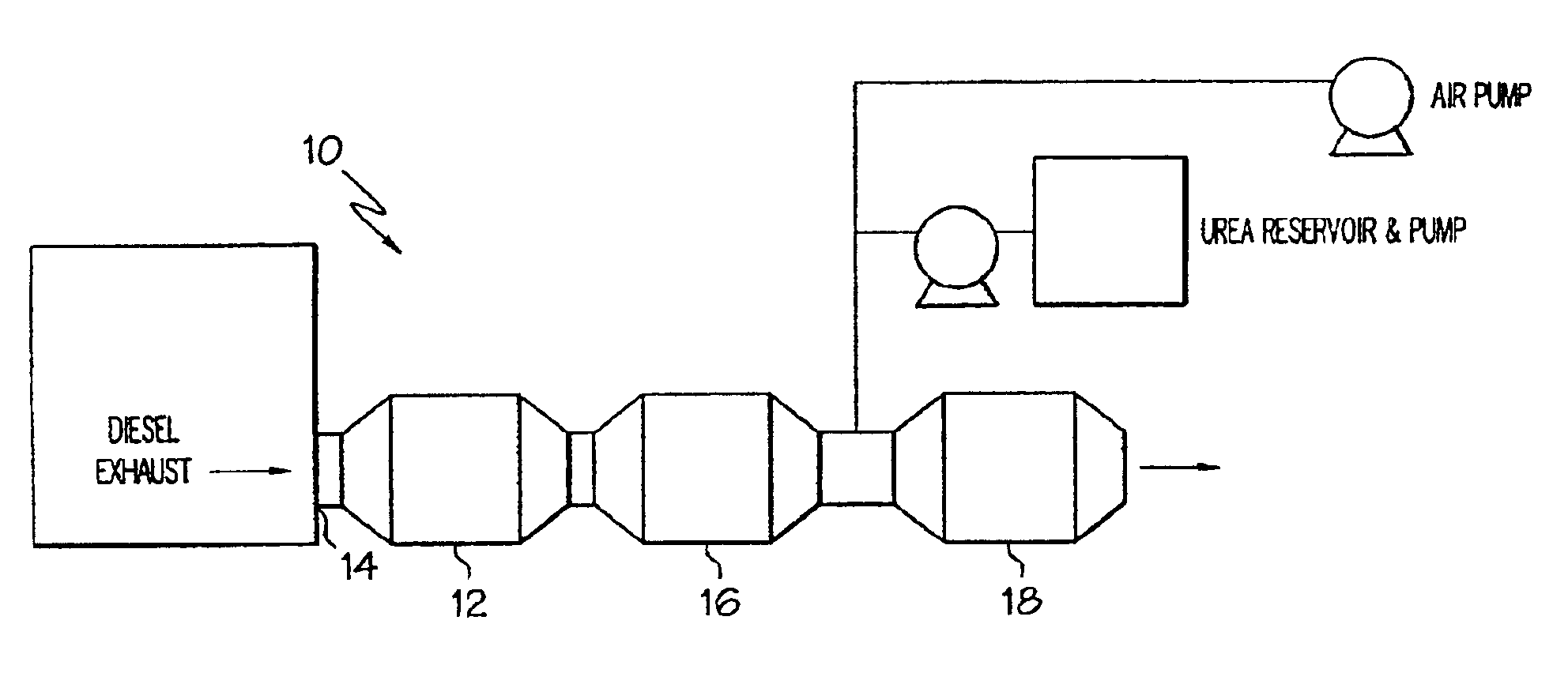

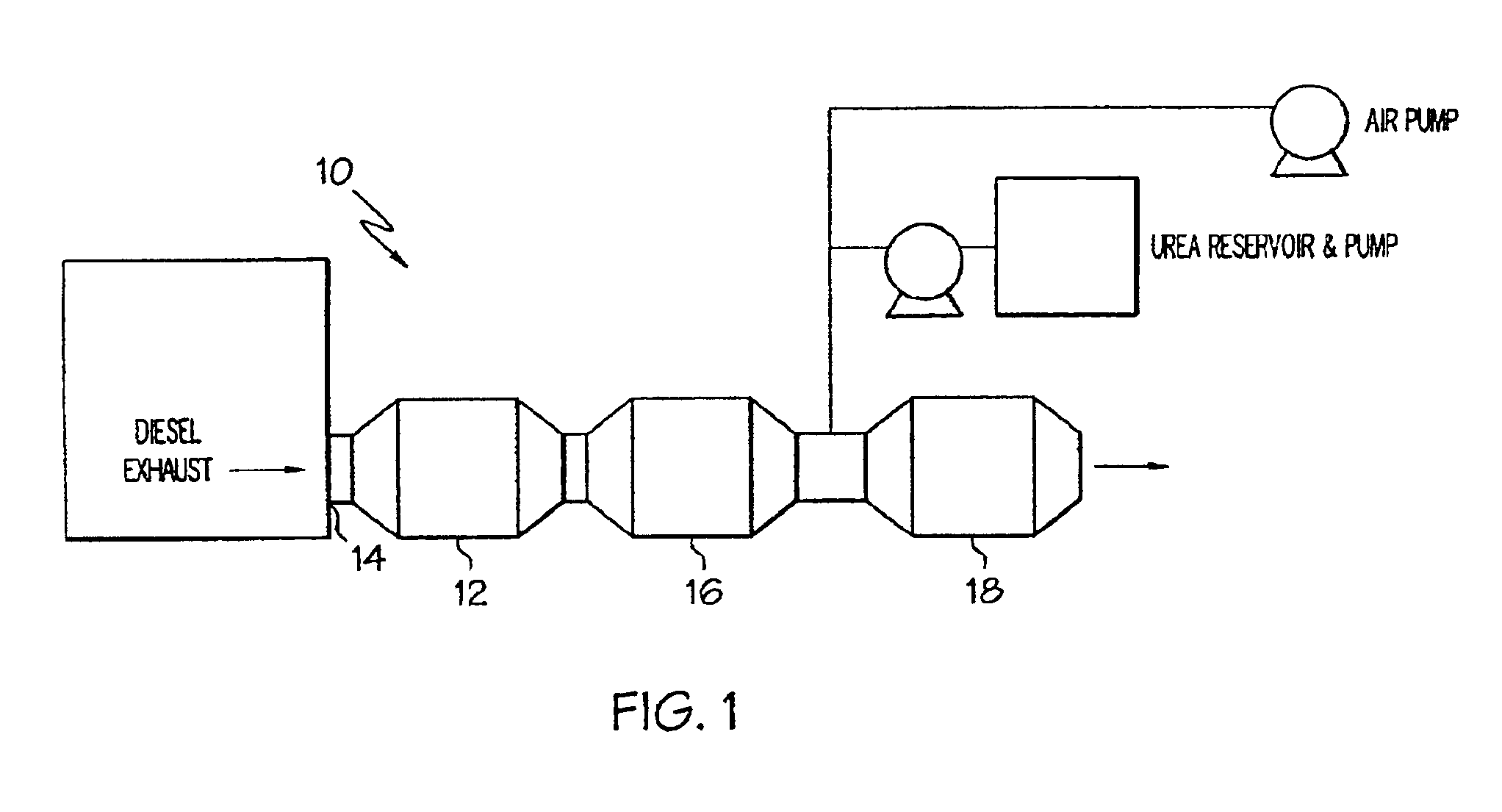

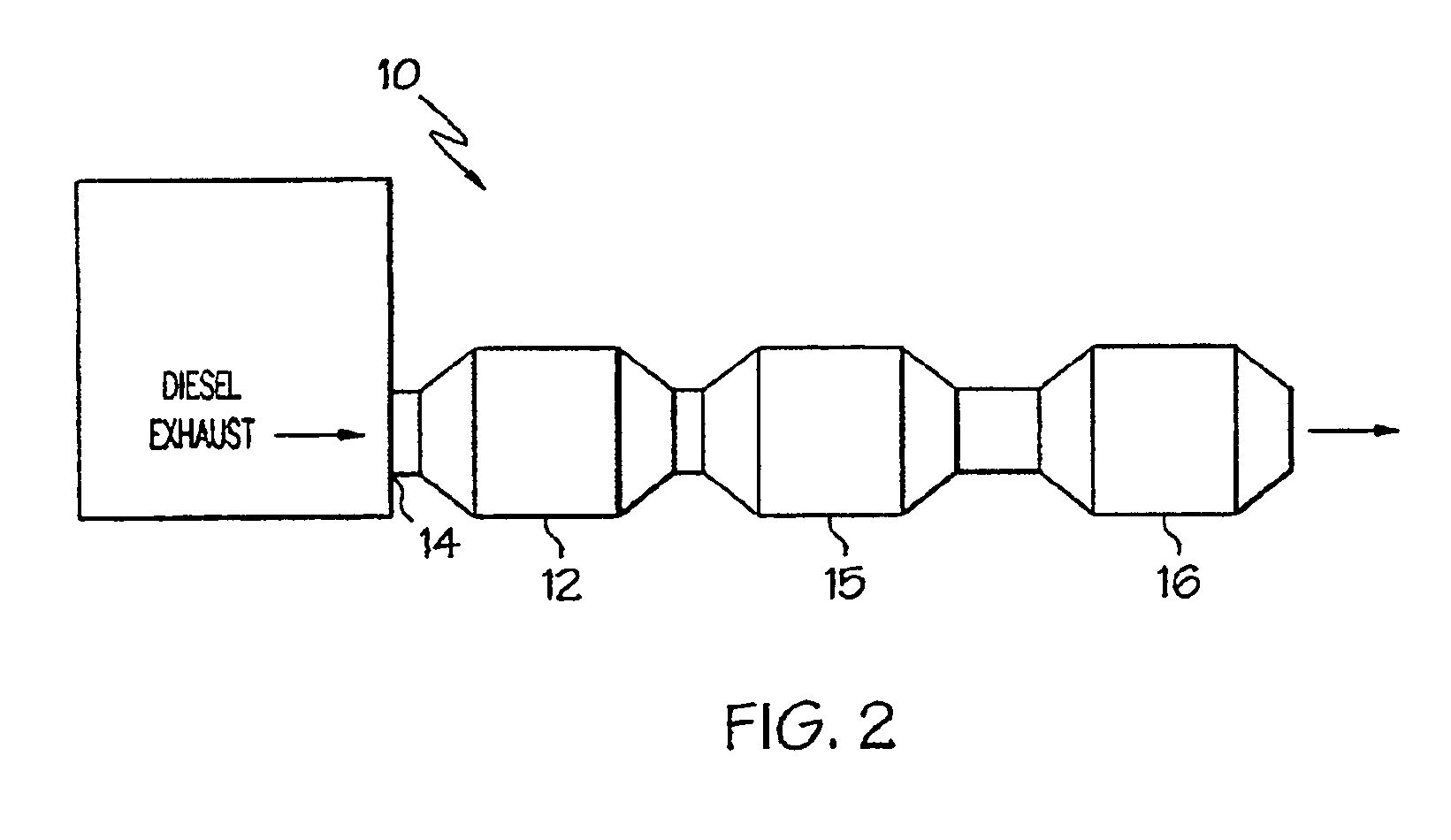

InactiveUS6813884B2Promote regenerationReduce NOxExhaust apparatusDispersed particle separationParticulatesNitrogen

A diesel exhaust treatment system and method of oxidizing NO to NO.sub.2 at low temperatures are provided. The system utilizes a platinum catalyst on a zirconia-stabilized silica support which oxidizes NO in the exhaust gas to NO.sub.2 and uses the NO.sub.2 in an amount sufficient to oxidize particulate trapped on a particulate filter. The catalyst is preferably pre-treated at a temperature of between about 500 to 650.degree. C. in a NO-oxygen-nitrogen mixture to increase conversion at low temperatures. The catalyst preferably includes an additional oxide component selected from the group consisting of TiO.sub.2, P.sub.2 O.sub.5, WO.sub.3, B.sub.2 O.sub.3, and Al.sub.2 O.sub.3. or a heteropolyacid component to further increase activity at low temperatures or to decrease platinum loading at the same level of performance.

Owner:FORD GLOBAL TECH LLC

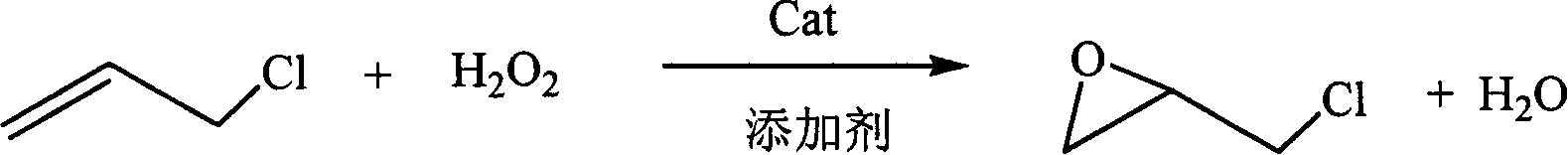

Process for preparing epoxy chloropropane

InactiveCN1900071AHas reaction controlled phase transfer propertiesOrganic chemistryPhosphomolybdic acidEpoxy

In the preparation of epoxy chloropropane, chloropropene is oxidized with H2O2 aqua as oxygen source in no solvent condition and under the action of heteropoly acid catalyst of phosphomolybdic acid or phosphotungestic acid to produce epoxy chloropropane, with the catalyst being recovered for reuse. The preparation process has mild reaction condition, high epoxy chloropropane yield, single product, high selectivity and no pollution, and is suitable for industrial production.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method of treating diesel exhaust gases

InactiveUS20030140620A1Add supportHigh catalytic activityExhaust apparatusDispersed particle separationParticulatesNitrogen

A diesel exhaust treatment system and method of oxidizing NO to NO2 at low temperatures are provided. The system utilizes a platinum catalyst on a zirconia-stabilized silica support which oxidizes NO in the exhaust gas to NO2 and uses the NO2 in an amount sufficient to oxidize particulate trapped on a particulate filter. The catalyst is preferably pre-treated at a temperature of between about 500 to 650° C. in a NO-oxygen-nitrogen mixture to increase conversion at low temperatures. The catalyst preferably includes an additional oxide component selected from the group consisting of TiO2, P2O5, WO3, B2O3, and Al2O3. or a heteropolyacid component to further increase activity at low temperatures or to decrease platinum loading at the same level of performance.

Owner:FORD GLOBAL TECH LLC

Methods for preparing ethylene glycol from polyhydroxy compounds

ActiveUS20120172633A1High yieldHigh selectivityOxygen-containing compound preparationOrganic compound preparationHydrogen pressureHeteropoly acid

This invention provides methods for producing ethylene glycol from polyhydroxy compounds such as cellulose, starch, hemicellulose, glucose, sucrose, fructose, fructan, xylose and soluble xylooligosaccharides. The methods uses polyhydroxy compounds as the reactant, a composite catalyst having active components comprising one or more transition metals of Groups 8, 9, or 10, including iron, cobalt, nickel, ruthenium, rhodium, palladium, iridium, and platinum, as well as tungsten oxide, tungsten sulfide, tungsten hydroxide, tungsten chloride, tungsten bronze oxide, tungsten acid, tungstate, metatungstate acid, metatungstate, paratungstate acid, paratungstate, peroxotungstic acid, pertungstate, heteropoly acid containing tungsten. Reacting at a temperature of 120-300° C. and a hydrogen pressure of 1-13 MPa under hydrothermal conditions to accomplish one-step catalytic conversion. It realizes efficient, highly selective, high yield preparation of ethylene glycol and propylene glycol from polyhydroxy compounds. The advantage of processes disclosed in this invention include renewable raw material and high atom economy. At the same time, compared with other technologies that converts biomass raw materials into polyols, methods disclosed herein enjoy advantages including simple reaction process, high yield of targeted products, as well as easy preparation and low cost for the catalysts.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Heteropolyacid-modified Zr-MOF catalyst as well as preparation method and application thereof

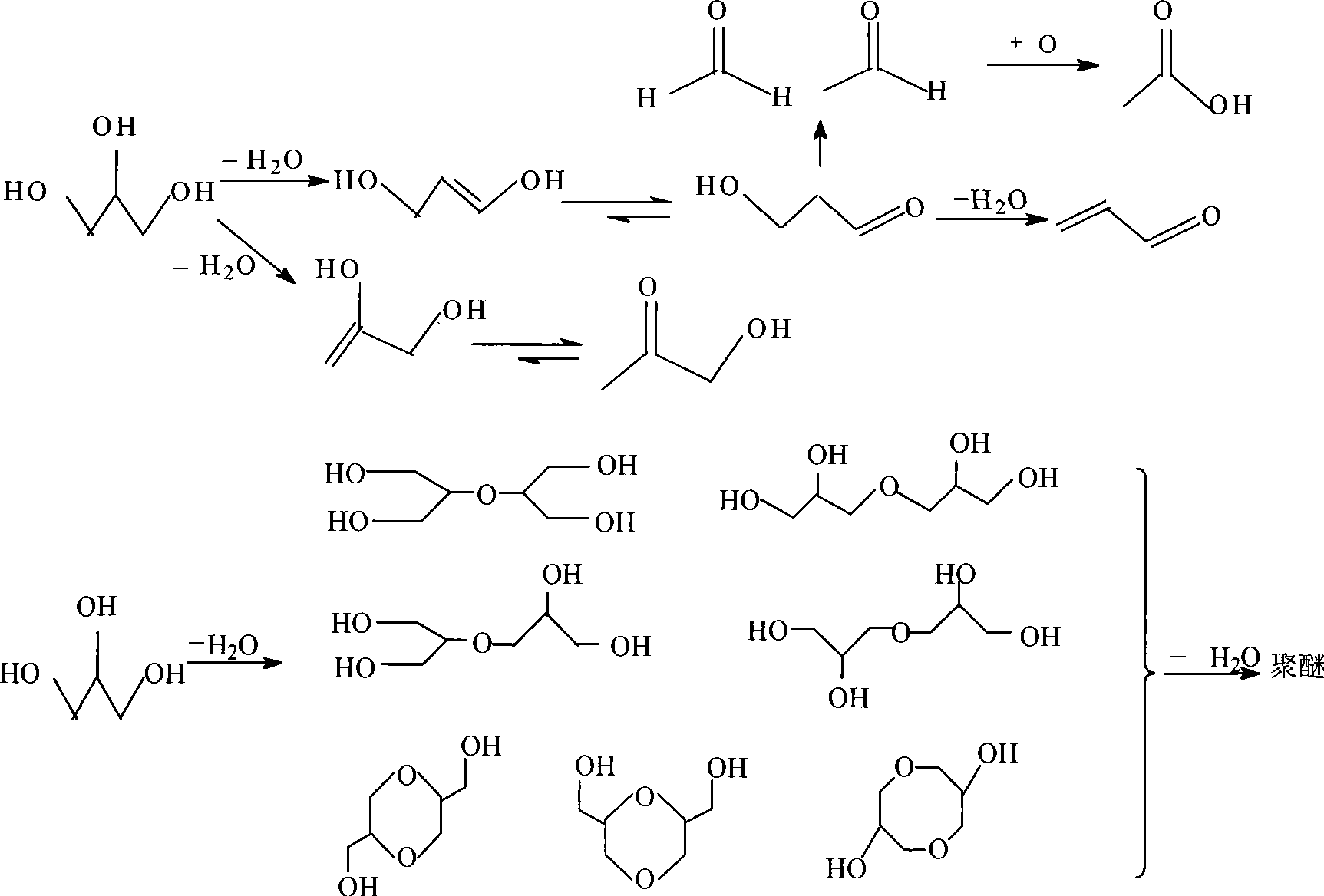

InactiveCN104857988ASolution to short lifeHigh selectivityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsThermal stabilityGlycerol dehydration

The invention discloses a heteropolyacid-modified Zr-MOF catalyst which is modified by heteropolyacid through a Zr-MOF carrier. The invention further discloses a preparation method for the catalyst and an application of the catalyst to reaction of preparing acraldehyde by catalyzing glycerol dehydration. Compared with the prior art, the obtained catalyst is long in service life, and the glycerol conversation rate and the acraldehyde selectivity are high; the Zr-MOF carrier is good in thermal stability and chemical stability, and the framework structure is kept stable; theacting force between the heteropolyacid and the Zr-MOF carrier is relatively strong, so that the heteropolyacid-modified Zr-MOF catalyst is not liable to lose.

Owner:YANCHENG INST OF TECH

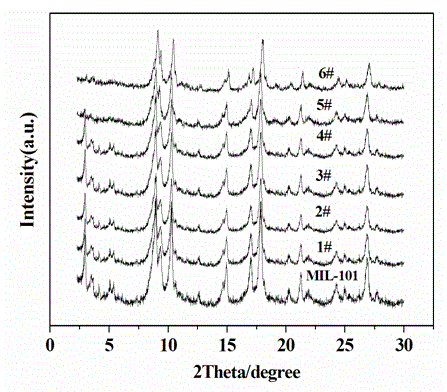

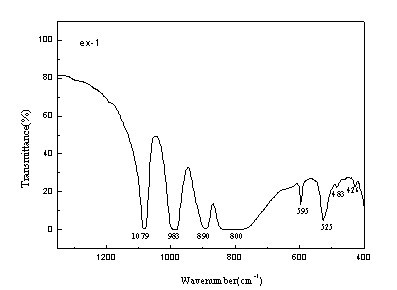

Preparation and application of hierarchical pore metal-organic framework loaded heteropolyacid catalyst

InactiveCN107694611AGuarantee structureImprove stabilityWater/sewage treatment by irradiationWater treatment compoundsMetal-organic frameworkCatalytic oxidation

The invention discloses a preparation method and application of a hierarchical pore metal-organic framework loaded heteropolyacid catalyst. The catalyst adopts hydrothermal-extraction method for preparation. The method includes: dissolving an organic ligand, a template agent, a metal salt and Keggin type heteropolyacid in a solvent, conducting hydrothermal synthesis of a crystal product, and thenperforming Soxhlet extraction to obtain a catalyst. The obtained catalyst has a meso-micro hierarchical porous structure, realizes high dispersion of the active component heteropolyacid and ultra-highloading capacity, and at the same time solves the problems of large mass transfer resistance, long diffusion path and small reaction place in microporous materials. The catalyst provided by the invention shows excellent catalytic performance in both photocatalytic degradation of dye wastewater and catalysis of oxidation-extraction desulfurization reaction, the catalysis reaction uses visible light and hydrogen peroxide respectively, the process is clean, environment-friendly and green, and after repeated use, the catalyst still maintains high activity, and has high industrial application value.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Olefin catalytic agent prepared by naphtha catalytic cracking and preparation method and application thereof

ActiveCN102861604AModerate acid distributionStable structureMolecular sieve catalystsBulk chemical productionMolecular sieveNaphtha

The invention discloses an olefin catalytic agent prepared by naphtha catalytic cracking, a preparation method of the olefin catalytic agent and application of the olefin catalytic agent. According to the weight content of a final catalytic agent, the olefin catalytic agent comprises 60%-90% of EU-1 / ZSM-5 composite molecular sieve and 0.5%-3% of heteropolyacid. The olefin catalytic agent is prepared by the following methods of: preparing or selecting the EU-1 / ZSM-5 composite molecular sieve, adding a binding agent to mold, and then adopting an impregnation method to load heteropolyacid to prepare the final catalytic cracking catalytic agent. The application of the catalytic agent in preparation of olefin by the naphtha catalytic cracking is that the reaction temperature is 500-700 DEG C, the reaction pressure is 0.01-0.5MPa, the naphtha quality airspeed is 0.3-2h<-1>, the water-oil volume ratio is 0.6-1.2, C5-C10 naphtha serves as a raw material, and total recovery of ethylene and propylene can achieve 67% (of the weight of naphtha). The olefin catalytic agent has the advantages of high olefin yield coefficient, stable catalytic agent, low reaction temperature and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

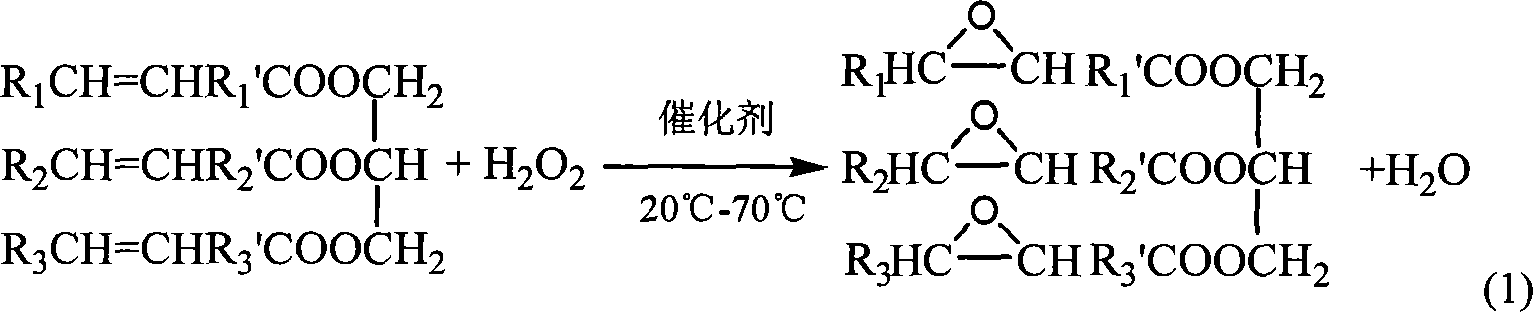

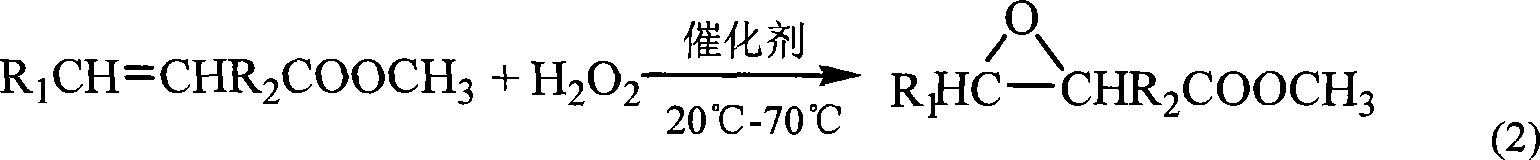

Method for preparing epoxidized soybean oil or epoxy fatty acid methyl(ethyl) ester by heteropolyacid liquid phase catalysis

InactiveCN101235021AReduce usageDisadvantages of Avoiding Recycling DifficultiesOrganic chemistryEpoxyHeteropoly acid

A heteropoly acid liquid-phase catalysis preparation method of epoxy soybean oil or epoxy fatty acid methyl ester (ethyl ester) belongs to liquid-phase catalysis oxidization technical field, which utilizes biomass soybean oil and unsaturated fatty acid methyl ester (ethyl ester) and uses solid heteropoly acid salt compound as catalyst, without carboxyl acid, protonic acid and solvent, to synthesize epoxy soybean oil or epoxy fatty acid methyl ester (ethyl ester) via hydrogen dioxide solution reaction, without acid waste water generation in epoxidation to protect environment. The epoxy soybean oil or epoxy fatty acid methyl ester (ethyl ester) can be used as plasticizer to be widely used in non-toxic polyvinyl chloride (PVC) product and transparent PVC product, as transparent bottle, transparent box, food and drug package, PVC medical blood bag and environment-friend uv-curing coating or the like.

Owner:JIANGNAN UNIV

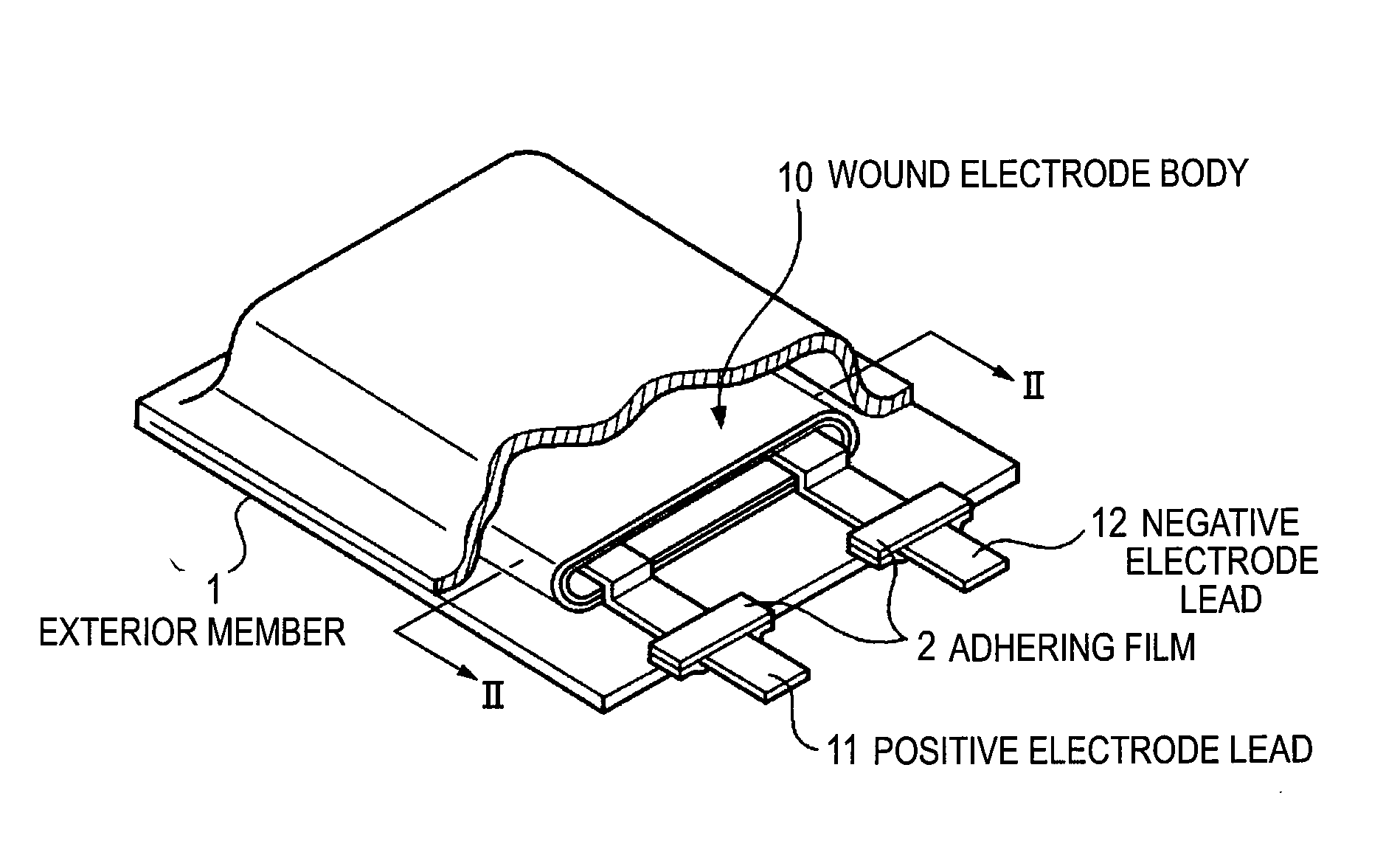

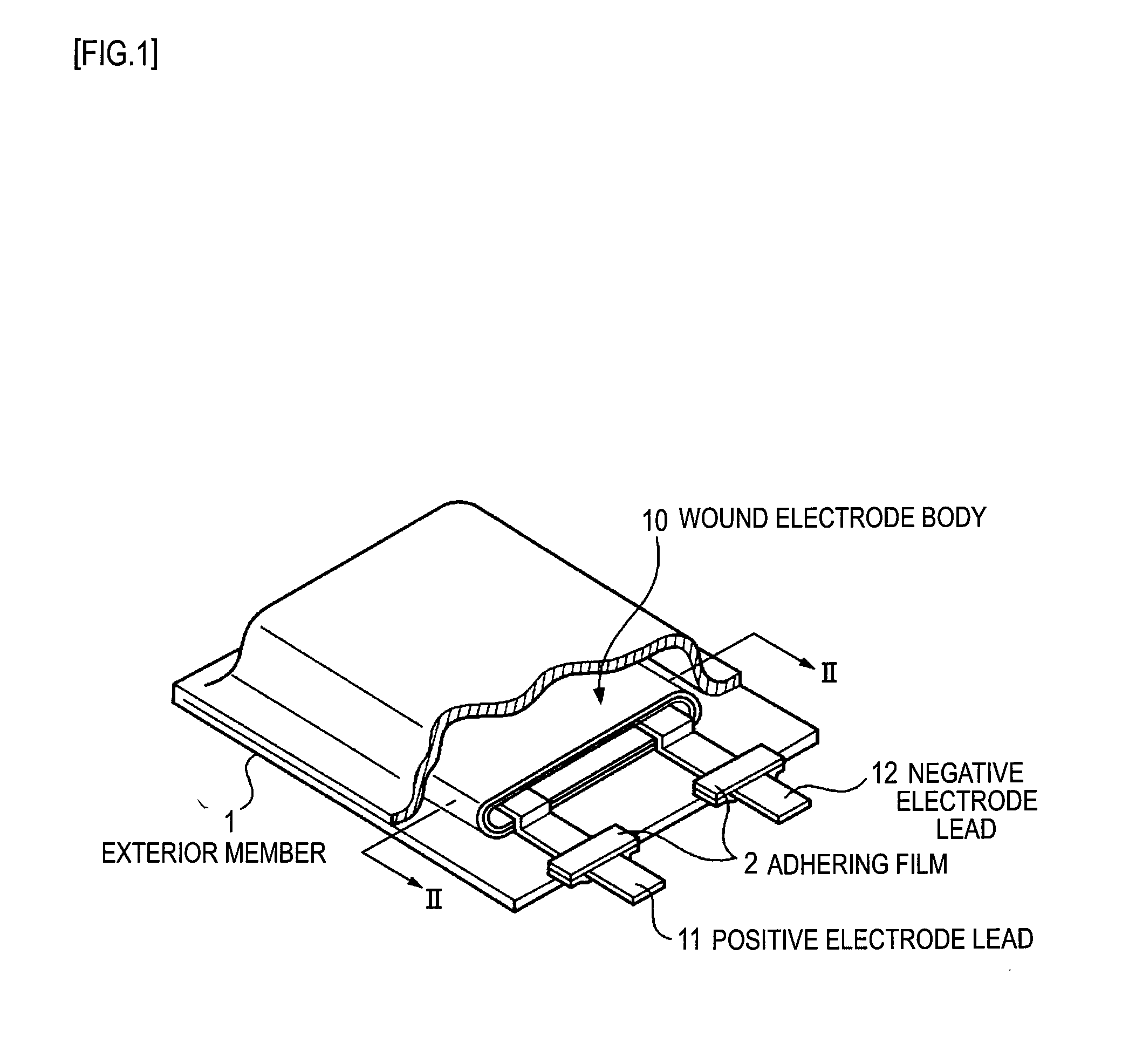

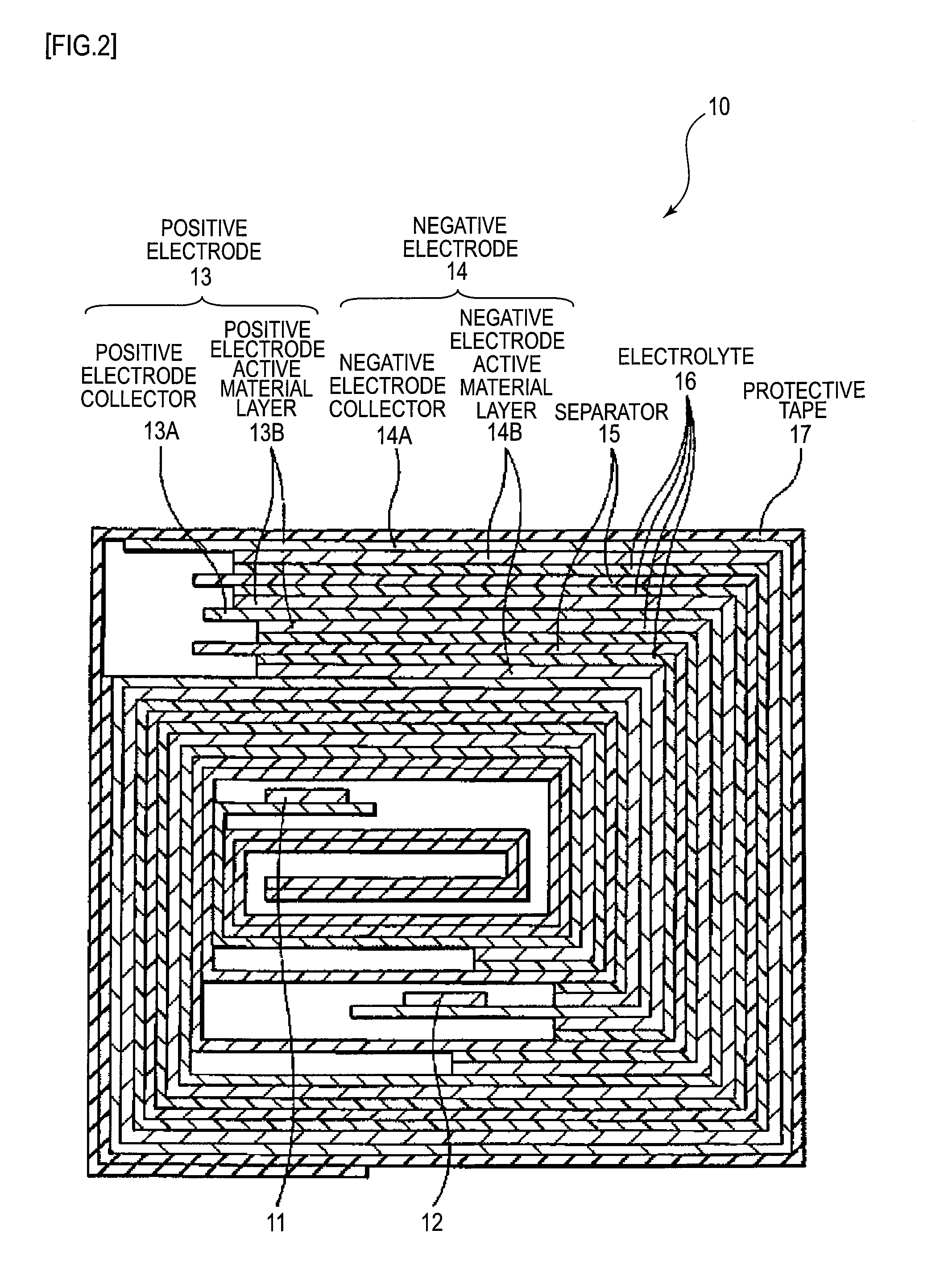

Non-aqueous electrolyte battery, non-aqueous electrolyte battery positive electrode, non-aqueous electrolyte battery negative electrode, non-aqueous electrolyte battery separator, electrolyte for non-aqueous electrolyte, and method of manufacturing non-aqeuous electrolyte battery separator

ActiveUS20120321911A1Suppress expansionImprove securityCell seperators/membranes/diaphragms/spacersFinal product manufactureElectrolytic agentHeteropoly acid

A battery is composed of a positive electrode in which a positive electrode active material layer including a positive electrode active material is formed on a positive electrode collector, a negative electrode in which a negative electrode active material layer including a negative electrode active material is formed on a negative electrode collector, a separator provided between the positive electrode and the negative electrode, and an electrolyte impregnated in the separator. The battery further includes at least one of a heteropoly acid and a heteropoly acid compound as an additive at least in one of the positive electrode, the negative electrode, the separator, and the electrolyte.

Owner:MURATA MFG CO LTD

Flue-gas denitration catalyst incapable of being deactivated by basic metallic oxides, preparation method thereof and applications thereof

InactiveCN103861628AStrong acidAvoid poisoningDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsGlass fiberActive component

The invention discloses a flue-gas denitration catalyst incapable of being deactivated by basic metallic oxides, a preparation method thereof and applications thereof. The catalyst comprises following components by weight: 70-85% of nanometer titanium dioxide, 1-3% of V2O5, 5-15% of heteropoly acid, 3-15% of glass fiber and 4-10% of an inorganic binder. In the preparation method, active components and the heteropoly acid are loaded step by step. The catalyst has high denitration performance and high performance of resistance to deactivation by the basic metallic oxides, and is particularly suitable for flue gas denitration of a power plant, an industrial boiler, an incinerator, a cement kiln, and the like, wherein the power plant, the industrial boiler, the incinerator, the cement kiln, and the like adopt biomass as fuel and contain a large amount of basic metallic oxides in flue gas.

Owner:SHANGHAI LANGT ELECTRIC POWER ENVIRONMENTAL PROTECTION TECH +1

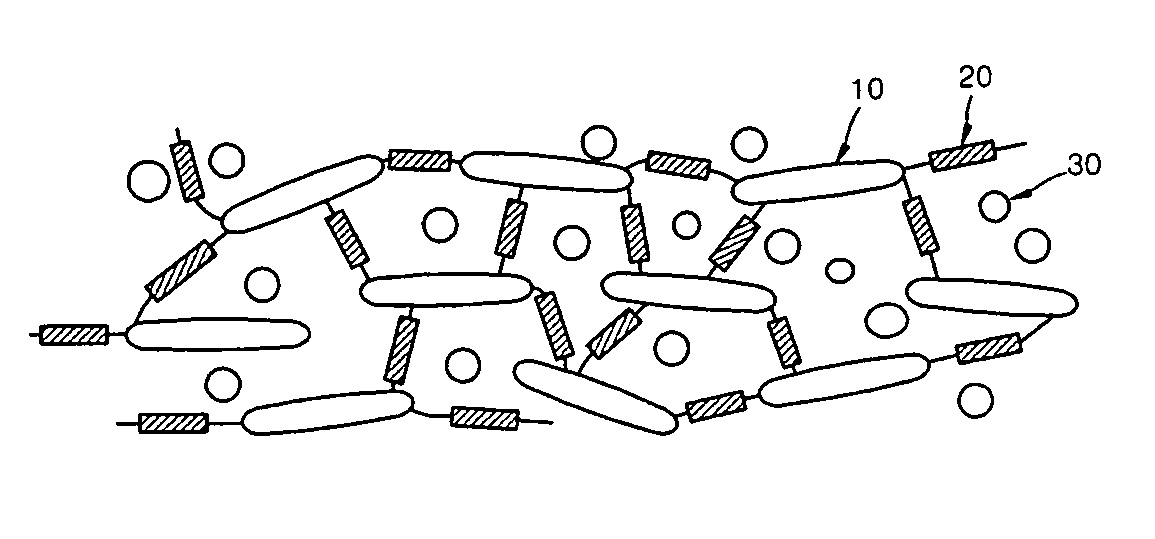

Ion conductive composite membrane using inorganic conductor and method of manufacturing the same

InactiveUS20070015022A1Effectively prevents crossoverReduce conductivitySolid electrolytesPhysical/chemical process catalystsFuel cellsHeteropoly acid

A ion-conductive composite membrane and a method of manufacturing the same, the membrane including phosphate platelets, a silicon compound, and a Keggin-type oxometalate and / or Keggin-type heteropoly acid, wherein the phosphate platelets are three-dimensionally connected to each other via the silicon compound and a method of manufacturing the same. An electrolyte membrane having an ion-conductive inorganic membrane or an ion-conductive organic / inorganic composite membrane effectively prevents crossover of liquid fuel without the reduction of ion conductivity in a liquid fuel cell, thereby allowing for the production of fuel cells having excellent performance.

Owner:SAMSUNG SDI CO LTD

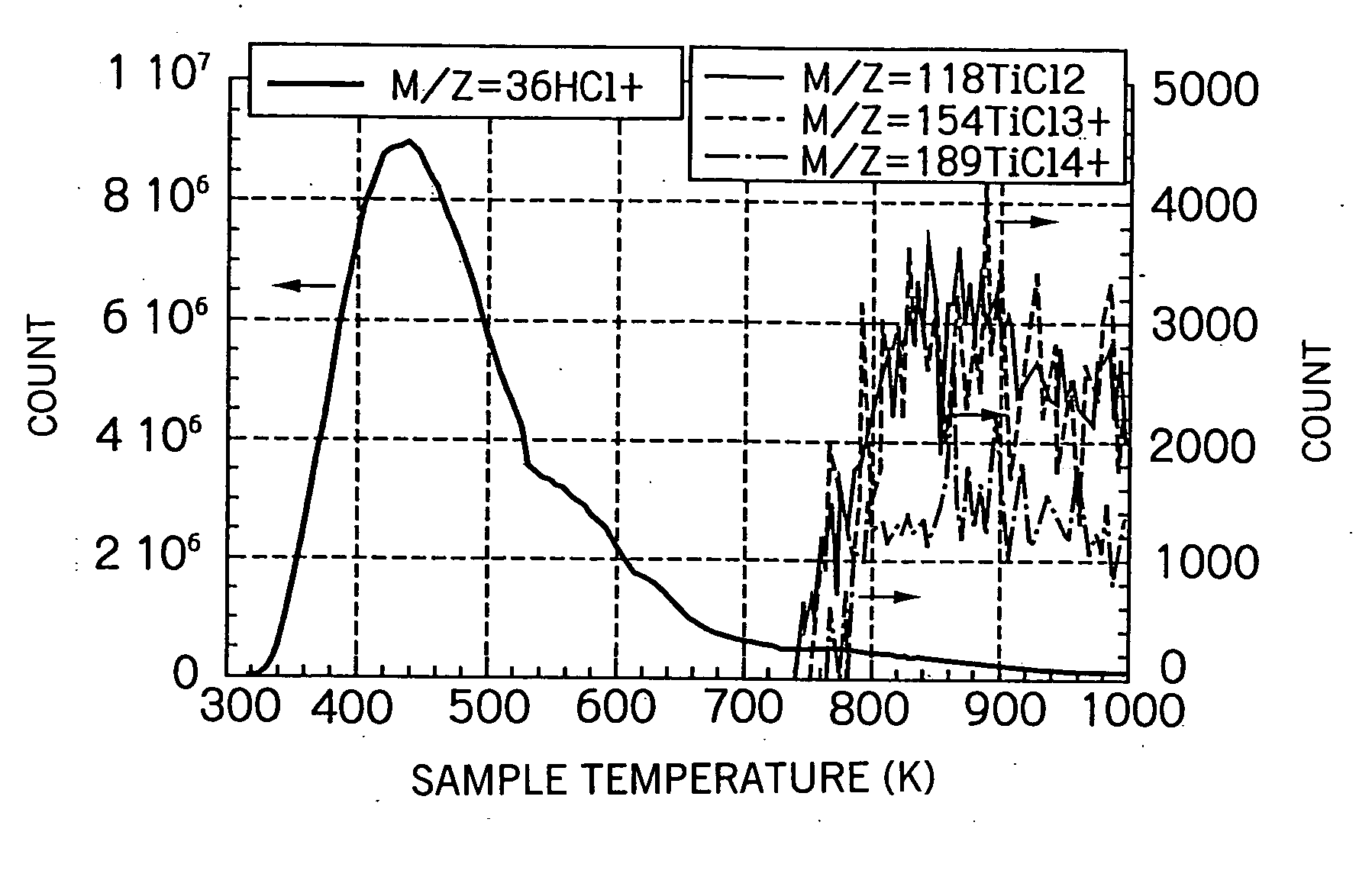

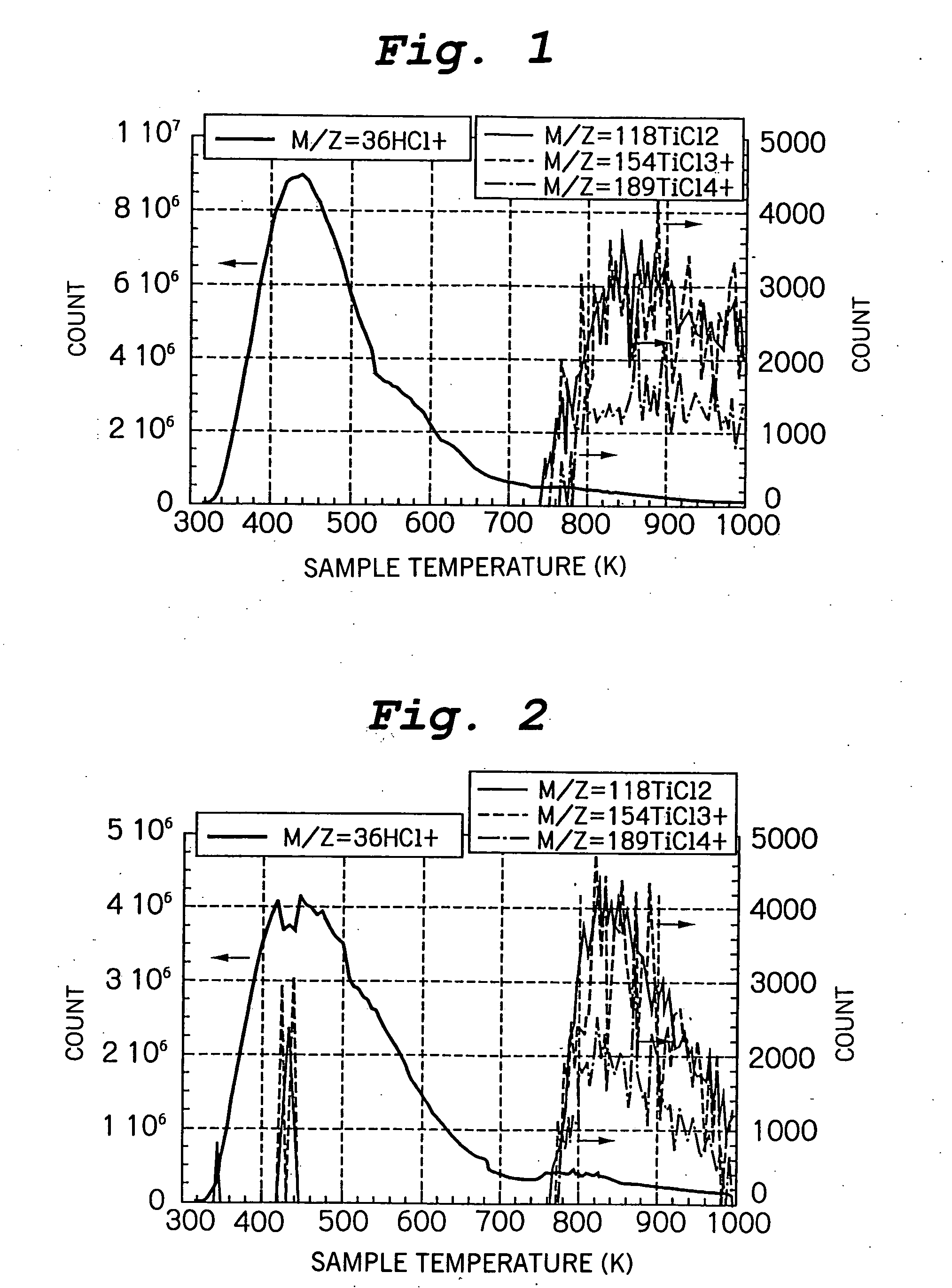

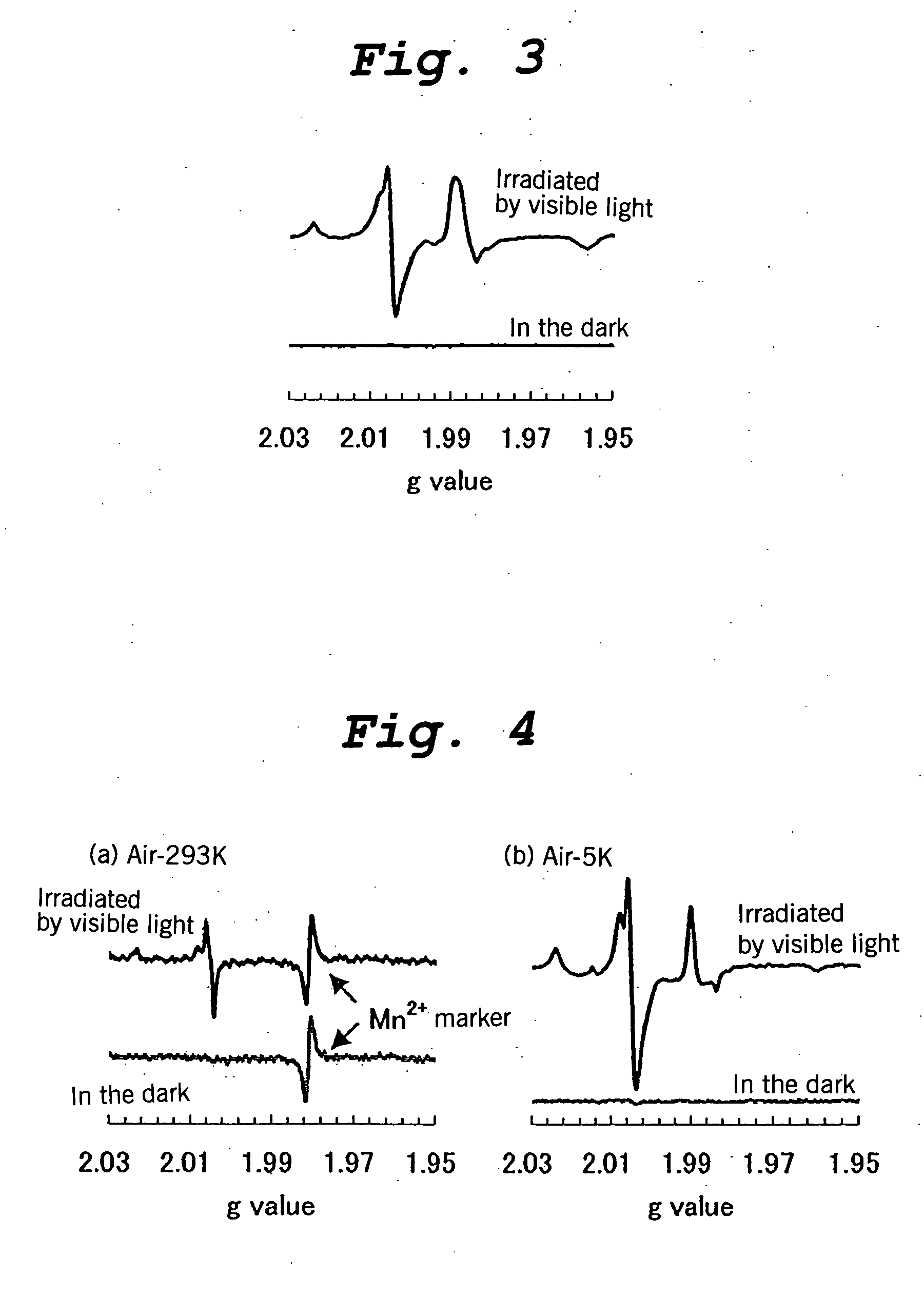

Titanium oxide photocatalyst, process for producing the same and application

InactiveUS20050227008A1Photocatalyst has increasedHigh activityDispersed particle separationPretreated surfacesHalogenHeteropoly acid

Titanium oxide-based photocatalysts which contain a metal halide in titanium oxide and which are prepared from titanium oxide and / or its precursor, which may optionally be heat treated, by contact with a reactive gas containing a metal halide of the formula MXn or MOXn (wherein M=a metal, X=a halogen, and n=an integer) with heating stably develop a high photocatalytic activity with visible light irradiation. The photocatalysts may subsequently be stabilized by contact with water or by heat treatment, and / or promoted by contact with a heteropoly acid and / or an isopoly acid so as to include a metal complex in the titanium oxide. Photocatalysts prepared in this manner exhibit novel ESR features. The present invention also provides methods for preparing these photocatalysts, a photocatalyst dispersion and a photocatalytic coating fluid containing such a photocatalyst, and photocatalytic functional products and methods for their manufacture using the photocatalyst.

Owner:NIPPON STEEL CORP +1

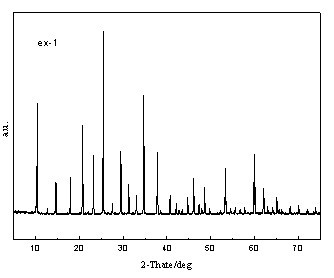

Heteropoly acid containing hydrocracking catalyst and its preparation method

InactiveCN1927461ASimple compositionStructure determinationCatalyst carriersHydrocarbon oil crackingHydrogenHeteropoly acid

The invention relates to a hydrocracking catalyst which contains heteropoly acid, with large diameter and high activity. Wherein, it comprises heteropoly acid, hydrogen component and carrier; the carrier is porous thermal-resistant inorganic material; the heteropoly acid is H3PW12O40 .nH2O, H3PMo12O40 .nH2O, H4SiW12O40 .nH2O or H4SiMo12O40 ..nH2O; the hydrogen component is transition metal element; the heteropoly acid is 20-70%, the hydrogen component is 1-20% and the left is carrier. And the production comprises: selecting inorganic thermal-resistant particle carrier as catalyst carrier, preparing the metal salt water solution of hydrogen component, emerging said carrier, drying the separated solid, baking; preparing heteropoly acid water solution; drying and baking the solid.

Owner:XIAMEN UNIV

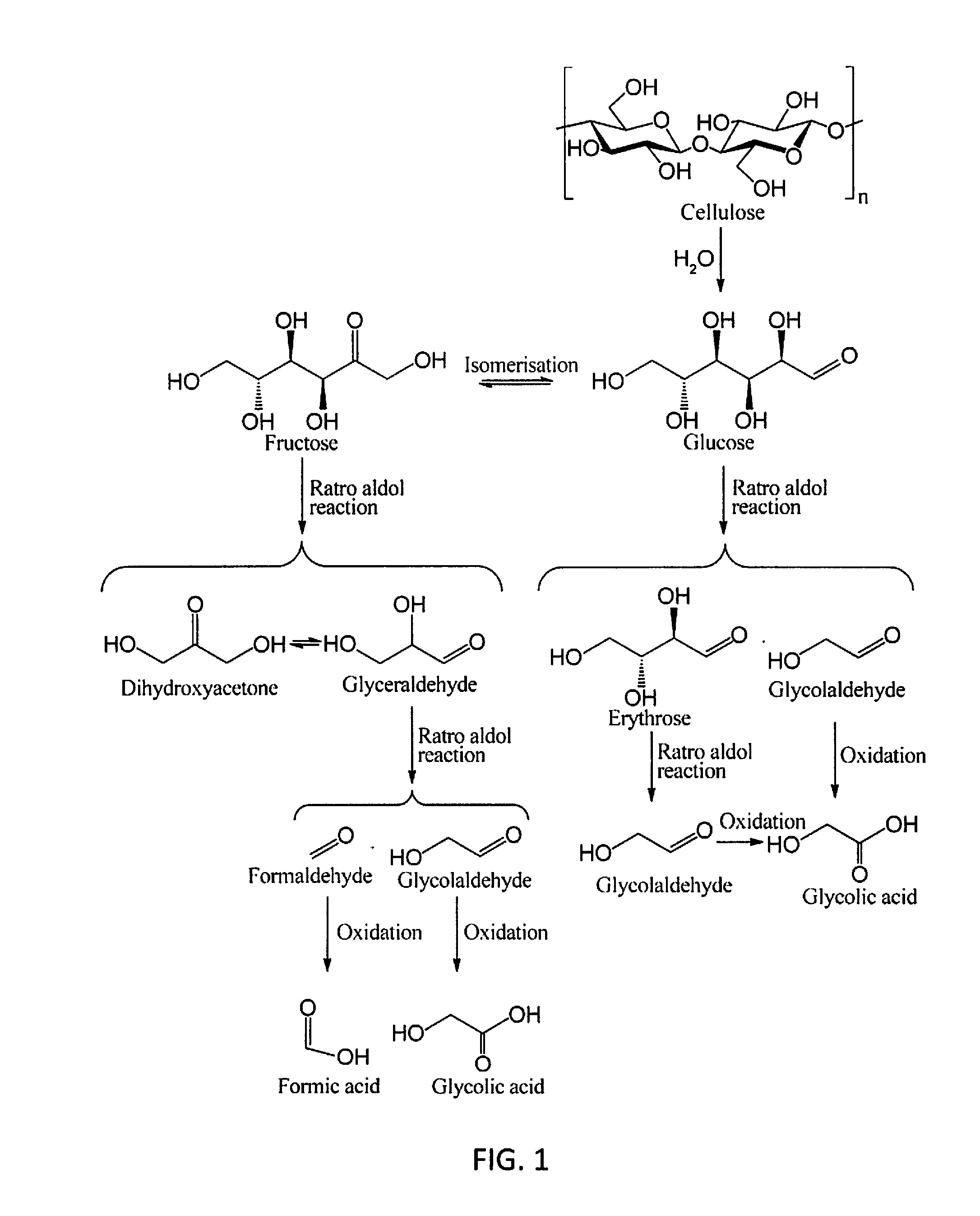

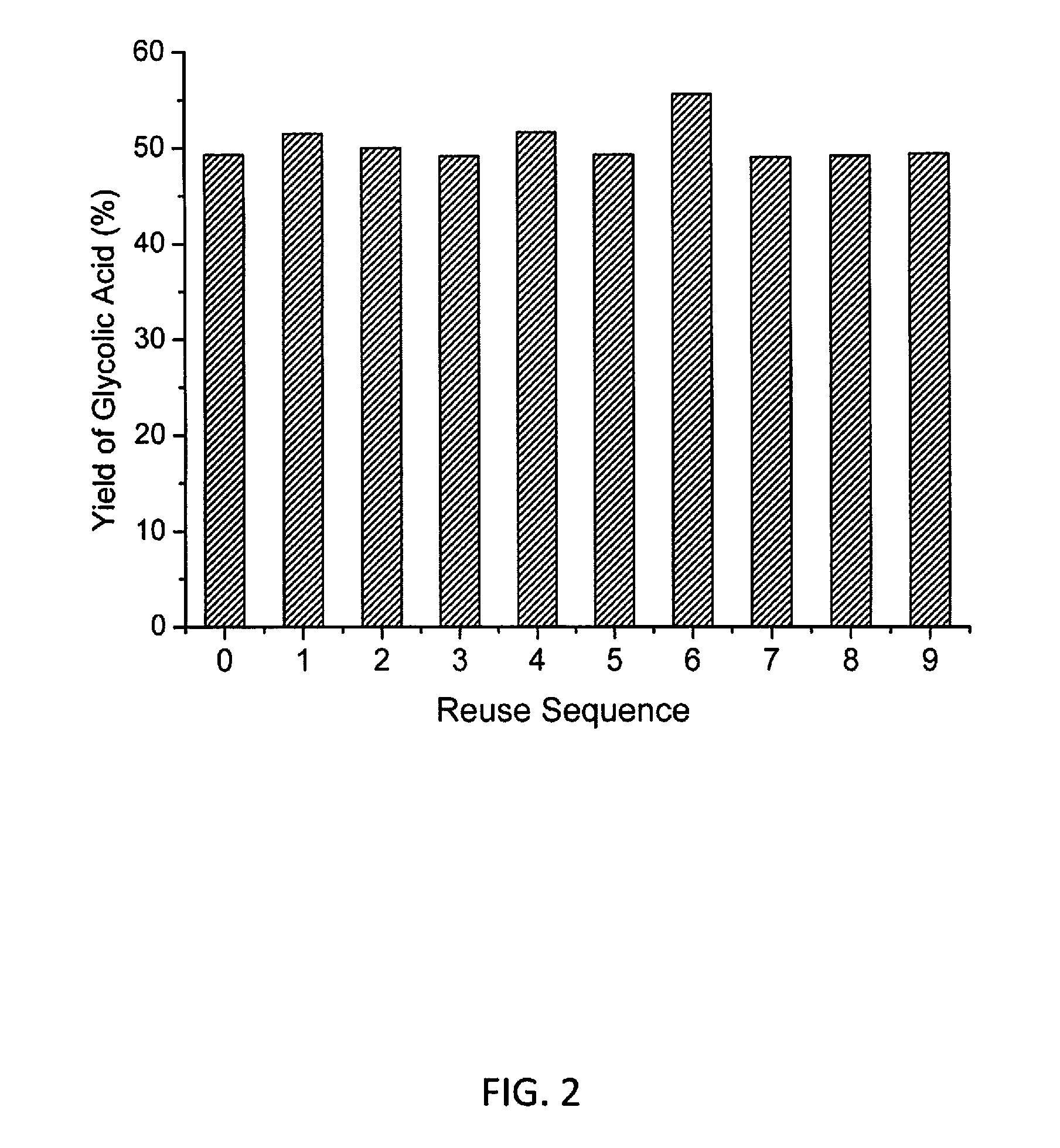

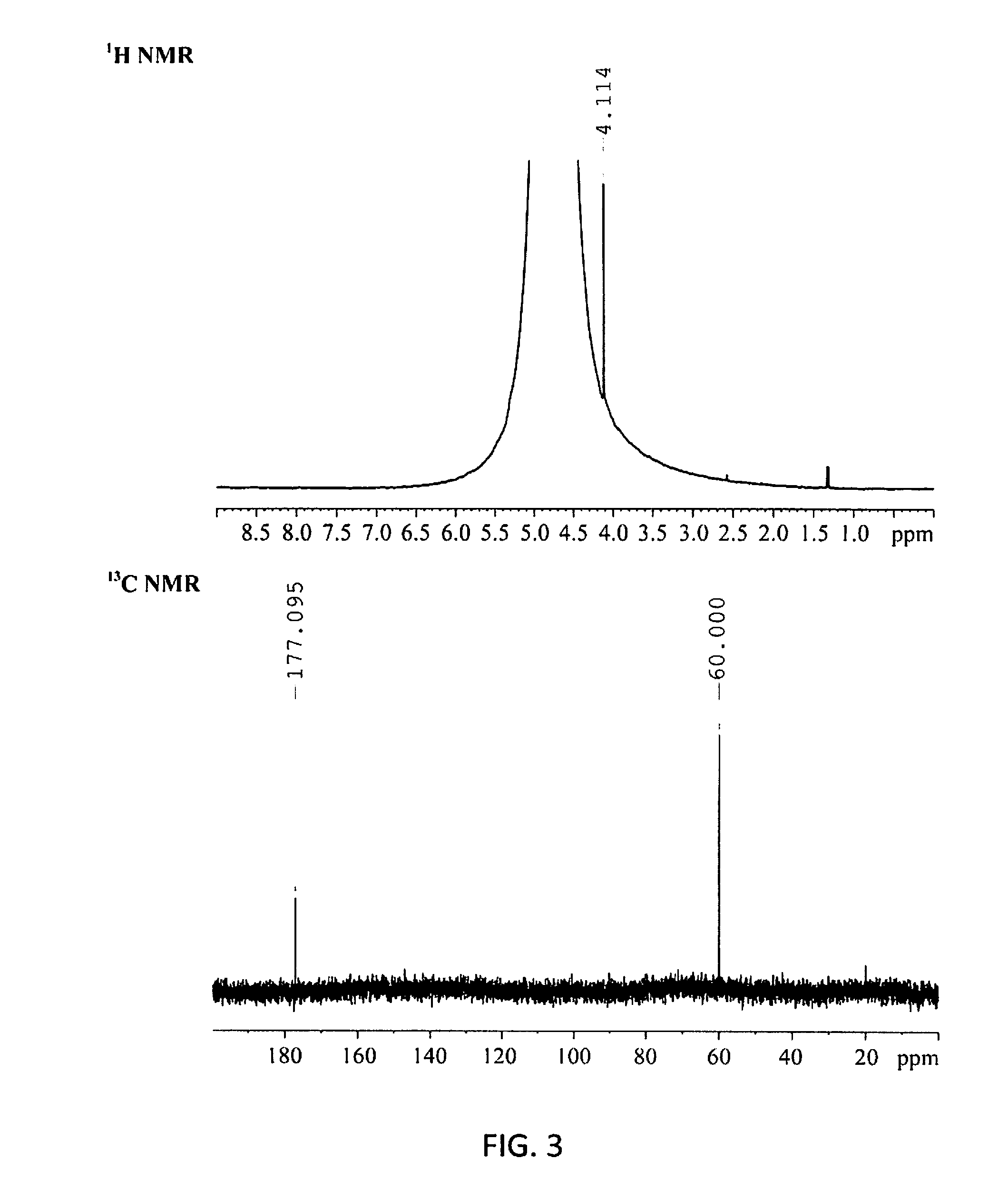

Molybdenum-containing Acidic Catalysts to Convert Cellulosic Biomass to Glycolic Acid

ActiveUS20130281733A1Greener and more cost-efficientOrganic compound preparationCarboxylic compound preparationCelluloseHeteropoly acid

Embodiments of the present invention include methods and compositions related to catabolic conversion of cellulosic biomass to glycolic acid using molybdenum-containing acidic catalysts. The invention includes the use of heteropoly and isopoly acids and salts as the molybdenum-containing multi-functional catalysts for biomass conversion. In embodiments of the invention, the reactions employ successive hydrolysis, retro-aldol fragmentation, and selective oxidation in a noble metal-free system.

Owner:KING ABDULLAH UNIV OF SCI & TECH

Method for preparing isosorbide taking supported heteropoly acid as catalyst

InactiveCN101691376AHigh selectivityEasy to separateOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsHeteropoly acidFixed bed

The invention discloses a method for preparing isosorbide by taking supported heteropoly acid as a catalyst. Sorbitol from a biological radical is used as a raw material to prepare the isosorbide directly through dehydration reaction. The method comprises the following steps: putting the catalyst into a constant temperature section of a fixed-bed reactor; introducing a reactant sorbitol solution into a reactor, and performing reaction through a catalyst bed after gasification; and separating a mixture obtained after the reaction to obtain the isosorbide. The method has simple operation process of the reaction, low production cost and light environmental pollution; the selectivity and yield of the isosorbide reaches up to 75.2 percent and 71.4 percent respectively, and the catalyst is easy to separate and recycle; and the method is a novel method which meets industrial demands and has strong practicality.

Owner:NANJING UNIV OF TECH

Metal-organic framework supported heteropoly acid catalyst for synthesizing glutaraldehyde and production method of metal-organic framework supported heteropoly acid catalyst

InactiveCN104437645AGood dispersionGood effectOrganic-compounds/hydrides/coordination-complexes catalystsCarbonyl compound preparation by oxidationCyclopentenePtru catalyst

The invention relates to a metal-organic framework supported heteropoly acid catalyst for synthesizing glutaraldehyde and a production method of the metal-organic framework supported heteropoly acid catalyst. The catalyst is prepared by a one-step synthesis method, namely a heteropoly acid component with catalytic oxidation activity is introduced into a duct of a metal-organic framework material UiO-66 in the process of synthesizing the metal-organic framework material UiO-66. The catalyst has the characteristics that the catalyst has a crystal framework structure, the active component is highly dispersed, and the heteropoly acid is over-high in load. The catalyst is applied to catalytic selective oxidation reaction of cyclopentene, so that the selectivity and the yield of the glutaraldehyde is greatly improved; the numerical value is much higher than the reported homogeneous catalysis level; and the metal-organic framework supported heteropoly acid catalyst has important industrial application value.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Application method of heteropoly acid type catalyst

InactiveCN1390643AImprove catalytic performancePrevent dehydrationPhysical/chemical process catalystsHeteropoly acidSolid acid

A process for improving the acid intensity stability of solid acid catalyst containing heteropoly acid or its salt (0.5-100 wt.%) features that said heteropoly acid or its salt has central atom (P or Si) and coordinating atom chosen from W, Mo and V, and there is water in reaction atmosphere.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for synthesizing sec-butyl acetate from acetic acid and linear butylene

InactiveCN101121656AOvercome intractabilityOvercoming the problem of increased consumptionOrganic compound preparationCarboxylic acid esters preparationCelsius DegreeHeteropoly acid

The invention relates to a synthetic method of the sec-butyl acetate with the acetic acid and linear butylene. The invention is characterized in that a fixed-bed reactor is used; the solid catalyst is used; when the butylenes pressure is between 2 and 15 kilograms per square centimeters and the reaction temperature is between 90 and 160 Celsius system, the acetic acid and olefin react and compose the sec-butyl acetate under the gas-liquid-solid reaction condition; therein, the ratio between the cetic acid and olefin is from 1 to 1.15 to 1 to 1.80; the material feeding airspeed of the acetic acid is 1.0 to 1.8 liters per hour; the solid catalyst is the modified resin catalyst, silica gel loading heteropoly acid catalyst, silica gel loading phosphoric acid catalyst or super acid catalyst. The invention overcomes the erosion of the equipment, the side reaction, the difficult treatment of the waste liquid of the reaction, and the difficult separation of water in the traditional process, which may cause the increase of the energy consumption; the invention can greatly lower the production cost of the product.

Owner:SOUTH CHINA UNIV OF TECH

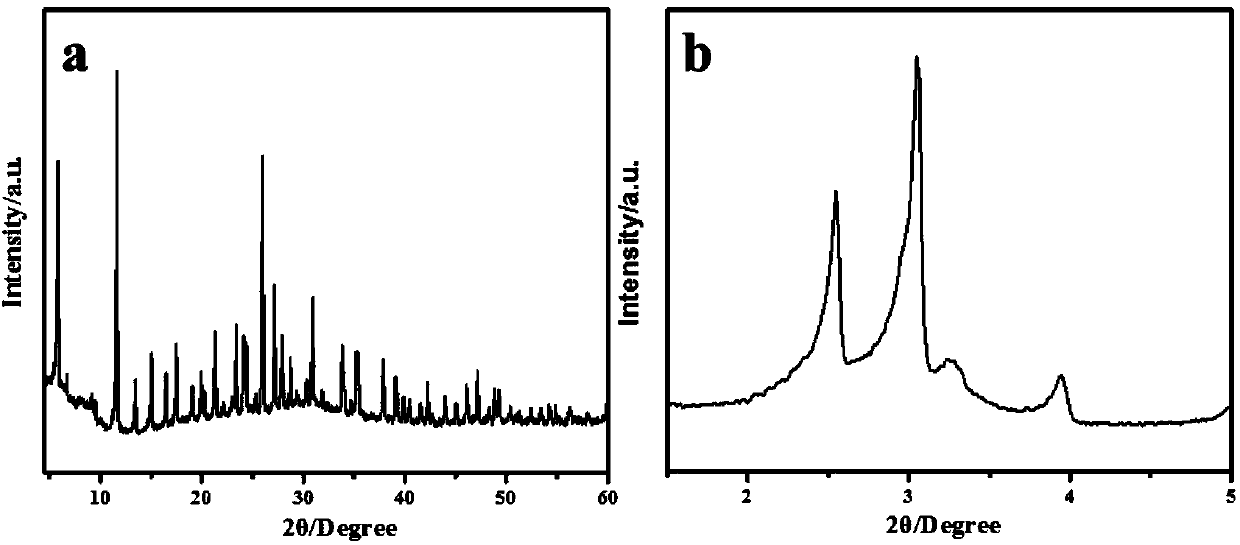

Method for preparing phosphotungstic heteropoly acid with Keggin structure

InactiveCN102659181ASimple preparation processIncrease productivityTungsten compoundsHigh concentrationInorganic salts

The invention discloses a method for preparing phosphotungstic heteropoly acid with a Keggin structure. The method comprises the following steps of: (1) contacting a tungstate solution and an inorganic acid solution; (2) transferring the solution to a high-pressure reaction kettle, and activating at high temperature under high pressure to obtain an active intermediate; (3) contacting the obtained substance and phosphoric acid to obtain a phosphotungstic acid solution; and (4) adding an inorganic salt precipitator into the phosphotungstic acid solution, precipitating phosphotungstic acid by salting-out and crystallization, filtering, purifying and drying to obtain the Keggin phosphotungstic heteropoly acid. By the method, a process flow is simple, the yield of the heteropoly acid is high, and the preparation cost is reduced obviously; high-concentration strong acid in the conventional method is not used in the preparation process, so that the corrosivity to equipment is reduced greatly; and an inflammable low-boiling point organic extractant is not used, and the safety of preparation is improved greatly.

Owner:CENT SOUTH UNIV

Heteropoly acid/multimetal oxacid salt catalyst

InactiveCN1284400AHigh yieldOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAlkaneHeteropoly acid

Owner:ROHM & HAAS CO +1

Method for directly synthesizing mesoporous material coated heteropolyacid functionalized MOF material

InactiveCN104338556AMild reaction conditionsHigh reaction yieldOrganic chemistryOrganic compound preparationTetramethylammonium hydroxideHeteropoly acid

The invention discloses a method for directly synthesizing a mesoporous material coated heteropolyacid functionalized MOF material, and relates to a method for a mesoporous material coated polyacid modified metal organic framework material, wherein a mesoporous molecular sieve, phosphorus molybdenum heteropoly acid, tetramethylammonium hydroxide, 1,3,5-trimesic acid, and Cu(NO3)2.3H2O are adopted as raw materials, a hydrothermal synthesis method is adopted, and water is adopted as a solvent to carry out one step synthesis at a temperature of 90-230 DEG C to obtain the target material. The catalysis material synthesized by the method is applied in the benzene hydroxylation reaction, wherein the good stability performance of the material is presented under the mild reaction conditions.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Silicon tungsten, phosphorus heteropoly tungstic acid load type catalyzer used for esterification reaction, manufacturing method and application thereof

The invention is a silicotungstic and phosphotungstic heteropoly acid load catalyst used for esterification reaction, which comprises the following components: Keggin structure silicotungstic acid H3SiW12O40.xH2O and phosphotungstic H3PW12O40.xH20, the content occupies 10 to 50 quality per centage of the amount of the catalyst; the carrier is H Beta zeolite. The invention adopts soaking method to prepare the solid silicotungstic and phosphotungstic heteropoly acid catalyst load on the H Beta zeolite, which can be used for catalyzing the esterification reaction of etic acid, isobutanol, isobutanol and ethanol, but also can be used for catalyzing esterification reaction of lactic acid and isobutanol to synthesis n-butyl acetate, isobutyl acetate, ethyl acetate and N-Butyl Lactate. The invention has the advantages of good stability, high activity and good selectivity, but also can used as inhomogeneous catalyst which is easy to be separated with reaction product and can use the prepared and formed catalyst powder in the continuous operating fixed bed reactor. The invention is used in the techinics of esterification reaction catalyzing rectifying.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

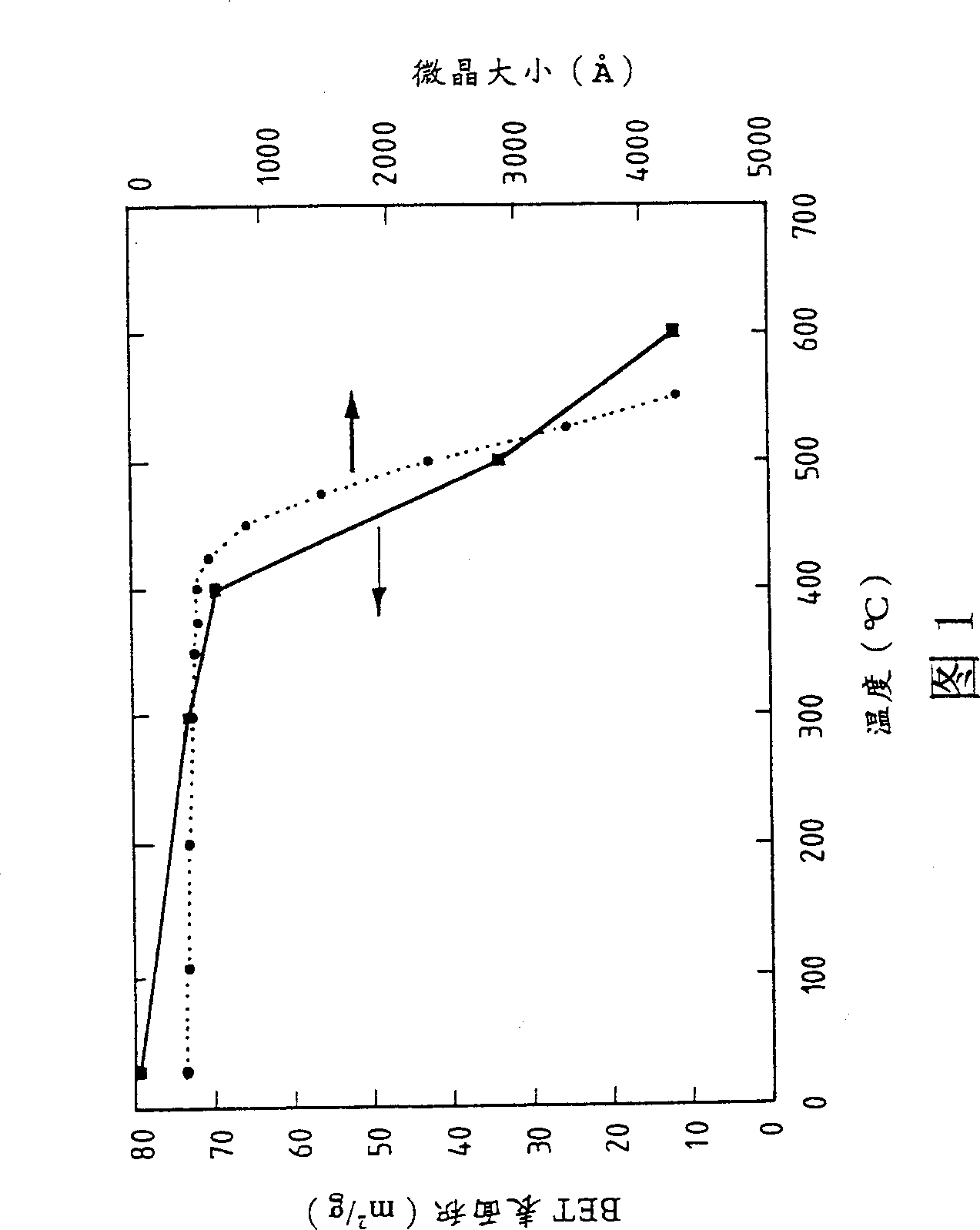

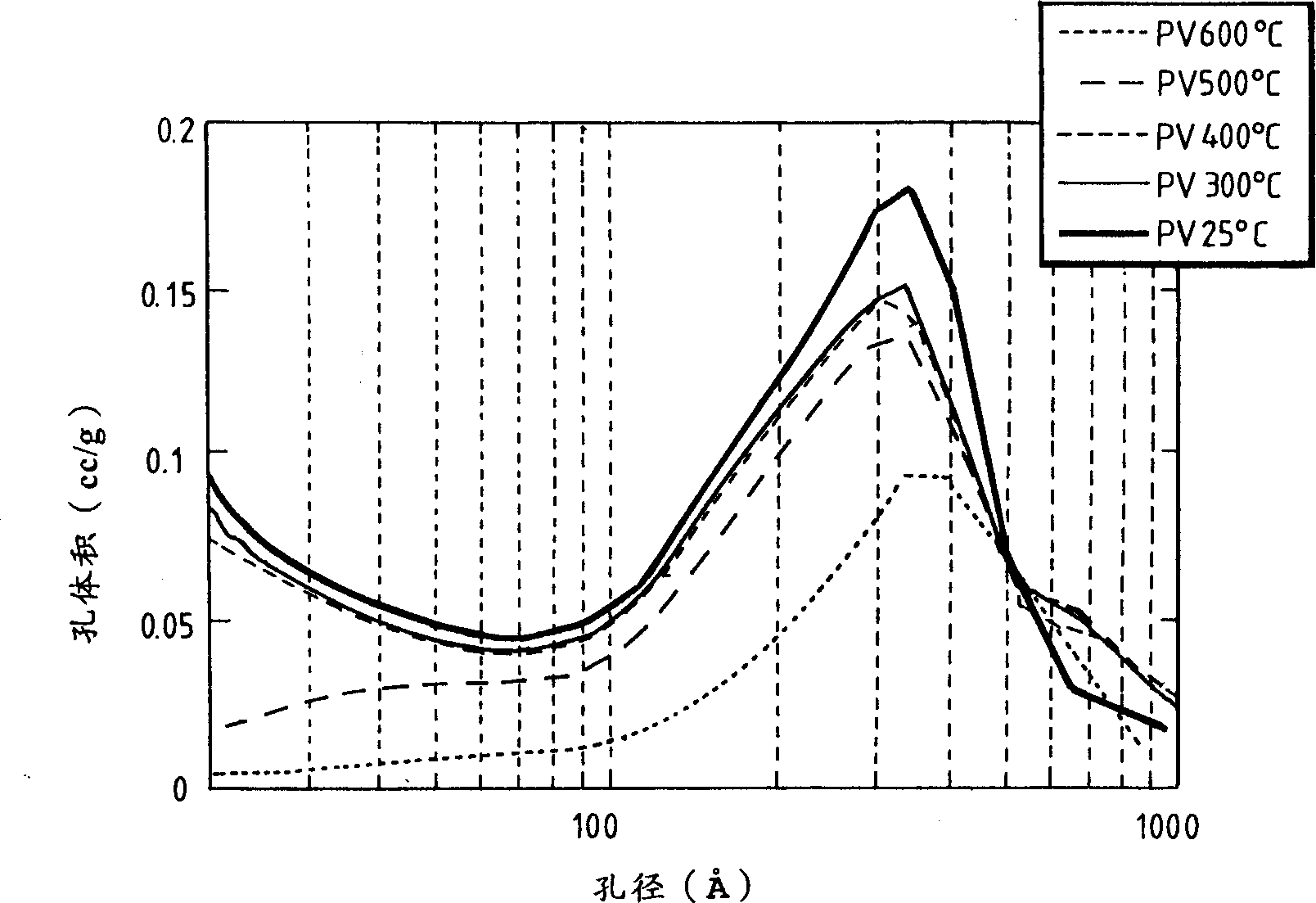

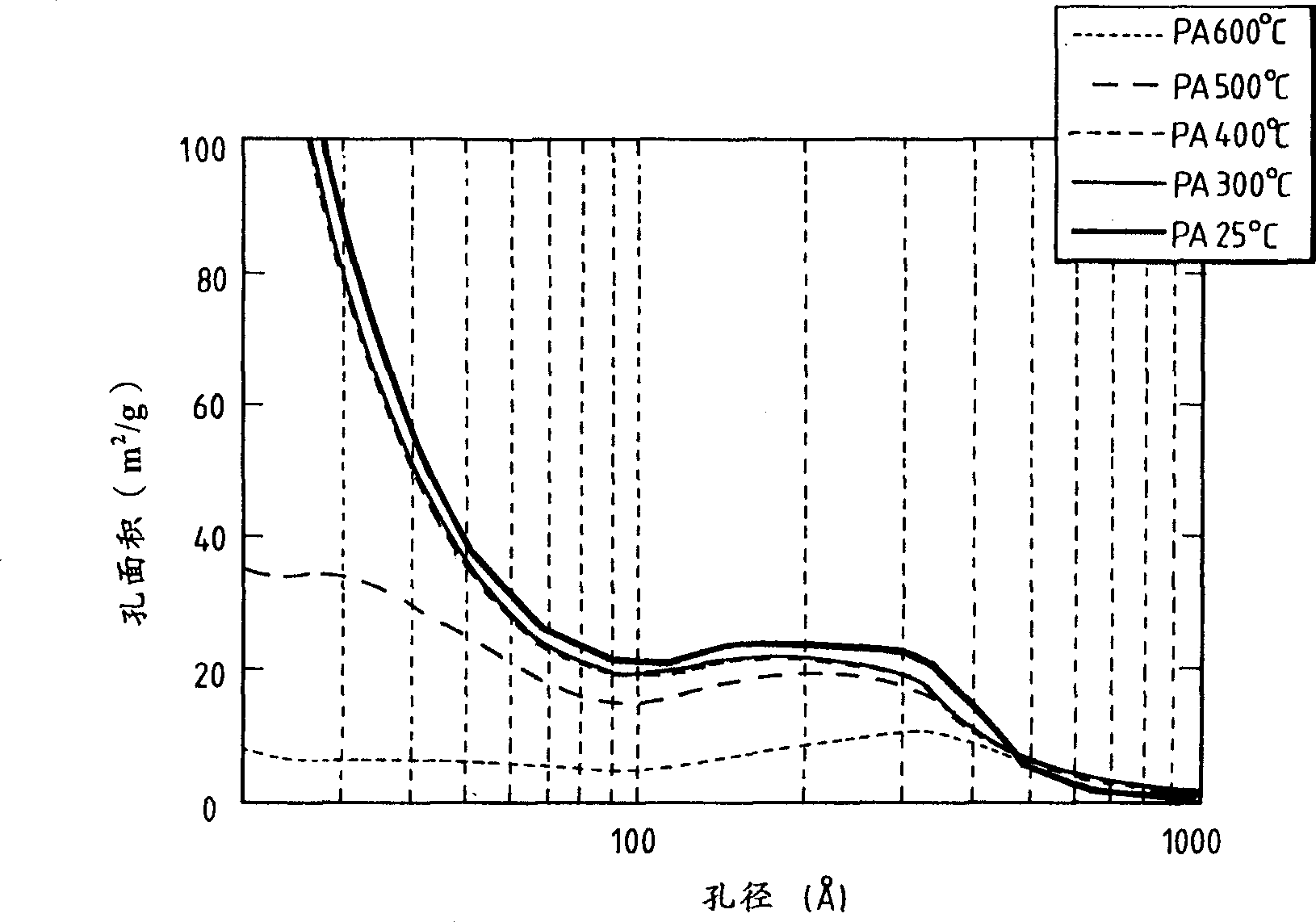

Catalyst for the oxidation of a mixed aldehyde feedstock to methacrylic acid and methods for making and using same

InactiveUS20070021296A1Improve distributionOrganic compound preparationHeterogenous catalyst chemical elementsIndiumCerium

A heteropolyacid catalyst for oxidation of isobutyraldehyde, methacrolein or mixtures or combinations thereof to methacrylic acid is disclosed where the heteropolyacid catalyst includes at least molybdenum (Mo), phosphorus (P), vanadium (V), and a first component including bismuth (Bi) and / or boron (B). The heteropolyacid catalyst can also optionally include a second component including potassium (K), rubidium (Rb), cesium (Cs), and / or thallium (Tl) and optionally a third component including antimony (Sb), cerium (Ce), niobium (Nb), indium (In), iron (Fe), chromium (Cr), cobalt (Co), nickel (Ni), manganese (Mn), arsenic (As), silver (Ag), zinc (Zn), germanium (Ge), gallium (Ga), zirconium (Zr), magnesium (Mg), barium (Ba), lead (Pb), tin (Sn), titanium (Ti), aluminum (Al), silicon (Si), tantalum (Ta), tungsten (W), and / or lanthanum (La). The heteropolyacid catalyst can also include an ammonium-containing compound designed to increase a value of medium pores in the final heteropolyacid catalyst. A method for oxidizing isobutanal to methacrylic acid using the heteropolyacid catalyst is also disclosed.

Owner:SAUDI BASIC IND CORP SA

Catalyst for methanol oxidation to methylal by one step, preparing method and applications thereof

InactiveCN101224431AEnable selective controlSimple processOrganic chemistryMolecular sieve catalystsMolecular sieveSynthesis methods

A methanol catalyst for the selective oxidation of methylal is composed of heteropoly acid and molecular sieve carrier, wherein, the heteropoly acid takes 3-45% of the catalyst by weight percentage, the metal content takes 0-5% of the catalyst by metal single mass, and remaining is silicon modular sieve. For the preparation of the catalyst, a mechanical mixing method, an immersion method, an in-situ synthesis method, and a surface grafting method are applied. The invention can realize the preparation of methylal by oxidation method in one step, shorten process flow and reduce production cost. Meanwhile, the catalyst is obviously characterized by high selectivity of methylal, good stability and long service life.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Molecular sieve catalyst, preparation method and use in preparing ethylene by dehydrating ethanol

InactiveCN101327443AExtended service lifeHigh selectivityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsHeteropoly acidHigh energy

The present invention discloses a molecular sieve catalyst, a preparation method thereof and the application of the molecular sieve catalyst for preparing for ethene by dehydrating ethanol. The catalyst uses ZSM-5 molecular sieve or HZSM-5 which is obtained by acidifying the ZSM-5 as a support; oxide or salt of heteropoly acid or vanadium (V) or titanium (Ti) is used as active component; the active component is introduced into the support by a dipping method or a surface chemical reaction modifying method to be dried and calcined in a muffle furnace to obtain the molecular sieve catalyst. The catalyst is used in ethanol dehydration to prepare for the ethene and not only has high ethanol conversion rate and ethene selectivity and long service life, the maximum conversion rate of ethanol dehydration reaction can be 100 percent, and the maximum selectivity of the ethene can be 99.4 percent; but the catalyst also solves the technical problems of low airspeed, high temperature, high energy consumption, and the like, in the reaction of preparing for the ethene by dehydrating the ethanol; the catalyst is applicable to the industrial production of preparing for the ethene by dehydrating the ethanol and has the effects of improving production efficiency and saving energy source.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

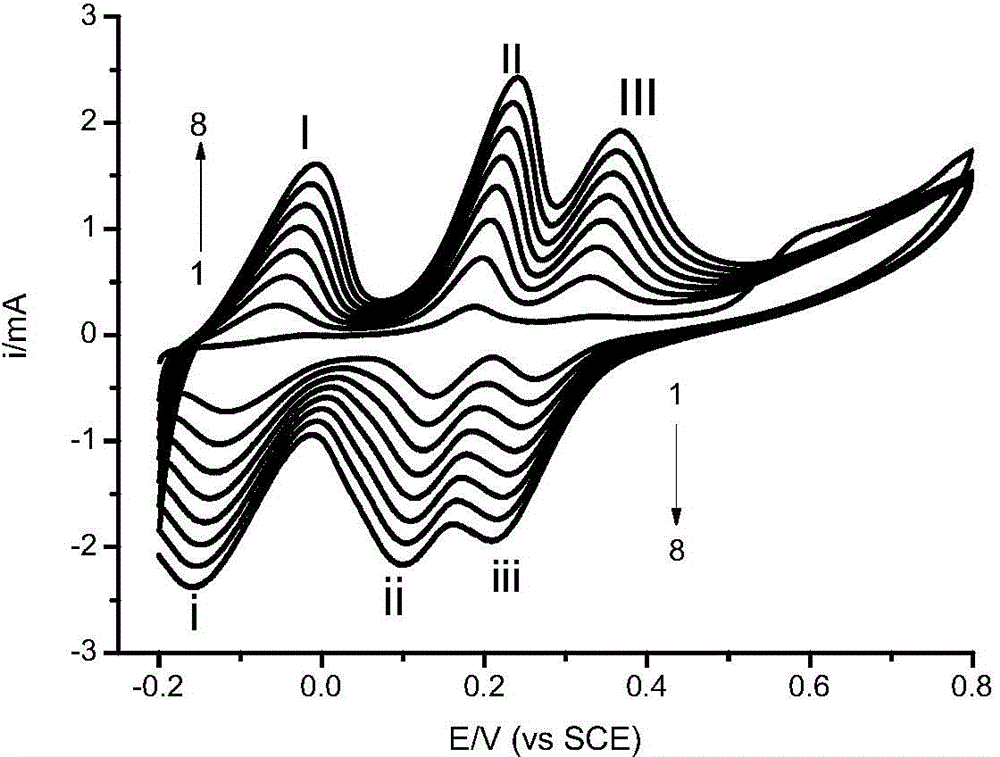

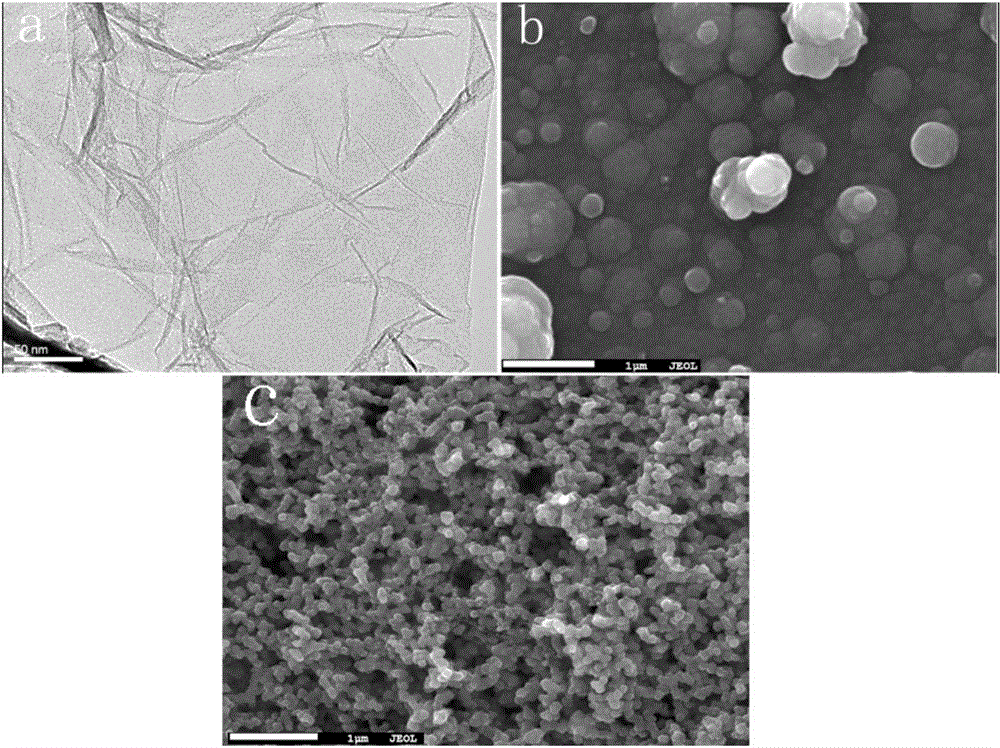

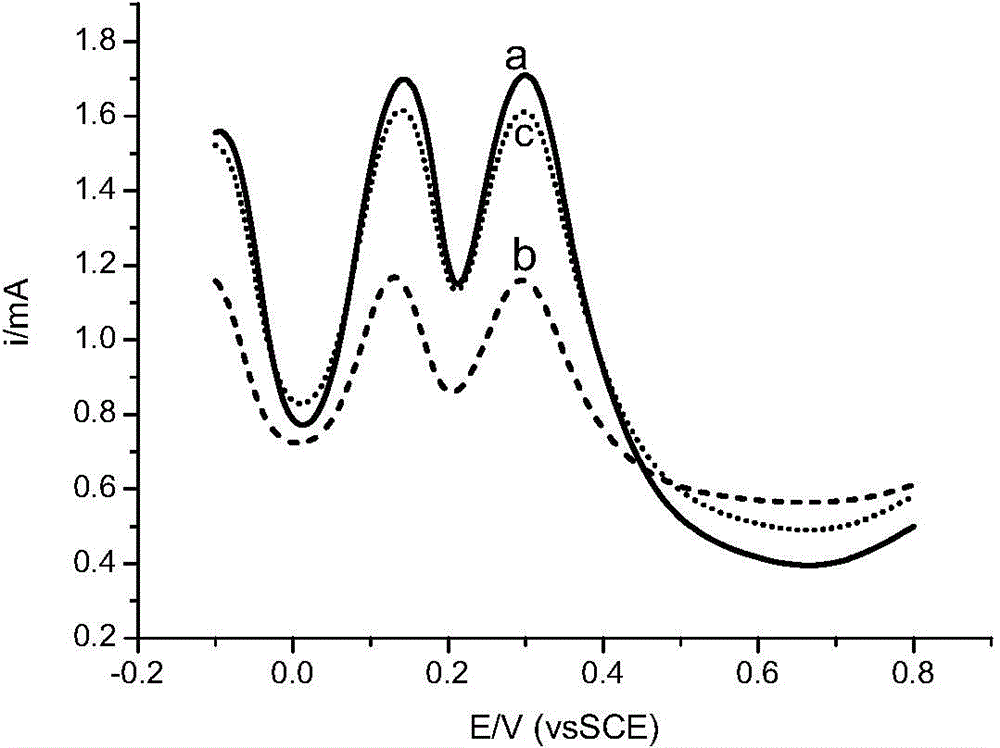

Keggin type heteropoly acid-polypyrrole-graphene composite material modified electrode as well as preparation method and application thereof

ActiveCN103913492AHigh sensitivityImprove stabilityMaterial electrochemical variablesInfrared lampHeteropoly acid

The invention discloses a preparation method of a Keggin type heteropoly acid-polypyrrole-graphene composite material modified electrode. The preparation method comprises the following steps: selecting a glassy carbon electrode and carrying out surface treatment on the glassy carbon electrode; dropping graphene dispersion liquid on the surface of the glassy carbon electrode and putting the glassy carbon electrode under an infrared lamp to be dried to prepare a graphene modified electrode; immersing the prepared graphene modified electrode into a sulfuric acid solution containing polypyrrole and Keggin type heteropoly acid; scanning by using a cyclic voltammetry; after scanning, taking out the graphene modified electrode and eluting with water for the second time; drying at room temperature to obtain the Keggin type heteropoly acid-polypyrrole-graphene composite material modified electrode. The Keggin type heteropoly acid-polypyrrole-graphene composite material modified electrode prepared by the preparation method has a sensitive inhibition effect based on an oxidization reduction reaction of folic acid on the Keggin type heteropoly acid and can be used for determining the folic acid; compared with a common electrode, the Keggin type heteropoly acid-polypyrrole-graphene composite material modified electrode has the advantages of small over-potential, high sensitivity, good stability, high reproducibility and the like; a preparation process is simple, raw materials are easy to obtain and the cost is low.

Owner:QINGDAO UNIV

Composite catalyst for preparing sec-butyl acetate with direct esterification of ethyl ester and butylene

InactiveCN101293210ASolve the problem of reduced catalytic efficiencyCatalyst carriersOrganic compound preparationHeteropoly acidCordierite

The present invention relates to a composite catalyst for preparing sec-butyl acetate by direct esterification of ethyl ester and butylene, which takes heteropoly acid as the catalyst active component and porous carrier as the dispersant; the weight proportion of the heteropoly acid and the porous carrier is 0.01:1 to 10:1. The heteropoly acid is one with Keggin structure, which consists of phosphotungstic acid, silicotungstic acid, germanium tungstic acid, arsenowolframic acid, phosphomolybdate, germanomolybdate or arsenicomolybdate. The porous carrier comprises porous SiO2, Al2O3, SBA-15, MCM-41, white carbon black, porous SiC, corallite, andalusite, cordierite, meerschaum, Attapulgite or kaolin. The composite catalyst of the present invention solves the problem that the catalysis efficiency is low if the heteropoly acid is separated out from the reaction system.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Method for preparing acrylic aldehyde by biological glycerol dehydration

ActiveCN101417928AReduce manufacturing costWide variety of sourcesMolecular sieve catalystsOrganic compound preparationHeteropoly acidGlycerol

The invention discloses a preparation method of acrolein, taking biological glycerol as the raw material and the modified zeolite supported heteropolyacid as catalyst, the method prepares acrolein directly by dehydration reaction. 18 to 30 catalyst are put in the middle section of a normal pressure continuous fixed bed reactor, with the volume space velocity of 1 to 10 h<-1>; under the protection of N2, the catalyst bed raises the temperature to 180 to 540 DEG C, and the biological glycerol solvent which is added with inhibitor is put into the fixed bed reactor from a micro pump; after gasified, the glycerine solution reacts by the catalyst bed. After reaction, the product is absorbed by acetone, then is separated and purified, thus obtaining acetone. The invention adopts the alkali metal, phosphoric oxides, alkali metal compound improved catalyst as carrier to carry heteropoly acid catalyst which is green and environmental catalyst and has the advantages of high activity, regeneration property, no pollution, simple reaction, operation process, low production cost, high mole selectivity of acrolein and high conversion rate of biological glycerol.

Owner:溧阳常大技术转移中心有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com