Molecular sieve catalyst, preparation method and use in preparing ethylene by dehydrating ethanol

A technology of ethanol dehydration and molecular sieve, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve the effects of improving production capacity, improving ethylene selectivity, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] [embodiment 1] measure 5ml titanium tetrachloride, at room temperature, N 2 Under the atmosphere and good stirring, slowly add 4.6ml of isopropanol to it, after the reaction is complete, add 20ml of acetone to dissolve the yellow precipitate, and obtain titanium isopropoxide-acetone solution; at room temperature and under rapid stirring, distilled water , nitric acid, and absolute ethanol are added dropwise into the titanium isopropoxide-acetone solution, and stirred for 0.5 to 3 hours to obtain an impregnation solution containing titanium ions. Among them, titanium isopropoxide-acetone, distilled water, nitric acid, and ethanol The volume ratio is 1:0.08:0.02:1;

[0028] Treat the ZSM-5 molecular sieve with a silicon-aluminum molar ratio of 25 with 1M ammonium acetate aqueous solution at 95°C for 2 to 4 times, each time for 4 hours, wherein 5ml of ammonium acetate aqueous solution is added to each gram of ZSM-5; Dry at 120°C, roast at 500°C for 3 hours to obtain HZSM-...

Embodiment 2

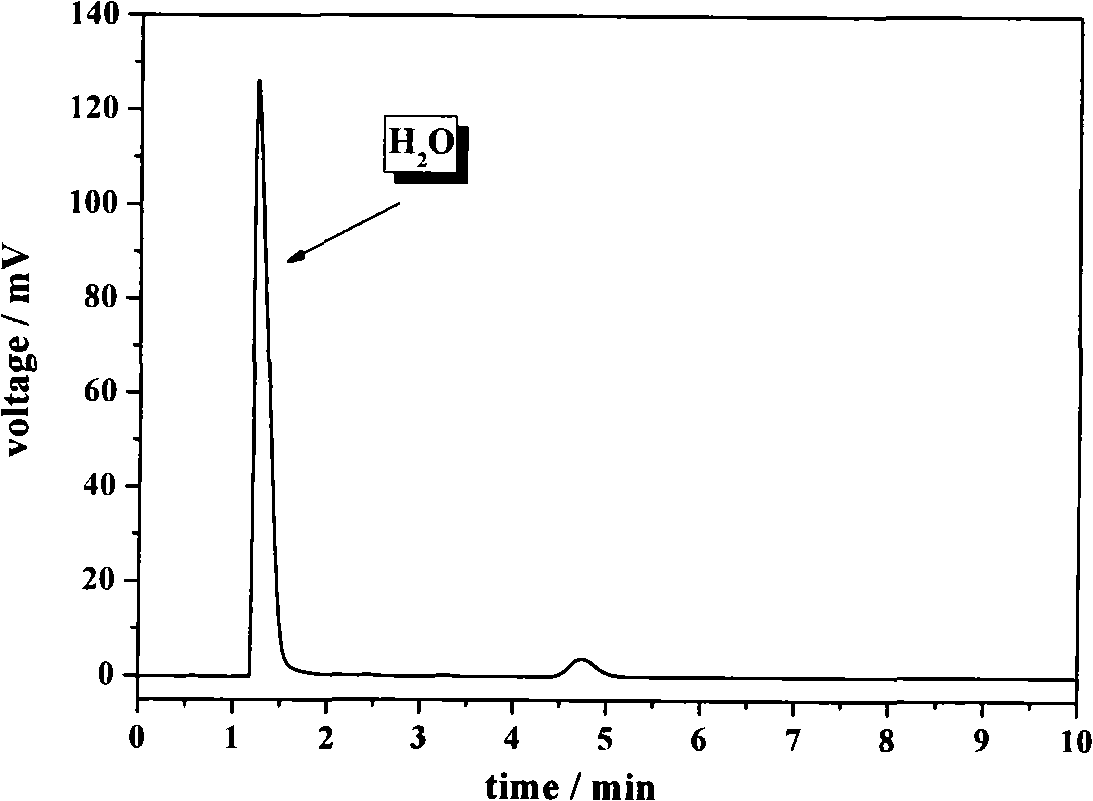

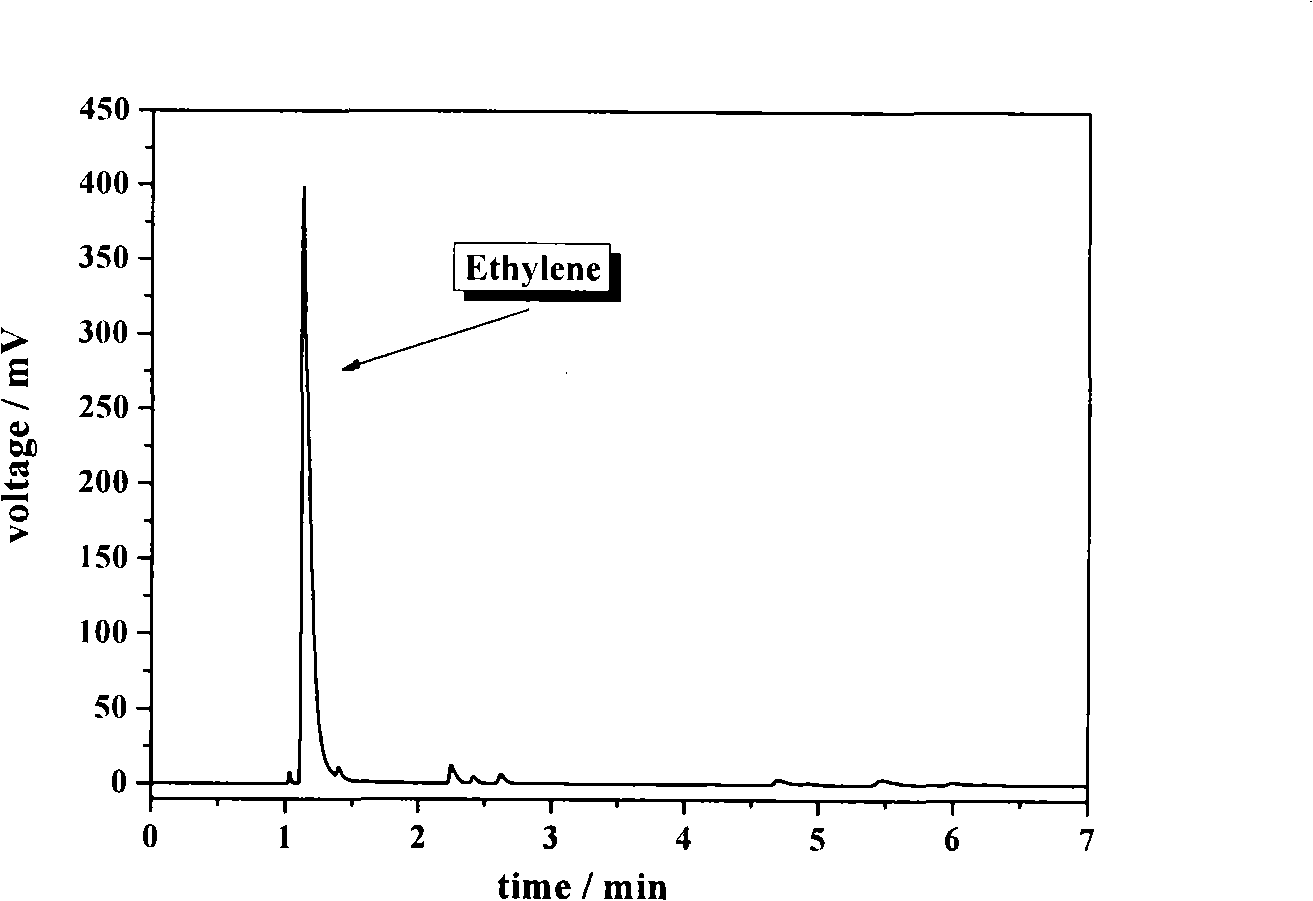

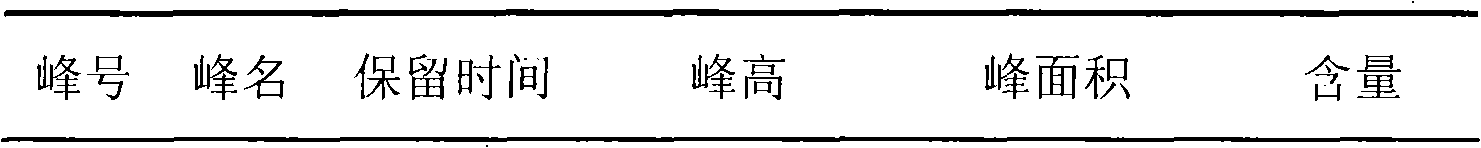

[0030] [Example 2] Put 6 grams of the catalyst Ti-1 / HZSM-5 prepared above into a fixed-bed reactor with an inner diameter of 32 mm and a height of 500 mm, and the upper and lower parts of the catalyst are filled with inert small ceramic balls or quartz sand , reaction temperature 350℃, space velocity 13.1h -1 , the weight ratio of water to ethanol in the raw material is 0.1:1. Under the above conditions, the catalyst Ti-1 / HZSM-5 catalyzed the dehydration of ethanol to prepare ethylene with a conversion rate of 90.8% and a selectivity of ethylene of 94.6%. The gas chromatographic analysis results of the liquid phase components are shown in Table 1, wherein the retention time is 1.24min is the water peak, and the retention time is 4.74min is the ethanol peak, the original spectrum of chromatographic analysis can refer to the attached figure 1 . After 72 hours of continuous operation under this condition, the activity of the catalyst did not decrease.

[0031] Table 1. Chromat...

Embodiment 3

[0034] [Example 3] Using HZSM-5 with a silicon-aluminum molar ratio of 48 as a carrier, the titanium ion-modified molecular sieve catalyst Ti-2 / HZSM-5 was prepared in the same method and material ratio as in Example 1. Put 3.2 grams of the catalyst Ti-2 / HZSM-5 prepared above into a fixed-bed reactor with an inner diameter of 32 mm and a height of 500 mm. The reaction temperature is 350 °C and the space velocity is 10.2 h. -1 , the raw material is analytically pure ethanol. Under the above conditions, the catalyst Ti-2 / HZSM-5 catalyzes the dehydration of ethanol to prepare ethylene with a conversion rate of 80.9% and a selectivity of ethylene of 99.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com