Patents

Literature

494 results about "Titanium ion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

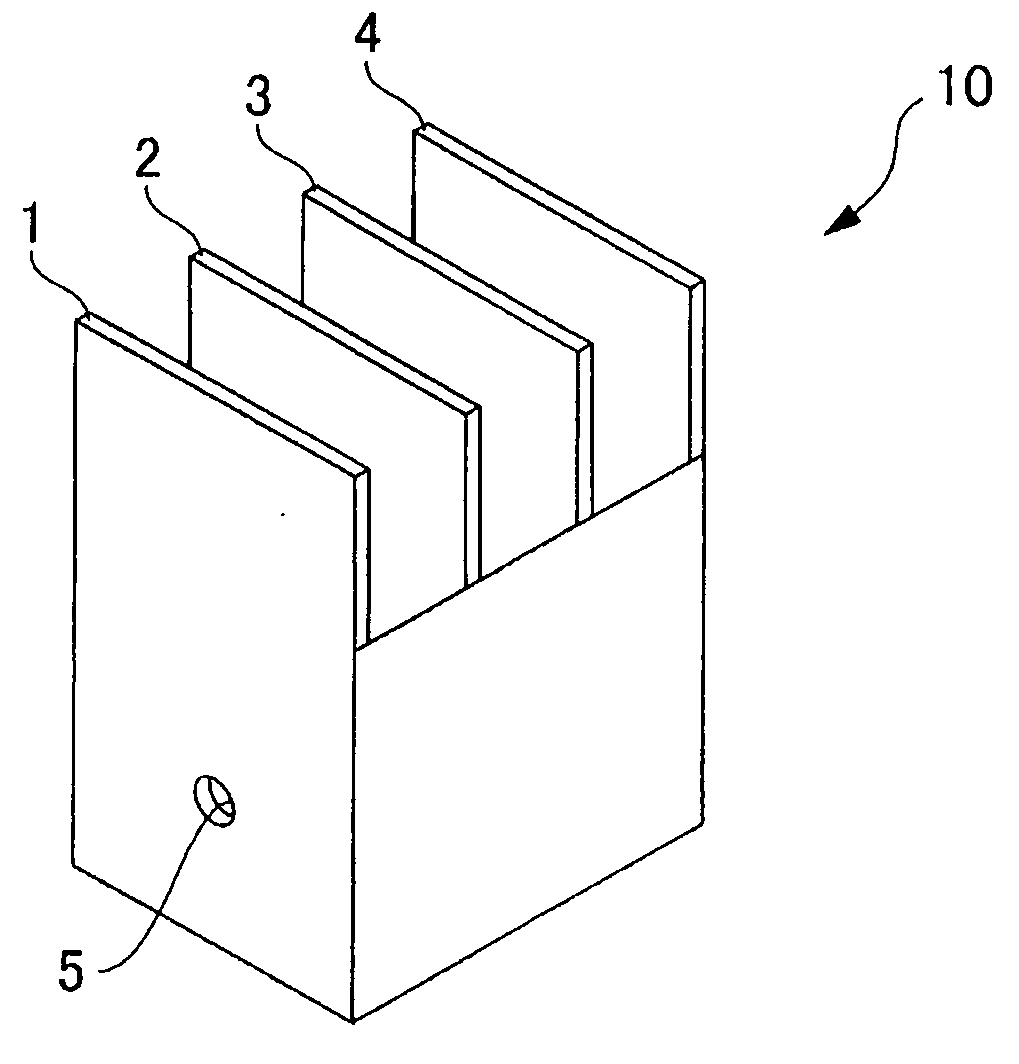

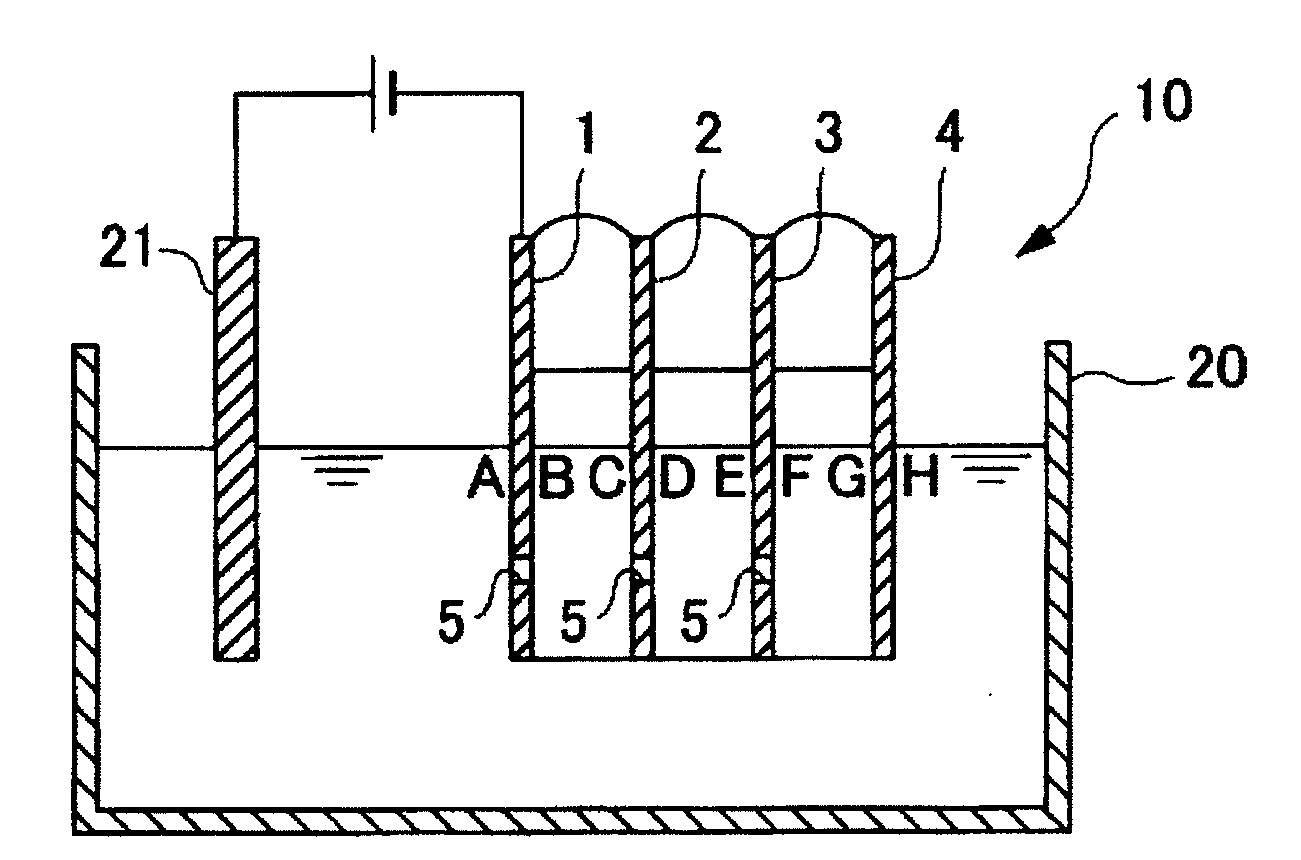

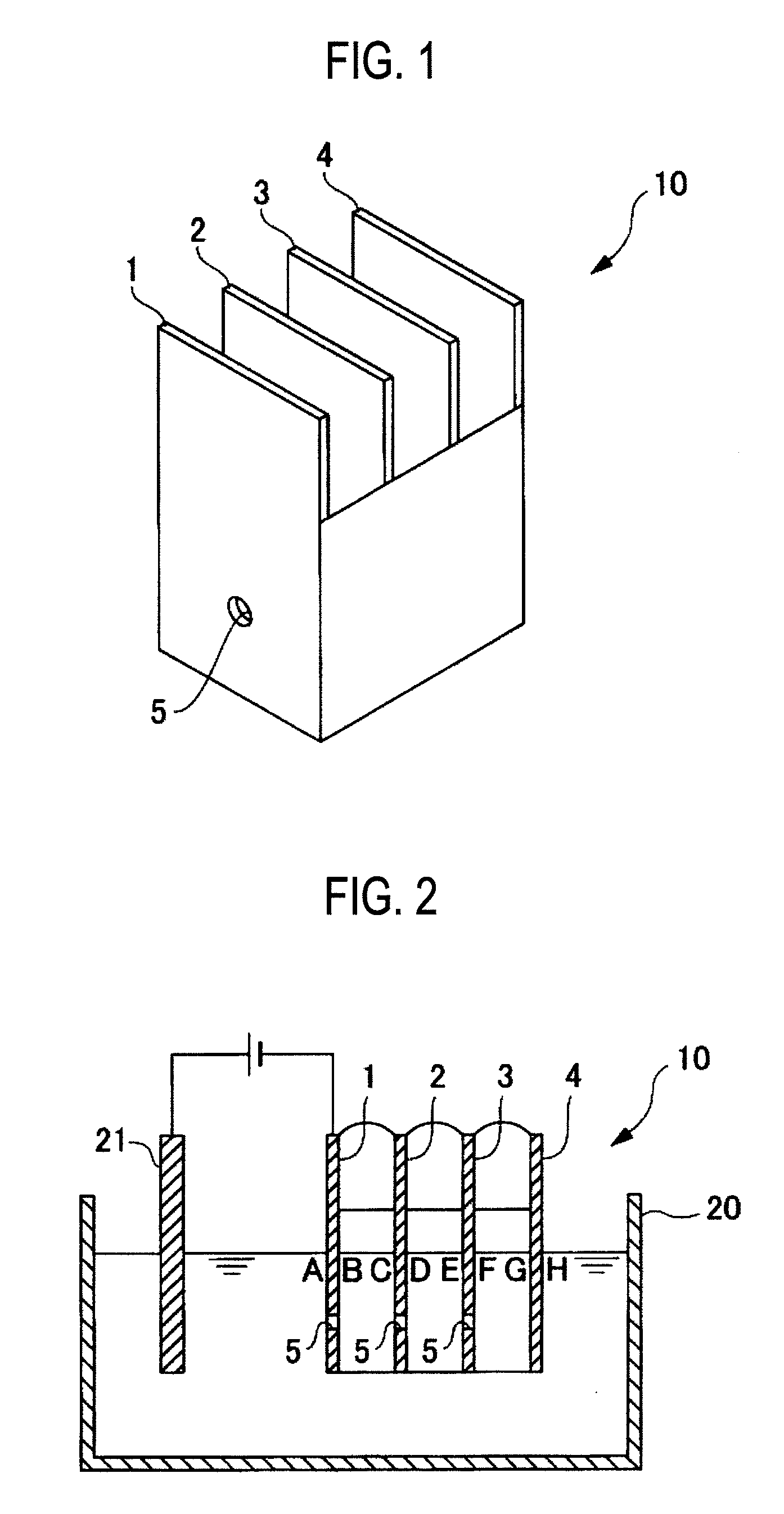

Redox flow battery

ActiveUS20120045680A1Suppress generationHigh electromotive forceElectrolyte moving arrangementsCell electrodesManganesePhysical chemistry

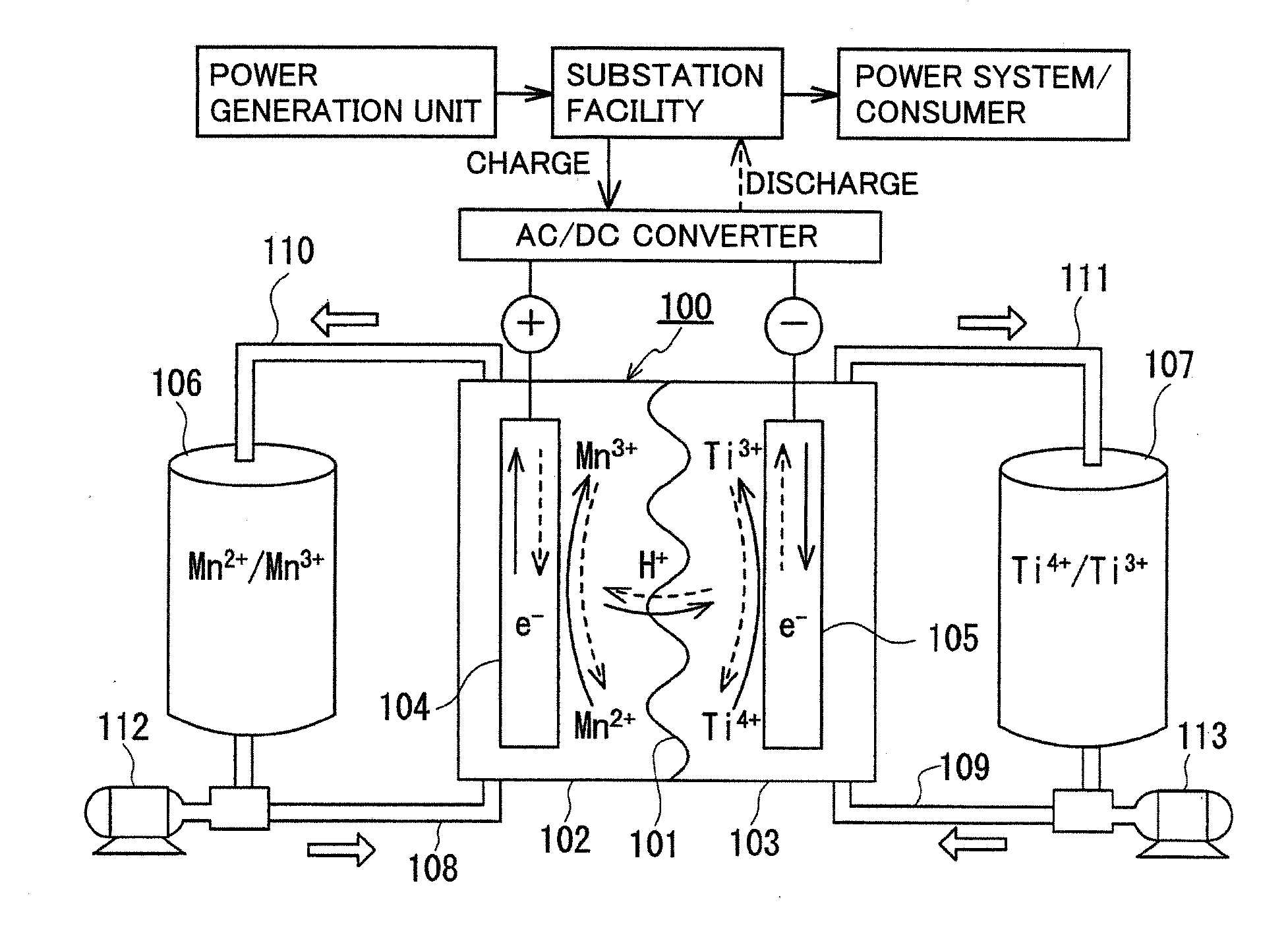

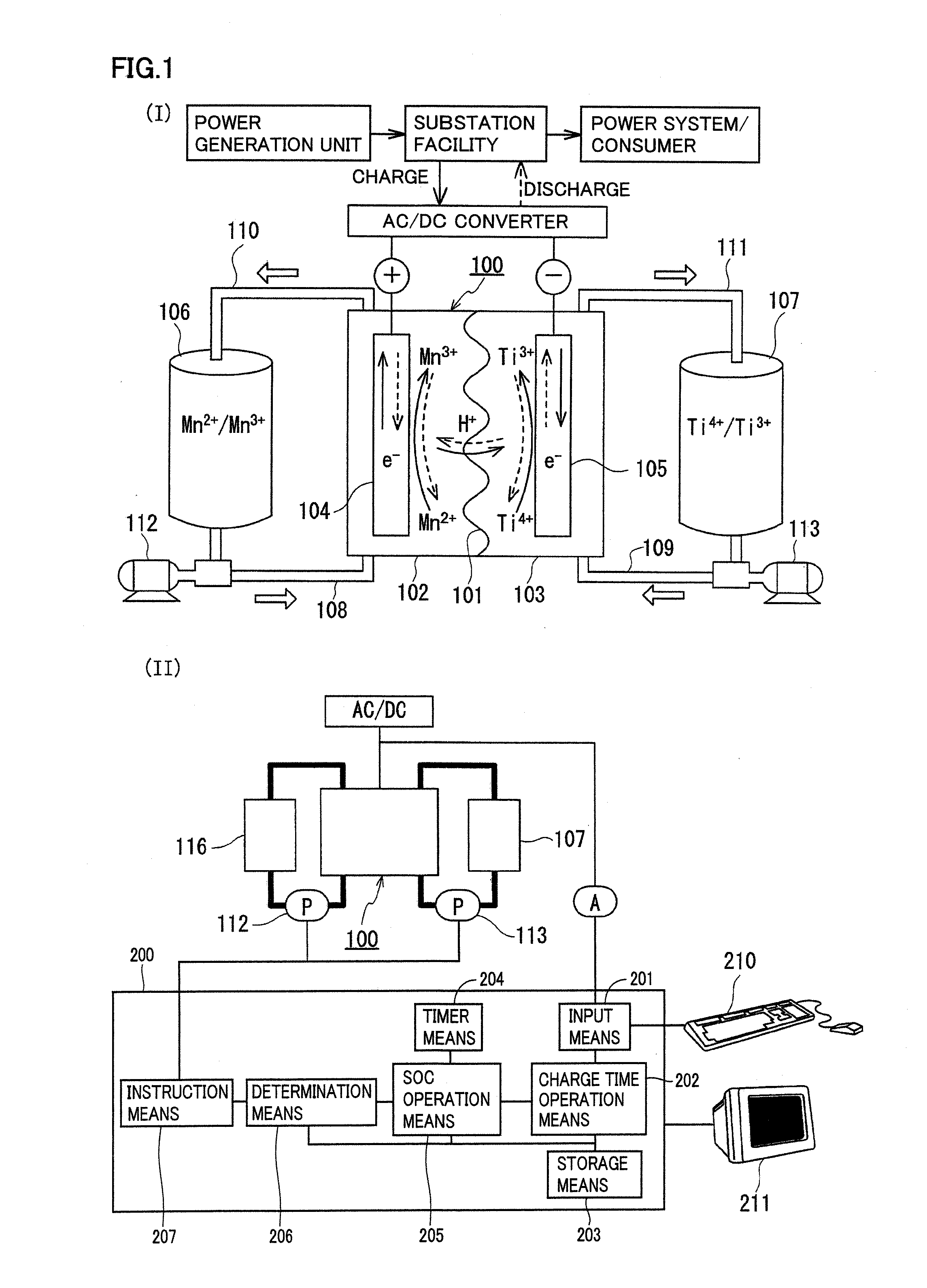

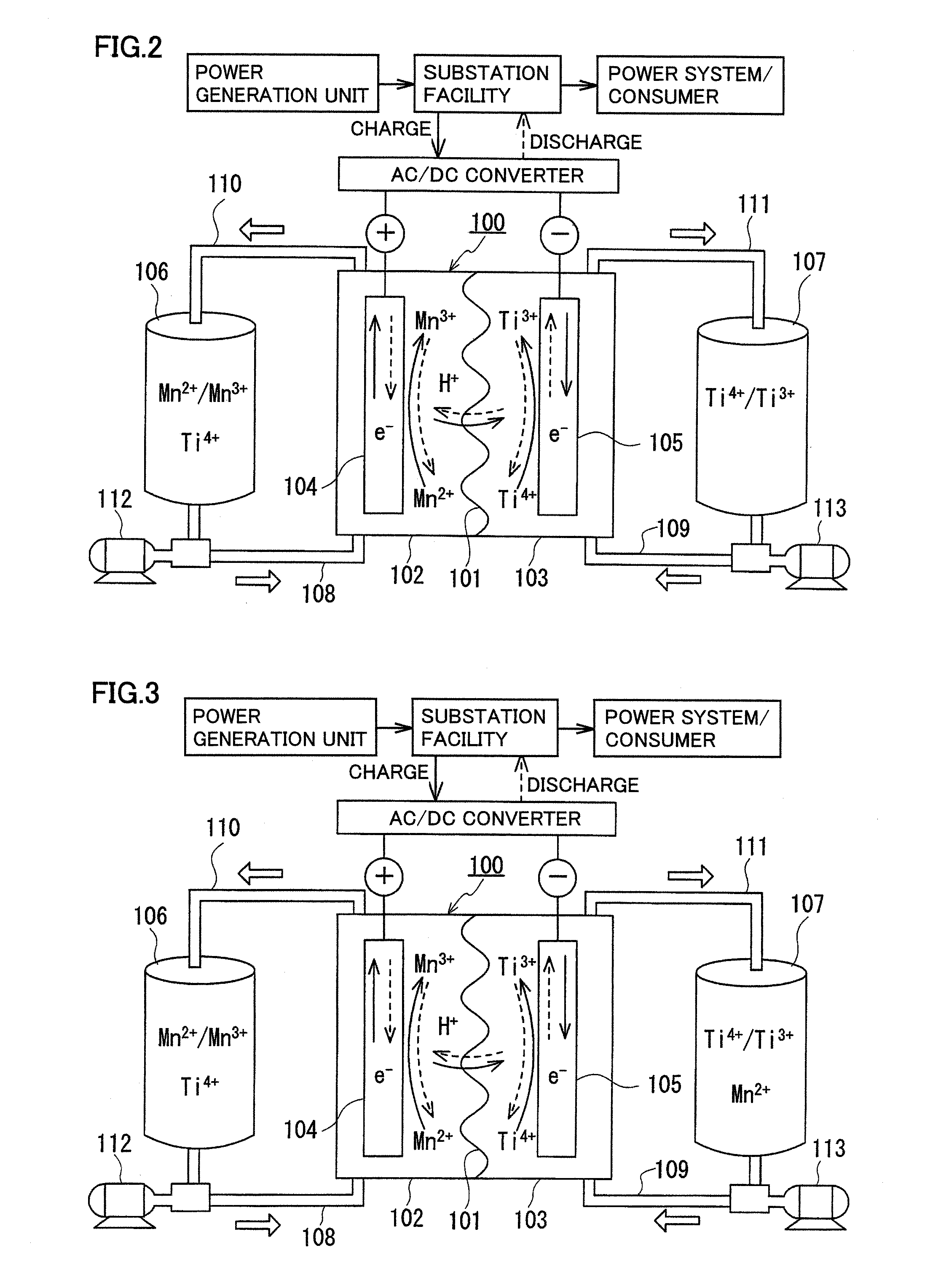

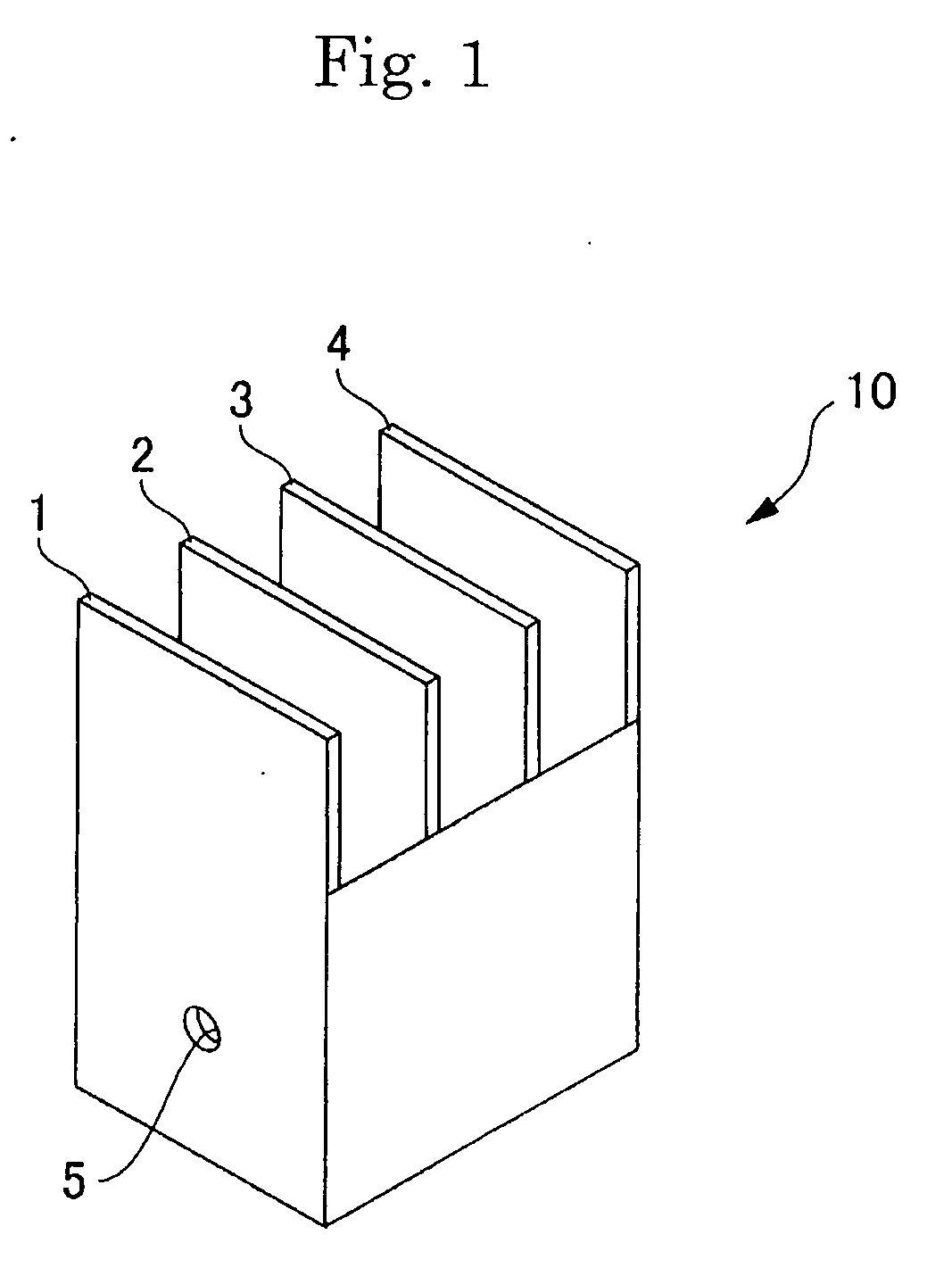

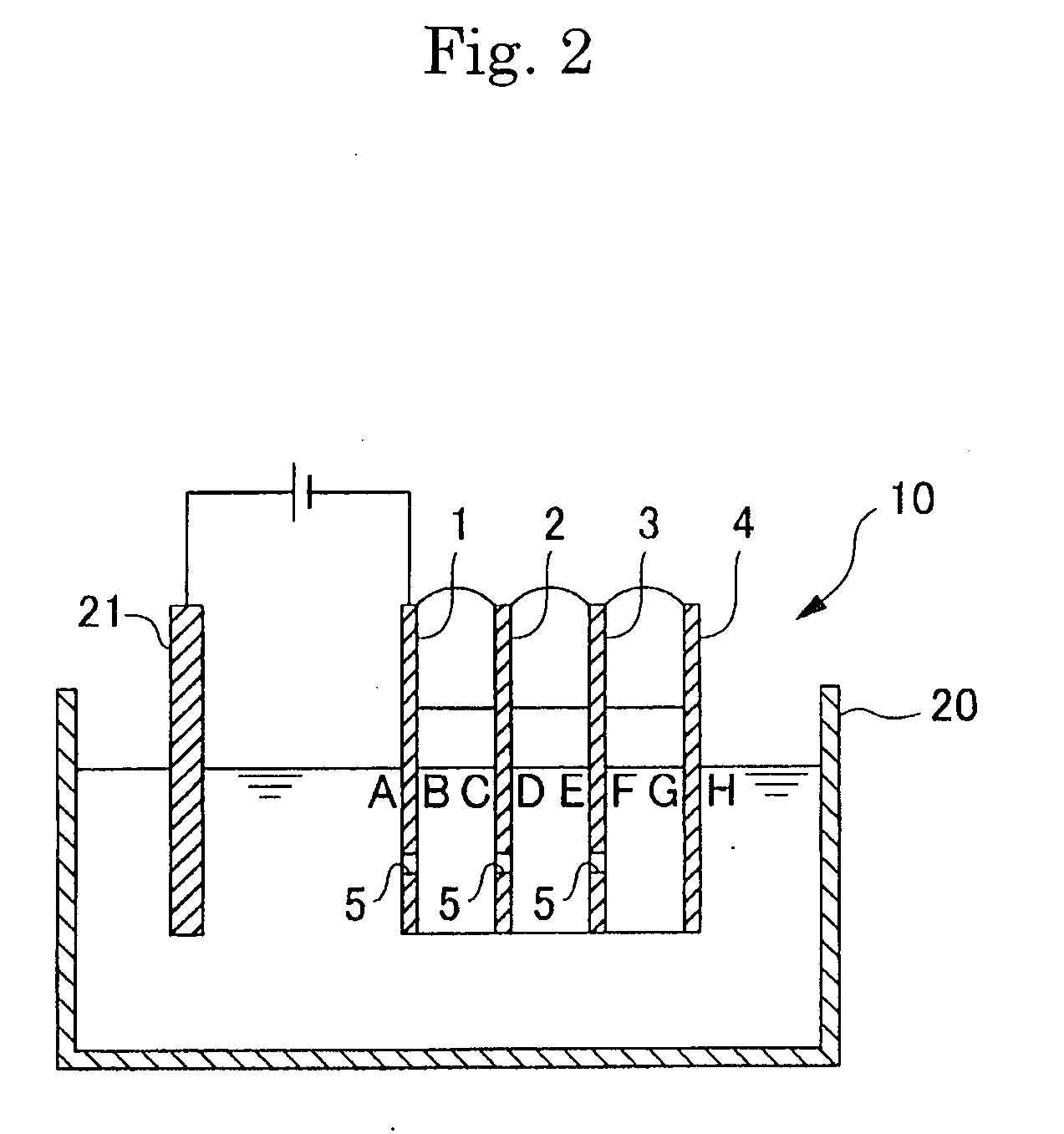

A redox flow battery having a high electromotive force and capable of suppressing generation of a precipitation is provided. In a redox flow battery 100, a positive electrode electrolyte and a negative electrode electrolyte are supplied to a battery cell including a positive electrode 104, a negative electrode 105, and a membrane 101 interposed between the electrodes 104 and 105, to charge and discharge the battery. The positive electrode electrolyte contains a manganese ion, or both of a manganese ion and a titanium ion. The negative electrode electrolyte contains at least one type of metal ion selected from a titanium ion, a vanadium ion, a chromium ion, a zinc ion, and a tin ion. The redox flow battery 100 can suppress generation of a precipitation of MnO2, and can be charged and discharged well by containing a titanium ion in the positive electrode electrolyte, or by being operated such that the positive electrode electrolyte has an SOC of not more than 90%. In addition, the redox flow battery 100 can have a high electromotive force equal to or higher than that of a conventional vanadium-based redox flow battery.

Owner:SUMITOMO ELECTRIC IND LTD

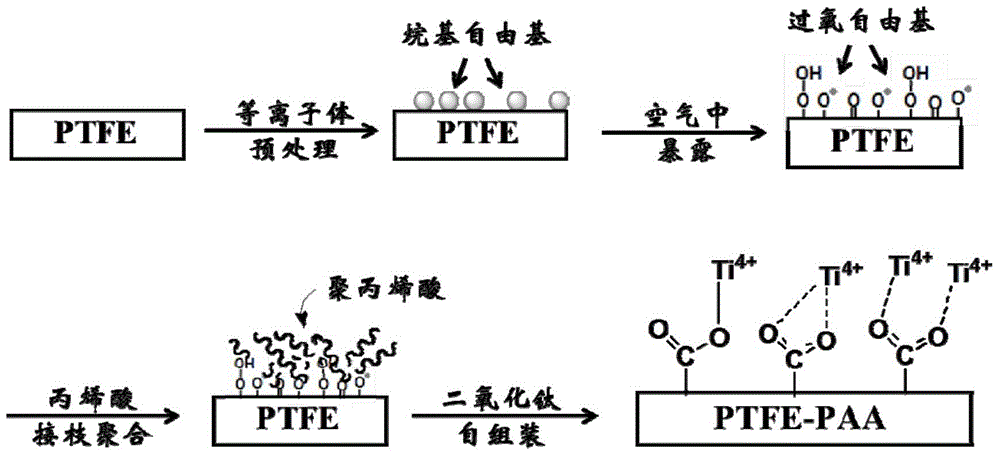

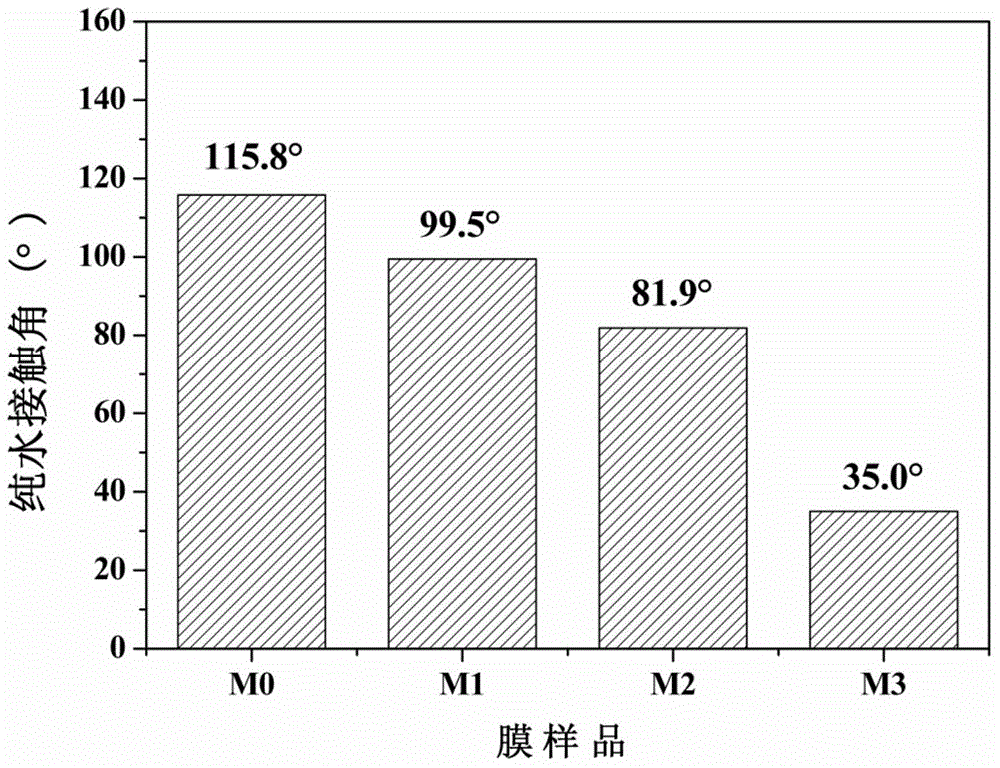

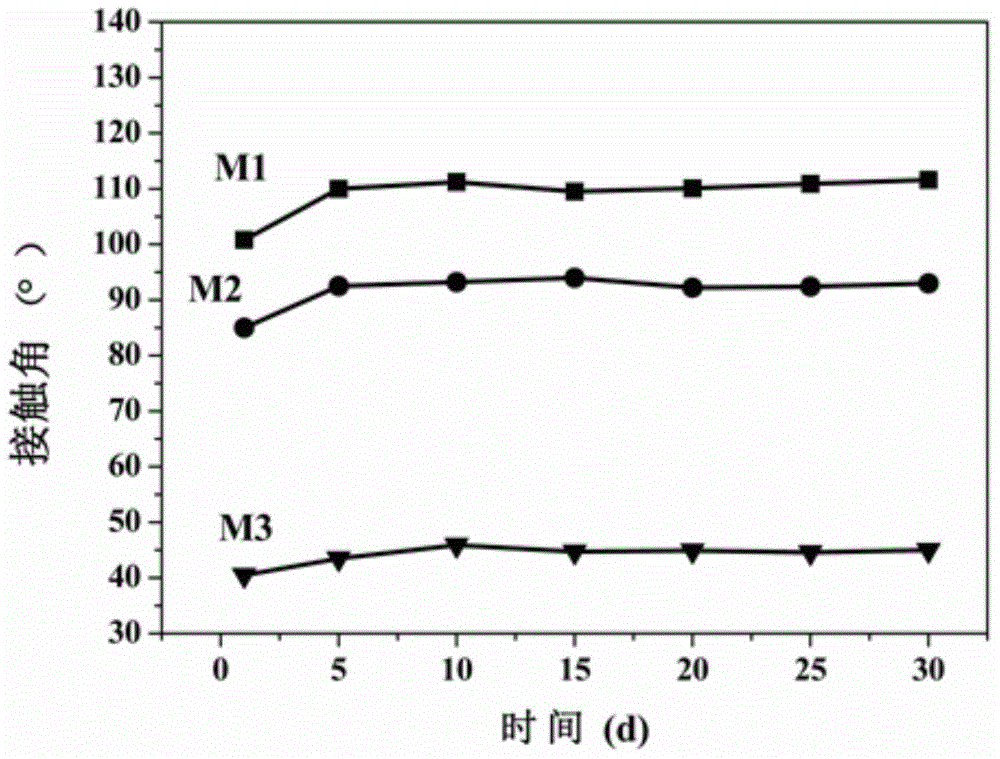

Hydrophilic modification method for polytetrafluoroethylene membrane

ActiveCN104998562AImprove featuresImprove filtering effectSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisGlass sheetVacuum drying

The inveniton provides a hydrophilic modification method for a polytetrafluoroethylene membrane. The method comprises the following steps: step 1, subjecting the polytetrafluoroethylene membrane to plasma treatment under a nitrogen atmosphere, and allowing the surface of the polytetrafluoroethylene membrane to generate relatively-stable free radicals and active sites; step 2, placing the polytetrafluoroethylene membrane into an acylic acid solution and carrying out static impregnation for a period of time, then taking the polytetrafluoroethylene membrane out of the solution and then placing the polytetrafluoroethylene membrane between two glase plates, and carrying out thermochemical polymerization in a vacuum drying oven so as to obtain the polytetrafluoroethylene membrane with the surface grafted with polyacrylic acid; and step 3, subjecting the polytetrafluoroethylene membrane to static impregnation in a titanium dioxide sol for a period of time, and allowing titanium dioxide to be assembled onto the surface of the polytetrafluoroethylene membrane through the coordination effect of metal titanium-ion Ti4+ and a carboxyl group on the polyacrylic acid so as to obtain a hydrophilic modified polytetrafluoroethylene membrane. The hydrophilic modified polytetrafluoroethylene membrane prepared by using the method in the invention retains excellent properties of a conventional polytetrafluoroethylene membrane and greatly improves filter performance, hydrophilic property, pollution resistant property and photocatalytic property of the polytetrafluoroethylene membrane.

Owner:深圳市新纳捷科技有限公司

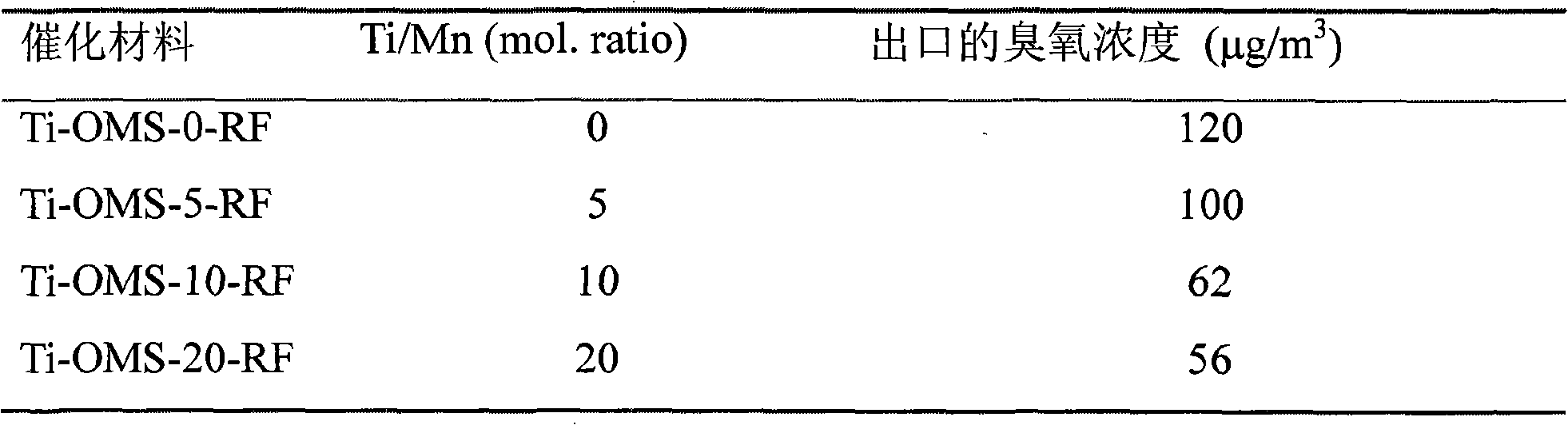

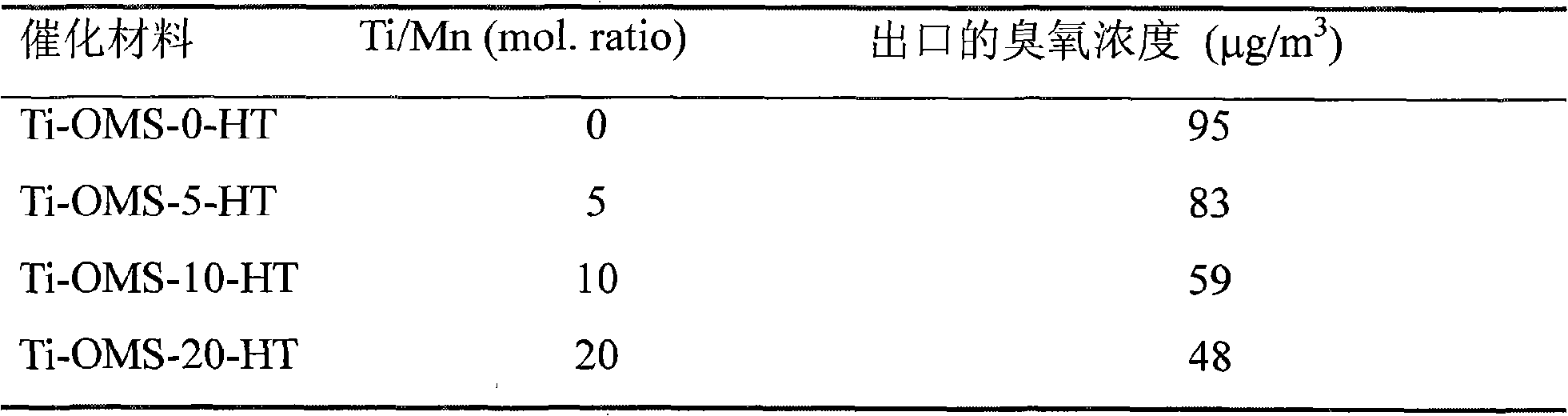

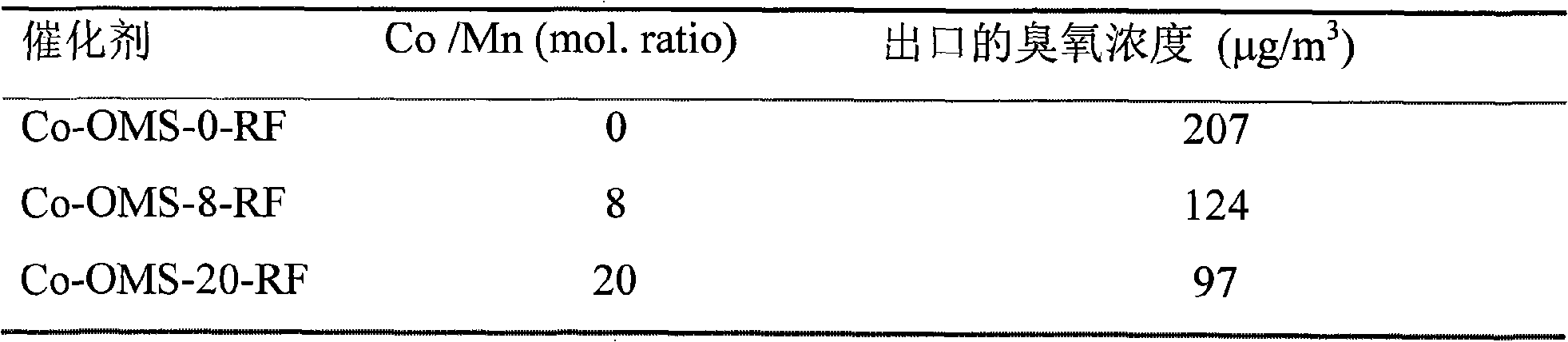

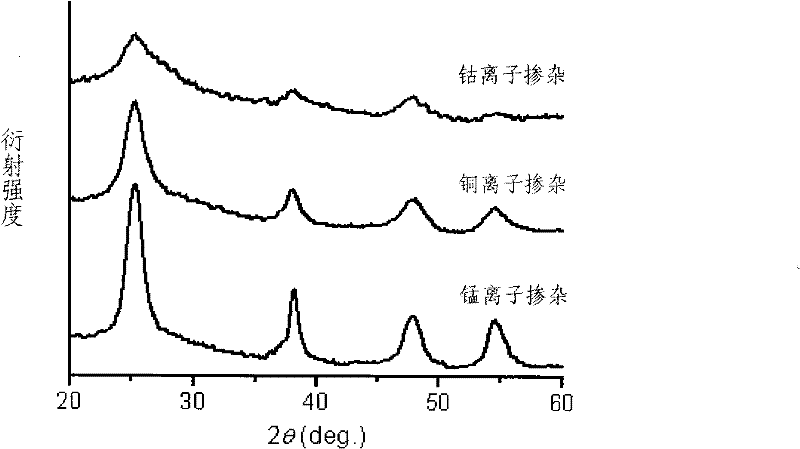

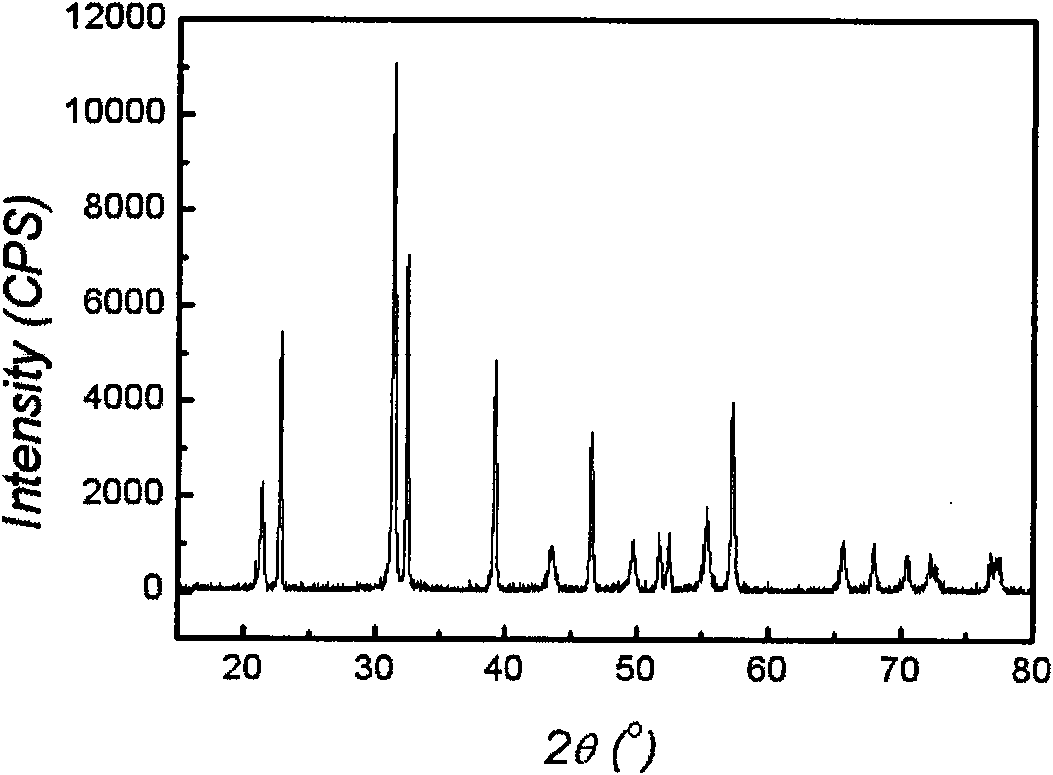

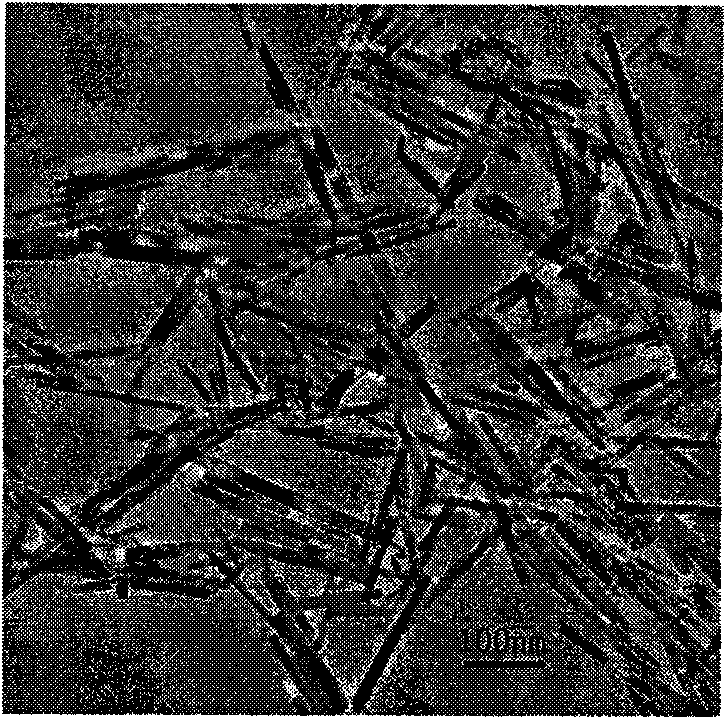

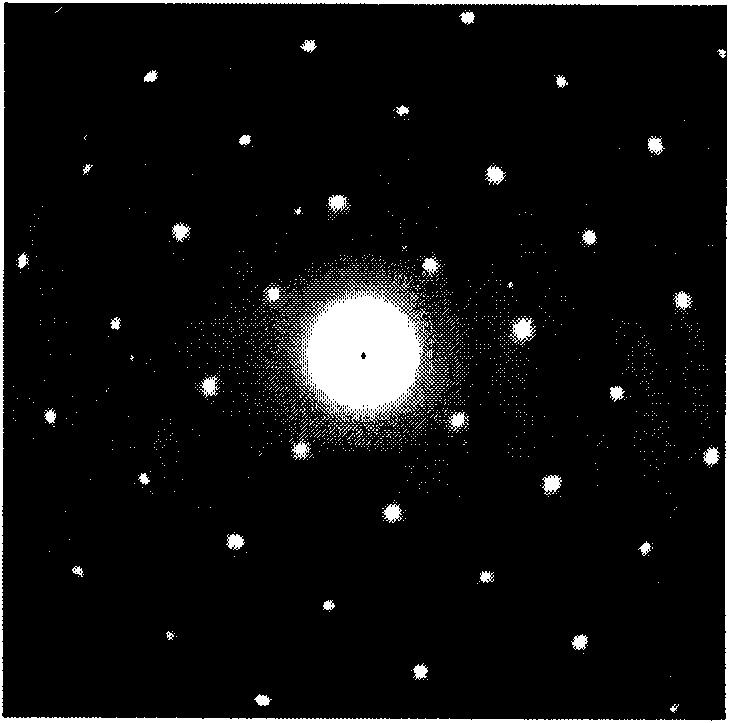

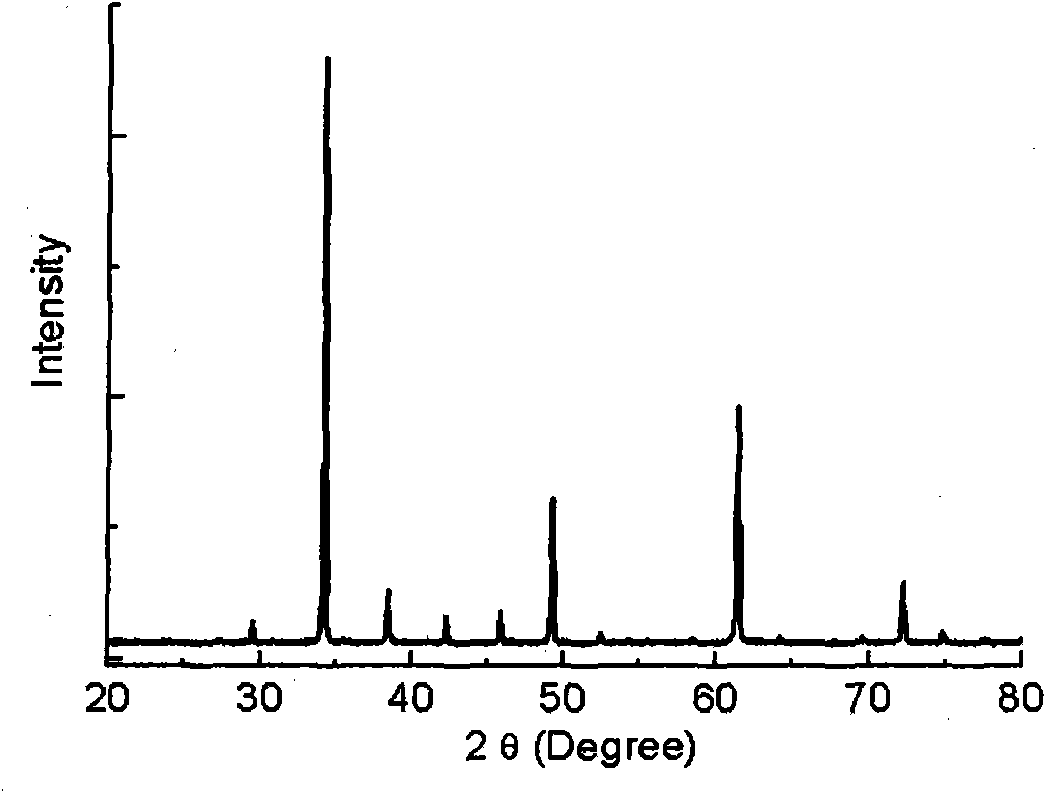

Room-temperature decomposition ozone catalysis material and preparation method thereof

InactiveCN101357331AImprove moisture resistanceImprove processing efficiencyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAir volumeDecomposition

The invention discloses a manganese oxide molecular sieve-doped monolithic catalyst for decomposing ozone (O3) at room temperature and a preparation method thereof, which relates to the fields of catalysis and environmental protection. The preparation method is characterized in that a ceramic honeycomb monolithic type or porous foam metal carrier is adopted, and the manganese oxide molecular sieve doped with cobalt or titanium is taken as an active component. The manganese oxide molecular sieve doped with the cobalt or titanium is characterized in that: 1) the manganese oxide molecular sieve has Hollandite-typed manganese oxide octahedral molecular sieves (OMS-2) structure, the pore size is about 0.46nm multiplied by 0.46nm; 2) cobalt or titanium ions are introduced on a framework of the Hollandite-typed manganese oxide octahedral molecular sieves to form the manganese oxide molecular sieve doped with cobalt or titanium. An ozone decomposition catalyst is prepared by an oxidation reduction-refluxing method or an oxidation reduction-hydrothermal synthesis method, namely, the solution with manganese salt and cobalt salt or titanium salt is added with a strong oxidizer to synthesize the ozone decomposition catalyst by refluxing at the temperature of 90-200 DEG or hydrothermal process for more than 12 hours. The monolithic catalyst is characterized in that the input of additional energy sources such as light, heat, electricity, and the like, is unnecessary, and the ozone can be stably decomposed into oxygen under the conditions of normal temperature, normal humidity and large air volume.

Owner:李永刚

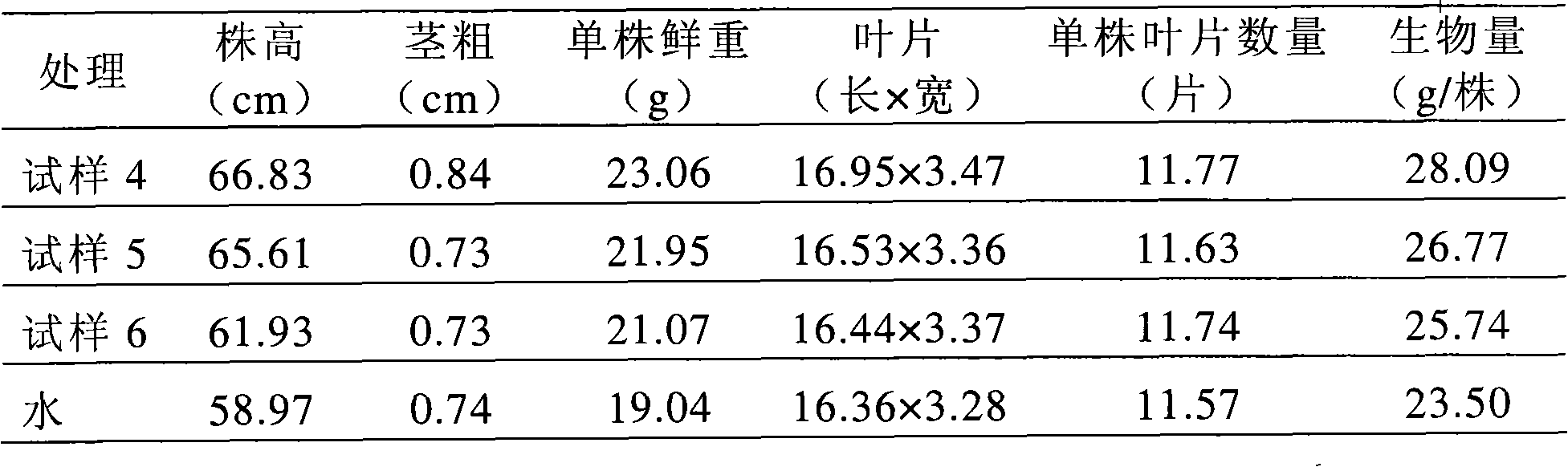

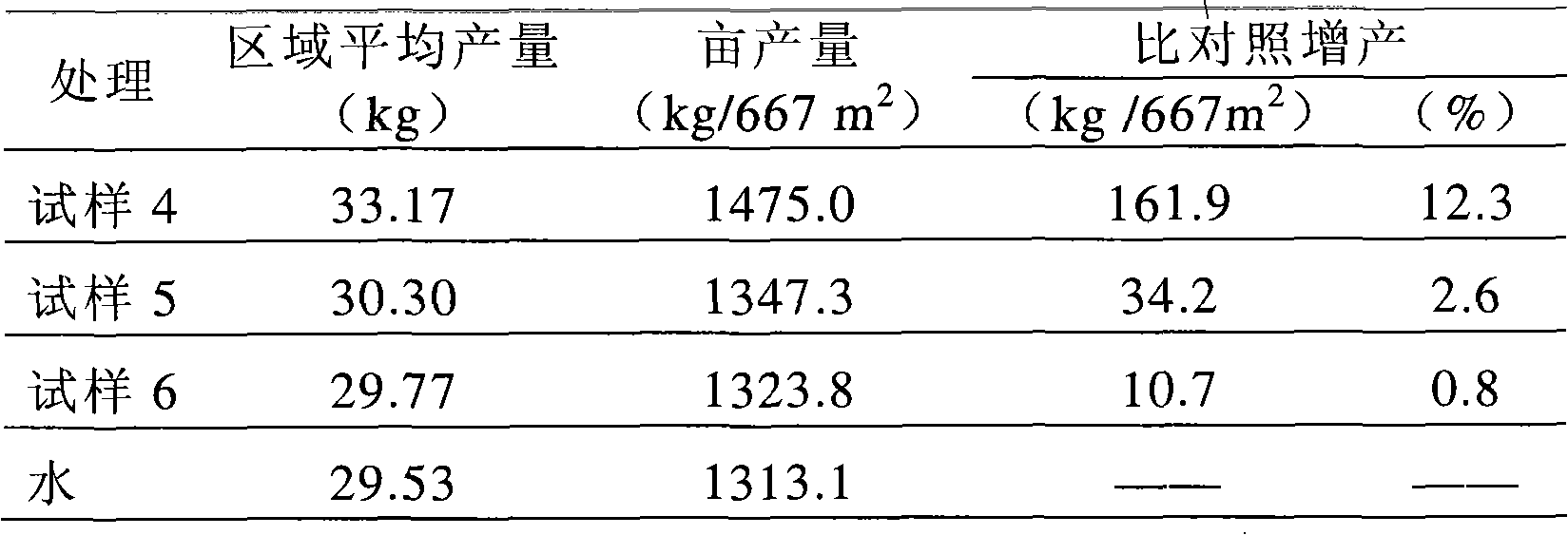

Titanium-complex-containing liquid fertilizer, preparation method thereof, and solid fertilizer containing the same

The invention relates to a preparation method of a titanium-complex-containing liquid fertilizer, which comprises the following steps: 1) dissolving titanyl sulfate or titanium sulfate in water; 2) adding a ligand A; 3) adding a ligand B; and 4) aging, wherein the ligand A and the ligand B are independently selected from tartaric acid, citric acid, malic acid, mandelic acid and lactic acid, and the ligand A and the ligand B are different; the ligand A, the ligand B and Ti (IV) meet the following relationship: 2 <= (the total mole number of the ligand A and the ligand B): the mole number of Ti (IV) <= 12. The invention also relates to the liquid fertilizer prepared by the method, and a solid fertilizer containing the liquid fertilizer. The titanium-complex-containing liquid fertilizer uses few ligands, has higher stability, and is still clear and transparent when being put for more than one year, and the concentration of titanium ion in a solution is almost unchanged, so the liquid fertilizer is of an excellent functional fertilizer.

Owner:SINOFERT HOLDINGS +1

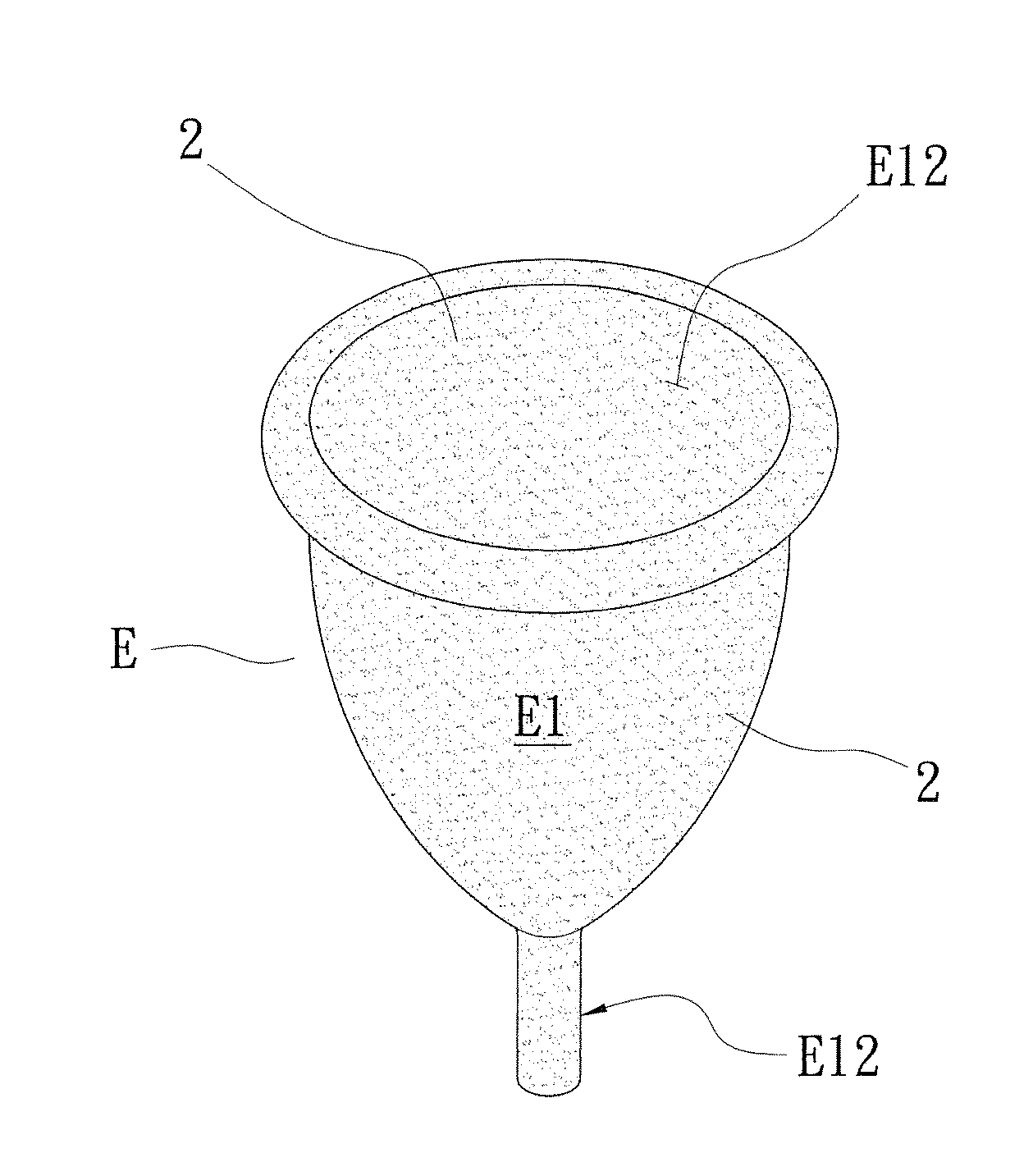

Sanitary product structure for human body with functions of sterilization and deodorization

InactiveUS20150164680A1Improve the bactericidal effectImprove securityNon-surgical orthopedic devicesBaby linensAluminum IonPlatinum

The invention relates to a sanitary product structure for human body with functions of sterilization and deodorization. It comprises a main body and at least one metal ion layer with the functions of sterilization and deodorization. The metal ion layer is at least disposed on the surface of the main body, wherein the metal ion layer is a cover layer composed of germanium ions, molybdenum ions, magnesium ions, manganese ions, chromium ions, vanadium ions, zinc ions, silicon ions, platinum ions, aluminum ions, selenium ions, calcium ions, titanium ions or any combinations thereof. Accordingly, the human body sanitary product has the effects of sterilization and deodorization.

Owner:CHEN TENG LAI

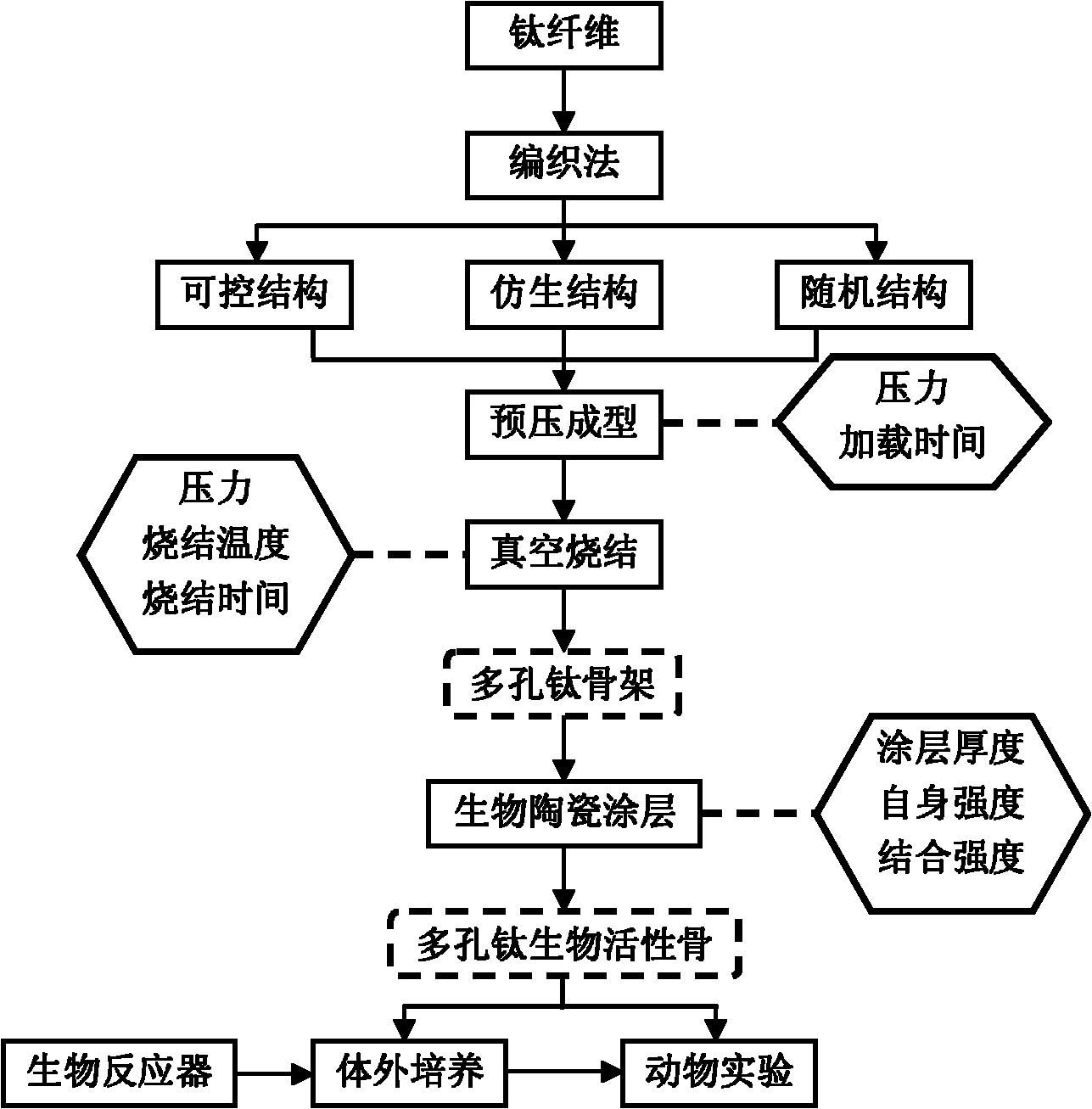

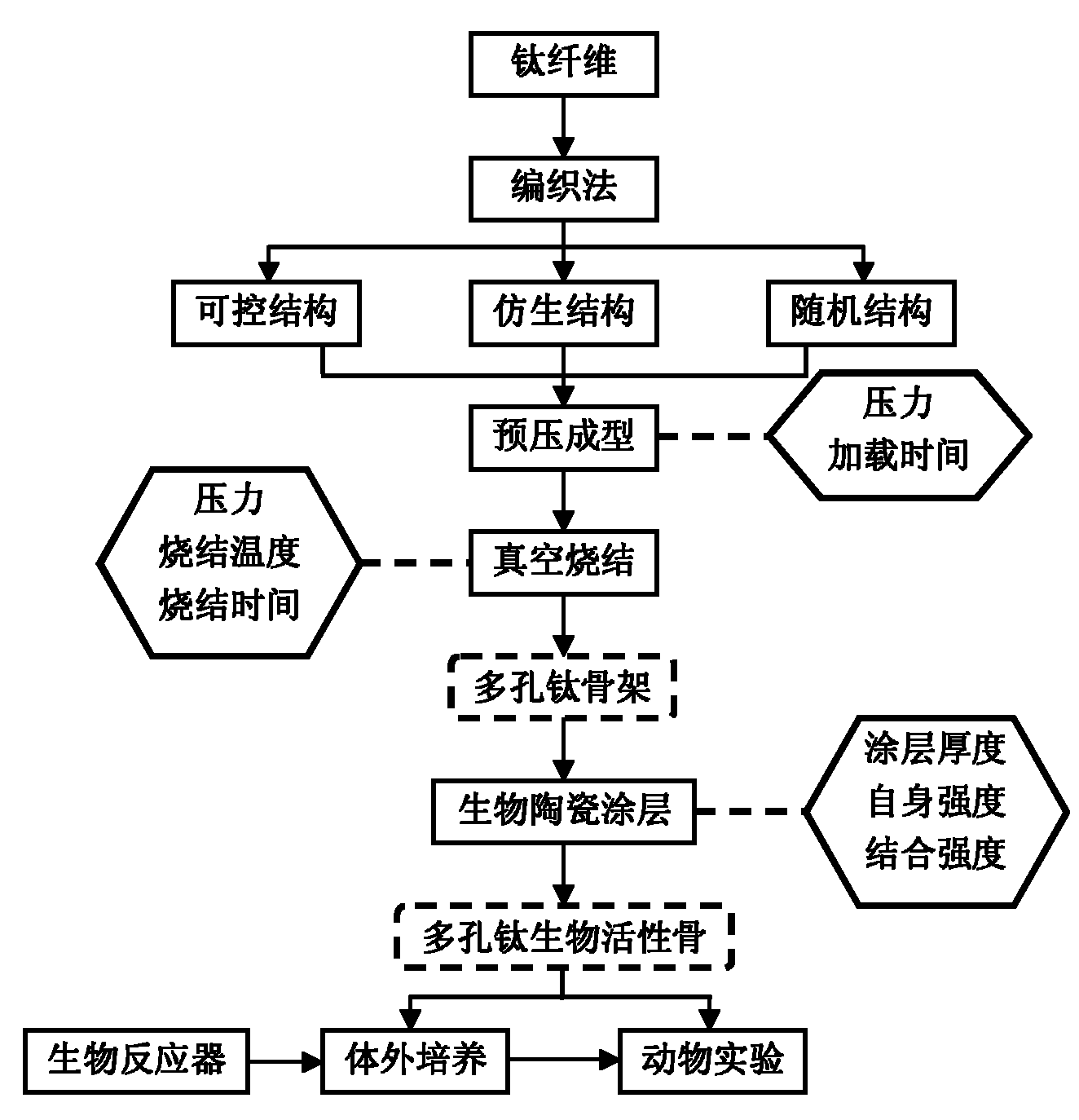

Preparation method of bio-ceramic coating titanium-wire sintering porous titanium artificial bone

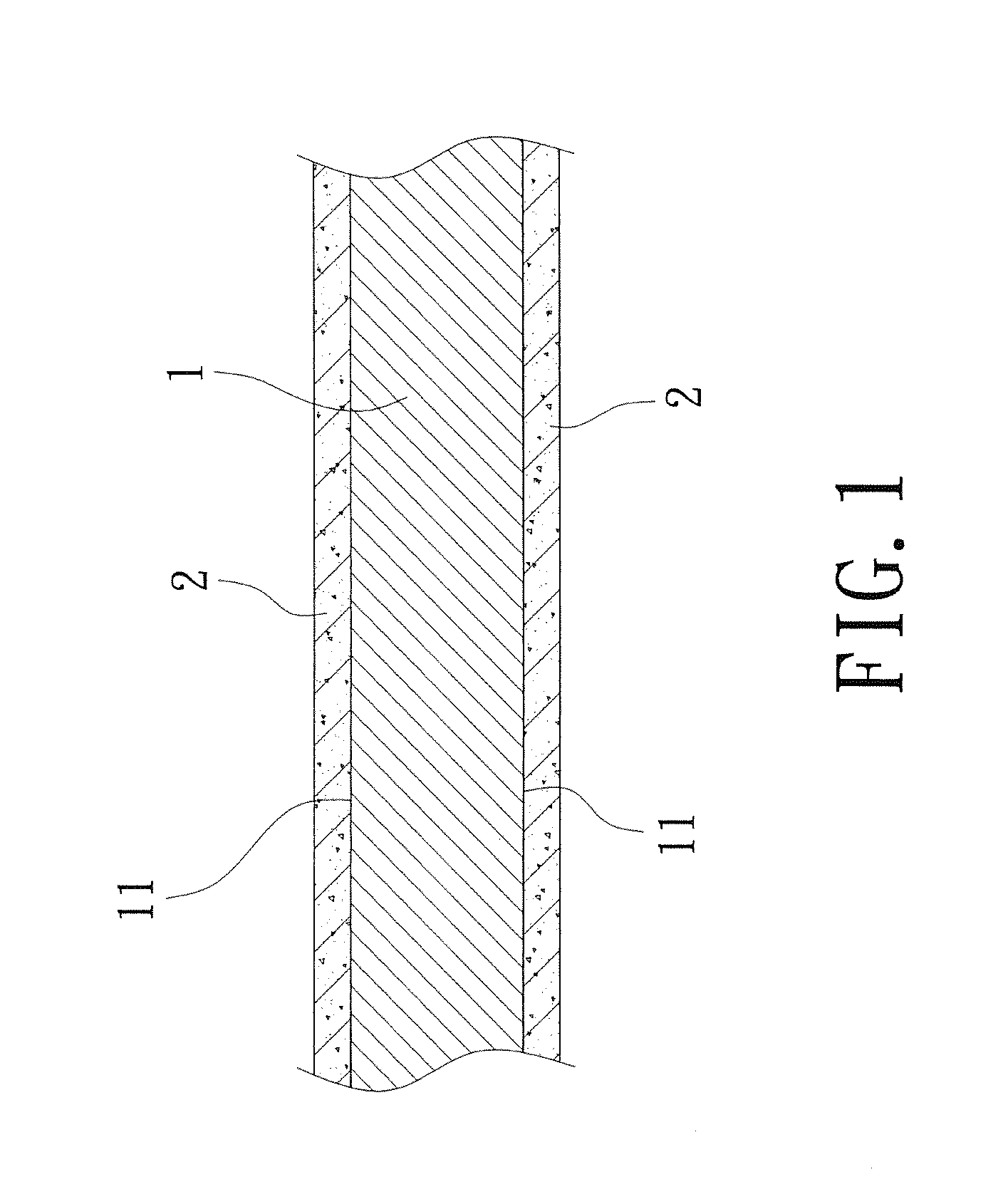

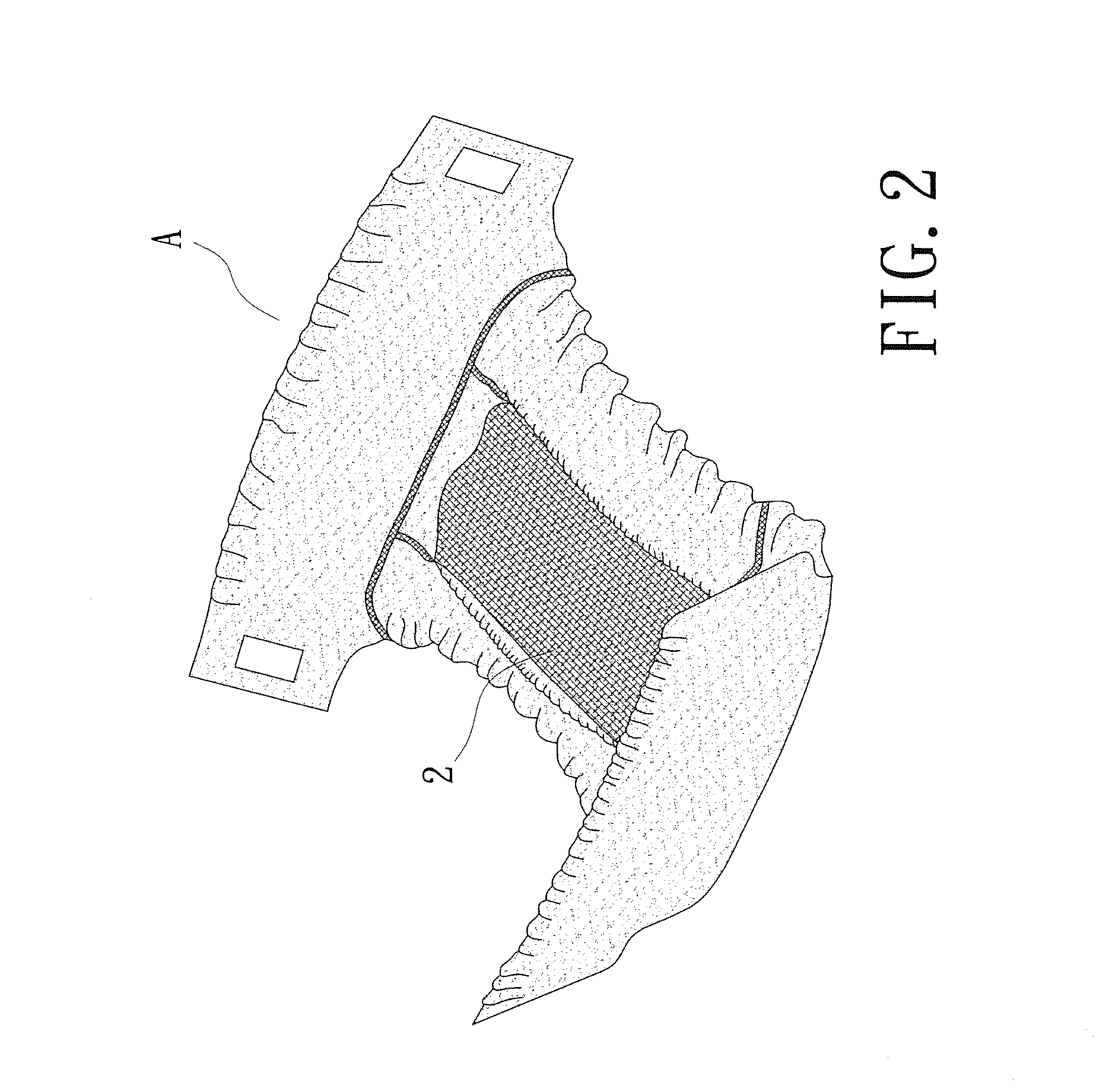

InactiveCN101889912AHave biological propertiesBiologically activeBone implantCoatingsFiberPrincipal stress

The invention discloses a preparation method of a bio-ceramic coating titanium-wire sintering porous titanium artificial bone, belonging to the biomedical engineering field. In the invention, a three-dimensional weaving method is utilized, a titanium metal fiber wire is constructed into a controllable structure model, a random structure model and a bionic structure model which can stimulate the bone trabecula and principal stress line of a human bone, and then is prepared into the porous titanium artificial bone through prepressing molding and vacuum sintering, after that, a sol-gel method is utilized to manufacture a gradient coating or a complex coating on the surface of the porous titanium artificial bone, so that the gradient coating transiting from titanium dioxide to bio-ceramics or the bio-ceramics-titanium dioxide complex coating is formed on the surface of the porous titanium artificial bone to obtain the bio-ceramic coating titanium-wire sintering porous titanium artificial bone. The preparation method not only can protect the titanium metal skeleton and prevent titanium ions from dissociating to enter a human body, but also can ensure that the titanium metal skeleton the surface of which is coated with the bio-ceramics has the biological characteristics, therefore, the bio-ceramic coating titanium-wire sintering porous titanium artificial bone can be applied to repairing clinical segmental defect of long bones.

Owner:SHANGHAI JIAO TONG UNIV

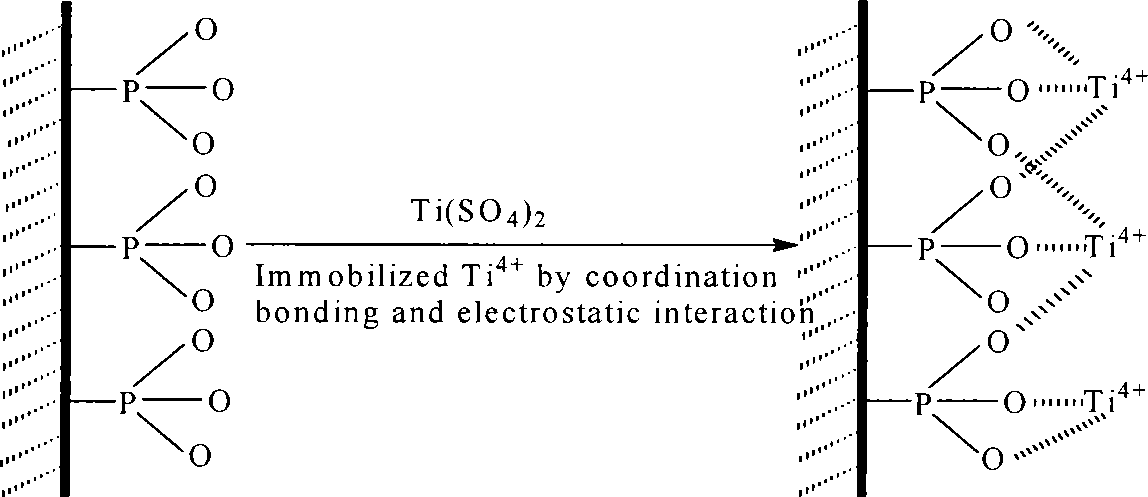

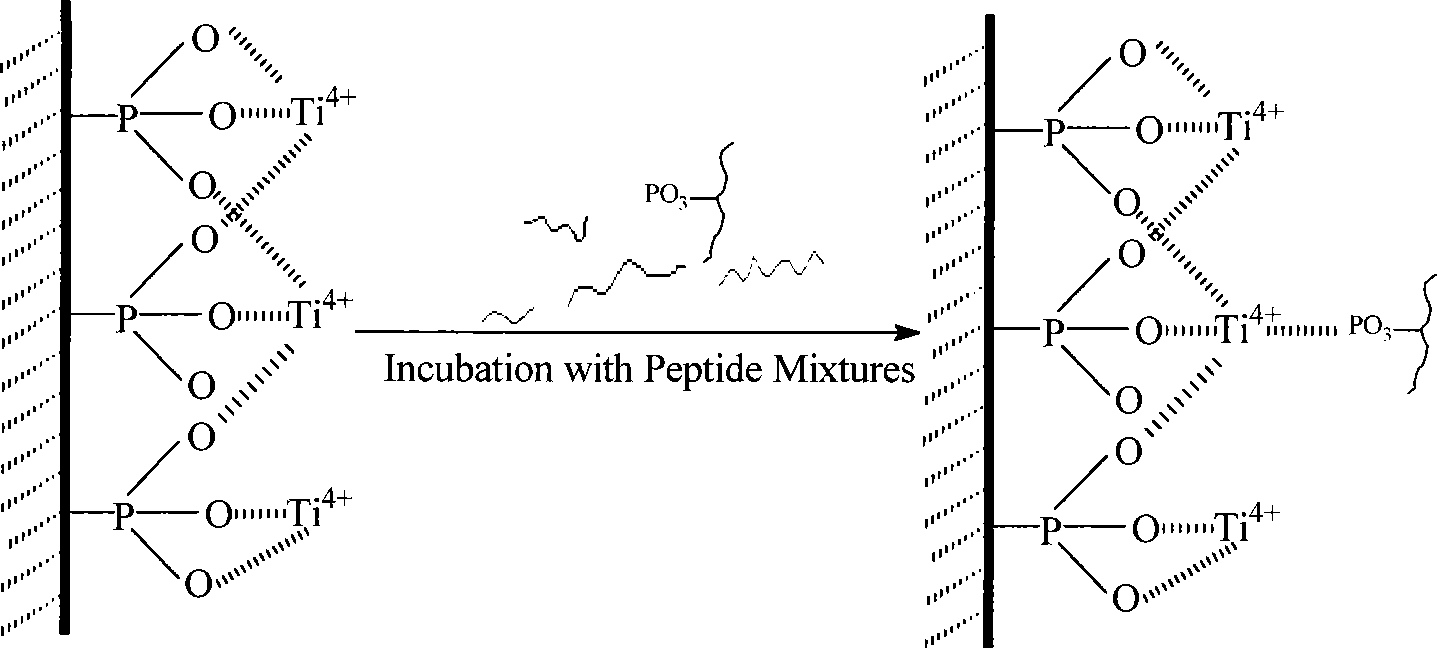

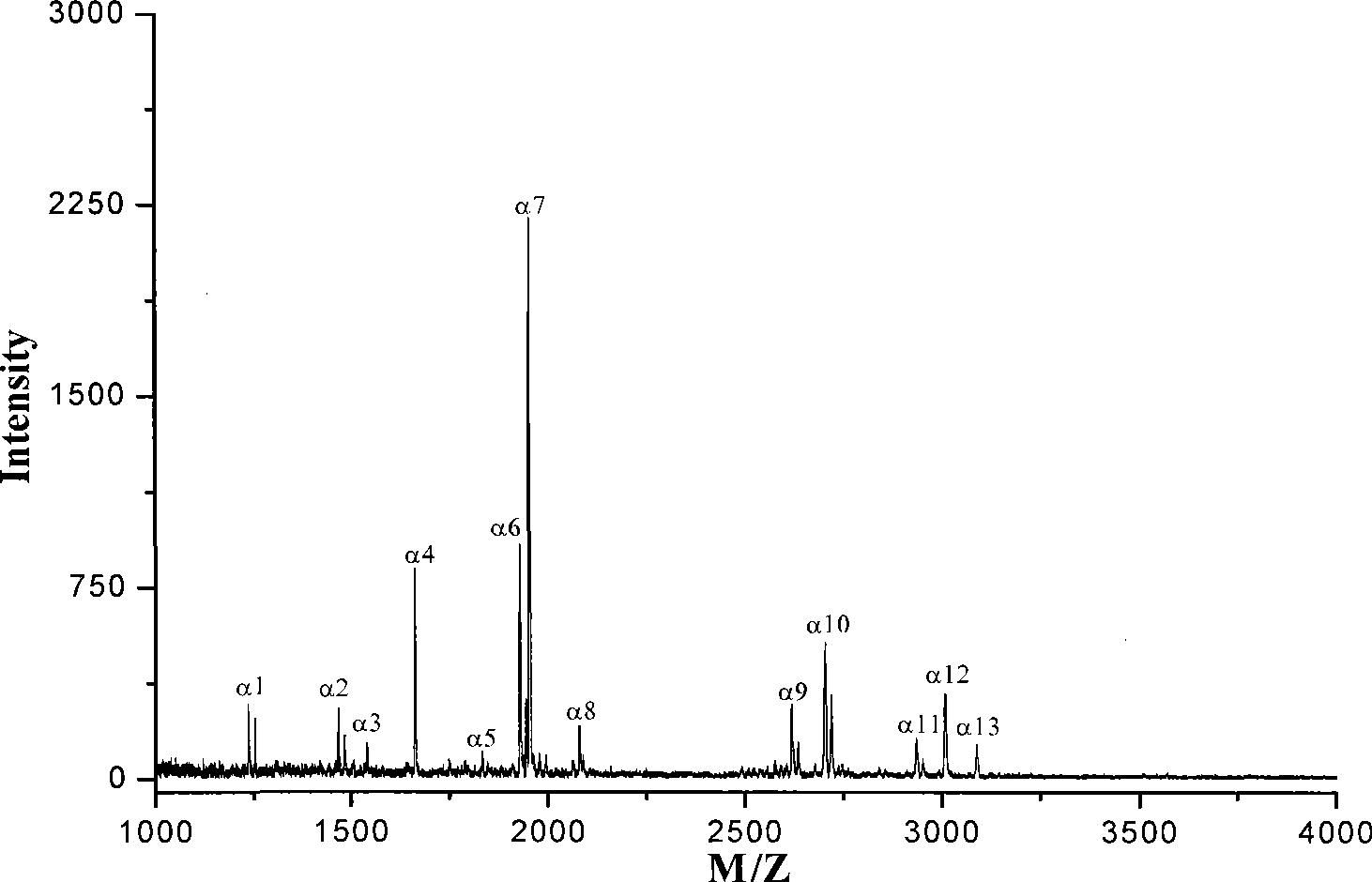

Titanium ion fixation affinity chromatography material and preparation and use thereof

ActiveCN101396650AStrong specificityImprove featuresOther chemical processesSolid sorbent liquid separationTitanium ionPhosphoric acid

The invention provides a fixed titanium ion affinity chromatographic material and the preparation and the application thereof. The strong mutual action between a titanium ion and a phosphate group on a phosphoric acid modified solid phase carrier is used for fixing the titanium ion on the carrier. The fixed titanium ion affinity chromatographic material which is enriched in phosphopeptide is used by the invention. Due to the strong chelating function between the fixed titanium ion and the phosphopeptide, the phosphopeptide is kept on the affinity chromatographic material to be separated from the fixed titanium ion.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

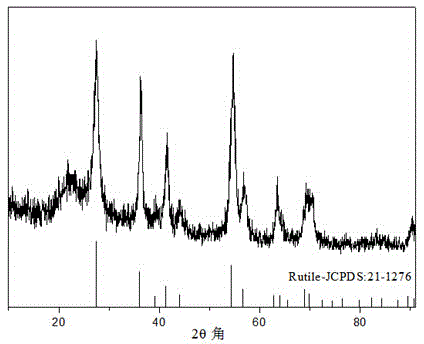

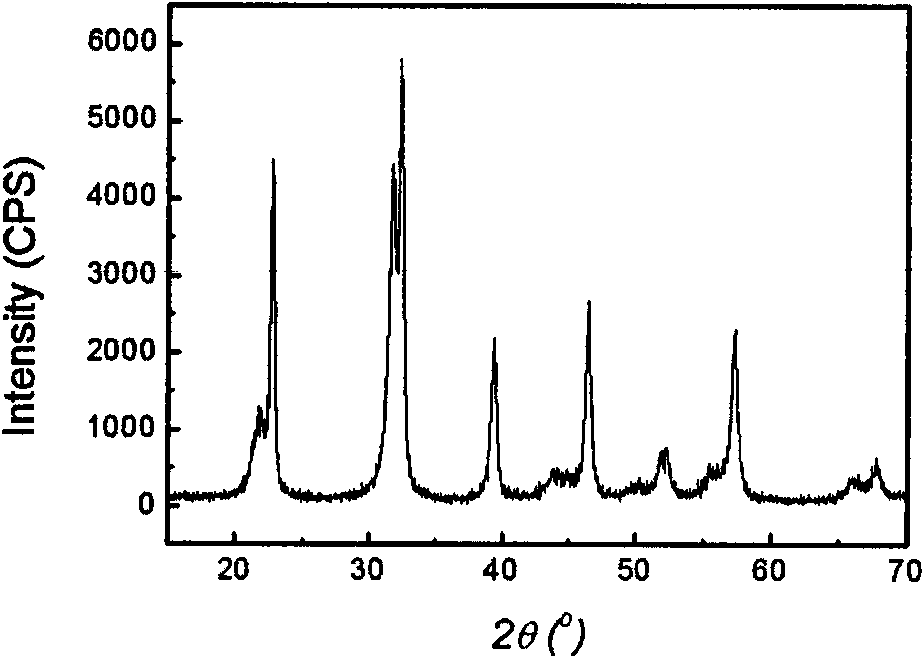

Method for hydrothermal method preparation of graphene-loaded flower-type titanium dioxide composite material

The invention discloses a method for hydrothermal method preparation of a graphene-loaded flower-type titanium dioxide composite material and belongs to the technical field of composite materials. The method utilizes graphite oxide and a titanium salt as precursors, a low carbon alcohol-water mixed solvent as a medium and a surfactant as a soft template and comprises carrying out functionalization modification on the graphite oxide, adding an acid solution of the titanium salt into the modified graphite oxide, carrying out stirring so that the titanium ions are combined to the functionalized graphite oxide, adding the functionalized graphite oxide into a reactor, and carrying out a hydro-thermal reaction process so that the graphene-loaded flower-type titanium dioxide composite material is prepared by one step. The graphene-loaded flower-type titanium dioxide composite material comprises a rutile phase titanium dioxide nanometer rod-assembled flower-type structure with nanometer rod diameters of 15-35nm on the graphene surface, and through graphene connection, the structure has high specific surface area and can promote electron transmission on the material. Therefore, the graphene-loaded flower-type titanium dioxide composite material has good application prospects in the fields of photocatalysis, solar cells and gas-sensitive sensors.

Owner:NORTHWEST NORMAL UNIVERSITY

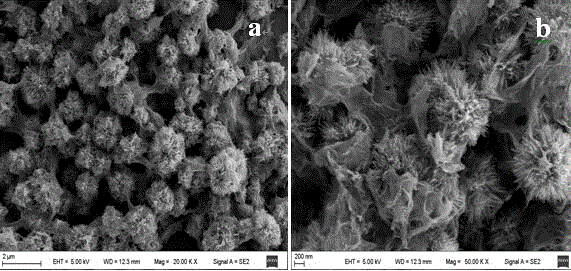

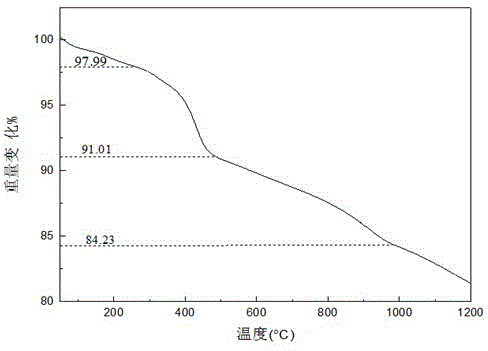

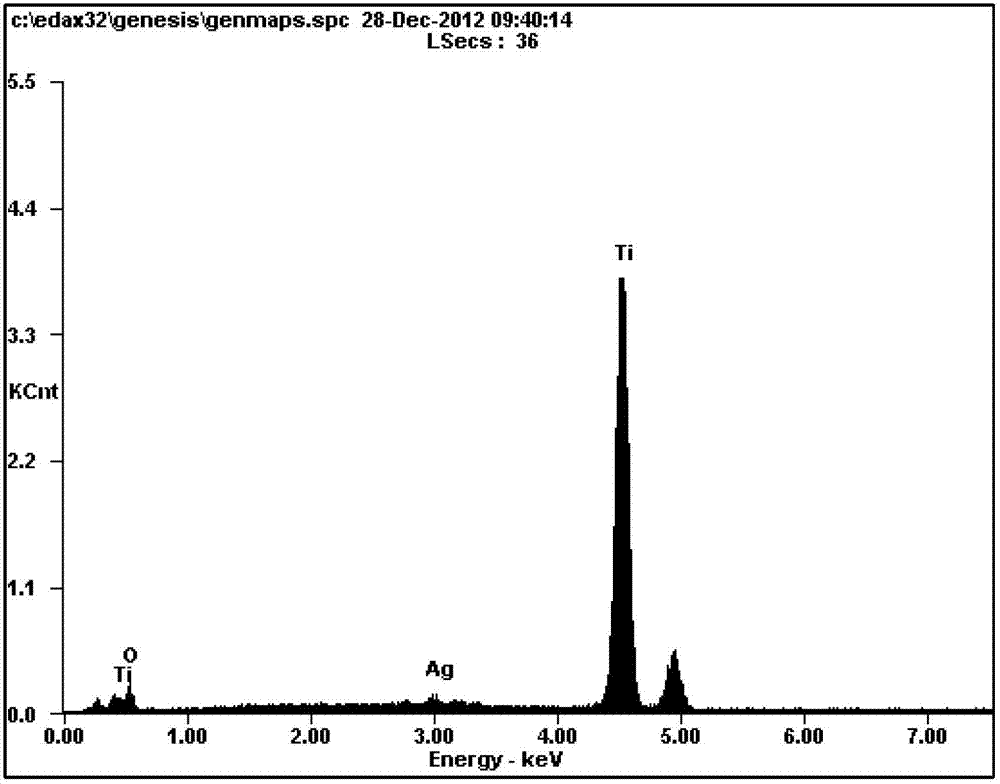

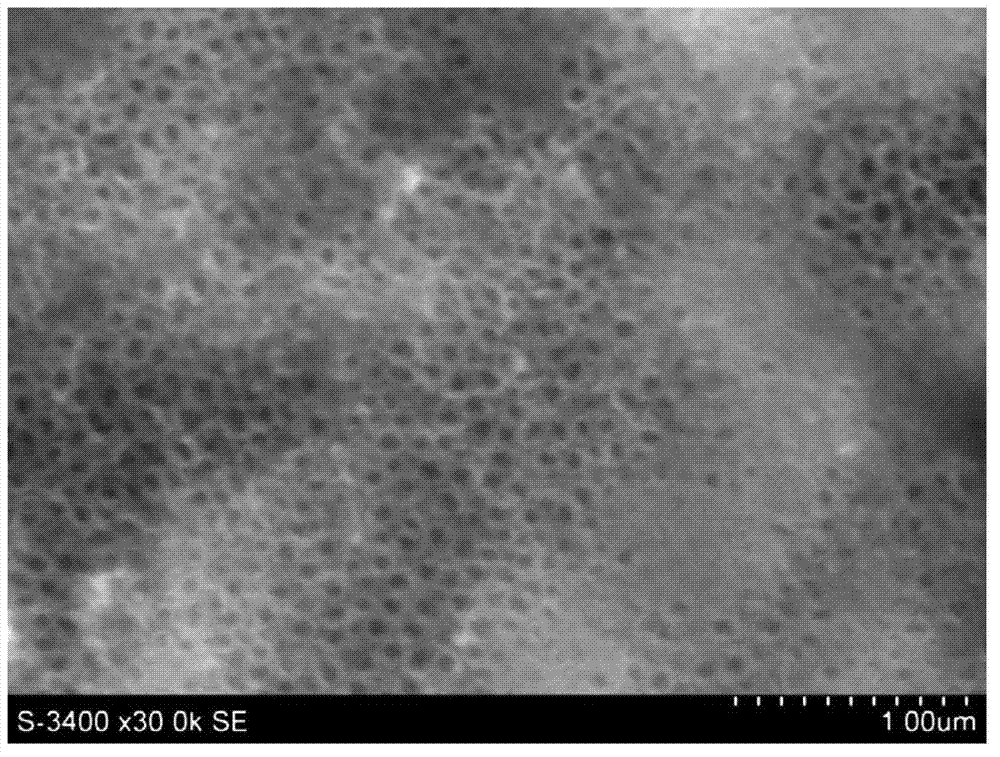

Method for preparing antibacterial active titanium oxide nanotube array composite coating material

InactiveCN103110981AAvoid dissociationLong-term antimicrobial stabilitySurface reaction electrolytic coatingLiquid/solution decomposition chemical coatingTio2 nanotubeElectrolysis

The invention discloses a method for preparing an antibacterial active titanium oxide nanotube array composite coating material. The method comprises the following steps of: performing electrolytic oxidation to prepare a titanium oxide nanotube array with biological activity by taking titanium and an alloy thereof as an anode, taking an electrolyte solution containing phosphate anion and fluorinion as electrolyte; soaking the titanium oxide nanotube array with biological activity in the solution of silver nitrate and polyethylene glycol which are taken as a soaking solution, taking the titanium oxide nanotube array out, inducing the light in the active titanium oxide nanotube array to deposit silver particles through UV-irradiation, and obtaining the titanium oxide nanotube array composite coating material with the antibacterial property and biological activity. According to the material prepared by the method, the silver particles enter the titanium alloy or a titanium alloy matrix, and the material has long-term antibacterial stability; the thickness of the active titanium oxide nanotube array can be controlled in a range from 100 to 1000nm, and bone cell growth and nutrition transfer are promoted; the active titanium oxide generated through anodic oxidation can prevent release of titanium ion in the matrix, and the corrosion resistance of the matrix is improved; and moreover, the coating material has obvious biological activity and can induce bone apatite formation.

Owner:INNER MONGOLIA METAL MATERIAL RES INST

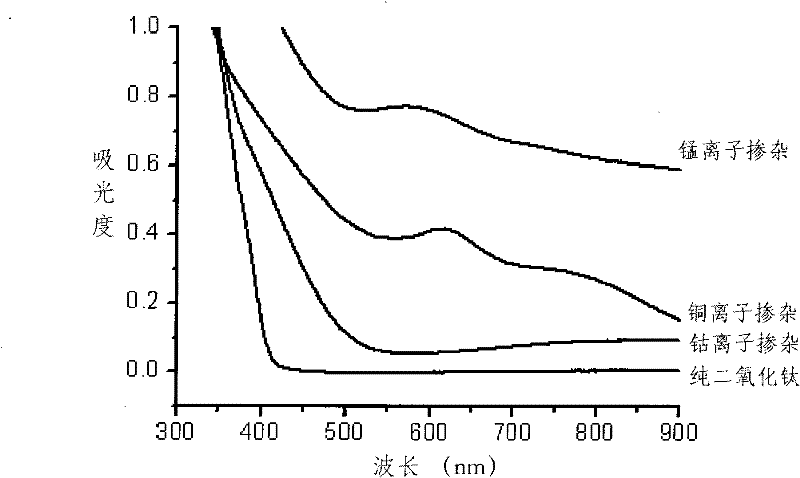

Preparation method of titanium dioxide transparent aqueous sol doped with metal ions

PendingCN102295310AImprove photocatalytic efficiencySolve pollutionTitanium dioxideMetal/metal-oxides/metal-hydroxide catalystsTitanium metalHYDROSOL

The invention relates to a class of titanium dioxide photocatalysts, in particular to a low-temperature preparation method of visible light-responsive titanium dioxide transparent aqueous sol doped with metal ions. The titanium inorganic salt and the metal inorganic salt as a dopant are dissolved in water together to form a mixed solution; wherein, the molar ratio of the metal ion in the metal inorganic salt as a dopant to the titanium ion in the titanium inorganic salt is 0.001~ 0.2; then dropwise add inorganic lye until the pH of the mixed solution is about 7-11 to obtain a composite titanic acid precipitate, wash the composite titanic acid precipitate with water and filter, then disperse with hydrogen peroxide aqueous solution, at a temperature of 50-100 Heating at ℃ for 1-24 hours to obtain a transparent aqueous sol of titanium dioxide doped with metal ions. The low-temperature preparation method of the metal ion-doped titanium dioxide transparent water-based sol avoids the problem of environmental pollution, and the obtained sol is transparent, neutral and water-based, and has good photocatalytic effect under visible light.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

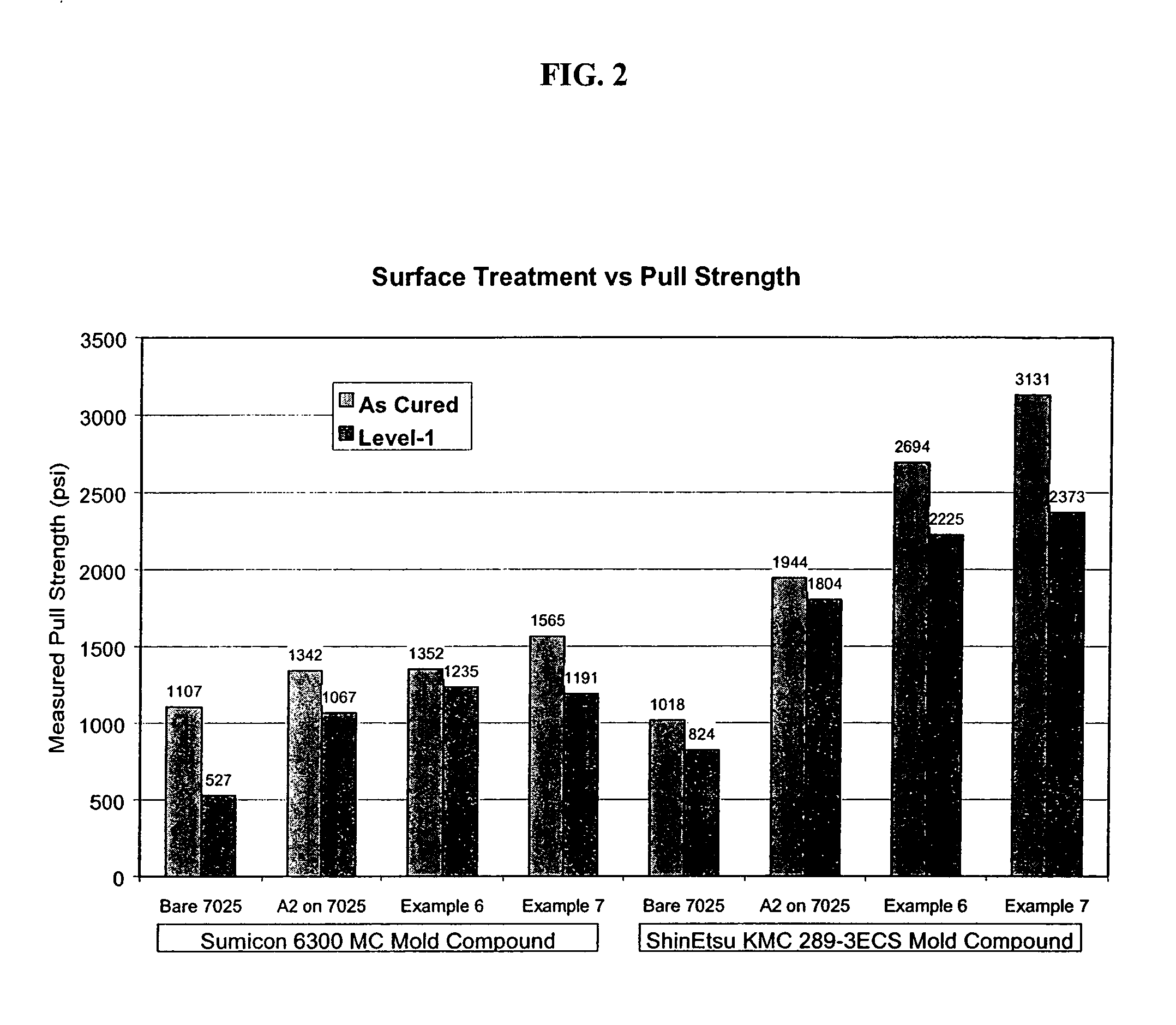

Method of treating surface of metal base metallic material treated by the surface treatment method and method of coating the metallic material

ActiveUS20100170594A1Lower electrical resistivityImprove uniformityElectrolytic inorganic material coatingDuplicating/marking methodsAdhesiveMetallic materials

A metal surface treatment method for a metal base material in order to improve the uniformity of a cathodic electrodeposition coating film, the method including: a surface treatment step for forming a chemical conversion film on a metal base material by contacting the metal base material with a metal surface treatment composition including zirconium and / or titanium ions and an adhesive imparting agent characterized in being at least one selected from the group consisting of (A) silicon-containing compound, (B) adhesive imparting metal ion, and (C) adhesive imparting resin; and a heating / drying step to heat and dry the metal base material, on which the chemical conversion film is formed, at 60° C. to 190° C. for at least 30 seconds.

Owner:CHEMETALLGMBH

Preparation method for lithium titanate and graphene composite electrode materials

ActiveCN102569769AHigh rate charge and discharge performance is goodImprove electronic conductanceCell electrodesActive agentIonic conductance

A preparation method for lithium titanate and graphene composite electrode materials comprises the following steps: solution A containing lithium ion is prepared by dissolving surface-active agent, template agent and lithium compound into deionized water; titanium compound is added into graphene solution with the concentration of 0.1 to 0.5 g / l, and solution B containing titanium ions is prepared through ultrasound and stirring; under the effect of ultrasonic wave field, the solution A is added into the solution B, then bonding agent is added, and solution C is prepared; the solution C is moved into a polytetrafluoroethylene reaction kettle, and reaction is performed under 140 to 200 DEG C; then leaching, washing and drying to the solution are performed, and eventually, composite products are produced under the atmosphere of argon gas. The lithium titanate in the composite product is nanosheet lithium titanate, can be fully mixed and contacted with the sheet graphene, and the electric conductance and ion electric conductance of the lithium titanate material are improved greatly; and the composite product is classified as electrode material with excellent and high rate charge-discharge performance.

Owner:深圳石墨烯创新中心有限公司

Method for preparing mesoporous titanium silicate molecular sieve

InactiveCN101456562ALarge specific surface areaHigh porosityCrystalline aluminosilicate zeolitesFiltrationMesoporous material

The invention relates to a method for preparing mesoporous titanium silicon molecular sieves, which belongs to the technical field of preparation of mesoporous molecular sieve catalytic materials. The method comprises: adopting a cationic surfactant as a template agent, dispersing the cationic surfactant into deionized water, adding ammonia water to adjust the pH value of the solution, and adding silicon sources after the template agent is completely dissolved; making the materials undergo filtration, washing, drying and roasting, removing the organic template agent, and obtaining silicon dioxide mesoporous materials; and dispersing the obtained silicon dioxide mesoporous materials into ethanol, slowly adding titanium sources, loading titanium ions after hydrolysis of the titanium sources on the silicon dioxide mesoporous molecular sieves to form an active center, and obtaining titanium-loaded mesoporous molecular sieves. The reaction is easy to control, and the product has good repeatability and is suitable for mass production. By adoption of the prepared titanium silicon molecular sieves as a catalyst and hydrogen peroxide as an oxygen source to catalyze olefin epoxidation and alcohol oxidation, the reaction conditions are mild and the reaction has good selectivity and conversion rate.

Owner:UNIV OF SCI & TECH BEIJING

Chromium-free antitarnish adhesion promoting treatment composition

InactiveUS20050121330A1Improve adhesionAnodisationInsulating substrate metal adhesion improvementChromium freeIndium

The present invention is directed to an aqueous, antitarnish and adhesion promoting treatment composition, comprising: zinc ions; metal ions selected from the group consisting of tungsten ions, molybdenum ions, cobalt ions, nickel ions, zirconium ions, titanium ions, manganese ions, vanadium ions, iron ions, tin ions, indium ions, silver ions, and combinations thereof; and optionally, an electrolyte that does not contain potassium or sodium ions; wherein the treatment composition is substantially free of chromium, and wherein the treatment composition forms a coating on a substrate or material that enhances adhesion of a polymer to the material. The present invention is also directed to materials coated with the above treatment composition, and methods of coating materials using the above composition.

Owner:HOWELL LEONARD R +1

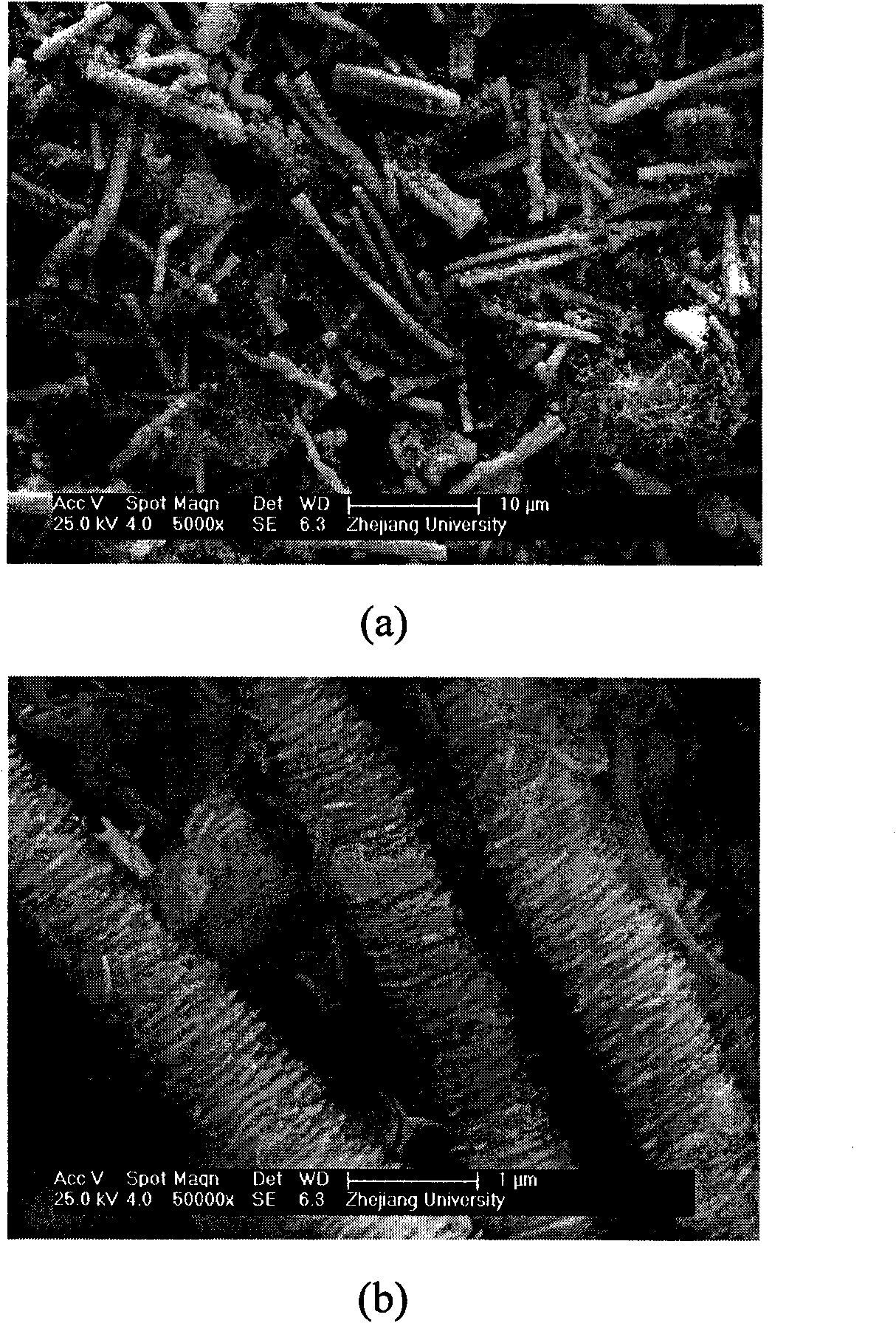

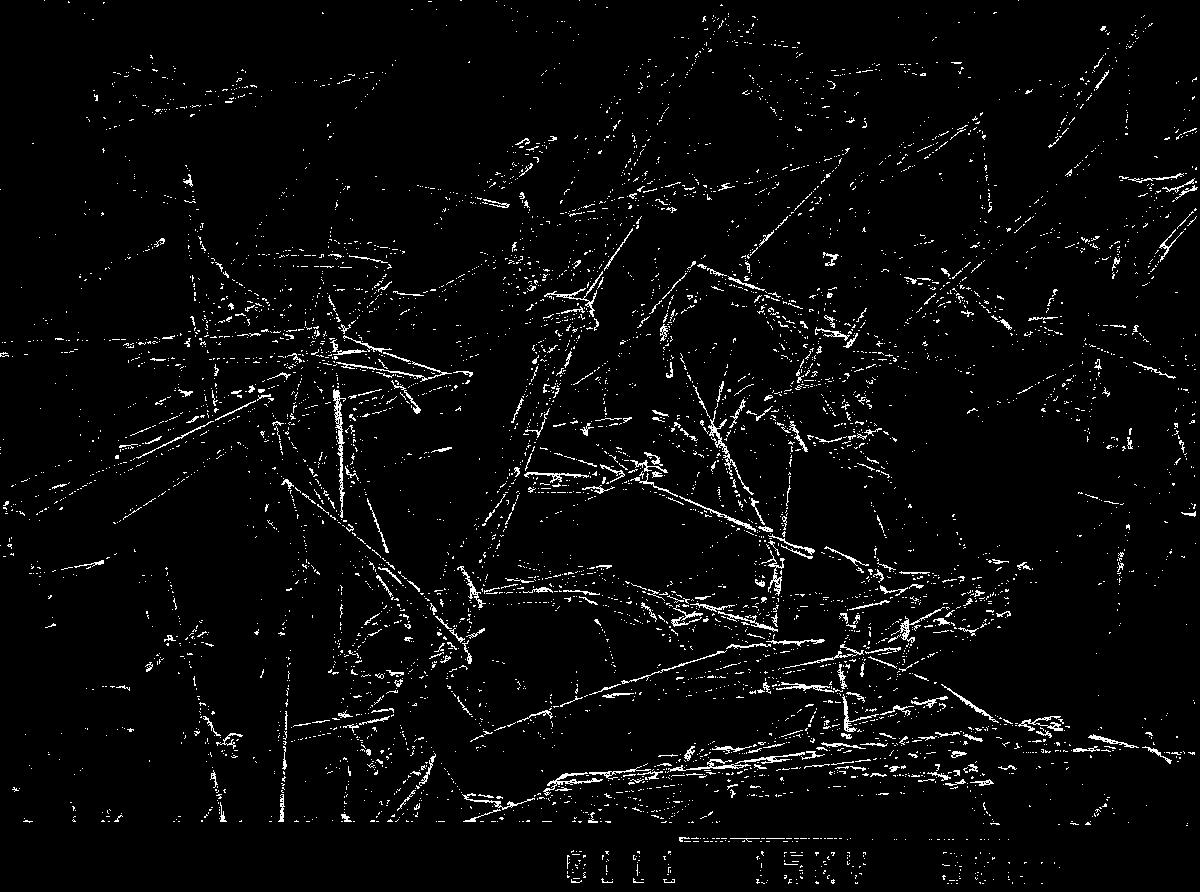

Method for preparing perovskite structure lead titanate monocrystal nano rod

InactiveCN101619494ASimple processEasy to controlPolycrystalline material growthFrom normal temperature solutionsLead nitratePotassium hydroxide

The invention relates to a method for preparing a perovskite structure lead titanate monocrystal nano rod. A titanium and lead oxyhydroxide mixed sediment for hydrothermal reaction is prepared by a two-step precipitation method. The method comprises the following steps: taking titanium sulfate as a raw material for precipitating titanium, taking lead nitrate as a raw material for precipitating lead and taking potassium hydroxide as a precipitating agent; precipitating titanium ions; precipitating lead ions; after the product is filtered and washed, obtaining the mixed sediment containing the titanium ions and the lead ions; mixing and dispersing the mixed sediment and the potassium hydroxide in deionized water; sealing the mixture in a reaction kettle; and carrying out hydro-thermal treatment at 160-240 DEG C for 5-48 hours to obtain the perovskite structure lead titanate monocrystal nano rod. The invention has simple technology process, no pollution and low cost and is easy to control and carry out mass production.

Owner:ZHEJIANG UNIV

Method for preparing titanium dioxide/silicate mineral nano composites

ActiveCN102580713AIncrease the areaImprove adsorption capacityPhysical/chemical process catalystsWater/sewage treatment by irradiationNano compositesDissolution

The invention relates to a method for preparing titanium dioxide / silicate mineral nano composites. The method comprises the following steps of: firstly, adding silicate minerals to a titanium tetrachloride solution to activate the silicate minerals and dissolve foreign ions; secondly, adding a certain alkaline solution to convert titanium ions to titanium dioxide hydrate precipitates and washing off other foreign ions to obtain titanium dioxide hydrate / silicate mineral complex filter cakes; and thirdly, adding the filter cakes to the titanium tetrachloride solution, adopting the acid environment of the titanium tetrachloride solution to realize dissolution of the titanium dioxide hydrates, secondary activation of the silicate minerals and low temperature crystallization and growth of nanotitanium dioxide on the silicate minerals and carrying out filtering, washing, drying and grinding, thus finally preparing the titanium dioxide / silicate mineral nano composites. The method has the following advantages that the method is simple and practical in steps; the reaction conditions are mild; the raw materials are simple and have low cost; and the method is suitable for large-scale production and can be beneficial to effective improvement of the photocatalytic efficiency of titanium dioxide.

Owner:CHANGZHOU UNIV

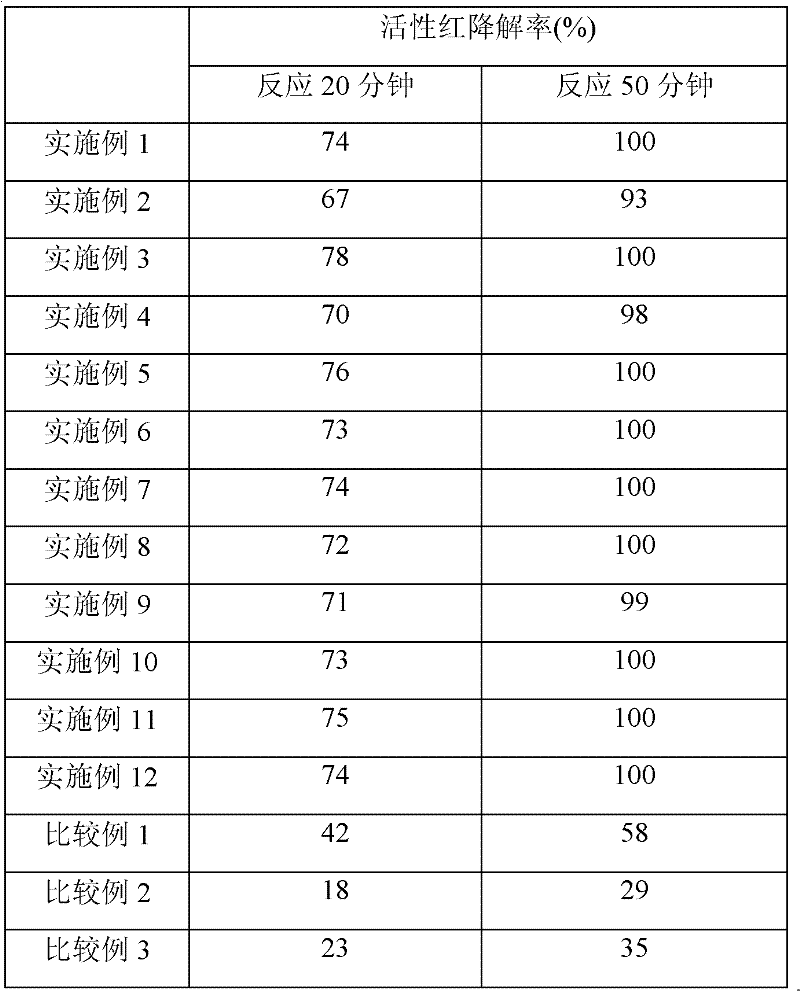

Method for preparing mesoporous crystal titanium dioxide using light-sensitive active matter as formboard

ActiveCN101024169ALarge specific surface areaFacilitated DiffusionPhysical/chemical process catalystsActive matterCarbon nanotube

The invention relates to a mesoporous TiO2 Crystal Preparation method with a photosensitive activity as template, it belongs to chemical engineering technology. Use of titanium alkoxides or ion-containing titanium ions titanate or salts or mixtures of these substances as TiO2 precursor, ethanol or acetone or a mixture of both as the diluents, used ethylene glycol or isopropyl alcohol or a mixture of both as dispersant, used Perylenequinone derivatives or other natural extract with photosensitive activity as the photosensitive activity object; the titanium dioxide precursor hydrolysis and crystal to get the mesoporous TiO2 precursor; mesoporous TiO2 precursor was sintering to get mesoporous TiO2 Crystal with photosensitive activity as template. The mesoporous materials of this invention through sol-gel method and the high-temperature burning, do visible catalyst, or get carbon nm tube by the separation and purification. The invention has low cost of production, product higher catalytic activity, stable performance, simple process.

Owner:YUNNAN UNIV

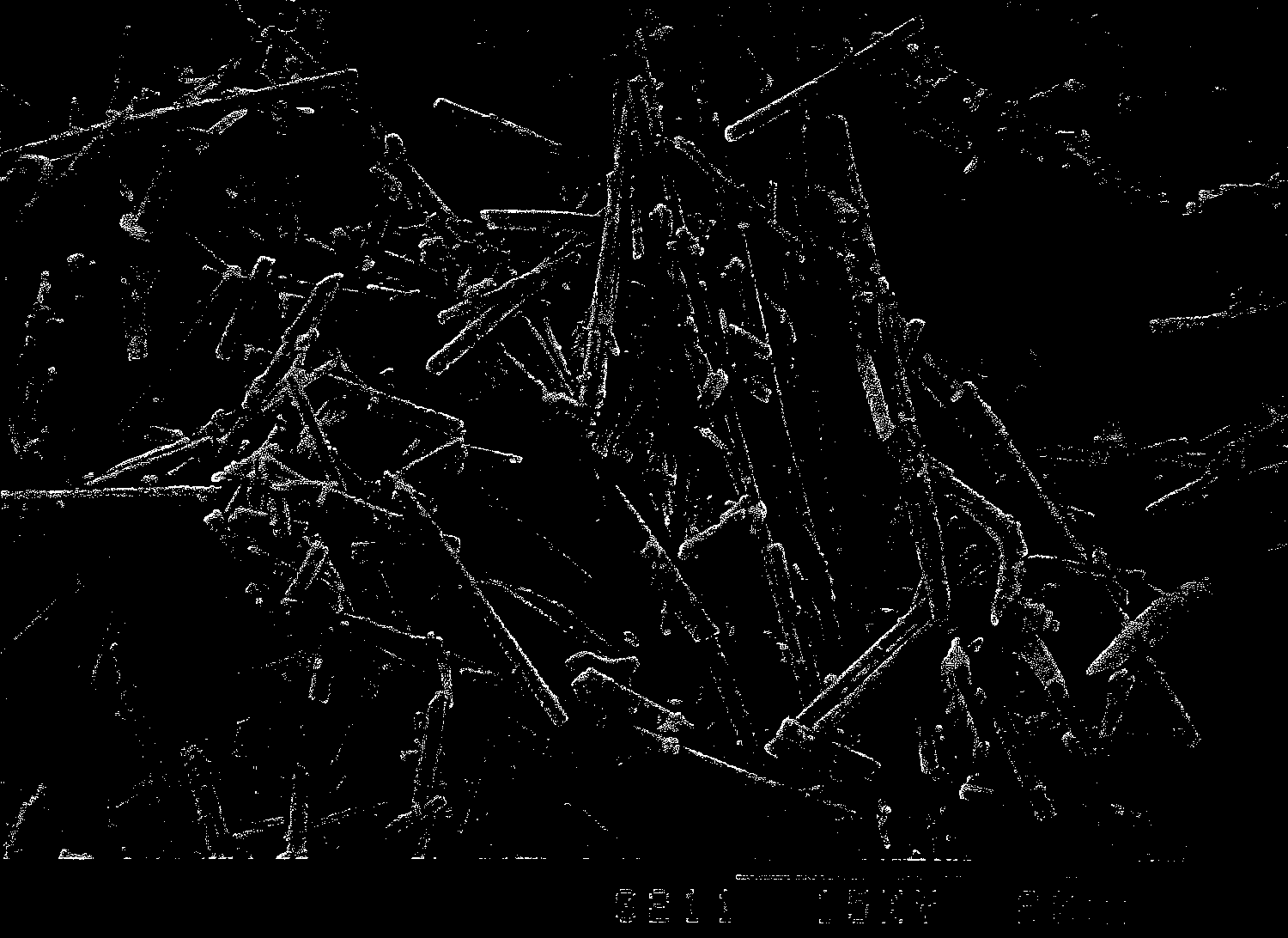

Method for preparing lead titanate nano column automatically assembled by perovskite structure nano pieces

InactiveCN101618889ASimple preparation processEasy to controlTitanium compoundsLead nitrateTitanium ion

The invention relates to a method for preparing a lead titanate nano column automatically assembled by perovskite structure nano pieces. A titanium and lead oxyhydroxide mixed sediment for hydrothermal reaction is prepared by a two-step precipitation method. The method comprises the following steps: hydrolyzing tetrabutyl titanate by ammonia solution to precipitate titanium ions; introducing lead nitrate in the ammonia solution suspended with a titanium oxyhydroxide sediment to precipitate lead ions; after the mixed sediment is filtered and washed, mixing the mixed sediment, potassium hydroxide and deionized water; and carrying out hydro-thermal treatment in a sealed reaction kettle at 160-240 DEG C for 5-48 hours to obtain the lead titanate nano column automatically assembled by the perovskite structure lead titanate nano pieces. The lead titanate nano column is 5-20 microns in length and 0.4-1 micron in diameter, and the perovskite structure lead titanate nano pieces of the lead titanate nano column are 2-10 microns in thickness. The invention has simple technology process, no pollution as well as low cost and is easy to control and carry out mass production.

Owner:ZHEJIANG UNIV

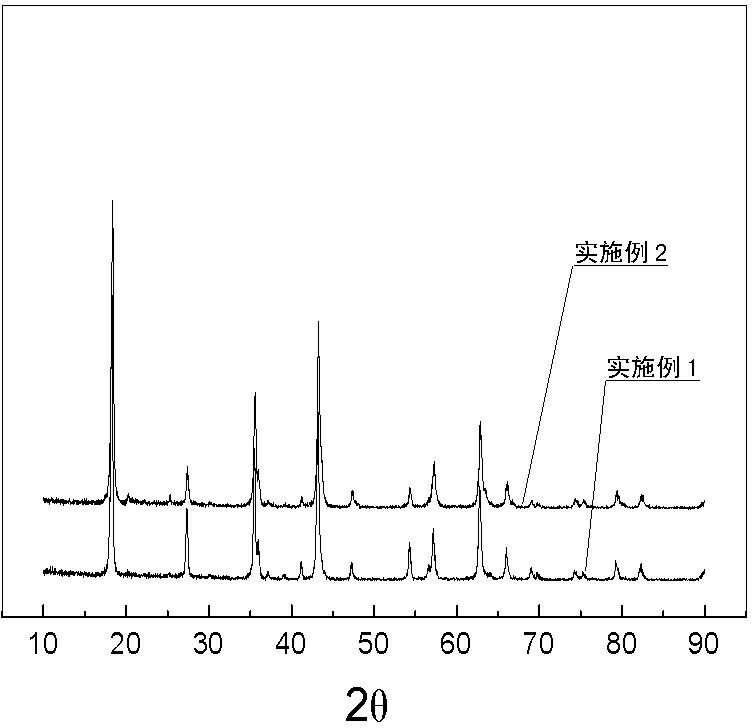

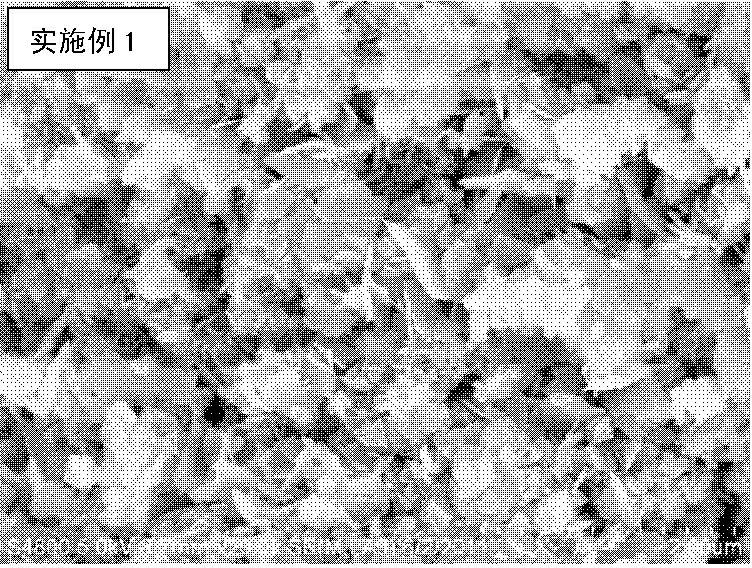

Titanium-doped barium ferrite ceramic material and preparation method thereof

The invention discloses a titanium-doped barium ferrite ceramic material and a preparation method thereof. Densification sintering of the ceramic material is achieved through titanium doping, and electron hopping and a nonuniform conduction structure are formed through the replacement of iron ions to titanium ions. The ceramic has high residual magnetization, and great dielectric constant can be produced by utilizing the nonuniform conduction structure. The preparation method of the titanium-doped barium ferrite ceramic comprises the following steps of: preparing a ceramic precursor through a citrate sol-gel method, and then molding and sintering at high temperature to obtain the titanium-doped barium ferrite ceramic, wherein the molar ratio of titanium to barium is controlled between 0.4 and 0.8; and the molar ratio of iron to barium is between 11.6 and 11.2. According to the titanium-doped barium ferrite ceramic material and preparation method thereof, the process is simple, the cost is low, and meanwhile extremely high dielectric constant, high saturation magnetization and residual magnetization can be obtained. The residual magnetization acts as an important multifunctional material and can be used for developing preparation of relative electronic components.

Owner:ZHEJIANG UNIV

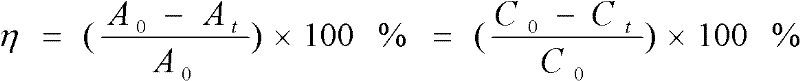

Trivalent titanium ion self-doped titanium dioxide nanosheet catalyst

InactiveCN105664902ACompletely degradedImprove photocatalytic performanceCatalyst activation/preparationPtru catalystTitanium ion

The invention discloses a trivalent titanium ion self-doped titanium dioxide nanosheet catalyst. A titanium dioxide nanosheet is firstly prepared by adopting a hydrothermal reaction method; then the titanium dioxide nanosheet is reduced by using sodium borohydride to obtain the trivalent titanium ion self-doped titanium dioxide nanosheet catalyst. According to the trivalent titanium ion self-doped titanium dioxide nanosheet catalyst disclosed by the invention, by adopting sodium borohydride, part of Ti<4+> on the titanium dioxide nanosheet is reduced into Ti<3+>, so that the aim of self doping is achieved; the proportions of the Ti<4+> and the Ti<3+> in the titanium dioxide nanosheet are controlled by controlling the dosage of the sodium borohydride serving as a reducing agent, thereby obtaining a photocatalytic material with excellent photocatalytic performance. Compared with an existing titanium dioxide material, a photocatalytic material has excellent photocatalytic performance and has a good application prospect in the field of treating organic pollutants by photocatalysis.

Owner:NANCHANG HANGKONG UNIVERSITY

High temperature and high salinity resistant plugging control system and plugging control method by using same

InactiveCN103589408AMeet the application requirements of plugging control with small treatment radiusMeet the application requirements of plugging regulationDrilling compositionSealing/packingSingle crystalHigh pressure

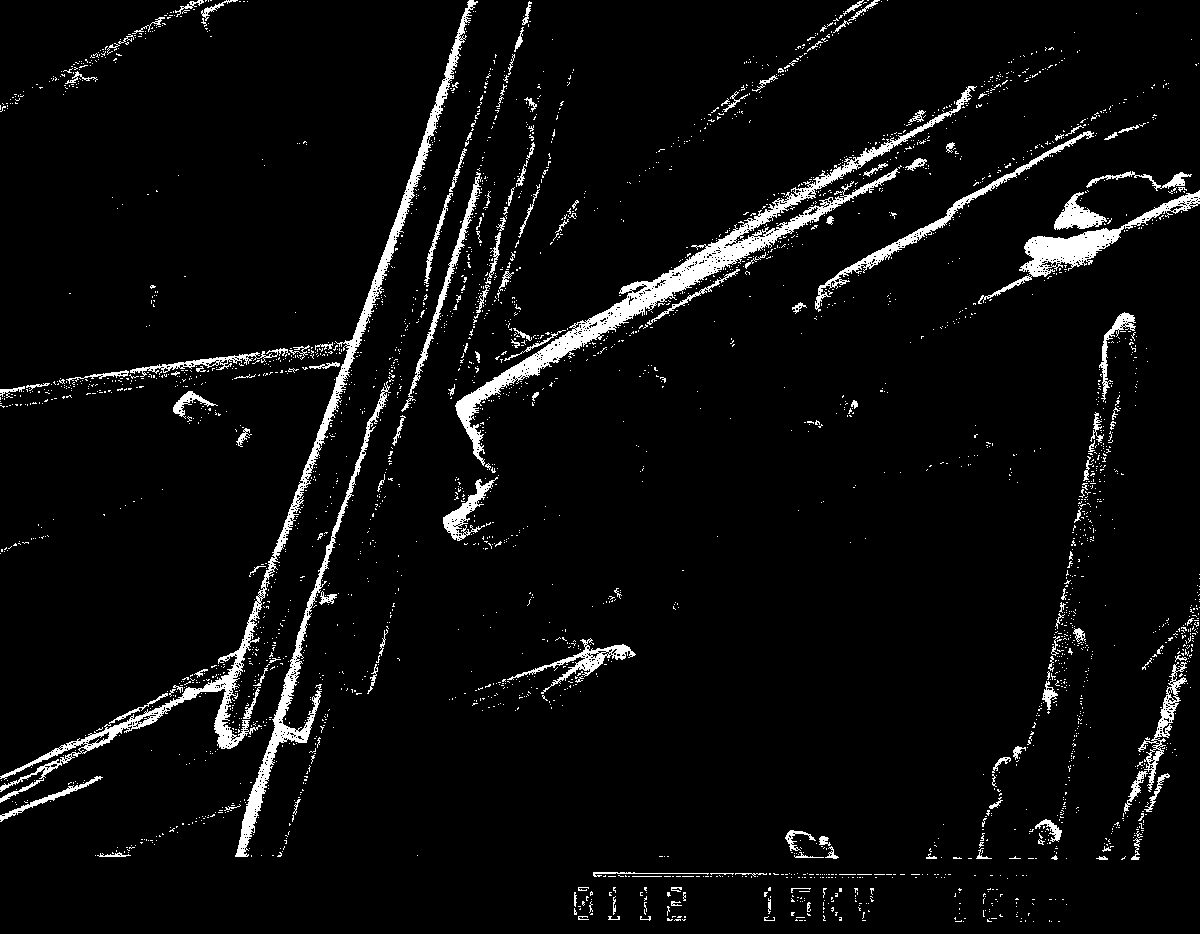

The invention discloses a high temperature and high salinity resistant plugging control system and a plugging control method by using the same. The plugging control system consists of a solution A and a solution B, wherein the solution A comprises titanium ions and potassium ions, and the solution B comprises sulfur ions. The solution A and the solution B are injected into a micropore of an oil well alternately, titanium salt whiskers are formed, and plugging control is achieved. The plugging control system has the benefits that the components solution A and solution B have low viscosity, accordingly, the injectivity is ideal, equipment and process requirements are low, the formed titanium salt whiskers are single crystals with extremely high pressure resistant strength and large compressive strength, an application requirement for plugging control in a small treatment radius of an oil field can be met, influences of the reservoir temperature and reservoir water salinity are avoided, and the plugging control effect has a long available period. For the particle size of the finally added whiskers in a filling manner, the size and shape of an actual pore throat are taken as models for natural regulation of the particle size, and the problem that the particles have to be matched with the diameter of the pore throat is solved. Furthermore, the solid whiskers naturally formed in the actual pore throat based on the size and shape still have certain permeability and can plug to certain extent.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Nonchromate metallic surface treating agent for PCM use, method for PCM surface treatment, and treated PCM steel panel

InactiveUS20010037748A1Easy to processIncrease resistancePretreated surfacesSolid state diffusion coatingSilanesZirconium compounds

The present invention has for its object to provide a metallic surface treating agent for PCM use, which is capable of imparting high processability and corrosion resistance to PCM steel panels with the additional advantage of improved storage stability, a method for surface treatment of a PCM steel panel, a method of producing a PCM steel panel, and a PCM steel panel as produced by said method. This invention provides a nonchromate metallic surface treating agent for PCM use which comprises, in each liter thereof, (a) a silane coupling agent and / or a hydrolytic condensation product thereof in an amount of 0.01 to 100 g / l, (b) water-dispersible silica in a proportion of 0.05 to 100 g / l (solids), and (c) a zirconium compound in an amount of 0.01 to 50 g / l in terms of zirconium ion and / or a titanium compound in an amount of 0.01 to 50 g / l in terms of titanium ion.

Owner:NIPPON PAINT CO LTD

Flexible substrate of OLED display panel and preparation method thereof

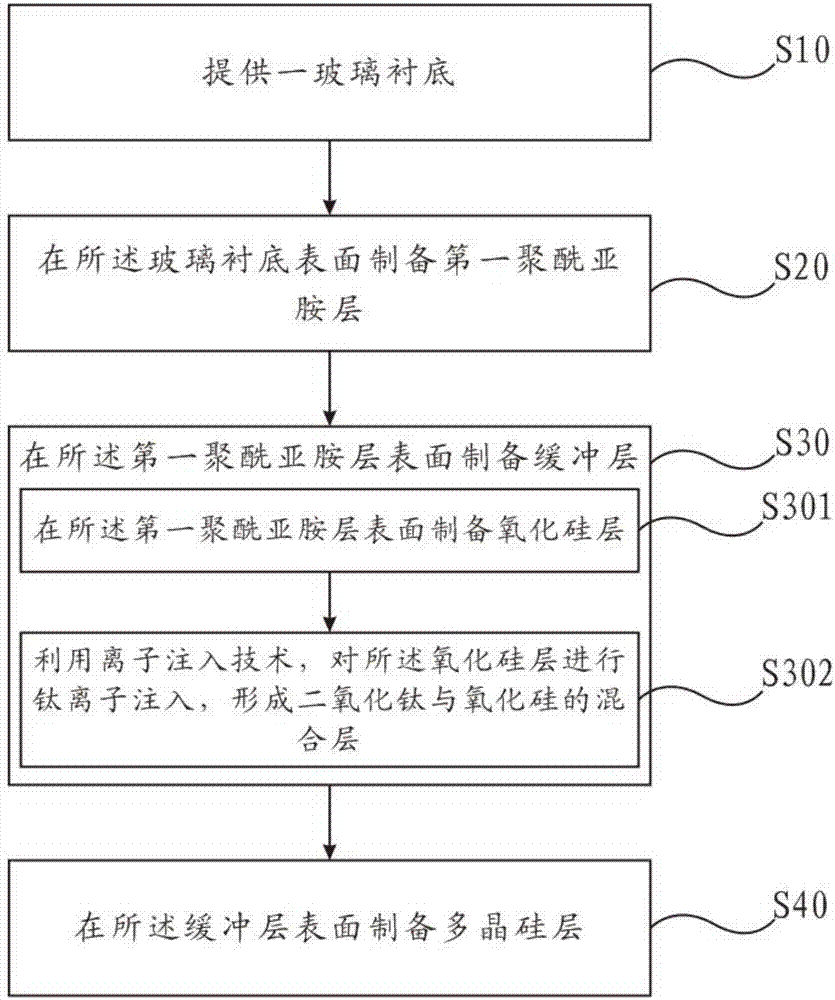

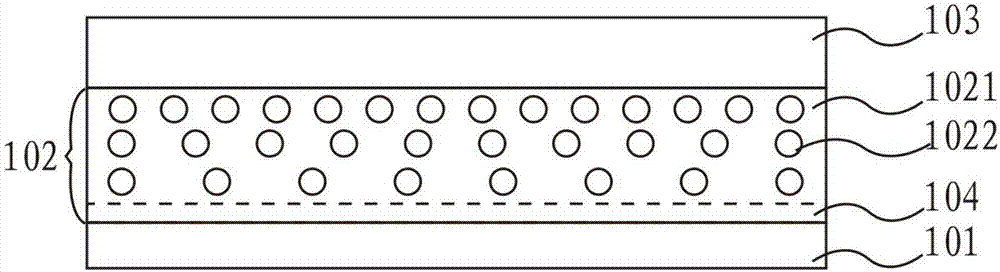

ActiveCN107507929APromote absorptionReduce transmittanceSolid-state devicesOpticsTitanium ionTransmittance

The invention provides the preparation method of the flexible substrate of an OLED display panel. The method comprises the steps that S10 a glass substrate is provided; S20 a first polyimide layer is prepared on the surface of the glass substrate; and S30 a buffer layer is prepared on the surface of the first polyimide layer. The step S30 comprises the steps that S301 a silicon oxide layer is prepared on the surface of the first polyimide layer; and S302 an ion implantation technology is used to carry out titanium ion implantation on the silicon oxide layer to form the mixed layer of titanium oxide and silicon oxide. The preparation method has the advantages that the buffer layer of the flexible substrate of the OLED display provided by the invention can absorb more ultraviolet laser; the transmittance of ultraviolet laser is reduced; the damage of laser annealing to a PI layer is reduced; and the product yield is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Non-chrome pssivation process for zinc and zinc alloys

A non-chrome containing composition and process are disclosed for enhancing the corrosion resistance of zinc or zinc alloy surfaces. The composition comprises a source of titanium ions or titanates, an oxidant and fluorides or complex fluorides. The composition also preferably comprises an organic acid and / or a group II metal compound, preferably a group II metal chloride.

Owner:MACDERMID INC

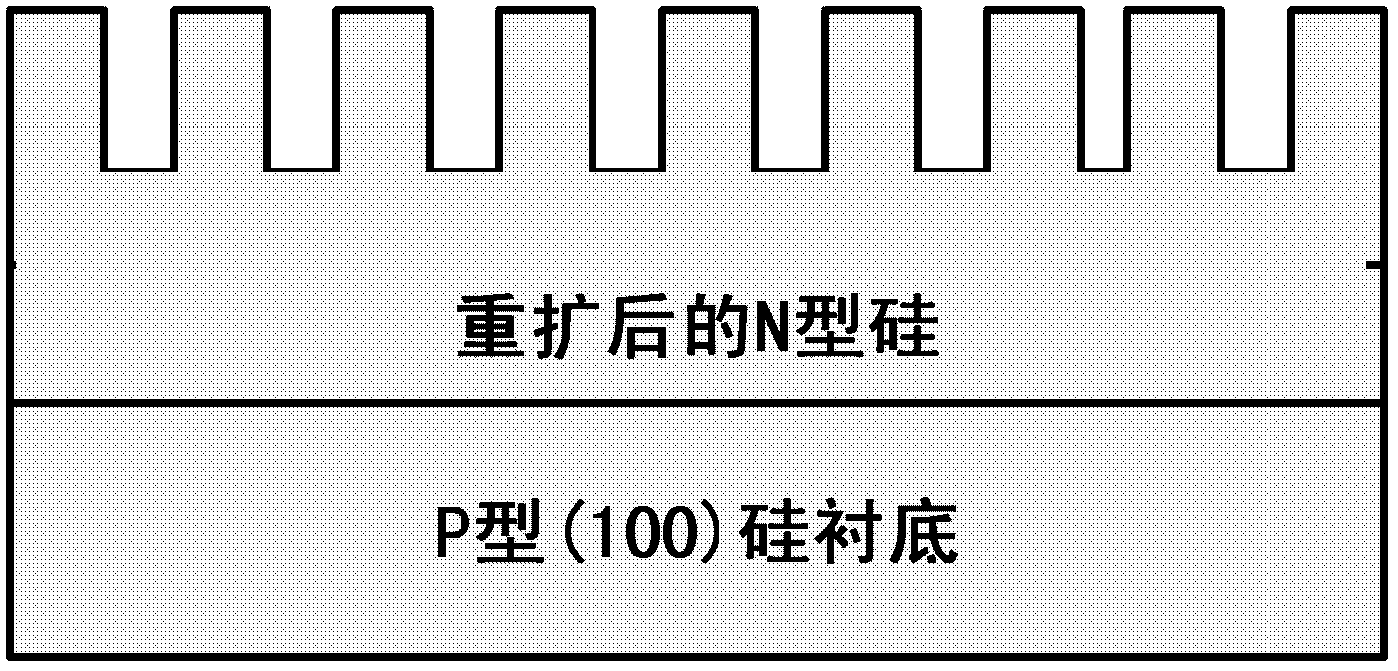

Method for realizing high-trapping-light nanostructure single-face texture surface making

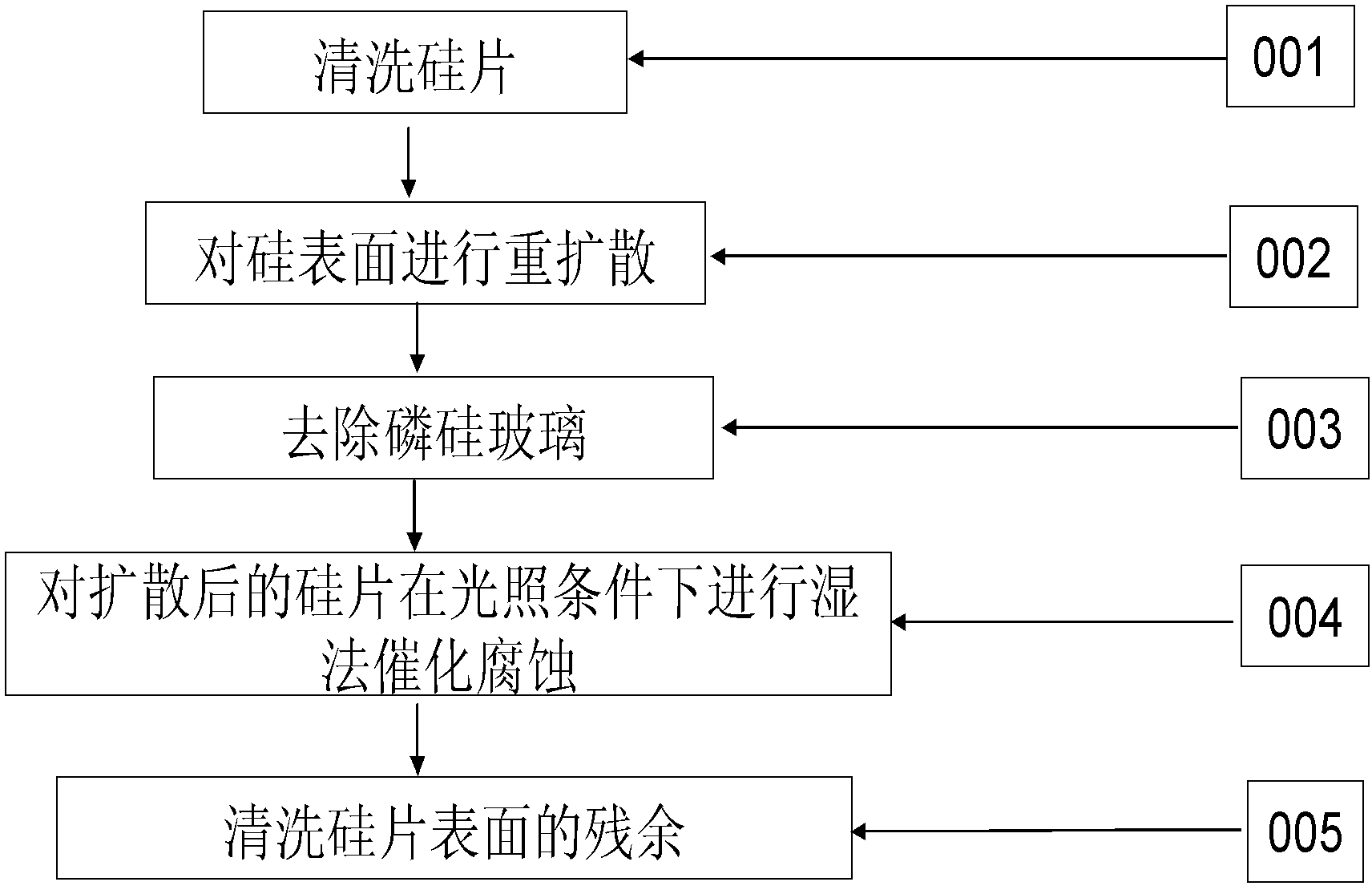

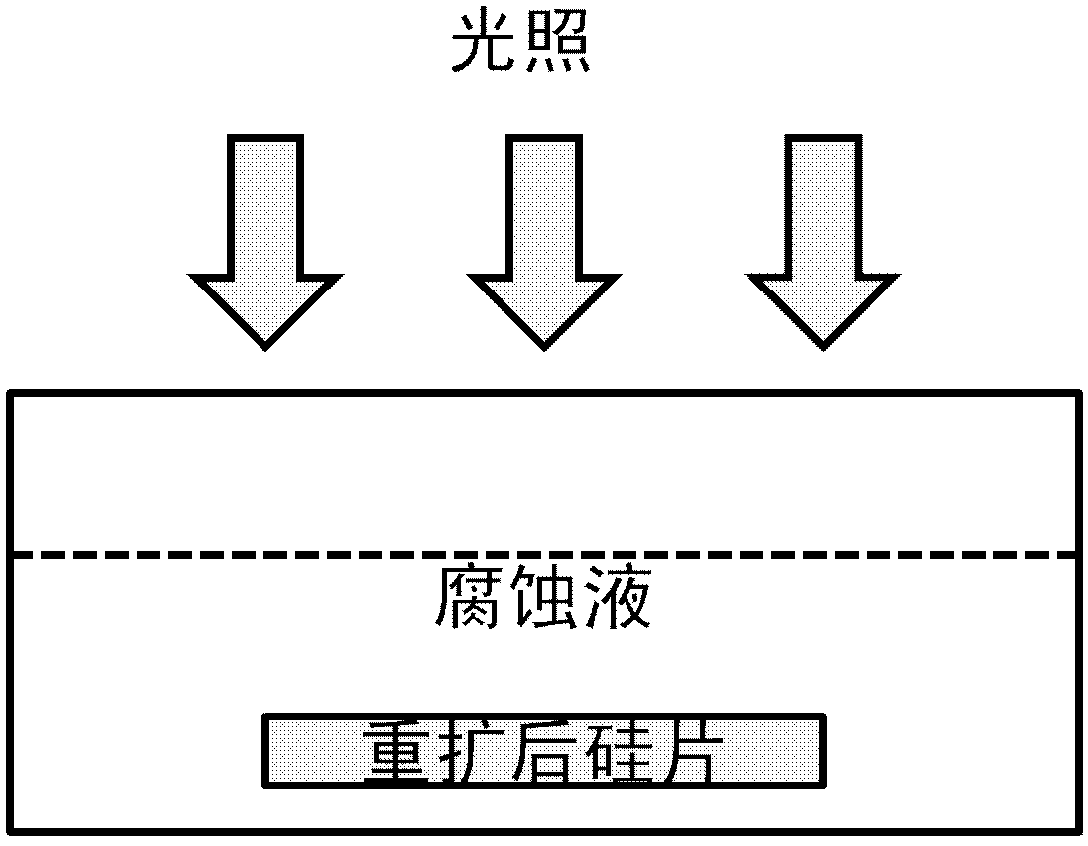

InactiveCN103219427AObvious advantagesGood effectAfter-treatment detailsFinal product manufactureEtchingTrapping

The invention discloses a method for realizing high-trapping-light nanostructure single-face texture surface making. The method comprises the steps: cleaning a silicon wafer; conducting re-spreading to the surface of the silicon wafer; removing residues on the surface of the silicon wafer which is re-spread; coating TiO2 of a nanostructure on the surface of the silicon wafer or depositing Ti on the surface of the silicon wafer, and rapidly annealing; conducting wet etching on the silicon wafer to form the nanostructure; and removing oxide and titanium ions which are not completely reacted on the surface of the silicon wafer. Compared with the prior art, the method is adopted to prepare the high-trapping-light nanostructure, only technology sequence is changed, and under the premise that key equipment is not increased, only one light source needs to be added or only sun light needs to be led in so that the purpose of single-face texture surface making can be achieved. The nanostructure has a good light trapping effect. Besides, the method is simple in process step, and suitable for mass production.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Method of producing surface-treated metal material and method of producing coated metal item

InactiveUS20100243465A1Improve corrosion resistanceGood throwing powerPretreated surfacesElectrophoretic coatingsTitanium ionTreatment use

Owner:CHEMETALLGMBH

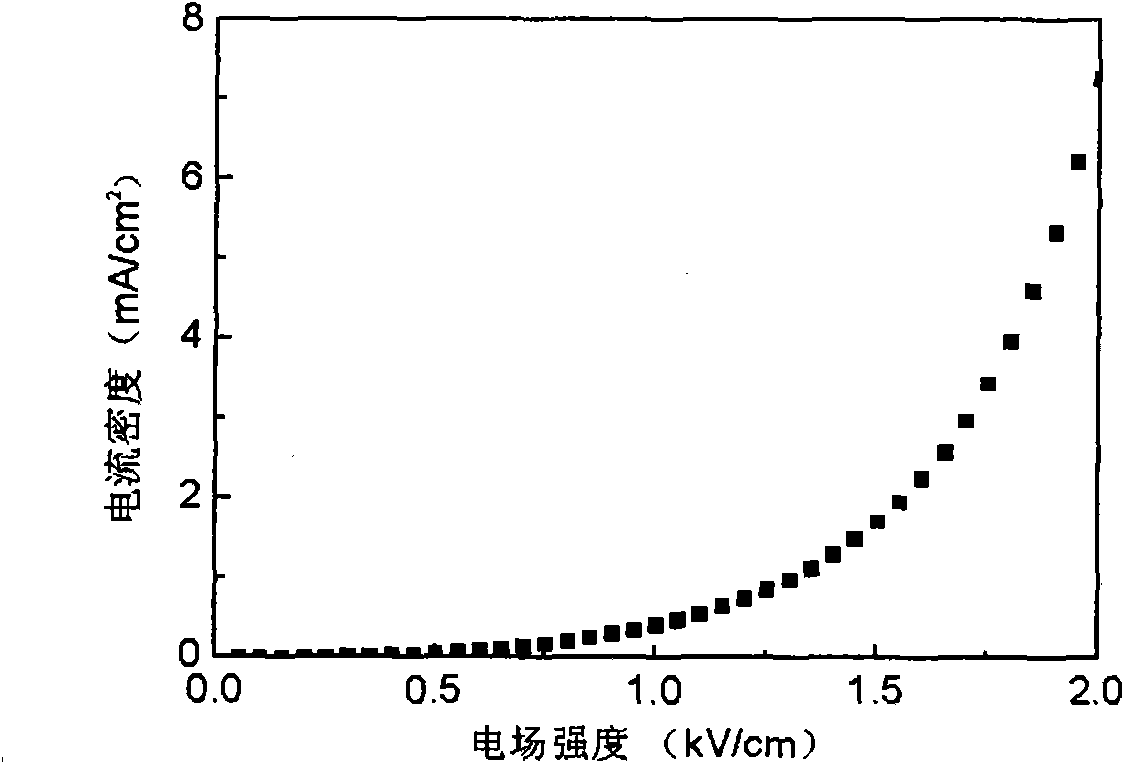

Group VB doping CaCu3Ti4O12 based pressure sensitive material and preparation method

InactiveCN101880159AIncrease intrinsic conductanceReduce the voltage gradientLow voltageChemical element

The invention discloses a group VB doping CaCu3Ti4O12 based pressure sensitive material and a preparation method. The general chemical composition formula of the group VB doping CaCu3Ti4O12 based pressure sensitive materia is CaCu3Ti4-xBxO12, wherein B represents one or combination of group VB elements in the periodic table of chemical elements, and x=0.001-1. The preparation method comprises thefollowing steps of compounding calcium carbonate, copper oxide, vanadium pentoxide, niobium pentaoxide and tantalum pentoxide in accordance with the stoichiometric ratio of CaCu3Ti4-xBxO12 (x=0.001-1, and B represents one or combination of group VB elements in the periodic table of chemical elements), ball milling, calcining, secondary ball milling, pelleting, forming, binder removing, high temperature sintering and the like so that Ca, Cu, Ti-O based ceramics with high permittivity and high pressure sensitive feature can be finally prepared. The invention compensates valence changes of copper ions and titanium ions in the sintering process, which can cause low voltage gradient and large leakage current, by partially replacing a +4 Ti element with a +5 element, thereby reducing the intrinsic conductivity of materials and improving the voltage gradient of the materials.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

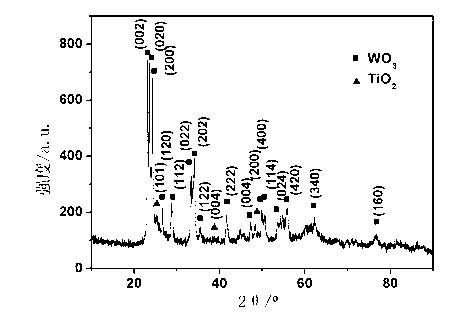

Method for preparing tungsten trioxide/titanium dioxide nanocomposite with core-shell structure

InactiveCN103191721AParticle size adjustmentControl photoelectricNanotechnologyMetal/metal-oxides/metal-hydroxide catalystsDextrose waterMicrosphere

The invention discloses a method for preparing tungsten trioxide / titanium dioxide nanocomposite with a core-shell structure. The method comprises the following processes of: transferring a dextrose water solution to a sealed container, obtaining carbon microspheres by hydrothermal reaction, then dispersing and soaking the carbon microspheres into an ethanol mixed solution of titanium tetrachloride and tungsten hexachloride, separating, cleaning and drying to obtain the carbon microspheres of absorbing titanium ions and tungsten ions, and finally burning the carbon microspheres to obtain the tungsten trioxide / titanium dioxide nanocomposite with the core-shell structure. The method is simple in process, low in synthesis cost, free of poison, and easy for realization of industrial large-scale production; and the obtained tungsten trioxide / titanium dioxide nanocomposite with the core-shell structure is uniform in size and good in dispersibility, and has wide practical application value in the aspect of preparation of a photoelectric material or a photocatalytic material.

Owner:TIANJIN UNIV

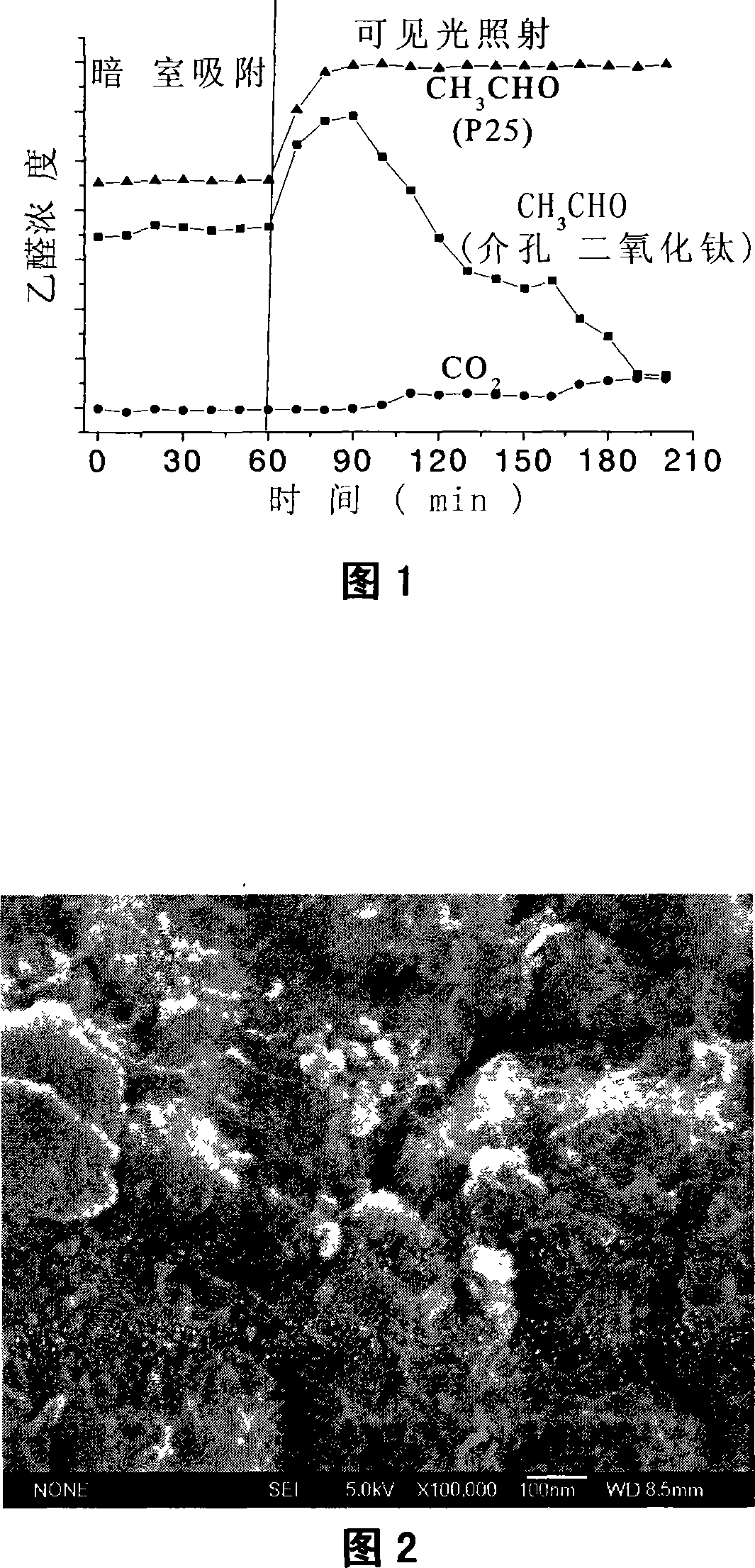

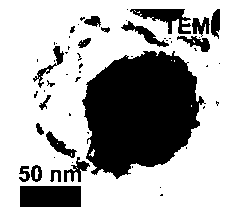

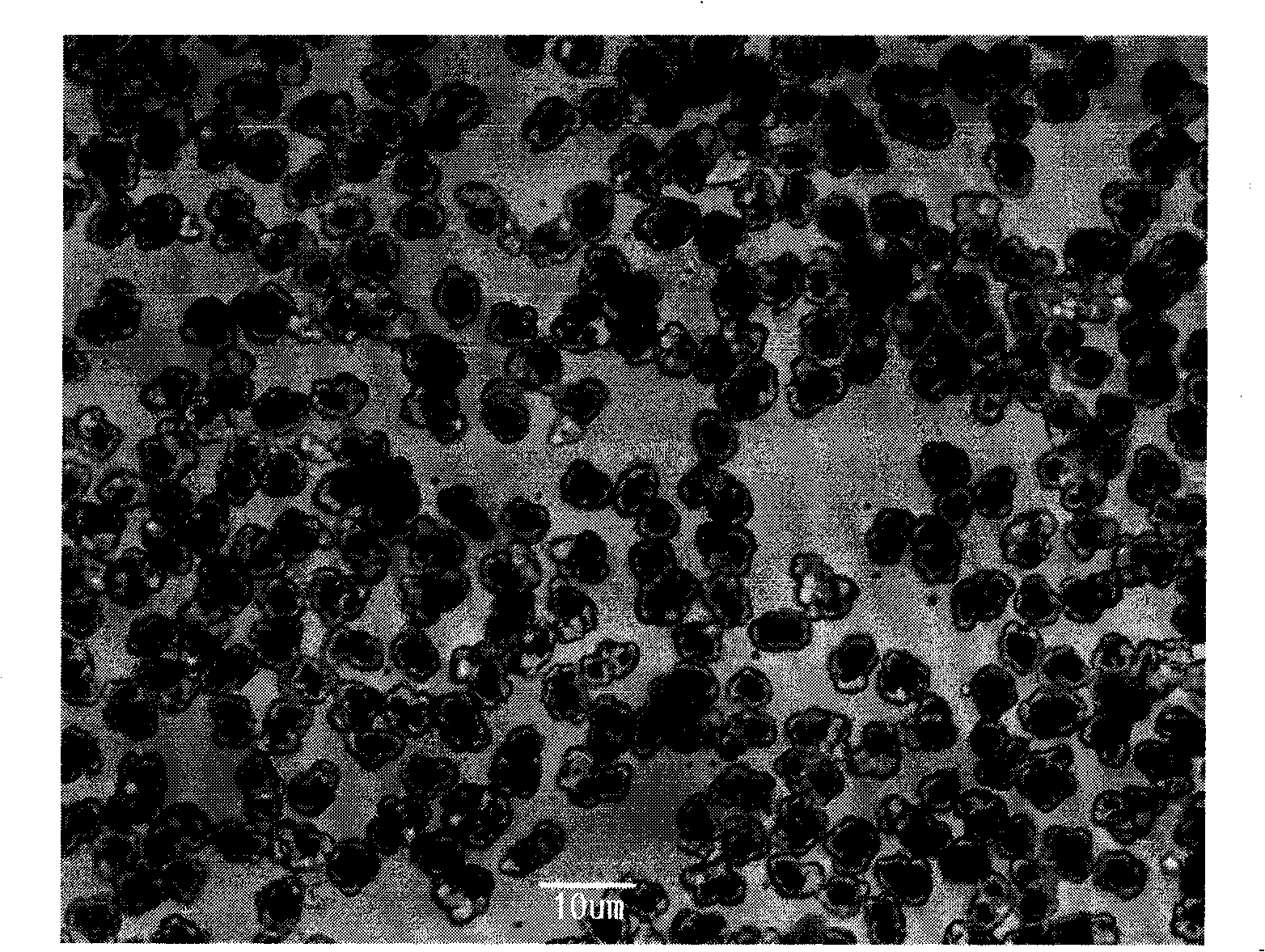

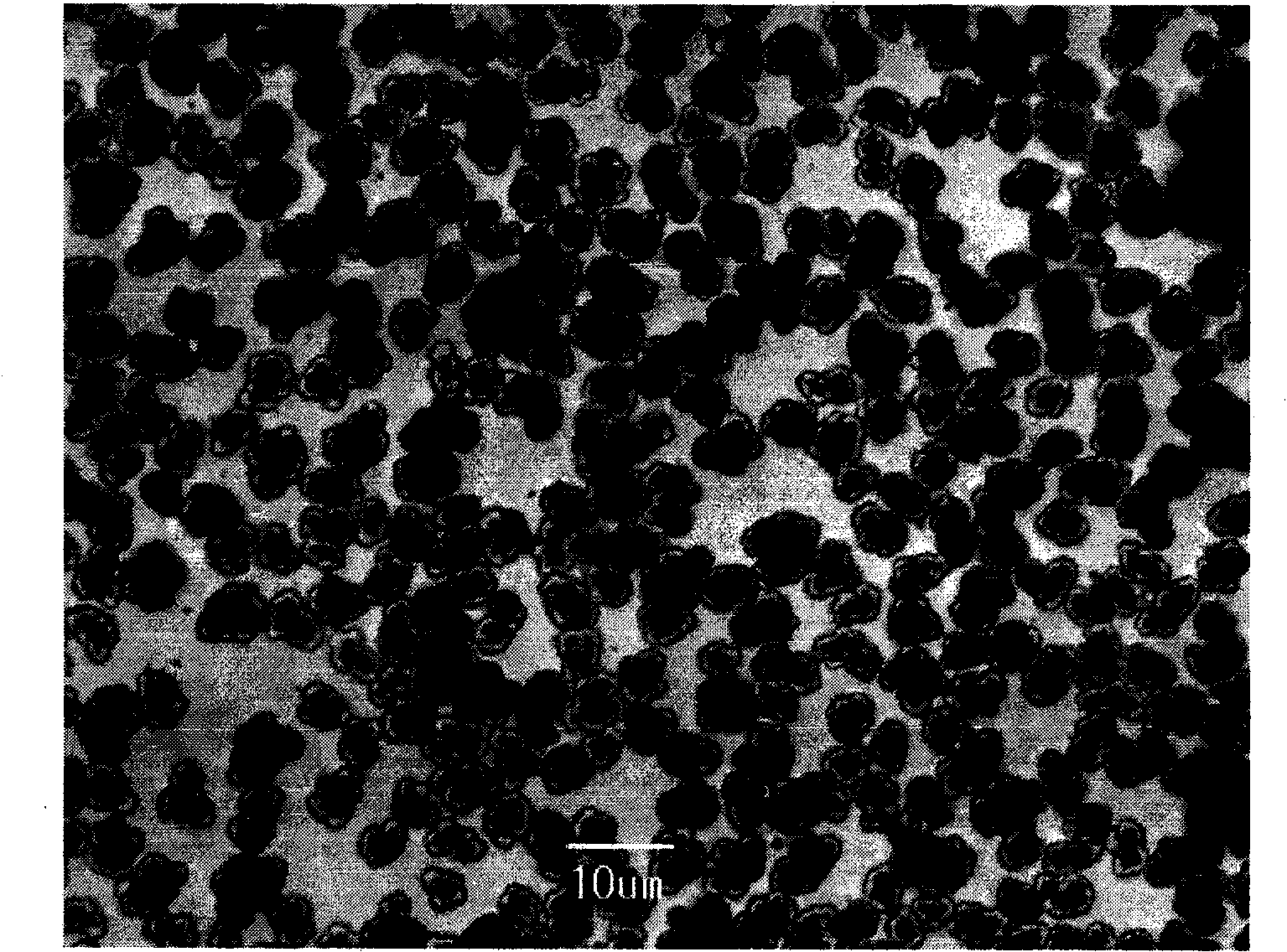

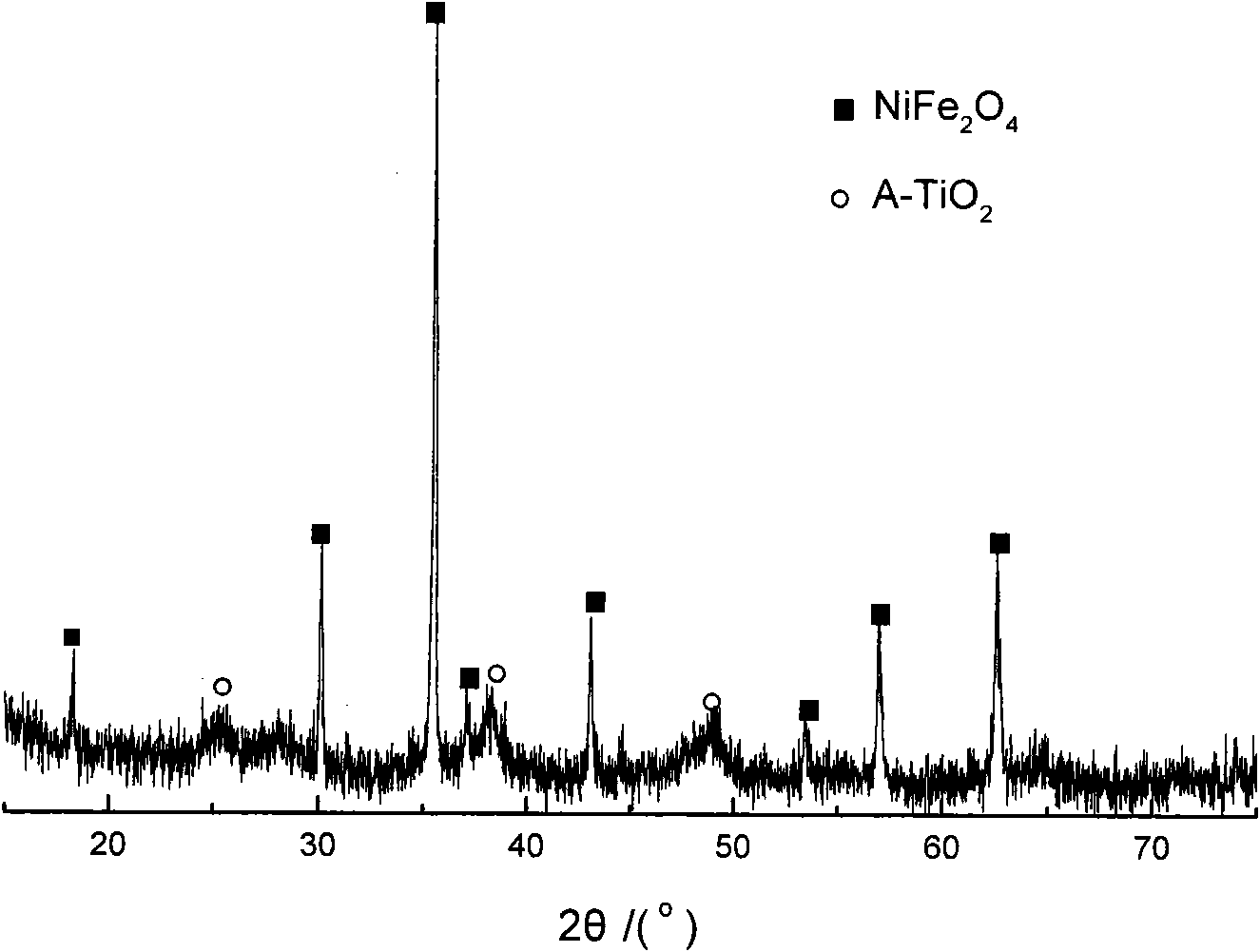

Preparation method of nickel ferrite based magnetic loaded type titanium dioxide photo-catalyst

ActiveCN101579628AGood dispersionLarge and adjustable package volumeWater/sewage treatment by irradiationWater contaminantsParticulatesNickel salt

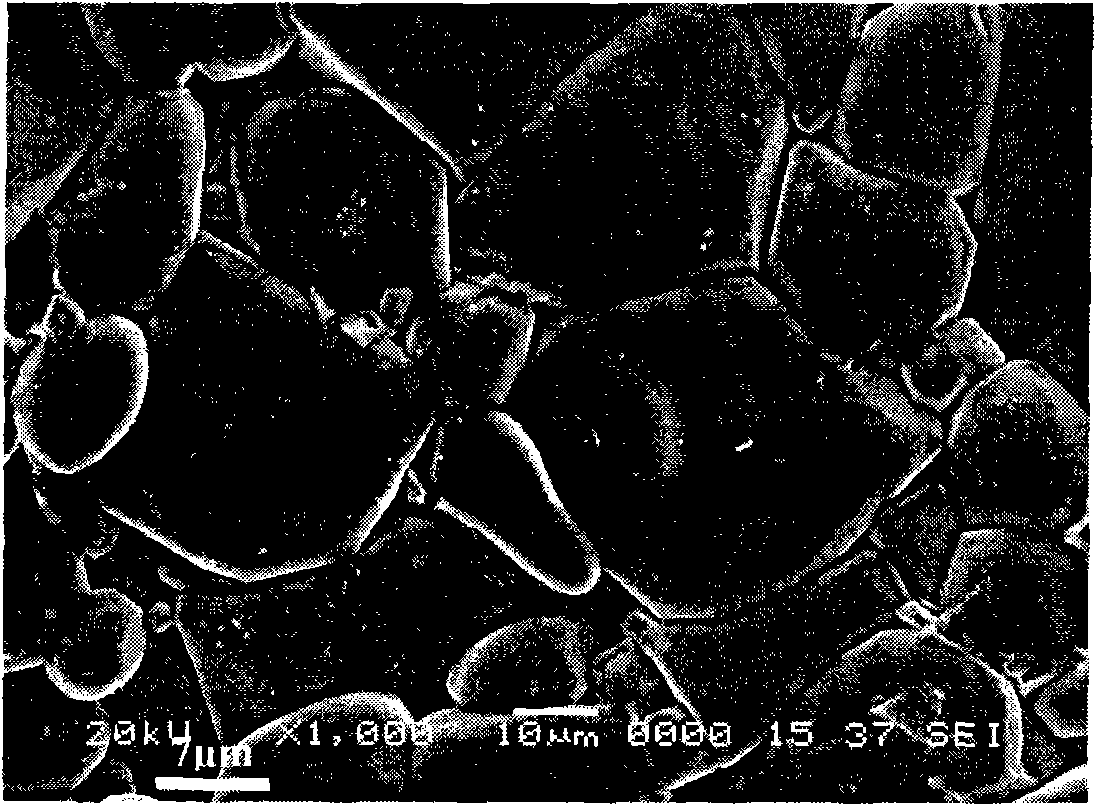

The invention provides a preparation method of nickel ferrite based magnetic loaded type titanium dioxide photo-catalyst with micron grade micron order as carrier; the preparation process includes the following steps: adding green copperas solution and oxalic acid solution into the nickel salt solution for reaction to obtain the mixture precipitate of oxalate of nickel oxalate and iron oxalate; then baking to obtain the micron grade nickel ferrite powder; adding the titanic sulfate solution into the suspension of micron grade nickel ferrite powder so as to crystallize the titanium ions on the suspended particulates in the suspension to form a wrapping layer and obtain the nickel ferrite based magnetic loaded type titanium dioxide photo-catalyst product. The magnetic loaded type titanium dioxide photo-catalyst prepared by the method of the invention has good dispersibility; and the particle diameter of the particles is about 5 mum; the titanium dioxide is obviously wrapping on the surface of the nickel ferrite to form a core / shell structure with large wrapping capacity as well as adjustable and homogenous distribution; the specific surface is 90-110 m / g; and the photo-catalyst has the feature of strong soft magnetism, can be rapidly recycled in aqueous solution and has higher catalytic activity, so that organic wastewater can be completely degraded. The preparation technology is simple, the cost is low, and large-scale production is easily realized.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Hydrotreated TiO2 nanotube array and preparation method thereof

ActiveCN102247828AWide variety of sourcesConvenient sourceWater/sewage treatment by irradiationWater contaminantsTio2 nanotubeTitanium ion

The invention discloses a hydrotreated TiO2 nanotube array. Ti<n+> contained in the hydrotreated TiO2 nanotube array accounts for 1-3 percent of the total number of titanium ions, wherein n is a positive integer which is not more than 3; the color of the hydrotreated TiO2 nanotube array is black or greenblack, and the conductivity is 0.01S.cm<-1>-8.9S.cm<-1>. The invention also discloses a preparation method of the hydrotreatedTiO2 nanotube array, comprising the following steps of: preparing the TiO2 nanotube array by adopting electrolytic oxidation; and then carrying out hydrotreating heat treatment on the prepared TiO2 nanotube array to obtain the hydrotreated TiO2 nanotube array. The hydrotreated TiO2 nanotube array disclosed by the invention has excellent capability in using visible light and infrared light, is obviously enhanced in electrical conductivity and is better enhanced in capability in photocatalytic degradation of homogenic organic pollutants compared with that of a non-hydrogenated TiO2 nanotube array.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com