Method for preparing titanium dioxide/silicate mineral nano composites

A technology of nanocomposite materials and silicate minerals, applied in chemical instruments and methods, chemical/physical processes, light water/sewage treatment, etc., can solve the problem of easy aggregation of nano-titanium dioxide particles, low recycling value, and influence on photocatalysis Effect and other issues, to achieve the effect of low price, improve photocatalytic efficiency and save cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

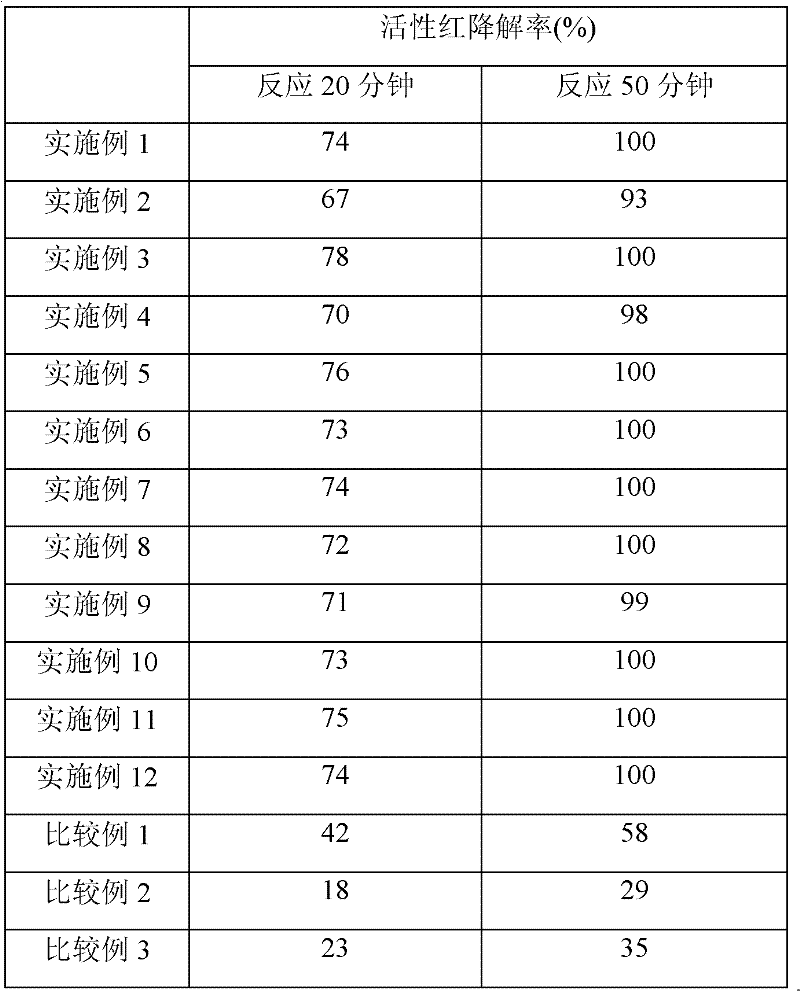

Embodiment 1

[0022] Example 1: Add 10 kilograms of attapulgite powder to 30 liters of 2.0 mol / liter titanium tetrachloride solution and immerse for 24 hours at room temperature to obtain a titanium dioxide precursor / attapulgite slurry. Control the temperature of the titanium dioxide precursor / attapulgite slurry to 30°C. While stirring, add 2.0 mol / L sodium hydroxide solution to the slurry. When the pH of the system reaches 2.5, filter and wash to the conductivity of the filtrate It is 150μS / cm, and the filter cake of titanium dioxide hydrate / attapulgite composite body is obtained. The filter cake was added to 30 liters of 0.5 mol / liter titanium tetrachloride solution, the temperature was raised to 80°C, and the reaction was kept at a temperature of 4 hours with stirring, then the pH of the system was adjusted to 7.0 with 2.0 mol / liter sodium hydroxide solution, and filtered, Washing, drying at 60° C., and pulverizing to obtain titanium dioxide / attapulgite nanocomposite powder. The titanium...

Embodiment 2

[0023] Example 2: Add 10 kilograms of attapulgite powder to 25 liters of 0.5 mol / liter titanium tetrachloride solution and immerse for 60 hours at room temperature to obtain a titanium dioxide precursor / attapulgite slurry. Control the temperature of the titanium dioxide precursor / attapulgite slurry to 10°C. While stirring, add 4.0 mol / L potassium hydroxide solution to the slurry. When the pH value of the system reaches 1.6, filter and wash to the conductivity of the filtrate It is 105μS / cm, and the filter cake of titanium dioxide hydrate / attapulgite composite body is obtained. The filter cake was added to 62.5 liters of 0.2 mol / liter titanium tetrachloride solution, the temperature was raised to 100°C, and the temperature was kept agitated for 1 hour, and the pH value of the system was adjusted to 6.5 with 4.0 mol / liter potassium hydroxide solution, and filtered, Washing, drying at 80°C, and pulverizing to obtain titanium dioxide / attapulgite nanocomposite powder. The titanium ...

Embodiment 3

[0024] Example 3: Add 10 kilograms of attapulgite powder to 33.3 liters of 3.0 mol / liter titanium tetrachloride solution and immerse for 3 hours at room temperature to obtain a titanium dioxide precursor / attapulgite slurry. Control the temperature of the titanium dioxide precursor / attapulgite slurry to 50°C. While stirring, add 0.5 mol / L of ammonia to the slurry. When the pH of the system reaches 3.0, filter and wash until the conductivity of the filtrate is 200μS / cm, get the titanium dioxide hydrate / attapulgite composite filter cake. The filter cake was added to 25 liters of 1.0 mol / liter titanium tetrachloride solution, the temperature was raised to 60°C, the temperature was kept and stirred for 12 hours, and the pH of the system was adjusted to 7.5 with 0.5 mol / liter ammonia water, filtered, washed, and 120 Drying and pulverizing at ℃ to obtain titanium dioxide / attapulgite nanocomposite powder. The titanium dioxide in the nanocomposite is a mixed crystal of anatase and rut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com