Patents

Literature

56results about How to "High rate charge and discharge performance is good" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of negative material for low-temperature lithium ion battery

ActiveCN103151497AWide variety of sourcesImprove the first charge and discharge efficiencyGraphiteCell electrodesHigh rateLithium-ion battery

The invented relates to a preparation method of a negative material for a low-temperature lithium ion battery. The preparation method comprises the steps of: carrying out ball-milling and refining treatment on natural graphite by adopting a ball mill, afterwards carrying out soft carbon coating for modification, then carrying out hard carbon coating, and finally curing and carbonizing the natural graphite modified by the soft-hard carbon double-layer coating to obtain final modified natural graphite. The preparation method provided by the invention is simple and convenient, low in cost, wide in raw material sources and easy to realize the industrial production; and the prepared negative material for the low-temperature lithium ion battery is high in first charging and discharging efficiency, and good in low-temperature performance and high-rate charging and discharging performance, and can satisfy the actual needs of people.

Owner:WUXI DONGHENGNEWENERGYTECHNOLOGYCO LTD

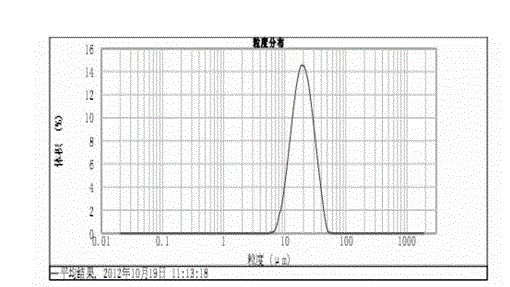

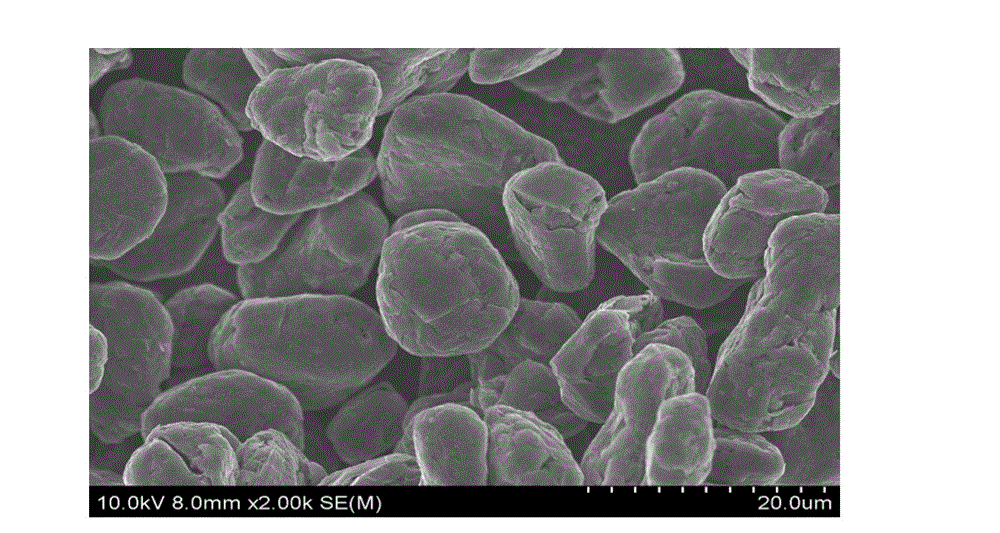

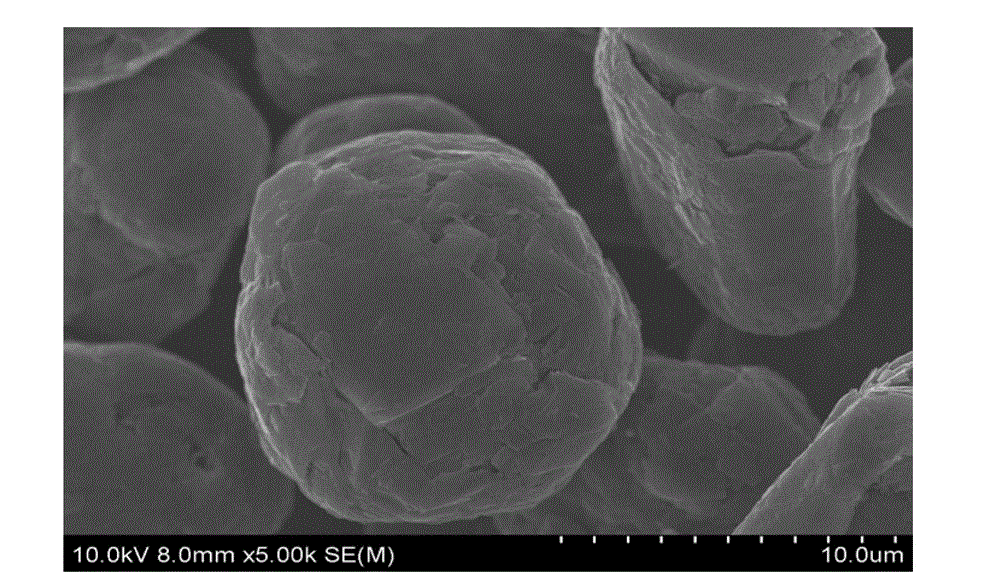

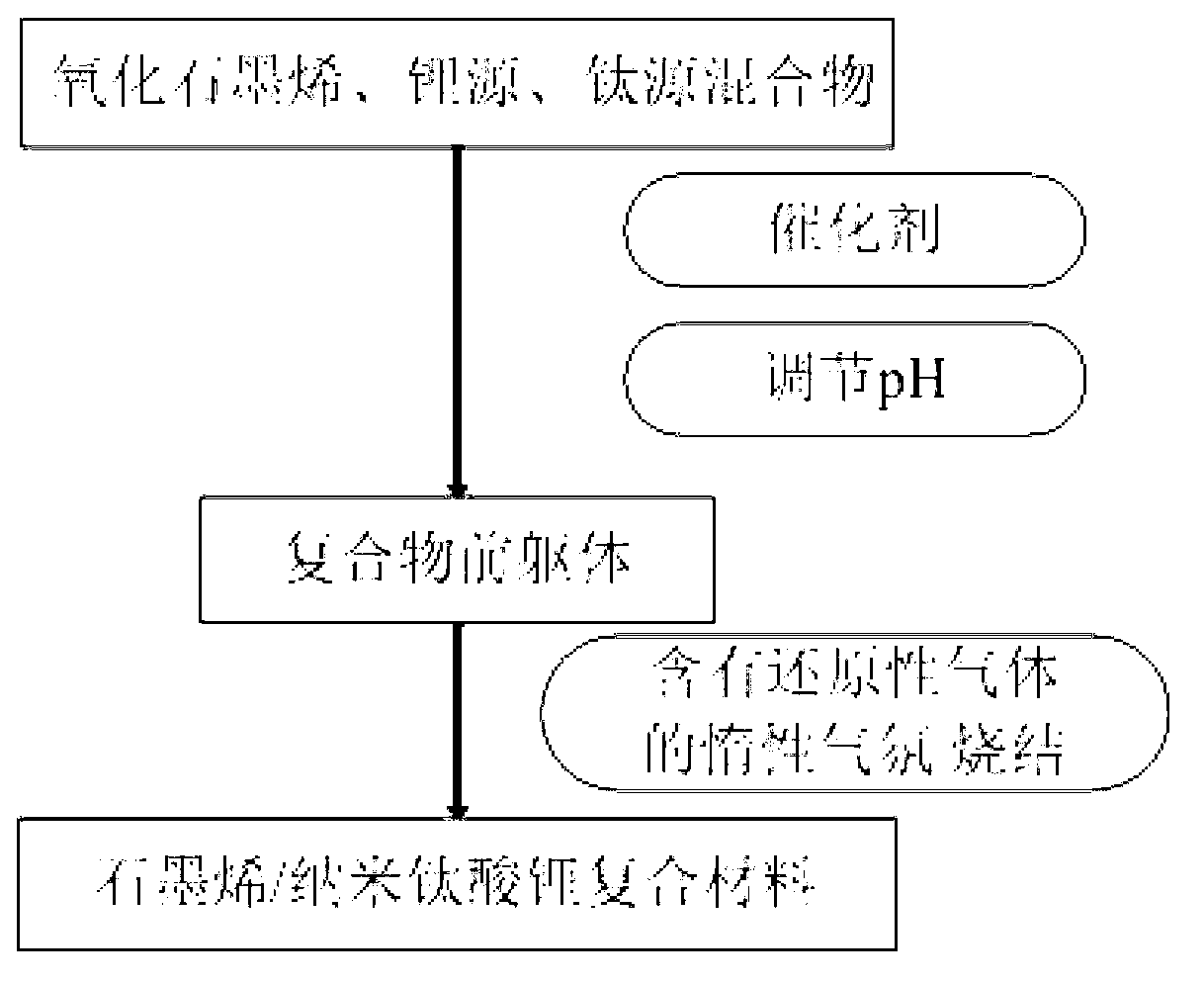

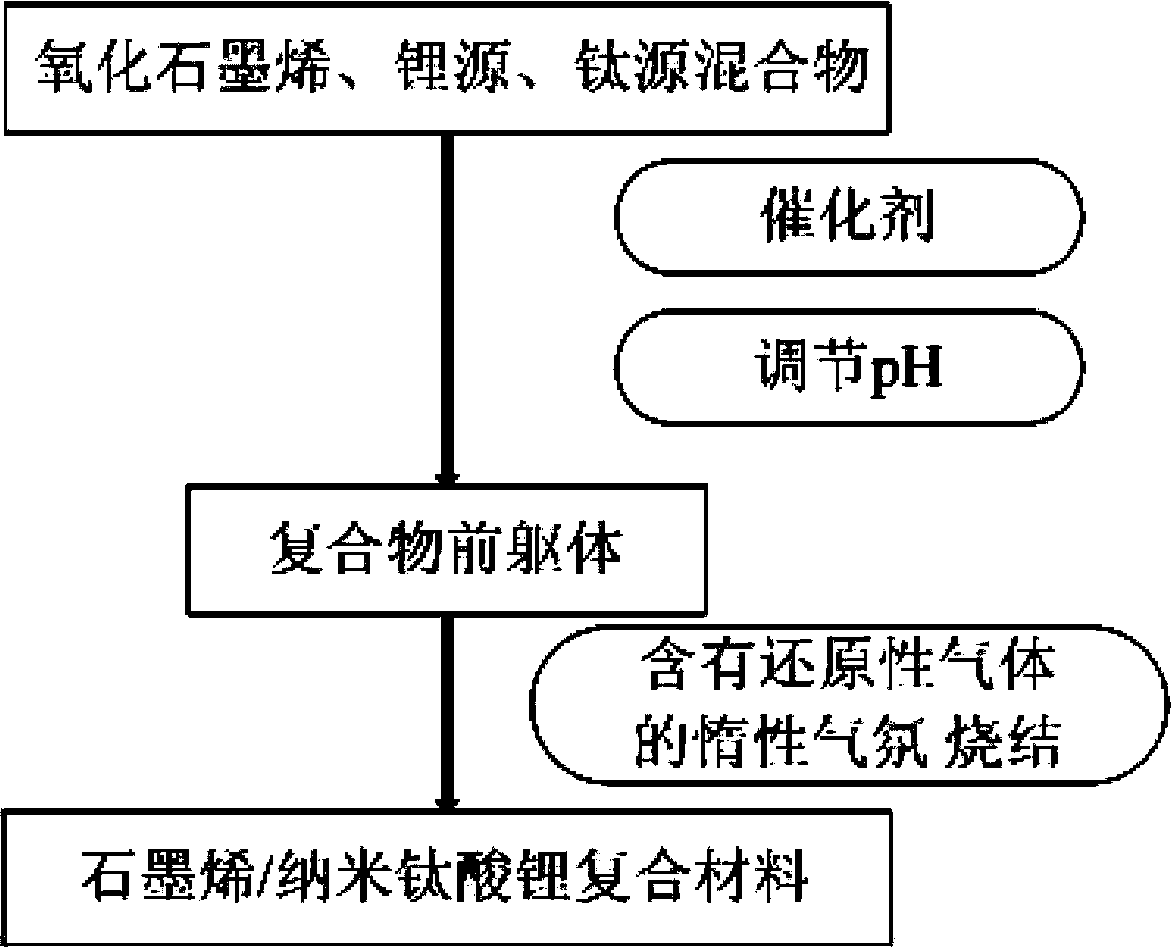

Preparation method of graphene/lithium titanate composite anode material

ActiveCN103022459AImprove electrochemical performanceGood magnificationCell electrodesHybrid/EDL manufactureActivated carbonSupercapacitor

The invention discloses a preparation method of a graphene / lithium titanate composite anode material, which comprises the following steps: compounding compounds serving as a lithium source and a titanium source and graphene oxide through a liquid-phase method and reducing graphene oxide of the compound in inert gas mixed with reducing gas into graphene so as to obtain the graphene / lithium titanate composite anode material. The method has the characteristic of realizing uniform distribution of graphene in lithium titanate through an in-situ compounding technique. Under the same conditions, the discharge time of a hybrid capacitor which respectively takes the graphene / lithium titanate composite anode material and activated carbon as the anode and cathode is obviously greater than that of an electric double-layer capacitor which takes activated carbon as an electrode and that of a hybrid capacitor which respectively takes lithium titanate and activated carbon as the anode and cathode. The lithium titanate phase purity of a hybrid supercapacitor and lithium ion battery composite anode materials prepared by the method disclosed by the invention is higher. Furthermore, the preparation method further has the characteristic of easily realizing the large-scale industrial production.

Owner:ZHANGJIAGANG IND TECH RES INST CO LTD DALIAN INST OF CHEM PHYSICS CHINESE ACADEMY OF SCI +1

Hydrothermal preparation method of graphene-coated sulfur/porous carbon composite positive electrode material

ActiveCN104064738AInhibition of dissolution lossPromote wettingCell electrodesSecondary cellsCvd grapheneGraphite oxide

The invention provides a hydrothermal preparation method of a graphene-coated sulfur / porous carbon composite material and relates to a preparation method of the graphene-coated sulfur / porous carbon composite material for a positive electrode material of a lithium-sulfur storage battery. The hydrothermal preparation method is used for solving the technical problem that the electrochemical property of the positive electrode material of an existing lithium-sulfur battery, namely a graphene-coated sulfur-containing composite material, is low. The hydrothermal preparation method comprises the steps of mixing and scattering the sulfur / porous carbon composite material with graphene slurry or oxidized graphene slurry, carrying out hydrothermal synthesis to prepare a hydrogel column, and drying to obtain the graphene-coated sulfur / porous carbon composite material. According to the graphene-coated sulfur / porous carbon composite material prepared by utilizing the hydrothermal preparation method, the outer surfaces of the graphene sheet layers are coated with sulfur / porous carbon composite material particles, a graphene conduction network is generated among the particles, and the obtained graphene-coated sulfur / porous carbon composite material is in a hierarchical core-shell structure; the positive electrode material has the high specific capacity, the long cycle life and the good rate capability; the composite positive electrode material can be used as a positive electrode material in a lithium secondary battery.

Owner:HARBIN INST OF TECH

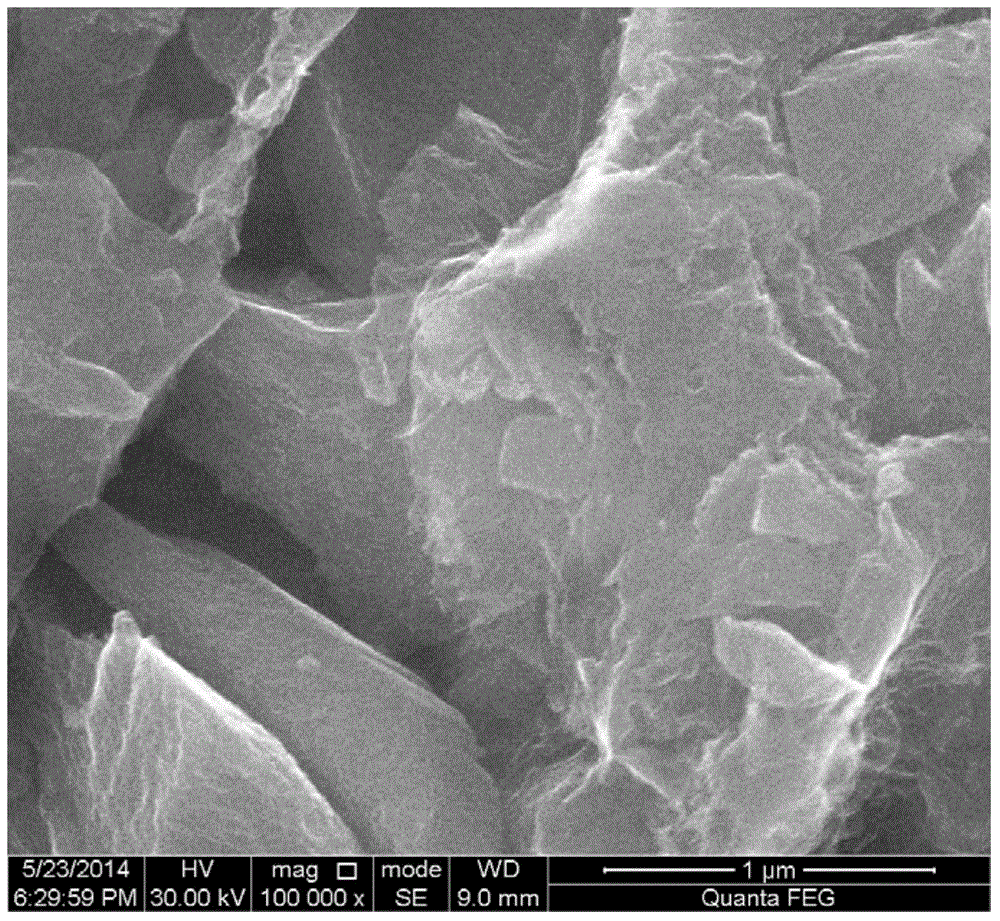

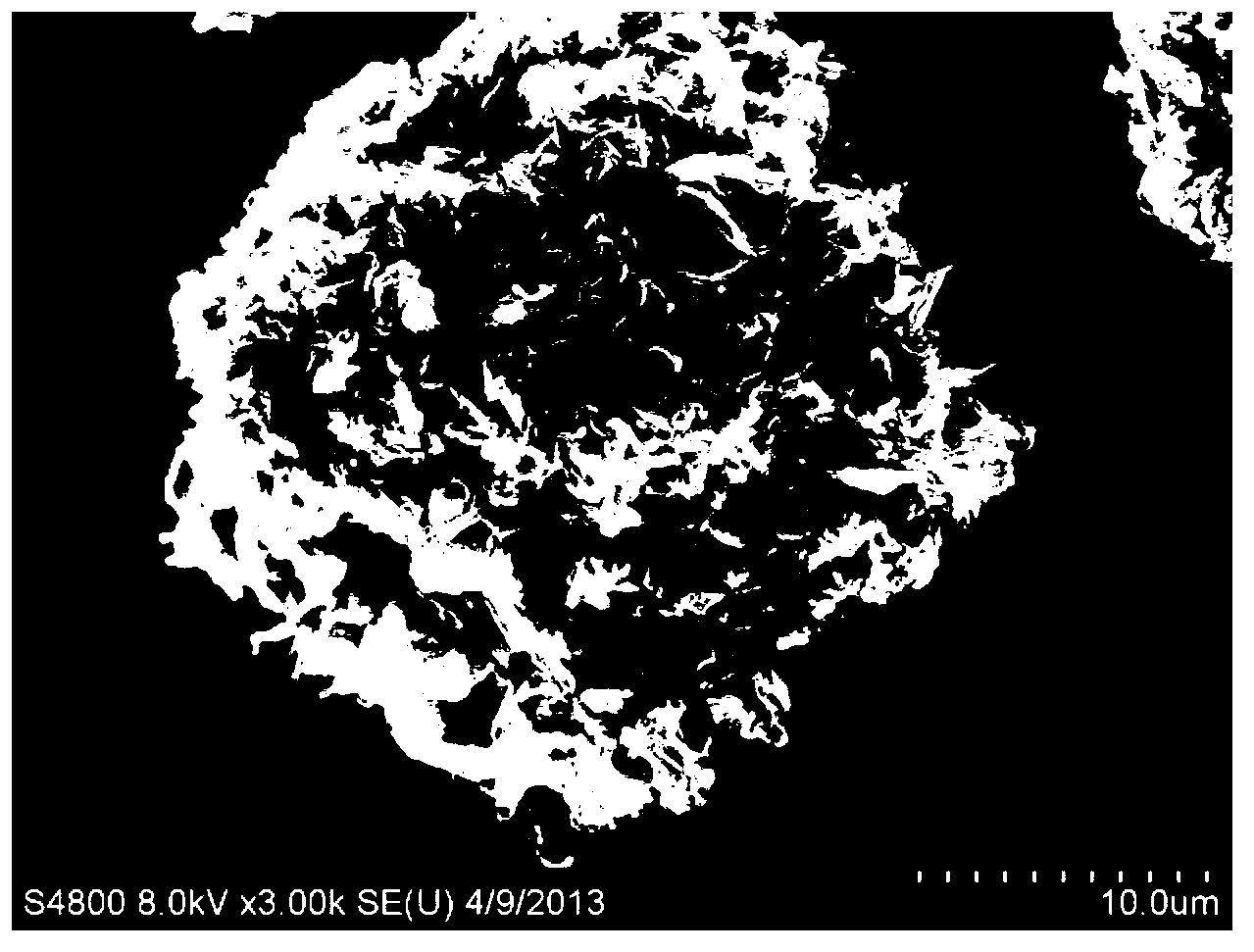

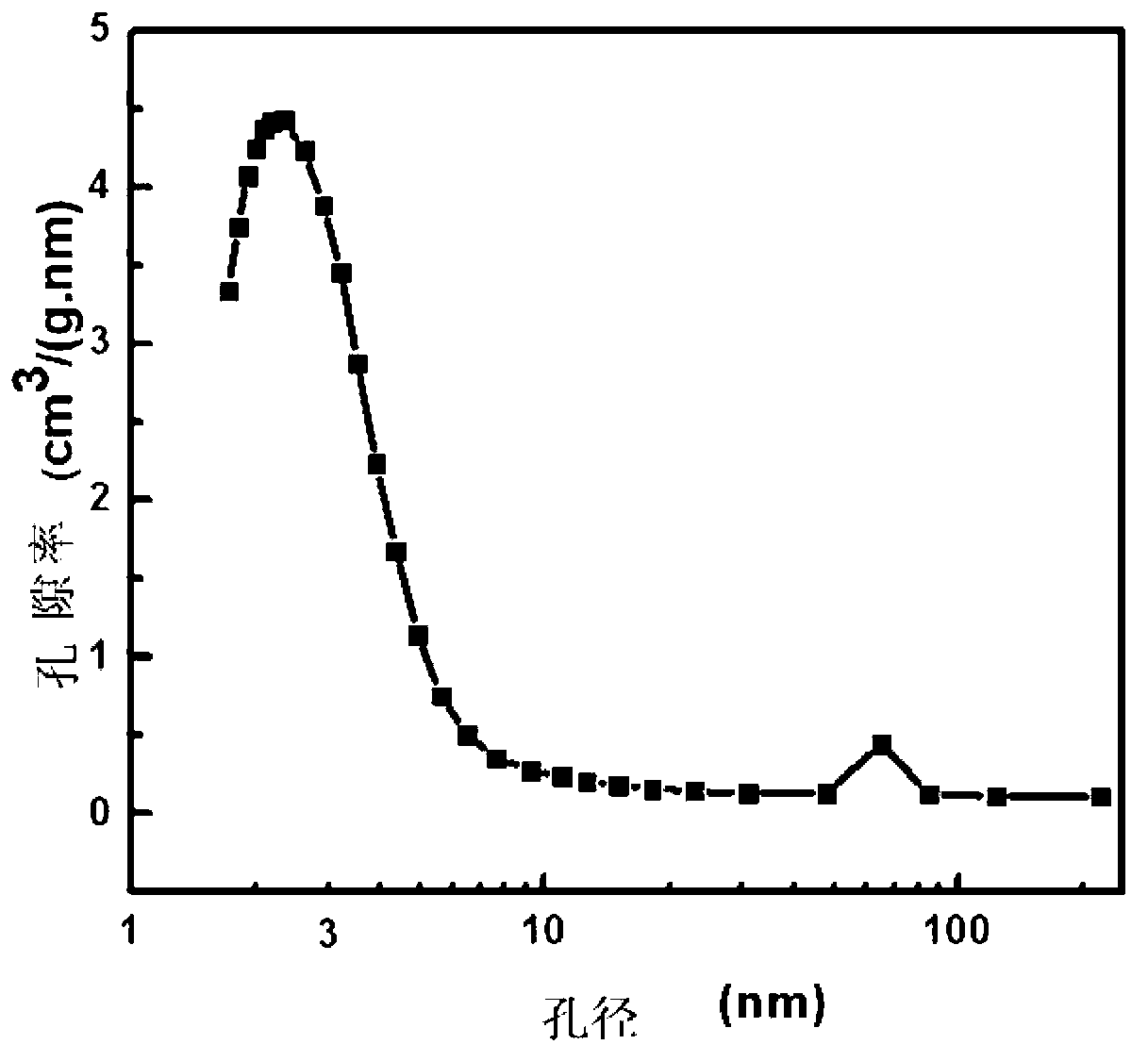

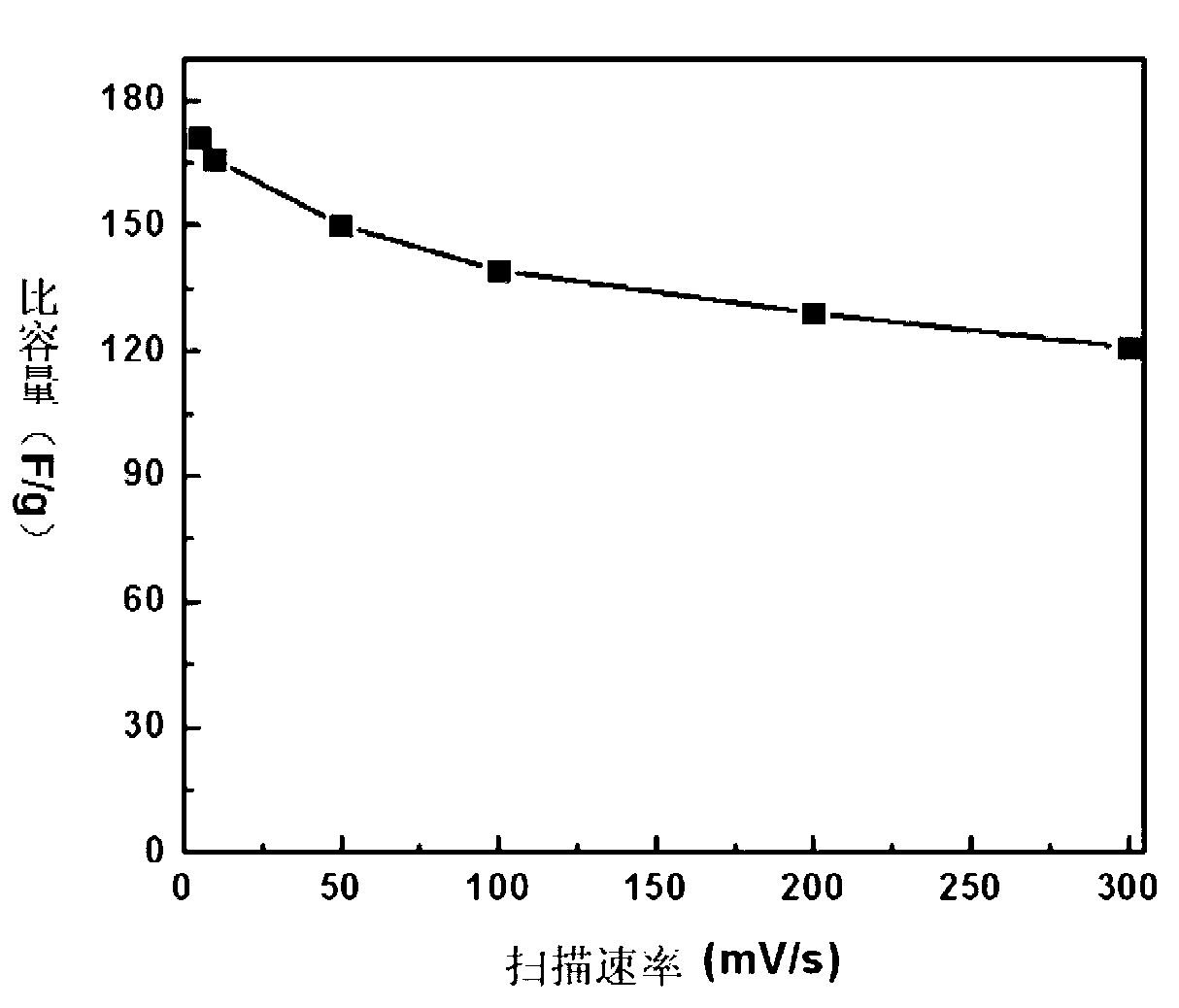

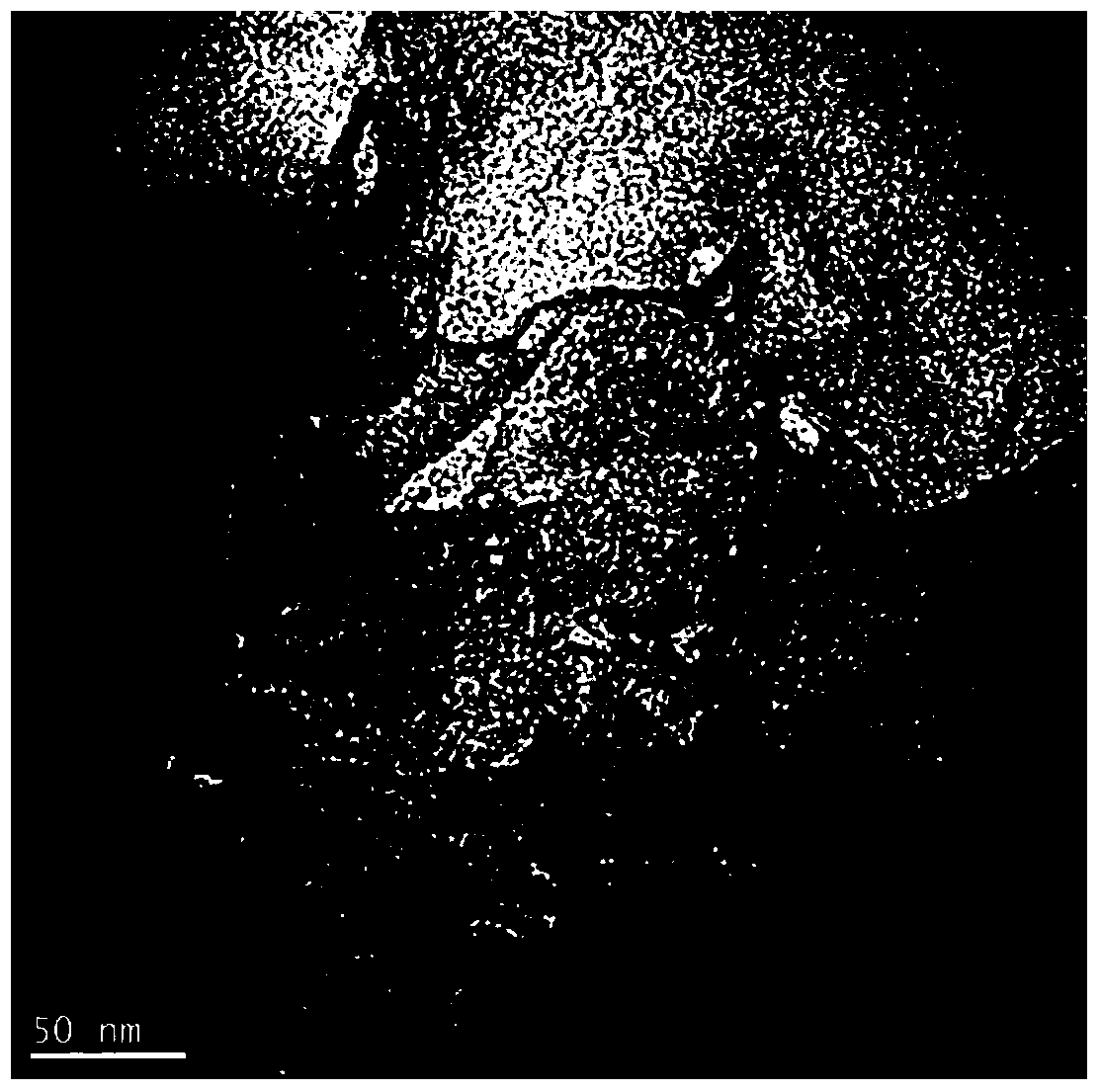

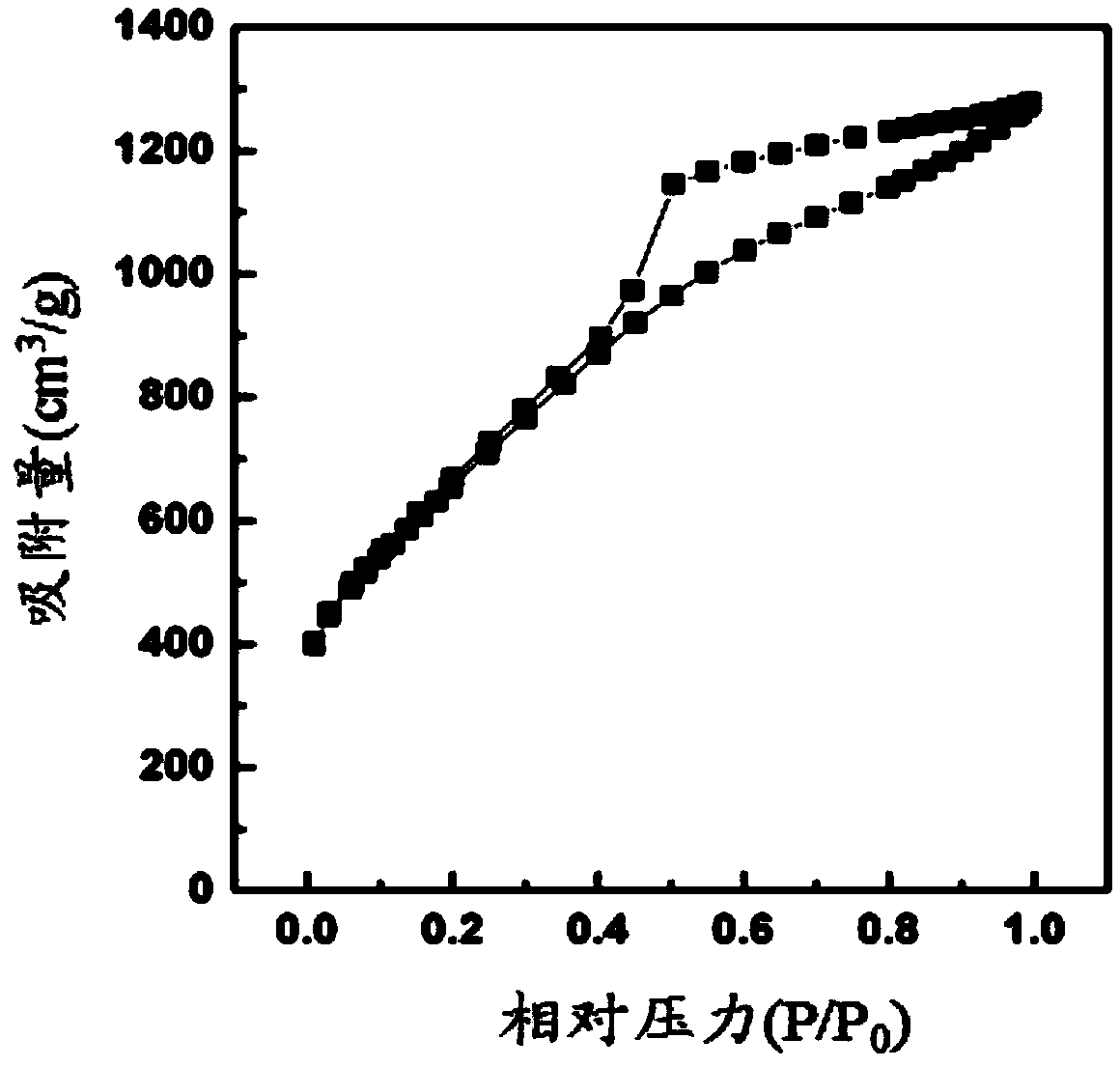

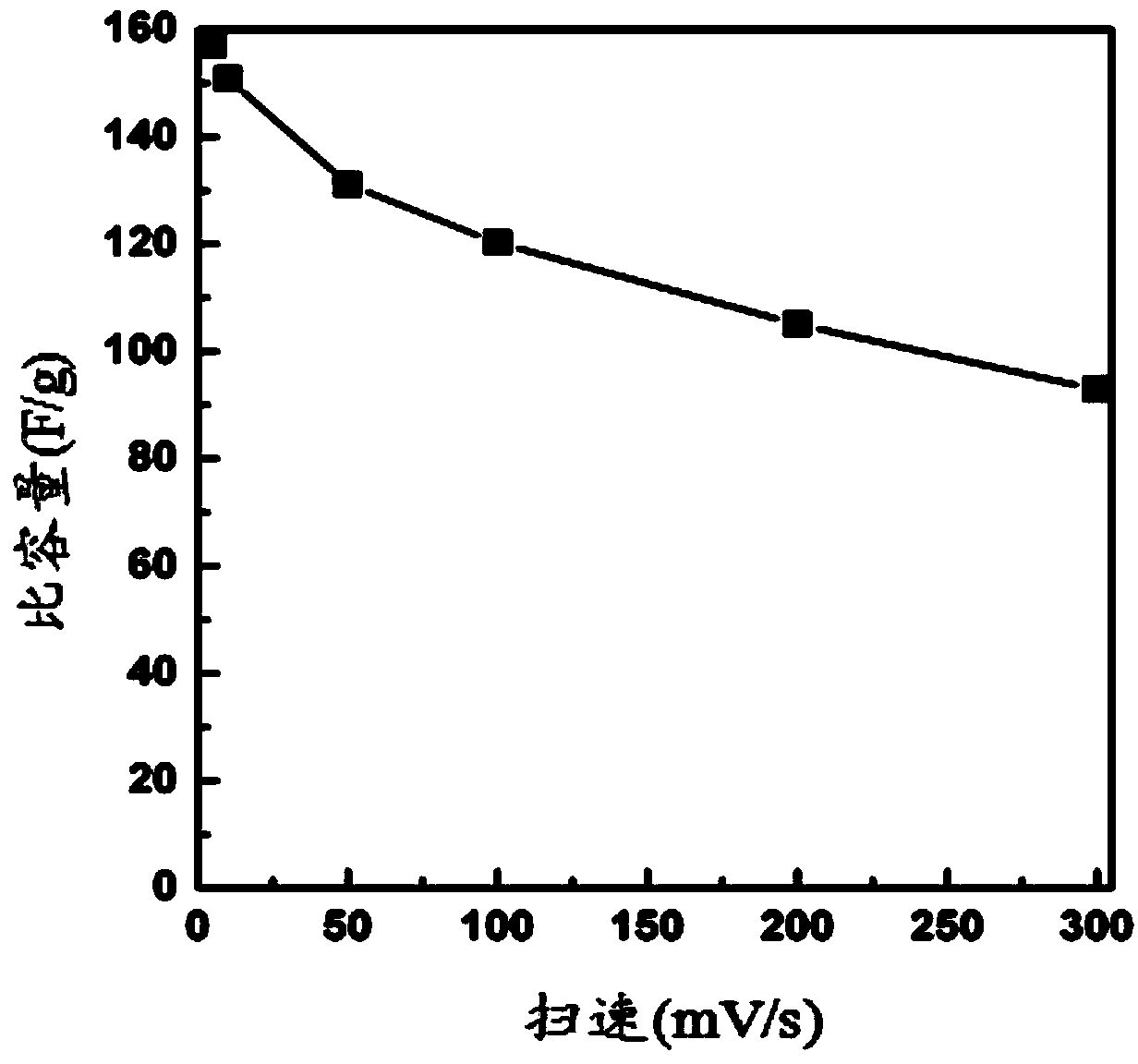

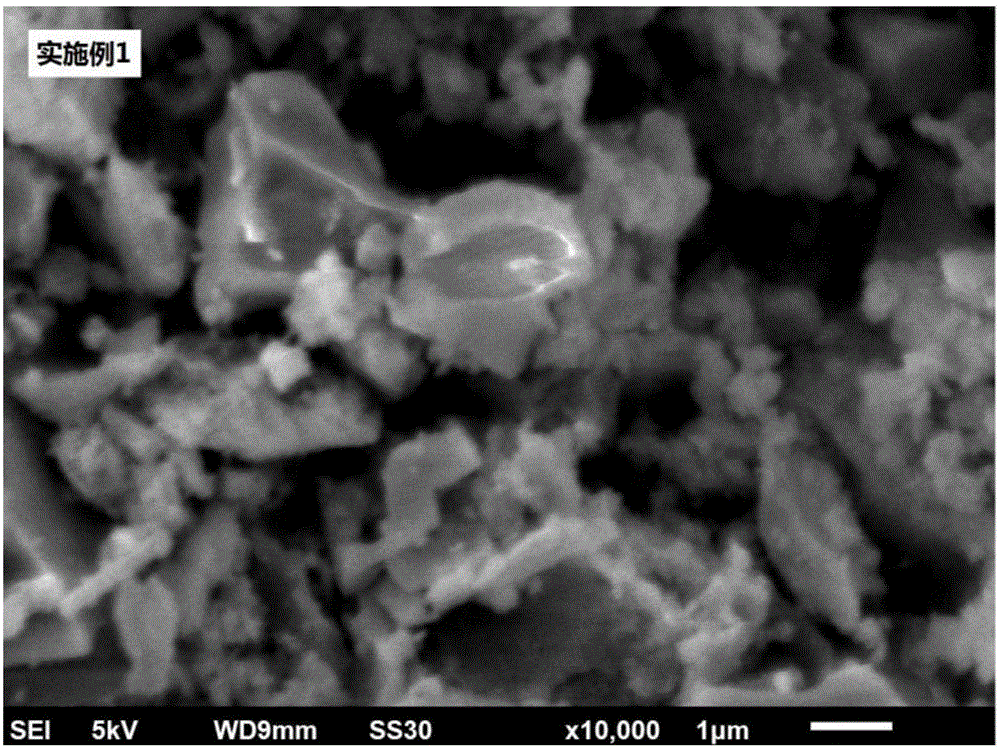

Porous graphene, preparation method thereof, and supercapacitor

ActiveCN103303913AHigh tap densityLarge specific surface areaHybrid capacitor electrodesGraphenePorous grapheneDesorption

The invention provides porous graphene, a preparation method of the porous graphene and a supercapacitor. The porous graphene simultaneously has a mesoporous structure and a macropore structure, and the tap density of the porous graphene is 0.3-0.5g / mL. Compared with the existing graphene at high specific surface area, the porous graphene provided by the invention has quite high tap density and simultaneously has the mesoporous structure and the macropore structure; the mesoporous structure and the macropore structure endow the porous graphene with quite high specific surface area; when the porous graphene is used as the material for the supercapacitor, the macropore structure provides a fast migration passage for an electrolyte; meanwhile the size of the mesoporous structure is equivalent to that of an ion in the organic electrolyte to facilitate the fast desorption and absorption of the ion, so that the capacitor has quite good large-multiplying power charge-discharge performance.

Owner:NINGBO GRAPHENE INNOVATION CENT CO LTD

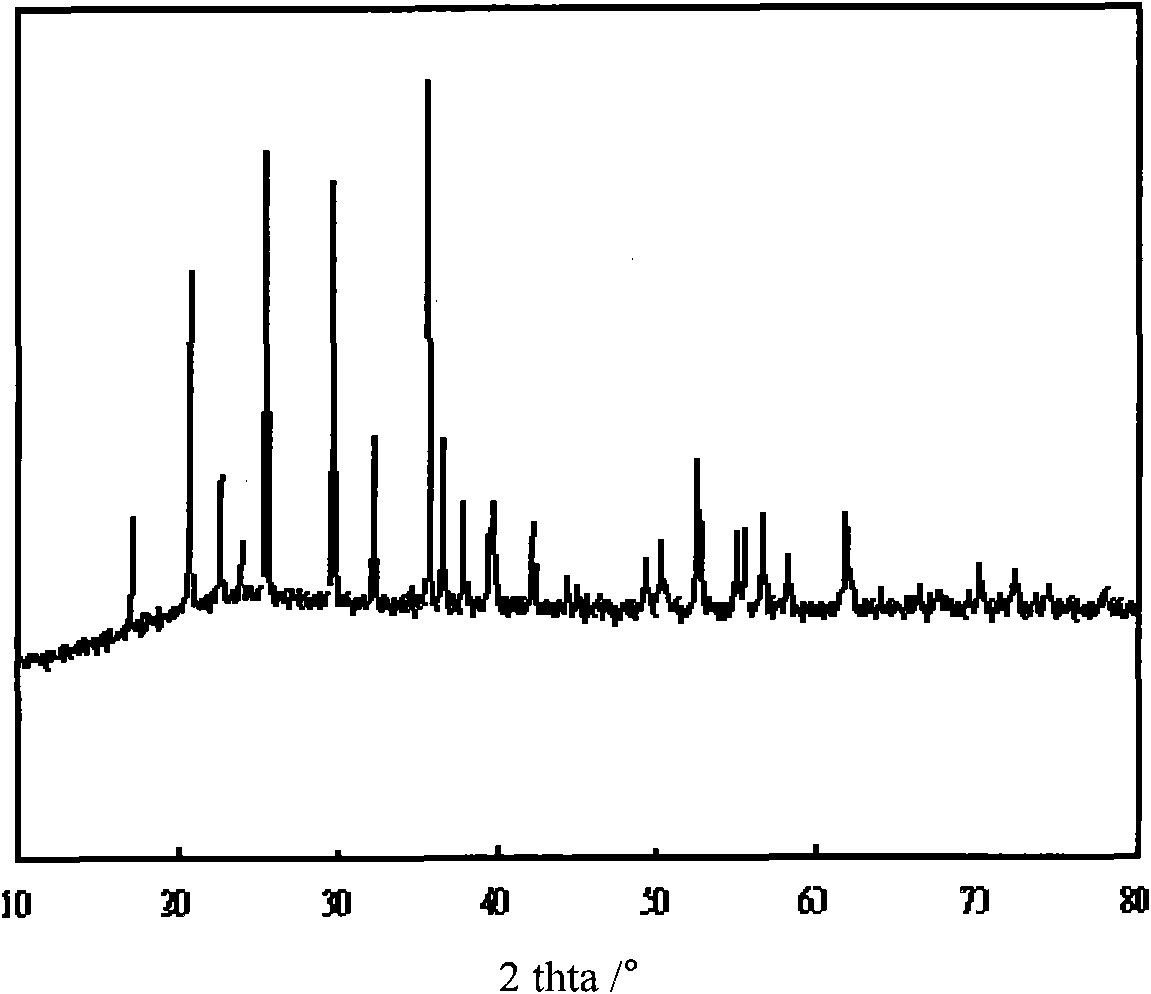

Lithium iron vanadium manganese phosphate nano oxide compound anode material and preparation method thereof

ActiveCN102891316AHigh crystallinityImprove conductivityCell electrodesCrystallinityLithium-ion battery

The invention relates to a lithium iron vanadium manganese phosphate nano oxide compound anode material and a preparation method thereof. The lithium iron vanadium manganese phosphate nano oxide compound anode material comprises a component A and a compound B carbon source, wherein the component A comprises 95-99.9wt% of lithium iron vanadium manganese phosphate compound Lix+3y+zFexV2yMnz(PO4)x+3y+z and 0.1-5wt% of nano oxide; and the component B carbon source accounts for 0.5-35wt% by mass of the lithium iron vanadium manganese phosphate compound Lix+3y+zFexV2yMnz(PO4)x+3y+z in the component A. The preparation method of the compound anode material comprises the steps of: firstly weighing a lithium source, an iron source, a vanadium source, a manganese source and a phosphorus source according to proportions, uniformly ball-grinding and mixing, pre-sintering after tabletting, crushing, adding the nano oxide and the component B carbon source, ball-grinding, calcining, crushing and refining. The lithium iron vanadium manganese phosphate nano oxide compound anode material provided by the invention has better crystallinity and conductivity as well as high specific capacity, and has wide application prospects in the field of lithium ion batteries.

Owner:中科(马鞍山)新材料科创园有限公司

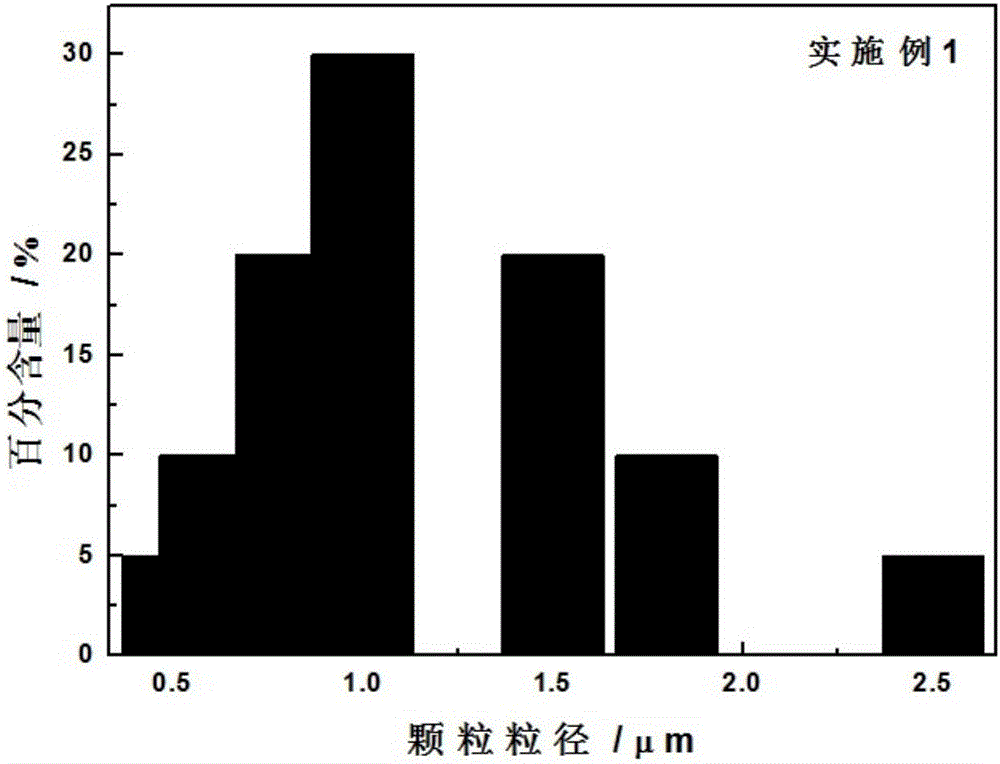

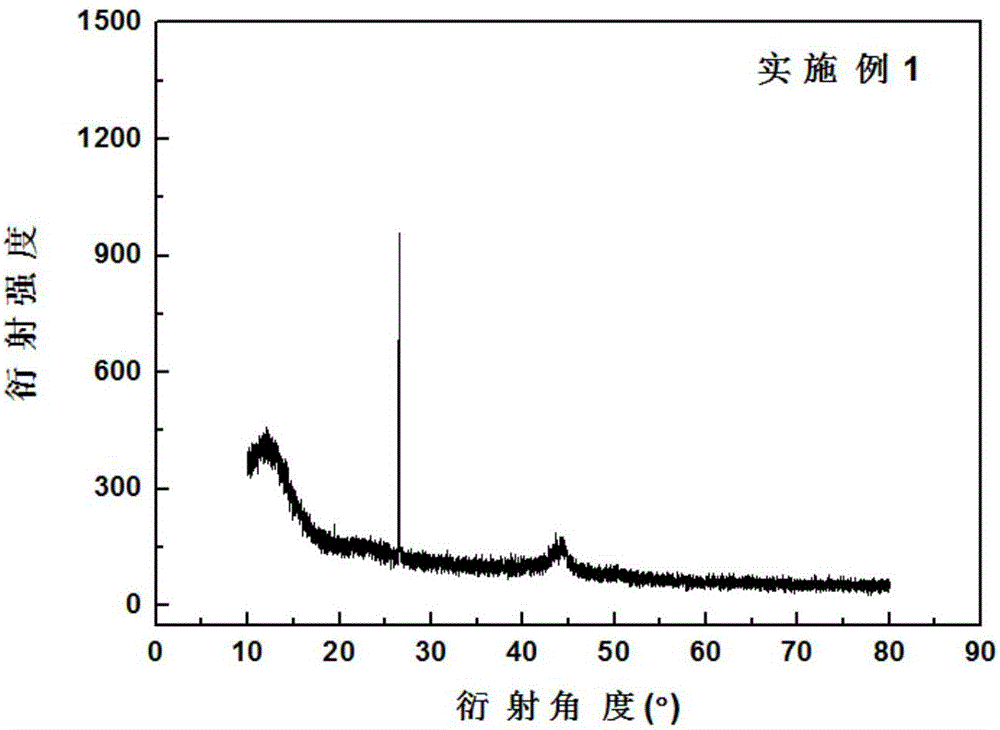

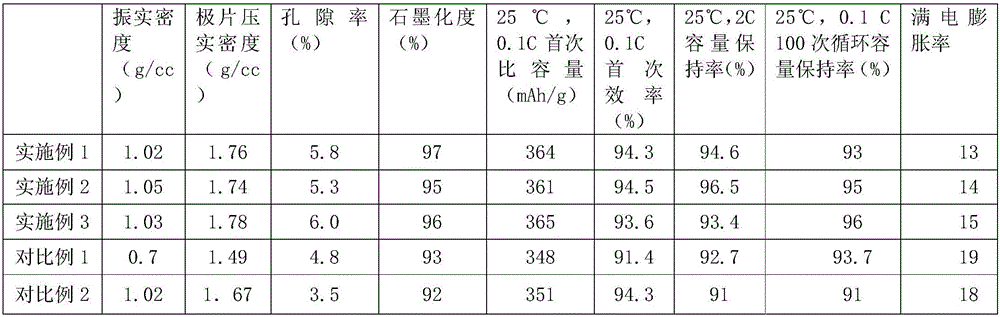

Modified microcrystal graphite cathode material of lithium ion battery as well as preparation method and application thereof

ActiveCN107814383APreserve structural propertiesHigh sphericityGraphiteCell electrodesSodium-ion batteryLithium-ion battery

The invention relates to the technical field of lithium ion battery carbon cathode materials and in particular to a modified microcrystal graphite cathode material of a lithium ion battery as well asa preparation method and application thereof. The material has the advantages that (1) a modified core-shell structured natural graphite cathode material with artificial graphite embedded into and onthe surface of natural graphite in situ is prepared, the overall structural properties of natural microcrystal graphite are maintained, pores of the natural microcrystal graphite is filled with the artificial graphite, and the outer surface of the natural microcrystal graphite is wrapped by the artificial graphite; (2) compared with a conventional cathode material, the cathode material prepared byusing the method provided by the invention is good in isotropy, is capable of inhibiting and absorbing expansion of electrodes in the charge and discharge process, is high in primary coulombic efficiency, long in service life and good in high-magnification charge and discharge performance and is capable of replacing artificial graphite to manufacture cathode materials of power batteries, so as tolower the cost greatly; and (3) the method is simple in preparation process, low in cost and relatively high in practicability.

Owner:GUANGDONG DONGDAO NEW ENERGY +1

Active material of super lead storage battery plate

InactiveCN102024946AImprove conductivityImprove low temperature resistanceLead-acid accumulator electrodesFiberHigh rate

The invention discloses an active material of a lead storage battery plate. An anode active material comprises the following components by weight: 100kg of lead powder, 0.01 to 2kg of conductive fiber, 0.1 to 5kg of metallic oxide, 0.1 to 2kg of conductive carbon material, 0.01 to 1kg of sodium carboxymethyl cellulose and 1 to 15kg of diluted sulfuric acid; and a cathode active material comprises the following components by weight: 100kg of lead powder, 0.01 to 2kg of conductive fiber, 0.1 to 5kg of conductive carbon material, 0.1 to 0.6kg of barium sulfate, 0.2 to 1kg of humic acid, 0.01 to 0.1kg of lignin and 1 to 15kg of diluted sulfuric acid. The components and ratio of the active material are improved and optimized, and the active material comprises various carbon materials, so a super lead storage battery consisting of the plate made of the active material has high low-temperature performance, high rate charge and discharge performance and long charge and discharge cycle life, and particularly has strong market competition advantages when applied to electrically-driven vehicles.

Owner:NANJING SHUANGDENG SCI TECH DEV RES INST

Manufacturing method of negative plate of safety lithium-ion battery

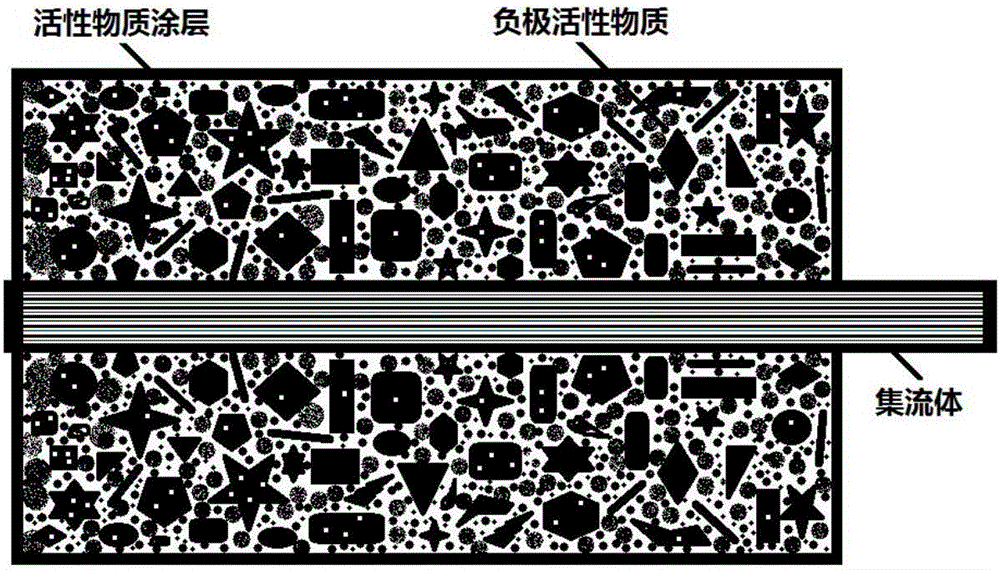

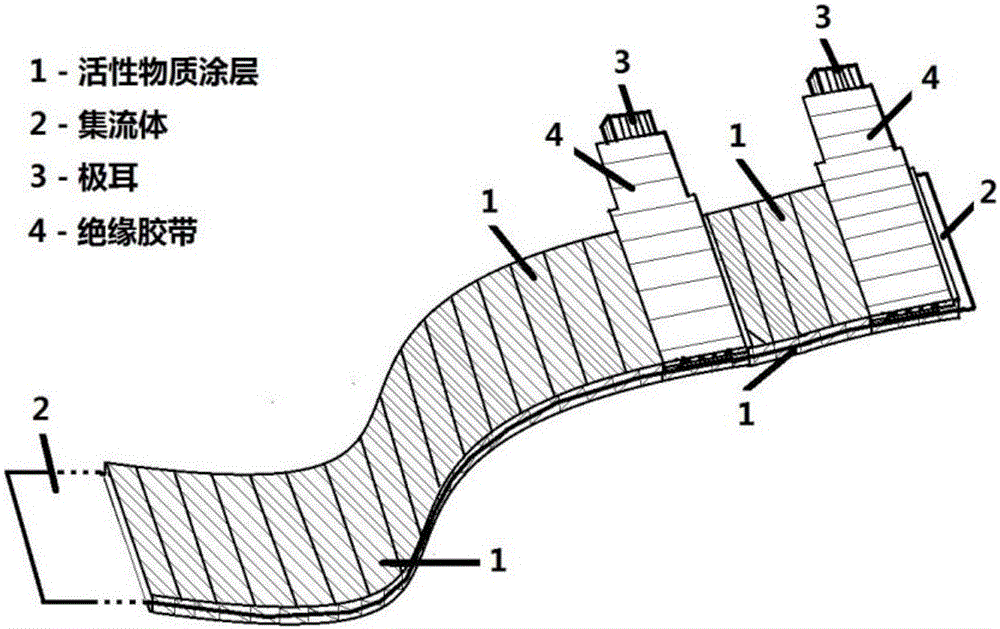

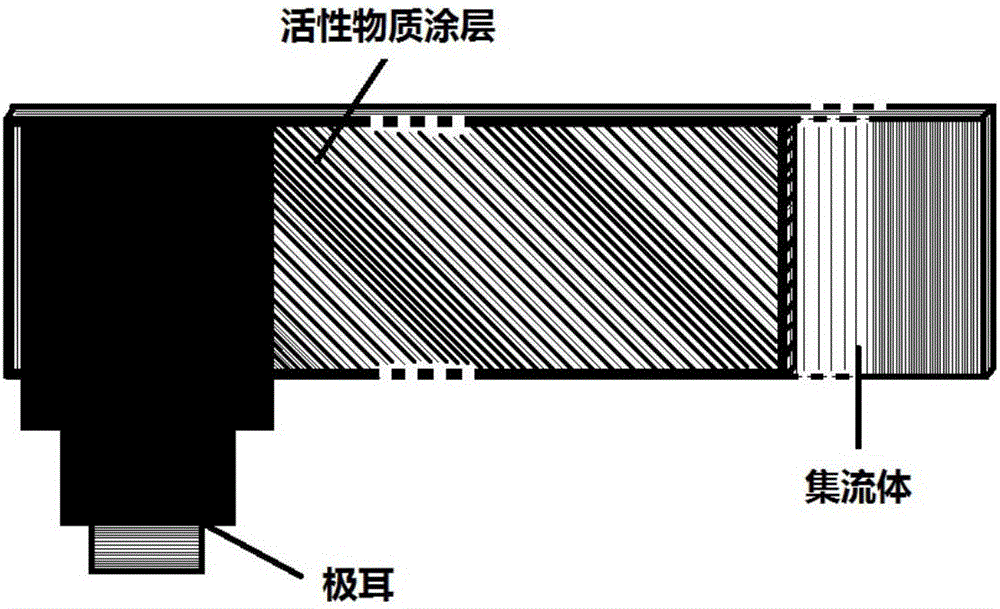

InactiveCN106450169AGood thermal stabilityStable performance during charge and discharge cyclesSecondary cellsElectrode collector coatingCopper foilCurrent collector

The invention discloses a manufacturing method of a negative plate of a safety lithium-ion battery. The method comprises the steps of mixing a negative active material with a conductive agent at a certain mass ratio to obtain a mixture A; carrying out ball-milling and mixing on an additive B and the mixture A at a certain mass ratio to form a mixture C; preparing a certain mass percent of water solution from CMC which accounts for a certain mass ratio of the mixture C, carrying out constant-temperature stirring, adding an SBR which accounts for a certain mass ratio of the mixture C in batches, simultaneously adding an NMP which accounts for a certain ratio of the mixture C and carrying out constant-temperature stirring to form a sizing material D; adding the mixture C to the sizing material D in batches, controlling the solid content of the mixture C and stirring to obtain slurry; adding a proper amount of water, adjusting, controlling the viscosity and stirring to obtain negative slurry E; employing copper foil as a current collector F, intermittently coating a single side or double sides of the current collector F with the negative slurry E, reserving a certain current collector, carrying out drying, controlling the surface density, carrying out rolling and controlling the compactness and the thickness of the negative plate; and dividing, cutting, welding and pasting a tab adhesive tape to obtain the negative plate of the safety lithium-ion battery. The lithium-ion battery assembled by the negative plate has good electric cycle performance and safety performance.

Owner:HUBEI UEE ENERGY TECH CO LTD

Porous graphene and preparation method thereof

ActiveCN103395779ALarge specific surface areaHas a mesoporous structureGraphenePorous grapheneSulfur

The invention provides a porous graphene and a preparation method thereof. The preparation method comprises the following steps: under the action of an oxidant, heating a graphite substance and sulfur in a solvent to react, thereby obtaining the porous graphene, wherein the graphite substance is one or more of graphene oxide, graphene and graphite microsheets. The porous graphene provided by the invention has a mesopore structure, and thus, has higher specific area. When the porous graphene provided by the invention is used in a supercapacitor electrode material, the supercapacitor has favorable high-power charging / discharging property.

Owner:NINGBO GRAPHENE INNOVATION CENT CO LTD

Preparation method of battery-grade graphite-activated carbon composite material

InactiveCN106099108AWide particle size distributionHigh porosityCell electrodesSecondary cellsMuffle furnaceActivated carbon

The invention discloses a preparation method of a battery-grade graphite-activated carbon composite material. The preparation method comprises the steps that 1, plant raw materials are washed clean with water and then contained in a metal tank, the metal tank is sealed and put into a muffle furnace, heating is conducted at the constant temperature of 450 DEG C to 650 DEG C, the temperature is naturally decreased to room temperature, and black solid activated carbon is obtained; 2, the obtained black solid activated carbon and graphite are put into a ball milling tank according to the mass ratio of 3:1-1:1, an appropriate amount of hydrochloric acid with the concentration of 0.2 M to1.0 M, an appropriate amount of sulfuric acid with the concentration of 0.1 M to 0.5 M, an appropriate amount of acetic acid with the concentration of 0.5 M to 1.2 M and an appropriate amount of water are sequentially added into the ball milling tank, ball milling is conducted for 0.5 hour to 2 hours under the condition that the ball-material ratio is equal to 1:10-1:20, and then acid washing and water washing are sequentially conducted, wherein sulfuric acid, hydrochloric acid and acetic acid are subjected to ball-milling washing three times to five times separately, and the water is subjected to ball-milling washing until the pH value of eluate is 6.8 to 7.2; 3, the washed graphite-activated carbon mixture is subjected to suction filtration and dried in an atmospheric environment, and the battery-grade graphite-activated carbon composite material is obtained. The preparation method has the advantages of being simple in process, rich in raw materials, short in manufacturing cycle and low in energy consumption and has good economic benefits, environmental benefits and social benefits.

Owner:HUBEI UEE ENERGY TECH CO LTD

Preparation method of high-performance graphite negative electrode material for lithium ion battery

InactiveCN105789627AEasy to processImprove cycle performanceCell electrodesSecondary cellsHigh rateMass ratio

The invention discloses a preparation method of a high-performance graphite negative electrode material for a lithium ion battery. The method comprises the following steps of 1) collecting petroleum coke micropowder in a shaper and a grinder in normal graphite production, and mixing the petroleum coke micropowder, ground expanded graphite powder, raw mesocarbon microbeads and an adhesive in a mixer for 0.5-3 hours according to a mass ratio of 1 to (0.01-0.3) to (0.7-1.5) to (0.1-0.2) to form a solid-phase coated mixture, wherein the frequency of the mixer is 30-50HZ; and 2) graphitizing the solid-phase coated mixture obtained in the step 1) to obtain the high-performance graphite negative electrode material for the lithium ion battery. The method is simple and feasible; micropowder wastes in a dust collector are recycled, so that the cost is reduced; the method is easy for large-scale industrial production; and the obtained graphite negative electrode material has the characteristics of high energy density, good liquid absorption and retention performance, good cycle performance, good isotropic performance, good high-rate charge / discharge performance and low expansion rate in a charge / discharge process.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

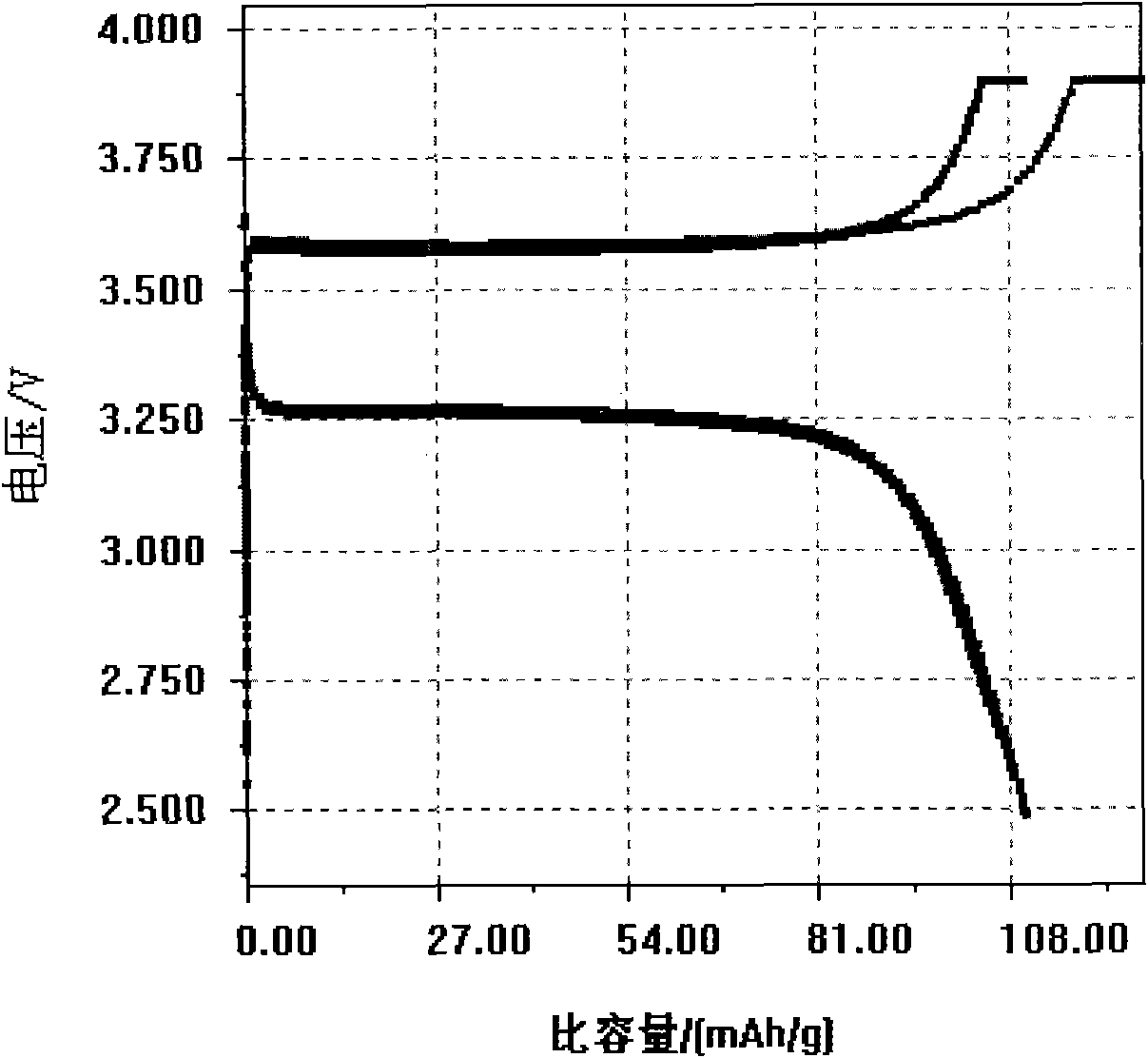

Lithium ion battery composite cathode material and preparation method thereof

InactiveCN101640263AHigh reversible capacityImproved high-magnification performanceElectrode manufacturing processesSecondary cellsArgon atmosphereLithium-ion battery

The invention relates to a lithium ion battery composite cathode material which is characterized by being prepared from powder which is formed by uniformly coating amorphous carbon on the surfaces ofin situ composite Li3V2(PO4)3 and LiFePO4, wherein the powder contains the components in percentage by weight: 75.0-74.0 percent of LiFePO4, 21.8-21.8 percent of Li3V2(PO4)3 and 2.3-4.8 percent of amorphous carbon. A preparation process of the composite cathode material adopts a carbothermic reduction solid phase sintering method which comprises the following steps: mixing raw materials of FePO4,Li2CO3, NH4H2PO4 and NH4VO3 according to a stoichiometric ratio; adding petroleum coke accounting for 15-25 percent of the total weight of the raw materials; and after adding acetone to ball mill andmix the raw materials on a ball milling machine, and calcining the raw materials in argon atmosphere at 600-700 DEG C for 8-12 hours. When used as a cathode of a lithium ion battery, the composite cathode material has the advantages of simple preparation method, high charge and discharge capacity, good performance of high multiplying power charge and discharge, good cyclical stability, and the like.

Owner:杭州海孚新能源科技有限公司 +1

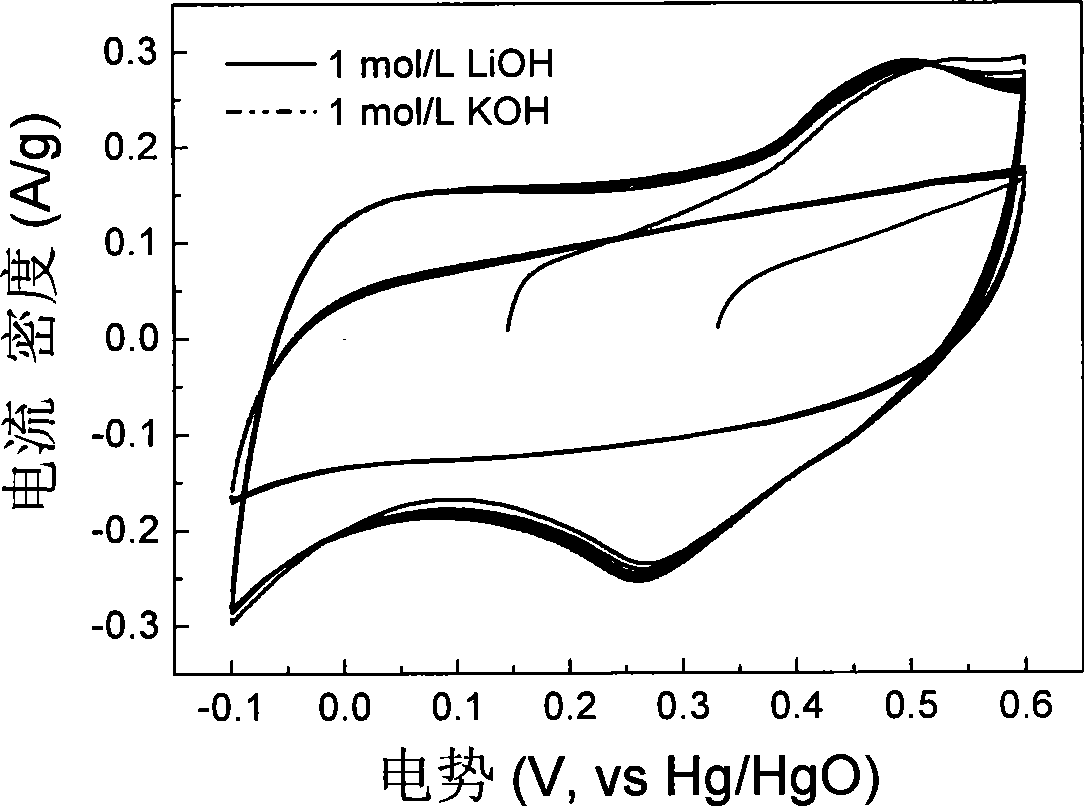

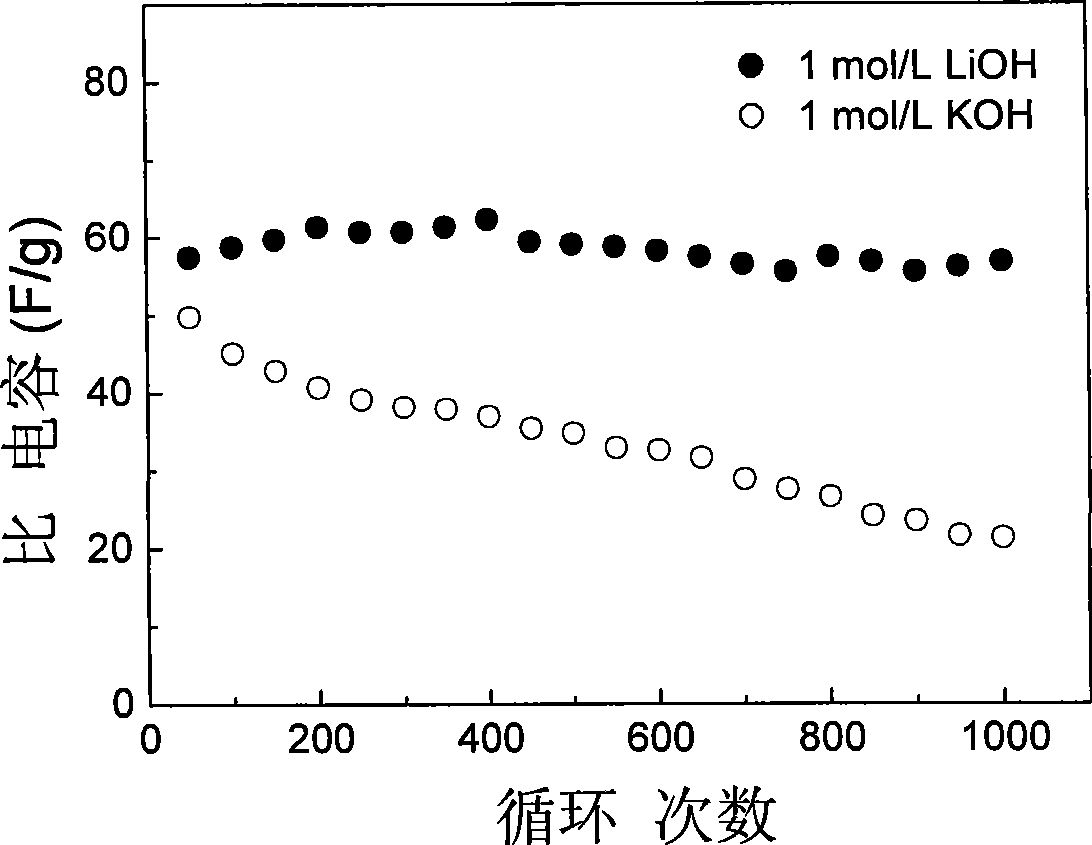

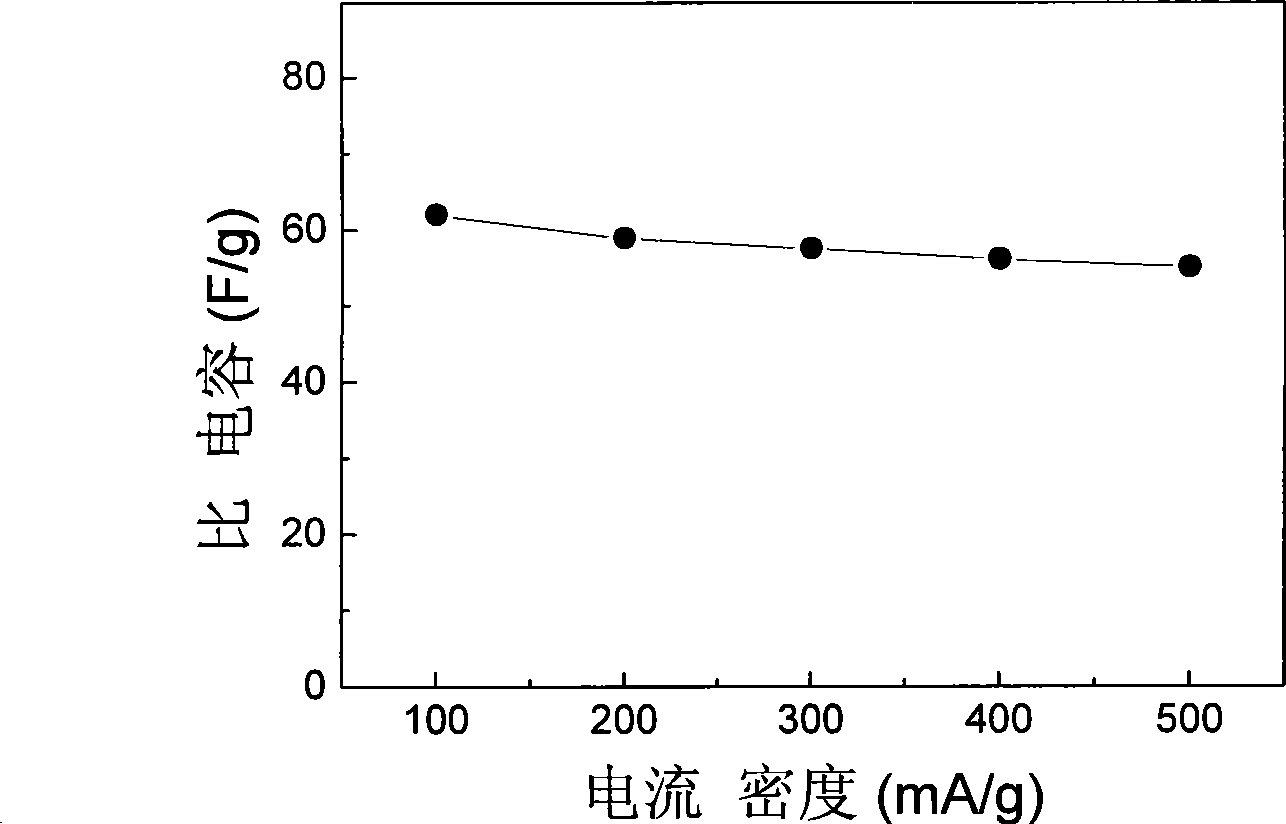

Novel mixed super capacitor

InactiveCN101399120AIncrease energy densityImprove power densityReduction and oxidation devicesCapacitanceHigh rate

The invention relates to a novel mixed super capacitor which adopts a nano MnO2 electrode as a positive electrode, an activated carbon electrode as a negative electrode and alkaline lithium hydroxide water solution as electrolyte. The positive electrode stores energy by a Faraday oxidation reduction mechanism, and the negative electrode stors energy by a double electrode layer mechanism. When the lithium hydroxide electrolyte is adopted, the reaction mechanism of the nano MnO2 electrode is different from the reaction mechanism in potassium hydroxide electrolyte or neutral water solution. Therefore, the nano MnO2 electrode has higher specific capacitance. The super capacitor has the advantages of perfect high energy intensity, high power intensity, high-rate charge and discharge performance, long circulation service life, low cost and no environmental damages and can be applied to large power charge and discharge occasions.

Owner:SHANGHAI UNIV

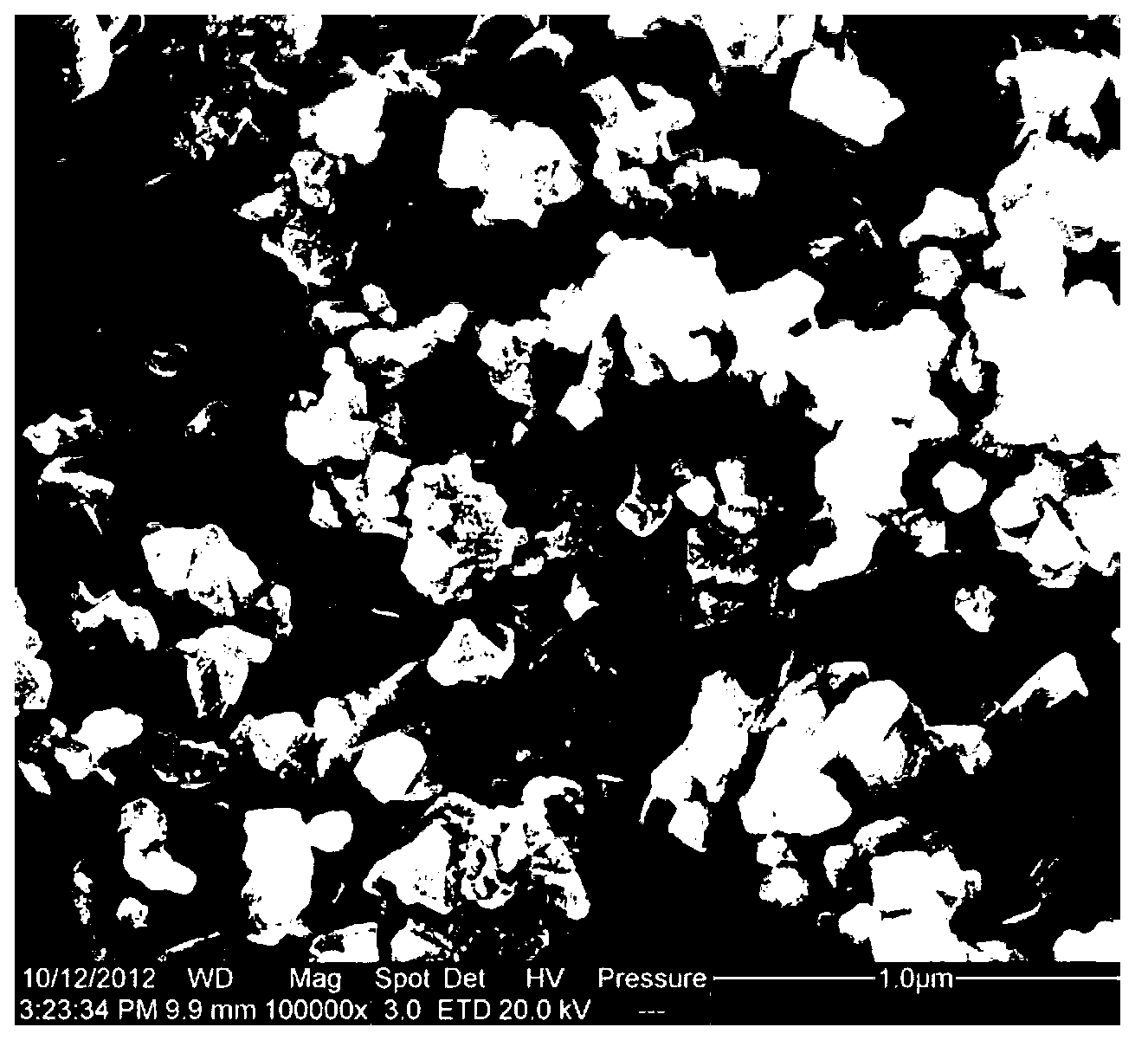

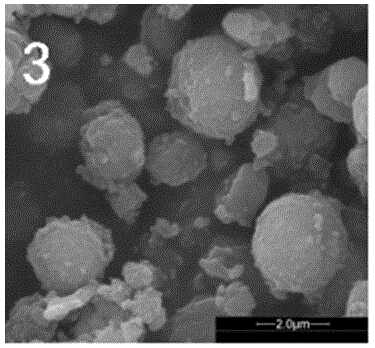

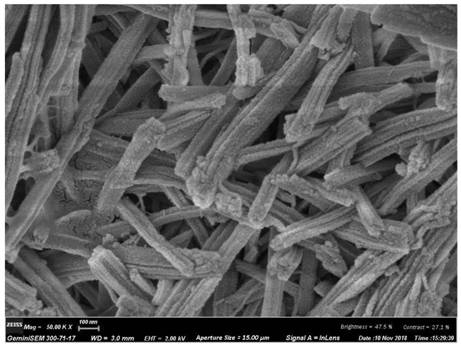

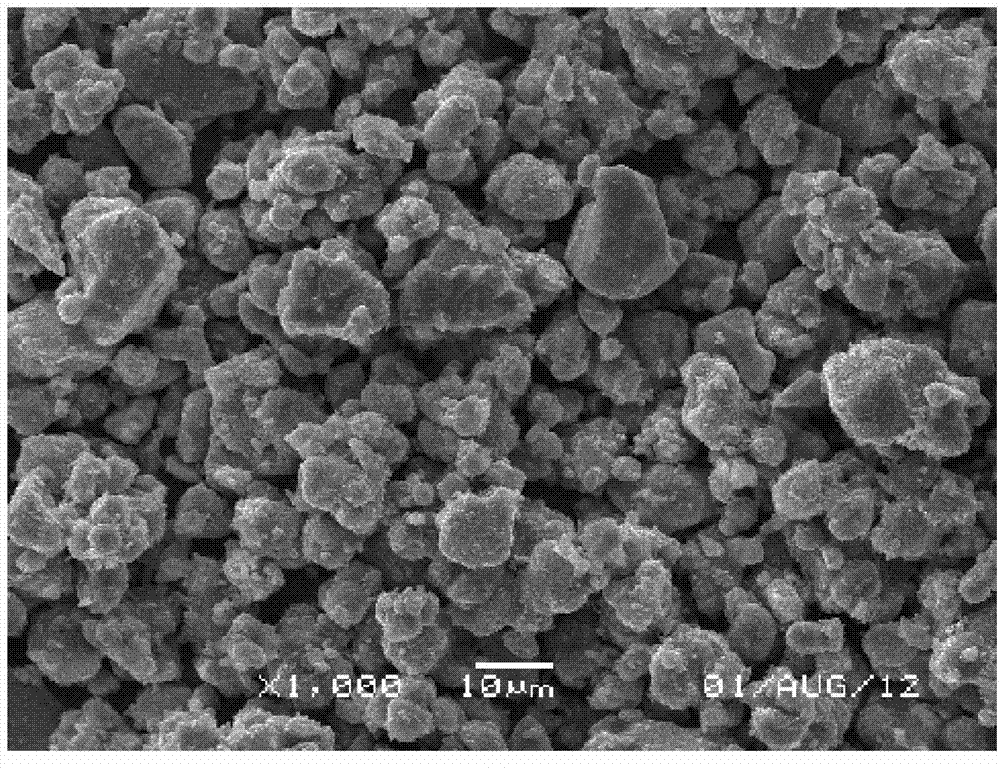

Preparation method of 3D micro/nano-structure spherical active iron phosphate

ActiveCN104085868AShorten the conduction pathImprove conductivityPhosphorus compoundsWater bathsNano structuring

The invention relates to a preparation method of 3D micro / nano-structure spherical active iron phosphate, which comprises the following steps: (1) preparing a surfactant solution; (2) preparing an iron nitrate nonahydrate solution; (3) dropwisely adding the iron nitrate nonahydrate solution into the surfactant solution to obtain a solution A; (4) weighing a H3PO4 solution, adding the phosphoric acid solution into the solution A, stirring and mixing for 30-240 minutes to obtain a clear transparent solution B; (5) reacting the obtained clear transparent solution B under the 80-100 DEG C water bath condition for 2-4 days or under the 150-200 DEG C oil bath condition for 2-8 hours; and (6) cooling, carrying out solid-liquid separation, washing, carrying out centrifugal separation to obtain a white precipitate, and drying the white precipitate at 80-110 DEG C. The iron phosphate material can be prepared into a LiFePO4 positive pole material after being lithiated, and has the advantages of favorable high-magnification charging / discharging performance and favorable tap density.

Owner:HUNAN INST OF TECH

Vehicle-mounted new energy battery pack

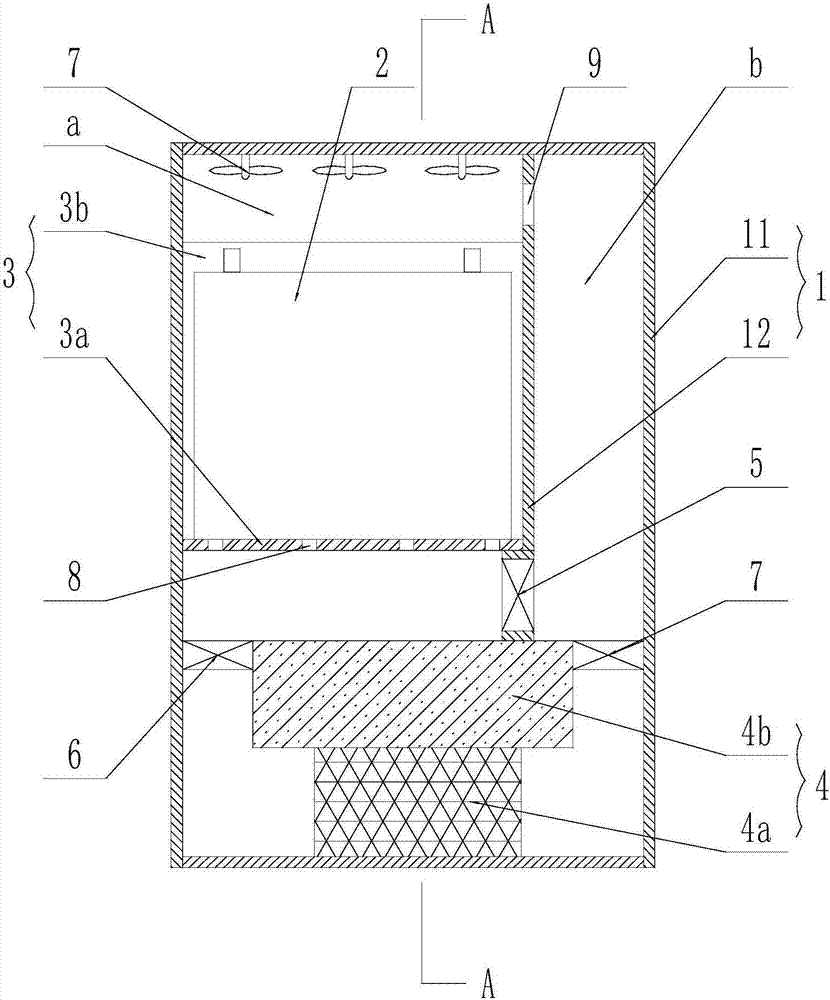

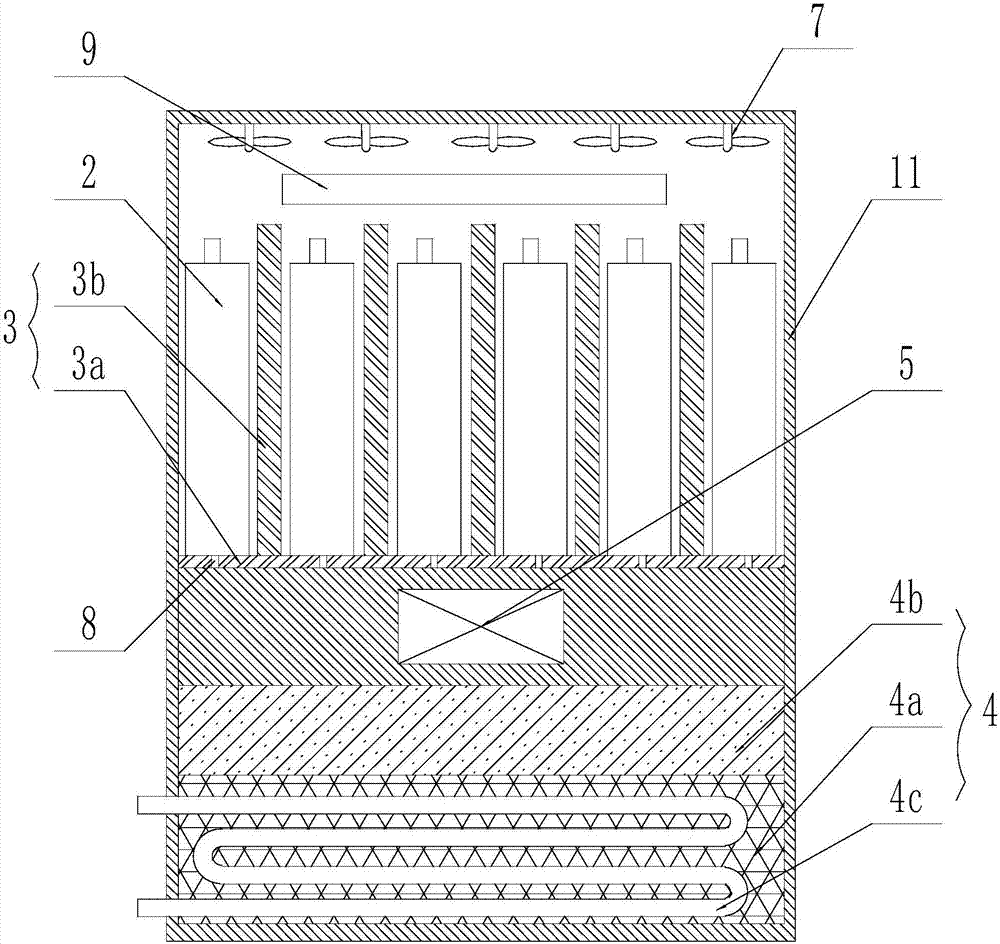

InactiveCN107230751ARealize the heat dissipation functionImprove high rate discharge performanceCell electrodesSecondary cellsHigh rateElectrical battery

The invention discloses a vehicle-mounted new energy battery pack. The vehicle-mounted new energy battery pack comprises a battery box and multiple battery bodies arranged in the battery box; the battery box comprises a sealed type box body; a space partition plate is vertically arranged in the sealed type box body; the battery box is divided by the space partition plate into a battery placement region and a heat dissipation region; a fan is arranged on the battery box top plate above the battery placement region; a temperature detector is arranged in the battery placement region; multiple ventilating holes are formed in a battery fixation frame in the battery placement region; the ventilating holes are connected with the heat dissipation region to from an air circulation channel; and an air cooling apparatus is arranged in the air circulation channel. Compared with the prior art, the battery pack is arranged in the sealed box body according to the structure of the vehicle-mounted new energy battery pack, so that effects of thermal insulation and waterproofness are realized; by virtue of divisional setting, the temperature field distribution in the battery box can be improved; and by virtue of the battery bodies, the high-rate discharging performance of the lithium battery is improved, and excellent electronic conductivity and ionic conductivity and high high-rate charging-discharging performance are represented.

Owner:江苏昊科汽车空调有限公司

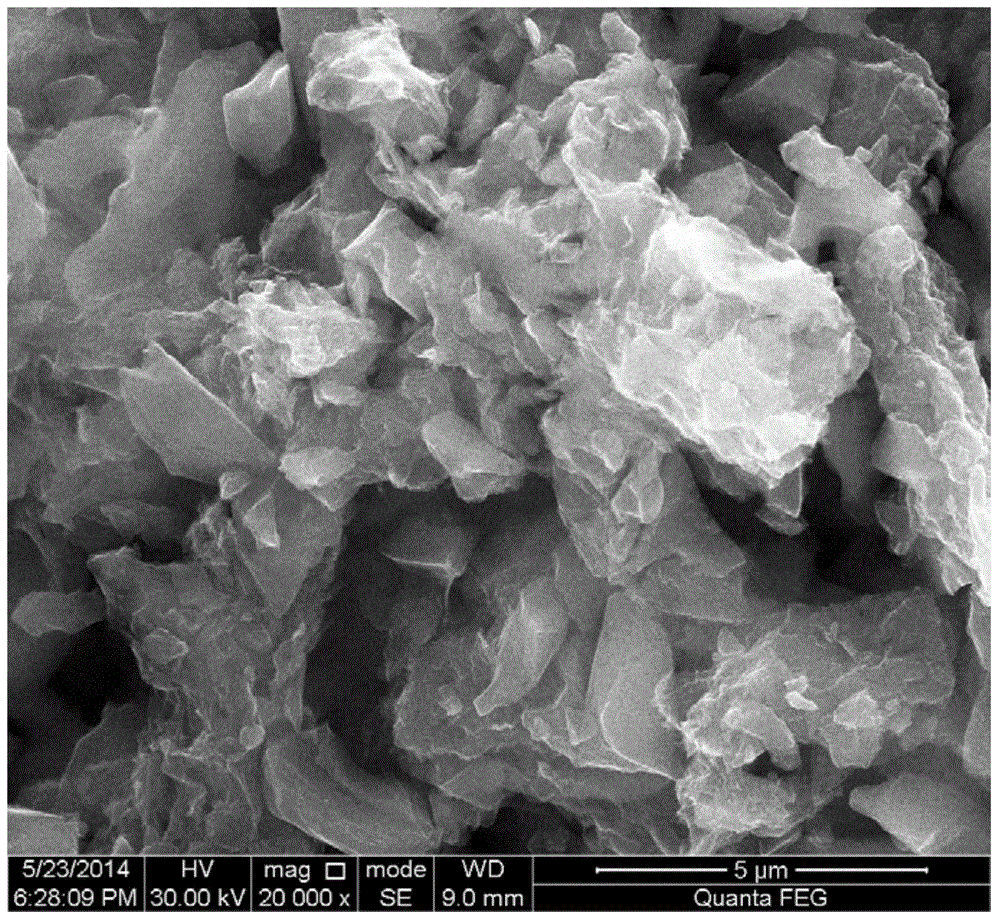

Method for preparing ferrum electrode material of ferro-nickel rechargeable secondary battery

InactiveCN104466169AInhibit growthImprove effective utilizationCell electrodesNickel accumulatorsElectrical batteryGraphene flake

The invention provides a method for preparing a ferrum electrode material of a ferro-nickel rechargeable secondary battery. The method comprises the following steps: dissolving ferric salt and oleate according to a substance ratio of (1:1)-(1:10) in a mixed solvent of absolute ethyl alcohol, deionized water and aliphatic hydrocarbon, thereby obtaining an oleic acid iron-based compound; dispersing expanded graphite carbon powder in a mixed solvent of oleylamine and aromatic hydrocarbon according to a volume ratio of (1:1)-(1:10), thereby obtaining oleylamine modified nano graphene sheets; dissolving the compound and the nano graphene sheets in the aromatic hydrocarbon, and drying after treatment, thereby obtaining a ferrum electrode precursor compound containing the graphene sheets; heating in a tubular furnace at a rate of 1 to 20 DEG C per minute under the inert gas or nitrogen protection, and performing heat treatment; and naturally cooling to room temperature, thereby obtaining the graphene sheet modified iron electrode material for the ferro-nickel rechargeable secondary battery. According to the method disclosed by the invention, the ferrum electrode of the ferro-nickel rechargeable secondary battery has excellent quick charge and discharge performance, the operation process is simple, the repeatability is high, the material test effect is obvious, and the commercial popularization and application are promoted.

Owner:CENT SOUTH UNIV

Preparation method of lithium iron phosphate

InactiveCN101962180AImprove conductivityHigh specific capacityPhosphorus compoundsCharge dischargeNitrogen gas

The invention discloses a preparation method of lithium iron phosphate. The preparation method comprises the following steps of: dissolving an iron salt, a lithium salt and a carbon source into aqueous solution of a phosphoric chelating agent, fully stirring the mixture, and filtering the mixture to remove water and obtain a precursor of the lithium iron phosphate; and putting the precursor into a high-temperature atmosphere furnace, heating to raise the temperature in an atmosphere with an argon gas, a nitrogen gas or a nitrogen-hydrogen gas mixture, and naturally cooling the precursor to the room temperature after constant temperature baking to obtain the lithium iron phosphate which is a lithium ion battery anode material. The lithium iron phosphate prepared by the method is suitable for a high-multiplying-power discharge power battery, and has the advantages of high conductivity, large specific capacity, high high-multiplying-power charge-discharge performance, and high electrochemical performance.

Owner:SHENZHEN KOTO NEW ENERGY MATERIAL

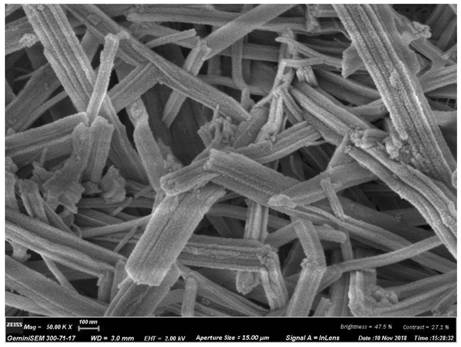

Grafted ceramic powder and preparation method thereof, ceramic diaphragm and preparation method thereof, lithium ion battery, battery module and battery pack

ActiveCN112521616AImprove stabilityImprove uniformitySecondary cellsCell component detailsPolyolefinCeramic coating

The invention relates to the field of ceramic diaphragms for lithium ion batteries, and discloses grafted ceramic powder, a preparation method of the grafted ceramic powder, a ceramic diaphragm, a preparation method of the ceramic diaphragm, a lithium ion battery, a battery module and a battery pack. The grafted ceramic powder comprises a ceramic nanomaterial and grafted polyolefin grafted on thesurface of the ceramic nanomaterial. The grafted ceramic powder is a one-dimensional rod-like material, has a modified surface, and can provide a more stable and uniform ceramic coating. The preparedceramic diaphragm is beneficial to improving the cycle performance of the lithium ion battery and the high-rate discharge performance of the battery.

Owner:BYD CO LTD

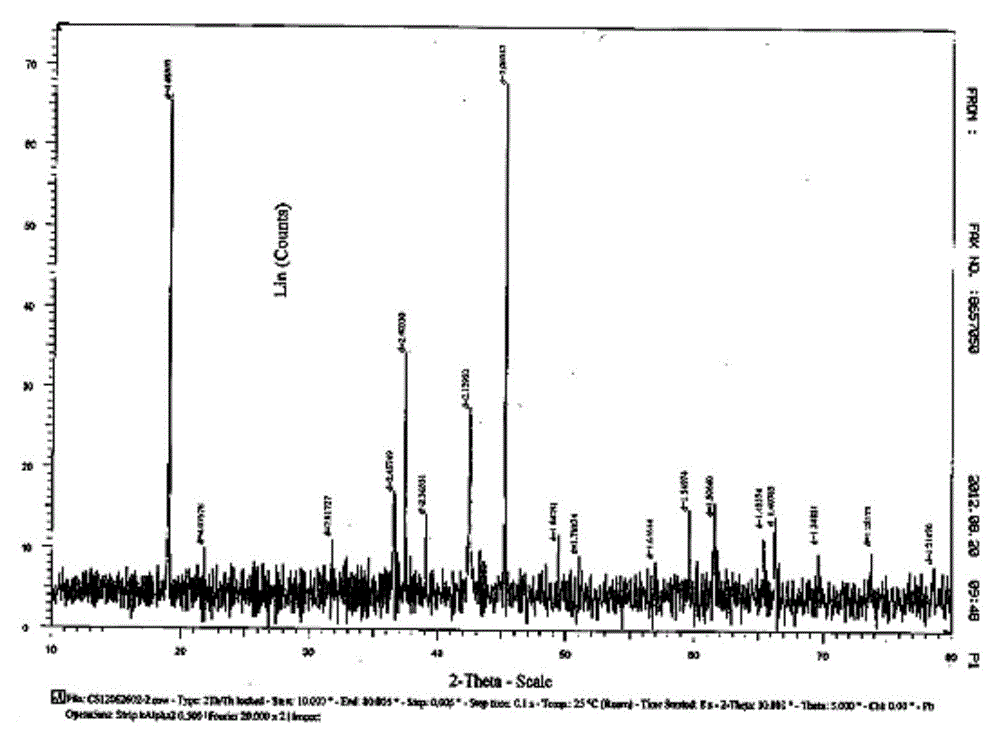

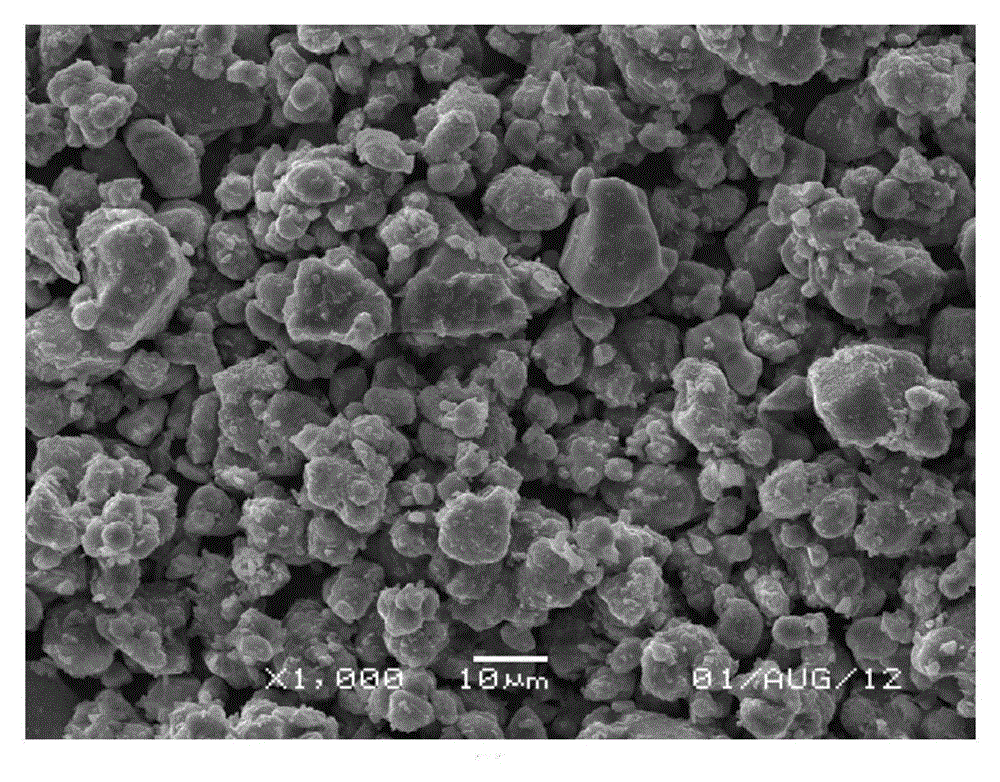

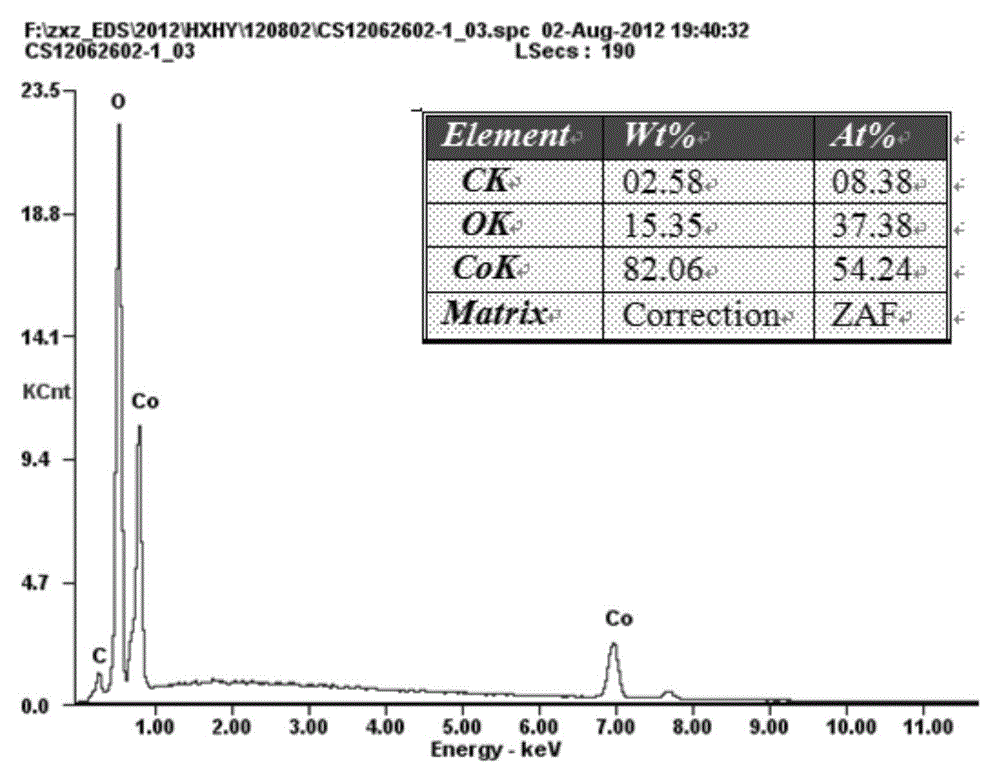

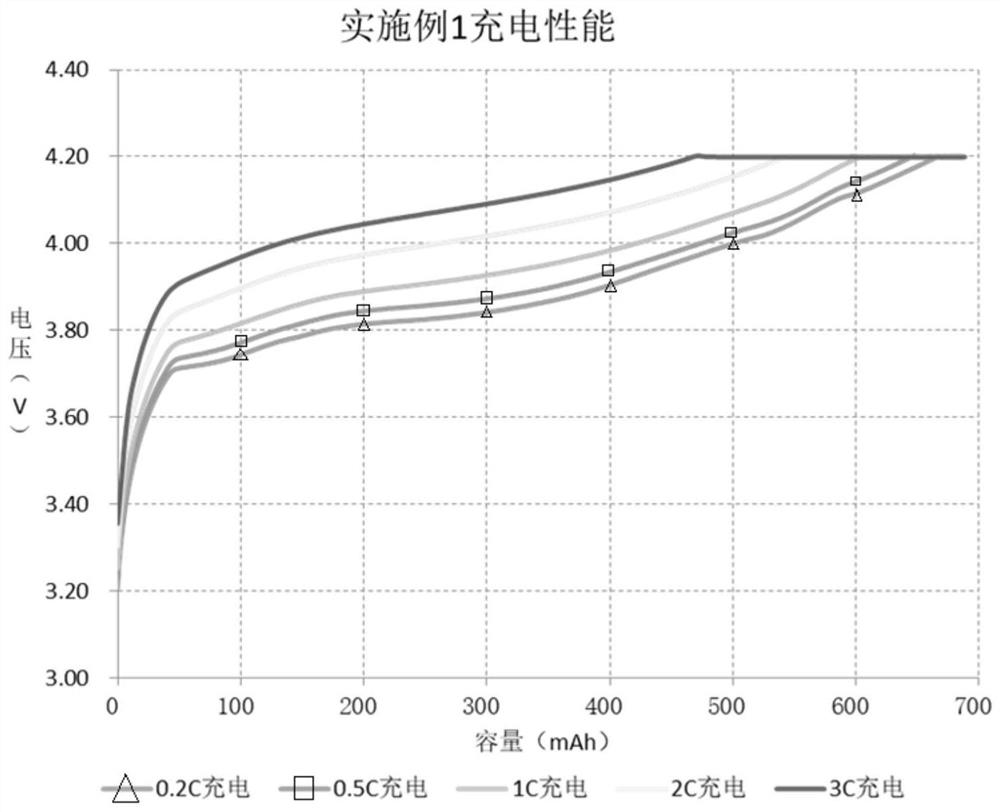

Preparation method for improving positive electrode material LiCoO2 electrical performance

InactiveCN103050685AIncrease compaction densityComplete structureCell electrodesCobalt compoundsHigh magnificationHigh current

The invention discloses a preparation method for improving the positive electrode material LiCoO2 electrical performance. The preparation method for improving the positive electrode material LiCoO2 electrical performance is completed according to the following steps of: mixing cobaltosic oxide and lithium salt (adding an additive T1); pretreating; sintering for the first time at the temperature of 600-11000 DEG C for 6-20 hours; carrying out surface treatment; mixing for the second time; pretreating; sintering in an inert atmosphere at 400-800 DEG C for 5-10 hours, and sintering for the second time at low temperature; and carrying out surface treatment, thereby obtaining the product. Modified lithium cobalt oxides prepared by the method provided by the invention not only have the original properties, but also can achieve high-magnification high-current charge and discharge; a battery prepared from lithium sheets as negative electrode materials tests, the test current magnification is 0.2C, and the voltage range is 2.9V-4.2V; the specific capacity of the tested material is greater than 160mAh / g in circulation for 100 times; the discharge platform retention rate is above 85%; and the capacity retention rate is above 95%.

Owner:TIANJIN GUOAN MGL NEW MATERIALS TECH CO LTD

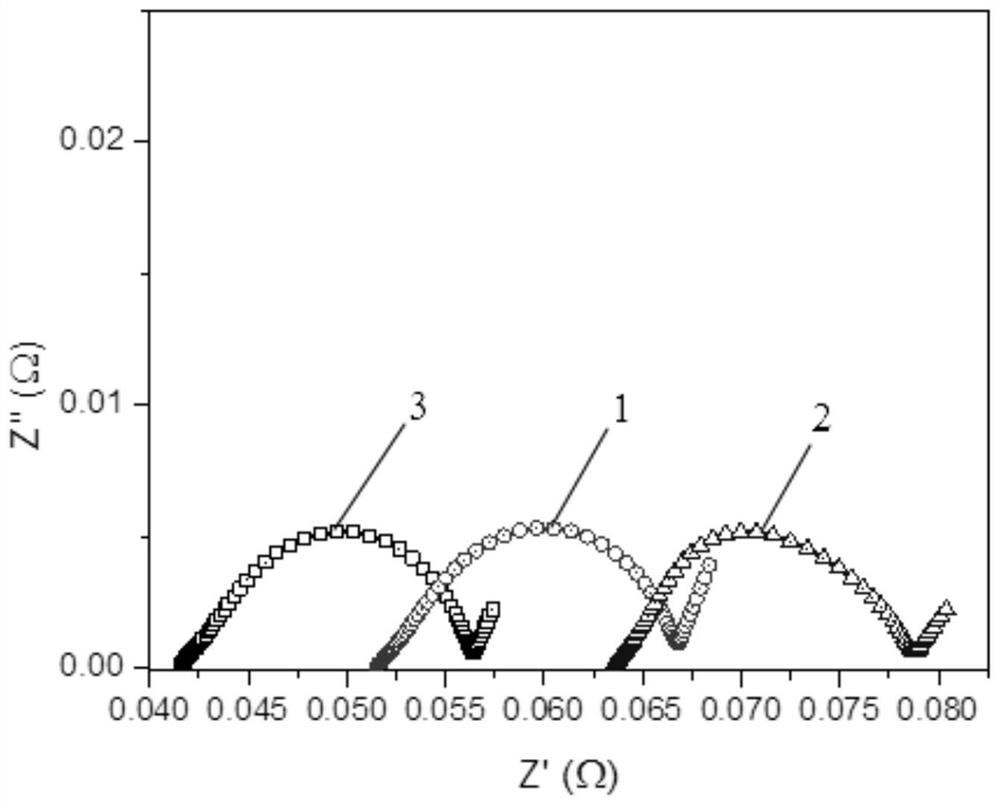

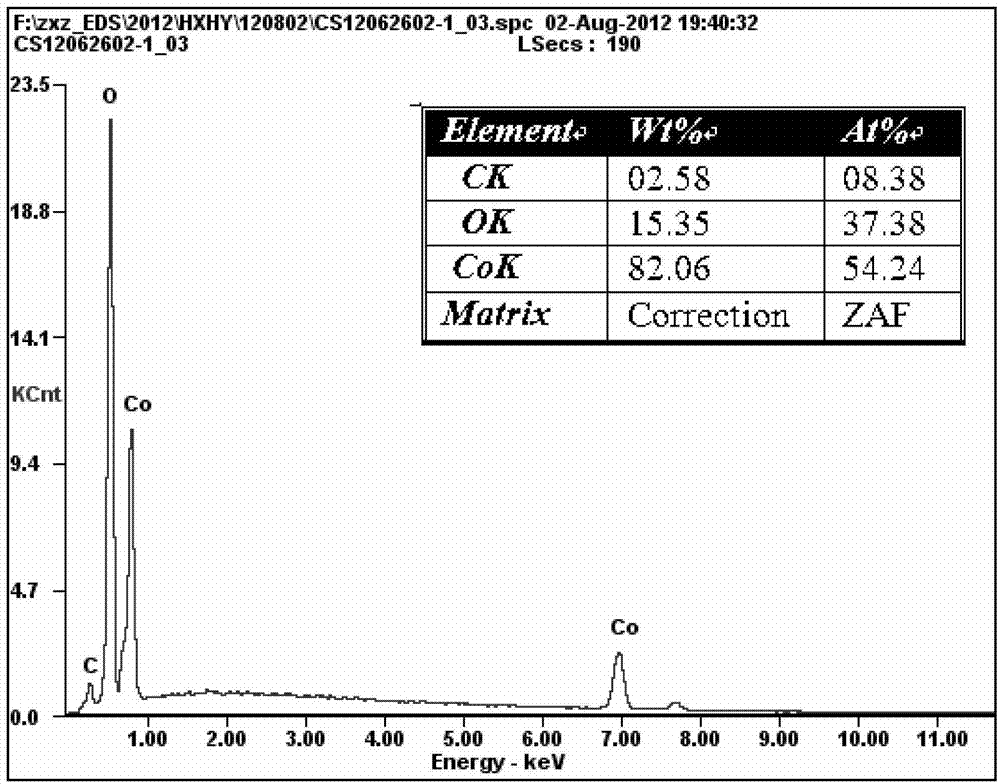

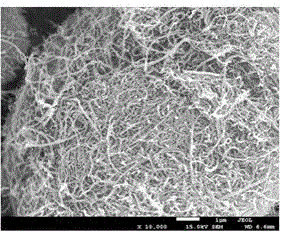

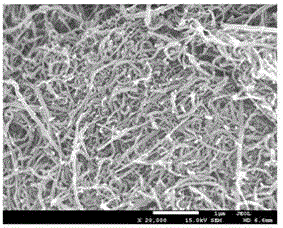

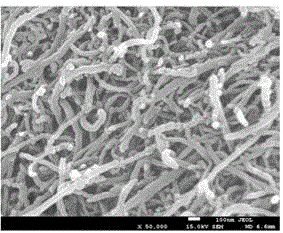

Modified carbon nano tube and preparation method thereof, lithium ion battery anode and preparation method thereof and lithium ion battery

ActiveCN105206839AIncrease repulsionEasy to disperseMaterial nanotechnologyCell electrodesAc impedanceCarbon nanotube

The invention provides a modified carbon nano tube and a preparation method thereof, a lithium ion battery anode and a preparation method thereof and a lithium ion battery. The modified carbon nano tube comprises a carbon nano tube and a polar group on the surface of the carbon nano tube, wherein the polar group is -COOLi. The modified carbon nano tube provided by the invention has the characteristics of being easy to disperse, low in dispersing cost and good in electrical conductivity; compared with a lithium ion battery adopting the dispersion liquid of an unmodified carbon nano tube as a conductive agent, the lithium ion battery adopting the dispersion liquid of the carbon nano tube as a conductive agent has a lower direct current impedance and alternating-current impedance, and is greatly improved in the high-rate charge-discharge capability.

Owner:BYD CO LTD

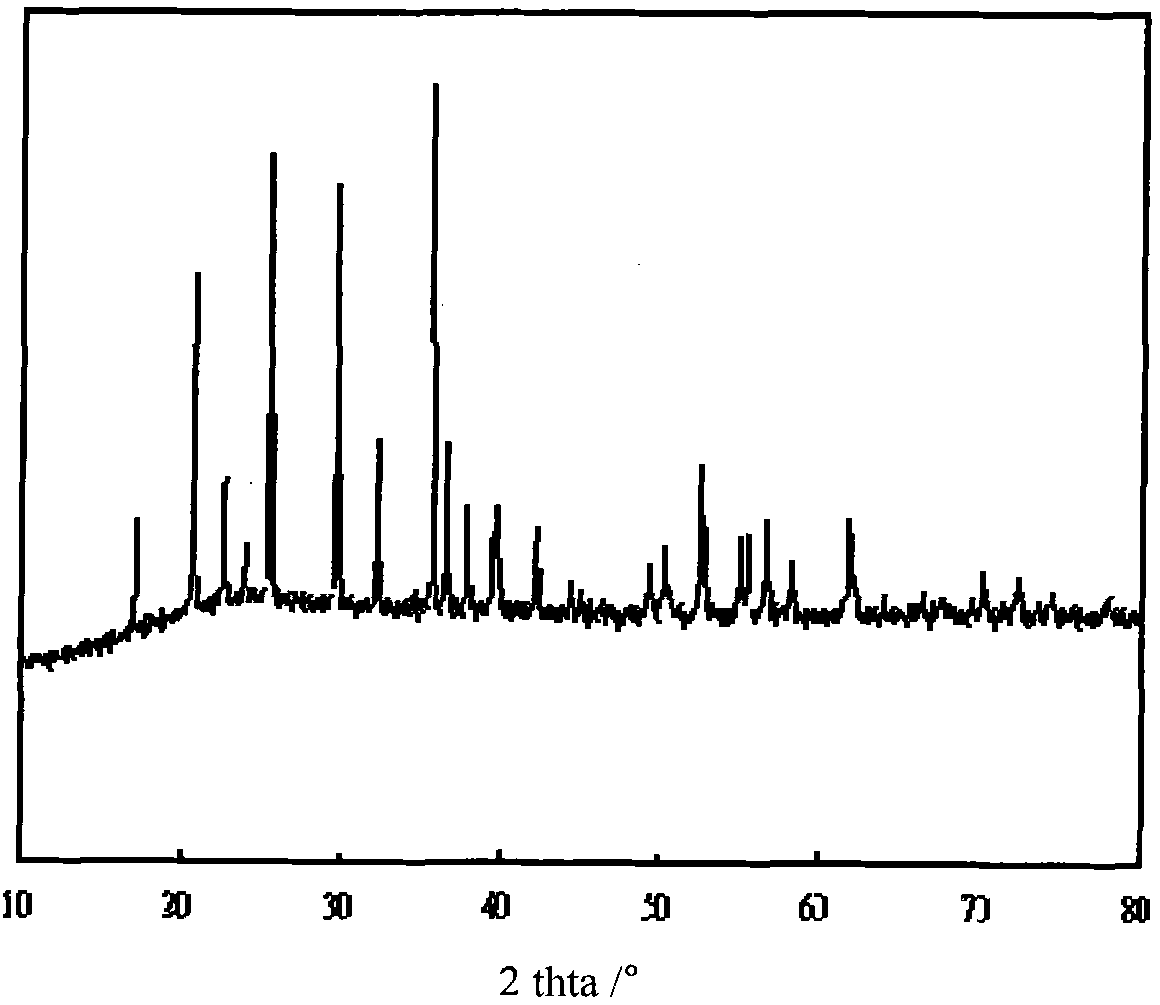

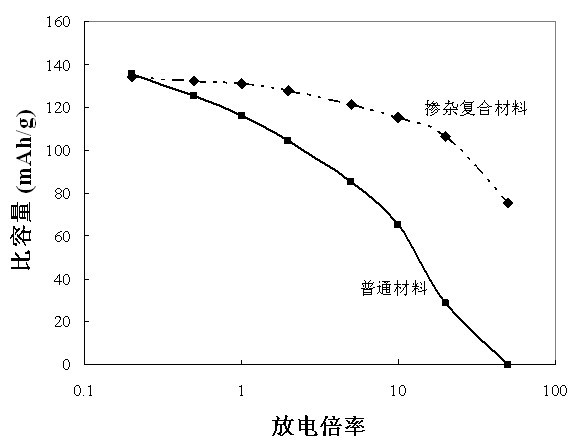

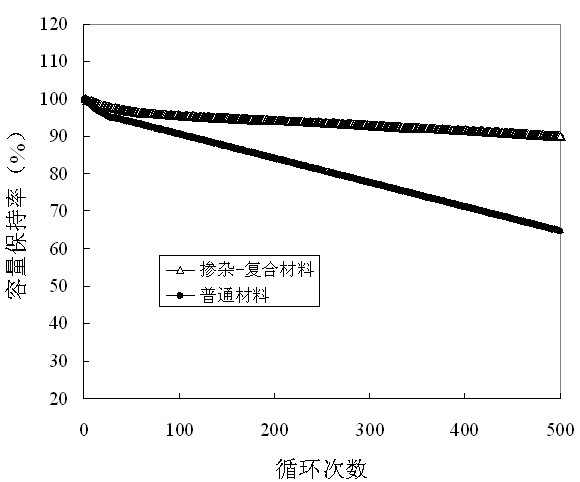

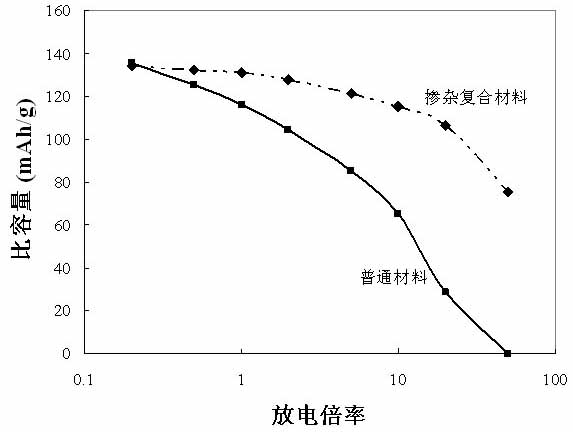

A kind of positive electrode material of lithium ion battery and preparation method thereof

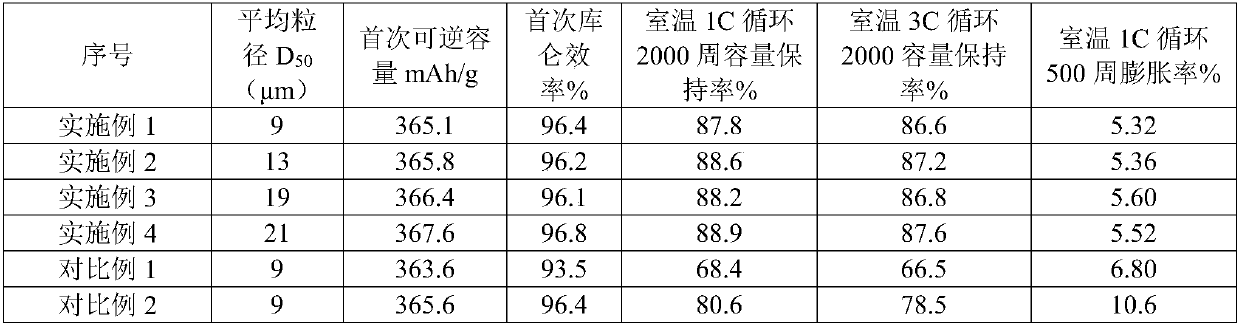

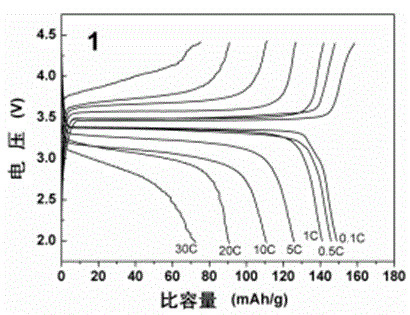

InactiveCN102280618AHigh rate charge and discharge performance is goodIncrease migration rateCell electrodesFree coolingRoom temperature

The invention discloses a preparation method of an anode material of a lithium ion cell, comprising the following steps of: (1) uniformly dispersing a Li source, a Mn source, a Ni source, a doping element and a metal element with superionic conductor attributes to prepare a precursor, wherein the metal element with the superionic conductor attributes is selected from two or two more of Ti, La andZr; (2) drying or igniting the precursor, then carrying out pretreatment to obtain pretreatment powder; (3) pressing the pretreatment powder into a sheet; (4) carrying out heat treatment for 6-24h; and (5) annealing, naturally cooling to room temperature, grinding, and sieving to obtain the anode material. In the invention, on the one hand, a crystal skeleton of the material and a Mn valence state are stabilized by using the doping element, on the other hand, a compound lithium ion superionic conductor improves a migration rate of the lithium ion in the material and improves the multiplying power property and cycling property of an electrode are improved.

Owner:SUZHOU UNIV

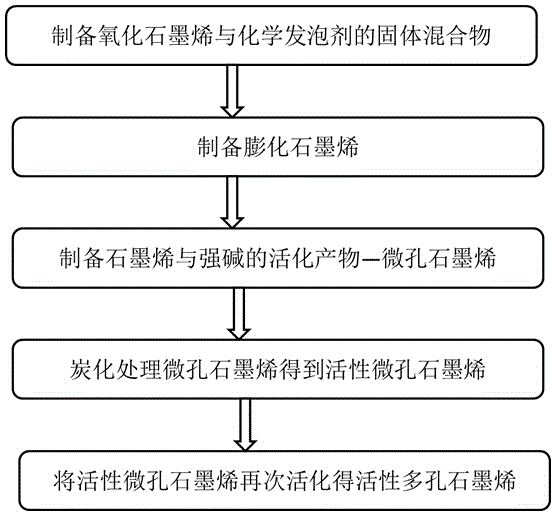

Preparation method of active porous graphene

The invention relates to a preparation method of active porous graphene, which is characterized by comprising the following steps: preparing a solid mixture of graphene oxide and a chemical foaming agent; preparing expanded graphene, and preparing an activation product of graphene and strong alkali; preparing active microporous graphene; and finally, carrying out secondary pore forming to obtain the finished product. The finished product has higher tap density, and has properly proportional mesoporous structure and macroporous structure; and the pores provide higher specific area. The carbonization treatment technique is performed to greatly enhance the activity of the porous graphene. When the active porous graphene is used in a capacitor electrode material, the macroporous structure provides quick migration channels for the electrolyte, and the mesoporous structure has equivalent size to ions in the organic electrolyte and is beneficial to quick adsorption and desorption of the ions, so that the capacitor has favorable high-rate charge / discharge performance.

Owner:苏州容电储能科技有限公司

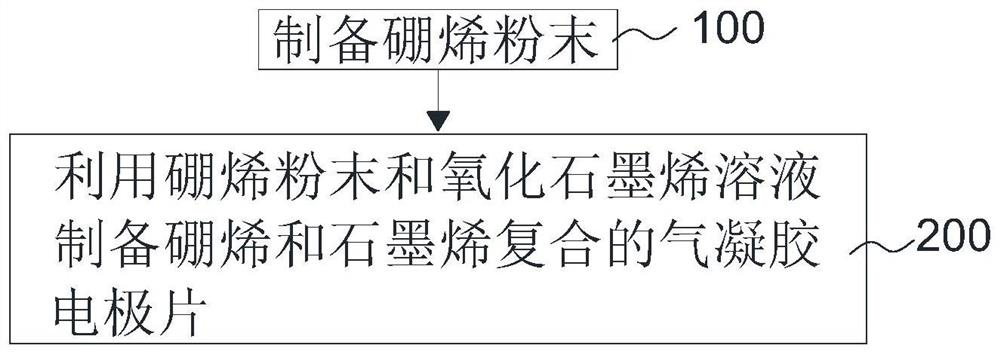

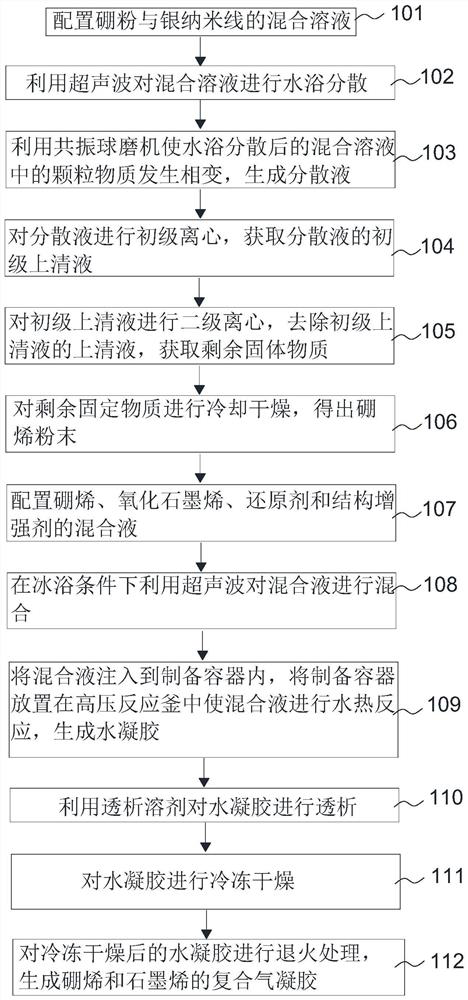

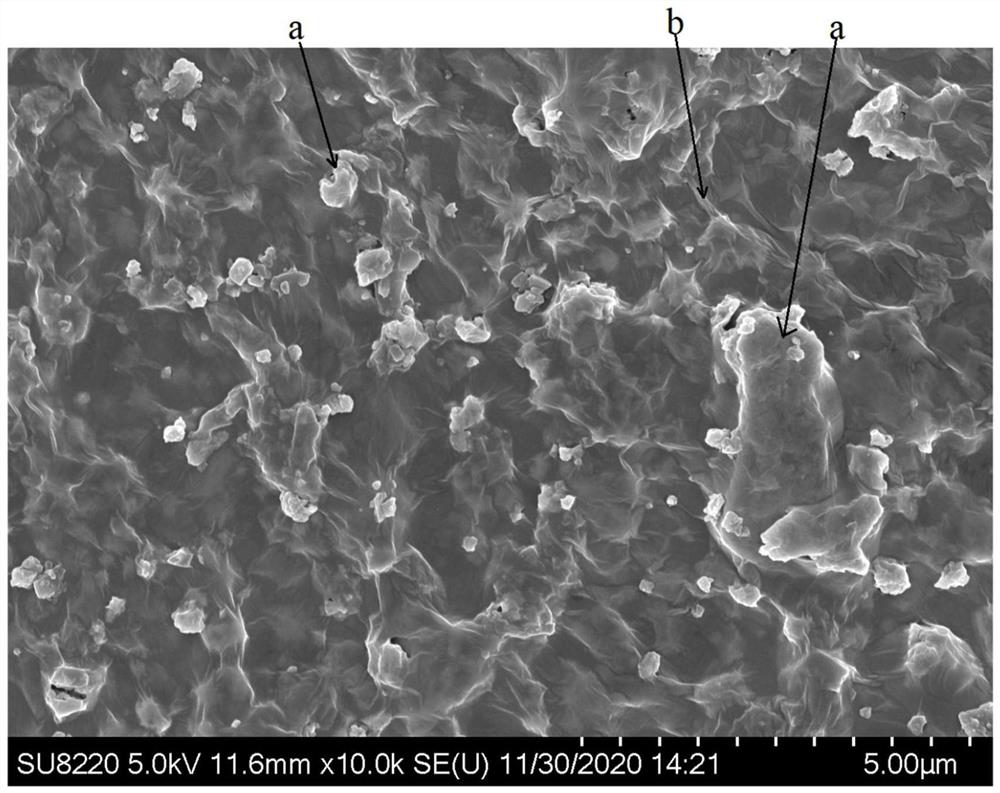

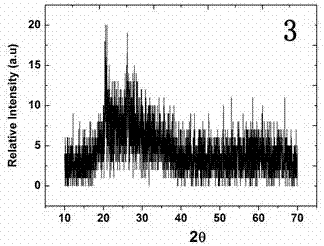

Preparation method and preparation container of boron alkene and graphene composite aerogel electrode plate

PendingCN114512656ASolve structural instability problemsImprove conductivityMaterial nanotechnologyCell electrodesHeterojunctionGel electrode

The invention provides a preparation method and a preparation container of a boron alkene and graphene composite aerogel electrode plate. The preparation method comprises the following steps: preparing boron alkene powder; and preparing the boron alkene and graphene composite aerogel electrode plate by using the boron alkene powder and the graphene oxide solution. The problem of structure instability after boron alkene loses metal substrate support is solved, the properties of boron alkene are fully utilized, boron alkene and graphene are combined to form a heterojunction, and the boron alkene / graphene heterojunction aerogel electrode plate is prepared and applied to a lithium ion battery negative electrode. The prepared aerogel electrode plate has excellent conductivity, an additional collector electrode is not needed in a battery, and the synthesized boron-alkene / graphene aerogel electrode plate has large specific capacity which is improved by 39% compared with a graphene skeleton without addition of boron-alkene. And meanwhile, the aerogel electrode plate is relatively good in high-rate charge-discharge performance.

Owner:TSINGHUA UNIV

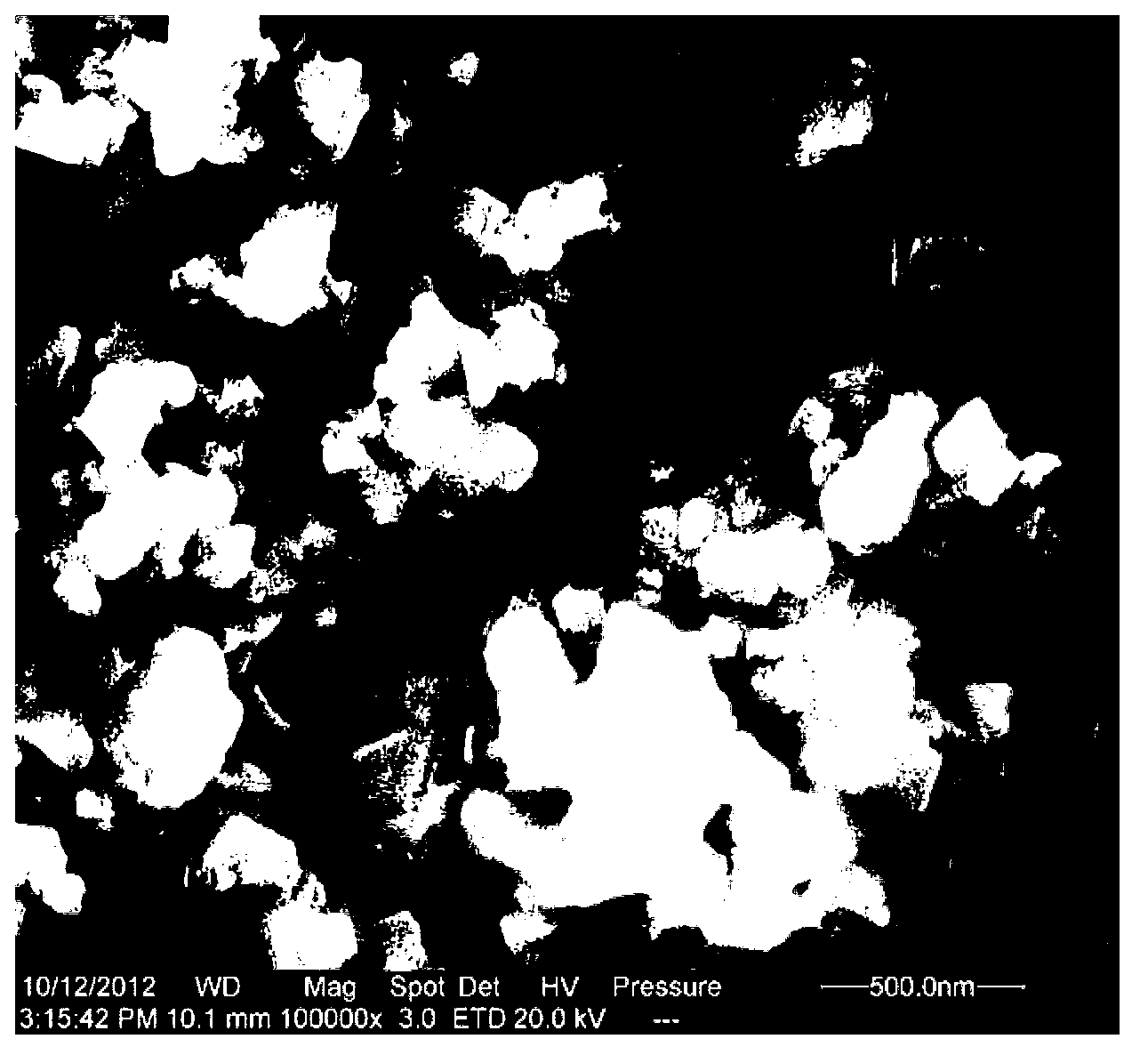

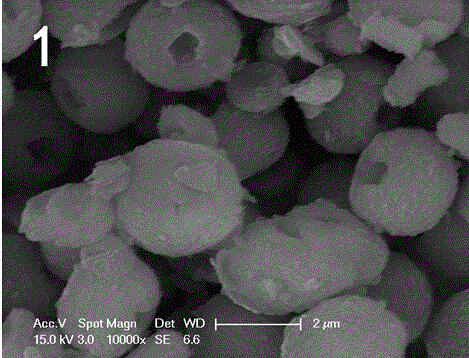

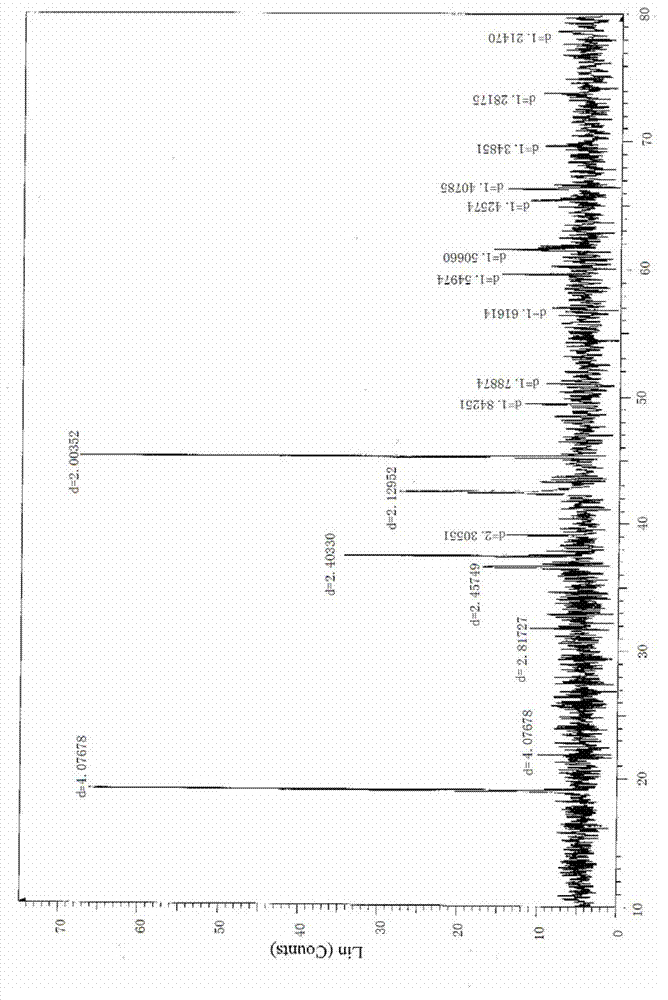

Amorphous nanospherical active ferric phosphate hydrate, and preparation method and application thereof

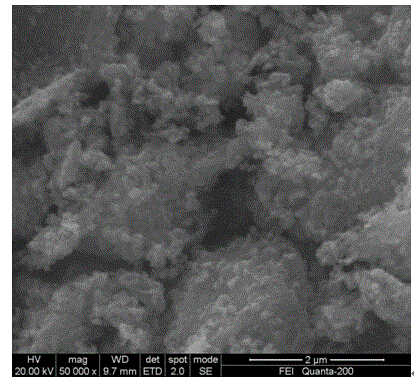

ActiveCN106946236AImprove conductivitySmall and uniform particle sizeCell electrodesSecondary cellsFerric nitrate nonahydratePhosphoric acid

The invention relates to an amorphous nanospherical active ferric phosphate hydrate, and a preparation method and an application thereof. The preparation method of the amorphous nanospherical active ferric phosphate hydrate comprises the following steps: 1, preparing a sustained release agent solution 1; 2, preparing a surfactant solution 2; 3, mixing the sustained release agent solution 1 with the surfactant solution 2 to obtain a solution A; 4, preparing a ferric nitrate nonahydrate solution; 5, dropwise adding the ferric nitrate nonahydrate solution into the solution A to prepare a solution B; 6, adding a phosphoric acid solution into the solution B to prepare a solution C; and 7, transferring the solution C into a polytetrafluoroethylene lined reaction kettle, carrying out a hydrothermal reaction, cooling the obtained reaction product, and carrying out separation and drying to obtain white powder which is the amorphous nanospherical active ferric phosphate hydrate. The method has the advantages of short reaction time, small and uniform product particle sizes, lithium iron phosphate obtained through the lithiation of the ferric phosphate hydrate prepared through the method has large tap density, and a battery product finally obtained through using the hydrate has good high-rate charge and discharge performances.

Owner:HUNAN INST OF TECH

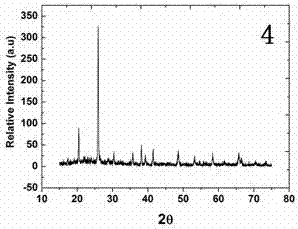

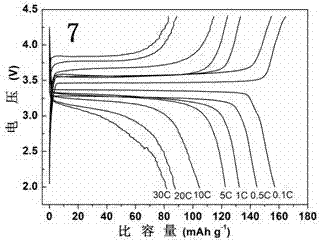

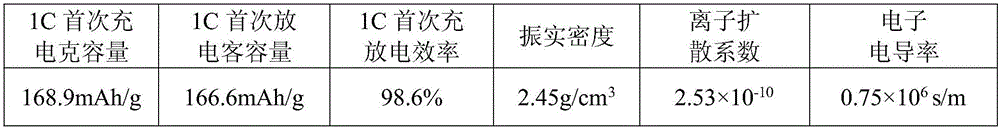

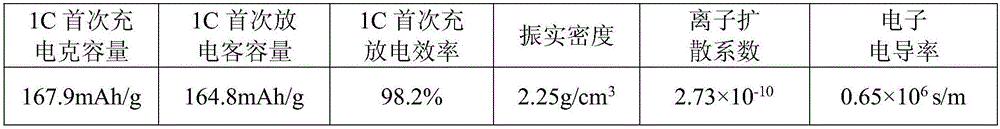

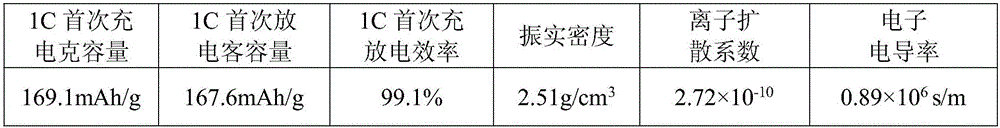

Preparation method of LiFePO4/GO/Mx+/C composite

ActiveCN105932254AImprove performanceHigh rate charge and discharge performance is goodCell electrodesSecondary cellsDischarge efficiencyIonic diffusion

The invention discloses a preparation method of a LiFePO4 / GO / Mx+ / C composite. The method comprises the following steps of (1) preparing a GO / Mx+ material; (2) preparing a LiFePO4 / GO / Mx+ material; and (3) preparing the LiFePO4 / GO / Mx+ composite. According to the method, the pollution in a production process is less and the cost of the production materials is low; the LiFePO4 / GO / Mx+ / C composite has good physical and chemical performance, and the initial charge gram volume is high and is close to an LiFePO4 theoretical value; the initial charge-discharge efficiency is high and is not less than 98%, and the national standard is more than 92%; the tap density is high to help to improve the pole piece processing capability and the energy density of the lithium ion battery; and the ionic diffusion coefficient and the electronic conductivity are higher, and the high-rate charge-discharge capability of the material is good.

Owner:湖南锂顺能源科技有限公司

Lead crystal accumulator

InactiveCN101369673AExtend your lifeExtended service lifeLead-acid accumulatorsCell electrodesHigh rateAlloy

The invention discloses an accumulator, specifically a lead accumulator. An electrode plate in the invention is implemented by taking lead as substrate, lead, stibium, arsenic, copper, sulphur alloys as plate materials with electrolyte replacing fluoro-sulphuric acid solution with silicate. Advantages of the invention lie in that the lead accumulator has long service life, great high-rate charging and discharging performance, rapid charge, great deep discharging performance, great low temperature resistance performance and environment protection features. Products of the invention can be widely applicable for various bicycle dynamos, automobiles and so on.

Owner:HANGZHOU QILINPU ELECTRIC AUTOMOBILE PROD

Preparation method of graphene/lithium titanate composite anode material

ActiveCN103022459BImprove electronic conductivityImprove ionic conductivityCell electrodesHybrid/EDL manufactureActivated carbonSupercapacitor

The invention discloses a preparation method of a graphene / lithium titanate composite anode material, which comprises the following steps: compounding compounds serving as a lithium source and a titanium source and graphene oxide through a liquid-phase method and reducing graphene oxide of the compound in inert gas mixed with reducing gas into graphene so as to obtain the graphene / lithium titanate composite anode material. The method has the characteristic of realizing uniform distribution of graphene in lithium titanate through an in-situ compounding technique. Under the same conditions, the discharge time of a hybrid capacitor which respectively takes the graphene / lithium titanate composite anode material and activated carbon as the anode and cathode is obviously greater than that of an electric double-layer capacitor which takes activated carbon as an electrode and that of a hybrid capacitor which respectively takes lithium titanate and activated carbon as the anode and cathode. The lithium titanate phase purity of a hybrid supercapacitor and lithium ion battery composite anode materials prepared by the method disclosed by the invention is higher. Furthermore, the preparation method further has the characteristic of easily realizing the large-scale industrial production.

Owner:ZHANGJIAGANG IND TECH RES INST CO LTD DALIAN INST OF CHEM PHYSICS CHINESE ACADEMY OF SCI +1

Preparation method for improving electrical property of positive electrode material LiCoO2

InactiveCN106450259ALarge particlesIncrease compaction densityCell electrodesSecondary cellsHigh rateMaterials science

The invention discloses a preparation method for improving electrical property of a positive electrode material LiCoO2. The preparation method is completed according to the following steps of mixing Co3O4 and a lithium salt (adding an additive T1), performing pre-processing, performing first sintering for 6-20 hours under a temperature of 600-1,100 DEG C, performing surface processing, performing secondary mixing, performing pre-processing, performing second sintering for 5-10 hours in an inert atmosphere at 400-800 DEG C, performing surface processing and obtaining a product. The modified LiCo produced according to the method has original property, and high-rate and large-current charge / discharge also can be achieved; and through test on a battery prepared by taking a lithium piece as a negative electrode material, the test current rate is 0.2C, the voltage range is 2.9-4.2V, the specific capacity of the test material is larger than 160mAh / g, the discharge platform retention rate is over 85% after circulation of 100 times, the capacity retention ratio is over 95%, the preparation method has favorable economic benefit and social benefit and is suitable for promotion and application.

Owner:TIANJIN GUOAN MGL NEW MATERIALS TECH CO LTD

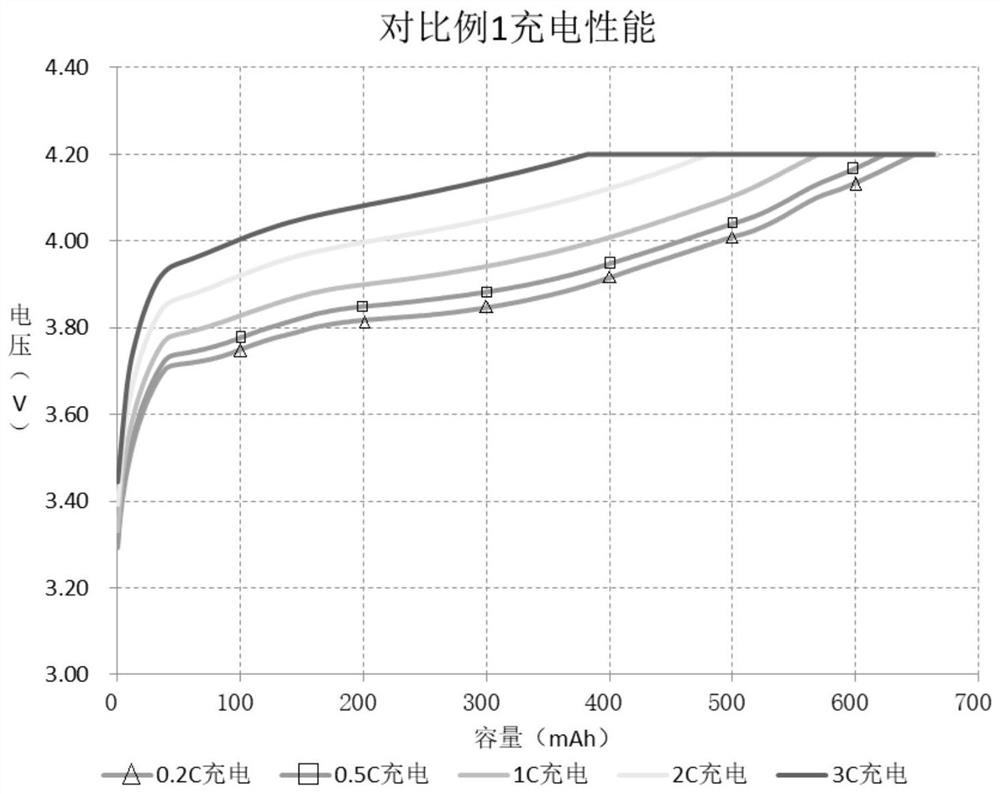

Preparation method of high-rate battery

ActiveCN112467225AHigh retention rateHigh rate charge and discharge performance is goodFinal product manufactureLi-accumulatorsElectrically conductiveCharge and discharge

The invention discloses a preparation method of a high-rate battery, which comprises the following steps: preparing positive electrode slurry, namely weighing a positive electrode conductive material,a positive electrode binder, a positive electrode conductive agent and a pore regulator in proportion, adding an auxiliary solvent, and mixing by a vacuum mixer to obtain the positive electrode slurry; preparing negative electrode slurry, namely weighing a negative electrode conductive material, a negative electrode conductive agent, a thickening agent, a negative electrode binder and a pore regulator in proportion, adding an auxiliary solvent, and mixing by virtue of a vacuum stirrer, so as to obtain the negative electrode slurry; preparing an electrolyte, namely weighing lithium salt, a solvent and an additive in proportion; and manufacturing a battery cell, namely preparing the lithium battery cell according to a specified design process flow; The preparation method has the advantagesof simple preparation conditions, no need of an ultrahigh temperature environment, low requirements on production conditions, and low production cost; and meanwhile, the lithium battery cell with thegap is prepared, the high-rate charging and discharging performance is excellent, and the high retention rate can be maintained during high-rate charging and discharging.

Owner:湖南美尼科技有限公司

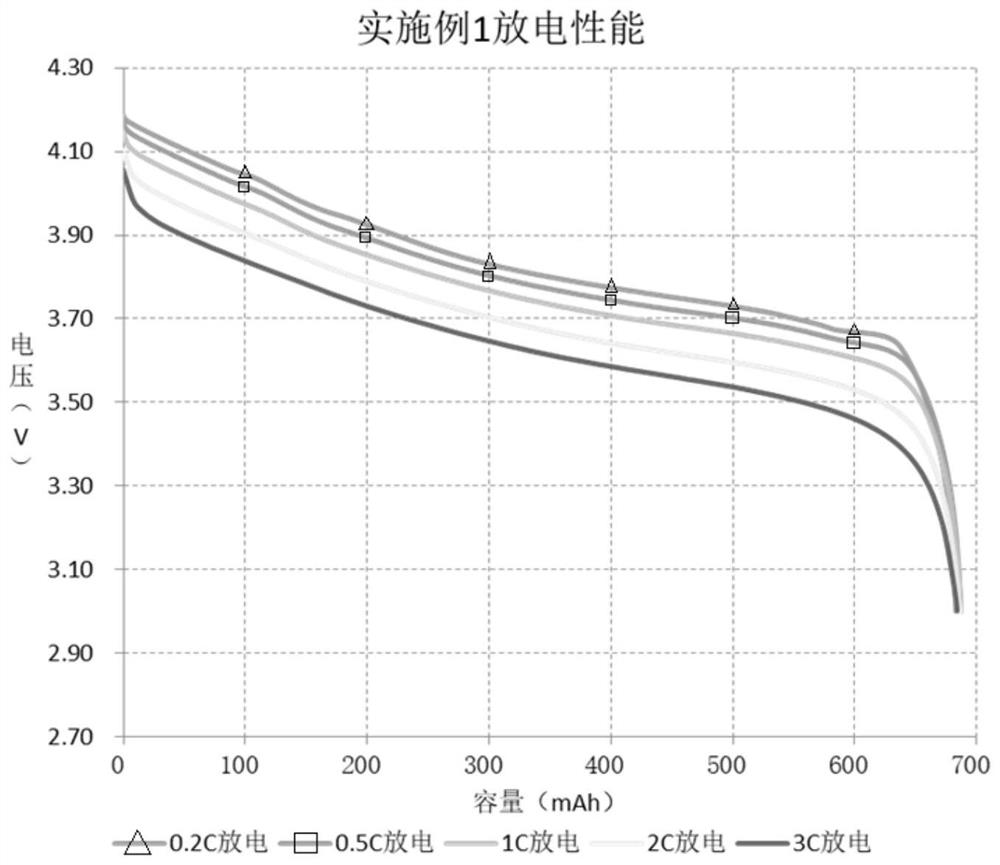

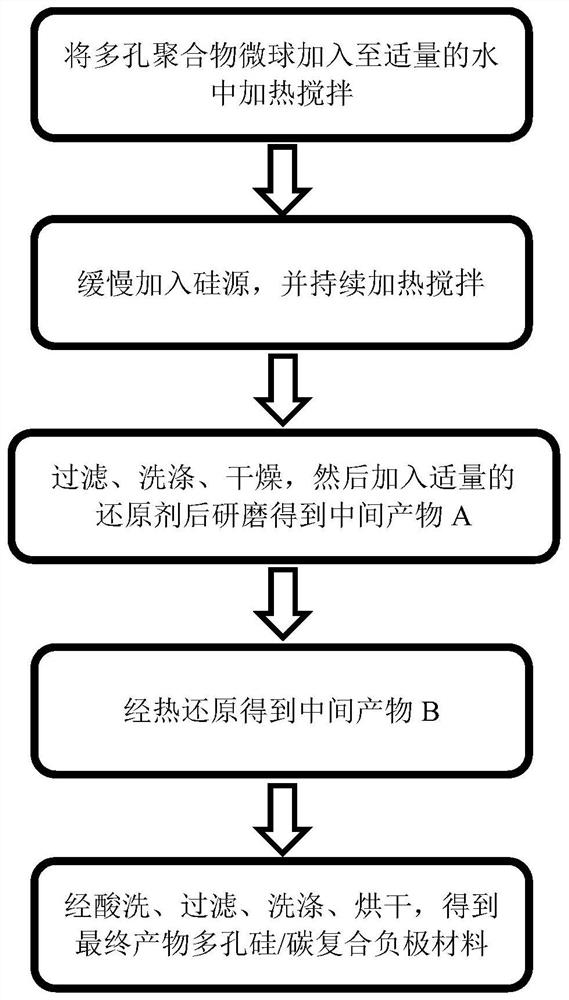

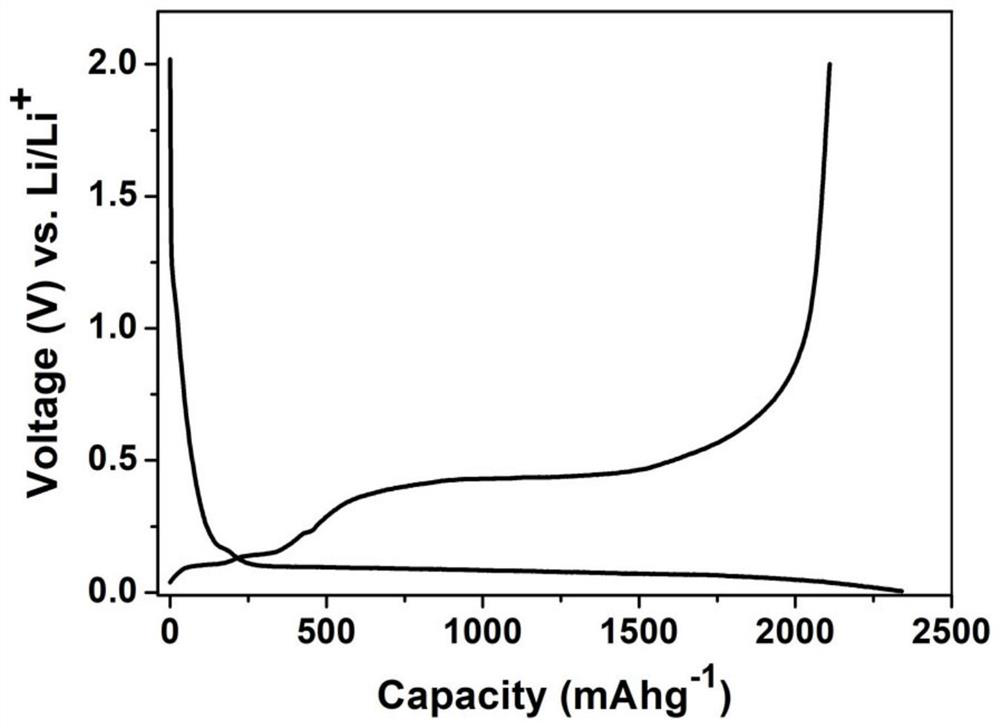

Porous silicon/carbon composite material synthesized in situ by taking porous polymer microspheres as template, preparation method and lithium ion battery

PendingCN114079045AInhibition of volume expansionImprove ionic conductivityNegative electrodesSecondary cellsCarbon compositesDischarge efficiency

The invention relates to a porous silicon / carbon composite negative electrode material in-situ synthesized by taking porous polymer microspheres as a template, a preparation method and a lithium ion battery. The preparation process comprises the following steps of: adding porous polymer microspheres into water, heating and stirring to obtain a suspension solution; adding a silicon source into the suspension solution to obtain a mixed solution; filtering the mixed solution, washing the mixed solution with deionized water and drying the mixed solution in sequence, then adding a reducing agent, and conducting grinding and mixing to obtain an intermediate product A; treating the intermediate product A through a thermal reduction process to obtain an intermediate product B; and carrying out acid pickling on the intermediate product B, washing with deionized water, filtering, and drying to obtain a final product. Compared with the prior art, a carbon layer obtained through in-situ compounding can better improve the electrical conductivity, the cycling stability, the charge-discharge efficiency, the rate capability and other electrochemical properties of a silicon negative electrode, and the unique micro-nano pores reserve a lithium-intercalation expansion space for silicon and reduces the absolute volume change of the composite material in the charge-discharge process.

Owner:昱瓴新能源科技(浙江)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com