Patents

Literature

518 results about "Ferric nitrate nonahydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iron(III) nitrate, or ferric nitrate, is the chemical compound with the formula Fe(NO3)3. Since it is deliquescent, it is commonly found in its nonahydrate form Fe(NO3)3·9H2O in which it forms colourless to pale violet crystals.

Method for preparing steady composite potassium ferrate solution

InactiveCN101318707AImprove stabilityLong storage timeIron compoundsWater/sewage treatment using germicide/oligodynamic-processChemical industryFiltration

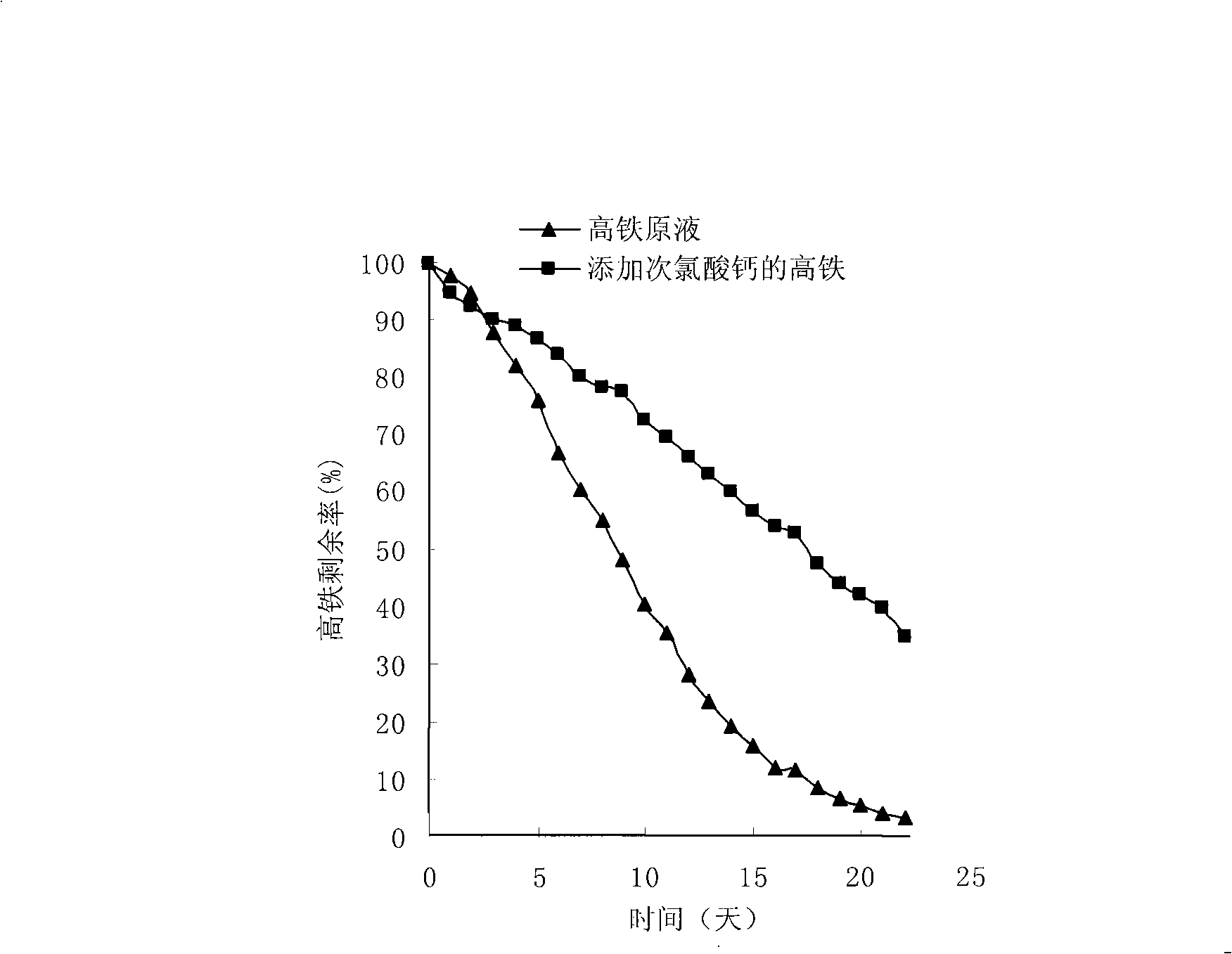

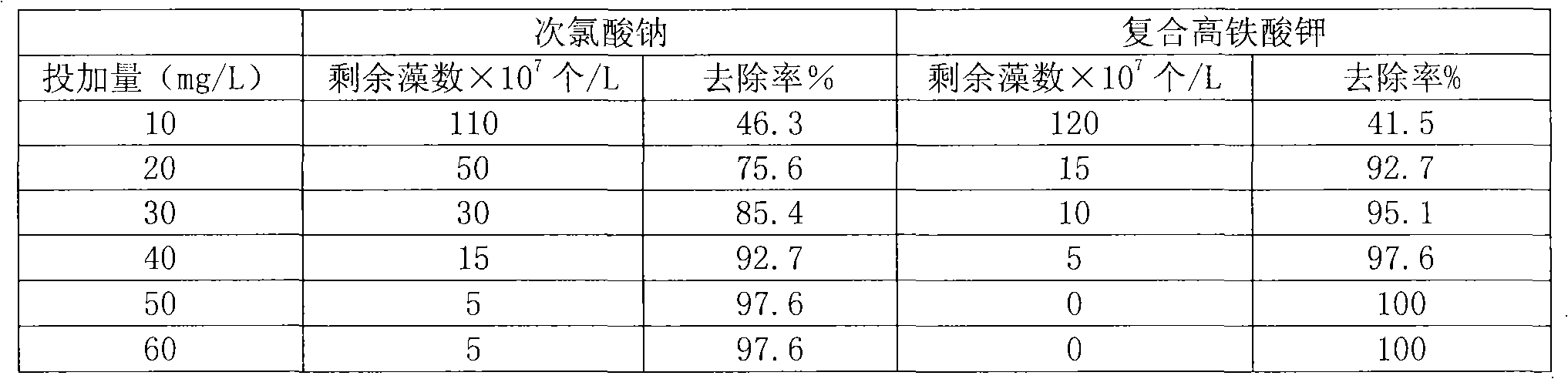

The invention relates to a method for preparing a composite potassium ferrate solution, which belongs to the chemistry and chemical industry and water treatment agent preparation process technical field. The method comprises the following preparation processes that: firstly, a sodium hypochlorite solution reacts with sodium hydroxide, a white salt substance is generated first and is subject to pumping filtration, then ferric nitrate is added according to a molar mass ratio of sodium hypochlorite to ferric nitrate being equal to between 1.5 and 2.0 to 1, the reaction temperature is between 20 and 45 DEG C, and the pumping filtration is performed after 1.5 to 2.0 hours of reaction; and then a filtrate is added with a saturated potassium hydroxide solution to ensure that the filtrate is transformed into a potassium ferrate solution. Then 0.06 to 0.16mol / L of calcium hypochlorite is added, the reaction temperature is controlled to between 10 and 30 DEG C, the reaction time is between 10 and 30 minutes, and finally the composite potassium ferrate solution with good stability is produced. The composite potassium ferrate solution prepared by the method has good stability, long preservation time, difficult decrease of high iron content, and easiness for industrialized production. The product can be widely used for purification treatment of algae-laden water, city domestic sewage and so on.

Owner:SHANGHAI UNIV

Preparation method of clay-perovskite composite material and application thereof

ActiveCN105688918ASmall particle sizeAvoid uneven loadWater/sewage treatment by irradiationWater treatment compoundsWater bathsChemical industry

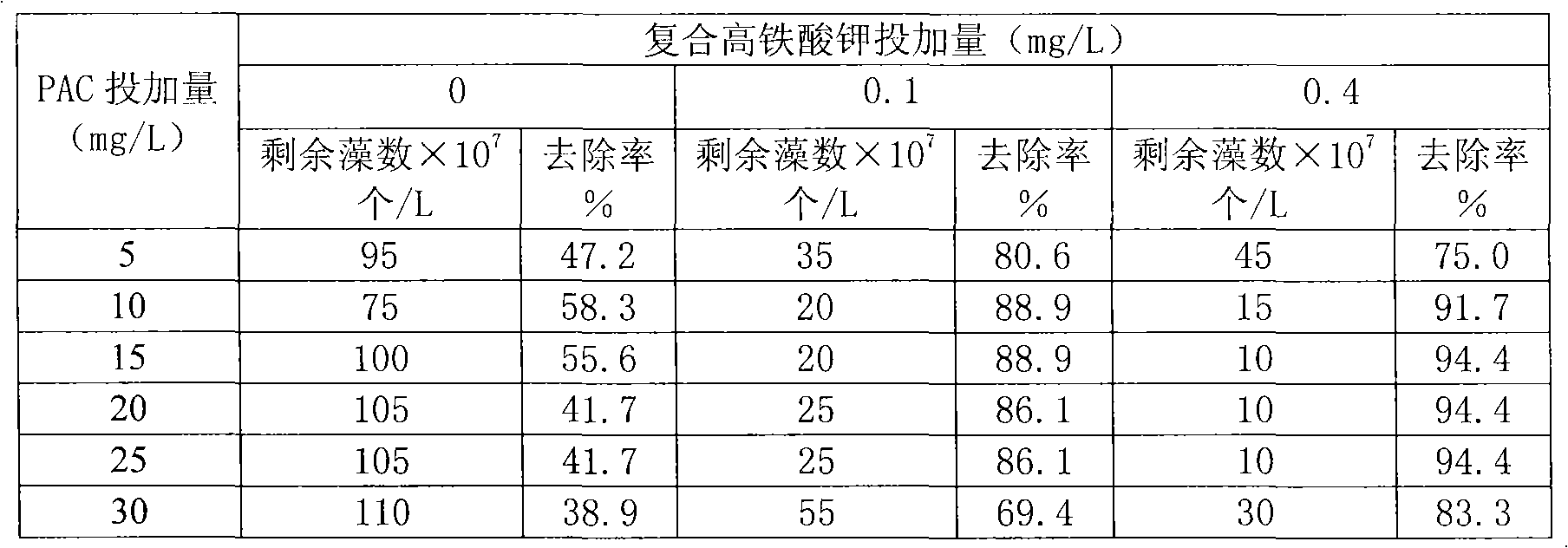

The invention belongs to the field of the energy and chemical industry and particularly relates to a preparation method of a nanometer material using clay as a carrier and using a perovskite type compound as an active component and application of the nanometer material in photocatalytic degradation of antibiotics.Lanthanum nitrate, ferric nitrate, cerous nitrate, citric acid and the clay are added to deionized water and are mixed, then the mixture is transferred to a water bath kettle for evaporation to obtain wet gel, and drying, calcinations and dry grinding are performed to obtain the lanthanum ferrite / clay nano-structure composite material.The antibiotics are subjected to the photocatalytic degradation by adopting the composite material and can be rapidly degraded under visible light by utilizing the high catalytic activity of (cerium doped) lanthanum ferrite.The clay carrier facilitates antibiotic molecular adsorption in the antibiotic degradation process, the antibiotics are in contact with the lanthanum ferrite after being absorbed to the catalyst surface, and antibiotic molecules are decomposed under visible light irradiation to produce other active species.

Owner:CHANGZHOU UNIV

Preparation method of composite nanomaterial of nano ZnO and graphene nanosheet

InactiveCN103252228AGood chemical stabilitySimple manufacturing methodMetal/metal-oxides/metal-hydroxide catalystsElectronic band structureChemical stability

The invention discloses a preparation method of a composite nanomaterial of a nano ZnO substrate and a graphene nanosheet. Nano ZnO and the graphene nanosheet are composited to form the composite nanomaterial in a sol-gel method and mechanical alloying combined mode, so that the preparation method is simple and easy to realize and short in reaction time; the finished composite nanomaterial is good in chemical stability; graphene has higher conductivity and can adjust an energy band structure of nano ZnO; nano ZnO has a higher seebeck coefficient, and the nano ZnO substrate and the graphene nanosheet are synthesized, so that interface scattering of phonons can be increased significantly; a recombination rate of an electron-hole pair can be reduced; the appearance of nano ZnO can be adjusted; the heat conductivity of nano ZnO can be reduced; and the photocatalytic efficiency of nano ZnO can be improved. Nitrate of to-be-doped ions comprises any one of aluminum nitrate, ferric nitrate, cobalt nitrate, nickel nitrate, silver nitrate and gold nitrate.

Owner:JIANGSU YUEDA NEW MATERIAL TECH +1

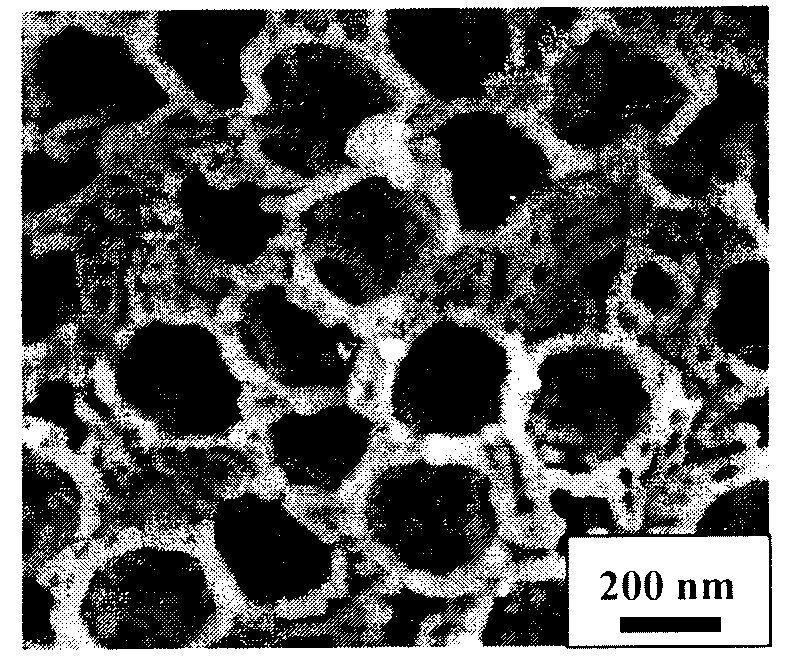

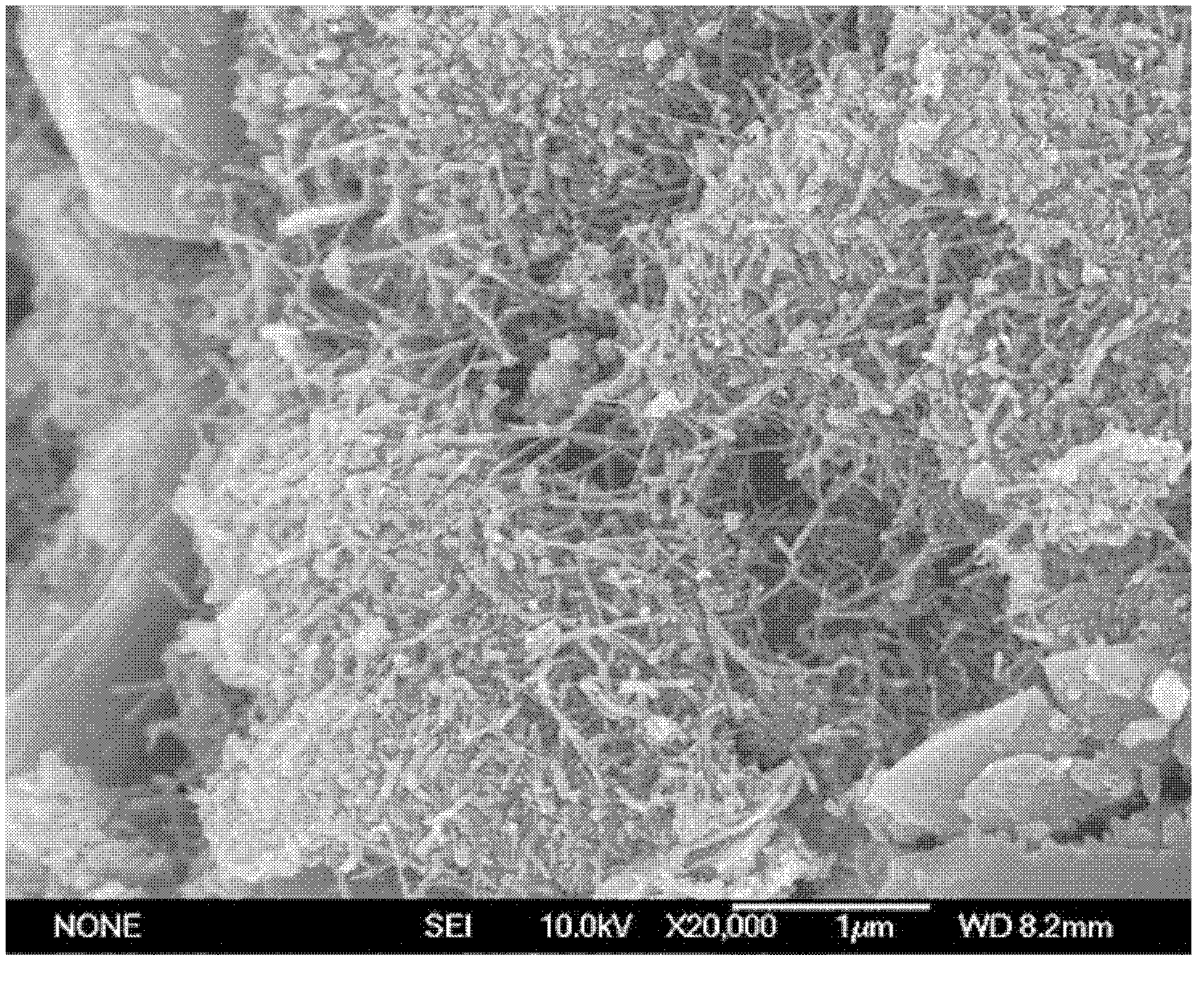

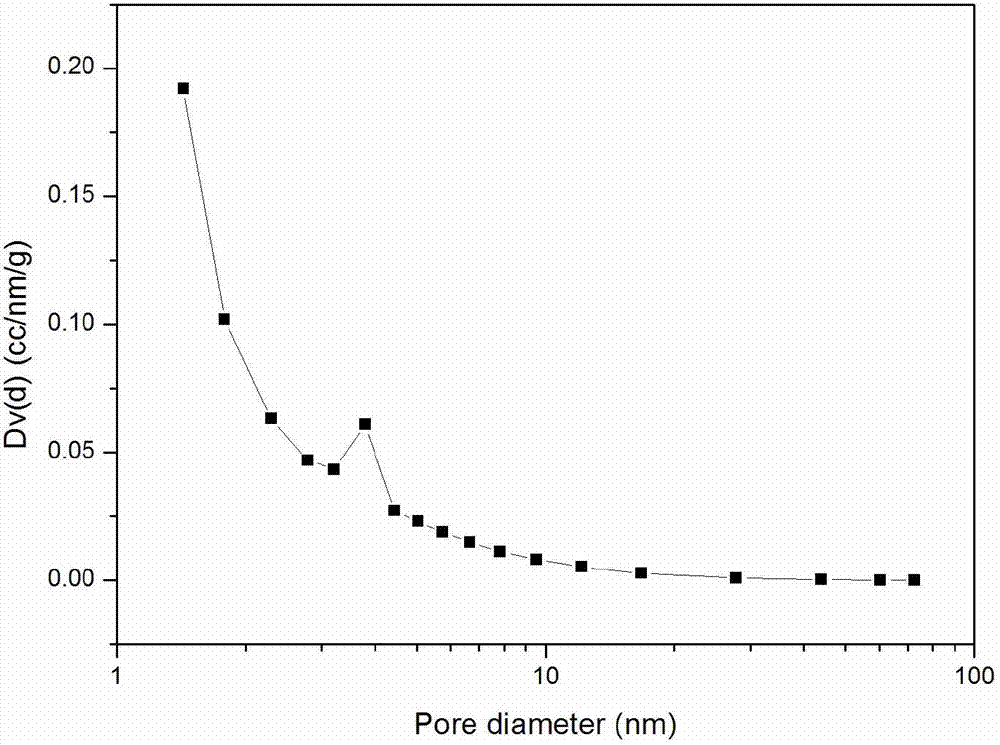

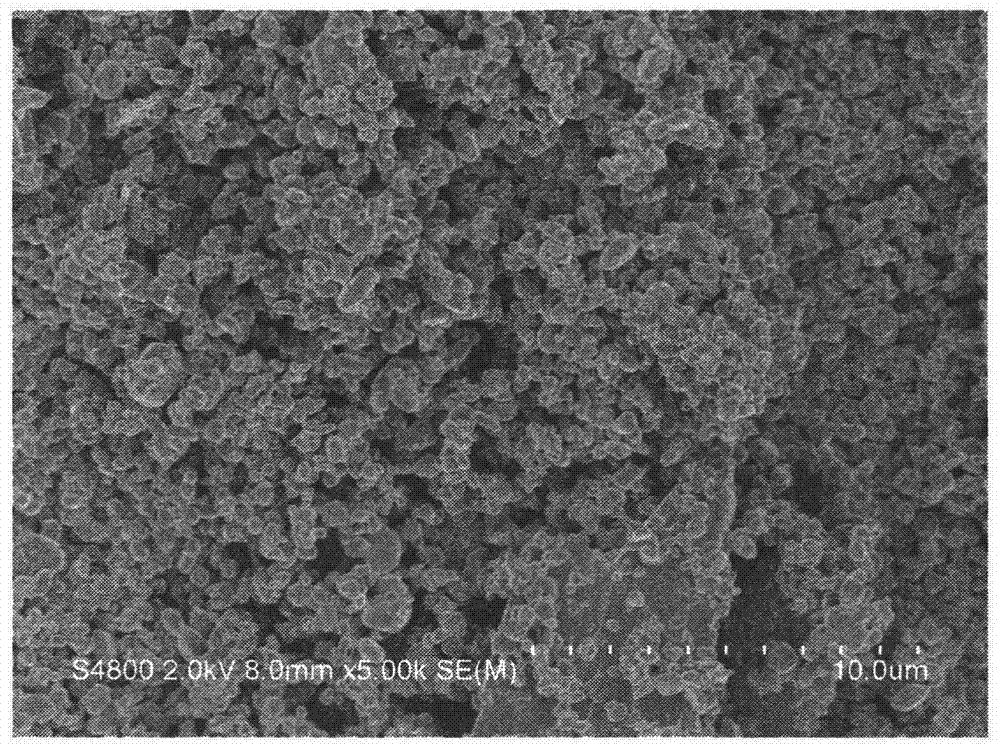

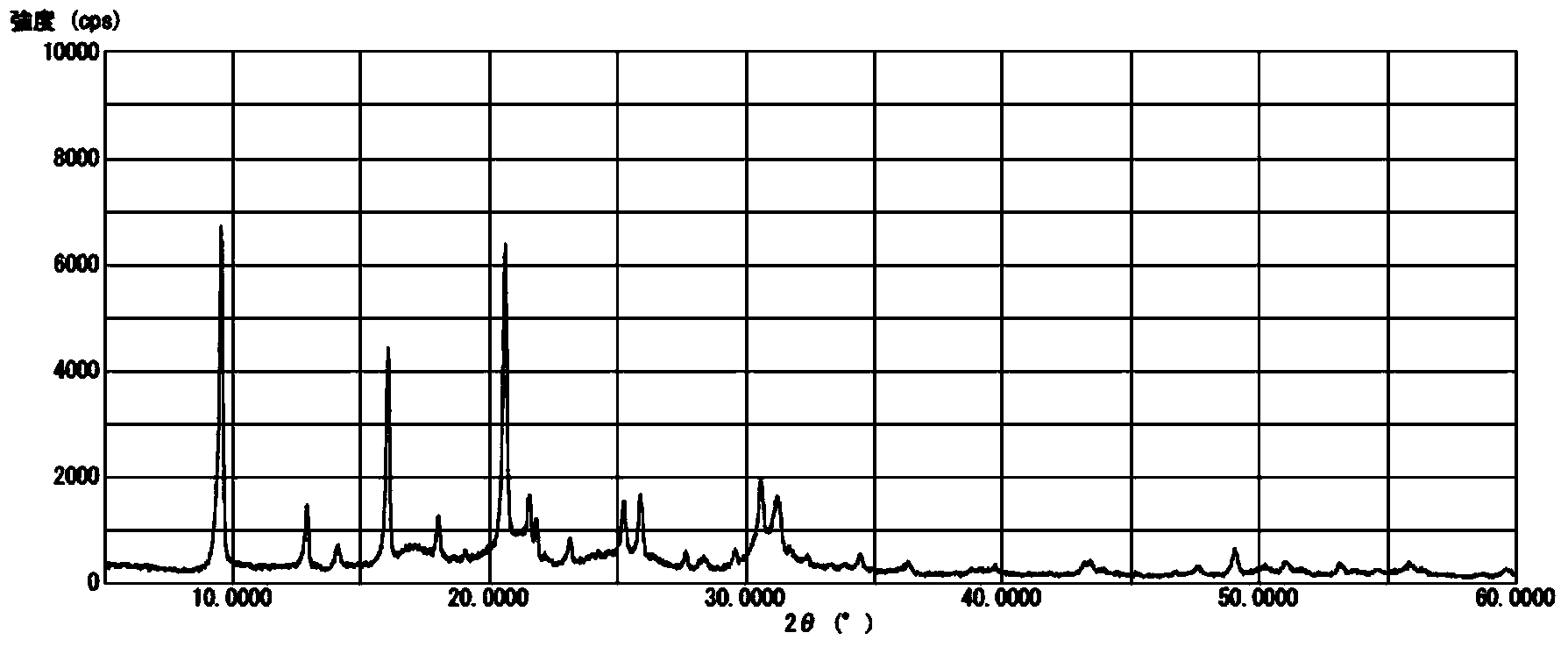

Soft and hard double template method for preparing three-dimensional ordered macroporous iron oxide with mesoporous pore wall

The invention relates to a soft and hard double template method for preparing three-dimensional ordered macroporous iron oxide with a mesoporous pore wall, belonging to the field of multi-phase catalysis. The method comprises the steps of: under the conditions of normal temperature, normal pressure and ultrasound, dissolving ferric nitrate nonahydrate and a soft template P123 into the mixed solution of absolute ethyl alcohol or absolute methanol and anhydrous ethylene glycol; soaking hard template PMMA microballoons which are arranged in a close packing way into the mixed solution; and finally, carrying out suction filtration by using the mixed solution containing the PMMA, drying and programming heating and calcining, and obtaining the hree-dimensional ordered macroporous iron oxide which has rhombohedral structure and the mesoporous pore wall. The iron oxide with macroporous and mesoporous double-mold pore channel structure has good application prospect in the fields such as multi-phase catalysis, absorption, pigment, etc.

Owner:BEIJING UNIV OF TECH

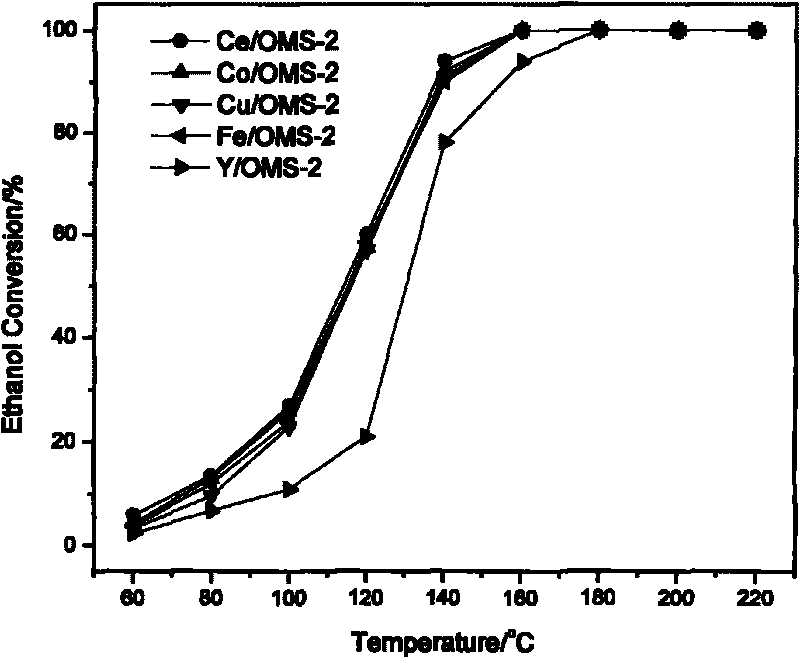

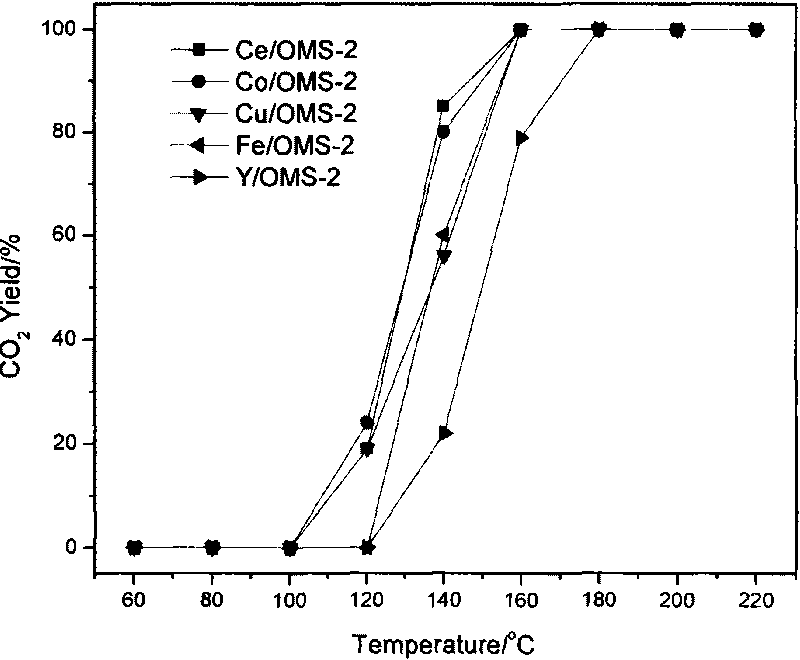

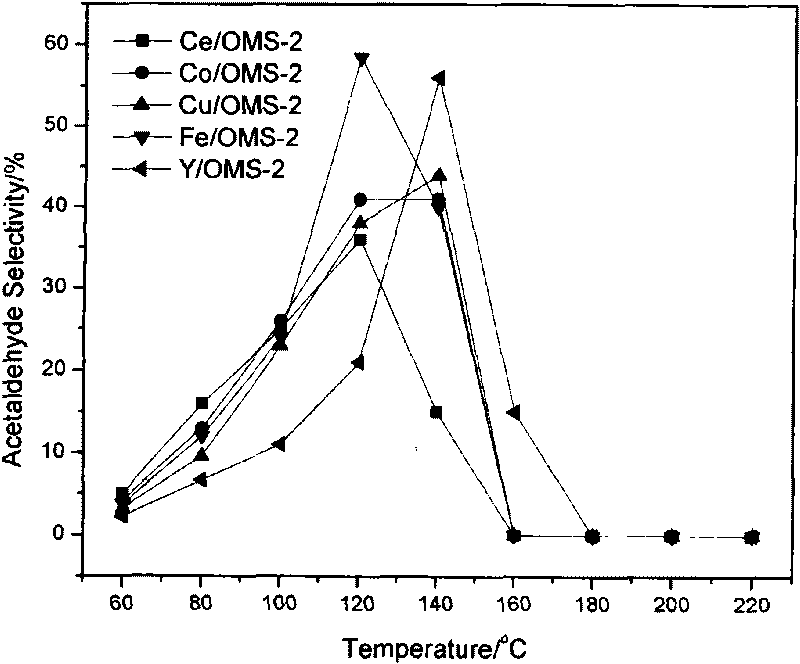

Metal oxide-loaded molecular sieve catalyst and preparation method thereof

ActiveCN101711990AStrong oxidizingReduce exhaust temperatureMolecular sieve catalystsDispersed particle separationMANGANESE ACETATECerium

A metal oxide-loaded molecular sieve catalyst comprises pure cryptomelane type manganese dioxide and transition metal. A method for preparing the molecular sieve catalyst comprises the following steps: 1, preparing solution of potassium permanganate; 2, preparing solution of manganese acetate; 3, adding the solution obtained by the step one into a three-neck flask, and heating, condensing and refluxing the solution; 4, adding the solution obtained by the step two into the three-neck flask of the step three, condensing and refluxing the solution, filtering and drying the obtained black pasty sediment, and roasting the sediment to obtain an octahedral manganese oxide molecular sieve catalyst (OMS-2) solid; 5, adding cerium ammonium nitrate, cobalt nitrate hexahydrate, copper nitrate trihydrate, ferric nitrate nonahydrate or yttrium nitrate into deionized water to form solution; and 6, mixing the solid taken from the step four and the solution in the step five, soaking cerium on the octahedral manganese oxide molecular sieve catalyst (OMS-2) solid, and drying and roasting the obtained solid to obtain the metal oxide-loaded molecular sieve catalyst. The metal oxide-loaded molecular sieve catalyst has the characteristics of high purification efficiency, low price and good thermal stability.

Owner:TSINGHUA UNIV

Method for preparing iron modified SBA-15 mesoporous molecular sieve

InactiveCN101837988AIncrease surface areaIncrease mass transfer rateCrystalline aluminosilicate zeolitesMolecular sieveRoom temperature

The invention relates to a method for preparing an iron modified SBA-15 mesoporous molecular sieve, which comprises the following steps of: 1) adding nonionic surfactant and ferric nitrate nonahydrate into solution prepared from hydrochloric acid and deionized water in a volume ratio of 1 to 10 with pH of about 1, and stirring the solution at the room temperature till the solution is clear and transparent; 2) adding tetraethoxysilane into the mixed solution obtained in the step 1), placing the mixed solution into an ultrasonic pool, acting ultrasonic wave on the mixed solution for 2 hours, adjusting the pH of the mixed solution to between 3 and 4, transferring the mixed solution to a reaction kettle, and hydro-thermally crystallizing the mixed solution for 24 hours at the temperature of 100 DEG C to form the iron modified SBA-15 mesoporous molecular sieve; and 3) filtering the reaction solution obtained in the step 2), repeatedly washing a filtered substance by using water and drying the filtered substance, and calcining the filtered substance for 6 hours at the temperature of 550 DEG C to obtain the SBA-15 mesoporous molecular sieve of which iron ions are high dispersed inside and outside a skeleton. The method reduces the reactive ageing time to 2 hours from 20 hours, does not need to use a mineralizing agent NH4F, greatly shortens the reaction period, and reduces the reaction cost.

Owner:CHONGQING UNIV OF TECH

Preparation method of carbon nanotube-alumina composite reinforced magnesium-based composite material

InactiveCN102206793AHighlight substantive featuresEvenly dispersedCatalytic pyrolysisMagnesium matrix composite

The invention discloses a preparation method of a carbon nanotube-alumina composite reinforced magnesium-based composite material, which relates to the manufacture of magnesium-based alloy by using a casting method. The preparation method comprises the steps of: step 1, calcining and reducing raw materials of ferric nitrate nonahydrate and alumina in the ratio of (0.07-1.00):1 to obtain an iron / alumina composite catalyst, and finally, performing catalytic pyrolysis reaction by using the mixed gas of nitrogen gas and ethylene in the volume ratio of (6-12):1 for uniformly dispersing carbon nanotubes on the surface of the alumina, so as to prepare a carbon nanotube-alumina composite reinforced phase; and step 2, adding the carbon nanotube-alumina composite reinforced phase to a molten magnesium base material, and stirring and casting to prepare the carbon nanotube-alumina composite reinforced magnesium-based composite material, wherein the added carbon nanotube-alumina composite reinforced phase accounts for 1-15% of the molten magnesium base material by mass percentage. According to the invention, the defect of a magnesium-based alloy texture in the magnesium-based composite material produced in the prior art is overcome, the excellent enhancing effect of the carbon nanotubes in a magnesium matrix can be brought into full play, and the comprehensive performance of the magnesium-based composite material is ensured to be enhanced.

Owner:HEBEI UNIV OF TECH +1

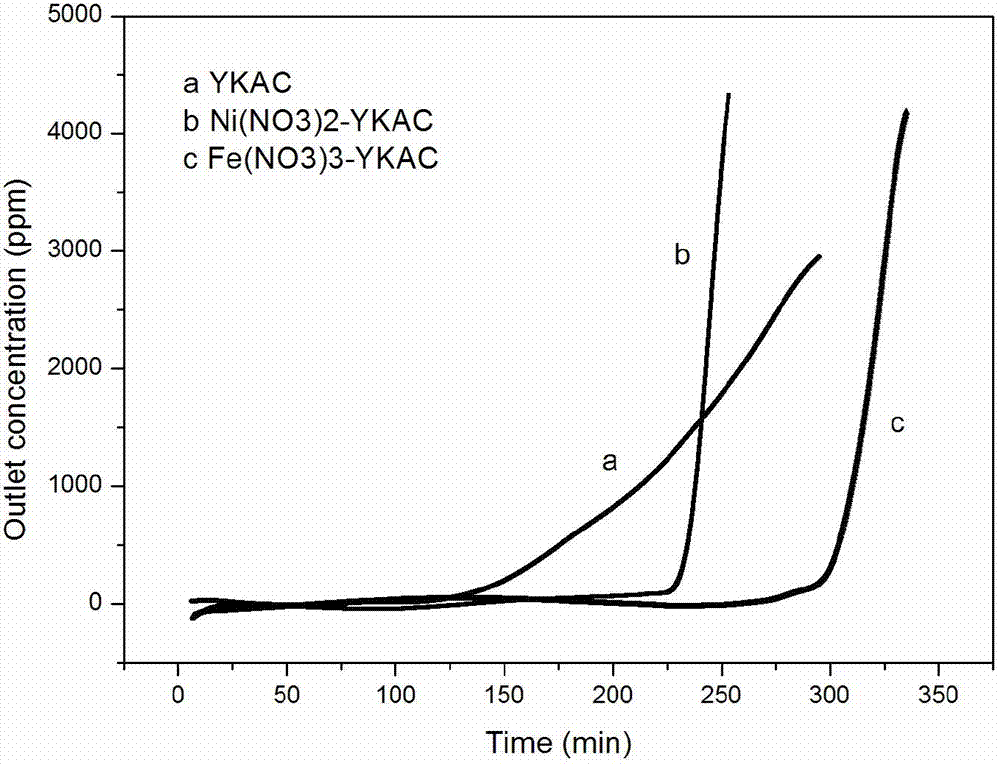

Preparation and application of efficient deodorant carbon-based adsorbent

InactiveCN102773074AEfficient removalImprove performanceOther chemical processesDispersed particle separationActivated carbonThiol

The invention discloses an efficient refuse landfill odor adsorbent and preparation and application thereof. According to the odor adsorbent, iron ions are loaded on the surface of active carbon. According to the preparation method, cocoanut active carbon is taken as a carrier, and ferric nitrate is taken as a precursor; and the preparation method comprises the steps of loading Fe(NO3)3 on the surface of the active carbon by an immersion method, and drying an obtained sample for removing water at a temperature of 100-120 DEG C to obtain the modified active carbon adsorbent. The modified active carbon adsorbent has a good effect when being used for removing malodorous components such as thiol and thioether in odor, is simple to prepare and easy in control of process and has a high industrial application value.

Owner:SICHUAN UNIV

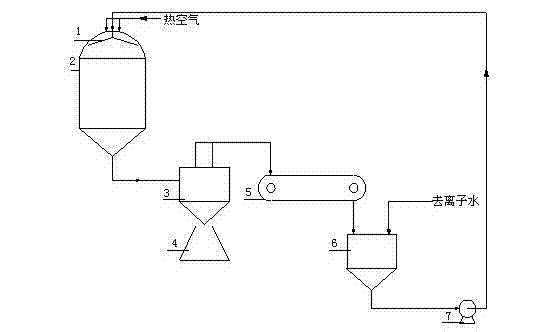

Preparation technology of butadiene catalyst by oxidative dehydrogenation of butene

ActiveCN102580749AAvoid secondary pollutionHigh mechanical strengthHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsActivated carbonCalcium hydroxide

The invention provides a preparation technology of butadiene catalyst by oxidative dehydrogenation of butane, which comprises the following steps of: dissolving an iron sheet by dilute nitric acid to prepare ferric nitrate solution, adding mixed serous fluid of calcium chloride, calcium hydroxide and zinc oxide, taking ammonia water as precipitator to gelatinize ferric nitrate solution, adding binder and activated carbon to age, cooling to be room temperature, filtering and washing, and retaining a filter cake; performing spray granulation for the filter cake; and activating in a rotary kiln in a roasting way, and screening out catalyst spherical particles with the particle size from 40 mu m to 200 mu m by a vibrating screen after roasting. The catalyst prepared by the preparation technology is high in yield, even in particle size, hard to smash, and good in wear resistance, so that the loss of the catalyst can be reduced, the use quantity of the catalyst can be saved, and the economic benefit can be improved.

Owner:中国石油集团东北炼化工程有限公司锦州设计院

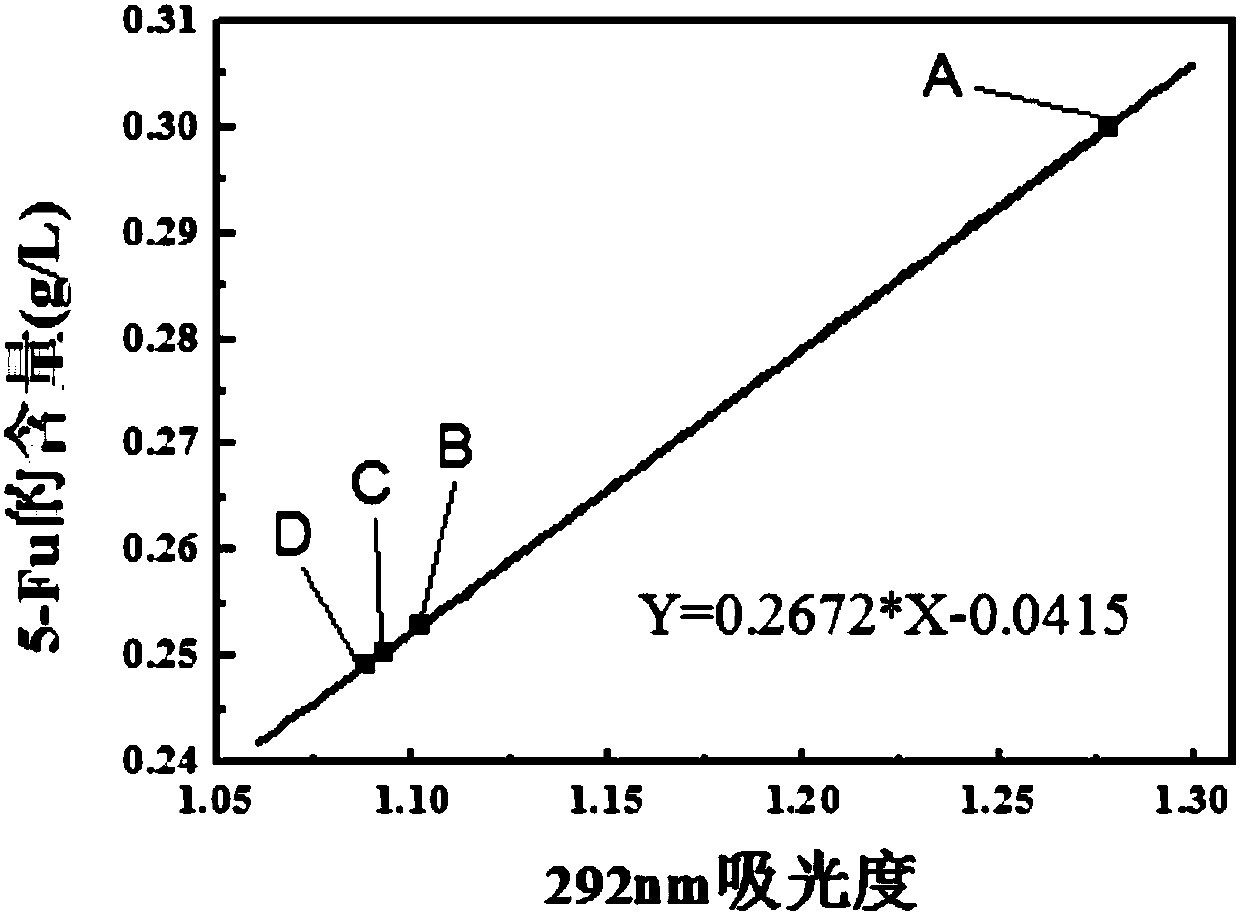

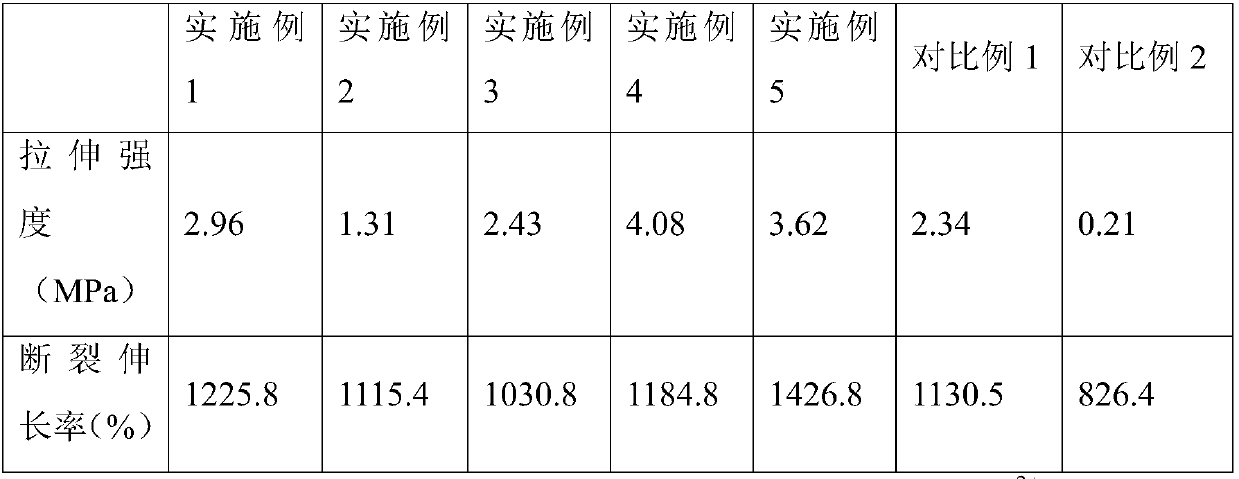

Preparation method for polyacrylamide-acrylic acid-VDT physical-crosslinking high-strength hydrogel

ActiveCN107814957AAdvantages and Notable ImprovementsSimple preparation processHydrogenHigh intensity

The invention discloses a preparation method and a use method of polyacrylamide-acrylic acid-VDT physical-crosslinking high-strength hydrogel. The preparation method comprises the steps: firstly, fully stirring acrylamide, VDT and acrylic acid in dimethyl sulfoxide to obtain an even mixed solution; thermally initiating the mixed solution at a certain temperature to obtain soft preformed gel; thensoaking the soft preformed gel in a water solution of ferric nitrate nonahydrate; forming multi-hydrogen bonds from the VDT, and forming physical-crosslinking high-strength hydrogel through a metal coordination interaction formed by ferric ions and carboxyl. The hydrogel material has the performance of quickly and selectively forming strong hydrogen bonds with target molecules in the water solution, adsorbing the target molecules of specific structures and gathering the target molecules. A preparation process of the preparation method disclosed by the invention has the advantage of simplenessand convenience in operation; furthermore, product performance is excellent; meanwhile, the hydrogel can be applied to the fields of matter separation and purification, sensing technologies, analysistechnologies and the like.

Owner:HUBEI UNIV OF TECH

Preparation method of BiFeO3 material, BiFeO3/TiO2 composite film and application thereof

InactiveCN103771532AReduce phase temperatureEasy to prepareIron compoundsPhotovoltaic energy generationComposite filmDevice material

The invention relates to a preparation method of a BiFeO3 material, a BiFeO3 / TiO2 composite film and an application thereof. The preparation method of the BiFeO3 material comprises the steps: firstly, dissolving bismuth nitrate and ferric nitrate into ethylene glycol monomethyl ether to obtain a solution I; then, dissolving citric acid into the solution I to obtain a solution II; and next, regulating the PH value of the solution II to 3-5 by using acetic acid to obtain a BiFeO3 sol. The BiFeO3 / TiO2 composite film comprises a substrate, wherein the substrate is coated with double layers of films which are respectively a BiFeO3 film layer and a TiO2 film layer. The absorptivity of the BiFeO3 / TiO2 composite film on a visible light wave band is greatly improved through the absorption spectrum test and theoretical analysis on the double layers of films. The BiFeO3 / TiO2 composite film is applied to the preparation of photovoltaic materials, solar cells, orientation controlled photoelectric functional device materials and visible light catalysis sterilization materials.

Owner:NORTHWEST UNIV

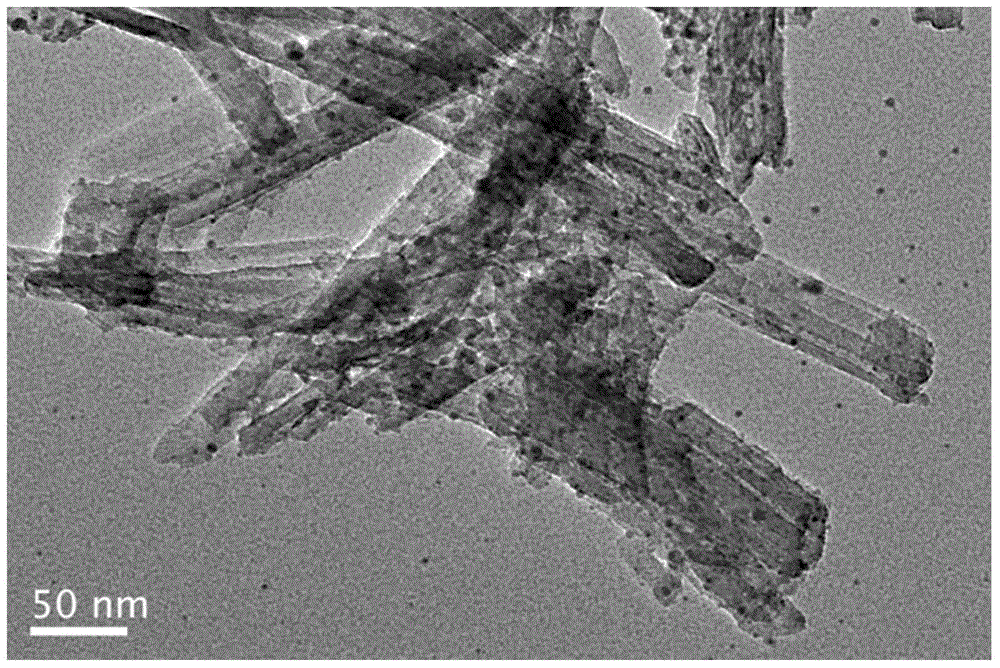

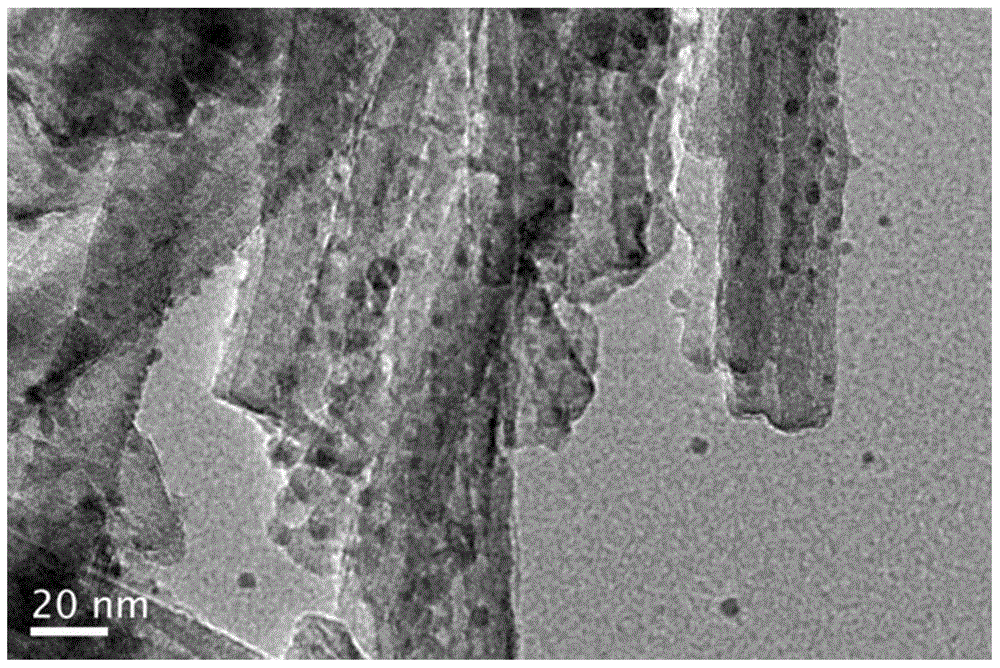

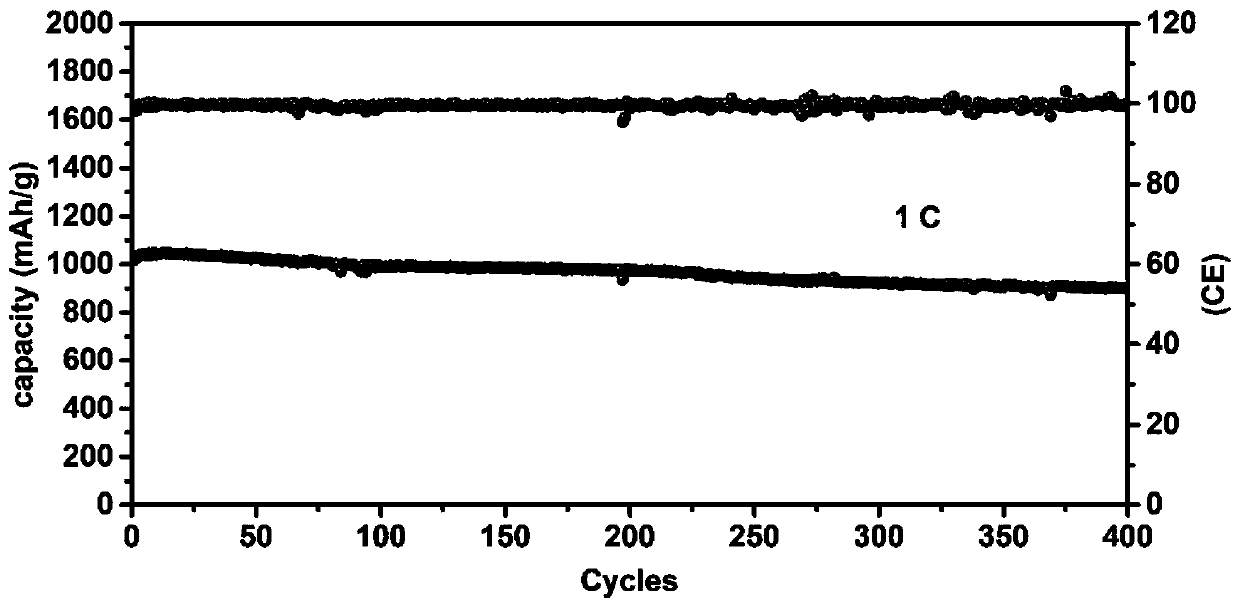

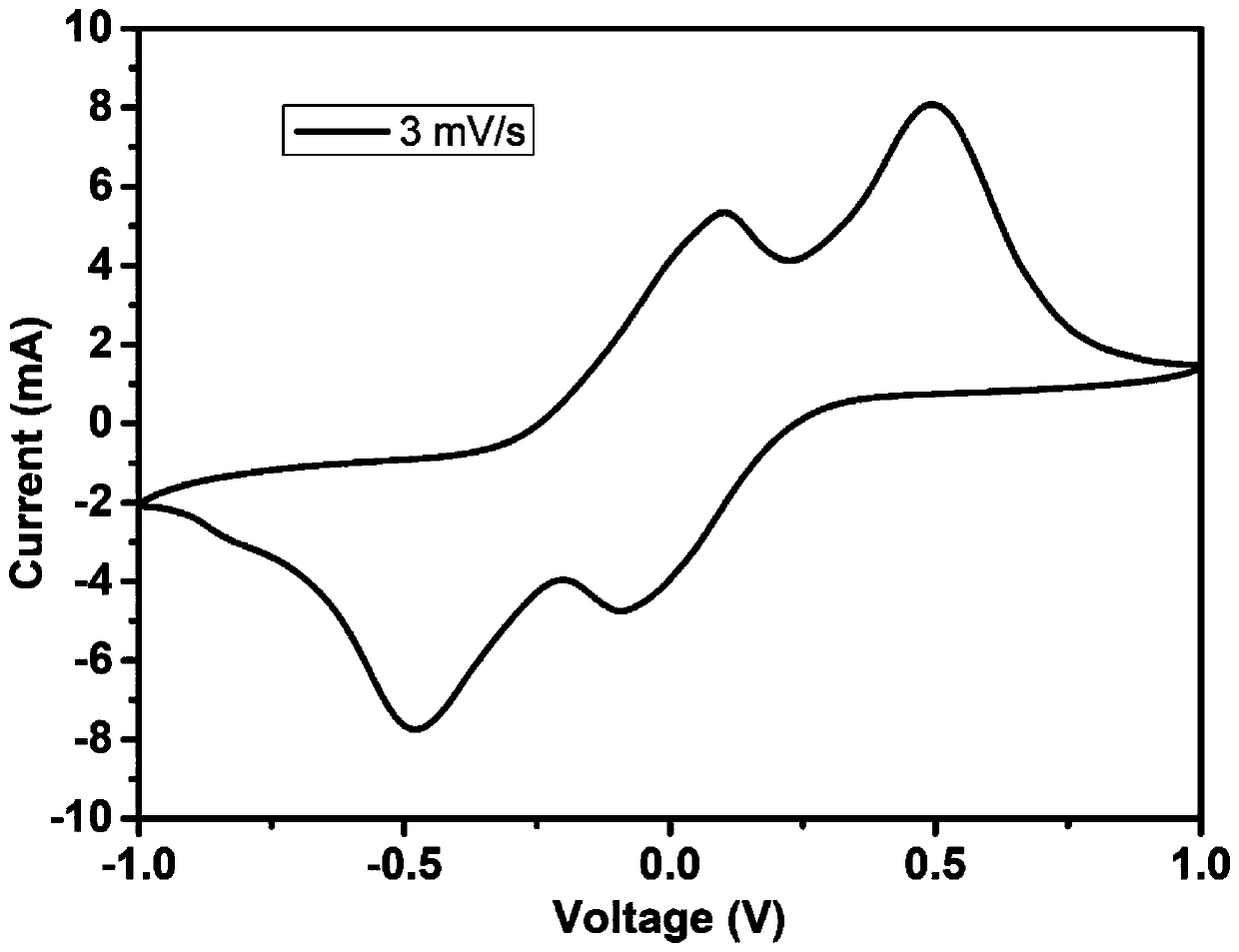

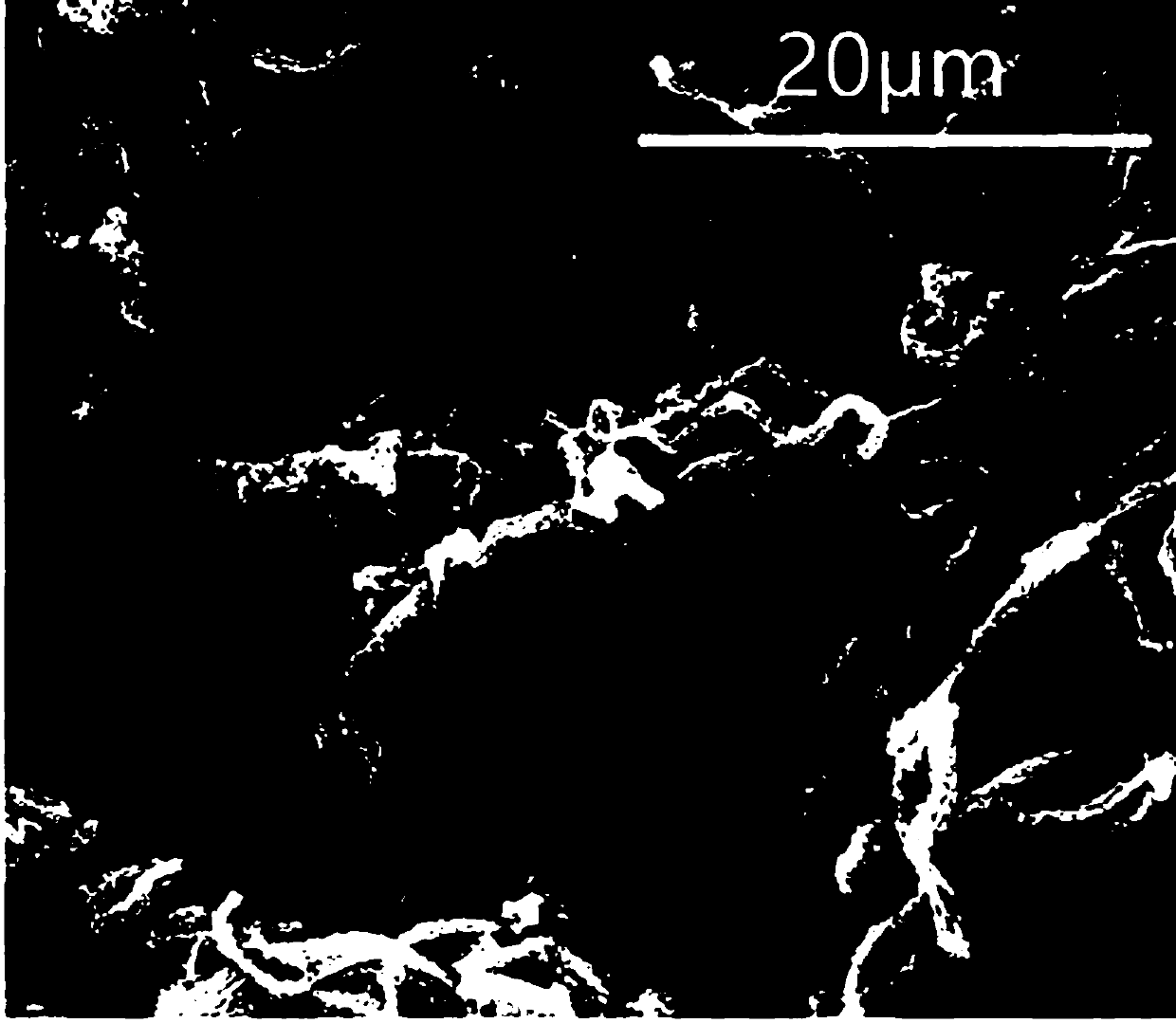

Preparation method of network-like carbon-loaded iron-based compound material and application of network-like carbon-loaded iron-based compound material in lithium-sulfur battery

InactiveCN109755442ADesign raw materials are cheap and easy to getSynthetic method is simpleLi-accumulatorsCell component detailsElectronMaterials science

The invention relates to a preparation method of a network-like carbon-loaded iron-based compound material and an application of the network-like carbon-loaded iron-based compound material in a lithium-sulfur battery, and belongs to the field of electrochemistry; the method comprises the following steps of taking slightly oxidized graphene as a substrate, taking ferric nitrate nonahydrate as an iron source, taking glucose hydrothermal carbon as a carbon source of iron carbide and a pore-forming substrate, taking ammonia gas generated in the high-temperature pyrolysis process of melamine as a nitrogen source of an iron-nitrogen compound, and meanwhile, enabling ammonia to corrode the glucose hydrothermal carbon substrate to generate a net-shaped structure. The method has the beneficial effects that 1) the process is simple, and the product cost is low; 2) the obtained positive electrode material has a rich hole structure and ion and electron transport channels, the conductivity of the material can be improved, and the loss of the polysulfide compound can be effectively inhibited, the stability of the electrode material is remarkably improved, and the electrochemical performance is improved; and 4) the adsorption and catalysis of the polysulfide compound are achieved by utilizing the synergistic effect of the iron carbide and the iron-nitrogen compound, and the catalytic action can be used for accelerating the reaction dynamics of the lithium-sulfur battery, so that the transition of the soluble polysulfide compound to insoluble sulfide is accelerated, and the shuttle effectis greatly inhibited.

Owner:DALIAN UNIV OF TECH

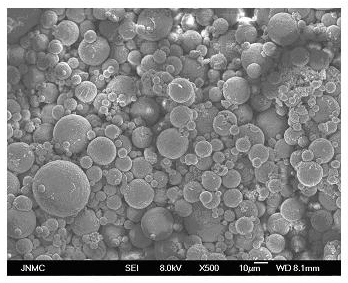

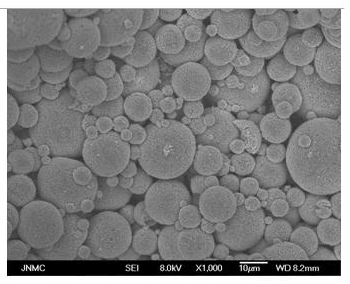

Method for preparing spherical LFP (lithium iron phosphate)/carbon doped composite powder

InactiveCN102044667AImprove conductivityWell mixedCell electrodesPhosphorous acidLithium iron phosphate

The invention discloses a method for preparing spherical LFP (lithium iron phosphate) / carbon doped composite powder, which relates to a method for preparing spherical LFP (lithium iron phosphate) for lithium-electron anode materials. The method is characterized in that the spherical LFP (lithium iron phosphate) / carbon doped composite powder is prepared by using ferric nitrate nonahydrate, phosphorous acids, lithium carbonates, doping metal ion salts and carbon sources as raw materials through the steps of (1) adding deionized water into the ferric nitrate nonahydrate and the phosphoric acid, reacting the obtained mixture so as to prepare an iron phosphate suspension; (2) adding the lithium carbonates, the doped metal ion salts and the carbon sources into the prepared suspension, grinding the obtained mixture so as to obtain mixed stock; and (3) carrying out spray drying on the mixed stock so as to obtain a precursor, then calcinating the precursor in an inert atmosphere or a weak reduction atmosphere so as to obtain the spherical LFP (lithium iron phosphate) / carbon doped composite powder. The appearance of the spherical LFP (lithium iron phosphate) / carbon doped composite powder synthesized by using the method of the invention seems like a spheroid, the composite powder has LFP (lithium iron phosphate) materials with good electrochemical performance, and the process is simple, therefore, the composite powder is suitable for industrial mass production.

Owner:LANZHOU JINCHUAN NEW MATERIAL SCI & TECH

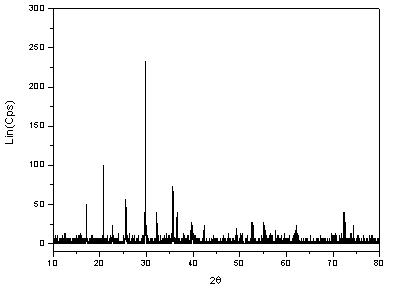

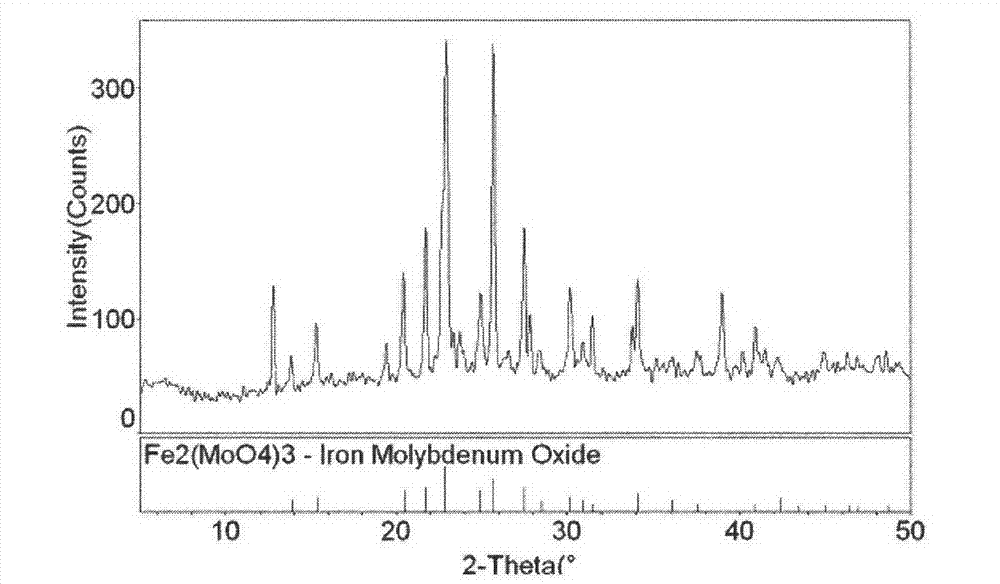

Preparation method of supported iron-molybdate catalyst and application of catalyst to degradation of dye wastewater

InactiveCN103357416AEasy to synthesizeNo pollution in the processMolecular sieve catalystsWaste water treatment from textile industrySludgeSynthesis methods

The invention relates to a preparation method of a supported iron-molybdate catalyst and an application of the supported iron molybdate catalyst to the degradation of dye wastewater. The supported iron-molybdate solid acid catalyst is synthesized from such raw materials as ammonium molybdate, ferric nitrate, diatomaceous earth, zeolite and a molecular sieve by adopting an aqueous precipitation method. The synthesis method of the supported iron-molybdate solid acid catalyst comprises the following steps of mixing a carrier with a solution of ammonium molybdate fully, adjusting the pH value of a medium by using aqueous ammonia until the medium is weakly alkaline; and dropwise adding a solution of ferric nitrate into the solution of ammonium molybdate, stirring the two solutions fully, ageing, filtering, washing, drying, and calcining in a muffle furnace for 2 hours at the temperature of 550 DEG C. The supported iron-molybdate solid acid catalyst can be used for degrading the methylene-blue simulated wastewater and the turquoise blue real wastewater quickly and effectively without adjusting the pH value of the dye and generating iron sludge, thus reagents are saved, and the separation becomes easy. The supported iron-molybdate solid acid catalyst can be recycled.

Owner:JIANGNAN UNIV

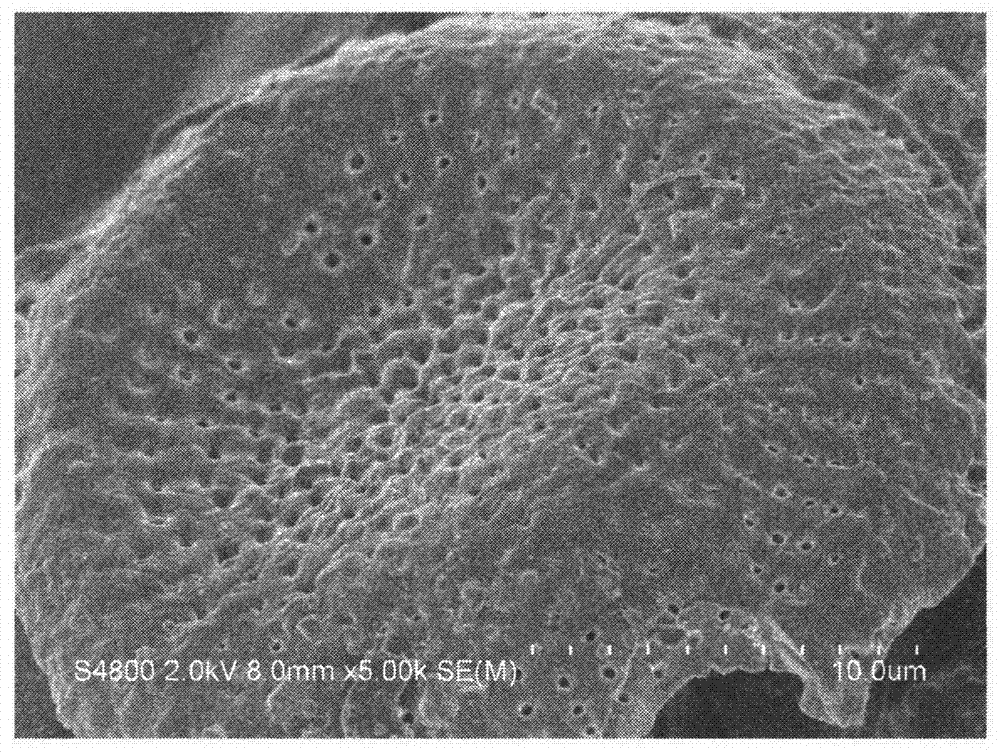

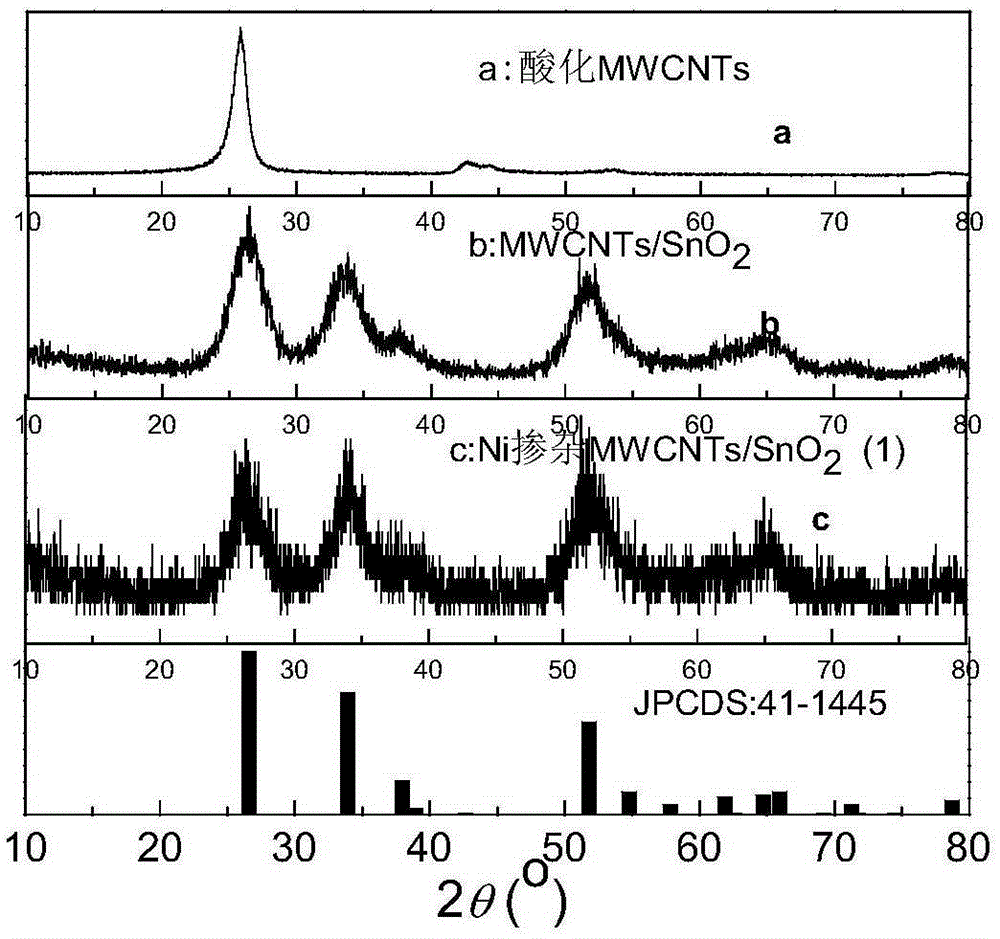

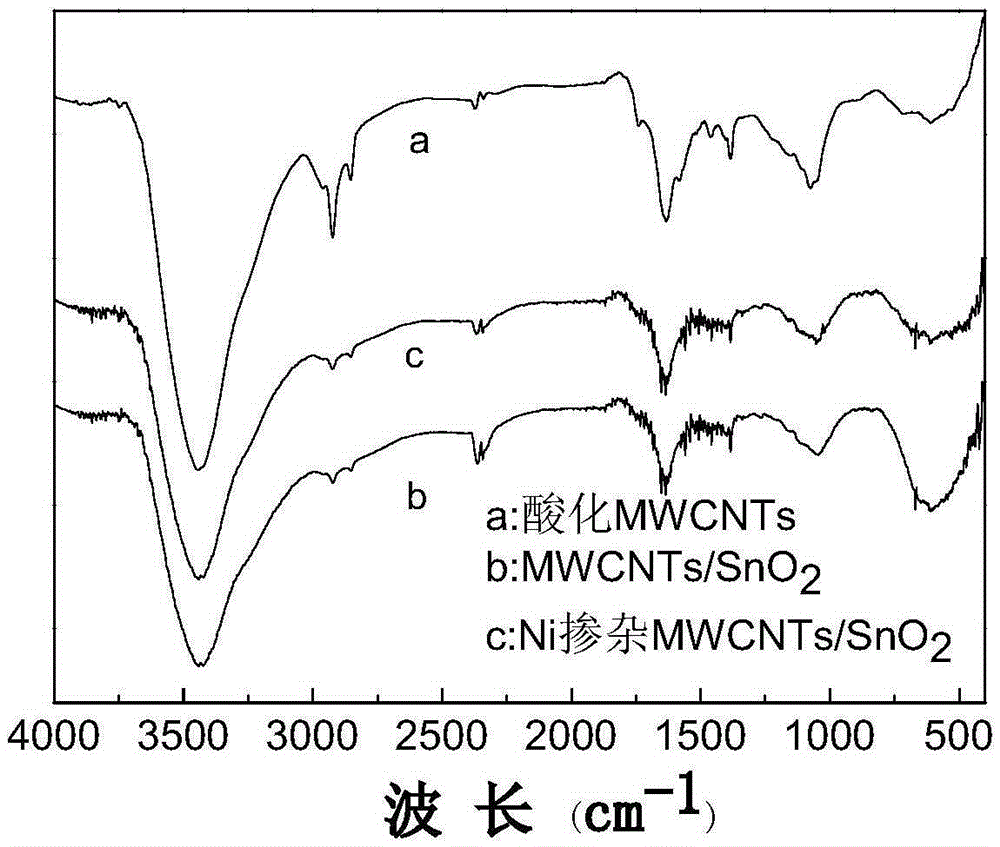

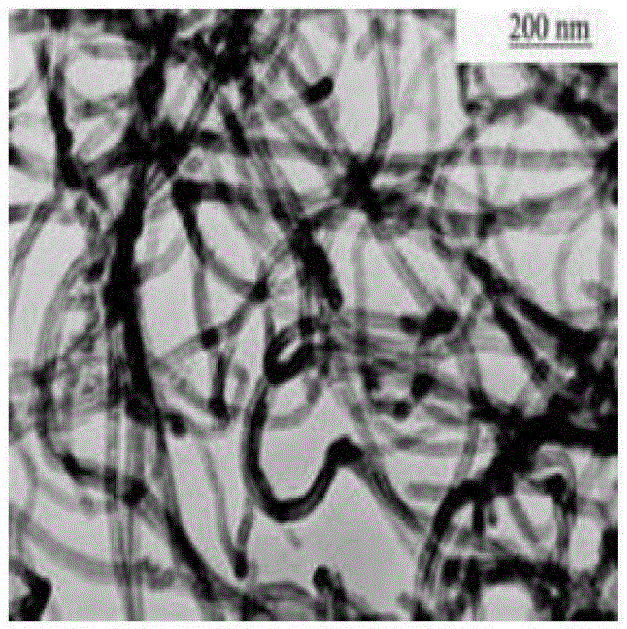

Nanocomposite made of magnetic-metal-doped multiwalled carbon nanotubes/tin dioxide

ActiveCN105338799ALight weightImprove conductivityMagnetic/electric field screeningTin dioxideNanocomposite

The invention discloses a nanocomposite made of magnetic-metal-doped multiwalled carbon nanotubes / tin dioxide, and the nanocomposite can be widely applied to the aspect of electromagnetic wave absorption. A preparation method of the nanocomposite comprises the following steps: 1, conducting acidificaiton on multiwalled carbon nanotubes; 2, dispersing the acidified multiwalled carbon nanotubes treated in step 1 into water, obtaining dispersion liquid of the multiwalled carbon nanotubes, adding tin tetrachloride pentahydrate, then adding nickel nitrate hexahydrate or ferric nitrate nonahydrate or cobalt nitrate hexahydrate, then adding acid, then slowly adding stronger ammonia water, adjusting pH to be 7-10, conducting a reaction for 8-24 hours at the temperature of 120-180 DEG C, and obtaining the nanocomposite made of the magnetic-metal (M)-doped multiwalled carbon nanotubes / tin dioxide through aftertreatment, wherein M represents Fe, Co and Ni, and the massic volume ratio of the acidified multiwalled carbon nanotubes to the tin tetrachloride pentahydrate to the nickel nitrate hexahydrate or the ferric nitrate nonahydrate or the cobalt nitrate hexahydrate to the acid is 0.04 g: 1-4 g: 0.5-3 g: 0.5-4 mL.

Owner:ANHUI UNIV OF SCI & TECH

Solder removing liquid, preparation method and application thereof

The invention provides solder removing liquid, a preparation method and application thereof. The solder removing liquid comprises the following components in percentage by weight: 15-50 percent of nitric acid, 1-20 percent of ferric nitrate or ferric chloride, 1-5 percent of sulfoacid and the balance of water. The solder removing liquid provided by the invention has the advantages of strong oxidability, high speed of dissolving solder, simpleness and easiness of raw materials, low preparation cost, no containing of a stabilizing agent and simple formulation and favorability of recycling valuable metals in waste liquid; and the waste solder removing liquid formed after desoldering can stand to generate beta-stannic acid sediment and is convenient for recovering tin metal.

Owner:GEM CO LTD

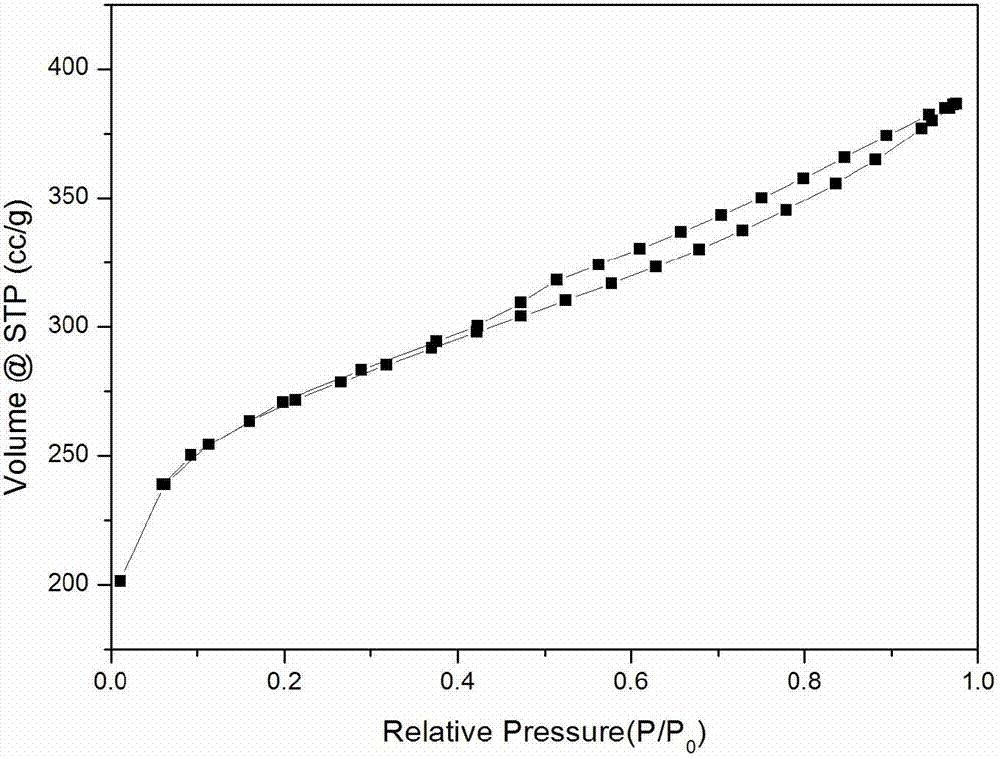

Hydrothermal method for preparing triclinic-phase FeVO4 micro particles

The invention discloses a hydrothermal method for preparing triclinic-phase FeVO4 micro particles. The method comprises the following steps of: mixing ferric nitrate nonahydrate, ammonium metavanadate and nitric acid solution in a molar ratio of 1:1:10, adjusting the pH value to 4 or 7 by using 14 weight percent of aqueous ammonia, transferring the solution to a stainless steel self-pressure kettle of which a lining is made of polytetrafluoroethylene, treating the solution for 2 or 6 hours at the constant temperature of 180 DEG C, filtering the solution, washing and drying the filtrate, and heating the filtrate to 600 DEG C from room temperature at the speed of 1 DEG C per minute under air atmosphere and keeping the temperature for 6 hours, wherein when the pH is 4 or 7 and the hydrothermal treatment is performed for 6 hours, the obtained product is a triclinic-phase FeVO4 mesoporous micro bar, and when the pH is 4 and the hydrothermal treatment is performed for 2 hours, the obtained product is a triclinic-phase FeVO4 imperforate micro block. The method is convenient to operate, the raw materials are cheap, and the topography, crystalline phase structure and specific surface area of the target product particles are controllable.

Owner:BEIJING UNIV OF TECH

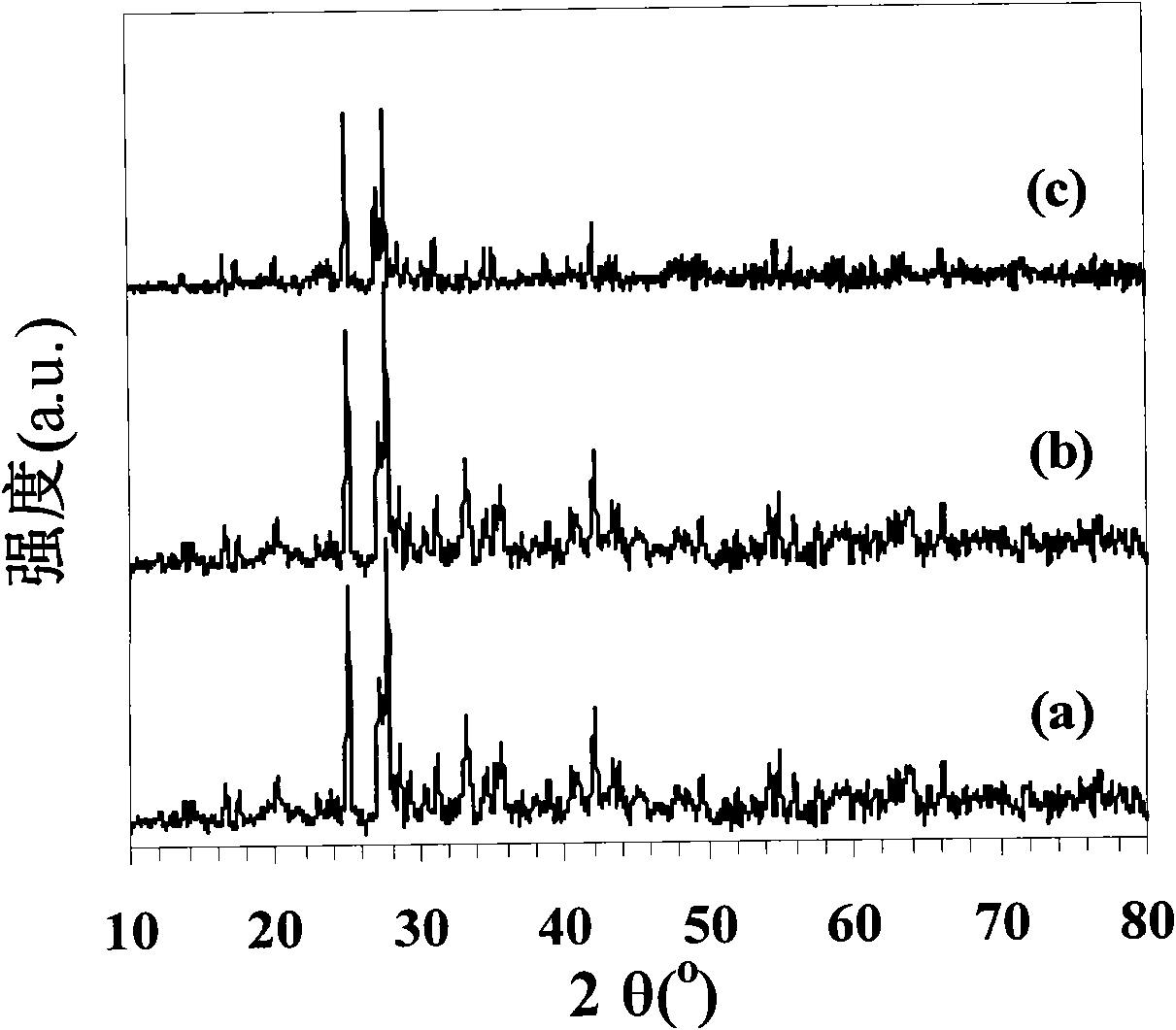

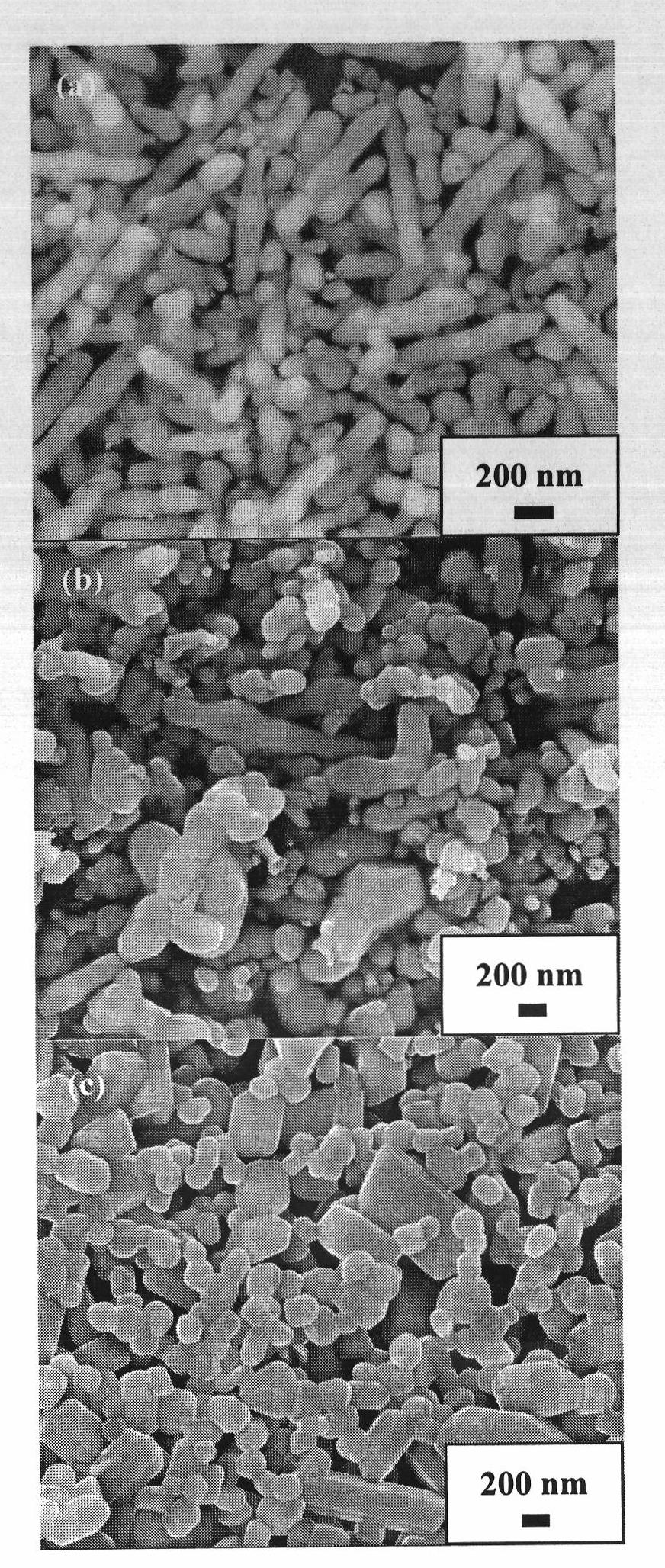

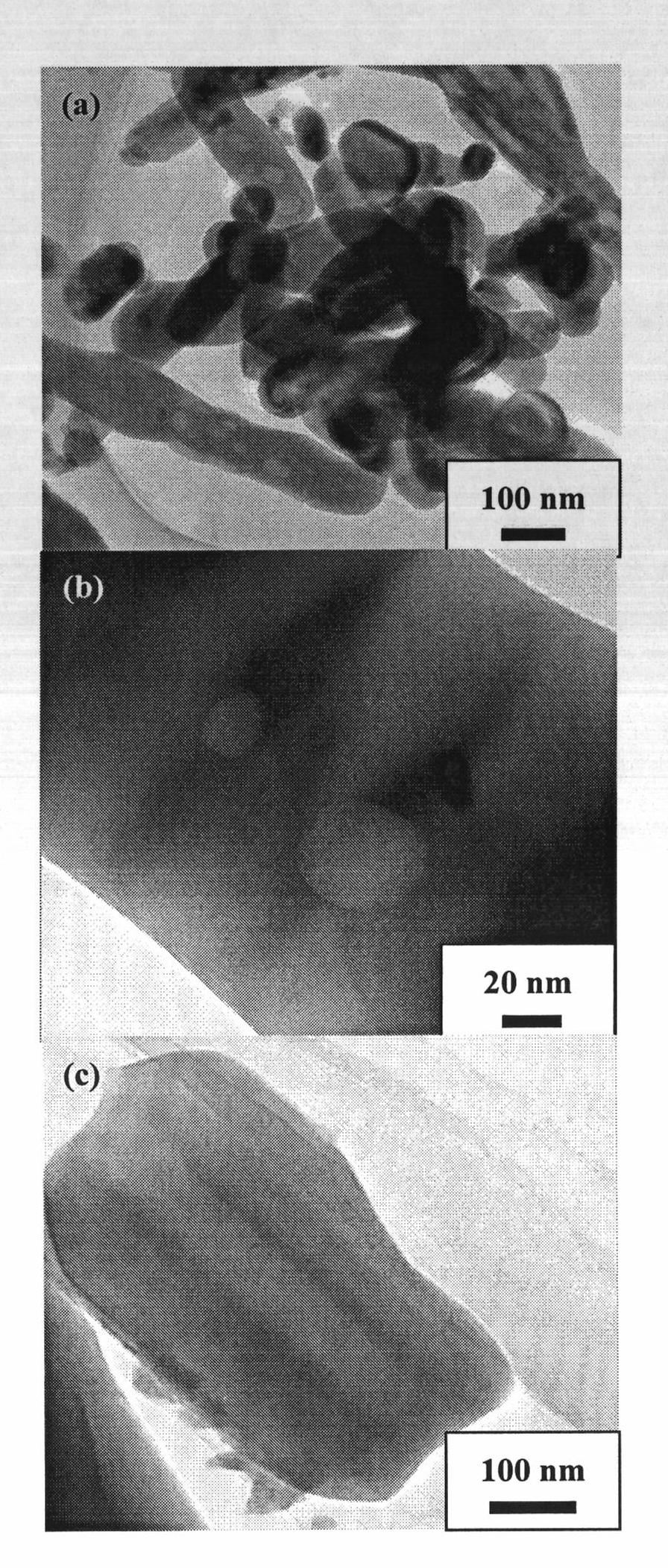

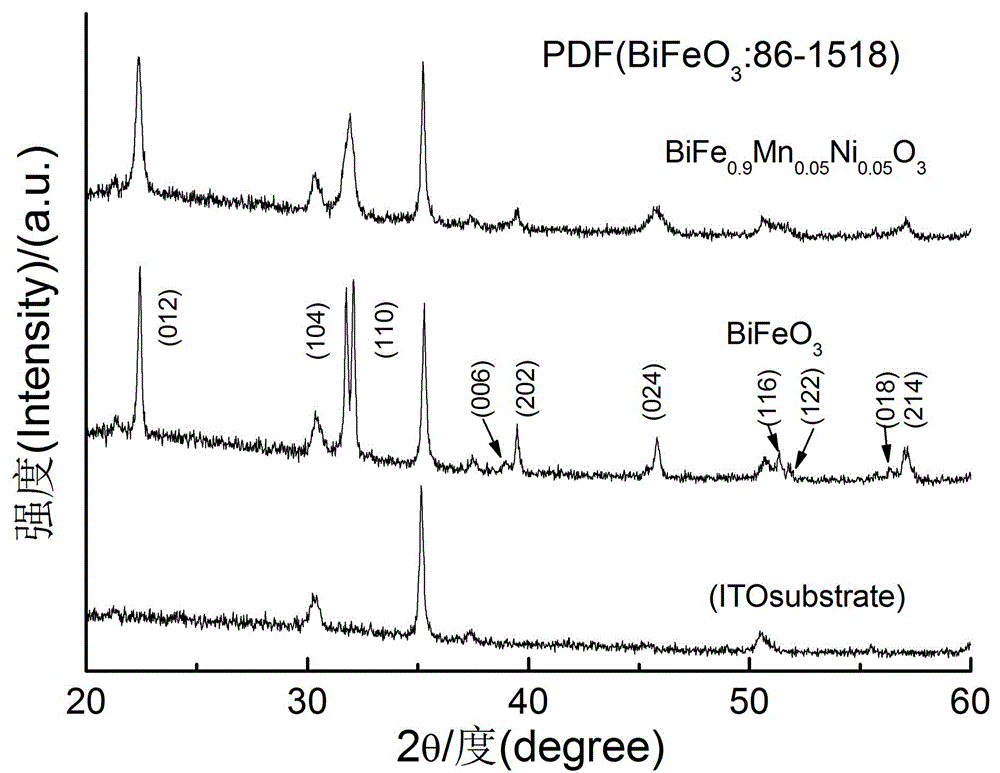

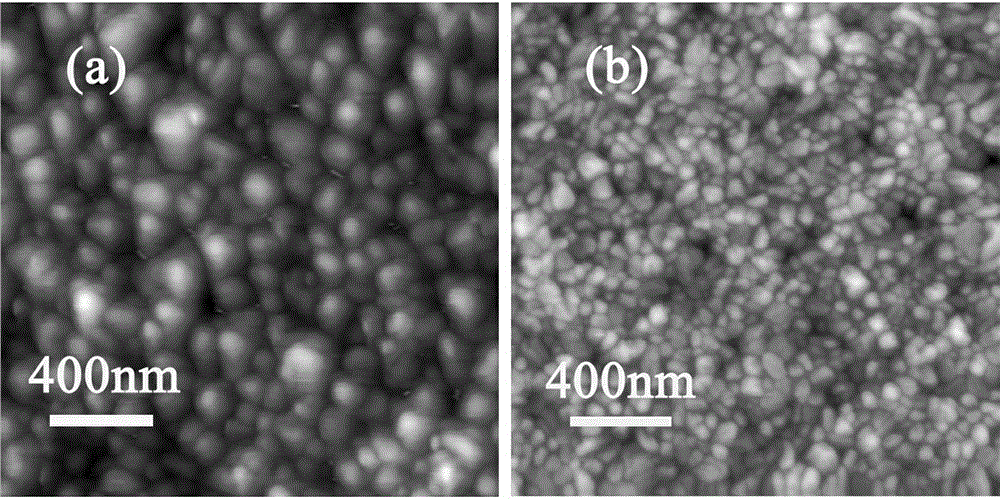

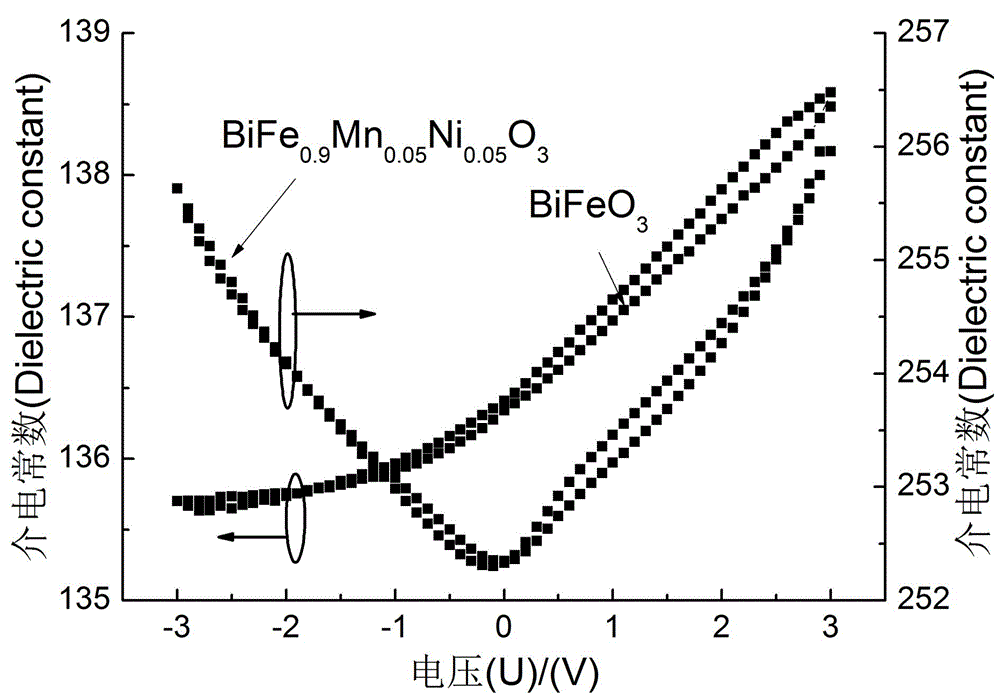

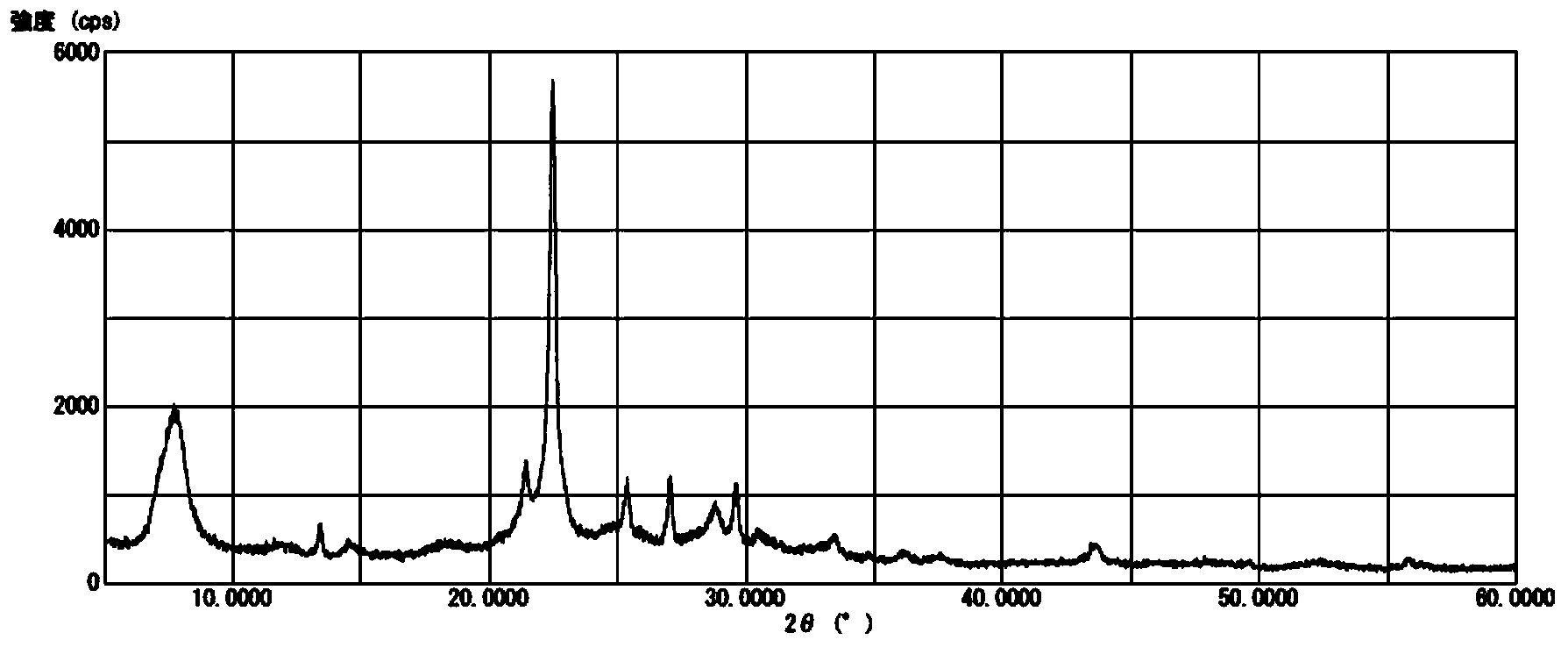

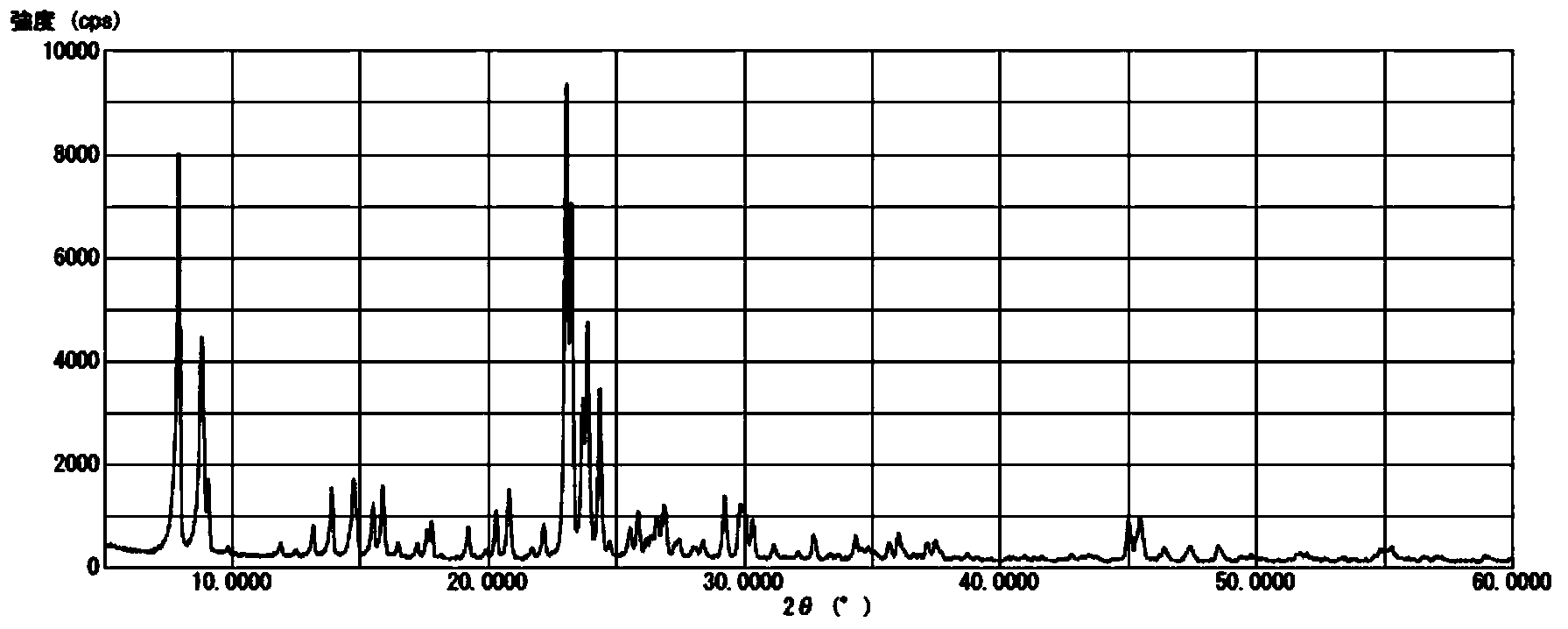

Method for preparing manganese, nickel codoped bismuth ferrite film by sol-gel process

The invention discloses a method for preparing manganese, nickel codoped bismuth ferrite film by a sol-gel process. The method comprises the steps of weighing material ferric nitrate, bismuth nitrate, manganese acetate and nickel acetate according to a general formula BiFe(1-2x)MnxNixO3 (x is smaller than or equal to 0.05 and greater than or equal to 0.0125); adding glacial acetic acid to agitate for 30 minutes at 80 DEG C; and adding ethylene glycol monomethyl ether to agitate for 180 minutes at room temperature to prepare into a liquid precursor of which the concentration is 0.1-0.2mol / L. The final sample is obtained by preparing a wet film on indium tin oxide / glass or a platinum substrate by a spin-coating method, pre-annealing, finally annealing the film, and repeating the pre-annealing and film annealing processes for 10-20 times. The method has the characteristics that the impurity phase in bismuth ferrite can be effectively restrained; the grain size and the root-mean-square roughness of the film surface are reduced; the insulating property, ferroelectric properties, the ferromagnetic property and the optical property of the sample are improved; and the method is simple in production technology, good in reproducibility, and low in cost.

Owner:XINJIANG UNIVERSITY

Iron-based SCR (Selective Catalytic Reduction) catalyst and preparation method thereof

ActiveCN104226361AExcellent purificationLow costMolecular sieve catalystsDispersed particle separationOxygen cycleOxygen

The invention discloses an SCR (Selective Catalytic Reduction) catalyst containing synthetic zeolite and iron, and particularly relates to an SCR catalyst which always has an NOx purifying property in a low-temperature region after being subjected to relatively long-term action of hot water and relatively long-term action of sulfur oxides. A preparation method of the SCR catalyst, disclosed by the invention, comprises the following steps: crystallizing a hydrogenised synthetic zeolite with maximal oxygen cycle number of 8-12 and a three-dimensional structure by using a mixing procedure, and blending with a ferric nitrate (III) water solution or ferric chloride (III) water solution with a pH value of 0.1-0.7 to obtain the SCR catalyst without a filtering procedure and a cleaning procedure.

Owner:清华大学苏州汽车研究院(吴江) +1

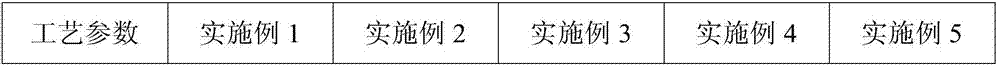

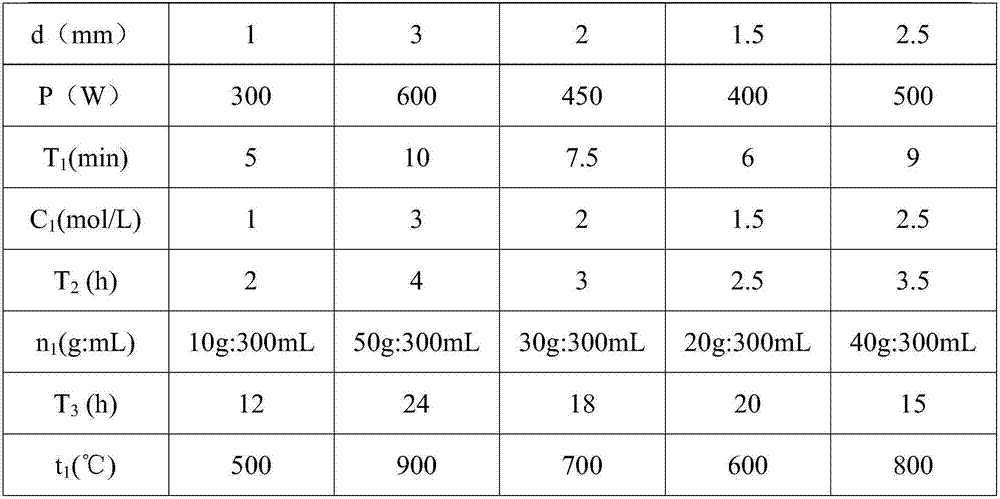

Preparation method of poly-metallic oxide-loaded catalytic ozonation catalyst and application

InactiveCN107051468AIncrease load capacityHeavy loadWater contaminantsNature of treatment waterMicrowaveNitrate

The invention discloses a preparation method of a poly-metallic oxide-loaded catalytic ozonation catalyst and an application. The preparation method of the catalyst comprises the following steps of: a, activating diatomite, the diameter of which is 1-3mm, in a microwave generator, then immersing the diatomite in a NaOH solution, and taking out the diatomite to dry to obtain pre-treated diatomite; b, immersing the pre-treated diatomite in a mixed solution of copper nitrate, nickel nitrate, manganese nitrate, cobalt nitrate and ferric nitrate to obtain a catalyst precursor; and c, drying the catalyst precursor, and roasting the catalyst precursor at a high temperature to obtain the poly-metallic oxide-loaded catalytic ozonation catalyst. By selecting diatomite as a carrier which is cheap and easily available, the preparation process is simple, and the catalyst is easy to recover and suitable for industrial production on a large scale. The poly-metallic oxide-loaded catalytic ozonation catalyst prepared by the preparation method is used for treating antibiotic industrial wastewater.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Phosphatizing liquid and preparation method thereof

InactiveCN101935831AReduce construction difficultyIncrease productivityMetallic material coating processesSodium fluoridePhosphoric acid

The invention discloses phosphatizing liquid. The phosphatizing liquid comprises the following components in percentage by weight: 7 percent of starter liquid, 0.38 to 0.4 percent of neutralizer, 0.2 to 0.6 percent of accelerator and the balance of water, wherein the starter liquid comprises the following components in percentage by weight: 30 to 36 percent of 85 percent phosphoric acid, 16 to 20 percent of 68 percent nitric acid, 15.6 to 18.4 percent of 99.7 percent zinc oxide, 0.4 to 0.6 percent of citric acid, 0.4 percent of sodium fluoride, 0.6 to 1 percent of nickel nitrate, 0.16 to 0.24 percent of ferric nitrate, 0.004 to 0.01 percent of copper nitrate and the balance of water.

Owner:景阳富

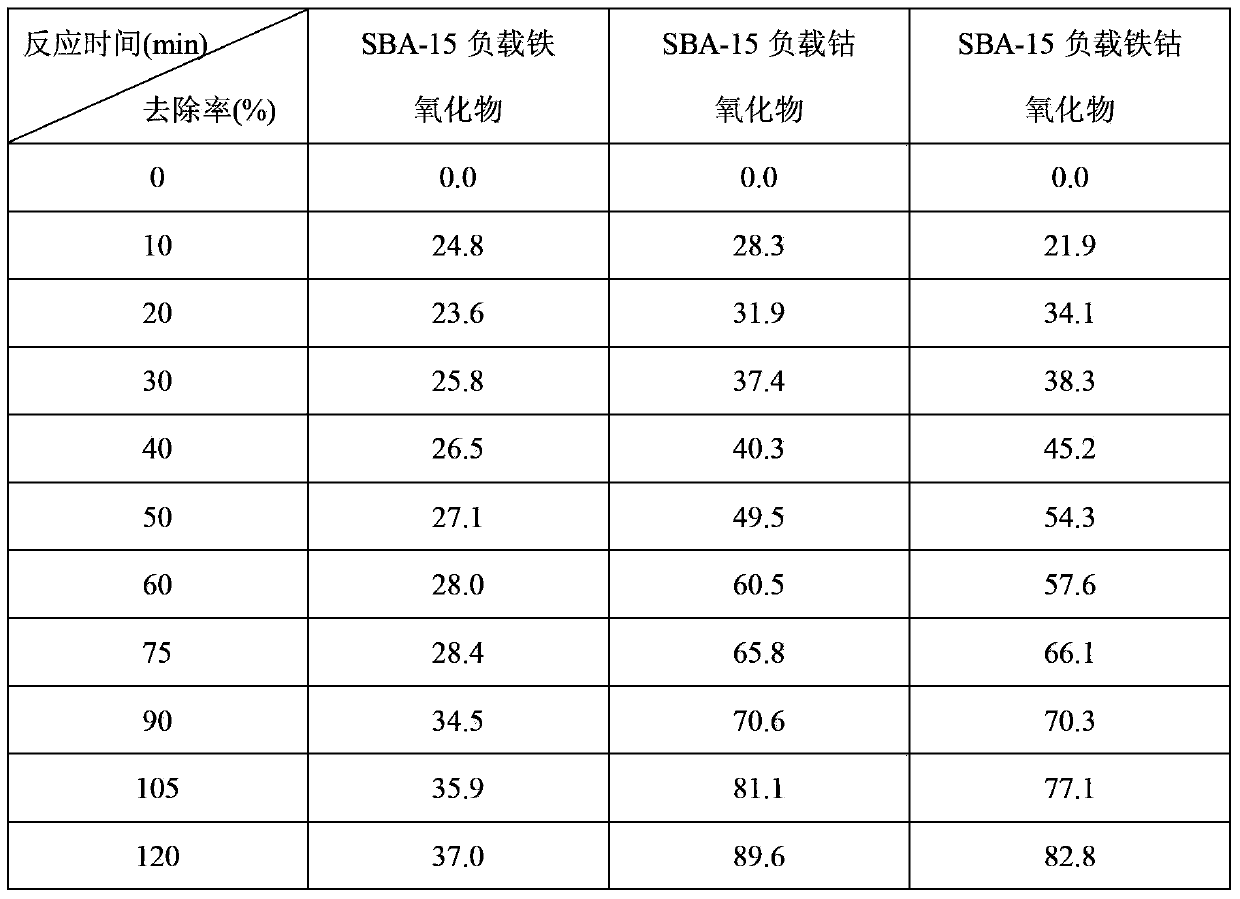

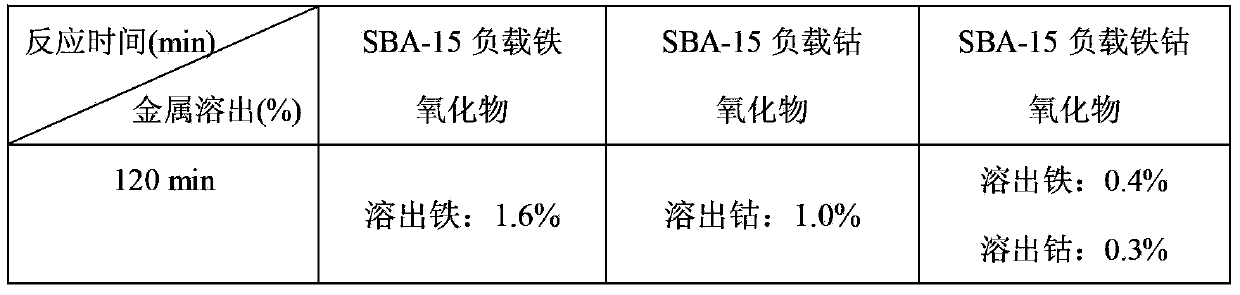

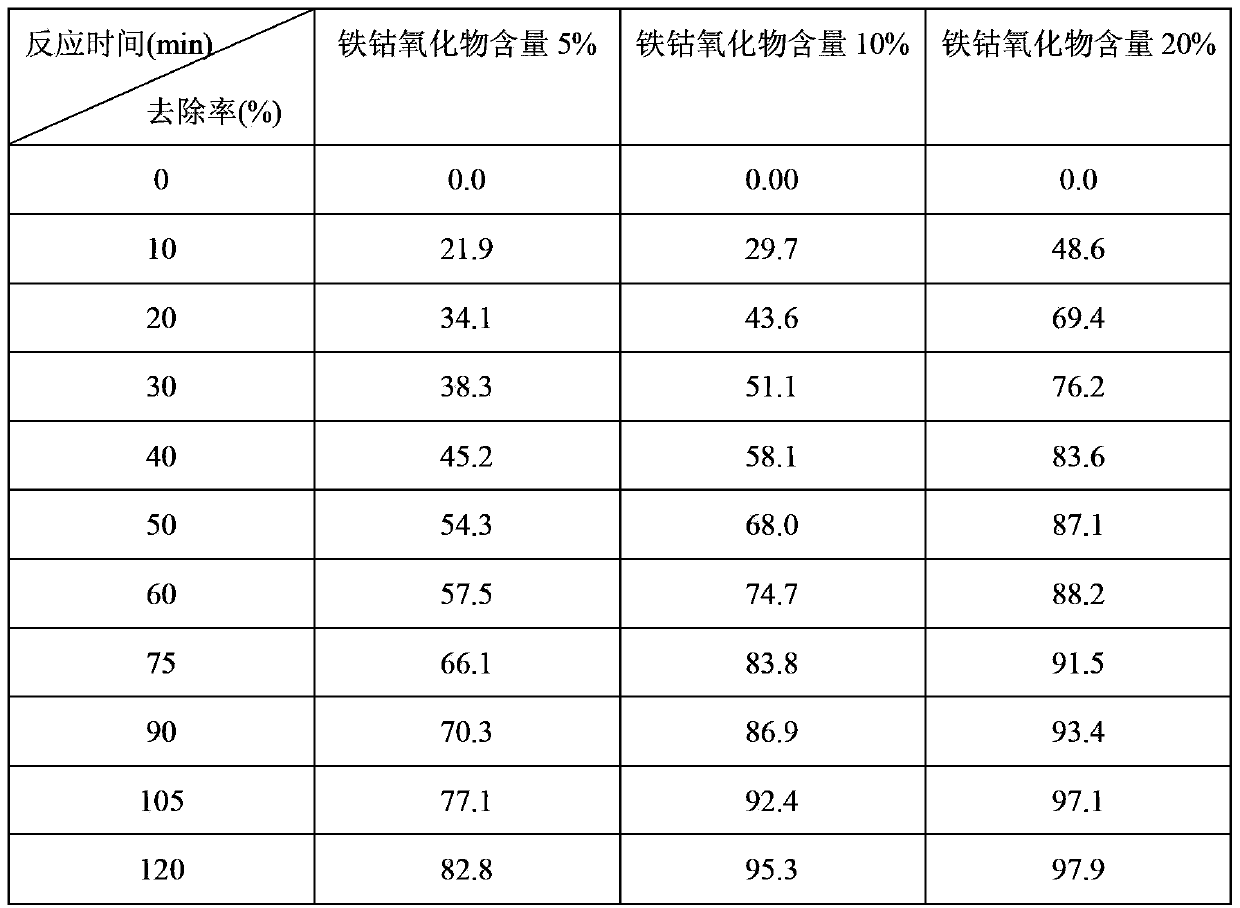

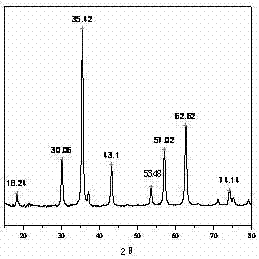

SBA-15 loaded iron-cobalt oxide catalyst, preparation method and application thereof in wastewater treatment

InactiveCN103357428AEasy to prepareLow priceMolecular sieve catalystsMultistage water/sewage treatmentDissolutionDyeing wastewater

Owner:WUHAN UNIV

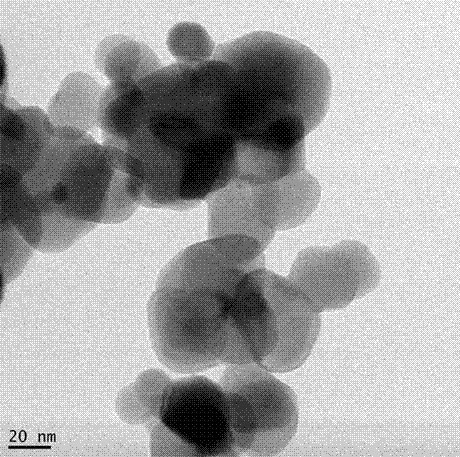

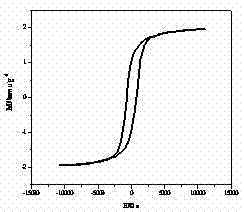

Preparation method of CoFe2O4 magnetic nano material

InactiveCN102923785AHigh saturation magnetizationSynthetic process conditions are mildMaterial nanotechnologyIron compoundsReaction temperaturePhysical chemistry

The invention provides a preparation method of a CoFe2O4 magnetic material. The preparation method comprises steps as follows: preparing a certain amount of ferric nitrate Fe(NO3)3.9H2O and a certain amount of cobalt nitrate Co(NO3)2.6H2O into a mixed solution; slowly adding to a NaOH solution with a certain concentration at a certain temperature; then agitating the reaction solution under reinforcement; maintaining the reaction temperature for a period of time; then filtering and washing until the filtrate is neutral; drying the product; grinding to obtain black brown precursors; and thermally processing the precursors for 1 hour at a certain temperature, so as to obtain the CoFe2O4 magnetic nano material.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Preparation method of graphene oxide/barium ferrite wave-absorbing material

InactiveCN104449561AHeating evenlyAvoid high temperature calcination processOther chemical processesBarium nitratePhysical chemistry

The invention relates to a novel material for absorbing electromagnetic waves, and in particular relates to a preparation method of a graphene oxide / barium ferrite wave-absorbing material. The preparation method comprises the following steps: forming a sol from analytically pure barium nitrate Ba(NO3)2 and ferric nitrate Fe(NO3)3 with a graphene oxide water solution by taking citric acid and ethylene glycol as a compound complexing agent; continuously heating and stirring the sol to form a gel; and igniting the gel by virtue of microwave-assisted auto-combustion to further prepare the graphene oxide / barium ferrite wave-absorbing material. The preparation method disclosed by the invention is simple and controllable in process, uniform in temperature distribution of the entire system through microwave field heating, and meanwhile, the preparation method can be used for greatly shortening reaction time and greatly improving the wave-absorbing performance of a barium ferrite material with the doping of the graphene oxide.

Owner:SHANGHAI YUEDA NEW MATERIAL TECH

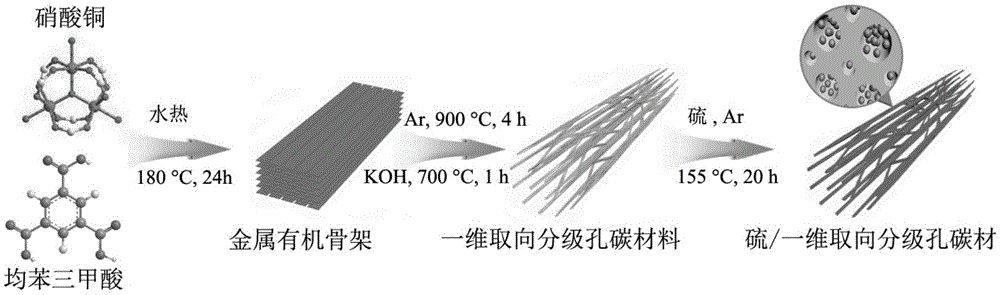

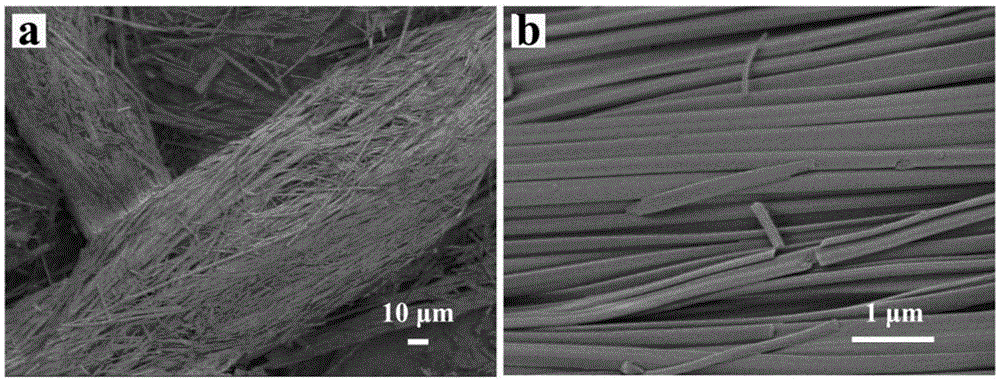

Preparation and application of an ordered crosslinked fibrous graded porous carbon material having one-dimensional orientation

ActiveCN106882784AIncrease profitImprove performanceCell electrodesCarbon preparation/purificationEtchingPorous carbon

The invention relates to preparation and application of an oriented ordered crosslinked fibrous graded porous carbon material having one-dimensional orientation. A metal salt and an organic ligand are adopted as raw materials to prepare a metal organic frame (MOF) having one-dimensional orientation. The ordered crosslinked fibrous graded porous carbon material having one-dimensional orientation is prepared through programmed heating and carbonization, template etching and activation. The organic ligand is one or two or above selected from a group consisting of trimesic acid, melamine, cyanuric acid and thiocyanuric acid. The metal salt is one or two or above selected from a group consisting of ferric nitrate, copper nitrate, nickel nitrate and zinc nitrate. The porous carbon material is adopted as a cathode material of a lithium sulfur cell, has huge advantages in the fields of material preparing processes, electron and ionic conduction, and the like and has a good application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

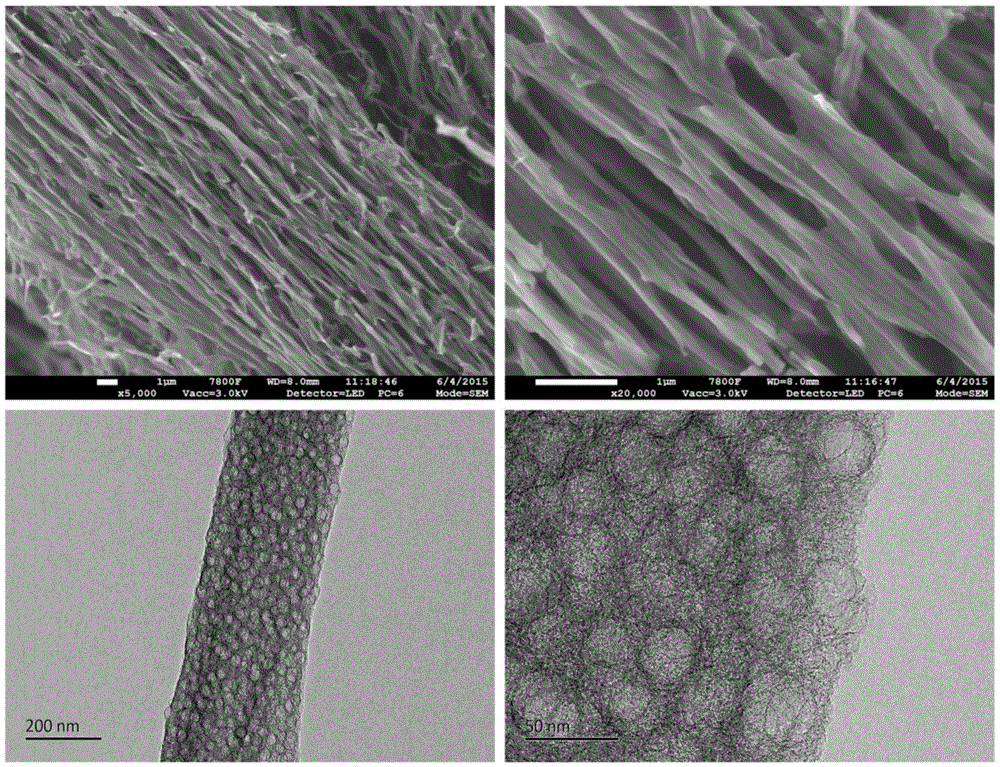

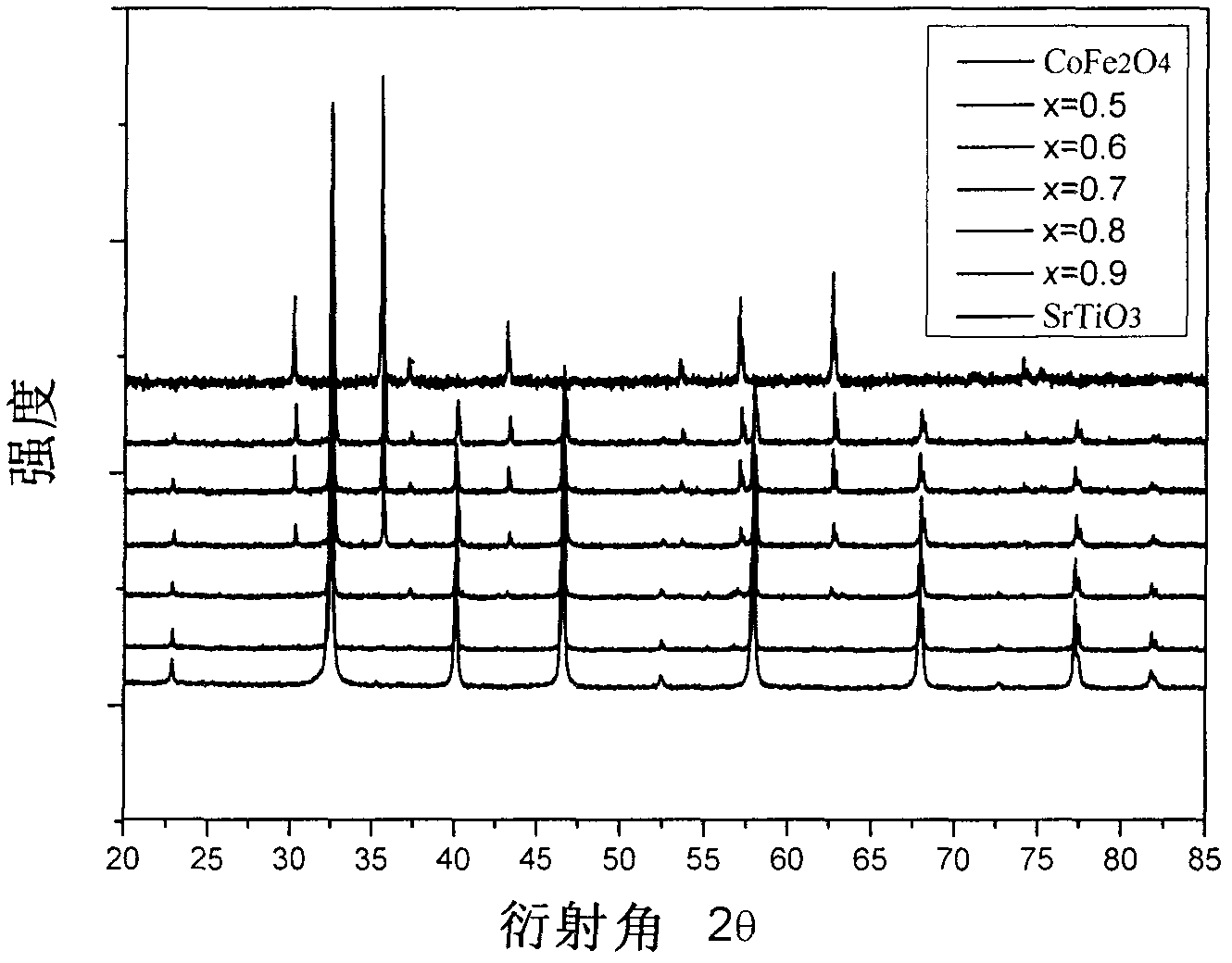

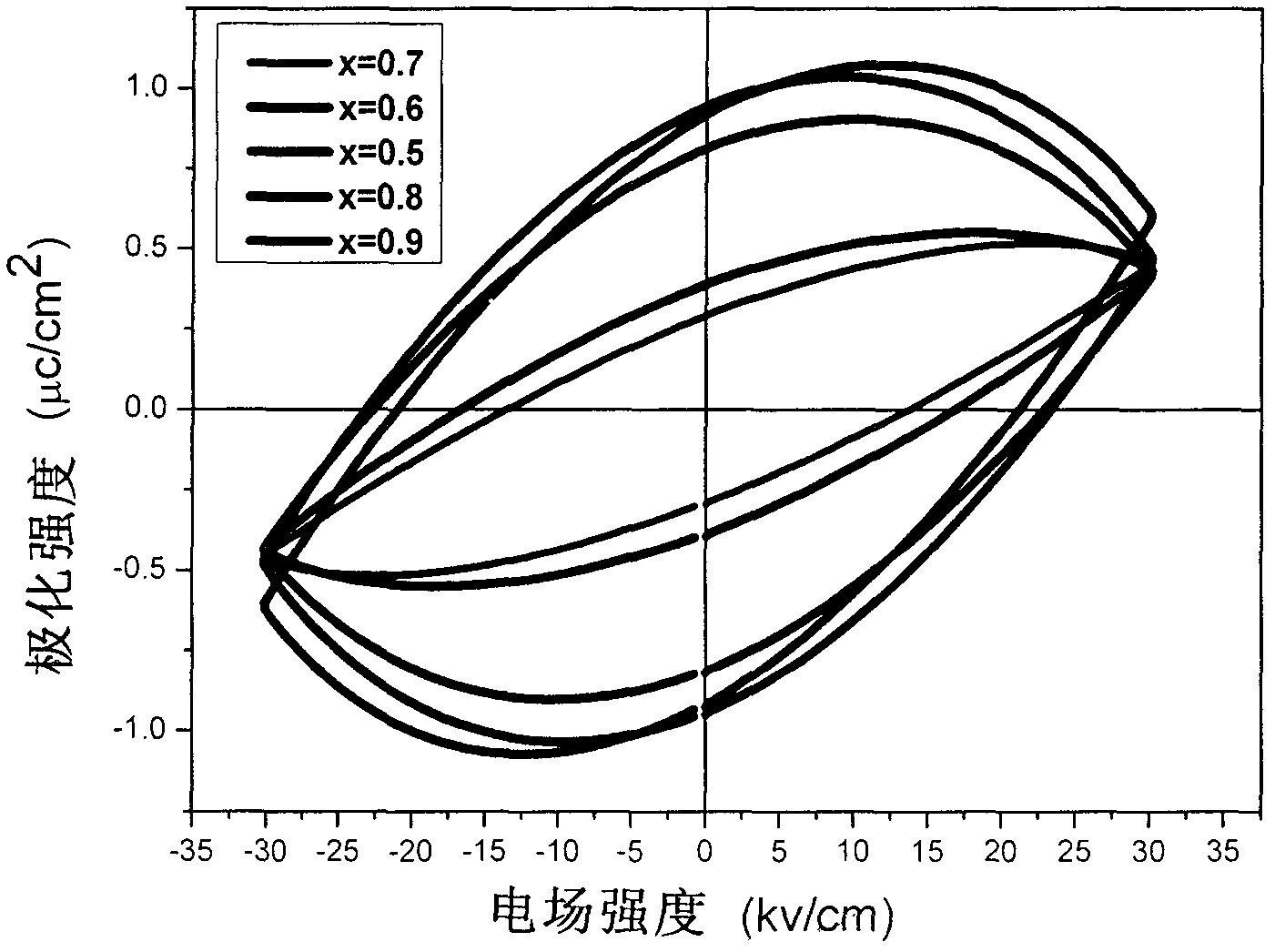

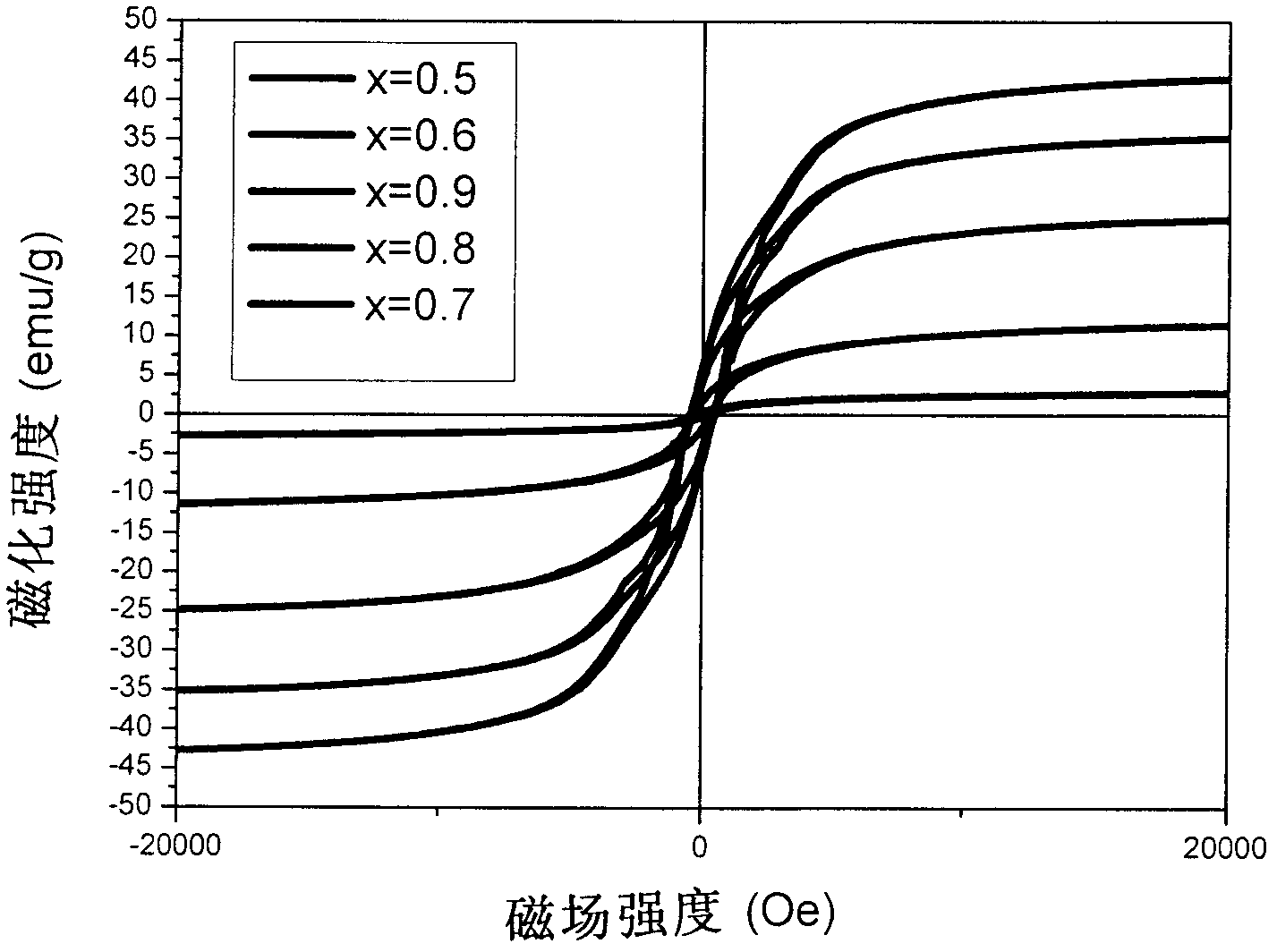

Xsrtio3-(1-x) cofe2o4 composite material and preparation method thereof

InactiveCN102643088AGood calcination temperatureHelpful for practical applicationComposite ceramicCobalt

The invention discloses an xSrTiO3-(1-x) CoFe2O4 composite material having ferromagnetism and ferroelectricity and a preparation method thereof. In the formula, x ranges from 0.5 or 0.6 or 0.7 or 0.8 or 0.9. Compared with single-phase ceramics, the composite ceramics have certain changes in ferroelectricity and ferromagnetism. The preparation method is an improved sol gel method and uses strontium nitrate, citric acid, cobalt nitrate, butyl titanate, absolute ethyl alcohol, glacial acetic acid and ferric nitrate as raw materials. The preparation method simplifies compound steps, effectively avoids outside affecting factors of particle compound, and reduces material compound temperature. The ferroelectricity of the xSrTiO3-(1-x) CoFe2O4 composite material is improved compared with single-phase SrTiO3, and a ferroelectric hysteresis loop tending to be saturated is obtained. The ferromagnetism has regularity along with increase of content of cobalt ferrite, and therefore actual application of composite materials is facilitated.

Owner:HEBEI NORMAL UNIV

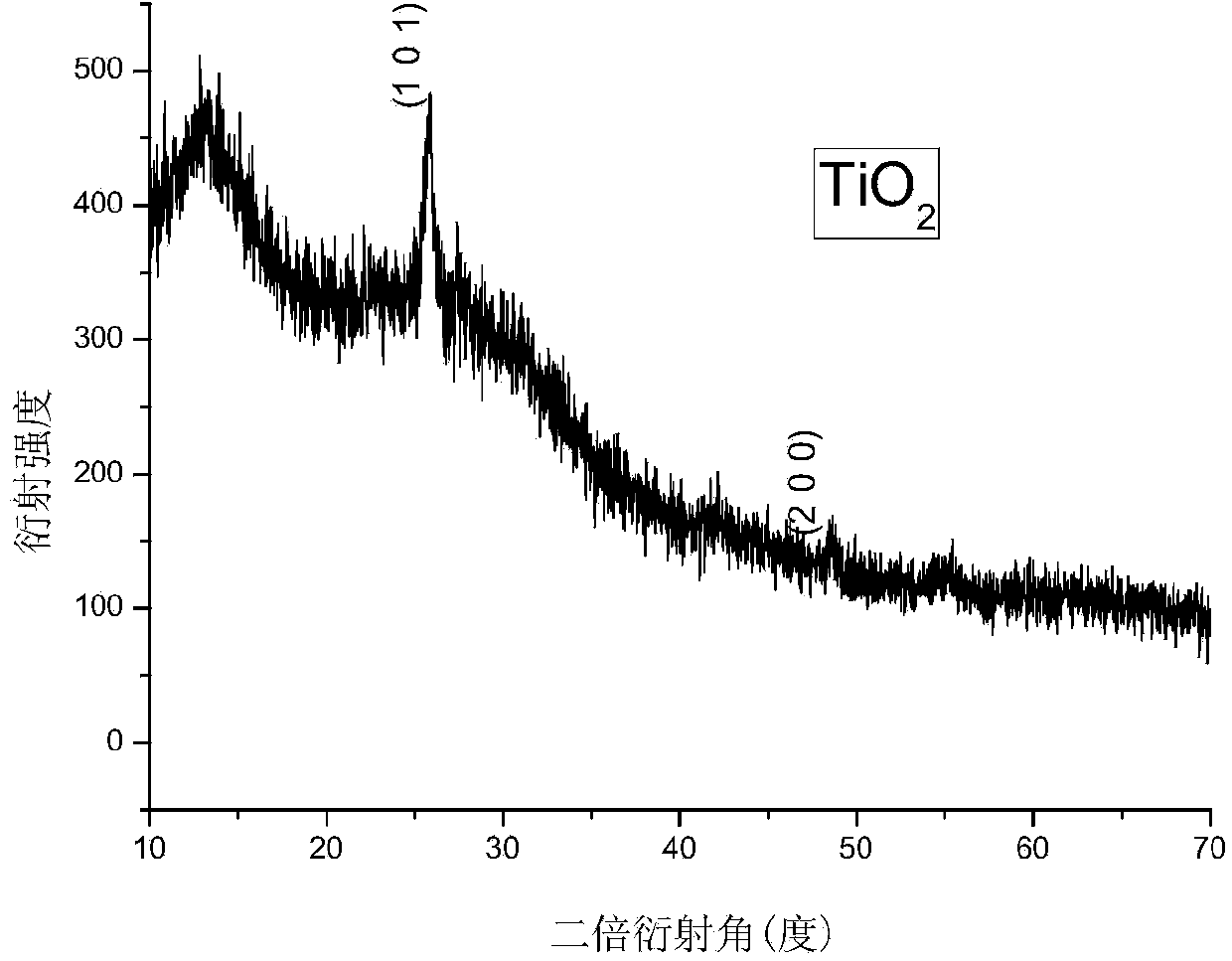

Preparation of multielement codoped nanaotitania film

The invention discloses a method for preparing a multielement co-doped nano titanium dioxide film comprising the following steps: 1) adding ferric nitrate nonahydrate, silver nitrate and guanidine hydrochloride solid into abatase titanium dioxide solution to prepare a mixed solution; 2) sustainably magnetically stirring the mixed solution under the water bath condition and obtaining an uniform sol; 3) storing the sol at room temperature for 10-12 days to obtain aging solution, preparing a coating glass slide by the aging solution and drying; 4) heat-treating the dried coating glass slide at 350-450 DEG C for 1 hour to obtain the multielement co-doped nano titanium dioxide film. The titanium dioxide film of the invention has functions of achievement the red shift of the ultraviolet absorbance, visible light response of the photocatalysis and no light antibacteria.

Owner:ZHEJIANG UNIV

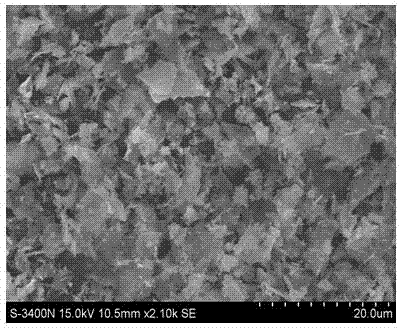

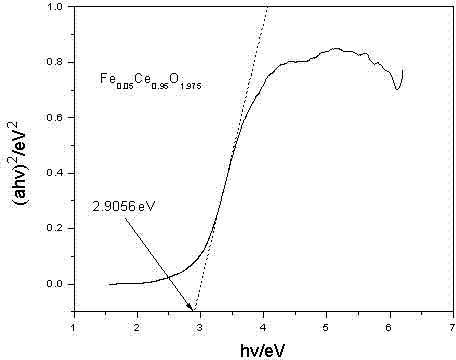

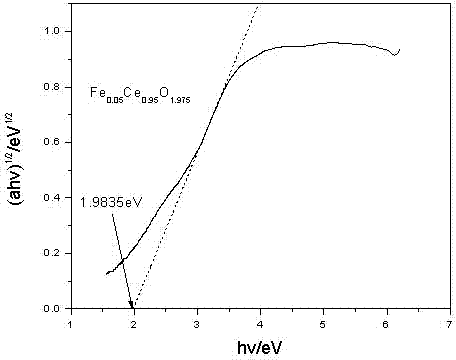

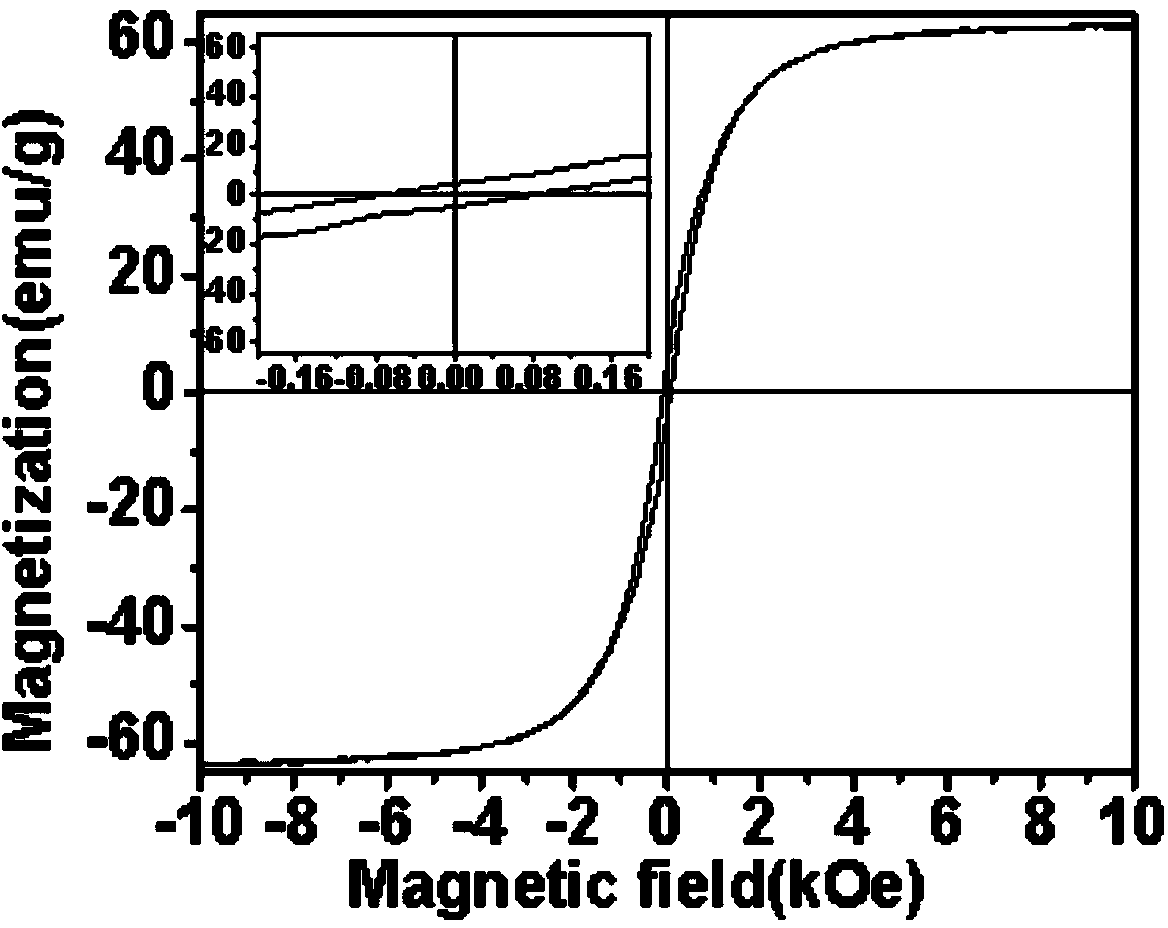

Iron-doped cerium dioxide photocatalyst and preparation method thereof

InactiveCN104759287ACrystal phase pureGood dispersionMetal/metal-oxides/metal-hydroxide catalystsCerium nitrateCerium(IV) oxide

The invention discloses an iron-doped cerium dioxide photocatalyst and a preparation method thereof, a molecular formula of the iron-doped cerium dioxide photocatalyst is FexCe1-xO2-0.5x, wherein X is 0.05-0.2. According to the preparation method, cerium nitrate, ferric nitrate and sodium carbonate are taken as initial raw materials, a coprecipitation method is employed to obtain flake-like FexCe1-xO2-0.5x, in the preparation process, x value is changed to obtain the FexCe1-xO2-0.5x with different composition. Doping of iron has obvious influence on CeO2 forbidden band width, the FexCe1-xO2-0.5x has good photocatalysis performance, the preparation method and the required equipment are simple, and industrial production can be easily realized.

Owner:SHANGHAI INST OF TECH

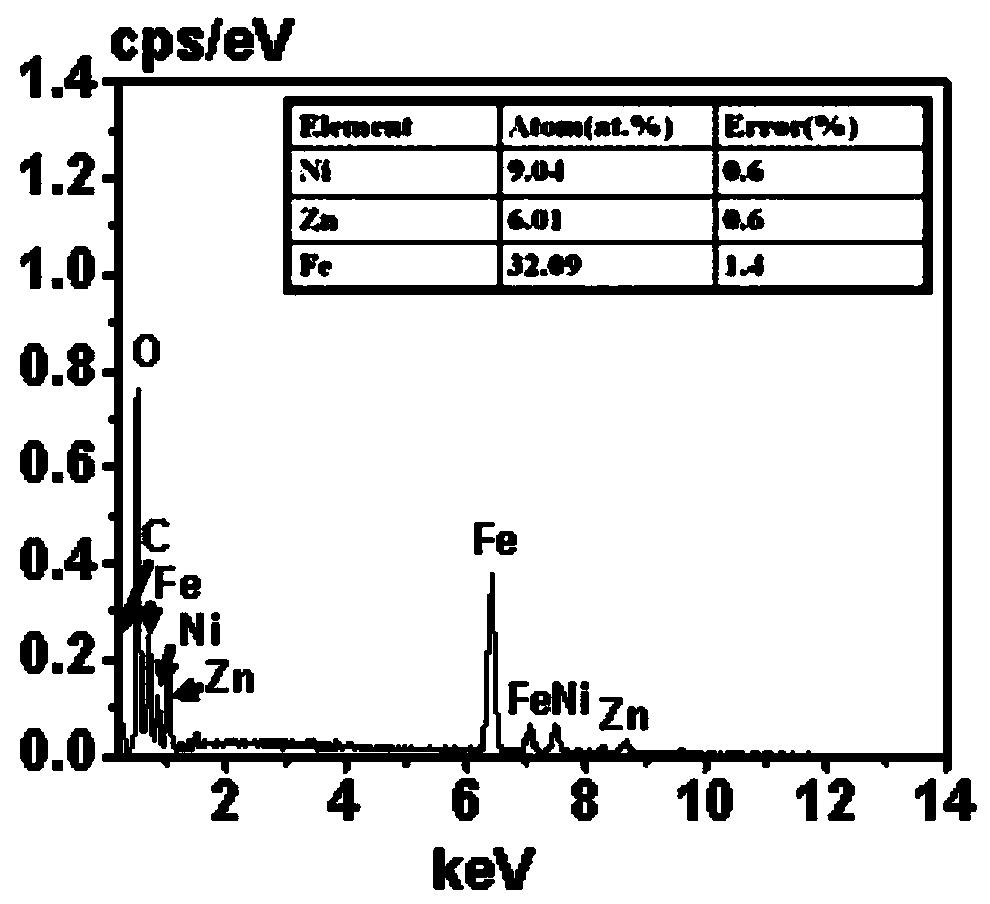

Preparation method of nickel-zinc ferrite/polyaniline composite material

The invention discloses a preparation method of a nickel-zinc ferrite / polyaniline composite material. The preparation method comprises the following steps: respectively weighing nickel nitrate, zinc nitrate and ferric nitrate in a stoichiometric ratio of 3:2:10 of Ni<2+>:Zn<2+>:Fe<3> in Ni0.6Zn0.4Fe2O4, adding distilled water, and mixing and dissolving under a magnetic stirring condition; dropwise adding a NaOH solution to an obtained mixing solution, regulating pH to 9-11, reacting under a water bath condition until the solution is in a colloidal form; repeatedly centrifuging and washing through distilled water and absolute ethyl alcohol to obtain a brown precipitate; drying the precipitate in an oven at 80-100 DEG C to obtain a ferrite precursor; calcining in a muffle for 2-2.5 hours at 900-1100 DEG C and naturally cooling to obtain the required nickel-zinc ferrite. Processability, stability and electric performance of the material disclosed by the invention are better improved.

Owner:NANJING UNIV

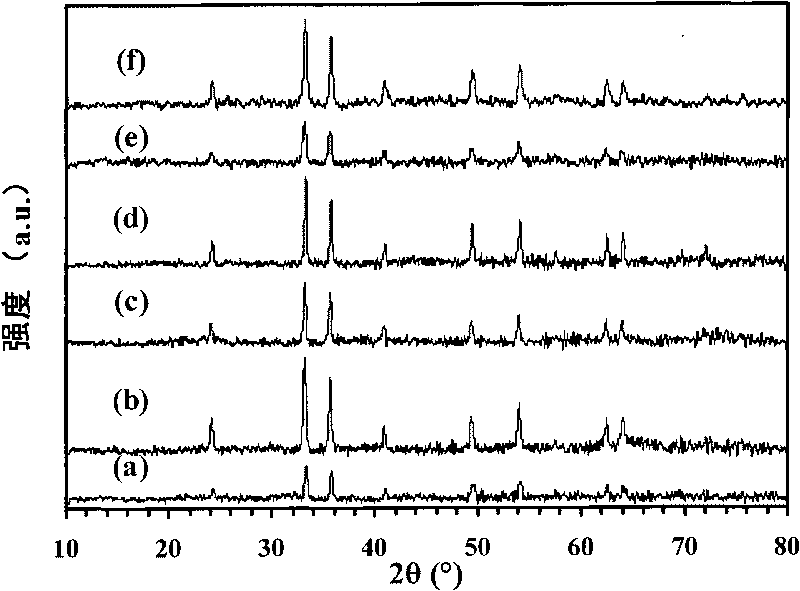

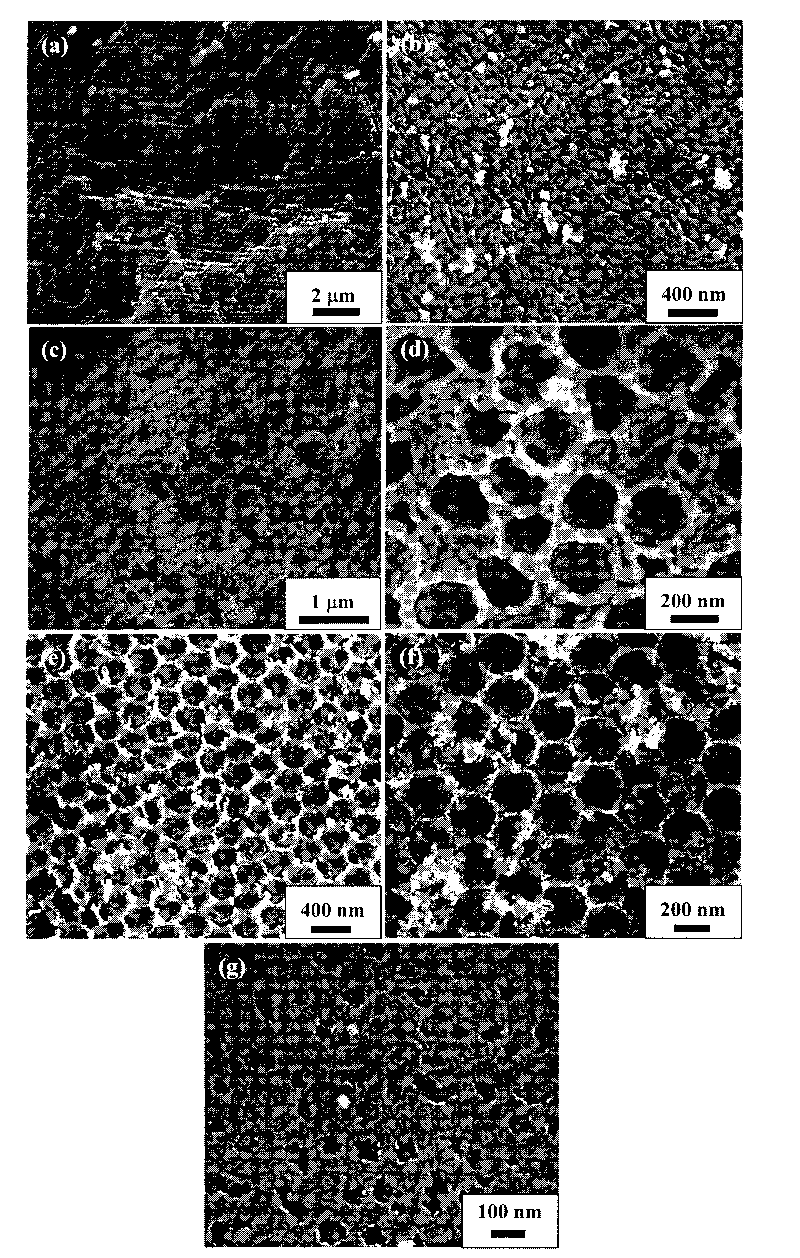

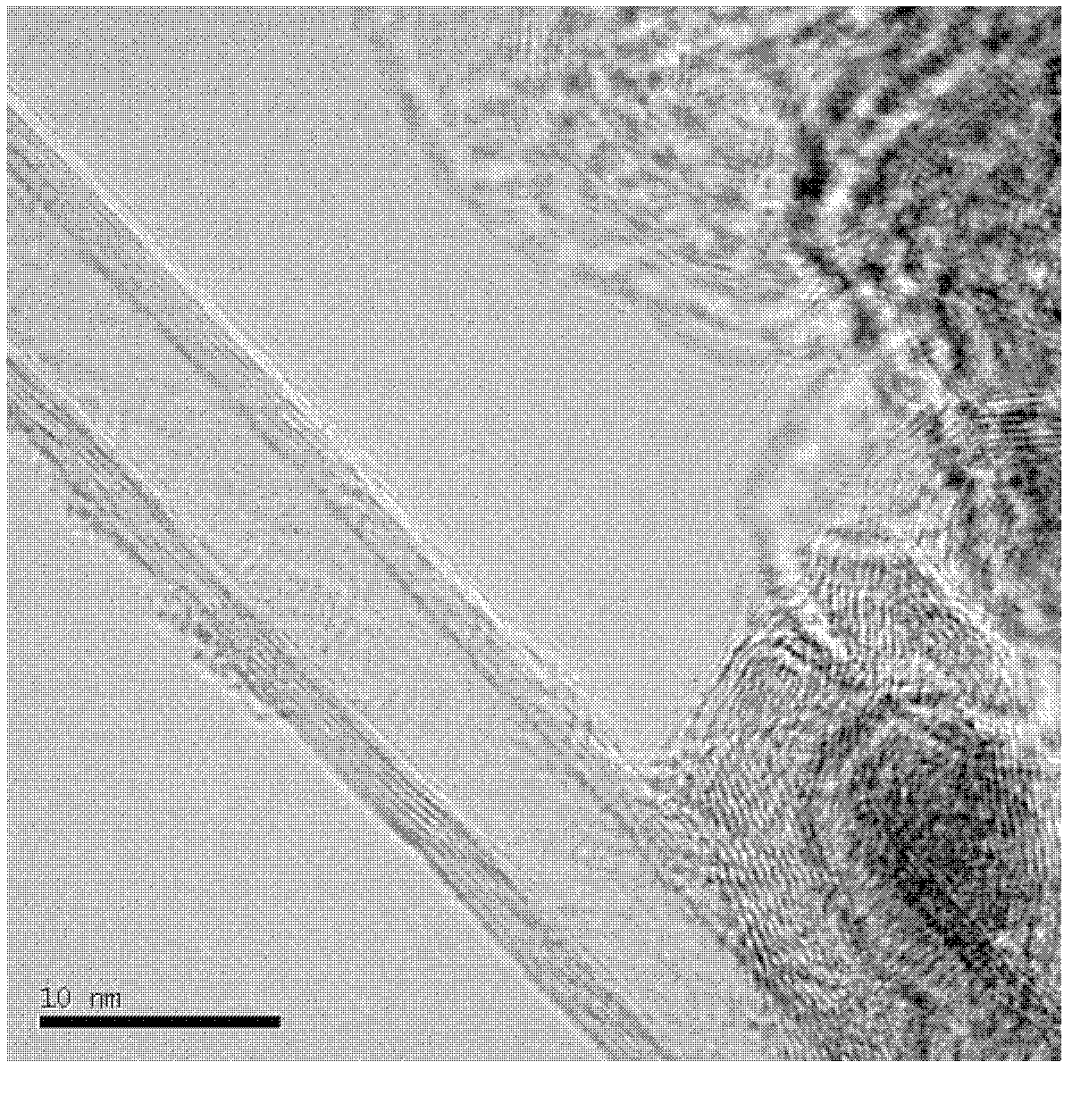

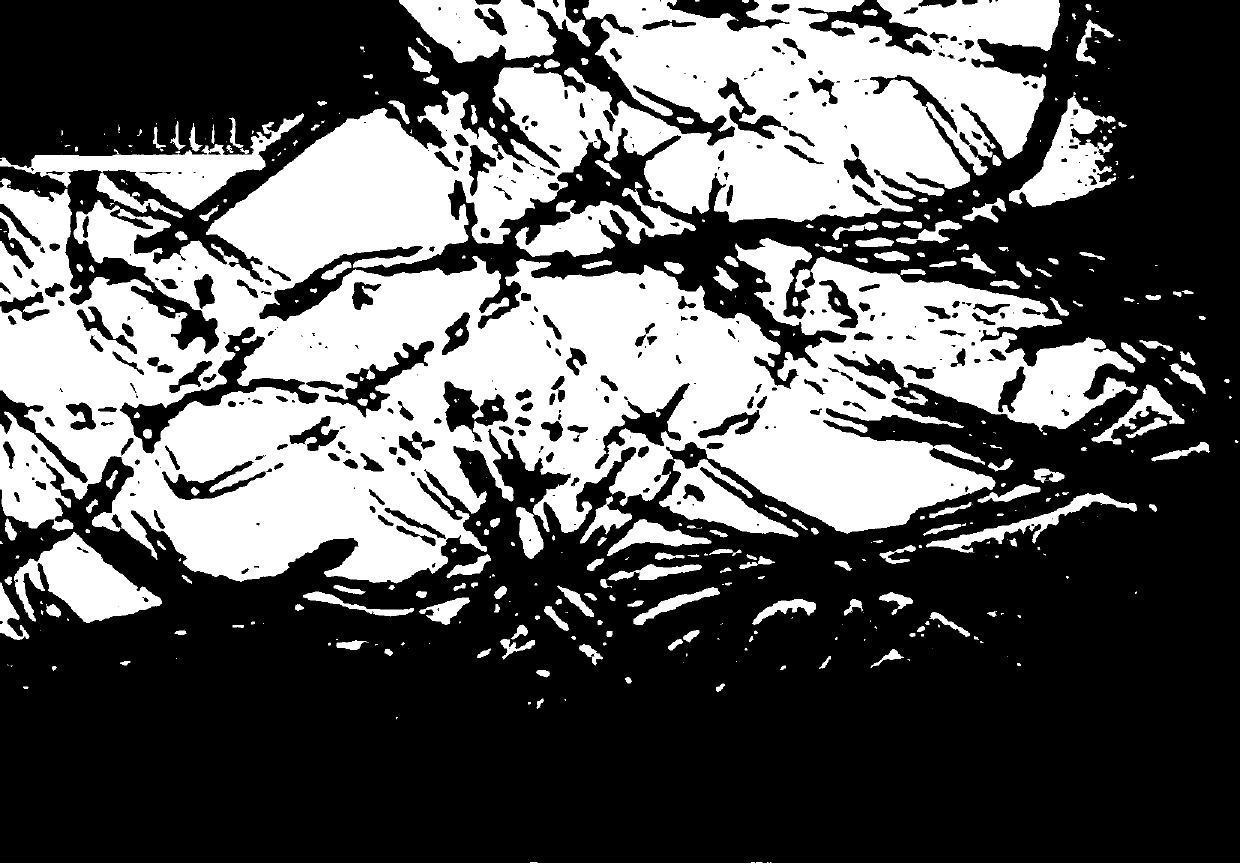

High-magnification carbon nanotubes having ultrafine tube diameter and prepared by two-stage method, catalyst and preparation method of catalyst

ActiveCN110801843ASmall particle sizeA large amountCarbon compoundsMetal/metal-oxides/metal-hydroxide catalystsPtru catalystMetal particle

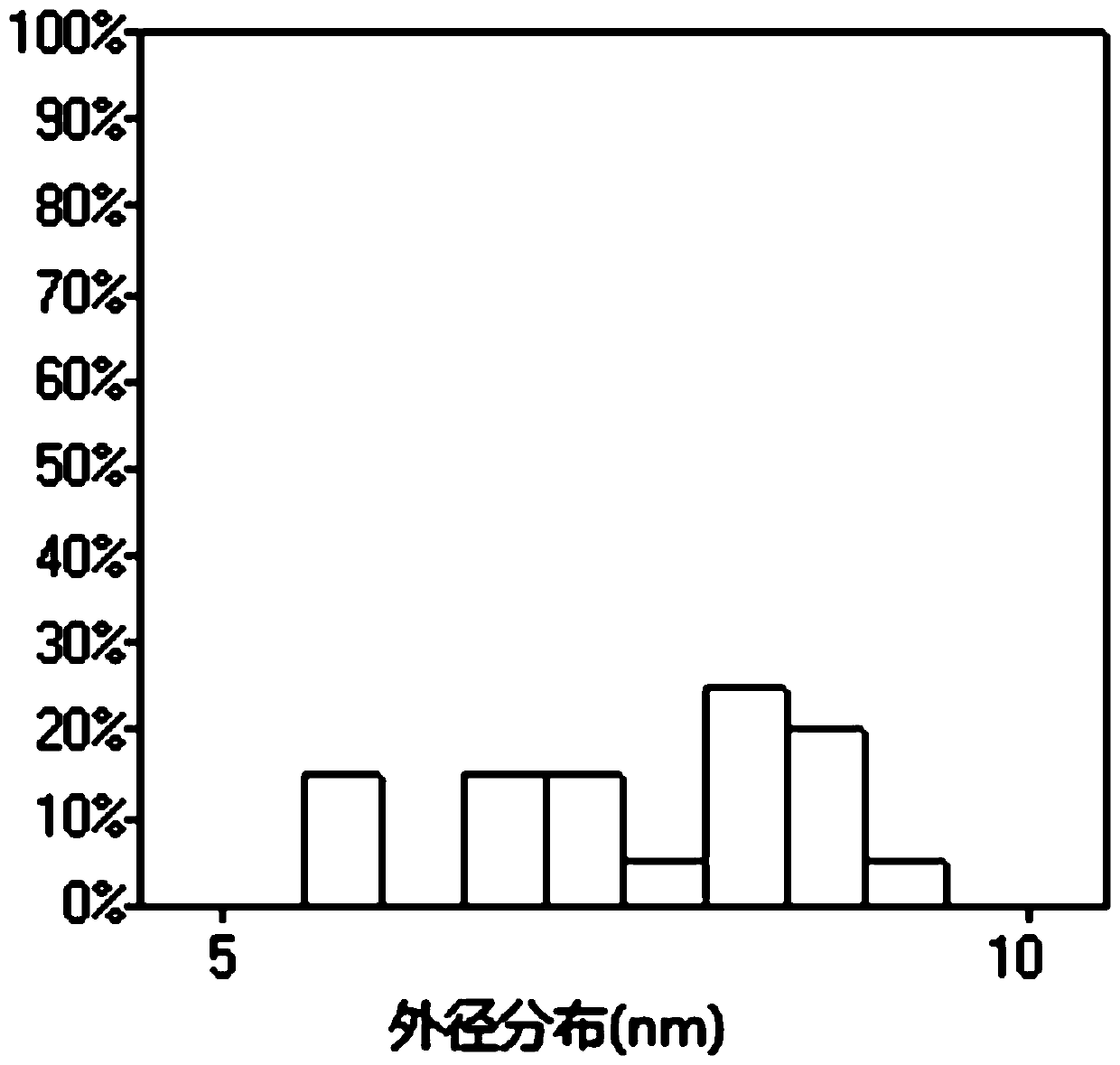

The invention belongs to the technical field of preparation of carbon nanotubes, and particularly relates to high-magnification carbon nanotubes having an ultrafine tube diameter and prepared by a two-stage method, a catalyst and a preparation method of the catalyst. The high-magnification carbon nanotube catalyst having the ultrafine tube diameter and prepared by the two-stage method is composedof the following components in parts by weight: an active metal dispersion phase comprising 14.6-25.9 parts of cobalt nitrate, 0.9-2.7 parts of ammonium molybdate, 0-10.9 parts of ferric nitrate and 0-8.4 parts of nickel nitrate; a carrier metal continuous phase comprising 30.9-54.6 parts of aluminum nitrate and 25.4-45.3 parts of magnesium nitrate; and 15.2-22.6 parts of a complexing agent. The active metal particles in the catalyst are small in particle size and large in number, the outer diameter of the carbon nanotubes generated through cracking is 5 nm-10 nm, the multiplying power can reach 45-55 times, and the yield is 1.3-2.0 times of the yield of a conventional superfine carbon nanotube catalyst; the preparation process of the catalyst can effectively control the particle size of the active metal particles in the catalyst, is simple and convenient in technological process, and is beneficial to industrial large-scale production.

Owner:内蒙古骏成新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com