Preparation and application of an ordered crosslinked fibrous graded porous carbon material having one-dimensional orientation

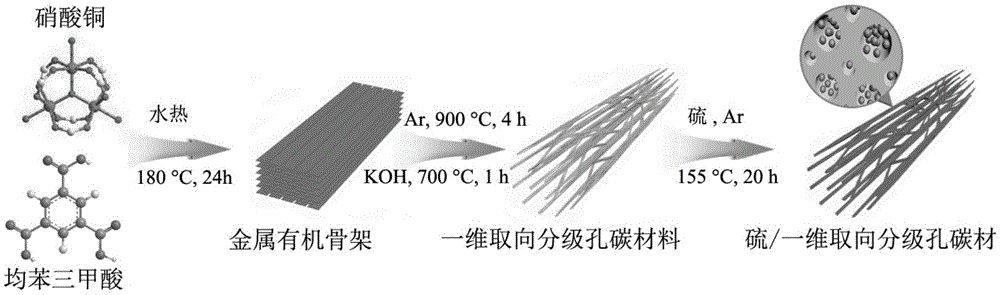

A graded porous carbon and fibrous technology, which is applied in the preparation/purification of carbon, electrical components, battery electrodes, etc. problems such as low surface and pore volume, to achieve the effect of improving sulfur fixation effect, fewer synthesis steps and large pore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

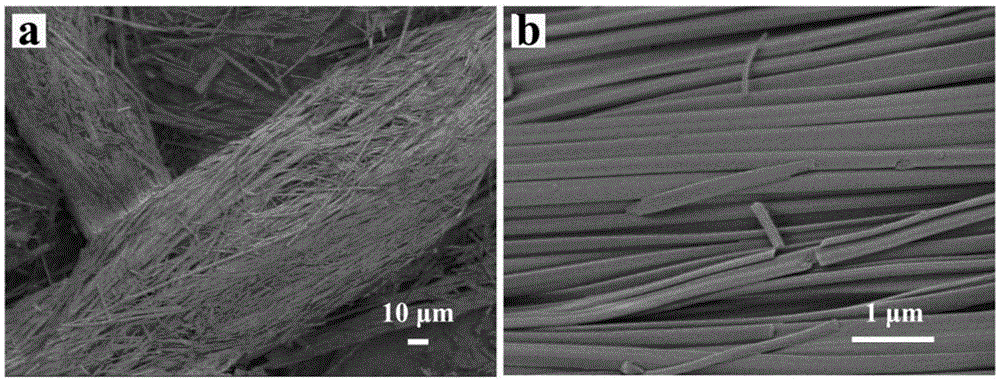

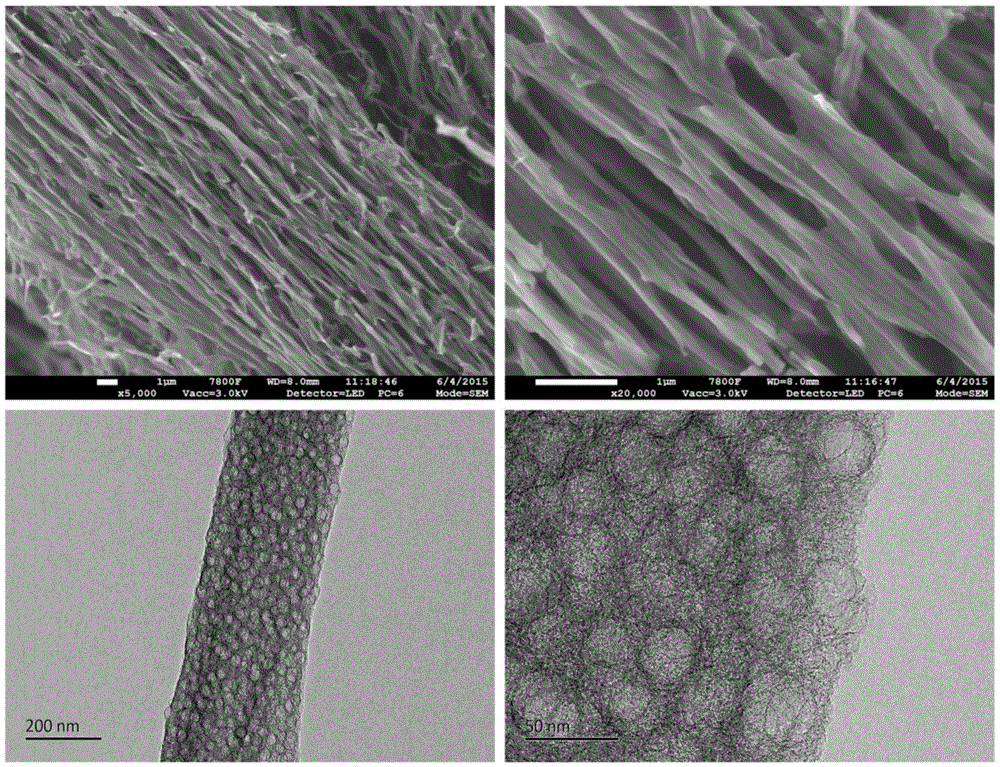

[0043] Weigh 0.42g of trimesic acid and 0.96g of copper nitrate, stir at room temperature for 0.5h, transfer to a 100mL hydrothermal reaction kettle, and -1 The heating rate is raised to 180°C, kept at a constant temperature for 24 hours, and then at 0.3°C min -1 The cooling rate was lowered to room temperature, and the resulting blue floc was washed and then transferred to a tube furnace at 3°C min -1 The heating rate is raised to 900°C, kept at a constant temperature for 4 hours, and then at 1°C min -1 cooling rate down to room temperature. The carbonized product was placed in 10wt% HNO 3 After standing for 24 hours, dried, mixed with KOH (mass ratio of KOH to carbon is 4:1), placed in a nickel tube furnace, heated at 10°C min -1 The heating rate is raised to 700°C, the temperature is maintained for 1h, and then at 2°C min -1 The cooling rate was lowered to room temperature, and the resulting product was again placed in 10wt% HNO 3 After standing for 24 hours, washing...

Embodiment 2

[0046] Weigh 0.42g of trimesic acid and 1.20g of zinc nitrate, stir at room temperature for 0.5h, transfer to a 100mL hydrothermal reaction kettle, and -1 The heating rate is raised to 180°C, kept at a constant temperature for 24 hours, and then at 0.3°C min -1 The cooling rate was lowered to room temperature, and the resulting white product was washed and transferred to a tube furnace at 3°C min -1 The heating rate is raised to 950°C, kept at a constant temperature for 4 hours, and then at 1°C min -1 cooling rate down to room temperature. The obtained product was used directly without post-treatment. Subsequent sulfur filling, battery assembly test steps are the same as in Example 1.

[0047] Under the 0.5C rate, the discharge specific capacity of the first cycle is 1384mA h g -1 , after 40 cycles, the discharge specific capacity is 344mA h g at 15C rate -1 .

Embodiment 3

[0049] Weigh 0.42g of trimesic acid and 1.20g of copper nitrate, stir at room temperature for 0.5h, let it stand for 24h, wash the resulting blue product and transfer it to a tube furnace, heat at 3°C min -1 The heating rate is raised to 900°C, kept at a constant temperature for 4 hours, and then at 1°C min -1 cooling rate down to room temperature. Subsequent activation, sulfur filling, battery assembly test steps are the same as in Example 1. .

[0050] Under the 0.5C rate, the discharge specific capacity of the first cycle is 1365mA h g -1 , after 40 cycles, the discharge specific capacity is 325mA h g at 15C rate -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com