Patents

Literature

701results about How to "Few synthetic steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

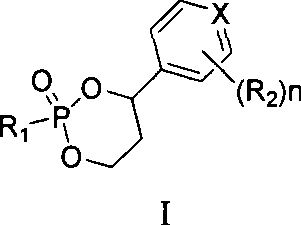

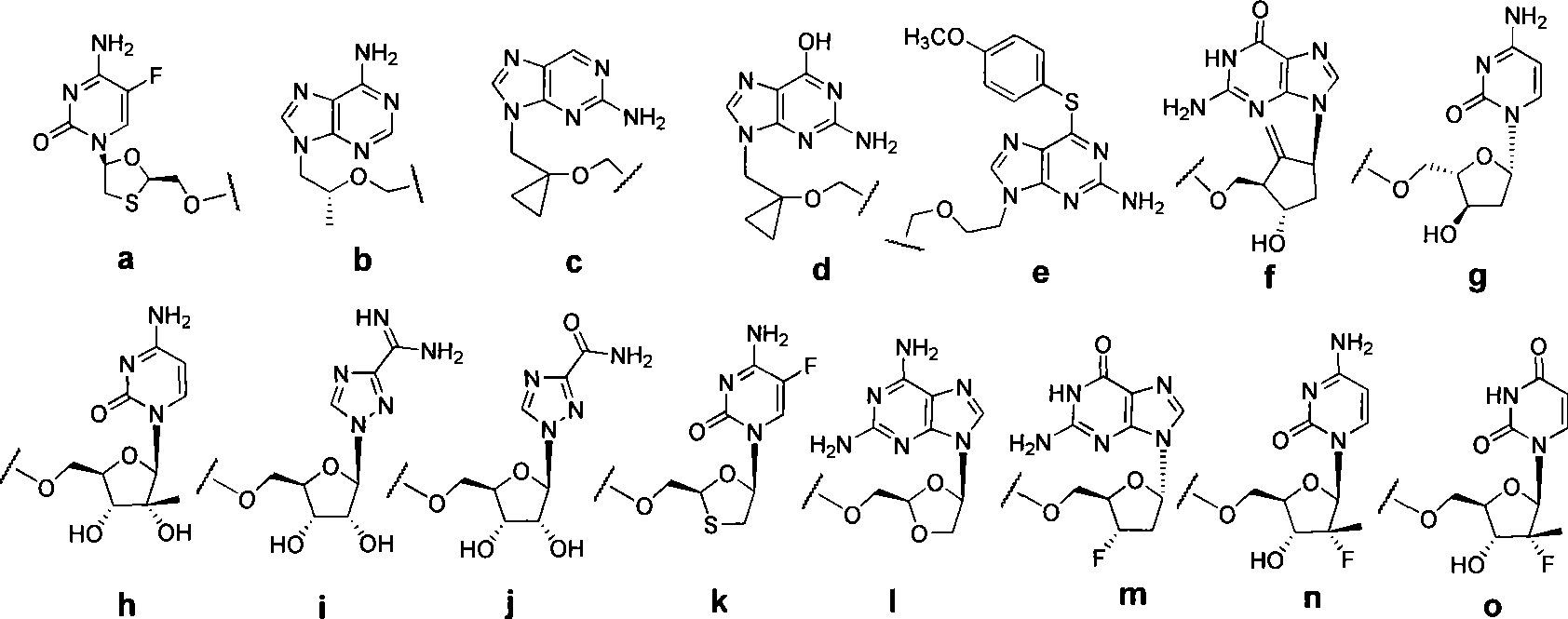

Liver targeted antivirus precursor medicament annular phosphoester and use thereof

InactiveCN101475594AFew synthetic stepsEasy to operateOrganic active ingredientsGroup 5/15 element organic compoundsDrugPhosphate

The invention provides a prodrug of an antiviral drug for use in liver of cyclic phosphate of a general formula (I) and isomers, pharmaceutical salts, hydrates, solvates and pharmaceutical compositions of the same. The invention provides uses of the compounds singly or together with other antiviral drugs in the treatment of viruses, in particular of hepatitis B viruses (HBV), hepatitis C virus (HCV), HIV viruses and / or human cytomegaloviruses (HCMV).

Owner:廖国超

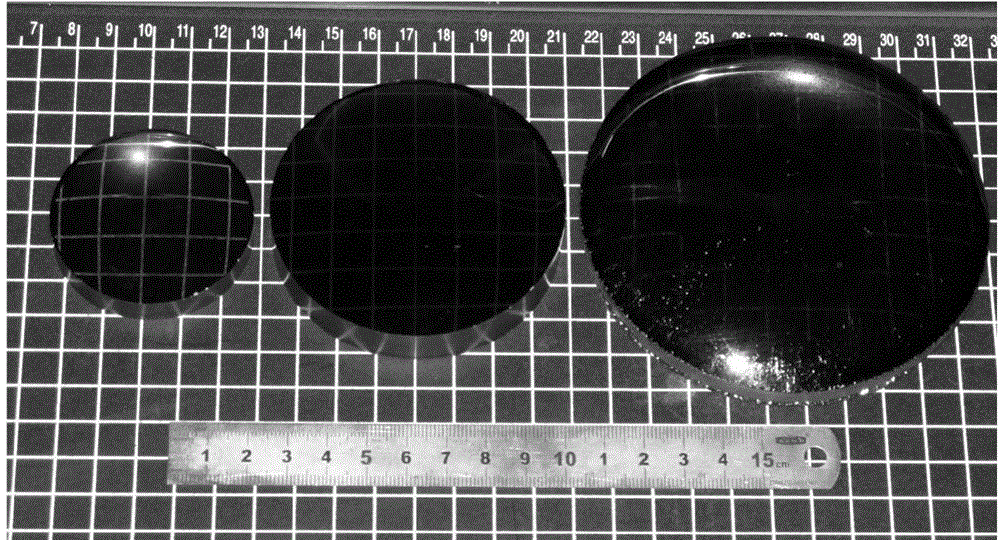

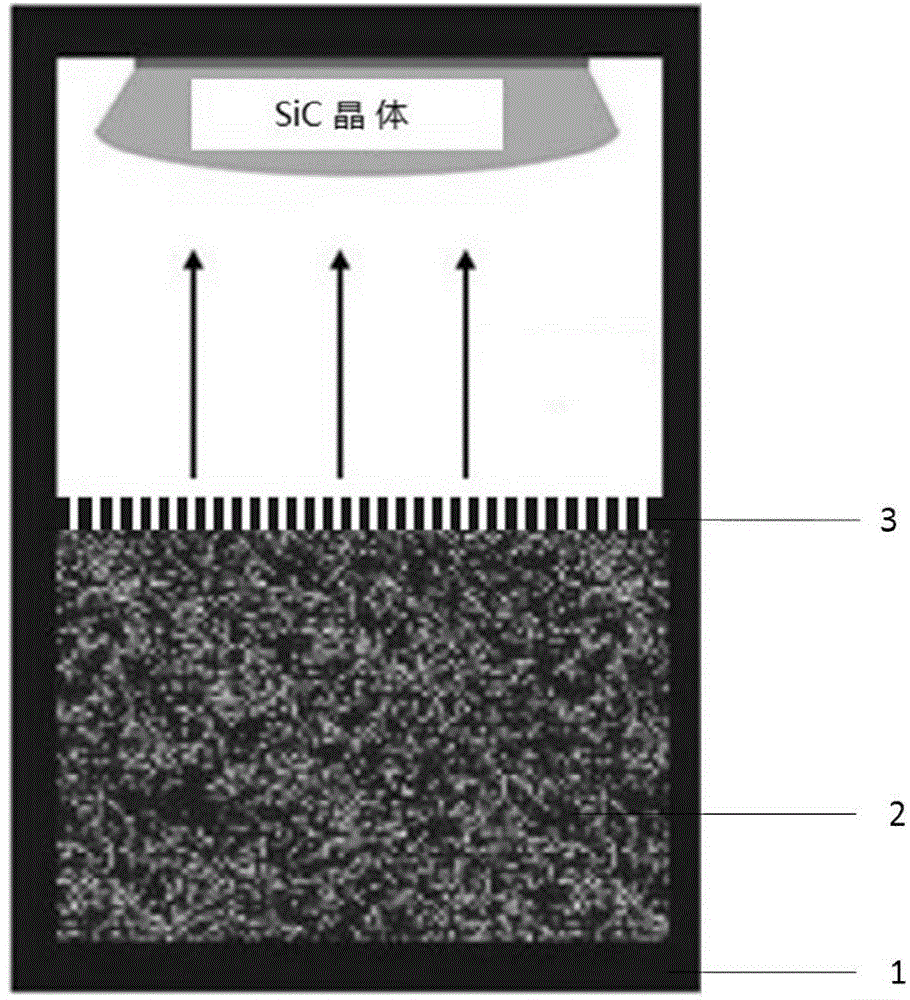

Method for quickly growing large-size SiC (Silicon Carbide) single crystal

ActiveCN104805504AReduce investmentAvoid transmissionPolycrystalline material growthFrom condensed vaporsSource materialLarge size

The invention relates to a method for quickly growing a large-size SiC (Silicon Carbide) single crystal. The method comprises the following steps: putting a mixture of silicon powder and carbon powder at the bottom of a graphite crucible, and placing a porous graphite flake on the surface; fixing a seed crystal to the top of the graphite crucible, vacuumizing a growth chamber, charging Ar gas or mixed gas of Ar and H2 into the growth chamber, heating the seed crystal until the temperature reaches 1,600-2,000 DEG C, and reacting for 2-5 hours under the pressure of 800-900mbar to obtain a SiC source material; raising the temperature to 2,200-2,500 DEG C, continuously charging the Ar gas, reducing the pressure, sublimating powder at the bottom to the surface of the seed crystal, and growing the seed crystal for 30-50 hours to obtain the large-size SiC single crystal. According to the method, SiC powder can be synthesized at one time, the SiC single crystal can be grown in situ, the cost is low, and the process is simple.

Owner:SHANDONG UNIV

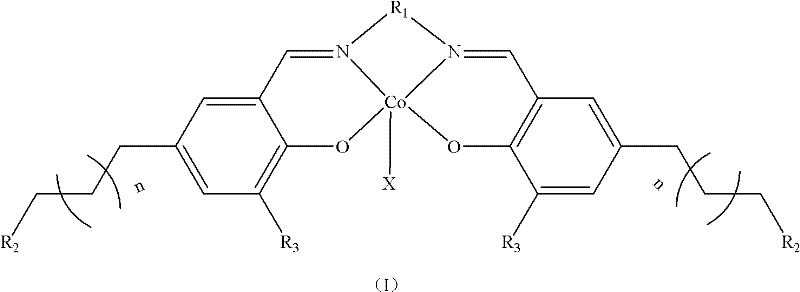

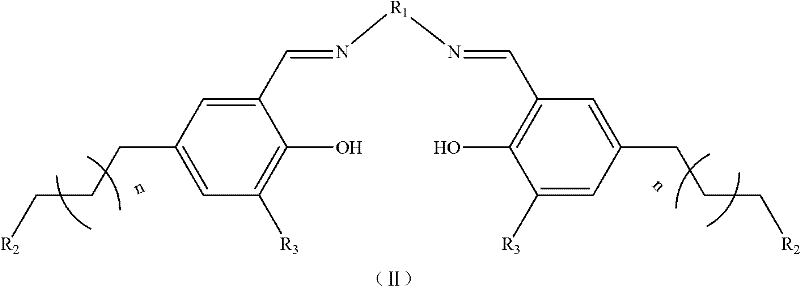

Method for preparing Salen-metal complex

InactiveCN102212085ALow costHigh catalytic efficiencyOrganic-compounds/hydrides/coordination-complexes catalystsCobalt organic compoundsSodium methoxideFiltration

The invention provides a method for preparing a Salen-metal complex. The method comprises the following steps of: under the argon atmosphere, adding ligands(II), sodium methoxide, absolute methanol soluble ligands(II) and sodium methoxide into a reactor in sequence; stirring the mixture for 2 minutes, and adding 1mol / L cobalt acetate anhydrous / methanol solution dropwise, wherein the molar ratio of the ligands(II) to sodium methoxide to cobalt acetate is 1:1:1; and making the mixture reacted at the room temperature for 24 hours, adding anionic salt which has the same molar weight as the cobalt acetate, stirring the mixture for three days in the air, stopping the reaction, concentrating the mixture, performing dissolution and filtration by adding methylene chloride, drying the filtrate by anhydrous sodium sulfate overnight, filtering the mixture, concentrating under reduced pressure, and drying the mixture under the vacuum condition to obtain the Salen-metal complex. The Salen-metal complex prepared by the method has the advantages of simple method, low cost and high catalytic efficiency.

Owner:HEBEI UNIV OF TECH

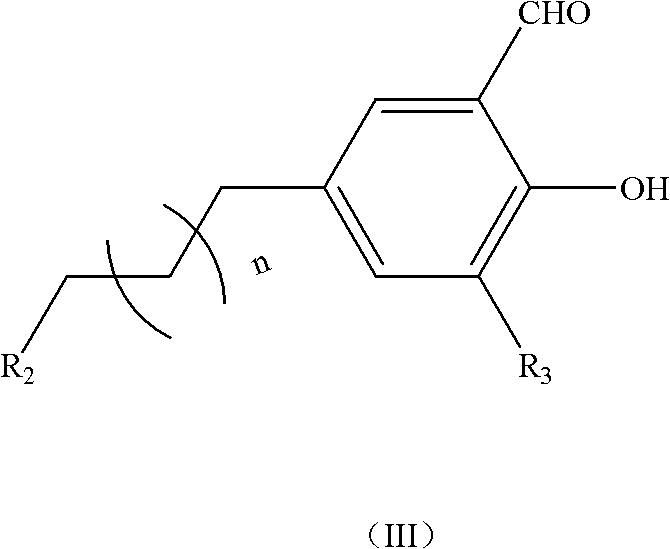

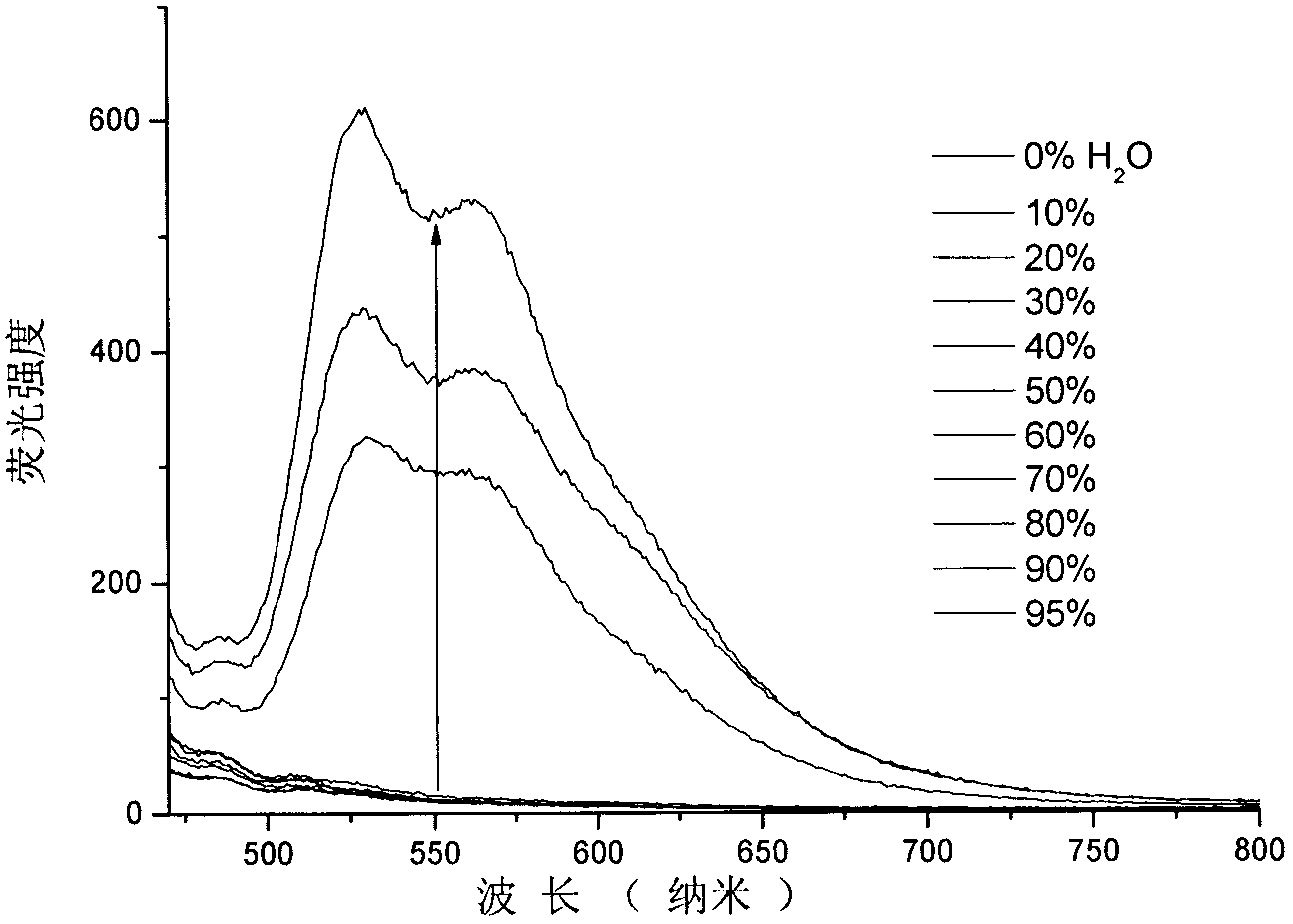

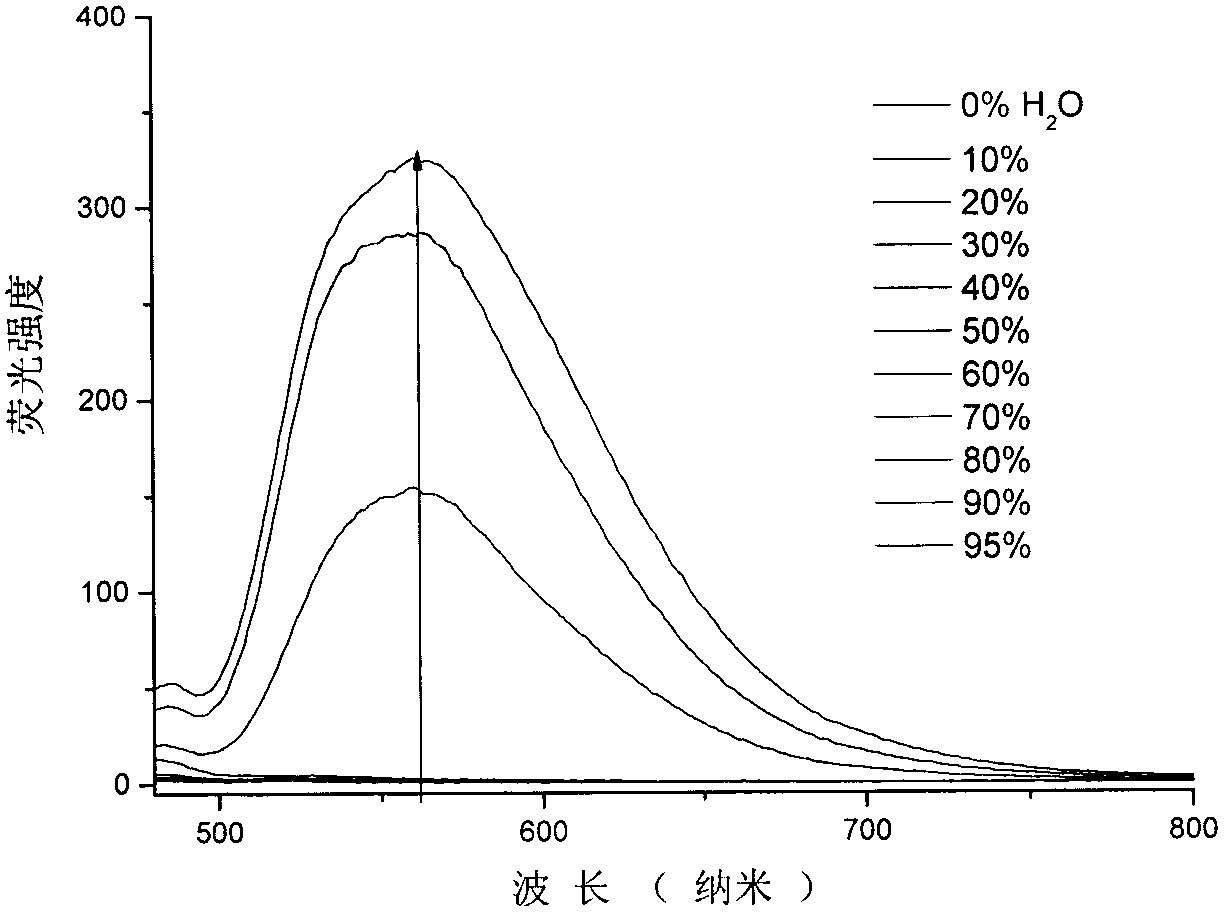

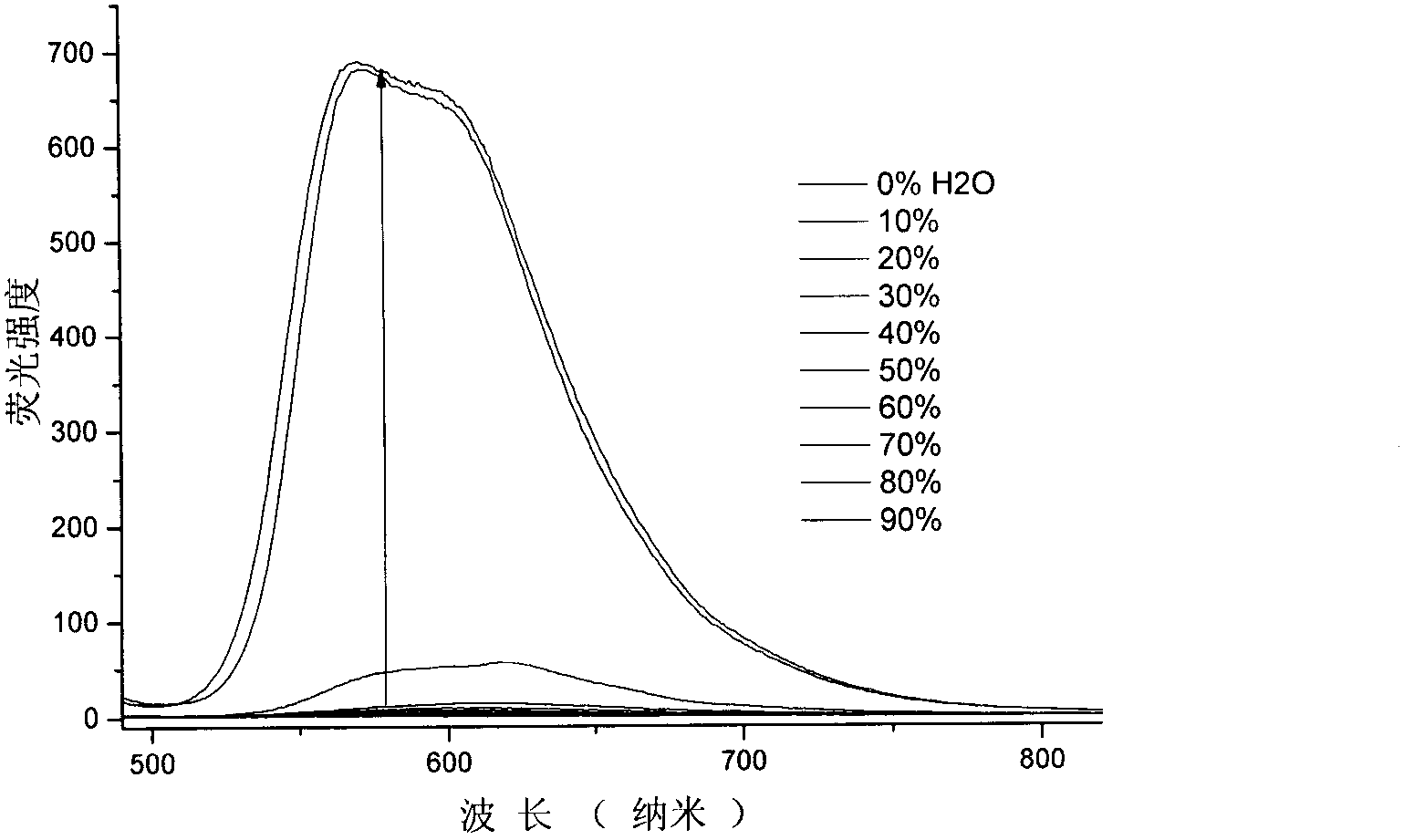

Quinoline nitrile derivative with aggregation-induced emission performance

ActiveCN102702096AStrong fluorescenceSignificant aggregation-induced luminescence characteristicsOrganic chemistryLuminescent compositionsQuinolineOrganism

The invention relates to a quinoline nitrile derivative. A method comprises the following steps of: reacting 2-methylquinoline serving as an initial raw material with the corresponding alkyl halide to obtain quaternary ammonium salt, performing Michael addition-elimination reaction on the quaternary ammonium salt and malononitrile, and performing Knoevenagel condensation reaction on the obtained compound and the corresponding aromatic aldehyde to obtain a target product. The aggregate or solid substance of the derivative has strong fluorescence and large wavelength, is a good aggregation-induced emission material, and has considerable application prospects in the fields of electroluminescent devices, fluorescent probes, intelligent materials, organism imaging and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

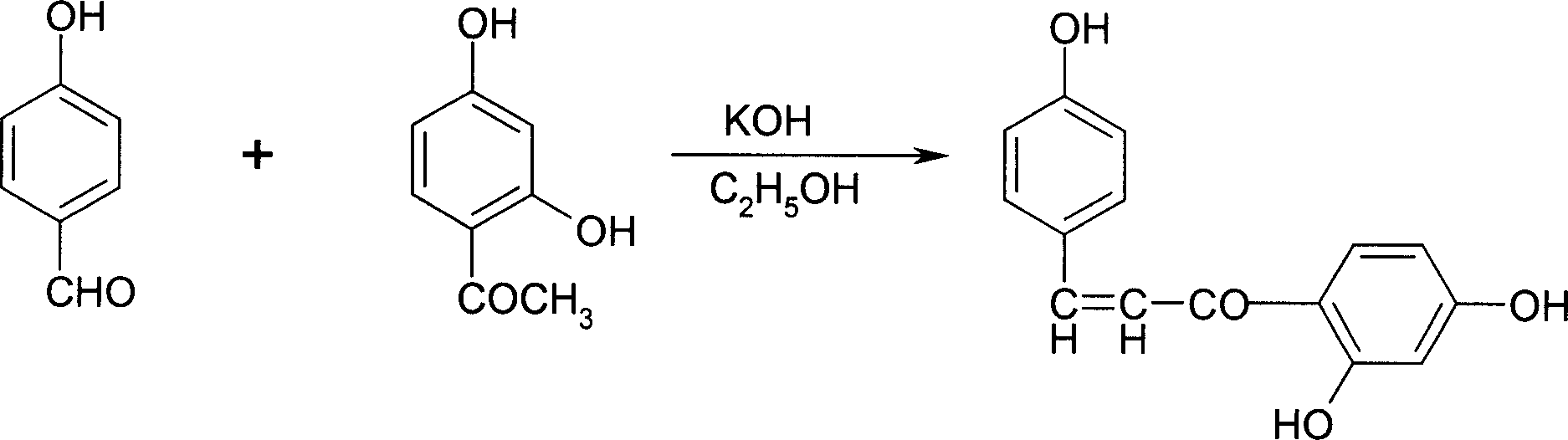

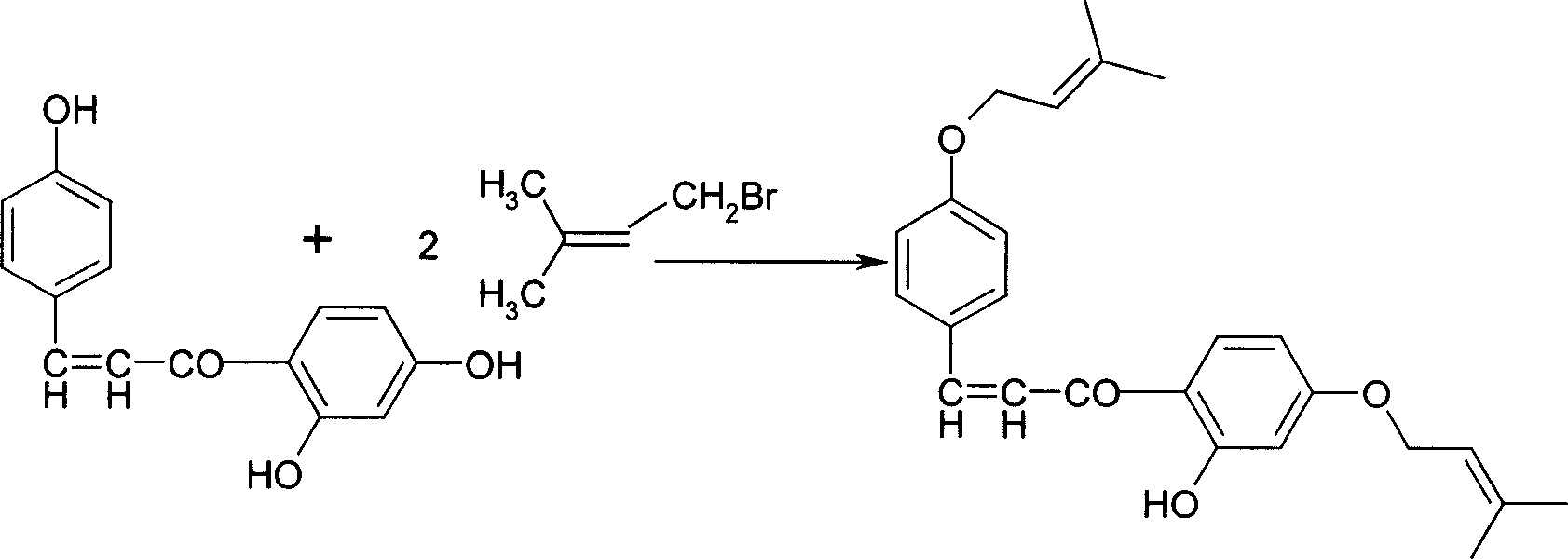

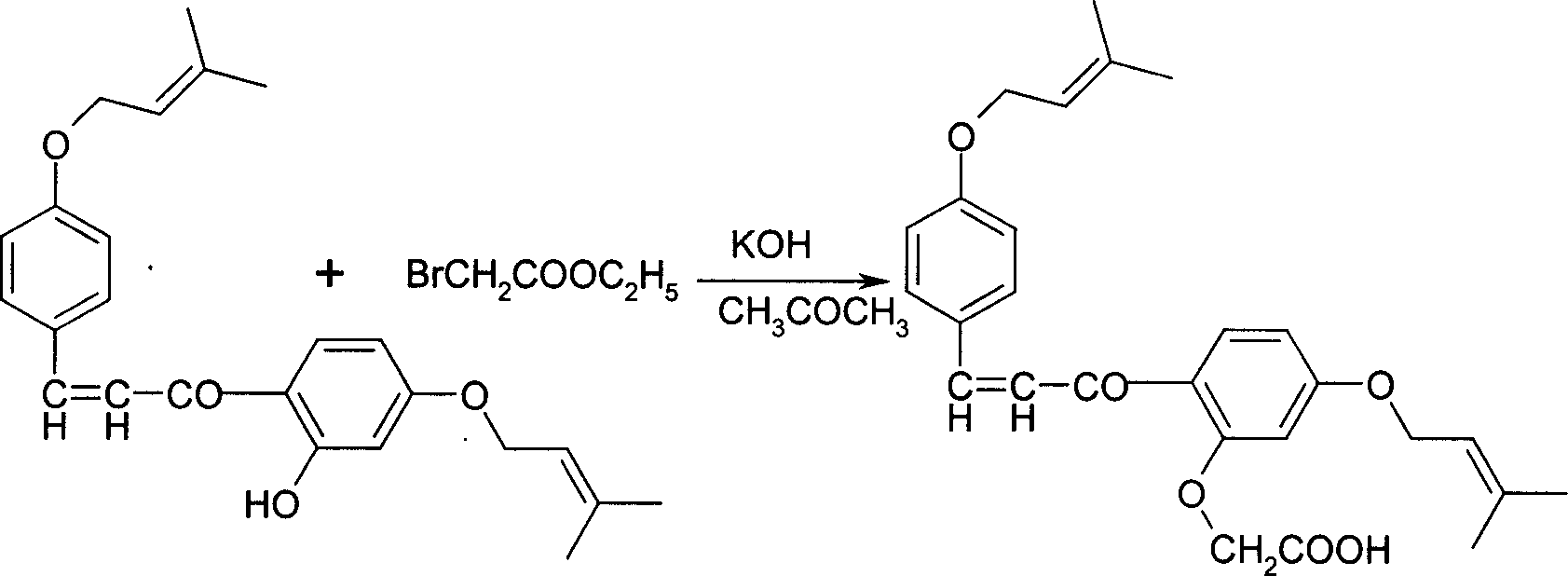

Sofalcone preparation method

InactiveCN1733682AFew synthetic stepsFew reaction stepsOrganic compound preparationCarboxylic compound preparationKetone2-Butene

Disclosed is a Sofalcone preparation method which mainly comprises, (1) subjecting p-hydroxybenzaldehyde and 2,4-ihydroxyacetophenone to condensation reaction under alkaline condition, obtaining 2,4,4-Trihydro-xychalcone, (2) subjecting 2,4,4-trihydro-xychalcone and 1-bromo-3-methyl-2-butene to condensation reaction, obtaining 2-hydroxyl-4,4-bis (3-methyl-2-butenyloxy) chalcone, (3) subjecting the 2-hydroxyl-4,4-bis (3-methyl-2-butenyloxy) chalcone and ethyl bromoacetate to condensation under the action of potasium carbonate, thus obtaining sofalcone. The mol ratio of p-hydroxybenzaldehyde, 2.4-dihydroxyacetophenone, 1-bromo-3-methyl-2-butene, and ethyl bromoacetate can be 1 : (0.90-1.50) : (1.60-2.55) : (0.60-1.25).

Owner:阮华君

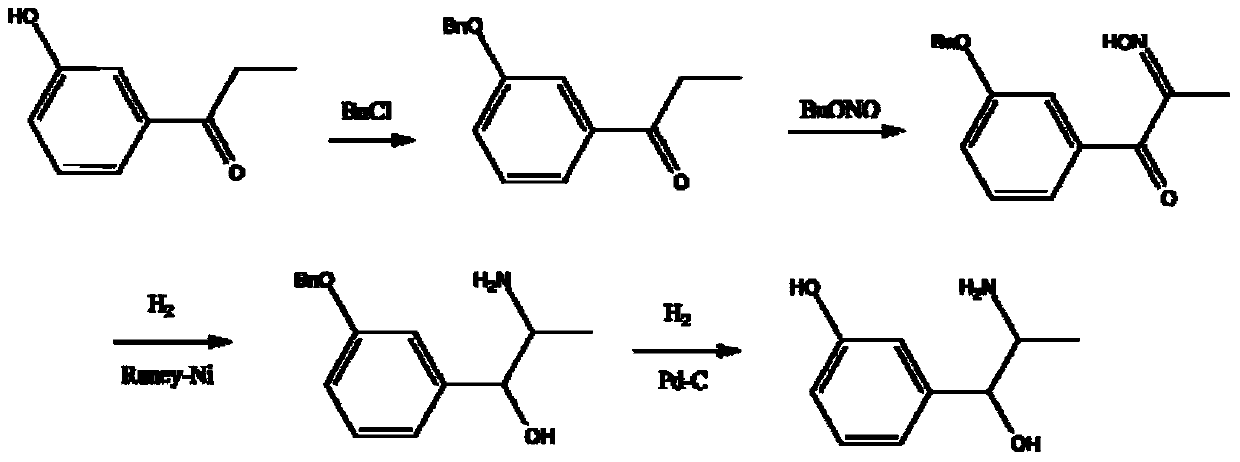

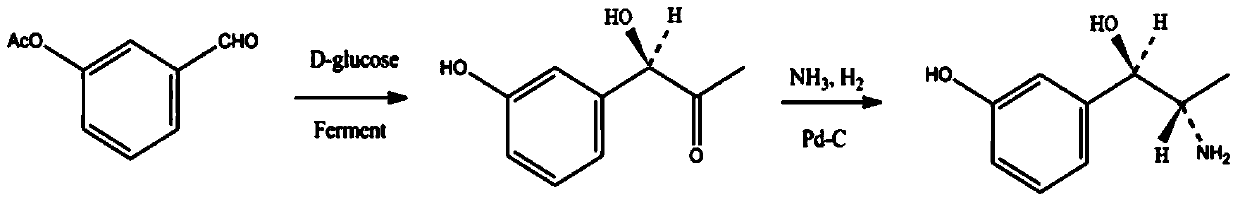

Synthesis method of metaraminol bitartrate

ActiveCN103739504AEasy to controlFew synthetic stepsOrganic compound preparationCarboxylic acid salt preparationSynthesis methodsSpatial configuration

The invention discloses a synthesis method of metaraminol bitartrate, and in particular provides a method for synthesizing metaraminol bitartrate by using a chiral catalysis method. The synthesis method comprises the steps: catalyzing a chiral addition reaction of hydroxybenzaldehyde and nitroethane by using a chiral catalyst system consisting of cinchona alkaloid, copper acetate hydrate and less imidazole to obtain an addition product with a dominant required spatial configuration, and then reducing nitro by using hydrogen in the presence of Pd-C to obtain amine to obtain aramine, and salifying the aramine with L(+)-tartaric acid to obtain a final product metaraminol bitartrate. According to the synthesis method, an enzyme catalyst is prevented from being used, a raw material of the synthesis reaction is easily available, the chiral catalyst is easily purchased or prepared self, the synthesis steps are relatively less, the chiral control efficiency is higher, the enantioselectivity is high, the yield is good, the reaction operation is easily controlled, and is safe and reliable, and the foundation is laid for the later industrialized amplification production.

Owner:广州普星药业有限公司

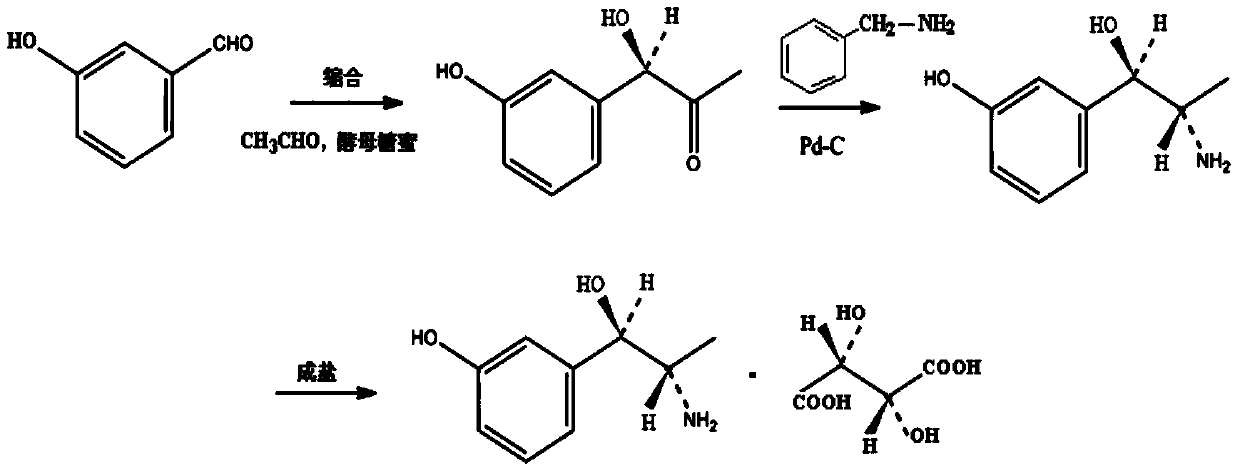

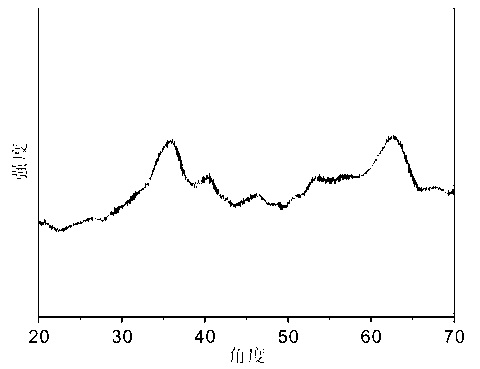

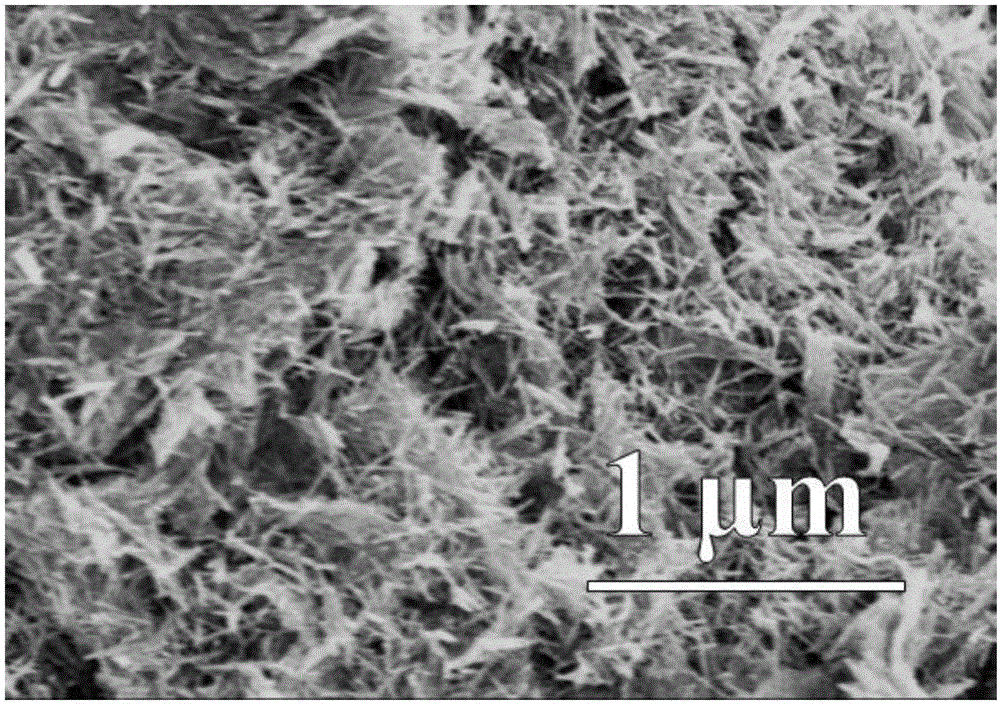

Preparation method of iron oxyhydroxide/graphene oxide composite material

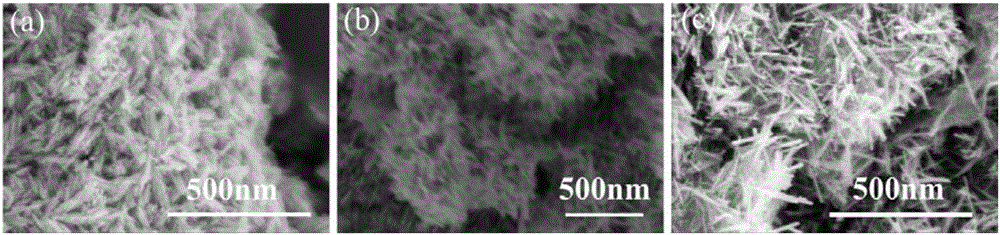

InactiveCN103224255ASmall sizeLarge specific surface areaMaterial nanotechnologyGrapheneActive agentNanoparticle

The invention relates to a preparation method of iron oxyhydroxide / graphene oxide composites. The method uses an improved Hummers method to regulate a proportion of a saturated ferric salt aqueous solution for preparing a precursor sol with boiling water, and a concentration of a graphene oxide aqueous solution, thereby preparing the iron oxyhydroxide / graphene oxide composite material with monodisperse nanoparticles and a size of less than 10 nanometer, and without a surfactant. The iron oxyhydroxide / graphene oxide composite material prepared by the method has characteristics of small particle size of the iron oxyhydroxide, monodispersed iron oxyhydroxide on surfaces of the graphene oxide, and large specific surface area; and the method is low in equipment investment, few in synthesis steps, simple in operation technology, low in production cost, easy to realize industrial production and wide in application prospect.

Owner:ANHUI UNIVERSITY

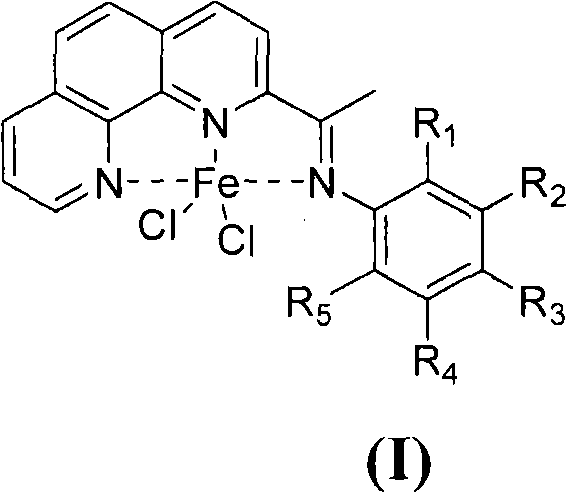

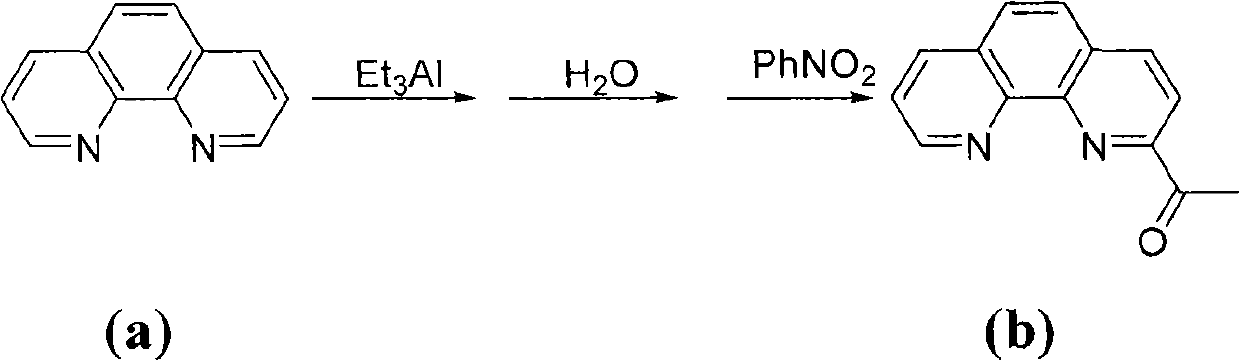

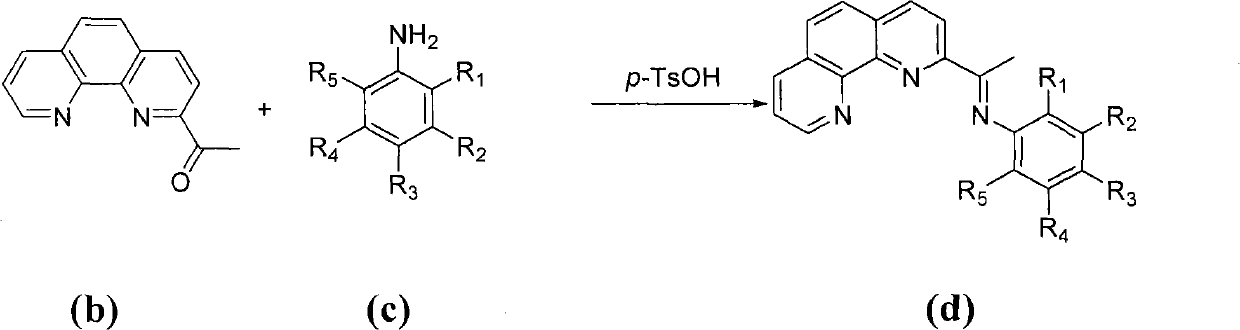

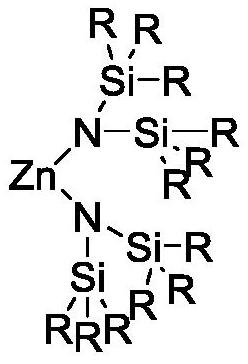

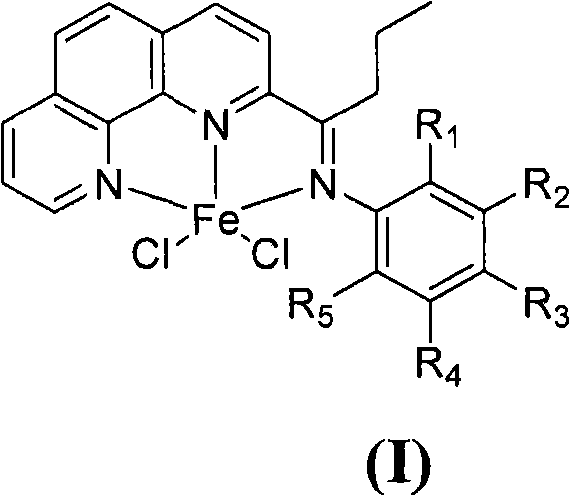

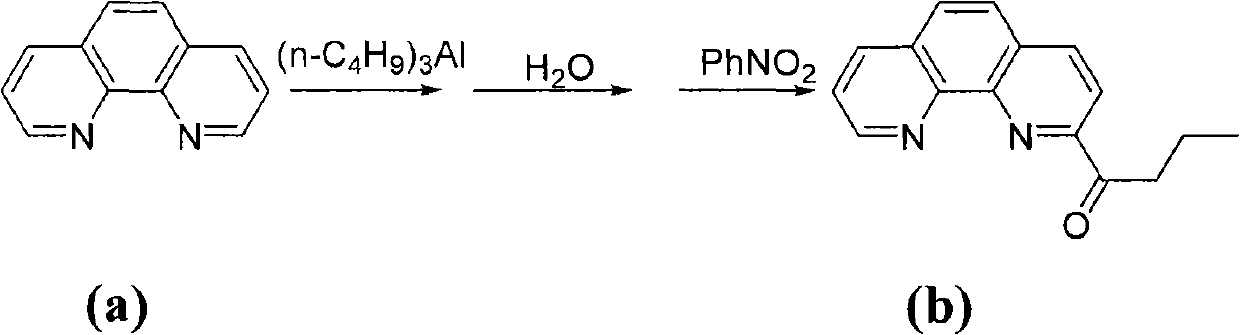

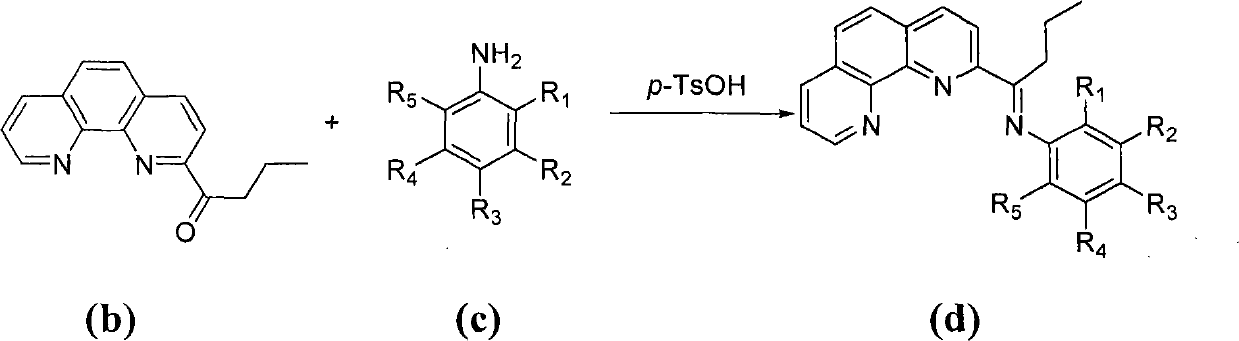

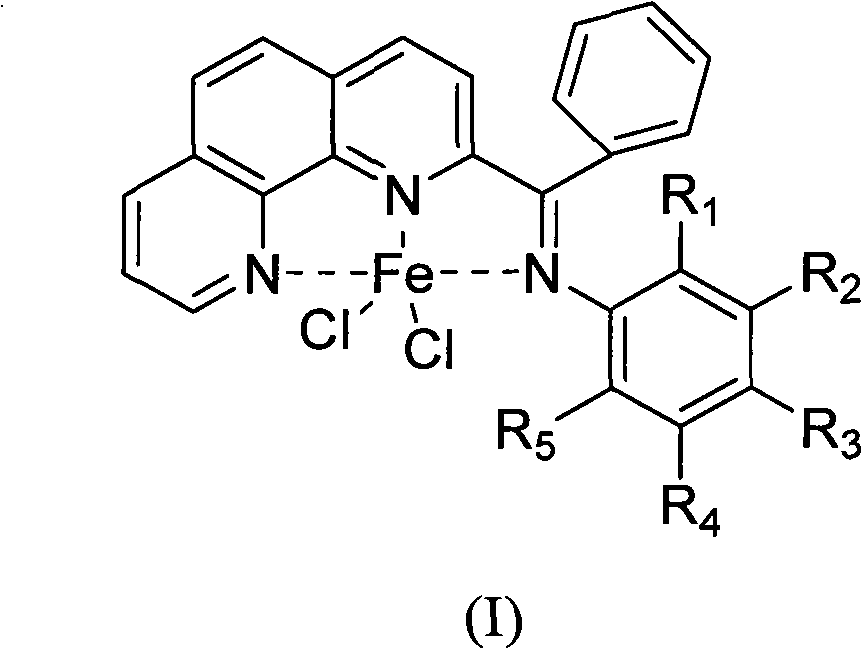

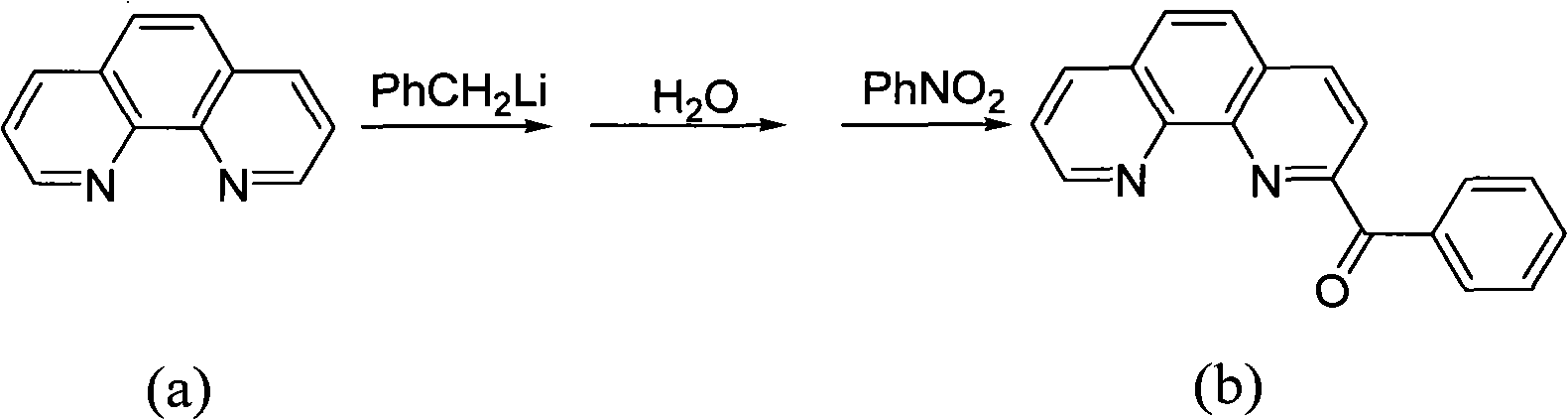

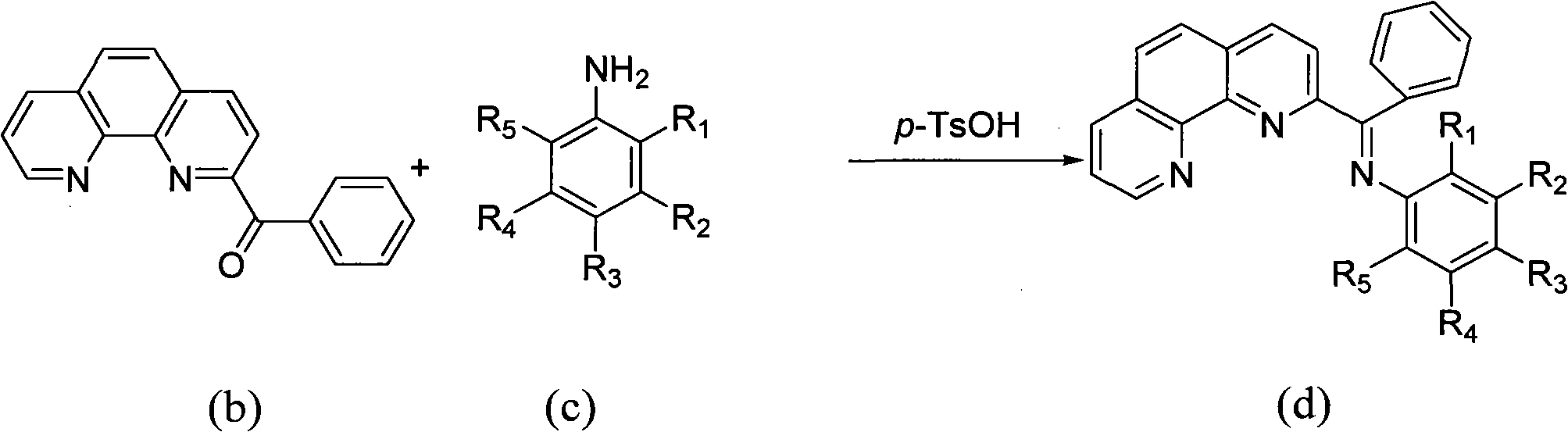

Preparation of acetyl-substituted-1,10-phenanthroline complex and application of prepared complex as catalyst

ActiveCN102485733AReduce manufacturing costLess varietyOrganic-compounds/hydrides/coordination-complexes catalystsIron organic compoundsPotassium cyanidePhenanthroline

The invention provides a method for preparing chlorinated-2-acetyl-1,10-phenanthroline amine iron (II) complex with the structural formula of formula (I) and an application of the obtained complex as an ethylene oligomerization catalyst, wherein variables in the formula (I) are defined in the specification. According to the method, triethyl aluminum which is adopted as an initial raw material in the process of the preparation of 2-acetyl-1,10-phenanthroline from 1,10-phenanthroline is hydrolyzed and undergoes an oxidation reaction with nitrobenzene to obtain 2-acetyl-1,10-phenanthroline, 2-acetyl-1,10-phenanthroline is condensed with substituted aniline to obtain a 2-acetyl-1,10-phenanthroline amine ligand, and the ligand is reacted with iron dichloride to obtain the complex. The synthetic method of the invention, which has the advantages of less step, simple technology, and catalyst preparation cost reduction, and adopts nontoxic triethyl aluminum to replace potassium cyanide used in routine preparation methods, has a wide industrialization prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

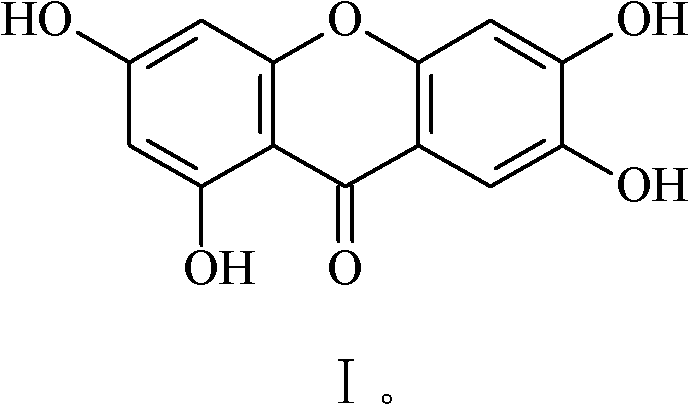

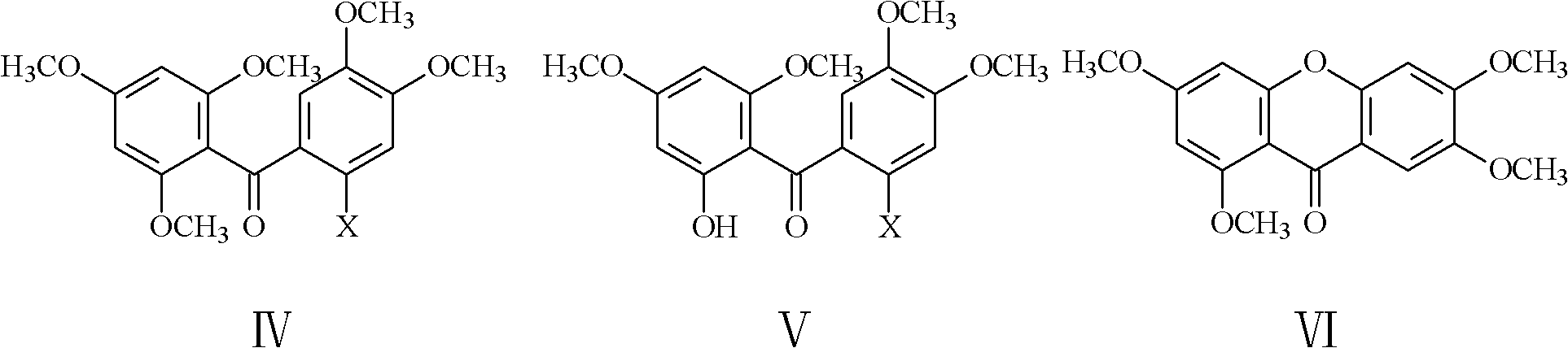

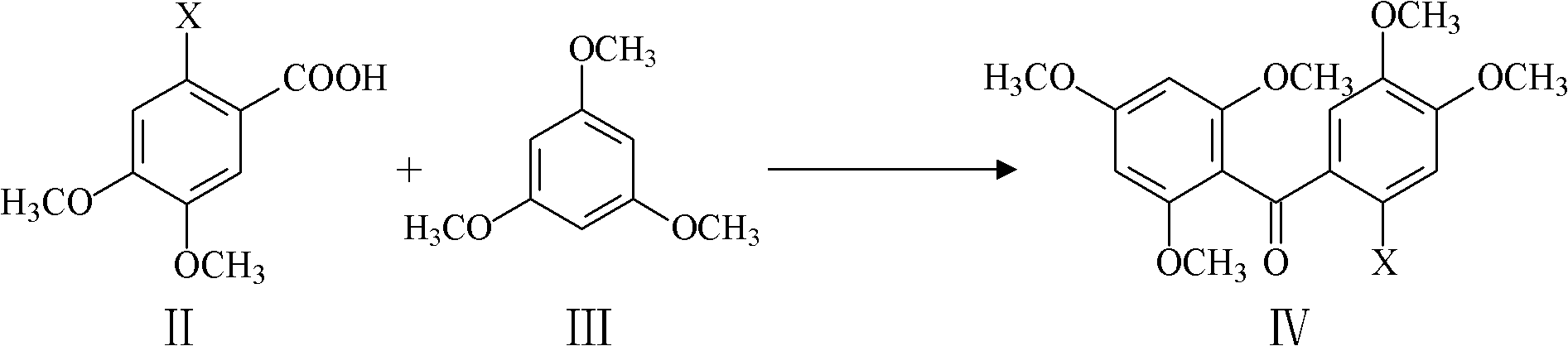

Method for preparing mangiferin aglycone

The invention relates to the field of medicinal chemistry, and discloses a method for preparing mangiferin aglycone. The method comprises that: step 1, 2-halogenate-4,5-dimethoxy benzoic acid and 1,3,5-trimethoxy benzene are subjected to Friedel-Crafts reaction, so a compound which has a structure in a formula IV is generated; step 2, the compound in the formula IV is selectively demethylated, and a compound which has the structure in the formula V is generated; step 3, the compound in the formula V is cyclized, and a compound which has the structure in the formula VI is generated; and step 4, the compound in the formula VI is completely demethylated, and mangiferin aglycone is generated. The method for preparing mangiferin aglycone improves the synthetic yield of the mangiferin aglycone, has the characteristics of cheap and easily-obtained raw materials, less synthetic steps, convenience in operation, easiness in control and high product purity, and can be widely applied in industrial production.

Owner:KPC PHARM INC +1

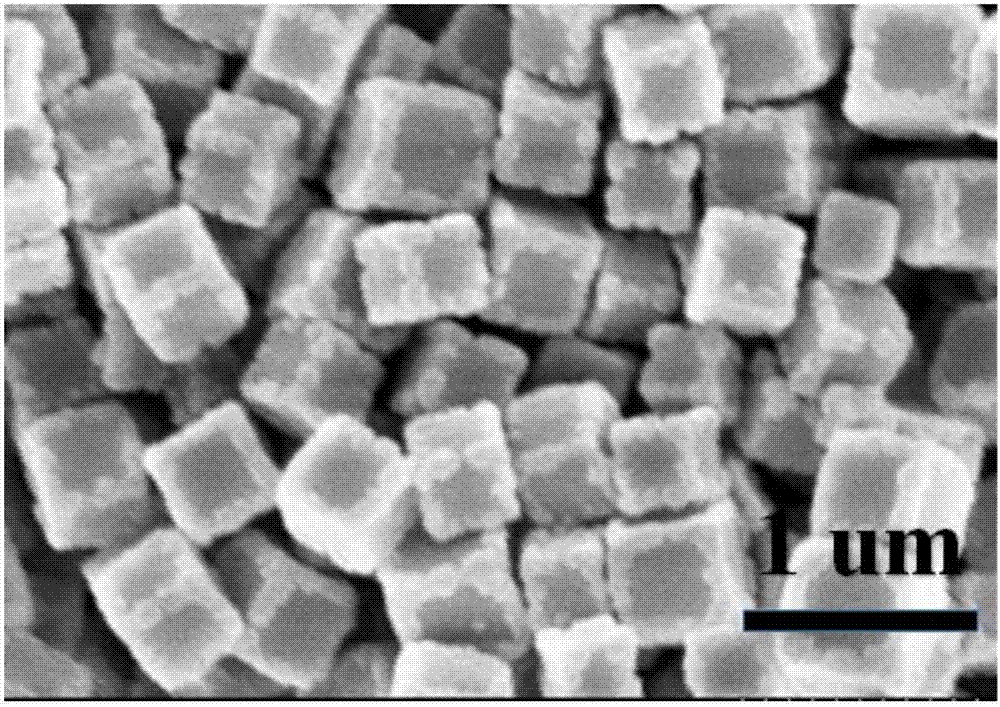

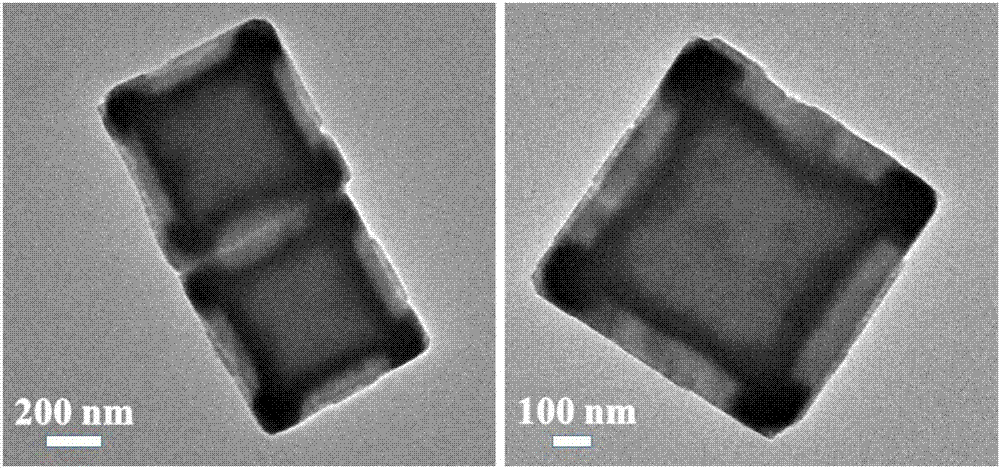

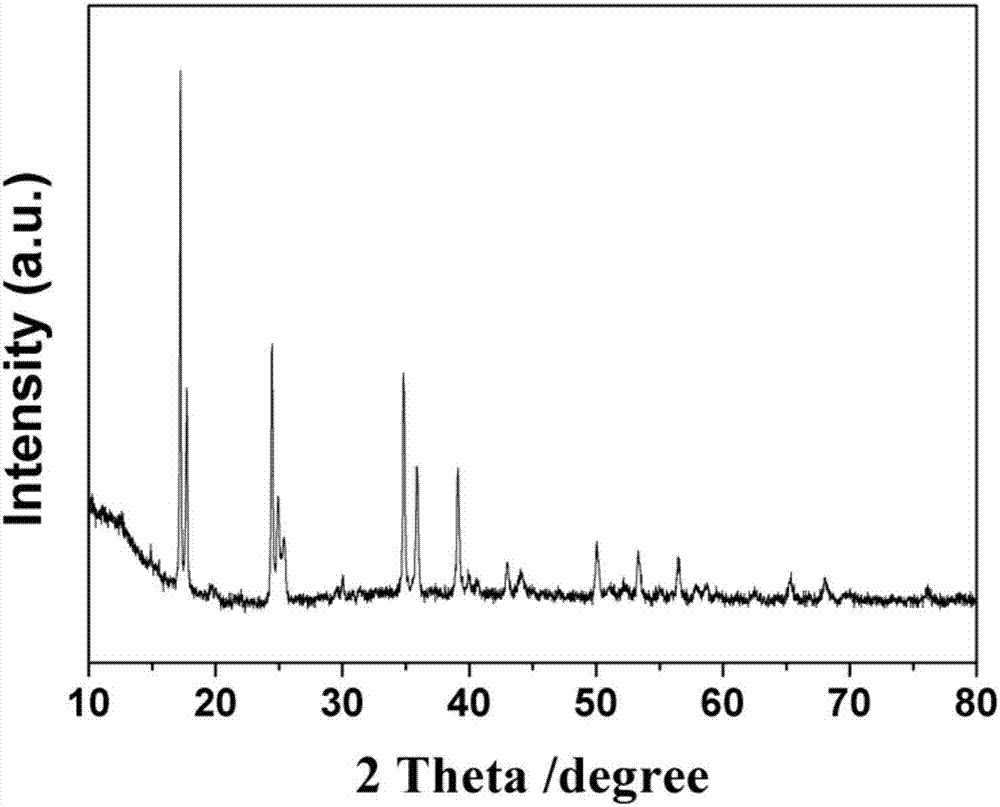

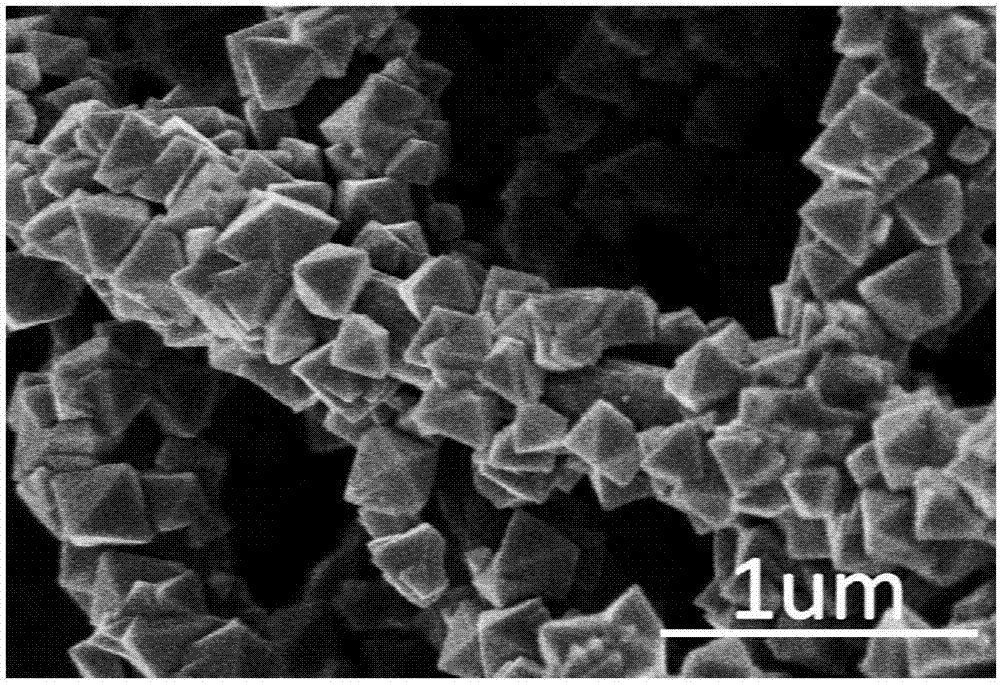

Edging cube-shaped cobalt-iron prussian blue nanometer material and preparation method thereof

InactiveCN107021510ANovel shape and structureControllableIron cyanidesPotassium ferricyanideCobalt salt

The invention relates to an edging cube-shaped cobalt-iron prussian blue nanometer material and a preparation method thereof. The preparation method comprises the following steps of firstly, stirring and dissolving a surfactant into water under the magnetic action; after dissolving, sequentially adding sodium citrate and cobalt salt to prepare a solution A; then, dissolving potassium ferricyanide solid into water to prepare a solution B; gradually dripping the solution A into the solution B while stirring; after dripping, continuing to stir for a period of time; standing and aging the reaction liquid for a period of time, naturally cooling, centrifuging, washing, and drying, so as to obtain the edging cube-shaped cobalt-iron prussian blue nanometer material. Compared with the prior art, the synthesizing method has the advantages that by changing the conditions, the edging cube-shaped cobalt-iron prussian blue nanometer material is prepared; the morphology and structure of the material are not reported in the literature; the preparation is simple, the implementing is easy, and the large-batch preparation effect is realized.

Owner:TONGJI UNIV

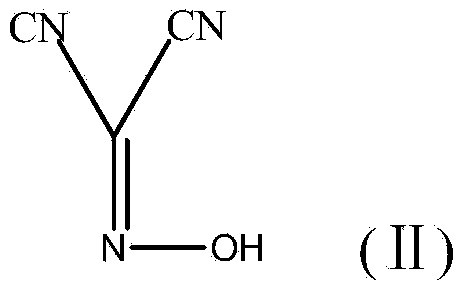

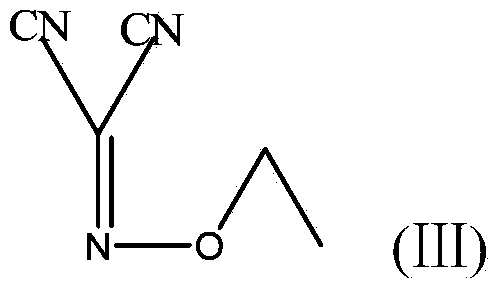

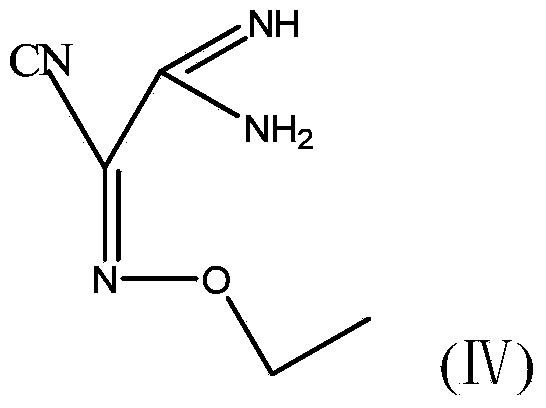

Method for preparing (Z)-5-amino-alpha-(ethoxy imino group)-1, 2, 4-thiadiazole-3-acetic acid

ActiveCN103804321AShort synthetic routeFew synthetic stepsOrganic chemistryAcetic acidPotassium thiocyanate

The invention discloses a method for preparing (Z)-5-amino-alpha-(ethoxy imino group)-1, 2, 4-thiadiazole-3-acetic acid. The method comprises steps of firstly, carrying out oximation reaction on malononitrile and sodium nitrite under the action of acetic acid so as to obtain a compound A, then carrying out Williamson synthesis on the compound A and bromoethane or diethyl sulfate under alkaline condition, so as to obtain a compound B, then carrying out amidine reaction on the compound B and ammonia water, so as to obtain a compound C, carrying out cyclization reaction on the compound C and potassium rhodanide for ring closing so as to obtain a compound D, and finally, hydrolyzing the compound D under the action of a strong base, so as to obtain (Z)-5-amino-alpha-(ethoxy imino group)-1, 2, 4-thiadiazole-3-acetic acid. The method has few synthesis steps, has low cost, uses the materials which are cheap and easy to obtain, is beneficial to industrial production, and has light contamination; the purity of the product can reach 99%, so that synthesis of high-purity ceftaroline fosamil in the subsequent step is guaranteed.

Owner:山西海泰电子材料有限公司

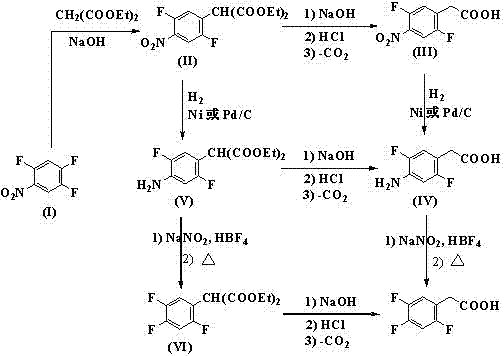

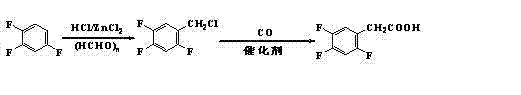

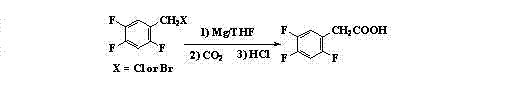

Preparation method 2,4,5-trifluorophenylacetic acid

ActiveCN103012111AFew synthetic stepsMild reaction conditionsOrganic compound preparationCarboxylic preparation by ozone oxidationPhenylacetic acidNitrobenzene

The invention discloses a preparation method 2,4,5-trifluorophenylacetic acid. The method is characterized by consisting of four reaction steps of: A, reaction of 2,4,5-trifluoronitrobenzene (I) and diethyl malonate which are condensed to prepare 2,5-difloro-4-nitrobenzophenone diethyl malonate; B, hydrolysis, acidification and decarboxylic reaction of dibasic ester; C, reduction reaction of nitryl; and D, diazotization fluoridation of amino. The four reaction steps can be sequentially carried out according to A, B, C and D, or A, C, B and D, or A, C, D and B. According to the preparation method provided by the invention, condensation of 2,4,5-trifluoronitrobenzene (I) and diethyl malonate is easy to realize by means of high substituting activity of nitryl p-fluorine, and the raw material 2,4,5-trifluoronitrobenzene (I) is low in cost and easy to obtain and can be easily prepared by nitration and fluorination of 2,4-dichlor fluorbenzene. Compared with the prior art, the preparation method provided by the invention has the characteristics of low-cost and easily obtained raw materials, mild reaction condition, high total yield, low production cost and the like, and is comparatively suitable for industrialized production.

Owner:江苏中丽新材料有限公司

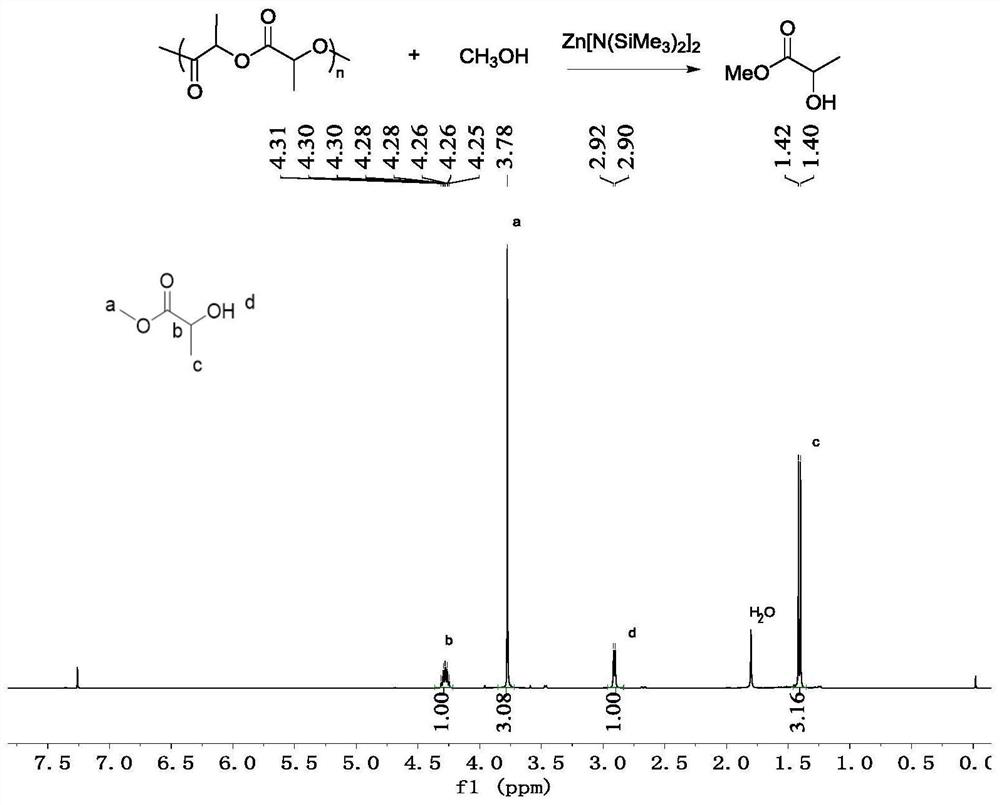

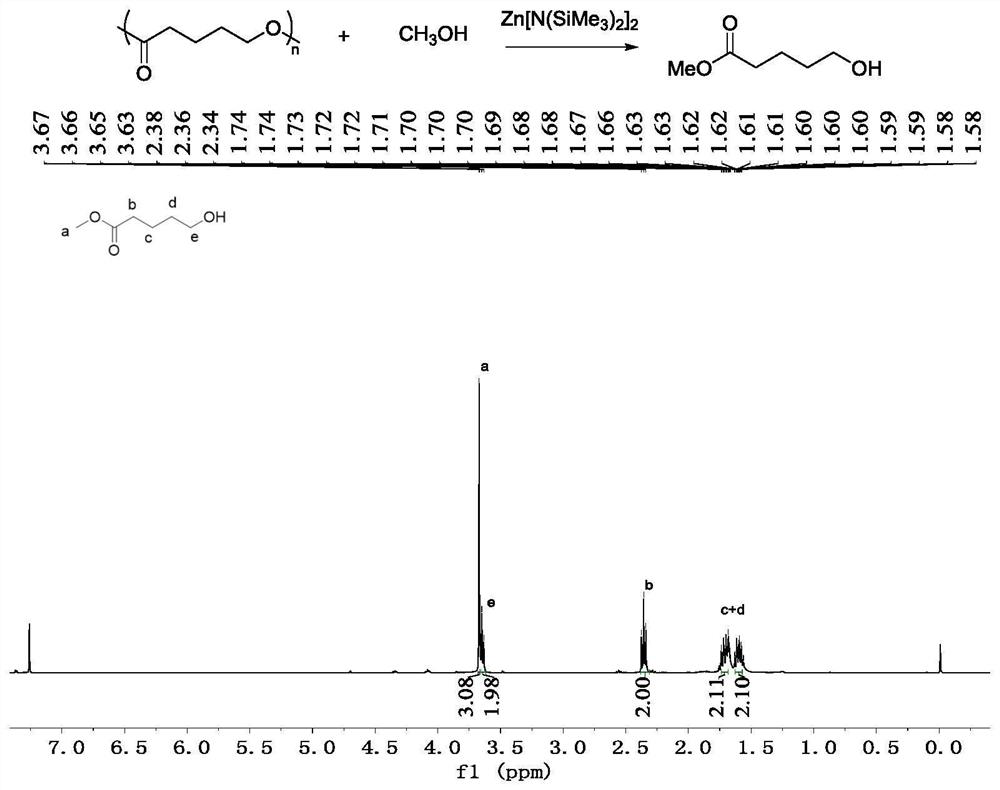

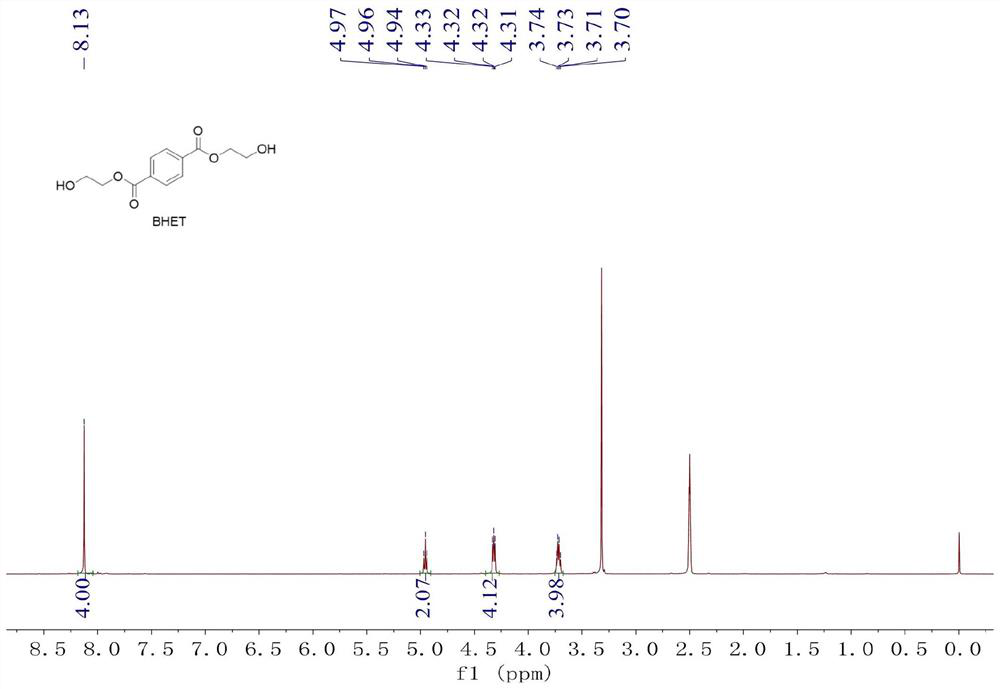

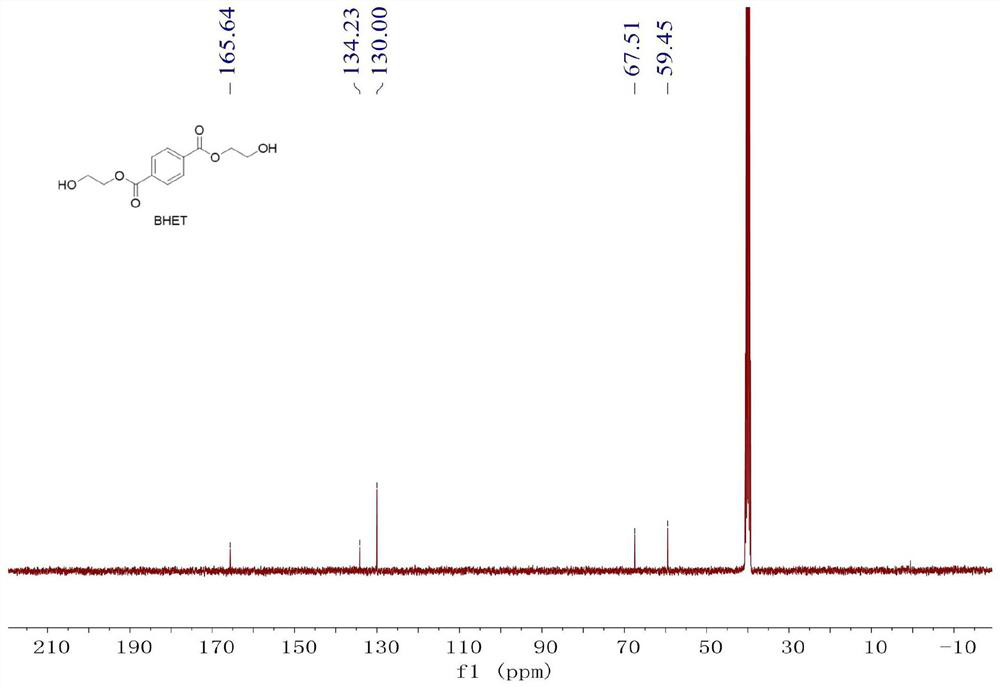

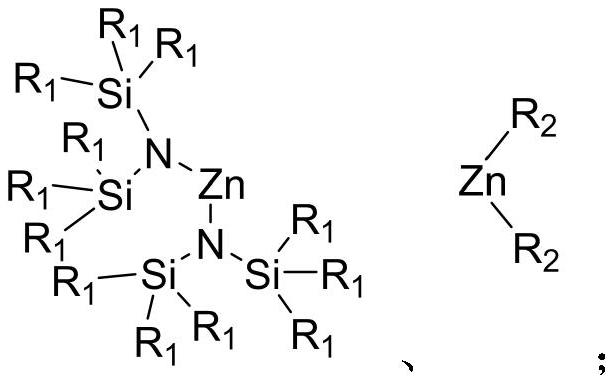

Zinc catalyst applicable to controllable depolymerization of polyester material and catalytic method thereof

ActiveCN112076790AAchieve reuseRealize secondary usePreparation by ester-hydroxy reactionOrganic-compounds/hydrides/coordination-complexes catalystsPolyesterTrans esterification

The invention discloses a zinc catalyst applicable to controllable depolymerization of a polyester material and a catalytic method thereof, and belongs to the technical field of polyester depolymerization. The problems that an existing zinc catalyst used for alcoholysis of waste polyester materials needs to synthesize complex ligands, and the number of synthesis steps is increased are solved. Thecatalyst adopted by the invention is a bis(hexaalkyldisilazane)zinc catalyst with a simple structure, and under the participation of an alcohol compound, the polyester material can be depolymerized into small organic molecules under mild conditions through the transesterification reaction catalyzed by the catalyst, so that the reutilization of waste polyester is realized. The zinc catalyst is adopted to catalyze polyester depolymerization, metal zinc is non-toxic, colorless, cheap and easy to obtain and serves as one of the microelements of a human body, biocompatibility is good, and the production process is more environmentally friendly; the catalyst is simple in structure, few in synthesis steps and more economical in production cost. The catalyst has very good universality, and has a very good depolymerization effect on various polyester materials with different structures.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Preparation of butyryl-substituted 1,10-phenanthroline complex and application of prepared complex as catalyst

ActiveCN102485732AReduce manufacturing costFew synthetic stepsOrganic-compounds/hydrides/coordination-complexes catalystsIron organic compoundsPotassium cyanideNitrobenzene

The invention provides a method of preparing a complex represented by formula (I) of 2-n-butyryl-1,10-phenanthroline condensation amine ferric chloride (II) and application of the prepared complex as a catalyst for ethylene oligomerization, wherein variables in formula (I) are defined in the specification. According to the method, in the process of preparing 2-n-butyryl-1,10-phenanthroline from 1,10-phenanthroline, tri-n-butylaluminum is used as a starting material, then hydrolysis and an oxidation reaction with nitrobenzene are sequentially carried out so as to obtain 2-n-butyryl-1,10-phenanthroline, 2-n-butyryl-1,10-phenanthroline and substituted aniline undergo a condensation reaction so as to prepare 2-n-butyryl-1,10-phenanthroline condensation amine ligand, and the ligand reacts with ferrous chloride so as to obtain a target product. The synthetic method comprises a few procedures, is a simple process, enables preparation cost for the catalyst to be reduced and uses nontoxic tri-n-butylaluminium to substitute potassium cyanide used in normal preparation methods, thereby having a wide industrial prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

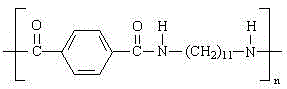

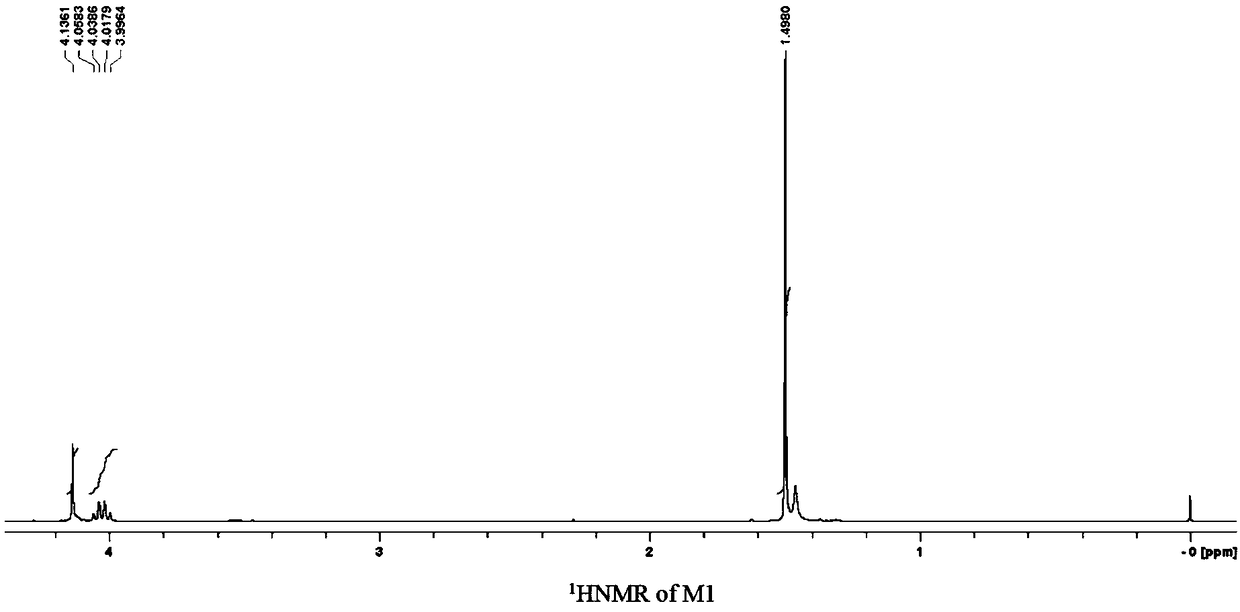

Semi-aromatic polyamide PA11T and preparation method thereof

ActiveCN104817693AHigh molecular weightHigh temperature high molecular weightPolymer scienceMaterial synthesis

The invention discloses a semi-aromatic polyamide PA11T and a synthetic method thereof and belongs to the technical field of high polymer material synthesis. The structure formula is shown in the description, wherein n is 10-200. The 1, 11-undecanedioic diamide and the terephthalic acid are taken as the raw materials and the synthetic process is finished in a drum type reaction kettle through a one-pot method. By adopting the method, the reaction devices and the synthetic steps are few, the reaction time is short, the polymerization temperature is low, and the method is pollution-free and suitable for the large-scale industrial production. The PA11T produced by the process is excellent in performance and has a good market prospect in the industries such as the electric products and the automobiles.

Owner:ZHENGZHOU UNIV +1

Medicine use of cyclodextrin derivs. and medicine composition thereof

InactiveCN1451390AEasy to prepareFew synthetic stepsOrganic active ingredientsAntipyreticDiseaseDiabetes mellitus

A cyclodextrin derivative for preventing and treating cardiovascular and cerebrovascular diseases, diabetes, liver injury, diseases in respiratory system, rheumatic and rheumatoid diseases, dermatopathy and tumor is disclosed. It is an artificial analogue enzyme with the activity of glutathion peroxidase.

Owner:JILIN UNIV

Perfluoropolyether group-containing silane compound, preparation method thereof, surface treatment agent and article

ActiveCN109071793AImprove hydrophobicityGood oleophobic effectAntifouling/underwater paintsPaints with biocidesSurface finishingWear resistant

The invention relates to a perfluoropolyether group-containing silane compound represented by a formula (1): Rf-X1-X2-NQkT2-k(1), and a preparation method therefor. The invention also relates to a perfluoropolyether group-containing silane compound shown in the description, and a preparation method therefor. The invention also relates to a perfluoropolyether group-containing silane compound represented by a formula (3) shown in the description, and a preparation method therefor. The perfluoropolyether group-containing silane compound can be used for a surface treatment agent so that the glassand other base materials processed by the surface treatment agent are excellent in anti-pollution, anti-fingerprint, scrape-resistant and wear-resistant performances, and the preparation methods for the compounds are simple in process, and are easy to operate and implement.

Owner:GUANGZHOU UR MATERIALS TECH CO LTD

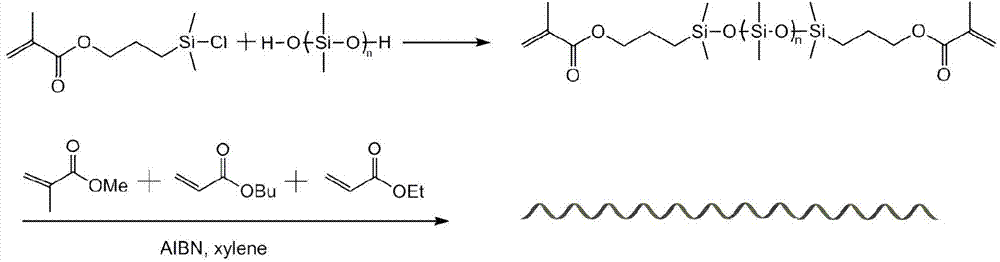

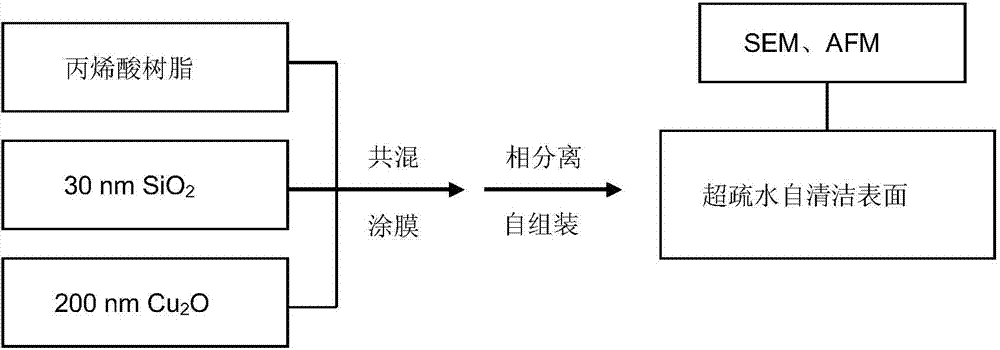

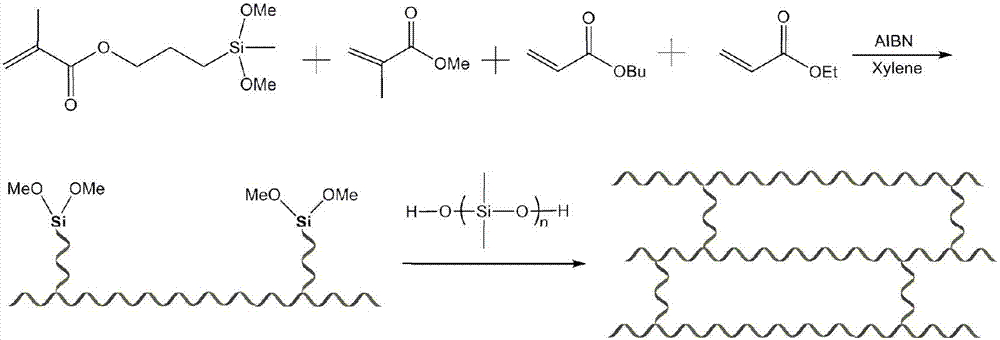

Compound super-hydrophobic ocean antifouling paint as well as preparation method and application thereof

InactiveCN104745038ASimple preparation processFew synthetic stepsAntifouling/underwater paintsPretreated surfacesAcrylic resinMarket oriented

The invention discloses a compound super-hydrophobic ocean antifouling paint which comprises the following components by weight: 170-200g of acrylic resin, 1-10g of silicon dioxide particles, 1-10 parts of cuprous oxide particles and 10-100 parts of n-butyl alcohol. The invention further discloses a preparation method and application method of the compound super-hydrophobic ocean antifouling paint. Compared with a market-oriented paint with low surface energy, the ocean antifouling paint is simple in preparation process, is synthesized by few steps and has obvious 'lotus leaf self-cleaning effect' and excellent storage stability.

Owner:ZHEJIANG MARINE DEV RES INST

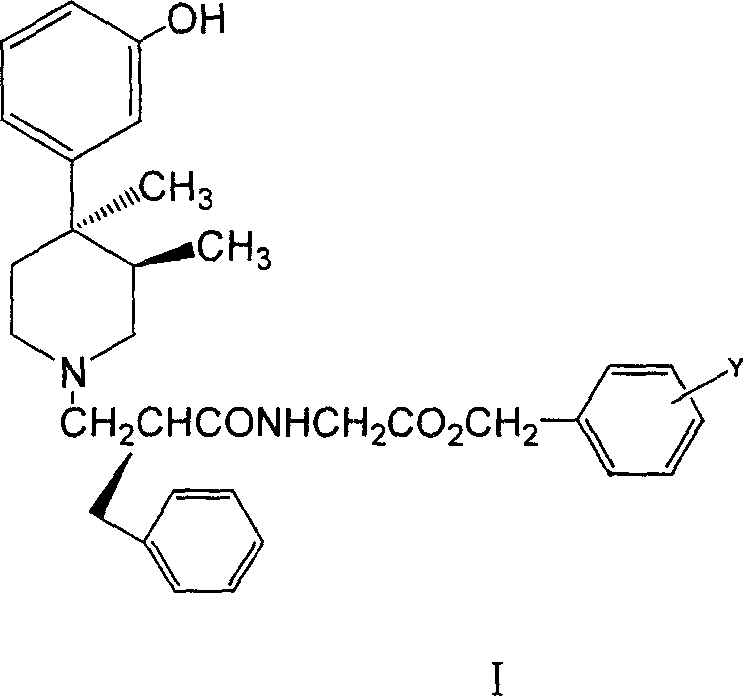

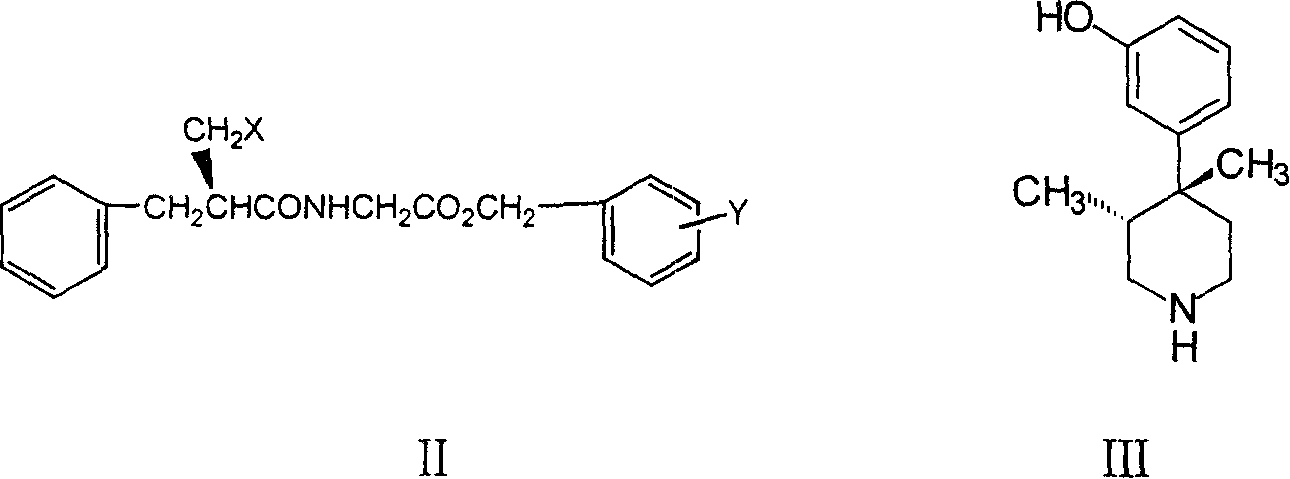

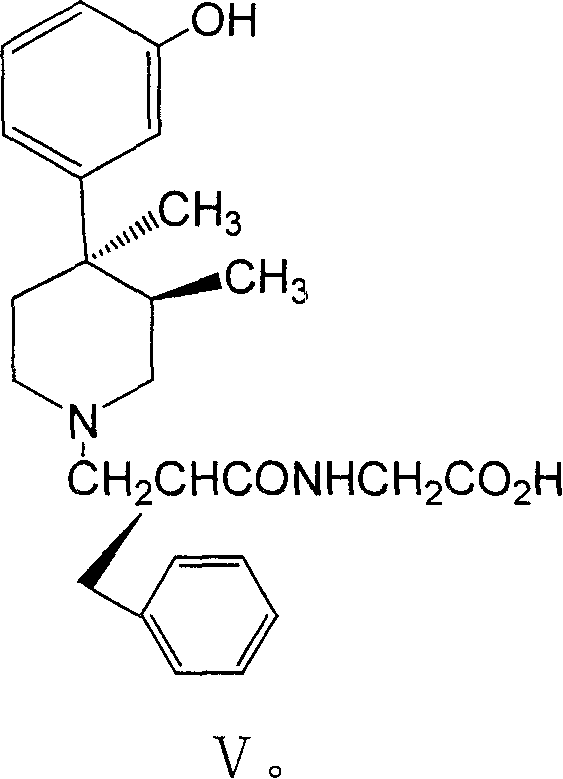

Substituted benzyl ester and its preparation process and novel process for preparing substituted mopipe therefrom

ActiveCN1827598AFew synthetic stepsLower synthesis costOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsChemistryBenzyl group

The invention discloses a (+)-(3R,4R)-[[2S-[[4-(3-hydroxyphenyl-3,4- dimethyl-1-nipecotic)-methyl]-1-oxo-3-phenylpropyl]amido]benzyl cetate compound and its process for preparing and a new technology for preparation of Mope by the said compound. The new technique of this invention changes the íŒone chainíŒ synthesis of the original patent method to the separate í‹two chainsíŒ preparation, by which the total compound steps are dramatically shortened, the compound cost is reduced to about one-half of the original patent method, and the method is more competitive on the market in price. Furthermore,the reaction condition is moderate, the operating procedure is simple, each reaction step is no need of given condition such as low temperature and absolute water-free, so it is more suitable for industrial production.

Owner:天津泰普制药有限公司 +1

Preparation method of benzoyl-substituted 1,10-phenanthroline complex and catalytic application in ethylene oligomerization

ActiveCN102964388AReduce manufacturing costLow priceOrganic-compounds/hydrides/coordination-complexes catalystsIron organic compoundsPotassium cyanidePhenanthroline

The invention provides a method for preparing a chlorinated 2-benzoyl-1,10-phenanthroline condensed amine iron (II) complex shown in formula I, and its catalytic application in ethylene oligomerization. The preparation method comprises the following steps: orderly performing hydrolysis and an oxidation reaction with nitrobenzene of initial reaction raw materials of 1,10-phenanthroline and benzyl lithium to obtain 2-benzoyl-1,10-phenanthroline, then performing condensation of 2-benzoyl-1,10-phenanthroline with substituted aniline to obtain 2-benzoyl-1,10-phenanthroline condensed amine ligand, and reacting the ligand with ferrous chloride to obtain a target product I. The synthetic method provided by the invention is few in steps, and simple in process, substitutes nitrobenzene for selenium dioxide in the prior art for the oxidation reaction, substitutes nontoxic benzyl lithium for hypertoxic potassium cyanide in the prior art, reduces the preparation cost of the catalyst, and has wide industrialization prospects.

Owner:CHINA PETROLEUM & CHEM CORP +1

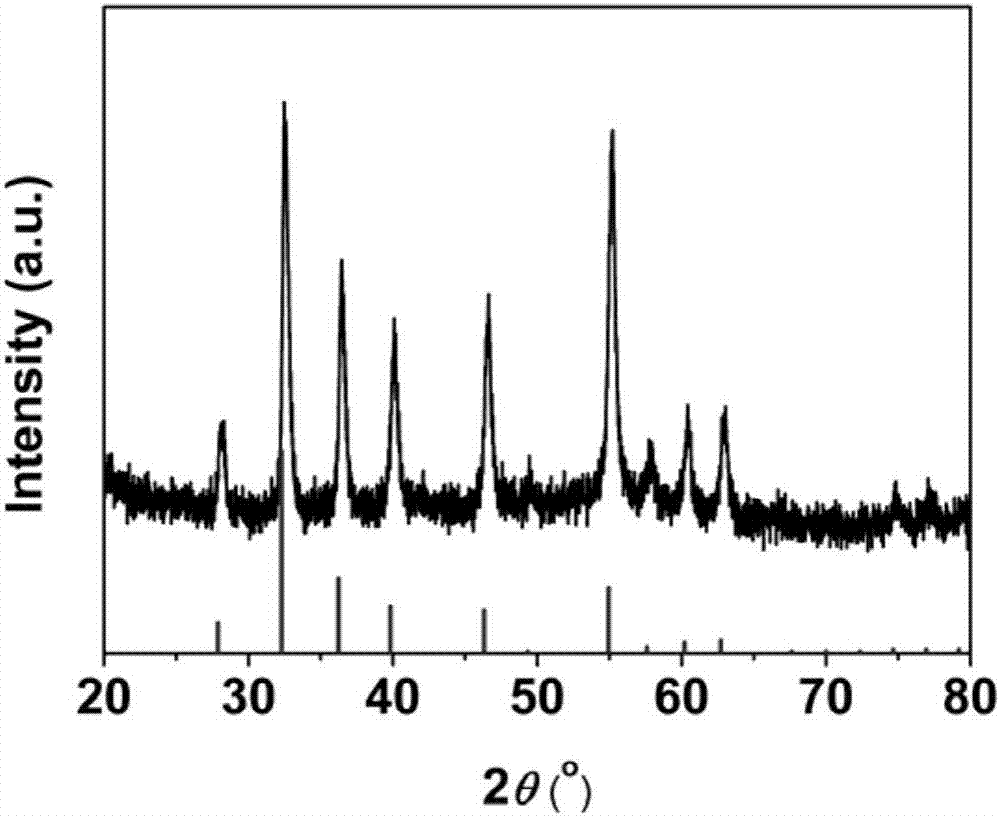

Nano stannic oxide-graphene composite as well as preparation method and application thereof

The invention relates to a nano stannic oxide-graphene composite as well as a preparation method and an application thereof. Firstly, a SnCl4*5H2O solution is added to a graphene oxide aqueous solution and stirred, graphene oxide sheets adsorb Sn<4+>,the graphene oxide sheets adsorbing Sn<4+> are dissolved in deionized water and subjected to ultrasonic treatment after being separated, and an obtained dispersing solution is used as a seed crystal adsorbing solution; a SnCl4*5H2O aqueous solution, a NaOH aqueous solution and a surfactant aqueous solution are prepared respectively; the seed crystal adsorbing solution and the SnCl4*5H2O aqueous solution are mixed, then the NaOH aqueous solution and the surfactant aqueous solution are dropwise added to the solution sequentially, the mixture is stirred, mixed evenly and ultrasonically and then transferred to a closed reaction kettle to be subjected to a hydrothermal reaction, and the nano stannic oxide-graphene composite is obtained after natural cooling, centrifugation, washing and drying. The nano stannic oxide-graphene composite is applied to specific response to ammonia gas under the room temperature condition. Compared with the prior art, the composite has the advantages that the synthesis method is simple and easy to implement, and the shape of a product is controlled.

Owner:TONGJI UNIV

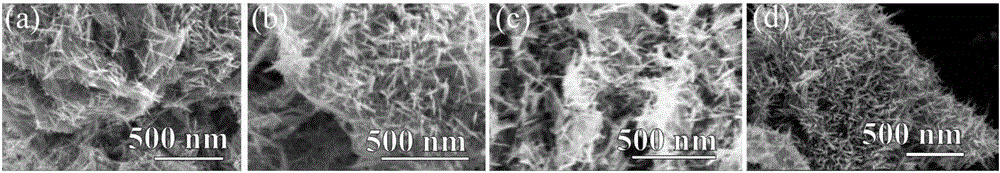

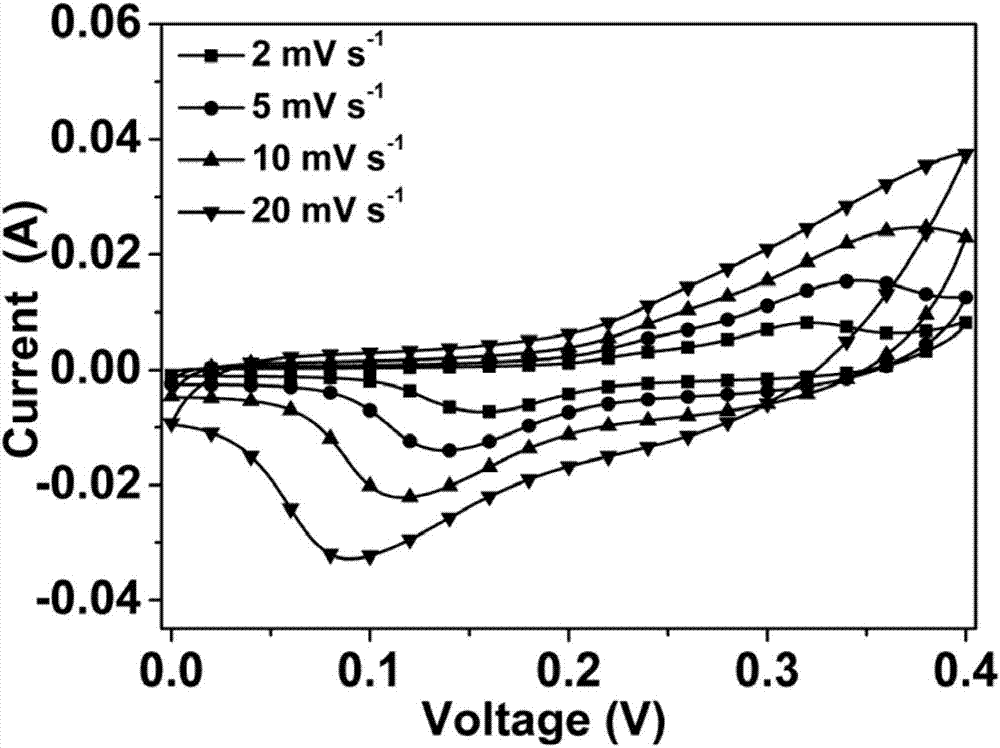

Preparation method and application of cobalt disulfide and carbon nano fiber composite material

ActiveCN107201573AFew synthetic stepsEasy to operateHybrid capacitor electrodesCarbon fibresElectrospinningDimethyl formamide

The invention relates to a preparation method and application of a cobalt disulfide and carbon nano fiber composite material. The preparation method comprises the following steps: firstly, preparing carbon nano fiber by using an electrostatic spinning method; by taking N-N dimethyl formamide (DMF) as a solvent, preparing a polyacrylonitrile spinning solution, uniformly stirring, sucking into an injector, and performing electrostatic spinning; cutting a white film obtained after spinning into long strips, and performing thermal treatment in a tubular furnace so as to obtain a black carbon fiber film; activating with concentrated nitric acid, adding cobalt nitrate hexahydrate and thioacetamide so as to obtain a solution, performing ultrasonic treatment, further transferring the solution into a reaction kettle, and performing hydrothermal reaction; after the reaction kettle is cooled after reaction, taking out the carbon fiber, respectively washing the carbon fiber with distilled water and ethanol for multiple times, and performing vacuum drying, thereby obtaining the cobalt disulfide and carbon nano fiber composite material. The cobalt disulfide and carbon nano fiber composite material is used as an electrode material of a supercapacitor, and properties of the supercapacitor can be tested.

Owner:TONGJI UNIV

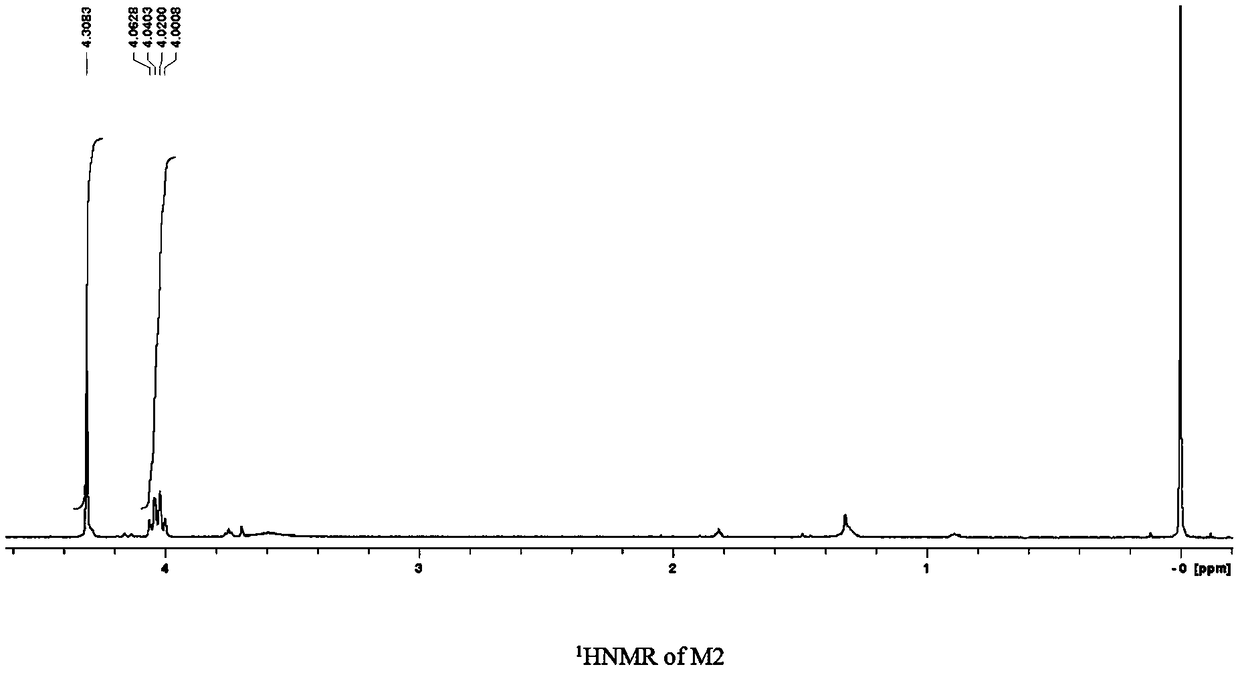

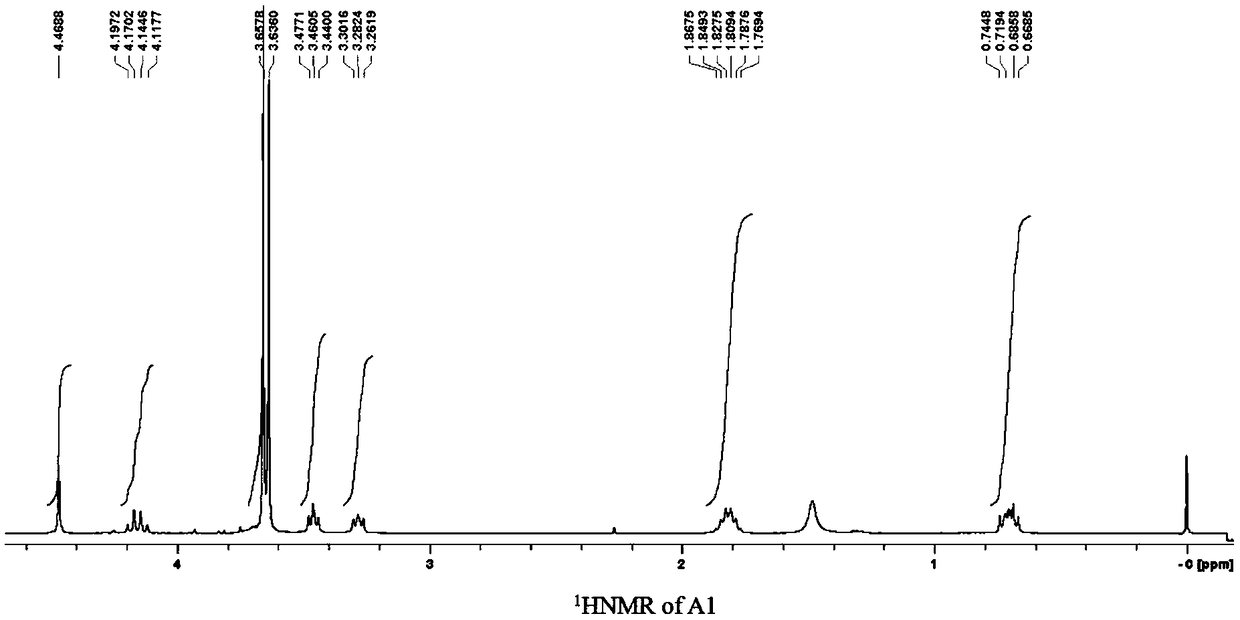

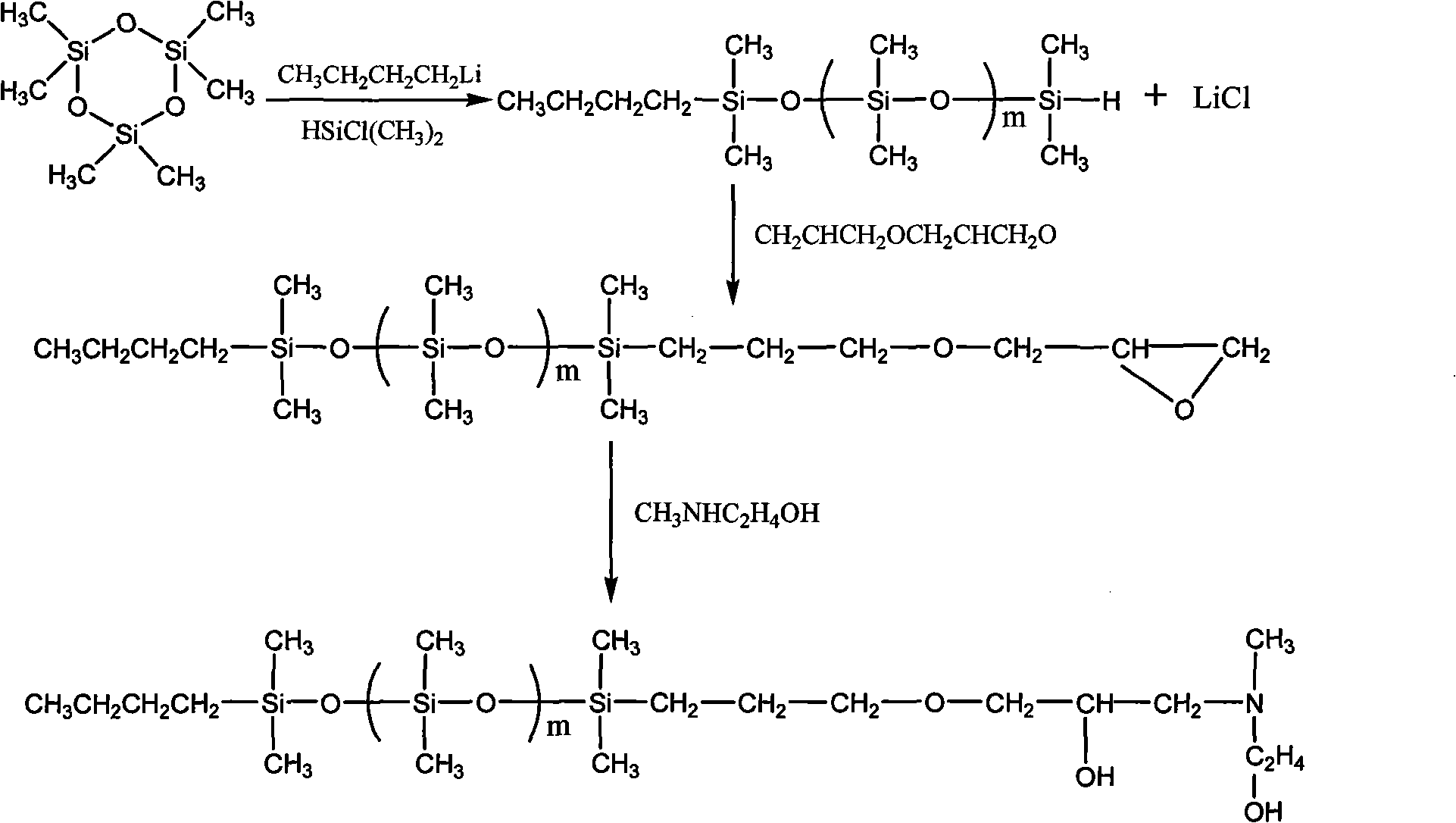

Dihydroxyl-terminated polydimethylsiloxane and preparation thereof

The invention provides a new method for preparing single-ended double-hydroxyl alkyl polydimethylsiloxane and the preparation method of the invention is different from prior synthetic methods. The preparation method takes D3 (Hexamethylcyclotrisiloxane), allyl glycidyl ether and methylaminoethanol as starting raw materials which go through three-step reactions of anion ring-opening polymerization, hydrosilylation and epoxy ring-opening to synthesize the target product of the single-ended double-hydroxyl alkyl polydimethylsiloxane of which the product purity is over 98 percent. The invention has the advantages of simple and convenient reaction steps, easily accessible raw materials, low production cost, high product yield, high purity, etc.

Owner:QILU UNIV OF TECH

Treatment method of organic wastewater through synthesis-free heterogeneous Fenton treatment

InactiveCN102765800AFew synthetic stepsShort purification timeWater/sewage treatment by oxidationCation-exchange capacitySodium Bentonite

The invention provides a treatment method of organic wastewater through synthesis-free heterogeneous Fenton treatment. The treatment method comprises the following steps of directly adding ferrous ion salt, H2O2 and bentonite powder in waste water, enabling solid-liquid mass ratio of bentonite and the waste water to be 1:1000-10000, enabling ferrous ionic charge mole number to be 50-100% of added bentonite cation exchange capacity, enabling molar ratio of Fe2+ and the H2O2 to be 500-1000:1, adjusting the pH value to be 5-6, stirring and reacting for 5-10min, conducting solid-liquid separation, and enabling the waste water to be discharged after reaching the standard. A series of complex synthesis steps of an original bentonite loaded ferric oxide catalytic agent before application are removed. Purification treatment time of the organic wastewater is shortened, and efficiency is improved. Cation exchange characteristics of the bentonite is used, iron ion is exchanged to a bentonite layer while the iron ion expresses catalytic action, loss of the iron ion is avoided, pollution of the iron ion in water is avoided, and possibility of reutilization is improved.

Owner:CHANGZHOU UNIV

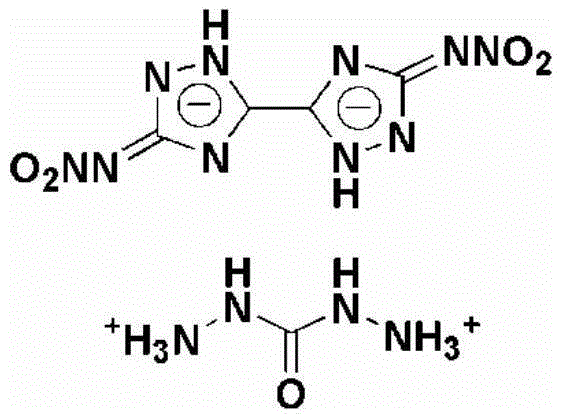

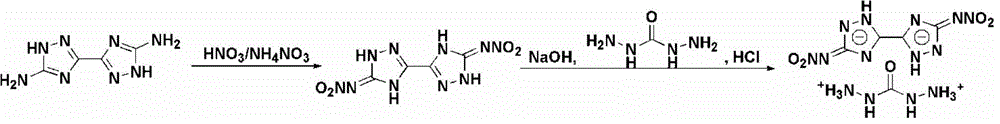

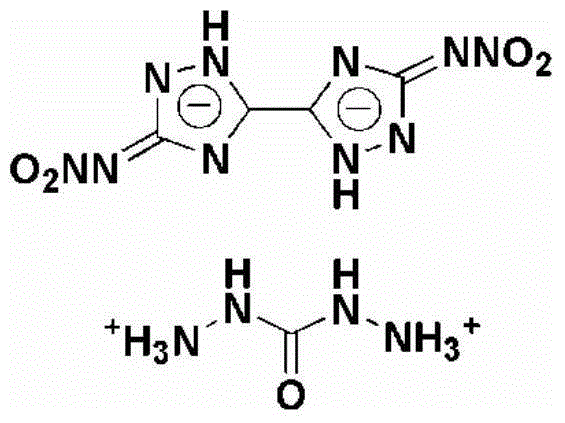

Method for synthesizing 5,5'-dinitroamino-3,3'-co-1,2,4-triazole carbohydrazide

The invention discloses a method for synthesizing 5,5'-dinitroamino-3,3'-co-1,2,4-triazole carbohydrazide. The carbohydrazide has the following structural formula, wherein the structural formula is as shown in the specification. In the method, 5,5'-diamino-3,3'-co-1,2,4-triazole serves as a raw material, and the method comprises the following steps: (1) adding the 5,5'-diamino-3,3'-co-1,2,4-triazole into a nitric acid and ammonium nitrate system in batches at the temperature of 0 DEG C, wherein a molar ratio of the 5,5'-diamino-3,3'-co-1,2,4-triazole, nitric acid to ammonium nitrate is 1:40: (4-8), stirring for 15 minutes, raising the temperature to 25 DEG C, reacting for 1.5 hours, pouring the reaction liquid into ice water, filtering, washing and drying to obtain 5,5'-dinitroamino-3,3'-co-1,2,4-triazole; and (2) adding the 5,5'-dinitroamino-3,3'-co-1,2,4-triazole, an aqueous liquid of sodium hydroxide and carbohydrazide into a reaction bottle under the temperature of 60 DEG C, wherein a molar ratio of the 5,5'-dinitroamino-3,3'-co-1,2,4-triazole, sodium hydroxide to carbohydrazide is 1:3:2.05, stirring for 20 minutes, dropwise adding 35 mass percent of hydrochloric acid until the pH value is 4-7, reducing the temperature to 25 DEG C, separating out a white product 5,5'-dinitroamino-3,3'-co-1,2,4-triazole carbohydrazide in the system. The method is mainly used for preparing the5,5'-dinitroamino-3,3'-co-1,2,4-triazole carbohydrazide.

Owner:XIAN MODERN CHEM RES INST

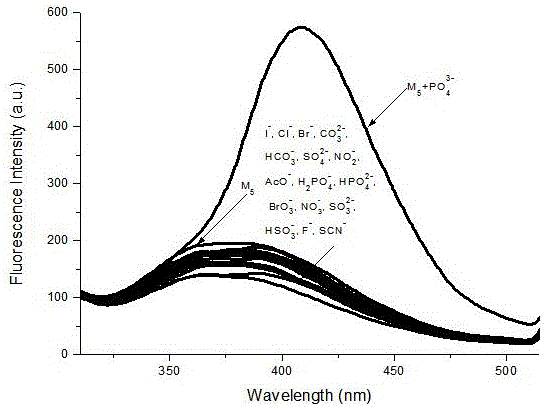

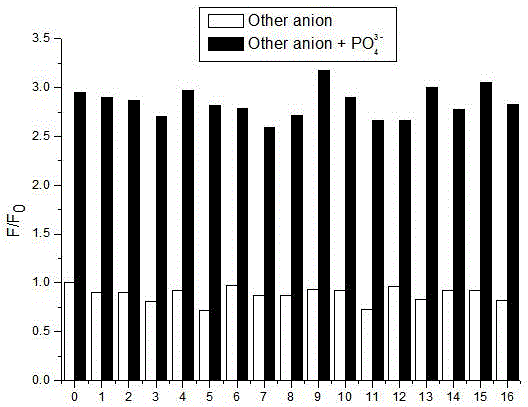

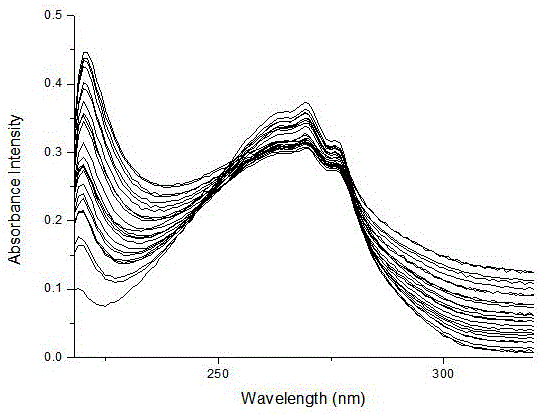

Benzimidazole derivative phosphate anion fluorescence probe synthesis and application method

ActiveCN106349167ASimple detection operationSimple and convenient detection operationOrganic chemistryFluorescence/phosphorescenceBenzimidazole derivativePhosphate ion

The invention discloses a method for synthesis of a benzimidazole derivative phosphate anion fluorescence probe and an application method thereof, and relates to the field of synthesis and application of the fluorescence probe. The synthesis of the benzimidazole derivative phosphate anion fluorescence probe can solve the problem that the florescence probes used for detecting PO43- are very scarce in kinds, that the identification of PO43- can be easily influenced by H2PO4- and HPO42-, and that the florescence probes can not directly carry out identification independently. The Benzimidazole derivative phosphate anion fluorescence probe is 1,4 phenyl double (carbamoyl methyl) N e alkylbenzimidazole ammonium chloride], which is obtained under quaterisation between Dichloro acetyl para-phenylene diamine and N-E alkyl benzene and imidazole. The fluorescence probe dissolves in HEPES buffered solution prepared by deionized water, and then test change in the absorbance value and fluorescence intensity to adjust the existence of PO43-. The Benzimidazole derivative phosphate anion fluorescence probe can be used to directly detect the po43- in water and blood.

Owner:QIQIHAR UNIVERSITY

One-step synthesis method for B-EU-1/ZSM-5 composite molecular sieve

ActiveCN104475150AFew synthetic stepsShort synthesis cycleMolecular sieve catalystsHydrocarbon from oxygen organic compoundsIon exchangeMolecular sieve

The invention discloses a one-step synthesis method for a B-EU-1 / ZSM-5 composite molecular sieve. The one-step synthesis method comprises the following steps: adding sodium hydroxide, a silicon source, an aluminum source, a boron-containing compound and a template agent into water at a molar ratio of Na2O:SiO2: Al2O3:B2O3: a template agent:H2O being 1.5 to (0.1-7) to (0.001-0.2) to (0.001-0.3) to (0.01-2.25) to (1-10), and uniformly stirring to obtain mixed gel; crystallizing the mixed gel at a constant temperature of 130-200 DEG C, roasting at 350-650 DEG C to remove the template agent, performing ion exchange by an acid solution, washing and keeping for 4 hours at 350-650 DEG C to obtain a B-EU-1 / ZSM-5 hydrogen composite molecular sieve, wherein the template agent consists of tetrapropylammonium bromide and hexamethonium bromide by mixing. The one-step synthesis method disclosed by the invention can be used for quickly and simply synthesizing a composite molecular sieve which simultaneously contains a EUO structure and an MFI structure, and is doped with a nonmetal element B, wherein the composite molecular sieve is used as a catalyst for preparing dimethylbenzene by methanol aromatization.

Owner:TAIYUAN UNIV OF TECH

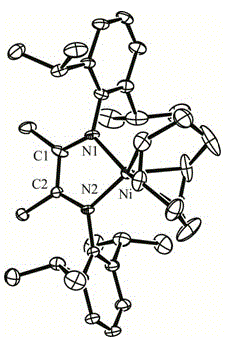

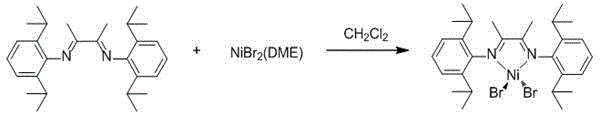

Alpha-diimine nickel metal organic compound and preparation method thereof

InactiveCN104892681AHigh yieldReaction raw materials are cheap and easy to obtainOrganic chemistry methodsNickel organic compoundsDiethyl etherOrganic compound

The invention relates to an alpha-diimine nickel metal organic compound and a preparation method thereof. The preparation method comprises the following steps: adding NiBr2 (DME) and alpha-diimine into a dichloromethane solution for reaction under the protection of an inert atmosphere, reducing an obtained product in a diethyl ether or n-hexane solution by using metallic sodium, and then reacting with 1,5-cyclooctadiene to obtain a mononuclear nickel metal organic compound of alpha-diimine. The preparation method provided by the invention is simple, is high in product yield and good in purity and can be used as an olefin polymerization catalyst.

Owner:NORTHWEST UNIV(CN)

Method for preparing scutellarin

ActiveCN105218606AEfficient chemical synthesis preparationFew synthetic stepsSugar derivativesSugar derivatives preparationMeth-Acylation

The invention discloses a method for preparing scutellarin. The method comprises the following steps: taking phenol as a starting material, preparing a chalcone intermediate compound 6 through bromination, methoxy substitution, friedel-crafts acylation and the like, performing oxidative cyclisation on the chalcone intermediate compound 6 to obtain a key flavone intermediate 4',6-dihydroxy-5,7-dimethoxy flavone-compound 7, and preparing high-purity scutellarin through benzoylation, selective demethylation, glycosylation and hydrolysis reaction of the key intermediate. According to the method, the adopted raw material reagents are all low in price and easy to obtain, the synthesis steps are less, the operation is simple and convenient, production control is easy, the product yield and purity are high, and the method is suitable for scutellarin production.

Owner:KUNMING UNIV OF SCI & TECH

Method for catalytically degrading waste polyester material by using zinc catalyst

PendingCN113173856ASimple structureFew synthetic stepsOrganic compound preparationOrganic chemistry methodsPolyesterTrans esterification

The invention discloses a method for catalytically degrading a waste polyester material by using a zinc catalyst, belongs to the technical field of polyester degradation, and aims to solve the problems that an existing polyester waste chemical recovery catalyst is low in catalytic efficiency and low in material universality. According to the method disclosed by the invention, a zinc catalyst with a simple structure is adopted, and various polyester materials are depolymerized into small organic molecules through an ester exchange reaction catalyzed by the zinc catalyst under the participation of an alcohol compound, so that the recycling of the waste polyester is realized; and the method disclosed by the invention has good universality, and has a good depolymerization effect on polyester materials with various different structures.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com