Semi-aromatic polyamide PA11T and preparation method thereof

A technology for semi-aromatic polyamide and polyamide, which is applied in the field of semi-aromatic polyamide PA11T and its preparation, semi-aromatic polyamide and its preparation field, can solve problems such as unseen semi-aromatic polyamide and the like, and achieves less reaction equipment and synthesis steps. , stable performance, uniform material dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

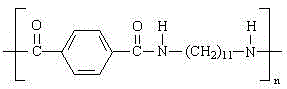

Image

Examples

Embodiment 1

[0022] Add 16.6kg of terephthalic acid, 18.6kg of 1,11-undecanediamine and 23.5kg of water into the drum reactor, replace the air in the reactor with argon, then heat up to 100°C, pressure 0.2 MPa, adjust the pH of the solution to 7.0 with 1,11-undecanediamine, and stir for 0.5 hours. Then the temperature was raised to 180°C in stages, and the pressure in the reactor was kept at 1Mpa. After 2 hours of reaction, the water was drained and the pressure was lowered, and the pressure in the reactor was reduced to normal pressure within 0.5 hour. Raise the temperature to 210°C, evacuate until the pressure in the reactor is 20Pa, continue the reaction for 10 hours, cool down and discharge to obtain a semi-aromatic nylon PA11T product, the melting point of the polymer is 303°C, the relative viscosity is 1.61, and the tensile strength is 83MPa.

Embodiment 2

[0024] Add 16.6kg of terephthalic acid, 18.6kg of 1,11-undecanediamine and 52.8kg of water into the drum reactor, replace the air in the reactor with carbon dioxide, and then heat up to 160°C with a pressure of 0.7 MPa, adjust the pH of the solution to 7.5 with 1,11-undecanediamine, and stir for 60 minutes. Then the temperature was raised to 225° C., and the pressure in the reactor was kept at 2.5 MPa. After 2 hours of reaction, the water was drained and the pressure was lowered, and the pressure in the reactor was reduced to normal pressure within 1 hour. The temperature was raised to 245°C, the pressure in the reactor was evacuated to 80 Pa, the reaction was continued for 3 hours, the temperature was lowered and the material was discharged to obtain the semi-aromatic polyamide PA11T product. The melting point of the polymer is 303°C, the relative viscosity is 1.70, the tensile strength is 87MPa, and the notched impact strength is 4.5 kJ / m 2 .

Embodiment 3

[0026] Add 16.6kg of terephthalic acid, 18.6kg of 1,11-undecanediamine and 140.8kg of water into the drum reactor, replace the air in the reactor with nitrogen, then heat up to 200°C and keep the pressure 1.6 MPa, adjust the pH of the solution to 7.2 with 1,11-undecanediamine, and stir for 30 minutes. Then the temperature was raised to 240° C., and the pressure in the reactor was kept at 3Mpa. After 1 hour of reaction, the water was drained and the pressure was lowered, and the pressure in the reactor was reduced to normal pressure within 3 hours. Raise the temperature to 260°C, evacuate until the pressure in the reactor is 50Pa, continue the reaction for 2 hours, cool down and discharge to obtain a semi-aromatic nylon PA11T product, the melting point of the polymer is 303°C, the relative viscosity is 1.68, and the tensile strength is 85MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com