Patents

Literature

3395 results about "Carbon chain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Naphtholactams and lactones as bone morphogenetic protein active agents

InactiveUS6030967AHigh toxicological thresholdReduce riskBiocideOrganic chemistryActive agentCarbon chain

PCT No. PCT / JP97 / 02858 Sec. 371 Date Oct. 30, 1997 Sec. 102(e) Date Oct. 30, 1997 PCT Filed Aug. 19, 1997 PCT Pub. No. WO98 / 07705 PCT Pub. Date Feb. 26, 1998A compound of the formula: wherein Q is an optionally substituted carbon atom or N(O)p wherein p is 0 or 1; Y is an optionally substituted methylene group, S(O)q wherein q is an integer of 0 to 2, or an optionally substituted imino group; Z1 is a C1-3 alkylene group which may have an oxo group or a thioxo group and may contain etherified oxygen or sulfur within the carbon chain; Z2 is an optionally substituted C1-3 alkylene group; Ar is an optionally substituted carbocyclic group or an optionally substituted heterocyclic group; one of R1 and R2 is a hydrogen atom, a halogen atom, a hydroxyl group, an optionally substituted lower alkyl group, or an optionally substituted lower alkoxy group; the other is a halogen atom, a hydroxyl group, an optionally substituted lower alkyl group, or an optionally substituted lower alkoxy group; or R1 and R2 taken together with adjacent -c=c- form a ring; and ring A is a benzene ring which may be substituted in addition to R1 and R2; or a salt thereof.

Owner:TAKEDA PHARMA CO LTD

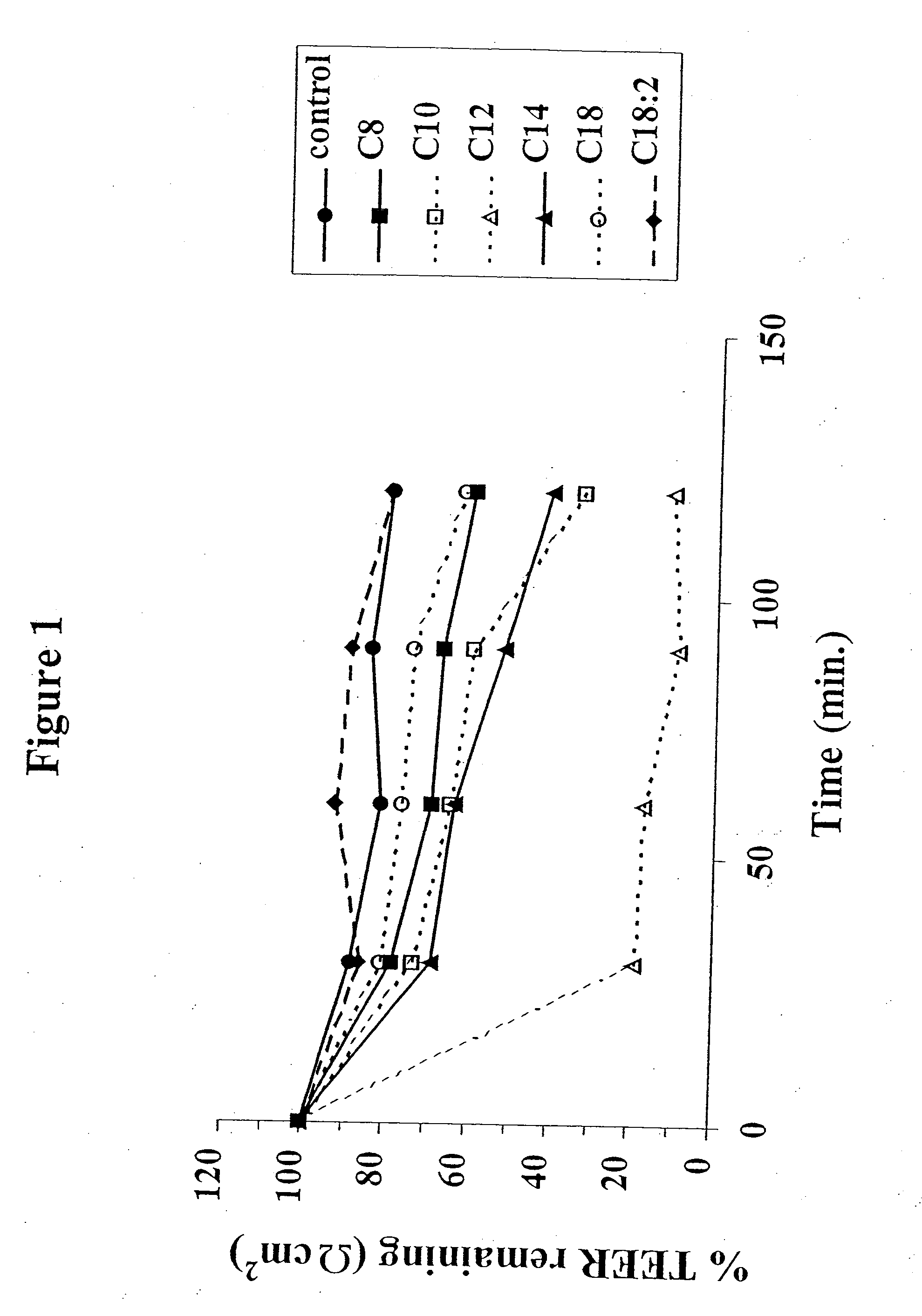

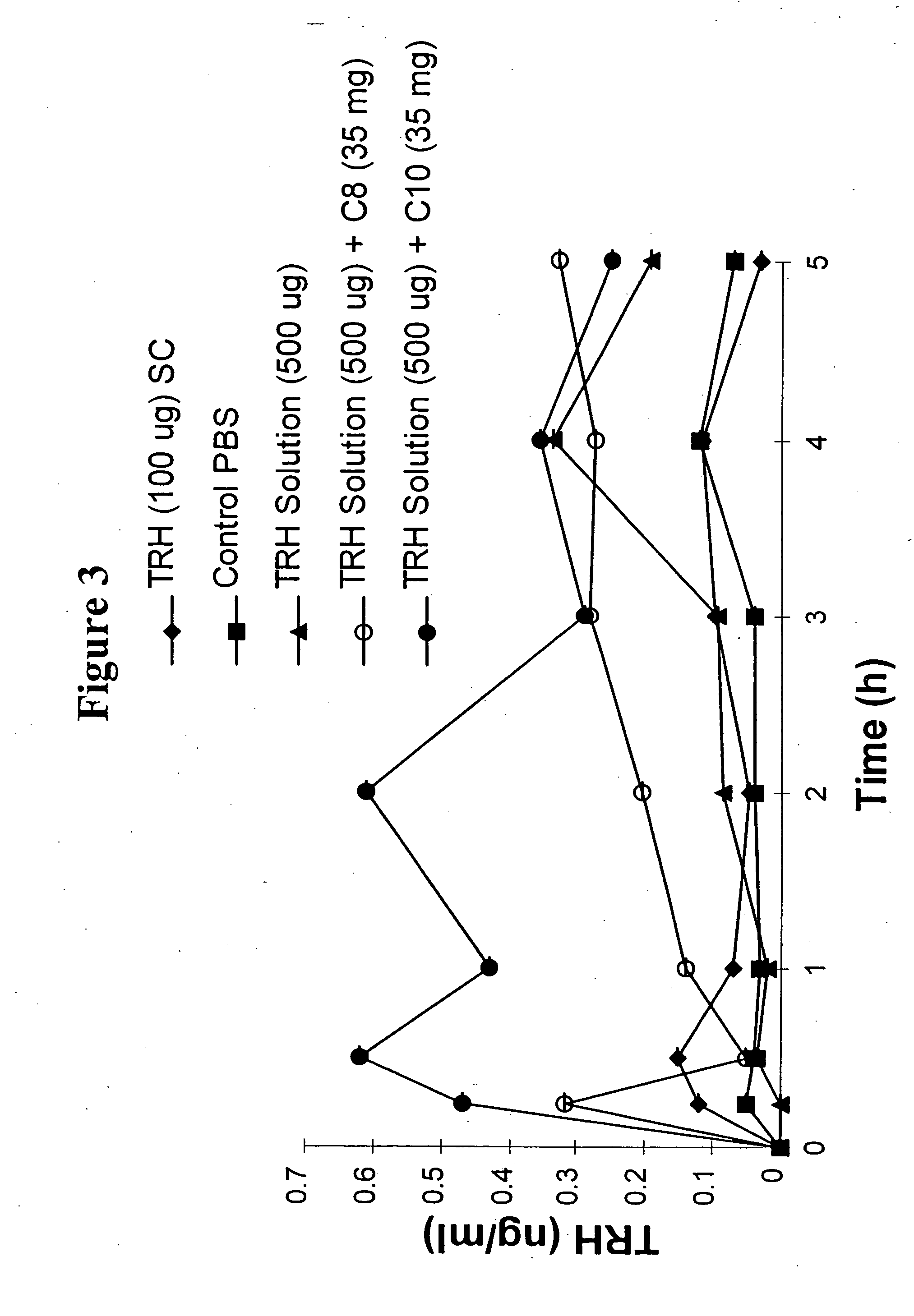

Solid oral dosage form containing an enhancer

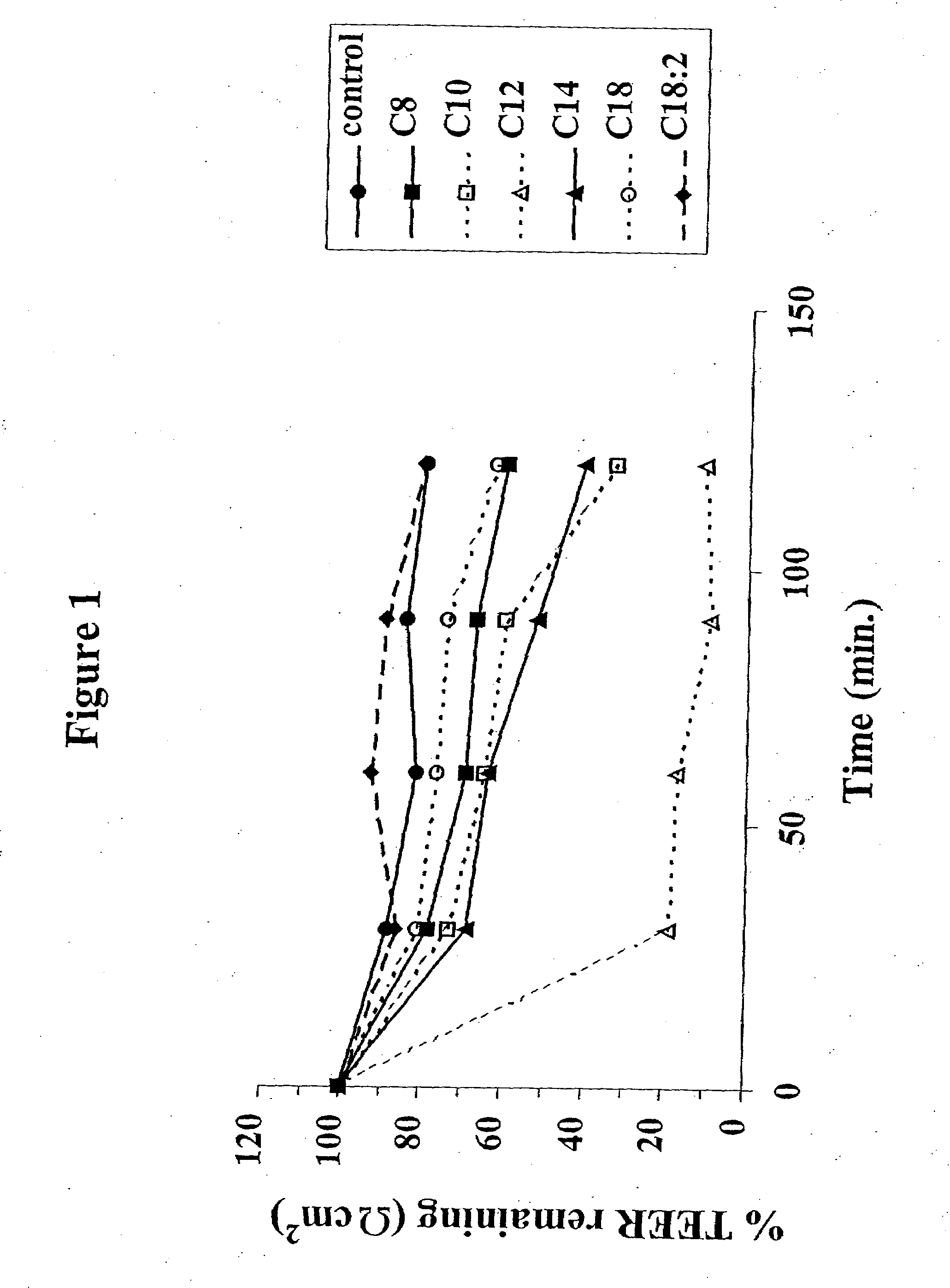

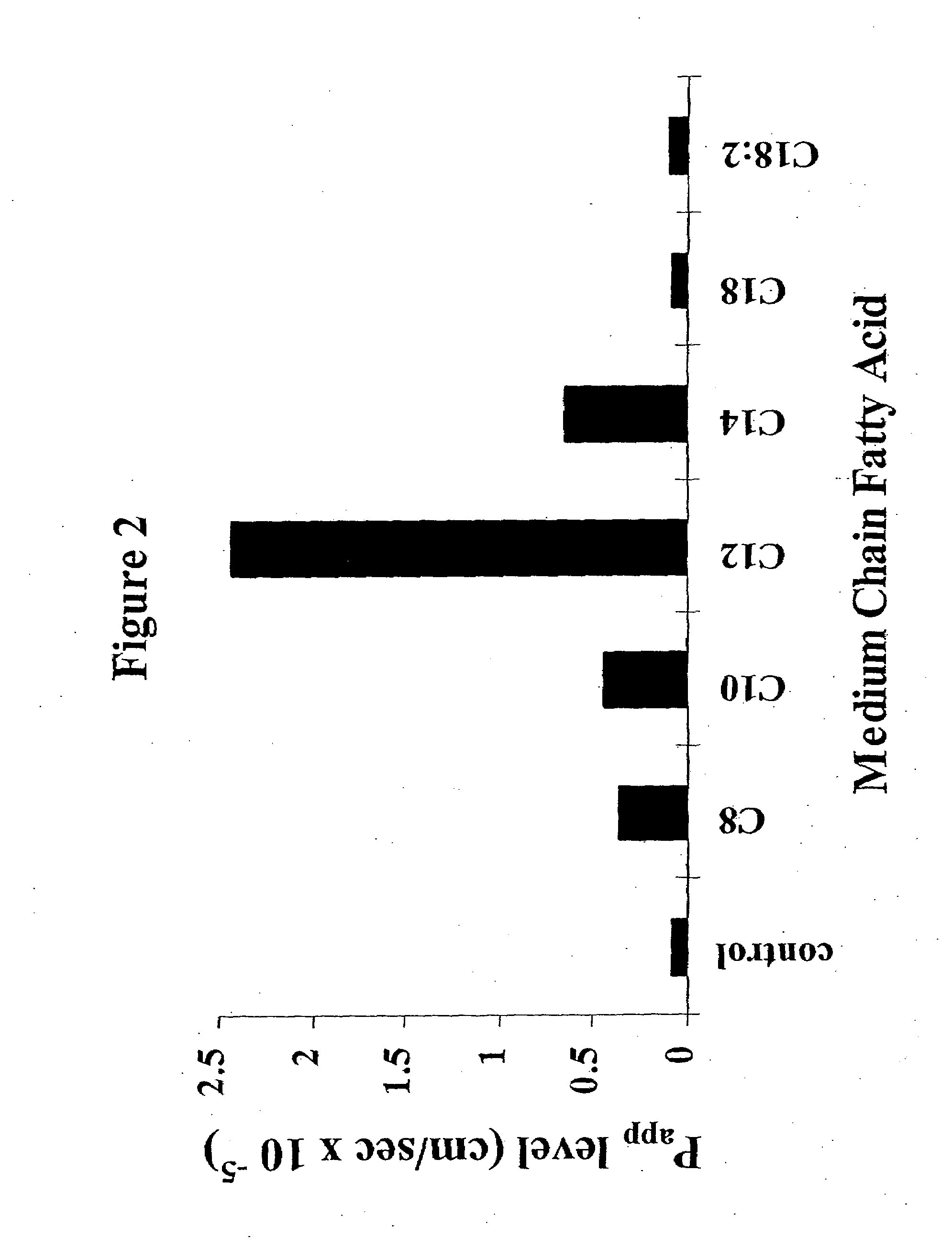

InactiveUS8119159B2Minimizes risk of local irritationImprove oral bioavailabilityBiocidePhosphorous compound active ingredientsDelayed Release Dosage FormCarbon chain

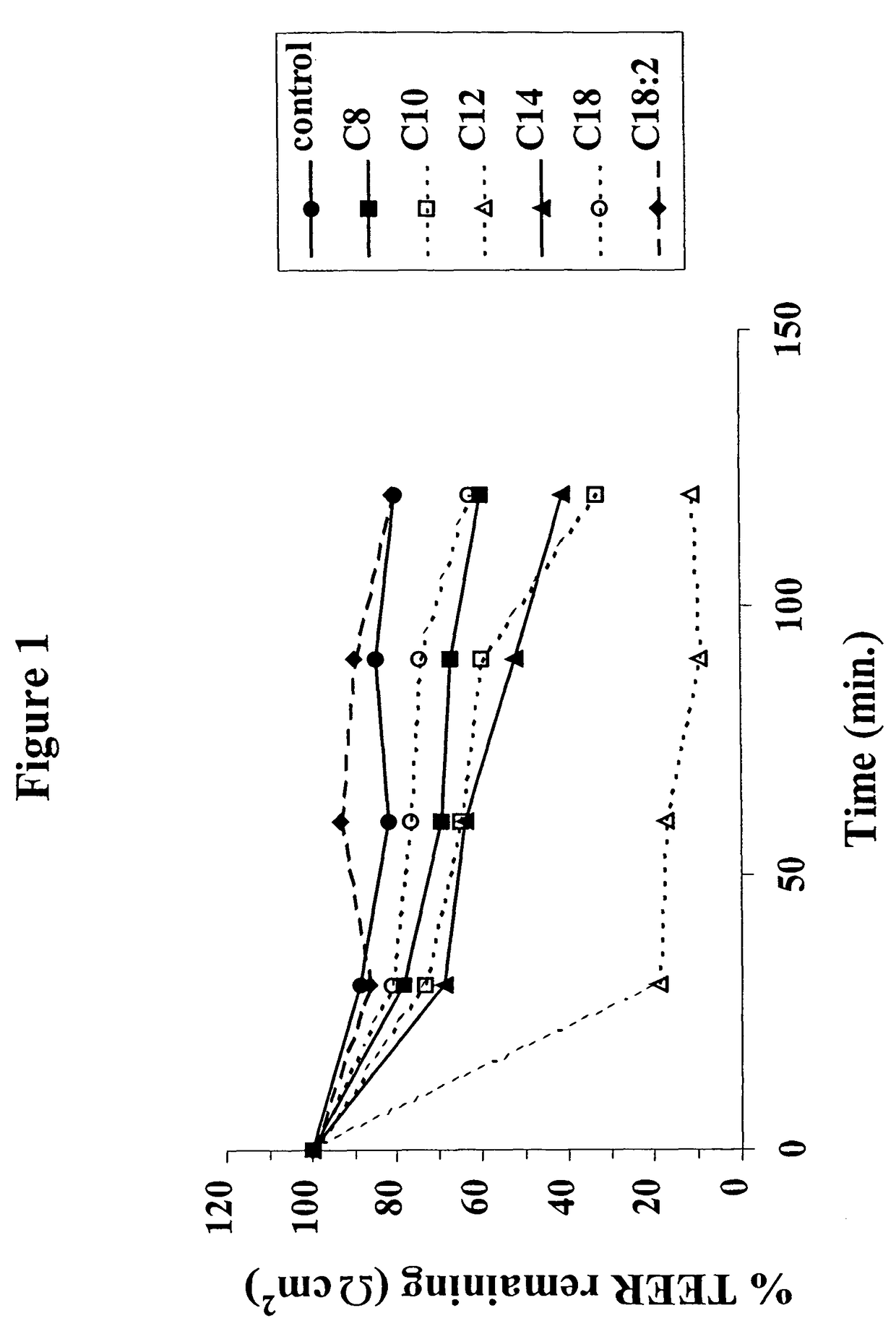

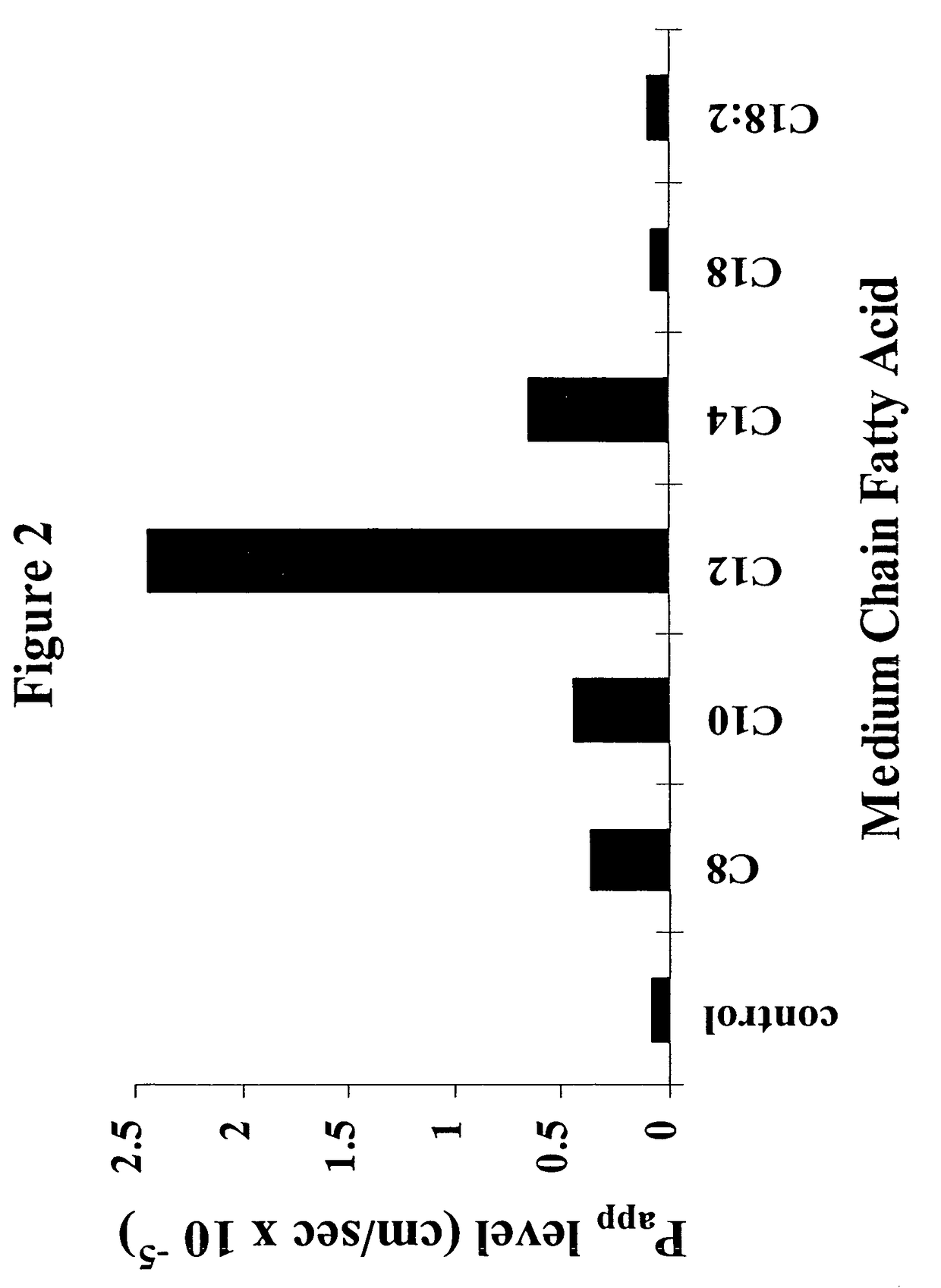

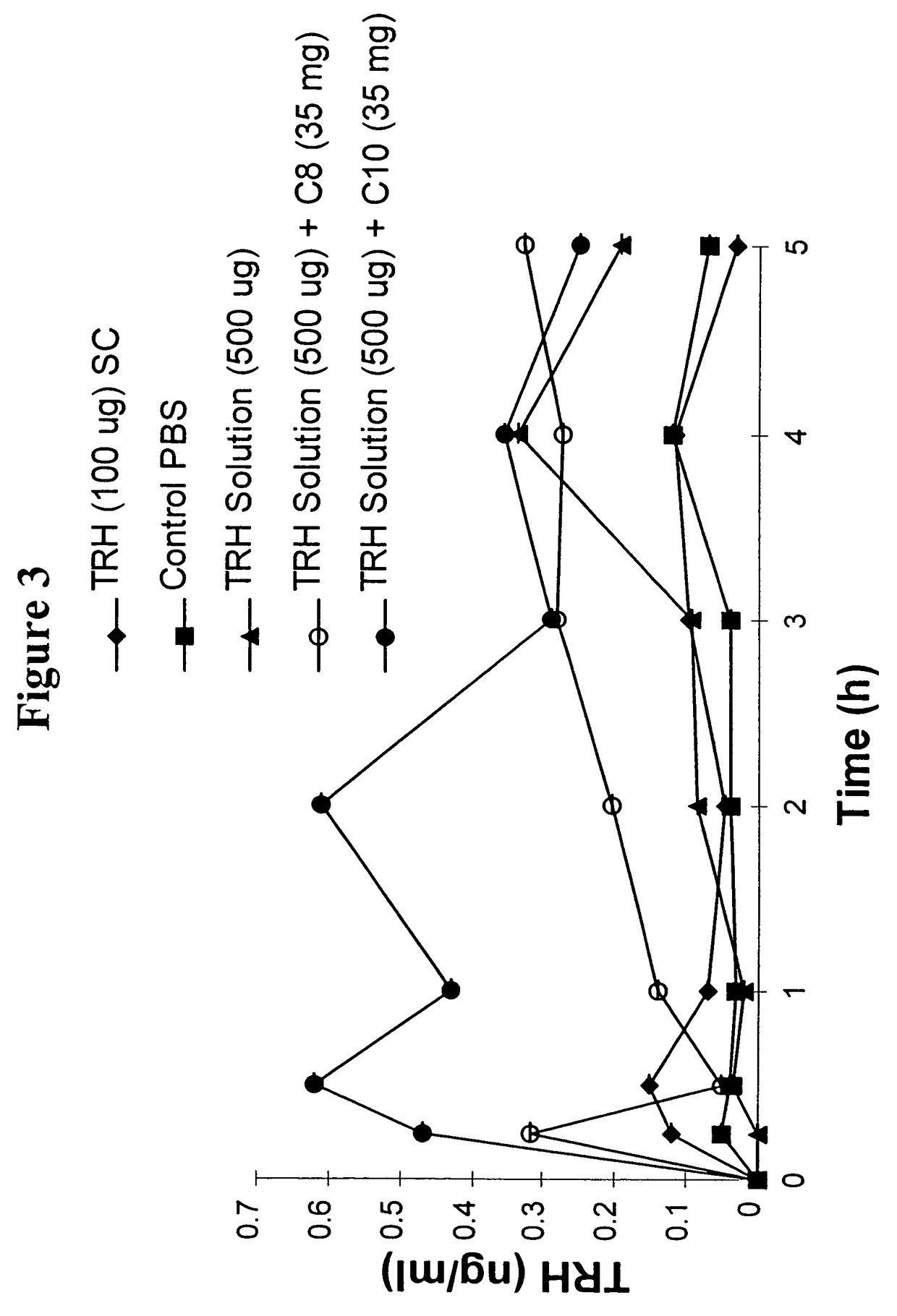

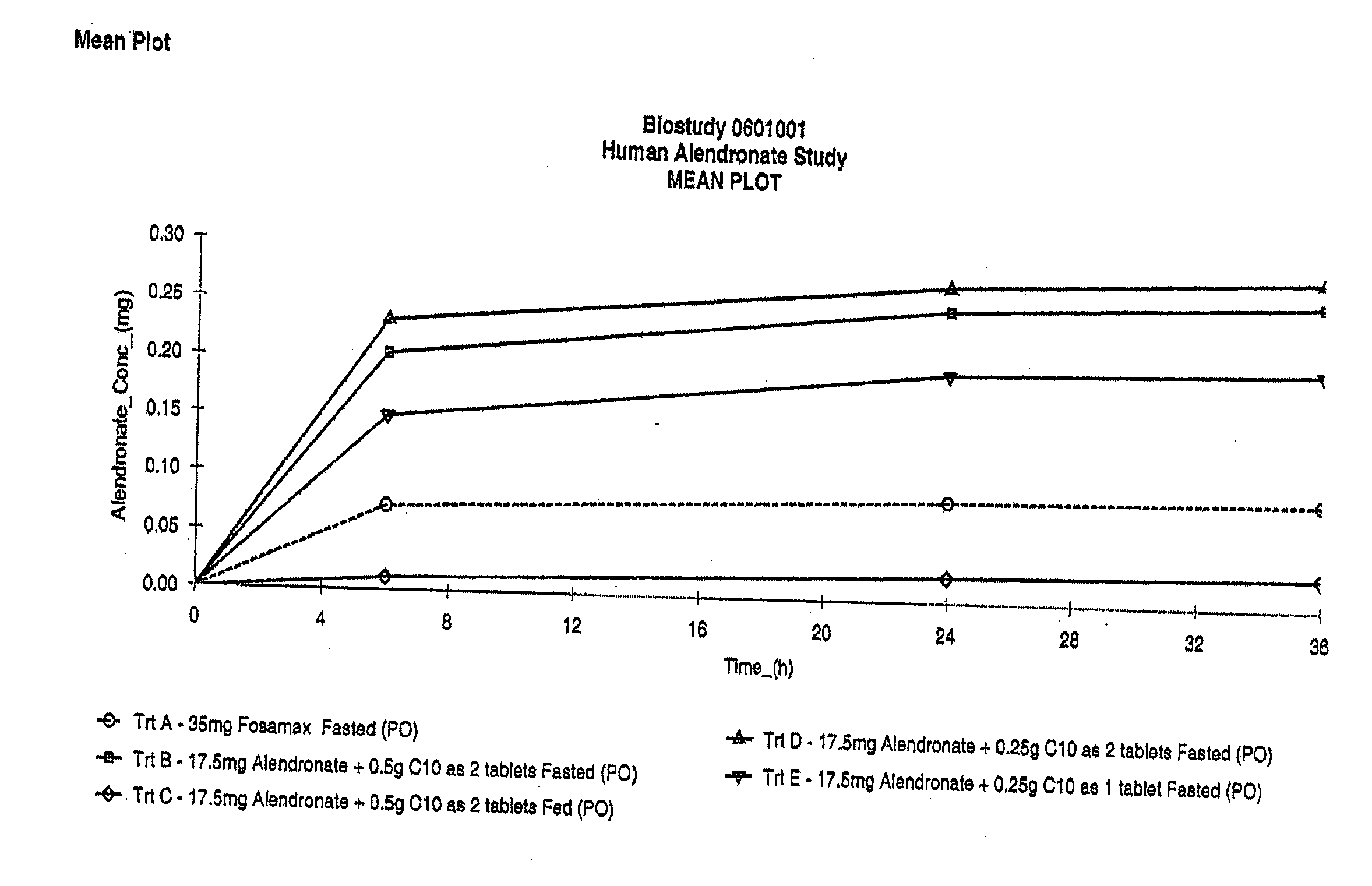

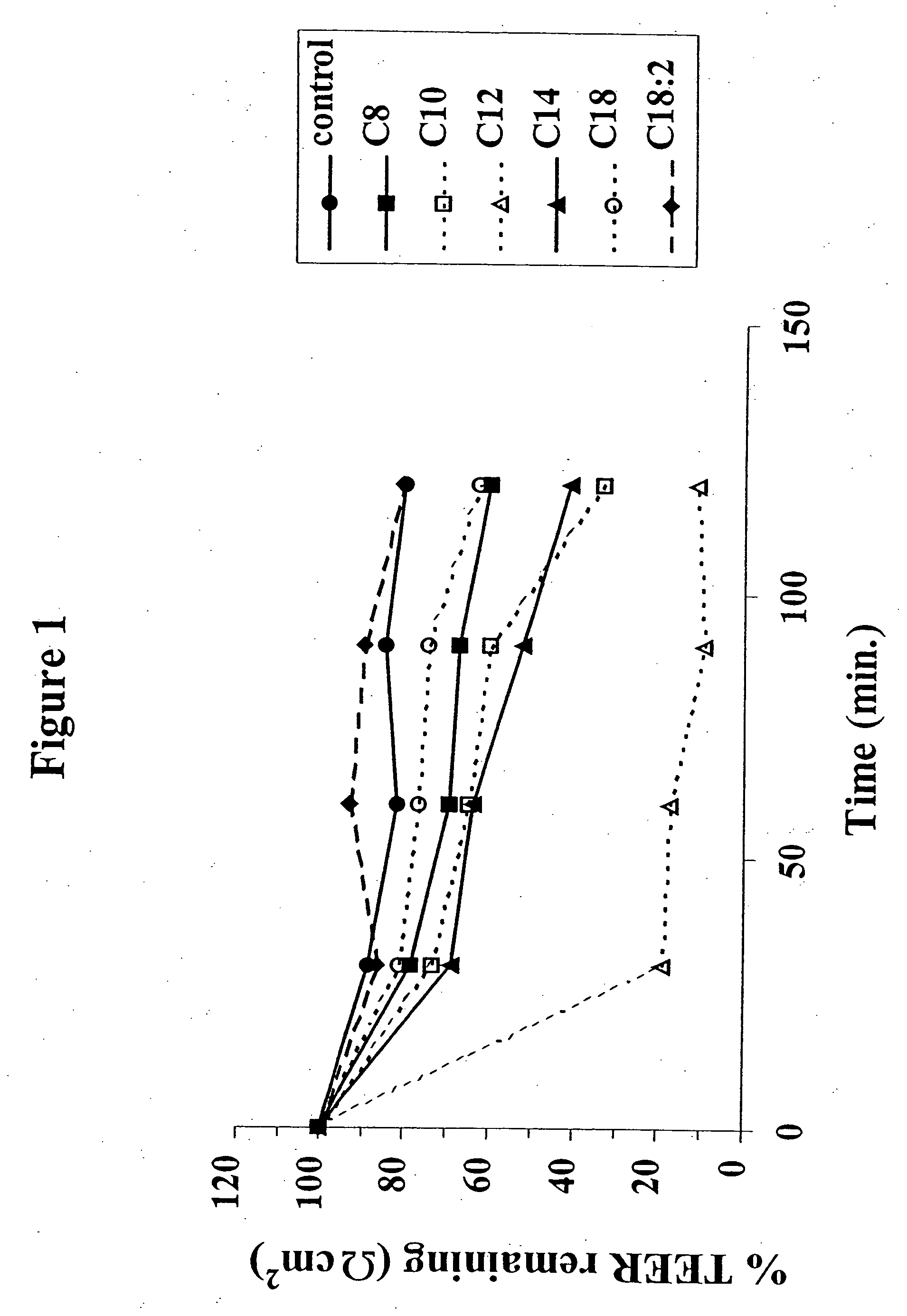

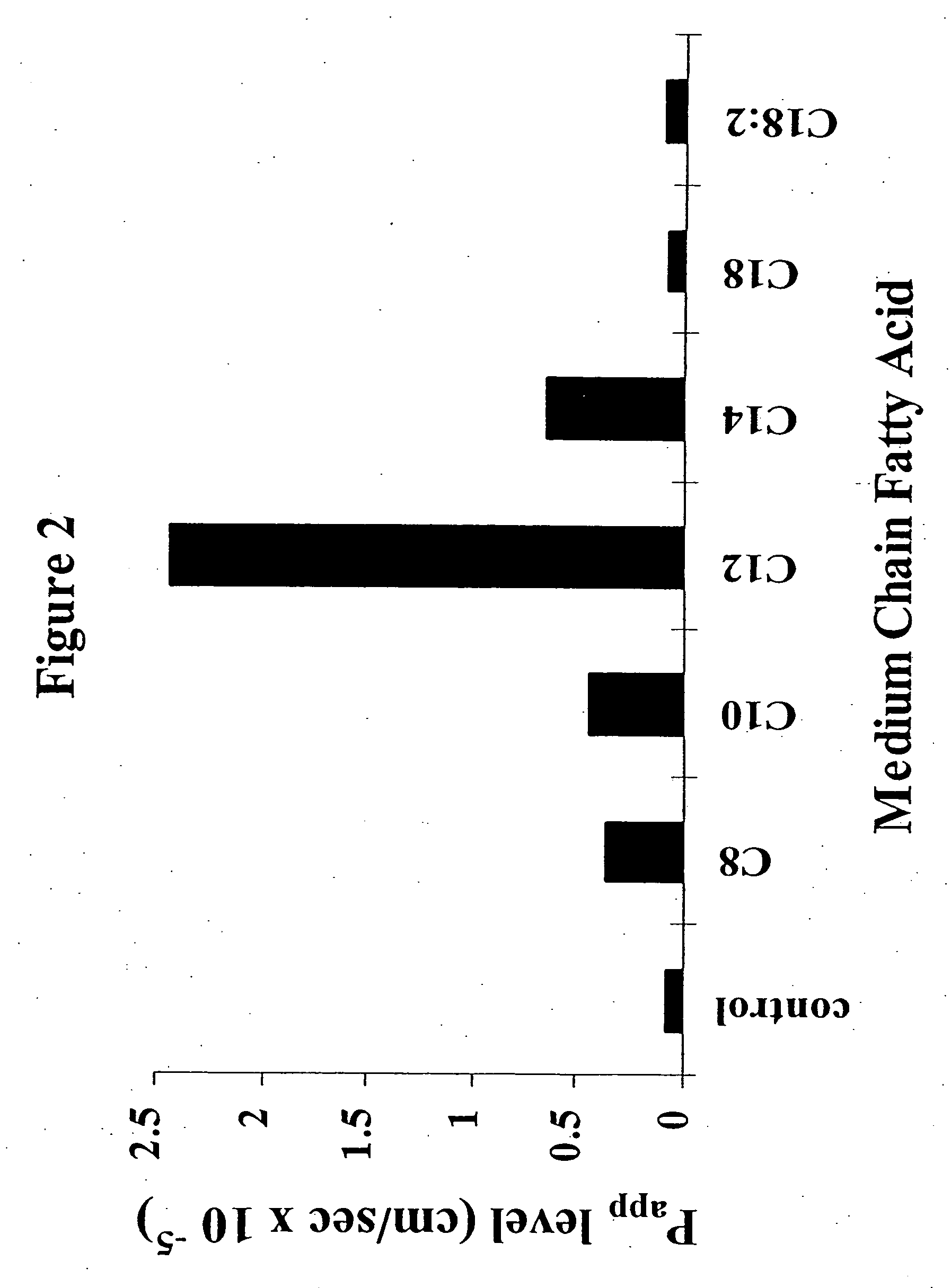

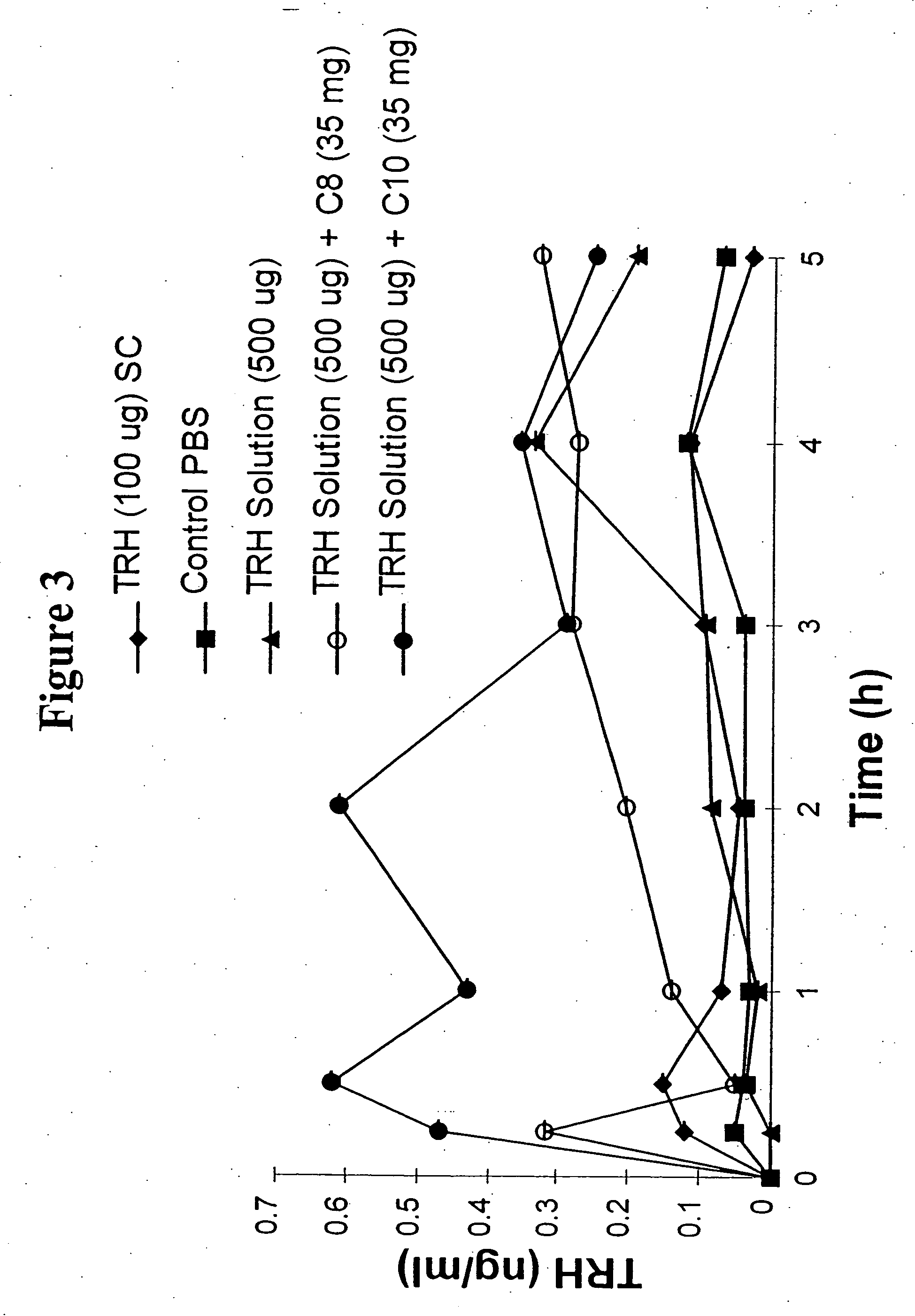

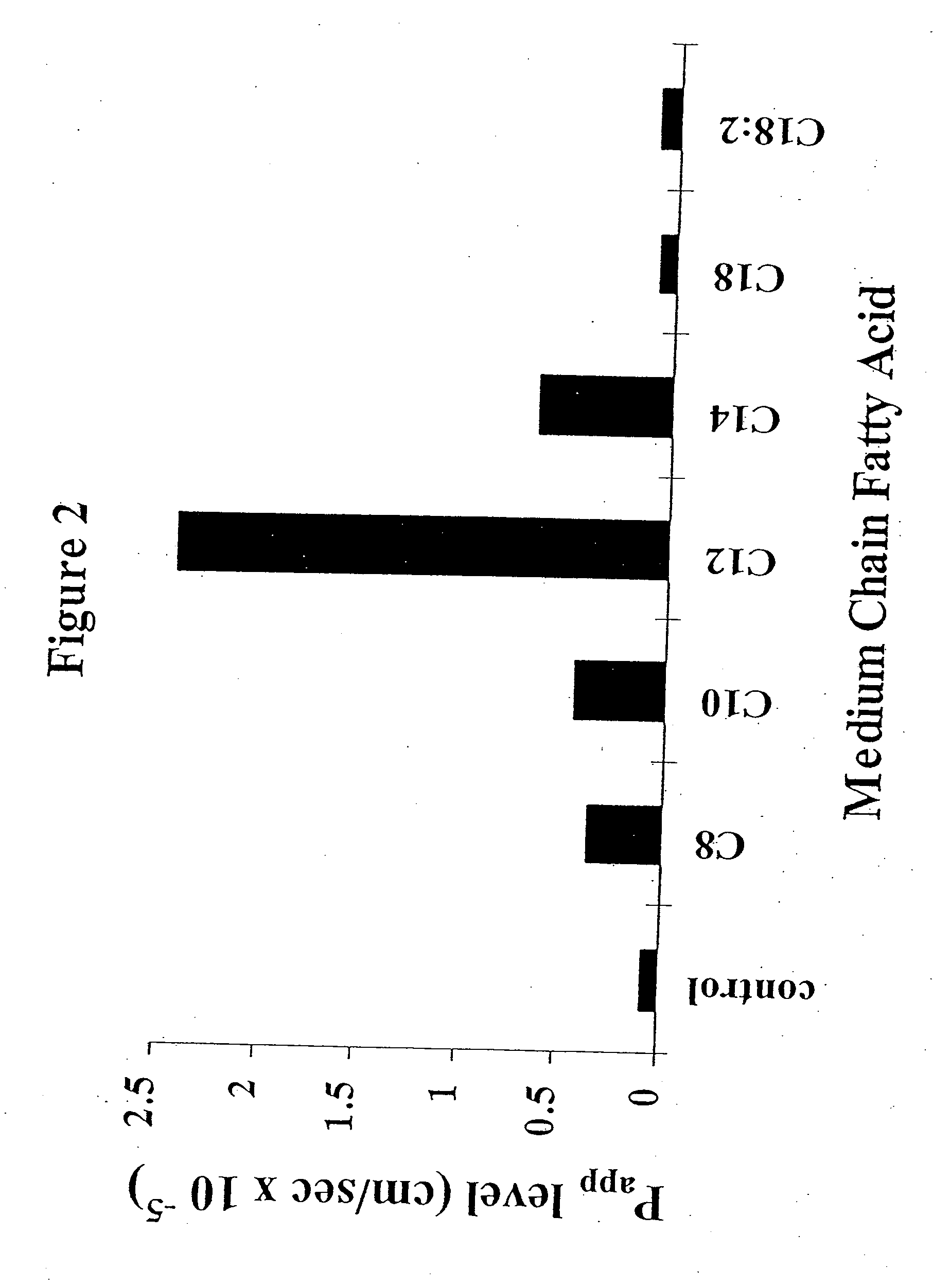

The invention relates to a pharmaceutical composition and oral dosage forms comprising a bisphosphonate in combination with an enhancer to promote absorption of the bisphosphonate at the GIT cell lining. The enhancer is a medium chain fatty acid or a medium chain fatty acid derivative having a carbon chain length of from 6 to 20 carbon atoms. Preferably, the solid oral dosage form is a controlled release dosage form such as a delayed release dosage form.

Owner:NOVO NORDISK AS

Solid Oral Dosage Form Containing an Enhancer

InactiveUS20070238707A1Improve oral bioavailabilityMinimizes risk of local irritationBiocideAntipyreticDelayed Release Dosage FormDiphosphonates

The invention relates to a pharmaceutical composition and oral dosage forms comprising a bisphosphonate in combination with an enhancer to enhance intestinal delivery of the bisphosphonate to the underlying circulation. Preferably, the enhancer is a medium chain fatty acid or a medium chain fatty acid derivative having a carbon chain length of from 6 to 20 carbon atoms, and the solid oral dosage form is a controlled release dosage form such as a delayed release dosage form.

Owner:NOVO NORDISK AS

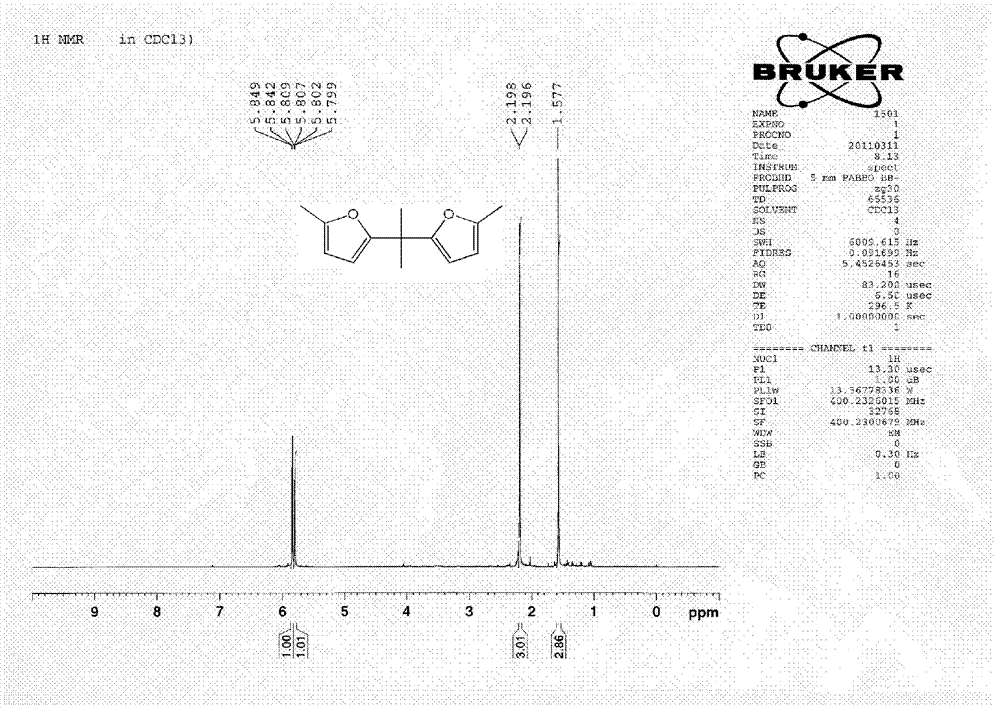

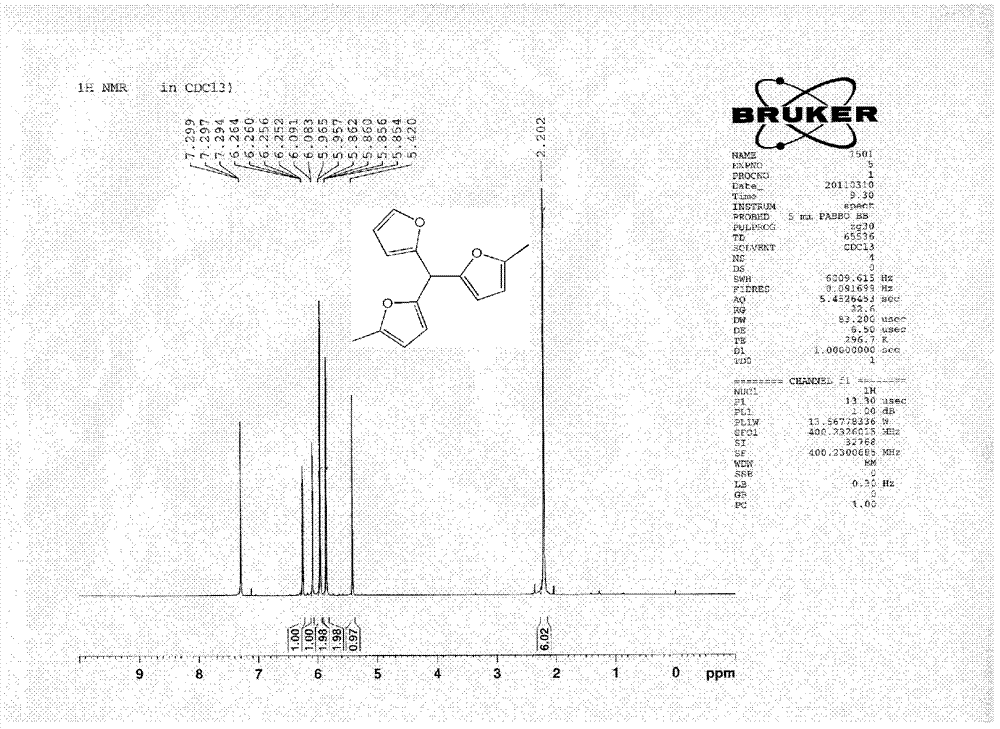

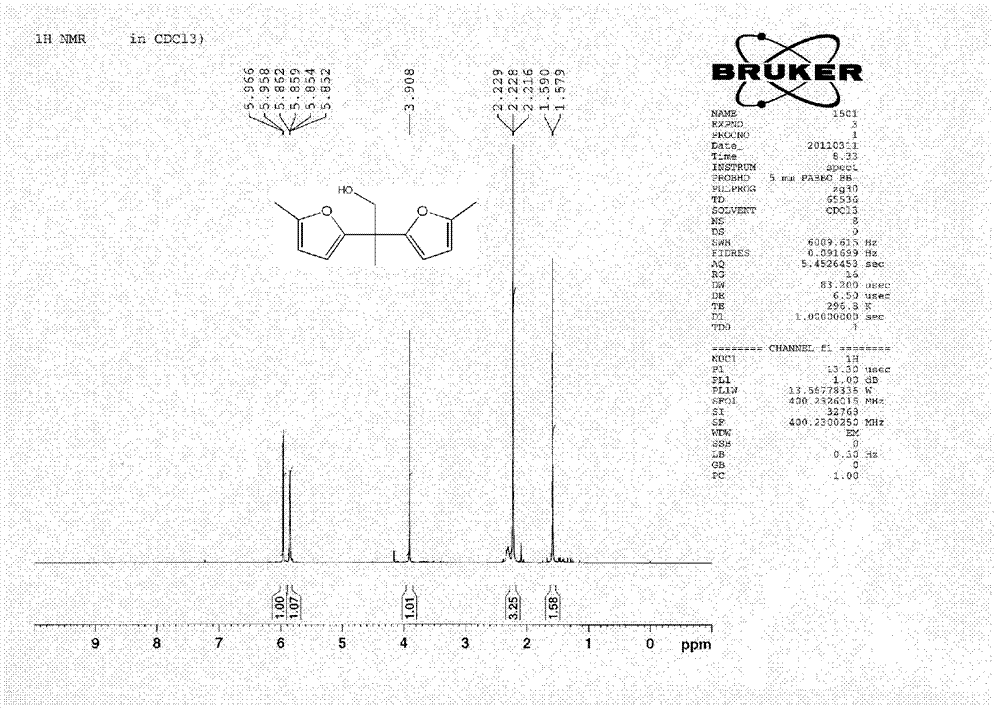

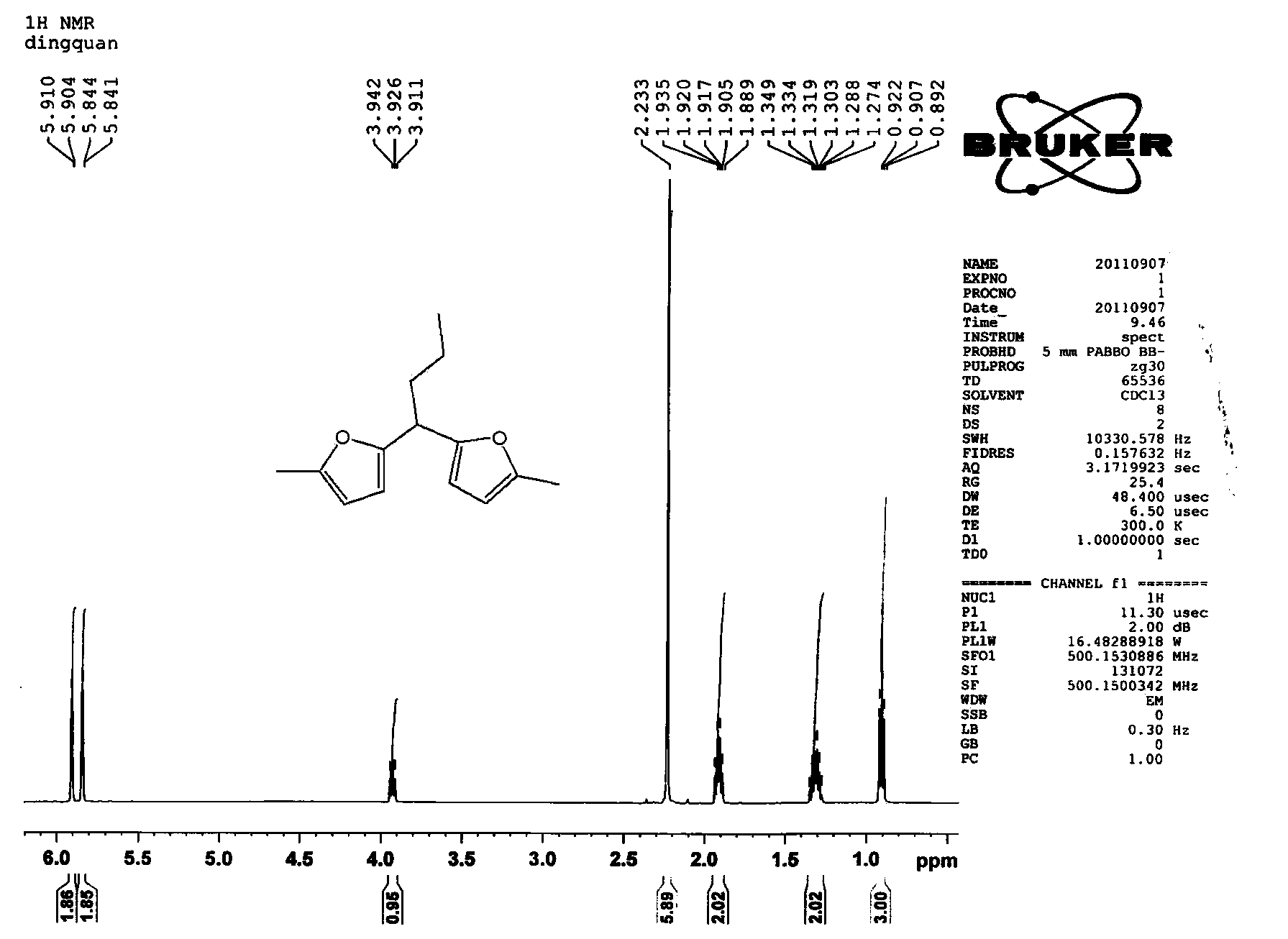

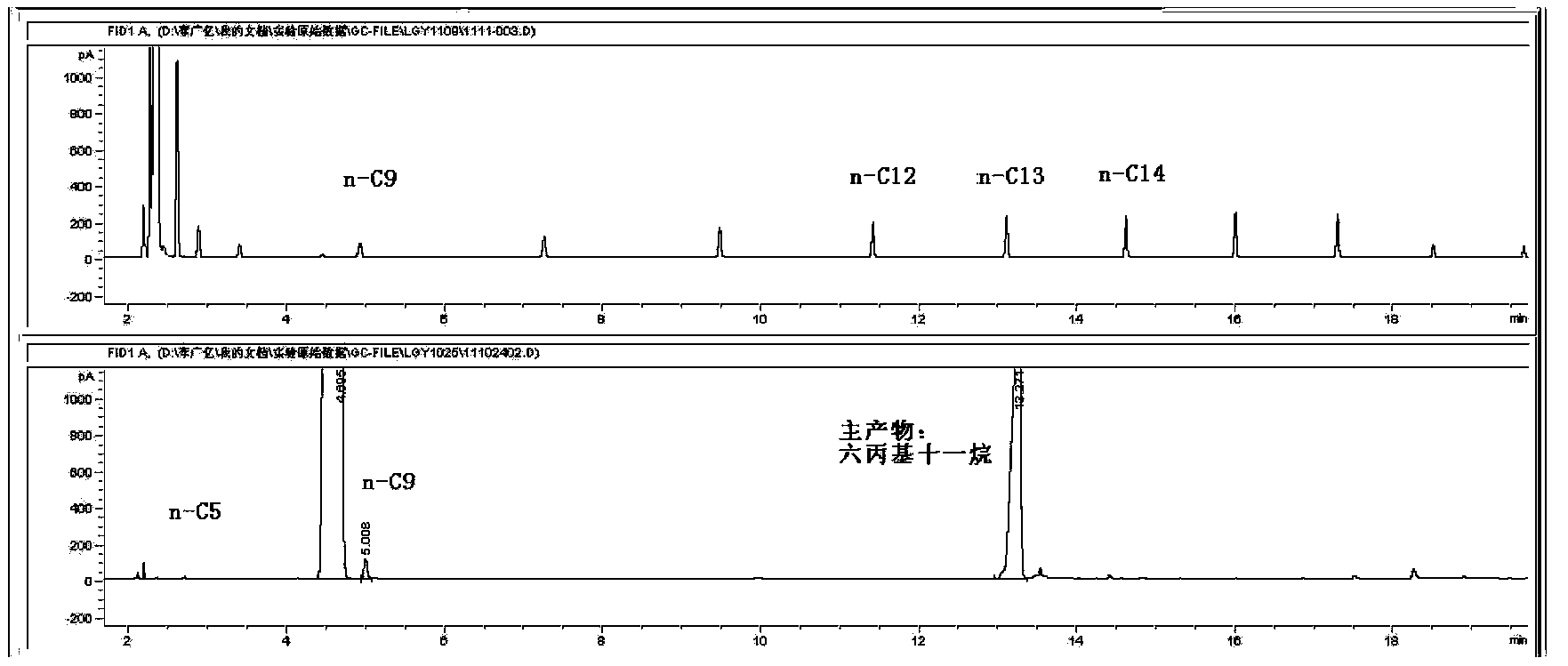

Preparation method of aviation kerosene or diesel

The present invention relates to a novel synthetic route of a liquid chain hydrocarbon fuel totally independent of fossil energy based on a lignocellulose raw material to obtain a platform compound. The method includes three parts: 1) preparing oxygen-containing organic compounds with carbon chain length of 8-16 through the acid-catalyzed alkylation reaction by taking lignocelluloses-based carbonyl-containing platform compounds and furan platform compounds as raw materials on a novel solid catalyst; 2) effectively removing carbon-carbon double bonds and carbon-oxygen double bonds to prepare saturated oxygen-containing organic compounds by hydrogenation of the alkylated product; and 3) conducting hydrodeoxygenation for the hydrogenated alkylation product by using a metal-solid acid bifunctional catalyst to obtain the biomass aviation kerosene or high grade diesel fuel with the carbon chain length of 8-16 and having a high energy density and stability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

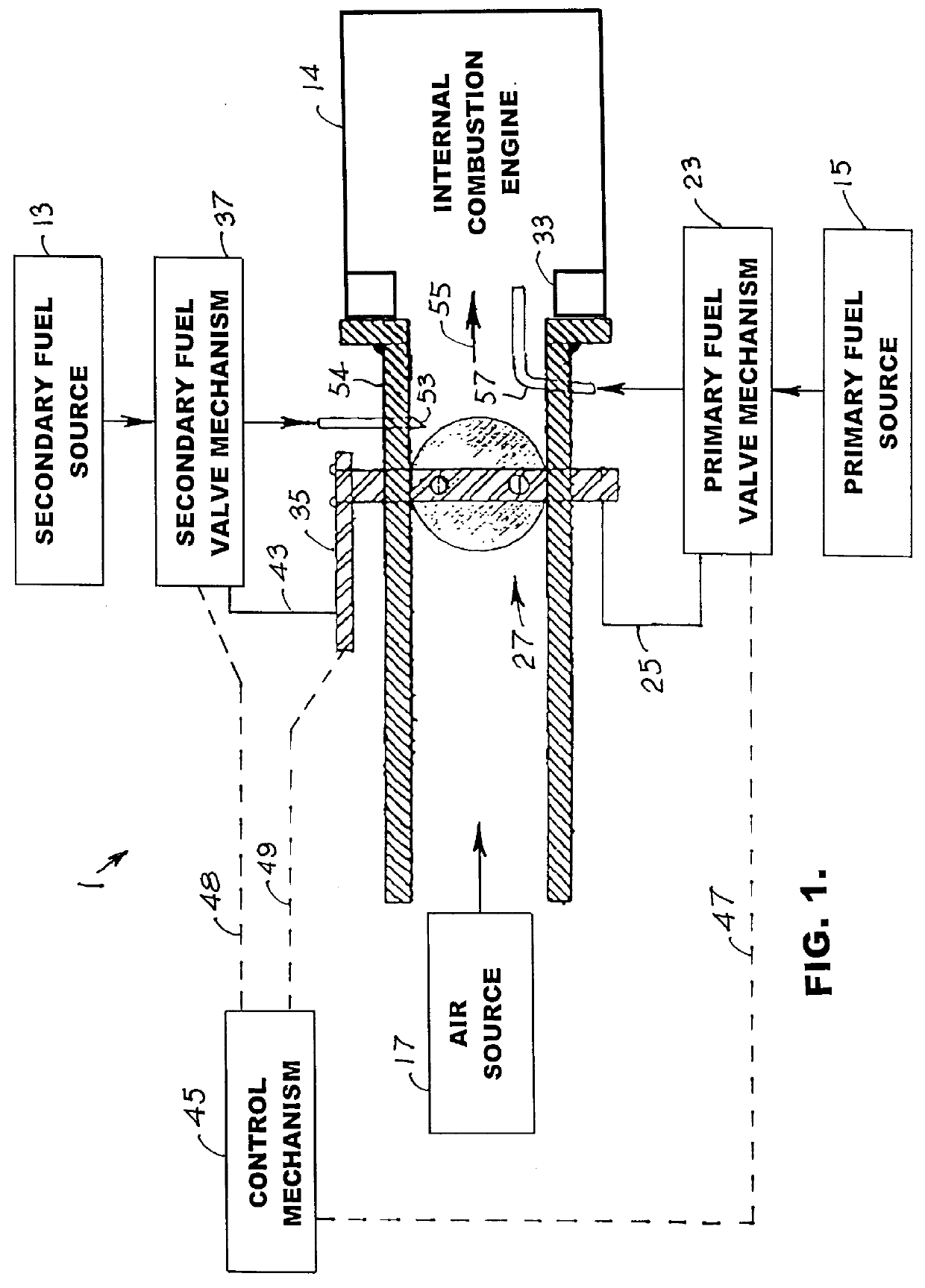

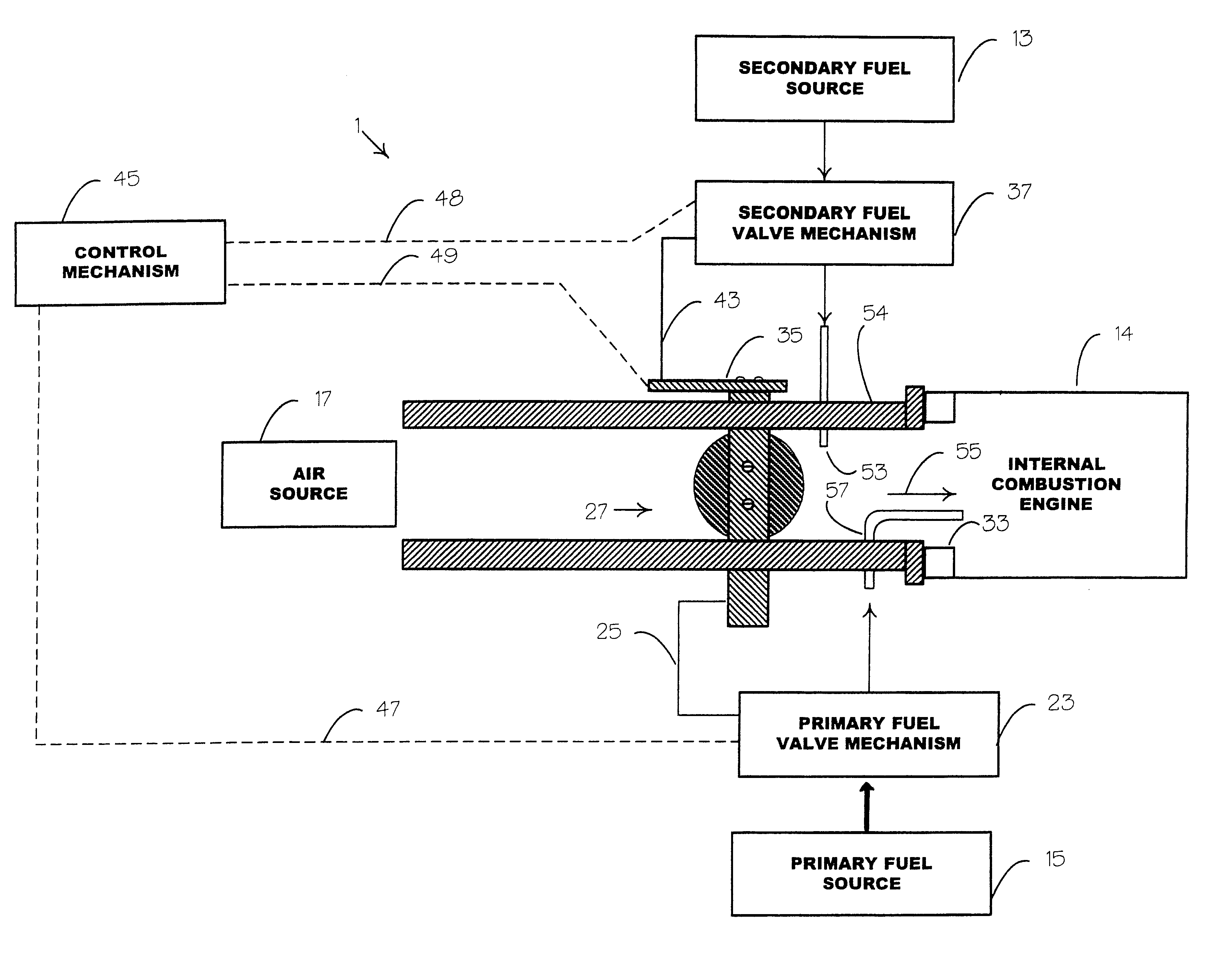

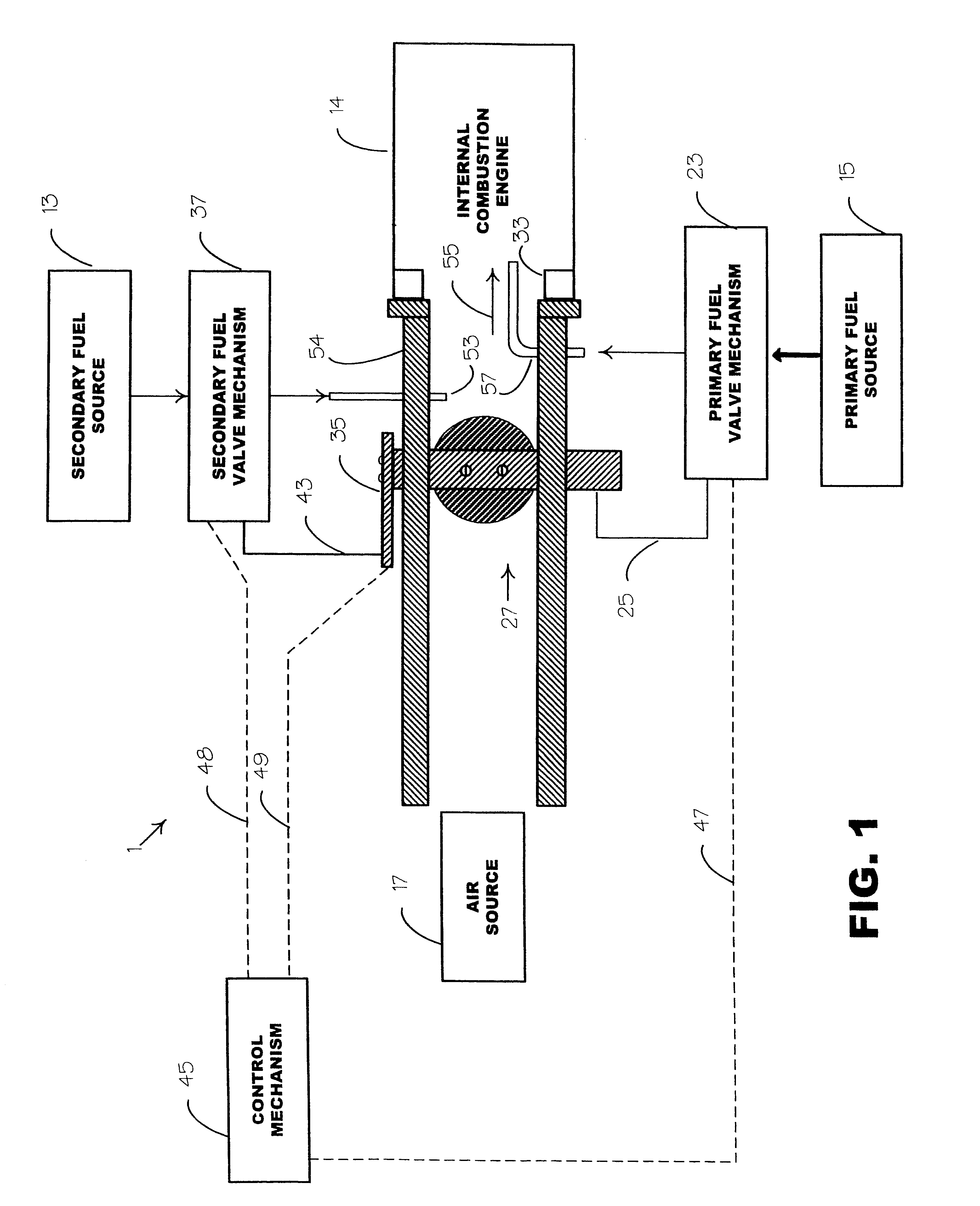

Internal combustion system using acetylene fuel

InactiveUS6076487AInternal combustion piston enginesNon-fuel substance addition to fuelCarbon chainInternal combustion engine

An environmentally clean dual fuel for an internal combustion engine, comprising acetylene as a primary fuel and a combustible fuel, such as one or more fluids selected from an alcohol such as ethanol, methanol or any other alcohol or alcohols from the group comprising C1-C20 carbon chains, ethers such as from the group comprising dimethyl ether, diethyl ether, methyl t-butyl ether, ethyl t-butyl ether, t-amyl methyl ether, di-isopropyl ether and the like, low-molecular-weight esters such as from the group comprising methyl formate, methyl acetate, ethyl acetate, methyl propionate, ethyl propionate and the like, or other suitable combustible fluid such as mineral spirits and the like, as a secondary fuel for operatively preventing early ignition and knock arising from the primary fuel. The dual fuel, internal combustion system, which generally utilizes a two-stage process for start-up and operation and can be operated with air- or liquid-cooling, is environmentally clean with hydrocarbon, CO, NOx, and SOx emissions substantially eliminated.

Owner:GOTEC

Internal combustion system adapted for use of a dual fuel composition including acetylene

InactiveUS6575147B2Easy to operateImprove performanceNon-fuel substance addition to fuelInternal combustion piston enginesCarbon chainMineral spirit

An internal combustion engine adapted to use an environmentally clean multi-fuel composition, comprising acetylene as a primary fuel and a combustible fuel, such as one or more fluids selected from an alcohol such as ethanol, methanol or any other alcohol or alcohols from the group comprising C1-C12 carbon chains, ethers such as from the group comprising dimethyl ether, diethyl ether, methyl t-butyl ether, ethyl t-butyl ether, t-amyl methyl ether, di-isopropyl ether and the like, low-molecular-weight esters such as from the group comprising methyl formate, methyl acetate, ethyl acetate, methyl propionate, ethyl propionate, ethyl malate, butyl malate, and the like, or other suitable combustible fluid such as mineral spirits and the like, as a secondary fuel for operatively preventing early ignition and knock arising from the primary fuel.

Owner:GOTEC INC

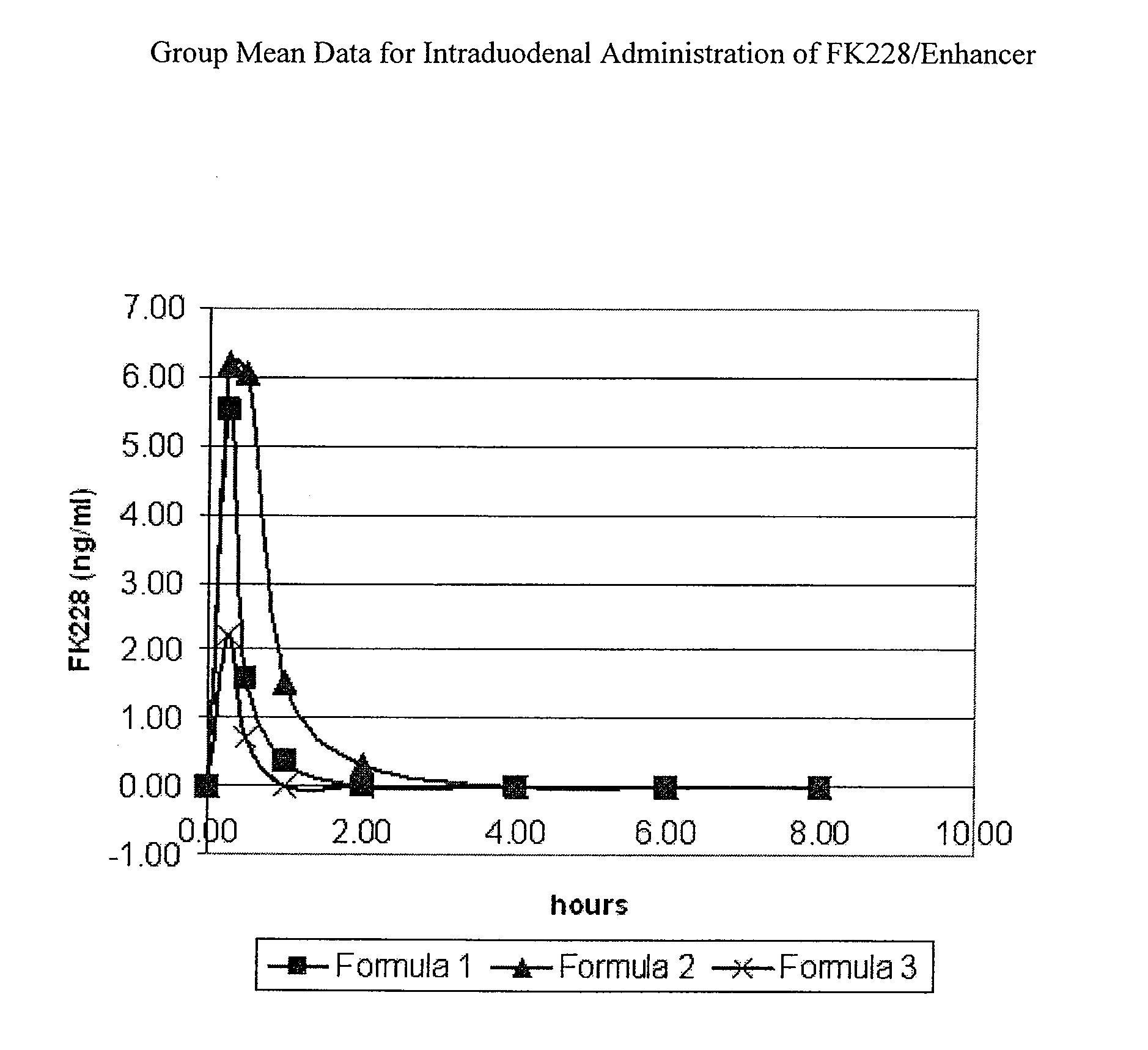

Solid oral dosage form containing an enhancer

InactiveUS20070148228A1BiocideCyclic peptide ingredientsDelayed Release Dosage FormPharmaceutical drug

The invention relates to a pharmaceutical composition and oral dosage forms comprising an HDAC inhibitor in combination with an enhancer to promote absorption of the HDAC inhibitor at the GIT cell lining. The enhancer is a medium chain fatty acid or a medium chain fatty acid derivative having a carbon chain length of from 6 to 20 carbon atoms. Preferably, the solid oral dosage form is a controlled release dosage form such as a delayed release dosage form.

Owner:MERRION RES I

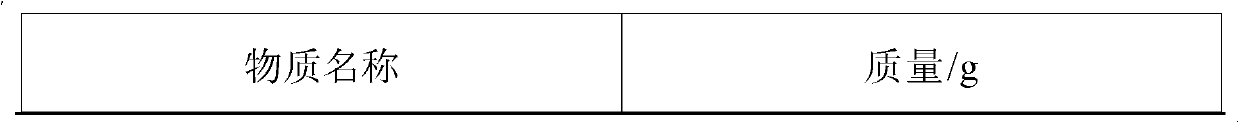

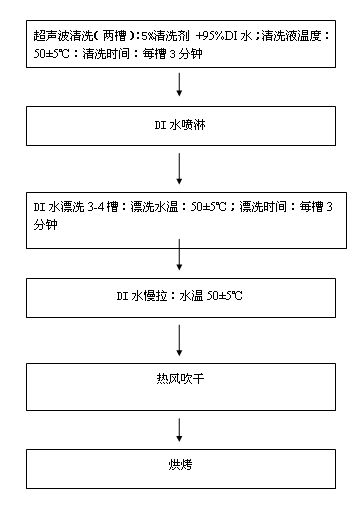

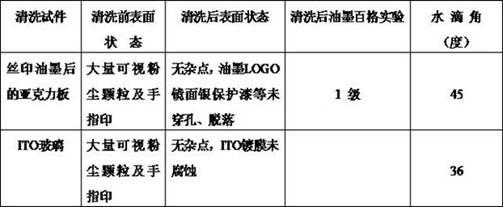

Anti-emulsification water-soluble metal washing agent

The invention relates to an anti-emulsification water-soluble metal washing agent. Every 100 parts of the anti-emulsification water-soluble metal washing agent include the following components according to parts by weight: 3-7 non-ionic surfactant, 3-7 bi-ion active agent, 1-5 chelator, 1-5 rust preventive, 5-10 inorganic builder and the balance water, wherein the non-ionic surfactant is any one of fatty amine polyoxypropylene ether, alkylphenol ether and fatty amine polyoxyethylene alkyl ether ammonium sulfate, the bi-ion active agent is any one of alkyl dimethylin acetic acid betaine, lauramidopropyl betaine and cocamidopropyl betaine, the chelator is any one of sodium citrate, ethylenediaminetetraacetic acid tetrasodium salt and nitrilotriacetic acid sodium salt, the rust preventive is any one of sodium borate, sodium nitrite, sodium benzoate and long carbon chain carboxylic acid amine, and the inorganic builder is any one of trisodium phosphate, sodium metasillcate, sodium carbonate, sodium bicarbonate and sodium hydroxide. The anti-emulsification water-soluble metal washing agent has the advantage of higher cleaning capacity and reutilization capacity.

Owner:NANJING KERUN LUBRICANTS

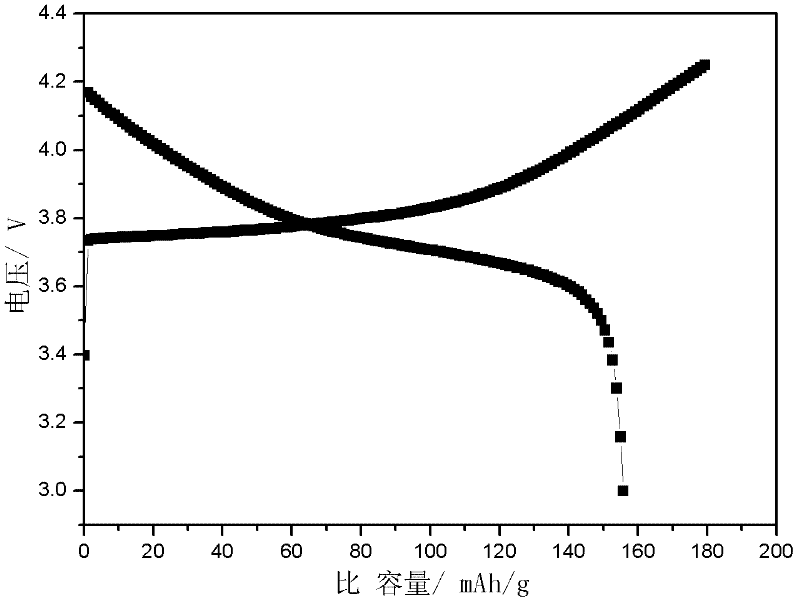

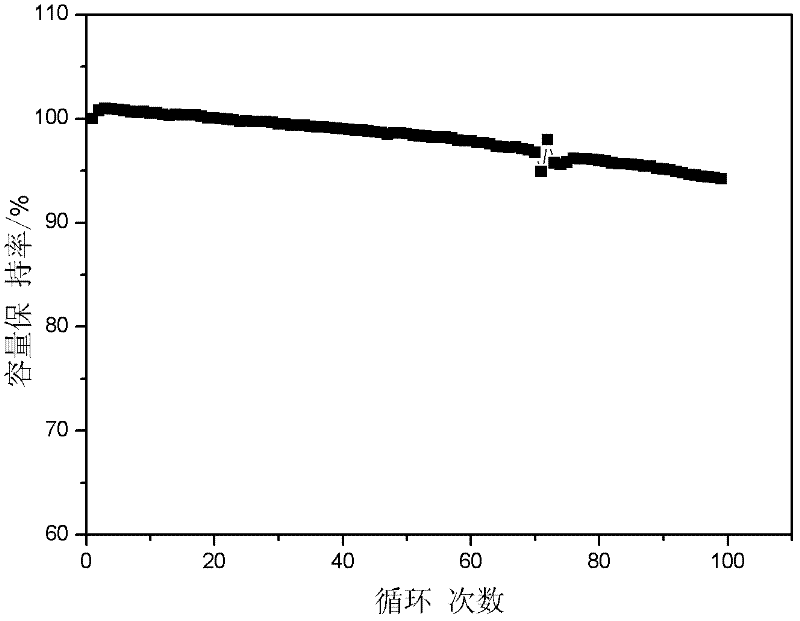

Preparation method of lithium ion battery ternary cathode material

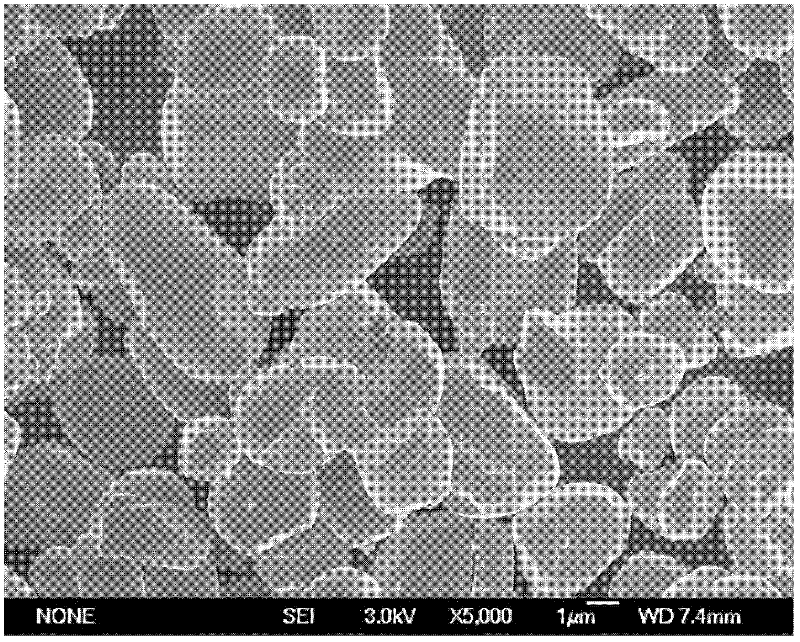

The invention discloses a preparation method of a lithium ion battery ternary cathode material. According to the preparation method, full grinding is performed through a colloid mill to improve the reactivity of a precursor and a lithium salt and the uniformity of a mixed material; and a carbon chain organic additive is added in the process of grinding to improve the viscosity of a sizing material, inhibit raw material segregation in the process of drying, quickly balance the temperature of each part of a system in the process of high-temperature reaction and inhibit agglomeration among particles, so that a uniform-appearance and regular mono-crystal ternary cathode material is obtained. Meanwhile, the ternary cathode material is doped and subjected to surface coating modification, so that the structure of the material is stabilized, the side reaction between the material and electrolyte is inhibited, and the high-temperature cycle performance of the material is improved.

Owner:PULEAD TAIAN TECH IND

Solid Oral Dosage Form Containing an Enhancer

The invention relates to a pharmaceutical composition, particularly oral dosage forms, comprising a DAC inhibitor in combination with an enhancer to promote absorption of the DAC inhibitor at the GIT cell lining. The enhancer is a medium chain fatty acid or derivative thereof having a carbon chain length of from 6 to 20 carbon atoms. In certain embodiments, the solid oral dosage form is a controlled release dosage form such as a delayed release dosage form.

Owner:MERRION RES I

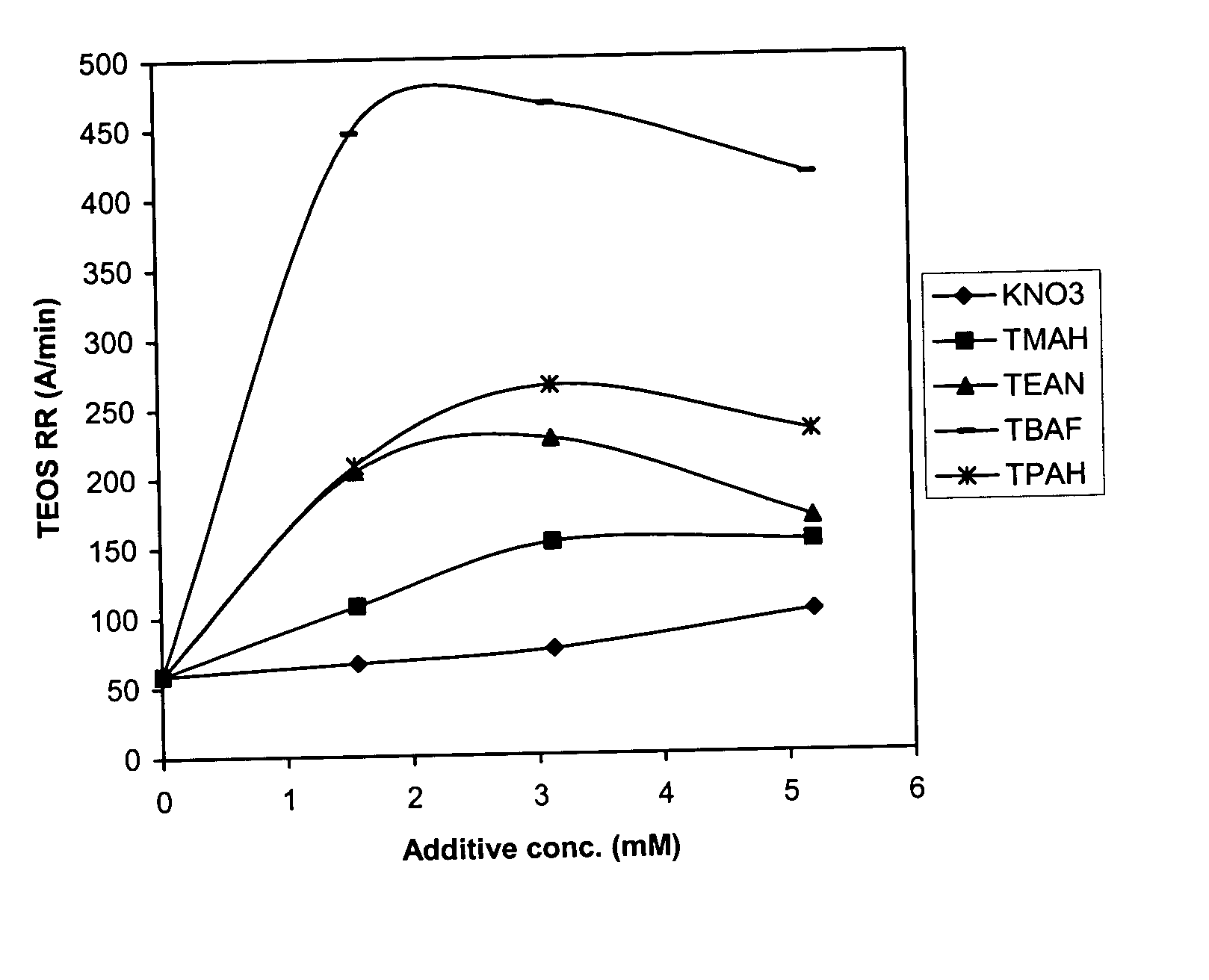

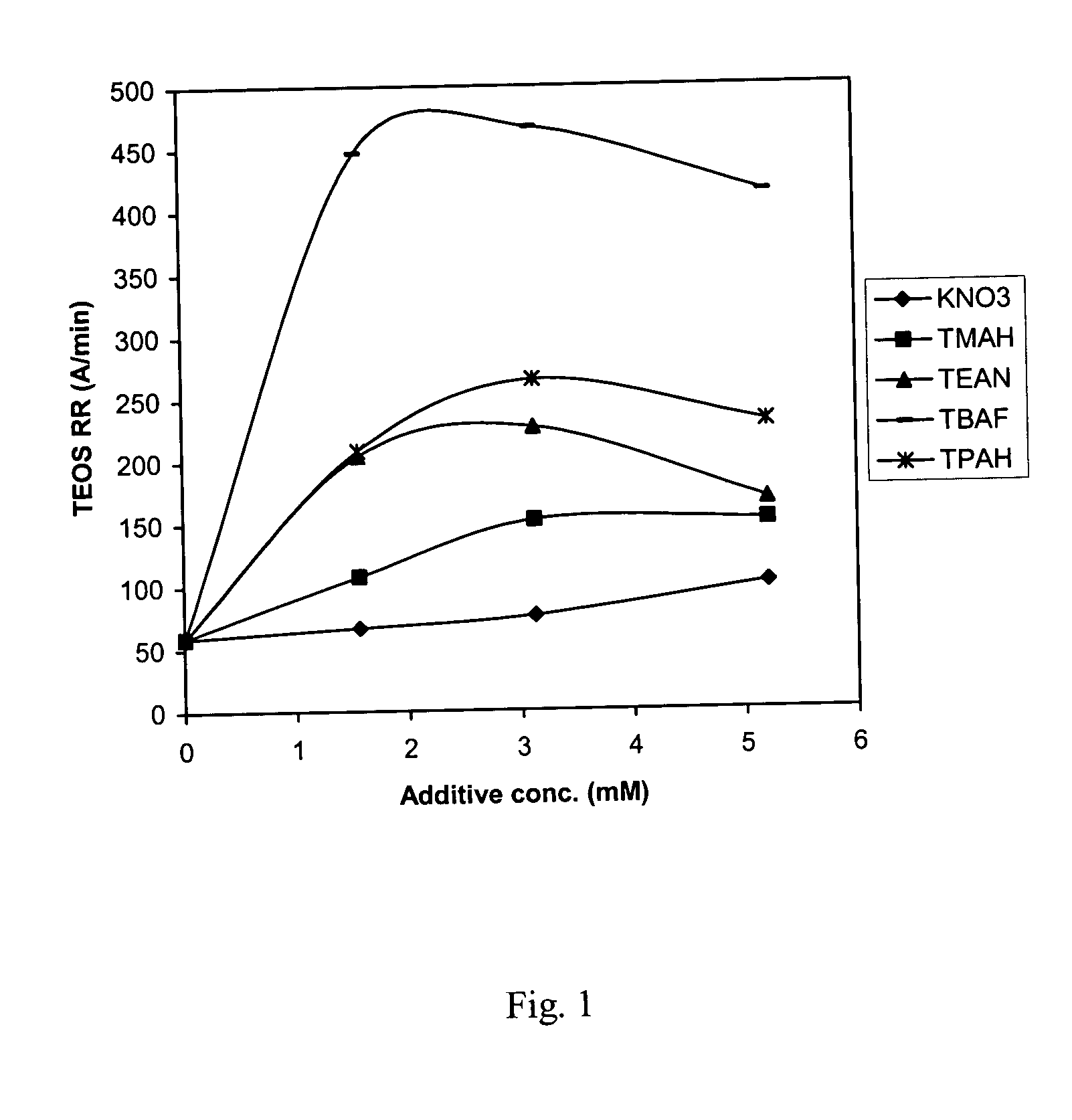

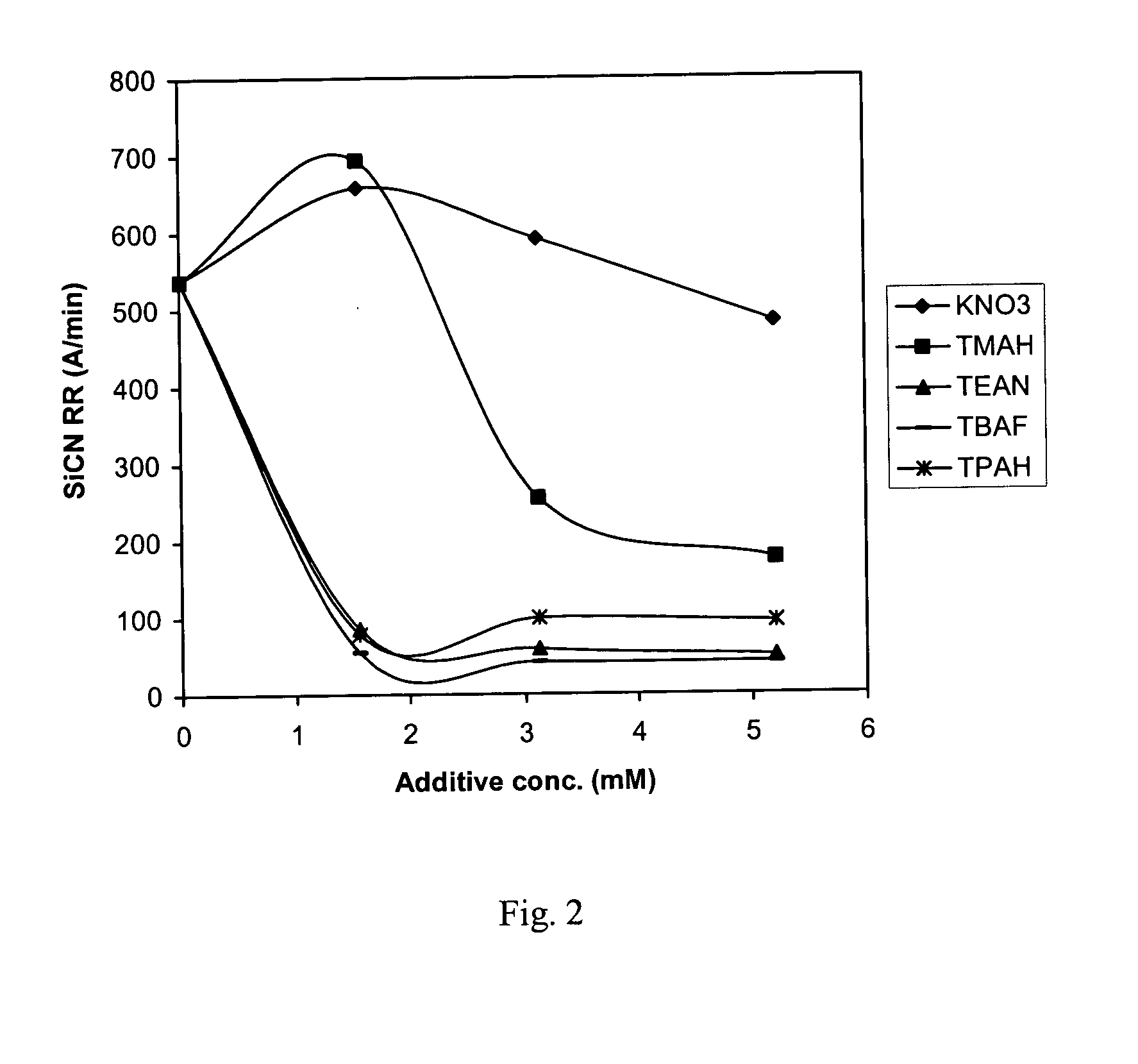

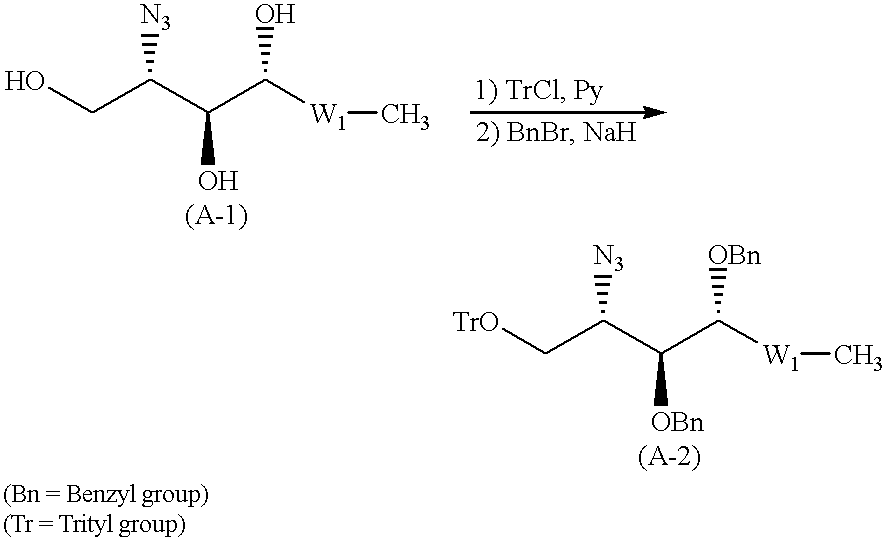

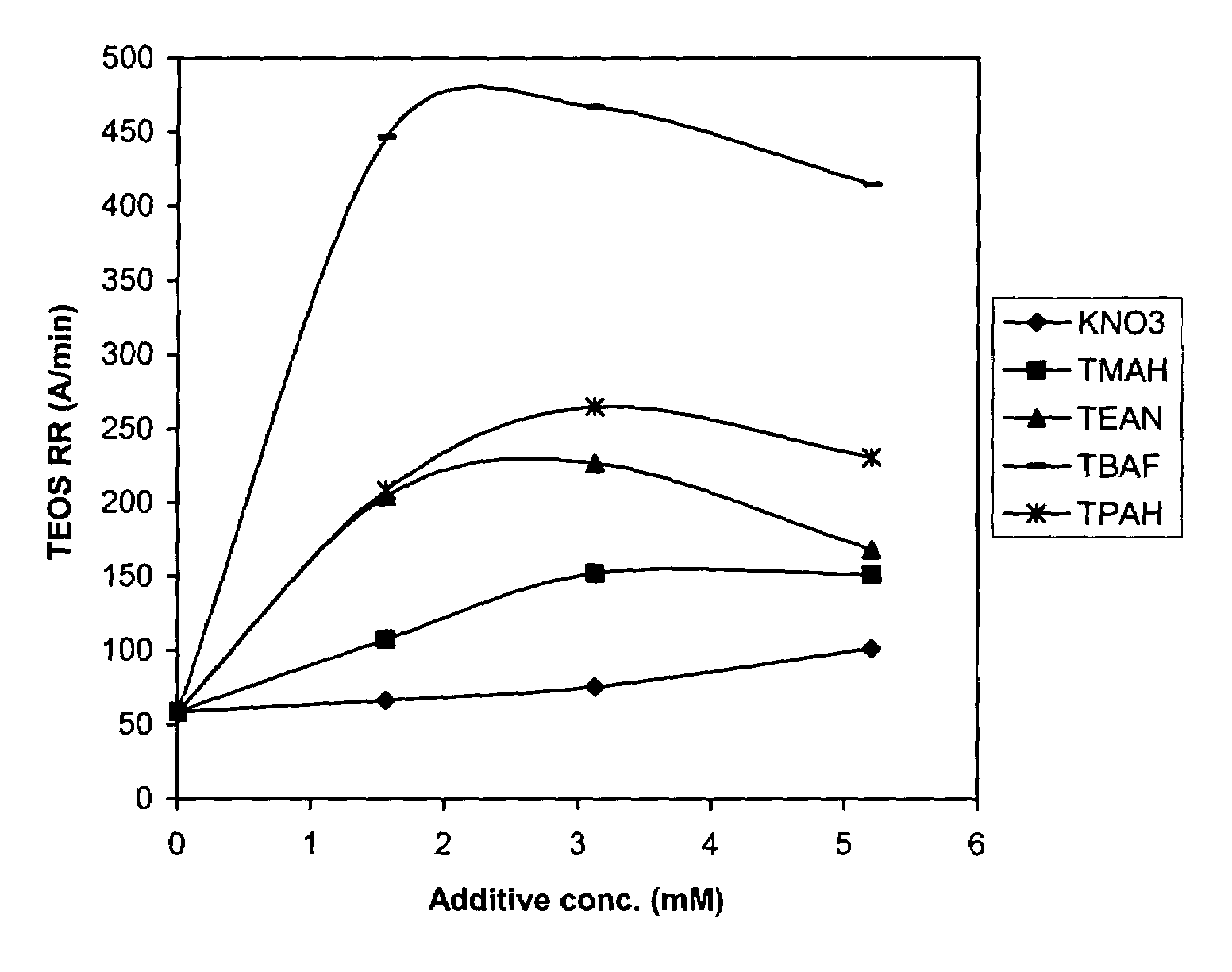

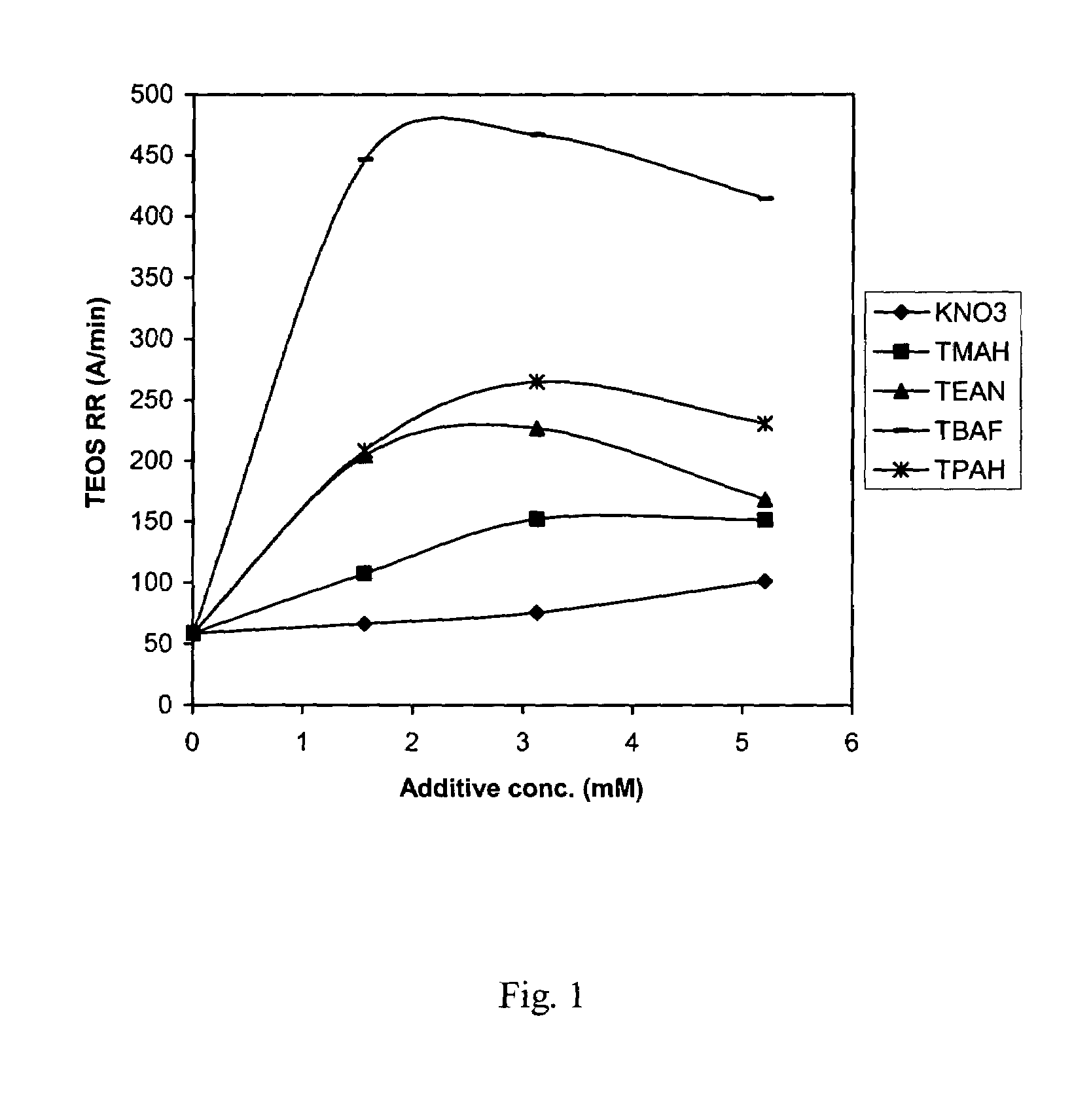

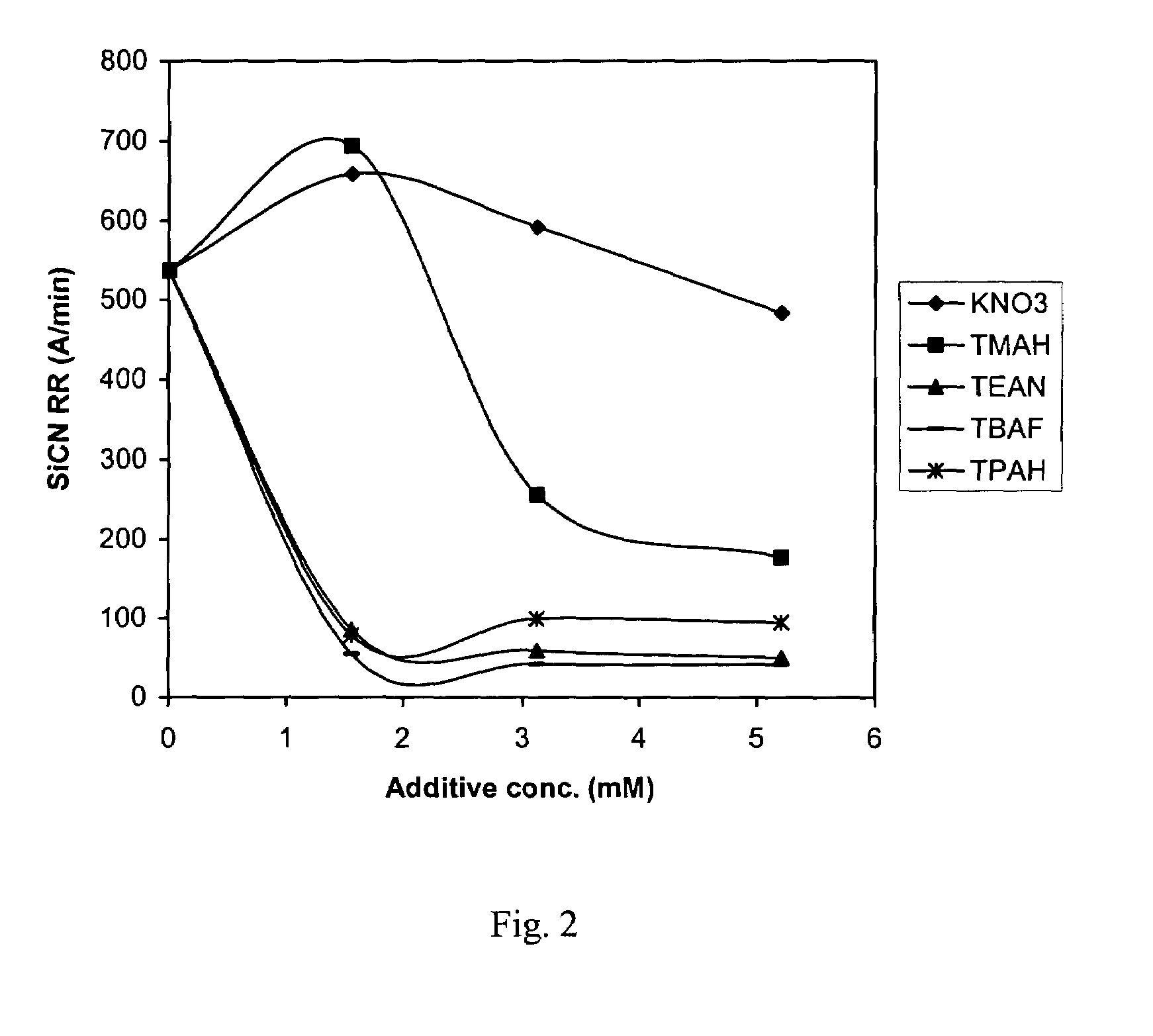

Composition for polishing semiconductor layers

ActiveUS20050031789A1Reduce defectsReduce removalInorganic/elemental detergent compounding agentsOther chemical processesCarbon chainSemiconductor

An aqueous polishing composition comprises a corrosion inhibitor for limiting removal of an interconnect metal with an acidic pH. The composition includes an organic-containing ammonium salt formed with R1, R2, R3 and R4 are radicals, R1 has a carbon chain length of 2 to 15 carbon atoms. The organic-containing ammonium salt has a concentration that accelerates TEOS removal and decreases removal of at least one coating selected from the group consisting of SiC, SiCN, Si3N4 and SiCO.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

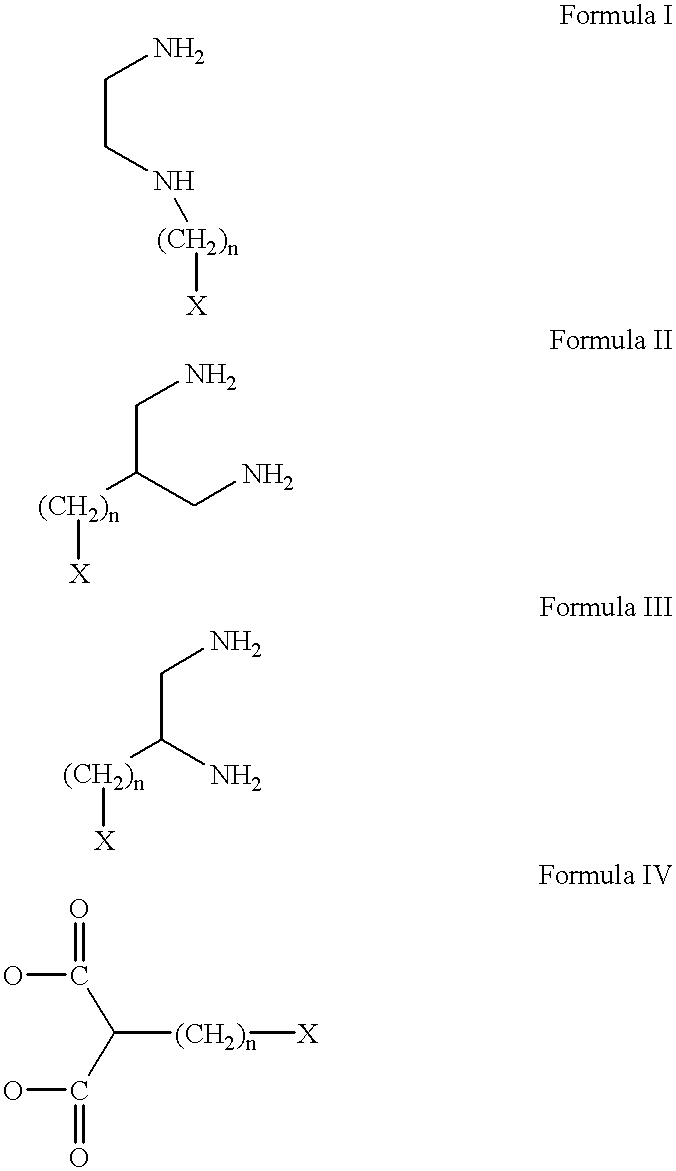

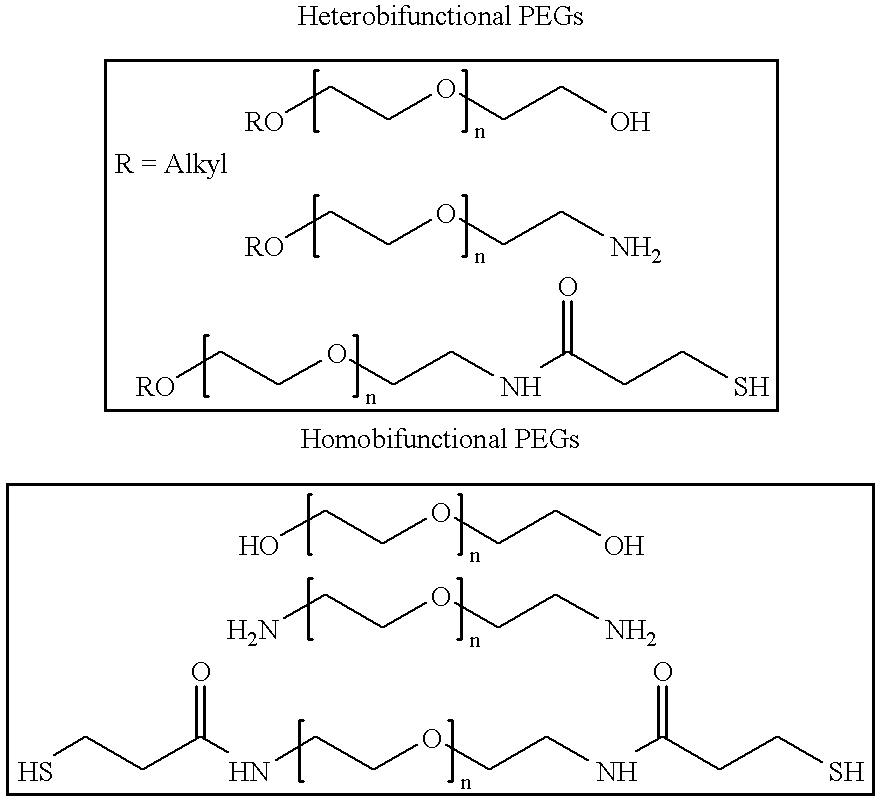

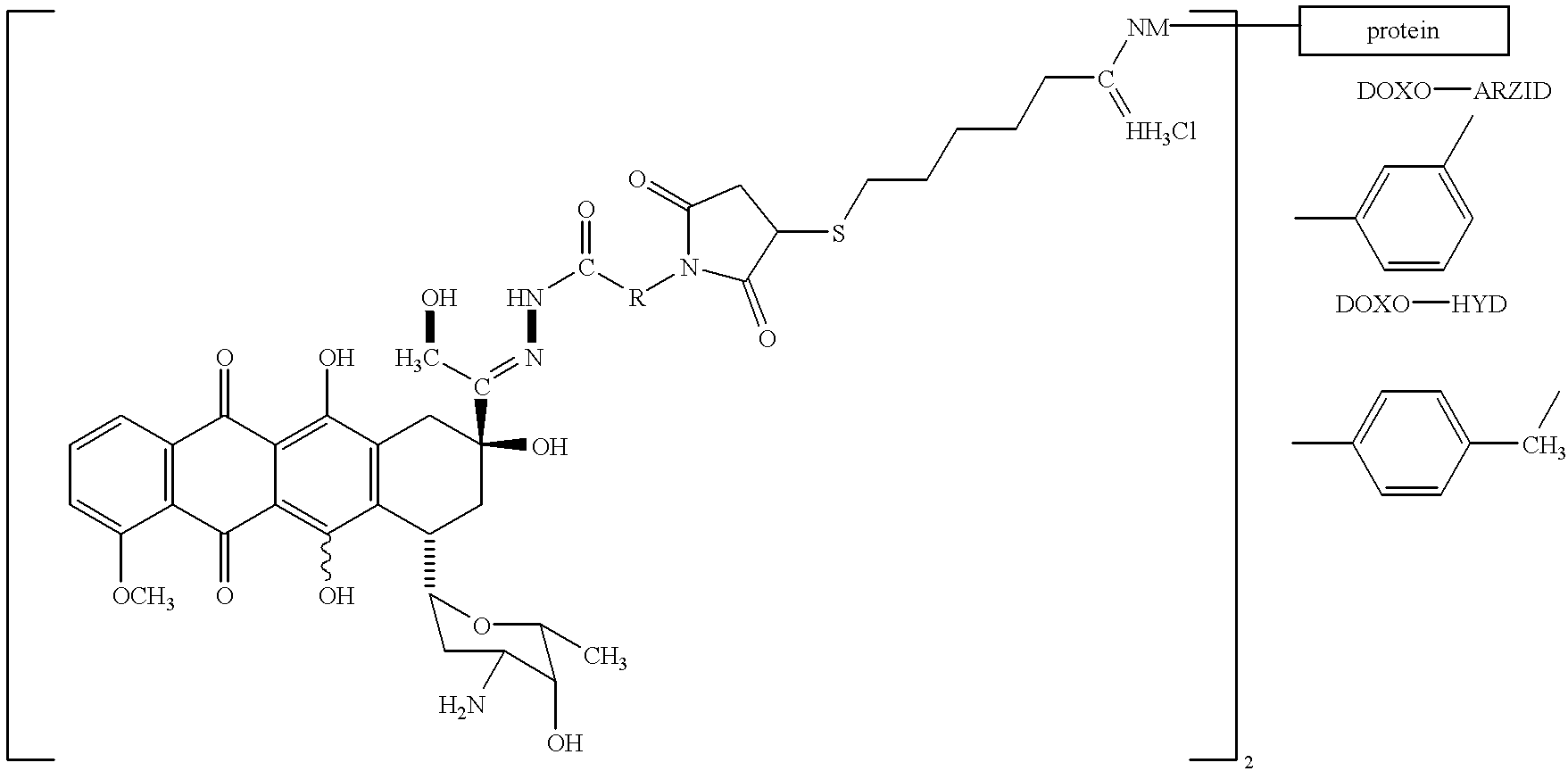

Antineoplastic conjugates of transferrin, albumin and polyethylene glycol

Conjugates of transferrin, albumin and polyethylence glycol consisting of native or thiolated transferrin or albumin or of polyethylene glycol (MW between approximately 5,000 and 20,0000) with at least one HS-, HO- or H2N group and cytostatic compounds derived through maleinimide or N-hydroxysuccinimide ester compounds, such as doxorubicin, daunorubicin, epirubicin, idarubicin, mitoxandrone, chloroambucil, melphalan, 5-fluorouracyl, 5'-desoxy-5-fluorouridine, thioguanine, methotrexate, paclitaxel, docetaxel, topotecan, 9-aminocamptothecin, etoposide, teniposide, mitopodoside, vinblastine, vincristine, vindesine, vinorelbine or a compound of general formula A, B, C or D, where n=0-6, X=-NH2, -OH, -COOH, -O-CO-R-COR*, -NH-CO-R-COR*, where R is an aliphatic carbon chain with 1-6 carbon atoms or a substituted or unsubstituted phenylene group and R* H, phenyl, alkyl with 1-6 carbon atoms.

Owner:KRATZ FELIX

Ceramic membranes with improved adhesion to plasma-treated polymeric supporting material and their production and use

InactiveUS20080190841A1Overcome disadvantagesMembranesSemi-permeable membranesCeramic coatingCarbon chain

Owner:EVONIK DEGUSSA GMBH

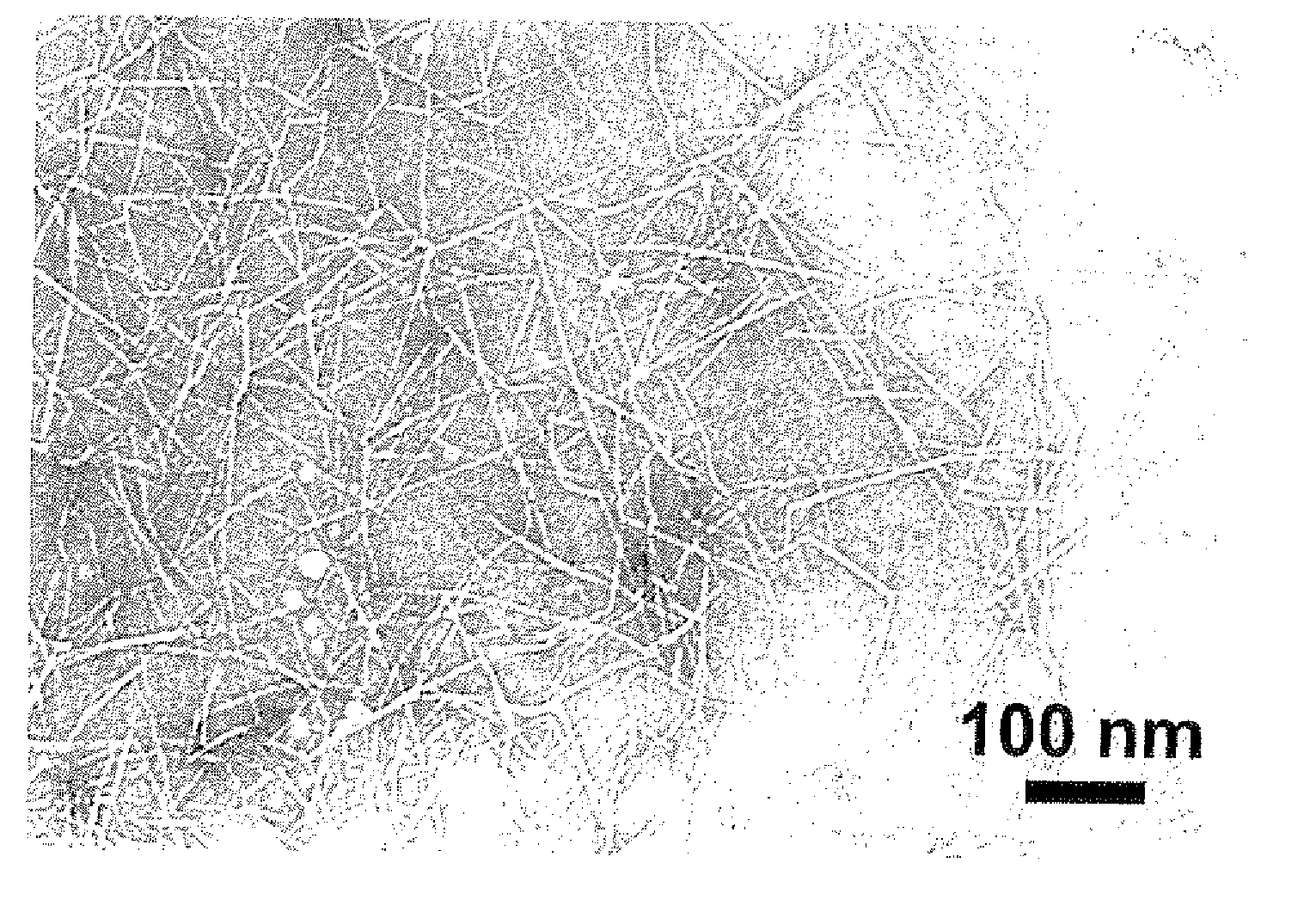

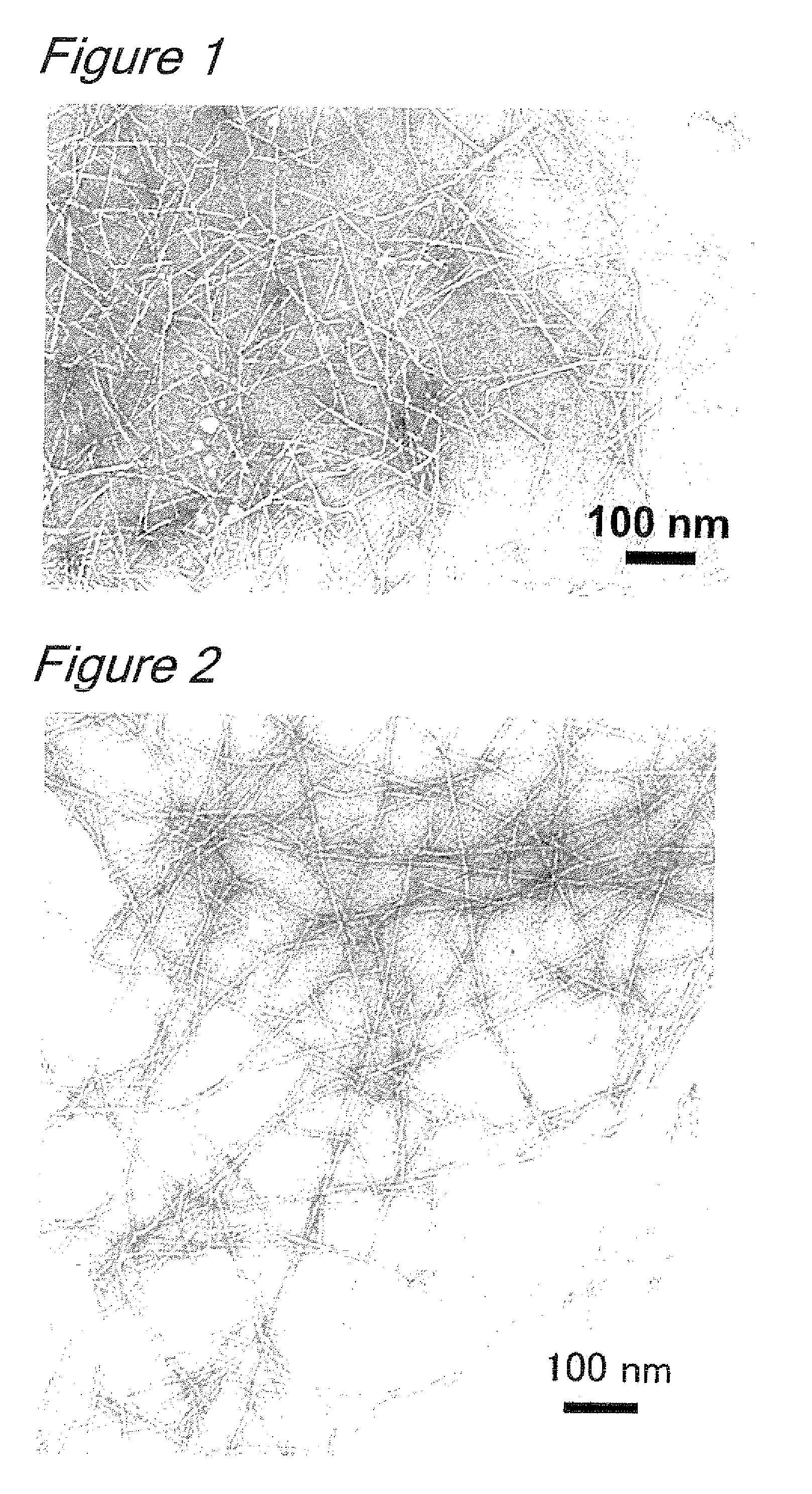

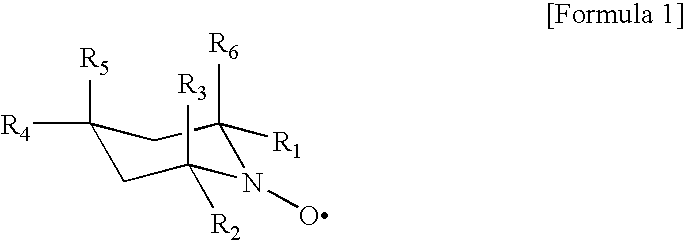

Processes for producing cellulose nanofibers, cellulose oxidation catalysts and methods for oxidizing cellulose

The present invention aims to provide a process for producing cellulose nanofibers using a 4-hydroxy TEMPO derivative less expensive than TEMPO and a process capable of rapidly producing homogeneous cellulose nanofibers. Wood cellulose can be efficiently converted into nanofibers by a process for producing cellulose nanofibers comprising treating a cellulosic material with an oxidizing agent in water in the presence of a cellulose oxidation catalyst comprising an N-oxyl compound represented by formula 1 below:wherein R1 and R2 are each independently hydrogen or a C1-C6 straight or branched alkyl group; and(i) one of R4 or R5 is —OR, —OCOR or —OSO2R wherein R is a straight or branched carbon chain having 4 or less carbon atoms, and the other of R4 or R5 is hydrogen, and R3 and R6 are methyl, or(ii) R4 is hydrogen, and R5, R3 and R6 are taken together with a piperidine ring to form an aza-adamantane compound having formula 2 below:or a mixture thereof, and a compound selected from the group consisting of bromides, iodides and mixtures thereof to prepare oxidized cellulose, and microfibrillating the oxidized cellulose to convert it into nanofibers.

Owner:NIPPON PAPER IND CO LTD

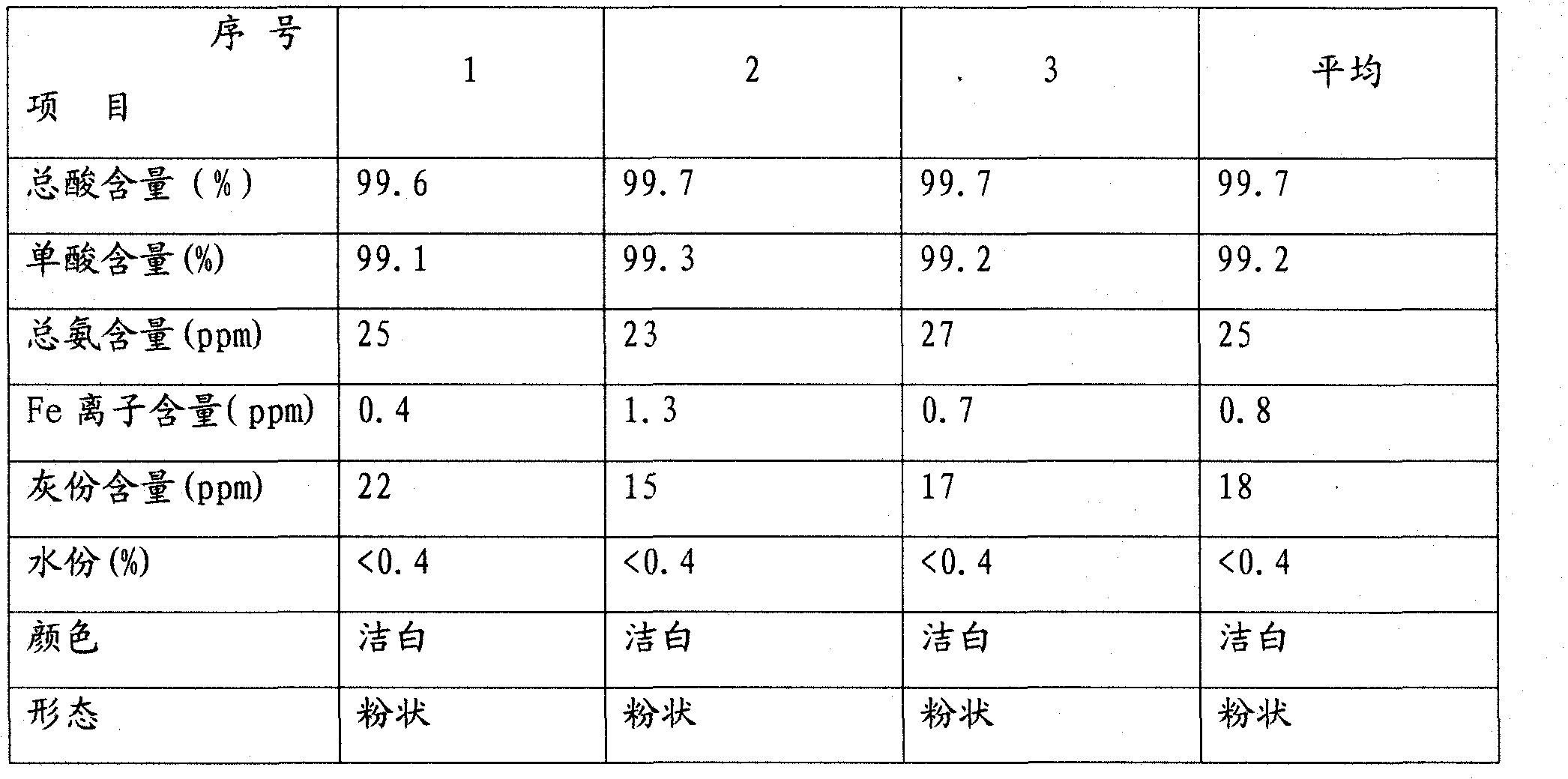

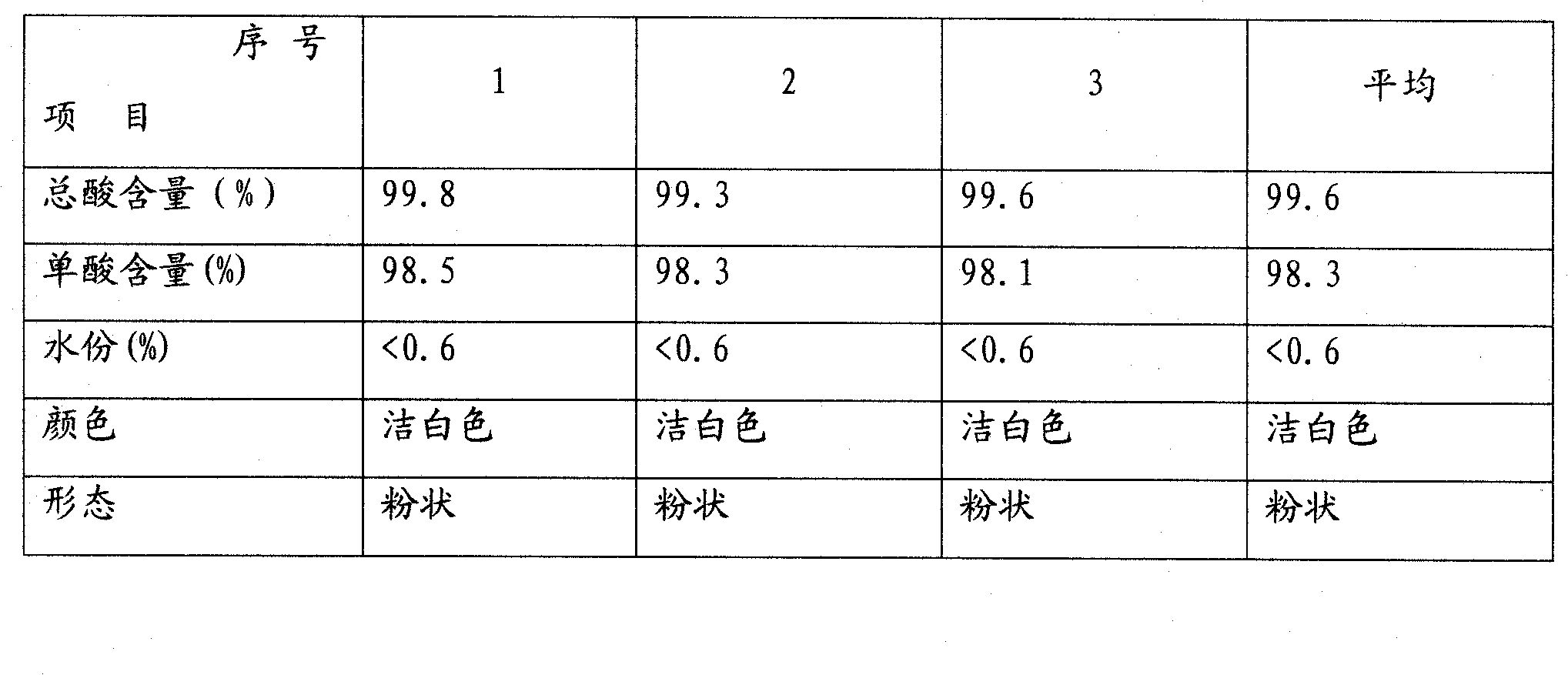

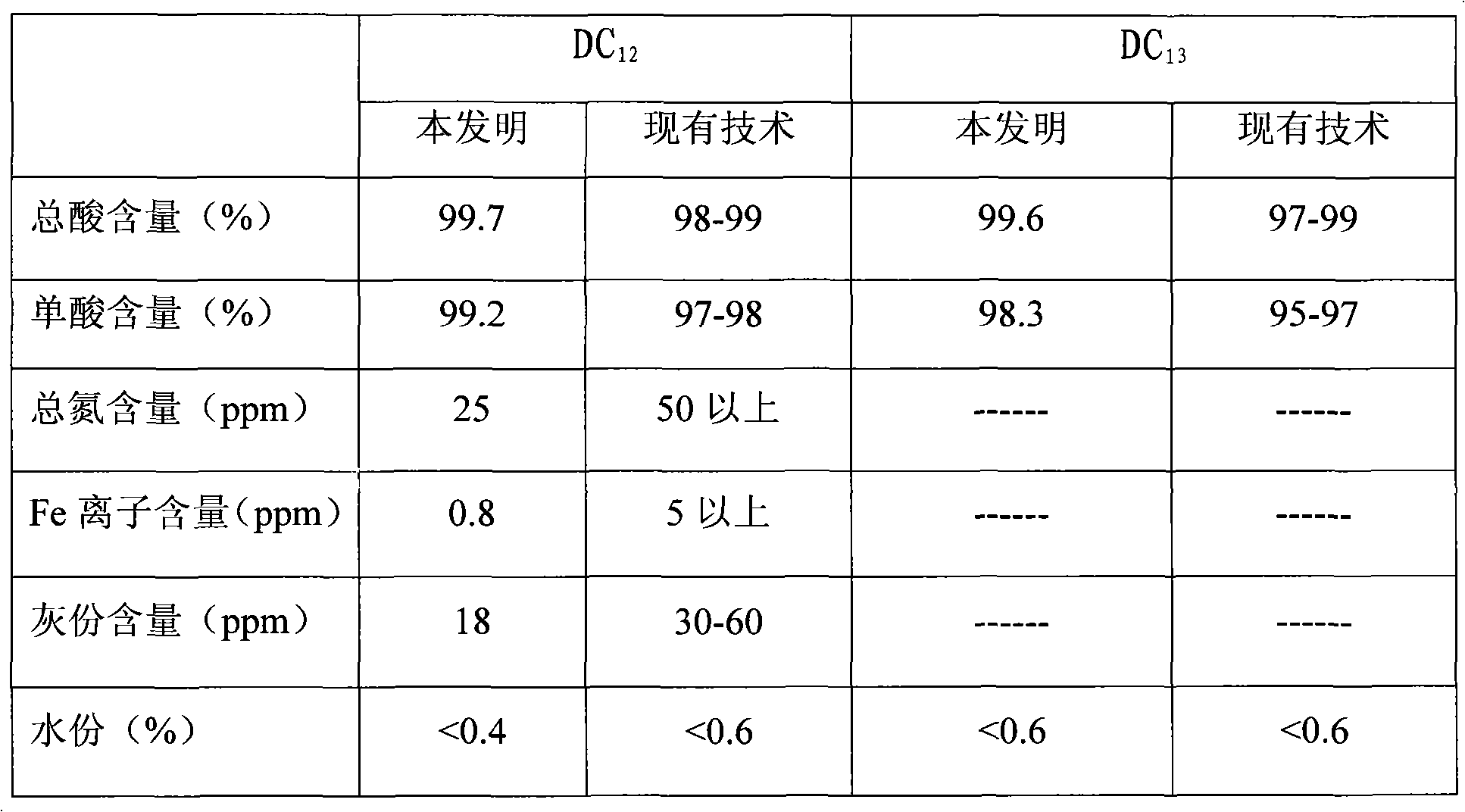

Long carbon-chain dibasic acid prepared from fatty acids or derivatives thereof and preparation method for the long carbon-chain dibasic acid

ActiveCN101121653AReduce dependencePromote the development of deep processingOrganic chemistryMicroorganism based processesAlkaneCarbon chain

The invention discloses a biological preparation method of the long carbochain biatomic acid with the fatty acid or the ramification of the fatty acid as the starting material. The number of carbon atoms is between 9 and 20. The long carbochain biatomic acid with the total content of the biatomic acid no less than 95 percent and the content of the atomic acid no more than 0.5 percent is further refined; then the total content of the biatomic acid is no less than 98.5 percent and the content of the atomic acid is no more than 0.05 percent. The long carbochain biatomic acid can replace the current long carbochain biatomic acid produced in a chemical or biological method (with the alkanes as the raw material) to be used in each field. At the same time, the invention provides the preparation process of the long carbochain biatomic acid; the process begins from the fatty acid or the ramification of the fatty acid; first the bio-fermentation is used to produce the long carbochain biatomic acid; then after the special purification process, the required biatomic acid can be acquired.

Owner:CATHAY R&D CENT CO LTD

Method for preparation of aviation kerosene and diesel oil from biomass derivative

The invention relates to a new liquid chain hydrocarbon fuel synthetic route that acquires a platform chemical compound based on a lignocellulose raw material and is completely independent of fossil energy. The liquid fuel obtained by the method can be used as a substitute of aviation kerosene and diesel oil or as an additive for improving the cetane number and cold hardiness of fuels, thereby reducing the national dependence on imported petroleum in terms of liquid fuels. The method provided in the invention consists of two parts: 1) on a novel solid acid catalyst, an aldehyde group-containing compound (such as formaldehyde, acetaldehyde, propionaldehyde, and butyraldehyde, etc.) and a furan platform compound (such as furan, methyl furan, and hydroxylmethyl furan, etc.) undergo an acid catalyzed alkylation reaction to prepare an oxygen-containing organic compound with a carbon chain length of 8-16; and 2) hydrogenation and hydrodeoxygenation are conducted on an alkylation product to hydrogenate unsaturated bonds and remove the oxygen therein, thus preparing aviation kerosene or high grade diesel oil with a carbon chain length ranging from 8 to 16.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

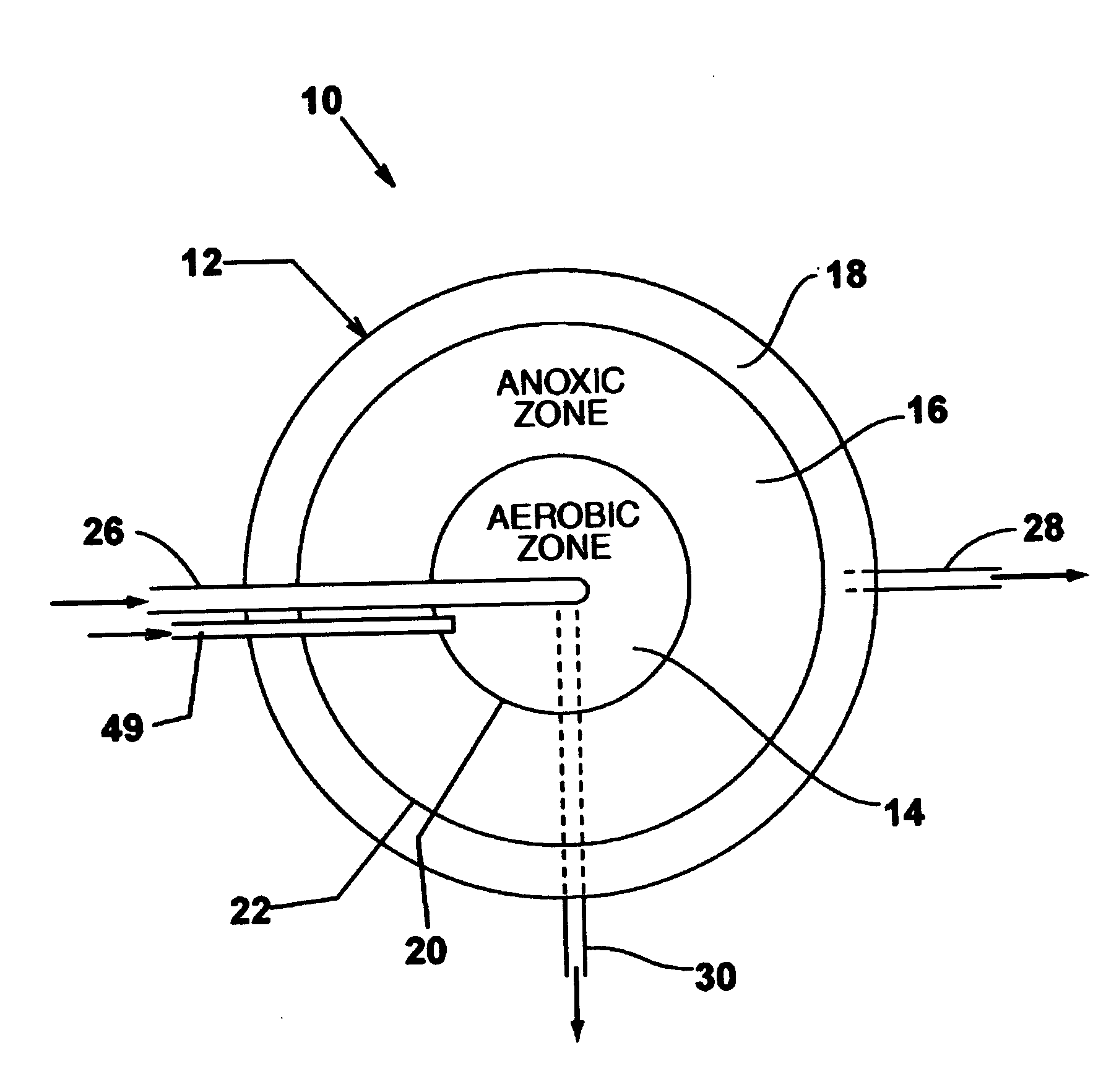

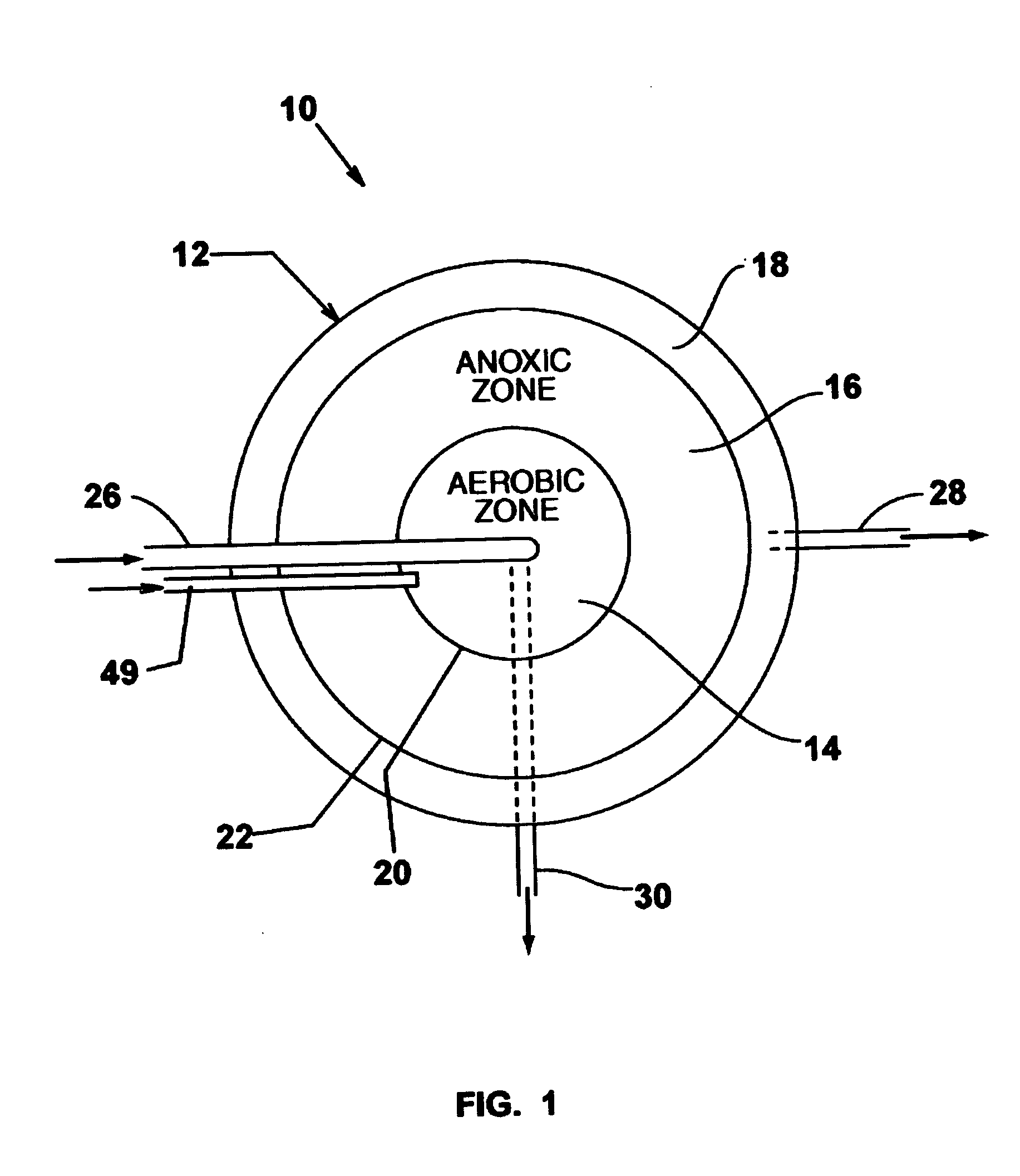

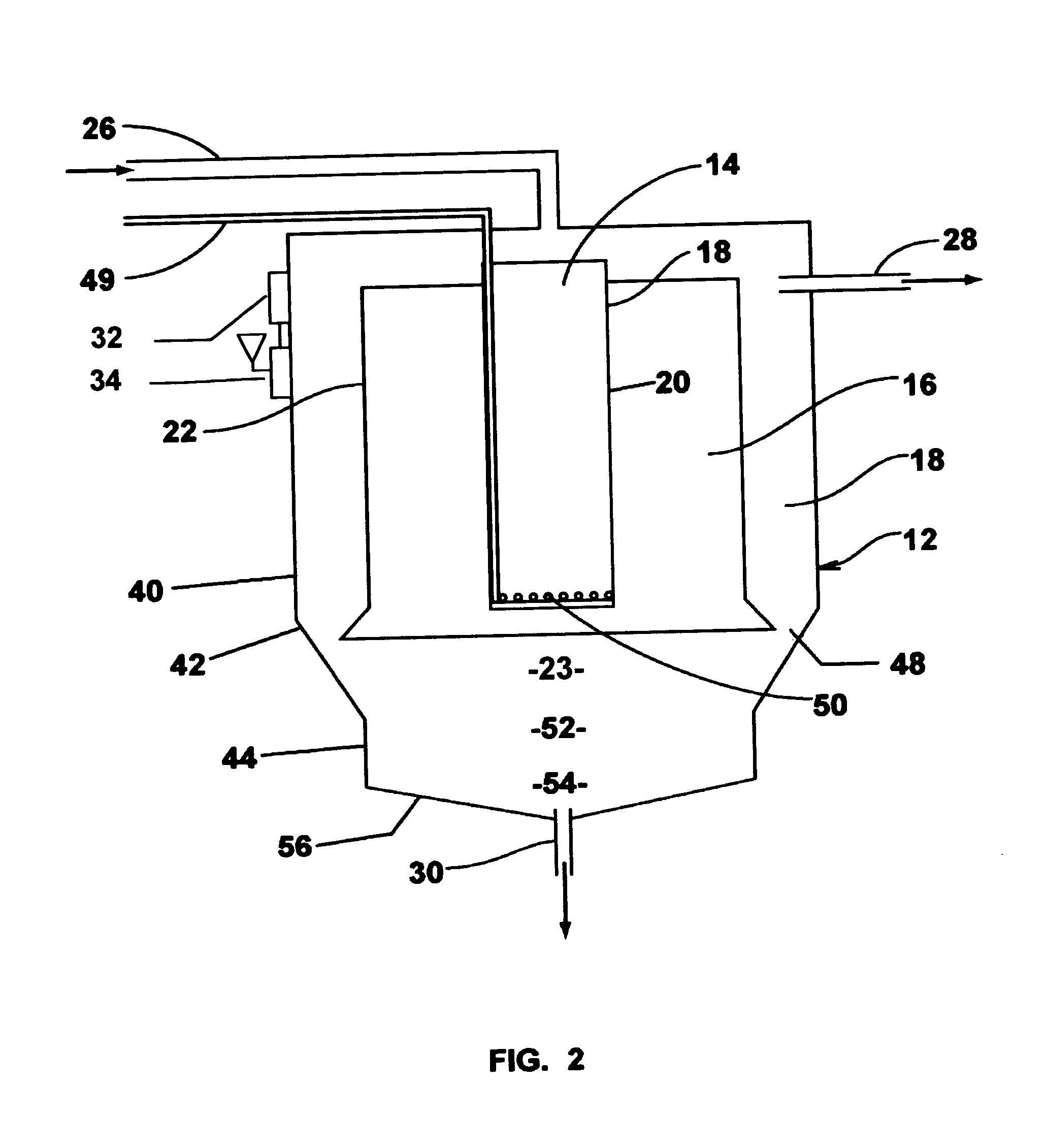

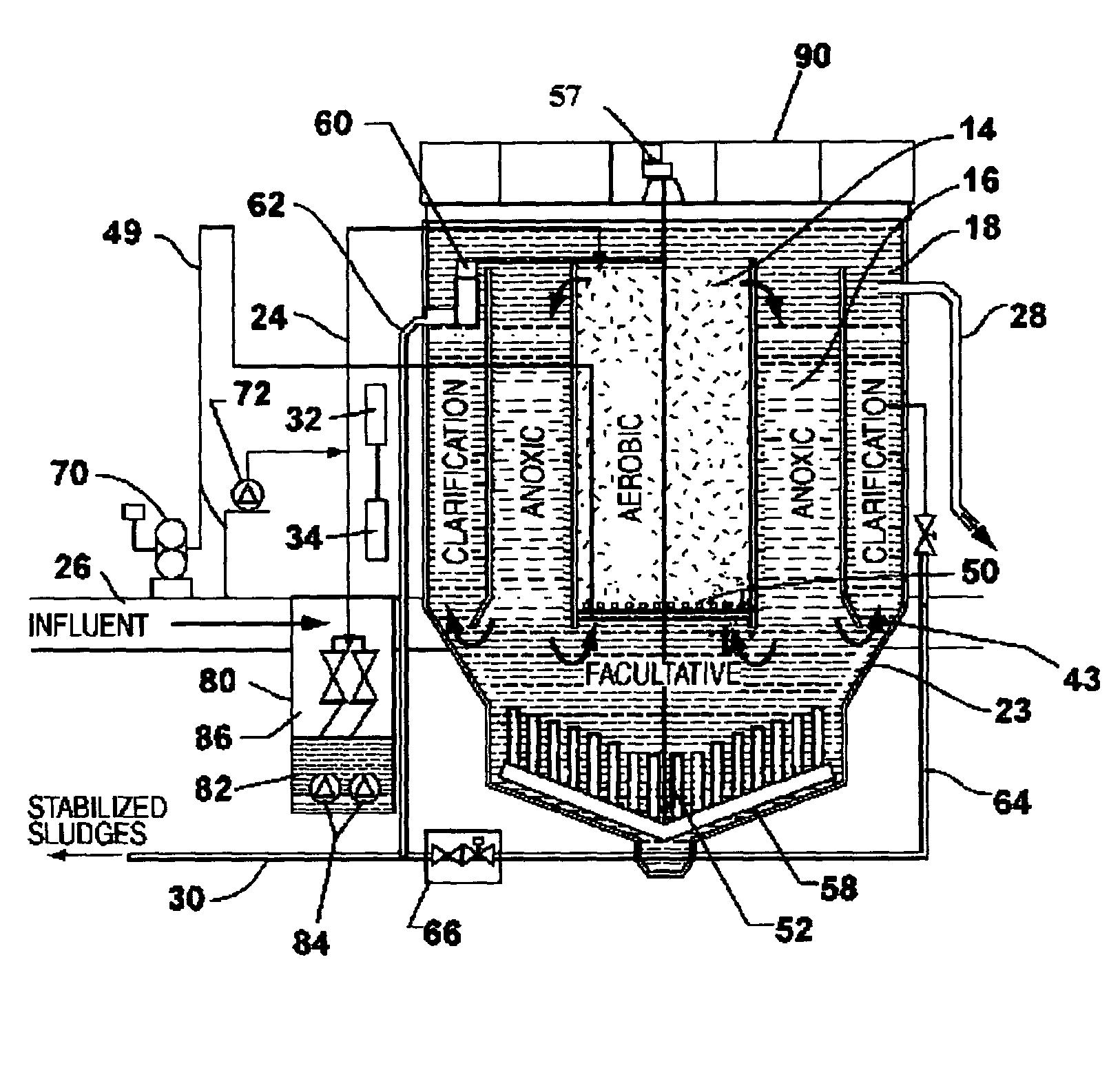

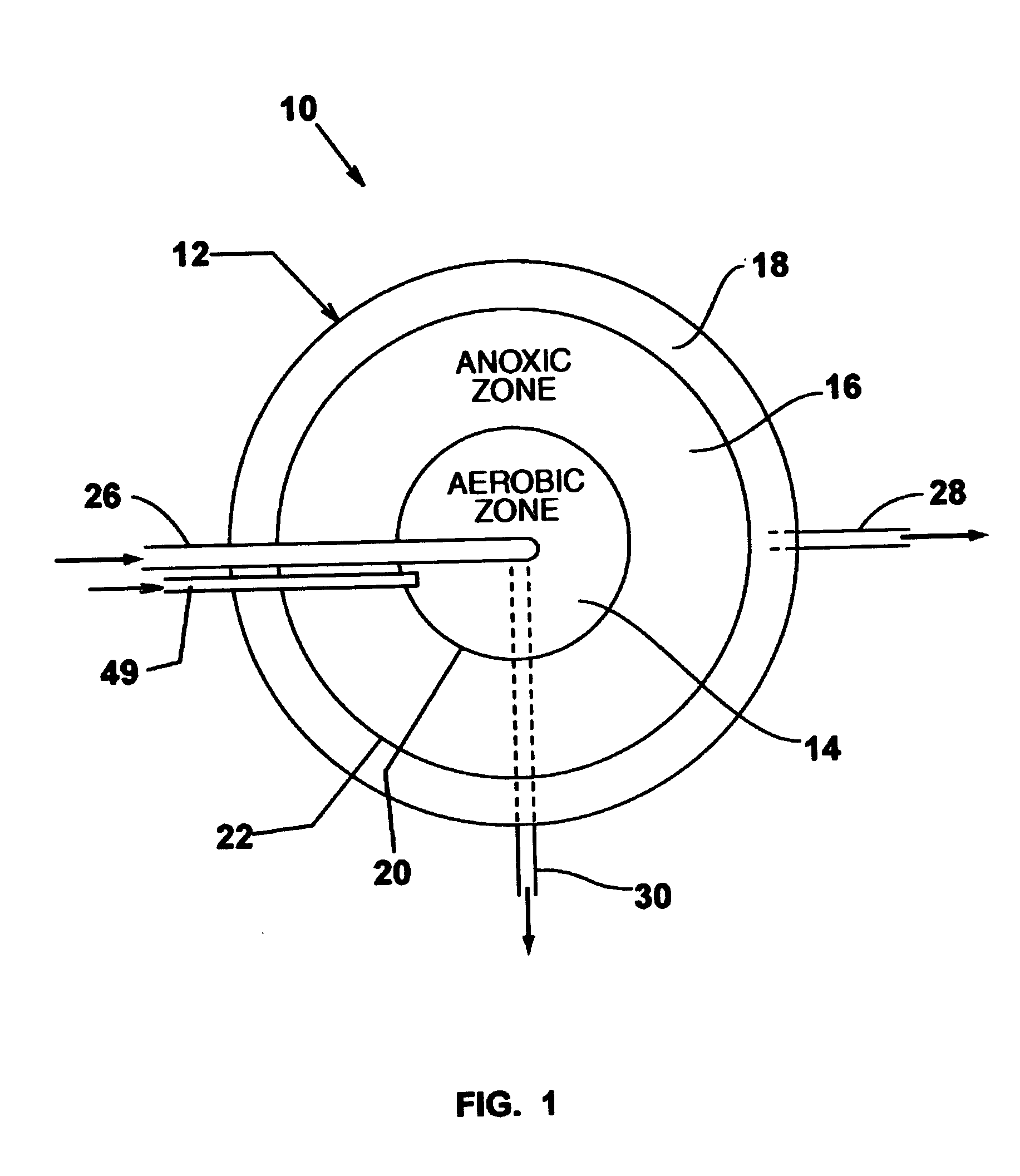

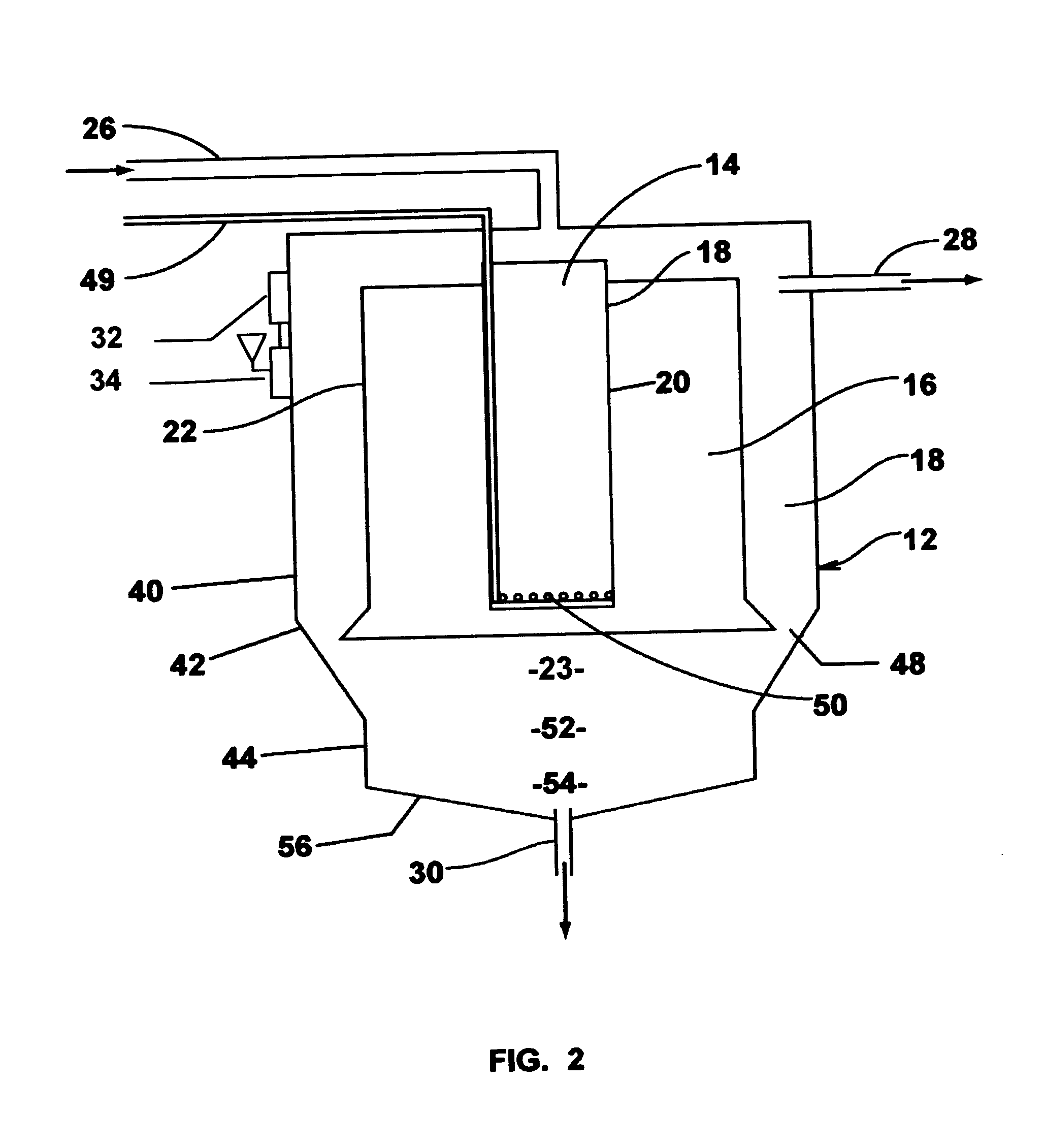

Single vessel multi-zone wastewater bio-treatment system

ActiveUS20050040107A1Suitable for processingSemi-permeable membranesTreatment using aerobic processesSingle vesselNitrate

A process for treating wastewater and a system for practicing the process includes: providing a plurality of zones within a single vessel wastewater treatment system; feeding wastewater into the system; maintaining an aerobic zone in the upper central portion of the vessel; feeding air into the aerobic zone for oxygenation and creating an upflow; maintaining an annularly disposed anoxic zone about said aerobic zone; causing the upflow from the aerobic zone to produce a downflow in the anoxic zone; causing at least a portion of the downflow from the anoxic zone to pass into the upflow of the aerobic zone; maintaining an annularly disposed clarification zone about said anoxic zone for clarified liquid, including an upflow; causing at least a portion of the downflow from the anoxic zone to pass into the upflow of the clarification zone; maintaining a facultative transition zone below the upper aerobic, anoxic and clarification zones; maintaining an anaerobic zone below the facultative zone for absorbing solids settled by gravity and synthesizing volatile fatty acids; withdrawing substantially clarified liquid from the upflow of the clarified liquid zone; withdrawing substantially solids from about the bottom of the anaerobic zone; employing the aerobic zone for breaking down carbon chains and oxidizing volatile fatty acids dispersed from the anaerobic zone; interacting the aerobic and anoxic zones for the removal of nitrates; and interacting the aerobic, anaerobic ananoxic zones for the removal of phosphorus.

Owner:KASPARIAN ANN

Single vessel multi-zone wastewater bio-treatment system

ActiveUS7008538B2Suitable for processingTreatment using aerobic processesMixing methodsSingle vesselNitrate

A process for treating wastewater and a system for practicing the process includes: providing a plurality of zones within a single vessel wastewater treatment system; feeding wastewater into the system; maintaining an aerobic zone in the upper central portion of the vessel; feeding air into the aerobic zone for oxygenation and creating an upflow; maintaining an annularly disposed anoxic zone about said aerobic zone; causing the upflow from the aerobic zone to produce a downflow in the anoxic zone; causing at least a portion of the downflow from the anoxic zone to pass into the upflow of the aerobic zone; maintaining an annularly disposed clarification zone about said anoxic zone for clarified liquid, including an upflow; causing at least a portion of the downflow from the anoxic zone to pass into the upflow of the clarification zone; maintaining a facultative transition zone below the upper aerobic, anoxic and clarification zones; maintaining an anaerobic zone below the facultative zone for absorbing solids settled by gravity and synthesizing volatile fatty acids; withdrawing substantially clarified liquid from the upflow of the clarified liquid zone; withdrawing substantially solids from about the bottom of the anaerobic zone; employing the aerobic zone for breaking down carbon chains and oxidizing volatile fatty acids dispersed from the anaerobic zone; interacting the aerobic and anoxic zones for the removal of nitrates; and interacting the aerobic, anaerobic ananoxic zones for the removal of phosphorus.

Owner:KASPARIAN ANN

Preparation method for aviation kerosene

The invention relates to a new synthesis route of a liquid branched paraffin fuel, the method adopts a lignocellulose based platform compound as a raw material and is completely independent of fossil energy. The liquid fuel obtained by the method can be used as an aviation kerosene (or diesel) substitute or as an additive to increase the cetane number and cold resistance of fuel. The method provided by the invention includes two steps of: 1) under the promotion of a base catalyst, subjecting a lignocellulose based furfural compound (including furfural, methylfurfural or 5 hydroxymethylfurfural) and branched chain keto (including methyl isobutyl ketone, and mesityl oxide, etc.) to aldol condensation reaction so as to synthesize an oxygen-containing organic compound with a carbon chain length of 9-16; and 2) conducting hydrodeoxygenation on the aldol condensation product generated in step1 to obtain biomass aviation kerosene branched hydrocarbon with a carbon chain length of 9-16, higher energy density, stability and low freezing point.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Buffered amino alcohol solutions of N-(n-butyl)thiophosphoric triamide (NBPT) and urea fertilizers using such solutions as urease inhibitors

InactiveUS8048189B2Low viscosityLimited spreadabilityBiocideOther chemical processesAlcoholCarboxylic acid

Owner:WHITEHURST ASSOCS

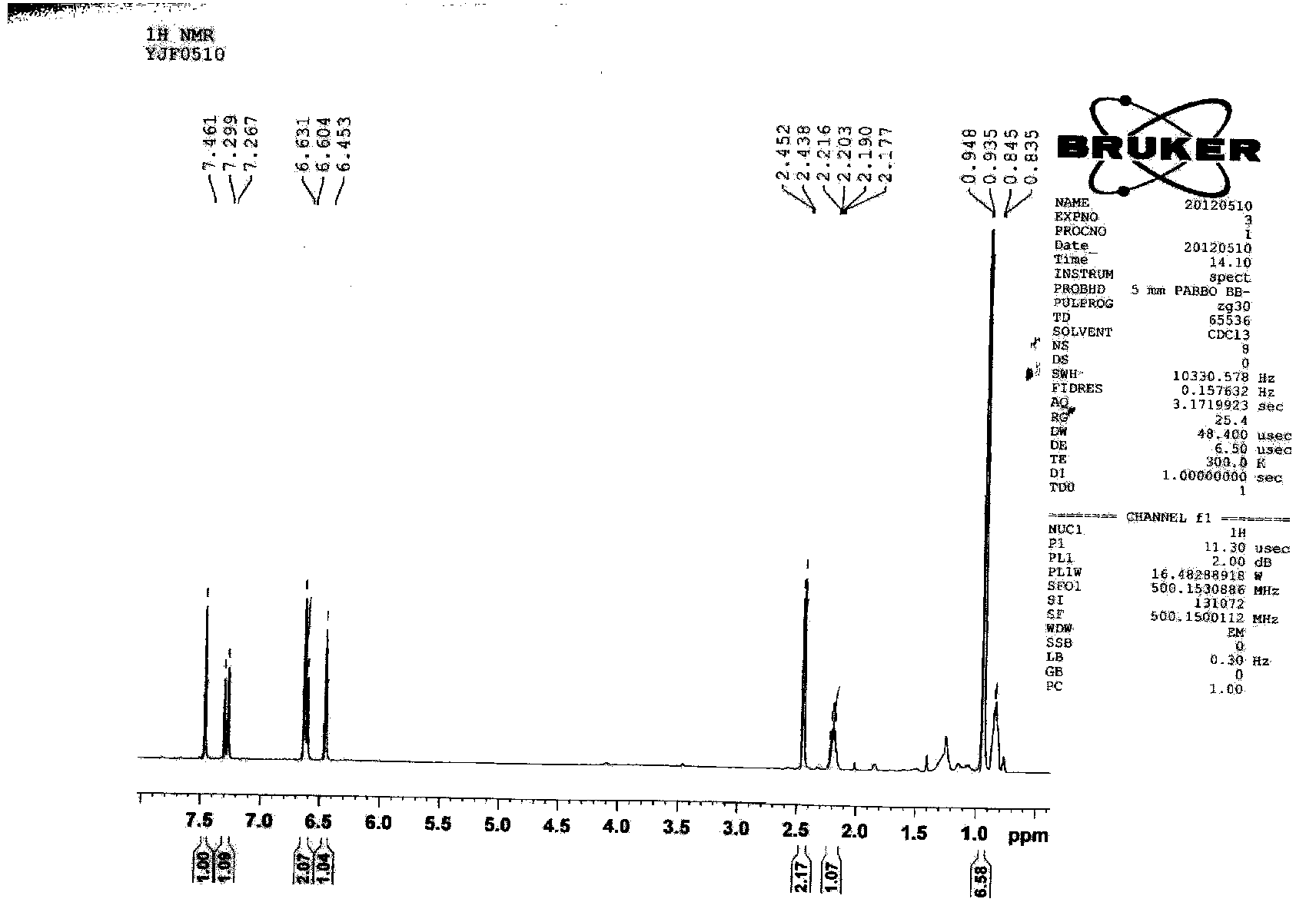

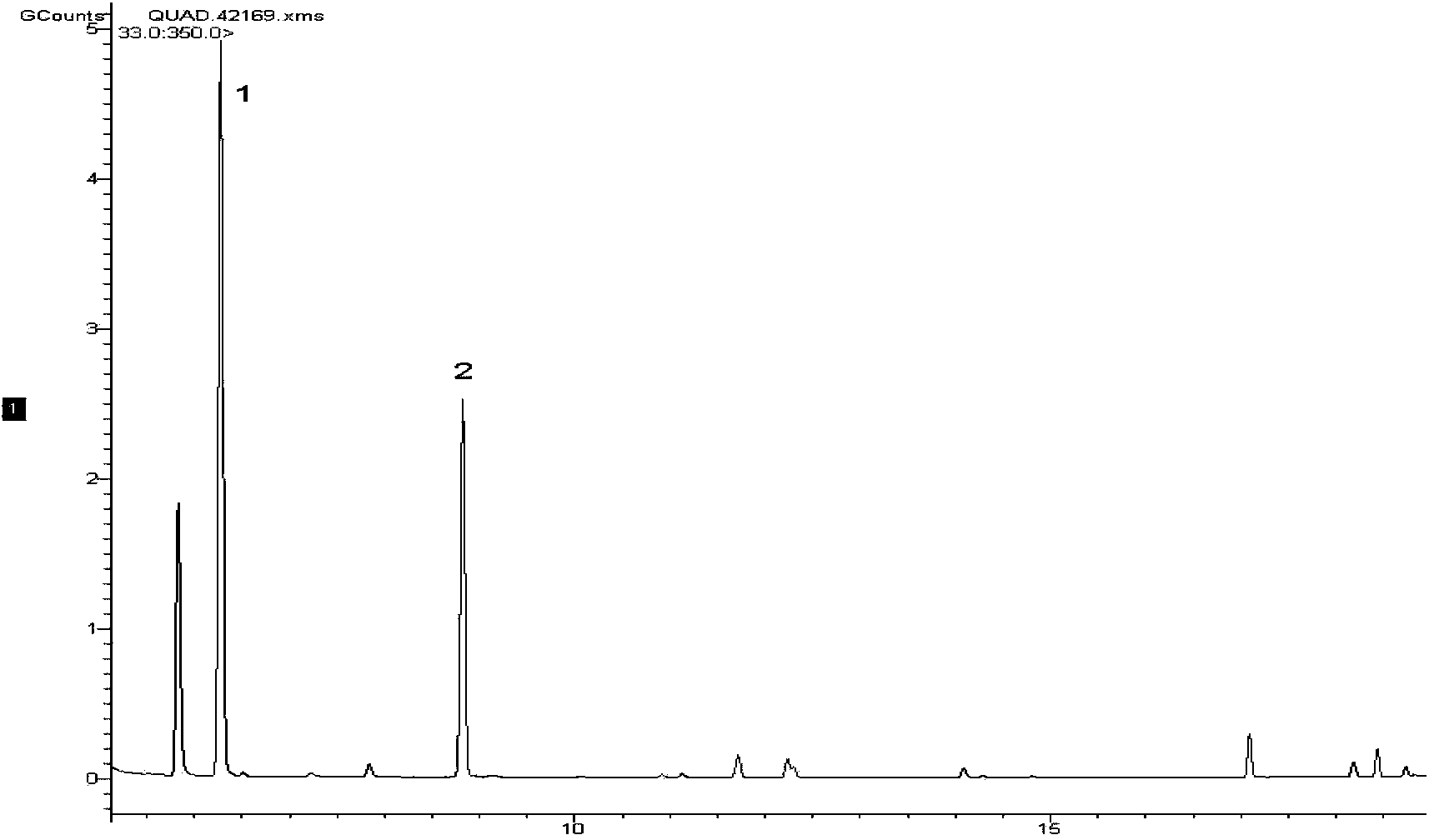

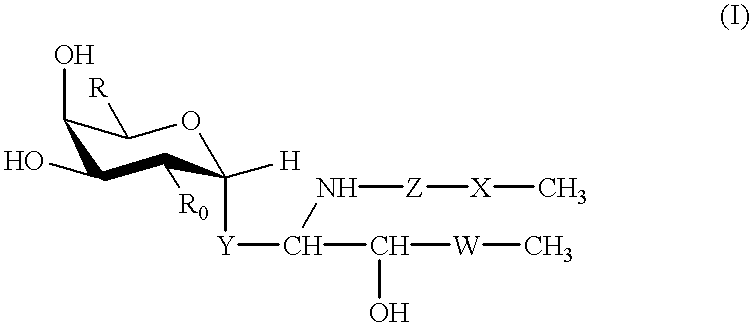

Glycolipid derivative

InactiveUS6635622B2Antitumor activitySave at room temperatureEsterified saccharide compoundsBiocideDouble bondCarbon chain

The present invention is a compound of general formula (I) or a pharmaceutically acceptable salt of,wherein W represents carbon chain from 9 to 17 which containing double bond or hydroxy group occasionally; X represents carbon chain from 11 to 25 which containing double bond or hydroxy group occasionally; Y represents -(CH2)a-CH=CH-(CH2)a'-, -(CH2)a- (a, a' denotes an integer of 0-5 and a+a' is 5 and under.), -S(O)0-2CH2-, -NHCH2-; Z represents -CO-, -SO2-; R represents -CH2OH, CO2H, CH2OCH2CO2SO3H; R0 represents -OH, -NH2, -NHAc.

Owner:KOTOBUKI PHARMA CO LTD

Composition for polishing semiconductor layers

ActiveUS7018560B2Reduce removalInorganic/elemental detergent compounding agentsOther chemical processesCarbon chainSemiconductor

An aqueous polishing composition comprises a corrosion inhibitor for limiting removal of an interconnect metal with an acidic pH. The composition includes an organic-containing ammonium salt formed with R1, R2, R3 and R4 are radicals, R1 has a carbon chain length of 2 to 15 carbon atoms. The organic-containing ammonium salt has a concentration that accelerates TEOS removal and decreases removal of at least one coating selected from the group consisting of SiC, SiCN, Si3N4 and SiCO.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

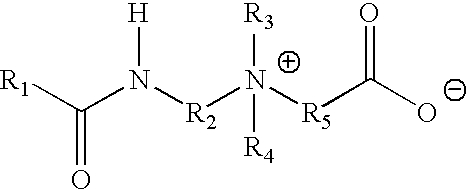

Composition of clean fracturing fluid additives and method for fracturing stratum

An additive for the clean fracturing liquid contains the quaternary ammonium salt with long-carbon-chain alkyl, ammonium dimethyloxide with long-carbon-chain alkyl, salicylate, ethanediol ether, low-carbon alcohol and water. A method for fracturing stratum includes such steps as preparing said clean fracturing liquid, pressing it into stratum via the jet hole of oil (or gas) well to form cracks in the stratum, pressing the sand-carrying liquid in it, releasing the pressure to close the crack, and returning the fracturing liquid back onto ground. Its advantages are simple apparatus and operation, and use of the fracturing liquid in very cold condition without heater.

Owner:PETROCHINA CO LTD

Refining technology for producing long carbon chain dicarboxylic acid by using biological fermentation process

ActiveCN101985416AHigh monoacid contentImprove thermal stabilityCarboxylic compound separation/purificationDielectricCarbon chain

The invention belongs to the technical field of preparing long carbon chain dicarboxylic acid by using a biological fermentation process, in particular relating to a refining technology for producing long carbon chain dicarboxylic acid by using a biological fermentation process. The technical scheme of the invention is the refining technology for producing long carbon chain dicarboxylic acid by using the biological fermentation process, which comprises the following steps: (1) decoloration and filtering; (2) primary crystallization and separation; (3) crystallization and separation of high-temperature water; and (4) drying. The obtained long carbon chain dicarboxylic acid product has the advantages of high single acid content, good photopermeability and high heat stability, can meet demands from different users, can be used for producing advanced spices, high-performance engineering plastics, high-temperature dielectric medium, advanced hot melt adhesive, cold-resistant plasticizer, advanced lubricating oil, advanced paint and coating and the like, and greatly broaden development space on down-stream products of the long carbon chain dicarboxylic acid.

Owner:CATHAY R&D CENT CO LTD

Compositions of peptides and processes of preparation thereof

InactiveUS20090280169A1Improve stabilityNervous disorderPeptide/protein ingredientsEtherCarbon chain

The present invention provides composition of comprising a therapeutically effective amount of at least one peptide, polypeptide, analog or derivative thereof and a sufficient amount of at least one stabilizing agent to improve the stability of the peptide, polypeptide, an analog or derivative thereof, wherein at least one stabilizing agent is a medium chain fatty acid salt, an ester, an ether, or a derivative of a medium chain fatty acid and has a carbon chain length of from about 4 to about 20 carbon atoms or is a surface active agent. The method for preparation of a composition of a peptide, polypeptide, protein, an analog and / or derivative thereof is also provided. The process comprises mixing the peptide, polypeptide, protein, an analog or derivative thereof with a sufficient amount of at least one stabilizing agents to improve the stability of the peptide, polypeptide, protein, an analog or derivative thereof, and the agent is a medium chain fatty acid salt, an ester, an ether, or a derivative of a medium chain fatty acid and has a carbon chain length of from about 4 to about 20 carbon atoms or is a surface active agent.

Owner:NOVO NORDISK AS

Method for Producing Hydrocarbons

A process is provided for the production of linear saturated alkanes from one or more primary alcohols, wherein the carbon chain of the one or more primary alcohols has one carbon atom more than the alkane, including conducting reductive dehydroxymethylation of one or more primary fatty alcohols containing 8 to 24 carbon atoms, at a temperature ranging from 100 to 300° C. and pressures from 1 to 250 bar in the presence of hydrogen and a catalyst, and removing water formed during the reaction.

Owner:COGNIS IP MANAGEMENT GMBH

Solid oral dosage form containing an enhancer

InactiveUS20070196464A1Improve oral bioavailabilityMinimizes risk of local irritationBiocidePhosphorous compound active ingredientsDelayed Release Dosage FormCarbon chain

The invention relates to a pharmaceutical composition and oral dosage forms comprising a bisphosphonate in combination with an enhancer to promote absorption of the bisphosphonate at the GIT cell lining. The enhancer is a medium chain fatty acid or a medium chain fatty acid derivative having a carbon chain length of from 6 to 20 carbon atoms. Preferably, the solid oral dosage form is a controlled release dosage form such as a delayed release dosage form.

Owner:NOVO NORDISK AS

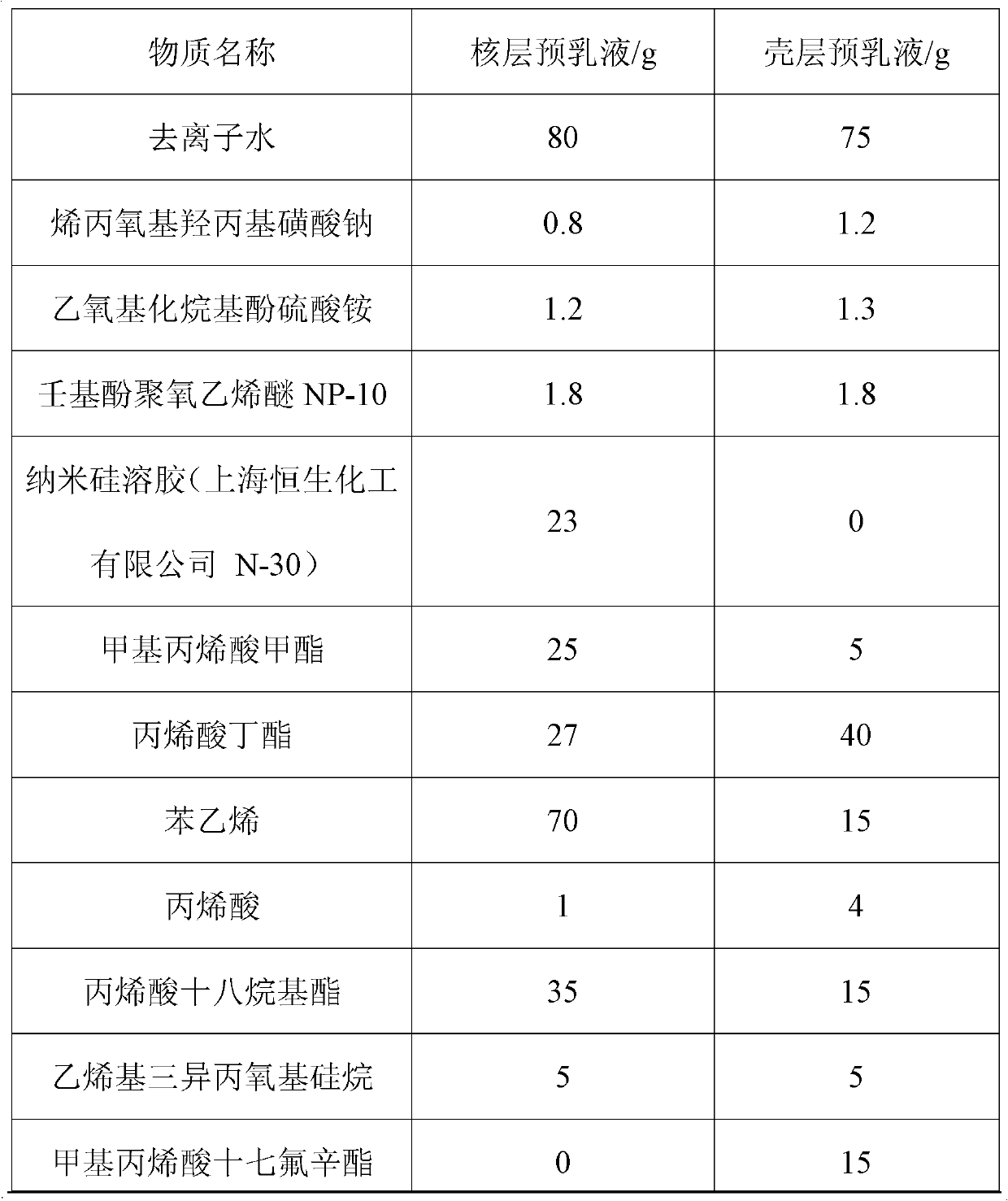

Fluorine silicon-modified acrylic ester emulsion and preparation method thereof

ActiveCN102585073ALow costImprove hydrophobicityAntifouling/underwater paintsPaints with biocidesPolymer scienceSilicon oxide

The invention discloses a fluorine silicon-modified acrylic ester emulsion and a preparation method thereof. The fluorine silicon-modified acrylic ester emulsion is a shell-core emulsion mainly prepared from a fluorine monomer, vinyl triisopropoxysilane, nano silica sol, a vinyl monomer, a long carbon chain monomer, an emulsifier, a pH buffer, an initiator, deionized water and the like. The fluorine monomer is delayed to be dripped during polymerization, so that the fluorine element is enriched on the surfaces of emulsion particles, the hydrophobic and oleophobic properties of fluorine elusion is given full play to, the use of the fluorine monomer is reduced, and the cost is reduced. The composition of inorganic silicon oxide particles and an organic polymer keeps the good film forming property of the polymer and has the weather resistance, high hardness and other characteristics of the inorganic matter, so as to improve the stain resistance of a varnish film.

Owner:SUN YAT SEN UNIV +1

Non-Damaging Fluid-Loss Pill and Method of Using the Same

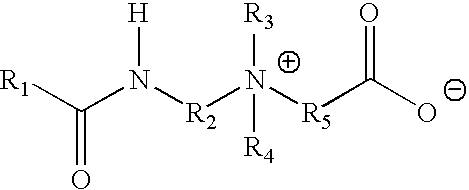

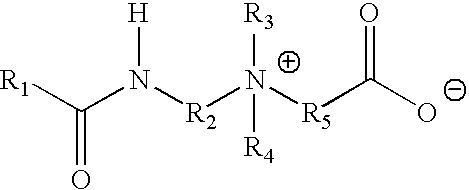

A fluid-loss pill that includes a brine solution and an effective amount of a viscoelastic surfactant is disclosed. The viscoelastic surfactant preferably includes at least one compound selected from the family of compounds described bywhere R1, R2, R3, R4 and R5 are carbon atom or carbon chains, saturated or unsaturated, single or multiple unsaturation, straight chain, branched chain or cyclic including aromatic or alicyclic groups, and R1 contains 16–26 carbon atoms, R2 contains 2–10 carbon atoms, R3, R4 and R5 contains 1–6 carbon atoms. Methods of treating a well that include injecting fluid-loss pill into a well to control lost-circulation or to kill a well.

Owner:SCHLUMBERGER TECH CORP

Cleaning agent for optical glass

ActiveCN102604751AEasy to cleanPromote wettingOrganic detergent compounding agentsNon-ionic surface-active compoundsOrganic baseCarbon chain

The invention discloses a cleaning agent for optical glass, which comprises the following components in weight percentage: 2-4% of long carbon chain dibasic acid; 6-10% of an anionic surfactant; 2-4% of an inorganic base; 2-6% of a nonionic surfactant; 2-4% of a special surfactant; 6-12% of a chelator; 10-20% of an organic base; and 40-70% of deionized water, wherein the long carbon chain dibasic acid is dicarboxylic acid with 21 carbon atoms, the anionic surfactant is dodecylbenzene sulfonic acid, the inorganic base is industrial NaOH, the nonionic surfactant is primary alcobol ethoxylate AEO9, the special surfactant is sodium POE nonylphenol ether sodiosulfosuccinate, the chelator is a mixture of Tetrasodium Ethylenediamine Tetraacetate and sodium gluconate, and the organic base is diethanol amine. The cleaning agent for optical glass provided by the invention has low corrosivity and good cleaning effect.

Owner:SHENZHEN FISHER NEW MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com