Patents

Literature

531 results about "Methyl propionate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methyl propionate, also known as methyl propanoate, is the organic compound with the molecular formula CH₃CH₂CO₂CH₃. It is a colorless liquid with a fruity, rum-like odor.

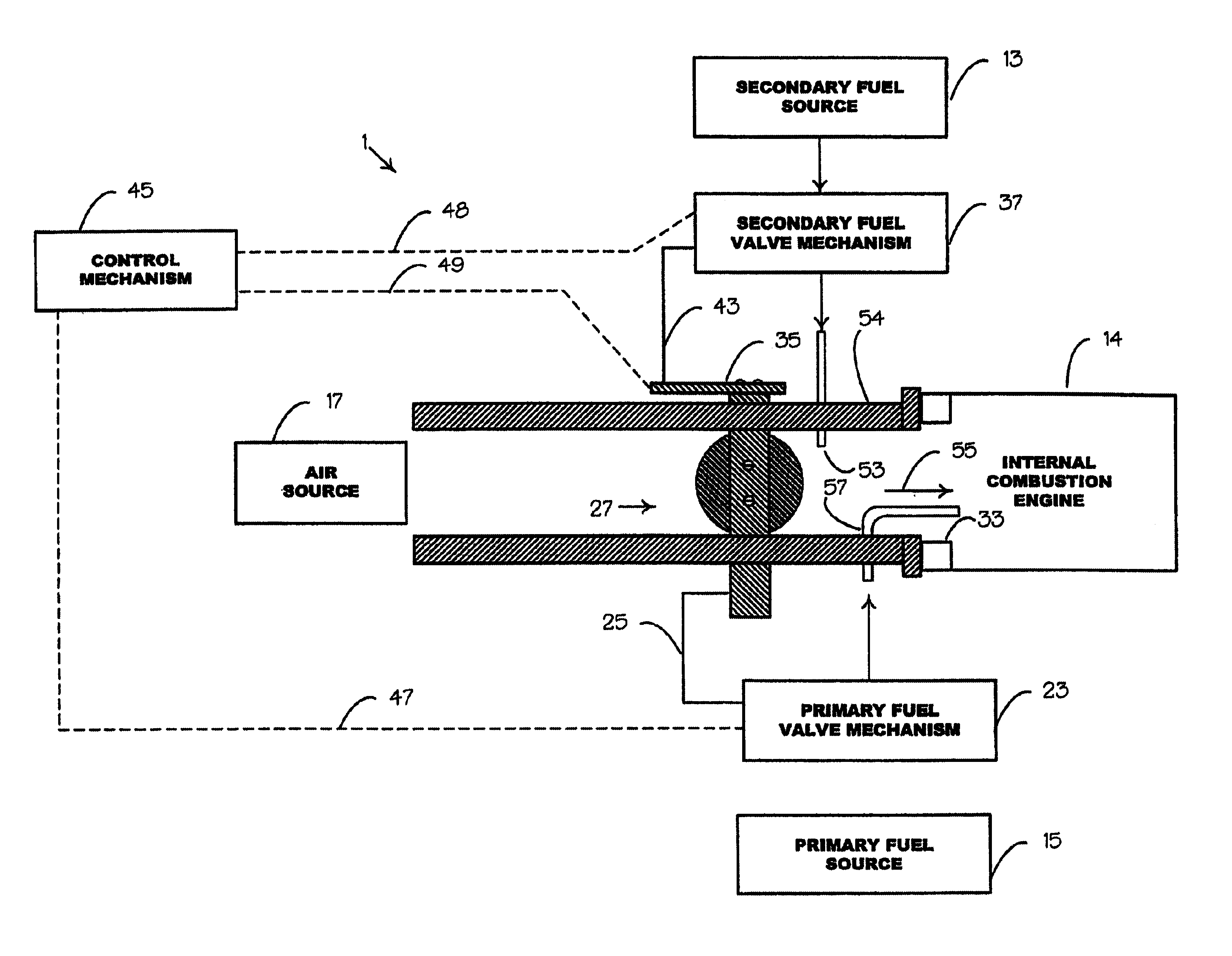

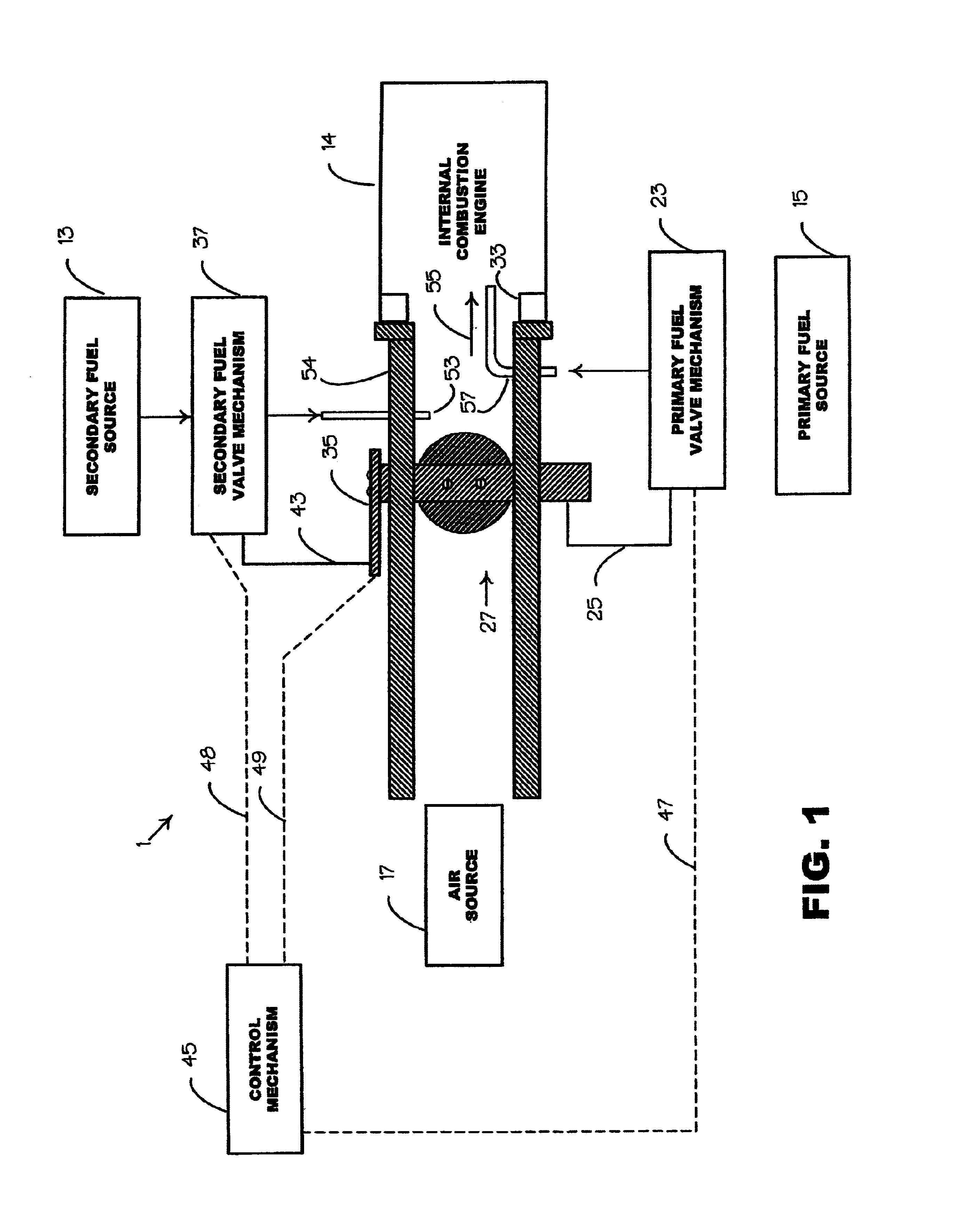

Internal combustion system using acetylene fuel

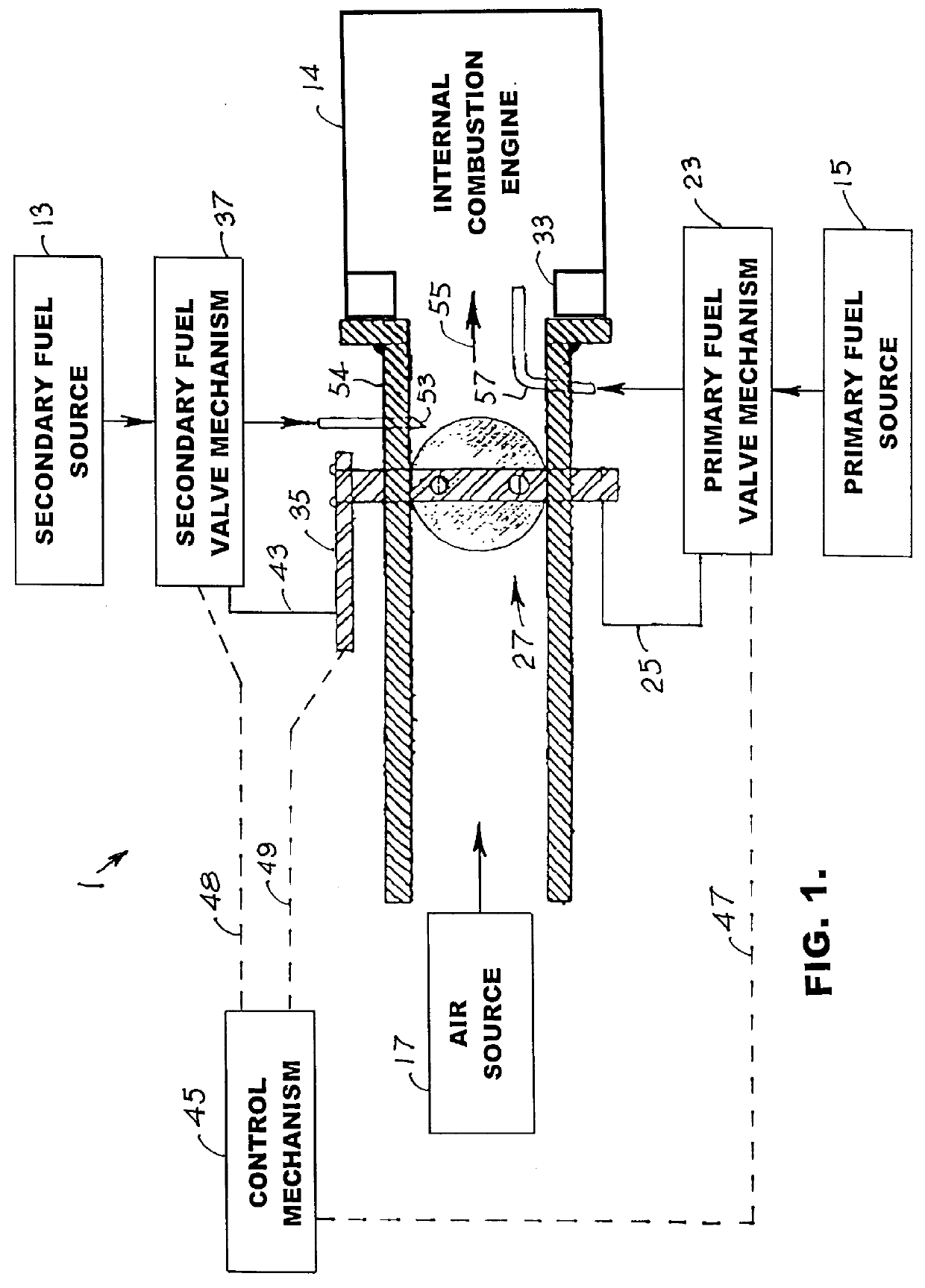

InactiveUS6076487AInternal combustion piston enginesNon-fuel substance addition to fuelCarbon chainInternal combustion engine

An environmentally clean dual fuel for an internal combustion engine, comprising acetylene as a primary fuel and a combustible fuel, such as one or more fluids selected from an alcohol such as ethanol, methanol or any other alcohol or alcohols from the group comprising C1-C20 carbon chains, ethers such as from the group comprising dimethyl ether, diethyl ether, methyl t-butyl ether, ethyl t-butyl ether, t-amyl methyl ether, di-isopropyl ether and the like, low-molecular-weight esters such as from the group comprising methyl formate, methyl acetate, ethyl acetate, methyl propionate, ethyl propionate and the like, or other suitable combustible fluid such as mineral spirits and the like, as a secondary fuel for operatively preventing early ignition and knock arising from the primary fuel. The dual fuel, internal combustion system, which generally utilizes a two-stage process for start-up and operation and can be operated with air- or liquid-cooling, is environmentally clean with hydrocarbon, CO, NOx, and SOx emissions substantially eliminated.

Owner:GOTEC

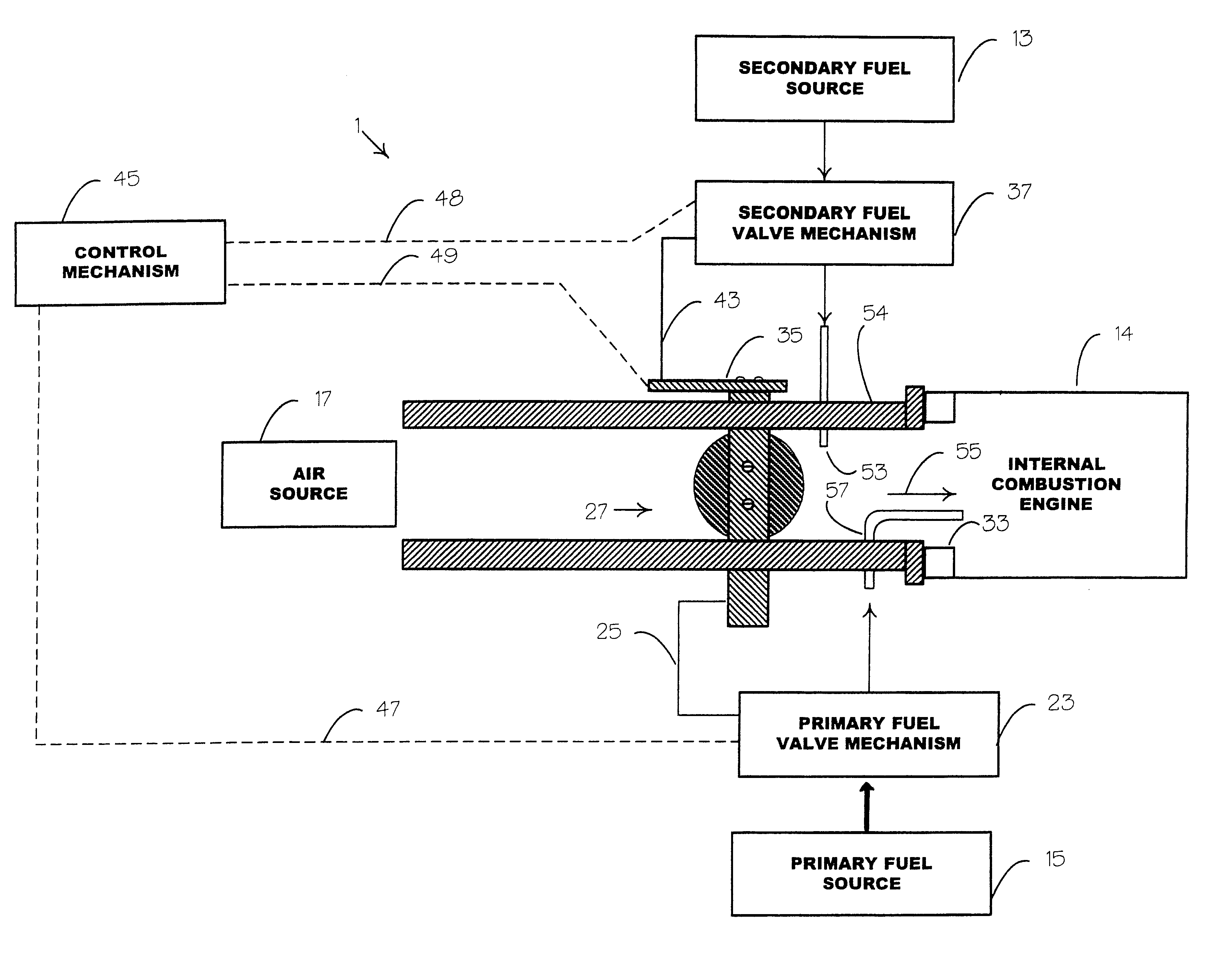

Internal combustion system adapted for use of a dual fuel composition including acetylene

InactiveUS6575147B2Easy to operateImprove performanceNon-fuel substance addition to fuelInternal combustion piston enginesCarbon chainMineral spirit

An internal combustion engine adapted to use an environmentally clean multi-fuel composition, comprising acetylene as a primary fuel and a combustible fuel, such as one or more fluids selected from an alcohol such as ethanol, methanol or any other alcohol or alcohols from the group comprising C1-C12 carbon chains, ethers such as from the group comprising dimethyl ether, diethyl ether, methyl t-butyl ether, ethyl t-butyl ether, t-amyl methyl ether, di-isopropyl ether and the like, low-molecular-weight esters such as from the group comprising methyl formate, methyl acetate, ethyl acetate, methyl propionate, ethyl propionate, ethyl malate, butyl malate, and the like, or other suitable combustible fluid such as mineral spirits and the like, as a secondary fuel for operatively preventing early ignition and knock arising from the primary fuel.

Owner:GOTEC INC

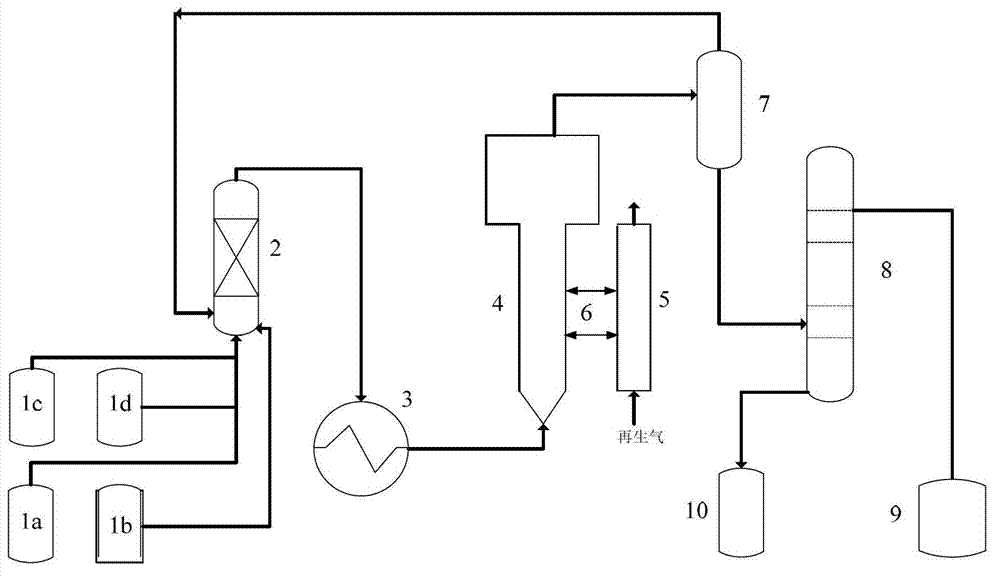

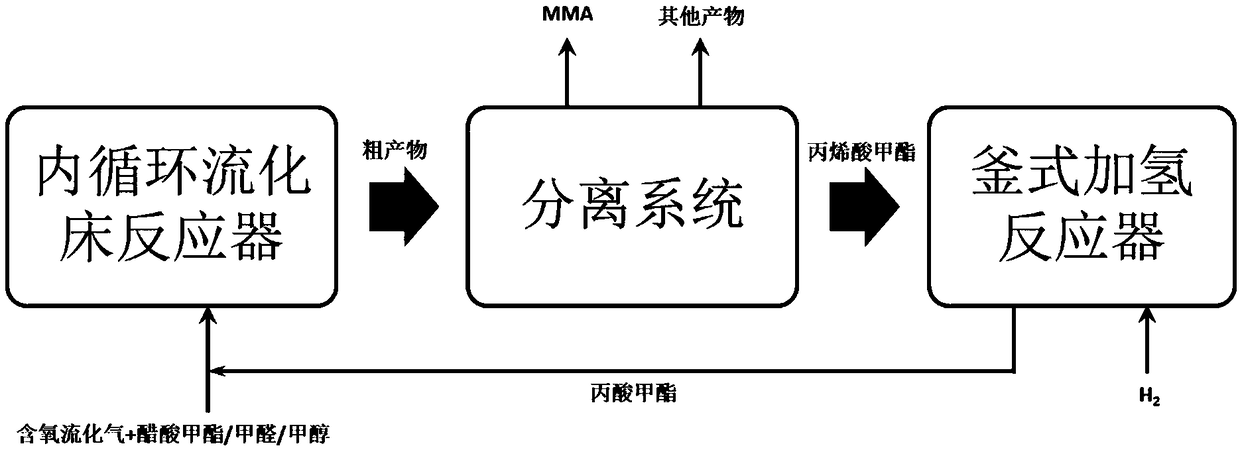

Method for preparing methyl methacrylate from methyl propionate and formaldehyde

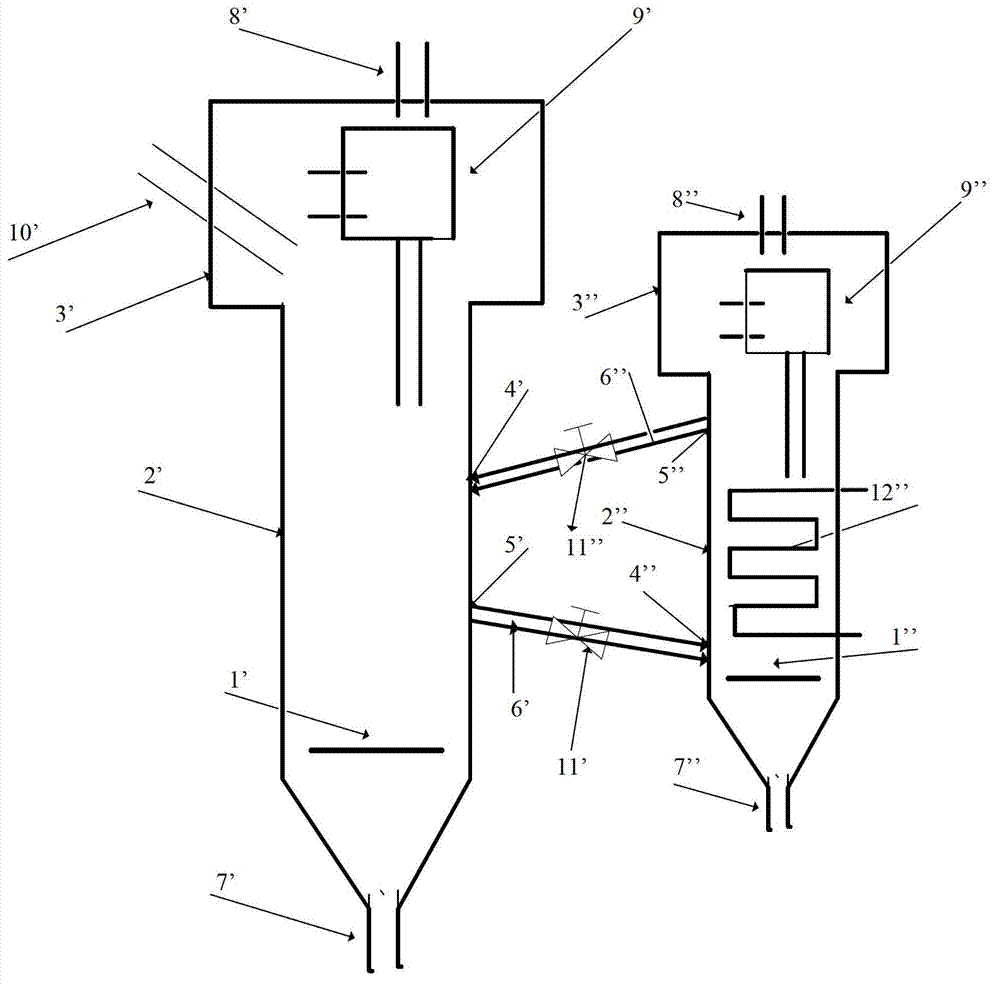

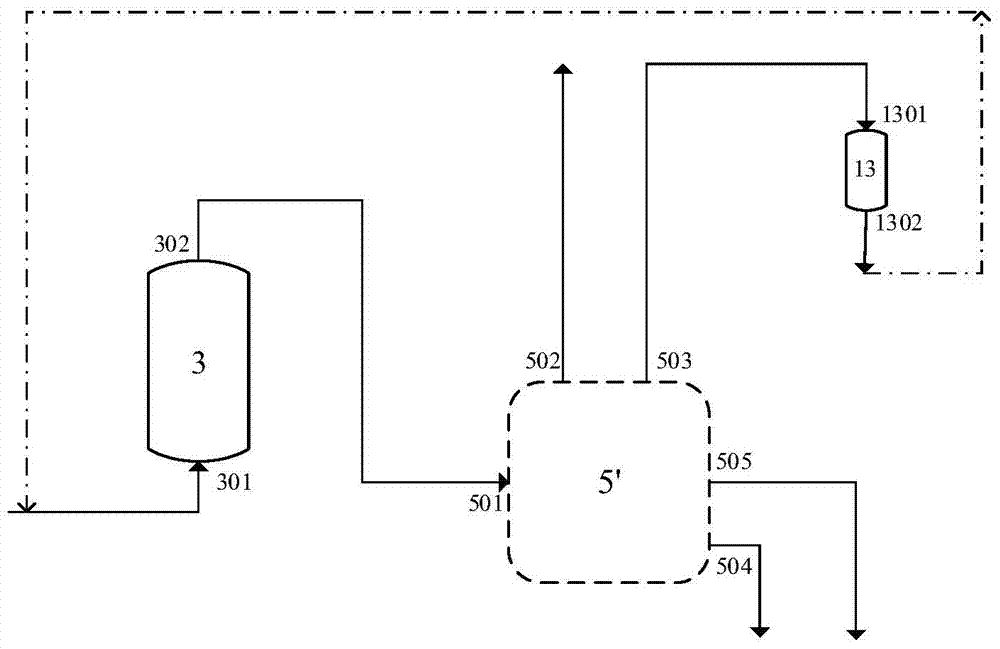

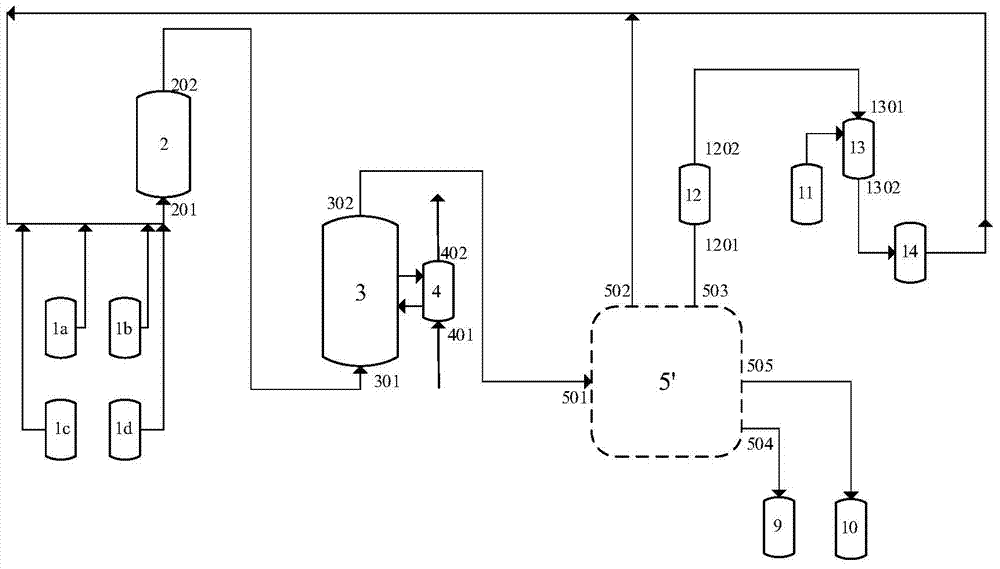

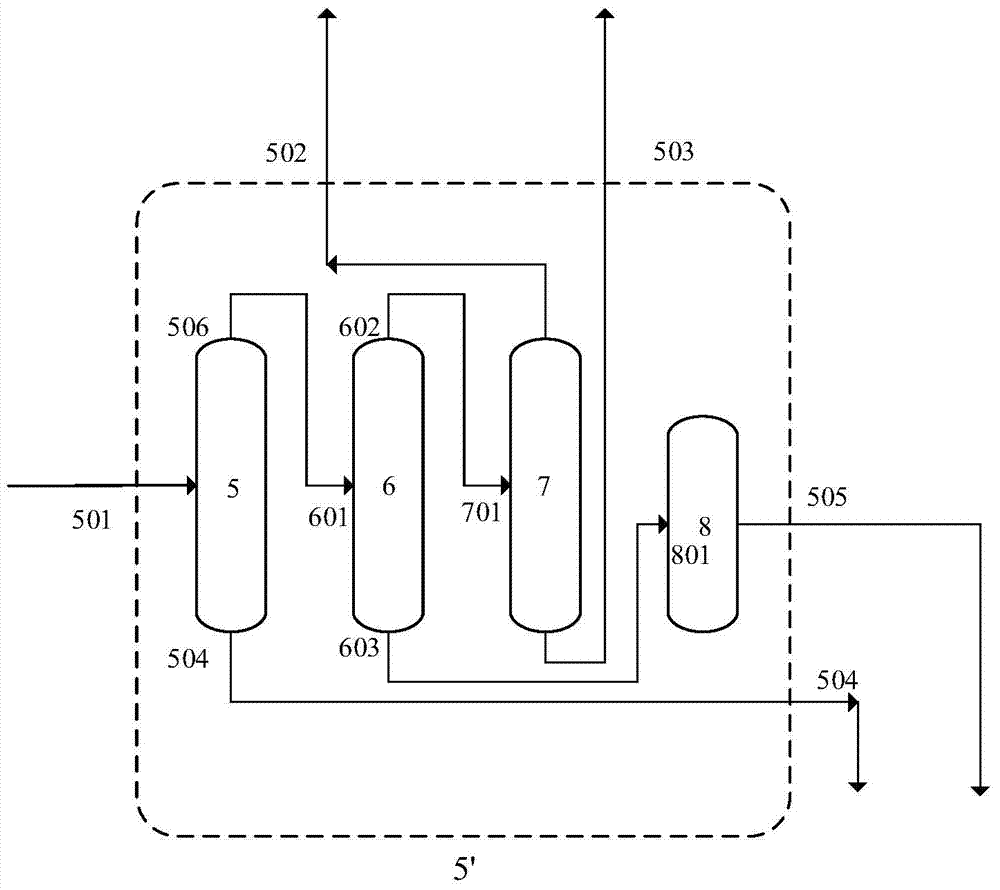

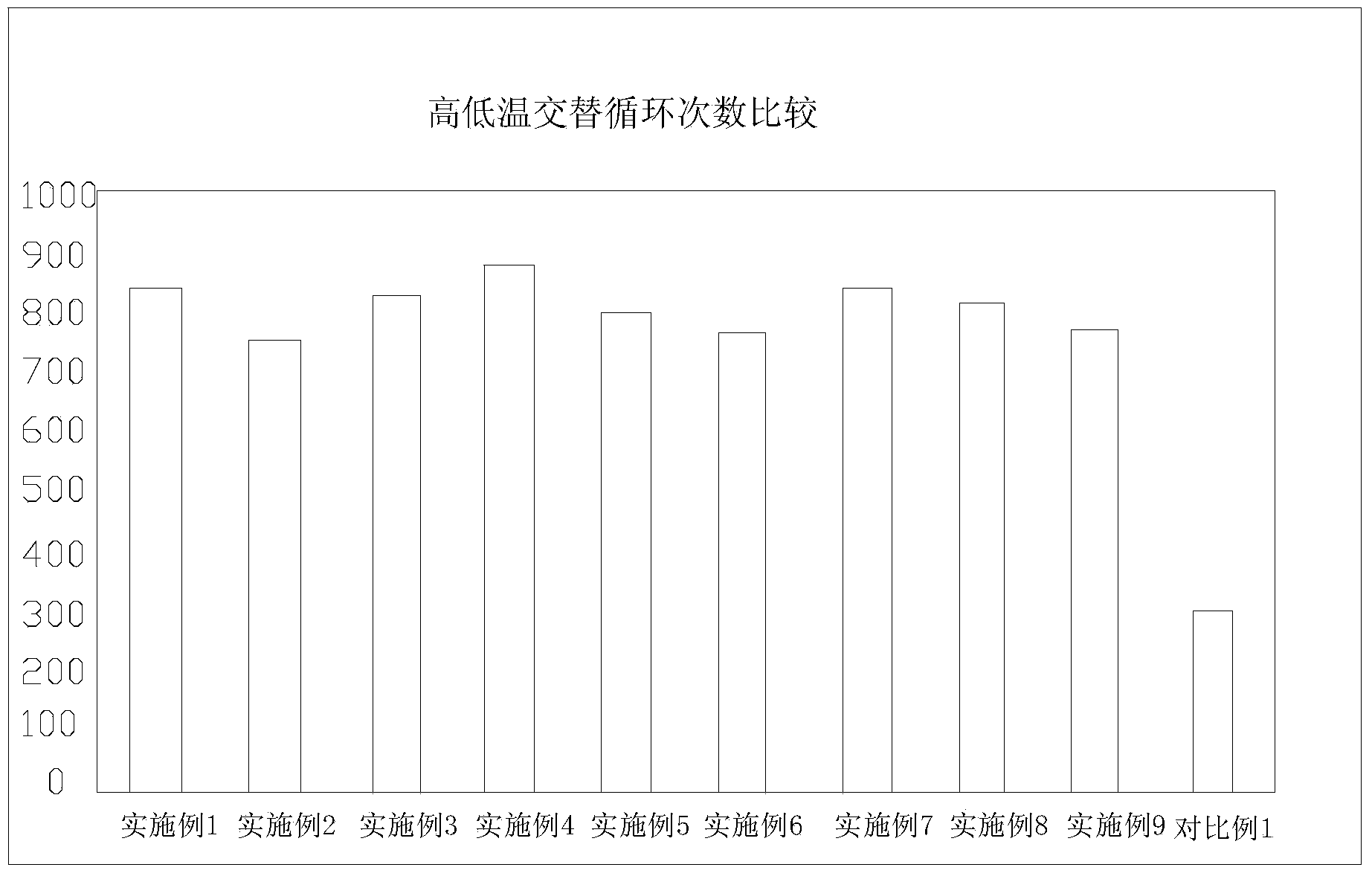

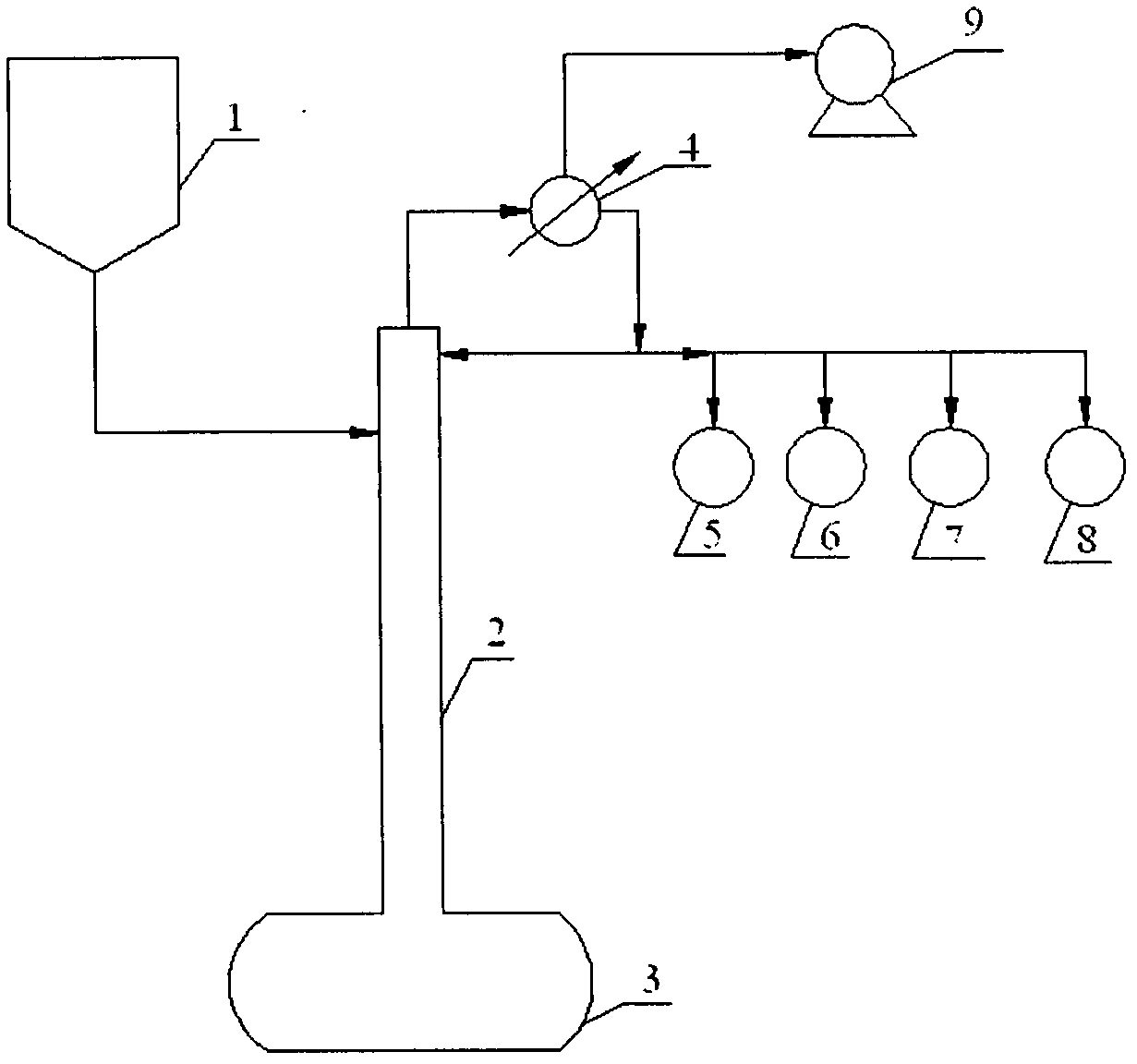

ActiveCN102775302AImprove utilization efficiencyImprove efficiencyOrganic compound preparationCarboxylic acid esters preparationFluidized bedEconomic benefits

The invention provides a method for preparing methyl methacrylate from methyl propionate and formaldehyde. According to the method for preparing the methyl methacrylate from the methyl propionate and the formaldehyde, the fluidized bed reactor and the catalyst regenerator are coupled, so that the problem on the rapid deactivation of the catalyst is solved effectively, and the continuous production is realized. The method achieves important economic benefits.

Owner:BEIJING RISUN TECH CO LTD

Preparation of benzotrizole light stabilizer

InactiveCN101029032AEasy to cleanReduce manufacturing costOrganic chemistryIce waterHydrazine compound

A process for preparing the benzotriazole as photostabilizer includes such steps as dissolving 2-nitro-2'-hydroxy-5'-methyl azobenzene and 2-nitro-2'-hydroxy-3'- tert-butyl-5'-methyl propionate azobenzene in the mixture of alcohol and alkali solution, adding hydrazine hydrate, heating, reflux reaction, using hydrochloric acid to neutralize the reaction liquid, depositing, filtering, water washing, drying to obtain an intermediate, dissolving it in the mixture of alcohol and alkali, adding sodium dithionate, stirring while reacting, adding ice water, neutralizing, filtering, drying, and recrystallizing in alcohol or isopropanol.

Owner:TIANJIN UNIV

Method for synthesizing methyl propionate by ethylene

ActiveCN103319337AGood choiceReduce consumptionOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide or formate reactionPtru catalystPropanoic acid

The invention discloses a method for synthesizing methyl propionate by ethylene. The methyl propionate is prepared from the materials: ethylene, methanol, carbon monoxide and water under existence of a catalyst in a carbonyl combination manner; and the adopted catalyst is a composite catalyst system taking palladium acetate as a main catalyst, and metal ions such as cobalt, nickel or ruthenium and the like as a promoter. The method disclosed by the invention has good catalytic activity and selectivity at a low temperature and low pressure; the composite catalyst system has the advantages of low consumption, good selectivity, long service life and the like; carbonyl synthesis of the methyl propionate from the ethylene can be efficiently catalyzed; the reaction result is based on the ethylene; the yield of the methyl propionate is greater than 95%; and the entire method has good commercial value.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Lithium ion electrolytes and lithium ion cells with good low temperature performance

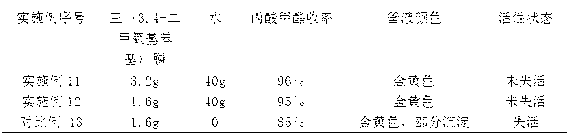

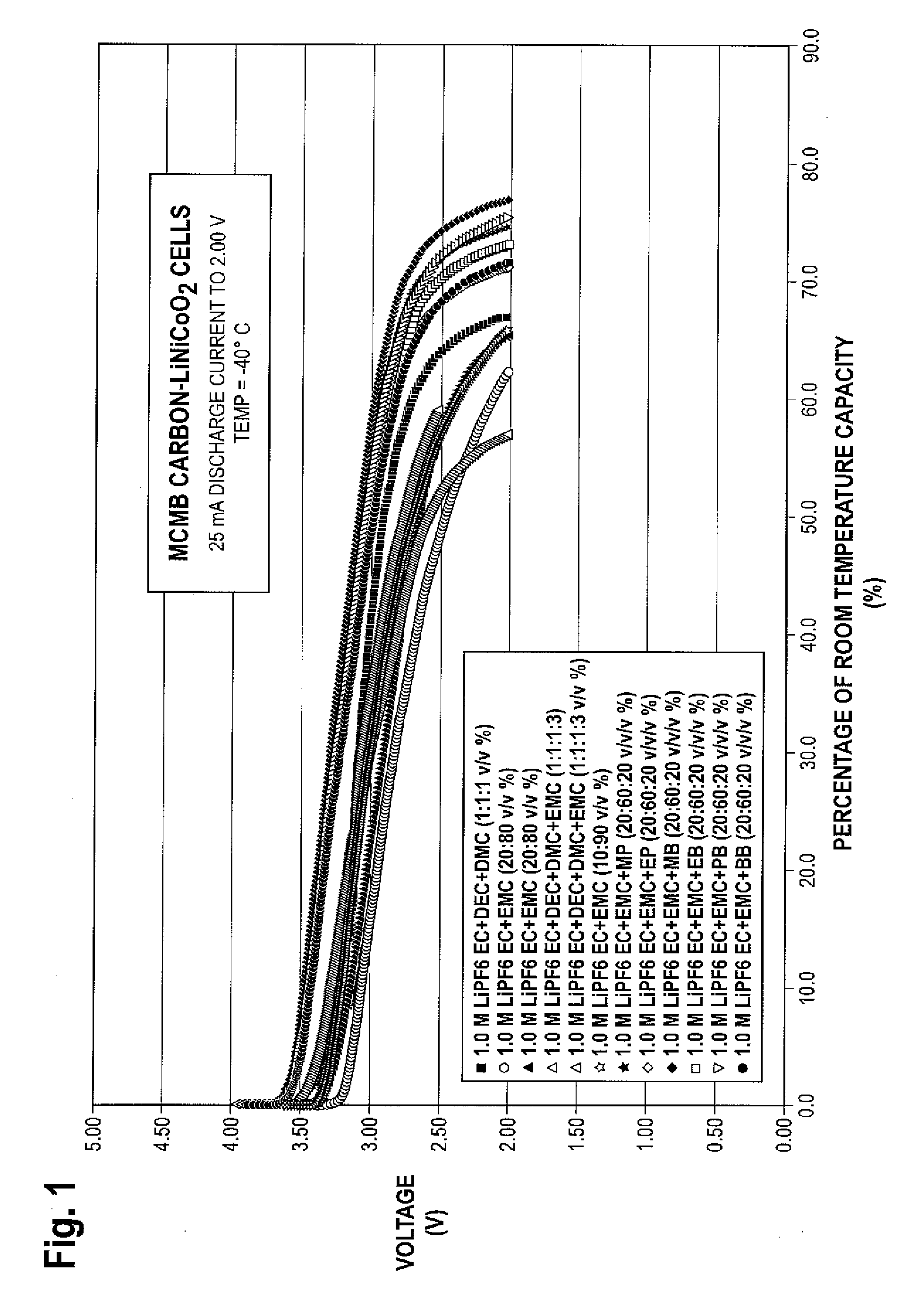

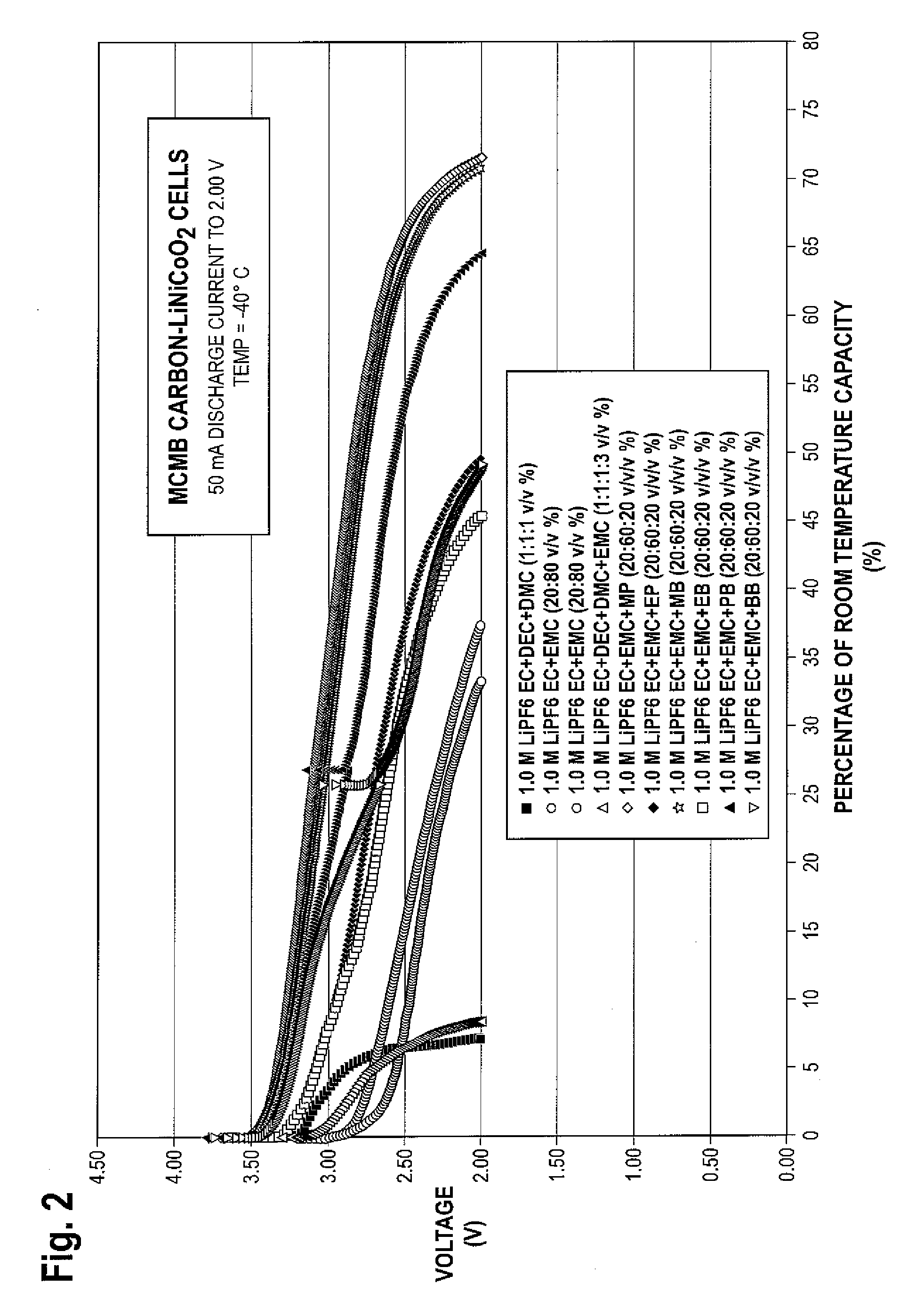

ActiveUS20090253046A1Improve low temperature performanceImprove stabilityOrganic electrolyte cellsNegative electrodesCelsius DegreeMethyl carbonate

There is provided in one embodiment of the invention an electrolyte for use in a lithium ion electrochemical cell. The electrolyte comprises a mixture of an ethylene carbonate (EC), an ethyl methyl carbonate (EMC), an ester cosolvent, and a lithium salt. The ester cosolvent comprises methyl propionate (MP), ethyl propionate (EP), methyl butyrate (MB), ethyl butyrate (EB), propyl butyrate (PB), or butyl butyrate (BB). The electrochemical cell operates in a temperature range of from about −60 degrees Celsius to about 60 degrees Celsius. In another embodiment there is provided a lithium ion electrochemical cell using the electrolyte of the invention.

Owner:CALIFORNIA INST OF TECH

Dynamic electrolyte for lithium ion battery

ActiveCN1925206ANo decomposition reactionImprove securityOrganic electrolyte cellsSecondary cellsFire retardantLithium-ion battery

Owner:GUANGZHOU TINCI MATERIALS TECH

Method for producing methyl methacrylate by methyl acetate and formaldehyde

InactiveCN104513163AImprove utilization efficiencyCan maintain high activity for a long timeOrganic compound preparationCarboxylic acid esters preparationFixed bedHigh activity

The invention relates to a method for producing methyl methacrylate, in particular to the method for producing the methyl methacrylate by taking methyl acetate and formaldehyde as raw materials. According to the adopted method, a fluidized bed reactor and a fixed bed reactor are used in a combined manner; unreacted methyl acetate serving as a raw material is cyclically utilized after being separated; methyl propionate generated by conducting hydrogenation on acrylic acid generated by the reaction can be sold as a byproduct, and can also be cyclically utilized with methyl acetate as a process raw material. An aldolization catalyst continuously flows between the fluidized bed reactor and a catalyst regenerator to realize a reaction regeneration process; the utilization rate of the catalyst is greatly improved; the continuity of production is realized. The fluidized bed reactor meets industrial production requirements; the high activity of the catalyst can be maintained for a long time; the use efficiency of the catalyst can be improved; the overall conversion rate is improved by the cycling of unreacted raw materials; the economic benefits are increased.

Owner:BEIJING RISUN TECH CO LTD

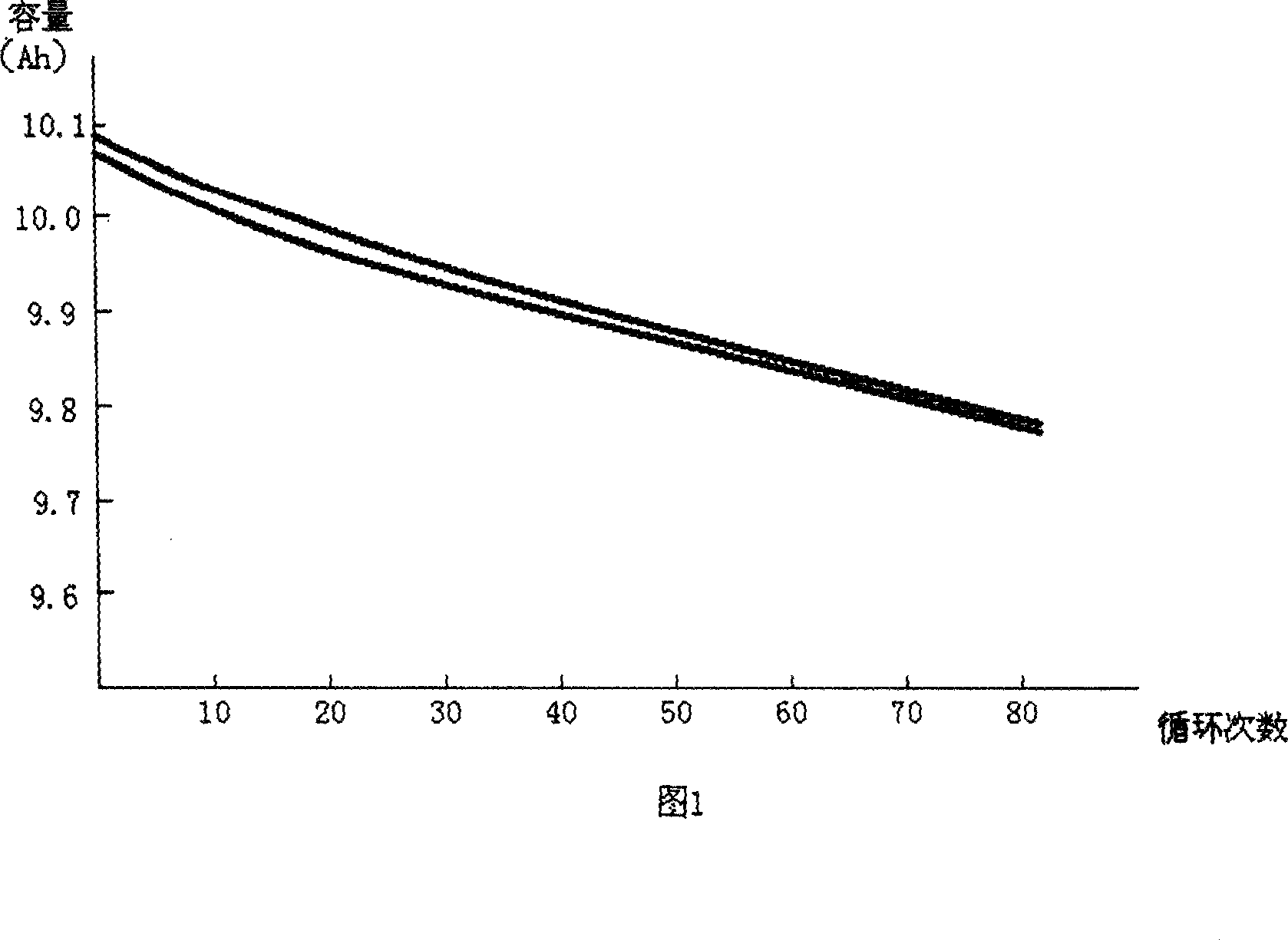

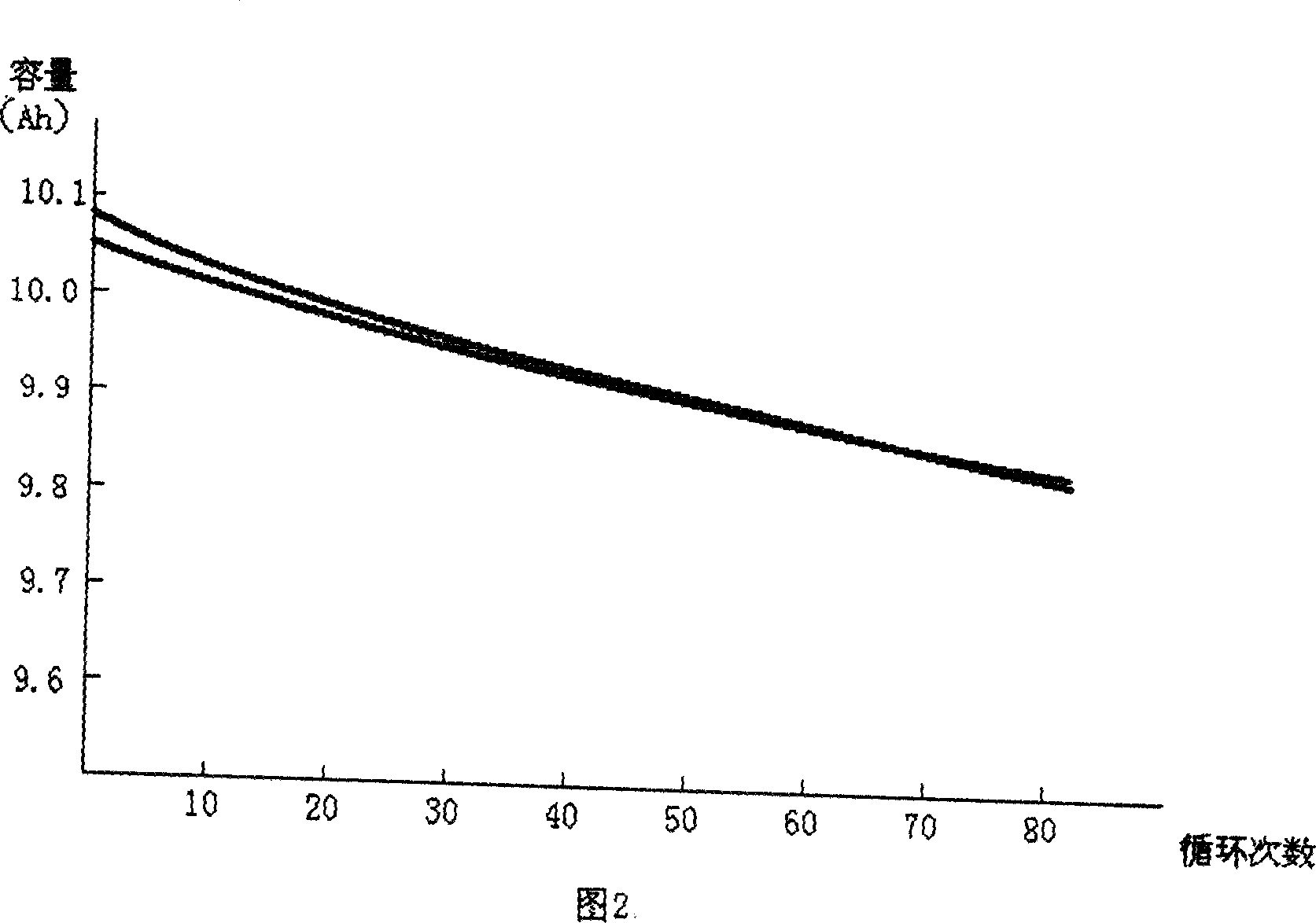

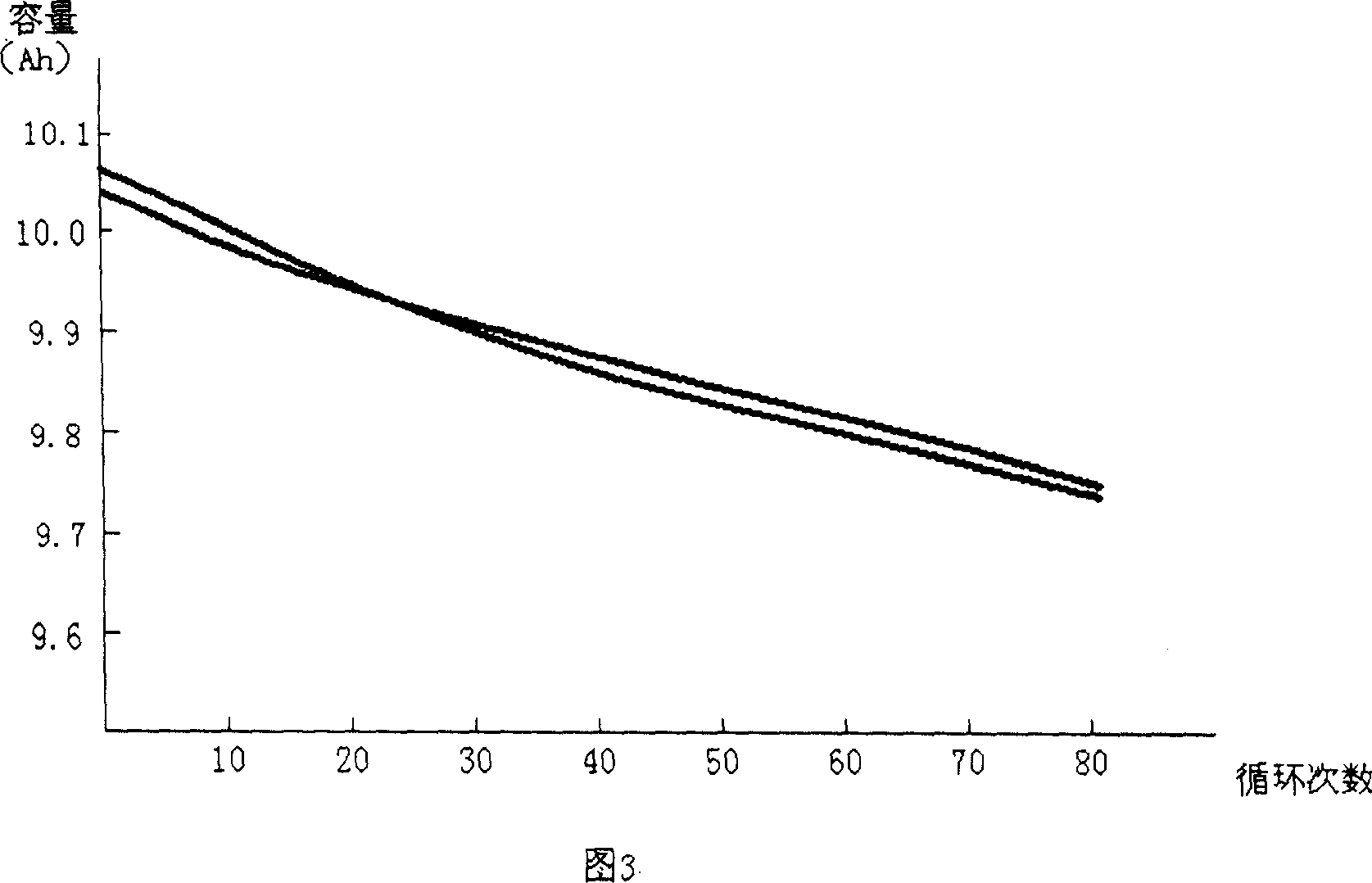

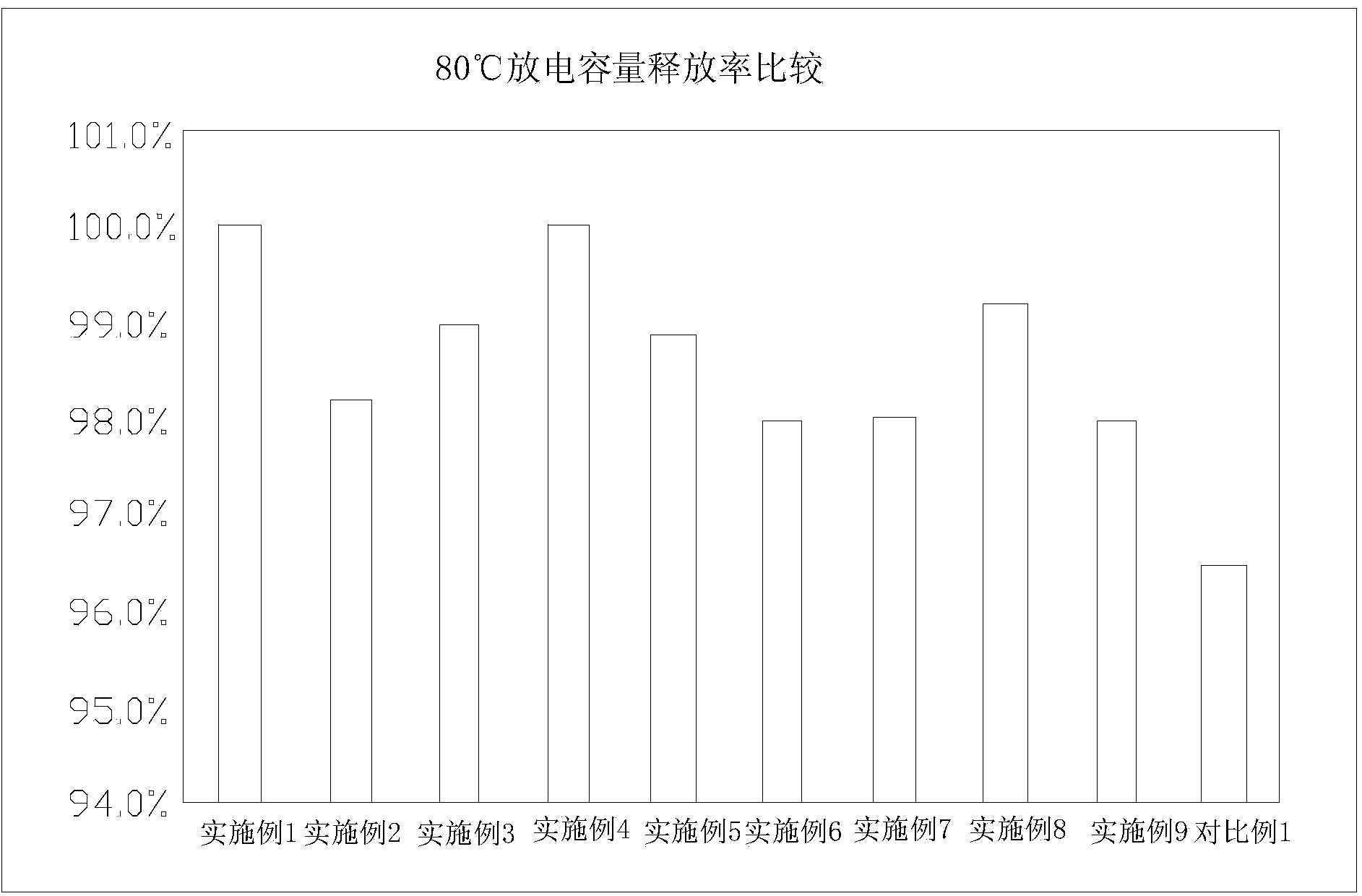

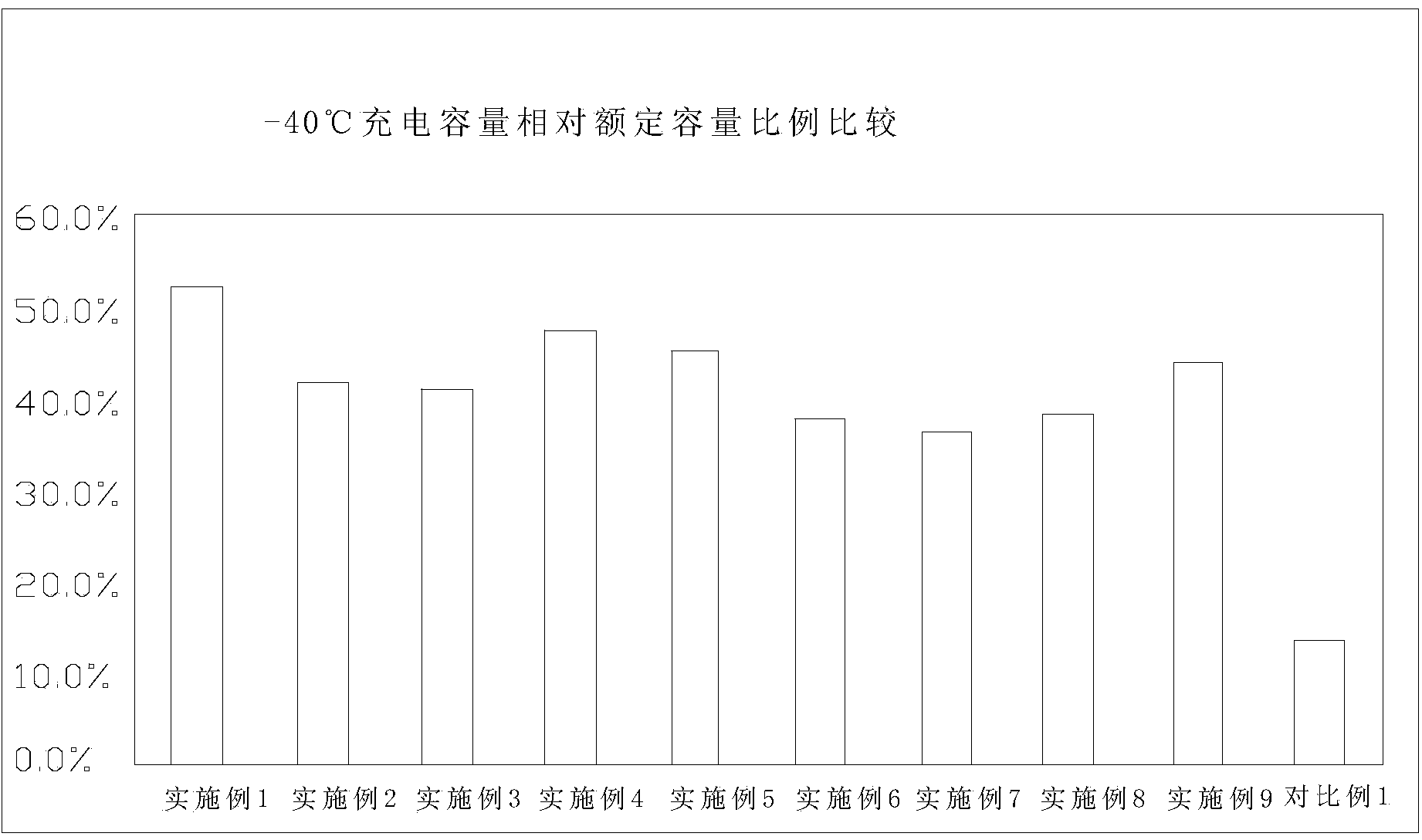

Lithium iron phosphate battery with lithium ion battery electrolyte suitable for ultralow-temperature charging and discharging

ActiveCN103367803AFacilitate quick migrationImprove ionic conductivitySecondary cellsMethyl carbonateEthyl butyrate

The invention relates to a lithium iron phosphate battery with lithium ion battery electrolyte suitable for ultralow-temperature charging and discharging. The lithium ion battery electrolyte comprises lithium salt, a multi-element organic solvent and additives, wherein the additives comprise a low-melting-point additive, a film forming additive and a high-temperature additive; the multi-element organic solvent contains at least three of ethylene carbonate, diethyl carbonate, dimethyl carbonate, methyl ethyl carbonate, propylene carbonate and butylene carbonate; the low-melting-point additive contains at least one of 4-methyl-1,3-dioxolane, methyl acetate, methyl propionate, methyl butyrate, ethyl butyrate, propyl butyrate and butyl acetate; the high-temperature additive is at least one of methyl ester, di-n-propyl carbonate and 1,3-propane sultone. The lithium iron phosphate battery with the electrolyte can charge and discharge at an ultralow temperature and in a high-temperature environment, and is stable in performance and long in recycling life.

Owner:HANGZHOU LIAO TECH

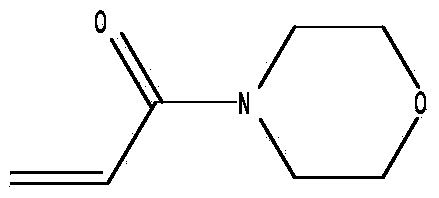

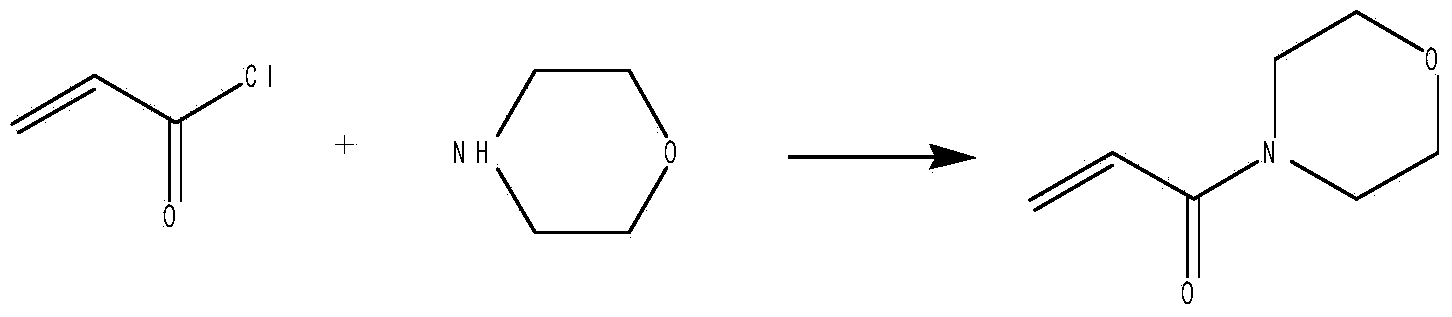

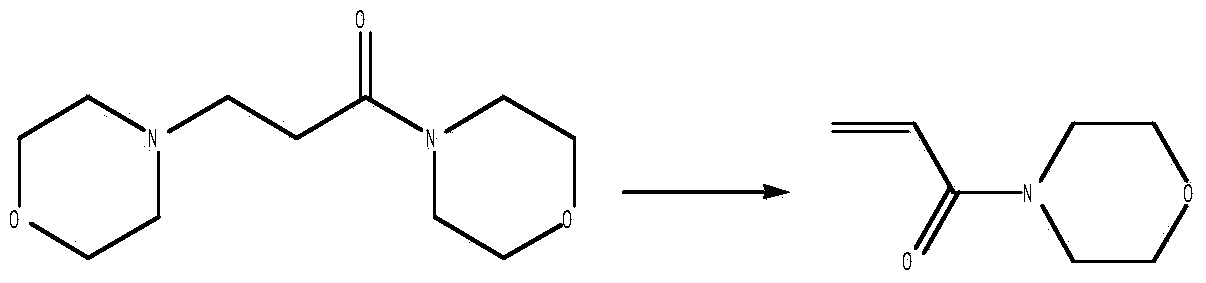

Synthetic improvement method of acryloylmorpholine

The invention relates to a synthetic improvement method of acryloylmorpholine, and belongs to the field of organic synthesis. The method comprises the following steps: performing Michael addition on diethylamine and methyl acrylate which are taken as raw materials so as to generate 3-methoxy-diethyl methyl propionate; then performing an amidation reaction by adding morpholine so as to generate 3-morpholinyl-diethyl propionamide; and finally performing a catalytic cracking reaction so as to obtain a target product, namely, the acryloylmorpholine. The method is simple and short in process, easy in raw material obtainment, simple in equipment, easy in reaction condition control, moderate in preparation condition and simple in purification refining process. The acryloylmorpholine is stable, easy to separate and is difficult to polymerize.

Owner:CHANGZHOU XIAOGUO INFORMATION SERVICES

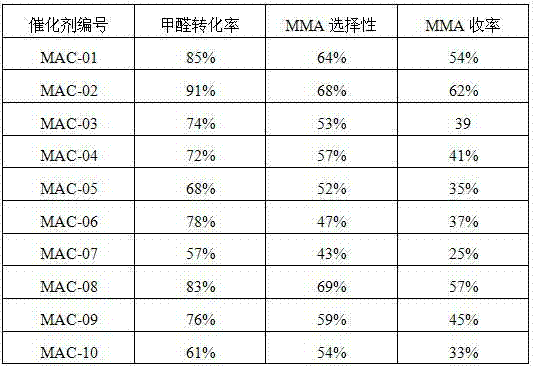

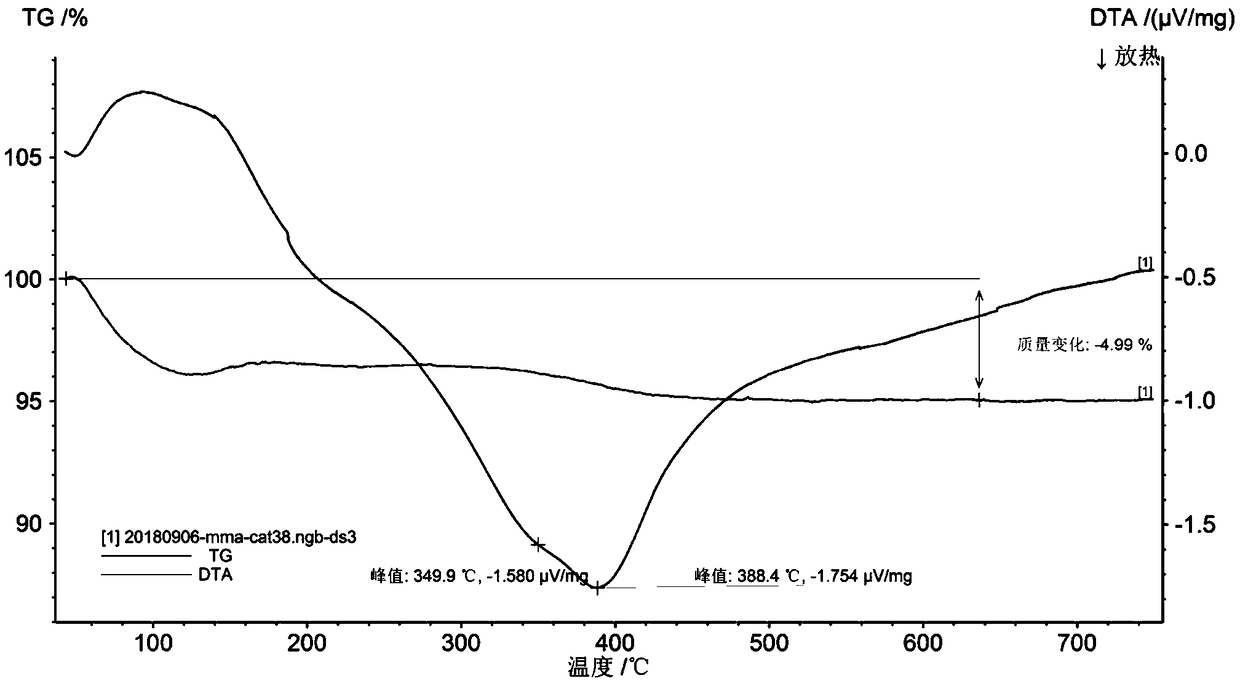

Catalyst for synthesis of methyl methacrylate by formaldehyde and methyl propionate and preparation method of catalyst

ActiveCN102962062ALarge specific surface areaImprove physicsOrganic compound preparationCarboxylic acid esters preparationPolymer sciencePtru catalyst

The invention discloses a catalyst for synthesis of methyl methacrylate by formaldehyde and methyl propionate and a preparation method of the catalyst. The catalyst mainly comprises a main active component, an activated auxiliary and a carrier, wherein the main active component is Cs, the activated auxiliary is selected from one or more of Sb, Nb and Ag, and the carrier is a nanometer SiO2 / Al2O3-ZrO2 composite carrier; and metered by oxides and according to mass percentage, the main active component Cs accounts for 5%-20%, the activated auxiliary accounts for 1%-5%, and the balance is the carrier. Simultaneously, the invention discloses a preparation method of the catalyst. The catalyst provided by the invention is good in activity, selectivity and stability, simple in manufacture technology, suitable for large-scale industrialized application and environment-friendly.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

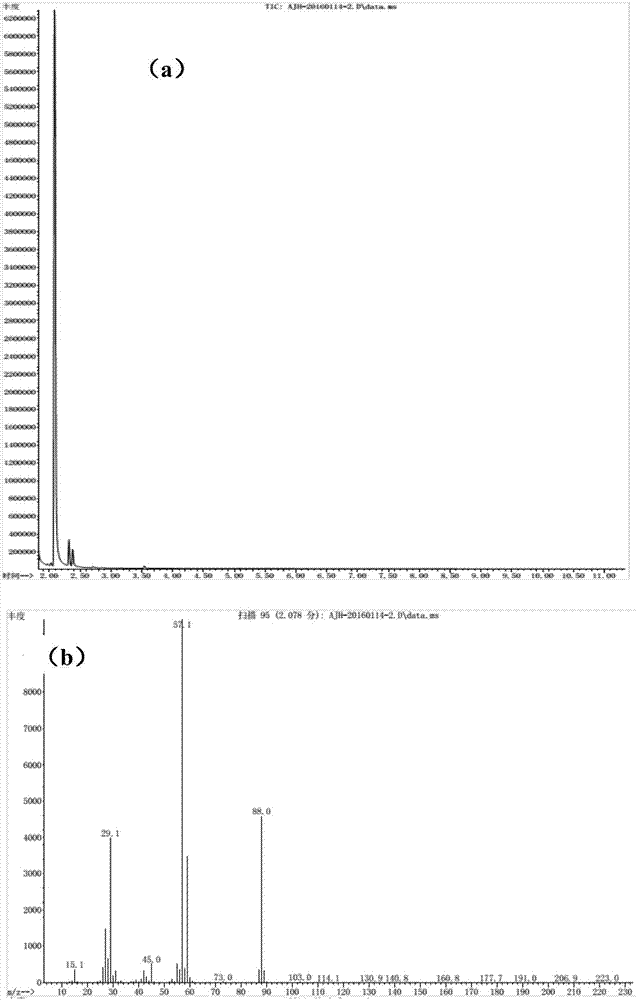

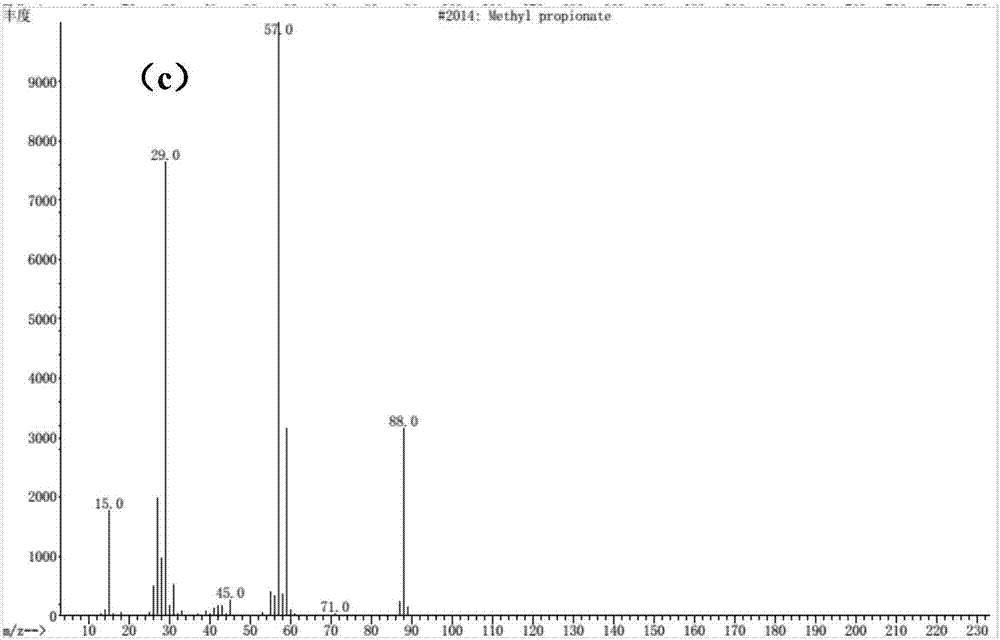

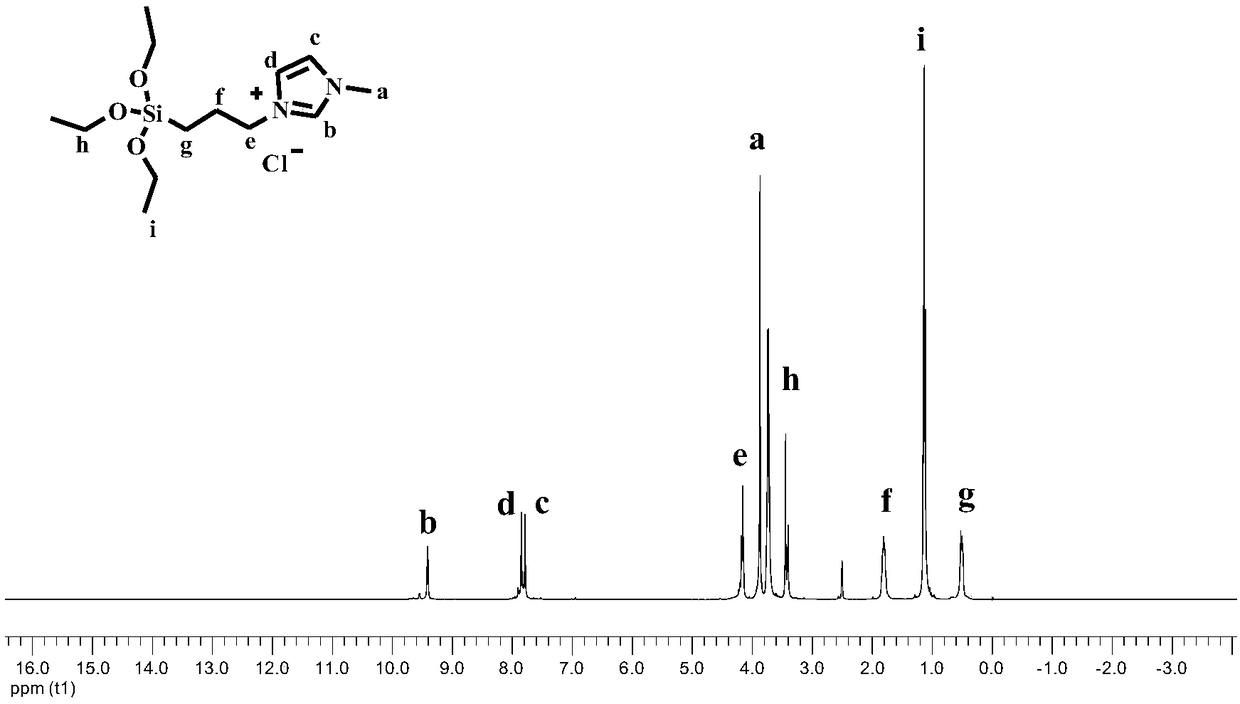

Preparation method of methyl propionate

InactiveCN102336661AEasy to manufactureHigh catalytic activityOrganic compound preparationCarboxylic acid esters preparationPropanoic acidMethyl propionate

The invention discloses a preparation method of methyl propionate. The method is characterized in that: propionic acid and methanol are reacted under the action of an acidic ion liquid catalyst to synthesize the methyl propionate. By the method, equipment corrosion can be reduced, and low-cost and large-scale production of the methyl propionate is realized.

Owner:BEIJING RISUN TECH CO LTD

Catalyst composition, preparation method thereof and method for preparing methyl propionate by using catalyst composition

ActiveCN104383918AOrganic compound preparationCarboxylic acid esters preparationActive componentSide reaction

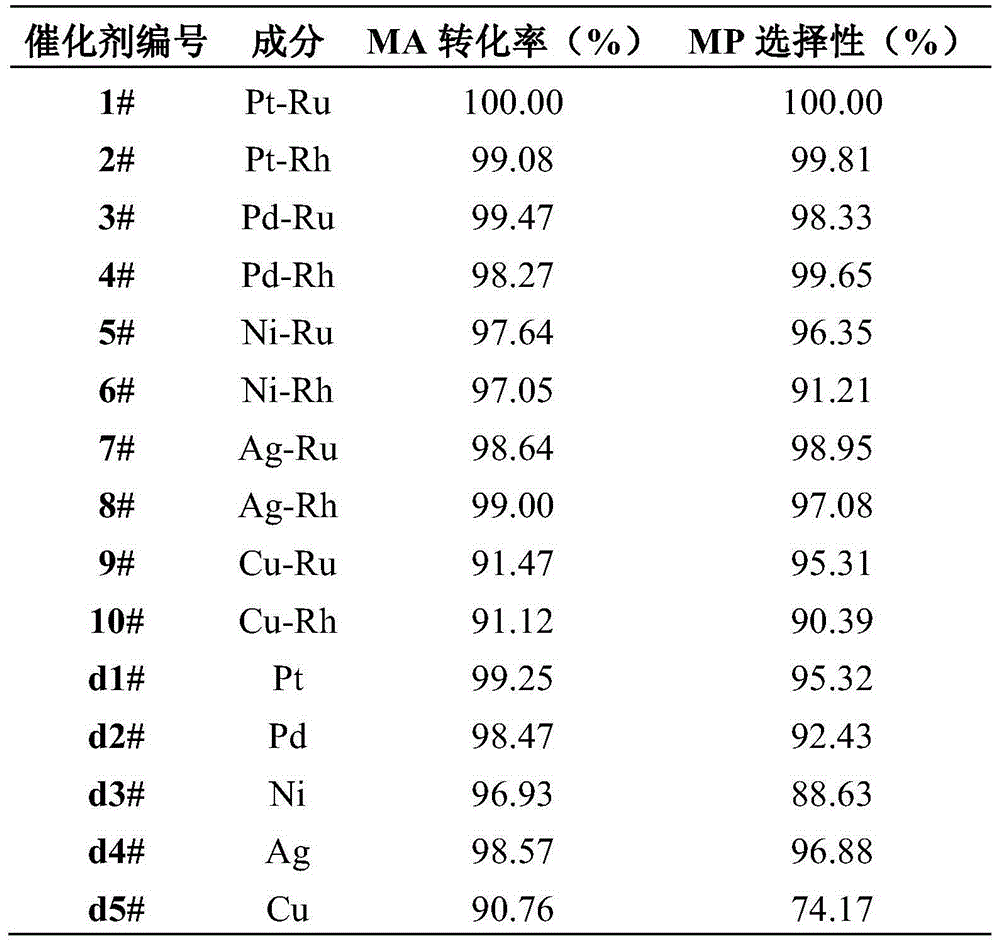

The application relates to a catalyst composition, a method thereof and a method for preparing methyl propionate by using the catalyst composition. According to the method disclosed by the invention, the side reaction is reduced and the selectivity of the methyl propionate product is improved by adding Ru and Rh to constitute a binary metallic active component system.

Owner:旭阳化学技术研究院有限公司

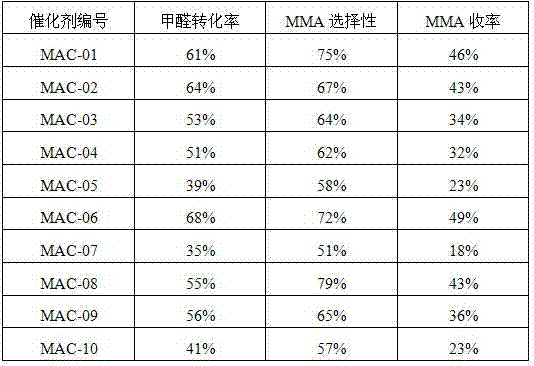

Water resistant catalyst for aldol condensation as well as preparation method and application thereof

ActiveCN103551148AGood physical and mechanical propertiesIncrease resistance to poisoningOrganic compound preparationCarboxylic acid esters preparationPtru catalystPropanoic acid

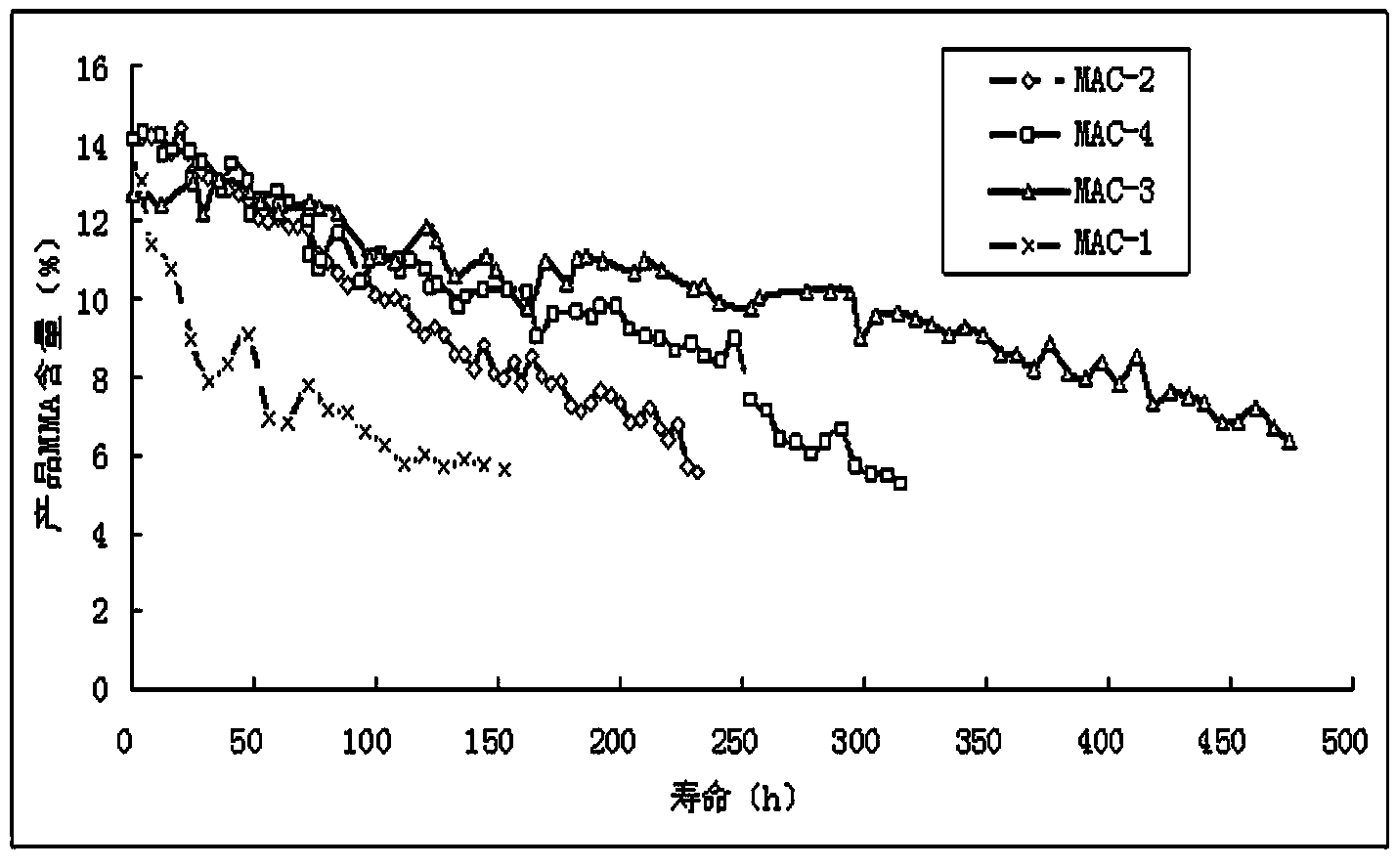

The invention discloses a water resistant catalyst for aldol condensation. The water resistant catalyst comprises a main active ingredient, an active agent and a carrier, wherein the main active ingredient is one or more selected from oxides or salts of Cs; the active agent is one or more selected from oxides or salts of Sb, Nb, Ag, Al and Zr; the carrier comprises SiO2 and a carrier aid; the carrier aid is one or more selected from Al2O3, ZrO2, diatomite and kaolin; the SiO2 is hydrophobic nano SiO2; or (2) the catalyst is subjected to water-resistant treatment. The water resistant catalyst is used for aldol condensation, has the characteristics of high activity, high selectivity and long service life, is especially used for synthesizing methyl methacrylate through formaldehyde and methyl propionate. With calculation of methyl propionate, the selectivity of methyl methacrylate is 94 percent, and the single service life of the catalyst is over 400 hours. The catalyst is simple in preparation method and is suitable for industrial application.

Owner:HAO HUA CHENGDU TECH

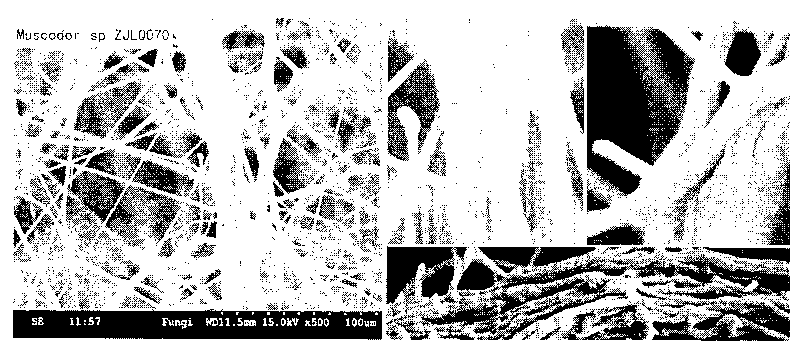

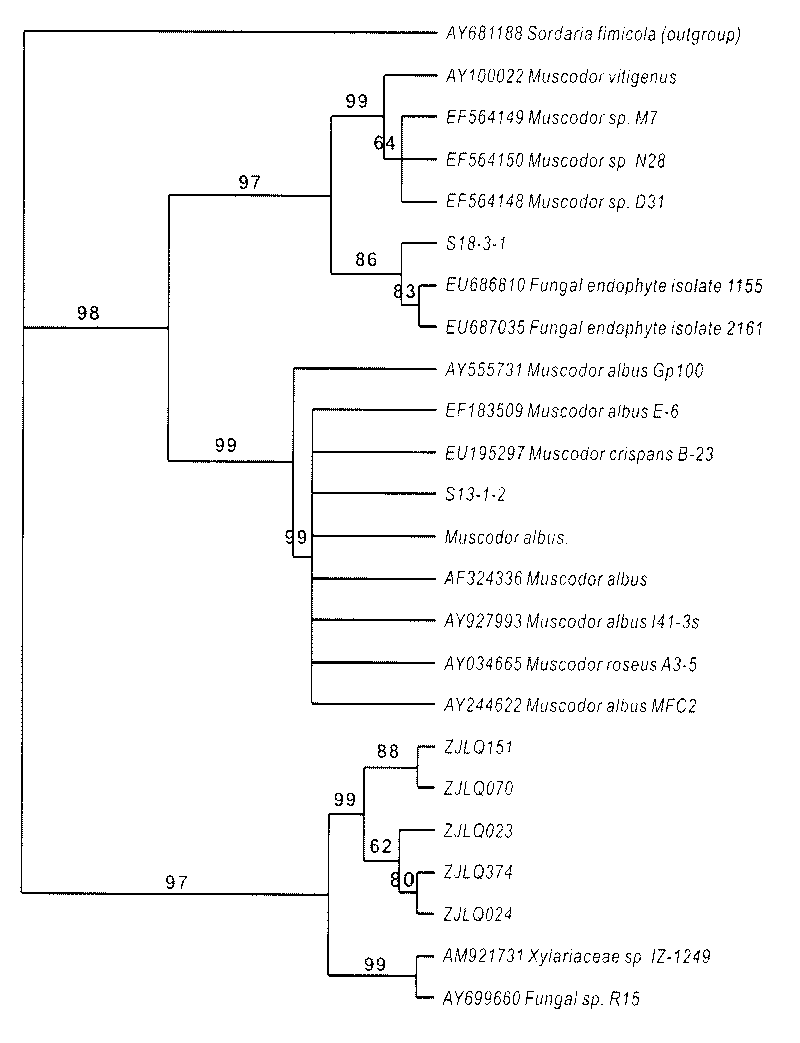

Muscodor endophytic fungi ZJLQ070 and application thereof and fungicide

The invention discloses endophytic fungi Muscodor sp. The preservation name of the strain is ZJLQ070, the preservation unit is China General Microbiological Culture Collection Center, the preservation date is January 8, 2009 and the preservation number is CGMCC 2864. The endophytic fungi can be prepared into living preparations and can be used for suppressing or killing pathogenic microorganisms or musty microorganisms. The invention simultaneously discloses a fungicide comprising 2-methyl-methyl propionate, 2-methylpropionate and the like, especially comprising alpha-phellandrene, beta-phellandrene, trans1-methyl-4-(1-methyl ethyl)-2-cyclohexene-1-alcohol, cis1- methyl-4-(1-methyl ethyl)-2-cyclohexene-1-alcohol, trans3-methyl-6-(1-methyl ethyl)-2-cyclohexene-1-alcohol and cis3-methyl-6-(1-methyl ethyl)-2-cyclohexene-1-alcohol.

Owner:ZHEJIANG DAYANG BIOTECH GROUP

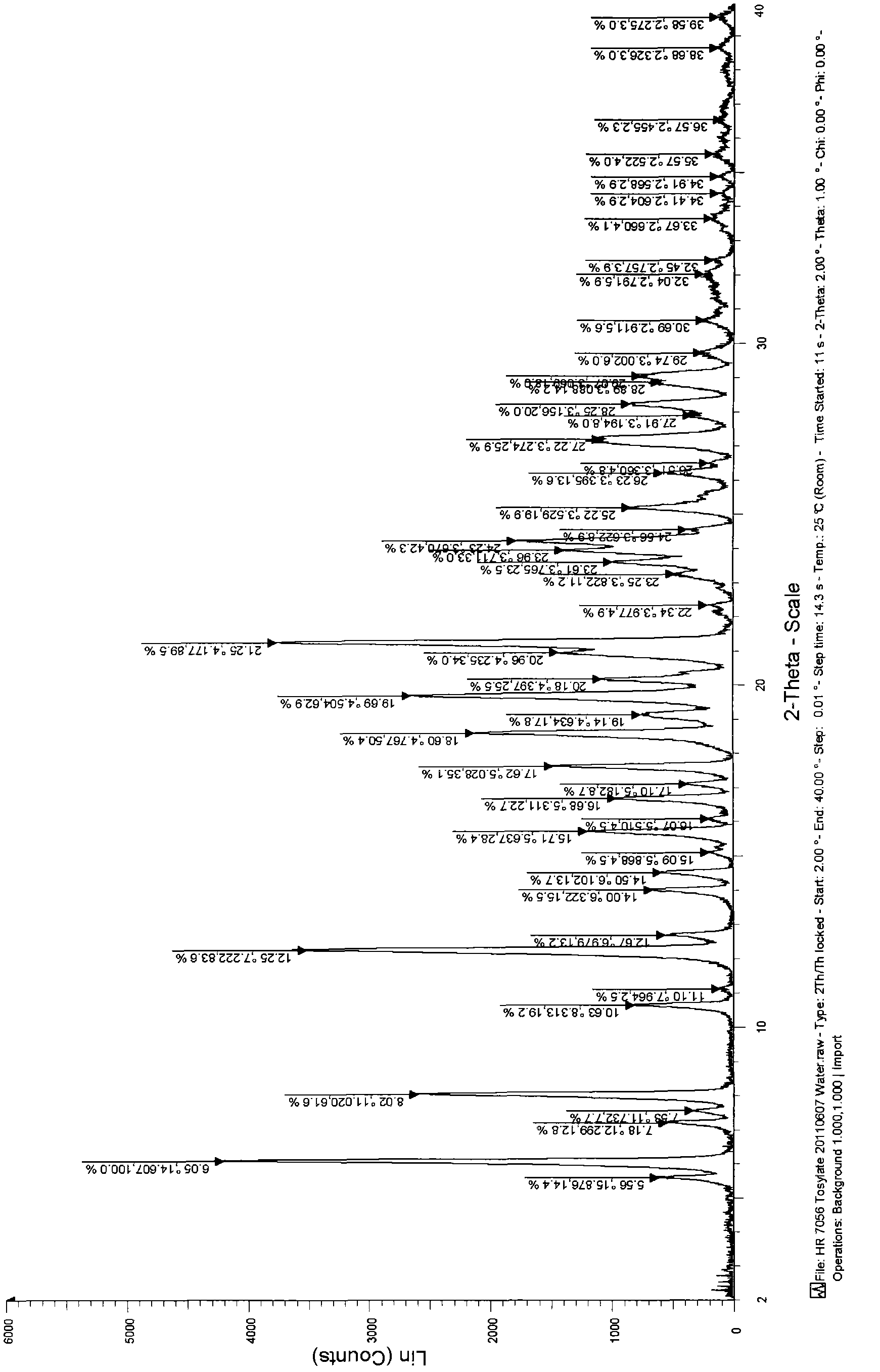

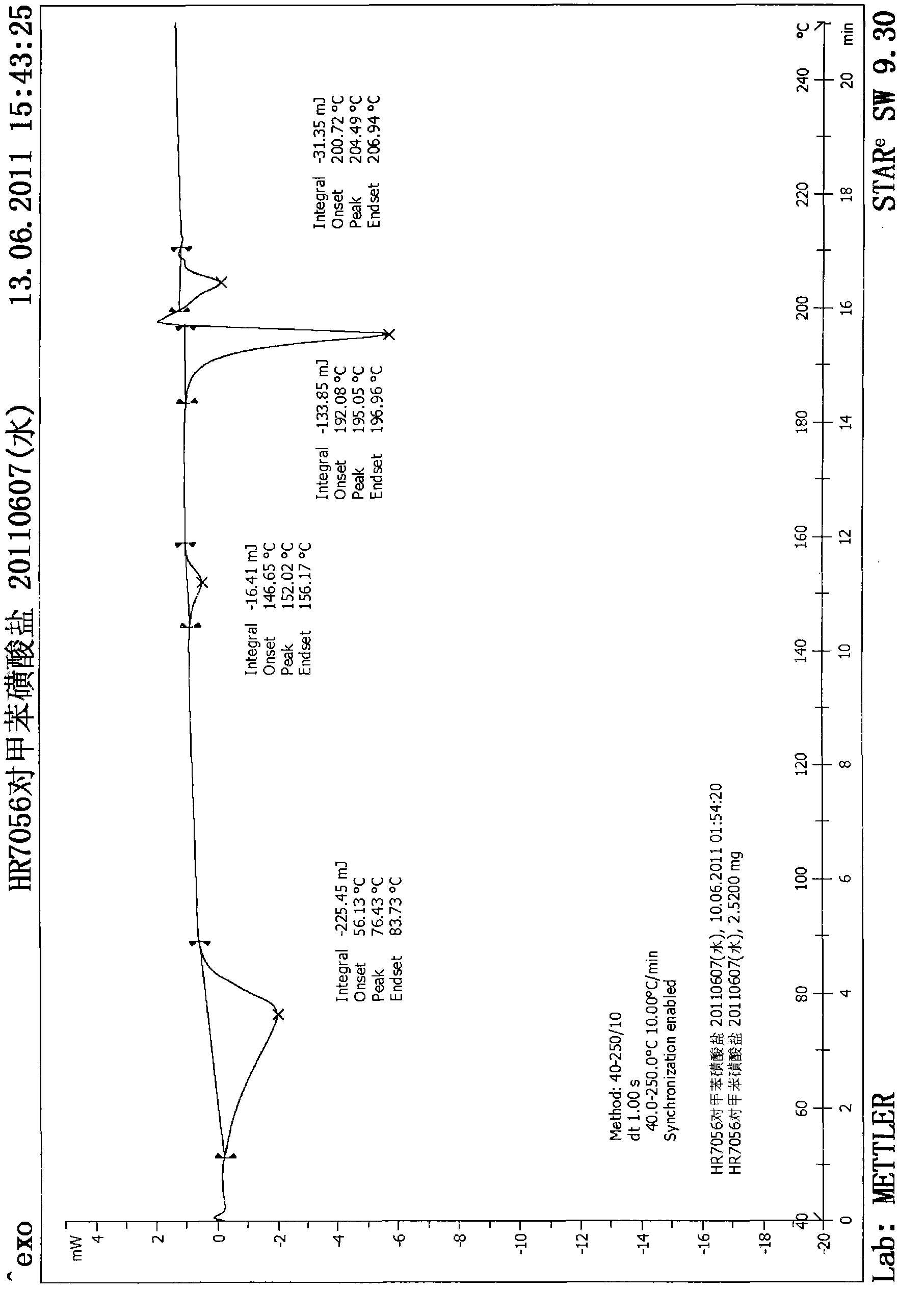

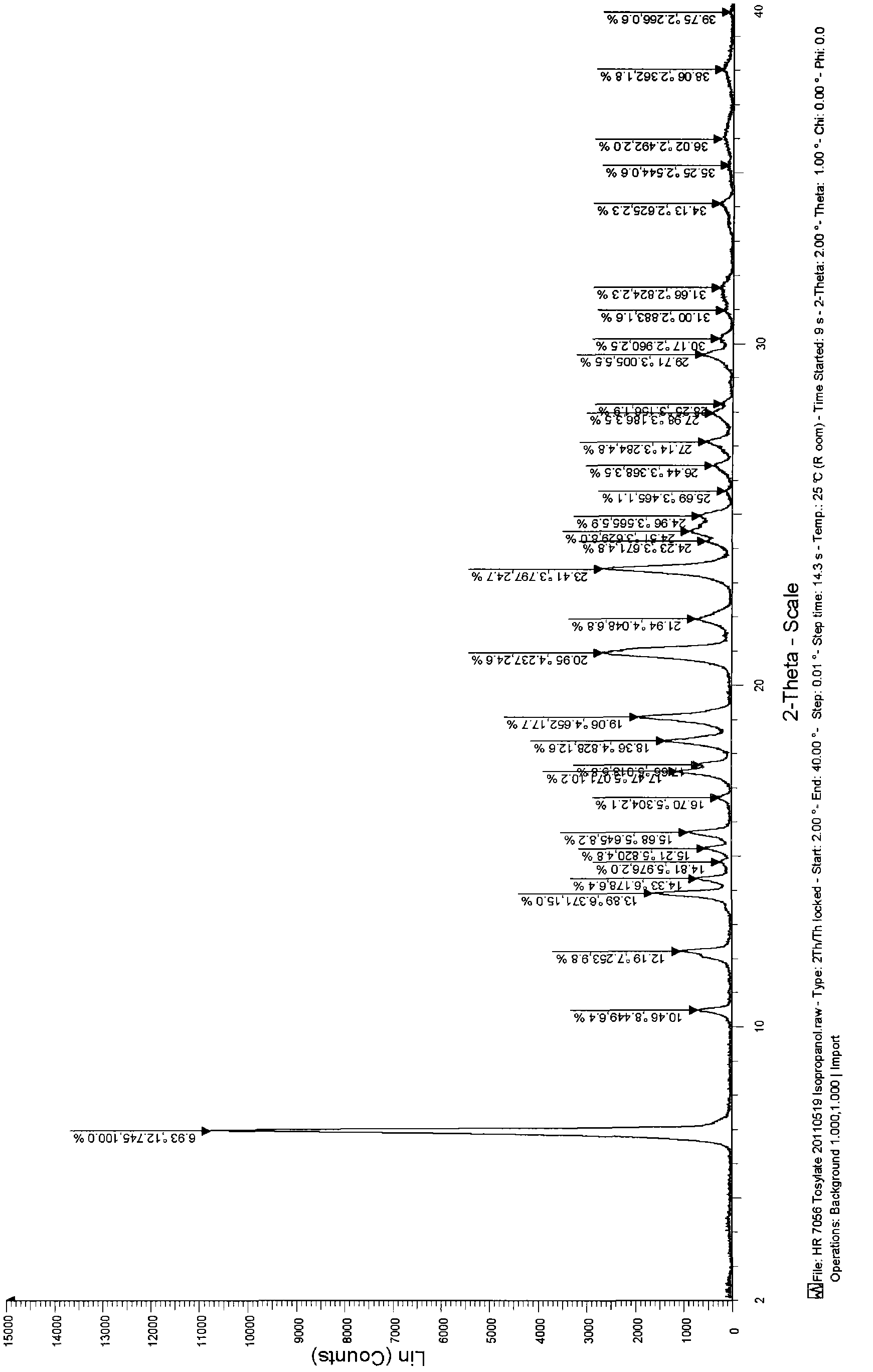

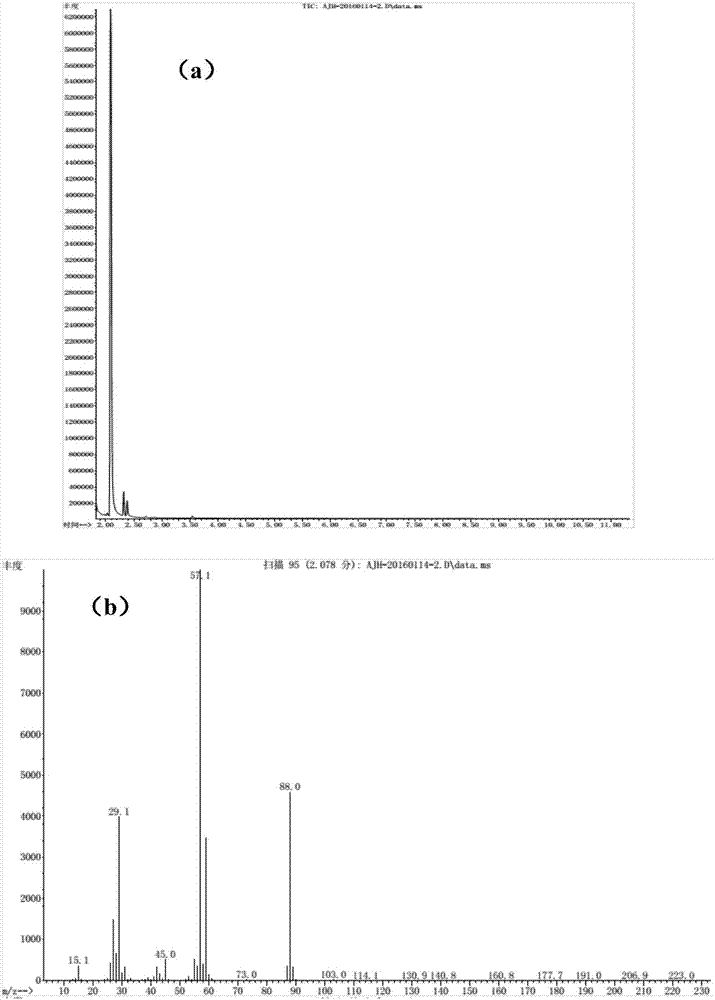

Tosilate of benzodiazepine derivative, its crystal forms, their preparation method and application

InactiveCN102964349AMeet the limit requirementsOrganic active ingredientsNervous disorderBenzodiazepineSolvent

The invention relates to a tosilate of a benzodiazepine derivative, its crystal forms, their preparation method and application, especially to the crystal forms of a 3-[(4S)-8-bromo-1-methyl-6-(2-pyridyl)-4H-imidazole[1, 2-a][1, 4]benzodiazepine-4-yl)methyl propionate (I) tosilate, their preparation method and application. The obtained crystals of the tosilate of a compound as shown in formula (I) has low solvent residual and good stability, and can be better used in clinical treatment.

Owner:JIANGSU HENGRUI MEDICINE CO LTD

Method for catalytic synthesis of methyl propionate

ActiveCN102320962AIncrease profitAvoid corrosionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsHydrogen SulfatePropanoic acid

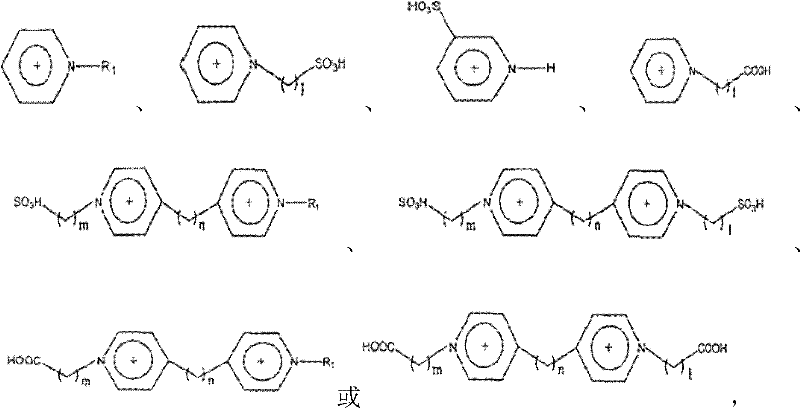

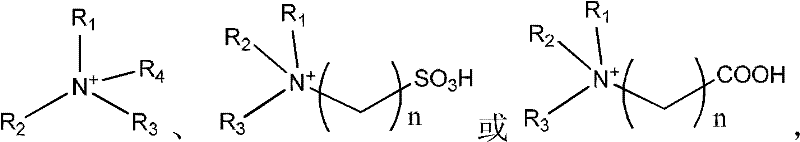

The invention discloses a method for catalytic synthesis of methyl propionate. The method comprises the steps of: uniformly mixing a catalyst and propanoic acid, adding to a reaction kettle, heating the reaction kettle in an oil bath, after the liquid in the kettle reaches a certain temperature, continuously adding a mixture of propanoic acid and methanol, beginning an esterification reaction, and rectifying with a rectifying tower to obtain methyl propionate, wherein the catalyst is selected from an ion liquid of pyridinium hydrogen sulfate, imidazolium hydrogen sulfate, pyridinium p-toluenesulfonate, imidazolium p-toluenesulfonate and imidazolium hydrogen phosphate or p-toluenesulfonic acid. The method has the advantages that the equipment corrosion caused by strong acidity when sulfuric acid is used as the catalyst is avoided, the industrial investment cost is lowered, the utilization rate of the catalyst is higher, and the yield of the esterification reaction can reach more than 93%.

Owner:沧州旭阳化工有限公司

Methyl propionate preparation method

ActiveCN108003024ANo generationAtom economyPreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsFixed bedReaction temperature

The invention relates to a methyl propionate preparation method, which comprises carrying out a reaction on raw materials including ethylene, carbon monoxide and methanol in a fixed bed reactor at a reaction temperature of 150-250 DEG C, wherein a reaction pipe is filled with a ruthenium-loaded metal oxide catalyst, and the reaction pipe with the catalyst is placed in the fixed bed reactor. According to the present invention, the reaction has the 100% atomic economy, does not produce by-products, and uses the noble metal-loaded metal oxide or the molecular sieve as the catalyst, wherein the catalyst is easily prepared and efficiently catalyzes the reaction, and the yield of methyl propionate can reach over 80% .

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method of hindered phenol antioxidant

InactiveCN106674002AReduce lossReduce energy consumptionPreparation by ester-hydroxy reactionOrganic compound preparationFiltrationDistillation

The invention discloses a preparation method of a hindered phenol antioxidant. The method comprises the steps of uniformly mixing 3-methyl-5-tertiary butyl-4-methyl hydroxyphenylpropionate or 3-(3,5-tert butyl-4-hydroxy phenyl) methyl propionate and corresponding alcohol or amine evenly under agitation, carrying out heating, decompression and light fraction removal, adding a catalyst and carrying out heating and decompression for transesterification; infiltrating reaction liquid into a scraper evaporator after reaction is completed or carrying out flash evaporation in short-range distillation equipment and evaporating unreacted 3-methyl-5-tertiary butyl-4-methyl hydroxyphenylpropionate or 3-(3,5-tert butyl-4-hydroxy phenyl) methyl propionate; and cooling and adding acid, carrying out heat preservation and neutralization, filtering out the catalyst through hot filtration, carrying out crystallization and drying to obtain a target product antioxidant. Compared with a traditional method, the preparation method has the advantages of being simple and convenient in operation, the material loss and energy consumption in recovery of 345 ester or 35 methyl ester are reduced, the problems of three wastes in a traditional recovery process is solved, and meanwhile, the yield and quality of the target antioxidant are improved.

Owner:RIANLON

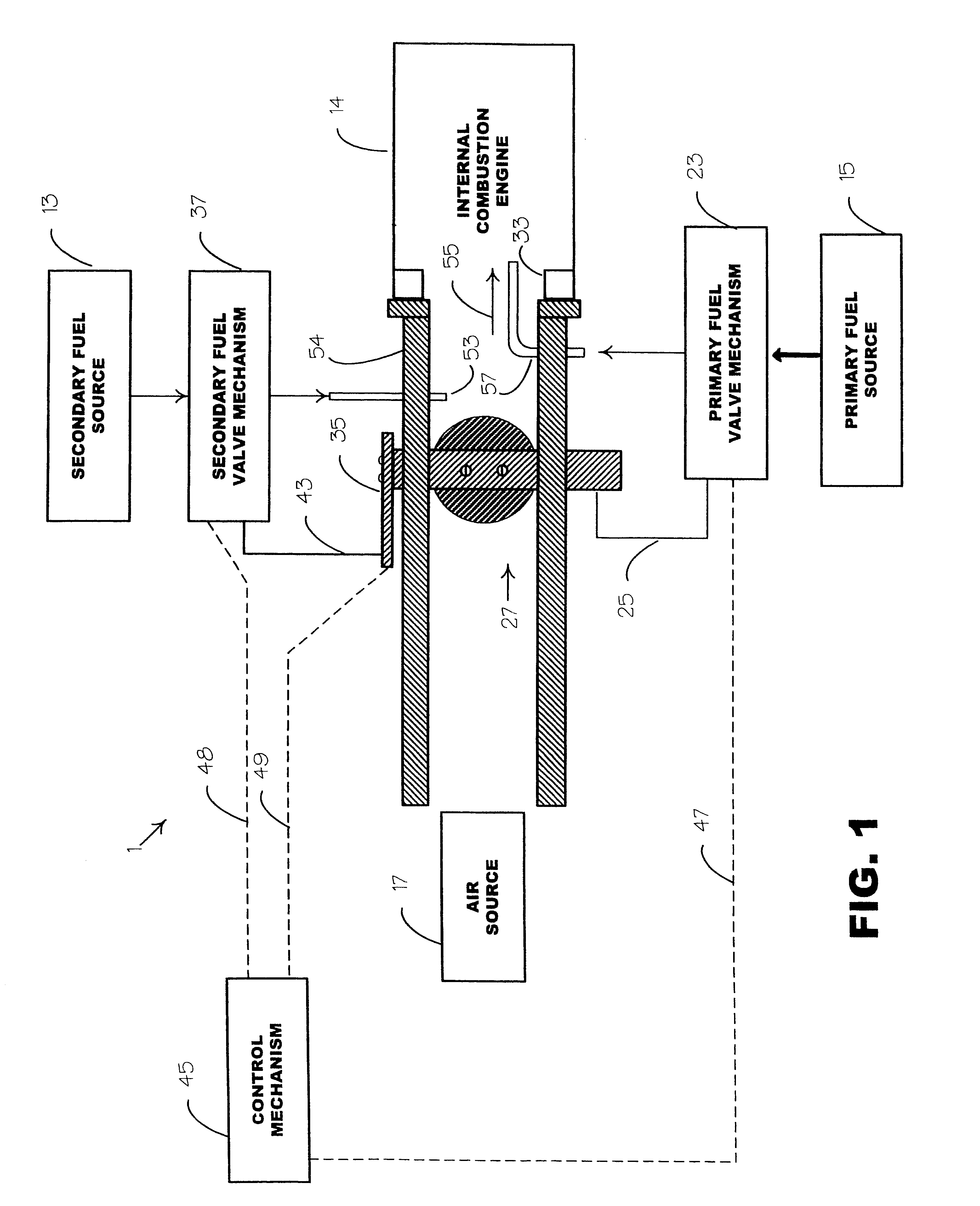

Dual fuel composition including acetylene

InactiveUS7288127B1Easy to operateImprove performanceInternal combustion piston enginesNon-fuel substance addition to fuelCarbon chainDiethyl ether

An environmentally clean dual fuel for use in an internal combustion engine, comprising acetylene as a primary fuel and a combustible fuel, such as one or more fluids selected from an alcohol such as ethanol, methanol or any other alcohol or alcohols from the group comprising C1-C20 carbon chains, ethers such as from the group comprising dimethyl ether, diethyl ether, methyl t-butyl ether, ethyl t-butyl ether, t-amyl methyl ether, di-isopropyl ether and the like, low-molecular-weight esters such as from the group comprising methyl formate, methyl acetate, ethyl acetate, methyl propionate, ethyl propionate, ethyl malate, and butyl malate, and the like, or other suitable combustible fluid such as mineral spirits and the like, as a secondary fuel for operatively preventing early ignition and knock arising from the primary fuel.

Owner:GOTEC

Methyl propionate preparation method

ActiveCN108003023AHigh activityEasy to makePreparation by carbon monoxide or formate reactionReaction temperatureRuthenium

The present invention relates to a methyl propionate preparation method, which comprises: mixing methanol and a ruthenium-supported metal oxide catalyst, placing the obtained mixture in a pressure container, filling with ethylene and carbon monoxide, sealing, and stirring, wherein the reaction temperature is more than or equal to 130 DEG C, the reaction time is more than or equal to 2 h, and the ruthenium-supported metal oxide catalyst is one or a plurality of material selected from Ru / TiO2, Ru / Nb2O5, Ru / CeO2 and Ru / Al2O3. According to the present invention, with the method, the catalyst is easily separated from the reaction system after the reaction, and can be used repeatedly, and the yield of propyl formate is up to 90%.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

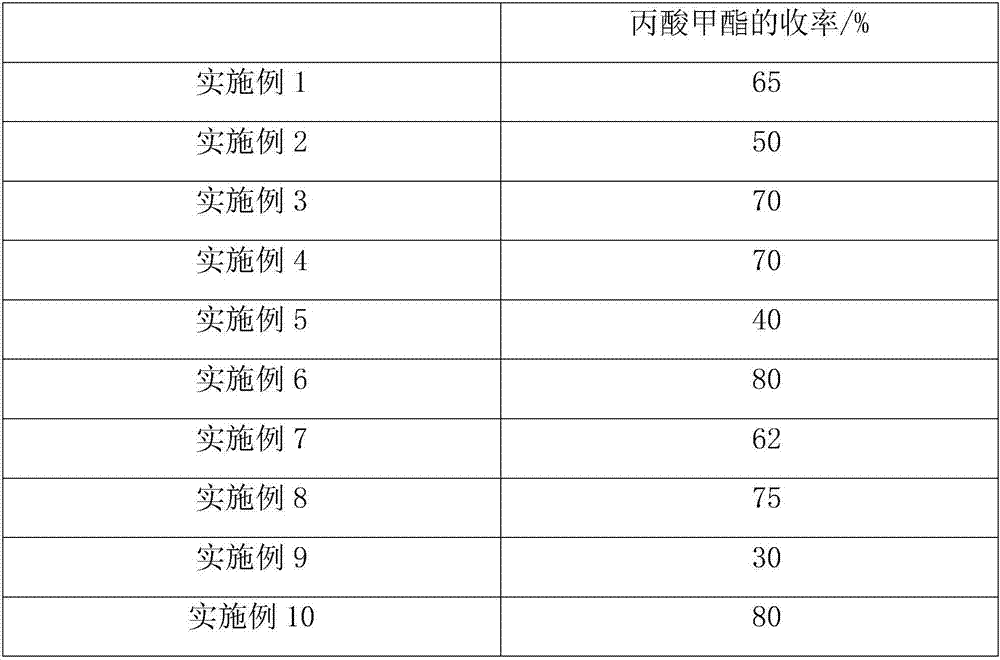

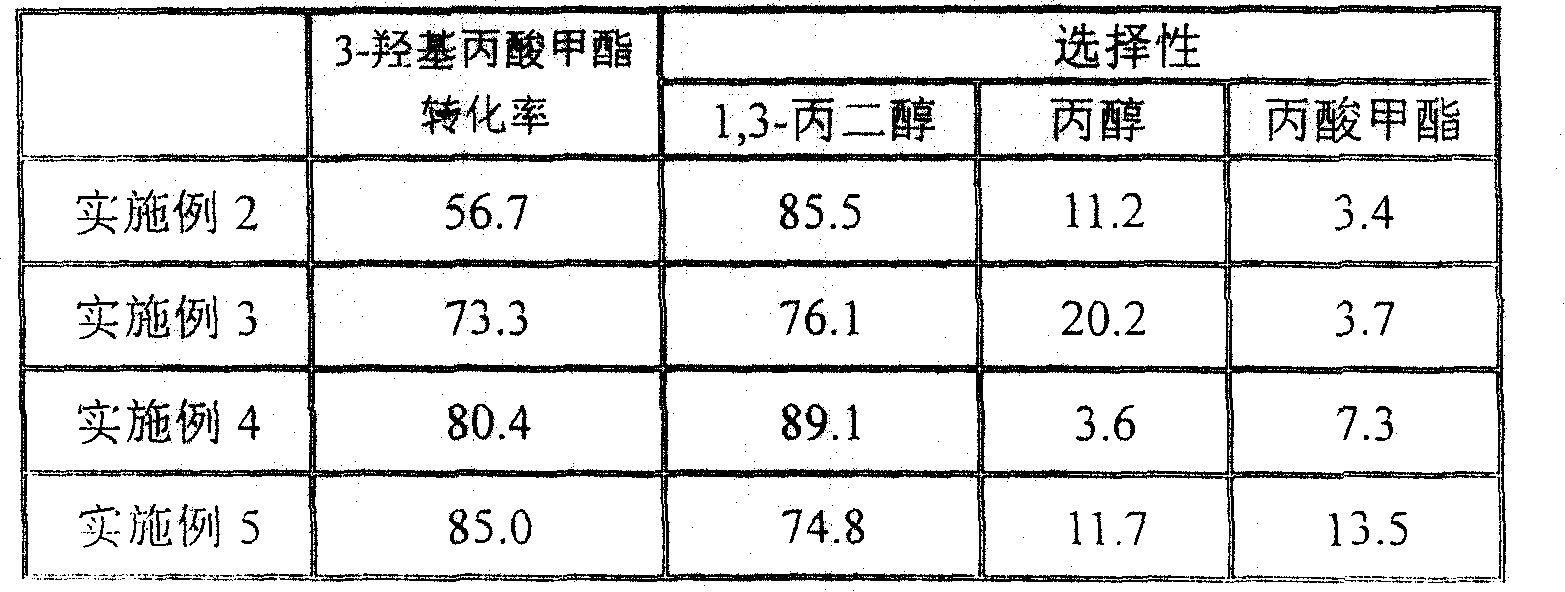

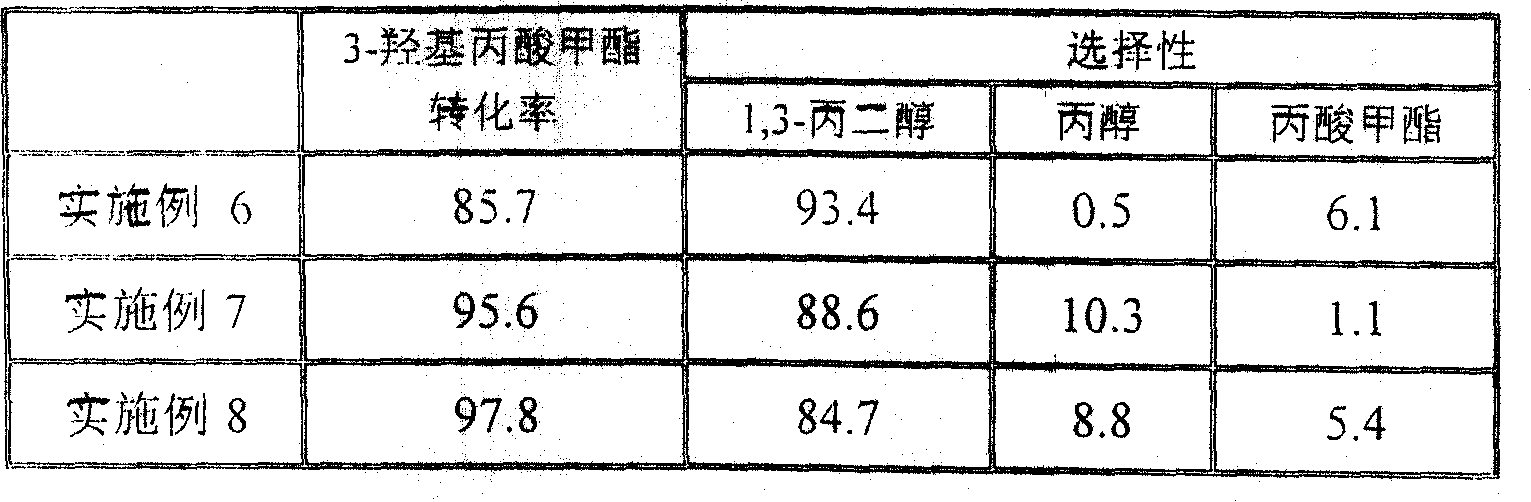

Method for producing 1-propylene glycol with 3-hydracrylic acid methyl ester

InactiveCN101195558AHigh catalytic activityHigh selectivityOxygen-containing compound preparationOrganic compound preparationPropylene glycolMethyl propionate

The invention relates to a method for preparing 1, 3-propylene glycol reaction hydrogenated by 3-hydroxy methyl propionate, which adopts CuO-SiO2 as catalyst and can realize 1, 3-propylene glycol reaction hydrogenated by 3-hydroxy methyl propionate under milder conditions, wherein the highest conversion rate of 3-hydroxy methyl propionate is 97.8% and the highest selectivity of 1, 3-propylene glycol is 93.4%.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

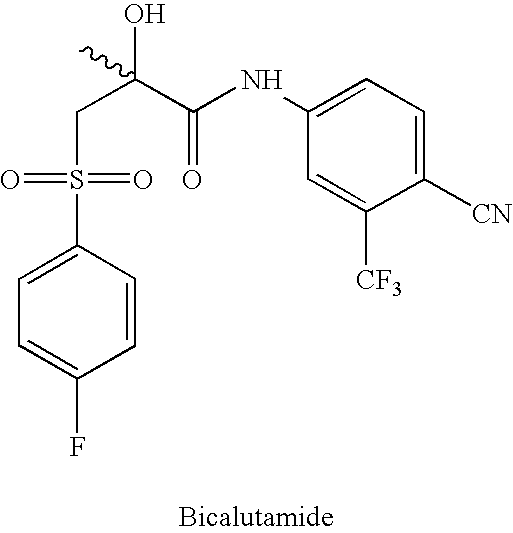

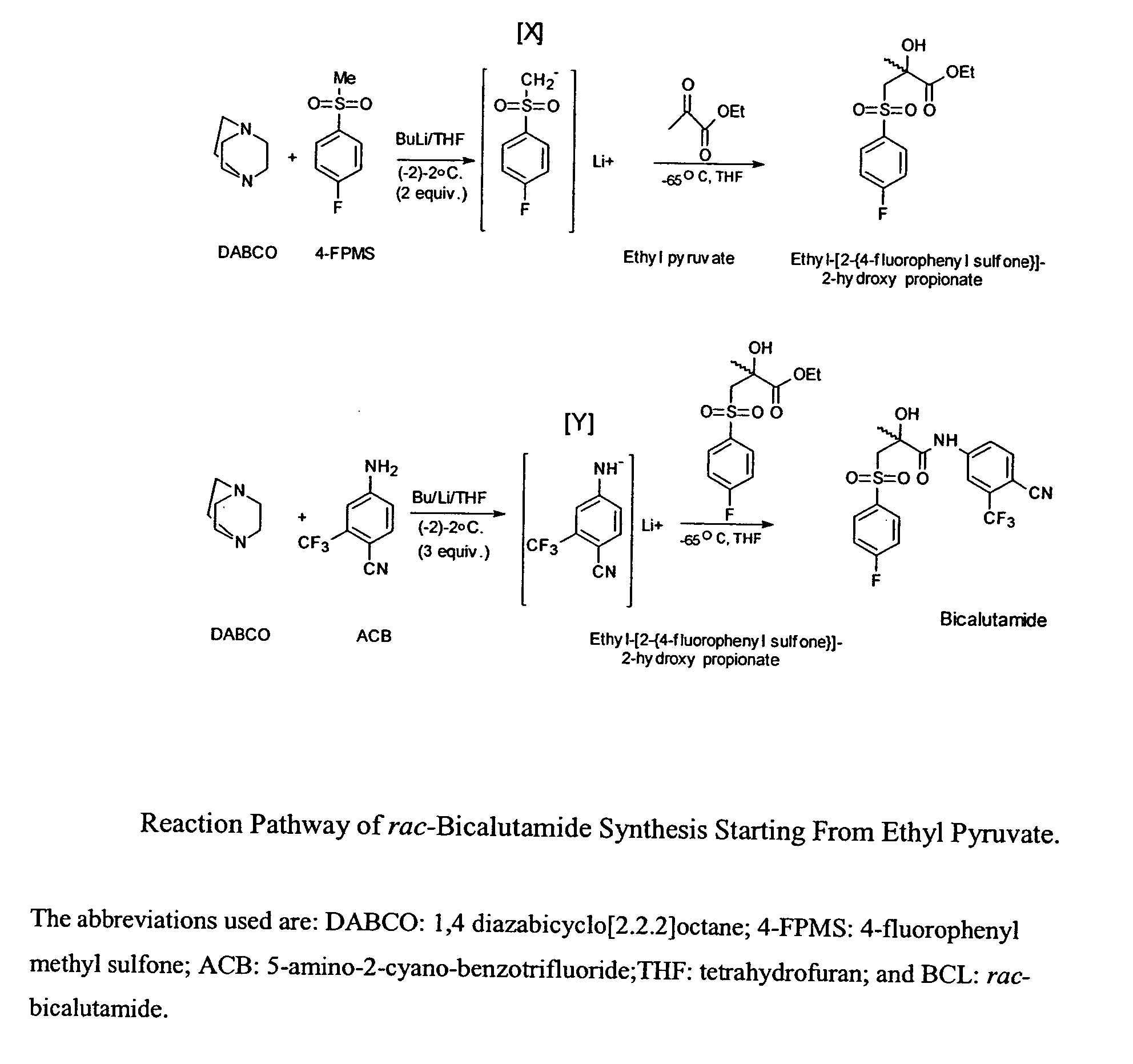

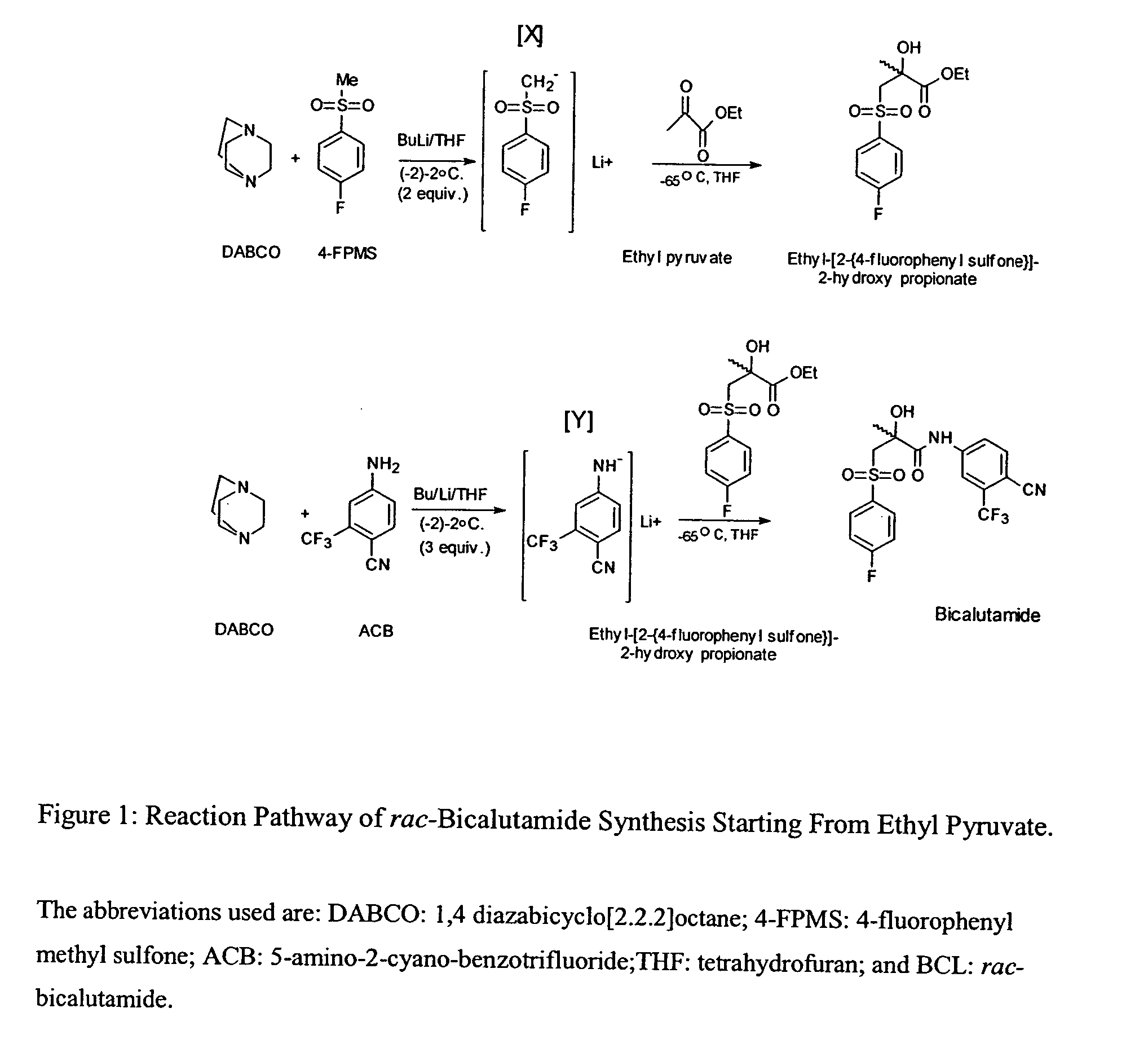

Novel process for preparing and isolating rac-bicalutamide and its intermediates

InactiveUS20040044249A1Increase ratingsGood reproducibilityLithium organic compoundsOrganic compound preparationPropionatePropanoic acid

The present invention relates to a new process for the synthesis of racemic and optically active bicalutamide starting from ethyl pyruvate and methyl methacrylate. The present invention discloses processes of preparing bicalutamide intermediates including ethyl-[2-{4-fluorophenyl sulfone}]-2-hydroxy propionate, 1,2-epoxy-2-methyl propionate and 2-hydrox-2-methyl-3-(4-fluorophenylthio) propionic acid. The present invention further discloses micronized rac-bicalutamide and the preparation thereof. The present invention further discloses a new process for the isolation and purification of racemic and optically active bicalutamide.

Owner:TEVA PHARM USA INC +1

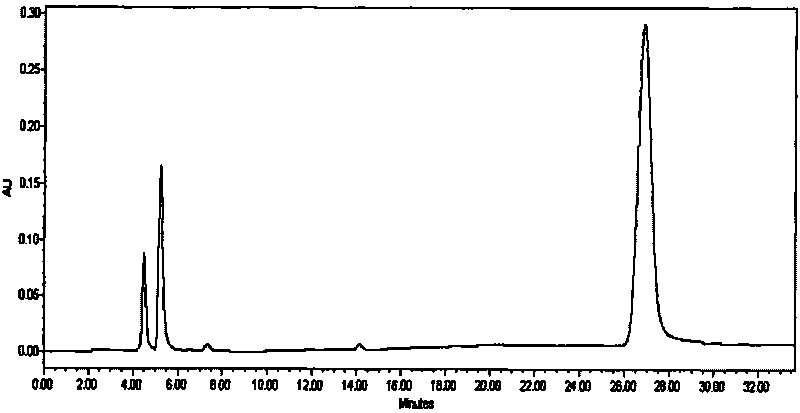

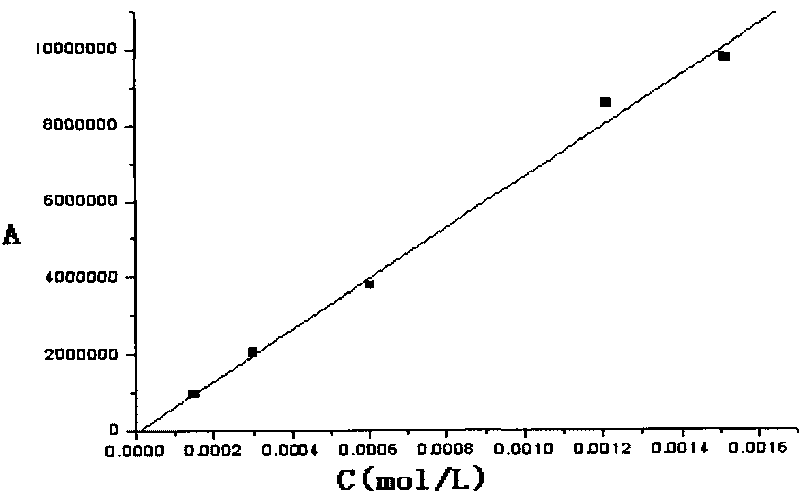

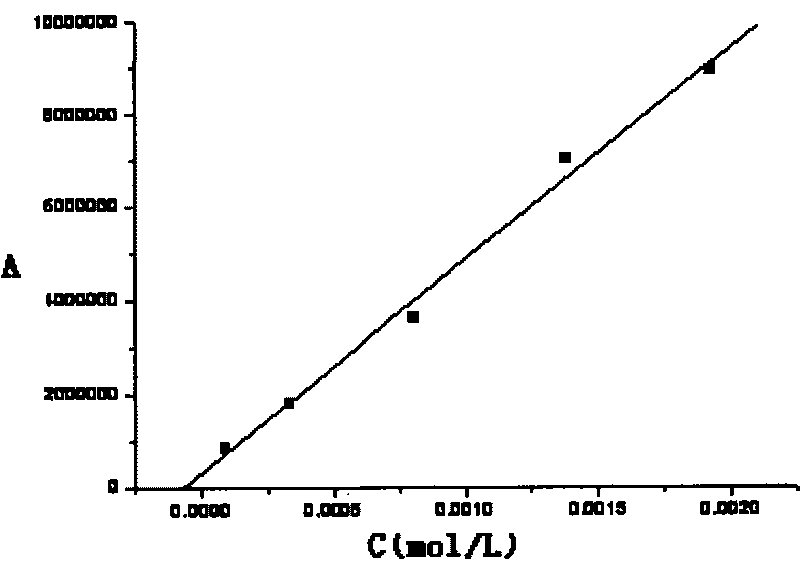

High performance liquid chromatographic analysis method for antioxidant 1076 content

ActiveCN101710108AAccurate contentAccurate measurementComponent separationColumn temperatureMethyl propionate

The invention discloses a high performance liquid chromatographic analysis method for antioxidant 1076, which adopts a reserved phase high performance liquid chromatography method. The reserved phase high performance liquid chromatography comprises the following conditions that: the chromatographic column is a C18 column and is of 5 mu m and 150*4.6 mm (I.D.); the mobile phase comprises the following components in a volume ratio with gradient conditions: 90 percent of methanol and 10 percent of water in 0 minute, 90 percent of methanol and 10 percent of water in 5 minutes, and 100 percent of methanol and 0 percent of water in 10 minutes; and the flow rate is 0.8 milliliter per minute, the column temperature is 25 DEG C, the detection wavelength is 220 nanometers, and the sampling volume is 20 microliters. The chromatographic analysis method of the invention accurately measures the main body content of the antioxidant 1076, further measures the contents of an intermediate beta-(3,5-tertbutyl-4-hydroxyphenyl) methyl propionate and a raw material 2,6-ditertbutyl phenol at the same time, and is suitable for quality control of the antioxidant 1076 in the industrialized production process.

Owner:SHANGHAI CHEM REAGENT RES INST

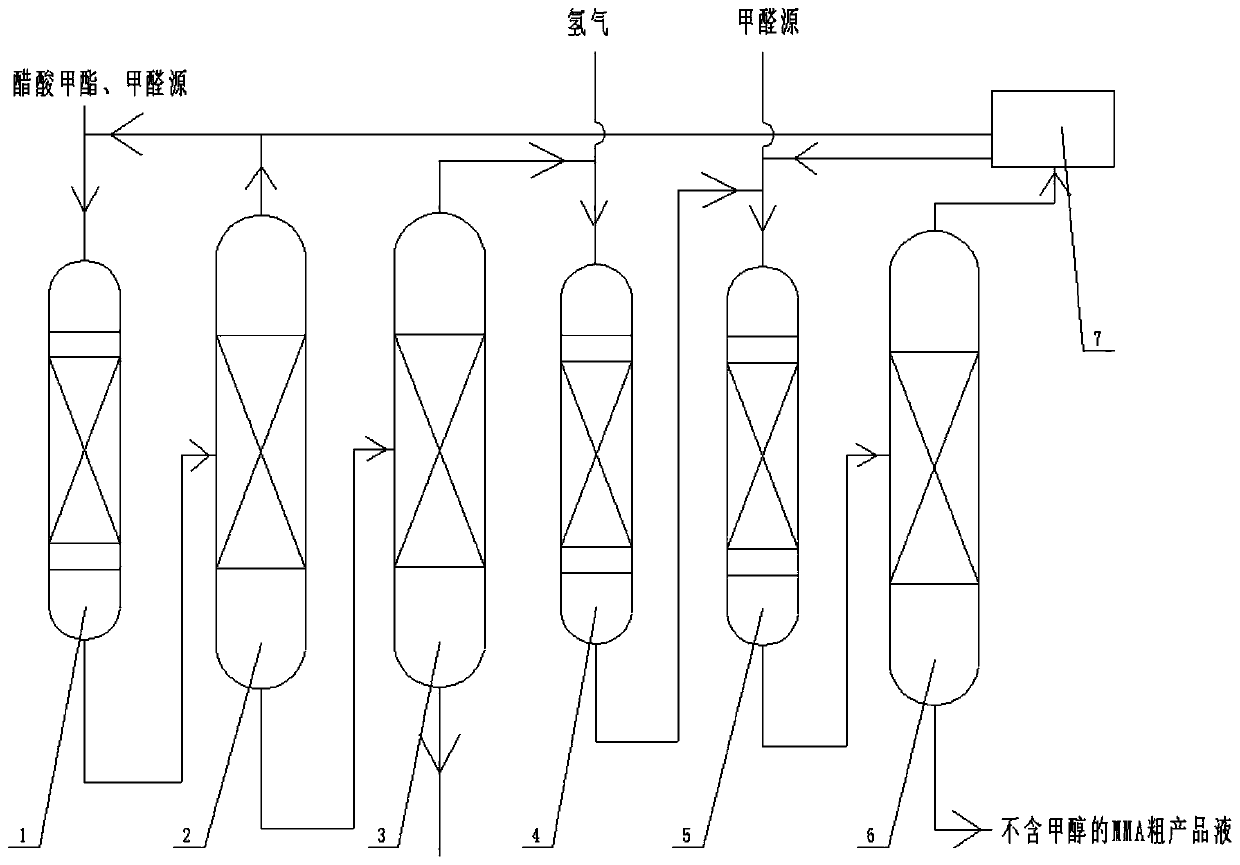

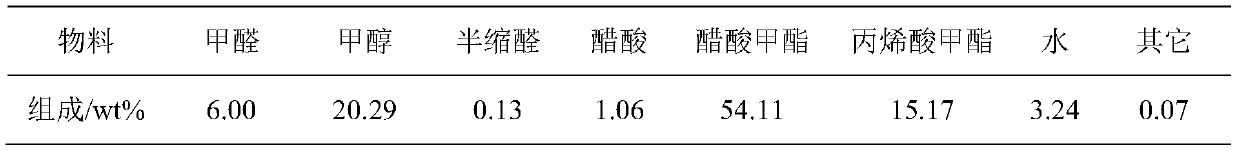

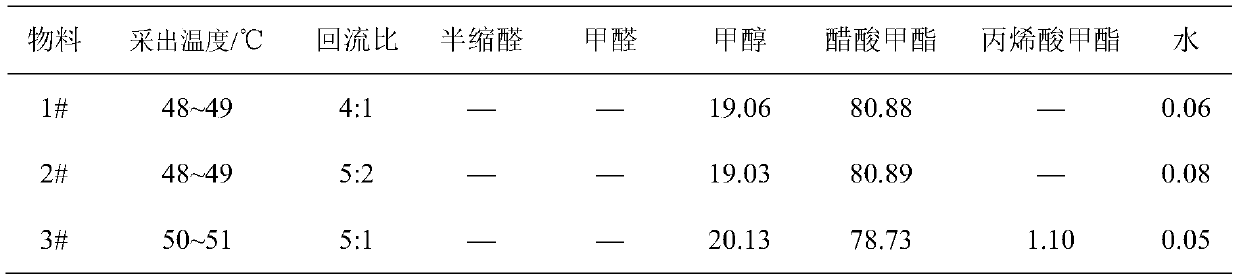

Methyl methacrylate synthesis process

ActiveCN110981727AReduce cycle energy consumptionCracking the separation puzzleOrganic compound preparationCarboxylic acid esters preparationPropanoic acidHydrogenation reaction

The invention discloses a methyl methacrylate synthesis process comprising the steps: carrying out condensation reaction on the reaction raw materials, liquefying and separating out a mixture of methanol and methyl acetate, circulating, separating out a mixture of methanol and methyl acrylate, carrying out hydrogenation reaction to obtain a mixture of methanol and methyl propionate, carrying out areaction on the mixture with a formaldehyde source, liquefying a reaction product gas flow, separating out a mixture of methanol and methyl propionate to obtain a methanol-free MMA crude product liquid, separating the mixture of methanol and methyl propionate, and respectively circulating. According to the method, the mixture of methanol and methyl acetate, the mixture of methanol and methyl acrylate and the mixture of methanol and methyl propionate are gradually separated in an azeotropic manner, so that the energy consumption of methanol separation circulation is reduced; methanol and methyl acrylate azeotrope is used as a raw material to be fed into a hydrogenation reactor, so that the separation difficulty is reduced; formaldehyde is separated from the methanol-free MMA crude productliquid, and the difficulty of further refining is lower; the separation problem of a methanol-containing multi-component complex easily-polymerized system is effectively solved, and a powerful supportis provided for MMA synthesis of a methyl acetate route.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

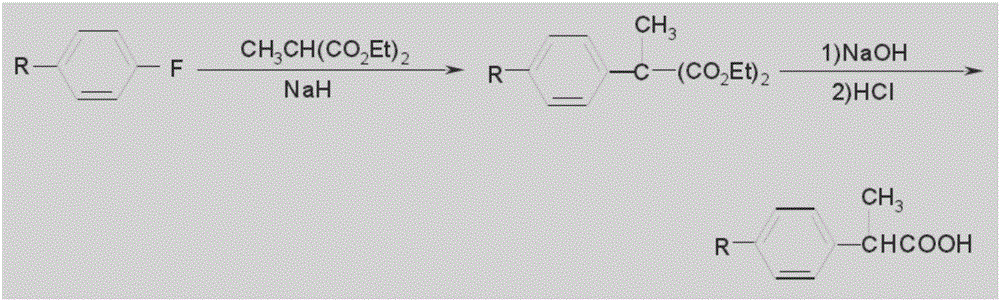

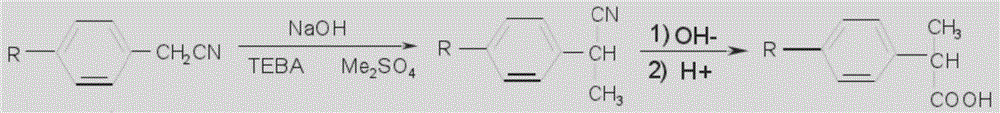

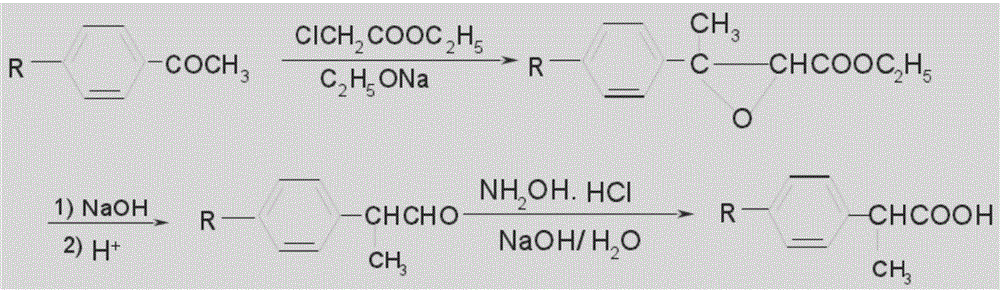

Method for preparing loxoprofen intermediate

InactiveCN105753685AAvoid bringing inHigh selectivityCarboxylic acid nitrile preparationOrganic compound preparationPropanoic acidPropionitrile

A method for preparing a loxoprofen intermediate comprises the following steps that 1, on the presence of sodium alkoxide, benzyl cyanide and dimethyl carbonate are subjected to methylation in an organic solvent, and 2-(phenyl cyano) sodium propionate is obtained; 2, 2-(phenyl cyano) sodium propionate and dimethyl sulfate react in an organic solvent to obtain 2-(phenyl cyano) methyl propionate; 4, 2-(phenyl cyano) methyl propionate reacts under the alkaline condition to obtain 2-phenyl propionitrile; 4, 2-phenyl propionitrile is hydrolyzed under the alkaline condition, acid is added for acidizing after the reaction to obtain 2-phenylpropionic acid; 5, 2-phenylpropionic acid, hydrobromic acid and paraformaldehyde are mixed and subjected to a bromine methylation reaction under the acidic condition, and 2-(4-tribromomethyl phenyl) propionic acid is obtained.According to the method, a new synthesis route is designed, product selectivity is good, the purity is high, the conversion rate is high, and few by-products are generated; the raw materials are simple and easy to obtain, the production conditions are mild, the process is simple, production cost is low, and pollution is small.

Owner:UPCHEM CHINA

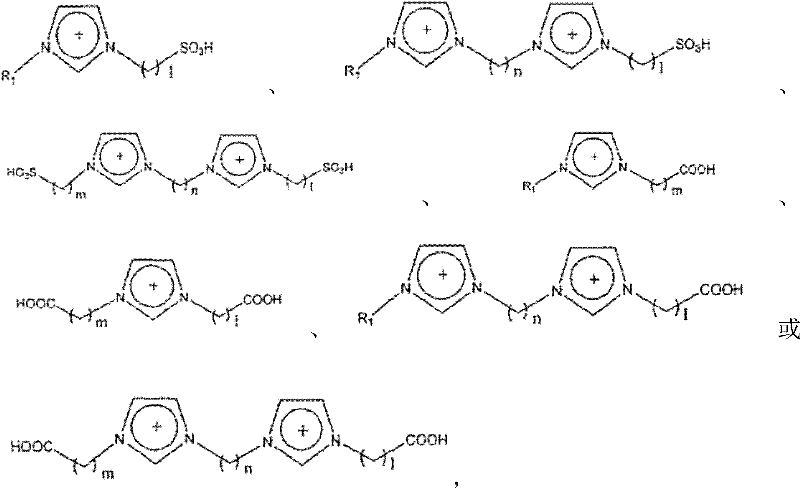

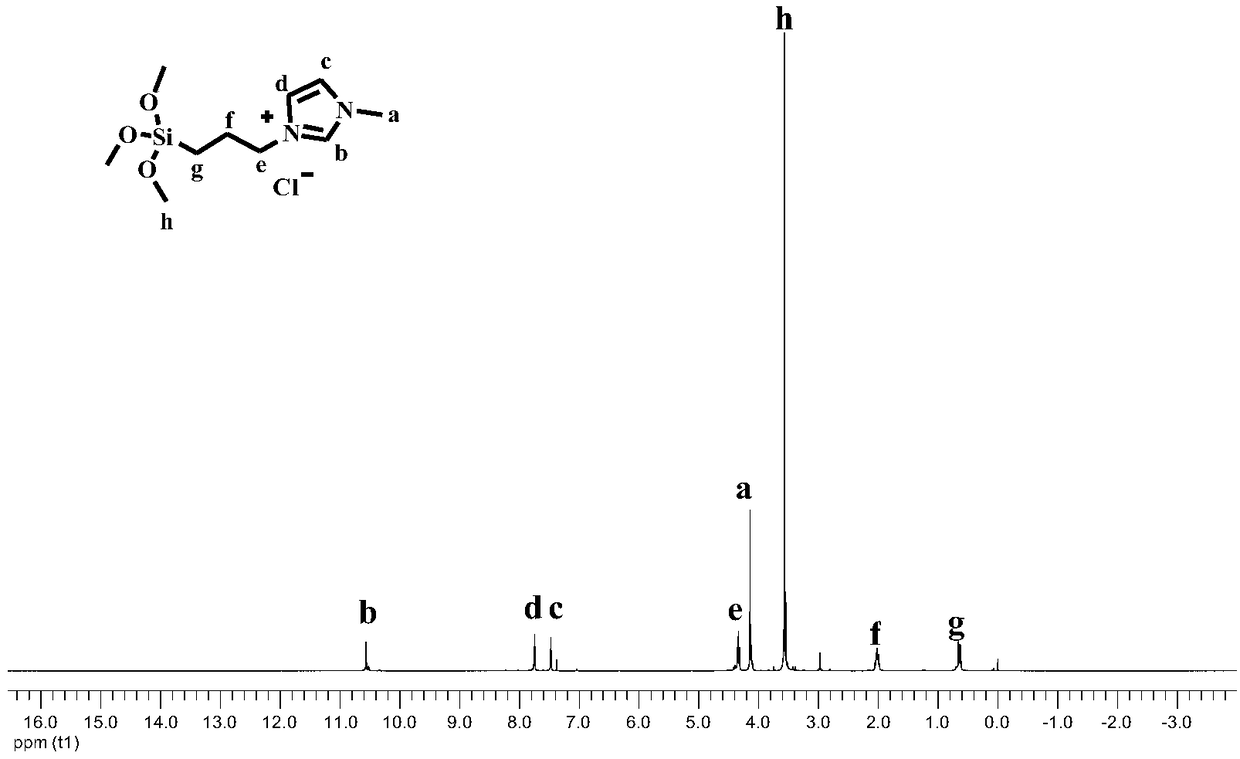

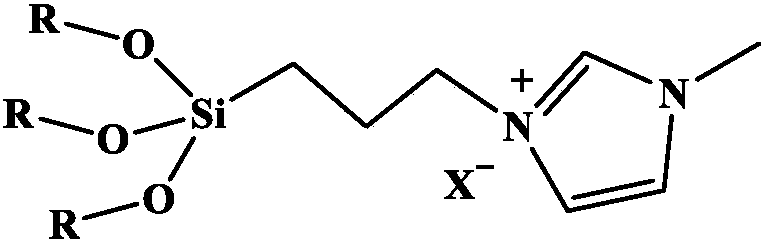

Catalysis system for synthesizing methyl propionate and application method thereof

ActiveCN108993602AHigh yieldEasy to useGroup 4/14 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsInorganic saltsLithium

The invention discloses a catalysis system for synthesizing methyl propionate and an application method thereof. The catalysis system is prepared from a ruthenium-cluster carbonyl complex, imidazoliumionic liquid and an inorganic salt accelerator, or the ruthenium-cluster carbonyl complex and the imidazolium ionic liquid, wherein the mole ratio of the imidazolium ionic liquid to the ruthenium-cluster carbonyl complex is (100-250):1; when the catalysis system comprises the accelerator, the mole ratio of the accelerator to the ruthenium-cluster carbonyl complex is (1-75):1; the accelerator is carbonate, halogenated lithium or transitional metallic chloride. The system uses the imidazolium ionic liquid to consume water produced in the reaction to accelerate the reaction to be performed towards the forward direction; by the adding of the inorganic salt accelerator, the catalytic activity is further improved, so as to catalyze ethylene, CO2 and methanol to prepare the methyl propionate. The catalysis system obviously shortens the reaction time, so that the yield of the methyl propionate is increased.

Owner:HEBEI UNIV OF TECH

Method for preparing methyl levulinate through clean conversion of biomass sugar and separating methyl levulinate

InactiveCN102399144AReduce generationStable pressureOrganic compound preparationCarboxylic acid esters separation/purificationChemical industryLiquid product

The invention discloses a method for preparing methyl levulinate through the clean conversion of biomass sugar and separating methyl levulinate. The method comprises the following steps: 1, calcinating a solid acid at 300-700DEG C for 1-5h; 2, adding a biomass sugar methanol solution with the mass concentration of 10-200g / L and the solid acid to a high pressure reactor to obtain a mixed solution; 3, heating the mixed solution to 180-220DEG C, and keeping the temperature for 1-5h; 4, cooling to room temperature, and separating a solid catalyst from a liquid product by filtering; 5, carrying out normal pressure distillation on the liquid product to remove low boiling point substances to obtain a residue; and 6, adding a distillation assistant to the residue, and carrying out reduced pressure distillation to obtain methyl levulinate. The method of the invention, which adopts the clean solid super acid to catalyze the conversion of the biomass sugar into methyl levulinate and has the advantages of no corrosion to equipment, easy separation of the catalyst from the product, environment protection and the like, accords with the greening development trend of the current chemical industry.

Owner:SOUTH CHINA UNIV OF TECH

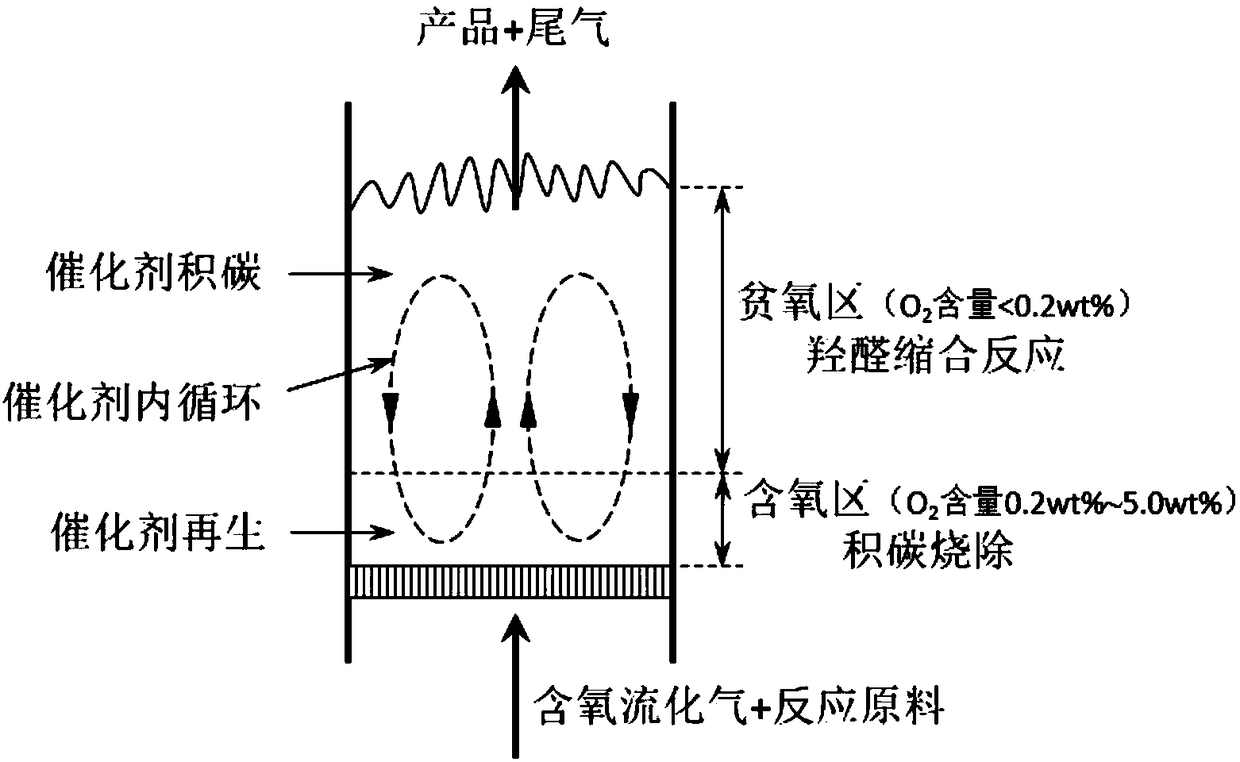

Method for preparing methyl methacrylate by aldol condensation of methyl acetate and formaldehyde

ActiveCN109232247AAvoid insufficient regenerationAvoid inhomogeneityOrganic compound preparationCarboxylic acid esters preparationFluidized bedMethyl acetate

The invention provides a method for preparing methyl methacrylate by aldol condensation of methyl acetate and formaldehyde, and belongs to the technical field of preparation of methyl methacrylate. The method comprises the following steps: preheating methyl acetate, returned methyl propionate, a formaldehyde source, methanol, water and oxygen-containing fluidized gas as materials, enabling the materials to enter a fluidized-bed reactor, under the action of a catalyst bed material in an internal-circulation fluidized bed, generating aldol condensation reaction to produce MMA, and finishing regeneration of a catalyst. The method provided by the invention has the beneficial effects that by utilization of the characteristic of internal-circulation movement of the fluidized-bed material, a little amount of oxygen is introduced at the lower part of the fluidized bed to form a local oxygen-containing area to carry out periodical regeneration on the catalyst bed material, so that the serious side reaction in the presence of a large amount of oxygen and insufficient and non-uniform regeneration of the fluidized-bed material are avoided, regeneration of the catalyst in the aldol condensationreaction is realized, the catalyst can maintain high activity for a long term, and the catalyst utilization efficiency is improved; the problems of inactivation and short service life of a catalyst due to easy carbon deposition in the aldol condensation process of the methyl acetate, the methyl propionate and the formaldehyde are solved.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Intermittent extractive distillation separation method of methanol-methyl propionate azeotropic mixtures

InactiveCN102584525AFlexible operationReduce cost inputOrganic compound preparationCarboxylic acid esters preparationChlorobenzeneExtractive distillation

The invention discloses an intermittent extractive distillation separation method of methanol-methyl propionate azeotropic mixtures, which belongs to the separation technology of the methanol-methyl propionate azeotropic mixtures and includes: ethylene glycol, 1,2-propylene glycol, glycerol, anisole and toluene or chlorobenzene are used as extracting agents, under operation conditions of an extracting rectifying tower, mass ratio of the extracting agents and overhead distillate is 0.5:1-10:1at ordinary pressure or reduced pressure, feeding temperature of the extracting agents is 20-60 DEG C, different temperatures and different reflux ratios at the top of the extracting rectifying tower are controlled, methanol products, a methanol-methyl propionate transition section I, methyl propionate products and a methyl propionate-extracting agent transition section II are respectively picked out through the extracting rectifying tower, and when extracting agent components of a heating kettle meet requirements, the extracting agents are pumped into a high-level storage groove and materials are fed for the next intermittent extractive distillation separation. The intermittent extractive distillation separation method has the advantages that the single tower is low in device cost and flexible in operation, and the extracting agents are adopted to damage a methanol-methyl propionate azeotropic system to separate out high-purity methanol products and high-purity methyl propionate products.

Owner:UNIV OF JINAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com