Water resistant catalyst for aldol condensation as well as preparation method and application thereof

A technology of aldol condensation and water resistance, which is applied in the preparation of organic compounds, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of unavoidable water and insufficient effects, and achieve enhanced physical and mechanical properties. The method is simple and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

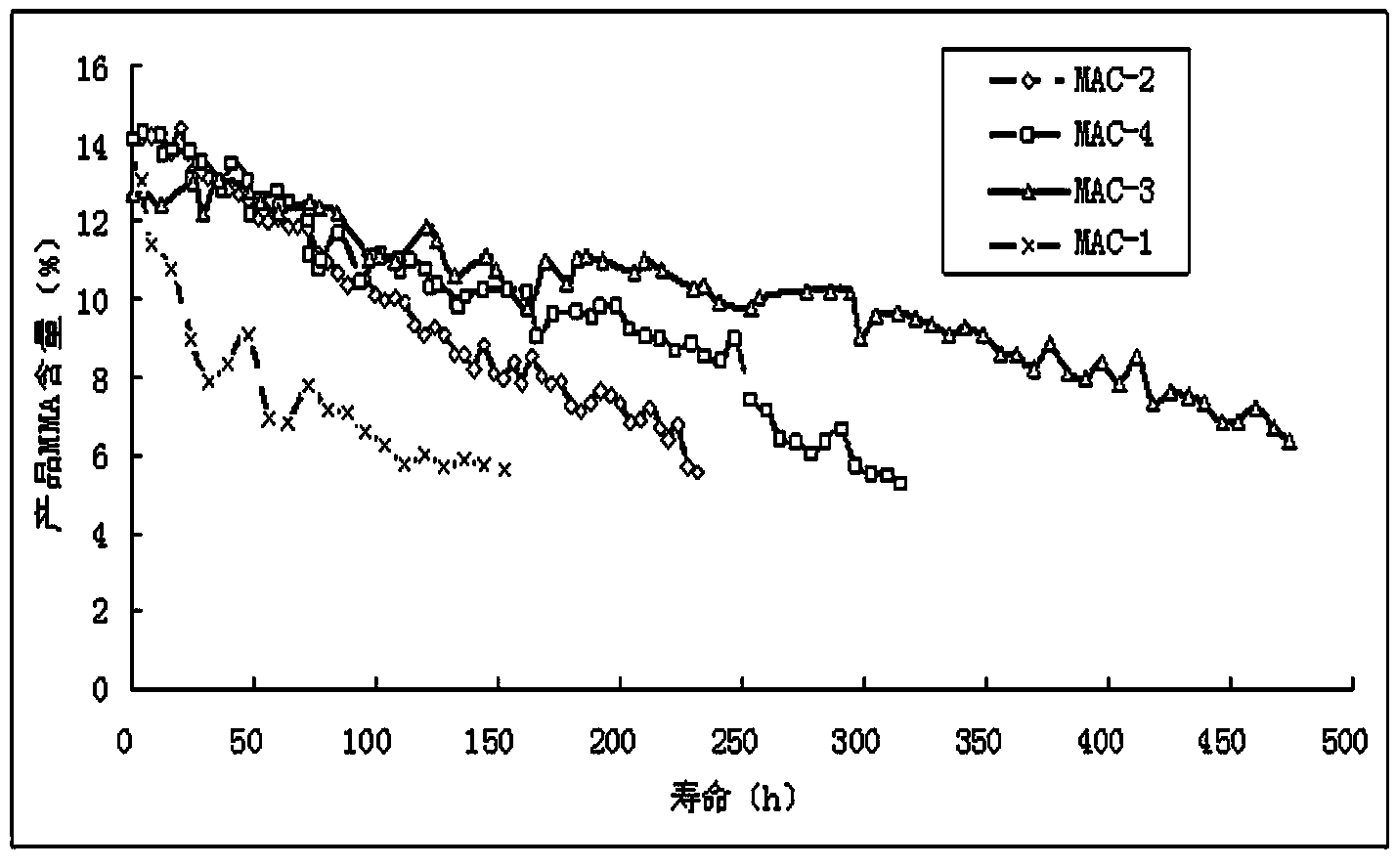

[0039] Example 1 Preparation of Water-resistant Catalyst MAC-02

[0040] Weigh 29.1g of cesium acetate and dissolve it in deionized water to make solution a with a concentration of 82% by mass; weigh 3.2g of AgNO 3 , add deionized water to dissolve, and make a solution b with a concentration of 62% by mass; weigh hydrophobic nano-SiO 2 85.2g, kaolin 14.1g, ZrO 2 2.0g, after mixing evenly, add the solution prepared in steps a and b, knead for 6 hours, extrude or roll ball, dry at 100°C for 3 hours, and roast at 500°C for 4 hours to obtain the catalyst, which is designated as MAC-02.

Embodiment 2

[0041] Example 2 Preparation of water-resistant catalyst MAC-03

[0042] Weigh 29.0g of cesium acetate and dissolve it in deionized water to make a solution a with a mass percentage concentration of 73%; weigh 3.2g AgNO3 and add deionized water to dissolve it to make a solution b with a mass percentage concentration of 56%; Propyltriethoxysilane was dispersed in 400g 2% trimethylethylammonium hydroxide aqueous solution by high-speed stirring, and the stirring time was 6h to form a mixed solution c; weigh nano-SiO 2 82.1g, kaolin 14.0g, ZrO 2 2.0g, after mixing evenly, add the solution prepared in steps a and b and knead for 6 hours; add the above mixed solution c, mix thoroughly at 60°C for 12 hours, evaporate water at the same time, extrude or roll, and dry at 100°C After 3 hours, it was calcined at 500°C for 4 hours to obtain a catalyst, which was designated as MAC-03.

Embodiment 3

[0043] Example 3 Preparation of Water-resistant Catalyst MAC-04

[0044] Weigh 29.0g of cesium acetate and dissolve it in ethanol to make a solution a with a concentration of 12% by mass; disperse 11g of chloropropyltriethoxysilane in 367g of 2% trimethylethylammonium hydroxide aqueous solution by high-speed stirring , stirring for 6 hours to form a mixed solution b; take 310ml of ethyl orthosilicate, slowly add it dropwise to absolute ethanol, add glacial acetic acid while stirring, and form a colloidal solution after stirring vigorously for a period of time, then slowly add 14.1g under stirring Kaolin, 2.0gZrO 2 and 3.2gAgNO 3 , add deionized water until a gel is formed. Then the gel was dried at constant temperature at 80°C for 10 hours, the dried crystals were calcined at 400°C for 10 hours, and ground to 30 mesh to 50 mesh to obtain the carrier precursor; Fully mixed at 120°C for 12 hours while evaporating water, extruded or ball-rolled; dried at 120°C for 2 hours, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com