Catalyst composition, preparation method thereof and method for preparing methyl propionate by using catalyst composition

A technology of methyl propionate and methyl acrylate, applied in the field of catalyst compositions, can solve the problem of low selectivity of hydrogenation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

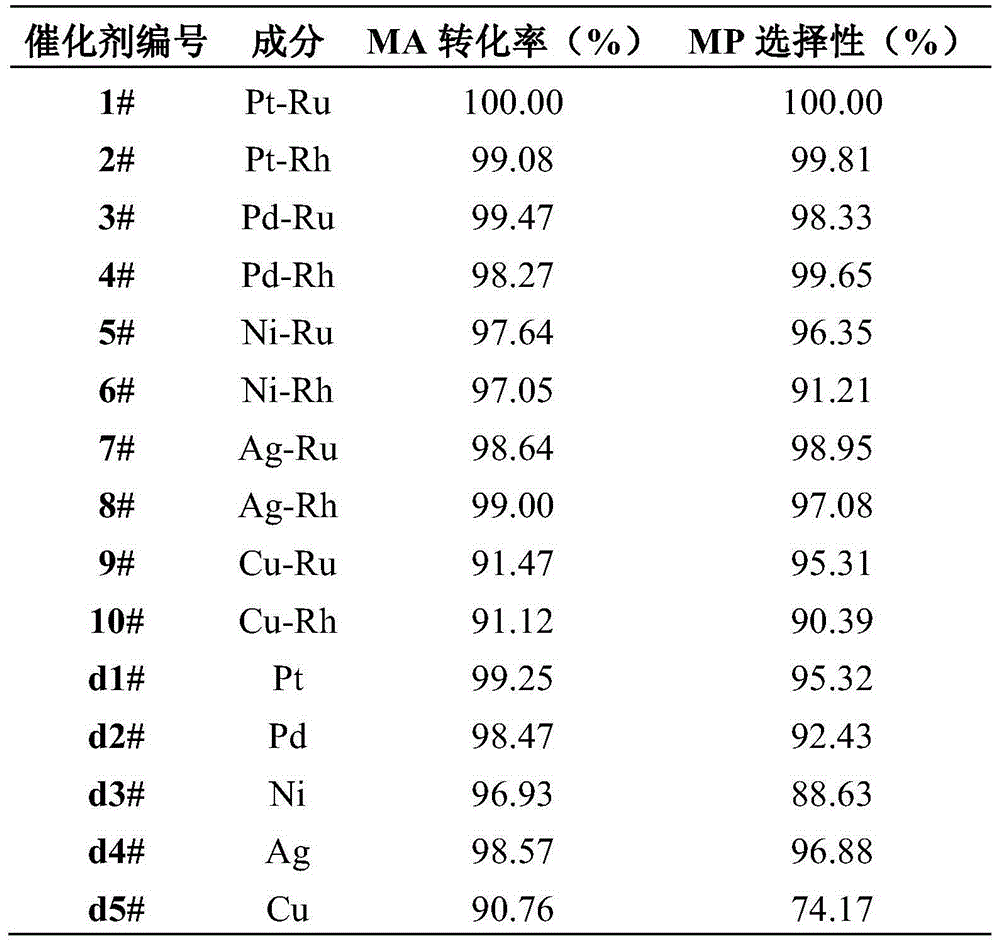

Examples

Embodiment 1

[0039] The carrier is γ-Al calcined at 550℃ 2 O 3 , Weigh out 10g of γ-Al 2 O 3 (BET: 245m 2 / g, 12.4nm), 11ml contains 0.0531g H 2 PtCl 6 ·6H 2 O and 0.0062gRuCl 3 ·3H 2 Aqueous solution of O, soaking the above γ-Al by equal volume immersion method 2 O 3 Carrier: After standing overnight at room temperature, it is dried in a water bath at 50°C, and then dried in an oven at 120°C for 6-8 hours. After calcination at 300°C for 5 hours, it is activated and reduced in a hydrogen gas stream at 350°C for more than 5 hours. Finally Pt-Ru / γRAl 2 O 3 Catalyst, number 1#.

[0040] Using methyl acrylate (MA) as the raw material, under the conditions of 300-350°C, 1.0-2.5 MPa, 0.05-0.20 ml / min of raw material feed, and 2-3 g of catalyst loading, the best result is obtained when evaluating 1# catalyst The result of the reaction is that the MA conversion rate is 100%, and the methyl propionate (MP) selectivity is 100%.

Embodiment 2

[0042] In addition to 0.0077g of RhCl 3 ·3H 2 O instead of RuCl in the dipping solution 3 ·3H 2 Except for the O component, Pt-Rh / γ-Al was prepared with the same material, form and procedure as in Example 1. 2 O 3 Catalyst, number 2#.

[0043] Under the same evaluation conditions as in Example 1, the performance of the 2# catalyst is 99.09% MA conversion and 99.81% MP selectivity.

Embodiment 3

[0045] In addition to 0.0333g PdCl 2 Instead of H in the dipping solution 2 PtCl 6 ·6H 2 Except for the O component, Pd-Ru / γ-Al was prepared with the same material, form and procedure as in Example 1. 2 O 3 Catalyst, number 3#.

[0046] Under the same evaluation conditions as in Example 1, the performance of the 3# catalyst is 99.47% MA conversion and 98.33% MP selectivity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com