Lithium iron phosphate battery with lithium ion battery electrolyte suitable for ultralow-temperature charging and discharging

A lithium-ion battery and electrolyte technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as restricting the use of lithium iron phosphate batteries, and achieve fast migration, improve stability, and improve ionic conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

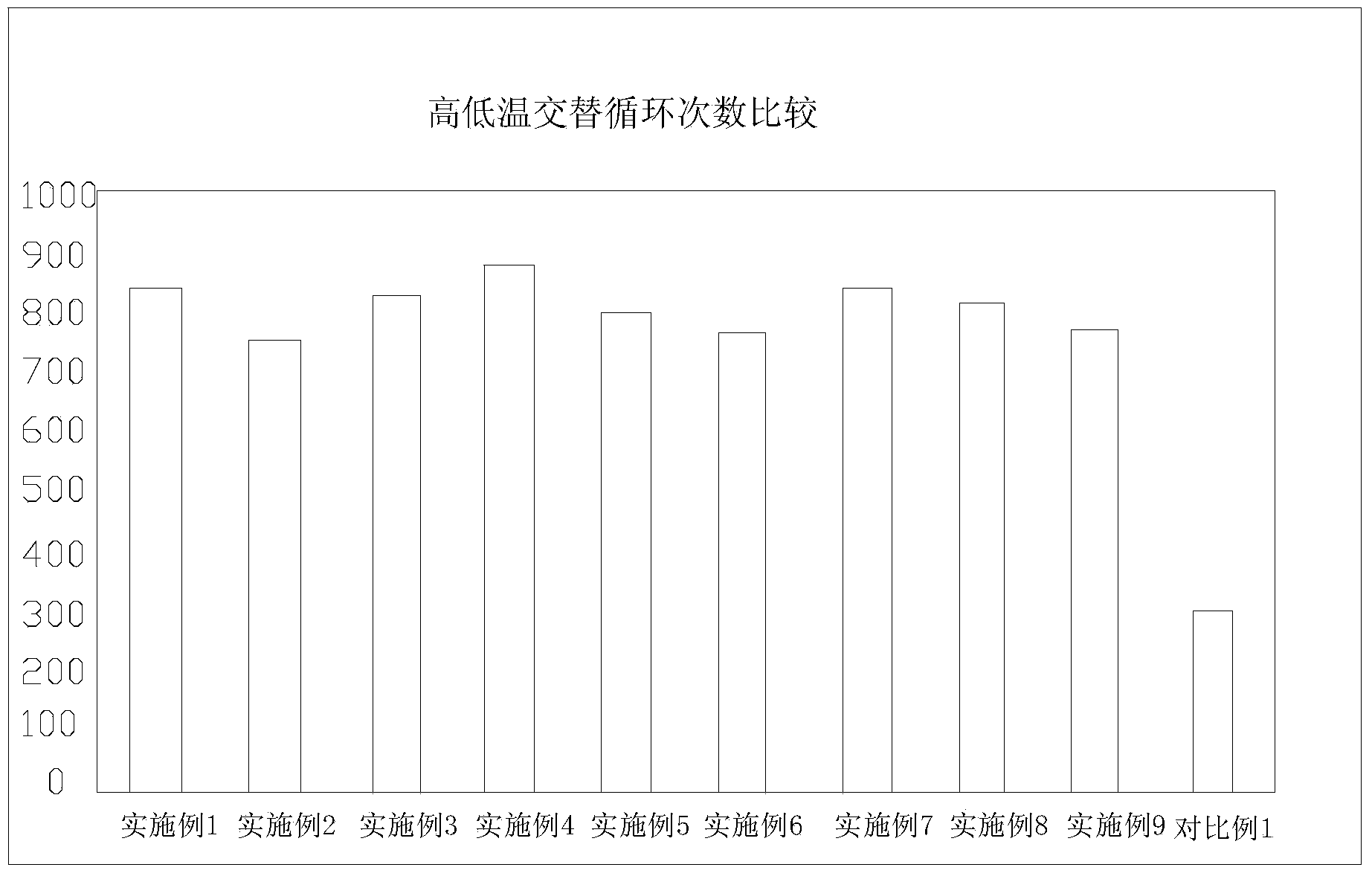

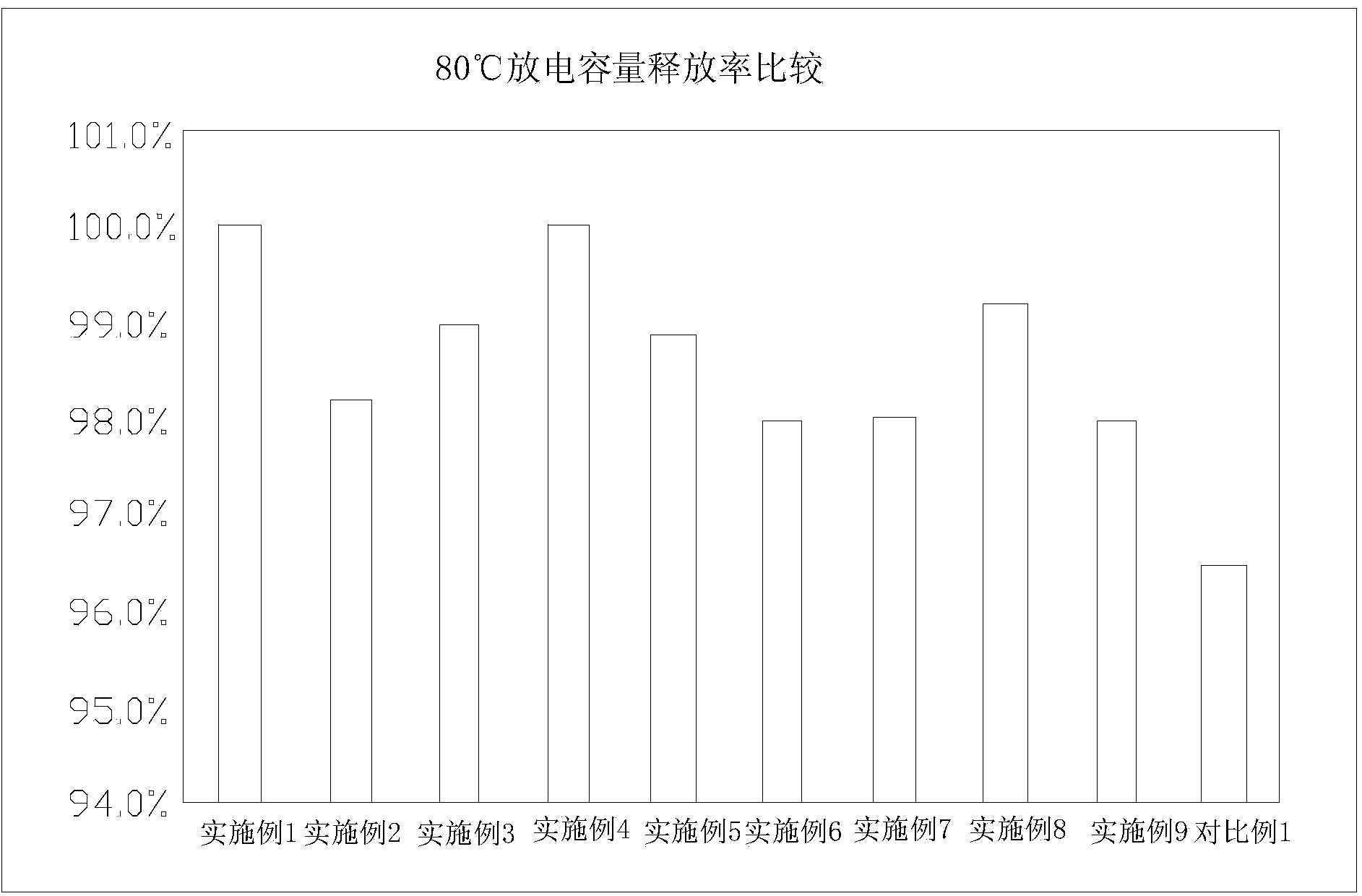

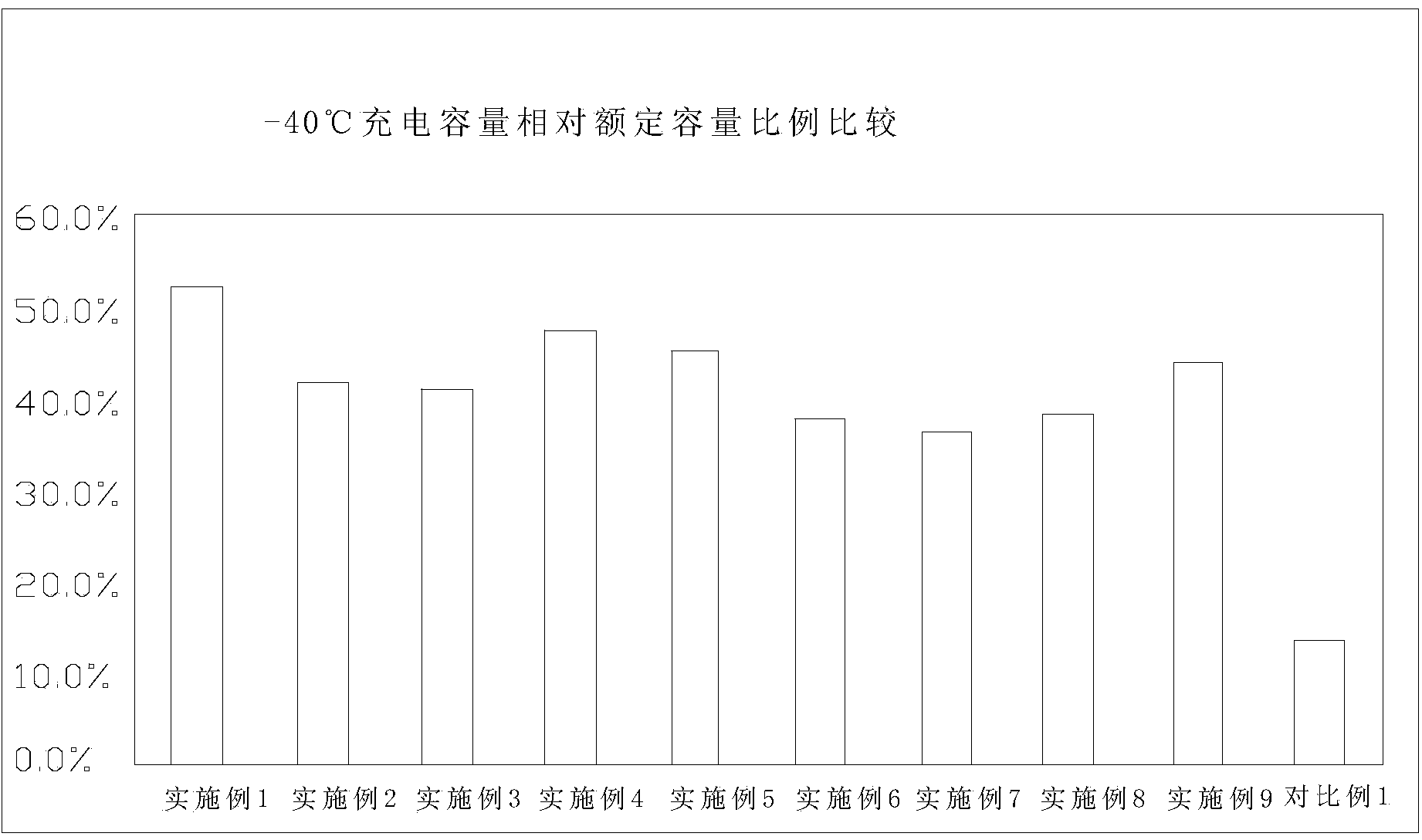

Embodiment 1

[0027] Disperse the lithium iron phosphate active material, the binder polyvinylidene fluoride, and the conductive agent in a solvent (N-methyl-2-pyrrolidone) according to a weight ratio of 92.5:4.5:3 to form a positive electrode slurry, and the above slurry The material is coated on a 15um thick aluminum foil, dried and rolled to form a positive electrode. The artificial graphite and the conductive agent are dispersed in the aqueous solution of sodium carboxymethylcellulose (CMC) according to the weight ratio of 98:2, and the binder is added Styrene-butadiene rubber (SBR) is used to form the negative electrode slurry, which is coated on a 9um thick copper foil, dried and rolled to form the negative electrode. The positive electrode, negative electrode and polyethylene or polypropylene separator with a thickness of 25um are wound or laminated to form a battery core, and then the resulting battery core is put into a steel case, an aluminum case or an aluminum-plastic composite f...

Embodiment 2

[0030] Example 1 was repeated except that 8% methyl acetate (MA) was added to the quaternary solvent as a low melting point additive and 1% 1,3-propane sultone was added as a high temperature additive.

Embodiment 3

[0032] Example 1 was repeated except that 5% of ethyl butyrate (EB) as a low melting point additive and 1% of 1,3-propane sultone as a high temperature additive were added to the quaternary solvent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com