Preparation of a zif-67/bismuth vanadate composite and its application as a photoanode material

A ZIF-67, composite technology, applied in electrodes, electrolysis components, electrolysis processes, etc., can solve problems such as MOF stability limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

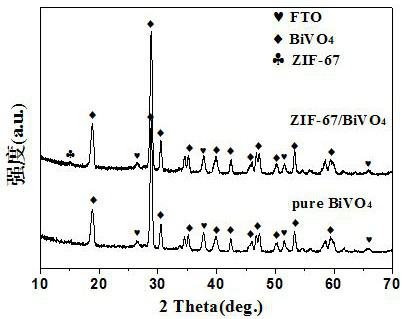

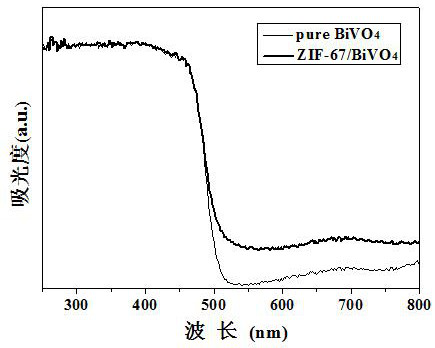

[0027] The preparation of the ZIF-67 / BiVO4 composite material of the present invention and its application as a photoanode in water splitting and hydrogen production will be further described below through specific examples.

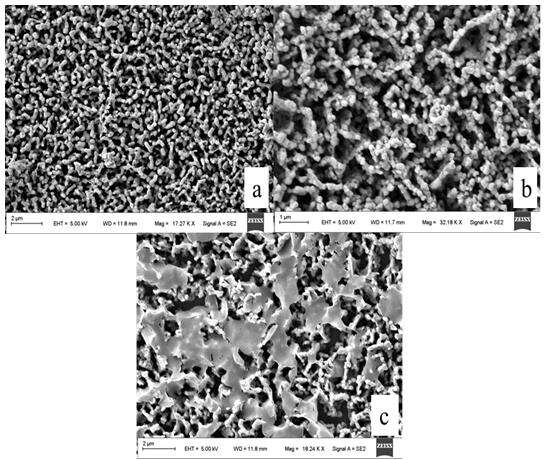

[0028] (1) Preparation of BiVO4: It was prepared according to the method of electrodeposition combined with heat treatment by Kim and Choi's research group. Specific steps: firstly, BiOI nanosheets were prepared by electrodeposition using CHI 660D electrochemical workstation. FTO glass cleaned ultrasonically with acetone / isopropanol / distilled water (volume ratio: 1:1:1) was used as the working electrode, the Ag / AgCl (3.5 M KCl) electrode was used as the reference electrode, and the Pt electrode was used as the counter electrode. with 6M HNO 3 Adjust the pH of 50 mL0.4 M KI solution to 1.5~1.7, then add 0.970g Bi(NO 3 ) 3 • 5H 2 O until dissolved and the solution color changed to orange-red. Then slowly add 20ml 0.498 g 1,4-benzoquinone ethanol solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com