A kind of silicon carbon composite material and preparation method thereof

A technology of silicon-carbon composite materials and nano-silicon powder, applied in the preparation/purification of carbon, nanotechnology for materials and surface science, silicon, etc., can solve the problem of high safety risk factor, unfavorable scale production, and inability to guarantee Issues such as micron product consistency, batch-to-batch stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation method of a kind of silicon carbon composite material proposed by the present invention, the steps are as follows:

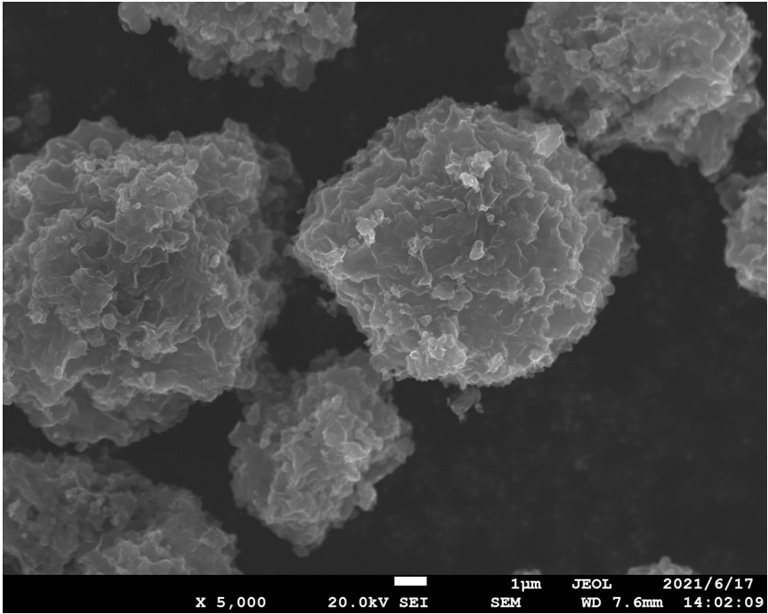

[0023] (1) At room temperature, add 200g of sweet potato starch to 10Kg of water solvent, stir to fully dissolve, and then add 500g of nano-silica powder, and its D50 particle size is 80nm. After the nano-silicon powder is uniformly dispersed, it is spray-dried and carbonized at high temperature to obtain the precursor A. The inlet temperature of the spray drying equipment was 195°C, the outlet temperature was 90°C, and the atomization frequency was 50Hz. The high-temperature carbonization equipment is a tube furnace with argon protection; the carbonization temperature is 600 °C, the carbonization time is 4 h, and the heating rate is 5 °C / min.

[0024] (2) At room temperature, in 4.95Kg pure water solvent, slowly add 50g graphene oxide to prepare a graphene oxide solution with a concentration of 1.0%; add 50g polydopamine and 250g precurs...

Embodiment 2

[0029] (1) At room temperature, add 300g of sweet potato starch to 10Kg of water solvent, stir to fully dissolve, and then add 500g of nano-silica fume. After the nano-silicon powder is uniformly dispersed, it is spray-dried and carbonized at high temperature to obtain the precursor A. The inlet temperature of the spray drying equipment was 200°C, the outlet temperature was 95°C, and the atomization frequency was 50 Hz. The high-temperature carbonization equipment is a tube furnace with argon protection; the carbonization temperature is 700 °C, the carbonization time is 3 h, and the heating rate is 8 °C / min.

[0030] (2) At room temperature, in 4.95Kg pure water solvent, slowly add 75g graphene oxide to prepare a graphene oxide solution with a concentration of 1.5%; add 56.25g polydopamine and 243.75g precursor to the solution respectively Body A, stir well and spray dry. The inlet temperature of the spray drying equipment was 200°C, the outlet temperature was 95°C, and the ...

Embodiment 3

[0035] (1) At room temperature, add 400g of sweet potato starch to 10Kg of water solvent, stir to fully dissolve, and then add 500g of nano-silica fume. After the nano-silicon powder is uniformly dispersed, it is spray-dried and carbonized at high temperature to obtain the precursor A. The temperature of the inlet of the spray drying equipment is 90 degrees, the temperature of the outlet is 60 degrees, and the atomization frequency is 50 Hz. The equipment used for high temperature carbonization is a tube furnace, protected by argon gas; the carbonization temperature is 800 degrees, the carbonization time is 2h, and the heating rate is 10℃ / min.

[0036] (2) At room temperature, in 9.9Kg pure water solvent, slowly add 100g graphene oxide to prepare a graphene oxide solution with a concentration of 1.0%; add 60g polydopamine and 220g precursor A to the solution respectively , Mix well and spray dry. The inlet temperature of the spray drying equipment was 205°C, the outlet tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com