Green-removing and yellow-removing fluffer for bamboo

A kind of yellow decompression machine, the technology of decompression machine, applied in the field of bamboo processing equipment, can solve the problems of complicated processing procedures, easy deformation, difficult removal of bamboo green wax and yellow film on the surface, and achieve the effect of simplifying the processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

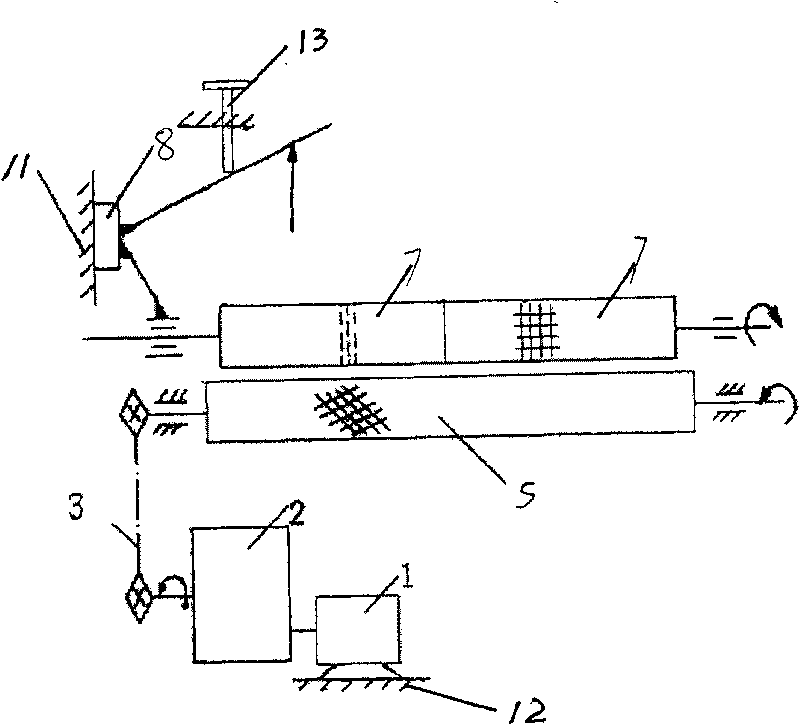

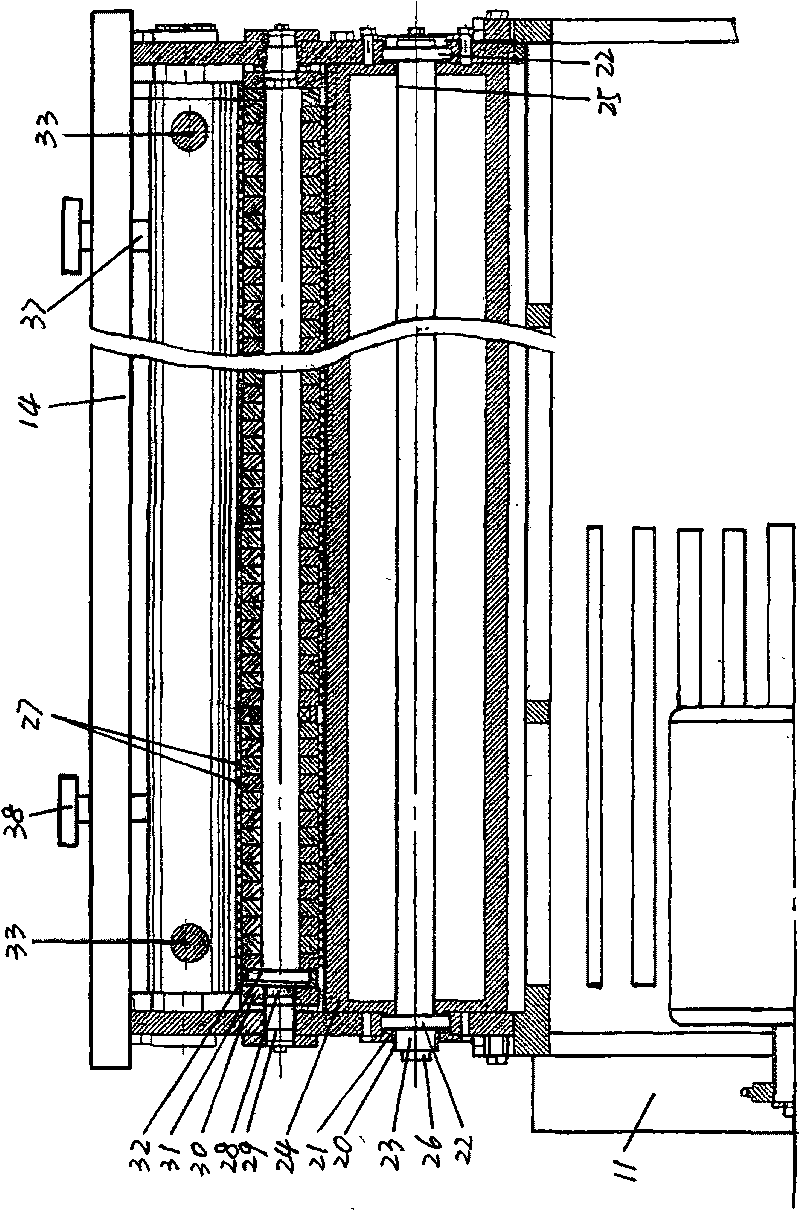

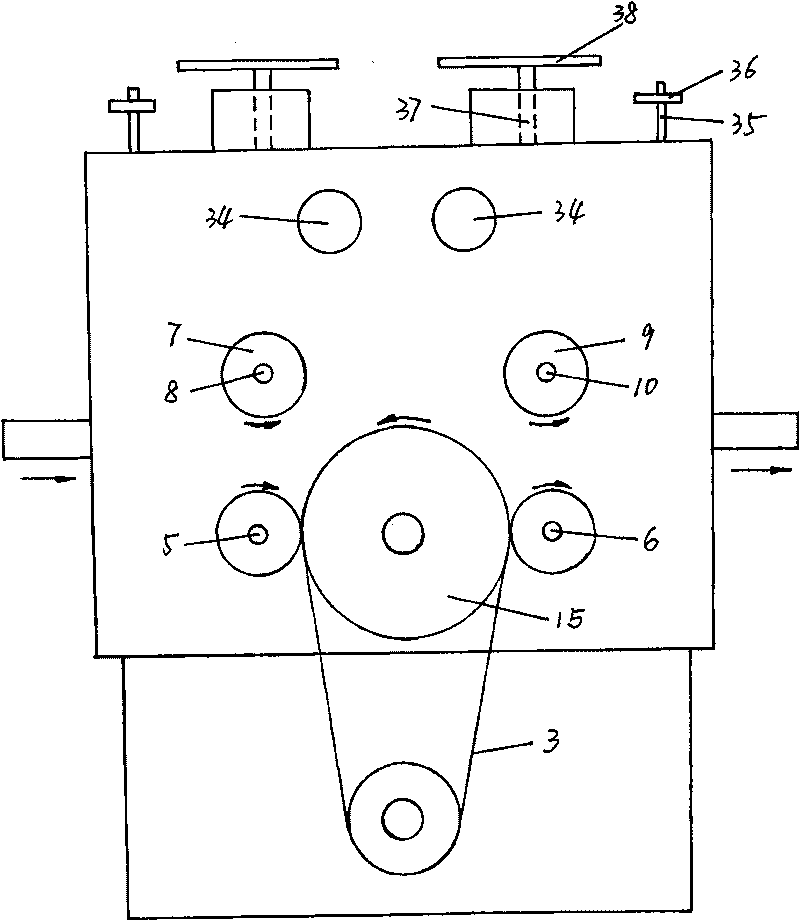

[0022] see Figure 1 to Figure 6 Shown, the composition of the present invention among the figure is as follows: main motor 1, final reduction device 2 are positioned at the bottom of base 12, and the top of base 12 is provided with casing 11, and casing loam cake 14 is positioned at casing 11 tops. On the box body 11, there are the first friction roller shafting 5 actively rotating and feeding, the first deflaker shafting support frame 8 and the passively rotating first deflaker installed on the first deflaker shafting support frame 8 Shafting 7, the second friction roller shafting 6 for active rotation and feeding supported on the box 11, the shafting support frame 10 of the second deflaker and the passive rotating shaft mounted on the shafting support frame 10 of the second deflaker The second deflaker shafting 9. The box body 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com