DLC (diamond-like carbon)/TiAlN (titanium aluminium nitride)/CrN (chromium nitride)/Cr (chromium) multilayer superhard film coating and preparation method thereof

A multi-layer coating and DLC film technology, applied in the coating, metal material coating process, ion implantation plating, etc., can solve the problems of poor bearing capacity, high load, high-speed internal combustion engine, etc., and improve mechanical properties , comprehensive performance improvement, and the effect of improving the binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

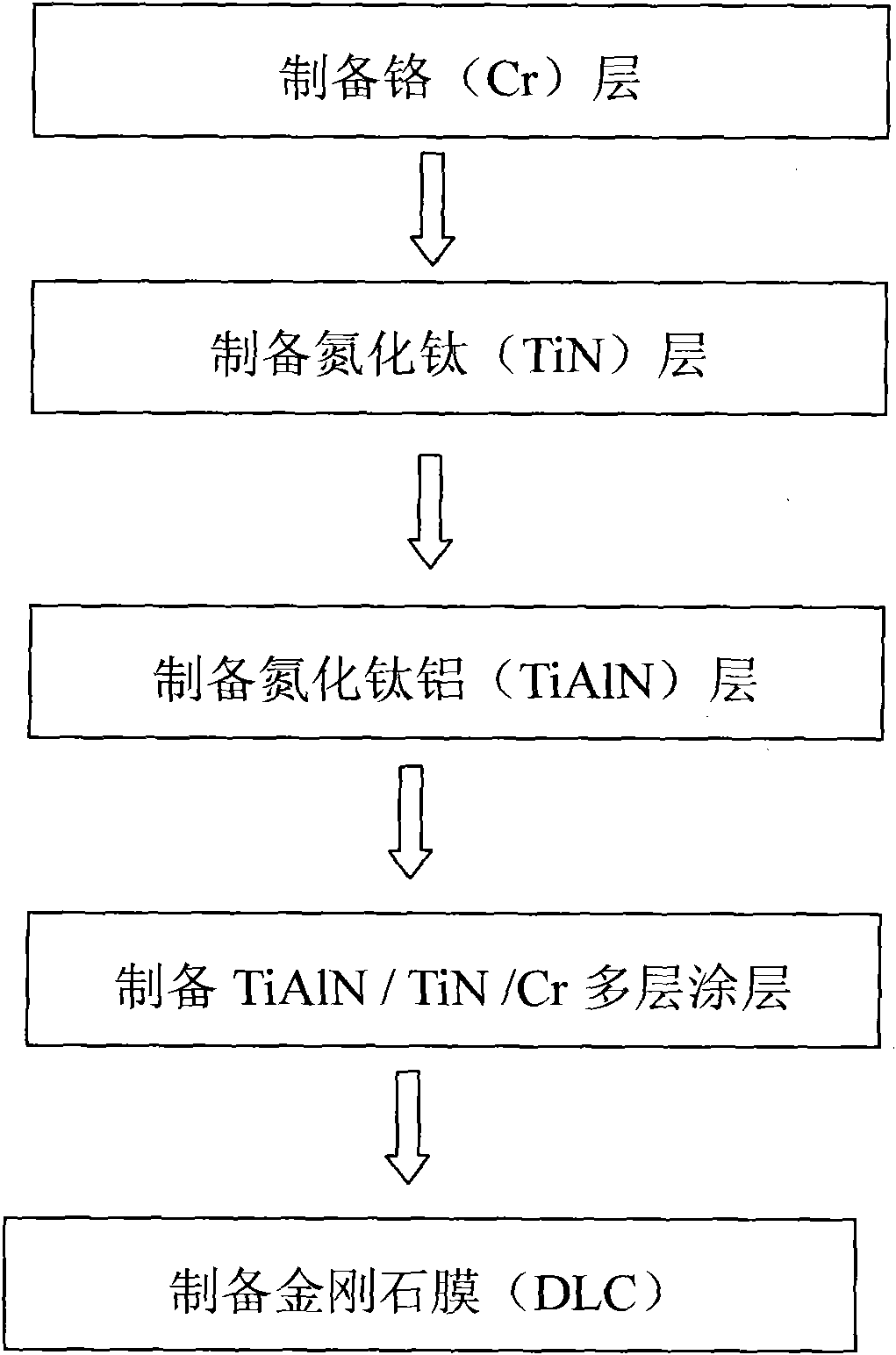

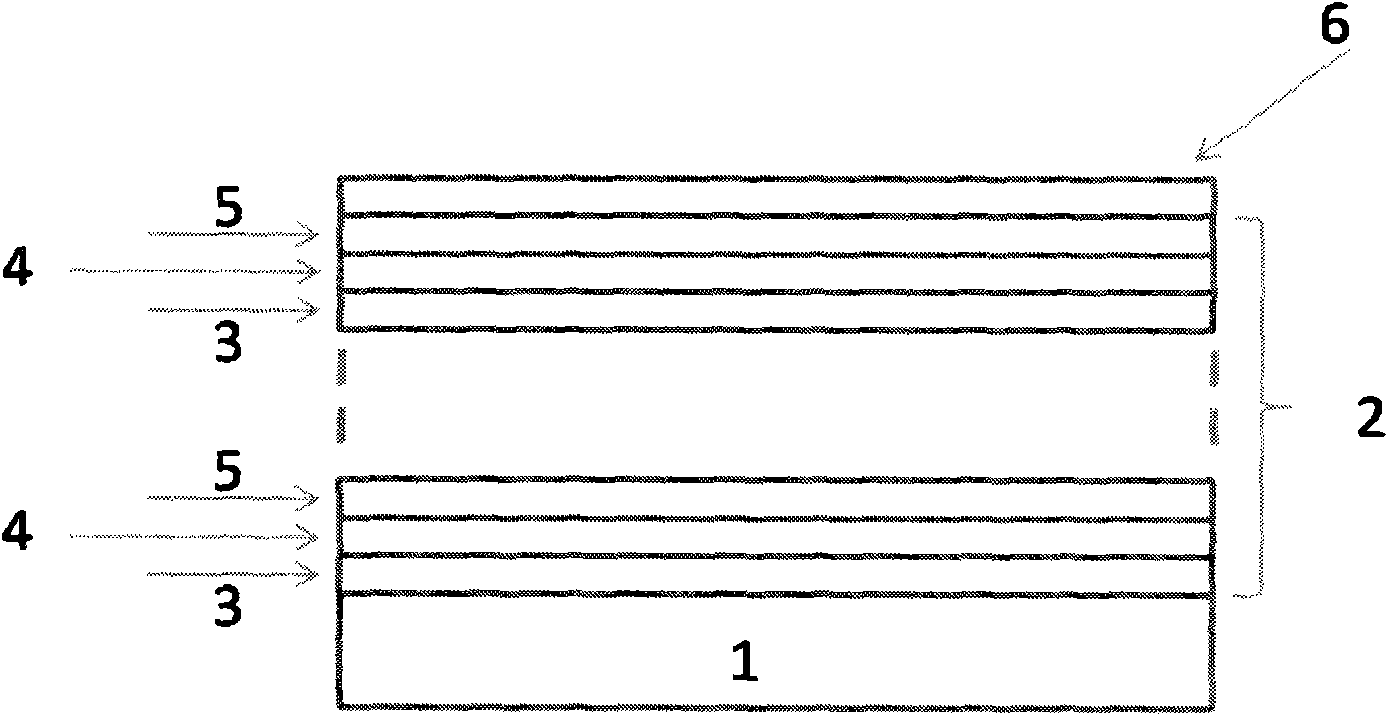

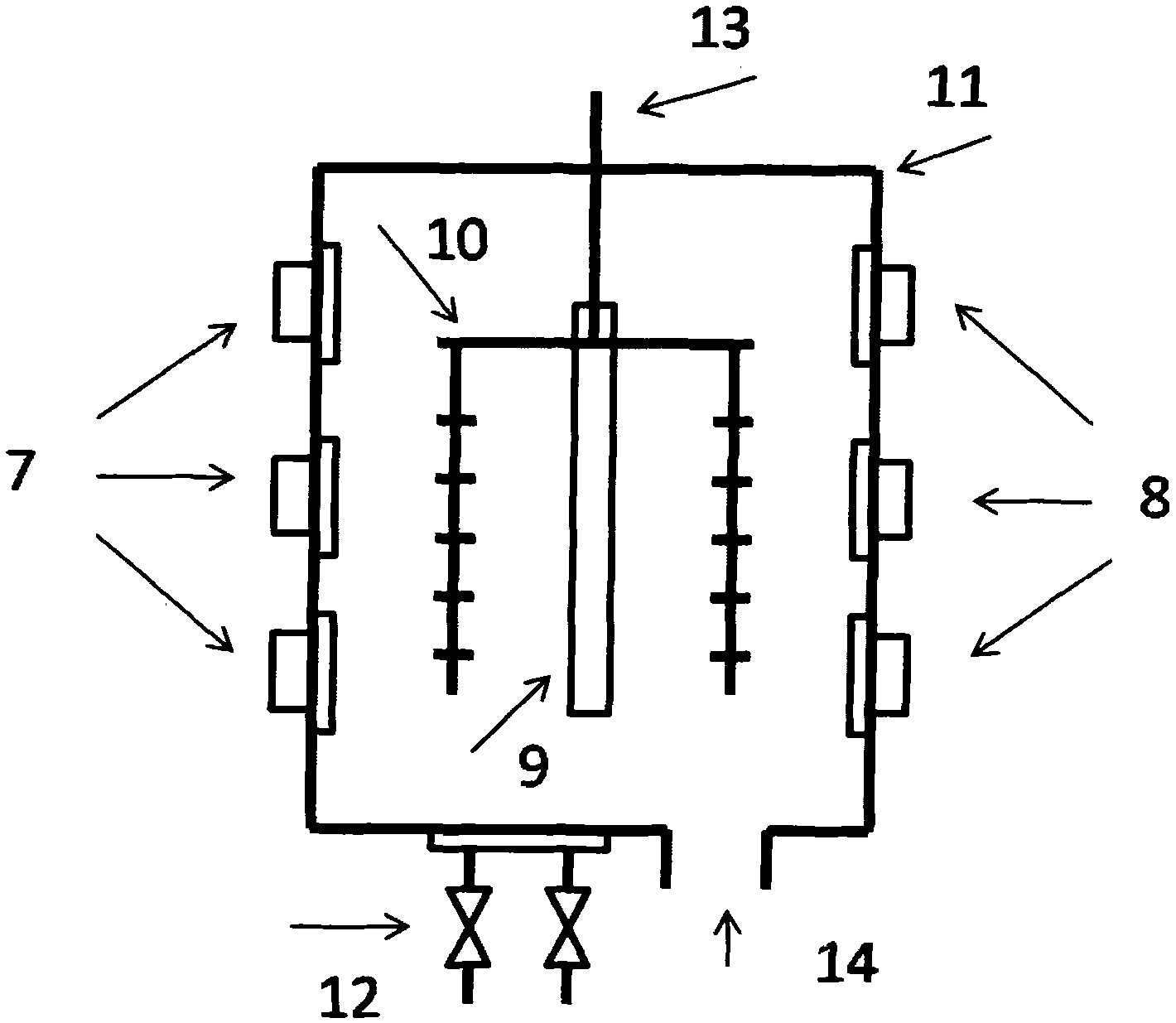

[0026] Such as figure 1 As shown, the method provided by the invention prepares a DLC / TiAlN / CrN / Cr multilayer superhard film coating on the substrate specifically comprises the following steps:

[0027] Step 1: A metal Cr layer with a thickness of 0.1-0.5 μm is prepared on the substrate; preferably, the vacuum degree is 4.0×10 -2 ~5.0×10 -4 Pa (Pa), the temperature is 50°C-200°C, the arc current is 50A-70A, and the negative bias is -150V--600V, the chromium arc target is sputtered for 5-15 minutes, and the deposition thickness is 0.1-0.5μm the Cr layer;

[0028] Step 2: On the Cr layer prepared in the above step 1, further prepare a CrN layer with a thickness of 0.1-0.5 μm; preferably, at a nitrogen pressure of 0.1-5Pa, a temperature of 50°C-200°C, and an arc current of 50A ~70A, under the condition of negative bias -150V~-600V, open the chromium arc target and sputter for 10~25 minutes, and deposit the CrN layer with a thickness of 0.1~0.5μm;

[0029] Step 3: On the CrN l...

Embodiment 2

[0039] Based on Example 1, the following steps can be used to prepare the DLC / TiAlN / CrN / Cr multilayer superhard film coating on the substrate:

[0040] Step 1: At a vacuum pressure of 7.0 x 10 -3 Pa, the temperature is 150°C, the arc current is 60A, and the negative bias is -300V, the chromium arc target is sputtered and deposited on the substrate for 11 minutes to obtain a Cr layer;

[0041] Step 2: further deposit a CrN layer on the Cr layer obtained in the above step 1; preferably, under the conditions of nitrogen pressure of 0.8Pa, temperature of 150°C, arc current of 60A, and negative bias of -300V, open the chromium Arc target sputtering is deposited on the Cr layer of the step 1 for 17 minutes to make the CrN layer;

[0042] Step 3: further prepare a TiAlN layer on the CrN layer prepared in the step 2; wherein, the preparation of the TiAlN layer preferably adopts the following steps:

[0043] Step 3.1: At a nitrogen pressure of 3.5Pa, a temperature of 150°C, an arc cu...

Embodiment 3

[0049] Based on Example 1, the following steps can be used to prepare the DLC / TiAlN / CrN / Cr multilayer superhard film coating on the substrate:

[0050] Step 1, step 2 and step 3 are respectively identical with this step 1, this step 2 and this step 3 in embodiment 2;

[0051] Step 4: Repeat step 1 to step 3 periodically to prepare the TiAlN / CrN / Cr multi-layer coating; preferably, repeat step 1 to step 3 periodically for 8 times; and

[0052] Step 5: Same as this step 5 in embodiment 2.

[0053] The thickness of the DLC / TiAlN / CrN / Cr multilayer superhard film coating prepared in this embodiment is 5.10 μm. The film mechanical properties were tested by nano-indentation method, and the hardness was found to be 40.0±0.3GPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com