Patents

Literature

1394 results about "Ion plating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ion plating (IP) is a physical vapor deposition (PVD) process that is sometimes called ion assisted deposition (IAD) or ion vapor deposition (IVD) and is a version of vacuum deposition. Ion plating uses concurrent or periodic bombardment of the substrate, and deposits film by atomic-sized energetic particles. Bombardment prior to deposition is used to sputter clean the substrate surface. During deposition the bombardment is used to modify and control the properties of the depositing film. It is important that the bombardment be continuous between the cleaning and the deposition portions of the process to maintain an atomically clean interface.

Multi-stage magnetic field straight pipe magnetic filtration and pulsed bias compounded electrical arc ion plating method

ActiveCN103276362ALow ionization rateLow pulse duty cycle to generate high ionization rateVacuum evaporation coatingSputtering coatingPlasmaMagnetic filtration

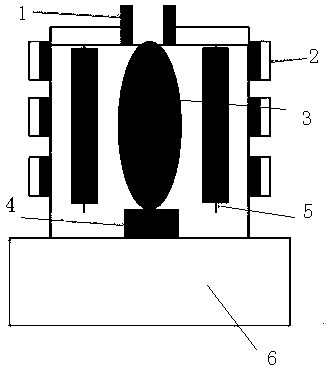

The invention relates to a multi-stage magnetic field straight pipe magnetic filtration and pulsed bias compounded electrical arc ion plating method, and belongs to the technical field of material surface treatments. In the prior art, plasma transmission efficiency is low and pulsed bias can not completely remove large particles due to applying of magnetic filtration on an arc source. A purpose of the present invention is to solve problems in the prior art. The method comprises: 1, connecting a workpiece to a pulsed bias power supply, connecting an electrical arc ion plating target source to a target power supply, and connecting a multi-stage magnetic field straight pipe magnetic filtration device in front of the target source; 2, carrying out thin film deposition, wherein work gas is introduced until achieving 0.01-10 Pa when a pressure in a vacuum chamber is less than 10<-2> Pa, the pulsed bias power supply is opened, a pulsed bias amplitude value, frequency and a duty ratio are adjusted, the target power supply is opened, plasma is generated, the multi-stage magnetic field straight pipe magnetic filtration device is opened, removal of large particles and efficient transmission of the plasma in the magnetic filtration device are achieved, process parameters are adjusted, and a thin film with no large particle defect is rapidly produced; and 3, adopting a single-stage magnetic field to combine direct current / pulsed bias to obtain a thin film with a certain thickness.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

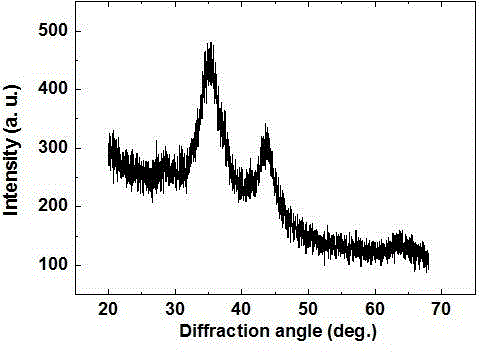

Hard film and hard film-coated tool

ActiveUS7166155B2Improve adhesionHigh hardnessVacuum evaporation coatingSputtering coatingCrystal structureX-ray

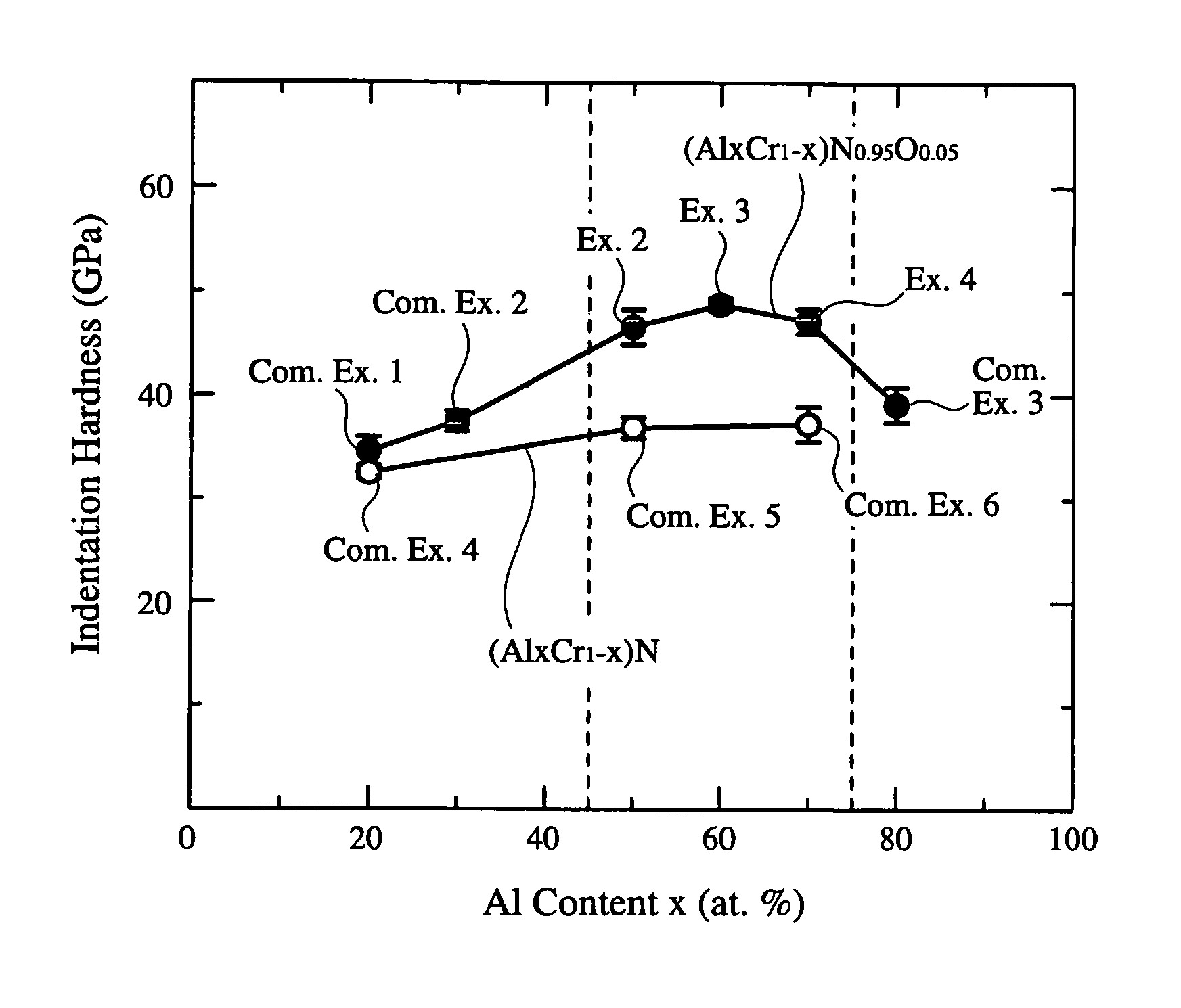

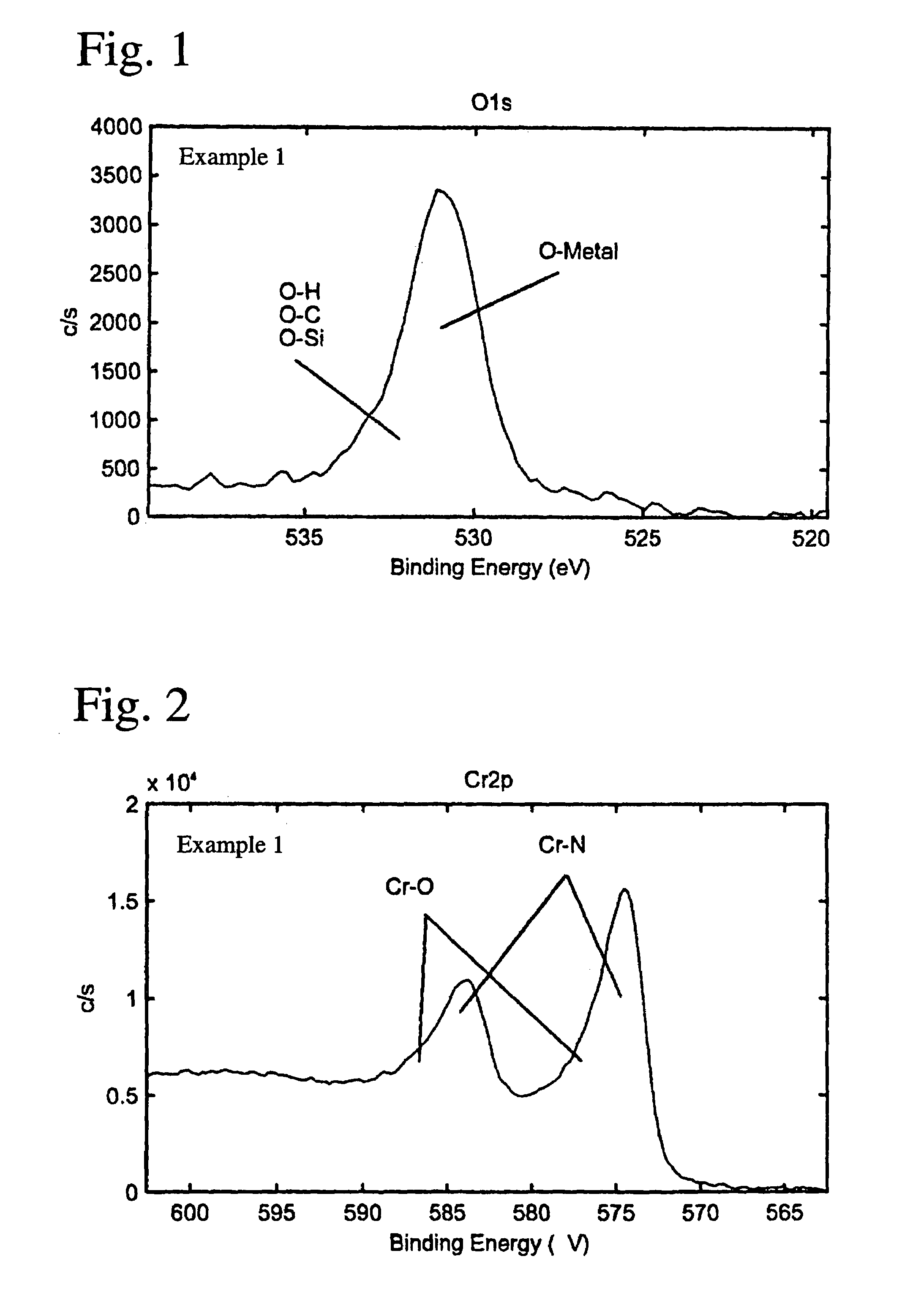

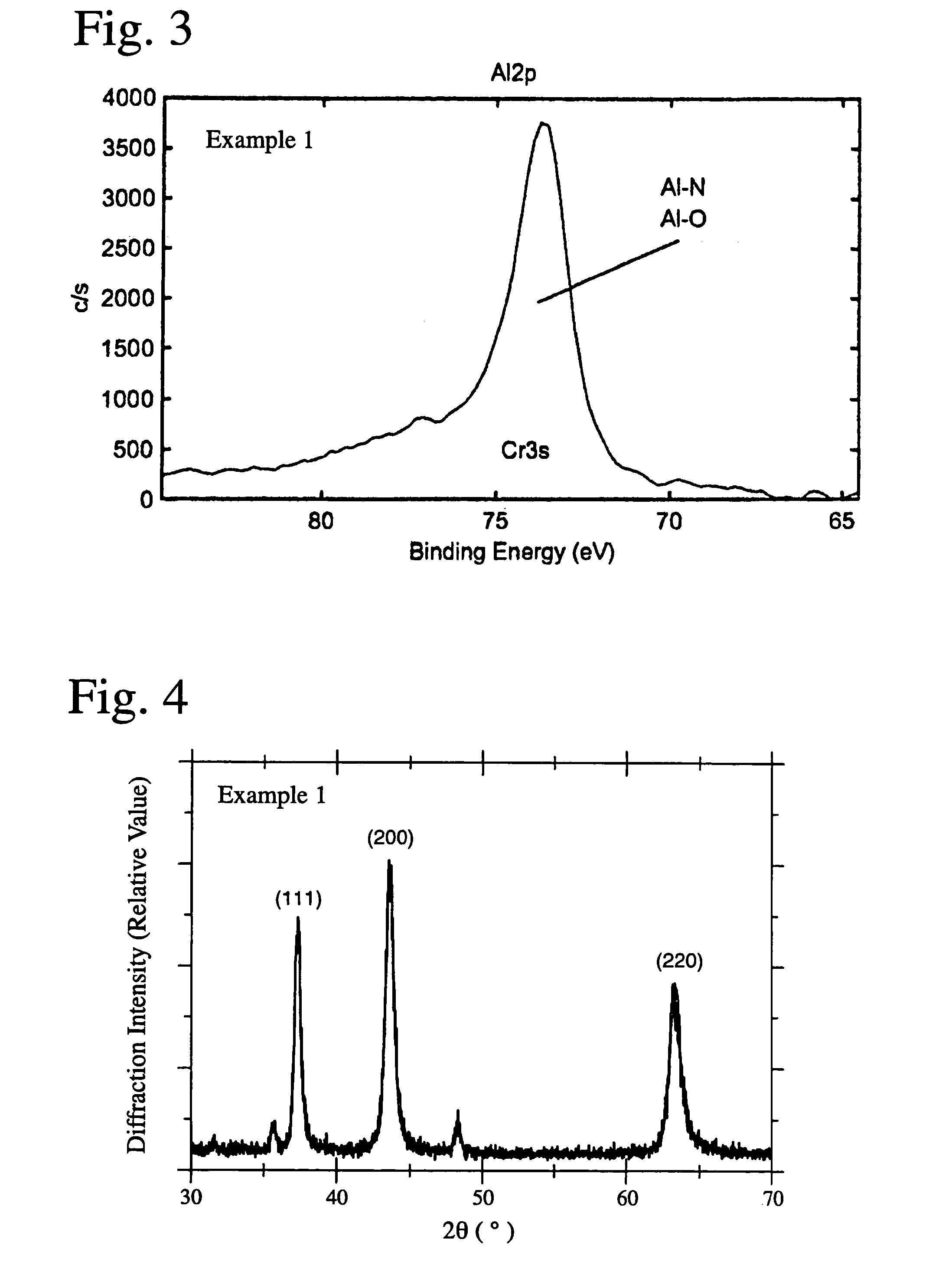

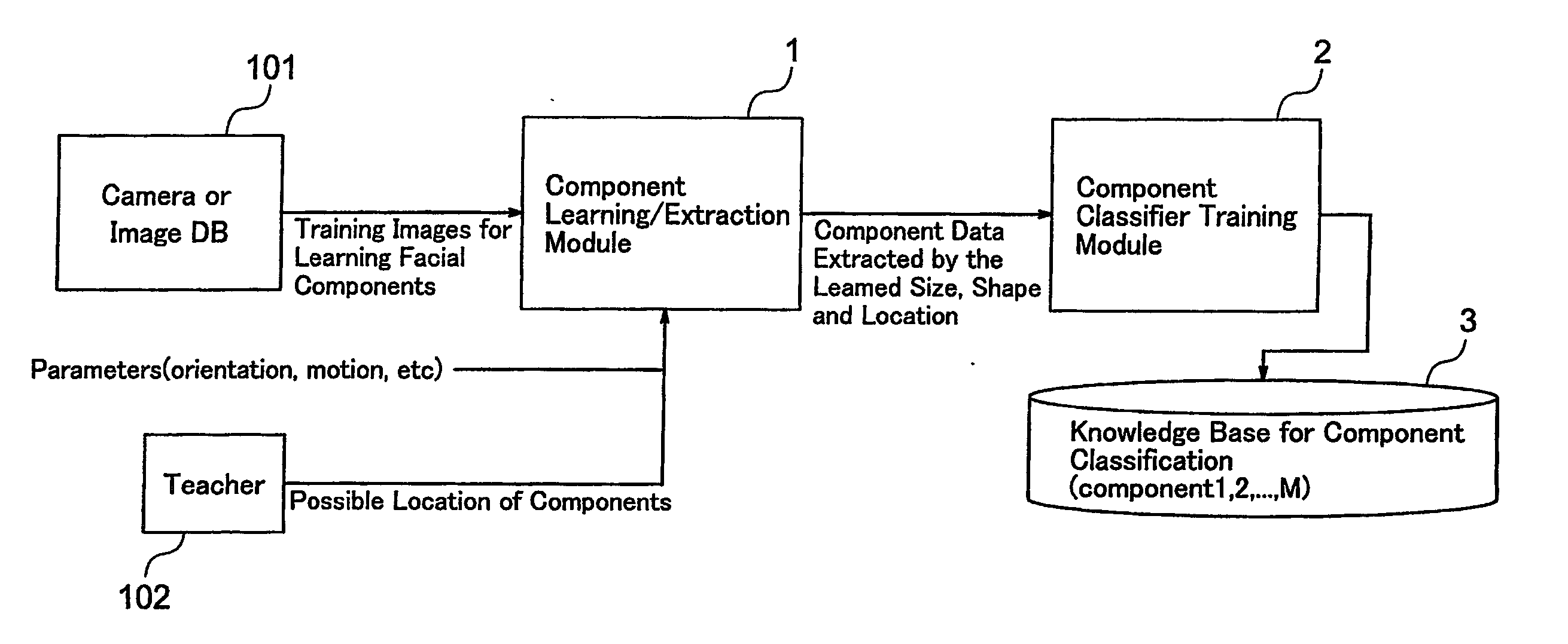

A hard film formed by an arc-discharge ion-plating method, having a composition comprising metal components represented by AlxCr1-x-ySiy, wherein x and y are respectively atomic ratios meeting 0.45≦x≦0.75, 0≦y≦0.35, and 0.5≦x+y<1, and non-metal components represented by N1-α-β-γBαCβOγ, wherein α,β and γ are respectively atomic ratios meeting 0≦α≦0.15, 0≦β≦0.35, and 0.003≦γ≦0.25, the hard film having an NaCl-type crystal structure, with a half width of 2θ at an X-ray diffraction peak corresponding to a (111) face or a (200) face being 0.5–2.0°, and the hard film containing oxygen more in grain boundaries than in crystal grains.

Owner:HITACHI TOOL ENG LTD

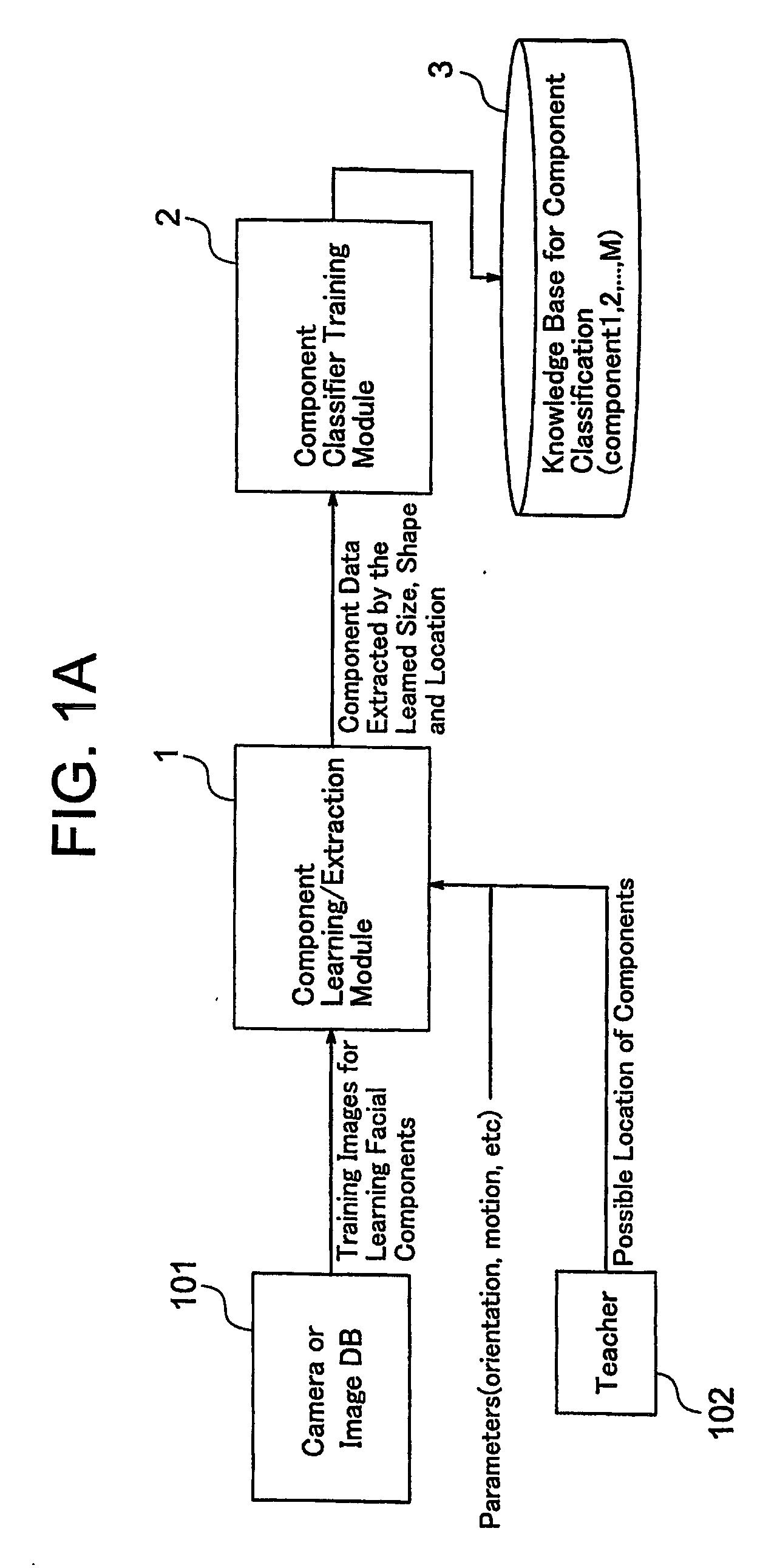

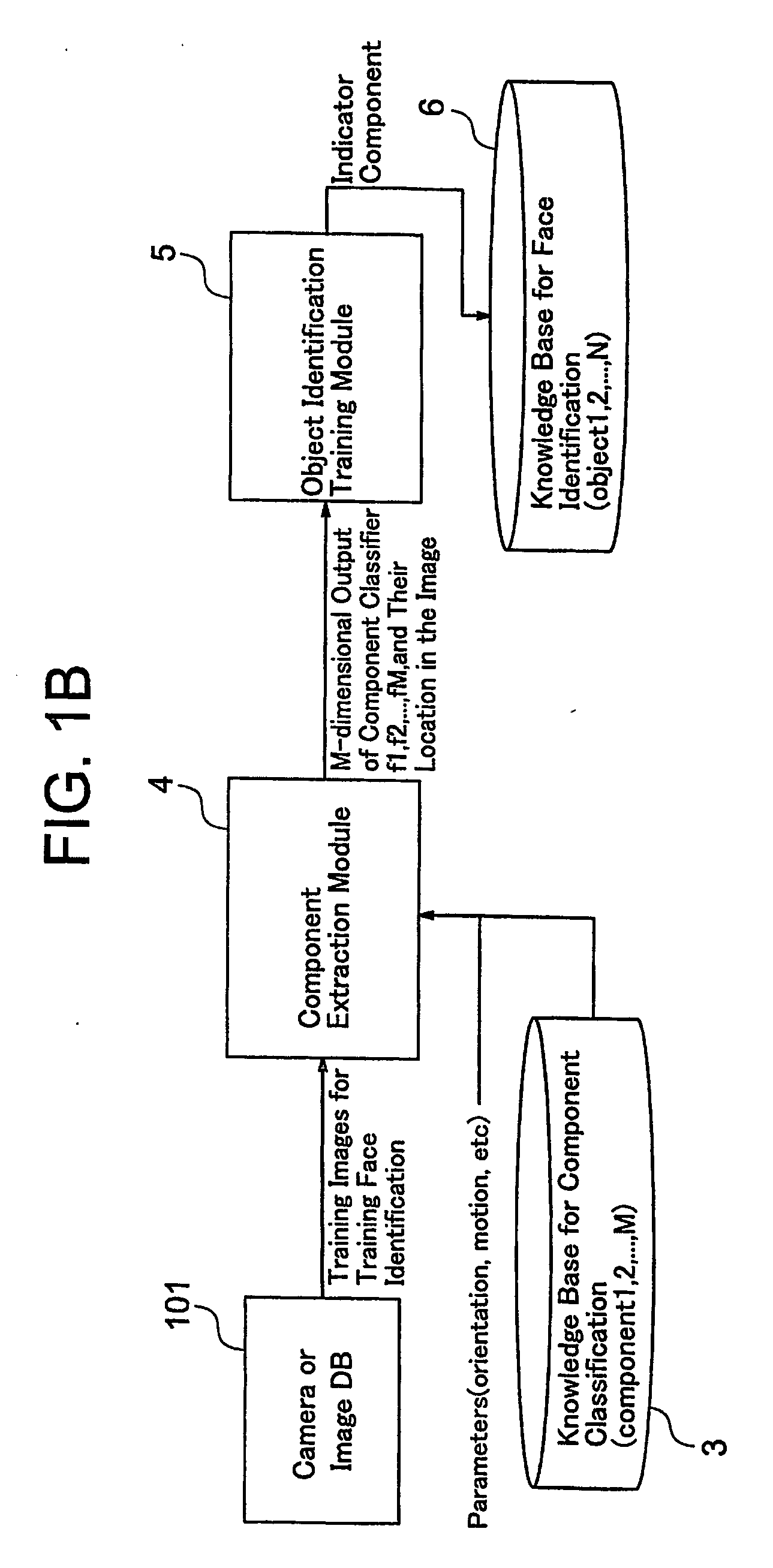

System and method for face recognition

ActiveUS20060280341A1Improve accuracyMinimized volumeCharacter and pattern recognitionEvaporationEngineering

A production device and method which produce a multiple-system film having metal components such as TiAlN greatly different in melting point by a melting-evaporation type ion plating method that provides a high material utilization efficiency and a good film quality. Power needed to evaporate a material (4) is first supplied, and then power gradually increased over the initail power is repeatedly supplied until a needed maximum power is reached. Concurrently, a plasma control is performed for converging plasma (7) onto an initial area needed to evaporate the material, and then a plasma control is performed for continuously and sequentially moving / expanding plasma from the initial plasma area up to a maximum plasma area to thereby gradually melt the non-melted portion of the material.

Owner:HONDA MOTOR CO LTD

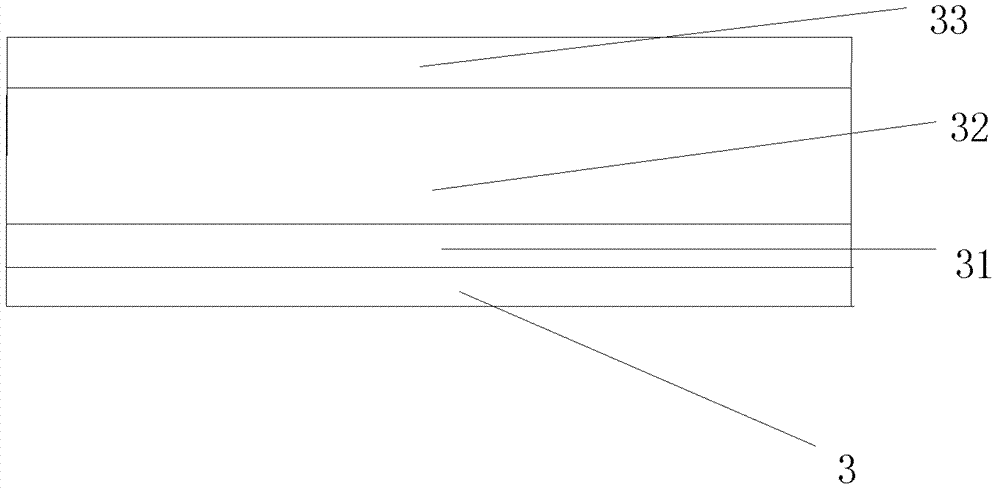

Laminate utilizing a metal layer activated by nitrogen plasma treatment

InactiveUS7026054B2Improve adherabilityImprove dynamical strengthLiquid surface applicatorsInsulating substrate metal adhesion improvementNitrogen plasmaShell molding

A laminate includes a metal layer which is formed on and covers a surface of an insulating substrate activated by a plasma treatment by any method selected from a sputtering method, a vacuum depositing method and an ion plating method. The substrate is obtained by molding a resin composition containing 20 to 150 parts by mass of a fibrous filler having an average fiber diameter of 0.1 to 5 μm and an average fiber length of 10 to 50 μm relative to 100 parts by mass of a base resin comprising a thermoplastic resin and a thermosetting resin.

Owner:MATSUSHITA ELECTRIC WORKS LTD

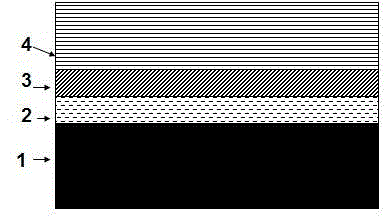

AlTiN-AlCrN super hard nano multilayer composite coating hob and preparation method thereof

InactiveCN102922052AHigh densityImprove corrosion resistanceVacuum evaporation coatingSputtering coatingAlloyCemented carbide

The invention discloses an AlTiN-AlCrN super hard nano multilayer composite coating hob and a preparation method thereof. The hob is provided with a nano composite coating consisting of Cr, CrN, AlTiN / CrhN and AlTiN / AlCr in sequence and generated by adopting an arc ion plating technology. The coating is reasonable in structural design and has gradually changed components and gradient hardness at the same time; and the prepared AlTiN / AlCr coating has good bonding force with the high-speed steel or hard alloy hob, high hardness and excellent temperature resistance. The problems of insufficient temperature resistance and abrasion resistance of the hob are well solved, the machining performance of the hob is greatly improved, and the hob has a good industrial application prospect.

Owner:SHENZHEN YUANSIDACHENG TECH

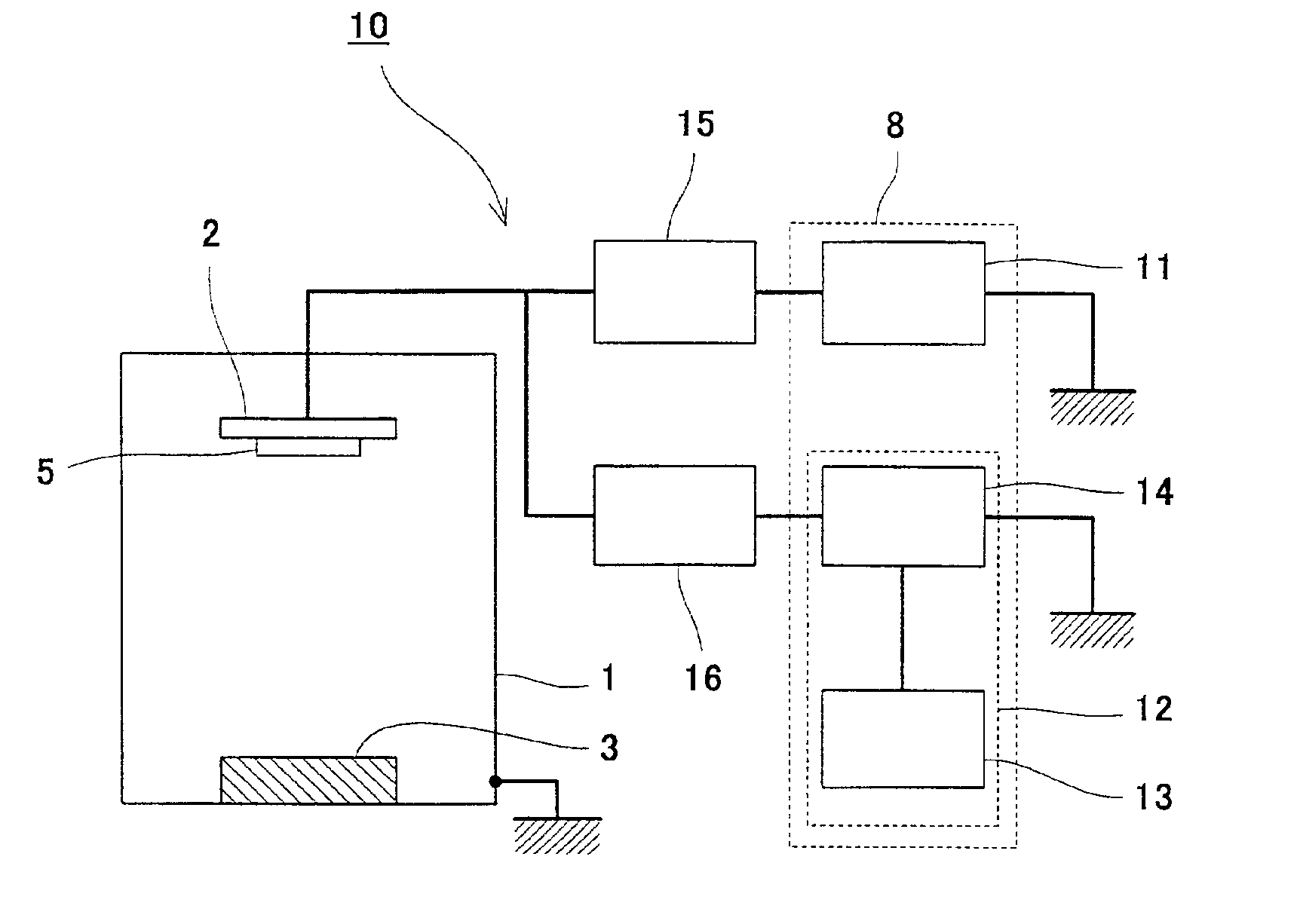

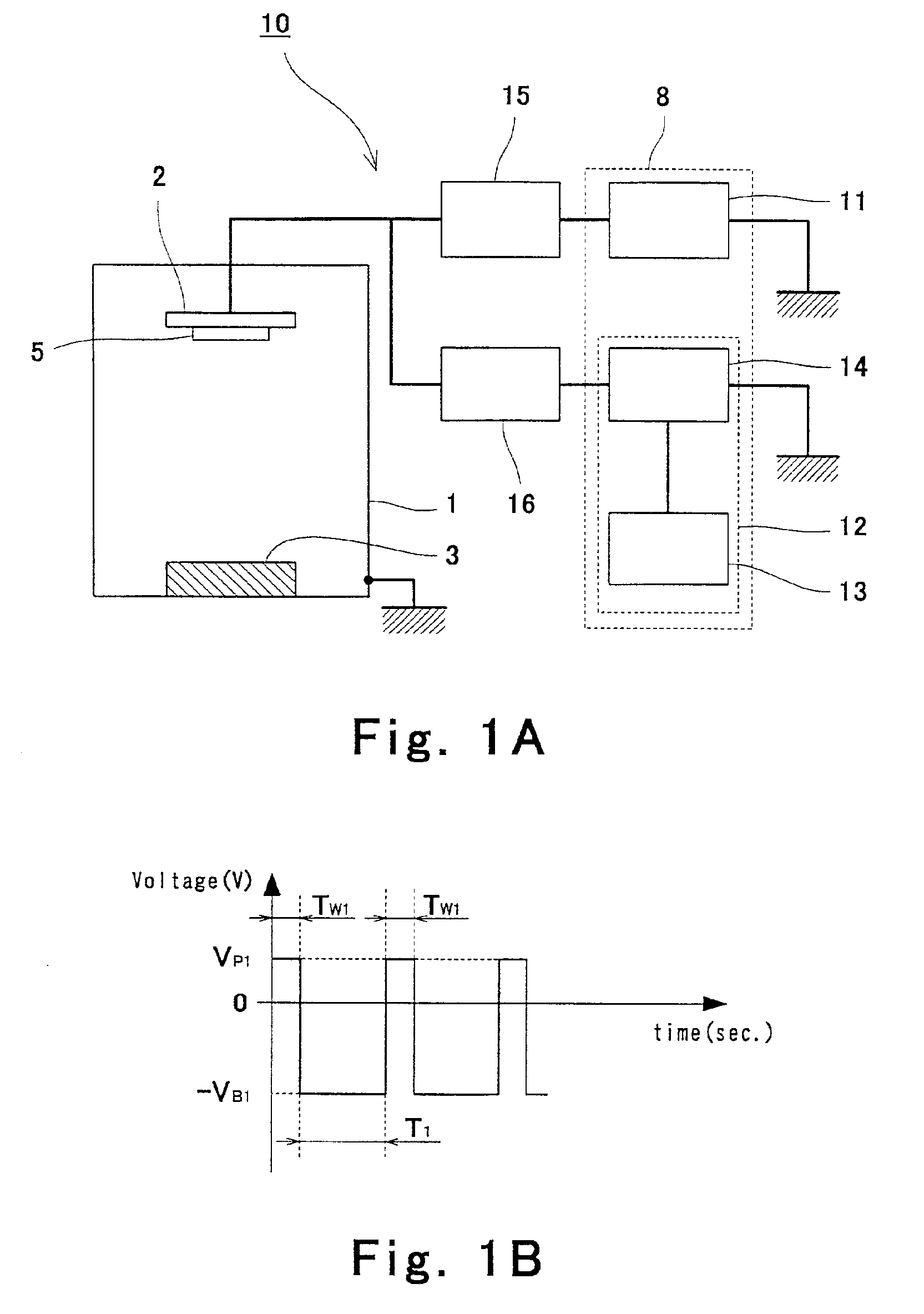

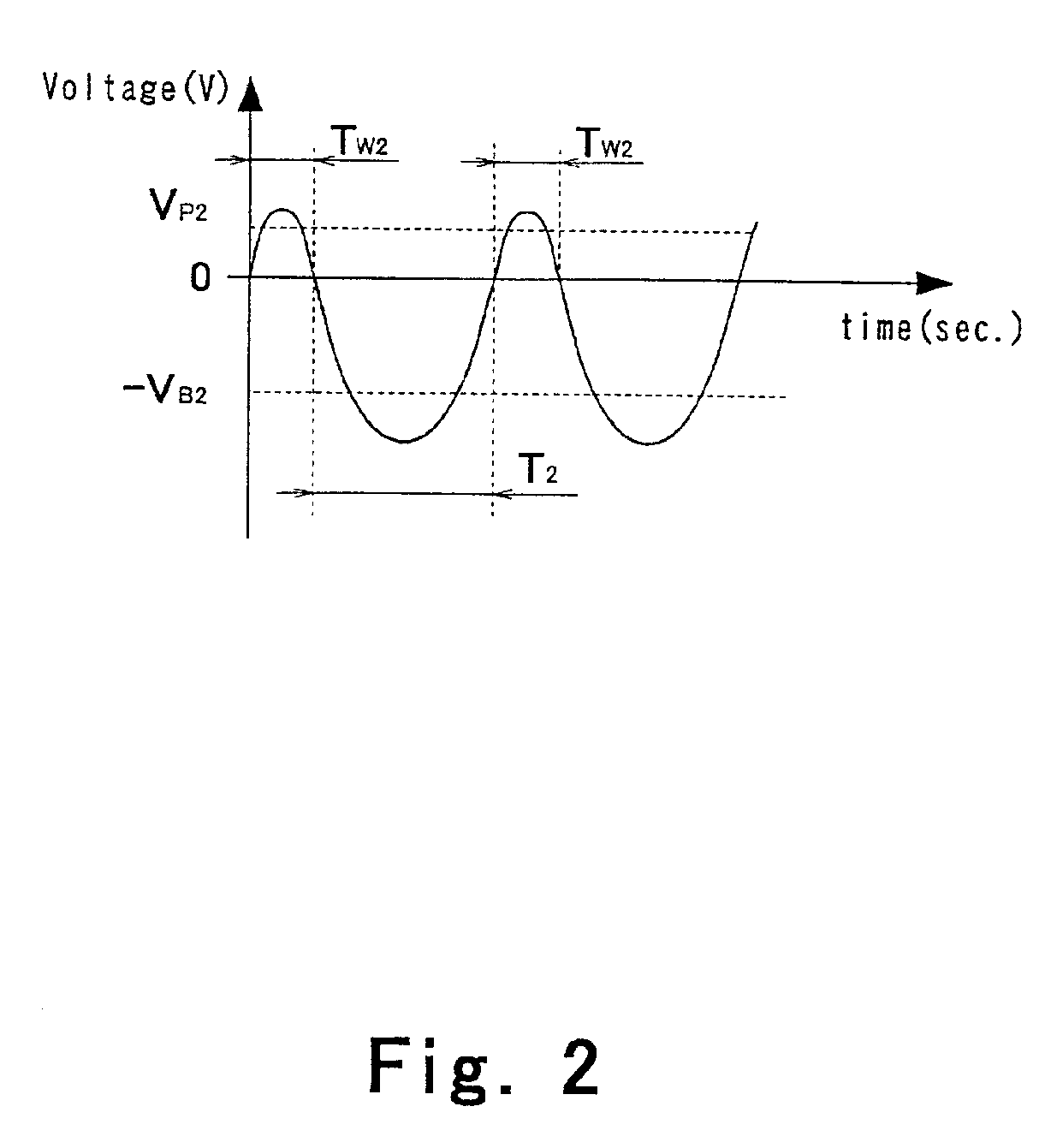

Ion plating device and ion plating method

InactiveUS6863018B2Avoid it happening againHigh densityElectric discharge tubesVacuum evaporation coatingEngineeringVacuum chamber

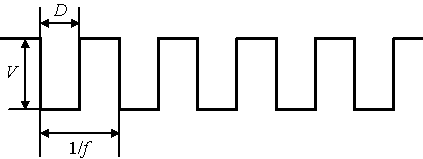

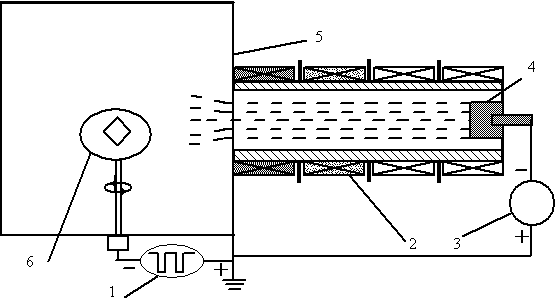

In ion plating in which a substrate is held on a substrate holder placed in an evacuated vacuum chamber and plasma is generated in the vacuum chamber to be formed into a film, a bias voltage composed of a negative bias component having a predetermined negative voltage value for a predetermined output time and a pulse bias component corresponding to a pulse output having a constant positive value for a predetermined time and output with a cycle set in the rage of 1 kHz-1 GHz is supplied to the inside of the vacuum chamber through the substrate holder by a power supply unit.

Owner:SHIN MEIWA IND CO LTD

Flexible material and method of manufacturing the same and use thereof

InactiveCN101108546AImprove corrosion resistanceImprove shielding effectVacuum evaporation coatingSputtering coatingElectrical resistance and conductanceElectricity

The invention provides a soft material and the preparation method and use, which precede ion plating or magnetic control sputtering metal plating to the soft material, then precede vacuum metal steaming plating, the produced soft material product has good adhering capability, the resistance value is between 0.03 to 103 Omega, can ensure the vertical electricity conduction to the air permeability textile fabric. Or precede ion plating or magnetic control sputtering metal plating to the soft material, then proceed copper plating, and proceed vacuum steaming plating metal then. The resistance of the produced soft electricity conduction is between 0.005 to 0.03 Omega, the adhesive force is good, the erosion performance is better, the material shielding performance is larger than 70bB. The soft material can be used print the base material of circuit board , shielding clothes and various packaging material.

Owner:TIANNUO PHOTOELECTRIC MATERIAL

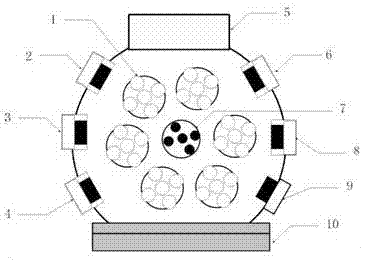

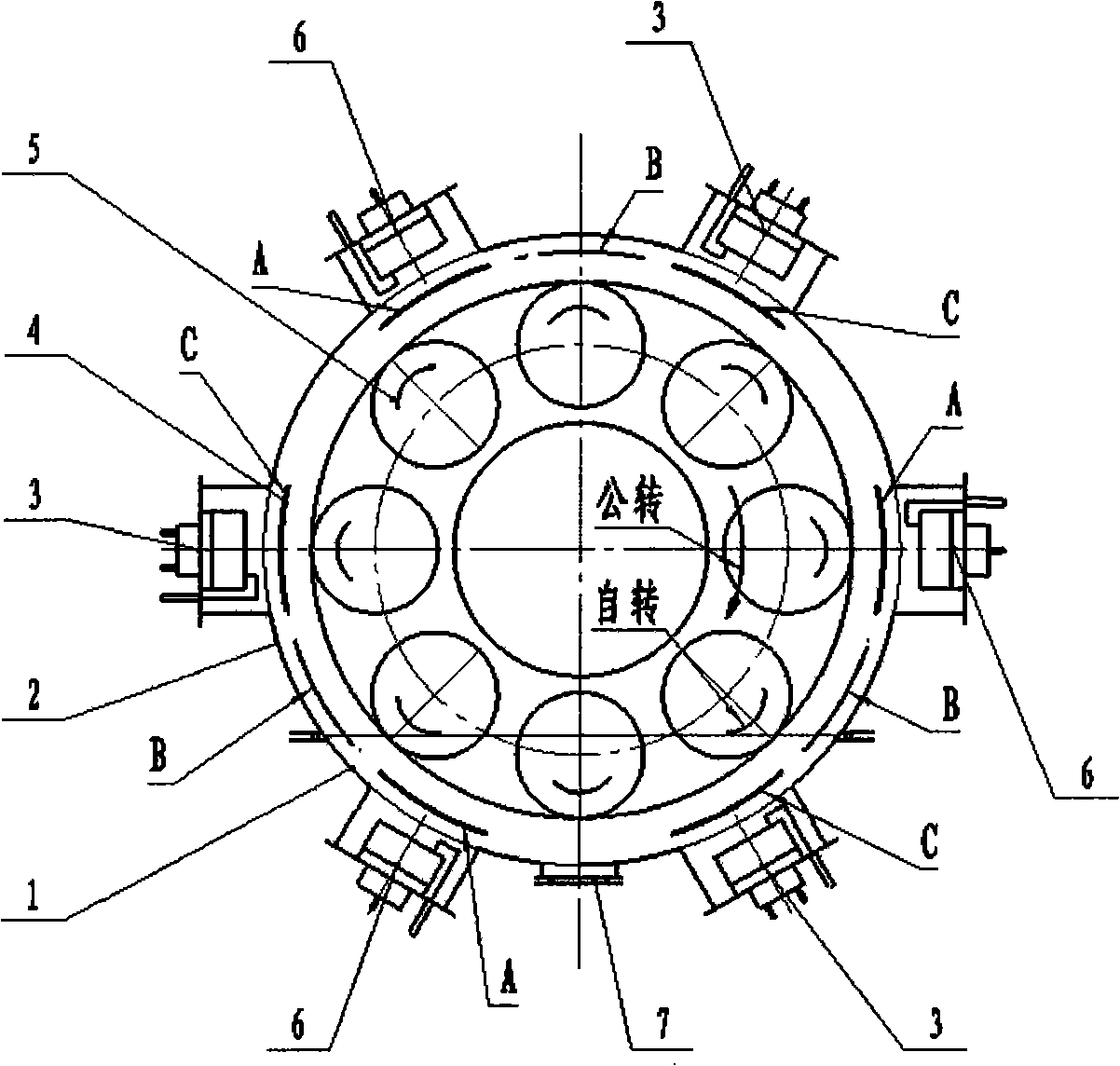

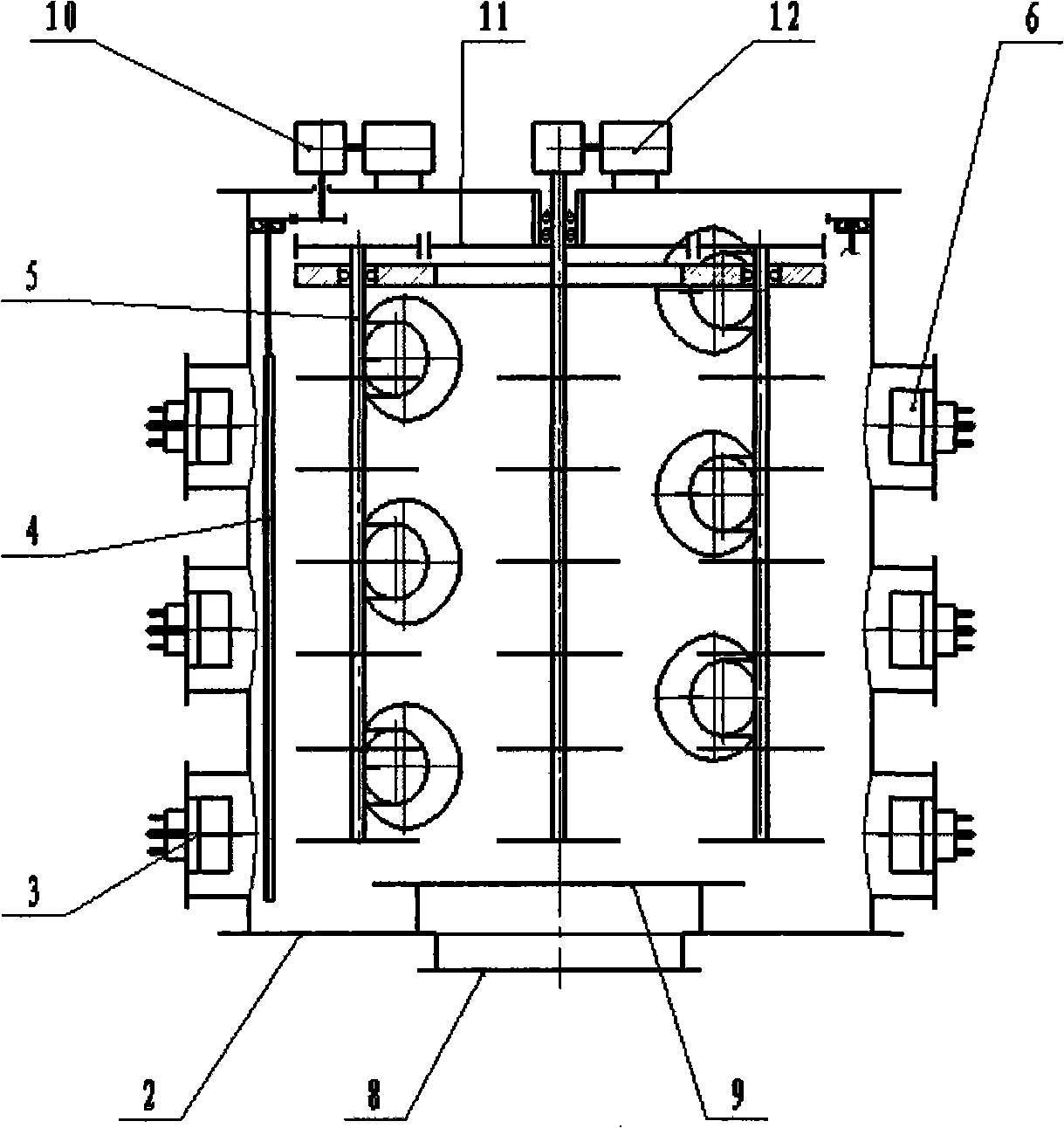

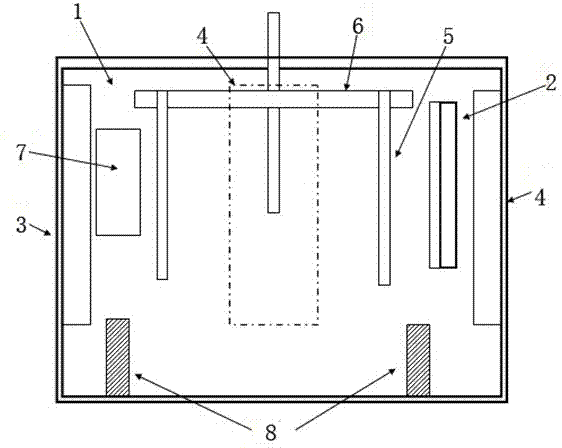

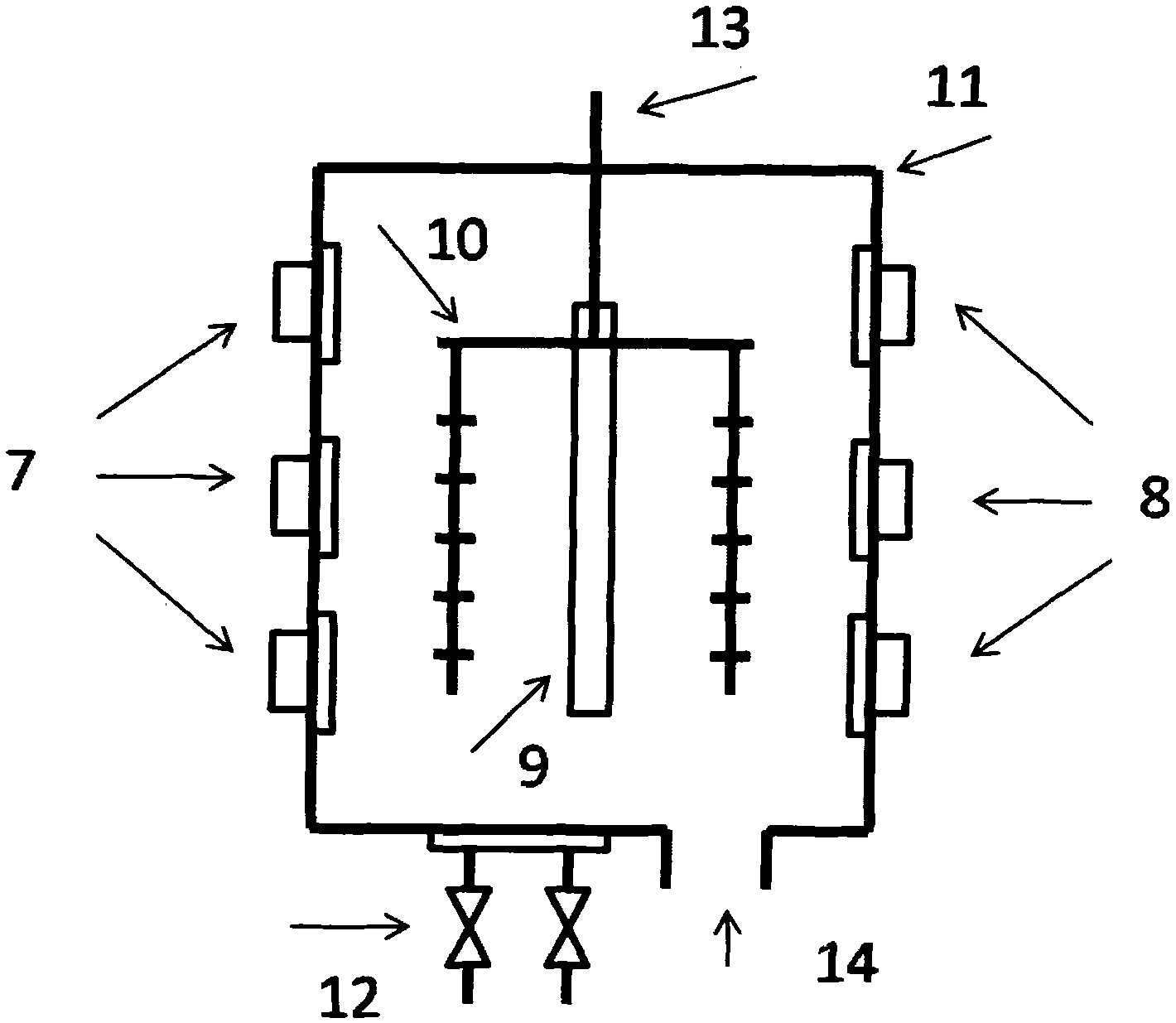

Equipment and method for producing nichrome composite plate with vacuum arc ion plating

InactiveCN101294270ACorrosion protectionHigh surface hardnessVacuum evaporation coatingSputtering coatingComposite plateVacuum chamber

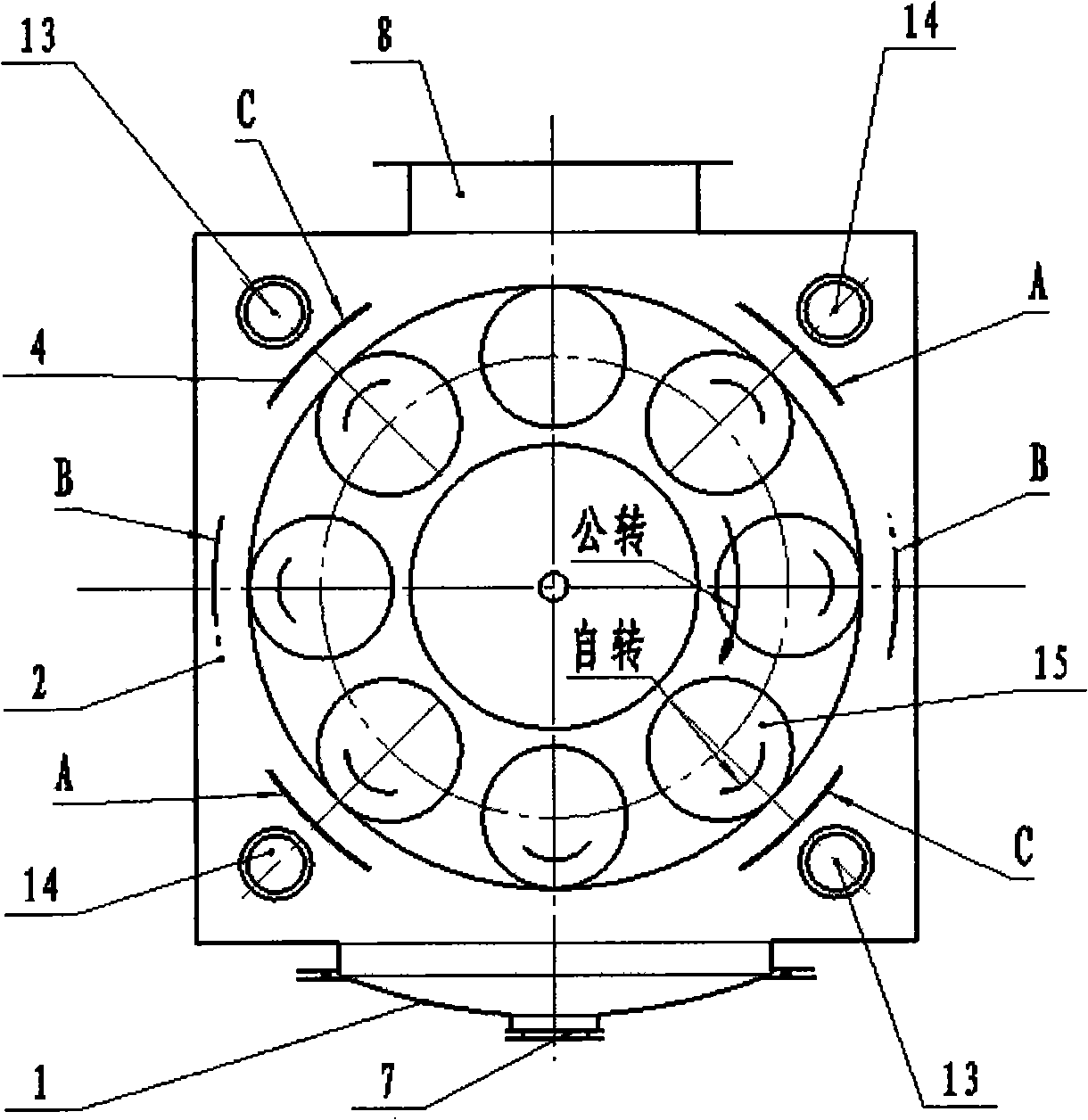

The invention relates to a device for manufacturing a nickel-chromium composite plate by using vacuum arc ion plating to replace electroplating and a method thereof, and is characterized in that the device of the vacuum arc ion plating and the method are utilized to replace water electroplating to sequentially prepare the nickel-chromium composite plate composed of a pure nickel film, a nickel-chromium gradient transition film and a pure chromium film on a copper substrate; the device for manufacturing the nickel-chromium composite plate by using the vacuum arc ion plating is of a vertical cylindrical shape or a regular polygon; arc target sources are evenly distributed around a vacuum chamber wall; a controllable mechanical baffle plate is arranged in front of each target source; a planetary type work rest with rotation and revolution is arranged in the middle part of a vacuum chamber; the technical process of a filming operation comprises three stages that are preliminary treatment, the filming operation and post treatment. The device and the method simplify the process flows and the operation links, increase the work efficiency, fully replace the traditional electroplating technology to coat a wearproof anticorrosion decoration coating on a coppery water heating component, and thoroughly eliminate the environmental pollution problems in the electroplating.

Owner:辽阳市弓长岭区光辉铁矿石加工厂

TiAlN/TiAlCN multilayer coating of substrate surface and preparing method thereof

ActiveCN102011090AMitigate defectsAlleviate dislocationVacuum evaporation coatingSputtering coatingSputteringHardness

The present invention discloses a TiAlN / TiAlCN multilayer coating of substrate surface and preparing method thereof, wherein a transitional layer is between a substrate and a TiAlN / TiAlCN multilayer coating; the multilayer coating is formed by alternating periodic arrangement of TiAlN films and TiAlCN films; in a period, the thickness sum of the TiAlN films and the TiAlCN films is 1-20 nano; the percentage by weight of C atom in the TiAlCN films is 0.1-5%. The multilayer coating of the present invention has the advantages of high hardness, low internal stress and high tenacity; the cutting efficiency and corrosion resistance of the substrate can be improved, and the service life of the substrate can be prolonged. In the present invention, the multilayer coating is deposited by high power pulse magnetron sputtering technique; the problems that cathode arc ion plating and depositing speed is too fast to prepare a nano epitaxial film and that target poisoning is caused during the procedure for preparing films by DC magnetron sputtering are solved; the nano modulation period is controlled via adjusting the autorotation and revolution speeds of the substrate and adjusting the quantity of targets.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

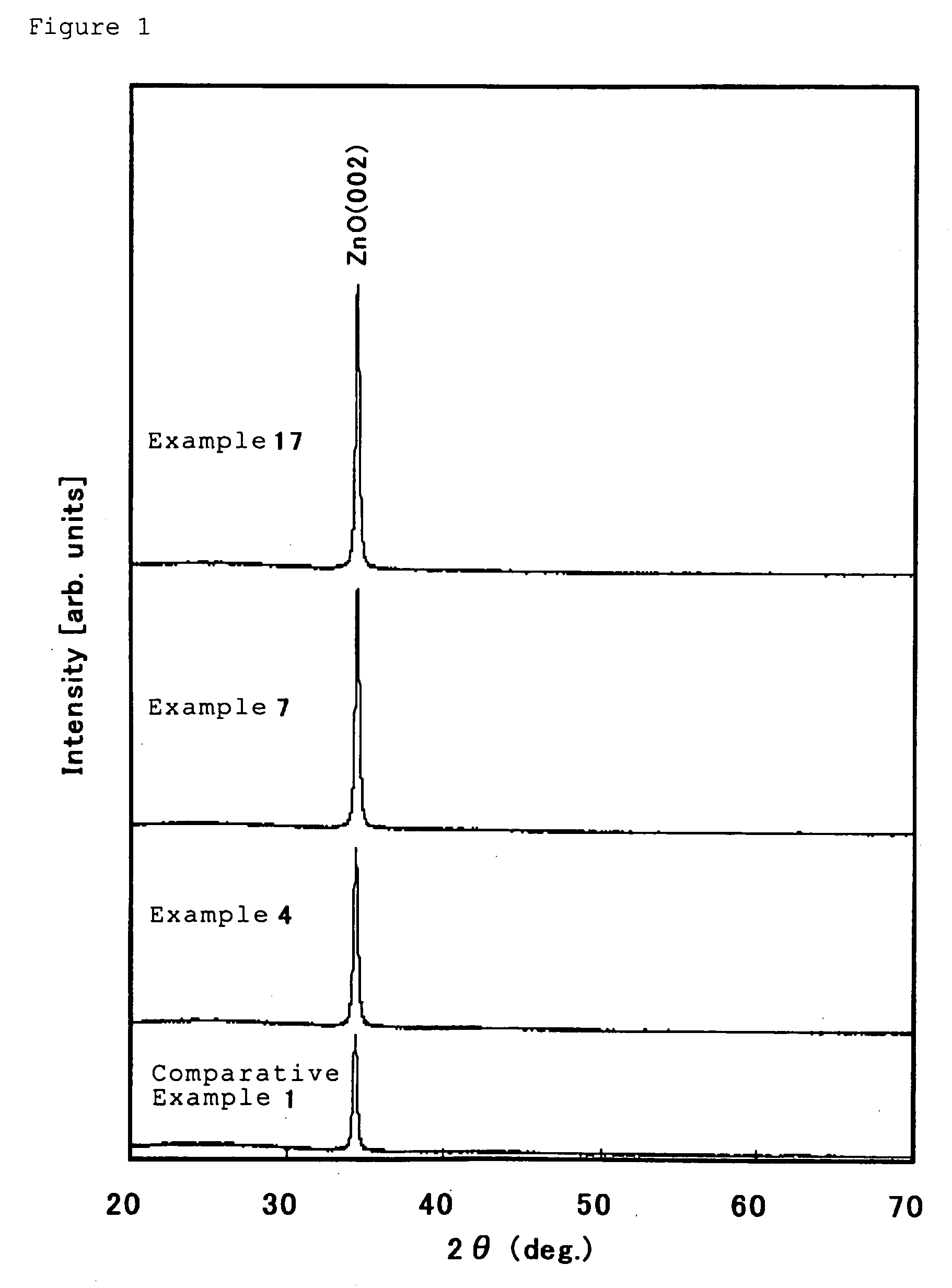

Oxide Sintered Body, Target, Transparent Conductive Film Obtained by Using the Same, and transparent Conductive Substrate

ActiveUS20090101493A1Good chemical resistanceImprove conductivityConductive layers on insulating-supportsVacuum evaporation coatingLow resistanceIon

Provided are an oxide sintered body having zinc oxide as a main component and still more containing magnesium, a target obtained by processing the same, a transparent conductive film having excellent chemical resistance and low resistance, obtained by a direct-current sputtering method or an ion plating method by using the same, and a transparent conductive substrate. Provided are an oxide sintered body having zinc oxide and magnesium, wherein content of magnesium is from 0.02 to 0.30 as atom number ratio of Mg / (Zn+Mg); still more, an oxide sintered body having zinc oxide, magnesium, gallium and / or aluminum, wherein content of gallium and / or aluminum is over 0 and equal to or lower than 0.09 as atom number ratio of (Ga+Al) / (Zn+Ga+Al), and content of magnesium is from 0.02 to 0.30 as atom number ratio of Mg / (Zn+Ga+Al+Mg); a target obtained by processing these oxide sintered bodies; and a transparent conductive film formed on a substrate by a sputtering method or an ion plating method, by using this target.

Owner:SUMITOMO METAL MINING CO LTD

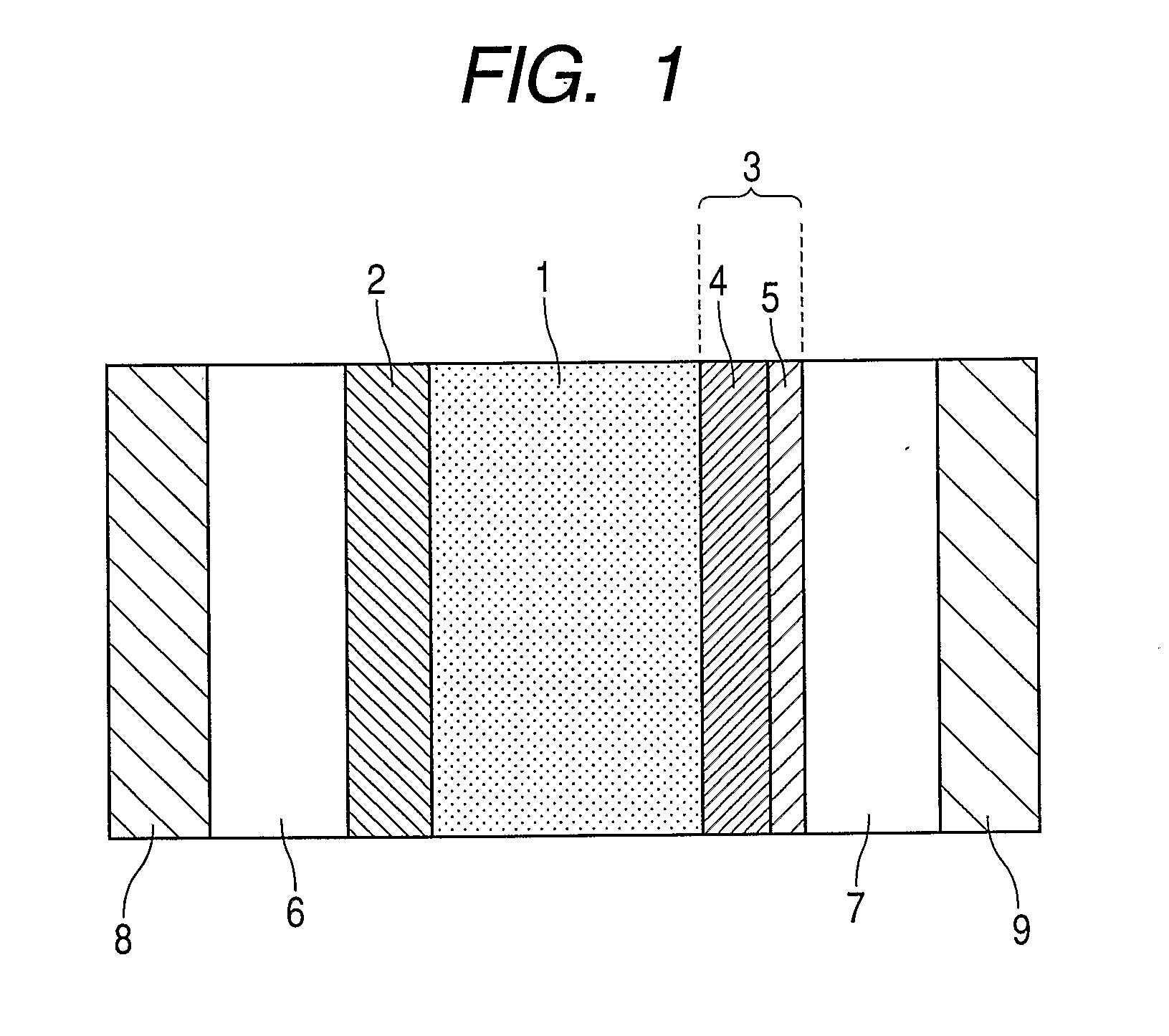

Transparent conductive laminate and touch panel

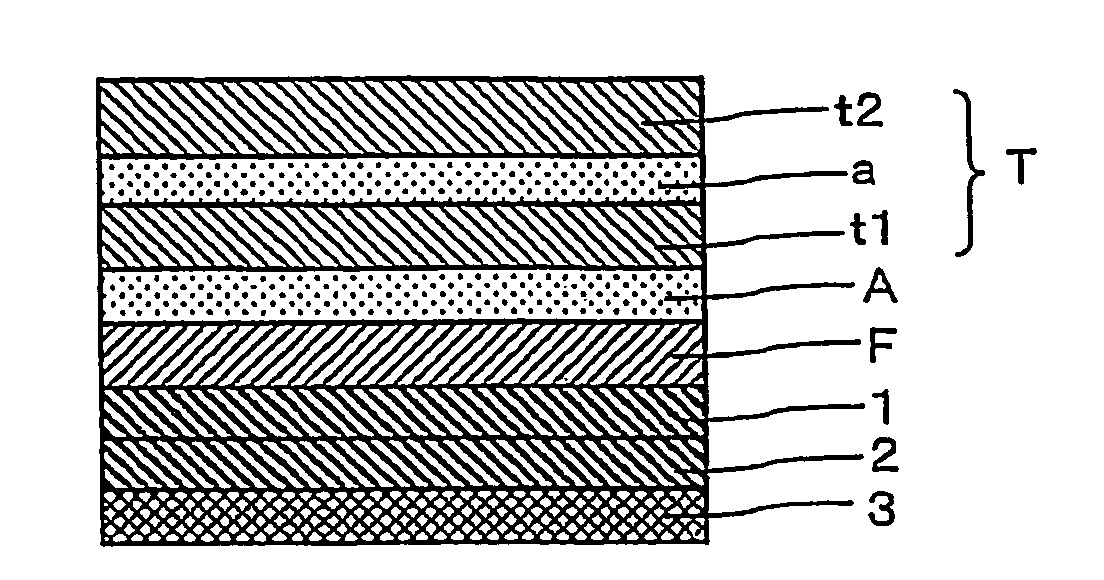

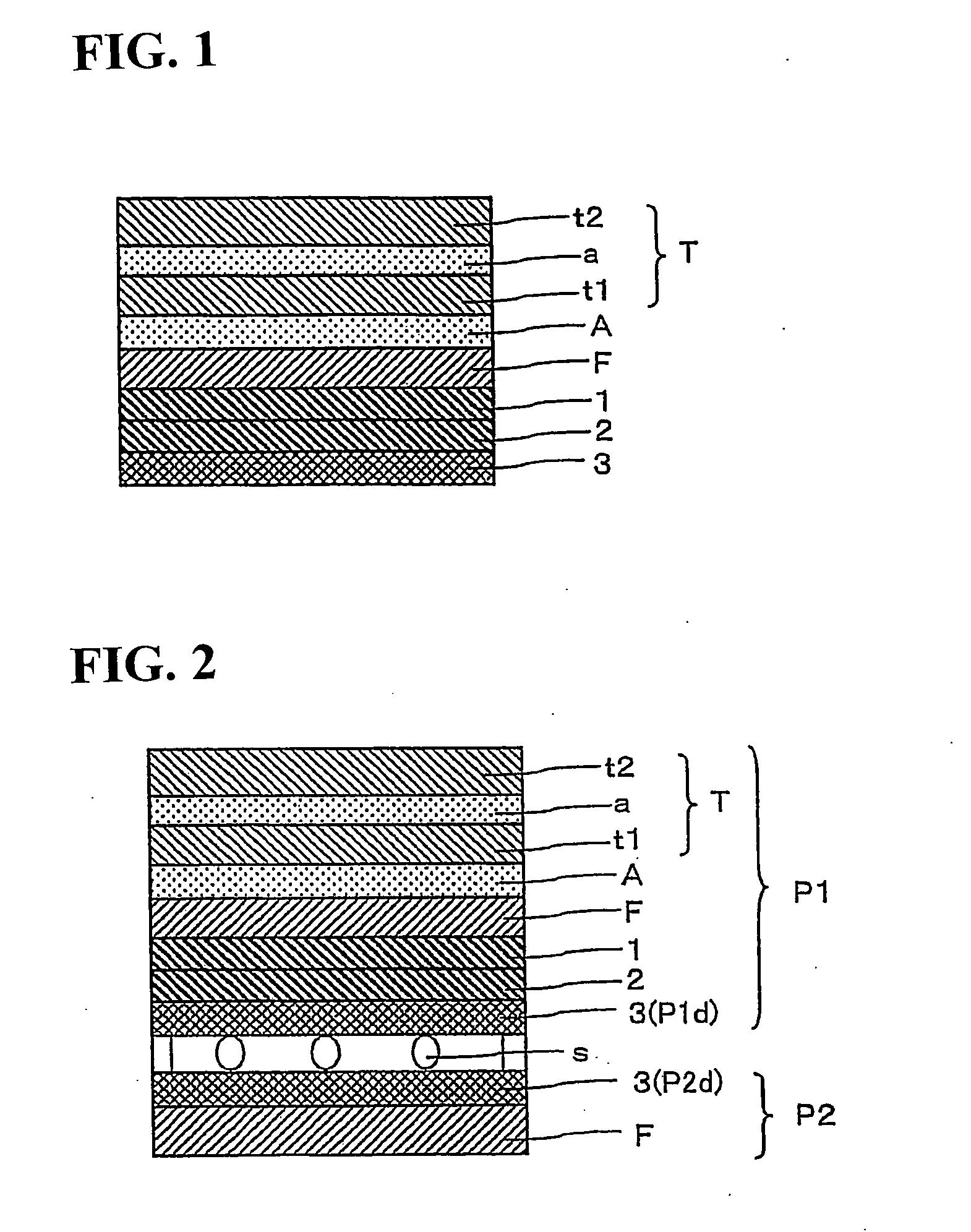

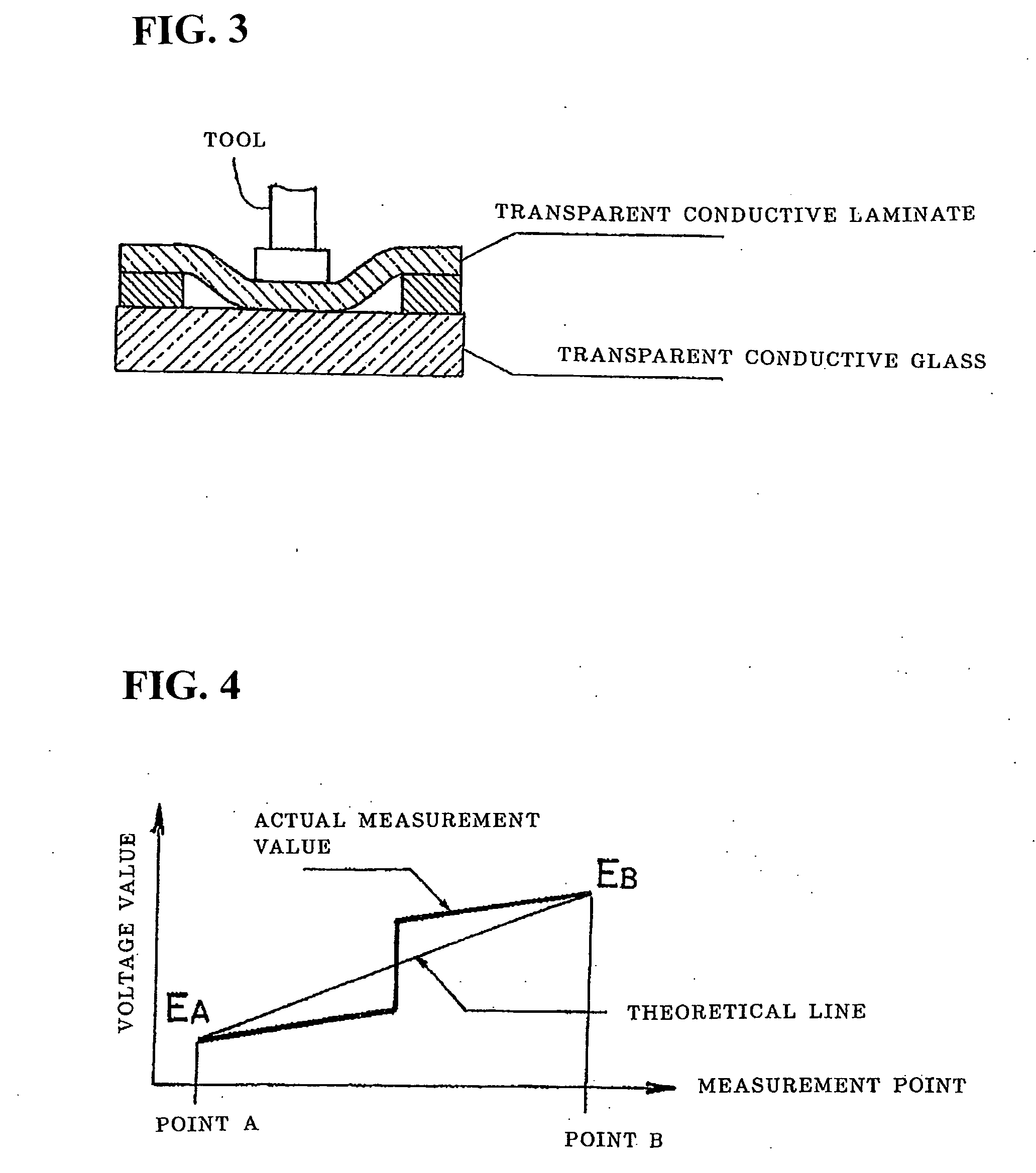

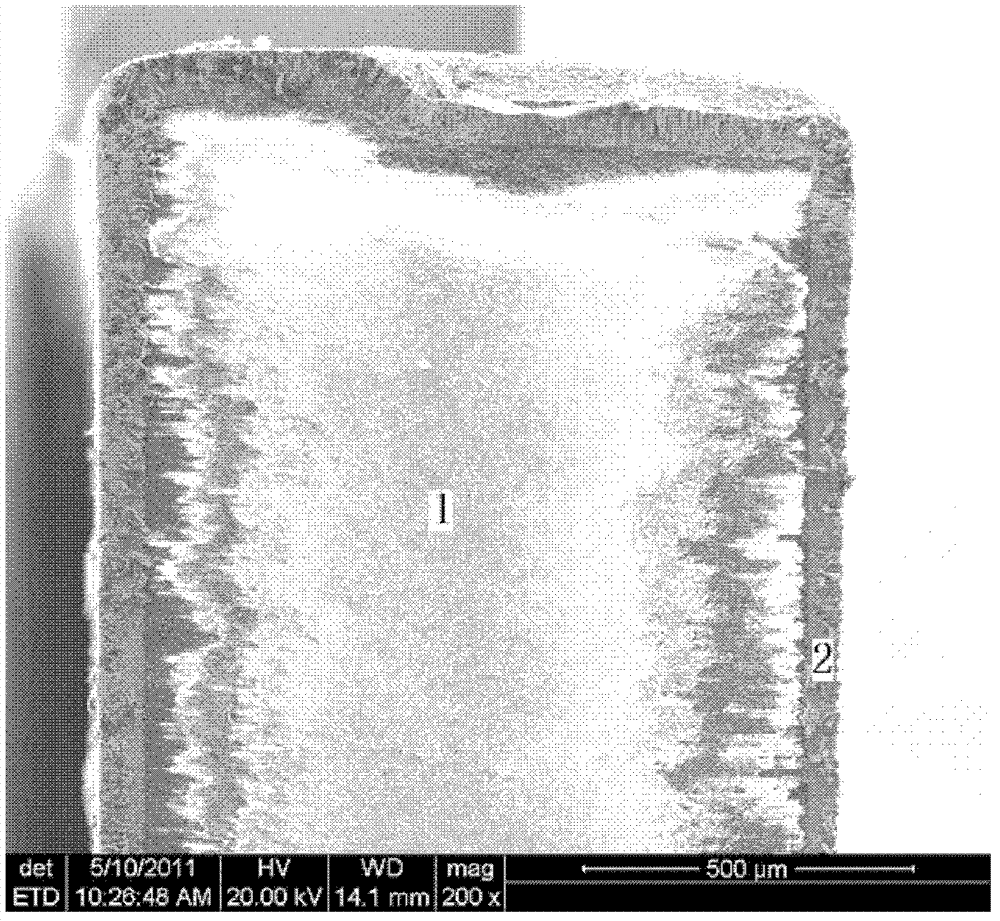

InactiveUS20080152879A1Improve bending performanceTransmitted light can be suppressedLayered productsVacuum evaporation coatingSputteringIndium

A transparent conductive laminate includes: a first transparent dielectric thin film; a second transparent dielectric thin film; a transparent conductive thin film; a transparent film substrate having a thickness of 2 μm to 200 μm, and the first transparent dielectric thin film, the second transparent dielectric thin film, and the transparent conductive thin film formed on one side of the substrate in this order; a transparent pressure-sensitive adhesive layer; and a transparent base substrate bonded to another side of the transparent film substrate with a transparent pressure-sensitive adhesive layer interposed therebetween, wherein the first transparent dielectric thin film is formed by vacuum deposition, sputtering or ion plating and comprises a complex oxide containing 100 parts by weight of indium oxide, 0 to 20 parts by weight of tin oxide and 10 to 40 parts by weight of cerium oxide, a refractive index n1 of the first transparent dielectric thin film, a refractive index n2 of the second transparent dielectric thin film, and a refractive index n3 of the transparent conductive thin film satisfy a relationship: n2<n3≦n1, and the transparent base substrate is a transparent laminated base substrate having at least two transparent base films that are laminated with the transparent pressure-sensitive adhesive layer interposed therebetween.

Owner:NITTO DENKO CORP

Power module metalized ceramic substrate and metallization method thereof

InactiveCN102896832AImprove bindingImprove antioxidant capacityVacuum evaporation coatingSputtering coatingChemical platingCeramic substrate

The invention, relating to the field of ceramic surface modification, discloses a power module metalized ceramic substrate and a metallization method thereof. The method disclosed herein comprises the following steps: firstly depositing copper or silver with a thickness of 0.1-5 mum on the surface of a power module ceramic substrate by magnetron sputtering or arc ion plating; then depositing copper, silver, copper alloy or silver alloy with a thickness of 50-1000 mum by chemical plating or electroplating; and finally depositing silver, gold, tin or nickel with a thickness of 0.1-5 mum by magnetron sputtering or arc ion plating, or depositing a tin or nickel layer with a thickness of 2-5mum by chemical plating or electroplating. According to the invention, the metalized ceramic component obtained by the method disclosed herein has large current-carrying capacity, strong thermal conductivity and heat dissipation capability, good gas tightness, reliable and stable quality, etc., is easily welded with other metals or ceramics and composite materials, and can be used in the fields of vacuum devices, aerospace, aviation, radio and television, communication, metallurgy, medicine, high-energy physics, etc.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

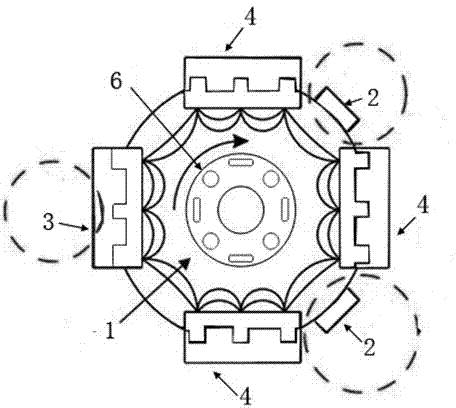

High-power pulse plasma reinforced composite magnetron sputtering deposition device and application method thereof

ActiveCN103668095AFast preparationImprove uniformityVacuum evaporation coatingSputtering coatingChemical compositionVacuum chamber

The invention relates to the technical field of thin-film materials and particularly relates to a high-power pulse plasma reinforced composite magnetron sputtering deposition device. The device comprises a vacuum chamber, magnetic control targets, a work rest and a rotary support, wherein the magnetic control targets comprise a high-power pulse magnetron sputtering target and pulse direct-current magnetic control targets, fixed in the vacuum chamber, and are arranged in opposite direction in a right angle, the magnetic field arrangement manners of all magnetic control targets are opposite, and a closed field is formed; the magnetic fields of all magnetic control targets are unbalanced magnetic fields; through the implementation of the structure, the better magnetic field distribution and ion plating effects are achieved, high-quality coating with good coating binding force, compact coating, good mechanical performance, accurate and controllable chemical components can be deposited conveniently and the device is applied to high-speed cutting tools.

Owner:GUANGDONG UNIV OF TECH

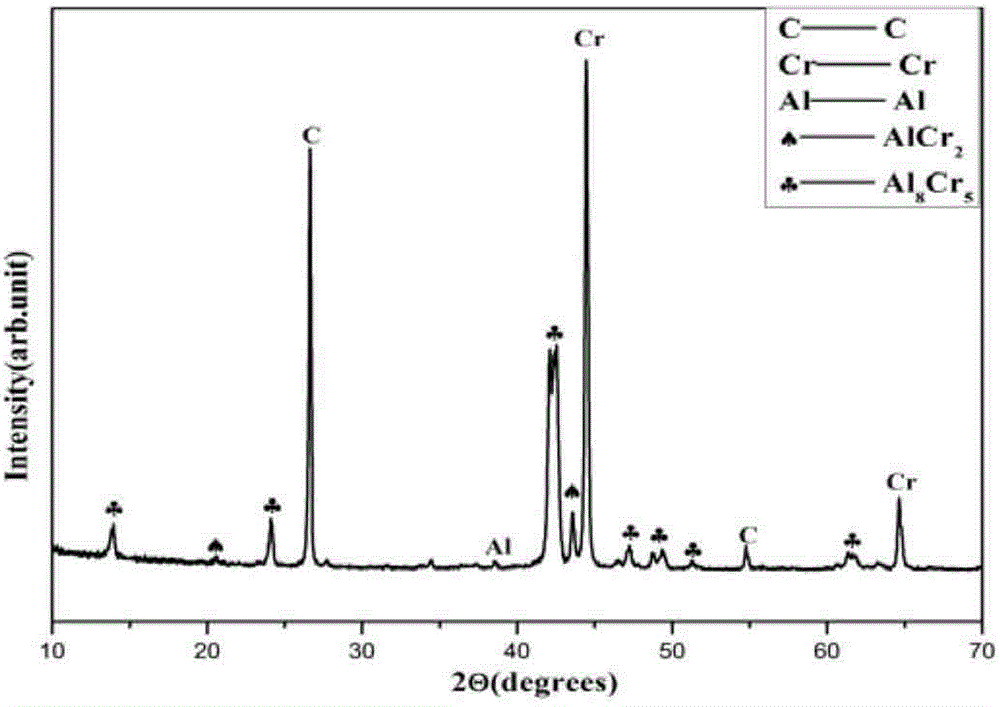

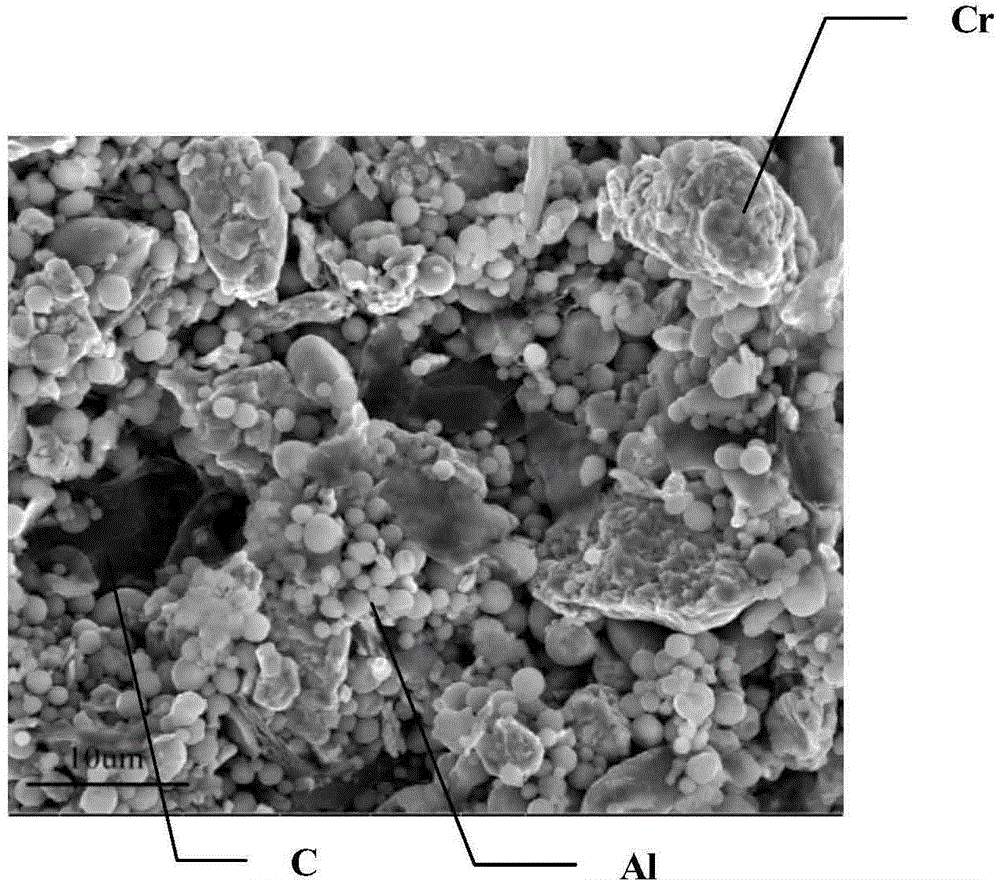

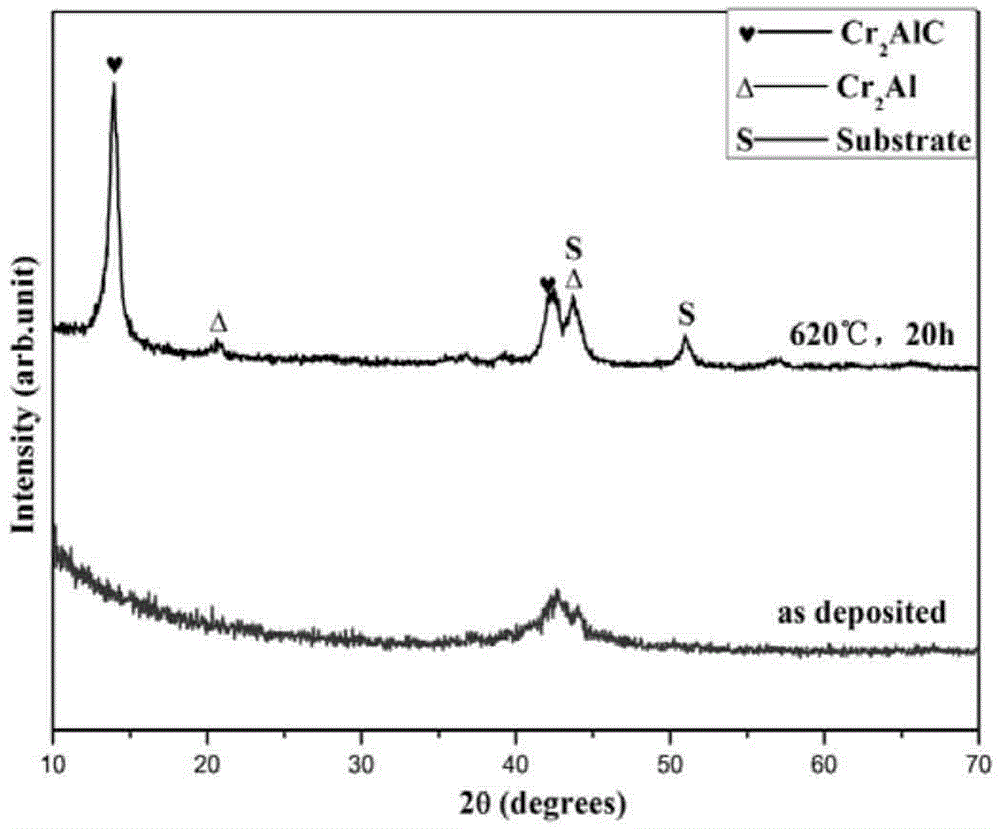

Method for efficiently preparing ternary laminar MAX phase ceramic coating layer at low temperature

InactiveCN104894516AReduce manufacturing costSimple processVacuum evaporation coatingSputtering coatingGas phaseCeramic coating

The invention relates to a preparation technology of a ternary laminar MAX phase ceramic coating layer, and in particular, provides a method for efficiently preparing a ceramic coating layer with a ternary laminar MAX phase as a main phase at low temperature by a physical vapor deposition technology. M, A and X element powders with a certain mol ratio or electrically conducted binary and ternary compound powders are uniformly mixed and pressed to produce a cathode target at a certain temperature; the physical vapor deposition (multi-arc ion plating or magnetron sputtering) is adopted under optimized process conditions; and then, the crystallization heat treatment is adopted, thereby realizing the preparation of the ceramic coating layer with the MAX phase as the main phase by a two-step method. The method has the characteristics of deposition at room temperature, easy adjustment of target components, simple process, high deposition efficiency and low cost, has obvious advantages in the aspect of preparing the MAX phase coating layer, can solve the problems of high cost and complicated process in traditional preparation of the MAX phase coating layer, and promotes the large-scale industrial production of the MAX phase coating layer.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

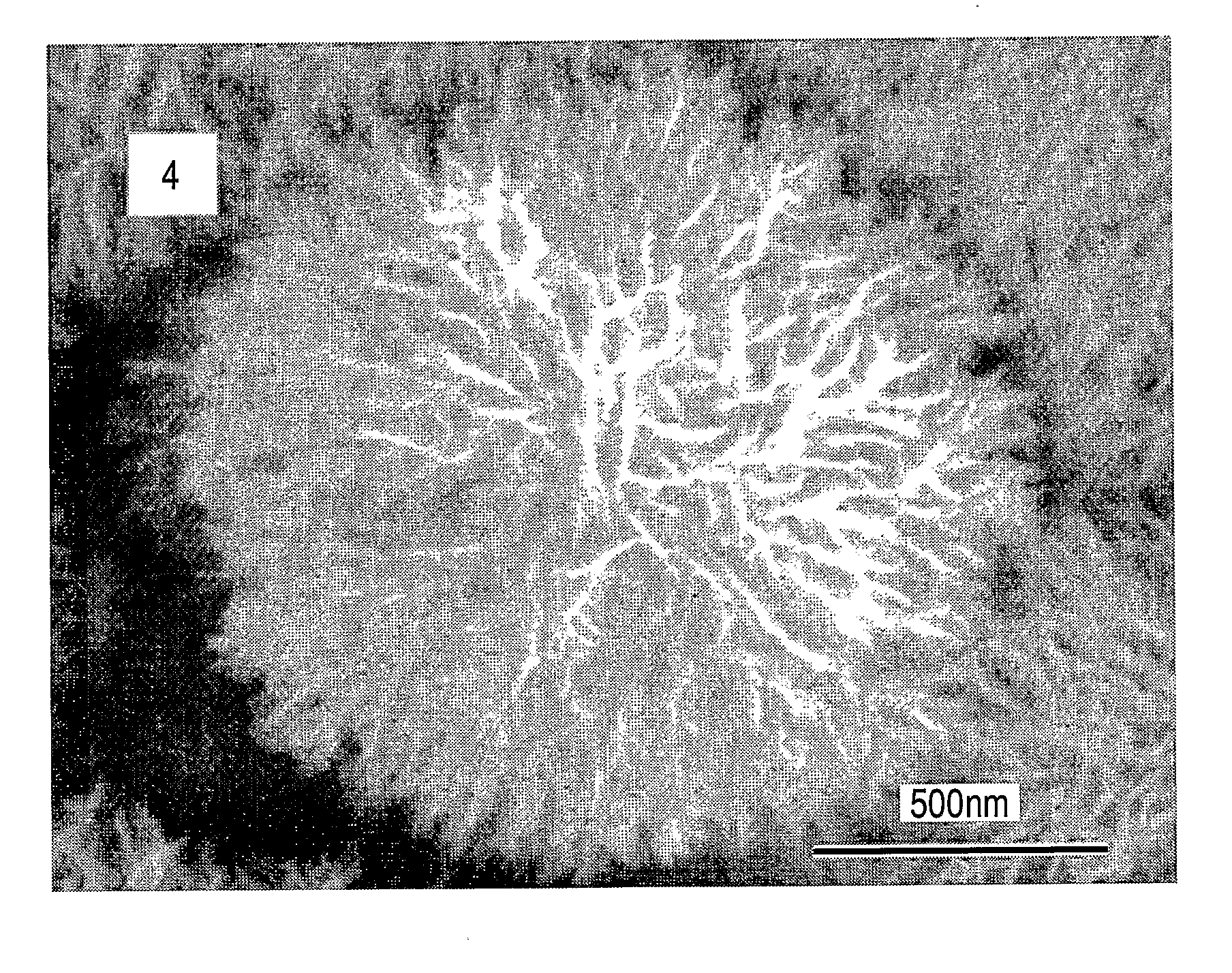

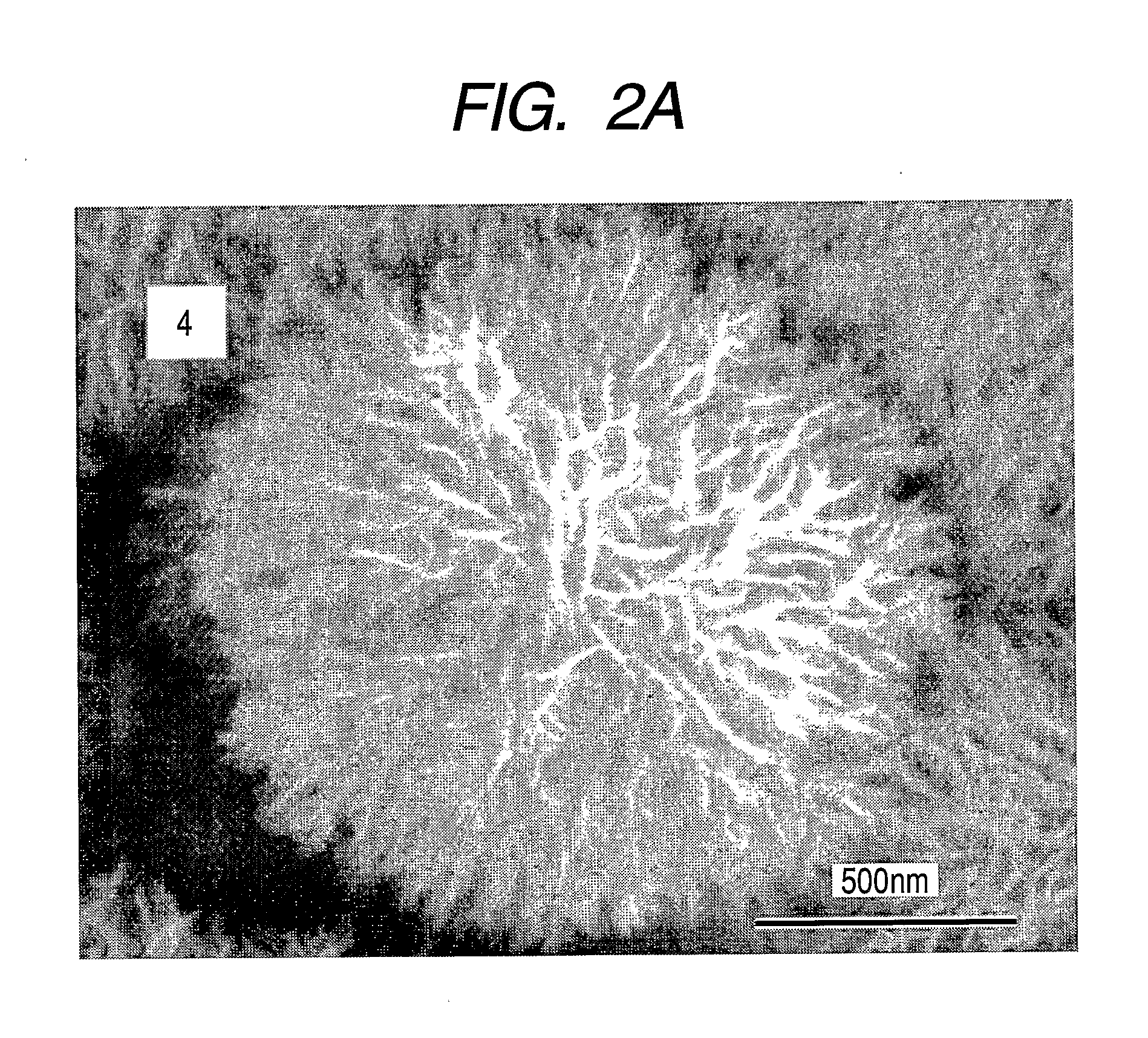

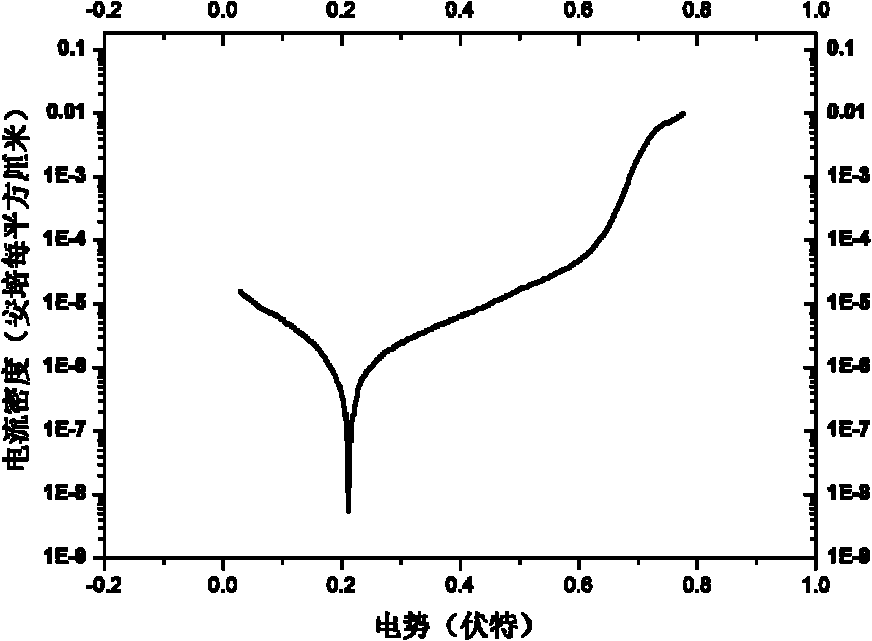

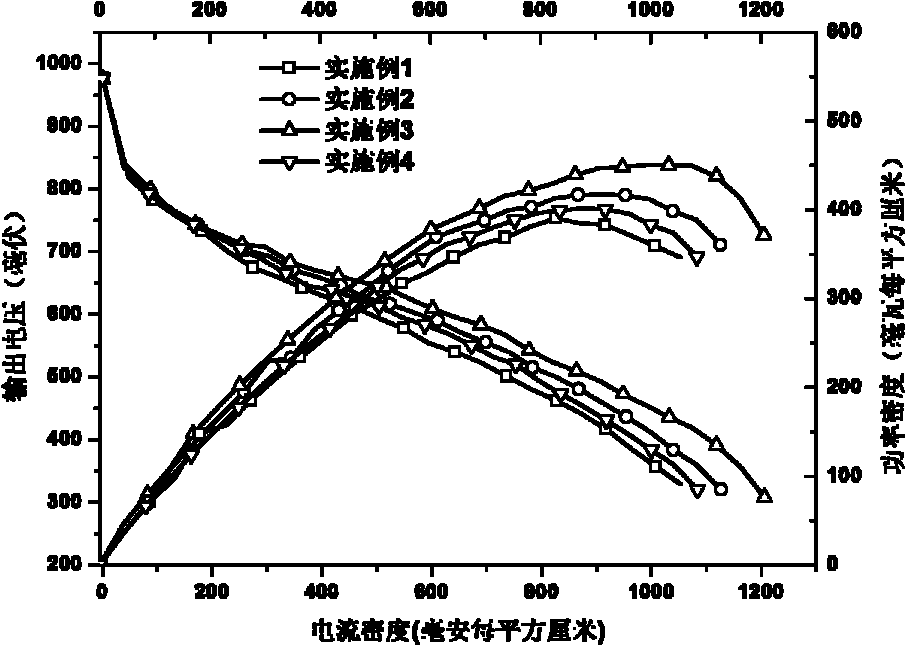

Catalyst Layer for Solid Polymer Electrolyte Fuel Cell and Method of Producing

InactiveUS20070212591A1High activityImprove utilizationFinal product manufactureActive material electrodesPolymer electrolytesFuel cells

There is provided a dendritic catalyst layer for a solid polymer electrolyte fuel cell including: a solid polymer electrolyte membrane; electrodes; and catalyst layers each provided between the solid polymer electrolyte membrane and the respective electrode, the catalyst layer for a solid polymer electrolyte fuel cell includes a catalyst with a dendritic structure. The catalyst with a dendritic structure is formed through vacuum evaporation such as reactive sputtering, reactive electron beam evaporation, or ion plating. The catalyst layer for a solid polymer electrolyte fuel cell can improve catalytic activity, catalyst utilization, and substance transport performance in the catalyst layer.

Owner:CANON KK

WS2/Zr soft coating micro-nano composite texture ceramic cutting tool and preparing method thereof

InactiveCN104014828AHigh hardnessImprove cutting performanceVacuum evaporation coatingSputtering coatingMicro nanoMicrometer

The invention belongs to the field of mechanical cutting tool manufacturing, and relates to a preparing method for a WS2 / Zr soft coating micro-nano composite texture ceramic cutting tool. Base materials of the cutting tool are ceramic. The method comprises the steps that firstly, the laser machining technology is adopted to machine micrometer textures of different morphologies and sizes on the front tool face of the ceramic cutting tool, then the laser machining technology is adopted to machine nanometer textures on a negative chamfer and the front tool face, and finally the medium frequency magnetron sputtering deposition plus multi-arc ion plating method is adopted to deposit a WS2 / Zr soft coating on the surface of the cutting tool, wherein the WS2 / Zr soft coating is arranged on the surface of the cutting tool, and a Zr transition layer is arranged between the soft coating and a base body. According to the ceramic cutting tool, friction between tool chips can be effectively reduced during cutting, the cutting force and the cutting temperature are reduced, and the abrasion resistance capacity of the cutting tool is improved, so that the service life of the cutting tool is prolonged. The ceramic cutting tool can be widely applied to dry cutting and cutting machining of difficult-to-machine materials.

Owner:SHANDONG UNIV

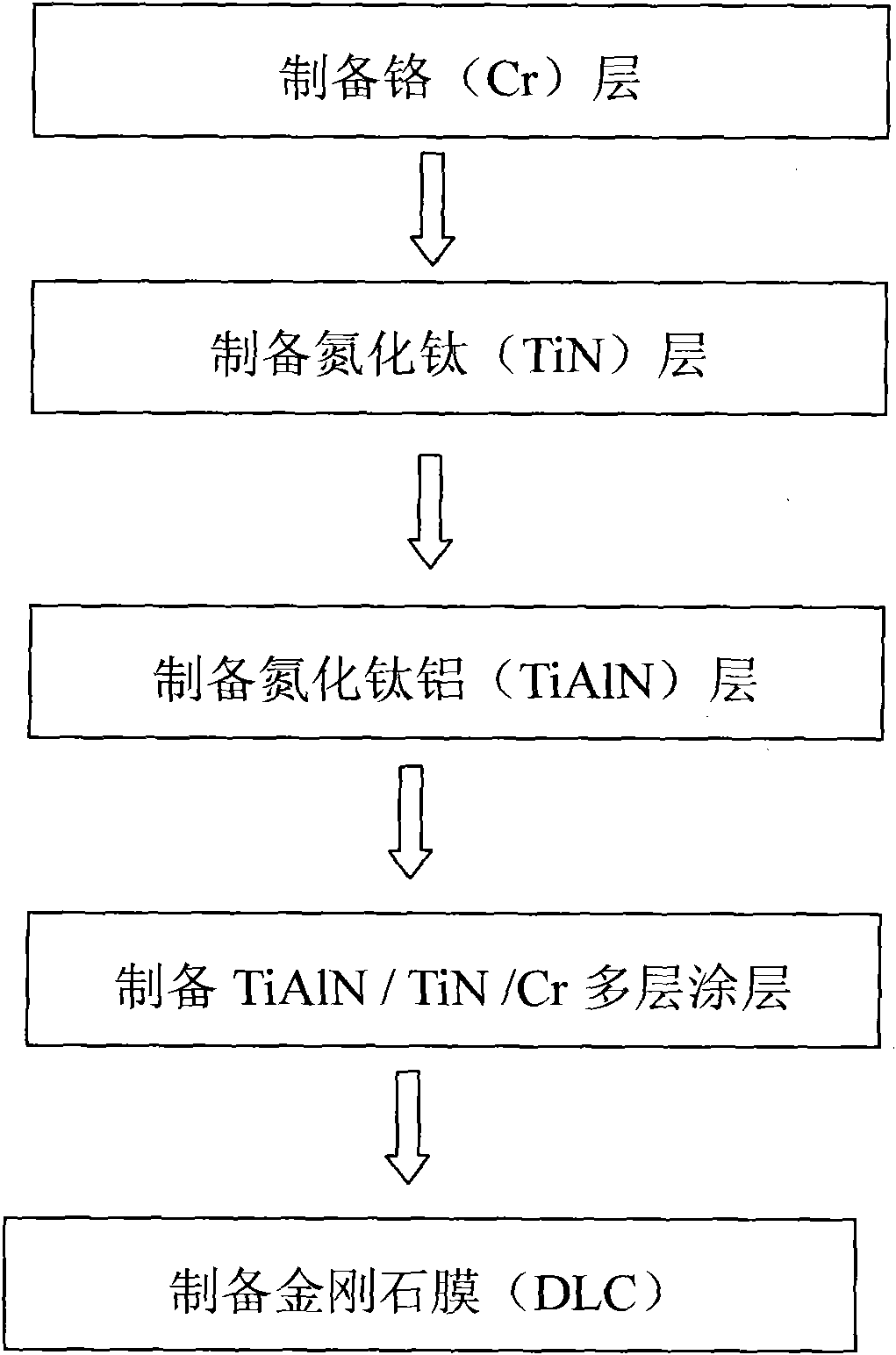

DLC (diamond-like carbon)/TiAlN (titanium aluminium nitride)/CrN (chromium nitride)/Cr (chromium) multilayer superhard film coating and preparation method thereof

InactiveCN102080207AImprove bindingImprove performanceVacuum evaporation coatingSputtering coatingTitanium aluminium nitrideDiamond-like carbon

The invention discloses a DLC (diamond-like carbon) / TiAlN (titanium aluminium nitride) / CrN (chromium nitride) / Cr (chromium) multilayer superhard film coating for the surface treatment of piston rings of automobile engines, and the multilayer superhard film coating is prepared by adopting a multi-arc ion plating technology and a magnetron sputtering technology. The thickness of the prepared multilayer superhard film coating is between 5 mu m and 20 mu m (micrometer), and the hardness of the coating is greater than 40GPa.

Owner:SHENZHEN GUANGDA NANO ENG

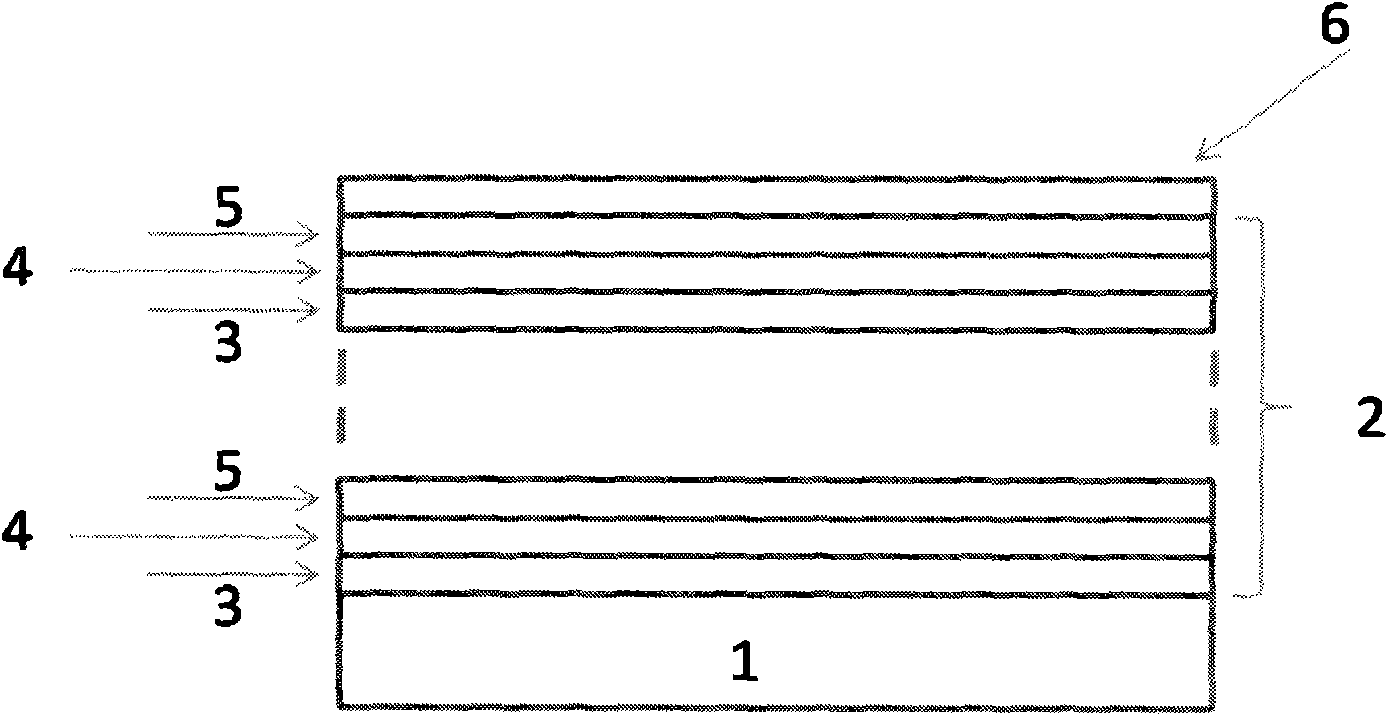

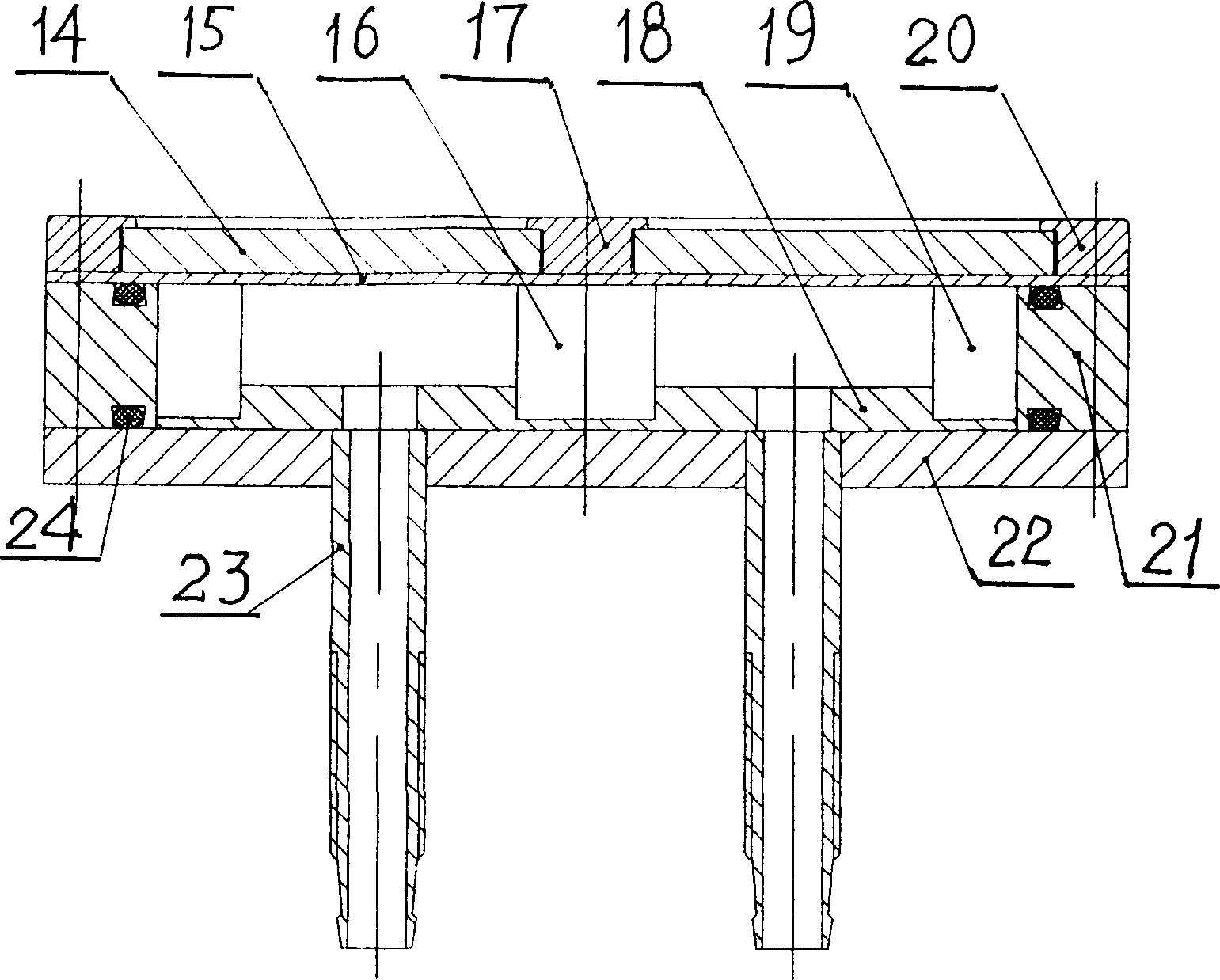

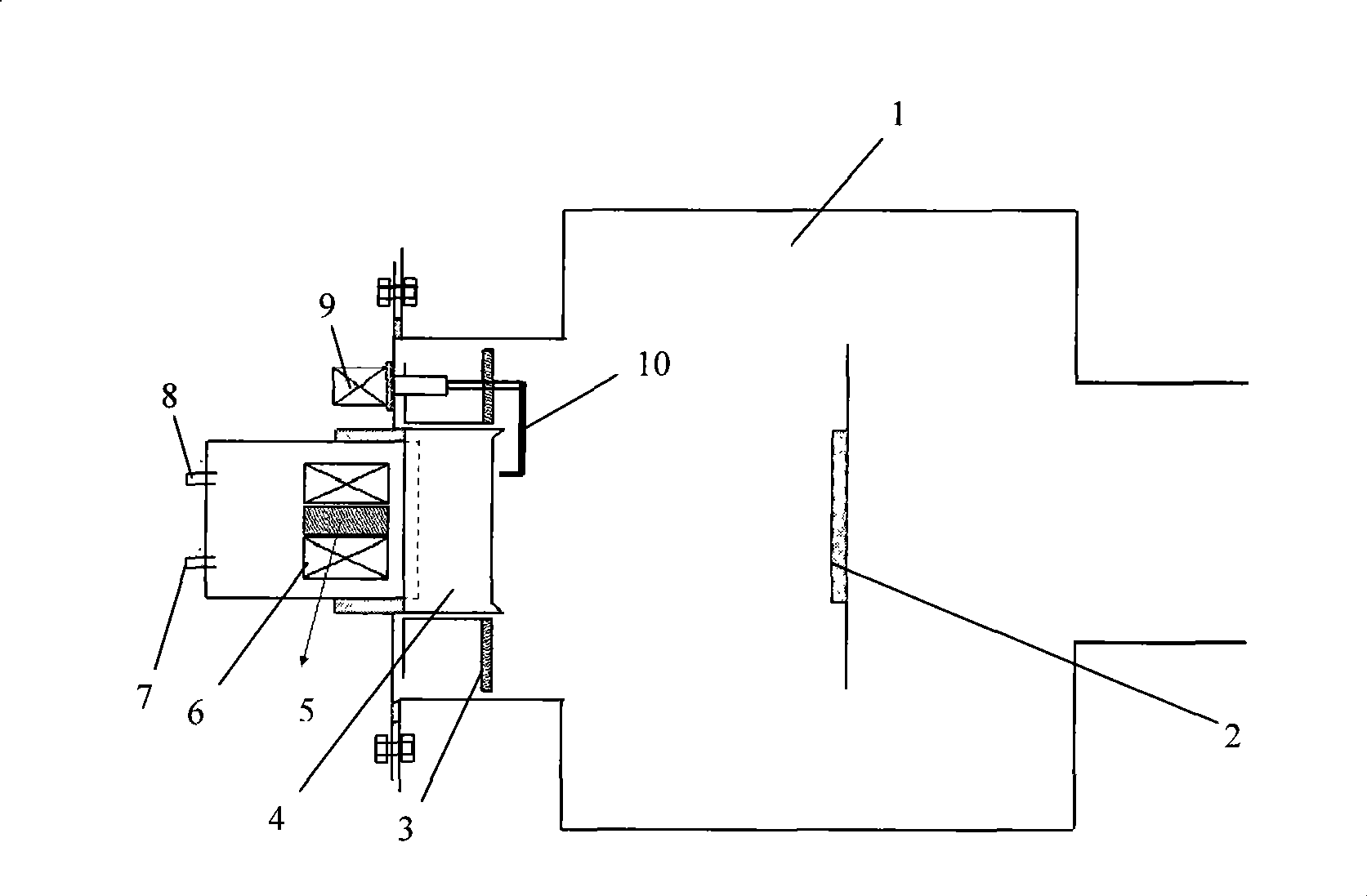

Process and apparatus for preparing porous metal by combined physical gas-phase deposition techinque

InactiveCN1397654AStrong noveltyCreativeElectrode carriers/collectorsVacuum evaporation coatingGas phaseWater jacket

A technology and apparatus for preparing porous metal by combined physical gas-phase deposition features that two of evaporating, sputtering and ion plating are combined in a coil-type vacuum coatingmachine. The said coil-type vacuum coating machine is composed of coiling-uncoiling reel and chamber, measuring roller, magnetically controlled plating chamber and its target, are evaporating chamberand its target, partition, cooling water jacket, etc.

Owner:HUNAN CORUN NEW ENERGY CO LTD

AlCrSiN-based multilayer nanometer composite cutter coating layer and preparation method thereof

InactiveCN104928638AExtend your lifeImprove mechanical propertiesVacuum evaporation coatingSputtering coatingWear resistantChromium

The invention relates to an AlCrSiN-based multilayer nanometer composite cutter coating layer and a preparation method thereof, and belongs to the technical field of preparation of cutter coating layers. A cutter basal body of the AlCrSiN-based multilayer nanometer composite cutter coating layer adopts a WC-Co hard allot or high-speed steel; the coating layer structure comprises a Ti metal bonding layer, an AlTiN transition layer and an AlCrSiN main wear resistant layer, wherein the AlTiN transition layer consists of 29-35 at.% of aluminum, 15-20 at.% of titanium, and 47-51 at.% of nitrogen; and the AlCrSiN main wear resistant layer consists of 25-30 at.% of aluminum, 20-25 at.% of chromium, 1-10 at.% of silicon, and 45-50 at.% of nitrogen. The transition layer AlTiN coating layer is prepared by a high-power pulse magnetron sputtering technology; and the AlCrSiN coating layer is prepared by an arc ion plating technology. The AlCrSiN-based multilayer nanometer composite cutter coating layer has the advantages of high hardness, low friction coefficient, low internal stress, high bonding strength and good high-temperature stability; a deposition coating cutter is suitable for cutting a high-hardness steel material under the condition of high speed; and the service life of the cutter can be largely prolonged.

Owner:GUANGDONG UNIV OF TECH

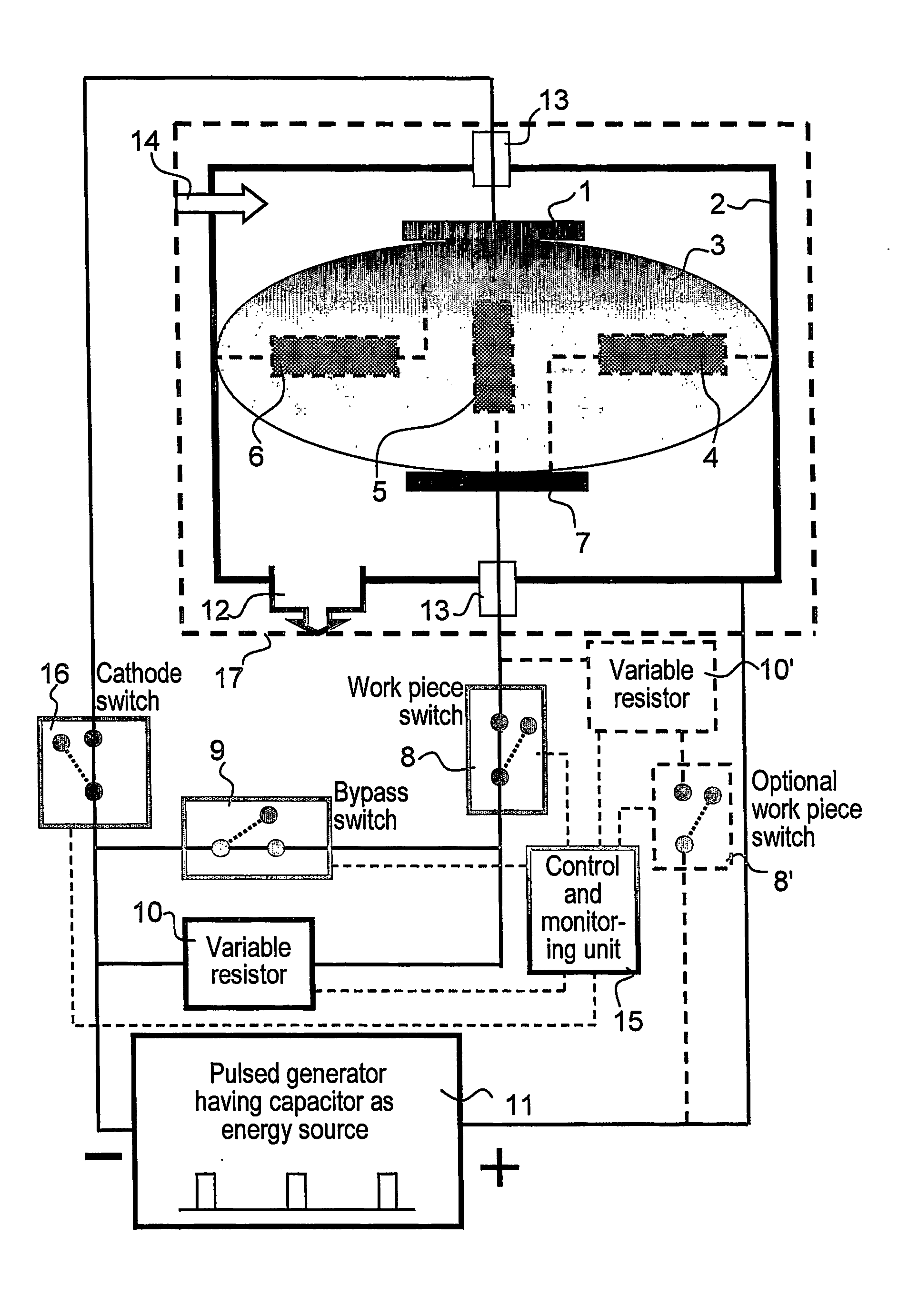

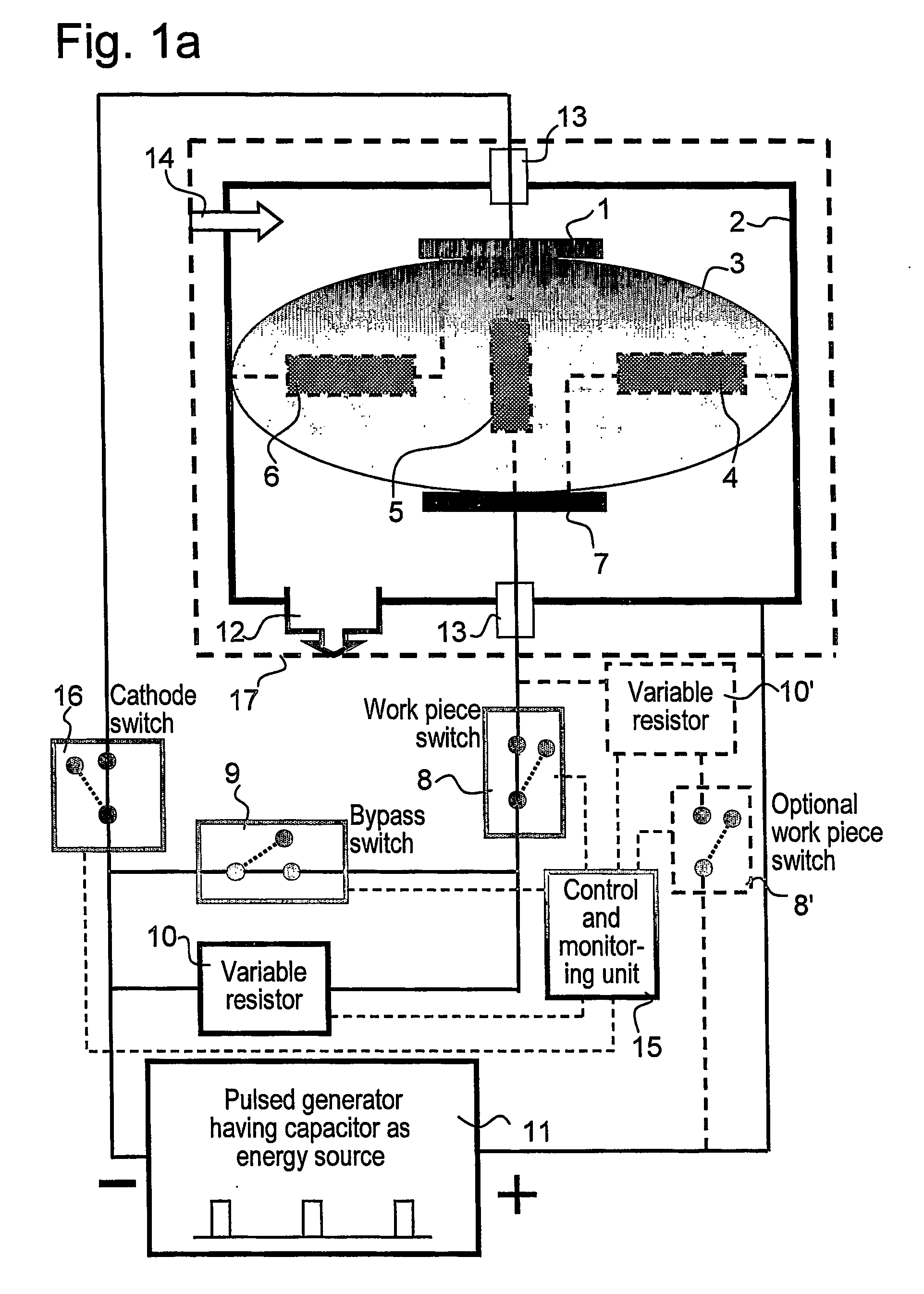

Work piece processing by pulsed electric discharges in solid-gas plasma

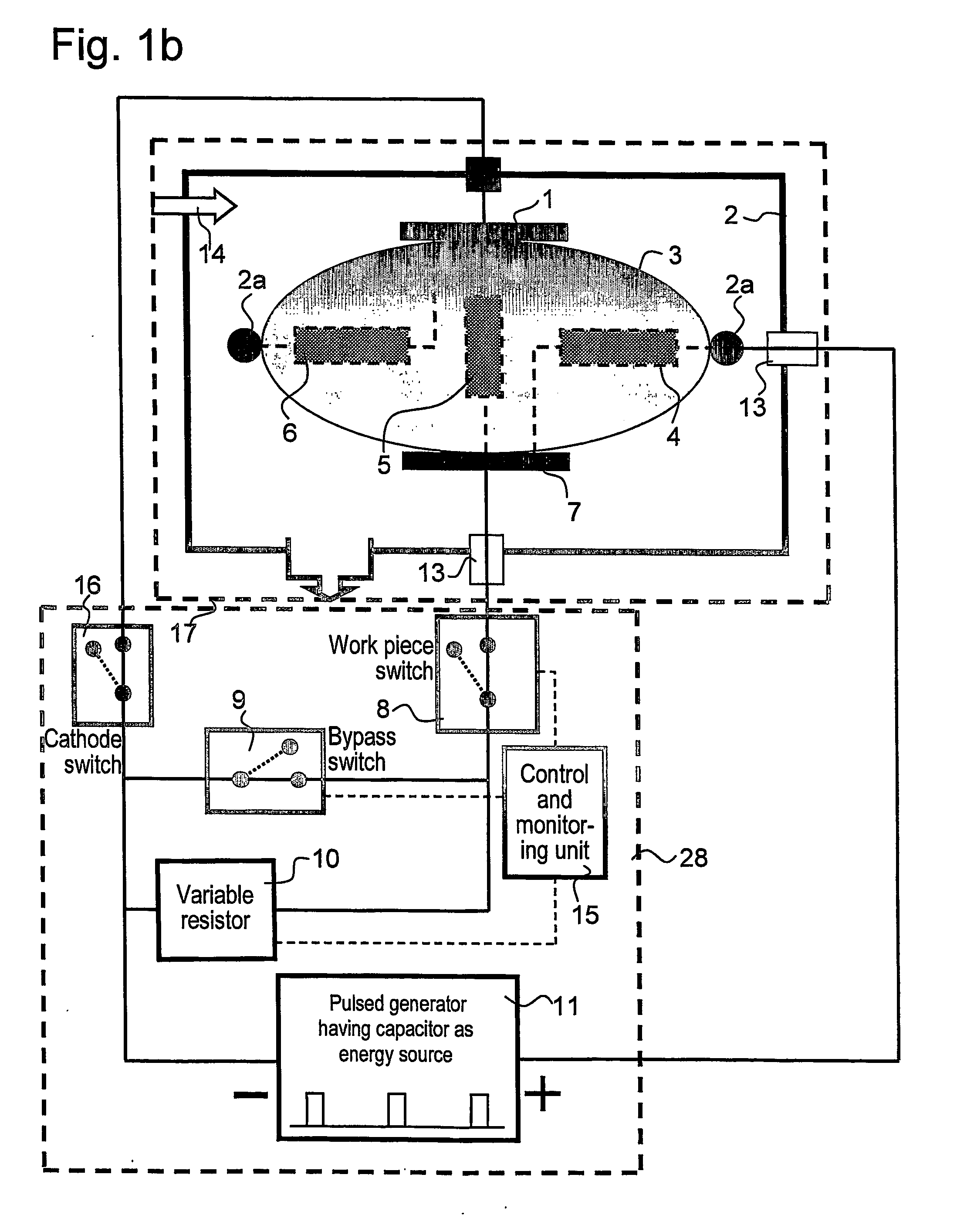

ActiveUS20060278518A1Easy to handleEfficient processing and modifyingCellsElectric discharge tubesEtchingElectric discharge

Work piece processing is performed by pulsed discharges between an anode (2) and a magnetron sputtering cathode (1) in solid-gas plasmas using a chamber (2) containing the work piece (7). A system (12) maintains a vacuum in the chamber and another system (14) provides sputtering and reactive gases. The pulses are produced in a plasma pulser circuit including the anode and the cathode, the discharges creating gas and partially ionized solid plasma blobs (3) moving or spreading from a region at a surface of the cathode towards the work piece and the anode. A potential is applied to the work piece so that a pulsed current comprising biasing pulses arises between the second electrodes. In particular biasing discharges are produced between the anode and the work piece when said plasma blobs have spread to regions at the anode and at the work piece so that the pulsed current is the current of these biasing discharges. The method is efficient for processing or modifying surface regions of work pieces of various kinds and configurations and can be employed for achieving efficient work piece etching, interface mixing, surface and balk diffusion, gas absorption and desorption, initial and further stages of thin film condensation, and for performing ion plating.

Owner:BRANNSTOM RUNE +1

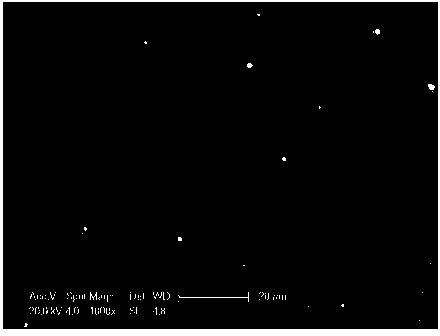

Antibacterial and wear-resistant nano-composite coating and preparation method thereof

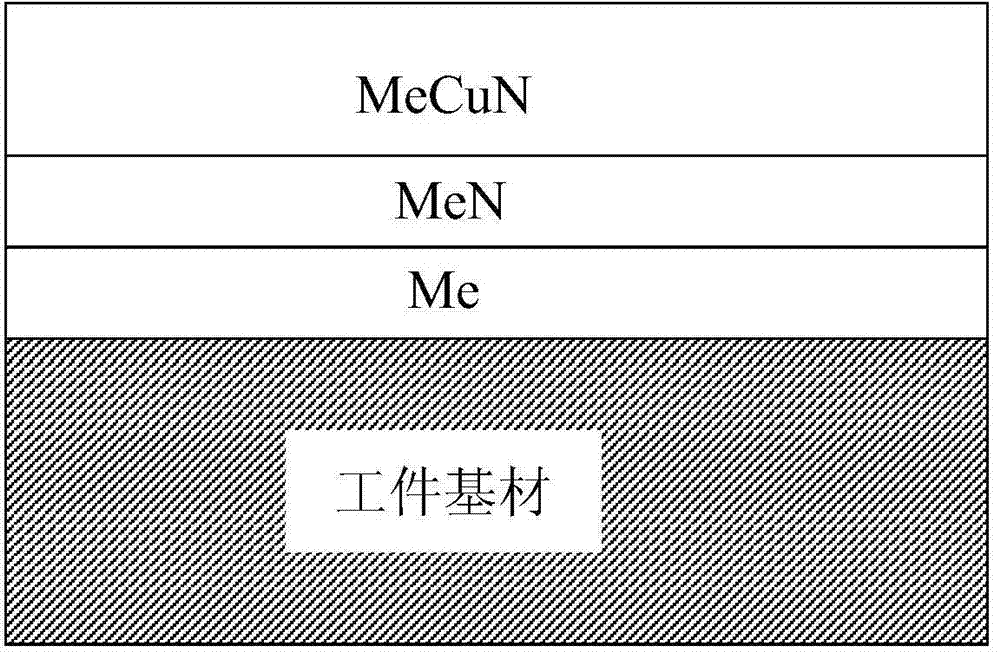

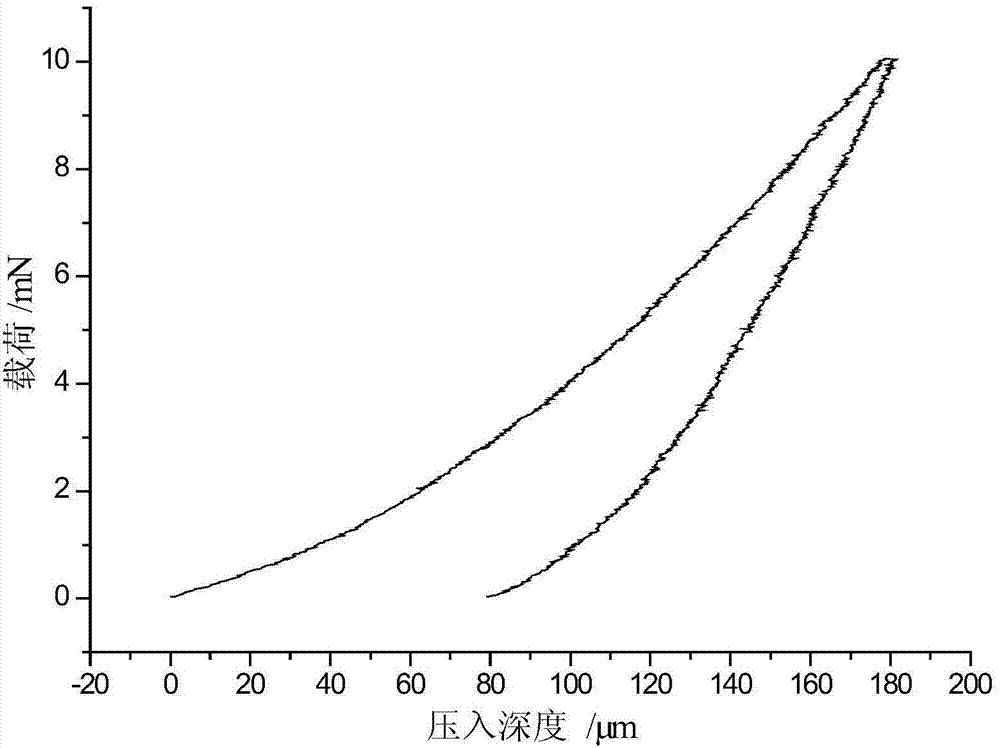

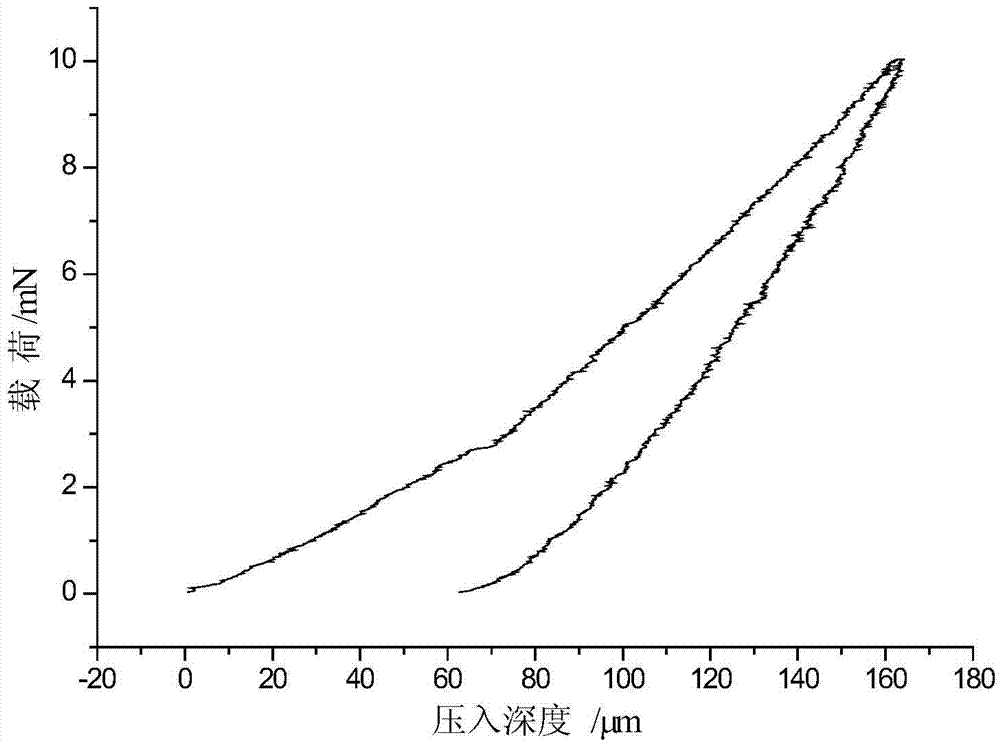

InactiveCN104494229AOptimizing Process ParametersVacuum evaporation coatingSputtering coatingWear resistantCeramic coating

The invention relates to an antibacterial and wear-resistant nano-composite coating and a preparation method thereof and relates to the field of preparation of nano-composite coatings. The nano-composite coating MeCuN with the functions of automatic sterilization, high rigidity and wear resistance is deposited on the surface of a workpiece requiring the antibacterial function by adopting a physical vapor deposition technology (including magnetron sputtering and arc ion plating). As Cu particles in nanometer scale are distributed on the surface of the coating; by utilizing such characteristic of the Cu particles as high surface free energy and large specific surface area, the nano-composite coating MeCuN is capable of automatically killing more than 99 percent of bacteria on the surface of the workpiece without the additional conditions including a sterilization material and sunlight. With hard nitride ceramic coating as a base, the antibacterial and wear-resistant nano-composite coating is high in rigidity and wear resistance and can be used for places needing sterilization for a long time, including medical devices such as scalpels, kitchen utensils such as vegetable basins and public transportation vehicles such as stainless steel handrails. As the thickness of the coating is about several microns, the size of the workpiece is not changed, and the antibacterial and wear-resistant nano-composite coating can be used for the surface antibacterial treatment of precision equipment.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

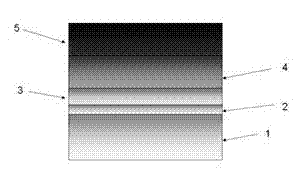

Prepn of heat shock resisting heat barrier coating

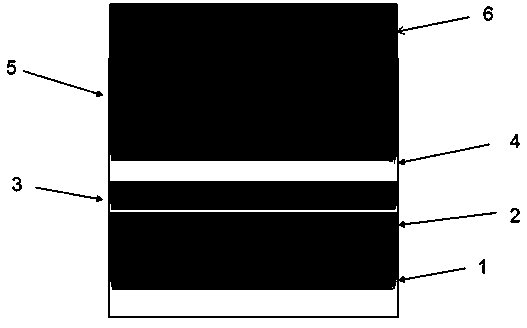

InactiveCN1548578AImprove thermal shock resistanceImprove antioxidant capacitySuperimposed coating processPorosityAlloy

The heat barrier coating capable of resisting heat shock includes an adhering layer of NiCoCrAlY alloy and a ceramic layer prepared with hollow spherical ZrO2-8Y2O3 powder. The preparation process of the heat barrier coating includes depositing NiCoCrAlY layer of 30-50 micron thickness via an arc ion plating process, and subsequent spraying the ceramic layer of 200-500 micron thickness on the NiCoCrAlY layer via a blasting spraying process. The present invention features that of the heat barrier coating, the adhering NiCoCrAlY layer is homogeneous and compact and has less faults, excellent antioxidant performance and high combining strength with the ceramic layer, and the ceramic layer has high porosity, high heat isolating performance, great strain tolerance and excellent heat shock resisting performance.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

AlTiSiN-AlCrSiN nanocrystalline-amorphous multilayer composite superhard toughness coating material and manufacturing method

InactiveCN104213075AReasonable designOvercome temperature resistanceVacuum evaporation coatingSputtering coatingWear resistanceIon plating

The invention discloses an AlTiSiN-AlCrSiN nanocrystalline-amorphous multilayer composite superhard toughness coating material. The material is composed of a bonding layer, a transition layer, a supporting layer and a high-temperature toughness wear-resisting layer. The manufacturing method comprises the steps that an arc source is adopted to perform etching cleaning on a chemically-cleaned base body, and then an arc ion plating method is adopted to enable the bonding layer, the transition layer, a hardening layer, the supporting layer and a super-toughness high-temperature-resisting wear-resisting layer to be sequentially deposited. The superhard characteristics and high-temperature-resisting characteristics of a nanocrystalline-amorphous composite structure are fully utilized, and AlTiSiN nanocrystalline coating materials and AlCrSiN nanocrystalline coating materials are combined to build the nanocrystalline-amorphous multilayer coating material. The coating structure is reasonable in design, composition gradual change exists, meanwhile, the hardness gradient gradual change is achieved, and the manufactured AlTiSiN-AlCrSiN coating has the good bonding force with a base body. The AlTiSiN-AlCrSiN coating has the good hardness and excellent temperature-resisting and wear-resisting performance, the problem that a base body coating is poor in temperature resistance and wear resistance is solved well, the use performance of the base body is greatly improved, and the good industrial application prospect is achieved.

Owner:WUHAN UNIV

TiSiN+ZrSiN composite nanometer coated cutting tool and preparation method thereof

InactiveCN103273687AImprove friction and wear propertiesReduce residual stressVacuum evaporation coatingSputtering coatingAlloyDry machining

The invention provides a TiSiN+ZrSiN composite nanometer coated cutting tool and a preparation method thereof and belongs to the field of mechanical machining. A base material of the coated cutting tool is a hard alloy or high-speed steel. The TiSiN+ZrSiN composite nanometer coated cutting tool is manufactured by adopting a multi-arc ion plating+intermediate frequency magnetron sputtering method. The TiSiN+ZrSiN composite nanometer coated cutting tool is of multilayered structure, a ZrSiN coating is formed on the surface of the cutting tool, a TiZrSiN transition coating is formed between the ZrSiN coating and a TiSiN coating, and a Ti transition coating is formed between the TiSiN coating and a substrate, wherein the atomic percentage of Si content in the TiSiN coating and the ZrSiN coating is 6%-10%. The TiSiN+ZrSiN composite nanometer coated cutting tool well combines the high hardness of the TiSiN coating and the low friction coefficient of the ZrSiN coating and has high hardness, good friction and wear property and excellent high-temperature oxidation resistance; and the bonding can be alleviated in the cutting process, and the wearing of the cutting tool is reduced, so that the service life of the cutting tool is prolonged. The coated cutting tool can be widely applied to drying machining and machining of difficult-to-machine materials.

Owner:SHANDONG UNIV

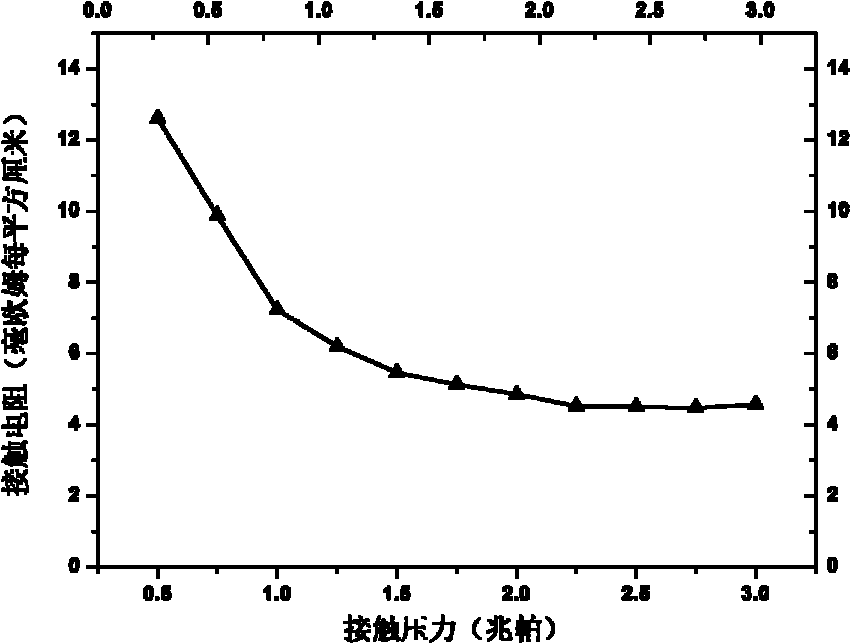

Metal gas diffusion layer used for fuel cell and preparation method thereof

ActiveCN102082277AImprove performanceMeet the challenge of weak acid working environmentCell electrodesCarbon coatingUltrasonic oscillation

The invention relates to a metal gas diffusion layer used for a fuel cell and a preparation method thereof. The preparation method comprises the following steps: preparing a stainless steel short fiber sintering felt by adopting a vacuum high temperature sintering method, then sequentially preparing a chromium layer and a graphite layer on the pretreated stainless steel short fiber sintering feltby adopting a closed field unbalanced magnetron sputtering ion plating technology, and then carrying out hydrophobic processing on the entire of the coated stainless steel short fiber sintering felt by utilizing polytetrafluoroethylene; and finally coating powdered carbon on the surface by adopting an ultrasonic oscillation method to obtain the metal gas diffusion layer used for the fuel cell. Inthe invention, stainless steel fiber with low price is taken as raw material, the high temperature vacuum sintering method is adopted to prepare the sintering felt, and the magnetron sputtering ion plating technology is utilized to prepare a carbon coating so as to improve the contact performance and anti-corrosion performance of the metal gas diffusion layer, thus the high-performance gas diffusion layer used for the fuel cell is prepared with low cost.

Owner:上海氢晨新能源科技有限公司

Neodymium-iron-boron magnet of aluminum or aluminum alloy composite coating and preparation method thereof

ActiveCN102031522AImprove processing efficiencyLow costVacuum evaporation coatingSputtering coatingHigh humidityAlloy composite

The invention discloses a neodymium-iron-boron magnet of an aluminum or aluminum alloy composite coating and a preparation method thereof. An aluminum or aluminum alloy film is deposited on the neodymium-iron-boron magnet by adopting multi-arc ion plating technology, and then phosphate treatment is performed. The coating is uniform and dense, and is well combined with a matrix. The neodymium-iron-boron magnet applied with the aluminum composite coating with thickness of 10 to 20 microns tolerates high pressure and high humidity (100 to 130 DEG C, 2 to 2.6atm, and 95 to 100 percent RH) for over 200 hours, and tolerates NaCl salt fog corrosion (3.5 to 5 weight percent of NaCl and 25 to 35 DEG C) for over 500 hours. The coating process has high efficiency and low cost; and the prepared composite coating has good corrosion resistance and adhesion performance, and has no influence on the magnetism of the neodymium-iron-boron matrix (mainly small-size magnet).

Owner:北京钐元新材料股份有限公司

Composite treating method for nitriding surface of metal material after coating

ActiveCN103805996ASmall grain sizeReduce defect densityVacuum evaporation coatingSputtering coatingMetallic materialsHigh surface

The invention belongs to the field of material surface modification, and particularly relates to a composite treating method for nitriding the surface of a metal material after coating. The composite treating method is suitable for surface strengthening of tools, molds and metal accessories. The composite treating method comprises the following steps: firstly depositing a layer of nitride thin film on the surface of a metal material substrate by adopting magnetron sputtering or arc ion plating, wherein the thickness of the thin film is 0.1-50 micrometers; then carrying out ion nitriding treatment on the surface of the coating film by adopting an ion nitriding technology for 0.5-10 hours. Due to adoption of the composite treating method, the problem of low film-substrate bonding strength and the like caused by a black layer easily occurring in a composite treating process of coating after nitriding are solved. The workpiece obtained by adopting the coating-nitriding composite treating method of carrying out ion nitriding treatment after depositing a layer of thin film has the characteristics of high surface hardness, good wear resistance, high film-substrate binding force, reliable quality, stability and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

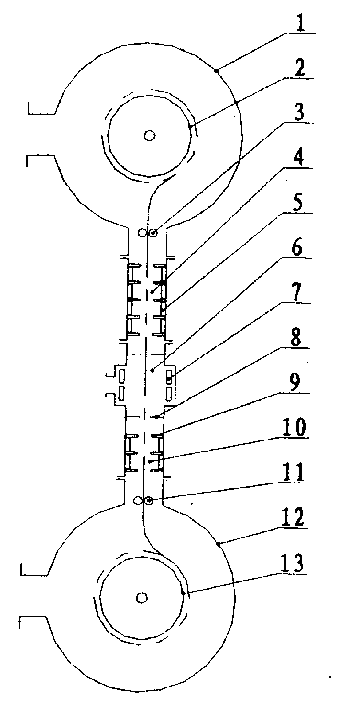

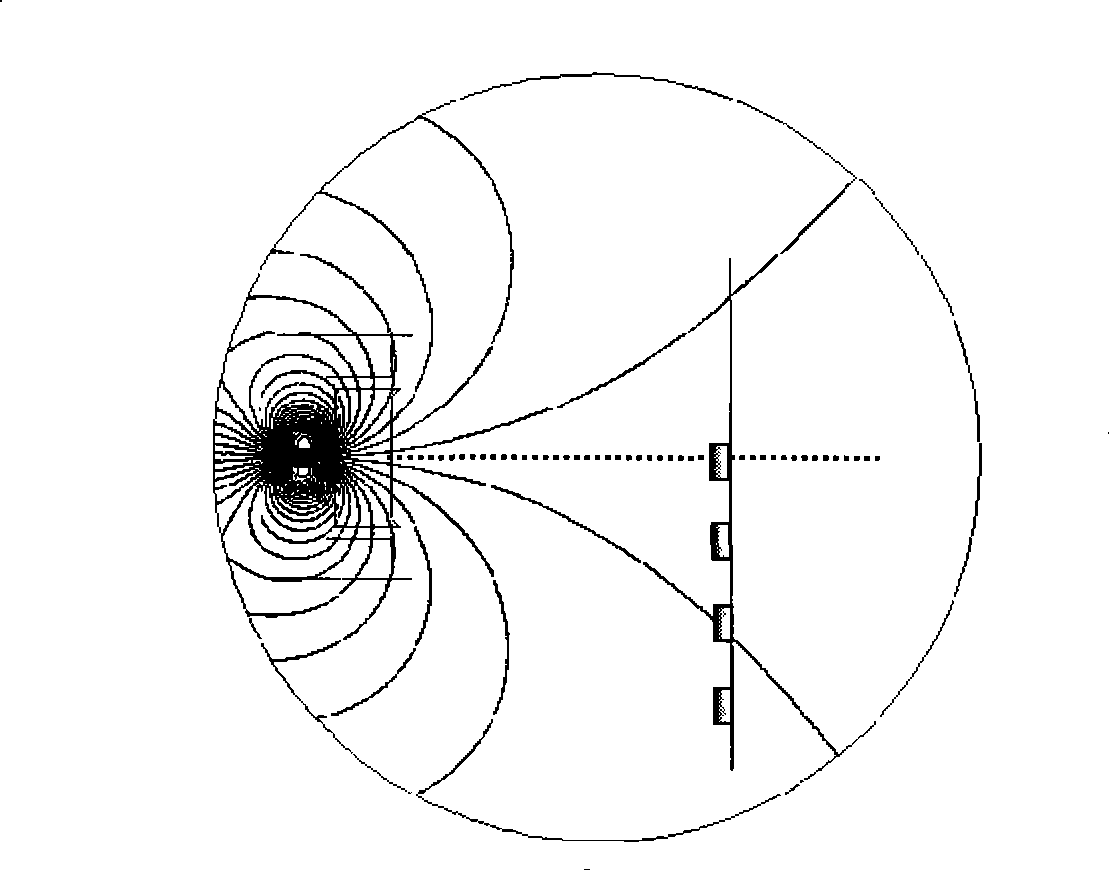

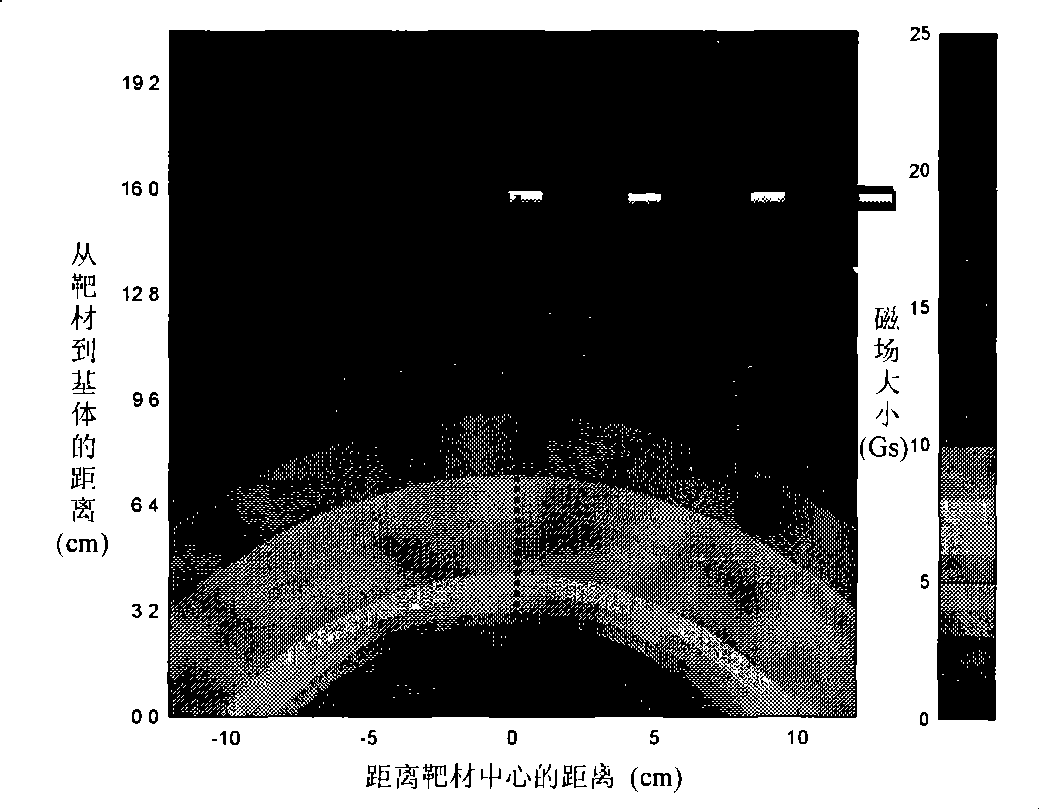

Deposition technique of arc ion plating enhanced by magnetic field

InactiveCN101363114AAvoid inhomogeneityIncrease deposition rateVacuum evaporation coatingSputtering coatingVacuum chamberLarge particle

The invention relates to the field of film preparation, in particular to a magnetic field enhanced arc ion plating deposition technology for improving the deposition rate and the deposition uniformity of the film, reducing large particle emission of a target material and improving the etching uniformity of the target material. An arc ion plating deposition device is provided with two sets of magnetic field generating devices, wherein, one set of the device is put at the back of the target material, and the other set is put inside a vacuum chamber, and deposition is carried out on a matrix by means of a coupling magnetic field generated by the two sets of coupling magnetic field generating devices. By virtue of the coupling magnetic field generated by the two sets of coupling magnetic field generating devices, the technology solves the non-uniformity of plasma distribution in a transmission space in the conventional technology, improves the deposition rate and the deposition uniformity of the film, reduces the large particle emission of the target material and the large particle content of the film, improves the film quality, expands the range of the process parameters and provides conditions for preparing films with different properties.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

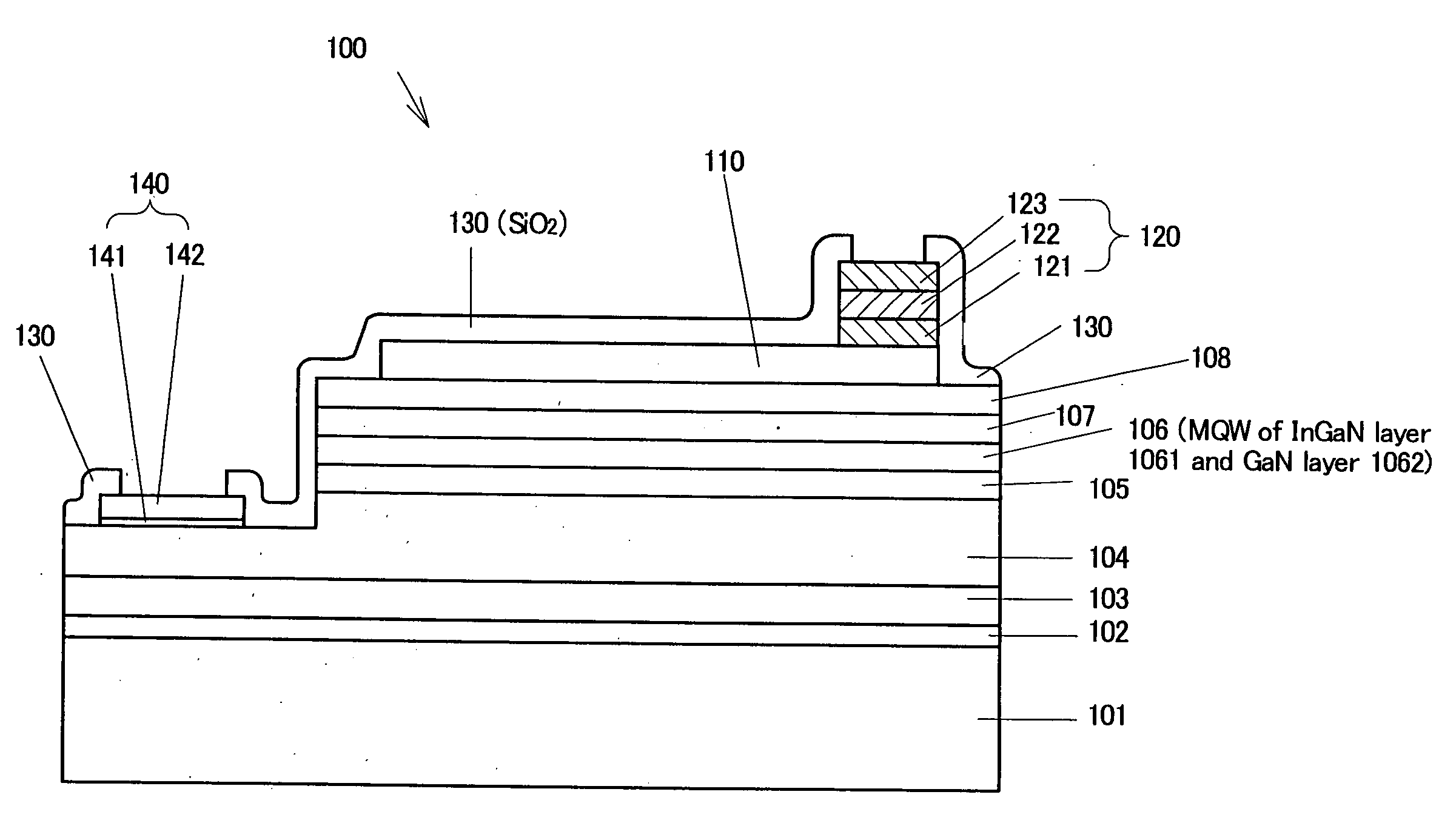

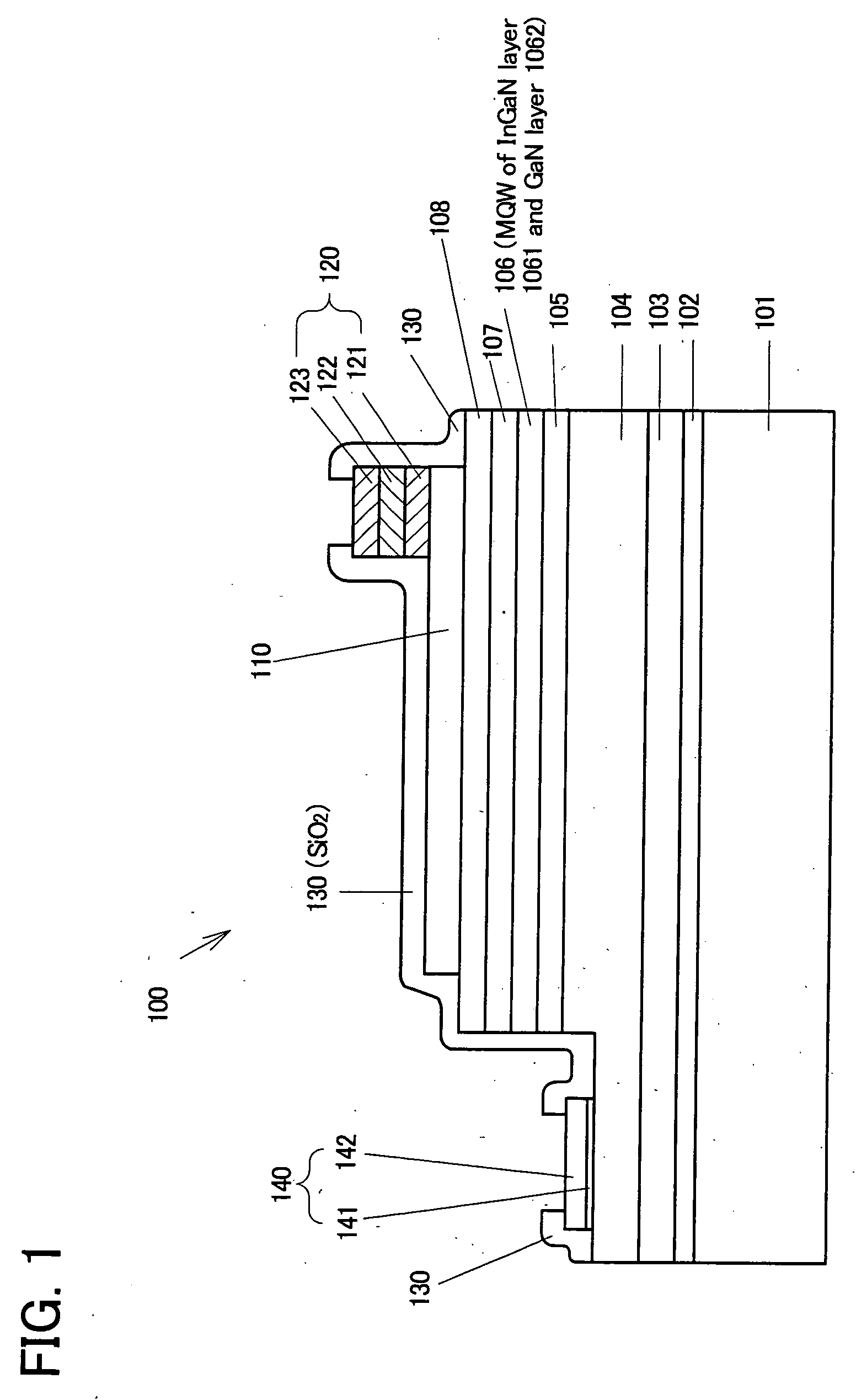

Method for forming an electrode

ActiveUS20060073692A1High light transmittanceLow resistivitySolid-state devicesSemiconductor/solid-state device manufacturingElectron beam depositionIndium tin oxide

In a semiconductor light-emitting device 100, a buffer layer 102, a undoped GaN layer 103, a high carrier concentration n+-layer 104, an n-type layer 105, an emission layer 106, a p-type layer 107, and a p-type contact layer 108 are deposited in sequence on a sapphire substrate. The semiconductor light-emitting device 100 comprises a light-transparent electrode 110 made of indium tin oxide (ITO) which is deposited in the low pressure vacuum chamber flowing at least oxygen gas through electron beam deposition or ion plating treatment and thermal process are carried out.

Owner:TOYODA GOSEI CO LTD

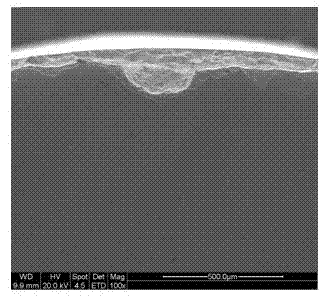

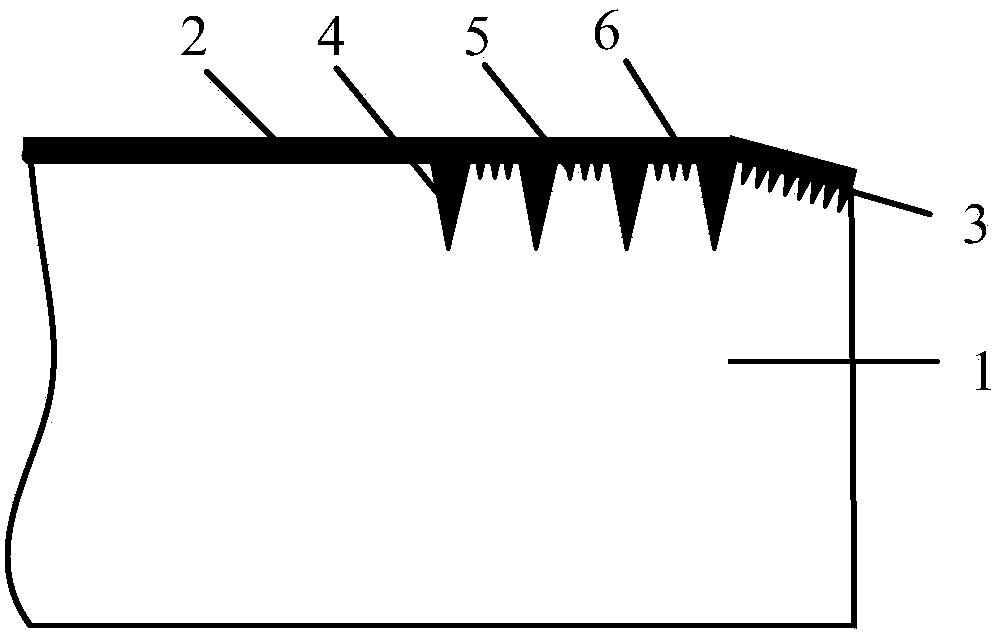

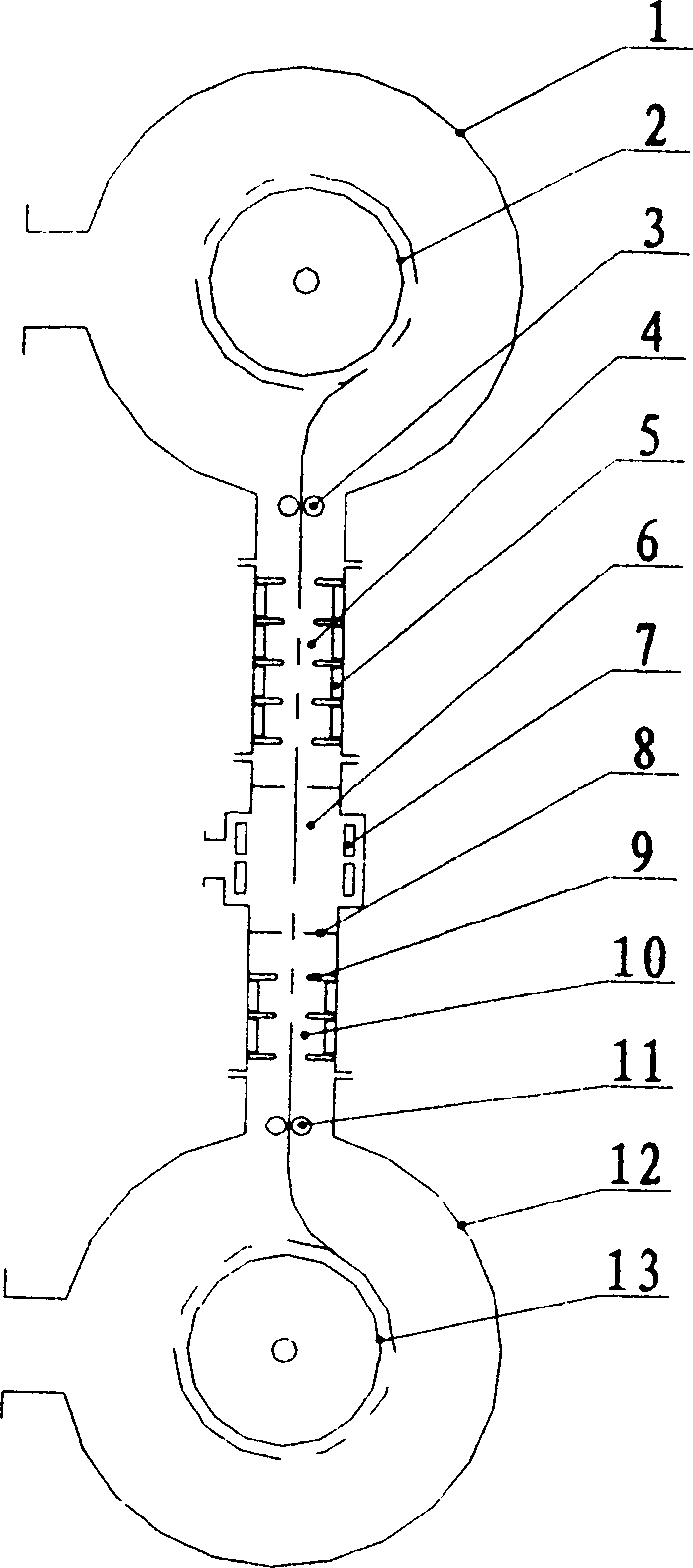

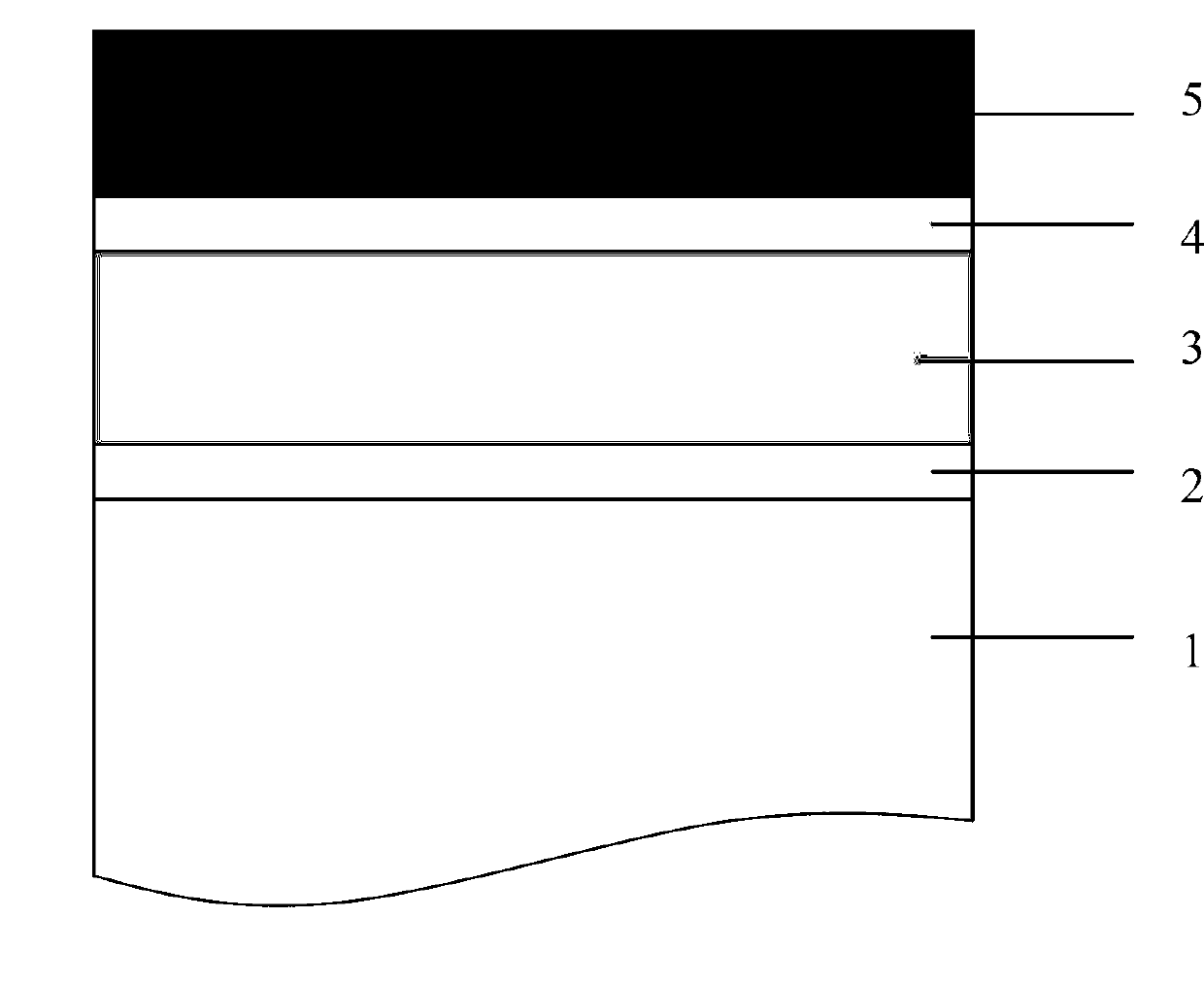

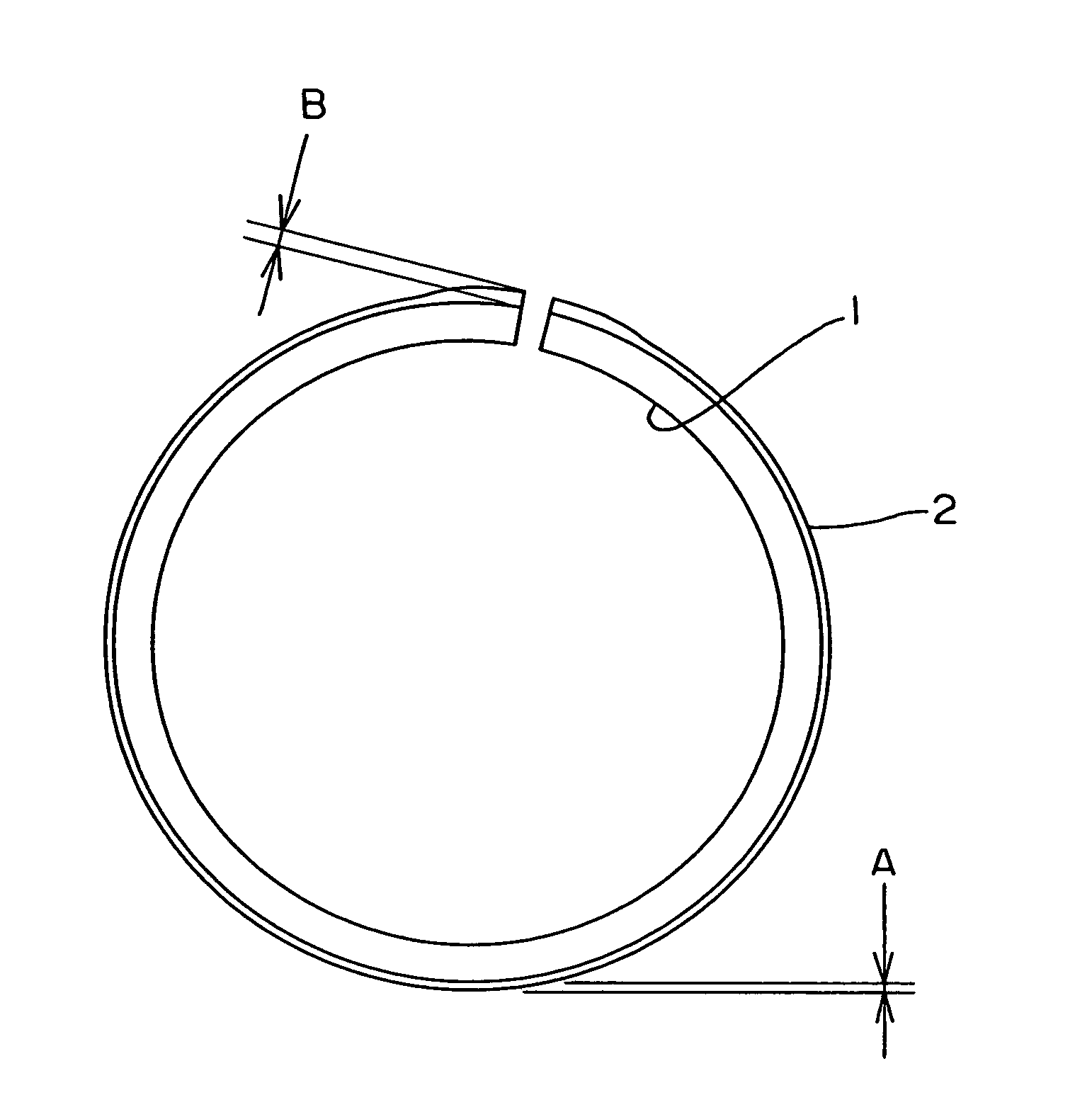

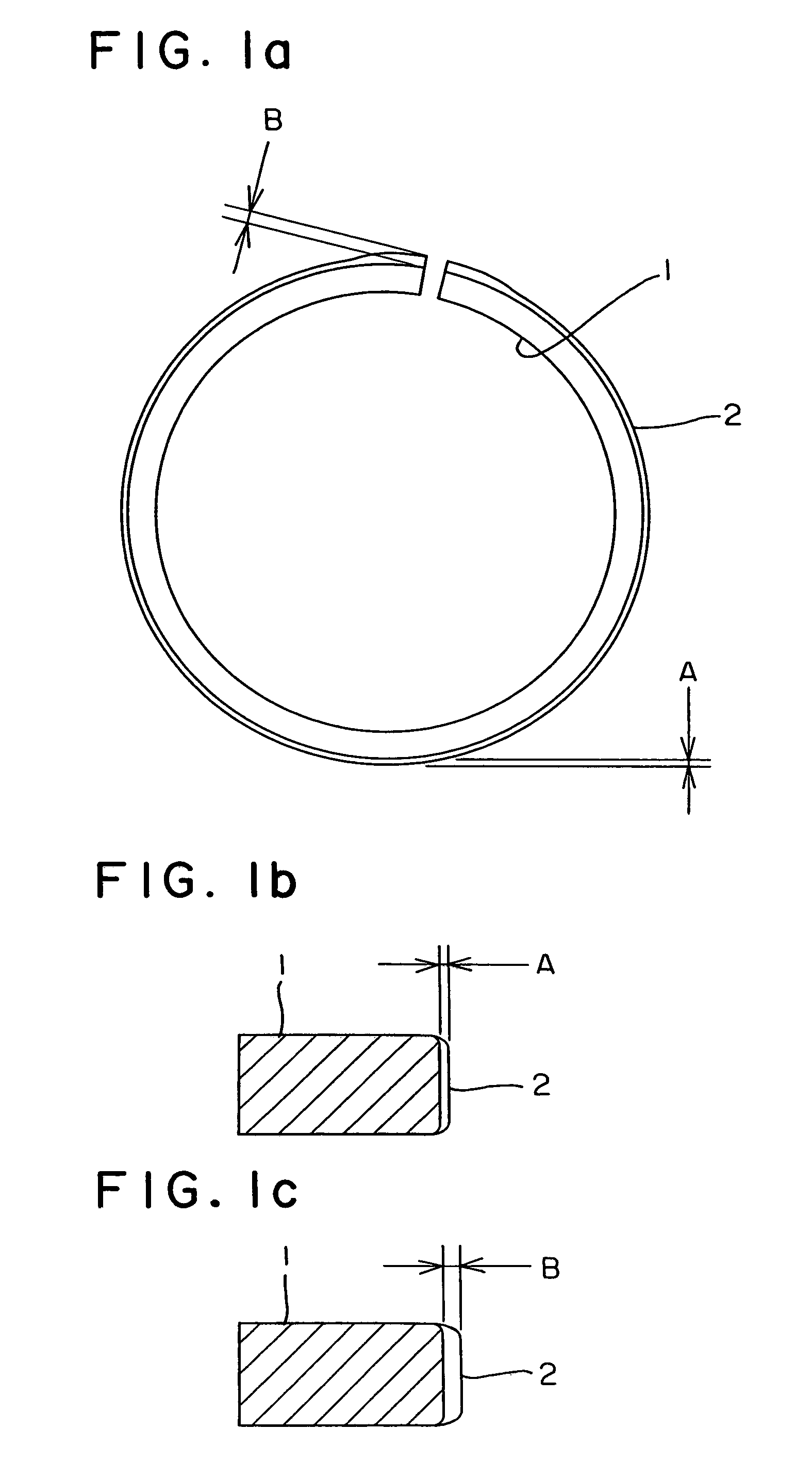

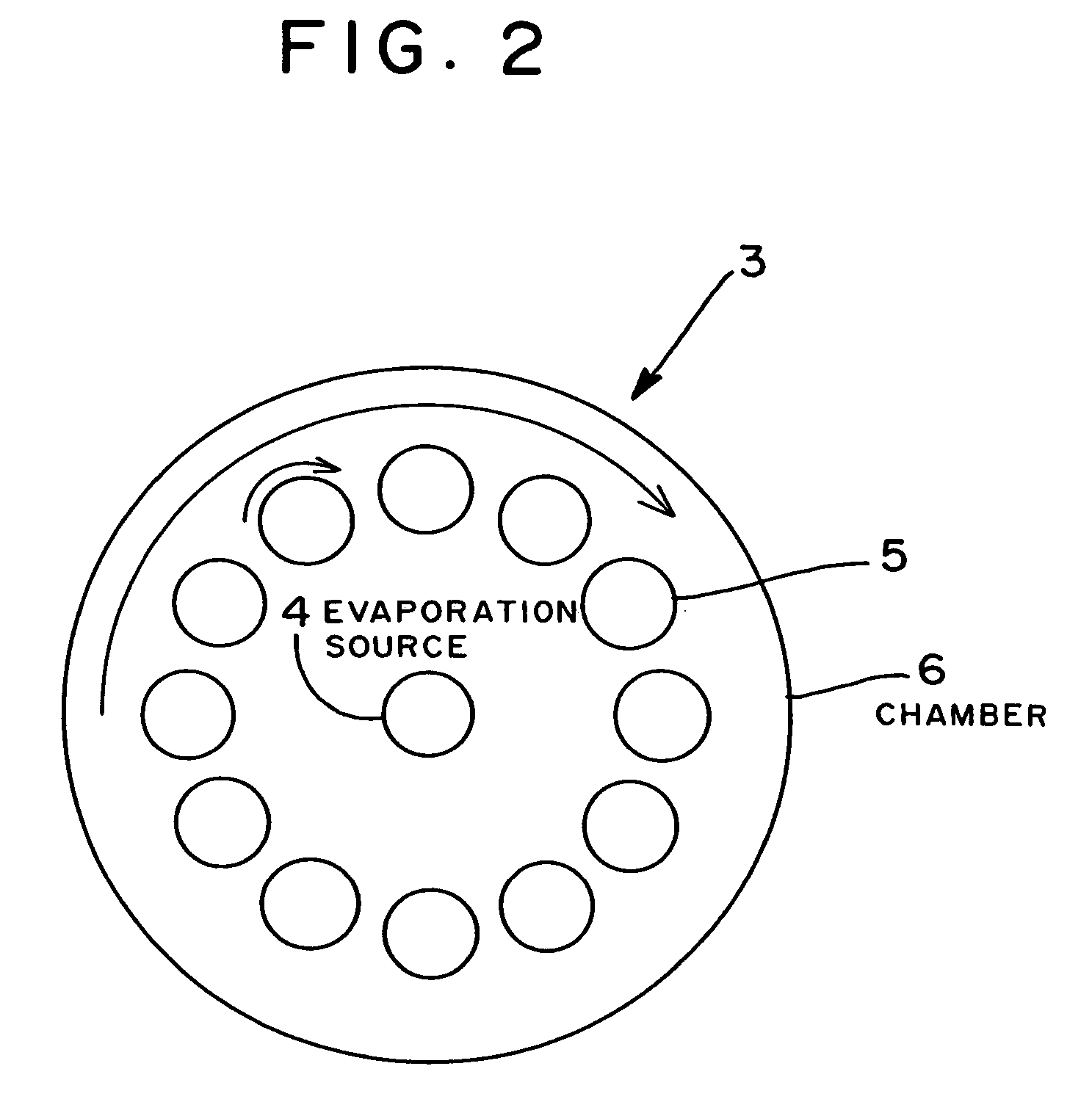

Piston ring and method of manufacturing the same

InactiveUS7052019B2Improve wear resistancePrevent peelingPiston ringsBraking action transmissionCountermeasurePiston ring

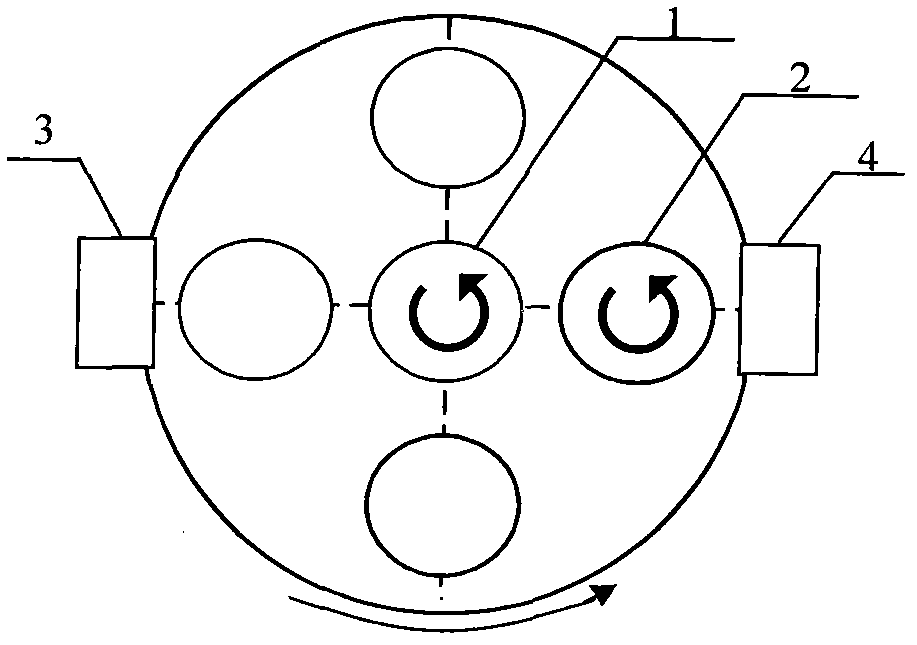

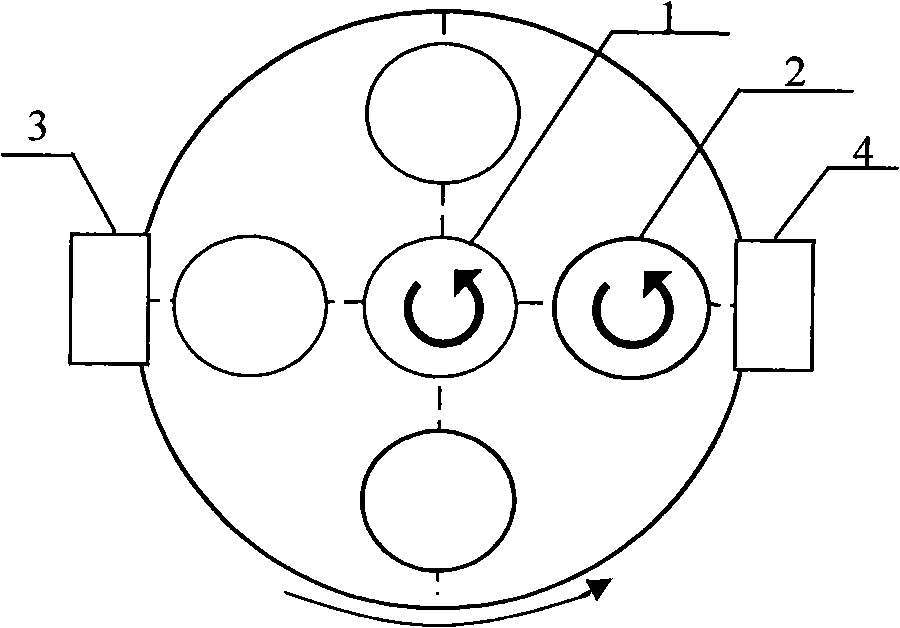

A manufacturing method of a piston ring is developed, wherein the method provides a countermeasure for wear of butt ends of the ion plating film coated piston ring and a countermeasure for breakage of the piston ring and the piston ring manufactured at a low cost. A thickness of the film (2) in the vicinity of butt ends (7) of a piston ring (1) is made greater than the thickness of the film (2) at other outer peripheral surface. Piston ring blanks (5) are rotated around their own axes toward an evaporation source (4) and a speed is lowered when the butt ends (7) face the evaporation source (4).

Owner:RIKEN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com