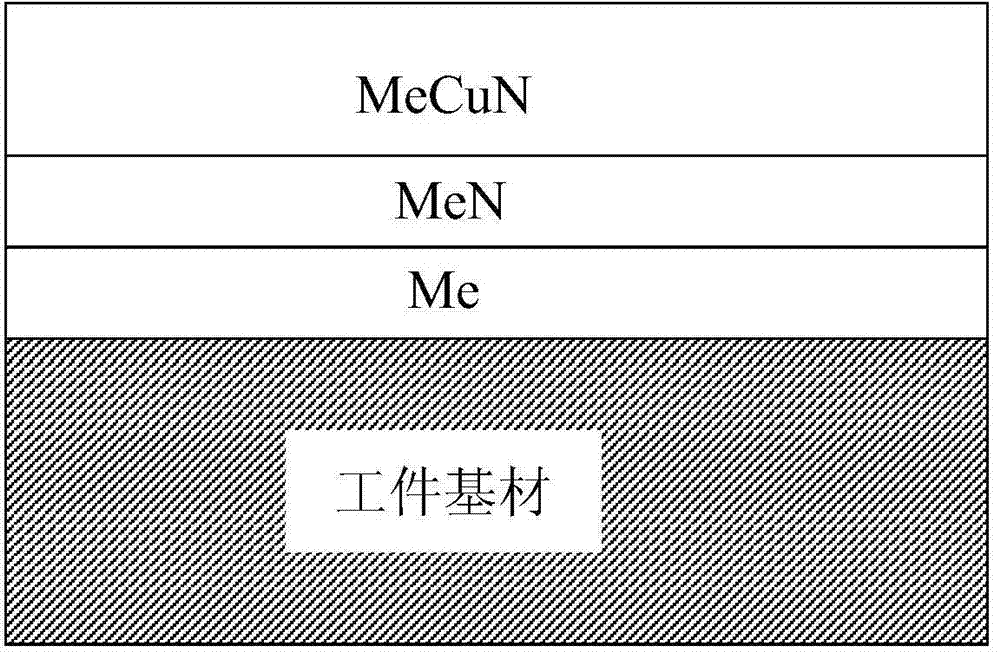

Antibacterial and wear-resistant nano-composite coating and preparation method thereof

A nano-composite coating, metal technology, applied in coatings, chemical instruments and methods, metal material coating processes, etc., to achieve the effect of optimizing process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

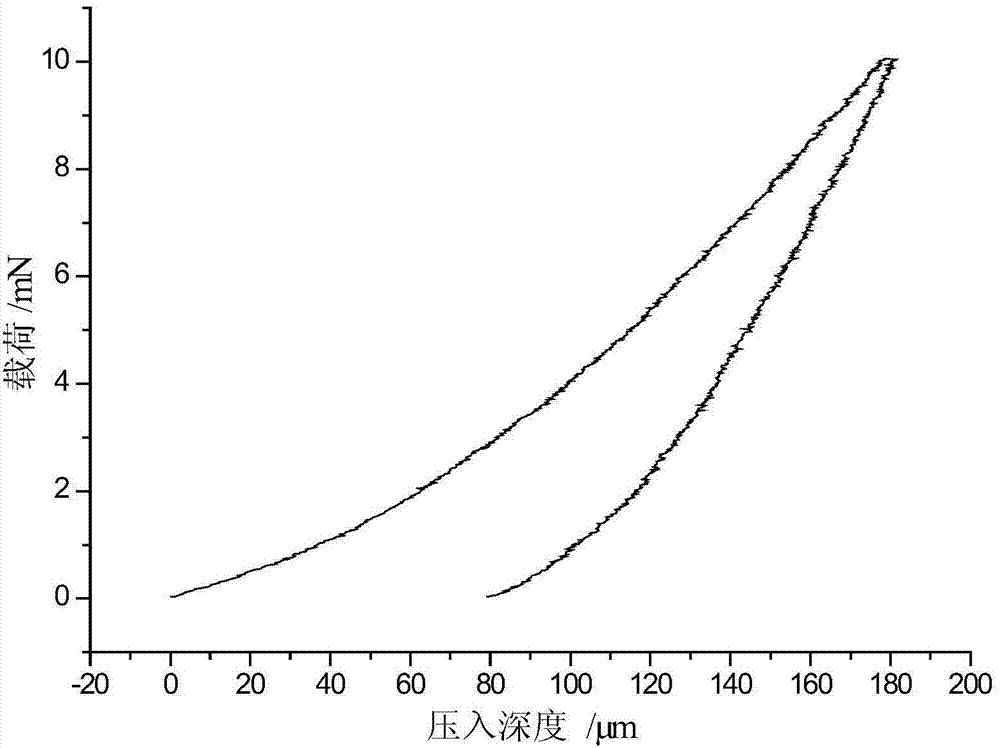

Embodiment 1

[0045] In this embodiment, the stainless steel 306 is used as the substrate, and the TiCuN coating is deposited by magnetron sputtering technology, so as to endow the surface of the stainless steel with automatic sterilization performance. Concrete preparation process is as follows:

[0046] (1) Preliminary cleaning of stainless steel: Use a metal cleaning agent to ultrasonically clean the sample for 15 minutes, then rinse it with tap water, then rinse it quickly in deionized water, and then put it into 0.5% dilute HCl for surface activation for 2 minutes, rinse it again Sonicate in acetone for 15 minutes, dry and place in a vacuum chamber.

[0047](2) Cleaning by argon sputtering in the vacuum chamber: After heating to 250° C., argon gas (volume percentage >99.99%) is introduced into the vacuum chamber to increase the pressure in the vacuum chamber to 1.0 Pa. At this time, the bias power supply was turned on, and under the action of a negative bias voltage of 800V, the argon...

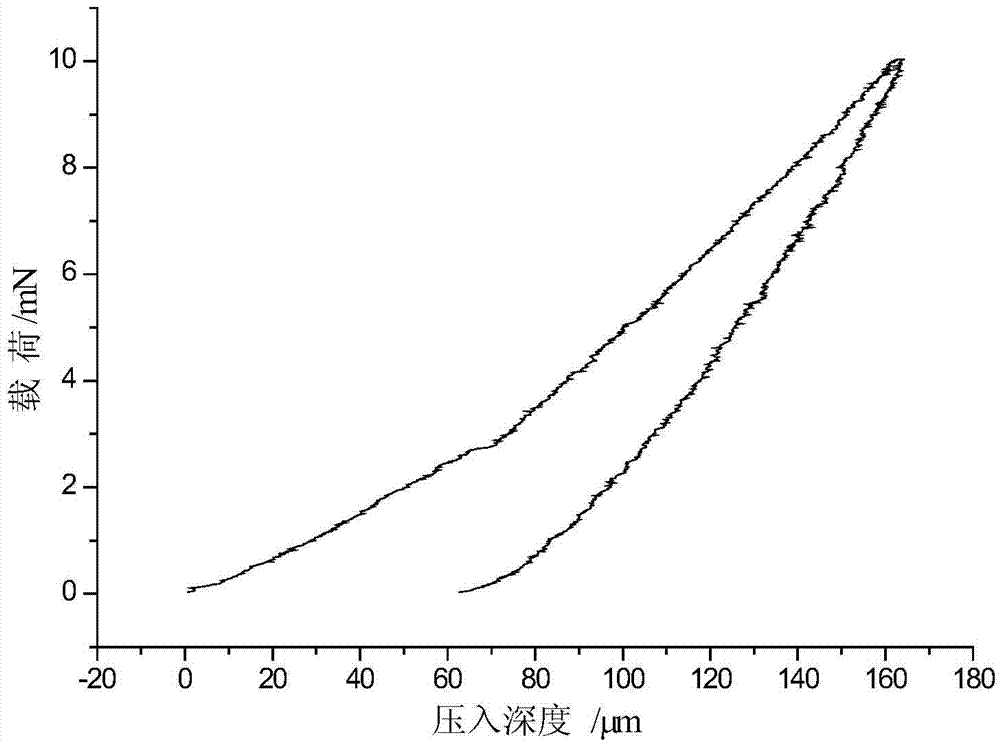

Embodiment 2

[0059] In this embodiment, the high-speed steel is used as the substrate, and the ZrCuN coating is deposited by magnetron sputtering technology, so as to endow the surface of the high-speed steel with automatic sterilization performance. Concrete preparation process is as follows:

[0060] (1) Preliminary cleaning of high-speed steel: Use a metal cleaning agent to ultrasonically clean the sample for 15 minutes, then rinse it with tap water, then rinse it quickly in deionized water, and then put 0.75% dilute H 3 PO 4 The middle surface is activated for 2 minutes, rinsed again, ultrasonically cleaned in acetone for 15 minutes, dried and placed in a vacuum chamber.

[0061] (2) Cleaning by argon sputtering in the vacuum chamber: after heating to 400° C., argon gas (volume percentage >99.99%) is introduced into the vacuum chamber to increase the pressure in the vacuum chamber to 3.0 Pa. At this time, the bias power supply was turned on, and under the action of a negative bias vo...

Embodiment 3

[0073] In this embodiment, the high-speed steel is used as the substrate, and the ZrCu(Ag)N coating is deposited by magnetron sputtering technology, so as to endow the surface of the high-speed steel with automatic sterilization performance. Concrete preparation process is as follows:

[0074] (1) Preliminary cleaning of high-speed steel: Use a metal cleaning agent to ultrasonically clean the sample for 15 minutes, then rinse it with tap water, then rinse it quickly in deionized water, and then put 0.75% dilute H 3 PO 4 The middle surface is activated for 2 minutes, rinsed again, ultrasonically cleaned in acetone for 15 minutes, dried and placed in a vacuum chamber.

[0075] (2) Cleaning by argon sputtering in the vacuum chamber: after heating to 400° C., argon gas (volume percentage >99.99%) is introduced into the vacuum chamber to increase the pressure in the vacuum chamber to 2.0 Pa. At this time, the bias power supply was turned on, and under the action of a negative bia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com