Patents

Literature

495results about How to "Avoid inhomogeneity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Prepn process of vulcanized hydrogenation catalyst

ActiveCN101088619AFull and even contactEvenly mixedCatalyst activation/preparationRefining by selective hydrogenationSulfurNitrogen

The present invention relates to one kind of vulcanized hydrocarbon oil hydrogenating catalyst and its preparation process. The preparation process includes the first supporting certain amount of VI and VIII metal precursor oxide, the subsequent introducing sulfur and heat treatment in dynamic heating equipment, and final adding the residual VI and VIII metal precursor oxide and drying treatment. The present invention combines the pre-vulcanizing into the preparation process of catalyst, and the catalyst has raised reaction performance, and is suitable for hydrocarbon oil hydroprocessing, especially light fraction oil desulfurizing reaction, hydrodenitrogenation reaction, arene hydrogenating saturation and other catalytic reaction process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process of treating hydrogenation catalyst before application

ActiveCN101088615AImprove performanceSolve the problem of concentrated heat releaseCatalyst activation/preparationRefining by selective hydrogenationAs elementOrganic acid

Owner:CHINA PETROLEUM & CHEM CORP +1

Prepn process of vulcanized catalyst

ActiveCN101088620AImprove vulcanization effectImprove hydrogenation reaction performanceCatalyst activation/preparationRefining by selective hydrogenationChemistryThiram

The present invention relates preparation process of vulcanized catalyst. During the preparation process, thiram in 0.5-25 wt% of the catalyst, sulfur element in 30-150 % of the theoretic sulfur demand of the catalyst and organic solvent in 0.1-50 wt% of the catalyst are first introduced into the catalyst in oxide state, and the catalyst is then heat treated in dynamic heating apparatus. The catalyst has raised sulfur holding rate, smooth heat release, shortened vulcanizing period and raised production efficiency. The method of the present invention may be used in the treatment of various kinds of hydrogenating catalyst before application.

Owner:CHINA PETROLEUM & CHEM CORP +1

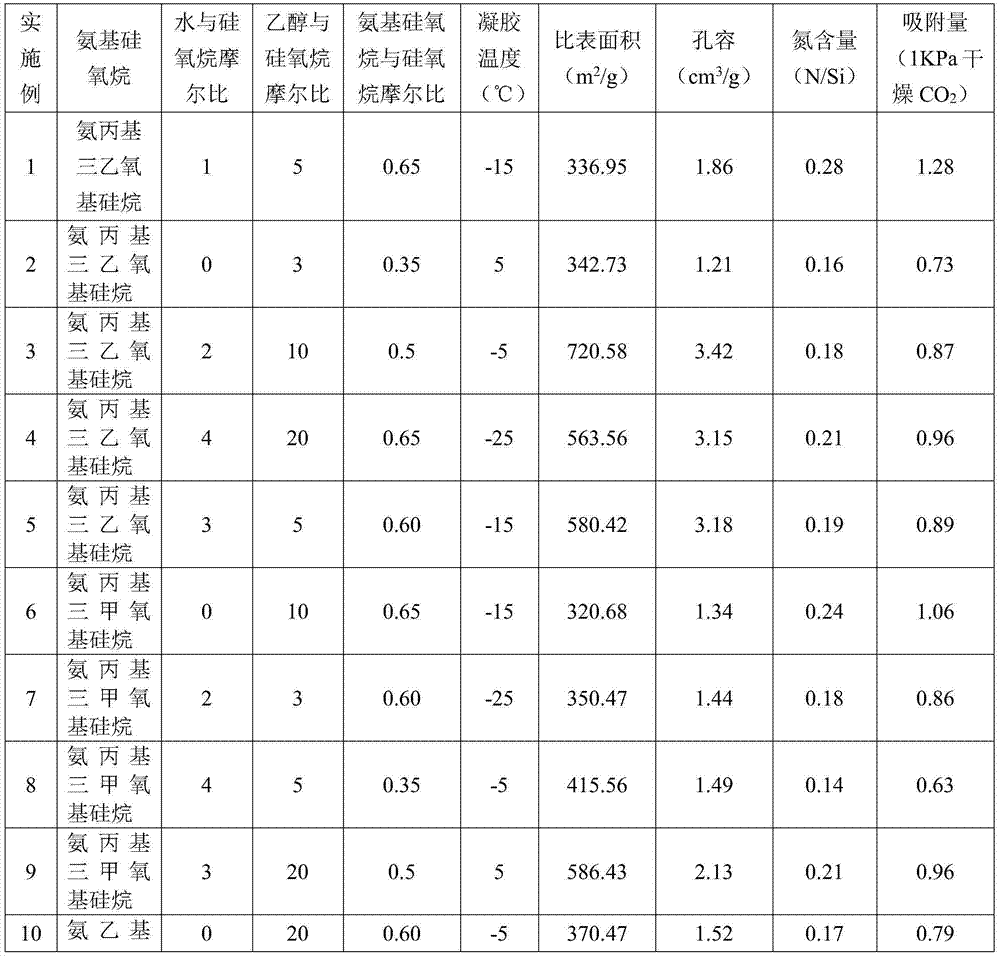

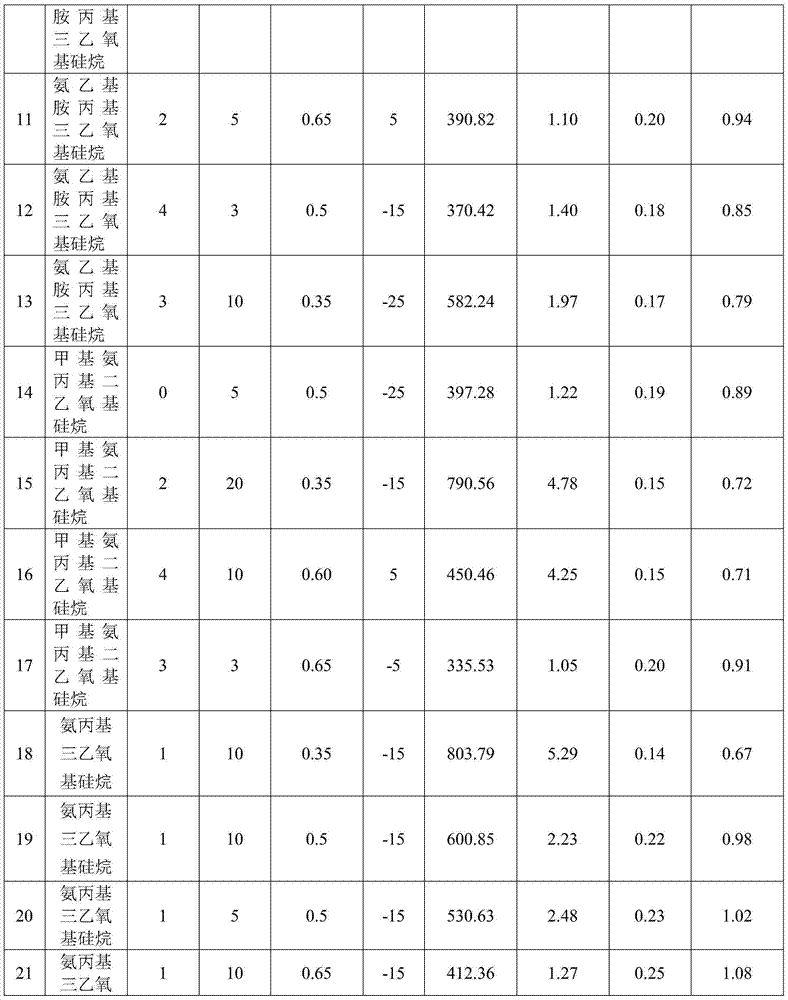

Preparation method of renewable low concentration CO2 high efficient absorption material

ActiveCN104117343AWell mixedAvoid inhomogeneityOther chemical processesDispersed particle separationSupercritical dryingLarge pore

The invention discloses a preparation method of a renewable low concentration CO2 high efficient absorption material, and aims to provide a preparation method of a renewable low concentration CO2 high efficient absorption material which has the advantages of low energy consumption, good absorption selectivity, and large absorption quantity of low partial pressure CO2. The technical scheme comprises the following steps: preparing silica sol and an amino siloxane solution, evenly mixing the silica sol and the amino siloxane solution, then mixing the mixed sol with dimethyl silicone oil, stirring to form suspension liquid, stirring at the same temperature of the sol until gel is formed; then heating the mixture to a temperature of 40 to 60 DEG C, allowing the mixture to stand still for aging for 1 to 9 days at a temperature of 40 to 60 DEG C, filtering to obtain the spherical gel; and finally putting the spherical gel and ethanol into supercritical drying equipment to dry the gel. The prepared renewable low concentration CO2 high efficient absorption material has the advantages of good uniformity, high nitrogen content, high specific surface area, large pore volume, and large CO2 absorption capacity.

Owner:NAT UNIV OF DEFENSE TECH

High-strength corrosion-resistant aluminum alloy profile and preparation method thereof

The invention discloses a high-strength corrosion-resistant aluminum alloy profile and a preparation method thereof. The aluminum alloy profile comprises an aluminum alloy base body and a ceramic coating. The aluminum alloy base body is prepared from Cu, Si, Fe, Cr, Mg, Mn, Zn, Ti, Li, Ni, Zr, Y, W, V and the balance Al. The ceramic coating is prepared from SiC, Cr2O3, NiO, Cr3C2, Al2O3 and Si3N4. According to the high-strength corrosion-resistant aluminum alloy profile, ceramic powder is arranged on the surface of the aluminum alloy base body through plasma cladding, and then laser remelting is conducted, so that the obtained aluminum alloy profile has good mechanical performance such as strength, hardness and impact toughness; and meanwhile, the high-strength corrosion-resistant aluminum alloy profile has the beneficial effects of being resistant to corrosion, good in abrasion resistance, long in service life and the like.

Owner:安徽省煜灿新型材料科技有限公司

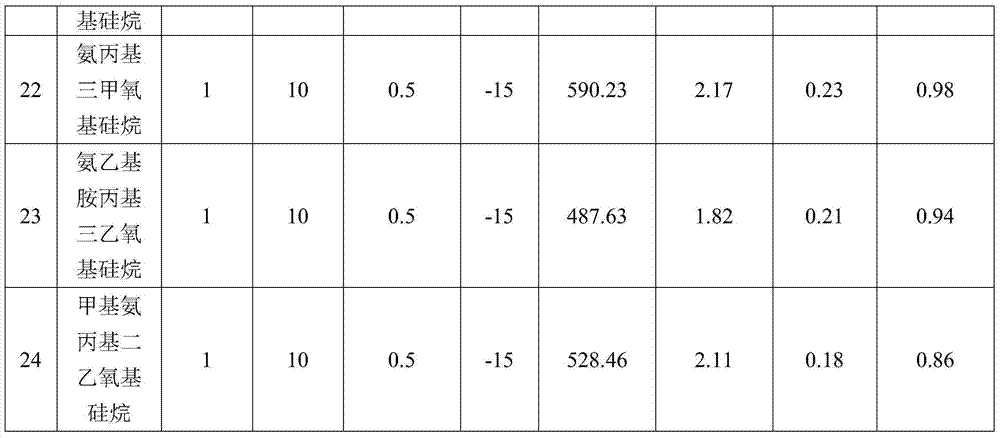

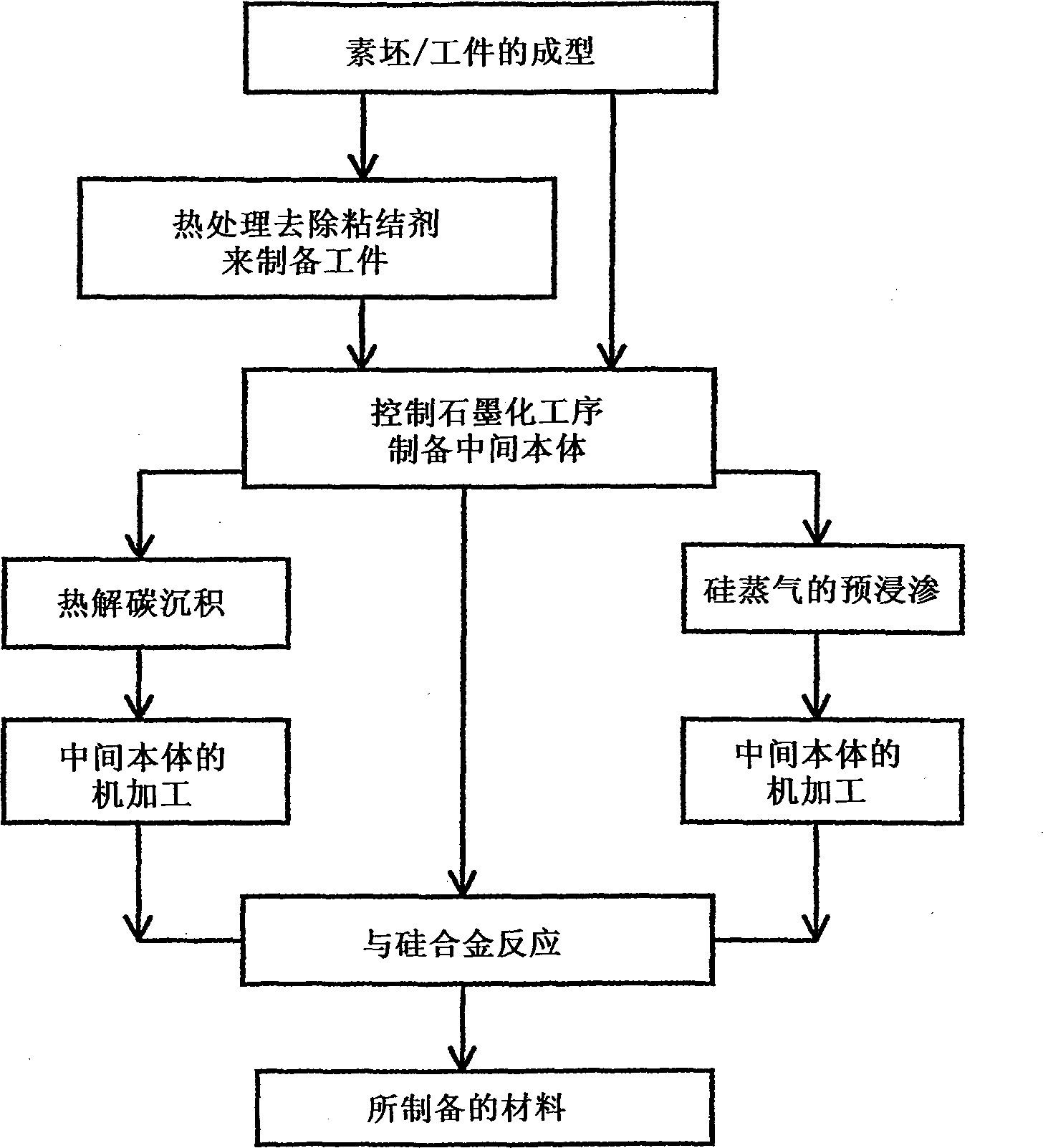

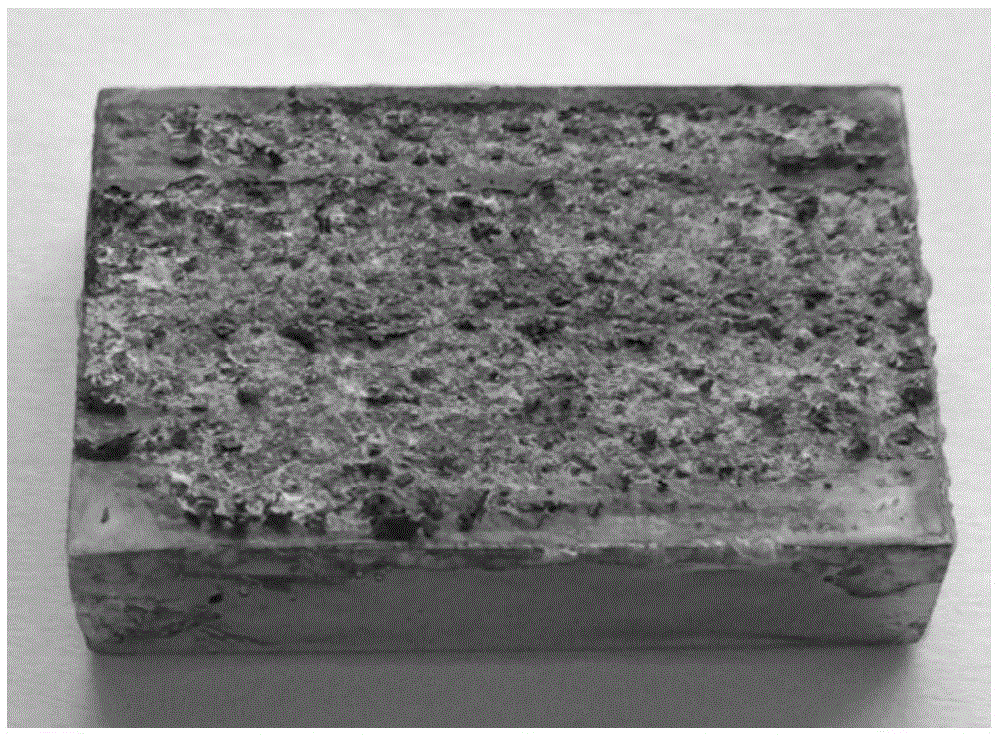

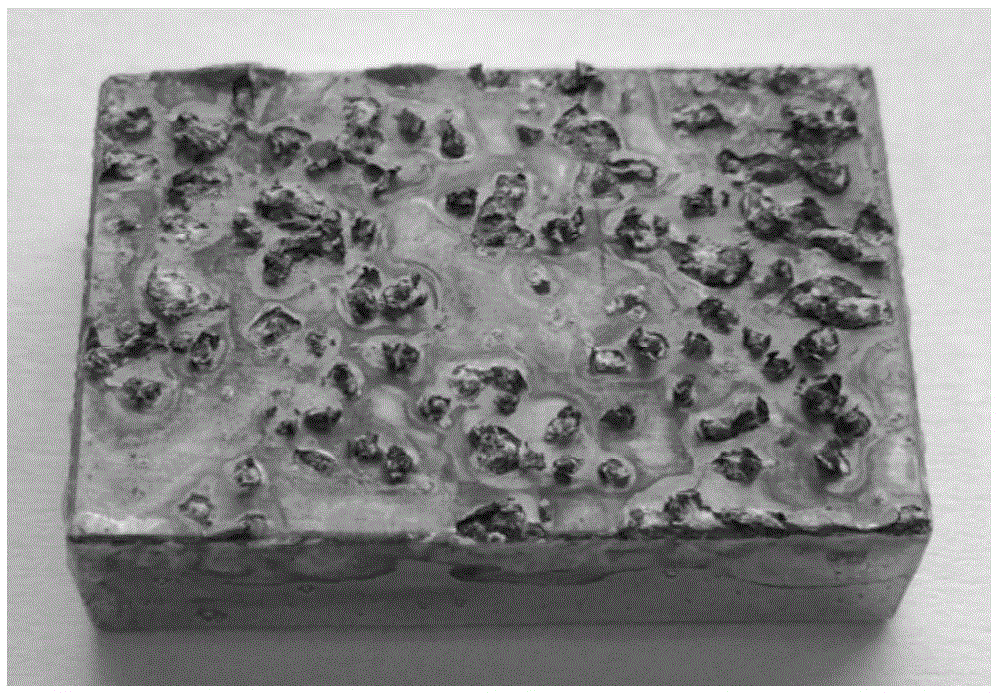

Method of manufacturing a diamond composite and a composite produced by same

InactiveCN1320108AWith strengthWith mechanical propertiesOther chemical processesTurning toolsHeating timeSilicon alloy

The present invention relates to a method for manufacturing a diamond composite from diamond particles, comprising the steps of forming a work piece, heating the work piece and controlling the heating temperature and heating time so that a certain desired amount of graphite is created by graphitization of diamond particles, thereby creating an intermediate body, and infiltrating silicon alloy into the intermediate body. The invention also relates to a diamond composite produced by this method.

Owner:FRENTON

Preparation method of large-diameter aluminum alloy tube

InactiveCN102416413AImprove welding strengthImprove plasticityNon-electric welding apparatusFriction weldingProduction rate

The invention relates to a preparation method of a large-diameter aluminum alloy tube, relating to a preparation method of an aluminum alloy tube and aiming to solve the problems in the prior art that the large-diameter aluminum alloy tube with the tube wall thickness less than 2mm and with an excellent performance cannot be prepared with low cost and high production efficiency. In the method, an aluminum alloy rolled plate is obtained at first through blanking with a plate shearing machine, a cylindrical tube blank is prepared with a plate rolling machine, a tube blank to be welded is obtained through clamping with a clamp, mixing friction welding is carried out for welding, a cylindrical welded tube is obtained through rounding, and the large-diameter aluminum alloy tube is obtained finally sequentially through spinning and thermal treatment. The invention has the advantages that: 1, a high-quality spinning blank can be obtained; 2, a large-diameter tube can be prepared; 3, the mechanical properties are good; 4, the number of spinning procedures is reduced, no annealing treatment is needed in the procedures, the production cycle is shortened, and the cost is decreased; and 5, the dimensional accuracy is high. The method is mainly applied in production of the large-diameter aluminum alloy tube.

Owner:HARBIN INST OF TECH

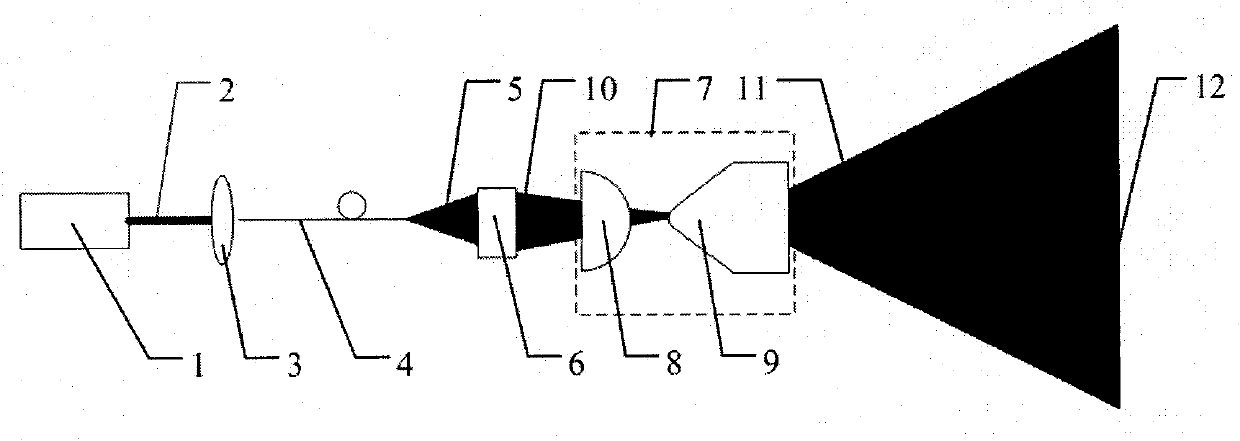

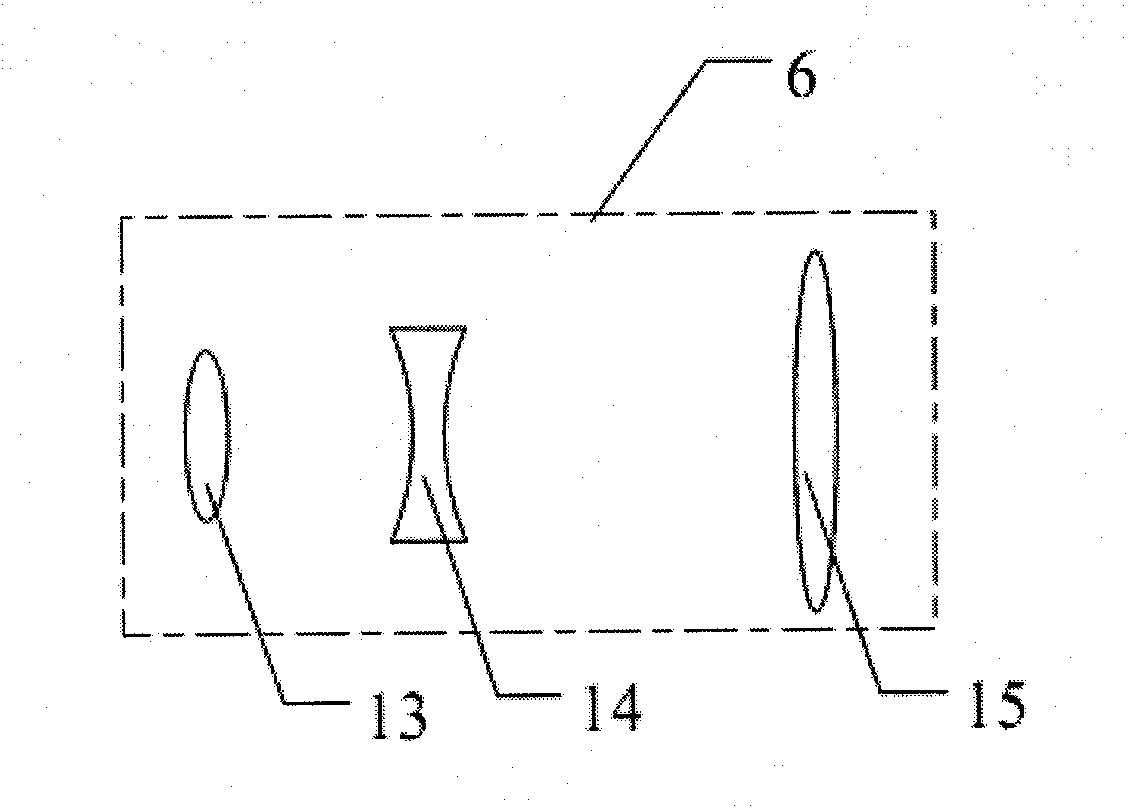

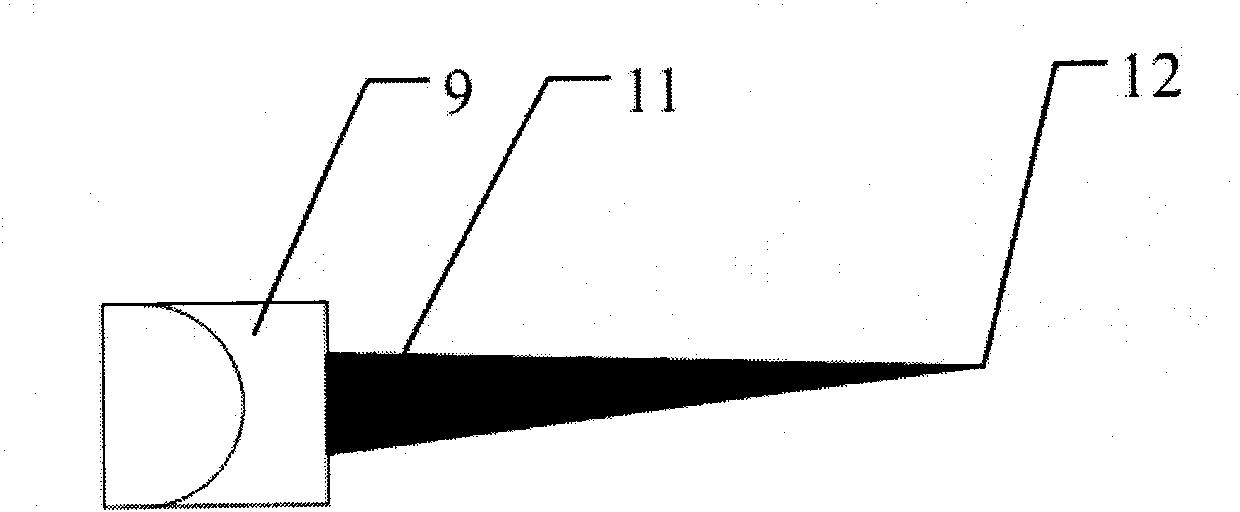

Linear beam shaping optical system

The invention relates to a linear beam shaping optical system, comprising a laser light source, an optical fiber coupling system, a transmission optical fiber, and a spherical surface lens set. The characteristics are as follows: the laser emitted from the light source enters the optical fiber through the fiber coupling system, is transmitted by the optical fiber, and is incident to the spherical surface lens set; the light beam outgoing from the spherical surface lens set passes through a cylindrical mirror and an improved Powell prism to form a broom-shaped beam in space, lastly, a linear light beam with evenly-distributed energy is formed at vertical focus point. The invention can effectively overcome the defect of uneven energy of the linear light beam caused by ordinary cylindrical mirror imaging and ordinary Powell prism imaging. The adoption of optical fiber transmission can separate the laser from the light beam shaping system and increase the stability, thereby providing needed light beam for track traffic, road test. The invention not only can be widely used for the linear light beam system needed by track traffic, road test, but also can be used for surveying and mapping of building and other application occasions.

Owner:WUHAN LINGYUN PHOTOELECTRONICS SYST

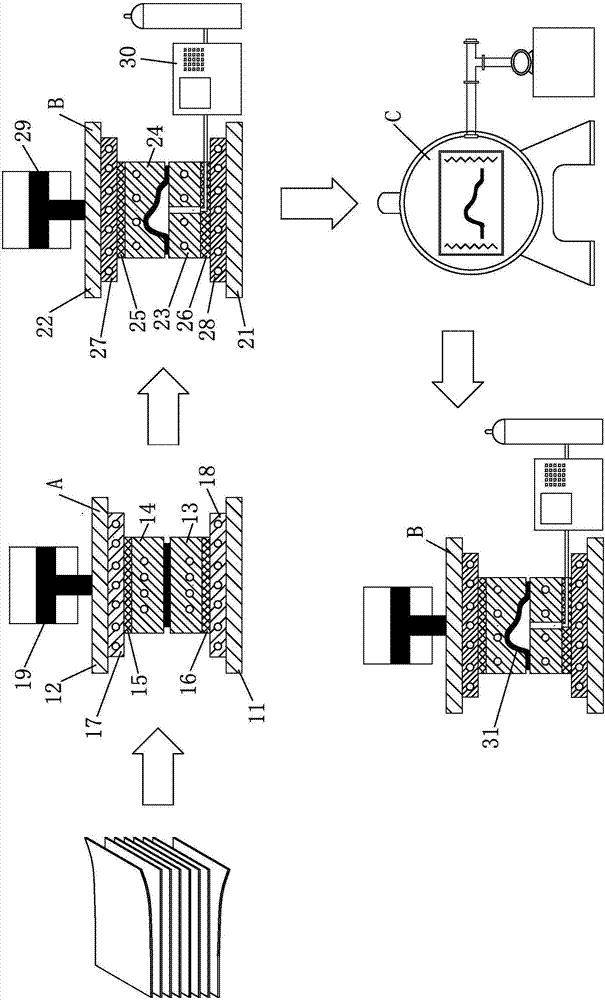

Synthesis, preparation and forming integrated method of NiAl alloy hook face plate component

The invention discloses a synthesis, preparation and forming integrated method of a NiAl alloy hook face plate component, relates to a synthesis, preparation and forming integrated method of an intermetallic compound hook face plate component, and aims to solve the technical problem that thermoforming of the hook face plate component is difficult because the existing NiAl alloy plate blank is poor in plasticity. The synthesis, preparation and forming integrated method comprises the following main steps: I, laminating and hot pressing Ni foils and Al foils alternately to obtain a Ni / Al lamination composite board; II, carrying out hot gas bulging forming on the Ni / Al lamination composite board to obtain the demanded shape and size, and enabling the Ni foils and the Al foils to react in a hot gas bulging forming die to synthesize a Ni-Al intermetallic compound; III, taking a forming piece out of the hot gas bulging forming die and putting the forming piece in a vacuum thermal treatment furnace for high-temperature vacuum thermal treatment to enable the generated Ni-Al intermetallic compound to completely react so as to generate NiAl alloy; and IV, putting the forming piece after thermal treatment in the hot gas bulging forming die, and carrying out densification treatment under the high-pressure gas bulging action. The synthesis, preparation and forming integrated method is suitable for preparation and forming of the NiAl alloy hook face plate component.

Owner:HARBIN INST OF TECH

Low-temperature high-toughness F460 grade super strength steel plate for building ship and manufacturing method thereof

ActiveCN101705439AAvoid inhomogeneityImprove mechanical propertiesHeat treatment process controlSheet steelUltimate tensile strength

The invention relates to a low-temperature high-toughness F460 grade super strength steel plate for building ship and a manufacturing method thereof. The steel plate comprises the following components in percentage by weight: 0.05-0.15 percent of C, 0.15-0.35 percent of Si, 1.20-1.70 percent of Mn, not more than 0.020 percent of P, not more than 0.010 percent of S, 0.02-0.04 percent of Nb, 0.04-0.06 percent of V, 0.010-0.020 percent of Ti, 0.15-0.40 percent of Cu, 0.10-0.30 percent of Cr, 0.15-0.40 percent of Ni, 0.02-0.05 percent of Al and the balance of Fe and inevitable impurities. The steel plate for building ship is obtained by the following steps: heating a continuous casting billet; heat insulation treatment; hot rolling; and finally cooling the steel plate. The invention considers the service environment of the steel plate and carries out composition and process design so as to ensure that products have excellent mechanical property under multi-element condition, and has simple preparation process and low cost.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

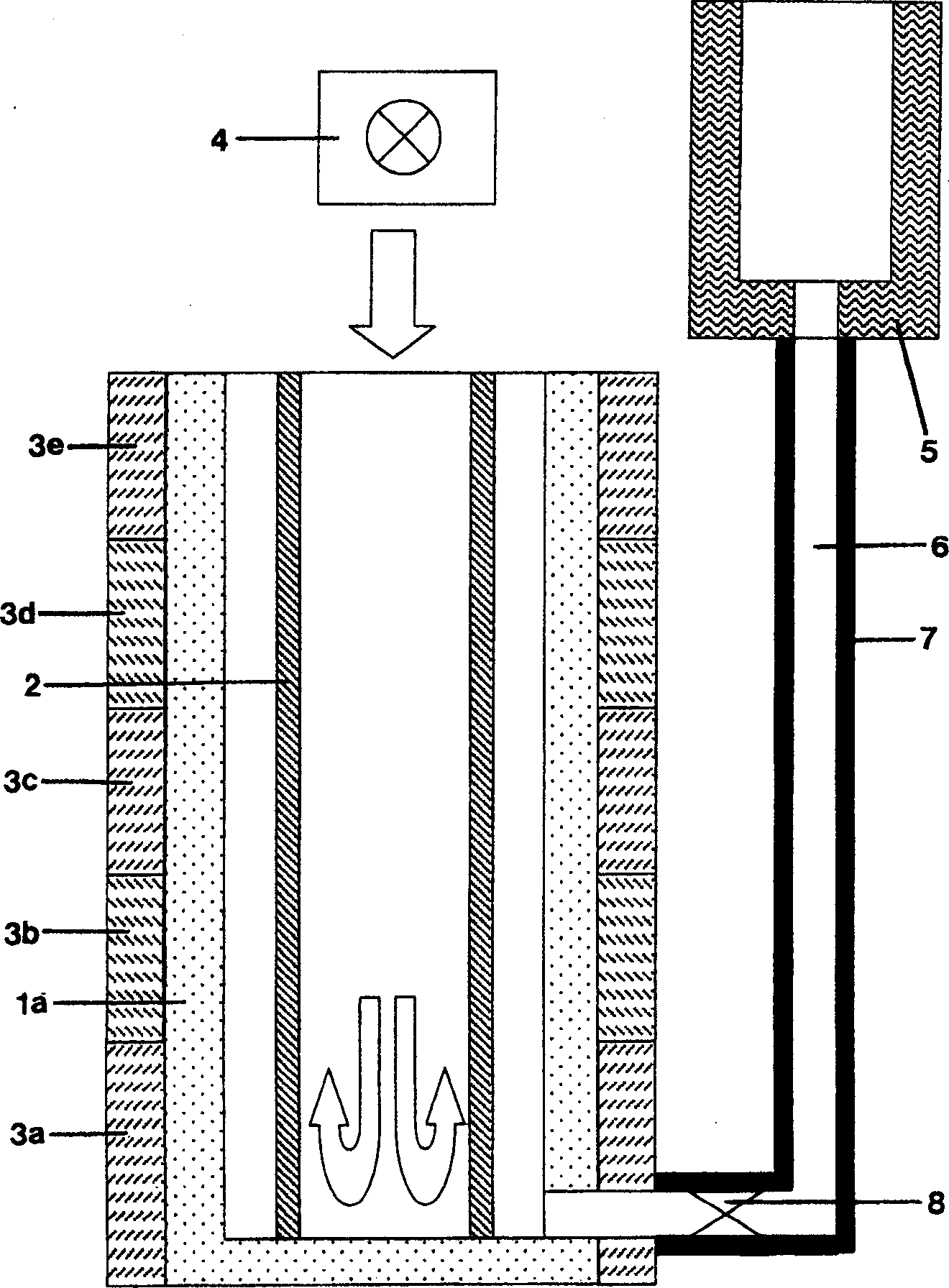

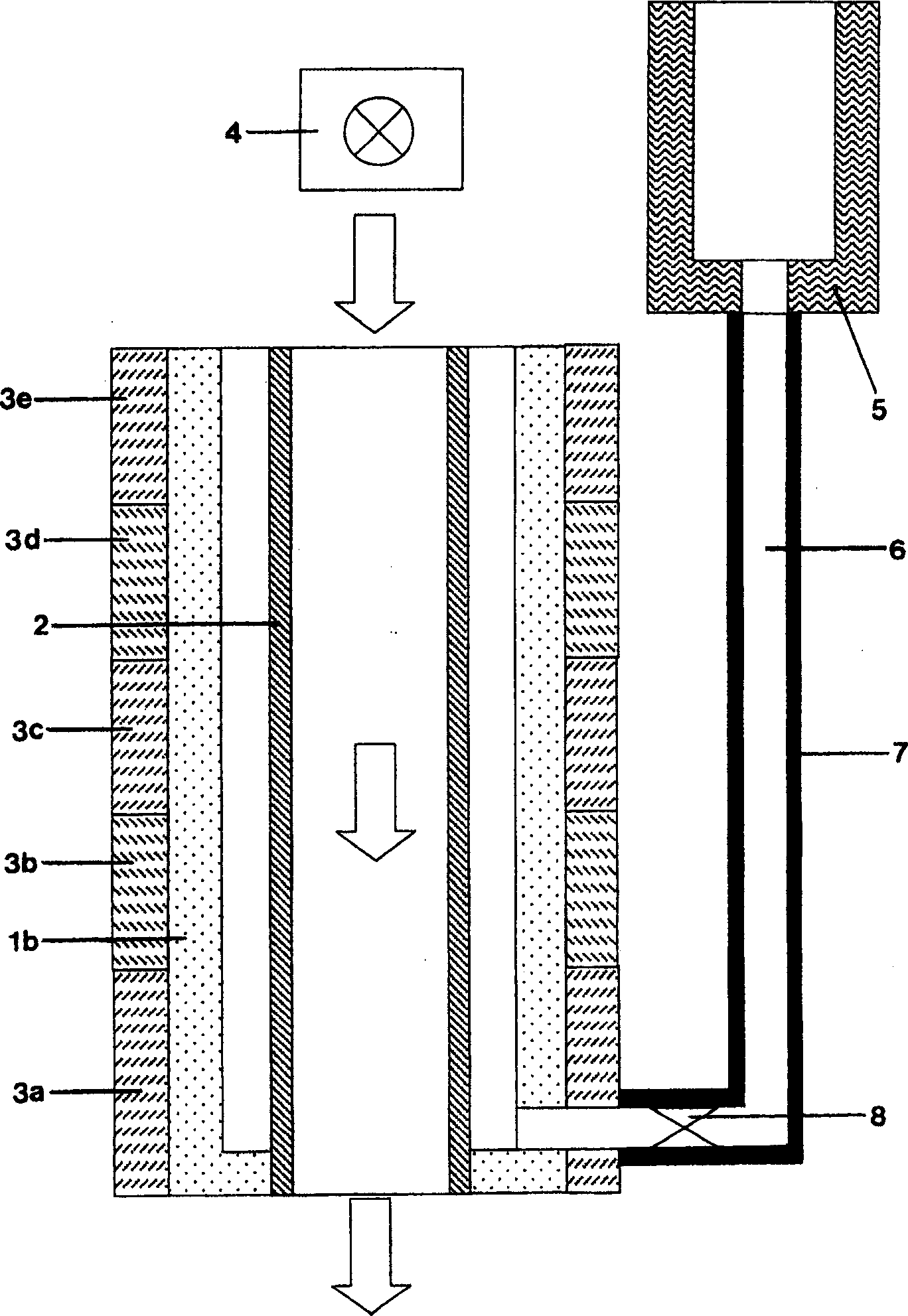

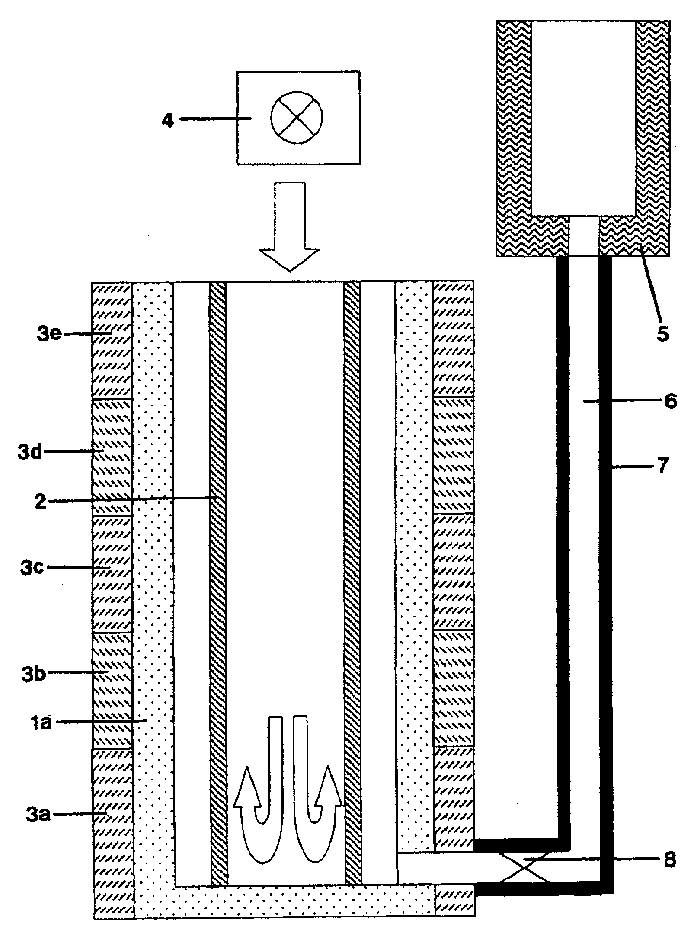

Manufacture of tubular targets

InactiveCN1363716APrevent solidificationAvoid inhomogeneityVacuum evaporation coatingIngot casting plantsMolten stateHeater Rod

A process for producing a tube target for cathode sputtering plants, in which the tube target is formed from a metallic inner tube made of a first material with a first melting point of Ts1>=900 K and a metallic outer tube that concentrically surrounds the inner tube and that is made of a second material with a second melting point of Ts2<=800 K. The inside diameter of the outer tube and the outside diameter of the inner tube are proportioned in such a way that the two tubes fit together tightly and are mechanically firmly joined. The outer tube is formed by casting the second material in a molten state in a heated, vertical, A cylindrical permanent mold, which has a heated mandrel that constitutes the inner tube. After a space between the mold and the inner tube has been filled with the molten second material, a first thermal gradient develops between the inner tube and the mold, a second thermal gradient develops between the bottom and the top of the mold, and the outer tube is simultaneously cooled from the inside to the outside and from the bottom to the top.

Owner:MATERION ADVANCED MATERIALS GERMANY GMBH

A preparation method for high-fiber recombinant asparagus chips

The present invention discloses a preparation method for high-fiber recombinant asparagus chips, and belongs to the deep processing field of fruits and vegetables. The asparagus chips use discarded scraps of old stems and old roots from asparagus production enterprises as raw materials, and are prepared by the following steps: pre-treating the raw materials, blanching the materials in hot water, preserving color, conducting beating, mixing the materials with adjuvant materials, cooking the mixture for a short time, placing the mixture on plates, drying the mixture under vacuum by two section-type microwave to a moisture content of 10% -15%, drying the mixture by short- and medium-wave infrared method under vacuum to a moisture content below 5%, and packaging the mixture to obtain the end products. The dietary fiber content of the asparagus chips is 8.35% - 10.27%, and every 100g of the chips contains flavonoids 12.73-16.86 mg, polysaccharide 9.34-11.28 mg. The preservation rate of chlorophyll is 70% to 75% after processing, and the chip breaking force is 1123-1443 g. The preparation method provides a novel method for taking full advantage of asparagus scraps, and the microwave vacuum drying and the short- and medium-wave infrared vacuum drying have advantages of quick drying, low temperature and higher nutrient retention rate, etc. The asparagus chips are high in cellulose content, rich in flavonoids, polysaccharide and other active substances, crispy and delicious in taste and high in nutritional value. Therefore, the asparagus chips are leisure crisps for people of all ages.

Owner:JIANGNAN UNIV +1

Soft magnetic iron core press formed from powdered iron in automobile ignition coil and its manufacturing method

InactiveCN1414577AHigh densityHigh strengthInorganic material magnetismTransformers/inductances magnetic coresAlcoholInitial permeability

A method to produce soft magnetic core formed by iron powder pressed in ignition coil of automobile uses iron powder and phenolic resin as a raw materials and the iron core is made in the shape of cylinders and rings which are formed by pressing with its manufacturing flow process as preparing iron magnetic powder to be formed by mould pressing-solidifying treatment. The detail process includes putting iron powder into alcohol solution of phenolic resin for obtaining the iron magnetic powder by granulating with sticking and cladding, putting the iron magnetic powder into a mould for obtainingthe primary piece by cold or warm pressing, carrying out the secondary solidifying as well as the treatments of antirust and insulation after the primary piece being processed by solidifying with thetemperature rising step by step.

Owner:李延军

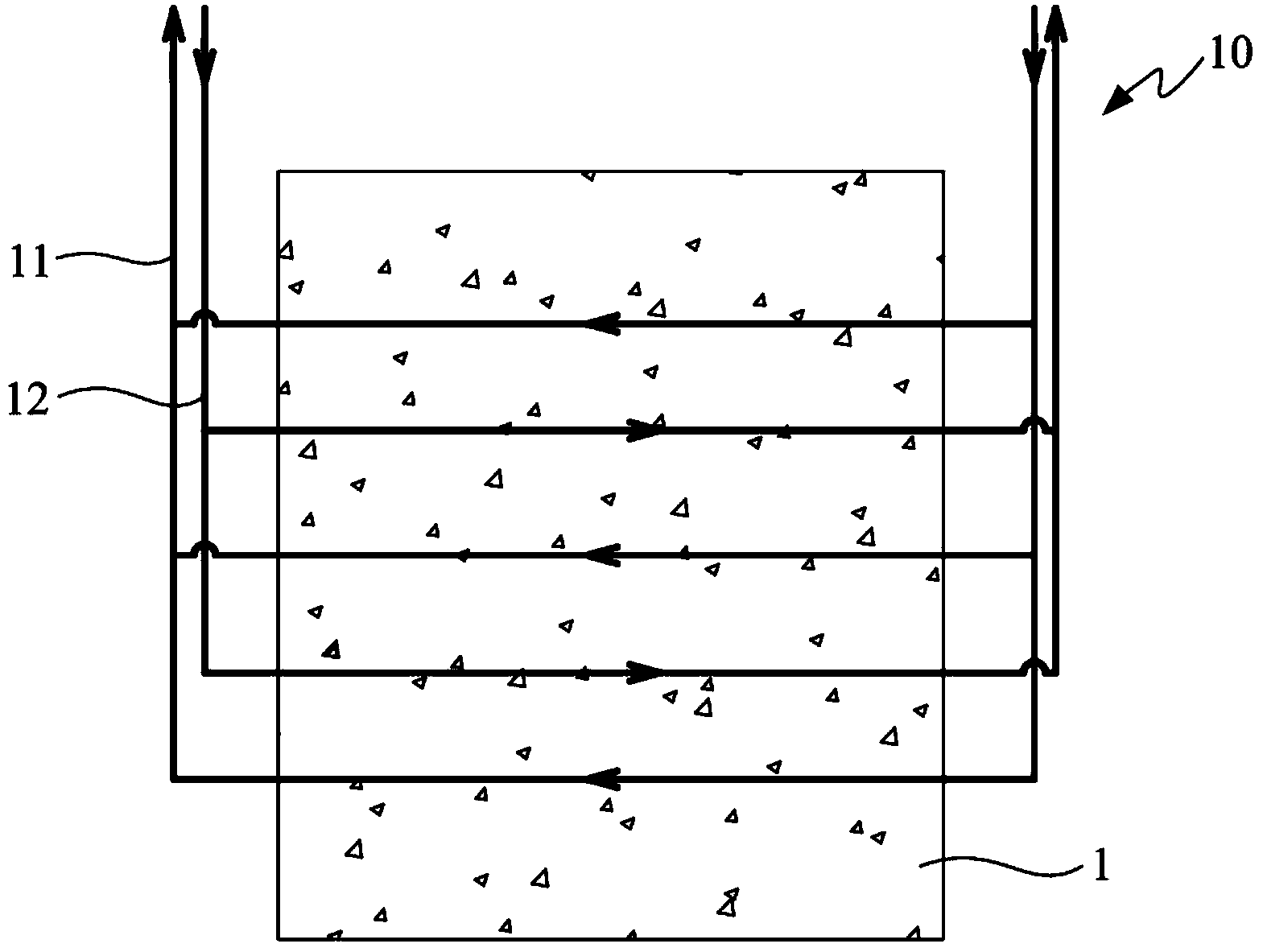

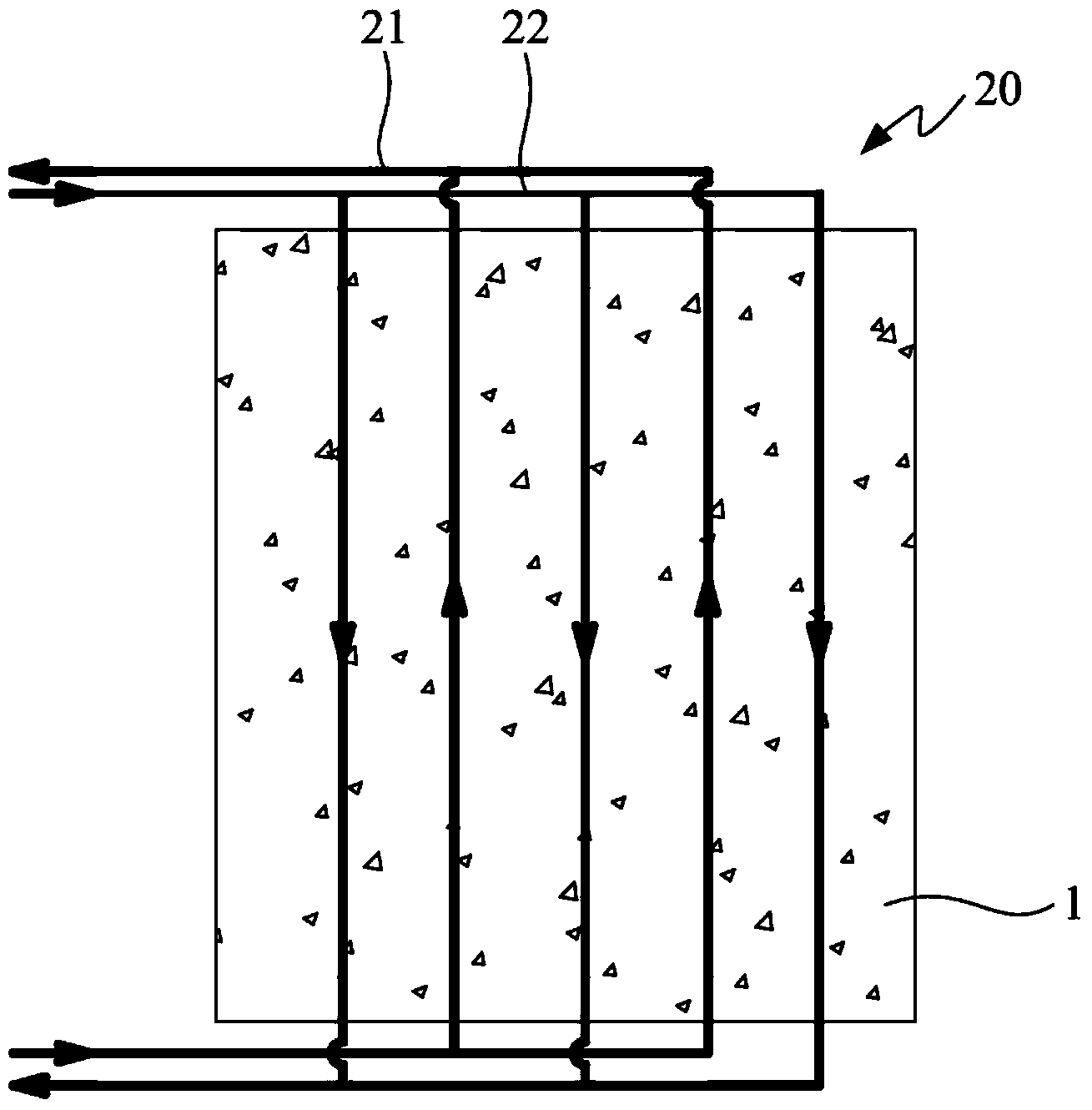

Temperature-control cooling system for large-size concrete structure and cooling control method of temperature-control cooling system

InactiveCN104234431AControl the phenomenon of uneven coolingChange asymmetryBuilding material handlingElement modelEngineering

The invention provides a temperature-control cooling system for a large-size concrete structure and a cooling control method of the temperature-control cooling system, and relates to the technical field of large-size concrete construction by aiming at the problems that in the existing method, the arrangement blindness of cooling pipes is great, the inside temperature distribution rule of the concrete cannot be well combined, and the inside temperature reduction uniformity of the cooling pipes cannot be effectively controlled. Cooling water pipe units are horizontally arranged in a template, and comprise two cooling water pipe groups, the two cooling water pipe groups are staggered and overlapped, the cooling water pipes of the two cooling water pipe groups are parallel and are separately arranged, and the flowing directions of cooling circulation water in the adjacent cooling water pipes are opposite. The method comprises the following steps that 1, a finite element model is created, and in addition, the water thermalization analysis is carried out for judging the highest temperature difference and the temperature gradient; 2, the arrangement scheme of the cooling water pipe units is primarily determined; 3, the information of the arrangement scheme is substituted into the finite element model for analogue simulation, when the judging result is assertive, the construction is carried out according to the arrangement scheme, and when the judging result is negative, the arrangement and the flow rate of the cooling water pipe units are regulated until the requirements are met.

Owner:SHANGHAI CONSTRUCTION GROUP

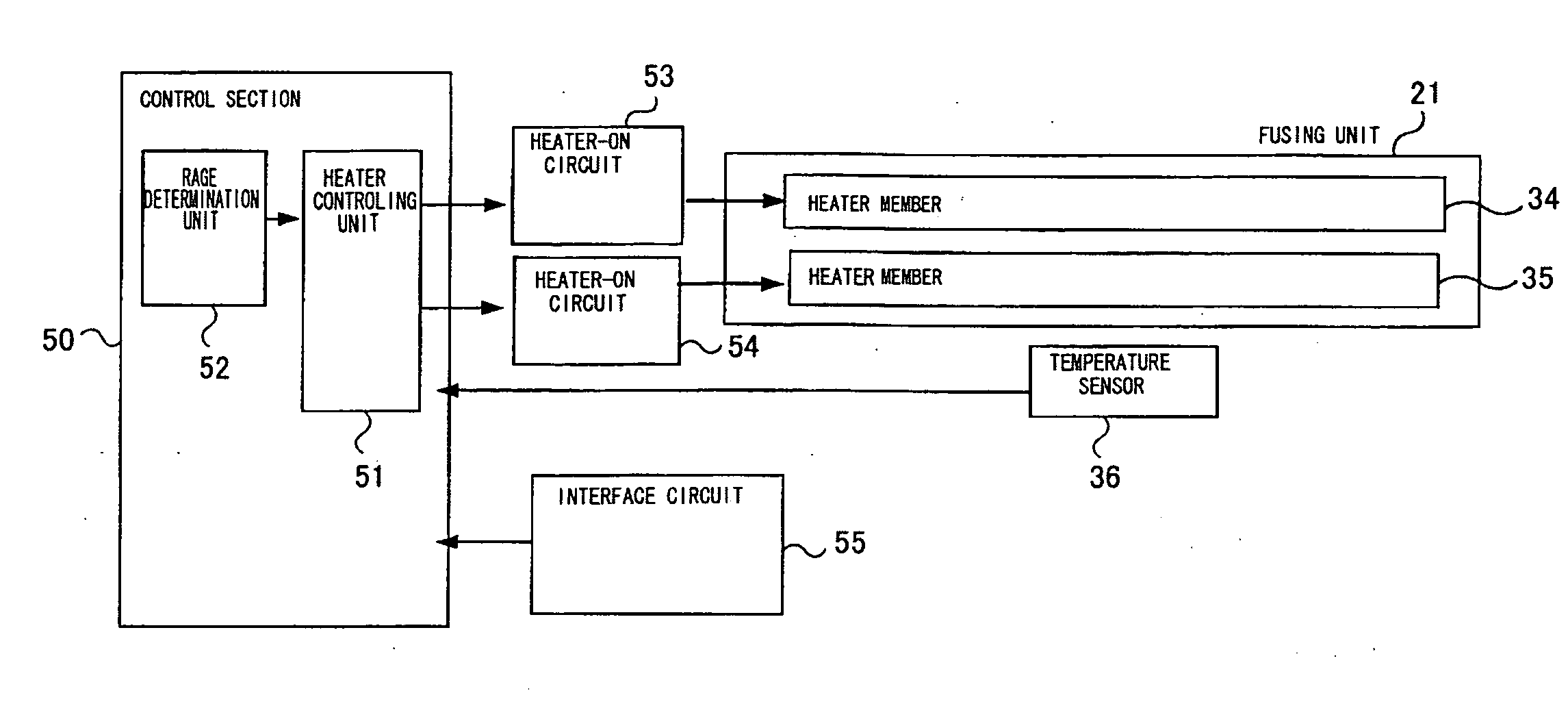

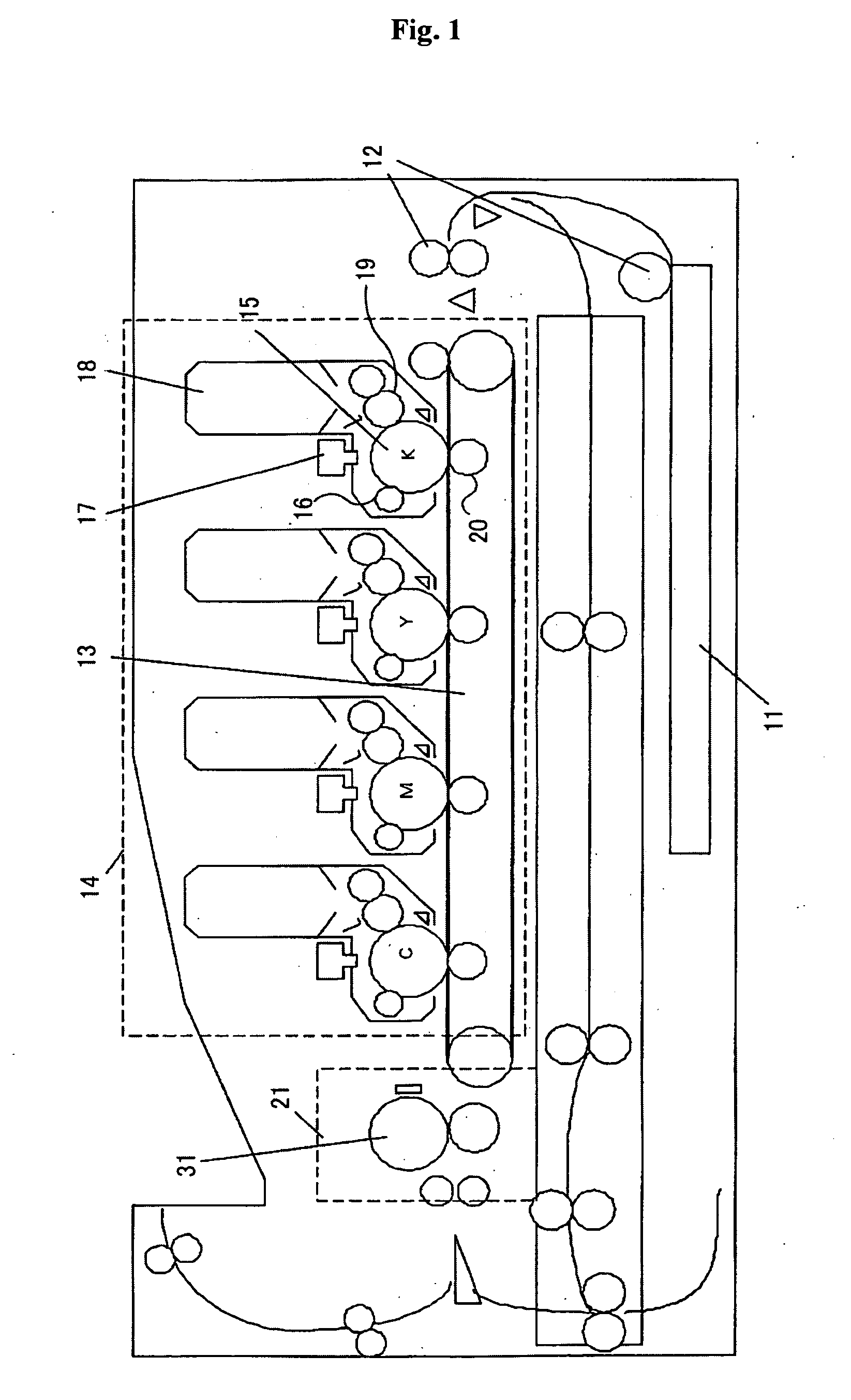

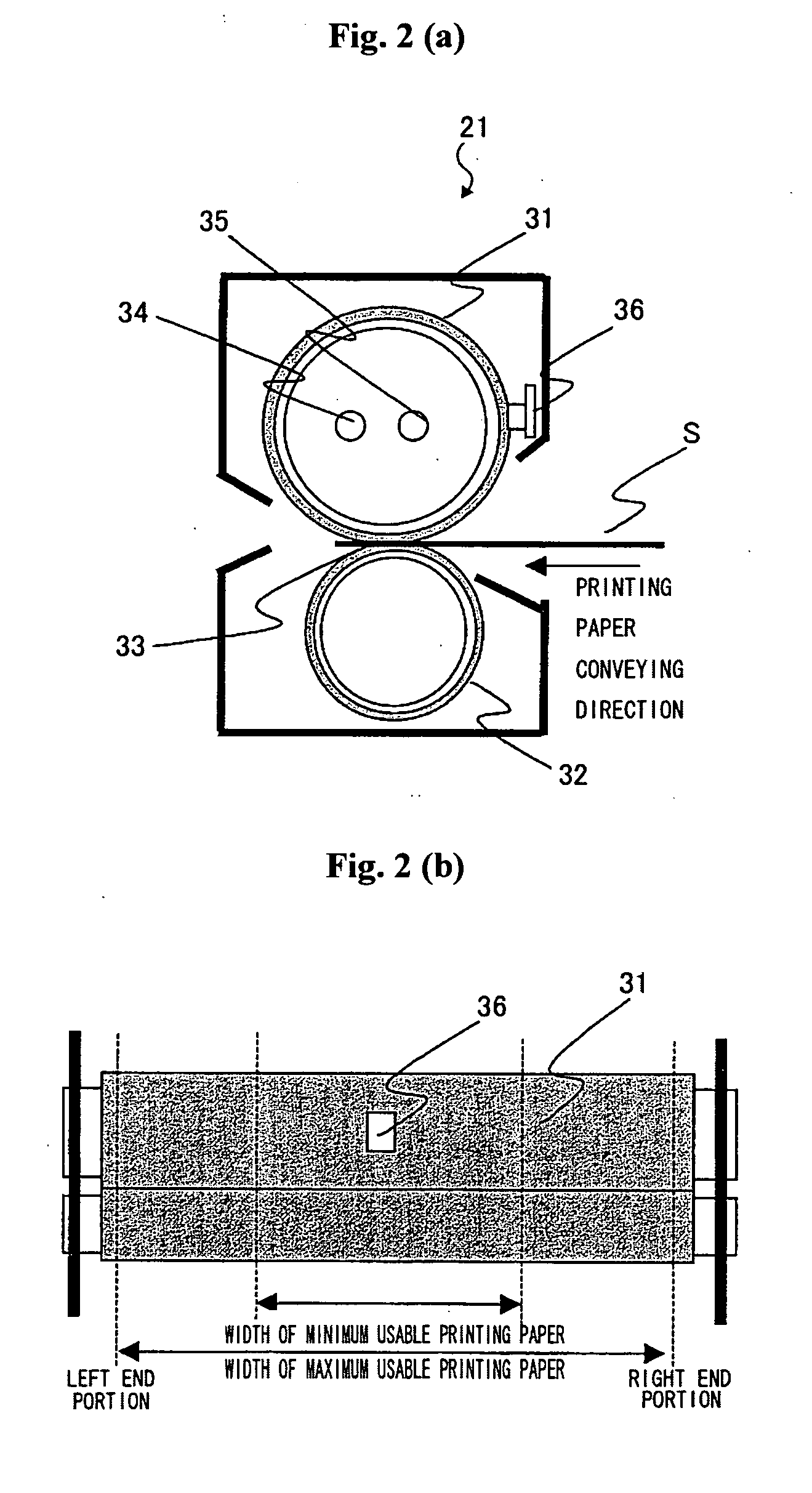

Image recording apparatus

InactiveUS20060204266A1Prevent any nonuniformityMinimize temperature differenceElectrographic process apparatusHeat distributionImage recording

A purpose of the present invention is to minimize a temperature difference between end portions and a central portion of a print medium caused by a difference of fusing conditions. The image recording apparatus according to the present invention includes a plurality of heater members 34, 35 having different heat distributions, a temperature detecting unit 36 for detecting a temperature of an area where a print medium passes through, a heat controlling unit 51 for controlling a fusing unit at a prescribed temperature by an individual heat controlling of the plurality of heater members on the basis of the temperature detected by the temperature detecting unit, a rate determination unit 52 for determining a divisional rate of heat amount to be charged per unit time to said fusing unit by means of said plurality of heater members. The rate determination unit determines the divisional rate of the heat amount to be charged per unit time to the fusing unit by means of the plurality of heater members on the basis of the fusing conditions input through a condition input unit and the heat controlling unit heat controls the plurality of heater members individually on the basis of the divisional rate determined by the rate determination unit.

Owner:OKI DATA CORP

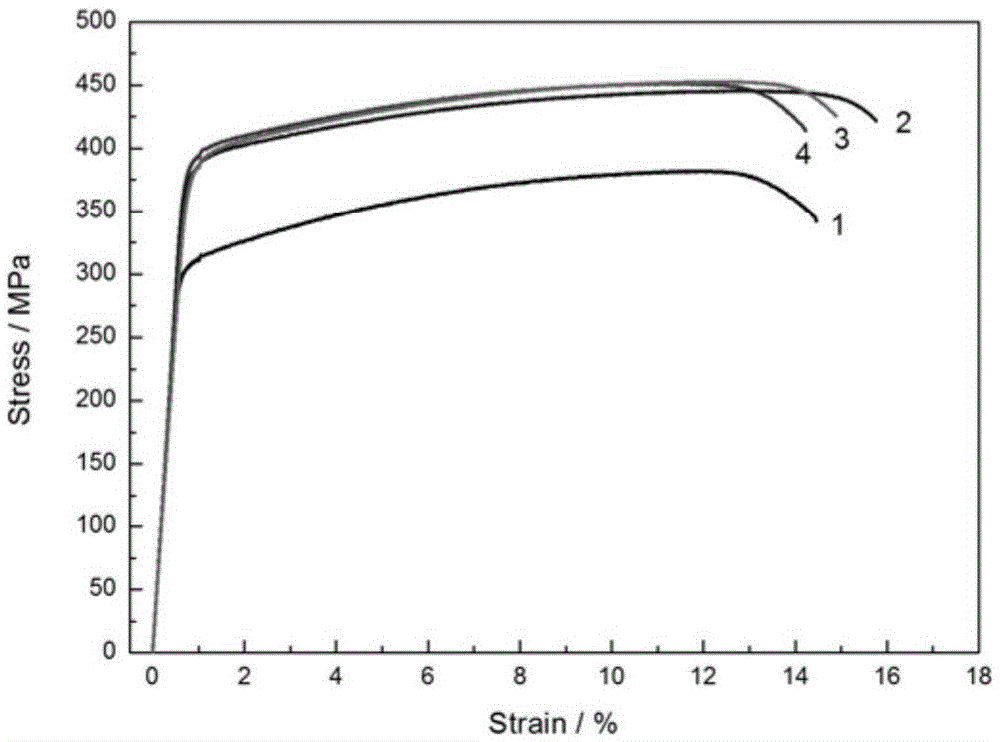

Heat treatment technique of thick-wall aluminum alloy hollow extruded section

ActiveCN105543742AReduce deformation energy storageEliminate internal stressCorrosion resistantDouble stage

The invention relates to a heat treatment technique of a thick-wall aluminum alloy hollow extruded section. After double-stage reinforced solution treatment is carried out on the aluminum alloy section, three-stage artificial aging is sequentially carried out. By adopting the double-stage reinforced solution treatment, part of soluble phases can be firstly dissolved, thereby lowering the stored energy of deformation of the alloy, eliminating most stress in the structure, and inhibiting the subsequent recrystallization and coarse crystal grains; and the second phase and insoluble phase in the structure are further dissolved, thereby enhancing the degree of supersaturation of the quenched alloy. The three-stage aging treatment is implemented by interrupting the traditional single-stage aging, so that the alloy has the structure characteristics of the dispersive and fine intracrystalline precipitated phase and the isolated and discontinuous grain boundary precipitated phase; and the three-stage aging treatment intercepts the intercrystalline corrosion channel and enhances the corrosion resistance of the alloy. Compared with the traditional technique, the technique provided by the invention enhances the strength of the aluminum alloy section by 15% or above on the premise of not lowering the plasticity, obviously improves the corrosion resistance, and is simple and easy to implement and convenient for industrial production. The technique is especially suitable for heat treatment reinforcement of aluminum alloy hollow extruded sections for rail transit.

Owner:CENT SOUTH UNIV

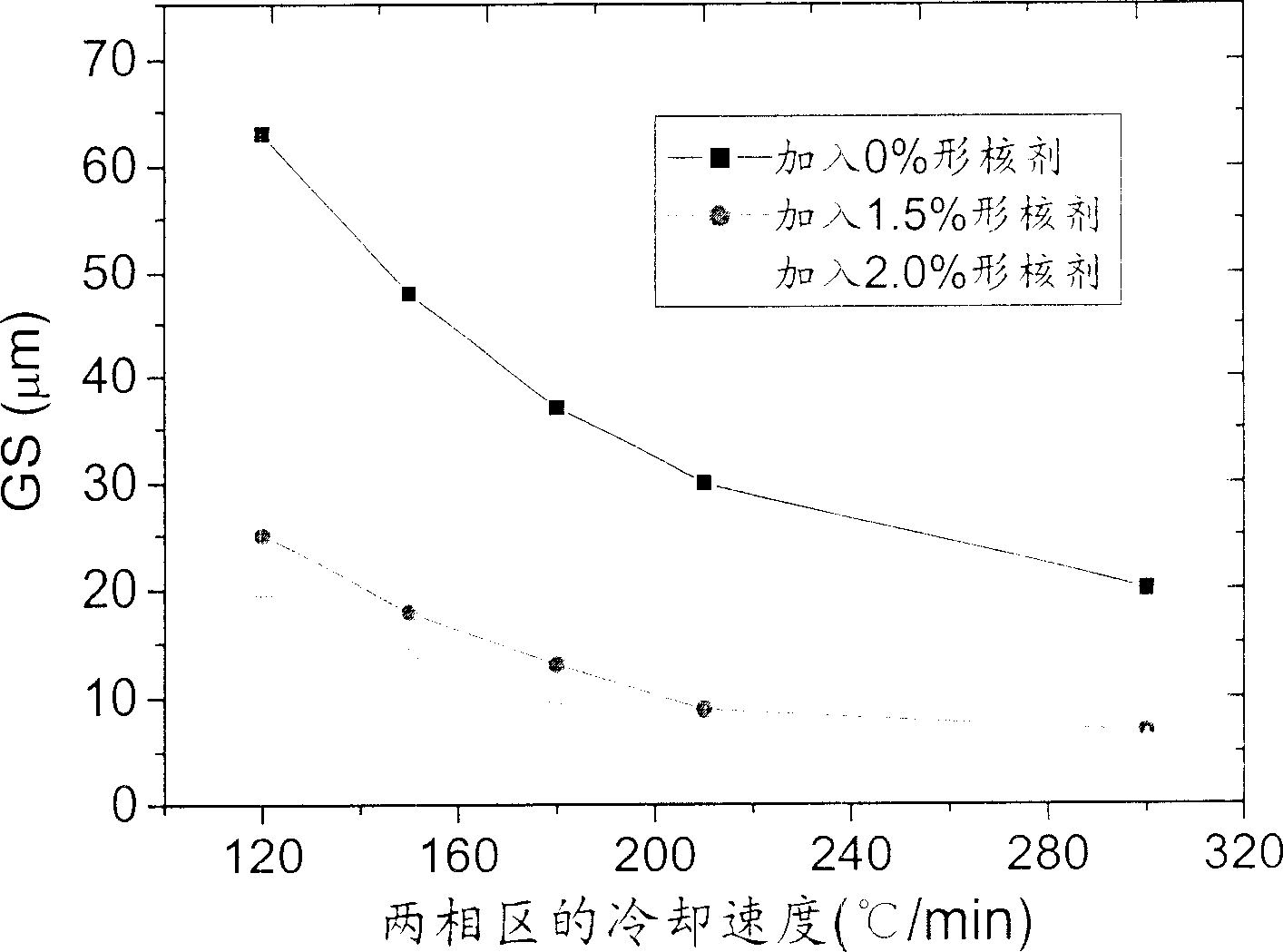

Manufacture method for obtaining superfine crystal grain steel

A manufacturing method for super fine crystal grain steel including the following steps: smelting in terms of the following composition and weight percentage: C0.02~0.20%, Nb 0.01~0.10%, Si 0.80%, Mn1.0~2.0%, Ti0.08~0.025%, Als is not greater than 0.20%, casting: the temperature for pouring is lower than or equal to +20deg.c nucleation agent is added when pouring, the cooling speed of the steel melt is greater than or equal to 180deg.c / min, the strand crystal grain is smaller than 15mum, rolling: heating it to over AC3 then to cool it to about Ar3 to continuously un-re crystallization to control the rolling, the accumulated step-down rate is greater than 80%, cooling: cooling it to below 450deg.C then cooling it naturally to the room temperature to get ferrite crystal grains smaller than 3.0mum.

Owner:BAOSHAN IRON & STEEL CO LTD

Optical film with sharpened bandedge

InactiveCN1288520AMelt viscosity reasonably matchedAdequate interfacial adhesionOptical articlesOptical elementsEngineeringRepeat unit

Owner:3M CO

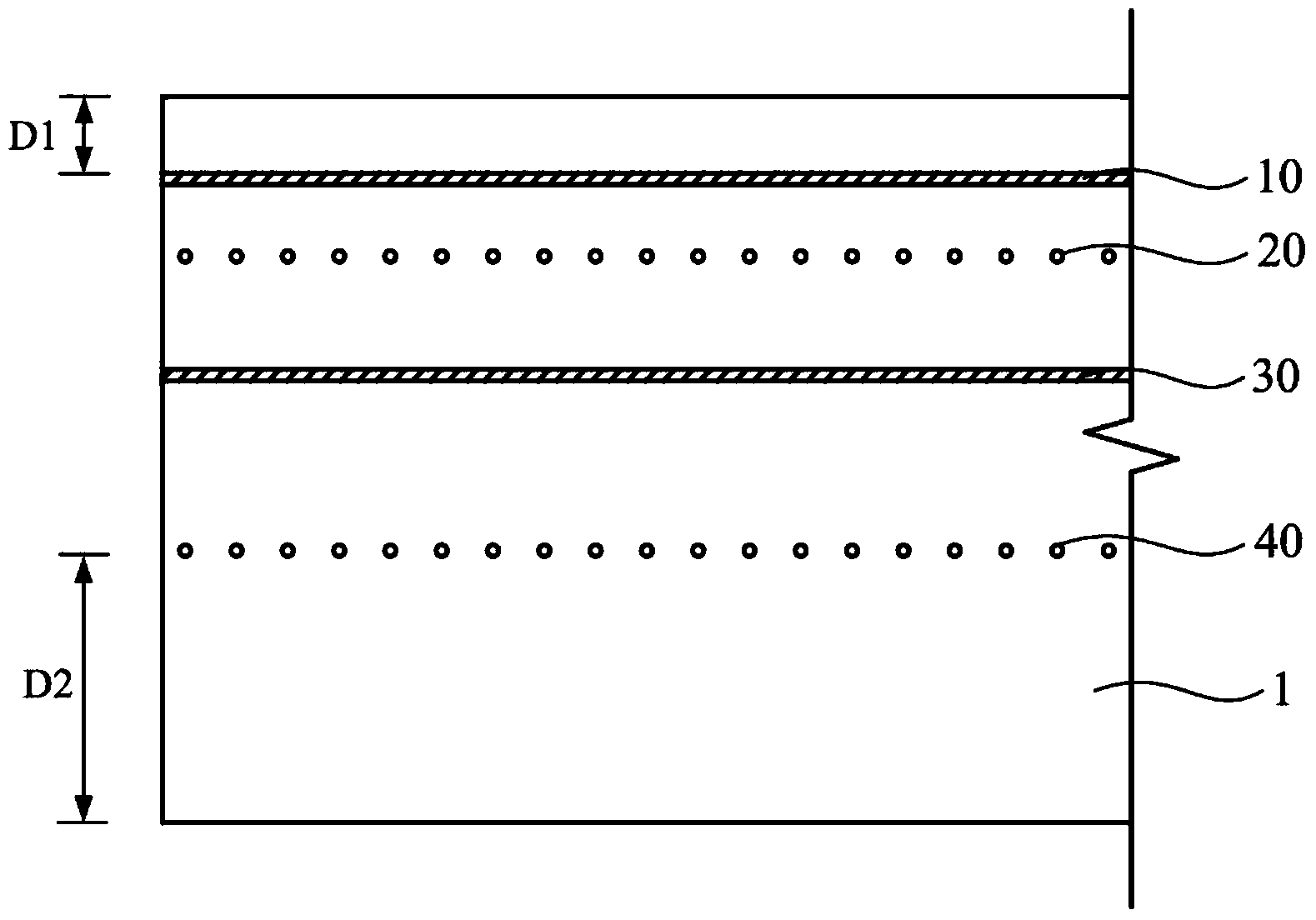

Lithium ion battery separator, preparation method thereof and lithium ion battery

InactiveCN108417762AStrong effectNot easy to fall offSecondary cellsCell component detailsThermal shrinkageLithium electrode

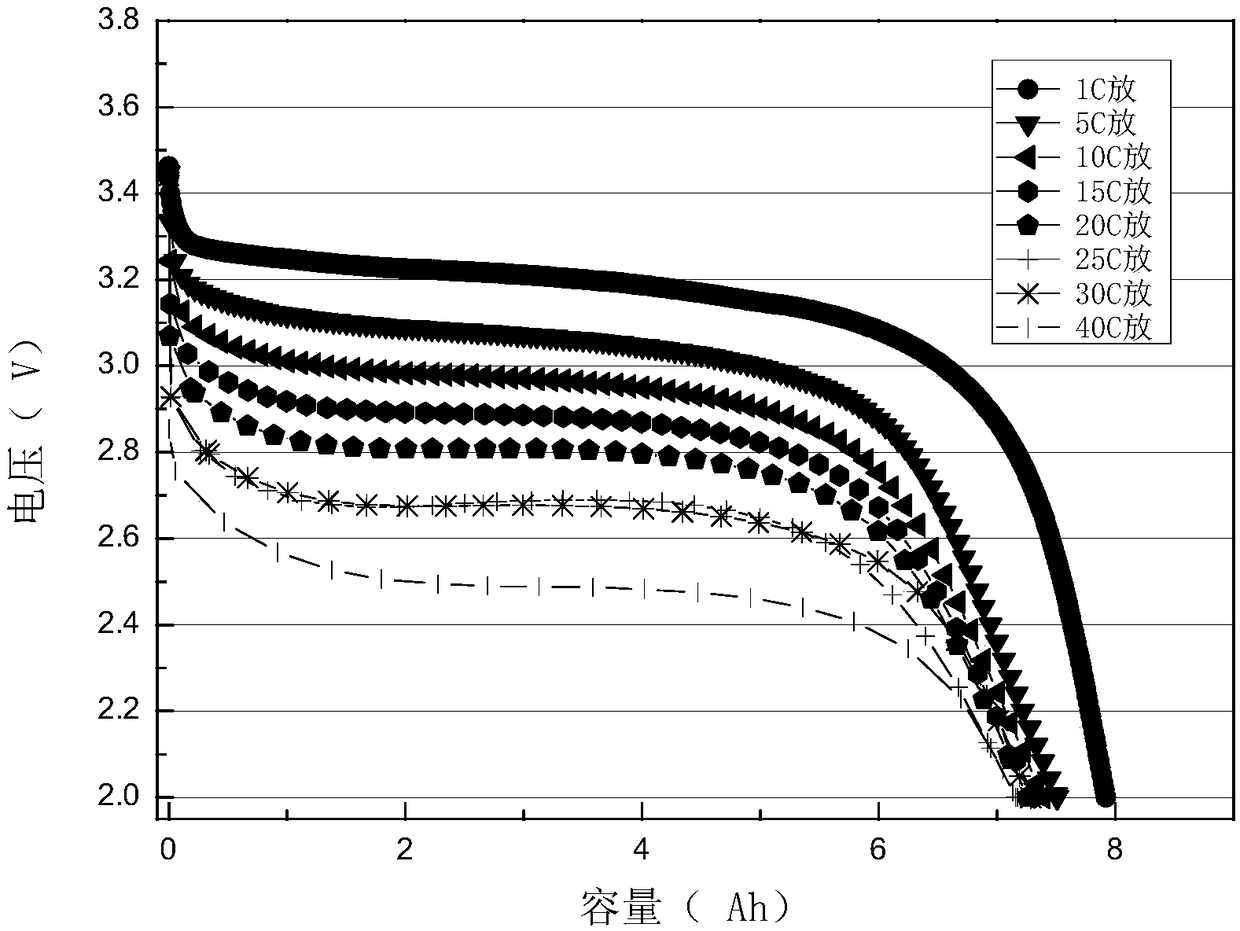

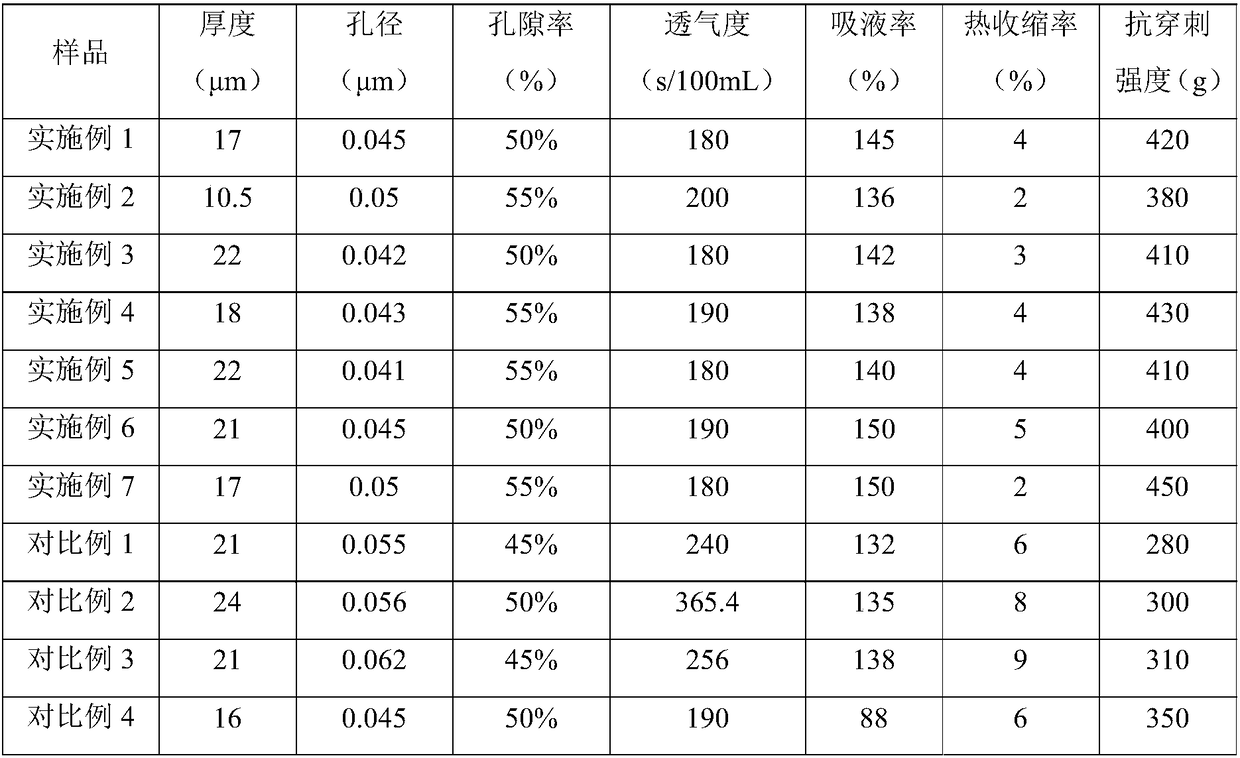

The invention discloses a lithium ion battery separator, a preparation method thereof and a lithium ion battery, and relates to the technical field of lithium ion batteries. The lithium ion battery separator comprises a PP / PE / PP porous film substrate and a cyclodextrin polymer layer. The preparation method of the lithium ion battery separator comprises the following steps of uniformly coating cyclodextrin polymer paste on the PP / PE / PP porous film substrate to form a cyclodextrin polymer layer, and obtaining the lithium ion battery separator after drying, wherein the cyclodextrin polymer pastecomprises a cyclodextrin polymer and water. By the lithium ion battery separator and the preparation method thereof, the defects that a traditional separator matrix material is not resistant to high temperature and is poor in safety and a ceramic coating separator is easy to damage are overcome, the cyclodextrin polymer layer of the lithium ion battery is difficult to fall off, and the coated separator has relatively good electrochemical performance and mechanical property, is low in thermal shrinkage rate and good in safety and is suitable for high-rate charging and discharging.

Owner:BEIJING NAT BATTERY TECH

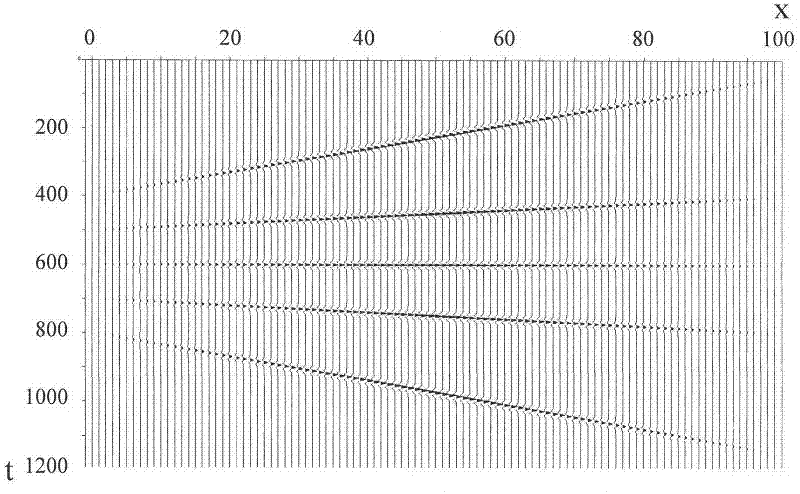

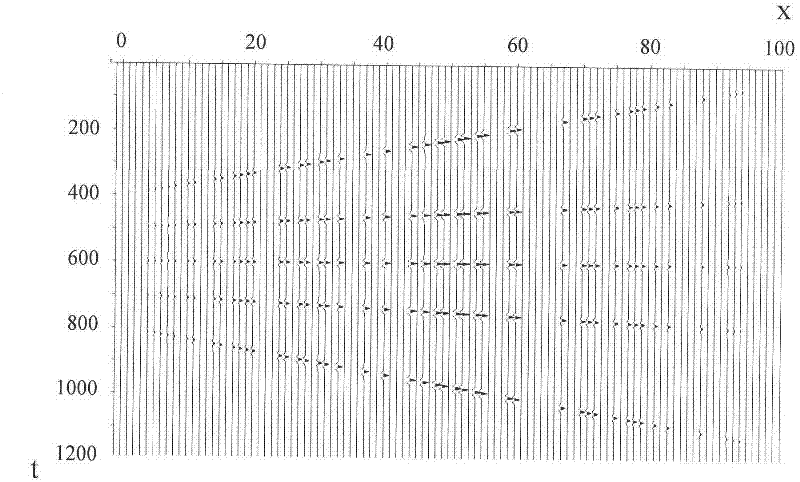

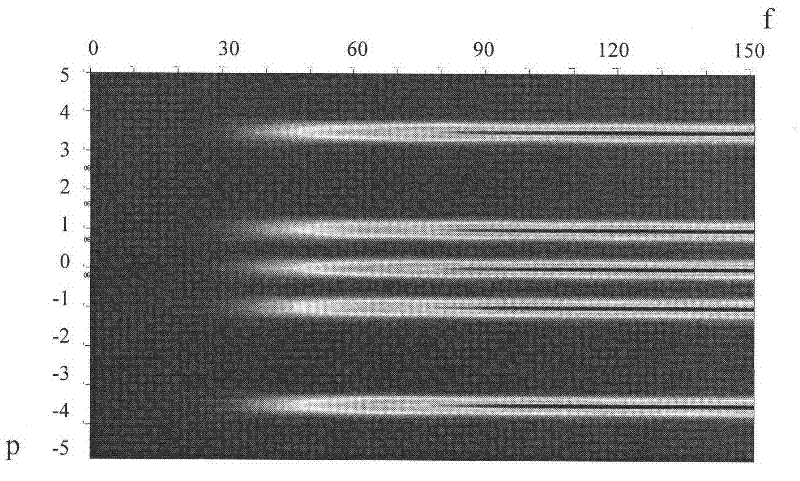

A Regularization Method for High-Dimensional Seismic Data Constrained by Radon Spectrum

InactiveCN102288994AImprove computing efficiencyOvercoming spatial aliasingSeismic signal processingWavefrontOriginal data

The invention discloses a method for regularizing high-dimensional seismic data under the constraint of a Radon spectrum. The method comprises the following steps of: acquiring original data of a wavefront of a section of plane wave; calculating a covariance matrix CD of a data space corresponding to seismic data; calculating a covariance matrix CM of a model space among energy of various wave number components in a spectrum of the seismic data (f, k); and constructing a target function by using the covariance matrix CD of the data space and the covariance matrix CM of the model space, and calculating the regularized seismic data. In the invention, the data are not required to be covered uniformly, so the method has higher applicability; false frequency components in the data can be removed effectively under the constraint of the Radon spectrum, so that the space false frequency problem of the data is solved; moreover, the method has higher calculation efficiency and can be applied toactual production more easily.

Owner:CHINA NAT OFFSHORE OIL CORP +2

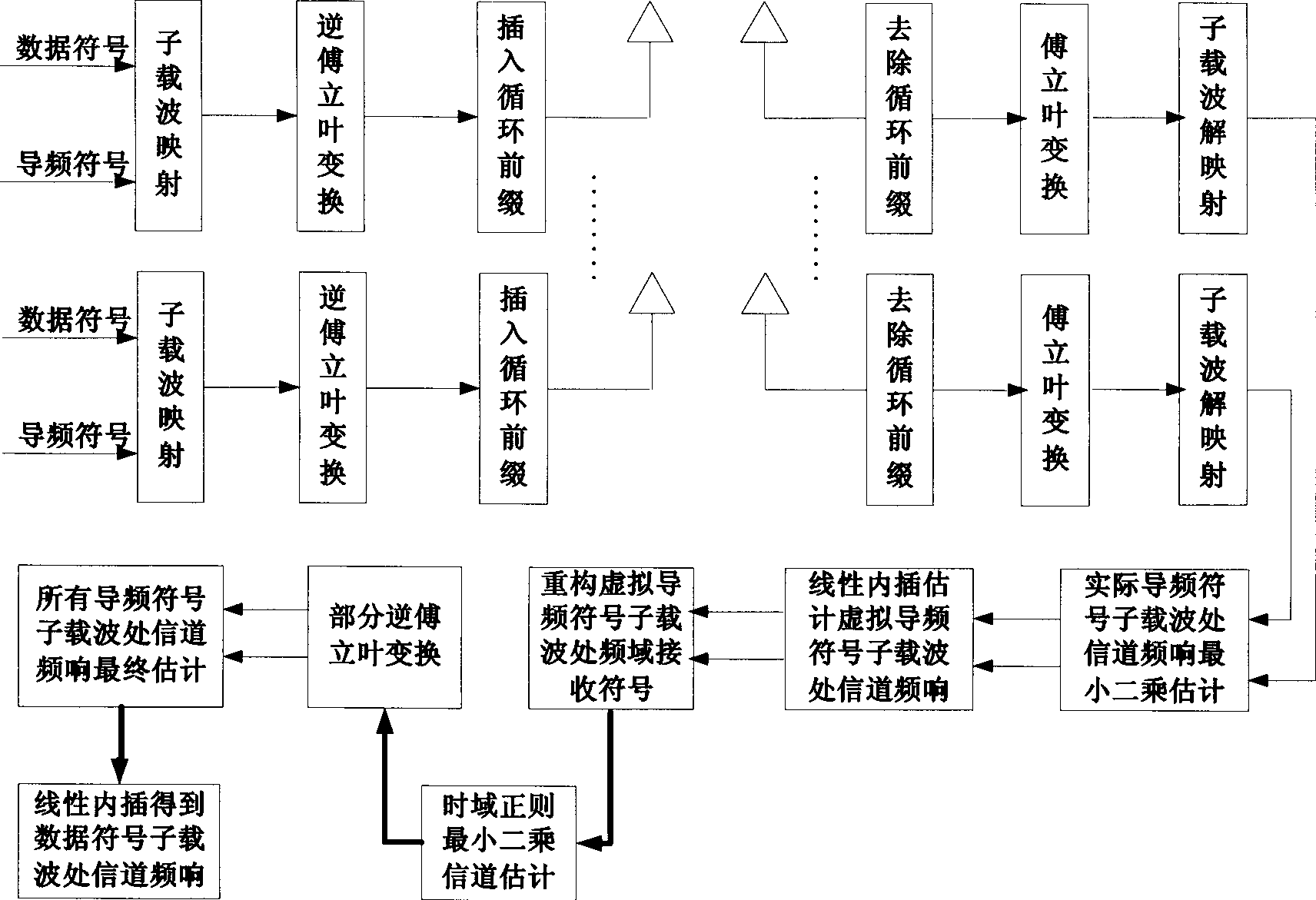

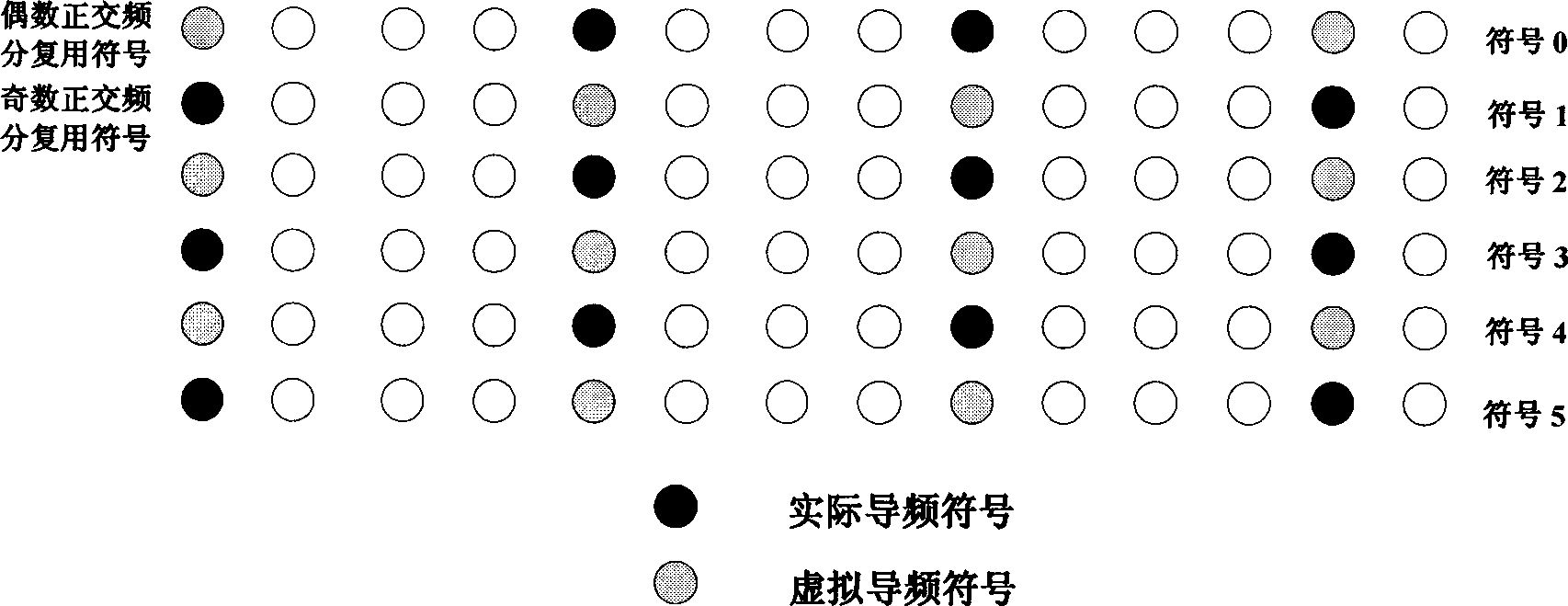

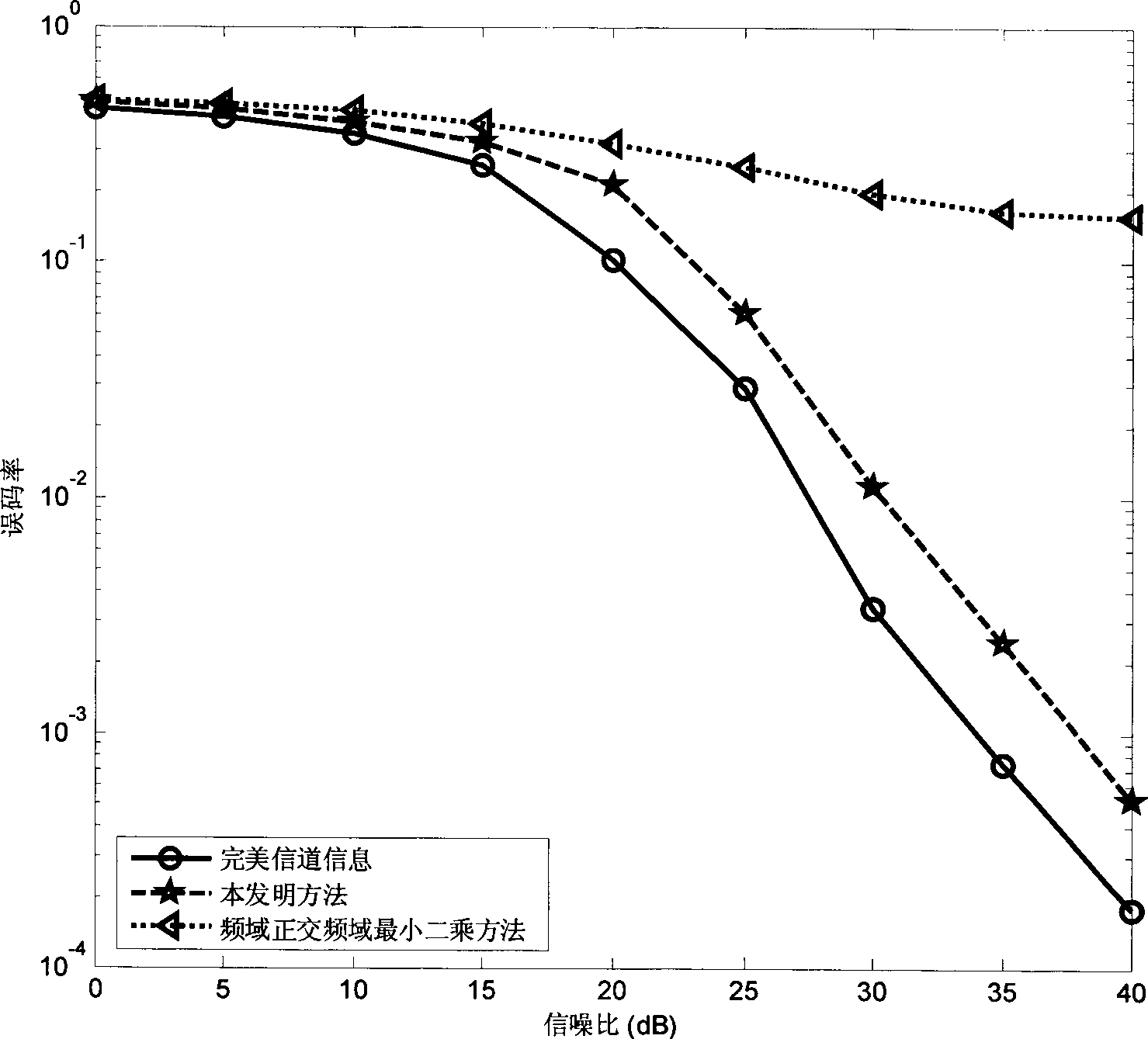

Time-domain channel estimation method for MIMO OFDM downlink system

InactiveCN101364966AHigh precisionAvoid inhomogeneityMulti-frequency code systemsTransmitter/receiver shaping networksCarrier signalFourier transform on finite groups

The invention relates to a time domain channel estimation method of a multiple-input multiple-output orthogonal frequency-division multiplexing down system. A pilot frequency symbol sequence using orthogonal virtual pilot frequency symbol and code domain is assumed to be used; firstly, a receiving terminal estimates the frequency response of each sub-channel at the actual pilot frequency symbol sub-carrier; then, the channel estimation for the virtual pilot frequency symbol sub-carrier is obtained through the linear interpolation of channel estimation of adjacent symbols used for orthogonal frequency division; the received symbol is re-constructed by utilizing the virtual pilot frequency symbol and the channel estimation thereof, the impulse response estimation of each sub-channel is obtained by ranking the received symbol of the actual pilot frequency symbol sub-carrier in ascending order according to the index value of the sub-carrier and then applying the least square method for time domain regularization, and the channel estimation of all the pilot frequency symbol sub-carriers is obtained after partial Fourier transformation; and finally, the channel frequency response of each user data symbol sub-carrier is obtained through the linear interpolation of channel estimation of the pilot frequency symbol sub-carrier. The invention has the advantages that the channel estimation precision is high, and larger quantity of transmitting antenna can be supported.

Owner:HENAN UNIV OF SCI & TECH

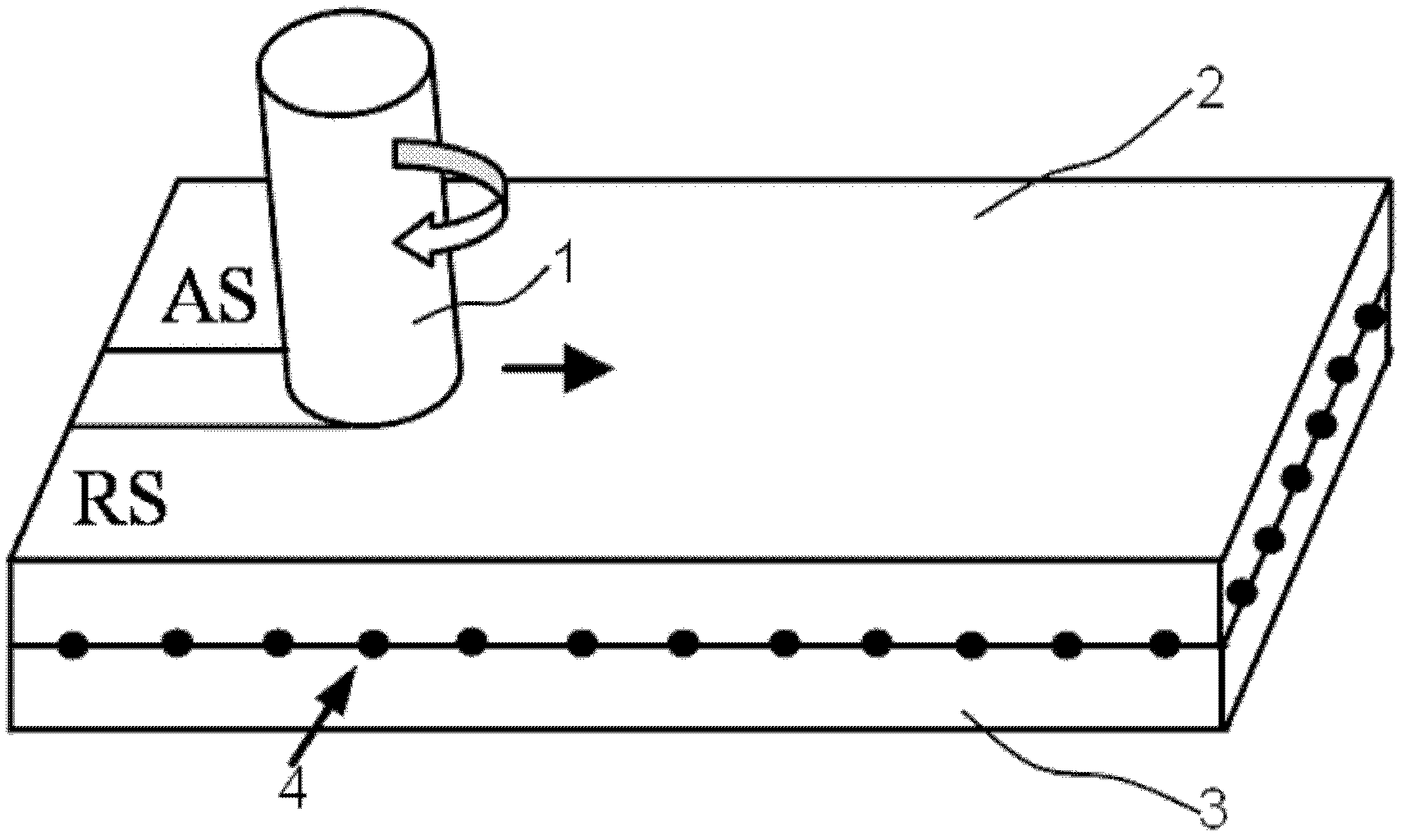

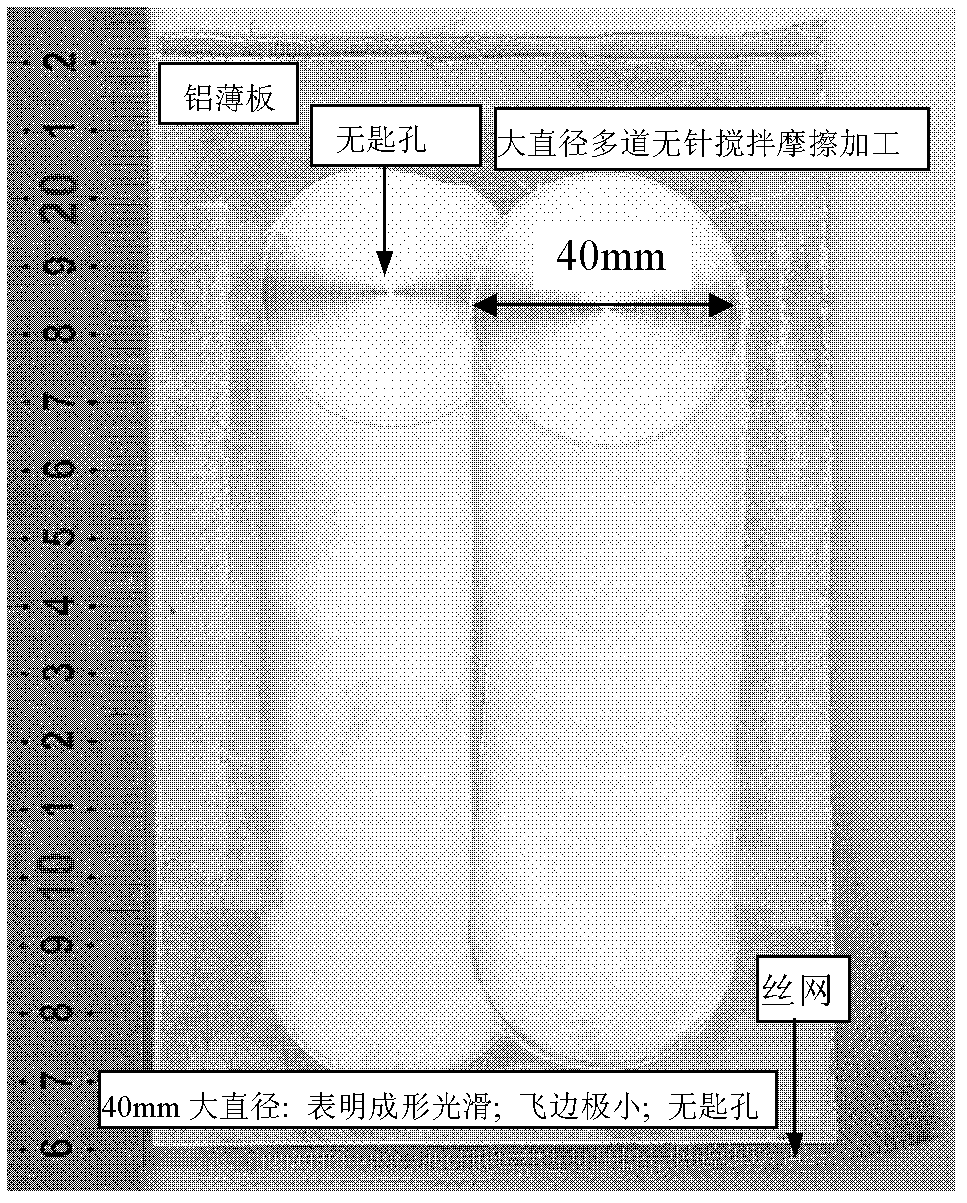

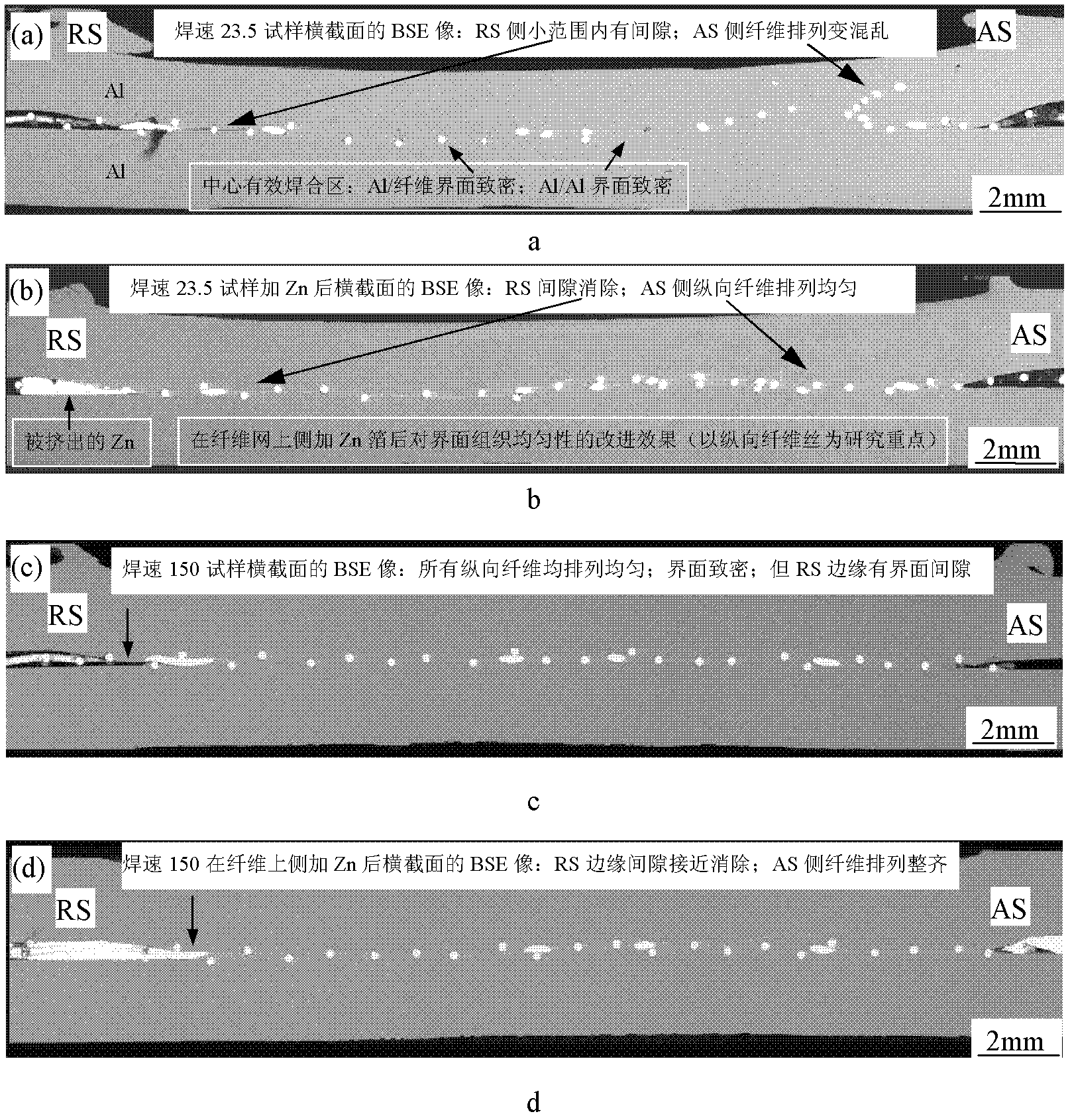

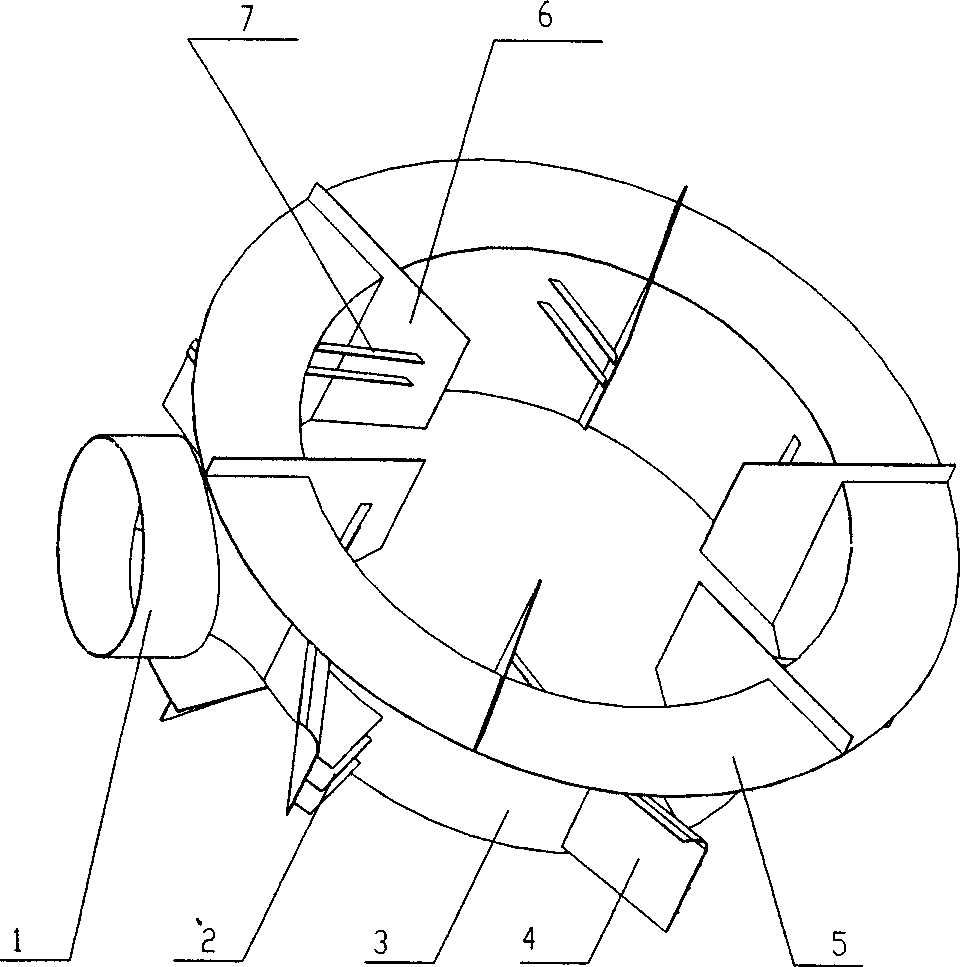

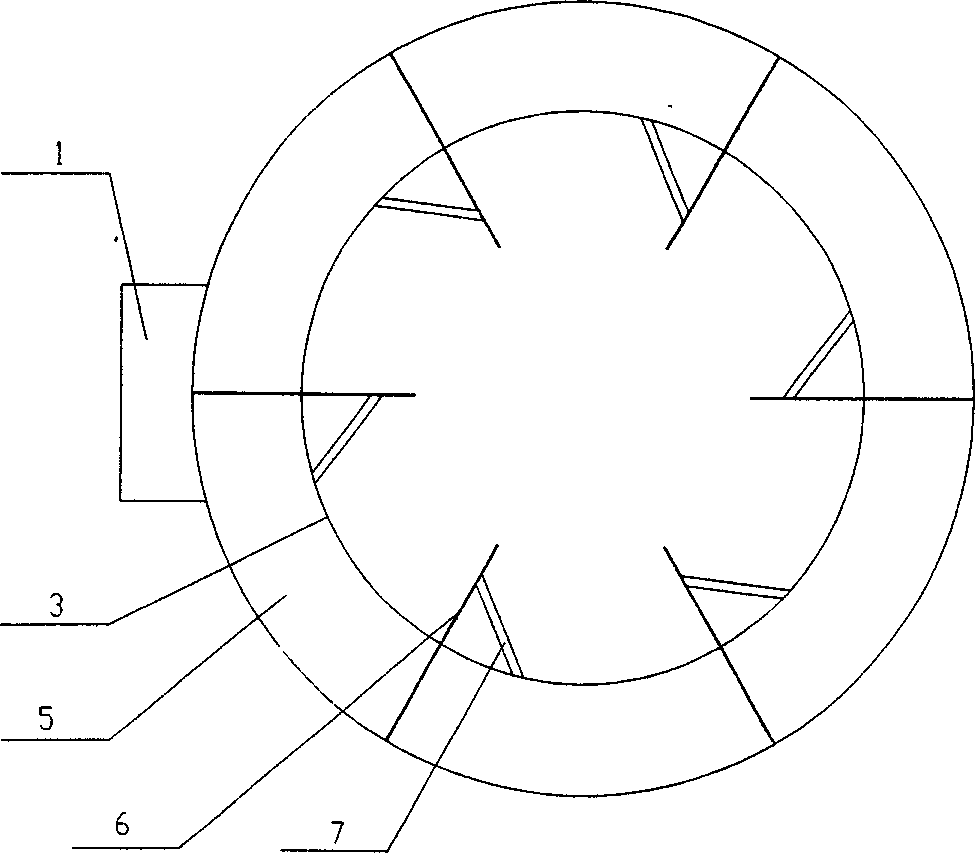

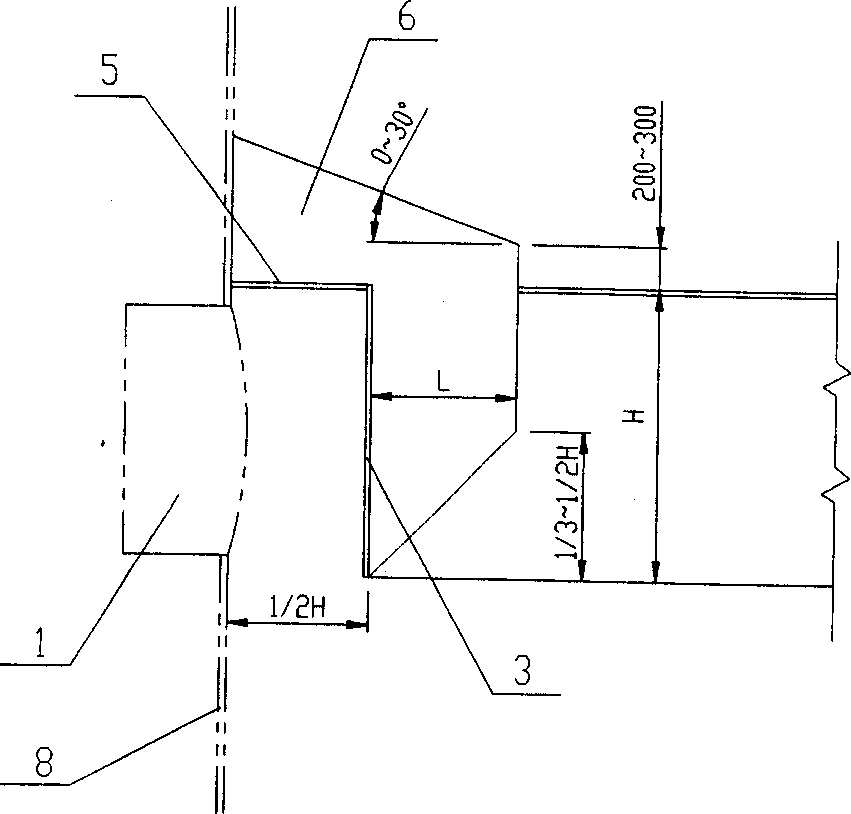

Large-diameter multi-pass pin-less friction stir processing method for fabricating fiber-reinforced metal matrix composites

InactiveCN102319954AImprove plastic fluidityClose contactNon-electric welding apparatusFiber bundleMetal matrix composite

The invention discloses a large-diameter multi-pass pin-less friction stir processing method for fabricating fiber-reinforced metal matrix composites. Firstly, metal matrix sheets are ground and cleaned in advance; secondly, a preprocessed fiber net or unidirectional fiber bundle is clamped between the two metal matrix sheets in a prearranging manner, and needs to be completely covered and sufficiently protected by the covering sheets; meanwhile, a pin-less friction stir tool is slightly inclined and mounted; the pin-less stool is started to rotate to rub the surface of the covering sheet and move, a plastic deformation gradient field generated by the forging and torsional effects of the shoulder is utilized, consequently, not only can the oxide skin of the metal matrix interface be broken, but also the metal matrix which heats to be softened can plastically flow around the fibers to wrap the fibers, and thereby the fiber / matrix and the matrix / matrix interfaces can be compactly combined. A pin-less stir head with a large diameter more than 40mm to 50mm is adopted to carry out multi-pass multi-layer friction stir processing, and thereby a large, thick fiber-reinforced metal matrix composite plate can be produced. The addition of brazing filler metal can solve the contradiction between fiber injury and interface bonding improvement.

Owner:XI AN JIAOTONG UNIV

Feeding distributor with anti-eddy flow baffle plate

InactiveCN1843567AEliminate relative rotationEliminate entrainmentDispersed particle separationDistillation separationEngineeringTower

The invention provides a feeding distributor with anti-cyclone baffle plate, which comprises an inner muffle, a cover plate, a guide plate and an anti-cyclone baffle plate. Wherein, the guide plate is arranged between the tower wall and the inner muffle; the surface of guide plate that back to the inlet has a strengthen bar; the anti-cyclone baffle plate is arranged at the inner side of inner muffle whose side surface has a tie-bar; another end of tie-bar is fixed on the inner muffle; the cover plate is annular at the top of inner muffle whose one end is fixed on the tower wall and another end is fixed on the inner muffle; the baffle plate is used to resist the revolution of ascending airflow to reduce the entrainment on the liquid and distribute the ascending airflow. The invention has the advantages that: it can eliminate the airflow revolution caused by cyclone material feeding and eliminate the entrainment on the liquid drops, to avoid the non-uniformity of gas caused by the break of flow area and speed.

Owner:TIANJIN UNIV

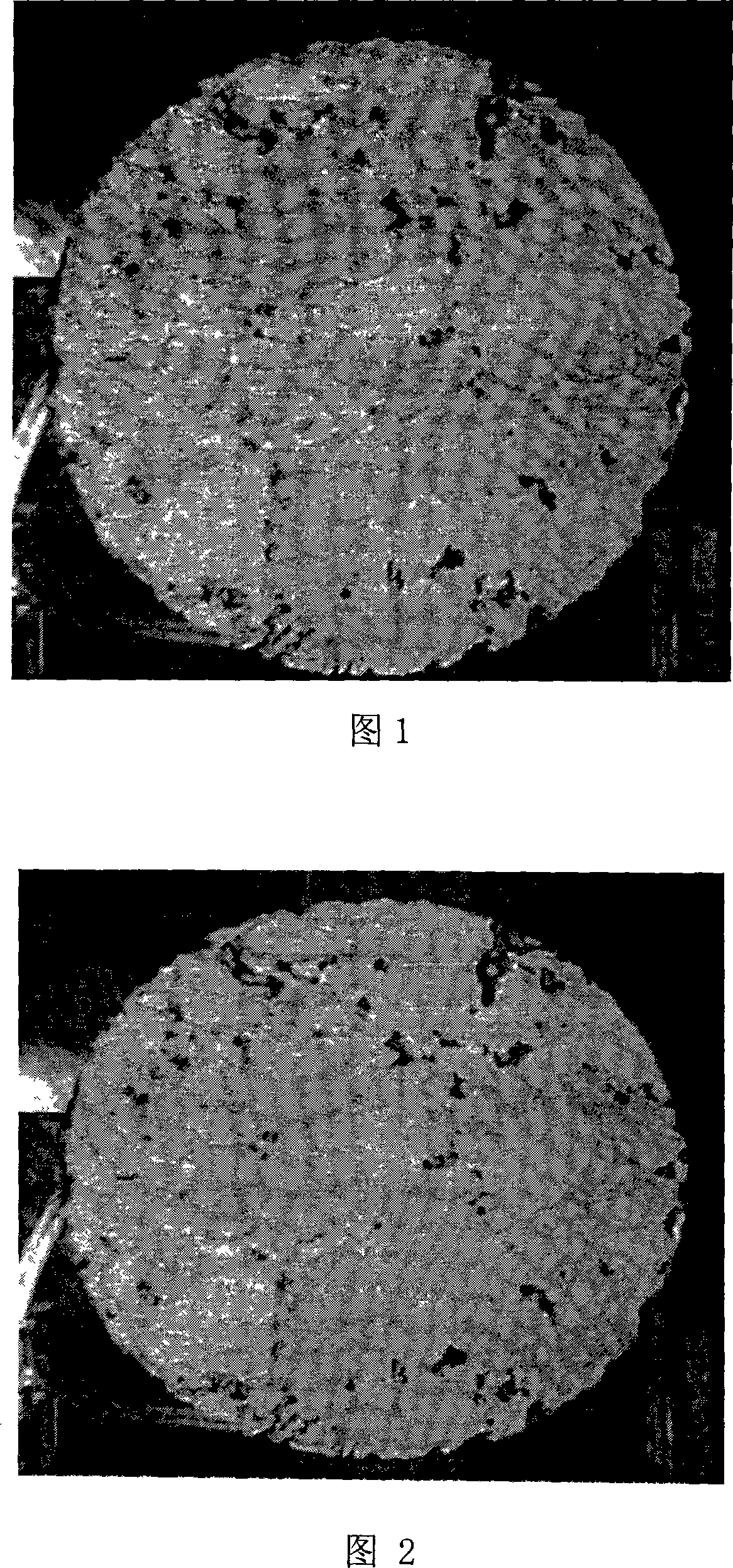

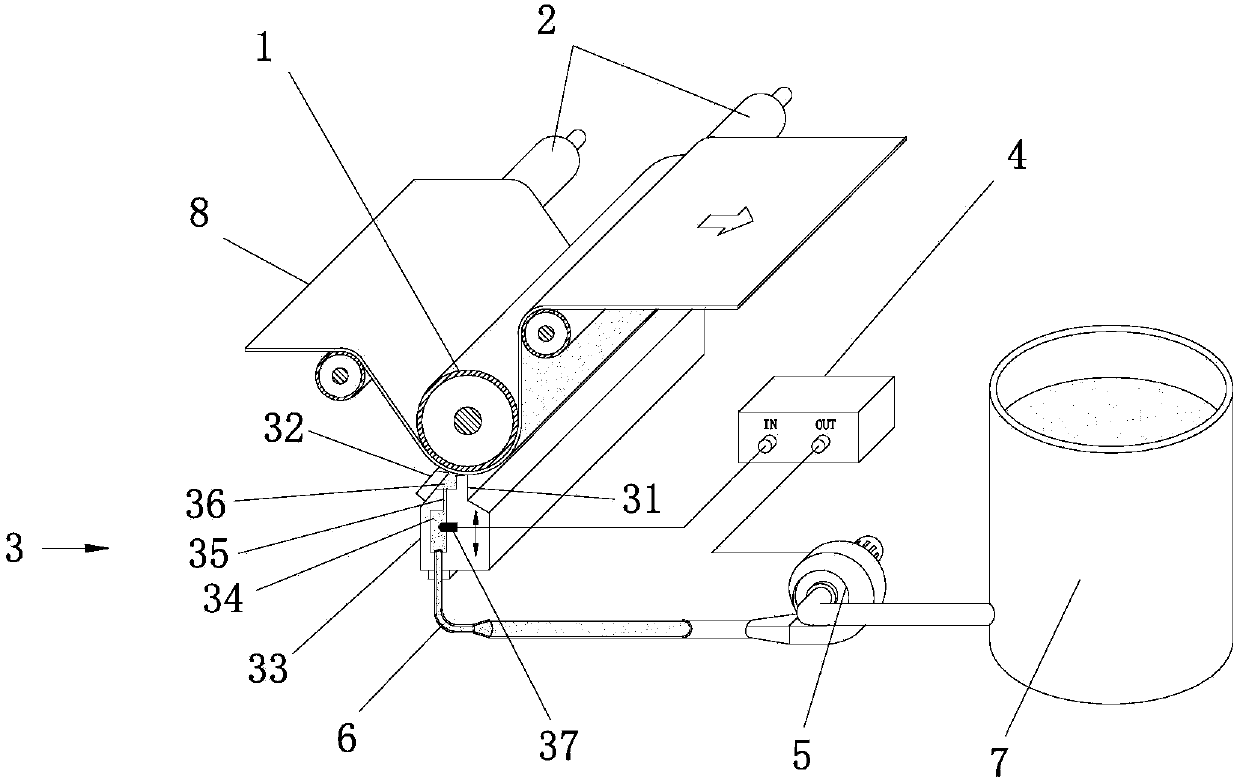

Non-contact type measurement indirect tensile strain method

InactiveCN101182994AHigh measurement accuracySimple stepsUsing optical meansTensile strainContact type

The invention provides a non-contact measuring method of indirect stretching strain and relates to a measuring method of stretching strain. The invention solves the problems that the prior measuring method of indirect stretching strain has low accuracy, small measuring range, limited measuring area, etc. In invention, the end surface of the measured component is artificially variegated and the image information of the artificial variegated end surface is recorded by a CCD camera in the loaded process of the measured component, and then the interrelated digital variegation method is adopted to analyze the image information, therefore, the strain information of the artificial variegated end surface of the measured component can be acquired. The invention adopts the developed interrelated digital variegation method of the prior art as the basis and combines the interrelated digital variegation method with the indirect stretching test, therefore, a novel measuring method of indirect stretching strain can be formed; the invention can be applied in the occasion with the requirement of measuring indirect stretching strain.

Owner:HARBIN INST OF TECH

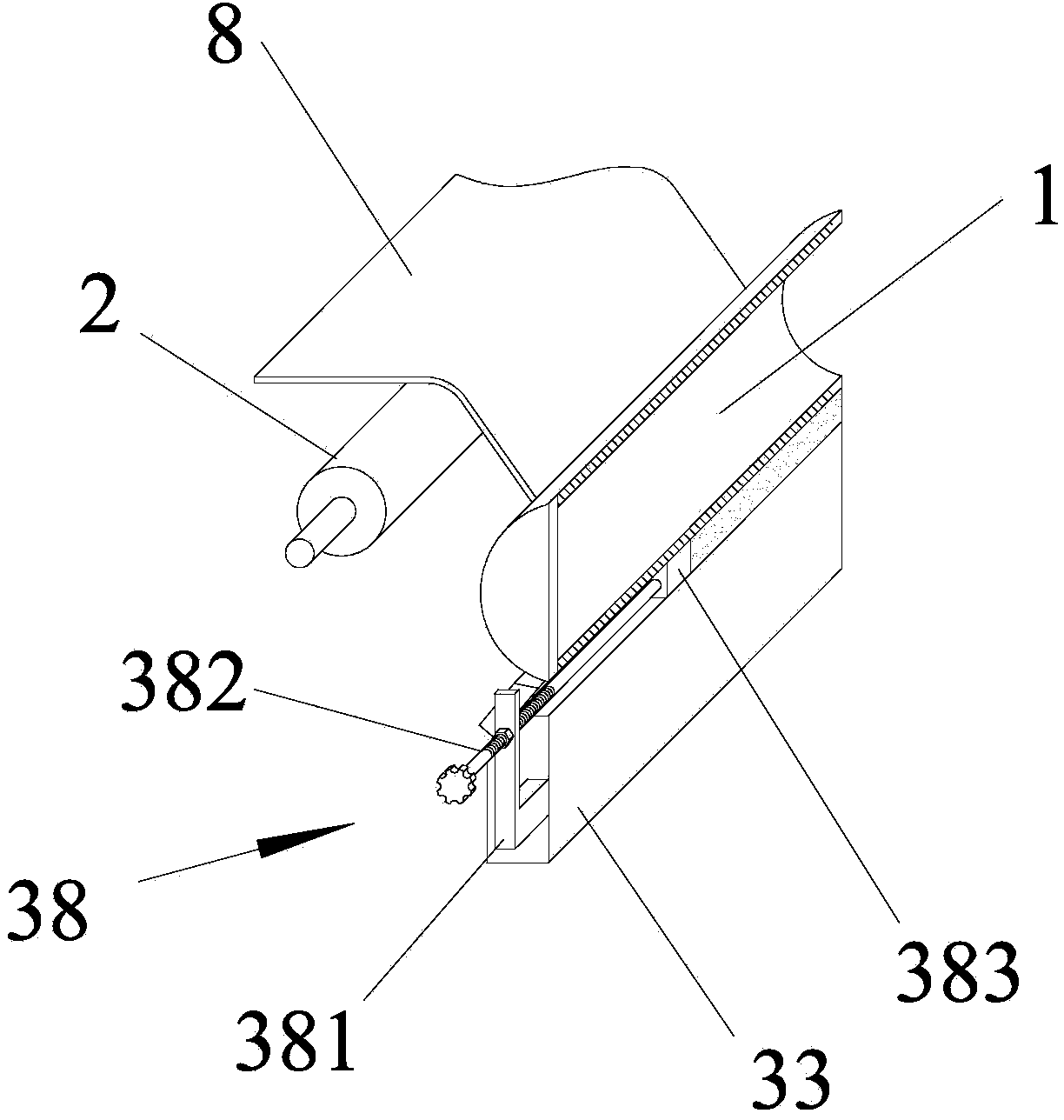

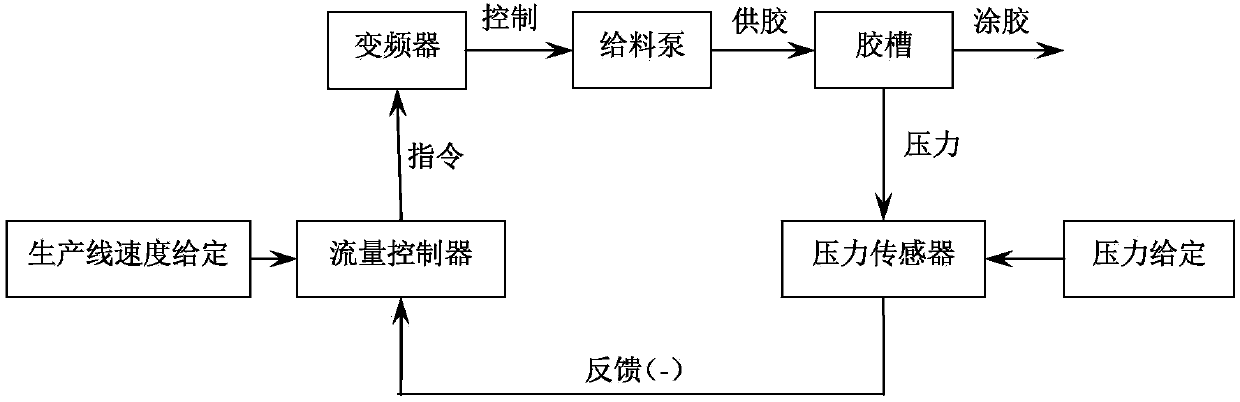

Quantitative gluing amount control device

ActiveCN104190597AAccurate amount of glueAccurate UniformityLiquid surface applicatorsCoatingsProduction lineAgricultural engineering

The invention discloses a quantitative gluing amount control device. The control device comprises a coating roller and auxiliary rollers arranged at two sides of the coating roller, wherein the coating roller is provided with a displacement sensor. The control device also comprises a scraper component arranged below the coating roller, wherein the scraper component is composed of a front scraper, a back scraper and a scraper holder; a feeding groove is formed between the front scraper and the back scraper; a feeding cavity is formed among the front scraper, the back scraper and the coating roller; a glue groove is formed inside the scraper holder; the upper part of the glue groove is communicated with the feeding groove through a glue solution channel, and the lower part of the glue groove is connected with a glue storage tank via a feeding pump through a feeding pipe; a substrate to be coated is placed in the feeding cavity so as to be coated, and the gap between the front scraper and the coating roller, and the gap between the back scraper and the coating roller are adjusted by the front scraper and the back scraper moving along the vertical direction. The control device is capable of accurately controlling the gluing amount and the gluing uniformity, and automatically adjusting the feeding flow according to the change of the gluing amount or the speed of a production line.

Owner:苏州市益维高机器制造有限公司

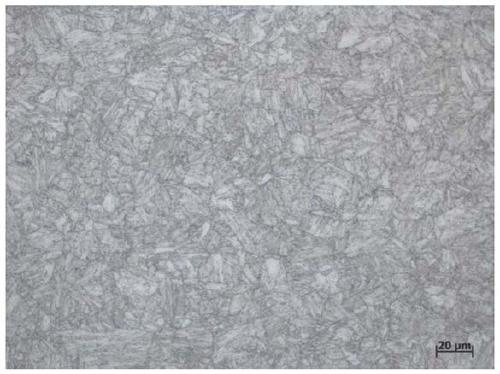

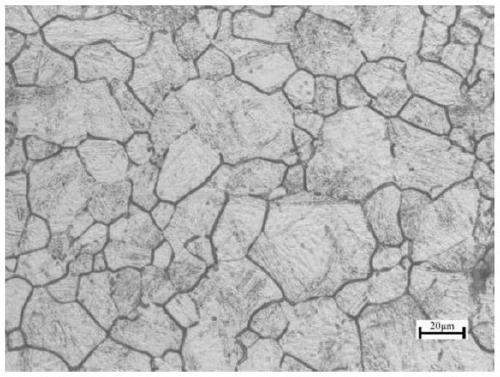

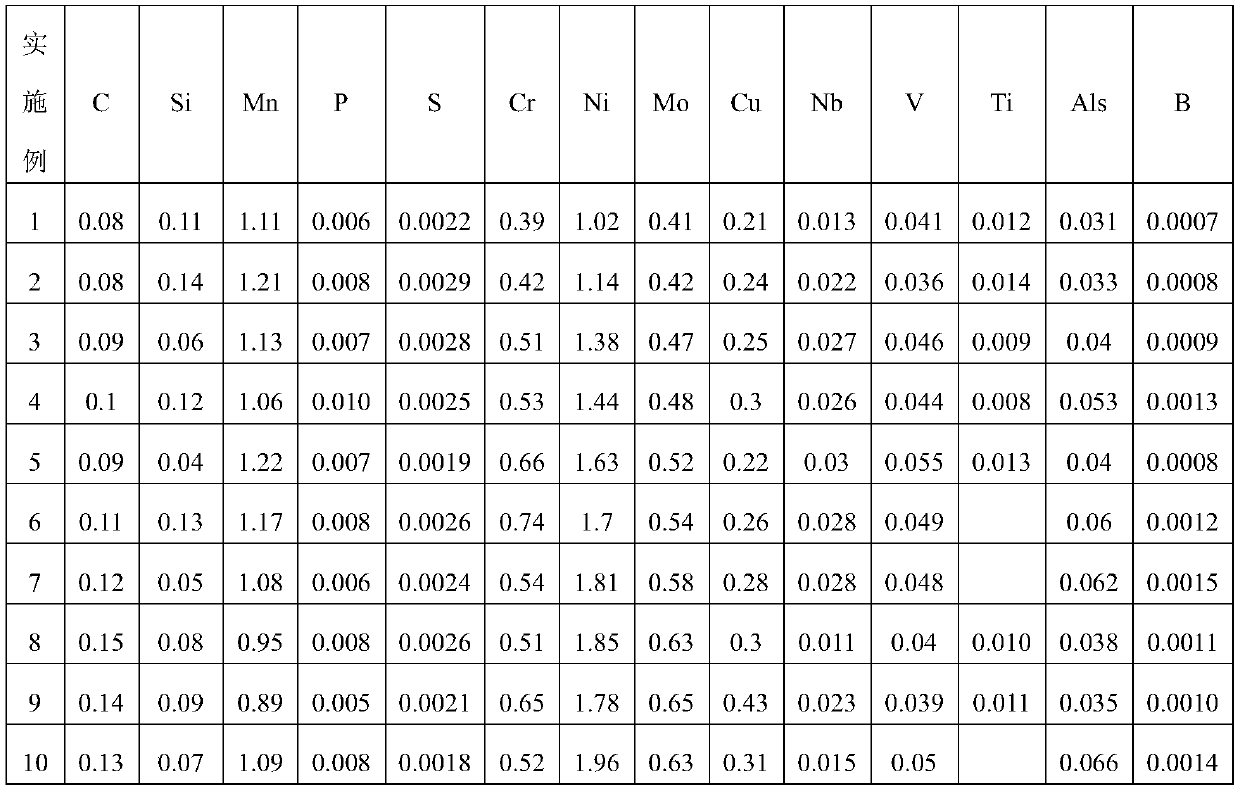

Ultrahigh-strength maritime steel plate with yield strength of 960MPa and manufacturing method thereof

The invention discloses an ultrahigh-strength maritime steel plate with the yield strength of 960MPa and a manufacturing method thereof. Steel comprises, 0.07%-0.15% of C, 0.02%-0.15% of Si, 0.80%-1.30% of Mn, no more than 0.010% of P, no more than 0.003% of S, 0.35%-0.80% of Cr, 1.00%-2.00% of Ni, 0.40%-0.70% of Mo, 0.20%-0.50% of Cu, 0.01%-0.03% of Nb, 0.03%-0.06% of V, no more than 0.014% of Ti, 0.03%-0.07% of Als, 0.0007%-0.0015% of B, and the balance Fe and inevitable impurities. The soaking temperature of a plate blank is 1130-1180 DEG C, the initial rolling temperature in the first stage is 1050-1150 DEG C, the initial rolling temperature in the second stage is equal to or less than 900 DEG C, the final rolling temperature is equal to or higher than 810 DEG C, the plate blank is placed in a slow cooling tank to be slowly cooled after being rolled, the slow cooling temperature is not lower than 350 DEG, and the slow cooling time is not less than 24h; and then, quenching and tempering is conducted, the thickness of the steel plate is 8-50mm, and the tenacity of the steel plate at the low temperature -40DEG C is good.

Owner:ANGANG STEEL CO LTD

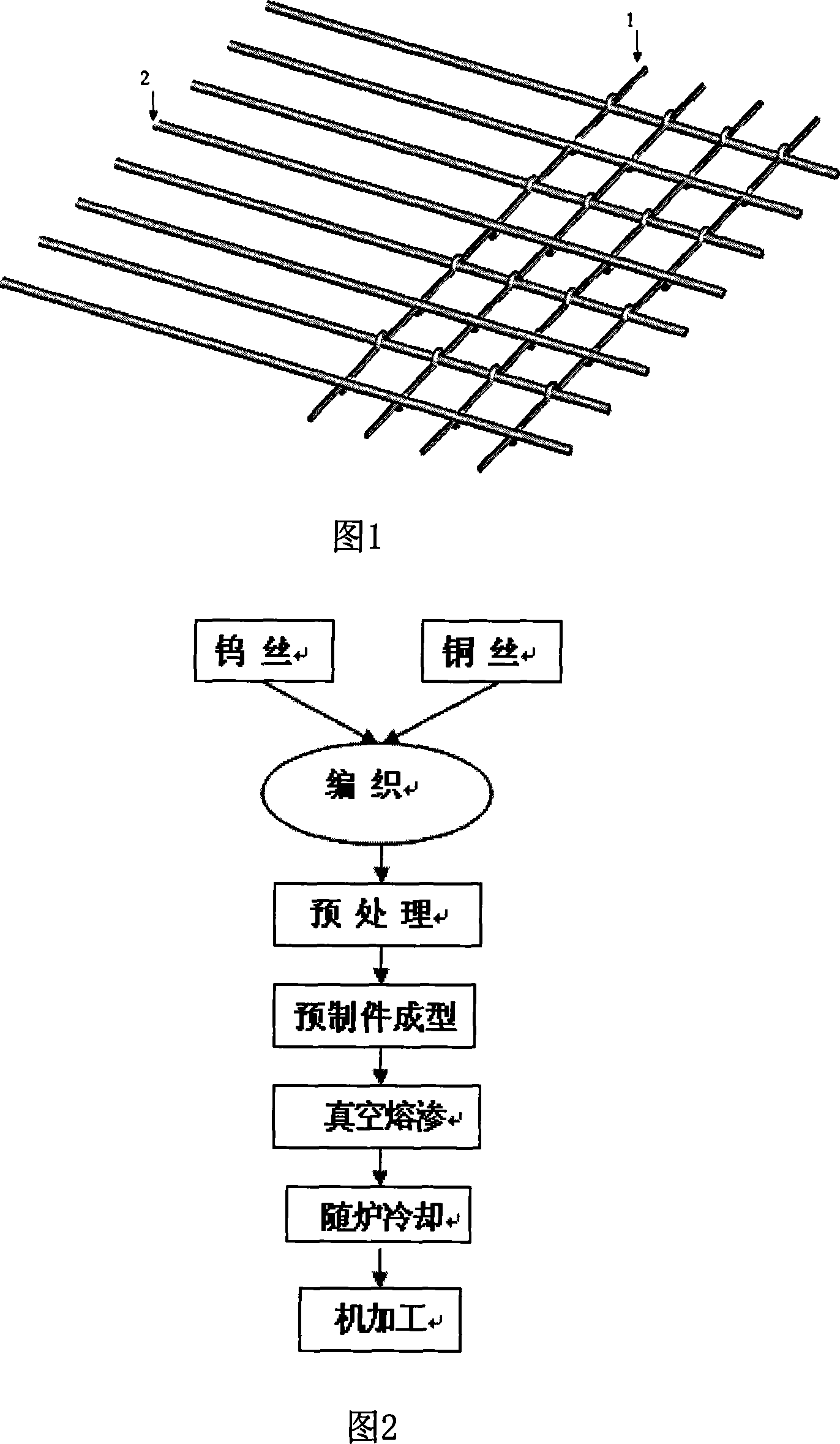

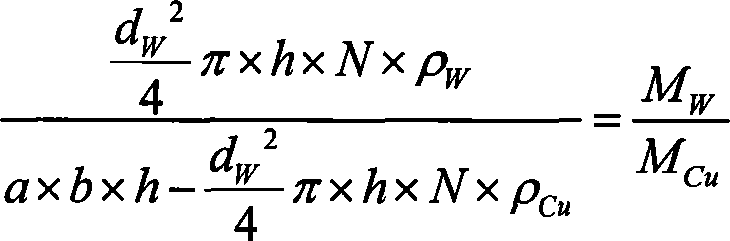

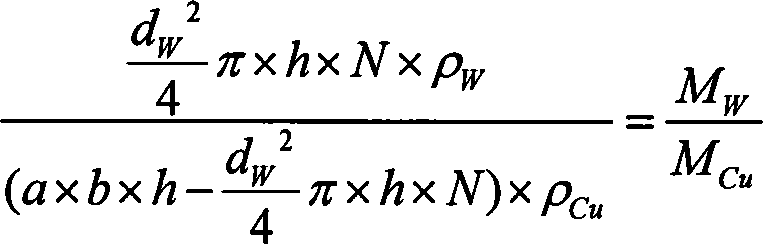

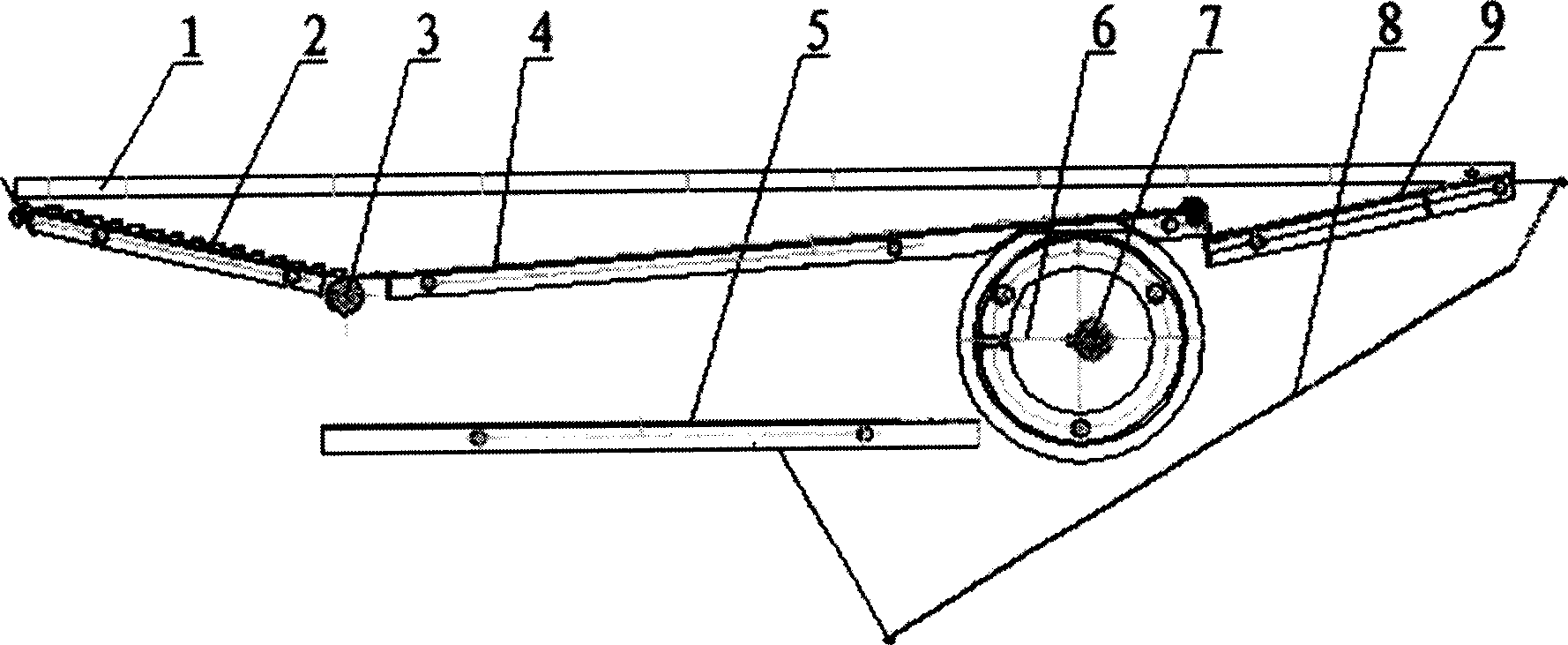

Method for preparing wolfram steel or composite material of tungsten and silver

InactiveCN101092669AImprove conductivityThe probability of arcing is smallCable/conductor manufactureComposite cathodeNitrogen

This invention discloses a process for preparing W-Cu or W-Ag composite material. The method comprises: (1) selecting W wires, washing with acid, and cleaning; (2) using Cu wires or Ag wires as the weft threads and W wires as the warp threads, and performing two-dimensional weaving to obtain a net; (3) tailoring the net into sheets according to the requirement, laminating and packing; (4) placing Cu ingot or Ag ingot above the packed sheets, and infiltrating in a vacuum sintering furnace; (5) cooling to room temperature, and taking out to obtain W-Cu or W-Ag composite cathode bar; (6) performing mechanical processing to obtain W-Cu or W-Ag composite material. The W-Cu or W-Ag composite material has such advantages as low oxygen, nitrogen and inclusion contents, and high compactness.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

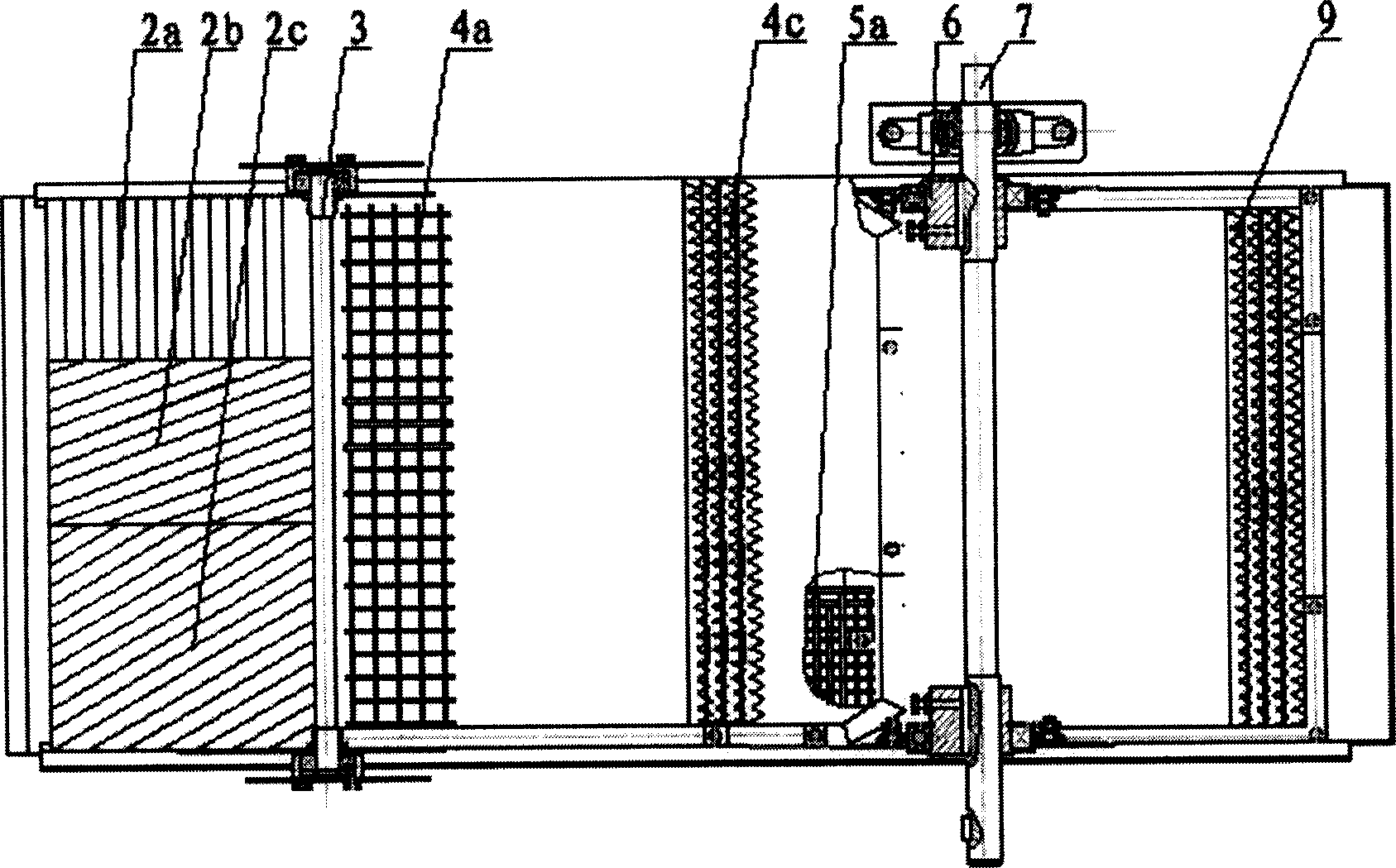

Vibration sorting screen

InactiveCN1817082AAvoid inhomogeneitySolve the problem of horizontal distribution uniformitySievingScreeningEngineeringSlide plate

A vibration-type screening sieve with high efficiency and productivity is composed of a sieve frame, a shaker board consisting of three corrugated boards with different corrugated angles, an upper sieve with longitudinally and segmentally combined structure, a middle sieve chosen from braided sieve and punched sieve, a lower sieve which is a scale sieve, a front axle, an active shaft, an eccentrical block and a slide plate.

Owner:JIANGSU UNIV

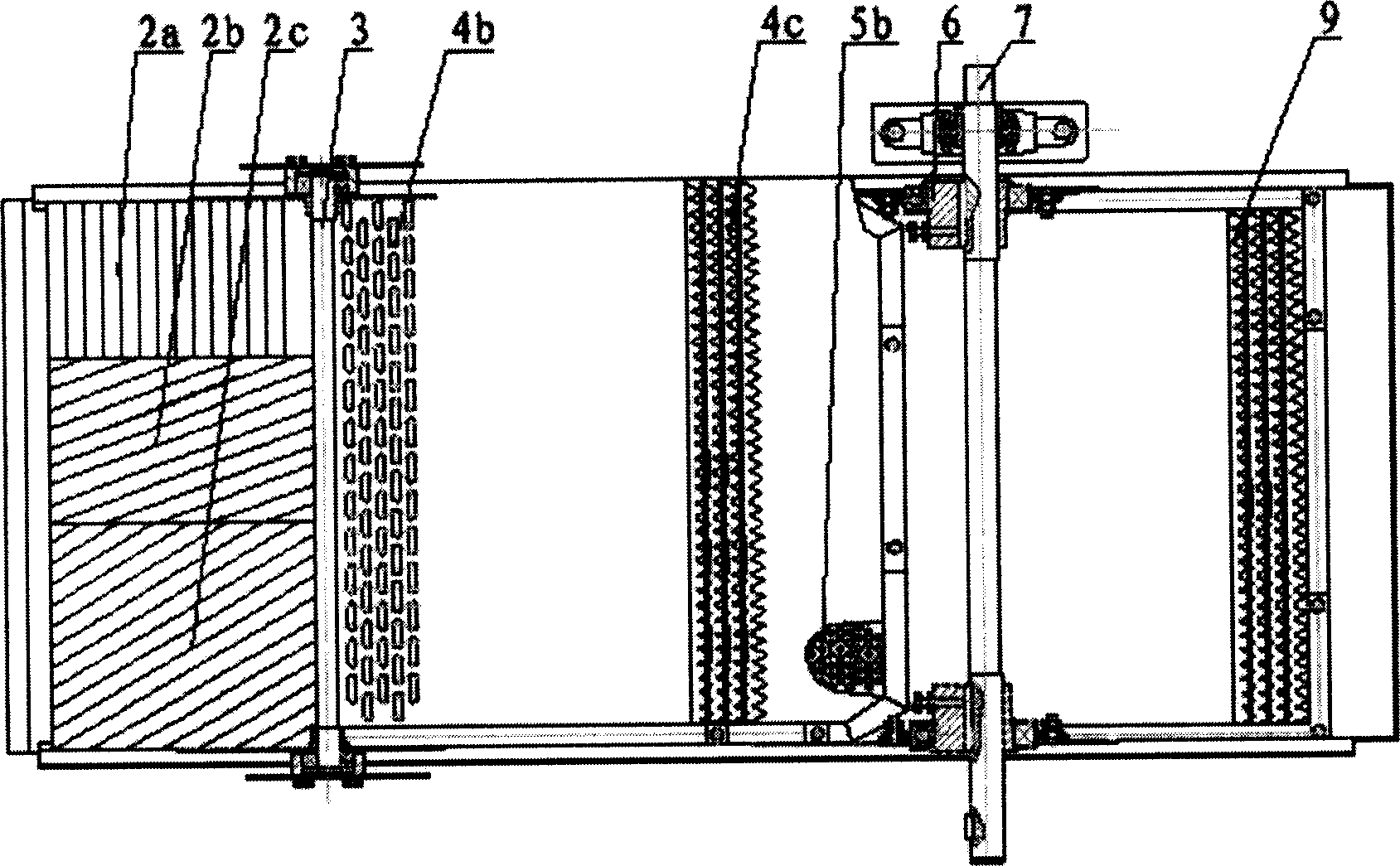

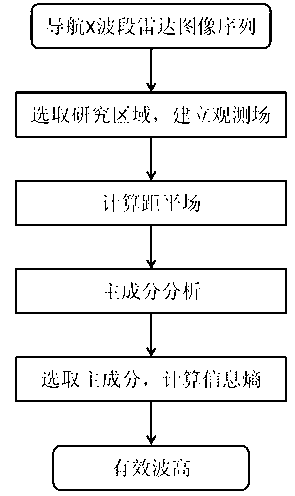

Navigation X-band radar wave height inverse calculation method based on information entropy

ActiveCN103323816AAvoid inhomogeneityAddress the effects of noiseWave based measurement systemsKernel principal component analysisRadar

The invention discloses a navigation X-band radar wave height inverse calculation method based on information entropy. The navigation X-band radar wave height inverse calculation method comprises the steps that first an anomaly field of an observation information field is calculated, principal component analysis is used for decomposing the anomaly field into different components, and then the relation between the information entropy of a principal component and an effective wave height is used for calculating the effective wave height. According to the navigation X-band radar wave height inverse calculation method based on the information entropy, the principal component analysis is used for decomposing a wave field into different components, the wave height information of waves is extracted from the principal component, the problems of the unevenness of the wave field and the influence caused by noise in radar images are effectively solved, and meanwhile the method for inversely calculating the effective wave height by the information entropy has the advantages of being simple and easy to achieve and high in precision.

Owner:江苏海兰船舶电气系统科技有限公司

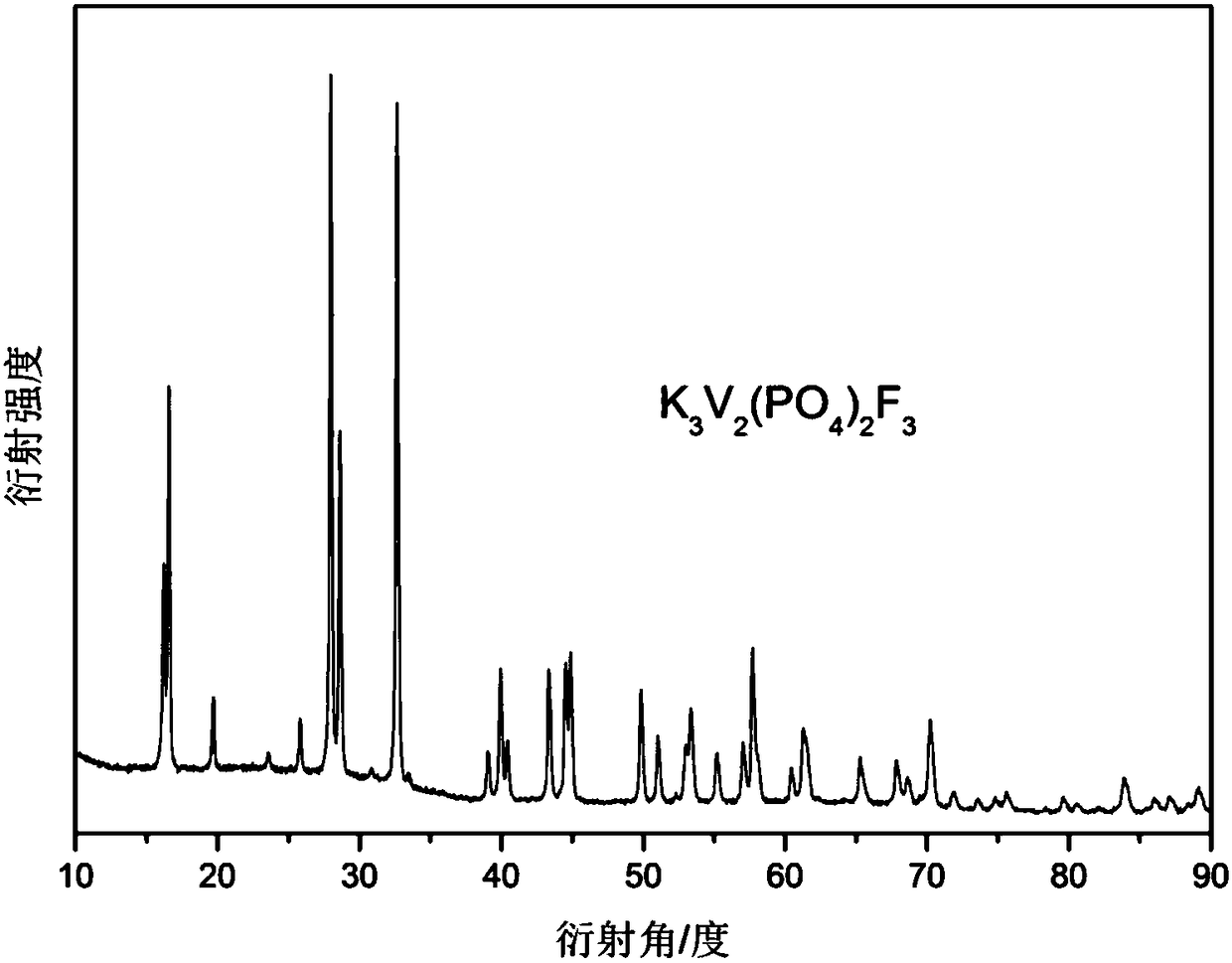

Preparation method of potassium ion battery positive electrode material potassium vanadium fluorophosphates/carbon

InactiveCN108258219AAvoid inhomogeneityAvoid coexistenceSecondary cellsPositive electrodesSolubilityPolyethylene glycol

The invention discloses a preparation method of a potassium ion battery positive electrode material potassium vanadium fluorophosphates / carbon. The preparation method comprises the following steps: mixing reaction raw materials and a polyethylene glycol solution to form a viscous solution, drying the mixture, roasting under the condition of high-temperature inert atmosphere and synthesizing the K3V2(PO4)2F3 / C composite material. The reaction solid raw materials are subjected to reaction in the mixing process by utilizing the high solubility characteristic of the polyethylene glycol to form a polyethylene glycol mixed solution dispersed uniformly, so that the defects of long conventional liquid phase reaction time and non-uniform solid phase reaction are overcome, the method is low in timeconsumption and simple in operation, and the synthesized material granules are fine and uniform. Saccharide compounds and the polyethyle glycol are pyrolyzed at high temperature and under inert atmosphere to generate high-conductivity carbon in situ, the surface of the active material is coated with the high-conductivity carbon, agglomeration and growth of the active material granules are prevented, the K3V2(PO4)2F3 / C potassium ion battery positive electrode material with high conductivity is obtained, and the material has excellent electrochemical performance.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com