Quantitative gluing amount control device

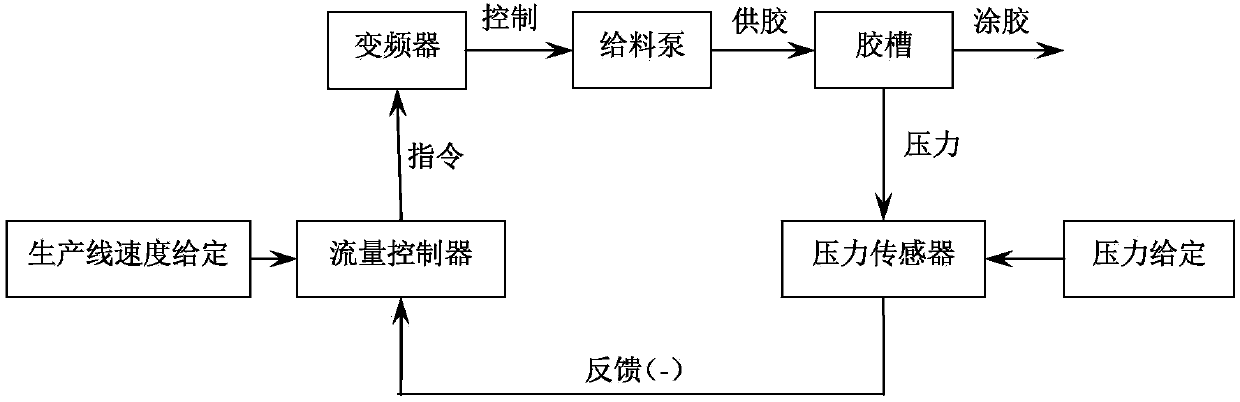

A quantitative control and flow controller technology, which is applied to the surface coating liquid device, coating, etc., can solve the problems affecting the coating amount and coating accuracy, and the instability of glue performance, so as to improve the coating quality , to maintain the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The above solution will be further described below in conjunction with specific embodiments. It should be understood that these examples are used to illustrate the present invention and not to limit the scope of the present invention. The implementation conditions used in the examples can be further adjusted according to the conditions of specific manufacturers, and the implementation conditions not indicated are usually the conditions in routine experiments.

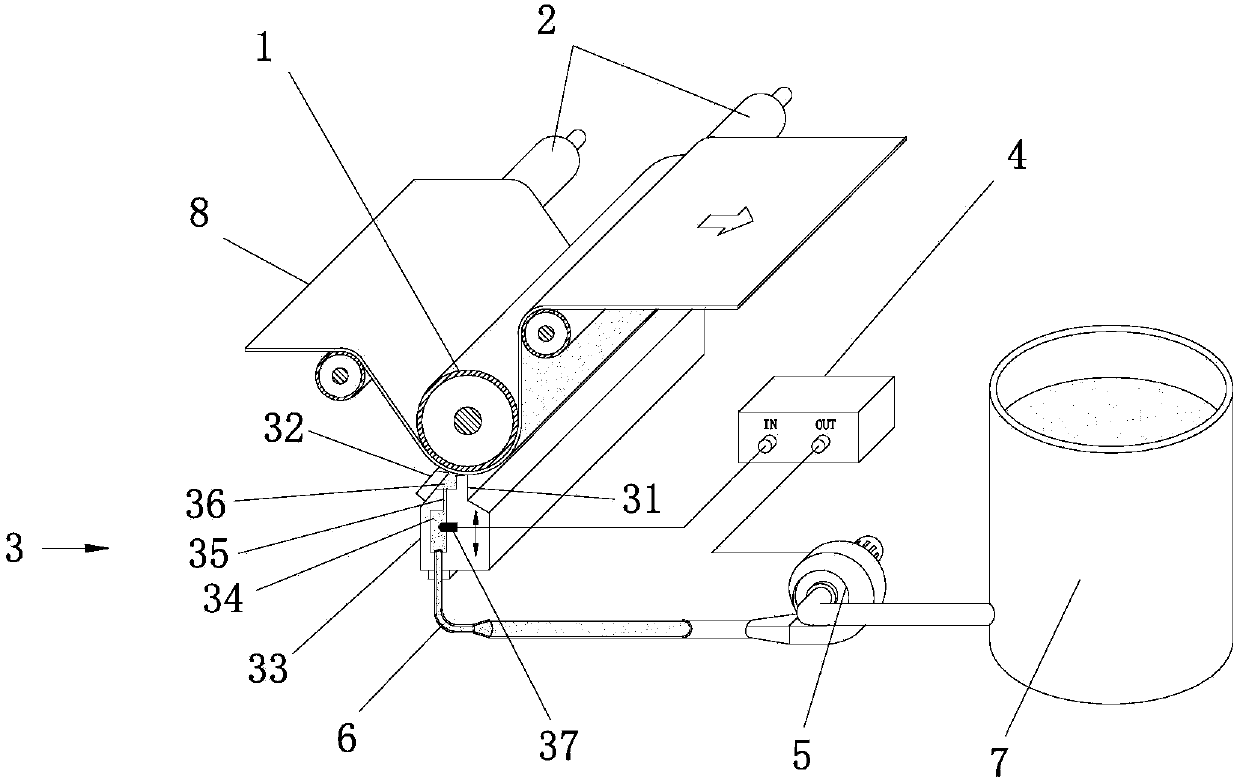

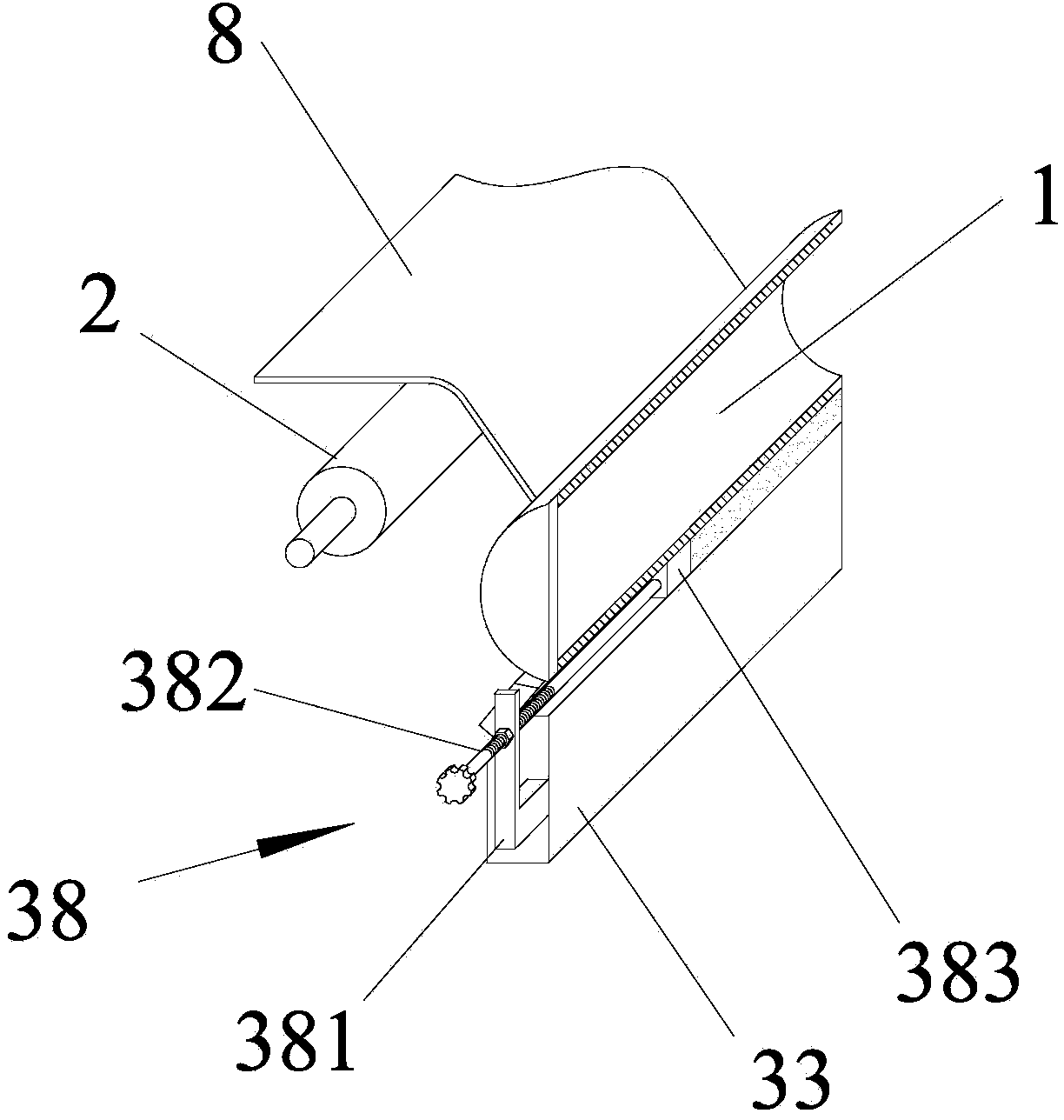

[0020] see Figure 1-2 , is a structural schematic diagram of an embodiment of the present invention, providing a quantitative control device for the amount of glue applied to a coating production line, which includes a coating roller 1 and auxiliary rollers 2 arranged on both sides of the coating roller 1. The coated substrate 8 is placed between the coating roll 1 and the auxiliary roll 2 and maintained in tension. During the production of the prior art, the base material to be coated is placed on the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com