Paper-plastic compounding-transfer process using single-component solvent-free glue

A paper-plastic compounding, solvent-free technology, applied in the process of producing decorative surface effects, printing process, printing of special varieties of prints, etc. , poor wet strength and other problems, to achieve the effect of superior folding resistance, reducing viscosity and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

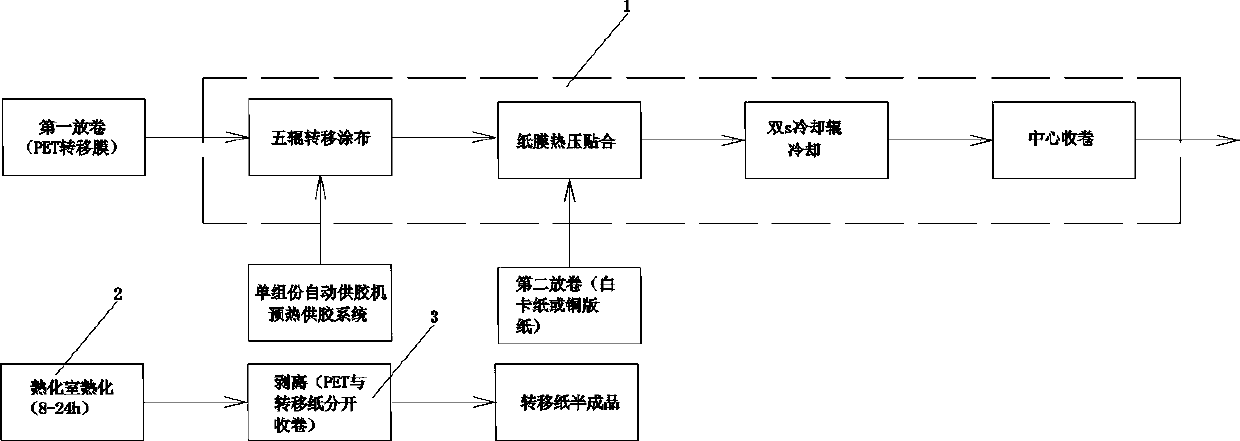

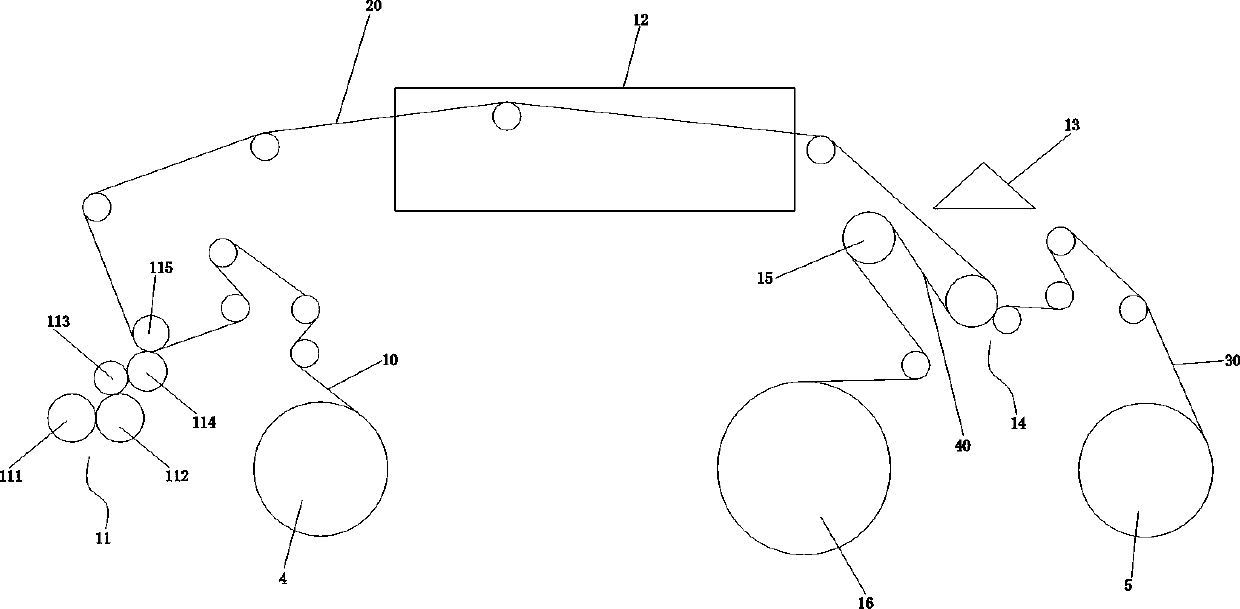

Method used

Image

Examples

Embodiment

[0027] 1. Glue Preparation

[0028] (1) Glue formula:

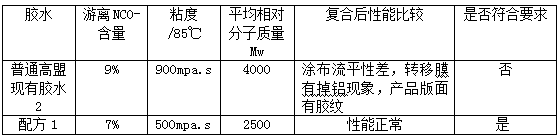

[0029] Table 1

[0030]

[0031] (2) Preparation method:

[0032] A. According to the above formula, put polyethylene glycol, polyoxypropylene diol and polyoxypropylene triol in a four-necked flask, heat up to 110-120°C, and dehydrate for 1-2 hours under vacuum-0.1MPa. The detection system The water content is less than 0.05% is qualified, cooled to 40 ℃, stand-by;

[0033] B. Add diphenylmethane diisocyanate into the four-necked flask, use organotin as a catalyst, add butanediol chain extender and triethyl orthoformate dewatering agent in sequence, heat up to 85-95°C, and react for 4 hours. Cool down to 40°C to obtain the target product.

[0034] (3) Detect the technical parameters of the target product prepared by the above method, the results are as follows:

[0035] Table 2

[0036]

[0037] 2. The technical parameters of the paper-plastic composite-transfer process are as follows:

[0038] table 3

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com