Patents

Literature

790results about How to "Improve folding resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Formula of soles of PU-simulated foaming sneakers through injection and manufacturing method

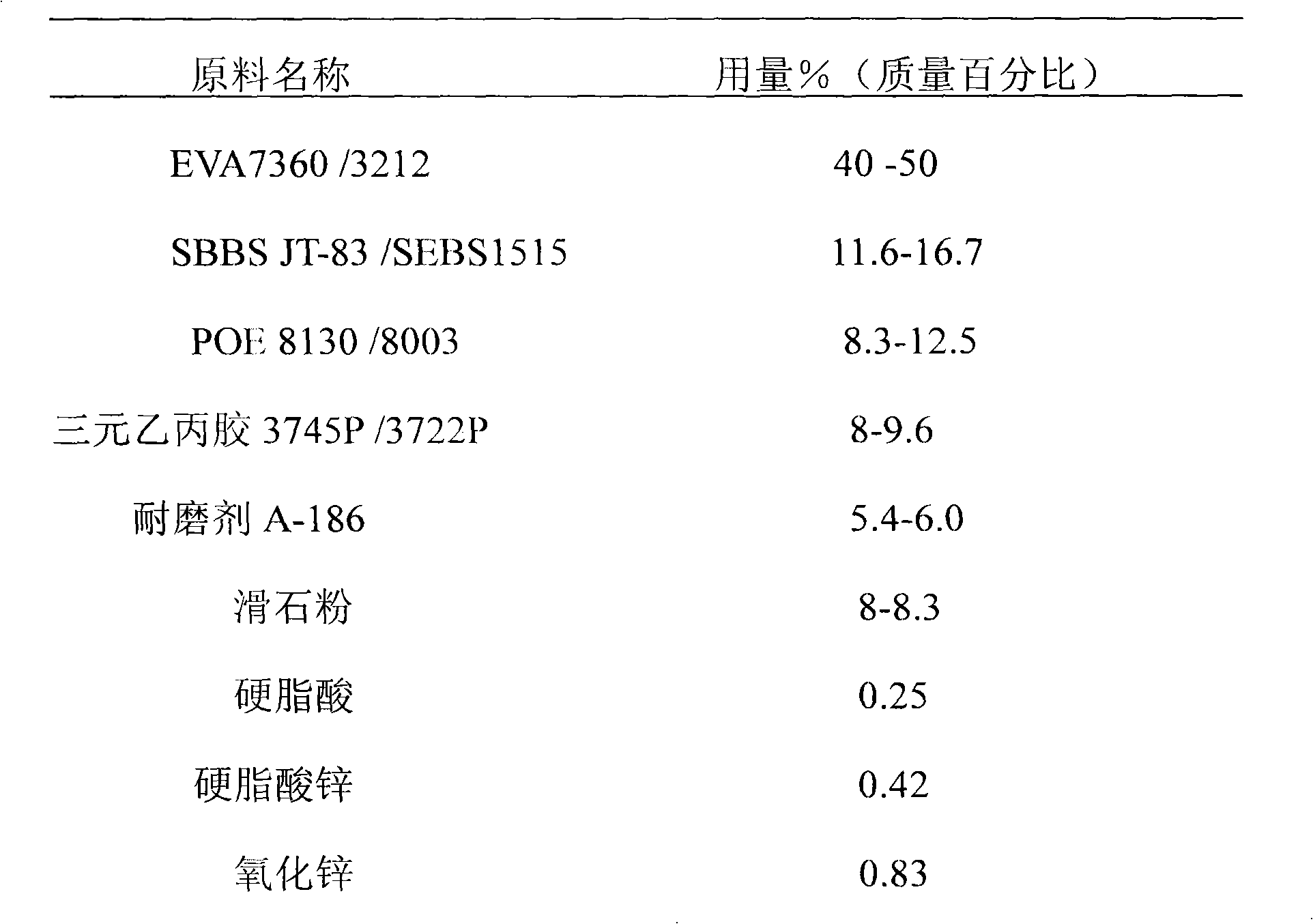

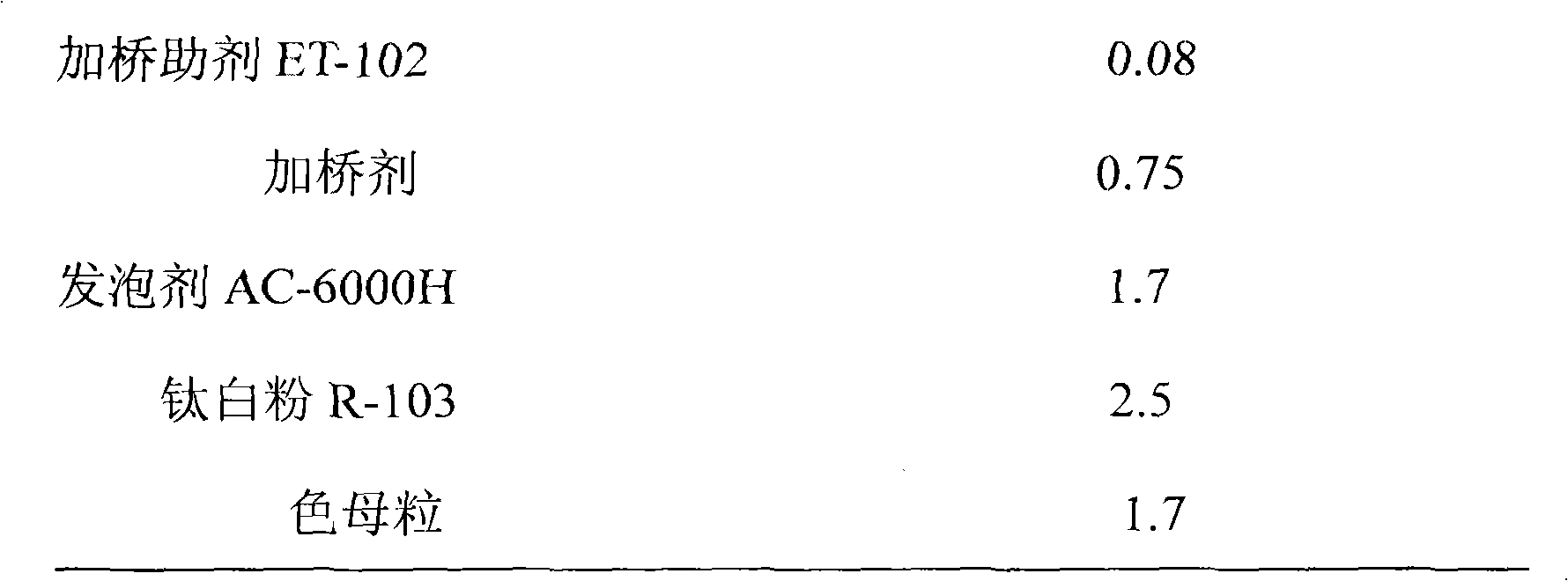

The invention relates to a formula of soles of PU-simulated foaming sneakers through injection, which comprises the following raw materials in percentage by mass: 40 percent of 21 percent ethylene-vinyl acetate copolymer (EVA 7360), 16.7 percent of styrene butadiene copolymer SBBSJT-83, 12.5 percent of ethylene octylene copolymer POE8130, 8.3 percent of ethylene-propylene-diene copolymer 3745P, 65.9 percent of wear-resisting agent A-18, 8.3 percent of talcpowder, 0.25 percent of stearic acid, 0.42 percent of zinc stearate, 0.9 percent of zinc oxide, 0.08 percent of bridging auxiliary agent ET-102, 0.75 percent of bridging agent DCP, 1.7 percent of high-temperature foaming agent AC-6000H, 2.5 percent of titanium white powder R-103 and 1.7 percent of master batch. The preparation method comprises the steps of banburying, mixing, granulation, injection molding, physical property tests and the like. Thus, in the research and development and application, the PU-simulated foaming soles not only have the physical and chemical properties of no crease marks, high elasticity, low compression and wear resistance of PU soles, and but also have the advantages of low production cost, light specific gravity, good limited-slip properties, no hydrolysis and long service life.

Owner:泰亚投资集团有限公司

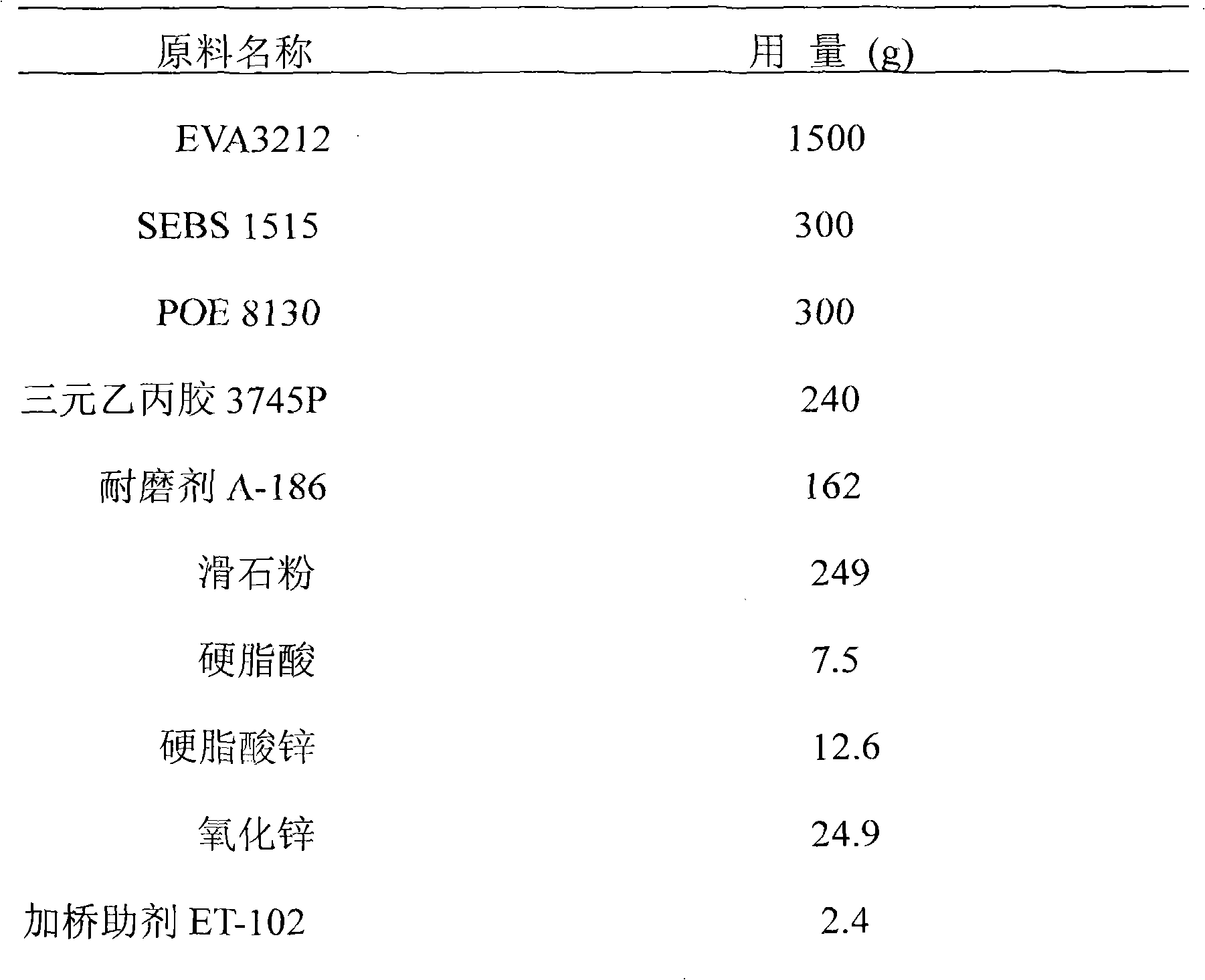

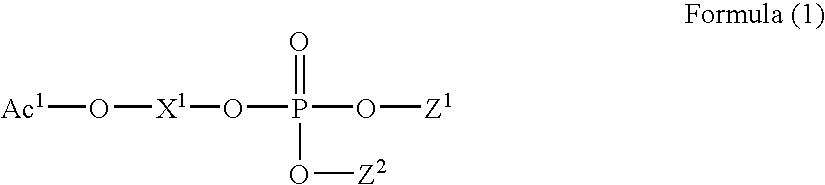

Gas-barrier laminate film and method for producing same, and image display device

InactiveUS20070231592A1Improve abilitiesImprove folding resistanceElectrical apparatusElectroluminescent light sourcesMonomer compositionPhosphate

A method for producing a gas-barrier laminate film comprising at least one inorganic layer and at least one organic layer on a substrate film, which comprises forming the organic layer by polymerizing a monomer composition comprising an acrylate monomer having a phosphate ester group, a monomer having a phosphate ester group or their mixture. The produced gas-barrier laminate film maintains its excellent gas-barrier property even when folded.

Owner:FUJIFILM CORP

A preparation method of gum-free flexible copper-coating plate

PendingCN101157077AImprove heat resistanceGood flexibilityPretreated surfacesCoatingsDielectricCopper foil

The invention discloses a preparation method for a non-glue type flexible copper clad laminate. The invention has the method that monomer aromatic diamine is dissolved in non-protonic polar solvent, and aromatic tetracid dianhydride with the equal molar is added into the solution, thereby generating polyamic acid solution with 10 to 30 percent of the solid content in a polyamic way; dehydrating agent and catalyst are dropwise added into the solution, and the chemical imidization is performed at 10 to 80 DEG C, thereby obtaining polyimide precursor solution; the polyimide precursor solution is coated on the copper foil surface with the 60 to 70 micron thickness, and heated to remove the solvent, and the thermal imidization is further performed at 250 to 300 DEG C, thereby obtaining the non-glue type flexible copper clad laminate. The non-glue type flexible copper clad laminate of the invention has the excellent heat resistant performance, is suitable for the non-lead welding meeting the environmental protective requirement, has small crimpability, good dimensional stability, better mechanical strength, high peel strength, and high flexibility resistance, and simultaneously has lower thermal expansion coefficient, dielectric constant, and water absorption.

Owner:湖北省化学研究院

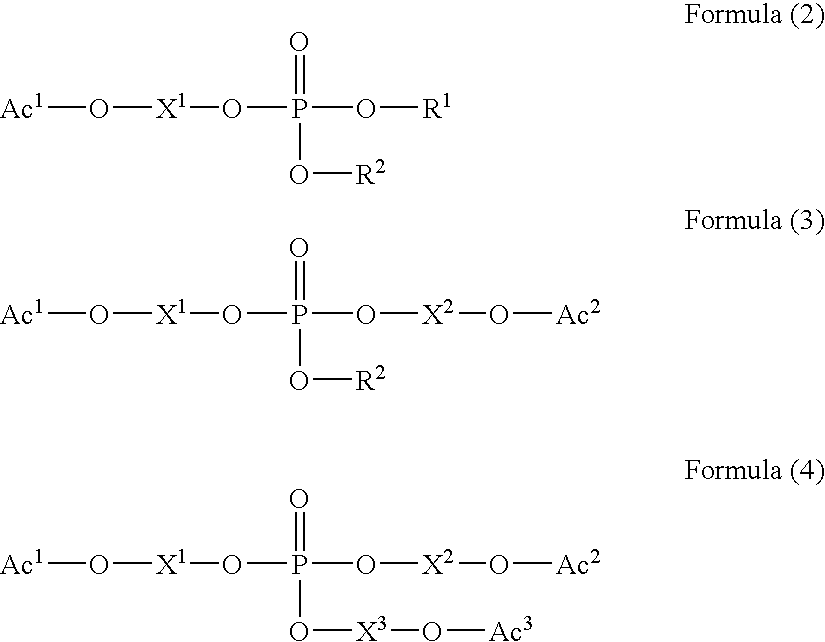

Preparation of Double-sided Photoelectrolytic Copper Foil for Special Lithium Batteries

ActiveCN102277597AStable production processHigh quality and efficient material selectionElectroforming processesElectrochemical responseCopper foil

The invention relates to the preparation of a double-sided photoelectrolytic copper foil for a special lithium battery, which comprises the following steps: preparing solution of a first additive, solution of a second additive, and copper sulfate electrolyte, wherein the copper ion concentration in the copper sulfate electrolyte is 70 to 100g / L, the sulfuric acid concentration is 100 to 170g / L and the chlorine ion concentration is 0.01 to 0.04g / L, and the temperature of the copper sulfate electrolyte is 40 to 60 DEG C; adding 60 to 200 milliliters of solution of the first additive and 35 to 100 milliliters of solution of the second additive into each cubic meter of electrolyte each hour, wherein the electrolyte formed by uniformly stirring enters an electrolytic cell and the electrolysis current density of the electrolyte in the electrolytic cell is 5,000 to 6,000A / m<2>; and after electrochemical reactions are accomplished, obtaining the double-sided electrolytic copper foil for a photic lithium battery. The preparation of the double-sided photoelectrolytic copper foil for the special lithium battery has the advantages that: the unit area weight of the prepared photoelectrolytic copper foil is 87 to 89g / m<2>, the tensile strength is more than 45Kgf / m<2>, the elongation rate is more than 5 percent, the surface roughness R2 is less than 1.5 mu m, and the uniform thickness of thecopper foil is 8.6 to 9.3 mu m according to actual measurement.

Owner:合肥铜冠电子铜箔有限公司

Surface sizing solution, and surface sizing solution used sized paper

The invention provides a surface sizing solution used in the papermaking field. The surface sizing solution contains a product and water, the product is obtained after a cross-linking reaction of nano fibrillated cellulose, starch and a cross-linking agent, the nano fibrillated cellulose is single microfibrils of cellulose having a length of 100-2000nm and a diameter of 3-200nm obtained through defibrating cellulose raw materials, wherein bone dry mass parts of the nano fibrillated cellulose, the starch and the cross-linking agent are 0.1-10, 85-99.75 and 0.15-5 respectively. The invention also provides a sized paper made by using the surface sizing solution. The surface sizing surface containing the nano fibrillated cellulose is coated on the surface of paper to realize enforcing and toughening effects in order to effectively improve the flexibility resistance of the sized paper.

Owner:GOLD EAST PAPER JIANGSU

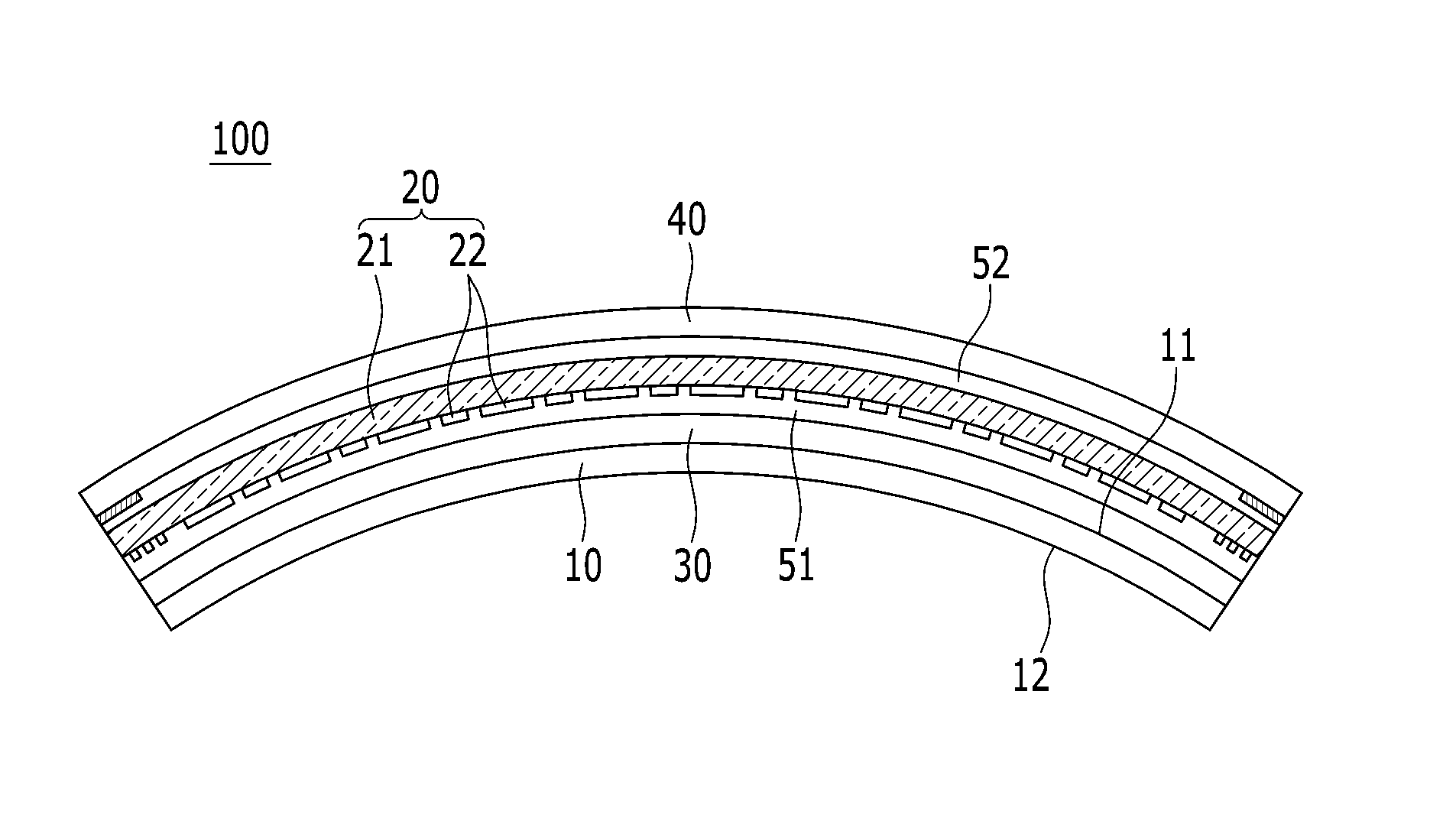

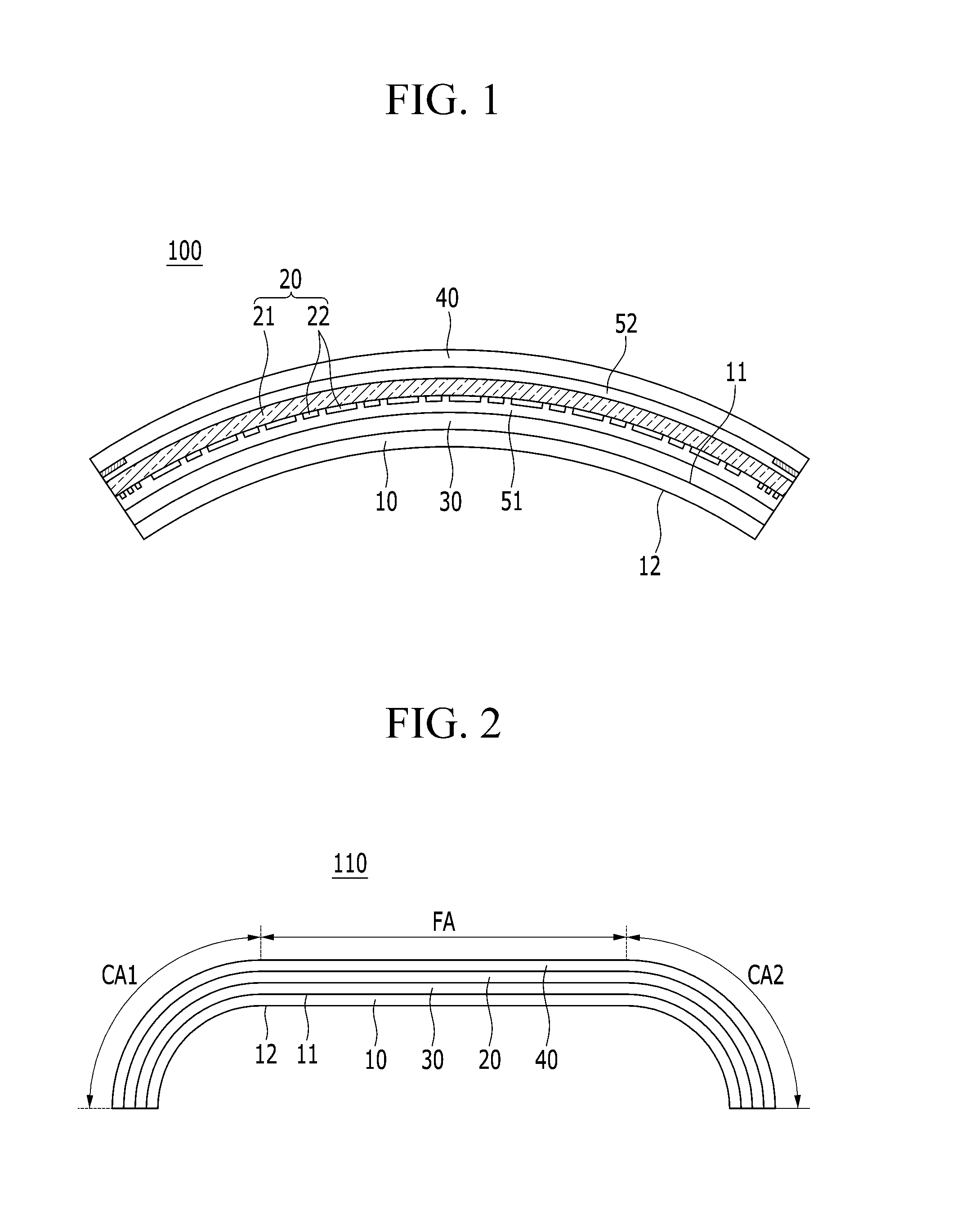

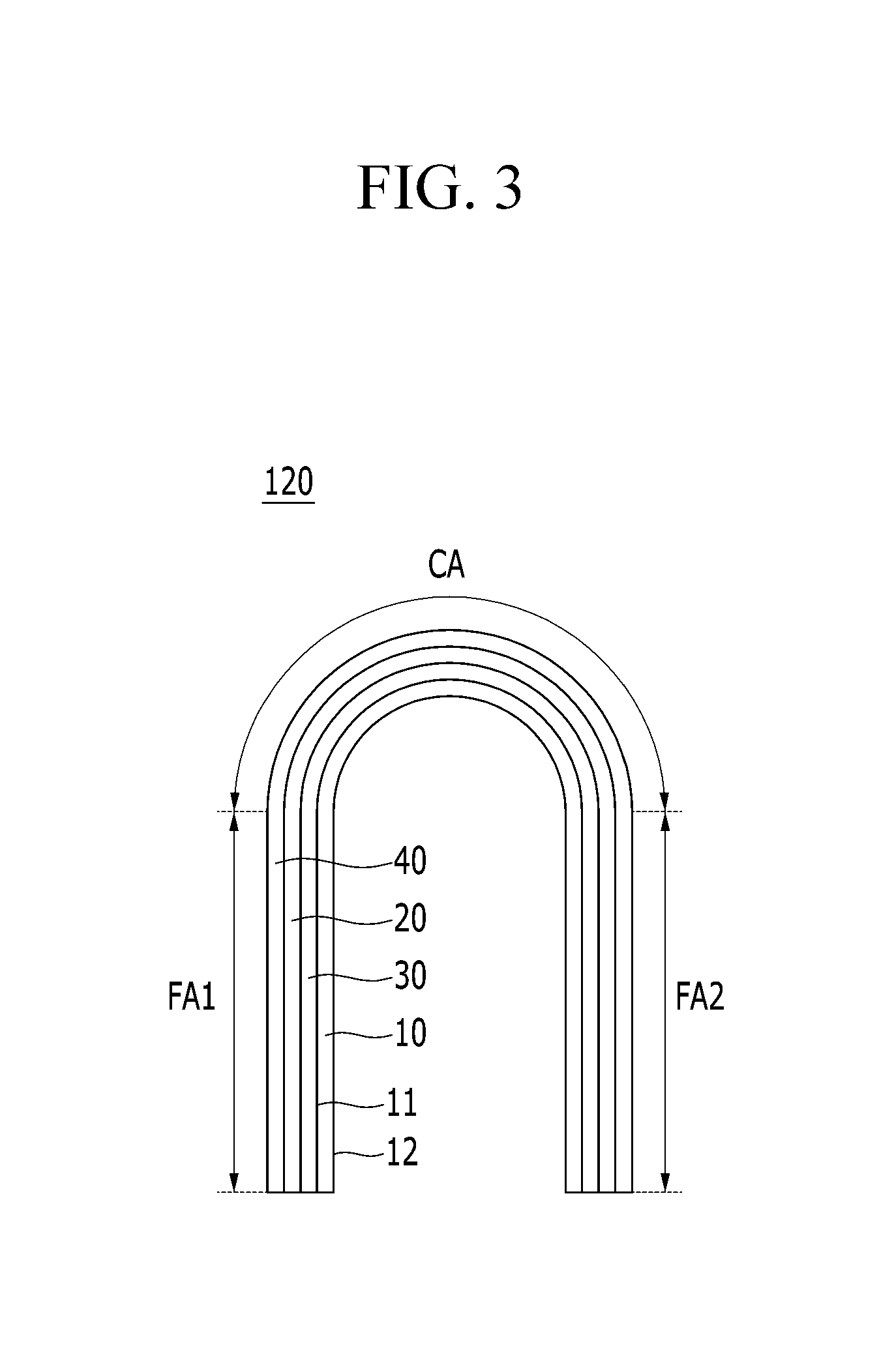

Flexible display device with touch panel

ActiveUS20160011689A1Crack suppressionInhibit the generation of cracksDigital data processing detailsInput/output processes for data processingFlexible displayComputer science

A flexible display device includes a display panel including a first surface including a display area configured to display an image, and a second surface disposed on the opposite side of the display panel from the first surface, and a touch panel disposed on the first surface, the touch panel including a base film and a transparent conductive layer disposed on a surface of the base film facing the display panel, in which at least a portion of each of the display panel and the touch panel is bendable such that centers of curvature of the display panel and the touch panel are positioned outside the second surface.

Owner:SAMSUNG DISPLAY CO LTD

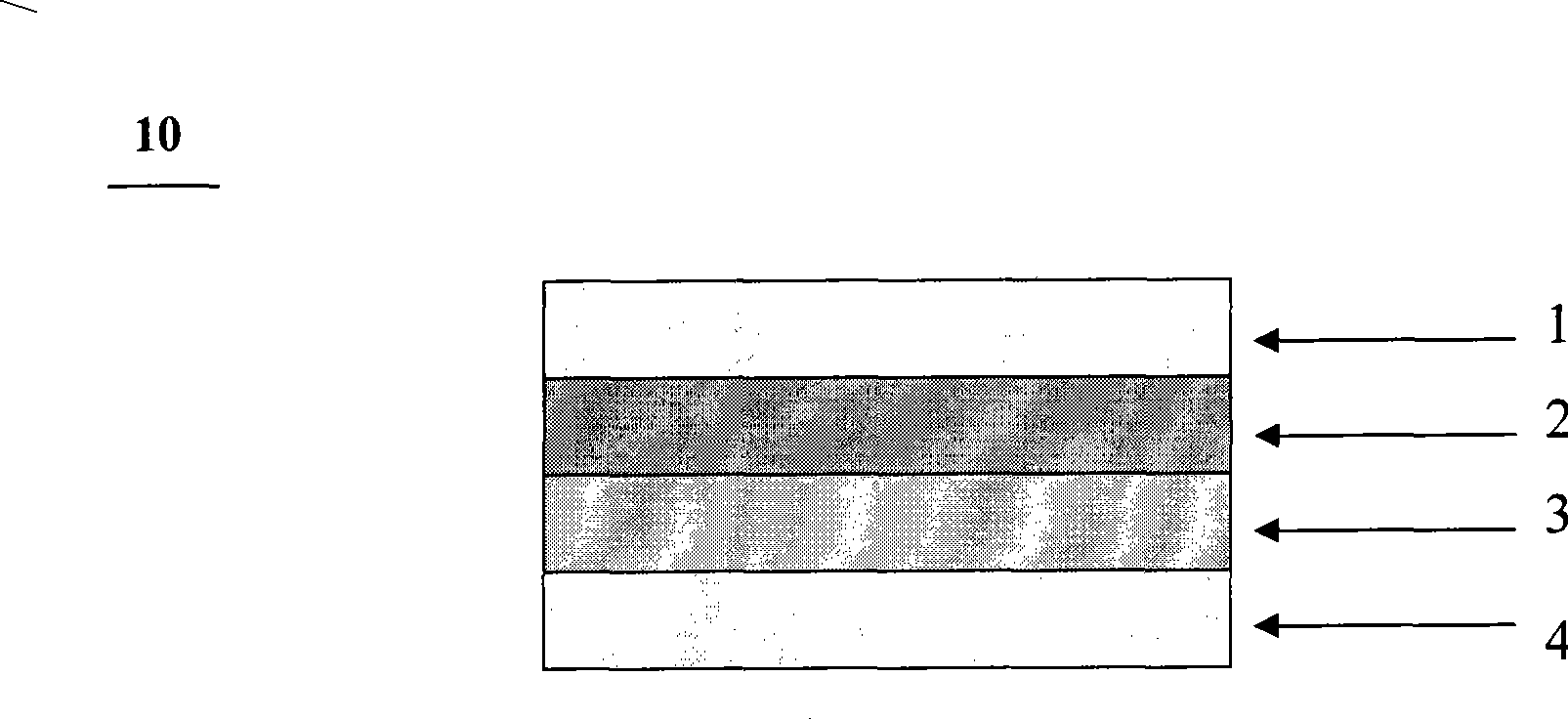

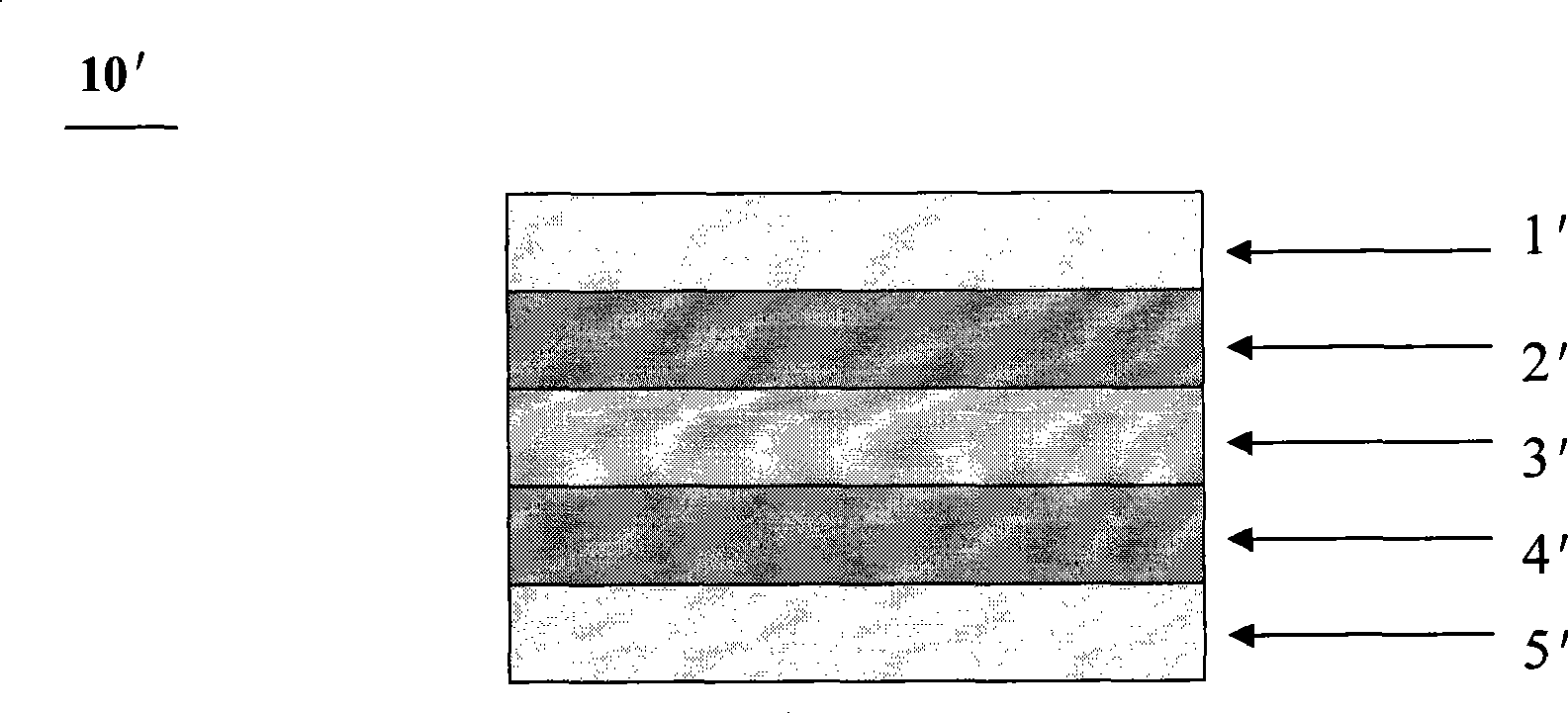

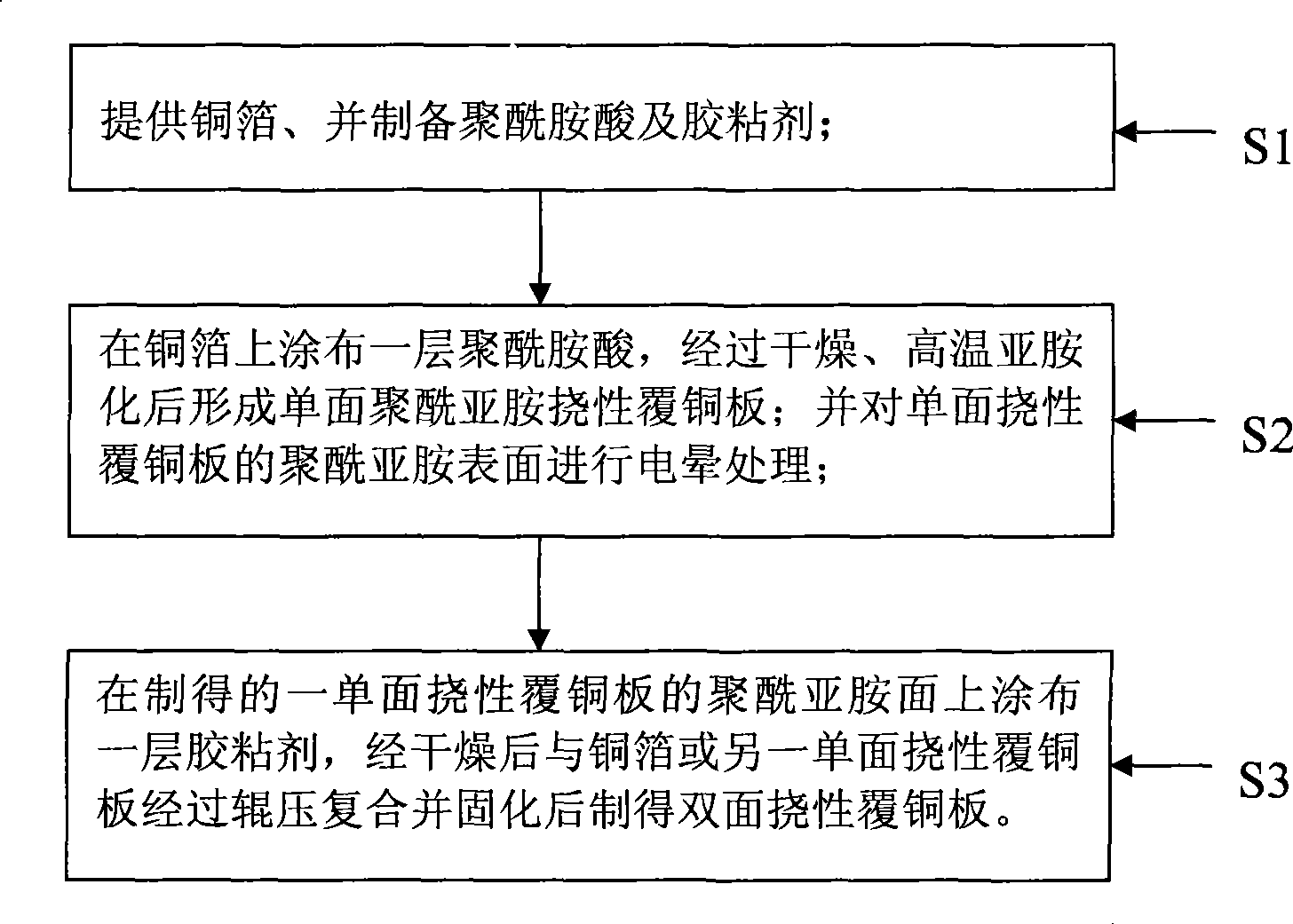

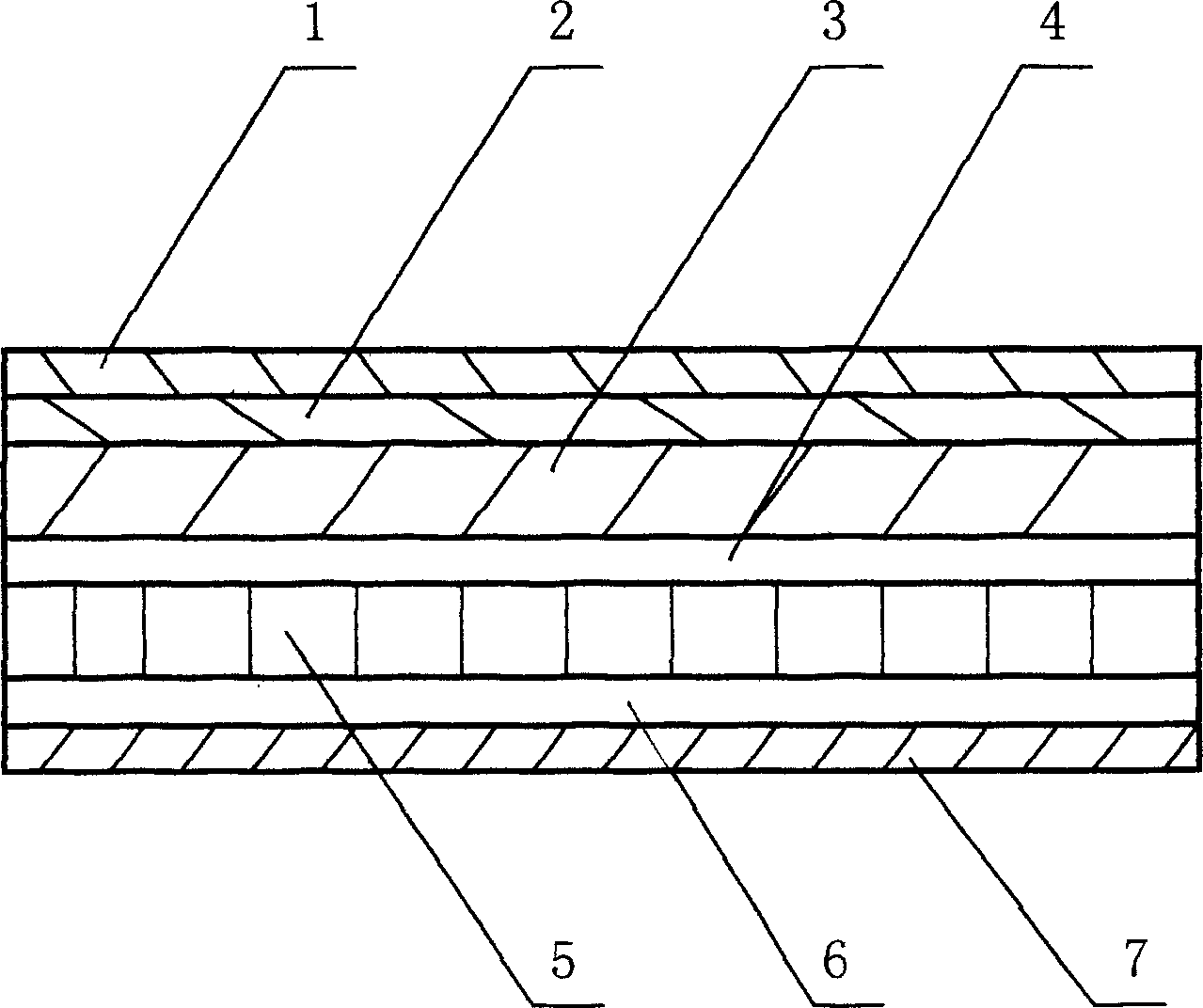

Double side flexible copper coated board and manufacturing method thereof

ActiveCN101420820AGood folding resistanceGood flame retardancyInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentAging propertyCopper foil

The invention relates to a double-sided flexible copper clad laminate and a production method thereof, the double-sided flexible copper clad laminate comprises a single-sided copper clad laminate, an adhesive layer which is coated on the single-sided copper clad laminate and the other copper foil or the other single-sided copper clad laminate which is coated on the adhesive layer by pressing, the single-sided copper clad laminate comprises one copper foil and a polyimide layer which is coated on the copper foil, wherein, the polyimide layer and the adhesive layer are adjacently arranged. The production method comprises the following steps: the copper foil is provided and polyamide acid and an adhesive are prepared; the polyamide acid is coated on the copper foil to prepare the single-sided copper clad laminate; the adhesive is coated between the single-sided copper clad laminate and the copper foil or the other single-sided copper clad laminate and carrying out the lamination to prepare the double-sided flexible copper clad laminate. The performances of size stability, folding resistance, anti-aging property, and the like of the double-sided flexible copper clad laminate are higher than the double-sided copper clad laminate which is produced by a traditional three-layer method, the appearance quality is better than the two-layer double-sided copper clad laminate produced by a lamination method, and the double-sided flexible copper clad laminate simultaneously has the low-cost advantage, thereby facilitating the mass production.

Owner:GUANGDONG SHENGYI SCI TECH

Conductive fabric and preparation method thereof

ActiveCN107938369AImprove wash resistanceImprove tensile propertiesTextiles and paperSurface layerLiquid metal

The invention provides a conductive fabric and a preparation method thereof. The conductive fabric comprises, from inside to outside, an adhesive force improving layer attached to the surface layer ofa fabric substrate, a liquid metal layer, an oxygen isolation protective layer and a packaging protective layer. The preparation method comprises: applying the adhesive force improving layer to the surface layer of a fabric substrate, coating the adhesive force improving layer with the liquid metal layer, coating the liquid metal layer with the oxygen isolation protective layer, and coating the oxygen isolation protective layer with the packaging protective layer. The coating manner includes spraying, brush coating, flow coating or printing. Compared with a conductive fabric in the prior art,the conductive fabric is excellent in conductivity, fold resistance, laundering durability and tensile property. The preparation method is simple and reliable.

Owner:BEIJING DREAM INK TECH CO LTD

Gas-barrier film and organic device comprising same

InactiveUS20090072230A1Improve water vapor barrier performanceImprove the immunityLiquid crystal compositionsLayered productsMaterials scienceGas barrier

Owner:FUJIFILM CORP

Rubber for sneaker sole and preparation method thereof

The invention discloses rubber for a sneaker sole, and the rubber provided by the invention comprises the following components in parts by weight: 30-70 parts of butadiene rubber, 10-30 parts of natural rubber, 10-30 parts of bromobutyl rubber, 15-40 parts of carboxylated nitrile rubber, 2-5 parts of polyethylene glycol, 0.5-2 parts of stearic acid, 2-5 parts of zinc oxide, 1.5-2 parts of vulcanizer, 1.6-2.1 parts of accelerator, 0.5-2.0 parts of tackifier, 30-70 parts of white carbon black, 3-3.2 parts of coupling agent, 2-5 parts of softening oils, 1-3 parts of anti-aging agent and 0.5-1 part of paraffin. The invention further discloses a preparation method of the rubber. The rubber for the sneaker sole, provided by the invention, has incomparable slip prevention performance compared with the ordinary rubber shoe sole, and has multiple functions such as excellent wear resistance, bend resistance, and the like.

Owner:ANTA CHINA

Ultraviolet light curable ink

The invention is a kind of ultraviolet radiation solidify printing ink., the quality percentage of the of the invention as follow: the first kind of ultraviolet solidify printing ink is 20%-30%, the second kind of ultraviolet solidify printing ink is 20%-38%, acrylate resin is 8%-30%, active thinner is 5%-30%, medicament causing light is 4%-32. the invention can be used widely in the top packaging and can form thin goffer such as shaping snowflake pattern felt unshaped. Under the sun, it can flash the light, besides, the invention has good ability of clinging and rigid. Used in silk screen printing, shined under the ultraviolet radiation, the invention. Invention name.

Owner:惠州市立美特环保油墨有限公司

High-heat-conductivity white adhesive composition, high-heat-conductivity white cover film made from same and preparation method thereof

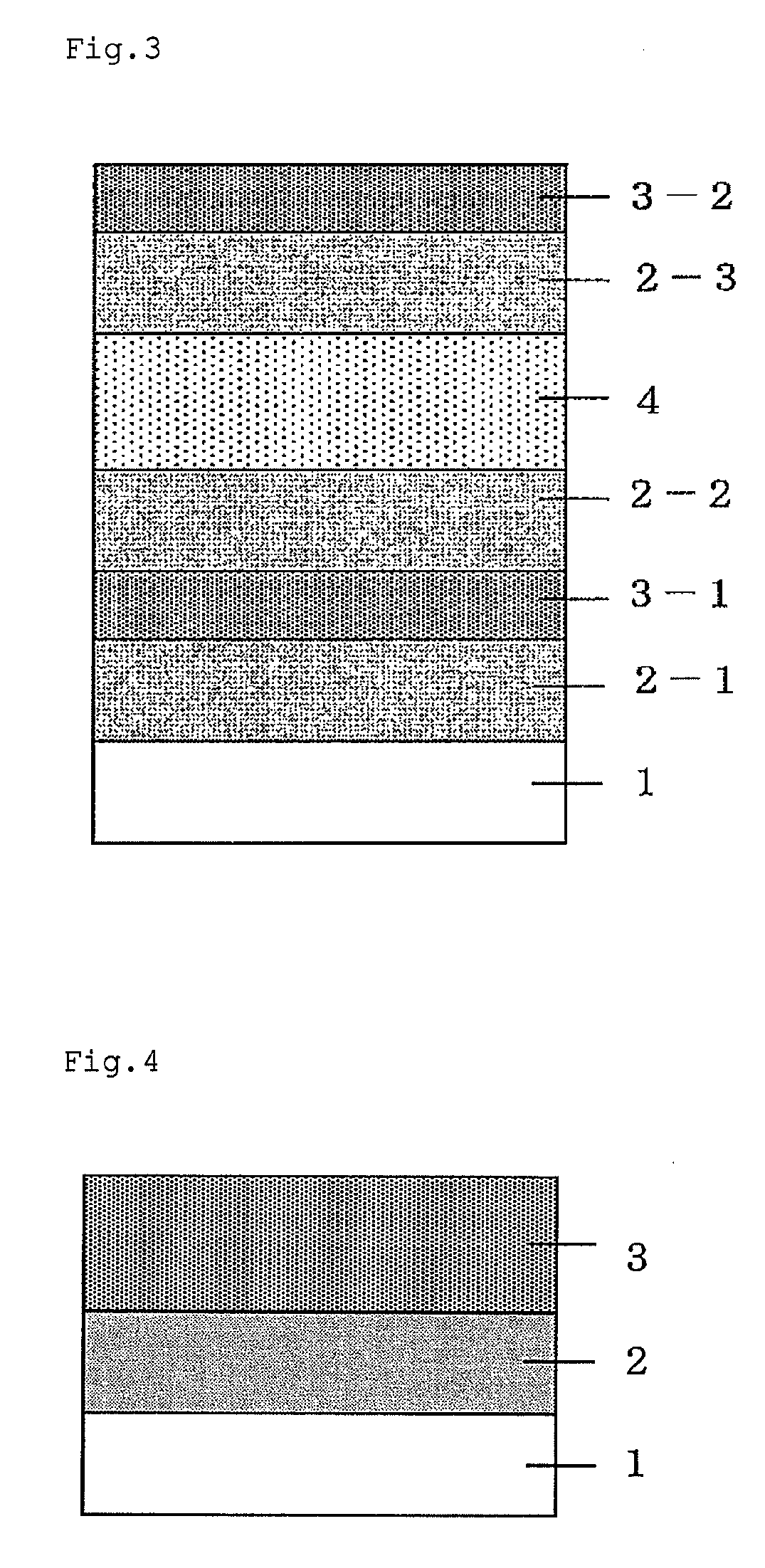

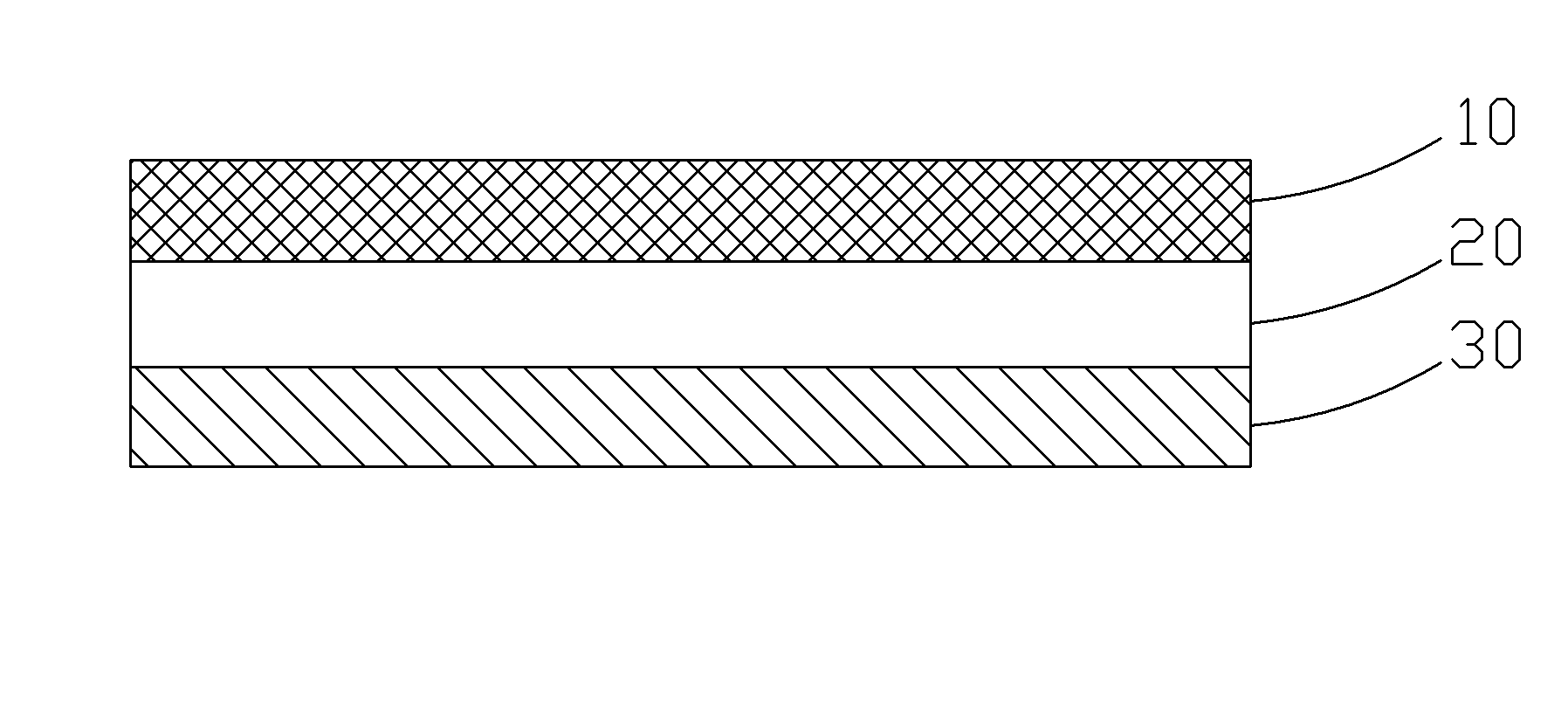

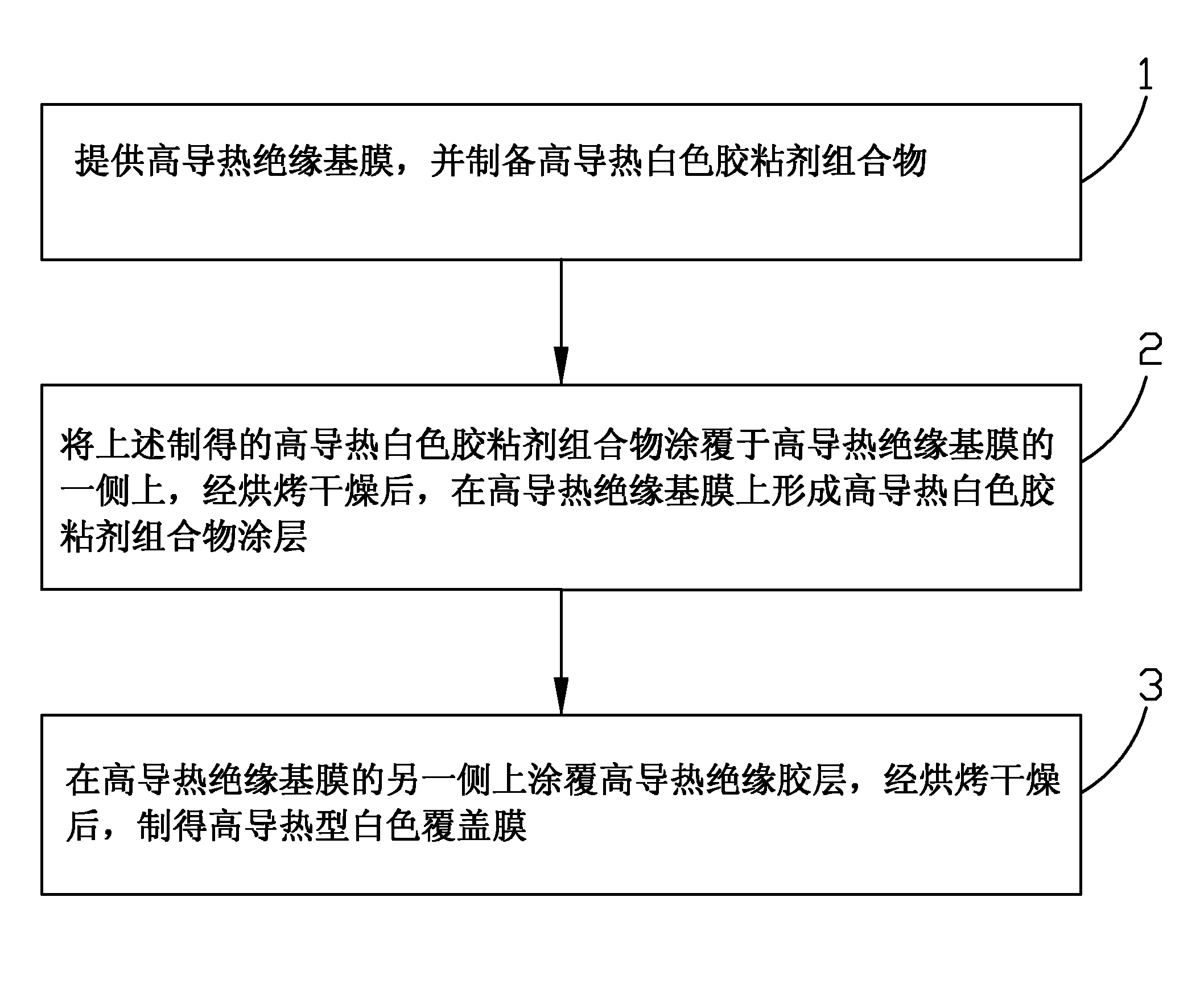

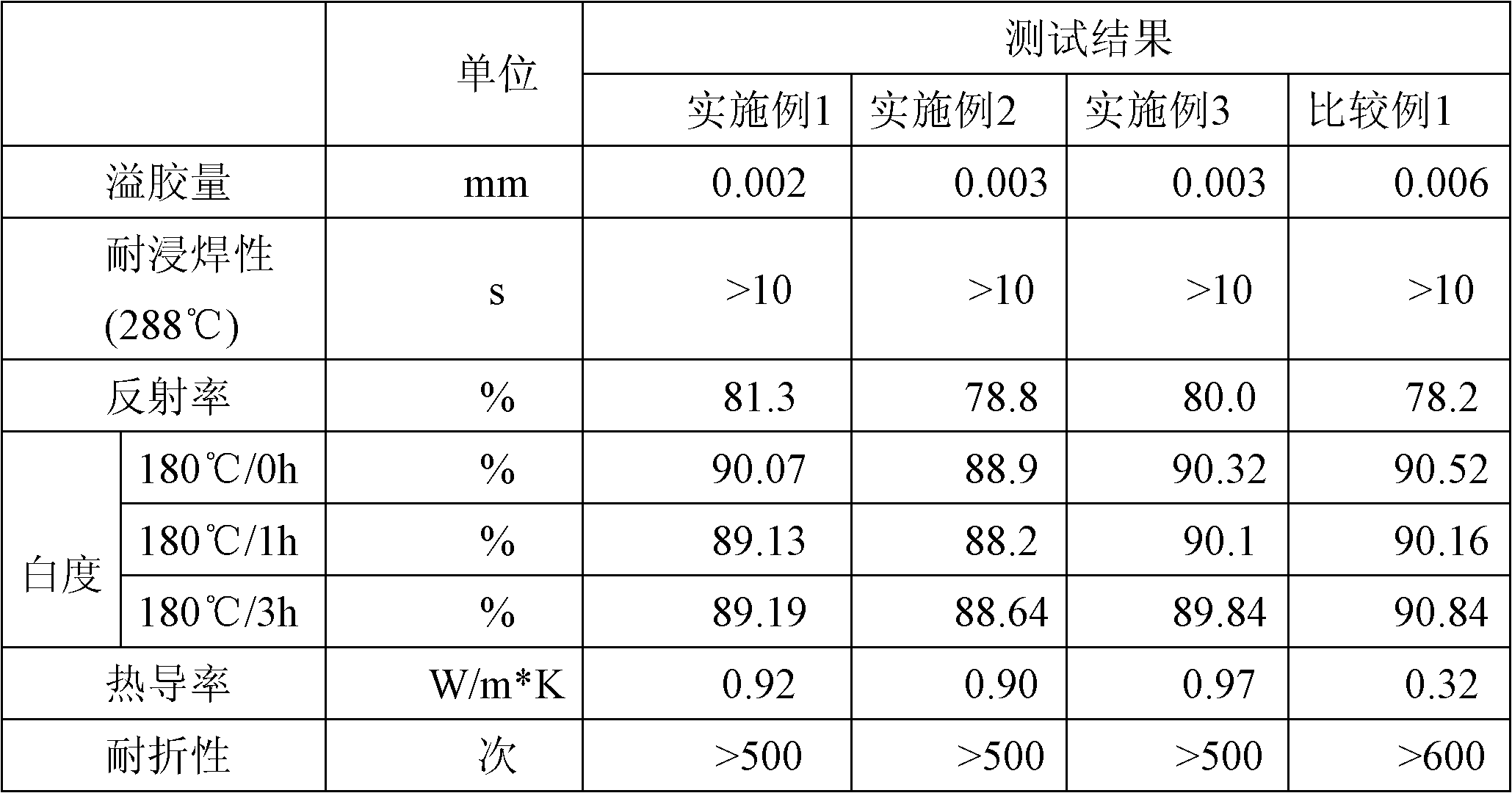

ActiveCN102079959AHigh whitenessImprove reflectivityPrinted circuit detailsFilm/foil adhesivesPolyesterAdhesive

The invention relates to a high-heat-conductivity white adhesive composition, a high-heat-conductivity white cover film made from the same and a preparation method thereof. The high-heat-conductivity white adhesive composition comprises flexible saturated polyester, hard saturated polyester, blocked isocyanate curing agent, pigment, high-heat-conductivity filler, fluorescent brightener, defoaming agent and solvent. The high-heat-conductivity white cover film comprises a high-heat-conductivity insulation basal film, a high-heat-conductivity white adhesive composition coating applied onto one side of the high-heat-conductivity insulation basal film, and a high-heat-conductivity insulation adhesive layer applied onto the other side of the high-heat-conductivity insulation basal film. By applying the heat-conduction adhesive layers onto the two sides of the high-heat-conductivity insulation basal film, the high-heat-conductivity white cover film has the advantages of high whiteness and high reflectivity of the cover film surface, low cost, favorable yellowing resistance, excellent folding resistance and high heat conductivity, and can be widely used in the fields of high-power LEDs (Light Emitting Diodes), backlight sources and the like.

Owner:GUANGDONG SHENGYI SCI TECH

Waterborne aluminium foil adhesive and preparation method thereof

InactiveCN102153971AGood adhesionHigh peel strengthMonocarboxylic acid ester polymer adhesivesEster polymer adhesivesFunctional monomerPolymer science

The invention discloses a waterborne aluminium foil adhesive and a preparation method thereof and belongs to the field of adhesives. The aluminium foil adhesive is a composite adhesive with solid content of 40 to 50 percent, which is prepared by using monomers, an emulsifier, protective colloid, an initiator, a buffer, a pH (potential of hydrogen) regulator, a plasticizer, a waterborne assistant and deionized water as the raw materials through pre-emulsification, seed reaction, polymerization reaction and compounding. The monomers in the raw materials comprise hard monomers, soft monomers andfunctional monomers, wherein the hard monomers adopt vinylacetate and methyl acrylate; the soft monomers adopt ethyl acrylate and butyl acrylate; and the functional monomers adopt any one of acrylic acid or methacrylic acid and N-hydroxymethyl acrylamide. The waterborne aluminium foil adhesive has the advantages of low cost, high stripping strength and good leveling property and is simple and convenient to operate.

Owner:BEIJING COMENS NEW MATERIALS

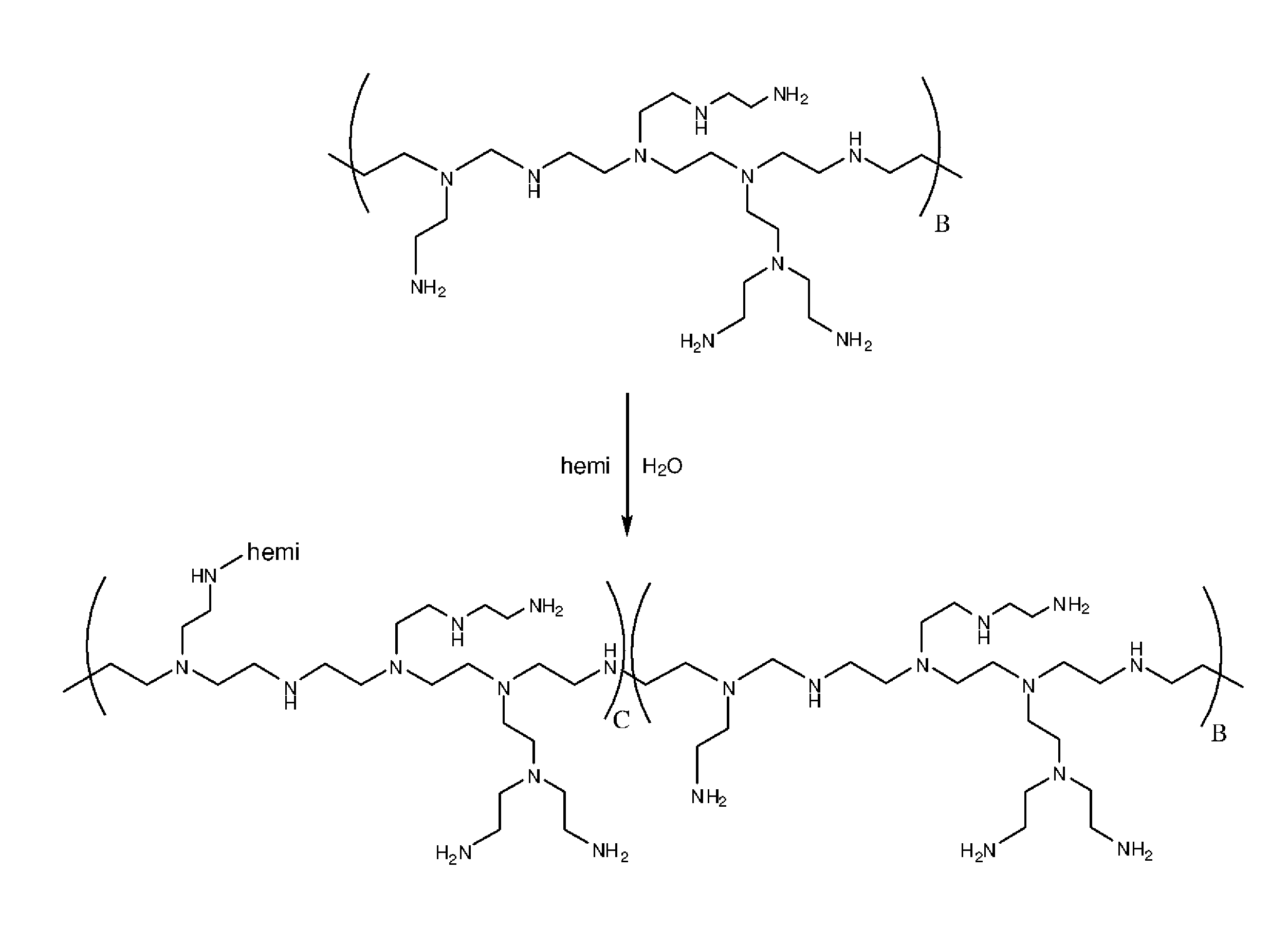

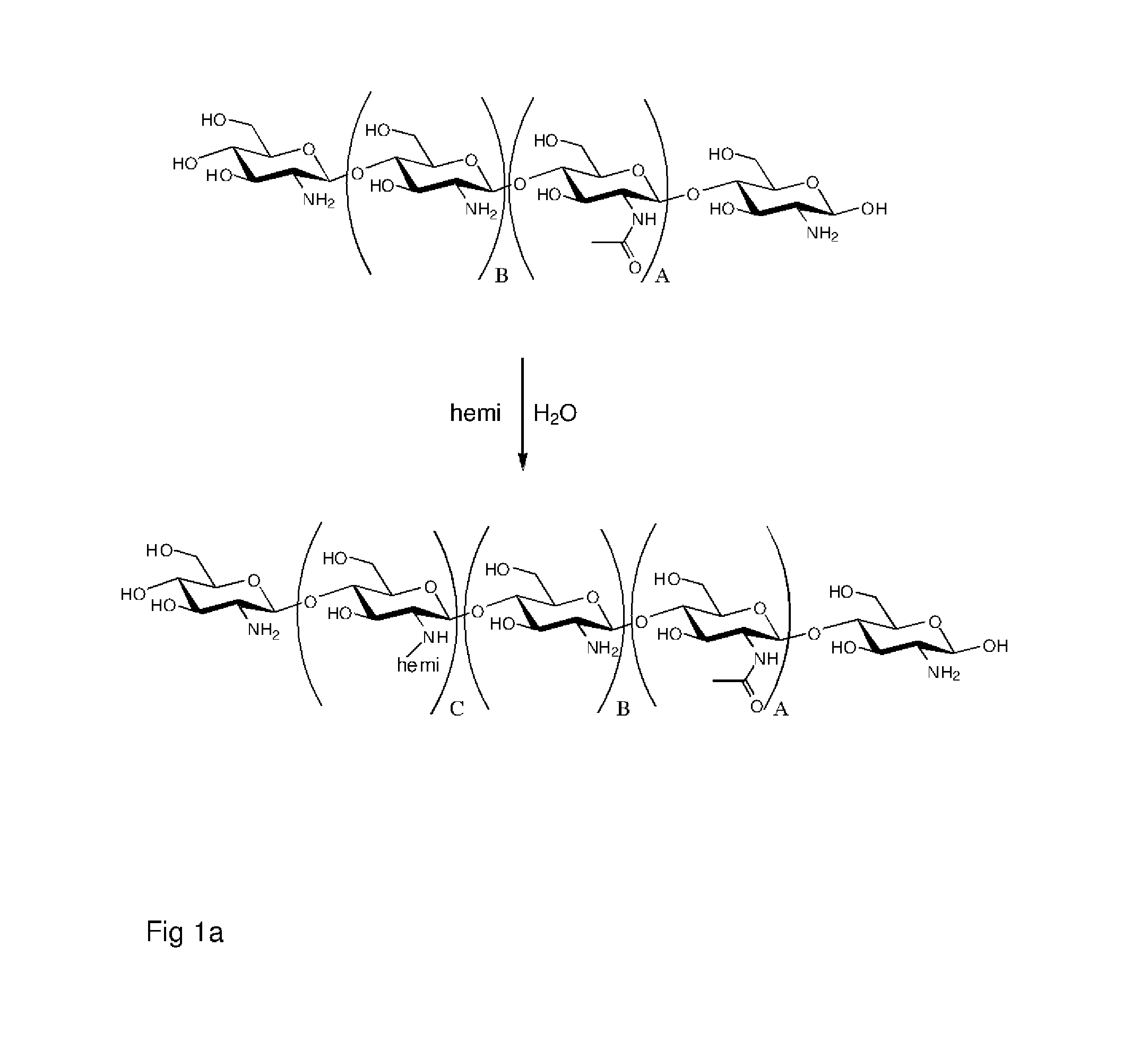

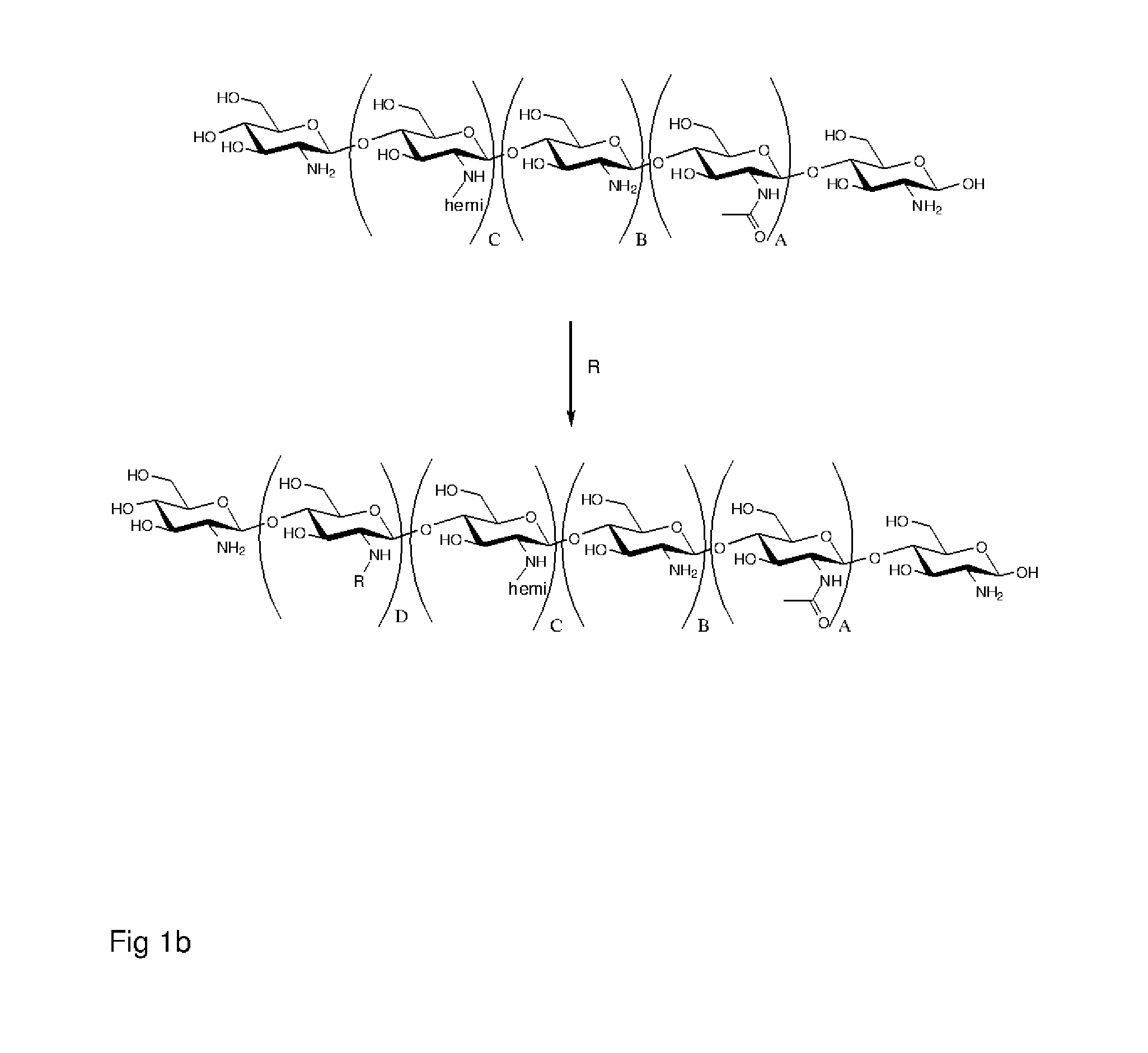

Polymer made of a primary amine functionalized polymer and a hemicellulose

ActiveUS20120058536A1Improve folding enduranceImprove indexingAntibacterial agentsFibre treatmentPolymer chemistryXyloglucan

The present invention relates to a polymer made of a primary amine functionalized polymer and a hemicellulose e.g. chitosan and xyloglucan, wherein the primary amine functionalized polymer is covalently bound to the hemicellulose, and to a cross-linking agent composition comprising the polymer. A method wherein manufacturing a cellulose containing product comprises the steps of; providing a cellulose containing product; treating said cellulose product with a cellulose adsorbing agent comprising a polymer made of a primary amine functionalized polymer and a hemicellulose e.g. chitosan and xyloglucan, and optionally other additives is also provided.

Owner:CELLUTECH

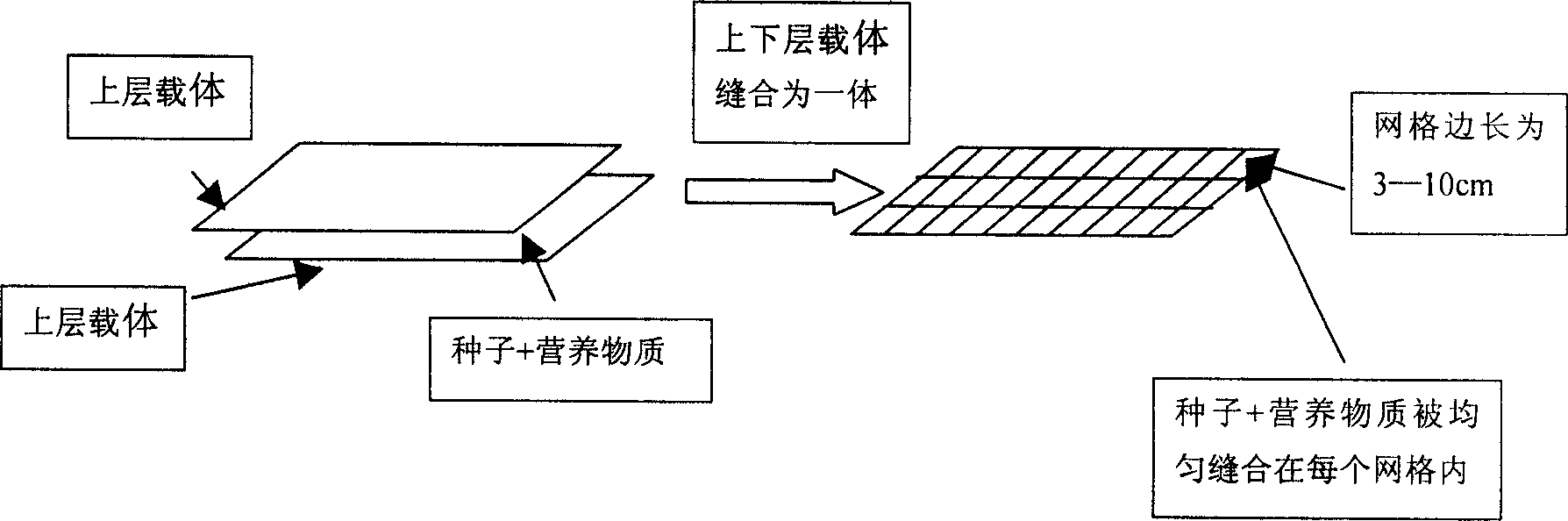

Lawn seed nursery belt sewn with household wastes and method for manufacturing the same

InactiveCN1732730AImprove performanceImprove folding resistanceCultivating equipmentsSeed arrangmentsPlanting seedElement composition

The invention relates to a stitched domestic waste lawn seeded strip and the producing method, which applies the domestic waste as raw material to make carrier with up and low layer, lawn plant seed and nutriment element composition, the said lawn plant seed and nutriment element is distributed in the up and low layer homogeneously, the said carrier is made up of waste newspaper, waste cotton fabric, gaze and face tissues. The productive technology of the invention is very simple, the resistance to folding and transport endurance are improved significantly, realizing 100% weeds controlling, with the cost dropping above 100%, promoting the city ecological construction and realizing the target of sustainable development with highly effective uniformity of the environment and economy.

Owner:TIANJIN NORMAL UNIVERSITY

High barrier aluminum-plating composite film for packing liquid dairy product

InactiveCN1880182AHigh gas barrierImprove water resistanceFlexible coversWrappersComposite filmFolding endurance

The invention relates to a high insulated aluminum composite film used to pack liquid milk, wherein it has multilayer structure, from outer to inner, as printing layer, adhesive layer, aluminum layer, adhesive layer, baffle layer, adhesive layer and thermal sealing layer; the baffle layer is made from polyvinylidene chloride polymer or ethane-ethenol polymer. Compared with traditional plastic soft film, the invention avoids the carbon black layer and increases the aluminum layer and oxygen baffle layer, to obtain high waterproof ability and high insulated property, etc.

Owner:ZHEJIANG BILI POLYMER TECH CO LTD

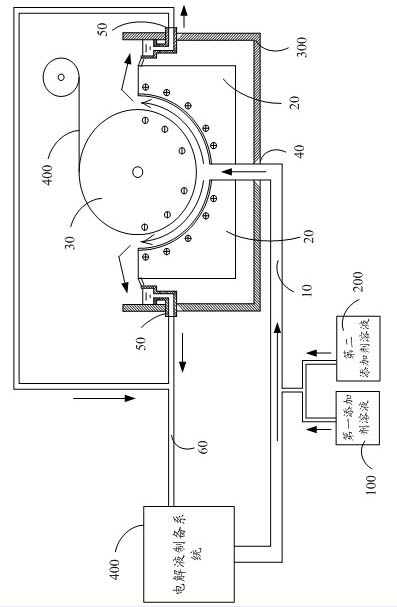

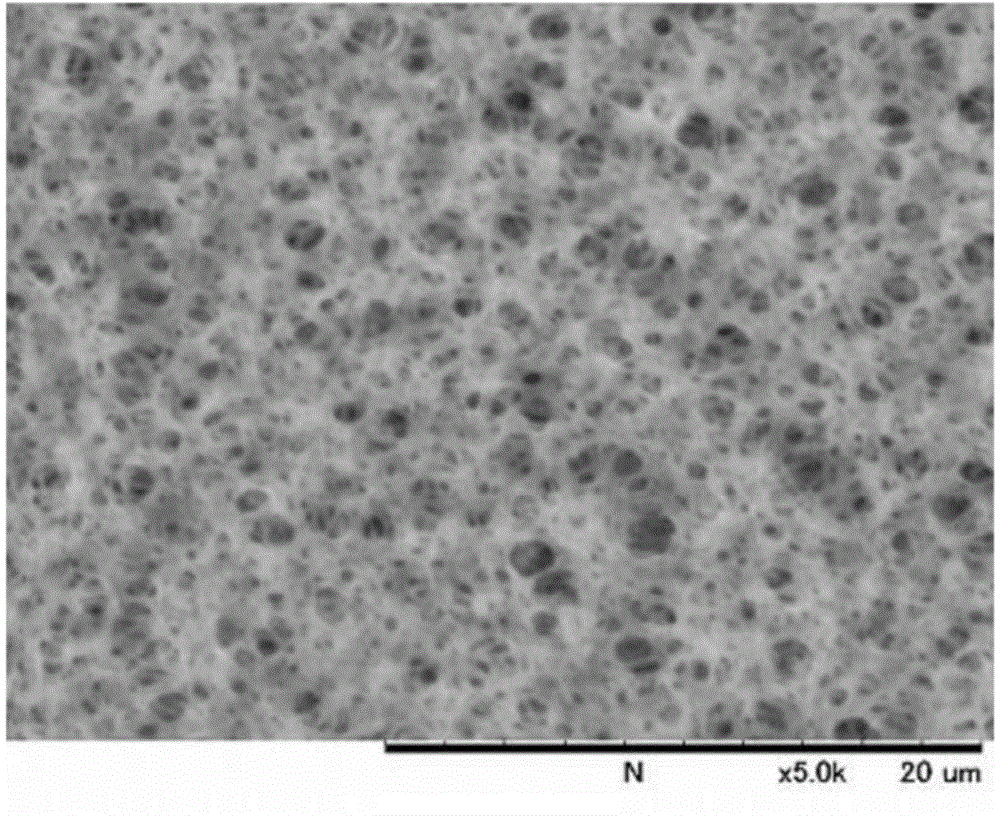

Microporous laminated membrane and method for producing the same

InactiveCN104999745AStable manufacturingGood flexibilitySievingHybrid capacitor separatorsSurface roughnessPore diameter

Disclosed is a microporous laminated membrane including a nonwoven-fabric substrate and a microporous membrane. The microporous membrane is disposed on at least one side of the nonwoven-fabric substrate. The microporous membrane includes a multiplicity of interconnecting micropores. The micropores have an average pore diameter of from 0.01 to 10 μm. The microporous membrane has an arithmetic mean surface roughness Sa of 0.5 μm or less. The microporous laminated membrane has an air permeability of from 0.5 to 30 seconds. The microporous laminated membrane has a tensile strength of 4.0 N / 15 mm or more. The microporous laminated membrane does not undergo interfacial peeling between the substrate and the microporous membrane as a result of a tape peel test.

Owner:DAICEL CHEM IND LTD

A kind of halogen-free flame-retardant film grade polycarbonate material and preparation method thereof

The invention discloses a halogen-free antiflaming thin-film polycarbonate material and a preparation method thereof, aiming to solve the problem that the antiflaming grade, mechanical property and appearance quality of the existing thin film can not achieve use requirements. Different fire retardants are used for generating the synergy effect, the additive amount is small, the antiflaming performance is high, the thin film appearance quality is improved, and the flexibility and fold resistance of the polycarbonate material are improved. The halogen-free antiflaming thin-film polycarbonate material comprises the following components: 88-95% of PC (polycarbonate) resin, 2-8% of copolymer, 1-3% of phosphorus-containing fire retardant, 0.1-0.5% of silicon-containing fire retardant, 0.1-0.8% of sulfur-containing fire retardant, 0.1-0.8% of anti-drippage agent and 0.5-2% of carbon black. The halogen-free antiflaming thin-film polycarbonate material is used for producing the antiflaming polycarbonate thin film of which the thickness is 0.25-0.76mm, the antiflaming performance of the produced PC thin film reaches the UL94V-0 grade and has better mechanical performance, and the PC thin film can be used for the insulation protection of electrical and electronic elements, such as mobile phones, computer substrates, flat televisions, power supplies and the like.

Owner:SICHUAN COREMER CO LTD

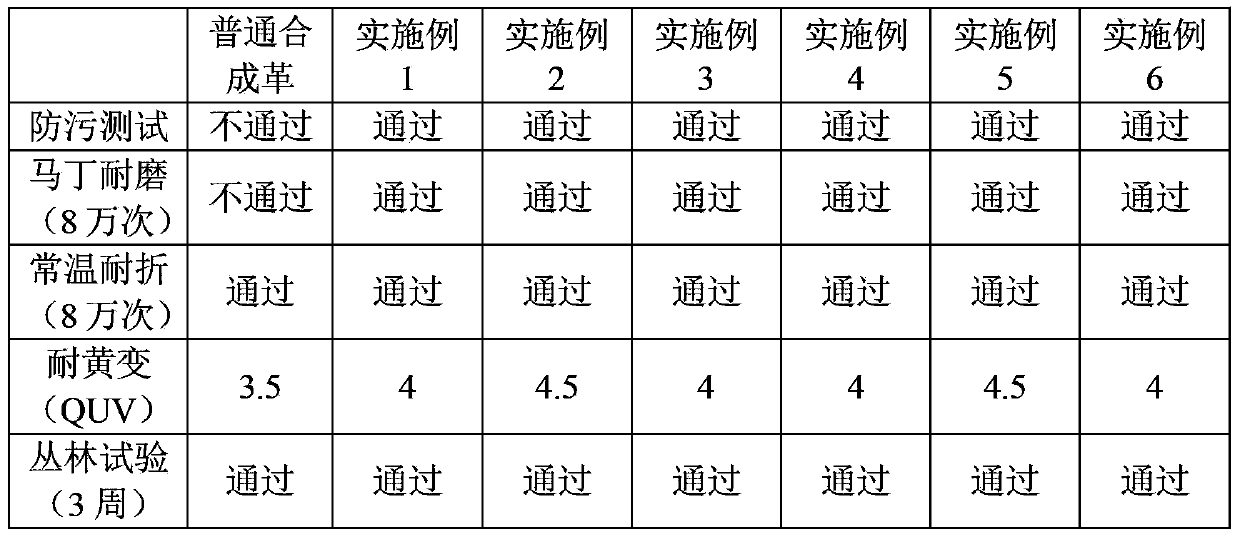

Manufacturing method for antifouling and doodle-preventing polyurethane (PU) synthetic leather

InactiveCN103361989ALower surface energyImprove wear resistanceSynthetic resin layered productsLaminationWork in processSlurry

The invention relates to a manufacturing method for antifouling and doodle-preventing polyurethane (PU) synthetic leather. The manufacturing method comprises the steps of (a) preparing a synthetic leather semi-product and unwinding the semi-product; (b) coating a layer of antifouling and doodle-preventing polyurethane work slurry on the surface of the semi-product by a post-finishing coating process; (c) drying the work slurry at a temperature of 130 DEG C-160 DEG C, wherein a drying and curing time is 1 min-5 min; and (d) cooling and winding to get the high antifouling and doodle-preventing polyurethane synthetic leather. By using a reactive organic fluorinated polyurethane resin or organic silicone polyurethane resin and curing and clinking at a high temperature after the post-finishing process, extremely low surface energy is given to the PU synthetic leather, so that the PU synthetic leather has excellent antifouling property and doodle-preventing property, and particularly can endure doodles by oil-based ink. The manufacturing method is simple in implementation process, and a finished product has excellent physical properties and hand feel.

Owner:慈文传媒股份有限公司

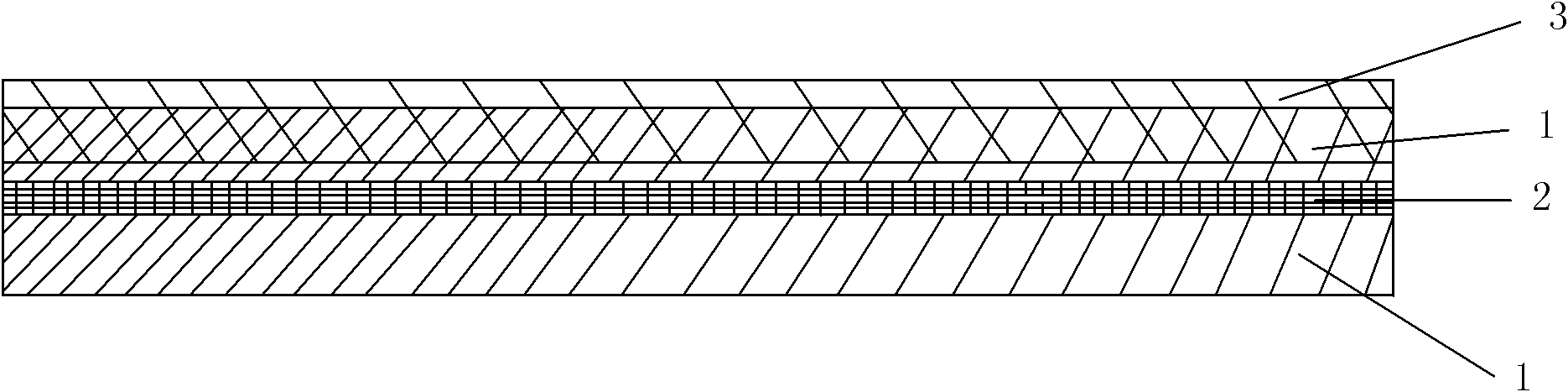

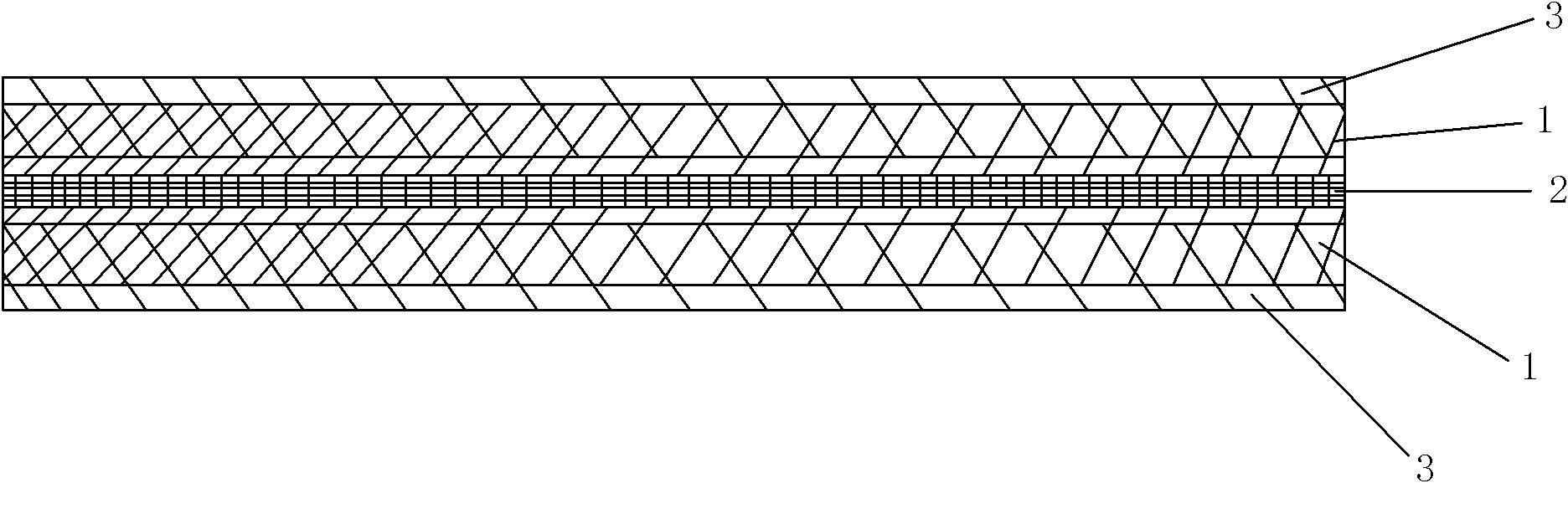

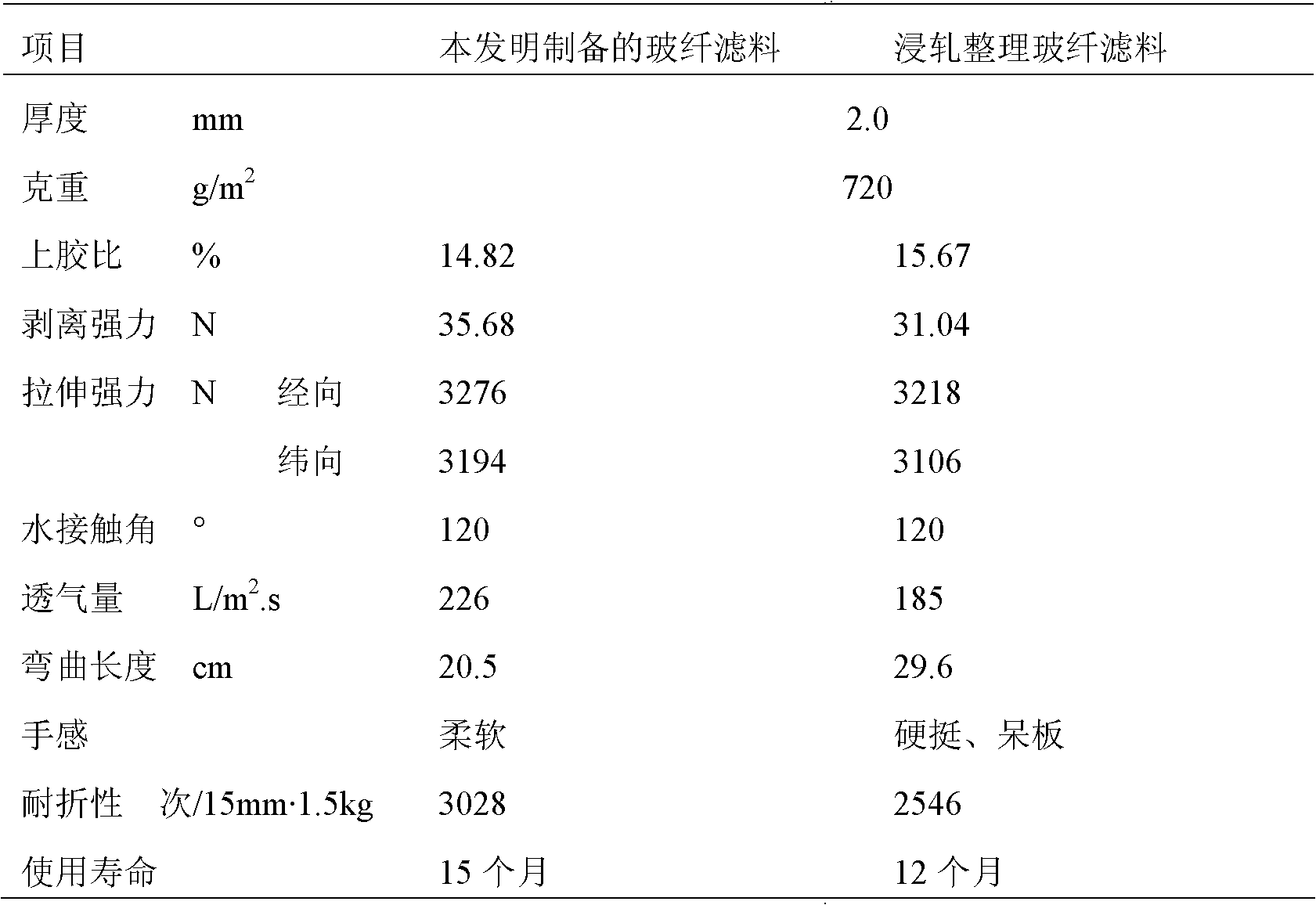

Glass fiber filter material and preparation method thereof

ActiveCN102151435AEvenly distributedReduce swimming phenomenonSynthetic resin layered productsGlass/slag layered productsGlass fiberFolding endurance

The invention discloses a glass fiber filter material and a preparation method thereof. The filter material comprises a base fabric, wherein the upper surface and the lower surface of the base fabric are respectively provided with a non-woven layer, and at least one of the non-woven layers is internally and externally provided with a foam coating layer respectively. The preparation method of the glass fiber filter material comprises the following steps of: manufacturing the glass fiber filter material, preparing finishing agent, generating foam, coating, and drying. The glass fiber filter material is subject to foaming layer arrangement, and the concentration of the finishing agent is increased, so that the finishing agent is distributed in the filter material more evenly, the migration phenomenon is reduced, and a mass of water resource, electric energy and heat energy are saved; after the glass fiber filter material is finished, and the gluing quantity of the filter material is decreased to 7-15% from 12-25% during finishing in a leaching way, so that the glass fiber filter material is even in distribution of the gluing quantity, good in flexibility, stable in quality, chemical corrosion-resistant, good in water resistance and oil resistance, easy to dedust, easy for industrial production, free of the existing water and energy-wasting step of finishing in a padding way, goodin folding endurance, and long in service life at about 15 months.

Owner:南京际华三五二一环保科技有限公司

Method for manufacturing high-performance electromagnetic wave shielding fabric

InactiveCN101302719AImprove folding resistanceImprove oxidation discolorationPhysical treatmentMagnetic/electric field screeningSputteringFolding endurance

The invention discloses a production method for a high-efficiency electromagnetic wave shielding fabric in the production of textile industries, comprises the working procedures of vacuum sputtering metallic film plating, chemical metallic film plating and protective layer applying of a fabric substrate, and is characterized in that an applied protective layer takes mixed wave absorbing materials, which comprises acrylic ester paste, carbon powder, ferrite, nano ferrite, titanium dioxide, an organic silicone softening agent and an dispersing agent, the mixed wave absorbing materials are applied onto the surface of a fabric that passes through the vacuum sputtering metallic film plating and the chemical metallic film plating through the ways of extrusion coating with a serum roller, blade coating with a knife or printing coating with a circular screen, and are solidified at high temperature. The invention has the advantages that the high-efficiency electromagnetic wave shielding fabric produced achieves the superimposed effect of electromagnetic wave reflecting and absorbing and plasma activating, improves the electromagnetic wave shielding performance further to be larger than 90 dB, simultaneously raises the combining fastness between a plated film and the fabric substrate, and improves the folding resistance of the product and the oxidative stain property of the metallic film.

Owner:SHANGHAI WEAVING SCIENCE RESEARCH INSTITUTE CO LTD

Compound filter material, method and application thereof

InactiveCN101596384AExtended service lifeHigh acid and alkali resistanceFiltration separationFolding enduranceAntistatic agent

The invention discloses a compound filter material, a method and application thereof, and relates to a filter material. The invention provides a compound filter material which has good folding endurance, corrosion resistance and wear resistance and can be used as a high-temperature environment filter material, a method and application thereof. The compound filter material comprises the following components in percentage by mass: 1 to 99 percent of basalt fiber and 1 to 99 percent of polytetrafluoroethylene fiber. The preparation method comprises the following steps of: mixing the basalt fiber and the polytetrafluoroethylene fiber to obtain a mixed fiber; and adding an antistatic agent to the mixed fiber for mixing to obtain the compound filter material. According to the mass percentage, the adding amount of the antistatic agent is 0.1 to 20 percent of the mixed fiber. The compound filter material can be used for directly preparing composite filter cloth with single-layer structure or multi-layer structure, and the prepared composite filter cloth with single-layer structure or multi-layer structure can be used for producing a filter device.

Owner:厦门美达斯环保工业有限公司

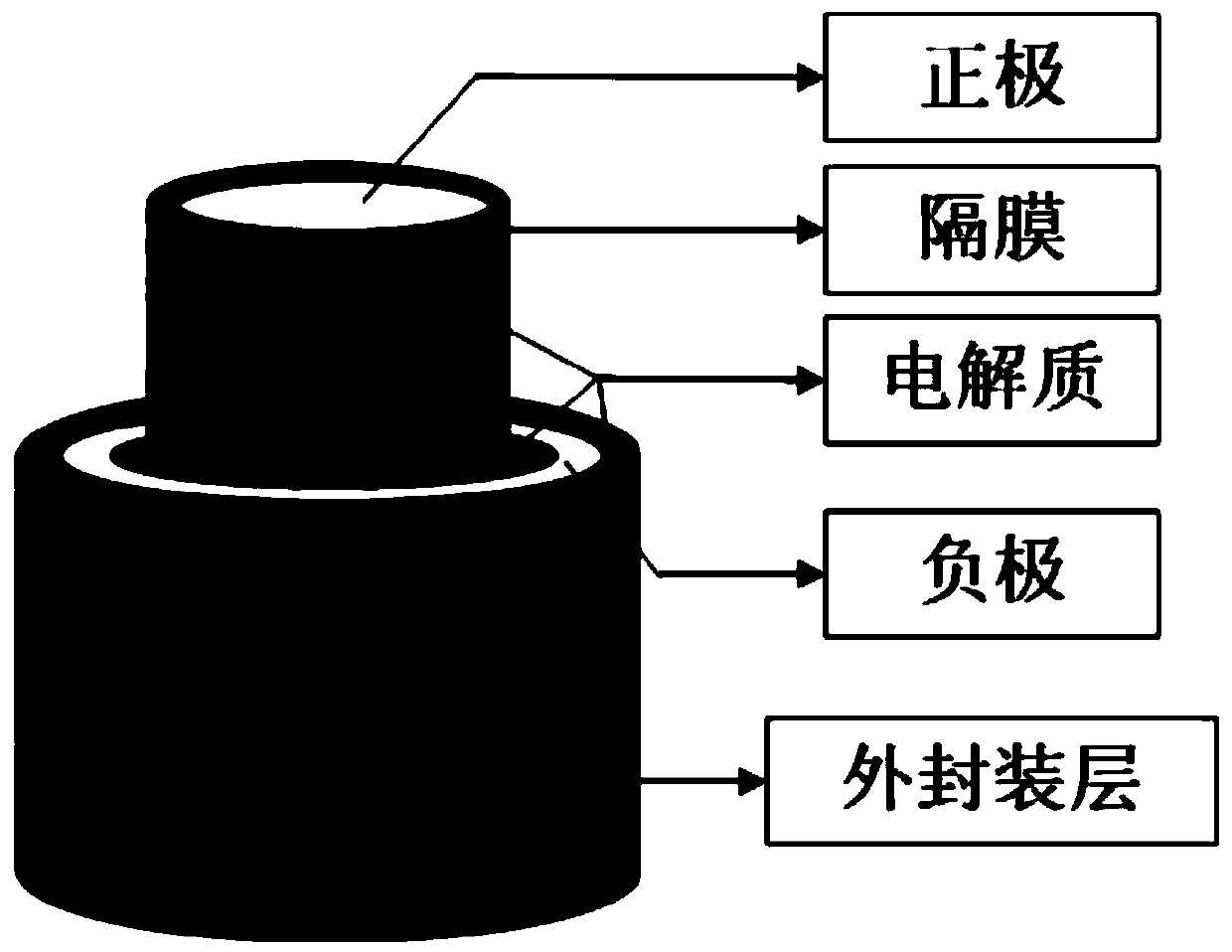

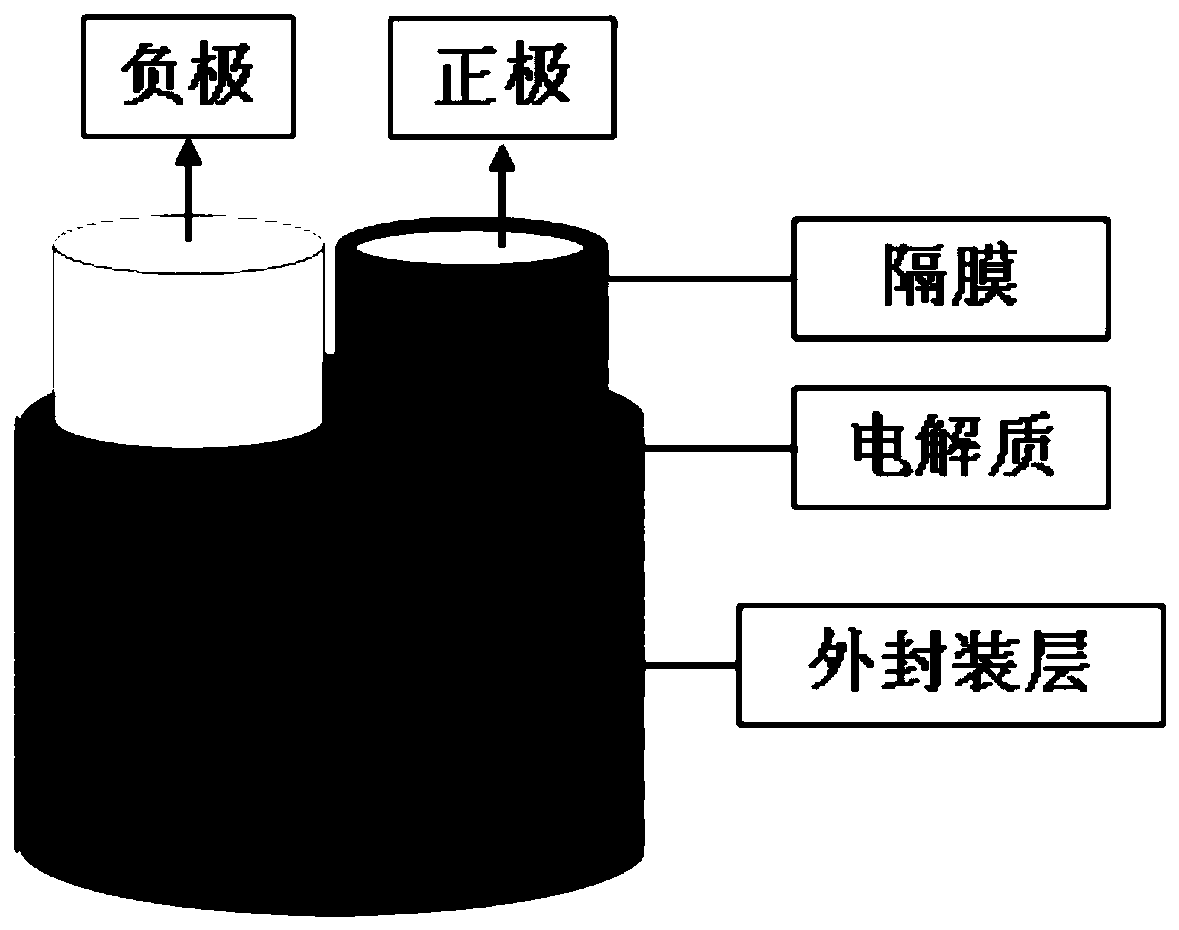

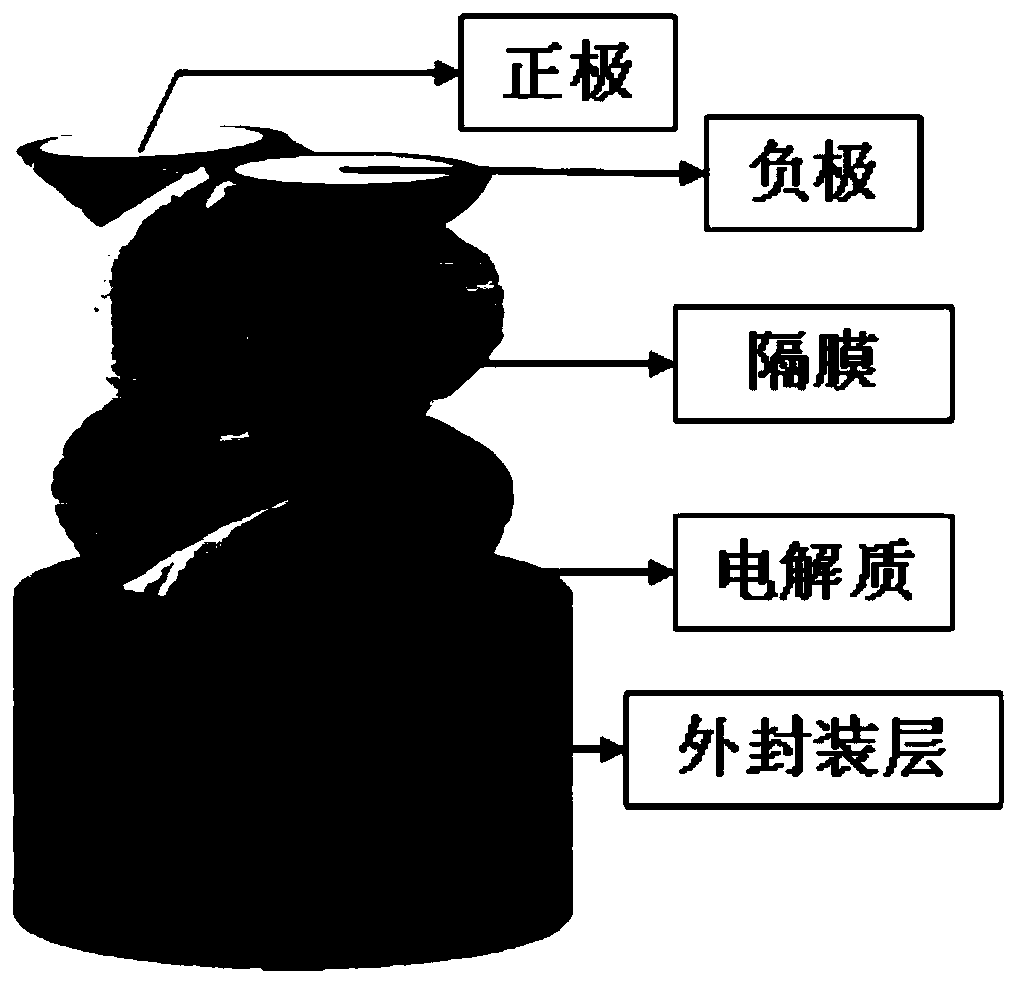

Folding-resistant one-dimensional fibrous flexible energy storage device and preparation method thereof

ActiveCN109979763AImprove folding resistanceImprove electrochemical stabilityHybrid capacitor separatorsFinal product manufactureFiberEngineering

The invention discloses a folding-resistant one-dimensional fibrous flexible energy storage device and a preparation method thereof. The preparation method comprises the following steps: at least by adopting an electrostatic spinning mode or a 3D printing mode, a first nano-fiber membrane used as a diaphragm on a surface of a first electrode in situ is formed, and the first nano-fiber membrane isused to wrap the first electrode; and the first electrode provided with the diaphragm in a wrapped way is assembled and combined with matched electrolyte and a second electrode to form the flexible energy storage device. According to the invention, the nano-fiber membrane is wrapped on the electrode of the flexible energy storage device in situ by adopting the electrostatic spinning way, the 3D printing way, and so on, so that the structure and the composition height of the membrane are controllable, and the membrane has very strong adsorbability and high flexibility; and especially, after theflexible energy storage device is repeatedly folded, the membrane can still be tightly combined with the electrode, so that the problem of short circuit caused by mutual contact of the electrodes canbe prevented, and the folding resistance and the electrochemical stability of the flexible energy storage device are greatly improved.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

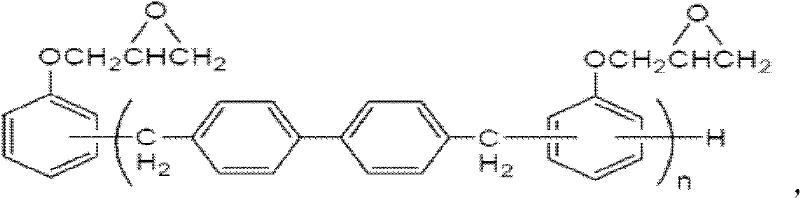

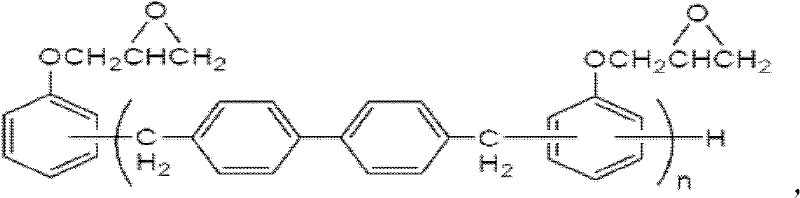

Thermosetting epoxy resin composition and epoxy fiberglass cloth-based copper clad laminate prepared from same

ActiveCN102304273AGood flexibilityReduced Tg loweredSynthetic resin layered productsGlass/slag layered productsPliabilityChemistry

The invention relates to a thermosetting epoxy resin composition and an epoxy fiberglass cloth-based copper clad laminate prepared from the same. The thermosetting epoxy resin composition comprises components of biphenyl epoxy resin, phenoxy oxygen epoxy resin and a curing agent. The epoxy fiberglass cloth-based copper clad laminate prepared from the thermosetting epoxy resin composition comprises a plurality of mutually overlapped prepregs, and copper foils arranged on one side or two sides of the overlapped prepregs, wherein each prepreg comprises fiberglass cloth and the thermosetting epoxy resin composition which is subjected to impregnated drying and attached to the fiberglass cloth. In the thermosetting epoxy resin composition, the phenoxy oxygen epoxy resin is adopted as a flexibilizer, and when the phenoxy oxygen epoxy resin is matched with the biphenyl epoxy resin, good flexibility is achieved and the amplitude of reducing the glass transition temperature (Tg) of a prepared board can be reduced. The epoxy fiberglass cloth-based copper clad laminate prepared from the thermosetting epoxy resin composition has good flexibility and folding resistance, and the flexibility is obviously improved, so that the epoxy fiberglass cloth-based copper clad laminate can partially replace high-cost flexible copper clad laminate in places such as rigid-flex boards, static flexibility, parallel lifting and the like.

Owner:GUANGDONG SHENGYI SCI TECH

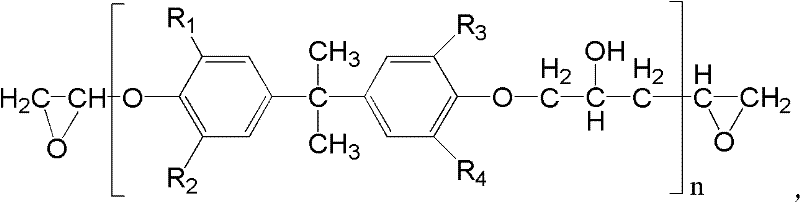

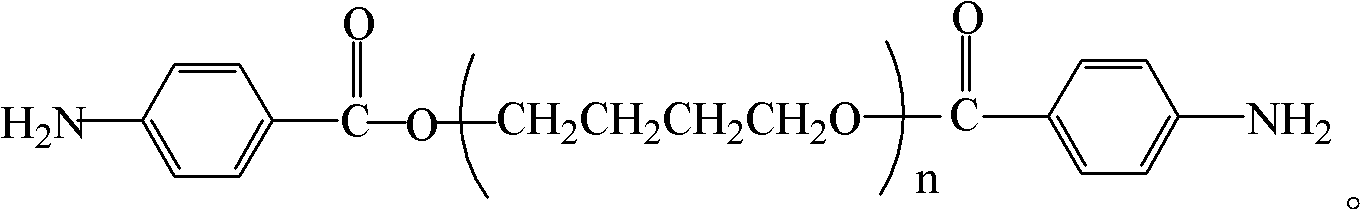

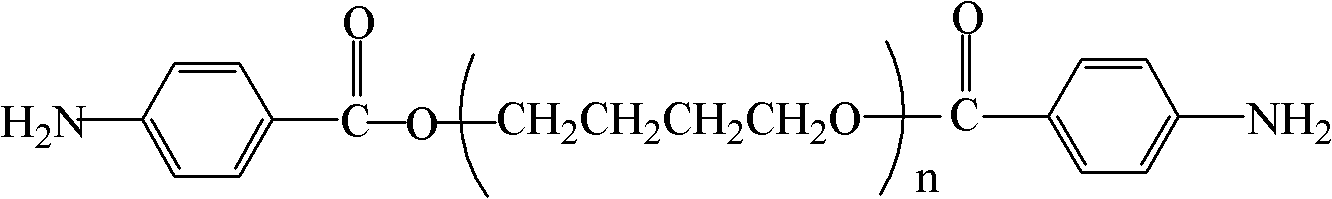

Epoxy resin composition and flexible copper-clad plate prepared from same

InactiveCN102127290AGood flexibilityLow in bromineNon-macromolecular adhesive additivesSynthetic resin layered productsEpoxyFolding endurance

The invention discloses an epoxy resin composition and a flexible copper-clad plate prepared from the same. The epoxy resin composition comprises brominated epoxy resin, rubber modified epoxy resin, butadiene-acrylonitrile rubber, a high-flexibility amine curing agent, an aromatic amine curing agent, a curing accelerator, an antioxidant, inorganic filler and an organic solvent. The flexible copper-clad plate prepared from the epoxy resin composition comprises a polyimide film, an epoxy resin composition coating coated on one or two faces of the polyimide film and a copper foil laminated on the epoxy resin composition coating. In the epoxy resin composition, the high-flexibility amine curing agent and the high-flexibility amine curing agent are taken as a composite curing system, so that the flexibility of the composition can be improved remarkably, the dosage of the butadiene-acrylonitrile rubber and the bromine content of the composition can be lowered, and the composition has high flexibility, flame retardance and heat resistance. The flexible copper-clad plate prepared from the composition has high heat resistance, peeling strength, dimensional stability, flexibility, folding endurance and processability.

Owner:GUANGDONG SHENGYI SCI TECH

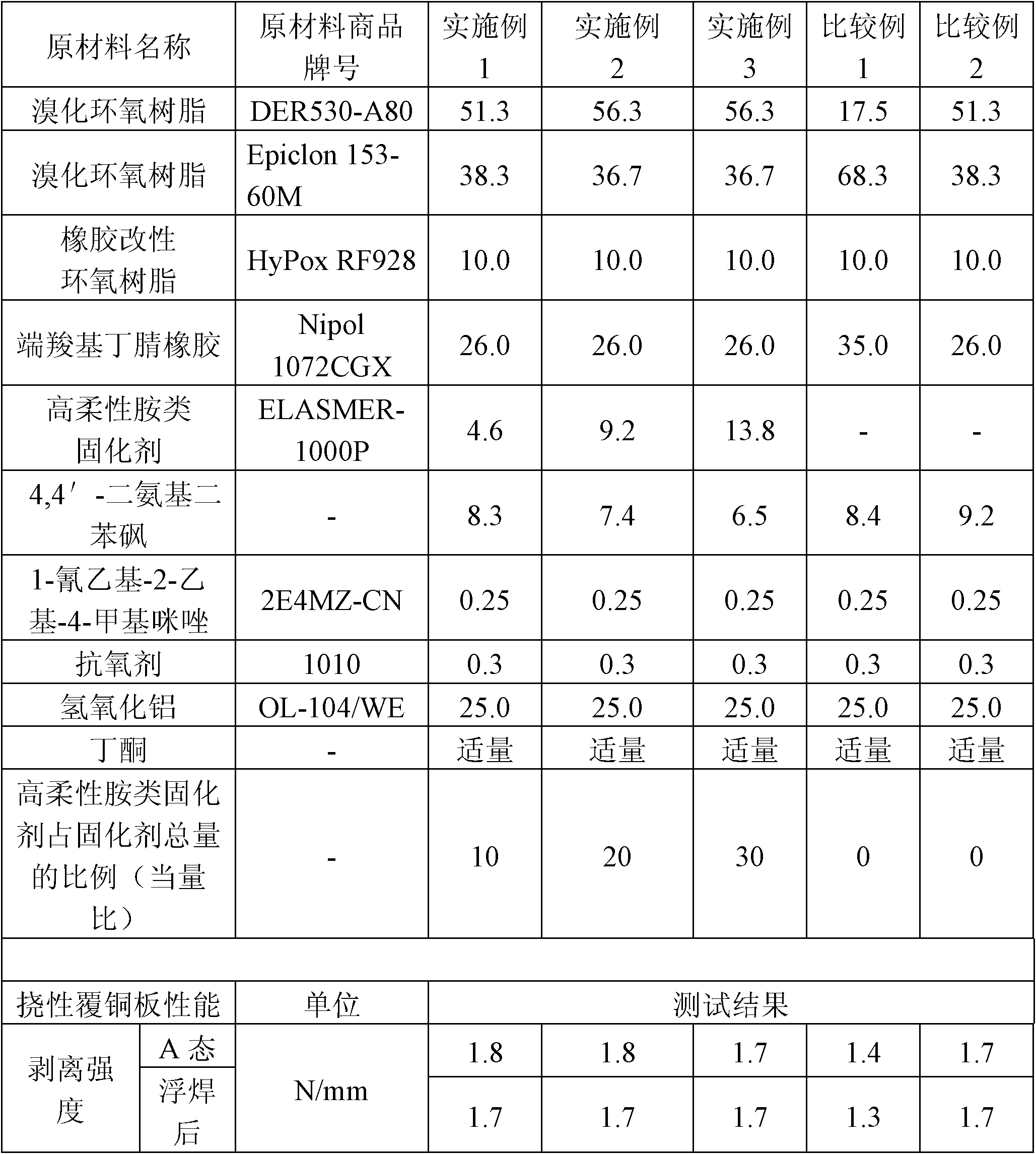

Organic silicon modified styrene-acrylate microemulsion reinforcing agent as well as preparation method and application thereof

ActiveCN104311716AStrong affinityImprove bindingReinforcing agents additionFunctional monomerChemistry

The invention discloses an organic silicon modified styrene-acrylate microemulsion reinforcing agent as well as a preparation method and application thereof. The preparation method comprises the following steps: firstly adding acrylic acid, hydroxyl-containing vinyl monomer, acrylate, styrene and organic silicon functional monomer into a reactor; adding a water-soluble initiator into the reactor for polymerisation; then cooling to room temperature and adding alkali for neutralizing; finally, slowly adding water into the reactor while stirring at a high speed to disperse so as to obtain the organic silicon modified styrene-acrylate microemulsion reinforcing agent. The organic silicon modified styrene-acrylate microemulsion reinforcing agent disclosed by the invention has the advantages of high binding force with paper fibers, good film forming performance and good water resistance and is applied to paper coating. Compared with the common styrene-acrylate emulsion, the organic silicon modified styrene-acrylate microemulsion reinforcing agent disclosed by the invention has the following advantages: the surface strength, folding endurance and wet-and-dry strength of the paper can be obviously improved, no organic solvent or surfactant is added in the preparation process, and the organic silicon modified styrene-acrylate microemulsion reinforcing agent is a high-performance environment-friendly paper-making and printing surface coating reinforcement product.

Owner:SHAANXI UNIV OF SCI & TECH

Heat-resistance type transfer aluminum plated paper and its producing process

InactiveCN101050605AImprove adhesionGood flexibilityNon-fibrous pulp additionPhysical paper treatmentAdhesiveHeat resistance

The present invention relates to a temperature-resistant type transfer aluminized paper and its production process. Said process successively includes the following steps: coating release layer on the film; coating anchoring layer on release layer; vacuum aluminizing on the anchoring layer; coating adhesive on the aluminized layer; then making them be combined with paper; stripping film from release layer so as to obtain the invented temperature-resistant type transfer aluminized paper.

Owner:SHAOGUAN DONGYANGGUANG PACKAGE PRINTING CO LTD

Semiconductive film, electric charge control member and process for production the semiconductive film

InactiveUS20070020450A1Improve the immunityNarrow in scatters of both thicknessSynthetic resin layered productsRecord information storageKetoneEther

A semiconductive film formed from a resin composition comprising poly(ether ether ketone) and a conductive filler, wherein the average value of its thickness is 30 to 250 μm, the maximum value of the thickness is 1 to 1.3 times as much as the minimum value thereof, the average value of its volume resistivity is 1.0×102 to 1.0×1014 Ωcm, the maximum value of the volume resistivity is 1 to 30 times as much as the minimum value thereof, and the number of reciprocating folds as determined in accordance with the testing method for folding endurance is at least 5,000 times, and a production process thereof.

Owner:KUREHA KAGAKU KOGYO KK

Method for producing environment-friendly false proof cover paper

ActiveCN101319475AImprove tear resistanceHigh folding resistanceNon-fibrous pulp additionNatural cellulose pulp/paperFiberTear resistance

The invention relates to a method for producing environment-friendly anti-counterfeiting cover paper. In the method, raw fibers with the purity of 100 percent are used to produce base paper; the raw fibers selected comprise the following components in weight portion: 50 to 65 percent of needle oil pulp,10 to 20 percent of silking pulp, and 20 to 30 percent of cotton pulp; the raw fibers are subjected to disintegration by a pulp plate, pulping treatment, blending, pulp conveying, forming by a head box, drying and dehydration and bundling reeling to produce the base paper, and the base paper is orderly subjected to dip dyeing, dip latex, base coating, anti-counterfeiting printing and top coating to produce the anti-counterfeiting cover paper. The cover paper has excellent tearing resistance and folding resistance and good anti-counterfeiting function. The method of the invention has the advantages of simple processing and manufacturing, low production cost and environmental protection, and has the tearing resistance and anti-counterfeiting function. The environment-friendly anti-counterfeiting cover paper is suitable for being manufactured into covers of all certificates, particularly a cover of an environment-friendly anti-counterfeiting passport.

Owner:SHANDONG KAILI SPECIAL PAPER

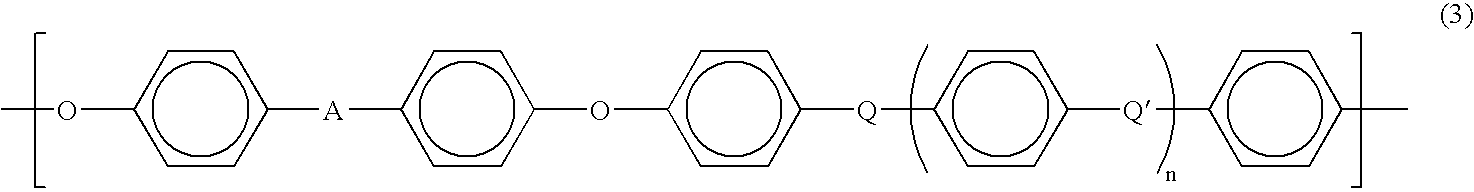

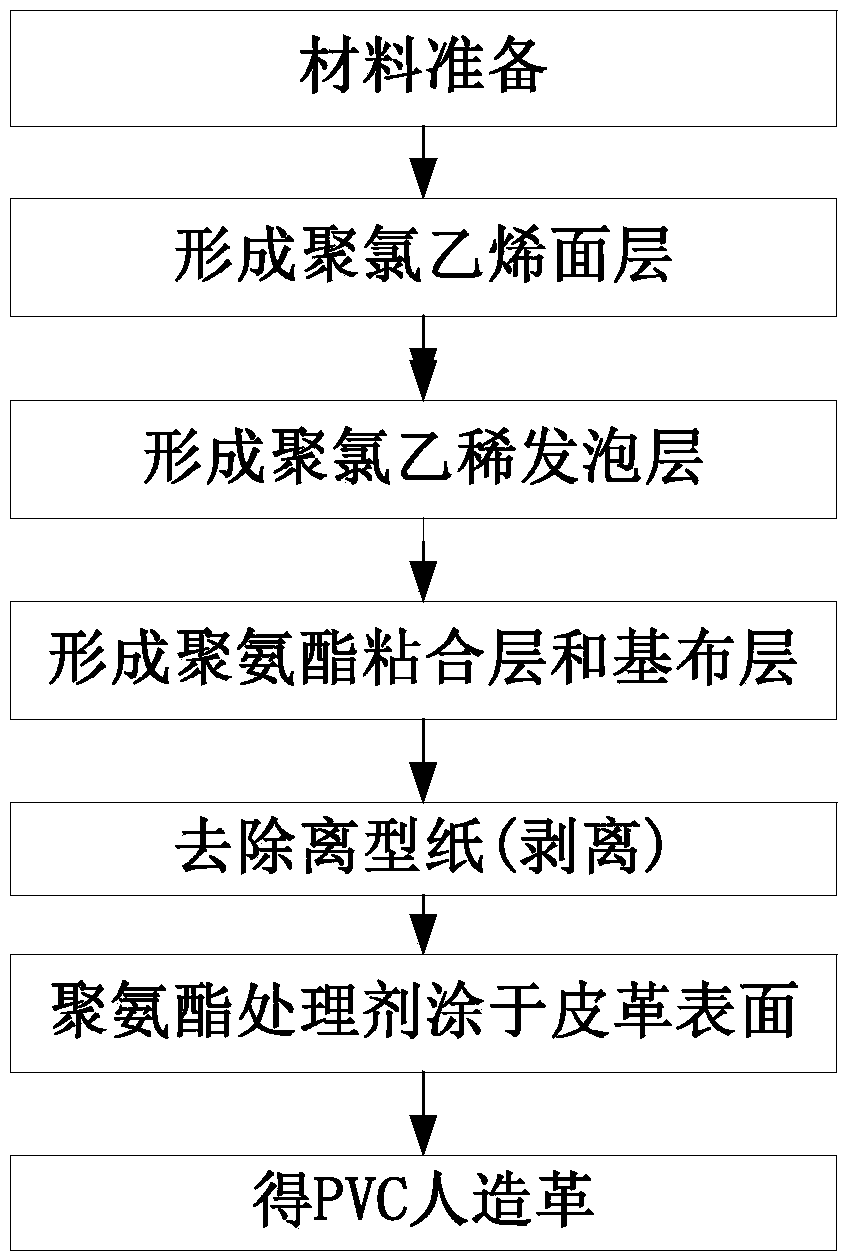

PVC artificial leather and its preparation method

InactiveCN104389194AImprove folding resistanceImprove scratch resistanceSynthetic resin layered productsCoatingsPolyurethane adhesiveSurface layer

The invention relates to the field of synthetic leather production, and especially relates to a PVC artificial leather and its preparation method. The preparation method of the PVC artificial leather comprises the following steps: 1, preparing materials; 2, coating release paper with a prepared PVC surface slurry to form a PVC surface layer; 3, coating the PVC surface layer with a prepared PVC foaming slurry to form a PVC foam layer; 4, coating the PVC foam layer with a prepared polyurethane adhesive to form a polyurethane adhesion layer and a base cloth layer; 5, removing the release paper; 6, carrying out roller coating on the surface of leather by using a prepared polyurethane treatment agent; and 7, drying, and carrying out cooling molding to form the PVC artificial leather. Compared with present products, the PVC artificial leather prepared through the method, having the PVC surface layer, has the advantages of increased bending strength and scraping resistance, firm handfeel and good physical properties, and can resist bending 100000 times.

Owner:FUJIAN POLYTECH TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com