Glass fiber filter material and preparation method thereof

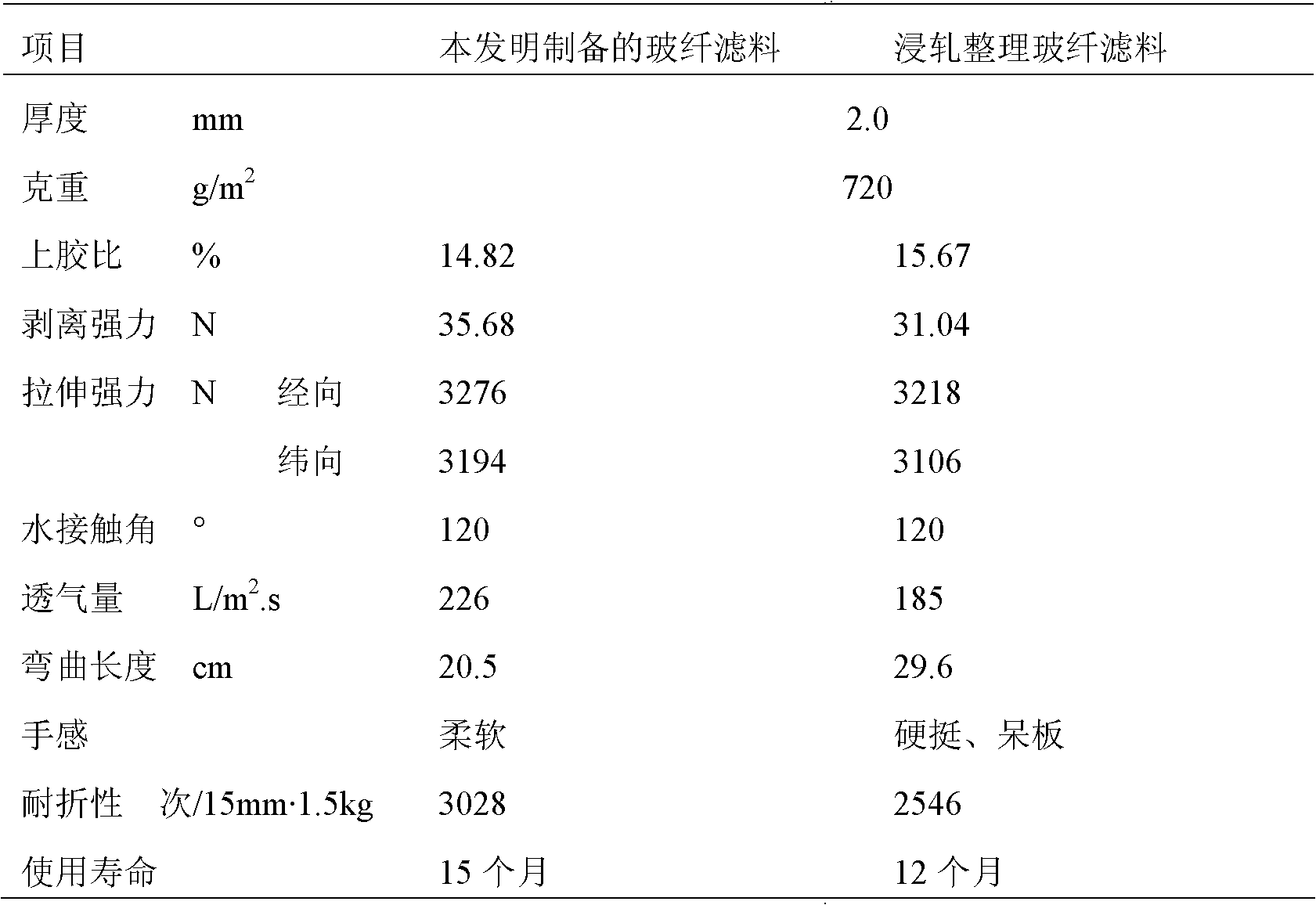

A filter material and glass fiber technology, which is applied in the field of glass fiber filter material post-processing technology, can solve the problems of slow production speed, poor softness, high cost, etc., achieve uniform distribution of glue, good water and oil repellency, The effect of easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

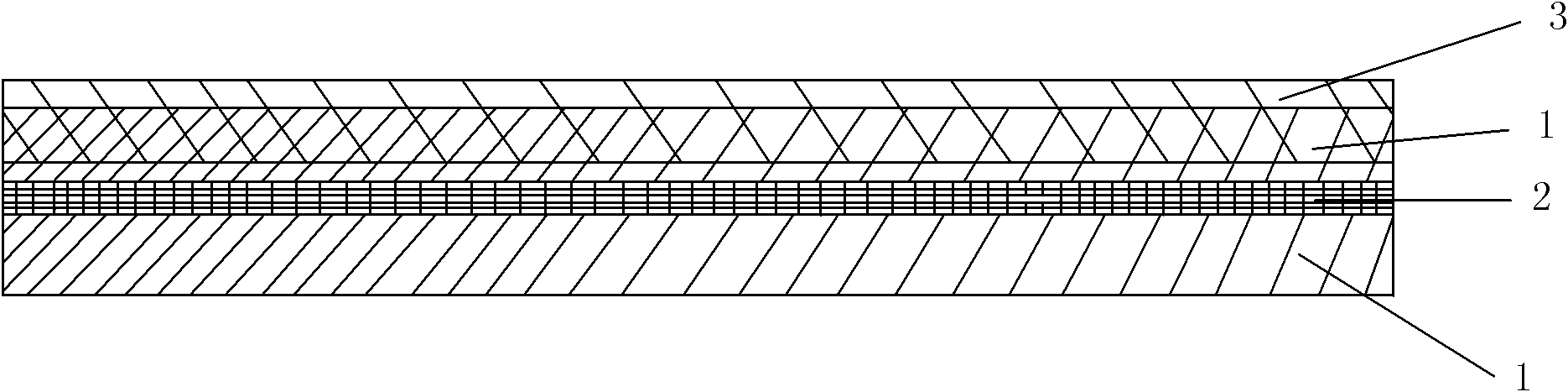

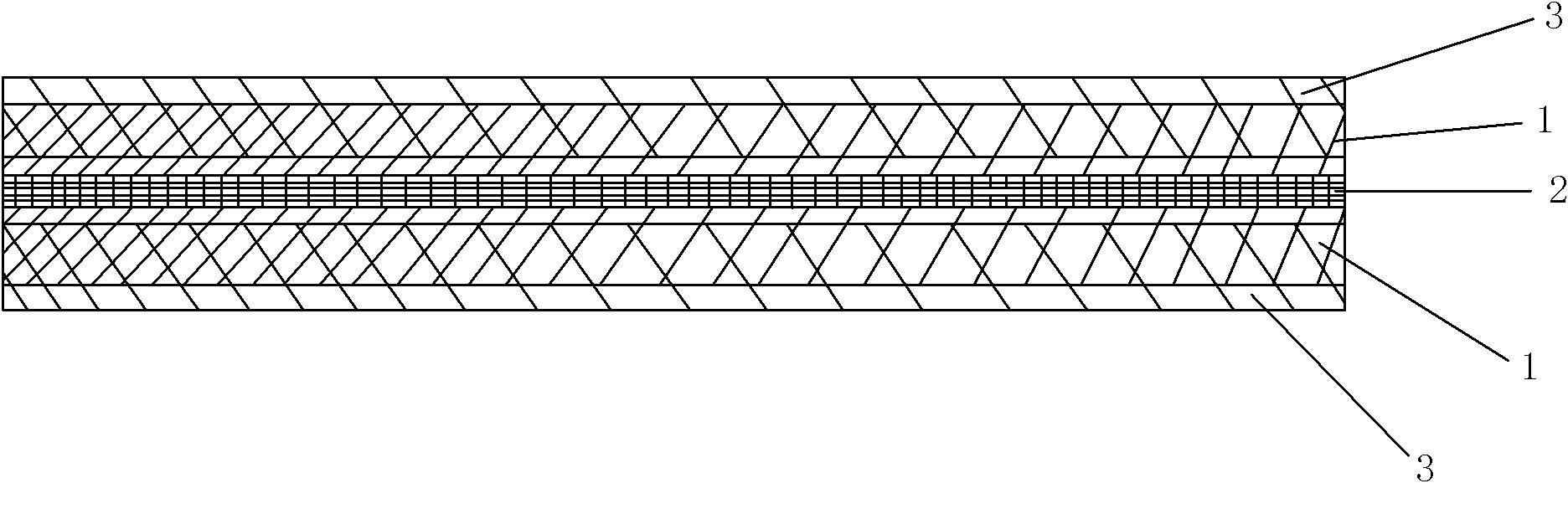

[0039] 1) Production of filter material: use glass fiber with a fineness of 5.5 μm and a length of 51 mm to prepare the filter material. The two layers are non-woven layers, and the middle layer is made of woven fabric. The weight is 708 g / m 2 , thickness 2.0mm.

[0040] 2) Preparation of finishing agent: polytetrafluoroethylene dispersion emulsion 350ml / L, high temperature resistant fluorine-containing polyacrylate softener 455ml / L, silicone water repellent agent 85ml / L, siloxane coupling agent 4.2ml / L , emulsifier 0.6ml / L, catalyst 0.10g / L, anionic foaming agent 3.0g / L, penetrant 2.8g / L, stabilizer 12.2g / L, mix the raw materials in the formula with water after stirring To 1 liter, the finishing liquid is uniform by mechanical stirring, and the viscosity of the finishing liquid is 68mPa·s.

[0041] Among them, the polytetrafluoroethylene dispersion emulsion has a solid content of 40% and a pH value of 7; the emulsifier is triethanolamine fatty acid salt; the inorganic salt c...

Embodiment 2

[0049] 1) Production of filter material: use glass fiber with a fineness of 4.5μm and a length of 60mm to prepare the filter material. The two layers are non-woven layers, and the middle layer is made of woven fabric. The weight is 685g / m 2 , thickness 1.9mm.

[0050] 2) Preparation of finishing agent: 400ml / L polytetrafluoroethylene dispersion emulsion, 400ml / L high temperature resistant fluorine-containing polyacrylate softener, 110ml / L silicone water repellent agent, 4.7ml / L silicone coupling agent , emulsifier 0.69ml / L, catalyst 0.22g / L, anionic foaming agent 9.8g / L, penetrant 16.6g / L, stabilizer 18.5g / L, mix the raw materials in the formula with water after stirring To 1 liter, the finishing solution is uniform through mechanical stirring, and the viscosity of the finishing solution is 82mPa·s.

[0051] Among them, the solid content of the polytetrafluoroethylene dispersion emulsion is 75%, and the pH value is 8; the emulsifier is polyoxyethylene alkylphenol ether sulfat...

Embodiment 3

[0059] 1) Production of filter material: use glass fiber with a fineness of 5.5 μm and a length of 51 mm to prepare the filter material. The two layers are non-woven layers, and the middle layer is made of woven fabric. The weight is 740 g / m 2 , thickness 1.8mm.

[0060] 2) Preparation of finishing agent: polytetrafluoroethylene dispersion emulsion 620ml / L, high temperature resistant fluorine-containing polyacrylate softener 100ml / L, silicone water repellent agent 170ml / L, silicone coupling agent 8.7ml / L , emulsifier 1.92ml / L, inorganic salt catalyst 1.55g / L, anionic foaming agent 20g / L, penetrant 38g / L, stabilizer 20g / L, mix each raw material in the formula with water after stirring To 1 liter, the finishing solution is uniform through mechanical stirring, and the viscosity of the finishing solution is 82mPa·s.

[0061] Wherein, the polytetrafluoroethylene dispersed emulsion has a solid content of 55%, and a pH value of 7.5; the emulsifier is an alkyl sulfonate; the catalyst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com