Patents

Literature

1235results about How to "Save heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

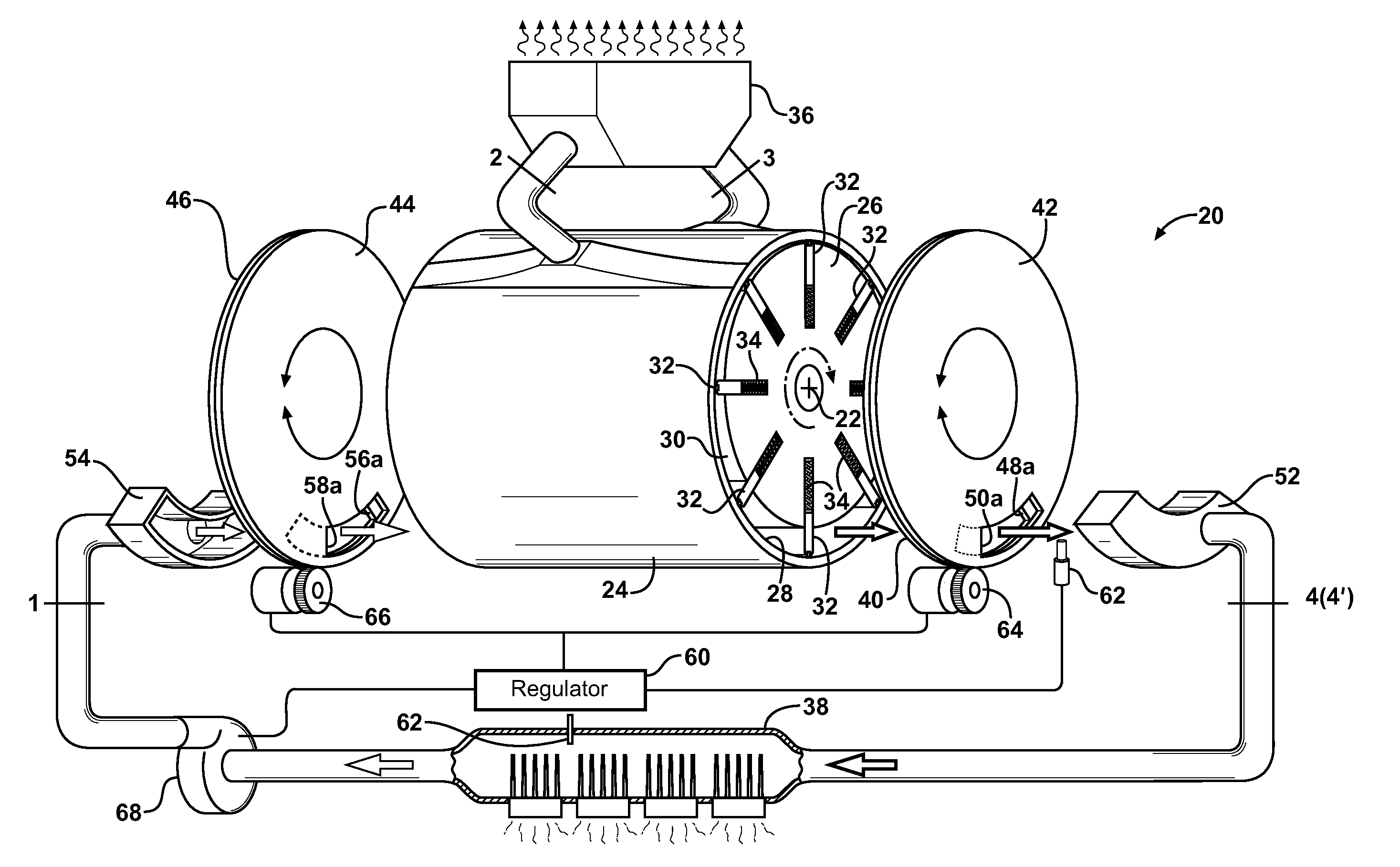

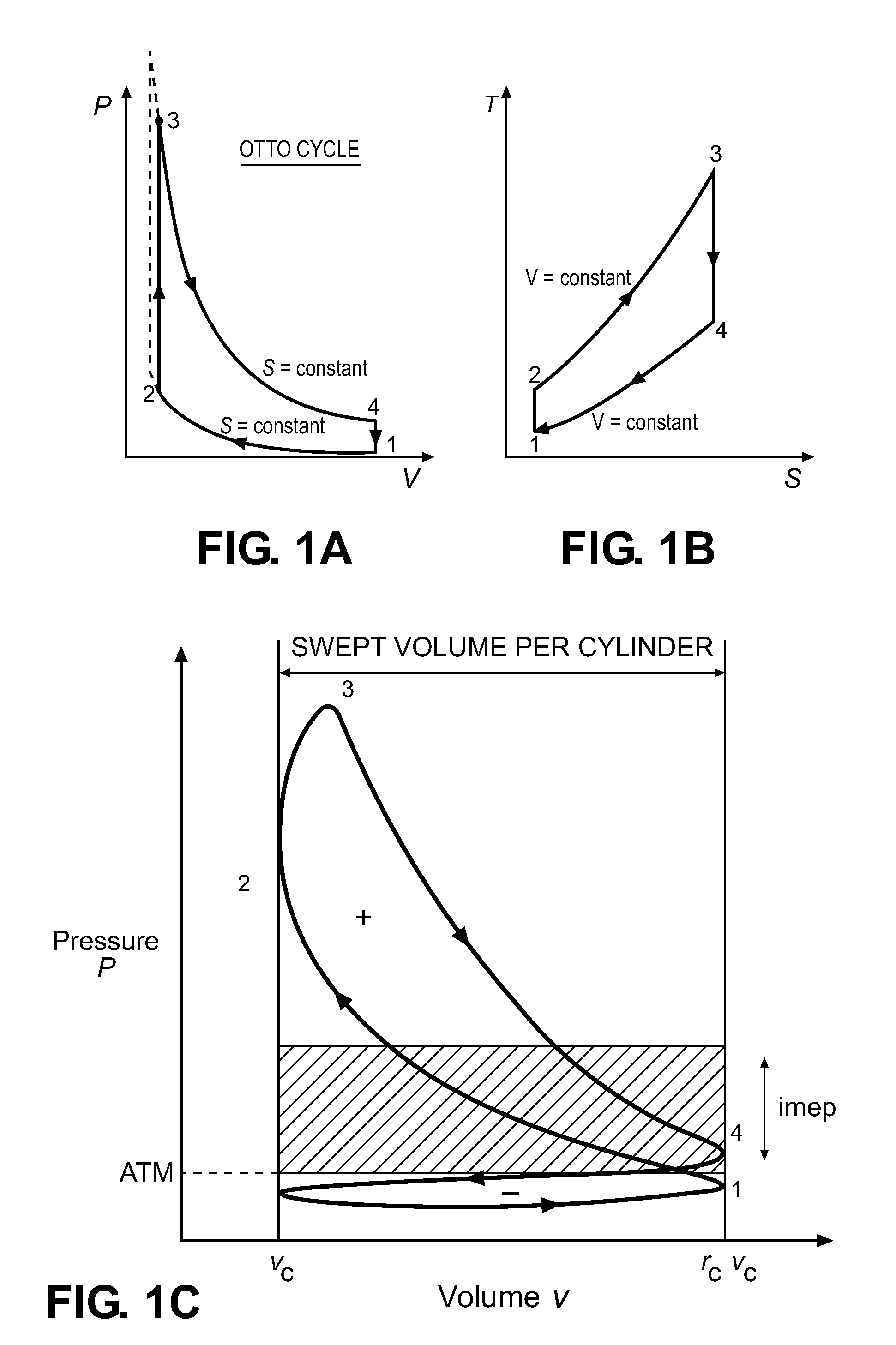

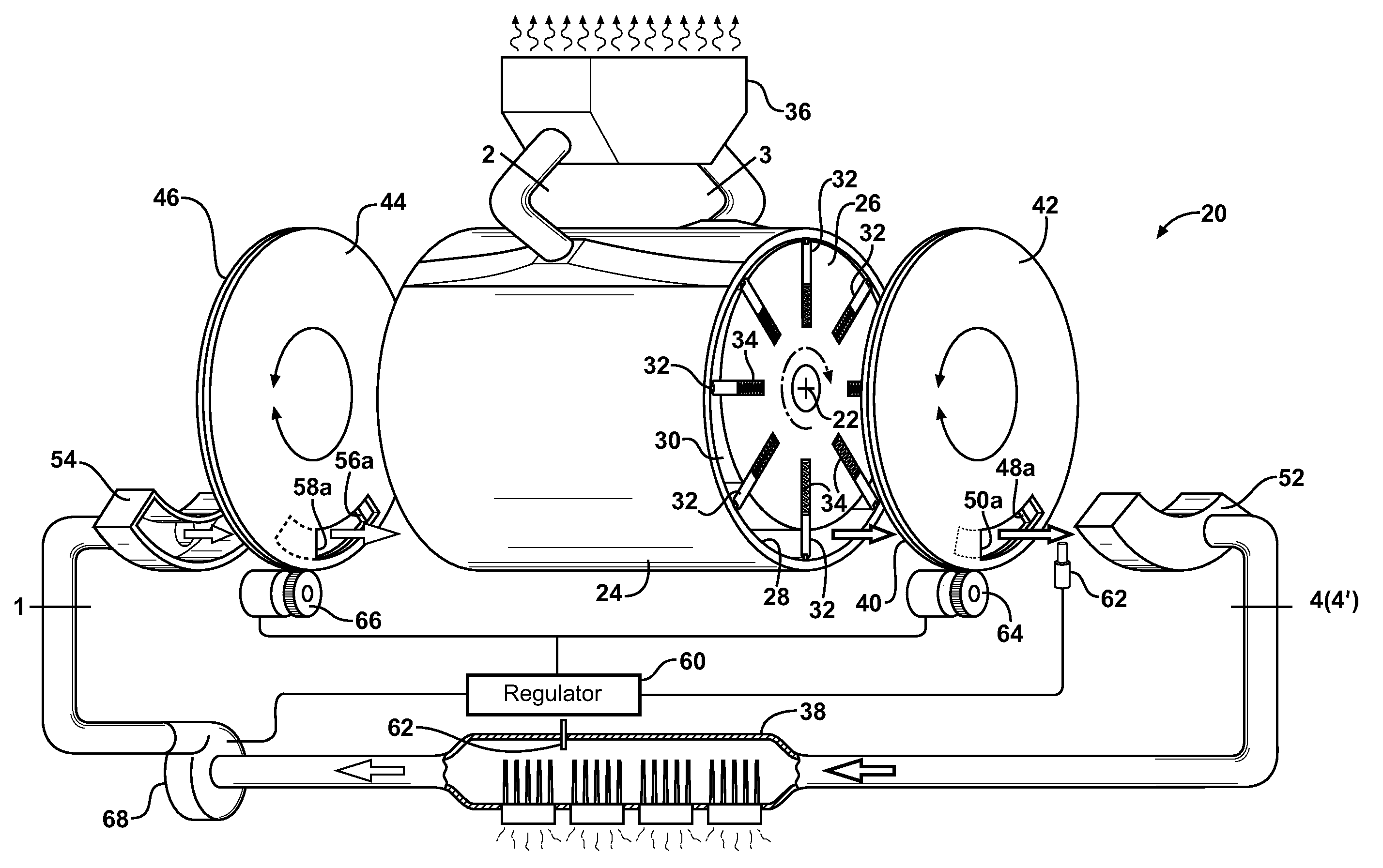

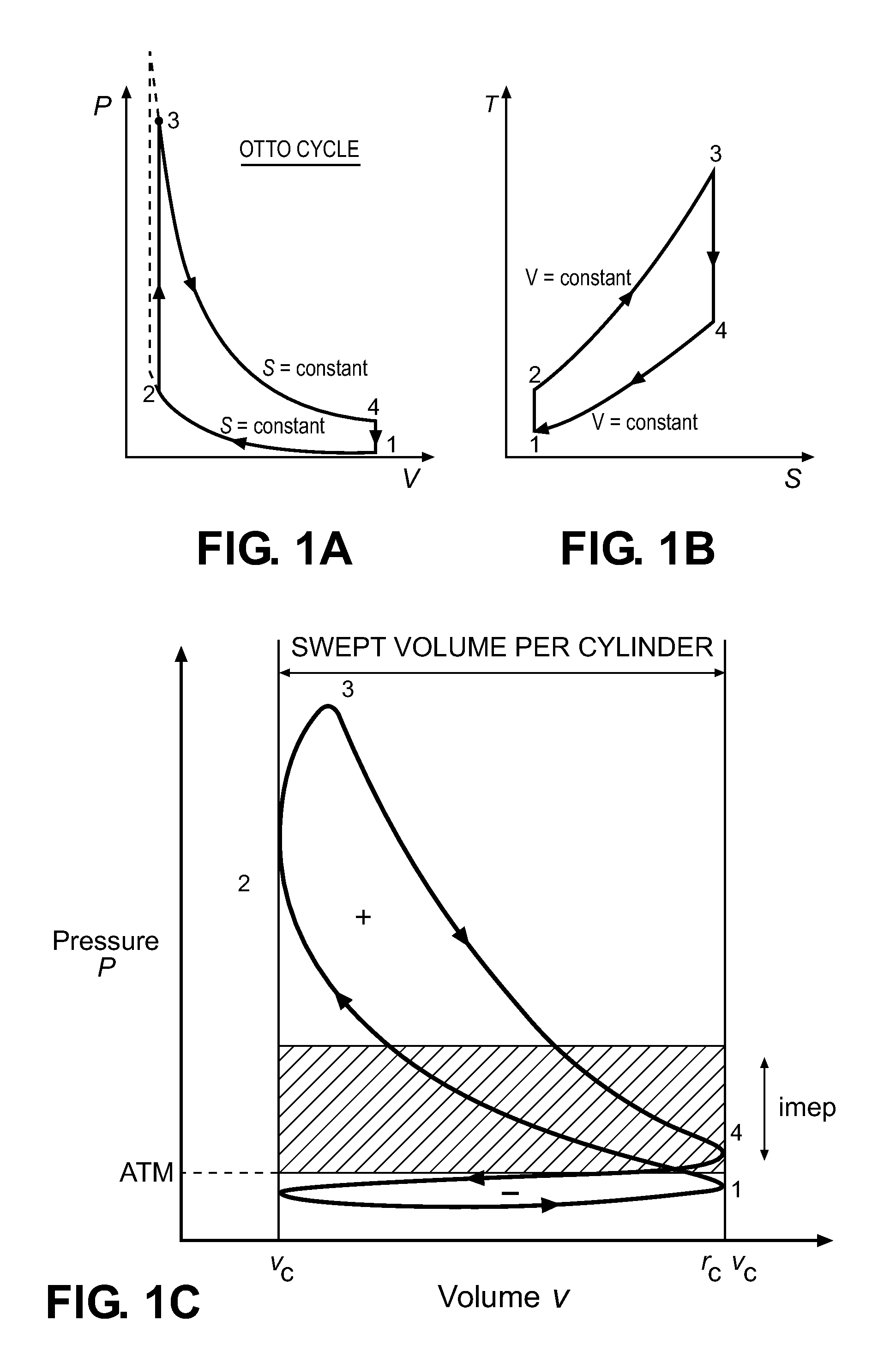

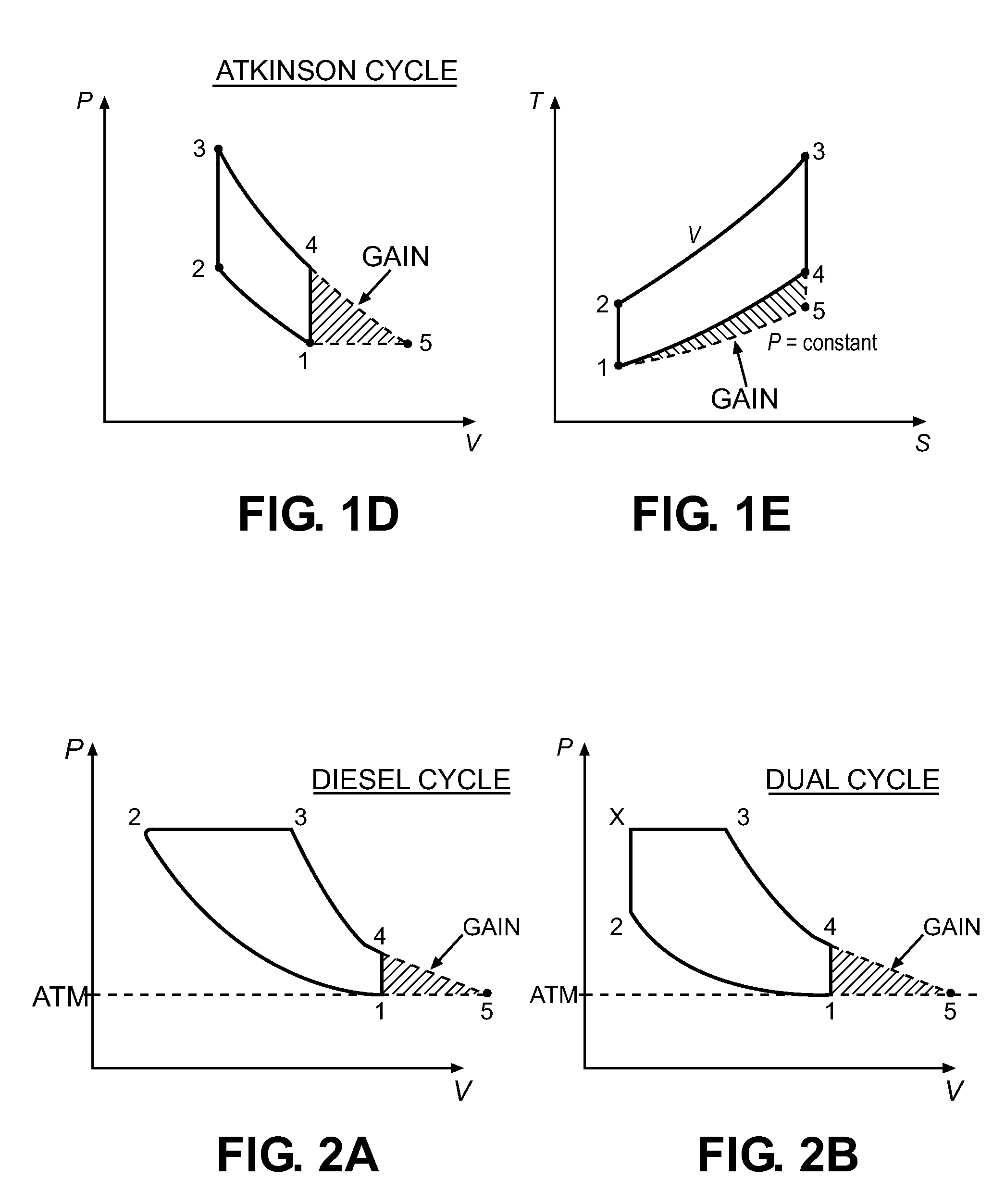

High efficiency positive displacement thermodynamic system

ActiveUS8424284B2Without decreasing volumetric efficiencySave heatInternal combustion piston enginesCombination enginesPower modeWorking fluid

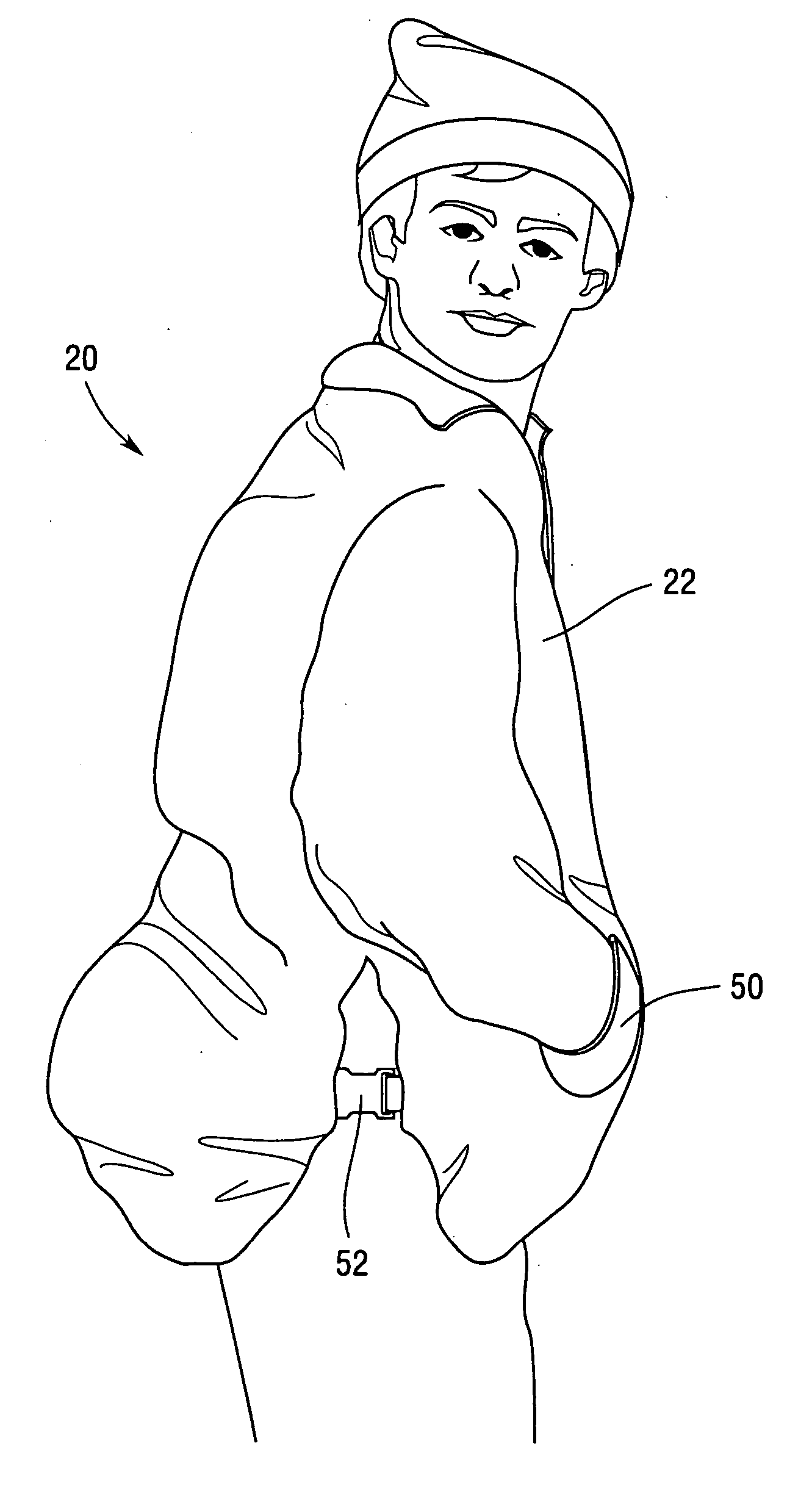

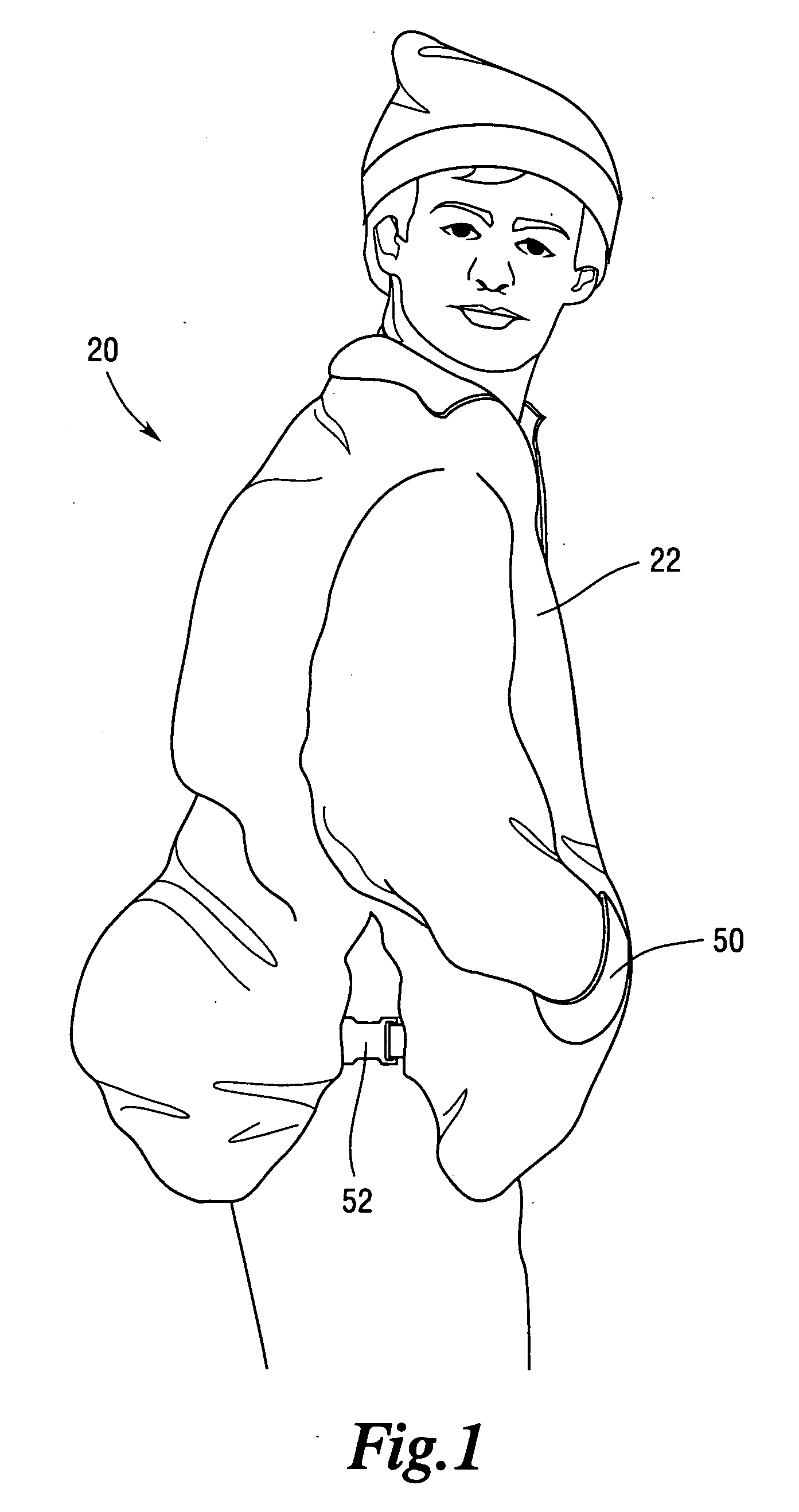

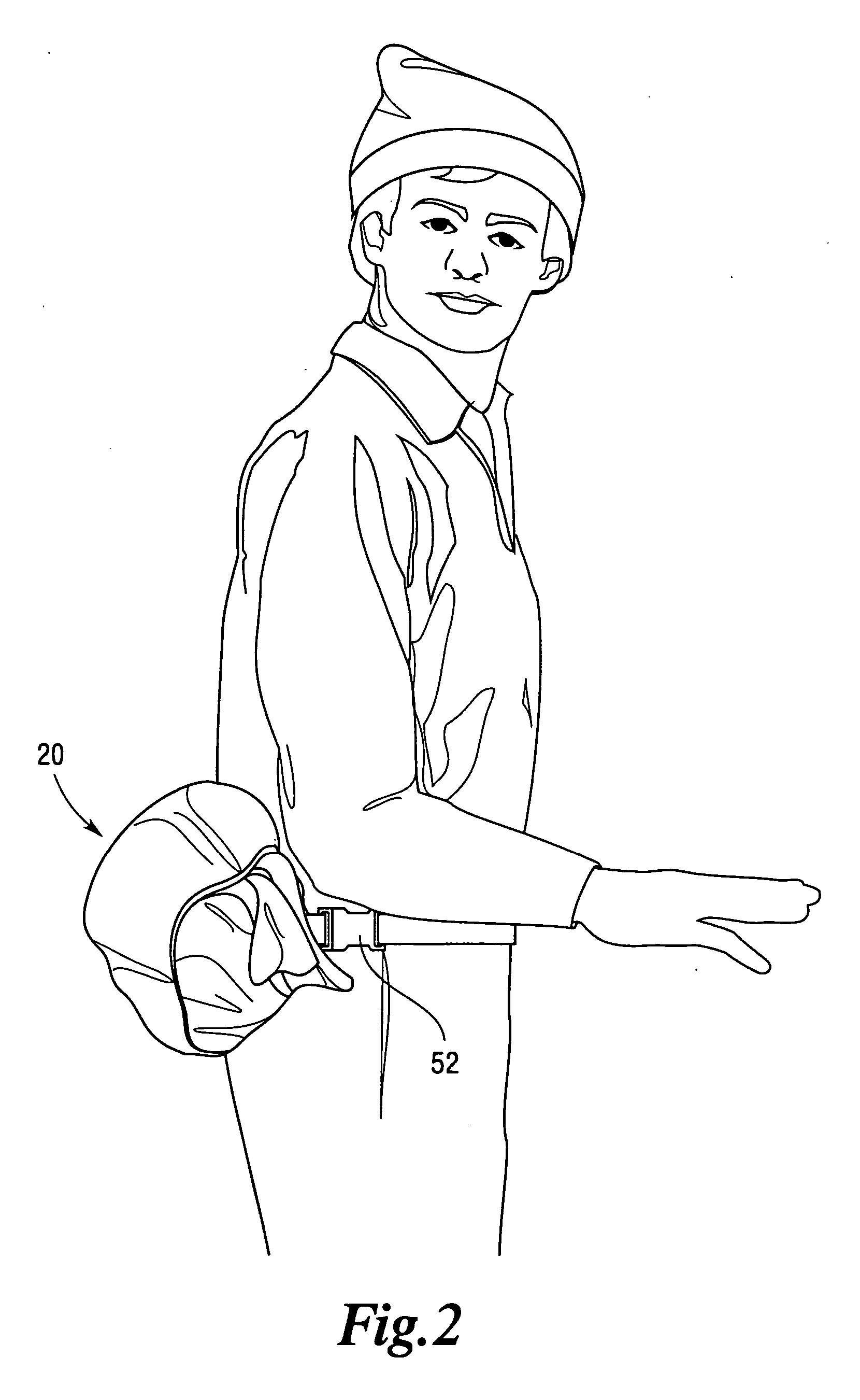

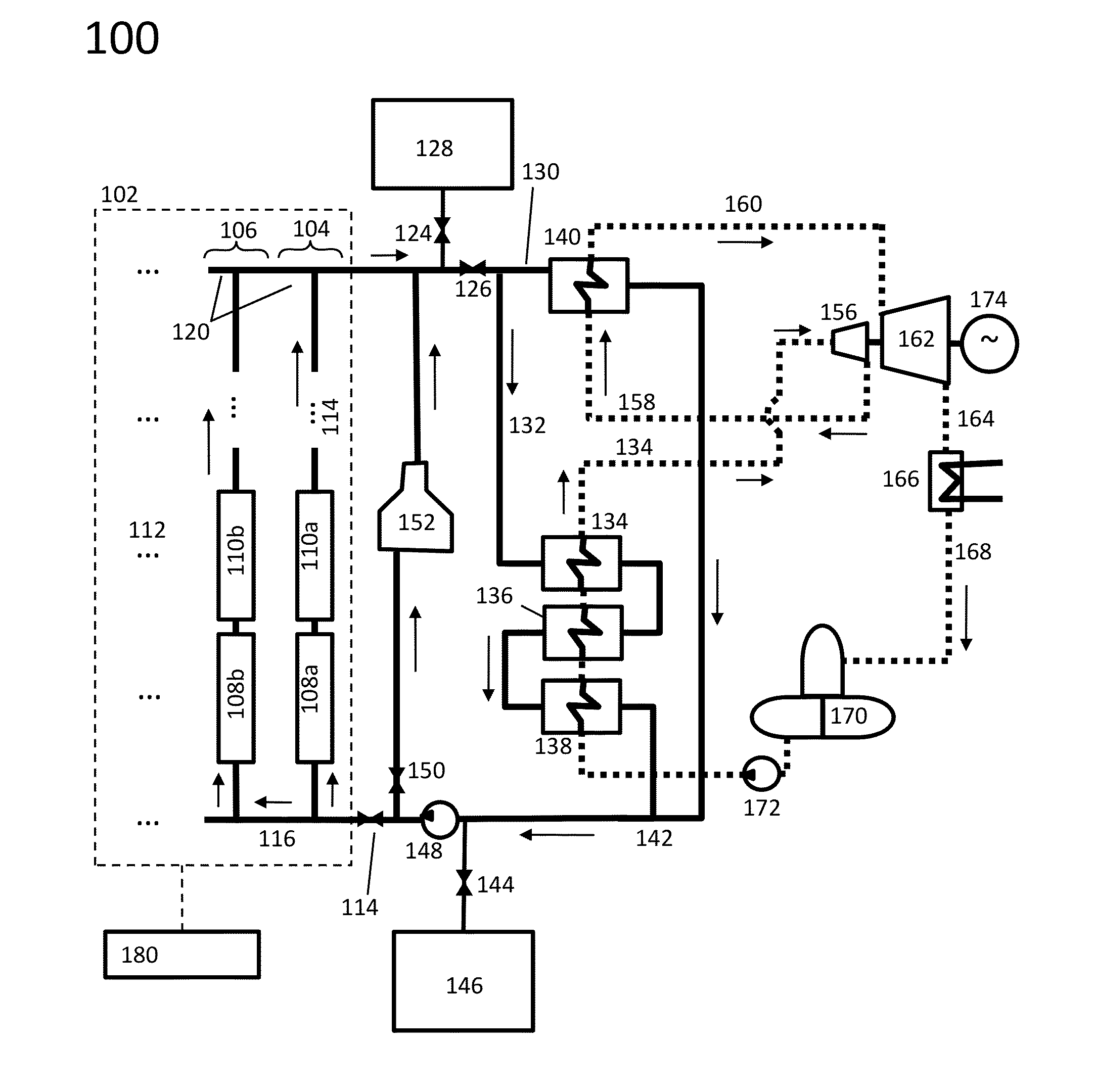

Devices and methods for moving a working fluid through a controlled thermodynamic cycle in a positive displacement fluid-handling device (20, 20′, 20″) with minimal energy input include continuously varying the relative compression and expansion ratios of the working fluid in respective compressor and expander sections without diminishing volumetric efficiency. In one embodiment, a rotating valve plate arrangement (40, 42, 44, 46) is provided with moveable apertures or windows (48, 50, 56, 58) for conducting the passage of the working fluid in a manner which enables on-the-fly management of the thermodynamic efficiency of the device (20) under varying conditions in order to maximize the amount of mechanical work needed to move the target quantity of heat absorbed and released by the working fluid. When operated in refrigeration modes, the work required to move the heat is minimized. In power modes, the work extracted for the given input heat is maximized.

Owner:STAFFEND GILBERT

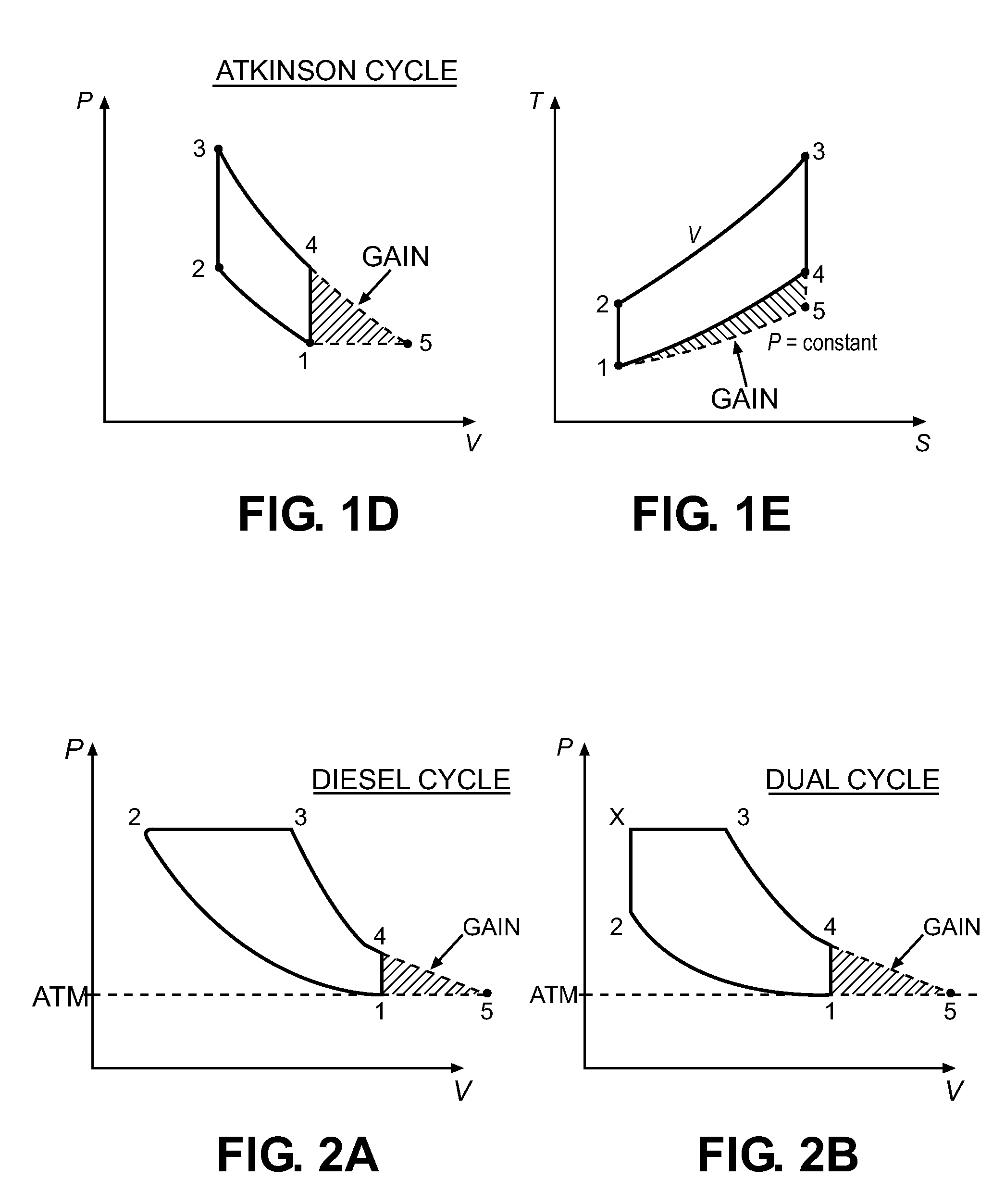

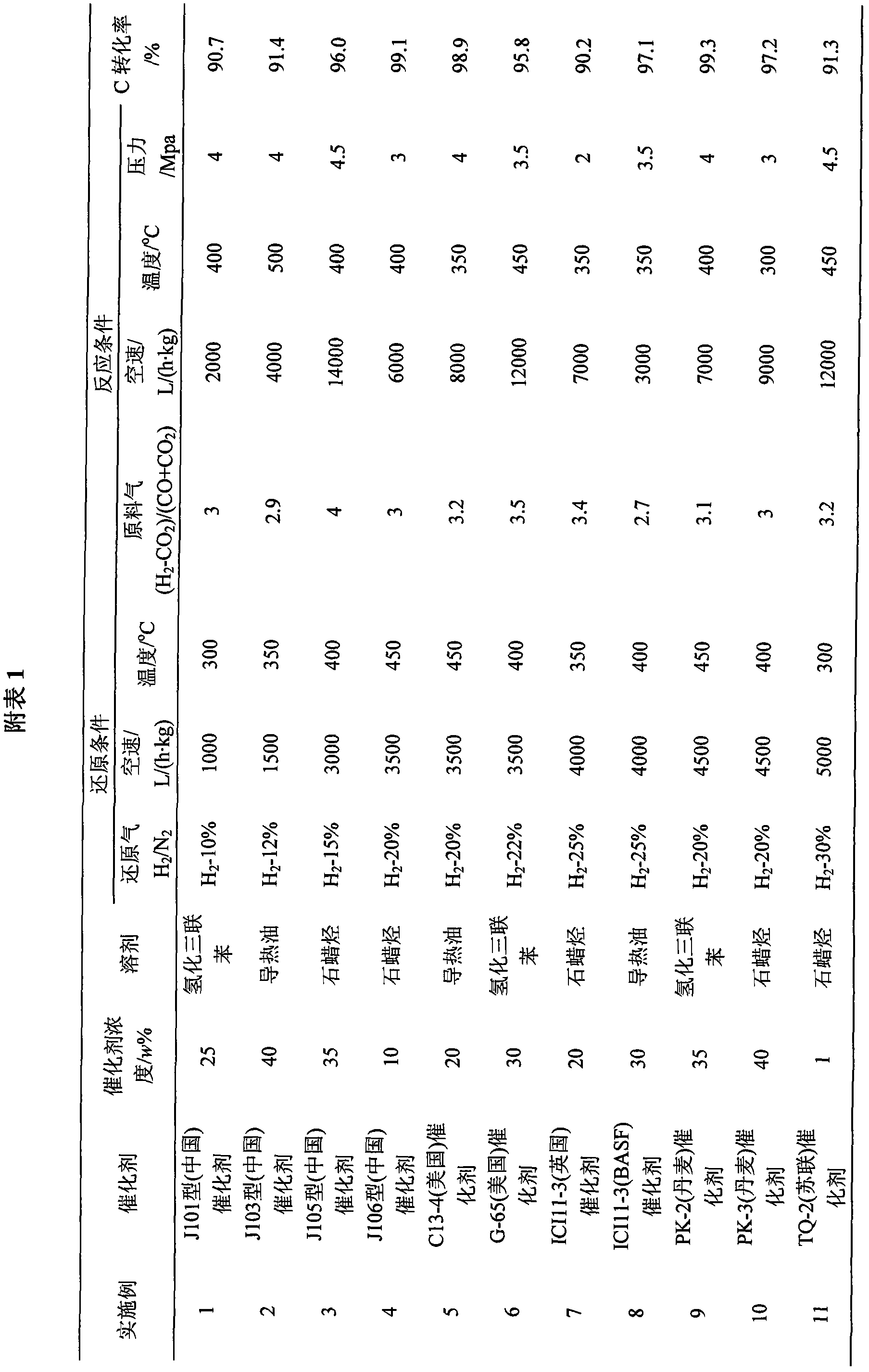

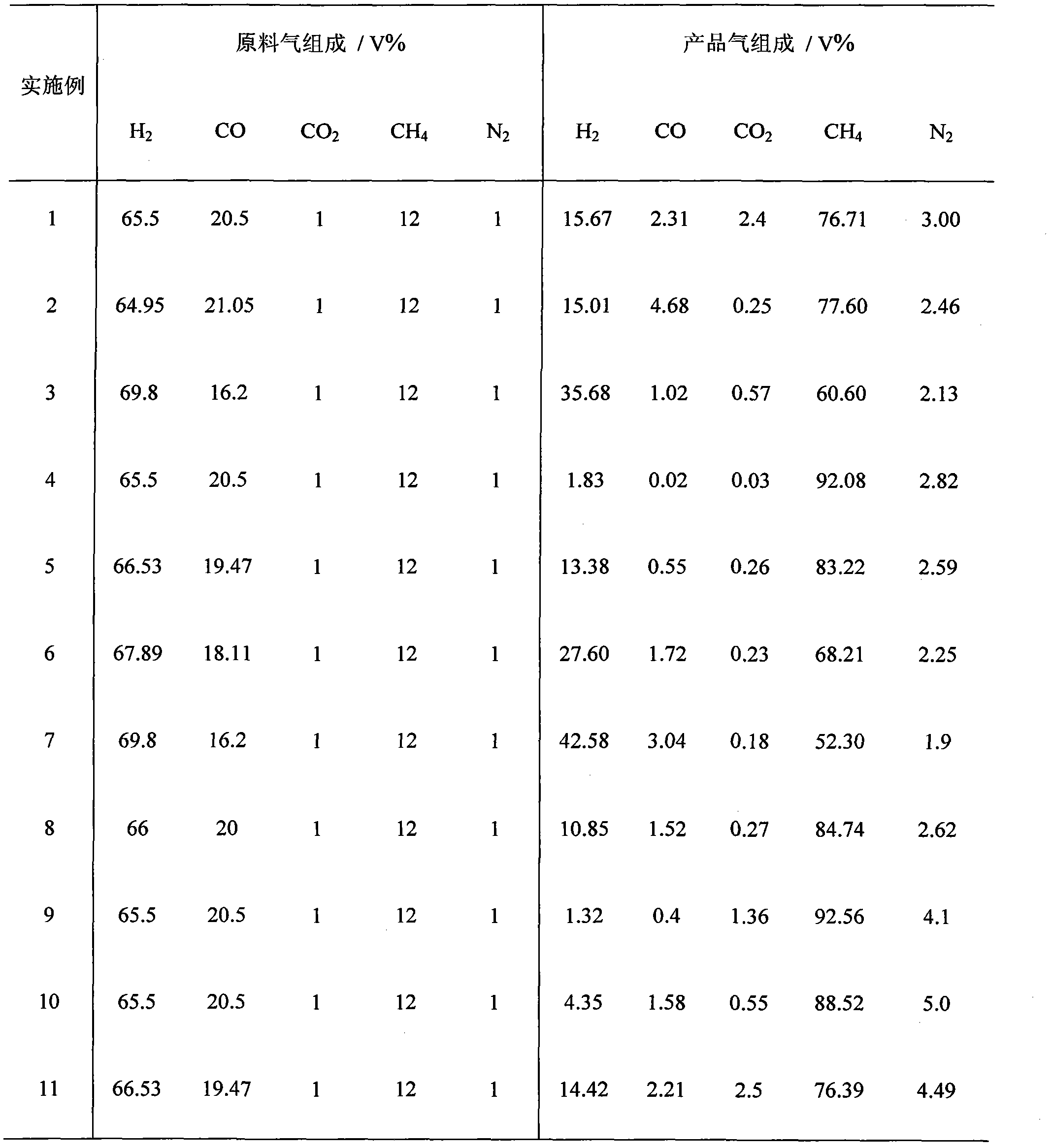

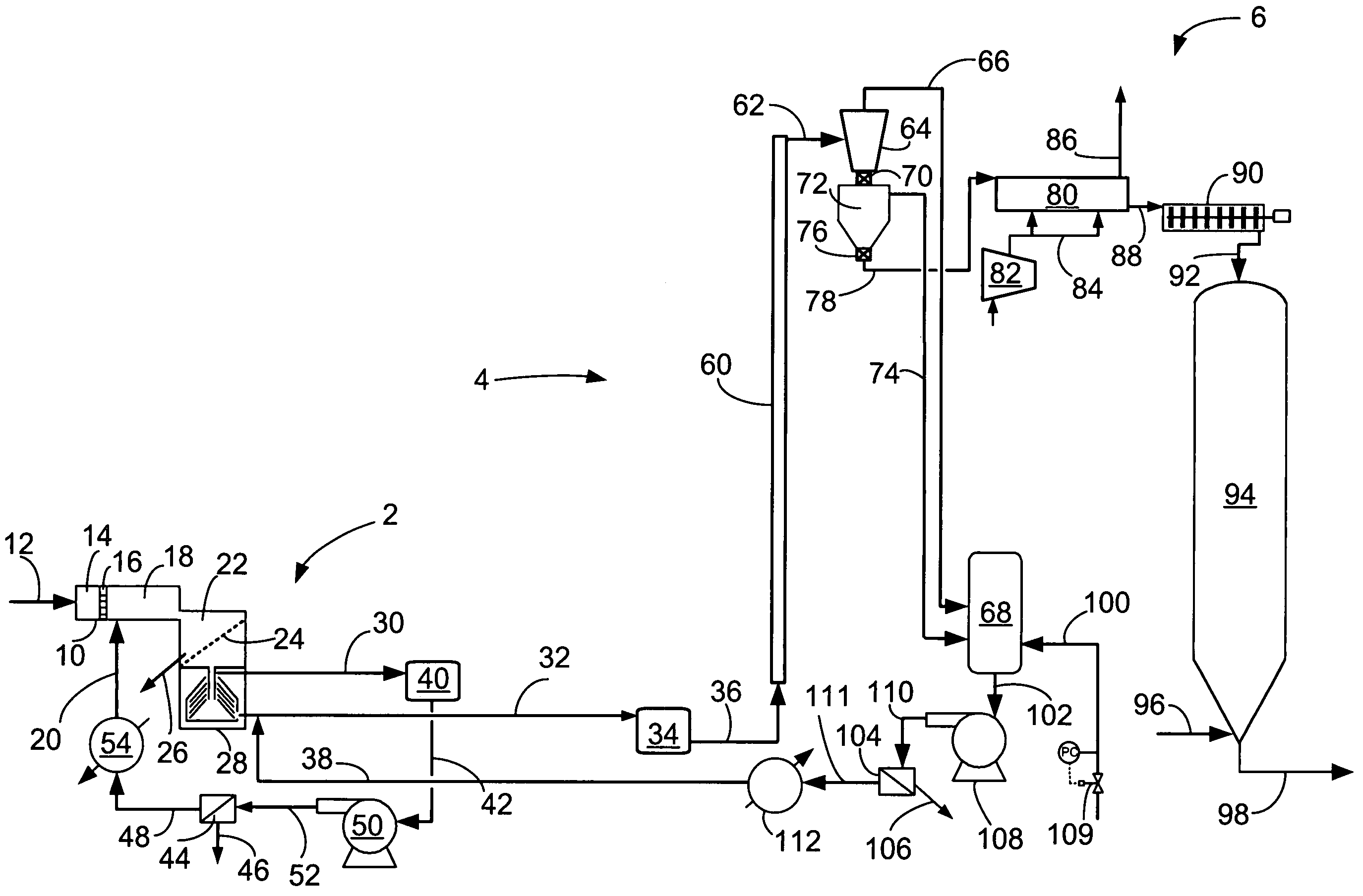

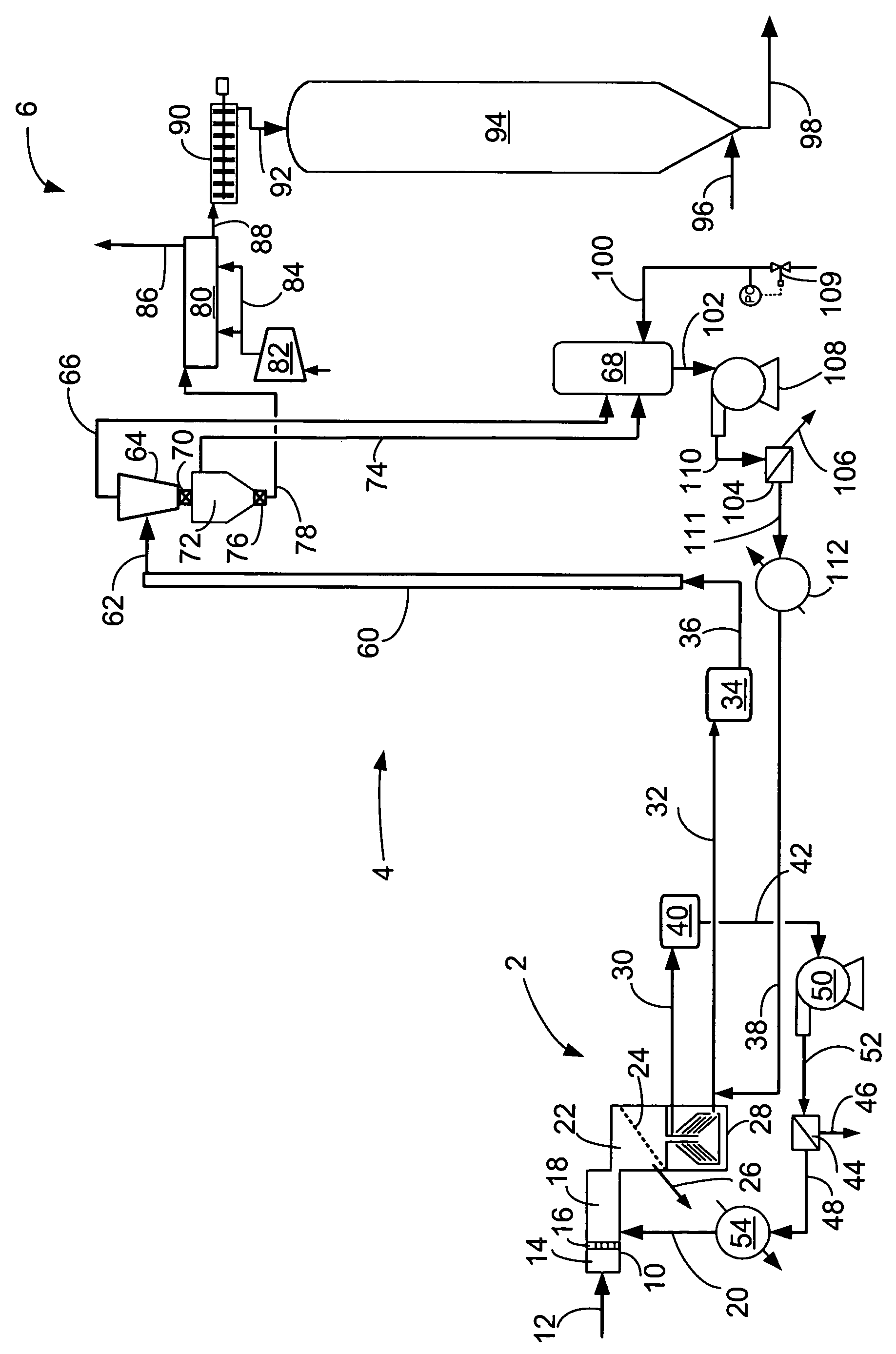

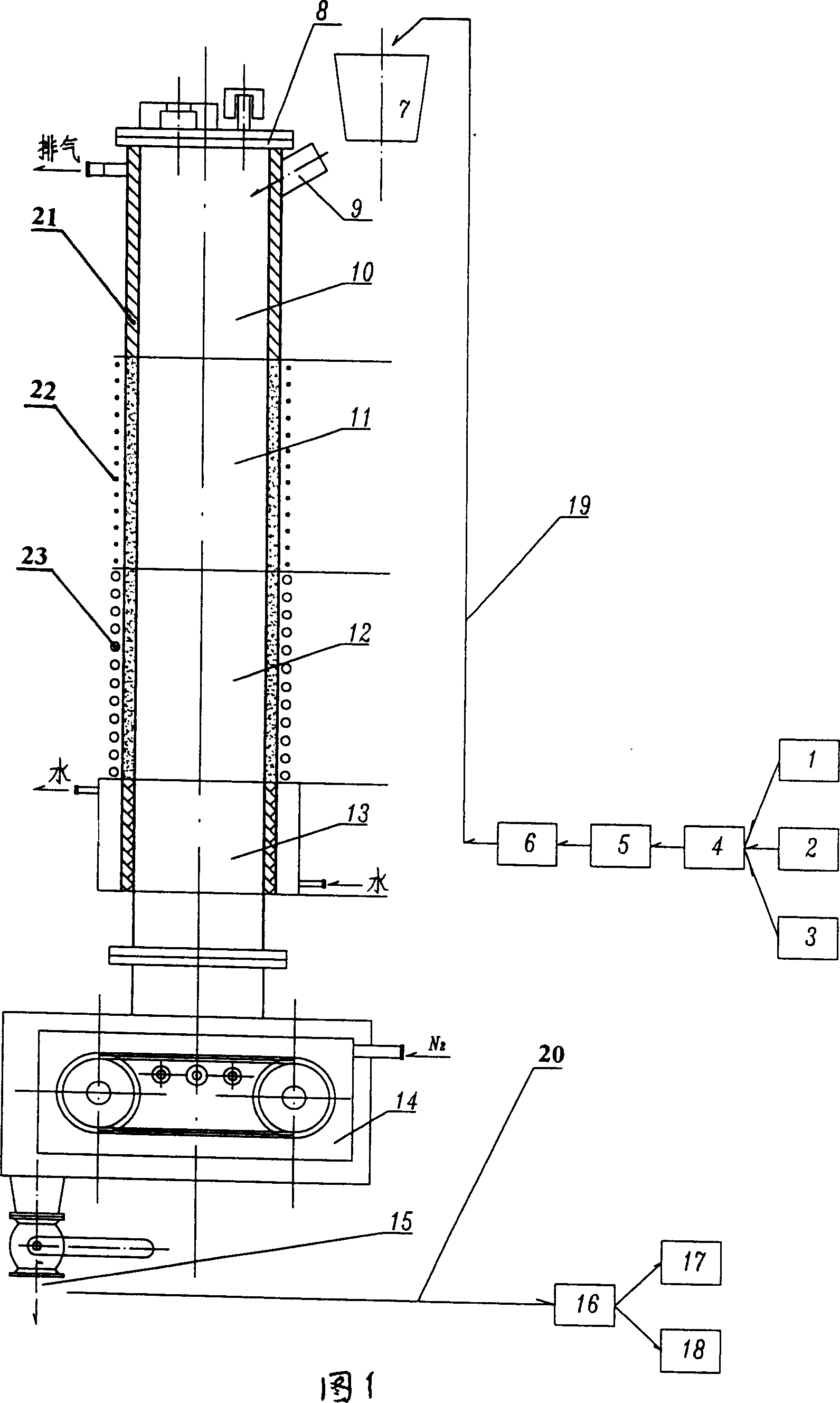

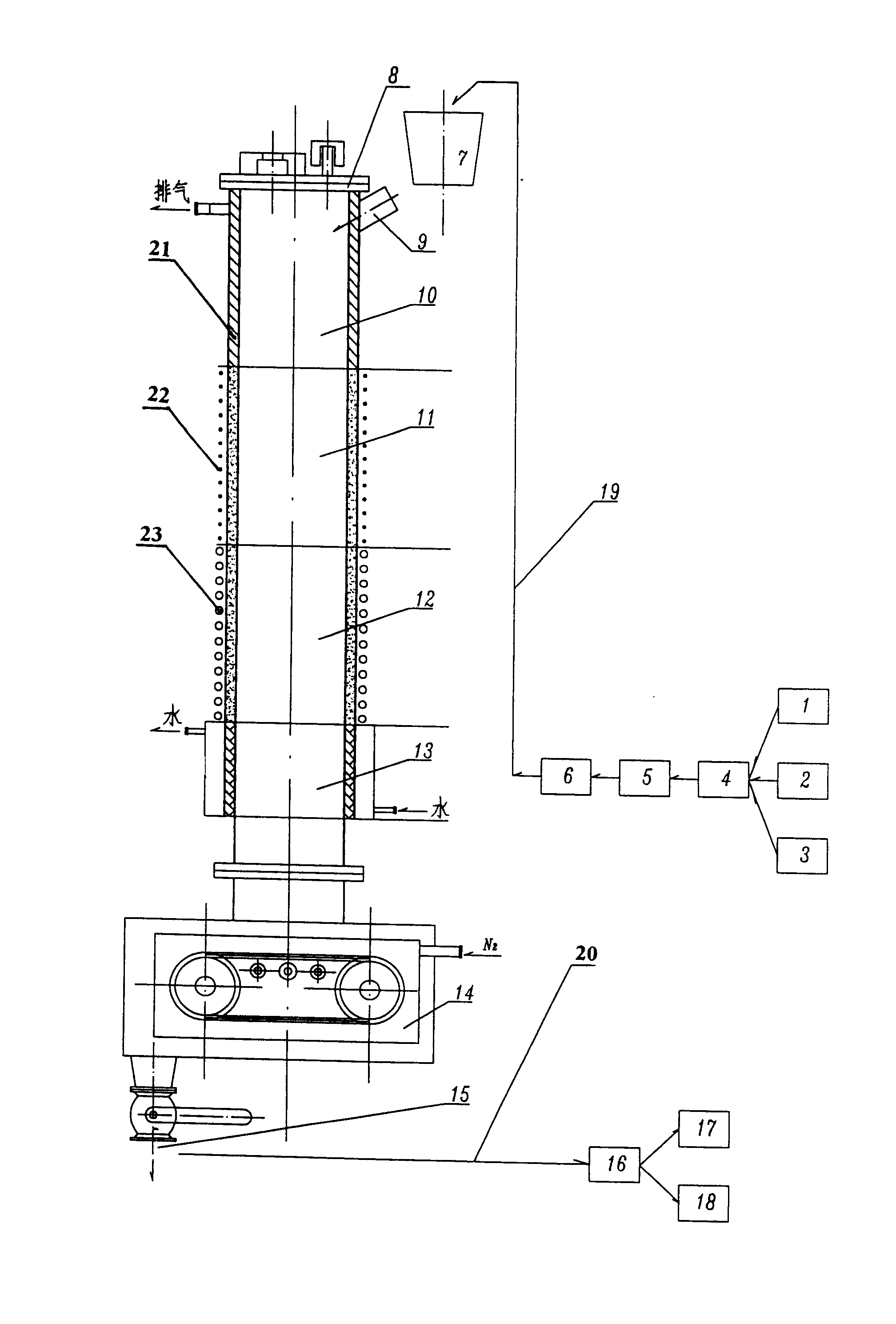

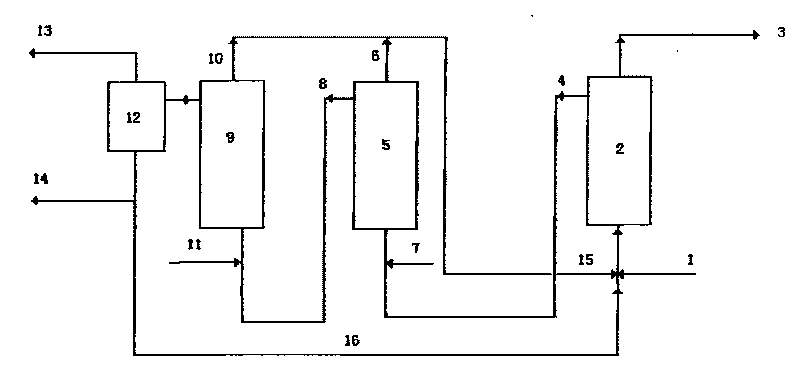

Process for synthesizing natural gas by methanation of coal synthesis gas

The invention discloses a process for synthesizing natural gas by methanation of coal synthesis gas, which comprises the following steps of: dispersing a fresh methanation catalyst into an inert liquid medium, delivering the medium into a slurry bed methanation reactor to perform reduction, performing methanation reaction on the transformed methanation raw gas after the reduction is finished, delivering the tail gas to a gas-liquid separator I, discharging the slurry liquid component and the catalyst in the tail gas from the bottom of the gas-liquid separator I, discharging the gas phase in the tail gas from the top of the gas-liquid separator I, delivering partial slurry liquid component containing the catalyst into a gas-liquid separator II, discharging the gas phase from the top of thegas-liquid separator II, merging the gas phases discharged from the tops of the gas-liquid separators I and II, cooling and purifying the gas phases to obtain synthesized natural gas, discharging theslurry liquid component containing the catalyst from the bottom of the gas-liquid separator II, merging the slurry liquid component discharged from the bottom of the gas-liquid separator II and the slurry liquid component and the catalyst discharged from the bottom of the gas-liquid separator I, discharging 1 to 5 percent of the weight sum of the slurry liquid component and the catalyst separatedfrom the two gas-liquid separators, and performing methanation reaction on the cooled rest slurry liquid component and catalyst and the fresh methanation catalyst dispersed into the insert liquid medium together. The process has the advantages of low power consumption and low equipment investment, and is easy to operate.

Owner:SEDIN ENG +1

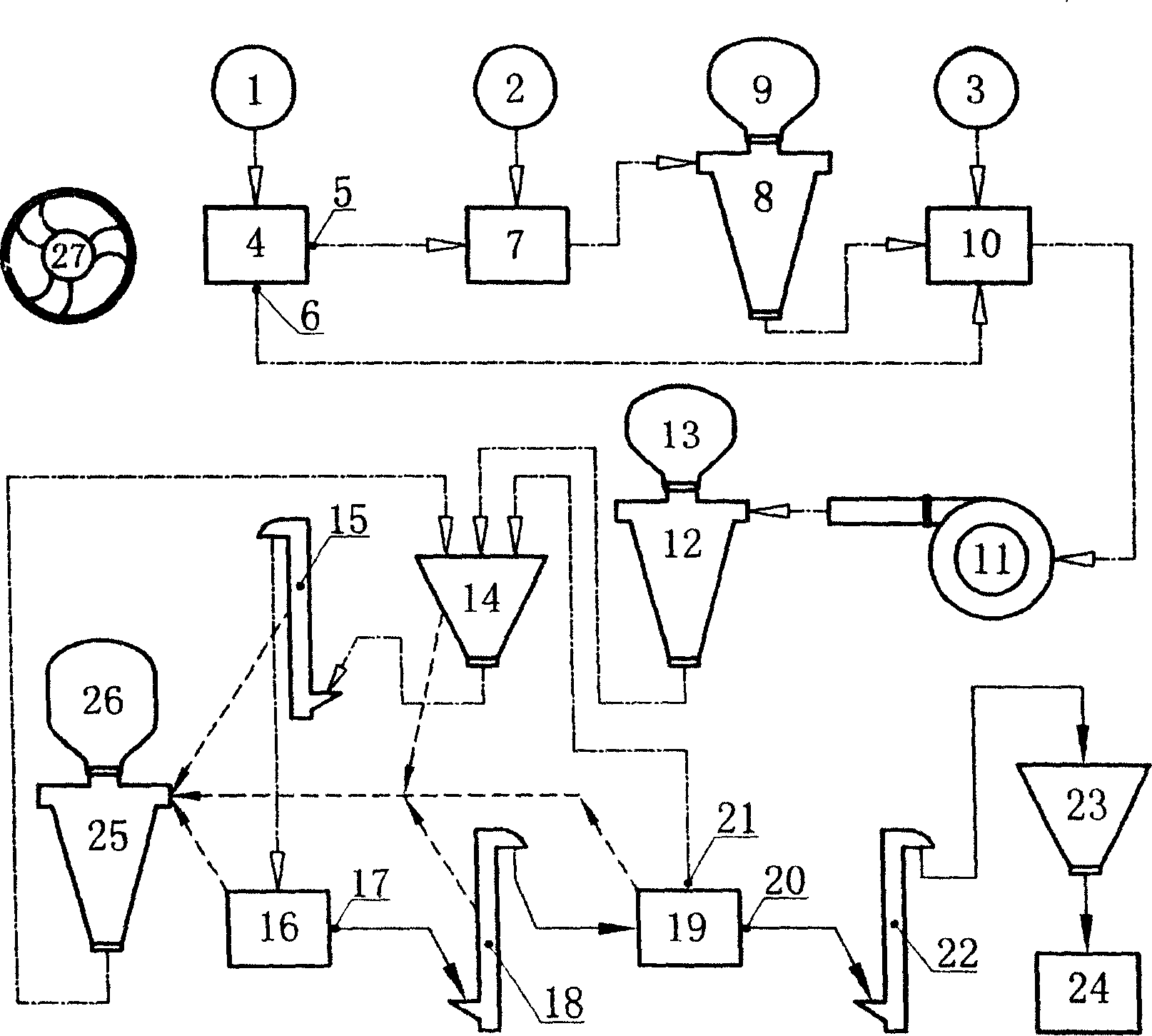

Method and apparatus for crystallizing polymer particles

ActiveUS7250486B1Save heatEfficiently formedChemical/physical/physico-chemical stationary reactorsPolymer scienceShell molding

The present invention is a process and apparatus for conserving loss of heat while forming and crystallizing polymer particles in a liquid. The cooling liquid quenches the polymer during particle molding to facilitate shaping. The cooling liquid cools the polymer particles not below a temperature that allows adequate crystallization to occur. Cooling liquid is quickly switched with a warming liquid, so the temperature of the polymer is in the crystallization range and the heat of crystallization self-heats the polymer to a higher temperature.

Owner:UOP LLC

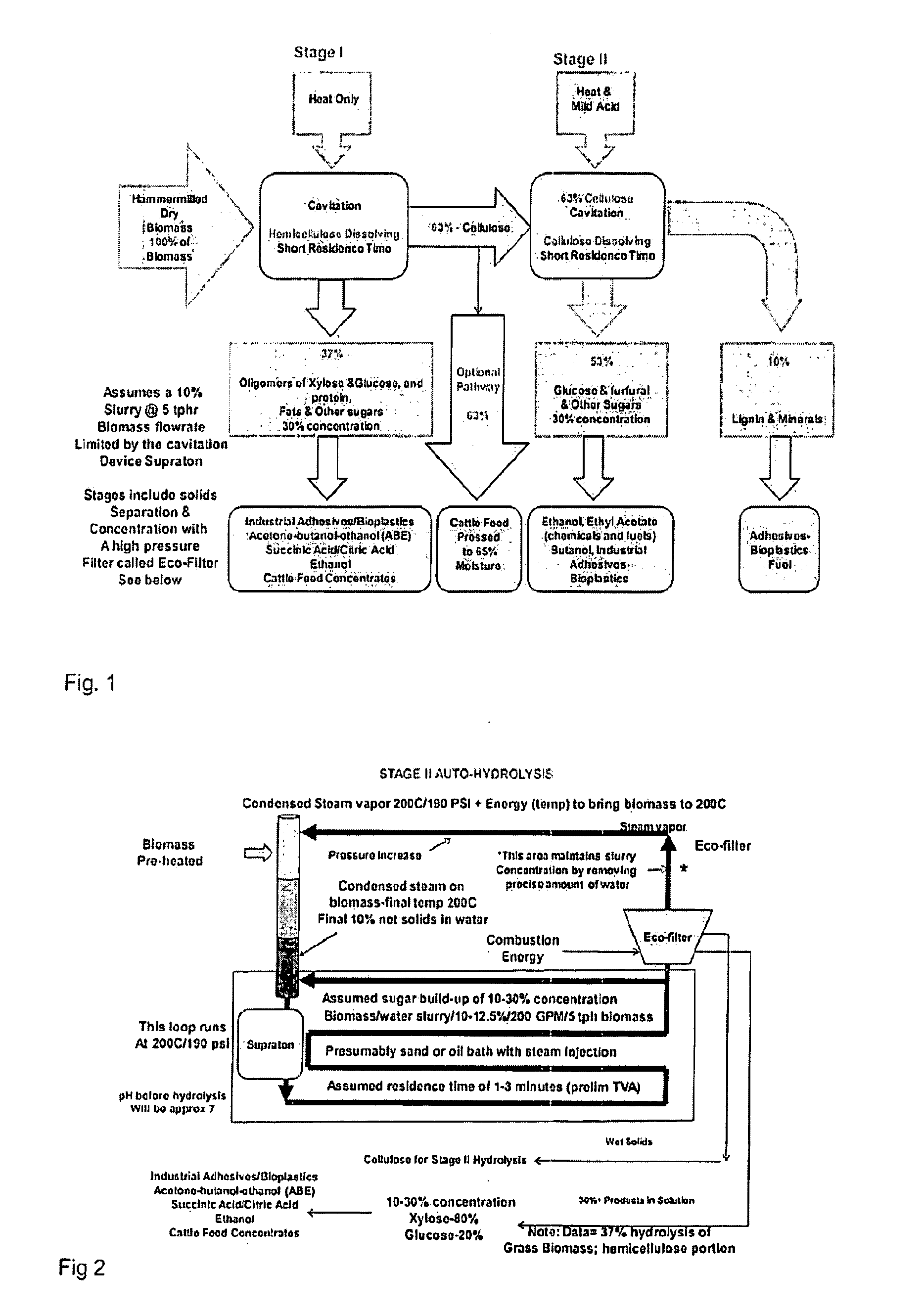

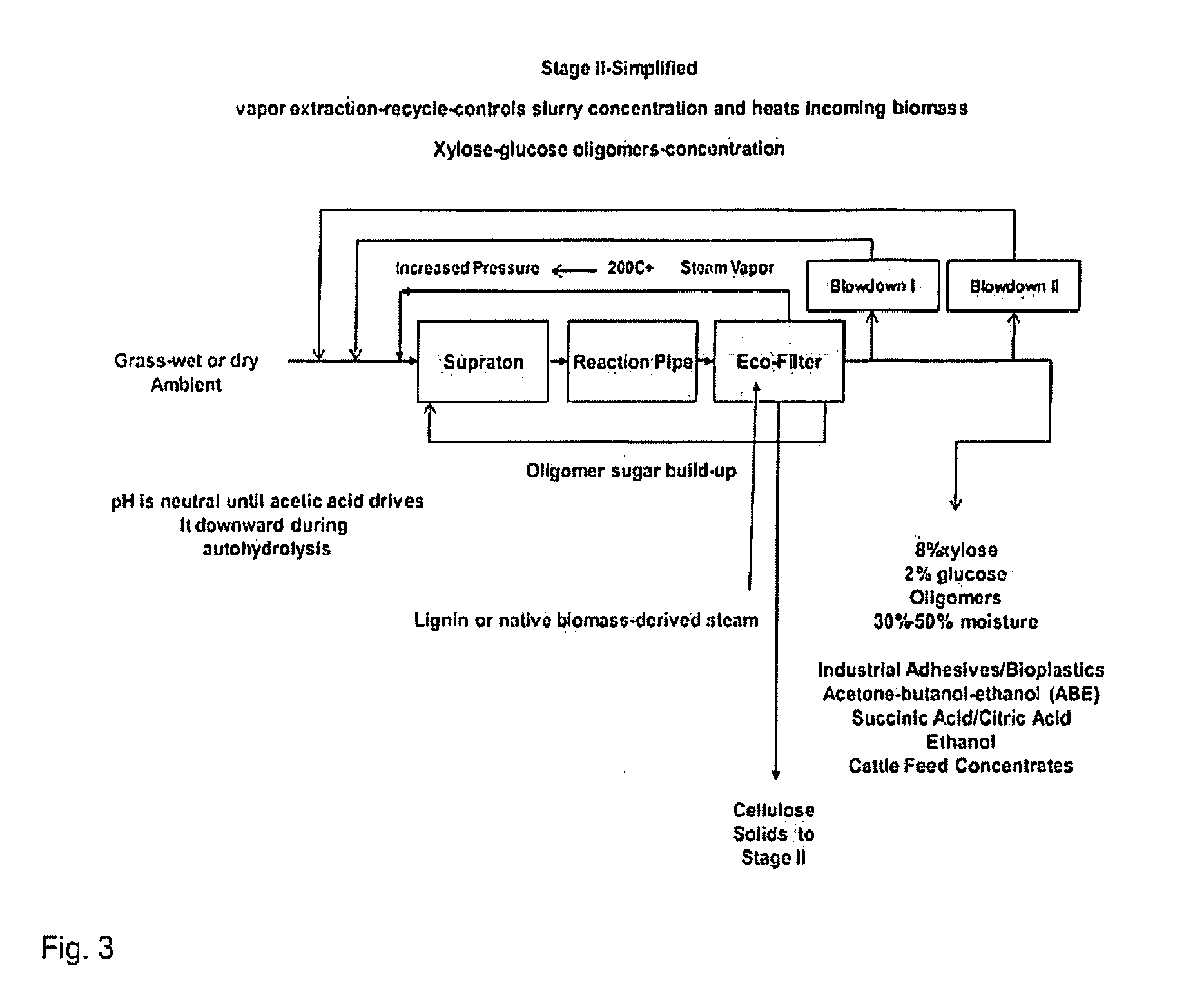

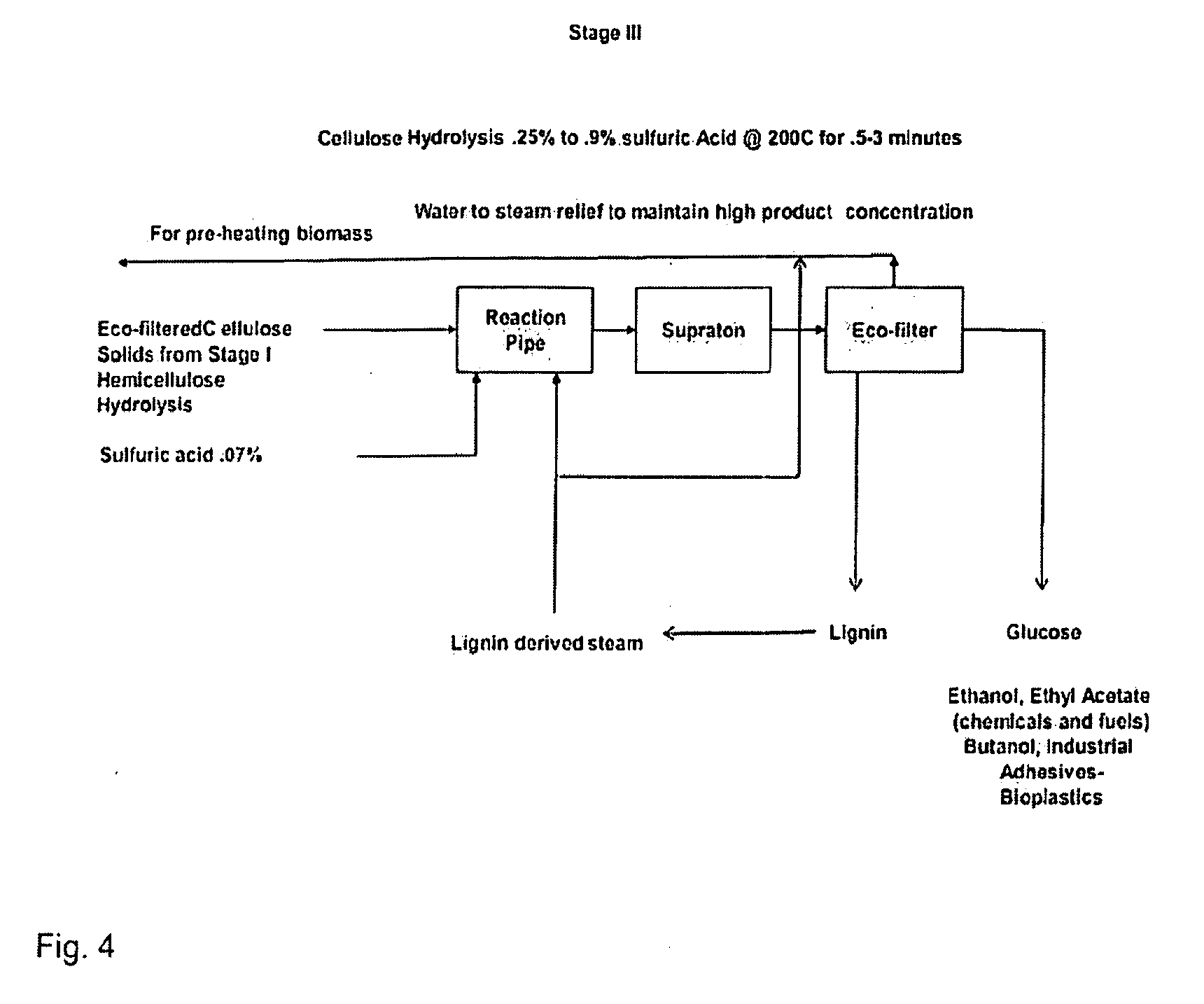

Advanced biorefinery process

The present invention is a method for refining native biomass to extremely fine and highly disrupted particles using high shear and / or cavitation in combination with high temperature and high or low pH conditions which dissolve biomass to a high percentage. The method of the present invention results in a high percentage of hydrolysis, in many cases near theoretical levels, in short residence times while minimizing inputs over other methods, using low chemical inputs, and optionally with no chemical inputs in certain stages compared to existing processes. The method of the present invention also uses minimal electrical energy inputs and conserves heat energy within the process and reduces equipment requirements while producing concentrated products.

Owner:RA ENERGY CORP

High efficiency positive displacement thermodynamic system

ActiveUS20100050628A1Without decreasing volumetric efficiencySave heatInternal combustion piston enginesCombination enginesPower modeWorking fluid

Devices and methods for moving a working fluid through a controlled thermodynamic cycle in a positive displacement fluid-handling device (20, 20′, 20″) with minimal energy input include continuously varying the relative compression and expansion ratios of the working fluid in respective compressor and expander sections without diminishing volumetric efficiency. In one embodiment, a rotating valve plate arrangement (40, 42, 44, 46) is provided with moveable apertures or windows (48, 50, 56, 58) for conducting the passage of the working fluid in a manner which enables on-the-fly management of the thermodynamic efficiency of the device (20) under varying conditions in order to maximize the amount of mechanical work needed to move the target quantity of heat absorbed and released by the working fluid. When operated in refrigeration modes, the work required to move the heat is minimized. In power modes, the work extracted for the given input heat is maximized.

Owner:STAFFEND GILBERT

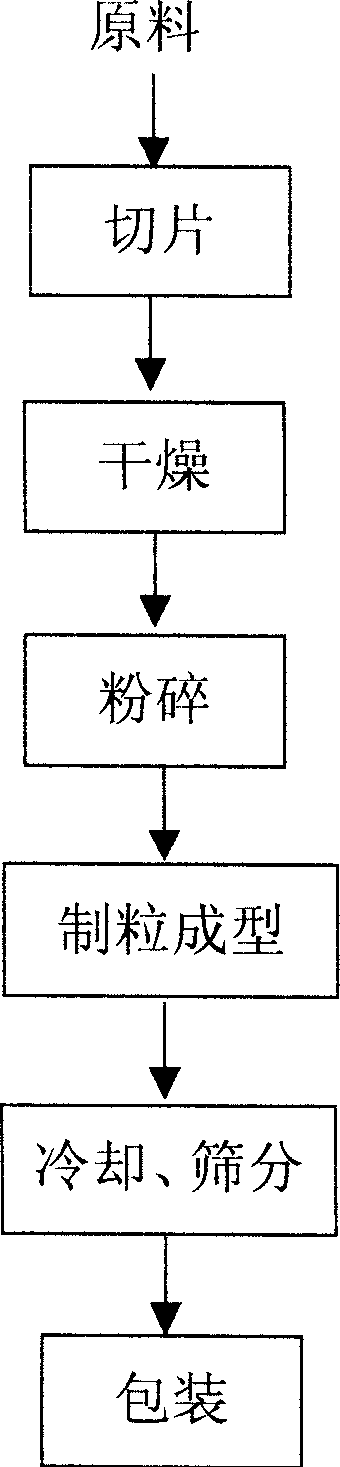

Environment-protecting granular wooden fuel and its production process

The present invention relates to granular wooden fuel and its production process, and features utilizing waste timber and forest cutting leftover as material. The production process includes cutting the raw material into coarse material, drying in airflow drier to certain water content, crushing into powder, pelletizing, granulating without adding additive through extrusion, cooling and sieving, backing the undersize to pelletizing step, packing the product. The said production process has low cost.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

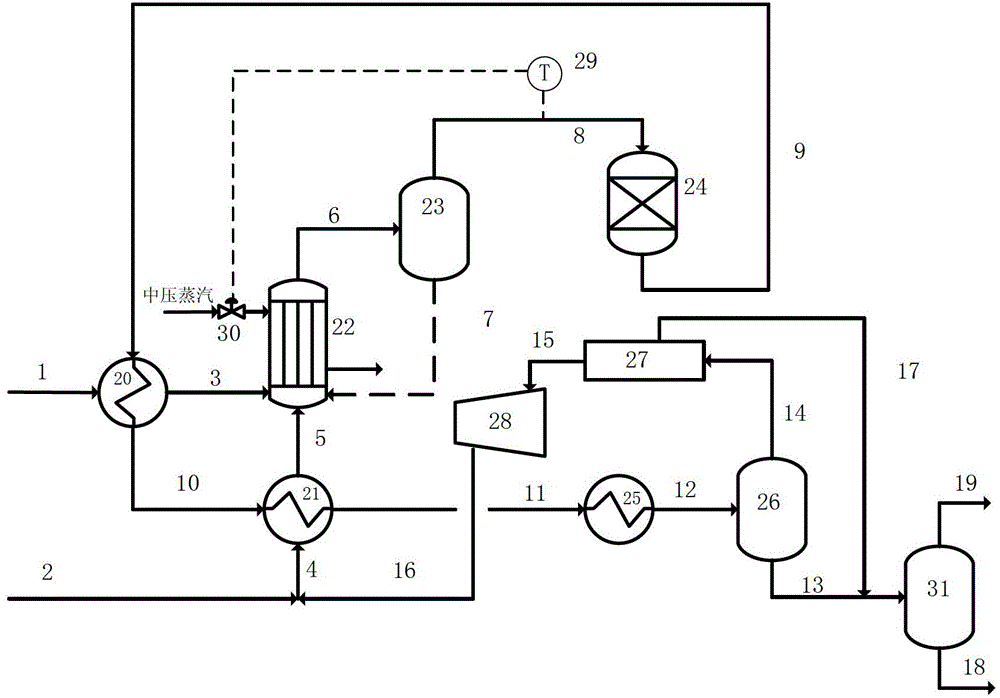

Method for preparing ethanol via hydrogenation of acetic ester based on recirculating of recovered hydrogen

ActiveCN102942446ALow costReduce heating effectOrganic compound preparationEnergy inputGas phaseProduct gas

The invention relates to a method for preparing ethanol via hydrogenation of acetic ester based on recirculating of recovered hydrogen. The method comprises the steps of: recycling hydrogen in the gas phase of a product by using a pressure swing adsorption (PSA) device and then increasing the pressure for recirculating; heating the mixed gas of acetic ester, circulated hydrogen and fresh hydrogen by using reaction heat; heating the preheated raw material gas by medium-pressure steam and then importing into a reactor so as to realize high acetic ester conversion rate and high ethanol selectivity in the presence of a catalyst; and carrying out gas-liquid separation on the product gas obtained via the reaction, and liquefying and separating the reaction principal product ethanol, a small amount of byproducts and unreacted acetic ester to obtain an initial product. According to the method, hydrogen is recycled and recirculated via PSA so that the use of the raw material hydrogen can be greatly reduced, the reaction raw materials are preheated by fully utilizing the reaction heat so that the energy consumption of the heating and the cooling is decreased, the flow is simple and the control is simple and convenient.

Owner:DATANG INT CHEM TECH RESINST

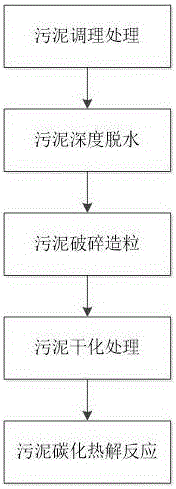

Sludge treatment and recycling method

ActiveCN105859105AReduce moisture contentAchieving processing powerSludge treatment by de-watering/drying/thickeningWater treatment compoundsExternal energyIron salts

The invention particularly relates to a sludge treatment and recycling method. The method comprises the following steps: sludge conditioning, sludge deep dewater, crushing and granulation, sludge drying, and sludge pyrolysis carbonization reaction. By using an iron salt as the main conditioner, deep dewatering is carried out on the sludge to lower the water content from 90% or above to 60% or below, thereby reducing the heat source required by the subsequent drying. The sludge drying adopts the heat energy released by combustion of combustible gas generated by the subsequent carbonization technique, thereby lowering the water content of the sludge to 20% or so on the premise of basically not adding any external energy source. Since the iron salt is added in the sludge conditioning stage, when the dried sludge is subjected to anoxic / anoxic pyrolysis reaction in the carbonization furnace, the iron oxides can be supported onto sludge-base activated carbon, thereby preparing the environment-friendly material with wide applicability. Therefore, the method implements harmless and recycling treatment on the sludge at lower cost, can treat waste with waste, produces the product with higher economic added value, and thus, has higher economic and social values.

Owner:SHENZHEN CHENZHONG TECH CO LTD

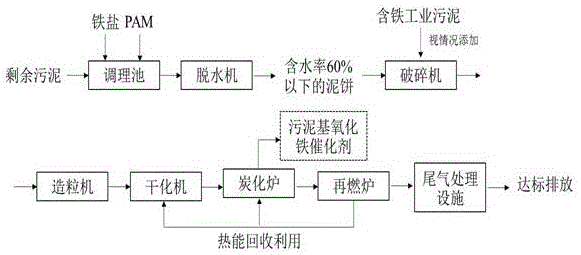

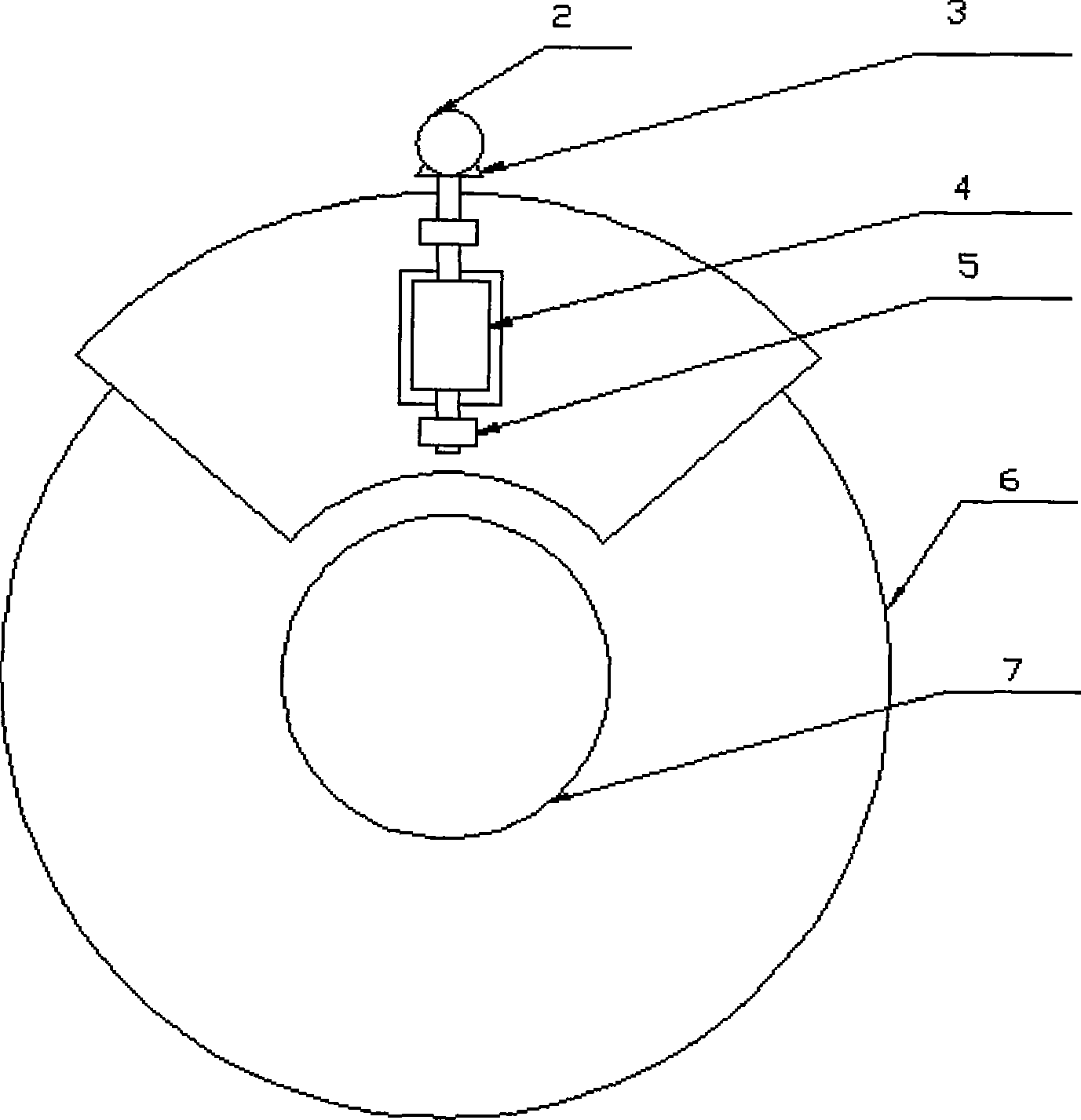

Automotive braking energy recovering device

InactiveCN101544194AReduce the temperatureSave heatElectrodynamic brake systemsElectric machinesPistonAutomotive engineering

The invention discloses an automotive braking energy recovering device. The outer lateral surface of a brakecaliper is provided with a notch, a friction wheel is arranged in the notch, projecting shafts at two ends of the friction wheel are arranged in holes of rolling bearings respectively, a hydraulic cylinder is fixed on an automotive chassis and arranged in a gap between a brake disc and the inner side of the brakecaliper, a piston is contacted with the inner lateral surface of the brakecaliper, the outer cylindrical surface of the brakecaliper is provided with a generator, and the shaft of the generator is provided with a first bevel gear meshed with a second bevel gear on the shaft at one end of the friction wheel. The device can recover most energy used in the braking of an automobile to supply power for vehicle-mounted electric appliances. Meanwhile, as most energy is converted into electric energy, heat energy generated during friction is reduced greatly, the temperature of the brake disc is reduced, and the service life of the brake disc is prolonged.

Owner:ZHEJIANG UNIV

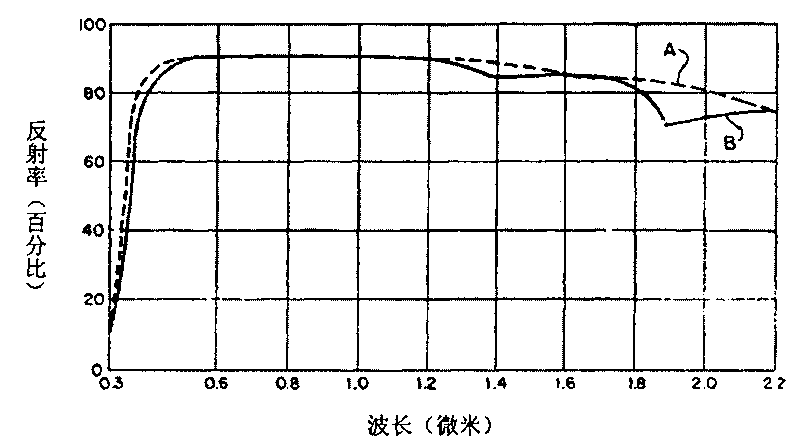

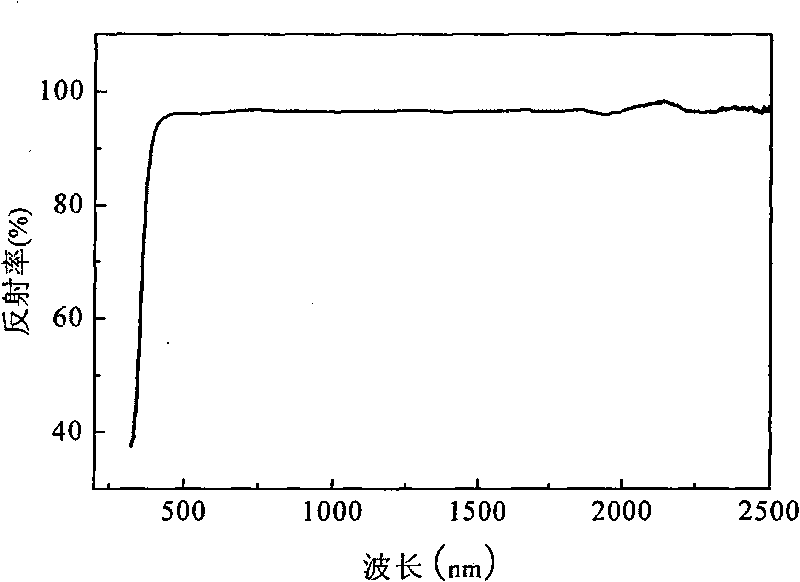

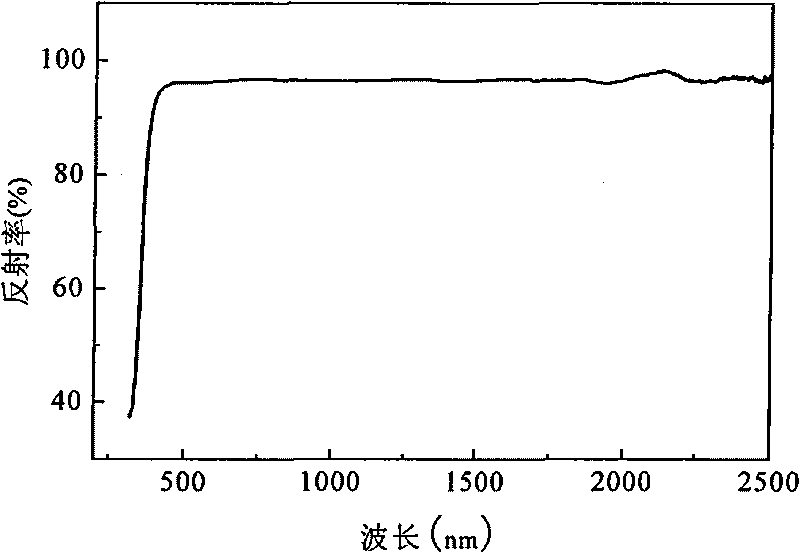

Method for preparing high-temperature resistant anti-infrared thermal radiation energy-saving coating

The invention discloses a method for preparing a high-temperature resistant anti-infrared thermal radiation energy-saving coating. The method comprises the following steps of: adding inorganic crystal whisker or / and fiber materials to sol containing titanium and kalium elements, evenly stirring the mixture to form pulp; and coating the pulp on the surface of heat insulating materials, fireproof materials or thermal insulating materials, and sintering the pulp at the temperature of between 200 and 700 DEG C for 0.5 to 5 hours to form compact coatings with the thickness of 0.1 to 5mm, wherein the content of the inorganic crystal whisker or / and fiber materials in the pulp is 5 to 70 weight percent. In the temperature range of between 400 and 1,200 DEG C, the reflectivity of the compact coating which is prepared by the method in a thickness of 0.1 to 5mm on the infrared thermal radiation with the wave length of 500 to 2,500nm is over 90 percent, and after the coating of the invention undergoes 5 thermal shock stability tests at the temperature of 1,000 DEG C, no crack occurs.

Owner:NANJING TECH UNIV +1

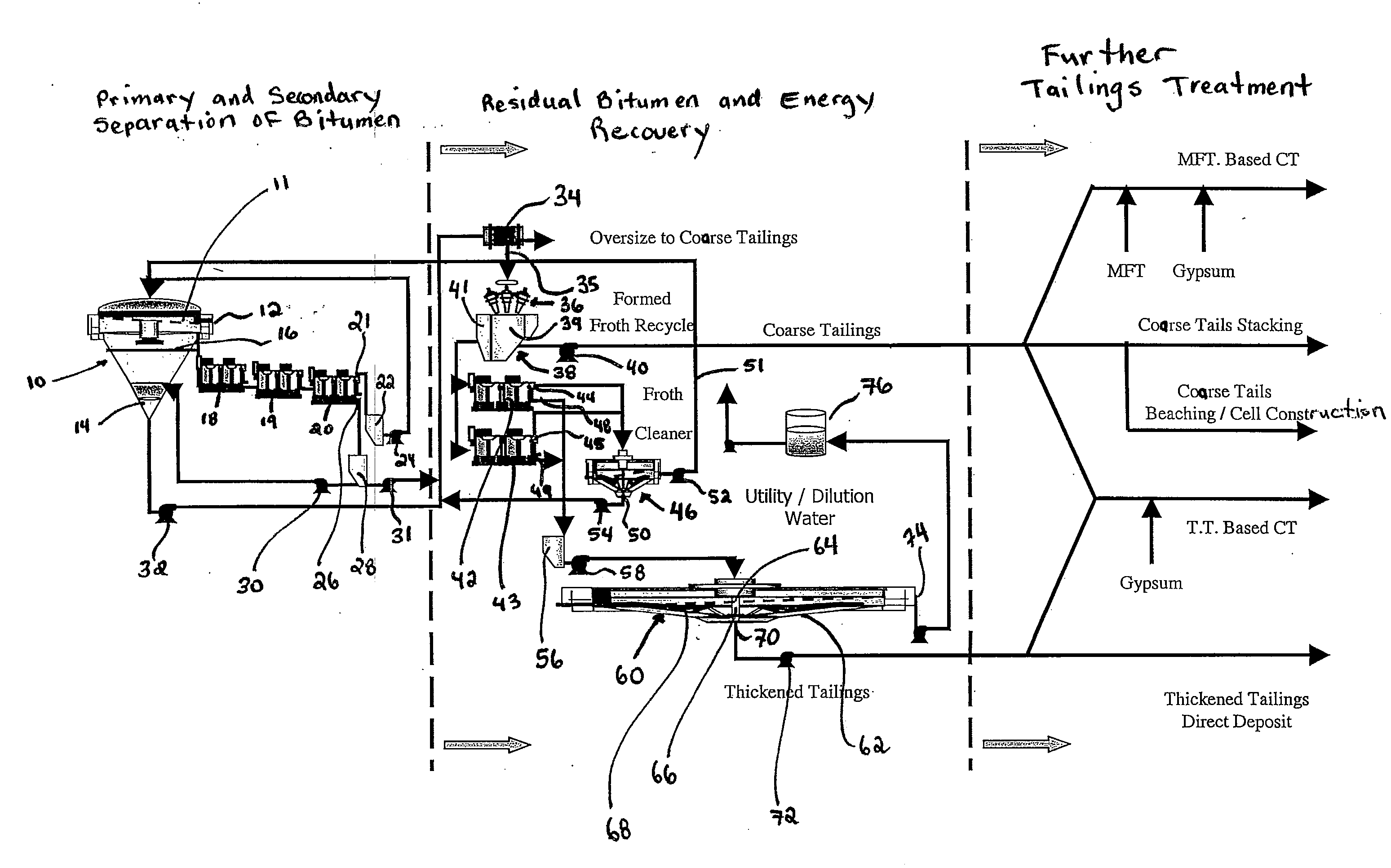

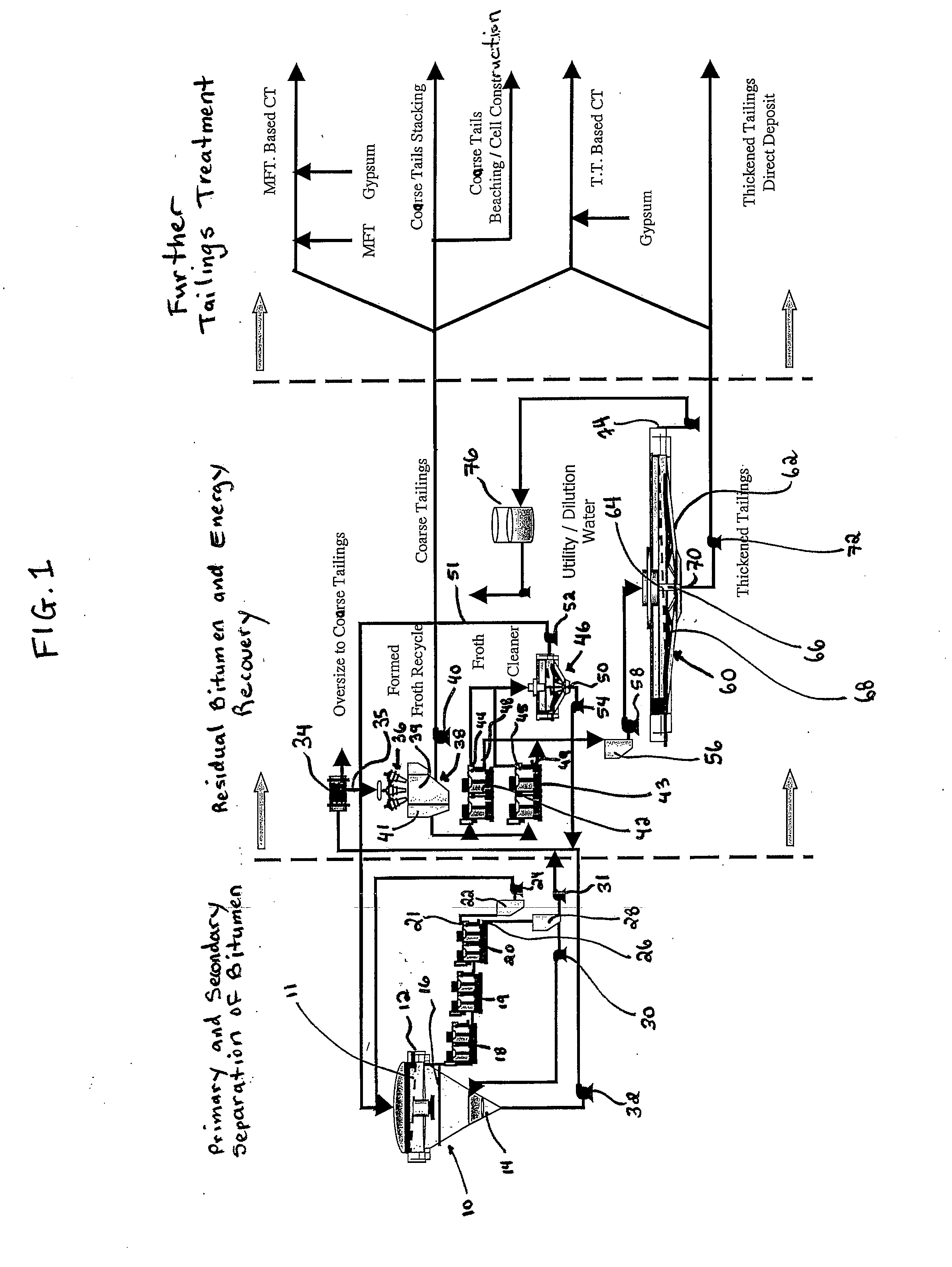

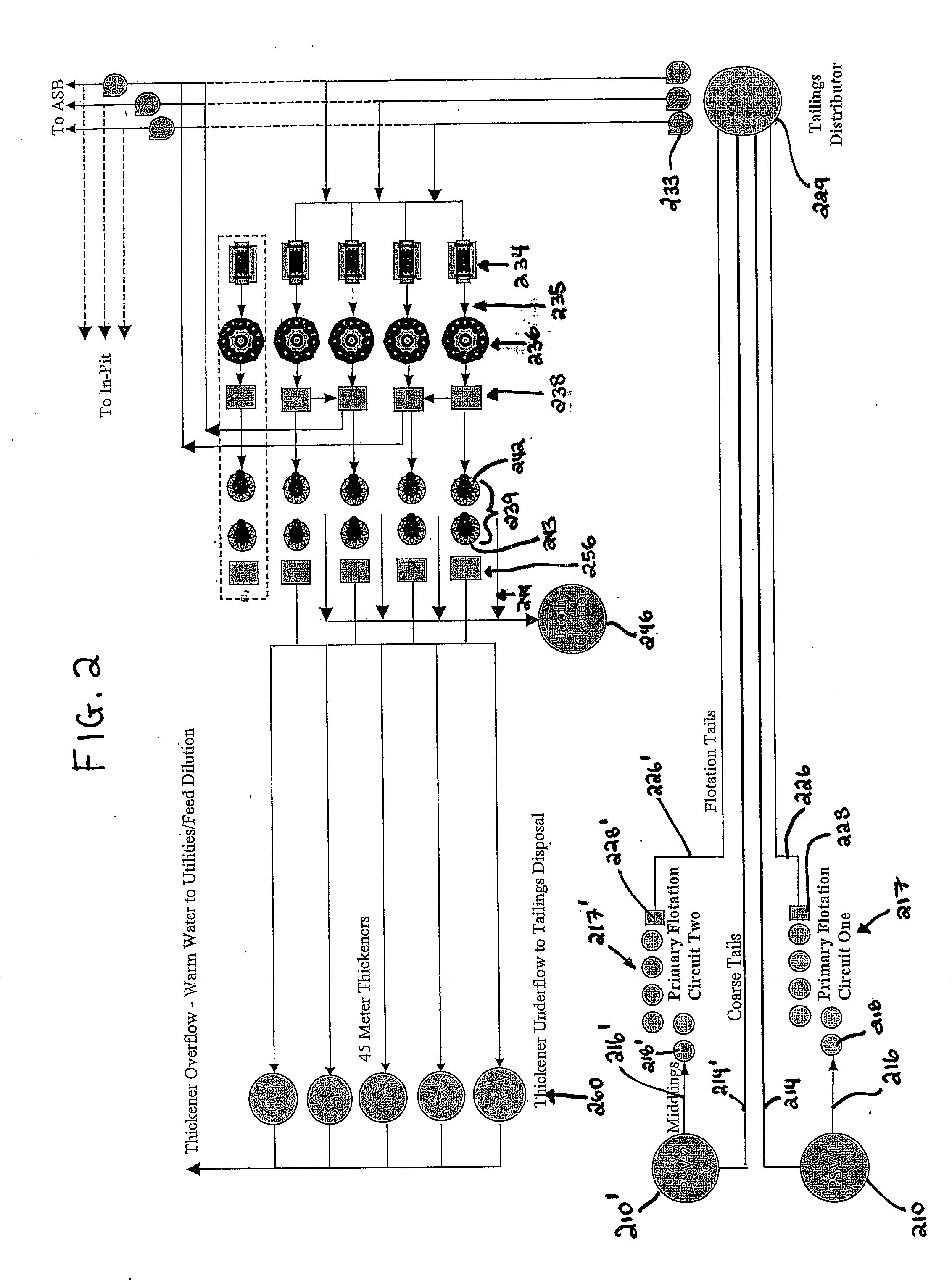

Bitumen and thermal recovery from oil sand tailings

InactiveUS20080099380A1Reduce thermal energySave heatLiquid hydrocarbon mixture productionHydrocarbon oils treatmentWarm waterEnvironmental engineering

A process and process line is provided for recovering heat in the form of cleaned warm water and residual bitumen from oil sand tailings produced during an oil sands extraction process. The process includes removing at least a portion of the coarse solids from the oil sand tailings to produce a reduced solids tailings fraction; separating at least a portion of the bitumen from the reduced solids tailings fraction to produce a bitumen fraction and a warm water and fines fraction; and removing at least a portion of the fines from the warm water and fines fraction to produce cleaned warm water and a concentrated fines fraction. The cleaned warm water can then be reused in the oil sands extraction process.

Owner:SYNCRUDE CANADA LTD

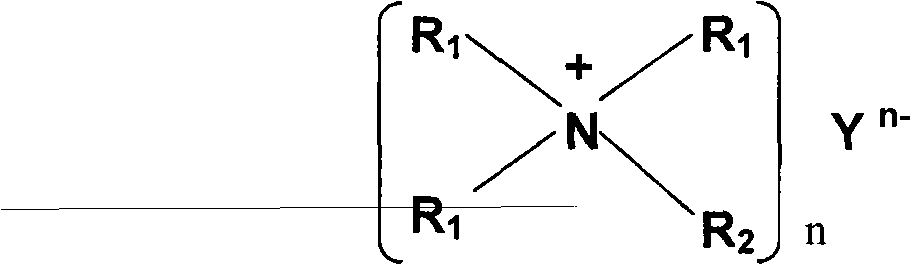

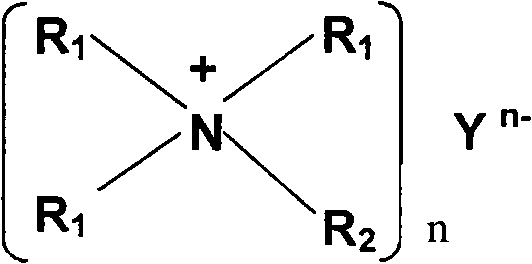

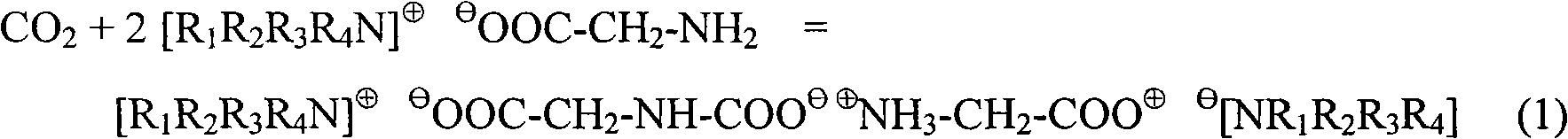

Special MDEA formula solution activated by functional ion liquid for CO2 gas absorption separation

InactiveCN101804292AReduce lossOvercome the disadvantage of high energy consumptionDispersed particle separationBy chemical separationSulfolanePoly(ethylene glycol) dimethyl ether

The invention relates to a special N-methyldiethanolamine formula solution activated by ion liquid for CO2 gas absorption separation, which consists of the following ingredients in mass percent: 35 to 50 percent of N-methyldiethanolamine, 5 to 20 percent of low-viscosity kalescent functional ion liquid, 15 to 30 percent of dimethyl ether of polyethlene glycol and / or sulfolane and 15 to 30 percent of water, wherein cations of the low-viscosity kalescent functional ion liquid are tetraalkylammonium ions, and anions of the low-viscosity kalescent functional ion liquid are amino acid radicals or organic carboxylate anions. The formula solution of the invention has the advantages that the high mass transfer performance of the absorption-desorption process is improved, the material consumption in the use process is low, the defect of high energy consumption because a large amount of water vapor is brought away during the absorbing agent regeneration, and the invention belongs to an energy-saving formula with high green degree. The regeneration temperature of the solution is lower than that of the traditional absorbing liquid, the grade of a heat source required to be provided in the regeneration process is reduced, energy sources can be saved, the stability of the absorbing agent solution in the operation is high, the consumption of each absorption-desorption circulation is low, and in addition, the cost is low.

Owner:NANJING UNIV

Convertible outerwear garment with thermal insulation

InactiveUS20070050882A1Improve mobilityLow extremityGarment special featuresConvertible garmentThermal insulationEngineering

Owner:EISENHUTH DAVID

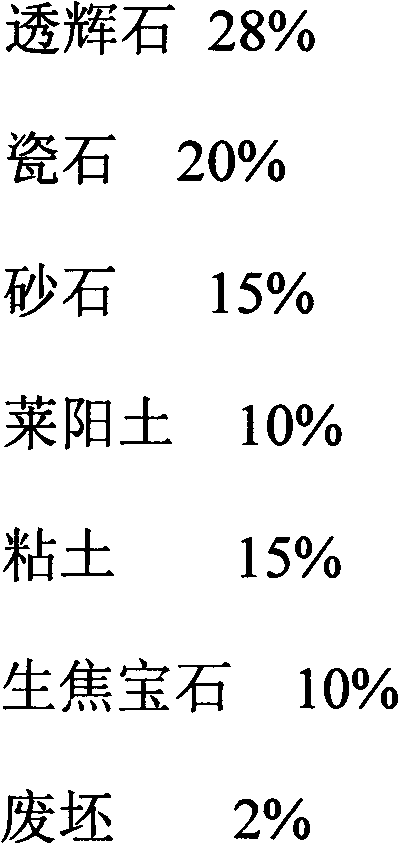

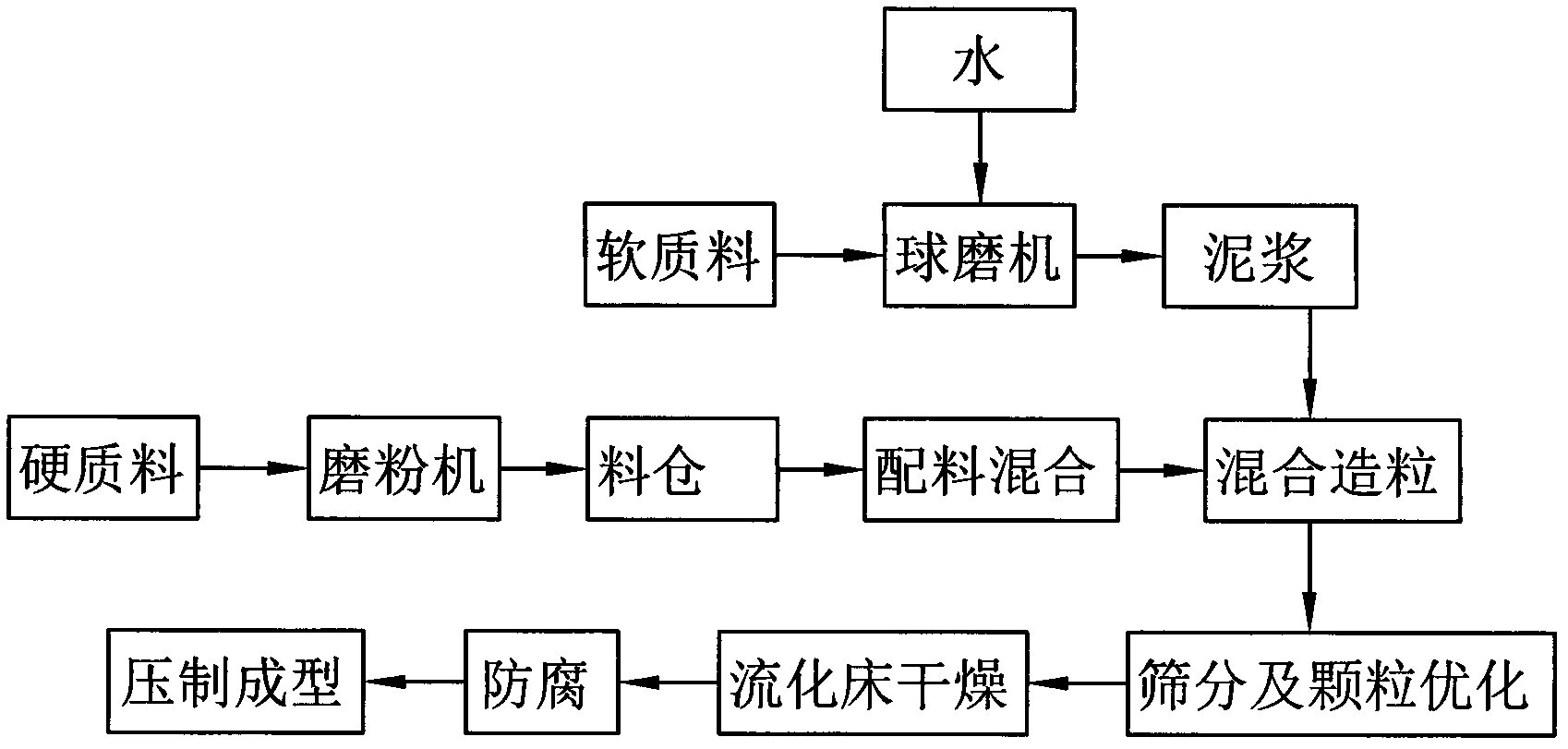

Energy-saving dry powder production method for building ceramics

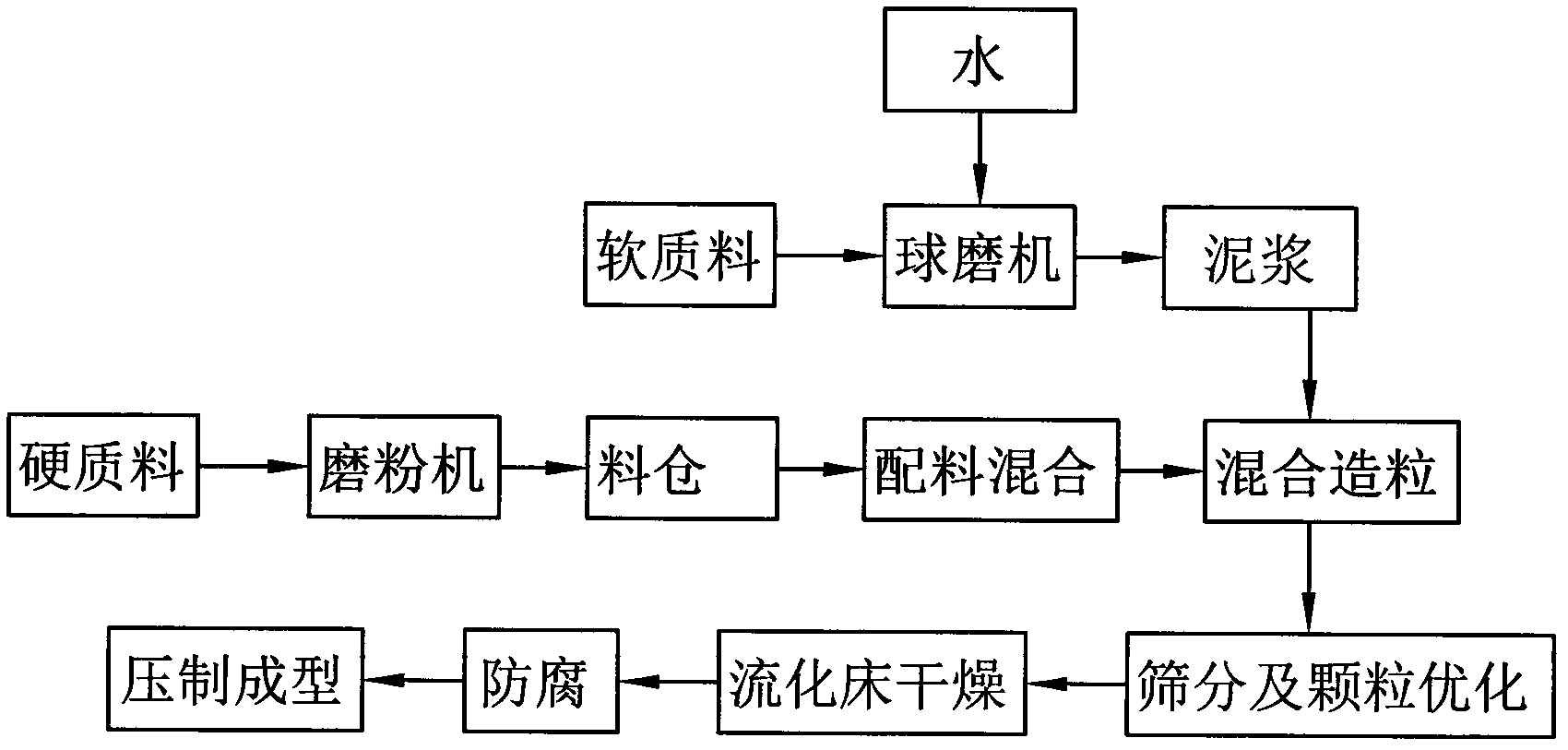

The invention relates to an energy-saving dry powder production method for building ceramics. The method is characterized in that the method includes the following steps: (1) hard materials and soft material in a green body formula are separated; (2) a ball mill is used for processing the soft material with high moisture content into slurry with 40 to 70 percent of moisture content for later use; (3) a pulverizer is used for respectively processing the hard materials into fine powders meeting requirement and conveying the fine powders into respective bins; (4) according to the green body formula, an automated batching system is used for mixing the processed fine hard material powders in batches according to proportion; and the prepared slurry as humidizer and the mixed fine hard material powders are forcibly mixed and granulated in a mixing granulator; (5) after granulation, granules are screened and optimized, and are then dried into the needed granular powder in a fluidized-bed dryer, and the granular powder can be used after being aged for 24 hours. The invention has the advantages of energy saving, consumption reduction and little pollution.

Owner:SHANDONG ECON ENERGY SAVING TECH

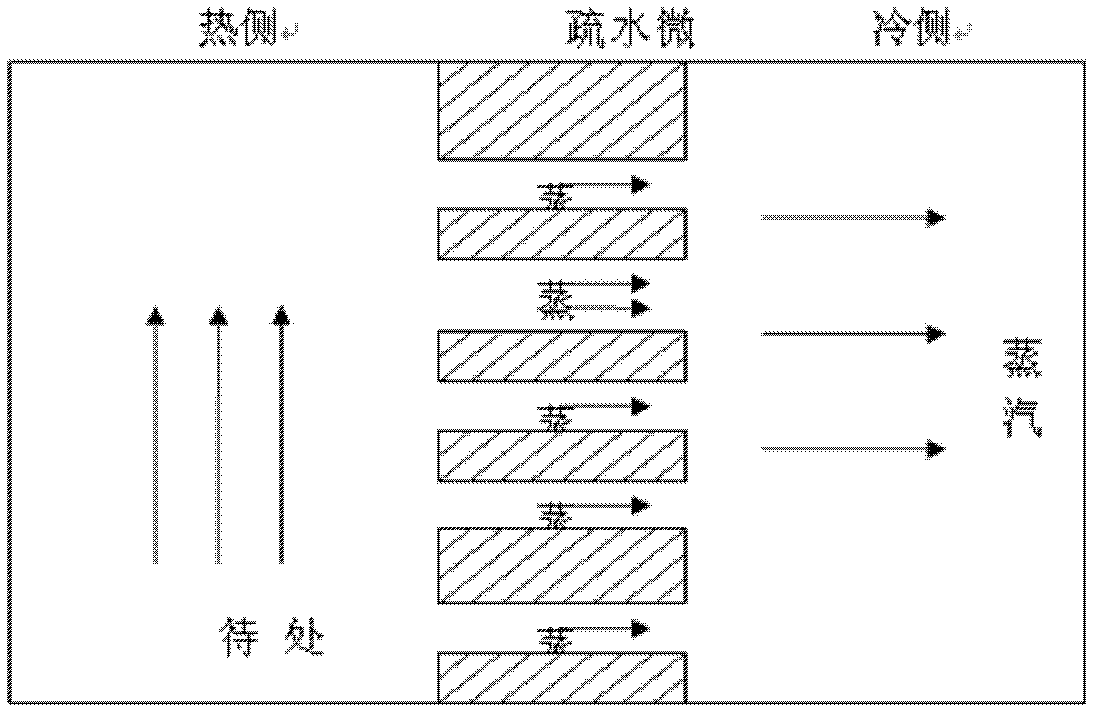

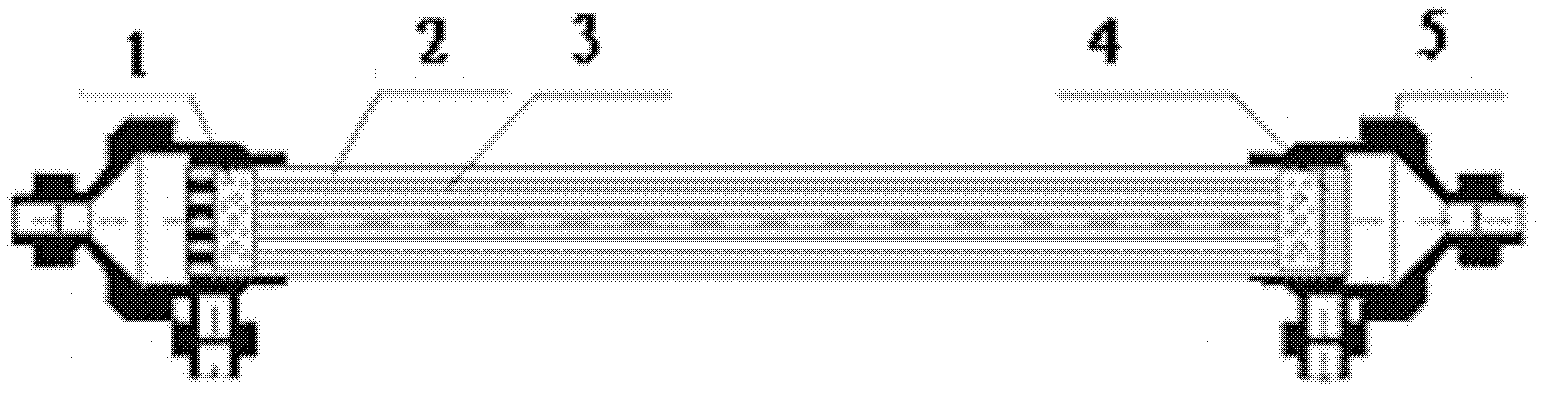

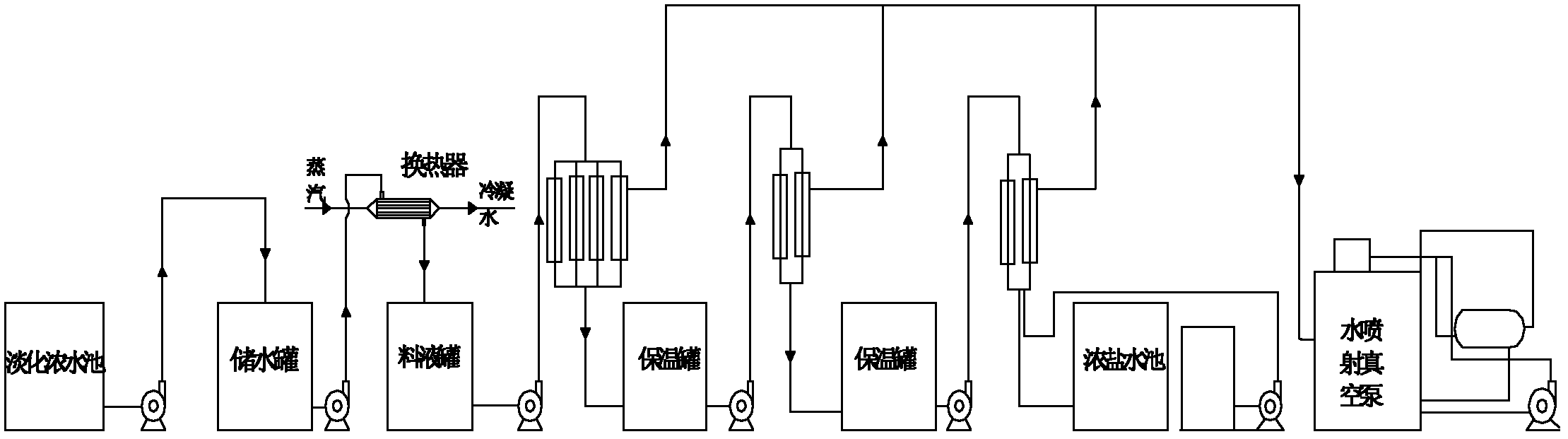

Multi-stage series membrane distillation strong brine desalting method and device

InactiveCN102491577AImprove heat utilizationSave heatSeawater treatmentMultistage water/sewage treatmentChemistryInlet temperature

The invention relates to a method for treating strong brine by using multi-stage series membrane distillation. The method comprises three steps of: preheating before performing strong brine membrane distillation, performing membrane distillation and condensing distilled steam to obtain desalted water, and is characterized in that: during membrane distillation, 3 to 5 stages of membrane distillation units are adopted; a membrane component (a membrane area) of each stage of the membrane distillation unit is different according to an operating scale; and the membrane components are connected in series with one another. In the multi-stage membrane distillation unit mode for treating the strong brine, the strong brine distilled by the previous stage is directly used as material inlet liquid in the next stage; as the whole process is continuous, the temperature required by the process is low; the temperature of the strong brine of the previous stage of the membrane distillation unit meets the requirement on the water inlet temperature of the next stage of the membrane distillation, so that heat sources required by the later stages of membrane distillation are saved, and the heat utilization rate during membrane distillation is increased; the heat sources for heat exchange can be low-level heat sources, such as raw stream, solar energy, terrestrial heat, factory waste heat and the like, so that energy can be saved effectively; and the comprehensive cost of the membrane distillation method for treating the liquid is reduced.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Edible insect full-powder and the production process and application thereof

InactiveCN101116472ARich varietyIncrease the number ofAnimal proteins working-upAdditive ingredientInternational market

The present invention relates to a method to fabricate a full edible insect powder, with the main raw material as the edible insects with the represent of the flour weevil, the cicada, the cryptympana atrata, the locust and the silkworm pupa. The exploited products in both domestic and international markets at present include the specific animal feeds and the dishes of edible insects, as well as the animal feed made from a certain amount of raw materials of insects. The present invention aims to exploit a full edible insect powder as well as the fabrication method and application thereof to accomplish the industrialized production with a large scale. The technical proposal is that the insects which undergoes both elimination of foreign bodies, toxins and cleaning up in the latter phase of cultivation are killed, dehydrated, roasted, (or dried through refrigeration) dried and refrigerated in vacuum, and then smashed and filtrateed to be the final product. The effect of the present invention is that the full insect powder contains all nutritious elements thereof, including proteins, lipids, vitamins and various trace elements. The present invention has unique characteristic, safety without toxins, wide application fields, feasibility to be the nutrition of serious snacks, and feasibility to be the stuffing of food of various cakes and candies.

Owner:西安市轻工业研究所

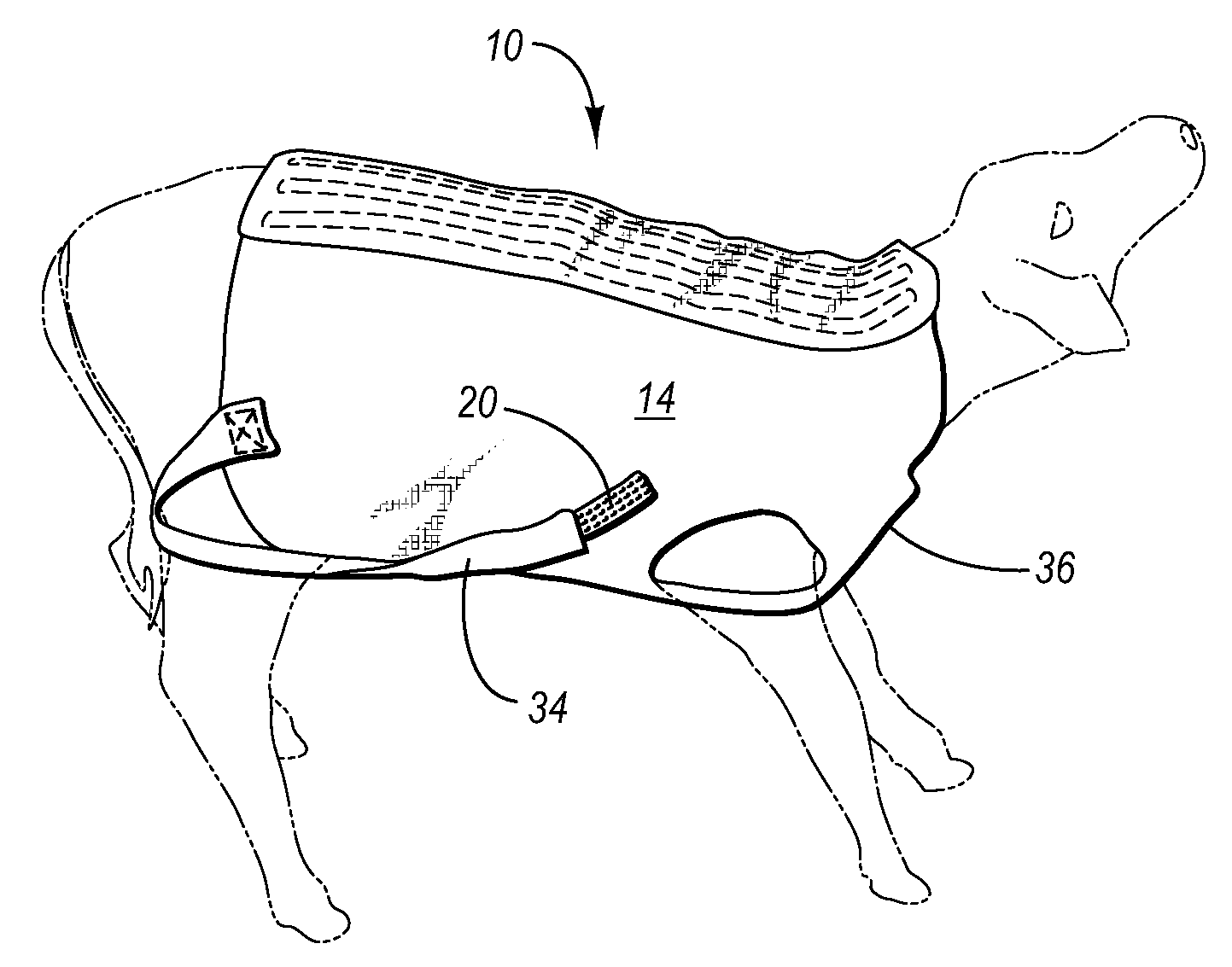

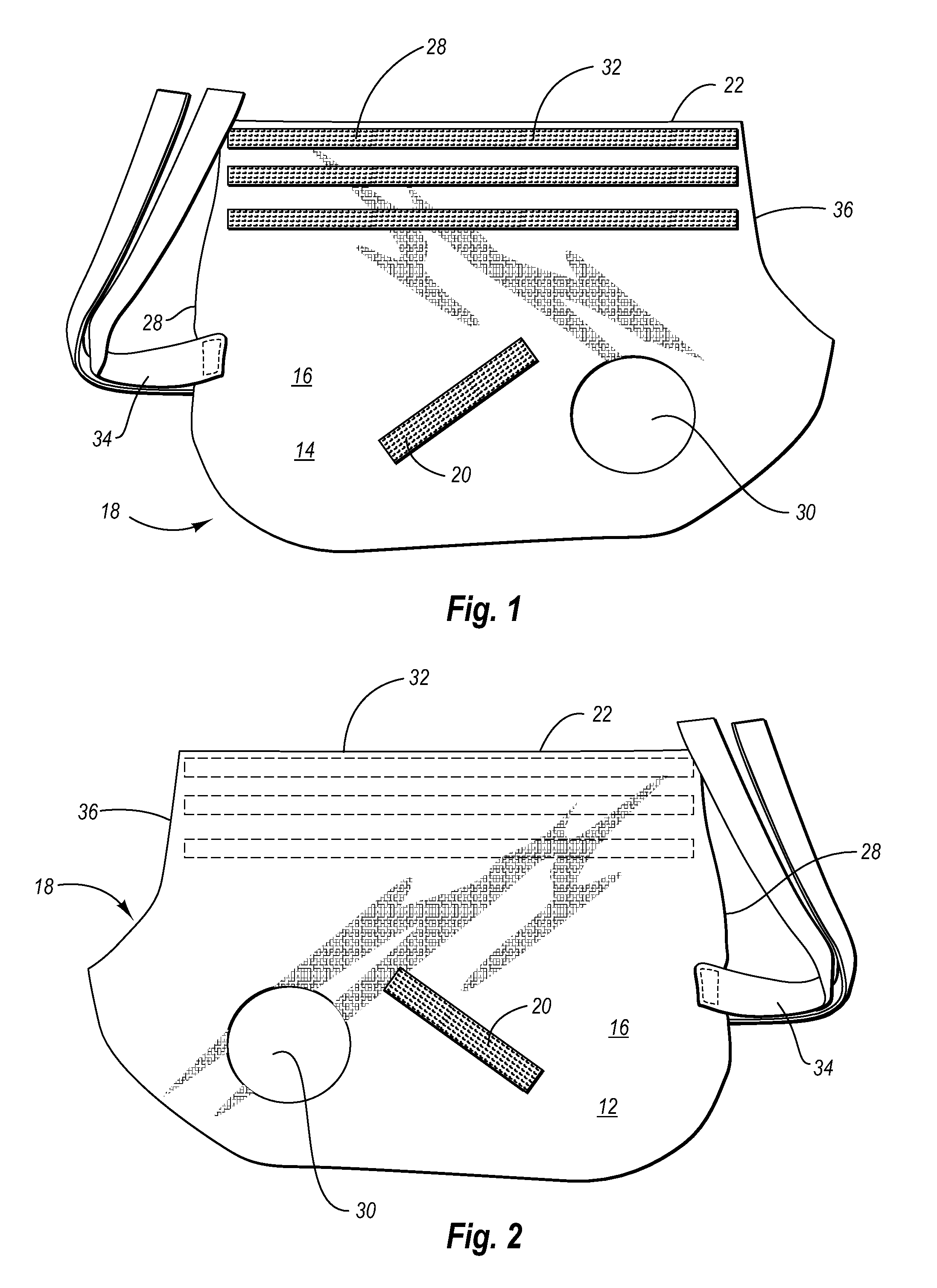

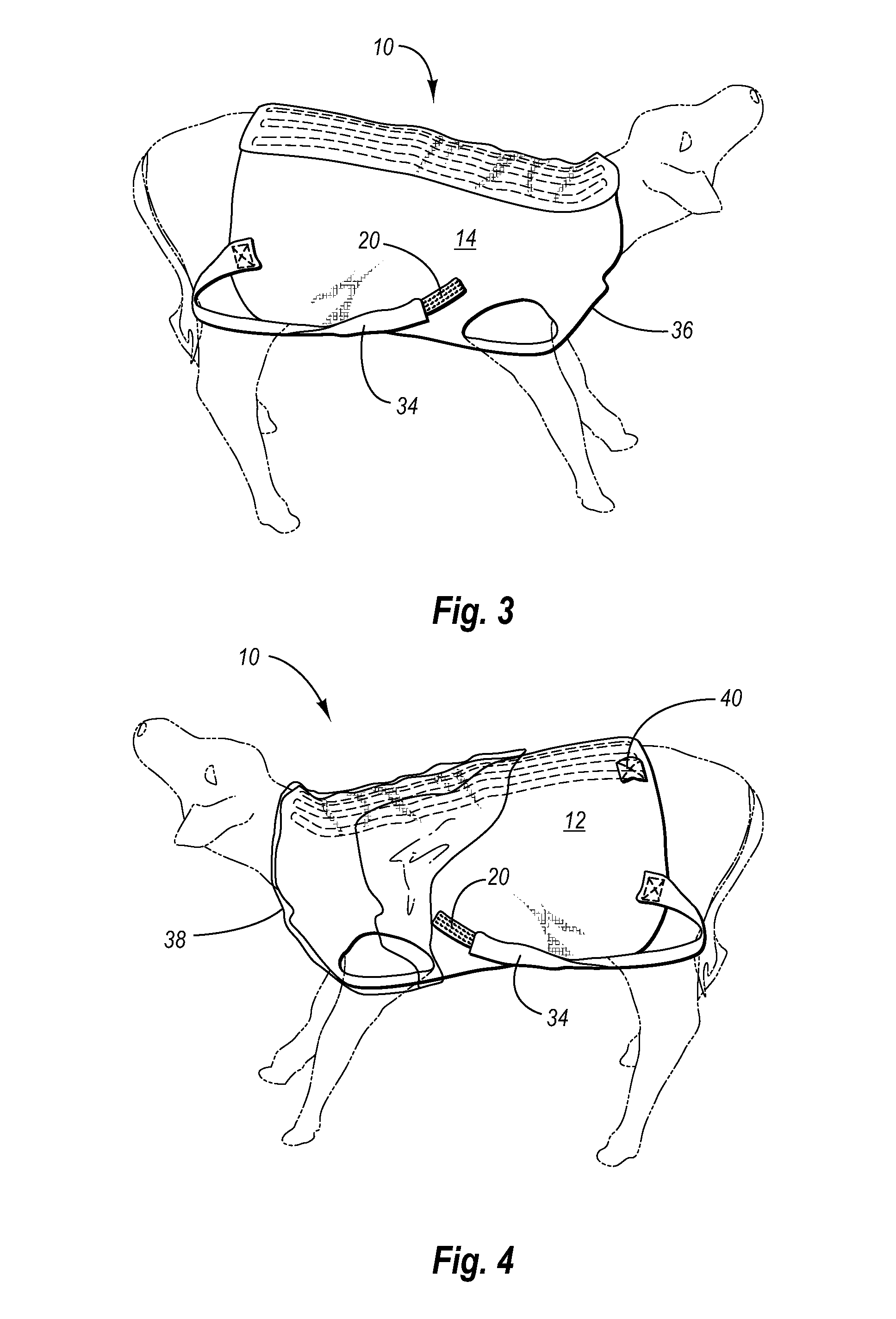

Animal garment

An animal garment for four-legged animals to protect such animals such as lambs and calves from cold and wet and to enhance their survivability. The garment is made up of connected halves and is adjustable along a portion that covers the back of the animal so as to allow for accommodation of the device to fit animals of different sizes or as an animal grows. The device includes holes for forelegs and detachable straps for hind legs, which hold the device in a secure position.

Owner:GERDES JANICE

Cavity Receivers for Parabolic Solar Troughs

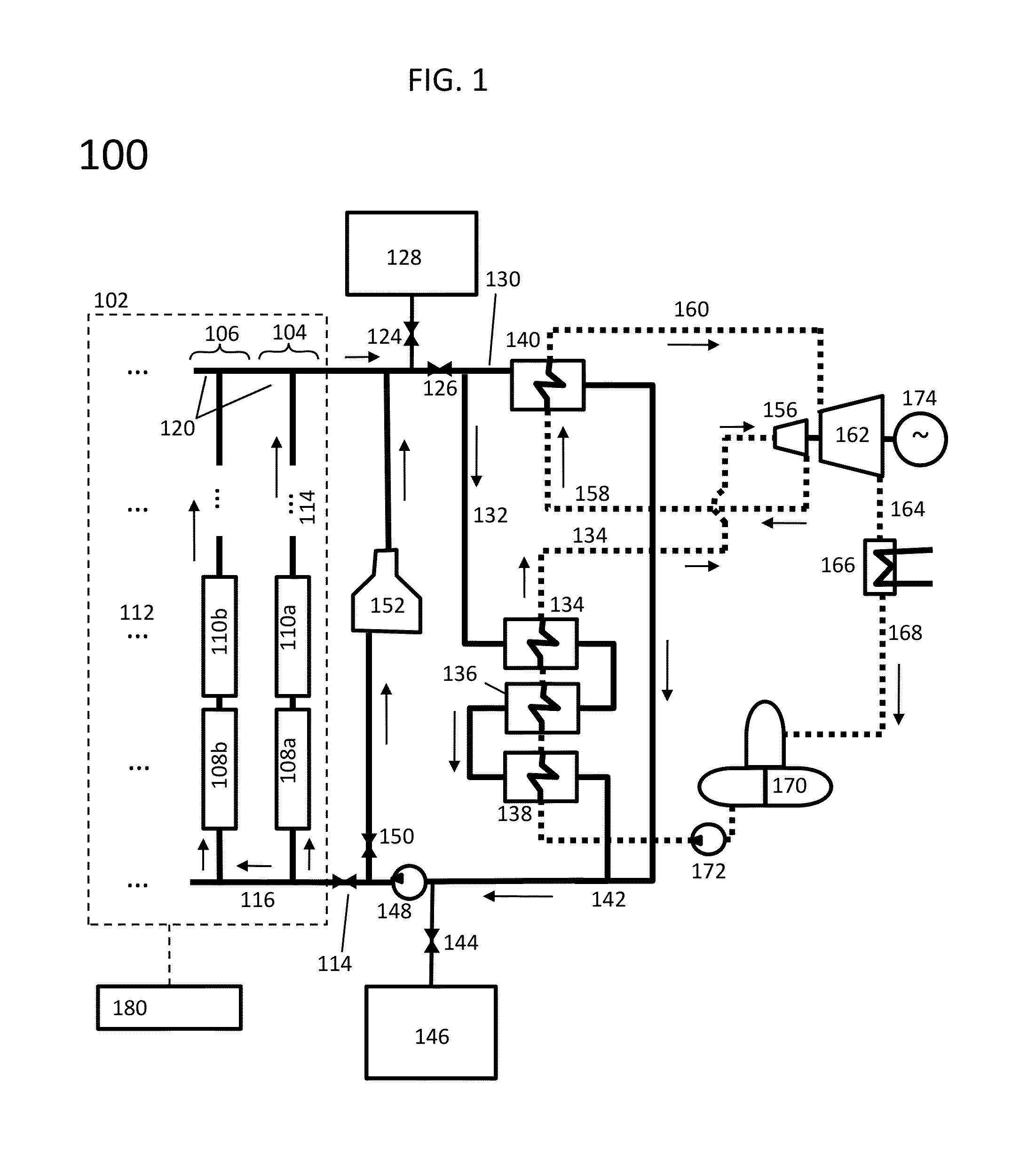

InactiveUS20130192226A1Levelized costLow costSolar heating energySolar heat devicesThermal insulationEngineering

A tubular heat-absorbing element partly enclosed in an insulating layer or jacket, has absorbing surface that is accessible to solar radiation. The thermal insulation is designed to provide entry to solar radiation by way of a cavity. The absorbing surface can be substantially planar.

Owner:NORWICH TECH

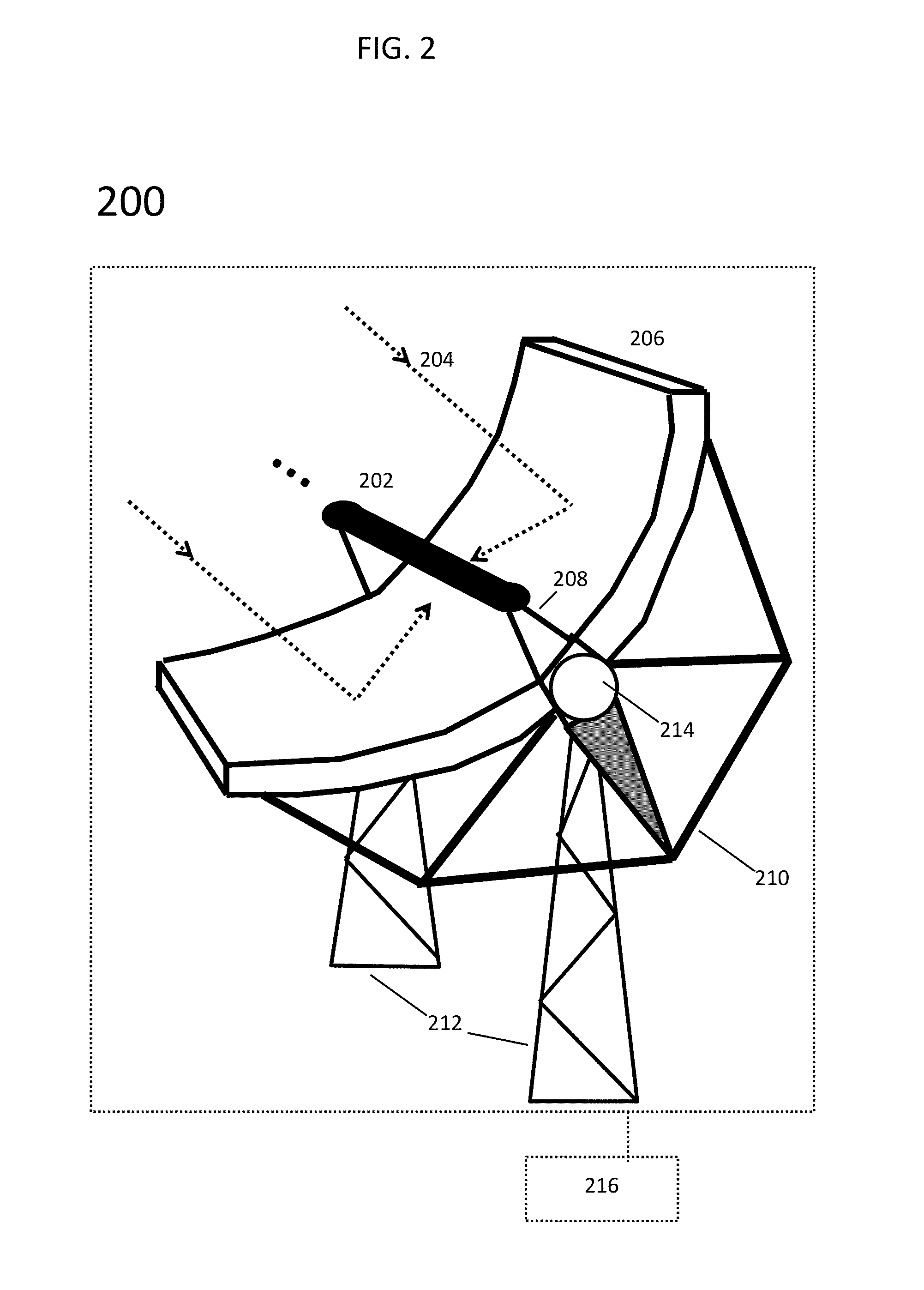

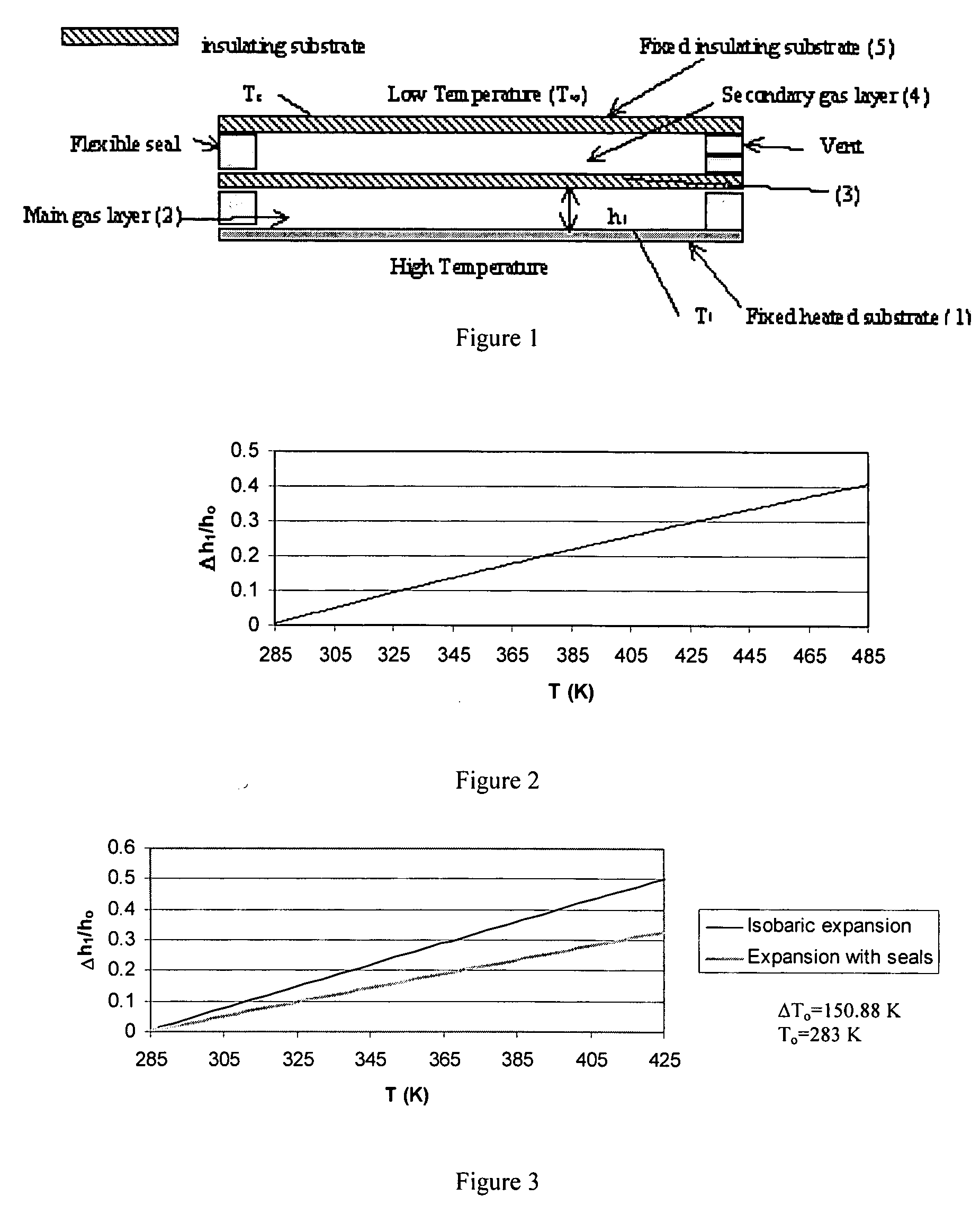

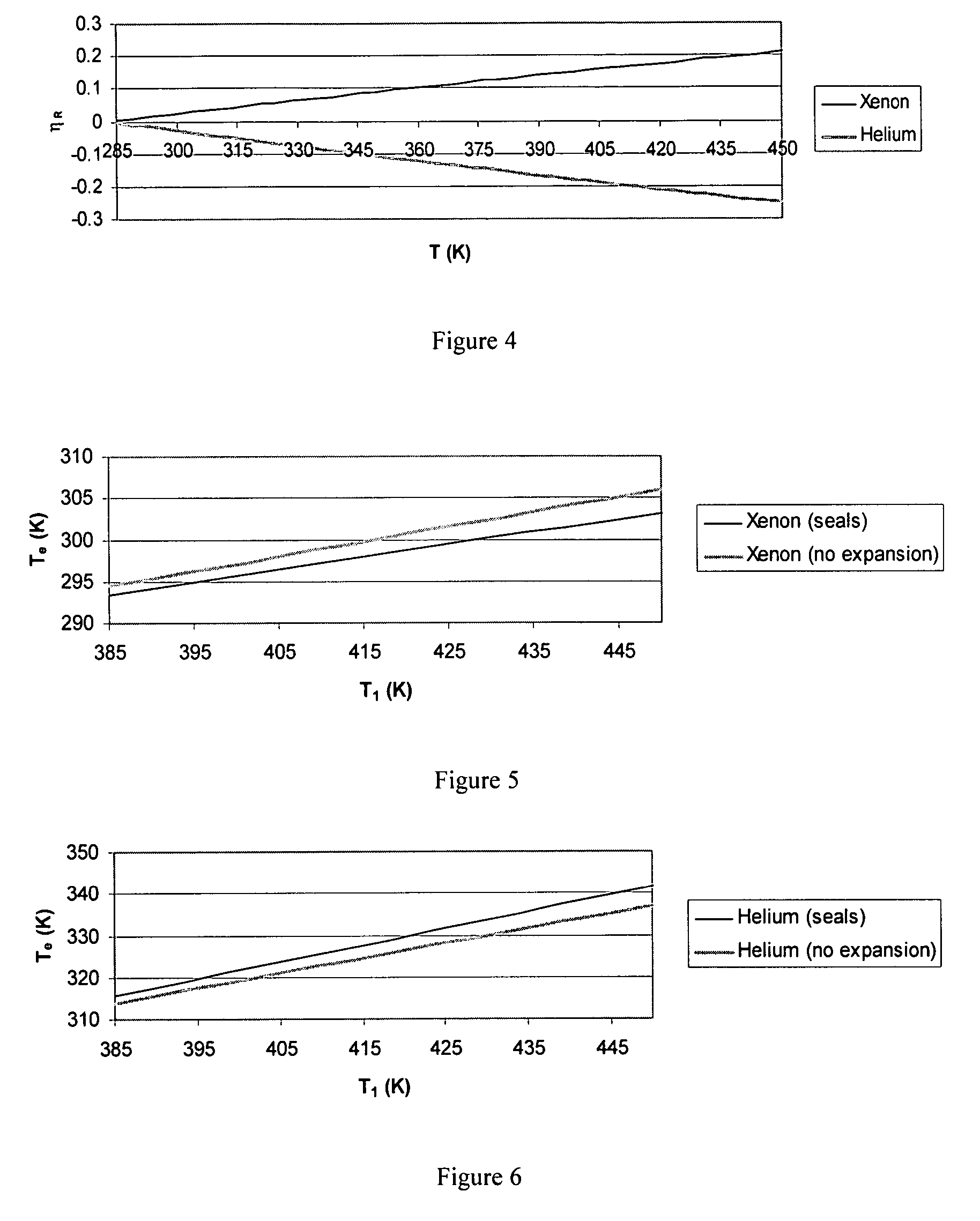

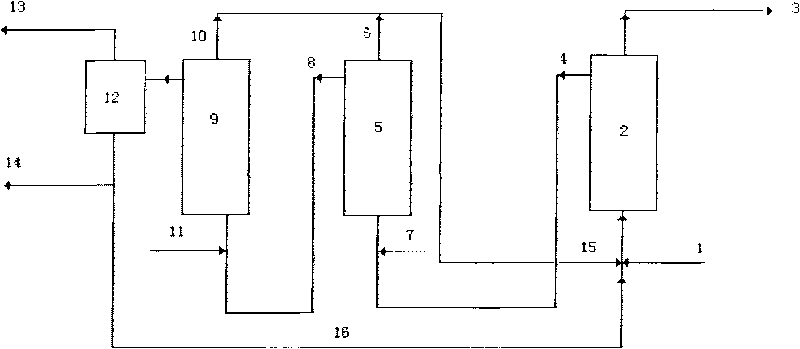

Methods and devices comprising flexible seals, flexible microchannels, or both for modulating or controlling flow and heat

InactiveUS20070084940A1Save heatReduce leakageMaterial nanotechnologyTemperature control without auxillary powerFluid layerEngineering

Disclosed herein are devices comprising at least one flexible seal, at least one flexible complex seal having at least one closed cavity containing a fluid, or a combination thereof. The devices may comprise at least one immobile and inflexible substrate and at least one mobile and inflexible substrate capable of movement due to the flexible seal, the flexible complex seal, or both. The flexible complex seals comprise at least one closed cavity comprising a fluid, such as a gas or a liquid. As disclosed, the presence or absence of heat will cause the mobile and inflexible substrate to move. The movement will increase or decrease the fluid amount or fluid flow rate in the primary fluid layer. Also disclosed are methods for enhancing the insulating properties of insulating assemblies.

Owner:RGT UNIV OF CALIFORNIA +1

Hydrogenation method of heavy hydrocarbon multi-segment fluidized bed

ActiveCN101724453AReduce heat loadSave heatHydrocarbon oil crackingTreatment with hydrotreatment processesGas phaseFuel oil

The invention discloses a hydrogenation method of a heavy hydrocarbon multi-segment fluidized bed. The technical process comprises the steps of: mixing thick heavy hydrocarbon raw materials with gas phase material flow which is discharged from a fluidized bed hydrogenation-desulfuration reactor and a hydrogenation-denitrification reactor to enter into a hydrogenation-demetalization reactor; cooling and purifying reacted gas phase material flow to be taken as recycle hydrogen; mixing the demetallized liquid phase material flow with hydrogen to enter into the fluidized bed hydrogenation-desulfuration reactor; mixing the desulfurated liquid phase material flow with hydrogen to enter into the hydrogenation-desulfuration reactor; and leading the denitrified liquid phase material flow to enter into a separating device. The technology adopts a new reactor assembly mode to machine heavy oil raw materials with high viscosity and bad quality, can provide a new flexible, high-efficiency and energy-saving operation mode, organically combines the performances of the raw materials with the characteristic of each hydrogenation reaction, makes full use of reaction heating on the premise that a device is guaranteed to be stably operated, provides a product with good quality, and can flexibly adjust the operation process according to the requirement of a refinery.

Owner:CHINA PETROLEUM & CHEM CORP +1

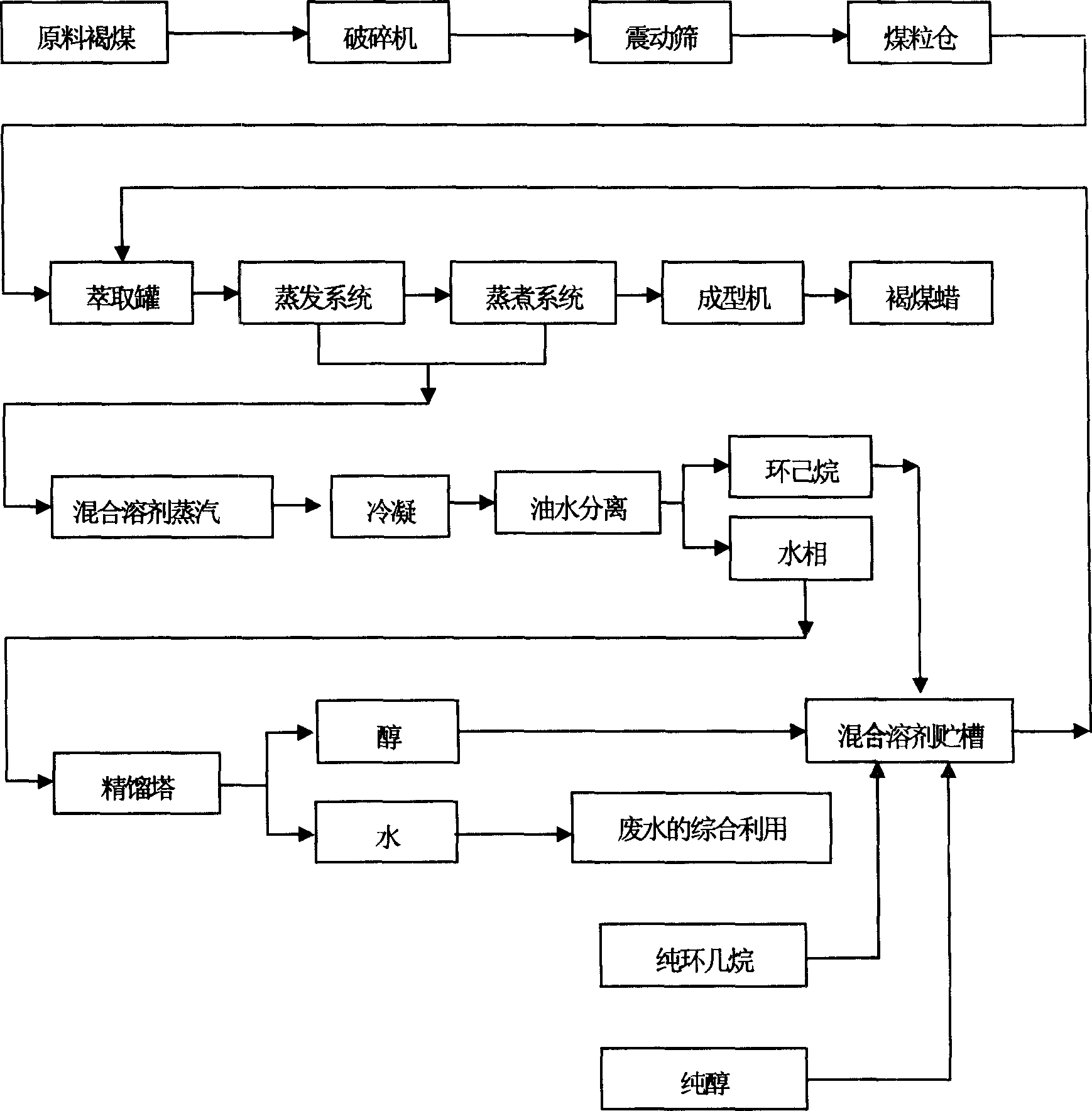

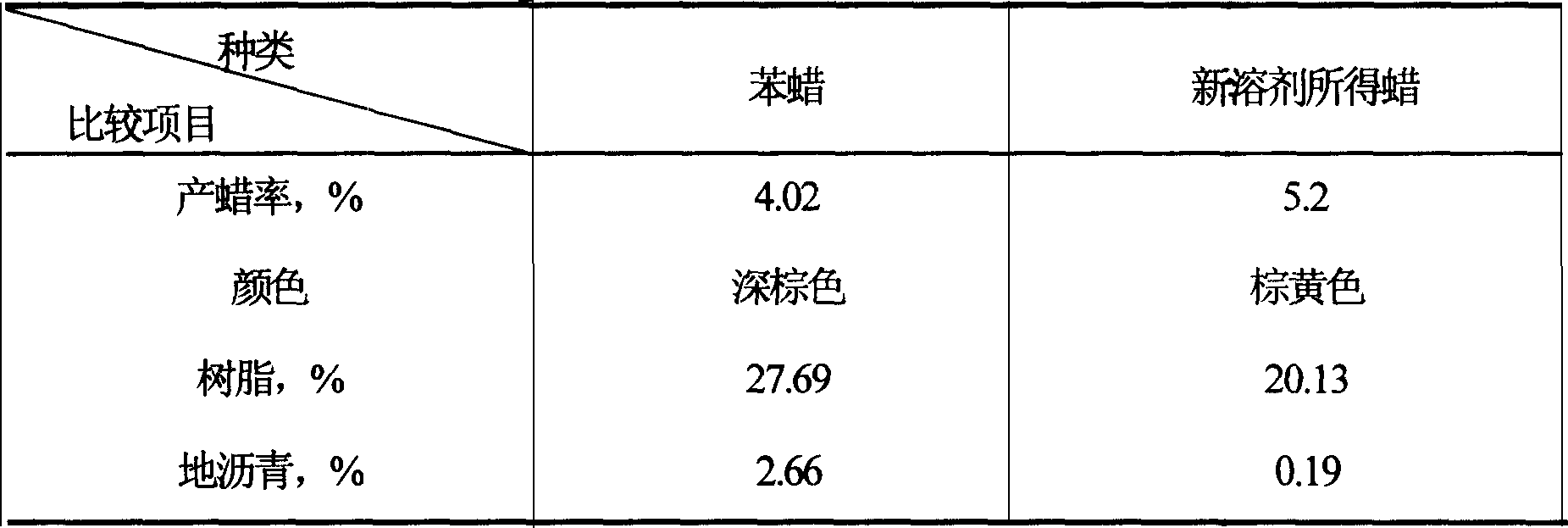

Brown-coal green extractive solvent and its production

InactiveCN101029255ALow asphalt contentImprove product qualityMineral wax recovery/refiningBrown coalWax

A lignite wax green extractive solvent and its production are disclosed. The process is carried out by taking mixed solvent of cyclohexane and alcohol, crushing for lignite, screening, putting lignite coal grain into extractor, mixing with solvent in proportion of 1:1-1:4 while extracting, flash evaporating, recovering solvent, evaporating for residual mixed solvent by stewing system to obtain crude lignite wax, condensing for mixed solvent steam by heat exchanger, oil-water separating, delivering cyclohexane to solvent trough, separating tert-butyl from water while rectifying, inducing tert-butyl into solvent trough, inspecting cyclohexane or tert-butyl content, supplement cyclohexane and alcohol, mixing proportionally and using. It's cheap, simple reliable, and economical, it has more wax yield and no environmental pollution.

Owner:CHINA UNIV OF MINING & TECH

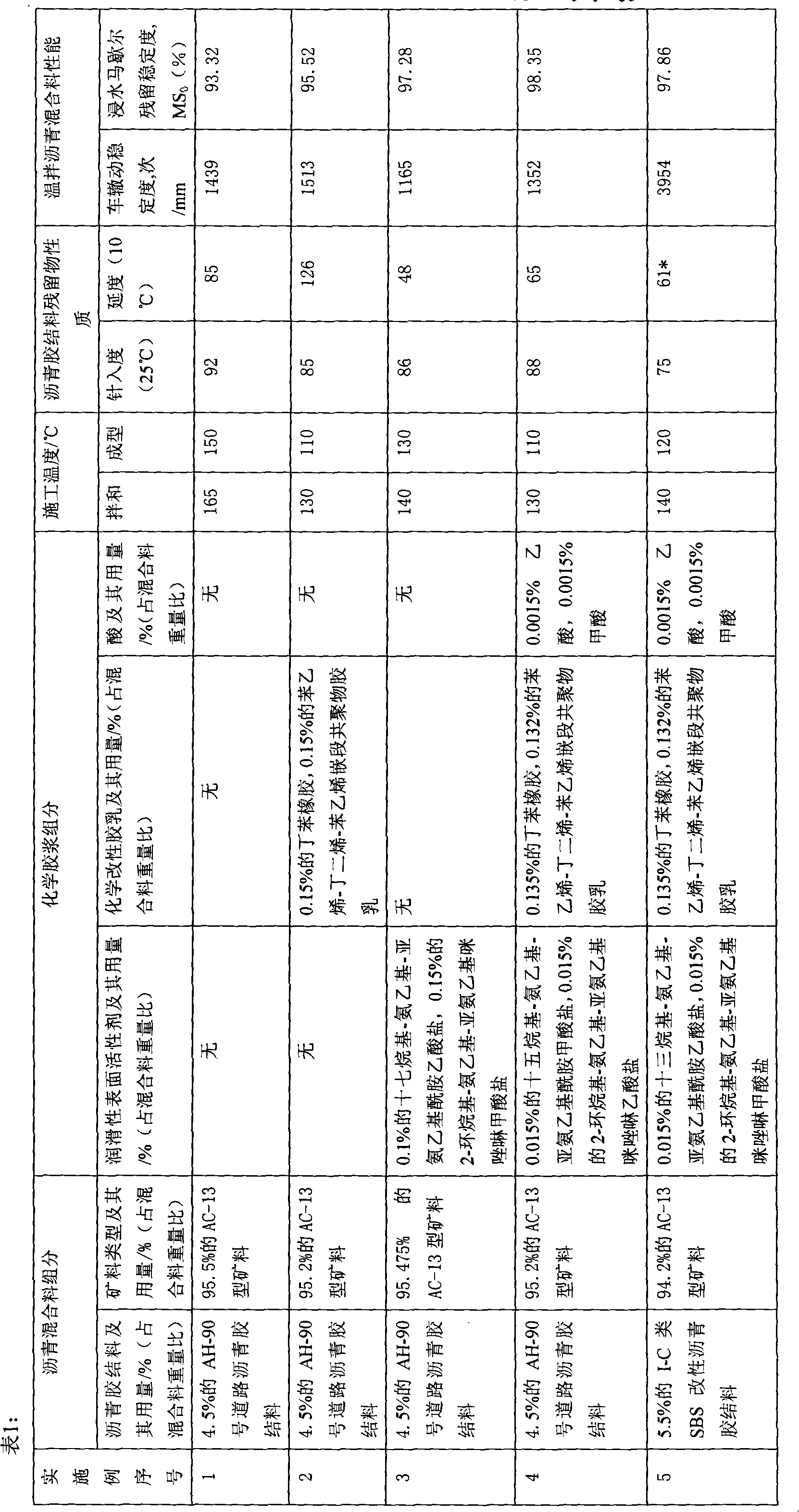

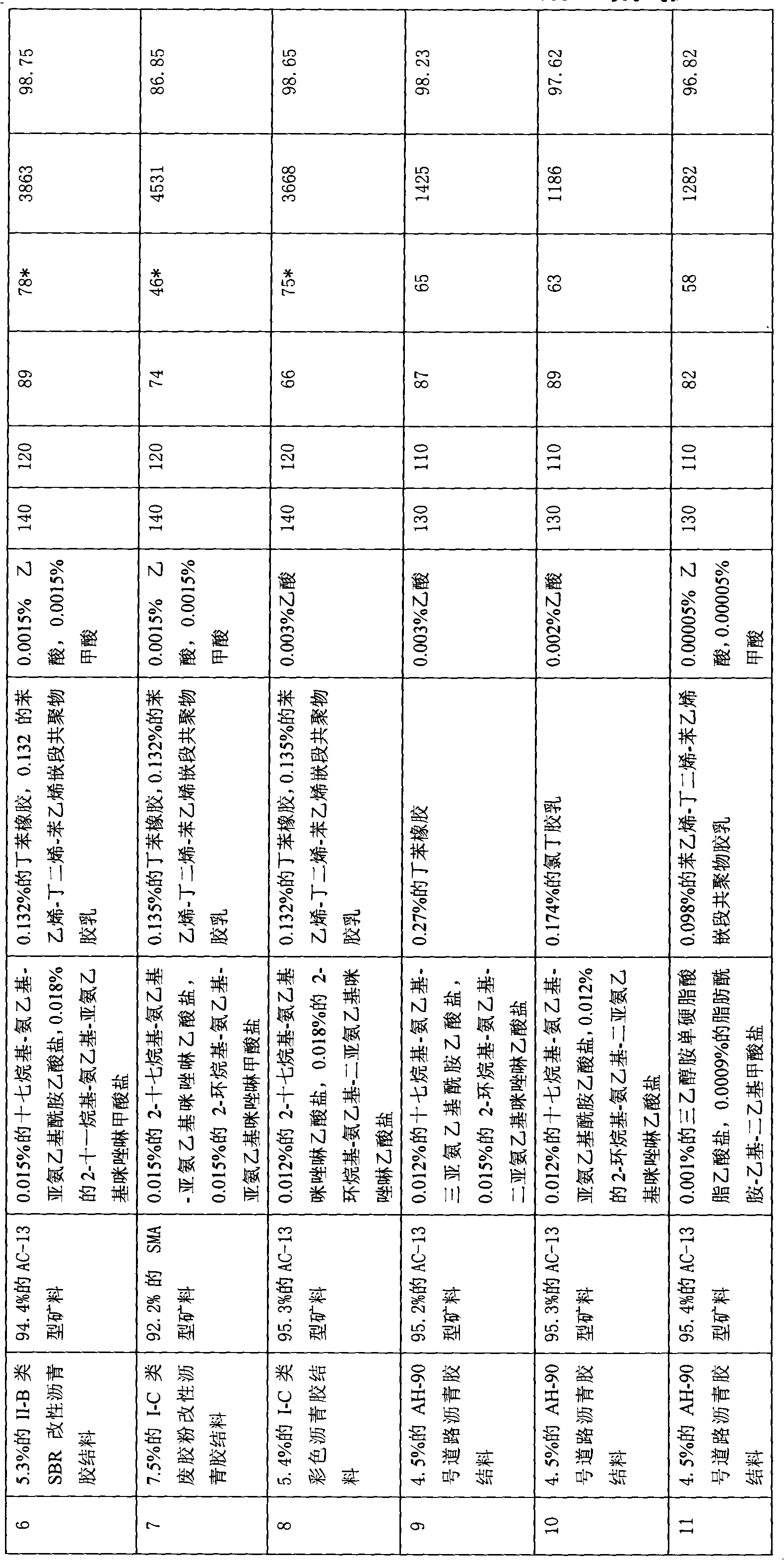

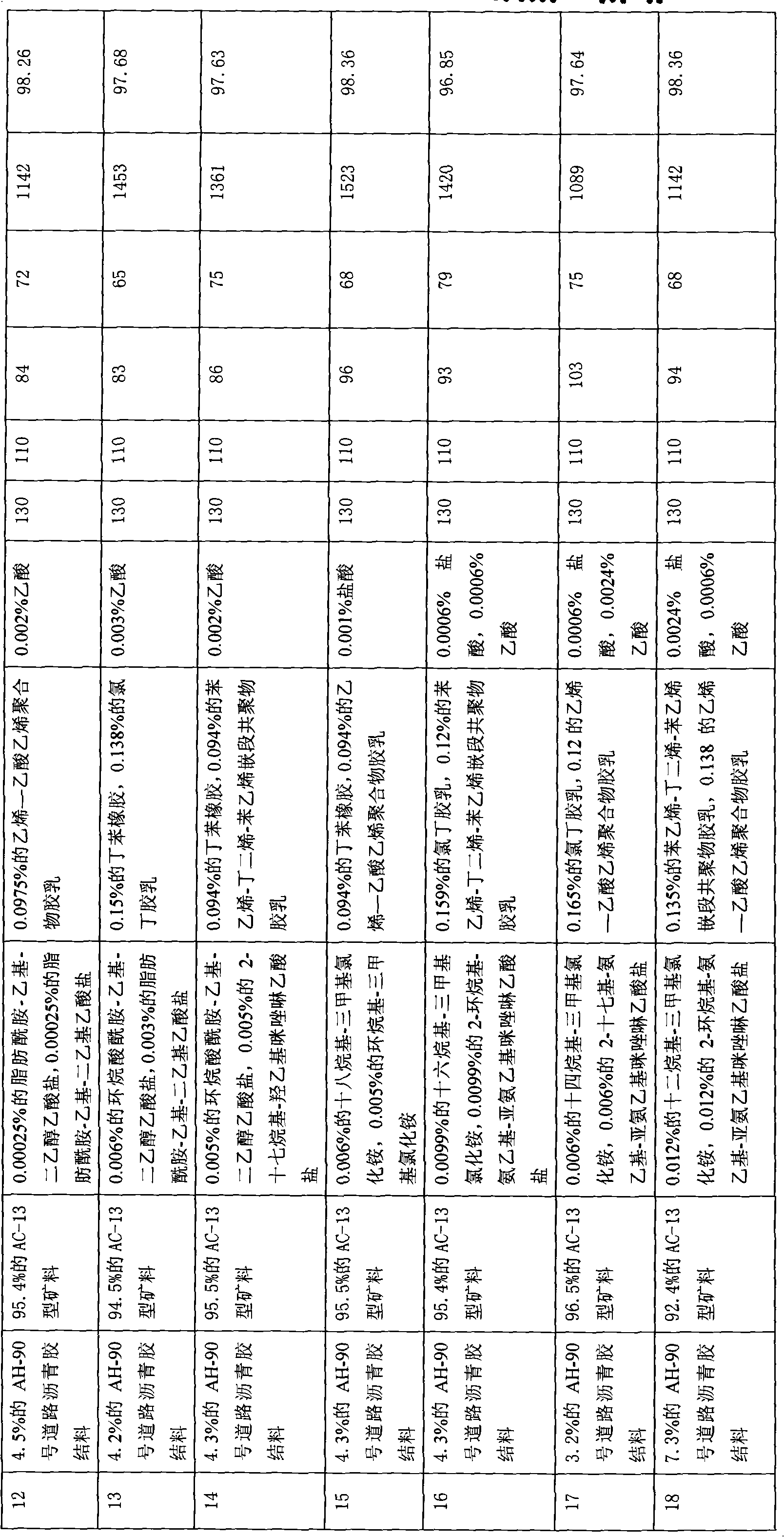

Warm-mixed asphalt mixture and preparation method thereof

ActiveCN102092988ALower the mixing temperatureHigh tensile strengthClimate change adaptationAdhesive cementHigh concentration

The invention relates to a warm-mixed asphalt mixture and a preparation method thereof. The warm-mixed asphalt mixture is mainly applied to new construction and maintenance of high-grade roads and common roads, and is particularly suitable for cities, parks, tunnels and the like with high environmentally-friendly requirements. The warm-mixed asphalt mixture mainly comprises about 92.4-96.5 percent by weight of mineral, about 3.4-7.5 percent by weight of asphalt cement and 0.05-1.0 percent by weight of chemical modified adhesive cement. The preparation method comprises the following steps of: simultaneously pumping the chemical modified adhesive cement and the hot asphalt cement to the spraying port of a foam generator, fully mixing to generate a foam-containing hot asphalt mixture, spraying the foam-containing hot asphalt mixture into a mixing pan, and further mixing the foam-containing hot asphalt mixture and the hot mineral to form the warm-mixed asphalt mixture. The chemical modified adhesive cement can effectively reduce the mixing, spreading and rolling temperature of the asphalt mixture, and solves the problems of environmental pollution, high energy consumption, asphalt ageing regression and the like. By selecting high-concentration cationic chemical modified latex as a matrix stock of the chemical modified adhesive cement and simultaneously matching a proper proportion of cationic surfactant with lubricating effect and peeling resistance, the influence of the conventional warm-mixed asphalt additive on poor reducing performance and poor adhesive performance of the asphalt cement is solved, and the properties of the warm-mixed asphalt mixture such as water damage resistance, rutting resistance, fatigue resistance, low temperature resistance and the like are improved.

Owner:PETROCHINA CO LTD

Sulfur tolerant zeolite catalyst

InactiveUS6063723AHigh yieldHigh selectivityAluminosilicate zeolite type ZSM-12SilicaSulfurDehydrogenation

A process is provided for catalyst dehydrogenation of light paraffinic hydrocarbons using a catalyst comprising a noble metal and an intermediate pore size zeolite having a specified alkali content. The catalyst is sulfur tolerant, so that the dehydrogenation process can be carried out in the presence of sulfur or with periodic exposure to sulfur.

Owner:CHEVROU USA INC

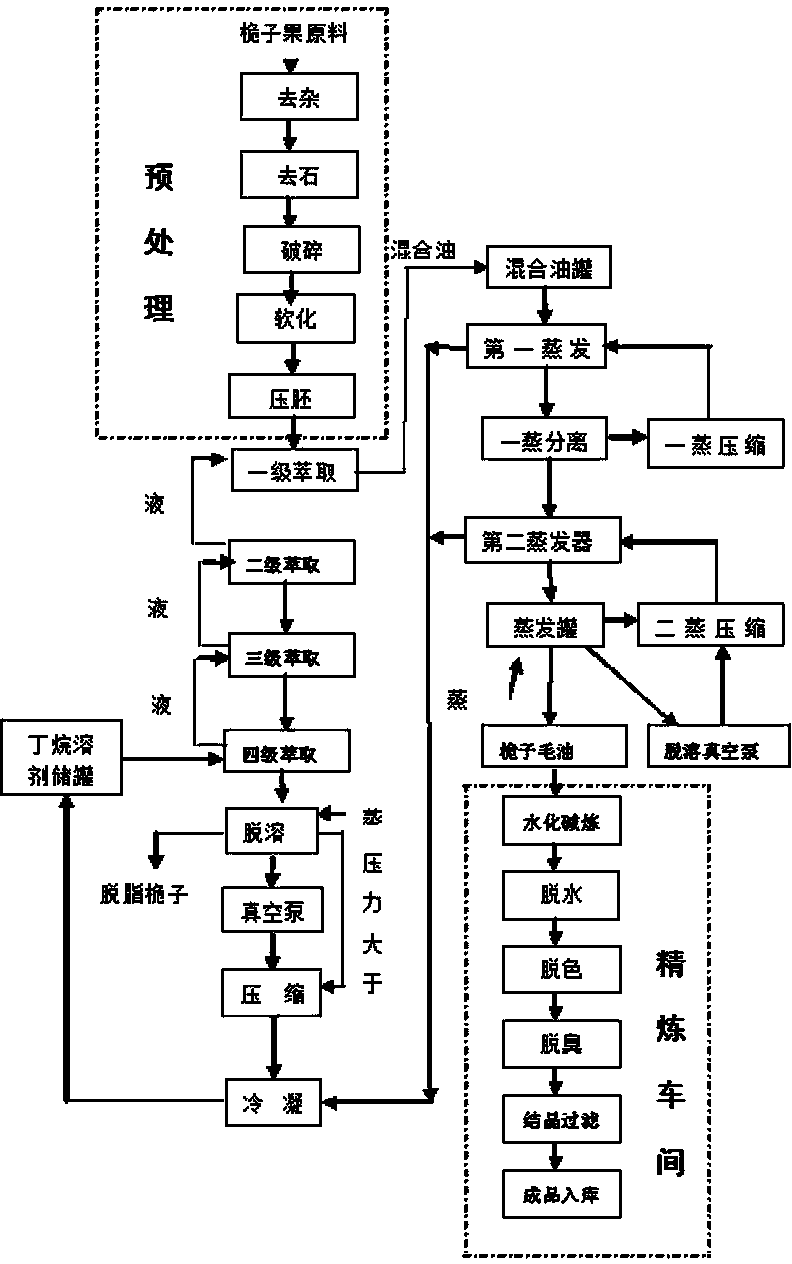

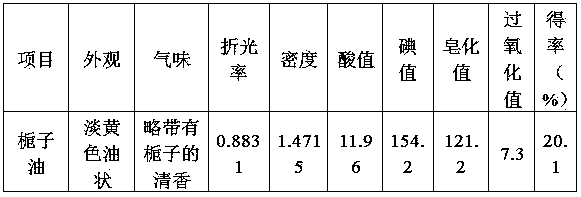

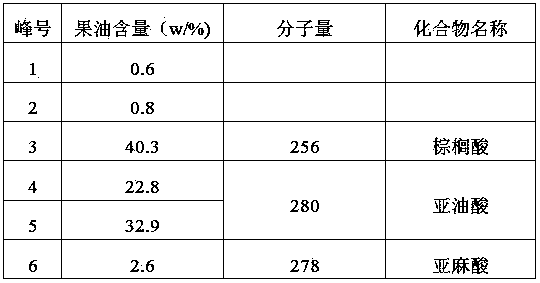

Method for extracting gardenia oil by using subcritical fluid

ActiveCN104212626ALess investmentReduce work stressFatty-oils/fats refiningFatty-oils/fats productionActive componentEvaporation

The invention discloses a method for extracting gardenia oil by using a subcritical fluid. The method comprises the following steps: preprocessing a gardenia fruit raw material, and adding a metered amount of the preprocessed raw material to an extraction tank; inspecting the air tightness of the extraction tank, conveying liquid butane into the extraction tank according to a solid / liquid mass ratio of 1:4 in order to carry out extraction, carrying out four-stage extraction on every tank, respectively introducing a second stage extraction liquid, a third stage extraction liquid and a fourth stage extraction liquid to previous stage extraction, and separating a first stage extraction liquid, wherein extraction in each of the four stages is carried out for 2h; and introducing the first stage extraction liquid into an evaporator, carrying out reduced pressure evaporation exsolution to prepare crude gardenia oil, and purifying the crude gardenia oil to prepare a finished product. The method is used to efficiently extract gardenia oil in the gardenia fruit raw material, and has the advantages of low energy consumption, no pollution, high quality, and especially no destroys to natural heat-sensitive oxidizable active components in the gardenia oil.

Owner:NANYANG TERRY BIOLOGICAL PROD

Process for manufacturing hot rolled steel strips by using compaction type continuous casting and rolling technique

InactiveCN101293257AEasy to produceIncrease production capacityFurnace typesHeat treatment process controlProduction lineStrip mill

The invention discloses a compact continuous casting and tandem rolling method for producing hot rolling strip steel, including the following steps: 1) liquid molten steel passes through a long nozzle from a ladle to be cast to a pouring box, flows through a submerged nozzle from the pouring box to be cast in a crystallizer of a continuous caster and is continuously cooled in the continuous caster to form a casting blank; 2) a shearing machine is used for cutting a flat blank into certain size; 3) the flat blank enters a tunnel roller hearth heating furnace for heating; 4) the continuous caster is provided with a plurality of casting flows, one of which is in collineation with a rolling mill, the casting blank of other flows passes through a swinging section and is converged with the casting blank of the collinear flow and then is descaled by high pressure water; 5) the casting blank carries out rough rolling into an intermediate blank by a roughing mill group; 6) the intermediate blank is coiled and decoiled by a hot coiling box; 7) the head and the tail of the decoiled intermediate blank are cut and descaling by high pressure water is carried out to the decoiled intermediate blank; 8) the intermediate blank carries out finish rolling into a steel strip with standard thickness; 9) the steel strip is coiled into a finished steel coil by laminar flow cooling. The method is characterized by stable production technique, shorter production line, low equipment investment and high utilization rate of energy in the whole production process, etc.

Owner:BAOSHAN IRON & STEEL CO LTD

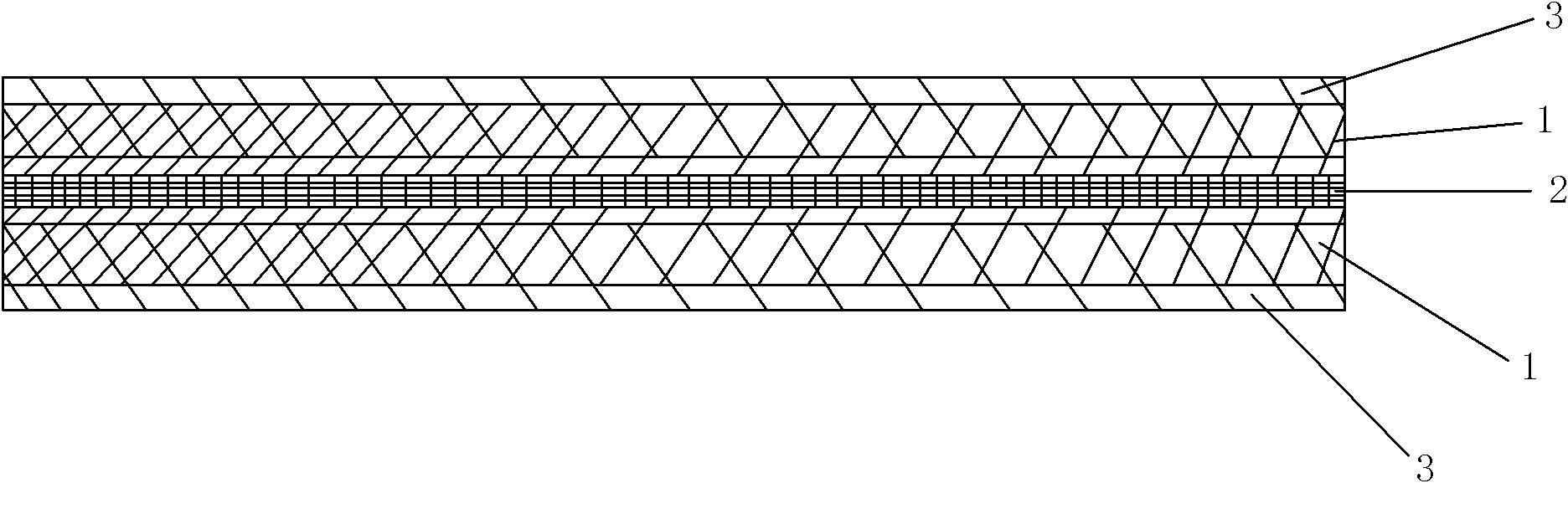

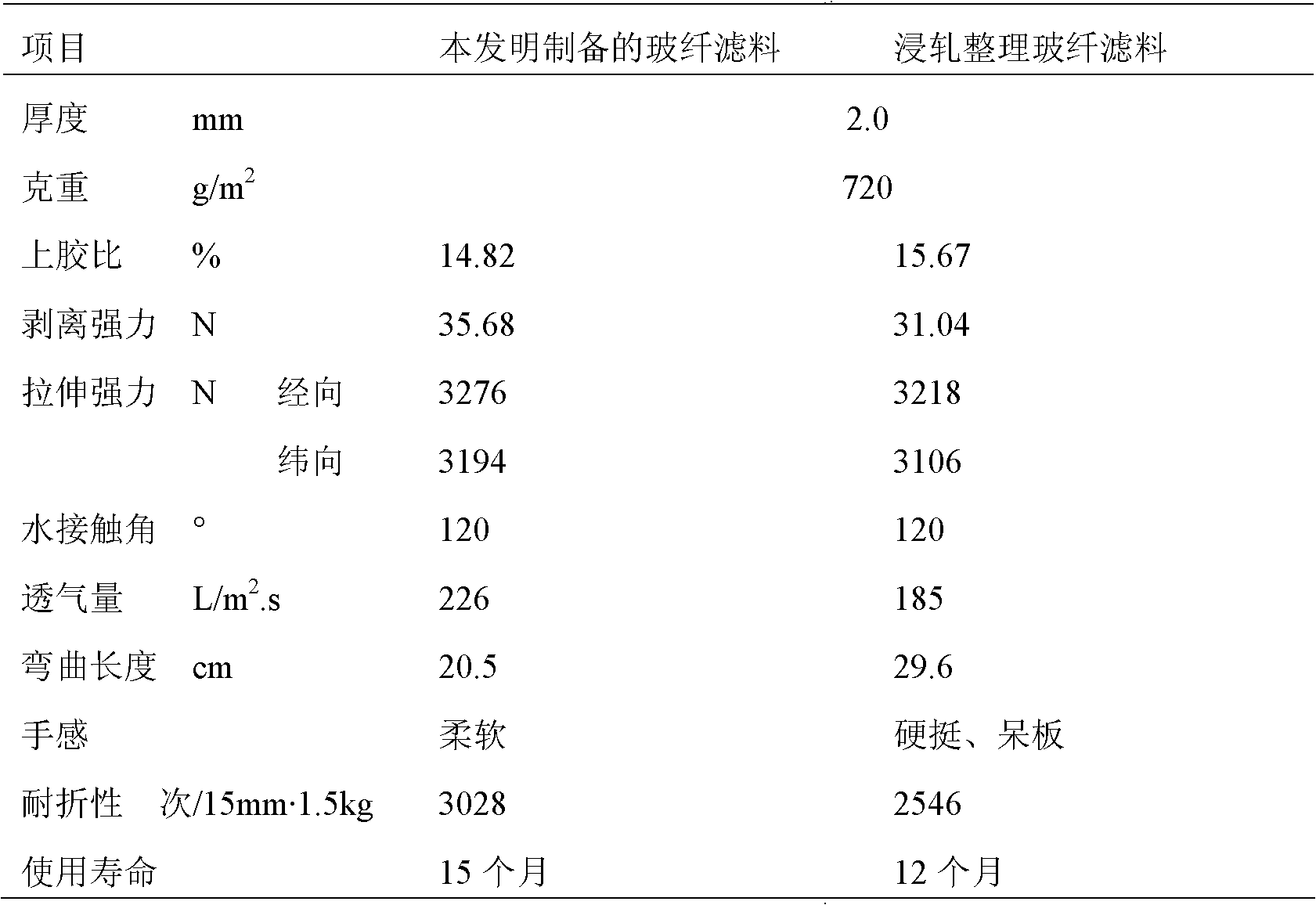

Glass fiber filter material and preparation method thereof

ActiveCN102151435AEvenly distributedReduce swimming phenomenonSynthetic resin layered productsGlass/slag layered productsGlass fiberFolding endurance

The invention discloses a glass fiber filter material and a preparation method thereof. The filter material comprises a base fabric, wherein the upper surface and the lower surface of the base fabric are respectively provided with a non-woven layer, and at least one of the non-woven layers is internally and externally provided with a foam coating layer respectively. The preparation method of the glass fiber filter material comprises the following steps of: manufacturing the glass fiber filter material, preparing finishing agent, generating foam, coating, and drying. The glass fiber filter material is subject to foaming layer arrangement, and the concentration of the finishing agent is increased, so that the finishing agent is distributed in the filter material more evenly, the migration phenomenon is reduced, and a mass of water resource, electric energy and heat energy are saved; after the glass fiber filter material is finished, and the gluing quantity of the filter material is decreased to 7-15% from 12-25% during finishing in a leaching way, so that the glass fiber filter material is even in distribution of the gluing quantity, good in flexibility, stable in quality, chemical corrosion-resistant, good in water resistance and oil resistance, easy to dedust, easy for industrial production, free of the existing water and energy-wasting step of finishing in a padding way, goodin folding endurance, and long in service life at about 15 months.

Owner:南京际华三五二一环保科技有限公司

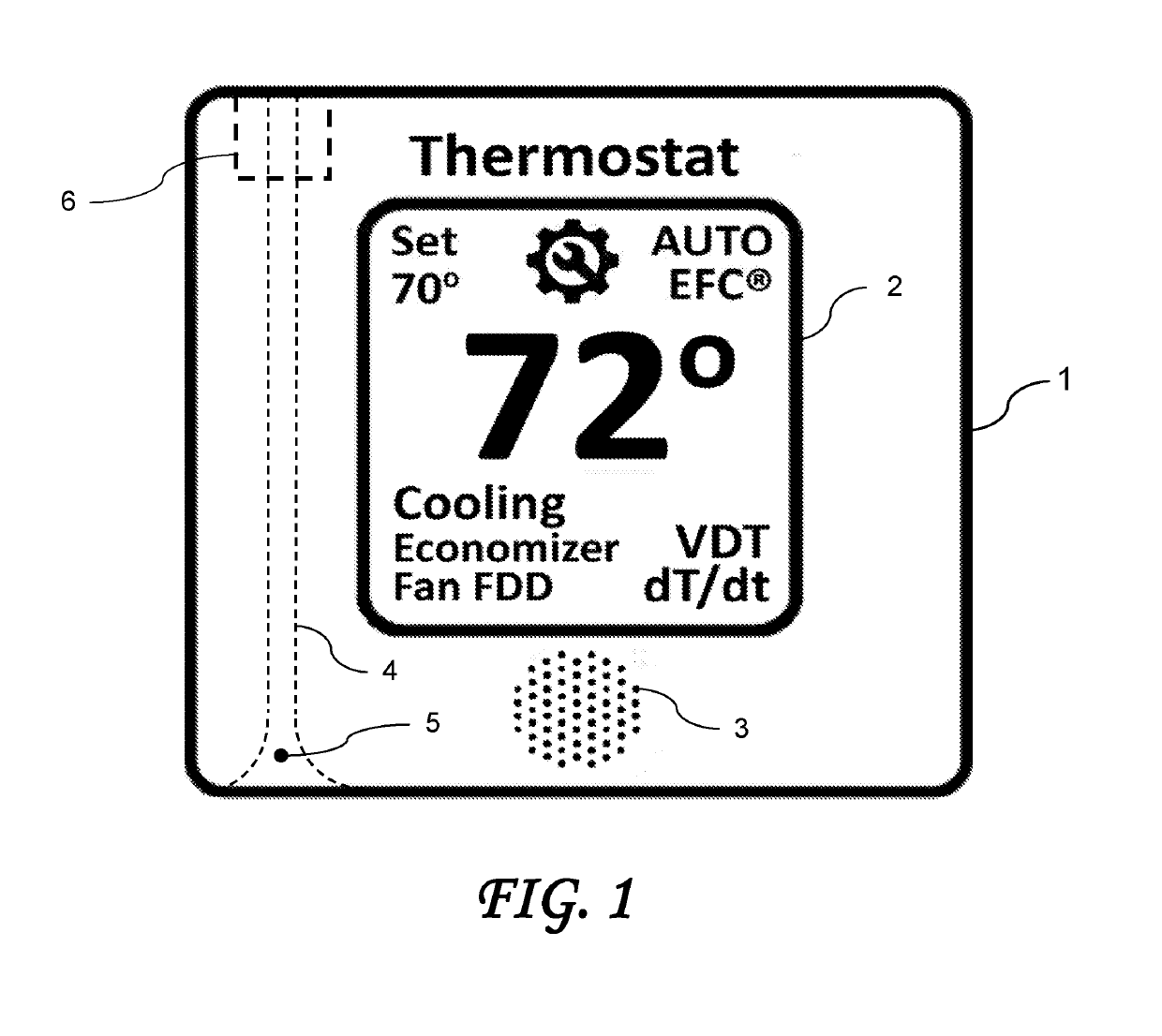

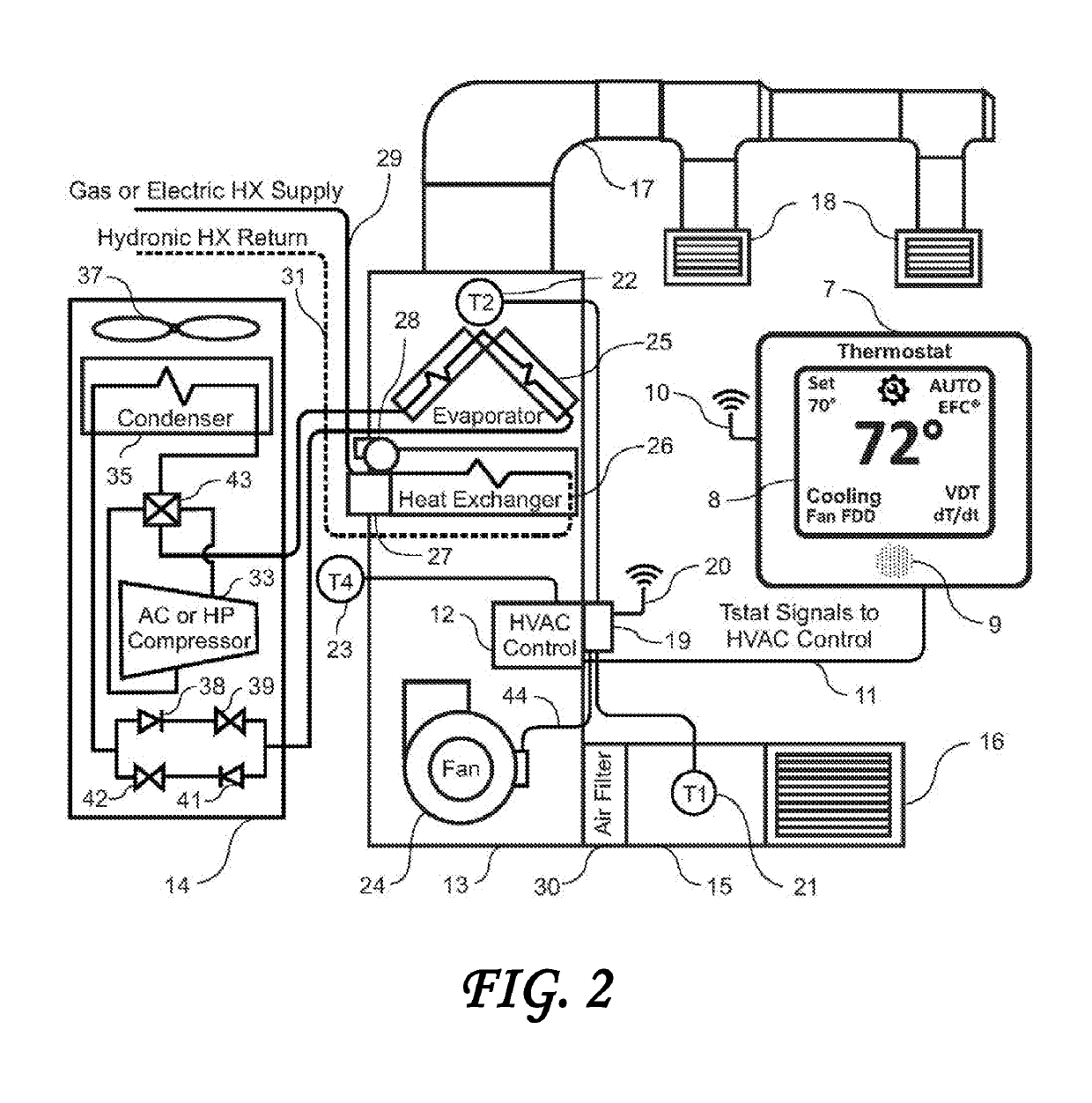

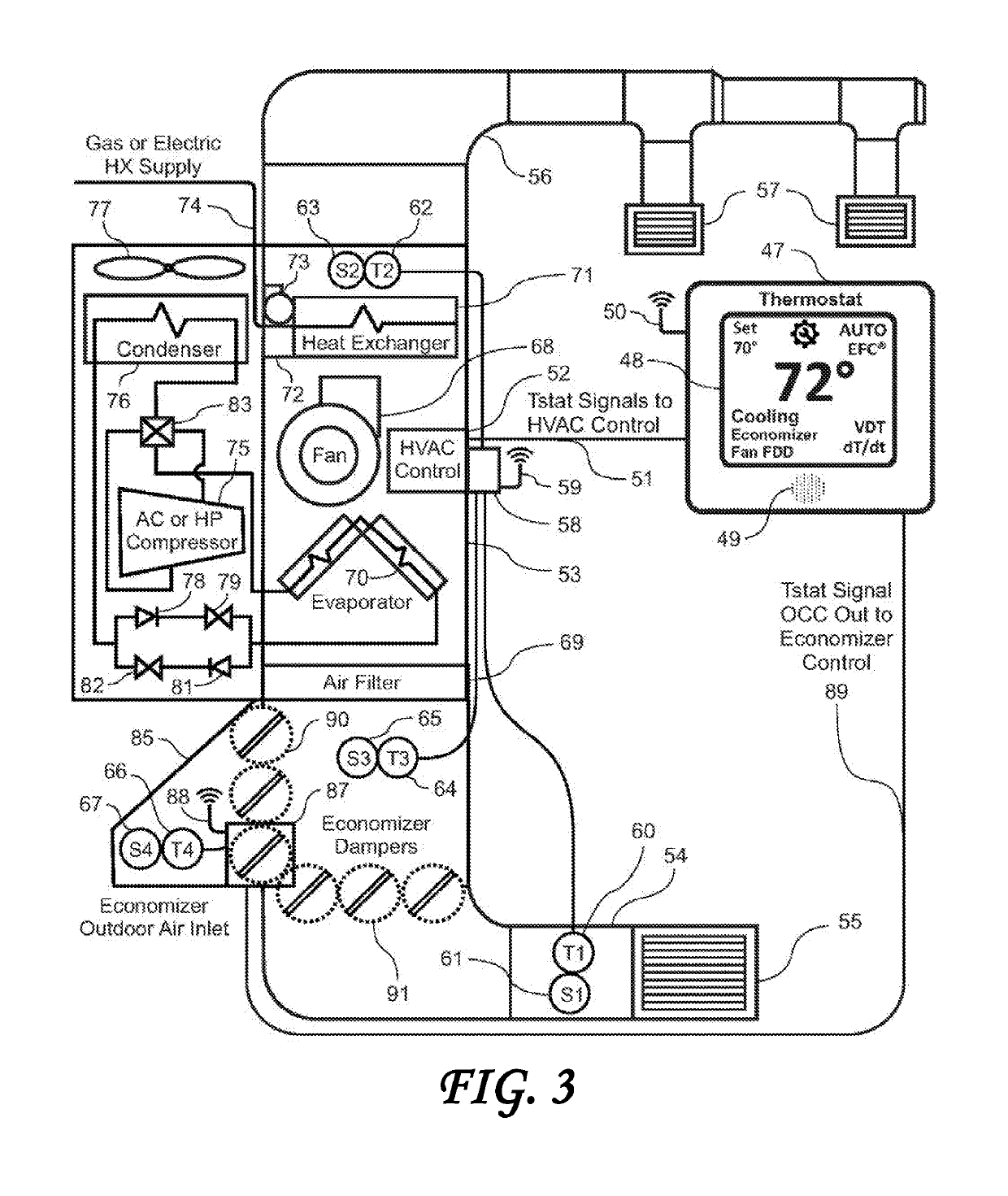

Variable Differential Variable Delay Thermostat

ActiveUS20190195523A1Improve efficiencyEnsure occupant comfortMechanical apparatusSpace heating and ventilation safety systemsCooling temperatureHeating system

A method for providing a cooling or heating variable fan-off delay based on a Conditioned Space Temperature (CST) measured during a current variable fan-off delay period compared to CST values measured during the current variable fan-off delay period. The method may also include turning off a cooling or heating system and continuing to operate an HVAC fan until the CST reaches an Inflection Point (IP) where a rate of change of the CST with respect to time (dT / dt) equals zero plus or minus a confidence interval tolerance. The method may also include providing a cooling or heating variable differential (or offset) and / or variable fan-off delay based on the duration of the thermostat call for cooling or heating, an off cycle time, a cooling temperature split, a heating temperature rise, outdoor air temperature, supply air temperature or a rate of change with respect to time of any of these HVAC parameters.

Owner:LAU JAMES

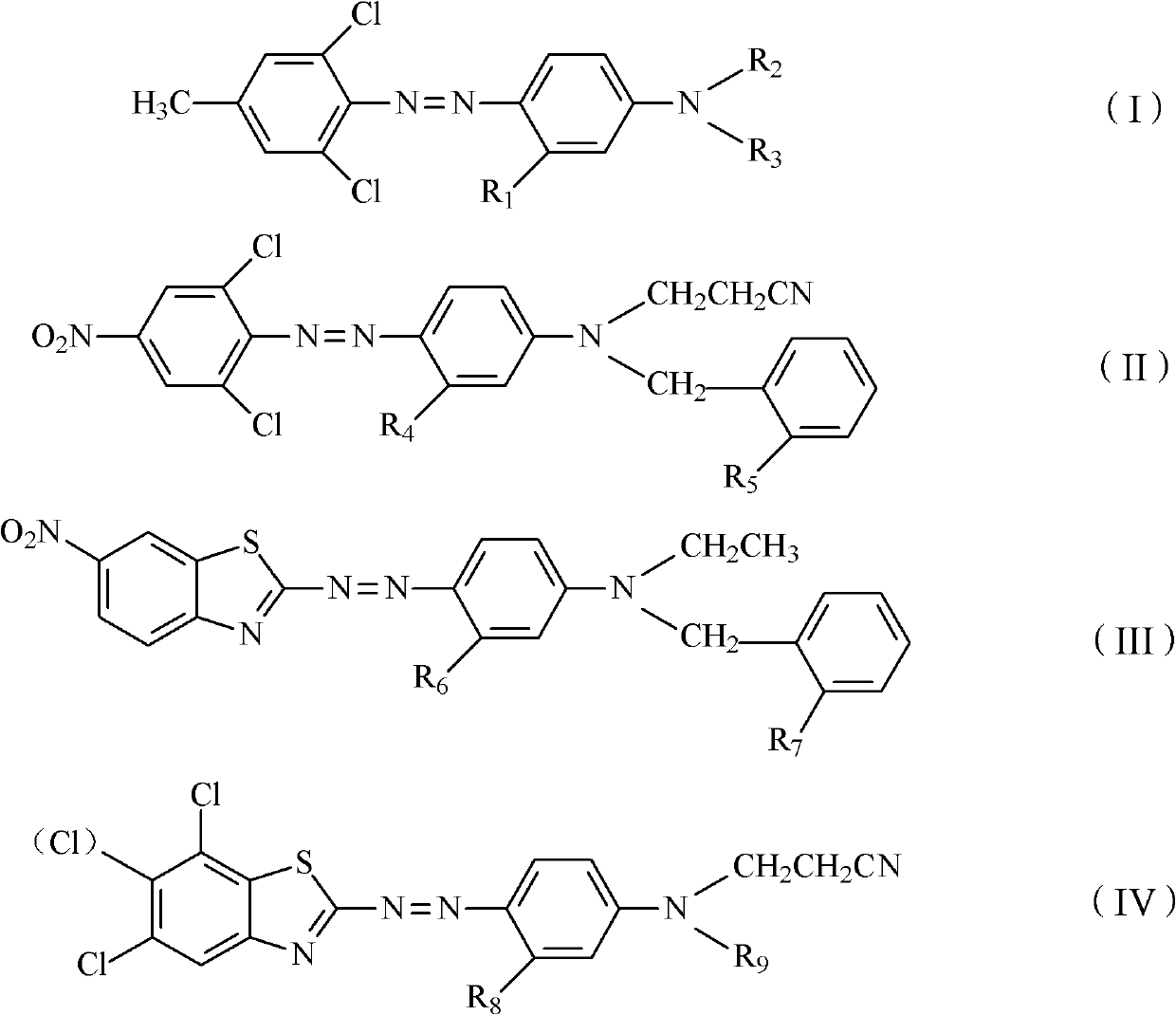

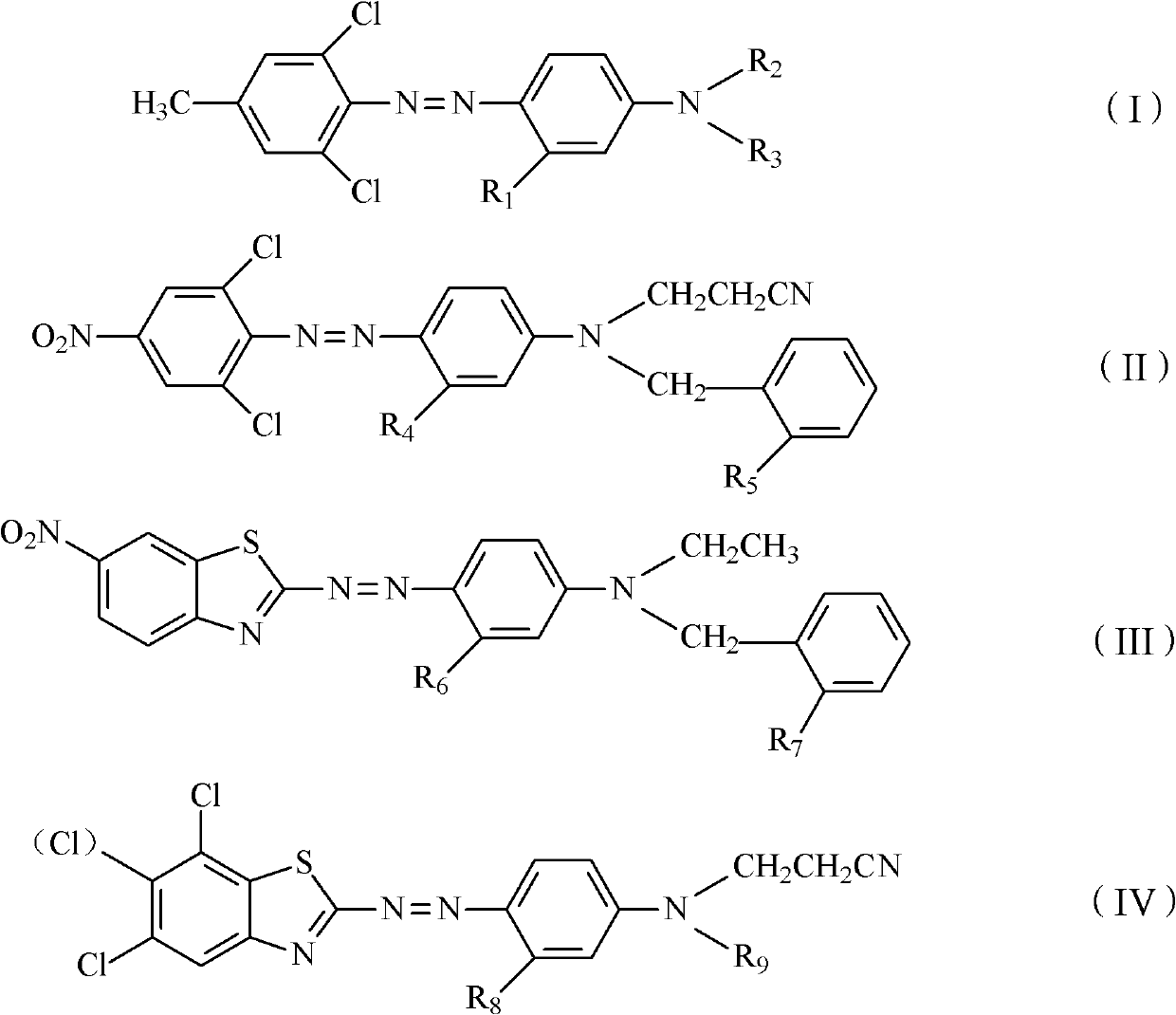

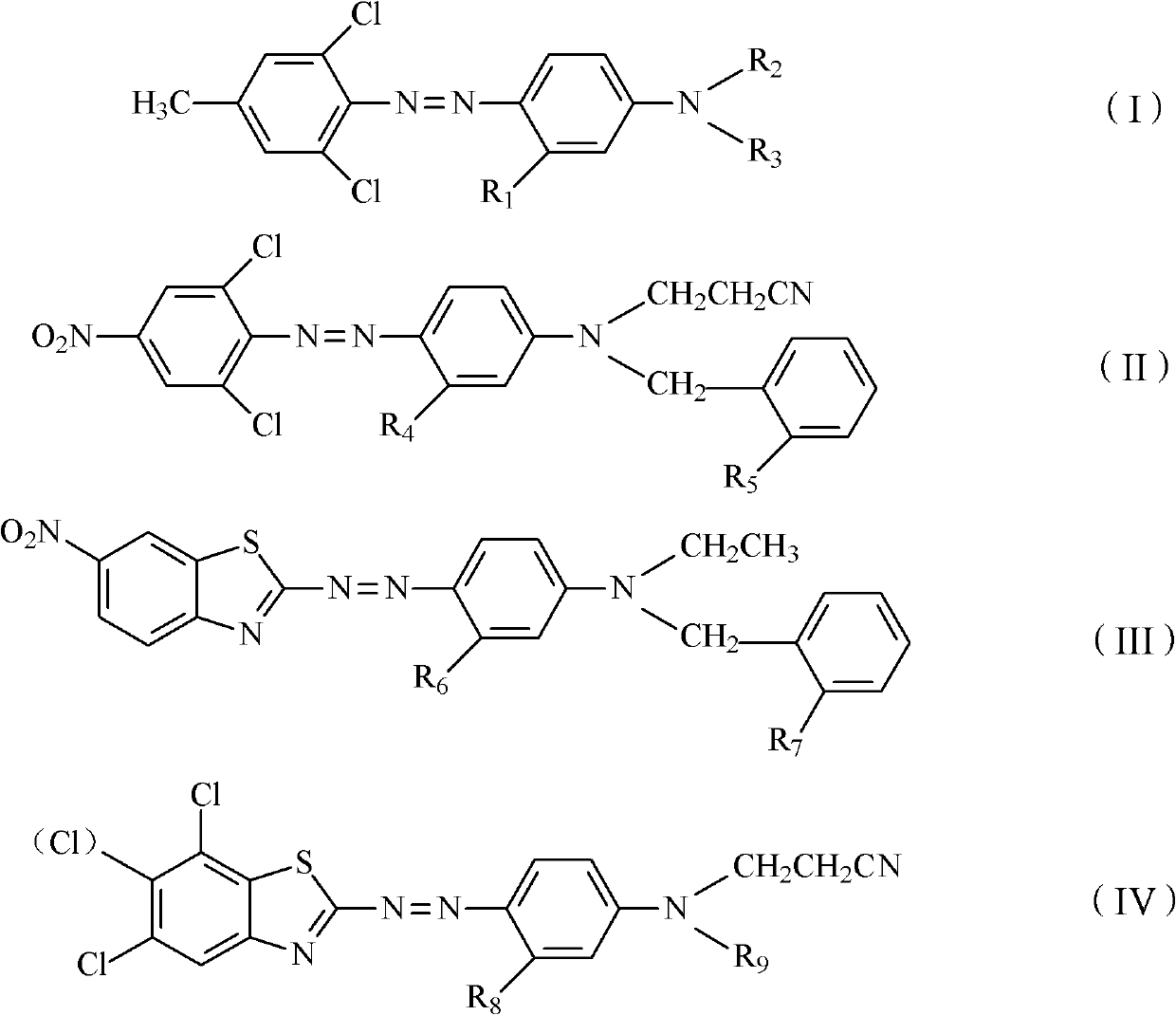

Disperse dye composition, dyeing method and preparation method of disperse dye composition

ActiveCN102618078AImprove oxidation resistanceGood alkali resistanceFibre treatmentOrganic dyesDisperse dyeHydrogen

The invention discloses a disperse dye composition, which consists of an original dye and an aid, wherein the original dye consists of any 2-4 kinds of dyes selected from 0-2 kinds of dyes shown as a general formula (I), 0-2 kinds of dyes shown as a general formula (II), 0-2 kinds of dyes shown as a general formula (III) and 0-2 kinds of dyes shown as a general formula (IV), wherein R1, R4, R6 and R8 in the formula (I), formula (II), formula (III) and formula (IV) are independently hydrogen, methyl or methoxy; when R2 is hydrogen, R3 is 2-nitrobenzophenone or 2,4-dinitrophenyl; when R2 is methyl, ethide or cyanoethyl, R3 is benzyl or 2-methyl benzyl; R5 and R7 are independently hydrogen, nitryl, methyl or ethyl; and R9 is methyl, ethyl, benzyl, 2-methyl benzyl or 2-nitrobenzophenone. The invention further discloses a dyeing method for a dacron. The disperse dye composition provided by the invention has the advantages of high dispersing property and high oxygen resistance.

Owner:ZHEJIANG WANFENG CHEM

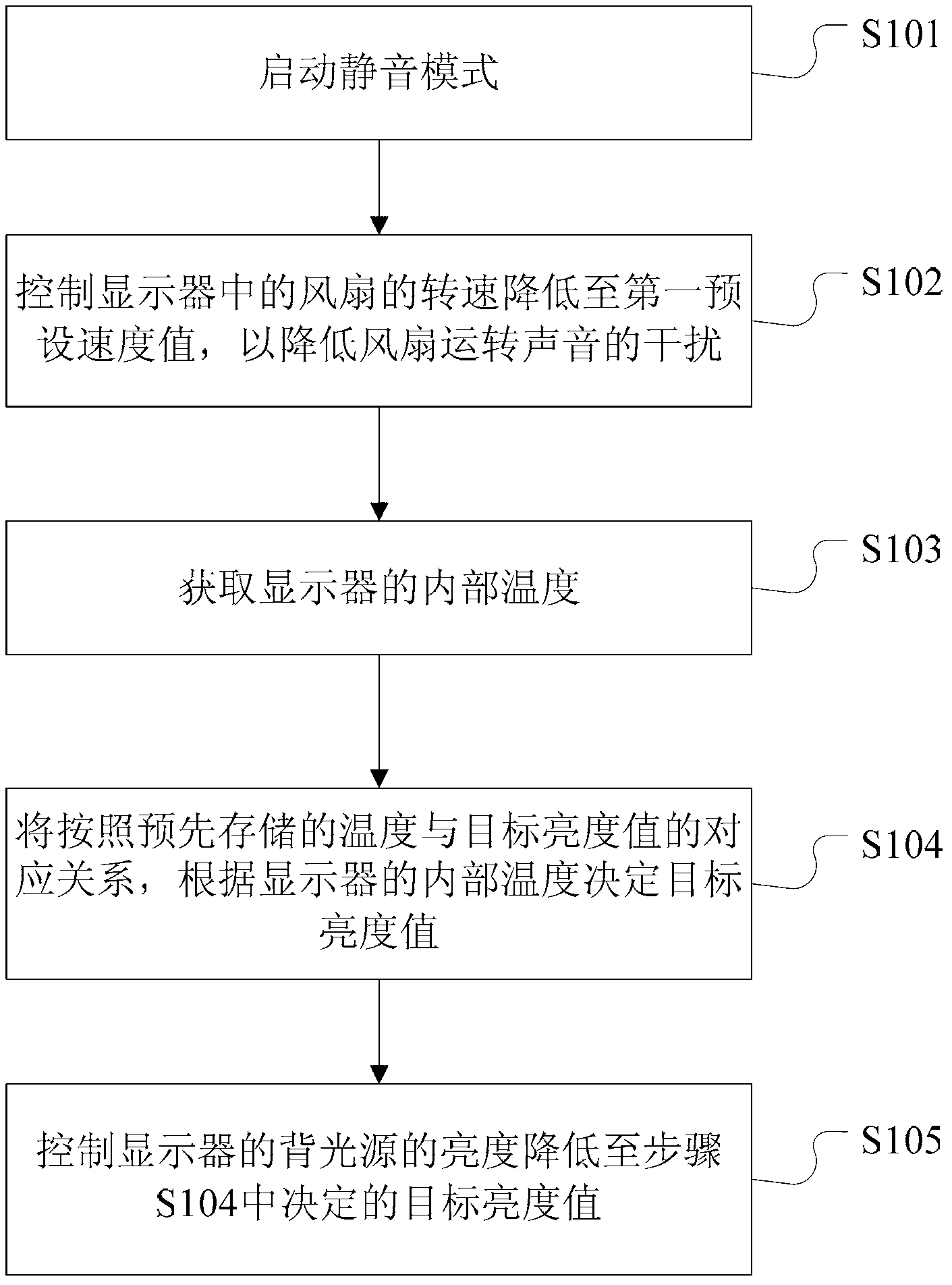

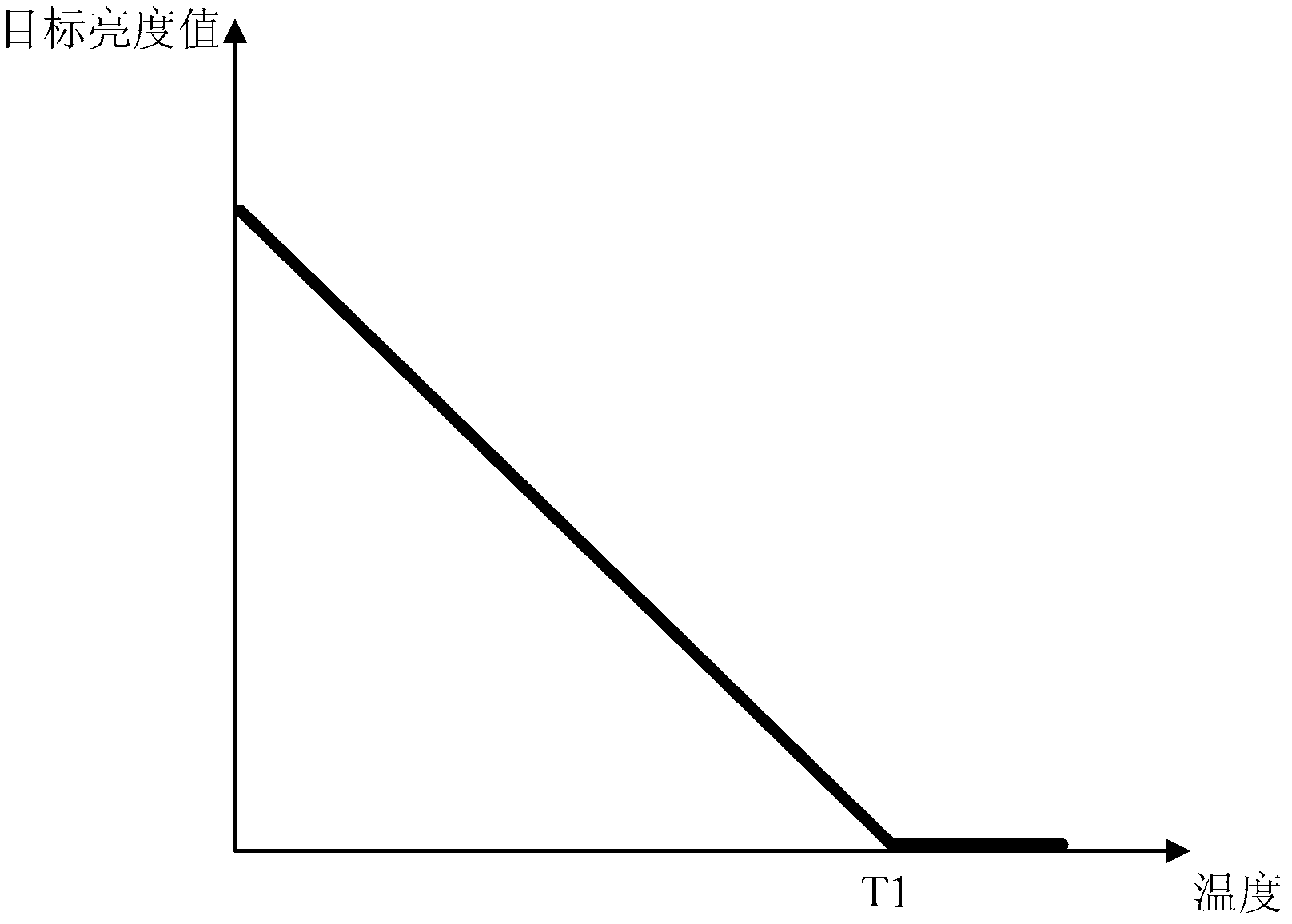

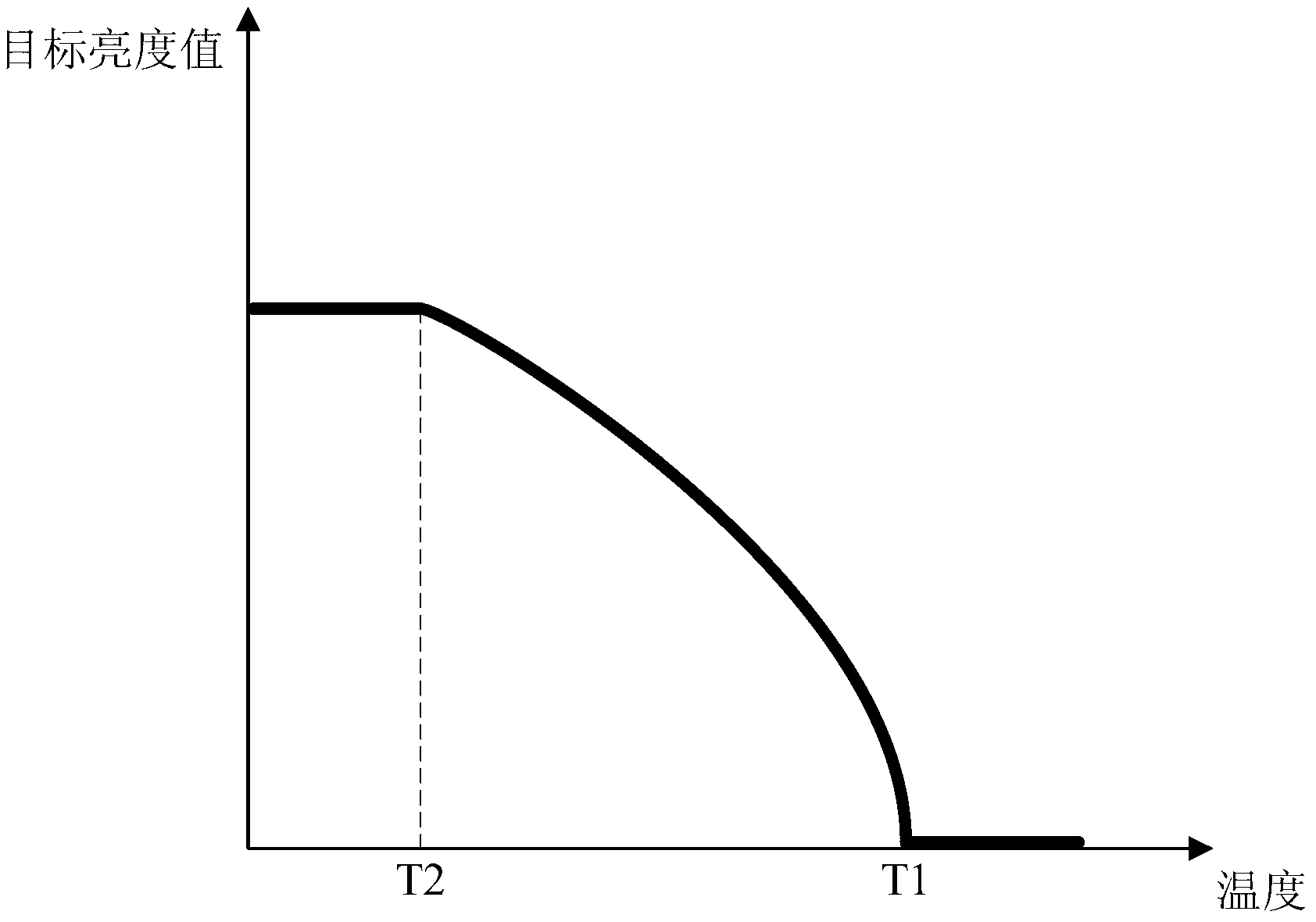

Internal temperature regulation method of displayer and displayer

The invention provides an internal temperature regulation method of a displayer and the displayer. A backlight and a fan dissipating heat for the displayer are arranged in the displayer. The method includes steps of a silent mode. The steps of the silent mode include starting the silent mode, controlling the rotation speed of the fan in the displayer to be reduced to a first preset speed value so that interference of fan operation sounds can be reduced, obtaining the internal temperature of the displayer, determining a target brightness value according to the internal temperature of the displayer and the corresponding relationship between a pre-stored temperature value and the target brightness value, and controlling the brightness of the backlight of the displayer to be reduced to the determined target brightness value. According to the corresponding relationship between the pre-stored temperature value and the target brightness value, the target brightness value is inclined to become smaller on the whole along with rising of the temperature. According to the technical scheme, normal operation of the displayer can be guaranteed, and meanwhile interference of the fan operation sounds is reduced.

Owner:QISDA SUZHOU +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com