Warm-mixed asphalt mixture and preparation method thereof

A warm-mix asphalt and mixture technology, applied in the field of asphalt mixture, can solve the problems of environmental pollution, low mixing, paving, compaction temperature, high energy consumption, etc., and achieve the goal of reducing pollution, reducing transportation costs and saving heat energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

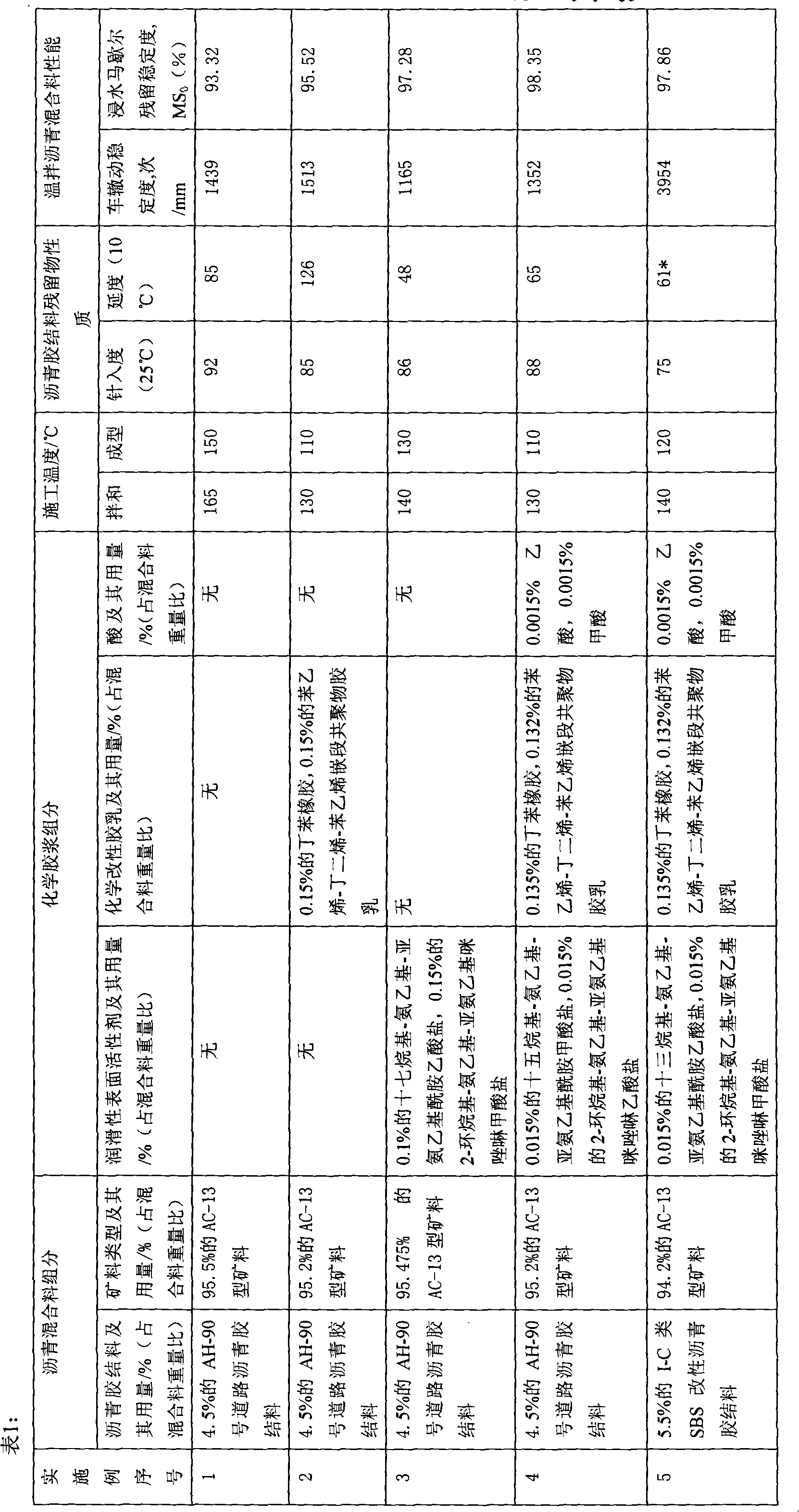

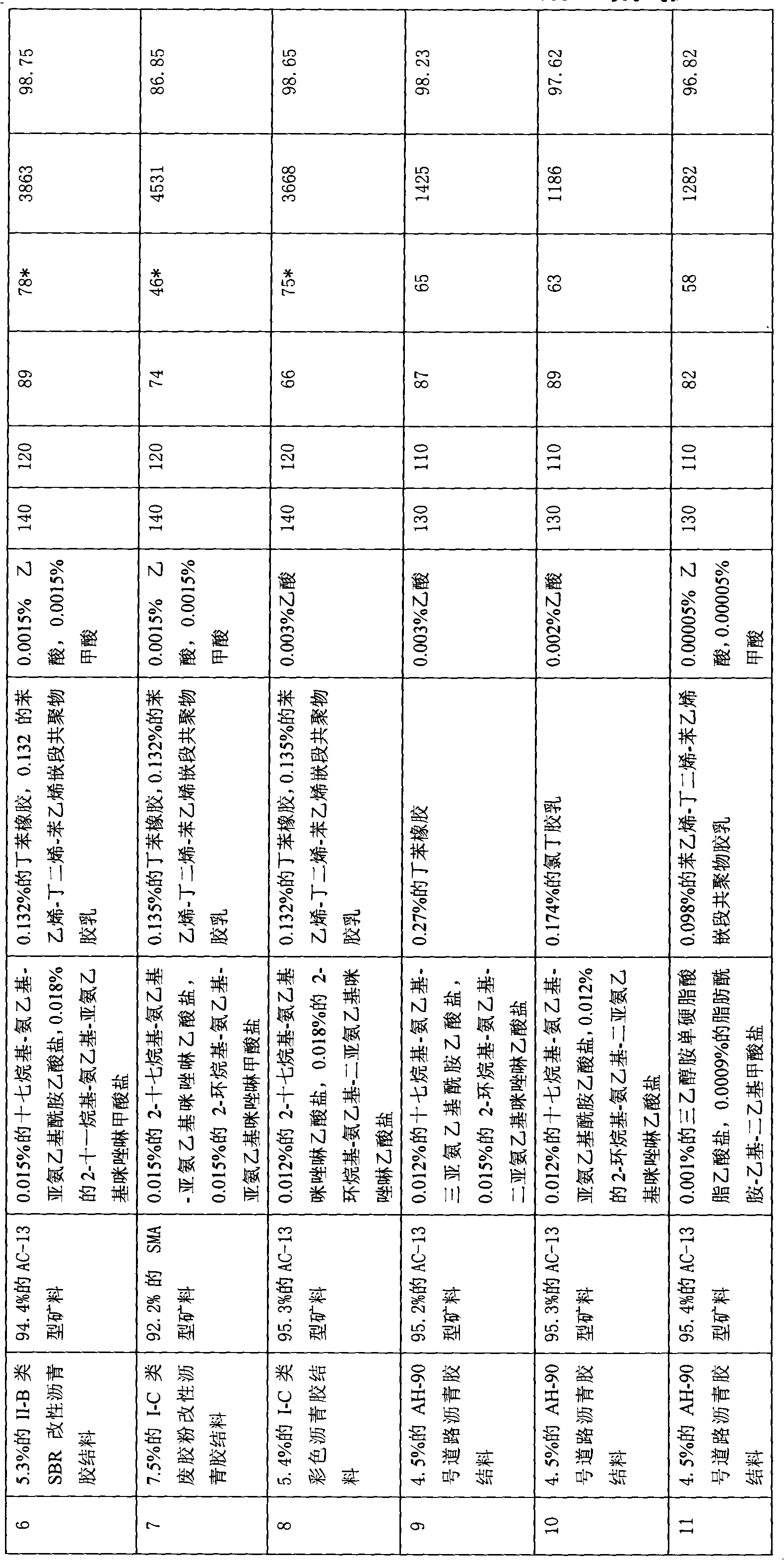

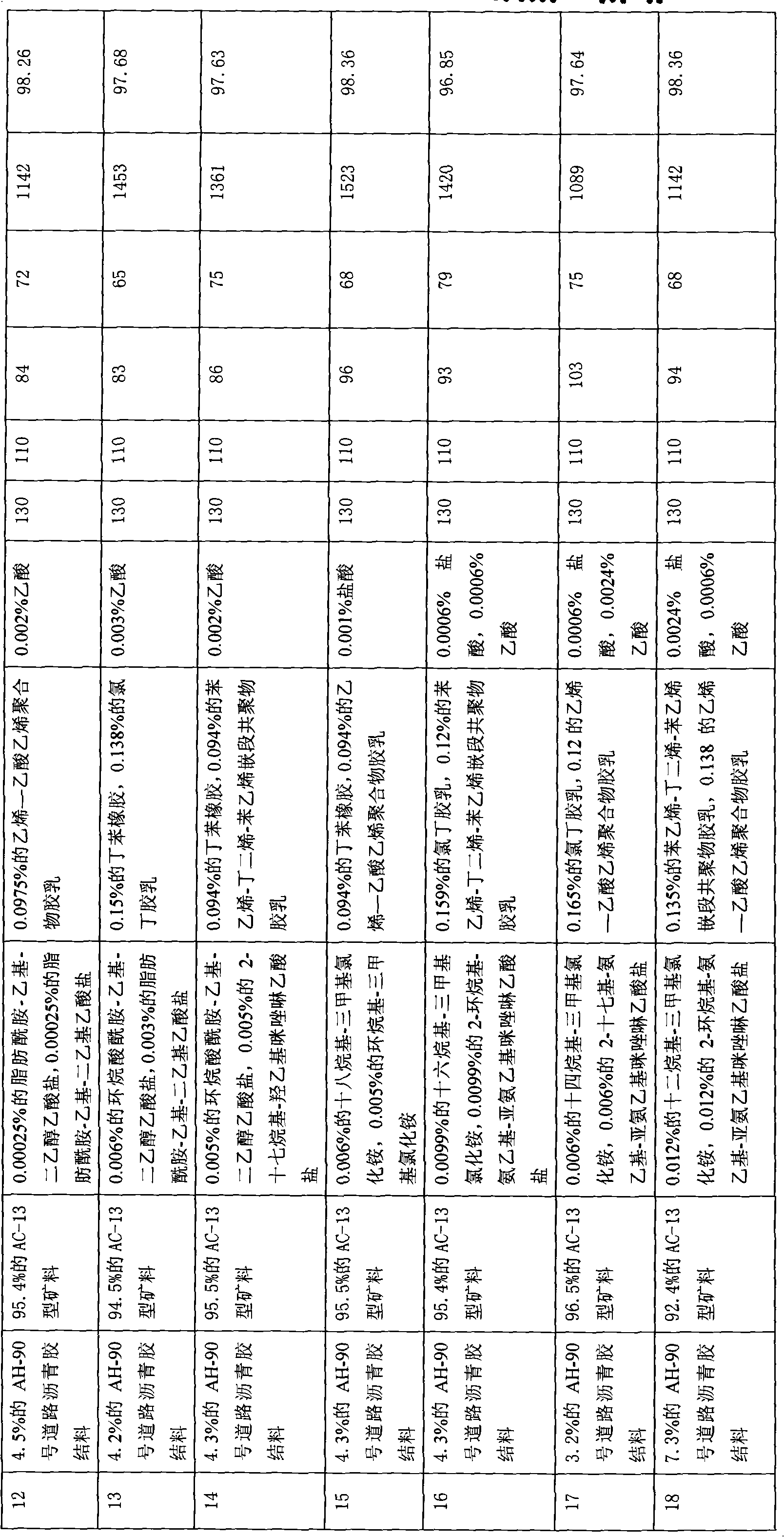

Examples

Embodiment

[0040] The present invention is not limited by the following examples, its lubricity and anti-stripping cationic surfactant, the combination mode and proportioning of chemically modified latex and the selection of compound gradation type can be based on the preparation method of the present invention and The actual situation will determine the specific implementation method.

[0041] According to the design ratio of the mixture, weigh about 92.4wt% ~ 96.5wt% of Karamay back mountain mineral material, about 3.4wt% ~ 7.5wt% of Karamay asphalt binder, and 0.05wt% ~ 1.0wt% chemical modification For the glue, keep the temperature at 120°C-150°C, 110°C-140°C, and 40°C-80°C for more than 4 hours (chemically modified glue can shorten the constant temperature time appropriately). According to the method for preparing warm asphalt mixture of the present invention, the hot asphalt binder and the chemically modified mortar are simultaneously pumped to a spray port provided with a foamer, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com