Patents

Literature

285results about How to "Improves resistance to water damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sulphur-modified asphalt mixed materials formulation and its construction process

A sulfur modified bituminous mixture, used for asphalt covering, the dispense of which is: sulfur 50-99.99 percent, carbon 0-49 percent, smoke inhibitor 0.01-1 percent and elasticizer 0-3 percent; the work craft of which is : the mixing temperature is not higher than 150 Deg.C and rolling temperature is not lower than 90 Deg.C. Such invention can effectively reduce the harmful gas during working process, so the pavement quality can be improved dramatically.

Owner:BEIJING RIONLON ASPHALT TECH DEV

High viscosity bitumen and preparation method thereof

ActiveCN101538408AGood dispersionImproves resistance to water damageBuilding insulationsAnti ageingHigh velocity

The invention relates to high viscosity bitumen and a preparation method thereof, and relates to the modified bitumen technology. The disclosed art is as follows: The bitumen consists of 100 portions of No.70 bitumen, 4 to 12 portions of thermal-plastic rubber, 2 to 80 portions of thermal-plastic resin, 1 to 10 portions of compatiblizing agent, 8 to 40 portions of viscosity regulator, and 0.5 to 4 portions of comprehensive anti-ageing agent. The preparation method comprises the following steps: metering the dehydrated No.70 road bitumen according to the weight ratio, adding the bitumen into a thermal insulated jacket stirring reaction kettle with a heating device, heating the bitumen to 140 DEG C, stirring the bitumen while adding the compatiblizing agent according to the weight ratio, continuing to raise the temperature to between 165 and 175 DEG C, adding the correctly metered thermal-plastic rubber, thermal-plastic resin, tackifier and comprehensive anti-ageing agent according to the weight ratio in order, keeping the temperature between 165 and 175 DEG C, stirring the mixture for 0.5 to 3 hours, carrying out high-velocity shearing through a high-velocity shearing machine for 5 to 40 minutes, setting the rotating speed to between 8,000 and 28,000 r / min, and obtaining the finished product. A common jacket heating stirring tank is adopted for stirring and the high-velocity shearing machine is adopted for shearing to prepare the high viscosity bitumen. The method has a simple process, low equipment investment, and convenient production.

Owner:重庆市智翔铺道技术工程有限公司

Steel slag and rubber asphalt concrete and preparation method thereof

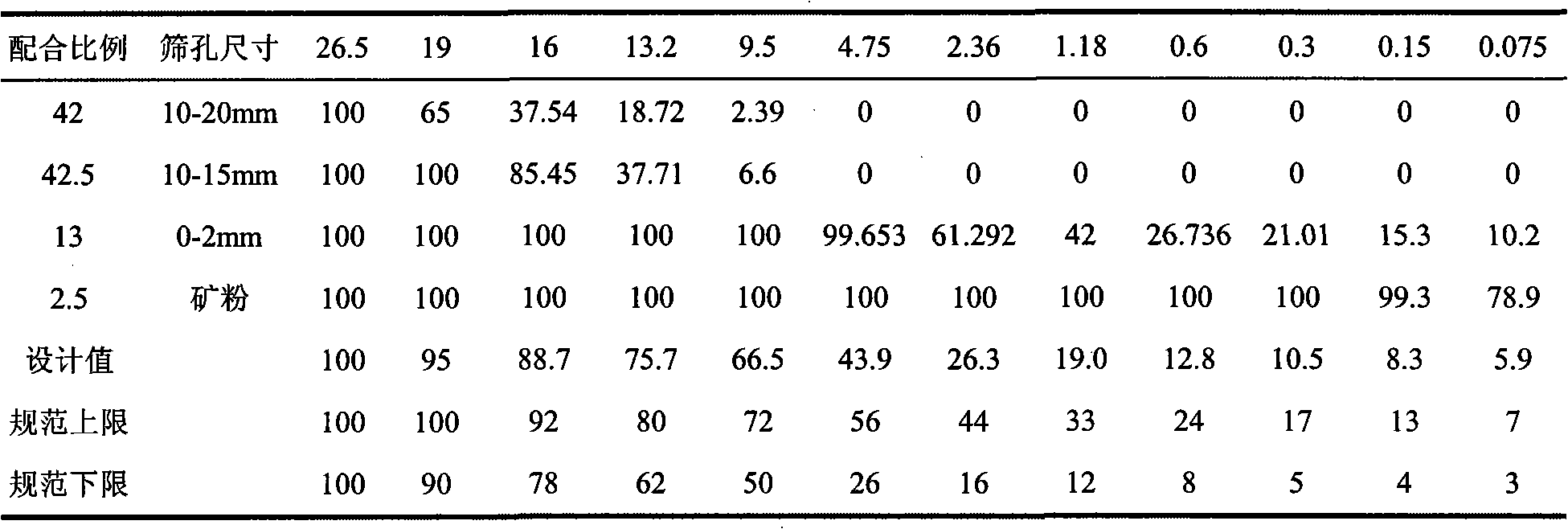

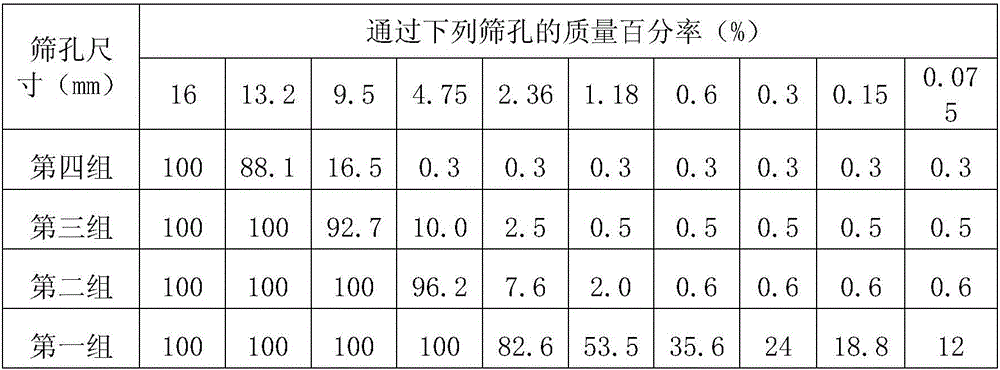

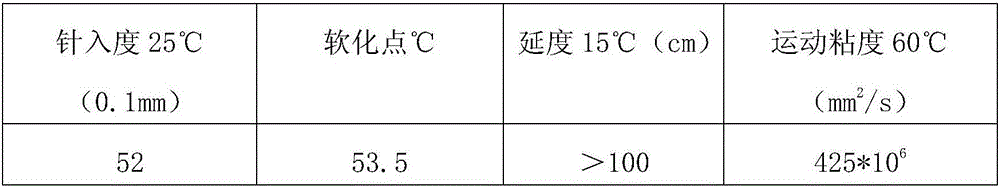

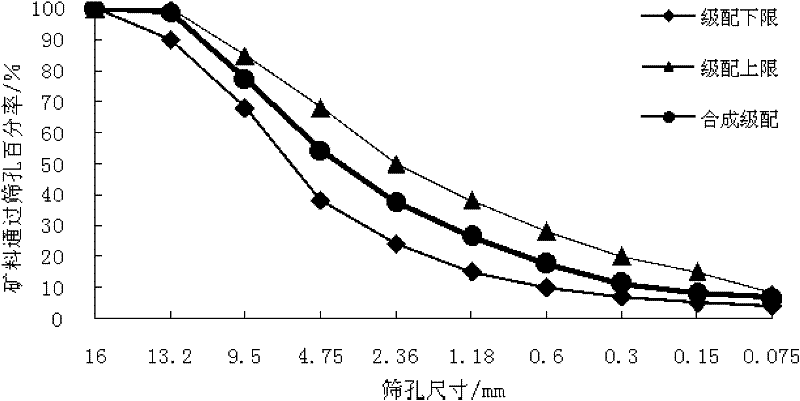

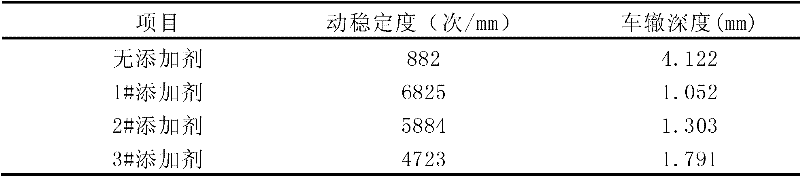

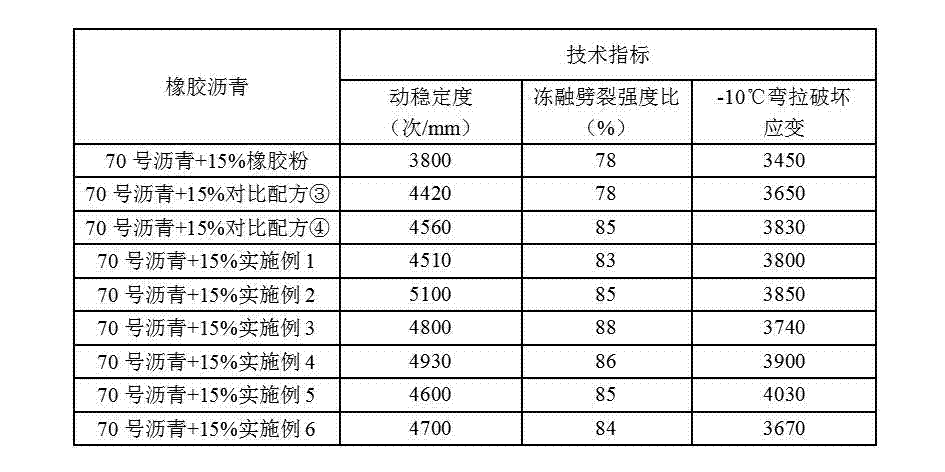

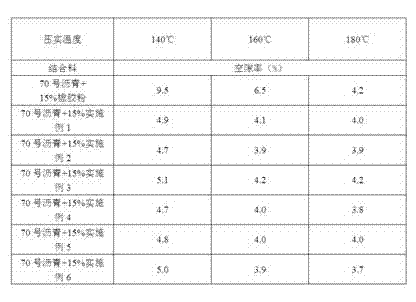

The invention provides a steel slag and rubber asphalt concrete and a preparation method thereof. In the concrete, the steel slag is selected as a coarse aggregate and rubber asphalt is selected as a binder, and the concrete further comprises a fine aggregate and a filler; the mineral aggregate of the asphalt mixture is graded to form a coarse aggregate gap gradation framework solid type; the ratio of the rubber asphalt to the mineral aggregate is comprehensively determined through a Marshall compacting experiment to determine the range via the volume parameter of a Marshall test piece and verification on the road properties such as high-temperature rutting resistance and water damage resistance; when the rubber asphalt and the mineral aggregate are mixed and stirred, the heating temperature of the rubber asphalt is 175-180 DEG C and the heating temperature of the mineral aggregate is 10-30 DEG C higher than that of the rubber asphalt; moreover, the dry mixing time of the mineral aggregate is 15-20 s and the wet mixing time of the mineral aggregate is 35-40 s; and the ex-factory temperature of the steel slag and rubber asphalt concrete formed after the mixing and the stirring is 175-185 DEG C. The invention replaces the mineral aggregate by the steel slag, and can recycle the waste materials, save the stone resources, and reduce the destruction from the stone mining to the environment.

Owner:RES INST OF HIGHWAY MIN OF COMM

Modified asphalt material for airport pavement, preparation method and applications thereof

ActiveCN106189290AImproved low temperature performance and fatigue resistanceImproved high temperature performance and resistance to water damageBuilding insulationsBituminous materialsMaterials science

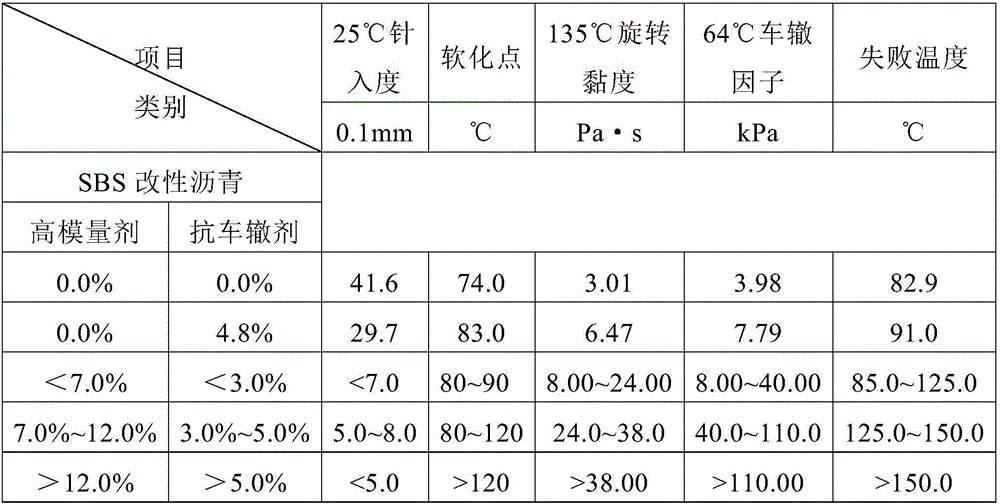

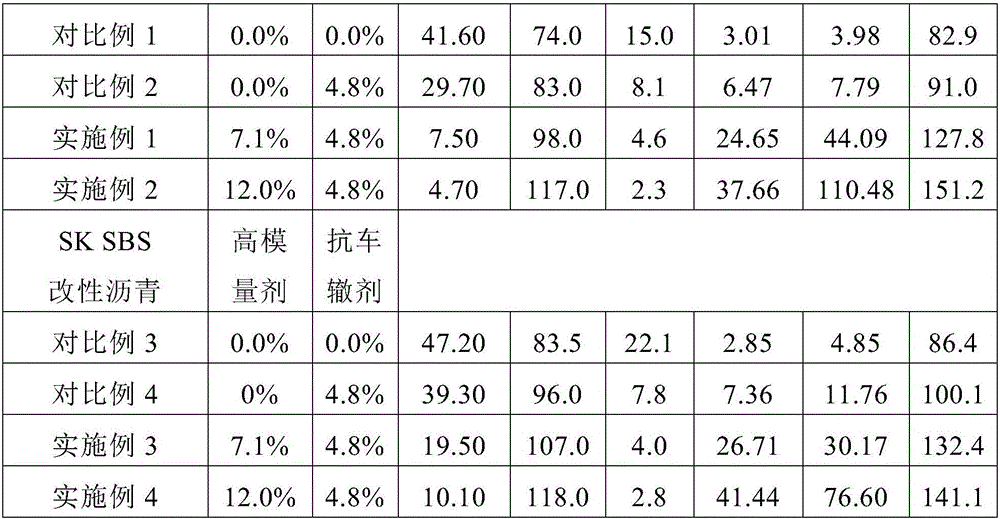

The invention relates to a modified asphalt material for airport pavement, a preparation method and applications thereof. The modified asphalt material comprises the following components in parts by weight: 100 parts of SBS modified asphalt, 7 to 12 parts of high modulus agent, and 3 to 5 parts of anti-rut agent. The modified asphalt material is prepared by the following steps: (1) heating SBS modified asphalt to a temperature of 180 to 185 DEG C, and stirring the SBS modified asphalt for 40 to 60 minutes under a rotation speed of 8000 to 12000 rpm by a shearing machine at a constant temperature; (2) maintaining a temperature of 180 to 185 DEG C, slowly adding an anti-rut agent and a high modulus agent in batches, and stirring for 40 to 60 minutes by the shearing machine under a rotation speed of 20000 to 30000 rpm to evenly disperse the anti-rut agent and high modulus agent; (3) at a constant temperature of 140 to 160 DEG C, shearing and developing the asphalt for 40 to 60 minutes under a rotation speed of 8000 to 10000 rpm to obtain the modified asphalt material. Compared with the prior art, the obtained asphalt can meet the requirements on low temperature performance and anti-fatigue performance, the high temperature performance and water damage resistant performance of asphalt are improved, the permanent deformation amount of asphalt pavement is reduced, and the problems of ruts and early stage damages on airport pavement are effectively solved.

Owner:TONGJI UNIV

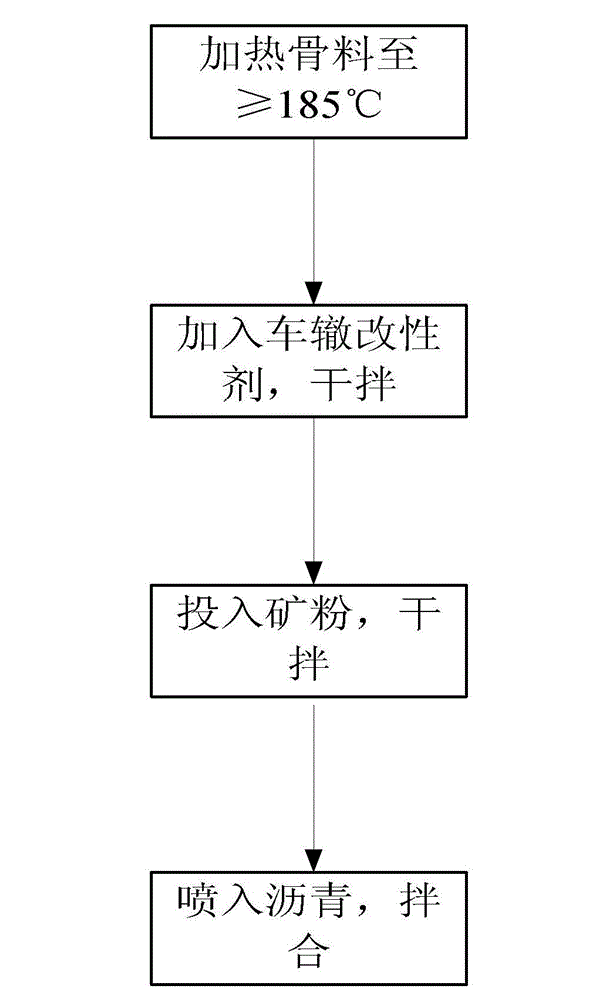

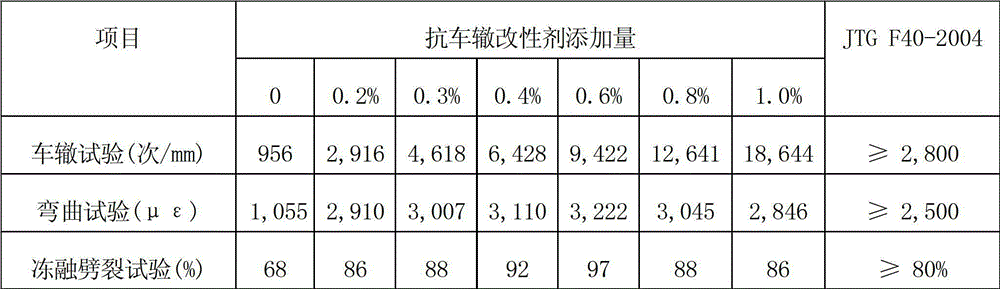

Anti-rutting asphalt modifier, preparation method thereof, modified asphalt and application thereof

InactiveCN101906224AImprove high temperature performanceGood value for moneyBuilding insulationsPolyolefinAntioxidant

The invention discloses a traffic anti-rutting asphalt modifier and a preparation method thereof, and the asphalt modifier is prepared by the following component in parts by weight: 10-20 parts of polyolefin, 1-80 parts of rubber powder and 0.5-1 part of antioxidant. The invention simultaneously discloses modified asphalt containing the asphalt modifier and an application of the modified asphalt in asphalt mixture. The invention can significantly improve the high-temperature performance and the anti-rutting capacity of the asphalt mixture, improve the resistance to water damage, the resistance to low temperature cracking and other performances and have high performance-price ratio. Compared with asphalt modification, the invention does not need to add an asphalt modification device and can significantly reduce the energy consumption and the loss during the production process, realize the long-term storage, avoid the problem of poor storage stability of the modified asphalt, not affect the design of the mixing proportion, not change the graduation of the asphalt mixture under any content and only need to carry out micro-adjustment on the asphalt-aggregate ratio; the construction process is simple; and the direct input method can realize the addition at will.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD +3

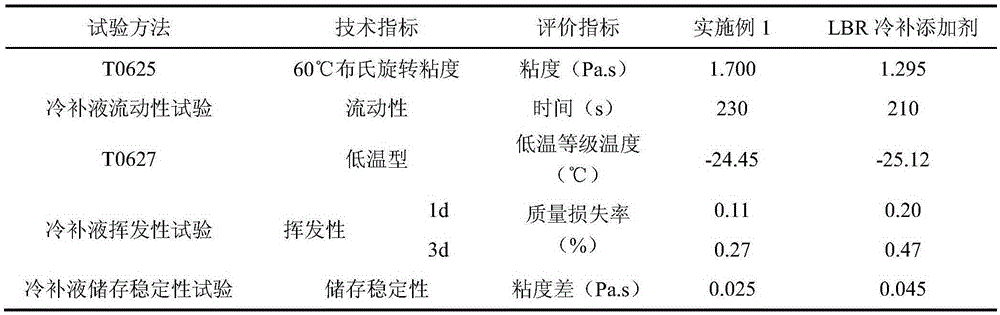

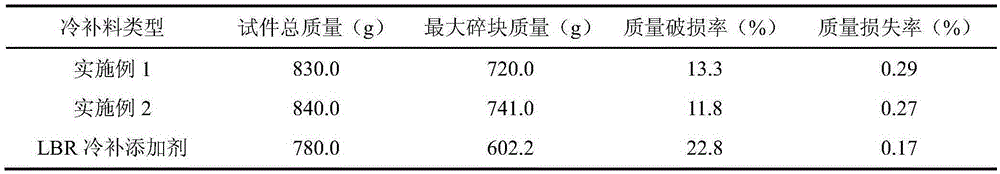

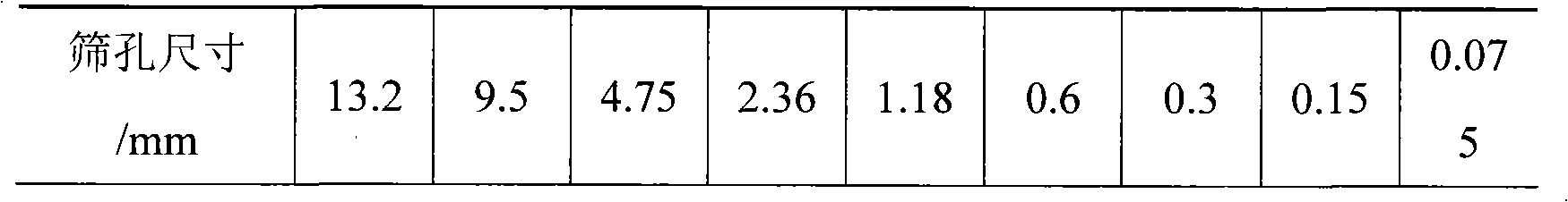

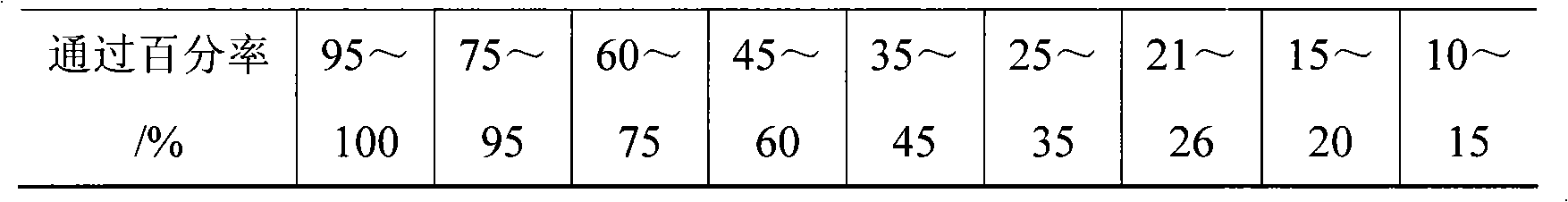

Solvent-type cold-patch asphalt liquid and preparation technology therefor

The invention relates to a solvent-type cold-patch asphalt liquid and a preparation technology therefor. The solvent-type cold-patch asphalt liquid comprises the following substances, by weight, 100 parts of petroleum asphalt, 10-15 parts of diluents, 10-15 parts of heavy oil, 10-15 parts of solvent naphtha, 1-5 parts of tackifier, 1-5 parts of strengthening agent, 0.2-0.8 part of surfactant and 0.5-0.8 part of anti-stripping agent. The above materials form performed polymers respectively and then are mixed uniformly, thus the obtained cold-patch liquid has good dispersibility, the stability of the obtained cold-patch asphalt liquid is raised, the storage stability is excellent, the employed tackifier, strengthening agent and anti-stripping agent can raise adhesion and strengthening effects of asphalt, and the surfactant can improve fluidity of asphalt substantially. The solvent-type cold-patch asphalt liquid is blended with aggregates when used to prepare cold-patch asphalt mixture for repairing pavement pits, no heating is needed during the blending process, the prepared cold-patch asphalt mixture has good initial and molding intensities and water damage resistance, and the construction workability is good.

Owner:CHANGAN UNIV +1

Asphalt mixture for rapid repair of hot-mix-cold-laid pavement

InactiveCN101353481AHigh porosityImprove the compaction effectIn situ pavingsBuilding insulationsDiluentMaterials science

The invention relates to a road restoration asphalt mixture, and discloses a hot-mixing cold-paving road restoration asphalt mixture which comprises modified asphalt, additives and aggregates, wherein, the additives include a diluent, petroleum resin and an anti-stripping agent, the aggregates include coarse aggregate, fine aggregate and mineral powder. While preparing liquid asphalt, using the weight of the modified asphalt as reference, the weight proportion of the diluent is 14 percent to 22 percent, the weight proportion of the petroleum resin is 1.8 to 2.2 percent and the weight proportion of the anti-stripping agent is 0.4 to 0.6 percent. The asphalt mixture of the invention has strong comprehensiveness, performs excellently in poriness, compactibility, initial strength, workability, the strength of formed mixture, anti-water damage property and storage property, can be mixed easily and operated conveniently and is suitable for practical application and generalization.

Owner:TONGJI UNIV

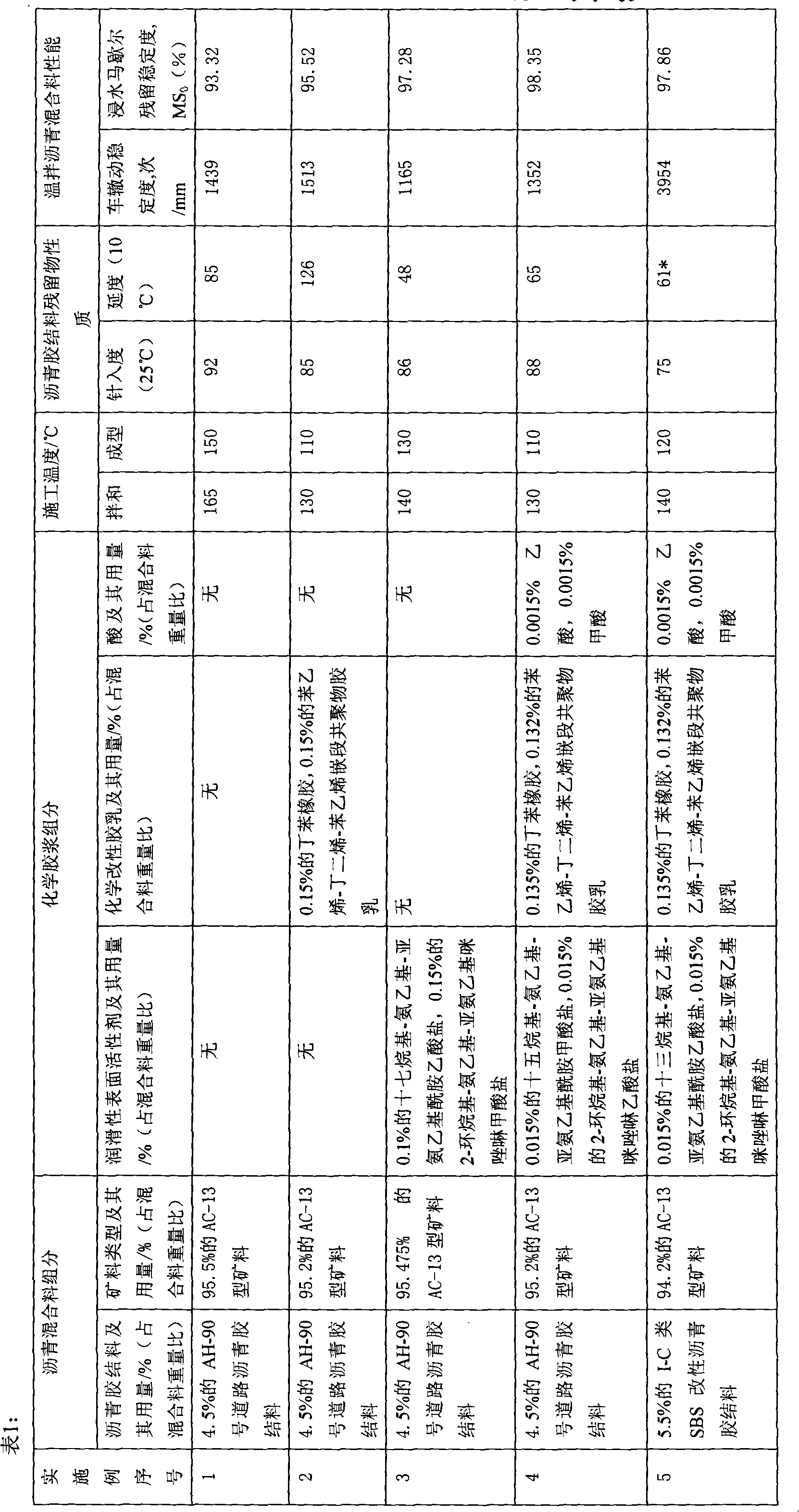

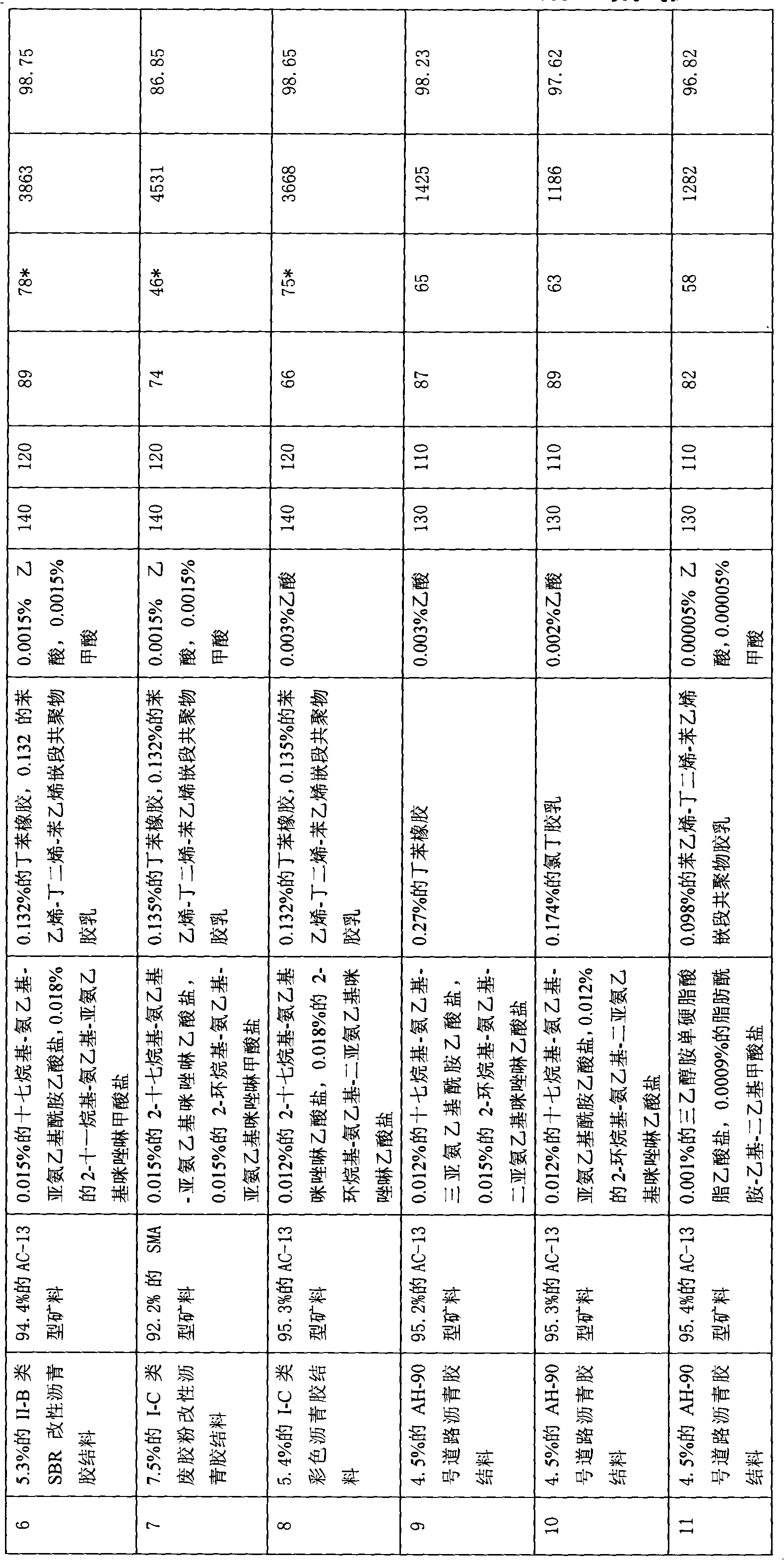

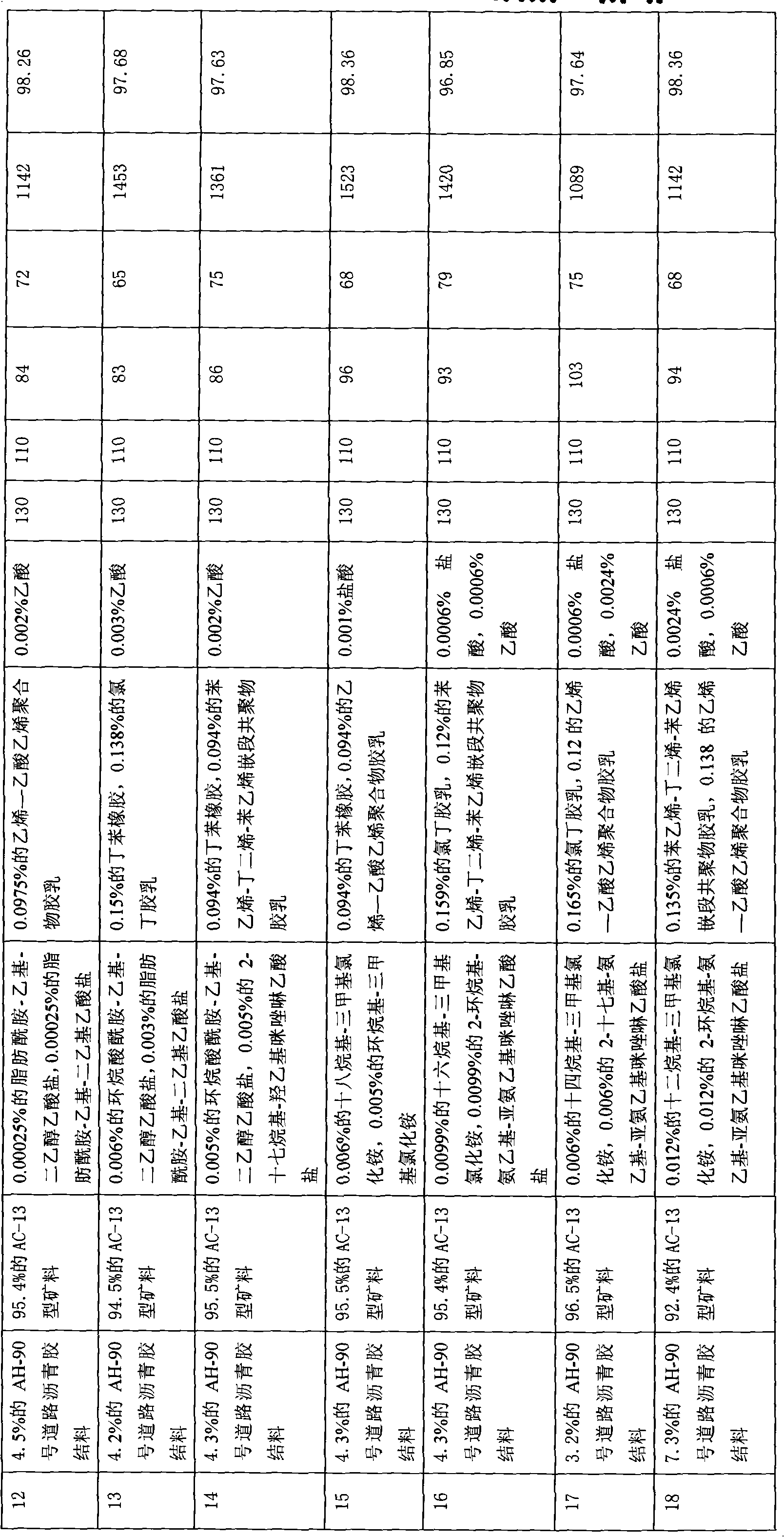

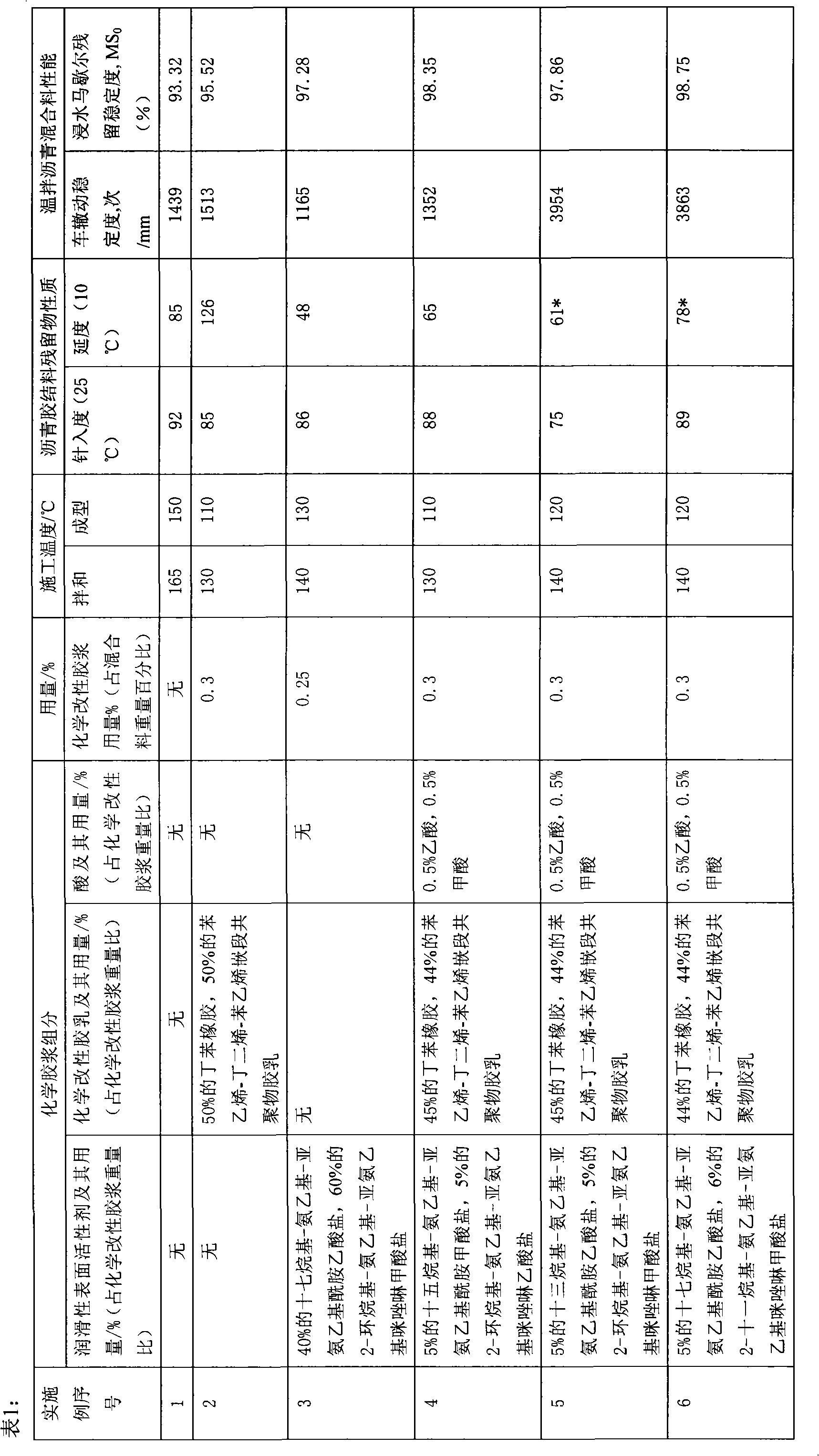

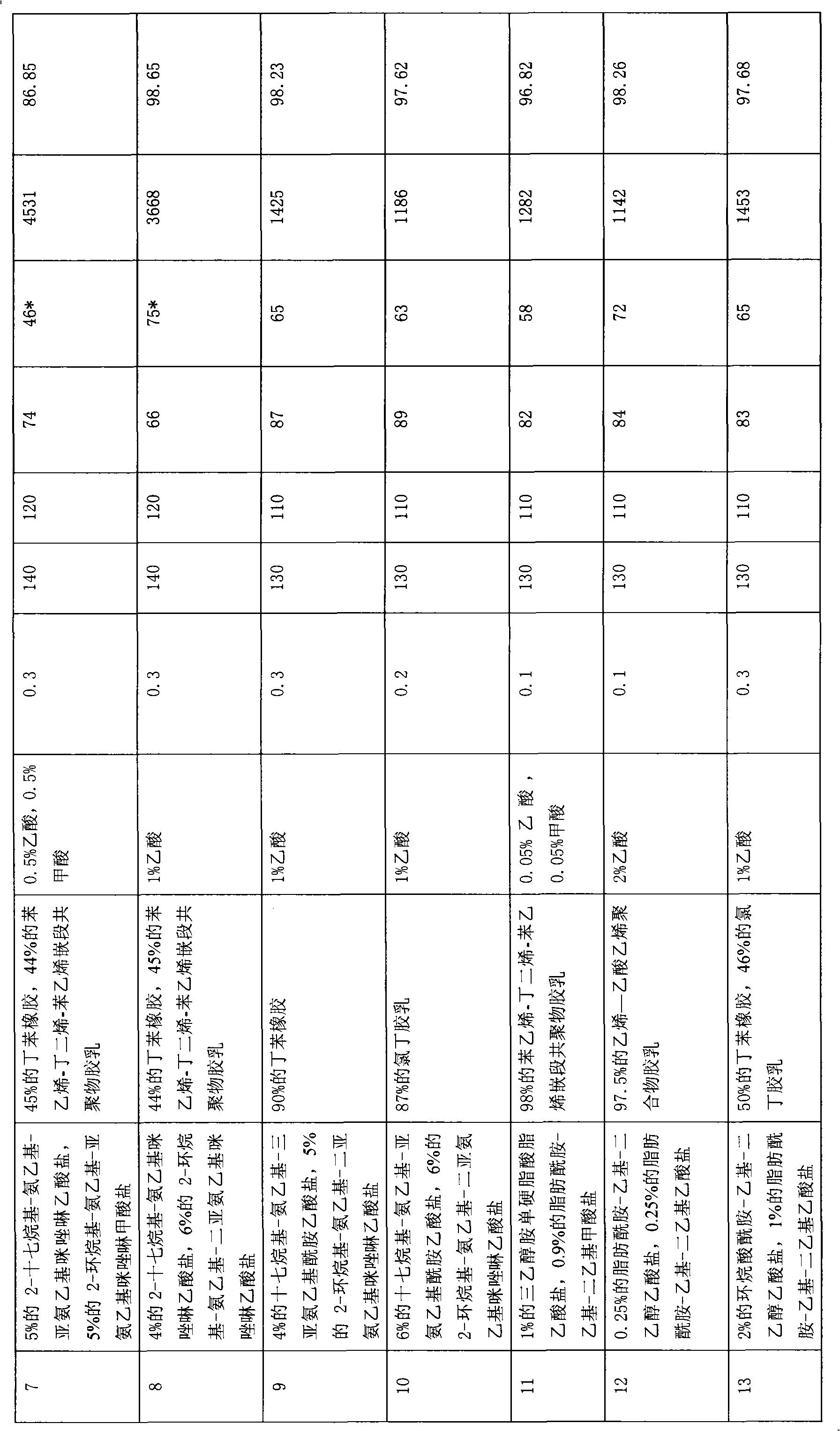

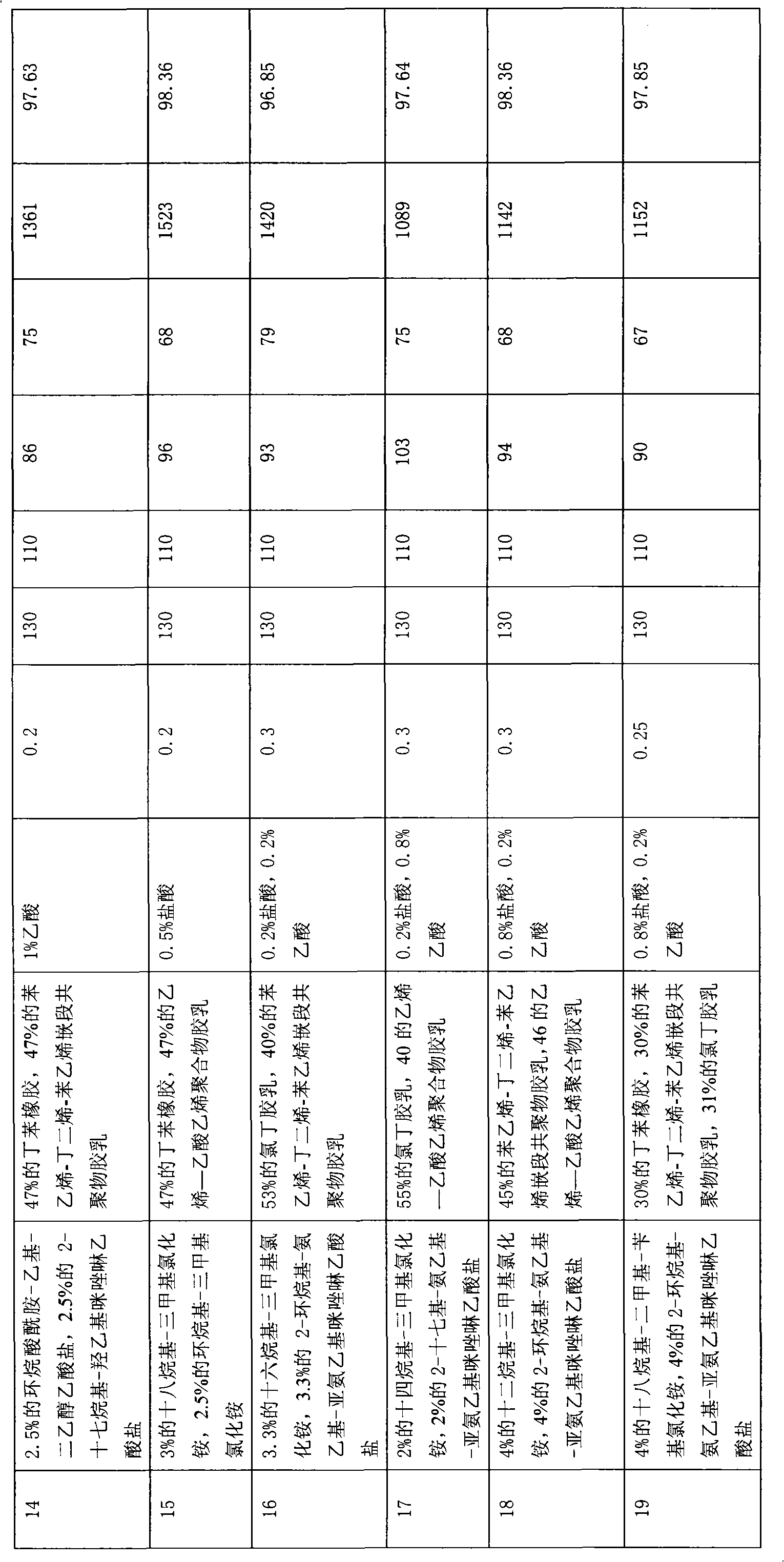

Warm-mixed asphalt mixture and preparation method thereof

ActiveCN102092988ALower the mixing temperatureHigh tensile strengthClimate change adaptationAdhesive cementHigh concentration

The invention relates to a warm-mixed asphalt mixture and a preparation method thereof. The warm-mixed asphalt mixture is mainly applied to new construction and maintenance of high-grade roads and common roads, and is particularly suitable for cities, parks, tunnels and the like with high environmentally-friendly requirements. The warm-mixed asphalt mixture mainly comprises about 92.4-96.5 percent by weight of mineral, about 3.4-7.5 percent by weight of asphalt cement and 0.05-1.0 percent by weight of chemical modified adhesive cement. The preparation method comprises the following steps of: simultaneously pumping the chemical modified adhesive cement and the hot asphalt cement to the spraying port of a foam generator, fully mixing to generate a foam-containing hot asphalt mixture, spraying the foam-containing hot asphalt mixture into a mixing pan, and further mixing the foam-containing hot asphalt mixture and the hot mineral to form the warm-mixed asphalt mixture. The chemical modified adhesive cement can effectively reduce the mixing, spreading and rolling temperature of the asphalt mixture, and solves the problems of environmental pollution, high energy consumption, asphalt ageing regression and the like. By selecting high-concentration cationic chemical modified latex as a matrix stock of the chemical modified adhesive cement and simultaneously matching a proper proportion of cationic surfactant with lubricating effect and peeling resistance, the influence of the conventional warm-mixed asphalt additive on poor reducing performance and poor adhesive performance of the asphalt cement is solved, and the properties of the warm-mixed asphalt mixture such as water damage resistance, rutting resistance, fatigue resistance, low temperature resistance and the like are improved.

Owner:PETROCHINA CO LTD

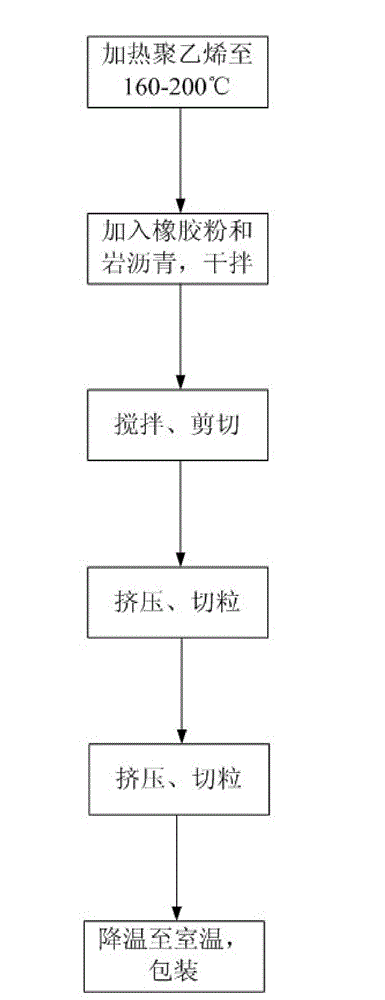

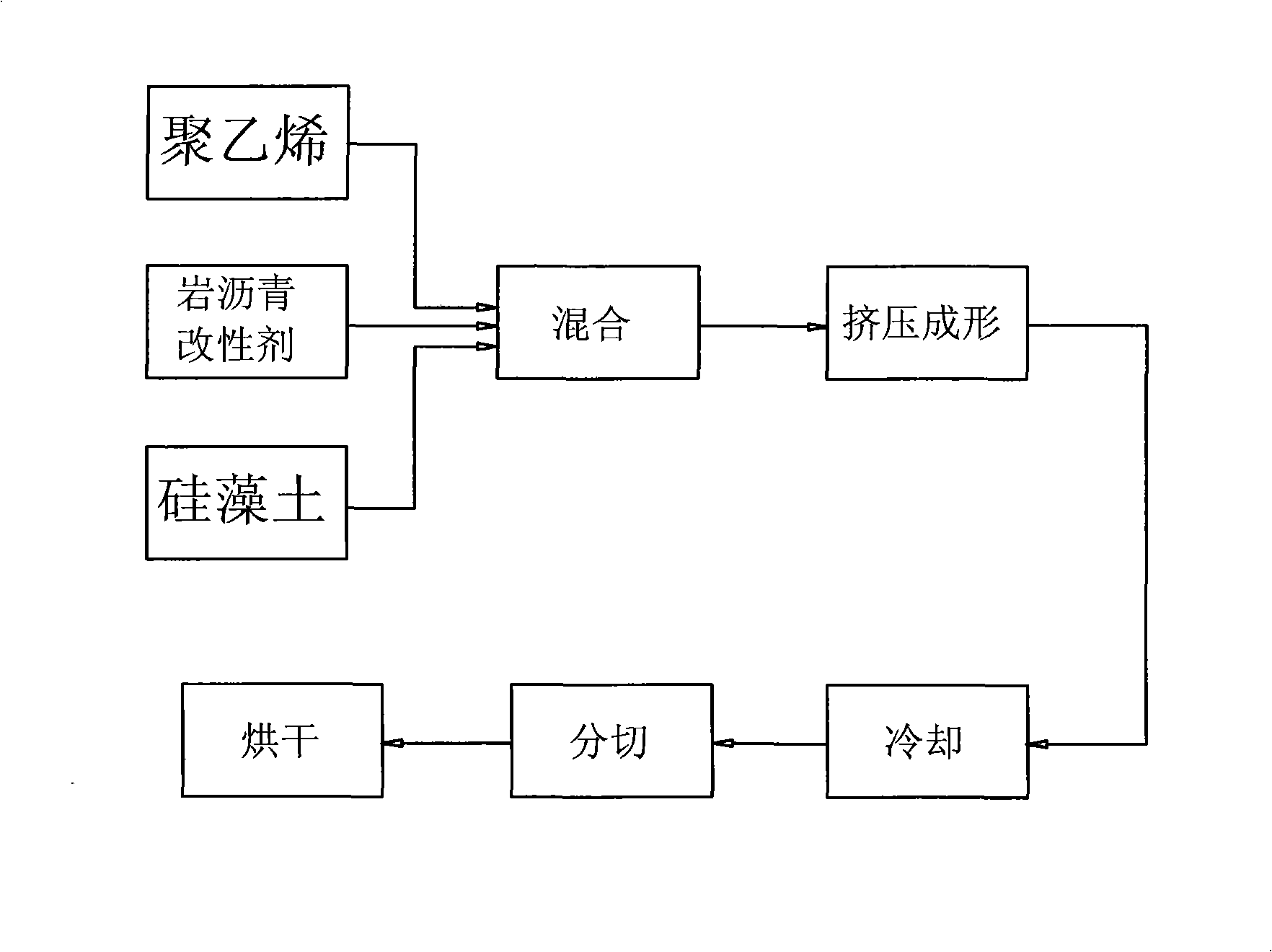

Rock asphalt composite modifier and its preparation method and use

The invention discloses a rock asphalt compound modifier and a preparation method and use of the rock asphalt compound modifier. The rock asphalt compound modifier is composed of rock asphalt and polymer, wherein, the amount of the rock asphalt is 10 percent to 90 percent and the amount of the polymer is 10 percent to 90 percent in weight percentage. The preparation method is that the rock asphalt and the polymer are mixed together by a twin screw extruder in proportion, and then are granulated by a cold bracing and granulating equipment. The use of the rock asphalt compound modifier is that the rock asphalt compound modifier is put into an asphalt mixture mixing plant to be mixed with hot mineral aggregation for 5 to 20 seconds, and then basic asphalt is sprayed in to be mixed with the hot mineral aggregation for 20 to 60 seconds, at last the compound modified asphalt mixture is prepared. The rock asphalt compound modifier is in granular shape and has the advantages of accurate adding measurement, fine dispersion, uniform mixing and convenient construction. The compound modified asphalt mixture is suitable for paving the roads in high grade with further improved performance.

Owner:交通部公路科学研究院 +1

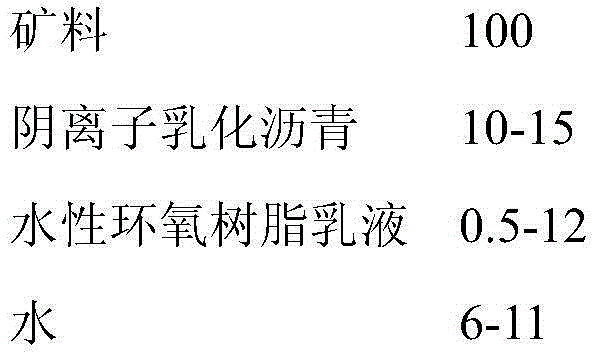

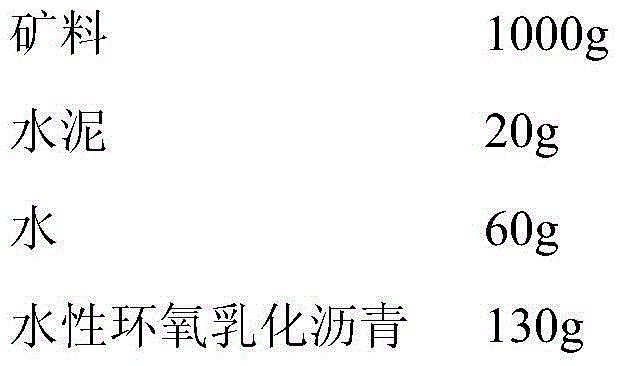

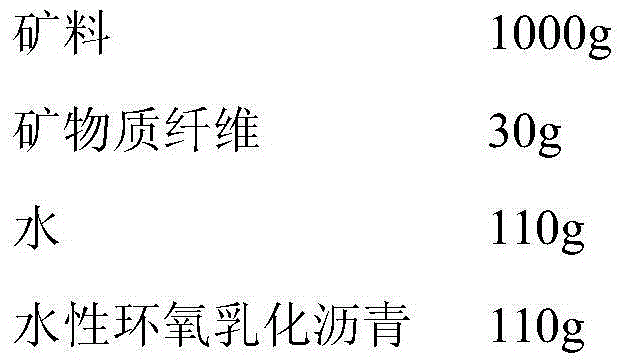

A water-borne epoxy resin-emulsified bitumen micro-surfacing mixture and a preparing method thereof

The invention discloses a water-borne epoxy resin-emulsified bitumen micro-surfacing mixture. The micro-surfacing mixture comprises following raw materials by weight: 100 parts of mineral aggregate, 10-15 parts of anionic emulsified bitumen, 0.5-12 parts of a water-borne epoxy resin emulsion and 6-11 parts of water. A preparing method of the micro-surfacing mixture is also disclosed. The method includes preparing the mineral aggregate, mixing the water-borne epoxy resin emulsion and the emulsified bitumen to obtain emulsified bitumen modified with water-borne epoxy resin, adding the water into the prepared mineral aggregate, adding the emulsified bitumen modified with the water-borne epoxy resin, fully stirring and curing, or the method includes preparing the mineral aggregate, adding the water into the prepared mineral aggregate, adding the water-borne epoxy resin emulsion and the emulsified bitumen, fully stirring and curing. The prepared micro-surfacing mixture is good in adhesiveness with stone, good in compatibility with the emulsified bitumen, good in stability, and capable of greatly improving wear resistance, resistance to water damage and rutting resistance of micro-surfacing and prolonging service lifetime of a road surface.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE +2

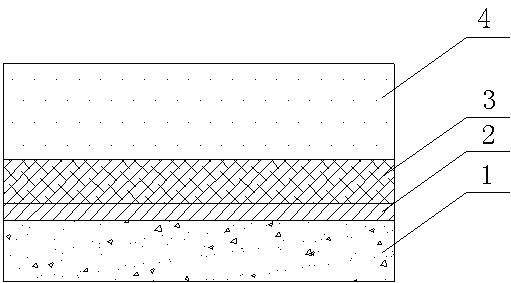

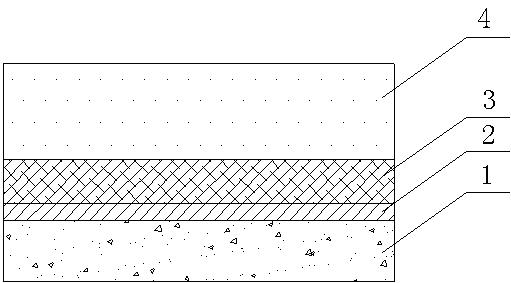

Pavement structure for cement concrete bridge deck and pavement method thereof

InactiveCN102002909AEfficient removalImprove interlayer adhesionBridge structural detailsEpoxyBridge deck

The invention relates to the technical field of traffic engineering, in particular to a pavement structure directly paved on a cement concrete bridge deck and a pavement method thereof. The pavement structure for the cement concrete bridge deck comprises a waterproof bonding layer, a stress absorption layer and a road surface layer, which are sequentially paved on the cement concrete bridge deck from bottom to top, wherein the waterproof bonding layer comprises a basalt gravel layer bonded on the cement concrete bridge deck through epoxy resin and a reactive waterproof binding agent layer coated on the basalt gravel layer. The invention also discloses a pavement method for the pavement structure. The pavement structure and the pavement method thereof enhance the bonding and shearing action between a pavement layer and a cement concrete slab, improve the using effect and service life of the pavement layer, reduce the temperature of mixing, transporting and paving, save energy and reduce environmental pollution; and the total thickness of the bridge deck pavement system is only 30 to 40 mm, so that the dead load of the bridge deck is greatly reduced, the pavement materials are saved and the construction cost is reduced.

Owner:CHONGQING JIAODA ROAD BRIDGE TECH RES

Plant-mixed warm recycled asphalt mixture and preparation method thereof

InactiveCN106009719AAffect low temperature crack resistanceAffects durabilityBuilding insulationsRoad surfaceAsphalt

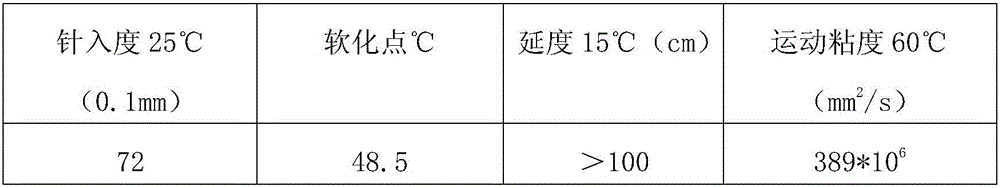

The invention relates to a road surface construction material, in particular to a plant-mixed warm recycled asphalt mixture and a preparation method thereof. The plant-mixed warm recycled asphalt mixture comprises the following components in percentage by mass: (20-70)% of RAP, (0 to 8)% of new aggregate, (0 to 8)% of limestone mineral powder, (0.5 to 5)% of new asphalt and (0 to 0.5)% of recycling agent, wherein the total mass percentage is 100%, the new asphalt has penetration of less than 75 (0.1mm) and a softening point of more than 48 DEG C, and the recycling agent has kinematic viscosity of (50-60000) mm2 / s at a temperature of 60 DEG C. The plant-mixed warm recycled asphalt mixture provided by the invention has the advantages of simple process, no grey material, good recycling effect, low cost, wide adaptability and good road performance.

Owner:JIANGSU TIANNUO ROAD MATERIAL TECH

Construction method for rubber grain asphalt concrete pavement

InactiveCN101153478AImprove deformation abilityGood flexibilityIn situ pavingsSnowpackWear resistant

A method for constructing rubber particles asphalt concrete road surfaces relates to a method for constructing asphalt concrete road surfaces, aiming to resolve the problems that: the asphalt concrete road surfaces have weak wear-resistant, and the attachment coefficient and the adhesive force are reduced and vehicles have the problem of braking stability when the road surfaces are covered by snow and ice. The construction method comprises the following steps that: compositions by weigh percentage of the following materials are adopted: 76.5 to 91.5 percent of mineral aggregate, 2.5 to 7.5 percent of asphalt, 4 to 10 percent of mineral powder and 2 to 6 percent of rubber particles; the mineral aggregate is heated up to 190 to 200 DEG C, the rubber particles are added into the mineral aggregate with mixing about 20 to 25 seconds, the asphalt heated up in advance and the mineral powder are added into the rubber particles and the mineral aggregate with mixing lasting for 70 to 80 seconds, and then the road surfaces are subject to the pavement, the first stage initial pressure, the first and the second stage re-pressure and the second stage final pressure. The invention can increase the deformation capabilities of the road surfaces effectively, improve the bond state between the road surfaces and snow, and the invention can improve the attachment coefficient, increase the adhesive force, and improve the braking and turning operation stability of vehicles when the road surfaces are cover by snow and ice.

Owner:HARBIN INST OF TECH

Warm-mix asphalt additive and preparation method thereof

ActiveCN102093724AImproved anti-ruttingGood anti-fatigueClimate change adaptationBuilding insulationsUltimate tensile strengthChemical modification

The invention relates to a warm-mix asphalt additive and a preparation method thereof. The additive comprises the following components in percentage by weight: 87 to 98 percent of chemical modification latex, 0.5 to 12 percent of lubricative and peeling resistant cation surfactant and 0.1 to 2.0 percent of acid. The method comprises the following steps of: heating the chemical modification latex to the temperature of between 40 and 80 DEG C with stirring, and dripping 0.1 to 0.5 percent of acid slowly; adding the lubricative and peeling resistant cation surfactant, stirring fully, and dispersing uniformly; and continuing to drip 0.1 to 1.5 percent of acid slowly, stirring uniformly, keeping the temperature of between 40 and 80 DEG C and storing for later use. By the warm-mix asphalt additive and the preparation method, the viscosity of asphalt binders during mixing can be reduced effectively, the reduction performance of asphalt cements and adhesivity between the asphalt cements and aggregates can be improved, the water damage resistance and durability of warm-mix asphalt mixtures can be improved, the tensile strength of asphalt can be improved, and the rutting resistance, fatigue resistance and low temperature resistance of the warm-mix asphalt mixtures can be enhanced.

Owner:PETROCHINA CO LTD +1

Light color cementing material and preparation method thereof

The invention relates to a light color cementing material which comprises the components mixed according to the parts by weight: 500-700 parts of base material oil, 190-450 parts of modifying agent, 45-100 parts of macromolecule copolymer, 1-10 parts of auxiliary agent and 2-6 parts of covering agent. The light color cementing material has the advantages of low cost, easy construction, good adhesion with aggregate, high temperature stability, good low temperature crack resistance and strong water damage resisting capability. After being mixed with pigments with different colors, the light color cementing material can be made into pavement materials with different colors, so as to be applicable to squares, parks, amusement parks and sidewalk road and have the function of beautifying the environment and guiding traffic; furthermore, the performance of the light color cementing material can reach the requirements of city expressway, highway and first class highway.

Owner:天津市市政工程研究院

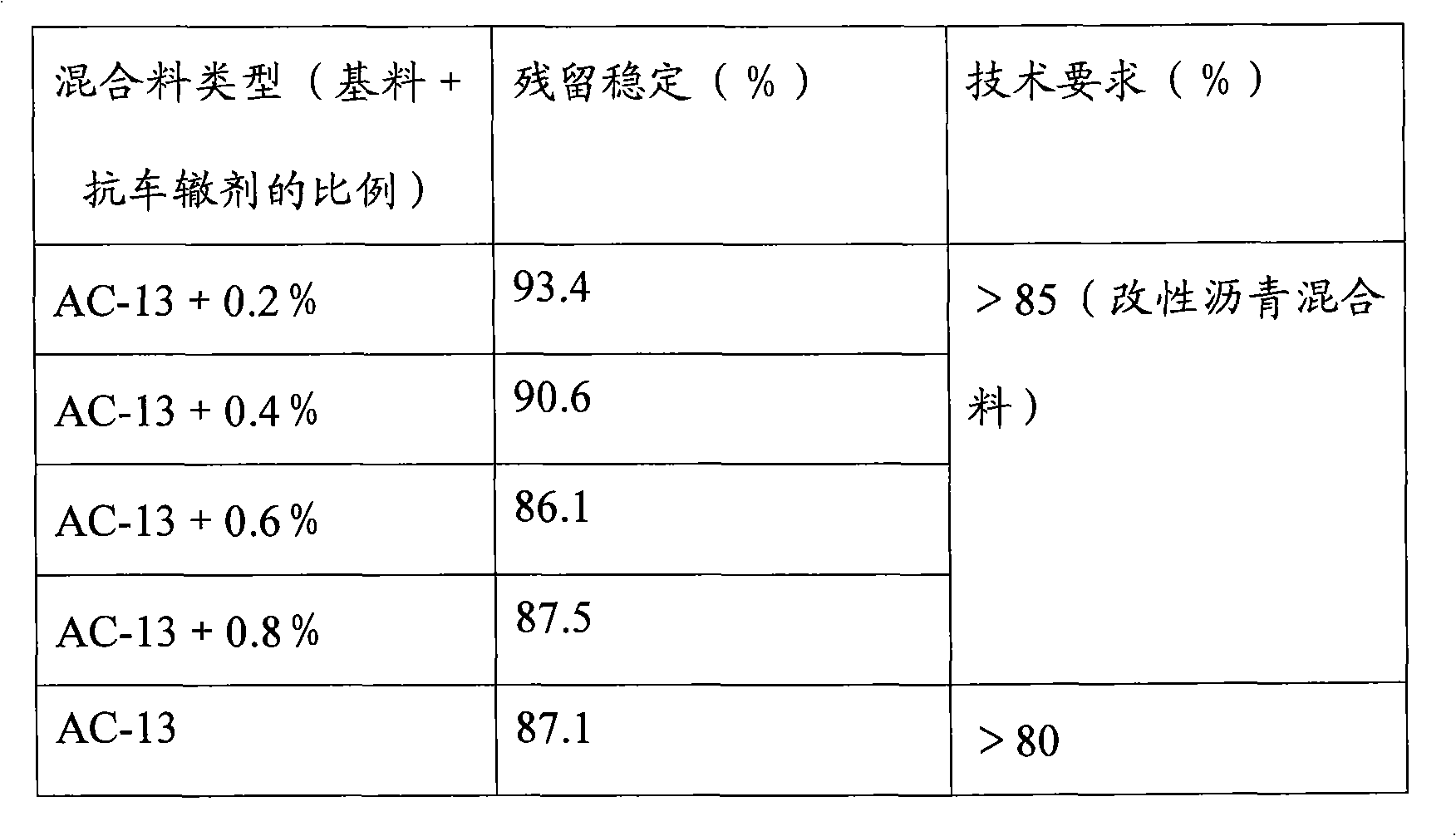

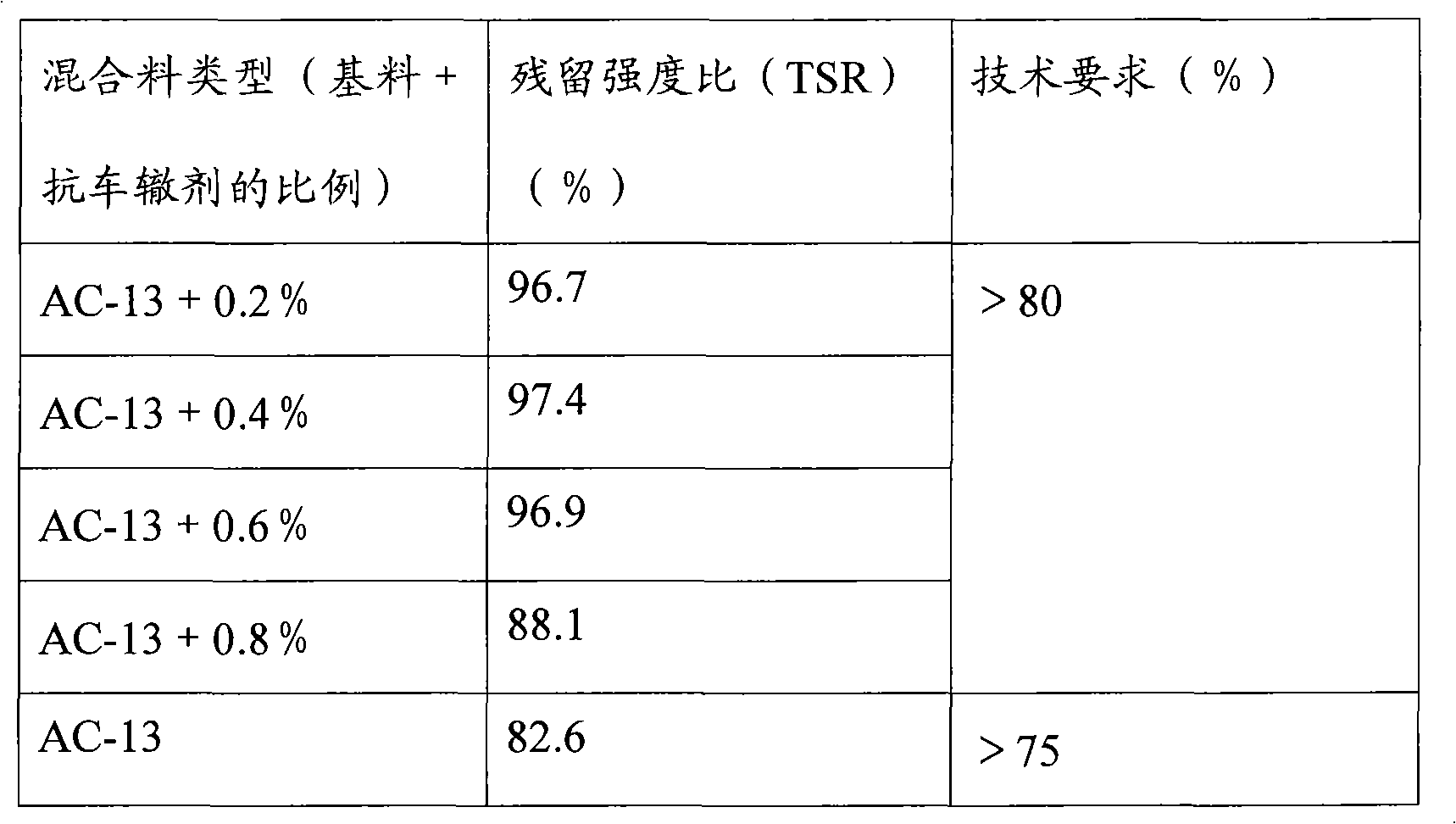

Anti-rutting modifying agent used for asphalt pavement and asphalt mixture containing anti-rutting modifying agent

ActiveCN103059587ASolve technical problemsRealize repeated recyclingBuilding insulationsPolymer scienceEngineering

The invention relates to an anti-rutting modifying agent. The anti-rutting modifying agent comprises (a) high-density low-pressure polyethylene, (b) rubber powder and (c) rock asphalt. The anti-rutting modifying agent is good in low-temperature cracking resistance, high in bonding strength, high in water damage resistance, good in non-deformability, low in cost, simple in preparation technology, convenient to operate and convenient to add in asphalt mixture.

Owner:北京中交路通科技发展有限公司

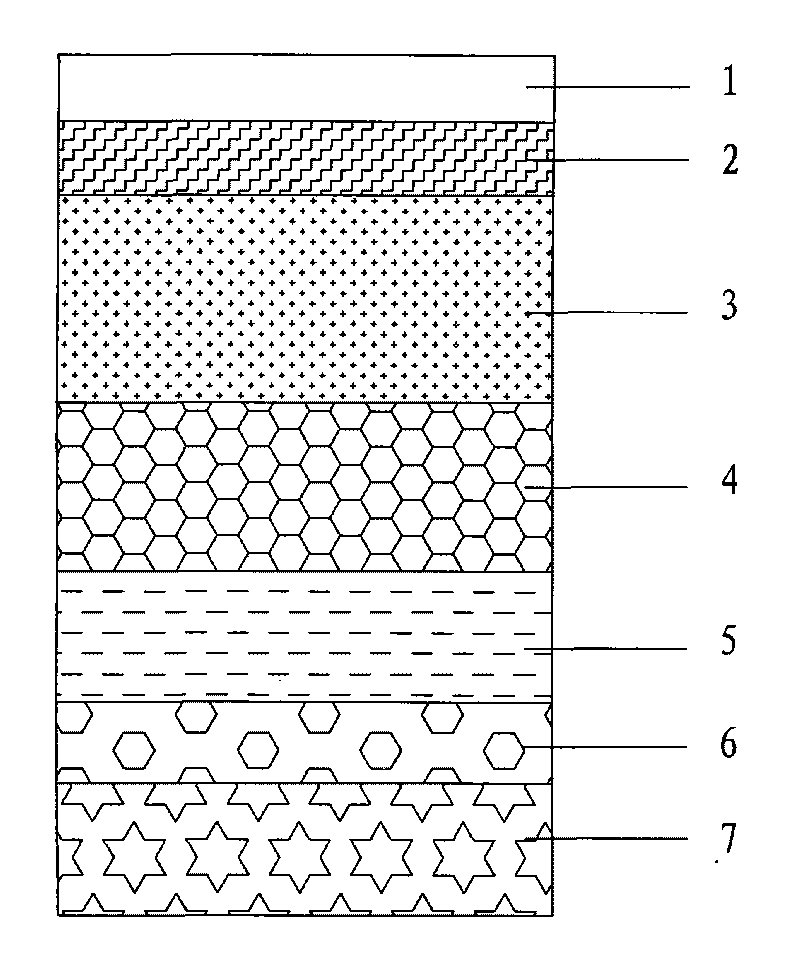

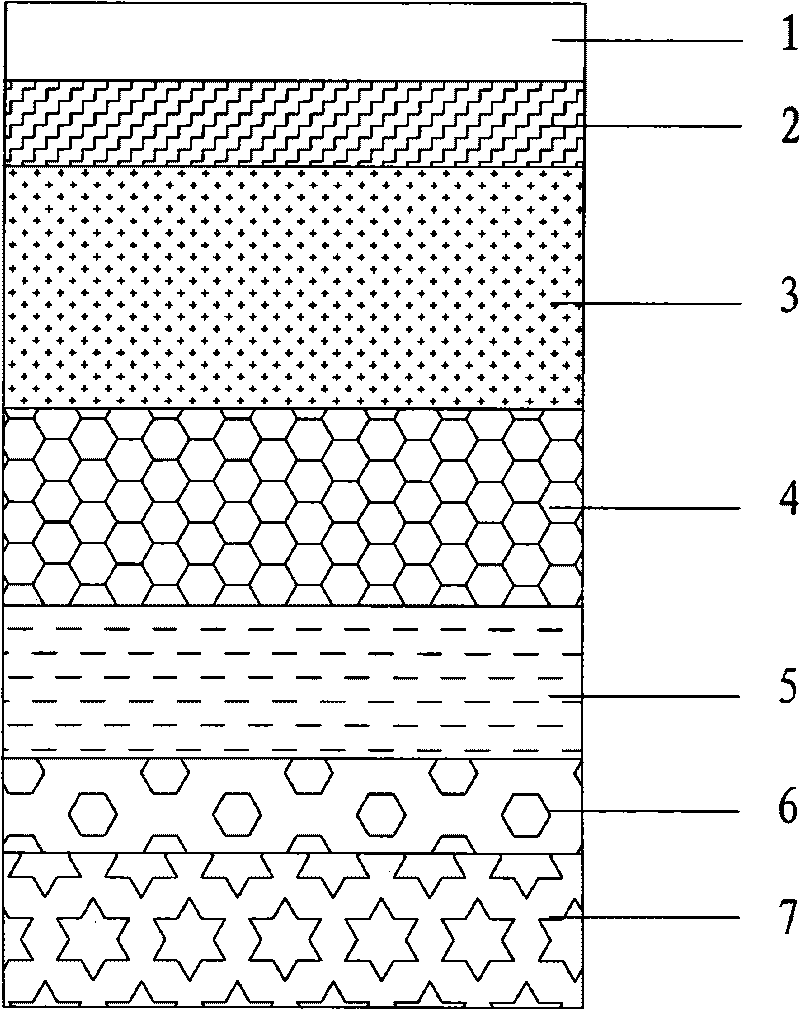

Permeable pavement structure

InactiveCN101718069AGood noise reductionGood high temperature stabilityIn situ pavingsGeotextileChipseal

The invention discloses a permeable pavement structure which is provided with a surface layer of a porous bitumen mixing material, a middle surface layer of the porous bitumen mixing material, a permeable open grading lower surface, a grading gravel base layer, a filtering layer, a geotextile layer and a soil base layer from top to bottom. The invention overcomes the defects caused by the watertightness of a traditional pavement, provides the pavement structure with good noise reducing and skidproof functions and good pavement performance of high temperature stability, abrasion resistance, fatigue resistance, water damage resistance and the like, and is widely applied to various roads of sidewalks, parkways, bicycle roads, parking lots, residential quarters and the like.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD +3

Novel anti-rutting agent

The invention relates to novel anti-rutting agent and a production method thereof, wherein the novel anti-rutting agent comprises rock asphalt and polymer and is characterized by also comprising diatomite. The parts by weight of the rock asphalt, the polymer and the diatomite are respectively 25-35 parts, 40-50 parts and 20-30 parts. The method comprises the following steps: the rock asphalt, the polymer and the diatomite are crushed, weighed according to proportions, put into a mixer and mixed; and then, the mixing materials are extruded into strips by a screw extruder and cut into particles after being cooled; and finally, the particles are dried. The invention has the advantages of safe, simple and convenient use, even dispersion, anti-rutting performance at the higher temperature, anti-cracking performance at the lower temperature, low cost and higher cost performance.

Owner:天成垦特莱赞皇科技有限公司

High-modulus asphalt based on natural asphalt modification, as well as preparation method and application thereof

InactiveCN104725882ASimple preparation processLow costRoads maintainenceBuilding insulationsRoad surfaceMaterials science

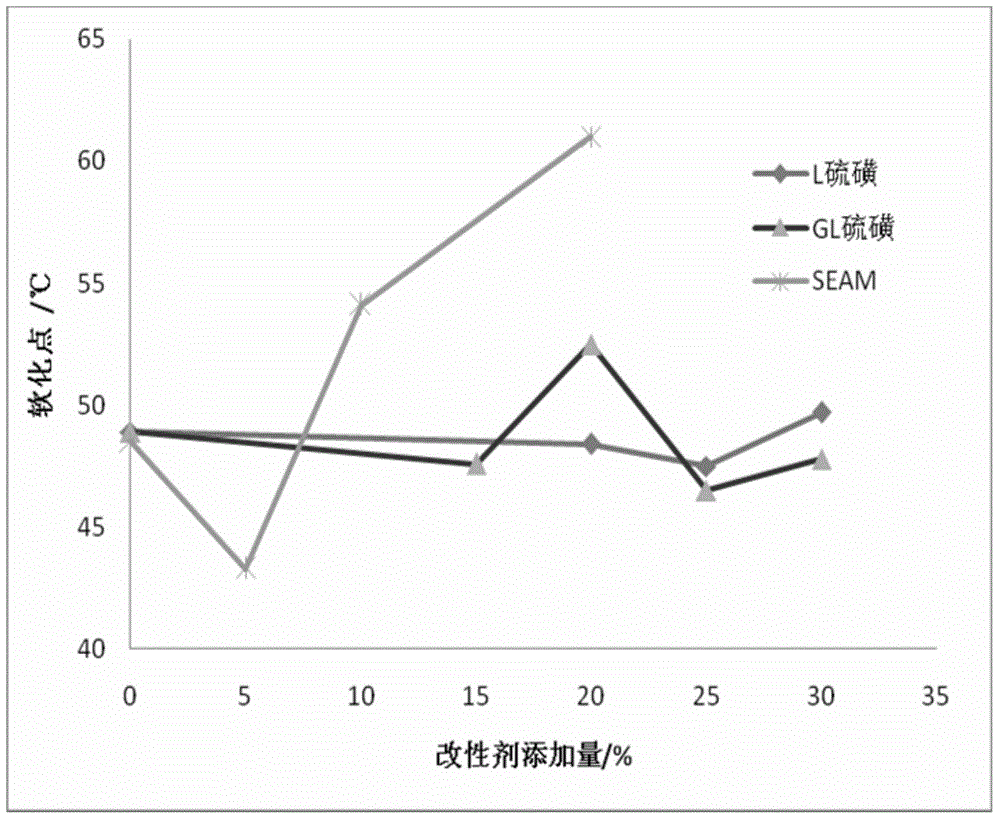

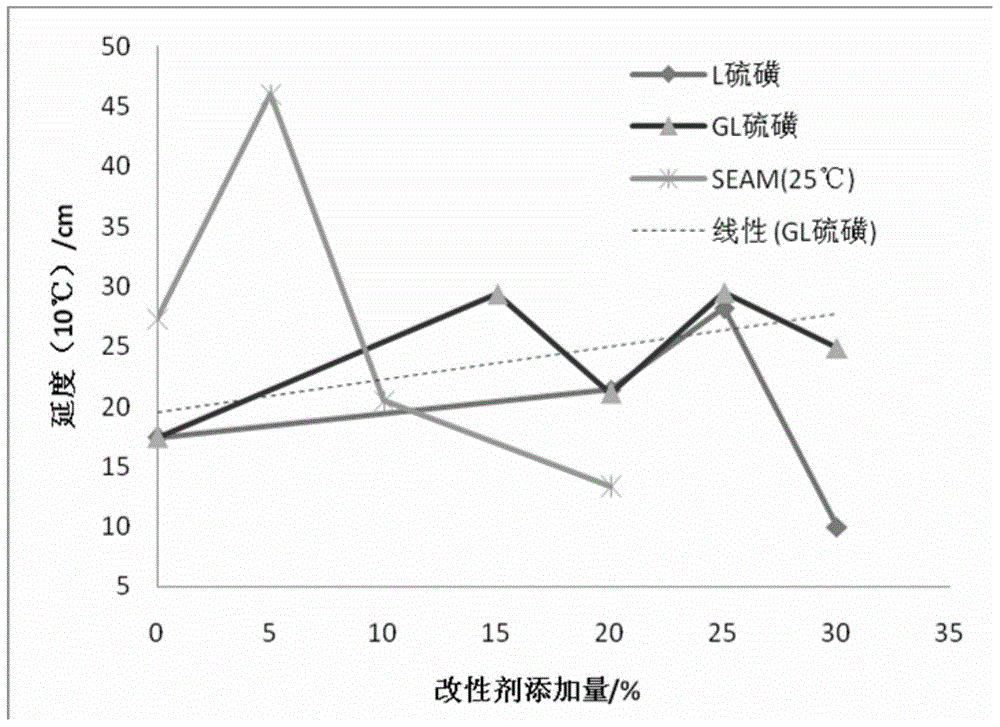

The invention provides high-modulus asphalt based on natural asphalt modification. The high-modulus asphalt is prepared by modifying natural asphalt with SEBS modifying agent, stabilizing agent, compatilizer and matrix asphalt, wherein the weight ratio of the natural asphalt to the matrix asphalt is (40-50):(50-60), the SEBS modifying agent is 1-3 percent of the total mass of the natural asphalt and the matrix asphalt, the stabilizing agent is 0.5-1.0 percent of the total mass of the natural asphalt and the matrix asphalt, and the compatilizer is 0.3-0.5 percent of the total mass of the natural asphalt and the matrix asphalt. The invention further provides a preparation method and application of the high-modulus asphalt. The high-modulus asphalt is simple in preparation process and low in cost, can be used for effectively improving the permanent deformation resistance, shearing resistance, high-temperature track resistance, water damage resistance and fatigue performance of asphalt mixture and achieving double aims of improving high-temperature track resistance and pavement durability of the asphalt pavement, and reducing construction cost in the total life cycle.

Owner:JIANGSU SOBUTE NEW MATERIALS

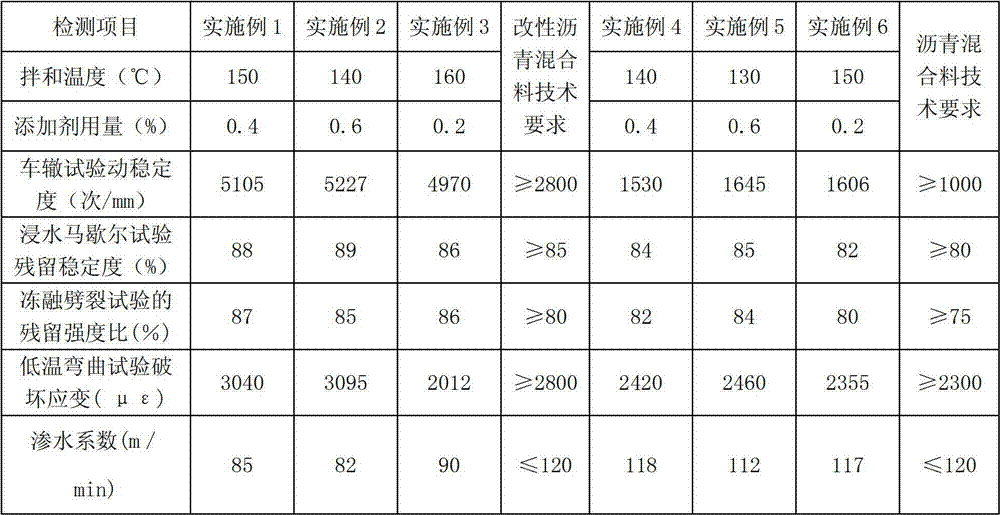

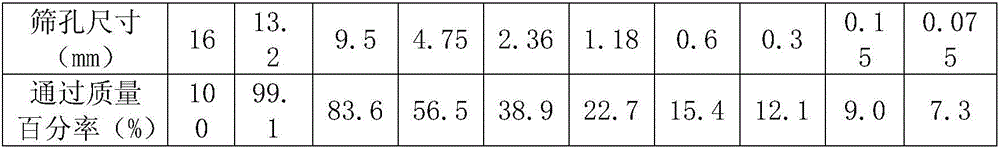

Asphalt modifier and industrial production method and application thereof

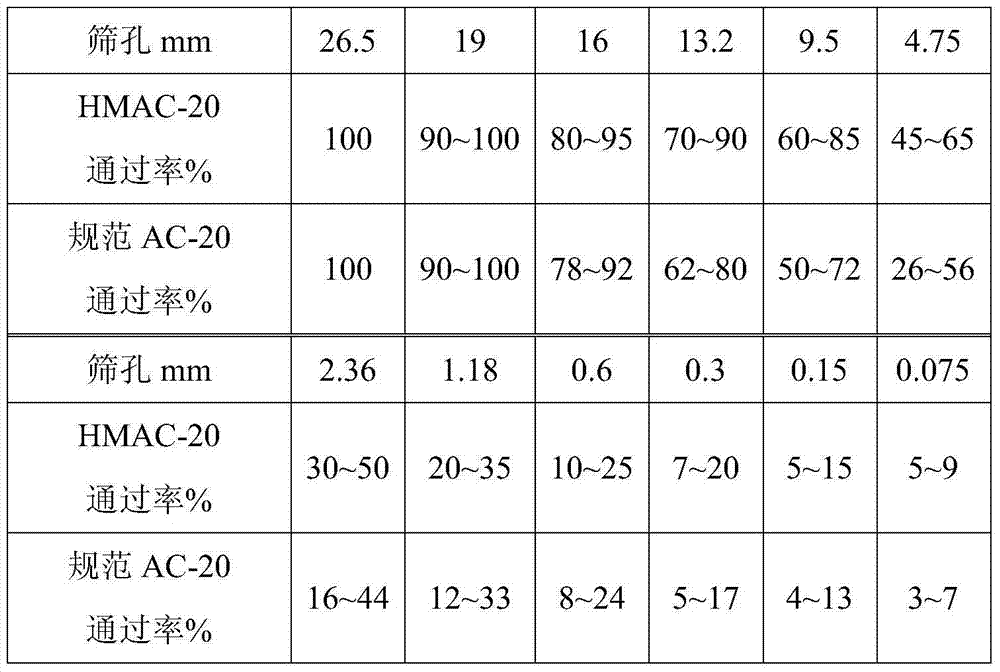

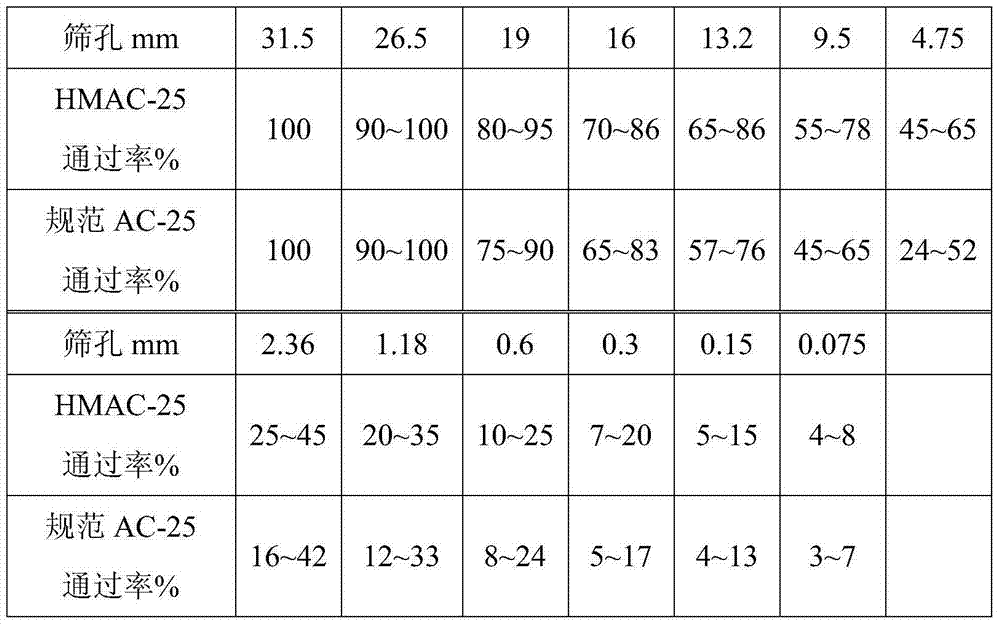

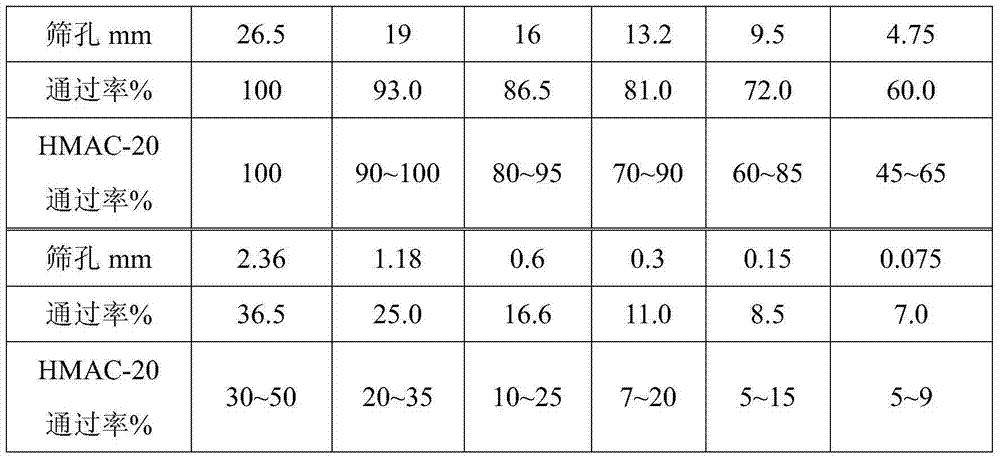

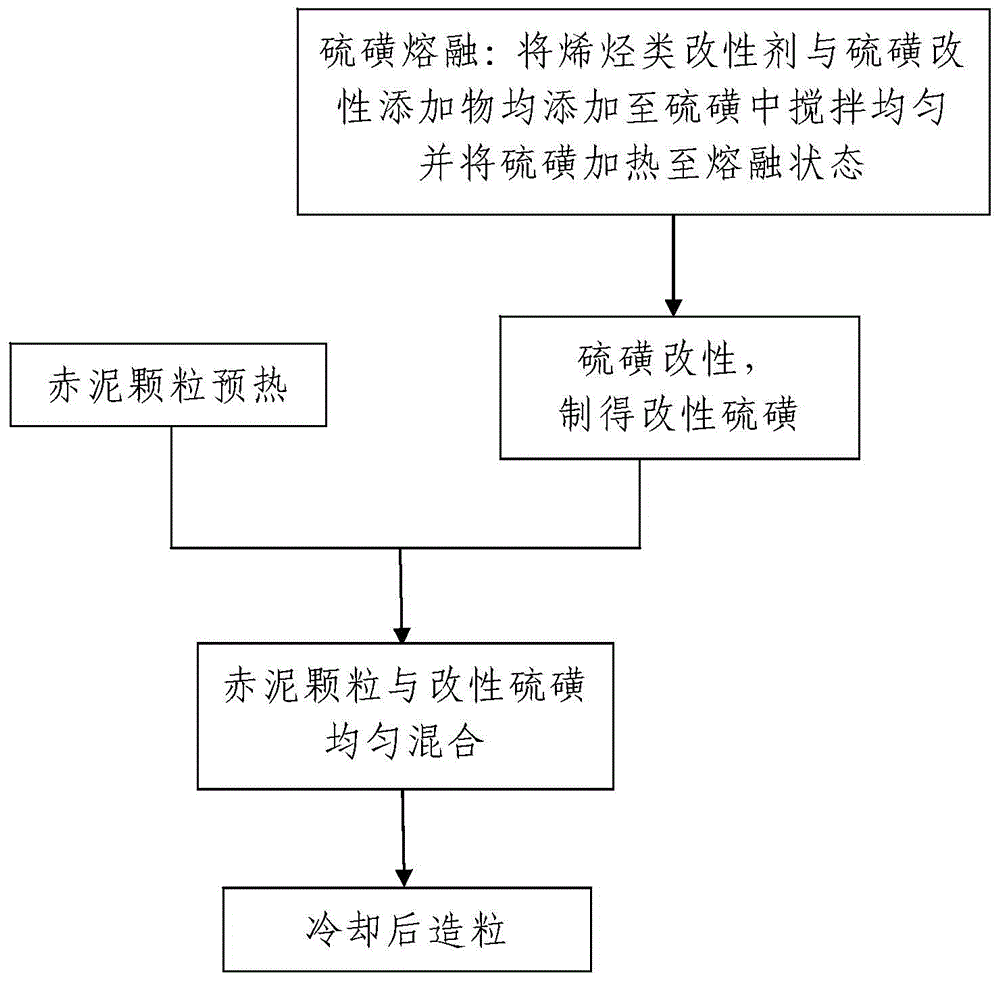

The invention discloses an asphalt modifier and an industrial production method and application thereof. The asphalt modifier is prepared by uniformly mixing modified sulfur and red mud particles. The industrial production method comprises the following steps: 1, preparing the modified sulfur, namely performing sulfur fusion and sulfur modification; and 2, adding the red mud particles. In the industrial production method, the modified sulfur is prepared in a way that an olefin modifier and a sulfur modification additive are added into sulfur for modifying sulfur; a weight ratio of the olefin modifier to sulfur is 2-6:100, and a weight ratio of the red mud particles to the sulfur is 10-30:100. The application process of the asphalt modifier comprises the following steps: I, preheating raw materials; and II, mixing, namely mixing the preheated asphalt modifier, mineral aggregate and matrix asphalt. The asphalt modifier adopted in the production method is simple in production process, low in construction cost, incombustible, safe to use and excellent in performance, the amount of discharged atmospheric pollutants in the production and application process is small, comprehensive performance of the modified asphalt concrete is excellent, and industrial waste red mud can be effectively utilized.

Owner:XIAN UNIV OF SCI & TECH

Rock asphalt composite modifier as well as preparation method and application thereof

InactiveCN102690522AImprove high temperature stabilityHigh softening pointBuilding insulationsNeedle penetrationRoad surface

The invention discloses a rock asphalt composite modifier as well as a preparation method and an application thereof. The rock asphalt composite modifier is prepared through the following steps: grinding 10-90% of rock asphalt and 10-90% of diatomite to be powder and then mixing the powder. The rock asphalt composite modifier can be used for mixing modified asphalt mixture and paved on the roads with the climatic features of high temperature, raininess and intense cold and / or the traffic conditions of heavy load, slow speed and canalization. After the rock asphalt composite modifier is added, the softening point of the composite modified asphalt is improved, the needle penetration is reduced and the high-temperature property of the mixed material is remarkably improved so as to obviously reduce the problems of tracking, pushing, upheaval and pit slots as a result of heavy-load traffic, high-temperature climate and canalization. The rock asphalt composite modifier can be used for remarkably enhancing the adhesive capacity between the asphalt and aggregate and improving the water damage resistance of the asphalt roads.

Owner:GUANGZHOU ZHONGGU BUILDING MATERIALS

Warm mixing additive of asphalt mixture, preparation method and application method thereof

ActiveCN102827484AImprove workabilityImprove toughnessClimate change adaptationBuilding insulationsEmulsionBituminous materials

The invention relates to technology of road asphalt materials, and discloses a warm mixing additive of asphalt mixture, a preparation method and an application method thereof. The warm mixing additive of the asphalt mixture comprises the following components by weight percent: 50 to 70 % of zeolite powder, 20 to 28 % of emulsion and the balance being dispersing auxiliary agents. The preparation method comprises adding the zeolite powder and then the emulsion into a feed mixer, uniformly stirring, adding the dispersing auxiliary agents, and then sending into a comminutor after uniformly stirring to obtain the warm mixing additive of the asphalt mixture. The application method comprises putting the warm mixing additive of the asphalt mixture accounting for 0.2 to 0.6 % of total weight of aggregates and the asphalt into a mixing plant to mix evenly.

Owner:CHANGAN UNIV +1

Preparation method of separated plant-mixed warm-hot regenerated asphalt mixed material

InactiveCN106746926AReduce effective utilizationPromote full accessSolid waste managementPavement engineeringBituminous materials

The invention relates to an asphalt material for pavement engineering and in particular to a preparation method of a separated plant-mixed warm-hot regenerated asphalt mixed material. The preparation method comprises the following steps: (1) detecting the asphalt content of a recovered asphalt pavement material, ageing the asphalt performance and mineral aggregate gradation; (2) determining the content of the recovered asphalt pavement material, a novel aggregate, limestone mineral powder, novel asphalt and a regenerator; (3) adding the mixture into a mixing pot for prestirring; (4) adding the regenerator; (5) discharging the obtained product out of a pot and developing at 40-150 DEG C; (6) adding the heated novel aggregate into the stirring pot, adding the developed product in the step (5) and stirring; and (7) adding the novel asphalt and limestone mineral powder into the product obtained in the step (6) and stirring, and then discharging and forming. The asphalt material provided by the invention is simple in process, good in regenerating effect, high in utilization ratio of the regenerator, relatively low in cost and good in comprehensive pavement performance of the product.

Owner:JIANGSU TIANNUO ROAD MATERIAL TECH

Anti-rutting additive with high modulus and high strength as well as preparation method and applications thereof

The invention relates to an anti-rutting additive with high modulus and high strength for an asphalt mixture as well as a preparation method and applications thereof. The polymer composite additive of the asphalt mixture is formed by mixing crosslinkable polyethylene, random polypropylene, tackifier, styrene-butadiene rubber and fiber, wherein the tackifier is terpene resin. The production method of the anti-rutting additive comprises the following steps: adding the raw materials in a proper processing device so that the raw materials are fully mixed and reacted; and granulating and shaping. The anti-rutting additive has cheap price, and can be used for increasing the road performances of the asphalt mixture such as high temperature stability, low temperature crack resistance and water stability, and prolonging the service life of pavement.

Owner:北京厚德交通科技股份有限公司

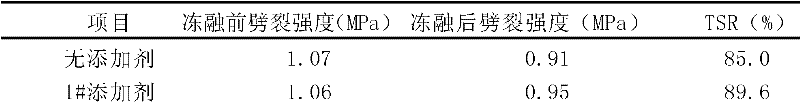

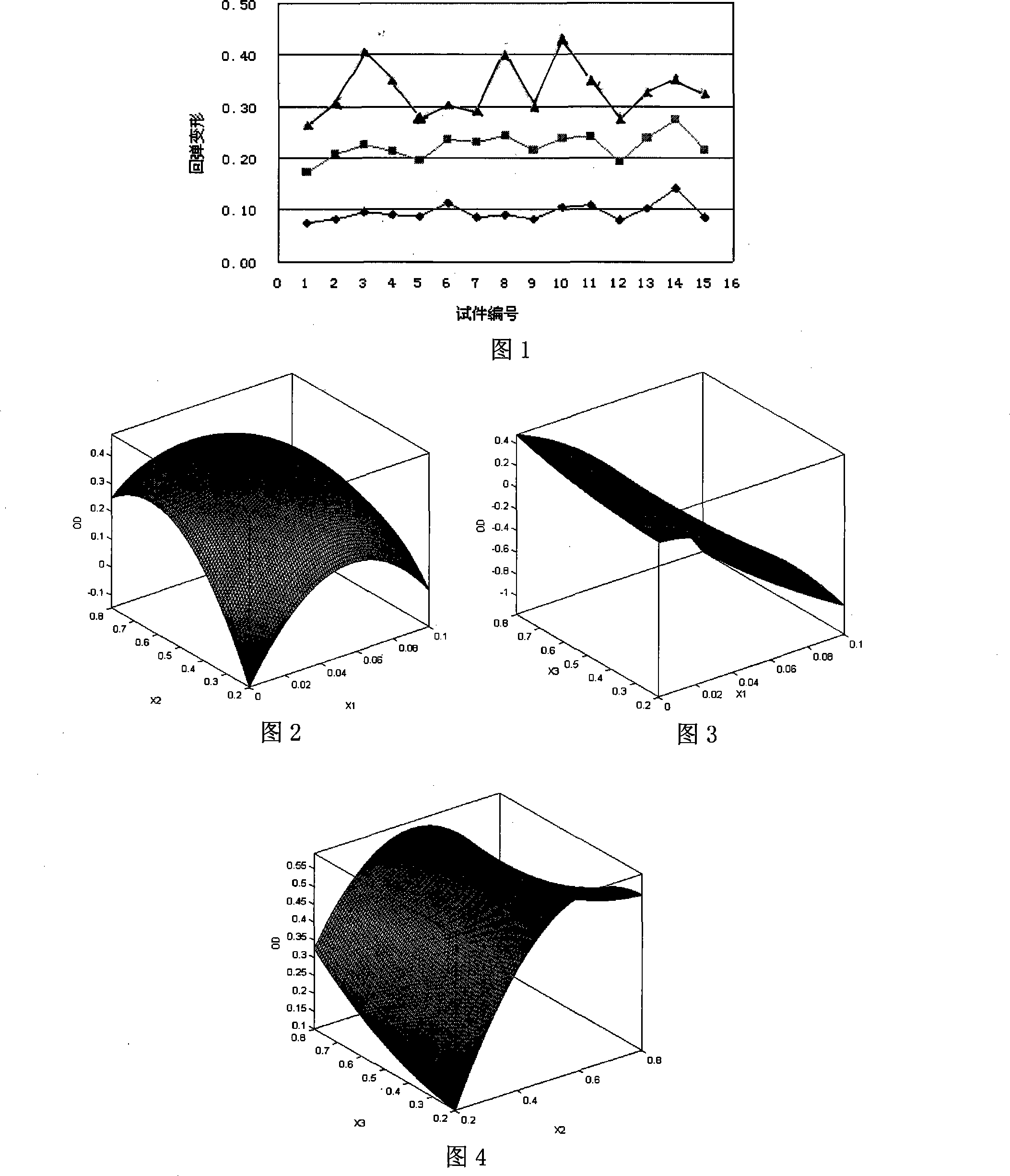

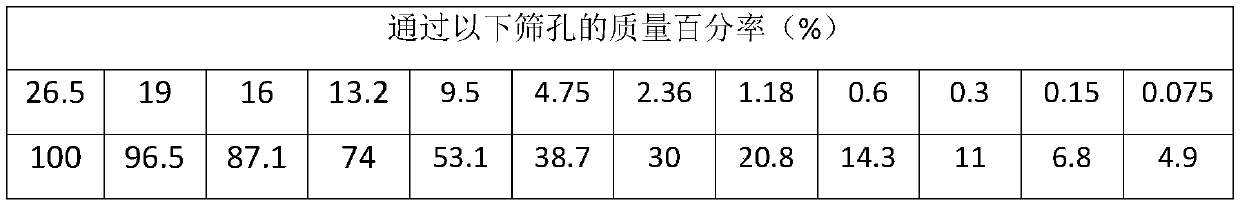

Method for determining composition ratio range of rubber particle asphaltum mixture

InactiveCN101161703AImprove skid resistanceImprove noise reductionBuilding insulationsSpecial data processing applicationsCrack resistanceControl objective

The present invention relates to a method for determining the proportioning range of components of rubberized bitumen composites, which can be realized in the following steps: 1. determining there factors and the numeric areas; 2. determining the control objectives; 3. calculating the overall rating value of the objectives and drawing response surface figure; and 4. analyzing the response surface figure to obtain the optimal value of the proportioning range of components of rubberized bitumen composites, wherein the composites comprises 2 percent-6 percent by mass of the admixture of rubber granules and 60 percent -75 percent by mass of coarse stone material, wherein the coarse rubber granules is 30 percent-60 percent based on the mass of rubber granules. The sliding resistance, the noise reducing performance, the set resistance at high-temperature, the crack resistance at low temperature, the water damage resistance and the fatigue resistance of road surface paved by the composites according to the proportioning range of the invention is raised substantially.

Owner:HARBIN INST OF TECH

A high-modulus warm-mix asphalt additive and a preparing method and application thereof

ActiveCN109777134AImprove overall performanceGood high temperature performanceClimate change adaptationBuilding insulationsAntioxidantPitch blende

The invention belongs to the field of traffic engineering admixtures, and relates to preparation and application of a high-modulus warm-mix asphalt additive. The additive is prepared mainly from a high modulus warm-mix main agent, a thermoplastic elastomer, vegetable oil, a crosslinking agent, a coupling agent, an antioxidant, an antiager and tackifying resin through single-screw low-temperature extrusion and granulation. The additive prepared can be direly added into a material mixture, and is suitable for high-modulus asphalt pavement engineering and winter low-temperature construction environments having high requirements on environment protection. An asphalt mixture prepared by utilizing the additive has excellent high-temperature performance, high dynamic modulus, good low-temperaturetoughness, excellent resistance to water damage, and the like, can reduce temperature for construction such as material mixture mixing, paving and grinding by 20-30 DEG C, achieves a warm mix effects, and is suitable for promotion and application.

Owner:WUHAN MUNICIPAL CONSTR GROUP +1

Medium-temperature rubber asphalt mixture modifier and preparation method thereof

The invention belongs to the field of a road material, and particularly relates to a medium-temperature rubber asphalt mixture modifier and a preparation method thereof. The modifier comprises the following components in parts by weight: 100 parts of rubber powder, 10-30 parts of polyethylene wax, 5-10 parts of butadiene styrene rubber, 2-6 parts of lubricative surfactant, and 0.1-1 part of stabilizer. The preparation method comprises the steps of heating and melting the rubber powder, the polyethylene wax, the butadiene styrene rubber, the lubricative surfactant and the stabilizer at 130-160 DEG C, evenly mixing, extruding by a screw extruder, cooling at normal temperature, and cutting into particles. The medium-temperature rubber asphalt mixture modifier and the preparation method thereof have the advantages that the effects of environmental friendliness, energy saving and emission reduction are achieved, junked tires are recycled, the mixing temperature of the rubber asphalt mixture can be effectively reduced by 20-40 DEG C, the high-temperature viscosity of asphalt is reduced, the workability in construction is ensured, the blocking property between the asphalt cement and aggregate is enhanced, the water damage resistance of the rubber asphalt mixture is improved, and the rut resistance and the low temperature resistance of the rubber asphalt mixture are enhanced.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

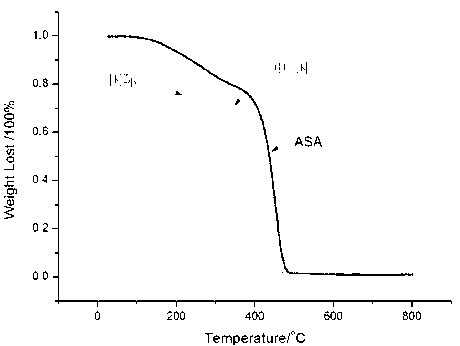

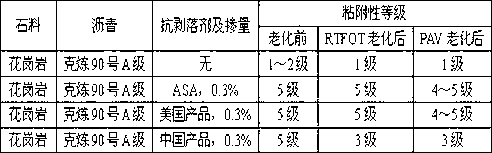

Preparation method of petroleum asphalt anti-stripping agent suitable for acid stone

InactiveCN103232716AImproved resistance to water damageEasy to useBuilding insulationsDimer acidDiethylenetriamine

The invention relates to a preparation method of a petroleum asphalt anti-stripping agent suitable for acid stone, which aims at improving the adhesion of the petroleum asphalt anti-stripping agent to the acid stone, improving the water damage resistance of the asphalt mixture, improving the aging resistance of the asphalt and prolonging the service life of an asphalt pavement. The preparation method comprises the following steps of (1) measuring 100 parts of eleostearic acid and 5 to 20 parts of organic bentonite to be mechanically stirred and gradually heated to 280 to 300 DEG C, and preserving the temperature for 2 to 4h to obtain nano layered silicate / tung oil dimmer acid; (2) slowly placing the nano layered silicate / tung oil dimmer acid into a diethylenetriamine system to be heated to 100 to 130 DEG C, introducing the nitrogen gas, preserving the temperature of 200 to 250 DEG C for 2 to 4h, carrying out the vacuum dehydration, recycling the diethylenetriamine to obtain a polyamide-based nano composite material; and (3) cooling the material to the temperature of 40 to 80 DEG C, adding diluting agent and phase solvent to be uniformly mixed, and then carrying out the blending of the asphalt mixture.

Owner:甘肃省交通规划勘察设计院股份有限公司

Chemically-modified hard asphalt and preparation method thereof

ActiveCN104559232AImprove low temperature performanceHigh viscosityBuilding insulationsCrack resistancePhosphoric acid

The invention discloses chemically-modified hard asphalt and a preparation method thereof. The chemically-modified hard asphalt comprises the following components in parts by weight: 100 parts of basic asphalt, 0.5-3.0 parts of polyphosphoric acid, 2-12 parts of ductility increasing agent mother liquor and 0.2-0.4 part of a surfactant. The preparation method comprises the following steps: adding polyphosphoric acid into the melted basic asphalt for chemically-modified reaction, then adding the ductility increasing agent mother liquor for further reaction, and finally adding the surfactant for further reaction for a period of time to prepare the chemically-modified hard asphalt. The whole process is implemented under a high-speed stirring condition. The chemically-modified hard asphalt prepared by the preparation method disclosed by the invention is high in flow resistance, high in softening point, high in low-temperature ductility, high in bonding property with aggregate, and excellent in high temperature stability, low temperature cracking resistance, fatigue resistance and water invasion resistance; the chemically-modified hard asphalt is particularly suitable for areas with high temperature, wet areas and areas with large diurnal temperature difference and can be used for paving a pavement of a traffic road, so that common pavement damage phenomena such pavement rutting, upheaval, fatigue cracking, low-temperature cracking and water invasion of the pavement are effectively prevented, and the service life of the pavement is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Environment-friendly asphalt mixture warm mix modifier and preparation method thereof

InactiveCN103923473AGood effectReduce the temperatureClimate change adaptationBuilding insulationsPlasticizerSURFACTANT BLEND

Belonging to the field of road materials, the invention in particular relates to an environment-friendly asphalt mixture warm mix modifier and a preparation method thereof. The modifier comprises the following components by weight: 100 parts of polyethylene wax, 20-40 parts of an organic lubricant, 10-30 parts of a lubricating surfactant, and 3-10 parts of a plasticizer. The preparation method includes: subjecting the polyethylene wax, the organic lubricant, the lubricating surfactant and the plasticizer to heating melting at 130-150DEG C, mixing them evenly, conducting extrusion by a screw extruder, carrying out cooling under normal temperature, and cutting the product into particles. The warm mix modifier provided by the invention is environment-friendly, energy-saving and emission reducing, can effectively lower the mixing temperature of the asphalt mixture by 20-40DEG C, enhance the adhesion performance between asphalt cement and aggregate, improve the anti-water damage performance of the warm mix asphalt mixture, and strengthen the rutting resistance and low temperature resistance of the warm mix asphalt mixture.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com