High viscosity bitumen and preparation method thereof

A high-viscosity asphalt, road asphalt technology, applied in building components, building insulation materials, construction and other directions, to improve fluidity, improve dispersion performance and water damage resistance, and reduce equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Add 1000kg of dehydrated Zhonghai 70# asphalt into the heat-insulating jacketed stirring tank with heating device, heat to 140°C, add 20kg of compatibilizer high aromatic oil; continue to heat to 170°C, add 70kg of thermoplastic rubber SBS, 20kg of thermoplastic resin low-density polyethylene, 150kg of viscosity modifier terpene resin, 10kg of comprehensive antioxidant, the comprehensive antioxidant is physically blended by 5kg of ultraviolet absorber, 2.5kg of antioxidant 1010, and 2.5kg of aniline rubber antioxidant. Stir for 2 hours, then cut for 20 minutes with a high-speed shear at a speed of 14,000 r / min, and the product is ready. Sampling and detection according to the prescribed method, the results are shown in Table 1.

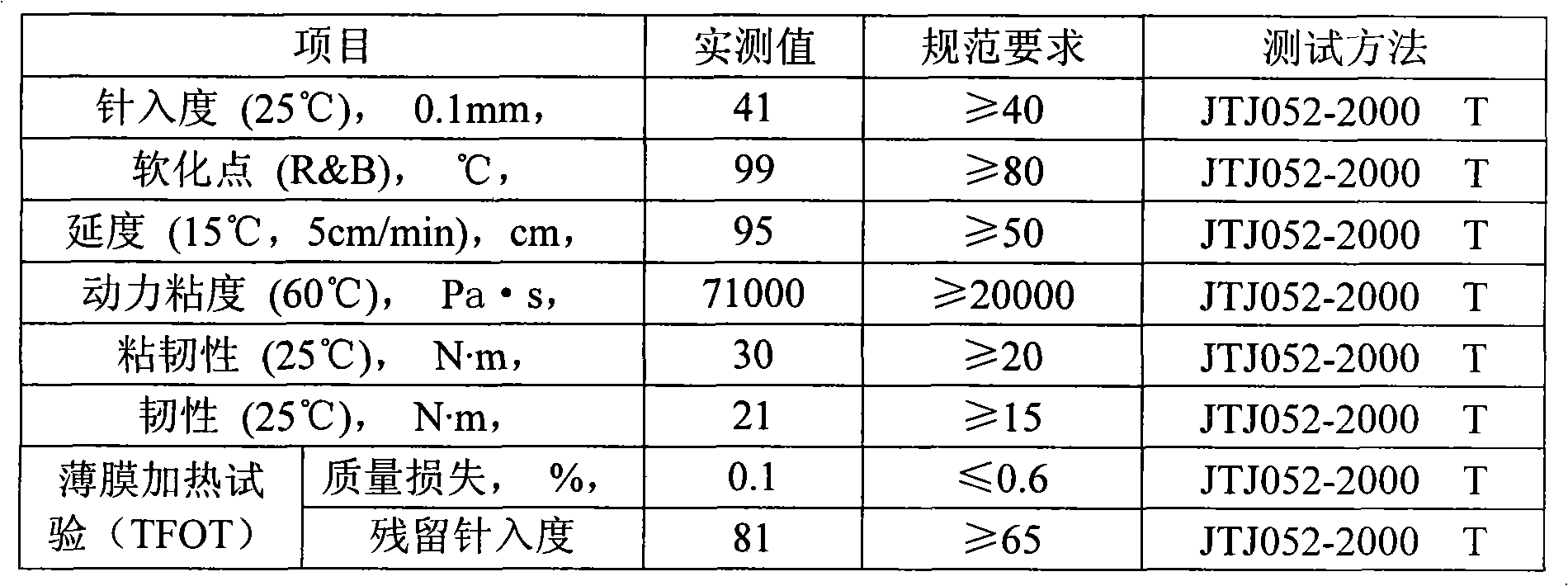

[0018] Table 1 Performance indicators of high-viscosity asphalt

[0019]

[0020] As shown in Table 1, the performance of the high-viscosity asphalt produced according to the formula of Example 1 of the present invention fully meets the req...

Embodiment 2

[0022] Add 1000kg of dehydrated Korean SK-70# asphalt into an insulating jacketed stirring tank with a heating device, heat to 140°C, add 10kg of compatibilizer furfural oil according to the weight ratio while stirring, and continue heating to 170°C, respectively, according to the weight ratio Add 70kg thermoplastic rubber SIS, 15kg thermoplastic resin ethylene-vinyl acetate copolymer, 120kg viscosity regulator C 9 Petroleum resin, 10kg comprehensive anti-aging agent, comprehensive anti-aging agent is formed by physical blending of 5kg ultraviolet absorber, 2.5kg antioxidant 1010, and 2.5kg aniline rubber anti-aging agent, stirring for 2h; Machine, cut for 20 minutes, ready-made product. Sampling and detection according to the prescribed method, the results are shown in Table 2.

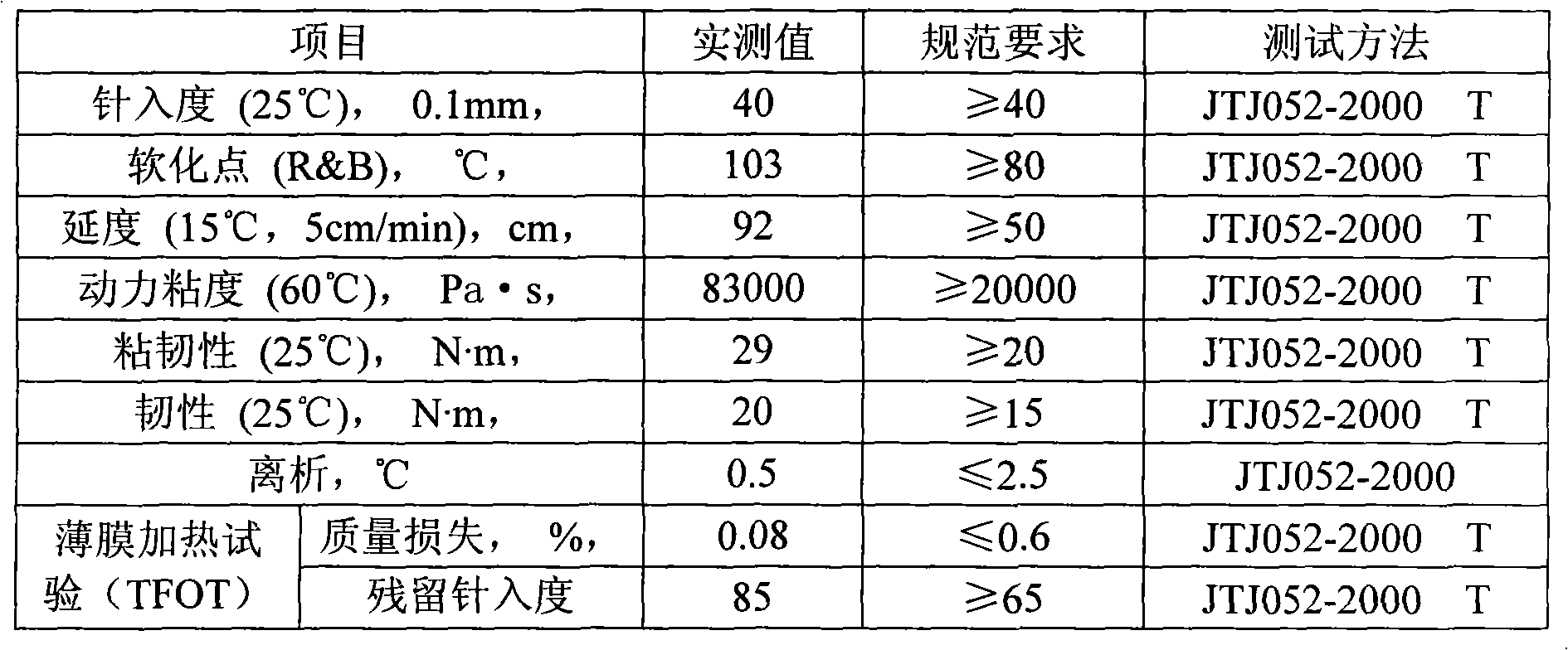

[0023] Table 2 Performance indicators of high-viscosity asphalt

[0024]

[0025] As shown in Table 2, the performance of the high-viscosity asphalt produced according to the formula of Example ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com